Page 1

Packaged Rooftop

Air Conditioners

IntelliPak™ Rooftops

20 - 130 Tons — 60 Hz

20 - 75 Tons

90 - 130 Tons

March 2003

RT-PRC010-EN

Page 2

Introduction

IntelliPak

™

Designed For Today and Beyond

Innovative technology and an

impressive lineup of features make the

Trane IntelliPak Rooftop line the number

one choice for today and the future.

Trane’s rooftop Unit Control Module

(UCM), an innovative, modular

microprocessor control design,

coordinates the actions of the IntelliPak

rooftop in an efficient manner and allows

for stand-alone operation of the unit.

Access to the unit controls, via a Human

Interface Panel, provides a high degree

of control, superior monitoring

capability, and unmatched diagnostic

information.

Optionally, for centralized building

control on-site, or from a remote

location, IntelliPak can be configured for

direct communication with a Trane

Tracer™ building management system

rd

party LonTalk building

or a 3

management system, using a twisted

pair of wires. With one of these systems,

the IntelliPak status data and control

adjustment features can be conveniently

monitored from a central location.

IntelliPak has the technology

flexibility

every building space.

to bring total comfort to

and

© 2003 American Standard Inc. All rights reserved

RT-PRC010-EN

Page 3

Contents

Introduction

Featur es and Benefits

Application Considerations

Selection Procedur e

Model Number Description

General Data

P erformance Data

Performance Adjustment Factors

Controls

Electric P o wer

Dimension and W eights

Mechanical Specifications

Options

2

4

9

16

20

22

29

28

75

83

86

99

96

RT-PRC010-EN

3

Page 4

Features and

Benefits

Standard Features

• 20 to 130 ton industrial/ commercial

rooftops

• Fully integrated, factory-installed/

commissioned microelectronic

controls

• Unit mounted Human Interface Panel

with a 2 line x 40 character English

display and a 16 function keypad that

includes Custom, Diagnostics, and

Service Test mode menu keys.

• Trane 3-D

(20 to 130 Tons)

• Compressor or circuit lead/lag

depending on unit

• Hinged access doors on control panel,

filter section, and gas heat section

• Horizontal discharge/return duct

connections (SX, SL, SS models)

• CV or VAV control

• Low ambient compressor lockout

control on units with economizers

• Frostat™ coil frost protection on

all units

• Daytime Warm-up (Occupied mode)

on VAV models and Morning Warm-up

operation on all units with heating

options

• Supply air static overpressurization

protection on units with inlet guide

vanes and VFD’s.

• Supply airflow proofing

• Exhaust airflow proofing on units with

exhaust option

• Supply air tempering control

• Supply air heating control on VAV

modulating hot water or steam heat

units

• Emergency stop input

• Liquid and Discharge Service Valves

• Mappable sensors and setpoint

sources

• Occupied/Unoccupied switching

• Timed override activation

• Forward-curved supply fans (20 - 75

ton models)

• Air foil supply fans (90 - 130 ton

models)

• Pitched roof over air handler section

• Stainless steel flue stack on gas heat

units

• 14-gauge, single-piece construction

base rails

™

Scroll compressors

• UL and CSA approval on standard

options

• Two-inch spring fan isolation

(90 to 130 tons)

• Meets 672 hours of salt spray testing in

accordance to ASTM B117 Standard

• Two inch standard efficiency

throwaway filters on 20 to 90 ton units

and two inch high efficiency

throwaway filters on 105 to 130 ton

units.

Optional Features

For a comprehensive listing of standard

options, special options, and

accessories, please see table O-1 starting

on page 96.

• Trane Communication Interface

Module: ICS interface control module

®

• LonTalk

module

• Remote Human Interface Panel

(controls up to 4 units)

• Five ventilation override sequences

• Heating options: natural gas, electric,

hot water or steam

• Generic BAS interface

• Choose from three economizer control

options: comparative enthalpy,

reference enthalpy, dry bulb control

• Variable frequency drive control of

supply/exhaust fan motor

• Inlet guide vanes on FC supply fans

(VAV only)

• Outside air CFM compensation on VAV

units with IGV (or VFD) and economizer

• Hot gas bypass to the evaporator inlet

• Copper evaporator/condenser coils

• Suction service valves

• Replaceable core filter driers

• Phenolic coated evaporator/condenser

coils

• High capacity evaporator coils

(20 to 105 tons)

• Special paint colors

• Extended casing (SX models)

• Double wall access doors

• Double wall construction/perforated

double wall

• Stainless steel drain pan in evaporator

section

• Pitched evaporator drain pan

Communication Interface

• Filter rack only (no filters)

• High efficiency throwaway filters

• 90-95 percent bag filters

• 90-95 percent cartridge filters

• Final filters

• Barometric relief

• 50 percent modulating exhaust with

forward-curved fans

• Trane’s air quality (Traq™) sensor

• Modulating Gas Heat

• 10 year limited warranty on Full

Modulation Gas Heat

• 100 percent modulating exhaust with

forward-curved fans

• 100 percent modulating exhaust with

FC fans and Statitrac™ direct space

sensing building pressurization control

• High duct temperature thermostats

• 0 F low ambient control

• 0-100 percent modulating fresh air

economizer

• Ultra low leak dampers for 0-100

percent modulating fresh air

economizers

• Dual electrical power connection

• Two-inch spring fan isolation

(20 to 75 tons)

• High efficiency motors

• U-frame motors

• Oversized motors

• Through the door non-fused

disconnect with external handle

• Electrical convenience outlet

• Power supply monitoring

• Correction capacitors

• Horizontal or Roof discharge w/gas

heat (20-75 tons “F” style units only)

Field Installed Accessories

• Roof curbs

• Programmable sensors with night set

back — CV and VAV

• Sensors without night set back — CV

and VAV

• Remote zone sensors — used for

remote sensing with remote panels.

• ICS zone sensors used with Tracer™

system for zone control

• Outdoor temperature sensor for units

without economizers

• Remote minimum position control for

economizer

• Field installed module kits available for

field upgrade of controls

Note: LonTalk and LonWorks are registered trademarks of Echelon Corporation.

RT-PRC010-EN4

Page 5

Features and

Benefits

Features Summary

IntelliPak™ rooftop features make

installation and servicing easy and

reliable operation a reality.

Installation Ease

• Factory-installed/commissioned

controls

—ease of start up

—single twisted wire pair

—communication for ICS interface

—full unit points access, no field wir-

ing of required points

• Unit mounted Human Interface Panel

standard

—user friendly keypad — edit

parameters

— through the access door interface

— start up adjustments

— unit mounted and remote in-

terface panel key pads are

identical

• Unit mounted lifting lugs facilitate

installation and can be used as unit

tiedown points.

Easy to Service

• The microprocessor unit controls

coordinates the operation of the

rooftop with quality, industry-accepted

components for service ease.

• Unit mounted Human Interface Panel

standard

— user friendly keypad — edit pa-

rameters

— through the access door interface

— start up adjustments

— unit mounted and remote interface

panel key pads are identical

• Modularity of unit control design

—individual replaceable functional

boards

• Advanced diagnostics

Reliability

• Advanced diagnostics

• Microprocessor controls

• Built-in safeties

• Modular control design

• UL approval as standard

• Forward-curved supply and exhaust

fans are Trane designed and factory

balanced.

• Fully insulated and gasketed panels

reduce ambient air infiltration.

• Fixed-speed evaporator fan and

exhaust drive for smooth fan operation

and belt durability.

• 200,000 average life fan bearings

enhance unit durability.

• Gas heater with free-floating stainless

steel heat exchanger relieves the

stresses of expansion and contraction.

Stainless steel provides corrosion

resistance through the entire material

thickness.

• Integral condenser subcooler improves

efficiency while helping avoid liquid

flashing.

• Factory-wired and commissioned

controls assure efficient and reliable

rooftop operation.

• Trane Scroll compressors are used on

20 to 130 ton units. They are designed

for tough industrial operation and

meet demanding operating conditions

both in efficiency and reliability.

• Roll-formed construction enhances

cabinet integrity and assures a

leakproof casing.

• Three-phase, direct-drive condenser

fan motors enhance dependability and

increase rooftop life.

• Trane industrial quality evaporator

and condensing coils help increase

rooftop life.

Application Flexibility

• Modularity in design

• Increased offering of standard options

• Generic BAS interface

• Five factory preset/re-definable in the

field ventilation override sequences

• Superior Tracer™ interface for ICS

applications

— factory-installed Trane

• Superior LonTalk interface for Tracer

and 3rd party applications

— factory-installed LonTalk

Communication Interface

• Unit mounted or Remote Human

Interface panels

— all parameter are editable from the

Human Interface Panel

• Comparative enthalpy, Reference

enthalpy, or Dry bulb control for

economizers

• Statitrac™ direct space building

pressure control

• Compensated outdoor air control —

IAQ

• Factory-installed filter rack includes

two-inch throwaway filters.

• CV controls stage both compressors

and heat based on space

requirements.

• Variable Frequency Drives (VFD)

Included With or Without Bypass

Control for Supply and Exhaust Fans.

• An array of heating options are

available, including Steam, Hot Water,

Electric and Natural Gas heat. The Gas

Heating option provides a choice of

two-stage gas heat, as well as full and

limited modulating gas heat.

5RT-PRC010-EN

Page 6

Integrated

Rooftop

Systems:

Profitable,

Simple

Trane integrated rooftop systems make

design and installation of building

management systems cost effective and

easy. Trane offers two choices for

building management controls: Tracer

Building Automation System with a

Trane Control Interface (TCI) or Tracer

with LonTalk® Communication Interface

(LCI).

Integrated

Comfort with

Trane Tracer™

TCI

The Tracer TCI Integrated Comfort™

System (ICS) improves job profit and

increases job control by combining Trane

rooftop units with the Trane Tracer

building management system. This

integrated system provides total building

comfort and control. Some of the

primary motivations for building

owners/managers in deciding to

purchase a HVAC controls system is

energy savings, cost control, and the

convenience of facility automation.

Simplifying the Comfort System

Trane’s technology and innovation brings

more capabilities, more flexibility, and at

the same time, offers equipment and

systems that are easy to use, easy to

install, commission, and service. The

Tracer TCI Integrated Comfort system

saves time and money by simplifying

system design and system installation.

When used with Trane’s DDC/VAV boxes

(or VariTrane™), system balancing

almost goes away because each VAV box

is commission and tested before it

leaves the factory. All the status

information and editing data from the

Features and

Benefits

rooftop units, VAV boxes, lighting,

exhaust and other auxiliary equipment is

available from Tracer TCI for control,

monitoring and service support of your

facility. Tracer, a family of building

automation products from Trane, is

designed with robust, application

specific software packages to minimize

custom programming requirements and

enable system setup and control

through simple editing of parameters in

the standard applications software.

Should you select an Integrated Comfort

system for your facility, the

accountability for equipment,

automation and controls is Trane’s,

Trane’s, and Trane’s!

The IntelliPak

Integrated Comfort system, provides

powerful maintenance monitoring,

control and reporting capabilities. The

Tracer places the rooftop in the

appropriate operating mode for

operation for: system on/off, night

setback, demand limiting , setpoint

adjustment based on outside

parameters and much more. Up to 56

different unit diagnostic conditions can

be monitored through Tracer to let you

know about things like: sensor failures,

loss of supply airflow, and a compressor

trip out. Further, the addition of Building

Management Network software offers

remote scanning, automatic receipt of

alarms, and easy dial-up access to over

100 various Tracer sites across town or

across the country.

Typical points available through Tracer:

IntelliPak Rooftops monitoring points

available through Tracer

• all active Rooftop diagnostics

• history of last 20 unit diagnostics

• all system setpoints

• system sensor inputs

• supply fan mode and status

• inlet guide vane position/VFD speed

• unit heat/cool mode

• exhaust fan status

• exhaust damper position

• economizer position, minimum

position setpoint, economizing

setpoint

• on/off status of each compressor

• refrigerant evaporator and saturated

condenser temperatures

• hydronic heat valve position

rooftop, as a part of an

• electric heat stage status

• ventilation override mode status

Tracer control points for IntelliPak

Rooftops

• cooling and heating setpoints

• zone setpoint offsets for use with

demand limiting

• VAV discharge air setpoints

• supply air pressure setpoint

• space pressure setpoint

• zone and outdoor temperature values

• cooling and heating enable/disable

• economizer enable/disable

• economizer setpoint

• economizer minimum position

• activation of ventilation override

modes

• diagnostics reset

• unit priority shutdown

IntelliPak Rooftops setup and

configuration information through Tracer

• supply fan mode

• configuration of supply air reset

• ventilation override mode

configuration

• default system setpoint values

• sensor calibration offsets

Interoperability

with LonTalk

The Trane Tracer LonTalk Control

Interface (LCI) for IntelliPak offers a

building automation control system with

outstanding interoperability benefits.

LonTalk, which is an industry standard, is

an open, secure and reliable network

communication protocol for controls,

created by Echelon Corporation and

adopted by the LonMark Interoperability

Association. It has been adopted by

several standards, such as: EIA-709.1, the

RT-PRC010-EN6

Page 7

Features and

Benefits

Electronic Industries Alliance (EIA)

Control Network Protocol Specification

and ANSI/ASHRAE 135, part of the

American Society of Heating,

Refrigeration, and Air-Conditioning

Engineer’s BACnet control standard for

buildings.

Interoperability allows application or

project engineers to specify the best

products of a given type, rather than one

individual supplier’s entire system. It

reduces product training and installation

costs by standardizing communications

across products. Interoperable systems

allow building managers to monitor and

control IntelliPak equipment with a Trane

Tracer Summit or a 3

automation system. It enables

integration with many different building

controls such as access/intrusion

monitoring, lighting, fire and smoke

devices, energy management, and a

wide variety of sensors (temperature,

pressure, light, humidity, occupancy,

CO2 and air velocity). For more

information on LonMark, visit

www.lonmark.org or Echelon,

www.echelon.com.

rd

party building

Optimum

Building

Comfort Control

The modular control design of the UCM

allows for greater application flexibility.

Customers can order exactly the options

required for the job, rather than one

large control package. Unit features are

distributed among multiple field

replaceable printed circuit boards. The

Trane UCM can be set up to operate

under one of three control applications:

1 stand-alone

2 interface with Trane’s Tracer™ building

management system

3 interface with a generic (non-Trane)

building management system. All

setup parameters are preset from the

factory, requiring less start-up time

during installation.

The unit mounted Human Interface and

the Remote Human Interface Panels’

functions are identical, except for the

Service mode is not available on the

Remote Human Interface Panel. This

common interface feature requires less

time for building maintenance personnel

to learn to interact with the unit. All of the

rooftop’s control parameters are

adjustable and can be set up through the

Remote Human Interface Panel such as,

but not limited to: system on/off,

demand limiting type, night setback

setpoints, and many other setpoints. No

potentiometers are required for setpoint

adjustment, all adjustments are done

through the Remote Human Interface

keypad. Also up to 56 different rooftop

diagnostic points can be monitored

through the human interfaces such as:

sensor failures, loss of supply airflow,

and compressor trip. No special tools are

required for servicing of the unit. All

diagnostic displays are available in clear

English at the Remote Human Interface

and will be held in memory, so that the

operator/servicer can diagnose the root

cause of failures.

Statitrac™ Direct Space

Building Pressurization Control

Trane’s Statitrac™ control is a highly

accurate and efficient method of

maintaining building pressure control

with a large rooftop air conditioner.

The efficiency is achieved with a 100

percent modulating exhaust system with

two forward-curved fans with

modulating discharge dampers that

operate only when needed, compared to

some systems that operate continually.

And most of the operating hours of the

100 percent modulating exhaust system

are at part load, saving more energy.

Trane’s Statitrac, with the 100 percent

modulating exhaust system, provides

comfort and economy for buildings with

large rooftop air conditioning systems.

Statitrac control is simple! The space

pressure control turns the exhaust fans

on and off as required and modulates

exhaust dampers to maintain space

pressure within the space pressure dead

band. Using the unit mounted Human

Interface Panel you can

1) adjust space pressure setpoint

2) adjust space pressure dead band

3) measure and read building space

pressure. The modulating exhaust

system maintains the desired building

pressure, saving energy while keeping

the building at the right pressure. Proper

building pressurization eliminates

annoying door whistling, doors standing

open, and odors from other zones.

The Statitrac™ direct space building

control sequence will be maintained

when a variable frequency drive is used.

Fans With Inlet Guide Vanes

Trane’s forward curved fans (20 through

75 tons) and air foil fans (90 through 130

tons) with inlet guide vanes pre-rotate

the air in the direction of the fan wheel,

decreasing static pressure and

horsepower, essentially unloading the

fan wheel. The unloading characteristics

result in superior part load performance.

Variable Frequency Drives

(VFD)

Variable Frequency Drives are factory

installed and tested to provide supply/

exhaust fan motor speed modulation.

VFD’s, as compared to inlet guide vanes

or discharge dampers, are quieter, more

efficient, and are eligible for utility

rebates. The VFD’s are available with or

without a bypass option. Bypass control

will simply provide full nominal airflow

in the event of drive failure.

7RT-PRC010-EN

Page 8

Features and

Benefits

Trane 3-D™ Scroll Compr essor

Simple Design with 70% Fewer Par ts

Fewer parts than an equal capacity

reciprocating compressor means

significant reliability and efficiency

benefits. The single orbiting scroll

eliminates the need for pistons,

connecting rods, wrist pins and valves.

Fewer parts lead to increased reliability .

Fewer moving parts, less rotating mass

and less internal friction means greater

efficiency than reciprocating

compressors.

The Trane 3-D S croll provides impor tant

reliability and efficiency benefits. The 3-D

Scroll allows the orbiting scrolls to touch

in all three dimensions, forming a

completely enclosed compression

chamber whic h leads to increased

efficiency . In addition, the orbiting scrolls

only touch with enough force to create a

seal; there is no wear between the scroll

plates. The fixed and orbiting scrolls are

made of high strength cast iron which

results in less thermal distortion, less

leakage, and higher efficiencies. The

most outstanding feature of the 3-D

Scroll compressor is that slugging will

not cause failure. In a reciprocating

compressor, however , the liquid or dir t

can cause serious damage.

Low T orque Variation

The 3-D Scroll compressor has a very

smooth compression cycle; torque

variations are only 30 percent of that

produced by a reciprocating compressor.

This means that the scroll compressor

imposes very little stress on the motor

resulting in greater reliability. Low torque

variation reduces noise and vibration.

Suction Gas Cooled Motor

Compressor motor efficiency and

reliability is further optimized with the

latest scroll design. Cool suction gas

keeps the motor cooler for longer life and

better efficiency.

Proven Design Through T esting and

Research

With over twenty years of development

and testing, Trane 3-D S croll

compressors have undergone more

than 400,000 hours of laboratory testing

and field operation. This work combined

with over 25 patents makes Trane the

worldwide leader in air conditioning

scroll compressor technology .

One of two matched scroll plates — the

distinguishing feature of the scroll

compressor.

Chart illustrates low torque variation of

3-D Scroll compressor vs reciprocating

compressor.

RT-PRC010-EN8

Page 9

Application

Considerations

EXHAUST AIR OPTIONS

When is it necessary to provide building

exhaust? Whenever an outdoor air

economizer is used, a building generally

requires an exhaust system. The purpose

of the exhaust system is to exhaust the

proper amount of air to prevent over or

underpressurization of the building. The

goal is to exhaust approximately 10

percent less air than the amount of

outside air going into the building. This

maintains a slightly positive building

pressure.

A building may have all or part of its

exhaust system in the rooftop unit. Often,

a building provides exhaust external to

the air conditioning equipment. This

external exhaust must be considered

when selecting the rooftop exhaust

system.

IntelliPak™ Rooftop units offer four types

of exhaust systems:

1

100 percent modulating exhaust with

Statitrac™ direct space sensing building

pressurization control (with or without

variable frequency drives).

2

100 percent modulating exhaust without

Statitrac.

3

50 percent power exhaust.

4

Barometric relief dampers.

Application Recommendations

1

100 per cent modulating exhaust with

Statitrac™ contr ol

For both CV and VAV rooftops, the 1 00

percent modulating exhaust discharge

dampers (or VFD) are modulated in

response to building pressure. A

differential pressure control system,

called Statitrac™, uses a dif ferential

pressure transducer to compare indoor

building pressure to atmospheric

pressure. The FC exhaust fan is turned on

when required to lower building static

pressure to setpoint. The Statitrac control

system then modulates the discharge

dampers (or VFD) to control the building

pressure to within the adjustable,

specified dead band that is set at the

Human Interface Panel.

Advantag es of the Statitrac™

100 per cent modulating exhaust

system are:

a

The exhaust fan runs only when needed

to lower building static pressure.

b

Statitrac compensates for pressure

variations within the building from

remote exhaust fans and makeup

air units.

c

The exhaust fan discharges in a single

direction resulting in more efficient fan

operation compared to return fan

systems.

d

Because discharge dampers modulate

the airflow, the exhaust fan may be

running unloaded whenever the

economizer dampers are less than 100

percent open.

With an exhaust fan system, the supply

fan must be sized to pull the return air

back to the unit through the return

system during non-economizer

operation. However, a supply fan can

typically overcome return duct losses

more efficiently than a return air fan

system. Essentially, one large fan by itself

is normally more efficient than two fans

in series because of only one drive loss

not two as with return air systems.

The reason for either a return air fan or

an exhaust fan is to control building

pressure. The Trane 100 percent

modulating exhaust system with

Statitrac does a better job controlling

building pressure than return fans simply

because 100 percent modulating exhaust

discharge dampers (or VFD) are

controlled directly from building

pressure, rather than from an indirect

indicator of building pressure such as

outdoor air damper position.

The 100 percent modulating exhaust

system with Statitrac may be used on

any rooftop application that has an

outdoor air economizer . However , when

most exhaust is handled external to the

rooftop or when building pressure is not

critical, one of the other less expensive

methods of exhaust may be used.

9RT-PRC010-EN

Page 10

Application

Considerations

2

100 P ercent Exhaust S yst em

Competitive rooftops use a return air fan

system for controlling the amount of

exhaust air during economizer

operation. The return fan is in series with

the supply fan and must operate

whenever the supply fan is operating.

During economizer operation, the

economizer outdoor air dampers control

the position of the return and exhaust air

dampers, to exhaust the proper amount

of air. The disadvantage of a return air

fan is that it runs continuously, versus an

exhaust fan system which runs only

when needed to lower or maintain

building static pressure. Also, the return

fan must discharge air in two directions,

through the return air dampers and/or

exhaust air dampers, resulting in less

efficient operation compared to an

exhaust fan.

The IntelliPak™ R ooftop unit of fers

modulating 100 percent exhaust system.

This fan system has performance

capabilities equal to the supply fan. The

FC exhaust fans are started by the

economizer’s outdoor air damper

position and the exhaust dampers track

the economizer outdoor air damper

position. The amount of air exhausted by

this fan is controlled by modulating

discharge dampers at the fan outlet. The

discharge damper position is controlled

by a signal that varies with the position

of the economizer dampers. When the

exhaust fans start, the modulating

discharge dampers are fully closed, and

exhaust airflow is 15 to 20 percent of

total exhaust capabilities.

3

50 Percent Exhaust Syst em

The 50 percent exhaust system is a

single FC exhaust fan with half the air moving capabilities of the supply fan

system. The experience of The T rane

Company is that a non-modulating

exhaust system selected for 40 to 50

percent of nominal supply CFM can be

applied successfully.

The 50 percent exhaust system generally

should not be selected for more than 40

to 50 percent of design supply airflow.

Since it is an on/off nonmodulating

system, it does not vary exhaust CFM

with the amount of outside air entering

the building. Therefore, if selected for

more than 40 to 50 percent of supply

airflow, the building may become underpressurized when economizer operation

is allowing lesser amounts of outdoor air

into the building. If, however , building

pressure is not of a critical nature, the

non-modulating exhaust system may be

sized for more than 50 percent of design

supply airflow.

4

Barometric Relief D ampers

Barometric relief dampers consist of

gravity dampers which open with

increased building pressure. As the

building pressure increases, the pressure

in the unit return section also increases,

opening the dampers and relieving air.

Barometric relief may be used to provide

relief for single story buildings with no

return ductwork and exhaust

requirements less than 25 percent.

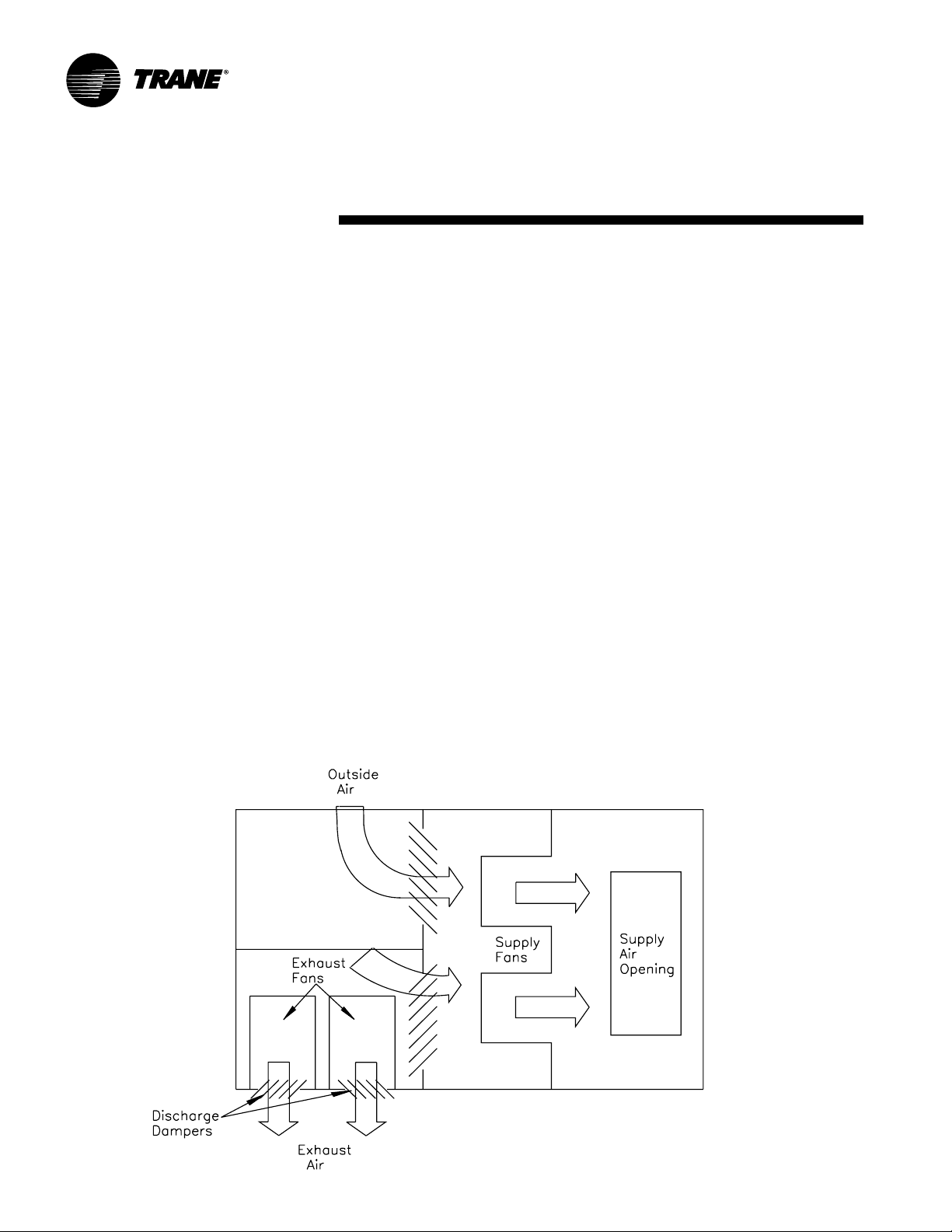

Figure AC-1 — Plan View of Modulating 100 P ercent Exhaust S yst em

RT-PRC010-EN10

Page 11

Application

Considerations

Horizontal Disc harg e

The typical rooftop installation has both

the supply and return air paths routed

through the roof curb and building roof.

However, man y roof top installations

require horizontal supply and/or return

from the rooftop because of a building’s

unique design or for acoustic

considerations.

T rane has two w ays to accomplish

horizontal supply and/or return. The first

applies to all IntelliPak™ Rooftop units.

Special field supplied curbs are installed

that use the unit’s standard discharge

and return openings. The supply and

return air is routed through the curb to

horizontal openings on the sides of the

curb. The second method available for

20 - 75 tons SXHF, SFHF, SLHF, SSHF, and

90 - 130 tons SXHG, SLHG and SSHG

design units ONLY. With this method the

standard discharge and return openings

are blocked in the field. Access panels

are removed as indicated in Figures A C-1

and A C-2. These openings are used for

the discharge and return. No special

curb is needed.

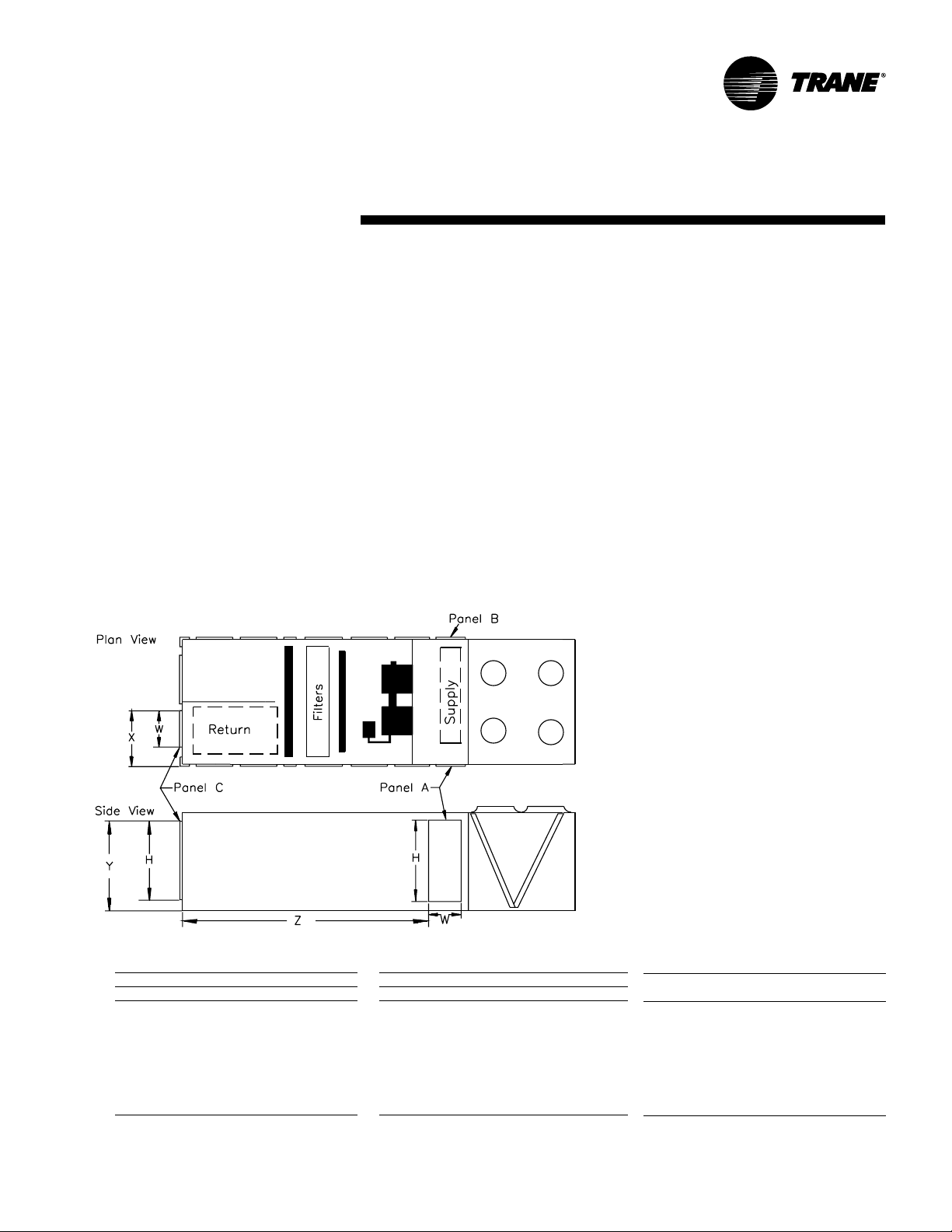

SXHF, SFHF, SLHF, SSHF Units

Figure A C-1 is a simplified sketc h of the

rooftop showing which panels can be

used for horizontal supply and/or return.

To supply air horizontally , the panels that

normally house the heat accessory

controls (Panel A) and the g as heat

barometric dampers (Panel B) can be

removed and either of the openings

horizontal supply and return applies to

Figure AC-2 Horizontal Discharge Panel Dimensions — 20 - 75 Tons SXHF, SFHF, SLHF, SSHF Units

Note: Cannot remove Panel A

for horizontal discharge on

SFHF, SLHF, SSHF Units.

used as a unit discharge (see note 1). To

return air horizontally , the exhaust fan

access door (Panel C) can be removed

and used as a return opening. T ables A C1, 2 and 3 show dimensions for those

panels.

Horizontal Disc har ge on SXHF, SFHF,

SLHF and SSHF Rooftops (20 to 75 tons)

The SXHF (extended casing cooling

only), SFHF (gas heat), SSHF (steam

heat) and SLHF (hot water heat) rooftops

can be field modified to supply and

return air horizontally without the use of

a horizontal supply/return curb.

To supply air horizontally on SXHF only ,

the panels that normally house the heat

accessory controls (Panel A) and the g as

heat barometric dampers (Panel B) can

be removed and either of the openings

used as a unit discharge. To return air

horizontally , the exhaust fan access door

(Panel C) can be removed and used as a

return opening.

1. For horizontal discharge on SFHF, SLHF and SSHF

units, only the Panel B can be removed. Panel A

cannot be used due to the location of the heating

coils.

2. For horizontal discharge on SFHF (gas heat) models,

the block off under the heater must be removed.

After removal, a support must be added for the drain

tube.

3. Supply and Return Base openings must be covered

when converting to a horizontal configuration.

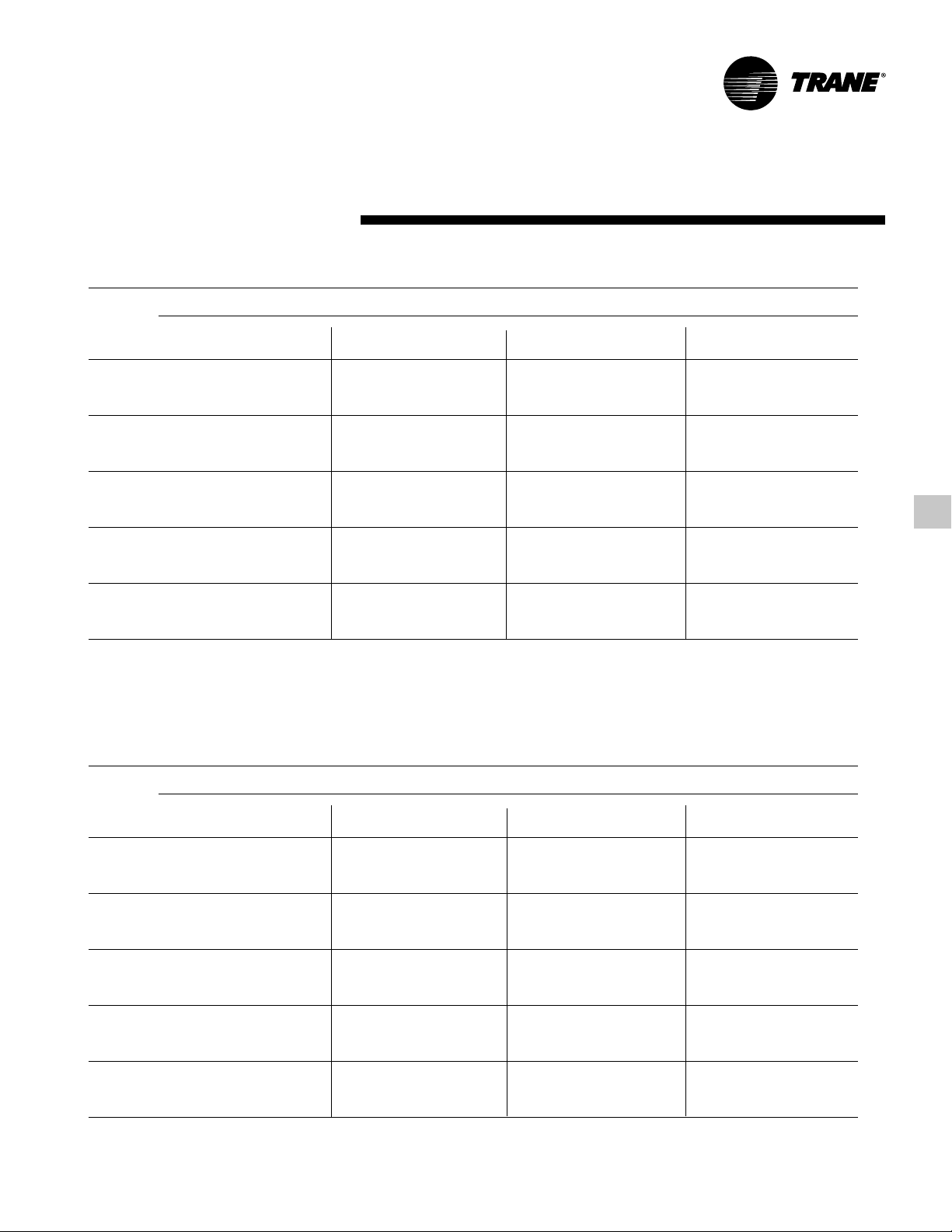

Tabl e AC-1 — SXHF, SFHF, SSHF, SLHF —

Panel A and B Dimensions

Model H (in.) W (in.) (in.2) (ft2)

S*HF C20 40.7 25.5 1038 7.2

S*HF C25 40.7 25.5 1038 7.2

S*HF C30 52.7 25.5 1344 9.3

S*HF C40 64.5 34.5 2225 15.5

S*HF C50 76.7 34.5 2646 18.4

S*HF C55 76.7 34.5 2646 18.4

S*HF C60 64.6 34.5 2229 15.5

S*HF C70 64.6 34.5 2229 15.5

S*HF C75 64.6 34.5 2229 15.5

Notes:

1. Add an extra 0.20-inches pressure drop to the supply external static to account for the extra turn the air is making.

2. The openings all have a 1.25-inch lip around the perimeter to facilitate ductwork attachment.

3. If exhaust fans are being used, provisions should be made for access to the exhaust components, since the access door is now being used as a return.

4. Use the dimensions provided and the supply Cfm to calculate the velocity (ft/min) through the openings to be sure they are acceptable.

Total Area (H X W)

Table AC- 2 — SXHF, SFHF, SSHF, SLHF —

Panel C Dimensions

Model H (in.) W (in.) (in.2) (ft2)

S*HF C20 40.7 34.5 1404 9.8

S*HF C25 40.7 34.5 1404 9.8

S*HF C30 52.7 34.5 1818 12.6

S*HF C40 64.5 34.5 2225 15.5

S*HF C50 76.7 34.5 2646 18.4

S*HF C55 76.7 34.5 2646 18.4

S*HF C60 64.6 34.5 2229 15.5

S*HF C70 64.6 34.5 2229 15.5

S*HF C75 64.6 34.5 2229 15.5

* = X, F , L, or S

T otal Area (H X W)

Tabl e AC-3 — SXHF, SFHF, SSHF, SLHF —

X, Y and Z Dimensions

Model X (in.) Y (in.) Z (in.)

S*HF C20 35.5 44.0 201.5

S*HF C25 35.5 44.0 201.5

S*HF C30 35.5 56.0 201.5

S*HF C40 44.5 67.8 237.0

S*HF C50 44.5 80.0 237.0

S*HF C55 44.5 80.0 237.0

S*HF C60 44.5 68.0 237.5

S*HF C70 44.5 68.0 237.5

S*HF C75 44.5 68.0 237.5

11RT-PRC01 0-EN

Page 12

Application

Considerations

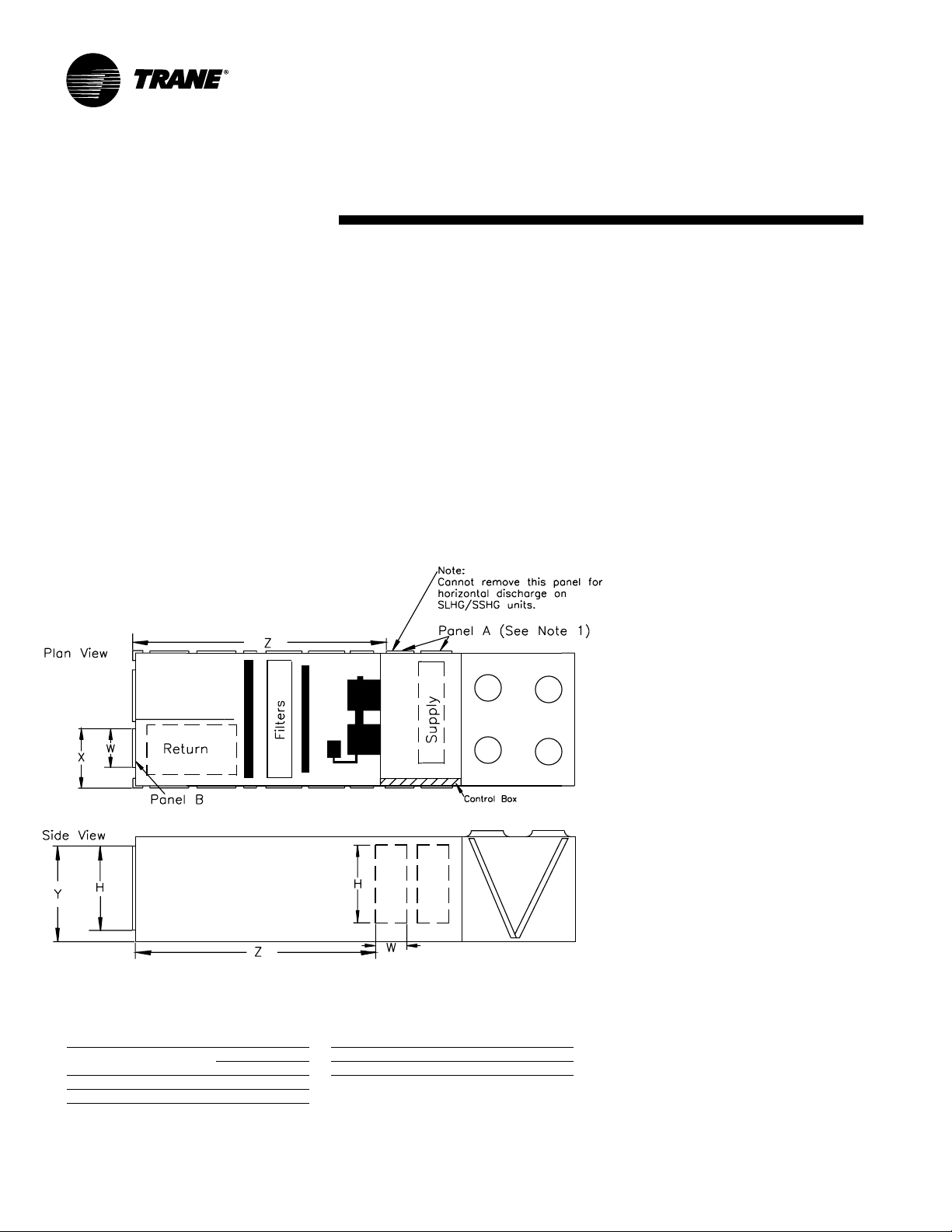

Figure AC-3 is a simplified sketc h

showing which panels can be used for

horizontal supply and/or return. On 90 to

130 ton units, only one side of the

extended casing may be used for

horizontal supply because of the

location of the unit control panel. There

are, however, on SXHF models two

panels (Panels A) on the side opposite

the control box which can be removed

along with the vertical support whic h

separates the two. Removal of the

vertical support is optional, but will

ensure maximum airflow. On SLHG,

SSHG models only one of the Panel A’s

may be used for horizontal supply

Figure AC-3 — Horizontal Dischar ge P anel Dimensions — 90 - 130 Tons SXHG, SLHG, SSHG Units

because of the location of the heating

coil. Horizontal return is accomplished in

much the same way as on S*HFs by

removing the exhaust fan access door

(Panel B). See Tables A C-4 and 5 for

S*HG panel dimensions.

When using an IntelliPak™ Rooftop for

horizontal supply and return, an

additional pressure drop must be added

to the supply external static to account

for the 90 degree turn the air is making.

This additional pressure drop depends

on airflow and rooftop size, but a range

of 0.10 inc hes to 0.30 inches can be

expected. The openings on the rooftop

all have a one inch lip around the

perimeter to facilitate ductwork

attac hment. If exhaust fans are being

used on an IntelliPak Rooftop unit with

horizontal return, provisions should be

made for access to the exhaust

components, since the access door

opening is now being used as a return.

Perhaps the return ductwork attac hment

to the rooftop can include a section of

removable duct. Use the dimensions

provided and the supply and exhaust

CFM to calculate the velocity (ft/min)

through the openings.

Horizontal Dischar g e SXHG, SLHG,

SSHG Rooftops (90 to 130 t ons)

The SXHG, SLHG, SSHG rooftops can be

field modified to supply and return air

horizontally without the use of a

horizontal supply/return curb.

To supply air horizontally , use Panel A

only. The Panel on the opposite side

cannot be used due to the location of the

unit control Panel. SXHG rooftop air

conditioners do not have a panel

configuration like the 20 to 75 ton

rooftops. To achieve maximum airflow,

vertical support can be removed af ter the

unit has been placed on the roof curb. It

is secured by four screws. (See Note 1)

For horizontal disc harge on SLHG and

SSHG units, only the Panel A next to the

condenser fan section can be removed.

The other Panel A next to the supply fan

cannot be used due to the location of the

heating coils.

To return air horizontally, the exhaust fan

access door (Panel B) can be removed

and used as a return opening.

Note:

1. SXHG units have two Panel A’s that can be removed. Once unit is installed, panel(s) and the 61/2” vertical

support channel in between may be removed.

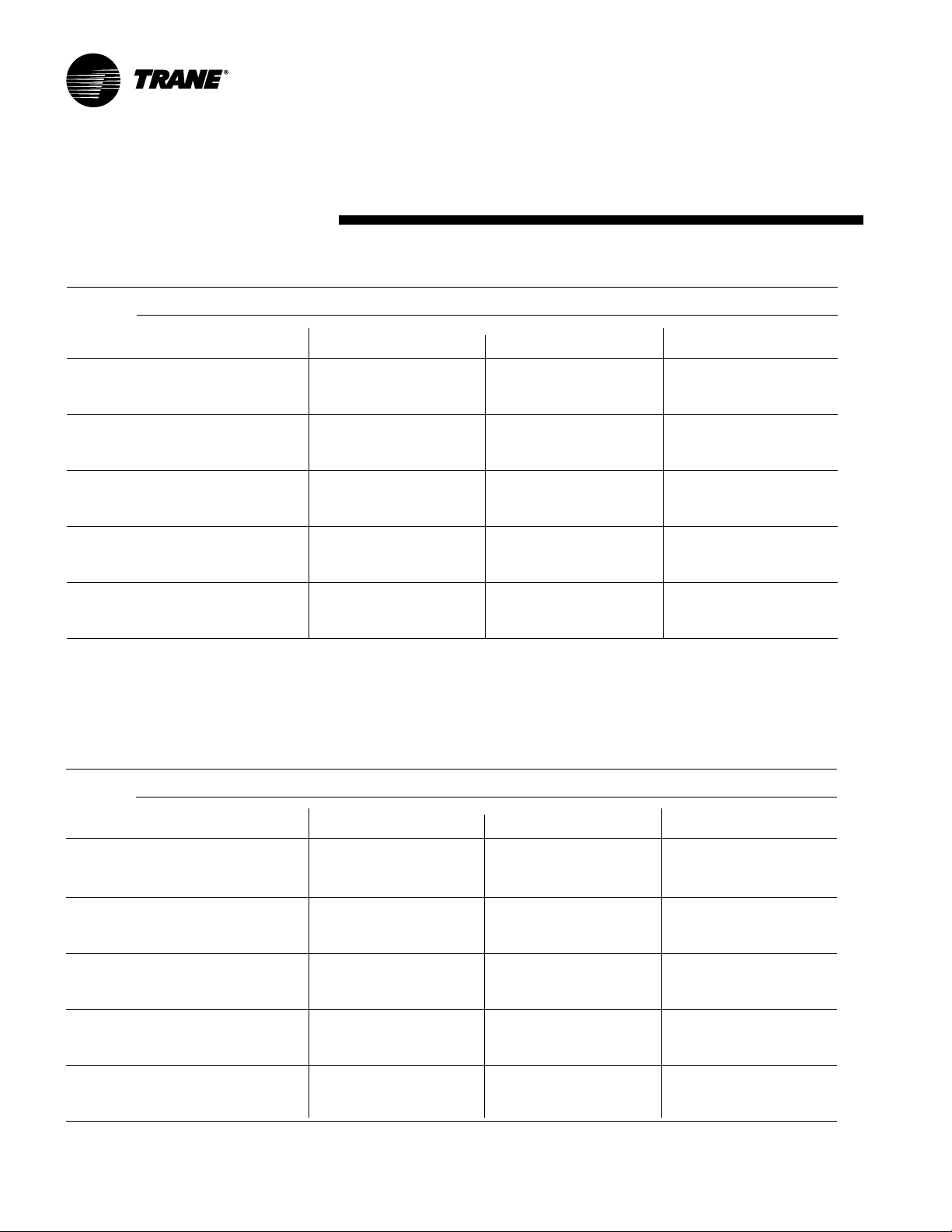

Table AC-4 — SXHG, SLHG, SSHG —

Panel A and B Dimensions

Panel H (in.) W (in.) (in.2) (ft2)

A 72.7 27.5 1999 13.9

B 72.7 34.5 2508 17.4

Notes:

1. Add an extra 0.20-inches pressure drop to the

supply external static to account for the extra turn

the air is making.

2. The openings all have a 1.25-inch lip around the

perimeter to facilitate ductwork attachment.

Total Area (H X W)

Table AC-5 — SXHG, SLHG, SSHG —

X, Y and Z Dimensions

Model X (in.) Y (in.) Z (in.)

S*HG 90-130 69.0 77.8 244.7

* = X, L, or S

3. If exhaust fans are being used, provisions should

be made for access to the exhaust components,

since the access door is now being used as a

return.

4. Use the dimensions provided and the supply Cfm

to calculate the velocity (ft/min) through the

openings to be sure they are acceptable.

RT-PRC010-EN12

Page 13

Application

Considerations

High Capacity Evaporat or Coil

Rooftops are popular because of their

“pac kaged” nature. Everything needed

is contained in one box; mix-matc hing is

neither necessary nor available. With this

convenience comes some

disadvantages; one is the rooftop’s

cooling capacity may not exactly match

the building load. It is conceivable that a

50 ton rooftop would need to be used on

an application that is 41 tons, simply

because the 40 ton rooftop does not

meet capacity.

In order to avoid such occur rences, and

to more closely match the roof top’s

capacity to the building load, a high

capacity evaporator coil option is

available on all IntelliPak™ R ooftops 20

to 105 tons. These high capacity coils

have an increased number of evaporator

coil rows as compared to standard and

enhanced evaporator tube surfaces,

resulting in a higher capacity. Capacity

tables for both standard and high

capacity coils are available in the cooling

data section of this catalog. See T able

PD-43 for the pressure drops associated

with the high capacity coil option. This

pressure drop should be added to the

total static pressure used to size the

supply fan motor.

Low Ambient Operation — Human

Interface Recommendations

Who wants to be on a roof at sub-zero

temperatures? W e can understand a

service technician’s reluctance to do this;

that’s why we recommend using a

remote mounted Human Interface Panel.

The service technician can troubleshoot

and diagnose in the comfort of a

mechanical room.

Corrosiv e Atmospheres

T rane’s IntelliPak Rooftops are designed

and built to industrial standards and will

perform to those standards for an

extended period depending on the hours

of use, the quality of maintenance

performed, and the regularity of that

maintenance. One factor that can have

an adverse effect on unit life is its

operation in a corrosive environment.

When rooftops are operated in corrosive

environments, T rane recommends that

copper fins be utilized on the condenser

and/or evaporator coil. Because copper

is more resistant to corrosion than

aluminum, coil life expectancy is greatly

increased. Some industry applications

expose equipment to corrosive agents

that even copper cannot fully resist. For

those special applications, a baked

phenolic resin coating (i.e. Heresite) is

highly desirable. Baked phenolic

coatings or copper fins on the condenser

and/or evaporator coils are available on

T rane’s IntelliPak Rooftops.

V entilation Ov er r ide Sequences

One of the benefits of using an exhaust

fan rather than a return fan, in addition

to the benefits of lower energy usage

and improved building pressurization

control, is that the rooftop can be used

as part of a ventilation override system.

Several types of sequences can be easily

done when exhaust fans are a part of the

rooftop system.

What would initiate the ventilation

override control sequence? Typically, a

manual switch is used and located near

the fire protection control panel. This

enables the fire department access to the

control for use during or after a fire. It is

also possible to initiate the sequence

from a field-installed automatic smoke

detector. In either case, a contact closure

begins the ventilation override control

sequence. CAUTION!: The ventilation

over r ide syst em should not be used to

signal the presence of smoke caused b y

a fire.

T rane can pro vide five (5) different

ventilation override sequences on both

CV and VAV IntelliP ak Roof tops. For your

convenience the sequences can be

factory preset or fully field editable from

the Human Interface Panel or T racer™.

Any or all five sequences may be

“loc ked” in by the user at the Human

Interface Panel.

The user can customize up to five (5)

different over ride sequences for

purposes such as smoke control. The

following parameters within the unit can

be defined for each of the five

sequences:

• Supply Fan — on/off

• Inlet Guide Vanes — open/closed/

controlling

• Variable Frequency Driv es — on (60

Hz)/off (0 Hz)/controlling

• Exhaust F an — on/off

• Exhaust Dampers — open/closed

• Economizer dampers — open/closed

• Heat — off/controlling (output for) VAV

Boxes — open/controlling

Compressors and condenser fans are

shut down for any V entilation Override

sequence. Factory preset sequences

include unit Off, Exhaust, P urge, Purge

with duct pressure control, and

Pressurization. Any of the user-defined

V entilation Override sequences can be

initiated by closing a field supplied

switch or contacts connected to an input

on the Ventilation Override Module. If

more than one ventilation override

sequence is being requested, the

sequence with the highest priority is

initiated. Refer to the Sequence of

Operation provided in the Control

section of this catalog for more details

on each over ride sequence.

Natural Gas Heating Considerations

The IntelliPak standard, or limited

modulation, gas heat exchangers are not

recommended for applications with

mixed air conditions entering the heat

exchanger below 50°F. Mixed air

temperatures below 50°F can cause

condensation to form on the heat

exchanger , leading to premature failure.

13RT-PRC01 0-EN

Page 14

Application

Considerations

For increased reliability , the

recommendation in these applications is

full modulation gas heat. For airflow

limitations and temperature rise across

the heat exchanger information, see

Table PD-24, 25 and RT-EB-104.

Acoustical Considerations

The ideal time to make provisions to

reduce sound transmission to the space

is during the project design phase.

Proper placement of rooftop equipment

is critical to reducing transmitted sound

levels to the building. The most

economical means of avoiding an

acoustical problem is to place any

rooftop equipment away from

acoustically critical area. If possible,

rooftop equipment should not be located

directly above areas such as: of fices,

conference rooms, executive office areas

and classrooms. Ideal locations are

above corridors, utility rooms, toilet

facilities, or other areas where higher

sound levels are acceptable.

Several basic guidelines for unit

placement should be followed to

minimize sound transmission through

the building structure:

1

Never cantilever the condensing section

of the unit. A structural cross member

must support this end of the unit.

2

Locate the unit’s center of gravity close

to or over a column or main support

beam to minimize roof deflection and

vibratory noise.

3

If the roof structure is very light, roof

joists should be replaced by a structural

shape in the critical areas described

above.

4

If several units are to be placed on one

span, they should be staggered to

reduce deflection over that span.

It is impossible to totally quantify the

effect of building structure on sound

transmission, since this depends on the

response of the roof and building

members to the sound and vibration of

the unit components. However, the

guidelines listed above are experience

proven guidelines which will help reduce

sound transmission.

There are several other sources of unit

sound, i.e., supply fan, compressors,

exhaust fans, condenser fans and

aerodynamic noise generated at the duct

fittings. Refer to the ASHRAE

Applications Handbook, Chapter 42, 1991

edition for guidelines for minimizing the

generation of aerodynamic noise

associated with duct fittings.

T rane’s Engineering Bulletin RT-EB-80

describes various duct installation

considerations specifically addressing

indoor sound level concerns. This

bulletin includes sound power data on

T rane’s IntelliPak Rooftops 20 to 1 30 tons.

Ask your local Trane representative for

this informative engineering bulletin.

The VariT rane™ Computeriz ed Duct

Design Program can be used to analyze

the truck duct, run-out duct, VAV control

unit and terminal unit noise attenuation.

This program quantifies the airborne

sound generation that can be expected

in each terminal so that the designer can

identify potential sound problems and

make design alterations before

equipment installation.

The Trane Acoustics Program (TAP)

allows modeling of rooftop installation

parameters. The output of this program

shows the resulting indoor NC level for

the modeled installation. This program is

available from Trane’s Customer Direct

Service Network™ (C.D.S.), ask your

local Trane representative for additional

information on this program.

Clearance Requirements

The recommended clearances identified

with unit dimensions should be

maintained to assure adequate

serviceability, maximum capacity and

peak operating efficiency . A reduction in

unit clearance could result in condenser

coil starvation or warm condenser air

recirculation. If the clearances shown are

not possible on a particular job, consider

the following:

• Do the clearances available allow for

major service work such as c hanging

compressors or coils?

• Do the clearances available allow for

proper outside air intake, exhaust air

removal and condenser airflow?

• If screening around the unit is being

used, is there a possibility of air

recirculation from the exhaust to the

outside air intake or from condenser

exhaust to condenser intake?

Actual clearances which appear

inadequate should be reviewed with a

local Trane sales engineer.

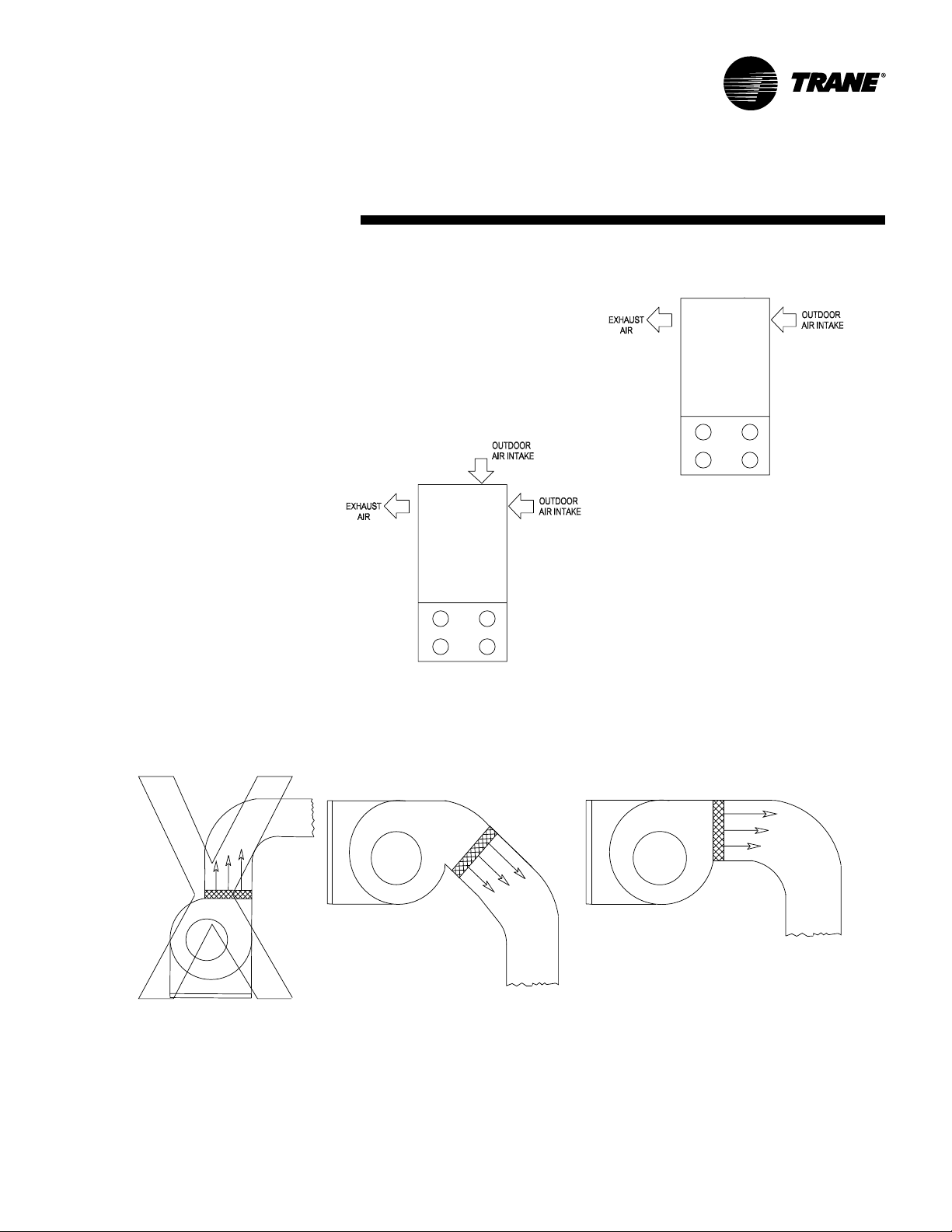

When two or more units are to be placed

side by side, the distance between the

units should be increased to 150 percent

of the recommended single unit

clearance. The units should also be

staggered as shown in Figure AC-4 for

two reasons:

1

To reduce span deflection if more than

one unit is placed on a single span.

Reducing deflection discourages sound

transmission.

2

To assure proper diffusion of exhaust air

before contact with the outside air intake

of adjacent unit.

RT-PRC010-EN14

Page 15

Application

Considerations

Duct Design

It is important to note that the rated

capacities of the rooftop can be met only

if the rooftop is properly installed in the

field. A well-designed duct system is

essential in meeting these capacities.

The satisfactory distribution of air

throughout the system requires that

there be an unrestricted and uniform

airflow from the rooftop discharge duct.

This discharge section should be straight

for at least several duct diameters to

allow the conversion of fan energy from

velocity pressure to static pressure.

However, when job conditions dictate

elbows be installed near the rooftop

outlet, the loss of capacity and static

pressure may be reduced through the

use of guide vanes and proper direction

of the bend in the elbow. The high

velocity side of the rooftop outlet should

be directed at the outside radius of the

elbow rather than the inside as

illustrated in Figure AC-5.

Figure AC-4 — Unit Placement

1

2

1. 20-40 ton models have only one outdoor air intake.

50 - 75 ton models have two outdoor air intakes.

2. 90-130 ton models have two outdoor air intakes on

the backside of the unit and one small air intake at

the end of the unit.

Improper

Figure AC-5 — Duct Design

Proper

15RT-PRC01 0-EN

Page 16

Selection

Pr ocedure

This section outlines a step-by-step

procedure that may be used to select a

T rane single-z one air conditioner . The

sample selection is based on the

following conditions:

• Summer outdoor design conditions —

95 DB/76 WB ambient temperature

• Summer room design conditions —78

DB/65 WB

• Total cooling load — 430 MBh (35.8

tons)

• Sensible cooling load — 345 MBh (28.8

tons)

• Outdoor air ventilation load — 66.9

MBh

• Return air temperature — 80 DB/65 WB

Winter Design:

• Winter outdoor design conditions —0 F

• Return air temperature — 70 F

• Total heating load — 475 MBh

• Winter outdoor air ventilation load —

133 MBh

Air Delivery Data:

• Supply fan cfm — 17,500 cfm

• External static pressure — 1.2 in wg

• Minimum outdoor air ventilation —

1,750 cfm

• Exhaust fan cfm — 12,000 cfm

• Return air duct neg ative static pressure

— 0.65 in wg

Electrical Charact er istics:

• V oltage/cycle/phase — 460/60/3 Unit

Accessories:

• Gas fired heat exc hanger — high heat

module

• Throwaway filters

• Economizer

• Modulating 1 00 percent exhaust/

return fan

COOLING CAP ACIT Y SELECTION

Step 1 — Nominal Unit Size Selection

A summation of the peak cooling load

and the outside air ventilation load

shows: 430 MBh + 66.9 MBh = 496.9

MBh required unit capacity. From

Table PD-9, a 50 ton unit capacity with

standard capacity evaporator coil at

80 DB/65 WB, 95 F outdoor air

temperature and 17,500 total supply cfm

is 551 MBh total and 422 MBh sensible.

Thus, a nominal 50 ton unit with

standard capacity evaporator coil

is selected.

Step 2 — Evaporator Coil Enter ing

Conditions

Mixed air dry bulb temperature

determination:

Using the minimum percent of OA (1,750

cfm ÷ 17,500 cfm = 1 0 percent),

determine the mixture dry bulb to the

evaporator.

RADB + % OA (O ADB - RADB) = 80 +

(0.10) (95 - 80) = 80 + 1.5 = 81.5 F

Approximate wet bulb mixture

temperature:

RAWB + % O A (O A WB - RA WB) = 65 +

(0.10) (7 6 - 65) = 65 + 1.1 = 66.1 F

Step 3 — Det er mine Supply Fan Mot or

Heat Gain

Having selected a nominal 50 ton unit,

the supply fan bhp can be calculated. The

supply fan motor heat gain must be

considered in final determination of unit

capacity.

Supply Air Fan

Determine unit total static pr essur e at

design supply cfm:

External Static Pressure 1 .2 inc hes

Evaporator Coil 0.25 inches

(Table PD-43)

Return Duct Negative 0.65 inches

Static Pressure

Heat Exchanger 0.31 inches

(Table PD-43)

Throwaway Filter 0.10 inc hes

(Table PD-43)

Economizer w/Exhaust Fan0.12 inches

(Table PD-43)

T rane R oof Curb 0.13 inches

(Table PD-43)

Unit T otal Static Pressure 2.7 6 inc hes

Using total of 17,500 cfm and total

static pressure of 2.76 inches, enter Table

PD-36. T able PD-36 shows 15.3 bhp with

924 rpm.

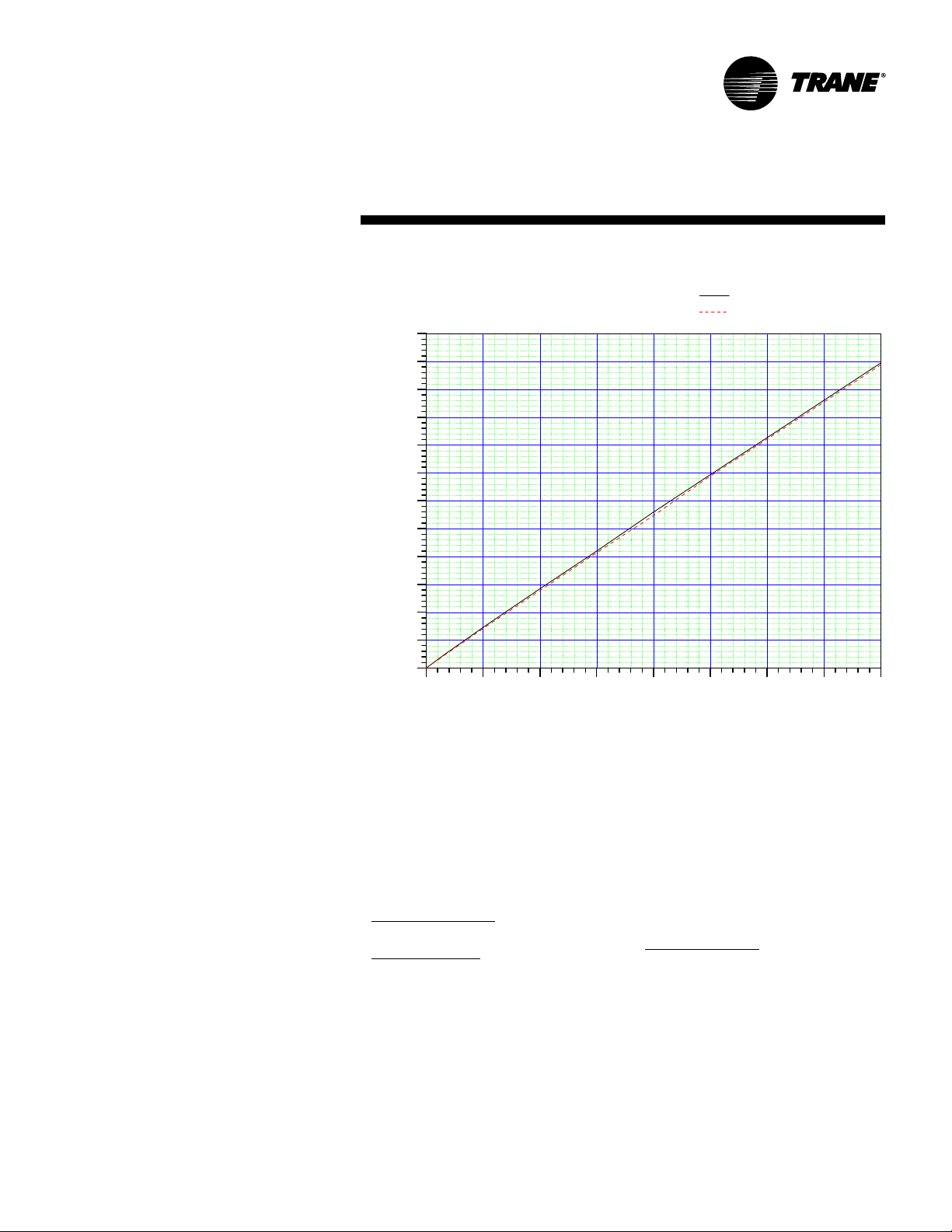

From Chart SP-1 supply fan motor heat

gain = 46.0 MBh.

Step 4 — Det ermine T otal Required

Cooling Capacity

Required capacity = T otal peak load + O A

load + supply air fan motor heat.

Required capacity = 430 + 66.9 +

46.0 = 543 MBh (45.2 tons)

Step 5 — Det ermine Unit Capacity

From Table PD-9, unit capacity at 81 .5 DB/

66.1 WB entering the evaporator , 1 7,500

supply air cfm, 95 F outdoor ambient, is

561 MBh (45.8 tons) with 426 MBh

sensible.

Step 6 — Det ermine Lea ving Air

Temperature

Unit sensible heat capacity corrected for

supply air fan motor heat = 426 MBh - 46

MBh = 380 MBh.

Supply air dry bulb temperature

difference =

Sensible Btu =

1.085 x Supply cfm

380 MBh ÷ (1.085 x 17,500 cfm)

= 20.0 F

Supply air dry bulb = 81.5 DB - 20.0

= 61.5 F

Unit enthalpy difference =

Total Btu =

4.5 x Supply cfm

561 MBh ÷ (4.5 x 17,500 cfm) =

7.12 Btu/lb

Leaving enthalpy = h(ent WB) -

h(diff). From Table 21-1 h(ent WB) =

30.9 Btu/lb

Leaving enthalpy = 30.9 Btu/lb - 7.12

Btu/lb = 23.78 Btu/lb

Supply air wet bulb = 55.9

Leaving air temperature = 61.5

DB/55.9 WB

RT-PRC010-EN16

Page 17

Selection

Pr ocedure

HEA TING CAPACITY SELECTION

Step 1 — Det er mine Air T emperat ure

Entering Heating Module

Mixed air temperature = RADB + % OA

(OADB - RADB) = 70 + (0.1 0) (0 - 70) = 63

F

Supply air fan motor heat temperature

rise = 46,000 Btu ÷ (1.085 x 17,500 cfm) =

2.42 F

Air temperature entering heating

module = 63.0 + 2.42 = 65.4 F

Step 2 — Det er mine Total Wint er Heating

Load

Total winter heating load = peak heating

load + ventilation load - supply fan

motor heat = 475 + 133 - 46.0 = 562 MBh

Electric Heating Syst em

Unit operating on 460/60/3 power supply.

From Table PD-30, kw may be selected

for a nominal 50 ton unit operating

460-volt power. The 170 kw heat module

(580.1 MBh) will satisfy the winter

heating load of 563 MBh.

Table PD-28 shows an air temperature

rise of 30.6 F for 17,500 cfm through

the 170 kw heat module.

Unit supply temperature at design

heating conditions = mixed air

temperature + air temperature rise = 65.4

F + 30.6 F = 96.0 F.

Gas Heating System (Natural Gas)

From Table PD-24 select the high heat

module (697 MBh output) to satisfy

winter heating load of 563 MBh at unit

cfm.

Table PD-26 also shows an air

temperature rise of 36.0 F for 17,500 cfm

through the heating module.

Unit supply temperature at design

heating conditions = mixed air

temperature + air temperature rise = 65.4

F + 36.0 F = 10 1.4 F.

Hot Water Heating

Assume a hot water supply temperature

of 190 F. Subtract the mixed air

temperature from the hot water

temperature to determine the ITD (initial

temperature difference).

Chart SP-1 — Fan Motor Heat

120

110

100

90

80

70

60

50

40

FAN MOTOR HEAT - MBH

30

20

10

0

0 5 10 15 20 25 30 35 40

MOTOR BRAKE HORSE POWER

ITD = 190 F - 65.4 F = 1 25 F. Divide the

winter heating load by ITD = 563 MBh ÷

125 F = 4.50 Q/ITD.

From Table PD-31, select the low heat

module. By interpolation, a Q/ITD of 4.50

can be obtained at a gpm at 25.7.

Water pressure drop at 25.7 gpm is 0.57

ft. of water. Heat module temperature

rise is determined by:

Total Btu = ∆T

1.085 x Supply cfm

563,000 = 29.7 F

(1.085 x 17,500)

Unit supply air temperature = mixed air

temperature + air temperature rise = 65.4

+ 29.7 = 95 F.

Steam Heating System

Assume a 15 psig steam supply .

From Table PD-27, the saturated

temperature steam is 250 F. Subtract

mixed air temperature from the steam

STANDARD MOTOR

HIGH EFFICIENCY MOTOR

temperature to determine ITD. ITD = 250

F - 65.4 F = 185 F.

Divide winter heating load by ITD =

563 MBh ÷ 185 F = 3.04 Q/ITD.

From Table PD-26, select the high heat

module. The high heat module at 17,500

cfm has a Q/ITD = 5.11.

Heat module capacity, Q = ITD x Q/ITD =

185 F x 5.11 Q/ITD = 945 MBh

Heat module air temperature rise

T otal Btu

=

1 .085 x Supply cfm

945 Btu ÷ (1.085 x 17,500 cfm) = 49.8 F.

Unit supply temperature at design

conditions = mixed air temperature + air

temperature rise = 65.4 F + 49.8 F = 115 F.

17RT-PRC01 0-EN

Page 18

Selection

Pr ocedure

AIR DELIVERY PROCEDURE

Supply fan performance tables include

internal resistance of rooftop. For total

static pressure determination, system

external static must be added to

appropriate component static pressure

drop (evaporator coil, filters, optional

economizer , optional exhaust fan,

optional heating system, optional

cooling only extended casing, optional

roof curb).

Supply Fan Motor Sizing

The supply fan motor selected in the

cooling capacity determination was 15.3

bhp and 924 rpm. Thus, a 20 hp supply

fan motor is selected. Enter T able PD-45

to select the proper drive. For a 50 ton

rooftop with 20 hp motor , a drive

number 9 — 900 rpm is selected.

Exhaust Fan Motor Sizing

The exhaust fan is selected based on

total return system negative static

pressure and exhaust fan cfm. Return

system negative static include return

duct static and roof curb static pressure

drop.

Return duct static pressure = 0.65 inches

T rane roof curb (Table PD-43) = 0.12

inches

Total return system negative static

pressure = 0.77 inches

Exhaust fan cfm = 12,000 cfm

From Table PD-47, the required bhp is

3.45 hp at 574 rpm. Thus, the exhaust fan

motor selected is 5 hp.

To select a drive, enter T able PD-49 for a 5

hp motor for a 50 ton unit. Drive

selection number 6 — 600 rpm.

Where altitudes are significantly above

sea level, use T ables PAF-2 and P AF-3 and

Figure P AF-1 for applicable correction

factors.

UNIT ELECTRICAL REQUIREMENTS

Selection procedures for electrical

requirements for wire sizing amps,

maximum fuse sizing, and dual element

fuses are given in the electrical service

section of this catalog.

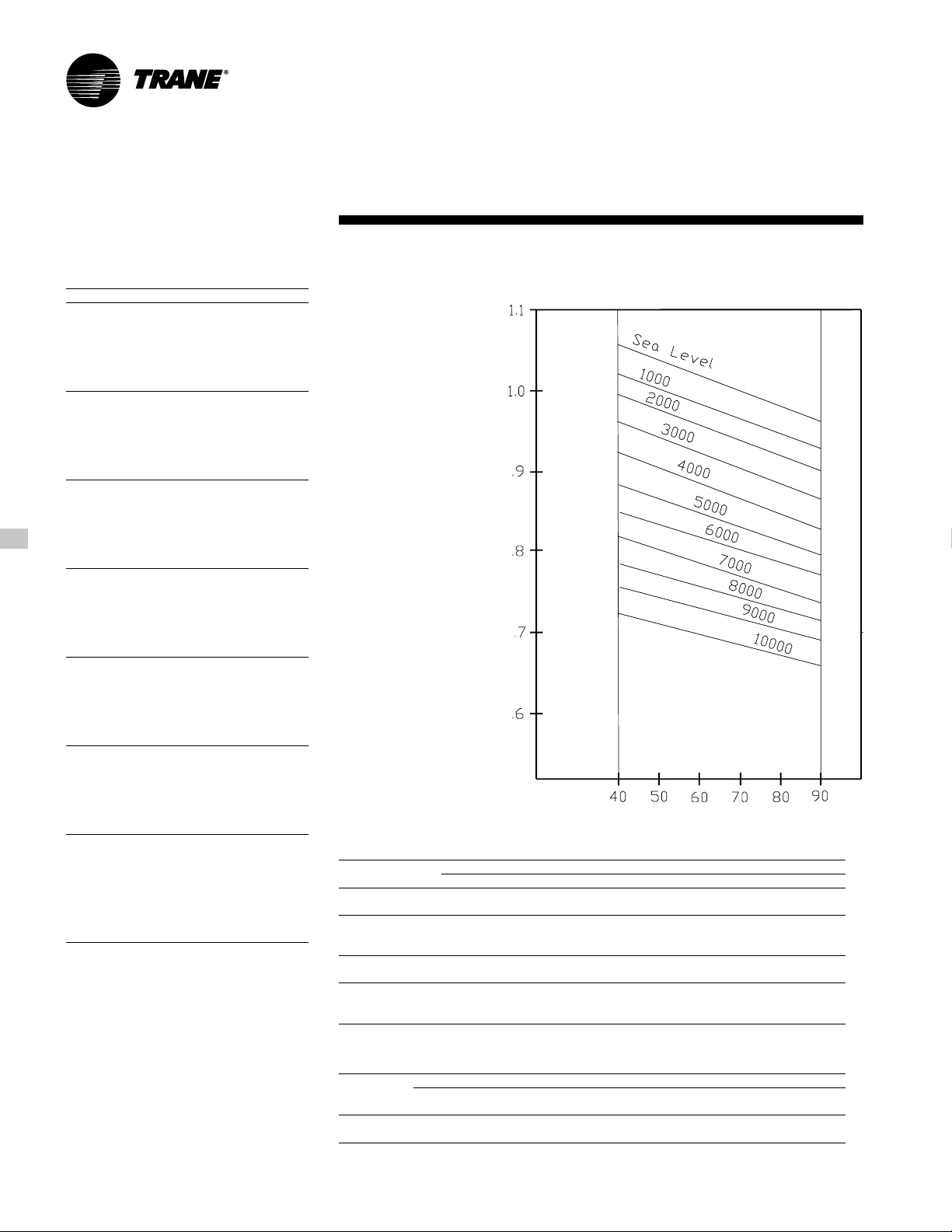

Altitude Corr ections

The rooftop performance tables and

curves of this catalog are based on

standard air (.075 lbs/ft). If the rooftop

airflow requirements are at other than

standard conditions (sea level), an air

density correction is needed to project

accurate unit performance.

Figure P AF-1 shows the air density ratio

at various temperatures and elevations.

T rane roof tops are designed to operate

between 40 and 90 degrees Fahrenheit

leaving air temperature.

The procedure to use when selecting a

supply or exhaust fan on a rooftop for

elevations and temperatures other than

standard is as follows:

1

First, determine the air density ratio

using Figure P AF-1 .

2

Divide the static pressure at the

nonstandard condition by the air

density ratio to obtain the corrected

static pressure.

3

Use the actual cfm and the corrected

static pressure to determine the fan rpm

and bhp from the rooftop performance

tables or curves.

4

The fan rpm is correct as selected.

5

Bhp must be multiplied by the air

density ratio to obtain the actual

operating bhp.

RT-PRC010-EN18

Page 19

Selection

Pr ocedure

In order to better illustrate this

procedure, the following example is

used:

Consider a 60 ton rooftop unit that is to

deliver 18,000 actual cfm at 3-inches total

static pressure (tsp), 55 F leaving air

temperature, at an elevation of 5,000 ft.

1

From Figure PAF -1, the air density ratio is

0.86.

2

Tsp = 3.0-inches / 0.86 = 3.49 inc hes tsp.

3

From the performance tables: a 60 ton

rooftop (without inlet vanes) will deliver

18,000 cfm at 3.49-inches tsp at 906 rpm

and 21 .25 bhp.

4

The rpm is correct as selected - 906rpm.

5

Bhp = 21 .25 x 0.86 = 18.3 bhp actual.

Compressor MBh, SHR, and kw should

be calculated at standard and then

converted to actual using the cor rection

factors in Table PAF-2. Apply these factors

to the capacities selected at standard cfm

so as to correct for the reduced mass

flow rate across the condenser.

Heat selections other than gas heat will

not be affected by altitude. Nominal gas

capacity (output) should be multiplied by

the factors given in Table P AF-3 before

calculating the heating supply air

temperature.

HEA TING CAPACITY SELECTION

Step 1 — Det er mine Air T emperat ure

Entering Heating Module

Mixed air temperature = RADB + % OA

(OADB - RADB) = 70 + (0.10) (0 - 70) = 63

F

Supply air fan motor heat temperature

rise = 46,000 Btu ÷ (1.085 x 1 7,500 cfm) =

2.42 F

Air temperature entering heating

module = 63.0 + 2.42 = 65.4 F

19RT-PRC01 0-EN

Page 20

Model

Number

Description

S F H F C 5 5 F H A 5 5 C 6 9 D 3 0 0 1 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0

1 2 3 4 5 6 7 8 9 101112131415161718192021222324252627 28 29 30 31 32 33 34 35 36 37 38

DIGIT 1 — UNIT TYPE

S = Self-Contained (Packaged Rooftop)

DIGIT 2 — UNIT FUNCTION

A = DX Cooling, No Heat

E = DX Cooling, Electric Heat

F = DX Cooling, Natural Gas Heat

L = DX Cooling, Hot Water Heat

S = DX Cooling, Steam Heat

X = DX Cooling, No Heat, Extended Casing

DIGIT 3 — UNIT AIRFLOW

H = Single Zone

DIGIT 4 — DEVELOPMENT SEQUENCE

F = Sixth

DIGITS 5,6,7 — NOMINAL CAPACITY

C20 = 20 T ons C55 = 55 T ons

C25 = 25 T ons C60 = 60 T ons

C30 = 30 T ons C70 = 70 T ons

C40 = 40 T ons C75 = 75 T ons

C50 = 50 T ons

DIGIT 8 — POWER SUPPLY (See Notes)

4 = 460/60/3 XL E = 200/60/3 XL

5 = 575/60/3 XL F = 230/60/3 XL

Note: SEHF units (units with electric heat)

utilizing 208V or 230V require dual power

source.

DIGIT 9 — HEATING CAPACITY

Note: When the second digit calls for “F”

(Gas Heat), the following values apply:

Additionally , please note G and M available

ONLY on 50 Ton models and above.

H = High Heat-2-Stage P = High Heat-Full

L = Low Heat-2-Stage Modulation

0 = No Heat M = Low Heat-Full

J = High Heat-Limited Modulation

Modulation

G = Low Heat-Limited

Modulation

Note: When the second digit calls for “E”

(electric heat), the following values appl y :

D = 30 KW R = 130 KW

H = 50 KW U = 150 KW

L = 70 KW V = 170 KW

N = 90 KW W = 190 KW

Q = 110 KW

Note: When the second digit calls for ‘’L’ ’

(Hot Water) or ‘’S’ ’(Steam) Heat, one of the

following valve size values must be in Digit 9:

High Heat Coil: 1 = .50”, 2 = .75”, 3 = 1”,

4 = 1.25”, 5 = 1.5”, 6 = 2”.

Low Heat Coil: A = .50”, B = .75”, C = 1”,

D = 1.25”, E = 1.5”, F = 2”.

DIGIT 10 — DESIGN SEQUENCE

A = First (Factory Assigned)

Note: Sequence may be any letter A thru Z,

or any digit 1 thru 9.

DIGIT 11 — EXHAUST OPTION

0 = None

1 = Barometric

2 = 100%, 1.5 HP W/Statitrac

3 = 100%, 3 HP W/Statitrac

4 = 100%, 5 HP W/Statitrac

5 = 100%, 7.5 HP W/Statitrac

6 = 100%, 10 HP W/Statitrac

7 = 100%, 15 HP W/Statitrac

8 = 100%, 20 HP W/Statitrac

A = 50%, 1.5 HP

B = 50%, 3 HP

C = 50%, 5 HP

D = 50%, 7.5 HP

E = 100%, 1.5 HP W/O Statitrac (CV Only)

F = 100%, 3 HP W/O Statitrac (CV Only)

G = 100%, 5 HP W/O Statitrac (CV Only)

H = 100%, 7.5 HP W/O Statitrac (CV Only)

J = 100%, 10 HP W/O Statitrac (CV Only)

K = 100%, 15 HP W/O Statitrac (CV Only)

L = 100%, 20 HP W/O Statitrac (CV Only)

DIGIT 12 — EXHAUST AIR FAN DRIVE

0 = None 8 = 800 RPM

4 = 400 RPM 9 = 900 RPM

5 = 500 RPM A = 1000 RPM

6 = 600 RPM B = 1100 RPM

7 = 700 RPM

DIGIT 13 — FILTER

A = Throwaway

B = Cleanable Wire Mesh

C = High-Efficiency Throwawa y

D = Bag With Prefilter

E = Cartridge With Prefilter

F = Throwaway Filter Rack Less Filter

Media

G = Bag Filter Rack Less Filter Media

DIGIT 14 — SUPPLY AIR FAN HP

1 = 3 HP 4 = 10 HP 7 = 25 HP

2 = 5 HP 5 = 15 HP 8 = 30 HP

3 = 7.5 HP 6 = 20 HP 9 = 40 HP

DIGIT 15 — SUPPLY AIR FAN DRIVE

5 = 500 RPM B = 1100 RPM

6 = 600 RPM C = 1200 RPM

7 = 700 RPM D = 1300 RPM

8 = 800 RPM E = 1400 RPM

9 = 900 RPM F = 1500 RPM

A= 1000 RPM G = 1600 RPM

DIGIT 16 — FRESH AIR

A = No F resh Air

B = 0-25% Manual

D = 0-100% Economizer

DIGIT 17 — SYSTEM CONTROL

1 = Constant Volume Control

2 = VAV Supply Air Temperature Control

w/o Inlet Guide Vanes

3 = VAV Supply Air Temperature Control

w/ Inlet Guide Vanes

4 = Space Pressure Control with Exhaust

VFD w/o Bypass

5 = Space Pressure Control with Exhaust

VFD and Bypass

6 = VAV Supply Air Temperature Control

with VFD w/o Bypass

7 = VAV Supply Air Temperature Control

with VFD and Bypass

8 = Supply and Exhaust Fan with VFD

w/o Bypass

9 = Supply and Exhaust Fan with VFD

and Bypass

DIGIT 18 — ACCESSOR Y PANEL

0 = None

A = BAYSENS008*

B = BAYSENS010*

C = BAYSENS013*

D = BAYSENS014*

E = BAYSENS019*

F = BAYSENS020*

G = BAYSENS021*

Note: *Asterisk indicates current model

number digit A, B, C, etc. These sensors

can be ordered to ship with the unit.

DIGIT 19 — AMBIENT CONTROL

0 = Standard

1 = 0° Fahrenheit

DIGIT 20 — AGENCY APPROVAL

0 = None (UL Gas Heater, see note)

1 = UL

2 = CSA

Note: Includes UL classified gas heating

section only when second digit of Model No.

is a “F .”

DIGITS 21 - 38 — MISCELLANEOUS

21 A = Unit Disconnect Switch

22 B = Hot Gas Bypass

23 0 = Without Economizer

C = Economizer Control w/

23 Z = Economizer Control w/

3

23 W = Economizer Control w/Dry Bulb

24 E = Low Leak Fresh Air Dampers

25 F = High Duct Temperature

26 G = High Capacity Evap. Coil

27 H = Copper Fins (Cond. Only)

28 K = Generic B.A.S. Module

29 L = High-Efficiency Motors (Supply

30 M = Remote Human Interface

31 N = Ventilation Override Module

32 R = Extended Grease Lines

33 T = Access Doors

34 V = Inter-Processor Communica

35 Y = Trane Communication

35 7 = LonTalk Communication

36 8 = Spring Isolators

37 6 = Factory-Powered 15A GFI

38 5 = VFD Line Reactor

Comparative Enthalp y

Reference Enthalpy

Thermostat

and Exhaust)

tion Bridge

Interface (TCI) Module

Interface (LCI) Module

Convenience Outlet

1

RT-PRC010-EN20

Page 21

Model

Number

Description

S X H G D 1 1 4 O A H 7 C F 9 D 3 0 0 1 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0

1 2 3 4 567 8 9 1011 12131415161718 19 20 21222324252627 282930313233343536

DIGIT 1 — UNIT TYPE

S = Self-Contained (Packaged Rooftop)

DIGIT 2 — UNIT FUNCTION

E = DX Cooling, Electric Heat

F = DX Cooling, Natural Gas Heat

L = DX Cooling, Hot Water Heat

S = DX Cooling, Steam Heat

X = DX Cooling, No Heat, Extended Casing

DIGIT 3 — UNIT AIRFLOW

H = Single Zone

DIGIT 4 — DEVELOPMENT SEQUENCE

G = Seventh

DIGITS 5,6,7 — NOMINAL CAPACITY

C90 = 90 T ons

D11 = 105 Tons

D12 = 115 Tons

D13 = 130 Tons

DIGIT 8 — POWER SUPPLY

4 = 460/60/3 XL

5 = 575/60/3 XL

E = 200/60/3 XL

F = 230/60/3 XL

DIGIT 9 — HEATING CAPACITY

0 = No Heat

H = High Heat - 2-Stage

J = High Heat - Limited Modulation

P = High Heat - Full Modulation

Note:

When the second digit calls for “E”

(electric heat), the following values apply

in the ninth digit:

W = 190 KW

When the second digit calls for ‘’L’’ or

‘’S’’, one of the following valve size

values must be in Digit 9:

High Heat Coil: 3 = 1.0”, 4 = 1.25”, 5 =

1.50”, 6 = 2.0”, 7 = 2.5”

Low Heat Coil: C = 1.0”, D = 1.25”, E =

1.50”, F = 2.0”, G = 2.5”

DIGIT 10 — DESIGN SEQUENCE

A = First (Factory Assigned)

Note: Sequence may be any letter A thru

Z, or any digit 1 thru 9.

DIGIT 11 — EXHAUST OPTION

0 = None

7 = 100%, 15 HP W/Statitrac

8 = 100%, 20 HP W/Statitrac

1. EXAMPLE: Model numbers: SFHFC55FHA55C69D3001N describes a unit with the following characteristics: DX cooling with

natural gas heating, 55 ton nominal cooling capacity, 230/60/3 power supply, high heat model. 100 percent exhaust with

Statitrac, 7.5 HP exhaust fan motor with drive selection No. 5 (500 RPM), high-efficiency throwaway filters, 20 HP supply

fan motor with drive selection No. 9 (900 RPM), 0-100% economizer, VAV supply air temperature control with inlet guide

vanes, no remote panel, standard ambient control, U.L. agency approval. The service digit for each model number

contains 38 digits; all 38 digits must be referenced.

2. EXAMPLE: Model numbers: SXHGD1140AH7CF8D3001 describes a unit with the following characteristics: DX cooling with

extended casing, no heat, 105 ton nominal cooling capacity, 460/60/3 power supply, no heat, 100 percent exhaust with

Statitrac, 30 h.p. exhaust fan motor with drive selection No. 7 — (700 RPM), high-efficiency throwaway filters, 60 hp supply

fan motor with drive selection No. 8 — (900 RPM), economizer, VAV supply air temperature control with inlet guide vanes,

no remote panel, standard ambient, UL agency approval. The service digit for each model number contains 36 digits; all 36

digits must be referenced.

3. Available as standard 460 volt only for 70 and 75 ton models.

9 = 100%, 25 HP W/Statitrac

F = 50%, 15 HP

H = 100%, 30 HP W/Statitrac

J = 100%, 40 HP W/Statitrac

K = 100%, 15 HP W/O Statitrac (CV Only)

L = 100%, 20 HP W/O Statitrac (CV Only)

M = 100%, 25 HP W/O Statitrac (CV Only)

N = 100%, 30 HP W/O Statitrac (CV Only)

P = 100%, 40 HP W/O Statitrac (CV Only)

DIGIT 12 — EXHAUST AIR FAN DRIVE

0 = None

5 = 500 RPM

6 = 600 RPM

7 = 700 RPM

8 = 800 RPM

DIGIT 13 — FILTER

A = Throwaway

C = High-Efficiency Throwaway

D = Bag With Prefilter

E = Cartridge With Prefilter

F = Throwaway Filter Rack Less Filter

Media

G = Bag Filter Rack Less Filter Media

DIGIT 14 — SUPPLY AIR FAN HP

C = 30 HP (2-15 HP)

D = 40 HP (2-20 HP)

E = 50 HP (2-25 HP)

F = 60 HP (2-30 HP)

G = 80 HP (2-40 HP)

DIGIT 15 — SUPPLY AIR FAN DRIVE

A = 1000 RPM

B= 1100 RPM

C= 1200 RPM

D= 1300 RPM

E= 1400 RPM

F = 1500 RPM