Page 1

Programming

Tracer™ MP580/581

Programmable

Controller

CNT-SVP01C-EN

Page 2

Page 3

Programming

Tracer™ MP581

Programmable Controller

CNT-SVP01C-EN

November 2005

Page 4

Tracer MP581 Programmable Controller Programming

This guide and the information in it are the property of American Standard Inc. and may not be used or reproduced in whole or in part,

without the written permission of American Standard Inc. Since Trane has a policy of continuous product improvement, it reserves the

right to change design and specification without notice.

Although Trane has tested the hardware and software described in this guide, no guarantee is offered that the hardware and software

are error free.

Trane reserves the right to revise this publication at any time and to make changes to its content without obligation to notify any

person of such revision or change.

Trane may have patents or patent applications covering items in this publication. By providing this document, Trane does not imply

giving license to these patents.

The following are trademarks or registered trademarks of American Standard Inc.: Climate Changer, Rover, Tracer, Tracer

®

™

™

Printed in the U.S.A.

© 2005 American Standard All rights reserved

Summit, and T-Series

The following are trademarks or registered trademarks of their respective companies or organizations: LonMark and LonTalk

®

and Neuron from Echelon Corporation.

CNT-SVP01C-EN

Page 5

Revision history

Document number

and date

CNT-SVP01C-EN

November 2005

Note: This document, in printed form or as an electronic file on a product CD, is accurate as of its publication date.

The electronic version of this document may display a more current publication date and a higher revision level than

this document.

Description

• Thumbwheel linear resistance values table added

CNT-SVP01C-EN

Page 6

NOTICE:

Warnings and Cautions appear at appropriate sections throughout this manual. Read these carefully:

WARNING

Indicates a potentially hazardous situation, which, if not avoided, could result in death or serious injury.

CAUTION

Indicates a potentially hazardous situation, which, if not avoided, may result in minor or moderate injury.

It may also be used to alert against unsafe practices.

CAUTION

Indicates a situation that may result in equipment or property-damage-only accidents.

The following format and symbol conventions appear at appropriate sections throughout this manual:

IMPORTANT

Alerts installer, servicer, or operator to potential actions that could cause the product or system to

operate improperly but will not likely result in potential for damage.

Note:

A note may be used to make the reader aware of useful information, to clarify a point, or to describe

options or alternatives.

CNT-SVP01C-EN

Page 7

Contents

Chapter 1 Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Tracer MP580/581 plug-in. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Using Rover service tool . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Accessing the Tracer MP580/581 . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Using online Help. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Chapter 2 Viewing status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Viewing the status of inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Viewing the status of binary and analog outputs . . . . . . . . . . . . . . . . . . 5

Overriding binary and analog outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Releasing binary and analog output overrides . . . . . . . . . . . . . . . . . . . . 9

Viewing the status of binary and analog variables . . . . . . . . . . . . . . . . . 9

Viewing application status. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Viewing Comm5 parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Viewing custom displays . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Changing binary and analog variables . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Overriding the occupancy mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Applying an occupancy override . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Releasing an occupancy override . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Chapter 3 Configuring the Tracer MP580/581 . . . . . . . . . . . . 19

CNT-SVP01C-EN v

Configuring EX2 expansion modules . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Configuring inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Configuring binary inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Configuring analog inputs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Configuring pulse inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Configuring outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Configuring binary outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Configuring analog outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Configuring variables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Configuring binary variables. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Configuring analog variables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Configuring user security. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Page 8

Contents

Setting the time and date . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Configuring timers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Configuring the operator display. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Configuring the home display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Configuring custom displays. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Configuring an SCC or DAC profile . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Configuring the SCC interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Configuring the DAC interface. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Configuration reports . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Saving configuration reports . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Printing configuration reports . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Memory reset . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Unlocking controller for flash download. . . . . . . . . . . . . . . . . . . . . . . . . 48

Chapter 4 Using the Schedule application . . . . . . . . . . . . . . 49

Viewing the status of the time-of-day schedule . . . . . . . . . . . . . . . . . . . 49

Setting up the daily schedule. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Clearing a start or stop time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Clearing the event times for a day . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Clearing all daily event times. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Copying a daily schedule . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Setting up the exception schedule. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Adding an exception. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Clearing an exception. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Editing an exception . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Setting up occupancy inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Synchronizing time with Tracer Summit . . . . . . . . . . . . . . . . . . . . . . . . . 59

Controlling the occupancy mode of the Tracer MP580/581. . . . . . . . . . 59

Manual command. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Time schedule. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Occupancy sensor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Occupancy binary input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Bypass timer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

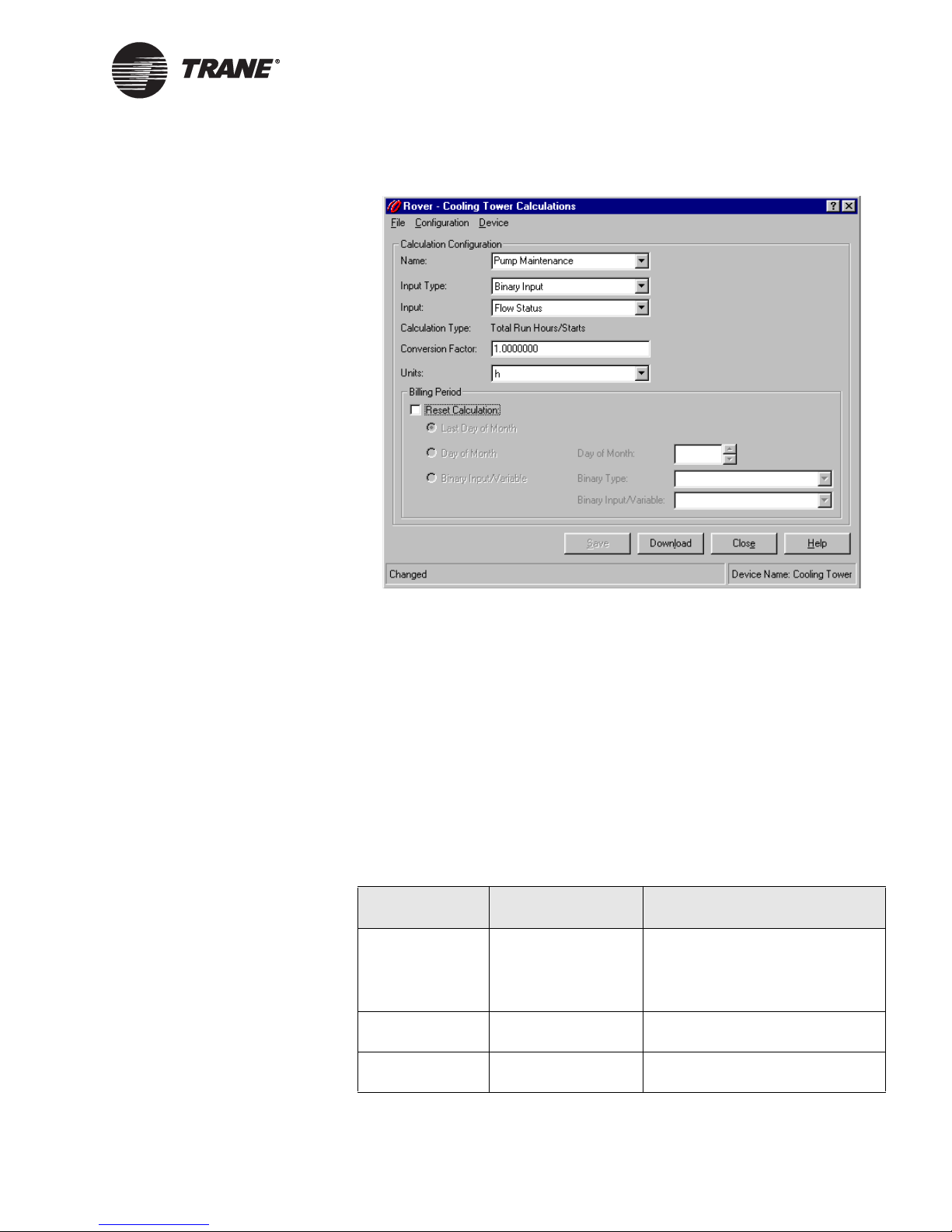

Chapter 5 Using the Calculations application . . . . . . . . . . . 65

Viewing the status of a calculation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Setting up a calculation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Clearing a calculation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

vi CNT-SVP01C-EN

Page 9

Contents

Chapter 6 Graphical programming overview . . . . . . . . . . . . 71

Opening the TGP editor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

TGP editor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

Design space. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

Output display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

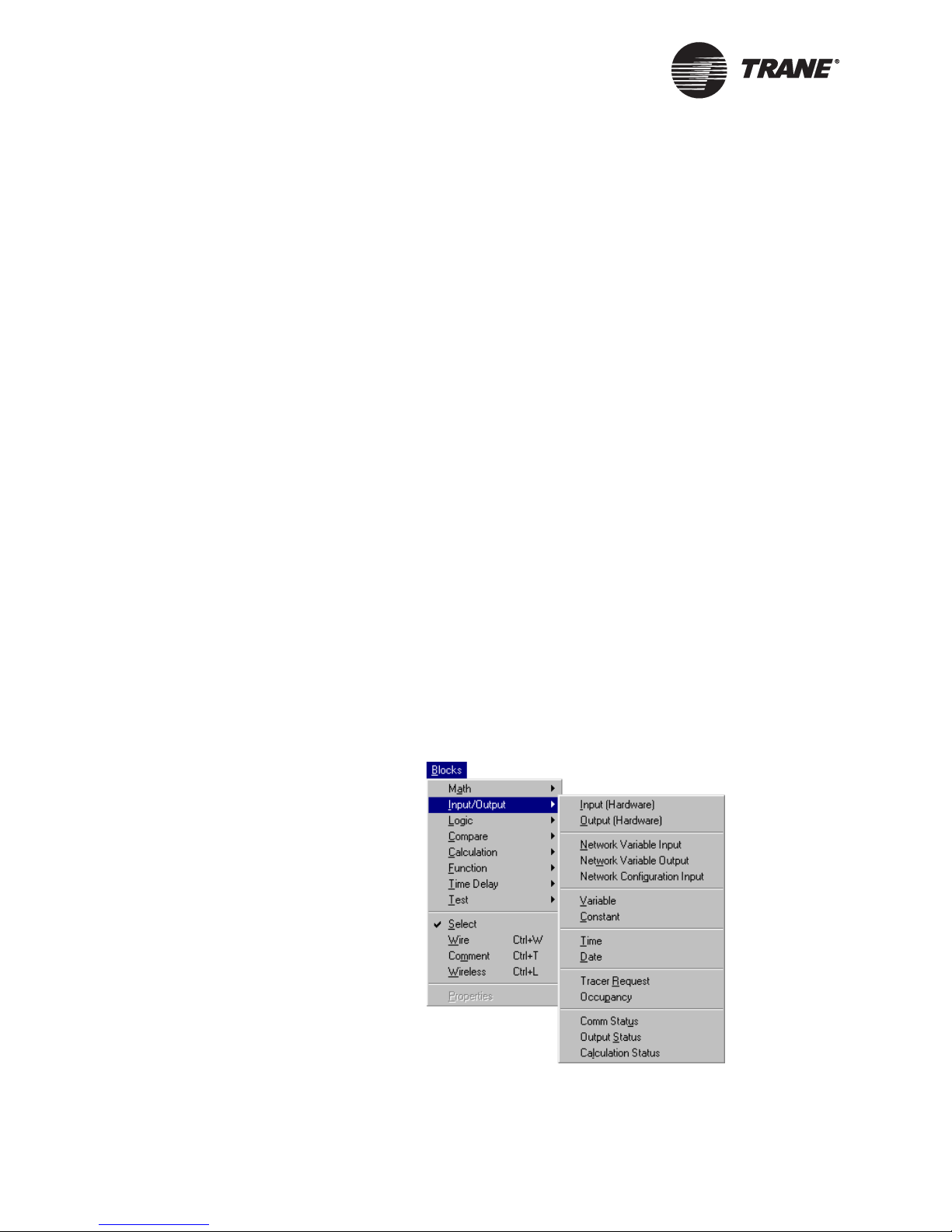

Blocks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

Menu bar. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

Toolbars . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

Standard toolbar . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

Alignment toolbar . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

Block toolbars. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

Program toolbar. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

Showing or hiding toolbars . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

Short cut menus. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

Keyboard short cuts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

Chapter 7 Creating a graphical program . . . . . . . . . . . . . . . . 79

Creating a new program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

Opening an existing program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

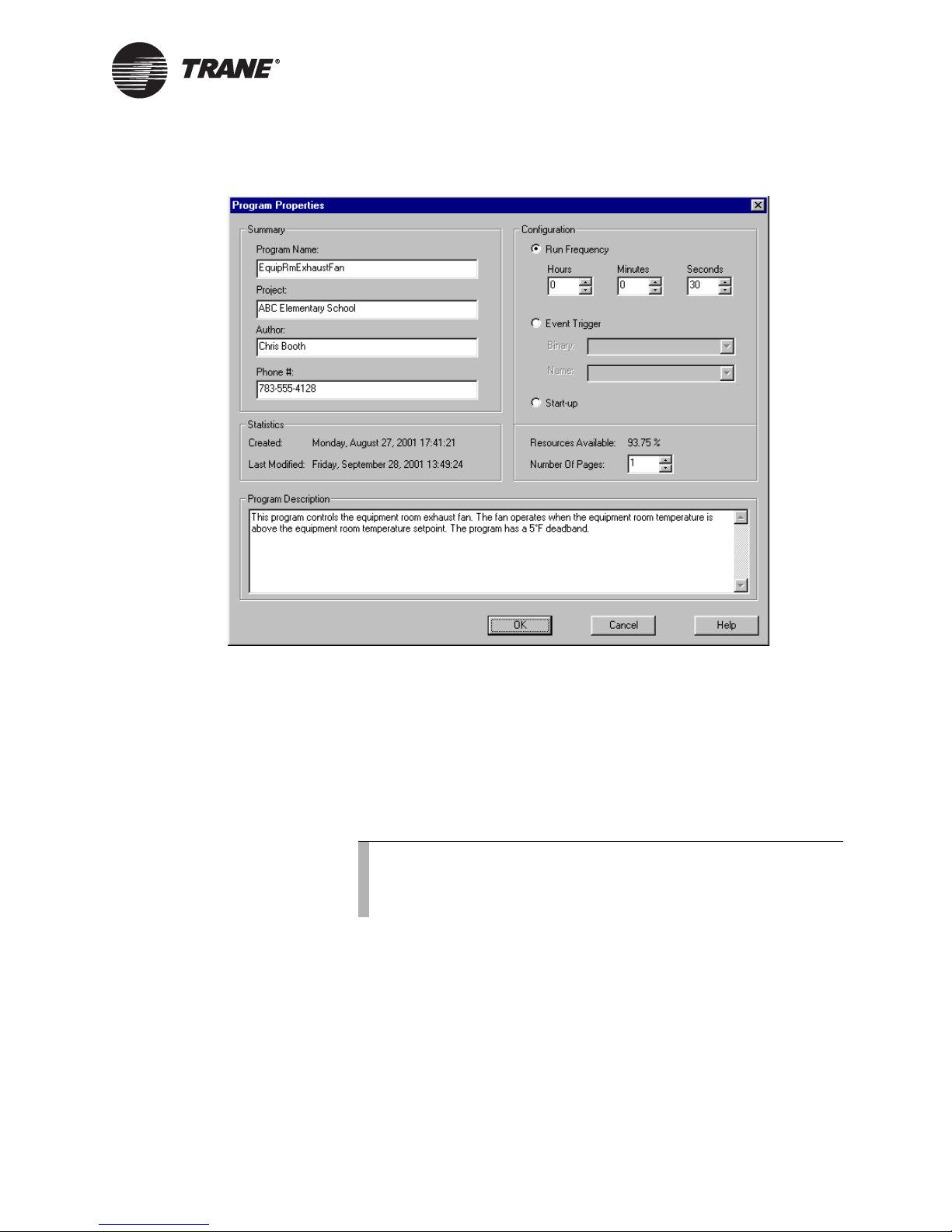

Editing program properties . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

Setting page width and size. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

Adding a block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

Editing block properties . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

Adding a comment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

Arranging blocks. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

Moving blocks. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

Aligning blocks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

Deleting a block. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

Connecting blocks using wired connections . . . . . . . . . . . . . . . . . . . . . 85

Connecting blocks using wireless connections . . . . . . . . . . . . . . . . . . . 86

Refreshing the TGP editor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

Saving a program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

Printing a program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

Closing a program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

Chapter 8 Using the Occupancy and PID blocks. . . . . . . . . . 93

CNT-SVP01C-EN vii

Using the Occupancy block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

Using the Occupancy block to turn on a supply fan . . . . . . . . . . . . 94

Using the Occupancy block to adjust setpoints. . . . . . . . . . . . . . . . 94

Page 10

Contents

Using the PID block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

Setting up the PID block properties. . . . . . . . . . . . . . . . . . . . . . . . . . 97

Incorporating the PID block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

Chapter 9 Implementing a graphical program . . . . . . . . . . 103

Compiling a program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

Downloading a program. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

Uploading a program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

Deleting a program from the Tracer MP580/581. . . . . . . . . . . . . . . . . . 104

Viewing program status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

Debugging a program. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

Simulating a program. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

Chapter 10 Network variable bindings . . . . . . . . . . . . . . . . . 109

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

Network variables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

Binding network variables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

Tracer MP580/581 bindings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

Receiving data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

Sending data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

Examples of network variable bindings . . . . . . . . . . . . . . . . . . . . . . . . 118

Example 1: Display sensor readings from a Tracer MP503 on a Tracer

MP581 operator display. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 118

Example 2: Display sensor readings from a Tracer MP503 on two

different Tracer MP581 operator displays . . . . . . . . . . . . . . . . . . 120

Example 3: Control a binary output on the Tracer MP503 from a

Tracer MP581 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 122

Example 4: Use a sensor reading on a Tracer MP503 to control a

pump VFD on a Tracer MP581. . . . . . . . . . . . . . . . . . . . . . . . . . . . 123

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 127

viii CNT-SVP01C-EN

Page 11

Chapter 1

Overview

The Tracer MP581 programmable controller is a general-purpose, input/

output device. The controller provides direct digital control of a variety of

HVAC equipment.

The Tracer MP580 is factory-installed on Modular Climate Changer and

on T-Series air handlers. The controller is factory wired to all sensors,

actuators, valves, starters, and other items shipped with the air handler.

Use this programming guide to configure and program the Tracer MP580/

581.

Tracer MP580/581 plug-in

The Rover service tool is the setup and configuration tool for the Tracer

MP580/581. It is analogous to PCM Edit for the PCM and UPCM Edit for

the UPCM. For more information about the Rover service tool, see the

Rover Operation and Programming guide (EMTX-SVX01E-EN).

To access the device through the Rover service tool, you must have the

Tracer MP580/581 plug-in. The plug-in is a software file that Rover connects with internally to display information and set up configuration for

the device. The plug-in also contains extensive online Help to help you

access and change device information.

The Tracer MP580/581 plug-in can be run with Rover Version 4 and

higher. You cannot run the Tracer MP580/581 plug-in with an earlier version of Rover. Updated versions of the Tracer MP580/581 plug-in may be

released independently from the Rover software. Contact your local sales

office for the latest versions of the Rover device plug-ins.

CNT-SVP01C-EN 1

Using Rover service tool

Within Rover, you can access not only status and configuration information but also other applications specific to the Tracer MP580/581.

Accessing the Tracer MP580/581

The Rover service tool communicates to Tracer MP580/581 controllers

through a connection to a Comm5 communication link. Comm5 is Trane’s

implementation of LonTalk

communication link, all communicating devices appear in the Active

Group tree. To access information for a specific device, click that device in

the tree. The device status information appears in the Active Device View

®

. When you start Rover on an active Comm5

Page 12

Chapter 1 Overview

workspace (Figure 1). Use the nine tabs of status information, the seven

command buttons, and this guide to work with the device.

Figure 1. Rover application window

Active

Group

tree

Status tabs

Plug-in

command

buttons

Workspace

Using online Help

The Rover service tool includes online Help for each screen and dialog box

in the plug-in. The extensive online Help does not appear in this guide. To

access Help for a tab or dialog box, click the Help button. For information

about a screen element, such as a field, option, or command button, click

the What’s This? help question mark icon and then click a field. You

can also choose What’s This? from the Help menu and then click a field.

2 CNT-SVP01C-EN

Page 13

Chapter 2

Viewing status

Before viewing the status or configuration of a Tracer MP580/581 controller, you must first select the Tracer MP580/581 you are working with on

the Comm5 link. To select the device, click the device name in the Active

Group tree. The Active Device View appears in the workspace (Figure 2).

The Active Device View contains nine tabs of status information. The

Unit tab is displayed when you first access a device.

The Unit tab displays general status information about the device. The

status information contains the operating status, today’s date and time,

active diagnostics, and expansion module communication status.

Figure 2. Tracer MP580/581 Active Device View in Rover service tool

CNT-SVP01C-EN 3

Page 14

Chapter 2 Viewing status

Viewing the status of inputs

Universal hardware inputs and an additional input for a pressure sensor

are provided on the Tracer MP580/581 controller. The configurable inputs

may be set up as analog or binary. Furthermore, analog inputs may be

configured to accommodate resistance, voltage, or current. You can view

the status of each input as well as its corresponding raw value. For information on configuring inputs, see “Configuring inputs” on page 21.

To view the status of inputs:

X In the Active Device View, click the Inputs tab (Figure 3).

Figure 3. Device status Inputs tab

4 CNT-SVP01C-EN

Page 15

Viewing the status of binary and analog outputs

Viewing the status of binary and

analog outputs

You can view the current status of each hardware output, binary and analog, on the Tracer MP580/581. The status table includes what is currently

controlling the output. Valid control sources, in order of priority, are as

follows (“None” is displayed if there is no control source):

• Operator display or Rover service tool (highest priority)

• Program within the Tracer MP580/581 controller

• Tracer Summit building automation system

To view the status of binary and analog outputs:

X In the Active Device View, click the BOs tab (Figure 4) for the status

of the binary outputs or the AOs tab (Figure 5 on page 6) for the sta-

tus of the analog outputs.

Figure 4. Device status BOs tab

CNT-SVP01C-EN 5

Page 16

Chapter 2 Viewing status

Figure 5. Device status AOs tab

Overriding binary and analog outputs

You can override both binary and analog outputs. Upon override, the

selected output value changes to the override value. The control source of

the output becomes the operator display/service tool so that other control

sources cannot change the value of the output.

Note:

Overrides are maintained through a power loss.

To override a binary or analog output:

1. In the Active Device View, click the BOs tab to view the binary outputs or the AOs tab to view the analog outputs.

2. Click the name of the output in the table that you want to override.

3. Click the Override button. The Override Binary Output dialog box

(Figure 6 on page 7) or the Override Analog Output dialog box

(Figure 7 on page 7) appears.

6 CNT-SVP01C-EN

Page 17

Overriding binary and analog outputs

Figure 6. Override Binary Output dialog box

Figure 7. Override Analog Output dialog box

4. Click the desired override option for binary outputs (Figure 6) or type

the desired override value for analog outputs (Figure 7).

5. Click the Override button. The Current Status field updates, and the

word “Override” appears in bold, blue text (Figure 8 on page 8).

The words “Minimum On/Off” may appear showing that the output

must remain in its current state for the amount of time specified on

the Configuration BOs tab.

CNT-SVP01C-EN 7

Page 18

Chapter 2 Viewing status

Figure 8. Binary output with override

Override

indicator

6. Click Close. The override status of the output appears in the table

(Figure 9). The control source becomes the operator display/service

tool.

Figure 9. BOs status table with an output override

8 CNT-SVP01C-EN

Note:

You can also override a binary or analog output from the Displays tab. Binary and analog outputs must be designated as

adjustable in the display configuration to apply an override to

them. For more information on setting an output to adjustable,

see “Configuring the operator display” on page 39.

Page 19

Releasing binary and analog output overrides

Releasing binary and analog output

overrides

You can release overrides of both binary and analog outputs. Upon

release, the selected output value is released back to normal control. The

control source of the output returns to its original source. To release a

binary or analog output override:

1. In the Active Device View, click the BOs tab to view the binary outputs or the AOs tab to view the analog outputs.

2. Click the output in the table that has its value overridden.

3. Click the Override button. The Override Binary Output dialog box

(Figure 8 on page 8) or the Override Analog Output dialog box

appears.

4. Click the Release button. The Current Status field returns to its original value.

5. Click Close. The status of the output appears in the list.

Note:

You can also release a binary or analog output override from

the Displays tab.

Viewing the status of binary and

analog variables

Variables may be changed using a variety of methods. Variables can be

communicated from the Tracer Summit system and changed using the

Rover service tool. Variables may also be calculated in a program, or they

may be made adjustable through the operator display. The Tracer MP580/

581 accommodates 150 binary and 150 analog variables.

Tracer Summit variables 1 through 30 are reserved for use with the

Tracer Summit building automation system. There are 120 variables controlled by the operator display/service tool and/or programs. These 120

variables are called local variables. You can view the status of each binary

and analog variable.

To aid in troubleshooting, the status table includes the control source

assigning the variable its value. For information on configuring binary

CNT-SVP01C-EN 9

Page 20

Chapter 2 Viewing status

and analog variables, see “Configuring variables” on page 31. Valid control sources include the following:

• Operator display or Rover service tool

• Program within the Tracer MP580/581 controller

• Tracer Summit building automation system

Note:

When Tracer Summit is the control source, no graphical programming is required. The variable can be controlled directly.

To view the status of binary and analog variables:

1. In the Active Device View, click the BVs tab (Figure 10) for the status

of the binary variables or the AVs tab (Figure 11 on page 11) for the

status of the analog variables.

2. Click the Tracer Summit Binary Variables option, the Local Binary

Variables option, the Tracer Summit Analog Variables option, or the

Local Analog Variables option to view the list of variables you want.

Uploading the variables may take a few seconds.

Figure 10. Device status BVs tab displaying local binary variables

Local Binary

Variables option

10 CNT-SVP01C-EN

Page 21

Tracer Summit Analog

Variables option

Viewing the status of binary and analog variables

Figure 11. Device status AVs tab displaying Tracer Summit analog

variables

CNT-SVP01C-EN 11

Page 22

Chapter 2 Viewing status

Viewing application status

You can view the status of the Schedule and standard Calculations applications. On the Application tab under Schedule, view the current occupancy state of the controller as well as the day and time in the controller.

Under Calculations, view the table that displays the calculations present

in the controller as well as the calculation type, units, and values.

To view the application status:

X In the Active Device View, click the Application tab (Figure 12).

Figure 12. Device status Application tab

12 CNT-SVP01C-EN

Page 23

Viewing Comm5 parameters

Viewing Comm5 parameters

To view information about the Tracer MP580/581 controller Comm5

parameters:

X In the Active Device View, click the General tab. Comm5 information

specific to the selected Tracer MP580/581 controller is displayed

(Figure 13).

Figure 13. Device status General tab

CNT-SVP01C-EN 13

Page 24

Chapter 2 Viewing status

Viewing custom displays

You can set up custom displays for the Tracer MP580/581 operator display through the Rover service tool. A custom display is a group of inputs,

outputs, and variables saved under a descriptive name. You can view the

status of the items in the group from the operator display or Rover by

accessing the custom display name. Variables and outputs may also be

changed or overridden from the display if they are configured as adjustable. For more information on configuring custom displays, see “Configuring custom displays” on page 41.

To view custom displays:

1. In the Active Device View, click the Displays tab.

2. In the Display drop-down list, click the custom display you want to

view. The names, values, and control sources for the items in the

group appear (Figure 14).

Figure 14. Device status Displays tab

14 CNT-SVP01C-EN

Page 25

Changing binary and analog variables

Changing binary and analog variables

Variables are often used for setpoints so that they can be changed by the

building operator or owner from the operator display. In the Rover service

tool, binary and analog variables can be changed from the Displays tab.

To make a change from the Displays tab or from the operator display, the

following must be true:

• The variable must be a local variable with the control source set to

the operator display/service tool. For information on configuring

binary and analog variables, see “Configuring variables” on page 31.

• The variable must be designated as adjustable in the display configu-

ration. For information on setting a variable to be adjustable, see

“Configuring custom displays” on page 41.

Note:

Variables cannot be changed from the home display on the operator display or in the Rover service tool.

Upon changing, the selected variable value changes to the requested

value. The control source of the variable does not change, so other control

sources, such as the operator display, can still affect the value of the variable.

To change a binary or analog variable in the Rover service tool:

1. In the Active Device View, click the Displays tab.

2. In the Display list, click the name of the custom display that contains

the variable you want to change.

3. In the table, click the name of the variable you want to change.

4. Click the Change button. The Change Local Analog Variable dialog

box appears (Figure 15 on page 16).

Note:

If the Change button is not available, the variable you chose

does not meet the criteria outlined previously.

CNT-SVP01C-EN 15

Page 26

Chapter 2 Viewing status

Figure 15. Change Local Analog Variable dialog box

5. Click the desired state for binary variables or type the desired value

for analog variables.

6. Click the Change button. The value of the variable is changed.

7. Click Close. The changed value appears in the table.

Overriding the occupancy mode

You can override the effective occupancy of the Tracer MP580/581 controller. An occupancy override from the operator display or the Rover service

tool takes priority over all other occupancy requests.

Applying an occupancy override

Upon override, the occupancy value of the Tracer MP580/581 controller

changes to the override value. The control source of the output becomes

the operator display/service tool, preventing other control sources from

changing the occupancy.

To apply an occupancy override:

1. In the Active Device View, click the Unit tab.

2. Click the Override Unit button. The Override Unit Occupancy dialog

box appears (Figure 16 on page 17).

16 CNT-SVP01C-EN

Page 27

Overriding the occupancy mode

Figure 16. Override Unit Occupancy dialog box

3. In the Override list, click the occupancy mode you want.

4. Click the Override button. The current status is changed to the override mode.

5. Click Close. The Override Unit Occupancy dialog box closes.

Releasing an occupancy override

You can release an occupancy override of the Tracer MP580/581. Upon

release, the occupancy value of the selected device is released to normal

control. The control source of the output becomes the normal source.

To release an occupancy override:

1. In the Active Device View, click the Unit tab.

2. Click the Override Unit Occupancy button. The Override Unit Occupancy dialog box appears.

3. Click the Release button. The current status is changed to the normal

mode.

4. Click Close. The Override Unit Occupancy dialog box closes.

CNT-SVP01C-EN 17

Page 28

Chapter 2 Viewing status

18 CNT-SVP01C-EN

Page 29

Chapter 3

Configuring the

Tracer MP580/581

Use the information in this chapter to configure your Tracer MP580/581

controller. Select the Tracer MP580/581 you want to configure from the

Active Group tree and then click the Configuration button. The Configuration dialog box appears with the same tab selected as the tab that was

showing in the Active Device View. You can jump from tab to tab within

the Configuration dialog box without going back to the status tabs in the

Active Device View.

Configuring EX2 expansion modules

The EX2 expansion module is a field-installed expansion module for the

Tracer MP580/581 programmable controller.

Note:

This feature applies to only Tracer MP580/581 Firmware Revision 2 or higher. Follow the procedure for “Viewing Comm5

parameters” on page 13 to view your current revision number.

Up to four EX2s can be connected to a Tracer MP580/581. Each EX2 adds

the following inputs and outputs to a Tracer MP580/581:

• 6 universal inputs

• 4 binary inputs

• 4 analog outputs

To set up an EX2 expansion module that has been connected to a Tracer

MP580/581:

1. In the Active Device View, click the Unit tab. The status information

for the controller appears.

2. Click the Configuration button. The Configuration dialog box appears

with the Unit tab displayed (Figure 17 on page 20).

3. Under Expansion Module Configuration, in the Expansion Module

Type column, choose the expansion module row for the module you

want to configure. In the list, click the appropriate module type. The

rest of the row fills in with indexes for universal inputs, binary outputs, and analog outputs.

CNT-SVP01C-EN 19

Page 30

Chapter 3 Configuring the Tracer MP580/581

Figure 17. Device configuration Unit tab

The expansion module number is configured by setting the DIP

switch on the module. See the Tracer MP581 Programmable Control-

ler Hardware Installation guide (CNT-SVN01B-EN) for more information.

4. Click the Download button to send your changes to the Tracer

MP580/581. (If the Security Logon dialog box appears, log on.) Click

Close to close the Configuration dialog box.

5. See “Configuring inputs” on page 21 and “Configuring outputs” on

page 28 for instructions on configuring inputs and outputs for the

expansion modules.

20 CNT-SVP01C-EN

Page 31

Configuring inputs

Configuring inputs

Universal hardware inputs and an additional input for a pressure sensor

are provided on the Tracer MP580/581 controller. The configurable inputs

on the controller may be set up as analog or binary. You can configure all

inputs on the controller and any of the expansion modules with the name

and type information. Futhermore, you can configure analog inputs to

accommodate various temperature sensors or to accept a linear resistance, voltage, or current signal. For example, on a zone temperature sensor the linear resistance values for a thumbwheel are displayed in

Table 1:

Table 1. Thumbwheel linear resistance values

Temperature

(°F)

50°F 889.4 Ω

90°F 110.6 Ω

Valu e (Ω)

Configuring binary inputs

A binary input detects whether a circuit is open or closed, indicating on or

off status.

To set up a binary input:

1. In the Active Device View, click the Inputs tab. The status information for the inputs appears.

2. Click the Configuration button. The Configuration dialog box appears

with the Inputs tab displayed (Figure 18, page 22).

CNT-SVP01C-EN 21

Page 32

Chapter 3 Configuring the Tracer MP580/581

Figure 18. Device configuration Inputs tab

3. In the Name list, click the input you want to configure. The configuration information for that input appears in the tab.

You can also select the input by clicking the input number in the

Input list. The Name and Input lists are linked so that input name

and input number are always displayed together.

4. If you want to change the input name, highlight the text and type a

new name.

Use a descriptive name because it appears in custom displays and

programs.

5. Under Type, click the Binary option. The binary input configuration

information appears (Figure 19).

22 CNT-SVP01C-EN

Page 33

Figure 19. Device configuration binary input

Configuring inputs

6. Under Input Definition, type descriptors for the open and closed

states of the binary input.

Use descriptive terms because they appear on the operator display

and the Rover status displays.

CNT-SVP01C-EN 23

Page 34

Chapter 3 Configuring the Tracer MP580/581

7. Complete one of the following options:

• Click another input name in the Name list to edit another input.

• Click another tab to set up another item.

• Click the Download button to send your changes to the Tracer

MP580/581. (If the Security Logon dialog box appears, log on.)

Click Close to close the Configuration dialog box.

Configuring analog inputs

An analog input is a varying voltage, current, or resistance signal that

can be converted to units of measurement, such as temperature, pressure,

and humidity.

To set up an analog input:

1. In the Active Device View, click the Inputs tab. The status information for the inputs appears.

2. Click the Configuration button. The Configuration dialog box appears

with the Inputs tab displayed (Figure 18 on page 22).

3. In the Name list, click the input you want to configure. The configuration information for that input appears in the tab.

You can also select the input by clicking the input number in the

Input list. The Name and Input lists are linked so that input name

and input number are always displayed together.

4. If you want to change the input name, highlight the text and type a

new name.

Use a descriptive name because it appears in custom displays and

programs.

5. Under Type, click the Analog option. The analog input configuration

information appears (Figure 20 on page 25).

24 CNT-SVP01C-EN

Page 35

Figure 20. Device configuration analog input

Configuring inputs

6. In the Type list, click the input type.

Note:

Only the first four universal inputs (Input 01 to Input 04) can

be configured as a Balco or platinum resistance temperature

detector (RTD). Only the first two universal inputs on each EX2

expansion module can be configured as Balco or platinum

RTDs.

7. In the Units list, click the units associated with the input.

8. In the Decimal Places list, click the number of digits you want to

appear to the right of the decimal when displaying the input value.

Determine how many digits appear to the right of the decimal in the

Rover Active Device View and on the Tracer MP580/581 operator display. Use the resolution of the sensor to determine the number of decimal places. For example, if a temperature sensor is accurate to 0.1°F,

do not display more than one decimal place. However, a differential

pressure sensor input may need to display two or three decimal

places.

CNT-SVP01C-EN 25

Page 36

Chapter 3 Configuring the Tracer MP580/581

9. Click to select the Fail at End of Range check box if you want the controller to generate a diagnostic whenever the analog input is within

3% of the end of its range.

For example, a 0–10 V sensor will generate a diagnostic whenever its

raw value is less than 0.3 V or greater than 9.7 V.

10. If the input requires calibration, type the amount you want to adjust

the value of the input in the Calibration Factor field.

For example, if you know a temperature sensor is reading 1°F too

high, type a calibration factor of –1°F.

11. For linear-voltage, -current, or -resistance inputs, type the low and

high sensor values and sensor outputs in the Low and High Sensor

Value and Sensor Output fields.

The Sensor Value Low is the lowest reading the sensor can provide,

while the Sensor Value High is the highest reading the sensor can

provide. For example, a humidity sensor provides a 4–20 mA signal

corresponding to 0–100% relative humidity. Type 0 as the low sensor

value and 100 as the high sensor value in this case. The sensor calibration is determined by these four parameters. In this example, type

4 mA as the low sensor output and 20 mA as the high sensor output.

12. Complete one of the following options:

• Click another input name in the Name list to edit another input.

• Click another tab to set up another item.

• Click the Download button to send your changes to the Tracer

MP580/581. (If the Security Logon dialog box appears, log on.)

Click Close to close the Configuration dialog box.

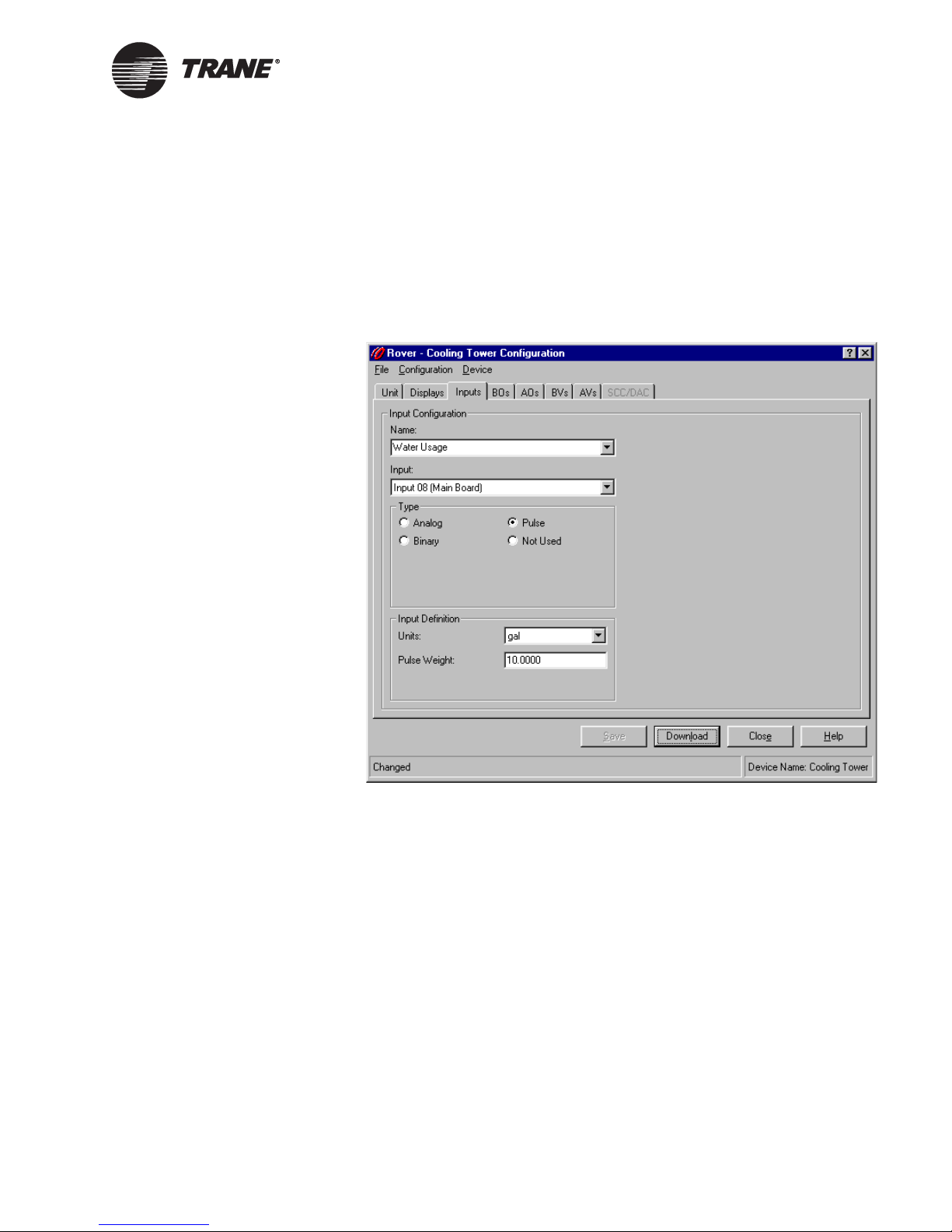

Configuring pulse inputs

A pulse input measures the number of contact closures over time. Typical

origins of contact closures include electric, gas, and water meters. The

meter must have a dwell time of 200 ms and a maximum pulse rate of

3 pulses per second.

To set up a pulse input:

1. In the Active Device View, click the Inputs tab. The status information for the inputs appears.

2. Click the Configuration button. The Configuration dialog box appears

with the Inputs tab displayed (Figure 18 on page 22).

3. In the Name list, click the input you want to configure. The configuration information for that input appears in the tab.

You can also select the input by clicking the input number in the

Input list. The Name and Input lists are linked so that the input

name and input number are always displayed together.

26 CNT-SVP01C-EN

Page 37

Configuring inputs

4. If you want to change the input name, highlight the text and type a

new name.

Use a descriptive name because it appears in custom displays and

programs.

5. Under Type, click the Pulse option. The pulse input configuration

information appears (Figure 21).

Figure 21. Device configuration pulse input

CNT-SVP01C-EN 27

6. In the Units list, click the units associated with the input.

7. In the Pulse Weight field, type the value per contact closure from the

meter.

8. Complete one of the following options:

• Click another input name in the Name list to edit another input.

• Click another tab to set up another item.

• Click the Download button to send your changes to the Tracer

MP580/581. (If the Security Logon dialog box appears, log on.)

Click Close to close the Configuration dialog box.

Page 38

Chapter 3 Configuring the Tracer MP580/581

Configuring outputs

The Tracer MP580/581 and expansion modules include binary and analog

hardware outputs.

Configuring binary outputs

You can name binary outputs, specify open and closed descriptors, and set

minimum on and off times.

To set up a binary output:

1. In the Active Device View, click the BOs tab. The status information

for the binary outputs appears.

2. Click the Configuration button. The Configuration dialog box appears

with the BOs tab displayed (Figure 22).

Figure 22. Device configuration BOs tab

3. In the Name list, click the output you want to configure. The configu-

28 CNT-SVP01C-EN

ration information for that output appears in the tab.

You can also select the output by clicking the output number in the

BO list. The Name and BO lists are linked so that the output name

and output number are always displayed together.

Page 39

Configuring outputs

4. If you want to edit the output name, highlight the text and type a new

name.

Use a descriptive name because it appears in custom displays and

programs.

5. Under Output Definition, type descriptors for the open and closed

states of the binary output.

Use descriptive terms because they appear on the operator display

and the Rover status displays.

6. Under On/Off Times, type the minimum on and off times.

The minimum off time is the least amount of time the output must be

off before it can go to on. The minimum on time is the least amount of

time the output must be on before it can go to off.

7. Complete one of the following options:

• Click another output name in the Name list to edit another out-

put.

• Click another tab to set up another item.

• Click the Download button to send your changes to the Tracer

MP580/581. (If the Security Logon dialog box appears, log on.)

Click Close to close the Configuration dialog box.

Configuring analog outputs

You can name an analog output, specify its type, display its units and

numeric format, and perform calibration.

To set up an analog output:

1. In the Active Device View, click the AOs tab. The status information

for the analog outputs appears.

2. Click the Configuration button. The Configuration dialog box appears

with the AOs tab displayed (Figure 23 on page 30).

CNT-SVP01C-EN 29

Page 40

Chapter 3 Configuring the Tracer MP580/581

Figure 23. Device configuration AOs tab

3. In the Name list, click the output you want to configure. The configuration information for that output appears in the tab.

You can also select the output by clicking the output number in the

AO list. The Name and AO lists are linked so that output name and

output number are always displayed together.

4. If you want to change the output name, highlight the text and type a

new name.

Use a descriptive name because it appears in custom displays and

programs.

5. In the Type list, click the analog output type. This selection sets the

default values under Calibration.

6. In the Units list, click the appropriate units.

7. In the Decimal Places list, click the number of digits you want to

appear to the right of the decimal.

You determine how many digits appear to the right of the decimal in

the Rover Active Device View and on the Tracer MP580/581 operator

display.

8. If the output requires calibration, type the amount by which you want

to adjust the value of the output in the Calibration Factor field.

30 CNT-SVP01C-EN

Page 41

Configuring variables

9. Verify the open and close values and the open and close outputs, and

type new values in the Close and Open Output and Value fields if necessary.

The output values are the hardware output voltage or current corresponding to the open and closed states of the wired device. The analog

output calibration is determined by these four parameters.

10. Click to select the Secondary Control (E-P) check box if a secondary

control device is used and type the open and close values and outputs

for the secondary control device.

11. Complete one of the following options:

• Click another output name in the Name list to edit another out-

put.

• Click another tab to set up another item.

• Click the Download button to send your changes to the Tracer

MP580/581. (If the Security Logon dialog box appears, log on.)

Click Close to close the Configuration dialog box.

Configuring variables

Variables may be changed using a variety of methods. Variables can be

communicated from the Tracer Summit system and changed using the

Rover service tool. Variables may also be calculated in a program, or they

may be made adjustable through the operator display. The Tracer MP580/

581 accommodates 150 binary variables and 150 analog variables.

Configuring binary variables

Tracer Summit binary variables 1 through 30 are reserved for use with

the Tracer Summit system. Use local binary variables 1 through 120 as

local variables. You can edit the Tracer Summit variables or the local

variables. For each binary variable, specify a name, control source, off and

on descriptors, and a communications loss value or initial value.

To set up a binary variable:

1. In the Active Device View, click the BVs tab. The status information

for the binary variables appears.

2. Click the Configuration button. The Configuration dialog box appears

with the BVs tab displayed.

3. Click the Tracer Summit Binary Variables option or the Local Binary

Variables option to view the type of variable you want to edit

(Figure 24 on page 32).

CNT-SVP01C-EN 31

Page 42

Chapter 3 Configuring the Tracer MP580/581

Figure 24. Device configuration BVs tab

4. In the Name list, click the variable you want to configure. The configuration information for that variable appears in the tab.

You can also select the variable by clicking the variable number in the

BV list. The Name and BV lists are linked so that the variable name

and variable number are always displayed together.

5. If you want to change the variable name, highlight the text and type a

new name.

Use a descriptive name because it appears in custom displays and

programs.

6. If the variable is not a Tracer Summit variable, click the control

source for the variable in the Source list.

7. If the variable is local and is controlled by the operator display/service

tool, click to select the Allow Program Control Source check box if you

want to also control this variable within a program.

It is not recommended you select this unless you have a specific purpose in mind, for example, you are using the program to return an

alarm reset variable to normal.

8. Under Variable Definition, type descriptors for the on and off states of

the binary variable.

Use descriptive terms because they appear on the operator display

and the Rover status displays.

32 CNT-SVP01C-EN

Page 43

Configuring variables

9. If the variable has Tracer Summit as its control source, under Communications Loss Value, click the On or Off option to determine what

value you want to appear as the value if Tracer Summit communications are lost to the Tracer MP580/581.

10. If the variable has the operator display and service tool as its control

source, under Value, click the On or Off option to determine what

value you want the variable to have.

Note:

The variable value is saved once every 24 hours. If a power loss

occurs, the variable value is set to the last saved value.

11. Complete one of the following options:

• Click another variable name in the Name list to edit another vari-

able.

• Click another tab to set up another item.

• Click the Download button to send your changes to the Tracer

MP580/581. (If the Security Logon dialog box appears, log on.)

Click Close to close the Configuration dialog box.

Configuring analog variables

Tracer Summit analog variables 1 through 30 are reserved for use with

the Tracer Summit system. The 120 local analog variables are to be used

as local variables. You can edit the Tracer Summit variables or the local

variables. For each analog variable, specify a name, control source, display units, numeric format, and communications loss or initial value.

To set up an analog variable:

1. In the Active Device View, click the AVs tab. The status information

for the analog variables appears.

2. Click the Configuration button. The Configuration dialog box appears

with the AVs tab displayed (Figure 25 on page 34).

CNT-SVP01C-EN 33

Page 44

Chapter 3 Configuring the Tracer MP580/581

Figure 25. Device configuration AVs tab

3. Click the Tracer Summit Analog Variables option or the Local Analog

Variables option to view the type of variable you want to edit.

4. In the Name list, click the variable you want to configure. The configuration information for that variable appears in the tab.

You can also select the variable by clicking the variable number in the

AV list. The Name and AV lists are linked so that the variable name

and variable number are always displayed together.

5. If you want to change the variable name, highlight the text and type a

new name.

Use a descriptive name because it appears in custom displays and

programs.

6. If the variable is not a Tracer Summit variable, click the control

source for the variable.

7. If the variable is local and is controlled by the operator display/service

tool, click to select the Allow Program Control Source check box if you

want to also control this variable within a program.

It is not recommended you select this unless you have a specific purpose in mind.

8. In the Units list, click the appropriate units.

34 CNT-SVP01C-EN

Page 45

Configuring user security

9. In the Decimal Places list, click the number of digits you want to

appear to the right of the decimal when the variable value is displayed.

10. If the variable has Tracer Summit as its source, under Communications Loss Value, type the value you want to appear if Tracer Summit

communications are lost to the Tracer MP580/581.

11. If the variable has the operator display and service tool as its source,

under Value, type the value you want the variable to have.

Note:

The variable value is saved once every 24 hours. If a power loss

occurs, the variable value is set to the last saved value.

12. Complete one of the following options:

• Click another variable name in the Name list to edit another vari-

able.

• Click another tab to set up another item.

• Click the Download button to send your changes to the Tracer

MP580/581. (If the Security Logon dialog box appears, log on.)

Click Close to close the Configuration dialog box.

Configuring user security

A user who has security supervisor access can set up security privileges

for up to eight users, giving each different access privileges, for both the

Tracer MP580/581 operator display and the Rover service tool. Any user

can view all displays on the Tracer MP580/581 operator display; however,

a security supervisor can set up security to prevent unauthorized users

from changing variables or overriding outputs at the operator display.

A security supervisor can also set up security to prevent unauthorized

users from downloading or deleting variables, overriding inputs, downloading or deleting a Tracer graphical program, clearing memory on the

controller, and performing a flash download to the controller.

After security is established, users are prompted to log on with a password when they attempt to perform security-protected functions.

Note:

A logged-on user loses access to security-protected functions if

an action is not performed for 30 minutes.

CNT-SVP01C-EN 35

Page 46

Chapter 3 Configuring the Tracer MP580/581

To configure security:

1. In the Active Device View, click the Unit tab. The status information

for the controller appears.

2. Click the Configuration button. The Configuration dialog box appears

with the Unit tab displayed.

3. Click the Security Setup button. The Security dialog box (Figure 26)

appears.

Figure 26. Security dialog box

4. In the User Name list, click the user name for which you want to set

5. If you want to change the user name, type the user’s name in the User

6. In the User Password field, type a four-digit password.

7. Click to select the Show Password check box to display the password

36 CNT-SVP01C-EN

up security.

Name field.

The user name can be up to 24 characters long.

The password can be only numbers; no letters or special characters

are allowed.

for the selected user name.

Page 47

Setting the time and date

8. If needed, click to select the Security Supervisor check box to set the

selected user as a security supervisor.

At least one user must be declared a security supervisor. After any

default settings have changed, only a security supervisor can change

the security configuration.

9. Under Operator Display Access, click to select the check boxes for the

displays and items you want the selected user to be able to adjust.

Click to clear the check boxes for the displays and items this user is

not allowed to adjust.

The first six check boxes are for the custom displays. The last three

check boxes are for standard displays.

10. Under Rover/TGP Options, click to select the check boxes to allow the

selected user to modify configurations and TGP programs and to be

able to clear memory or download a new program to the Tracer

MP580/581.

11. Repeat steps 4–10 to set up additional users.

12. Click the Download button to send your changes to the Tracer

MP580/581. If the Security Logon dialog box appears, log on. Click

Close to close the Configuration dialog box.

Setting the time and date

Set the time and date for the Tracer MP580/581 and the format in which

you want the time to appear in the Rover service tool and on the operator

display.

To set the time and date:

1. In the Active Device View, click the Unit tab. The status information

for the controller appears.

2. Click the Configuration button. The Configuration dialog box appears

with the Unit tab displayed (Figure 17 on page 20).

3. Under Time Format, click the option for the format in which you want

the time to appear.

4. Under Display, click the Set Date/Time button. (If the Security Logon

dialog box appears, log on.) The Set Date/Time dialog box appears

(Figure 27 on page 38).

CNT-SVP01C-EN 37

Page 48

Chapter 3 Configuring the Tracer MP580/581

Figure 27. Set Date/Time dialog box

5. To select the date and time you want to use, choose one of the following options:

• If you want to apply the current date and time settings of the PC

to the controller, click to select the Use PC System Date/Time

check box.

• If you want to set the date and time for the controller yourself,

click to clear the Use PC System Date/Time check box. Then click

the date in the calendar and type the time. Click to select the

check box if you want to automatically adjust the time for Daylight Savings Time.

6. Click the Set button to apply your changes.

7. Click the Download button to send your changes to the Tracer

MP580/581. If the Security Logon dialog box appears, log on. Click

Close to close the Configuration dialog box.

Configuring timers

Set up the occupied bypass, power-up control wait, and minimum send

times for the Tracer MP580/581.

To set up timers:

1. In the Active Device View, click the Unit tab. The status information

for the controller appears.

2. Click the Configuration button. The Configuration dialog box appears

with the Unit tab displayed (Figure 17 on page 20).

3. In the Occupied Bypass Timer field, type the amount of time you

want the controller to remain in occupied bypass mode.

When a user overrides the controller to occupied bypass mode, it stays

in this mode for the time specified here. This field is not available if

38 CNT-SVP01C-EN

Page 49

Configuring the operator display

an SCC or DAC profile is active. If a profile is active, you must set the

occupied bypass timer on the SCC or DAC Configuration tab.

4. In the Power-up Control Wait field, type the amount of time after

power-up you want the controller to wait before controlling analog or

binary outputs.

5. In the Minimum Send Time field, type the minimum number of seconds between the automatic output of network variable transmissions. Only one output network variable can be updated within a

single minimum-send-time period.

6. Click the Download button to send your changes to the Tracer

MP580/581.

7. Click Close to close the Configuration dialog box.

Configuring the operator display

You can view custom displays from the Rover service tool as well as from

the Tracer MP580/581 operator display. So, custom displays are useful

even when the Tracer MP580/581 does not have a local operator display

connected. In addition, a portable operator display temporarily connected

to the device uses the custom displays.

Use custom displays to logically group the information available in the

Tracer MP580/581. Seven custom displays are available. The first display

is a home display that contains a name and two items. The home display

name appears as the title on the operator display. You can also name the

other six custom displays. Each custom display consists of four screens of

four items, for a total of up to 96 items.

Within a custom display, assign each line to display an input, output, or

variable. Leave a display item blank to break a display into subgroups.

Custom displays allow you to group information by category or by equipment, rather than by point type. For example, all the information pertinent to the cooling tower may be shown on one custom display. Variables

and outputs may be changed or overridden from the custom displays if

the items are configured as adjustable.

CNT-SVP01C-EN 39

Configuring the home display

The home display contains a name or title and two items. The home display name appears as the title on the home screen of the operator display.

The status of the two items is displayed on the home screen as well.

To set up the home display:

1. In the Active Device View, click the Displays tab. The status information appears for the custom displays.

2. Click the Configuration button. The Configuration dialog box appears

with the Displays tab displayed (Figure 28).

Page 50

Chapter 3 Configuring the Tracer MP580/581

Figure 28. Device configuration Displays tab

3. In the Name list, click Home Display. The configuration information

appears in the tab.

4. If you want to change the display name, highlight the text and type a

new name.

Use a descriptive name because it appears on the operator display

and the Active Device View workspace.

5. Click in the first row of the Type column. Click the down arrow. The

Type list appears.

6. In the Type list, click the type of item you want to display.

The types include: inputs, outputs, and variables.

7. Click in the first row of the Display Item Name column. Click the

down arrow. The Display Item Name list appears.

8. In the Display Item Name list, click the name of the item you want to

display.

9. Repeat steps 5–8 for row 2.

10. Complete one of the following options:

• Click another display name in the Name list to edit another dis-

play.

• Click another tab to set up another item.

40 CNT-SVP01C-EN

Page 51

Configuring the operator display

• Click the Download button to send your changes to the Tracer

MP580/581. (If the Security Logon dialog box appears, log on.)

Click Close to close the Configuration dialog box. The changes

appear on the operator display touch screen (Figure 29).

Figure 29. Home display on the operator display

Configuring custom displays

You can set up six custom displays to be displayed in the Rover Active

Device View workspace or on the operator display. Give each display a

descriptive name and assign up to 16 items to the display.

To set up custom displays:

1. In the Active Device View, click the Displays tab. The status information for the custom displays appears.

2. Click the Configuration button. The Configuration dialog box appears

with the Displays tab displayed (Figure 30 on page 42).

CNT-SVP01C-EN 41

Page 52

Chapter 3 Configuring the Tracer MP580/581

Figure 30. Device configuration Displays tab custom display

3. In the Name list, click the display you want to configure. The configuration information for that display appears in the tab.

You can also select the display by clicking the display number in the

Display list. The Name and Display lists are linked so that display

name and display number are always displayed together.

4. If you want to change the display name, highlight the text and type

the new name.

Use a descriptive name because it appears on the operator display

and the Active Device View workspace.

5. Click in the first row of the Type column. Click the down arrow. The

Type list appears.

6. In the Type list, click the type of item you want to display.

The types include: inputs, output, and variables.

7. Click in the first row of the Display Item Name column. Click the

down arrow. The Display Item Name list appears.

8. In the Display Item Name list, click the name of the item you want to

display.

42 CNT-SVP01C-EN

Page 53

Configuring the operator display

9. For outputs and variables with an operator display/service tool control source, click to select the check box in the Adjustable column if

you want the item to be adjustable.

If a variable is adjustable, it can be changed from the operator display. For information on setting a variable control source, see “Configuring variables” on page 31. If an output is adjustable, it can be

overridden from the operator display.

10. If the item is an analog output or variable, and it is adjustable, type

the low and high limits in the columns.

11. Repeat steps 5 through 10 for additional items you want in the custom display.

Leave blank rows to separate groups of items in the display. Four

items appear per screen on the operator display.

12. Complete one of the following options.

• Click another display name in the Name list to edit another dis-

play.

• Click another tab to set up another item.

• Click the Download button to send your changes to the Tracer

MP580/581. (If the Security Logon dialog box appears, log on.)

Click Close to close the Configuration dialog box. The changes

appear on the operator display custom screen (Figure 31).

Figure 31. Custom screen on the operator display

CNT-SVP01C-EN 43

Page 54

Chapter 3 Configuring the Tracer MP580/581

Configuring an SCC or DAC profile

You can set up the Tracer MP580/581 to provide a network interface

according to the Space Comfort Controller (SCC) or Discharge Air Controller (DAC) profile. To implement a one of these profiles, you must complete the following:

• Activate the profile.

• Configure the interface.

• Write a program to implement the configured information. See sam-

ple programs in the Tracer graphical programming library.

To set up an SCC or DAC profile:

1. In the Active Device View, click the Unit tab. The status information

for the controller appears.

2. Click the Configuration button. The Configuration dialog box appears

with the Unit tab displayed (Figure 17 on page 20).

3. Click to select the Activate Profile check box.

4. Click the SCC option to provide a network interface following the

SCC profile or click the DAC option to provide a network interface following the DAC profile.

5. Complete one of the following options:

• Click the SCC or DAC tab to set up the interface. See the follow-

ing sections for more information on configuring the interface.

• Click the Download button to send your changes to the Tracer

MP580/581 and click Close to close the Configuration dialog box

Configuring the SCC interface

To set the configuration parameters associated with the SCC profile:

1. In the Active Device View, click the Configuration button. The Configuration dialog box appears.

2. Click the SCC tab. The SCC configuration information appears

(Figure 32).

Note:

This tab is available only when the SCC profile is active in the

Tracer MP580/581.

44 CNT-SVP01C-EN

Page 55

Configuring an SCC or DAC profile

Figure 32. Device configuration SCC tab

3. Under Units, click the display units option for the SCC profile configuration data.

4. Under Default Setpoints, type the heating and cooling default setpoints for the occupied, unoccupied, and standby modes.

Note:

You need to address only those fields that are used in the program to control the air-handling unit.

5. Under Space, type the CO

limit and the relative humidity setpoint.

2

6. In the Damper Minimum Position field, type the lowest position you

want the outdoor air damper to reach.

7. In the Occupied Bypass Timer field, type the amount of time you

want the controller to remain in occupied bypass mode.

When a user overrides the controller to occupied bypass mode, it stays

in this mode for the time specified here.

8. Click the Download button to send your changes to the Tracer

MP580/581.

9. Click Close to close the Configuration dialog box.

Configuring the DAC interface

To set the configuration parameters associated with the DAC profile:

CNT-SVP01C-EN 45

Page 56

Chapter 3 Configuring the Tracer MP580/581

1. In the Active Device View, click the Configuration button. The Configuration dialog box appears.

2. Click the DAC tab. The DAC configuration information appears

(Figure 33).

Note:

This tab is available only when the DAC profile is active in the

Tracer MP580/581.

Figure 33. Device configuration DAC tab

3. Under Units, click the display units option for the DAC profile config-

4. Under Default Setpoints, type the heating and cooling default set-

5. Under Discharge Air Setpoints, type the discharge air setpoints for

6. Under Static Pressure, type the duct static pressure setpoint and

46 CNT-SVP01C-EN

uration data.

points for the occupied, unoccupied, and standby modes.

Note:

You need to address only those fields that are used in the program to control the air-handling unit.

the DAC profile.

limit and the building static pressure setpoint.

Page 57

Configuration reports

7. Under Air Temperature, type the mixed air temperature low-limit

setpoint and the outdoor air temperature setpoint.

8. In the Occupied Bypass Timer field, type the amount of time you

want the controller to remain in occupied bypass mode.

When a user overrides the controller to occupied bypass mode, it stays

in this mode for the time specified here.

9. Click the Download button to send your changes to the Tracer

MP580/581. Click Close to close the Configuration dialog box.

Configuration reports

After configuring the Tracer MP580/581 controller, you can save and

print reports that include the configuration parameters set up for the controller. These reports can be used to verify the appropriate specifications

for the consulting engineer or to document the specifications for the

customer.

Saving configuration reports

To save a configuration report:

1. In the Active Device View, click the Reports button. The Report Selection dialog box appears.

2. Click to select the check boxes for the configuration items you want in

the report.

3. Click the Save to File button. A Save As dialog box appears.

4. Select or enter a file name for the data that will be saved. Click OK.

The file is saved as a comma-separated values (CSV) file. Use a

spreadsheet program, such as Microsoft Excel, to view the report.

Printing configuration reports

To print a configuration report:

1. In the Active Device View, click the Reports button. The Report Selection dialog box appears.

2. Click to select the check boxes for the configuration items you want in

the report.

3. Click the Print button. The Print dialog box appears.

4. Select the appropriate printer and set the print properties. Click OK.

5. Click OK. The report prints.

CNT-SVP01C-EN 47

Page 58

Chapter 3 Configuring the Tracer MP580/581

Memory reset

If you have security privileges to do so, you can reset the memory of the

controller. Resetting the memory removes all data in the controller database and returns the controller settings back to factory defaults.

Note:

This features applies to only Tracer MP580/581 Firmware Revision 2 or higher. Follow the procedure for “Viewing Comm5

parameters” on page 13 to view your current revision number.

To reset memory:

1. In the Active Device View, click the Configuration button. The Configuration dialog box appears.

2. From the Devices menu, choose Reset Memory. The Reset Memory

dialog appears. (If the Security Logon dialog box appears, log on.)

3. Click the Yes button. The Reset Memory dialog box closes, and the

Rover service tool loses communication with the controller.

4. Click Close to close the Configuration dialog box.

5. From the Group menu, choose Discover to re-establish communication between the Rover service tool and the controller.

Unlocking controller for flash download

The Tracer MP580/581 controller is a host-based controller. Host-based

controllers with flash memory can receive a flash download of new firmware. If security is enabled and you have security privileges, you can

unlock the controller to enable flash downloading. If security is disabled

for all users, unlocking is not required.

Note:

Unlocking the controller applies to only Tracer MP580/581

Firmware Revision 2 or higher. If you have a Revision 1.xx controller, you can perform a flash download without unlocking the

controller. Follow the procedure for “Viewing Comm5 parameters” on page 13 to view your current revision number.

To unlock the controller:

1. In the Active Device View, click the Configuration button. The Configuration dialog box appears.

2. From the Devices menu, choose Unlock Device. (If the Security Logon

dialog box appears, log on.)

3. Backup files as necessary.

4. For details regarding flash downloading (refer to “Performing a Flash

48 CNT-SVP01C-EN

Download” in the Rover Operation and Programming guide, EMTXSVX01C-EN).

Page 59

Chapter 4

Using the Schedule

application

The Tracer MP580/581 plug-in includes a schedule application that you

can use to set up a local schedule. The local schedule functions only when

a non-portable operator display is connected the controller. The local

schedule is used only if Tracer Summit is not communicating on the link.

Use the information in this chapter to set up the local daily schedule and

exceptions for the Tracer MP580/581 controller.

Viewing the status of the time-of-day

schedule

To view the status of the time-of-day schedule:

X In the Active Device View, click the Application tab. The status of the

Tracer MP580/581 applications appears. The current mode of the

schedule and the current day and time of the controller appear under

Schedule (Figure 34).

Figure 34. Time of day schedule status

CNT-SVP01C-EN 49

Page 60

Chapter 4 Using the Schedule application

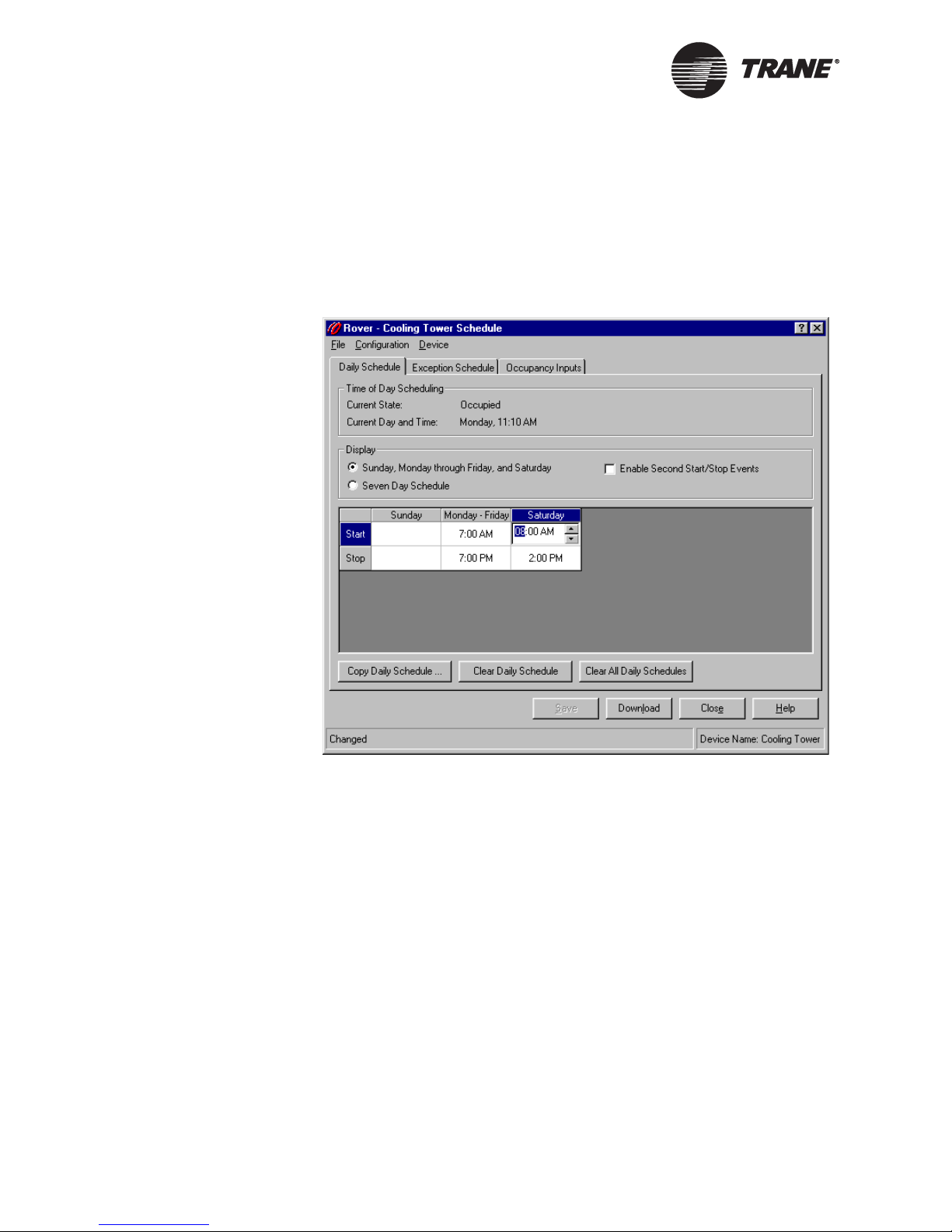

Setting up the daily schedule

To set up the daily schedule:

1. In the Active Device View, click the Schedule button. The Schedule

dialog box appears (Figure 35).

Figure 35. Daily Schedule tab in Schedule application

2. Under Display, click the option for the type of schedule you want. The

3. Under Display, click to select the Enable Second Start/Stop Events

50 CNT-SVP01C-EN

daily schedule table changes to include the appropriate number of columns.

If you want to use the same schedule for Monday through Friday, click

the Sunday, Monday through Friday, and Saturday option. Click the

Seven Day Schedule option if you want to specify a different schedule

for each day of the week.

check box if you want to include a second set of start and stop times to

Page 61

the daily schedules. Another set of Start and Stop rows appears in the

daily schedule table.

Note: