Page 1

INSTALLATION INSTRUCTIONS

14 SEER

14 SEER

Split System Air Conditioner & Heat Pump

1.5-5 Tons

R410A

NOTE: Appearance of unit may vary.

RECOGNIZE THIS SYMBOL AS AN INDICATION OF IMPORTANT SAFETY INFORMATION

WARNING

These instructions are intended as an aid to qualified

licensed service personnel for proper installation, adjustment and operation of this unit. Read these instructions

thoroughly before attempting installation or operation.

Failure to follow these instructions may result in improper

installation, adjustment, service or maintenance possibly

resulting in fire, electrical shock, property damage,

personal injury or death.

DO NOT DESTROY THIS MANUAL

Please read carefully and keep in a safe place for future reference by a serviceman.

Page 2

TABLE OF CONTENTS

1. KEY TO SYMBOLS AND SAFETY INSTRUCTIONS............................................1

2. UNIT LOCATION CONSIDERATIONS.................................................................2

3. UNIT PREPARATION..........................................................................................3

4. SETTING UP THE UNIT.......................................................................................3

5. REFRIGERANT LINE CONSIDERATIONS.........................................................4

6. REFRIGERANT LINE ROUTING........................................................................5

7. REFRIGERANT LINE BRAZING..........................................................................7

8. REFRIGERANT LINE LEAK CHECK...................................................................8

9. EVACUATION......................................................................................................8

10. SERVICE VALVE...............................................................................................8

11. ELECTRICAL - LOW VOLTAGE.........................................................................9

12. ELECTRICAL - HIGH VOLTAGE......................................................................10

13. START UP........................................................................................................10

14. SYSTEM CHARGE ADJUSTMENT..................................................................11

15. SYSTEM OPERATION AND TROUBLESHOOTING.......................................16

16. WARRANTY.....................................................................................................19

17. WIRING DIAGRAMS.......................................................................................20

18 . MATCHING TABLE AND CHECKOUT PROCEDURES.................................22

Page 3

All phases of this installation must comply with NATIONAL, STATE, AND

LOCAL CODES.

1. Key to symbols and safety instructions

1.1 Key to symbols

WARNING: HAZARDOUS VOLTAGE

Failure to follow this warning could result in property damage,

severe personal injury or death.

Disconnect all electric power, including remote disconnects

before servicing. Follow proper lockout/tagout procedures to

ensure the power cannot be inadvertently energized.

Warnings in this document are identified by a warning

triangle. Keywords at the start of a warning indicate the

type and seriousness of the ensuing risk if measures to

prevent the risk are not taken.

This symbol indicates important information where there

is no risk to people or property.

The following keywords are defined and can be used in this document:

DANGER indicates a hazardous situation which, if not avoided, will

result in death or serious injury.

WARNING indicates a hazardous situation which, if not avoided, could

result in death or serious injury.

CAUTION indicates a hazardous situation which, if not avoided, could

result in minor to moderate injury.

NOTICE is used to address practices not related to personal injury.

1.2 Safety

CAUTION:

This document is customer property and is to remain with

this unit. Please return to service information pack upon

completion of work.

These instructions do not cover all variations in systems

or provide for every possible contingency to be met in

connection with the installation.

Should further information be desired or should particular

problems arise which are not covered sufficiently for the

purchaser’s purposes, the matter should be referred to your

installing dealer or local distributor.

WARNING: REFRIGERANT OIL

These units use R-410A refrigerant which operates at 50% to 70%

higher pressures than

equipments. Refrigerant cylinders are painted a “Rose” color to

indicate the type of refrigerant and may contain a “dip” tube to allow

for charging of liquid refrigerant into the system. All R-410A systems

use a POE oil that readily absorbs moisture from the atmosphere. To

limit this “hygroscopic” action, the system should remain sealed

whenever possible. If a system has been opening to the atmosphere

for more than 4 hours, the compressor oil must be replaced. Never

break a vacuum with air and always change the driers when opening

the system for component replacement.

R-22. Use only R-410A approved service

CAUTION: HOT SURFACE

May cause minor to severe burning. Failure to follow this Caution

could result in property damage or personal injury. Do not touch

the top of compressor.

CAUTION: CONTAINS REFRIGERANT

Failure to follow proper procedures can result in personal illness

or injury or severe equipment damage. System contains oil and

refrigerant under high pressure. Recover refrigerant to relieve

pressure before opening system.

CAUTION: GROUNDING REQUIRED

Failure to inspect or use proper service tools may result in

equipment damage or personal injury. Reconnect all grounding

devices. All parts of this product that are capable of conducting

electrical current are grounded. If grounding wires, screws,

straps, clips, nuts or washers used to complete a path to ground

are removed for service, they must be returned to their original

position and properly fastened.

This document contains a wiring diagram and service information.

CAUTION:

This information is intended for use by individuals possessing

adequate backgrounds of electrical and mechanical experience. Any

attempt to repair a central air conditioning product may result in

personal injury and/or property damage.

WARNING: SERVICE VALVES

Failure to follow this warning will result in abrupt release of

system charge and may result in personal injury and/or property

damage. Extreme caution should be exercised when opening the

Liquid Line Service Valve. Turn valve stem counterclockwise only

until the stem contacts the rolled edge. No torque is required.

WARNING: BRAZING REQUIRED

Failure to inspect lines or use proper service tools may result in

equipment damage or personal injury.

All outdoor unit and evaporator coil connections are

copper-to-copper and should be brazed with a

phosphorous-copper alloy material such as Silfos-5 or

equivalent. Do not use soft solder.

1

Page 4

WARNING: HIGH CURRENT LEAKAGE

Unit Dimensions

Failure to follow this warning could result in property damage,

severe personal injury or death. Grounding is essential before

connecting electrical supply.

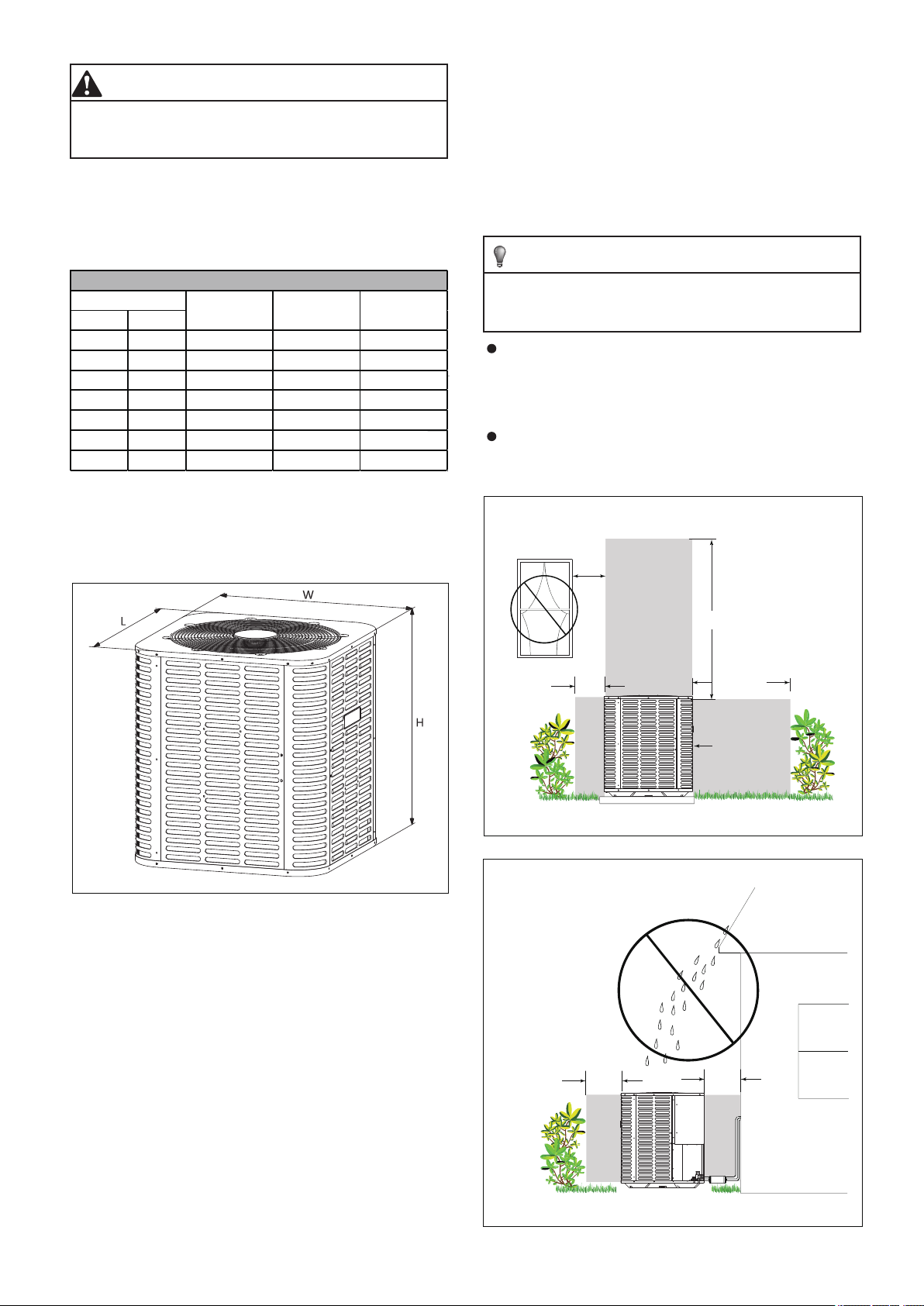

Position unit where water, snow or ice from roof or overhang cannot fall

directly on unit.

Position the outdoor unit a minimum of 12’’ from any wall or surrounding

shrubbery to ensure adequate airflow.

See Figure 2 and Figure 3.

2. Unit location considerations

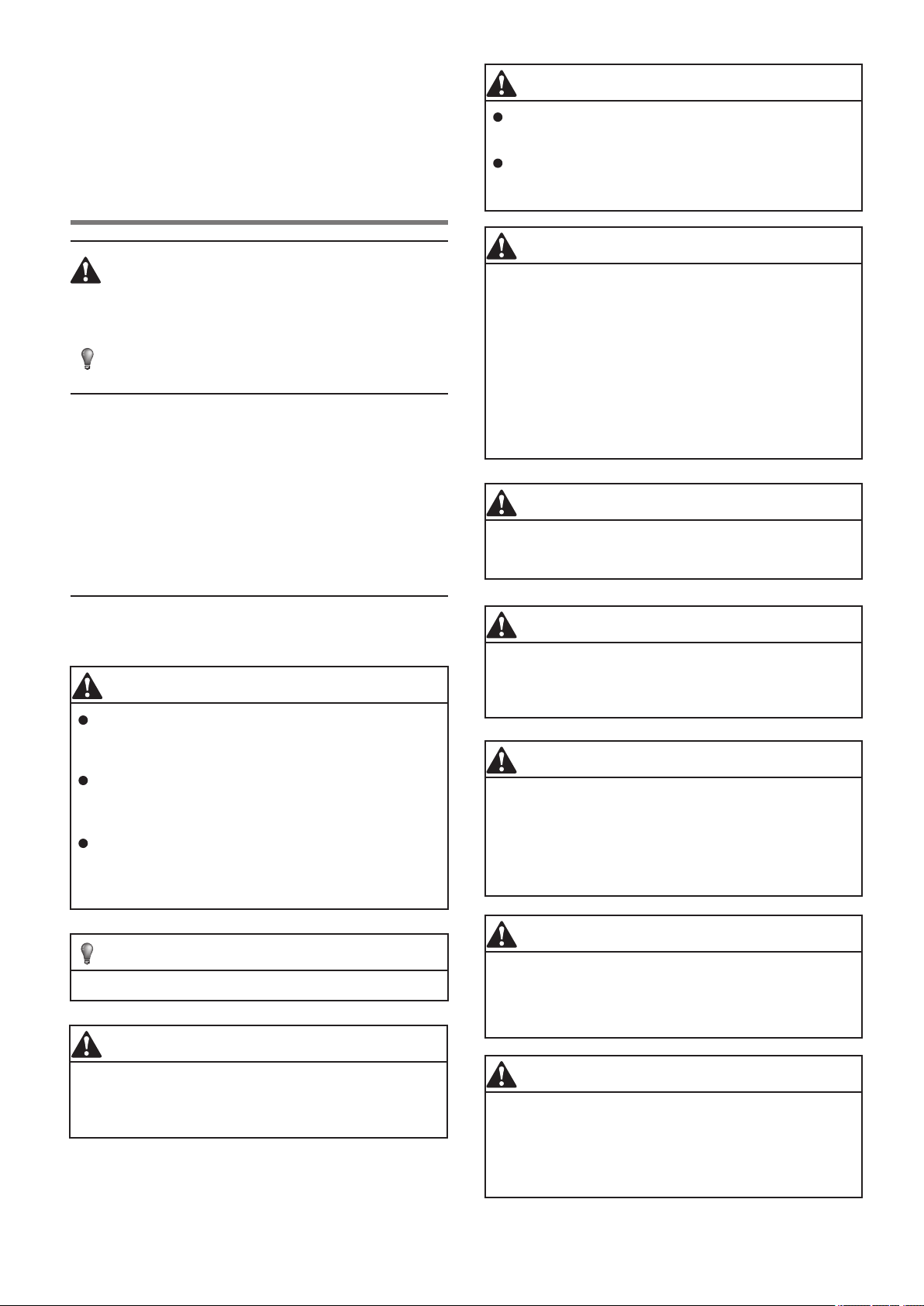

2.1 Unit dimensions

Model

AC HP

18 24-15/16 21-7/8 21-7/8

/

24 18/24 24-15/16 23-5/8 23-5/8

30 30 24-15/16 28 28

36 36 24-15/16 29-1/8 29-1/8

4242 33-3/16 28 28

48 48 33-3/16 28 28

60 60 33-3/16 29-1/8 29-1/8

Table 1

The unit’s weight value is on the cardboard box.

When mounting the outdoor unit on a roof, be sure the roof will support

the unit’s weight. Properly selected isolation is recommended to prevent

sound or vibration transmission to the building structure.

H(Inches) W(Inches) L(Inches)

Cold climate considerations (heat pump only)

Precautions must be taken for units being installed in areas where

snow accumulation and prolonged below-freezing temperatures

occur.

Units should be elevated 3-12 inches above the pad or rooftop,

depending on local weather. This additional height will allow

drainage of snow and ice melted during defrost cycle prior to its

refreezing. Ensure that drain holes in unit base pan are not

obstructed, preventing drainage of defrost water (Figure 4).

If possible, avoid locations that are likely to accumulate snow

drifts. If not possible, a snow drift barrier should be installed

around the unit to prevent a build-up of snow on the sides of the

unit.

Avoid Install

Near Bedrooms

Min. 60” Unrestricted

Figure 1

2.2 Location restrictions

Ensure the top discharge area is unrestricted for at least 60 inches above

the unit.

Do not locate outdoor unit near bedrooms since normal operational

sounds may be objectionable.

Position unit to allow adequate space for unobstructed airflow, wiring,

refrigerant lines, and serviceability.

Maintain a distance of 24 inches between units.

Min. 12’’ to

Shrubbery

Figure 2

Min. 12” to

Shrubbery

Min. 24’’

Unrestricted

Access Panel

Min. 12” to

Wall

24 inches clearance must be provided in front of the control box (access

panels) and any other side requiring service.

2

Figure 3

Page 5

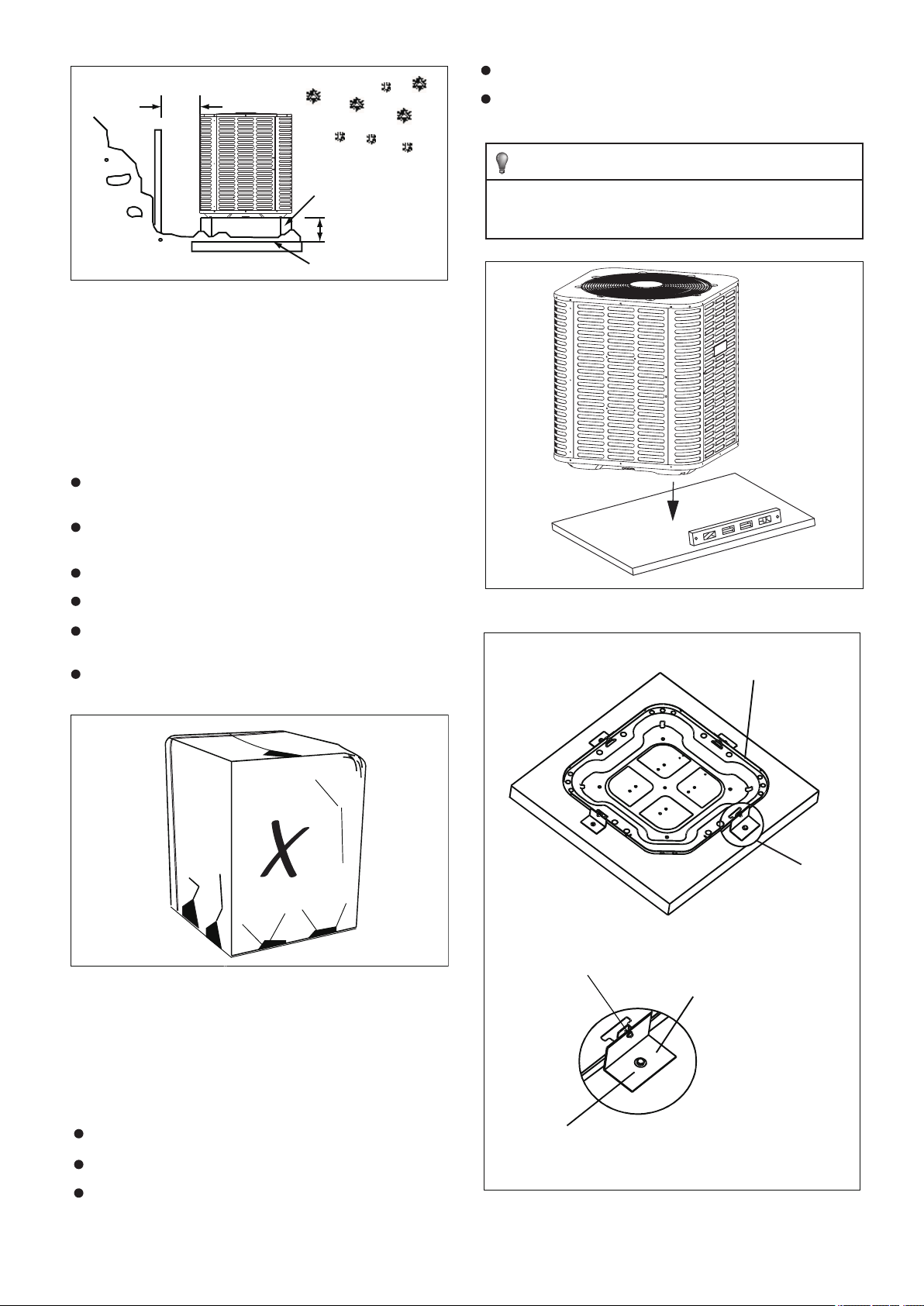

The pad must be high enough above grade to allow for drainage.

Min. 12"

Snow

barrier

Snow legs

3- 12" Elevation

pad

Figure 4

3. Unit preparation

3.1 Pre-installation

STEP 1 - Check for damage and report promptly to the carrier any

damage found to the unit (Figure 5).

STEP 2 - Instruments must be designed to install/serve R410A

equipmens.

Gauge sets, hoses, refrigerant containers and recovery system

must be designed to handle the POE type oils.

Manifold sets should be 800 PSIG high side and 250 PSIG low

side.

The pad location must comply with National, State and Local codes.

These instructions are intended to provide a method to tie-down

system to concrete slab as a securing procedure for high wind

areas. Check Local Codes for tie-down methods and protocols.

All hoses must have a 700 PSIG service pressure rating.

Leak detectors should be disigned to detect R410A.

Recovery equipments (including refrigerant recovery containers

) must be specifically designed to handle R410A.

Do not use an R22 TXV.

Figure

5

4. Setting up the unit

Figure

6

#7 X 3/8” Self Tapping Screws

(Don’t Exceed 3/8” long)

Detail A

The dimension

see Unit Dimensions.

See Detail A

Brackets:

2" width, 1/16" thickness,

height as required.

Available from distributor

or in market place.

4.1 Pad installation

When installing the unit on a support pad, such as a concrete slab,

consider the following:

The pad must be at least 1-2” larger than the unit on all sides.

The pad must be separate from any structure.

The pad must be level.

1/4” Χ 1-1/2” Hex Washer Head Concrete Screws

(3/16” Pilot Hole Needed. Pilot Hole Should Be 1/4” Deeper

Than The Fastener Embedment)

Figure

7

3

Page 6

5. Refrigerant line considerations

optional standard optional standard

Suction line

Liquid line

25 50 75 100 125 150

3/8 25 50 56 44 32 20

Total equivalent length(Feet)

Maximum vertical length(Feet)

25 50 100 150

1-1/8 1.00 0.99 0.98 0.97

Coefficient

Total suction line length(Feet)

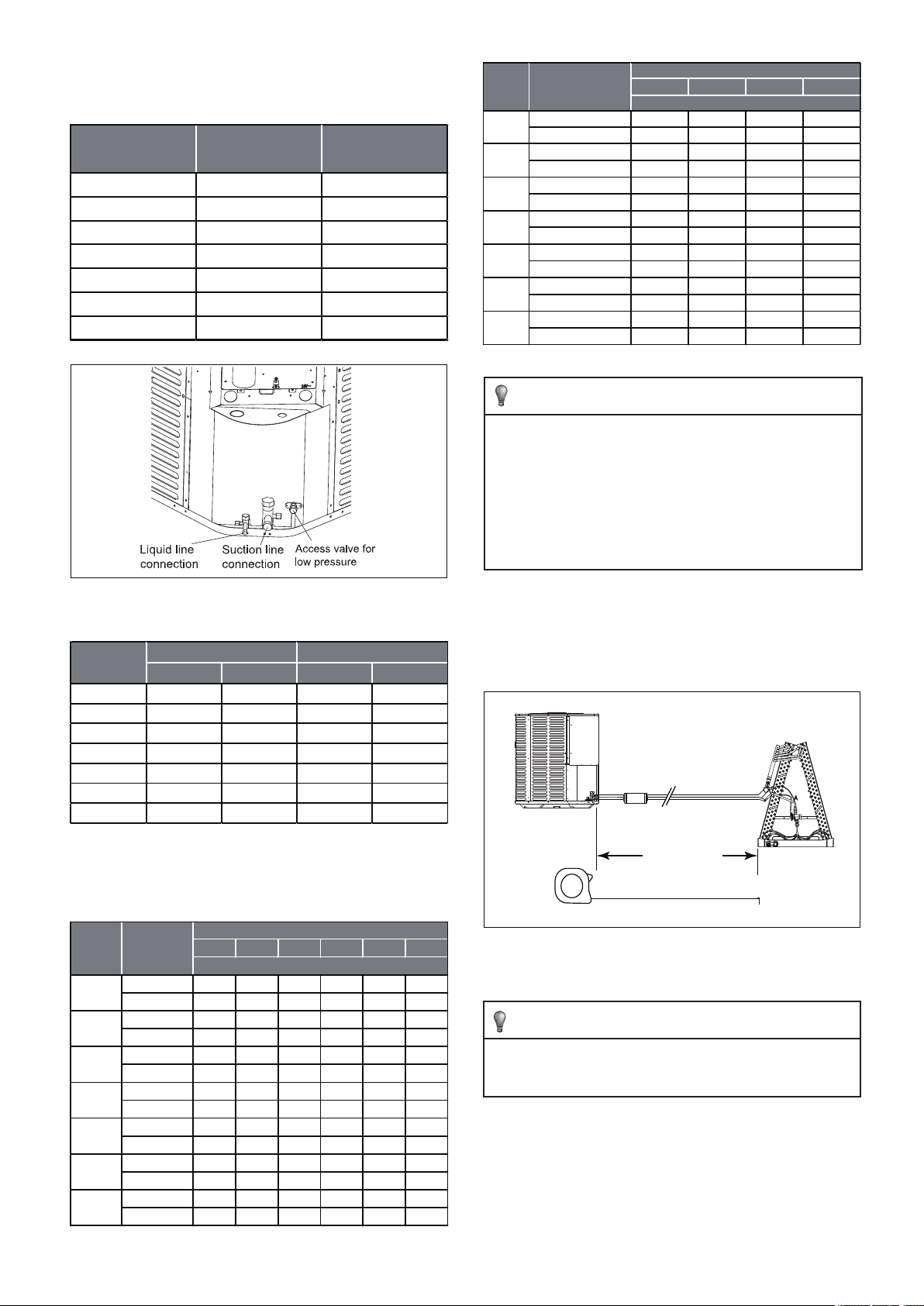

5.1 Service valve connection sizes

Model

18 3/4 3/8

24 3/4 3/8

30 3/4 3/8

36 3/4 3/8

42 3/4 3/8

48 7/8 3/8

60 7/8 3/8

Table 2

Suction line

connection

Liquid line

connection

Model

18

24

30

36

42

48

60

Table 5 Suction line length/size VS capcaity multiplier

Using suction line larger than shown in chart will result in poor oil

return and is not recommended.

For example: the system capacity published in AHRI is 17800

Btu/h. This data is based on the AHRI test condition and 25 feet

line set with standard suction tube size (3/4" tube). If you need to

add the line set more than 25 feet or use the optional suction

tube size, you need to recalculate the capacity with the

coefficient in the table. For 50 feet line and 5/8" suction tube, the

capacity will be 17800*0.97=17266 Btu/h.

Suction line

(Inches)

5/8 1.00 0.97 0.94 0.90

3/4 1.00 0.98 0.95 0.92

5/8 1.00 0.97 0.94 0.90

3/4 1.00 0.98 0.95 0.92

5/8 1.00 0.97 0.94 0.90

3/4 1.00 0.98 0.96 0.93

5/8 1.00 0.97 0.94 0.90

3/4 1.00 0.99 0.97 0.96

5/8 1.00 0.98 0.95 0.91

3/4 1.00 0.98 0.97 0.96

3/4 1.00 0.98 0.95 0.92

7/8 1.00 0.98 0.97 0.96

7/8 0.99 0.98 0.94 0.90

Figure

8

5.2 Refrigerant line sizes

Model

18 5/8 3/4 5/16 3/8

24 5/8 3/4 5/16 3/8

30 5/8 3/4 5/16 3/8

36 5/8 3/4 5/16 3/8

42 5/8 3/4 5/16 3/8

48 3/4 7/8 1/2 3/8

60 7/8 1-1/8 1/2 3/8

Table 3

5.3 Refrigerant piping limits and required refrigerant

line length

18

24

30

36

42

48

60

Liquid line

(Inches)

5/16 25 50 60 58 40 30

3/8 25 50 60 60 40 30

5/16 25 36 29 23 16 9

3/8 25 50 60 60 40 30

5/16 25 49 38 27 17 6

3/8 25 50 60 60 40 30

5/16 25 50 37 22 7 N/A

3/8 25 50 60 60 40 30

5/16 25 23 4 N/A N/A N/A

3/8 25 50 43 36 30 24

1/2 25 50 56 55 40 30

3/8 25 46 38 30 22 15

1/2 25 50 60 60 40 30

Model

Determine required line length and lift. You will need this later in Section

14.

Total Line Length = __________ Feet.

Total vertical Change(Lift) = __________ Feet.

Line Length

Figure 9

5.4 Refrigerant line insulation

The suction line must always be insulated. DO NOT allow the

Liquid Line and Suction Line to come in direct (metal to metal)

contact.

Table 4

4

Page 7

Figure 10

5.5 Reuse existing refrigerant lines

CAUTION:

If using existing refrigerant lines make certain that all joints are

brazed, not soldered.

For retrofit applications, where the existing refrigerant lines will be used,

the following precautions should be taken:

Ensure that the refrigerant lines are the correct size. Refer to

Section 5.1 listed and Table 3.

Ensure that the refrigerant lines are free of leaks, acid, and oil.

The manufacturer recommends installing only approved matched

indoor and outdoor systems. All of the manufacturer’s split

systems are AHRI certified. Some of the benefits of installing

approved matched indoor and outdoor split systems are maximum

efficiency, optimum performance and the best overall system

reliability.

Figure 11

6. Refrigerant line routing

6.1 Precautions

Take precautions to prevent noise within the building structure

due to vibration transmission from the refrigerant lines. For

example:

When the refrigerant lines have to be fastened to floor joists or

other framing in a structure, use isolation type hangers.

Isolation hangers should also be used when refrigerant lines are

run in stud spaces or enclosed ceilings.

Where the refrigerant lines run through a wall or sill, they should

be insulated and isolated.

Isolate the lines from all ductwork.

Minimize the number of 90º turns.

Use PVC piping as a conduit for all underground installations as

shown in Figure 15. Buried lines should be keep as short as

possible.

The lines should not obstruct service access to the coil, air

handling system or filter.

Care must also be taken to isolate the refrigerant lines to

minimize noise transmission from the equipment to the

structure.

Comply with National, State, and Local Codes when isolating line

sets from joists, rafters, walls or other structural elements.

Figure 12

Side Vi ew

8 Feet Maximum

8 Feet Maximum

Secure Suction li n e from jois ts us ing isolators every 8 feet. Secure

Liquid Line directly to Suc tion line using tape, wire, or other

approp riate m ethod ever y 8 feet.

Isolation From Joist/Rafter

5

Joist/Raft er

Isolator

Line Set

Page 8

8 Feet Maximum

Wall

Isolator

Figure 13

Wall

Side View

Sealant

Insulation

8 Feet Maximum

Secure Suc tion Line using isolators ever y 8 feet.

Secure Liqu id Line directly t o Suction Line using

tape, wir e, or other approp ri ate m ethod every 8 feet.

Isolation In Wall Spaces

Sucti o n Li ne

Line Set

Ductwork

Is

olator

Isolation Through Wall

Figure 14

Line Set

DO NOT han g line s ets from d uctwork

Figure 15

6

Page 9

7. Refrigerant line brazing

7.1 Braze the refrigerant lines

1.

Remove caps or plugs. Use a deburing tool to debur the pipe ends.

Clean both internal and external surfaces of the tubing using an emery

cloth.

Figure 16

Wrap a wet rag around the valve body to avoid heat damage and

4.

continue the dry nitrogen purge (Figure 19).

Braze the refrigerant lines to the service valves.

Check liquid line filter drier’s directional flow arrow to confirm correct

direction of refrigeration flow (away from outdoor unit and toward

evaporator coil) as illustrated. Brazing the filter drier to the Liquid

Line.

Continue the dry nitrogen purge. Do not remove the wet rag until all

brazing is completed.

Remove the wet rag before stopping the dry nitrogen purge.

Field supplied

and installed

2. Remove the pressure tap cap from both service valves.

Figure 17

3. Purge the refrigerant lines and indoor coil with dry nitrogen.

3-4" from valve

Figure 19

5. Replace the pressure tap caps after the service valves have cooled.

Note: Do not over tighen (between 40 and 60 inch-lbs. maximum).

This pipe

must have

a thimble

Figure 18

Figure 20

7

Page 10

8. Refrigerant line leak check

150 PSI

G

8.1 Check for leaks

1.

Pressurize the refrigerant lines and evaporator coil to 150 PSIG using

dry nitrogen.

Figure 21

Check for leaks by using a soapy solution or bubbles at each brazed

2.

location.

Evacuate until the micron gauge reads no higher than 350 microns,

1.

then close off the valve to the vacuum pump.

0350

Microns

ON

OFF

Figure 23

Observe the micron gauge. Evacuation is complete if the micron

2.

gauge does not rise above 500 microns in one (1) minute.

Once evacuation is complete blank off the vacuum pump and micron

gauge, and close the valves on the manifold gauge set.

1 MIN.

Figure 22

Remove nitrogren pressure and repair any leaks before continuing.

9. Evacuation

9.1 Evacuate the refrigerant lines and indoor coil

Do not open the service valves until the refrigerant lines and

indoor coil leak check and evacuation are complete.

Figure 24

10. Service valves

10.1 Open the service valves

WARNING:

Extreme caution should be exercised when opening the Liquid

Line Service Valve. Turn counterclock wise until the valve stem

just touches the rolled edge. No torque is required. Failure to

follow this warning will result in abrupt release of system charge

and may result in personal injury and /or property damage.

Leak check and evacuation must be completed before opening the

service valves.

Remove service valve cap (Figure 25).

1.

Fully insert hex wrench into the stem and back out counterclockwise

2.

until valve stem just touches the rolled edge.

Replace the valve stem cap to prevent leaks. Tighten finger tight

3.

plus an additional 1/6 turn.

8

Page 11

Cap

5/16” Hex Wrench

for Su cti on Ser vi ce Val ve

11. Electrical - low voltage

11.1 Low Voltage Maximum Wire Length

Unit S ide

of Serv ice

Valve

3/16” Hex Wrench

for L iqu id Ser vice Val ve

Roll ed Edg e to

Capti vate Stem

Serv ic e Port

Figure 25

11.2 Low voltage hook-up diagrams

Air Handler Hook-up Diagram

Hex Headed

Valve System

Table 6 defines the maximum total length of low voltage wiring from

the outdoor unit to the indoor unit and to the thermostat.

24 Volts - Wire size Max. wire length

18 AWG 150 Ft.

16 AWG 225 Ft.

14 AWG 300 Ft.

Table 6

Low Voltage connection

Figure 26

must be made inside the

W

B

C

R

Y

G

FOR ONE STAGE

HEAT THERMOSTAT

RED

GREEN

WHITE

BLACK

C

RG Y

w1 w2

BLACK

C

INDOOR UNIT OUTDOOR UNIT

Control Wiring for A/C Systems

Figure 27

Notes: “-----”The electric auxiliary heat connection(optional).

W:Electric auxiliary heat signal.

W1 :The first Electric auxiliary heat signal.

W2 :The second Electric auxiliary heat signal.

YELLOW

outdoor unit case.

W2

W1

B

C

R

Y

G

FOR TWO STAGE

HEAT THERMOSTAT

RED

GREEN

BLACK

w1

R

C

G

INDOOR UNIT

WHITE

w2

Panel

Access

BLACK

YELLOW

C

Y

OUTDOOR UNIT

9

Page 12

Support 2H thermostat

Support 3H thermostat

W

B

C

R

Y

G

*

THERMOSTAT

Figure 28

Notes:

“-----”The electric auxiliary heat connection(option).

W:Electric auxiliary heat signal.

W1 :The first Electric auxiliary heat signal.

W2 :The second Electric auxiliary heat signal.

D signal is connect to the Electric auxiliary heat or The first Electric auxiliary heat.

“*”:Outdoor unit signal. Only for single-stage compressor systems.

RED

GREEN

BLACK

R

C

G

INDOOR UNIT

WHITE

w1

w2

12. Electrical - high voltage

YELLOW

BLACK

R

C B

OUTDOOR UNIT

W2

W1

B

C

R

Y

G

BLUE

PURPLE

Y

D

THERMOSTAT

Control Wiring for H/P Systems

12.2 High voltage disconnect switch

BLACK

GREEN

RED

R

C

G

INDOOR UNIT

WHITE

w1

w2

*

BLACK

R

C B

OUTDOOR UNIT

YELLOW

Y

BLUE

PURPLE

D

12.1 High voltage power supply

WARNING: LIVE ELECTRICAL COMPONENTS!

During installation, testing, servicing, and trouble shooting of this

product,

it may be necessary to work with live electrical

Failure to follow all electrical safety precautions when exposed to

live electrical components could result in death or serious injury.

The high voltage power supply must agree with the equipment

nameplate.

Power wiring must comply with National, State and Local Codes.

Follow instructions on unit wiring diagram located on the inside of the

access panel.

n

a

m

e

p

l

a

e

t

components.

Install a separate disconnect switch at the outdoor unit.

Field provided flexible electrical conduit must be used for high voltage

wiring.

Figure 30

12.3 High voltage ground

Ground the outdoor unit per National, State and Local Code

requirements.

Figure 29

10

Page 13

0.4 oz/ft 0.6 oz/ft 1.2 oz/ft

The data on

nameplate

Wait one (1) hour before starting the unit if compressor crankcase

O

CO

O

4.

heater is used and the outdoor ambient temperature is below 70 ºF.

60 MIN.

Figure 34

Set system thermostat to ON.5.

Figure 31

13. Start up

13.1 System start up

Ensure Sections 7, 8, 9, 10, 11 and 12 have been completed.

1.

Set System Thermostat to OFF.

2.

OFF

D

N

Figure 32

Turn on disconnect to apply power to the indoor and outdoor units.3.

CANCEL

TUE

Inside Set To

Following

EM HEAT

FF

L

D

NE CANCEL

Schedule

Figure 35

14. System charge adjustment

14.1 Charging: Weigh-In Method

Weigh-In method can be used for the initial installation, or anytime a

system charge is being replaced. Weigh-In Method can also be used

when power is not available to the equipment site or operating

conditions (indoor/outdoor temperatures) are not in range to verify

liquid line pressure

with the

Model Factory Charge

charging method.

Charge multiplier for

liquid line length

Figure 33

ON

OFF

All models

5/16'' 3/8'' 1/2''

Table 7

The factory charge in the outdoor unit is sufficient for 15 feet of

standard size interconnecting liquid line.

New Installations — Calculating additional charge for lineset

greater than 15 feet.

1. Total Line Length (ft)

2. Standard Line set (ft)

3. (a) minus (b)

4. Refrigerant Multiplier

5. Refrigerant Adder (c*d)

*If lineset is less than 15 feet, (e) = 0

= (a)

= 15 (b)

= (c)

= (d)

= (e*)

11

Page 14

Sealed-System Repairs — Calculating total system charge.

1. Total Line Length (ft)

2. Standard Line set (ft)

3. (a) minus (b)

4. Refrigerant Multiplier

5. Refrigerant Adder (c*d)

6. Factory Charge (nameplate)

7. Total System Charge (e+f)

*If line set is less than 15 feet, (e) = 0

= (a)

= 15 (b)

= (c)

= (d)

= (e*)

= (f)

= _

Ensure Sections 7, 8, 9, 10,11,12 and 13 have been completed.

2.

Stabilize the system by operating for a minimum of 20 minutes. 3.

At startup, or whenever charge is removed or added, the system

must be operated for a minimum of 20 minutes to stabilize before

accurate measurements can be made.

The only mode approved for validating system charge is while in

Cooling Mode. Outdoor Temperature must be between 55°F and

115°F with Indoor Temperature kept between 70°F and 80°F.

14.2 Liquid line pressure charging and refrigerant

adjustment in cooling (above 55°F outdoor temp.)

Check the outdoor ambient temperatures.

1.

Liquid line pressure (in cooling mode) is the only recommended

method of charging above 55ºF outdoor ambient temperatures.

For outdoor ambient temperatures below 55ºF , use weigh-in charge

method.

Note:It is important to return in the spring or summer to accurately

charge the system in the cooling mode when outdoor ambient

temperature is above 55ºF.

Outdoor

Temperature

Above 55ºF

115ºF

Outdoor

Temperature

Below 55ºF

20 MIN.

Figure 38

Calculate liquid line pressure (According to Refrigerant Charging

4.

Chart)

Measured Suction Line Pressure = ________PSIG

Outdoor Ambient Temperature = _______ ºF

Calculate Liquid Line Pressure = ________PSIG

55ºF

Outdoor Temp.1

Figure 36

For best results the indoor temperature should be kept between 70ºF

to 80ºF.

55ºF

Outdoor Temp. 2

80ºF

70ºF

Indoor Temp.

Figure 37

Figure 39

12

Page 15

REFRIGERANT CHARGING CHART FOR AC SYSTEM

105

14 SEER R410A AC Charge Chart 2 TON

Outdoor Ambient Temperature(℉)

Liquid Pressure at Small Service Valve(psig)

105

14 SEER R410A AC Charge Chart 1.5 TON

Outdoor Ambient Temperature(℉)

Liquid Pressure at Small Service Valve(psig)

105

14 SEER R410A AC Charge Chart 2.5 TON

Outdoor Ambient Temperature(℉)

Liquid Pressure at Small Service Valve(psig)

Liquid Pressure at Small Service Valve(psig)

Cooling

Mode

Suction Pressure at

Large Service Valve(psig)

Cooling

Mode

Suction Pressure at

Large Service Valve(psig)

165

161

157

153

149

145

141

137

133

129

125

121

117

113

109

165

161

157

153

149

145

141

137

133

129

125

121

117

113

109

55 60 65 70 75 80 85 90 95 100 105 110 115

253 274 296 317 336 354 373 400 428 455 482

251 272 294 315 334 352 371 398 426 453 480

249 270 292 313 332 350 369 396 424 451 478

231 247 268 290 311 330 348 367 394 422 449 476

229 245 266 288 309 328 346 365 392 420 447 474

227 243 264 286 307 326 344 363 390 418 445 472

208 225 241 262 284 305 324 342 361 388 416 443 470

206 223 239 260 282 303 322 340 359 386 414 441 468

204 221 237 258 280 301 320 338 357 384 412 439 466

202 219 235 256 278 299 318 336 355 382 410 437 464

200 217 233 254 276 297 316 334 353 380 408 435 462

198 215 231 252 274 295 314 332 351 378 406 433 460

196 213 229 250 272 293 312 330 349 376 404 431 458

194 211 227 248 270 291 310 328 347 374 402 429 456

192 209 225 246 268 289 308 326 345 372 400 427 454

190 207 223 244 266 287 306 324 343 370 398 425 452

55 60 65 70 75 80 85 90 95 100 105 110 115

256

275 295 31

254 273 293 312 334 355 377 403 429 455 481

252 271 291 310 332 353 375 401 427 453 479

233 250 269 289 308 330 351 373 399 425 451 477

231 248 267 287 306 328 349 371 397 423 449 475

229 246 265 285 304 326 347 369 395 421 447 473

210 227 244 263 283 302 324 345 367 393 419 445 471

208 225 242 261 281 300 322 343 365 391 417 443 469

206 223 240 259 279 298 320 341 363 389 415 441 467

204 221 238 257 277 296 318 339 361 387 413 439 465

202 219 236 255 275 294 316 337 359 385 411 437 463

200 217 234 253 273 292 314 335 357 383 409 435 461

198 215 232 251 271 290 312 333 355 381 407 433 459

196 213 230 249 269 288 310 331 353 379 405 431 457

194 211 228 247 267 286 308 329 351 377 403 429 455

192 209 226 245 265 284 306 327 349 375 401 427 453

4 336 357 379 405 431 457 483

Cooling

Mode

165

161

157

153

149

145

141

137

133

129

125

Suction Pressure at

121

Large Service Valve(psig)

117

113

109

Cooling

Mode

165

161

157

153

149

145

141

137

133

129

125

121

Suction Pressure at

117

Large Service Valve(psig)

113

109

105

55 60 65 70 75 80 85 90 95 100 105 110 115

250 272 293 315 334 353 372 398 425 451 477

248 270 291 313 332 351 370 396 423 449 475

246 268 289 311 330 349 368 394 421 447 473

227 244 266 287 309 328 347 366 392 419 445 471

225 242 264 285 307 326 345 364 390 417 443 469

223 240 262 283 305 324 343 362 388 415 441 467

204 221 238 260 281 303 322 341 360 386 413 439 465

202 219 236 258 279 301 320 339 358 384 411 437 463

200 217 234 256 277 299 318 337 356 382 409 435 461

198 215 232 254 275 297 316 335 354 380 407 433 459

196 213 230 252 273 295 314 333 352 378 405 431 457

194 211 228 250 271 293 312 331 350 376 403 429 455

192 209 226 248 269 291 310 329 348 374 401 427 453

190 207 224 246 267 289 308 327 346 372 399 425 451

188 205 222 244 265 287 306 325 344 370 397 423 449

186 203 220 242 263 285 304 323 342 368 395 421 447

14 SEER R410A AC Charge Chart 3 TON

55 60 65 70 75 80 85 90 95 100 105 110 115

257 277 296 316 339 361 384 410 436 462 488

255 275 294 314 337 359 382 408 434 460 486

253 273 292 312 335 357 380 406 432 458 484

235 251 271 290 310 333 355 378 404 430 456 482

233 249 269 288 308 331 353 376 402 428 454 480

231 247 267 286 306 329 351 374 400 426 452 478

212 229 245 265 284 304 327 349 372 398 424 450 476

210 227 243 263 282 302 325 347 370 396 422 448 474

208 225 241 261 280 300 323 345 368 394 420 446 472

206 223 239 259 278 298 321 343 366 392 418 444 470

204 221 237 257 276 296 319 341 364 390 416 442 468

202 219 235 255 274 294 317 339 362 388 414 440 466

200 217 233 253 272 292 315 337 360 386 412 438 464

198 215 231 251 270 290 313 335 358 384 410 436 462

196 213 229 249 268 288 311 333 356 382 408 434 460

194 211 227 247 266 286 309 331 354 380 406 432 458

Outdoor Ambient Temperature( )

℉

13

Page 16

Cooling

Liquid Pressure at Small Service Valve(psig)

105

14 SEER R410A AC Charge Chart 4 TON

Outdoor Ambient Temperature(℉)

Liquid Pressure at Small Service Valve(psig)

105

14 SEER R410A AC Charge Chart 5 TON

Outdoor Ambient Temperature(℉)

Liquid Pressure at Small Service Valve(psig)

Mode

165

161

157

153

149

145

141

137

133

129

125

121

Suction Pressure at

117

Large Service Valve(psig)

113

109

105

Cooling

Mode

165

161

157

153

149

145

141

137

133

129

125

Suction Pressure at

121

Large Service Valve(psig)

117

113

109

14 SEER R410A AC Charge Chart 3.5 TON

55 60 65 70 75 80 85 90 95 100 105 110 115

250 269 288 307 329 351 373 400 426 453 479

248 267 286 305 327 349 371 398 424 451 477

246 265 284 303 325 347 369 396 422 449 475

227 244 263 282 301 323 345 367 394 420 447 473

225 242 261 280 299 321 343 365 392 418 445 471

223 240 259 278 297 319 341 363 390 416 443 469

204 221 238 257 276 295 317 339 361 388 414 441 467

202 219 236 255 274 293 315 337 359 386 412 439 465

200 217 234 253 272 291 313 335 357 384 410 437 463

198 215 232 251 270 289 311 333 355 382 408 435 461

196 213 230 249 268 287 309 331 353 380 406 433 459

194 211 228 247 266 285 307 329 351 378 404 431 457

192 209 226 245 264 283 305 327 349 376 402 429 455

190 207 224 243 262 281 303 325 347 374 400 427 453

188 205 222 241 260 279 301 323 345 372 398 425 451

186 203 220 239 258 277 299 321 343 370 396 423 449

55 60 65 70 75 80 85 90 95 100 105 110 115

258 277 297 316 339 361 384 411 4 38 465 492

256 275 295 314 337 359 382 409 4 36 463 490

254 273 293 312 335 357 380 407 4 34 461 488

234 252 271 291 310 333 355 378 405 432 459 486

232 250 269 289 308 331 353 376 403 430 457 484

230 248 267 287 306 329 351 374 401 428 455 482

210 228 246 265 285 304 327 349 372 399 426 453 480

208 226 244 263 283 302 325 347 370 397 424 451 478

206 224 242 261 281 300 323 345 368 395 422 449 476

204 222 240 259 279 298 321 343 366 393 420 447 474

202 220 238 257 277 296 319 341 364 391 418 445 472

200 218 236 255 275 294 317 339 362 389 416 443 470

198 216 234 253 273 292 315 337 360 387 414 441 468

196 214 232 251 271 290 313 335 358 385 412 439 466

194 212 230 249 269 288 311 333 356 383 410 437 464

192 210 228 247 267 286 30

Outdoor Ambient Temperature(℉)

9 331 35

4 381 408 435 462

Cooling

Mode

Suction Pressure at

Large Service Valve(psig)

165

161

157

153

149

145

141

137

133

129

125

121

117

113

109

55 60 65 70 75 80 85 90 95 100 105 110 115

265 285 305 325 348 372 395 423 450 478 505

263 283 303 323 346 370 393 421 448 476 503

261 281 301 321 344 368 391 419 446 474 501

242 259 279 299 319 342 366 389 417 444 472 499

240 257 277 297 317 340 364 387 415 442 470 497

238 255 275 295 315 338 362 385 413 440 468 495

219 236 253 273 293 313 336 360 383 411 438 466 493

217 234 251 271 291 311 334 358 381 409 436 464 491

215 232 249 269 289 309 332 356 379 407 434 462 489

213 230 247 267 287 307 330 354 377 405 432 460 487

211 228 245 265 285 305 328 352 375 403 430 458 485

209 226 243 263 283 303 326 350 373 401 428 456 483

207 224 241 261 281 301 324 348 371 399 426 454 481

205 222 239 259 279 299 322 346 369 397 424 452 479

203 220 237 257 277 297 320 344 367 395 422 450 477

201 218 235 255 275 295 318 342 365 39

REFRIGERANT CHARGING CHART FOR HP SYSTEM

Cooling

Mode

Suction Pressure at

Large Service Valve(psig)

55 60 65 70 75 80 85 90 95 100 105 110 115

165

161

157

153

149

145

141

137

133

129

125

121

117

113

109

105

221 240 259 278 297 317 337 358 384 410 435 461

219 238 257 276 295 315 335 356 382 408 433 459

217 236 255 274 293 313 333 354 380 406 431 457

196 215 234 253 272 291 311 331 352 378 404 429 455

195 213 232 251 269 288 309 328 350 376 402 427 453

193 211 230 249 267 286 306 326 347 373 399 425 451

191 209 228 247 265 284 304 323 344 370 397 423 449

190 209 227 245 264 282 302 320 341 368 394 421

190 208 226 244 262 280 300 320 341 367 393 419 445

188 206 224 242 260 278 298 318 339 365 391 417 443

186 204 222 240 258 276 296 316 337 363 389 415 441

184 202 220 238 256 274 294 314 335 361 387 413 439

182 200 218 236 254 272 292 312 333 359 385 411 437

14SEER R410A HP Charge Chart 1.5 TON(Cooling mode)

Liquid Pressure at Small Service Valve(psig)

246 265 284 303 323 343 364 390 416 441 467

244 263 282 301 321 341 362 388 414 439 465

242 261 280 299 319 339 360 386 412 437 463

3 420 448 475

Outdoor Ambient Temperature(℉)

447

14

Page 17

Cooling

Mode

Suction Pressure at

Large Service Valve(psig)

14SEER R410A HP Charge Chart 2 TON(Cooling mode)

55 60 65 70 75 80 85 90 95 100 105 110 115

165

161

157

153

149

145

141

204 224 243 262 282 301 323 346 369 395 422 449 474

137

203 222 241 260 279 298 320 344 367 393 420 447 472

133

201 220 239 258 277 296 318 342 365 391 418 445 470

129

199 218 237 256 275 294 316 340 363 389 416 443 468

125

197 216 235 254 273 292 314 338 361 387 414 441 466

121

195 214 233 252 271 290 312 336 359 385 412 439 464

117

193 212 231 250 269 288 310 334 357 383 410 437 462

113

191 210 229 248 267 286 308 332 355 381 408 435 460

109

189 208 227 246 265 284 306 330 353 379 406 433 458

105

187 206 225 244 263 282 304 328 351 377 404 431 456

255 274 294 313 335 358 381 407 434 461 486

253 272 292 311 333 356 379 405 432 459 484

251 270 290 309 331 354 377 403 430 457 482

230 249 268 288 307 329 352 375 401 428 455 480

228 247 266 286 305 327 350 373 399 426 453 478

226 245 264 284 303 325 348 371 397 424 451 476

Outdoor Ambient Temperature(℉)

Liquid Pressure at Small Service Valve(psig)

Cooling

Mode

Suction Pressure at

Large Service Valve(psig)

Cooling

Mode

Suction Pressure at

Large Service Valve(psig)

14SEER R410A HP Charge Chart 2.5 TON(Cooling mode)

55 60 65 70 75 80 85 90 95 100 105 110 115

165

161

157

153

149

145

141

208 225 241 257 276 293 315 336 358 378 402 423 449

137

206 223 239 255 274 291 313 334 356 376 400 421 447

133

204 221 237 253 272 289 311 332 354 374 398 419 445

129

202 219 235 251 270 287 309 330 352 372 396 417 443

125

199 215 232 249 267 285 307 328 350 370 394 415 441

121

195 213 230 247 267 285 306 327 348 368 392 413 439

117

193 211 228 245 265 283 304 325 346 366 390 411 437

113

191 209 226 243 263 281 302 323 344 364 388 409 435

109

189 207 224 241 261 279 300 321 342 362 386 407 433

105

187 205 222 239 259 277 298 319 340 360 384 405 431

253 269 288 305 327 348 370 390 414 435 461

251 267 286 303 325 346 368 388 412 433 459

249 265 284 301 323 344 366 386 410 431 457

231 247 263 282 299 321 342 364 384 408 429 455

229 245 261 280 297 319 340 362 382 406 427 453

227 243 259 278 295 317 338 360 380 404 425 451

14SEER R410A HP Charge Chart 3 TON(Cooling mode)

55 60 65 70 75 80 85 90 95 100 105 110 115

165

161

157

153

149

145

212 230 248 266 284 302 323 345 366 388 413 442 470

141

210 228 246 264 282 300 321 342 363 385 411 439 468

137

208 226 244 262 280 298 319 339 360 382 408 437 466

133

206 224 242 260 278 296 316 337 357 379 406 435 464

129

204 222 240 258 276 294 314 335 355 377 404 433 462

125

202

121

200 218 236 254 272 290 310 331 351 373 400 429 458

117

198 216 234 252 270 288 308 329 349 371 398 427 456

113

196 214 232 250 268 286 306 327 347 369 396 425 454

109

194 212 230 248 266 284 304 325 345 367 394 423 452

105

260 278 296 314 336 359 381 402 427 454 482

258 276 294 312 334 357 379 400 425 452 480

256 274 292 310 332 355 377 398 423 450 478

236 254 272 290 308 330 352 374 395 420 448 476

234 252 270 288 306 328 350 372 393 418 446 474

232 250 268 286 304 326 347 369 390 416 444 472

220 238 256 274 292 312 333 353 375 402 431 460

Outdoor Ambient Temperature(℉)

Liquid Pressure at Small Service Valve(psig)

Outdoor Ambient Temperature(℉)

Liquid Pressure at Small Service Valve(psig)

Cooling

Mode

Suction Pressure at

Large Service Valve(psig)

14SEER R410A HP Charge Chart 3.5 TON(Cooling mode)

55 60 65 70 75 80 85 90 95 100 105 110 115

165

161

157

153

149

145

208 225 242 259 276 293 315 336 358 382 405 429 452

141

206 223 240 257 274 291 313 334 356 380 403 427 450

137

204 221 238 255 272 289 311 332 354 378 401 425 448

133

202 219 236 253 270 287 309 330 352 376 399 423 446

129

200 217 234 251 268 285 307 328 350 374 397 421 444

125

198 215 232 249 266 283 305 326 348 372 395 419 442

121

196 213 230 247 264 281 303 324 346 370 393 417 440

117

194 211 228 245 262 279 301 322 344 368 391 415 438

113

192 209 226 243 260 277 299 320 342 366 389 413 436

109

190 207 224 241 258 275 297 318 340 364 387 411 434

105

254 271 288 305 327 348 370 394 417 441 464

252 269 286 303 325 346 368 392 415 439 462

250 267 284 301 323 344 366 390 413 437 460

231 248 265 282 299 321 342 364 388 411 435 458

229 246 263 280 297 319 340 362 386 409 433 456

227 244 261 278 295 317 338 360 384 407 431 454

Outdoor Ambient Temperature(℉)

Liquid Pressure at Small Service Valve(psig)

15

Page 18

Cooling

Mode

Suction Pressure at

Large Service Valve(psig)

14SEER R410A HP Charge Chart 4 TON(Cooling mode)

55 60 65 70 75 80 85 90 95 100 105 110 115

165

161

157

153

149

145

206 225 243 261 279 298 318 339 359 384 408 433 457

141

204 223 241 259 277 296 316 337 357 382 406 431 455

137

204 222 240 258 275 294 314 335 355 380 404 429 453

133

129

202 220 238 256 273 292 312 333 353 378 402 427 451

125

200 218 236 254 271 290 310 331 351 376 400 425 449

121

198 216 234 252 269 288 308 329 349 374 398 423 447

117

196 214 232 250 267 286 306 327 347 372 396 421 445

113

194 212 230 248 265 284 304 325 345 370 394 419 443

109

192 210 228 246 263 282 302 323 343 368 392 417 441

105

190 208 226 244 261 280 300 321 341 366 390 415 439

255 273 291 310 330 351 371 396 420 445 469

253 271 289 308 328 349 369 394 418 443 467

251 269 287 306 326 347 367 392 416 441 465

231 249 267 285 304 324 345 365 390 414 439 463

229 247 265 283 302 322 343 363 388 412 437 461

227 245 263 281 300 320 341 361 386 410 435 459

Outdoor Ambient Temperature(℉)

Liquid Pressure at Small Service Valve(psig)

Cooling

Mode

165

161

157

153

149

145

141

137

133

129

125

Suction Pressure at

121

Large Service Valve(psig)

117

113

109

105

Adjust refrigerant level to attain proper gage pressure.

5.

55 60 65 70 75 80 85 90 95 100 105 110 115

249 267 285 303 323 344 364 392 415 441 466

247 265 283 301 321 342 362 391 413 439 464

245 263 281 299 319 340 360 389 411 437 462

225 243 261 279 297 317 338 358 387 409 435 460

223 241 259 277 295 315 336 356 385 407 433 458

221 239 257 275 293 313 334 354 383 405 431 456

201 219 237 255 273 291 311 332 352 381 403 429 454

199 217 235 253 271 289 309 330 350 379 401 427 452

197 215 233 251 269 287 307 328 348 377 399 425 450

195 213 231 249 267 285 305 326 346 375 397 423 448

193 211 229 247 265 283 303 324 344 373 395 421 446

191 209 227 245 263 281 301 322 342 371 393 419 444

189 207 225 243 261 279 299 320 340 369 391 417 442

187 205 223 241 259 277 297 318 338 367 389 415 440

185 203 221 239 257 275 295 316 336 365 387 413 438

183 201 219 237 255 273 293 314 334 363 385 411 436

14SEER R410A HP Charge Chart 5 TON(Cooling mode)

Outdoor Ambient Temperature(℉)

Liquid Pressure at Small Service Valve(psig)

Add refrigerant if the design liquid line pressure is lower than the

chart value.

Connect gages to refrigerant bottle and unit as illustrated (Figure

40).

Purge all hoses.

Open bottle.

Stop adding refrigerant when liquid line pressure matches the

Refrigerant Charging Chart.

Stabilize the system.

6.

Wait 20 minutes for the system condition to stabilize between

adjustments.

When the liquid line pressure match the chart, the system is

properly charged.

Remove gages.

Replace service port caps to prevent leaks. Tighten finger tight plus

an additional 1/6 turn.

20 MIN.

Recover refrigerant if the design liquid line pressure is lower than

the chart value.

Figure 40

Figure 41

Record system Information for reference (Table 8).

7.

Record system pressures and temperatures after charging is

complete.

Description Value

Outdoor model number

Measured Outdoor Ambient °F

Measured Indoor Ambient °F

Liquid Gage Pressure PSIG

Suction Gage Pressure PSIG

Table 8

16

Page 19

15. System operation and troubleshooting

15.5 Defrost mode (Heat pump only)

15.1 Compressor crankcase heater (CCH)

(Heat pump only)

The crankcase heating start must meet two conditions:

A. Outdoor temperature<37.4

B. At power up or if the compressor has been off for more than 3

hours

The crankcase heating stop must meet the following condition:

Outdoor temperature>44.6°F or compressor starts.

°F

15.2 Reversing valve (Heat pump only)

Reversing valve energizes at the heating conditions, and cuts off at

the cooling condition.

15.3 Protection function (Heat pump only)

T3 = Outdoor Coil Temperature

T3>143.6°F, compressor stops working

T3<125.6°F, compressor restarts working

T4 = Ambient Temperature

T4 < 5°F, compressor stops working

T4 > 10.4°F, compressor restarts working

If 55°F ≤ T4 ≤ 115°F, unit can operate in cooling

If 5°F ≤ T4 ≤ 75°F, unit can operate in heating

When T4< 5°F, the outdoor unit would provide a signal to drive up

the heater installed in the indoor unit.

Discharge temperature protection

Discharge temperature > 275°F, compressor stops working.

Discharge temperature < 194°F, compressor restarts working.

High pressure protection

High pressure > 638 PSIG, compressor and outdoor fan motor

stop working.

High pressure < 464 PSIG, compressor and outdoor fan motor

restart working (3 minutes delay necessary).

Manual defrost mode

When the switch SW3-1 is set to “ON”, the system turns to the

defrost mode. The defrost mode exits by the logic of shut-down

conditions of defrost mode.

Once the manual defrost mode is finished, please turn the switch

SW3-1 back to “off ”.

Start-up conditions of defrost mode

When SW3-3 switch is set to “ON” (Figure 4), the mode will start up

in any of the following conditions:

Compressor operates and T3 < 32°F for a period of 30

minutes.

T3 < 28.4°F and compressor operates for the first time after

connected to the power source.

When T3 < 28.4°F and the system is on standby for two hours

continuously.

When SW3-3 switch is set to “OFF”(Figure 41), the mode will start

up in any of the following conditions:

Compressor operates and T3 < 32 °F for a period of 60

minutes.

T3 < 28.4 °F and compressor operates for the first time after

connected to the power source.

When T3 < 28.4 °F and the system is on standby for two hours.

Shut-down conditions of defrost mode:

The mode will shut down in any of the following conditions:

The defrosted time lasts 10 minutes

T3 ≥ 64.4°F and T4 ≥ 28.4

Compressor stops operating

T3 ≥ 64.4°F lasts 60 seconds when T4 < 28.4

°F

°F

Low pressure protection

Low pressure < 21 PSIG, compressor and outdoor fan motor

stop working.

Low pressure > 44 PSIG, compressor and outdoor fan motor

restart working (3 minutes delay necessary).

In stand-by status, the compressor will not start in low pressure

protection. Within 30 minutes, if 4 protection cycles occur. The

system will be locked. It will be restore after power cycle.

15.4 Protection function (Air conditioner only)

High pressure protection

High pressure > 638 PSIG, compressor and outdoor fan motor

stop working.

High pressure < 464 PSIG, compressor and outdoor fan motor

restart working (3 minutes delay necessary).

SW3 Switch

The location of SW3 Switch in the PCB Board

Figure 42

17

Page 20

15.6 Temperature sensor resistance table

Temperature

°F

Resistance kΩ Temperature

°F

Resistance kΩ Temperature

°F

Resistance kΩ Temperature

°F

Resistance kΩ

36 30.76 77 10.00 118 3.77 159 1.60

-4 106.73 37 29.87 78 10.00 119 3.69

-3 103.25 38 29.22 79 9.50 120 3.61

-2 99.89 39 28.19 80 9.26 121 3.53

-1 96.65 40 27.39 81 9.03 122 3.45

0 93.53 41 26.61 82 8.81 123 3.38

1 90.53 42 25.85 83 8.59 124 3.30

2 87.62 43 25.12 84 8.38 125 3.23

3 84.83 44 24.42 85 8.17 126 3.16

4 82.13 45 23.73 86 7.97 127 3.10

5 79.52 46 23.07 87 7.78 128 3.03

6 77.01 47 22.42 88 7.59 129 2.96

7 74.58 48 21.80 89 7.40 130 2.90

8 72.24 49 21.20 90 7.22 131 2.84

9 69.98 50 20.61 91 7.05 132 2.78

10 67.80 51 20.04 92 6.88 133 2.72

11 65.69 52 19.49 93 6.72 134 2.67

12 63.65 53 18.96 94 6.56 135 2.61

13 61.68 54 18.44 95 6.40 136 2.56

14 59.78 55 17.94 96 6.25 137 2.50

15 57.95 56 17.45 97 6.10 138 2.45

16 56.17 57 16.98 98 5.96 139 2.40

17 54.46 58 16.52 99 5.82 140 2.35

18 52.80 59 16.08 100 5.68 141 2.30

19 51.20 60 15.65 101 5.55 142 2.25

20 49.65 61 15.23 102 5.42 143 2.21

21 48.16 62 14.83 103 5.30 144 2.16

22 46.71 63 14.43 104 5.18 145 2.12

23 45.31 6

24 43.95 65 13.68 106 4.94 147 2.03

25 42.64 66 13.32 107 4.83 148 1.99

26 41.38 67 12.97 108 4.72 149 1.95

27 40.15 68 12.64 109 4.61 150 1.91

28 38.97 69 12.31 110 4.51 151 1.88

29 37.82 70 11.99 111 4.41 152 1.84

30 36.71 71 11.68 112 4.31 153 1.80

31 35.64 72 11.38 113 4.21 154 1.77

32 34.60 73 11.09 114 4.12 155 1.73

33 33.59 74 10.80 115 4.03 156 1.70

34 32.61 75 10.53 116 3.94 157 1.66

35 31.67 76 10.00 117 3.85 158 1.63

Table 9

4 14.05 105 5.06 146 2.08

15.7 Electrical data table

Model

18 24 30 36 42 48 60 18 24 30 36 42 48 60

Minimum circuit ampacity(A) 10.4 13.4 14.7 19.4 21.6 24.6 29.6 10.4 13.4 16.5 19.4 21.6 24.6 29.6

Maximum circuit protecetor(A) 15 20 25 30 35 40 50 15 20 25 30 35 40 50

Table 10

AC HP

18

Page 21

15.8 Troubleshooting table

AHW T OT KCEHC EDOM

HGIH OV TL GA E G NIRIW

OP REW LPPUS Y

SYSTEM FAULTS

REFRIGERANT CIRCUIT

Head Pressure Too High

Head Pressure Too Low

Suction Pressure Too High

Suction Pressure Too Low

Liquid Refrig. Floodback

(TXV)

I.D. Coil Frosting

Compressor Runs Inadequate or

No Cooling/Heating

ELECTRICAL

Compressor & O.D. Fan Won’t Start

Compressor Will Not Start But

O.D. Fan Runs

O.D. Fan Won’t Start

Compressor Hums But Won’t Start

I.D. Blower Won’t Start

DEFROST

Unit Won’t Initiate Defrost

Defrost Terminates on Time

Unit Icing Up

COMPRESSR

I.D. BLOWER CAPACITOR

O.D. FAN

I.D. CONTROL DEF.

P AC A T IC R O

PAC A TIC RO

C

H

C

H

C

H

C

H

C

H

C

H

C

H

C

P

P

H

P

P

C

P

H

C

H

C

H

C

P

H

P

C

H

C

H

C

H

P

P

P

P

P

P

P

S

P

S

P

OL W OV T L GA E GNIRIW

TNOC C A O T R C T NO C A S T

P

P

P

P

RTNOC LO T R EMROFSNAR

T4

T3

.O .D RIA A LUCRICER NOIT

OL W O V T L G A E F E SU

TNOC CA O T R LIOC

TSOMREHT TA

S

P

S

S

S

S

S

S

P

S

S

P

S

S

P

S

KCUTS R OSSERPMOC

P P

P

FER . E GRAHCREDNU

FER . O EGRAHCREV

TNEICIFFENI M OC .

P

S

S

S

S

S

S

P

P

P

P

P

S

S

EVISSECXE V E P A . O L DA

P

P

P

P

P

P

P

P

P

P

P

P

SER . . O .D OLFRIA W

SELBASNEDNOCNON

P

S

P

S

P

S

S

S

FER . C . RI NOITCIRTSER

OS V LIOC E VITCEFED

ER . S D .I . O LFRIA W

VXT

P

S

S

S

S

OS

KCUTS NEPO

S

S

S

S

V N IKAEL G

AEHREPUS T

P

S

S

S

S

S

S

S

P

S

P

P

S

P

S

P

S

LPC SENSOR DEF.

KCEHC AV VL E GNIKAEL

S

S

S

S

S

S

P

P

S

S

S

S

S

S

RFED TSO R TNOC LO F ED .

S

S

S

P

P

HPC/HGS SENSOR DEF.

TEMP. SENSOR DEF.

TEMP. SENSOR DEF.

P

P

P

P

P

S

S

S

S

S

S

P

P

P

S S S

S

S

S

C- Cooling H - Heating P - Primary Causes S - Secondary Causes

16. Warranty

Assist owner with processing Warranty cards and/or online regi-

stration.

16.1 Maintenance

Dirt should not be allowed to accumulate on the indoor or

outdoor coils or other parts in the air circuit. Clean as often as

necessary to keep the unit clean. Use a brush, vacuum

cleaner attachment or other suitable means.

The outdoor fan motor is permanently lubricated and does

not require periodic oiling.

Refer to the furnace or air handler instructions for filter and

blower motor maintenance.

The indoor coil and drain pan should be inspected and

cleaned regularly to assure proper drainage.

It is unlawful to knowingly vent, release or discharge refrigerant

into the open air during repair, service, maintenance or the

final disposal of this unit. When the system is functioning

properly and the owner has been fully instructed, secure the

owner’s approval.

16.2 Changing motor

When motor requires changing, follow the steps below:

STEP 1 - Go into electrical panel, disconnect motor power lines.

Note: Disconnect main power to unit. Severe burns and electrical

shock will occur if you do not disconnect main power.

STEP 2 - Remove cover (be careful of motor wires).

STEP 3 - Be sure to place fan cover unit on the ground (Figure 43

).

Note: Do not place or lean fan blades on ground or against surface.

19

Page 22

STEP 4 - Remove fan motor by removing 5/16” nuts from cover.

STEP 5 - Remove fan blade from motor by removing 1/2” nut and

place fan on the ground.

STEP 6 - Reverse removal process to reinstall the fan and motor.

Note: When connecting motor wires be sure to check motor direction.

Figure 43

17. Wiring diagrams

Damage will occur to condenser unit if you remove 5/16’’ nuts

prior to cover removal.

1/2”nut

5/16”nuts

17.1 For AC

T1

BLACK

T2

A1

BLACK

RC 1

BLACK

RC 3

CC

YELLOW

C

WHITE OR YELLOW

BLACK

PLUG PLATE

L1

RED

BLACK

L2

A2

GREEN

COMP

S

R

RED

BLACK

BLACK

HPS

ORANGE

RC 2

BROWN

YELLOW

BLACK

GROUND

L1

L2

FAN

POWER

C

Y

GREEN

LINE VOLTAGE

FACTORY STANDARD

FIELD INSTALLED

LOW

FACTORY STANDARD

FIELD INSTALLED

FACTORY OPTIONAL

USE COPPER CONDUCTORS ONLY

HPS HIGH PRESSOR SWITCH

CC COMPRESSOR CONTACTOR

COMP COMPRESSOR

RC 1 RUN CAPACITOR 1

OT TATSOMREHT

RC 2 RUN CAPACITOR 2

RC 3 RUN CAPACITOR 3

WARNING: CABINET MUST BE PERMANMENTLY

GOUNDED ANDALL WIRING TO CONFORM TO

I.E.C,N.E.C,C.E.C,C.L.C,AND LOCAL CODESAS APPLICABLE

REPLACEMENT WIRE MUST BE THE SAME GAUGE AND

INSULATION TYPE AS ORIGINAL WIRE

OPTIONALFACTORY

VOLTAGE

Figure 44

20

Page 23

17.2 For HP

MANUAL DEFROST

AUTOMATIC DEFROST

RESERVED

NORMAL DEFROST

DEFROSTING CYCLE:30MIN

DEFROSTING CYCLE:60MIN

0

1

2

3

Figure 45

21

Page 24

18. Matching table and Checkout Procedures

J4AH4P18A1A00AA 0.052/(4AYTXVH3G 2436A) 14 YES

J4AH4E24A1A00AA 0.052/(4AYTXVH3G 2436A) 14 YES

J4GXCA001AC6HUA 0.052/(4AYTXVH3G2436A) 14 YES

J4MXCA001AC6HCA 0.052/(4AYTXVH 3G2436A) 14 YES

J4AH4P24A1B00AA 0.058/(4AYTXVH3G 2436A) 14 YES

J4AH4E24A1A00AA 0.058/(4AYTXVH3G 2436A) 14 YES

J4GXCA001AC6HUA 0.058/(4AYTXVH3G2436A) 14 NO

J4MXCA001AC6HCA 0.058/(4AYTXVH 3G2436A) 14 NO

J4AH4P30A1B00AA 0.065/(4AYTXVH3G 2436A) 14 YES

J4AH4E36A1B00AA 0.065/(4AYTXVH3G 2436A) 14 YES

J4GXCA001AC6HUA 0.063/(4AYTXVH3G2436A) 14 YES

J4MXCA001AC6HCA 0.063/(4AYTXVH 3G2436A) 14 YES

J4AH4P36A1B00AA 0.073/(4AYTXVH3G 2436A) 14 YES

J4AH4E36A1B00AA 0.073/(4AYTXVH3G 2436A) 14 YES

J4AH4E60A1C00AA 0.073/(4AYTXVH3G2436A) 14 YES

J4GXCB004AC6HUA 0.070/(4AYTXVH3G2436A) 14 NO

J4MXCB004AC6HCA 0.070/(4AYTXVH 3G2436A) 14 NO

J4AH4P42A1C00AA 0.075/(4AYTXVH3G4248A) 14 YES

J4AH4E60A1C00AA 0.075/(4AYTXVH3G4248A) 14 YES

J4GXCC009AC6HUA 0.075/(4AYTXVH3G4248A) 14 YES

J4MXCC009AC6HCA 0.075/(4AYTXVH3G4248A) 14 YES

J4AH4P48A1C00AA 0.083/(4AYTXVH3G4248A) 14 NO

J4GXCC009AC6HUA 0.083/(4AYTXVH3G4248A) 14 YES

J4MXCC009AC6HCA 0.083/(4AYTXVH3G4248A) 14 YES

J4AH4P60A1C00AA 4AYTXVH3G6000A 14 YES

J4AH4E60A1C00AA 4AYTXVH3G6000A 14 YES

J4GXCC009AC6HUA 4AYTXVH3G6000A 14 YES

J4MXCC009AC6HCA 4AYTXVH3G6000A 14 YES

J4AH4P18A1A00AA 0.050/(4AYTXVH3G 2436A) 14 NO

J4AH4E24A1A00AA 0.052/(4AYTXVH3G 2436A) 14 YES

J4AH4P24A1B00AA 0.056/(4AYTXVH3G 2436A) 14 NO

J4AH4E36A1B00AA 0.058/(4AYTXVH3G 2436A) 14 YES

J4AH4P30A1B00AA 0.063/(4AYTXVH3G 2436A) 14 NO

J4AH4E36A1B00AA 0.065/(4AYTXVH3G 2436A) 14 YES

J4GXCB016AC6HUA 0.065/(4AYTXVH3G2436A) 14 YES

J4M XCB016AC6HCA 0.065/(4AYTXVH3G2436A) 14 YES

J4AH4P36A1B00AA 0.068/(4AYTXVH3G 2436A) 14 NO

J4AH4E60A1C00AA 0.073/(4AYTXVH3G2436A) 14 YES

J4AH4P42A1C00AA 0.076/(4AYTXVH3G4248A) 14 NO

J4AH4E60A1C00AA 0.075/(4AYTXVH3G4248A) 14 YES

J4AH4P48A1C00AA 0.083/(4AYTXVH3G4248A) 14 NO

J4AH4E60A1C00AA 0.083/(4AYTXVH3G4248A) 14 YES

J4HP4060A1000AA J4AH4E60A1C00AA 0.090/(4AYTXVH3G6000A) 14 NO

J4AC4018A1000AA

J4AC4024A1000AA

J4AC4030A1000AA

J4AC4060A1000AA

J4HP4030A1000AA

J4AC4036A1000AA

J4AC4042A1000AA

J4AC4048A1000AA

J4HP4018A1000AA

J4HP4048A1000AA

J4HP4024A1000AA

J4HP4036A1000AA

J4HP4042A1000AA

18.1 Matching table

Condensing Unit Air Handle / A-Coil

Piston Size / TXV

Valve Model

SEER

If Preinstalled Piston

Replac e Required

NOTE: Since the manufacturer has a policy of continuous product and product data improvement, if the system

combination you are looking for is not listed, check for the latest version of this document at www.oxboxhvac.com.

18.2 Operational and Checkout Procedures

Final phases of this installation are the unit Operational and Checkout Procedures. To obtain proper performance,

all units must be operated and charge adjustments made in accordance with procedures found in the Service Facts

of the Outdoor Unit.

After installation has been completed, it is recommended that the entire system be checked against the following list:

Be sure unit suspension(if used) is secure and that

1.

there are no tools or loose debris in or around or on

top of the unit......................................................

2. Properly insulate suction lines and fittings............

3. Properly secure and isolate all refrigerant lines...

4. Verify that all electrical connections are tight. .....

[]

[]

[]

[]

5.Check all duct outlets; they must be open and unrestricted.

6.Check drain lines and be sure all joints are tight...............

7.Be sure that a return air filter is installed...........................

8.Operate complete system in each mode to verify proper

performance. Verify operation of supplementary electric

heater. ...............................................................................

22

[]

[]

[]

[]

BX-SVN-J4ACHP4-1A-EN

Loading...

Loading...