Page 1

Installation, Operation,

and Maintenance

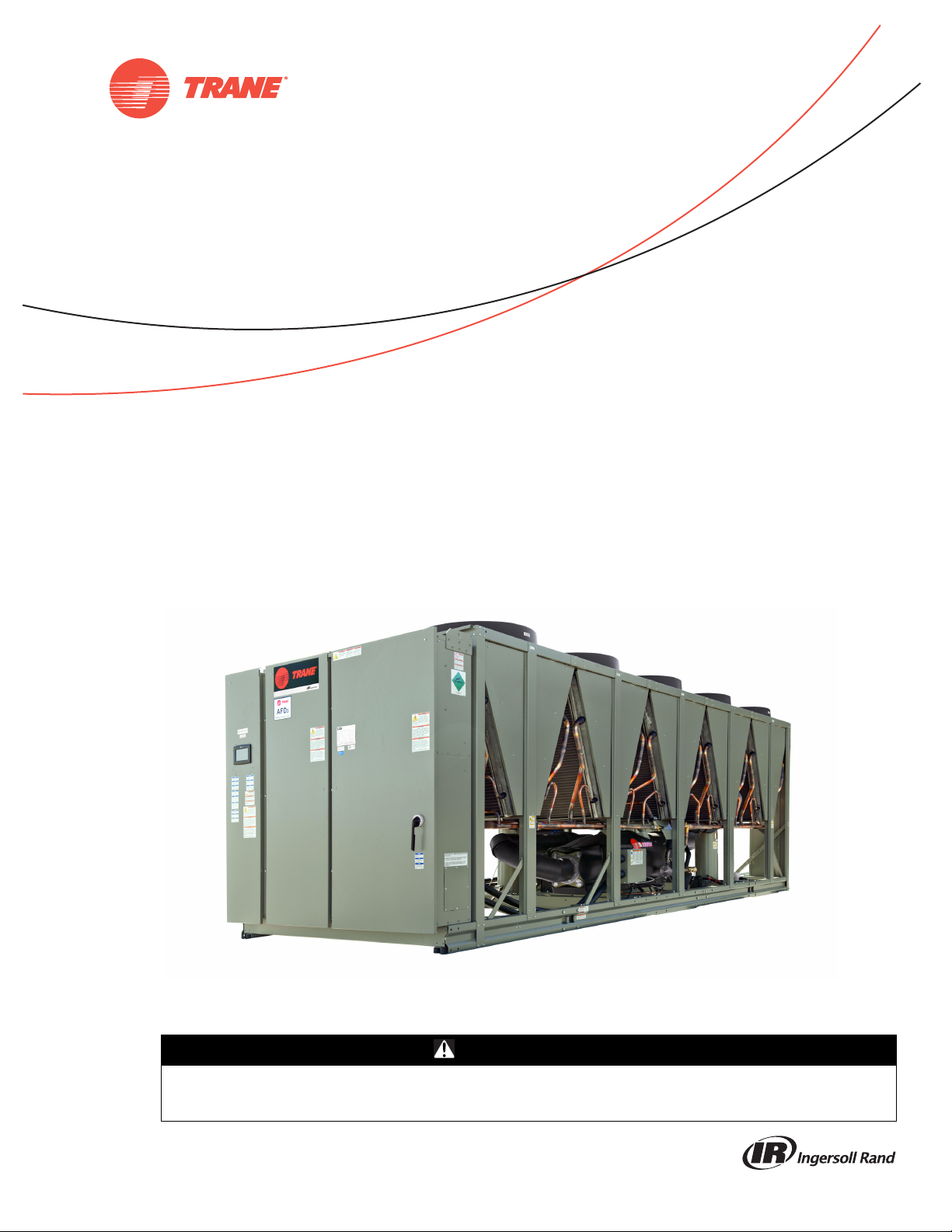

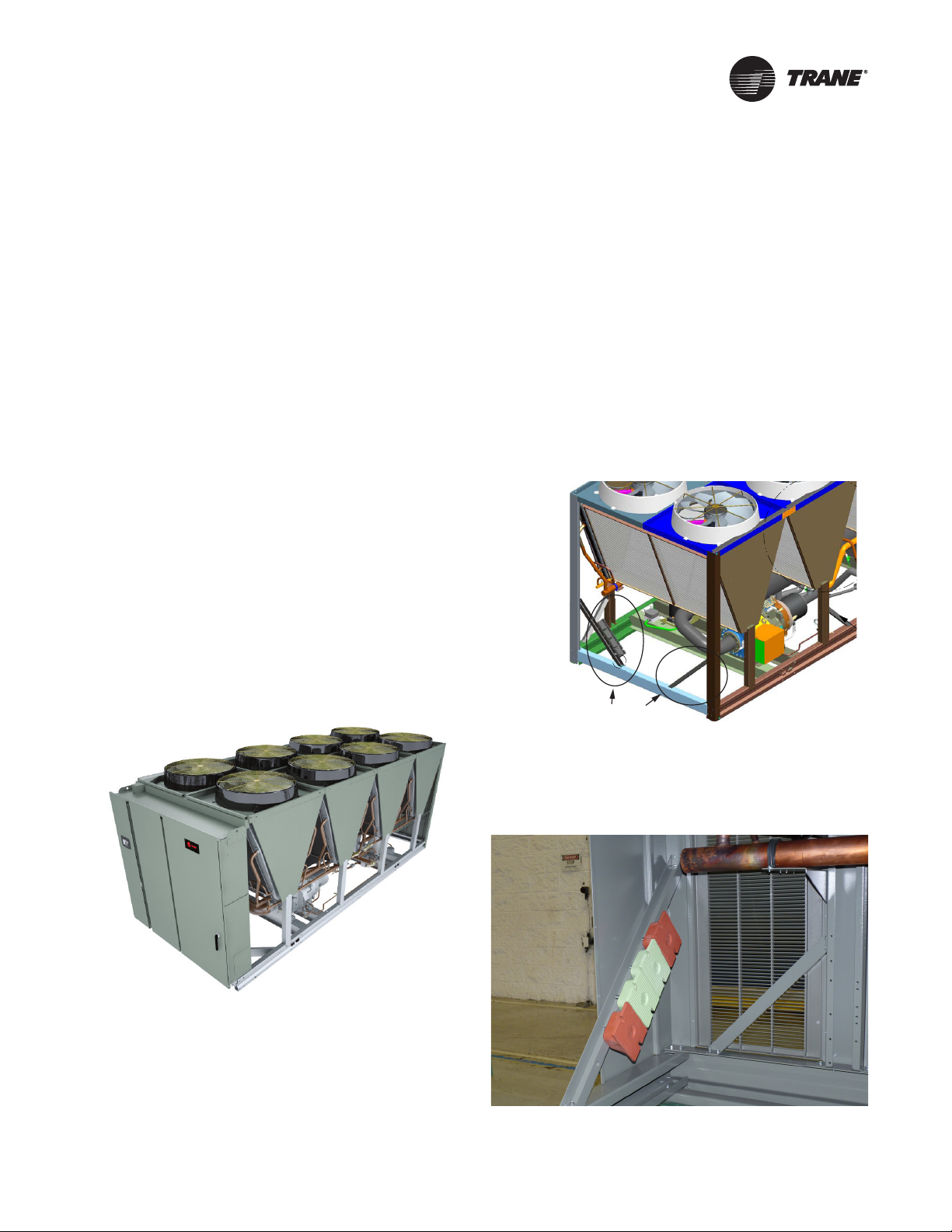

Stealth™ Air-Cooled Chiller

Model RTAE

150 to 300 Nominal Tons

SAFETY WARNING

Only qualified personnel should install and service the equipment. The installation, starting up, and servicing of heating, ventilating, and airconditioning equipment can be hazardous and requires specific knowledge and training. Improperly installed, adjusted or altered equipment

by an unqualified person could result in death or serious injury. When working on the equipment, observe all precautions in the li terature and

on the tags, stickers, and labels that are attached to the equipment.

October 2014

RTAE-SVX001B-EN

Page 2

Warnings, Cautions and Notices

Warnings, Cautions and Notices. Note that warnings,

cautions and notices appear at appropriate intervals

throughout this manual. Warnings are provided to alert

installing contractors to potential hazards thatcould result

in death or personal injury. Cautions are designed to alert

personnel to hazardous situations that could result in

personal injury, while notices indicate a situation that

could result in equipment or property-damage-only

accidents.

Your personal safety and the proper operation of this

machine depend upon the strict observance of these

precautions.

Read this manual thoroughly beforeoperating or servicing

this unit.

ATTENTION: Warnings, Cautions and Notices appear at

appropriate sections throughout this literature. Read

these carefully:

WARNING

CAUTIONs

NOTICE:

Indicates a potentially hazardous

situation which, if not avoided, could

result in death or serious injury.

Indicates a potentially hazardous

situation which, if not avoided, could

result in minor or moderate injury. It

could also be used to alert against

unsafe practices.

Indicates a situation thatcould result in

equipment or property-damage only

Important

Environmental Concerns!

Scientific research has shown that certain man-made

chemicals can affect the earth’s naturally occurring

stratospheric ozone layer when released to the

atmosphere. In particular, several of the identified

chemicals that may affect the ozone layer are refrigerants

that contain Chlorine, Fluorine and Carbon (CFCs) and

those containing Hydrogen, Chlorine, Fluorine and

Carbon (HCFCs). Not all refrigerants containing these

compounds have the same potential impact to the

environment.Trane advocates the responsible handling of

all refrigerants-including industry replacements for CFCs

such as HCFCs and HFCs.

Responsible Refrigerant Practices!

Trane believes that responsible refrigerant practices are

important to the environment, our customers, and the air

conditioning industry. All technicians who handle

refrigerants must be certified.The Federal Clean Air Act

(Section 608) sets forth the requirements for handling,

reclaiming, recovering and recycling of certain

refrigerants and the equipment that is used in these

service procedures. In addition, some states or

municipalities may have additional requirements that

must also be adhered to for responsible management of

refrigerants. Know the applicable laws and follow them.

WARNING

Refrigerant under High Pressure!

System contains oil and refrigerant under high

pressure. Recover refrigerant to relieve pressure before

opening the system. See unit nameplate for refrigerant

type. Do not use non-approved refrigerants, refrigerant

substitutes, or refrigerant additives. Failure to recover

refrigerant to relieve pressure or the use of nonapproved refrigerants, refrigerant substitutes, or

refrigerant additives could result in an explosion which

could result in death or serious injury or equipment

damage.

WARNING

Personal Protective Equipment (PPE)

Required!

Installing/servicing this unit could result in exposure to

electrical, mechanical and chemical hazards.

• Before installing/servicing this unit, technicians

MUST put on all PPE required for the work being

undertaken (Examples; cut resistant gloves/sleeves,

butyl gloves, safety glasses, hard hat/bump cap, fall

protection, electrical PPE and arc flash clothing).

ALWAYS refer to appropriate Material Safety Data

Sheets (MSDS)/Safety Data Sheets (SDS) and OSHA

guidelines for proper PPE.

• When working with or around hazardous chemicals,

ALWAYS refer to the appropriate MSDS/SDS and

OSHA/GHS (Global Harmonized System of

Classification and Labelling of Chemicals) guidelines

for information on allowable personal exposure

levels, proper respiratory protection and handling

instructions.

• If there is a risk of energized electrical contact, arc, or

flash, technicians MUST put on all PPE in accordance

with OSHA, NFPA 70E, or other country-specific

requirements for arc flash protection, PRIOR to

servicing the unit. NEVER PERFORM ANY

SWITCHING, DISCONNECTING, OR VOLTAGE

TESTING WITHOUT PROPER ELECTRICAL PPE AND

ARC FLASH CLOTHING. ENSURE ELECTRICAL

METERS AND EQUIPMENT ARE PROPERLY RATED

FOR INTENDED VOLTAGE.

Failure to follow instructions could result in death or

serious injury.

© 2014 Trane All rights reserved RTAE-SVX001B-EN

Page 3

WARNING

Proper Field Wiring and Grounding

Required!

All field wiring MUST be performed by qualified

personnel. Improperly installed and grounded field

wiring poses FIRE and ELECTROCUTION hazards.To

avoid these hazards, you MUST follow requirements for

field wiring installation and grounding as described in

NEC and your local/state electrical codes. Failure to

follow code could result in death or serious injury.

Factory Warranty Information

Compliance with the following is required to preserve the

factory warranty:

All Unit Installations

Startup MUST be performed byTrane, or an authorized

agent ofTrane, to VALIDATE this WARRANTY. Contractor

must provide a two-week startup notification to Trane (or

an agent of Trane specifically authorized to perform

startup).

Warnings, Cautions and Notices

Copyright

This document and the information in it are the property of

Trane, and may not be used or reproduced in whole or in

part without written permission. Trane reserves the right

to revise this publication at any time, and to make changes

to its content without obligation to notify any per son of

such revision or change.

Trademarks

All trademarks referenced in this document are the

trademarks of their respective owners.

Revision History

RTAE-SVX001B-EN (29 Oct 2014)

• Added transformer option.

• Added harmonic filter option.

• Added 150T and 165T single circuit units.

• Added extreme low ambient option.

• Added seismic isolation option.

• Added CE/PED option.

• Updated unit weights and isolator information.

• Updated drive cooling fluid volumes.

• Modified oil sump check procedure.

RTAE-SVX001A-EN (24 Sep 2013)

New release.

RTAE-SVX001B-EN 3

Page 4

Table of Contents

Warnings, Cautions and Notices .......... 2

Factory Warranty Information ........... 3

Copyright ............................. 3

Trademarks ........................... 3

Revision History ....................... 3

Model Number Description ............... 6

Outdoor Unit Nameplate ............... 6

Compressor Nameplate ................ 6

Model Number Descriptions .............. 7

Unit Model Number .................... 7

Compressor Model Number ............ 8

Compressor Serial Number ............. 8

General Information ..................... 9

Unit Description ....................... 9

Accessory/Option Information ........... 9

General Data ........................... 10

Drive Cooling System ................. 11

Pre-Installation ......................... 12

Unit Inspection ..................... 12

Inspection ......................... 12

Storage ........................... 12

Installation Requirements .............. 13

Dimensions and Weights ................ 14

Weights ............................. 14

Unit Dimensions ...................... 14

Service Clearances .................... 14

Installation Mechanical .................. 15

Location Requirements ................ 15

Sound Considerations ............... 15

Foundation ........................ 15

Clearances ......................... 15

Center of Gravity ..................... 20

Isolation and Sound Emission .......... 20

Unit Isolation and Leveling ........... 20

Compressor Shipping Bolt Removal .... 23

Units with InvisiSound™ Ultimate Option

(Model Number Digit 12 = 3) .......... 23

Pressure Relief Valves ..................26

Evaporator Waterside Pressure Drop

Curves

...............................27

Freeze Protection ......................29

Low Evaporator Refrigerant Cutout,

Glycol Requirements

...................30

Installation Electrical .....................31

General Recommendations .............31

Adaptive Frequency™ Drive (AFD3)

Capacitor Discharge ..................32

Units with Nitrogen Charge Option .....32

Installer-Supplied Components ..........32

Power Supply Wiring .................33

Control Power Supply ................34

Service Power Connection ............34

Heater Power Supply .................34

Interconnecting Wiring .................35

Chilled Water Pump Control ...........35

Programmable Relays ..................35

Relay Assignments Using Tracer™ TU ...36

Low Voltage Wiring ....................36

Emergency Stop .....................36

External Auto/Stop ...................36

External Circuit Lockout –

Circuit #1 and #2 .....................36

Ice Building Option ..................37

External Chilled Water Setpoint (ECWS)

Option .............................37

External Demand Limit Setpoint (EDLS)

Option .............................37

Chilled Water Reset (CWR) ............38

Transformer Power Rating ..............39

Communications Interface ..............39

LonTalk Interface (LCI-C) ..............39

BACnet Interface (BCI-C) ..............39

Modbus Remote Terminal Unit Interface .39

Operating Principals .....................40

Refrigeration Circuits ..................40

Refrigeration Cycle ....................40

Drainage ............................ 23

Refrigerant R-134a .....................40

Evaporator Piping Components ....... 25

4 RTAE-SVX001B-EN

Page 5

Compressor and Lube Oil System ...... 40

Condenser and Fans .................. 40

Evaporator ........................... 41

Drive Cooling System ................. 41

Controls ............................... 42

UC800 Specifications .................. 42

Wiring and Port Descriptions ......... 42

Communication Interfaces ............ 43

Rotary Switches .................... 43

LED Description and Operation ........ 43

Tracer AdaptiView TD7 Display ......... 43

Operator Interface .................. 43

Main Display Area/Home Screen ...... 44

Viewing Chiller Operating Modes ..... 44

Alarms ........................... 46

Reports ........................... 47

Equipment Settings ................. 49

Display Settings .................... 51

Viewing the Settings Screen ......... 51

Cleaning the Display ................ 52

Security Settings ................... 52

Disabling/Enabling Security .......... 52

InvisiSound Ultimate - Noise Reduction

Mode ............................. 54

Tracer™ TU .......................... 55

Pre-Start ............................... 56

Start-Up and Shutdown ................. 57

Unit Start-Up ......................... 57

Temporary Shutdown And Restart ...... 57

Extended Shutdown Procedure ......... 57

Seasonal Unit Start-Up Procedure ...... 58

System Restart After Extended Shutdown 58

Sequence of Operation ................ 59

Software Operation Overview ......... 59

Timelines .......................... 59

Power Up Diagram .................. 60

Power Up to Starting ................ 61

Stopped to Starting ................. 62

Running (Lead Compressor/Circuit Start

and Run) .......................... 63

Running (Lag Compressor/Circuit

Start and Run) ......................63

Satisfied Setpoint ....................64

Normal Shutdown to Stopped or

Run Inhibit .........................65

Immediate Shutdown to Stopped or

Run Inhibit .........................65

Ice Making (Running to Ice Making to

Running) ...........................66

Ice Making (Auto to Ice Making to Ice

Making Complete) ...................67

Maintenance ............................68

Recommended Maintenance ............69

Weekly .............................69

Monthly ............................69

Annual .............................69

Refrigerant and Oil Charge Management .69

Lubrication System ....................69

Oil Sump Level Check ................69

Drive Cooling System ..................71

Service Intervals .....................71

Unit Diagnostics .....................71

pH Test ............................71

Pressure Relief Cap ..................71

Drive Cooling Expansion Tank .........71

Condenser Coils — Cleaning and

Inspection

Coil Cleaning and Inspection Interval ....72

Cleaning Air Side of RTAE Coils ........72

Cleaning Coated Coils ................72

Coil Corrosion Protection Inspection ....72

............................72

Reinstallation of Compressor Shipping

Bolts

.................................72

Servicing Chiller Roof ................72

Diagnostics .............................73

AFD Diagnostics .......................73

Main Processor Diagnostics .............76

Communication Diagnostics ............85

Operator Display Diagnostics and

Messages

............................88

Unit Wiring .............................89

Log and Check Sheet ....................90

RTAE-SVX001B-EN 5

Page 6

Model Number Description

Nameplates

The Stealth™ outdoor unit nameplates are applied to the

exterior of the Control Panel. A compressor nameplate is

located on each compressor. When the unit arrives,

compare all nameplate data with ordering, submittal, and

shipping information.

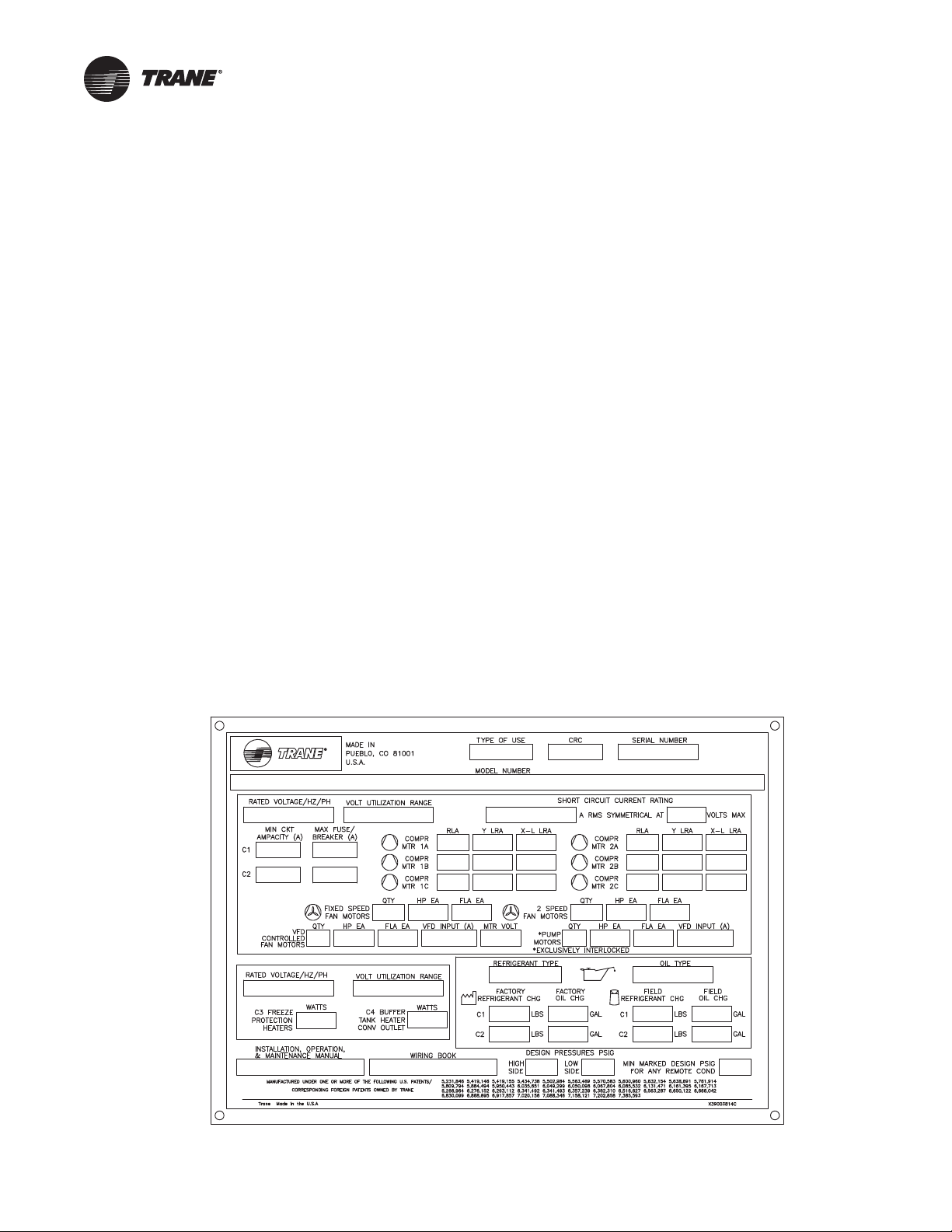

Outdoor Unit Nameplate

See Figure 1 for a typical unit nameplate.The outdoor unit

nameplate provides the following information:

• Unit model and size description.

• Unit serial number.

• Identifies unit electrical requirements.

• Lists correct operating charges of R-134a and

refrigerant

• Lists unit test pressures.

• Identifies installation, operation and maintenance and

service

• Lists drawing numbers for unit wiring diagrams.

Model Number Coding System

The model numbers for the unit and the compressor are

composed of numbers and letters that represent features

of the equipment. Shown in the following table is a sample

oil (Trane OIL00311).

data literature.

of typical unit model number and the coding system for

each.

Each position, or group of positions, in the model number

is used to represent a feature. For example, in the first

table, position 08 of the unit model number, Unit Voltage,

contains the number“4”.A 4 in this position means that the

unit voltage is 460/60/3.

Unit Model Number. An example of a typical unit

model number (M/N) is:

RTAE 200F UA01 AA1F N1X1 A1A0 0CB0 X02X AA03 000

Model number digits are selected and assigned in

accordance with the definitions as listed in “Unit Model

Number,” p. 7.

Compressor Nameplate

The compressor nameplate provides the following

information:

• Compressor model number. See “Compressor Model

Number,” p. 8.

• Compressor serial number. See “Compressor Serial

Number,” p. 8.

• Compressor electrical characteristics.

• Utilization range.

• Recommended refrigerant.

Figure 1. Typical unit nameplate

6 RTAE-SVX001B-EN

Page 7

Model Number Descriptions

Unit Model Number

Digits 1,2 — Unit Model

RT = Rotary Chiller

Digits 3— Unit Type

A = Air-cooled

Digits 4 — Development

Sequence

E = Development Sequence

Digits 5-7 — Nominal Capacity

149 = 150 NominalTons Single Circuit

164 = 165 NominalTons Single Circuit

150 = 150 NominalTons

165 = 165 NominalTons

180 = 180 NominalTons

200 = 200 Nominal Tons

225 = 225 Nominal Tons

250 = 250 Nominal Tons

275 = 275 Nominal Tons

300 = 300 Nominal Tons

Digit 8— Unit Voltage

A = 200/60/3

B = 230/60/3

C = 380/50/3

D = 380/60/3

E = 400/50/3

F = 460/60/3

G = 575/60/3

H = 400/60/3

Digit 9 — Manufacturing

Location

U = Trane Commercial Systems,

Pueblo, CO USA

Digits 10, 11— Design Sequence

** = Factory assigned

Digit 12 — Unit Sound Package

1 = InvisiSound™ Standard Unit

2 = InvisiSound Superior

(Line Wraps, Reduced Fan

Speed)

3 = InvisiSound Ultimate

(Compressor Sound Attenuation,

Line Wraps, Reduced Fan Speed)

Digit 13 — Agency Listing

0 = No Agency Listing

A = UL/CUL Listing

C = CE European Safety Standard

Digit 14 — Pressure Vessel Code

A = ASME Pressure Vessel Code

D = Australia PressureVessel Code

C = CRN or Canada Equivalent

Pressure Vessel Code

L = Chinese Pressure Vessel Code

P = PED European Pressure Vessel

Code

Digit 15 — Factory Charge

1 = Refrigerant Charge HFC-134a

2 = Nitrogen Charge

Digit 16 — Evaporator

Application

F = Standard Cooling

(40 to 68°F/5.5 to 20°C)

G = LowTemp Process

(<40°F LeavingTemp)

C = Ice-making (20 to 68°F/-7 to 20°C)

w/ Hardwired Interface

Digit 17 — Evaporator

Configuration

N = 2 Pass Evaporator

P = 3 Pass Evaporator

Digit 18 — Evaporator Fluid

Type

1 = Water

2 = Calcium Chloride

3 = Ethylene Glycol

4 = Propylene Glycol

5 = Methanol

Digit 19 — Water Connection

X = Grooved Pipe

F = Grooved Pipe + Flange

Digit 20 — Flow Switch

1 = Factory Installed - Other Fluid

(15 cm/s)

2 = Factory Installed - Water 2

(35 cm/s)

3 = Factory Installed - Water 3

(45 cm/s)

Digit 21 — Insulation

A = Factory Insulation - All Cold Parts

0.75”

B = Evaporator-Only Insulation -

High Humidity/Low EvapTemp

1.25”

Digit 22 — Unit Application

1 = Standard Ambient

(32 to 105°F/0 to 40.6°C)

2 = Low Ambient

(0 to 105°F/-17.7 to 40.6°C)

3 = Extreme Low Ambient

(-20 to 105°F/-28.9 to 40.6°C)

4 = High Ambient

(32 to 125°F/0 to 52°C)

5 = Wide Ambient

(0 to 125°F/-17.7 to 52°C)

Digit 23 — Condenser Fin

Options

A = Aluminum Fins with Slits

D = CompleteCoat™ Epoxy Coated

Fins

Digits 24, 25 — Not Used

Digit 26 — Power Line

Connection Type

A = Terminal Block

C = Circuit Breaker

D = Circuit Breaker w/ High Fault

Rated Control Panel

Digit 27 — Short Circuit Current

Rating

A = Default A Short Circuit Rating

B = High A Short Circuit Rating

Digit 28 — Transformer

0 = NoTransformer

1 = Factory Installed Transformer

Digit 29 — Line Voltage

Harmonic Mitigation

X = Line Reactors (~30%TDD)

1 = Filter circuit (IEEE519 Compliant)

Digit 30 — Electrical

Accessories

0 = No Convenience Outlet

C = 15A 115V convenience Outlet

(Type B)

Digit 31 — Remote

Communication Options

0 = No Remote Digital

Communication

1 = LonTalk®Interface LCI-C

(Tracer™ Compatible)

2 = BACnet®MS/TP Interface

(Tracer compatible)

3 = ModBus™ Interface

Digit 32 — Hard Wire

Communication

X = None

A = Hard Wired Bundle - All

B = Remote LeavingWaterTemp

Setpoint

C = Remote Leaving temp and

Demand Limit Setpoints

D = Programmable Relay

E = Programmable Relay and

Leaving Water and Demand

Limit

Setpoint

F = Percent Capacity

G = Percent Capacity and Leaving

Water and Demand Limit

Setpoint

H = Percent Capacity and

Programmable Relay

Digit 33 — Not Used

RTAE-SVX001B-EN 7

Page 8

Model Number Descriptions

Digit 34 — Structural Options

A = Standard Unit Structure

B = Seismic to International Building

Code (IBC)

C = California Office of Statewide

Health Planning and

Development (OSHPD)

Certification

D = Wind Load for Florida Hurricane

175 MPH

E = Seismic (IBC) and Wind Load

F = OSHPD andWind Load

Digit 35 — Appearance Options

0 = No Appearance Options

A = Architectural Louvered Panels

Digit 36 — Unit Isolation

0 = No Isolation

1 = Elastomeric Isolators

3 = Seismic Rated Isopads

Digit 37 — Not Used

0 = Not Used

Digit 38 — Not Used

0 = Not Used

Digit 39 — Special

0 = None

S = Special

Compressor Model Number

Digits 1-4 — Compressor Type

CHHS= Positive displacement, helical

rotary (twin screw) hermetic

compressor

Digit 5 — Frame Size

R = R Frame: 70 - 100 tons

S = S Frame: 112 - 165 tons

Digit 6— Motor Length

B=145mm

C=170mm

E=165mm

F=190mm

Digit 7 — Motor Winding

Characteristics

* = Factory assigned

Digit 8 — Volume Ratio

B = High Volume Ratio

Digit 9 — Refrigerant

1 = R-134a

Digits 10-11— Design Sequence

** = Factory assigned

Compressor Serial Number

Digits 1-2 — Year

YY = Last two digits of year of

manufacture

Digit 3— Week

WW= Week of build, from 00 to 52

Digit 5 — Day

1 = Monday

2 = Tuesday

3 = Wednesday

4 = Thursday

5 = Friday

6 = Saturday

7 = sunday

Digits 6-8 — Coded Time Stamp

TTT = Used to ensure uniqueness of

serial number

Digit 9 — Assembly Line

Assembly line compressor was built on.

Varies with facility

Digit 10— Build Location

A = Monterrey

8 RTAE-SVX001B-EN

Page 9

General Information

Unit Description

The 150-300 ton Stealth™ units are helical-rotary type, air-

cooled liquid chillers designed for installation outdoors.

The compressor circuits are completely assembled,

hermetic packages that are factory-piped, wired, leaktested, dehydrated, and tested for proper control

operation before shipment.

Chilled water inlet and outlet openings are covered for

shipment.The Stealth featuresTrane’s exclusive Adaptive

Control ™ logic, which monitors the control variables that

govern the operation of the chiller unit. Adaptive Control

logic can adjust capacity variables to avoid chiller

shutdown when necessary, and keep producing chilled

water. All unit sizes are available with two independent

refrigerant circuits. A single refrigeration circuit option is

available for 150 and 165T units. Each compressor is

controlled by a variable speed Adaptive Frequency™

Drive Generation 3 (AFD

provided with filter, sight glass, electronic expansion

valve, and charging valves.The shell-and-tube type

evaporator is manufactured in accordance with ASME

standards or other international codes. Each evaporator is

fully insulated and is equipped with water drain and vent

connection. As an option, a convenience outlet can be

supplied.

Units are shipped with full oil charge and can be ordered

with either a factory refrigerant charge, or optional

nitrogen charge.

). Each refrigerant circuit is

3

Accessory/Option Information

Check all the accessories and loose parts which are

shipped with the unit against the shipping list. Included in

these items will be water vessel drain plugs, electrical

diagrams, and service literature, which are placed inside

the control panel for shipment.

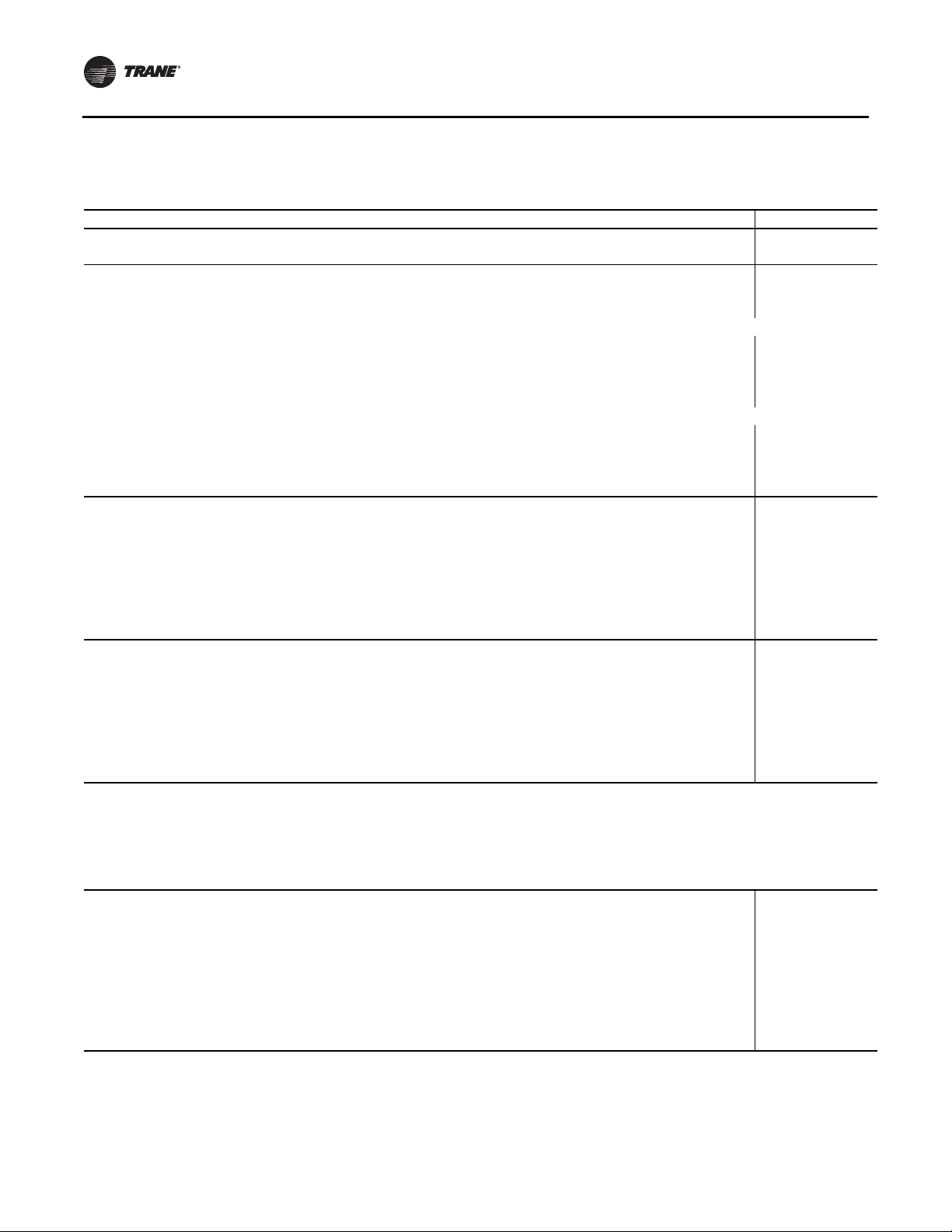

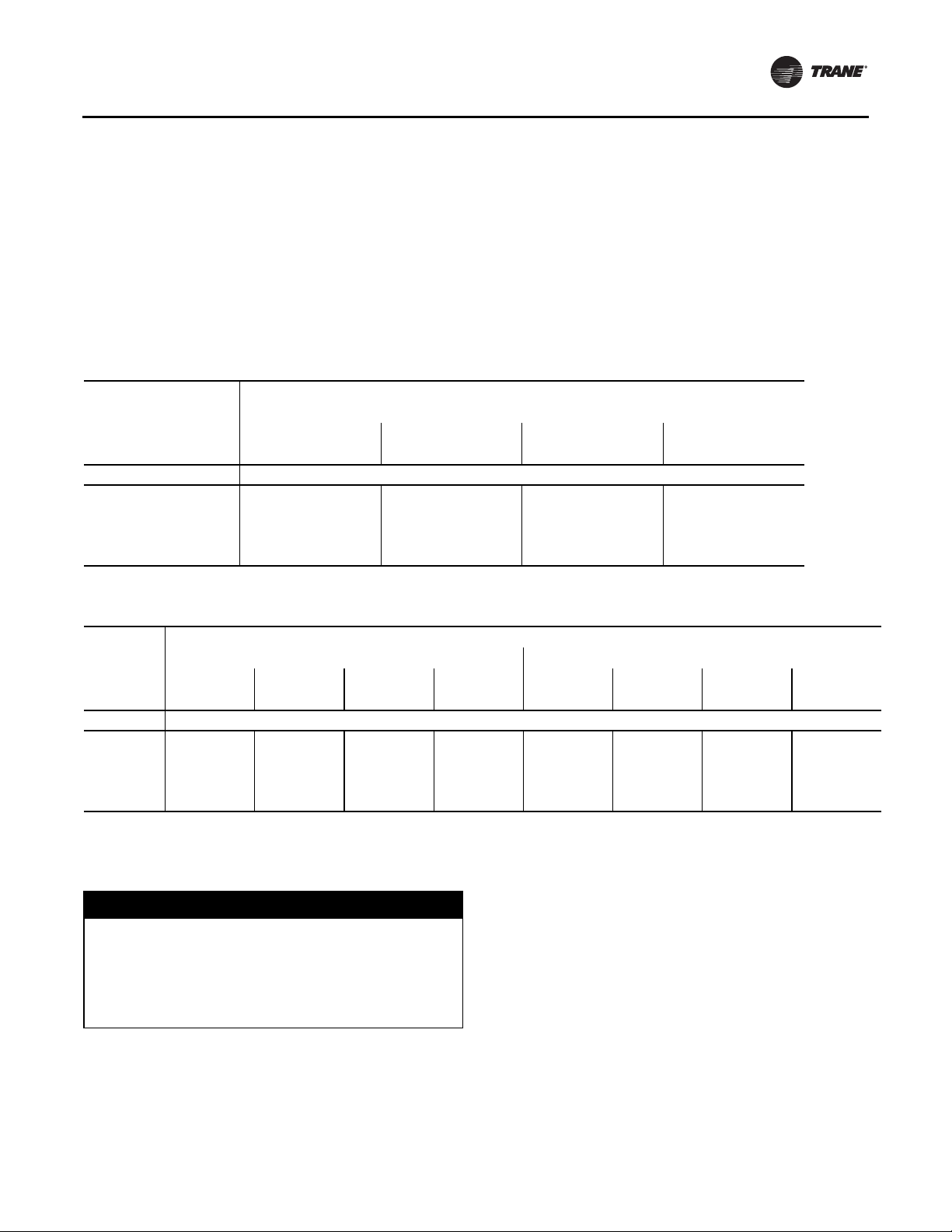

If optional elastomeric isolators are ordered with unit

(model number digit 36 = 1), they are shipped mounted on

diagonal supports on the end of the unit opposite control

panel. See Figure 3 and Figure 4.

If optional seismic isopads are selected (model number

digit 36= 2), they will be shipped inside the unit control

panel.

Figure 3. Elastomeric isolator shipping location

Figure 2. Typical Stealth RTAE

Elastomeric Isolator

Shipping Locations

(not all isolators shown quantity varies with unit configuration)

Figure 4. Elastomeric isolators attached for shipping

RTAE-SVX001B-EN 9

Page 10

General Data

General Data

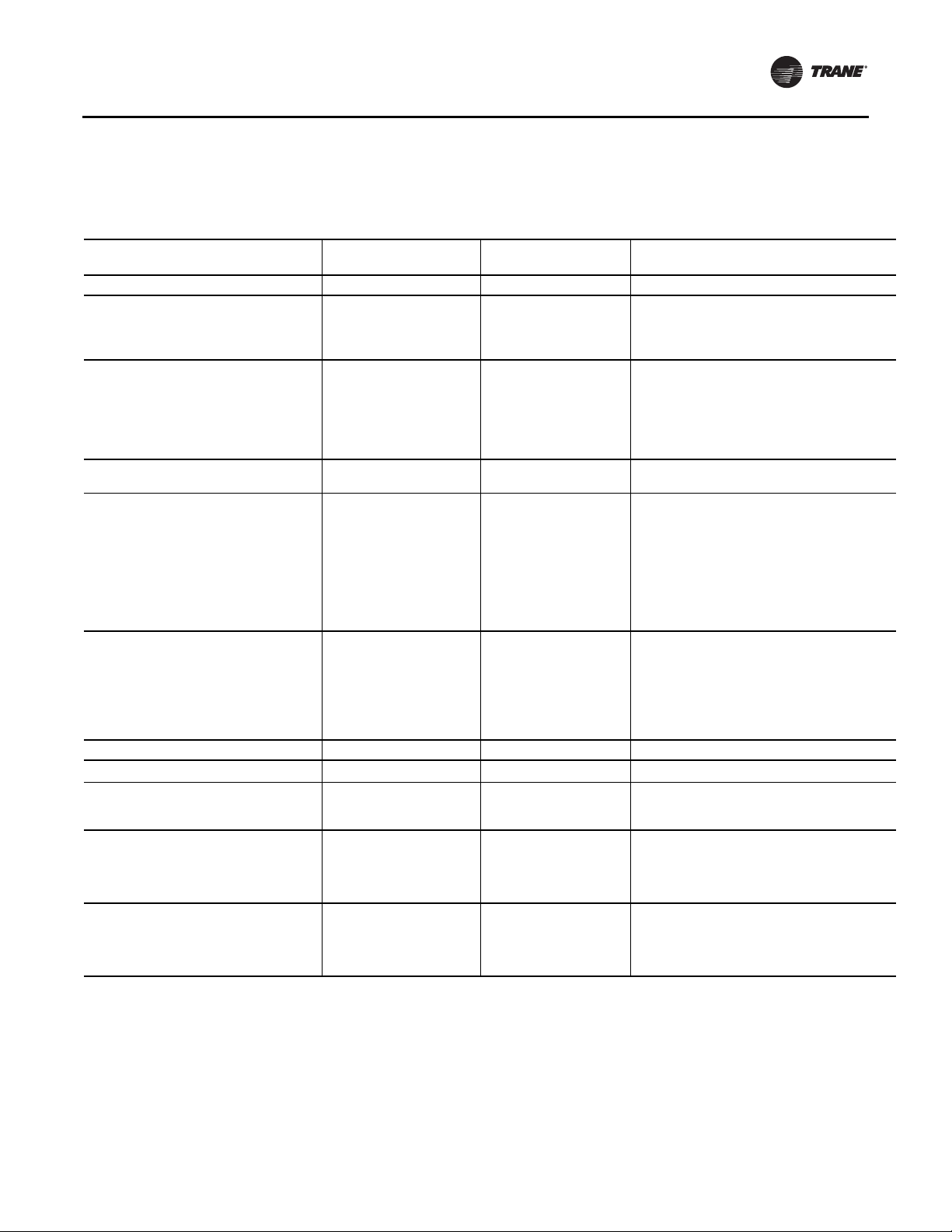

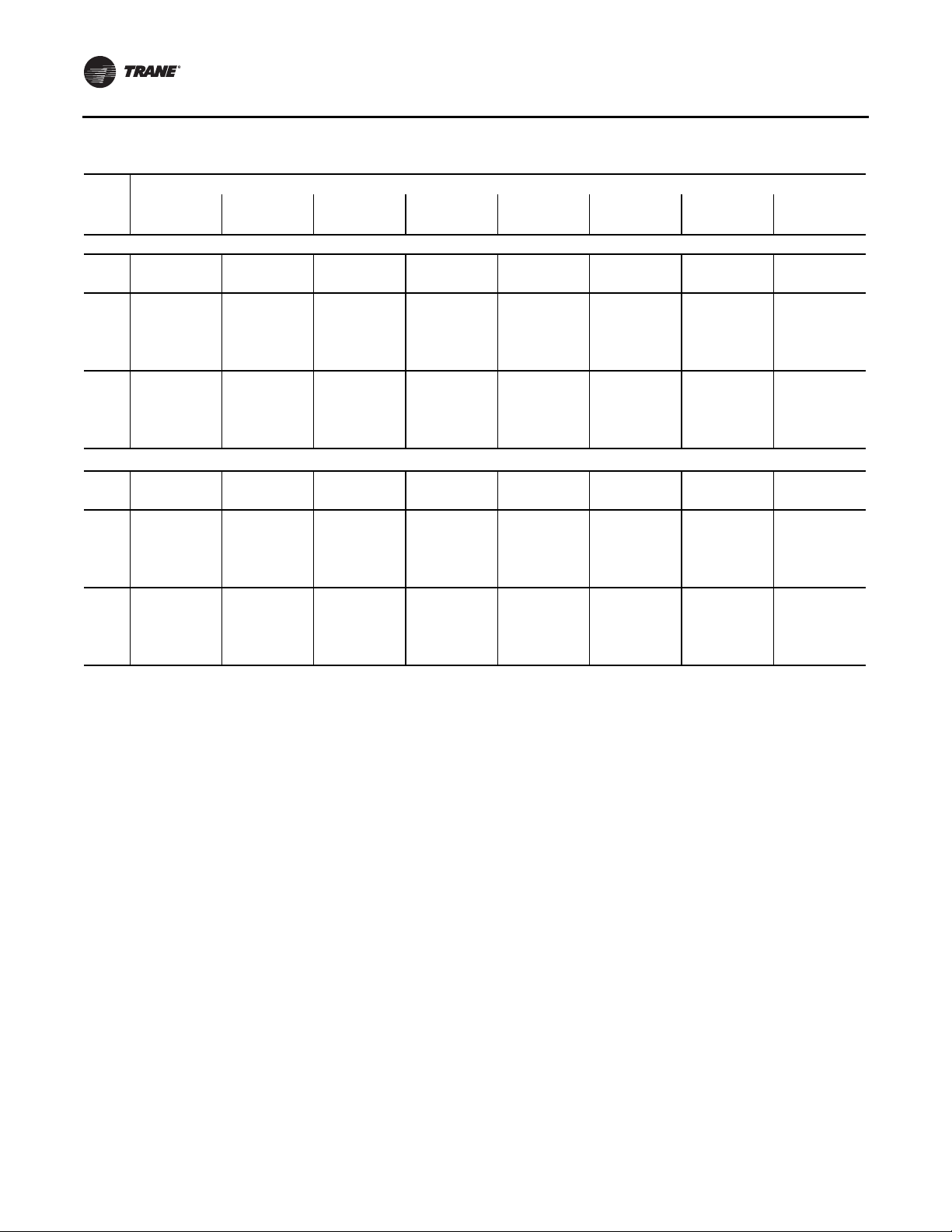

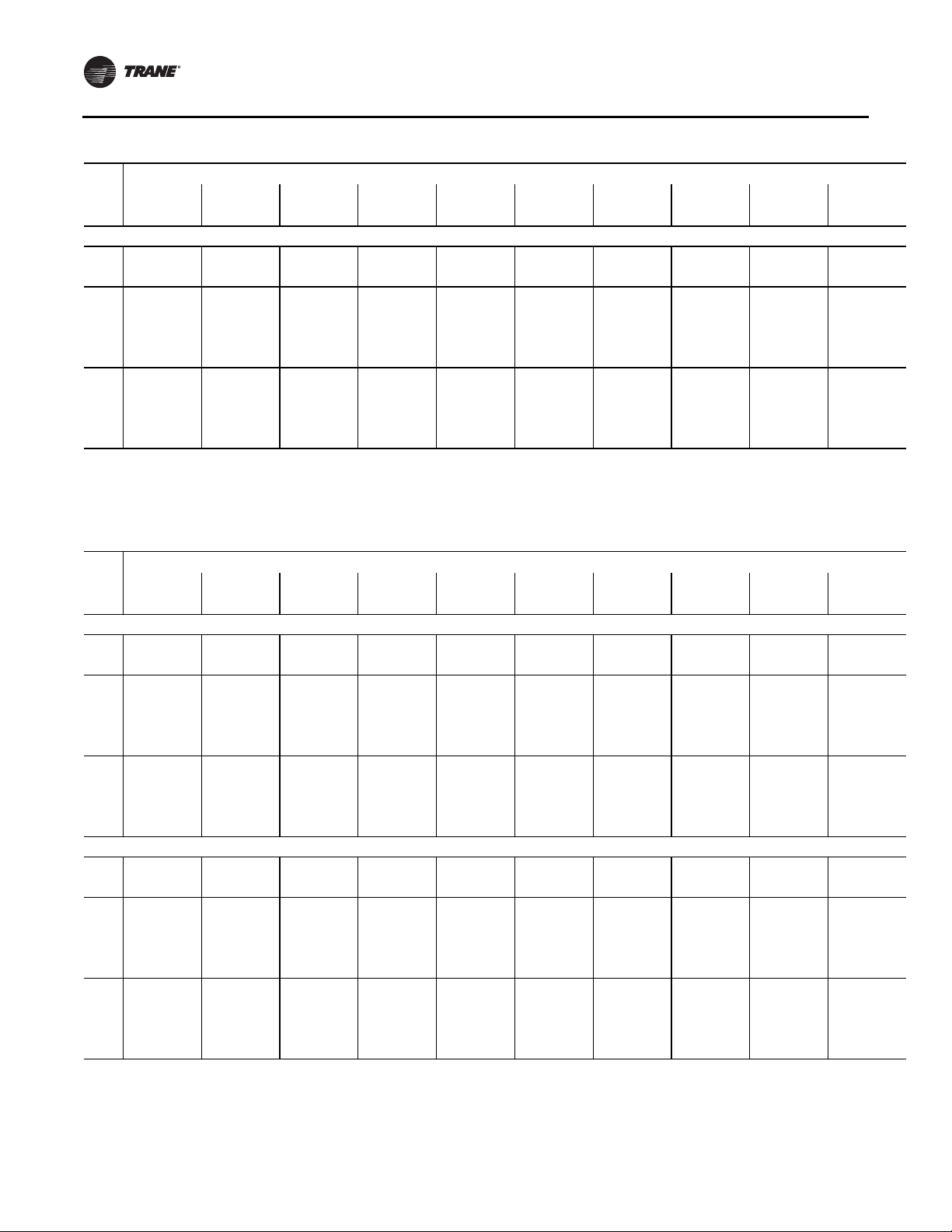

Table 1. General data table

Unit Size (tons) 150 165 180 200 225 250 275 300 150SC 165SC

Compressor Model CHHSR CHHSR CHHSR CHHSR CHHSS CHHSS CHHSS CHHSS CHHSS CHHSS

Quantity # 2 2 2 2 2 2 2 2 1 1

Evaporator

Water Storage (gal) 17.5 18.7 21.9 23.9 26.6 28.7 33.0 36.0 17.3 17.3

(L) 66.1 70.9 82.8 90.5 100.6 108.8 125.0 136.1 65.6 65.6

2 Pass arrangement

Minimum Flow (gpm) 171 187 202 228 261 288 318 354 169 169

(l/s) 10.8 11.8 12.7 14.4 16.5 18.2 20.1 22.3 10.7 10.7

Maximum Flow (gpm) 626 684 742 835 957 1055 1165 1299 620 620

(l/s) 39.5 43.1 46.8 52.7 60.4 66.5 73.5 81.9 39.1 39.1

3 Pass arrangement

Minimum Flow (gpm) 114 124 135 152 174 192 212 236 113 113

(l/s) 7.2 7.8 8.5 9.6 11.0 12.1 13.4 14.9 7.1 7.1

Maximum Flow (gpm) 417 456 495 557 638 703 777 866 414 414

(l/s) 26.3 28.8 31.2 35.1 40.2 44.3 49.0 54.6 26.1 26.1

Condenser

Qty of Coils 8 10 10 12 12 12 14 16 8 10

Coil Length (in) 78.74 78.74 78.74 78.74 78.74 78.74 78.74 78.74 78.74 78.74

(mm) 2000 2000 2000 2000 2000 2000 2000 2000 2000 2000

Coil Height (in) 50 50 50 50 50 50 50 50 50 50

(mm) 1270 1270 1270 1270 1270 1270 1270 1270 1270 1270

Fins/Ft 192 192 192 192 192 192 192 192 192 192

Rows 3333333333

Condenser Fans

Quantity # 8 10 10 12 12 12 14 16 8 10

Diameter (in) 37.5 37.5 37.5 37.5 37.5 37.5 37.5 37.5 37.5 37.5

(mm) 953 953 953 953 953 953 953 953 953 953

Total Airflow (cfm) 107,392 134,240 134,240 161,088 161,088 161,088 187,936 214,784 107,392 132,240

(m3/hr) 182,460 228,075 228,075 273,690 273,690 273,690 319,305 364,920 182,460 228,075

Tip Speed (ft/min) 8700 8700 8700 8700 8700 8700 8700 8700 8700 8700

(M/S) 44.2 44.2 44.2 44.2 44.2 44.2 44.2 44.2 44.2 44.2

Ambient Temperature Range

Standard Ambient °F (°C) 32 to 105 (0 to 40.6)

Low Ambient °F (°C) 0 to 105 (-17.7 to 40.6)

Extreme Low Ambient °F (°C) -20 to 105 (-28.9 to 40.6)

High Ambient °F (°C) 32 to 125 (0 to 52)

Wide Ambient °F (°C) 0 to 125 (-17.7 to 52)

General Unit

Refrigerant HFC-134a HFC-134a

Refrigerant Ckts # 2 1

Minimum Load % 20 18 17 15 20 18 16 15 30 27

Refrigerant Charge/ckt (lbs) 172 181 210 218 265 261 318 325 322 346

(kg) 78 82 95 99 120 118 144 148 146 157

Oil Trane OIL00311 (bulk)/OIL00315 (1 gal)/OIL00317 (5 gal)

Oil Charge/ckt (gal) 3.0 3.0 3.0 3.0 4.0 4.0 4.0 4.0 4.0 4.0

(L) 11.4 11.4 11.4 11.4 15.1 15.1 15.1 15.1 15.1 15.1

10 RTAE-SVX001B-EN

Page 11

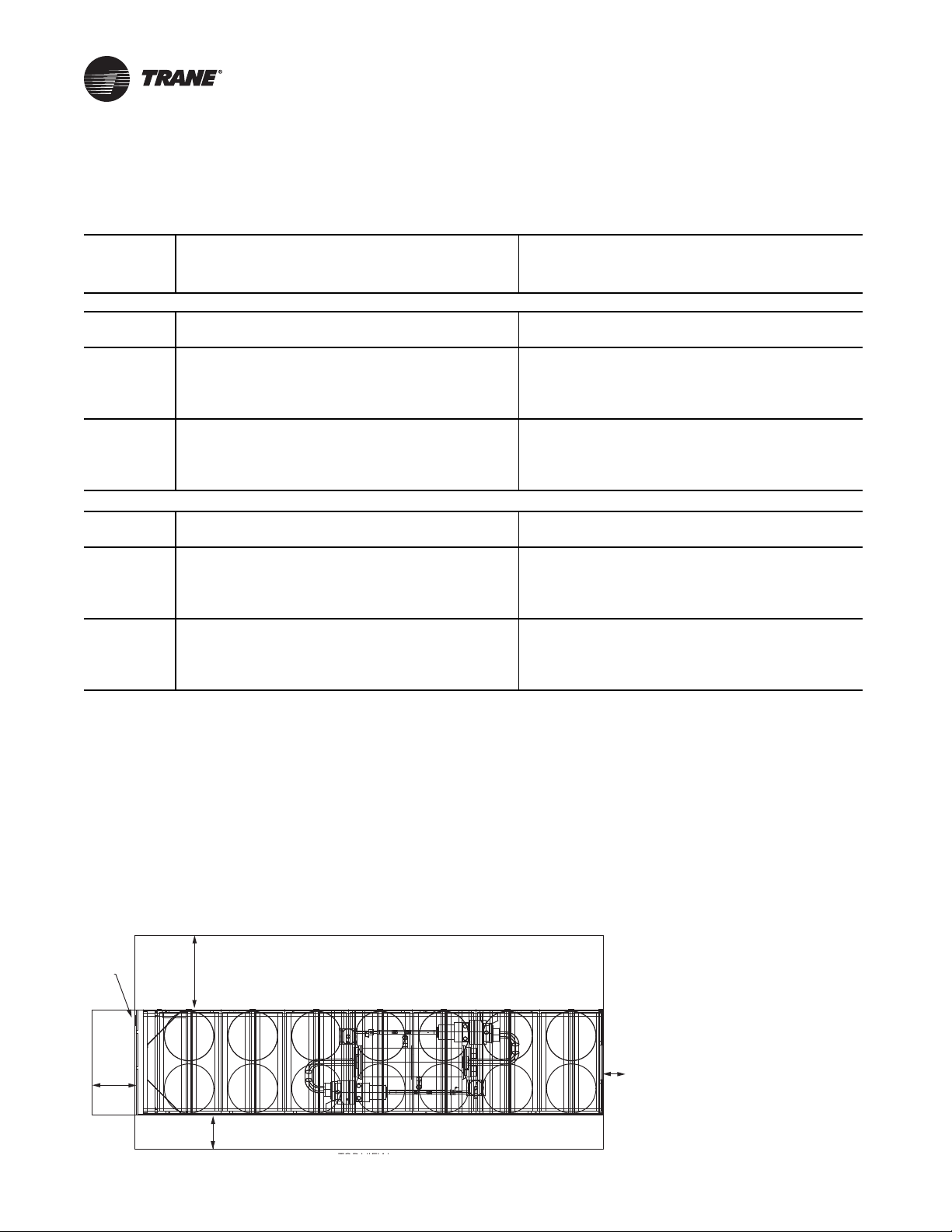

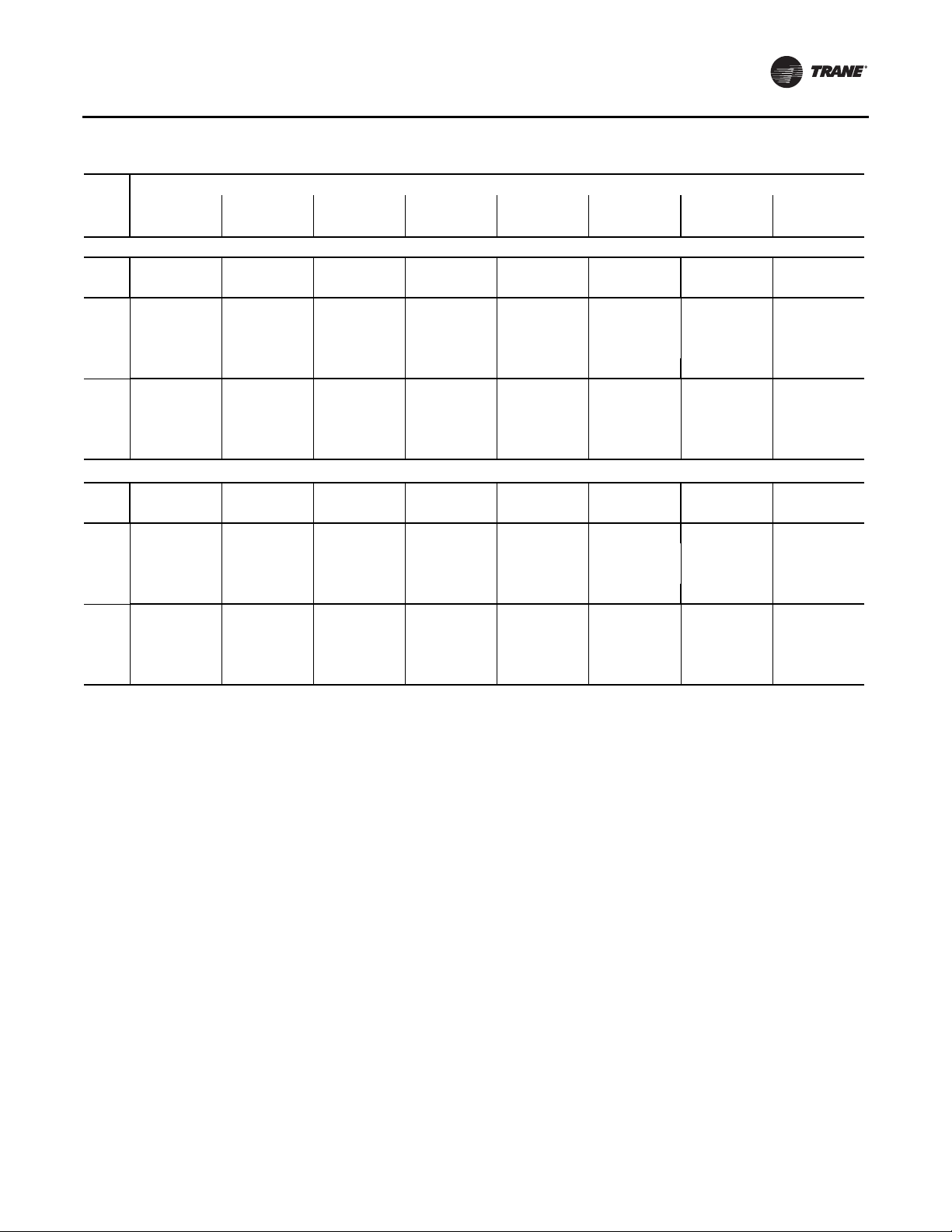

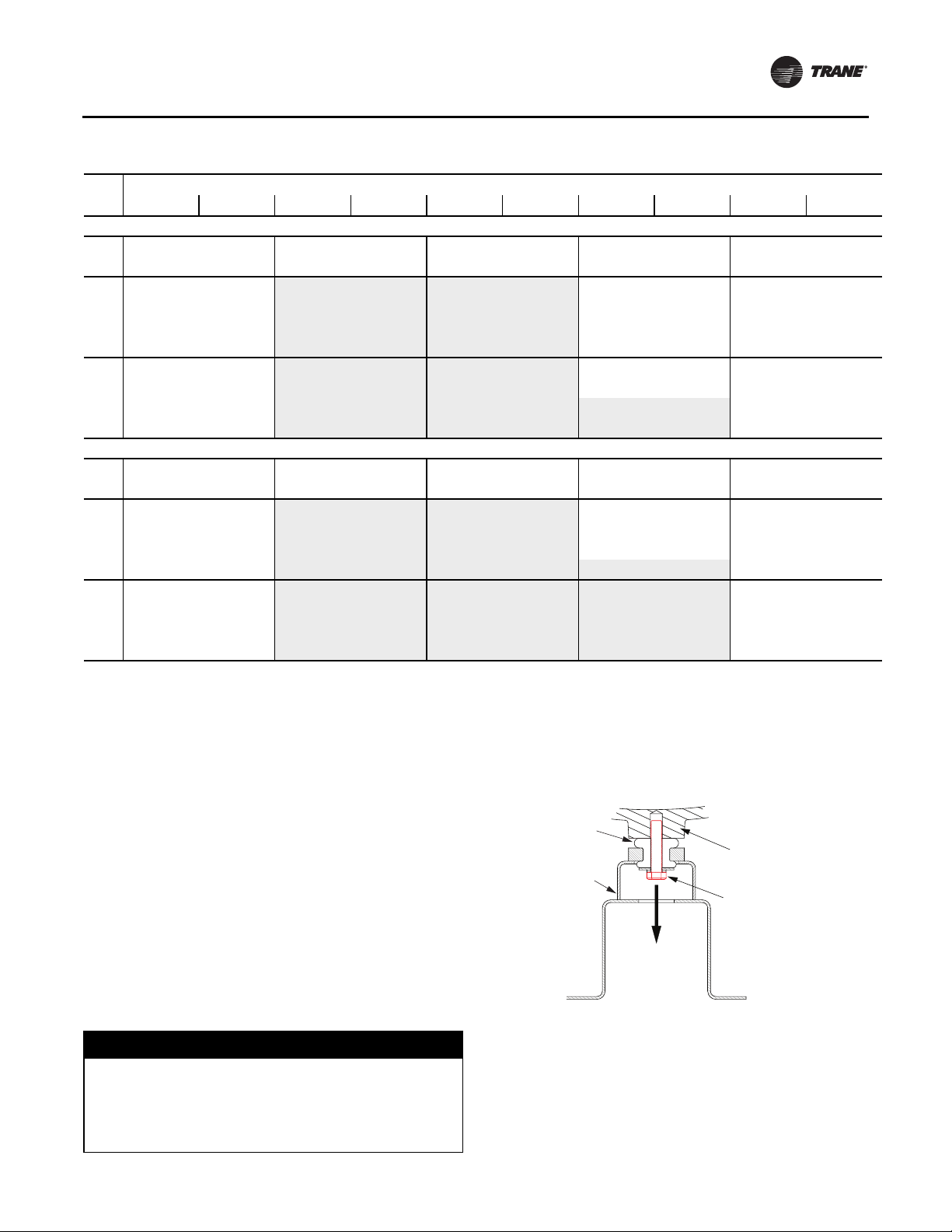

Drive Cooling System

Drive cooling fluid volumes are dependent on unit

configuration.

• Use Table 2 for units that meet the following criteria:

• Model number digits 10, 11 = AA

• Use Table 2 for units that meet the following criteria:

• Model number digits 10, 11 = AB

• AND Digits 28, 29 = 0X

Table 2. Drive cooling with load inductor

Unit Size (tons)

Standard Length Unit

150 165-200 225-250 275-300

gal l gal l gal l gal l

Fluid Type Trane Heat Transfer Fluid CHM01023

Fluid Volume

Ckt 1 1.74 6.58 1.83 6.92 2.00 7.58 2.09 7.92

Ckt2 1.93 7.30 2.27 8.59 2.44 9.24 2.58 9.78

Total 3.67 13.88 4.10 15.51 4.44 16.82 4.67 17.69

• Use Table 2 for units that meet the following criteria:

• Model number digits 10, 11 = AC

• AND Digits 3-7 = 225, 250, 275 or 300

• AND Digit 22=1or2

• AND Digits 28, 29 = 0X

• Use Table 3 for all other unit configurations.

General Data

Table 3. Drive cooling without load inductor

Unit Size (tons)

Standard Length Unit Extended Length Units

150S - 165S 150 165-250 275-300 150S - 165S 150 165-250 275-300

gal l gal l gal l gal l gal l gal l gal l gal l

Fluid Type Trane Heat Transfer Fluid CHM01023

Fluid Volume

Ckt 1 1.28 4.86 1.14 4.30 1.23 4.64 1.32 4.98 1.37 5.20 1.30 4.93 1.32 4.98 1.41 5.33

Ckt2 n/a n/a 1.32 5.01 1.67 6.31 1.81 6.84 n/a n/a 1.67 6.31 1.81 6.84 1.95 7.38

Total 1.28 4.86 2.46 9.31 2.89 10.95 3.12 11.83 1.37 5.20 2.97 11.23 3.12 11.83 3.36 12.71

(a) Units are extended length if either of the following are selected:

Transformer (model number digit 28 = 1)

Harmonic Filtration Option (model number digit 29 = 1)

Units without Harmonic Filtration Option or Transformer (digits 28, 29 = 0X) are standard length.

NOTICE:

Equipment Damage!

Use only Trane Heat Transfer Fluid P/N CHM01023. This

fluid is a direct use concentration and is not to be

diluted. Do not top off with water or any other fluid.

Use of unapproved fluids, or dilution of approved fluid

could result in catastrophic equipment damage.

Note: The use of incorrect compounds in the drive

cooling system may result in scaling, erosion,

corrosion or freezing.TheTrane Company

warranty specifically excludes liability for

corrosion, erosion, freezing or deterioration of

Trane equipment.

Proper fluid level is important to the operation of the unit.

See “Drive Cooling ExpansionTank,” p. 71 for fluid level

Non-Trane approved chemicals could react with system

components and result in failure. Contact a qualified

service technician and your localTrane Parts Center.

check instructions. The circuit capacities are shown in

tables above.

If the level is below the recommended minimum levels,

contact your localTrane office.

Note: Drive cooling fluid service life is 5 years. See“Drive

Cooling System,” p. 71.

(a)

RTAE-SVX001B-EN 11

Page 12

Pre-Installation

Unit Inspection

When unit is delivered, verify it is the correct unit and is

properly equipped. Compare information on the unit

nameplate with ordering and submittal information.

Inspect all exterior components for visible damage.Report

any apparent damage or material shortage to carrier and

make a “unit damage” notation on carrier’s delivery

receipt. Specify extent and type of damage found and

notifyTrane Sales Office. Do not proceed with installation

of a damaged unit without sales office approval.

Inspection

To protect against loss due to damage in transit, complete

the following steps upon receipt of unit.

• Inspect the individual pieces of the shipment before

accepting the unit. Check for obvious damage to the

unit or packing material.

• Inspect the unit for concealed damage as soon as

possible after delivery and before it is stored.

Concealed damage must be reported within 15 days.

• If concealed damage is discovered, stop unpacking the

shipment. Do not remove damaged material from the

receiving location.Take photos of the damage, if

possible.The owner must provide reasonable

evidence that the damage did not occur after delivery.

• Notify the carrier’s terminal of the damage

immediately, by phone and by mail. Request an

immediate, joint inspection of the damage with the

carrier and the consignee.

NotifyTrane sales representative and arrange for repair.

Do not repair unituntil damage is inspectedby the carrier’s

representative.

Storage

Extended storage of outdoor unit prior to installation

requires these precautionary measures:

• Store the outdoor unit in a secure area.

• For units that have been charged with refrigerant,

verify the following valves are closed on each circuit:

• Suction service valve (butterfly valve)

• Liquid line angle valve or EXV (EXV is driven closed

whenever circuit is powered)

• Oil line shutoff valves to brazed plate heat

exchangers

Note: Units with factory refrigerant charge (model

number digit 15 = 1) are shipped with suction,

liquid and oil line shutoff valves closed, isolating

most of refrigerant charge in the evaporator. If unit

goes directly into long term storage, it is

recommended that these valve positions be

confirmed.

• For units with nitrogen charge option (model number

digit 15 = 2), units are shipped with valves open. If unit

goes directly into storage prior to refrigerant charge,

confirm all service valves are open.

• At least every three months (quarterly), check the

pressure in the refrigerant circuits to verify that the

refrigerant charge is intact. If it is not, contact a

qualified service organization and the appropriate

Trane sales office.

12 RTAE-SVX001B-EN

Page 13

Installation Requirements

A list of the contractor responsibilities typically associated

with the unit installation process is provided in Table 4.

Table 4. Installation requirements

Pre-Installation

Type

Foundation • Meet foundation requirements

Rigging

Disassembly/Reassembly

(as required)

Isolation

Electrical

Water piping • Flow switch

Insulation • Insulation • Insulation

Water Piping Connection Components • Grooved pipe

Other Materials

“Stealth™ RTAE Installation

Completion Check Sheet and Request

for Trane Service”

(RLC-ADF002-EN,

see “Log and Check Sheet,” p. 90)

Chiller Start-up Commissioning

(a) Trane, or an agent of Trane specifically authorized to perform start-up and warranty of Trane® products, will perform or have direct on-site supervision of

the disassembly and reassembly work.

(b) Start-up must be performed by Trane or an agent of Trane specifically authorized to perform start-up and warranty of Trane

provide Trane (or an agent of Trane specifically authorized to perform start-up) with notice of the scheduled start-up at least two weeks prior to the scheduled

start-up.

(a)

(b)

Trane Installed

• Trane, or an agent

of Trane specifically

authorized to perform

start-up of Trane

products (contact

your local Trane

office for pricing)

• Circuit breakers

(optional)

• Unit mounted starter

• R-134a refrigerant

• Dry nitrogen

(optional)

• Trane, or an agent of

Trane specifically

authorized to perform

start-up of Trane

products

®

®

Trane Supplied

Trane Supplied

Field Installed

• Elastomeric isolators

(optional)

• Flange kit (optional)

Field Supplied

Field Installed

• Safety chains

• Clevis connectors

• Lifting beam

• Spreader bar

• Elastomeric isolators (optional)

• Circuit breakers (optional)

• Electrical connections to unit mounted starter

• Wiring sizes per submittal and NEC

• Terminal lugs

• Ground connection(s)

• BAS wiring (optional)

• Control voltage wiring

• Chilled water pump contactor and wiring

• Option relays and wiring

• Taps for thermometers and gauges

• Thermometers

• Water flow pressure gauges

• Isolation and balancing valves in water piping

• Vents and drain

• Waterside pressure relief valves

• Water strainer

®

products. Contractor shall

RTAE-SVX001B-EN 13

Page 14

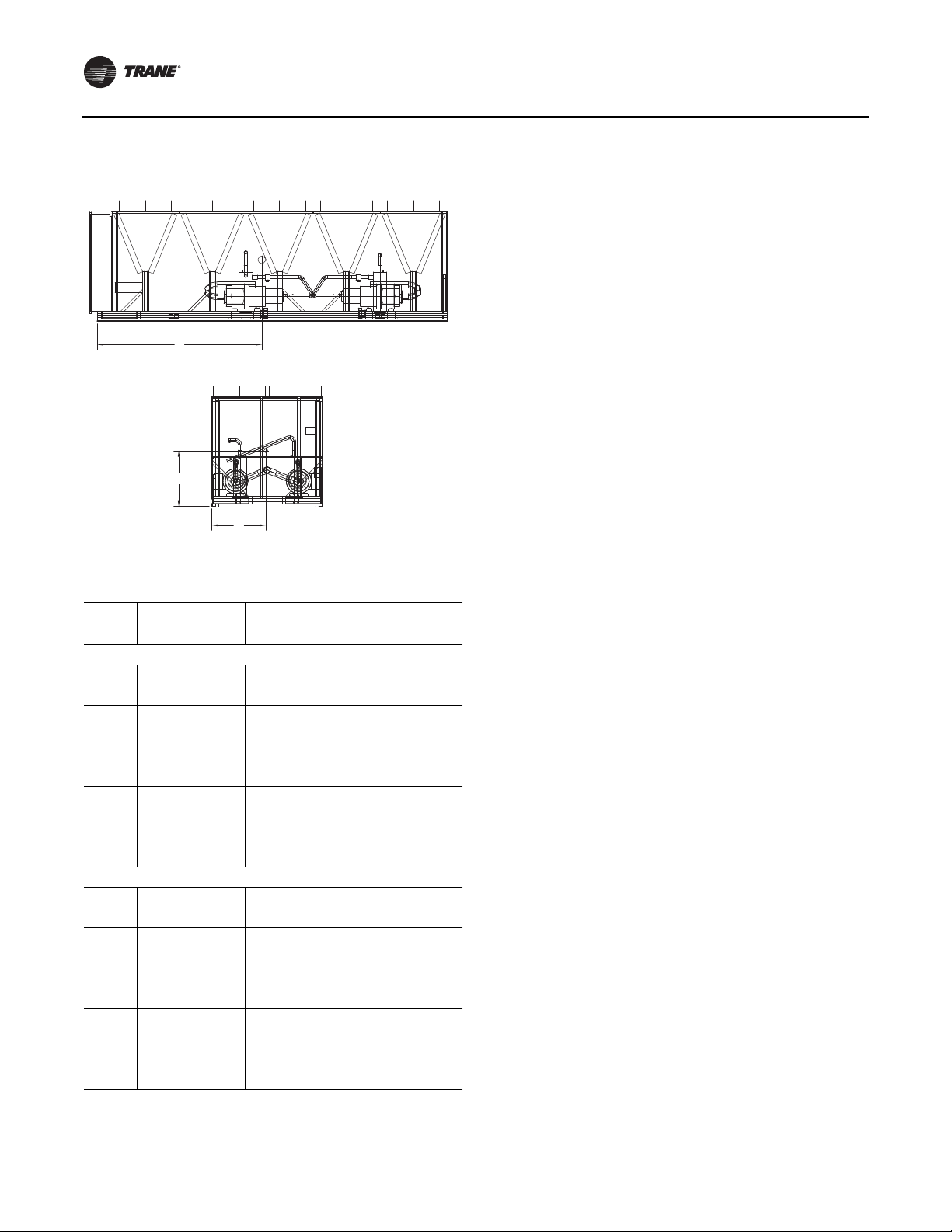

Dimensions and Weights

Weights

Table 5. Weights

Standard Length Unit

Unit Size

(tons)

Shipping Operating Shipping Operating

lbs kg lbs kg lbs kg lbs kg

InvisiSound™ Standard or Superior

150S 9436 4280 9596 4353 11013 4995 11173 5068

165S 10451 4741 10611 4813 12011 5448 12171 5521

150 11333 5141 11479 5207 13492 6120 13638 6186

165 12377 5614 12533 5685 14532 6592 14688 6662

180 12698 5760 12880 5843 14853 6737 15035 6820

200 13808 6263 14007 6354 15991 7254 16213 7354

225 15244 6915 15466 7015 17427 7905 17649 8005

250 15622 7086 15861 7195 17805 8076 18044 8185

275 16820 7630 17095 7754 18975 8607 19250 8732

300 17965 8149 18265 8285 20121 9127 20421 9263

InvisiSound Ultimate

150S 10236 4643 10396 4716 11813 5358 11973 5431

165S 11251 5103 11411 5176 12811 5811 12971 5884

150 12133 5504 12279 5570 14292 6483 14438 6549

165 13177 5977 13333 6048 15332 6955 15488 7025

180 13498 6123 13680 6205 15653 7100 15835 7183

200 14608 6626 14807 6716 16791 7616 17013 7717

225 16044 7278 16266 7378 18227 8268 18449 8368

250 16422 7449 16661 7557 18605 8439 18844 8548

275 17620 7992 17895 8117 19775 8970 20050 9095

300 18765 8512 19065 8648 20921 9490 21221 9626

(a) Units are extended length if either of the following are selected:

Transformer (model number digit 28 = 1)

Harmonic Filtration Option (model number digit 29 = 1)

Units without Harmonic Filtration Option or Transformer (digits 28, 29 = 0X) are standard length.

(b) Model number digit 12 = 1 or 2

(c) Model number digit 12 = 3

Extended Length Unit

(b)

(c)

(a)

Unit Dimensions

See unit submittals for specific unit dimensions and water connection locations.

Service Clearances

Figure 5. RTAE service clearances - top view

NO OBSTRUCTIONS ABOVE UNIT

Control

Panel

40”

(1016

mm)

See

note 1

85” (2160mm)

See note 2

36” (914.4mm)

24”

(600.1mm)

14 RTAE-SVX001B-EN

NOTES:

1. A full 40” clearance

is required in front

of the control panel.

Must be measured

from front of panel,

not end of unit base.

2. Clearance of 85”

on the side of the

unit is required for

coil replacement.

Preferred side for

coil replacement is

shown (left side of

unit, as facing control

panel), however either

side is acceptable.

Page 15

Installation Mechanical

Location Requirements

Sound Considerations

• Refer toTrane Engineering Bulletin Chiller Sound

Ratings and Installation Guide RLC-PRB035-EN for

sound consideration applications.

• Locate the unit away from sound-sensitive areas.

• Install the optional elastomeric isolators under the

unit. See

• Chilled water piping should not besupported by chiller

frame.

• Install rubber vibration isolators in all water piping.

• Use flexible electrical conduit.

• Seal all wall penetrations.

Note: Consult an acoustical engineer for critical

Foundation

Provide rigid, non-warping mounting pads or a concrete

foundation of sufficient strength and mass to support the

applicable operating weight (i.e., including completed

piping, and full operating charges of refrigerant, oil and

water). See Table 5, p. 14 for unit operating weights. Once

in place, the unit must be level within 1/4”(6.4 mm) across

the length and width of the unit.TheTrane Company is not

responsible for equipment problems resulting from an

improperly designed or constructed foundation.

“Isolation and Sound Emission,” p. 20.

applications.

WARNING

Heavy Objects!

Ensure that all the lifting equipment used is properly

rated for the weight of the unit being lifted. Each of the

cables (chains or slings), hooks, and shackles used to

lift the unit must be capable of supporting the entire

weight of the unit. Lifting cables (chains or slings) may

not be of the same length. Adjust as necessary for even

unit lift. Other lifting arrangements could cause

equipment or property damage. Failure to follow

instructions above or properly lift unit could result in

unit dropping and possibly crushing operator/

technician which could result in death or serious injury.

WARNING

Proper Lifting Configuration Required!

Use only lift locations designated with label shown in

Figure 6. Do NOT use locations marked with label

shown in Figure 7. Use unit lifting configurations as

shown in Table 6 and Figure 8, p. 16 thru Figure 10,

p. 17. Other lifting arrangements could result in death,

serious injury or equipment damage.

Figure 6. Label - lift location

Clearances

Provide enough space around the unit to allow the

installation and maintenance personnel unrestricted

access to all service points. See submittal drawingsfor the

unit dimensions, to provide sufficient clearance for the

opening of control panel doors and unit service. See

Figure 5, p. 14 for minimum clearances. In all cases, local

codes which require additional clearances will take

precedence over these recommendations.

For close spacing information, see RLC-PRB037-EN.

Rigging

WARNING

Improper Unit Lift!

Test lift unit approximately 24 inches to verify proper

center of gravity lift point. To avoid dropping of unit,

reposition lifting point if unit is not level. Failure to

properly lift unit could result in unit dropping and

possibly crushing operator/technician which could

result in death or serious injury and possible

equipment or property-only damage.

X39003897001A

Figure 7. Label - do not lift

X39003894001A

Important:

• Do not fork lift unit.

• See unit nameplate and/or unit submittal for total

shipping weight.

• See Table 6 and Figure 8 thru Figure 10 for unit lifting

configuration.

• See Table 7, p. 18 and Table 8, p. 19 for lift weights and

dimensions at each lifting point locations.

• See Table 9, p. 20 for center of gravity information.

RTAE-SVX001B-EN 15

Page 16

Installation Mechanical

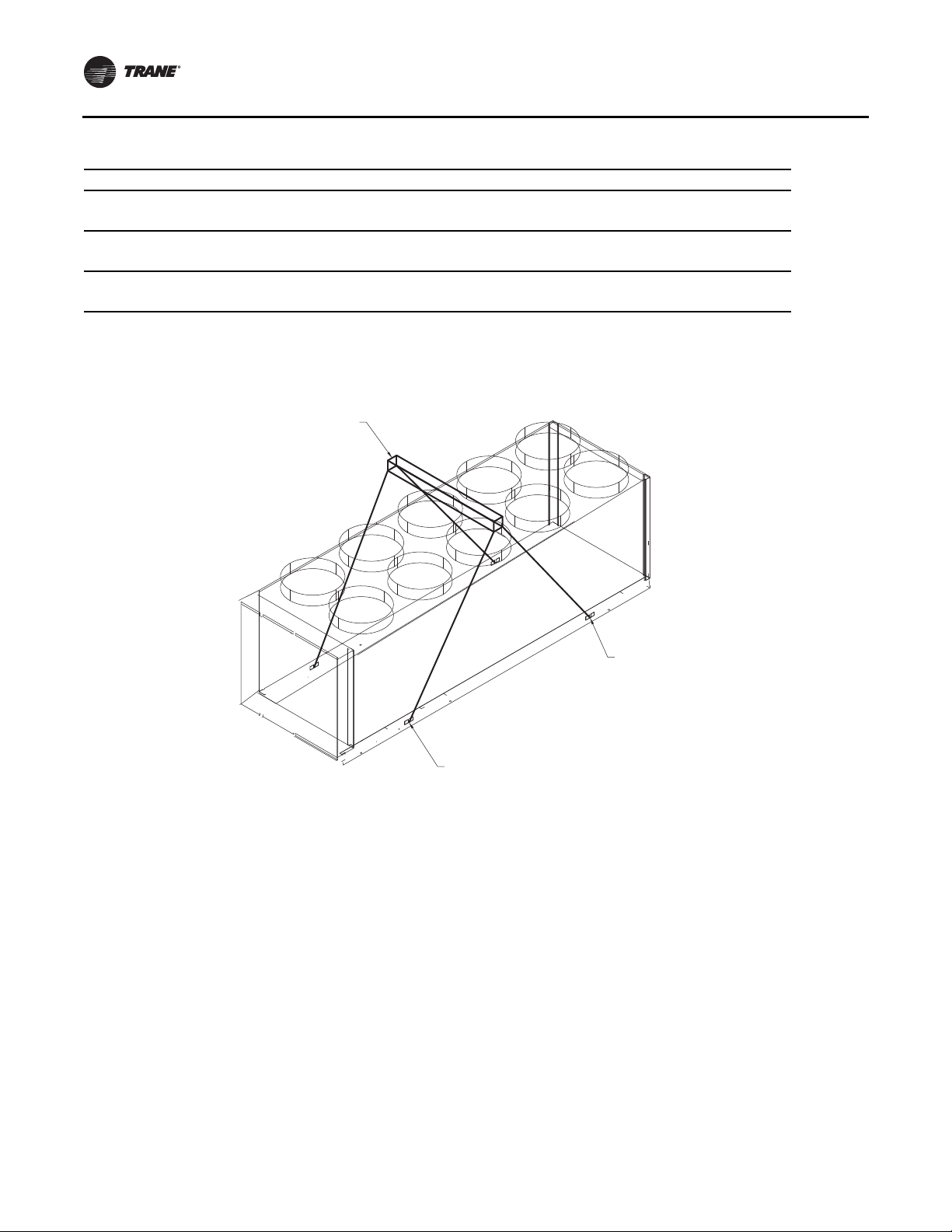

Table 6. Lifting configuration selection

Tons Unit Length

150S, 165S, 150 Standard and Extended

165, 180, 200, 225, 250 Standard

165, 180, 200, 225, 250 Extended

275 Standard

275 Extended

300 Standard and Extended

(a) Units are extended length if either of the following are selected:

Transformer (model number digit 28 = 1)

Harmonic Filtration Option (model number digit 29 = 1)

Units without Harmonic Filtration Option or Transformer (digits 28, 29 = 0X) are standard length.

Figure 8. 4-point lift configuration

96” (2438mm) Spreader Bar

(a)

Lift Configuration See

4-point Figure 8, p. 16

6-point Figure 9, p. 17

8-point Figure 10, p. 17

Control Panel

Lifting Location 1

(Lifting location 4

located on other side of unit)

Lifting Location 2

(Lifting location 3

located on other side of unit)

16 RTAE-SVX001B-EN

Page 17

Figure 9. 6-point lift configuration

96” (2438mm) Spreader Bar

96”

(2438mm)

Spreader Bar

Installation Mechanical

Lifting Location 3

(Lifting location 4

located on other

side of unit)

Lifting Location 2

(Lifting location 5

located on other side of unit)

Control Panel

Figure 10. 8-point lift configuration

96” (2438mm) Spreader Bar

Qty 2

Control Panel

Lifting Location 1

(Lifting location 6

located on other side of unit)

Lifting Location 4

(Lifting location 5

located on other

side of unit)

Lifting Location 3

(Lifting location 6

located on other side of unit)

Lifting Location 2

(Lifting location 5

located on other side of unit)

Lifting Location 1 (Lifting location 8 located on other side of unit)

RTAE-SVX001B-EN 17

Page 18

Installation Mechanical

Table 7. Lift weights by location

Location

12345678

Tons lb kg lb kg lb kg lb kg lb kg lb kg lb kg lb kg

Standard Length Unit

150S 2540 1152 2451 1112 2164 981 2281 1034 - - - - - - - -

165S 2656 1205 2352 1067 2730 1238 2713 1230 - - - - - - - -

150 3426 1554 2638 1197 2234 1014 3035 1377 - - - - - - - -

165 3452 1566 2876 1304 2810 1275 3239 1469 - - - - - - - -

180 3528 1600 2941 1334 2896 1314 3333 1512 - - - - - - - -

200 3586 1627 3325 1508 3316 1504 3581 1624 - - - - - - - -

225 4003 1816 3551 1611 3617 1641 4073 1847 - - - - - - - -

250 4098 1859 3637 1650 3711 1683 4176 1894 - - - - - - - -

275 2484 1127 1943 881 3683 1671 3829 1737 2255 1023 2625 1191 - - - -

300 2061 935 2289 1038 2515 1141 1682 763 2729 1238 3008 1364 1737 788 1943 881

Extended Length Unit

150S 2698 1224 2597 1178 2837 1287 2881 1307 - - - - - - - -

165S 2988 1356 2841 1289 3135 1422 3047 1382 - - - - - - - -

150 3825 1735 3363 1525 2920 1324 3384 1535 - - - - - - - -

165 2653 1203 2629 1192 2570 1166 1959 889 2046 928 2675 1213 - - - -

180 2685 1218 2674 1213 2641 1198 1946 883 2100 953 2807 1273 - - - -

200 2919 1324 2640 1198 2797 1269 2846 1291 2274 1032 2514 1141 - - - -

225 3065 1391 2705 1227 3237 1468 3144 1426 2406 1091 2870 1302 - - - -

250 3117 1414 2749 1247 3322 1507 3229 1465 2458 1115 2930 1329 - - - -

275 2145 973 2668 1210 3279 1487 1513 686 2412 1094 2482 1126 1644 746 2831 1284

300 2056 933 2440 1107 3452 1566 2241 1017 3089 1401 2993 1358 1460 662 2389 1084

(a) Units are extended length if either of the following are selected:

Low Harmonic Distortion Option (model number digit 29 = 1)

Autotransformer (model number digit 28 = 1 or 2)

Units without Low Harmonic Distortion Option or Autotransformer (digits 28, 29 = X0) are standard length.

(a)

18 RTAE-SVX001B-EN

Page 19

Installation Mechanical

Table 8. Lifting locations (from control panel end of frame)

Location

12345678

Tons in mm in mm in mm in mm in mm in mm in mm in mm

Standard Length Unit

150S 45.5 1156 45.5 1156 153.9 3909 153.9 3909 --------

165S 23.5 596 23.5 596 189.7 4818 189.7 4818 --------

150 39.6 1006 39.6 1006 171.4 4353 171.4 4353 --------

165 60.4 1534 60.4 1534 224.6 5705 224.6 5705 --------

180 60.4 1534 60.4 1534 224.6 5705 224.6 5705 --------

200 53.3 1355 53.3 1355 258.7 6570 258.7 6570 --------

225 53.3 1355 53.3 1355 258.7 6570 258.7 6570 --------

250 53.3 1355 53.3 1355 258.7 6570 258.7 6570 --------

275 75.8 1926 75.8 1926 190.7 4845 190.7 4845 311.9 7922 311.9 7922 - - - -

300 47.6 1210 47.6 1210 171.3 4350 171.3 4350 242.8 6168 242.8 6168 365.1 9274 365.1 9274

Extended Length Unit

150S 23.5 596 23.5 596 207.1 5261 207.1 5261 --------

165S 23.5 596 23.5 596 242.9 6170 242.9 6170 --------

150 44.7 1136 44.7 1136 224.6 5705 224.6 5705 --------

165 61.1 1552 61.1 1552 171.3 4350 171.3 4350 277.8 7057 277.8 7057 - - - -

180 61.1 1552 61.1 1552 171.3 4350 171.3 4350 277.8 7057 277.8 7057 - - - -

200 47.6 1210 47.6 1210 190.7 4845 190.7 4845 311.9 7922 311.9 7922 - - - -

225 47.6 1210 47.6 1210 190.7 4845 190.7 4845 311.9 7922 311.9 7922 - - - -

250 47.6 1210 47.6 1210 190.7 4845 190.7 4845 311.9 7922 311.9 7922 - - - -

275 75.8 1926 75.8 1926 182.0 4623 182.0 4623 258.5 6565 258.5 6565 365.1 9274 365.1 9274

300 47.6 1210 47.6 1210 168.5 4280 168.5 4280 296.1 7520 296.1 7520 418.3 10626 418.3 10626

(a) Units are extended length if either of the following are selected:

Low Harmonic Distortion Option (model number digit 29 = 1)

Autotransformer (model number digit 28 = 1 or 2)

Units without Low Harmonic Distortion Option or Autotransformer (digits 28, 29 = X0) are standard length.

(a)

RTAE-SVX001B-EN 19

Page 20

Installation Mechanical

Center of Gravity

Figure 11. Center of gravity

CG

X

SIDE VIEW

CG

Z

Y

END VIEW

(Non-Control Panel End)

Table 9. Centers of gravity

CGx CGy CGz

Tons

150S 96.6 2454 43.8 1112 40.4 1025

165S 110.0 2793 45.2 1149 42.8 1087

150 105.5 2679 43.9 1115 37.5 953

165 142.4 3617 43.9 1115 39.7 1008

180 142.8 3628 43.9 1115 39.4 1002

200 155.5 3951 43.9 1115 41.2 1047

225 156.1 3964 43.9 1115 39.8 1011

250 156.4 3973 43.9 1115 39.7 1008

275 194.1 4930 43.9 1115 41.1 1043

300 207.1 5260 43.9 1115 42.4 1076

150S 118.8 3017 44.1 1121 37.2 944

165S 136.4 3464 44.7 1137 39.4 1002

150 134.7 3421 43.9 1115 33.3 846

165 169.1 4295 43.9 1115 35.4 898

180 169.9 4314 43.9 1115 35.2 894

200 181.6 4613 43.9 1115 36.9 937

225 183.6 4665 43.9 1115 36.0 915

250 184.2 4680 43.9 1115 36.0 913

275 220.2 5594 43.9 1115 37.4 950

300 232.3 5900 43.9 1115 38.7 984

(a) Units are extended length if either of the following are selected:

Low Harmonic Distortion Option (model number digit 29 = 1)

Autotransformer (model number digit 28 = 1 or 2)

Units without Low Harmonic Distortion Option or Autotransformer (digits

28, 29 = X0) are standard length.

in mm in mm in mm

Standard Length Unit

Extended Length Unit

(a)

Isolation and Sound Emission

The most effective form of isolation is to locate the unit

away from any sound sensitive area. Structurally

transmitted sound can be reduced by elastomeric

vibration eliminators. Spring isolators are not

recommended. Consult an acoustical engineer in critical

sound applications.

For maximum isolation effect, isolate water lines and

electrical conduit.Wall sleeves and rubber isolated piping

hangers can be used to reduce the sound transmitted

through water piping.To reduce the sound transmitted

through electrical conduit, use flexible electrical conduit.

State and local codes on sound emissions should always

be considered. Since the environment in which a sound

source is located affects sound pressure, unit placement

must be carefully evaluated. Sound power levels for

Stealth chillers are available on request.

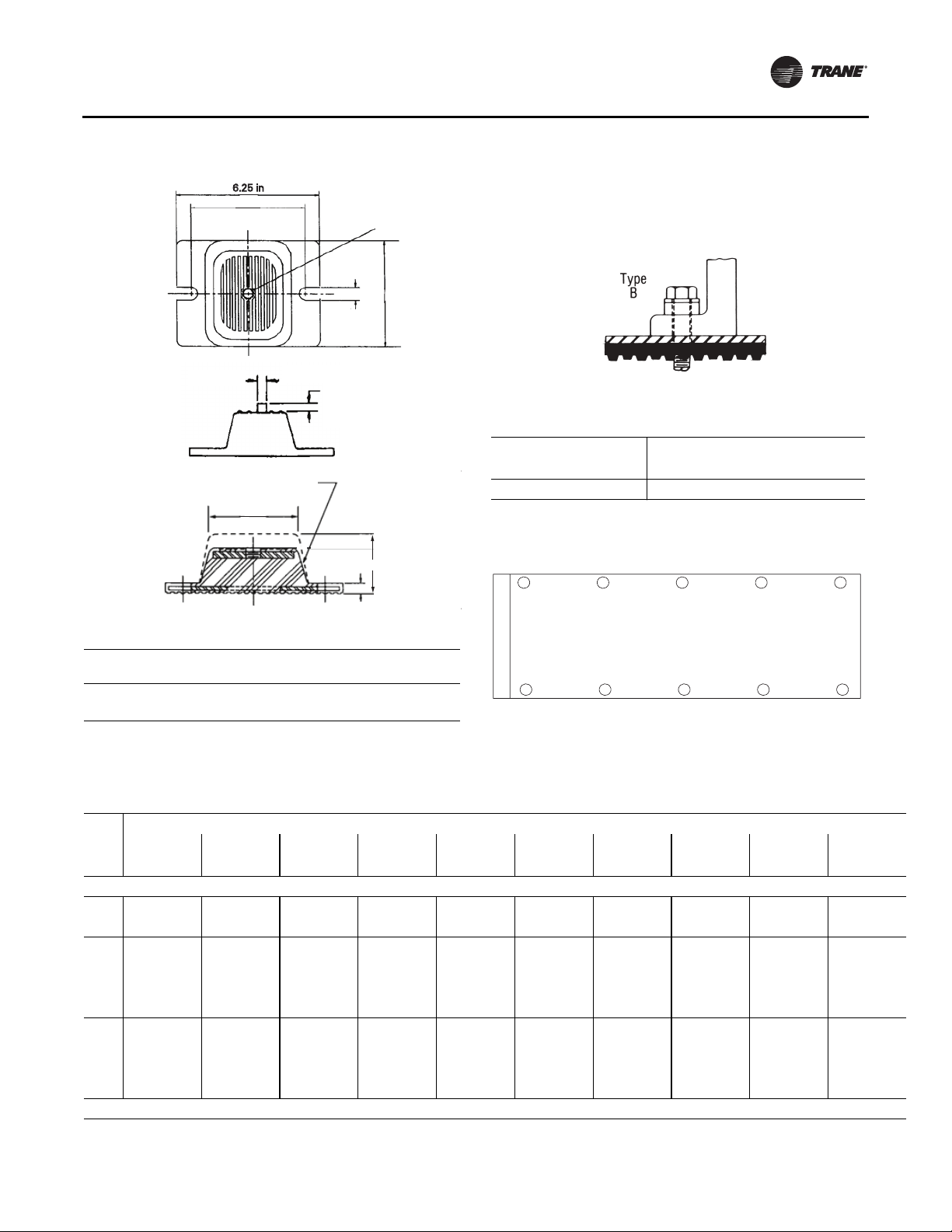

Unit Isolation and Leveling

For additional reduction of sound and vibration, install the

optional elastomeric isolators.

Construct an isolated concrete pad for the unit or provide

concrete footings at the unit mounting points. Mount the

unit directly to the concrete pads or footings.

Level the unit using the base rail as a reference.The unit

must be level within 1/4-in (6 mm) over the entire length

and width. Use shims as necessary to level the unit.

Elastomeric Isolators

(Optional for units without seismic rating)

Note: See unit submittal, or Table 11, p. 21 thru Table 13,

p. 23 for point weights, isolator location and

isolator selections.

1. Secure the isolators to the mounting surface using the

mounting slots in the isolator base plate. Do not fully

tighten the isolator mounting bolts at this time.

2. Align the mounting holes in the base of the unit with

the threaded positioning pins on the top of the

isolators.

3. Lower the unit onto the isolators and secure the

isolator to the unit with a nut.

4. Level the unit carefully. Fully tighten the isolator

mounting bolts.

20 RTAE-SVX001B-EN

Page 21

Installation Mechanical

5.

Figure 12. Elastomeric isolator

5.0 in

0.50 in

Mounting molded in neoprene

3.0 in

0.56 in

1.60 ± .25 in

2.75 in

1/2 - 13NC - 2B

4.63 in

Elastomeric Isolation Pads for Seismic Option

Elastomeric pads ship inside the unit control panel.They

are provided with an isolation washer and 3/4” free hole in

the center of the plate.

Figure 13. Seismic isolation pad — installed

Table 10. Seismically rated elastomeric isolation pad

Dimension (in)

Model Max Load Length Width Height

B-36 2520 6 6 .625

Figure 14. Mounting point locations

2468 10

(a)

0.38 in

Max Load

(lbs) Color

2250 RED 0.50 RDP-4

3000 GREEN 0.50 RDP-4

Maximum

Deflection (in) Type

Control panel

13579

(a) Quantity of isolators varies with unit. Shorter units will not use locations

5 and 6. See submittal for actual number required for specific unit.

Table 11. Point weights

Location

12345678910

Tons lb kg lb kg lb kg lb kg lb kg lb kg lb kg lb kg lb kg lb kg

Standard Length

150S 1731 785 1664 755 1834 832 1773 804 1219 553 1375 624 --------

165S 1666 756 1559 707 1886 855 1870 848 1914 868 1716 778 --------

150 1452 659 1543 700 1326 602 1446 656 1464 664 1350 612 1490 676 1262 572 ----

165 1539 698 1341 608 1622 736 1553 704 1657 752 1607 729 1522 690 1536 697 ----

180 1536 697 1338 607 1676 760 1620 735 1709 775 1659 753 1579 716 1581 717 ----

200 1442 654 1764 800 1696 769 1810 821 1836 833 1694 768 1986 901 1580 717 ----

225 1430 649 1792 813 1999 907 2058 933 2111 958 1994 905 2139 970 1721 781 ----

250 1426 647 1803 818 2064 936 2144 973 2182 990 2055 932 2195 996 1753 795 ----

275 1624 737 1627 738 1802 817 1746 792 1795 814 1530 694 1653 750 1831 830 1577 715 1634 741

300 1634 741 1850 839 1871 849 1925 873 1898 861 1938 879 1887 856 1695 769 1752 795 1515 687

RTAE-SVX001B-EN 21

Page 22

Installation Mechanical

Table 11. Point weights (continued)

Location

12345678910

Tons lb kg lb kg lb kg lb kg lb kg lb kg lb kg lb kg lb kg lb kg

Extended Length Unit

150S 1553 704 1795 814 1974 895 1959 889 2088 947 1804 818 --------

165S 1344 610 1236 561 1537 697 1494 678 1686 765 1668 757 1636 742 1570 712 ----

150 1563 709 1621 735 1705 773 1875 850 1952 885 1575 714 1601 726 1601 726 ----

165 1776 806 1827 829 1956 887 1925 873 2058 933 1958 888 1517 688 1515 687 ----

180 1774 805 1822 827 1990 903 1975 896 2128 965 2030 921 1577 715 1557 706 ----

200 1706 774 1524 691 1662 754 1294 587 1938 879 1738 788 1267 575 1753 795 1457 661 1652 749

225 1857 842 1669 757 1844 836 1412 640 2156 978 1860 844 1378 625 1985 900 1501 681 1766 801

250 1852 840 1664 755 1885 855 1439 653 2219 1006 1936 878 1438 652 2046 928 1530 694 1795 814

275 1874 850 1860 844 1626 737 1700 771 2204 1000 2101 953 2017 915 2131 967 1820 826 1642 745

300 1946 883 1826 828 1854 841 1795 814 2143 972 2106 955 2408 1092 2338 1060 1808 820 1898 861

(a) Units are extended length if either of the following are selected:

Low Harmonic Distortion Option (model number digit 29 = 1)

Autotransformer (model number digit 28 = 1 or 2)

Units without Low Harmonic Distortion Option or Autotransformer (digits 28, 29 = X0) are standard length.

(a)

Table 12. Isolator locations

(a)

Location

12345678910

Tons in mm in mm in mm in mm in mm in mm in mm in mm in mm in mm

Standard Length

150S 23.6 600 27.6 700 102.4 2600 94.5 2400 187.0 4750 187.0 4750 --------

165S 15.7 400 23.0 585 98.4 2500 102.2 2595 196.9 5000 204.7 5200 --------

150 24.4 620 11.8 300 47.2 1200 82.7 2100 100.4 2550 153.5 3900 188.2 4780 188.2 4780 ----

165 17.7 450 23.0 585 98.6 2505 102.2 2595 155.5 3950 190.6 4840 242.1 6150 242.9 6170 ----

180 17.7 450 23.0 585 98.6 2505 102.2 2595 155.5 3950 190.6 4840 242.1 6150 242.9 6170 ----

200 23.6 600 23.6 600 102.4 2600 137.8 3500 155.5 3950 198.8 5050 255.9 6500 263.8 6700 ----

225 23.6 600 23.6 600 102.4 2600 137.8 3500 155.5 3950 198.8 5050 255.9 6500 263.8 6700 ----

250 23.6 600 23.6 600 102.4 2600 137.8 3500 155.5 3950 198.8 5050 255.9 6500 263.8 6700 ----

275 21.7 550 18.9 480 141.3 3590 125.2 3180 196.1 4980 236.2 6000 236.2 6000 259.8 6598 328.0 8330 324.4 8240

300 19.7 500 27.6 700 143.1 3634 143.1 3634 202.4 5142 235.6 5984 257.9 6551 296.6 7534 347.8 8834 339.5 8624

Extended Length Unit

150S 19.7 500 15.7 400 102.4 2600 133.9 3400 204.7 5200 208.7 5300 --------

165S 23.6 600 23.6 600 86.6 2200 78.7 2000 149.6 3800 157.5 4000 259.8 6600 259.8 6600 ----

150 25.0 635 23.6 600 84.6 2150 98.4 2500 147.6 3750 190.9 4850 240.2 6100 240.2 6100 ----

165 19.7 500 19.7 500 129.9 3300 129.9 3300 204.7 5200 234.3 5950 293.3 7450 299.2 7600 ----

180 19.7 500 19.7 500 129.9 3300 129.9 3300 204.7 5200 234.3 5950 293.3 7450 299.2 7600 ----

200 25.6 650 19.7 500 118.1 3000 98.4 2500 208.7 5300 196.9 5000 255.9 6500 255.9 6500 315.0 8000 315.0 8000

225 25.6 650 19.7 500 118.1 3000 98.4 2500 208.7 5300 196.9 5000 255.9 6500 255.9 6500 315.0 8000 315.0 8000

250 25.6 650 19.7 500 118.1 3000 98.4 2500 208.7 5300 196.9 5000 255.9 6500 255.9 6500 315.0 8000 315.0 8000

275 6.3 160 9.8 250 177.2 4500 139.8 3550 198.8 5050 242.1 6150 309.1 7850 313.0 7950 354.3 9000 370.1 9400

300 9.8 250 9.8 250 177.2 4500 139.8 3550 206.7 5250 242.1 6150 311.8 7920 313.4 7960 393.7 10000 393.7 10000

(a) Dimensions are referenced from end of frame on the control panel side.

(b) Units are extended length if either of the following are selected:

Low Harmonic Distortion Option (model number digit 29 = 1)

Autotransformer (model number digit 28 = 1 or 2)

Units without Low Harmonic Distortion Option or Autotransformer (digits 28, 29 = X0) are standard length.

(b)

22 RTAE-SVX001B-EN

Page 23

Installation Mechanical

Table 13. Isolator selections

Location

Tons 1 2 3 4 5 6 7 8 9 10

Standard Length Unit

150S Red 62 Red 62 Red 62 Red 62 Red 62 Red 62 - - - -

165S Red 62 Red 62 Red 62 Red 62 Red 62 Red 62 - - - -

150 Red 62 Red 62

165 Red 62 Red 62

180 Red 62 Red 62

200 Red 62 Red 62

225 Red 62 Red 62

250 Red 62 Red 62

275 Red 62 Red 62

300 Red 62 Red 62

150S Red 62 Red 62 Green 63 Green 63 Green 63 Red 62 - - - -

165S Red 62 Red 62 Red 62 Red 62 Red 62 Red 62 Red 62 Red 62 - -

150 Red 62 Red 62

165 Red 62 Red 62

180 Red 62 Red 62

200 Red 62 Red 62

225 Red 62 Red 62

250 Red 62 Red 62

275 Red 62 Red 62

300 Red 62 Red 62

(a) Units are extended length if either of the following are selected:

Low Harmonic Distortion Option (model number digit 29 = 1)

Autotransformer (model number digit 28 = 1 or 2)

Units without Low Harmonic Distortion Option or Autotransformer (digits 28, 29 = X0) are standard length.

Green 63 Green 63 Green 63 Green 63 Red 62 Red 62 - -

Green 63 Green 63 Green 63 Green 63 Red 62 Red 62 - -

Green 63 Green 63 Green 63 Green 63 Red 62 Red 62 - -

Green 63 Green 63 Green 63 Green 63 Red 62 Red 62 - -

Green 63 Green 63 Green 63 Green 63 Red 62 Red 62 - -

Green 63 Green 63 Green 63 Green 63 Red 62 Red 62 - -

Green 63 Green 63 Green 63 Green 63 Green 63 Green 63 Red 62 Red 62

Green 63 Green 63 Green 63 Green 63 Green 63 Green 63 Red 62 Red 62

Extended Length Unit

Green 63 Green 63 Green 63 Green 63 Red 62 Red 62 - -

Green 63 Green 63 Green 63 Green 63 Red 62 Red 62 - -

Green 63 Green 63 Green 63 Green 63 Red 62 Red 62 - -

Green 63 Green 63 Green 63 Green 63 Green 63 Green 63 Red 62 Red 62

Green 63 Green 63 Green 63 Green 63 Green 63 Green 63 Red 62 Red 62

Green 63 Green 63 Green 63 Green 63 Green 63 Green 63 Red 62 Red 62

Green 63 Green 63 Green 63 Green 63 Green 63 Green 63 Red 62 Red 62

Green 63 Green 63 Green 63 Green 63 Green 63 Green 63 Red 62 Red 62

(a)

Compressor Shipping Bolt Removal

Units with InvisiSound™ Ultimate Option (Model Number Digit 12 = 3)

For chillers built with InvisiSound Ultimate option,

compressor shipping bolts must be removed to assure

minimum noise during operation. Use a 24mm socket to

remove the (3) M15 x 75mm shipping bolts for each

compressor.They are located under compressor

mounting feet. See Figure 15.

Important:

• DO NOT DISCARD SHIPPING BOLTS. Store bolts in the

control panel for future use.

• All shipping bolts MUST be reinstalled prior to

compressor removal or unit move.

Figure 15. Compressor shipping bolt removal

Isolator

Compressor

Compressor

Mounting

Foot

Shipping Bolt

Drainage

NOTICE:

Equipment Damage!

Do not remove compressor or move unit without

reattaching compressor shipping bolts. Failure to

reinstall bolts could cause shifting of parts and result in

equipment damage.

RTAE-SVX001B-EN 23

Locate the unit near a large capacity drain for water vessel

drain-down during shutdown or repair. Evaporators are

provided with drain connections. A vent on top of

evaporator waterbox prevents vacuum byallowing airinto

evaporator for complete drainage. All local and national

codes apply.

Page 24

Installation Mechanical

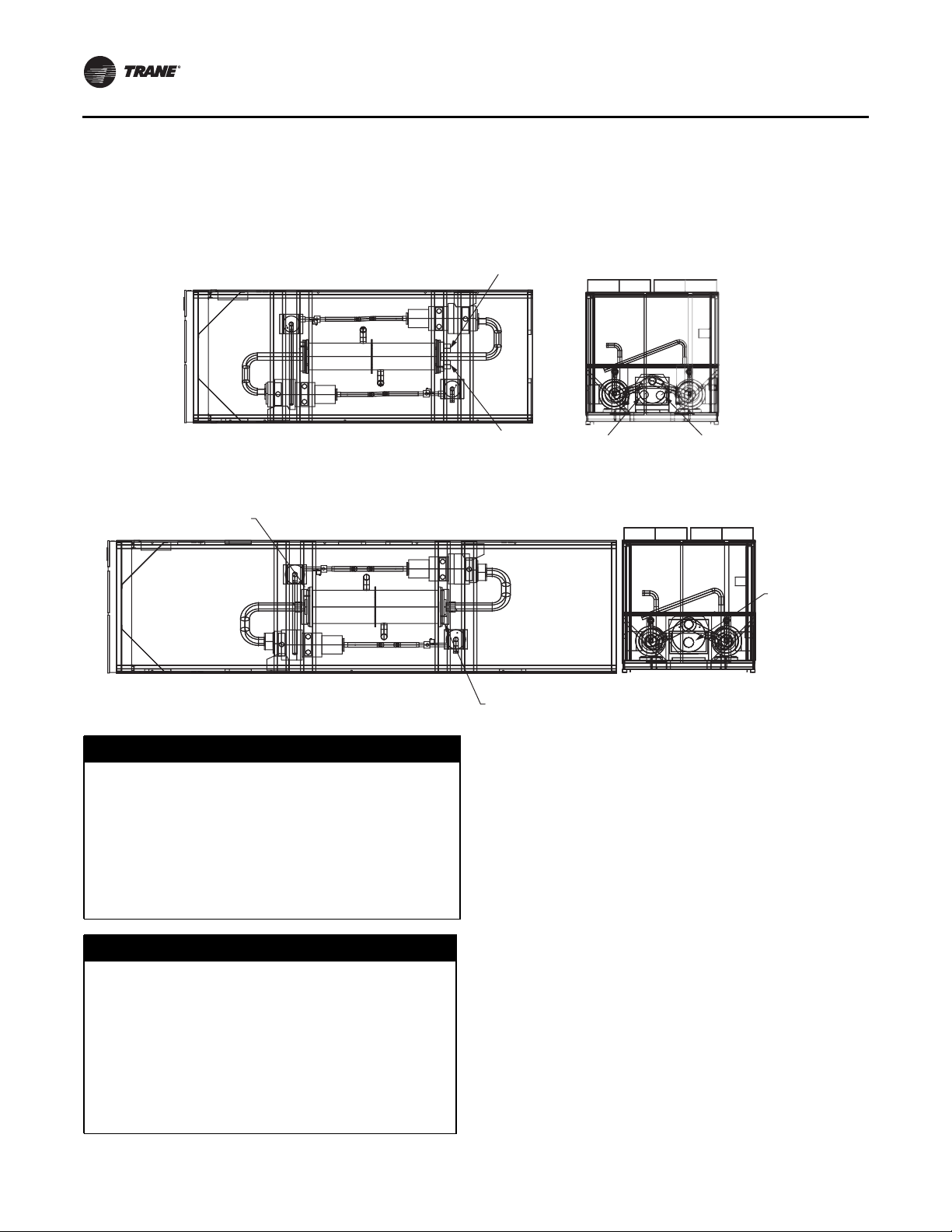

Evaporator Piping

RTAE units are available with 2 or 3 pass configurations.

See Figure 16.

Figure 16. Evaporator pass configurations

Control Panel End

Control Panel End

Outlet Waterbox

2-Pass Evaporators

Top V i ew

(Condenser removed for clarity)

3-Pass Evaporators

Top V i ew

(Condenser removed for clarity)

Inlet Water

Connection

Outlet Water

Connection

Inlet Waterbox

Outlet

End View

(Non-control panel end)

(Non-control panel end)

Inlet

End View

Inlet Waterbox

(Outlet waterbox

opposite end)

NOTICE:

Evaporator water connections are grooved.

Thoroughly flush allwater piping tothe unitbefore making

Proper Water Treatment!

The use of untreated or improperly treated water could

result in scaling, erosion, corrosion, algae or slime. It is

recommended that the services of a qualified water

treatment specialist be engaged to determine what

water treatment, if any, is required. Trane assumes no

responsibility for equipment failures which result from

untreated or improperly treated water, or saline or

brackish water.

the final piping connections to the unit.

Components and layout will vary slightly, depending on

the location of connections and the water source.

A vent is provided on the top of the evaporator at the

chilled water inlet. Be sure to provide additional vents at

high points in the piping to bleed air from the chilled water

system. Install necessary pressure gauges to monitor the

entering and leaving chilled water pressures.

Provide shutoff valves in lines to the gauges to isolate

NOTICE:

Evaporator Damage!

The chilled water connections to the evaporator are to

be “victaulic” type connections. Do not attempt to

weld these connections, as the heat generated from

welding can cause microscopic and macroscopic

fractures on the cast iron waterboxes that can lead to

premature failure of the waterbox. To prevent damage

to chilled water components, do not allow evaporator

pressure (maximum working pressure) to exceed 150

them from the system when they are not in use. Use

rubber vibration eliminators to prevent vibration

transmission through the water lines.

If desired, install thermometers in the lines to monitor

entering and leaving water temperatures. Install a

balancing valve in the leaving water line to control water

flow balance. Install shutoff valves on both the entering

and leaving water lines so that the evaporator can be

isolated for service

psig (10.5 bar).

24 RTAE-SVX001B-EN

Page 25

Installation Mechanical

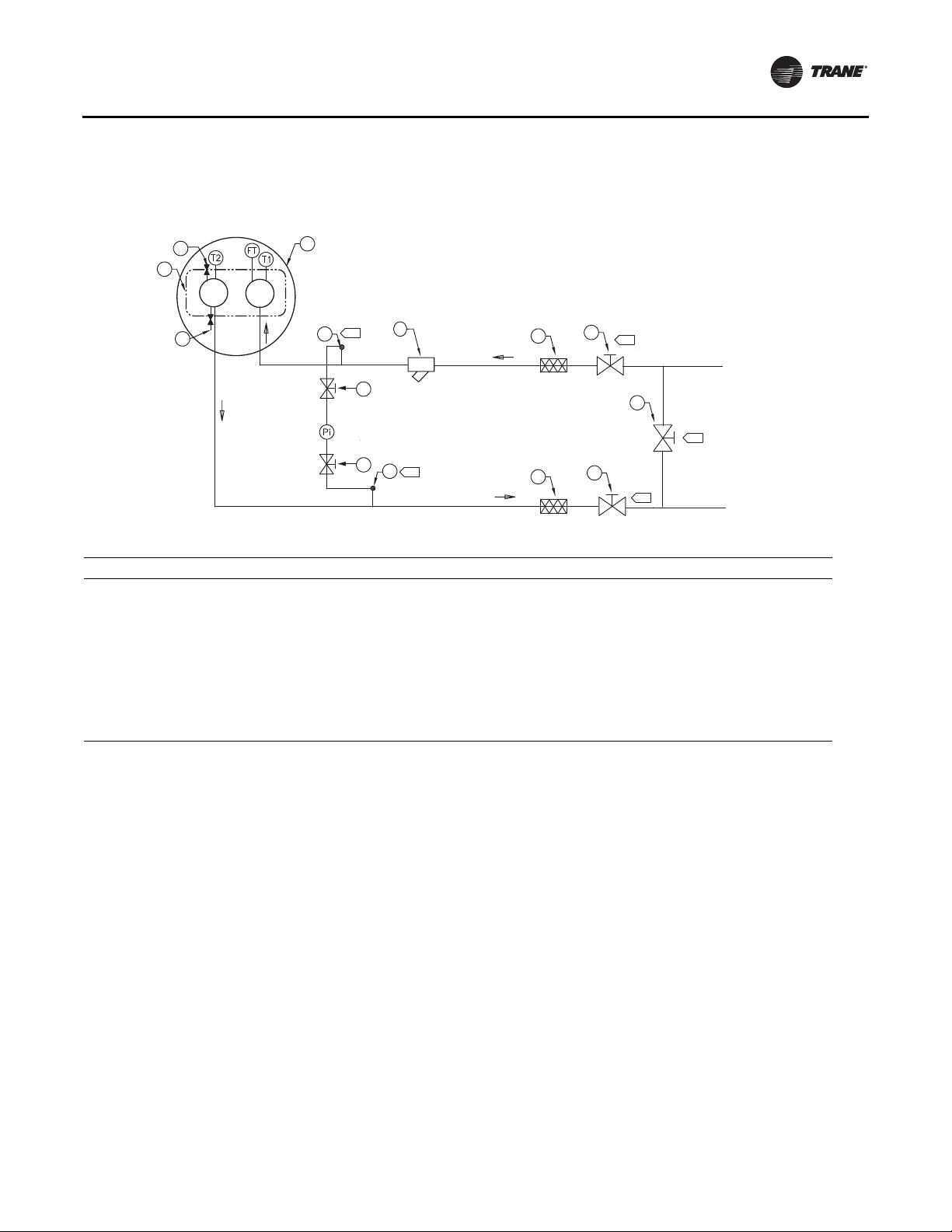

Evaporator Piping Components

operating safety. SeeThese components and their general

locations are given below.

Piping components include all devices and controls used

to provide proper water system operation and unit

Figure 17. Typical Stealth™ water piping

6

5

8

4

B

7

2

2

8

C

3

3

2

A

1

A

2

A

Table 14. Water piping components

Item Description Item Description

1 Bypass Valve Pi Pressure Gauge

2 Isolation Valve FT Water Flow Switch

3 Vibration Eliminator T1 Evap Water Inlet Temp Sensor

4 Evaporator - End View (2-pass) T2 Evap Water Outlet Temp Sensor

5 Evaporator Waterbox (2-pass)

6 Vent A Isolate unit for initial water loop cleaning

7 Strainer B Vent must be installed at the high point of the line

8 Drain C Drain must be installed at the low point of the line

NOTES

Entering Chilled Water Piping

• Air vents (to bleed air from system).

• Water pressure gauges with shutoff valves.

• Vibration eliminators.

• Shutoff (isolation) valves.Thermometers (if desired).

• Clean-out tees.

• Pipe strainer.

Leaving Chilled Water Piping

• Air vents (to bleed air from system).

• Water pressure gauges with shutoff valves.

• Vibration eliminators.

• Shutoff (isolation) valves.

• Thermometers.

Drains

A 1/2” drain connection is located under outlet end of

evaporator waterbox for drainage during unit servicing.A

shutoff valve must be installed on drain line.

Pressure Gauges

Install field-supplied pressure components as shown in

Figure 17, p. 25. Locate pressure gauges or taps in a

straight run of pipe; avoid placement near elbows, etc. Be

sure to install the gauges at the same elevation on each

shell if the shells have opposite-end water connections.

To read manifolded pressure gauges, open one valve and

close the other (depending upon the reading desired).This

eliminates errors resulting from differently calibrated

gauges installed at unmatched elevations.

• Clean-out tees.

• Balancing valve.

RTAE-SVX001B-EN 25

Page 26

Installation Mechanical

Pressure Relief Valves

NOTICE:

Evaporator Damage!

To prevent shell damage, install pressure relief valves in

the evaporator water system.

Install a water pressure relief valve in the evaporator inlet

piping between the evaporator and the inlet shutoff valve,

as shown in Figure 17, p. 25. Water vessels with close-

coupled shutoff valves have a high potential for

hydrostatic pressure buildup on a water temperature

increase. Refer to applicable codes for relief valve

installation guidelines.

Evaporator Flow Switch

NOTICE:

Equipment Damage!

Flow switch is on a 24V circuit. Do NOT apply 120V to

the flow switch. Incorrect voltage application could

cause damage to the flow switch.

The flow switch is factory-installed and programmed

based on the operating conditions submitted with the

order.The leaving evaporator temperature, fluid type and

fluid concentration affect the selected flow switch. If the

operating conditions on the job site change, the flow

switch may need to be replaced. Contact your localTrane

Sales office for more information.

The sensor head includes 3 LEDs, two yellow and one

green.Wait 15 seconds after poweris applied to the sensor

before evaluating LEDs for flow status. When wired

correctly and flow is established, only the green LED

should be lit. Following are the LED indicators:

• Green ON, both yellow OFF — Flow

• Green and outside yellow ON — No Flow

• Center yellow ON continuously — Miswire

Factory installed jumper wire W11 must be removed if

using auxiliary contacts and/or additional proof of flow.

See schematics in RTAE-SVE01*-EN for more details.

Indexing Flow Switch

To properly index the flow switch, the following

requirements must be met:

• The dot must be at a position no greater than 90° off

Index.

• The torque must be between 22 ft-lb minimum and 74

ft-lb maximum.

• A minimum distance of 5x pipe diameter must be

maintained between flow switch and any bends,

valves, changes in cross sections, etc.

Figure 18. Proper flow switch indexing

Top V ie w

Flow

Index

The flow switch must have the dot

in the shaded area to the left of this line

for proper indexing (±90° off Index)

NOTICE:

Equipment Damage!

Incorrect wiring of auxiliary contacts could cause

equipment damage.

If using auxiliary flow sensing, both yellow LEDs come on

initially when flow is stopped.The center yellow LED will

turn off after approximately 7 seconds.The LED indicators

are otherwise the same as indicated above.

26 RTAE-SVX001B-EN

Page 27

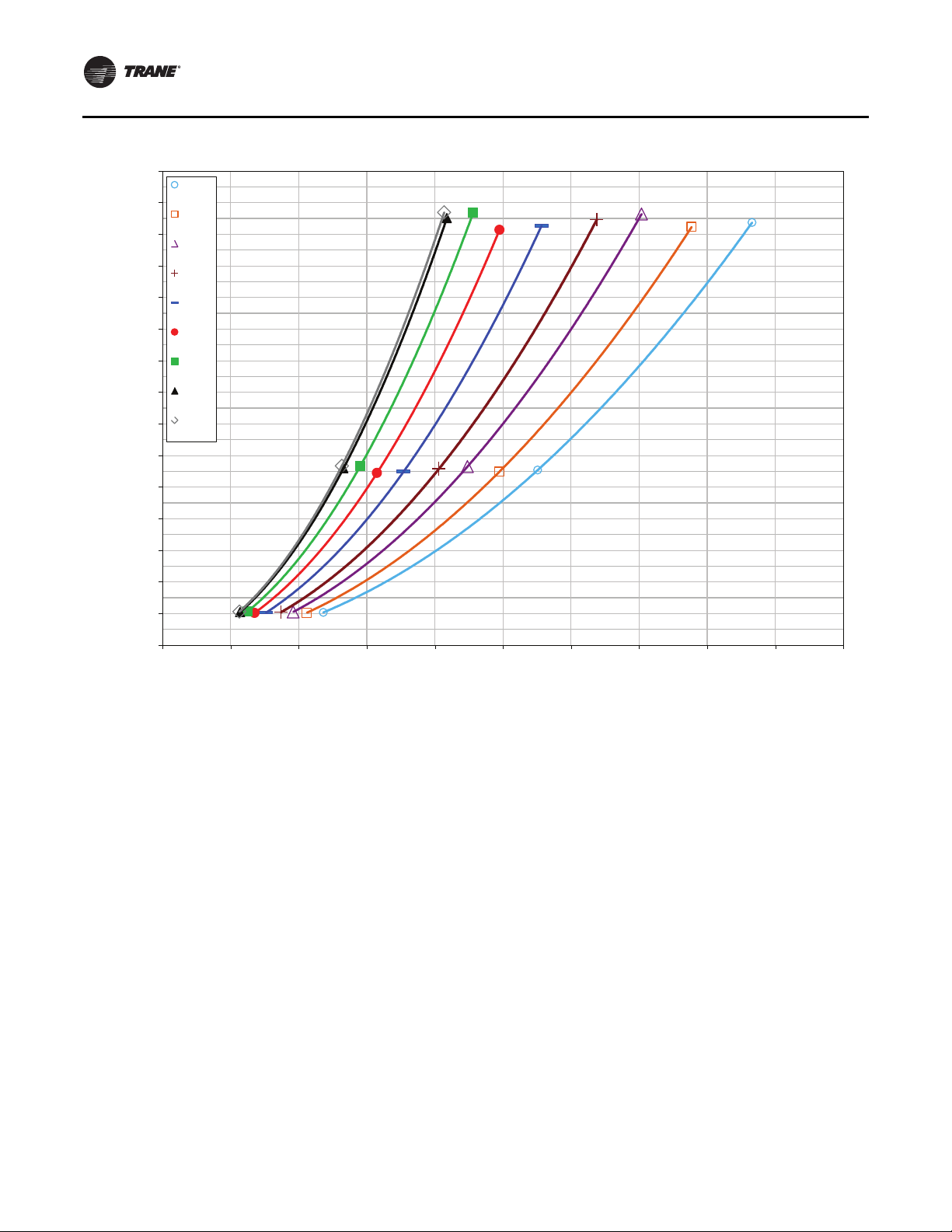

Evaporator Waterside Pressure Drop Curves

0

2.5

5

7.5

10

12.5

15

17.5

20

22.5

25

27.5

30

32.5

35

37.5

40

42.5

45

47.5

50

0 200 400 600 800 1000 1200 1400

Pressure Drop (ft. H2O)

Water Flow (GPM)

pp

300T

275T

250T

225T

200T

185T

165T

150T

150S,

165S

Figure 19. Evaporator waterside pressure drop curve — 2-pass

Installation Mechanical

RTAE-SVX001B-EN 27

Page 28

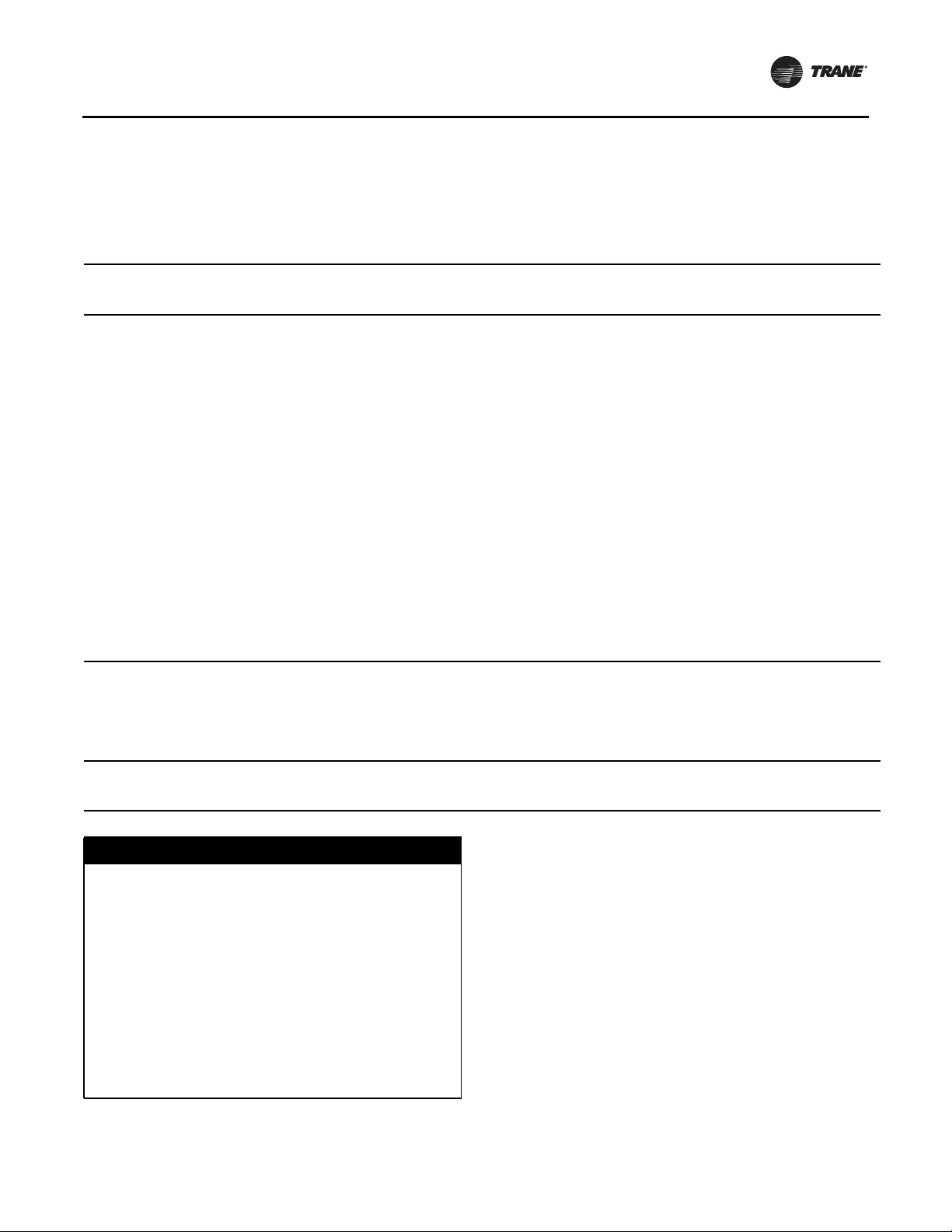

Installation Mechanical

0

5

10

15

20

25

30

35

40

45

50

55

60

65

70

75

0 100 200 300 400 500 600 700 800 900 1000

Pressure Drop (ft. H2O)

Water Flow (GPM)

300T

275T

250T

225T

200T

185T

165T

150T

150S,

165S

Figure 20. Evaporator waterside pressure drop curve — 3-pass

28 RTAE-SVX001B-EN

Page 29

Freeze Protection

One or more of the ambient freeze avoidance methods in

Table 15 must be used to protect the Stealth chiller from

ambient freeze damage.

Table 15. RTAC freeze avoidance methods

Protects to

Method

Water Pump Control

AND Heaters

Freeze Inhibitor

Drain Water Circuit Below -20°F

ambient

temperature Notes

• Heaters alone will provide low ambient protection down to -20°F (-29°C), but will NOT

protect the evaporator from freezing as a result of charge migration. Therefore, it is

required that water pump control be used in conjunction with heaters.

• Heaters are factory-installed on the evaporator and water piping and will protect them from freezing

• Install heat tape on all water piping, pumps, and other components that may be damaged if exposed

to freezing temperatures. Heat tape must be designed for low ambient temperature applications. Heat

tape selection should be based on the lowest expected ambient temperature.

• Tracer™ UC800 controller can start the pump when freezing conditions are detected. For this option

the pump must to be controlled by the Stealth unit and this function must be validated.

• Water circuit valves need to stay open at all times.

• Water pump control and heater combination will protect the evaporator down to any

Down to -20°F

Varies.

See “Low

Evaporator

Refrigerant Cutout,

Glycol

Requirements,”

p. 30

ambient temperature provided power is available to the pump and the controller. This

option will NOT protect the evaporator in the event of a power failure to the chiller unless

backup power is supplied to the necessary components.

• When no chiller operation is possible and the pump is already off, UC800 pump control for freeze

protection will command the pump to turn:

ON if average of the evaporator entering water temperature, the evaporator leaving water

temperature, and the evaporator refrigerant pool temperature is less than Low Evaporator Refrigerant

Temperature Cutout (LERTC) + 4°F for a period of time.

OFF again if the evaporator refrigerant pool temperature rises above the LERTC + 6°F for a period

of time.

Note: Time period referenced for ON and Off conditions above is dependent on past running conditions

and present temperatures measured.

ON if entering OR leaving water temperature< LWTC for 30°F-sec (17°C-sec)

OFF again if water temperature > LWTC for 30 min

• Freeze protection can be accomplished by adding sufficient glycol to protect against freezing below

the lowest ambient expected.

• Use of glycol type antifreeze reduces the cooling capacity of the unit and must be

considered in the design of the system specifications.

• Shut off the power supply to the unit and to all heaters.

• Purge the water circuit.

• Blow out the evaporator to ensure no liquid is left in the evaporator.

Installation Mechanical

NOTICE:

Evaporator Damage!

If insufficient concentration or no glycol is used, the

evaporator water flow must be controlled by the UC800

AND heaters must be used to avoid catastrophic

damage to the evaporator due to freezing. It is the

responsibility of the installing contractor and/or the

customer to ensure that a pump will start when called

upon by the chiller controls. Refer to RLC-PRB012-EN.

Even with water pump control, a power loss of as little

as 15 minutes under freezing conditions can damage

the evaporator. Only the proper addition of freeze

inhibitor or complete drainage of the water circuit can

ensure no evaporator damage in the event of a power

failure.

RTAE-SVX001B-EN 29

Page 30

Installation Mechanical

Low Evaporator Refrigerant Cutout, Glycol Requirements

The table below shows the low evaporator temperature

cutout for different glycol levels. Additional glycol beyond

the recommendations will adversely effect unit

performance.The unit efficiency will be reduced and the

saturated evaporator temperature will be reduced. For

Note: Table below is not a substitute for full unit

simulation for proper prediction of unit

performance for specific operating conditions. For

information on specific conditions, contact Trane

product support.

some operating conditions this effect can be significant.

If additional glycol is used, then use the actual percent

glycol to establish the low refrigerant cutout setpoint.

Table 16. Low evaporator refrigerant temperature cutout (LERTC) and low water temperature cutout (LWTC)

Ethylene Glycol Propylene Glycol

Glycol

Percentage

(%)

0 32.0 28.6 35.0 0 32.0 28.6 35.0

2 31.0 27.6 34.0 2 31.0 27.6 34.0

4 29.7 26.3 32.7 4 29.9 26.5 32.9

5 29.0 25.6 32.0 5 29.3 25.9 32.3

6 28.3 24.9 31.3 6 28.7 25.3 31.7

8 26.9 23.5 29.9 8 27.6 24.2 30.6

10 25.5 22.1 28.5 10 26.4 23.0 29.4

12 23.9 20.5 26.9 12 25.1 21.7 28.1

14 22.3 18.9 25.3 14 23.8 20.4 26.8

15 21.5 18.1 24.5 15 23.1 19.7 26.1

16 20.6 17.2 23.6 16 22.4 19.0 25.4

18 18.7 15.3 21.7 18 20.9 17.5 23.9

20 16.8 13.4 19.8 20 19.3 15.9 22.3

22 14.7 11.3 17.7 22 17.6 14.2 20.6

24 12.5 9.1 15.5 24 15.7 12.3 18.7

25 11.4 8.0 14.4 25 14.8 11.4 17.8

26 10.2 6.8 13.2 26 13.8 10.4 16.8

28 7.7 4.3 10.7 28 11.6 8.2 14.6