Page 1

Product Catalog

Commercial Self-Contained

Integral Air-Cooled Units

5 to 15 tons

January 2014

PKG-PRC019C-EN

Page 2

Introduction

Integral Air-Cooled Units — Perfect for the Retrofit Market

• High efficiencies – up to 11.2 EER – with all units ARI certified

• Fits through a standard doorway, hallway, or elevator

• Most flexible and widely used integral self-contained in the industry

• Applications include high rise office complexes, single story buildings, factories, prefab

buildings

• Qualifies for most energy rebates

Features Summary

• Rugged yet aesthetic exterior made of 24-gage steel and one-inch double-wall foamed panels

• Maximum 31 1/2 -inch wide base fits through standard door openings

• Drive assemblies for evaporator and condenser motors have variable pitch sheaves

• High and low pressure switches with easily accessible service ports

• Front and side panels are quickly removable, making components easily reached for servicing.

• Field-installed accessories include plenums, hot water & steam coils, low ambient dampers on

SCIH models, thermostats, one & two-inch throwaway filters, two-inch permanent filters, and

oversized motor kits for both the evaporator and condenser.

• Units are available with an industrial phenolic coating on the unit’s exterior and both coils

• Micro-Channel Condenser Coils used on all units. Use of Micro-Channel Condenser coils

reduces the amount of refrigerant used verses R-22 units by an average of 35.8%.

Revision Summary

PKG-PRC019C-EN (29 Jan 2014)

Remove corrosion resistant coating option.

Trademarks

Trane and the Trane logo are trademarks ofTrane in the United States and other countries. All

trademarks referenced in this document are the trademarks of their respective owners.

© 2014Trane All rights reserved PKG-PRC019C-EN

Page 3

Table of Contents

Introduction ......................................................2

Features and Benefits ..............................................4

Selection Procedure ................................................ 5

Model Number Description ..........................................7

General Data ...................................................... 8

Performance Data .................................................9

Electrical Data .................................................... 20

Dimensions and Weights ..........................................22

Mechanical Specifications .......................................... 30

PKG-PRC019C-EN 3

Page 4

Features and Benefits

Trane deluxe integral air-cooled self-contained air conditioners are single packaged units, built for

the needs of the retrofit market.The unit’s design makes it perfect for buildings where the roof

cannot support additional load and/or there is no outside area for a remote condenser.The SCIJ

models with R-410A, meet today’s need for a high efficiency, high capacity, air conditioning unit in

a compact, versatile package. All models are AHRI certified to ASHRAE standard 90.1-2010.

These units can handle the increased capacity demands of today’s buildings without the expense

of an increase in ductwork or power wiring size.They will easily pass through doors, hallways, and

elevators without having to tear out walls or use expensive rigging. The units are designed for

quick, easy installation.

Flexibility is the key toTrane's integral air-cooled vertical self contained units. Verticalunits are field

convertible to horizontal discharge. Industrial coatings for the condenser and evaporator coils, hot

water and steam coils are standard options offered to meet any application need.

Standard Features

• Fits through standard 36-inch door

• Vertical discharge with front or rear return

• Allen head fasteners on panels for quick removal

• Scroll compressor

• Hi/Low pressure cut out switches

• Single point power connection

• Constant volume airflow

• FC evaporator and condenser fans

• Oversized evaporator motors

• Variable pitch drive sheaves

• Flanged supply and return for duct installations

• One-inch throw away filters

• C ETL listed

• AHRI certified

• Micro-Channel Condenser coils

Factory Installed Options

• Phenolic unit and coil coating

• Horizontal or vertical discharge

Field Installed Accessories

• Hot water and steam coils

• Low ambient control (0°F ambient operation)

• Plenums

• Thermostats

• Oversized evaporator and condenser motors

• Two-inch throwaway or permanent filters

• Low ambient kit

4 PKG-PRC019C-EN

Page 5

Selection Procedure

The selection of an integral air-cooled unit can be accomplished in three easy steps.

1. Select unit

2. Fan speed and bhp for:

a. Evaporator fan

b. Condenser fan

3. Supply air temperature DB

Sample Unit Selection

Following is an example unit selection procedure.

Design Conditions

• 80°F/67°F DB/WB return air

• 95°F ambient

• 109,300 Btu/h total net

• 76,500 Btu/h sensible net

• 0.3 external static pressure (evaporator fan)

• 4400 cfm

• 0.2 external static pressure (condenser fan)

• 3000 feet altitude

1. Select Unit

109,300 Btu/h

12,000 Btu/h per ton

Therefore, initially select a 10-ton unit.

- Using Table 11, p. 15

• 80/67°F EAT

• 4400 cfm

• 95°F ambient = 10 ton capacity = 118.2 MBh total Gross, 93.6 MBh sensible Gross

– Determine the altitude correction using Table 5, p. 10:

• 3000 feet = correction factor of 0.965

• Corrected total capacity = 118.2 x 0.965 = 114.06 MBh

• Corrected sensible capacity = 93.6 x 0.965 = 90.32 MBh

2. Fan Speed and bhp Determination

First, calculate the total static pressure, as shown below:

Evaporator Condenser

0.3 esp 0.2 esp

UsingTables Table 7, p. 11, and Table 6, p. 10,

• Evaporator

– 10-ton unit at 4400 cfm and 0.3 esp: rpm = 728, bhp = .91

• Condenser

– 10-ton unit at 0.2 esp: rpm = 585, bhp = 1.25

= 9.1 tons

PKG-PRC019C-EN 5

Page 6

Selection Procedure

Note: If values fall between cfm or esp values, interpolate values. Do not extrapolate beyond

• Calculate fan motor heat using the equation:

Therefore, 3.0 x .91 = 2.73 MBh.

• Calculate the required net total capacity using the following formula: net MBh

3. Supply Air Temperature

values in this catalog. Contact your local Trane representative for assistance as needed.

– fan motor heat (MBh) = 3.0 x fan motor bhp (see the evaporator fan performance tables)

– capacity = gross MBh capacity - fan motor heat (MBh)

Total net capacity = 114.06 - 2.73 = 111.33 MBh

Sensible net capacity = 90.32 - 2.73 = 87.59 MBh

Required - 109,300 Btu/h total net

76,500 Btu/h sensible net

Provided - 111.33 MBh total net

87.59 MBh sensible net

The 10-ton unit is the correct choice for this application.

Leaving Air Temperature (F) =T1 - Hs / (CFM x 1.08)

T1 = Entering Dry Bulb Temperature (F)

Hs = Net Sensible Heat (Btuh)

CFM = Total air flow in cubic feet/min

80 -

87590

(4400 x 1.08)

= 61.56 F Supply Air

6 PKG-PRC019C-EN

Page 7

Model Number Description

S C I J 0 7 5 3 1 A 0 1 0 1 0

1 2 3 4 5, 6, 7 8 9 10, 11 12 13 14 15

Following is a complete description of the

integral air-cooled unit model number.

Each digit in the model number has a

corresponding code that identifies

specific unit options.

Digit 1 - Unit Model

S = Self contained

Digit 2 - UnitType

C = Commercial

Digit 3 - Condenser Medium

I = Integral air-cooled

Digit4-Development Sequence

J = Development series

Digit 5, 6, 7- Unit Nominal

Capacity

050 = 5.0 Tons

075 = 7.5 Tons

100 = 10 Tons

150 = 15T ons

Digit 8 - Unit Voltage

3 = 208 - 230 volt/60 hz/3 ph

4 = 460 volt/60 hz/3 ph

5 = 575 volt/60 hz/3 ph

Digit 9 - Air Flow Configuration

1 = Horizontal discharge / rear return

2 = Vertical discharge / front return

3 = Vertical discharge / rear return

Digit 10, 11 - Design Sequence

VO = Factory assigned

Digit 12 - Air FilterType

1 = One-inch fiberglass throwaway

Digit 13 - Control

0 = Control interface

Digit 14 - Unit Finish

1 = Painted

Digit 15 - Coil Finish

0 = None

C = Condenser coated + silver solder

braze joints

E = Evaporator coated + silver solder

braze joints

H = Condenser coated + evaporator

coated + silver solder braze joints

PKG-PRC019C-EN 7

Page 8

General Data

Table 1. Integral air cooled general data (with Micro channel condenser coil)

Nominal Tons 5 7.5 10 15

AHRI capacity - btu/h 60500 89000 117000 170000

System Power - kW Data 5.41 7.68 10.40 15.50

(S)EER/IEER 13.00 11.20/11.40 11.20/11.40 11.00/11.20

R-410A charge/circuit (lbs.) 6.94 8.75 4.75 / 4.88 8.50 / 8.50

Shipping weight-lbs. 945 1342 1474 2077

Operating weight-lbs. 856 1210 1342 1923

Compressor, qty-hp1122

Circuits 1122

Condenser - Micro channel

Face area, sq/ft. 11.35 16.58 16.58 24.05

Rows / fpf 1 / 276 1 / 276 1 / 276 1 / 276

Fans, qty. 1223

Fan size, in. 15 x 15 15 x 15 15 x 15 15 x 15

Motorhp 1.0 1.5 2.0 3.0

Evaporator

Face area, sq/ft. 8.37 12.89 12.89 17.60

Rows / fpf 4 / 168 3 / 144 3 / 144 4 / 144

Filter qty. - size, in. 2 - 23.7 x 25 3 - 23.7 x 25.6 3 - 23.7 x 25.6

Fans qty. - size, in 1 - 12 x 12 2 - 12 x 12 2 - 12 x 12 3 - 12 x 9

Motorhp 1.0 1.0 1.5 3.0

Min. airflow 1800 2700 3600 5400

Rated airflow Data 2000 3000 4000 6000

Max. airflow 2200 3300 4400 6600

Notes:

1. Net cooling capacity is rated at 95°F ambient, 80°F entering dry bulb and 67°F entering wet bulb at scfm air

condition. 2. EER is rated at AHRI conditions per AHRI standards 210/240 and 340/360.

2. SEER applies to 5 ton unit - AHRI 210-240 Certified.

3 - 23.7 x 18 +

2 - 23.7 x 25.6

8 PKG-PRC019C-EN

Page 9

Performance Data

Table 2. Air pressure drop, in. wg.

Unit Size Cfm

1800

1850 0.03 0.01

1900 0.04 0.02

5 ton

7.5 ton

10 ton

15 ton

2000

2100 0.06 0.03

2150 0.06 0.04

2200 0.09 0.08 0.06 0.04

2700

2800 0.06 0.05

2900 0.06 0.05

3000

3100 0.06 0.06

3200 0.07 0.06

3300 0.07 0.07 0.07 0.06

3600

3750 0.08 0.08

3900 0.09 0.08

4000

4100 0.10 0.09

4250 0.10 0.09

4400 0.13 0.14 0.11 0.10

5400

5600 0.10 0.09

5800 0.10 0.09

6000

6200 0.11 0.10

6400 0.12 0.11

6600 0.13 0.16 0.12 0.11

Hot Water

Coil

0.04 0.03

0.06 0.05

0.05 0.06

0.06 0.06

0.09 0.10

0.11 0.12

0.10 0.12

0.12 0.14

Steam

Coil

Throwaway

Permanent Wire

Filter

0.03 0.01

0.05 0.03

0.05 0.05

0.06 0.05

0.08 0.07

0.09 0.08

0.09 0.08

0.11 0.10

Mesh Filter

Table 3. Cfm capacity correction table, hot water heating coil

Cfm Compared To

Rated Quanitity

-20% 0.89

-10% 0.94

Hot Water Heating

Std 1.00

+10% 1.06

+20% 1.12

PKG-PRC019C-EN 9

Heating Capacity

Multiplier

Page 10

Performance Data

Table 4. Cfm capacity correction table, steam heating coil

Cfm Compared To

Rated Quanitity

-20% 0.89

-10% 0.94

Steam Heating

Std 1.00

+10% 1.06

+20% 1.12

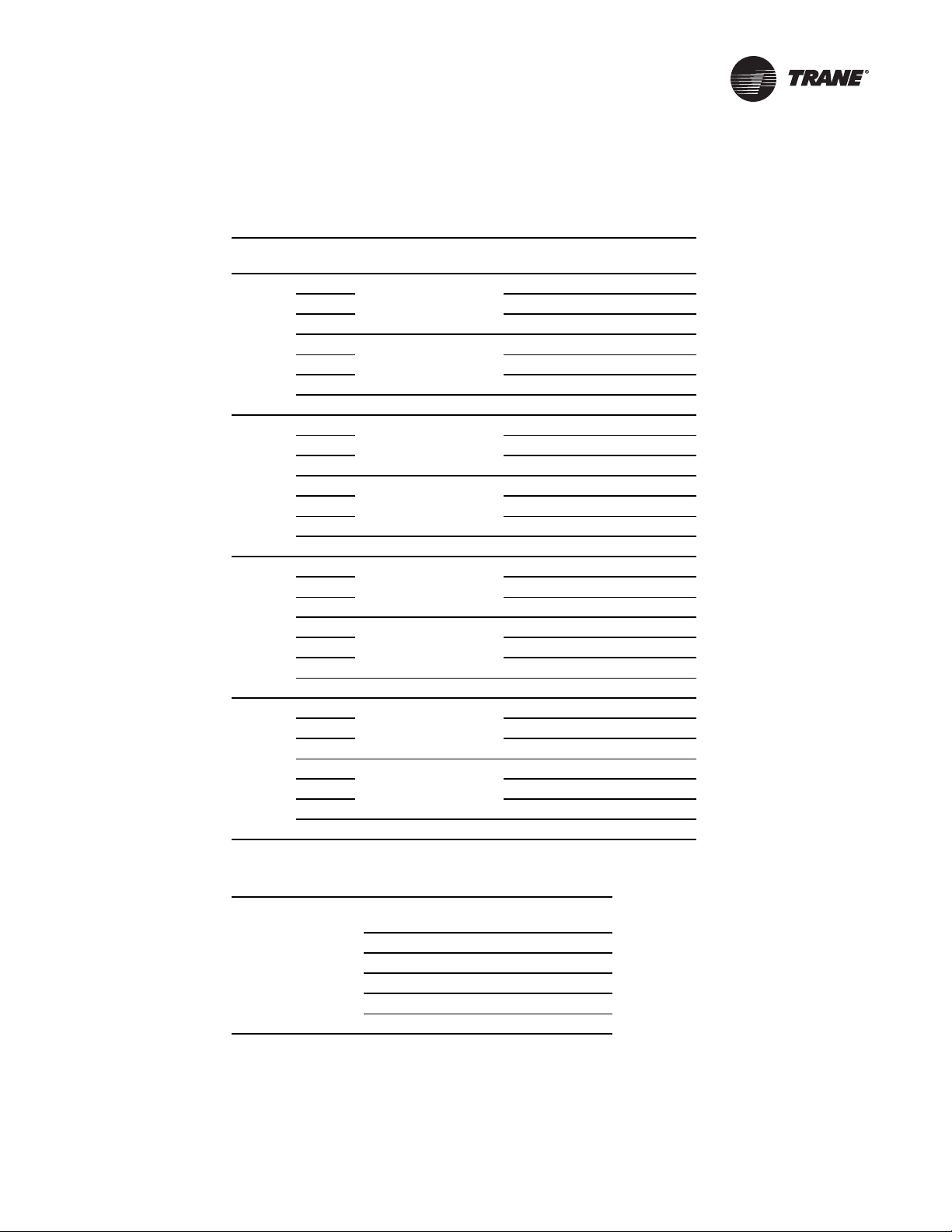

Table 5. Altitude correction factors

Altitude 2000 4000 6000 8000 10,000

Cooling Capacity Multiplier 0.98 0.95 0.92 0.89 0.86

Table 6. SCIJ condenser fan performance

Unit

Size

CFM

5 3700 483 0.63 522 0.70 559 0.78 595 0.87 632 0.95

7.5 4500 465 0.58 521 0.71 576 0.85 625 1.00 — —

10 6000 492 0.95 538 1.09 585 1.25 629 1.41 — —

15 9000 606 1.92 650 2.15 693 2.40 738 2.69 778 2.95

Note: Shaded area requires oversized motor

0.0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 0.9

RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP

External Static Pressure (In Wg)

Heating Capacity

Multiplier

667 1.04 702 1.13 737 1.22 770 1.32 803 1.43 834 1.53

716 1.30 757 1.47 795 1.63 833 1.80 867 1.96 901 2.14

714 1.77 753 1.94 793 2.14 829 2.33 864 2.52 899 2.73

819 3.27 855 3.56 892 3.85 928 4.17 961 4.46 995 4.78

10 PKG-PRC019C-EN

Page 11

Performance Data

Table 7. Evaporator fan performance

External Static Pressure (InWg)

Unit

Size CFM

1800 — — 587 0.25 644 0.29 696 0.33 749 0.38

1850 — — 591 0.26 648 0.30 699 0.35 754 0.40

1900 — — 596 0.27 651 0.32 706 0.36

2000 — — 607 0.30 661 0.35 715 0.40

5

2100 563 0.29 619 0.33 671 0.38 723 0.43

2150 571 0.30 623 0.35 677 0.40 726 0.45

2200 576 0.32 630 0.36 681 0.41 731 0.46

2700 513 0.27 589 0.35 655 0.43

2800 521 0.29 593 0.37 658 0.45

2900 526 0.30 598 0.38 665 0.47

3000 531 0.32 604 0.41 668 0.50

7.5

3100 539 0.35 608 0.43 672 0.52

3200 545 0.37 615 0.45 678 0.54

3300 553 0.39 619 0.48 684 0.57

3600 — — 612 0.52 673 0.61 732 0.72

3700 — — 619 0.55 681 0.65 738 0.75

3800 — — 626 0.58 687 0.68 743 0.78

3900 — — 634 0.61 693 0.71 748 0.82

4000 582 0.56 643 0.65 700 0.75

10

4100 592 0.59 650 0.69 708 0.79

4200 601 0.63 659 0.73 714 0.83

4300 611 0.67 666 0.76 722 0.87

4400 619 0.70 676 0.81 728 0.91

5400 — — 693 1.03 739 1.15 785 1.28 829 1.38

5600 661 1.03 706 1.12 752 1.25 797 1.35 839 1.47

5800 676 1.09 723 1.22 766 1.35 808 1.47 851 1.60

6000 692 1.22 735 1.31 780 1.44 821 1.57 861 1.70

15

6200 708 1.31 751 1.44 793 1.57 834 1.70

6400 725 1.41 766 1.54 807 1.67 846 1.70

6600 741 1.54 782 1.67 821 1.80 861 1.92

Notes:

1. External Static Pressure considering clean construction throwaway one-inch fiberglass filter (75% average efficiency

filter @ ASHRAE 52.1-1992)

2. Standard Motor - TEFC Type - Standard Drive

3. Dark gray area is Standard Motor - TEFC Type - High Static Pressure Drive Kit (Field Installed)

4. Light gray area is Oversized Motor TEFC Type - Oversized Motor Kit (Field Installed)

0.1 0.2 0.3 0.4 0.5 0.6 0.7

RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP

799 0.44 845 0.49

801 0.45 848 0.51

756 0.41 804 13.31 850 0.52

764 0.45 810 0.50 856 0.56

771 0.48 817 0.54 862 0.59

775 0.50 821 0.56 865 0.61

778 0.52 823 0.57 868 0.63

715 0.52 768 0.61 818 0.71 868 0.81

719 0.54 772 0.64 823 0.74 870 0.84

723 0.56 776 0.66 827 0.76 873 0.87

727 0.59 782 0.69 831 0.79 878 0.90

732 0.62 785 0.71 836 0.82 882 0.93

735 0.64 791 0.74 840 0.85 887 0.96

741 0.67 794 0.77 845 0.88 890 0.99

786 0.82 838 0.94 885 1.05

791 0.86 843 0.97 890 1.09

796 0.89 847 1.01 894 1.12

803 0.93 852 1.05 898 1.16

756 0.86 807 0.97 856 1.08 904 1.21

761 0.90 812 1.01 862 1.13 908 1.25

766 0.93 819 1.05 867 1.17 914 1.30

774 0.98 823 1.09 873 1.22 918 1.34

781 1.02 830 1.14 877 1.26 924 1.39

872 1.51 915 1.63

882 1.60 922 1.73

891 1.73 932 1.86

902 1.83 941 1.96

873 1.83 913 1.96 950 2.08

886 1.96 923 2.08 961 2.21

897 2.08 934 2.21 972 2.37

PKG-PRC019C-EN 11

Page 12

Performance Data

Table 8. Evaporator fan performance - continued

External Static Pressure (InWg)

Unit

Size CFM

1800

1850

1900

2000

5

2100

2150

2200

2700

2800

2900

3000

7.5

3100

3200

3300

3600

3700

3800

3900

4000

10

4100

4200

4300

4400

5400

5600

5800

6000

15

6200

6400

6600

Notes:

1. External Static Pressure considering clean construction throwaway one-inch fiberglass filter (75%

average efficiency filter @ ASHRAE 52.1-1992)

2. Standard Motor - TEFC Type - Standard Drive

3. Dark gray area is Standard Motor - TEFC Type - High Static Pressure Drive Kit (Field Installed)

4. Light gray area is Oversized Motor TEFC Type - Oversized Motor Kit (Field Installed)

0.8 0.9 1.0 1.2 1.4 1.6

RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP

887 0.55 928 0.60 965 0.66 1038 0.78 1107 0.91 — —

889 0.56 931 0.62 968 0.68 1040 0.80 1108 0.93 — —

892 0.58 933 0.64 971 0.70 1043 0.82 1110 0.95 1175 1.08

898 0.61 940 0.68 977 0.74 1049 0.86 1116 1.00 1178 1.13

904 0.65 945 0.72 983 0.78 1056 0.91 1122 1.04 1184 1.18

908 0.67 947 0.73 987 0.80 1058 0.93 1125 1.07 1187 1.21

910 0.69 951 0.76 989 0.82 1061 0.95 1128 1.09 1190 1.23

887 0.85 ——————————

916 0.95 ——————————

920 0.98 961 1.07 ————————

922 1.01 965 1.12 995 1.18 ——————

925 1.04 969 1.16 1011 1.27 ——————

930 1.07 972 1.19 1014 1.31 1061 1.45 ————

935 1.11 976 1.23 1016 1.35 1094 1.60 ————

929 1.17 973 1.29 1012 1.41 1089 1.67 1162 1.95 — —

936 1.21 977 1.33 1017 1.46 1093 1.72 1165 2.00 — —

940 1.25 982 1.37 1021 1.50 1097 1.77 1168 2.05 1237 2.34

944 1.29 986 1.42 1027 1.55 1101 1.81 1171 2.10 1239 2.39

948 1.33 — — 1031 1.59 1107 1.87 1177 2.15 1242 2.44

954 1.38 — — 1035 1.64 1111 1.92 1180 2.21 1247 2.51

958 1.42 — — 1041 1.69 1116 1.97 1184 2.26 1250 2.56

963 1.47 1005 1.61 1044 1.74 1120 2.02 1190 2.32 1255 2.63

967 1.52 1010 1.66 1050 1.80 1125 2.08 1195 2.38 1259 2.69

955 1.76 997 1.89 1035 2.02 1111 2.31 1184 2.60 1252 2.88

962 1.86 1002 2.02 1040 2.15 1116 2.44 1187 2.72 1256 3.01

971 1.99 1009 2.12 1048 2.28 1121 2.56 1190 2.85 1258 3.14

981 2.12 1017 2.24 1054 2.37 1126 2.69 1196 2.98 1263 3.30

989 2.24 1026 2.37 1062 2.53 1133 2.82 1201 3.14 1267 3.43

999 2.37 1035 2.50 1070 2.66 1139 2.95 1206 3.27 1272 3.59

1008 2.50 1044 2.66 1079 2.82 1147 3.11 1214 3.43 1277 3.75

12 PKG-PRC019C-EN

Page 13

Table 9. 5-Ton capacity data (with Micro-channel condenser coil)

Ambient Temperature

75 ºF 85 ºF 95 ºF 105 ºF 115 ºF

CFM EDB EWB

62 69.1 45.0 66.6 44.8 63.8 42.8 58.6 40.9 55.0 37.9

70

67 75.4 36.4 72.2 28.4 69.3 29.0 64.7 27.9 60.9 27.8

70 79.5 28.6 76.3 27.2 72.3 25.7 68.6 23.0 64.3 21.9

62 67.1 54.1 65.1 64.6 62.9 52.1 58.8 50.2 55.3 48.6

75

67 74.2 44.7 71.7 53.6 69.2 43.0 65.1 37.7 61.2 39.2

1800

2000

2200

Note: All capacities shown are gross and have not considered the indoor fan heat.

70 78.5 36.3 76.2 41.0 73.1 34.5 68.9 30.6 64.8 32.1

62 65.2 62.9 63.6 62.2 61.7 61.4 59.4 59.4 56.5 56.5

80

67 72.3 53.4 70.1 52.1 68.0 52.0 64.8 50.5 60.7 48.9

70 76.4 48.6 74.4 47.0 72.2 47.2 68.5 43.6 64.3 42.7

62 66.4 66.4 65.6 65.6 64.1 64.1 62.8 62.8 59.7 59.7

85

67 69.4 62.1 67.8 61.6 65.8 60.7 64.2 60.0 60.3 58.4

70 74.1 56.8 72.1 55.6 70.1 55.2 68.1 54.4 63.8 52.6

62 69.6 47.6 66.3 45.9 62.9 42.5 59.5 42.8 56.9 40.7

70

67 76.6 32.2 72.1 35.3 69.3 27.3 66.1 32.7 62.3 25.8

70 80.8 27.2 77.0 25.7 73.5 25.9 69.7 24.1 65.5 21.2

62 69.9 57.9 66.6 56.3 63.2 54.8 56.9 51.9 54.6 50.9

75

67 77.1 47.4 73.6 45.6 70.0 44.7 63.5 41.7 60.8 41.3

70 81.2 37.2 77.8 37.9 74.1 35.0 68.3 36.1 64.8 32.6

62 70.2 68.9 67.2 67.2 64.3 64.3 57.5 57.5 55.4 55.4

80

67 77.1 58.4 73.3 56.7 69.6 55.1 60.5 51.4 58.1 50.4

70 81.3 52.8 77.7 51.0 74.1 48.8 64.9 43.5 62.2 42.6

62 73.7 73.7 70.8 70.8 68.1 68.1 59.0 59.0 57.4 57.4

85

67 76.3 68.7 72.6 67.2 69.3 65.6 59.0 59.0 57.5 57.5

70 80.9 62.3 77.2 60.9 73.1 59.3 61.4 54.7 58.8 53.7

62 70.6 46.2 67.3 46.0 63.8 46.4 60.4 44.7 56.6 41.5

70

67 77.7 35.3 74.2 32.3 71.3 34.6 67.2 29.0 62.7 29.0

70 82.0 28.3 78.5 26.8 74.6 25.5 70.6 22.6 66.3 22.3

62 71.0 60.9 64.3 57.7 60.9 56.3 57.7 54.8 54.2 53.2

75

67 78.2 48.7 72.2 44.6 68.5 46.2 64.4 42.3 60.6 41.8

70 82.8 38.4 77.2 39.5 73.1 36.2 69.0 35.0 64.7 33.7

62 72.0 72.0 65.0 65.0 62.4 62.4 59.1 59.1 55.7 55.7

80

67 78.1 61.4 68.9 57.4 64.9 55.5 60.9 54.1 57.0 52.5

70 82.5 53.8 73.7 49.0 69.7 47.1 65.3 45.5 61.1 44.4

62 76.1 76.1 69.6 60.7 63.9 63.9 60.6 60.6 57.5 57.5

85

67 77.6 72.8 73.8 71.2 64.1 64.1 60.9 60.9 57.7 57.7

70 81.7 65.7 78.0 63.9 65.8 59.5 61.8 57.9 57.7 56.3

TC SC TC SC TC SC TC SC TC SC

Performance Data

PKG-PRC019C-EN 13

Page 14

Performance Data

Table 10. 7.5-Ton capacity data (with Micro-channel condenser coil)

Ambient Temperature

75 ºF 85 ºF 95 ºF 105 ºF 115 ºF

CFM EDB EWB

62 88.3 50.6 84.9 49.3 81.1 47.8 77.1 46.3 72.8 44.7

70

67 95.1 32.3 91.4 31.0 87.3 29.6 83.0 28.2 78.4 26.4

70 99.1 20.5 95.2 19.2 90.9 17.6 86.5 16.6 81.8 15.2

62 89.0 66.1 85.6 64.7 81.8 63.3 77.7 61.7 73.4 60.3

75

67 95.6 47.9 91.9 46.7 87.9 45.3 83.6 43.9 79.0 42.6

2700

3000

3300

Note: All capacities shown are gross and have not considered the indoor fan heat.

70 99.8 36.6 96.0 35.2 91.9 34.3 87.4 32.9 82.6 31.5

62 89.6 81.5 86.3 80.1 82.6 78.7 78.8 77.3 74.4 74.2

80

67 96.0 63.4 92.3 62.2 88.4 60.8 83.9 59.7 79.6 58.2

70 100.2 52.2 96.3 51.1 92.2 49.7 87.6 48.6 83.1 47.3

62 90.7 90.7 87.8 87.8 84.6 84.6 81.2 81.2 77.6 77.6

85

67 96.4 78.9 92.7 77.7 88.8 76.5 84.6 75.2 80.1 73.8

70 100.4 67.7 96.6 66.4 92.4 65.4 88.1 64.2 83.4 62.8

62 90.2 53.1 86.6 51.7 82.7 50.3 78.5 48.7 74.0 47.2

70

67 96.9 32.9 93.1 31.3 88.9 30.4 84.4 28.7 79.7 27.4

70 100.9 20.1 97.0 18.8 92.6 17.5 88.0 16.0 83.1 14.7

62 90.7 70.0 87.3 68.9 83.4 67.4 79.2 65.8 74.8 64.3

75

67 97.4 50.3 93.6 48.8 89.5 47.7 85.1 46.3 80.4 44.9

70 101.7 37.7 97.7 36.6 93.5 35.4 88.9 34.1 84.0 32.6

62 91.6 87.2 88.2 85.8 84.5 83.8 80.1 80.0 75.7 75.7

80

67 97.8 67.2 94.1 66.1 90.0 64.9 85.6 63.5 80.9 62.1

70 102.0 55.2 97.9 53.9 93.9 52.7 89.2 51.5 84.4 50.1

62 93.6 93.6 90.6 90.6 87.3 87.3 83.8 83.8 80.0 80.0

85

67 98.1 84.5 94.5 83.3 90.4 82.1 86.2 80.8 81.7 79.5

70 102.1 72.4 98.5 71.4 94.1 70.0 89.5 68.8 84.8 67.5

62 91.7 55.5 88.2 54.2 84.0 52.7 79.8 51.2 75.3 49.6

70

67 98.5 33.5 94.8 32.2 90.3 30.8 85.8 29.5 81.0 27.9

70 102.6 19.6 98.7 18.5 94.0 17.1 89.4 15.7 84.4 14.4

62 92.4 74.2 88.9 72.8 84.7 71.4 80.6 70.0 76.2 68.5

75

67 99.0 52.5 95.4 51.4 90.9 50.4 86.5 48.7 81.7 47.2

70 103.3 38.9 99.6 37.9 94.8 36.7 90.3 35.2 85.4 33.9

62 93.5 92.3 90.1 89.8 85.6 85.6 81.7 81.7 77.9 77.9

80

67 99.5 71.3 96.0 70.1 91.4 68.9 87.1 67.6 82.4 66.3

70 103.5 58.0 100.0 57.1 95.2 55.7 90.8 54.5 85.9 53.0

62 96.2 96.2 93.5 93.5 89.7 89.7 86.2 86.2 82.3 82.3

85

67 99.9 90.2 96.6 89.2 92.0 87.7 88.0 86.4 83.5 83.3

70 103.8 76.8 100.2 75.9 95.4 74.5 91.4 73.6 86.4 72.4

TC SC TC SC TC SC TC SC TC SC

14 PKG-PRC019C-EN

Page 15

Table 11. 10-Ton capacity data (with Micro-channel condenser coil)

Ambient Temperature

75 ºF 85 ºF 95 ºF 105 ºF 115 ºF

CFM EDB EWB

70

75

3600

80

85

70

75

4000

80

85

70

75

4400

80

85

Note: All capacities shown are gross and have not considered the indoor fan heat.

TC SC TC SC TC SC TC SC TC SC

62 117.9 70.7 112.6 68.5 108.0 66.2 103.0 64.5 97.4 62.2

67 126.1 46.5 120.4 44.2 115.6 42.5 110.2 40.6 104.3 38.2

70 131.5 31.2 125.4 29.2 120.3 27.2 114.6 25.2 108.4 23.0

62 118.4 90.9 113.0 88.7 108.5 86.8 103.6 84.8 98.1 82.6

67 126.5 67.2 120.6 64.7 115.9 63.4 110.7 61.4 104.8 59.2

70 131.6 52.1 125.1 50.0 120.4 48.4 115.0 46.5 109.1 44.9

62 120.2 111.5 113.6 108.5 109.5 106.5 104.9 103.6 99.5 99.3

67 128.0 88.1 120.5 85.3 115.9 83.7 110.8 81.9 105.3 79.9

70 133.2 73.4 125.2 70.7 120.5 69.0 115.1 67.6 109.4 65.5

62 121.6 121.6 115.3 115.3 111.7 111.7 107.6 107.6 103.0 103.0

67 128.4 108.5 120.6 105.5 116.1 103.9 111.3 102.3 105.9 100.4

70 133.4 93.9 124.9 91.1 120.3 89.6 115.2 88.0 109.5 86.2

62 119.7 73.8 114.6 71.5 109.3 69.5 103.6 67.2 97.6 64.6

67 128.0 47.2 122.5 45.2 116.7 43.2 110.7 40.8 104.2 39.0

70 133.2 30.5 127.4 28.3 121.2 26.3 115.0 24.1 108.1 22.0

62 121.2 96.5 116.1 94.4 109.6 91.7 104.0 89.5 98.1 87.2

67 129.4 70.8 123.9 68.6 116.8 65.9 110.8 63.6 104.3 61.8

70 134.6 54.1 128.8 52.1 121.3 49.7 115.0 48.3 108.5 45.9

62 123.2 118.6 118.3 115.9 110.6 110.2 104.7 104.7 99.0 99.0

67 130.7 93.5 125.1 91.4 116.6 88.5 110.5 86.3 104.3 84.2

70 135.9 77.4 129.9 75.6 121.1 72.5 114.8 70.6 108.2 68.6

62 125.6 125.6 120.9 120.9 113.8 113.8 108.7 108.7 103.4 103.4

67 131.5 116.0 125.6 113.8 116.9 110.7 111.1 108.2 105.0 104.2

70 136.2 100.2 130.1 98.2 120.7 95.1 114.6 93.3 108.0 91.3

62 121.6 77.1 116.4 74.8 110.9 72.8 105.1 70.5 98.9 68.6

67 129.9 48.1 124.3 46.3 118.4 43.8 112.2 42.0 105.5 39.8

70 135.2 30.0 129.1 27.6 122.9 25.9 116.3 23.6 109.4 21.5

62 121.8 101.2 116.7 99.1 111.3 96.9 105.5 94.5 99.4 92.1

67 130.0 73.4 124.3 71.1 118.4 69.0 112.2 67.0 105.7 64.9

70 135.0 55.2 129.2 53.3 122.8 51.4 116.6 49.4 109.8 47.3

62 125.6 124.2 117.7 117.5 111.9 111.9 106.5 106.5 101.1 101.1

67 129.7 97.5 124.1 95.7 118.2 93.6 112.2 91.6 105.5 89.4

70 137.8 81.3 129.0 78.3 122.8 76.5 116.2 74.6 109.2 72.5

62 126.2 126.2 121.5 121.5 116.5 116.5 111.3 111.3 105.6 105.6

67 130.2 121.7 124.5 119.5 119.1 116.8 113.0 112.4 106.0 105.9

70 134.5 104.9 128.6 103.0 122.5 101.2 116.1 99.2 109.3 97.2

Performance Data

PKG-PRC019C-EN 15

Page 16

Performance Data

Table 12. 15-Ton capacity data (with Micro-channel condenser coil)

Ambient Temperature

75 ºF 85 ºF 95 ºF 105 ºF 115 ºF

CFM EDB EWB

62 173.0 99.0 169.0 105.1 161.0 105.8 147.1 97.7 138.4 92.8

70

67 184.2 54.0 181.8 64.7 173.8 70.7 159,8 58,7 150.4 55.8

70 195.8 21.3 191.1 39.2 181.7 43.2 167,7 46,8 157.8 44.5

62 172.7 132.3 166.3 130.9 158.7 127.9 150.5 124.5 141.7 121.6

75

67 187.7 87.1 180.0 99.3 171.8 90.7 163.1 90.9 153.6 81.0

5400

6000

6600

Note: All capacities shown are gross and have not considered the indoor fan heat.

70 195.0 53.0 188.6 57.7 180.5 58.3 172.4 72.1 162.2 71.7

62 171.7 162.4 166.1 160.1 159.1 157.8 152.2 152.2 145.0 145.0

80

67 186.5 129.8 180.0 126.2 172.2 124.9 163.6 120.9 154.6 119.0

70 196.3 109.2 189.2 107.3 180.8 104.0 172.0 102.0 162.9 98.5

62 177.1 177.1 172.5 172.5 166.8 166.8 160.9 160.9 153.8 153.8

85

67 183.9 158.5 178.1 156.2 171.1 154.3 163.5 151.7 154.9 149.0

70 193.3 138.4 187.7 135.7 180.2 134.6 171.7 131.9 161.9 100.2

62 173.5 109.5 167.0 107.2 159.4 104.6 149.6 96.6 140.9 94.7

70

67 188.1 77.5 181.9 73.5 174.2 66.6 162.9 44.5 153.7 64.3

70 197.8 54.4 189.6 39.1 181.3 34.5 170.3 46.0 160.6 40.3

62 170.5 139.8 164.6 137.4 157.9 135.2 146.9 131.0 139.0 128.5

75

67 185.8 102.4 180.1 105.5 172.9 103.0 161.2 88.0 152.2 88.7

70 195.2 69.4 188.8 65.9 180.8 81.9 170.5 70.9 160.0 61.9

62 170.2 170.2 164.9 164.9 160.3 160.3 150.4 150.4 143.7 143.7

80

67 182.7 135.8 176.7 133.7 169.6 131.5 157.0 127.6 148.9 125.1

70 192.6 113.6 186.4 110.7 178.7 109.3 166.0 107.6 157.2 100.6

62 177.7 177.7 172.5 172.5 167.9 167.9 157.1 157.1 150.8 150.8

85

67 179.7 168.2 174.6 165.8 168.2 164.5 157.4 157.4 150.9 150.9

70 188.2 145.7 182.0 143.2 174.9 141.7 161.2 138.0 152.7 135.8

62 179.2 111.8 168.6 110.5 160.4 105.2 152.0 103.4 143.3 99.7

70

67 189.0 48.9 182.9 47.4 174.5 72.4 165.3 69.4 155.7 58.5

70 197.0 53.0 192.3 45.0 182.5 49.3 173.1 34.3 163.2 43.4

62 171.0 147.2 165.1 145.1 156.9 142.7 150.1 140.2 143.0 138.0

75

67 188.4 67.4 182.2 110.8 172.4 99.1 163.8 100.1 154.9 96.5

70 198.6 65.9 190.1 71.3 181.4 72.4 173.7 67.6 163.0 79.4

62 174.6 174.6 168.2 168.2 162.2 162.2 156.4 156.4 148.3 148.3

80

67 182.6 143.3 176.0 140.8 167.6 138.5 160.1 136.4 151.4 134.0

70 193.4 120.1 186.6 117.9 177.6 111.7 169.1 111.8 160.0 108.0

62 181.8 181.8 176.0 176.0 168.8 168.8 162.2 162.2 153.9 153.9

85

67 181.2 179.8 175.9 175.9 168.7 168.7 162.3 162.3 155.3 155.3

70 187.0 154.3 180.7 152.3 171.7 150.4 164.2 148.3 156.7 146.2

TC SC TC SC TC SC TC SC TC SC

16 PKG-PRC019C-EN

Page 17

Table 13. Hot water coil capacity, EWT = 180ºF

Water Temperature Drop

Unit

Size CFM EAT

1800

5 ton

7.5 ton

10 ton

15 ton

200

2200

2700

3000

3300

3600

4000

4400

5400

6000

6600

40 18.6 182.0 133.0 11.4 166.0 125.0 7.7 151.0 117.2

60 15.5 151.0 137.4 9.3 136.0 129.6 6.2 121.0 121.8

80 12.5 121.0 142.0 7.2 106.0 134.2 4.6 91.0 126.5

40 20.3 197.0 130.7 12.3 180.0 122.9 8.4 163.0 115.1

60 16.8 164.0 135.5 10.1 147.0 127.8 6.7 131.0 130.1

80 13.5 131.0 140.4 7.8 114.0 132.7 5.0 98.0 125.1

40 21.8 212.0 128.6 13.2 193.0 120.9 9.0 175.0 113.2

60 18.1 176.0 133.8 10.8 158.0 126.1 7.2 140.0 118.5

80 14.5 141.0 139.0 8.4 123.0 131.4 3.4 105.0 123.9

40 28.0 280.7 135.9 17.6 264.8 130.4 12.4 247.9 124.7

60 23.6 236.2 140.7 14.7 220.1 135.2 10.1 202.9 129.3

80 19.2 191.7 145.5 11.7 175.3 139.9 7.9 157.1 133.6

40 30.5 305.7 134.0 19.2 288.1 128.5 13.5 269.5 122.8

60 25.7 257.2 139.1 16.0 239.4 133.6 11.0 220.4 127.8

80 20.8 208.7 144.1 12.7 190.5 138.6 8.5 170.7 132.5

40 32.9 329.7 132.1 20.7 310.4 126.7 14.5 290.1 121.1

60 27.7 277.3 137.5 17.2 257.8 132.0 11.9 237.2 126.3

80 22.5 224.9 142.8 13.7 205.1 137.3 9.2 183.7 131.3

40 35.4 354.0 130.7 22.2 332.8 125.2 15.5 310.6 119.6

60 29.7 297.6 136.2 18.4 276.3 130.8 12.7 253.8 125.0

80 24.1 241.2 141.8 14.6 219.6 136.2 9.8 196.3 130.3

40 38.2 382.3 128.1 23.9 359.0 122.8 16.7 334.7 117.2

60 32.1 321.3 134.1 19.9 297.9 128.7 13.7 273.3 123.0

80 26.0 260.3 140.0 15.8 236.6 134.5 10.6 211.3 128.7

40 40.9 409.1 125.7 25.6 383.8 120.4 17.9 357.4 114.9

60 34.3 343.7 132.0 21.2 318.3 126.7 14.6 291.6 121.1

80 27.8 278.3 138.3 16.8 252.6 132.9 11.3 225.3 127.2

40 52.5 525.7 129.8 33.2 498.1 125.0 23.5 469.1 120.1

60 44.2 443.0 135.6 27.7 415.1 130.9 19.3 385.5 125.8

80 36.0 360.2 141.5 22.1 331.8 136.7 15.1 301.4 131.5

40 56.8 568.6 127.4 35.9 538.2 122.7 25.3 506.4 117.8

60 47.8 479.0 133.6 29.9 448.3 128.9 20.8 415.9 123.9

80 38.9 389.3 139.8 23.9 358.1 135.0 16.2 324.8 129.9

40 60.8 609.1 125.1 38.4 576.1 120.5 27.1 541.6 115.7

60 51.2 513.0 131.7 32.0 479.7 127.0 22.2 444.6 122.1

80 41.6 416.8 138.2 25.5 383.0 133.5 17.3 347.0 128.5

20 ºF 30 ºF 40 ºF

gpm MBh LAT gpm MBh LAT gpm MBh LAT

Performance Data

PKG-PRC019C-EN 17

Page 18

Performance Data

Table 14. Hot water coil capacity, EWT = 200ºF

Water Temperature Drop

Unit

Size CFM EAT

1800

5 ton

7.5 ton

10 ton

15 ton

200

2200

2700

3000

3300

3600

4000

4400

5400

6000

6600

40 22.0 213.0 149.0 13.6 198.0 141.3 9.4 183.0 133.5

60 18.8 183.0 153.4 11.5 168.0 145.8 7.8 153.0 138.1

80 15.7 152.0 157.9 9.4 137.0 153.3 6.3 122.0 142.7

40 23.8 231.0 146.4 14.7 215.0 138.7 10.2 198.0 131.1

60 20.4 198.0 151.2 12.5 182.0 143.6 8.5 165.0 136.0

80 17.0 165.0 156.0 10.2 149.0 148.5 6.8 132.0 140.9

40 25.6 249.0 144.0 15.8 231.0 136.4 10.9 212.0 128.8

60 22.0 213.0 149.2 13.4 195.0 141.5 9.1 177.0 134.1

80 18.3 178.0 157.3 11.0 160.0 146.8 7.3 142.0 139.4

40 32.5 326.3 151.4 20.7 311.1 146.2 14.7 295.2 140.8

60 28.1 281.8 156.2 17.7 266.5 151.0 12.5 250.4 145.5

80 23.7 237.4 161.1 14.8 221.9 155.8 10.2 205.4 150.1

40 35.4 355.4 149.2 22.5 338.6 144.1 16.0 321.0 138.7

60 30.6 307.0 154.3 19.3 290.0 149.1 13.6 272.2 143.7

80 25.8 258.5 159.4 16.0 241.3 154.2 11.1 223.1 148.6

40 38.2 383.4 147.1 24.3 365.0 142.0 17.3 345.8 136.6

60 33.0 331.1 152.5 20.8 312.5 147.3 14.6 293.0 141.9

80 27.8 278.7 157.9 17.3 259.9 152.6 12.0 240.1 147.1

40 41.0 411.8 145.5 26.0 391.6 140.3 18.5 370.6 134.9

60 35.4 355.5 151.1 22.3 335.2 145.8 15.7 313.9 140.4

80 29.8 299.1 156.6 18.5 278.6 151.4 12.8 257.0 145.8

40 44.3 445.0 142.6 28.1 422.7 137.4 19.9 399.6 132.1

60 38.3 384.0 148.5 24.0 361.7 143.4 16.9 338.3 138.0

80 32.2 323.0 154.5 20.0 300.5 149.3 13.8 276.8 143.8

40 47.5 476.3 139.8 30.0 452.0 134.7 21.3 427.0 129.5

60 40.9 410.9 146.1 25.7 386.6 141.0 18.0 361.3 135.7

80 34.4 345.5 152.4 21.3 321.1 147.3 14.7 295.4 141.9

40 60.8 610.1 144.2 38.8 583.5 139.6 27.7 555.9 134.9

60 52.6 527.4 150.1 33.3 500.6 145.5 23.6 472.6 140.7

80 44.3 444.7 155.9 27.8 417.6 151.3 19.4 389.1 146.4

40 65.8 660.0 141.4 41.9 630.7 136.9 30.0 600.4 132.3

60 56.8 570.4 147.7 36.0 541.0 143.1 25.5 510.3 138.4

80 47.9 480.8 153.9 30.0 451.1 149.3 20.9 419.8 144.5

40 70.5 707.3 138.8 44.9 675.4 134.4 32.1 642.5 129.8

60 60.9 611.2 145.4 38.5 579.2 140.9 27.2 545.8 136.3

80 51.3 515.0 151.9 32.1 482.7 147.4 22.4 448.8 142.7

20 ºF 30 ºF 40 ºF

gpm MBh LAT gpm MBh LAT gpm MBh LAT

18 PKG-PRC019C-EN

Page 19

Table 15. Steam coil capacity data

Unit

Size

5 ton

7.5 ton

10 ton

15 ton

CFM EAT LAT MBh Cond LAT MBh Cond LAT MBh Cond LAT MBh Cond

40 138.8 190.1 197.1 141.9 196.0 204.0 148.4 208.8 219.2 158.7 229.2 243.9

1800

2000

2200

2700

3000

3300

3600

4000

4400

5400

6000

6600

60 149.1 169.1 175.4 152.1 175.0 182.2 158.6 187.9 197.2 169.0 208.2 221.5

80 159.4 148.1 153.7 162.4 154.0 160.4 169.0 166.9 175.2 179.3 187.2 199.3

40 134.7 202.2 209.7 137.6 208.5 217.0 143.8 222.2 233.3 153.8 243.8 259.5

60 145.4 179.9 186.6 148.4 186.2 193.9 154.6 199.9 209.9 164.5 221.5 235.8

80 156.2 157.7 163.6 159.0 163.9 170.7 165.3 177.6 186.4 175.3 199.2 212.0

40 131.1 213.7 221.5 133.8 220.3 229.3 139.9 234.7 246.4 149.3 257.6 274.2

60 142.2 190.1 197.1 144.9 196.7 204.8 151.0 211.2 221.7 160.5 234.0 249.1

80 153.4 166.6 172.8 156.1 173.2 180.2 162.1 187.7 197.0 171.6 210.5 224.1

40 143.4 308.8 320.3 146.5 318.3 331.4 153.5 339.3 356.2 164.3 372.3 396.1

60 152.9 274.8 285.0 156.1 284.3 295.9 163.0 305.2 320.5 173.8 338.2 359.9

80 162.5 240.7 249.6 165.6 250.3 260.6 172.6 271.2 284.7 183.4 304.2 323.6

40 139.2 329.2 341.4 142.2 339.4 353.3 148.9 361.7 379.8 159.4 396.9 422.3

60 149.3 292.9 303.8 152.3 303.1 315.6 159.0 325.5 341.7 169.4 360.6 383.7

80 159.3 256.6 266.1 162.3 266.8 277.8 168.9 289.2 303.6 179.3 324.3 345.1

40 135.6 348.4 361.3 138.5 359.2 373.9 144.8 382.8 401.9 154.9 420.0 446.9

60 146.0 310.0 321.5 148.9 320.8 334.0 155.2 344.4 361.6 165.3 381.7 406.1

80 156.4 271.7 281.7 159.3 282.4 294.0 165.7 306.0 321.3 175.7 343.3 365.3

40 138.0 384.6 398.8 141.0 396.4 412.7 147.7 422.5 443.5 158.1 463.6 493.4

60 147.2 342.2 354.8 150.2 354.0 368.6 156.9 380.1 399.0 167.3 421.2 448.3

80 156.4 299.8 310.9 159.4 311.7 324.5 166.1 337.7 354.5 176.5 378.8 403.2

40 134.0 410.0 425.2 136.9 422.7 440.0 143.3 450.4 472.9 153.4 494.3 526.0

60 143.7 364.8 378.3 146.6 377.5 393.0 153.0 405.3 425.4 163.0 449.1 478.0

80 153.3 319.6 331.5 156.2 332.3 345.9 162.6 360.1 378.0 172.6 403.9 429.9

40 130.5 433.9 450.0 133.3 447.3 465.7 139.4 476.7 500.5 149.1 523.1 556.8

60 140.5 386.1 400.4 143.3 399.5 415.9 149.4 428.9 450.3 159.1 475.3 505.9

80 150.5 338.3 350.8 153.3 351.7 366.1 159.5 381.1 400.1 169.1 427.5 455.0

40 137.7 577.7 599.0 140.7 595.4 619.8 147.4 634.6 666.3 157.8 696.3 740.9

60 146.9 514.0 533.0 149.9 531.7 553.5 156.6 570.9 599.5 167.0 632.6 673.1

80 156.1 450.3 467.0 159.1 468.2 487.4 165.8 507.2 532.6 176.1 569.0 605.4

40 133.7 615.8 638.6 136.6 634.9 660.9 143.0 676.5 710.3 153.1 742.4 790.0

60 143.4 547.9 568.2 146.3 567.0 590.3 152.7 608.8 639.2 162.7 674.5 717.7

80 153.0 480.0 497.8 155.9 499.1 519.6 162.3 540.9 567.9 172.3 606.7 645.5

40 130.2 651.7 675.8 133.0 671.8 699.4 139.1 716.0 751.8 148.8 785.7 836.0

60 140.2 579.9 601.4 143.0 600.0 624.7 149.1 644.2 676.4 158.8 713.9 759.6

80 150.2 508.1 526.9 153.0 528.3 549.9 159.2 572.4 601.0 168.8 642.1 683.2

3 psig 5 psig 10 psig 20 psig

Performance Data

Steam Pressure

PKG-PRC019C-EN 19

Page 20

Electrical Data

Electrical Data Calculations

RLA = Rated Load Amps

Compressor LRA = Locked Rotor Amps

Fan Motor LRA = Locked Rotor Amps, N.E.C.Table 430 - 151

FLA = Full Load Amps, N.E.C. Table 430 - 150

Voltage utilization range is ±10 percent

Determination of Minimum Circuit Ampacity (MCA)

MCA = 1.25 x largest motor amps (FLA or RLA) + the sum of the remaining motor amps.

Determination of Maximum Fuse Size (MFS)

MFS = 2.25 x largest motor amps (FLA or RLA) + the sum of the remaining motor amps.

If the rating value determined does not equal a standard current rating of over current protective

device, use the next lower standard rating for the marked maximum rating.

Table 16. Integral air-cooled standard electrical data (with Micro-channel condenser coil)

Unit

Size Voltage

208-230/60/3 16.0 110.0

5

460/60/3 7.8 52.0 1.48 1.48 12.7 20

575/60/3 5.7 38.9 1.18 1.18 9.5 15

208-230/60/3 25.0 164.0

7.5

Notes:

1. Voltage range:nominal voltage: 208-230V, acceptable range: 187 - 253Vnominal voltage: 460V,

2. Ampacity is calculated per UL formula: ampacity = (1.25 x compressor RLA) + the sum of the second

3. Maximum fuse size is calculated per UL formula: MFS = (2.25 x compressor RLA) + the sum of the

4. There are two compressors on 10 and 15-ton units and only one RLA & LRA value is shown in table. The

460/60/3 12.8 100.0 2.05 1.48 19.6 30

575/60/3 9.6 78.0 1.64 1.18 14.8 20

208-230/60/3 16.0 110.0

10

460/60/3 7.8 52.0 2.77 2.05 22.3 30

575/60/3 5.7 38.9 2.22 1.64 16.7 20

208-230/60/3 25.0 164.0

15

460/60/3 12.8 100.0 4.15 4.15 37.1 50

575/60/3 9.6 78.0 3.32 3.32 28.3 35

acceptable range: 414 - 506Vnominal voltage: 575V, acceptable range: 518 - 633V

compressor RLA (is used) and all other motor FLAs

second compressor RLA (if used) and all other motor FLAs

data is the same for both compressors.

Compressor

Condenser Fan

Motor

3.27

1.0

4.53

1.5

6.13

2.0

9.18

3.0

Evaporator

Fan Motor

MCA MFSRLA LRA HP FLA HP FLA

3.27 26.5 40

1.0

3.27 39.1 60

1.0

4.53 46.6 60

1.5

9.18 74.6 90

3.0

20 PKG-PRC019C-EN

Page 21

Electrical Data

Table 17. Integral air-cooled oversized electrical data (with Micro-channel condenser coil)

Unit

Size Voltage

208-230/60/3 16.0 110.0

5

7.5

10

15

460/60/3 7.8 52.0 2.77 2.05 14.5 20

575/60/3 5.7 38.9 2.22 1.64 11.0 15

208-230/60/3 25.0 164.0

460/60/3 12.8 100.0 4.15 2.05 22.2 30

575/60/3 9.6 78.0 3.32 1.64 17.0 25

208-230/60/3 16.0 110.0

460/60/3 7.8 52.0 4.15 4.15 25.8 4.46 26.1 30

575/60/3 5.7 38.9 3.32 3.32 19.5 3.57 19.7 25

208-230/60/3 25.0 164.0

460/60/3 12.8 100.0 6.80 6.80 42.4 7.45 43.1 50

575/60/3 9.6 78.0 5.44 5.44 32.5 5.96 33.0 40

Compressor

Condenser

Fan Motor

Evaporator Fan

Motor

Evaporator 2-Speed

Motor

RLA LRA HP FLA HP FLA MCA HP FLA MCA MFS

6.13

2.0

9.18

3.0

9.18

3.0

15.00

5.0

1.5

1.5

3.0

5.0

4.53 30.6

4.53 45.0

9.18 54.3

15.00 86.3

45

N/A

70

N/A

8.92 54.0 70

3.0

14.9 86.2 110

5.0

PKG-PRC019C-EN 21

Page 22

Dimensions and Weights

Table 18. Unit dimensions (with Micro-channel condenser coil), in-lbs.

Unit Size A B C D E Ship. Wgt.

Wgt.

5 ton 56.69 20.63 20.63 18.92 18.92 945 856

7.5 ton — — — — — 1342 1210

10 ton — — — — — 1474 1342

15 ton — — — — — 2077 1923

Note: 7.5-ton and 10-ton in Figure 2, p. 23, 10 and 15-ton in Figure 3, p. 24

Figure 1. 5-ton unit

Oper.

BC15.43

24.90

74.80

A

D

24.90

0.75

74.80

34.25

18.86

CONDENSER COIL

E

2.76

FORKLIFT ACCESS

front view

RETURN

AIR

31.50

13.64

SUPPL

AIR

2.76

SUPPL

AIR

2.74

back view

SIDE

ACCESS

CONDENSER

DISCHARGE

CONDENSER

RETURN

SIDE

ACCESS

side view

22 PKG-PRC019C-EN

Page 23

Figure 2. 7.5 and 10-ton units

85.83

22.70 15.20

10.03

15.20

16.67

Dimensions andWeights

18.86 14.77

18.86

2.68

74.80

24.90

COMPRESSOR

ACCESS

FORKLIFT ACCESS

front view

CONTROLS

ACCESS

RETURN

AIR

CONDENSER

DISCHARGE

CONDENSER

RETURN

GRILL

0.75

34.25

31.50

SIDE

ACCESS

SIDE

ACCESS

13.64

SUPPL

AIR

CONDENSER COIL

back view

2.74

SUPPL

AIR

side view

PKG-PRC019C-EN 23

Page 24

Dimensions andWeights

Figure 3. 15-ton units

15,50

10,00

114,00

15,50

10,00

15,5024,00 19,50 19,5014,50

13,50

14,50 19,50

25,00

75,00

3,00

COMPRESSOR

ACCESS

COMPRESSOR

ACCESS

FORKLIFTACESS

front view

L

GRIL

CONTROLS

ACCESS CONDENSER COIL

34,50 0,50

back view

31,50

13,5

0

2,50

SUPPLY

AIR

RETURN

AIR

CONDENSER

CHARG

DIS

S

CONDE

N

RETURN

SIDE

ACCESS

E

SIDE

E

ACCESS

R

SUPPL

A

Y

I

R

s

ide view

24 PKG-PRC019C-EN

Page 25

Figure 4. Component overview

Dimensions andWeights

vent

inlet

filter frame

Accessories

Figure 5. Plenum

A

Table 19. Plenum Dimensions, in.

Unit Size A B C

5 ton 56 ¾ 16 ¼ 31 ½ 52 ¾ x 12 ¾ 95

B

7.5 & 10 ton 85 7/8 16 ¼ 31 ½ 81 ¾ x 12 ¾ 141

15 ton 114 16 ¼ 31 ½ 110 x 12 ¾ 188

Grill Size

(W x H) Weight

C

PKG-PRC019C-EN 25

Page 26

Dimensions andWeights

Low Ambient Controls

Figure 6. Low ambient kit SCIJ050-075

LIQUID

SENSOR

AMBIENT

SENSOR

CONTROL

MODULE

AMBIENT

SENSOR

LIQUID

SENSOR

26 PKG-PRC019C-EN

Page 27

Figure 7. Low ambient kit SCIJ100-150

LIQUID

SENSOR

Dimensions andWeights

AMBIENT

SENSOR

CONTROL

MODULE

AMBIENT

SENSOR

LIQUID

SENSOR

PKG-PRC019C-EN 27

Page 28

Dimensions andWeights

Coils

Figure 8. Hot water coil

3.239

OD

CONNECTION

OD

CONNECTION

B

A

Note: Coils are field-installed.

Note: Coil connections are mirror-image and can be mounted with either left or right-hand connections.

Table 20. Hot water coil dimensions, in./lbs.

Unit Size A B

5 ton 52 ½ 47 1/16 63 50

7.5 & 10 ton 81 5/8 76 ¼ 96 75

15 ton 109 ¼ 104 ¼ 137 108

Wet Coil

Weight

Dry Coil

Weight

28 PKG-PRC019C-EN

Page 29

Figure 9. Steam coil

Dimensions andWeights

Note: Coils are field-installed.

Note: Coil connections are mirror-image and can be mounted with either left or right-hand connections.

Table 21. Steam coil dimensions, in./lbs.

Unit Size A B

5 ton SCIJ 52 ½ 45 7/8 1 ½ 2 68

7.5 & 10 ton SCIJ 81 5/8 74 2 3 93

15 ton SCIJ 109 ¾ 102 1/8 2 3 132

Return CSupply

D Weight

PKG-PRC019C-EN 29

Page 30

Mechanical Specifications

General

The units shall be completely factory assembled, tested, piped, internally wired, and fully charged

with R-410A. Units are in compliance with ASHRAE 90.1 equipment efficiency requirements. All

units shall go through a factory run-test before shipment. All equipment shall have factory-installed

decals and labels to aid in servicing and indicate caution areas.

Cabinet

The cabinet shall be constructed with galvanized steel with aluminum channels. All exterior panels

shall be 24 gage, 1” double wall, foamed panels with allen head fasteners for easy removal and

access. All panels shall be painted with anticorrosive primer and high resistance synthetic enamel.

The unit shall be constructed for vertical discharge with front or rear return.

Return Air Grill

A decorative return air grill shall be provided and shall be anodized aluminum with vertical blades.

Discharge Plenum

The discharge plenum shall allow air discharge either vertically or horizontally. The plenum will

be constructed to match the unit.

Evaporator and Condenser Coils

The evaporator coil shall be constructed with 3/8" OD for the, internally enhanced copper tubes,

which are mechanically bonded to aluminum fins.The condenser coils are a micro-channel

construction - all aluminum with brazed fins and headers. Coils shall be factory leak tested to 450

psig.The drain pan shall be constructed of galvanized steel and positively sloped.

Fans

The evaporator and condenser fans shall be forward curve centrifugal fans, constructed of

galvanized steel, that are statically and dynamically balanced. The fans shall be provided with

permanently lubricated bearings with a design life (L10) of at least 200,000 hours.

Motors shall be open drip proof. Drive assemblies shall consist of V-belts, variable pitch drive

sheaves for both the evaporator and condensers.

Filters

Units shall come standard with one-inch, fiberglass throwaway filters. The filter rack can

accommodate a one-inch or two-inch filter.

Compressors

The compressors shall all be scroll compressors each with their own independent circuit.

Compressors shall be mounted on rubber isolators for vibration isolation.The 5 and 7-ton units

shall have a single compressor.The 10 and 15-ton units shall have dual compressors.

Refrigeration Circuit

Refrigeration circuits shall be independent and completely piped including: filter driers,

distributors, and thermal expansion valves. Each circuit shall be equipped with high and low

pressure switches.The high pressure switch shall be rated at 650 +/- 10 psig / 550 +/- 10 psig and

the low pressure switch shall be rated at 51 +/-7 / 94 +/- 7 psig. Each circuit shall be leak tested,

dehydrated and charged with oil and R-410A refrigerant at the factory.

Electrical /Controls

Each unit shall have single point power connections with a terminal block.The unit shall come

standard with a control interface that will include terminal strip and 24V transformer.

30 PKG-PRC019C-EN

Page 31

Factory Provided Options

Evaporator and Condenser Coils with Corrosion Resistant Treatment and Silver Solder

Braze Joints. Phenolic coating applied to evaporator and condenser coils for protection in harsh

environments. Silver solder braze joints are provided on coils and refrigerant piping with coated

coil options.

Horizontal Discharge. The units shall be constructed to provide horizontal discharge with a rear

return.

Field Installed Accessories

Thermostats. A 1H/1C remote mounted thermostat shall be provided with 5 and 7.5-ton units. A

2H/2C or 2C remote mounted thermostat shall be provided with 10and 15-ton units.All thermostats

are available with auto, manual, or auto/manual bases.

ProgrammableThermostat. A 1H/1C remote mounted programmable thermostat shall be

provided with 5 and 7.5-ton units. A 2H/2C remote mounted programmable thermostat shall be

provided with 10 and 15-ton units.

Low Ambient Control Damper (SCIH Models Only). A low ambient head pressure control

damper kit shall allow unit operation down to 0°F (-17.8°C) ambient.The kit shall include low

pressure cut-out bypass timers, damper actuator, mounting hardware and an installation/

operation manual for field installation.

Mechanical Specifications

Hot Water Coil. The hot water coil shall be designed for use with 180°F to 200°F water.The hot

water coil shall be a field installed item. The coil shall be mountable to the unit with right or lest

hand connections. The unit filter rack shall mount to the coil on the air inlet side.

Steam Coil. Field installed steam coil designed for use with 3, 5, 10, or 20 psig steam.The coil

shall be mounted to the unit with right and left hand connections. Unit filter rack mounts to coil on

air inlet side.

Filters. Two-inch pleated or permanent filters shall be provided for field installation.

Discharge Plenum. The discharge plenum shall allow air to discharge horizontally. The plenum

shall be constructed of 20 gage sheet metal with 1” fiberglass insulation to match the unit.

Low Ambient Kit. The low ambient operation kit consists of an electronic control module, an

outdoor ambient temperature sensor, and liquid line temperature sensor(s).This is a simple on/off

control that cycles the condenser fan(s) to maintain a liquid line temperature set point. Unit will cool

down to 0 (zero) °F ambient temperature.The fan will only cycle when the ambient temperature

is below 70 °F.

Oversized/2-Speed Motor Kit. Oversized/2-speed motor kit and drives shall be provided for

those applications where external static pressure exceeds the capability of the standard fan motor.

The 2-speed motor reduces energy consumption of the equipment when the system is at part load

conditions. Approximate turn down ratio on the 2-speed motor is 66% rated. Oversized/2-speed

motors shall be totally-enclosed fan-cooled (TEFC) type.

Note: The 2-speed motor kit is optional and available only on 10 and 15 ton units.

PKG-PRC019C-EN 31

Page 32

Trane optimizes the performance of homes and buildings around the world. A business of Ingersoll Rand, the leader in

creating and sustaining safe, comfortable and energy efficient environments, Trane offers a broad portfolio of advanced

controls and HVAC systems, comprehensive building services, and parts. For more information, visit www.Trane.com.

Trane has a policy of continuous product and product data improvement and reserves the right to change design and specifications without notice.

© 2014Trane All rights reserved

PKG-PRC019C-EN 29 Jan 2014

Supersedes PKG-PRC019-EN (02 Apr 2012)

We are committed to using environmentally

conscious print practices that reduce waste.

Loading...

Loading...