Page 1

Electric Unit Heaters

Model UHWA

Model UHAA

Model UHRA

Model UHCA

Model UHXA

Model UHEC

UH-PRC003-ENAugust 2005

Page 2

Introduction

Introduction

Electric unit heaters have been a traditional means of heating hard-to-warm spaces for many years. Their uncomplicated

approach in auxiliary heating make them easy to install and maintain. Their versatile characteristics allow Trane’s

electric unit heaters to fill nearly every heating application gap, while their structural integrity makes them a reliable

heat source to blend into today’s building décor.

Trane’s electric unit heaters are available in 6 variations. The following chart presents a brief overview of the different

electric unit heater models Trane offers.

Model

UHEC 3 to 50 kW

Description

Horizontal and Vertical Spot

Heating Electric Unit Heater

Applied as an auxiliary heat source

in walkways, stairways, vestibules,

and entrances. The horizontal and

vertical spot heater may be used in

commercial, industrial and

institutional applications.

Application

UHRA 3 to 48 kW

UHXA 3 to 25 kW Explosion-Proof Electric Unit Heater Designed for hazardous locations, the

UHCA 2 to 5 kW

UHWA 2 to 5 kW Heavy Duty, Wall Mounted

Hose-Down, Corrosion-Resistant

Electric Unit Heater

Commercial, Ceiling-Mounted

Electric Unit Heater

Electric Unit Heater

Series 20 and 50

Used in industrial applications where

dirt or dust may be extensive. The

totally enclosed, watertight casing is

corrosion-resistant for non-hazardous

locations.

UHXA model may be applied where

flammable gases, vapors, powdered

metals or dust may be present.

The surface- or recessed mounted

model may be applied in restricted

areas or where wall space is limited.

This may included vestibules, lobbies,

rest rooms, small-offices or guard

buildings.

Suited for public buildings such as

schools, stores, offices, dormitories,

hospitals and transportation

terminals.

UHAA 1.5 to 4.8 kW

© 2005 American Standard Inc. All rights reserved.

Architectural Wall Mounted

Electric Unit Heater

The rugged construction and

attractive design of the UHAA model

make them appropriate for offices,

lobbies, and reception areas for

schools and dormitories.

UH-PRC003-EN

Page 3

Contents

Introduction

Features and Benefits

Application Considerations

Selection Procedure

Model Number

General Data

Control Wiring

Dimensional Data

Options

Mechanical Specifications

2

4

13

14

15

19

29

32

39

42

UH-PRC003-EN

3

Page 4

Features and

Electric Unit Heaters

Thirty-seven models to choose from

•

ranging from 3.3 to 50 kW. Available for

208, 240/208, 277 or 480-volt operation.

One unit can be used for either

•

horizontal or vertical discharge.

Specially designed inlet louvers, venturi

•

and outlet diffuser provide uniform air

temperature and throw characteristics.

Single-phase units, easily converted to

•

three-phase power, are available in 3.3

to 10 kW for 208 and 240-volt

operation.

Two-speed fan operation standard on

•

25 kW units and above.

Meets all requirements of UL listing

•

standard 1278 when installed as

directed.

UHEC electric unit heaters are ideal for

applications ranging from new

construction to auxiliary heat to

renovation. They are available in 37

models ranging from 3.3 kW to 50 kW. In

addition to a wide capacity range, each

compact, attractive unit can be mounted

in either a horizontal or vertical discharge

arrangement.

Benefits

Flexibility

The Trane electric unit heater shows its

flexibility in installation and operation.

Intended for industrial, commercial or

institutional use, the Trane electric unit

heater is available for 208 to 480-volt,

single or three-phase operation. Units

from 3.3 to 10 kW for 208 and 240-volt

operation may be converted easily from

single to three-phase operation in the

field. Two-speed fan operation on 25 kW

units and above provides greater airflow

flexibility.

Uniform Air Distribution

The Trane unit heater uniformly directs

the air to exactly where it’s needed. A

specially designed deep-drawn venturi

assures uniform air distribution. The

outward-drawn venturi channels the air

forward for maximum, uniform air throw.

Outlet diffusers are provided to properly

direct the heated discharge air.

In order to minimize the potential for hot

spots on the heating coil, inlet louvers

evenly distribute intake air over the entire

heating element.

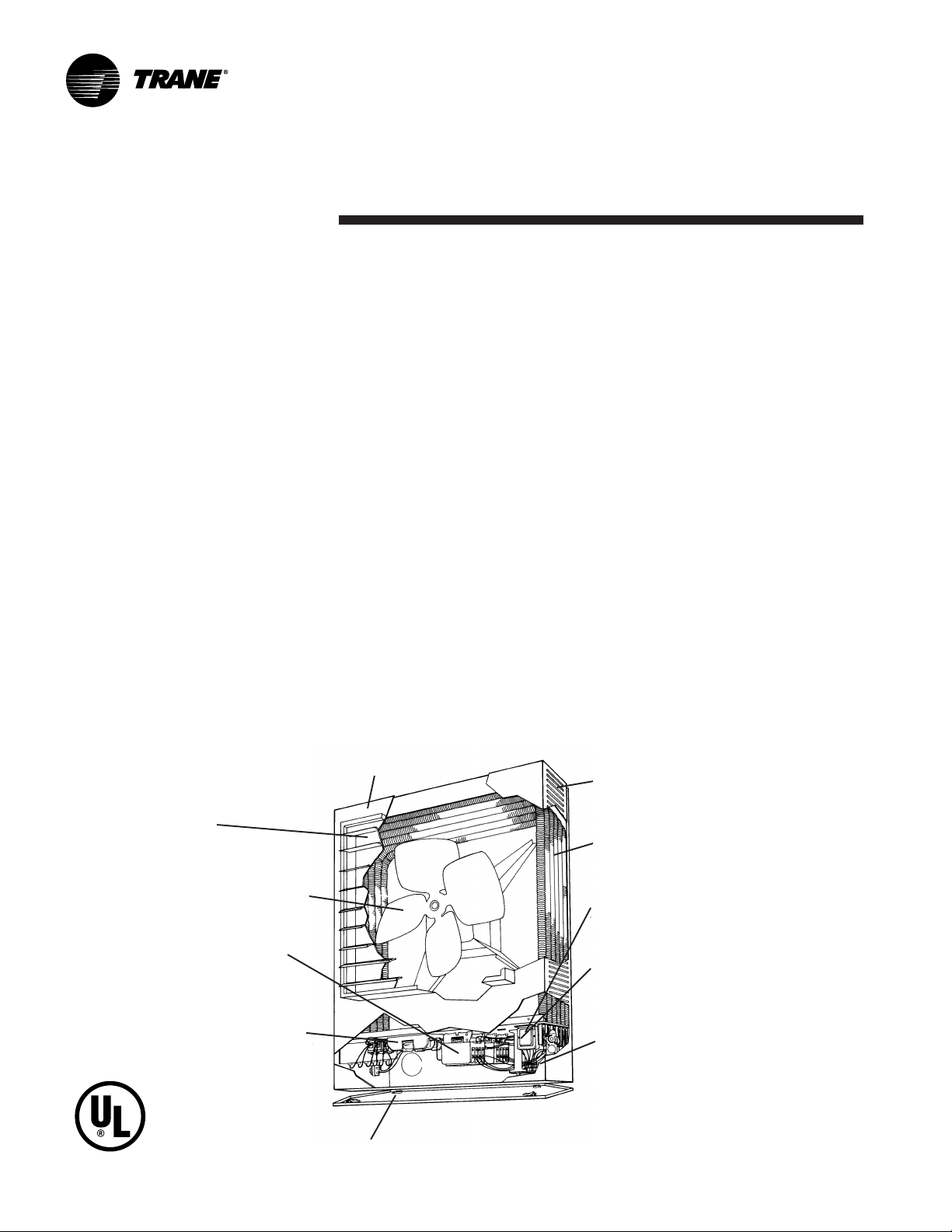

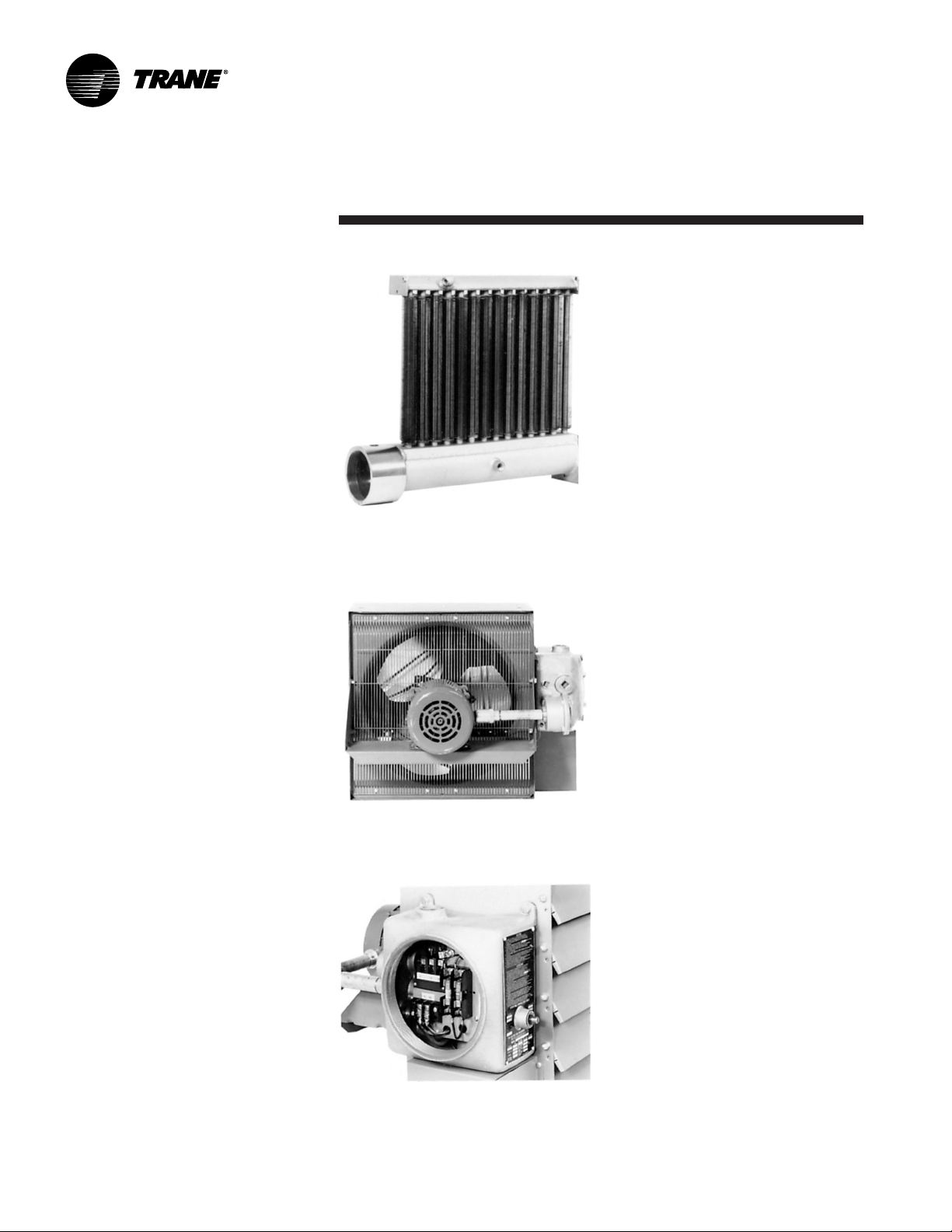

Model UHEC

Trane electric unit heaters are designed

with totally enclosed, permanently

lubricated industrial motors. The

air-over-motor design reduces operating

temperatures, promoting long motor life.

Thermal overloads provide additional

protection for major circuits, in case

normal operating temperatures are

exceeded.

Quick and Easy

Low-Cost Installation

Installation time and costs are minimized.

Compact and completely factory wired,

the Trane electric unit heater requires

only a single-source power supply

connection. The units are available with

factory installed 24-volt control

transformers and contactors.

Outlet Louvers — Individually adjustable

from 30° up to 45° down.

Motor and Fan — Totally enclosed,

permanently lubricated, sealed bearing,

all-angle motor and fan combination

through 20 kW and two-speed permanent

capacitor-type motor on 25 through 50

kW units.

Contactors — All units 25 kW and larger

are equipped with two contactors and

two element banks for either single or

two-stage heating operation.

Fusing — Element, motor and transformer

primary fusing are factory installed and

wired where required to NEC. Branch

circuit fusing installed where required on

48 amps and up.

LISTED

Casing — Die-formed heavy-gauge steel

with baked enamel finish.

Intake Louvers — Designed to provide

uniform air distribution across entire

heating element.

Element — High mass, all steel finned,

tubular heating element.

Transformer — 24-volt control circuit for

closer temperature control and added

safety. Standard on most models,

optional on 3.0 and 5 kW 208, 240/208,

277-volt models.

Thermal Overloads — Automatic reset

thermal cutouts disconnect motor and

element in the event normal operating

temperatures are exceeded.

Terminal Panel — Single-point terminal

board wiring for easy control accessories

installation.

Access Panel — Full width access panel

secured by quarter-turn fasteners.

UH-PRC003-EN4

Page 5

Features and

Benefits

Mounting the unit is easily accomplished

with the use of hanger rods connected to

weld nuts on the unit casing. An

accessory mounting bracket is available

for single-point mounting. Field installed

accessories such as built-in thermostats,

disconnect switches and summer fan

switches are provided with spade

terminals for easy installation to a singlepoint terminal board.

Reliable Operation

Trane electric UHEC unit heaters operate

reliably when installed and operated as

directed. In addition to meeting all

requirements of UL listing standard 1025,

the heating element is backed with a fiveyear warranty.

Easy Access

In the event that service is required, easy

access to the control components is

provided with a full-length access panel

secured by quarter-turn fasteners. For

added convenience, unit wiring diagrams

are located inside the access panel for

easy reference during installation and

servicing.

Model UHEC

Horizontal Discharge

Vertical Discharge

5UH-PRC003-EN

Page 6

Features and

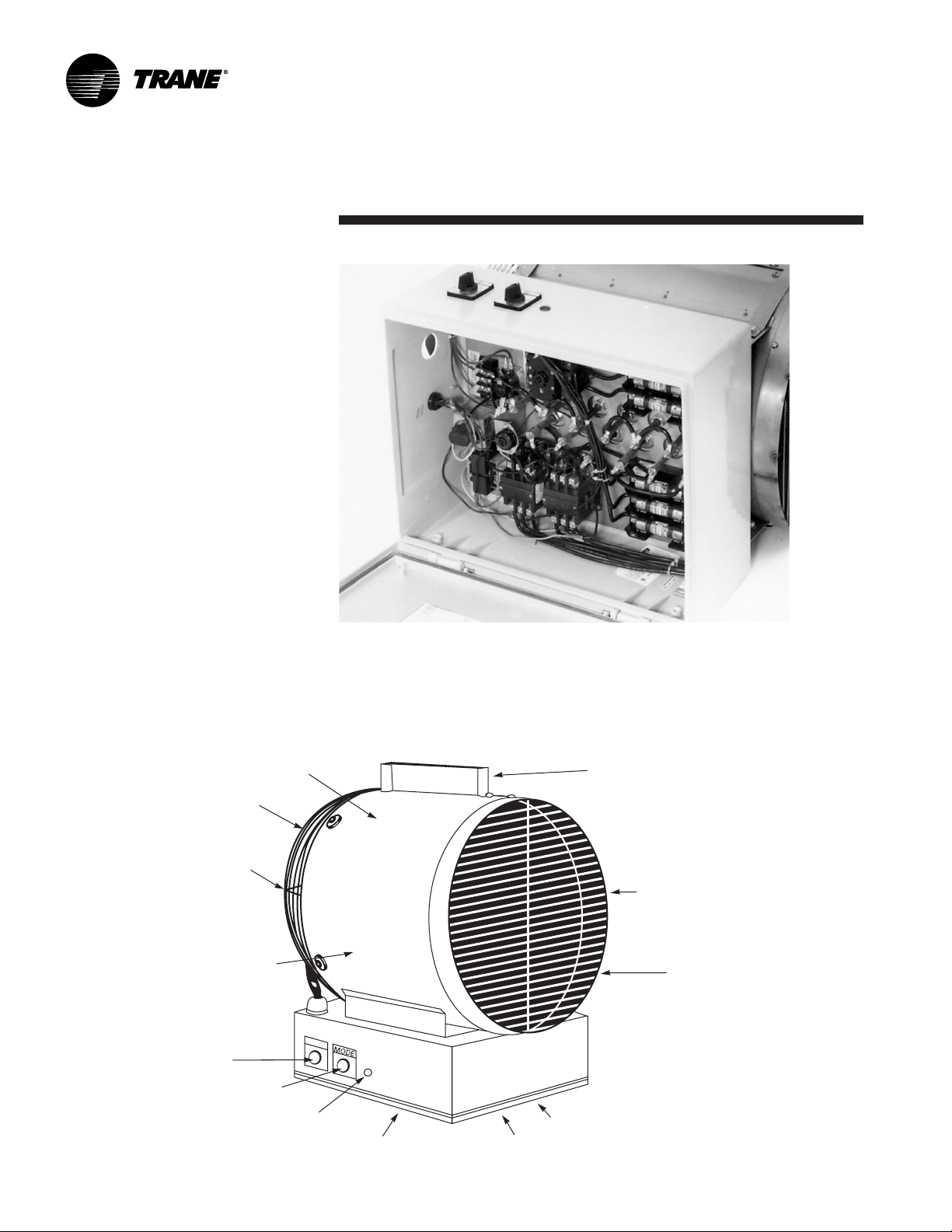

Hose-Down Electric Unit Heaters

Trane UHRA hose-down electric unit

heaters are constructed for use in areas

that require washing or hosing of

equipment due to a dirty or dusty

industrial environment in

non- hazardous locations. The

totally enclosed, watertight casing made

with corrosion-resistant material, makes

the unit ideal for industrial heating

applications. All controls are built-in and

the safety temperature controls are

wired in a nonmetallic NEMA 4x control

panel with single-point power

connections.

Standard Features

Heavy-duty 304 stainless steel casing

•

NEMA 4x nonmetallic control panel

•

24-volt transformer and control circuit

•

Three-position switch (off - heat - fan)

•

Disconnect switch with enclosure

•

interlock

Capillary thermostat with stainless steel

•

sensor

Automatic reset thermal cutout

•

Totally enclosed UL listed motor

•

Pilot light (power on indicator)

•

Chrome-plated finned tubular element

•

Control panel on bottom of unit for ease

•

of installation and service

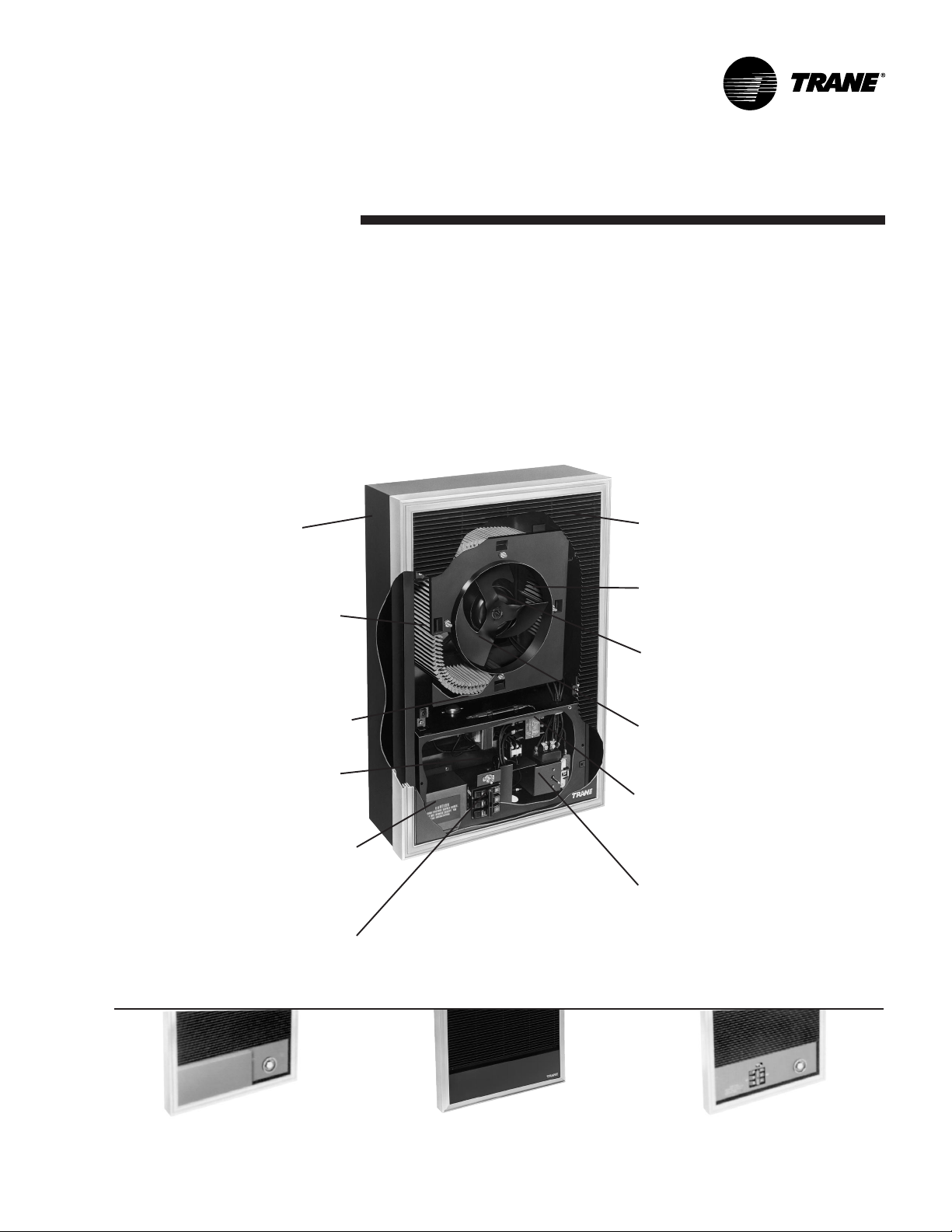

304 Stainless Steel Casing

Plated Inlet Grille

Benefits

Control Enclosure

Single-point power connection

•

Meets all UL, NEC and OSHA

•

requirements (when installed as

directed)

Model UHRA

Corrosion-resistant in high humidity and

•

water-saturated areas (for areas where

corrosion-resistance is needed in

non-hazardous areas).

Easy-mount bracket for Use with

Field- Installed Hanger or Optional

Mounting Brackets

Totally Enclosed Motor

Aluminum Fan Blade

Thermostat

Three-Position Fan Switch

Pilot Light (Heater

Energized)

Door Interlock

Disconnect Switch

(Optional)

Stainless Steel

Discharge Grille

Element

NEMA 4x Non-Metallic Enclosure

Control Components (24-Volt Standard)

UH-PRC003-EN6

Page 7

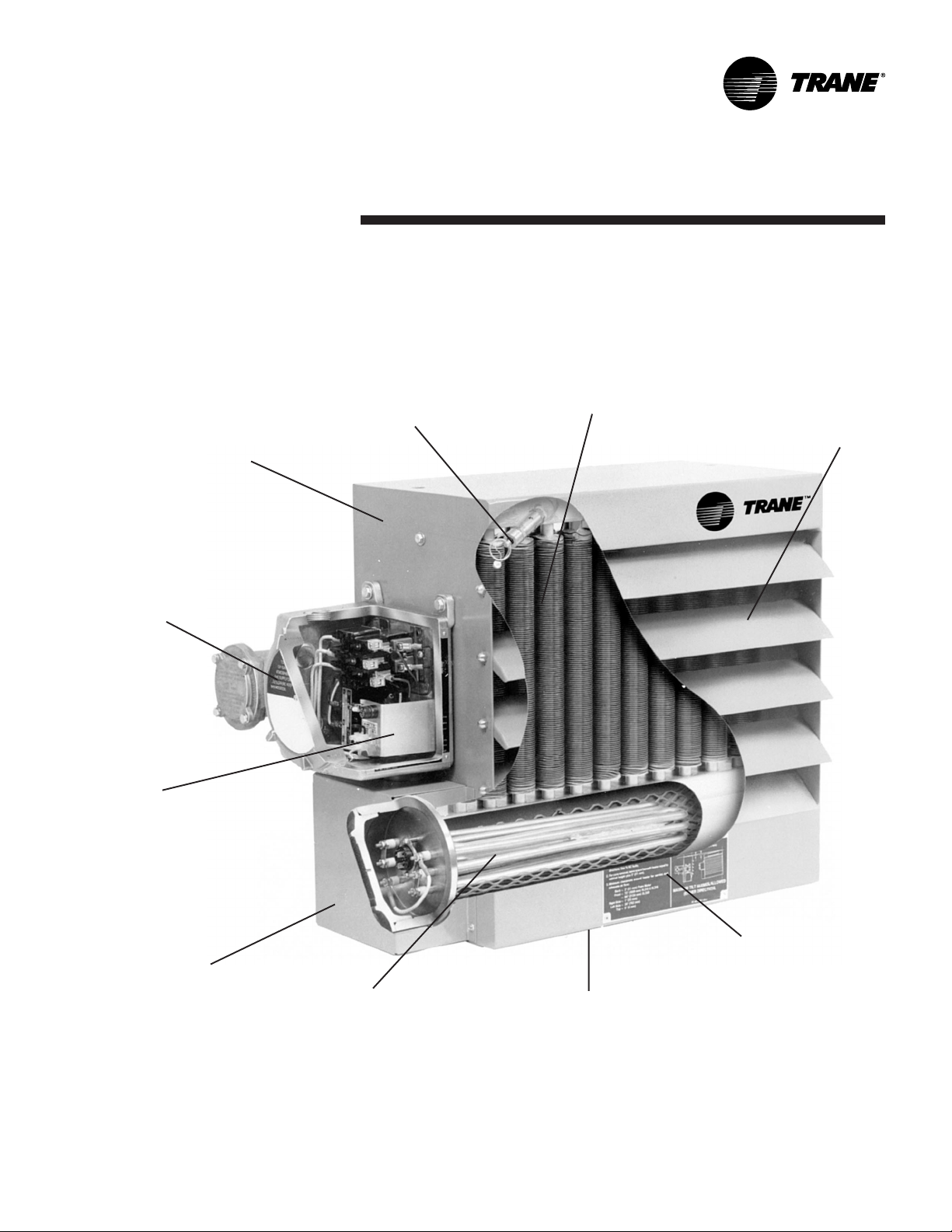

Features and

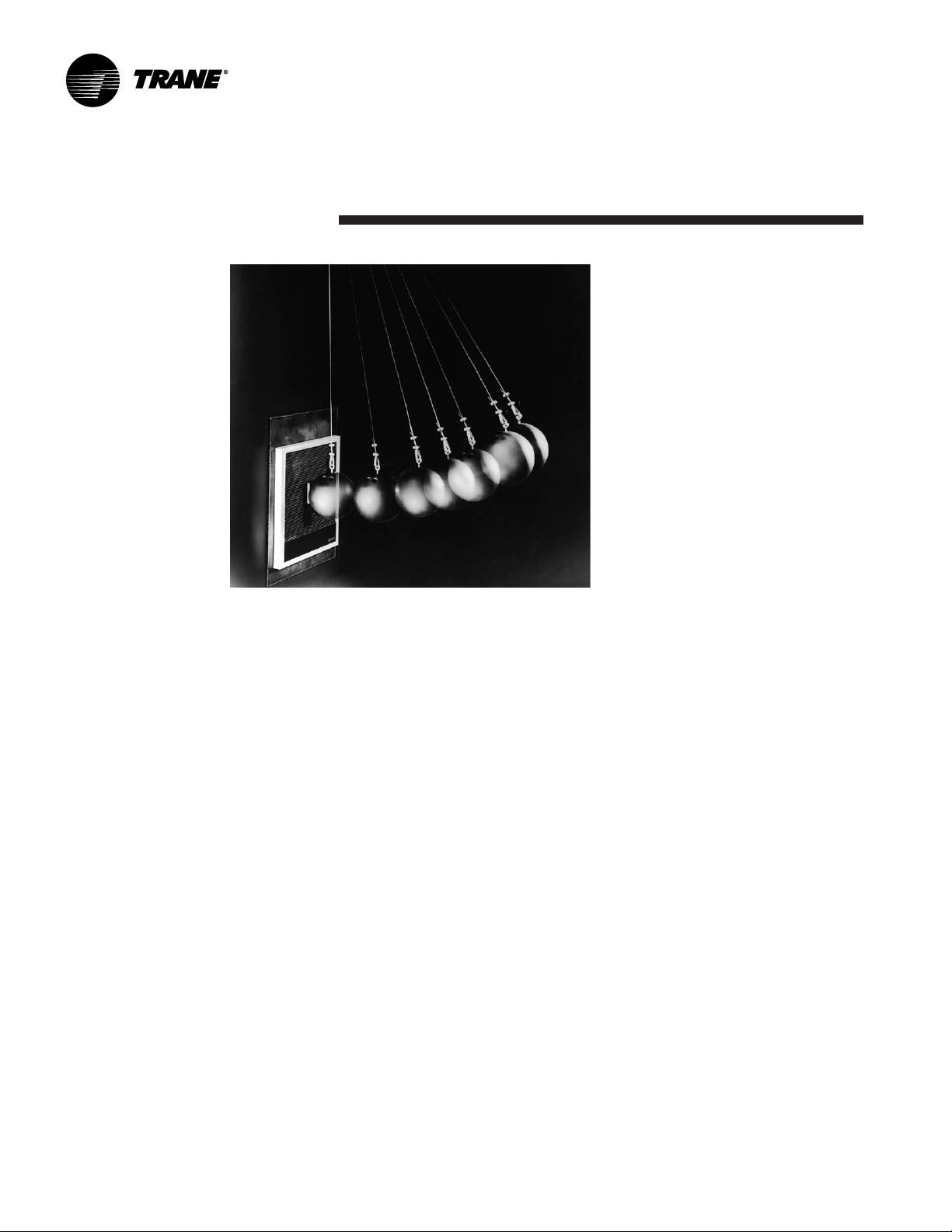

Epoxy Coated 14-Gauge Cold Rolled

Steel Cabinet

Cast Aluminum Control Enclosure

with Oversized Opening

Benefits

Trane Explosion-Proof

Electric Unit Heaters

Pressure Relief Valve

Rated at 200 PSI

Model UHXA

Spiral Aluminum Finned Tubular Steel

Heat Exchanger Core Liquid Filled

Operation (see page 3)

14-Gauge Steel Adjustable

Louvers with Minimum

Position Stops

Built-In Load Carrying Contactor

Protective Heating Element Cover

Copper Sheathed Immersion Type

Heating Element

Etched Aluminum Data Plates

Riveted to Case

High Performance Aluminum Fan

Blades (not shown)

7UH-PRC003-EN

Page 8

Features and

Benefits

Liquid to air heat exchanger with low

watt density heating elements in

ethylene glycol solution that provides

freeze protection to -45°C.

Ball bearing permanently lubricated

explosion-proof motor. Chrome plated

guard meets OSHA requirements.

Model UHXA

Designed for rugged industrial

applications in hazardous locations

where the possibility of explosion or fire

exists due to the presence of certain

flammable gases, vapors, powdered

metals or dusts.

Permanently sealed, liquid to air, finned

•

tube heat exchanger core.

Ethylene glycol water mixture used as

•

heat transfer fluid in the heater core,

providing -45°C, (-49°F) freeze damage

protection.

High-performance electric motor

•

driven fan blows air across finned tubes

to effect uniform heat transfer and area

heat distribution.

Automatic reset capillary type high limit

•

provides high temperature regulation

and is rated for 100,000 cycles of

service.

Stainless steel and aluminum pressure

•

relief valve handles any over-pressure.

14-gauge steel cabinet contains heater

•

core, motor and fan assembly.

Narrow gap safety fan guard shields all

•

moving parts.

Adjustable louvers allow directional

•

control of air.

Copper conductor wires enclosed in

•

rigid metal conduits carry all electrical

power.

Box lugs are furnished for field

•

connections within an approved

enclosure.

Heavy-duty control contactor with

24-volt control circuit provided on all

models.

UH-PRC003-EN8

Page 9

Features and

Model UHWA

Heavy-Duty Wall Heaters

Trane heavy-duty wall mounted electric

forced-air unit heaters are

architecturally styled in a

vandal- resistant design for all

commercial, institutional and many

industrial applications. They are

particularly suited for schools, office

buildings, dormitories, stores, hospitals

and other public buildings.

Solid Construction and

Dependable Components

Sleeve

Sleeve for surface or semi-recessed

installation. 16 gauge (1.5 mm

thickness) zinc coated steel.

Element

Totally enclosed, corrosion-resistant.

Maximum finning for lower operating

temperature and longer life. Will not

become dust clogged. (No filter

required.)

Thermal Cut-Out

Exclusive “zero voltage reset” type for

high degree of effectiveness if normal

operating temperatures are exceeded.

Transformer

Optional factory assembled and wired

in 50 Series. Choice of 24 or 120 volt

secondary.

Entrance Terminals

Line side termination enclosed for safe

servicing of heaters when supplied with

circuit breakers.

Circuit Breakers

Reduces installation cost by allowing

one or more heaters to be wired from

feeder and feeder tap. Separate control

circuit switch supplied when required.

All power can be turned off before front

cover is removed.

Benefits

The high capacity and wide range of

voltage/phase and control systems

provides application versatility to meet

most installation requirements. A wide

selection of built-in factory installed and

wired, pre-engineered control systems

minimizes system design and

installation time.

Series 20 and 50

All units are equipped with zero voltage

reset thermal cut-outs for overheat

protection and a totally enclosed,

permanently lubricated motor. Optional

circuit breaker, control transformer and

a selection of integral or wall-mounted

thermostat controls are part of the unit

package.

Louvered Grille

Heavy-duty welded steel for maximum

impact resistance. Closely spaced

(pencil proof), tamperproof.

Motor Shield

Protects motor by separating return air

from heated air.

Motor

Heavy-duty unit bearing, permanently

lubricated, totally enclosed, impedance

protected.

Blade

Highly efficient, space saving bladeover-motor design, individually

balanced.

Contactor

Optional, definite purpose, heavy-duty

type with flame path separators and

dust covers. Choice of heater voltage,

120 volt or 24 volt holding coil.

Thermostat

Optional heavy-duty hydraulic snap

action type with sensing bulb in return

airstream. Disconnects all ungrounded

conductors in OFF position.

Series 50 with exposed thermostat knob

and covered circuit breaker and control

switch only

Series 20 and 50 with tamper-resistant

thermostat cover plate which is included

with each heater.

Series 50 with tamper-resistant cover

removed.

9UH-PRC003-EN

Page 10

Features and

Model UHWA

Benefits

Series 20 and 50

Architecturally styled and

•

vandal- resistant for schools, churches,

stores, office buildings, transportation

terminals, dormitories, hospitals.

Use in vestibules, entrance ways,

•

lobbies, corridors, stairways, reception

rooms, rest rooms, offices.

Simple application design — Wide

•

selection of built-in, factory installed and

wired, pre-engineered control systems.

Saves design and on-the-job time.

Versatile application — Higher capacity

•

and wider range of voltage/phase and

control systems than any similar

heaters previously available.

Heater front withstands with less than

•

1

/16” (1.6 mm) permanent distortion,

10.8 ft lbs (324 poundals) impact and

400 lbs (181.4 kg) static force applied to

an 8 sq. in. (5160 sq. mm) area at center

grille location.

UH-PRC003-EN10

Page 11

Features and

Model UHCA

Series 80

Recess mounted for 2’ (609.6 mm) x

2’ (609.6 mm) “T” bar or plaster

ceilings

Mounting Bracket — features swing up

installation on surface mounted 70

Series. Bracket center notched to

accept screws of ceiling outlet box

(installed by others). Recessed heater

80 Series has junction box attached to

heater can.

Motor — heavy-duty unit bearing,

permanently lubricated, totally

enclosed, impedance protected.

Blade — highly efficient, space-saving

blade over motor design, individually

balanced.

Thermal Cut-Out — exclusive “zero

voltage reset” type for highest degree

of effectiveness in event normal

operating temperatures are exceeded.

Heater must be manually shut off for

five minutes to reset. (See page 8.)

Element — totally enclosed and

corrosion resistant. Maximum finning

for lower operating temperatures and

long life. Will not become dust clogged.

(No filter required.)

Discharge Venturi — bull’s-eye design

permitting heated air to leave in

uniform pattern.

Plaster Trim — optional plaster trim for

recessed mounted heaters (series 80)

only. Provides finished ceiling

appearance.

Benefits

Series 70 and 80

Commercial and Industrial

Ceiling - Mounted Fan Forced Heaters

Series 70 and 80 Features

Crisp, unique styling to blend into any

•

architectural design — unit designed for

long life and warranted for five years.

Higher velocity ceiling-mounted heater

•

gets air down to warm those hard to

heat areas where public accessibility is

not desired or where wall area is

restricted.

Single or multiple installations at a

•

fraction of the cost of cabinet unit

heaters.

Five-year warranty.

•

2,000 to 5,000 watts.

•

208, 204 V single and three-phase.

•

277 V single-phase.

UL listed and conform to Underwriters’

•

Standard 1025.

Commercial and Institutional

Applications

Use in vestibules, entrance ways,

•

lobbies, restrooms and small office and

guard building applications.

A unique design offers surface and

•

recessed applications with higher

wattage capacity and wider range of

voltage and phase capabilities than

other heaters of this type.

Control: Line voltage and low voltage

•

control capabilities using accessory

thermostat (see page 8).

Unit mounted controls for Series 80

•

only with fan purge.

11UH-PRC003-EN

Page 12

Features and

Model UHAA

Benefits

Series 3320

Architectural Quality

Built - in tamper resistant thermostat

•

Built - in tamper resistant disconnect

•

switch

Richly styled, rugged grille

•

Whisper-quiet sound level

•

Fan delay

•

Decorator designed for functional

•

beauty and versatility.

Five-year element, limited warranty

•

UL listed

•

Optional Accessories

3320EX33 Surface Mounting Adapter

Factory-Installed Accessories

Suffix R Day/Night Relay

Rugged Grille — Grille made of 18

gauge (1.2 mm thickness) steel painted

with a dark brown baked enamel finish.

Richly Styled Grille — Grille is

highlighted by a snap-on, 14-gauge

(1.9 mm thickness) aluminum frame,

secured to the heater with an

inconspicuous fastener.

Element — Steel sheath with plate heat

exchanger.

Fan Delay Switch — To allow the fan to

continue to run for a short period after

the thermostat is satisfied, to expel

warm air from inside the heater. Also

delays fan on start up to insure delivery

of heated air. This switch also prolongs

element life.

“Unique” Vane Axial Fan Wheel —

Draws in large volumes of air then

quietly and gently discharges 175 cfm

(82.6 l/s) of heated air downward into

the room.

UH-PRC003-EN12

Page 13

Application

Considerations

Abbreviated descriptions of UL classes,

groups and divisions. Before selecting any

heater for a particular application, refer to

Article 500 as well as other standards

referenced in the National Electric Code.

Class I: Equipment does not have

•

surface operating temperature in

excess of the ignition temperature of

the specific gas or vapor.

Class II: Equipment does not have

•

surface temperature greater than the

ignition temperature of the specified

dust.

Group D: Atmospheres such as but not

•

limited to acetone, alcohol, gasoline,

lacquer solvent vapors, natural gas,

propane or other gases or vapors of

equivalent hazard.

Group E: Atmospheres containing

•

combustible metal dust regardless of

resistivity, or other combustible dust

of similar hazard characteristics

having resistivity of less than

5

ohm-centimeter.

10

Group F: Atmospheres containing

•

carbon black, charcoal, coal or coke

dust.

Group G: Atmospheres containing

•

combustible dust having resistivity of

5

ohm-centimeter or greater.

10

Division I: A location in which ignitable

•

concentrations of flammable material

exist under normal operating conditions.

Division II: Locations in which flammable

•

materials will normally be confined

within closed containers and escape

only in the case of accidental rupture,

breakdown or during maintenance

operations. Any equipment approved

for Division I is automatically also

approved for Division II.

Selection and application of electric unit

heaters should consider the location,

classification and properties of flammable

vapors, liquids, gases, dusts and fibers

which may be present. Each room,

section or area should be considered

individually.

For further information consult National

Electric Code and National Fire Prevention

Association (ANSI) standards. All models

conform to OSHA requirements when

mounted at any height.

Installation Conditions

1

Refer to owner’s manual.

Model UHXA

2

The Trane explosion-proof electric unit

heaters have been listed by the

Underwriters Laboratories for maximum

surface temperatures. Use only in

atmospheres having an ignition

temperature higher than 165°C (T3B) for

Class I and Class II operation.

3

Altitude restrictions — see specification

table.

4

Heater must be installed in permanently

mounted upright position and connected

to fixed power supply.

5

Do not operate in atmospheres corrosive

to steel and aluminum.

13UH-PRC003-EN

Page 14

Selection

Procedure

Model UHEC, UHRA, UHXA, UHWA,

UHCA, UHAA

Calculate the heating loads using the

NEMA, ASHRAE, or other accepted

heating load calculation method.

Determine the quantity and size of unit

heaters to be used. To maintain uniform

temperature and recommended air

circulation, it is suggested that cfm should

be adequate to accomplish three air

changes per hour.

For maximum comfort, the use of smaller

units with lower airflows is suggested to

provide more uniform temperature and

even airflow. In warehouses and storage

areas where uniform heat distribution

and temperature control is of lesser

importance, it is desirable to use fewer

units with greater capacity.

Unit heaters mounted in the horizontal

discharge position are most effective

when heat is directed along the perimeter

of the building wall with the airflow of

each unit supporting the airflow of the

other units to create a constant flow of

warm air.

Model UHEC and Model UHRA

Unit heaters in the vertical position are

ideal for use in high ceiling areas and

areas where low mounting heights

would interfere with personnel or

equipment activity. Units mounted in the

vertical discharge position should not be

mounted higher than the unit’s published

maximum mounting height ratings.

When unit heaters are used to temper

areas such as loading dock doors, one or

more units should be arranged to

blanket the exposed opening.

UH-PRC003-EN14

Page 15

Model Number

Model UHEC,

Model UHEC

Digits 1-3 — Electric Unit Heater

Digit 4 — Development Sequence

Digits 5-6 — Unit Capacity

03 — 3.3 kW

05 — 5 kW

07 — 7.5 kW

10 — 10 kW

15 — 15 kW

20 — 20 kW

25 — 25 kW

30 — 30 kW

40 — 40 kW

50 — 50 kW

Digit 7 — Element Phase

1 — Single-phase

2 Single-phase/three-phase

(field convertible)

3 — Three-phase

Digit 8 — Element and Motor Voltage

A — 208 V

B — 240/208 V

C — 277 V — Single-phase only

D — 480 V — Three-phase only

Digit 9 — 24-Volt Control Transformer

0 — None - wired for direct line voltage

A — Transformer - for 24-volt control

circuits

Digit 10 — Design Sequence

Digit 11 — Contactors

0 — None - wired for direct line voltage

A — Contactor - for 24-volt control circuits

Description

Model UHRA

Digits 1-3 — Electric Hose-Down Corrosion

Resistant Unit Heater

Digit 4 — Development Sequence

Digits 5-6 — Unit Capacity

03 — 3.3 kW

05 — 5 kW

07 — 7.5 kW

10 — 10 kW

15 — 15 kW

20 — 20 kW

25 — 25 kW

30 — 30 kW

40 — 40 kW

48 — 48 kW

Digit 7 — Element Phase

1 — Single-phase

3 — Three-phase

Digit 8 — Element Voltage

A — 208 V

G — 240 V

C — 277 V

D — 480 V

F — 600 V

Digit 9 — 24-Volt Control

Transformer/Relay

A — Transformer/Relay — Standard

Digit 10 — Design Sequence

Digit 11 —Thermostat/off/on/fan switch

— Factory installed and wired

T — Thermostat/off/on/fan switch —

Standard

UHRA, UHXA

Model UHXA

Digits 1-3 —

Electric Explosion-Proof

Unit Heater

Digit 4 — Development Sequence

Digits 5-6 — Unit Capacity

03 — 3 kW

05 — 5 kW

07 — 7.5 kW

10 — 10 kW

15 — 15 kW

20 — 20 kW

25 — 25 kW

Digit 7 — Element Phase

1 — Single Phase

3 — Three Phase

Digit 8 — Voltage

A — 208 Volts

B — 240 Volts

D — 480 Volts

F — 600 Volts

Digit 9 — Control Voltage

1 — 24 Volts (STD)

2 — 120 Volts (For 208, 240 & 480 Volts only)

3 — 208 Volts (For 208 Volts only)

4 — 240 Volts (For 240 Volts only)

Digit 10 — Design Sequence

Notes:

1. Available in 3 phase only.

2. Available in 480 volts or 600 volts,

3 phase only.

3. Available for 3 kW, 5 kW and 7.5 kW in

208 and 240 volts and 10 kW in 240 volts

only.

15UH-PRC003-EN

Page 16

Model Number

Description

Model UHWA

Digits 1-3: Unit Type

UHW = Electric Wall Mounted Unit Heater

Digit 4: Development Sequence

Digits 5 - 6: Unit Capacity

02 = 2 kW

03 = 3 kW

04 = 4 kW

05 = 5 kW

Digit 7: Element Phase

1 = 1 Phase/60 Cycle

3 = 3 Phase/60 Cycle

Digit 8: Element and Motor Voltage

A = 208 Volt

B = 240 Volt

C = 277 Volt

Digit 9: Unit Series

2 = Unit Series 20

5 = Unit Series 50

Model UHWA

A = 4” (102 mm) Ext Surface Mounted

(20 Series)

B = 2” (51 mm) Ext Semi-Recessed

(20 Series)

C = 1” (25 mm) Ext Semi-Recessed

(20 Series)

D = 4” (102mm) Ext Surface Mounted

(50 Series)

E = 2” (51 mm) Ext Semi-Recessed

(50 Series)

F = 1” (25 mm) Ext Semi-Recessed

(50 Series)

Digit 14: Wall Mounted Line Voltage Thermostat

1 = DPST 1-Phase Line Voltage

2 = DPST 1-Phase Tamper Resistant

3 = DPST 3-Phase Line Voltage

4 = SPST Pilot Duty Line Voltage

5 = SPST Pilot Duty Tamper Resistant

Digit 15: Contactors

H = Line Voltage

J = 24V

K = 120V

Digit 10: Current Design Sequence

Digit 11: Built-in Thermostat

0 = None

T = Unit Mounted Tamper Proof

Thermostat

Digit 12: Wall Box

2 = Series 20 Wall Box

5 = Series 50 Wall Box

Digit 13: Extension Sleeves

0 = No Extension Sleeves

Digit 18: Circuit Breaker

L = Unit Mounted

Digit 19: Transformer 24 Volt

M = 24V Transformer

Digit 20: Transformer 120 Volt

P = 120V Transformer

UH-PRC003-EN16

Page 17

Model Number

Description

Model UHCA

Digit 1-3: Unit Type

UHC = Electric Ceiling Mounted Commercial

Heater

Digit 4: Development Sequence

Digits 5-6: Unit Capacity

02 = 2 kW

03 = 3 kW

04 = 4 kW

05 = 5 kW

Digit 7: Element Phase

1 = 1 Phase/60 Cycle

3 = 3 Phase/60 Cycle

Digit 8: Element and Motor Voltage

A = 208 Volt

B = 240 Volt

C = 277 Volt

Digit 9: Unit Series

2 = Surface Mounted, Unit Series 70

5 = Recess Mounted, Unit Series 80

Digit 10: Current Design Sequence

Digit 12-13: Unit Mounted Thermostat

T1 = Single Pole Thermostat

T2 = Double Pole Thermostat

Model UHCA

Digit 19: Control Panels

A = 24V Control Panel for 208V, 1-Contactor

B = 24V Control Panel for 240V, 1-Contactor

C = 24V Control Panel for 277V, 1-Contactor

D = 24V Control Panel for 208V, 2-Contactor

E = 24V Control Panel for 240V, 2-Contactor

F = 24V Control Panel for 277V, 2-Contactor

G = 24V Control Panel for 208V, 3-Contactor

H = 24V Control Panel for 240V, 3-Contactor

J = 24V Control Panel for 277V, 3-Contactor

1 = 120V Control Panel for 208V, 1-Contactor

2 = 120V Control Panel for 240V, 1-Contactor

3 = 120V Control Panel for 277V, 1-Contactor

4 = 120V Control Panel for 208V, 2-Contactor

5 = 120V Control Panel for 240V, 2-Contactor

6 = 120V Control Panel for 277V, 2-Contactor

7 = 120V Control Panel for 208V, 3-Contactor

8 = 120V Control Panel for 240V, 3-Contactor

9 = 120V Control Panel for 277V, 3-Contactor

Digit 20: Low Voltage Thermostat Option

0 = No Low Voltage T-Stat

7 = Low Voltage T-Stat

Digit 21: Thermal Relay with Transformer

0 = No Thermal Relay

A = SPST Relay w/Transformer

Digit 22: Tamper Proof Kit

8 = Tamper Proof Kit

Digit 14: Unit Mounted Disconnect

S = Unit Mounted Disconnect Switch

Digit 15-16: Unit Mounted Relay

R1 = Unite Mounted 24 Volt Transformer/Relay

R = Unit Mounted Line Voltage Relay

R2 = Unit Mounted 120 Volt Relay

Digit 17: Plaster Trim

A = Plaster Trim

Digit 18: Wall Mounted Line Voltage Thermostat

1 = DPST 1-Phase Line Voltage Thermostat

2 = DPST 1-Phase Tamper Resistant Thermostat

3 = DPST 3-Phase Line Voltage Thermostat

4 = SPST Pilot Duty Line Voltage Thermostat

5 = SPST Pilot Duty Tamper Resistant

Thermostat

17UH-PRC003-EN

Page 18

Model Number

Description

Model UHAA

Digit 1 - 3: Unit Type

UHA = Electric Architectural Wall Heater

Digit 4: Development Sequence

Digits 5–6: Unit Capacity

15 = 1.5 kW

02 = 2 kW

03 = 3 kW

04 = 4 kW

48 = 4.8 kW

Digit 7: Element Phase

1 = 1 Phase/60 Cycle

Digit 8: Element and Motor Voltage

A = 208 Volt

B = 240 Volt

C = 277 Volt

E = 120 Volt

Model UHAA

Digit 9: Built-in Thermostat

T = Unit Mounted Tamperproof Thermostat

Digit 10: Current Design Sequence

Digit 11: Unit Mounted Disconnect

D = Unit Mounted Disconnect Switch

Digit 12: Day/Night Relay

0 = None

R = Unit Mounted Day/Night Relay

Digit 13: Surface Mounting Adapter Option

0 = None

A = 3320EX33 Surface Mounting Adapter

UH-PRC003-EN18

Page 19

General Data Model UHEC

Table GD-1 — Model UHEC

Unit Capacity and Std. Max. Circuit Wire At Air Rise Air Mounting

Model kW Btu/Hr Motor Element Control Amp Fuse Gauge Motor Data Outlet @ Outlet Throw Height (Ft)

Number Rating (000) Voltage Phase Voltage Rating Size (60°C) Hp Rpm (Cfm) (F) (Ft) Horiz. Vert.

UHEC-031A0C0 3.3 11.2 208 1 208 15.9 20A 12G 1/125 1550 400 26 12 9 9

UHEC-031B0C0 3.3/2.5 11.2/8.5 240/208 1 240/208 13.7/11.9 20A/15A 12GA/14GA 1/1 25 1550 400 26 12 9 9

UHEC-031AACA 3 .3 11.2 208 1 24 15.9 20A 12G 1/125 1550 400 26 12 9 9

UHEC-032A0C0 3.3 11.2 208 1-3 208 15.9/9.2† 20A 12GA 1/125 1550 400 26 12 9 9

UHEC-032B0C0 3.3/2.5 11.2/8.5 240/208 1-3 240/208 13.7/11.9 20A/15A 12GA/14GA 1/125 1550 400 26 12 9 9

UHEC-031C0C0 3.3 11.2 277 1 277 11.9 15A 14GA 1/125 1550 400 26 12 9 9

UHEC-031CACA 3.3 11.2 277 1 24 11.9 15A 14G 1/125 1550 400 26 12 9 9

UHEC-033DACA 3 .3 11.2 480 3 24 4.0 15A 14GA 1/125 1550 400 26 12 9 9

UHEC-031BACA 3.3/2.5 11.2/8.5 240/208 1 24 13.7/11.9 20A/15A 12GA/14GA 1/125 1550 400 26 12 9 9

UHEC-032AACA 3 .3 11.2 208 1-3 24 15.9/9.2† 20A 12GA 1/125 1550 400 26 12 9 9

UHEC-032BACA 3.3/2.5 11.2/8.5 240/208 1-3 24 13.7/11.9 20A/15A 12GA/14GA 1/125 1550 400 26 12 9 9

UHEC-051A0C0 5.0 17.1 208 1 208 24.1 35A 8GA 1/125 1550 400 40 12 9 9

UHEC-052AACA 5 .0 17.1 208 1-3 24 24.1/13.9 35A 8GA 1/125 1550 400 40 12 9 9

UHEC-051B0C0 5.0/3.7 17.1/12.8 240/208 1 240/208 20.9/18.1 30A/25A 10GA/10GA 1/1 25 1550 400 40 12 9 9

UHEC-052A0C0 5.0 17.1 208 1-3 208 24.1/13.9†35A 8GA 1/125 1550 400 40 12 9 9

UHEC-052B0C0 5.0/3.7 17.1/12.8 240/208 1-3 240/208 20.9/18.1 30A/25A 10GA/10GA 1/1 25 1550 400 40 12 9 9

UHEC-052BACA 5.0/3.7 17.1/12.8 240/208 1-3 24 20.9/18.1 30A/25A 10GA/10GA 1/125 1550 400 40 12 9 9

UHEC-051C0C0 5.0 17.1 277 1 277 18.1 25A 10GA 1/125 1550 400 40 12 9 9

UHEC-053DACA 5 .0 17.1 480 3 24 6.1 15A 14GA 1/125 1550 400 40 12 9 9

UHEC-051AACA 5 .0 17.1 208 1 24 24.1 35A 8GA 1/125 1550 400 40 12 9 9

UHEC-051BACA 5.0/3.7 17.1/12.8 240/208 1 24 20.9/18.1 30A/25A 10GA/10GA 1/125 1550 400 40 12 9 9

UHEC-05ACACA 5.0 17.1 277 1 24 18.1 25A 10GA 1/125 1550 400 40 12 9 9

UHEC-072AACA 7 .5 25.6 208 1-3 24 36.1 20.8 50A 6GA 1/50 1550 700 34 22 10 12

UHEC-072BACA 7.5/5.6 25.6/19.2 240/208 1-3 24 31.3/27.1 40A/35A 8GA/8GA 1/50 1550 700 34 22 10 12

UHEC-071CACA 7.5 25.6 277 1 24 27.1 35A 8GA 1/50 1550 700 34 22 10 12

UHEC-073DACA 7 .5 25.6 480 3 24 9.1 15A 14GA 1/50 1550 700 34 22 10 12

UHEC-102AACA 10.0 34.1 208 1-3 24 47.8/27.7†60A 4GA 1/50 1550 700 45 22 10 14

UHEC-102BACA 10.0/7.5 34.1/25.6 240/208 1-3 24 42.2/36.1 60A/50A 4GA/6GA 1/50 1550 700 45 22 10 14

UHEC-101CACA 10.0 34.1 277 1 24 36.1 50A 6GA 1/50 1550 700 45 22 10 14

UHEC-103DACA 10.0 34.1 480 3 24 12.1 20A 12GA 1/50 1550 700 45 22 10 14

UHEC-153AACA 15.0 51.2 208 3 24 41.7 60A 4GA 1/20 1550 1100 43 32 11 20

UHEC-153BACA 15.0/11.2 51.2/38.4 240/208 3 24 36.1/31.3 50A/40A 6GA/6GA 1/20 1550 1100 43 32 11 20

UHEC-153DACA 15.0 51.2 480 3 24 18.1 25A 10GA 1/20 1550 1100 43 32 11 20

UHEC-203BACA 19.7/14.8 67.2/50.5 240/208 3 24 47.8/41.1 70A/60A 4GA/4GA 1/20 1550 1100 57 32 12 18

UHEC-203DACA 20.0 68.3 480 3 24 24.1 35A 8GA 1/20 1550 1100 57 32 12 18

UHEC-253AACA 25.0 85.3 208 3 24 69.5 90A 2GA 1/12 1550 2000/1800 40/44 45 12 22

UHEC-253BACA 25.0/18.7 85.3/64.0 240/208 3 24 60.2/52.1 80A/70A 3GA/4GA 1/12 1550 2000/1800 40/44 45 12 22

UHEC-253DACA 25.0 85.3 480 3 24 30.1 40A 8GA 1/15 1550 2000/1800 40/44 45 12 22

UHEC-303AACA 30.0 102.4 208 3 24 83.4 110A 1GA 1/12 1550 2000/1800 47/53 40 12 20

UHEC-303BACA 30.0/22.5 102.4/76.8 240/208 3 24 72.3/62.5 100A/80A 1GA/3GA 1/12 1550 2000/1800 47/53 40 12 20

UHEC-303DACA 30.0 102.4 480 3 24 36.2 50A 6GA 1/15 1550 2000/1800 47/53 40 12 20

UHEC-403AACA 40.0 136.5 208 3 24 111.2 150A 1/0* 1/4 1550 3100/2800 40/45 55 15 24

UHEC-403BACA 40.0/30.0136.5/102.4 240/208 3 24 96.4/83.4 125A/110A 1/0/1GA 1/4 1550 3100/2800 40/45 55 15 24

UHEC-403DACA 39.0 133.1 480 3 24 47.0 70A 4GA 1/5 1550 3100/2800 40/45 55 15 24

UHEC-503AACA 50.0 170.6 208 3 24 139.0 175A 2/0* 1/4 1550 3100/2800 51/56 50 15 22

UHEC-503BACA 50.0/37.5170.6/128.0 240/208 3 24 120.5/104.3 175A/175A 2/0/2/0 1/4 1550 3100/2800 51/56 50 15 22

UHEC-503DACA 50.0 170.6 480 3 24 60.3 80A 3GA 1/5 1550 3100/2800 51/56 50 15 22

Notes: 1. Maximum amp rating indicates single-phase on those units suitable for both single and three-phase. 2. 25 through 50 kW models are wired for two-stage, low voltage control. These units

are also equipped with two-speed motors for Hi-Lo fan operation with addition of fan switch option. 3. Dual voltage unit ratings indicate highest voltage performance. 4. 1 kW equals 3,413 BTU.

*Supply wire on these models should have insulation rated 75°C minimum.

† Amp Rating for three-phase operation.

Element Min. Supply Airflow Approx. Horiz. Rec. Max.

Electrical Data Air Delivery Data

7.9/6.9†

7.9/6.9†

12.1/10.4†

12.1/10.4†

20.8

†

18.1/15.6†

24/20.8†

19UH-PRC003-EN

Page 20

General Data Model UHEC

Table GD-2 — Model UHEC — Metric

Unit Heater Airflow Approx. Horiz. Rec. Max

Capacity at Air Rise Air Mounting

kW Motor Data Outlet @ Outlet Throw Height (M)

Rating Watts R.P.S. (L/S) (C) (M) Horizontal Vertical

3.3 6 25.8 189 14.4 3.7 2.7 2.7

5.0 6 25.8 189 22.2 3.7 2.7 2.7

7.5 14 25.8 330 18.9 6.7 3.0 3.7

10 14 25.8 330 25.0 6.7 3.0 4.3

15 37 25.8 519 23.9 9.8 3.4 6.1

20 37 25.8 519 31.7 9.8 3.7 5.5

25 62 25.8 944/ 22.2/ 13.7 3.7 6.7

25 50 25.8 944/ 22.2/ 13.7 3.7 6.7

480/3 Mtr 849 24.4 13.7 3.7 6.7

30 62 25.8 944/ 26.1/ 12.2 3.7 6.1

30 50 25.8 944/ 26.1/ 12.2 3.7 6.1

480/3 Mtr 849 29.4 12.2 3.7 6.1

40 186 25.8 1463/ 22.2/ 16.8 4.6 7.3

40 149 25.8 1463/ 22.2/ 16.8 4.6 7.3

480/3 Mtr 1321 25.0 16.8 4.6 7.3

50 186 25.8 1463/ 28.3/ 15.2 4.6 6.7

50 149 25.8 1463/ 28.3/ 15.2 4.6 6.7

480/3 Mtr 1321 31.1 15.2 4.6 6.7

Note 1. 25 through 50 kW models are equipped with two-speed motors for Hi-Lo fan operation with addition of fan switch

option.

849 24.4 13.7 3.7 6.7

849 29.4 12.2 3.7 6.1

1321 25.0 16.8 4.6 7.3

1321 31.1 15.2 4.6 6.7

UH-PRC003-EN20

Page 21

General Data Model UHRA

Table GD-3 — Model UHRA

Unit Motor &

Model Heater Max

Number kW Volts/ Control Amp Motor Motor

UHRA Rating Btu/Hr Phase Volts Rating H P RPM

031AAAT 208/1 15.9

033AAAT 208/3 9.2

031GAAT 240/1 13.8

033GAAT 3.3 11,200 240/3 24 8.0 35 mhp 1550

031CAAT 277/1 12.0 (21 w) (26 rps)

033DAAT 480/3 4.0

033FAAT 600/3 3.2

051AAAT 208/1 24.1

053AAAT 208/3 13.9

051GAAT 240/1 20.9

053GAAT 5.0 17,100 240/3 24 12.1 35 mhp 1550

051CAAT 277/1 18.1 (21 w) (26 rps)

053DAAT 480/3 6.1

053FAAT 600/3 4.9

071AAAT 208/1 36.1

073AAAT 208/3 20.9

071GAAT 240/1 31.3

073GAAT 7.5 25,600 240/3 24 18.1 35 mhp 1550

071CAAT 277/1 27.1 (21 w) (26 rps)

073DAAT 480/3 9.1

073FAAT 600/3 7.3

101AAAT 208/1 48.1

103AAAT 208/3 27.8

101GAAT 240/1 41.7

103GAAT 10 34,130 240/3 24 24.1 35 mhp 1550

101CAAT 277/1 36.2 (21 w) (26 rps)

103DAAT 480/3 12.1

103FAAT 600/3 9.7

151AAAT 208/1 72.2

153AAAT 208/3 41.7

151GAAT 240/1 62.5

153GAAT 15 51,200 240/3 24 36.2 35 mhp 1550

153DAAT 480/3 18.1 (21 w) (26 rps)

153FAAT 600/3 14.5

203AAAT 208/3 55.6

203GAAT 2 0 68,260 240/3 24 48.2 1/3 1625

203DAAT 480/3 24.1 (249 w) (27 rps)

203FAAT 600/3 19.3

253AAAT 208/3 69.5

253GAAT 2 5 85,325 240/3 24 60.3 1/3 1625

253DAAT 480/3 30.2 (249 w) (27 rps)

253FAAT 600/3 24.1

303AAAT 208/3 83.4

303GAAT 3 0 102,390 240/3 24 72.3 1/3 1625

303DAAT 480/3 36.2 (249 w) (27 rps)

303FAAT 600/3 29.0

403DAAT 40 136,520 480/3 24 48.2 1/3 1625

403FAAT 600/3 38.6 (249 w) (27 rps)

483DAAT 48 163,824 480/3 24 57.9 1/3 1625

483FAAT 600/3 46.3 (249 w) (27 rps)

Table GD-4 — Air Delivery Data

Unit F Deg.

Model Temp. Ai r Rec.

Number Cfm FPM Rise Throw Mtg.

UHRA kW Outlet Outlet Outlet Feet Height

031AAAT

033AAAT

031GAAT

033GAAT 3.3 400 500 26°F 20 Ft. 6 Ft.

031CAAT (189 L/S) (2540 MM/S) (-3.3°C) (6.1 M) (1.8 M)

033DAAT

033FAAT

051AAAT

053AAAT

051GAAT

053GAAT 5.0 400 500 40°F 20 Ft. 6 Ft.

051CAAT (189 L/S) (2540 MM/S) (4.4°C) (6.1 M) (1.8 M)

053DAAT

053FAAT

071AAAT

073AAAT

071GAAT

073GAAT 7.5 400 500 60°F 20 Ft. 6 Ft.

071CAAT (189 L/S) (2540 MM/S) (16°C) (6.1 M) (1.8 M)

073DAAT

073FAAT

101AAAT

103AAAT

101GAAT

103GAAT 10 700 660 45°F 28 Ft. 6 Ft.

101CAAT (330 L/S) (3353 MM/S) (7.2°C) (8.5 M) (1.8 M)

103DAAT

103FAAT

151AAAT

153AAAT

151GAAT

153GAAT 15 700 660 68°F 28 Ft. 6 Ft.

153DAAT (330 L/S) (3353 MM/S) (20°C) (8.5 M) (1.8 M)

153FAAT

203AAAT

203GAAT 2 0 1400 1000 45°F 35 Ft. 6 Ft.

203DAAT (661 L/S) (5080 MM/S) (7.2°C) (10.7 M) (1.8 M)

203FAAT

253AAAT

253GAAT 2 5 1400 1000 56°F 35 Ft. 6 Ft.

253DAAT (661 L/S) (5080 MM/S) (13.3°C) (10.7 M) (1.8 M)

253FAAT

303AAAT

303GAAT 3 0 1400 1000 68°F 35 Ft. 6 Ft.

303DAAT (661 L/S) (5080 MM/S) (20°C) (10.7 M) (1.8 M)

303FAAT

403DAAT 40 1800 1000 70°F 42 Ft. 6 Ft.

403FAAT (849 L/S) (5080 MM/S) (21°C) (12.8 M) (1.8 M)

483DAAT 48 1800 1000 84°F 42 Ft. 6 Ft.

483FAAT (849 L/S) (5080 MM/S) (29°C) (12.8 M) (1.8 M)

21UH-PRC003-EN

Page 22

General Data

Model UHRA

Table GD-5 — Air Delivery Characteristics

Heater Distance from Heater

Capacity 6 Ft. 12 Ft. 24 Ft. Throw

(kW Rating) (1.8 M) (3.7 M) (7.3 M) Distance Weight

3.3, 5.0 210 80 25 36 Ft. 45 lbs.

7.5 (12.8 M/S) (4.9 M/S) (1.5 M/S) (11 M) (20.4 Kg)

10, 15 270 95 45 46 Ft. 55 lbs.

Velocity of Air Movement (FPM)

(16.5 M/S) (5.8 M/S) (2.7 M/S) (14 M) (24.9 Kg)

Table GD-6 — Air Delivery Characteristics

Heater Distance from Heater

Capacity 10 Ft. 20 Ft. 30 Ft. Throw

(kW Rating) (3.0 M) (6.1 M) (9.1 M) Distance Weight

20, 25, 750 450 300 55 Ft. 85 lbs.

30 (45.7 M/S) (27.4 M/S) (18.3 M/S) (16.8 M) (39 Kg)

40, 48 900 500 350 65 Ft. 130 lbs.

Velocity of Air Movement (FPM)

(54.9 M/S) (30.5 M/S) (21.3 M/S) (19.8 M) (59 Kg)

Table GD-7 — Unit Electrical Data

Model BTU/Hr.

Number Watts Output

UHRA-03 3.300 11,261

UHRA-05 5,000 17,062

UHRA-07 7,500 25,594

UHRA-10 10,000 34,125

UHRA-15 15,000 51,188

UHRA-20 20,000 68,250

UHRA-25 25,000 85,313

UHRA-30 30,000 102,375

UHRA-40 40,000 136,500

UHRA-48 48,000 163,800

UH-PRC003-EN22

Page 23

General Data

Model UHXA

Table GD-8 — Model UHXA

Unit Size UHXA Phase H P Amps Amps Hr. Deg. F Deg. C Ampacity Amps AWG

3 kW 033B1B 240/1

5 kW 051B1B 240/1

7.5 kW 071B1B 240/1

10 kW 103B1B 240/3

15 kW 153B1B 240/3

20 kW 203F1B 600/3 (373 W) 19.2 20.0 68260 26.2 14.6 25.1 30 10

25 kW 253F1B 600/3 (373 W) 24.1 24.9 85325 32.8 18.2 31.1 35 8

*Supply conductors must be suitable for 90°C

1. 1 watt equals 3.413 Btu.

2. 1 kW equals 3,413 Btu.

3. 24 volt control voltage is standard and includes built-in contactor and 24 volt control transfer.

Model No. Volts/ Motor Heater Line BTU/ Rise Rise Min. Cir. Fuse Wire

031A1B 208/1 14.4 16.3 20.4 25 10

033A1B 208/3 8.3 9.8 12.3 15 14

033B1B 240/3 (186W) 7.2 8.6 10.8 15 14

033D1B 480/3 3.6 4.3 5.4 15 14

033F1B 600/3 2.9 3.5 4.4 15 14

051A1B 208/1 24.0 26.0 32.4 35 8

053A1B 208/3 13.9 15.4 19.2 20 12

053B1B 240/3 (186 W) 12.0 13.4 16.8 20 12

053D1B 480/3 6.0 6.7 8.4 15 14

053F1B 600/3 4.8 5.4 6.8 15 14

071A1B 208/1 36.1 38.0 47.5 50 8

073A1B 208/3 20.8 22.3 27.9 30 10

073B1B 240/3 (186 W) 18.0 19.4 24.3 25 10

073D1B 480/3 9.0 9.7 12.2 15 14

073F1B 600/3 7.2 7.8 9.8 15 14

103A1B 208/3 27.8 29.3 36.6 40 8

101B1B 240/1 41.7 44.0 55.0 60 6

103D1B 480/3 (186 W) 12.0 12.7 15.9 20 12

103F1B 600/3 9.6 10.2 12.8 15 14

153A1B 208/3 41.6 43.5 54.4 60 6

153D1B 480/3 (186 W) 18.0 19.0 23.8 25 10

153F1B 600/3 14.4 15.2 19.0 20 12

203D1B 480/3

253D1B 480/3

1

/4 12.5 14.8 10239 16.6 9.2 18.5 20 12

1

/4 20.8 23.1 17065 27.6 15.3 28.9 30 10

1

/4 31.3 33.6 25598 41.4 23.0 42.0 45 8

1

/4 24.1 25.5 34130 21.7 12.1 31.8 35 8

1

/2 36.1 38.1 51195 19.2 10.7 47.6 50 8

1

/2 24.1 25.1 31.3 35 8

1

/2 30.1 31.1 38.8 40 8

Air Temp. Air Temp. Max Min*

23UH-PRC003-EN

Page 24

General Data Model UHXA

Table GD-9 — Model UHXA with 120 Volt Control Voltage

Unit Size UHXA Phase H P Amps Amps H r. Deg. F Deg. C Ampacity Amps AWG

Model No. Volts/ Motor Heater Line BTU/ Rise Rise Min. Cir. Fuse Wire

031A2B 208/1 14.4 16.3 20.4 25 10

3 kW 033B2B 240/1

033A2B 208/3 8.3 9.8 12.3 15 14

1

/4 12.5 14.8 10239 16.6 9.2 18.5 20 12

033B2B 240/3 (186W) 7.2 8.6 10.8 15 14

033D2B 480/3 3.6 4.3 5.4 15 14

051A2B 208/1 24.0 26.0 32.4 35 8

5 kW 051B2B 240/1

053A2B 208/3 13.9 15.4 19.2 20 12

1

/4 20.8 23.1 17065 27.6 15.3 28.9 30 10

053B2B 240/3 (186 W) 12.0 13.4 16.8 20 12

053D2B 480/3 6.0 6.7 8.4 15 14

071A2B 208/1 36.1 38.0 47.5 50 8

7.5 kW 071B2B 240/1

073A2B 208/3 20.8 22.3 27.9 30 10

1

/4 31.3 33.6 25598 41.4 23.0 42.0 45 8

073B2B 240/3 (186 W) 18.0 19.4 24.3 25 10

073D2B 480/3 9.0 9.7 12.2 15 14

103A2B 208/3 27.8 29.3 36.6 40 8

10 kW 103B2B 240/3

101B2B 240/1 41.7 44.0 55.0 60 6

1

/4 24.1 25.5 34130 21.7 12.1 31.8 35 8

103D2B 480/3 (186 W) 12.0 12.7 15.9 20 12

15 kW 153B2B 240/3

153A2B 208/3 41.6 43.5 54.4 60 6

153D2B 480/3 (186 W) 18.0 19.0 23.8 25 10

20 kW 203D2B 480/3

25 kW 253D2B 480/3

*Supply conductors must be suitable for 90°C.

1. 120 volt control voltage is standard and includes built-in contactor and 120 volt control transformer.

2. Not available for 600 volt heaters.

1

/2 36.1 38.1 51195 19.2 10.7 47.6 50 8

1

/2 (373 W) 24.1 25.1 68260 26.2 14.6 31.3 35 8

1

/2 (373 W) 30.1 31.1 85325 32.8 18.2 38.8 40 8

Air Temp. Air Temp. Max Min*

Table GD-10 — Model UHXA with 208 or 240 Volt Control Voltage

Unit Size UHXA Phase H P Amps Amps H r. Deg. F Deg. C Ampacity Amps AWG Voltage

Model No. Volts/ Motor Heater Line BTU/ Rise Rise Min. Cir. Fuse Wire Control

3 kW 033A3B 208/3

031A3B 208/1 14.4 16.3 20.4 25 10 208

1

/4 8.3 9.8 12.3 15 14 208

033B4B 240/1 (186 W) 12.5 14.8 10239 16.6 9.2 18.5 20 12 240

033B4B 240/3 7.2 8.6 10.8 15 14 240

5 kW 053A3B 208/3

051A3B 208/1 24.0 26.0 32.4 35 8 208

1

/4 13.9 15.4 19.2 20 12 208

051B4B 240/1 (186 W) 20.8 23.1 17065 27.6 15.3 28.9 30 10 240

053B4B 240/3 12.0 13.4 16.8 20 12 240

7.5 kW 073A3B 208/3

071A3B 208/1 36.1 38.0 47.5 50 8 208

1

/4 20.8 22.3 27.9 30 10 208

071B4B 240/1 (186 W) 31.3 33.6 25598 41.4 23.0 42.0 45 8 240

073B4B 240/3 18.0 19.4 24.3 25 10 240

10 kW 101B4B 240/1

103A3B 208/3 27.8 29.3 36.6 40 8 208

103B4B 240/3 (186 W) 24.1 25.5 31.8 35 8 240

15 kW 153A3B 208/3

1

/4 41.7 44.0 34130 21.7 12.1 55.0 60 6 240

1

/2 41.6 43.5 54.4 60 6 208

153B4B 240/3 (186 W) 36.1 38.1 51195 19.2 10.7 47.6 50 8 240

*Supply conductors must be suitable for 90°C.

1. Not available for 480 and 600 volt heaters.

Air Temp. Air Temp. Max Min*

UH-PRC003-EN24

Page 25

General Data Model UHXA

Table GD-11 — Model UHXA

Unit Size 3 kW, 5 kW & 7.5 kW 10 kW 15 kW, 20 kW & 25 kW

Capacities 3 kW 10,236 Btu 10 kW 34,120 Btu 15 kW 51,180 Btu

Available 5 kW 17,060 Btu 20 kW 68,240 Btu

UL Listing Class I, Group D, Divisions 1 & 2

UL Temperature Class I: T3B 165°C (329°F)

Code Class II: T3B 165°C (329°F)

CFM @ 70°F (21°C) 580 1500 2450

L/S @ 21°C (70°F) 274 708 1156

FPM 1000 1600 2000

MM/S 5080 8128 10160

Air Temperature Rise 3 kW 16.3°F 10 kW 21.0°F 15 kW 19.0°F

Horizontal 24 ft. 40 ft. 43 ft.

Throw 7.3 M 12.2 M 13.1 M

Max. Mtg. Height 8 ft. 10 ft. 13 ft.

from floor 2.4 M 3.1 M 4.0 M

Max. Operational 3 kW, 5 kW, 10 kW & 15 kW - 8000 ft. (2438 M)

Altitude 20 kW - 7000 ft. (2134 M)

Ambient Temperature Limits Min. -45°C, (-49°F)

RPM/RPS 1725/29 1725/29 1725/29

Propeller Fan — 3 wing, Aluminum 12” Dia. (305 mm) 16” Dia. (406 mm) 20” Dia. (508 mm)

Motor Motor Voltage/Phase same as element. PSC, Explosion-Proof, Permanently Lubricated, Ball Bearing

Heat Exchanger Heavy wall, liquid filled with immersion elements.

Core Material Steel with aluminum fins.

Heat Transfer Fluid Ethylene-glycol solution, protected to -45°C (-49°F).

Heating Elements Three, low watt density, immersion type copper sheathed.

Thermal Cut-Out Snap action capillary type rated 100,000 cycles pilot duty.

Relief Valve Stainless steel and aluminum construction, opens @ 200 PSI (1379 kPa).

Cabinet 14-gauge cold rolled steel, epoxy coated, individually adjustable louvers.

Fan Guard Wire, less than 1/4” (6.4 mm) spacing, plated, split design for easy removal.

Fasteners Zinc plated.

Conduit Material

Control Box Cast aluminum with oversized opening. (2) 1” (25.4 mm) NPS with conduits stops for field wiring.

Hanger Connections

Contactors Heavy-duty, break all ungrounded conductors rated 100,000 cycles @ full load. Built-in and prewired.

Control Transformer Built-in and prewired - 24 volt secondary (standard) and 120 volt (optional).

Control Circuits 24 volt standard on all models.

Remote wall mounted Explosion-proof 40-90°F operating range

Thermostats Models 22A, 125-277 VAC - 3/4 HP @ 125 VAC; 11/2 HP

TW161 & TW162 @ 250-277 VAC.

Built-in “T” Option 125 VA pilot duty Sensing Bulb and Capillary made from 300 Series Stainless Steel ASW Tube.

Heater Net Weight 3, 5 & 7.5 kW 10 kW 15, 20 & 25 kW

Shipping Weight 3, 5 & 7.5 kW 10 kW 15, 20 & 25 kW

7.5 kW 25,590 Btu 25 kW 85,300 Btu

Class II, Groups E, F & G, Divisions 1 & 2

9.1°C 11.7°C 10.6°C

5 kW 27.2°F 20 kW 25.5°F

15.1°C 14.2°C

7.5 kW 40.8°F 25 kW 32.3°F

22.7°C 17.9°C

7.5 kW & 25 kW - 5500 ft. (1676 M)

Max. 40°C, (104°F)

1/4 HP (186 W) 1/4 HP (186 W) 1/2 HP (373 W)

3

/4 (19.1 mm) rigid metal.

5

/8” (15.9 mm) NC tap, 2 holes.

120 volt optional on 208, 240 and 480 volt models.

Line voltage on 208 and 240 volt models only.

132 lbs (60 Kg) 158 lbs (72 Kg) 190 lbs (86 Kg)

167 lbs (76 Kg) 193 lbs (88 Kg) 225 lbs (102 Kg)

25UH-PRC003-EN

Page 26

Model UHWA

General Data

Series 20 and 50

Table GD-12 — Electric Wall-Mounted Unit Heaters — Series 20

Watts UHWA 233 + Motor Voltage Phase Lbs Kg BTU Air Rise Air Rise

2000 Watts 021B2AT -402 240 1 41 18.6 6,826 27 15

3000 Watts 031B2AT -408 240 1 41 18.6 10,239 41 23

4000 Watts 041C2AT -416 277 1 41 18.6 13,652 57 32

5000 Watts 051C2AT -426 277 1 41 18.6 17,065 73 41

Note: ONLY thermostat and/or contactor may be built-in on Series 20 wall heaters.

Model No. Order No. Element Element Ship Wt. Ship Wt. Degree F Degree C

021A2AT -400 208 1

021C2AT -404 277 1

031A2AT -406 208 1

031C2AT -410 277 1

041A2AT -412 208 1

041B2AT -414 240 1

043A2AT -418 208 3

043B2AT -420 240 3

051A2AT -422 208 1

051B2AT -424 240 1

053A2AT -428 208 3

053B2AT -430 240 3

Table GD-13 — Electric Wall-Mounted Unit Heaters — Series 50

Watts UHWA 2 33 + Motor Voltage Phase Lbs Kg BTU Air Rise Air Rise

2000 Watts 021B5AT -433 240 1 54 24.5 6,826 27 15

3000 Watts 031B5AT -439 240 1 55 24.9 10,239 41 23

4000 Watts 041C5AT -447 277 1 55 24.9 13,652 57 32

5000 Watts 051C5AT -457 277 1 55 24.9 17,065 73 41

Note: If circuit breaker and/or transformers are required, the Series 50 wall heater must be ordered. 1 Watt Equals 3.413 Btu.

Model No. Order No. Element Element Ship Wt. Ship Wt. Degree F Degree C

021A5AT -431 208 1

021C5AT -435 277 1

031A5AT -437 208 1

031C5AT -441 277 1

041A5AT -443 208 1

041B5AT -445 240 1

043A5AT -449 208 3

043B5AT -451 240 3

051A5AT -453 208 1

051B5AT -455 240 1

053A5AT -459 208 3

053B5AT -461 240 3

UH-PRC003-EN26

Page 27

Model UHCA

General Data

Series 70 and 80

Table GD-14 — Series 70 Electric Ceiling Surface Heaters

Model Order Element

Wa tt s UHCA 233 Voltage Phase Application Rating BTU Air Rise Air Rise

2000 021B7A -302 240 1 Surface 8.3 6,826 15 13.9

3000 031B7A -308 240 1 Surface 12.5 10,239 32 17.8

4000 041C7A -316 277 1 Surface 14.4 13,652 40 22.2

5000 051C7A -326 277 1 Surface 18.1 17,065 44 24.4

Surface Mounted Ceiling Heaters — Series 70 designed to be mounted to standard 4 inch (101.6 mm) ceiling

box furnished and installed by others. Approximate weight 32 lbs (14.5 kg) packed and shipped as complete

No. No. + Motor Element Mounting Amp *Degree F *Degree C

021A7A -300 208 1 Surface 9.6

021C7A -304 277 1 Surface 7.2

031A7A -306 208 1 Surface 14.4

031C7A -310 277 1 Surface 10.8

041A7A -312 208 1 Surface 19.2

041B7A -314 240 1 Surface 16.7

043A7A -318 208 3 Surface 11.1

043B7A -320 240 3 Surface 9.6

051A7A -322 208 1 Surface 24.1

051B7A -324 240 1 Surface 20.8

053A7A -328 208 3 Surface 13.9

053B7A -330 240 3 Surface 12.1

unit.

Table GD-15 — Series 80 Electric Ceiling Recessed Heaters

Model Order Element

Wa tt s UHCA 233 Voltage Phase Application Rating BTU Air Rise Air Rise

2000 021B8A -333 240 1 Recessed 8.3 6,826 15 13.9

3000 031B8A -339 240 1 Recessed 12.5 10,239 32 17.8

4000 041C8A -347 277 1 Recessed 14.4 13,652 40 22.2

5000 051C8A -357 277 1 Recessed 18.1 17,065 44 24.4

Recessed Mounted Ceiling Heaters — Series 80 packed as a complete unit. Contains junction box, heater box and grille. For

finished ceiling application, use plaster trim (PT3480) which is an optional accessory. Approximate weight 35 lbs (15.9 kg) for

use with 2’ (609.6 mm) x 2’ (609.6 mm) T-bar or hard surface.

* Use PT3480 plaster trim for Series 80 when recessed in a hard finished ceiling. Option Accessory.

Performance Data —

*Degree F (c) air rise measured at 710 fpm (3606.8 mm/s) and 425 cfm (201 l/s) in both 70 and 80 Series.

Throw designed for 8 foot (2438.4 mm) to 12 foot (3657.6 mm) ceilings.

DB RE 10-12 WATT = 63.9

No. No. + Motor Element Mounting Amp *Degree F *Degree C

021A8A -331 208 1 Recessed 9.6

021C8A -335 277 1 Recessed 7.2

031A8A -337 208 1 Recessed 14.4

031C8A -341 277 1 Recessed 10.8

041A8A -343 208 1 Recessed 19.2

041B8A -345 240 1 Recessed 16.7

043A8A -349 208 3 Recessed 11.1

043B8A -351 240 3 Recessed 9.6

051A8A -353 208 1 Recessed 24.1

051B8A -355 240 1 Recessed 20.8

053A8A -359 208 3 Recessed 13.9

053B8A -361 240 3 Recessed 12.1

27UH-PRC003-EN

Page 28

Model UHAA

General Data

Table GD-16 – Electrical Specifications and Ordering Information

Unit No. Volts kW Watts Btu/Hr Output Wgt Lbs Wgt Kg

UHAA151ETAD 120

UHAA151BTAD 240 1 .5 1500 5119 22 10

UHAA151ATAD 208

UHAA151CTAD 277

UHAA021BTAD 240

UHAA021ATAD 208 2 .0 2000 6825 22 10

UHAA021CTAD 277

UHAA031BTAD 240

UHAA031ATAD 208 3 .0 3000 10240 22 10

UHAA031CTAD 277

UHAA041BTAD 240

UHAA041ATAD 208 4 .0 4000 13650 22 10

UHAA041CTAD 277

UHAA481BTAD 240

UHAA481ATAD 208 4 .8 4800 16380 22 10

UHAA481CTAD 277

Notes: 1 watt equals 3.413 btu.

1000 Watts Equals 1 kW.

Series 3320

UH-PRC003-EN28

Page 29

Control Wiring Model UHXA

The Trane heaters have been designed

for explosion-proof service with single

and 3-phase inputs of 208, 240, 480 and

Single Phase Heater

with 24 Volt Control

L2

L1

Single Phase Heater

with 120 Volt Control

WD1

WD3 WD4

600 volts. They meet stringent UL

requirements. However, it is essential

that correct installation procedures be

24 Volt Control

WD1 – Single Phase

208, 240 Volt

WD2 – Three Phase

208, 240, 480 Volt

Three Phase Heater

with 24 Volt Control

WD2

120 Volt Control

WD3 – Single Phase

208, 240 Volt

WD4 – Three Phase

208, 240, 480 Volt

Three Phase Heater

with 120 Volt Control

followed to eliminate all potential hazards

arising from faulty installation.

Single Phase Heater

Line Voltage Control

208V or 240V Models

Only

600 Volt

Three Phase Heater

with 24 Volt Control

WD5

WD7

Line Voltage Control

WD5 – Single Phase

208, 240 Volt

WD6 – Three Phase

208, 240 Volt

600 Volt

WD7 – Three Phase

24 Volt Only

WD8 – Three Phase

120 Volt Only

Three Phase Heater

Line Voltage Control

208V or 240V Models

Only

WD6

600 Volt

Three Phase Heater

with 120 Volt Control

WD8

29UH-PRC003-EN

Page 30

Model UHWA

Controls

Control Systems

Type of Control WD Heater Type

Built-in thermostat control 1 20 & 50 (1)

Wall mounted thermostat, heater voltage, line duty. For single phase heaters use SP or DP (DP if used as a disconnect) 2 20 & 50 (1)

of sufficient capacity. For three-phase heaters use TW1512 which cycles two poles simultaneously.

Wall mounted, heater voltage, pilot duty, one or more heaters. Heater has built-in contactor with heater voltage coil. 3 20 & 50 (1)

Wall mounted, 120 V, pilot duty, one or more heaters. Heater has built-in contactor with 120 V coil. 4 20 & 50

Wall mounted, 24 V, pilot duty, one or more heaters. Heater has built-in contactor with 24 V coil. 4 20 & 50

Wall mounted, 24 V. Heater has built-in contactor with 24V coil and heater voltage/24 V transformer. 5 50 Only

Wall mounted, pilot duty, 120 V. Heater has built-in contactor with 120V coil and heater voltage/120 V transformer. 5 50 Only

(1) If built-in circuit breaker and/or built-in transformer are desired, 50 Series must be ordered.

Transformer with 24 V secondary (A1) available on all models.

Transformer with 120 V secondary (A2) available on following models only:

All three-phase models

277 V one-phase up to 4000 watts

208 and 240 V one-phase up to 3000 watts

Accessories

For accessory built-in controls:

T Built-in thermostat breaks all

ungrounded conductors in OFF

position.

C Circuit breaker (Series 50 only)

arranged to be disconnected

before removal of front with line

side terminals covered for safe

maintenance. Additional control

circuit switch installed if required.

R Built-in contactor holding coil same

as heater voltage.

R1 Built-in contactor 24V holding coil.

R2 Built-in contactor 120V holding coil.

A1 Built-in control transformer, (Series

50 only) 24V secondary.

A2 Built-In control transformer, (Series

50 only) 120V secondary available

For semi-recessed and surface

mounting:

20 Series

20 EX 34 Extension sleeve for

full surface mounting.

20 EX 16 Extension sleeve for

extending front additional

2” (50.8 mm) from finished

wall.

Heater recesses 2

1

/4”

(57.2 mm).

20 EX 8 Extension sleeve for

extending front additional

1” (25.4 mm) from finished

wall.

Heater recesses 3

1

/4”

(82.6 mm).

20 Box Must be used on all heater

installations.

Series 20 and 50

50 Series

50 EX 34 Extension sleeve for full

50 EX 16 Extension sleeve for

50 EX 8 Extension sleeve for

50 Box Must be used on all heater

surface mounting.

extending front additional

2” (50.8 mm) from finished

wall.

Heater recesses 2

1

/4”

(57.2 mm).

extending front additional

1” (25.4 mm) from finished

wall.

Heater recesses 3

1

/4”

(82.6 mm).

installations.

on all three-phase heaters, up to

3000 watts on 208 and 240V,

one - phase and up to 4000 watts on

277V, 1-phase.

UH-PRC003-EN30

Page 31

Model UHCA

Control Wiring

Optional Control Systems

Heaters operated from wall mounted,

•

line voltage, heavy-duty thermostats.

Direct Line Voltage. More than one

•

heater may be controlled from one

thermostat providing total amperage of

heaters does not exceed thermostat

rating.

Single-Phase Heaters. Use any good

•

quality single pole thermostat of sufficient

ampacity. Use double pole thermostat if

positive off is desired. Knob operated and

tamper resistant type available.

Three-Phase Heaters. Use TW1512.

•

Makes and breaks two poles

simultaneously.

Control Panels. For control of one or

•

more single or three-phase ceiling

heaters from one 24V or 120V

thermostat. Panels are in NEMA 1

enclosures and have one or more

30 amp, three-pole, 600 VAC contactor(s),

operating voltage to control voltage

transformer and transformer fusing.

(User must provide separate circuit for

each contactor.)

Series 70 and 80

Optional

Unit Mounted Controls for Series 80

•

Recessed Ceiling Heater only shall be

factory installed and wired on the

Heater.

T2 = Tamper Proof Built-in Thermostat

Double Pole.

S = Disconnect Switch.

R1 = Transformer with 24 volt

Secondary and Relay for low

voltage control.

R = Relay — Coil operates on heater

supply voltage.

R2 = Relay — Provided with 120 volt

control coil.

Three-phase heaters shall be used with

•

a control panel when controlled by a low

voltage (24V or 120V) thermostat.

Low Voltage Thermostat (Wall

•

Mounted). Heaters operated from wall

mounted, low voltage thermostats.

Thermal Relay With Built-In Line

•

Voltage/24 Volt Transformer. Relay with

built-in line volt/24 V transformer are

provided for use with wall mounted low

voltage thermostat. For remote mounting

only.

Single Phase

Typical heater element, motor, zero

voltage reset thermal cut-out

Three Phase

Fan purge (off delay to dissipate

residual heat on shut off) supplied as a

standard control on heaters with factory

installed options.

31UH-PRC003-EN

Page 32

Dimensional

Unit Casing

Unit Casing (Inches)

Unit Size H W D

3.3-5 17 3/4 (451) 14 15/32 (368) 6 1/2 (165)

7.5-10 24 5/16 (618) 21 1/2 (546) 6 1/2 (165)

15-20 28 11/16 (729) 21 1/2 (546) 6 1/2 (165)

25-50 34 (864) 29 1/4 (743) 10 1/16 (256)

Data

Horizontal Air Discharge Vertical Air Discharge

Model UHEC

Weld-Nut Location Dimensions, Inches (mm)

Unit Size A B C D E F

3.3-5 3 1/32 (77) 5 1/4 (133) 2 7/16 (62) 1 5/32 (29) 11 5/32 (283) 5 7/16 (138)

7.5-10 7 17/32 (191) 5 1/4 (133) 3 1/2 (89) 1 7/8 (48) 16 1/16 (408) 6 3/8 (162)

15-20 7 17/32 (191) 5 1/4 (133) 3 1/2 (89) 1 7/8 (48) 20 7/16 (519) 6 3/8 (162)

25-50 10 27/32 (275) 8 13/16 (224) 6 13/16 (173) 1 7/8 (48) 26 1/2 (673) 5 5/8 (143)

Horizontal Vertical

Horizontal Air Discharge

HEATER

All dimensions approximate.

Certified prints available on request.

A

C

A

CEILING

B

Horizontal Wall/Ceiling Swivel Bracket Clearance Requirements (Inches)

Minimum Distance

Model Adjacent Mounting

Unit Mounting Ceiling Surface Floor Bracket Wt. Dimensions

Size Bracket To Unit To Unit To Unit* lbs. (Kg) A B C

3.3-5 A5105 12 (305) 12 (305) 84 (2134) 6 (2.7) 19 15/64 (487) 10 1/2 (267) 9 1/4 (235)

7.5-20 A5120 18 (457) 12 (305) 84 (2134) 9 (4.1) 23 (584) 12 (305) 19 1/8 (486)

25-50 A5150 18 (457) 12 (305) 84 (2134) 11 (5.0) 26 21/32 (677) 13 1/2 (343) 19 7/8 (505)

*Do not exceed unit’s maximum mounting height.

Vertical Mounting Bracket Clearance Requirements (Inches)

Minimum Distance

Model Adjacent Mounting

Unit Mounting Ceiling Surface Floor Bracket Wt. Dimensions

Size Bracket To Unit To Unit To Unit* lbs. (Kg) E F G

3.3-5 V5105 12 (305) 12 (305) 84 (2134) 9 (4.1) 26 (660) 9 1/8 (232) 18 3/4 (476)

7.5-20 V5120 18 (457) 24 (610) 84 (2134) 13 (5.9) 36 9/16 (929) 13 7/8 (352) 24 1/2 (622)

25-50 V5150 18 (457) 24 (610) 84 (2134) 13 (5.9) 42 (1067) 13 7/8 (352) 28 1/16 (713)

*Do not exceed unit’s maximum mounting height.

UH-PRC003-EN32

Page 33

Dimensional

Data

Vertical Air Discharge

Model UHEC

Louver Cone Diffuser

Louver Cone Diffuser Dimensions, in. (mm)

Unit Size P R S T

03 & 05 N/A N/A N/A N/A

07 & 10 11 5/8 (295.3) 14 1/4 (362.0) 6 1/2 (165.1) 1 3/4 (44.5)

15 & 20 11 5/8 (295.3) 14 1/4 (362.0) 6 1/2 (165.1) 1 3/4 (44.5)

25-50 17 1/8 (435.0) 21 (533.4) 9 3/4 (247.7) 2 3/4 (69.9)

33UH-PRC003-EN

Page 34

Dimensional

Data

3 kW thru 15 kW

Model UHRA

Dimensions shown in ( ) are in

millimeters

20 kW thru 48 kW

Unit Size A B C D E F G H

03,05,07 12” (305) 18” (457) 19 3/4” (502 15 1/4” (387) 16 1/2” (419) 6 Ft. (1.8 M) 8” (203) 6” (152)

10,15 14” (356) 19” (483) 21 3/4” (552) 15 1/4” (387) 18” (457) 6 Ft. (1.8 M) 8” (203) 6” (152)

20,25,30 16” (406) 27” (686) 28 3/4” (730) 19 1/2” (495) 17 1/2” (445) 6 Ft. (1.8 M) 15 1/2” (394) 4 1/2” (114)

40,48 18” (457) 31” (787) 30 3/4” (781) 19 1/2” (495) 19 1/2” (495) 6 Ft. (1.8 M) 21 3/4” (552) 2 3/4” (70)

Dimensions, in. (mm)

UH-PRC003-EN34

Page 35

Dimensional

Data

Physical Dimensions, in. (mm)

Unit C

Size A B 3 PH. 1 PH. D E F G

3-5 7.5 kW 17 3/4” 22 3/8” 19 3/4” 20 5/8” 16 1/4” 10 1/2” 14” 3”

10 kW 20 3/4” 26 3/8” 20 3/4” 21 5/8” 20 1/4” 11 1/2” 18” 4”

15-20 25 kW 24 3/4” 30 3/8” 22 1/2” — 24 1/4” 12 1/2” 22” 4 1/2”

Unit C

Size A B 3 PH. 1 PH. D E F G

3-5 7.5 kW (450.9) (568.3) (501.7) (523.9) (412.8) (266.7) (355.6) (76.2)

10 kW (527.1) (669.9) (527.1) (549.3) (514.4) (292.1) (457.2) (101.6)

15-20 25 kW (628.7) (771.5) (571.5) — (616.0) (317.5) (558.8) (114.3)

Dimensions shown in ( ) are in millimeters

Model UHXA

Mounting Bracket Kit

In examples HLPM and HLWM, heater

may be rotated horizontally at attachment

point as required.

HLHM

Ceiling Mounting Bracket

Simple and economical if adequate

overhead structure exists. Requires

1

/2” (13 mm) pipe, cut and threaded (not

supplied).

HLPM

Floor Mounting Bracket

Particularly useful in buildings with

insufficient strength to use other types of

mounts. Requires 3

(102 mm) O.D. — not supplied].

1

/2” (89 mm) pipe [4”

HLWM

Wall Mounting Bracket

Ideal for use in buildings that have

substantial walls. Arm only can also be

bolted directly to structural steel.

35UH-PRC003-EN

Page 36

Dimensional

Model UHWA

Dimensions shown in are inches (mm)

Data

Series 20 and 50

Typical Heater Element, Motor, “Zero Voltage Reset” Thermal

Cutout

Control System Wiring

Diagrams

UH-PRC003-EN36

Page 37

Dimensional

Model UHCA

Series 70 — Surface Mounted

Note: Dimensions shown in in inches

(mm)

Data

Series 70 and 80

Series 70 — Surfaced Details

Series 80 — Recessed

Mounted

37UH-PRC003-EN

Page 38

Dimensional

Model UHAA

Dimensions are shown in inches (mm)

Data

Series 3320

UH-PRC003-EN38

Page 39

Options Model UHEC

Dust Shield

Horizontal

Used On Wall Brackets Dust Shield

3.3 kW A5105 DS5105

7.5 kW to 20.0 kW A5120 DS5120

25.0 kW to 50.0 kW A5150 DS5150

Heater and

OSHA Fan Guards

Stratification Control Option

Electric UHEC unit heaters are an

efficient way to provide quick, efficient

heat when and where it’s required. A

wall thermostat with an optional

stratification thermostat makes the

Trane unit heater even more energy

efficient. The stratification thermostat

recovers trapped ceiling heat, saving

electrical energy. When ceiling

temperatures are high, the stratification

Accessory

Fan Guard

Installation

thermostat allows the fan to operate

without energizing the heating element.

Recovering this otherwise wasted heat

assures substantial energy savings.

Diffuser Options

Optional diffusers lend added air pattern versatility to individual vertical down blown installations as shown in illustrations.

Description Used On No. Max. Mtg. Ht. Dim. A Dim. B Pattern

1. Louver Diffuser (Standard) 3.3 & 5.0 kW STD 9’ (2.7 M) 20’ (6.1 M) 10’ (3.0 M)

Louvers can be individually 7.5 & 10.0 kW STD 12’ (3.7 M) 40’ (12.2 M) 22’ (6.7 M)

adjusted for rectangular 15.0 & 20.0 kW STD 18’ (5.5 M) 52’ (15.8 M) 30’ (9.1 M)

coverage over doorways as 25.0 & 30.0 kW STD 22’ (6.7 M) 75’ (22.9 M) 42’ (12.8 M)

an air curtain or to meet 40.0 & 50.0 kW STD 24’ (7.3 M) 84’ (25.6 M) 47’ (14.3 M)

rectangular floor pattern

heating requirements.

2. General Distribution 3.3 & 5.0 kW N/R 9’ (2.7 M) 15’ (4.6 M)

(No Diffuser) 7.5 & 10.0 kW N/R 12’ (3.7 M) 30’ (9.1 M)

Trane’s Airchute Venturi 15.0 & 20.0 kW N/R 18’ (5.5 M) 40’ (12.2 M)

permits general downflow air 25.0 & 30.0 kW N/R 22’ (6.7 M) 55’ (16.8 M)

pattern distribution as 40.0 & 50.0 kW N/R 24’ (7.3 M) 64’ (19.5 M)

required at a higher mounting

height.

3. Anemostat Diffuser (Optional) 3.3 & 5.0 kW N/A — — — —

For application where draft 7.5 & 10.0 kW AD5120 1 0’ (3.0 M ) 3 0’ (9.1 M)

restriction is required at lower 15.0 & 20.0 kW AD5120 15’ (4.6 M) 38’ (11.6 M)

unit mounting heights. 25.0 & 30.0 kW AD5150 1 7’ (5.2 M ) 50’ (15.2 M)

40.0 & 50.0 kW AD5150 20’ (6 .1 M) 60’ (18.3 M)

4. Louver Cone Diffuser 3.3 & 5.0 kW N/A 45 ° 90° 45° 90°

(Optional) 7.5 & 10.0 kW RD5120 — — — —

Individually adjustable blades 15.0 & 20.0 kW RD5120 10’ 3.0 M 14’ 4.3 M) 36’ 11.0 M 30’ 9.1 M

permit increased floor 25.0 & 30.0 kW RD5150 14’ 4.3 M 21’ 6.4 M 42’ 12.8 M 35’ 10.7 M

coverage at 45° open. 40.0 & 50.0 kW RD5150 20’ 6.1 M 30’ 9.1 M 62’ 18.9 M 44’ 13.4 M

Additional throw is 18’ 5.5 M 28’ 8.5 M 68’ 20.7 M 54’ 16.5 M

accomplished when blades

are 90° vertical. Allow higher

mounting height.

STD = Standard N/R = None Required N/A = Not Applicable

Model Diffuser

39UH-PRC003-EN

Page 40

Model UHEC

Model UHEC

Unit-Mounted Room and Stratification

Thermostats

Unit-mounted thermostats for field

installation are available in low voltage

(24V) for either single or two-stage

operation, and line voltage (up to 277V)

for single-stage operation. All room

thermostats have an adjustable

temperature setting range of 45°F (7.2°C)

to 90°F (32.2°C); and the stratification

thermostat has a range of 70°F (21.1°C) to

130°F (54.4°C).

Low voltage thermostats should only be

used with units provided with contactors

and a low voltage control transformer.

Line voltage thermostats can be used

with all units provided the thermostat’s

maximum amp and voltage ratings are

not exceeded. Line voltage thermostats

have a maximum amp rating of 25 amps,

and maximum voltage rating of 277V.

Two-stage thermostats can be used on

unit sizes 25 kW and above to provide

automatic two-stage heating operation.

Unit and Wall Mounted Summer-Fan

Switches

Unit mounted and wall mounted summerfan switches are available for line voltage

(up to 277V) and low voltage (24V).

Summer fan switches allow

fan only operation without energizing the

unit’s heating element. During the

nonheating season, the summer fan

switch will allow the unit’s fan to provide

air circulation without providing heat.

Options

Wall-Mounted Room Thermostat

Wall-mounted thermostats are available

in low voltage (24V) for either single or

two-stage operation, and line voltage (up

to 277V) for single-stage operation. All

Line voltage thermostats have an

adjustable temperature setting range of

40°F (4.4°C) to 90°F (32.2°C).

Single stage low voltage thermostats

have a range of 50°F (10°C) to 80°F

(26.7°C), and two-stage low voltage

thermostats have a range of 45°F (7.2°C)

to 85°F (29.4°C).

The same guidelines for the application of

unit-mounted thermostats are also

applicable to wall-mounted thermostats.

Unit and Wall Mounted Power

Disconnect Switches

Unit and wall mounted power disconnect

switches are available to provide a

positive disconnect of the unit from the

power supply. Two-pole and three-pole

power disconnect switches are available

with voltage ratings from 25 to 63 amps.

Model UHRA

Model UHRA

Remote 24-volt thermostat

•

Stainless steel wall/ceiling mounting

•

bracket (3.3-15 kW)

Cast iron painted mounting bracket

•

available on all units for wall/ceiling or

pipe mounting

Hanging bracket for use with

•

threaded rod

UH-PRC003-EN40

Page 41

Options Model UHXA

Mounting Bracket Kits

Trane makes three mounting kits

available — the HLPM Pipe Mounting

Bracket, the HLHM Ceiling Mounting

Bracket, and the HLWM Wall Mounting

Bracket. Each of these is illustrated and

described on page 20 of this brochure. To

order, specify the type of bracket with the