Page 1

Programming Guide

IntelliPak™ with Symbio™ 800, 20 to 75 Ton

with the Tracer®TD7 Display

Only qualified personnel should install and service the equipment. The installation, starting up, and servicing

of heating, ventilating, and air-conditioning equipment can be hazardous and requires specific knowledge and

training. Improperly installed, adjusted or altered equipment by an unqualified person could result in death or

serious injury. When working on the equipment, observe all precautions in the literature and on the tags,

stickers, and labels that are attached to the equipment.

December 2018

SAFETY WARNING

RT-SVP011A-EN

Page 2

Introduction

Warnings, Cautions, and Notices

Safety advisories appear throughout this manual as required. Your personal safety and the proper

operation of this machine depend upon the strict observance of these precautions.

The three types of advisories are defined as follows:

WARNING

CAUTIONs

NOTICE

T

Indicates a potentially hazardous situation which, if not avoided, could result in

death or serious injury.

Indicates a potentially hazardous situation which, if not avoided, could result in

minor or moderate injury. It could also be used to alert againstunsafepractices.

Indicates a situation that could result in equipment or property-damage only

accidents.

WARNING

Proper Field Wiring and Grounding Required!

Failure to follow code could result in death or serious injury. All field wiring MUST be

performed by qualified personnel. Improperly installed and grounded field wiring poses FIRE

and ELECTROCUTION hazards. To avoid these hazards, you MUST follow requirements for field

wiring installation and grounding as described in NEC and your local/state electrical codes.

Failure to follow code could result in death or serious injury.

WARNING

Personal Protective Equipment (PPE) Required!

Failure to wear proper PPE for the job being undertaken could result in death or serious injury.

Technicians, in order to protect themselves from potential electrical, mechanical, and chemical

hazards, MUST follow precautions in this manual and on the tags, stickers, and labels, as well

as the instructions below:

• Before installing/servicing this unit, technicians MUST put on all PPE required for the work

being undertaken (Examples; cut resistant gloves/sleeves, butyl gloves, safety glasses, hard

hat/bump cap, fall protection, electrical PPE and arc flash clothing). ALWAYS refer to

appropriate Material Safety Data Sheets (MSDS)/Safety Data Sheets (SDS) and OSHA

guidelines for proper PPE.

• When working withor around hazardous chemicals, ALWAYS refer to the appropriate MSDS/

SDS and OSHA/GHS (Global Harmonized System of Classification and Labelling of

Chemicals) guidelines for information on allowable personal exposure levels, proper

respiratory protection and handling instructions.

• If there is a risk of energized electrical contact, arc, or flash, technicians MUST put on all PPE

in accordance with OSHA, NFPA 70E, or other country-specific requirements for arc flash

protection, PRIOR to servicing the unit. NEVER PERFORM ANY SWITCHING,

DISCONNECTING, OR VOLTAGE TESTING WITHOUT PROPER ELECTRICAL PPE AND ARC

FLASH CLOTHING. ENSURE ELECTRICAL METERS AND EQUIPMENT ARE PROPERLY RATED

FOR INTENDED VOLTAGE.

© 2018 Ingersoll Rand All rights reserved RT-SVP011A-EN

Page 3

Copyright

This document and the information in it are the property of Trane, and may not be used or

reproduced in whole or in part without written permission. Trane reserves the right to revise this

publication at any time, and to make changes to its content without obligation to notify any person

of such revision or change.

Trademarks

All trademarks referenced in this document are the trademarks of their respective owners.

Agency Listings and Compliance

The European Union (EU) Declaration of Conformity is available from your local Trane® office.

Revision History

New

Introduction

RT-SVP011A-EN 3

Page 4

Table of Contents

Introduction ......................................................6

Hardware ...................................................... 6

Touchscreen Guidelines .......................................... 6

Dimensions .................................................... 7

Specifications and Agency Compliance ............................. 8

Controller and Service Tool Requirements ........................... 8

Supported Languages ............................................ 9

Screen Overview ............................................... 10

Alarms ..........................................................13

Active Alarms ................................................. 13

Alarm Icons ................................................... 14

Sorting Alarms ................................................ 15

Configuring Alarms ............................................. 15

Communication ............................................... 6

Screen Characteristics .......................................... 6

Tracer TU ....................................................8

WebUI ...................................................... 8

Top Display Area ............................................. 10

Main Display Area (Home Screen) ............................... 11

Bottom Display Area .......................................... 11

Viewing Active Alarms ........................................ 14

Reports .........................................................17

Custom Reports ................................................ 17

Creating a Custom Report ..................................... 17

Editing a Custom Report ....................................... 19

All Points Report ............................................... 20

Points Overrides ............................................... 21

Binary Overrides ............................................. 22

Multistate Overrides .......................................... 23

Analog Overrides ............................................. 23

Setting Up a Temporary Override ............................... 24

............................................................. 24

Override Summary ............................................. 24

About ........................................................ 25

Expansion Modules ............................................. 27

TGP2 Programs ................................................ 29

Data Logs ..................................................... 29

Using the Trend Viewer ......................................... 30

Data Graphs .....................................................31

4 RT-SVP011A-EN

Page 5

Table of Contents

Creating a Data Graph .......................................... 31

Settings ......................................................... 36

Control Settings ................................................ 36

Equipment Settings ............................................. 37

Unit Settings ................................................ 37

Feature Settings .............................................. 37

Manual Overrides ............................................ 37

Display Settings ................................................ 38

Display Preferences ........................................... 38

Language ................................................... 41

Date and Time ............................................... 42

Clean Touchscreen ........................................... 43

Schedules ..................................................... 43

Optimal Start/Stop ............................................ 44

Exceptions and Calendars ..................................... 44

Creating a Schedule .......................................... 44

The Tools Menu ................................................ 45

Backup and Restore ........................................... 45

Programs ................................................... 46

System Logs ................................................ 46

Recent Usage ................................................ 46

BACnet Information ........................................... 46

Configuring Basic Settings for the Symbio 800 ...................... 46

Regional Specifications ........................................ 47

Symbio 800 System Units ..................................... 47

Identification and Communication ............................... 47

USB Ports and microSD ....................................... 48

Licensing ................................................... 48

Configuring Additional Settings .................................. 49

Defaults for User Preferences ...................................49

Application Defaults .......................................... 49

SMTP Settings ............................................... 50

Priority Levels ............................................... 50

Login Page .................................................. 51

Troubleshooting ..................................................52

Identifying and Diagnosing Issues ................................. 52

Notes ...........................................................85

RT-SVP011A-EN 5

........................................................... 83

TD7 Automatic Rediscover and Automatic Hardware Reboot ........ 83

Page 6

Introduction

The purpose of this guide is to assist you in installing, programming, and operating with the

TracerTD7 Display and the Web UI, which interacts with the unit controls. This guide describes how

to access the screens and the types of information that appear on the screens.

The Tracer TD7 display is mounted to the unit and allows you to view data and make operational

changes to the equipment.

The Web UI is a built in service tool that allows users to set up, operate, and troubleshoot the

equipment.

Hardware

The Tracer TD7 is a durable factory-mounted touch screen display that is designed to operate in

both indoor or outdoor environments. The TD7 display utilizes a standard 75mm VESA mounting

pattern for installation in a Trane Large enclosure. Alternatively, it can be installed with a usersupplied VESA mount.

Communication

A separate Ethernet cable provides communication between the Tracer TD7 display and the unit

controller.

Screen Characteristics

The 7-inch WVGA 800 x 480 resolution touch-sensitive color screen is backlit, which enables

viewing in poor light conditions including outdoor usage (with the exception of direct sunlight).

Touchscreen Guidelines

The touch screen registers the downward pressure of a touch. Light, quick, yet deliberate touches

are most effective. Touching with more pressure has no effect.

Recommended tools to use:

• finger

• thumb

• pencil eraser

Do not use:

• a screwdriver

• a pen

• a pencil point

• any other sharp or pointed object that might scratch the screen surface

6 RT-SVP011A-EN

Page 7

Dimensions

Introduction

7.9 in. (200.7 mm)

1.7 in. (41.9 mm)

5.5 in. (139.9 mm)

8.3 in. (211.6 mm)

Note: The power cable is permanently attached to the

TD7 display. The power connector provides

strain relief and protection from the elements.

2.1 in. (53.2 mm)

6.3 in. (158.8 mm)

RT-SVP011A-EN 7

Page 8

Introduction

Specifications and Agency Compliance

Specification

Input power: 24 Vac +/- 15%, 21 VA, 50 or 60 Hz

Storage temperature:

Operating temperature:

Mounting weight:

Environmental rating (enclosure): IP56 (dust and strong water protected) with use of an optional Sealed Ethernet Cable

Agency Compliance

• UL916 PAZX, Open Energy Management Equipment

• UL94-5V, Flammability

• FCC CFR Title 47, Part 15.109: Class A Limit, (30 MHz—4 GHz)

• CE EMC Directive 2004/108/EC

• CE EMC Directive 2004/108/EC

-67°F to 203°F (-55°C to 95°C)

Humidity: Between 5% and 100% (non-condensing)

Temperature: -40°F to 158°F (-40°C to 70°C)

Humidity: Between 5% and 100% (non-condensing)

Mounting surface must support 1.625 lb (0.737 kg)

Mounting Type: VESA (75 mm x 75 mm)

Controller and Service Tool Requirements

Tracer TU

Tracer TU Service Tool Version 10.2 or higher is only required for TGP2 and modifications done in

the field.

Note: Tracer TU is not needed for normal operation. If you need to perform configuration changes,

add new features, or customize the operation of the equipment, contact your local Trane

office.

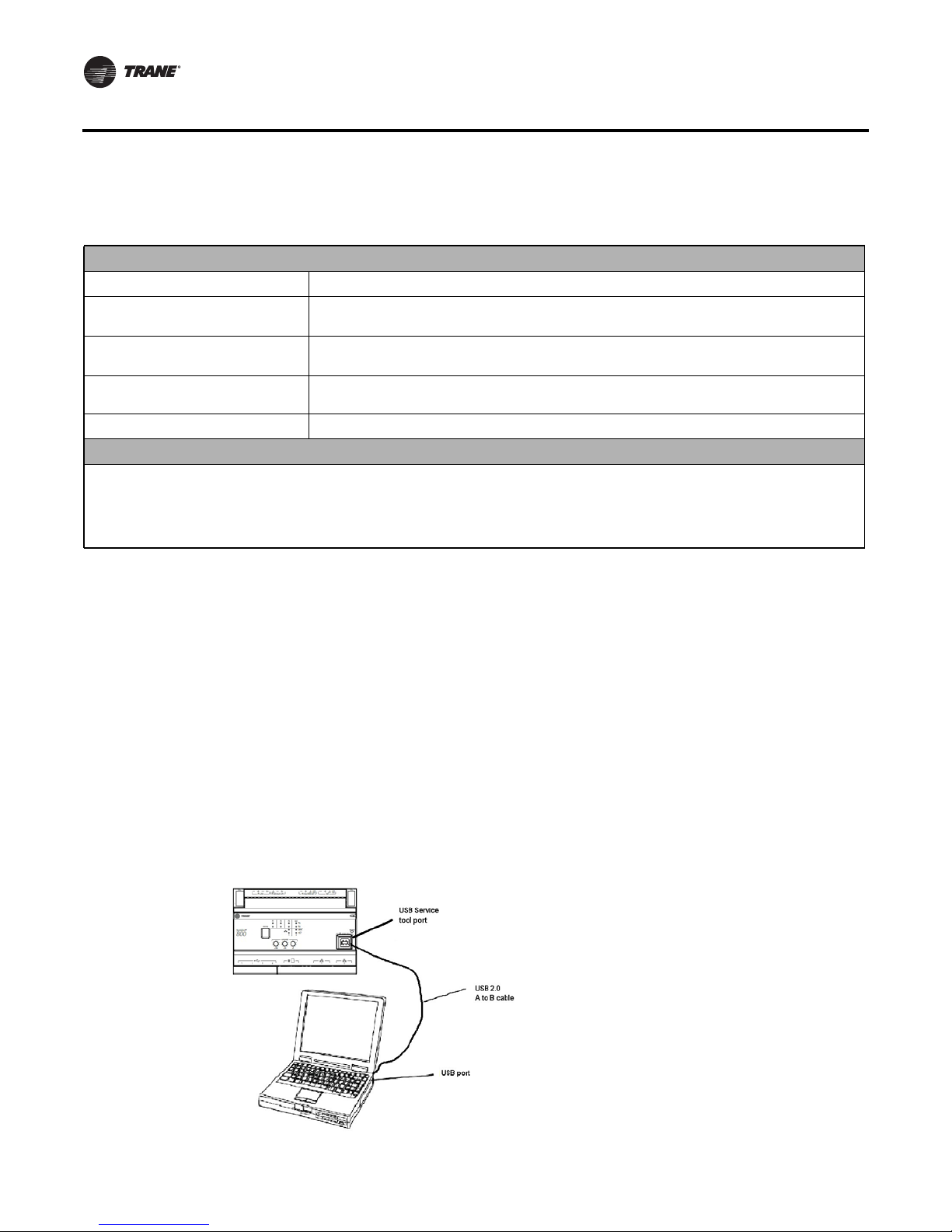

Web UI

To perform firmware updates, setup communication protocols, backup and restore, scheduling,

and create users or custom trend views connect using Web UI:

1. Connect a laptop to the USB service tool port using a USB 2.0 A to Be cable.

2. Open a web browser and connect to http://198.80.81.1 to access Web UI.

Figure 1. Web UI connection

8 RT-SVP011A-EN

Page 9

Supported Browsers for Tracer Symbio Web UI

Microsoft Windows 7:

• Internet Explorer 11 (limited support)

• Mozilla Firefox (most recent version)

• Google Chrome (most recent version)

Microsoft Windows 8.1: (no support)

Microsoft Windows 10:

• Internet Explorer 11 (no support)

• Microsoft Edge (most recent version)

• Mozilla Firefox (most recent version)

• Google Chrome (most recent version)

Apple Mac OS (latest version -1)

• Mozilla Firefox (most recent version)

• Google Chrome (most recent version)

• Safari (most recent version)

Introduction

Creating a New User in Web UI

Note: For more detailed instructions on creating a new user, click the help icon in the global

navigation bar within Web UI.

To create a new user:

1. From the global navigation bar, select Admin > Users.

2. Click the Create User button.

3. Enter the user’s personal information, and click Next.

4. On the Preferences page, determine how certain attributes on the Symbio 800 user interface

will display. Click Next.

5. On the Data Display Units Preference page, determine the unit type in which data will be

displayed. Click Next.

6. On the Data Display Units Preference page, determine the preferred display units. Click Next.

7. On the summary page, review your selections. Click Finish to save the new user.

Supported Languages

The TD7 display supports built-in languages:

• English

• French (Canadian)

• Spanish (Latin American)

RT-SVP011A-EN 9

Page 10

Introduction

Screen Overview

There are three distinct areas on the TD7 screens:

• Top display area

• Main display area

• Bottom display area

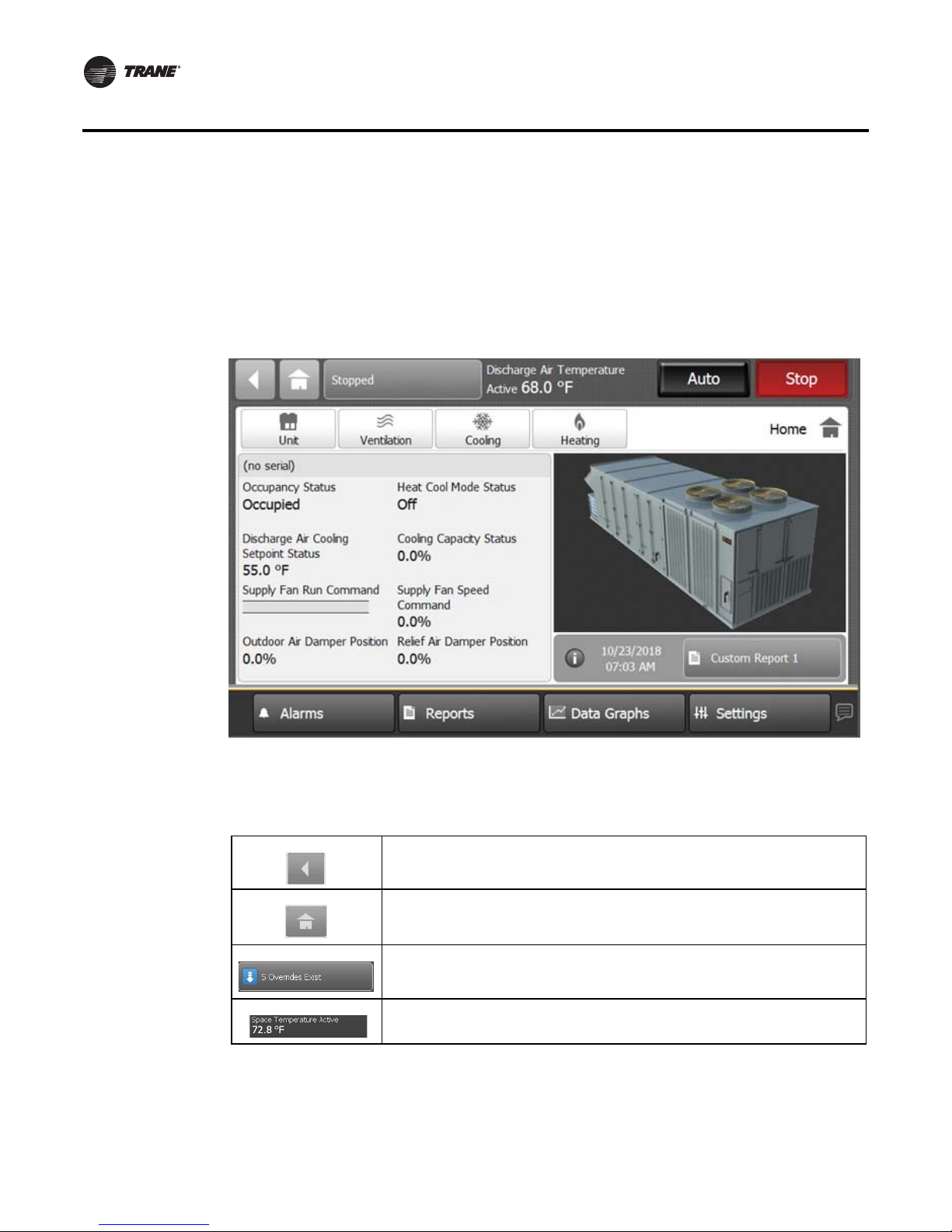

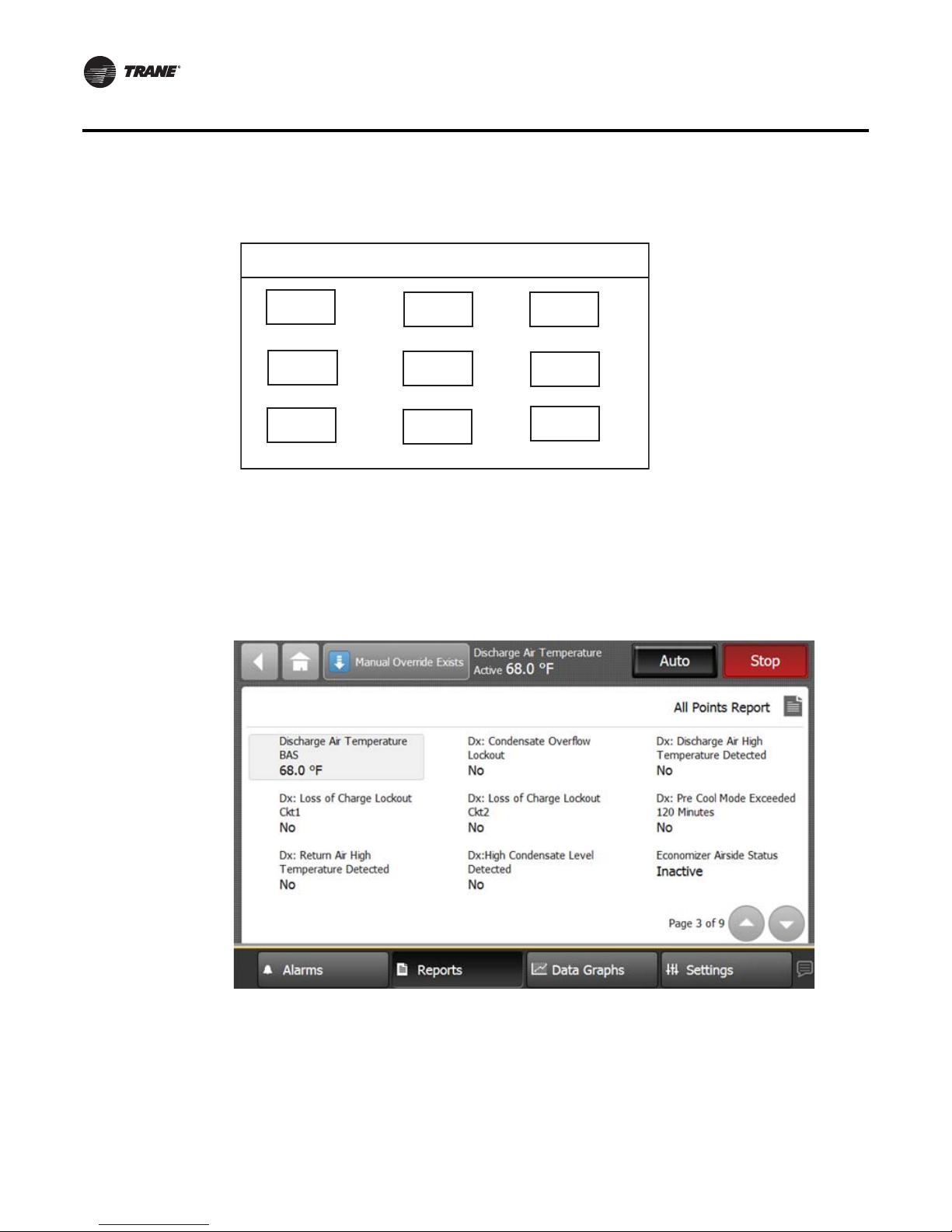

Figure 2. Tracer TD7 display screen

Top display area

Main display area

Bottom display area

Top Display Area

The Back button, when touched, returns to the previous screen visited.

The Home button, when touched, navigates to the All Points Report by default. Home Can

be configured to display any of the three custom reports, All Points Report, All Points in

Override Report, Alarms, or custom graphic. See “Display Preferences,” p. 43.

The Overrides Summary button provides an at-a-glance view of how many user overrides

exist and provides a link to the Override Summary report.

The Space Temperature Active or Discharge Air Temperature Active, depending on

configuration is displayed in the header Data Area.

10 RT-SVP011A-EN

Page 11

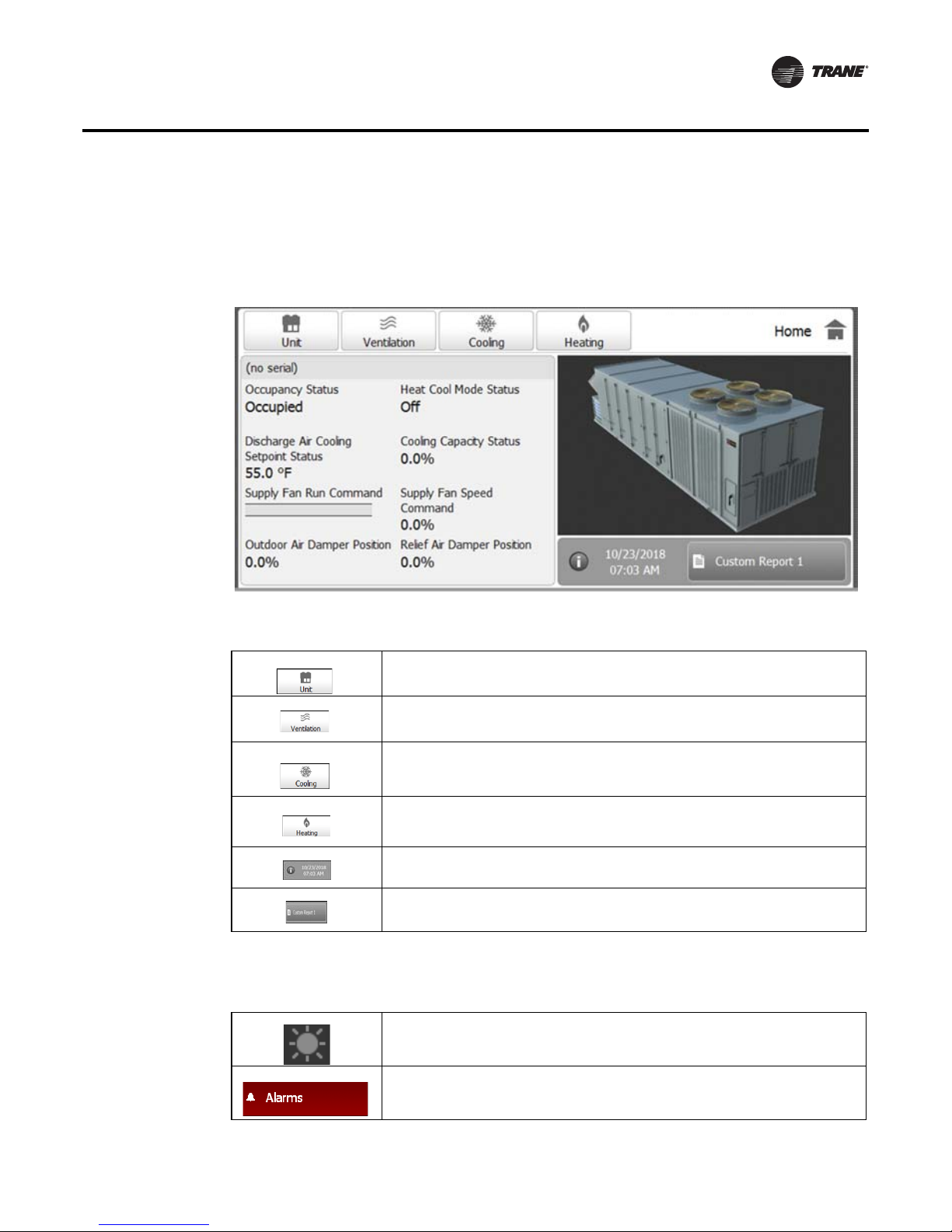

Main Display Area (Home Screen)

The Home screen is an overview of the unit and its operation. High-level status information is

presented so that a user can quickly understand the mode of operation of the unit and navigate

quickly to other areas of the display for more detail.

Figure 3. Tracer TD7 Main display area of home screen

Introduction

Main display are buttons:

Bottom Display Area

The bottom display area contains functional buttons that provide a link to the appropriate screen.

Touch this button to view the status of unit features. Setpoints, Capacities, and damper

positions.

Touch this button to view the status of ventilation components.

Touch this button to view the status of the cooling.

Touch this button to view the status of heating components.

Touch this button to access the adjust the date and time. Touch the information icon to

view hardware part numbers and software version numbers.

Touch this button to access custom reports.

Screen brightness settings: Touch this icon to open the brightness screen.

Touch this button to open the Alarms screen. When an alarm is present, this button will

flash red.

RT-SVP011A-EN 11

Page 12

Introduction

Touch this button to navigate to the Reports screen.

Touch this button to open the Data Graphs screen to view and/or edit data logs in

graphical format.

Touch this button to open the Settings screen, which contains options for manual

controls, Feature settings, Binding, Unit Settings, and display settings.

Language selection: Touch this icon to select a language that will be displayed on all

screens.

12 RT-SVP011A-EN

Page 13

Alarms

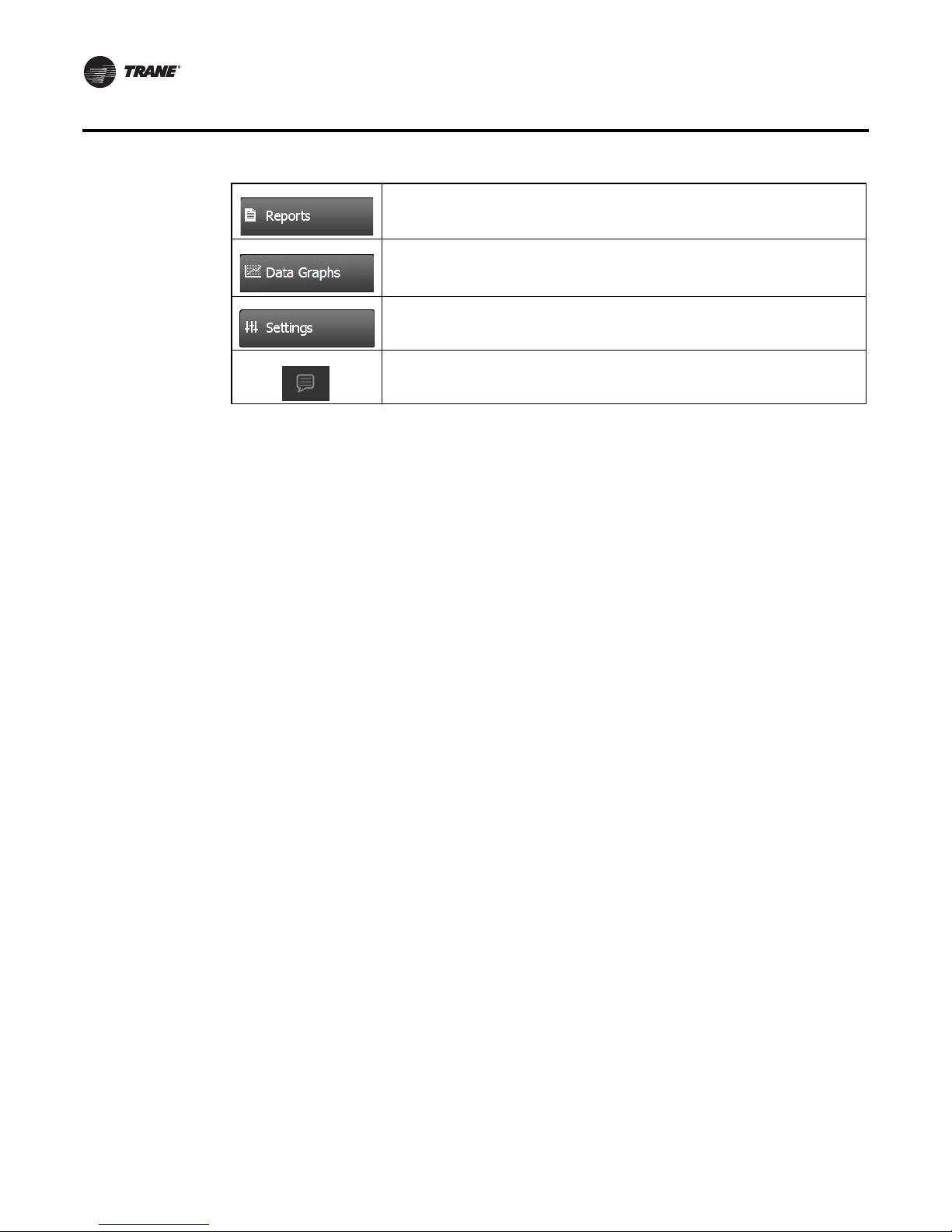

Alarms appear on the Tracer TD7 display immediately upon detection. Touch the Alarms button in

the bottom display area to view the Alarms screen.

Active Alarms

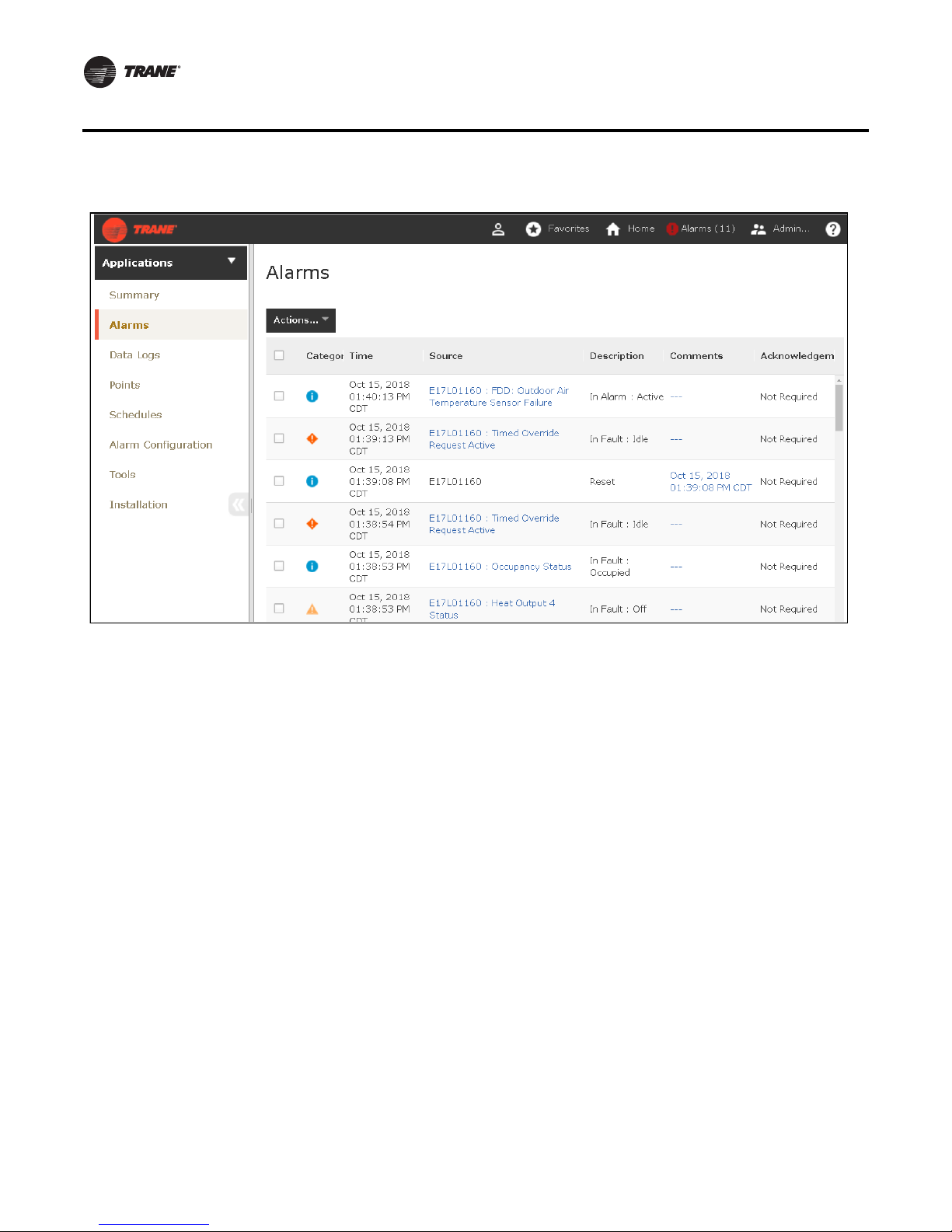

Figure 4 shows the Active Alarms screen and commonly used functions. Configuration is not

required in order for points in alarm to appear in the Active Alarms screen. When the alarm clears

and the point returns to normal, the alarm will automatically be removed from the list.The number

of active alarms is displayed in the top right portion of the screen. When an active alarm is present,

the alarm button at the bottom of the screen will flash.

The Alarms screen defaults to Active Alarms. The Active Alarms button has a shaded appearance

which indicates that you are viewing active alarms.

Figure 4. Active Alarms screen

Sortable

Columns

Number of Active Alarms

Alarm Severity

Active Alarms

Button

Figure 5.

On the Alarms screen, touch the Alarms button to view all alarms, commonly referred to as the

event log. For the alarms to appear on the TD7 display, the point must have an alarm notification

class selected. Additionally, the point must have entered the appropriate notification (In Alarm,

When Failed, Return to Normal, or the notification class set to a value other than None).

RT-SVP011A-EN 13

Page 14

Alarms

Figure 6. Web UI Alarms screen

Viewing Active Alarms

• Active alarms: These are alarms that require attention. All alarms that are currently active

appear when you view this category. Active alarms are not reset by way of the display. Active

alarms will clear automatically when the condition causing the alarm is removed.

• Historic alarms: Touch this button to view previous alarms.

Alarm Severity

A color-code icon representing the severity of each alarm is shown under the severity ( ! ) column.

For a description of the five alarm icons, see Table 1, p. 15.

Sortable Alarms

You can sort active alarms by touching one of the column headers. Choose to sort by

severity(!),date and time, point name, or description.

Reset Alarms

Touch this button to clear alarm that are no longer active.

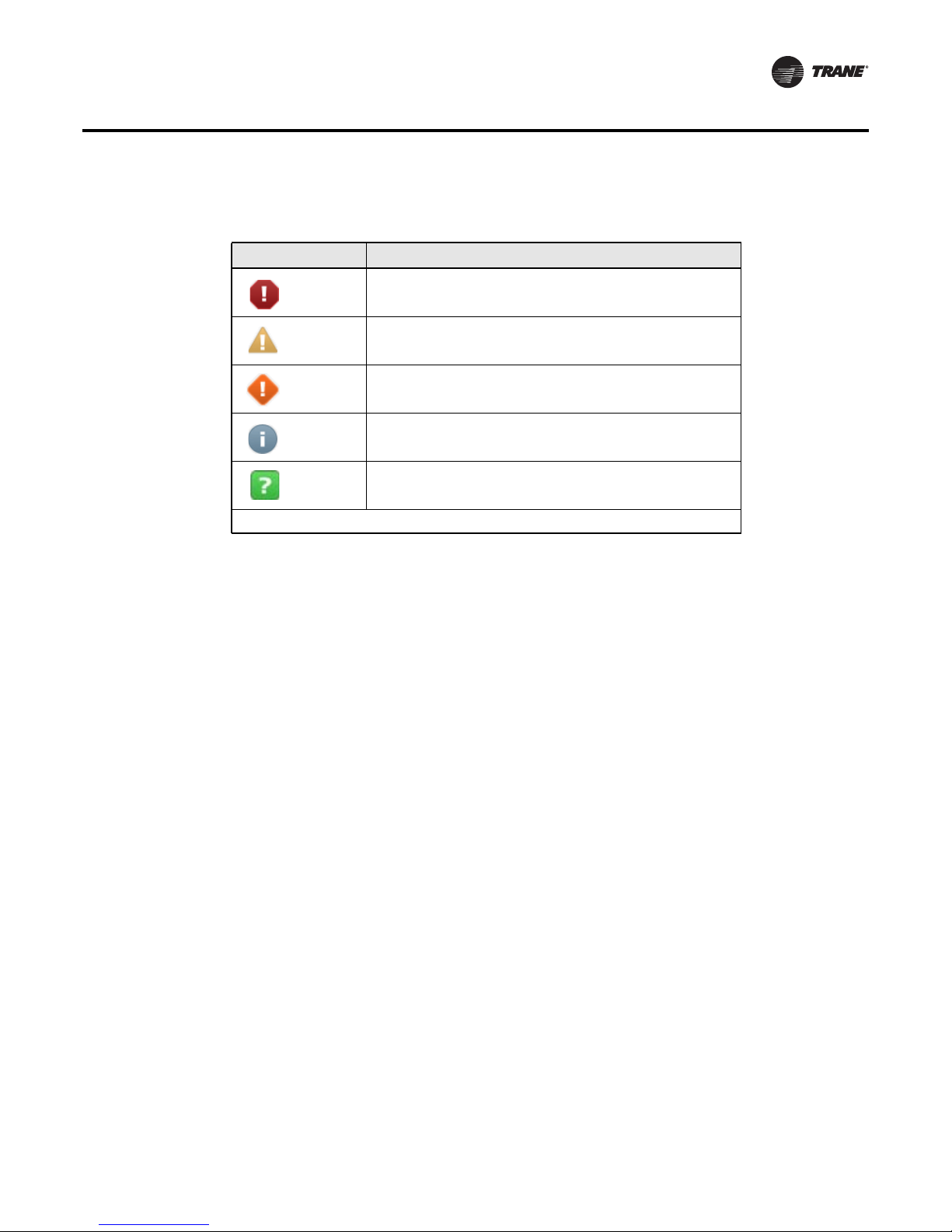

Alarm Icons

Alarms icons appear in the left-most column of the alarms screen. They are identifiable by their

shape and color.

14 RT-SVP011A-EN

Page 15

Table 1. Alarm icons

Active Alarm Icons Notification Class

Critical

Service Required

Warning

Information

None

Note: Notifications classes are configured in point alarm settings section in Tracer TU.

Alarms

Sorting Alarms

To sort alarms by a category other than date and time, touch one of the other column headings in

the table. The column heading responds by changing to blue, and the alarms table re-sorts

according to the blue column heading. By touching the blue column heading again, the column will

change the sort direction.

• Severity (!): Active alarms are at the top, followed by the most severe, followed by the most

recent.

• Date and Time (the default sort): Most recent alarms are at the top.

• Point Name: Alphabetical sort based on the point name.

• Description: Alarms are sorted alphabetically by description.

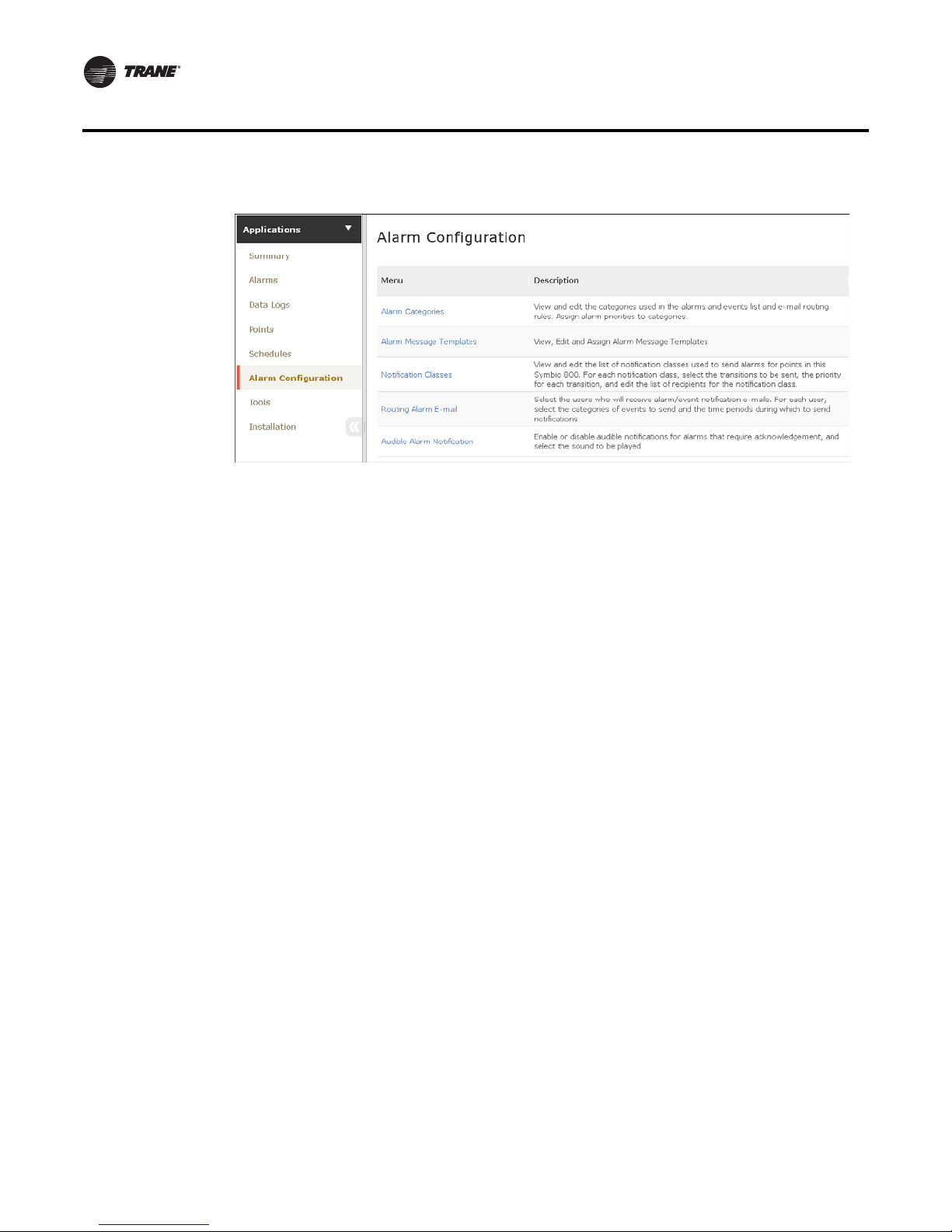

Configuring Alarms

In the web user interface, select Applications \ Alarm Configuration. From the Alarm

Configuration screen, you can view and edit alarm categories and routing, alarm message

template, and notification classes.

RT-SVP011A-EN 15

Page 16

Alarms

Figure 7. Web UI Alarm Configuration screen

16 RT-SVP011A-EN

Page 17

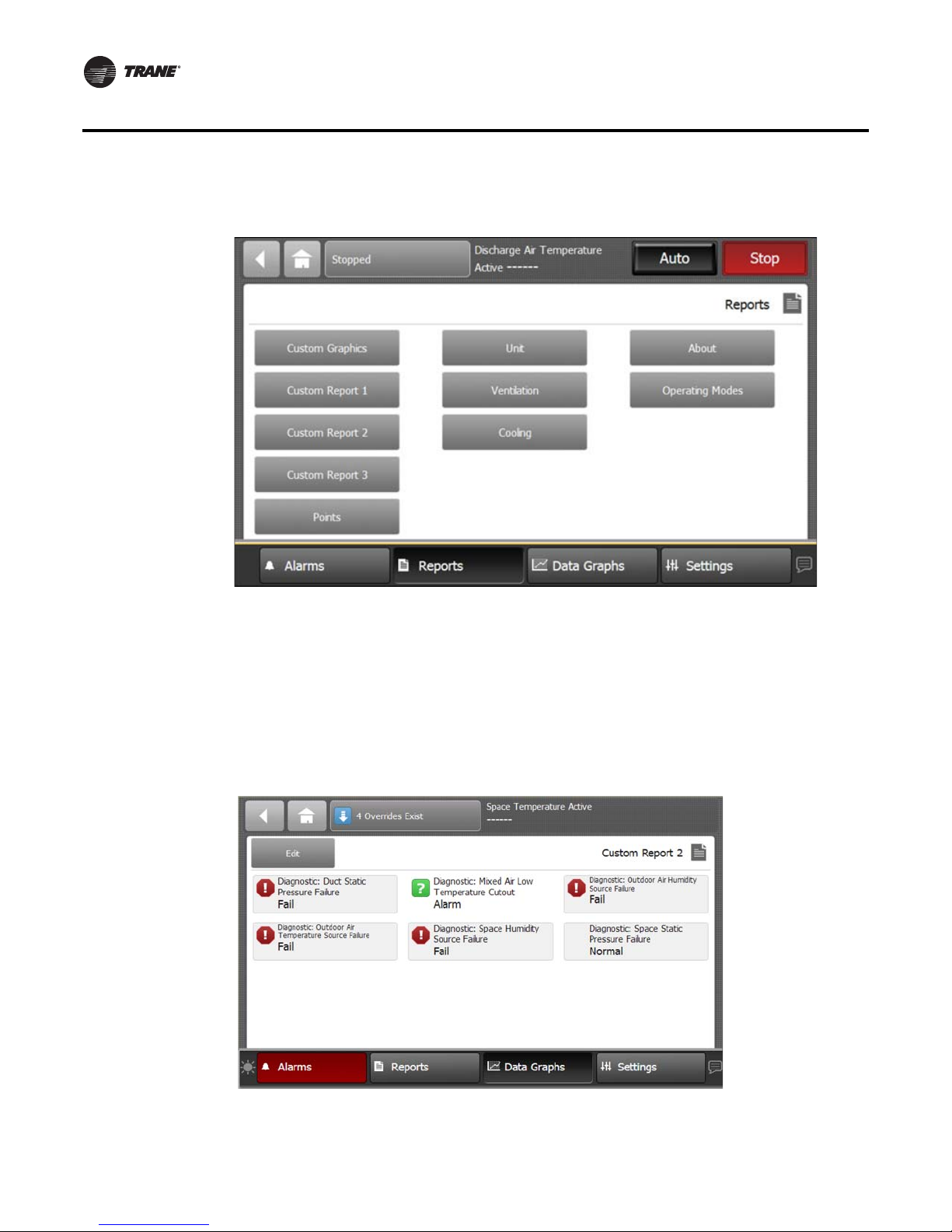

Reports

You can use the Tracer TD7 Display to view a variety of reports and create and edit custom reports.

Touch the Reports button in the bottom display area to view the Reports screen. The Reports screen

contains the following buttons:

• Custom Report 1

• Custom Report 2

• Custom Report 3

• Points

• Override Summary

• All Points Report

• About

• Expansion Modules

• TGP2 Programs

Figure 8. Reports screen

Custom Reports

You can create up to three custom reports using the Tracer TD7 Display. Reports may contain all

nine point types. A maximum of 36 pieces of data is allowed per custom report. Available reports

are labeled Custom Report 1, 2, or 3.

Creating a Custom Report

1. Navigate to the Reports screen, then touch one of the three custom report buttons.

The Custom Report (1, 2, or 3) screen appears.

2. Touch the Edit button.

The Edit Custom Report screen appears (Figure 9).

RT-SVP011A-EN 17

Page 18

Reports

Figure 9. Creating a custom report

3. Use the up and down arrow buttons to select a point type. Add items by touching the item that

is highlighted blue, then touch the Add button.

4. Continue adding values to your report. When you are finished, touch the Save button.

The Custom Report screen, populated with your selected values, appears (Figure 10).

To view the items in the selected list, touch a value in this list and use the up and down arrows

to the right of the list. To change the location of an item in the list, select the item and then use

the up and down arrows above the table to move the items.

Figure 10. New custom report screen

18 RT-SVP011A-EN

Page 19

Editing a Custom Report

n

1. Touch Reports to view the Reports screen.

2. Touch the report that you want to edit.

Follow steps 2 through 4 in “Creating a Custom Report,” p. 17. to complete your edits.

Figure 11. Editing a custom report

Up and down

arrows:

moves 1

space per

touch

Reports

Up and dow

arrows:

moves 1

space per

touch

Up and down

arrows:

moves 2

spaces per

touch

Up and down

arrows:

moves 2

spaces per

touch

Changing the Order of Items in a Custom Report

Items in a custom report can be rearranged according to personal preference by using the editing

tools as described in Editing a Custom Report.

For example, you created the custom report shown in Figure 10, p. 18, but would prefer to move

item “Diagnostic: Space Static Pressure Failure” to the top left portion of the report.

To change the order for the example described above:

1. Touch the Edit button on the Custom Report screen.

2. Use the arrow buttons to locate the item to be reordered. When located, touch the item which

will then be highlighted blue (see

3. Use the arrow buttons to move the highlighted item to the top of the list (number 1 position).

4. Touch Save. You will be returned to the Custom Report screen, where the reordering changes

now appear.

Note: On the TD7 display, report items are ordered from left to right with the first item appearing

at the top left portion of the screen. Up to nine items can appear on each Custom Report

screen with a maximum of 4 screens and 36 items per report.

The model in Figure 12 depicts a custom report screen with the first nine items displayed on the

screen. Use this model to accurately reorder items in your custom reports.

Figure 11).

RT-SVP011A-EN 19

Page 20

Reports

Figure 12. Custom Report (order of items)

Custom Report

All Points Report

Touch the All Points Report button to view the All Points Report screen, which contains all

configured points for the unit controller. Use the up and down arrows located at the right most

bottom of the screen to page up or down.

Figure 13. All points report screen

1

4

7

23

5

8

6

9

20 RT-SVP011A-EN

Page 21

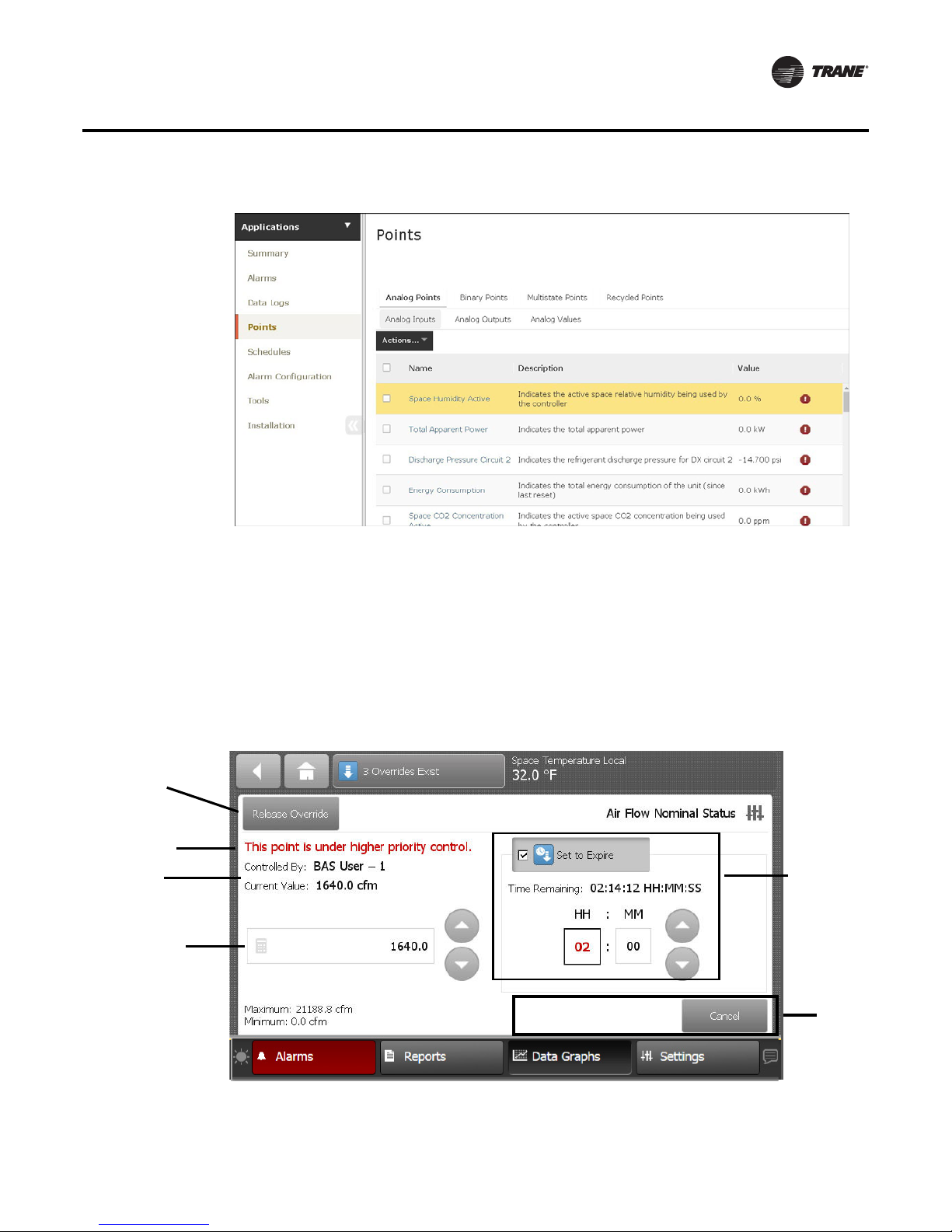

Figure 14. Web UI Points

Reports

Points Overrides

Point Overrides are used to allow control of values, such as setpoints used for the operation of the

equipment. These can be time based or persist until they are released.

From the Point Override screen you can perform overrides, set them to expire in a user-defined

interval, or release a point that is currently overridden. All Point Override screens, (analog, binary,

or multistate), are comprised of the same basic components.

Figure 15. Point Override screen components

Release

Override

See Note

“Releasing an

Override.”

Override

Status Area

Override Value

Setting Area

Temporary

Override Area

Action

Area

RT-SVP011A-EN 21

Page 22

Reports

Override Status Area

This area shows who is controlling the point, followed by the active priority level and the current

value of the point. If security is enabled, the name of the user that performed the override will be

shown in the Controlled By field. If security is disabled, “Front Panel” is displayed for all overrides

performed by the TD7 display.

Override Value Setting Area

This area contains buttons that when pressed, change the override status. The button that is active

has a shaded appearance in color. The exception is analog points, which require manually entering

a value.

Temporary Override Area

This area allows you to set up a temporary override.

Action Area

This area allows you to apply, save, or cancel edits made to the point override.

Releasing an Override

Touch the Release Override button to release the current override. This action returns you to the

Override Summary screen.

Note: If a point is under a higher priority control , you can still proceed with releasing the override.

However, it will not take effect until the higher priority level is removed in Tracer TU, Tracer

SC, or Tracer ES.

Binary Overrides

The Binary Override screen provides buttons with point state text that is used to set the current

value. Multistate overrides with four or fewer states have similar screen functions as the binary

override screen.

Touch a button in the override setting area to select a state. Touch the Apply or Save button to retain

your changes.

Figure 16. Binary Override screen

22 RT-SVP011A-EN

Page 23

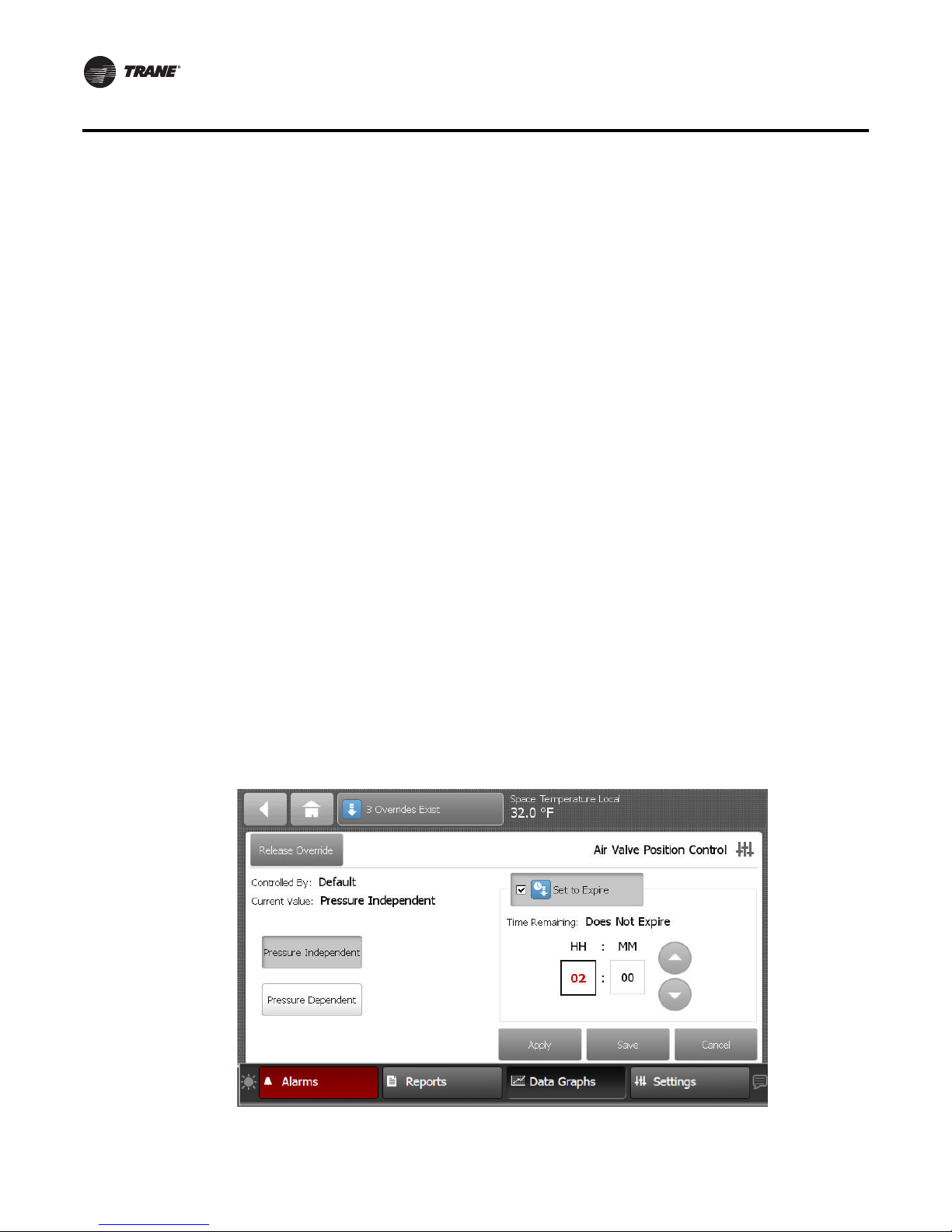

Multistate Overrides

Multistate override screens that contain five or more items will contain up and down arrow buttons

in the Override setting area.

Use the up and down arrow buttons to select a state. Touch the Apply or Save button to retain your

changes.

Figure 17. Multistate override screen (five or more states)

Reports

Analog Overrides

The Analog Override screen contains up and down arrows in the Override setting area, as well as

a keypad icon that when touched, opens the Analog Keypad.

Use the up and down arrow buttons to select a value. Touch the Apply or Save button to retain your

changes. To manually enter a value, touch the keypad icon.

RT-SVP011A-EN 23

Page 24

Reports

Figure 18. Displaying the analog keypad screen

Touch the keypad icon to open the Analog

keypad screen.

Enter a value by tapping the numerals on the

keypad. Touch Enter to save and return to the

Override screen.

Keypad Icon

Analog Keypad Screen

Setting Up a Temporary Override

You can set up a temporary override by using the buttons in the Temporary Override area. The

default for temporary overrides is 2 hours 0 minutes. The maximum duration for a temporary

override is 99 hours 59 minutes. If more time is needed, consider setting up a permanent override.

1. Touch the Set to Expire button.

A check mark appears in the check box, the override icon becomes blue, and the Time

Remaining area appears.

2. Touch either the hours (HH) or minutes (MM) button, then use the up and down arrows to set

the override.

The HH and MM buttons, when pressed change by one increment. Press down on the buttons

to accelerate. A second touch of the (HH) or (MM) buttons will open the Analog keypad screen.

Touch the Apply or Save button to set the temporary override.

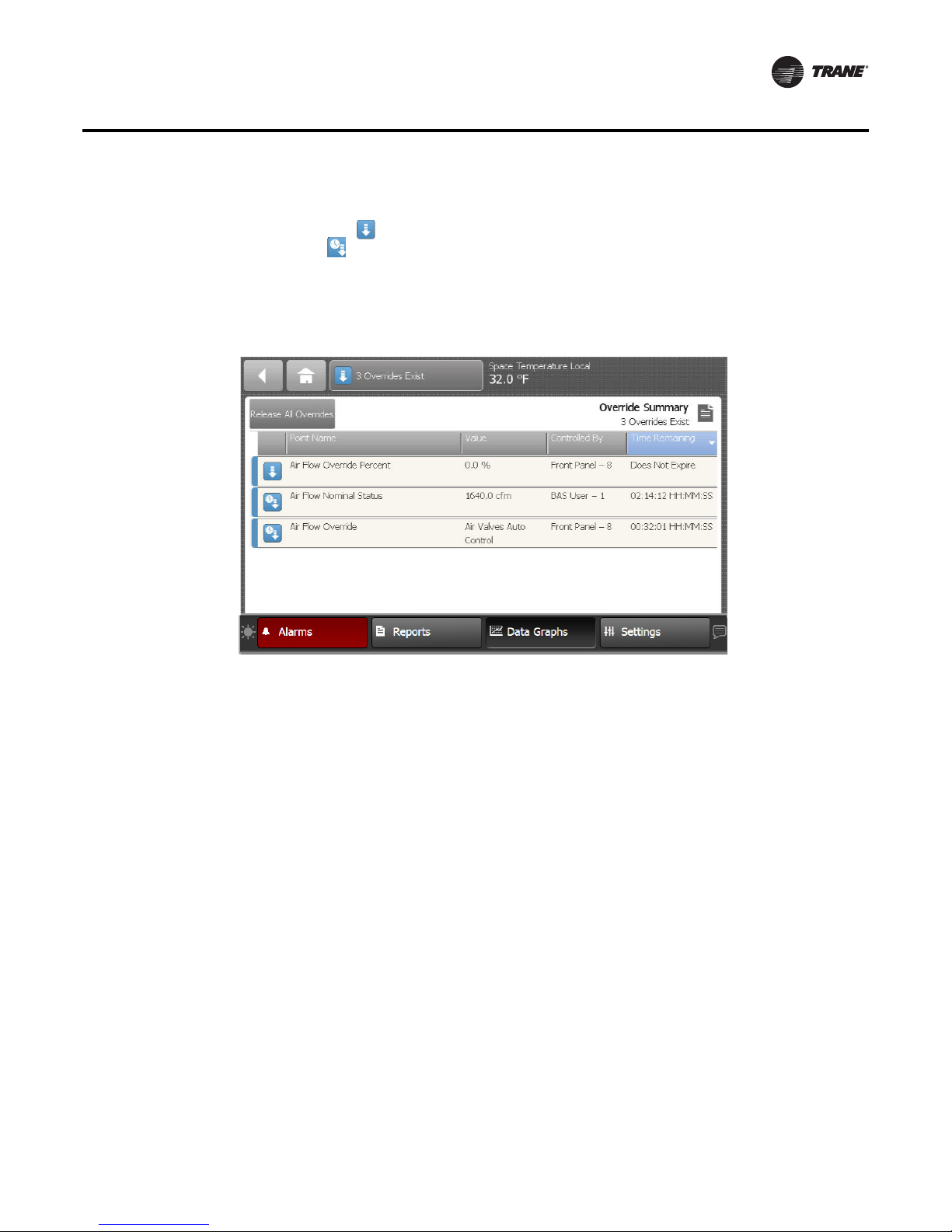

Override Summary

The TD7 has a built in override summary report that can be accessed in one of two ways:

The preferred method is to access the report by touching the Override Summary button located in

the top display area of each TD7 screen.

An alternate method is to touch the Override Summary button on the Reports screen.

24 RT-SVP011A-EN

Page 25

Reports

The Override Summary screen contains all active overrides. Columns are sortable and

automatically default to Time Remaining.

The override icon ( ) indicates that a point override is in effect indefinitely. The temporary

override icon ( ) indicates that an override will expire after a specified duration.

To release all overrides in the list, touch the Release All Overrides button (only points that are

controlled at priority level 8 will be released). Touch anywhere in a point row to navigate to the

corresponding Point Override screen.

Figure 19. Override summary screen

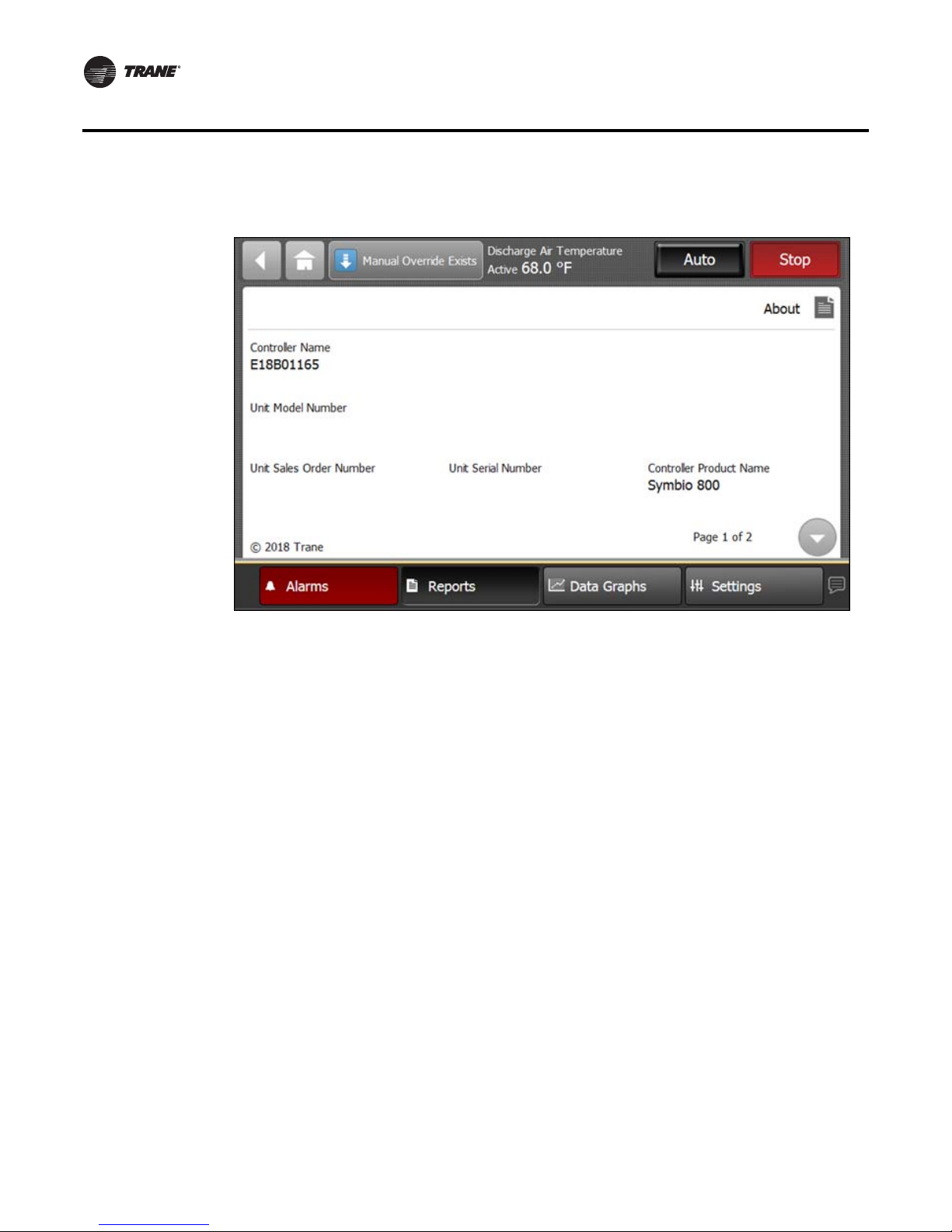

About

Touch the About button to view the About screen. View information about the unit controller and

the TD7 display to which it is connected. Touch the arrow button to scroll to the next screen.

RT-SVP011A-EN 25

Page 26

Reports

Figure 20. About screen

Controller Name

This is the name that was assigned to the Symbio 800.

Unit Model Number

This is the model number of the IntelliPak/equipment on which the Symbio 800controller is

installed. This value is typically entered in the factory, but can be entered in the controller.

Unit Sales Order Number

This is the order number for the equipment that the Symbio800 controller is controlling. This

number is typically entered at the factory, but can be entered in the controller.

Unit Serial Number

This number applies to the piece of equipment that the Symbio 800 controller is controlling. This

number is typically entered at the factory, but can be entered in the controller.

Controller Product Name

The controller product name will always be Symbio 800.

Controller Hardware Part Number

This is the part number for the Symbio 800 controller.

26 RT-SVP011A-EN

Page 27

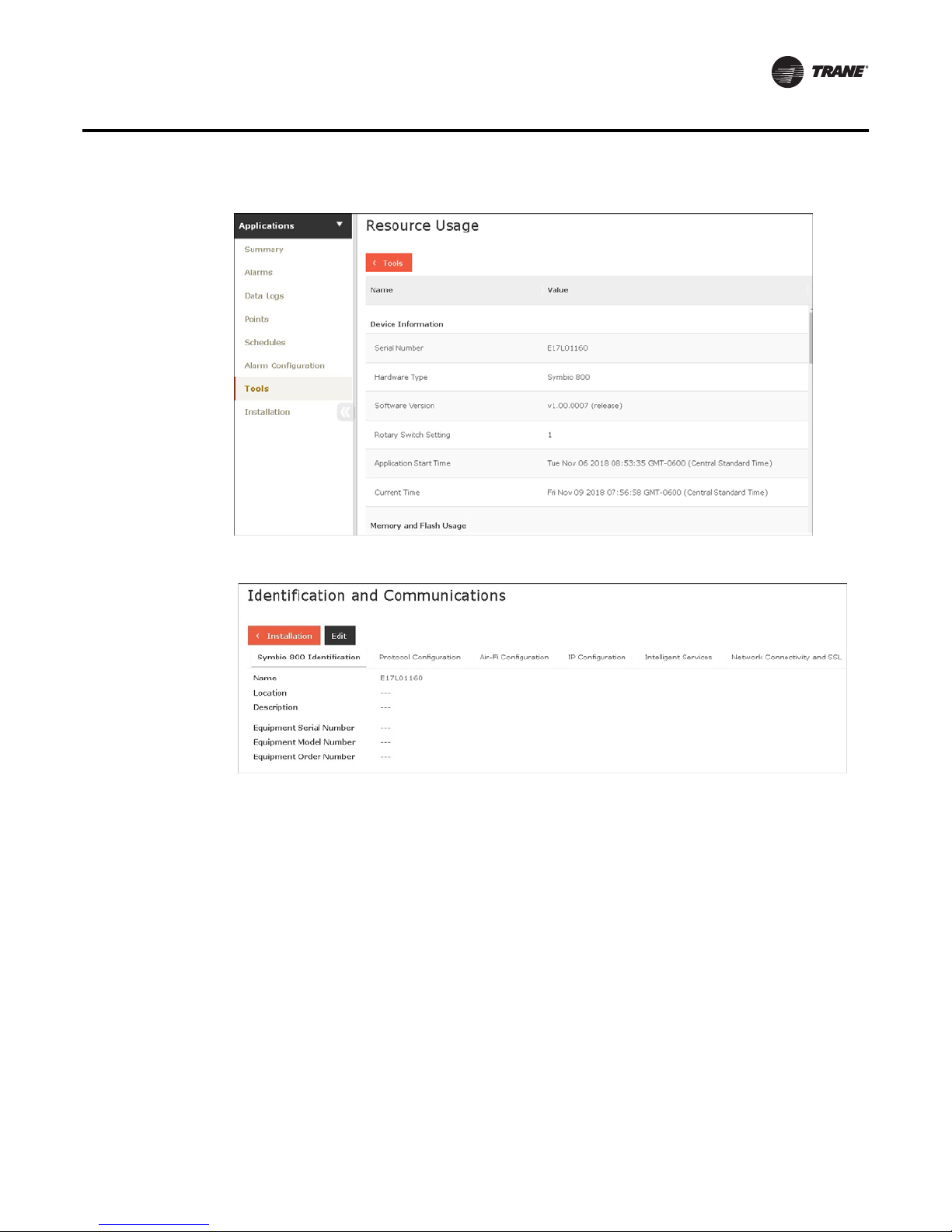

Figure 21. Web UI Resource Usage

Figure 22. Web UI Identification and Communications

Reports

Expansion Modules

Touch the Expansion Module button to view the Expansion Modules screen. If expansion modules

have been installed, they will appear in Expansion Modules screen (Figure 23).

RT-SVP011A-EN 27

Page 28

Reports

Figure 23. Expansion modules screen

Expansion module screen columns:

Address — This is the rotary address of the defined or discovered expansion module.

Status — Under normal conditions, OK will display in this column. If not refer to “Tracer XM30,

XM32, XM70, and XM90 Expansion Modules IOM,” BAS SVX46-EN.

Hardware part number — This is the part number for the expansion module.

Software part number — This is the version number of the software running in the expansion

module.

28 RT-SVP011A-EN

Page 29

TGP2 Programs

Touch the TGP2 Programs button to view the TGP2 Programs screen. All TGP2 programs that have

been installed on the controller appear here. The program name, status, run type, and interval for

each program is provided. Interval is the scheduled run interval for the program and is displayed

in HH:MM:SS. If the run type is Startup or Event, the interval field will display all zeros.

Figure 24. TGP2 Programs screen

Reports

Data Logs

Figure 25. Web UI TGP2 Programs

Data Logging, also referred to as trending, records in real-time the value of a data point in the

system and the time at which the value was recorded.

By default, Symbio 800 automatically generates system-created data logs (for equipment and

standard applications) on a 15-minute interval and then stores that data for seven days. Data

storage is a continuous window where only the most recent seven days of data are stored. Data

older than seven days is discarded in

RT-SVP011A-EN 29

Page 30

Reports

order to make room for the newest data.

A list of data logs can be accessed by clicking Data Logs from the left navigation menu. From this

page you can take action on a data log, such as comparing or exporting, by selecting one or more

data logs and then clicking the Actions button.

Figure 26. Web UI Data Logs

Using the Trend Viewer

The trend viewer displays trend data in a chart. The trend viewer supports a time comparison mode

that allows you to compare trend data at different points in time (day-to-day, month-to-month, yearto-year). A maximum of six data logs are supported (up to two data logs when time comparison

mode is enabled). A maximum of two types of dimensionality are supported on the left and right

y axis. Samples are plotted on a date/time scale on the x axis. Samples in fault (due to

communication loss) are not plotted and will result in an interpolation gap within the plotted line.

If all samples are in fault, no line will be displayed.

The trend viewer is available on the data logs tab of status pages for equipment and systems. To

view trends graphically, select up to six data logs from the Data logs page and then select View

datafrom the Actions button.

30 RT-SVP011A-EN

Page 31

Data Graphs

Data graphs allow users to view trend logs from the controller in graphical format on the TD7

Display. Up to eight data graphs can be created with a maximum of four data logs per graph. Data

graphs are user-defined and can be edited by changing the scale on the left and right Y-axis and

choosing the line color.

Touch the Data Graphs button in the bottom display area to view the Data Graphs screen

(Figure 27). The Data Graphs screen contains eight buttons that allow you to view and edit a

particular configuration.

Figure 27. Data Graphs screen

Creating a Data Graph

1. Navigate to the Data Graphs screen, then touch an available data graph button.

The Custom Data Graph screen appears.

2. Touch the Edit Data Graph button.

The Edit Data Graph screen appears (Figure 28, p. 32).

RT-SVP011A-EN 31

Page 32

Data Graphs

Figure 28. Edit Data Graph screen

3. Touch the Add/Remove button to add values to the custom data graph.

The Add/Remove screen appears.

4. Use the arrow buttons to select a datalog type: analog, binary, or multistate, which then

populates the box directly below.

5. Select the values, then touch the Add button (up to four selections are allowed).

6. Touch the Save button. The Edit Data Graph screen appears, which reflects the selected values.

Figure 29. Adding data logs to the custom graph

32 RT-SVP011A-EN

Page 33

Data Graphs

7. Use the Edit Data Graph screen to modify the data graph. Touch the Edit button that

corresponds with the value that you want to change. Only one value can be edited at a time.

Figure 30. Edit Data Graph screen (after values have been added)

8. From the Edit screen you can choose which Y-axis to display the value, a color, and whether or

not to show data samples. Touch the Save button when finished. Repeat the process with

remaining values.

Figure 31. Customizing the data graph

RT-SVP011A-EN 33

Page 34

Data Graphs

9. Touch the View Data Graph button to display the new graph (Figure 32).

Note: Depending on the sampling rate, the custom data graph may be empty for several hours.

You can make changes to the way data is presented on the graph at anytime. Touch the zoom-in

icon and zoom-out icon to either increase or decrease the viewable time frame. This action

also enables back and forward arrows that allow you to view data at various times of the day.

Figure 32. Viewing the data graph

Editing the Y-Axis

The default values on the right and left Y-axes can be changed according to your specifications.

1. Touch the Edit Y-Axis button located on the top portion of the Custom Data Graph screen.

The Edit Y-Axis screen appears.

2. Touch the Manually Select Range box for either the left or right Y-axis.

3. Touch the edit button next to one of the two value ranges.

The Keypad screen appears.

4. Select a new value and then touch Enter to save.

34 RT-SVP011A-EN

Page 35

Data Graphs

Figure 33. Repeat steps 2 through 4 until all preferred changes have been made. Editing the Y-Axis

RT-SVP011A-EN 35

Page 36

Settings

The Settings screen provides options for display settings, language, overrides and security.Touch

the Settings button in the bottom display area to view the Settings screen.

Three categories for settings appear on the screen:

• Control Settings

• Equipment Settings

• Display Settings

Figure 34. Settings screen

Basic

parameters for

unit operation

Turn on/off

features and

functions

Resets the

discharge air

setpoint

(discharge air

units only)

Control Settings

This category contains the LLID Binding.

36 RT-SVP011A-EN

Page 37

Figure 35. LLID Binding

Settings

Equipment Settings

Unit Settings

Unit Settings are the basic parameters for unit operation.

Feature Settings

Features Settings allows you to enable or disable features and functions.

Manual Overrides

Manual Overrides are temporary overrides that can be used to test equipment and features. The

override time is adjustable from1-78hours.

Navigate to the Manual Override screen by touching the Settings button, then the Manual Control

Settings button. From there select the appropriate unit or circuit level button.

RT-SVP011A-EN 37

Page 38

Settings

Figure 36. Manual Override screen

Override Status Area

This area shows who is controlling the point, followed by the active priority level and the current

value of the point. If security is enabled, the name of the user that performed the override will be

shown in the Controlled By field. If security is disabled, “Front Panel” is displayed for all overrides

performed by the TD7 display.

Override Value Setting Area

This area contains buttons that when pressed, change the override status. The button that is active

has a shaded appearance in color. The exception is analog points, which require manually entering

a value.

Display Settings

The selections in this category contain settings that affect the way in which information is displayed

on all of the TD7 display screens. From each screen, the current settings can be viewed. To change

a setting, touch the preferred value.

Display Preferences

Touch the Display Preferences button to open the associated screen (Figure 38). On this screen, all

available options to display information on the TD7 screens are available. There are two pages on

this screen, accessed by using the arrow button at the bottom of the screen.

38 RT-SVP011A-EN

Page 39

Figure 37. Web UI User Preferences

Figure 38. Display Preferences screen

Settings

Date Format

Touch the Date Format button to open the associated screen. Three options are available to display

the current date: MMDDYYYY, DDMMYYYY, and YYYYMMDD.

Date Separator

Touch the Date Separator button to open the associated screen. Three options are available to

display separators in the date format: None, Hyphen (-), or Slash (/).

Time Format

Touch the Time Format button to open the associated screen. Two options are available: 12-Hour

format and 24-Hour format (also referred to as “military time”).

Unit System

Touch the Unit System button to open the associated screen. Two options are available: SI (system

international) or IP (Inch-Pound).

RT-SVP011A-EN 39

Page 40

Settings

Number Format

Touch the Number Format button to open the associated screen. Two options are available: period

format (1000.0) or comma format (1000,0).

First Day of the Week

Touch the First Day of the Week button to open the associated screen. Specify the starting day for

the week when viewing schedules and adding events. Options available: Saturday, Sunday, or

Monday.

Brightness

Touch the Brightness button, or the brightness icon ( )located at the bottom left of each screen,

to open the associated screen. Screen brightness is measured in percentage. Use the keypad to

enter a new brightness number.

Backlight Timeout

Touch the Backlight Timeout button to open the associated screen. This value is measured in

minutes, with 30 being the maximum limit. Use the keypad to enter a backlight timeout value. This

value is the amount of time that the display will remain lit without activity. When the backlight times

out, users will be automatically logged off due to inactivity.

Header Data Point

Use the arrow button on the Display Preferences screen to advance to page 2. Touch the Header

Data Point button to open the associated screen. The Header Data Point appears in the top right

display area on all screens. Use the arrow buttons to scroll through the points. Click Add to move

the highlighted point to the right side of the screen(Figure 39, p. 40). Click Save.

Figure 39. Setting the header data point

Header data

point

Home Page

Use the arrow button on the Display Preferences screen to advance to page 2. Touch the Home Page

button to open the associated screen. This function allows you to choose what will display when

the home button is touched. Available options are: the All Points report, the Override Summary

Report, Active Alarms, any of the three Custom Reports, or any custom graphic.

40 RT-SVP011A-EN

Page 41

Figure 40. Home Page screen

Figure 41. Web UI Home Page

Settings

Language

Touch the Language button, or the language icon ( ) located at the bottom right of each screen,

to open the open the Language screen. Three languages are available and represented on the

selection buttons. Select a language that you want displayed on each TD7 screen and then touch

Save.

RT-SVP011A-EN 41

Page 42

Settings

Figure 42. Language screen

Figure 43. Web UI Login screen

Date and Time

Touch the Date and Time button to open the associated screen. To enter a new date or time, touch

the digit you want to change. When enabled for editing, the digit will appear red with a black border.

when finished, touch Apply or Save. Or,

tap the digit twice which opens the keypad screen where you can make date and time entries. When

finished, touch Enter; you will be returned to the Date and Time screen. Touch Apply or Save.

42 RT-SVP011A-EN

Page 43

Figure 44. Date and Time screen

Clean Touchscreen

Touch the Clean Touchscreen button to safely clean the TD7 touchscreen using any brand of

common household glass cleaner. When this button is touched, the screen background color

becomes black, allowing dirt and fingerprints to become more visible. It also displays a countdown

timer (five to zero seconds).Touch the screen anytime within the 5-second countdown to begin

cleaning the screen (each touch resets the 5-second countdown).

Settings

Schedules

Scheduling is based on the BACnet schedule object implementation. Scheduling is one of a facility’s

most important energy-saving strategies. It ensures that equipment runs only when needed.

Scheduling facilitates the following tasks:

• Creating, editing, and deleting schedules

• Creating, editing, and deleting calendars and exception schedules

• Viewing all effective schedules in a facility

The Schedules page contains four tabs: Active Schedules, All Schedules, All Exceptions, and All

Calendars.

Figure 45. Web UI Schedules

RT-SVP011A-EN 43

Page 44

Settings

Optimal Start/Stop

Optimal start and stop times can be defined for HVAC schedules. HVAC refers to both Area and

equipment.

The schedule coordinates with the Area application or equipment to calculate when the optimal

start and stop occurs. Optimal start/stop times are based on outside air conditions, space

temperature, and occupied setpoints.

Exceptions and Calendars

Exceptions are temporary modifications to a schedule. Exceptionscontain one set of dates or one

repeating pattern of dates. If a schedule has an exception applied, a red box outline will appear.

Calendars

For multiple dates and repeating patterns a calendar can be created, which is then applied to the

exception.

Calendars are used to group dates, which can then have exceptions applied to these dates on a

schedule. For example, a school might create a calendar to group the days that require extended

operating hours for after-school meetings.

Release Function

The release function is a predetermined time in which the present schedule or the event releases

control over to the next event based on priority. Conceptually, a scheduled release is very similar

to a timed override. For example, after the daily schedule ends at 12:00 am (midnight), the schedule

releases control over to the next event.

Creating a Schedule

The system controller leads you through the process of creating a schedule for your facility by

navigating through a series of steps and pages, often referred to as a "wizard." If you need help

completing the steps, click the help icon located on each page. You can create a schedule to control

the following points and applications based on time and date:

• Binary outputs and values

• Analog outputs and values

• Multistate outputs and values

• Equipment, spaces, and system applications (typically referred to as HVAC schedules)

Points and applications are referred to as members when they are assigned to a schedule.

Members can be assigned to only one schedule during the same effective period. Members must

be the correct type; that is, a binary point cannot be included in an analog schedule.

To create a schedule:

1. Click the create schedule button. The Create Schedule—Schedule Information page

2. Enter a name for the schedule, and select the schedule type and effective dates.

3. Click next to continue. The Create Schedule—Select Members page appears.

4. From the selection tree, select members (spaces and areas) for the schedule, then click Add

5. Click next to continue. The Create Schedule – Schedule Times page appears.

6. Select a schedule default. Each day is independent of the others and always begins with the

appears.

to move to selected items.

schedule default value. The schedule default value is applied to each day of the week and is

the value that the schedule defaults to at 12:00 a.m. for any given day. Select Release (see

below), Occupied, or Unoccupied.

44 RT-SVP011A-EN

Page 45

Note: A Release is a predetermined time in which the present schedule or the event releases

7. Add events to the schedule: click add event, which opens the event dialog box.

8. Enter a time for when the event will start and select a value.

9. Enter a time for when the event will stop (this is optional).

10. Select the days of the week to which the event will be applied.

11. Click Add. The event appears in the schedule viewer. (To edit or delete an event, click on the

12. Click next to continue. The Create Schedule – Summary page appears.

13. Review the schedule. Click finish to save the new scheduled as summarized.

The Tools Menu

To effectively manage Symbio 800, a selection of task-based tools are available. The following tools

described in this section are accessible from the Tools page:

• Backup and Restore

• Programs

• System Logs

• Resource Usage

• BACnet Information

Settings

control over to the next event based on priority. A scheduled Release is very similar to a

timed point override.

event in the schedule viewer.)

Figure 46. Tools menu

Backup and Restore

From the left navigation menu click Tools > Backup and Restore. Backup and Restore is a process

that involves creating an exact duplication of a Symbio 800, exporting (saving) the duplicated copy,

and then restoring that copy at a later time. Use the Restore tool to restore the Symbio 800

configuration file that was produced by the backup tool.

It is important to back up Symbio 800 controllers in the event that a system failure occurs. Backups

should also be performed prior to upgrading software, adding devices, or adding new applications.

RT-SVP011A-EN 45

Page 46

Settings

Programs

System Logs

Follow best practices when implementing a backup and restore procedure plan for your system.

Backups do not include license files.

Important: If a microSD card has been installed in the Symbio 800, it will store up to ten backups

(FIFO).

Tracer Graphical Programming (TGP2) programs are created and downloaded to Symbio 800 by

using the Tracer TU service tool. To view the status of programs after they have been downloaded

to Symbio 800, select Tools > Programs from the left navigation menu. The Programs list page

shows the how often programs in Symbio 800 run and the most recent run time.

Custom TGP2 routines for installed equipment can now be viewed in real-time. Data points in the

routine will reflect present value and gets updated for every 15 seconds.

Note: See the Tracer TU Service Tool Getting Started Guide (TTU-SVN01).

System logs that are currently on the system are available for viewing or exporting. System logs

can be the standard “hydra” log files (hydra.log, hydra.log.0, hydra.log.1, hydra.log.2, hydra. log.3,

hydra.log.4), any stack dump log files (stackdump.log.x), or any additional log files that may be

generated by a Symbio 800 application and/or process.

From the left navigation menu click Tools > System Logs.

Recent Usage

Resource Usage displays system usage among applications, memory, and points. This is primarily

used by Trane Technical support.

BACnet Information

Information about BACnet configurations is shown on this page. This information is typically used

by Trane Technical Support.

Configuring Basic Settings for the Symbio 800

These settings are for regional specifications, system units, communications, and licensing. These

settings were configured during initial configuration at the factory. Some of these settings can be

edited.

Figure 47. Basic Settings

46 RT-SVP011A-EN

Page 47

Regional Specifications

This link contains time zone, and date and time selections that were made during initial

configuration.

Figure 48. Regional Specifications

Symbio 800 System Units

This link enables you to view the system units that were selected for the Symbio 800 during initial

installation. They cannot be edited.

Settings

Figure 49. Symbio 800 System Units

Identification and Communication

The Identification and Communications page allows you to view and edit configurations for the

equipment name, location name, Protocol, IP and network address settings, Air-Fi configuration,

Trane Intelligent Services, and network connectivity. It is divided into seven tabs.

RT-SVP011A-EN 47

Page 48

Settings

Figure 50. Identification and Communications

USB Ports and microSD

On this page, you can view the USB ports and microSD for your Symbio 800. In addition, you can

enable and disable individual USB ports and safely unmount mass storage devices from the USB

ports and microSD.

Figure 51. USB Ports and microSD

Licensing

This link opens the Product License page, which allows you to browse for and install a Symbio 800

license.

48 RT-SVP011A-EN

Page 49

Figure 52. Product License

Configuring Additional Settings

Additional settings such as user preferences, application defaults, SMTP settings, languages, and

background may be modified here.

Defaults for User Preferences

The Defaults page shows the formats in which the system displays data. This page is divided into

two sections: Regional Preferences and Data Display Units.

Settings

Figure 53. Defaults for User Preferences

Application Defaults

For setting the alarm capacity for Symbio 800 and hardware alarms priority. Valid range is from 100

to 500 events. Default hardware alarms priority is 250: Information.

RT-SVP011A-EN 49

Page 50

Settings

SMTP Settings

Figure 54. Application Defaults

Use to set up your Simple Mail Transfer Protocol (SMTP) so that events can be routed to users by

e-mail.

Figure 55. SMTP Settings

Priority Levels

Priority levels establish a strategy used by the system to avoid conflicting control by giving

precedence to applications with a higher level of priority. Priority levels are set up in user

administration. They are numbered 1 through 16, with 1 being the highest and 16 lowest.

Figure 56. Priority Levels

50 RT-SVP011A-EN

Page 51

Login Page

Settings

On the Login page you can upload language packs and personalize your login page by adding

background images.

Figure 57. Login Page

RT-SVP011A-EN 51

Page 52

Troubleshooting

Troubleshooting

This section describes the possible error messages and other issues that you may encounter while

using the Tracer TD7 display.

Identifying and Diagnosing Issues

Diagnostic Name

and Source

VFD Fault Supply

Fan - 1

VFD Fault Supply

Fan - 1

VFD Fault Supply

Fan - 1

VFD Fault Supply

Fan - 2

VFD Fault Supply

Fan - 2

VFD Fault Supply

Fan - 2

Affects

Target

Unit Warning with

Unit Warning with

Severity Persistence

Special Action

Special Action

Active

Modes

[Inactive

Modes]

Latching All VFD Fault. Numerous drive faults can cause this general

Latching All VFD Fault. Numerous drive faults can cause this general

Criteria

fault. Reference the TR150 Installation and Operating

manual for a list of fault codes and descriptions.

Failure with Supply Fan 2 available:

Generate Supply Fan 1 Proving Failure

Diagnostic and Lockout all heating operation.

Failure with Supply Fan 2 NOT available:

Generate Supply Fan 1 Proving Failure

and Shutdown the unit

The Latching behavior for this diagnostic is latched in the

drive. When the drive diagnostics are reset this diagnostic

will be cleared in the Symbio 800 controller.

fault. Reference the TR150 Installation and Operating

manual for a list of fault codes and descriptions.

Failure with Supply Fan 1 available:

Generate Supply Fan 2 Proving Failure

Diagnostic and Lockout all heating operation.

Failure with Supply Fan 1 NOT available:

Generate Supply Fan 2 Proving Failure

And Shutdown the unit

Reset

Level

Local

Local

52 RT-SVP011A-EN

The Latching behavior for this diagnostic is latched in the

drive. When the drive diagnostics are reset this diagnostic

will be cleared in the Symbio 800 controller.

Page 53

Troubleshooting

Diagnostic Name

and Source

VFD Supply Fan

Motor Current

Overload - 1

VFD Supply Fan

Motor Current

Overload - 1

VFD SF Motor

Current Ovld

VFD Supply Fan

Motor Current

Overload - 2

VFD Supply Fan

Motor Current

Overload - 2

VFD SF Motor

Current Ovld

Affects

Target

Unit Warning with

Unit Warning with

Severity Persistence

Special Action

Special Action

Active

Modes

[Inactive

Modes]

Latching All The inverter peak current of approximately 200% of rated

Latching All The inverter peak current of approximately 200% of rated

Criteria

current was exceeded for 1.5 seconds.

This is a drive enforced lockout.

Failure with Supply Fan 2 available:

Generate Supply Fan 1 Proving Failure

Diagnostic and Lockout all heating operation.

Failure with Supply Fan 2 NOT available:

Generate Supply Fan 1 Proving Failure

and Shutdown the unit

The Latching behavior for this diagnostic is latched in the

drive. When the drive diagnostics are reset this

diagnostic will be cleared in the Symbio 800 controller.

This drive alarm may be Trip Locked at the TR150 drive.

If the drive determines that the condition could cause

damage the drive protects itself by generating a Trip Lock

that can only be cleared by cycling power.

current was exceeded for 1.5 seconds.

This is a drive enforced lockout.

Failure with Supply Fan 1 available:

Generate Supply Fan 2 Proving Failure

Diagnostic and Lockout all heating operation.

Failure with Supply Fan 1 NOT available:

Generate Supply Fan 2 Proving Failure

And Shutdown the unit

Reset

Level

Local

Local

The Latching behavior for this diagnostic is latched in the

drive. When the drive diagnostics are reset this diagnostic

will be cleared in the Symbio 800 controller.

This drive alarm may be Trip Locked at the TR150 drive.

If the drive determines that the condition could cause

damage to the drive, the drive protects itself by

generating a Trip Lock that can only be cleared by cycling

power.

RT-SVP011A-EN 53

Page 54

Troubleshooting

Diagnostic Name

and Source

VFD Supply Fan

Ground Fault – 1

VFD Supply Fan

Ground Fault – 1

VFD Supply Fan

Ground Fault

VFD Supply Fan

Ground Fault – 2

VFD Supply Fan

Ground Fault – 2

VFD Supply Fan

Ground Fault

Affects

Target

Unit Warning with

Unit Warning with

Severity Persistence

Special Action

Special Action

Active

Modes

[Inactive

Modes]

Latching All An earth ground fault has resulted in a discharge from the

Latching All An earth ground fault has resulted in a discharge from the

Criteria

output phases to ground, either in the cable between the

adjustable frequency drive and the motor or in the motor

itself. Further fan operation is not recommended until

measurements to ground can be taken from the motor

leads and the ground fault removed.

Failure with Supply Fan 2 available:

Generate Supply Fan 1 Proving Failure

Diagnostic and Lockout all heating operation.

Failure with Supply Fan 2 NOT available:

Generate Supply Fan 1 Proving Failure

and Shutdown the unit

The Latching behavior for this diagnostic is latched in the

drive. When the drive diagnostics are reset this

diagnostic will be cleared in the Symbio 800 controller.

This drive alarm may be Trip Locked at the TR150 drive.

If the drive determines that the condition could cause

damage to the drive, the drive protects itself by

generating a Trip Lock that can only be cleared by cycling

power.

output phases to ground, either in the cable between the

adjustable frequency drive and the motor or in the motor

itself. Further fan operation is not recommended until

measurements to ground can be taken from the motor

leads and the ground fault removed.

Reset

Level

Local

Local

Failure with Supply Fan 1 available:

Generate Supply Fan 2 Proving Failure

Diagnostic and Lockout all heating operation.

Failure with Supply Fan 1 NOT available:

Generate Supply Fan 2 Proving Failure

And Shutdown the unit

The Latching behavior for this diagnostic is latched in the

drive. When the drive diagnostics are reset this

diagnostic will be cleared in the Symbio 800 controller.

This drive alarm may be Trip Locked at the TR150 drive.

If the drive determines that the condition could cause

damage to the drive, the drive protects itself by

generating a Trip Lock that can only be cleared by cycling

power.

54 RT-SVP011A-EN

Page 55

Troubleshooting

Diagnostic Name

and Source

VFD Supply Fan

Short Circuit – 1

VFD Supply Fan

Short Circuit – 2

VFD Supply Fan

Short Circuit

VFD Supply Fan

Short Circuit – 2

VFD Supply Fan

Short Circuit – 2

VFD Supply Fan

Short Circuit

Affects

Target

Unit Warning with

Unit Warning with

Severity Persistence

Special Action

Special Action

Active

Modes

[Inactive

Modes]

Latching All A short circuit in the motor windings or the motor terminals was

Latching All A short circuit in the motor windings or the motor terminals was

Criteria

detected. Fan operation is not recommended until the short circuit

is removed.

Failure with Supply Fan 2 available:

Generate Supply Fan 1 Proving Failure

Diagnostic and Lockout all heating operation.

Failure with Supply Fan 2 NOT available:

Generate Supply Fan 1 Proving Failure

and Shutdown the unit

The Latching behavior for this diagnostic is latched in the

drive. When the drive diagnostics are reset this

diagnostic will be cleared in the Symbio 800 controller.

This drive alarm may be Trip Locked at the TR150 drive.

If the drive determines that the condition could cause

damage to the drive, the drive protects itself by

generating a Trip Lock that can only be cleared by cycling

power.

detected. Fan operation is not recommended until the short circuit

is removed.

Failure with Supply Fan 1 available:

Generate Supply Fan 2 Proving Failure

Diagnostic and Lockout all heating operation.

Reset

Level

Local

Local

VFD Supply Fan

In Hand Mode – x

VFD Supply Fan

In Hand Mode – x

VFD SF In Hand

Mode

Failure with Supply Fan 1 NOT available:

Generate Supply Fan 2 Proving Failure

And Shutdown the unit

The Latching behavior for this diagnostic is latched in the

drive. When the drive diagnostics are reset this

diagnostic will be cleared in the Symbio 800 controller.

This drive alarm may be Trip Locked at the TR150 drive.

If the drive determines that the condition could cause

damage to the drive, the drive protects itself by

generating a Trip Lock that can only be cleared by cycling

power.

Unit Warning Non-Latching All The drive has been put into hand mode at the drive

interface. This will cause issues for normal startup and

running

Local

RT-SVP011A-EN 55

Page 56

Troubleshooting

Diagnostic Name

and Source

VFD Fault Relief

Fan - x

VFD Fault Relief

Fan - x

VFD Fault Relief

Fan - x

VFD Relief Fan

Locked Motor - x

VFD Relief Fan

Locked Motor - x

VFD Relief Fan

Lock Motor - x

VFD Relief Fan

Motor

Overheated – x

VFD Relief Fan

Motor

Overheated – x

VFD Relief Fan

Motor Overheat –

x

VFD Relief Fan

Power Mod

Overheated – x

VFD Relief Fan

Power Mod

Overheated – x

VFD PM Overheat

Relief Fan – x

Affects

Target

Unit Normal

Unit Normal

Unit Normal

Unit Normal

Severity Persistence

Shutdown with

Special Action

Shutdown with

Special Action

Shutdown with

Special Action

Shutdown with

Special Action

Active

Modes

[Inactive

Modes]

Latching All VFD Fault. Numerous drive faults can cause this general

Latching All Something has blocked the rotor from turning. Ice is a

Latching All The motor thermocouples have reached a too-high

Latching All The Rectifier thermocouple has reached a too-high

Criteria

fault. Reference the EBM-PAPST Installation and

Operating manual for a list of fault codes and

descriptions. (Clears on Reset)

Other fans available: Warning only.

No fans available: Relief damper is closed, relief fan

commanded off and the Economizing will be disable and

the outside air damper will be driven to the active

minimum position.

The Latching behavior for this diagnostic is latched in the

drive. When the drive diagnostics are reset this diagnostic

will be cleared in the Symbio 800 controller.

common one in some applications. (Motor Auto Reset)

Other fans available: Warning only.

No fans available: Relief damper is closed, relief fan

commanded off and the Economizing will be disable and

the outside air damper will be driven to the active

minimum position.

The Latching behavior for this diagnostic is latched in the

drive. When the drive diagnostics are reset this

diagnostic will be cleared in the Symbio 800 controller.

temperature. Typically caused by excessively high

ambient temp. (Motor Manual Reset)

Other fans available: Warning only.

No fans available: Relief damper is closed, relief fan

commanded off and the Economizing will be disable and

the outside air damper will be driven to the active

minimum position.

The Latching behavior for this diagnostic is latched in the

drive. When the drive diagnostics are reset this

diagnostic will be cleared in the Symbio 800 controller.

temperature. Typically caused by excessively high

ambient temp. (Motor Manual Reset)

Other fans available: Warning only.

No fans available: Relief damper is closed, relief fan

commanded off and the Economizing will be disable and

the outside air damper will be driven to the active

minimum position.

Reset

Level

Local

Local

Local

Local

VFD Relief Fan

Speed Parameter

Failure – x

VFD Relief Fan

Speed Parameter

Failure – x

VFD Relief Fan

Speed Param Fail

– x

Unit Normal

Shutdown with

Special Action

56 RT-SVP011A-EN

The Latching behavior for this diagnostic is latched in the

drive. When the drive diagnostics are reset this diagnostic

will be cleared in the Symbio 800 controller.

Latching All The motors Maximum Speed parameter does not match

the Maximum Permissible Speed parameter. (EC-Clone

Required)

Other fans available: Warning only.

No fans available: Relief damper is closed, relief fan

commanded off and the Economizing will be disable and

the outside air damper will be driven to the active

minimum position.

The Latching behavior for this diagnostic is latched in the

drive. When the drive diagnostics are reset this diagnostic

will be cleared in the Symbio 800 controller.

Local

Page 57

Troubleshooting

Diagnostic Name

and Source

VFD Fault

Condenser Fan Cktx

VFD Fault

Condenser Fan Cktx

VFD Fault

Condenser Fan

VFD Condenser

Fan Motor

Current Overload

– Cktx

VFD Condenser

Fan Motor

Current Overload

- Cktx

VFD Cond Fan

Current Ovld

VFD Condenser Fan

Ground Fault - Cktx

VFD Condenser Fan

Ground Fault - Cktx

VFD Cond Fan

Ground Fault

Affects

Target

Circuit Warning

Circuit Warning

Circuit Warning

Severity Persistence

with

Special Action

with

Special Action

with

Special Action

Active

Modes

[Inactive

Modes]

Latching All VFD Fault. Numerous drive faults can cause this general

Latching All The inverter peak current of approximately 200% of rated

Latching All An earth ground fault has resulted in a discharge from the

Criteria

fault. Reference the TR170 Installation and Operating

manual for a list of fault codes and descriptions.

Condenser fan control will revert to fixed-speed fan

algorithm using remaining fans.

The Latching behavior for this diagnostic is latched in the

drive. When the drive diagnostics are reset this

diagnostic will be cleared in the Symbio 800 controller.

current was exceeded for 1.5 seconds. Condenser fan

control will revert to fixed-speed fan algorithm using

remaining fans.

The Latching behavior for this diagnostic is latched in the

drive. When the drive diagnostics are reset this diagnostic

will be cleared in the Symbio 800 controller.

This drive alarm may be Trip Locked at the TR170 drive.

If the drive determines that the condition could cause

damage to the drive, the drive protects itself by

generating a Trip Lock that can only be cleared by cycling

power.

output phases to ground, either in the cable between the

adjustable frequency drive and the motor or in the motor

itself. Condenser fan control will revert to fixed-speed fan

algorithm using remaining fans. Further operation of the

failed fan is not recommended until measurements to

ground can be taken from the motor leads and the ground

fault removed.

Reset

Level

Local

Local

Local

The Latching behavior for this diagnostic is latched in the

drive. When the drive diagnostics are reset this

diagnostic will be cleared in the Symbio 800 controller.

This drive alarm may be Trip Locked at the TR170 drive.

If the drive determines that the condition could cause

damage to the drive, the drive protects itself by

generating a Trip Lock that can only be cleared by cycling

power.

VFD Condenser Fan

Short Circuit - Cktx

VFD Condenser Fan

Short Circuit - Cktx

VFD Cond Fan

Short Circuit

Circuit Warning

with

Special Action

Latching All A short circuit in the motor windings or the motor terminals was

detected. Condenser fan control will revert to fixed-speed fan

algorithm using remaining fans. Further operation of the failed fan

is not recommended until the short circuit is removed.

The Latching behavior for this diagnostic is latched in the

drive. When the drive diagnostics are reset this

diagnostic will be cleared in the Symbio 800 controller.

This drive alarm may be Trip Locked at the TR170 drive.

If the drive determines that the condition could cause

damage to the drive, the drive protects itself by

generating a Trip Lock that can only be cleared by cycling

power.

Local

RT-SVP011A-EN 57

Page 58

Troubleshooting

Diagnostic Name

and Source

VFD Condenser

Fan In Hand Mode

– Cktx

VFD Condenser

Fan In Hand Mode

– Cktx

VFD Cond In

Hand Mode

VFD Fault

Compressor –

Cprsr1A

VFD Fault

Compressor Cprsr1A

VFD Fault –

Cprsr1A

VFD Compressor

Current Overload

– Cprsr1A

VFD Comp

Current Overload

– Cprsr1A

VFD Comp

Current Ovld

Affects

Target

Unit Warning Non-latching All The drive has been put into hand mode at the drive

Cprsr Immediate

Cprsr Immediate

Severity Persistence

Latching Cprsr

Shutdown

Latching Cprsr

Shutdown

Active

Modes

[Inactive

Modes]

Energized

Energized

Criteria

interface. This will cause issues for normal sequences

and operation

VFD Fault. Numerous drive faults can cause this general

fault including High Pressure Cutout for VFD

compressors. See Service Literature xxxx for a list of fault

codes and description.

The Latching behavior for this diagnostic is latched in the

drive. When the drive diagnostics are reset this

diagnostic will be cleared in the Symbio 800 controller.

The inverter peak current of approximately 200% of rated

current was exceeded for 1.5 seconds.

This is a drive enforced lockout.

NOTE: There is Drive behavior that results from a Drive

Overcurrent where the drive continues to operate at

reduced RPM

The Latching behavior for this diagnostic is latched in the

drive. When the drive diagnostics are reset this

diagnostic will be cleared in the Symbio 800 controller.

Reset

Level

Local

Local

Local

VFD Compressor

Ground Fault–

Cprsr1A

VFD Compressor

Ground Fault–

Cprsr1A

VFD Comp

Ground Fault

Circuit Immediate

Shutdown

Latching Cprsr

Energized

This drive alarm may be Trip Locked at the TR200 drive.

If the drive determines that the condition could cause

damage to the drive, the drive protects itself by

generating a Trip Lock that can only be cleared by cycling

power.

An earth ground fault has resulted in a discharge from the

output phases to ground, either in the cable between the

adjustable frequency drive and the motor or in the motor

itself. Further compressor operation is not recommended

until measurements to ground can be taken from the

motor leads and the ground fault removed.

The Latching behavior for this diagnostic is latched in the

drive. When the drive diagnostics are reset this

diagnostic will be cleared in the Symbio 800 controller.

This drive alarm may be Trip Locked at the TR200 drive.

If the drive determines that the condition could cause

damage to the drive, the drive protects itself by

generating a Trip Lock that can only be cleared by cycling

power.

Local

58 RT-SVP011A-EN

Page 59

Troubleshooting

Diagnostic Name

and Source

VFD Compressor

Short Circuit–

Cprsr1A

VFD Compressor

Short Circuit –

Cprsr1A

VFD Compressor

Short Circuit

VFD Compressor

High Pressure

Trip – Cprsr1A

VFD Compressor

High Press Trip –

Cprsr1A

VFD Compressor

High Press

VFD Torque Limit

Exceeded–

Cprsr1A

VFD Torque Limit

Exceeded –

Cprsr1A