Page 1

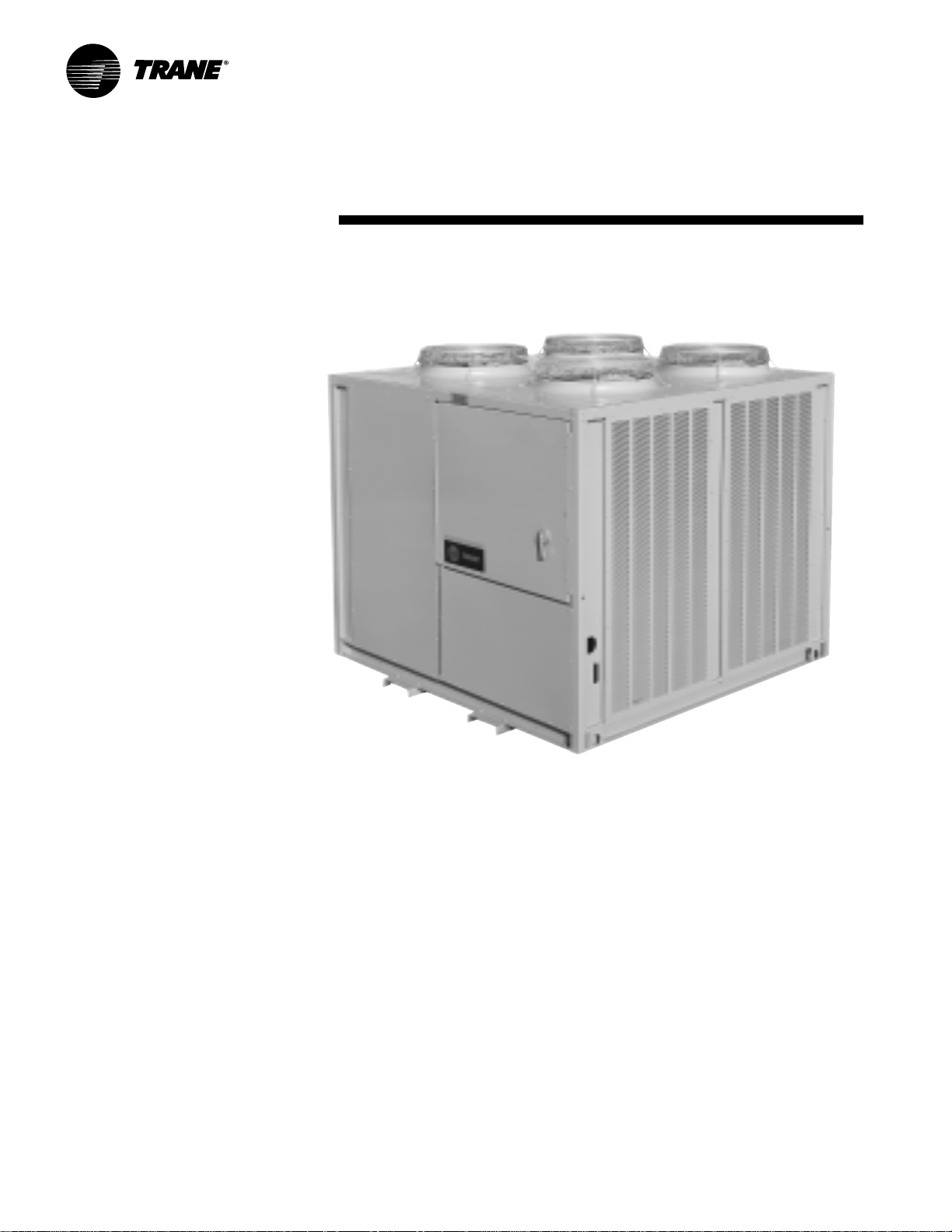

Split System Condensing

Units and Remote Chillers

20 to 120 Tons

50 and 60 Hz

November 2001

SS-PRC005-EN

Page 2

Introduction

©American Standard Inc. 2001

T rane 20 through 120-ton air-cooled

condensing units are the leaders in the

split system marketplace. Designed for

efficiency , reliability and flexibility , the

T rane units have the most advanced

design in the industry.

Twenty through 120-ton units feature

the Trane 3-D™ Scroll compressor, solidstate controls and Trane’s exclusive

Pac ked Stock Plus availability for quick

shipment. These inno vations make an

already proven product even better!

SS-PRC005-EN

Page 3

Contents

Introduction

Featur es and Benefits

Application Considerations

Selection Procedur e

Model Number Description

General Data

P erformance Data

Performance Adjustment Factors

Controls

Electric P o wer

Dimension and Weights

Mechanical Specifications

2

4

6

7

8

10

12

11

25

27

29

46

SS-PRC005-EN

3

Page 4

Trane 3-D Scr oll Compressor

Simple Design with 70% Fewer Par ts

Fewer parts than an equal capacity

reciprocating compressor means

significant reliability and efficiency

benefits. The single orbiting scroll

eliminates the need for pistons,

connecting rods, wrist pins and valves.

Fewer parts lead to increased reliability .

Fewer moving parts, less rotating mass

and less internal friction means greater

efficiency than reciprocating

compressors.

The Trane 3-D Scroll pro vides important

reliability and efficiency benefits. The 3-D

Scroll allows the orbiting scrolls to touch

in all three dimensions, forming a

completely enclosed compression

chamber whic h leads to increased

efficiency . In addition, the orbiting scrolls

only touch with enough force to create a

seal; there is no wear between the scroll

plates. The fixed and orbiting scrolls are

made of high strength cast iron which

results in less thermal distortion, less

leakage, and higher efficiencies. The

most outstanding feature of the 3-D

Scroll compressor is that slugging will

not cause failure. In a reciprocating

compressor, however , the liquid or dir t

can cause serious damage.

Low T orque Variation

The 3-D Scroll compressor has a very

smooth compression cycle; torque

variations are only 30 percent of that

produced by a reciprocating compressor.

This means that the scroll compressor

imposes very little stress on the motor

resulting in greater reliability. Low torque

variation reduces noise and vibration.

Suction Gas Cooled Motor

Compressor motor efficiency and

reliability is further optimized with the

latest scroll design. Cool suction gas

keeps the motor cooler for longer life

and better efficiency.

Proven Design Through T esting and

Research

With over twenty years of development

and testing, Trane 3-D Scroll

compressors have undergone more

than 400,000 hours of laboratory testing

and field operation. This work combined

with over 25 patents makes Trane the

Features and Benefits

worldwide leader in air conditioning

scroll compressor technology .

V oltage P o wer Supply

20 through 120-ton units have four

voltage options in 200, 230, 460 and

575, resulting in improved stock

coverage.

Passive Manif olding

T rane of fers a parallel manifolding

scheme that uses no moving

mechanical parts. This feature assures

continuous oil return, again providing

greater system reliability. And greater

reliability means optimal performance

over the life of the unit.

System Control Options

T rane of fers four system control

options on 20 through 60-ton units and

three system control options on the 80

through 120-ton units, each using

solid- state electronics. These options

allow the unit to be ordered only with

the controls needed. In addition, they

come factory installed, saving field

installation costs.

Coil Frost Pr otection

T rane of fers FROSTA T™ with the V A V

system control option on the 20

through 120-ton units. FROST AT is the

industry’s most reliable method of coil

frost protection and assures that your

system will provide energy efficient

comfort at part load conditions.

Remote Evapor ative Liquid Chiller

(EVP) Control Option

This option allows chilled water to be

generated remotely from the

condensing section.

SS-PRC005-EN4

Page 5

Features and

Benefits

20 Through 60-T on Units

Standard Featur es

• Trane 3-D™ Scroll compressors

• Factory-installed Discharge and Liquid

Line Service V alves

• Passive manifolding for 3-D Scroll

compressors

• Standard ambient operating range

40°F to 115°F

• 14-gauge galvaniz ed steel frame

• Louvered panels for coil protection

• Slate gray air -dry paint finish (exceeds

672 hour salt spray test in accordance

with ASTM B1 17)

Optional Features

• Non-fused disconnect

• Low ambient option

• Hot gas bypass to the evaporator inlet

• Suction service valve

• Pressure gauges

• Return air sensor

• Copper finned condenser coil

• Flow switch

• Unit spring isolators

• Neoprene-in-shear isolators

• UL/CSA approval (not available for 50

Hz)

• Pac ked Stock Plus program

• Extended Compressor W ar ranty

• Special coil coating for corrosion

resistance

• Four systems control options

80 Through 120-T on Units

Standard Featur es

• Trane 3-D Scroll compressors

• Factory-installed discharge and liquid

line service valves

• Standard ambient operating range 40°F

to 115°F

• Independent refrigerant circuits

• 14-gauge g alvanized steel frame

• Louvered panels for coil protection

• Slate gray air -dry paint finish (exceeds

672 hour salt spray test in accordance

with ASTM B1 1 7)

Optional Features

• Low ambient option

• Hot gas bypass to the evaporator inlet

• Suction service valve

• Pressure gauges

• Copper finned condenser coil

• Spring isolators

• Flow switch

• UL/CSA approval

• Pac ked Stoc k Plus A vailability

• Extended Compressor W ar ranty

• Special coil coating for corrosion

resistance

• Three system control options

Pac ked St oc k Plus

T rane 20 through 120-ton air-cooled

condensing units are available through

the most flexible packed stoc k program

in the industry. T rane knows that you

want your units on the job site, on time,

with the options you need.

Pac ked Stock Plus pro vides you with the

controls and options you need — options

like hot gas bypass, isolators and

refrigerant gauges. You no longer have to

settle for a basic unit requiring many field

installed options to meet your job

schedule. Now , you can get a customiz ed

unit from the factory in record time.

The Trane Pa c ked Stoc k Plus program

provides more control over unit selection

and scheduling than ever before. T rane

wants to make it easy for you to do

business with them.

5SS-PRC005-EN

Page 6

Application Considerations

Certain application constraints should be

considered when sizing, selecting and

installing Trane air-cooled condensing

units. Unit reliability is dependent upon

these considerations. Where your

application varies from the guidelines

presented, it should be reviewed with the

local Trane sales engineer .

Unit Sizing

Unit capacities are listed in the

performance data section on pages 11 to

24. Intentionally oversizing a unit to

assure adequate capacity is not

recommended. Erratic system operation

and excessive compressor cycling are

often a direct result of an oversized

condensing unit. In addition, an

oversized unit is usually more expensive

to purchase, install and operate. If

oversizing is desired, consider using two

units.

Unit Placement

A base or foundation is not required if

the selected unit location is level and

strong enough to support the unit’s

operating weight (as listed on page 45).

Isolation and Sound Emission

The most effective form of isolation is to

locate the unit away from any sound

sensitive area. Structurally transmitted

sound can be reduced by using spring or

rubber isolators. The isolators are

effective in reducing the low frequency

sound generated by compressors and,

therefore, are recommended for sound

sensitive installations. An acoustical

engineer should always be consulted on

critical applications.

For maximum isolation effect, the

refrigeration lines and electrical conduit

should also be isolated. Use flexible

electrical conduit. State and local codes

on sound emissions should always be

considered. Since the environment in

which a sound source is located affects

sound pressure, unit placement must be

carefully evaluated.

Servicing

Adequate clearance for compressor

servicing should be provided.

Recommended minimum space

envelopes for servicing are located in the

dimensional data section of this catalog

and can serve as guidelines for providing

adequate clearance. The minimum space

envelopes also allow for control panel

door swing and rountine maintenance

requirements. Local code requirements

may take precedence.

Unit Location

Unobstructed flow of condenser air is

essential for maintaining condensing

unit capacity and operating efficiency .

When determining unit placement,

careful consideration must be given to

assure proper air flow across the

condenser heat transfer surface. Failure

to heed these considerations will result

in warm air recirculatioin and coil air

flow starvation.

Warm air recirculation occurs when

discharge air from the condenser fans is

recycled back at the condenser coil inlet.

Coil starvation occurs when free air flow

to the condenser is restricted.

Both warm air recirculation and coil

starvation cause reductions in unit

efficiency and capacity . In addition, in

more severe cases, nuisance unit

shutdowns will result from exessive

head pressures. Accurate estimates of

the degree of efficiency and capacity

reduction are not possible due to the

unpredictable effect of varying winds.

When hot gas bypass is used, reduced

head pressure increases the minimum

ambient condition for proper operation.

In addition, wind tends to further reduce

head pressure. Therefore, it is advisable

to protect the air -cooled condensing unit

from continuous direct winds exceeding

10 miles per hour.

Debris, trash, supplies, etc., should not

be allowed to accumulate in the vicinity

of the air -cooled condensing unit. Supply

air movement may draw debris between

coil fins and cause coil starvation.

Special consideration should be given to

units operating in low ambient

temperatures. Condenser coils and fan

discharge must be kept free of snow and

other obstructions to permit adequate air

flow for satisfactory unit operation.

Effect of Altitude on Capacity

Condensing unit capacities given in the

performance data tables on pages 11 to

24 are at sea level. At elevations

substantially above sea level, the

decreased air density will decrease

condenser capacity and, therefore, unit

capacity and efficiency. The adjustment

factors in Table PAF -1 can be applied

directly to the catalog performance data

to determine the unit’s adjusted

performance.

Ambient Considerations

Start-up and operation at lower

ambients requires sufficient head

pressure be maintained for proper

expansion valve operation. At higher

ambients, excessive head pressure may

result. Standard operating conditions are

40°F to 115°F. With a low ambient

damper, operation down to 0°F is

possible. Minimum ambient

temperatures are based on still

conditions (winds not exceeding five

mph). Greater wind velocities will result

in increased minimum operating

ambients. Units with hot gas bypass

have a minimum operating ambient

temperature of 10°F. For proper

operation outside these

recommendations, contact the local

T rane sales of fice.

Coil Frost Pr otection

FROST AT™ is standard on condensing

units when the VAV option is ordered.

FROST AT consists of a ship-with

thermostat for field installation on the

suction line. A timer is also factoryinstalled to avoid short cycling. FROSTAT

cycles the compressor off when the

suction line is below 30°F. Refer to

S/S-EB-43 for more detail.

When hot gas valves must be used on 20

to 120-ton units, they can be ordered as

a miscellaneous option. 20 to 30-ton

units require one valve; 40 to 60-ton

units also require one valve except when

no system control option is selected; this

option requires two valves. 80 to 120-ton

units require one valve when Supply Air

VAV control is selected. Two valves are

required on all other 80 to 120-ton

control options.

Refriger ant Piping

Special consideration must always be

given to oil return. Minimum suction gas

velocities must always be maintained for

proper oil return. Utilize appropriate

piping tools for line sizing such as the

CDS Refrigerant Piping Program. Fo r

special applications, call Clarksville

Product Support.

SS-PRC005-EN6

Page 7

Selection Pr ocedure

RAUC/AIR HANDLER

Selection Procedure

Net capacity curves for the RAUC

condensing units are given on pages 14

through 23. These graphs can be used to

cross plot an evaporator (EVP)

performance curve. The resultant point

of intersection will be the system design

balance point. The design operating

suction temperature and capacity can

then be read directly from the graph.

(Note: It is usually necessary to account

for suction and liquid line losses in the

performance accordingly. The actual

losses are determined by the

interconnecting piping.)

To plot the evaporator performance

curve it is only necessary to obtain gross

evaporator capacities for the given

entering air conditions and cfm at two

different saturated suction temperatures.

The Trane Refrigeration Coil Computer

Selection Program can be used to

conveniently provide the necessary

evaporator capacity values at the

selected suction temperatures.

RAUC/EVP Selection

Procedure

Preselected RAUC/EVP capacities are

provided on pages 12 and 13. To select

for other RAUC/EVP combinations or

conditions, four quantities must be

known. They are:

a.

Entering (EWT) or leaving (L WT) water

temperature.

b.

Net cooling load (T).

c.

Water temperature drop (dt).

d.

Waterflow rate in g allons per minute

(gpm). Knowing any two of the last three

variables (T, dt, and gpm) will determine

the third since

T = (Gpm x dt)/24.

Standard Selection Procedur e

1.

Determine: EWT, T, dt, gpm.

2.

Select an evaporator (EBP) and split

condensing unit (RAUC) to mix -matc h.

3.

Enter Charts PD-18, PD-20, and PD-21 to

find ITD/dt.

4.

From Step 3 calculate the saturated

suction temperature (SST) of the chiller

at the given load using the formula

SST = EWT - [(ITD/dt) x dt].

5.

Enter the appropriate RAUC capacity

char t on pages 1 4-23 with the result on

SST and given load, T. If this point is

below or on the proper condensing unit

performance curve at the same suction

temperature, the RAUC/EVP

combination will meet the desired load.

If above, try a larger chiller and/or

condensing unit. Repeat Steps 2 through

5 until the most economical mix-matc h

has been achieved.

Example

Given:

Ambient Air = 95°F

Supply Water T emperature = 45°F

Waterflow = 230 Gpm

Water Temperature Drop = 10°F

Step 1:

EWT = L WT + dt = 45°F + 1 0°F =

55°F

Gpm = 230 gpm (given)

dt = 10°F (given)

Step 2:

Choose a nominal RAUC and EVP:

RAUC-D1 0 and 1 00-ton EVP

Step 3:

Gpm/nominal tonnage = 230/100 = 2.30

ITD/dt is read from Chart PD-21 as 1.70,

assuming .0005 fouling factor.

Step 4:

SST =

EWT - [(ITD/dt) x dt] =

[55 - (1 .70 x 10)] = 38.0°F = SST

Enter Chart PD-14 at 38.0°F SST and 95

ambient air. The condensing unit will

produce 1182 MBh at 38.0°F SST,

therefore the 100-ton EVP/RAUC-D1 0 is

the proper selection.

Alternative Selection Pr ocedur e

Given: The same information as in the

standard selection procedure plus a

predetermined condensing unit.

Enter the specified RAUC condensing

unit performance curve with the

appropriate cooling load T, to determine

the minimum required suction

temperature.

Enter Chart PD-14 with ITD/dt (EWTsaturated suction temperature/dt) to

determine a gpm/nominal tonnage.

Since the gpm is known, the smallest

nominal size EVP can therefore be

calculated.

Example:

Given:

Ambient Air = 95°F

Condensing Unit - RAUC-C80

Supply Water T emperature - 45°F

dt = 10°F

T = 80.0 Tons

Step 1:

EWT = L WT + dt = 45°F + 1 0°F =

55°F

dt = 10°F

T = 80.0 Tons (960 MBh)

Gpm = 152

Step 2:

Enter Chart PD-13 at 95°F and 80.0 tons

to read the saturated suction

temperature (SST) as 39.7.

Step 3:

Enter Chart PD-21 at an ITD/dt = (EWT SST)/dt = (55 - 39.7)/1 0 = 1.53

Then read the maximum gpm/nominal

tons as 1 .87 (assume .0005 fouling

factor). Therefore since 1.87 = Gpm/

Nominal T on = 152/1.87 = 81.4 T ons. An

80-ton EVP is the optimum selection.

7SS-PRC005-EN

Page 8

Model

Number

20 - 60 Ton

Description

Air-Cooled Condensing Units

20 TO 60-T ON AIR-COOLED CONDENSING UNITS

R A U C C20 E B A 1 0 A 0 0 0 0 0 0 0 0

1 2 3 4 5,6,7 8 9 10 1 1 12 13 14 15 16 17 18 1 9 20 21

DIGIT 1 — UNIT TYPE

R = Condensing Unit

DIGIT 2 — CONDENSER

A = Air Cooled

DIGIT 3 — AIRFLOW

U = Upflow

DIGIT 4 — DEVELOPMENT SEQUENCE

C = Third

DIGITS 5,6,7 — NOMINAL CAP ACIT Y

C20 = 20 Tons

C25 = 25 Tons

C30 = 30 Tons

C40 = 40 Tons

C50 = 50 Tons

C60 = 60 Tons

Remote Chillers

20 TO 60-TON REMOTE CHILLERS

EVP B C20 A 1 *

1,2,3 4 5,6,7 8 9 1 0

DIGIT 1,2,3 — UNIT TYPE

EVP = Evaporative Liquid Chiller

DIGIT 4 — DEVELOPMENT SEQUENCE

(Factory Assigned)

A = First

B = Second

Etc.

Definition of Abbr eviations Used in This Catalog

AL — Aluminum

ASTM — American Society of Testing and Materials

CFM — Cubic Feet Per Minute

Conn. — Connection

CSA — Canadian Standards Association

CU — Copper

DIA. — Diameter

dt — T emperature Dif ference

EER — Energy Efficiency Ratio (Btu/W at t-Hour)

1. The service digit for each model number contains 21 digits; all 21 digits must be referenced.

1

DIGIT 8 — VOL TAGE AND START

CHARACTERISTICS

E = 200/60/3 XL

D = 415/50/3 XL

F = 230/60/3 XL

4 = 460/60/3 XL

5 = 575/60/3 XL

9 = 380/50/3 XL

DIGIT 9 — SY STEM CONTROL

B = No System Control

C = Constant Volume Control

E = Supply Air V A V Control

P = EVP Control

DIGIT 10 — DESIGN SEQUENCE

(Factory Assigned)

A = First

B = Second

Etc.

DIGITS 5,6,7 — NOMINAL CAP ACIT Y

C20 = 20 Tons

C25 = 25 Tons

C30 = 30 Tons

C40 = 40 Tons

C50 = 50 Tons

C60 = 60 Tons

EWT — Entering Water (Solution) T emperature

(F) — Units of Temperature in Degrees F ahrenheit

GPM — Gallons Per Minute

ID — Inside Diameter

(INT) — Internal

IPLV — Integrated Part Load Value

ITD — Initial Temperature Dif ference

k — Thermal Conductivity

KO — Knock Out

DIGIT 1 1 — AMBIENT CONTROL

0 = Standard

1 = 0°F (Low Ambient Dampers)

DIGIT 12 — AGENC Y APPROVAL

0 = None

3 = UL/CSA (not available for 50 Hz)

DIGIT 13-21 — MISCELLANEOUS

A = Unit Disconnect Switch

B = Hot Gas Bypass

D = Suction Service V alve

F = Pressure Gauges

G = Return Air S ensor

H = Copper Fins

T = Flow Switch (EVP Control Option

Only)

1 = Spring Isolators

2 = Rubber Isolators

4 = 5-Y ear Compressor Warranty

9 = Pac ked Stoc k Designator

DIGIT 8 — NUMBER OF CIRCUITS

A = Single (20-30 Ton Units)

D = Dual (40-60 Ton Units)

DIGIT 9 — TUBE MATERIAL

1 = Copper

DIGIT 10 — DESIGN SEQUENCE

(Factory Assigned)

A = First

B = Second

Etc.

SS-PRC005-EN8

Page 9

Model

Number

80 - 120 Ton

Description

Air-Cooled Condensing Units

80 TO 120-TON AIR-COOLED CONDENSING UNIT

R A U C C80 4 B A 0 0 2 B 0 0 0 0 0

1 2 3 4 5,6,7 8 9 10 11 12 13 14 15 16 17 18 19

DIGIT 1 — UNIT TYPE

R = Remote Condensing Unit

DIGIT 2 — CONDENSER

A = Air-Cooled

DIGIT 3 — AIRFL OW

U = Upflow

DIGIT 4 — DEVELOPMENT SEQUENCE

C = Third

DIGITS 5,6,7 — NOMINAL CAP ACIT Y

C80 = 80 Tons

D10 = 1 00 T ons

D12 = 120 T ons

1

DIGIT 8 — VOLTAGE AND S TART

CHARACTERISTICS

E = 200/60/3 XL

D = 415/50/3 XL

F = 230/60/3 XL

4 = 460/60/3 XL

5 = 575/60/3 XL

9 = 380/50/3 XL

DIGIT 9 — SY STEM CONTR OL

B = No System Control

E = Supply Air V A V Control

P = EVP Control

DIGIT 10 — DESIGN SEQUENCE

(Factory Assigned)

A = First

B = Second

Etc.

DIGIT 1 1 — AMBIENT CONTROL

0 = Standard

1 = 0°F (Low Ambient Dampers)

DIGIT 12 — AGENC Y APPROVAL

0 = None

3 = UL/CSA (not available for 50 Hz)

DIGIT 13 — NUMBER OF CIRCUITS

2 = Dual (All 80-120 T on)

DIGIT 14-19 — MISCELLANEOUS

B = Hot Gas Bypass Valve

D = Suction Service V alve

F = Pressure Gauges

H = Copper Fins

1 = Spring Isolators

3 = Flow Switch (EVP Control Option

Only)

Remote Chillers

80 TO 120-TON REMOTE CHILLERS

EVP B C80 D 1 A

1,2,3 4 5,6,7 8 9 10

DIGIT 1,2,3 — UNIT TYPE

EVP = Evaporator Liquid Chiller

DIGIT 4 — DEVELOPMENT SEQUENCE

(Factory Assigned)

A = First

B = Second

Etc.

Definition of Abbreviations Used in This Catalog

KW – Kilowatt (Unit of Power)

lbs. – Pounds (Unit of W eight)

Loc. – Location

LRA –Loc ked Rotor Amps

L WT – Leaving Water (Solution) Temperature

(MBH) – 1 x 10

MTG. – Mounting

NPS – Nominal Pipe Size

1. The service digit for each model number contains 19 digits; all 19 digits must be referenced.

3

Btuh

DIGITS 5,6,7 — NOMINAL CAP A CITY

C80 = 80 Tons

D10 = 1 00Tons

D12 = 120 T ons

DIGIT 8 — NUMBER OF CIRCUITS

D = Dual (80-120 T on Units)

DIGIT 9 — TUBE MATERIAL

1 = Copper

DIGIT 10 — DESIGN SEQUENCE

(Factory Assigned)

A = First

B = Second

Etc.

OD – Outside Diameter

PD – Pressure Drop (Units are Feet of Water)

RLA – Rated Load Amps

SST – Saturated Suction Temperature

UL – Underwriters Laboratories Inc.

VA V – Variable Air Volume

W/ – With

W/O – Without

XL – Across-the-Line-Star t

9SS-PRC005-EN

Page 10

General Data

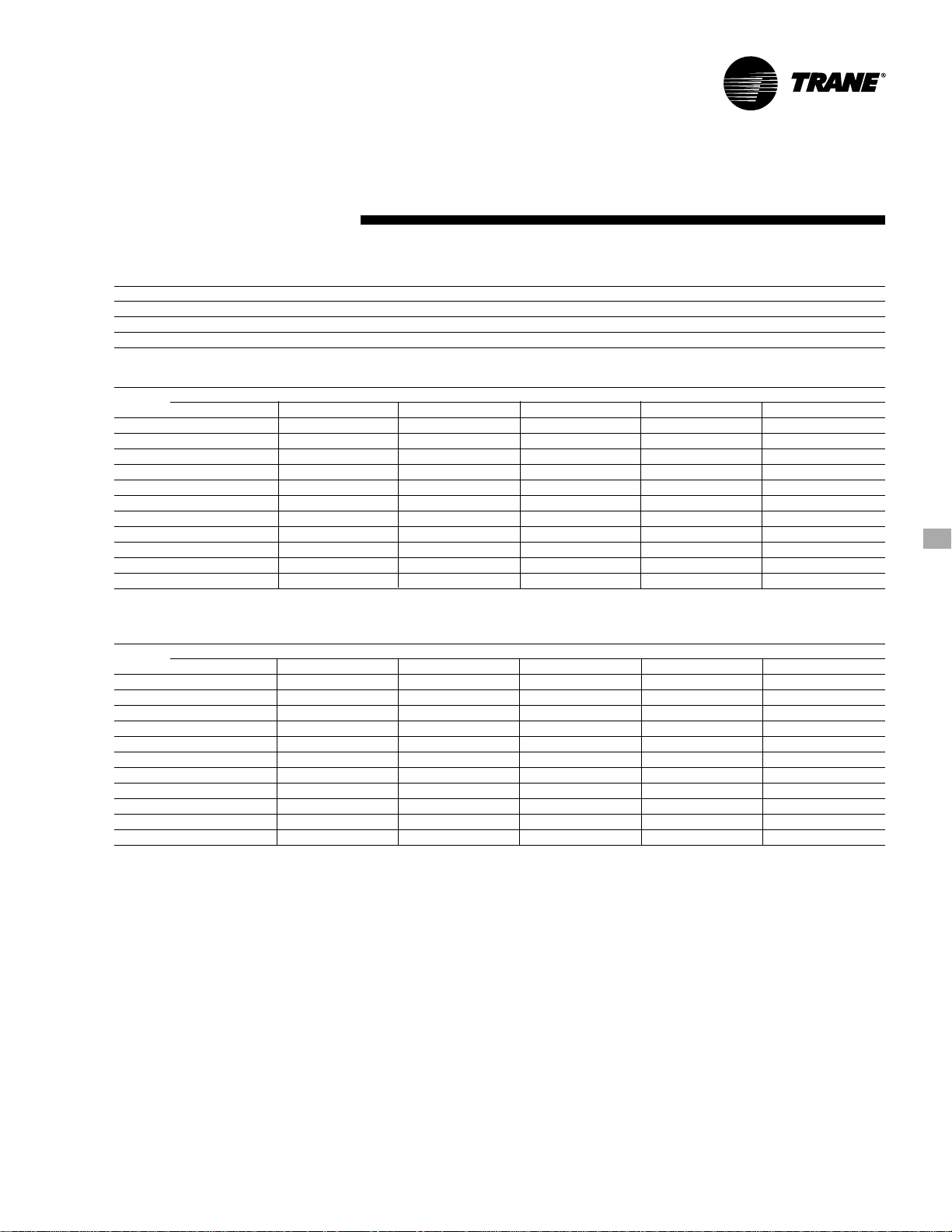

Table GD-1 — General Data — 20-120 Ton Condensing Units

Nominal Tonnage 20 25 30 40 50 60 80 100 120

Model Number RAUC-C20 RAUC-C25 RAUC-C30 RAUC-C40 RAUC-C50 RAUC-C60 RAUC-C80 RAUC-D10 RAUC-D12

Compressor Data

Type Scroll Scroll Scroll Scroll Scroll Scroll Scroll Scroll Scroll

Manifolded Sets

Circuit #1 10T + 10T 10T + 15T 15T + 15T 10T + 10T 10T + 15T 15T + 15T 10T + 15T + 15T 10T + 10T 15T + 15T

Circuit # 2 N/A N/A N/A 10T + 10T 10T + 15T 15T + 15T 10T + 15T + 15T 10T + 10T 15T +15T

Unit Capacity Steps (%) 100-50 100-40 100-50 100-75-50-25 100-80-60-30 100-75-50-25

No Control & *19-38-50- *20-40-55 *25-50-63

VAV Option 63-81-100 70-85-100 75-88-100

EVP Option *19-38-50 *20-40-55 *25-50-63

Condenser Fan Data

Quantity/Fan Dia./Type 2/26”/Prop. 3/26”/Prop. 3/26”/Prop. 4/26”/Prop. 6/26”/Prop. 6/26”/Prop. 8/26”/Prop. 12/26”/Prop. 12/26”/Prop.

Fan Drive Type Direct Direct Direct Direct Direct Direct Direct Direct Direct

No. of Motors/Hp Each 2/1.0 3/1.0 3/1.0 4/1.0 6/1.0 6/1.0 8/1.0 12/1.0 12/1.0

Nominal Total Cfm 1400 0 18300 20900 28200 35600 4080 0 49600 6680 0 76000

Condenser Coil Data

Number of Coils/Size 1/71x71 1/71x71 1/45x71 2/65x70 2/51x96 2/66x96 4/65x70 4/51x96 4/66x96

(Inches) 1/49x71

Face Area (Sq. Ft.) 35.0 35.0 46.1 63.2 67.1 88.0 126.4 134.2 176.0

Rows/Fins Per Ft. 3/144 3/144 3/144 3/144 3/144 3/144 3/144 3/144 3/144

Condenser Storage 76 76 96 136 142 184 272 284 368

Capacity (Lbs.) (2)

Refrigerant Data (3)

No. Refrigerant Circuits1 11222 222

Refrigerant Type R-22 R-22 R-22 R-22 R-22 R-22 R-22 R-22 R-22

Refrigerant Operating 28 31 40 58 62 80 116 124 160

Charge (Lbs) (1) (4) See note 4 See note 4 See note 4 See note 4 See note 4 See note 4 See note 4 See note 4 See note 4

Minimum Outdoor Air Temperature for Mechanical Cooling

Standard Ambient 40-115 40-115 40-115 40-115 40-115 40-115 40-115 40-115 40-115

Operating Range (F)

Low Ambient Option (F)0 00000 000

Notes:

1. Operating charge is approxmate for condensing unit only, and does not include charge for low side or interconnecting lines.

2. Condenser storage capacity is given at conditions of 95°F outdoor temperature, and 95% full.

3. Refer to Refrigerant Piping under Application Considerations on Page 6.

4. Condensing units are shipped with a nitrogen holding charge only.

Table GD-3 — EER Data — Condensing Unit Only (1)

Nominal Model Capacity Compressor KW Control Condensing Unit

Tonnage Number (MBH) KW Each/Total KW Total KW EER IPLV

20 RAUC-C20 239 19.8 0.9/1.8 0.25 21.9 10.9 15.5

25 RAUC-C25 314 25.3 0.9/2.7 0.25 28.3 11.1 15.2

30 RAUC-C30 376 30.4 0.9/2.7 0.25 33.3 11.3 16.2

40 RAUC-C40 507 40.3 0.9/3.6 0.40 44.3 11.5 16.4

50 RAUC-C50 626 51.2 0.9/5.4 0.40 57.0 11.0 15.7

60 RAUC-C60 748 61.2 0.9/5.4 0.40 67.0 11.2 16.2

80 RAUC-C80 1045 87.9 0.9/7.2 0.50 95.6 10.9 16.1

100 RAUC-D10 1300 110.9 0.9/10.8 0.50 122.1 10.7 15.3

120 RAUC-D12 1560 131.5 0.9/10.8 0.50 142.6 10.9 16.2

Notes:

1. Condensing unit only ratings are in accordance with ARI standard 365. Full load ratings are at 95°F entering air temperature, and refrigerant conditions entering the

condensing unit of 45°F saturated and 60°F actual temperature. Part load ratings are at 80°F entering air temperature and refrigerant conditions entering the condensing

unit of 50°F saturated suction and 65°F actual temperature.

Net Total Unit Condenser Fan

Table GD-2 — Evaporator Chillers — 20-120 Tons

Nominal Tonnage 20 25 30 40 50 60 80 100 120

No. Of Circuits 111222222

Volume Shell (Gal) (1) 11.7 10.7 16.3 13.8 21.0 18.5 43.1 35.0 47.9

Tube Pull (In.) (2) 73 73 74 74 96 96 95 95 95

Refrigerant Operating Charge 8 10 12 16 20 24 26.8 33.4 40.4

Notes:

1. Shell volume is for waterside only.

2. Tube pull given is length of the evaporator.

3. Operating charge is approximate and for the evaporator chiller only.

63-81-100 70-85-100 75-88-100

+15T +15T +15T +15T

+15T +15T +15T +15T

SS-PRC005-EN10

Page 11

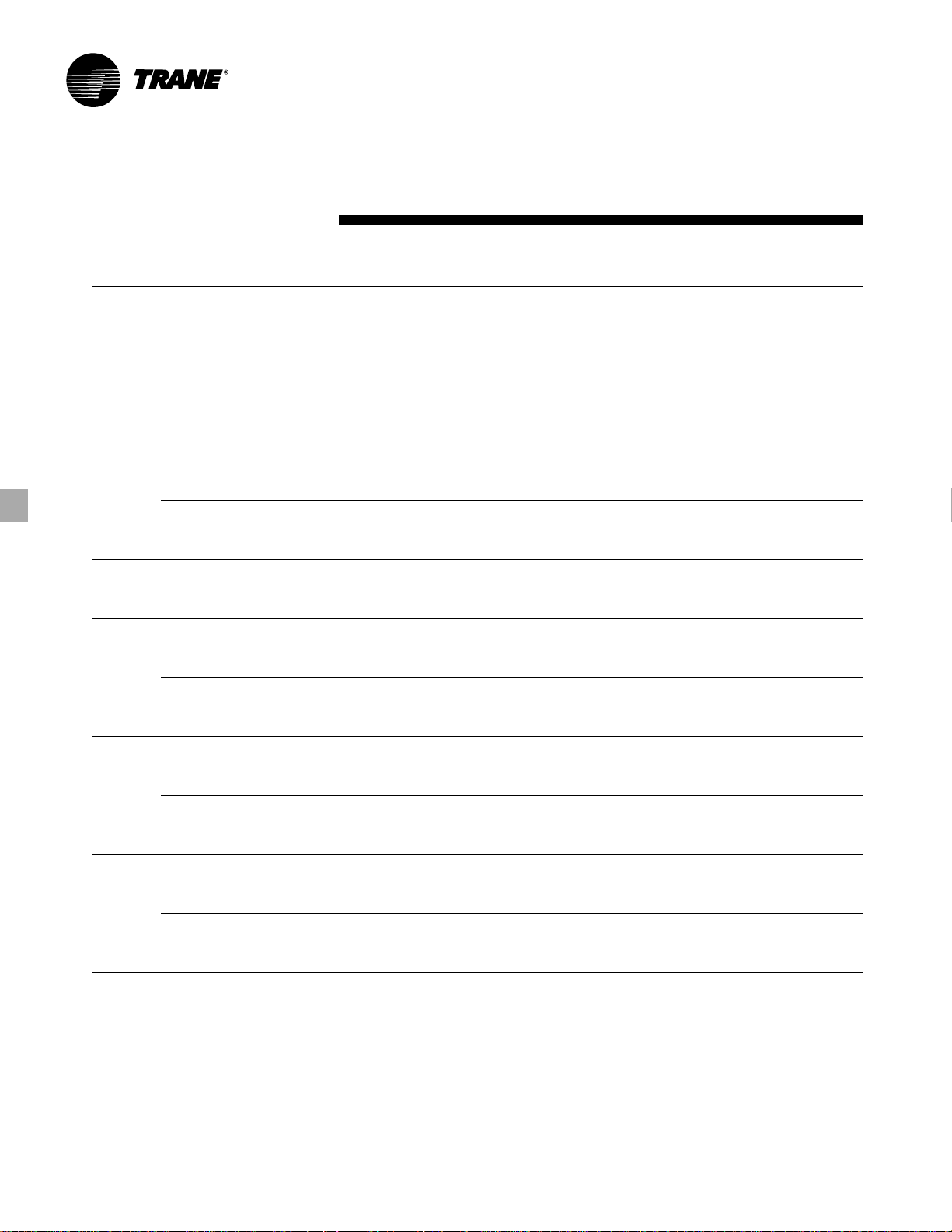

P erformance Adjustment Factors

Table P AF -1 — Altitude Corr ection Multiplier f or Capacity

Altitude (Ft.) 2,000 4,000 6,000 8,000 10,000

Condensing Unit Only 0.982 0.960 0.933 0.902 0.866

Condensing Unit / Air Handling Unit Combination 0.983 0.963 0.939 0.911 0.881

Condensing Unit With Evap. 0.986 0.968 0.947 0.921 0.891

Table P AF -2 — Glycol Adjustment Factor for 20-60 Ton Split Condensing Units with the Remote Chiller (EVP) Option

Leaving 0% 10% 20% 30% 40% 50%

Solution Freezing Point = 32°F Freezing Point = 24°F Freezing Point = 1 5°F Freezing Point = 5°F Freezing P oint = -12°F Freezing Point = -33°F

T emp. CAP GPM KW CAP GPM KW CAP GPM KW CAP GPM KW CAP GPM KW CAP GPM KW

10°F — — — — — — .833 .875 .952 .822 .912 .952 .811 .954 .945 .800 1.005 .945

15°F — — — — — — .850 .904 .959 .850 .937 .959 .840 .983 .959 .830 1.029 .953

20°F — — — — — — .882 .928 .971 .873 .962 .965 .864 1.008 .965 .855 1.057 .960

25°F — — — .909 .924 .977 .901 .952 .977 .901 .990 .972 .893 1.031 .972 .876 1.083 .972

30°F — — — .925 .947 .983 .925 .972 .983 .917 1.009 .978 .910 1.053 .978 .895 1.1 01 .978

35°F — — — .945 .963 .989 .938 .989 .989 .931 1.023 .984 .924 1.066 .984 .917 1.115 .978

40°F 1.000 1.000 1.000 .956 .974 .984 .949 1.000 .984 .943 1.034 .984 .937 1.077 .984 .930 1 .124 .979

45°F 1.000 1.000 1.000 .965 .981 .990 .959 1.005 .990 .953 1.039 .985 .947 1.080 .985 .936 1 .1 29 .979

50°F 1.000 1.000 1.000 .962 .982 .990 .957 1.007 .990 .951 1.038 .990 .946 1.079 .985 .935 1 .1 24 .985

Table P AF -3 — Glycol Adjustment Factor for 80-120 Ton Split Condensing Units with the Remote Chiller (EVP) Option

Leaving 0% 10% 20% 30% 40% 50%

Solution Freezing Point = 32°F Freezing Point = 24°F Freezing Point = 15°F Freezing Point = 5°F Freezing P oint = -12°F Freezing Point = -33°F

T emp. CAP GPM KW CAP GPM KW CAP GPM KW CAP GPM KW CAP GPM KW CAP GPM KW

10°F — — — — — — .931 .980 .959 .924 1 .023 .954 .916 1.075 .949 .907 1.131 .944

15°F — — — — — — .943 .991 .967 .936 1 .035 .962 .928 1.085 .957 .919 1.140 .952

20°F — — — .998 1.010 1.000 .955 1.003 .973 .948 1.044 .973 .941 1.094 .969 .933 1 .1 49 .964

25°F — — — .998 1.01 4 1.000 .967 1 .016 .979 .961 1.056 .979 .954 1.106 .975 .946 1.160 .970

30°F — — — .998 1.015 .996 .978 1.030 .984 .973 1.068 .984 .966 1.117 .980 .958 1 .173 .976

35°F — — — .998 1.016 1.000 .987 1.039 .992 .982 1.078 .992 .975 1.124 .989 .968 1 .1 78 .981

40°F 1.000 1.000 1.000 .998 1 .0 1 6 1.000 .994 1.042 .996 .988 1.081 .993 .982 1.127 .989 .974 1.178 .986

45°F 1.000 1.000 1.000 .997 1 .0 1 6 .997 .996 1.045 .997 .991 1.083 .993 .985 1.126 .990 .977 1 .1 78 .986

50°F 1.000 1.000 1.000 .997 1 .0 1 6 1.000 .997 1.046 1.000 .992 1.082 .997 .985 1.124 .990 .978 1.175 .987

Percent of Ethylene Glycol by Weight

Percent of Ethylene Glycol by Weight

11SS-PRC005-EN

Page 12

P erformance Data

20 - 60 Tons

Table PD-1 — Gross Syst em Capacity D ata — 20-60 T on Condensing Unit with Ev aporator Chiller

Condensing Leaving Outside Ambient Temperature Entering Condenser (F)

Unit-Nominal Chilled 85 95 105 115

Tons Model Water T emp. Tons Kw T ons Kw Tons Kw Tons Kw

RAUC C20 40 16.3 17.1 15.5 18.8 14.6 20.9 13.7 23.2

With 42 16.8 17.2 16.0 19.0 15.1 21.1 14.2 23.4

20 T on 45 17 .6 17 .4 16.8 19.2 15.9 21.3 14.9 23.7

20 50 19.0 17.8 18.1 19.6 17.2 21.7 16.2 24.1

25 50 24.6 22.8 23.4 25.2 22.2 27.9 20.9 31 .0

30 30 T on 45 27 .5 26.7 26.2 29.6 24.8 32.9 23.4 36.5

40 50 40.1 35.4 38.2 39.2 36.2 43.4 34.2 48.4

50 50 49.1 46.0 46.7 50.8 44.3 56.4 41.7 62.6

60 50 58.5 54.8 55.7 60.8 52.8 67.4 49.8 75.0

Chiller 48 18.5 17.6 17.6 19.5 16.7 21.6 15.7 24.0

RAUC C20 40 16.8 17.2 16.0 19.0 15.1 21.0 14.1 23.4

With 42 17.4 17.4 16.5 19.2 15.6 21.2 14.6 23.6

25 T on 45 18.2 17 .6 17 .3 19.4 16.4 21 .5 15.4 23.8

Chiller 48 19.1 17.8 18.2 19.6 17 .2 21.8 16.2 24.1

RAUC C25 40 21.0 21.8 20.0 24.1 18.9 26.8 17.8 29.8

With 42 21.7 22.0 20.7 24.4 19.5 27.0 18.4 30.1

25 T on 45 22.8 22.3 21.7 24.7 20.5 27 .4 1 9.3 30.4

Chiller 48 23.9 22.6 22.7 25.0 21.5 27.7 20.3 30.8

RAUC C25 40 21.9 22.1 20.8 24.4 19.7 27.1 18.4 30.1

With 42 22.7 22.3 21.5 24.6 20.3 27.3 19.1 30.3

30 T on 45 23.8 22.6 22.6 24.9 21 .4 27 .6 20.1 30.7

Chiller 48 24.9 22.9 23.7 25.3 22.4 28.0 21.1 31.1

RAUC C30 40 25.4 26.1 24.2 28.9 22.9 32.2 21.5 35.8

With 42 26.3 26.3 25.0 29.2 23.6 32.5 22.3 36.1

Chiller 48 28.9 27.1 27.5 30.0 26.0 33.3 24.5 37.0

RAUC C40 40 34.3 34.2 32.6 37.6 30.8 41.8 28.9 46.4

With 42 35.4 34.4 33.7 38.0 31.8 42.2 29.9 46.8

40 T on 45 37 .1 34.8 35.3 38.4 33.5 42.6 31 .5 47 .4

Chiller 48 38.9 35.2 37.0 39.0 35.1 43.2 33.1 48.0

RAUC C40 40 35.4 34.4 33.6 38.0 31.8 42.0 29.8 46.8

With 42 36.6 34.6 34.8 38.2 32.8 42.4 30.9 47.2

50 T on 45 38.4 35.0 36.5 38.8 33.5 43.0 32.5 47 .8

Chiller 48 40.7 35.6 38.3 39.2 36.2 43.4 34.1 48.4

RAUC C50 40 42.1 44.0 40.0 48.8 37.8 54.0 35.5 60.2

With 42 43.4 44.4 41.3 49.2 39.0 54.6 36.7 60.6

50 T on 45 45.5 45.0 43.3 49.8 40.9 55.2 38.5 61 .4

Chiller 48 47.6 45.6 45.3 50.4 42.9 55.8 40.4 62.0

RAUC C50 40 43.3 44.4 41.1 49.0 38.8 54.4 36.4 60.6

With 42 44.7 44.8 42.4 49.6 40.1 54.8 37.6 61.0

60 T on 45 46.9 45.4 44.5 50.2 42.1 55.6 39.6 61 .8

Chiller 48 49.1 46.0 46.7 50.8 44.2 56.4 41.5 62.4

RAUC C60 40 50.0 52.2 47.6 58.0 45.0 64.6 42.4 71.8

With 42 51.7 52.8 49.2 58.6 46.5 65.2 43.8 72.4

60 T on 45 54.2 53.4 51.6 59.4 48.8 66.0 46.0 73.4

Chiller 48 56.7 54.2 54.0 60.2 51.2 67.0 48.3 74.4

RAUC C60 40 55.1 53.8 52.2 59.6 49.2 66.2 46.1 73.4

With 42 56.9 54.2 54.0 60.2 50.9 66.8 47.8 74.2

80 T on 45 59.8 55.2 56.7 61 .0 53.5 67 .8 50.3 75.2

Chiller 48 62.7 56.0 59.5 62.0 56.2 68.8 52.8 76.2

50 1 9.7 17.9 18.8 19.8 17.8 21 .9 16.7 24.3

50 25.7 23.1 24.4 25.5 23.1 28.2 21.8 31.3

50 29.8 27.3 28.3 30.3 26.9 33.6 25.3 37.3

50 41 .5 35.8 39.5 39.6 37.4 43.8 35.2 48.6

50 50.6 46.4 48.1 51.2 45.6 56.8 42.9 63.0

50 64.7 56.6 61.4 62.6 58.0 69.4 54.6 77.0

SS-PRC005-EN12

Page 13

P erformance

Data

80 - 120 Tons

Table PD-2 — Gross System Capacity D ata — 80-120 T on Condensing Unit with Ev aporator Chiller

Condensing Leaving Outside Ambient Temperature Entering Condenser (F)

Unit-Nominal Chilled 85 95 105 115

T ons Model Water T emp. T ons Kw Tons Kw Tons Kw T ons Kw

RAUC C80 40 65.1 73.9 61.8 81.9 58.3 90.9 54.6 100.9

With 42 67.5 74.7 64.1 82.7 60.5 91.8 56.7 101.8

60 T on 45 71.3 75.8 67 .7 84.0 63.9 93.1 59.8 103.2

Chiller 48 75.1 77.0 71.3 85.2 67.3 94.4 63.1 104.6

RAUC C80 40 70.5 75.6 66.8 83.7 62.9 92.7 58.8 102.8

80 80 T on 45 77 .1 77 .6 73.1 85.8 68.8 95.0 64.4 105.2

100 100 T on 45 96.9 99.7 91.8 1 10.0 86.5 121.6 80.9 134.3

120 50 122.2 120.7 115.9 133.5 109.2 147.8 102.1 163.4

With 42 73.1 76.4 69.3 84.5 65.3 93.6 61.0 103.7

Chiller 48 81.2 78.9 77.0 87.2 72.5 96.4 67.9 106.6

RAUC C80 40 71.4 75.9 67.7 84.0 63.7 93.1 59.5 103.1

With 42 74.1 76.7 70.2 84.9 66.1 94.0 61.8 104.0

100 T on 45 78.2 77 .9 74.1 86.2 69.7 95.4 65.2 105.5

Chiller 48 82.4 79.2 78.0 87.5 73.5 96.8 68.7 107.0

RAUC D10 40 87.1 96.4 82.6 106.6 77.8 118.0 72.7 130.6

With 42 90.3 97.5 85.6 107.7 80.6 11 9.1 75.4 131.8

80 T on 45 95.2 99.1 90.3 109.4 85.0 121.0 79.6 133.7

Chiller 48 100.2 100.8 95.0 111.2 89.6 122.8 83.8 135.6

RAUC D10 40 88.6 96.9 83.9 107.1 79.0 119.7 73.9 131.1

With 42 91.9 98.0 87.1 108.2 73.9 118.5 76.6 132.4

Chiller 48 102.1 101.4 96.7 111.8 91.1 123.5 85.2 136.3

RAUC D10 40 89.4 97.2 84.7 107.4 79.7 118.8 74.5 131.4

With 42 92.7 98.3 87.9 108.5 82.7 120.0 77.3 132.7

120 T on 45 97 .9 100.0 92.7 11 0.4 87 .3 121.9 81 .6 134.6

Chiller 48 103.1 101.8 97.7 112.2 92.0 123.8 86.0 136.6

RAUC D12 40 102.8 114.5 97.4 126.9 91.7 140.8 85.7 156.1

With 42 106.5 115.7 101.0 128.2 95.1 142.1 88.9 157.5

100 T on 45 112.3 11 7 .6 106.4 130.2 100.3 144.2 93.8 159.7

Chiller 48 118.2 119.4 112.0 132.2 105.6 146.3 98.8 161.9

RAUC D12 40 104.1 114.9 98.6 127.3 92.9 141.2 86.8 156.6

With 42 108.0 116.2 102.3 128.7 96.3 142.6 90.0 158.0

120 T on 45 113.9 118.1 107 .9 130.7 101 .6 144.7 95.0 160.3

Chiller 48 120.0 120.0 113.7 132.7 107.1 146.9 100.1 162.5

50 77.7 77.8 73.8 86.1 69.6 95.3 65.3 105.6

50 84.0 79.7 79.6 88.1 75.0 97.4 70.2 107.6

50 85.2 80.1 80.7 88.5 76.0 97.8 71.1 108.0

50 103.7 10 1.9 98.3 1 12.4 92.6 124.1 86.7 136.9

50 105.6 102.6 100.0 11 3.1 94.3 124.7 88.2 137.6

50 106.7 102.9 101 .1 113.5 95.2 125.1 89.1 138.0

50 124.1 121.3 1 1 7.6 134.1 11 0.8 148.4 103.6 164.1

Table PD-3 – Evaporator Chiller Water Pressur e Drop

20 Ton 25 Ton 30 Ton 40 Ton 50 Ton

GPM PD GPM PD GPM PD GPM PD GPM PD

25.0 3.8 30.0 3.7 35.0 2.1 50.0 4.1 60.0 4.0

30.0 5.4 35.0 5.0 40.0 2.7 60.0 5.8 70.0 5.4

35.0 7 .2 40.0 6.4 45.0 3.4 70.0 7.7 80.0 6.9

40.0 9.2 45.0 7.9 50.0 4.1 80.0 9.9 90.0 8.6

45.0 11.5 50.0 9.6 60.0 5.8 90.0 12.3 100.0 10.4

50.0 14.0 60.0 13.5 70.0 7.7 100.0 15.0 120.0 14.7

60.0 19.6 70.0 18.1 80.0 9.9 120.0 21.1 140.0 19.6

70.0 26.1 80.0 23.2 90.0 12.3 140.0 28.1 160.0 25.1

––––100.015.0––––

60 T on 80 T on 100 T on 120 Ton

GPM PD GPM PD GPM PD GPM PD

80.0 5.6 100.0 4.5 120.0 3.2 140.0 3.2

90.0 7.0 120.0 6.5 140.0 4.3 160.0 4.1

100.0 8.5 140.0 8.7 160.0 5.6 180.0 5.2

120.0 12.0 160.0 11.2 180.0 7.0 200.0 6.3

140.0 15.9 180.0 14.1 200.0 8.5 240.0 9.0

160.0 20.5 200.0 17.2 240.0 12.2 280.0 12.0

180.0 25.5 240.0 24.8 280.0 16.3 320.0 15.8

200.0 31.0 – – 320.0 21.0 360.0 19. 7

– – – – 360.0 26.0 400.0 24.0

Notes:

— All capacites are at 10°F Delta water temp. Kw is

total of all compressors, but does not include

condenser fan, water pump and control power.

— 25’ line loss is included.

GPM = Gallons Per Minute

PD = Pressure Drop (Feet of Water)

13SS-PRC005-EN

Page 14

P erformance

20 & 25 Ton

Data — 60 Hz

Chart PD-1 — 20 Ton Condensing Unit Performance — RAUC-C20 (60 HZ)

Condensing Units

Chart PD-2 — 25 Ton Condensing Unit Performance — RAUC-C25 (60 HZ)

SS-PRC005-EN14

Page 15

P erformance

RA UC-C20 & C25

Data — 50 Hz

Chart PD-3 — 20 Ton Condensing Unit P erfor mance — RA UC-C20 (50 HZ)

Condensing Units

Chart PD-4 — 25 Ton Condensing Unit P erfor mance — RA UC-C25 (50 HZ)

15SS-PRC005-EN

Page 16

P erformance

30 & 40 Ton

Data — 60 Hz

Chart PD-5 — 30 Ton Condensing Unit Performance — RAUC-C30 (60 HZ)

Condensing Units

Chart PD-6— 40 Ton Condensing Unit Performance — RAUC-C40 (60 HZ)

SS-PRC005-EN16

Page 17

P erformance

RA UC-C30 & C40

Data — 50 Hz

Chart PD-7 — 30 Ton Condensing Unit P erfor mance — RA UC-C30 (50 HZ)

Condensing Units

Chart PD-8 — 40 Ton Condensing Unit P erfor mance — RA UC-C40 (50 HZ)

17SS-PRC005-EN

Page 18

P erformance

50 & 60 Ton

Data — 60 Hz

Chart PD-9 — 50 Ton Condensing Unit Performance — RAUC-C50 (60 HZ)

Condensing Units

Chart PD-10— 60 Ton Condensing Unit Performance — RAUC-C60 (60 HZ)

SS-PRC005-EN18

Page 19

P erformance

RA UC-C50 & C60

Data — 50 Hz

Chart PD-1 1 — 50 Ton Condensing Unit Perfor mance — RAUC-C50 (50 HZ)

Condensing Units

Chart PD-12 — 60 Ton Condensing Unit P erformance — RAUC-C60 (50 HZ)

19SS-PRC005-EN

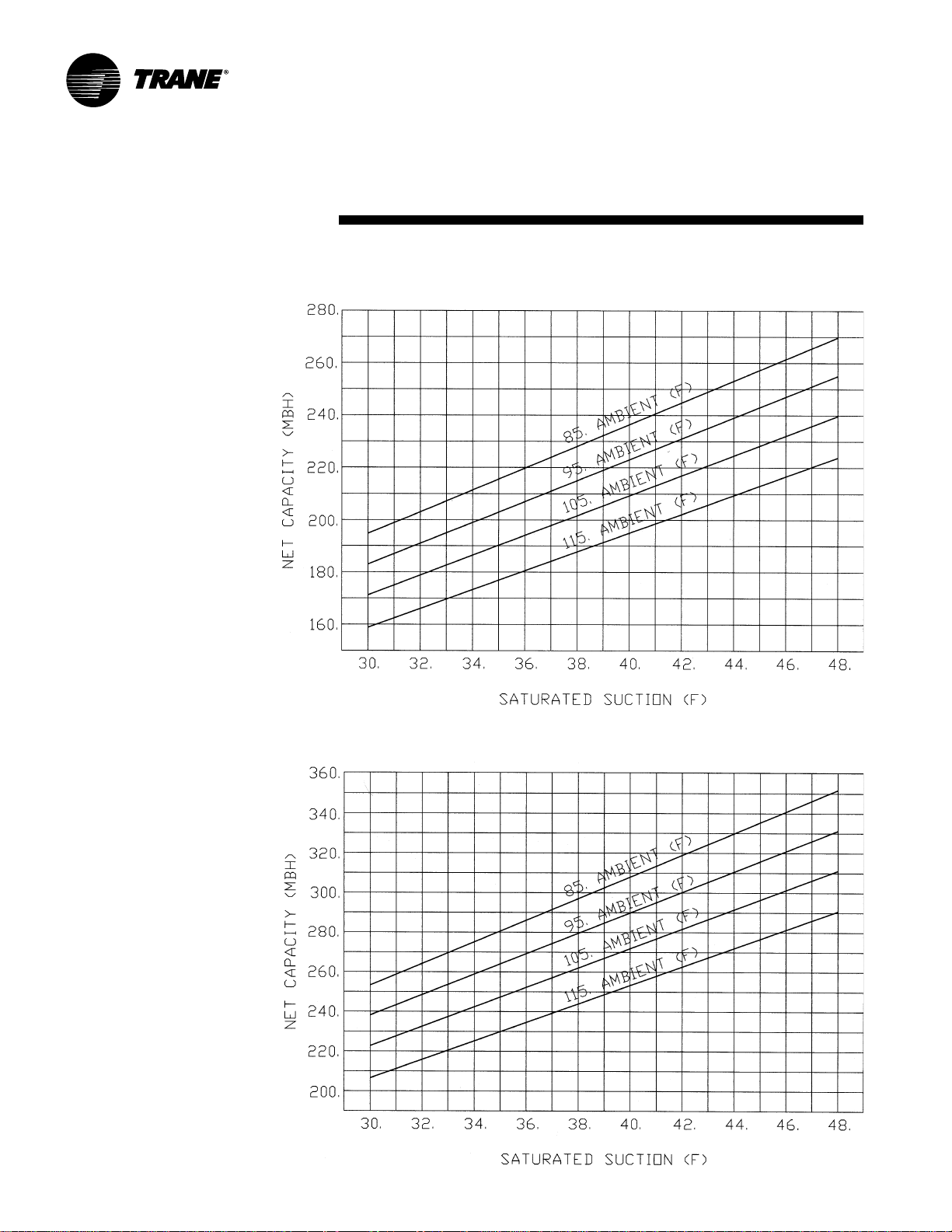

Page 20

P erformance

80 & 1 00 Ton

Data — 60 Hz

Chart PD-13 — 80 Ton Condensing Unit Performance — RAUC-C80 (60 HZ)

Condensing Units

Chart PD-14 — 100 T on Condensing Unit P erfor mance — RA UC-D1 0 (60 HZ)

SS-PRC005-EN20

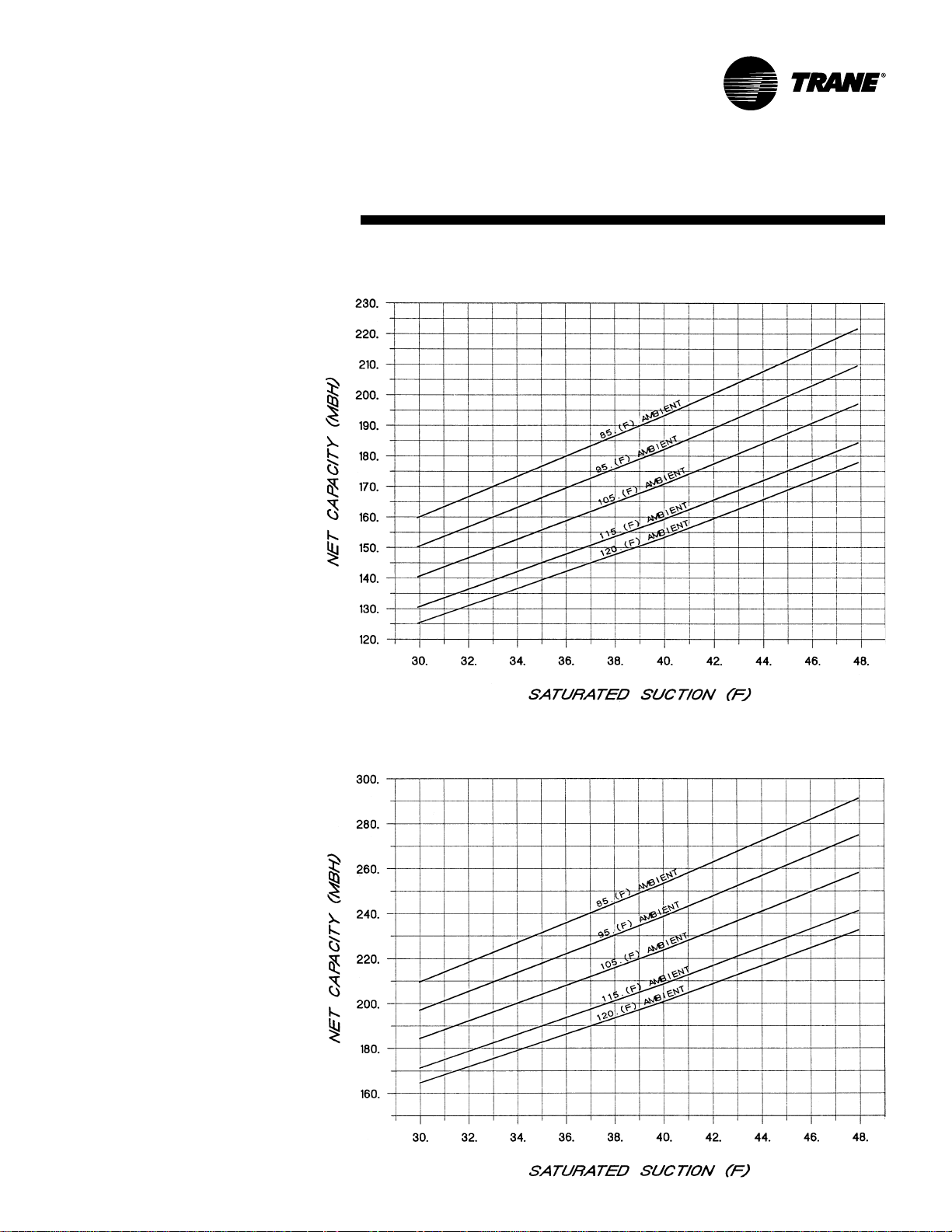

Page 21

P erformance

RA UC-C80 & D1 0

Data — 50 Hz

Chart PD-15 — 80 Ton Condensing Unit P erfor mance — RA UC-C80 (50 HZ)

Condensing Units

Chart PD-16 — 1 00 Ton Condensing Unit P erf or mance — RAUC-D10 (50 HZ)

21SS-PRC005-EN

Page 22

P erformance

120 Ton

Data — 60 Hz

Chart PD-17 — 120 T on Condensing Unit P erfor mance — RA UC-D12 (60 HZ)

Condensing Units

20-60 Ton Evaporator Chiller Option

Chart PD-18 – EVP Perf ormance Curv e – 20 thr ough 40 T ons

SS-PRC005-EN22

Page 23

P erformance

RA UC-D12

Data — 50 Hz

Chart PD-19 — 120 Ton Condensing Unit P erf or mance — RAUC-D12 (50 HZ)

Condensing Units

23SS-PRC005-EN

Page 24

P erformance

20-60 Ton Evaporator

Data — 60 HZ

Chart PD-20 — EVP Perfor mance Curve — 50 and 60 Tons

Chiller Option

80-120 Ton Evaporator Chiller Option

Chart PD-21 — EVP Perfor mance Curve — 80 thr ough 120 Tons

SS-PRC005-EN24

Page 25

Controls 20-60 Tons

Standard Options

20 through 60-Ton Condensing Units

System Control Options

Select one of the four following control

options to meet your application

requirements.

• No System Control pro vides the

compressors wired to a terminal strip

inside the control panel. The temperature

controller must be field provided and

installed. The 20, 25 and 30-ton have two

capacity steps. The 40, 50 and 60-ton

sizes have four steps available.

• Constant V olume Control includes a

W973 controller with two cool, four heat

steps on the 20, 25 and 30-ton sizes. Four

cool, four heat steps are provided on the

40, 50 and 60-ton sizes. The heating

contacts are wired to terminals in the

condensing unit control panel for easy

interface with a field supplied electric

duct heater or gas duct furnace. An

optional return air sensor is available

with this controller which provides the

zone temperature input to the

thermostat, thus generating the loading

demand signal to the Honeywell W973

constant volume controller .

• Supply Air V A V Control provides a

Honeywell W71 00A control system. This

option is for use with shut-off VAV or

other applications requiring control of

supply air temperature. The control

provides a voltage output for interface

with field supplied components to

provide simultaneous economizer

operation. The discharge air sensor

ships with the unit for field mounting.

The standard VAV unit is provided with

reliable coil frost protection in the form

of Trane’s proven and patented

FROST AT™. FROSTA T is used in place

of hot gas bypass.

• EVP Control consists of an interface

panel in the main unit control box and a

remote mounted control box that is

customer installed. The remote mounted

box contains the Honeywell W7100G

controller. This water c hiller controller

has built in fixed-off timers and chiller

freeze protection. No provision for

periodic pumpout or lead-lag is

provided. Multiple chiller control is not

provided. There are two capacity steps

on 20, 25 and 30-ton sizes. Four capacity

steps are provided on the 40, 50 and 60ton sizes.

Low Ambient Control Option

• Standard — Unit start-up and operation

down to approximately 40°F at

minimum compressor load.

• Low Ambient — Factory-installed head

pressure control damper assembly

permits operation down to 0°F by

maintaining proper head pressure. Ten

minute timer is standard for protection

against nuisance trips.

Miscellaneous Options

20 through 60-Ton Condensing Units

Select the miscellaneous options to meet

your project requirements.

• Non-Fused Unit Disconnect Switch– A

non-fused disconnect switch is mounted

in the control box and provides for

interruption of power for servicing the

unit. Lugs are suitable for copper wires

only. No overcur rent or shor t circuit

protection is provided for the unit by this

switch.

• Hot Gas Bypass V alv e — Hot gas

bypass valves are stocked and shipped

with the unit for field installation. When

suction pressure falls below the valve

adjustable set point, the valve modulates

hot gas to the inlet of the evaporator .

(Note: FROST AT is standard on V A V units

and is recommended in place of hot gas

bypass).

25SS-PRC005-EN

Page 26

Controls 80-120 Ton

Standard Options

80 through 120-Ton Condensing Units

System Control Options

Select one of the three following control

options to meet your application

requirements.

• Supply Air V A V includes a multi-step,

demand oriented, microprocessor -based

Honeywell W7100 discharge air

controller. W7100 control is designed for

shut-off VAV systems. A verage disc harge

air temperature is maintained by

modulating an economizer and if

needed, simultaneously sequencing

stages of mechanical cooling. Field

installation of the factory supplied

discharge air sensor is required.

• No System Control option does not

provide any temperature control

components. The temperature control

components are supplied by others and

specifically designed for the unit’s

application. This option includes all

compressor steps wired to a terminal

strip for easy customer connection of

field provided controls. Fixed-on and

off timers are provided for compressor

protection.

• EVP Control consists of an interface

panel in the main unit control box and

a remote mounted control box that is

customer installed. The remote

mounted box contains the Honeywell

W7100G controller. This water c hiller

controller has built in fixed-off timers

and chiller freeze protection. No

provision for periodic pumpout or leadlag is provided. Multiple chiller control

is not provided. There are six capacity

steps on 80-120 ton models.

Low Ambient Control Option

• Standard — Unit start-up and

operation down to approximately 40°F

at minimum compressor load.

• Low Ambient — Factory or fieldinstalled head pressure control damper

assembly permits operation down to

0°F by maintaining proper head

pressure. Ten minute time is standard

for protection against nuisance trips.

Miscellaneous Options

80 through 120-Ton Condensing Units

Select the options to meet project

requirements.

• Hot Gas Bypass V alv e maintains

minimum refrigerant volume through

compressor for proper motor cooling

while holding suction temperature above

the minimum during low load conditions.

When suction pressure falls below the

valve adjustable set point, the valve

modulates hot gas to the inlet of the

evaporator. Connections include ¼-inc h

SAE flare connection to suction line for

external equalizer line and 115-volt

electrical connection for the integral liquid

line solenoid valve. (Note: FROST AT is

standard on V AV units and is

recommended in place of hot gas bypass.)

• Spring Isolators — Vibration isolators

field-installed under unit to reduce

transmission of vibration to building

structure and adjacent areas.

• Pressure Gauges available for suction and

discharge for eac h refrigerant circuit.

Gauges mount adjacent to compressors.

SS-PRC005-EN26

Page 27

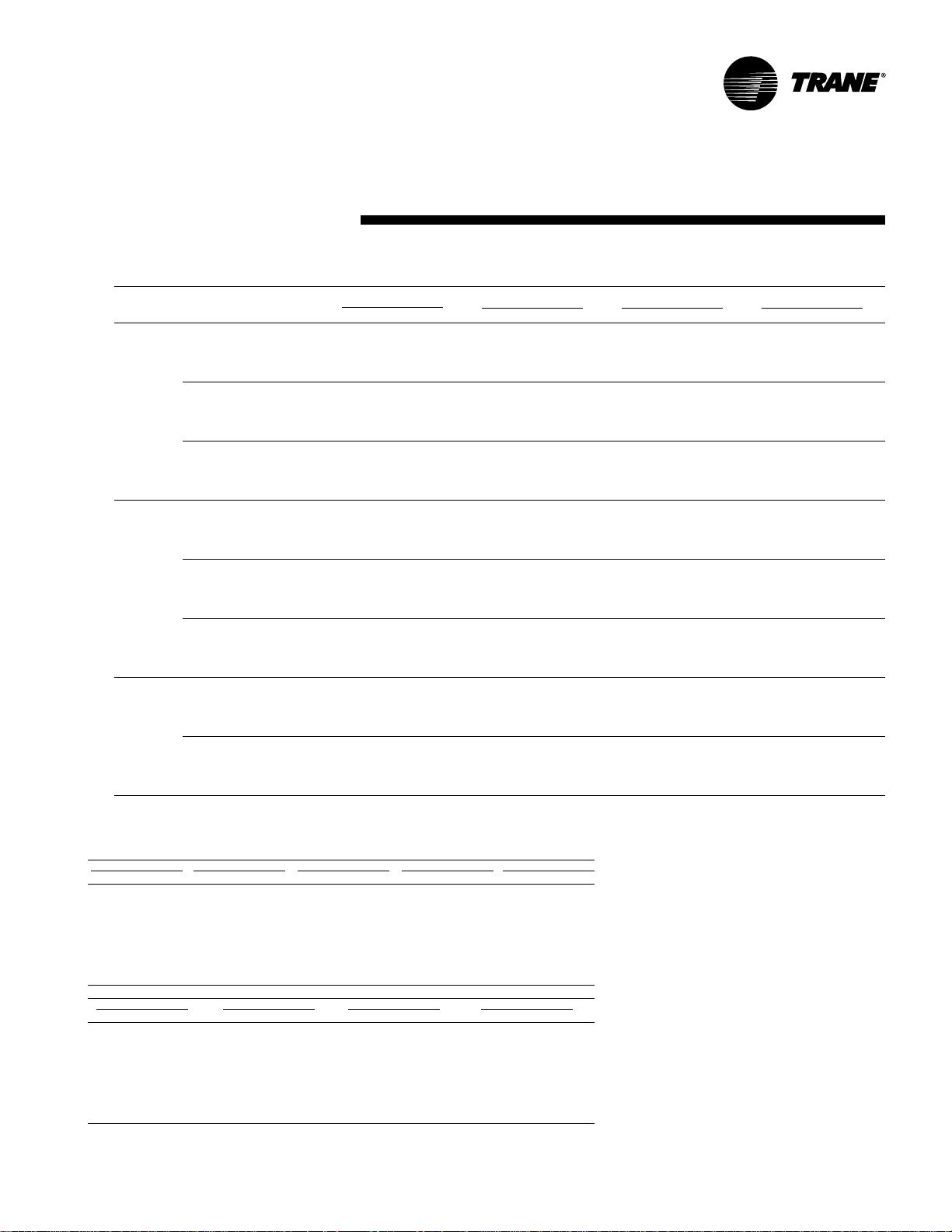

Electrical Data

Table ED-1 — Condensing Units — 60 Hz

Nominal Model V oltage/Start V oltage Circuit Ampacity Protection Device Element Fuse Size Of

T on s Number Characteristics Utilization Range (1), (4) (2), (4) (3), (4) Compressors

20 RAUC-C204 460/60/3XL 414-506 44 60 50 2

25 RAUC-C254 460/60/3XL 414-506 56 80 70 2

30 RAUC-C304 460/60/3XL 414-506 65 90 80 2

40 RAUC-C404 460/60/3XL 414-506 84 100 90 4

50 RAUC-C504 460/60/3XL 414-506 106 125 125 4

60 RAUC-C604 460/60/3XL 414-506 123 125 125 4

80 RAUC-C804 460/60/3XL 414-506 162 175 175 6

100 RAUC-D104 460/60/3XL 414-506 206 225 225 8

120 RAUC-D124 460/60/3XL 414-506 239 250 250 8

Notes:

1. Minimum circuit ampacity (MCA) is 125 percent of the RLA of one compressor motor plus the total RLA of the remaining motors.

2. Maximum Overcurrent Protection Device permitted by NEC 440-22 is 225 percent of the RLA of one compressor motor plus the total RLA of the remaining motors.

3. Recommended dual element fuse size is 150 percent of the RLA of one compressor motor plus the total RLA of the remaining motors.

4. Local codes may take precedence.

RAUC-C20E 200/60/3XL 180-220 101 125 125 2

RAUC-C20F 230/60/3XL 207-253 101 125 125 2

RAUC-C205 575/60/3XL 517-633 35 45 40 2

RAUC-C25E 200/60/3XL 180-220 129 175 150 2

RAUC-C25F 230/60/3XL 207-253 129 175 150 2

RAUC-C255 575/60/3XL 517-633 45 60 60 2

RAUC-C30E 200/60/3XL 180-220 148 200 175 2

RAUC-C30F 230/60/3XL 207-253 148 200 175 2

RAUC-C305 575/60/3XL 517-633 52 70 60 2

RAUC-C40E 200/60/3XL 180-220 192 225 225 4

RAUC-C40F 230/60/3XL 207-253 192 225 225 4

RAUC-C405 575/60/3XL 517-633 67 80 80 4

RAUC-C50E 200/60/3XL 180-220 244 300 300 4

RAUC-C50F 230/60/3XL 207-253 244 300 300 4

RAUC-C505 575/60/3XL 517-633 84 100 90 4

RAUC-C60E 200/60/3XL 180-220 282 300 300 4

RAUC-C60F 230/60/3XL 207-253 282 300 300 4

RAUC-C605 575/60/3XL 517-633 98 110 11 0 4

RAUC-C80E 200/60/3XL 180-220 373 400 400 6

RAUC-C80F 230/60/3XL 207-253 373 400 400 6

RAUC-C805 575/60/3XL 517-633 129 150 150 6

RAUC-D10E 200/60/3XL 180-220 472 500 500 8

RAUC-D10F 230/60/3XL 207-253 472 500 500 8

RAUC-D105 575/60/3XL 517-633 164 175 175 8

RAUC-D12E 200/60/3XL 180-220 548 600 600 8

RAUC-D12F 230/60/3XL 207-253 548 600 600 8

RAUC-D125 575/60/3XL 517-633 190 200 200 8

Allowable Minimum Max. Overcurrent Recommended Dual Number

Unit Characteristics

Table ED-2— Condensing Units — 50 Hz

Unit Characteristics

Nominal Model Voltage/Start Voltage Circuit Ampacity Protection Device Element Fuse Size Of

Tons Number Characteristics Utilization Range (1), (4) (2), (4) (3), (4) Compressors

20 RAUC-C20 380/415/50/3XL 360-440 42 50 50 2

25 RAUC-C25 380/415/50/3XL 360-440 55 80 70 2

30 RAUC-C30 380/415/50/3XL 360-440 64 90 80 2

40 RAUC-C40 380/415/50/3XL 360-440 80 90 90 4

50 RAUC-C50 380/415/50/3XL 360-440 104 125 125 4

60 RAUC-C60 380/415/50/3XL 360-440 122 125 125 4

80 RAUC-C80 380/415/50/3XL 360-440 159 175 175 6

100 RAUC-D10 380/415/50/3XL 360-440 201 225 225 8

120 RAUC-D12 380/415/50/3XL 360-440 237 250 250 8

Notes:

1. Minimum circuit ampacity (MCA) is 125 percent of the RLA of one compressor motor plus the total RLA of the remaining motors.

2. Maximum Overcurrent Protection Device permitted by NEC 440-22 is 225 percent of the RLA of one compressor motor plus the total RLA of the remaining motors.

3. Recommended dual element fuse size is 150 percent of the RLA of one compressor motor plus the total RLA of the remaining motors.

4. Local codes may take precedence.

Allowable Minimum Max. Overcurrent Recommended Dual Number

27SS-PRC005-EN

Page 28

Electrical

Data

Table ED-3 — Compressor Motor and Condenser Fan Data — 60 Hz

Nominal Compressor 1A (1) Compressor 1B Compressor 2A Compressor 2B Condenser Fans

T o ns Model V oltage RLA LRA RLA LRA RLA LRA RLA LRA Qty. FLA

20 RAUC-C20 460 XL 18.1 117 18.1 1 17 — — — — 2 1.8

25 RAUC-C25 460 XL 18.1 117 26.3 178 — — — — 3 1.8

30 RAUC-C30 460 XL 26.3 178 26.3 178 — — — — 3 1.8

40 RAUC-C40 460 XL 18.1 117 18.1 1 17 18.1 117 18.1 117 4 1.8

50 RAUC-C50 460 XL 18.1 117 26.3 178 18.1 117 26.3 178 6 1.8

60 RAUC-C60 460 XL 26.3 178 26.3 178 26.3 178 26.3 178 6 1.8

Nominal Compressor 1A/2A(2) Compressor 1B/2B Compressor 1C/2C Compressor 1D/2D Condenser Fans

T ons Model Voltage RLA LRA RLA LRA RLA LRA RLA LRA Qty. FLA

80 RAUC-C80 460 XL 18.1 117 26.3 178 26.3 178 — — 8 1.8

100 RAUC-D10 460 XL 26.3 178 26.3 178 18.1 1 17 18.1 117 12 1.8

120 RAUC-D12 460 XL 26.3 178 26.3 178 26.3 178 26.3 178 12 1.8

Notes:

1. Value given is per compressor on 20-60 ton units.

2. For 80 through 120-ton units, electrical values shown are for each compressor.

200 XL 41.4 269 41.4 269 — — — — 2 4.1

230 XL 41.4 251 41.4 251 –– –– –– –– 2 4.1

575 XL 14.4 94 14.4 94 — — — — 2 1.4

200 XL 41.4 269 60.5 409 — — — — 3 4.1

230 XL 41.4 251 60.5 376 –– –– –– –– 3 4.1

575 XL 14.4 94 21.0 143 — — — — 3 1.4

200 XL 60.5 409 60.5 409 — — — — 3 4.1

230 XL 60.5 376 60.5 376 –– –– –– –– 3 4.1

575 XL 21.0 143 21.0 143 — — — — 3 1.4

200 XL 41.4 269 41.4 269 41.4 269 41.4 269 4 4.1

230 XL 41.4 251 41.4 251 41.4 251 41.4 251 4 4.1

575 XL 14.4 94 14.4 94 14.4 94 14.4 94 4 1.4

200 XL 41.4 269 60.5 409 41.4 269 60.5 409 6 4.1

230 XL 41.4 251 60.5 376 41.4 251 60.5 376 6 4.1

575 XL 14.4 94 21.0 143 14.4 94 21.0 143 6 1.4

200 XL 60.5 409 60.5 409 60.5 409 60.5 409 6 4.1

230 XL 60.5 376 60.5 376 60.5 376 60.5 376 6 4.1

575 XL 21.0 143 21.0 143 21.0 143 21.0 143 6 1 .4

200 XL 41.4 269 60.5 409 60.5 409 — — 8 4.1

230 XL 41.4 251 60.5 376 60.5 376 –– –– 8 4.1

575 XL 14.4 94 21.0 143 21.0 143 — — 8 1.4

200 XL 60.5 409 60.5 409 41.4 269 41.4 269 12 4.1

230 XL 60.5 376 60.5 376 41.4 251 41.4 251 12 4.1

575 XL 21.0 143 21.0 143 14.4 94 14.4 94 12 1.4

200 XL 60.5 409 60.5 409 60.5 409 60.5 409 12 4.1

230 XL 60.5 376 60.5 376 60.5 376 60.5 376 12 4.1

575 XL 21.0 143 21.0 143 21.0 143 21.0 143 12 1.4

Table ED-4 — Compressor Motor and Condenser Fan Data — 50 Hz

Nominal Compressor 1A (1) Compressor 1B Compressor 2A Compressor 2B Condenser Fans

T o ns Model V oltage RLA LRA RLA LRA RLA LRA RLA LRA Qty. FLA

20 RAUC-C20 380/415 17.2 1 1 0 17.2 11 0 — — — — 2 1.7

25 RAUC-C25 380/415 17.2 1 1 0 26.2 174 — — — — 3 1.7

30 RAUC-C30 380/415 26.2 174 26.2 174 — — — — 3 1.7

40 RAUC-C40 380/415 17.2 1 1 0 17.2 11 0 — — — — 4 1.7

50 RAUC-C50 380/415 17.2 1 1 0 26.2 174 — — — — 6 1.7

60 RAUC-C60 380/415 26.2 174 26.2 174 — — — — 6 1.7

Nominal Compressor 1A/2A(2) Compressor 1B/2B Compressor 1C/2C Compressor 1D/2D Condenser Fans

T ons Model Voltage RLA LRA RLA LRA RLA LRA RLA LRA Qty. FLA

80 RAUC-C80 380/415 17.2 174 26.2 174 26.2 174 — — 8 1.7

100 RAUC-D10 380/415 26.2 174 26.2 174 17.2 11 0 17.2 11 0 12 1.7

120 RAUC-D12 380/415 26.2 174 26.2 174 26.2 174 26.2 174 12 1.7

Notes:

1. Value given is per compressor on 20-60 ton units.

2. For 80 through 120-ton units, electrical values shown are for each compressor.

SS-PRC005-EN28

Page 29

Dimensional

20 Ton

Data

Figure DD-1 — Air -Cooled Condensing Unit — RA UC 20 T on

Condensing Unit

29SS-PRC005-EN

Page 30

Dimensional

25 Ton

Data

Figure DD-2 — Air -Cooled Condensing Unit — RA UC 25 T on

Condensing Unit

SS-PRC005-EN30

Page 31

Dimensional

30 Ton

Data

Figure DD-3 — Air -Cooled Condensing Unit — RA UC 30 T on

Condensing Unit

31SS-PRC005-EN

Page 32

Dimensional

40 Ton

Data

Figure DD-4 — Air -Cooled Condensing Unit — RA UC 40 T on

Condensing Unit

SS-PRC005-EN32

Page 33

Dimensional

50 Ton

Data

Figure DD-5 — Air -Cooled Condensing Unit — RA UC 50 T on

Condensing Unit

33SS-PRC005-EN

Page 34

Dimensional

60 Ton

Data

Figure DD-6 — Ai r-Cooled Condensing Unit — RAUC 60 T on

Condensing Unit

SS-PRC005-EN34

Page 35

Dimensional

80 Ton

Data

Figure DD-7 — Air -Cooled Condensing Unit — RA UC 80 T on

Condensing Unit

NOTES:

1. Hot gas bypass, suction and liquid line connection

locations shown in the front view do not represent

holes in the unit panel. Access to these

connections are provided by the customers.

2. Dimensional tolerance is ±1/8”.

35SS-PRC005-EN

Page 36

Dimensional

100 Ton

Data

Figure DD-8 — Air -Cooled Condensing Unit — RA UC 100 Ton

Condensing Unit

NOTES:

1. Hot gas bypass, suction and liquid line connection

locations shown in the front view do not represent

holes in the unit panel. Access to these

connections are provided by the customers.

2. Dimensional tolerance is ±1/8”.

SS-PRC005-EN36

Page 37

Dimensional

120 Ton

Data

Figure DD-9 — Air -Cooled Condensing Unit — RAUC 120 Ton

Condensing Unit

NOTES:

1. Hot gas bypass, suction and liquid line connection

locations shown in the front view do not represent

holes in the unit panel. Access to these

connections are provided by the customers.

2. Dimensional tolerance is ±1/8”.

37SS-PRC005-EN

Page 38

Dimensional

20 and 25 Ton

Data

Figure DD-1 0 — 20 and 25-Ton Evapo rator Chiller

Evaporator Chiller

NOTES:

1. DIMENSIONAL TOLERANCE IS ± 1/8”.

2. ALLOW 6’1” TUBE REMOVAL CLEARANCE EITHER END OF EVAPORATOR

Evaporator Flange Connection.

Flange adapter and O-ring supplied by Trane.

SS-PRC005-EN38

Page 39

Dimensional

30 Ton

Data

Figure DD-11 — 30-Ton Evaporator Chiller

Evaporator Chiller

NOTES:

1. DIMENSIONAL TOLERANCE IS ± 1/8”.

2. ALLOW 6’2” TUBE REMOVAL CLEARANCE EITHER END OF EVAPORATOR

Evaporator Flange Connection.

Flange adapter and O-ring supplied byT rane.

39SS-PRC005-EN

Page 40

Dimensional

40 Ton

Data

Figure DD-12 — 40-Ton Evaporator Chiller

Evaporator Chiller

NOTES:

1. DIMENSIONAL TOLERANCE IS ± 1/8”.

2. ALLOW 6’2” TUBE REMOVAL CLEARANCE EITHER END OF EVAPORATOR

SS-PRC005-EN40

Page 41

Dimensional

50 Ton and 60 Ton

Data

Figure DD-13 — 50 and 60-Ton Evaporator Chiller

Evaporator Chiller

NOTES:

1. DIMENSIONAL TOLERANCE IS ± 1/8”.

2. ALLOW 8’0” TUBE REMOVAL CLEARANCE EITHER END OF EVAPORATOR

41SS-PRC005-EN

Page 42

Dimensional

80 Ton

Data

Figure DD-14 — 80-Ton Evaporator Chiller

Evaporator Chiller

Evaporator Flange Connection.

Flange adapter and O-ring supplied byT rane

SS-PRC005-EN42

Page 43

Dimensional

100 Ton

Data

Figure DD-15 — 1 00-Ton Evaporator Chiller

Evaporator Chiller

Evaporator Flange Connection.

Flange adapter and O-ring supplied byT rane

43SS-PRC005-EN

Page 44

Dimensional

120 Ton

Data

Figure DD-16 — 120-Ton Evaporator Chiller

Evaporator Chiller

Evaporator Flange Connection.

Flange adapter and O-ring supplied byT rane

SS-PRC005-EN44

Page 45

Weights

Table W-1 — 20-60 T on Air-Cooled Condensing Units

Nominal Weight (Lbs.) Loc. 1 Loc. 2 Loc. 3 Loc. 4 Loc. 5 Loc. 6

T ons Model AL CU AL CU AL CU AL CU AL CU AL CU AL CU

20 RAUC-C20 1522 1720 509 559 398 439 345 404 270 317 — — — —

25 RAUC-C25 1640 1842 555 602 421 467 378 436 286 338 — — — —

30 RAUC-C30 1824 2115 580 640 635 708 291 364 318 403 — — — —

40 RAUC-C40 2769 3102 480 523 457 501 473 528 450 506 466 533 443 51 1

50 RAUC-C50 3148 3540 586 643 562 620 536 601 514 579 485 559 465 538

60 RAUC-C60 3480 4050 640 722 618 703 590 684 570 666 540 646 522 629

Note:

Shipping weight is approximately equal to operating weight.

AL = Aluminum Coil Fin

CU = Copper Coil Fin

Figure W -1 — 20-30 T on Air-Cooled Condensing Units

Operating Weight On Isolator At Mounting Locations (Lbs.)

Figure W -2 — 40-60 T on Air-Cooled Condensing Units

T op View (Mounting Locations)

Table W-2 — 80-120 Ton Air Condensing Units

Nominal Coil Operating Weight On Isolator At Mounting Location (Lbs.)

T ons Model Fin Weight (Lbs.) Loc. 1 Loc.2 Loc. 3 Loc.4 Loc. 5 Loc. 6 Loc. 7 Loc. 8

80 RAUC-C80 AL 5500 855 557 835 544 830 541 810 528

RAUC-C80 CU 6099 926 629 909 618 906 616 890 605

100 RAUC-D10 AL 6472 1010 656 983 639 979 636 951 618

RAUC-D10 CU 7272 1104 762 1083 738 1080 736 1058 721

120 RAUC-D12 AL 7000 11 00 694 1075 678 1071 676 1046 660

RAUC-D12 CU 8199 1241 838 1225 827 1222 825 1206 815

Table W -3 — Evapor ativ e Chillers 20

Figure W -3—80-120 T on Air-Cooled Condensing Units

through 120 Ton

Nominal Operating Shipping

T ons Weight (Lbs.) Weight (Lbs.)

20 360 280

25 360 280

30 470 360

40 480 380

50 580 430

60 600 470

80 1205 875

100 1230 960

120 1535 1150

45SS-PRC005-EN

Page 46

Mec hanical Specifications

20 through 60-ton

Condensing Units

General

All air -cooledcondensing units have

scroll compressors and are factory

assembled and wired. Each unit is

shipped from the factory with a nitrogen

holding charge. Units are constructed of

14-gauge welded g alvanized steel frame

with 14 and 16-gauge galvaniz ed steel

panels and access doors. Unit surface is

phosphatized and finished with an air -dry

paint. This air-dry paint finish is durable

enough to withstand a 1000-consecutivehour salt spray application in accordance

with standard AS TM B117.

Compressor

T rane 3-D

simple mechanical design with only

three major moving parts. Scroll type

compression provides inherently low

vibration. The 3-D Scroll provides a

completely enclosed compression

chamber whic h leads to increased

efficiency . Exhaustive testing on the 3-D

Scroll, including start up with the shell

full of liquid, has proven that slugging

does not fail involutes. Direct-drive, 3600

rpm, suction gas-cooled hermetic motor.

T rane 3-D Scroll compressor includes

centrifugal oil pump, oil level sightglass

and oil charging valve.

Condenser

Condenser coils have configured

aluminum fins mechanically bonded to

copper tubing with an integral subcooler.

Condensers are factory leak tested at 450

psig air pressure underwater. Direct

drive vertical discharge fans are statically

and dynamically balanced. Three-phase

motors have permanently lubricated ball

bearings and thermal overload

protection. Optional low ambient allows

operating down to 0°F with external

damper assembly for head pressure

control.

Refriger ant Circuits and Capacity

Modulation

20 through 30-ton sizes are single circuit

and have two steps of capacity. The 40

through 60-ton sizes are two circuits with

four capacity steps. Each circuit has two

compressors piped in parallel. Discharge

and liquid line service valves are

standard on each circuit.

™

Scroll compressors have

Unit Control

Factory-provided 115-volt control circuit

includes fusing and control power

transformer. The unit is wired with

magnetic contactors for compressor and

condenser motors, three-leg, solid-state

compressor overload protection, and

high-low pressure cutouts. Charge

isolation, reset relay and anti-recycle

compressor timer are provided.

80 through 120-t on

Condensing Units

Casing

The unit frame is a one-piece welded

assembly of heavy gauge zinc-coated

steel. Exterior surfaces are phosphatized

and finished with slate gray air -dry paint.

This air -dry paint finish exceeds 672

consecutive hour salt spray resistance in

accordance with AS TM B117. Decorative

louvered panels provide factory standard

condenser coil protection.

Compressors

T rane 3-D

simple mechanical design with only

three major moving parts. Scroll type

compression provides inherently low

vibration. The 3-D Scroll provides a

completely enclosed compression

chamber whic h leads to increased

efficiency . Exhaustive testing on the 3-D

Scroll, including start up with the shell

full of liquid, has proven that slugging

does not fail involutes. Direct-drive, 3600

rpm, suction gas-cooled hermetic motor.

T rane 3-D Scroll compressor includes

centrifugal oil pump, oil level sightglass

and oil charging valve.

Split systems can have significantly more

refrigerant than packaged systems and

thus require controls to reliably manage

this excess refrigerant. Each compressor

shall have crankcase heaters installed,

properly sized to minimize the amount of

liquid refrigerant present in the oil sump

during off cycles. Additionally, the

condensing unit shall have controls to

initiate a refrigerant pump down cycle at

system shut down on each refrigerant

circuit. To be operational, the refrigerant

pump down cycle requires a fieldinstalled isolation solenoid valve on the

liquid line near the evaporator.

®

Scroll compressors have a

Condenser Fan and Motors

V ertical discharge direct-drive fans are

statically and dynamically balanced. Fan

motors are three-phase with

permanently lubricated ball bearings,

built-in current and thermal overload

protection.

Condenser Coil

Condenser coils have configured

aluminum fins mechanically bonded to

3/8-inch OD copper tubing. T wo

refrigerant circuits with separate

subcooling circuits are standard. Coils

are factory-tested at 450 psig air pressure

underwater and vacuum dehydrated.

Unit Control

Factory-provided 115-volt control circuit

includes fusing and control power

transformer. The unit is wired with

magnetic contactors for compressor and

condenser motors, three-leg, solid-state

compressor overload protection, and

high-low pressure cutouts. Charge

isolation, reset relay and anti-recycle

compressor timer are provided.

20 through 120-ton

Evapor ator Chiller

Shell and tube design with seamless

copper tubes expanded into tube sheets

with removable heads. 20, 25 and 30-ton

units are single-circuited; 40 through

120-ton are dual-circuited. The 20-60 ton

evaporators are designed for a water

side working pressure of 300 psig.

70-120 ton evaporators are designed for

150 psig water side working pressure.

The units are designed, tested and

stamped in accordance with the ASME

Code for unfired pressure vessels for a

refrigerant side working pressure of 225

psig. Evaporator chillers are provided

with fittings for temperature sensors and

a drain plug for cleaning.

SS-PRC005-EN46

Page 47

Page 48

Tr an e

A business of American

Standard Companies

www.trane.com

For more information contact your

local district office, or e-mail us at

comfort@trane.com

Literature Order Number SS-PRC005-EN

File Number PL-UN-SS-PRC005-EN-11-2001

Supersedes SS-PRC005-EN-07-2001

Stocking Location Webb/Mason

Trane has a policy of continuous product and product data improvement and reserves the right to change

design and specifications without notice.

Loading...

Loading...