Trane J4PG4024A1060AA, J4PG4030A1060AA, J4PG4036A1090AA, J4PG4042A1090AA, J4PG4048A1090AA Installation Instructions Manual

...Page 1

INSTALLATION INSTRUCTIONS

PACKAGE GAS ELECTRIC UNITS

FEATURING R-410A

14 SEER SERIES - (2-5T

ons)

C

RECOGNIZE THIS SYMBOL

CONFORMS TO

STD. 1995

CERTIFIED TO CSA

STD. C22.2 NO. 236

CENTRAL FURNACE

CONFORMS TO ANSI

STD Z21.47-2016,

CERTIFIED

STD 2.3-2016

AS AN INDICATION OF IMPORTANT SAFETY INFORMATION

UL

TO CSA

WARNING:

FIRE OR EXPLOSION HAZARD

Failure to follow safety warnings exactly could result in serious injury death or property damage.

WARNING

— Do not store or use gasoline or other flammable

other appliance.

— WHAT TO DO IF YOU SMELL GAS

• Do not try to light any appliance; do not touch any electrical switch; do not use any phone in your building.

• Immediately call your gas supplier from a neighbor’s phone. Follow the gas supplier’s instructions.

• If you cannot reach your gas supplier, call the fire department.

• Do not return to your home until authorized by the gas supplier or fire department.

— Improper installation, adjustment, alteration, service or maintenance can cause property damage, personal injury or death.

Refer to this manual, installation and service must be performed by a qualified installer, service agency or the gas supplier. In

the commonwealth of Massachusetts, installation must be performed by a licensed plumber or gas fitter for appropriate fuel.

vapors and liquids, or other combustible materials in the vicinity of this or any

NOTE: Do not use this furnace if any part has been under water

to use the furnace can result in fire or explosion. A qualified service agency should be contacted to inspect the

furnace and to replace all gas controls, control system parts, electrical parts that have been wet or the furnace if

deemed necessary.

. A flood-damaged furnace is extremely dangerous. Attempts

DO NOT DESTROY THIS MANUAL

Please read carefully and keep in a safe place for future reference by a serviceman.

Page 2

Installation Start-up,Operating and Service and Maintenance Instructions

CONTENTS PAGE

1.0 SAFETY...............................................................................................4

1.1 INSPECTION.................................................................................6

1.2 LIMITATIONS................................................................................6

2.0 INTRODUCTION...................................................................................7

3.0 INSTALLATION..................................................................................10

3.1 PRE-INSTALLATION CHECK-POINTS...........................................10

3.2 LOCATION CONSIDERATIONS.....................................................10

3.3 OUTSIDE INSTALLATION............................................................10

3.4 ATTACHING EXHAUST AND COMBUSTiON AIR INLET HOODS...10

3.5 COVER PANEL INSTAlLATiON / CONVERSION POCEDURE..........10

3.6 CLEARANCE................................................................................11

3.7 RIGGING AND HANDING ............................................................11

3.8 DUCTWORK................................................................................16

3.9 RETURN AIR...............................................................................16

3.10 FILTERS....................................................................................16

4.0 GAS SUPPLY, CONDENSATE DRAIN AND PIPING.............................16

4.1 GAS CONNECTION......................................................................16

4.2 LP CONVERSION.........................................................................17

4.3 ADJUSTING OR CHECKING FURNACE INPUT..............................18

4.4 CONDENSATE DRAIN..................................................................18

5.0 WIRING............................................................................................18

5.1 POWER SUPPLY.........................................................................18

5.2 HOOK-UP....................................................................................18

5.3 INTERNAL WIRING......................................................................19

5.4 THERMOSTAT.............................................................................19

6.0 FURNACE SECTION CONTROLS AND IGNITION SYSTEM..................19

6.1 NORMAL FURNACE OPERATING SEQUENCE...............................19

6.2 OPERATING INSTRUCTIONS.......................................................19

6.3 TO START THE FURNACE............................................................19

6.4 TO SHUT DOWN FURNACE.........................................................20

6.5 BURNERS...................................................................................20

6.6 MANUAL RESET OVERTEMPERATURE CONTROL.......................20

6.7 PRESSURE SWITCH....................................................................20

6.8 LIMIT CONTROL..........................................................................20

7.0 SYSTEM OPERATING INFORMATION.................................................20

7.1 ADVISE THE CUSTOMER..............................................................20

7.2 FURNACE SECTION MAINTENAECE..............................................20

7.3 LUBRICATION..............................................................................21

7.4 COOLING SECTION MAINTENANCE..............................................21

7.5 REPLACEMENT PARTS................................................................21

7.6 TROUBLESHOOTING....................................................................21

7.7 WIRING DIAGRAMS.....................................................................21

7.8 CHARGING...................................................................................21

7.9 BLOWER MOTOR SPEED TAPS.....................................................21

8.0 OPERATION.......................................................................................22

8.1 CONTROL SYSTEM OPERATION.................................................22

8.2 FAN DELAY ADJUSTMENT .........................................................22

9.0 PHYSICAL DATA................................................................................23

10.0 AIRFLOW PERFORMANCE...............................................................25

11.0 TROUBLE SHOOTING.......................................................................30

Page 3

This document is customer property and is to remain with this unit.

These instructions do not cover all the different variations of systems

nor does it provide for every possible contingency to be met in

connection with installation.

All phases of this installation must comply with NATION, STATE AND

LOCAL CODES. If additional information is required please contact

your local distributor.

1.0 SAFETY

When you see the symbols below on labels or in the manual, be alert

to the potential or immediate hazards of personal injury, property

and/or product damage. It is the owner’s or installer’s responsibility to

comply with all safety instructions and information accompanying

these symbols.

WARNING: This is a safety alert symbol indicating a potential

hazardous situation, which could result in personal injury,

property and/or product damage or death.

CAUTION: This is a safety alert symbol indicating a potential

hazardous situation, which could result in moderate personal

injury, and/or property and product damage.

WARNING

Proposition 65: This appliance contains fiberglass insulation.

Respirable particles of fiberglass are known to the state of

California to cause cancer. Exhaust gas from this appliance

contains chemicals, including carbon monoxide, known to the

state of california to cause birth defects of other reproductive

harm.

WARNING

Never allow products of combustion or the flue products to enter

the return air ductwork, or the circulating air supply. All return

ductwork must be adequately sealed and secured to the furnace

with sheet metal screws, and joints taped. All other duct joints

must be secured with approved connections and sealed airtight.

Failure to prevent products of combustion from being circulated

into the living space can create potentially hazardous conditions,

including Carbon Monoxide poisoning that could result in

personal injury or death.

WARNING

These instructions are intended as an aid to qualified, licensed

service personnel for proper installation, adjustment and

operation of this unit. Read these instructions thoroughly before

attempting installation or operation. Failure to follow these

instructions may result in improper installation, adjustment,

service or maintenance possibly resulting in fire, electrical shock,

property damage, personal injury or death.

WARNING

The manufacturer’s warranty does not cover any damage or

defect to the gas/electric unit caused by the attachment or use of

any components, accessories or devices (other than those

authorized by the manufacturer) into, onto or in conjunction with

the gas/electric unit. You should be aware that the use of

unauthorized components, accessories or devices may

adversely affect the operation of the gas/electric unit and may

also endanger life and property. The manufacturer disclaims any

responsibility for such loss or injury resulting from the use of such

unauthorized components, accessories or devices.

WARNING

Do not, under any circumstances, connect return ductwork to any

other heat producing device such as a fireplace insert, stove, etc.

Unauthorized use of such devices may result in fire, Carbon

Monoxide poisoning, explosion, property damage, severe

personal injury or death.

WARNING

This unit is designed certified for outdoor installation only.

Installation inside any part of a structure can result in inadequate

unit performance as well as property damage. Installation inside

can also cause recirculation of flue products into the conditioned

space resulting in personal injury or death.

WARNING

The spark ignitor and ignition lead from the ignition control are

high voltage. Keep hands or tools away to prevent electrical

shock. Shut off electrical power before servicing any of the

controls. Failure to adhere to this warning can result in personal

injury or death.

WARNING

Holes in the exhaust transition or heat exchanger can cause toxic

fumes to enter the home. The exhaust transition or heat

exchanger must be replaced if they have holes or cracks in them.

Failure to do so can cause Carbon Monoxide poisoning resulting

in personal injury or death.

WARNING

Do not attempt to manually light this furnace with a match or any

open flame. Attempting to do so can cause fire or explosion

resulting in property damage, personal injury or death.

WARNING

Should overheating occur or the gas supply fail to shut off. Shut

off the Manual Gas valve to the appliance before shutting off the

supply. Failure to do so can result in an explosion or fire causing

property damage, severe personal injury or death.

WARNING

Disconnect all power to the unit before starting maintenance.

Failure to do so can result in severe electrical shock or death.

Regular maintenance will reduce the buildup of contaminants

and help to protect the unit’s finish.

WARNING

Turn off the main electrical power at the branch circuit disconnect

closest to the unit before attempting any wiring. Failure to do so

can cause electrical shock resulting in personal injury or death.

WARNING

DO NOT JUMPER THIS DEVICE! Do not reset the

overtemperature control without taking corrective action to

assure that an adequate supply of combustion air is maintained

under all conditions of operation. Failure to do so can result in

Carbon Monoxide poisoning or death. Replace this control only

with the identical replacement part.

WARNING

Label all wires prior to disconnection when servicing controls.

Wiring errors can cause improper and dangerous operation

resulting in fire ,electrical shock, property damage, personal

injury or death.

installation & owner’s manual

4

Page 4

WARNING

CAUTION

This unit is equipped at the factory for use on Natural Gas only.

Conversion to LP Gas requires a special kit enclosed instructions

with. DO NOT BURN ANY LIQUID FUEL OR SOLID FUEL IN

THIS UNIT. Burning any unapproved fuel will result in damage to

this unit heat exchanger, which could result in fire, Carbon

Monoxide poisoning, explosion, personal injury, property

damage or death.

WARNING

Install this unit only in a location and position as specified in the

location requirements and considerations section of these

instructions. Provide adequate combustion and ventilation air to

the unit space as specified in the venting section of these

instructions.

WARNING

Do not use this unit during construction if air laden corrosive

compounds are present such as chlorine and fluorine. Otherwise,

provisions must be taken to provide clean, uncontaminated

combustion and ventilation air to the unit, combustion and

ventilation air contaminated with these compounds forms acids

during combustion which corrodes the heat exchanger and

component parts, some of these contaminates are found in, but

not limited to, paneling, dry wall, adhesives, paints, stains,

varnishes, sealers, and masonry cleaning materials.

R410A systems operate at higher pressures than R22 systems.

Do not use R22 service equipment or components on R410A

equipment.

WARNING

ELECTRICAL SHOCK, FIRE OR EXPLOSION HAZARD

Failure to follow safety warnings exactly could result in

dangerous operation, serious injury, death or property damage.

Improper servicing could result in dangerous operation, serious

injury, death or property damage.

• Before servicing, disconnect all electrical power to furnace.

• When servicing controls, label all wires prior to disconnecting.

Reconnect wires correctly.

• Verify proper operation after servicing.

Improper installation, adjustment, alteration, service, Maintenance, or

use can cause explosion, fire, electrical shock, or other conditions

which may cause death, personal injury, or property damage. Consult

a qualified installer, service agency, or your distributor or branch for

information or assistance. The qualified installer or agency must use

factory-authorized kits or accessories when modifying this product.

Refer to the individual instructions packaged with the kits or

accessories when installing.

WARNING

FIRE, EXPLOSION, ELECTRICAL SHOCK,

AND CARBON MONOXIDE POISONING HAZARD

Failure to follow this warning could result in dangerous

operation, serious injury, death or property damage.

Improper installation,adjustment,alteration,service,

maintenance or use could cause carbon monoxide poisoning,

explosion,fire,electrical shock or other conditions which

may cause personal injury or property damage. Consult a

qualified service agency,local gas supplier or your distributor

or branch for information or assistance. The qualified service

agency must use only factory-authorized and listed kits or

accessories when modifying this product.

WARNING

Always install unit to operate within the unit’s intended

temperature-rise range with a duct system which has an external

static pressure within the allowable range, as specified in ducting

section of these instructions, see also unit rating plate.

CAUTION

FURNACE RELIABILITY HAZARD

Improper installation or misapplication of furnace may require

excessive servicing or cause premature component failure.

Application of this furnace should be outdoors with special

attention given to vent sizing and material, gas input rate, air

temperature rise, unit leveling, and unit sizing.

CAUTION

Follow all safety codes. Wear safety glasses, protective clothing, and

work gloves. Have a fire extinguisher available. Read these

instructions thoroughly and follow all warnings or cautions include in

literature and attached to the unit. Consult local building codes,the

current editions of the National Fuel Gas Code (NFGC) NFPA

54/ANSI Z223.1 and the National Electrical Code (NEC) NFPA 70.

In Canada, refer to the current editions of the National Standards of

Canada CAN/CSA-BI49.1 and .2 Natural Gas and Propane

Installation Codes, and Canadian Electrical Code CSA C22.1

Recognize safety information. This is the safety-alert symbol . When

you see this symbol on the unit and in instructions or manuals, be alert

to the potential for personal injury. Understand the signal words

DANGER, WARNING, and CAUTION. These words are used with the

safety-alert symbol.

DANGER identifies the most serious hazards which will result in

severe personal injury or death. WARNING signifies hazards which

could result in personal injury or death. CAUTION is used to identify

unsafe practices which may result in minor personal injury or product

and property damage. NOTE is used to highlight suggestions which

will result in enhanced Installation, reliability, or operation.

● Use only with type of gas approved for this unit. Refer to the unit

rating plate.

● Install this unit only in a location and position as specified in the

"Installation" section of these instructions.

● Provide adequate combustion and ventilation air to the unit space

as specified in "Safety" section.

● Never test for gas leaks with an open flame. Use a commercially

available soap solution made specifically for the detection of leaks

to check all connections, as specified in the "Gas Supply,

Condensate drain and Piping" section.

CUT HAZARD

Failure to follow this caution may result in personal injury.

Sheet metal parts may have sharp edges or burrs. Use care

and wear appropriate protective clothing, safety glasses and

gloves when handling parts and servicing furnaces.

● Always install unit to operate within the furnace's intended

temperature-rise range with a duct system which has an external

static pressure within the allowable range, as specified in the

"Safety" section. See also unit rating plate.

installation & owner’s manual

5

Page 5

● When unit is installed so that supply ducts carry air circulated by the

furnace to areas outside the space containing the furnace, the return

air shall also be handled by duct(s) sealed to the furnace casing and

terminating outside the space containing the furnace. See “Ductwork”

and "Return Air" section.

● The unit may be used for construction heat provided that the

furnace installation and operation complies with the CAUTION

and WARING instructions in this manual.

● The unit is design-certified for use with natural and propane gases

(see unit rating plate) and for installation in outside only. The unit is

factory-shipped for use with natural gas. A listed accessory gas

conversion kit is required to convert unit for use with propane gas. The

LP conversion kit is included with the unit.

● The unit must be kept free and clear of insulating materials. Inspect

surrounding area to ensure insulation material is in safe distance

when installing furnaces or adding insulation materials. Insulation

materials may be combustible.

See Table 3-1 for required clearances to combustible construction.

● Before heating season begins, exam the unit to determine that:

a. All flue gas carrying areas external to the unit (i.e. chimney, vent

connector) are clear and free of obstructions.

b. The vent connector is in place, slopes upward and is physically sound

without holes or excessive corrosion.

c. The return-air duct connection(s) is physically sound, is sealed to the

furnace casing, and terminates outside the space containing the

furnace.

d. The physical support of the unit is sound without sagging,

cracks, gaps, etc around the base so as to provide a seal

between the support and the base.

e. There are no obvious sign of deterioration of the unit.

f. The burner flames are in good adjustment (by comparison

with pictorial sketches of the main burner flame.

● Furnace operation needs air for combustion and ventilation.

Do not block or obstruct air openings on furnace or spacing

around furnace required for supplying sufficient combustion

air and ventilation.

1.1 INSPECTION

As soon as unit is received, it should be inspected and noted for

possible shipping damage during transportation. It is shipper’s

responsibility to cover the cost of shipping damage. Manufacturer or

distributor will not accept the claims from dealer for any transportation

damage.

1.2 LIMITATIONS

Refer to Fig. 2-2, 2-3 for unit physical data and to Table 7-1 for

electrical data. If components are to be added to a unit they must

meet local codes, they are to be installed at the dealer’s and /or the

customer’s expense. Size of unit for proposed installation should be

based on heat loss / heat gain calculations made in accordance with

industry recognized procedures identified by the Air conditioning

contractors of America.

Note: Rating plate must be left visible for future reference.

FOR YOUR SAFETY READ BEFORE OPERATING

WARNING

A.

This appliance does not have a pilot. it is equipped with an

ignition device which automatically lights the burner.

Do not try to light the burner by hand.

BEFORE OPERATING smell all around the appliance

B.

area for gas. Be sure to smell next to the floor because

some gas is heavier than air and will settle on the floor.

FOR YOUR SAFETY

WHAT TO DO IF YOU SMELL GAS

• Do not try to light any appliance.

• Do not touch any electrical switch; do not use

any phone in your building.

• Immediately call your gas supplier from a

If you do not follow these instructions exactly, a fire or explosion may result

causing property damage, personal injury or loss of life.

OPERATING INSTRUCTIONS

1. STOP! Read the safety information above on this

label.

2. Set the thermostat to lowest setting.

3. Turn off all electric power to the appliance.

4. This appliance is equipped with an ignition device

which automatically lights the burner. Do not try to

light the burner by hand.

SWITCH SHOWN IN

THE “OFF” POSITION

neighbors’ phone. Follow the gas suppliers

Instructions.

• If you cannot reach your gas supplier, call the

fire department.

Use only your hand to turn the gas control switch. Never use

C.

tools. If the switch will not turn by hand, don’t try to repair it;

call a qualified service technician. Force or attempted repair

may result in a fire or explosion.

Do not use this appliance if any part has been under water.

D.

Immediately call a qualified service technician to inspect the

appliance and to replace any part of the control system and

any gas control which has been under water.

5. Remove control access panel.

6. Wait five (5) minutes to clear out any gas. if you

then smell gas, STOP! Follow “B” in the safety

information above on this label. If you don’t smell

gas, go to the next step.

7. Push gas control switch to “ON”.

NOTE: Do not force.

8. Replace control access panel.

9.Turn on all electric power to the appliance.

10.Set thermostat to desired setting

11.If the appliance will not operate, follow instructions

“To Turn Off Gas To Appliance” and call your

service technician or gas supplier.

TO TURN OFF GAS TO APPLIANCE

1. Set the thermostat to lowest setting.

2. Turn off all electric power to the appliance if service is to be

performed.

See Fig: Instruction of lighting/ shutdown operation. Should the gas supply fail to shut off or if overheating occurs, shut off the gas valve to the

furnace before shutting of the electrical supply.

installation & owner’s manual

3. Remove control access panel.

4. Push gas control to “OFF”. Do not force.

5. Replace control access panel.

6

Page 6

2. INTRODUCTION

A Package Gas Electric Unit is a fully self-contained, combination gas

heating/electric cooling unit designed for outdoor installation. All unit

sizes have return and discharge openings for both horizontal and

downflow configurations, and are factory shipped with all downflow

duct openings covered. Units may be installed either on a rooftop or

on a cement slab.

In gas heating mode, this unit is designed for a minimum continuous

return-air temperature and a maximum continuous return-air

temperature. Failure to follow these return-air temperature limits may

affect reliability of heat exchangers, motors, and other components.

This booklet contains the installation and operating instructions for

your Package Gas Electric Unit. There are some precautions that

should be taken to derive maximum satisfaction from it. Improper

installation can result in unsatisfactory operation or dangerous

conditions. Read this booklet and any instructions packaged with

separate equipment required to make up the system prior to

installation. Give this booklet to the owner and explain its provisions.

The owner should retain this booklet for future reference.

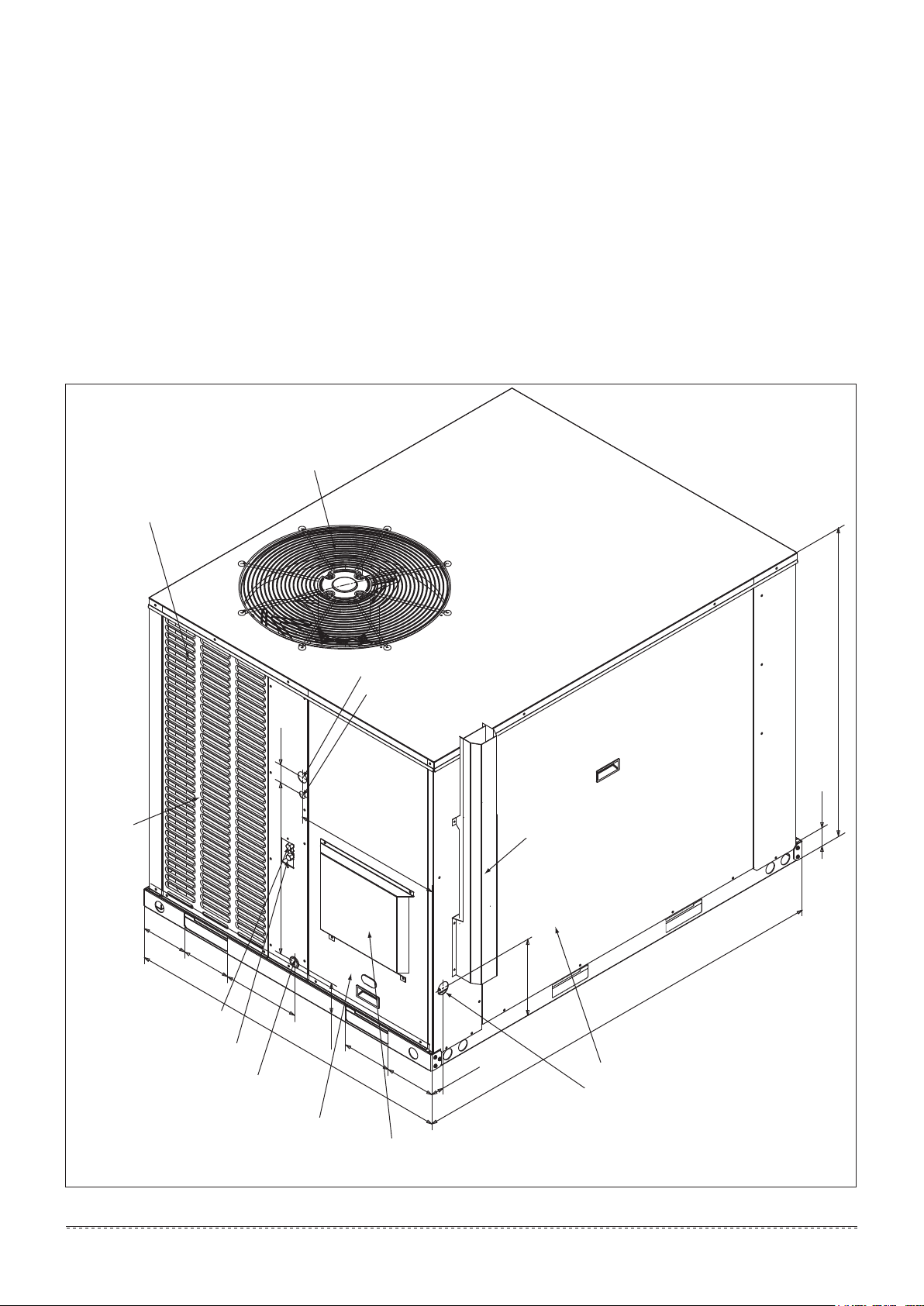

Outdoor fan grille and compressor access

Outdoor coil protective grille

A Package Gas Electric Unit includes a hermetically-sealed

refrigerating system consisting of a compressor, condenser coil,

evaporator coil with thermal expansion valve (TXV) or throttle valve, a

circulation air blower, a condenser fan, a heat exchanger assembly,

gas burner and control assembly, combustion air motor and fan, and

all necessary internal electrical wiring. The cooling system of these

units is factory-evacuated, charged and performance tested. All units

are factory charged with Refrigerant R410A.

Front

6-5/16″

6-5/8″

10″

High pressure detected valve

1/4’’ SAE

Low pressure detected valve

1/4’’ SAE

Condensate drain conn. 3/4” NPTI

(Trap required)

Electrical service access compartment panel

Combustion air inlet hood

2-3/8″

23″

44-5/8″

High voltage conn. 1-23/64” Dia.

Low voltage conn. 7/8” Dia.

20-7/16″

6-5/8″

3-3/4″

6-3/4″

1-3/4″

41-7/16″

2-3/8″

Flue exhaust hood

10-5/16″

57-15/32″

Blower/Evaporator access panel

Gas supply entrance

Fig. 2-1 Unit Dimensions

installation & owner’s manual

7

Page 7

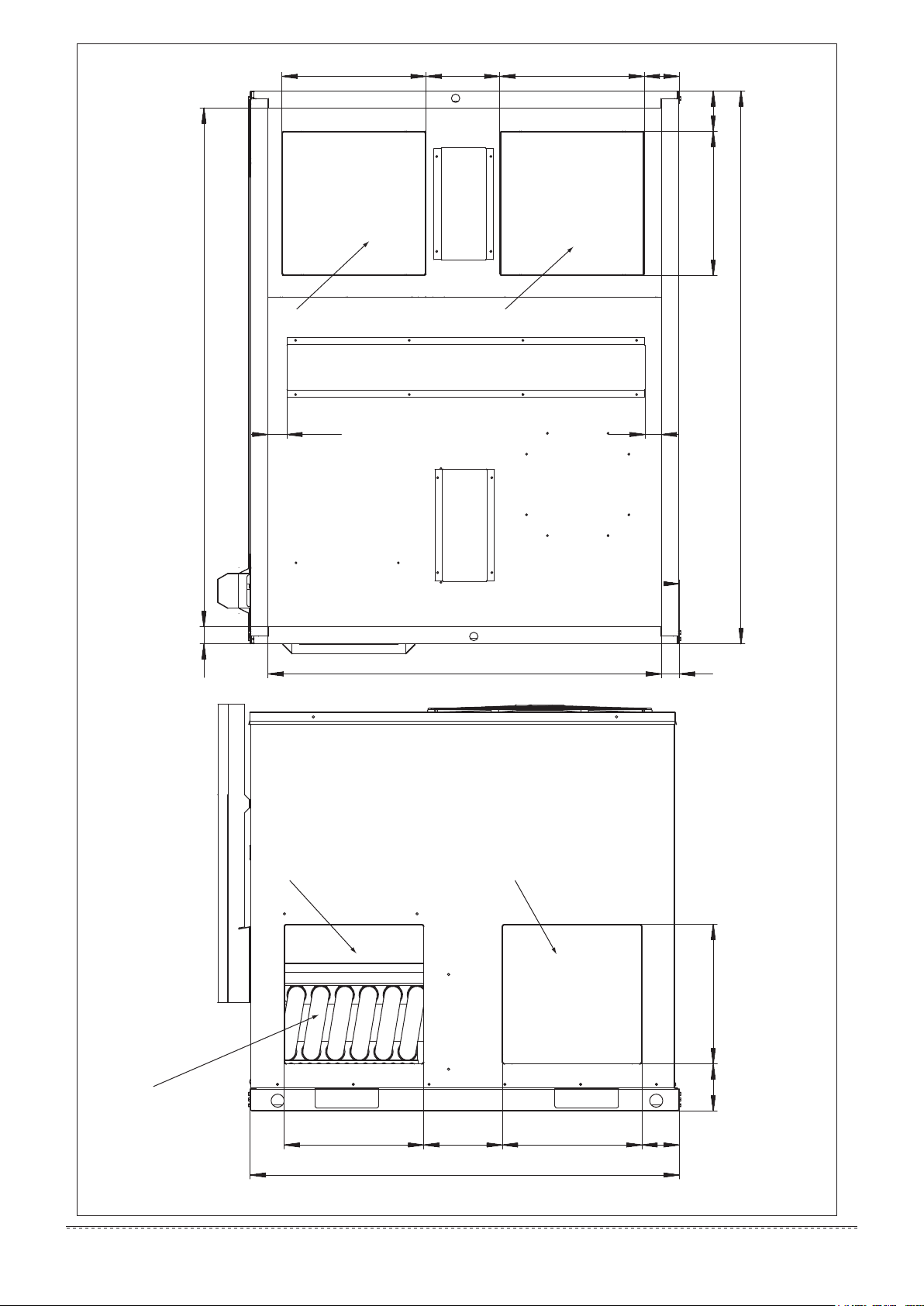

15″ 7-5/8″ 3-5/8″

Bottom supply air opening Bottom return air opening

15″

4-3/16″

15″

53-29/32″1-3/4″

57-15/32″

1-5/8″1-15/16″

Bottom View

1-7/8″40-7/8″

Back View

Heat exchanger

installation & owner’s manual

8

Side supply air opening

44-5/8″

Side return air opening

Fig. 2-2 Dimensions Back and Bottom

4-7/8″ 14-1/2″

14-1/2″14-1/2″ 8-5/32″

3-7/8″

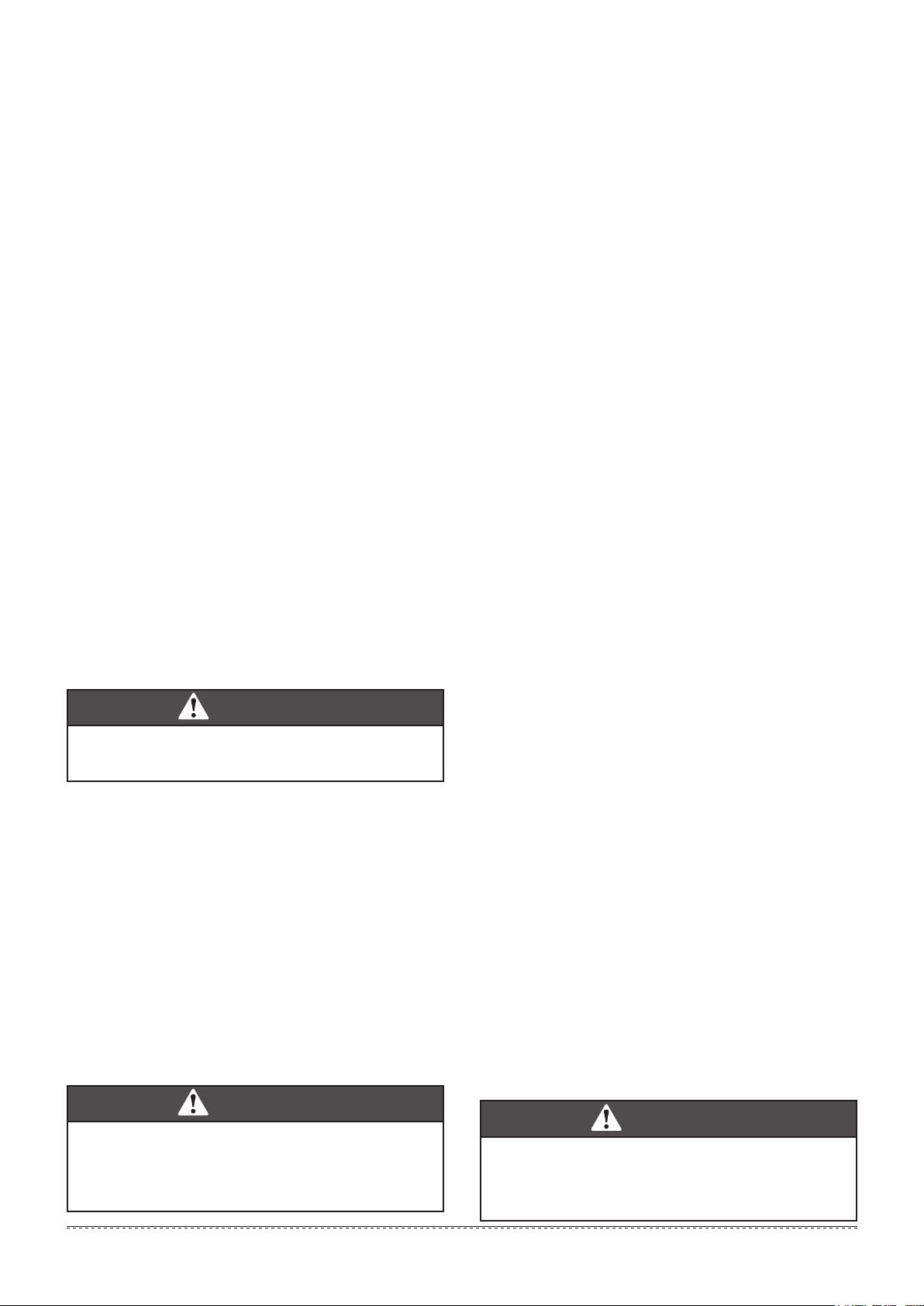

Page 8

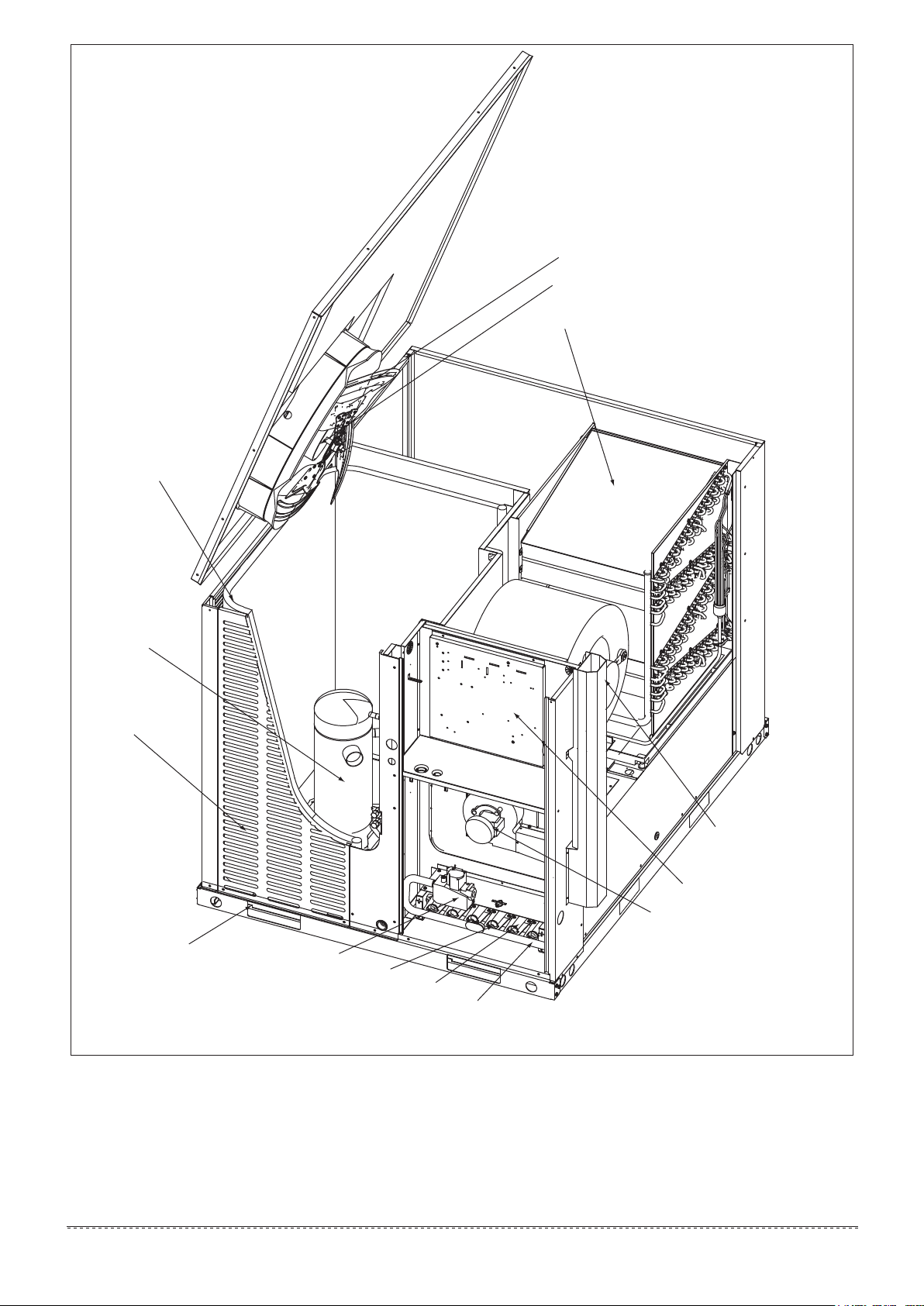

Highly efficient enhanced

microchannel outdoor coil

Compressor

Axial flow fan

Condenser fan motor

Highly efficient enhanced aluminum/copper tube

and aluminum fin indoor coil

Decorative protective

coil guard

Heavy gauge

removable base rails

Blower motor with slide-out

blower assembly

Electrical control box

Combustion air motor and fan

Gas valve

Copper nozzle

Gas burner

Gas tube

Fig. 2-3 Component Location

installation & owner’s manual

9

Page 9

3.0 INSTALLATION

Install the unit in accordance with The American National Standard

Z223.1-latest edition booklet entitled “National Fuel Gas Code”, and

the requirements or codes of the local utility or other authority having

jurisdiction.

Unit should be installed in accordance with national and local safety

codes, including but not limit to ANSI/NFPS No. 70 or Canadian

Electrical Code Part 1, C22.1, local plumbing and wastewater codes

and any other applicable codes.

Additional helpful publications available from the “National Fire

Protection Association” are: NFPA-90A - installation of Air

Conditioning and Ventilating Systems 1985 or latest edition.

NFPA-90B - Warm Air Heating and Air Conditioning Systems 1984.

3.1 PRE-INSTALLATION CHECK-POINTS

Before installation, carefully check the following:

1. For rooftop installation, be sure the structure has enough strength

to support the weight of unit.

2. Clearances and provision for servicing.

3. Power supply and wiring.

4. Gas supply and piping.

5. Air duct connections and sizing.

6. Drain facilities and connections.

7. Location for minimum noise and vibration.

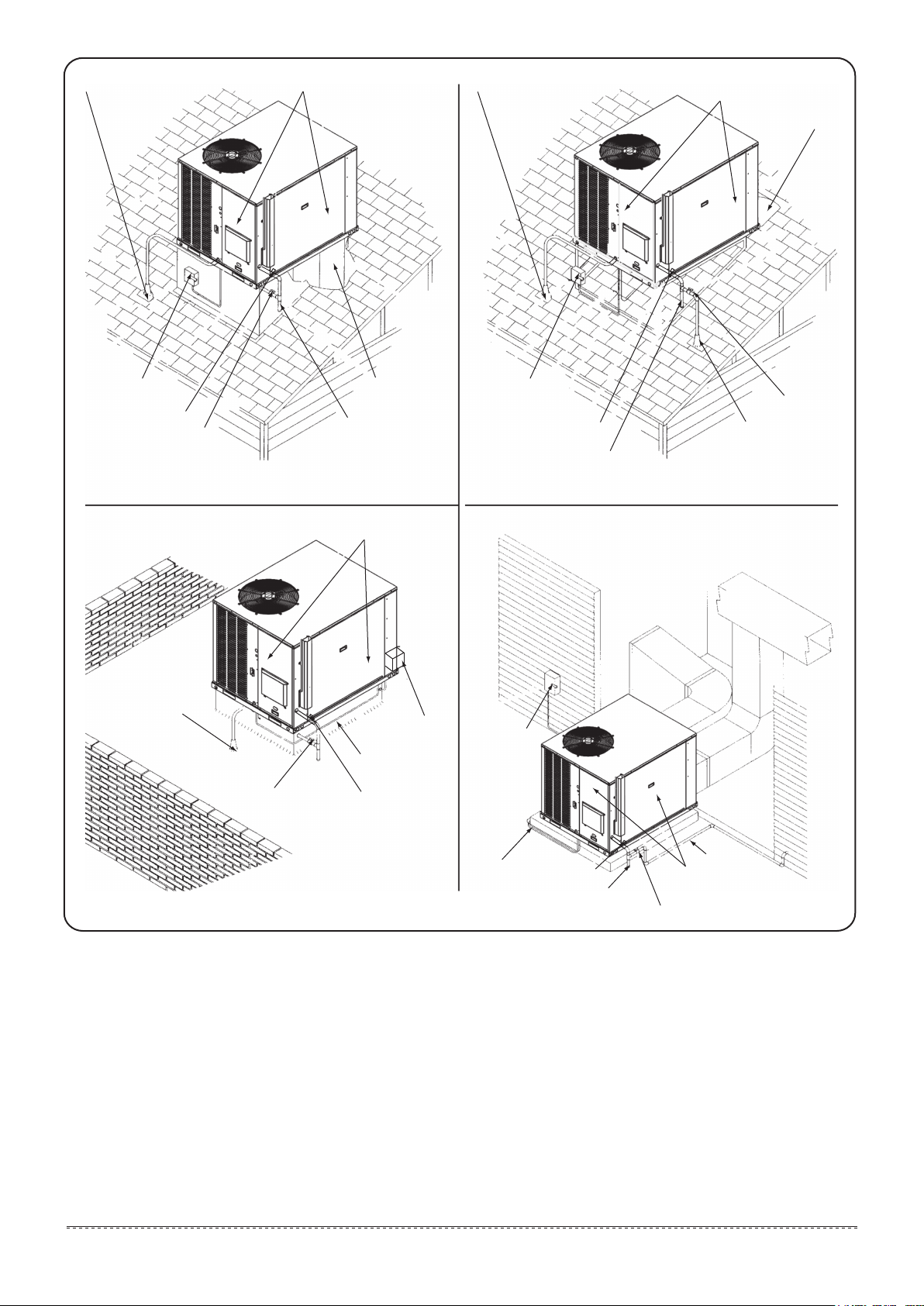

Typical outdoor installation in shown in Figure 3-2:

1. Select a location where external water drainage cannot collect

around unit.

2. Locate unit where operating sounds will not disturb owner or

neighbors.

3. The location of the unit should allow proper access for inspection

and servicing.

4. Locate unit so roof runoff water does not pour directly on the unit.

Provide gutter or other shielding at roof level. Do not locate unit in

an area where excessive snow drifting may occur or accumulate.

5. Provide a concrete slab extending 3″ beyond all four sides of the

unit. The slab should be sufficiently high enough above grade to

prevent surface water from entering the unit. The slab should be

isolated from the foundation wall.

6. Pitch the slab approximately 1/2″ so that the unit will be pitched

toward the drain. See Figure 3-3.

7. It is essential that the unit be elevated above the base pad to allow

for defrost water runoff, condensate drainage, and possible

refreezing or condensate. Route condensation off the base pad to

an area that will not become slippery and result in personal injury.

Important: Do not interfere with opening in bottom of unit.

8. Where snowfall is anticipated, the height of the unit above the

ground level must be considered. Mount unit high enough to be

above average area snowfall to prevent snow from blocking the

outdoor coil, to allow condensate runoff, and to allow combustion

air to enter the combustion air inlet.

3.2 LOCATION CONSIDERATIONS

The metal parts of the unit may be subject to rust or deterioration in

adverse environmental conditions. This oxidation could shorten the

equipment’s useful life. Salt spray, fog or mist in seacoast areas,

sulphur or chlorine from lawn watering systems, and various chemical

contaminants from industries such as paper mills and petroleum

refineries are especially corrosive.

If the unit is to be installed in an area where contaminants are

likely to be a problem, give special attention to the equipment

location and exposure:

1. Avoid having lawn sprinkler heads spray directly on the unit

cabinet.

2. In coastal areas locate the unit on the side of the building away

from the waterfront.

WARNING

Disconnect all power to the unit before starting maintenance.

Failure to do so can cause electrical shock resulting in personal

injury or death.

3. Shielding by a fence or shrubs may give some protection.

4. Elevate the unit off its slab or base enough to allow air circulation

and avoid holding water against the base pan.

5. Frequent washing of the cabinet, fan blade and coil with fresh water

will remove most of the salt or other contaminants that build up on

the unit.

6. Regular cleaning and waxing of the cabinet with a good automobile

polish will provide some protection.

7. Use a good liquid cleaner several times a year to remove matter

that will not wash off with water.

Several different types of protective coatings are offered in some

areas. These coatings may provide some benefit, but the

effectiveness of such coating materials cannot be verified by the

equipment manufacturer. The best protection is frequent cleaning,

maintenance and minimal exposure to contaminants.

3.3 OUTSIDE INSTALLATION

WARNING

This unit is designed certified for outdoor installation only.

Installation inside any part of a structure can result in inadequate

unit performance as well as property damage. Installation inside

can also cause recirculation of flue products into the conditioned

space resulting in personal injury or death.

3.4 ATTACHING EXHAUST AND COMBUSTiON

AIR INLET HOODS

IMPOPTANT: Do not operate this unit without the exhaust and

combustion air inlet hood property installed. These hoods are

shipped in a carton in the return air compartment inside the unit

and must be attached the unit is installed. See Fig. 2-1.

To attach exhaust and combustion air inlet hood:

1. Remove 3 screws securing filter access panel and remove filter

access panel. For location of filter access panel, see Fig.3-4.

2. Remove both exhaust and combustion air inlet hoods from their

carton, located inside the return air compartment.

3. Attach filter access panel.

4, Attach the combustion air inlet hood and the exhaust hood with 4

and 6 screws as shown in Fig. 2-1. Screws are in parts bag

shipped in the burner compartment.

5. Vent the unit using the flue exhaust hood, as supplied from the

factory, without alteration addition. The only exception is with

factory approved additions. Consult your local unity or other

authority having jurisdiction for accepted venting techniques.

3.5 COVER PANEL INSTAlLATION /

CONVERSION POCEDURE

All unit sizes have return and discharge openings for both horizontal

and downflow configurations, and are factory shipped with all

downflow duct openings covered, HORIZONTAL is factory shipped.

HORIZONTAL TO DOWNFLOW

1. Remove screws and covers from the supply and return bottom

section.

2. Install gasket (supplied with parts bag) around perimeter of cover

on the insulate side.

3. Secure covers to the side of the unit using existing screws and

those supplied in the parts bag. See Fig. 3-4.

4. Seal duct covers with silicone caulk.

DOWNFLOW TO HORIZONTAL

1. Remove screws and covers from the supply and return bottom

section.

2. Install gasket (factory shipped) around perimeter of cover on the

insulate side.

3. Secure covers to the bottom of the unit using existing screws and

those supplied in the parts bag. See Fig. 3-5.

WARNING

This unit must not be installed directly on wood flooring, Class A,

Class B or Class C roof covering materials, or any other

combustion structure except as specified in Fig.3-1. Failure to

adhere to this warning can cause a fire or explosion resulting in

property damage, personal injury or death.

installation & owner’s manual

10

Page 10

Back View

Nominal 4×4 timber

(Sides only)

Sideflow supply

plenum connection

Sideflow return

plenum connection

3-1/2″ MIN

1″ MIN

Supply plenum

(Downflow)

Return plenum

(Downflow)

Fig. 3-1 Exception to non-combustible flooring requirement

Both ends must be

open for downflow or

sideflow ductwork to

provide ventilation

Combustible structure

3.6 CLEARANCE

All units require certain clearance for proper operation and service.

Refer to Table 3-1 for the minimum clearances required for

construction, servicing and proper unit operation.

Table 3-1: Unit Clearance

3

Distance (in.)

24

4

12

0

Direction

1

Top

Front

Rear

Distance (in.)

60

48

2

18

Direction

Right

Left

Bottom

Duct clearance: 1 inch clearance for all sides of air supply duct.

1. Units must be installed outdoors. Over hanging structure or shrubs

should not obscure condenser air discharge outlet.

2. The minimum clearance without economizer/fresh air damper. For

distance with Economizer/fresh air damper, please refer to the

relevant Install requirement.

3. Units may be installed on combustible floors made from wood or

class A, B or C roof covering materials.

4. If Economizer/fresh air damper is used, a 24″ minimum clearance

is required on left side of unit.

NOTE

For units applied with a roof curb, the minimum clearance may

be reduced from 1 inch to 1/2 inch between combustible roof

curb material and this supply air duct.

3.7 RIGGING AND HANDING

Exercise care when moving the unit. Do not remove any packaging

until the unit is near the place of installation. Rig the unit by attaching

chain or cable slings to the lifting holes provided in the base rails.

Spreader bars, whose length exceeds the largest dimension across

the unit, MUST be used across the top of the unit.

CAUTION

Before lifting, make sure the unit weight is distributed equally

on the rigging cables so it will lift evenly.

Units may be moved or lifted with a forklift. Slotted openings in the

base rails are provided for this purpose.

CAUTION

All panels must be secured in place when the unit is lifted.

The condenser coils should be protected from rigging cable

damage with plywood or other suitable material.

installation & owner’s manual

11

Page 11

Condensate drain into roof drain

if required by local codes

Service access panels

Do not block access

Condensate drain into roof drain

if required by local codes

Service access panels

Do not block access

Supply plenum

Branch circuit

disconnect

Union

Gas shut-off valve

Condensate drain into roof

drain if required by local codes

Gas shut-off valve

Supply plenum

Trap

Service access panels

Do not block access

Branch circuit

disconnect

Power supply

conduit

Union

Branch circuit

disconnect

Branch circuit

disconnect

Union

Trap

Gas shut-off valve

Gas supply

Supply duct at

closet ceiling

Filter grill

Slab floor

installation & owner’s manual

12

Power supply

conduit

Fig. 3-2 Typical Installations

Union

Trap

Gas supply

Service access panels

Do not block access

Gas shut-off valve

Page 12

Front

This end approx. 1/2″

higher than front

Level plane Condensate drain connection

Fig. 3-3 Slab installation

Filter access panel

(For unit mounted filter

accessory)

Return/Supply duct cover

(attach with 4 screws)

Fig. 3-4 Duct cover installation side mounting

Return/Supply duct cover

(attach with 4 screws)

Fig. 3-5 Duct cover installation base pan mounting

installation & owner’s manual

13

Page 13

Recommended air supply

duct opening size 15”×15”

Recommended air return

duct opening size 15”×15”

40”

7-11/16”

15-5/32”

1”

1”

16-25/32”

4-7/16”

53-9/16”

10-7/16”

15-5/32”

Insulation layer

Front

Supply and return air (including duct support rails)

shown are typical for bottom duct applications.

For location of horizontal duct applications (on back

of unit), refer to unit dimension details.

Fig. 3-6 Roof Curb Dimension

* The above figures for reference purpose only.

NOTE

Be sure to note supply and return openings.

Refer to Fig.3-6, 3-7 for information concerning rear and bottom supply and return air duct openings.

ROOF CURB

On applications when a roof curb is used, the unit must be positioned on the curb so the front of the

unit is tight against the curb. (See Fig. 3-6 ROOF CURB DIMENSION)

installation & owner’s manual

14

Page 14

D

1:2

A-A

D

53-9/16”

1”

1”

A

15-5/32”

B

16-25/32”

4-7/16”

15-5/32”

5/16”

1-3/4”

B-B

A

40”

7-11/16”

B

Fig.3-7 Roof Curb Details

installation & owner’s manual

15

Page 15

3.8 DUCTWORK

Ductwork should be made and sized by installer and in accordance

with Air Manual from Conditioning Contractors of America and local

codes.

NOTE

On ductwork exposed to outside air conditioning space, use at

least 2” of insulation and a vapor barrier. Flexible joint may be

used to reduce noise.

These units are adaptable to horizontal use as well as rear supply and

return air duct openings. To convert to downflow, use the steps is

shown in 3.5.

A closed return duct system shall be used. This shall not preclude use

of economizers or ventilation air intake. Flexible joints may be used in

the supply and return duct work to minimize the transmission of noise.

CAUTION

When fastening duct work to the side duct flanges on the unit,

insert the screws through the duct flanges only. DO NOT insert

the screws through the casing. Outdoor duct work must be

insulation and waterproofed.

NOTE: The Commonwealth of Massachusetts requires the gas

shut-off valve to be a T-handle gas cock.

2. Connect the gas line to the gas pipe inlet opening provided into the

1/2″ inlet valve. See Fig. 4-1 for typical piping.

3. Size the gas line to the furnace adequate enough to prevent undue

pressure drop and never less than 1/2″ nominal pipe size.

4. Install a drip leg or sediment trap in the gas supply line as close to

the unit as possible.

5. Install an outside ground joint union to connect the gas supply to

the control assembly at the burner tray, Unions may not be

installed inside the unit.

6. Gas valves have been factory installed. Install a manual gas valve

where local codes specify a shut-off valve outside the unit casting.

7. Make sure piping is tight. A pipe compound resistant to the action of

liquefied petroleum gases must be used at all threaded pipe

connections.

8. IMPORTANT: Any additions, changes or conversions required for

the furnace to satisfactorily meet the application should be made

by a qualified installer, service agency or the gas supplier, using

factory-specified or approved parts. In the commonwealth of

Massachusetts, installation must be performed by a licensed

plumber or gas fitter for appropriate fuel.

IMPORTANT: Disconnect the furnace and its individual shutoff valve

the gas supply piping during any pressure testing of that system at

test pressures in excess of 1/2 psig or isolate the system from the gas

supply piping system by closing its individual manual shutoff valve

during any pressures equal to or less than 1/2 psig.

Gas line

NOTE

Be sure to note supply and return openings. Refer to Fig. 3 and

4 for information concerning rear and bottom supply and return

air duct openings.

3.9 RETURN AIR

WARNING

Never allow products of combustion to the flue products to

enter the return air ductwork, or the circulating air supply.

All return ductwork must be adequately sealed and

secured to the furnace with sheet metal screws, and joints

taped. All other duct joints must be secured with approved

connections and sealed airtight.

Failure to prevent products of combustion from being

circulated into the living space can create potentially

hazardous conditions, including carbon monoxide

poisoning that could result in personal injury or death.

3.10 FILTERS

The installer must install field supplied filters in the return air duct. A

field installed filter grille is recommended for easy and convenient

access to the filters for periodic inspection and cleaning. Filters must

have adequate face area for the rated air quantity of the unit. See air

delivery tables for recommended filter size.

4.0 GAS SUPPLY, CONDENSATE DRAIN AND

PIPING

4.1 GAS CONNECTION

IMPORTANT: Connect this unit only to gas supplied by a commercial

utility.

1. Install gas piping in accordance with local codes and regulations of

the local utility company. In the absence of local codes, the

installation must conform to the specifications of the National Fuel

Gas Code, ANSI Z223.1 - latest edition.

NOTE: The use of flexible gas connectors is not permitted. If local

codes allow the use of a corrugated stainless steel flexible gas

appliance connector, always use a new listed connector. Do not

use a connector which has previously serviced another gas

appliance.

Manual gas shut-off valve

(Installed Ahead of Ground

Joint Pipe Union)

Drip leg or Trap

Ground Joint Pipe Union

To Be Installed Ahead of

Gas Valve

Gas line to unit

Fig. 4-1 Typical Gas Pipe Arrangement

WARNING

FIRE OR EXPLOSION HAZARD

Failure to follow the safety warnings exactly could result in

serious injury, death of property damage.

Never test for gas leaks with an open flame. Use a commercially

available soap solution made specifically for the detection of

leaks to check all connections. A fire or explosion may result

causing property damage, personal injury or loss of life.

TO CHECK FOR GAS LEAKS, USE A SOAP AND WATER

SOLUTION OR OTHER APPROVED METHOD. DO NOT USE AN

OPEN FLAME.

IMPORTANT: Check the rating plate to make certain the appliance is

equipped to burn the type of gas supplied. Care should be taken after

installation of this equipment that the gas control valve not be

subjected to high gas supply the pressure.

In making gas connections, avoid strains as they may cause noise

and damage the controls. A backup wrench is required to be used on

the valve to avoid damage.

The capacity of gas pipe of different diameters and lengths in CFH

with pressure drop of 0.5 in. and specific gravity of 0.60 (natural gas)

are shown in Table 4-1.

installation & owner’s manual

16

Page 16

Table 4-1: Natural gas pipe capacity table

4.2 LP CONVERSION

(CFH - Cubic Feet of Gas Per Hour)

Nominal iron

pipe size (in.)

1/2 132 92 73 63 56 50 46 43

3/4 278 190 152 130 115 105 96 90

1 520 350 285 245 215 195 180 170

1-1/4 1050 730 590 500 440 400 370 350

1-1/2 1600 1100 890 760 670 610 560 530

After determining the pipe length, select the pipe size which will

provide the minimum cubic feet per hour required for the gas input

rating of the furnace. By formula:

The gas input of the furnace is marked on the furnace rating plate.

The heating value of the gas (BTU/Cubic FT) may be determined by

consulting the local natural gas utility or the L.P. gas supplier.

10 20 30 40 50 60 70 80

CFH=

Heating Value of Gas (BTU/Cubic Foot)

Equivalent length of pipe (ft.)

Furnace input (BTU/HR)

This unit is equipped at the factory for use on Natural Gas only.

Conversion to LP Gas requires a special kit which is included with

the unit. DO NOT BURN ANY LIQUID FUEL OR SOLID FUEL IN

THIS UNIT. Burning any unapproved fuel will result in damage to

this unit heat exchanger, which could result in fire, Carbon

Monoxide poisoning, explosion, personal injury, property

damage or death.

Convert the valve to use liquefied petroleum (LP) gas by replacing the

pressure regulator spring with the conversion kit spring. This LP kit

spring allows the regulator to maintain the proper manifold pressure

for LP gas. The correct burner LP orifices are included in the kit.

NOTE: The LP conversion kit is included with the unit. See

Conversion Kit Index shipped with unit for proper LP kit number.

Furnace conversion to LP gas must be performed by a qualified

technician.

Table 4-2: LP gas pipe capacity table (CFH - Cubic Feet of Gas Per Hour)

WARNING

Nominal iron

pipe size (in.)

1/2 275 189 152 129 114 103 96 89 83 78 69 63

3/4 567 393 315 267 237 217 196 182 173 162 146 132

1 1071 732 590 504 448 409 378 346 322 307 275 252

1-1/4 2205 1496 1212 1039 913 834 771 724 677 630 567 511

1-1/2 3307 2299 1858 1559 1417 1275 1181 1086 1023 976 866 787

2 6221 4331 3465 2992 2646 2394 2205 2047 1921 1811 1606 1496

Example (LP): Input BTU requirement of unit, 150000

Equivalent length of pipe, 60 ft. =3/4″ IPS r

10 20 30 40 50 60 70 80 90 100 125 150

Flame sensor

Temperature sensor

Igniter

Burner Box

Equivalent length of pipe (ft.)

on/off Lever

Gas Valve

Burner

Inlet

Orifice

Gas Manifold

Fig. 4-2 Burner and Gas Valve Arrangement

installation & owner’s manual

17

Page 17

4.3 ADJUSTING OR CHECKING FURNACE INPUT

- Natural Gas Inlet Pressure 5″ -10.5″ W.C.

- LP Gas Inlet Pressure 11″ -13″ W.C.

- Natural Gas Outlet Pressure 3.5″ W.C.

- LP Gas Outlet Pressure 10″ W.C.

Supply and manifold pressure taps are located on the gas valve body

1/8″ N.P.T.

Use a properly calibrated manometer gauge for accurate gas

pressure readings.

Only small variations in the gas flow should be made by means of the

pressure regulator adjustment. Furnaces functioning on LP gas must

be set by means of the tank or branch supply regulators. The furnace

outlet pressure should be set at 10″ W.C. at the gas control valve.

To adjust the pressure regulator, remove the regulator cap and turn

the adjustment screw clockwise to increase pressure or counterclockwise to decrease pressure. Then replace the regulator cap

securely.

Any necessary major changes in the gas flow rate should be made by

changing the size of the burner orifices. To change orifice spuds, shut

off the manual main gas valve and remove the gas manifold.

For elevations up to 2000 feet, rating plate input rating apply. For high

altitudes (elevations over 2000 feet), see conversion kit index for

derating and orifice spud sizes.

Check of input is important to prevent over-firing of the furnace

beyond its designated input, NEVER SET INPUT ABOVE THAT

SHOWN ON THE RATING PLATE. Use the following formula to

determine input rate.

C.F.H. Required=

Start the furnace and measure the time required to burn on cubic foot

of gas. Prior to checking the furnace input, make certain that all other

gas appliances are shut off, with the exception of pilot burners. Time

the meter with only the furnace in operation.

IMPORTANT NOTE FOR ALL ALTITUDES ABOVE 2000 FEET: The

main burner orifices in your furnace and in these kits are sized for the

nameplate input and intended for installations at elevations up to

2000 feet in the USA or Canada, or for elevations of 2000-4500 feet in

Canada if the unit has been derated at the factory. For elevations

above 2000 feet IN THE USA ONLY (see ANSI-Z223.1), the burner

orifices must be sized to reduce the input 4% for each 1000 feet

above sea level.

NOTICE: Derating of the heating input for high altitude in the field is

unlawful in Canada (refer to CAN/CGA 2.17). Units installed in

altitudes greater than 2000 feet must be shipped from the factory or

from a factory authorized conversion station with the heating input

derated by 10% so as to operate properly in altitudes from 2000-4500

feet.

Heating value of gas (BTU/Cubic Ft) ×3600

Time of Seconds (for 1 Cubic Ft.) of gas

4.4 CONDENSATE DRAIN

The evaporator coil condensate drain ends with a threaded 3/4″

nominal PVC stub. A trap is built in for proper condensate drainage

and to prevent debris from being drawn into the unit. Do not connect

the drain to a closed sewer line. It is recommended that a PVC

cement not be used so that the drain line can be easily cleaned in the

future.

IMPORTANT: Do not install an external trap. Doing so can cause

improper drainage of the condensate and result in flooding within the

unit.

5.0 WIRING

5.1 POWER SUPPLY

2. It is important that proper electrical power is available at the unit.

Voltage should not vary more than 10% from that stamped on the

unit nameplate. On three phase units, phases must be balanced

within 3%.

3. For branch circuit wiring (main power supply to unit disconnect), the

minimum wire size for the length of run can be determined from

Table 5-1 using the circuit ampacity found on the unit rating plate.

Use the smallest wire size allowable in Table 5-1 from the

disconnect to unit. The disconnect must be in sight and readily

accessible of the unit.

Table 5-1: Branch circuit copper wire size (in.)

Branch circuit ampacity

15 20 25 30 35 40 45 50

200 6 4 4 4 3 3 2 2

Supply wire

length (Ft.)

NOTES:

1. Wire size based on 60°C rated wire insulation and 30°C Ambient

Temp.

2. For more than 3 conductors in a raceway or cable, see the N.E.C.

for derating the ampacity of each conductor. When installed, the

unit must be electrically grounded in accordance with local codes

or, in the absence of local codes, with the National Electrical Code,

ANSI/NFPA 70, if an external electrical source is utilized.

IMPORTANT: This unit is approved for use with copper

conductors only connected to unit contactor. Warranty may be

jeopardized if aluminum wire is connected to unit contactor.

Special instructions apply for power wiring aluminum

conductors: Warranty is void if connections are not made per

instructions.

Attach a length (6″ or more) of recommended size copper wire to the

unit contactor terminals L1 and L3 for single phase.

Select the equivalent aluminum wire size from the tabulation below:

Splice copper wire pigtails to aluminum wire with U.L. recognized

connectors for copper-aluminum splices. Please exercise the follow

ing instructions very carefully to obtain a positive and lasting

connection:

1. Strip insulation from aluminum conductor.

2. Coat the stripped end of the aluminum wire with the recommended

inhibitor, and wire brush the aluminum surface through inhibitor.

INHIBITORS: Brundy-Pentex ”A”; Alcoa-No. 2EJC; T & B-KPOR

Shield.

3. Clean and recoat aluminum conductor with inhibitor.

4. Make the splice using the below listed wire nuts or split bolt

connectors.

5. Coat the entire connection with inhibitor and wrap with electrical

insulating tape.

AWG Copper

Wire Size

150 8 6 6 4 4 4 3 3

100 10 8 8 6 6 6 4 4

50 14 12 10 10 8 8 6 6

AWG Aluminum

Wire Size

#12 #10 T & B Wire Nut PT2

#10 #8 T & B Wire Nut PT3

#8 #6 Sherman Split Bolt TSP6

#6 #4 Sherman Split Bolt TSP4

#4 #2 Sherman Split Bolt TSP2

Connector Type and Size

(or equivalent)

WARNING

Turn off the main electrical power at the branch circuit disconnect

closest to the unit before attempting any wiring. Failure to do so

can cause electrical shock resulting in personal injury or death.

1. All wiring should be made in accordance with the National Electrical

Code. Consult the local power company to determine the

availability of sufficient power to operate the unit. Check the

voltage at power supply to make sure it corresponds to the unit’s

rated voltage requirement. Install a branch circuit disconnect near

the rooftop, in accordance with the N.E.C., C.E.C. or local codes.

installation & owner’s manual

18

5.2 HOOK-UP

To wire unit, refer to the following Fig. 5-1.

Wiring to be done in the field between the unit and devices not

attached to the unit, or between separate devices which are field

installed and located, shall conform with the temperature limitation for

Type T wire [63°F rise] when installed in accordance with the

manufacturer’s instructions.

Page 18

THERMOSTAT

R

G

Y

W

C

UNIT CONTROL BOX

THERMINAL STRIP

R

G

Y

1

W

C

24 volt

transformer

240V

208V

COM

Fig. 5-1 Typical Field Control Wiring Diagram

CONTACTOR

Field-supplied disconnect

GROUND

LUG

Refer to electrical data tables

to size the disconnect

Single

phase

power

supply

Fig. 6-2 Typical Field Power Wiring Diagram

5.3 INTERNAL WIRING

IMPORTANT: Some single phase units are equipped with a single

pole contactor. Caution must be exercised when servicing as only one

leg of the power supply is broken with the contactor.

Some models are equipped with an electronically commutated blower

motor which is constantly energized unless the main unit disconnect

is in the off position.

A diagram of the internal wiring of this unit is located under the

electrical box cover and in this manual. If any of the original wire as

supplied with the appliance must be replaced, the wire gauge and

insulation must be the same as the original wiring.

Transformer is factory wired for 230 volt on 208/230 volt models and

must be changed to 208 volt applications. See unit wiring diagram for

208 volt wiring.

4. 15 seconds after the pressure switch closes, the gas valve opens

and the spark is initiated for a 7 second trial for ignition.

5. Burners ignite and flame sensor proves all burners have lit.

6. The circulating air blower is energized after 45 seconds.

7. The control board enters a normal operation loop in which all safety

controls are monitored continuously.

8. Thermostat is satisfied and opens.

9. The gas valve is de-energized and closes, shutting down the burner

flame.

10.The control board will de-energized the inducer after a five second

post purge.

11.The circulating air blower BLOWER-LOW is de-energized after

max. 90 seconds.

· The integrated control board has a three times ignition system.

· After a total of 3 trials for ignition without sensing main burner flame,

the system goes into lockout mode.

· After 1 hour, the ignition control repeats the prepurge and ignition

cycles for 3 tries and then goes into lockout mode again.

· It continues this sequence of cycles and lockout each hour until

ignition is successful or power is interupted.

· During the lockout mode, neither the spark ignition control or gas

valve will be energized until the system is reset by turning the

thermostat to the “OFF” position or interrupting the electrical power

to the unit for 3 seconds or longer.

· The induced draft blower and main burner will shut off when the

thermostat is satisfied.

· The circulating air blower will start and run on the heating speed if

the thermostat fan switch is in the ”ON” position.

The integrated furnace control is equipped with diagnostic LED. The

LED is lit continuously when there is power to the control without a call

for heat. If the LED is not lit, there is either no power to the control or

there is an internal component failure within the control, and the

control should be replaced.

If the control detects the following failures, the LED will flash for

designated failure detections.

2 Flash: Failed to detect or sustain flame,system locked out.

3 Flash: Pressure switch or induced draft blower problem detected.

4 Flash: High limit or auxiliary limit open.

5 Flash: Flame sensed and gas valve not energized or flame sensed

with no “W” signal.

6 Flash: Overtemperature switch open.

7 Flash: Thermostat miswired; W1 and W2 swapped.

Slow flash rate:Normal,call for heat.

6.2 OPERATING INSTRUCTIONS

This appliance is equipped with a direct spark intermittent ignition

device. This device lights the main burners each time the room

thermostat (closes) calls for gas heat. See operating instructions on

the back of the furnace/controls access panel.

WARNING

Do not attempt to manually light this furnace with a match or any

open flame. Attempting to do so can cause an explosion or fire

resulting in property damage, personal injury or death.

5.4 THERMOSTAT

The room thermostat must be specifically designed to control

package gas electric units.

6.0 FURNACE SECTION CONTROLS AND

IGNITION SYSTEM

6.1 NORMAL FURNACE OPERATING SEQUENCE

This unit is equipped with an integrated direct spark ignition control.

1. The thermostat calls for gas heat.

2. The control board will run a self check to verify that the limit control

and manual reset overtemperature control are closed and that the

pressure switch is open. If so, the induced draft blower (inducer)

begin a prepurge cycle.

3. The air proving negative pressure switch closes.

6.3 TO START THE FURNACE

1. Set the thermostat to its lowest setting.

2. Turn off all electric power to the appliance.

3. This appliance does not have a pilot. It is equipped with an ignition

device which automatically lights the burner. Do not try to light the

burner by hand.

4. Remove control door.

5. Turn the gas valve to the “OFF” position.

6. Wait five (5) minutes to clear out any gas. Then smell for gas,

including near the floor. If you smell gas, STOP! Follow B in the

safety information on the Operating Instructions located on the

back of the controls/access panel. If you don’t smell gas, go to the

next step.

7. Turn the gas valve to the “ON” position.

8. Replace the control door.

9. Turn on all electric power to the appliance.

10. Set the thermostat to the desired setting.

11. If the appliance will not operate, follow the instructions below to

shut down the furnace.

installation & owner’s manual

19

Page 19

WARNING

The spark ignitor and ignition lead from the ignition control are

high voltage. Keep hands or tools away to prevent electrical

shock. Shut off electrical power before servicing any of the

controls. Failure to adhere to this warning can result in personal

injury or death.

The initial start-up on a new installation may require the control

system to be energized in some time until any air has bled through the

system and fuel gas is available at the burners.

6.4 TO SHUT DOWN FURNACE

1. Set the thermostat to the lowest setting.

2. Turn off all electric power to the appliance if service is to be

performed.

3. Remove control door.

4. Move gas valve to the“OFF”position.

5. Replace control door.

WARNING

Should overheating occur or the gas supply fail to shut off. Shut

off the Manual Gas valve to the appliance before shutting off the

electrical supply. Failure to do so can result in an explosion or fire

causing property damage, severe personal injury or death.

6.5 BURNERS

Burners for these units have been designed so that field adjustment is

not required. Burners are tray-mounted and accessible for easy

cleaning when required.

7.0 SYSTEM OPERATING INFORMATION

7.1 ADVISE THE CUSTOMER

1. Keep the air filters clean. The heating system operates better, more

efficiently and more economically.

2. Arrange the furniture and drapes so that the supply air registers and

the return air grilles are unobstructed.

3. Close doors and windows. This reduces the heating load on the

system.

4. Avoid excessive use of exhaust fans.

5. Do not permit the heat generated by television, lamps or radios to

influence the thermostat operation.

6. Except for the mounting platform, keep all combustible articles

three feet from the unit and exhaust system.

7. IMPORTANT: Replace all blower doors and compartment after

servicing the unit. Do not operate the unit without all panels and

doors securely in place.

8. Do not allow snow or other debris to accumulate in the vicinity of the

appliance.

7.2 FURNACE SECTION MAINTENANCE

The unit’s furnace should operate for many years without excessive

scale build-up in flue passageways; and it should have a qualified

installer, service agency, or gas supplier annually inspect the flue

passageways, the exhaust system and the burners for continued safe

operation, paying particular attention to deterioration from corrosion

or other sources.

If during inspection the flue passageways and exhaust system are

determined to require cleaning, the following procedures should be

followed (by a qualified installer, service agency, or gas supplier):

1. Turn off the electrical power to the unit and set the thermostat to the

lowest temperature.

2. Shut off the gas supply to the unit either at the meter or at manual

valve in the supply piping.

6.6 MANUAL RESET OVERTEMPERATURE CONTROL

A manual reset overtemperature control is located on the burner

shield. This device senses blockage in the heat exchanger or

insufficient combustion air. This shuts off the main burners if

excessive temperatures occur in the burner compartment.

Operation of this control indicates an abnormal condition. Therefore,

the unit should be examined by a qualified installer, service agency, or

the gas supplier before being placed back into operation.

WARNING

DO NOT JUMPER THIS DEVICE! Do not reset the

overtemperature control without taking corrective action to

assure that an adequate supply of combustion air is maintained

under all conditions of operation. Failure to do so can result in

Carbon Monoxide poisoning or death. Replace this control only

with the identical replacement part.

6.7 PRESSURE SWITCH

This furnace has a negative pressure switch for sensing a blocked

exhaust or a failed induced draft blower. It is normally closed when the

induced draft blower starts, indicating air flow through the combustion

chamber.

6.8 LIMIT CONTROL

The supply air high temperature limit cut-off is set at the factory and

cannot be adjusted. It is calibrated to prevent the air temperature

leaving the furnace from exceeding the maximum outlet air

temperature. WARNING: DO NOT JUMPER THIS DEVICE! Replace

this control only with the identical replacement part.

WARNING

Label all wires prior to disconnection when servicing controls.

Wiring errors can cause improper and dangerous operation

resulting in fire ,electrical shock, property damage, personal

injury or death.

3. Remove the furnace controls access panel and the control box

cover.

4. Disconnect the gas supply piping from the gas valve.

5. Disconnect the wiring to the induced draft blower motor, gas valve,

flame sensor, and flame roll-out control, and igniter cable. Mark all

wires disconnected for proper reconnection.

6. Remove the screws (4) connecting the burner tray to the heat

exchanger mounting panel.

7. Remove the burner tray and the manifold assembly from the unit.

8. Remove the screws (4) connecting the induced draft blower to the

collector box and screws (16) connecting the collector box to the

heat exchanger mounting panel. Remove the induced draft blower

and the collector box from the unit.

9. Remove the turbulators from inside the heat exchangers by

inserting the blade of a screwdriver under the locking tabs. Pop the

tabs out of the expanded grooves of the heat exchanger. Slide the

turbulators out of the heat exchangers.

10. Direct a water hose into the outlet of the heat exchanger top. Flush

the inside of each heat exchanger tube with water. Blow out each

tube with air to remove excessive moisture.

11. Reassemble (steps 1 through 10 in reverse order). Be careful not

to strip out the screw holes used to mount the collector box

and inducer blower. Replace inducer blower gasket and

collector box gasket with factory replacements if damaged.

WARNING

installation & owner’s manual

20

Holes in the exhaust transition or heat exchanger can cause toxic

fumes to enter the home. The exhaust transition or heat

exchanger must be replaced if they have holes or cracks in them.

Failure to do so can cause Carbon Monoxide poisoning resulting

in personal injury or death.

Page 20

The manufacturer recommends that a qualified installer, service

agency or the gas suppler visually inspect the burner flames for the

desired flame appearance at the beginning of the heating season and

approximately midway in heating season.

The manufacturer also recommends that a qualified installer, service

agency or the gas supplier clean the flame sensor with steel wool at

the beginning of the heating season.

WARNING

Disconnect main electrical power to the unit before attempting

maintenance. Failure to do so may result in electrical shock or

severe personal injury or death.

7.3 LUBRICATION

IMPORTANT: DO NOT attempt to lubricate the bearings on the blower

motor or the induced draft blower motor. Addition of lubricants can

reduce the motor life and void the warranty.

The blower motor and induced draft blower motor are prelubricated by

the manufacturer and do not require further attention.

A qualified installer, service agency or the gas supplier must

periodically clean the motors to prevent the possibility of overheating

due to an accumulation of dust and dirt on the windings or on the

motor exterior. And, as suggested elsewhere in these instruct ions,

the air filters should be kept clean because dirty filters can restrict air

flow and the motor depends upon sufficient air flowing across and

through it to prevent overheating.

7.4 COOLING SECTION MAINTENANCE

It is recommended that at the beginning of each cooling season a

qualified installer or service agency inspect and clean the cooling

section of this unit. The following areas should be addressed:

evaporator coil, condenser coil, condenser fan motor and venturi

area.

To inspect the evaporator coil:

1. Remove the filter access panel and the blower/evaporator coil

access panel.

WARNING

Label all wires prior to disconnection when servicing controls.

Wiring errors can cause improper and dangerous operation

resulting in fire ,electrical shock, property damage, personal

injury or death.

2. Unplug the wires from the circulating air blower and the limit control.

Remove the two screws and slide the blower out of the unit

sideways.

3. Shine a flashlight on the evaporator coil (both sides) and inspect for

accumulation of lint, insulation, etc.

4. If coil requires cleaning, follow the steps shown below.

Cleaning Evaporator Coil, Drain Pan,

Condensate Drain, Condenser Fan, Circulation

Air Blower and Venturi

1. Remove the screws from the filter access panel and the

blower/evaporator coil access panel from the unit. Remove the

filter access panel and the blower/evaporator coil access panel.

2. The coil should be cleaned when it is dry. If the coil is coated with

dirt or lint, vacuum it with a soft brush attachment. Be careful not to

bend the Coil fins.

3. If the coil is coated with oil or grease, clean it with a mild

detergent-and-water solution. Rinse the coil thoroughly with water.

IMPORTANT: Do not use excessive water pressure. Excessive

water pressure can bend the tins and tubing of the coil and lead to

inadequate unit performance. Be careful not to splash water

excessively into unit.

4. Inspect the drain pan and condensate drain at the same time the

evaporator coil is checked. Clean the drain pan by flushing with

water and removing any matters of obstructions which may be

present.

5. Flush the drain tube with water. If the drain tube is blocked, it can

usually be cleared with high pressure water.

6. The venturi should also be inspected for items of obstruction such

as collections of grass, dirt or spider webs. Remove any that are

present.

7. Inspect the circulating air blower wheel and motor for accumulation

of lint, dirt or other obstruction and clean if necessary. Inspect the

blower motor mounts and the blower housing for loose mounts or

other damage. Repair or replace it necessary.

Re-assembly

1. Place the condenser coil protective grille back on unit and replace

all screws.

2. Place top panel back on unit and replace all screws.

3. Set condenser fan grille assembly on top of the unit with the fan on

top and the motor wires on the venturi side. Run the fan motor

wires through the bulkhead and pull wires through the hole on the

bottom of the control box on the left side and into the control box.

Reconnect fan motor wires per the wiring diagram attached to the

back of the control box cover.

4. Replace wire strain relief in bulkhead after the slack is pulled out of

the wires on the fan side. This will assure wires will not be

damaged by the fan during unit operation.

5. Turn the condenser fan grille assembly over and into the recess in

the unit top. Secure the grille to the unit with the four long #8

screws removed earlier.

6. Replace the circulating air blower, making sure that all wires are

properly reconnected per the unit wiring diagram.

7. Replace the filter and blower/evaporator coil access panels.

8. Replace the control box cover and controls access panel.

9. Restore electrical power to the unit and check for proper operation,

especially the condenser fan motor.

7.5 REPLACEMENT PARTS

Contact your local distributor for a complete parts list.

Cleaning Condenser Coil

1. Remove screws from condenser fan grille assembly and lay grille

over on the unit top panel.

2. Remove the controls access panel and the control box cover.

3. Disconnect the outdoor fan motor wiring from the compressor

contactor and capacitor. Remove the strain relief in the bulkhead

and pull the fan motor wires through. Set grille assembly to the

side.

4. Remove the screws that secure the unit top to the unit. Remove the

top and set the unit top to the side.

5. The coil should be cleaned when it is dry. If the coil is coated with

dirt or lint, vacuum it with a soft brush attachment. Be careful not to

bend the coil fins.

6. If the coil is coated with oil or grease, clean it with a mild

detergent-and-water solution. Rinse the coil thoroughly with water.

IMPORTANT: Do not use excessive water pressure. Excessive

water pressure can bend the fins and tubing of the coil and lead to

inadequate unit performance. Be careful not to splash water

excessively into unit.

7. Go to next section for cleaning the evaporator coil.