Page 1

Quick Select

High Rise Fan Coil

Riser Selection How-To

June 2010 UNT-PRC015-EN

Page 2

Introduction

The purpose of this manual is to aid in the selection and pricing of water pipe risers for high rise

fan coils. Because of the volatility in copper cost, the proper selection of riser diameter is critical

to designing a cost effective job. If the riser diameter is too small, the water velocity through the

riser pipe may cause excessive water pressure drop due to friction loss and/or erosion of the pipe.

If the riser diameter is too large, the cost of the fan coil unit and riser system may become

unnecessarily high making the equipment bid uncompetitive. Therefore riser sizes are chosen to

minimize initial cost while avoiding the undesirable effects of high water velocities.

Noise, erosion, and installation and operating costs all limit the maximum and minimum velocities

in the riser system.

Trademarks

Trane and the Trane logo are trademarks of Trane in the United States and other countries. All

trademarks referenced in this document are the trademarks of their respective owners.

© 2010 Trane All rights reserved UNT-PRC015-EN

Page 3

Table of Contents

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

General Information on Riser Systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Know the Riser Design—Design Return versus Reverse Return . . . . . . . . . . . . . 6

Riser Selection and Sizing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Riser Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Expansion Compensation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Determining Riser Length . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

UNT-PRC015-EN 3

Page 4

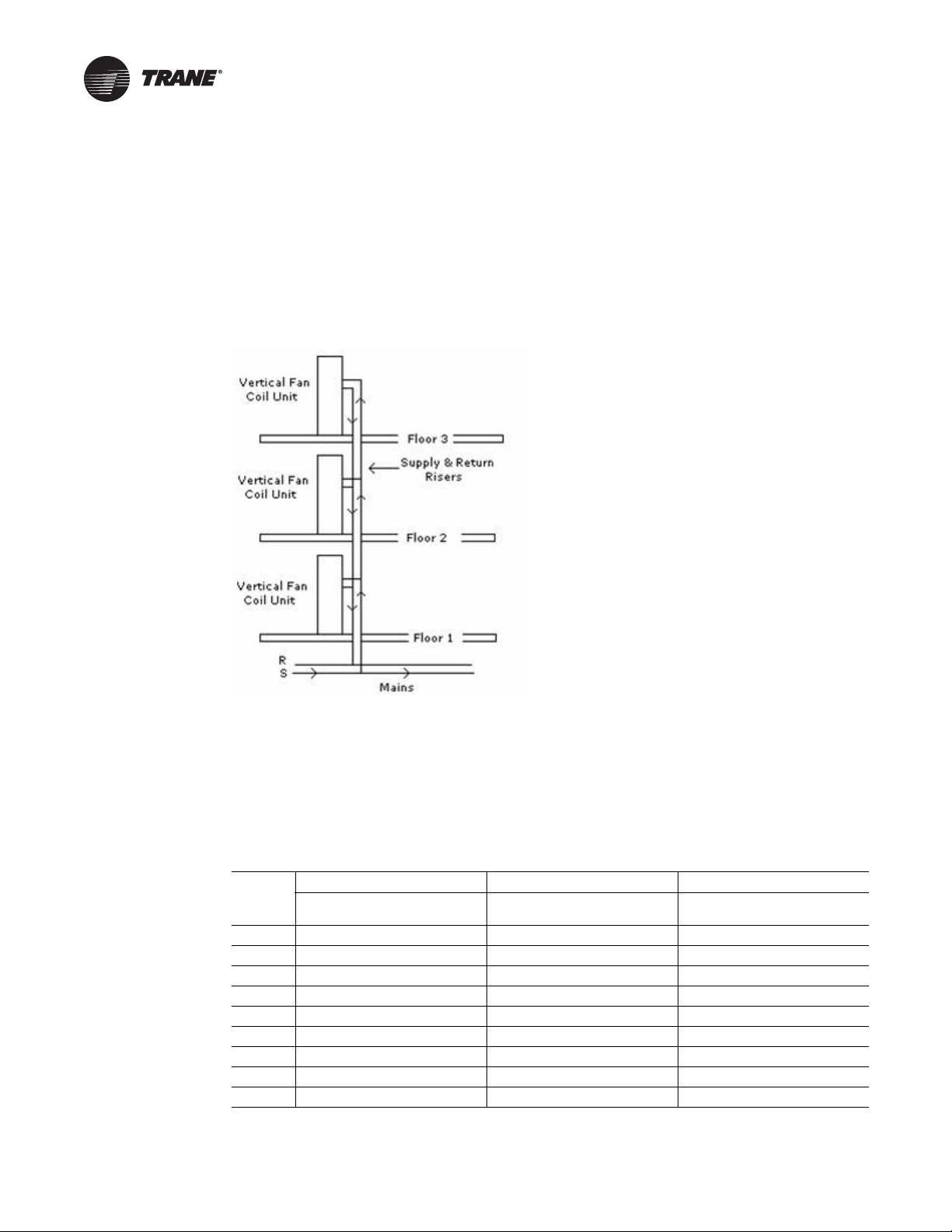

General Information on Riser Systems

The riser is a vertical pipe system, usually copper, that carries the chilled water and hot water supply

and return and coil condensate to and from a fan coil air handler. Other materials can be used, but

copper pipe is desirable due to its light weight, ease of installation, widespread availability,

durability and reasonable cost. Riser systems are installed in multi-story buildings where high rise

fan coil units are installed floor-by-floor on top of each other. The risers interconnect floor-by-floor

as the fan coil units are installed on top of each other. This allows the riser to ascend vertically to

each of the individual units.

Figure 1.

Installation of the fan coil units is quick with no lateral runs of copper piping off the main riser lines.

Copper tubing is commonly used for the risers. Job specifications will dictate the type of piping

used. There are three types of copper risers available, type K, L, and M, the difference being the

thickness of the wall of the copper pipe. For most applications, type L or type M copper is adequate.

Type K copper risers are used in high pressure applications, are very high priced and usually not

necessary for most high rise fan coil applications. Type K copper risers should not be bid unless

specified. Tab l e 1 provides dimensional data of type M, L, and K copper risers.

Table 1. Dimensional data of type M, L, and K copper risers (in.)

Type M Type L Type K

Riser Size

1/2 0.625 0.569 0.028 0.625 0.545 0.04 0.625 0.527 0.049

3/4 0.875 0.811 0.032 0.875 0.785 0.045 0.875 0.745 0.065

1 1.125 1.055 0.035 1.125 1.025 0.05 1.125 0.995 0.065

1-1/4 1.375 1.291 0.042 1.375 1.265 0.055 1.375 1.245 0.065

1-1/2 1.625 1.527 0.049 1.625 1.505 0.06 1.625 1.481 0.072

2 2.125 2.009 0.058 2.125 1.985 0.07 2.125 1.959 0.083

2-1/2 2.625 2.495 0.065 2.625 2.465 0.08 2.625 2.435 0.095

3 3.125 2.981 0.072 3.125 2.945 0.09 3.125 2.907 0.109

4 4.125 3.935 0.095 4.125 3.905 0.11 4.125 3.857 0.134

4 UNT-PRC015-EN

OD ID

Wall

Thickness OD ID

Wall

Thickness OD ID

Wall

Thickness

Page 5

General Information on Riser Systems

Hot water, cold water, and condensate risers are factory insulated to avoid condensation and/or

heat loss. Factory insulation is recommended to minimize installation costs and assure quality

control on the insulation application.

Two-pipe and four-pipe riser systems are available. Two-pipe risers provide pipes for hot or chilled

water supply and return only, but not both hot and chilled water simultaneously. Four-pipe risers

provide pipes for hot plus chilled water supply and return simultaneously. Riser systems may be

selected without a condensate riser—not required for a heating-only system. Very tall buildings

may have more than one riser system with each system independent of the other.

UNT-PRC015-EN 5

Page 6

Know the Riser Design—Design Return versus Reverse

BASEMENT

4TH FLOOR

3RD FLOOR

2ND FLOOR

1ST FLOOR

RISERS

MAI NS

S

R

CAPPED

SYSTEM 1

DIRECT RETURN

FLUSH/ VENT

ROOF

LOOP

SYSTEM 1 – DIRECT RETURN

2-pipe example

Return

There are two typical methods used for piping a riser column:

Direct return is the most common/popular method.

Advantages of this system are:

• It is cost-effective and simple.

• Straightforward installation.

• Very little confusion about properly sizing the risers.

Disadvantages of this system are:

• The pressure drop is not equal at each unit on the column. A means of balancing water flows

at each floor must be provided. The total pressure drop on the path that the water takes to the

unit on the top floor is much greater than the path to the unit on the lower floors(s) nearer the

pump. If a balance means is not provided, it is possible that there will be no water flow through

the upper units due to its height and friction loss.

Figure 2. System 1—Direct return

6 UNT-PRC015-EN

Reverse return is less common but is a better arrangement as far as pure piping design is

concerned.

Note: It is not the purpose of this section to make the readers expert piping designers. Rather to

give some familiarity of different piping designs which affect the risers (and pricing) picked

for the job.

Advantages of this system are:

• The system can be designed so the total system pressure drop through each unit is equalized.

• The overall pressure drop is lower—some energy saving potential.

Disadvantages of this system are:

• Water flow balancing at each unit is still required.

Page 7

Know the Riser Design—Design Return versus Reverse Return

4TH FLOOR

2ND FLOOR

3RD FLOOR

1ST FLOOR

BASEMENT

MAINS

R

S

REVERSE

RETURN

ROOF

SYSTEM 2 – REVERSE RETURN

2-pipe example

•

•

•

S

BASEMENT

1ST FLOOR

2ND FLOOR

3RD FLOOR

4TH FLOOR

ROOF

R

S

MAI NS

SYSTEM 3 – REVERSE RETURN

2-pipe example

• Higher cost and complexity—An additional riser pipe is required for each riser column (one

additional pipe for a 2-pipe system and two additional pipes for a 4-pipe system).

• There is additional complexity with the riser design and installation:

– The supply-side risers will begin with the larger diameter riser at the bottom of the column

and the smaller diameter riser at the top.

– The return-side risers will begin with the smaller diameter riser at the top of the column and

the largest diameter riser at the bottom.

– These details make the reverse return riser system difficult to coordinate during

construction.

Figure 3. System 2—Reverse Return Figure 4. System 3—Reverse Return

UNT-PRC015-EN 7

Be sure all competitors are bidding the same riser system design to avoid an uncompetitive price

bid. The direct return method is usually preferred.

Page 8

Riser Selection and Sizing

• Determine gpm through the riser pipes.

Total the flow rates (gpms) of all units on the riser column. Individual units’ flow rates are

determined by their specific selection.

Direct-return riser columns begin with the largest diameter riser pipe carrying the most gpm

at the bottom of the column. As water is diverted out of a riser into a fan coil, water volume is

subtracted and riser pipe diameters will decrease (within specified velocity limits).

The gpm for the second floor is determined by taking the total gpm and subtracting the gpm

from the first floor.

The gpm for the third floor is determined by taking the total gpm and subtracting the gpm from

the first and second floors.

Reiterate this process to determine the gpms for each floor.

• Determine water velocity.

Once the water flow is known for each riser, the proper size of the riser is determined by

calculating the water velocity in the riser. Use this formula to calculate the velocity (ft/sec) for

water:

2

V = (GPM * 0.102)/R

where:

V is water velocity, ft per sec

GPM is the water flow rate, gallons per minute

R is the inside radius of the pipe, inches

The maximum water velocity recommendations are:

6 fps and/or 10 ft head loss/100 ft pipe length.

• Determine riser pipe size

Refer to Figure 5 to determine water velocity and pipe size, or to the Vertical Stack FC Pipe Size

Picker (

http://www.trane.com/commercial/uploads/xls/Vertical%20Stack%20FC%20Pipe%20Size%20Picker.xls

)

Figure 5. Friction loss for water in copper tubing (Types K, L, M)

Note: Figure 5 is Copyright ©2005, ASHRAE (www.ashrae.org

ASHRAE (2005 ASHRAE Handbook Fundamentals, Chapter 36, Page 36.7, Fig. 5).

8 UNT-PRC015-EN

). Used with permission from

Page 9

Riser Selection and Sizing

Actual project velocity limits may be different than these based on the type of service or annual

operating hours or other guidelines as defined in job specifications.

UNT-PRC015-EN 9

Page 10

Riser Connections

Each branch run-out in the coil section must be centered in the expansion slot on the side or back

panel before joining risers. Risers are coupled/connected together with a swaged connection. (A

swage connection might be referred to as a ”bell” connection also.) The swage or bell is the

expanded portion of the riser pipe where an adjoining pipe of nominal diameter is inserted. A riser

can be swaged on the top or bottom.

Important: The type of connection on the top and bottom of the riser must be specified

and configured correctly. Field remedy of these errors is costly!

Figure 6.

The adjoining unit’s riser is inserted into the swage joint and brazed together. Riser joints must be

made with phos-copper, silfos, or other high temperature alloys. Soft solders (50-50, 60-40 and

85-15) or other low temperature lead alloys are NOT suitable for this application. It is important to

configure the upper and lower end of each unit’s riser to accommodate the upper and lower

adjoining unit riser. Pay particular attention to the riser design in a reverse return system where the

larger diameter riser may be at the top of the riser column. Job site coordination is critical to avoid

costly error correction.

The length of the swage joint is 3 inches. This length allows some tolerance to account for

miscalculations in riser length or tolerance of building structures and floor-to-floor distances. Each

riser joint must be vertically aligned, with a minimum of one-inch penetration (although two inches

is preferable and allowed for), into each swaged joint. This condition will be met if floor-to-floor

dimensions are as specified and each branch run is properly centered. Wide variations in floor-tofloor dimensions may necessitate cutting off or extending individual risers.

A capped connection is installed on the top or bottom when there are no more adjoining riser

connections.

Swage connections are not available on risers made with type K copper pipe. Separate couplings

and bell reducers must be used.

10 UNT-PRC015-EN

Page 11

Riser Connections

An alternate to swage and braze connections is a compression-coupling system like the Viega

®

ProPress

system (see www.viega-na.com). This system eliminates the need for swage

connections and brazing. It provides for quick, secure, leak-free connections on riser systems.

Check with local suppliers, contractors and plumbing codes for suitability on a job site.

UNT-PRC015-EN 11

Page 12

Expansion Compensation

Do not rigidly fasten the risers within each unit. They must be free to move within the pipe chase

with normal vertical expansion and contraction movements. The built-in risers must be anchored

at some point to the building structure by the installing contractor. The unit design will

accommodate up to 1-1/8 inch expansion and contraction (2-1/4 inch total movement) of the riser

assemblies. If the total calculated riser expansion exceeds 2-1/4 inches (minimum-to-maximum),

the installing contractor must provide and install additional expansion compensation devices in

each riser.

12 UNT-PRC015-EN

Page 13

Determining Riser Length

The required riser length is determined by knowing the floor-to-floor height of the building and

adding the length of the riser that fits into the swaged connection.

When a unit is ordered, the riser length and the desired vertical location of the riser on the unit must

be specified. The positioning of the riser is important. This determines the location along the

building structure or in-between floors where the riser brazing joints will be made. Care must be

taken to assure that the brazing location is not in between floors or in other difficult to reach areas.

Coordination with the installing contractor should be done before risers are ordered to determine

their exact location and length.

• Riser Extensions

“Between-the-floor” riser extensions are used when standard riser lengths are not long enough

to reach the floor-to-floor height.

Note: Maximum riser length is 10 feet.

“Between-the-floor” riser extensions are available and made with a swage connection on one

end.

Riser diameters in a column may not be equal size throughout their length, therefore riser

extensions are also used when a change in riser diameter is needed between floors.

Figure 7.

Note: All riser extensions are shipped loose for field installation.

UNT-PRC015-EN 13

Page 14

Produced on 20% post-consumer recycled paper, using

environmentally friendly print practices that reduce waste.

Trane optimizes the performance of homes and buildings around the world. A business of Ingersoll Rand, the leader in

creating and sustaining safe, comfortable and energy efficient environments, Trane offers a broad portfolio of

advanced controls and HVAC systems, comprehensive building services, and parts.

For more information, visit www.Trane.com

Trane has a policy of continuous product and product data improvement and reserves the right to change design and specifications without notice.

© 2010 Trane All rights reserved

UNT-PRC015-EN June 2010

Loading...

Loading...