Page 1

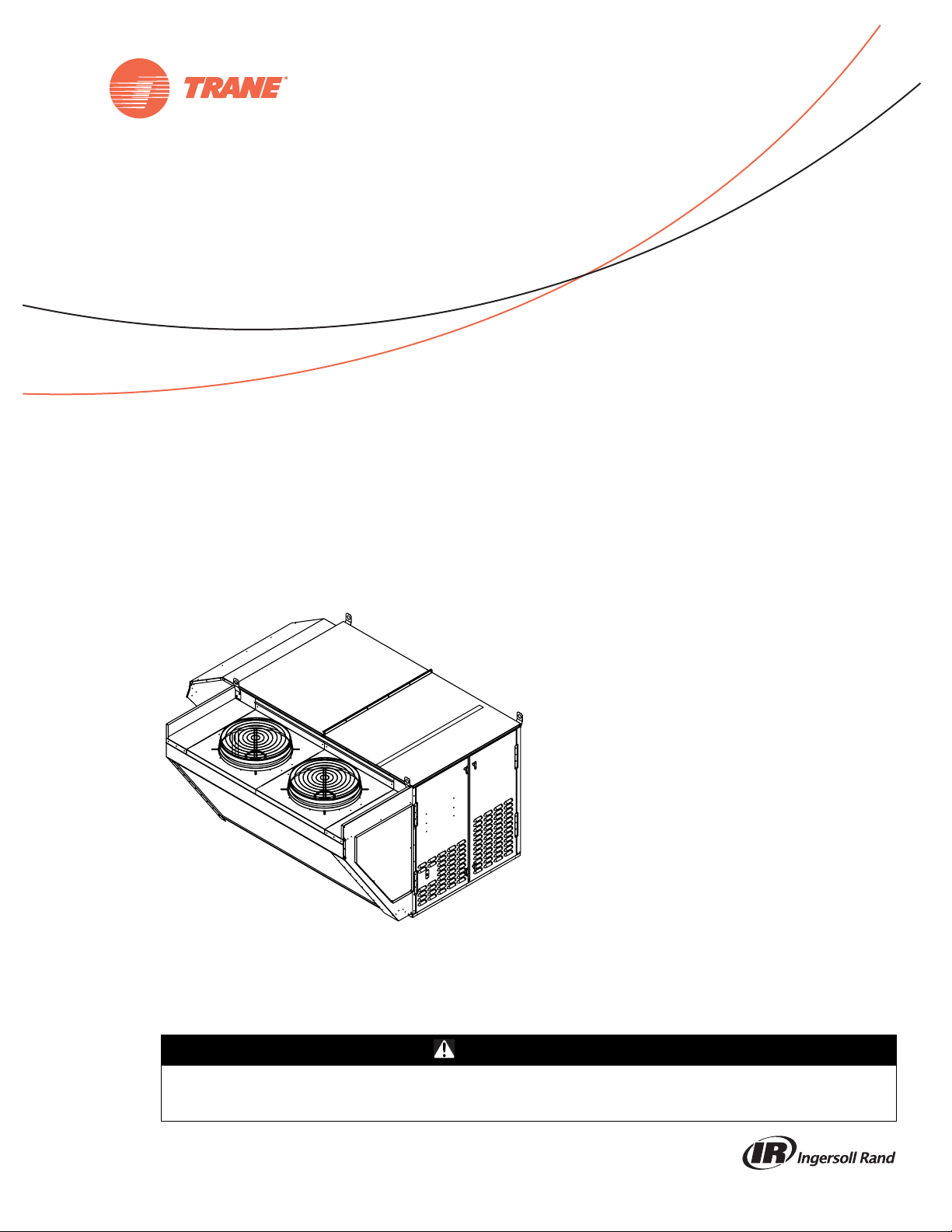

Installation, Operation,

and Maintenance

Horizon™ Outdoor Air Unit

Indirect Gas-Fired/Electric Heat

Models: OA1D, OA2D, OA3D

Important: Proper execution of the tasks outlined in this Installation, Operation, and Maintenance manual

require and assume the tec hnician has been certified as a start up technician for the Horiz on Outdoor

Air unit. This includes working knowledge of the Tracer TU program.

SAFETY WARNING

Only qualified personnel should install and service the equipment. The installation, starting up, and servicing of heating, ventilating, and airconditioning equipment can be hazardous and requires specific knowledge and training. Improperly installed, adjusted or altered equipment

by an unqualified person could result in death or serious injury. When working on the equipment, observe all pr ecautions in the literature and

on the tags, stickers, and labels that are attached to the equipment.

April 2014

OAU-SVX01E-EN

Page 2

Introduction

Read this manual thoroughly before operating or servicing

this unit.

Warnings, Cautions, and Notices

Safety advisories appear throughout this manual as

required. Y our personal safety and the proper operation of

this machine depend upon the strict observance of these

precautions.

The three types of advisories are defined as follows:

WARNING

Proper Field Wiring and Grounding

Required!

Failure to follow code could result in death or serious

injury. All field wiring MUST be performed by qualified

personnel. Improperly installed and grounded field

wiring poses FIRE and ELECTROCUTION hazards. To

avoid these hazards, y ou MUST f ollow r equir ements for

field wiring installation and grounding as described in

NEC and your local/state electrica l codes.

WARNING

CAUTIONs

NOTICE:

Indicates a potentially hazardous

situation which, if not avoided, could

result in death or serious injury.

Indicates a potentially hazardous

situation which, if not avoided, could

result in minor or moderate injury. It

could also be used to alert against

unsafe practices.

Indicates a situation that could result in

equipment or property-damage only

accidents.

Important Environmental Concerns

Scientific research has shown that certain man-made

chemicals can affect the earth’s naturally occurring

stratospheric ozone layer when released to the

atmosphere. In particular, several of the identified

chemicals that may af fect the ozone layer are refrigerants

that contain Chlorine, Fluorine and Carbon (CFCs) and

those containing Hydrogen, Chlorine, Fluorine and

Carbon (HCFCs). Not all refrigerants containing these

compounds have the same potential impact to the

environment. T rane advocates the responsible handling of

all refrigerants-including industry replacements for CFCs

such as HCFCs and HFCs.

Important Responsible Refr iger ant Pr actices

Trane believes that responsible refrigerant practices are

important to the environment, our customers, and the air

conditioning industry. All technicians who handle

refrigerants must be certified. The Federal Clean Air Act

(Section 608) sets forth the requirements for handling,

reclaiming, recovering and recycling of certain

refrigerants and the equipment that is used in these

service procedures. In addition, some states or

municipalities may have additional requirements that

must also be adhered to for responsible management of

refrigerants. Know the applicable laws and follow them.

WARNING

Personal Protective Equipment (PPE)

Required!

Installing/servicing this unit could result in exposure to

electrical, mechanical and chemical hazards.

• Before installing/servi cin g th is un it, technicians

MUST put on all PPE required for the work being

undertaken (Examples; cut r esistant glo v es/sleeves,

butyl gloves, saf ety glasses, hard hat/bump cap, fall

protection, electrical PPE and arc flash clothing).

ALWAYS refer to appropriate Material Safety Data

Sheets (MSDS)/Safety Data Sheets (SDS) and OSHA

guidelines for proper PPE.

• When working with or ar ound hazar dous chemi cals,

ALWAYS refer to the appropriate MSDS/SDS and

OSHA/GHS (Global Harmonized System of

Classification and Labelling of Chemicals) guidelines

for information on allowable personal exposure

levels, proper respiratory protection and handling

instructions.

• If there is a risk of ener gized electr ical contac t, arc, or

flash, technicians MUS T put on all PPE in accor dance

with OSHA, NFPA 70E, or other country-specific

requirements for arc flash protection, PRIOR to

servicing the unit. NEVER PERFORM ANY

SWITCHING, DISCONNECTING, OR VOLTAGE

TESTING WITHOUT PROPER ELECTRICAL PPE AND

ARC FLASH CLOTHING. ENSURE ELECTRICAL

METERS AND EQUIPMENT ARE PROPERLY RATED

FOR INTENDED VOLTAGE.

Failure to follow instructions could result in death or

serious injury.

© 2014 Trane All rights reserved OAU-SVX01E-EN

Page 3

WARNING

Contains Refrigerant!

System contains oil and refrigerant under high

pressure. Recover refriger ant to relieve pressure before

opening the system. See unit nameplate for refrigerant

type. Do not use non-approved refrigerants, refrigerant

substitutes, or refrigerant additives.

Failure to follow proper procedures or the use of nonapproved refrigerants, refrigerant substitutes, or

refrigerant additives could result in death or serious

injury or equipment damage.

WARNING

Hazard of Explosion and Deadly Gases!

Never solder, braze or weld on refrigerant lines or any

unit components that are above atmospheric pressure

or where refrigerant may be present. Always remove

refrigerant by following the guidelines established by

the EPA Federal Clean Air Act or other state or local

codes as appropriate. After refrigerant removal, use dry

nitrogen to bring system back to atmospheric pressure

before opening system for repairs. Mixtures of

refr igerants and air under pressure may become

combustible in the presence of an ignition source

leading to an explosion. Excessive heat from soldering,

brazing or welding with refrigerant vapors present can

form highly toxic gases and extremely corrosive acids.

Failure to follow all proper safe refrigerant handling

practices could result in death or serious injury.

Introduction

Copyright

This document and the information in it are the property of

Trane, and may not be used or reproduced in whole or in

part without written permission. Trane reserves the right

to revise this publication at any time, and to make changes

to its content without obligation to notify any person of

such revision or change.

Trademarks

All trademarks referenced in this document are the

trademarks of their respective owners.

Revision History

OAU-SVX01E-EN (17 Apr 2014)

• Model number updates

OAU-SVX01E-EN 3

Page 4

Table of Contents

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Warnings, Cautions, and Notices . . . . . . . . 2

Important Environmental Concerns . . . . . 2

Important Responsible Refrigerant Practice s

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Model Number Descriptions . . . . . . . . . . . . . . 6

Horizon Outdoor Air Unit . . . . . . . . . . . . . . . 6

General Information . . . . . . . . . . . . . . . . . . . . . 9

Overview of Manual . . . . . . . . . . . . . . . . . . 9

Model Number Description . . . . . . . . . . . . 9

Unit Nameplate . . . . . . . . . . . . . . . . . . . . . 9

Compressor Nameplate . . . . . . . . . . . . . . . 9

Unit Description . . . . . . . . . . . . . . . . . . . . . 9

Indoor Fan Failure Input . . . . . . . . . . . . . . 9

Low Pressure Control ReliaTel Control . . 9

Refrigerant Circuits . . . . . . . . . . . . . . . . . . 9

High Pressure Control ReliaTel Control . . 9

Space Temperature / RH Sensor (Optional)

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

High Temperature Sensor . . . . . . . . . . . . 10

Outdoor Air Temperature and Relative Hu-

midity Sensor . . . . . . . . . . . . . . . . . . . . . . 10

Control Input (Occupied / Unoccupied) . 10

Hot Gas Reheat . . . . . . . . . . . . . . . . . . . . . 10

100 Percent Outdoor Air Hood with Damper

and Filters . . . . . . . . . . . . . . . . . . . . . . . . . 10

Modulating Indirect Gas-Fired Burner . . 10

Through the Base Electrical with Disconnect

Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Through the Base Gas Piping . . . . . . . . . 10

Hinged Access Doors . . . . . . . . . . . . . . . . 10

Modulating Electric Heat . . . . . . . . . . . . . 10

Unit Inspection . . . . . . . . . . . . . . . . . . . . . . . 11

First Aid Measures . . . . . . . . . . . . . . . . . . 11

Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Unit Clearances . . . . . . . . . . . . . . . . . . . . 11

Unit Clearances, Curb Dimensions, and Dimensional Data

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

OA1 Units . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Unit Clearances . . . . . . . . . . . . . . . . . . . . 12

Curb Dimensions . . . . . . . . . . . . . . . . . . . .12

Dimensional Data . . . . . . . . . . . . . . . . . . . .13

OA2 Units . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Unit Clearances . . . . . . . . . . . . . . . . . . . . .14

Curb Dimensions . . . . . . . . . . . . . . . . . . . .15

Dimensional Data . . . . . . . . . . . . . . . . . . . .15

OA3 Units . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Unit Clearances . . . . . . . . . . . . . . . . . . . . .16

Curb Dimensions . . . . . . . . . . . . . . . . . . . .17

Dimensional Data . . . . . . . . . . . . . . . . . . . .17

Unit Weight and Rigging . . . . . . . . . . . . . . . . .18

Unit Weight . . . . . . . . . . . . . . . . . . . . . . . . .18

Corner Weight . . . . . . . . . . . . . . . . . . . . . .19

Rigging . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

Sequence of Operation . . . . . . . . . . . . . . . . . . .21

Space Control with Indirect Gas-Fired or Electric Heat and Modulating HGRH, ERV, and

Powered Ex.

Sequence of Operation—”Occupied” . . .21

Sequence of Operation—”Unoccupied” .22

. . . . . . . . . . . . . . . . . . . . . . . . . .21

Discharge Air Control with Indirect Gas-Fired

or Electric Heat and Modulating HGRH, ERV,

and Powered Ex.

Sequence of Operation—”Occupied” . . .23

Sequence of Operation—”Unoccupied” .24

. . . . . . . . . . . . . . . . . . . . . .23

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

Ductwork . . . . . . . . . . . . . . . . . . . . . . . . . . .25

General Unit Requirements . . . . . . . . . . . .25

Main Electrical Power Requirements . . . .26

Condensate Drain Configuration . . . . . . .26

Filter Installation . . . . . . . . . . . . . . . . . . . . .26

Field Installed Power Wiring . . . . . . . . . . .26

Main Unit Power . . . . . . . . . . . . . . . . . . . . . .28

Standard Wiring . . . . . . . . . . . . . . . . . . . . .28

Voltage Imbalance . . . . . . . . . . . . . . . . . . .28

Electrical Phasing (Three-Phase Motors) .29

Compressor Crankcase Heaters . . . . . . . .29

Main Unit Display and Relia T el Controls .30

Field-Installed Control Wiring . . . . . . . . . .30

Control Power Transformer . . . . . . . . . . .30

4 OAU-SVX01E-EN

Page 5

Controls Using 24 Vac . . . . . . . . . . . . . . . 30

Controls Using DC Analog Input/Output

(Standard Low Voltage Multiconductor Wire)

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

DC Conductors . . . . . . . . . . . . . . . . . . . . . . . 31

System Configuration and Pre-Start . . . . . . 33

Start-Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Indirect Gas-Fired Heating Start-Up . . . . . 36

Start-Up Procedure . . . . . . . . . . . . . . . . . 36

Safety Controls . . . . . . . . . . . . . . . . . . . . . 39

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Monthly Maintenance . . . . . . . . . . . . . . . . . 40

Filters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Supply/Return Air Smoke Detector Mainte-

nance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Cooling Season . . . . . . . . . . . . . . . . . . . . 40

Heating Season . . . . . . . . . . . . . . . . . . . . 40

Condenser Coil Cleaning . . . . . . . . . . . . . 40

Final Process . . . . . . . . . . . . . . . . . . . . . . . . . 41

Performance Data . . . . . . . . . . . . . . . . . . . . . . 42

Superheat and Refrigeration Circuit Data 48

Alarms and Troubleshooting . . . . . . . . . . . . 52

Microprocessor Control . . . . . . . . . . . . . . 52

System Alarms . . . . . . . . . . . . . . . . . . . . . 52

Sensor Failure Alarm Display . . . . . . . . . 52

RTRM Failure Modes . . . . . . . . . . . . . . . . 54

Appendix . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

OAU Filter Guide . . . . . . . . . . . . . . . . . . . . . 55

OAU-SVX01E-EN 5

Page 6

Model Number Descriptions

OA2D300A4 -D1A1A0GM-G1KB0AC3CJ -A41B102A0

1 2 3 4 5 6 7 8 9 101112131415161718192021222324252627282930313233343536373839

Horizon Outdoor Air Unit

Digit 1, 2 — Unit Type

OA = Outdoor Air

Digit 3 — Cabinet Size

1 = 625 cfm–4,000 cfm

2 = 1,500 cfm–9,000 cfm

3 = 3,750 cfm–13,500 cfm

Digit 4 — Major Design

Sequence

C = Revision 4

D = Revision 5

E = Heat Pump

Digit 5, 6, 7 — Normal Gross

Cooling Capacity (MBh)

000= No Cooling

060= 5 Tons High Efficiency

072= 6 Tons High Efficiency

084= 7 Tons High Efficiency

096= 8 Tons High Efficiency

120 = 10 Tons High Efficiency

144 = 12 Tons High Efficiency

180 = 15 Tons High Efficiency

210 = 17 Tons High Efficiency

240= 20 Tons High Efficiency

264= 22 Tons High Efficiency

300 = 25 Tons High Efficiency

360= 30 Tons High Efficiency

420= 35 Tons High Efficiency

480= 40 Tons High Efficiency

540= 45 Tons High Efficiency

600 = 50 Tons High Efficiency

648= 54 Tons High Efficiency

Digit 8 — Minor Design

Sequence

A

B

Digit 9 — Voltage Selection

1 = 115/60/1

2 = 208-230/60/1

3 = 208-230/60/3

4 = 460/60/3

5 = 575/60/3

Digit 10 — Reserved for Future

Use

Digit 11 — Evaporator Type

0 = No Cooling

A = DX 3-Row

B = DX 4-Row

C = DX 4-Row Interlaced

D = DX 6-Row Interlaced

E = DX 8-Row

F = Glycol/Chilled Water Coil

G = DX 4-Row with

MSP

®

Technology

Digit 12 — Hot Gas Reheat

0= No HGRH

1 = Fin and Tube Modulating

2 = Fin and Tube On/Off

3 = Microchannel Modulating

4 = Microchannel On/Off

Digit 13 — Compressor

0= No Compressors

A = Scroll Compressors

B = Digital Scroll (1

C = Digital Scroll (1

D = Variable Speed Scroll (1

E = Variable Speed Scroll (1

Circuit Only)

nd

2

Circuit)

st

Circuit Only)

st

and 2nd Circuit)

st

st

and

Digit 14 — Condenser

0 = No Condenser

1 = Air-Cooled Fin and Tube

2 = Air-Cooled Fin and Tube

3 = Water-Cooled DX Condenser

4 = Air-Cooled Fin and Tube

5 = Air-Cooled Microchannel

6 = Air-Cooled Microchannel

7 = Air-Cooled Microchannel

8 = Water-Cooled DX Condenser

w/Head Pressure On/Off Control

Copper/Steel

w/Head Pressure Variable Speed

w/Head Pressure On/Off Control

Variable Speed

Copper/Nickel

Digit 15 — Refrigerant Capacity

Control

0 = No RCC Valve

A = RCC Valve on 1

B = RCC Valve on 1

C = ERCC Valve on 1

D = ERCC Valve on 1

E = HGBP Valve on 1

F = HGBP Valve on 1

nd

2

Circuit

st

Circuit

st

and 2nd Circuit

st

Circuit

st

and 2nd Circuit

st

Circuit

st

and

Digit 16 — Indoor Fan Motor

(IFM)

0 = Direct Drive w/VFD

1 = Direct Drive (VFD by Others)

2 = Belt Drive

3 = Belt Drive w/VFD

4 = Direct Drive w/Shaft Grounding

5 = Special Motor Option

Ring w/VFD

Digit 17 — Indoor Fan Wheel

A=122

B = 122.6

C=150

D = 150.6

E=165

F = 165.6

G=182

H = 182.6

J=200

K = 200.6

L = 182 X 2

M = 182.6 X 2

Digit 18 — Indoor Fan Motor

Power (hp)

A = 1/2 hp—1800 rpm

B = 1/2 hp—3600 rpm

C = 3/4 hp—1800 rpm

D = 3/4 hp—3600 rpm

E = 1 hp—1800 rpm

F = 1 hp—3600 rpm

G = 1.5 hp—1800 rpm

H = 1.5 hp—3600 rpm

J = 2 hp—1800 rpm

K = 2 hp—3600 rpm

L = 3 hp—1800 rpm

M = 3 hp—3600 rpm

N = 5 hp—1800 rpm

P = 5 hp—3600 rpm

R = 7.5 hp—1800 rpm

S = 7.5 hp—3600 rpm

T = 10 hp—1800 rpm

U = 10 hp—3600 rpm

V = 15 hp—1800 rpm

W = 15 hp—3600 rpm

Digit 19 — Reserved for Future

Use

Digit 20 — Heat Type (PRI/SEC)

0 = No Heat

A = Indirect-Fired (IF)

B = Direct-Fired (DF)

C = Electric—4-Stage

D = Electric—SCR Modulating

E = Dual Fuel (PRI-IF/SEC-DF)

F = Dual Fuel (PRI-ELEC/SEC-DF)

G = Dual Fuel (PRI-IF/SEC-ELEC)

H = Dual Fuel (PRI-ELEC/SEC-ELEC)

J= Hot Water

K = Steam

Digit 21 — Primary Fuel Type

0 = No Heat

1= Natural Gas

2= Propane

3 = Electric—Open Coil

4 = Electric—Sheathed Coil

5=Hot Water

6 = Steam

6 OAU-SVX01E-EN

Page 7

Model Number Descriptions

Digit 22 — Heat Capacity

(Primary Heat Source)

Digit IF ELEC

0 No Heat No Heat

A50 MBh10 kW

B75 MBh20 kW

C100 MBh24 kW

D125 MBh28 kW

E150 MBh32 kW

F200 MBh40 kW

G250 MBh48 kW

H300 MBh60 kW

J350 MBh68 kW

K400 MBh79 kW

L500 MBh99 kW

M 600 MBh 111 kW

N 700 MBh 119 kW

P 800 MBh 139 kW

R 1000 MBh 159 kW

S179 kW

T199 kW

U215 kW

X Special Heater Option

Digit 23 — Heat Capacity

(Secondary Heat Source)

Digit

0 No Heat/No Secondary Heat

A 50 MBh 10 kW 300 MBh

B 75 MBh 20 kW 600 MBh

C 100 MBh 24 kW 900 MBh

D 125 MBh 28 kW 1200 MBh

E150 MBh32 kW

F200 MBh40 kW

G250 MBh48 kW

H300 MBh60 kW

J350 MBh68 kW

K400 MBh79 kW

L500 MBh99 kW

M 600 MBh 111 kW

N 700 MBh 119 kW

P 800 MBh 139 kW

R 1000 MBh 159 kW

S179 kW

T199 kW

U215 kW

IF ELEC DF

Digit 24 — Corrosive

Environment Package

0 = No Corrosive Package

1 = S/S Cabinet, Basepan,

2 = S/S Cabinet, Basepan

3 = S/S Basepan, Eco-Coated Coils

4 = S/S Coil Casing

5 = S/S Interior Casing

6 = Eco-Coated Coils

7 = S/S Coil Casing with

8 = Copper/Copper Condenser,

Eco-Coated Coils

Eco-Coated Coils

Evap, HGRH Coils

Digit 25, 26 — Unit Controls

00 = Non-DDC—Electromechanical

AA = Trane—Discharge Air Control

w/LON Read-Write w/Display

AB = Trane—Space Control w/LON

Read-Write w/Display

AC = Trane—Discharge Air Control

w/BACnet

®

(No Display)

AD = Trane—Space Control

w/BACnet (No Display)

AF = Trane—Discharge Air Control

w/BACnet w/Display

AG = Trane—Space Control

w/BACnet w/Display

AH = Trane—Discharge Air Control

w/BACnet w/Display

AI = Trane—Discharge Air Control

w/LON Read-Write (No Display)

AJ = Trane—Space Control

w/LON Read-Write (No Display)

AK = Trane—Multi-Zone VAV Control

w/LON Read-Write w/Display

AL = Trane—Multi-Zone VAV Control

w/BACnet w/Display

AM= Trane—Multi-Zone VAV Control

w/LON Read-Write (No Display)

AN = Trane—Multi-Zone VAV Control

w/BACnet (No Display)

AO = Trane—Single-Zone VAV Control

w/LON Read-Write w/Display

AP = Trane—Single-Zone VAV Control

w/BACnet w/Display

AQ = Trane—Single-Zone VAV Control

w/LON Read-Write (No Display)

AR = Trane—Single-Zone VAV Control

w/BACnet (No Display)

Digit 27 — Pow ered Exhaust Fan

Motor (PFM) and Exhaust

Dampers

0 = No Powered Exhaust

1 = Direct Drive w/VFD and Gravity

Dampers

2 = Direct Drive (VFD by Others)

3 = Belt Drive

4 = Belt Drive w/VFD

5 = Special Motor Option

6 = Direct Drive w/VFD and

Barometric Relief Damper

7 = Direct Drive w/VFD and Isolation

Dampers w/End Switch

8 = Barometric Relief Dampers

(NO PFM)

Digit 28 — Pow ered Exhaust Fan

Wheel

0 = No Powered Exhaust

A= 122

B = 122.6

C= 150

D = 150.6

E= 165

F = 165.6

G= 182

H = 182.6

J= 200

K = 200.6

L = 182 X 2

M = 182.6 X 2

Digit 29 — Pow ered Exhaust Fan

Motor Power

0 = No Powered Exhaust

A = 1/2 hp—1800 rpm

B = 1/2 hp—3600 rpm

C = 3/4 hp—1800 rpm

D = 3/4 hp—3600 rpm

E = 1 hp—1800 rpm

F = 1 hp—3600 rpm

G = 1.5 hp—1800 rpm

H = 1.5 hp—3600 rpm

J = 2 hp—1800 rpm

K = 2 hp—3600 rpm

L = 3 hp—1800 rpm

M = 3 hp—3600 rpm

N = 5 hp—1800 rpm

P = 5 hp—3600 rpm

R = 7.5 hp—1800 rpm

S = 7.5 hp—3600 rpm

T = 10 hp—1800 rpm

U = 10 hp—3600 rpm

V = 15 hp—1800 rpm

W = 15 hp—3600 rpm

Digit 30 — Reserved for Future

Use

Digit 31 — ERV (Requires

Powered Exhaust)

0= No ERV

A = ERV-Composite Construction

B = ERV—Composite Construction

with Frost Protection w/VFD

C = ERV—Composite Construction

with Bypass

D = ERV—Composite Construction

with Frost Protection and Bypass

E = ERV—Aluminum Construction

F = ERV—Aluminum Construction

with Frost Protection w/VFD

G = ERV—Aluminum Construction

with Bypass

H = ERV—Aluminum Construction

with Frost Protection and Bypass

Digit 32 — ERV Size

0= No ERV

1= 3014

2 = 3622

3 = 4136

4 = 4634

5 = 5856

6 = 6488

7 = 6876

8= 74122

Digit 33 — Damper Options

0 = 100% OA 2-Position Damper

1 = 100% OA 2-Position Damper

w/RA 2-Position Damper

2 = Modulating OA and RA Da mpers

w/Economizer

OAU-SVX01E-EN 7

Page 8

Model Number Descriptions

Digit 34 — Filtration Options

A = Aluminum Mesh Intake Filters

(ALM)

B = MERV-8,30%, and ALM

C = MERV-13, 80%, and ALM

D = MERV-14, 95%, and ALM

E = MERV-8 30%, MERV-13 80%, and

ALM

F = MERV-8 30%, MERV-14 95%, and

ALM

G = MERV-8, 30%, and ALM, with

UVC

H = MERV-13, 80%, and ALM, with

UVC

J = MERV-14, 95%, and ALM, with

UVC

K = MERV-8 30%, MERV-13 80%,

ALM, and UVC

L = MERV-8 30%, MERV-14 95%,

ALM, and UVC

M = MERV-8 30%, ALM, and TCACS

N = MERV-13 80%, ALM, and TCACS

P = MERV-14 95%, ALM, and TCACS

Q = MERV-8 30%, MERV-13 80%,

ALM, and TCACS

R = MERV-8 30%, MERV-14 95%,

ALM, and TCACS

X = Special Filter Options

Digit 35 — Smoke Detector

(Factory-Installed)

0= No Smoke Detector

1 = Supply Smoke Detector

2 = Return Smoke Detector

3 = Supply and Return Smoke

Detector

Digit 36 — Electrical Options

0 = Non-Fused Disconnect

A = Fused Disconnect Switch

B = Non-Fused Disconnect

w/Convenience Outlet

C = Fused Disconnect Switch

w/Convenience Outlet

D=Dual Point Power

w/Convenience Outlet

F = 65 SCCR Electrical Rating

w/Non-Fused Disconnect

G = 65 SCCR Electrical Rating

w/Fused Disconnect

H = 65 KAIC Electrical Rating

w/Non-Fused Disconnect

J = 65 KAIC Electrical Rating

w/Fused Disconnect

Digit 37 — Air Flow Monitoring

0 = No Airflow Monitoring

1 = Airflow Monitoring—IFM

Piezo Ring

2 = Airflow Monitoring—PE

Piezo Ring

3 = Airflow Monitoring—Outdoor Air

with Display and IFM

w/Piezo Ring

4 = Airflow Monitoring—IFM

Piezo Ring and PE Piezo Ring

5 = Airflow Monitoring—Outdoor Air

Monitoring w/Display Supply

Air and Exhaust Air

w/Piezo Rings

Digit 38 — Accessories

0 = No Options

A = Hailguards

B = LED Service Light and

C = Hailguards and LED Service

Light

Digit 39 — Altitude

0 = Sea Level to 1,000 Feet

1 = 1,001 to 2,000 Feet

2 = 2,001 to 3,000 Feet

3 = 3,001 to 4,000 Feet

4 = 4,001 to 5,000 Feet

5 = 5,001 to 6,000 Feet

6 = 6,001 to 7,000 Feet

7 = Above 7,000 Feet

8 OAU-SVX01E-EN

Page 9

General Information

Overview of Manual

Note: One copy of this document ships inside the control

panel of each unit and is customer property . It must

be retained by the unit’s maintenance personnel.

This booklet describes proper installation, operation, and

maintenance procedures for air cooled systems. By

carefully reviewing the information within this manual

and following the instructions, the risk of improper

operation and/or component dama ge will be minimized.

It is important that periodic maintenance be performed to

help assure trouble free operation. A maintenance

schedule is provided at the end of this manual. Should

equipment failure occur, contact a qualified service

organization with qualified, experienced HVAC technicians

to properly diagnose and repair this equipment.

Model Number Description

All products are identified by a multiple-character model

number that precisely identifies a particular type of unit.

An explanation of the alphanumeric identification code is

provided (see “Model Number Descriptions,” p. 6). Its use

will enable the owner/operator , installing contractors, and

service engineers to define the operation, specific

components, and other options for any specific unit.

When ordering replacement parts or requesting service,

be sure to refer to the specific model number and serial

number printed on the unit nameplate.

Unit Nameplate

A Mylar® unit nameplate is located on the unit’s corner

support next to the control box. It includes the unit model

number, serial number, electrical characteristics,

refrigerant charge, as well as other pertinent unit data.

receive information from sensors and customer binary

contacts to satisfy the applicable request for ventilation,

cooling, dehumidification and heating.

Indoor Fan Failure Input

The Indoor Fan Fa ilure Switc h (IFFS) is connected to verify

indoor fan operation.

When there is a call for the indoor fan to be energized, the

differential pressure switch, connected to the Main Unit

Display, must pro ve airflow within 30 seconds or the Main

Unit Display will shut off all mechanical operations, lock

the system out and send a diagnostic alarm to the Unit

Display. The system will remain locked out until a reset is

initiated through the MCM via the Alarm Reset Function on

the Unit Display.

Low Pressure Control ReliaTel Control

This input incorporates the compressor low pressure

control (CLP 1/2) of each refrigeration circuit and can be

activated by opening a field supplied contact installed on

the OAUTS.

If this circuit is open before the compressor is started, the

ReliaT el™ control will not allow the af fected compressor to

operate. Anytime this circuit is opened for 1 continuous

second during compressor operation, the compressor for

that circuit is immediately turned “Off.” The compressor

will not be allowed to restart for a minimum of 3 minutes

should the contacts close.

If four consecutive open conditions occur during the first

three minutes of operation, the compressor for that circuit

will be locked out, and a manual reset will be required to

restart the compressor.

Refrigerant Circuits

Compressor Nameplate

The nameplate for the compressors are located on the side

of the compressor.

Unit Description

Before shipment, each unit is leak tested, dehydrated,

charged with refrigerant and compressor oil, and run

tested for proper control operation.

The condenser coils are aluminum fin, mechanically

bonded to copper tubing.

Direct-drive, vertical discharge condenser fans are

provided with built-in thermal overload protection.

The Outdoor Air Unit Main Unit Display and ReliaTel™

Control Module (RTRM) are microelectronic control

systems. The acronym RTRM is extensively throughout

this document when referring to the control system

network.

The Main Unit Display and the RTRM are mounted in the

Main Control Panel. The Main Unit Display and RTRM

OAU-SVX01E-EN 9

For 5–7 ton units, one refrigerant circuit shall incorporate

a standard 6-row coil. For 8–54 ton units, two independent

refrigerant circuits shall incorporate an interlaced coil. All

circuits shall have thermal expansion valves (TXVs),

service pressure ports and refrigerant line filter driers as

standard. An area will be provided for replacement suction

line driers. Refrigerant circuit one (1

with a factory installed and preset refrigerant capacity

control (RCC) to prevent evaporator coil temperatures

below approximately 38°F (1 14 lb suction). The refrigerant

capacity device is not installed when the unit is equipped

with a digital scroll.

st

Stage) is equipped

High Pressure Control ReliaTel Control

The compressor high pressure controls (CHP 1/2/3/4) are

wired in series between the compressor outputs on

RTRM1 (CHP 1/2) and RTRM2 (CHP 3/4) and the

compressor contactor coils. If one of the high pressure

control switches opens, the re spective RTRM senses a lack

of current while calling for cooling and locks the

compressor out.

Page 10

General Information

On dual circuit units, if the high pressure control opens,

the compressor on the affected circuit is locked out. A

manual reset for the affected circuit is required.

Space Temperature / RH Sensor (Optional)

Field installed, wall mounted temperature sensor

(BAYSENS036A) and humidity to control space cooling,

heating and dew point. Refer to “Space Control with

Indirect Gas-Fired or Electric Heat and Modulating HGRH,

ERV, and Powered Ex.,” p. 21 for specific details.

High Temperature Sensor

The Discharge Air Temperature Sensor (DTC) supplies a

continuous signal to the MCM. Factory setting for

Discharge Air Temperature (DTC) Discharge Air

Temperature Setpoint (MDTS) is 90°F (adj 70–100°F), the

unit will be shut down, and require a manual restart if

Disch arge Air Temperature exceeds MDTS for 10 minutes

(adj 10–25 minutes). If DAT exceeds Discharge Air High

Temperature Cutoff (DHCS) of 125°F for 10 minutes, the

unit will shut down and require manual restart.

Outdoor Air Temperature and Relative Humidity Sensor

This factory installed combination outdoor air sensor

located in the outdoor air hood is designed to sens e both

outdoor air temperature and relative humidity for use by

the microprocessor controller to make required

ventilation, cooling, dehumidification and heating

decisions. Refer to “Sequence of Operation,” p. 21 for

detailed unit control and operational modes.

Control Input (Occupied / Unoccupied)

Terminals are provided on the terminal strip labeled

OAUTS for a field installed dry contact or switc h closure to

put the unit in the Occupied or Unoccupied modes.

Hot Gas Reheat

This option shall consist of a hot-gas reheat coil located on

the leaving air side of the evaporator. Refer to the

“Sequence of Operation,” p. 21 for detailed unit control

and operational modes.

high turn-down burners and a stainless steel tubular heat

exchanger. The heat exchanger will be constructed of

type 439 stainless steel and be a tubu lar design capable of

draining internal condensate. External flue to be

constructed of type 430 stainless steel.

Units will be suitable for use with natural gas or Liquid

Propane (LP) gas.

Through the Base Electrical with Disconnect Switch

Factory installed 3-pole, molded case disconnect switch

with provisions for through the base electri cal connections

will be included. The disconnect switch, with integral

overcurrent circuit breaker , will be installed in the unit in a

water tight enclosure with access through a hinged door.

Factory wiring will be provided from the switc h to the unit

high voltage terminal block. The switch will be UL/CSA

agency recognized.

Through the Base Gas Piping

The unit will include provisions for installing through the

base gas piping. The factory installed option will have all

piping necessary including an external shutoff piping yoke

with pre-assembled, manual gas shut-off valve, elbows,

and union. The manual shut-off valve will include an 1/8 in.

(3.17 mm) NPT pressure tap. This assembly will require

minor field labor to install.

Hinged Access Doors

Hinged access doors with hold open brackets will be

factory-installed.

Modulating Electric Heat

The unit may have fully modulating, SCR, or Verniercontrolled, electric heat. The primary heating section will

include open coil heating elements, automatic and manual

cut-outs, low voltage controls, air proving switch,

maximum 48 amps per circuit and fusing for heaters over

48 amps. For ductwork installation, refer to “Ductwork,”

p. 25.

100 Percent Outdoor Air Hood with Damper and Filters

Factory-installed an d -in t eg rated 100 percent outdoor air

hood with damper controlled by a direct coupled actuator

and 2 in. (50.80 mm) permanent and washable aluminum

mesh filters (mist eliminators) removable through a

hinged access panel. The unit is factory equipped with

provisions to accept an optional field installed 100 percent

return air damper controlled by a direct coupled actuator

that is electrically interlocked with the outdoor air damper .

Modulating Indirect Gas-Fired Burner

The unit will have fully modulating, high turndown,

indirect gas-fired heat. The heating section will include

10 OAU-SVX01E-EN

Page 11

General Information

Unit Inspection

WARNING

Fiberglass Wool!

Product may contain fiberglass wool. Disturbing the

insulation in this product during installation,

maintenance or rep air will expose you to airborne

particles of glass wool fibers and ceramic fibers known

to the state of California to cause cancer through

inhalation. Glass wool fibers may also cause

respiratory, skin or eye irritation.

As soon as the unit arrives at the job site:

Verify that the nameplate data matches the data on

the sales order and bill of lading (including electrical

data).

Verify that the power supply complies with the unit

nameplate specifications.

Visually inspect the exterior of the unit, including the

roof, for signs of shipping damage.

Visually inspect the internal components for shipping

damage as soon as possible after delivery and before

it is stored. Do not walk on the sheet metal base pans.

If concealed damage is discovered, notify the carrier’s

terminal of damage immediately by phone and by

mail. Concealed damage must be reported within

15 days .

Request an immediate joint inspection of the damage

by the carrier and the consignee. Do not remove

damaged material from the receiving location. Take

photos of the damage, if possible. The owner must

provide reasonable e vidence that the damage did not

occur after delivery.

Notify the appropriate sales representative before

installing or repairing a damaged uni t.

Skin Contact

Wash affected areas gently with soap and warm water

after handling.

Storage

Take precautions to prevent condensate from forming

inside the unit’s electrical compartments and motors if:

• the unit is stored before it is installed; or,

• the unit is set on the roof curb, and temporary heat is

provided in the building. Isolat e al l side p anel servi ce

entrances and base pan openings (e.g., conduit holes,

S/A and R/A openings, and flue openings) from the

ambient air until the unit is ready for start-up.

Note: Do not use the unit’s heater for temporary heat

without first completing the start-up procedure

detailed in “Start-Up,” p. 36.

The manufacturer will not assume any responsibility for

equipment damage resulting from condensate

accumulation on the unit’s electrical and/or mechanical

components.

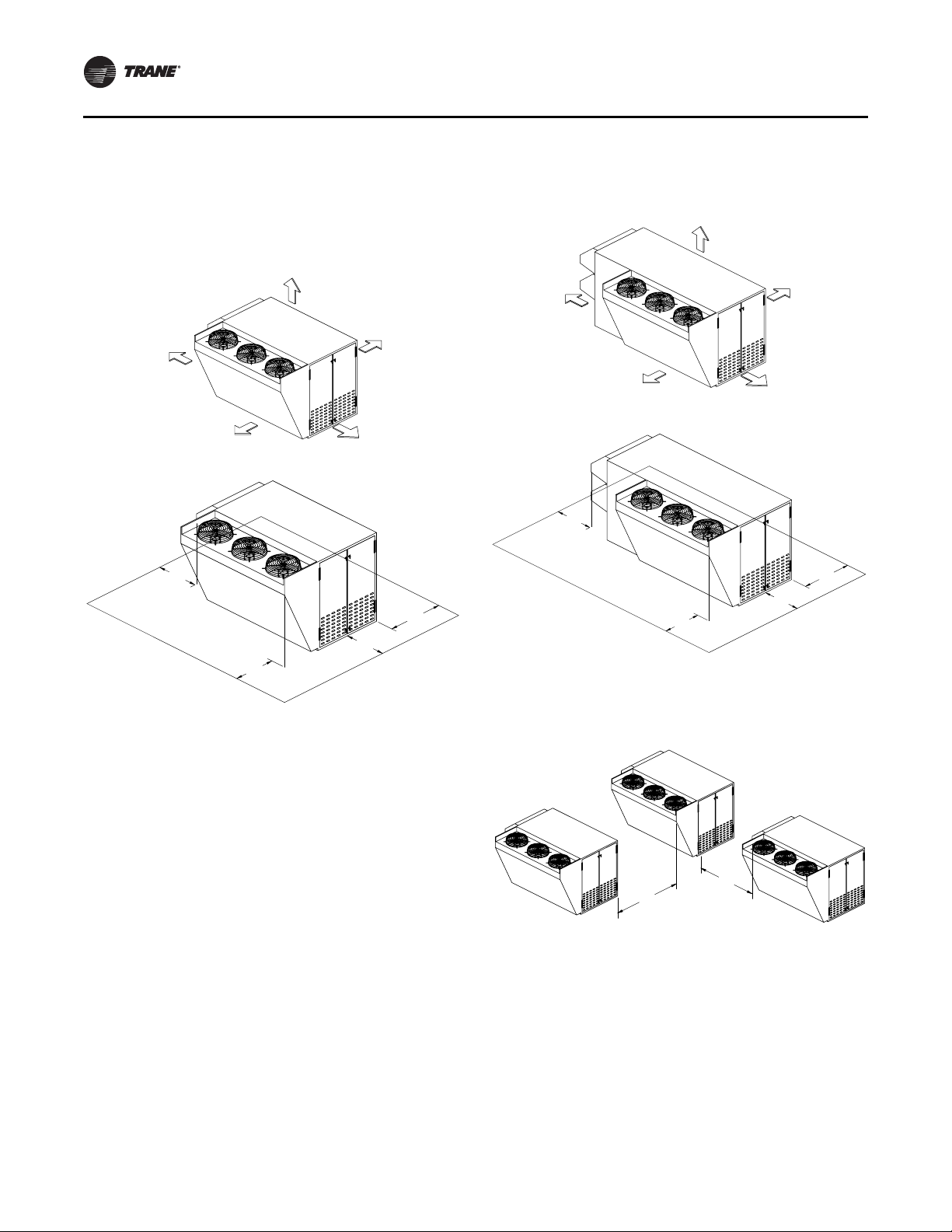

Unit Clearances

“Unit Clearances, Curb Dimensions, and Dimensional

Data,” p. 12 contains figures that illustrate the minimum

operating and service clearances for either a single or

multiple unit installation: Figure 1, p. 12 and Figure 2, p. 12

for OA1 units,Figure 7, p. 14 through Figure 10, p. 15 for

OA2 units, and Figure 15, p. 16 through Figure 18, p. 17 for

OA3 units. These clearances are the minimum distances

necessary to assure adequate serviceability, cataloged

unit capacity, an d peak operating efficiency.

Providing less than the recommended clearances may

result in condenser coil starvation, “short-circuiting” of

exhaust or recirculation of hot condenser air.

• Avoid breathing fibergl as s dust.

• Use a NIOSH approved dust/mist respirator.

• Avoid contact with the skin or eyes. W ear long-sleeved,

loose-fitting clothing, gloves, and eye protection.

• Wash clothes separately from other clothing: rinse

washer thoroughly.

• Operations such as sawing, blowing, tear-out, and

spraying may generate fiber concentrations requiring

additional respiratory protection. Use the appropriate

NIOSH approved respiration in these situations.

First Aid Measures

Eye Contact

Flush eyes with water to remove dust. If symptoms persist,

seek medical attention.

OAU-SVX01E-EN 11

Page 12

Unit Clearances, Curb Dimensions, and Dimensional

CLEARANCE 36"

TOP OF UNIT 72"

CLEARANCE 60"

CLEARANCE 36"

CLEARANCE FROM

CLEARANCE 48"

3'-0"

3'-0"

3'-0"

4'-0"

7'0"

6'0"

3'0"

3'0"

4'0"

3'0"

S

U

P

PL

Y

R

E

T

U

R

N

2öļ

8õļ

7öļ

19ļ

õļ

1ôļ

4ôļ

49ļ

1õļ

öļ

1.00

TYP.

Data

WARNING

Combustible Materials!

Maintain proper clearance between the unit heat

exchanger, vent surfaces and combustible materials.

Refer to unit nameplate and installation instructions for

proper clearances. Improper clearances could result in a

fire hazard. Failure to maintain proper clearances could

result in death or serious injury or property damage.

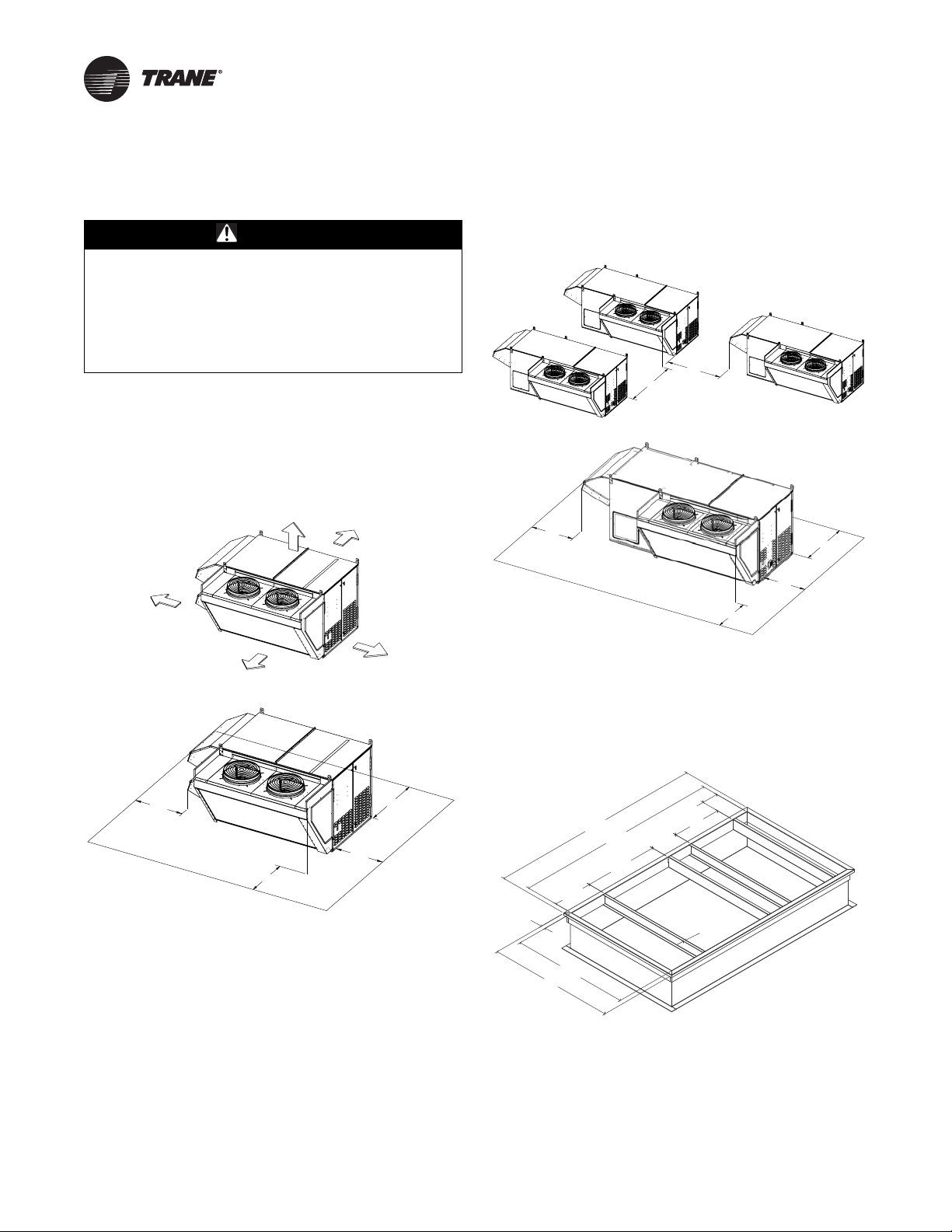

OA1 Units

Unit Clearances

Figure 1. Typical installation clearances for OA1 unit

Figure 2. Typical installation clearances for OA1 unit

with auxiliary cabinet

Note: Certain options require auxiliary cabinet. Refer to

project-specific unit submittals.

Curb Dimensions

Figure 3. Unit curb data for OA1 5–15 tons

12 OAU-SVX01E-EN

Page 13

Unit Clearances, Curb Dimensions, and Dimensional Data

GUTTER DETAIL

Ɍļ

ôļ

S

U

P

PL

Y

GUTTER

R

E

T

U

R

N

õļ

19"

8õļ

40"

12ɍļ

3ôļ

Ɍļ

1ôļ

7öļ

4ôļ

49"

1õļ

öļ

1.00

TYP.

28öļ

53.00

59.45

87.12

36.71

87.33

59.23

87.18

29.63

87.33

59.23

53.00

131.26

87.12

59.45

35.24

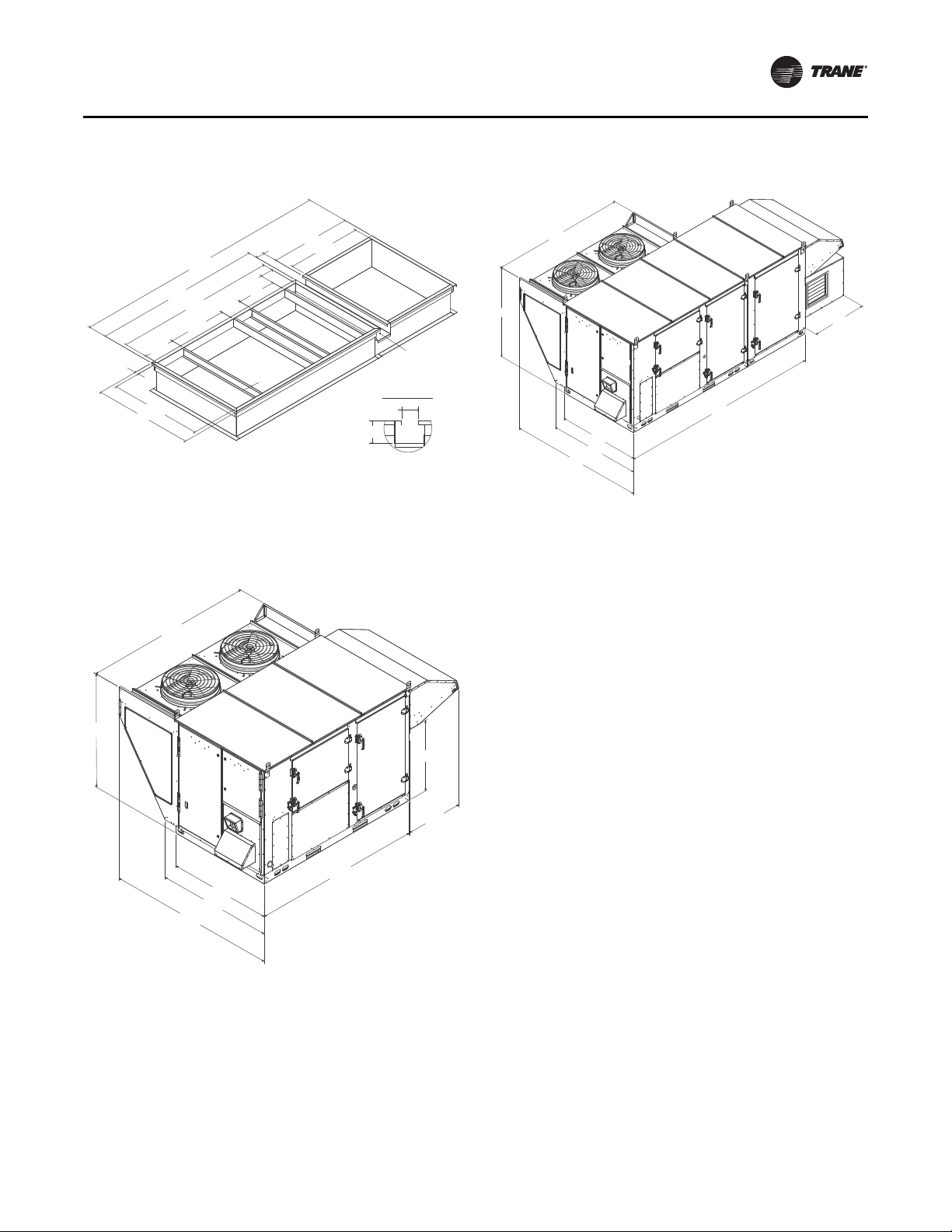

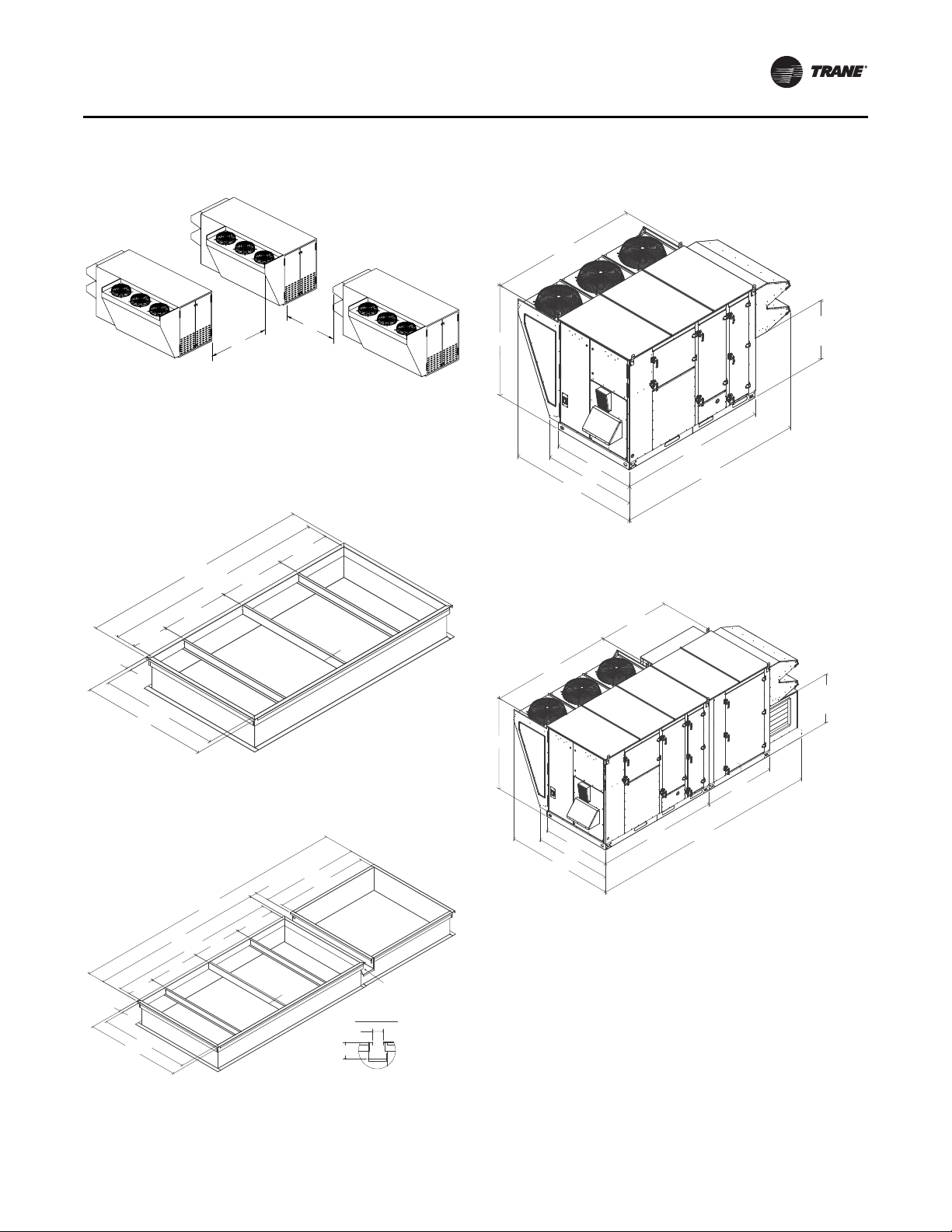

Figure 4. Unit curb data for OA1 5–15 tons with

auxiliary cabinet

Note: Certain options require auxiliary cabinet. Refer to

project-specific unit submittals.

Dimensional Data

Figure 5. Unit dimensional data for OA1 5–15 tons (in.)

Figure 6. Unit dimensional data for OA1 5–15 tons

with auxiliary cabinet (in.)

Note: Certain options require auxiliary cabinet. Refer to

project-specific unit submittals.

OAU-SVX01E-EN 13

Page 14

Unit Clearances, Curb Dimensions, and Dimensional Data

CLEARANCE 36"CLEARANCE 60"

TOP OF UNIT 72"

CLEARANCE 36"

CLEARANCE FROM

CLEARANCE 48"

3'0"

3'0"

4'0"

3'0"

TOP OF UNIT 72"

"63 ECNARAELC"06 ECNARAELC

CLEARANCE 36"

CLEARANCE FROM

CLEARANCE 48"

3'0"

3'0"

4'0"

3'0"

7'0"

6'0"

OA2 Units

Unit Clearances

Figure 7. Typical installation clearances for OA2 unit

Figure 8. Typical installation clearances for OA2 unit

with auxiliary cabinet

Note: Certain options require auxiliary cabinet. Refer to

project-specific unit submittals.

Figure 9. Typical installation clearances for OA2 unit

14 OAU-SVX01E-E N

Page 15

Unit Clearances, Curb Dimensions, and Dimensional Data

7'0"

6'0"

SU

PPL

Y

R

ET

UR

N

öļ

1ļ

TYP.

30ļ

29ļ

56ļ

2õļ

5ôļ

9ôļ

ļ

1õļ

S

U

P

PL

Y

R

E

T

U

R

N

GUTTER

1õļ

ļ

16Ɍļ

29ļ

9Ɏļ

56ļ

5ôļ

öļ

õļ

30ļ

58ļ

5ôļ

Ɍļ

1ļ

TYP.

GUTTER DETAIL

Ɍļ

ôļ

80.57

OF AIR INLET

106.45

66.83

106.00

135.52

94.21

43.02

BASE TO BOTTOM

60.00

80.57

106.00

94.21

62.11

66.83

60.00

106.10

200.99

OF AIR INLET

43.02

BASE TO BOTTOM

62.51

Figure 10. Typical installation clearances for OA2 unit

with auxiliary cabinet

Note: Certain options require auxiliary cabinet. Refer to

project-specific unit submittals.

Curb Dimensions

Figure 11. Unit curb data for OA2 12–30 tons (in.)

Dimensional Data

Figure 13. Unit dimensional data for OA2 12–30 tons

Figure 14. Unit dimensional data for OA2 12–30 tons

with auxiliary cabinet

Figure 12. Unit curb data for OA2 12–30 tons with

auxiliary cabinet (in.)

Note: Certain options require auxiliary cabinet. Refer to

Note: Certain options require auxiliary cabinet. Refer to

OAU-SVX01E-EN 15

project-specific unit submittals.

project-specific unit submittals.

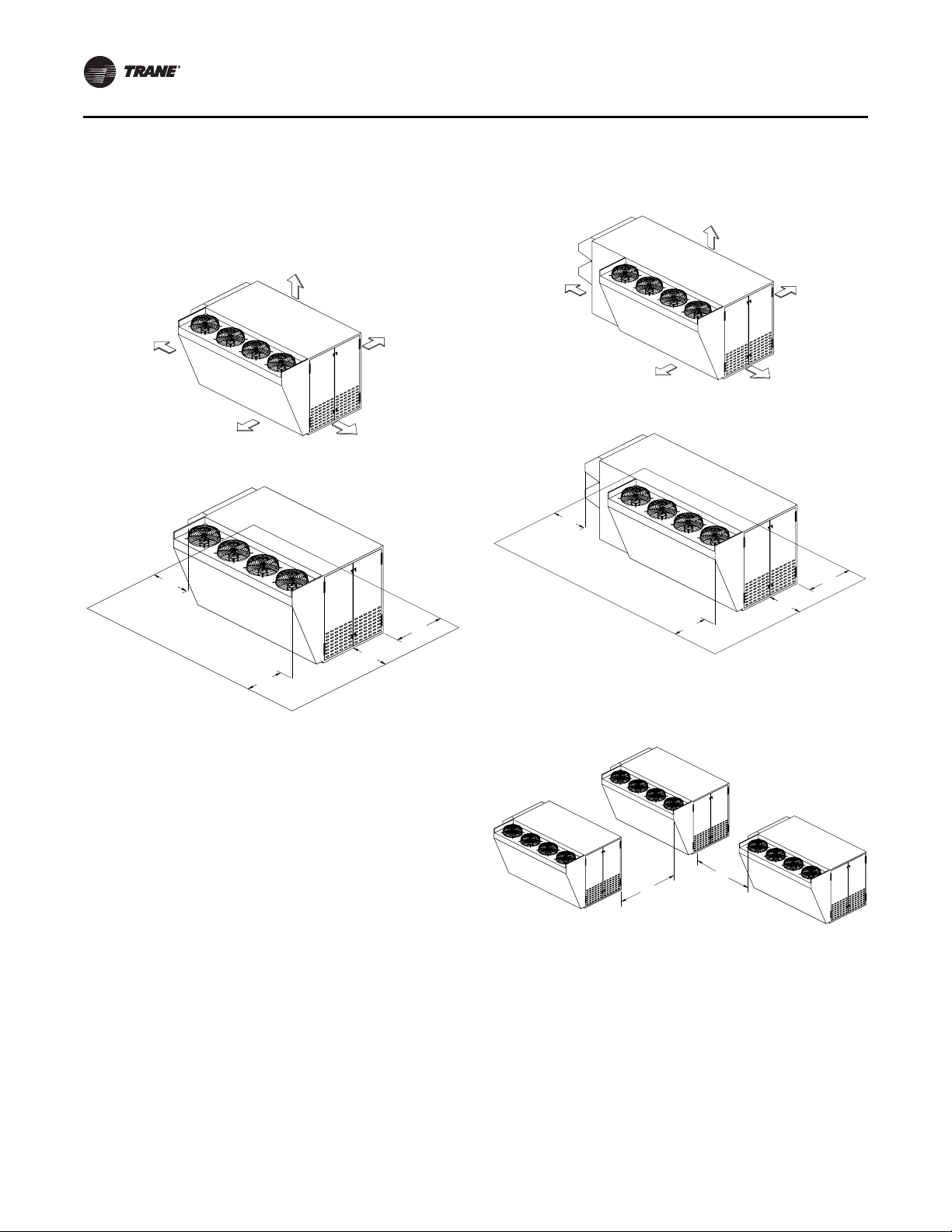

Page 16

Unit Clearances, Curb Dimensions, and Dimensional Data

TOP OF UNIT 72"

"63 ECNARAELC"06 ECNARAELC

CLEARANCE 36"

CLEARANCE FROM

CLEARANCE 48"

3'0"

3'0"

4'0"

3'0"

CLEARANCE 36"

TOP OF UNIT 72"

CLEARANCE 36"CLEARANCE 60"

CLEARANCE FROM

CLEARANCE 48"

3'0"

3'0"

4'0"

3'0"

7'0"

6'0"

OA3 Units

Unit Clearances

Figure 15. Typical installation clearances for OA3 unit

Figure 16. Typical installation clearances for OA3 unit

with auxiliary cabinet

Note: Certain options require auxiliary cabinet. Refer to

project-specific unit submittals.

Figure 17. Typical installation clearances for OA3 unit

16 OAU-SVX01E-EN

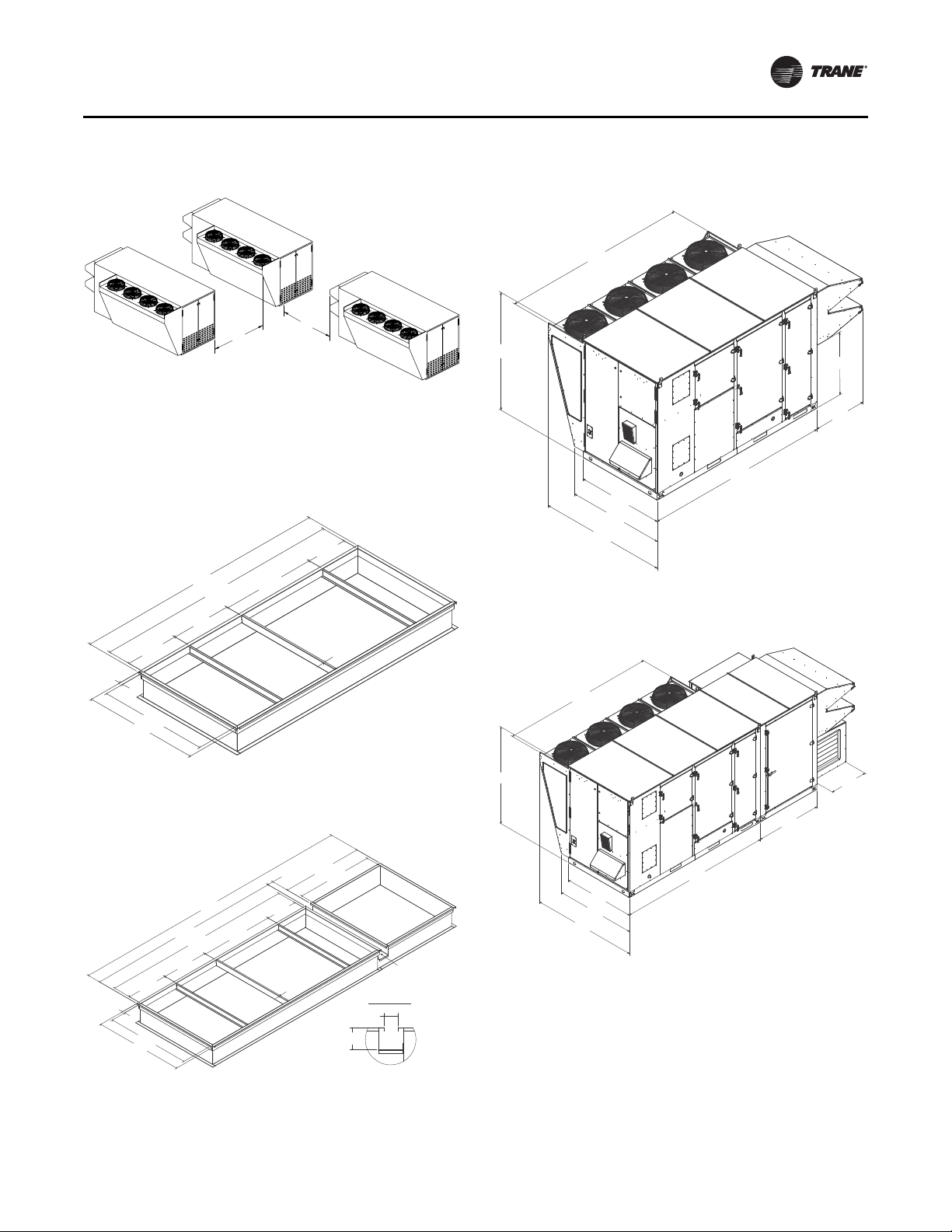

Page 17

Unit Clearances, Curb Dimensions, and Dimensional Data

7'0"

6'0"

S

U

P

PL

Y

R

E

T

U

R

N

öļ

33ļ

63ļ

5ôļ

140ļ

13ôļ

1ļ

TYP.

5ɏļ

2õļ

2ɍļ

S

U

P

PL

Y

R

E

T

U

R

N

GUTTER

1ļ

TYP.

63ļ

202ļ

5ɏļ

5ôļ

140ļ

33ļ

öļ

5ɏļ

2õļ

13ôļ

Ɍļ

5ɍļ

2ɍļ

GUTTER DETAIL

Ɍļ

ôļ

144.00

67.00

74.63

144.17

42.00

92.07

98.49

48.62

62.00

67.00

74.63

98.49

144.00

92.07

144.17

35.84

Figure 18. Typical installation clearances for OA3 unit

with auxiliary cabinet

Note: Certain options require auxiliary cabinet. Refer to

project-specific unit submittals.

Curb Dimensions

Figure 19. Unit curb data for OA3 30–54 tons

Dimensional Data

Figure 21. Unit dimensional data for OA3 30–54 tons

Figure 22. Unit dimensional data for OA3 30–54 tons

with auxiliary cabinet

Figure 20. Unit curb data for OA3 30–54 tons with

auxiliary cabinet

Note: Certain options require auxiliary cabinet. Refer to

project-specific unit submittals.

Note: Certain options require auxiliary cabinet. Refer to

OAU-SVX01E-EN 17

project-specific unit submittals.

Page 18

Unit Weight and Rigging

WARNING

Heavy Objects!

Do not use cables (chains or slings) except as shown.

Each of the cables (chains or slings) used to lift the unit

must be capable of supporting the entire weight of the

unit. Lifting cables (chains or slings) may not be of the

same length. Adjust as necessary for even unit lift.

Other lifting arrangements may cause equipment or

property-only damage. F ailure to pr operly lift unit could

result in death or serio us in jury. See details below.

WARNING

Improper Unit Lift!

Test lift unit approximately 24 inches to verify proper

center of gravity lift point. To avoid dropping of unit,

reposition lifting point if unit is not level. Failure to

properly lift unit could result in death or serious injury

or possible equipment or property-only damage.

Unit Weight

Table 1. Typical unit weight and center-of-gravi ty

(CG)—units without auxiliary cabinet

Operating

Model

Number

OA1D060* 1811 2275 1898 2362 40 30

OA1D072* 1811 2330 1898 2417 40 30

OA1D084* 1811 2330 1933 2452 40 30

OA1D096* 1901 2596 2059 2754 40 30

OA1D120* 1901 2596 2089 2784 40 30

OA1D144* 1901 2596 2112 2807 40 30

OA1D180* 1901 2734 2192 3025 40 30

OA2D144* 3125 3790 3335 4000 49 34

OA2D180* 3289 3954 3580 3871 49 34

OA2D210* 3344 4161 3687 4030 49 34

OA2D240* 3372 4189 3764 4156 49 34

OA2D264* 3372 4189 3764 4156 49 34

OA2D300* 3530 4390 4012 4494 49 34

OA2D360* 3338 4198 3820 4302 49 34

OA3D360* 4931 5914 5576 6221 67 38

OA3D420* 5246 6229 5892 6538 67 38

OA3D480* 5339 6351 6014 6689 67 38

OA3D540* 5406 6363 6026 6646 67 38

OA3D600* 5570 6652 6343 7116 67 38

OA3D648* 5582 6664 6355 7128 67 38

Note: Minimum and maximum weights vary widely due to the highly

configurable nature of the product.

Weight (lb)

Min Max Min Max Length Width

Shipping

Weight (lb)

Center-of-

gravity (in.)

18 OAU-SVX01E-EN

Page 19

Unit Weight and Rigging

OALCabinet

AB

INTAKE

HOOD

DC

OA1,OA2,andOA3Cabinets

AB

INTAKE

HOOD

DC

CONDENSERSECTION

Table 2. Typical unit weight and center-of-gravity

(CG)—units with auxiliary cabinet

Operating

Model

Number

OA1D060* 2798 3262 2885 3349 56 29

OA1D072* 2743 3262 2830 3349 56 29

OA1D084* 2775 3294 2897 3416 56 29

OA1D096* 2927 3622 3085 3780 56 29

OA1D120* 2927 3622 3115 3810 56 29

OA1D144* 2927 3622 3138 3833 56 29

OA1D180* 2927 3760 3218 4051 56 29

OA2D144* 4508 5173 4718 5383 72 33

OA2D180* 4715 5380 4632 5297 72 33

OA2D210* 5028 5845 4897 5714 72 33

OA2D240* 5056 5873 5023 5840 72 33

OA2D264* 5056 5873 5023 5840 72 33

OA2D300* 5194 6054 5298 6158 72 33

OA2D360* 4936 5796 5040 5900 72 33

OA3D360* 6907 7890 7214 8197 81 37

OA3D420* 7222 8205 7531 8514 81 37

OA3D480* 7315 8327 7653 8665 81 37

OA3D540* 7382 8339 7665 8622 81 37

OA3D600* 7527 8609 7991 9073 81 37

OA3D648* 7539 8621 8003 9085 81 37

Note: Minimum and maximum weights vary widely due to the highly

configurable nature of the product.

Weight (lb)

Min Max Min Max Length Width

Shipping

Weight (lb)

Center-of-

gravity (in.)

Figure 23. Cabinet corners

Corner Weight

Table 3. Corner weights (percent of total weight)

Percentage (%)

Cabinet Size

OA1* without

auxiliary cabinet

OA1* with

auxiliary cabinet

OA2* without

auxiliary cabinet

OA2* with

auxiliary cabinet

OA3* without

auxiliary cabinet

OA3* with

auxiliary cabinet

Note: Actual corner weights will vary depending on components selected.

Corner A Corner B Corner C Corner D

16.3 20.7 33.3 29.7

18.2 23.2 27.5 31.1

20.1 17.2 34.0 28.7

18.3 24.0 32.5 25.2

14.9 24.2 29.9 31.0

16.8 23.6 28.5 31.1

OAU-SVX01E-EN 19

Page 20

Unit Weight and Rigging

SPREADER BARS

LENGTH

WIDTH

LIFTING POINTS

(4 LOCATIONS)

4-point lift

SPREADER BARS

LENGTH

WIDTH

LIFTING POINTS

(6 LOCATIONS)

DETAIL A

SCALE 1 : 12

6-point lift

Rigging

Figure 24. Rigging and center-of-gravity data

sure that the gasket on the curb is not damaged while

positioning the unit.

Refer to Table 1, p. 18, Table 2, p. 19, and Figure 24, p. 20

for typical unit operating weights rigging before

proceeding.

1. Remove the shipping crate from around the unit.

2. Rig the unit as shown in Figure 24, p. 20. Attach

adequate strength lifting slings to all four lifting

brackets in the unit base rail. Do not use cables, chains,

or slings except as shown.

3. Install a lifting bar, as shown in Figure 24, p. 20, to

protect the unit and to facilitate a uniform lift. The

minimum distance between the lifting hook and the

top of the unit should be 7 feet.

4. Test-lift the unit to ensure it is properly rigged and

balanced, make any necessary rigging adjustments.

5. Lift the unit and position it into place. Remove fork

pockets prior to setting on the curb.

6. Downflow units; align the base rail of the unit with the

curb rail while lowering the unit onto the curb. Make

20 OAU-SVX01E-EN

Page 21

Sequence of Operation

Space Control with Indirect GasFired or Electric Heat and

Modulating HGRH, ERV, and

Powered Ex.

Sequence of Operation—”Occupied”

Optional space temperature and/or humidity sensor s

must be installed and wired to unit and configured as

“installed” at the main unit controller.

Emergency Stop. When the contacts at Terminal

OAUTS 9 and 10 are open, the unit’s operation will be in

Alarm Status. The Alarm must be reset from either the BAS

or the optional on-board unit display.

Alarms must be reset from the optional on-board unit

display or remote BAS to restart the control sequence. If

optional display is not installed; T racer TU must be used to

diagnose and clear alarm. If Tracer TU is not available,

cycle main power to unit to clear alarm.

Important: Cycling power to unit to clear alarm may not

resolve alarm condition.

Starting Sequence

When 3-phase is powered to unit the main unit controller

and the RTRM will initializ e. Initialization process requires

approximately 3 minutes.

The unit is placed in occupied operation via either the BAS

or by closing connection between unit terminals OAUTS 7

and 8. The unit must not be in lockout.

Starting Sequence with No Retur n Air D amper

Installed

The outdoor air damper will be commanded to open. The

damper end switch will make causing the main unit

controller to initialize the indoor fan star tin g sequence by

sending a preset run signal (field adjustable betwe en

50 percent and 100 percent) to the indoor fan VFD. If after

30 seconds the indoor fan proving switch does not prove

the indoor fan on, the main unit controller will co mmand

the indoor fan off and signal an alarm.

Starting Sequence with Optional Return Air

Damper Installed

Identical to sequence with no return air damper except the

outdoor air and return air dampers will be commanded to

move to their preset occupied positions. Outdoor air

damper end switch is disabled when the return air damper

is installed.

C. Dehumidification

D. Cooling

All modes are enabled by the main unit control module.

The control module calculates dewpoint based on sensed

air temperature and humidity.

A. Economizer Mode. Economizer mode is enabled

based on outdoor air dewpoint. Operation in economizer

mode is enabled when the outdoor air dewpoint remains

below the outdoor air economizer enable dewpoint

setpoint. Operation in economizer mode continues until

outdoor air conditions call for either dehumidi fication,

cooling or heating mode. Space call for h eating,

dehumidification or cooling will cancel call for economiz er

operation.

B. Heating Mode. Heating mode is enabled on space

heating setpoint. The main unit controller will modulate

the heating output to maintain the space heating setpoint.

Maximum discharge air heating temperature is

adjustable—default maximum is 90ºF. Hot gas reheat is

disabled when heating is enabled.

C. Dehumidification Mode. Dehumidification mode is

enabled on space dewpoint setpoint if no call for heat ing

is enabled. The unit’s controller will activate the

dehumidification mode when space dewpoint is higher

than or equal to space dewpoint setpoint. Compressor

control is based on evaporator leaving air tempera ture

setpoint. With dehumidification enabled, if evaporator

leaving air temperature is above setpoint first stage

dehumidification (Compressor 1) will start. If after a

3-minute minimum delay the evapor a t o r le av ing air

temperature is still above the setpoint, the second, third,

and fourth stages of dehumidification (Compressor 2, 3,

and 4) will be staged on sequentially following individual

3-minute minimum delays between each call.

Dehumidification mode will remain active if outdoor air is

above outdoor air dehumidification setpoint. Space call

for heating will cancel outdoor air dehumidification.

During operation in dehumidification mode, the main unit

controller will enable hot gas reheat. Hot gas reheat will

modulate to maintain the space cooling setpoint.

D. Cooling Mode . Cooling mode is enabled on space

cooling setpoint if no call for heating or dehumidification

is present. Compressor staging is identical to

dehumidification however control temperature is space

cooling setpoint.

During operation in cooling mode hot gas reheat is

enabled. Hot gas reheat is controlled to maintain space

cooling setpoint.

Operating Modes

A. Economizer (Ventilation)

B. Heating

OAU-SVX01E-EN 21

Page 22

Sequence of Operation

Optional Features

Digital Compressors

Main unit controller will modulate digital compressor to

maintain either evaporator leaving or space temperature

setpoints depending on mode of operation. Remaining

compressors will be staged as described in mode.

ERV and Powered Exhaust

ERV and powered exhaust are interlocked with indoor fan

operation in occupied heating, dehumidification or

cooling modes. Outdoor air sensors sending temperature

and Rh signals to the main unit controller to make mode

calls are relocated downstream of the ERV. Outdoor air

heating and dehumidification override setpoints will be

based on ERV leaving conditions. Additional sensors will

be installed in the non-ERV outdoor air position for

information purposes and those outdoor air readings may

be viewed at the main unit co ntroller or via the BAS. When

operating in economizer mode the ERV is disabled and the

ERV by-pass damper(s) open, powered exhaust remains

on and is adjusted to 100 percent capacity by the main unit

controller. The m ain unit controller will end ERV operation

and open ERV bypass dampers if outdoor air/return air

conditions could cause ERV frosting, powered exhaust

remains on.

Note: For units with optional ERV defrost heater, the

control sequence will engage heater at frost

condition rather than stop ERV.

The powered exhaust fan speed is factory set to run

between 50 percent and 100 percent (field adjustable).

Hot Gas Reheat

Following continuous 30-minute hot gas reheat operation

at less than 100 percent reheat capacity a purge cycle will

be initiated. During the purge cycle the, hot gas reheat

signal is set and held at 100 percent for a period of

3 minutes. Following the purge cycle, normal operation

resumes.

Sequence of Operation—”Unoccupied”

Emergency Stop. When the contacts at Terminal

OAUTS 9 and 10 are open, the unit’s operation will be in

Alarm Status. The Alarm must be reset from either the BAS

or the optional on-board unit display.

Starting Sequence with No Return Air Damper

Installed.

damper installed.

Identical to occupied sequence no return air

Operating Modes

A. Unoccupied Heating

B. Unoccupied Dehumidification

C. Unoccupied Cooling

A. Heating Mode. Unoccupied heating is enabled

based on unoccupied space heating setpoint. Unoccupied

heating is enabled when space temperature reaches

unoccupied space heating setpoint - 2°. The modulating

gas heat or SCR electric heat will continue to raise the

discharge air temperature to a maximum of 90°F and

continue to supply heated 90° air to the space until the

space temperature reaches setpoint + 2°. Unit operation is

discontinued when unoccupied space heating is sati sfied.

B. Dehumidification Mode. When no call for

unoccupied heating exists, unoccupied dehu midification

is enabled based on unoccupied space dewpoint set point.

During unoccupied dehumidification operation

dehumidification capacity is restricted to 50 percent (only

half of the compressors are allowed to come on).

Unoccupied dehumidification is enabled when space

temperature reaches unoccupied space dehumidification

setpoint + 1°. Dehumidification stops at setpoint - 1°. Unit

operation is discontinued when unoccupied space

dehumidification is satisfied.

C. Cooling Mode. When no call for unoccupied heating

or unoccupied dehumidification exists, unoccupied

cooling is enabled based on unoccupied space cooling

setpoint. During unoccupied space cooling operation

cooling capacity is restricted to 50 percent (only half of the

compressors are allowed to come on). Unoccupied

cooling is enabled when space temperature reaches

unoccupied space cooling setpoint + 2°. Cooling stops at

setpoint - 2°. Unit operation is discontinued when

unoccupied space cooling is satisfied.

Powered Exhaust/ERV Sequence of Operation

Powered Exhaust/ERV operation is disabled during unit

“Unoccupied” operating modes.

Starting Sequence

Indoor fan proving sequence is identical to occupied

operation.

Starting Sequence with Optional Return Air

Damper Installed

The outdoor air damper will be commanded to close and

the return air damper will open. Outdoor air damper end

switch is disabled when the return air damper is installed.

22 OAU-SVX01E-EN

Page 23

Sequence of Operation

Dischar ge Air Control with Indirect Gas-Fired or Electric Heat and Modulating HGRH, ERV, and Powered Ex.

Sequence of Operation—”Occupied”

Emergency Stop. When the contacts at Terminal

OAUTS 9 and 10 are open, the unit’s operation will be in

Alarm Status. The Alarm must be reset from either the BAS

or the optional on-board unit display.

Alarms must be reset from the optional on-board unit

display or remote BAS to restart the control sequence. If

optional display is not installed; T racer TU must be used to

diagnose and clear alarm. If Tracer TU is not available,

cycle main power to unit to clear alarm.

Important: Cycling power to unit to clear alarm may not

resolve alarm condition.

Starting Sequence

When 3-phase is powered to unit the main unit controller

and the RTRM will initializ e. Initialization process requires

approximately 3 minutes.

The unit is placed in occupied operation via either the BAS

or by closing connection between unit terminals OAUTS 7

and 8. The unit must not be in lockout.

Starting Sequence with No Retur n Air D amper

Installed

The outdoor air damper will be commanded to open. The

damper end switch will make causing the main unit

controller to initialize the indoor fan star tin g sequence by

sending a preset run signal (field adjustable betwe en

50 percent and 100 percent) to the indoor fan VFD. If after

30 seconds the indoor fan proving switch does not prove

the indoor fan on, the main unit controller will co mmand

the indoor fan off and signal an alarm.Starting Sequence

with Optional Return Air Damper Installed

Identical to sequence with no return air damper except the

outdoor air and return air dampers will be commanded to

move to their preset occupied positions. Outdoor air

damper end switch is disabled when the return air damper

is installed.

Operating Modes

A. Economizer (Ventilation)

B. Heating

C. Dehumidification

D. Cooling

All modes are enabled by the main unit control module.

The control module calculates dewpoint based on sensed

outdoor air temperature and humidity.

A. Economizer Mode. Operation in economizer mode

is enabled when the outdoor air temperature is between

the Outdoor Air Cooling Setpoint and the Outdoor Air

Heating setpoint and no call for dehumidification exists.

Operation in economizer mode continues until o utdoor air

conditions call for either dehumidification, cooling or

heating mode.

B. Heating Mode. Heating mode is enabled on outdoor

air heating setpoint. The main unit controller will

modulate the heating capacity to maintain the discharge

air heating setpoint. Hot gas reheat is disabled when

heating is enabled. Heating will be disabled at outdoor air

heating setpoint + 2°.

C. Dehumidification Mode. Dehumidification mode is

enabled on outdoor air dewpoint enable setpoi nt if no call

for heating is enabled. The unit’s controller will activate the

dehumidification mode when outdoor air dewpoint is

higher than or equal to outdoor air dewpoint setpoint.

Compressor control is based on evaporator leaving air

temperature setpoint. With dehumidification enabled, if

evaporator leaving air temperature is above setpoint first

stage dehumidification (Compressor 1) will start. If after a

3-minute minimum delay the evapor a t o r le av ing air

temperature is still above the evaporator leaving air

temperature setpoint, the second, third, and four th stages

of dehumidification (Compressor 2, 3, and 4) will be

staged on sequentially following individual 3-minute

minimum delays between eac h cal l. Deh um id ifi cati on

mode will be disabled at outdoor air dewpoint setpoint

- 2°.

During operation in dehumidification mode, the main unit

controller will enable hot gas reheat. Hot gas reheat will

modulate to maintain the discharge air cooling setpoint.

C. Cooling Mode. Cooling mode is enabled on outdoor

air cooling setpoint if no call for heating or

dehumidification is present. Compressor staging is

identical to dehumidification; however, control

temperature is discharge air cool ing setpoint. Cooling will

be disabled at outdoor air cooling setpoint - 2°.

During operation in cooling mode hot gas reheat is

enabled. Hot gas reheat is controlled to maintain discharge

air cooling setpoint.

Optional Features

Digital Compressors

Main unit controller will modulate digital compressor to

maintain either evaporator leaving or discharge air

temperature setpoints depending on mode of operation.

Remaining compressors will be staged as described in

mode.

ERV and Powered Exhaust

ERV and powered exhaust are interloc ked with indoor fan

operation in occupied heating, dehumidification or

cooling modes. Outdoor air sensors sending temperature

and Rh signals to the main unit controller to make mode

OAU-SVX01E-EN 23

Page 24

Sequence of Operation

calls are relocated downstream of the ERV . Mode calls will

be based on ERV leaving conditions. Additional sensors

will be installed in the non-ERV outdoor air position for

information purposes and those outdoor air readings may

be viewed at the main unit co ntroller or via the BAS. When

operating in economizer mode the ERV is disabled and the

ERV by-pass damper(s) open, powered exhaust remains

on and is adjusted to 100 percent capacity by the main unit

controller. The m ain unit controller will end ERV operation

and open ERV bypass dampers if outdoor air/return air

conditions could cause ERV frosting, powered exhaust

remains on.

Note: For units with optional ERV defrost heater, the

control sequence will engage heater at frost

condition rather than stop ERV.

The powered exhaust fan speed is factory set to run

between 50 percent and 100 percent (field adjustable).

Hot Gas Reheat

Following continuous 30-minute hot gas reheat operation

at less than 100 percent reheat capacity a purge cycle will

be initiated. During the purge cycle the, hot gas reheat

signal is set and held at 100 percent for a period of

3 minutes. Following purge cycle normal operation

resumes.

Sequence of Operation—”Unoccupied”

Optional space temperature and/or humidity sensor s

must be installed and wired to unit and configured as

“installed” at the main unit controller to enable

unoccupied sequences.

Emergency Stop. When the contacts at Terminal

OAUTS 9 and 10 are open, the unit’s operation will be in

Alarm Status. The Alarm must be reset from either the BAS

or the optional on-board unit display.

A. Heating Mode. Unoccupied heating is enabled

based on unoccupied space heating setpoint. Unoccupied

heating is enabled when space temperature reaches

unoccupied space heating setpoint - 2°. The modulating

gas heat or SCR electric heat will continue to raise the

discharge air temperature to a maximum of 90°F and

continue to supply heated 90° air to the space until the

space temperature reaches setpoint + 2°. Unit operation is

discontinued when unoccupied space heating is sati sfied.

B. Dehumidification Mode. When no call for

unoccupied heating exists, unoccupied dehu midification

is enabled based on unoccupied space dewpoint set point.

During unoccupied dehumidification operation

dehumidification capacity is restricted to 50 percent (only

half of the compressors are allowed to come on).

Unoccupied dehumidification is enabled when space

temperature reaches unoccupied space dehumidification

setpoint + 1°. Dehumidification stops at setpoint - 1°. Unit

operation is discontinued when unoccupied space

dehumidification is satisfied.

C. Cooling Mode. When no call for unoccupied heating

or unoccupied dehumidification exists, unoccupied

cooling is enabled based on unoccupied space cooling

setpoint. During unoccupied space cooling operation

cooling capacity is restricted to 50 percent (only half of the

compressors are allowed to come on). Unoccupied

cooling is enabled when space temperature reaches

unoccupied space cooling setpoint + 2°. Cooling stops at

setpoint - 2°. Unit operation is discontinued when

unoccupied space cooling is satisfied.

Powered Exhaust/ERV Sequence of Operation

Powered Exhaust/ERV operation is disabled during unit

“Unoccupied” operating modes.

Starting Sequence

Indoor fan proving sequence is identical to occupied

operation.

Starting Sequence with Optional Return Air

Damper Installed

The outdoor air damper will be commanded to close and

the return air damper will open. Outdoor air damper end

switch is disabled when th e return air damper is installed.

Starting Sequence with No Retur n Air D amper

Installed

Identical to occupied sequence no return air damper

installed.

Operating Modes

A. Unoccupied Heating

B. Unoccupied Dehumidification

C. Unoccupied Cooling

24 OAU-SVX01E-EN

Page 25

Installation

48" Minimum

Airflow

WARNING

Hazardous Service Procedures!

The maintenance and troubleshooting procedures

recommended in this section of the manual could result

in exposure to electr ical, mechanical or other potential

safety hazards. Always refer to the safety warnings

provided throughout this manual concerning these

procedures. When possible, disconnect all electrical

power including remote disconnect and discharge all

energy storing devices such as capacitors before

servicing. Follow proper lockout/tagout procedures to

ensure the pow er can not be inadvertently energized.

When necessary to work with live electrical

components, have a qualified licen sed el ectrician or

other individual who has been trained in handling live

electrical components perf o rm these tasks. Failure to

follow all of the safety warnings provided could result

in death or serious injury.

Ductwork

Elbows with turning vanes or splitters are recommended

to minimize air noise due to turbulence and to reduce static

pressure.

When attac hing the ductwork to the unit, provide a w atertight flexible connector at the unit to prevent operating

sounds from transmitting through the ductwork.

All outdoor ductwork between the unit and the structure

should be weather proofed after installation is completed.

Note: For sound consideration, cut holes in the roof deck

only for the ductwork penetrations. Do not cut out

the roof deck within the entire curb perimeter. All

duct work must be installed and connected to top of

roof curb before the unit is set on curb.

If a Curb Accessory Kit is not used:

1. Be sure to use flexible duct connections at the unit.

2. Gaskets must be installed around the curb perimeter

flange and the supply and return air opening flanges.

Note: For units will electric heat in the primary heating

position, refer to Figure 25.

Figure 25.

Important: Bottom discharge units with open coil

electric heater in primary heat location

require discharge duct with 90° elbow . This

is a MANDATORY installation requirement.

General Unit Requirements

The checklist listed below is a summary of the steps

required to successfully install a commercial unit. This

checklist is intended to acquaint the installing personnel

with what is required in the installation process. It does

not replace the detailed instructions called out in

the applicable sections of this manual.

Check the unit for shipping damage and material

shortage. File a freight claim and notify appropriate

sales representative if damage or sho rtage is

discovered.

Verify that the unit nameplate model, options, and

voltage are correct.

Verify that the installation location of the unit will

provide the required clearance for proper operation.

Assemble and install the roof curb (if applicable).

Refer to the latest edition of the curb installers guide

that ships with each curb kit. Check curb for level

installation; if not level, shim as required.

Rigging unit (refer to “Unit Weight and Rigging,”

p. 18).

Set the unit onto the curb; check for level.

Ensure unit-to-curb seal is tight and without buckles

or cracks.

Install and connect proper condensate drain line to

the evaporator condensate pan drain connection (see

Figure 26, p. 26).

OAU-SVX01E-EN 25

Page 26

Installation

PANEL ENCLOSURE

D" NPT FEMALE

CONNECTOR

CLEANOUT PLUG

Main Electrical Power Requirements

Verify that the power supply complies with the unit

nameplate specifications.

Inspect all control panel components; tighten any

loose connections.

Connect properly sized and protected power supply

wiring to a field-supplied/-installed disconnect switc h

and to the main power terminal block (HTB1) in the

unit control panel.

Connect properly-sized earth ground.

Note: All field-installed wiring must comply with NEC

and applicable local codes.

Condensate Drain Configuration

OAU un its are selected based on dehum id ification

capability. As such, condensate can form at a high rate.

Therefore, the OAU drain pan and condensate line are

sized and designed accordingly. However, an oftenoverlooked element of proper condensate drainage is

proper P-Trap and drain line sizing and installation. An

incorrectly-designed and -installed P-Trap can restrict

condensate flow or cause water in the condensate drain

pan to “spit” or “geyser” which may cause condensate

overflow. Carefully instal l and trap the drain pan to ensure

adequate condensate removal under all conditions.

An evaporator condensate drain connection is provided

on each unit. Refer to Figure 28, p. 27, Figure 29, p. 27, and

Figure 30, p. 27 for the appropriate drain location.

A condensate trap must be installed at the unit due to the

drain connection being on the “negative pressure” side of

the fan. Install the P -Trap using the guidelines in Figure 26.

Pitch drain lines connect ed to P-Trap at least 1/2 inch for

every 10 feet of horizontal run to assure proper

condensate flow. Do not allow the horizontal run to sag

causing a possible double-trap condition which could

result in condensate backup due to “air lock”.

Figure 26. Condensate trap installation

D = Pipe diameter; see Figure 28, p. 27, Figure 29, p. 27, and

Figure 30, p. 27 for correct pipe diameter

H = Internal static pressure (in wg) +1 in.

J = H + 0.5

L = H + J +D

Notes:

1. Pitch drain at least 1/2 in. per 10 ft horizontal run.