Page 1

WSHP-IOP-2

May 1998

Installation, Operation,

and Programming

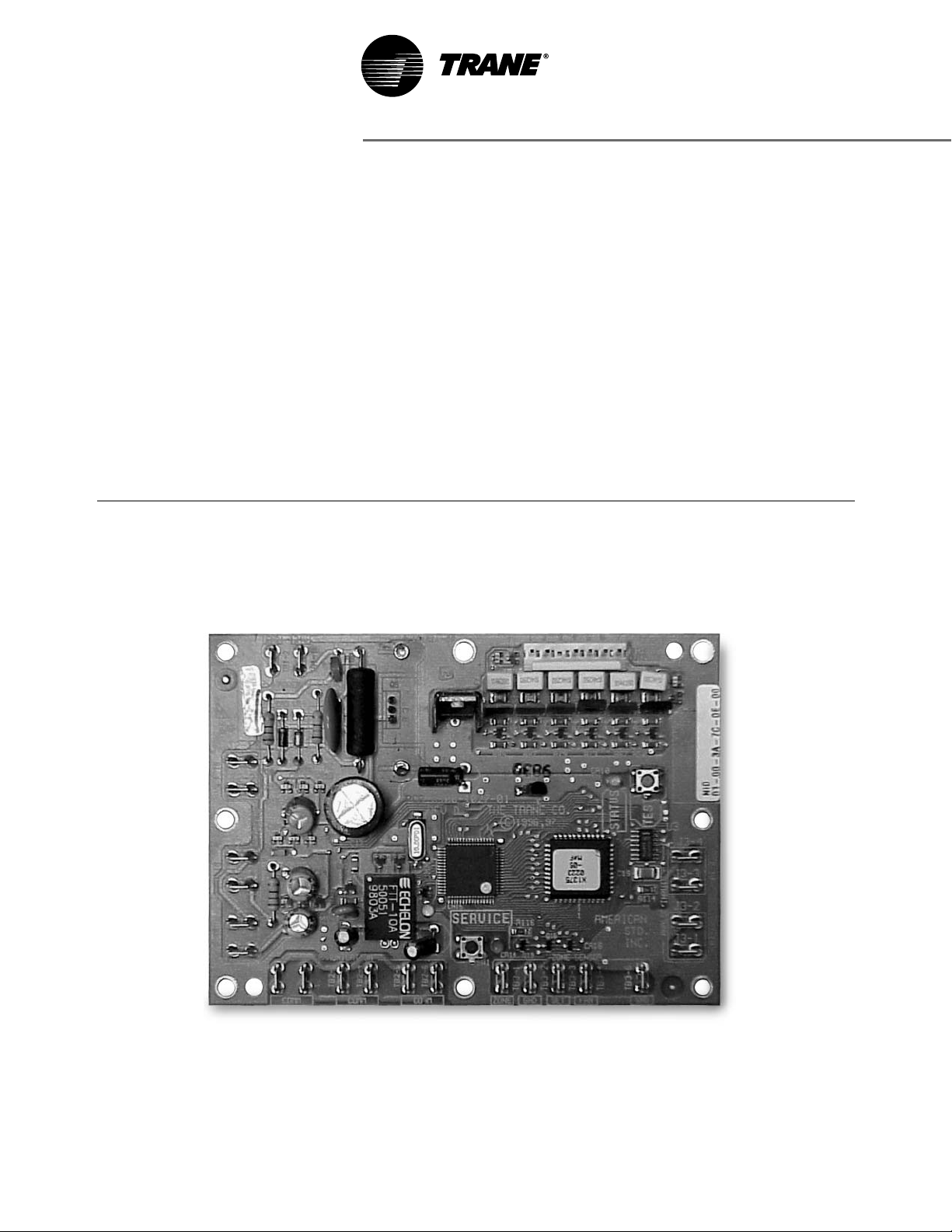

Tracer™ ZN510 Controller

Page 2

Literature

History

The Trane Company has a policy of continuous product improvement and it reserves the right to change

specifications and design without notice.

Installation, Operation,

and Programming

Library Service Literature

Product Section Unitary

Product Water-Source Heat Pumps

Model 000

Literature Type

Sequence 1

Date April 1998

File No. SL-UN-000-WSHP-IOP-2-0498

Supersedes New

Related Literature

z CNT-IOP-1 ZN510 1 Controller:

Installation, Operation, and Programing

z WSHP-PD-1 Water-Source Heat

Pump Controller Product Data

Sheet

WSHP-IOP-2

Installation, Operation,

and Programming

z WMCA-PD-1 ZN510 Loop Con-

troller Product Data sheet

z WSHP-IOP-3 ZN510 Water-

Source Heat Pump Controller

Installation, Operation, and Programming Guide

z WMCA-IOP-1 ZN510 Controller

Installation, Operation, and Programming Guide

© 1998, American Standard Company

Page 3

Table of Contents

Start-up Procedure 4

Power-up Sequence 5

Unit Identification Tag 6

Unit Operation 7

General Information 7

Communication 7

Power 8

Binary Outputs 8

Analog Outputs 9

Binary Inputs 9

Analog Inputs 12

Zone Sensors 15

Heating or Cooling Control

Mode Operation

Single or Dual Compressor

Operation

Data Sharing 20

Configuration 21

Troubleshooting 22

Diagnostics 27

ZN510 Controller Replacement 28

Wiring Diagram 29

Hardware Specifications 31

Appendix 33

18

19

Page 4

Start-up Procedure

Installation of New Units

1. Follow all instruction for

installation of water source

heat pumps as detailed in the

IOM (Installation Operation

Maintenance manual).

2. Disconnect power or disable

the circuit breaker to unit.

3. Run communication link wire to

field terminal strips 14 and 16.

(See wiring diagram in the

unit).

4. Install zone sensor to low

voltage control terminals 1

through 6. (See wiring diagram

in the unit and zone sensor

submittals).

Zone Sensor Placement

Zone sensor location is an important

element of effective room control

and comfort.

The best sensor location is typically

on a wall, remote from the

Readings at this location assure that

the desired setpoint is achieved

across the space, not just near the

unit itself. It may be necessary to

subdivide the zone with multiple

units to ensure adequate control

and comfort.

HVAC unit.

5. Verify that water connections

have been made to unit, then

ensure that water is circulating

through the unit.

6. Reapply power.

7. Check for STATUS GREEN LED

operation to ensure power and

communication has been made

to the ZN510

Peel IDENTIFICATION TAG from unit

and place in the ZN510 IOP, on a

copy of Sheet 6 of this document, or

on building plans for future location

use. The actual room location on the

tag may be hand written.

The following are typical areas

where the zone sensor should not

be mounted:

z Near drafts or “dead spots”

(e.g., behind doors or corners)

z Near hot or cold air ducts

z Near radiant heat (e.g., heat

emitted from appliances or the

sun)

z Near concealed pipes or

chimneys

z On outside walls or other non-

conditioned surfaces

™

.

z In air flows from adjacent zones

or other units

4

Page 5

Power Up Sequence

Power Up Sequence

When 24 VAC power initially is

applied to the ZN510 controller, the

following sequence occurs:

1. All outputs are controlled off.

2. The controller reads all inputs

to determine their initial values.

Note: Because the space temperature can be hardwired to the controller or communicated, the

controller waits for several minutes

to check for the presence of a communicated value.

3. A random start time is hard

coded on every board and

cannot be disabled. The board

generates a random time delay

between 0 and 25 seconds.

Once this time expires, the

power up control wait time (if

configured) will wait for 120

seconds. The power up control

wait allows ample time for a

communicated request to

arrive. If the power up control

wait time expires, and the

controller does not receive a

communicated occupancy

command, the unit assumes

stand alone operation.

4. Normal operation begins.

5

Page 6

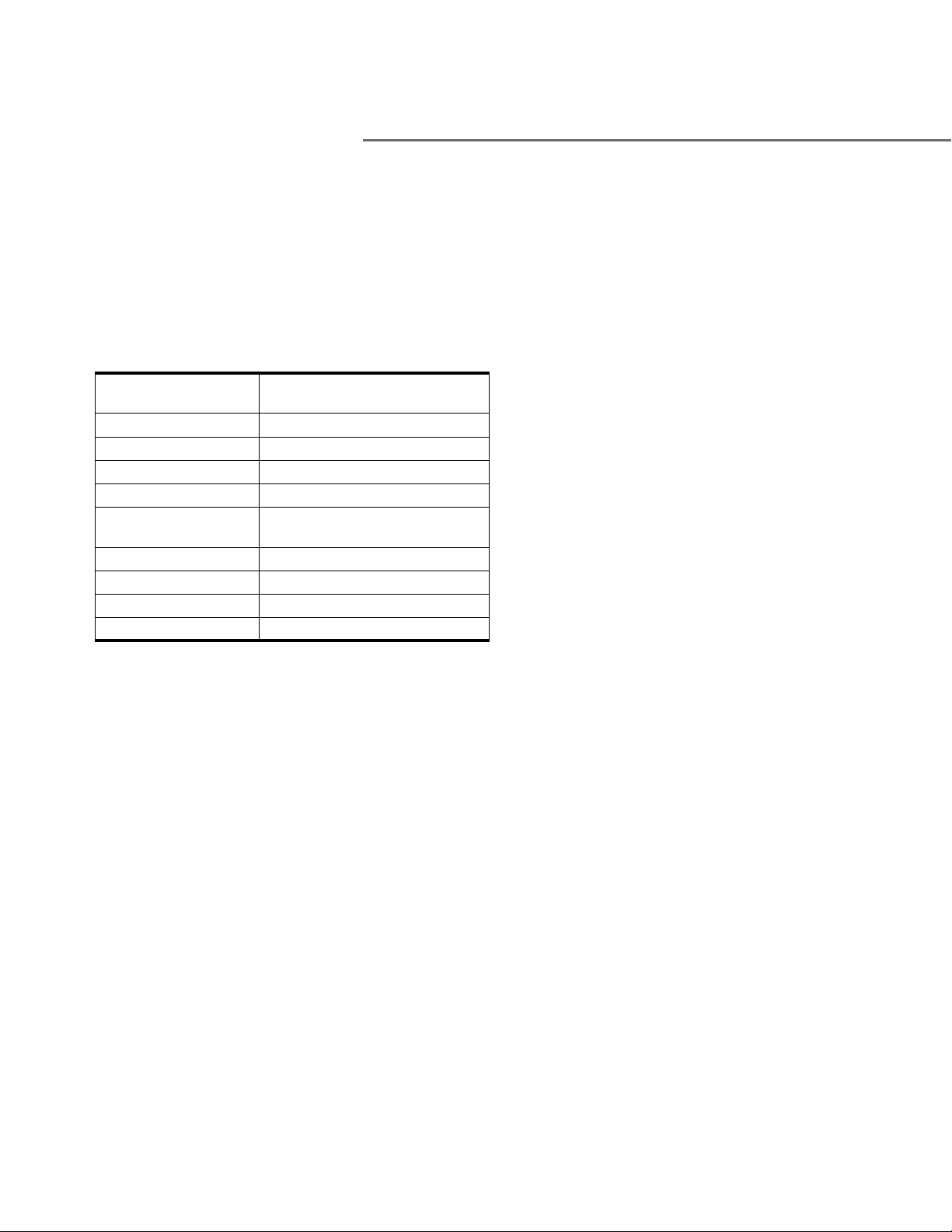

Unit Identification Tag

The unit identification tag is factory

mounted and provided for easy

identification of an installed unit. It

contains model number, tagging,

and location information. See

Figure 1.

The top portion of the unit

identification tag remains

permanently affixed to the unit for

identity purposes. The bottom

portion of the tag provides pertinent

information that is removable to be

placed on building plans or in the

ZN510 IOP on page 33. This provides

identification history about the unit’s

location for quick reference.

These tags provide information

about unit location, unit serial

number, and NID (neuron

identification number). The NID is

similar to the serial number of the

unit but is specific to the

identification of the ZN510 Board.

The location identification is a

customer defined, clear English

description, of the unit’s physical

location. This is a 27 character

description of the location. For

example, if the location identification

for a unit is “Conference Room 101”,

the ZN510 and Rover (the Trane

Comm 5 service tool) will recognize

this clear English description so

maintenance can be performed on

the appropriate unit. If location

identification is not defined, it will

default to the unit serial number. This

provides some information so the

user has multiple references to the

unit. The blank location is provided

for field modification in case the unit

is moved from the initial location.

Unit

Identification

Tag

Figure 1: Unit Identification Tag

Note: Fold and tear carefully along dashed

removable line.

6

Page 7

Unit Operation

General Information

The ZN510 controller is a

microprocessor-based direct digital

controller that controls a variety of

water source heat pump equipment

including:

z Standard efficiency horizontal

and vertical units up to 10 tons.

z High efficiency horizontal and

vertical units.

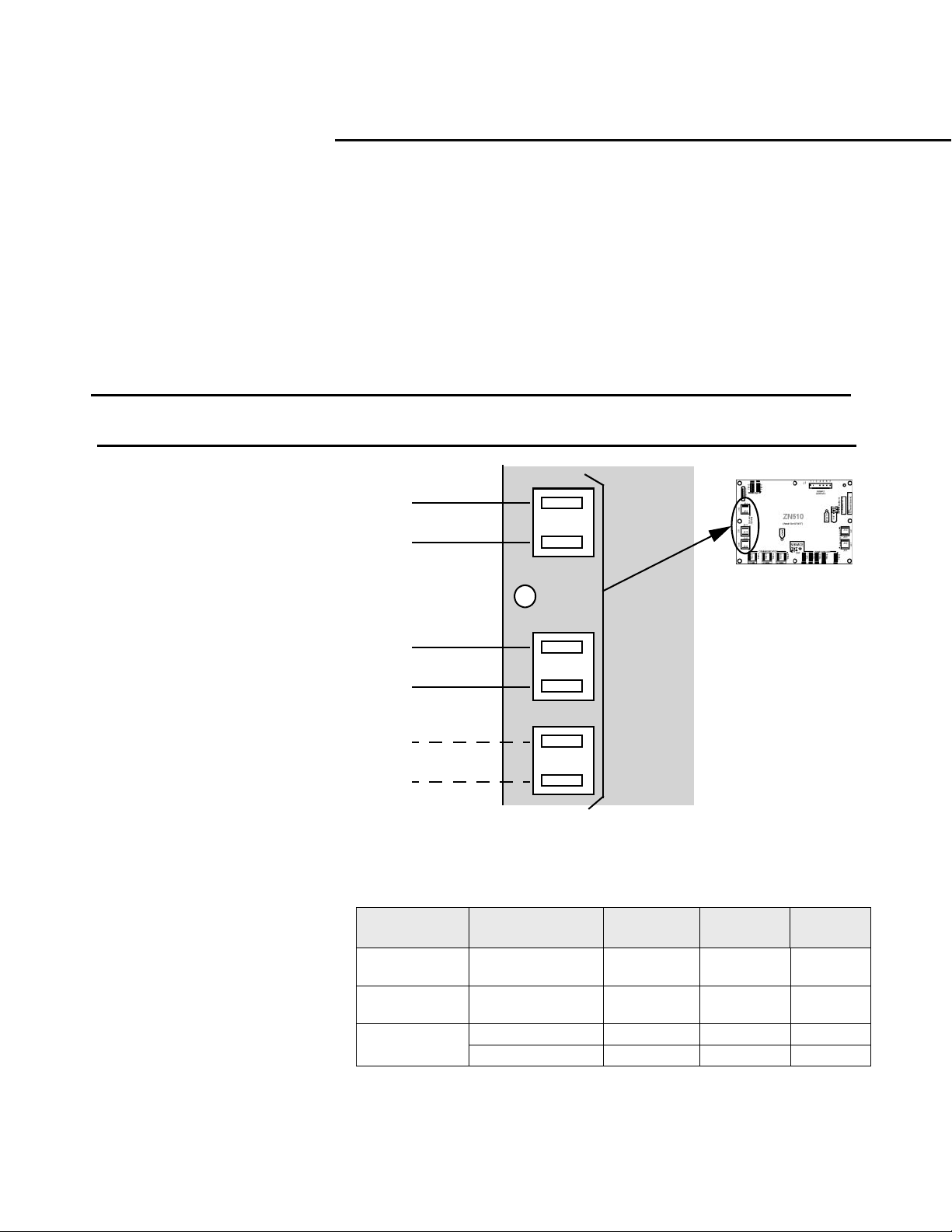

Figure 2: Communication connections

Communication

The ZN510 controller communicates

via Trane’s Comm5 protocol.

Typically, a communication link is

applied between unit controllers and

a building automation system.

Communication is also possible

™

with Trane’s service tool Rover

.

ZN510 provides a total of six 1/4-inch

quick-connect terminals for

connection to the Comm5

communication link. These

connections include:

z Two terminals (TB2-1, TB2-2)

z Console water source heat

pumps.

ZN510 is designed to provide

accurate and reliable zone

temperature control by using

custom proportional integral (PI)

algorithms. The controller is factory

installed and configured to support:

z Single fan speed.

are provided for direct connection of Rover to the ZN510

Board or provided as spare terminals.

z Two terminals (TB2-3, TB2-4)

are connected to the field

terminal strip (1TB1-14,

1TB1-16) for connection to the

communication link (daisy

chain).

z Up to two compressors.

z Reversing valve.

z 2-position outdoor air damper

or generic binary output.

Peer-to-peer communication across

controllers is possible even when a

building automation system is not

present. ZN510 is also adaptable as

a standalone system.

z Two terminals (TB2-5, TB2-6)

are connected to the field

terminal strip (1TB1-5, 1TB1-6)

which should be connected to

the zone sensor communication

jack. This provides direct

connect of Rover to the communication link without having to

connect directly to the ZN510

board or provided as spare terminals.

z The field terminal strip 1TB1

provides screw terminations for

all field connections.

TB2-1

COMM COMM COMM

Space

Communication

Connection

20 pole low voltage

terminal strip screw

connections for

field hook-up

Figure 3: Communication Wiring

7

TB2-2

TB2-3

1TB1-14

Communication

Link

1TB1-16

TB2-4

TB2-5

TB2-6

1TB1-5

1TB1-6

Zone

Sensor

Page 8

Unit Operation

Power

The ZN510 controller is powered by 24

VAC. A total of two 1/4-inch quick-

connect terminals are provided for 24

VAC connection to the board. See

Figure 4 for ZN510 power requirement.

Note: Power for field installed ancillary devices is not available from the

board. It must be tapped at transformer. See Table 21 for excess power

available.

Binary Outputs

The ZN510 uses five of its binary

outputs to control heat pump units.

Outputs are load side switching triacs.

The triac acts as a switch by either

making or breaking the circuit

between the load (reversing valve,

damper, contactor, relay) and ground.

See Figure 5 for the configuration of

the five binary outputs.

Factory Supplied Transformer

Line

Vol tage

24VAC

Figure 4: Power Connections

Field installed

2 position

damper actuator

24VAC

1TB1-17

1TB1-18

2-Position Damper Actuator or

Generic Binary Output

Binary output 6 (BOP 6) is factory

configured to control a normally

closed 2-position outdoor air damper.

It may be field modified to control a

generic output for control by a

building automation system. If set up

as a generic output, the controller

does not use BOP 6 as part of the

normal control. A building automation

system must issue commands to

control the generic binary output.

Note:

z During occupied mode, the

outdoor air damper is closed

when the fan is controlled off.

z During unoccupied mode, the

outdoor air damper normally

remains closed.

z 2-position damper must not

exceed 10 VA power output from

board.

Figure 5: Binary outputs

BOP 1 (Fan)

BOP 2 (Reversing Valve)

J1-1

J1-2

BOP 4 (Not Used)

J1-4

BOP 5 (Compressor 1)

J1-5

BOP 3 (Not available)

J1-3

Binary Outputs

.

Table 1: BOP 6 control of a 2-position outdoor air damper

Model Fan Operation Outdoor Air Damper

Occupied

Occupied warm up or

cool down

Occupied standby On or cycling Closed

Unoccupied Cycling Closed

Diagnostic present Diagnostic dependent Closed

On or cycling

Off

On or cycling Closed

Open

Closed

BOP 6 (Compressor 2)

J1-6

BOP 7

J1-7

8

Page 9

Unit Operation

Output Overrides

The ZN510 controller includes a

manual output test function. Use this

feature to manually exercise the

outputs in a defined sequence. The

purpose of the test sequence, is to

verify output and end device

operation. Use the manual output

test to:

z Verify output wiring and

operation without using Trane’s

service tool, Rover.

Analog Outputs

Binary Inputs

The ZN510 controller has three

available binary inputs (BI). These

inputs are factory-configured for

the following functions:

z BI 1= Low temperature

detection (freezestat) (Circuit 2).

z BI 2 = Condensate overflow.

z BI 3 = Occupancy or generic

binary input.

Each binary input may be

configured as not used depending

on options selected. BI 3 is

configured as a normally open

occupancy input, but may be field

modified for generic binary input

which is only supported by a building automation system.

Note:

The diagnostic functions related to

binary inputs such as low temperature detection and condensate

overflow are fixed sequences.

Each binary input associates an

input signal of 0 VAC with open

contacts and 24 VAC with closed

contacts. See Figure 6 for typical

binary input configurations for the

heat pump.

z Force compressor operation,

allowing the technician to use

refrigerant gauges or other test

equipment to verify unit

operation.

The test sequence resets unit

diagnostics and attempts to restore

normal unit operation prior to

testing the outputs. If the diagnostics

remains after a reset, the status LED

indicates the diagnostic condition is

still present and has affected the

ZN510 does not use analog outputs.

Low Temperature

Detection (Circuit 2)

Condensate Overflow

Field Wired

Occupancy Input

J2-1

BI 1

J2-2

J2-3

BI 2BI 3

J2-4

J2-5

J2-6

Figure 6: Binary inputs.

Table 2: Binary input configurations

Binary Input Description

BI 1

BI 2 Condensate Overflow

BI 3

Low Temperature

Detection (Cir 2)

Occupancy Normally open Unoccupied Occupied

Generic Normally open Normal Normal

manual output test. See

Troubleshooting section for Green

LED and Testing Heat Pump

Configurations on page 21 & 22.

Binary Inputs

ConfigurationContact

Closure

Normally

closed

Normally

closed

Normal Diagnostic

Normal Diagnostic

Contact

Open

Note:

See Page 10 for specific information concerning BI 1, BI 2 and BI 3.

9

Page 10

Unit Operation

Low Temperature Detection

The low temperature detection

temperature condition exists for that

circuit.

outdoor air damper also operates

normally.

diagnostic protects the heat

exchanger by using an analog

leaving water temperature sensor to

protect refrigerant circuit 1 and a

binary low temperature detection

device to protect refrigerant circuit

2. Each individual refrigerant circuit

is disabled when the low

For two compressor units, the

controller responds to low

temperature detection by allowing

the fan to operate, while disabling

the compressor for the faulty circuit.

The compressor for the normal

circuit continues to operate. The

All unit operation is disabled when

the heat pump shuts down both

circuits, due to low temperature

conditions. See Table 3 for more

information.

Table 3: ZN510 response to low temperature detection diagnostic

Description

Low Temperature Detection

(Circuit 1)

Low Temperature Detection

(Circuit 2)

Low Temperature Detection

(Circuits 1 and 2)

Fan

Operation

Enabled

Enabled

Disabled

Compressor Operation

Circuit 1-Disabled

Circuit 2-Normal Operation

Circuit 1-Normal Operation

Circuit 2-Disabled

Circuit 1-Disabled

Circuit 2-Disabled

Damper

Operation

Normal

operation

Normal

operation

Closed

Note:

z The low temperature detection device automatically resets when the heat exchanger temperature returns to

normal. However, you must manually reset the low temperature detection diagnostic to clear the diagnostic and

restart the unit. Refer to page 28 on how to reset a unit.

z If BOP 6 is configured as a generic binary output, the state of the output is not affected by the low temperature

detection diagnostic or by other diagnostics.

Condensate Overflow

A condensate overflow switch

detects the condensate condition.

The condensate overflow switch is a

normally closed device. This switch

is physically connected to the binary

input 2 (BI 2). When the

condensation reaches the trip point,

the binary input detects the

diagnostic condition. A condensate

overflow signal generates a

diagnostic which disables the fan,

disables all compressors, and closes

the 2-position outdoor air damper

(when present). The condensate

overflow diagnostic does not affect

the generic binary output (when

present).

Note:

The condensate overflow switch,

located in the condensate pan, automatically resets when the condensation returns to normal levels.

However, you must manually reset

the controller’s condensate overflow diagnostic to clear the diagnostic and restart the unit. Refer to page

28 on how to reset a unit.

Occupancy

ZN510 uses the occupancy binary

input for two occupancy-related

functions. For standalone

controllers (any unit not receiving a

communicated occupancy request,

typically from a building automation

system), the occupancy binary input

determines the unit’s occupancy

based on the hardwired signal.

Typically, the signal is a dry set of

binary contacts which is either

connected to a switch or timeclock

contacts.

When a hardwired occupancy signal

is open, the unit switches to

occupied mode (if the occupancy

input is configured as normally

open). When a hardwired

occupancy signal is closed, the

controller switches to Unoccupied

mode.

10

Page 11

Unit Operation

In Occupied mode, the controller

operates according to the occupied

setpoints. In Occupied Standby

Mode, the unit controller operates

according to the Occupied Standby

setpoints. When the controller

receives a communicated

unoccupied request, the controller

Table 4: Normally open hardwired input configuration (BI 3)

Description Communicated Request Hardwired State Result

Standalone NA Open = Occupied Occupied

Standalone NA Closed = Unoccupied Unoccupied

Communicating Occupied Open = Occupied Occupied

Communicating Unoccupied Open = Occupied Unoccupied

Communicating Occupied Standby Open = Occupied Occupied Standby

Communicating Occupied Closed = Occupied Standby Occupied Standby

Communicating Unoccupied Closed = Occupied Standby Unoccupied

Communicating Occupied Standby Closed = Occupied Standby Occupied Standby

Note:

If configured for normally closed, all states are opposite of Table 4.

operates according to the

unoccupied setpoints regardless of

the state of the hardwired

occupancy input.

If neither the binary input nor the

communicated input is used to

select the occupancy mode, the

controller defaults to occupied

mode because the occupancy binary

input (if present) typically is

configured as normally open

without an occupancy device

connected.

Generic Binary Input

Building automation systems can

monitor the status of the generic

binary input. This input does not

affect controller operation.

High and Low Pressure

Switches

The high and low pressure cutout

switches are wired in series with the

compressor contactor in the unit.

The ZN510 controller detects the

state of each switch circuit by

monitoring the controller’s

compressor triac outputs. If either

the high pressure switch (HPC) or

the low pressure switch (LPC) switch

opens, a fault condition occurs. This

open circuit prevents the

compressor contactor from

energizing keeping the compressor

from running. The controller

automatically detects the fault

condition by measuring the

compressor triac output signal.

By default, when the HPC or LPC

switches detect a high or low

pressure condition in the refrigerant

circuit, the special input detects the

diagnostic and disables all

compressor operation for that

circuit. The unit fan continues to

operate, if only one circuit is

disabled in a two compressor unit.

When the HPC/LPC diagnostic is

present on both circuits, the ZN510

shuts off the unit fan and disables

unit operation. See Figure 7 for high

and low pressure switch.

When the refrigerant circuit returns

to normal, the HPC and the LPC

switches automatically reset. The

high or low pressure cutout

diagnostic may need to be manually

reset to clear the diagnostic and

enable compressor operation for the

fault circuit.

11

Page 12

24 VAC

Unit Operation

Compr 2

HPC LPC

Figure 7: High and low pressure switch

Note:

The ZN510 controller includes an automatic diagnostic reset function that allows the controller to

automatically recover after a high or low pressure cutout diagnostic. After 30 minutes the controller will reset the diagnostics. Most

diagnostics occur due to intermittent water temperature or flow problem. The “smart reset” may

eliminate many service calls.

Analog Inputs

The ZN510 controller has five

available analog inputs (AI). These

inputs are factory-configured for the

following functions:

Compr 1

Binary Outputs

12 456 73

z Zone = Space temperature.

z Set = Local setpoint.

z Fan = Fan mode input.

z AI 1 = Leaving water tem-

perature (Circuit 1).

z AI 2 = Discharge air tem-

perature.

See Figure 8 for analog inputs.

Zone

J3-4

J3-3

J3-2

Analog Inputs

Zone Sensor

TB3-3

TB3-2

TB3-1

Ground

(1TB1-1)

(1TB1-2)

TB3-4

Fan

Setpoint

(1TB1-3)

(1TB1-4)

TB3-5

J3-1

Figure 8: Analog inputs.

Discharge Air

Sensor

AI 2

Leaving Water

AI 1

Sensor (Circuit)

12

Page 13

Unit Operation

Space Temperature

ZN510 controls the space

temperature according to the active

space temperature, the active

heating/cooling setpoint, and the

space temperature control

algorithm. The ZN510 controller

receives the space temperature

from either a wired zone sensor or

as a communicated value. When

neither a zone sensor nor

communicated space temperature is

present, the ZN510 controller

generates a space temperature

failure diagnostic.

Note:

The ZN510 controller cannot operate without a valid space temperature value (either hardwired or

communicated).

The space temperature input can

communicate timed override

CANCEL requests to the ZN510

controller. If the ON button is

temporarily pressed, the zone

sensor sends a signal to the

controller. This signal is then

interpreted as a timer override

request which places the unit into

occupied.

The controller uses the timed

override request (while the zone is

unoccupied) as a request to switch

to the Occupied Bypass mode

(occupied bypass). This Occupied

Bypass mode lasts for the duration

of the occupied bypass time,

typically 120 minutes.

or

The controller’s Occupancy mode is

determined from either a system

level controller or another peer

controller.

CANCEL button cancels the timed

The

override request and returned the

unit to unoccupied mode. If the

CANCEL button is temporarily

ON or

pressed, the zone sensor sends a

signal to the controller. This signal is

then interpreted as a timed override

cancel which places the unit into

unoccupied.

Local Setpoint

The local setpoint analog input is

designed as the local (hardwired)

setpoint input. This input cannot be

used for any other function. The

local input is a resistance input

intended for use with Trane zone

sensors.

If neither a hardwired nor

communicated setpoint is present,

the controller uses the stored default

setpoints:

z Occupied setpoints:

In the occupied mode, the unit

attempts to maintain the space

temperature at the active

occupied heating or cooling

setpoint based on the measured

space temperature, the active

setpoint, and the proportional/

integral control algorithm.

z Occupied standby setpoints:

In occupied standby mode, the

controller uses the occupied

standby cooling and heating

setpoints. Because the occupied

standby setpoints typically

cover a wider range than the

occupied setpoints, the ZN510

controller reduces the demand

for heating and cooling the

space. Also, the outdoor air

damper is normally closed

during occupied standby mode

to further reduce the heating

and cooling demands.

z Unoccupied setpoints:

In unoccupied mode, the unit

attempts to maintain the space

temperature at the stored unoccupied heating or cooling

setpoint based on the measured

space temperature, the active

setpoint, and the proportional/

integral control algorithm,

regardless of the presence of a

hardwired or communicated

setpoint.

Once a valid setpoint is established

(through the hardwired input or

through communication) and when

neither a local setpoint or

communicated setpoint is present,

the controller generates a setpoint

failure diagnostic.

When a setpoint failure diagnostic

occurs, the controller operates using

the default heating and cooling

setpoints. These setpoints are

factory-configured, but may be

changed using the Trane service

tool, Rover.

The ZN510 controller uses the

following validation sequence for

the setpoints:

1. Check for a communicated

setpoint. If present, validate this

setpoint.

2. Check for a hardwired setpoint

and validate the setpoint.

3. Use the default setpoint and

validate this setpoint.

Fan Mode Input

The fan mode analog input (Fan) is

designed to operate as the fan mode

switch input. This input cannot be

used for any other function. The fan

switch on a Trane zone sensor

generates the fan mode signal.

The ZN510 controller detects the

unique resistance corresponding to

each position of the fan switch. By

measuring the resistance, the

controller determines the requested

fan mode.

13

Page 14

Unit Operation

Possible

Fan Modes

OFF Fan Off

AUTO

AUTO

Heat Pump

(1-speed)

Continuous: (Field

Modified)

z In occupied mode, the

fan runs continuously.

In unoccupied mode,

the fan cycles

when no heating or

cooling is required.

Cycling: (Factory Default)

z The fan cycles

OFF with compressor

operation.

OFF

ON and

The ZN510 controller receives the

fan mode from either a wired zone

sensor or as a communicated valve.

When neither a zone sensor nor

communicated fan mode are

present, the ZN510 controller will

default unit operation to

AUTO.

Note:

z A building automation system

can also generate a fan mode

request and communicate this

request to the controller.

z If the ZN510 controller does not

receive a hardwired or communicated request for the fan

mode, the unit recognizes the

fan input as

AUTO and the fan

operates according to the

default configuration.

Fan Off Delay

When the heating output is

controlled off, the ZN510

automatically runs the fan

ON for an

additional 30 seconds to give the fan

time to blow off any residual heat.

Leaving Water Temperature

ZN510 uses analog input 1 (AI 1) as

the leaving water temperature input

for use with a thermistor. This input

(AI 1) is automatically assigned as a

leaving water temperature input. As

explained in the binary input

section, the leaving water

temperature input protects the heat

exchanger (circuit 1) from low

temperatures. The second heat

exchanger, present in units with two

compressors is protected with a

binary low temperature detection

device. Based on the application of

the unit, circuit operation is

terminated when the leaving water

temperature falls below 35 F or

20 F. This is set when the unit is

ordered.

The ZN510 controller compares the

measured leaving water

temperature to the leaving water

temperature low limit value to

determine a fault condition. When

the measured leaving water

temperature is less than the leaving

water temperature low limit, the

controller generates a Low Temp

Detect diagnostic. If the Leaving

Water Temp Sensor fails to open or

close the controller generates a

Leaving Water Temp Failure

diagnostic. This disables unit

operation.

Note:

A low temperature detection failure

diagnostic for compressor 1 may

require you to manually reset the

unit to restore compressor operation.

Similarly, the ZN510 controller uses

a binary low temperature detection

device (fixed low limit trip point) to

lock-out circuit 2 when a fault condition is detected.

See the Diagnostics section on page

28 for information about the

automatic diagnostic reset function.

Filter Maintenance Timer

The controller’s filter maintenance

timer is based on the unit fan’s

cumulative run hours. The controller

compares the fan run time against

an adjustable fan run hours limit

(maintenance required setpoint

time, stored in the controller) and

recommends unit maintenance (i.e.

changing the filter).

Use Rover or BAS system to edit the

maintenance required setpoint time.

Once the setpoint limit is exceeded

the controller generates a filter

maintenance timer diagnostic.

When the maintenance required

setpoint time is zero, the controller

disables the diagnostic feature.

Discharge Air Temperature

Analog input 2 (AI 2) is used as the

discharge air temperature input for

use with a 10,000 ohm thermistor.

Typical factory placement of the

thermistor is at the discharge area of

the unit. The discharge air

temperature sensor does not affect

unit operation. The measured

temperature is for information only

to be read by the building

automation system or for

troubleshooting unit operation with

Rover.

Once a valid discharge air

temperature signal has been

established by the thermistor or

communicated and the value is no

longer present, the controller

generates a discharge air

temperature failure diagnostic. This

will not disable unit operation. If the

sensor returns with a valid

temperature, the diagnostic

automatically clears

14

Page 15

Zone Sensor

Zone Sensor

The ZN510 controller accepts the

following zone sensor inputs:

z Space temperature mea-

surement.

z Local setpoint (internal or

external on the zone sensor).

z Fan switch. (Optional)

z Timed override (ON and CANCEL).

z Communication Jack.

If both hardwired and

communicated space temperature

Table 5: Methods of setpoint operation.

Method Situation used

Zone Sensor

(with an adjustable hardwired

setpoint)

Communicated source

Stored default setpoints

A hardwired, adjustable setpoint is connected to the controller. Local setpoints are

enabled in the unit configuration. No communicated setpoint is present.

A setpoint is communicated to the unit controller (typically from a building automation

system or a peer controller). If both a hardwired setpoint and a communicated setpoint

exist, the controller uses the communicated value. The configuration feature for enabling

or disabling the local setpoint does not affect the setpoint handling when communicated

setpoints are used. The communicated setpoint always takes priority over the hardwired

setpoint, even when the local setpoint is enabled.

The controller uses the locally stored default heating and cooling setpoints when neither

a local hardwired setpoint or communicated setpoint is present. When a building

automation system is present, the controller uses the default setpoints when no setpoint

is communicated to the controller and no hardwired setpoint exists. The controller uses

stored default setpoints when only a local setpoint exists, but the local setpoint is

disabled in the configuration of the controller. The controller always uses the stored

default (unoccupied) setpoints in unoccupied mode.

values exist, the controller ignores

the hardwired space temperature

input and uses the communicated

value.

Internal and External Setpoint

Adjustment

Zone sensors with an internal or

external setpoint adjustment

provide the ZN510 controller with a

local setpoint (50 to 85 F or 10 to 29.4

C). The internal setpoint adjustment

is concealed under the zone sensor’s

cover. To reveal the adjustable

setpoint wheel, remove the zone

sensor cover. The external setpoint

(when present) is exposed on the

zone sensor’s front cover.

When the hardwired setpoint

adjustment is used to determine the

setpoints, all unit setpoints are

calculated based on the hardwired

setpoint values, the configured

setpoints, and the active mode of

the controller.

Setpoint Operation

The controller has three methods of

heating and cooling setpoints

operation. See Table 5 for the

methods of setpoint operation.

15

Page 16

Zone Sensor

Zone Sensor Features

Fan Switch (Optional)

The zone sensor fan switch provides

the controller with an occupied (and

occupied standby) fan request signal

OFF or AUTO. If the fan control

of

request is communicated to the

controller, the controller ignores the

hardwired fan switch input and uses

the communicated value. The zone

sensor fan switch signal can be

enabled or disabled through

configuration in the ZN510

controller.

ON or CANCEL Buttons

Momentarily pressing the ON button

Table 6: Zone Sensor Options

Part Number:

X13510628010

Description:

z Space temperature (0.2 C

resolution).

z Internal setpoint.

z Communication jack.

z Vertical case with Trane logo

during unoccupied mode places the

controller in occupied bypass mode

for 120 minutes. You can adjust the

number of minutes in the unit

controller configuration using

Trane’s service tool, Rover. The

controller remains in occupied

standby mode until the override

timer expires or until the

CANCEL

button is pressed.

Communication Jack

Use the RJ-11 communication jack

as the connection point from Rover

to the communication link (when the

communication jack is wired to the

communication link at the

ADJUSTABLE

SETP OINT

COMMUNICATIONS

MJ1

JACK

controller). By accessing the

communication jack via Rover,

entrance to all controllers on the link

may be gained.

RT1

10K OHM @

R7 1K

25 °C ± 2°C

VR1

SIGNAL (COMMON)

200

COMM HIGH (+ )

COMM LOW (-)

ZONE

CSP

1

2

3

4

5

Part Number:

X13510606010

Description:

z Space temperature (0.2 C

resolution).

z External setpoint.

z Communication jack.

z Vertical case with Trane logo

16

ADJUSTABLE

SETP OINT

COMMUNICATIONS

MJ1

JACK

R7 1K

RT1

10K OHM @

25 °C ± 2°C

VR1

200

ZONE

SIGNAL (COMMON)

CSP

COMM HIGH (+ )

COMM LOW (-)

1

2

3

4

5

Page 17

Zone Sensor Specifications

Part Number:

X13510606020

Description:

z Space temperature (0.2 C

resolution).

z External setpoint.

z

ON and CANCEL buttons.

z Communication jack.

z Vertical case with Trane

logo.

Part Number:

X135 10635010

Description:

z Space temperature (0.2 C

resolution).

z External setpoint.

z Fan Switch (

AUTO).

z ON and

z Communication jack.

z Vertical case with Trane

logo.

OFF and

CANCEL buttons.

ON

17

Page 18

Heating or

Cooling Control

Mode Operation

Heating or Cooling

Operation

For both single and dual compressor

operation, the ZN510 controller

unit capacity and pulse width

modulation (PWM) logic along with

minimum on/off timers to determine

the operation for compressor 1.

cycles the compressor(s) on and off

to meet heating or cooling zone

demands. The controller uses the

With a dual compressor unit, if the

desired conditions are not met by

Table 7: Heat pump heating or cooling operation*

Unit

Single compressor

Dual (Two) compressors

Compressor

continuously.

Both compressors

OFF continuously.

0%

OFF

Compressor output is controlled according to pulse width

modulation (PWM) logic between 0 and 100%. The

controller calculates the compressor on/off times based

on PWM logic and heating/cooling capacities. The

compressor is controlled on for longer periods as the

capacity increases and shorter periods as the capacity

decreases.

ON PWM.

#1:

#2:

OFF continuously.

*Note: No diagnostics present.

Certain heat pump configurations

may use one or two compressors for

cooling control. Heat pumps use

reversing valve control to switch

simultaneously de-energizing the

reversing valve. The reversing valve

only changes state when the

controller turns on compressor 1.

between heating and cooling. The

controller supports cooling only

configurations and heat pump

configurations.

When a power failure occurs, the

reversing valve output defaults to

the heating (de-energized) state. To

reduce noise due to refrigeration

For heat pump configurations, the

unit’s reversing valve is energized in

cooling and de-energized in heating.

For cooling, the reversing valve

output is energized simultaneously

with the compressor (compressor 1

in two compressor applications).

migration after compressor

shutdown, the controller does not

immediately operate the reversing

valve. The reversing valve changes

state only when the compressor

controls on, except when the

controller is in off mode.

The reversing valve remains

energized until the controller turns

on the compressor for heating,

For cooling only configurations, no

reversing valve is present and the

Between

0 and 50%

Capacity

#1:

#2:

controlling only the first

compressor, the controller runs

compressor 1 continuously and

controls compressor 2 according to

PWM logic along with the minimum

on/off timers. See Table 6 for heat

pump heating or cooling operation.

Between

50 and 100%

ON continuously.

ON PWM.

controller uses the compressor

stages for cooling.

Compressor Minimum

ON/OFF Timers

z When fan mode = OFF, Com-

pressor minimum

ignored.

z When fan mode = AUTO, Com-

pressor minimum

observed.

z The diagnostic reset ignores the

compressor timers

z A communicated compressor

disabled or unoccupied signal

ignores minimum

100%

Compressor

continuously.

Both compressors

continuously.

ON

ON timers are

OFF timers are

ON and OFF.

ON times.

ON

18

Page 19

Single and Dual

Compressor

Operation

Other Modes

Occupancy Operation

Unoccupied operation normally is

associated with evening hours when

the space is vacant. In unoccupied

mode, the controller always uses the

default unoccupied heating and

cooling setpoints stored in the

controller. As the unit goes

unoccupied, the compressors

timers are ignored and the

compressors are disabled.

When ZN510 controls the space to

unoccupied mode, the occupant

may have the ability to request

timed override through the Trane

zone sensor’s

the controller or system setup, the

ON button. Based on

ON

controller interprets the request and

initiates the occupied setpoint

operation. During a timed override,

the controller applies the occupied

heating and cooling setpoint, but

reports the effective occupancy

mode as occupied bypass mode. In

the occupied bypass mode, a

building automation system can

detect whether the occupancy mode

was overrode.

Morning Warm Up

The damper (field installed or for the

console product) remains closed

during morning warm up until the

space temperature is within two

degrees of the effective heating

setpoint. The 2-position outdoor air

damper normally is open during the

occupied mode when the controller

turns on the unit fan. The damper is

normally closed during:

z occupied mode when the fan is

OFF.

z warm up/cool down mode.

z occupied standby mode.

z unoccupied mode.

z certain diagnostic conditions.

ZN510 keeps the 2-position outside

air damper closed on a transition

from unoccupied mode to occupied

mode as part of the morning warm

up sequence.

19

Page 20

Master Controller

ZN510 can send or receive data

(such as setpoint, heat/cool mode,

fan request and space temperature)

to and from other controllers on the

communication link, with or without

a building automation system. This

includes applications where

multiple unit controllers share a

common space temperature sensor,

both for standalone and building

automation applications.

The master controller (the unit

controller with the hardwired zone

sensor) in peer-to-peer

communication can send its zone

temperature to one or more slave

controllers which allows the slave

controllers to track each other’s

zone temperature. For these

applications, Rover is used in set up

of the controller.

See Figure 9 for Master/Slave

setpoint operation for peer-to-peer

set up.

Data Sharing

Master Controller

ON

CANCEL

Zone Sensor

Communication Link

24V

GND

TB1-2

TB1-1

P

O

W

E

R

98 0010155

J2-1

J2-2

BINARY

INPUTS

ComfortLin k 10

J2-3

U6

J2-4

J2-5

ECHELON

J2-6

COMMMU NICAT ION

TB2-2

TB2-3

TB2-1

COMM COMM COMM

Slave Controller Slave Controller

Figure 9: Master/slave setpoint operation for peer-to-peer setup

FTT-10A

TB2-4

(Actual Size 4.0"x5.5")

COMM

TB2-5

TB2-6

SERVICE

1234567

J1

BINARY

OUTPUTS

SW2

X13650607-01 A

NID:

12-34-56-78-9A -BC

ComfortLink(tm) 10

TEST

STATUS

J3-4

AI 2AI 1

J3-3

J3-2

ANALOG INPUTS

J3-1

ZONE SENSOR

SW1

TB3-1

TB3-2

TB3-3

TB3-4

TB3-6

SET

FAN

ZONE

GND

GND

Setpoint Operation

Controllers sharing information

peer-to-peer can share a variety of

data, including the heating/cooling

setpoint (communicated from a

master to a slave).

The standalone master controller

derives its setpoint from either the

local hardwired setpoint input or

from its default setpoints. Peer-topeer applications often require the

use of one hardwired setpoint to be

shared across two or more

controllers. This can be achieved by

wiring the adjustable setpoint

(typically included as a part of the

Trane zone sensor module) to the

controller defined as the master.

Trane’s service tool, Rover may be

used to set up the master and one or

more slaves to share that setpoint.

For this application, each

communicating controller uses the

same setpoint.

Note:

Each controller derives it’s effective

setpoint and default setpoints

(including deadbands between setpoints) from the setpoint input

(hardwired or communicated). To

make sure the peer-to-peer setpoint

application results in identical setpoints for each communicating controller, each controller must have

exactly the same default setpoints.

Simplified Peer-to-Peer (Master/

Slave) Setup

To simplify setting up master/slave

applications, the controller provides

information that groups all

necessary shared data into one

communication variable. This

master/slave variable includes the

following information:

z Space temperature.

z Setpoint.

z Heating/cooling mode.

z Occupancy.

z Fan status.

z Unit control algorithm capacity.

This information is communicated

from the master to the slave to

ensure similar unit operation.

Use Rover, Trane’s service tool, to

set up peer-to-peer applications.

Refer to the Rover

product literature

for more information on setting up

applications.

20

Page 21

Configuration

Configurable Parameters

Rover, Trane’s service tool, uses the

unit type “heat pump” to determine

and download unit configuration

information, such as the default

analog inputs, the default binary

inputs, and the default binary output

configurations. See Table 7 for

Table 8: Heat pump heating or cooling operation.

Unit Type Heat pump

Cooling Source Compressor

Heating Source Compressor (none for cooling only units)

Compressors 1 (2 for 2-compressor units)

BOP 1: Fan on (normally open)

BOP 2: Reversing valve (normally open)*

Binary Outputs

Binary Inputs

Analog Inputs

Fan

Setpoints

Occupied Bypass

Timer

Leaving Water

Temperature

Low Limit

Location Identifier Unit specific (maximum of 30 characters)

BOP 3: Not used

BOP 4: Compressor 1 (normally open)

BOP 5: Compressor 2 (normally open)**

BOP 6: Outdoor Air Damper (normally open)***

BI 1: Low temperature detection, circuit 2 (normally closed)*

**

BI 2: Condensate overflow (normally closed)†

BI 3: Occupancy (normally open)

Zone: Space temperature (0.0 F calibration)

Set: Setpoint (0.0 F calibration)

Fan: Fan mode

AI 1: Leaving water temperature

AI 2: Discharge air temperature

Fan operation (heating): Cycling

Fan operation (cooling): Cycling

Fan speed default (heating): On/high

Fan speed default (cooling): On/high

Fan switch (hardwired): Enabled

Unoccupied cooling setpoint: 85 F

Occupied standby cooling: 78 F

Occupied cooling setpoint: 74 F

Occupied heating setpoint: 71 F

Occupied standby heating: 67 F

Unoccupied heating setpoint: 60 F

Cooling setpoint high limit: 115 F

Cooling setpoint low limit: 40 F

Heating setpoint high limit: 115 F

Heating setpoint low limit: 40 F

Thumbwheel set point: Enabled

120 minutes

Unit specific (20 F ground source or 35 F standard)

* BOP 2, BI1: Not used on cooling only units.

** BOP 5: Not used on signal compressor unit.

*** Configured but not required.

† Optional model number dependent

default configurations for heat

pumps.

The heating and cooling setpoint

high and low limits only apply to the

occupied and occupied standby

setpoints. These limits never apply

to the unoccupied setpoints.

The occupied bypass time is used for timed

override applications. The timed override

timer is maintained in the unit controller.

When the timed override is applicable, the

controller reports “Occupied Bypass” as its

effective occupancy mode.

The leaving water temperature low

limit is used for freeze protection of

circuit 1 on heat pumps. Circuit 2 is

protected by a binary low

temperature detection device

(freezestat) with a fixed trip point.

21

Page 22

Troubleshooting

Red Service LED

Table 9: Red LED activity

Red LED Activity Description

LED off continuously when power is applied to the

controller.

LED on continuously, even when power is applied to

the controller.

LED flashes once every second.

!Warning! Service Button

The black Service button on the ZN510 board allows the user to send a service pin message, which allows

efficient identification of the unit's location. However, if the Service button is held for more than 10

seconds, the ZN510 will shut down the software application and disable the unit's operation. The only

method to restore the unit is through the use of Rover service tool. We strongly suggest that this function

only be exercised under the strict direction of factory service personnel.

Normal operation.

Someone is pressing the service button or the controller has

failed.

Use Rover, Trane’s service tool, to restore the unit to normal

operation or unconfigured.

Green Status LED

The green LED normally indicates

whether the controller is powered

on (24 VAC).

Table 10: Green LED activity

Green LED Activity Description

LED on continuously. Power on (normal operation).

LED blinks (one blink).

LED blinks (two blinks).

LED blinks (1/4 second on,

1/4 second off for 10 seconds.

LED off.

Yellow Service LED

Table 11: Yellow LED activity

Yellow LED Activity Description

LED off continuously.

LED blinks.

LED on continuously. Abnormal condition.

The controller is not detecting any communication.

(Normal for standalone applications).

The controller detects communication. (normal for

communicating applications, including data sharing).

Manual output test mode (2-second hold), No

diagnostics present.

Manual output test mode (2-second hold),

One or more diagnostics are present.

“Wink” mode.

This feature allows the identification of a

controller. By sending a request from a device,

such as Rover, Trane’s service tool or ZN510

Loop Controller, a request to the controller

can be made to “wink” a notification that the

controller received the signal. When the zone

sensor

ON button is held for 10 seconds

“Wink” mode is sent from Comfort Link

Controller.

z

Power off.

z Abnormal condition.

z Test button is pressed.

22

Page 23

Troubleshooting

Manual Output Testing the Heat

Pump Configurations

The procedure for testing heat pump

configurations is:

1. Press and hold the Test button

for at least three seconds to

start the test mode.

2. The test sequence resets

diagnostics and turns off all

outputs.

3. Press the Test button several

more times (no more than once

per second) to advance through

the test sequence.

Table 12: Test sequence

Step

1. Off Off Off Off Off Closed

2. Fan on (At the beginning of step 2, the

controller attempts to clear all diagnostics).

3. Reversing Valve On On Off Off Closed

4. Cool 1 On On On Off Closed

5. Cool 2 OnOn OnOnClosed

6. Compressor(s) off

This stage helps avoid compressor cooling

and heating in sequential steps by turning the

compressors off prior to changing the

reversing valve state.

7. Heat 1 On Off On Off Closed

8. Heat 2 On Off On On Closed

9. Outdoor air damper On Off Off Off Open

10. Exit

After the outdoor air damper step, the test

sequence performs the exit step. This

initiates a reset and attempts to return the

controller to normal operation.

Fan

BOP 1

On Off Off Off Closed

On Off Off Off Closed

Reversing Valve

BOP 2

Compr 1

BOP 4

Compr 2

BOP 5

Damper

BOP 6

Testing the Heat Pump

Configurations

The outputs are not subject to

minimum times during the test

sequence. However, the test

sequence only permits one step per

second which limits output time.

All outputs are exercised regardless

what timer they are or are not

configured for. For example, single

compressor heat pumps function

the same as two compressor units.

For single compressor units, the

cool 2 and heat 2 steps control the

appropriate binary outputs, but do

not affect unit operation.

Reversing valve and damper

outputs cycle independent of

configuration.

23

Pump Operation for

Systems with ZN510

Loop Controller

During Unoccupied, the pumps will

OFF but should be energized to

be

test compressor operation. The user

must override the pumps either at

the ZN510 Loop Controller or by

pushing the

ON button of the zone

sensor. This will send the units to an

occupied bypass, which

will turn the

pumps on prior to operating

manual output test.

Page 24

Troubleshooting

Questionable Unit

Operation

Table 13: Fan output does not energize

Probable Cause Explanation

Random start observed.

Power up control wait.

Cycling fan operation.

Unoccupied operation.

Fan mode off.

Requested mode off.

Diagnostic present.

No power to the controller.

Unit configuration.

Manual output test.

Unit wiring.

After power up, the controller always observes a random start from 0 to 25

seconds. The controller remains off until the random start time expires.

When power up control wait is enabled (non-zero time), the controller remains

off until one of two conditions occurs:

z

The controller exits power up control wait once it receives communicated information.

z The controller exits power up control wait once the power up control

wait time expires.

When configured to cycle with capacity, normally the unit fan cycles off with

heating or cooling. The heating/cooling sources cycle on or off periodically with

the unit fan to provide varying amounts of capacity to the space.

Even when the controller is configured for continuous fan operation, the fan

normally cycles with capacity during unoccupied mode. While unoccupied, the

fan cycles on or off with heating/cooling to provide varying amounts of heating

or cooling to the space.

When a local fan mode switch determines the fan operation, the off position

controls the unit fan off.

The desired operating mode (such as off, heat and cool) can be communicated to

the controller. When off is communicated to the controller, the unit controls the

fan off. There is no heating or cooling.

A specific list of diagnostics affects fan operation. See Diagnostics section on

page 27.

If the controller does not have power, the unit fan does not operate. For the

ZN510 controller to operate normally, it must have an input voltage of 24 VAC.

When the green LED is off continuously, the controller does not have sufficient

power or has failed.

The controller must be properly configured based on the actual installed end

devices and application.

The controller includes a manual output test sequence that may be used to verify

output operation and associated output wiring. However, based on the current

step in the test sequence, the unit fan may not be on. Refer to the manual output

overrides on page 9.

The wiring between the controller outputs and the fan relays and contacts must

be present and correct for normal fan operation.

24

Page 25

Questionable Unit

Operation

Table 14: Compressor(s) not running

Probable Cause Explanation

Normal operation.

Requested mode off.

Communicated disable.

Manual output test.

Diagnostic present.

Unit configuration.

No power to the controller.

Unit wiring.

Troubleshooting

The controller compressor(s) turn on and off to meet the unit capacity

requirements.

The desired operating mode (such as off, heat and cool) can be communicated to

the controller. When off is communicated to the controller, the unit shuts off all

unit compressor(s).

Numerous communicated requests may disable the compressor, including a

compressor enable input. Depending on the state of the communicated request,

the unit may disable the compressor.

The controller includes a manual output test sequence that may be used to verify

output operation and associated output wiring. However, based on the current

step in the test sequence, the compressor(s) may not be on. Refer to the manual

output overrides on page 9.

A specific list o f diagnostics affects compressor operation, depending whether

the unit is configured as heat pump. For more information, see the Diagnostics

section on page 27.

The controller must be properly configured based on the actual installed end

devices and application. When the unit configuration does not match the actual

end device, the compressor may not work correctly.

If the controller does not have power, the compressor does not operate. For the

ZN510 controller to operate normally, a voltage input of 24 VAC must be applied.

When the green LED is off continuously, the controller does not have sufficient

power or has failed.

The wiring between the controller outputs and the compressor contacts must be

present and correct for normal compressor operation.

Table 15: Outdoor air damper stays open

Probable Cause Explanation

The controller opens and closes the outdoor air damper based on the controller’s

Normal operation.

Manual output test.

Unit configuration.

Unit wiring.

occupancy mode and fan status. Normally, the outdoor air damper is open

during occupied mode when the fan is running and closed during unoccupied

mode. Refer to the outdoor air damper section on page 8.

The controller includes a manual output test sequence that may be used to verify

output operation and associated output wiring. However, based on the current

step in the test sequence, the outdoor air damper may not open. Refer to the

manual output overrides on page 9.

The controller must be properly configured based on the actual installed end

devices and application. When the unit configuration does not match the actual

end device, the outdoor air damper may not work correctly.

The wiring between the controller outputs and the compressor contacts must be

present and correct for normal damper operation.

25

Page 26

Troubleshooting

Questionable Unit

Operation

Table 16: Outdoor air damper stays closed

Probable Cause Explanation

The controller opens and closes the outdoor air damper based on the controller’s

Normal operation.

Warm up and cool down.

Requested mode off.

Manual output test.

Diagnostic present.

Unit configuration.

No power to the controller.

Unit wiring.

occupancy mode and fan status. Normally, the outdoor air damper is open

during occupied mode when the fan is running and closed during unoccupied

mode. Refer to the outdoor air damper section on page 8.

The controller includes both a morning warm-up and cool down sequence to

keep the outdoor air damper closed during the transition from unoccupied to

occupied. This is an attempt to bring the space under control as quickly as

possible.

The desired operating mode (such as off, heat and cool) can be communicated to

the controller. When off is communicated to the controller, the unit closes the

outside air damper.

The controller includes a manual output test sequence that may be used to verify

output operation and associated output wiring. However, based on the current

step in the test sequence, the outdoor air damper may not be open. Refer to the

manual output overrides on page 9.

A specific list o f diagnostics affects outdoor air damper operation, depending

whether the unit is configured as heat pump. For more information, see the

Diagnostics section on page 27.

The controller must be properly configured based on the actual installed end

devices and application. When the unit configuration does not match the actual

end device, the outdoor air damper may not work correctly.

If the controller does not have power, the compressor does not operate. For the

ZN510 controller to operate normally, a voltage input of 24 VAC must be applied.

When the green LED is off continuously, the controller does not have sufficient

power or has failed.

The wiring between the controller outputs and the outdoor air damper must be

present and correct for normal outdoor air damper operation.

26

Page 27

Diagnostics

Table 17: ZN510 controller diagnostics

Diagnostic Fan Other Outputs

Condensate overflow Off

Low temp detect - Crt 1 Enabled

Low temp detect - Crt 1 Enabled

Low temp detect - Crt 1 and 2 Off

High/low press cutout - Crt 1 Enabled

High/low press cutout - Crt 2 Enabled

High/low press cutout - Crt 1 and 2 Off

Space temperature failure* Off

Leaving water temp failure Enabled

Compressors: Off

Damper: Closed

Compressor 1: Off

Compressor 2: See note below.

Damper: See note below.

Compressor 1: See note below.

Compressor 2: Off

Damper: See note below.

Compressor 1: Off

Compressor 2: Off

Damper: Closed

Compressor 1: Off

Compressor 2: See note below.

Damper: See note below.

Compressor 1: See note below.

Compressor 2: Off

Damper: See note below.

Compressor 1: Off

Compressor 2: Off

Damper: Closed

Compressor(s): Off

Damper: Closed

Compressor 1: Off

Compressor 2: See note below.

Damper: See note below.

Discharge air temp failure* Enabled

Maintenance required

(example: Filter Status)

Local setpoint failure* Enabled

Local fan mode failure* Enabled

Invalid unit configuration Disabled

Enabled

Compressor(s): No action

Damper: No Action

Compressor(s): No action

Damper: No Action

Compressor(s): Enabled

Damper: Enabled

Compressor(s): Enabled

Damper: Enabled

Compressor(s): Disabled

Damper: Disabled

High/low pressure cutout and low temperature detection diagnostics for heat pump configurations isolate

each circuit and independently disable compressor operation. For single compressor units, these diagnostics cause

the compressor to shut down, the unit fan to be controlled off, and the outdoor air damper to be closed (when

present).

When BOP 6 is configured as a generic binary output, BOP 6’s state is unaffected by all unit diagnostics.

* Note: Non-latching diagnostics automatically reset when the input is present and valid.

27

Page 28

Diagnostics

Translating Multiple

Diagnostics

The controller senses and records

each diagnostic independently of

the diagnostics. It is possible to have

multiple diagnostics present

simultaneously. The diagnostics are

reported in the order they occur.

Resetting Diagnostics

1. Automatically by the controller.

2. By initiating a manual output

test at the controller.

3. By cycling power to the

controller.

4. Through a building automation

system such as ZN510 Loop

Controller.

5. Through Rover, Trane’s service

tool.

6. Through any communicating

device with the ability to access

the controller’s alarm reset

input.

Automatic Diagnostic Reset

The ZN510 controller includes an

automatic diagnostic reset function.

This function attempts to

automatically recover a unit when

the following diagnostics occur:

z Low temperature detection,

Circuit 1

z Low temperature detection,

Circuit 2

z Low temperature detection,

Circuit 1 and 2

z High/low pressure cutout,

Circuit 1

z High/low pressure cutout,

Circuit 2

z High/low pressure cutout,

Circuit 1 and 2

When one or more of these special

diagnostics occurs, the controller

responds to the diagnostic as

defined in the table 17 on page 27.

After the controller detects the first

special diagnostic (listed on page

27), the unit waits 30 minutes before

invoking the automatic diagnostic

reset function. The automatic

diagnostic reset function clears all

special diagnostics and attempts to

restore the controller to normal

operation. The controller resumes

normal operation until another

diagnostic occurs.

If a special diagnostic occurs within

24 hours after an automatic

diagnostic reset, the diagnostic

must be manually reset.

Cycling Power

When the 24

controller has been turned off, the

unit cycles through a power up

sequence. By default, the controller

attempts to reset all diagnostics at

power up. Diagnostics present at

power up and those that occur after

power up are handled according to

the table on page 27.

Building Automation System

(CLC)

Some building automation systems

can reset diagnostics in the ZN510

controller. The ZN510 Loop

Controller can reset diagnostics in

the ZN510 Controller. For complete

information, refer to the building

automation system product

literature.

VAC power to the

Rover Service Tool

Trane’s service tool, Rover, can reset

diagnostics in the ZN510 controller.

For complete information about

Rover, refer to the Rover product

literature.

Alarm Reset

Any device that can communicate

alarm reset information can reset

diagnostics in the ZN510 controller.

ZN510 Controller Replacement

1. Disconnect power or disable

the circuit breaker to unit.

2. Remove bad or questionable

ZN510 Controller.

3. Install controller in the unit with

the heatsink placement at the

top of the control box. (See

page 32).

4. Connect the power to the ZN510

ONLY. (TB1-1 & TB1-2 on ZN510)

5. Connect Rover and properly

configure the controller, unless

a previously configured board

is purchased.

6. Power down.

7. Connect the remaining input

and output wiring to the

controller.

8. Reapply power.

9. Complete sequence 7 and 8

above in the installation section

of this manual.

10. Refer to BAS manual for

instructions on how to install

the new ZN510 into BAS

system.

28

Page 29

Wiring Diagram

29

Page 30

Wiring Diagram

30

Page 31

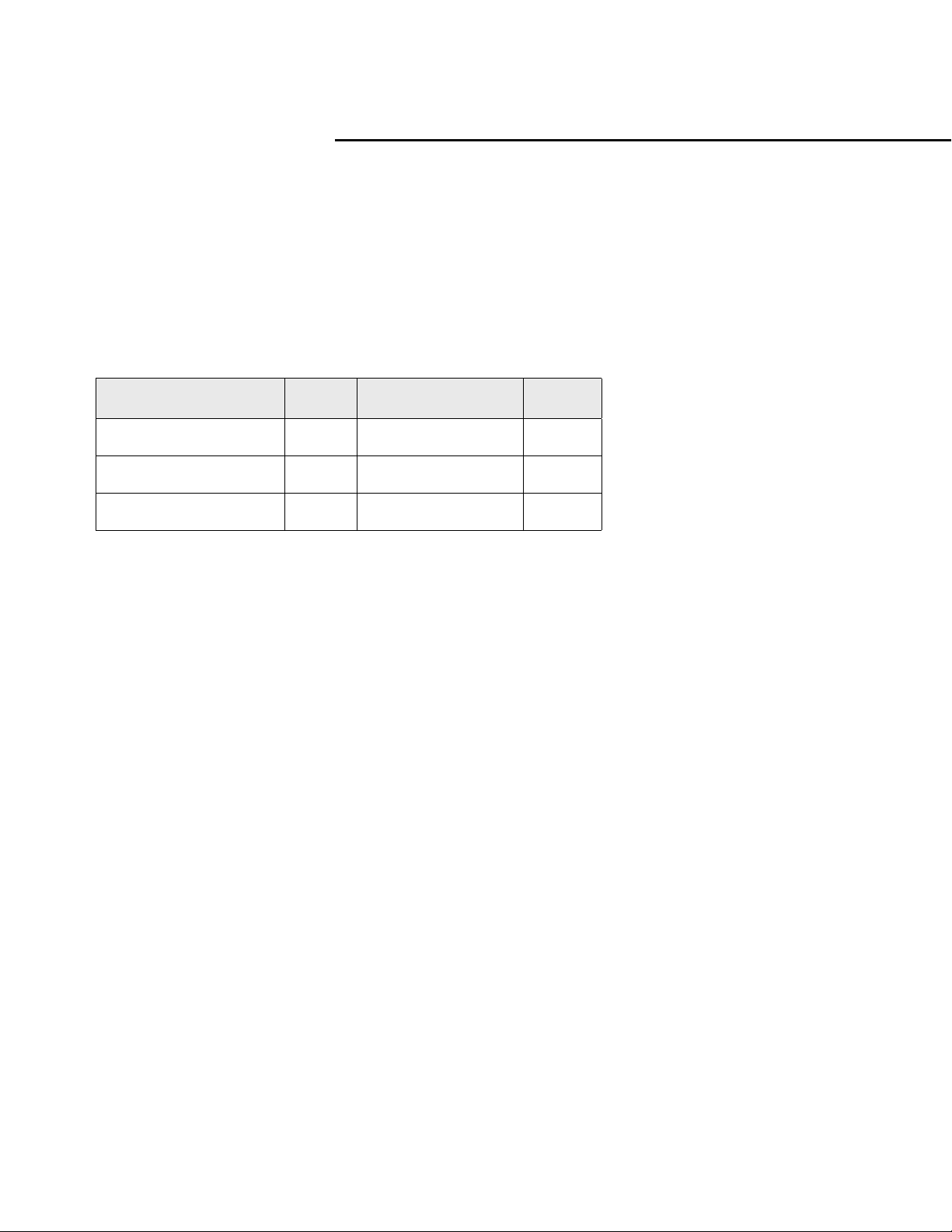

Hardware

Specifications

Specifications

Board Dimensions

Height: 4” (102 mm)

Width: 5-1/2” (140 mm)

Depth: 2-1/4” (57mm)

Operating Environment

32 to 140 F (0 to 60 C)

5 to 95% non-condensing

Storage Environment

-40 to 185 F (-40 to 85 C)

5 to 95% non-condensing

Power Requirements

18 to 32 VAC (24 VAC nominal)

50 or 60 Hz

300 mA

Agency Listings

UL and CUL 916 Energy

Management System

Agency Compliance

IEC 1000-4-2 (ESD), IEC 1000-4-4

Heat sink is mounted to the top

of the control box

(EFT), IEC 1000-4-5 (Surge), FCC Part

15, Class A.

Input/Output Summary

z Three binary inputs.

z Six binary outputs only five are

used.

z Five analog inputs.

z Timed override ON and CANCEL.

z Comm5 communication.

4”

Figure 10: ZN510 Circuit Board

5 1/2”

31

Page 32

Hardware

Specifications

Table 18: Binary Inputs

Description Te r mi na l s Function

Binary Input 1 J2-1 24

J2-2 Input

Binary Input 2 J2-3 24

J2-4 Input

Binary Input 3 J2-5 24

J2-6 Input

Table 19: Binary Outputs

VAC

VAC

VAC

Description Te r mi na l s

Binary Output 1 J1-1 12 VA 1 VAC RMS (typical) 24 VAC RMS (typical)

Binary Output 2 J1-2 12 VA 1 VAC RMS (typical) 24 VAC RMS (typical)

Binary Output 3 J1-4 NOT USED

Binary Output 4 J1-5 12 VA 1 VAC RMS (typical) 24 VAC RMS (typical)

Binary Output 5 J1-6 12 VA 1 VAC RMS (typical) 24 VAC RMS (typical)

Binary Output 6 J1-7 12 VA 1 VAC RMS (typical) 24 VAC RMS (typical)

Output

Rating

Load Energized Load De-energized

Table 20: Analog Inputs

Description Te rm in al s Function Range

Zone TB3-1 Zone temperature input 5 to 122 F (-15 to 50 C)

Ground TB3-2 Analog ground NA

Set TB3-3 Setpoint input 40 to 115 F (4.4 to 46.1 C)

Fan TB3-4 Fan switch input

Ground TB3-6 Analog ground NA

Analog Input 1 J3-1 Leaving water

temperature

J3-2 Analog ground NA

Analog Input 2 J3-3 Discharge air temperature -40 to 212 F (-40 to 100 C)

J3-4 Analog ground NA

OFF = 4821 to 4919 Ohms

AUTO = 2297 to 2342 Ohms

-40 to 212 F (-40 to 100 C)

32

Loading...

Loading...