Trane Unit Ventilator Energy Recovery System Catalogue

Classroom Unit Ventilator Accessories

Accessories from A to Z

Wall Boxes, Energy Recovery System,

Shelving, Side Wall Exhaust, Gravity Relief

Damper

UV-PRC005-ENMarch 2006

Introduction

Unit Ventilator Accessories

from A to Z

As a leader in applied unit ventilator

systems, Trane brings more than just

an authentic approach for HVAC design to the drawing table. Trane also

provides aesthetically pleasing solutions through their matching classroom accessories. Trane accessories

are intended to complement the unit

ventilator in order to provide a complete classroom system to the administrative staff.

Our full line of add-on accessories enhance the classroom unit ventilator

system by affording a seamless approach to a classroom layout.

Trane’s accessories include:

• Shelving

• Wall boxes

• Pipe covers

• Gravity relief damper (exhaust

stale air naturally from the classroom).

• Side wall power exhaust system

(exhaust stale air mechanically

from the classroom).

• and Unit ventilator energy recovery system (treats and filters incoming fresh air into the

classroom as well as exhausts

stale air from the classroom).

Trane has over 80-years of application

and design experience with indoor

comfort system. Our offices are

staffed with HVAC engineering professionals ready to work with you and

your system designer to help determine the best solution for your school.

©2006 American Standard Inc All rights reserved UV-PRC005-EN

Table of Contents

Introduction 2

Features and Benefits 4

Application Considerations 9

Model Number Description 10

Shelving

Energy Recovery Ventilator

Side Wall Exhaust / Gravity Relief Damper

10

11

12

General Data 13

Performance Data 14

Electrical Performance

14

Controls 15

Energy Recovery Control Operation

Wiring

15

16

Dimensional Data 19

Mechanical Specifications 30

UV-PRC005-EN 3

Features and Benefits

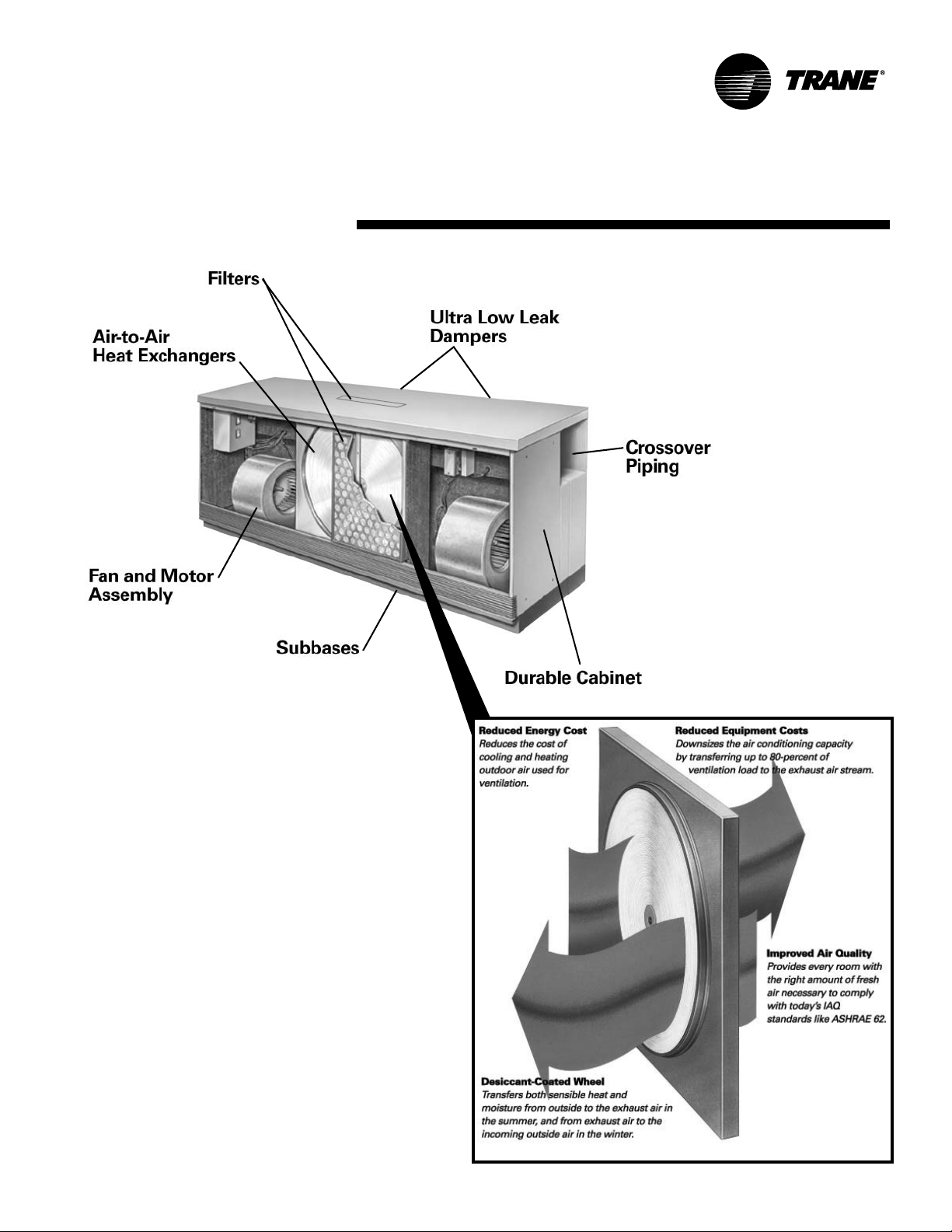

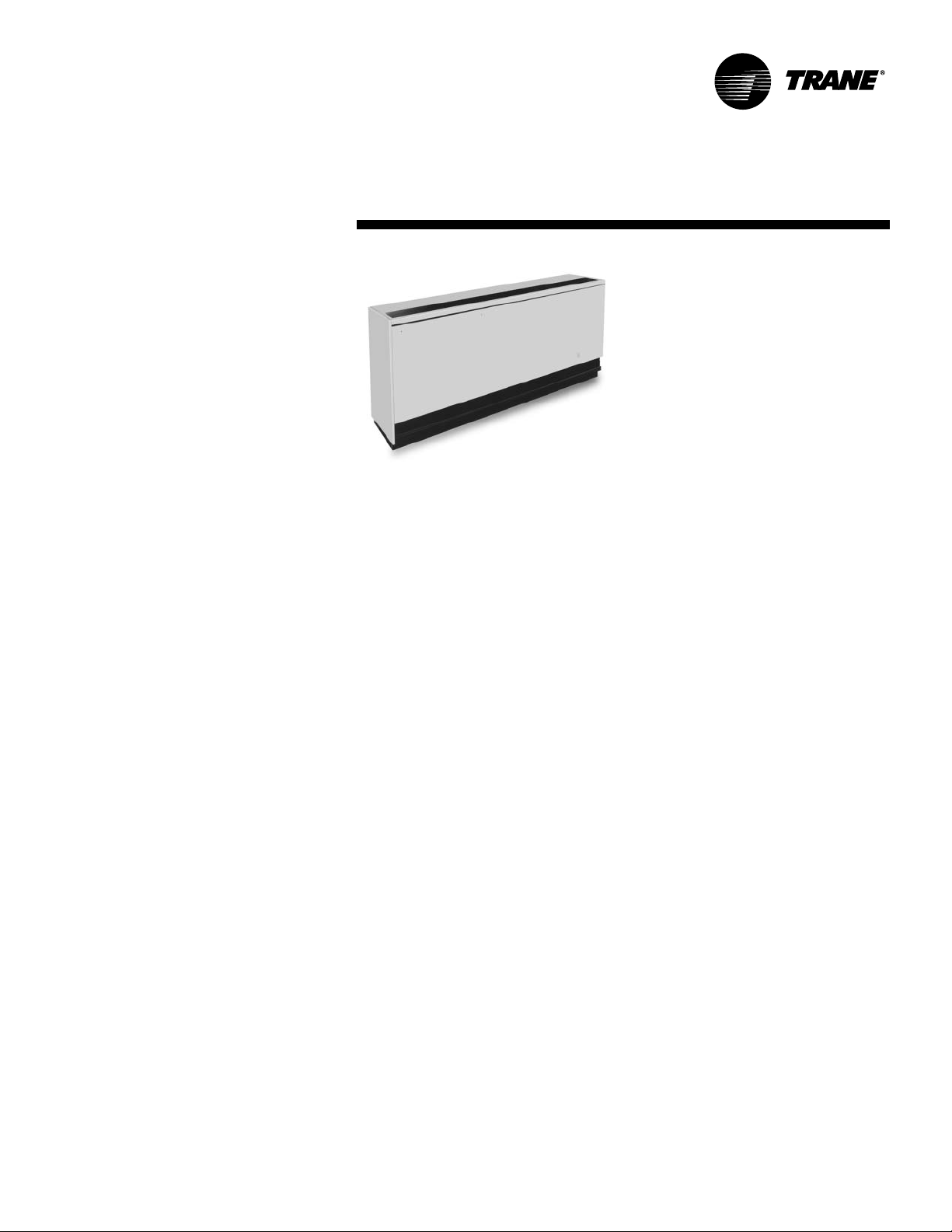

Energy Recovery Unit Ventilator

Energy Recovery Unit

Ventilator

Air conditioning systems have always

had one primary responsibility: deliver

sufficient amounts of conditioned air

into buildings. As indoor air quality issues grow proportionally, along with

the rising cost of energy, more is being

asked of these air conditioning systems.

To provide your facility with the best

possible balance of energy efficiency,

air quality and comfort, Trane offers

an energy recovery unit ventilator.

The job of the unit ventilator energy

recovery system is to provide every

room with the right amount of fresh air

necessary to comply with IAQ standards like ASHRAE 62, while minimizing installed cost and energy use. To

do this, it uses a desiccant-coated

wheel to transfer both sensible heat

and moisture from outside air to exhaust air in the summer, and from exhaust air to the incoming outside air in

the winter.

Traditionally, there has been a choice

when bringing in outdoor air. Either locally, or through centralized ventilation systems. With the unit ventilator

energy recovery system, the ductwork

associated with centralized systems is

eliminated, and possible humidity and

energy consumption problems encountered when locally introducing

outside air are also decreased.

Leading unit ventilator technology for

decades, Trane has developed a unit

ventilator that is as cost-effective, as it

is IAQ-smart.

Equipment Size

The energy recovery system allows up

to 500 cfm of outside air to be brought

into the space without putting a large

ventilation load on the unit ventilator

system.

Cabinet Finish

The unit cabinetry is made of a durable

industrial grade metal to withstand

student contact. An appliance grade

paint treatment increases the aesthetics of the equipment while making it

long-lasting for typical classroom environments.

An interior pipe channel on the energy

recovery unit ventilator allows the installer to easily connect the HVAC’s

unit ventilator piping with existing

system piping.

Access

A single panel access design of the

unit is easily removable, and provides

complete access to the unit fan, wheel,

filter, and controls.

Fan and Motor Assembly

Fans for the energy recovery unit ventilator are double-inlet, forwardcurved centrifugal variety. They have a

maximum speed of 1,050 rpm with

permanent split capacitor motors. The

fan housing is constructed of heavy

gauge metal to help reduce air noise

during operation. Wheel motors are

single-speed, permanent split capacitor with overload protection. Each fan

is equipped with a three speed switch

for air balancing.

Ultra Low Leak Dampers

An ultra-low leak, blade type outside

air damper is installed on every energy

recovery unit ventilator system. This

helps ensure low leakage of the outside air when the equipment is off. The

unit is available with two separate

damper assemblies.

The fresh air damper is a positive closure damper operated by a 24-volt, 3point floating control motor. The exhaust air damper is a gravity relief type

damper in order to help avoid overpressurization of the classroom.

Defrost Controls: In most cases,

Trane’s ultra low leak dampers effectively protect against unwanted air infiltration and possible desiccant wheel

frosting. Yet many buildings face outdoor air temperatures lower than 10°F

while still requiring outdoor air. For

this reason, the energy recovery unit

ventilator may be equipped with a

unique defrost control. Electric preheat is used to prevent frost from

building up on the heat exchange

wheel and other components.

Filters

Each unit comes equipped with two

separate filters. Depending on usage,

the outside air filters can either be 1 or

2-inches thick (disposable or pleated

style). They are easily removed,

thrown away and replaced. There is

also a 1-inch thick throwaway filter for

exhaust air.

Subbases

Subbases may be ordered to create

the desired height of the equipment if

mating up to an existing or retrofit application.

Controls

The unit may be controlled through

the ZN520 controller, or through a 24V

binary signal. All units are shipped

from the factory fully assembled, and

run-tested to assure that a quality

product is delivered.

4 UV-PRC005-EN

Features and Benefits

Energy Recovery Unit Ventilator

Air-to-Air Heat Exchanger

The air-to-air heat exchanger is designed to support two separate air

streams in a counter-flow direction.

The heat exchanger matrix prevents

less than one percent of cross contamination between the air streams. The

heat exchanger has the effectiveness

of up to 80-percent with equal airflow.

For extremely cold climates, it may be

necessary to provide a means to prevent the wheel from frosting. The controls for the electric preheat are

interlocked with a differential pressure

switch to prevent the element from

coming on without the fan operating.

The electric preheat (frost prevention)

kW should be sized based on the winter design dry bulb temperature and

the frost threshold temperature. See

selection procedure section to acquire

the sizing equation.

UV-PRC005-EN 5

Features and Benefits

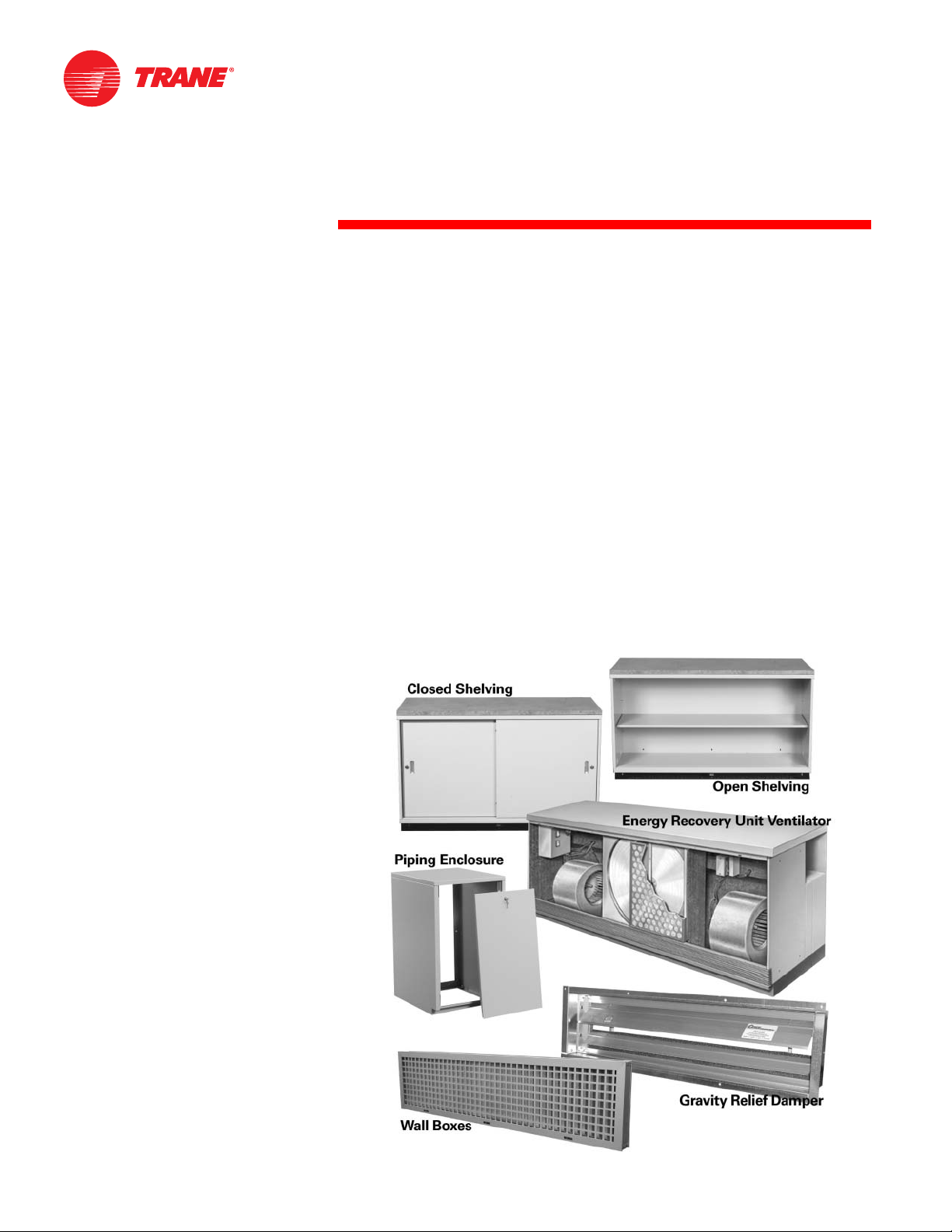

Shelving

Unit Ventilator Shelving

Trane’s unit ventilator shelving was inspired by the needs of a classroom setting. The design supports applications

from simple book or file storage to a

draft barrier design. Piping compartments, a choice in tops and cut-to-fit

fillers creates a custom approach to

the space design. Trane’s shelving is

easy to install, and durable enough to

withstand even the most rigorous

classroom environment.

Cabinet Finish

The unit cabinetry is made of a durable

industrial grade metal to withstand

typical student wear/tear. An appliance grade paint treatment increases

the aesthetics of the equipment while

making it long-lasting.

All selections are equipped with leveling legs for proper matching to the

classroom unit ventilator, energy recovery system or side wall exhaust

system.

For units that include a dynamic (draft)

barrier design, a floor spacer will be installed at the back of the shelving unit

in order to block air flow under the

unit.

Each shelving component ships from

the factory with a standard set of installation hardware to help minimize

the need for field supplied components.

The Formica® top option is available

as a 1-inch particle board, finished with

a choice of Formica laminate to compliment and coordinate with paint color of the shelving unit. The laminate is

available in sections or continuous

lengths for a seamless appearance. A

flanged drop-in grille eliminates exposed edges, and is permanently fastened to prevent removal. The top may

be ordered with or without a grille.

An attractive metal top, painted in the

same color as the shelving unit, is a

low cost option to flatter the classroom space.

6 UV-PRC005-EN

Trane Unit Ventilator Shelving Configurations:

Closed Shelving

The closed shelving design is

available in 2, 3, 4 and 5-feet lengths.

Shelving depth includes 16 5/8" or 21

1/4" to accommodate retrofit and new

equipment installations. The units are

equipped with adjustable shelves that

are reinforced with a formed channel

for maximum strength. Closed

shelving doors include two locks as

standard. A bottom door guide adds

stiffness and durability for the sliding

doors.

Open Shelving

The open shelving design is available

in 2, 3, 4 and 5-feet lengths. Shelving

depth includes

16 5/8" or 21 1/4" to accommodate

retrofit and new equipment

installations. The units are equipped

with adjustable shelves that are

reinforced with a formed channel for

maximum strength.

Cut-to-fit Filler

The cut-to-fit filler piece is designed

to fill the gaps between small spaces.

The filler is available in an 18" or 36"

length, and may be cut-to-fit an area

as small as 4-inches. The fill-in

section has a removable front panel

to allow access to piping or electrical

connections.

Piping Compartment

The piping compartment is equipped

with a metal top, leveling legs and a

locking front panel. It is a standalone

piece of equipment that is best suited

for housing piping equipment for the

unit ventilator.The compartment is

designed to attached to either end of

the unit ventilator.

Formica Laminate Top

The laminate top selection is available

in many decorative colors, and in

lengths up to 12-feet. The tops may be

cut in the field to match any specific

length requested. A Gator Ply™ underside seals out moisture that could

potentially cause warping. It is available with or without a grille.

Features and Benefits

Side Wall Power Exhaust

Equipment Size

The side wall power exhaust provides

a nominal 500 (single fan) or 750 (dual

fan) cfm with a two speed switch. The

unit is available in a 15 1/4", 16 1/4" or

21 1/4" depth to support all retrofit and

new construction applications.

Cabinet Finish

The unit cabinetry is made of a durable

industrial grade metal to withstand

typical student wear/tear. An appliance grade paint treatment increases

the aesthetics of the equipment while

Side Wall Power Exhaust

Quick removal of concentrated air

contaminants and building pressurization are two reasons to include an

exhaust systems into the IAQ design.

Building areas that often contain a

build-up of these contaminants are

science labs, vocational/technical

shops, cafeterias, and indoor pools.

These areas should be maintained

under negative pressure relative to

adjacent spaces.

Trane’s side wall power exhaust system is designed to aid in the removal

of these contaminants from the classroom environment. As a standalone

unit design, the side wall power

exhaust may be utilized with or without the complete unit ventilation system. Unit control may also be

delivered through a ZN520 controller

connection, allowing the side wall

power exhaust to blend seamlessly

with the vertical unit ventilator system

to sustain complimentary unity of the

entire classroom design.

making it long-lasting. Adjustable leveling legs are designed into the base

corners providing flexibility to mate

the unit with the unit ventilator, shelving or the energy recovery system.

The single front panel is secured by

three camlock fasteners.

A polyurethane gasket seal is placed

along the perimeter of the discharge

opening to secure the back draft

damper at the wall opening.

Motor and Drive

All motors are a two-speed, 115/60/1

voltage and fans are direct-drive. The

motors are permanently lubricated,

sleeve type bearings which do not require oiling.

Unit Switch

The unit’s on-off switch is housed in

the left hand end pocket below the discharge air grille.

UV-PRC005-EN 7

Wall Boxes

Wall boxes are to be installed prior to

mounting the Classroom Unit Ventilator, Side Wall Exhaust, or Energy Recovery Unit Ventilator. Its intended use

is to help deter animals, trash, or rainfall from entering into the mechanical

system providing a year-round outdoor intake for the HVAC equipment.

Finish

Trane’s wall boxes are constructed of

heavy gauge aluminum and designed

to last the life of the building. Internal

parts are interlocked, in addition to being held securely in place by the

frame-within-a-frame design. This assures proper louver alignment.

Louvers are vertically or horizontally

aligned, and held in position by an integral spacing guide. The boxes are

available with an anodized aluminum

finish, or a baked enamel finish.

Wall box arrangements are furnished

with a diamond pattern, expanded aluminum bird screen to eliminate objects from blowing into the building.

The grilles are aluminum and the

same finish as the frame.

Wall Box Types

Trane offers a variety of wall boxes to

support different needs and applications. Each are sized to match the

classroom unit ventilator intake, and

may be ordered with or without a recessing flange. See dimensional data

for free area velocity of each wall box

design.

Features and Benefits

Wall Boxes and Gravity Damper

Gravity Relief Damper

The gravity relief damper is a barometrically operated design which prevents

over pressurization of the classroom.

The damper is typically located in a

plenum, or behind the 21 1/4" classroom shelving with a grilled top. An

optional wall box is recommended to

deter objects from easy entry into the

building.

Finish

Trane’s gravity relief damper is constructed from high grade aluminum

and is designed for durability and

long-stay. The dampers are horizontally arranged into the assembly.

Pipe Cover

The pipe cover assembly consists of

the pipe enclosure, mounting strip and

pipe hangers. It adds a decorative

touch to the room decor by removing

the supply/return/condensate pipe exposure.

The enclosure is constructed from

heavy gauge metal and finished to

match the classroom unit ventilator.

The steel cover is locked to the mounting strip with non-visible fasteners.

The mounting strip is a continuous roll

formed steel and contains a full length

channel for the enclosure. The pipe

hangers are .148-inch in diameter, zinc

plated steel wire. The hangers are designed to support up to two, 2 1/8" O.D.

insulated pipes.

8 UV-PRC005-EN

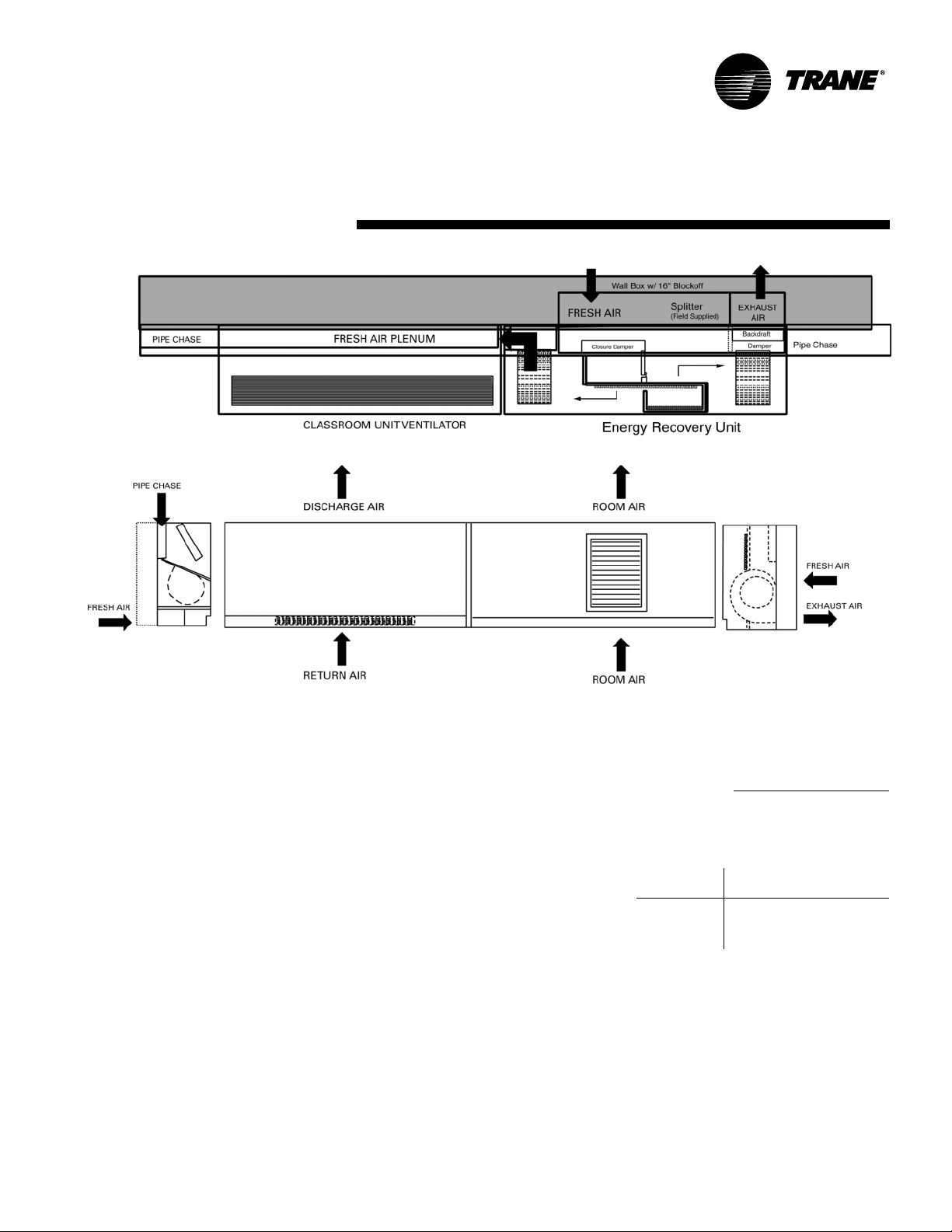

Application

Considerations

Energy Recovery Unit Ventilator

Operation

An energy recovery ventilator can

help make mechanical ventilation

more cost effective by transferring

energy between the outdoor air and

the building exhaust air.This desiccant-coated wheel revolves through

the outdoor and exhaust air streams.

During the cooling season, sensible

heat and moisture are transferred

from the outdoor air to the exhaust air

stream, and rejected from the building. During the heating season, sensible heat and moisture are transferred

from the exhaust air to the outdoor air

stream, heating and humidifying the

entering outdoor air.

After passing through the energy

recovery unit ventilator, the warmed

or cooled fresh air goes through the

classroom unit ventilator for further

air treatment.

In extremely cold climates, it may be

necessary to provide some means to

prevent the wheel from frosting.

Trane’s energy recovery unit ventilator

is equipped with a UL-listed electric resistance preheat element for frost prevention.

The controls for the electric preheat

coil are interlocked with a differential

pressure switch to prevent the element from coming on without the fan

operating.

The electric preheat coil should be

sized based on winter design dry bulb

temperature (T

)and the frost thresh-

OA

old temperature (TTH). Example:

kW required = 1.08 x 500 cfm x (TTH-TOA)

3134

Where frost threshold is determined

by the relative humidity of the space in

the winter.

Room Relative

Humidity

30% 5

40% 10

50% 15

Frost Threshold Temp - T

(F)

TH

UV-PRC005-EN 9

Model Number

Shelving

SHL B G 2 05 D0 0 F A D 0 0 0

5

10 15

DIGIT 1-3: UNIT CONFIGURATION

SHL = Classroom Shelving

DIGIT 4: DEVELOPMENT

SEQUENCE

B = Current Sequence

DIGIT 5: SHELVING STYLE

0 = Continuous Top ONLY/No

Shelving

2 = 18-inch Cut-to-Fit Filler

3 = 36-inch Cut-to-Fit Filler

4 = 12-inch Piping Compartment

5 = 18-inch Piping Compartment

A = 2-ft Open Shelving

B = 3-ft Open Shelving

C = 4-ft Open Shelving

D = 5-ft Open Shelving

E = 3-ft Closed Shelving

F = 4-ft Closed Shelving

G = 5-ft Closed Shelving

H = 3-ft Open Shelving

with Dynamic Air Barrier

J = 4-ft Open Shelving

with Dynamic Air Barrier

K = 5-ft Open Shelving

with Dynamic Air Barrier

L = 3-ft Closed Shelving

with Dynamic Air Barrier

M = 4-ft Closed Shelving

with Dynamic Air Barrier

N = 5-ft Closed Shelving

with Dynamic Air Barrier

DIGIT 6: SHELVING TOP DEPTH/

GRILLE

0 = Not Required

1 = 16 5/8-inch Shelving and Top

Depth

2 = 21 1/4-inch Top Depth w/o Grille

3 = 21 1/4-inch Top Depth w/ Steel

Grille

4 = 21 1/4-inch Top Depth

w/Aluminum Grille and Damper

5 = 21 1/4-inch Top Depth

w/Aluminum Grille

6 = 16 5/8-inch Deep Piping

Compartment

7 = 21 1/4-inch Deep Piping

Compartment

DIGIT 7&8: LENGTH of FORMICA

TOP

00 = No Formica Top for Shelving

Selected

01 = Formica Top w/Same Size and

Shelving

02 = 2-ft Top Only (no shelving)

03 = 3-ft Top Only (no shelving)

04 = 4-ft Top Only (no shelving)

05 = 5-ft Top Only (no shelving)

06 = 6-ft Continuous Top

07 = 7-ft Continuous Top

08 = 8-ft Continuous Top

09 = 9-ft Continuous Top

10 = 10-ft Continuous Top

11 = 11-ft Continuous Top

12 = 12-ft Continuous Top

18 = 18-inch Top Only (no shelving)

DIGIT 9&10: DESIGN SEQUENCE

Current Sequence

DIGIT 11: DECORATOR FORMICA

TOPS

0 = No Top

1 = Metal Top

A = Champagne Papyrus Formica®

To p

E = Almond Formica Top

F = Ivory Blushing Formica Top

G = Natural Canvas Formica Top

H = Glacier Slate Formica Top

J = Birch Formica Top

K = Folkstone Formica Top

M = Fog Formica Top

N = Tundra Terra Formica Top

Q = Stone Dust Formica Top

DIGIT 12: SHELVING PAINT

COLOR

0 = No Color Shelving Finish

A = Cameo White Shelving Finish

B = Soft Dove Shelving Finish

C = Deluxe Beige Shelving Finish

D = Driftwood Grey Shelving Finish

E = Rose Mauve Shelving Finish

F = Stone Grey Shelving Finish

G = Bronze Tone Shelving Finish

DIGIT 13: END COVERS

0 = No End Covers

A = 16 5/8-inch Deep End Covers

w/o Cutouts

B = 16 5/8-inch Deep End Covers

w/Std. Cutouts

C = 16 5/8-inch Deep End Covers

w/Extended Cutouts

D = 21 1/4-inch Deep End Covers

w/o Cutouts

E = 21 1/4-inch Deep End Covers

w/Std. Cutout

F = 21 1/4-inch Deep End Covers

w/Extended Cutouts

DIGIT 14: SUBBASE

0 = No Subbase Feature

2 = 2-inch Subbase

4 = 4-inch Subbase

6 = 6-inch Subbase

DIGIT 15: KICKPLATE

0 = Louver Front Kickplate (no side)

1 = Louver Front and Side Kickplate

2 = Solid Front Kickplate (no side)

3 = Solid Front and Side Kickplate

DIGIT 16: KEY LOCK

0 = Standard Lock

1 = Master Key for Lock

ADDITIONAL ACCESSORIES

SGRL: Extra Steel Grille

2ft: Extra 2-ft Steel Grille

3ft: Extra 3-ft Steel Grille

4ft: Extra 4-ft Steel Grille

5ft: Extra 5-ft Steel Grille

AGRL: Extra Aluminum Grille

2ft: Extra 2-ft Aluminum Grille

3ft: Extra 3-ft Aluminum Grille

4ft: Extra 4-ft Aluminum Grille

5ft: Extra 5-ft Aluminum Grille

10 UV-PRC005-EN

Loading...

Loading...