Trane VariTrac VAV-SVN03A-EN, VariTrac X13650940010, VariTrac X13650942010 Installation Manual

Page 1

Installation Manual

VariTrac

™

Central Control Panel

June 2002 VAV-SVN03A-EN

Page 2

VariTrac Central Control Panel Installation Manual

This manual and the information in it are the property of American Standard

Inc. and shall not be used or reproduced in whole or in part, except as

intended, without the written permission of American Standard Inc. Since

Trane has a policy of continuous product improvement, it reserves the right

to change design and specification without notice.

Use of the software contained in this package is provided under a software

license agreement. Unauthorized use of the software or related materials

discussed in this manual can result in civil damages and criminal penalties.

The terms of this license are included with the compact disk. Please read

them thoroughly.

Trane has tested the system described in this manual. However, Trane does

not guarantee that the system contains no errors.

Trane reserves the right to revise this publication at any time and to make

changes to its content without obligation to notify any person of such

revision or change.

Trane may have patents or pending patent applications covering items in

this publication. By providing this document, Trane does not imply giving

license to these patents.

The following are trademarks or registered trademarks of Trane: Reliatel,

Tracker, Trane, VariTrac, VariTrane, and Voyager.

VAV-SVN03A-EN

Printed in the U.S.A.

© 2002 American Standard Inc. All rights reserved.

Page 3

Contents

About This Manual ............................................ 1

Contents .............................................................................................................. 1

Compliance Information .............................................................................. 1

Specifications ............................................................................................... 1

VariTrac Changeover Bypass System ......................................................... 1

Overview ................................................................................................ 1

Getting Started ...................................................................................... 1

Installing and Configuring the System ................................................ 1

Troubleshooting .................................................................................... 1

Delivered VAV System ................................................................................. 1

Overview ................................................................................................ 1

Getting Started ...................................................................................... 1

Installing and Configuring the System ................................................ 1

Naming Conventions ......................................................................................... 2

Cautionary Statements ...................................................................................... 2

Related Literature ............................................................................................... 2

FCC Information ............................................... 3

VariTrac and Delivered VAV Radio and Television Interference ........................ 3

VariTrac Changeover-Bypass System ................ 5

Overview ............................................................................................................. 5

Central Control Panel ................................................................................... 5

Unit Control Module (UCM) ........................................................................ 5

VariTrac Damper........................................................................................... 5

Communicating Sensor/Bypass Damper Control ...................................... 6

VariTrac Bypass Damper ....................................................................... 6

Communicating Sensor/Bypass Control .............................................. 6

Auxiliary Temperature Sensor ..................................................................... 6

Zone Temperature Sensors .......................................................................... 6

CO2 Sensor ................................................................................................... 7

Occupancy Sensor ....................................................................................... 7

Operator Display (optional) ......................................................................... 7

Service Model Number Description ........................................................... 7

Specifications ................................................... 9

VariTrac Central Control Panel ........................................................................... 9

Operator Display .............................................................................................. 10

VAV-SVN03A-EN i

Page 4

UCM Damper .................................................................................................... 10

Communicating Sensor/Bypass Control Assembly ........................................ 11

Relay Board Binary Outputs ............................................................................. 11

Wire Specifications ........................................................................................... 11

Getting Started ............................................... 13

Unpack and Inspect the Components ............................................................. 13

Mount the Wiring Base ..................................................................................... 14

Mounting Requirements............................................................................ 14

Location................................................................................................ 14

Operating Environment....................................................................... 14

Clearances ............................................................................................ 14

Secure Termination Module Wall ............................................................... 15

Secure Termination Module to Conduit Box ............................................. 16

Install VariTrac CCP Relay Board ............................................................... 16

Wire AC Power .................................................................................................. 17

CCP Field Wiring ......................................................................................... 17

AC Power Wiring .................................................................................. 18

AC Power Checkout ............................................................................. 18

Binary Input Wiring .......................................................................................... 18

Priority Shutdown Input Wiring .......................................................... 18

Occupied/Unoccupied Input Wiring ................................................... 19

Output Wiring ................................................................................................... 19

Install the Bypass Dampers and Communicating

Sensor/Bypass Control Assembly ................................................................... 20

Install Bypass Dampers ............................................................................. 20

Bypass Damper Wiring .............................................................................. 21

Mount the Communicating Sensor/Bypass Control ................................ 21

Connect the Communicating Sensor/Bypass Control Wiring ................. 22

Install the VariTrac Dampers ............................................................................ 23

Connect UCM Wiring ................................................................................. 24

Set the UCM DIP Switches ........................................................................ 25

Slaved Dampers ............................................................................................... 26

Install the Zone Temperature Sensors ............................................................. 28

Location ...................................................................................................... 28

Mounting Standard and Digital Zone Temperature Sensors ................... 29

Wall Mount........................................................................................... 29

Junction Box Mount ............................................................................ 29

Zone Temperature Sensor Wiring .............................................................. 30

Communication Link Wiring ............................................................................ 32

Mount Main Module .................................................................................. 36

Install Operator Display (optional) ............................................................ 37

Connecting Modem Devices ..................................................................... 38

VAV-SVN03A-ENii

Page 5

Connecting PC with VariTrac Software to CCP ......................................... 39

Installation Checklist...................................... 41

Shipment .................................................................................................... 41

Unit Location .............................................................................................. 41

AC Power Wiring ........................................................................................ 41

Communicating Sensor/Bypass Assembly .............................................. 41

Input Wiring ................................................................................................ 41

Output Wiring ............................................................................................. 41

VariTrac Dampers ....................................................................................... 42

Zone Temperature Sensors ........................................................................ 42

UCM Wiring ................................................................................................ 42

Communication Link Wiring ...................................................................... 42

System Start-Up and Checkout ...................... 43

Pre-power-Up Checkout ................................................................................... 43

Central Control Panel ................................................................................. 43

UCM ............................................................................................................ 43

Occupied Mode ................................................................................... 44

Unoccupied Mode ............................................................................... 44

Powering Down the System ...................................................................... 44

UCM LEDs .................................................................................................. 44

Green LED ............................................................................................ 45

Yellow LED ........................................................................................... 45

Tests and Troubleshooting .............................. 47

Displayed Failures ............................................................................................ 47

Static Sensor Calibration Failure............................................................... 47

Discharge Air Temperature Sensor Failure ............................................... 47

Communication Failure ............................................................................. 47

Zone Sensor Failure ................................................................................... 48

Zone Setpoint Failure ................................................................................ 48

Auxiliary Sensor Failure ............................................................................ 48

Static Pressure Sensor Troubleshooting ................................................... 48

Zone, Auxiliary and System Temperature Sensor Checkout ................... 48

UCM Local Heat Checkout ......................................................................... 50

Central Control Panel Input/Output Test .......................................................... 50

Binary Input Tests ....................................................................................... 50

Communicating Sensor/Bypass Control Test ........................................... 50

Supply Air Temperature Input Test ...................................................... 50

Static Pressure Sensor Input Test ....................................................... 51

Binary Output Test ............................................................................... 51

System Troubleshooting .................................................................................. 51

VAV-SVN03A-EN iii

Page 6

Delivered VAV System .................................... 53

Overview ........................................................................................................... 53

What is Delivered VAV? ............................................................................. 53

What Delivered VAV is Not ........................................................................ 53

Central Control Panel ................................................................................. 55

Unit Control Module (UCM) ...................................................................... 55

VariTrane VAV Terminal Units .................................................................... 55

VariTrane VAV Terminal Unit Types ............................................................ 55

Single Duct ........................................................................................... 55

Parallel Fan-Powered ........................................................................... 55

Series Fan-Powered ............................................................................. 55

Auxiliary Temperature Sensor ............................................................. 56

Zone Temperature Sensors ................................................................. 56

CO

Sensor ........................................................................................... 56

2

Occupancy Sensor............................................................................... 56

Operator Display.................................................................................. 56

Getting Started ............................................... 57

Installing the Central Control Panel................................................................. 57

Install VariTrane VAV Terminal Units ................................................................ 57

Connect UCM Wiring ................................................................................. 57

Set UCM DIP Switches ............................................................................... 57

Installing Zone Temperature Sensors ....................................................... 57

Communications Link Wiring .................................................................... 57

Installation Checklist...................................... 63

Shipment .................................................................................................... 63

Unit Location .............................................................................................. 63

AC Power Wiring ........................................................................................ 63

Input Wiring ................................................................................................ 63

VariTrane Terminal Units ............................................................................ 63

Zone Temperature Sensors ........................................................................ 63

UCM Wiring ................................................................................................ 63

Communication Link Wiring ...................................................................... 64

Completing Central Control Panel Assembly ................................................. 64

Mount Main Module .................................................................................. 64

Install Operator Display ............................................................................. 64

Connecting Modem Devices ..................................................................... 64

VAV-SVN03A-ENiv

Page 7

About This Manual

Contents

This manual describes the steps required to install and configure VariTrac

Changeover Bypass Zoning and Delivered VAV Systems. Sections in this

manual are highlighted below:

Compliance Information

Information about FCC approval and possible radio and telephone interference, and the CE compliance statement.

Specifications

Technical specifications for VariTrac Central Control Panel unit and system

components.

VariTrac Changeover Bypass System

Overview

A brief description of a typical VariTrac changeover bypass system.

Getting Started

Pre-installation and setup information.

Installing and Configuring the System

Installation and configuration information, including an installation checklist.

™

VAV-SVN03A-EN 1

Troubleshooting

General troubleshooting guidelines for common problems.

Delivered VAV System

Overview

A brief description of a typical delivered VAV system.

Getting Started

Pre-installation and setup information.

Installing and Configuring the System

Installation and configuration information, including an installation checklist.

Page 8

About This Manual

Naming Conventions

The following is a list of naming conventions used in this manual:

• CCP: Refers to the system Central Control Panel

• VariTrac: Refers to the CCP used in a pressure dependent bypass zoning

system

• Delivered VAV: Refers to the CCP used with a Commercial Voyager VAV

rooftop unit and VariTrane pressure independent VAV boxes

• VAV: Variable air volume

Cautionary Statements

The following cautionary statements signal procedures or conditions that

require particular attention.

WARNING

Indicates a potentially hazardous situation, which, if not avoided, could

result in serious injury or death.

CAUTION

Indicates a potentially hazardous situation, which, if not avoided, may

result in minor or moderate injury.

CAUTION

Indicates a situation in which property-damage-only accidents could occur.

It is also used to alert against unsafe practices.

IMPORTANT

Alerts installer, servicer, or operator to potential actions that could cause

the product or system to operate improperly, but will not likely result in

potential for damage.

Related Literature

VAV-SVX01B-EN: UCM 4.0 and Wireless VAV Communication

VAV-SLB006-EN: Zone Occupancy Sensor

VAV-SLB007-EN: Digital Display Zone Sensor

VAV-SLB008-EN: Zone and Duct CO2 Sensor

VAV-SVP01A-EN: VariTrac Operator’s Guide

VAV-SVN03A-EN2

Page 9

FCC Information

VariTrac and Delivered VAV Radio and

Television Interference

VariTrac and Delivered VAV generate, use, and can radiate radio frequency

energy. If not installed and used in accordance with the instruction manual,

interference to radio and television reception may occur. VariTrac and

Delivered VAV are tested and comply with the limits for Class A computing

devices in accordance with the specifications in Subpart J of Part 15 of FCC

rules, to provide reasonable protection against such interference in a

commercial installation.

There is no guarantee that interference will not occur in a particular

installation. If interference does occur, consult a radio or television

technician for suggestions to correct the problem. Also, the booklet

Identify and Resolve Radio-TV Interference Problems

U.S. Government Printing Office, Washington, DC 20402.

Order stock #004-000-00345-4.

is available from the

How to

VAV-SVN03A-EN 3

Page 10

FCC Information

The manufacturer hereby declares that the product:

Conforms to the following standards or other normative documents:

'HFODUDWLRQRI&RQIRUPLW\

Manufacturer’s Name:

Manufacturer’s Address:

Product Name:

Product Number:

Product Option:

Electromagnetic Emission:

(by Council Directive 89/336/EEC)

Electromagnetic Immunity:

Trane

4833 White Bear Parkway

Saint Paul, Minnesota 55110

USA

VariTrac CCP Controller

X13650940010; X13650942010

Operator Display

EN 50081-1:1998

Radiated EN55022: 1998 Class B limit

Conducted EN55022: 1998 Class B limit

EN61326-1:1997 +A1: 1998

EN61000-4-2 ±4 kV contact discharge

±8 kV air discharge

EN61000-4-3 3 V/m

EN61000-4-4 ±1 kV

EN61000-4-5 ±1 kV

EN61000-4-6 3 V

EN61000-4-8 30 A/m

EN61000-4-11 1 cycle/100%

When and where issued

Electromagnetic Emission : 4/3/2001 Bounheng Saycocie

Electromagnetic Immunity: 4/17/2001 Design/Compliance Engineer

Saint Paul, Minnesota USA

Mark of Compliance European Contact

Societe Trane (Epinal, France)

1, rue des Ameriques, B.P. 6

F-88191 Golbey Cedex, France

Phone: (33) 329.31.73.00

Fax: (33) 329.81.24.98

This document validates CE conformity of the VariTrac CCP controller.

VAV-SVN03A-EN4

Page 11

VariTrac Changeover-Bypass

System

Overview

VariTrac Changeover-bypass VAV is a comfort system solution designed for

light commercial applications. As the name implies, these systems deliver a

varying volume of air to multiple zones, each with its own thermostat, while

still utilizing a unitary machine with a constant volume fan. Changeoverbypass VAV combines the comfort benefits of VAV with the cost effectiveness and simplicity of packaged unitary equipment.

Central Control Panel

The VariTrac Central Control Panel is the central source of communications

and decision making between the individual zones and the air conditioning

unit. Connections to the central control panel are:

• 24 Vac power

• binary inputs for an occupied/unoccupied signal and external priority

shutdown signal (optional)

• ICS communication bus to the Trane building automation system (optional)

• UCM communication bus to the zone dampers and communicating

sensor/bypass damper control and Trane Voyager™/Reliatel™ rooftop unit

• binary outputs to heating, cooling, and fan of non-Voyager or Reliatel

rooftop units

Unit Control Module (UCM)

A unit control module is mounted to each individual zone damper. Inputs

and outputs consist of the twisted shielded pair communication link, zone

temperature sensor, optional CO2 and occupancy sensors, 24 Vac power,

damper motor control, and local heat outputs. Local heat may be duct or

space mounted, and can be staged electric, pulse-width modulating electric,

and modulating or staged two-position hot water.

VariTrac Damper

Each VariTrac damper consists of an integrated 24 Vac actuator and control

box that encloses the UCM circuit board. The damper is designed to operate

in static pressures up to 1.75 inches wg.

VariTrac dampers are referred to by their dimensions:

• round damper sizes are 6, 8, 10, 12, 14, and 16 inches. The dampers consists of an 18 gage galvanized steel frame with a round damper blade

assembly.

VAV-SVN03A-EN 5

Page 12

VariTrac Changeover-Bypass System

• rectangular damper sizes are 8 x 12, 8 x 14, 8 x 16, 10 x 16, 10 x 20, and

Communicating Sensor/Bypass Damper Control

The communicating sensor/bypass damper assembly is a bypass damper

and communicating sensor/bypass control that resides on the same bus as

the VariTrac dampers and Voyager/Reliatel rooftop unit.

VariTrac Bypass Damper

Bypass dampers are non-communicating VariTrac dampers which include an

integrated actuator with a pre-wired interconnect cable that plugs into the

communicating sensor/bypass control.

• round bypass damper sizes are 6, 8, 10, and 12 inches. The damper con-

• rectangular bypass damper sizes are 14 x 12, 16 x 16, 20 x 20, and 30 x 20

14 x 16 inches. The damper consists of a 16 gage galvanized steel frame

and opposed blade damper assembly.

sists of an 18 gage galvanized steel frame with a round damper blade

assembly. The round bypass damper operates in duct static pressures up

to 1.75 inches wg.

inches. The damper consists of a 13 gage galvanized steel frame and

opposed blade damper assembly. The rectangular bypass damper operates in duct static pressures up to 2.00 inches wg.

Communicating Sensor/Bypass Control

The Communicating Sensor/Bypass Control is composed of an integrated

UCM board, static pressure, and discharge air temperature sensors. It

directly controls the bypass damper and communicates duct conditions to

the central control panel.

The static pressure sensor measures duct static pressure and positions the

bypass damper(s) to maintain the static pressure setpoint.

The discharge air temperature sensor allows the CCP to determine the heat/

cool action of each individual UCM and cycles the heating and cooling

stages to maintain the discharge air temperature. Discharge air temperature

setpoints are also edited through the operator display or PC software.

Auxiliary Temperature Sensor

The auxiliary temperature sensor allows the operator to monitor air

temperature leaving a reheat device or measure duct temperature for

automatic operation of a standalone UCM.

Zone Temperature Sensors

Five zone temperature sensor configurations are available:

• sensor only

• sensor with adjustable setpoint and communications jack

• sensor with night setback override button, cancel button, and communications jack

• sensor with adjustable setpoint, night setback override button, cancel

button, and communications jack

VAV-SVN03A-EN6

Page 13

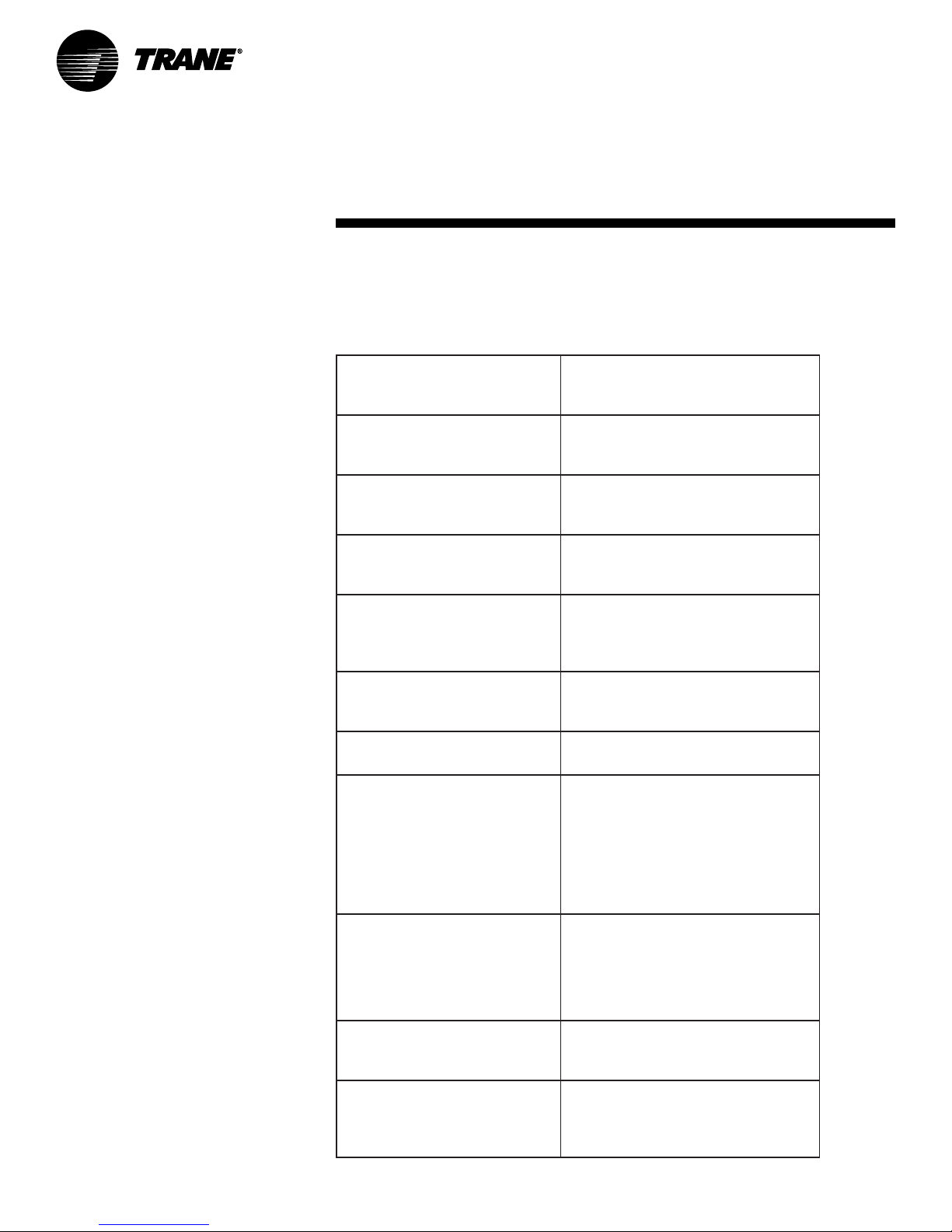

VA DA06 BYP 1

ProductType

Damper Size

VA = VariTrac Product Families

D = Damper

R = Rectangular Damper

A = Development Sequence

DA06 = 6” Damper

DA08 = 8” Damper

DA10 = 10” Damper

DA12 = 12” Damper

DA14 = 14” Damper

DA16 = 16” Damper

RA0812 = 8” x 12” Zone Damper

RA0814 = 8” x 14” Zone Damper

RA0816 = 8” x 16” Zone Damper

RA1016 = 10” x 16” Zone Damper

RA1020 = 10” x 20” Zone Damper

RA1418 = 14” x 18” Zone Damper

RA1412 = 14” x 12” Bypass Damper

RA1616 = 16” x 16” Bypass Damper

RA2020 = 20” x 20” Bypass Damper

RA3020 = 30” x 20” Bypass Damper

Inventory Number

Damper Control

BYPS = Bypass Control

BYR = Rectangular Bypass Control

CHGR = Changeover Control

ELEC = 3 Stage, Primary Heat Disabled Control

NCHW = 1 Stage, Primary Heat Enabled

CO2 Sensor

• sensor with digital display, adjustable setpoint, night setpoint override

button, cancel button, and communications jack

CO2 Sensor

A CO2 sensor may be connected to the UCM damper control to sense CO

levels in the space. This signal is communicated to the CCP for demand

ventilation calculation and control.

2

Occupancy Sensor

A normally open occupancy sensor contact may be connected to the UCM

damper control binary input to indicate zone occupancy.

Operator Display (optional)

A 1/4 VGA monochrome LCD touch screen display is available for the CCP.

This display provides setup, diagnostic, and seven-day scheduling functions

to the system.

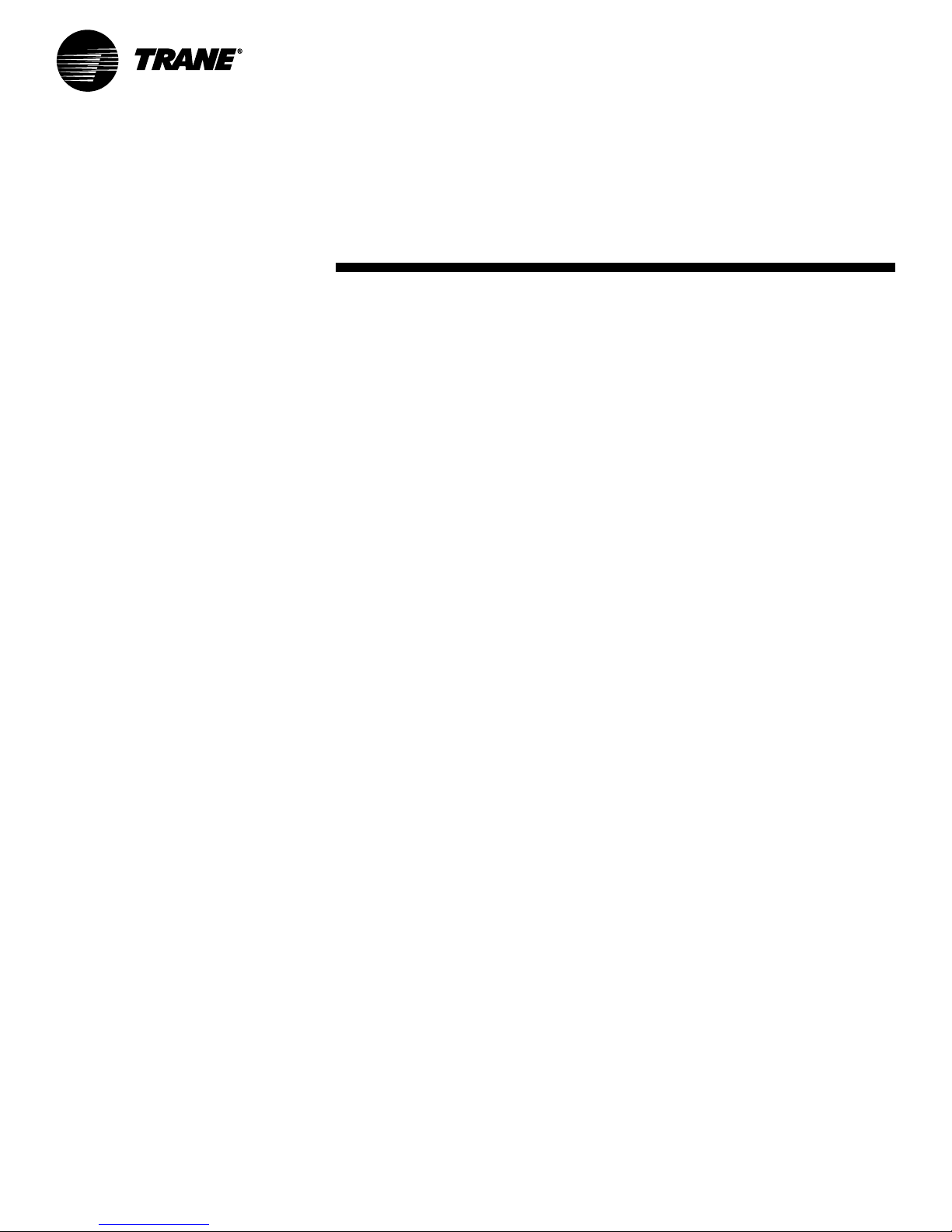

Service Model Number Description

Service model numbers determine product characteristics and are used

when ordering replacement parts. Each digit signifies product characteristics. See Figure 1.

Figure 1: Service Model Number Description

VAV-SVN03A-EN 7

Page 14

VariTrac Changeover-Bypass System

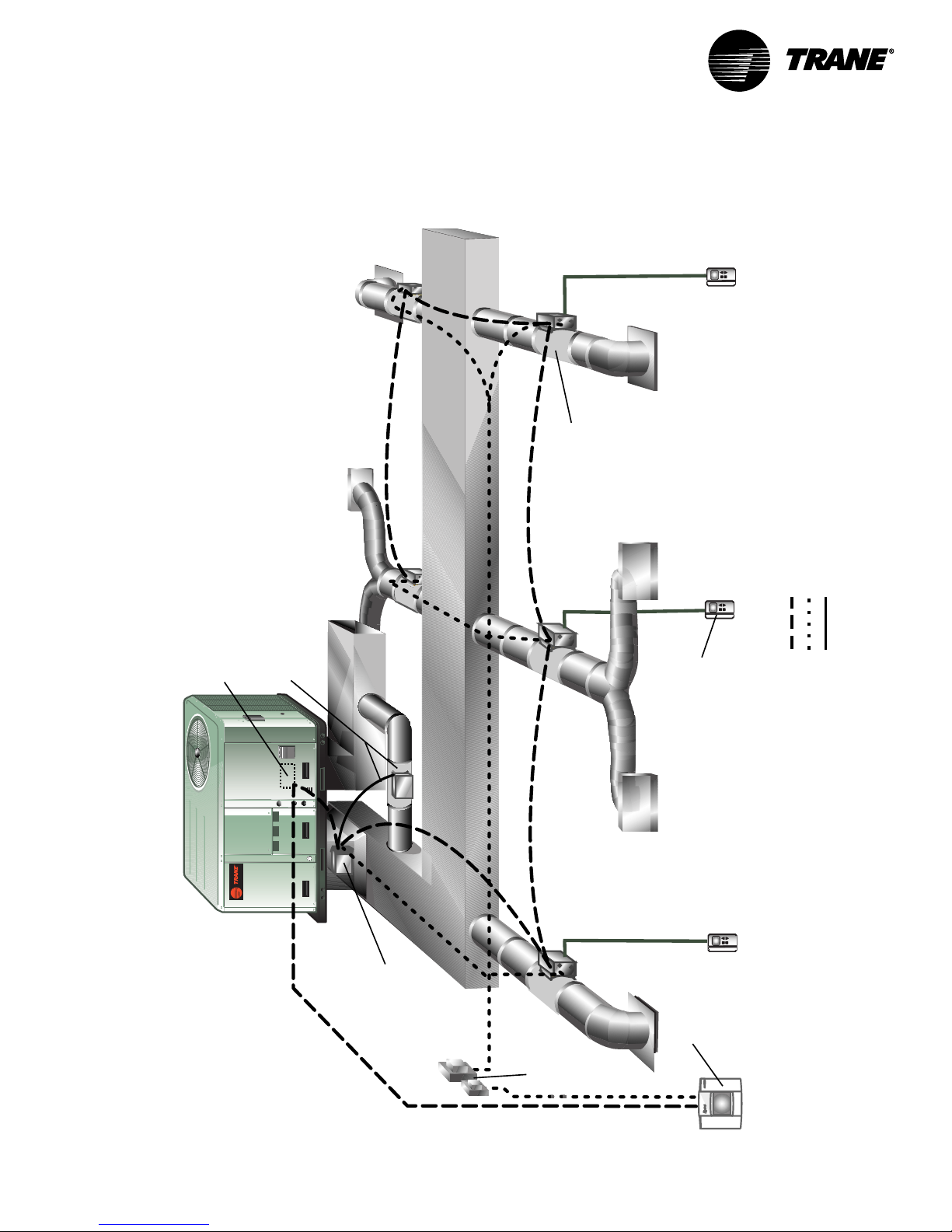

Figure 2: VariTrac Changeover Bypass System Configuration

VariTrac

Zone Damper

Voyager or

Reliatel TCI-3

Bypass Damper

(w/connecting cable assembly)

Zone

Sensor

Communications Link (2 cond, Level 4 comm wire)

24 Vac

Sensor wiring

Legend

Communicating

Sensor/Bypass

Control Assembly

24 Vac

Transformer

VariTrac Central

Control Panel

VAV-SVN03A-EN8

Page 15

Specifications

VariTrac Central Control Panel

stnemeriuqeRrewoP

deriuqer

AV03,esahpelgnis,zH06,caV03-02

remrofsnart2ssalCmuminim

tnemnorivnEgnitarepO

tnemnorivnEegarotS

tenibaC

gnitnuoM

snoisnemiD

thgieW

gniriWkniLnoitacinummoC

tupnIyraniB

detar

.xobtiudnoc

.peed.ni

sdnuop5.1

”.snoitacificepS

cdV41ot01

Am41ot01

evitaler%09ot01,F°221otF°23

gnisnednoc-non,ytidimuh

evitaler%59ot5,F°581otF°04-

gnisnednoc-non,ytidimuh

munelp,erusolcneniser1AMEN

roecafrusllawnoyltceridtnuoM

.ni4x.ni4dessecernotnuom

57.2xediw.ni52.01xhgih.ni57.8

ebtsumgniriwknilnoitacinummoC

riapdedleihsdetsiwtGWA224leveL

reppocdennitdednartshtiweriw

eriwlatotmumixaM.srotcudnoc

teemtsumeriW.teef0053sihtgnel

eeS.snoitacificepsenarT

eriWkniLnoitacinummoC“

:)PCCcarTiraVybdedivorp(egatloV

:)PCCcarTiraVybdedivorp(tnerruC

ebyamstcatnoc”yrd“ylnO:etoN

.stupniyranibotdehcatta

VAV-SVN03A-EN 9

lavorppALU

pukcaByromeM

.devorppaLU

.yltnenamrep

silenaPlortnoClartneCcarTiraVehT

-rotarepolla,ssolrewopanopU

carTiraVehtniderotsataddetide

deniatniamsilenaPlortnoClartneC

Page 16

Specifications

Operator Display

stnemeriuqeRrewoP

tnemnorivnEgnitarepO

tnemnorivnEegarotS

tenibaC

gnitnuoM

snoisnemiD

thgieW

.PCCeht

F°221otF°23

gnisnednoc

F°581otF°04-

gnisnednoc

detar

.peed

sdnuop3

ybderewopsiyalpsidrotarepoehT

-non,ytidimuhevitaler%09ot01

-non,ytidimuhevitaler%59ot5

munelp,erusolcneniser1AMEN

PCCcarTiraVotnoyltceridsgulP

.ni5.1xediw.ni52.01xhgih.ni57.8

UCM Damper

stnemeriuqeRrewoP

tnemnorivnEegarotS

xoBlortnoC

01,esahpelgnis,zH06,caV03ot02

lanoitpofodaolsulp(muminiMAV

remrofsnart2ssalC)stuptuotaeh

deriuqer

F°021otF°23

tnemnorivnEgnitarepO

gnisnednoc

F°002otF°05-

gnisnednoc

detarmunelp

gniriWkniLnoitacinummoC

”.snoitacificepS

-non,ytidimuhevitaler%09ot01

-non,ytidimuhevitaler%59ot5

,erusolcnelatem1AMEN

ebtsumgniriwknilnoitacinummoC

riapdedleihsdetsiwtGWA224leveL

reppocdennitdednartshtiweriw

eriwlatotmumixaM.srotcudnoc

teemtsumeriW.teef0053sihtgnel

:1elbaTeeS.snoitacificepsenarT

eriWkniLnoitacinummoC“

VAV-SVN03A-EN10

Page 17

Communicating Sensor/Bypass Control Assembly

Communicating Sensor/Bypass Control

Assembly

51,esahpelgnis,zH06,caV03ot02

stnemeriuqeRrewoP

deriuqer

F°021otF°23

tnemnorivnEgnitarepO

gnisnednoc

F°002otF°05-

tnemnorivnEegarotS

gnisnednoc

remrofsnart2ssalCmuminimAV

-non,ytidimuhevitaler%09ot01

-non,ytidimuhevitaler%59ot5

xoBlortnoC

gniriWkniLnoitacinummoC

detarmunelp

”.snoitacificepS

,erusolcnelatem1AMEN

ebtsumgniriwknilnoitacinummoC

riapdedleihsdetsiwtGWA224leveL

reppocdennitdednartshtiweriw

eriwlatotmumixaM.srotcudnoc

teemtsumeriW.teef0053sihtgnel

:1elbaTeeS.snoitacificepsenarT

eriWkniLnoitacinummoC“

Relay Board Binary Outputs

Voltage provided: 24 Vac from air conditioning unit

Current: 10 VA maximum

Wire Specifications

Shielded Level 4 communication wire is now recommended for all communication link wiring on the new VariTrac CCP. This is the same wire which is

recommended for the Tracker Version 10 Comm5 communication link.

The term “Level 4” is used to specify a particular performance of communication wire and is normally associated with LonTalk™. Level 4 wire is different from Category IV (four) wire and Category V (five) wire. The specification

information for Level 4 wire can be found in the “LonWorks™ FTT-10A Free

Topology Transcei ver User’s Guide” at www.echelon.com.

VAV-SVN03A-EN 11

Shielded Level 4 communication wire can be purchased from two qualified

suppliers: Windy City Wire and Connect-Air.

Page 18

Specifications

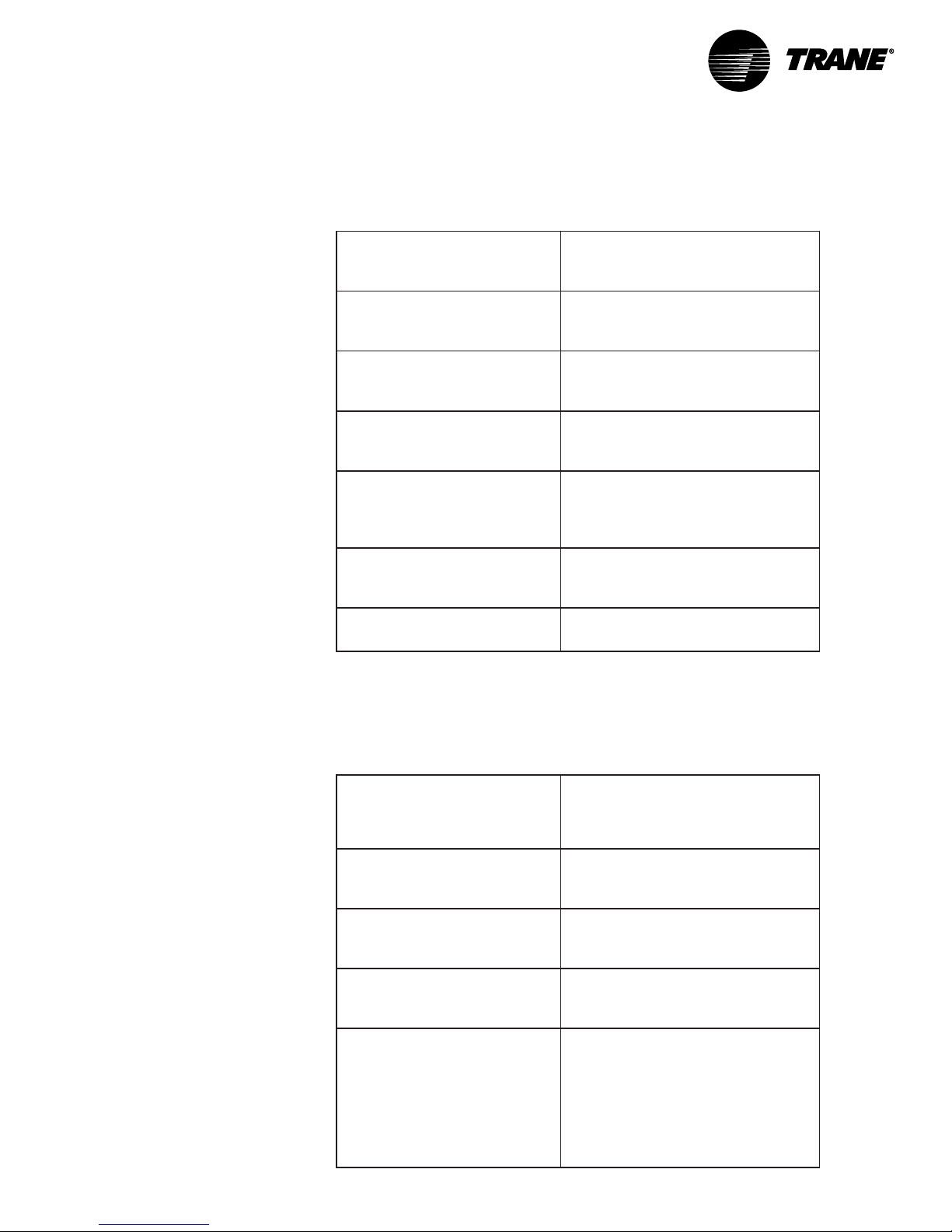

Table 1: Communication Link Wire Specifications

.rp1:dnoCforebmuN

eulbthgil:roloCtekcaJ

noitacificepS

03/7:dnartS.dnoC

"900.0:hcni.kcihttekcaJ.moN

"671.0:hcniDOmoN

22:TFMrepthgieW

detaRPMCmunelP4leveL,dedleihS,srotcudnoCGWA22

"510.0:nillaw.kcihttekcaJ.moN

noitalusnI

remylopdedocrolocedargmuimerP

)munelp(yollaremyloplarutanedargmuimerP•

tekcaJ

)munelp-non(CVPRSedargmuimerP•

C°57+otC°0morfesurofelbatiuS•

V003fognitardetsegguS•

dleihS

gnigakcaP

noitacilppA

sleer

®

skroWnoLetaroprocni

ygolonhcet

gnidnuorgetatilicafoteriwniardreppocdennit

tahtsnoitacilppahtiwelbitapmoceraselbacllA

yrtsudnI

slavorppA

noitallatsni527ro/dna008elcitrACENniesurof

dednartsasulp,liofmunimuladetroppusretseylopllarevO

rosloops)m503(.tf0001snotractuo-yap;)m503(.tf0001

selbacCTLPro/dnaP2LC,PMC,MCepyTsaLUybdetsiL

4mmoC:etoN

rofstimilknil

carTiraVwen

secived53,)niahcysiad(teef0053

PCC

VAV-SVN03A-EN12

Page 19

Getting Started

Familiarize yourself with the system components and preview the

installation procedures before installing and configuring the VariTrac

system.

Installation and configuring procedures appear in suggested order of

performance:

• Unpack and inspect the components

• Mount the wiring base

• Wire AC power

• Binary input wiring

• Output wiring

• Install communicating sensor/bypass damper control

• Install bypass damper(s) and connect to communicating sensor/bypass

control assembly

• Install VariTrac dampers

• Connect UCM wiring

• Set UCM DIP switches

• Install slaved dampers (if used)

• Install zone temperature sensors

• Communication link wiring

• Mount main module

• Install operator display (optional)

• Connecting modem devices

IMPORTANT

The CCP is designed to work with UCM III and IV VariTrac damper and

VariTrane VAV controllers produced beginning January 1995. If any other

dampers are used (especially on a retrofit job), please consult the factory

to confirm VariTrac Central Control Panel compatibility prior to installation.

Unpack and Inspect the Components

Inspect components for damage. Match each component to the packing list

to ensure that nothing was lost during shipment. Make sure that the literature is not lost or discarded with the packing material. Visually inspect the

central control panel for damage. All components are thoroughly inspected

before leaving the factory. Any claims for damage incurred in shipping must

be filed with the carrier.

VAV-SVN03A-EN 13

Page 20

Getting Started

Mount the Wiring Base

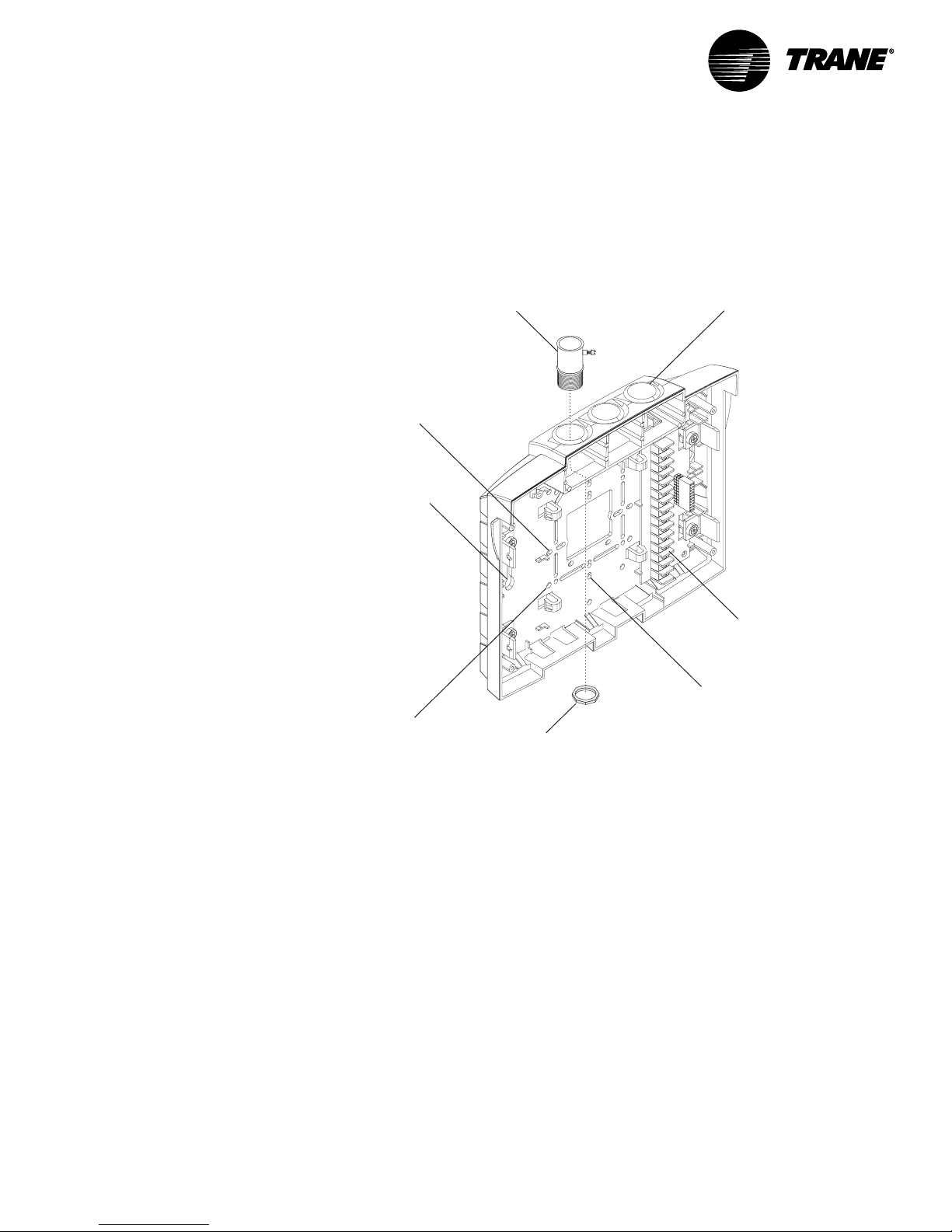

Figure 3: Termination module conduit access and mounting holes

Conduit connector

Holes for mounting on a 2 in. x 4 in.

conduit box horizontally

(left and right)

Two holes for mounting on a wall

(one on each side)

Conduit access

(three places)

Termination board

Holes for mounting on a 2 in. x 4 in.

Holes for mounting on a

4 in. x 4 in. conduit box

(four corners)

Jamb nut

(attaches to

conduit connector)

conduit box vertically

(top and bottom)

Mounting Requirements

Location

The VariTrac Central Control Panel should be mounted at a convenient level

and located where it will be easily accessible. If possible, locate the CCP

near the controlled equipment to reduce wiring cost.

Operating Environment

The VariTrac Central Control Panel is designed for indoor use only. It should

be located in a dust-free and corrosive-free environment, and within a range

of 32° to 120°F, and 10 to 90 percent humidity (non-condensing).

Clearances

Mount the VariTrac Central Control Panel on any vertical flat surface. The CCP

is approximately 8.75 inches high, 10.25 inches wide and 2.75 inches deep.

VAV-SVN03A-EN14

Page 21

Secure Termination Module to Wall

The VariTrac Central Control Panel should be easily accessible for making

wiring connections and for servicing. Provide two inches of clearance on the

left and right sides, and sufficient clearance above the unit to make conduit

connections. Sufficient space should be available in front of the unit to

making wiring connections and perform maintenance.

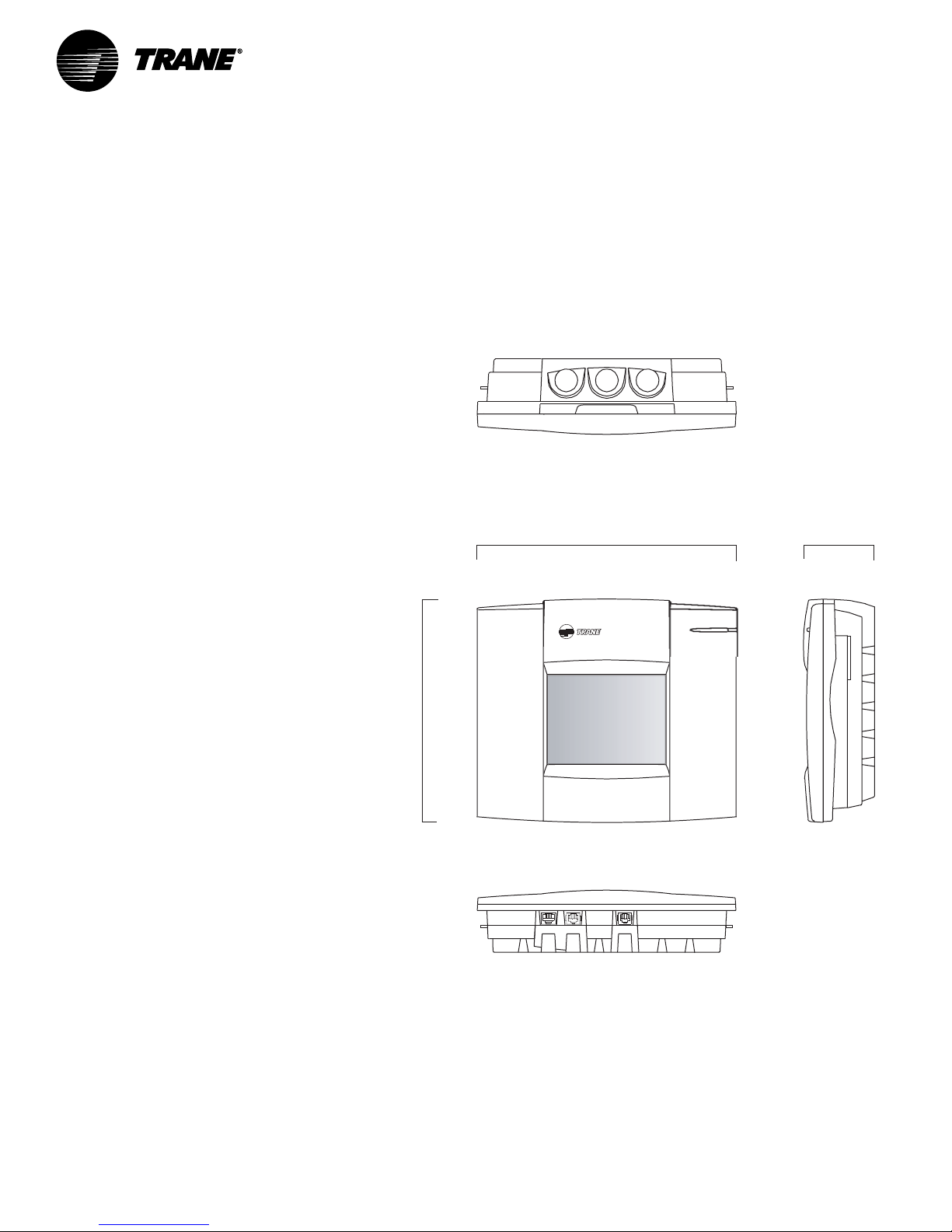

Figure 4: Dimensions for VariTrac Central Control Panel Components

Top view

8.75 in.

(22.38 cm)

10.25 in.

(26.04 cm)

Front view

2.75 in.

(6.99 cm)

Side view

VAV-SVN03A-EN 15

Bottom view

Secure Termination Module to Wall

1 Mark the location of the two mounting holes on the wall.

2 Set the termination module aside and drill mounting holes.

3 Secure the termination module to the wall with the supplied hardware

(#10 x 1 in. screw with plastic anchor).

Page 22

Getting Started

Secure Termination Module to Conduit Box

1 Remove the screws from the conduit box.

2 Line up the conduit box screw holes on the termination module (Figure 3)

with the screw holes on the conduit box.

3 Install the screws.

NOTE: When mounting the termination module to a 4 in. x 4 in. conduit box,

remove the plastic cover over the box for easier access. Do not attempt to break

away excess plastic. Use a hack saw blade and carefully cut away the plastic.

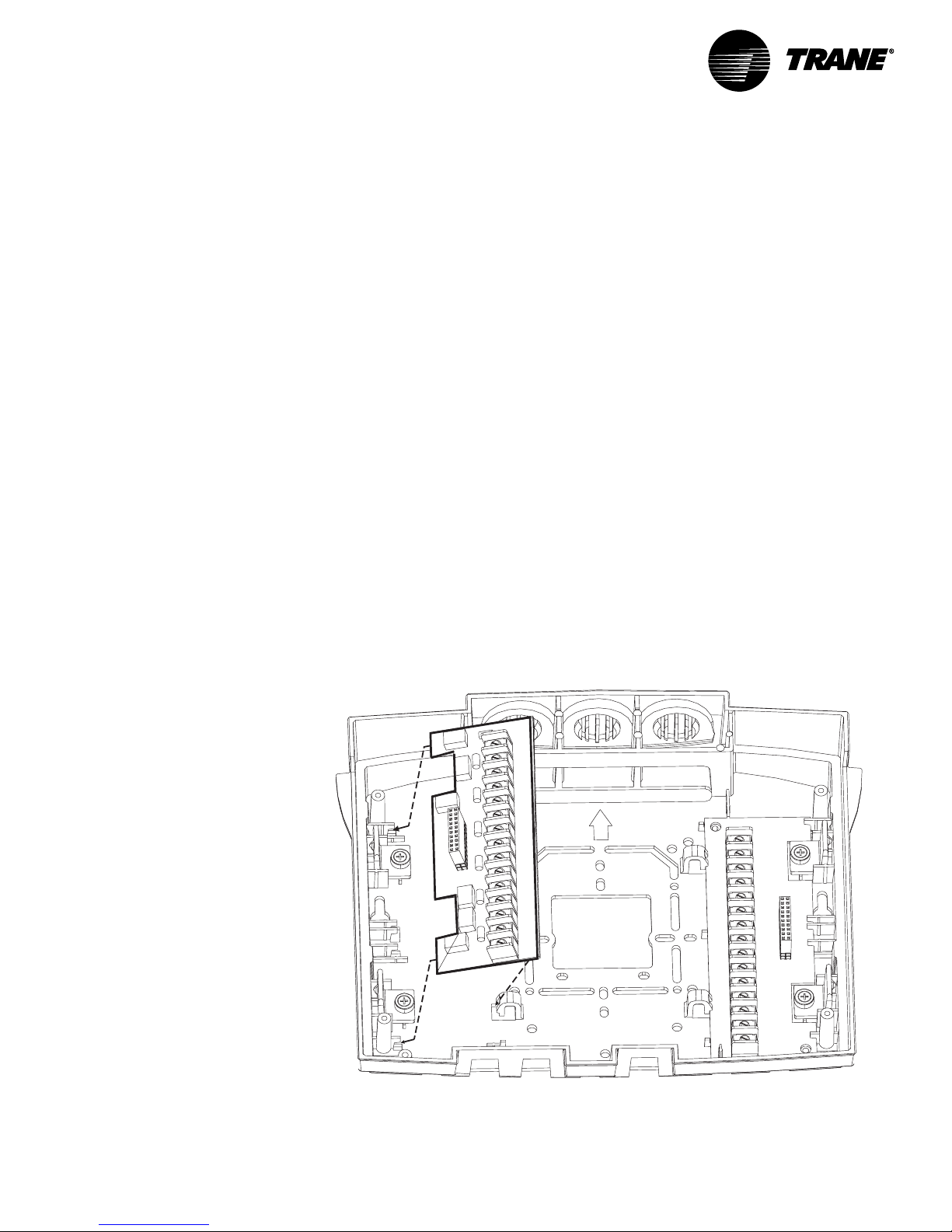

Install VariTrac CCP Relay Board

1 Separate the main module and front panel from the termination module.

2 Remove the relay board from its packaging.

3 Orient the relay board so that its 20-pin socket connector faces left (see

Figure 5).

4 Slide the left edge of the board underneath the catches on the left side.

5 Rotate the board to the catches on the right side.

6 Snap the board into place by pressing on the terminal block or on the

right side of the board.

Figure 5: Installing Optional Relay Board

VAV-SVN03A-EN16

Page 23

US

O

U

/

3

0

3

5

ge

5

er

3

3

4

n

d

Wire AC Power

Wire AC Power

CCP Field Wiring

Field wiring to the VariTrac Central Control Panel includes:

• AC power wiring

• binary input wiring

• communication link wiring

• binary output wiring (requires optional relay board)

These procedures are detailed in the following sections. Refer to Figure 6 for

wiring connections.

Figure 6: Field Wiring

Termination Board TB2

Line volta

Legen

mm

li

mm

Transformer

=

Figure note

=

Termination resistor

Twisted pair, shielded wire

=

per Trane specifications

=

Shield termination

=

Contact points

=

Earth ground

Shield ground

=

Vac

ED

T

W

RI

RI

H

UNOC

Comm4 UCMComm4 UCM

+

+

Comm4

link

-

-

Splice

Comm5 UCMTrack

AA

Comm5

link

BB

Splice

Figure Notes

1 All customer wiring must be in acordance with

national, state, and local electrical codes.

2 Trane recommends a dedicated transformer

for 24 Vac power.

3 Do not apply voltage to the priority shutdown

and occupancy inputs.

4 Example of Comm5 communication link wiring.

See product-specific literature for Comm5 wire

connection details.

OCC

1

MM4

1

M

1

VAV-SVN03A-EN 17

Page 24

Getting Started

AC Power Wiring

A dedicated 24 Vac, 30 VA Class 2 transformer is required to power the

VariTrac Central Control Panel.

The VariTrac Central Control Panel requires 3-wire service with a nominal

voltage of 24 Vac and a utilization range of 20 to 30 Vac. All wiring must

comply with the National Electrical Code and local codes.

The 24 Vac line can enter the VariTrac Central Control Panel cabinet through

the 4 in. x 4 in. knockout or through the knockouts in the top of the panel.

Figure 3 shows the 24 Vac conduit entry holes. Connect the 24 Vac power

wires to TB2-1 and TB2-2 and the ground wire from the circuit breaker panel

ground to TB2-3 as shown in Figure 6. Use copper conductor wire only.

AC Power Checkout

After the 24 Vac connections have been made at TB2, apply AC power by

closing the circuit breaker for the Class 2 transformer.

Measure the voltages at TB2. The voltage between:

• TB2-1 and TB2-2 should be 20 to 30 Vac.

• TB2-1 and TB2-3 (ground) should be 20 to 30 Vac.

• TB2-2 and TB2-3 (ground) should be 20 to 30 Vac.

IMPORTANT

The 24 Vac power supplies must not be used to power any devices other

than the VariTrac Central Control Panel. This could result in malfunction of

the VariTrac Central Control Panel due to electrical noise.

WARNING

To prevent death or injuries from electrical shock, disconnect external

power to the VariTrac Central Control Panel before making power connections.

WARNING

When measurements are made with power on, use care to prevent injuries

or death from electrical shock.

Binary Input Wiring

Use 18-22 AWG twisted pair copper conductor wire for binary input wiring.

Wire run should be limited to less than 1,000 feet to avoid electrical noise

problems.

Refer to Figure 6 for proper connection of binary inputs.

Priority Shutdown Input Wiring

This input closes the connection between TB2-6 and TB2-7. The most likely

source of this input is a building management system or fire control panel,

but any other device allowing a dry contact connection may be used. When

the connection is open, the VariTrac Central Control Panel operates normally.

When the connection is closed, the CCP goes into priority shutdown.

VAV-SVN03A-EN18

Page 25

Occupied/Unoccupied Input Wiring

Occupied/Unoccupied Input Wiring

This input closes the connection between TB2-8 and TB2-9. This is most likely

from an external time clock, but any other device allowing a dry contact

connection may be used. When the connection is open, the VariTrac Central

Control Panel operates in the occupied mode. When the connection is

closed, the CCP operates in the unoccupied mode.

CAUTION

Do not run binary input wires and AC power wires together in the same

conduit or wire bundles.

CAUTION

Controlling the binary inputs on multiple VariTrac Central Control Panels

from a single contact closure is not permitted.

Output Wiring

Use only copper conductors for output wiring. The recommended wire size

is 16-22 AWG. Do not run output wires in the same conduit or wire bundle

with any AC power wires other than VariTrac Central Control Panel 24 V

power.

ac

Output wires should enter the cabinet through the conduit entry holes

shown in Figure 3. Output wiring connections at the VariTrac Central Control

Panel are shown in Figure 7.

The wire from the air conditioning unit to the CCP consists of one wire from

each stage of heating, cooling, the supply fan, and the leg of the 24 Vac

power source at the air conditioning unit. 24 Vac power single transformer

systems terminate power at Rh and Rc (TB1-1 andTB1-2). Two transformer

systems terminate the heating transformer at Rh (TB1-2) and the cooling

transformer at Rc (TB1-1).

The remaining wires are terminated per the diagram in Figure 7.

Binary output relay contacts are rated at 24 Vac, 1 amp 24 VA pilot duty.

IMPORTANT

All output wiring must comply with applicable electrical codes. Metal

conduit may be required by local codes.

IMPORTANT

Output wires run in the same conduit or wire bundle with any AC power

wires other than VariTrac Central Control Panel 24 Vac power could cause

the VariTrac Central Control Panel to malfunction due to electrical noise.

VAV-SVN03A-EN 19

Page 26

Getting Started

Figure 7: Binary Output Wiring for Optional Relay Board

Termination Board TB1

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

24 V*

Ht. Pump

W1 Y2 Y 1 G Rh Rc

AUX W2/O

*24 Vac from the rooftop unit. For single transformer systems,

connect Rc to Rh. For two transformer systems, connect the

cooling transformer to RC and the heating transformer to Rh.

NOT USED NC NO

FAN

COMP1

C1

COMP2

C2 Ht1

EM HT

Ht22H/2C

C/O24 V* FAN

Install the Bypass Dampers and

Communicating Sensor/Bypass Control

Assembly

Install Bypass Dampers

Bypass damper(s) should be located before the first zone runs out from the

supply air duct. VariTrac dampers or supply duct branches should be

installed downstream of bypass dampers. The distance between bypass

dampers and the communicating sensor/bypass control should be two to

three equivalent duct diameters.

In a ducted return system, bypass dampers will be ducted directly to the

return air duct.

In systems with plenum return, bypass damper(s) should be ducted into the

return air riser. Confirm that sufficient relief or exhaust exists to prevent

return plenum pressurization. See Figure 8.

IMPORTANT

The use of a relief fan or backdraft damper is strongly recommended in the

return air system. This will prevent bypassed air from pressurizing the

return air duct system and spilling out of return grills into conditioned

space, especially when the unit is in economizer mode.

VAV-SVN03A-EN20

Page 27

Bypass Damper Wiring

Bypass Damper Wiring

The interconnect cable is pre-wired to the bypass damper and may be

lengthened if necessary.

IMPORTANT

Mounting screws must be located towards the ends of the damper when

hanging straps are used to avoid interference with the rotating damper. A

label attached to the dampers indicates the acceptable areas for mounting

screws.

IMPORTANT

The bypass damper must be positioned to orient the drive shaft horizontally. Failure to do this may result in drive train malfunction (see Figure

11).

IMPORTANT

It is important to note the airflow direction when installing dampers. A

label for this is present on each damper assembly.

Mount the Communicating Sensor/Bypass Control

Figure 8: Mounting the Bypass Damper Communicating Sensor/Bypass

Control Assembly

Voy ag er

Micro

Control

Heating and

Cooling Coils

3

1

Bypass

Damper

Ductwork

1. Avoid high pressure turns and transitions

2. Use hard duct

3. Mount communicating Sensor/Bypass Controller

2-3 duct diameters upstream of bypass damper

2

Return

Air

Duct

VAV-SVN03A-EN 21

The communicating sensor/bypass control is located between the supply

fan and the bypass damper in the least turbulent location possible. It is

recommended that the distance between the control and the nearest upstream transition be two to three equivalent duct diameters.

Page 28

Getting Started

If the supply duct branches out at the riser, install the control in the largest

supply duct.

A two-inch hole is required to insert the temperature and static pressure

sensor. Use the supplied gasket to seal off air leaks. Secure the sensor to

the duct with a minimum of three sheet metal screws.

IMPORTANT

The sensor assembly should be mounted on the side of the duct to keep

the pressure transducer in a vertical orientation. Do not install horizontally

on the top or bottom of a duct.

Connect the Communicating Sensor/Bypass Control

Wiring

The pre-wired interconnect cable plugs into the actuator connector inside

the control. The cable is designed to connect in one orientation only.

Refer to the diagram and connect as follows:

1 Plug the red actuator connector brom the BYPS damper onto the master

damper UCM socket (ACT) as shown in Figure 9.

2 If two bypass dampers are used, connect the second bypass damper’s

red actuator plus to the spare connector socket pigtailed on the first

BYPS damper cable assembly.

3 If cable assembly needs to be extended, cut and splice additional wire on

the BYPS damper end of the cable.

Figure 9: Wiring the Communicating Sensor/Bypass Control

Close

Step 2

Address

Switch

Open

Hot

Actuator

Step 1

DDC/UCM

Control Board

To NEC Class 2

24V Transformer

Load 8 VA (without actuator)

Static

Pressure

Port

Pressure

Transducer

Female plug end of bypass

sensor assembly cable

Male plug end located on

DDC/UCM control board

Shielded Twisted Pair

Communications Wiring

Air Supply

Temp Sensor

DDC/UCM

Control Board

Step 1

VAV-SVN03A-EN22

Page 29

Install the VariTrac Dampers

Install the VariTrac Dampers

A sketch of basic damper installation is shown in Figure 10. The damper may

be connected with hard duct or flex duct at either end.

If two bypass dampers are installed, a pigtail socket is provided on the cable

so the second damper can be plugged into the UCM.

IMPORTANT

Mounting screws must be located towards the ends of the damper when

hanging straps are used to avoid interference with the rotating damper. A

label attached to the dampers indicates the acceptable areas for mounting

screws.

IMPORTANT

It is important to note airflow direction when installing the damper. A

label for this is present on each damper assembly.

IMPORTANT

The control box on each damper must be positioned to orient the drive

shaft horizontally. Failure to do this may result in drive train malfunction.

(See Figure 11.)

Figure 10: VariTrac Damper Installation

VAV-SVN03A-EN 23

Page 30

Getting Started

Figure 11: Proper Damper Mounting Positions

Connect UCM Wiring

Connect the power to terminals TB1-1 (24V) and TB1-2 (ground). 24 Vac is

required to power the UCM control. 20 Vac to 28 Vac is acceptable. Use 18 to

20 AWG for power wiring.

The power consumption for an auto-changeover cooling-only UCM (model

CHGR) is 10VA.

Local heat outputs are rated at 10VA maximum for each output. To

determine the total UCM power requirements, add the power consumption

of local heat to the circuit board power.

CAUTION

Use wires with copper conductors only. The use of aluminum or other

types of wire may result in overheating and equipment damage.

CAUTION

Connecting a shared UCM power supply with reversed polarity will cause

damage to the UCM, TCI, and central control panel.

CAUTION

When powering multiple UCMs from one transformer, polarity must be

maintained. Terminal TB1-1 is designated positive (+) and Terminal TB1-2 is

negative (–) to unit casing ground.

IMPORTANT

UCM control box cover must be replaced after field wiring to prevent

electromagnetic interference.

VAV-SVN03A-EN24

Page 31

Figure 12: UCM Wiring

Set the UCM DIP Switches

VAV-SVN03A-EN 25

Set the UCM DIP Switches

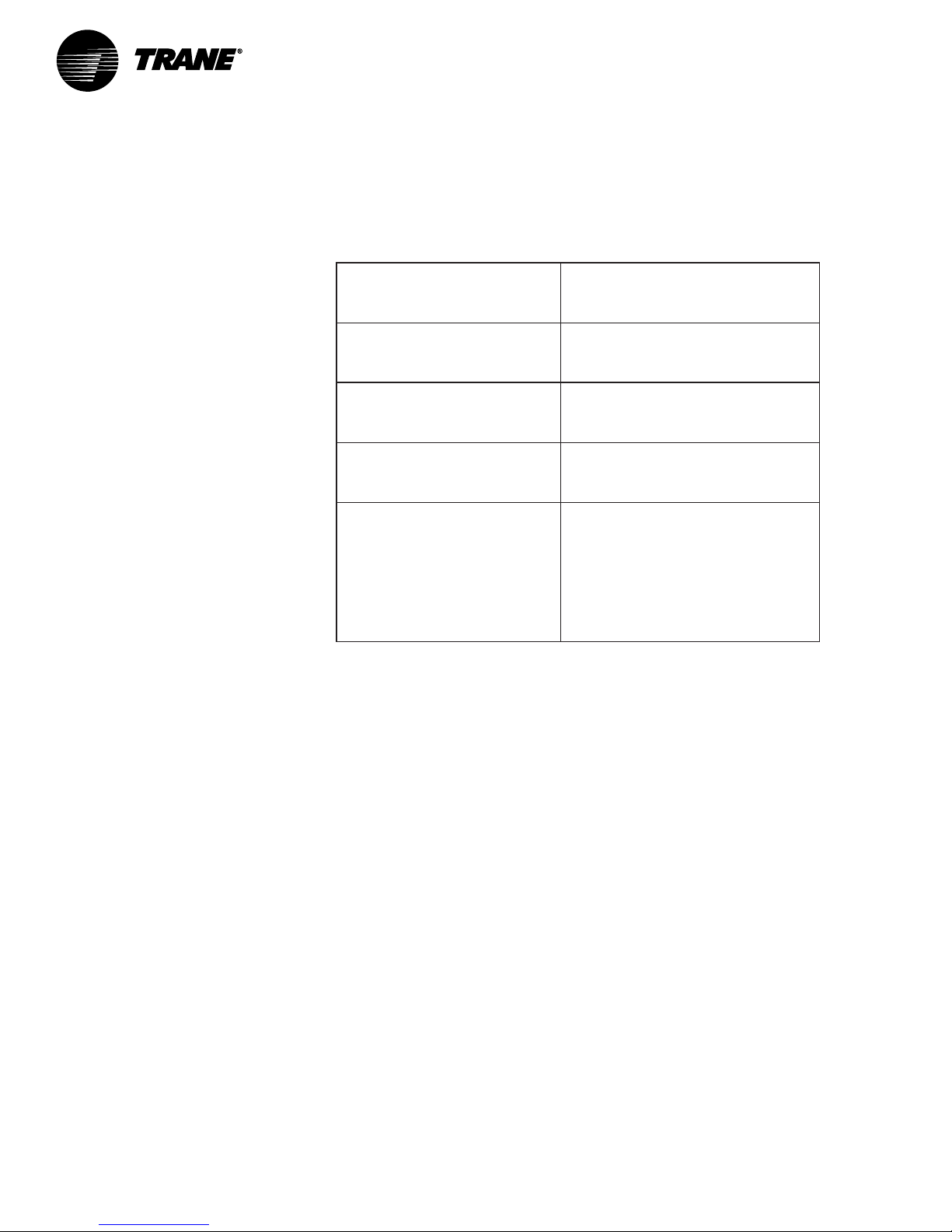

Each device connected to the VariTrac Central Control Panel must a unique

address. No two devices (of the same type) can have the same address.

Table 2 lists the address settings for UCM DIP switches connected to the

VariTrac Central Control Panel.

IMPORTANT

The UCM located in the communicating sensor/bypass control must always

be addressed as #33.

Page 32

DIP Switch Settings

Addresses 25-32 used for Delivered VAV only

UCM

Number

1

2

3

4

6

5

ON

ON

ON ON

ON

ON

ON ON

ON

ON

ON

ON

ON

ON

ON ON

ON

ON ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON ON

ON

ON

ON ON

ON

ON

ON

ON

ON

ON

ON ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

= Off

01

02

03

04

05

06

07

08

09

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

ON ON ON ON ON

32

ON ON ON ON

33

Communicating Sensor/Bypass Control only

Getting Started

Table 2: DIP Switch Settings for UCM Damper Addresses

Slaved Dampers

In some applications it may be desirable to control an additional damper

from a single UCM. The slaved damper does not require a UCM circuit

board. For this reason a model BYPS damper is paralleled directly to the

ON

Example of Address #5

VAV-SVN03A-EN26

Page 33

Close

Open

Hot

Actuator

Slaved Dampers

outputs of the UCM controlling the primary damper by using the BYPS

damper cable assembly shipped with the BYPS damper.

Refer to diagram and connect as follows:

1 Disconnect the red actuator plug from the master damper UCM.

2 Plug the red actuator connector from the BYPS damper onto the master

damper UCM socket (ACT) as shown in Figure 13.

3 Reconnect the master damper actuator’s red connector to the spare

connector socket pigtailed on the BYPS damper cable assembly.

4 If cable assembly needs to be extended, cut and splice additional wire on

the BYPS damper end of the cable.

Figure 13: Wiring for Slaved Damper

To NEC Class 2

24V Transformer

Load 8 VA (without actuator)

Step 3

Address

Switch

Steps

1 & 2

DDC/UCM

Control Board

Female plug end of bypass

sensor assembly cable

Male plug end located on

DDC/UCM control board

DDC/UCM

Control Board

Steps

1 & 2

Shielded Twisted Pair

Communications Wiring

VAV-SVN03A-EN 27

Page 34

Getting Started

Install the Zone Temperature Sensors

Five types of zone temperature sensors are available. The sensors are

shown below in Figure 14:

• sensor with night setback override button, cancel button, and communications jack

• sensor with adjustable setpoint, night setback override button, cancel

button, and communications jack

• sensor with adjustable setpoint and communications jack

• sensor with night setback override button, cancel button, and communications jack

• sensor only

• sensor with digital display, adjustable setpoint, night setpoint override

button, cancel button, and communications jack.

Figure 14: Zone Sensor Options

Location

Proper temperature sensor location is crucial to occupant comfort. The

sensor should be placed in the most critical area of the zone where there is

free circulation of air. It should be mounted on a flat interior surface

approximately 54 inches from the floor, or as specified by the project plans

and specifications.

Avoid locating sensors in the following places:

• areas of direct sunlight

• areas blanketed by air from diffusers or subject to drafts

• surfaces with unconditioned areas behind them (such as an outside wall

or the wall of a storeroom)

VAV-SVN03A-EN28

Page 35

Mounting Standard and Digital Zone Temperature Sensors

• areas near heat sources like equipment (appliances, computers, copiers,

etc.) or concealed pipes or chimneys

• dead spots behind doors, draperies, or in corners.

Mounting Standard and Digital Zone Temperature

Sensors

Zone temperature sensors consist of two basic pieces: the base and cover.

Externally adjustable versions have an external adjustment knob. To remove

the sensor cover from the base:

1 Note the position of the adjustment knob (if present).

2 Use a small screwdriver to gently pry the adjustment knob from the

cover.

3 Before mounting a zone temperature sensor, remove zone sensor cover

by easing the tip of a small screwdriver between the base and the cover.

Gently lift the top of the screwdriver up. Do not force.

Follow these steps to replace the zone temperature sensor cover and (if

present) adjustment knob after mounting:

1 Align the cover with the sides of the base.

2 Press the cover toward the wall until it snaps into place.

3 Align the knob to the position noted prior to its removal.

4 Push the stem through the cover hole until the stem sits firmly in setpoint

potentiometer.

5 Turn the knob to assure that it rotates freely through the entire range of

temperature settings.

Wall Mount

With the cover removed, feed the control wires through the rectangular

opening in the base. Follow these steps if mounting the sensor to a wall:

1 Assuring that the base is level, position the back of the base over the wire

entry in the wall.

2 Mark the centers of the two oblong mounting holes, then set aside the

base.

3 Drill a 3/16 in. diameter hole approximately 1 in. deep at the marked

locations.

4 Insert plastic anchors into the holes until they are firmly seated.

5 Feed the control wires through the base and fasten the base to the wall

with the supplied mounting screws.

VAV-SVN03A-EN 29

6 Connect the control wires to the proper terminals on the temperature

sensor (See Figure 15).

7 Replace the sensor cover.

Junction Box Mount

1 With the cover removed, feed the control wires through the rectangular

opening in the base.

Page 36

Getting Started

2 Using two #6-32 screws, fasten the base to the junction box’s threaded

mounting holes.

3 Connect the control wires to the proper terminals on the temperature

sensor (See Figure 15).

4 Replace the sensor cover.

Zone Temperature Sensor Wiring

A zone temperature sensor designed specifically for UCM damper control

must control each unit. Field wiring for the zone temperature sensors must

meet local code. If local codes require enclosed conductors, the zone temperature sensor wires should be installed in conduit

Do not route zone temperature sensor wires in conduit with 24V or any

other high power conducting wires.

Different numbers of conductors are required based on the zone

temperature sensor used. The following table lists the options and number

of wires required.

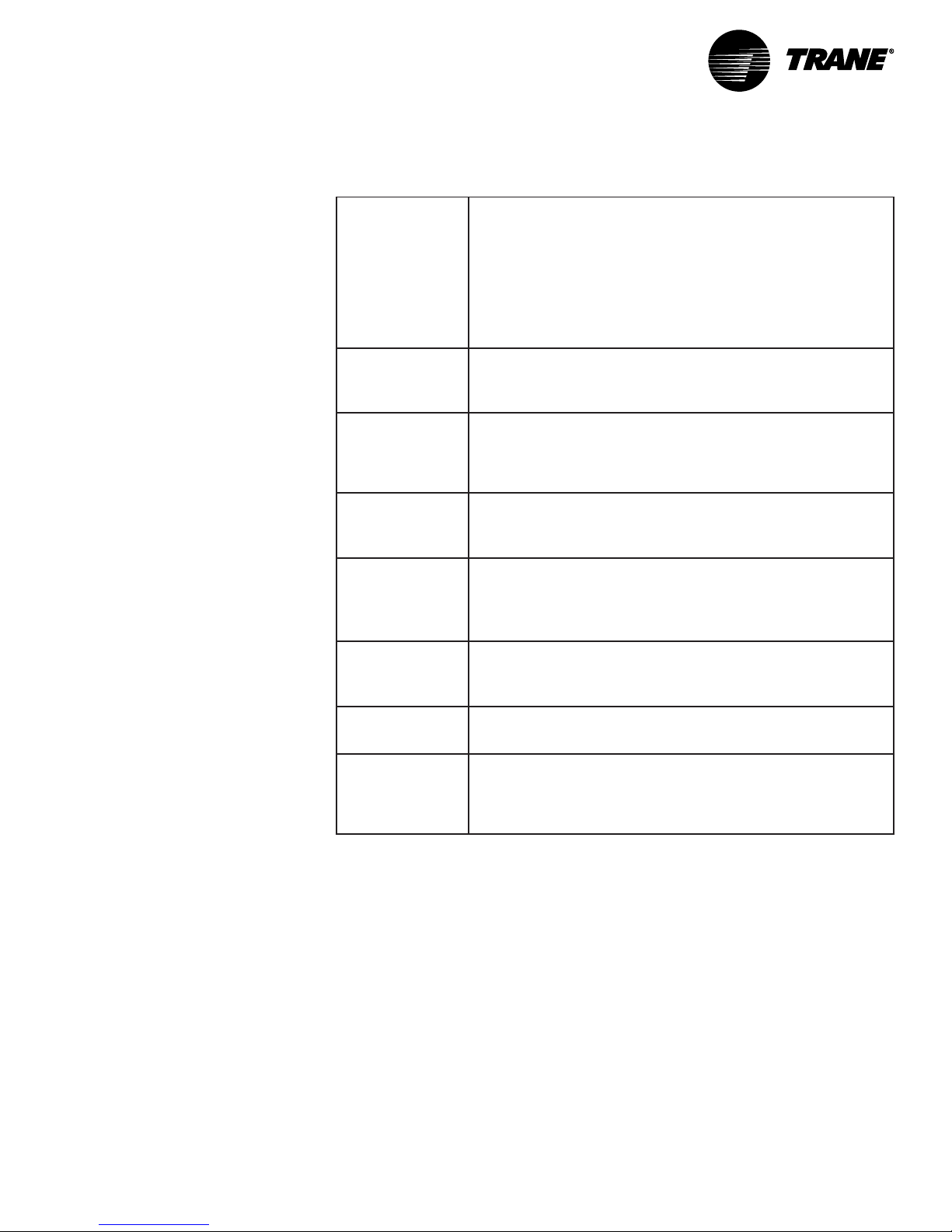

Table 3: Zone Sensor Options

forebmuN

noitpOrosneSenoZ

deriuqeR

1

seriW

ylnorosneS2

tniopteselbatsujdahtiwrosneS3

edirrevokcabtesthginhtiwrosneS

snottublecnacdna

2

dnatniopteselbatsujdahtiwrosneS

lecnacdnaedirrevokcabtesthgin

3

snottub

dnayalpsidDCLhtiwrosneS

thgindnatniopteselbatsujda

2

5

snottublecnacdnaedirrevokcabtes

1. Some sensors have a communication jack available as an option. If these jacks

are used, they must be wired to the UCM using a separate two-conductor,

shielded cable that meets the specification for communication link wiring. Tape

back the shield of the communication link (if used) at the zone temperature

sensor and splice the other end into the adjoining communication link shield. The

communication jacks do not need to be wired for the system to operate properly.

VAV-SVN03A-EN30

Page 37

Zone Temperature Sensor Wiring

2. 3 wires are required for sensor connection. 2 wires are required for 24 Vac power

connection. For wire lengths less than 75 feet, an 18 gage, 5 conductor cable may

be used. For wire lengths greater than 75 feet, use 18 gage, 2 conductor cable for

the power wiring (TB1-TB1), and 18 gage, 3 conductor cable for signal wiring

(TB2-TB3).

Figure 15: Zone Temperature Sensor Controller Wiring

VAV-SVN03A-EN 31

Page 38

Getting Started

Communication Link Wiring

The VariTrac Central Control Panel communication link (TB2-10, 11, and 12)

connects the CCP, UCM dampers, communicating sensor/bypass damper

control assembly, and Voyager/Reliatel rooftop units. Field wiring for the

communication link must meet the following requirements:

• All wiring must be in accordance with the National Electrical Code and

local codes.

• Communication link wiring must be Level 4 22 AWG twisted, shielded pair

wire (meets or exceeds Trane specifications. See wiring specifications

sections in this manual for further information).

• The maximum total wire length is 3,500 feet for the communication link.

At the VariTrac Central Control Panel, the communication link wires must be

connected to Terminals TB2-10 (+) and TB2-11 (−). Refer to Figure 17. This

connection is polarity sensitive.

IMPORTANT

Connections between lengths of link wiring should be soldered and taped.

Wire nuts are not acceptable.

CAUTION

Connecting the communication link with reversed polarity will lead to

system malfunction and possible equipment damage.

The shield on the communication link wiring must be connected to TB2-12.

The shield wire should be spliced with the shield from the next section of

communication link wiring at every junction. Tape each splice to prevent any

contact between the shield and ground. The shield should be cut and taped

back at the end of the link.

Communication link wiring cannot pass between buildings.

IMPORTANT

Improper communication link shield connections will lead to system

malfunction.

IMPORTANT

Improper communication link routing will lead to system malfunction.

Connect UCMs on the communication link in a daisy-chain configuration.

With this configuration, it is easier to solve communication problems by

isolating portions of the communication link. See Figure 16 for an example

of a daisy-chain configuration.

VAV-SVN03A-EN32

Page 39

Communication Link Wiring

Figure 16: Daisy Chain Configuration for Communication Link Wiring

VariTrac

Central Control Panel

UCM Dampers

UCM Dampers

UCM Dampers

UCM Dampers

UCM Dampers

UCM Dampers

Each Voyager/Reliatel Rooftop requires a Trane communications interface

(TCI) board for connection to the VariTrac Central Control Panel

communication link.

Refer to the TCI installation manual for more information on connecting a

rooftop to the communication link.

VAV-SVN03A-EN 33

Page 40

Getting Started

Figure 17: UCM Communication Link Wiring

VariTrac

1

2

3

4

5

6

Termination Board TB2

Static

Pressure Port

VOUT

DDC / UCM

Control Board

Pressure

Transducer

Assembly Address #33

Switch

Address

Communicating Sensor / Bypass Control

+

7

8

9

10

Air Supply Temp Sensor

COM

M 4

COMM 5

-

11

12

e

Splic

15

13

14

2

DDC / UCM

Control Board

Zone UCM Address #1

Switch

Address

DDC / UCM

Control Board

Zone UCM Address #2

Switch

Address

2

Splice

1 2

3 through 24

To Zone Dampers

Note

The UCM order in this drawing is for demonstration purposes only.

Figure Notes

1 Shield must be cut back and taped at last unit controller.

2 A continuous shield is required. At each unit controller, splice shield

wire and tape back to prevent grounding.

Twisted pair, shielded wire

per Trane specifications

=

end

No specific order is required on the Comm link.

Figure note

Shield ground

=

=

Leg

VAV-SVN03A-EN34

Page 41

Figure 18: Voyager Communication Link Wiring

VariTrac Communications

Interface (Comm4)

Comm Termination Details for Voyager RTU

Voyager Communication Link Wiring

Voyager (UPC)

Unit Control Panel

1

2

(TCI-V)

Figure Notes

1 All dip switches off.

2 Comm board to non-isolated

Comm3 or Comm4 option.

VAV-SVN03A-EN 35

Page 42

Getting Started

VariTrac Communications

Comm Termination Details for Voyager RTU

Figure 19: Precedent Communication Link Wiring

Interface (Comm4)

Trane Communication

Interface-Precedent

1

2

(TCI-P)

Figure Notes

1 All dip switches off.

2 Comm board to non-isolated

Comm3 or Comm4 option.

Mount Main Module

After mounting and wiring the wiring base, attach the main module.

NOTE: It is not necessary to turn off 24 Vac power to the wiring base prior to mounting and removing the main module.

• Verify that all the wires on the wiring base are securely fastened in place.

• Carefully line up the alignment pins on the wiring base with the back of

the main module (Figure 20).

Precedent (UCP)

Unit Control Panel

VAV-SVN03A-EN36

Page 43

Figure 20: Mounting Main Module

Termination module

Main module

Alignment pin

(four places)

Mounting Main Module

VAV-SVN03A-EN 37

IMPORTANT

Do not use excessive force when mounting the module. If the module does

not snap easily into place, slightly reposition it on the alignment pins.

Failure to comply may cause damage to the module.

Firmly push the main module onto the wiring base until it snaps into place.

If 24 Vac is applied, the main module will start. The LEDs on the main

module will flash on and off after a few seconds

Install Operator Display (optional)

An operator display is available to provide monitoring and control of

VariTrac systems and UCM zones from one central location. The display

provides a ¼ VGA touch screen to allow the operator to interface with the

system. Temperature and system failure diagnostics and Voyager and

Precedent Rooftop unit alarms are indicated on the operator display screen

and in PC software.

NOTE: It is not necessary to turn off 24 Vac power to the wiring base prior to mounting and removing the operator display.

After mounting the main module, attach the operator display.

• Tilt the top of the operator display about 30 degrees towards you.

Page 44

Getting Started

• Align the three tabs on the bottom of the display with the slots in the

bottom of the main module. (Figure 21).

• Starting with the center tab, insert the tabs into the slots.

Figure 21: Install operator display

IMPORTANT

Do not use excessive force when mounting the module. If the module does

not snap easily into place, slightly reposition it on the alignment pins.

Failure to comply may cause damage to the module.

Push the top of the display module toward the main module until it snaps

into place.

If 24 Vac is applied, the operator will turn on and display data.

Connecting Modem Devices

Remote communications may be accomplished through a Trane building

management system or with stand-alone modem attached to a single CCP

via the RS-232 port.

A US Robotics Sportster™ fax/data external modem is recommended for

CCP applications. Modems require hardware and software configurations

for use with the CCP

Physical connection of the modem to the VariTrac Central Control Panel is

shown in Figure 22.

VAV-SVN03A-EN38

Page 45

Figure 22: Modular Adapters, Cable, and Connections for External

Modems

Termination module bottom view

RJ-12 port

(PC direct connection)

Connecting Modem Devices

RJ-12 port for PC

direct connection

(bottom side)

To modem

serial port

RJ-12 cable

(PN: 35914260)

Connect RJ-12 to

25-pin male

adapter

(PN: 35914269)

Connecting PC with VariTrac Software to CCP

The VariTrac PC Software provides a graphic user interface for VariTrac and

Delivered VAV systems. Advanced status and set-up information are available via a PC serial port connection.

Install the PC software on your PC following the instructions provided with

the software CD.

Connect your PC to the Central Control Panel as shown in Figure 23. The

connection is made using a PC serial port adapter and cable:

Adapter: DB9 female to RJ12 (PN: 3591 4262)

Cable: RJ12 to RJ12 (PN: 3591 4260)

VAV-SVN03A-EN 39

Page 46

Getting Started

Figure 23: Typical VariTrac Central Control Panel to PC serial port connec-

tions

Termination module bottom view

RJ-12 port

(PC direct connection)

RJ-12 port for PC

direct connection

(bottom side)

Connect RJ-12 to

9-pin female

adapter

(PN: 35914262)

To PC

serial port

RJ-12 cable

(PN: 35914260)

VAV-SVN03A-EN40

Page 47

Installation Checklist

Complete this checklist as the VariTrac Central Control Panel is installed to

verify that all recommended procedures are performed. This checklist does

not replace the detailed instructions provided in the manual. Read the entire

manual carefully to become familiar with the installation procedures before

installing the unit.

Shipment

o Inspect VariTrac Central Control Panel for shipping damage. File claim if

necessary.

o Inspect zone dampers and accessories for shipping damage. File claim if

necessary.

Unit Location

o Install VariTrac Central Control Panel in environment that meets tempera-

ture and humidity requirements.

o Securely mount VariTrac Central Control Panel on wall at an accessible

location with proper clearances.

AC Power Wiring

o Field installed AC power wiring complies with all applicable codes.

o 24 Vac line from dedicated Class 2 transformer connected to VariTrac

Central Control Panel at TB2.

o Voltage measured at TB2-1 to TB2-2 is 20 to 30 Vac.

o Assure that a reliable earth ground has been attached to TB2-3.

Communicating Sensor/Bypass Assembly

o Bypass damper(s) properly installed between supply/return ductwork per

instructions.

o Communicating Sensor/Bypass Control mounted and wired to the

bypass damper(s).

o Communication cable properly terminated at the Communicating Sensor/

Bypass Control and routed back to VariTrac Central Control Panel.

Input Wiring

o Field installed input wiring complies with all applicable codes.

o Optional time clock and priority shutdown inputs terminated at TB2-6

through TB2-9 per instructions.

VAV-SVN03A-EN 41

Output Wiring

o Field installed output wiring complies with all applicable codes. If used,

relay wiring is terminated at TB1-1 through 11 per instructions.

Page 48

Installation Checklist

VariTrac Dampers

o UCM dampers mounted and secure according to recommendations.

Zone Temperature Sensors

o Sensors are properly mounted and wired per instructions and in the

correct space.

UCM Wiring

o UCM power is properly wired to TB1-1 and TB1-2.

NOTE: TB1-2 is COMMON (case ground) if grounded secondary transformers are

being used. Confirm polarity from one UCM to the next if more than one UCM is

being powered from a single transformer.

o Confirm voltage present between 20 Vac and 28 Vac.

o Ensure that the sensor is properly terminated.

o If optional local heat is being used, confirm wiring per appropriate

diagram.

Communication Link Wiring

o Field installed communications wiring complies with all applicable codes.

o VariTrac Central Control Panel communication link wiring to UCMs is

connected at TB2-10, TB2-11, and TB2-12 on the CCP.

o Communication link wiring is properly terminated at each zone damper

UCM on terminals TB2-1 through TB2-6. Ensure that polarity (+ -) has

been maintained through the link.

o Communication link wire shields spliced at each device junction and

taped to prevent contact with earth ground.

VAV-SVN03A-EN42

Page 49

System Start-Up

and Checkout

Pre-power-Up Checkout

Central Control Panel

• Measure the supply voltage to the CCP TB2-1 and TB2-2. The supply

voltage should be between 20 Vac and 30 Vac.

• Assure that a reliable ground is attached to TB2-3 on the CCP.

• Check the UCM communication link to assure that the wire designated (+)

is connected to the TB2-10 and the wire designated (–) is terminated at the

TB2-11. The shield must be connected to TB2-12.

WARNING

The following test should not be performed until all people and equipment

are clear of the air conditioning unit.

If the air handling unit is controlled by the optional field installed relay

board, check the operation of the supply fan and heating and cooling stages

by jumping the appropriate terminals of the binary output terminal block

TB1. This check assures that the wires are properly terminated at the CCP

and that the air conditioning unit is operational.

UCM

• Verify that the damper is installed with the drive shaft horizontal. See the

Installation and Wiring section of this manual for more details.

• Check to assure that all mounting screws are a minimum of three inches

away from the center damper bead if hanging straps are used. This allows

full rotation of the damper.

• Check the supply voltage at TB1-1 and TB1-2. Polarity is important. Notice

that TB1-1 is designated 24V and TB1-2 is designated ground to unit casing