Page 1

Product Catalog

Horizon™ Outdoor Air Unit Water Source Heat Pump

For 100% Outdoor Air Applications

Models: OABE, OADE, OAKE, OANE

August 20 14

OAU-PRC003A-EN

Page 2

Introduction

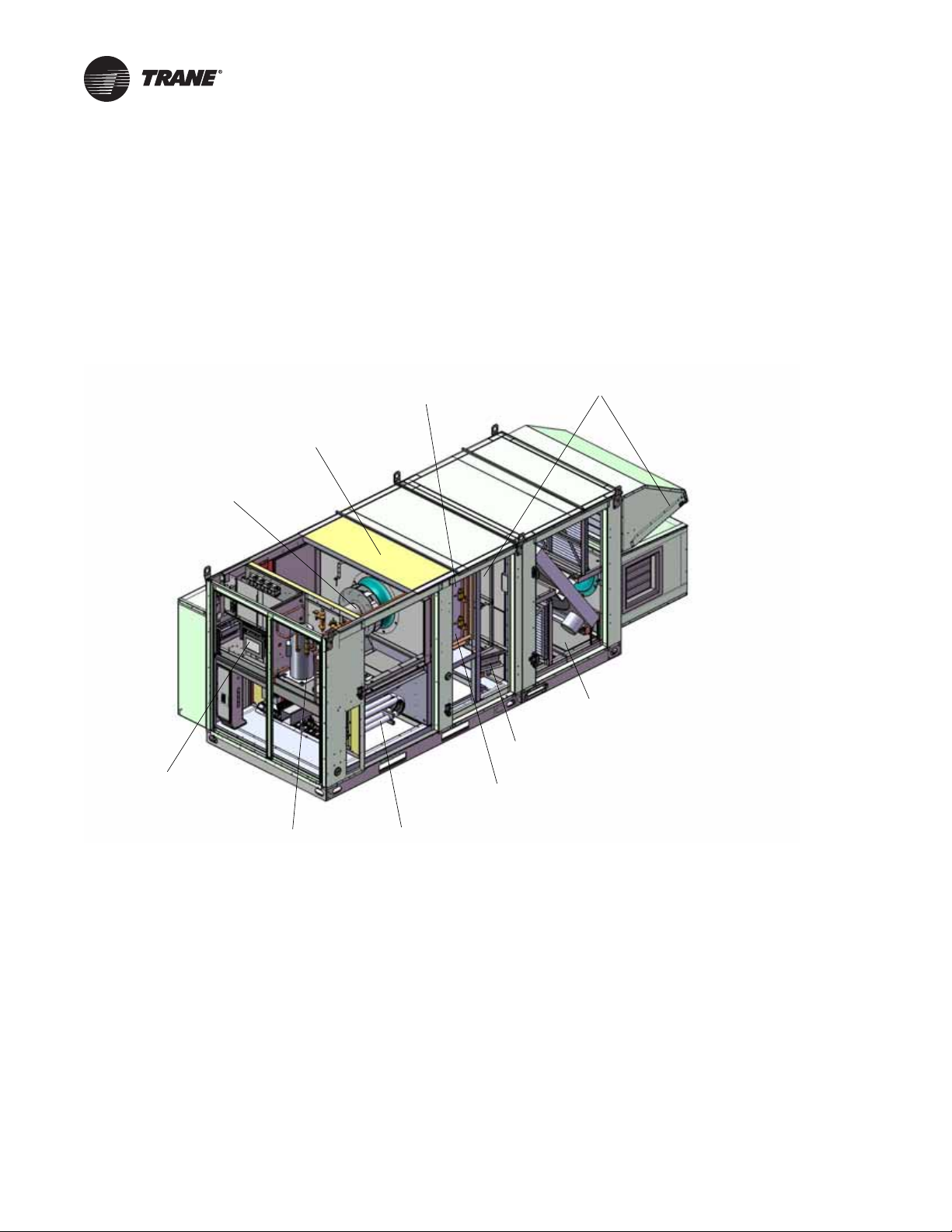

HIGH TURNDOWN INDIRECT GAS-FIRED BURNER

OPTIONAL RETURN-AIR

WITH EASY TO READ HUMAN INTERFACE

PLUS 2" MAXIMUM EXTERNAL CAPACITY

DAMPER

WITH STAINLESS STEEL HEAT EXCHANGER

MICROPROCESSOR BASED CONTROL

REHEAT COIL SEPARATED

FROM EVAPORATOR

FOR ERV, POWERED EXHAUST, AND

SECONDARY ELECTRIC HEAT OPTIONS

SLIDE IN FILTER FRAMES WITH

6" MAXIMUM INTERNAL CAPACITY

AVAILABLE AUXILIARY CABINET

2" SOLID DOUBLE WALL

WITH FOAM INSULATION

DIGITAL SCROLL

COMPRESSORS

DIRECT DRIVE PLENUM FAN WITH

SLIDE OUT SERVICE ACCESS

INTERLACED EVAPORATOR

COIL WITH STAINLESS STEEL

DRAIN PAN

The Horizon Outdoor Air Unit Water Source Heat Pump...

The T rane Horizon™ Outdoor Ai r Water Source Heat P ump for 100 percent outdoor air or dew point

design applications leads the industry in:

• Indoor Air Quality (IAQ) Features

• Moisture Management

• High Quality and Durability

• Advanced Controls

Copyright

Trademarks

Revision History

© 2014 Trane All rights reserved OAU-PRC003A-EN

This document and the information in it are the property of Trane, and may not be used or

reproduced in whole or in part without written permission. Trane reserves the right to revise this

publication at any time, and to make changes to its content without obligation to notify an y person

of such revision or change.

All trademarks referenced in this document are the trademarks of their respective owners.

OAU-PRC003A-EN (10 Aug 2014)

• First version of this literature

Page 3

Table of Contents

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Model Number Descriptions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Horizon Outdoor Air Unit Water Source Heat Pump . . . . . . . . . . . . . . . . . . . 5

Features and Benefits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Application Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

System Configurations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Horizon OAU Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

OAU with Reheat . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

OAU Outdoor Air Control without Reheat . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Establishing Capacity Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Cooling & Dehumidification Selection Criteria . . . . . . . . . . . . . . . . . . . . . . . 17

Outdoor Airflow Balancing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Air to Air Energy Recovery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

The Horizon Outdoor Air Unit Water Source Heat Pump... . . . . . . . . . . . . 2

Model: OABE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Models: OADE, OAKE, OANE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Indoor Air Quality (IAQ) Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Energy Efficiency . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

High Quality and Durability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Advanced Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Flexibility . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Enhanced Serviceability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Standard Unit Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Standard Control Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Optional Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Outdoor Air Unit Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Dehumidification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Cooling or Heating . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Dehumidification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Cooling or Heating . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Evaporator Design Entering Conditions . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Evaporator Design Leaving Conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Reheat . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Heating . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Capacity Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Discharge Air Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Cooling Setpoint . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Unoccupied Space Humidity Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Space Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Controlling the Total-Energy Wheel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Cross Leakage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

OAU-PRC003A-EN 3

Page 4

Condensate Drain Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Acoustical Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Clearance Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Duct Design . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Controls Sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Selection Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Horizon OAU WSHP Selection Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

General Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Unit Clearances, Curb Dimensions, and Dimensional Data . . . . . . . . . . . . . . . 34

OABE Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Unit Clearances . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Curb Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Dimensional Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

OADE Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Unit Clearances . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Curb Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Dimensional Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

OAKE Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Unit Clearances . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Curb Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Dimensional Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

OANE Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Unit Clearances . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Curb Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Dimensional Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Unit Weight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Unit Weight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Rigging . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Mechanical Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Horizon Outdoor Air Mechanical Specifications . . . . . . . . . . . . . . . . . . . . . . 58

Refrigeration and Dehumidification Systems . . . . . . . . . . . . . . . . . . . . . . 58

Electrical and Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Appendix . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

OAU Filter Guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

4 OAU-PRC003A-EN

Page 5

Model Number Descriptions

Horizon Outdoor Air Unit Water Source Heat Pump

Model: OABE

Typical model number (example):

OABE036A4 -D1A1A0AB-G1CB0AC3AB-A11B102A0

1 2 3 4 5 6 7 8 9 101112131415161718192021222324252627282930313233343536373839

Digit 1, 2 — Unit Type

OA = Outdoor Air

Digit 3 — Cabinet Size

B = 500–3000 CFM

Digit 4 — Major Design

Sequence

E = Heat Pump

Digit 5, 6, 7 — Normal Gross

Cooling Capacity (MBh)

000= No Cooling

036= 3 Tons High Efficiency

048= 4 Tons High Efficiency

060= 5 Tons High Efficiency

072= 6 Tons High Efficiency

084= 7 Tons High Efficiency

096= 8 Tons High Efficiency

108 = 9 Tons High Efficiency

Digit 8 — Minor Design

Sequence

A

B

Digit 9 — Voltage Selection

3 = 208-230/60/3

4 = 460/60/3

5 = 575/60/3

Digit 10 — Reserved for Future

Use

Digit 11 — Evaporator Type

B = DX 4-Row

C = DX 4-Row Interlaced

G = DX 4-Row with

MSP

®

Technology

Digit 12 — Hot Gas Reheat

0=No HGRH

1 = Fin and Tube Modulating

2 = Fin and Tube On/Off

3 = Microchannel Modulating

4 = Microchannel On/Off

Digit 13 — Compressor

B = Digital Scroll—1st Circuit Only

C = Digital Scroll—1

D = Variable Speed Scroll—1

E = Variable Speed Scroll—1

Circuit Only

nd

2

Circuit

st

and 2nd Circuit

st

st

and

Digit 14 — Condenser

3 = Water-Cooled DX Condenser

Copper/Steel

8 = Water-Cooled DX Condenser

Copper/Nickel

Digit 15 — Refrigerant Capacity

Control

0 = No RCC Valve

Digit 16 — Indoor Fan Motor

(IFM)

0 = ECM w/Backward Curved

Plenum Fan

4 = Special Motor Option

Digit 17 — Indoor Fan Wheel

A = 355

B = 450

Digit 18 — Indoor Fan Motor

(hp)

A = 1 kW–1.5 hp

B = 2 kW–2.5 hp

C = 3 kW–4.0 hp

Digit 19 — Reserved for Future

Use

Digit 20 — Heater Type

(PRI/SEC)

0 = No Auxiliary Heat

A = Indirect-Fired (IF)

B = Direct-Fired (DF)

C = Electric—4-Stage

D = Electric—SCR Modulating

E = Dual Fuel (PRI-IF/SEC-DF)

F = Dual Fuel (PRI-ELEC/SEC-DF)

G = Dual Fuel (PRI-IF/SEC-ELEC)

H = Dual Fuel (PRI-ELEC/SEC-ELEC)

J=Hot Water

K=Steam

Digit 21 — Primary Fuel Type

0 = No Auxiliary Heat

1=Natural Gas

2=Propane

3 = Electric—Open Coil

4 = Electric—Sheathed Coil

5=Hot Water

6=Steam

Digit 22 — Heater Capacity—

Primary Heat Source

IF ELEC

0 = No Auxiliary

Heat

A = 50 MBh 5 kW

B = 75 MBh 10 kW

C = 100 MBh 15 kW

D = 125 MBh 20 kW

E = 150 MBh 24 kW

F = 200 MBh 28 kW

G = 32 kW

H = 40 kW

J = 48 kW

X = Special Heater Option

No Auxiliary

Heat

Digit 23 — Heat Capacity—

Secondary Heat Source

ELEC DF

0 = No Heat/No Secondary Heat

A = 5 kW 300 MBh

B=10 kW

C=15 kW

D = 20 kW

E = 24 kW

F = 28 kW

G = 32 kW

H = 40 kW

J = 48 kW

Digit 24 — Corrosive

Environment Package

0 = No Corrosive Package

1 = S/S Cabinet, Basepan,

2 = S/S Cabinet, Basepan

3 = S/S Basepan, Eco-Coated Coils

4 = S/S Coil Casing

5 = S/S Interior Casing

6 = Eco-Coated Coils

7 = S/S Coil Casing with

8 = Copper/Copper Evap, HGRH

Coils

Eco-Coated Coils

Eco-Coated Coils

OAU-PRC003A-EN 5

Page 6

Model Number Descriptions

OABE Units

Digit 25, 26 — Unit Controls

00 = Non DDC—Electromechanical

AA = Trane—Discharge Air Control

AB = Trane—Space Control w/LON

AC = Trane—Discharge Air Control

AD = Trane—Space Control

AF = Trane—Discharge Air Control

AG = Trane—Space Control

AI = Trane—Discharge Air Control

AJ = Trane—Space Control

AK = Trane—Multi-Zone VAV Control

AL = Trane—Multi-Zone VAV Control

AM = Trane—Multi-Zone VAV Control

AN = Trane—Multi-Zone VAV Control

AO = Trane—Single-Zone VAV Control

AP = Trane—Single-Zone V AV Control

AQ = Trane—Single-Zone VAV Control

AR = Trane—Single-Zone VAV Control

w/LON Read-Write w/Display

Read-Write w/Display

w/BACnet

w/BACnet (No Display)

w/BACnet w/Display

w/BACnet w/Display

w/LON Read-Write (No Display)

w/LON Read-Write (No Display)

w/LON Read-Write w/Display

w/BACnet w/Display

w/LON Read-Write (No Display)

w/BACnet (No Display)

w/LON Read-Write w/Display

w/BACnet w/Display

w/LON Read-Write (No Display)

w/BACnet (No Display)

®

(No Display)

Digit 27 — Po wered Exhaust Fan

Motor (PFM) and Exhaust

Dampers

0 = No Powered Exhaust

5 = Special Motor Option

6 = ECM w/Backward Curved

7 = ECM w/Backward Curved

8 = ECM w/Backward Curved

9 = Barometric Relief Dampers

Plenum Fan

Plenum Fan and Barometric

Relief Damper

Plenum Fan and Isolation

Dampers w/End Switch

(No PFM)

Digit 28 — Po wered Exhaust Fan

Wheel

0 = No Powered Exhaust

A = 355

Digit 29 — Po wered Exhaust Fan

Motor HP

0 = No Powered Exhaust

A = 1 kW–1.5 hp

B = 2 kW–2.5 hp

C = 3 kW–4.0 hp

DIGIT 30 — Reserved for Future

Use

Digit 31 — ERV (Requires

Powered Exhaust)

0=No ERV

A = ERV—Composite Construction

w/Bypass

B = ERV—Composite Construction

with Frost Protection w/VFD

C = ERV—Aluminum Construction

w/Bypass

D = ERV—Aluminum Construction

with Frost Protection w/VFD

Digit 32 — ERV Size

0=No ERV

1=3014

2 = 3622

Digit 33 — Damper Options

0 = 100% OA 2-Position Damper

1 = 100% OA 2-Position Damper

w/RA 2-Position Damper

2 = Modulating OA and RA Dampers

w/Economizer

Digit 34 — Filtration Options

A = No Filters

B = MERV-8, 30%

C = MERV-13, 80%

D = MERV-14, 95%

E = MERV-8 30%, MERV-13 80%

F = MERV-8 30%, MERV-14 95%

G = MERV-8, 30%, and UVC

H = MERV-13, 80%, with UVC

J = MERV-14, 95%, with UVC

K = MERV-8 30%, MERV-13 80%,

and UVC

L = MERV-8 30%, MERV-14 95%,

and UVC

M = MERV-8 30%, and TCACS

N = MERV-13 80%, and TCACS

P = MERV-14 95%, and TCACS

Q = MERV-8 30%, MERV-13 80%,

and TCACS

R = MERV-8 30%, MERV-14 95%,

and TCACS

X = Special Filter Options

Digit 35 — Smoke Detector—

Factory Installed

0 = No Smoke Detector

1 = Supply Smoke Detector

2 = Return Smoke Detector

3 = Supply and Return Smoke

Detectors

Digit 36 — Electrical Options

0 = Terminal Block

A = Non-Fused Disconnect

B = Fused Disconnect Switch

C = Non-Fused Disconnect

w/Convenience Outlet

D = Fused Disconnect Switch

w/Convenience Outlet

E = Dual Point Power

F = Dual Point Power

w/Convenience Outlet

G = 65 SCCR Electrical Rating

w/Non-Fused Disconnect

H = 65 SCCR Electrical Rating

w/Fused Disconnect

J = 65 KAIC Electrical Rating

w/Non-Fused Disconnect

K = 65 KAIC Electrical Rating

w/Fused Disconnect

Digit 37 — Air Flow Monitoring

0 = No Airflow Monitoring

1 = Airflow Monitoring—IFM

Piezo Ring

2 = Airflow Monitoring—PE

Piezo Ring

3 = Airflow Monitoring—Outdoor Air

with Display and IFM

w/Piezo Ring

4 = Airflow Monitoring—IFM

Piezo Ring and PE Piezo Ring

5 = Airflow Monitoring—Outdoor Air

Monitoring w/Display Supply Air

and Exhaust Air w/Piezo Rings

Digit 38 — Accessories

0 = No Options

B = LED Service Light

Digit 39 — Altitude

0 = Sea Level to 1,000 feet

1 = 1,001 to 2,000 feet

2 = 2,001 to 3,000 feet

3 = 3,001 to 4,000 feet

4 = 4,001 to 5,000 feet

5 = 5,001 to 6,000 feet

6 = 6,001 to 7,000 feet

7 = Above 7,000 feet

6 OAU-PRC003A-EN

Page 7

Model Number Descriptions

Models: OADE, OAKE, OANE

Typical model number (example):

OAKE300A4-D1A1A0GM-G1KB0AC3CJ -A41B102A0

1 2 3 4 5 6 7 8 9 101112131415161718192021222324252627282930313233343536373839

Digit 1, 2 — Unit Type

OA = Outdoor Air

Digit 3 — Cabinet Size

D = 625–4,000 cfm

K = 1,500–9,000 cfm

N = 3,750–13,500 cfm

Digit 4 — Major Design

Sequence

E = Heat Pump

Digit 5, 6, 7 — Normal Gross

Cooling Capacity (MBh)

000= No Cooling

060= 5 Tons High Efficiency

072= 6 Tons High Efficiency

084= 7 Tons High Efficiency

096= 8 Tons High Efficiency

120 = 10 Tons High Efficiency

144 = 12 Tons High Efficiency

180 = 15 Tons High Efficiency

210 = 17 Tons High Efficiency

240= 20 Tons High Efficiency

264= 22 Tons High Efficiency

300 = 25 Tons High Efficiency

360= 30 Tons High Efficiency

420= 35 Tons High Efficiency

480= 40 Tons High Efficiency

540= 45 Tons High Efficiency

600 = 50 Tons High Efficiency

648= 54 Tons High Efficiency

Digit 8 — Minor Design

Sequence

A

B

Digit 9 — Voltage Selection

3 = 208-230/60/3

4 = 460/60/3

5 = 575/60/3

Digit 10 — Reserved for Future

Use

Digit 11 — Evaporator Type

B = DX 4-Row

C = DX 4-Row Interlaced

Digit 12 — Hot Gas Reheat

0=No HGRH

1 = Fin and Tube Modulating

2 = Fin and Tube On/Off

3 = Microchannel Modulating

4 = Microchannel On/Off

Digit 13 — Compressor

B = Digital Scroll—1st Circuit Only

C = Digital Scroll—1

D = Variable Speed Scroll—1

E = Variable Speed Scroll—1

Circuit Only

nd

2

Circuit

st

and 2nd Circuit

st

st

and

Digit 14 — Condenser

3 = Water-Cooled DX Condenser

8 = Water-Cooled DX Condenser

Copper/Steel

Copper/Nickel

Digit 15 — Refrigerant Capacity

Control

0 = No RCC Valve

Digit 16 — Indoor Fan Motor

(IFM)

0 = Direct Drive w/VFD

1 = Direct Drive (VFD by Others)

4 = Direct Drive w/Shaft

5 = Special Motor Option

Grounding Ring w/VFD

Digit 17 — Indoor Fan Wheel

A=122

B = 122.6

C=150

D = 150.6

E=165

F = 165.6

G=182

H = 182.6

J=200

K = 200.6

L = 182 X 2

M = 182.6 X 2

Digit 18 — Indoor Fan Motor HP

A = 1/2 hp—1800 rpm

B = 1/2 hp—3600 rpm

C = 3/4 hp—1800 rpm

D = 3/4 hp—3600 rpm

E = 1 hp—1800 rpm

F = 1 hp—3600 rpm

G = 1.5 hp—1800 rpm

H = 1.5 hp—3600 rpm

J = 2 hp—1800 rpm

K = 2 hp—3600 rpm

L = 3 hp—1800 rpm

M = 3 hp—3600 rpm

N = 5 hp—1800 rpm

P = 5 hp—3600 rpm

R = 7.5 hp—1800 rpm

S = 7.5 hp—3600 rpm

T = 10 hp—1800 rpm

U = 10 hp—3600 rpm

V = 15 hp—1800 rpm

W = 15 hp—3600 rpm

Digit 19 — Reserved for Future

Use

Digit 20 — Heat Type (PRI/SEC)

0 = No Auxiliary Heat

A = Indirect-Fired (IF)

B = Direct-Fired (DF)

C = Electric—4-Stage

D = Electric—SCR Modulating

E = Dual Fuel (PRI-IF/SEC-DF)

F = Dual Fuel (PRI-ELEC/SEC-DF)

G = Dual Fuel (PRI-IF/SEC-ELEC)

H = Dual Fuel (PRI-ELEC/SEC-ELEC)

J=Hot Water

K = Steam

Digit 21 — Primary Fuel Type

0 = No Auxiliary Heat

1=Natural Gas

2=Propane

3 = Electric—Open Coil

4 = Electric—Sheathed Coil

5=Hot Water

6 = Steam

OAU-PRC003A-EN 7

Page 8

Model Number Descriptions

OADE, OAKE, OANE Units

Digit 22 — Heat Capacity—

Primary Heat Source

IF ELEC

0 = No Auxiliary

Heat

A = 50 MBh 10 kW

B = 75 MBh 20 kW

C = 100 MBh 24 kW

D = 125 MBh 28 kW

E = 150 MBh 32 kW

F = 200 MBh 40 kW

G = 250 MBh 48 kW

H = 300 MBh 60 kW

J = 350 MBh 68 kW

K = 400 MBh 79 kW

L = 500 MBh 99 kW

M = 600 MBh 111 kW

N = 700 MBh 119 kW

P = 800 MBh 139 kW

R = 1000 MBh 159 kW

S = 179 kW

T = 199 kW

U = 215 kW

X = Special Heater Option

No Auxiliary

Heat

Digit 23 — Heat Capacity—

Secondary Heat Source

IF ELEC DF

0 = No Heat/No Secondary Heat

A = 50 MBh 10 kW 300 MBh

B = 75 MBh 20 kW 600 MBh

C = 100 MBh 24 kW 900 MBh

D = 125 MBh 28 kW 1200 MBh

E = 150 MBh 32 kW

F = 200 MBh 40 kW

G = 250 MBh 48 kW

H = 300 MBh 60 kW

J = 350 MBh 68 kW

K = 400 MBh 79 kW

L = 500 MBh 99 kW

M = 600 MBh 111 kW

N = 700 MBh 119 kW

P = 800 MBh 139 kW

R = 1000 MBh 159 kW

S = 179 kW

T = 199 kW

U = 215 kW

Digit 24 — Corrosive

Environment Package

0 = No Corrosive Package

1 = S/S Cabinet, Basepan,

2 = S/S Cabinet, Basepan

3 = S/S Basepan, Eco-Coated Coils

4 = S/S Coil Casing

5 = S/S Interior Casing

6 = Eco-Coated Coils

7 = S/S Coil Casing with

8 = Copper/Copper Evap, HGRH

Coils

Eco-Coated Coils

Eco-Coated Coils

Digit 25, 26 — Unit Controls

00 = Non DDC—Electromechanical

AA = Trane—Discharge Air Control

AB = Trane—Space Control

AC = Trane—Discharge Air Control

AD = Trane—Space Control

AF = Trane—Discharge Air Control

AG = Trane—Space Control

AI = Trane—Discharge Air Control

AJ = Trane—Space Control

AK = Trane—Multi-Zone VAV Control

AL = Trane—Multi-Zone VAV Control

AM= Trane—Multi-Zone VAV Control

AN = Trane—Multi-Zone VAV Control

AO = Trane—Single-Zone VAV Control

AP = Trane—Single-Zone V AV Control

AQ = Trane—Single-Zone VAV Control

AR = Trane—Single-Zone VAV Control

w/LON Read-Write w/Display

w/LON Read-Write w/Display

w/BACnet

w/BACnet (No Display)

w/BACnet w/Display

w/BACnet w/Display

w/LON Read-Write (No Display)

w/LON Read-Write (No Display)

w/LON Read-Write w/ Display

w/BACnet w/Display

w/LON Read-Write (No Display)

w/BACnet (No Display)

w/Lon Read-Write w/Display

w/BACnet w/Display

w/LON Read-Write (No Display)

w/BACnet (No Display)

®

(No Display)

Digit 27 — Pow ered Exhaust Fan

Motor (PFM) and Exhaust

Dampers

0 = No Powered Exhaust

1 = Direct Drive w/VFD and

2 = Direct Drive (VFD by Others)

3 = Belt Drive

4 = Belt Drive w/VFD

5 = Special Motor Option

6 = Direct Drive w/VFD and

7 = Direct Drive w/VFD and

8 = Barometric Relief Dampers

Gravity Dampers

Barometric Relief Damper

Isolation Dampers w/End Switch

(NO PFM)

Digit 28 — Pow ered Exhaust Fan

Wheel

0 = No Powered Exhaust

A=122

B = 122.6

C=150

D = 150.6

E=165

F = 165.6

G=182

H = 182.6

J=200

K = 200.6

L = 182 X 2

M = 182.6 X 2

Digit 29 — Pow ered Exhaust Fan

Motor (hp)

0 = No Powered Exhaust

A = 1/2 hp—1800 rpm

B = 1/2 hp—3600 rpm

C = 3/4 hp—1800 rpm

D = 3/4 hp—3600 rpm

E = 1 hp—1800 rpm

F = 1 hp—3600 rpm

G = 1.5 hp—1800 rpm

H = 1.5 hp—3600 rpm

J = 2 hp—1800 rpm

K = 2 hp—3600 rpm

L = 3 hp—1800 rpm

M = 3 hp—3600 rpm

N = 5 hp—1800 rpm

P = 5 hp—3600 rpm

R = 7.5 hp—1800 rpm

S = 7.5 hp—3600 rpm

T = 10 hp—1800 rpm

U = 10 hp—3600 rpm

V = 15 hp—1800 rpm

W = 15 hp—3600 rpm

Digit 30 — Reserved for Future

Use

Digit 31 — ERV (Requires

Powered Exhaust)

0=No ERV

A = ERV—Composite Construction

B = ERV—Composite Construction

with Frost Protection w/VFD

C = ERV—Composite Construction

with Bypass

D = ERV—Composite Construction

with Frost Protection and Bypass

E = ERV—Aluminum Construction

F = ERV—Aluminum Construction

with Frost Protection w/VFD

G = ERV—Aluminum Construction

with Bypass

H = ERV—Aluminum Construction

with Frost Protection and Bypass

8 OAU-PRC003A-EN

Page 9

Model Number Descriptions

OADE, OAKE, OANE Units

Digit 32 — ERV Size

0=No ERV

1=3014

2 = 3622

3 = 4136

4 = 4634

5 = 5856

6 = 6488

7 = 6876

8=74122

Digit 33 — Damper Options

0 = 100% OA 2-Position Damper

1 = 100% OA 2-Position Damper

w/RA 2-Position Damper

2 = Modulating OA and RA Da mpers

w/Economizer

Digit 34 — Filtration Options

A = Aluminum Mesh Intake Filters

(ALM)

B = MERV-8,30%, and ALM

C = MERV-13, 80%, and ALM

D = MERV-14, 95%, and ALM

E = MERV-8 30%, MERV-13 80%, and

ALM

F = MERV-8 30%, MERV-14 95%, and

ALM

G = MERV-8, 30%, and ALM, with

UVC

H = MERV-13, 80%, and ALM, with

UVC

J = MERV-14, 95%, and ALM, with

UVC

K = MERV-8 30%, MERV-13 80%,

ALM, and UVC

L = MERV-8 30%, MERV-14 95%,

ALM, and UVC

M = MERV-8 30%, ALM, and TCACS

N = MERV-13 80%, ALM, and TCACS

P = MERV-14 95%, ALM, and TCACS

Q = MERV-8 30%, MERV-13 80%,

ALM, and TCACS

R = MERV-8 30%, MERV-14 95%,

ALM, and TCACS

X = Special Filter Options

Digit 35 — Smoke Detector—

Factory Installed

0=No Smoke Detector

1 = Supply Smoke Detector

2 = Return Smoke Detector

3 = Supply and Return Smoke

Detector

Digit 36 — Electrical Options

0 = Non-Fused Disconnect

A = Fused Disconnect Switch

B = Non-Fused Disconnect

w/Convenience Outlet

C = Fused Disconnect Switch

w/Convenience Outlet

D = Dual Point Power

w/Convenience Outlet

F = 65 SCCR Electrical Rating

w/Non-Fused Disconnect

G = 65 SCCR Electrical Rating

w/Fused Disconnect

H = 65 KAIC Electrical Rating

w/Non-Fused Disconnect

J = 65 KAIC Electrical Rating

w/Fused Disconnect

Digit 37 — Air Flow Monitoring

0 = No Airflow Monitoring

1 = Airflow Monitoring—IFM

Piezo Ring

2 = Airflow Monitoring—PE

Piezo Ring

3 = Airflow Monitoring—Outdoor Air

with Display and IFM

w/Piezo Ring

4 = Airflow Monitoring—IFM

Piezo Ring and PE Piezo Ring

5 = Airflow Monitoring—Outdoor Air

Monitoring w/ Display Supply

Air and Exhaust Air

w/Piezo Rings

Digit 38 — Accessories

0 = No Options

B = LED Service Light

Digit 39 — Altitude

0 = Sea Level to 1,000 feet

1 = 1,001 to 2,000 feet

2 = 2,001 to 3,000 feet

3 = 3,001 to 4,000 feet

4 = 4,001 to 5,000 feet

5 = 5,001 to 6,000 feet

6 = 6,001 to 7,000 feet

7 = Above 7,000 feet

OAU-PRC003A-EN 9

Page 10

Features and Benefits

We designed the Horizon™ Outdoor Air Unit based on customer requirements from across the

country. Thorough analysis of the performance requirements resulted in a robust design with the

ability to effectively operate over an expansive performance envelope required for the year -round

treatment of outdoor air.

Also, we took into account today’s HVAC market issues, such as indoor air quality (IAQ). We

equipped the Horizon Outdoor Air Unit to meet your ventilation needs—in direct response to the

ventilation and humidity control requirements of ASHRAE standard 62.1.

Trane’s Horizon Outdoor Air Unit leads the industry in the key areas of:

• indoor air quality (IAQ)

• energy efficiency

• high quality and durability

• advanced, integrated controls

• flexibility (including indoor installation)

• enhanced serviceability

Indoor Air Quality (IAQ) Features

• Stainless steel drain pan sloped in two directions to ensure proper drainage and reduce the

potential for microbial growth.

• Double-wall foamed panel construction throughout the indoor section of unit to provide, nonporous, cleanable interior surfaces.

• Inlet hood with moisture eliminators.

• High efficiency throwaway filter option with standard 2-, 4-, or 6-inch adjustable filter rack.

• Piezometer airflow measurement option.

• Easy filter access encourages frequent changing.

• Refrigerant hot gas reheat for low dewpoint supply air for superior humidity control.

• Capable of providing low dew point supply air for superior humidity control.

Energy Efficiency

• Total energy wheel option for recovered energy from centralized building exhaust.

• Optional modulating recovered refrigerant reheat for unit supply air.

High Quality and Durability

• Robust unit construction with 2-inch double-wall panels and reversible, hinged access doors.

• High quality, long-lasting latches and hinges for all access doors.

• Protective standard prepainted finish on cabinet exterior with optional corrosion inhibiting

coatings available for the unit exterior, interior and coils.

Advanced Controls

• All controls are factory-engineered, mounted, configured and tested to minimize field startup

time.

• UC600 microprocessor control with easy-to-read human interface and display for monitoring,

setting, editing, and controlling.

• Human interface with touch-pad screen for monitoring, setting, editing and controlling.

• Capable of supply-air control or zone control of both temperature and relative humidity

• Occupied and unoccupied control sequences.

• Optional remote human interface for ease of control access without going outdoors.

• Optional LonTalk

building management system or other control systems that support LonTalk.

®

communications interface communication link with a Tracer Summit™

10 OAU-PRC003A-EN

Page 11

Flexibility

Features and Benefits

• Numerous heater options and temperature rise capabilities available.

• Multiple roof curb options (1- or 2-inch vibration isolation, horizontal discharge, multiple

heights)

• Dual fuel (indirect/electric) option

•Custom colors

Figure 1. Condenser side view of the Trane Horizon™ Outdoor Air Unit Water Source Heat

Pump

Enhanced Serviceability

• Hinged access doors for ease of maintenance and service

• Easy-open door latches

• Slide out access direct-drive plenum fan

• Optional slide out, self-cleaning total-energy wheel

• Sight glass for each refrigeration circuit

• Optional control display

• High voltage cover

Standard Unit Features

• Multiple cabinet sizes with airflow range from 500 to 13,500 cfm

• Two-inch double-wall, R-13 construction with heavy gauge galvanized metal skin

• Outdoor air inlet hood

• Prepainted exterior finish

• Water-cooled DX refrigeration system

• Completely factory-piped and leak-tested refrigeration system

• Stainless steel drain pans sloped in two planes

• Digital scroll compressors

OAU-PRC003A-EN 11

Page 12

Features and Benefits

• Single-point power connections for units with optional total-energy wheel, powered exhaust,

and electric heat

• Filter rack adjustable for 2-, 4-, or 6-inch filters

• Factory-assembled inlet hood with 2-inch mist eliminators (OAD, OAK, OAN)

• Non-fused disconnect switc h

• Type 439 stainless steel heat exchanger

• Low leak parallel blade outdoor air damper with edge seals

• High-efficiency fan motors

Standard Control Features

• Fully integrated, factory-installed and commissioned microelectronic controls

• Supply airflow proving

• Emergency stop

• Occupied/unoccupied control modes

• High turn-down (up to 20:1) modulating indirect gas-fired heat

• Clogged filter switch

• Low ambient control down to 0°F

Optional Features

• Modulating electric heat

•Hot water coils

• Steam heat (future)

• Low leak parallel blade return air damper with edge seals

• Modulating damper control systems

• Pleated media filters (2-inch MERV-8, 2-inch MERV-13, 4-inch MERV-14, or a combination

2-inch/4-inch filter)

• 24 V electrostatic filters

• 120 V UVC downstream of evaporator coil

• High static fan

• Adjustable powered exhaust

• Exhaust dampers (gravity, barometric relief, and 2-position isolation)

• Fused disconnect switch

• Factory-installed smoke detectors (supply and/or return)

• Integral total-energy wheel

• Protective coatings for the unit and/or coils

• Remote human interface

• Factory or field-wired convenience outlet

• LED service lights

• Direct drive BI airfoil plenum fan

• Factory-installed variable frequency drive (VFD)

• Unit mounted human interface panel

12 OAU-PRC003A-EN

Page 13

Application Considerations

Overview

Outdoor Air Unit Functions

The Horizon™ Outdoor Air Unit (OAU) provides conditioned outdoor air suitable for mec hanical

ventilation or make-up air. The OAU conditions outdoor air as necessary to meet system

performance requirements by ventilation with filtration, cooling, dehumidification, and/or heating.

The OAU may deliver ventilation air in a number of ways. Refer to “System Configurations,” p. 13

and Figure 5, p. 15, Figure 6, p. 15, and Figure 8, p. 16 for more information.

• V entilation with Filtration

• Cooling

• Dehumidification

•Heating

System Configurations

Dedicated outdoor air systems can deliver conditioned outdoor air in one of the following ways:

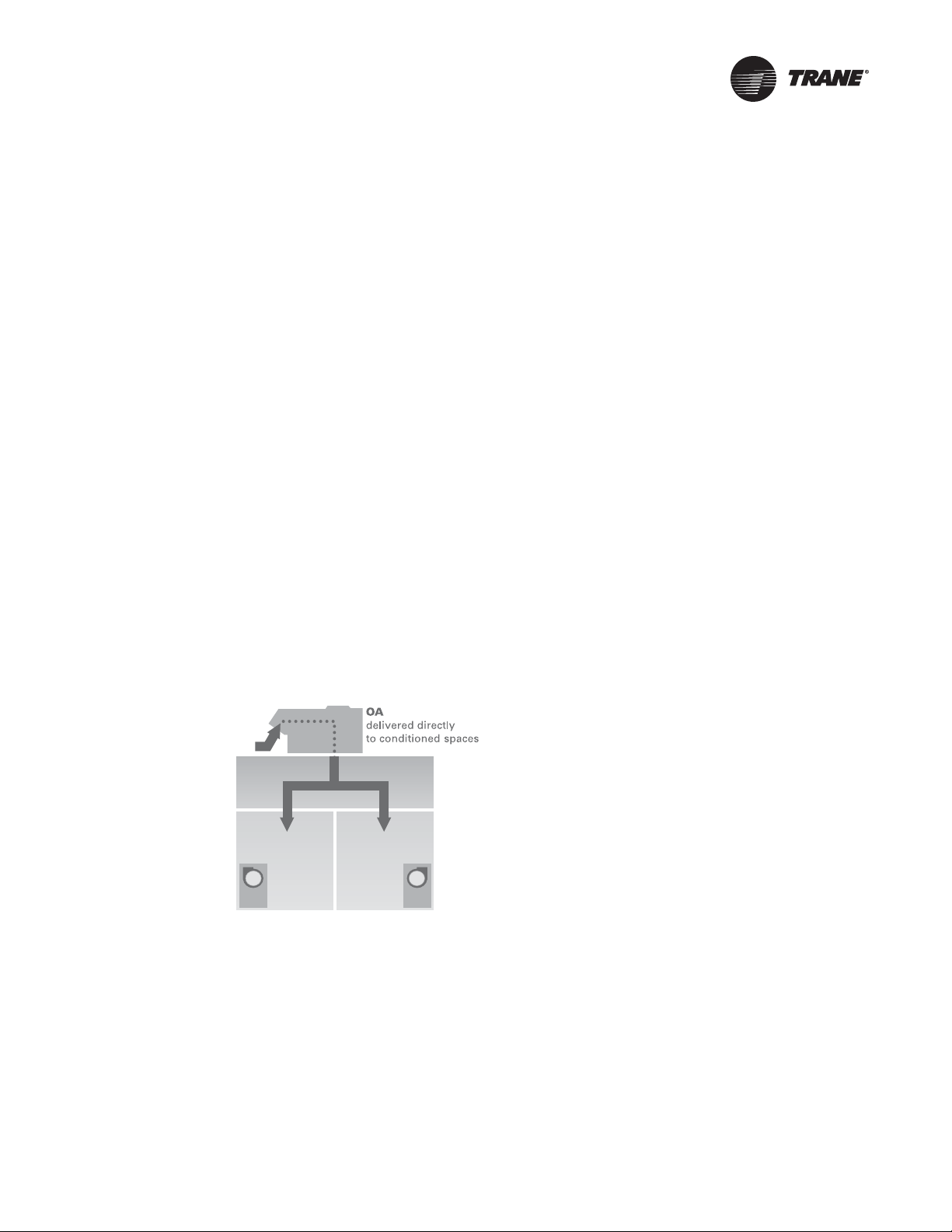

1. Conditioned outdoor air supplied directly to each occupied space, with the local terminal unit

controlling the space dry-bulb temperature. Refer to Figure 2, p. 13.

2. Conditioned outdoor air supplied directly to local terminal units, or return ducts of lo cal RTUs,

which deliver a mixture of the conditioned outdoor air and (conditioned) recirculated air to the

space. Refer to Figure 3, p. 14.

3. Conditioned outdoor air supplied directly to a single space to control the space temperature

and humidity. F o r example, this application will provide temperature and humidity control of

ventilated spaces, such as commercial kitchens or laboratories.

Figure 2. Direct discharge to conditioned space

OAU-PRC003A-EN 13

Page 14

Application Considerations

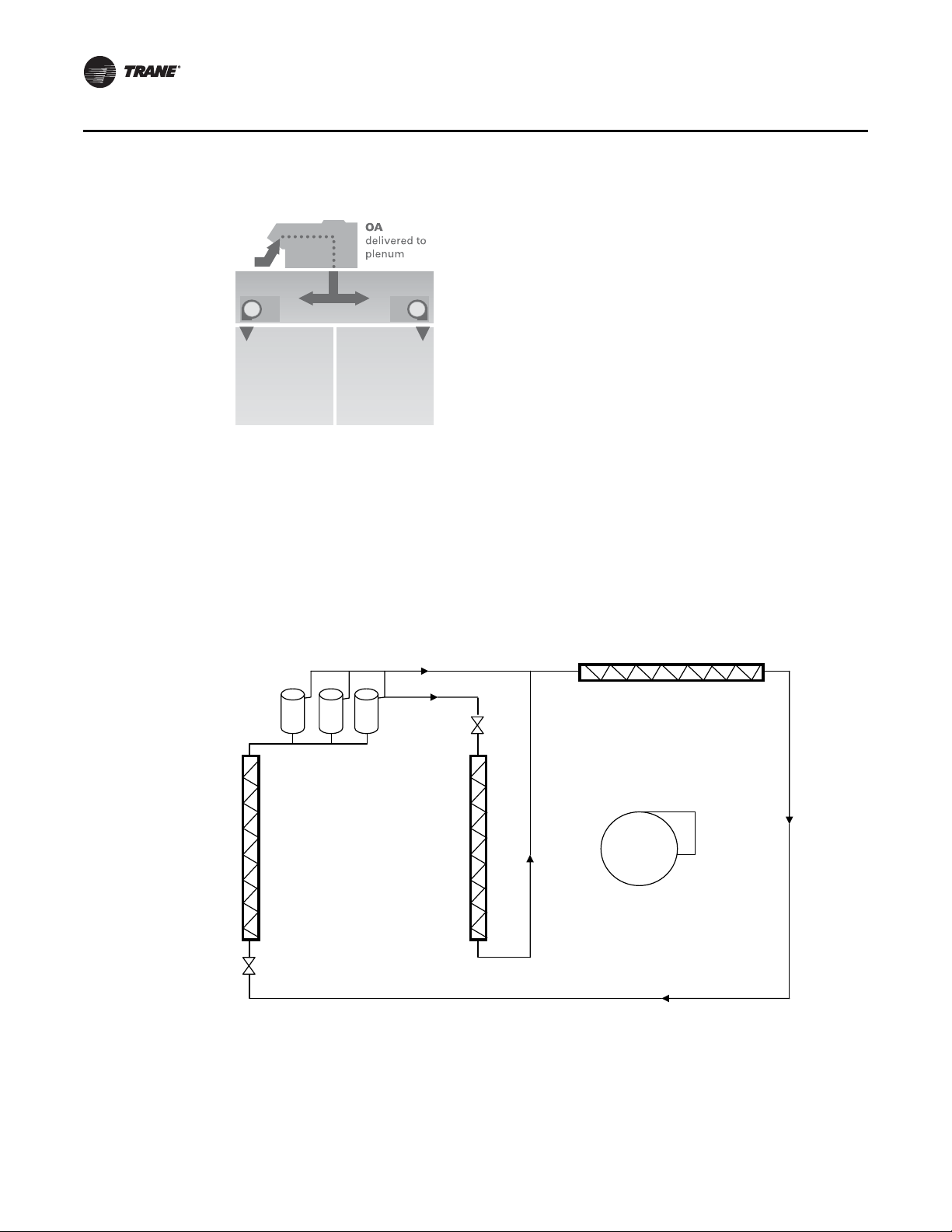

Main Condenser

Reheat Coil

Main Evaporator

Expansion Valves

Compressors

Indoor Fan

Figure 3. Indirect discharge to fan-coil units

Horizon OAU Operation

The Horizon™ OAU can use either DX cooling, condenser reheat, electric or gas heat to condition

outdoor air. The unit controls modulate cooling and heating capacity, reducing the supply air

temperature swings associated with staged heating and cooling.

OAU with Reheat

Dehumidification

14 OAU-PRC003A-EN

Figure 4, p. 14 shows the OAU system with a DX refrigerant circuit design using reheat.

Figure 4. Refrigeration system diagram with reheat

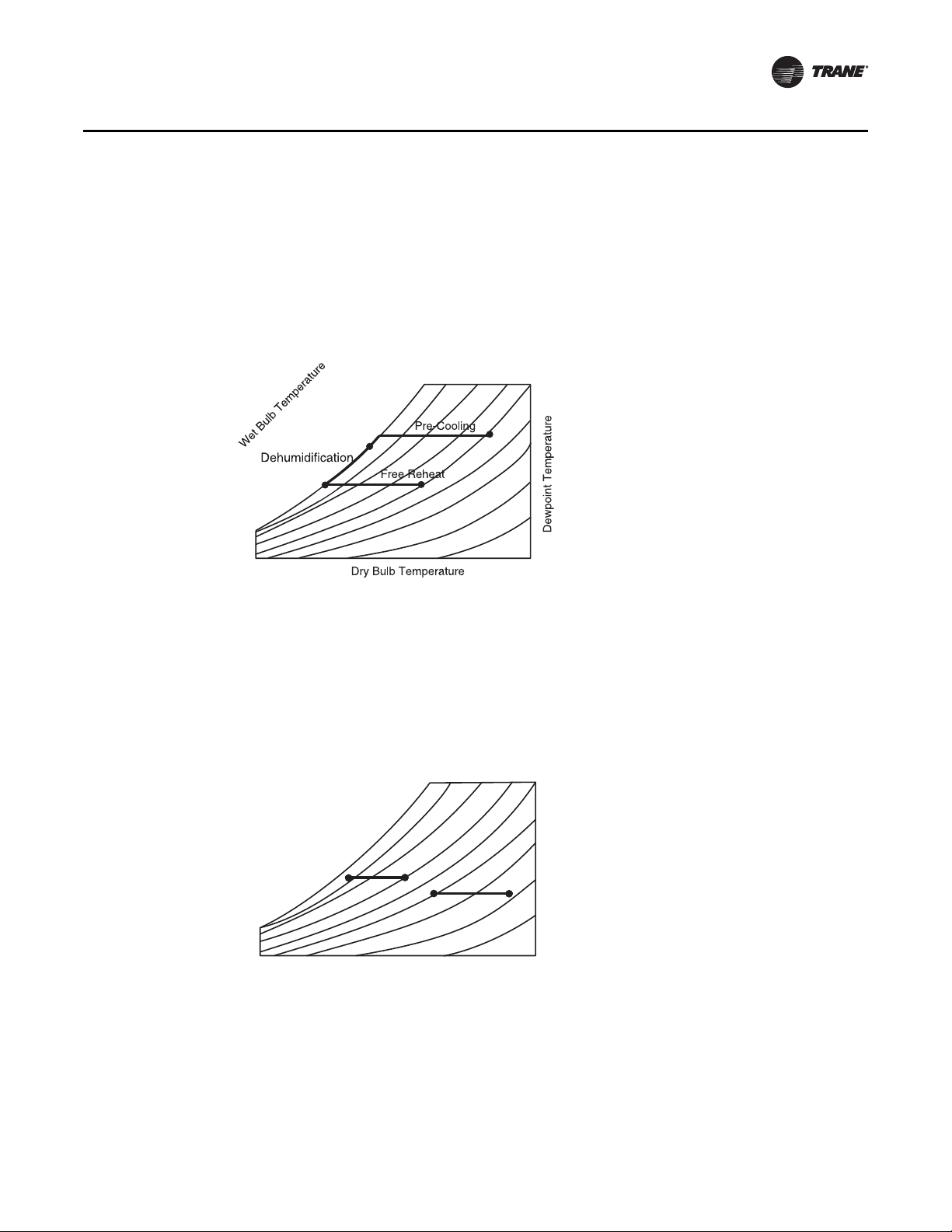

Consider Figure 5, p. 15. If the outdoor air dew point is above the dehumidification setpoint (or in

the case of zone control, the zone RH is above the RH setpoint), the OAU will:

• cool the outdoor air to remove required moisture and

• reheat to meet the discharge temperature setpoint.

Page 15

Application Considerations

h1

h3

h4

h2

Dry Bulb Temperature

Dewpoint Temperature

Wet Bulb Temperature

t3

t4

heating

t1

t2

cooling

At h1, 100 percent outdoor air enters the O AU . Th e O A U filters, cools, and dehumidifies the air as

it moves through the evaporator coil. Air leaves the evaporator coil saturated at the preset dew

point condition (h3) and is reheated by the reheat coil to the pre-set reheat temperature setpoint

(h4). The reheat coil transfers energy to the airstream. A liquid solenoid valve effectively modulates

the reheat capacity. The outdoor condenser rejects surplus heat. The reheat circuit is first on and

last off, so reheat energy is available at full and part load conditions. Since both the dew point

setpoint and discharge temperature setpoint are fully adjustable, the desired supply air conditions

are maintained at all load conditions.

Figure 5. Psychrometric chart with dehumidification and reheat

Cooling or Heating

OAU Outdoor Air Control without Reheat

OAU-PRC003A-EN 15

Consider Figure 6, p. 15. If the outdoor air dew point or zone RH is equal to or below the

dehumidification setpoint, the O AU will heat or cool the outdoor air to separate cooling or heating

setpoints. At t1 or t3, 100 percent outdoor air enters the OA U . The O A U filters, and cools or heats

the air as it is drawn through the evaporator and heating section. The air leaves the OAU at the

cooling or heating discharge setpoint (t2 or t4).

Figure 6. Psychrometric chart with cooling or heating only

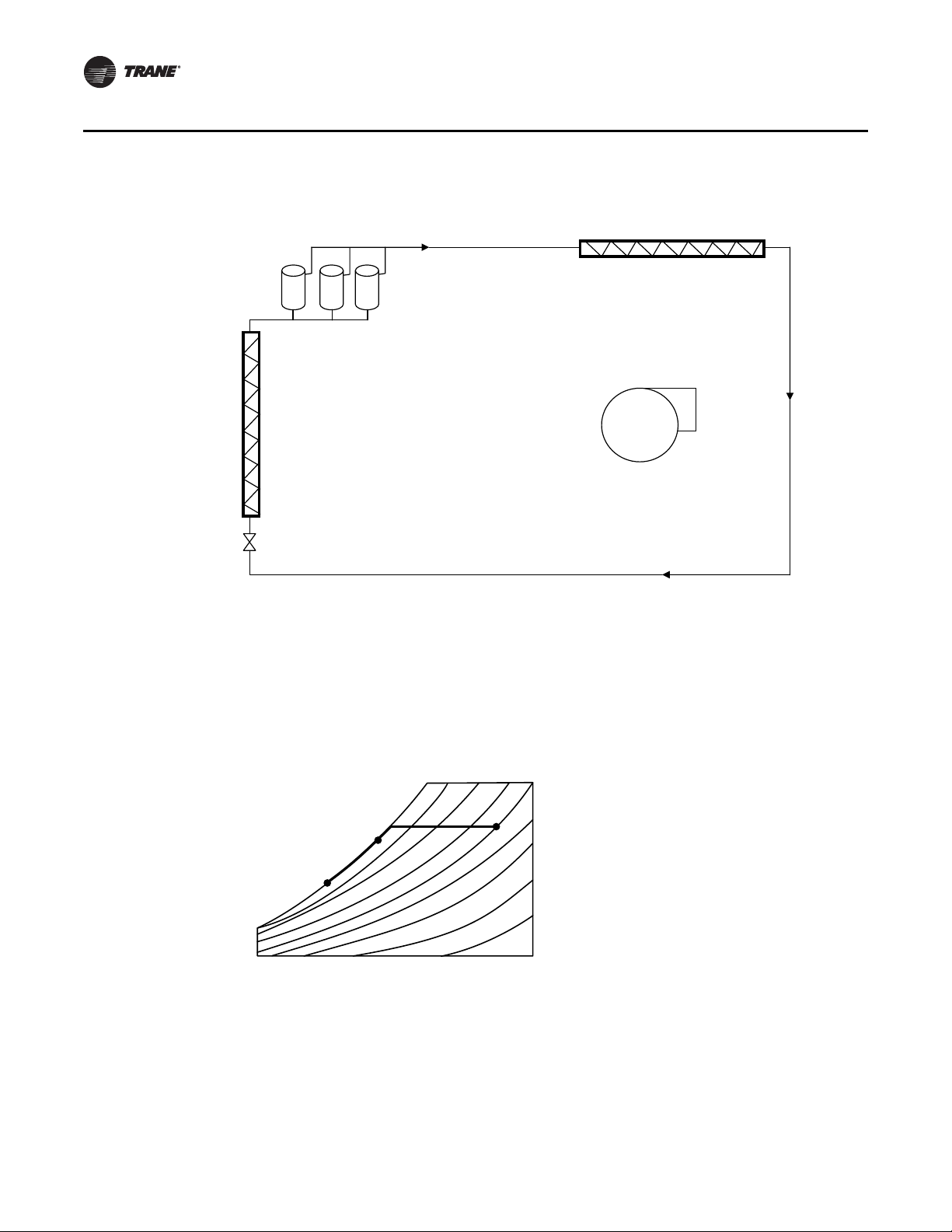

Figure 7, p. 16 shows the Horizon™ OAU DX system, using a refrigerant circuit design without

reheat.

Note: Space control not available without reheat.

Page 16

Application Considerations

Main Condenser

Main Evaporator

Expansion Valves

Compressors

Indoor Fan

Dry Bulb Temperature

Dewpoint Temperature

Wet Bulb Temperature

Dehumidification

h1

h2

h3

Figure 7. Refrigeration system diagram without reheat

Dehumidification

Cooling or Heating

Consider Figure 8, p. 16. If the outdoor air dew point is above the dehumidification setpoint, the

OA U will dehumidify the outdoor air. 100 percent outdoor air enters the OAU (h1). The unit filters,

cools and dehumidifies the air as it is drawn through the evaporator coils. Air leaves the evaporator

coils saturated at a preset dew point setpoint (h3) . Since the dew point setpoint is fully adjustable,

the desired dew point condition is maintained at all load conditions.

Figure 8. Psychrometric chart with dehumidification, no reheat

Consider Figure 9, p. 17. If the outdoor air dew point is below the dehumidification setpoint, the

OAU will heat or cool the outdoor air to separate cooling or heating setpoints. 1 00 percent outdoor

air enters the OAU (t1 or t3). The unit filters and cools or heats the air as it is drawn through the

evaporators and heating section. The air leaves the OAU at the cooling or heating setpoint.

16 OAU-PRC003A-EN

Page 17

Figure 9. Psychrometric chart with cooling and heating only

Dry Bulb Temperature

Dewpoint Temperature

Wet Bulb Temperature

t3

t4

heating

t1

t2

cooling

Establishing Capacity Requirements

Determining the OAU capacity requirements requires careful thought. Light Commercial

equipment is typically selected based on design sensible conditions. Since latent loads drive the

need for the OAU, base the selection on design latent conditions.

Application Considerations

Cooling & Dehumidification Selection Criteria

Evaporator Design Entering Conditions

Evaporator Design Leaving Conditions

OAU-PRC003A-EN 17

For many climates the peak outdoor air enthalpy occurs at a time when the outdoor dry-bulb

temperature is not the highest. Refer to the ch apter on climatic design information in the A SHRAE

Handbook of Fundamentals. The cooling and dehumidification design condition data is provided

three ways:

1. Design dry-bulb temperature with mean coincident wet bulb temperature

2. Design wet-bulb temperature with mean coincident dry-bulb temperature

3. Design dew point temperature with mean coincident dry-bulb temperature

The design wet-bulb condition typically represents a significantly higher ou tdoor air enthalpy than

the design dry-bulb condition. Use the condition that represents the highest enthalpy as the

entering evaporator selection condition.

Due to the uncertainty of the local terminal unit’s latent capacity at part load, it is usually most

straightforward to size the OAU to handle the entire latent load on the system, both indoor and

outdoor. With this design approach, the terminal units may do some latent cooling

(dehumidification) during periods of higher sensible load. At these times, the space will run slightly

drier than the design RH limit. This is why it makes sense to select the OAU to limit the space RH

to a maximum allowable level for those conditions when the terminal units are pro viding no space

latent cooling, such as 60 percent RH. Using lower humidity limits may result in an unnecessary

increase in system operating energy use.

Use Table 1, p. 18, Table 2, p. 18, and Table 3, p. 19 to identify the appropriate supply air dew point

for specific design conditions. Fo r a more detailed discussion on determining the selection criteria

of a OA U, refer to SYS-APG00 1-EN (Application Guide: Designing Dedicated Outdoor -Air Systems)

or SYS-APM004-EN (Applications Engineering Manual: Dehumidific ati on in HVAC Systems).

Page 18

Application Considerations

Reheat

Table 1. Supply air dew point temperature, 75°F at 60 percent RH space limit

Latent Load

Btu/h per Person

100 54.6 56.6 57.5 58.1 58.4 58.7 58.9 59.0 59.2 59.2 59.3

120 53.3 55.8 57.0 57.6 58.1 58.4 58.6 58.8 58.9 59.1 59.2

140 52.0 55.0 56.4 57.2 57.7 58.1 58.3 58.6 58.7 58.9 59.0

160 50.6 54.2 55.8 56.7 57.3 57.8 58.1 58.3 58.5 58.7 58.8

180 49.2 53.3 55.2 56.3 57.0 57.4 57.8 58.1 58.3 58.5 58.6

200 47.7 52.5 54.6 55.8 56.6 57.1 57.5 57.8 58.1 58.3 58.4

220 46.1 51.6 54.0 55.3 56.2 56.8 57.2 57.6 57.9 58.1 58.3

240 — 50.6 53.3 54.8 55.8 56.5 57.0 57.3 57.6 57.9 58.1

260 — 49.7 52.7 54.3 55.4 56.1 56.7 57.1 57.4 57.7 57.9

280 — 48.7 52.0 53.8 55.0 55.8 56.4 56.8 57.2 57.5 57.7

300 — 47.7 51.3 53.3 54.6 55.5 56.1 56.6 57.0 57.3 57.5

320 — 46.6 50.6 52.8 54.2 55.1 55.8 56.3 56.7 57.1 57.3

340 — 45.5 49.9 52.3 53.8 54.8 55.5 56.1 56.5 56.8 57.1

360 — — 49.251.753.354.455.255.856.356.657.0

380 — — 48.551.252.954.154.955.556.056.456.8

400 — — 47.750.652.553.754.655.355.856.256.6

420 — — 46.950.152.053.354.355.055.656.056.4

440 — — 46.149.551.653.054.054.755.355.856.2

460 — — 45.348.951.152.653.654.455.155.656.0

480 — — — 48.350.652.253.354.254.855.455.8

500 — — — 47.750.251.853.053.954.655.155.6

Note: Minimum dew point selectable is 45°F.

10 15 20 25 30 35 40 45 50 55 60

cfm per person

Table 2. Supply air dew point temperature, 75°F at 55 percent RH space limit

Latent Load

Btu/h per Person

100 51.6 53.8 54.9 55.5 55.9 56.1 56.3 56.5 56.6 56.7 56.8

120 50.2 53.0 54.2 55.0 55.5 55.8 56.1 56.2 56.4 56.5 56.6

140 48.8 52.1 53.6 54.5 55.1 55.5 55.8 56.0 56.2 56.3 56.4

160 47.2 51.2 53.0 54.0 54.6 55.1 55.5 55.7 55.9 56.1 56.2

180 45.6 50.2 52.3 53.5 54.2 54.8 55.2 55.5 55.7 55.9 56.1

200 — 49.3 51.6 53.0 53.8 54.4 54.9 55.2 55.5 55.7 55.9

220 — 48.3 50.9 52.4 53.4 54.1 54.5 54.9 55.2 55.5 55.7

240 — 47.2 50.2 51.9 53.0 53.7 54.2 54.6 55.0 55.2 55.5

260 — 46.2 49.5 51.4 52.5 53.3 53.9 54.4 54.7 55.0 55.3

280 — 45.1 48.8 50.8 52.1 53.0 53.6 54.1 54.5 54.8 55.1

300 — — 48.0 50.2 51.6 52.6 53.3 53.8 54.2 54.6 54.9

320 — — 47.2 49.7 51.2 52.2 53.0 53.5 54.0 54.3 54.6

340 — — 46.4 49.1 50.7 51.8 52.6 53.3 53.7 54.1 54.4

360 — — 45.6 48.5 50.2 51.4 52.3 53.0 53.5 53.9 54.2

380 — — — 47.9 49.8 51.0 52.0 52.7 53.2 53.7 54.0

400 — — — 47.2 49.3 50.6 51.6 52.4 53.0 53.4 53.8

420 — — — 46.6 48.8 50.2 51.3 52.1 52.7 53.2 53.6

440 — — — 46.0 48.3 49.8 50.9 51.8 52.4 53.0 53.4

460 — — — 45.3 47.8 49.4 50.6 51.5 52.2 52.7 53.2

480 — — — — 47.2 49.0 50.2 51.2 51.9 52.5 53.0

500 — — — — 46.7 48.6 49.9 50.9 51.6 52.2 52.7

Note: Minimum dew point selectable is 45°F.

10 15 20 25 30 35 40 45 50 55 60

cfm per person

18 OAU-PRC003A-EN

Page 19

Application Considerations

Table 3. Supply air dew point temperature, 75°F at 50 percent RH space limit

Latent Load

Btu/h per Person

100 48.4 50.8 51.9 52.6 53 53.3 53.6 53.8 53.9 54 54.1

120 46.8 49.8 51.3 52.1 52.6 53 53.3 53.5 53.6 53.8 53.9

140 45.2 48.9 50.6 51.5 52.2 52.6 52.9 53.2 53.4 53.5 53.7

160 — 47.9 49.8 51 51.7 52.2 52.6 52.9 53.1 53.3 53.5

180 — 46.8 49.1 50.4 51.3 51.8 52.3 52.6 52.9 53.1 53.3

200 — 45.7 48.4 49.8 50.8 51.5 51.9 52.3 52.6 52.8 53.0

220 — — 47.6 49.3 50.3 51.1 51.6 52 52.3 52.6 52.8

240 — — 46.8 48.7 49.8 50.7 51.3 51.7 52.1 52.4 52.6

260 — — 46 48.149.450.350.951.451.852.152.4

280 — — 45.2 47.4 48.9 49.8 50.6 51.1 51.5 51.9 52.2

300 — — — 46.848.449.450.250.851.351.651.9

320 — — — 46.2 47.9 49 49.8 50.5 51 51.4 51.7

340 — — — 45.547.348.649.550.250.751.151.5

360 — — — — 46.8 48.2 49.1 49.8 50.4 50.9 51.3

380 — — — — 46.3 47.7 48.7 49.5 50.1 50.6 51

400 — — — — 45.7 47.3 48.4 49.2 49.8 50.4 50.8

420 — — — — 45.2 46.8 48 48.9 49.6 50.1 50.6

440 — — — — — 46.3 47.6 48.5 49.3 49.8 50.3

460 — — — — — 45.9 47.2 48.2 49 49.6 50.1

480 — — — — — 45.4 46.8 47.9 48.7 49.3 49.8

500 — — — — — — 46.4 47.5 48.4 49.1 49.6

Note: Minimum dew point selectable is 45°F.

10 15 20 25 30 35 40 45 50 55 60

The Trane OAU utilizes recovered energy from the cooling process to reheat the air leaving the

evaporator coil as required to meet the discharge air setpoint. The reheat refrigeration circuit is

adequate to deliver enough reheat to supply neutral-temperature air (e.g., 75°F dry-bulb) under

most operating conditions. On very low load days, the reheat circuit may not contain enough

energy to meet the desired reheat setpoint.

cfm per person

Heating

The OA U has electric, heat pump, or g as heat option s. The elec tric he at option is available in 0°F–

80°F temperature rise offerings with SCR modulation. This means that the lowest temperature rise

provided depends only on heater size and unit airflow . Cal cul at e the tem perature rise to confirm

that it provides acceptable control. The electric heat will modulate to maintain heating setpoint.

When using hot water heat, the unit controller will modulate a field-provided coil control valve.

Provide an ethylene glycol and water mixture or other means of freeze protection for the hot water

coil if the OAU will be subject to sub-freezing temperatures.

Capacity Control

The capacity control system on the Horizon™ Outdoor Air Unit is flexible enough to accommodate

a variety of system applications. These applications include:

• treating outdoor air to supply a single space or multiple spaces or

• simultaneously meet building make-up air needs while controlling the temperature and relative

humidity of a single space.

Each of these applications requires careful consideration to achieve the desired results.

Discharge Air Control

For many multiple spac e, dedicated outdoor air systems, the O AU will continuously supply outdoor

air at a dry-bulb setpoint and a dew point that does not exceed its dew point setpoint. Th is control

approach is simple because it allows the OAU to function independent of local terminal unit

operation or actual space conditions. If the unit selection cri teria is determined using the method

suggested in“Establishing Capacity Requirements,” p. 17, the Outdoor Air Unit will limit the space

relative humidity to the target level.

OAU-PRC003A-EN 19

Page 20

Application Considerations

Many dedicated outdoor air systems supply reheated air directly to terminal units or to spaces that

have terminal units performing local sens ible cooling. This results in the local terminal units recooling the previously re-heated outdoor air . Resetting the supply air dry-bulb temperature of the

Outdoor Air Unit offers the opportunity to minimize the amount of time re-cooling occurs. Refer to

“Cooling Setpoint,” p. 20 for more information.

Cooling Setpoint

Because the T rane O AU dehumidifies the outdoor air by cooling it, th is cool outdoor air can reduce

the sensible cooling load on the local terminal unit. At low space sensible loads, the cool outdoor

air may sub-cool the space, causing the local terminal unit to add heat (new energy heat).

Therefore, reset occupied Space Cooling Setpoint (SPCS—Space Control Sequ ence) or Evaporator

Cooling Setpoint (ECS—Outdoor Air Contro l Sequence) of the O A U to minimize space sensible recooling so the terminal unit with the lowest sensible load is almost at zero cooling capacity (within

the limit of the dew point setpoint). To take full advantage of space demand based dry-bulb reset,

you may need to size some of the local terminal units based on neutral outdoor air temperature.

This strategy will more effectively manage occupant comfort during seasonal changeover for twopipe terminal unit systems. Because the OAU is not connected to the chiller or boiler plant,

accomplish this by resetting the Outdoor Air Unit SPCS or ECS to keep the critical zone at zero

heating capacity when the boiler is off and zero cooling capacity when the chiller is off. A Trane

Integrated Comfort™ system can provide this control capability.

Unoccupied Space Humidity Control

The Horizon™ O AU pro vides conditioned outdoor air for the ventilation and/or make-up air needs

of a building during occupied hours. It can also limit building relative humidity during unoccup ied

hours. To do this, provide a return air path to the OAU and place a relative humidity sensor in the

space served by the OAU or in a common relief air path (like a return corridor) if the OAU serves

multiple spaces. The unit will cycle as required to limit the space humidity to the unoccupied

Dewpoint Setpoint (NSDS) setpoint. Reheat and return air damper options are required for this

operation. For dedicated outdoor air systems ducted to terminal units, these units must cycle with

the operation of the Horizon OA U. A Trane Integrated Comfort™ system can provide this control

capability.

Space Control

For single space applications, the Horizon OAU can control space temperature and limit space

relative humidity. To do this, size the airflow to meet whichever is the highest: the space loads and

ventilation and/or make-up air needs of the application. Install a temperature sensor in the space

to provide temperature control and reset the supply air temperature. If reset of the supply air dew

point is desired, install a space relative humidity sensor in the space to provide relative humidity

limit control.

Outdoor Airflow Balancing

Establish final unit airflow through a field air balancing procedure. Change the fan speed through

replacement or fan sheave adjustment (belt drive indoor fan motor) or VFD Setpoint via the UC600

controller (direct drive fan motor).

Air to Air Energy Recovery

Energy recovery can significantly reduce HVAC system first-cost and operating energy costs.

You can use recovered energy for two purposes:

1. to temper or reheat supply air for independent control of sensible and latent capacity, or

2. to precondition outdoor air as it enters the building for ventilation.

The Horizon™ OAU offers refrigerant heat recovery for reheating the supply air. To precondition

20 OAU-PRC003A-EN

Page 21

the outdoor air, use the optional total-energy wheel to recover energy from building exhaust.

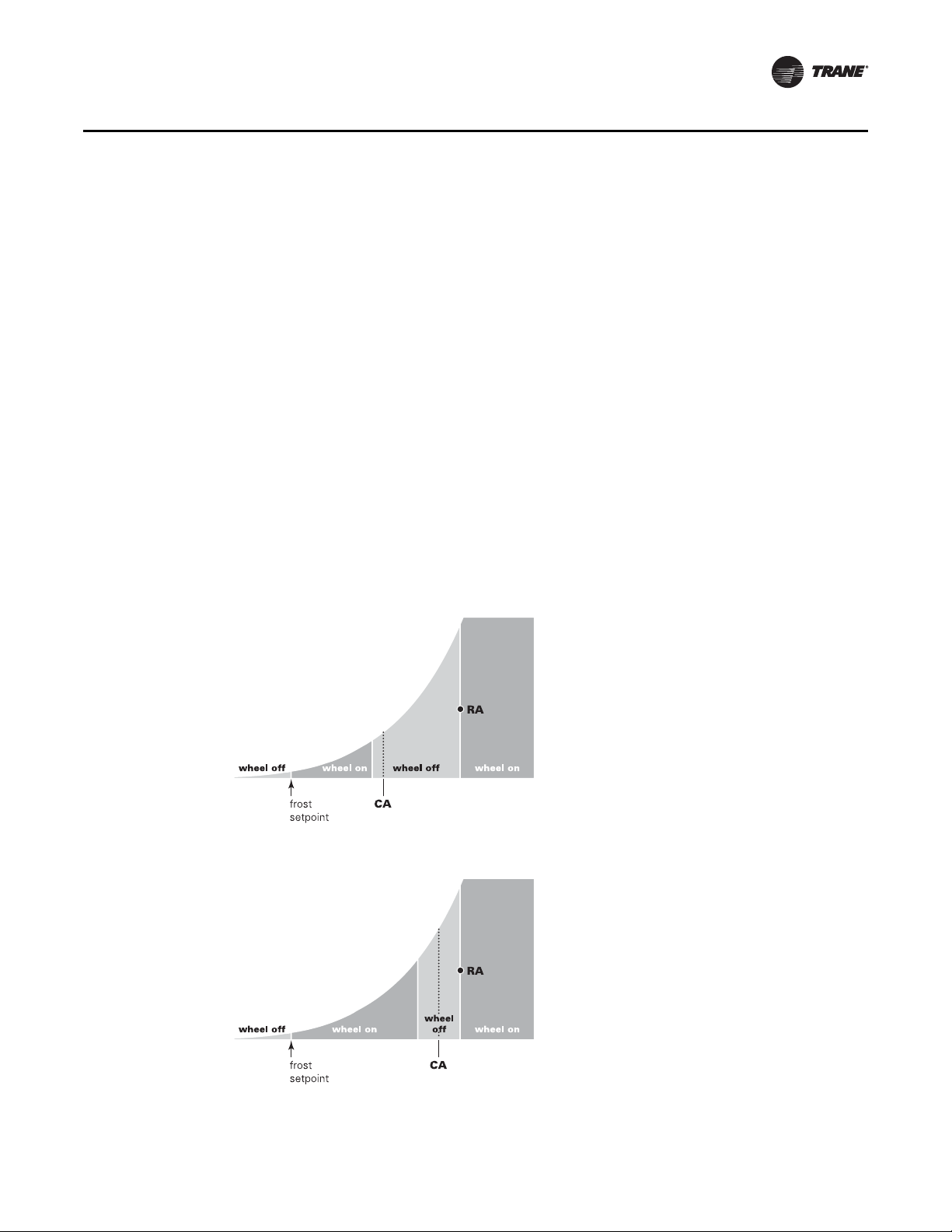

Controlling the Total-Energy Wheel

One way to control an energy recovery device is to turn it on and off with the OAU system

exhaust fan. In this case, the total energy wheel enables when the unit is in occupied mode and

the exhaust fan is running. While this control method is certainly simple and effective in some

applications, it may not provide the expected energy saving benefit, particularly when cold air

(vs. neutral air) is supplied to the building.

Another more effective approach is to use the outdoor air dry-bulb to determine when to energize or de-energize the energy recovery device. See Figure 11, p. 21 for an example of this simpli-

fied control. In addition to being more effective from a control standpoint, it’s also a very simple

control method because the wheel is enabled when all of the following are true:

• unit is in occupied mode,

• exhaust fan is enabled,

• Unit Main Control Module (MCM) calls for unit to operate in dehumidification, cooling, or

heating modes, and

• outside air temperature is above the frost protection setpoint (default setpoint 12°F).

If using the O AU to deliver cold, dry conditioned air to th e building (ou tdoor air is cooled to a low

dew point but not reheated), use the cooling setpoint control strategy (see “Cooling Setpoint,”

p. 20).

Application Considerations

Figure 10. Dry-bulb control in a cold DB/dry DP application

Figure 11. Dry-bulb control in a neutral DB/dry DP application

OAU-PRC003A-EN 21

Page 22

Application Considerations

PANEL ENCLOSURE

D" NPT FEMALE

CONNECTOR

CLEANOUT PLUG

D = PIPE DIAMETER

H = INTERNAL STATIC PRESSURE (IN W.G.) + 1"

J = H * 0.5

L = H + J + D

NOTES: 1. PITCH DRAIN AT LEAST 1/2" PER 10' HORIZ ONTAL RUN

2. CONDENSATE DRAIN PAN WILL NOT DRAIN PROPERLY IF

P-TRAP IS NOT PRIMED & OF ADEQUATE HEIGHT TO

A

L

L

OW FOR CABINETOPERATING NEGATIVE PRESSURE

Cross Leakage

All energy wheels have some cross leakage. Therefore, do not use energy wheels in applications

involving toxic or hazardous air streams. The percentage of cross leakage depends on the pressure

differentials across the wheel section. With Trane Horizon™ OAU energy wheels, the exhaust air

transfer ratios are typically low (less than 4 percent).

Condensate Drain Configuration

OAU units are selected based on dehumidification capability. As such, condensate can form at a

high rate. Therefore, the OAU drain pan and condensate line are siz ed and designed accordingly.

However, an often-o verlooked element of proper condensate drainage is proper P-T rap and drain

line sizing and installation. An incorrectly-designed and -installed P-Trap can restrict condensate

flow or cause water in the condensate drain pan to “spit” or “geyser” which may cause condensate

overflow. Carefully install and trap the drain pan to ensure adequate condensate removal under all

conditions.

An evaporator condensate drain connection is provided on each unit. For more inform ation, to the

Installation, Operation, and Maintenance for your specific product:

• OAU-SVX004*-EN (Installation, Operation, and Maintenance: Horizon™ Outdoor Air Unit -

Water Sou r ce Heat Pump - Model: OABE, OADE, OAKE, OANE)

A condensate trap must be installed at the unit due to the drain connection being on the “negative

pressure” side of the fan. Install the P-Trap using the guidelines in Figure 12.

Pitch drain lines connected to P-Trap at least 1/2 inch for every 10feet of horizontal run to assure

proper condensate flow. Do not allow the horizontal run to sag causing a possible double-trap

condition which could result in condensate backup due to “air lock”.

Figure 12. Condensate trap installation

22 OAU-PRC003A-EN

Page 23

Acoustical Considerations

Proper unit placement is critical to reducing transmitted sound levels from the OAU to the building.

Therefore, consider acoustic concerns during the design phase and place the unit accordingly. The

most economical means of avoiding an acoustical problem is to place the unit(s) away from

acoustically critical areas. If possible, do not locate units directly above areas such as: offices,

conference rooms, executive office areas, and classrooms. Instead, ideal locations to consider are:

over corridors, utility rooms, toilets, o r oth er areas where hi gh er so un d levels directly below the

unit(s) are acceptable.

Follow these basic guidelines for unit placement to minimize sound transmission through the

building structure.

1. Never cantilever the compressor side of the unit. A structural cross member or full perimeter

roof curb, supported by roof structural members, must support this side of the unit.

2. Locate the unit’s center of gravity close to or over column or main support beam.

3. If the roof structure is very light, replace roof joists by a structural shape in the critical areas

described above.

4. If several units are to be placed on one span, stagger them to reduce deflection over that span.

It is impossible to totally quantify the building structure effect on sound transmissio n because it

is dependent on how the roof and building members respond to the O AU’s sound and vibration.

However, following the guidelines listed above will help reduce sound transmissions.

Application Considerations

Clearance Requirements

Follow the recommended unit clearances to assure adequate serviceability, maximum capacity,

and peak operating efficiency . Reducing unit clearances may result in condenser coil starvation or

warm condenser air recirculation. If the recommended clearances are not possible on a par ticular

job, consider the following:

• Do the clearances available allow for major service work, such as changing compressors or

coils?

• Do the clearances available allow for proper outside air intake, exhaust air removal, and

condenser airflow?

• If screening around the unit is used, is there a possibility of air recirculation from the exhaust

to the outside air intake or from condenser exhaust to condenser intake.

Review any actual clearances that appear inadequate with your local Trane sales engineer.

When two or more units are placed side by side, increase the distance between the units to twice

the recommended single unit clearance. Stagger the units for these two reasons:

1 . T o reduce span deflection if more than one unit is placed on a single span. Reducing deflection

discourages sound transmission.

2. To assure proper exhaust ai r diffusion before contact with the adjacent unit’s outside air intake.

Duct Design

It is important to note that the rated capacities of the OAU can be met only if the unit is properly

installed. A well-designed duct system is essential to meet these capacities.

Satisfactory air distri bution throughout the system requires an unrestricted and uniform airflow

from the OAU discharge duct.

However, when job conditions dictate installation of elbows near the OAU outlet, using guide vanes

may reduce capacity loss and static pressure loss.

OAU-PRC003A-EN 23

Page 24

Application Considerations

Controls Sequence

For sequence of operation, please refer to the Installation, Operation, and Maintenance for your

specific product:

• OAU-SVX004*-EN (Installation, Operation, and Maintenance: Horizon™ Outdoor Air Unit -

Water Sou r ce Heat Pump - Model: OABE, OADE, OAKE, OANE)

24 OAU-PRC003A-EN

Page 25

Selection Procedure

Horizon OAU WSHP Selection Procedure

The Horizon™ Outdoor Air Unit (OAU) is designed to efficiently dehumidify outdoor air. As such,

the selection of an OA U is somewhat more complex than a standard recirculation roof top. T o make

it easier, there is an online selection tool provided. Before launching the program, the following

information about the specific project will be required:

1. Entering Air Temperature (DB/WB)

a. Summer

b. Winter

2. Entering Water Temperature (EWT) Cooling

3. Fluid Flow

4. Fluid Type (Water, Propylene, or Ethylene)

5. Volume Glycol (if Propylene or Ethylene is used)

6. EAT—Heating

7. EWT—H ea ti ng

8. Condenser Material (copper inner tubes are recommended for fresh and cooling tower water

applications while cupro-nickel is recommended for ground and sea water applications)

9. CFM

a. Total CFM

b. Outdoor Air CFM

10. External Static Pressure

11. Altitude

12. Electrical Voltage/Phase/Hertz

13. Heat Type

After initial entry, the tool will search all possible options, and display those which may be

acceptable. If a certain tonnage is not available given the project specifics, there is an option to view

the reason for that unit’ s rejectio n. Of the units available, select the one that is most suited to the

project, based on CFM, motor speed, or leaving air conditions. Leaving air conditions off the coil

as well as unit leaving air temperature are displayed. For distributors, a price is displayed. The unit

selected will be saved as its current configuration. If circumstances c hange af ter the unit is saved,

the program will require a reconfiguration, at which time the price will be adjusted as well.

OAU-PRC003A-EN 25

Page 26

General Data

Table 4. OABE General Data—Cooling 3–5 Ton s H igh Efficiency

3 Tons 4 Tons 5 Tons

OABE036A OABE048A OABE060A

Performance

Gross Cooling Capacity, Btu (kW) 41,800 (12.25) 57,439 (16.83) 70,304 (20.60)

Gross Heating Capacity, Btu (kW)

Nominal cfm (m

3

/h) 500–2000 (849–3398) 500–2000 (849–3398) 500–2000 (849–3398)

Compressor

Number 1 1 / Scroll 1 / Scroll

Type

Fluid/Refrigerant Water Coil

Type Coaxial Coaxial Coaxial

Connection Size/Circuit, in. (mm) 3/4 (19.05) 3/4 (19.05) 1 (25.4)

Pressure Drop/Circuit, ft wc (kPa) 4.3 (12.85) 6.4 (19.13) 4.8 (14.35)

Water Flow/Circuit, gpm (L/s) 9 (0.57) 12 (0.76) 15 (0.95)

Indoor Coil

Type High Performance High Performanc e High Performance

Tube Size—OD, i n. (mm)

Face Area, ft

Rows

FPI

Refrigerant Control

Drain Connection Size, in. (mm)

2

(m2) 4.17 (0.39) 4.17 (0.39) 4.17 (0.39)

Indoor Fan

Type Backward Curved Backward Curved Backward Curved

Number Used

Diameter

Drive Type

Number Motors

Motor HP (kW), Standard–Oversized

Motor RPM

Filters

Type Furnished Varies Varies Varies

Evap Size, in. (Qty) 20 x 24 x 2 (2) 20 x 24 x 2 (2) 20 x 24 x 2 (2)

Type Furnished MERV-8 MERV-8 MERV-8

ERV Size, in. (Qty) 20 x 24 x 2 (4) 20 x 24 x 2 (4) 20 x 24 x 2 (4)

Refrigerant Charge, lb of R-410A

36,779 (10.78) 44,667 (13.09) 63,402 (18.58)

Scroll 1 / Scroll 1 / Scroll

1/2 (12.7) 1/2 (12.7) 1/2 (12.7)

4 4 4

12 12 12

TXV TXV TXV

3/4 (19.05) 3/4 (19.05) 3/4 (19.05)

1 1 1

Varies Varies Varies

Direct Drive Direct Drive Direct Drive

1 1 1

2.68–4.0 (2–3) 2.68–4.0 (2–3) 2.68–4.0 (2–3)

Varies Varies Varies

See Nameplate See Nameplate See Nameplate

26 OAU-PRC003A-EN

Page 27

General Data

OABE Units

Table 5. OABE General Data—Cooling 6–9 Ton s H igh Efficiency

6 Tons 7 Tons 8 Tons 9 Tons

OABE072A OABE084A OABE096A OABE108A

Performance

Gross Cooling Capacity, Btu (kW) 81,059 (23.76) 93,010 (27.26) 105,293 (30.86) 115,859 (33.95)

Gross Heating Capacity, Btu (kW)

Nominal cfm (m

3

/h) 625–3000 (1062–5097) 625–3000 (1062–5097) 625–3000 (1062–5097) 625–3000 (1062–5097)

Compressor

Number 1 1 1 1

Type Scroll Scroll Scroll Scroll

Fluid/Refrigerant Water Coil

Type Coaxial Coaxial Coaxial Coaxial

Connection Size/Circuit, in. (mm)

Pressure Drop/Circuit, ft wc (kPa)

Water Flow/Circuit, gpm (L/s)

Indoor Coil

Type High Performance High Performance High Performance High Performance

Tube Size—OD, i n. (mm)

Face Area, ft

Rows

FPI

Refrigerant Control

Drain Connection Size, in. (mm)

2

(m2) 6.56 (0.61) 6.56 (0.61) 6.56 (0.61) 6.56 (0.61)

Indoor Fan

Type Backward Curved Backward Curved Backward Curved Backward Curved

Number Used

Diameter

Drive Type

Number Motors

Motor HP (kW), Standard–Oversized

Motor RPM

Filters

Type Furnished Varies Varies Varies Varies

Evap Size, in. (Qty) 20 x 24 x 2 (2) 20 x 24 x 2 (2) 20 x 24 x 2 (2) 20 x 24 x 2 (2)

Type Furnished MERV-8 MERV-8 MERV-8 MERV-8

ERV Size, in. (Qty) 20 x 24 x 2 (4) 20 x 24 x 2 (4) 20 x 24 x 2 (4) 20 x 24 x 2 (4)

Refrigerant Charge, lb of R-410A

75,344 (22.08) 85,183 (24.96) 100,455 (29.44) 108,943 (31.93)

1 (25.4) 1 (25.4) 2 (50.8) 2 (50.8)

6.3 (18.83) 8.2 (24.51) 5.9 (17.64) 7.4 (22.12)

18 (1.14) 21 (1.32) 24 (1.51) 27 (1.70)

1/2 (12.7) 1/2 (12.7) 1/2 (12.7) 1/2 (12.7)

4 4 4 4

12 12 12 12

TXV TXV TXV TXV

3/4 (19.05) 3/4 (19.05) 3/4 (19.05) 3/4 (19.05)

1 1 1 1

Varies Varies Varies Varies

Direct Drive Direct Drive Direct Drive Direct Drive

1 1 1 1

2.68-4.0 (2-3) 2.68-4.0 (2-3) 2.68-4.0 (2-3) 2.68-4.0 (2-3)

Varies Varies Varies Varies

See Nameplate See Nameplate See Nameplate See Nameplate

OAU-PRC003A-EN 27

Page 28

General Data

OADE Units

Table 6. OADE Gener a l Data—Cooling 5–8 Tons High Efficiency

5 Tons Downflow 6 Tons Downflow 7 Tons Downflow 8 Tons Downflow

OADE060A OADE072A OADE084 OADE096

Performance

Gross Cooling Capacity, Btu (kW) 71,522 (20.96) 81,032 (23.75) 101,129 (29.64) 110,880 (32.50)

Gross Heating Capacity, Btu (kW) 63,292 (18.55) 74,463 (21.82) 82,750 (24.25) 101,852 (29.85)

Nominal cfm (m

Compressor

Number 1112

Type Scroll Scroll Scroll Scroll

Fluid/Refrigerant Water Coil

Type Coaxial Coaxial Coaxial Coaxial

Connection Size/Circuit, in. (mm) 1 (25.4) 1 (25.4) 1 (25.4) 1/1 (25.4/25.4)

Pressure Drop/Circuit, ft wc (kPa) 4.8 (14.35) 7.9 (23.61) 8.2 (24.51) 6.4/6.4 (19.13/19.13)

Water Flow/Circuit, gpm (L/s) 15 (0.95) 18 (1.14) 21 (1.32) 12/12 (0.76/0.76)

Indoor Coil

Type High Performance High Performance High Performance High Performance

Tube Size—OD, in. (mm) 1/2 (12.7) 1/2 (12.7) 1/2 (12.7) 1/2 (12.7)

Face Area, ft

Rows 4444

FPI 12121212

Refrigerant Control TXV TXV TXV TXV

Drain Connection Size, in. (mm) 3/4 (19.05) 3/4 (19.05) 3/4 (19.05) 3/4 (19.05)

Indoor Fan

Type Backward Inclined Backward Inclined Backward Inclined Backward Inclined

Number Used 1111

Diameter Varies Varies Varies Varies

Drive Type Direct Drive Direct Drive Direct Drive Direct Drive

Number Motors 1111

Motor HP (kW), Standard–Oversized 1.0–3.0 1.0–3.0 1.0–3.0 1.0–5.0

Motor RPM 1750–3500 1750–3500 1750–3500 1750–3500

Motor Frame Size (Standard/Oversized) Varies Varies Varies Varies

Filters

Type Furnished Refer to “OAU Filter

Number/Size Recommended

Refrigerant Charge, lb of R-410A

Downflow See Nameplate See Nameplate See Nameplate See Nameplate

3

/h) 625–1250 (1062–2124) 750–1500 (1274–2548) 875–1750 (1487–2973) 1000–2000 (1699–3398)

2

(m2) 6 (0.56) 6 (0.56) 6 (0.56) 9 (0.84)

Guide” in “Appendix, ”

p. 65

Refer to “OAU Filter

Guide” in “Appendix,”

p. 65

Refer to “OAU Filter

Guide” in “Appendix,”

p. 65

Refer to “OAU Filter

Guide” in “Appendix,”

p. 65

28 OAU-PRC003A-EN

Page 29

General Data

OADE Units

Table 7. OADE General Data—Cooling 10–15 Tons High Efficiency

10 Tons Downflow 12 Tons Downflow 15 Tons Downflow

OADE120A OADE144A

Performance

Gross Cooling Capacity, Btu (kW) 143,044 (41.92) 162,064 (47.50) 202,258 (59.28)

Gross Heating Capacity, Btu (kW) 126,584 (37.10) 148,926 (43.65) 165,500 (48.50)

Nominal cfm (m

3

/h) 1250–2500 (2124–4247) 1500–3000 (2548–5097) 1500–3000 (2548–5097)

Compressor

Number 222

Type Scroll Scroll Scroll

Fluid/Refrigerant Water Coil

Type Coaxial Coaxial Coaxial

Connection Size/Circuit, in. (mm) 1/1 (25.4/25.4) 1/1 (25.4/25.4) 1/1 (25.4/25.4)

Pressure Drop/Circuit, ft wc (kPa) 4.8/4.8 (14.35/14.35) 7.9/7.9 (23.61/23.61) 8.2/8.2 (24.51/24.51)

Water Flow/Circuit, gpm (L/s) 15/15 (0.95/0.95) 18/18 (1.14/1.14) 21/21 (1.32/1.32)

Indoor Coil

Type High Performance High Performance High Performance

Tube Size—OD, in. (mm) 1/2 (12.7) 1/2 (12.7) 1/2 (12.7)

Face Area, ft

Rows 444

FPI 121212

Refrigerant Control TXV TXV

Drain Connection Size, in. (mm) 3/4 (19.05) 3/4 (19.05) 3/4 (19.05)

2

(m2) 9 (0.84) 9 (0.84) 9 (0.84)

Indoor Fan

Type Backward Inclined Backward Inclined Backward Inclined

Number Used 1 1 1

Diameter Varies Varies Varies

Drive Type Direct Drive Direct Drive

Number Motors 1 1

Motor HP (kW), Standard–Oversized 1.0–5.0 1.0–5.0

Motor RPM 1750–3500 1750–3500

Motor Frame Size (Standard/

Oversized)

Varies Varies

Filters

Type Furnished Refer to “OAU Filter

Number/Size Recommended

Guide” in “Appendix,”

p. 65

Refer to “OAU Filter

Guide” in “Appendix,”

p. 65

Refrigerant Charge, lb of R-410A

Downflow See Nameplate See Nameplate See Nameplat e

OADE180A

TXV

Direct Drive

1

1.0–5.0

1750–3500

Varies

Refer to “OAU Filter

Guide” in “Appendix,”

p. 65

OAU-PRC003A-EN 29

Page 30

General Data

OAKE Units

Table 8. OAKE Gener a l Data—Cooling 12–20 Tons High Efficiency

12 Tons Downflow 15 Tons Downflow 17 Tons Downflow 20 Tons Downflow

OAKE144A OAKE180A OAKE210A OAKE240A

Performance

Gross Cooling Capacity, Btu (kW) 164,280 (48.15) 208,912 (61.23) 239,236 (70.11) 279,374 (81.88)

Gross Heating Capacity, Btu (kW) 148,018 (43.38) 190,654 (55.88) 208,973 (61.24) 219,466 (64.32)

Nominal cfm (m

Compressor

Number 2222

Type Scroll Scroll Scroll Scroll

Fluid/Refrigerant Water Coil

Type Coaxial Coaxial Coaxial Coaxial

Connection Size/Circuit, in. (mm) 1/1 (25.4/25.4) 1/1 (25.4/25.4) 2/2 (50.8/50.8) 2/2 (50.8/50.8)

Pressure Drop/Circuit, ft wc (kPa) 7.9/7.9 (23.61/23.61) 8.2/8.2 (24.51/24.51) 7.0/7.0 (20.92/20.92) 9.0/9.0 (26.90/26.90)

Water Flow/Circuit, gpm (L/s) 18/18 (1.14/1.14) 21/21 (1.32/1.32) 26.25/26.25 (1.66/1.66) 30/30 (1.89/1.89)

Indoor Coil

Type High Performance High Performance High Performance High Performance

Tube Size—OD, in. (mm) 1/2 (12.7) 1/2 (12.7) 1/2 (12.7) 1/2 (12.7)

Face Area, ft

Rows 4444

FPI 12 12 12 12

Refrigerant Control TXV TXV TXV TXV

Drain Connection Size, in. (mm) 1 (25.4) 1 (25.4) 1 (25.4) 1 (25.4)

Indoor Fan

Type Backward Inclined Backward Inclined Backward Inclined Backward Inclined

Number Used 1 1 1 1

Diameter Varies Varies Varies Varies

Drive Type Direct Drive Direct Drive Direct Drive Direct Drive

Number Motors 1111

Motor HP (kW), Standard–Oversized 1–5.0 1–5.0 1–7.5 1–7.5

Motor RPM 1750–3500 1750–3500 1750–3500 1750–3500

Motor Frame Size (Standard/Oversized) Varies Varies Varies Varies

Filters

Type Furnished Refer to “OAU Filter

Number/Size Recommended

Refrigerant Charge, lb of R-410A

Downflow See Nameplate See Nameplate See Nameplate See Nameplate

3

/h) 1500–3000 (2548–5097) 1875–3750 (3186–6371) 2125–4250 (3610–7221) 2500–5000 (4247–8495)

2

(m2) 9 (0.84) 10 (0.93) 16 (1.49) 16 (1.49)

Guide” in “Appendix,”

p. 65

Refer to “OAU Filter

Guide” in “Appendix, ”

p. 65

Refer to “OAU Filter

Guide” in “Appendix,”

p. 65

Refer to “OAU Filter

Guide” in “Appendix,”

p. 65

30 OAU-PRC003A-EN

Page 31

General Data

OAKE Units

Table 9. OAKE General Data—Cooling 22–30 Tons Hi gh Efficiency

22 Tons Downflow 25 Tons Downflow 30 Tons Downflow

OAKE264A OAKE300A OAKE360A

Performance

Gross Cooling Capacity, Btu (kW) 314,806 (92.26) 348,788 (102.22) 394,638 (115.66)

Gross Heating Capacity, Btu (kW) 289,850 (84.95) 328,446 (96.26) 368,582 (108.02)

Nominal cfm (m3/h)

2750–5500

(4672–9344)

Compressor

Number 222

Type Scroll Scroll Scroll

Fluid/Refrigerant Water Coil

Type Coaxial Coaxial Coaxial

Connection Size/Circuit, in. (mm) 2/2 (50.8/50.8) 2/2 (50.8/50.8) 2/2 (50.8/50.8)

Pressure Drop/Circuit, ft wc (kPa) 11.7/11.7 (34.97/34.97) 13.2/13.2 (39.46/39.46) 18.6/18.6 (55.60/55.60)

Water Flow/Circuit, gpm (L/s) 33/33 (2.08/20.8) 37.5/37.5 (2.37/2.37) 45/45 (2.84/2.84)

Indoor Coil

Type High Performance High Performance High Performance

Tube Size—OD, in. (mm) 1/2 (12.7) 1/2 (12.7) 1/2 (12.7)

Face Area, ft

Rows 444

FPI 121212

Refrigerant Control TXV TXV TXV

Drain Connection Size, in. (mm) 1 (25.4) 1 (25.4) 1 (25.4)

2

(m2) 16 (1.49) 20 (1.86) 20 (1.86)

Indoor Fan

Type Backward Inclined Backward Inclined Backward Inclined

Number Used 1 1 1

Diameter Varies Varies Varies

Drive Type Direct Drive Direct Drive Direct Drive

Number Motors 111

Motor HP (kW), Standard–Oversized 1–7.5 1.0–15.0 1.0–15.0

Motor RPM 1750–3500 1750–3500 1750–3500

Motor Frame Size (Standard/

Oversized)

Varies Varies Varies

Filters

Type Furnished Refer to “OAU Filter

Number/Size Recommended

Guide” in “Appendix,”

p. 65

Refrigerant Charge, lb of R-410A

Downflow See Nameplate See Nameplate See Nameplate

3125–6250

(5309–10619)

Refer to “OAU Filter

Guide” in “Appendix,”

p. 65

3750–7500

(6371–12742)

Refer to “OAU Filter

Guide” in “Appendix,”

p. 65

OAU-PRC003A-EN 31

Page 32

General Data

OANE Units

Table 10. OANE General Data—Cooling 30–40 Tons High Efficiency