Trane UniTrane Fan Coil, Force Flo Cabinet Heater Installation, Operation And Maintenance Manual

Page 1

Installation, Operation,

and Maintenance

UniTrane™ Fan Coil and Force-Flo™ Cabinet Heater

200 - 1200 CFM

Models FC and FF, Low Vertical Models FCKB and FCLB

Only qualified personnel should install and service the equipment. The ins tallation, starting up, and servicing of heating, ventilating, and airconditioning equipment can be hazardous and requires specific knowledge and training. Improperly installed, adjusted or altered equipment

by an unqualified person could result in death or serious injury. When w orking on the equipment, observe all preca utions in the literature and

on the tags, stickers, and labels that are attached to the equipment.

Marc h 2014

SAFETY WARNING

UNT-SVX07E-EN

Page 2

Warnings, Cautions and Notices

Warnings, Cautions and Notices.

cautions and notices appear at appropriate intervals

throughout this manual. Warnings are provided to alert

installing contractors to potential hazards that could result

in death or personal injury. Cautions are designed to alert

personnel to hazardous situ ations that could result in

personal injury, while notices indicate a situation that

could result in equipment or property-damage-only

accidents.

Your personal safety and the proper operation of this

machine depend upon the strict observance of these

precautions.

Read this manual thoroughly before operating or servicing

this unit.

ATTENTION:

appropriate sections throughout this literature. Read

these carefully:

WARNING

CAUTION

NOTICE:

Warnings, Cautions, and Notices appear at

Indicates a potentially hazardous

situation which, if not avoided, could

result in death or serious injury.

Indicates a potentially hazardous

s

situation which, if not avoided, could

result in minor or moderate injury. It

could also be used to alert against

unsafe practices.

Indicates a situation that could result in

equipment or property-damage only

accidents.

Note that warnings,

Important

Environmental Concerns!

Scientific research has shown that certain man-made

chemicals can affect the earth’s naturally occurring

stratospheric ozone layer when released to the

atmosphere. In particular, several of the identified

chemicals that may affect the oz one layer are refrigerants

that contain Chlorine, Fluorine and Carbon (CFCs) and

those containing Hydrogen, Chlorine, Fluorine and

Carbon (HCFCs). Not all refrigerants containing these

compounds have the same potential impact to the

environment. T rane advocates the responsible handling of

all refrigerants-including industry replacements for CFCs

such as HCFCs and HFCs.

municipalities may have additional requirements that

must also be adhered to for responsible management of

refrigerants. Know the applicable laws and follow them.

WARNING

Proper Field Wiring and Grounding

Required!

All field wiring MUST be performed by qualified

personnel. Improperly installed and grounded field

wiring poses FIRE and ELECTROCUTION hazards. To

avoid these hazards, you MUST follow r equirements f or

field wiring installat ion and grounding as described in

NEC and your local/state electrical codes. Failure to

follow code could result in death or serious injury.

WARNING

Personal Protective Equipment (PPE)

Required!

Installing/servicing this unit coul d result in exposure to

electrical, mechanical and chemical hazards.

• Before installing/servi cing this unit, technicians

MUST put on all P ersonal Protectiv e Equipment (PPE)

recommended for the work being undertaken.

AL WAYS r efer to appropr iate MSDS sheets and OSHA

guidelines for proper PPE.

• When work ing with or ar ound hazar dous c hemicals,

ALWAYS refer to the appropriate MSDS sheets and

OSHA guidelines for information on allowable

personal exposure levels, proper respiratory

protection and handling recommendations.

• If there is a risk of arc or flash, tec hnicians MUST put

on all Personal Protective Equipment (PPE) in

accordance with NFPA 70E or other country-specific

requirements for arc flash protection, PRIOR to

servicing the unit.

Failur e to f ollow r ecommendation s could resul t in death

or serious injury.

Responsible Refrigerant Practices!

Trane believes that responsible refrigerant practices are

important to the environment, our customers, and the air

conditioning industry. All technicians who handle

refrigerants must be certified. The Federal Clean Air Act

(Section 608) sets forth the requirements for handling,

reclaiming, recovering and recycling of certain

refrigerants and the equipment that is used in these

service procedures. In addition, some states or

© 2014 Trane All rights reserved UNT-SVX07E-EN

Page 3

Table of Contents

Warnings, Cautions and Notices

Model Number Descriptions

. . . . . . . . . . 2

. . . . . . . . . . . . . . 7

UniTrane™ Fan Coil/ Force Flo™ Cabinet

Heater

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

UniTrane™ Fan Coil Low Vertical Model

General Information

Pre-Installation

Receiving and Handling

Inspection . . . . . . . . . . . . . . . . . . . . . . . . . 13

Packaging/Shipping . . . . . . . . . . . . . . . . . 13

Identification . . . . . . . . . . . . . . . . . . . . . . . 13

Handling . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Receiving Checklist . . . . . . . . . . . . . . . . . 13

Jobsite Storage

Site Preparation

Dimensions and Weights

Service Clearances

Component Data

Available Models

Model A Vertical Concealed . . . . . . . . . . 18

Model B Vertical Cabinet . . . . . . . . . . . . . 20

Model C Horizontal Concealed . . . . . . . . 22

Model D Horizontal Cabinet . . . . . . . . . . 24

Model E Horizontal Recessed . . . . . . . . . 26

Model F Vertical Wall Hung Cabinet . . . . 28

Model H Vertical Recessed . . . . . . . . . . . 30

Model J Vertical Slope Top Cabinet . . . . 32

Model K Low Vertical Concealed . . . . . . 34

Model L Low Vertical Cabinet . . . . . . . . . 36

Model M Inverted Vertical Cabinet . . . . . 38

Model N Inverted Vertical Recessed . . . . 40

Mode P Compact Concealed . . . . . . . . . . 42

Coil Connections

Fan Coil Vertical Units . . . . . . . . . . . . . . . 43

Fan Coil Horizontal Units . . . . . . . . . . . . . 44

Force Flo Vertical Units . . . . . . . . . . . . . . 45

Force Flo Horizontal and Inverted Uni ts . 46

Fresh Air Opening Locations

Horizontal Units . . . . . . . . . . . . . . . . . . . . 47

. . . . . . . . . . . . . . . . . . . . 12

. . . . . . . . . . . . . . . . . . . . . . . . . 13

. . . . . . . . . . . . . . . 13

. . . . . . . . . . . . . . . . . . . . . . 13

. . . . . . . . . . . . . . . . . . . . . . 14

. . . . . . . . . . . . . . . . 15

. . . . . . . . . . . . . . . . . . . . 15

. . . . . . . . . . . . . . . . . . . . . 16

. . . . . . . . . . . . . . . . . . . . . 17

. . . . . . . . . . . . . . . . . . . . . 43

. . . . . . . . . . . 47

. 10

Vertical Units . . . . . . . . . . . . . . . . . . . . . . .48

Wall Box

Projection Panel

Installation—Mechanical

Installation Checklist

Installing the Unit

Vertical Units . . . . . . . . . . . . . . . . . . . . . . .52

Horizontal Units . . . . . . . . . . . . . . . . . . . . .52

Cabinet Units . . . . . . . . . . . . . . . . . . . . . . .53

Recessed Units . . . . . . . . . . . . . . . . . . . . . .53

Duct Connections

Ductwork Recommendations . . . . . . . . . .54

Coil Piping and Connections

. . . . . . . . . . . . . . . . . . . . . . . . . . . . .49

. . . . . . . . . . . . . . . . . . . . . . .50

. . . . . . . . . . . . . . . . .51

. . . . . . . . . . . . . . . . . . .51

. . . . . . . . . . . . . . . . . . . . .52

. . . . . . . . . . . . . . . . . . . . . .54

. . . . . . . . . . . . . .55

Factory-Installed Piping Packages

Hydronic Coil Piping

Connecting Field Piping to Coil . . . . . . . . .56

Water Piping Connections

Connecting to Factory Piping . . . . . . . . . .56

. . . . . . . . . . . . . . . . . . .56

. . . . . . . . . . . . . .56

Condensate Drain Connections

Condensate Overflow Detection Device . .57

Automatic Changeover Sensor . . . . . . . . .57

Venting the Hydronic Coil . . . . . . . . . . . . .58

External Insulating Requirements

Balancing Manual Circuit Setter Valve

Installation - Zone Sensors

Zone Sensor Options

ZN010 Controller Options . . . . . . . . . . . . .61

ZN510, ZN520, UC400 Controller Options 61

Installation Considerations

Location . . . . . . . . . . . . . . . . . . . . . . . . . . .62

Placement . . . . . . . . . . . . . . . . . . . . . . . . . .63

Height Requirements . . . . . . . . . . . . . . . . .63

Mounting Surfaces . . . . . . . . . . . . . . . . . . .63

Installation

Fan Mode Switch . . . . . . . . . . . . . . . . . . . .63

Wired Zone Sensor . . . . . . . . . . . . . . . . . .64

Wireless Zone Sensors . . . . . . . . . . . . . . .64

Receivers . . . . . . . . . . . . . . . . . . . . . . . . . . .65

. . . . . . . . . . . . . . . . . . . . . . . . . . .63

. . . . . . . . . . . . . . .61

. . . . . . . . . . . . . . . . . .61

. . . . . . . . . . . . .62

. . . . . . .55

. . . . . . . . . .56

. . . . . . . .58

. . . .58

UNT-SVX07E-EN 3

Page 4

Zone Sensor Settings

Address Setting . . . . . . . . . . . . . . . . . . . . 65

Observing Receiver for Readiness . . . . . 66

Associating Sensor to Receiver . . . . . . . 67

Testing Signal Strength and Battery . . . 67

Sensor Operations

Temporary Occupancy (Timed Override) 68

End-of-Range Temperature Values . . . . . 68

Receiver Power-up Sequence . . . . . . . . . 68

Transmission Variables . . . . . . . . . . . . . . 68

Wireless Sensor Specifications

Agency Compliance

Wireless Display Sensor (WDS)

Configuration Procedure . . . . . . . . . . . . . 70

Displaying Setpoint or Temperature . . . 71

Locking or Unlocking Settings . . . . . . . . 72

WDS Operating Mode . . . . . . . . . . . . . . . 72

Changing Room Temperature . . . . . . . . . 72

Changing Heating/Cooling Settings . . . . 73

Changing Fan Settings . . . . . . . . . . . . . . . 73

Requesting Temporary Occupancy . . . . 73

Error Codes . . . . . . . . . . . . . . . . . . . . . . . . 73

Lock Symbol . . . . . . . . . . . . . . . . . . . . . . . 73

Testing Signal Strength . . . . . . . . . . . . . . 73

Testing Battery Status . . . . . . . . . . . . . . . 73

Installation - Controllers

Tracer ZN510 and ZN520 Controllers

Communication Wire Specifications . . . 74

General Wiring Guidelines . . . . . . . . . . . 74

Recommended Wiring Practices . . . . . . . 74

Device Addressing . . . . . . . . . . . . . . . . . . 74

Tracer UC400 Controller

Communication Wire Specifications . . . 75

General Wiring Guidelines . . . . . . . . . . . 75

Setting the Address . . . . . . . . . . . . . . . . . 75

Power Supply

Transformer Recommendations . . . . . . . 76

Wiring Requirements . . . . . . . . . . . . . . . . 77

Connecting Wires . . . . . . . . . . . . . . . . . . . 77

Power ON Check . . . . . . . . . . . . . . . . . . . . 77

4 UNT-SVX07E-EN

. . . . . . . . . . . . . . . . . . . . . . . . 76

. . . . . . . . . . . . . . . . . 65

. . . . . . . . . . . . . . . . . . . . 68

. . . . . . . . . 69

. . . . . . . . . . . . . . . . . . . 69

. . . . . . . . . 70

. . . . . . . . . . . . . . . . . 74

. . . . 74

. . . . . . . . . . . . . . . 75

Wireless Comm Interface (WCI)

Quantity of WCIs per Network . . . . . . . . .78

Quantity of Networks per Tracer SC . . . . .78

Automatic Network Formation . . . . . . . . .78

Specifications . . . . . . . . . . . . . . . . . . . . . . .78

Mounting . . . . . . . . . . . . . . . . . . . . . . . . . .78

Wireless protocol . . . . . . . . . . . . . . . . . . . .78

Installation - Electrical

Unit Wiring Diagrams

Supply Power Wiring

. . . . . . . . . . . . . . . . . . . .79

. . . . . . . . . . . . . . . . . .79

. . . . . . . . . . . . . . . . . .79

. . . . . . . . .78

Electrical Grounding Restrictions

Interconnection Wiring

MCA and MOP Calculations

ECM Overview and Setup

Overview

. . . . . . . . . . . . . . . . . . . . . . . . . . . . .83

. . . . . . . . . . . . . . . . .79

. . . . . . . . . . . . .81

. . . . . . . . . . . . . . . .83

Electronically Commutated Motor (ECM)

VelociTach Motor Control Board

Manual Fan Speed Switch (FSS)

. . . . . . . . .84

. . . . . . . . .85

Customer Supplied Thermostat Interface

Installation and Initial Setup

Safety Requirements

Setup

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .87

VelociTach Motor Control Board . . . . . . .88

User Interface . . . . . . . . . . . . . . . . . . . . . . .89

Priority/Error Display . . . . . . . . . . . . . . . . .91

Adjustments . . . . . . . . . . . . . . . . . . . . . . . .92

. . . . . . . . . . . . . . . . . . .87

. . . . . . . . . . . .86

CSTI Adapter Board Configuration

VelociTach Control Board Configuration

Motor Control Board Settings . . . . . . . . . .98

Fan Speed Response Verification . . . . . .101

Startup

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .102

Pre-Startup Checklist

General Checks . . . . . . . . . . . . . . . . . . . . .102

Fan-Related Checks . . . . . . . . . . . . . . . . .102

Coil-Related Checks . . . . . . . . . . . . . . . . .102

Electrical Checks . . . . . . . . . . . . . . . . . . . .102

Ductwork Checks . . . . . . . . . . . . . . . . . . .102

Unit Startup

. . . . . . . . . . . . . . . . . . . . . . . . .103

. . . . . . . . . . . . . . . . . .102

Tracer ZN010 and ZN510 Controllers

ZN510 Stand-Alone Operation . . . . . . . .103

. . . . . . . .79

.83

.86

. . . . . . .95

. .97

. . . .103

Page 5

ZN010 and ZN510 Operation . . . . . . . . . 103

Sequence of Operation . . . . . . . . . . . . . 103

Binary Inputs . . . . . . . . . . . . . . . . . . . . . . 104

Binary Outputs . . . . . . . . . . . . . . . . . . . . 104

Zone Sensors . . . . . . . . . . . . . . . . . . . . . 104

Tracer ZN520 Controllers

ZN520 Stand-Alone Operation . . . . . . . 105

ZN520 Operation . . . . . . . . . . . . . . . . . . 105

Sequence of Operation . . . . . . . . . . . . . 106

Occupancy Modes . . . . . . . . . . . . . . . . . 106

Cooling Operation . . . . . . . . . . . . . . . . . 107

Heating Operation . . . . . . . . . . . . . . . . . 107

Fan Mode Operation . . . . . . . . . . . . . . . 108

Electric Heat Operation . . . . . . . . . . . . . 109

Damper Options . . . . . . . . . . . . . . . . . . . 109

Dehumidification . . . . . . . . . . . . . . . . . . 110

Data Sharing . . . . . . . . . . . . . . . . . . . . . . 110

Binary Inputs . . . . . . . . . . . . . . . . . . . . . . 110

Zone Sensor . . . . . . . . . . . . . . . . . . . . . . 112

Tracer UC400 Controller

UC400 Stand-Alone Operation . . . . . . . 113

UC400 Operation . . . . . . . . . . . . . . . . . . 114

Sequence of Operation . . . . . . . . . . . . . 114

Occupancy Modes . . . . . . . . . . . . . . . . . 114

Timed Override Control . . . . . . . . . . . . . 115

Zone Temperature Control . . . . . . . . . . 115

Discharge Air Tempering . . . . . . . . . . . . 116

Heating or Cooling Mode . . . . . . . . . . . 116

Fan Operation . . . . . . . . . . . . . . . . . . . . . 116

Exhaust Control . . . . . . . . . . . . . . . . . . . 117

Valve Operation . . . . . . . . . . . . . . . . . . . 117

Modulating Outdoor/Return Air Damper 118

Electric Heat Operation . . . . . . . . . . . . . 119

Dehumidification Operation . . . . . . . . . 119

Peer-to-Peer Communication . . . . . . . . 119

Unit Protection Strategies . . . . . . . . . . . 119

Routine Maintenance

Maintenance Checklist

Air Filters

Coils

. . . . . . . . . . . . . . . . . . . . . . . . . . . 121

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 122

. . . . . . . . . . . . . 105

. . . . . . . . . . . . . . 113

. . . . . . . . . . . . . . . . . . 121

. . . . . . . . . . . . . . . 121

Steam and Water Coils . . . . . . . . . . . . . .122

Coil Winterization . . . . . . . . . . . . . . . . . . .122

Moisture Purge Cycle . . . . . . . . . . . . . . . .123

Cleaning Non-Porous Surfaces . . . . . . . .123

Cleaning Porous Surfaces . . . . . . . . . . . .124

Control Device Replacement

Drain Pans

Removing Main Drain Pan . . . . . . . . . . .124

Removing Auxiliary Drain Pan . . . . . . . .124

Replacing Drain Pan . . . . . . . . . . . . . . . . .125

Cleaning Drain Pan . . . . . . . . . . . . . . . . .125

Fans

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .126

Inspecting and Cleaning Fans . . . . . . . . .126

Fan Motors . . . . . . . . . . . . . . . . . . . . . . . .126

Torque Rating . . . . . . . . . . . . . . . . . . . . . .126

Fan Board Assembly . . . . . . . . . . . . . . . .126

Replacing Motors . . . . . . . . . . . . . . . . . . .127

. . . . . . . . . . . . . . . . . . . . . . . . . . .124

. . . . . . . . . . .124

Diagnostics and Troubleshooting

Fan Coil and Cabinet Heater

. . . . . . . . . . .129

Wireless Zone Sensors (WZS)

Receiver Diagnostics . . . . . . . . . . . . . . . .131

Sensor Diagnostics . . . . . . . . . . . . . . . . .131

Testing Signal Strength . . . . . . . . . . . . . .132

Testing Battery Status . . . . . . . . . . . . . . .133

24 V Power Status Indicator . . . . . . . . . .133

Check Signal Strength on a Site . . . . . . .133

Replacing Sensor Batteries . . . . . . . . . . .133

Manual Association . . . . . . . . . . . . . . . . .134

Disassociation . . . . . . . . . . . . . . . . . . . . .134

Sensor/Receiver Compatibility . . . . . . . .134

Replacing a Failed Sensor or Receiver . .134

Servicing and Testing WZS

Servicing and Testing Tools . . . . . . . . . .135

Procedure for Testing Zone Sensor . . . .135

Procedure for Testing Receiver . . . . . . . .135

Forcing a Sensor to Transmit . . . . . . . . .135

Output Power Level . . . . . . . . . . . . . . . . .135

Failure and Default Modes . . . . . . . . . . .135

Measuring Output Resistance . . . . . . . . .136

Cleaning the Sensor . . . . . . . . . . . . . . . . .136

. . . . . . . . . . . .135

. . . . . . . .129

. . . . . . . . . .130

UNT-SVX07E-EN 5

Page 6

ZN010, ZN510, and ZN520 Controllers

LED Activity . . . . . . . . . . . . . . . . . . . . . . . 136

Manual Output Test . . . . . . . . . . . . . . . . 137

Manual Output Test Procedure . . . . . . . 137

Diagnostics

Translating Multiple Diagnostics . . . . . 138

Resetting Diagnostics . . . . . . . . . . . . . . 138

Cycling Power . . . . . . . . . . . . . . . . . . . . . 139

Controller Diagnostics . . . . . . . . . . . . . . 139

. . . . . . . . . . . . . . . . . . . . . . . . . 138

Troubleshooting ZN010, ZN510, and ZN520

Controllers

Fans . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 141

Valves . . . . . . . . . . . . . . . . . . . . . . . . . . . 141

Electric Heat . . . . . . . . . . . . . . . . . . . . . . 142

Fresh Air Damper . . . . . . . . . . . . . . . . . . 142

. . . . . . . . . . . . . . . . . . . . . . . . . . 141

. . . 136

Troubleshooting Other Unit Functions .153

Wiring Diagrams

. . . . . . . . . . . . . . . . . . . . . . .154

Tracer UC 400 Controller

LED Activity . . . . . . . . . . . . . . . . . . . . . . . 143

Overriding Outputs . . . . . . . . . . . . . . . . 144

Diagnostics

Diagnostics Types . . . . . . . . . . . . . . . . . 144

Controller Diagnostics . . . . . . . . . . . . . . 145

. . . . . . . . . . . . . . . . . . . . . . . . . 144

. . . . . . . . . . . . . . . 143

Troubleshooting UC400 Controller

Fans . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 146

Valves . . . . . . . . . . . . . . . . . . . . . . . . . . . 147

DX Coils or Electric Heat . . . . . . . . . . . . 147

Outdoor Air Dampers . . . . . . . . . . . . . . . 148

ECM Motors

General Information . . . . . . . . . . . . . . . . 149

Troubleshooting Tips . . . . . . . . . . . . . . . 149

Motor . . . . . . . . . . . . . . . . . . . . . . . . . . . . 149

. . . . . . . . . . . . . . . . . . . . . . . . . . . 148

Replacing ECM Components

Replacement Guidelines . . . . . . . . . . . . 151

Replacement Checklist . . . . . . . . . . . . . . 151

Circuit Module Replacement . . . . . . . . . 152

Application Notes

RPM Mode . . . . . . . . . . . . . . . . . . . . . . . 153

Field Power Wiring . . . . . . . . . . . . . . . . . 153

Performance Boundaries . . . . . . . . . . . . 153

MCA/MOP and Power Draw . . . . . . . . . 153

Electric Heat Relays . . . . . . . . . . . . . . . . 153

. . . . . . . . . . . . . . . . . . . 153

. . . . . 146

. . . . . . . . . . 151

6 UNT-SVX07E-EN

Page 7

Model Number Descriptions

UniTrane™ Fan Coil/

Force Flo™ Cabinet

Heater

Following is a complete description of

the UniTrane fan coil and Force Flo

cabinet heater model number. Each digit

in the model number has a

corresponding code that identifies

specific unit options.

Note: Not all options are available on all

cabinet styles. Contact your local

Trane sales representative for

more information.

Digits 1, 2 — Unit Type

FC = UniTrane fan coil

FF = Force Flo cabinet heater

Digit 3 — Cabinet Type

A = Vertical concealed

B = Vertical cabinet

C = Horizontal concealed

D = Horizontal cabinet

E = Horizontal recessed

F = Wall-hung cabinet (FF only)

H = Vertical recessed

J = Vertical slope-top cabinet

M = Inverted vertical cabinet

(FF only)

N = Inverted vertical recessed

(FF only)

P = Compact concealed

Digit 4 — Development

Sequence “B”

Digits 5, 6, 7 — Unit Size

020 040 080

030 060 100

120

Digit 8 — Unit Voltage

1 = 115/60/1

2 = 208/60/1

3 = 277/60/1

4 = 230/60/1

5 = 208/60/3 (FF only)

6 = 230/60/3 (FF only)

7 = 480/60/3 (FF only)

8 = 110-120/50/1 (FF only)

9 = 220/50/1

A = 220-240/50/3 (FF only)

B = 380-415/50/3 (FF only)

Digit 9 — Piping System/

Placement

A = No piping, RH, no auxiliary

drain pan

B = No piping, LH, no auxiliary

drain pan

C = No piping, RH, with auxiliary

drain pan

D = No piping, LH, with auxiliary

drain pan

E = No piping, RH, no auxiliary

drain pan, Extended End Pocket

F = No piping, LH, No Auxiliary

Drain Pan, extended end pocket

G = No piping, RH, with auxiliary

drain pan, extended end pocket

H = No piping, LH, with auxiliary

drain pan, extended end pocket

J = With piping package, RH

K = With piping package, LH

L = With piping package, RH,

extended end pocket

M = With piping package, LH,

extended end pocket

Digits 10, 11 — Design

Sequence

Digit 12 — Inlets

A = Front toe space

B = Front bar grille

C = Front stamped louver

D = Bottom stamped louver

E = Bottom toe space

F = Back duct collar

G = Back open return

H = Back stamped louver

J = Top duct collar (FF only)

K = Exposed fan (Model P only)

L = Bottom filter (Model P only)

Digit 13 — Fresh Air Damper

0=None

A = Manual, bottom opening

B = Manual, back opening

C = Manual, top opening

D = Auto, 2-position, bottom

opening

E = Auto, 2-position, back opening

F = Auto, 2-position, top opening

G = Auto, economizer, bottom

opening

H = Auto, economizer, back opening

J = Auto, economizer, top opening

K = No damper, bottom opening

L = No damper, back opening

M = No damper, top opening

Digit 14 — Outlets

A = Front duct collar

B = Front bar grille

C = Front stamped louver

D = Front quad grille

E = Bottom duct collar (FF only)

F = Bottom stamped louver

(FF only)

G = Top quad grille

H = Top bar grille

J = Top duct collar

Digit 15 — Color

0 = No paint (concealed units only)

1 = Deluxe Beige

2=Soft Dove

3=Cameo White

4 = Driftwood Grey

5 = Stone Grey

6=Rose Mauve

Digit 16 — Tamperproof Locks/

Leveling Feet

0=None

B = Keylock access door

C = Keylock panel and access door

D = Leveling feet

F = Keylock access door with

G = Keylock panel and access door

leveling feet

with leveling feet

Digit 17 — Motor

A = Free discharge ECM

B = High static ECM

Digit 18 — Coil

A = 2-row cooling/heating

B = 3-row cooling/heating

C = 4-row cooling/heating

D = 2-row cooling/1-row heating

E = 2-row cooling/2-row heating

F = 3-row cooling/1-row heating

G = 2-row cooling only

H = 3-row cooling only

J = 4-row cooling only

K = 2-row cooling/heating

L = 3-row cooling/heating

M = 4-row cooling/heating

N = Electric heat, single-stage

P = 2-row cooling/heating

Q = 2-row cooling/heating

R = 3-row cooling/heating

U = Electric heat, two-stage

V = Electric heat, low kW, one-stage

W = Steam distributing (FF only)

X = 2-row cooling only, electric

Y = 3-row cooling only, electric

Z = 4-row cooling only, electric

Note:

electric heat

electric heat

electric heat

(FF only)

1-row heating

2-row heating

1-row heating

(FF only)

(FF only)

heat

heat

heat

1

Designates coils provided with a

changeover sensor.

1

1

1

1

with

1

with

1

with

1

with

1

with

1

with

Digit 19 — Drain Pan Material

(Fan Coil) or Coil Series (Force

Flo)

1 = 108 FPF (steam only)

2 = 144 FPF (hot water only)

3 = Polymer drain pan

4 = Stainless steel main drain pan

UNT-SVX07E-EN 7

Page 8

Model Number Descriptions

Digit 20 — Coil Air Vent

A = Automatic air vent

M = Manual air vent

Digits 21, 22, 23 — Electric Heat

kW — ( ) = 208V Derate

00 0= No electric heat

010 = 1.0 kW (0.75 kW)

015 = 1.5 kW (1.1 kW)

020= 2.0 kW (1.5 kW)

025= 2.5 kW (1.9 kW)

030= 3.0 kW (2.3 kW)

040= 4.0 kW (3.0 kW)

045 = 4.5 kW (3.3 kW) (FF only)

050= 5.0 kW (3.8 kW)

060= 6.0 kW (4.5 kW)

070= 7.0 kW (5.3 kW)

075= 7.5 kW (5.7 kW) (FF only)

080= 8.0 kW (6.0 kW)

090 = 9.0 kW (6.6 kW) (FF only)

100 = 10.0 kW

105 = 10.5 kW (7.9 kW) (FF only)

110 = 11.0 kW (9.0 kW) (FF only)

120= 12.0 kW (FF only)

135= 13.5 kW (10.2 kW) (FF only)

150= 15.0 kW (FF only)

180= 18.0 kW (13.5 kW) (FF only)

200= 20.0 kW (15.0 kW) (FF only)

Digit 24 — Reheat Coil (Fan Coil

only)

0=None

A = Steam coil

B = Hot water coil

D = High capacity hot water coil

Digit 25 — Disconnect Switch

0=None

D = Disconnect switch

Digit 26 — Filter

0=None

1 = 1-in. throwaway filter

2 = 1-in. throwaway MERV 8 filter

3 = 1-in. throwaway, one extra

4 = 1-in. throwaway MERV 8,

one extra

5 = 1-in. throwaway, two extras

6 = 1-in. throwaway MERV 8,

two extras

7 = 1-in. throwaway, three extras

8 = 1-in. throwaway MERV 8,

three extras

A = 1-in. throwaway MERV 13 filter

B = 1-in. throwaway MERV 13,

one extra

C = 1-in. throwaway MERV 13,

two extras

D = 1-in. throwaway MERV 13,

three extras

Digit 27 — Main Control Valve

0=None

A = 2-way, 2-position, NO (30 psig)

B = 3-way, 2-position, NO (28 psig)

C = 2-way, 2-position, NC (30 psig)

D = 3-way, 2-position, NC (20 psig)

E = 2-way, 2-position, NO (50 psig)

F = 3-way, 2-position, NO (28 psig)

G = 2-way, 2-position, NC (50 psig)

H = 3-way, 2-position, NC (28 psig)

J = 2-way, 3-wire modulating,

0.6 Cv (60 psig)

K = 3-way, 3-wire modulating,

0.6 Cv (60 psig)

L = 2-way, 3-wire modulating,

1.1 Cv (60 psig)

M = 3-way, 3-wire modulating,

1.1 Cv (60 psig)

N = 2-way, 3-wire modulating,

2.3 Cv (60 psig)

P = 3-way, 3-wire modulating,

2.7 Cv (60 psig)

Q = 2-way, 3-wire modulating,

3.3Cv (60 psig)

R = 3-way, 3-wire modulating,

3.8 Cv (60 psig)

X = Field-supplied, NO

Y = Field-supplied, NC

Z = Field-supplied 3-wire modulating

1 = Field supplied analog valve

2 = 2-way, analog (2-10VDC),

CV=0.6 (60 psig)

3 = 3-way, analog (2-10VDC),

CV=0.6 (60 psig)

4 = 2-way, analog (2-10VDC),

CV=1.1 (60 psig)

5 = 3-way, analog (2-10VDC),

CV=1.1 (50 psig)

6 = 2-way, analog (2-10VDC),

CV=2.3 (50 psig)

7 = 3-way, analog (2-10VDC),

CV=2.7 (60 psig)

8 = 2-way, analog (2-10VDC),

CV=3.3 (60 psig)

9 = 3-way, analog (2-10VDC),

CV=3.8 (60 psig)

Digit 28 — Auxiliary Control

Valve (Fan Coil only)

0=None

A = 2-way, 2-position, NO (30 psig)

B = 3-way, 2-position, NO (28 psig)

C = 2-way, 2-position, NC (30 psig)

D = 3-way, 2-position, NC (20 psig)

E = 2-way, 2-position, NO (50 psig)

F = 3-way, 2-position, NO (28 psig)

G = 2-way, 2-position, NC (50 psig)

H = 3-way, 2-position, NC (28 psig)

J = 2-way, 3-wire modulating,

0.6 Cv (60 psig)

K = 3-way, 3-wire modulating,

0.6 Cv (60 psig)

L = 2-way, 3-wire modulating,

1.1 Cv (60 psig)

M = 3-way, 3-wire modulating,

1.1 Cv (60 psig)

N = 2-way, 3-wire modulating,

2.3 Cv (60 psig)

P = 3-way, 3-wire modulating,

2.7 Cv (60 psig)

Q = 2-way, 3-wire modulating,

3.3Cv (60 psig)

R = 3-way, 3-wire modulating,

3.8 Cv (60 psig)

X = Field-supplied, NO

Y = Field-supplied, NC

Z = Field-supplied 3-wire modulating

1 = Field supplied analog valve

2 = 2-way, analog (2-10VDC),

CV=0.6 (60 psig)

3 = 3-way, analog (2-10VDC),

CV=0.6 (60 psig)

4 = 2-way, analog (2-10VDC),

CV=1.1 (60 psig)

5 = 3-way, analog (2-10VDC),

CV=1.1 (50 psig)

6 = 2-way, analog (2-10VDC),

CV=2.3 (50 psig)

7 = 3-way, analog (2-10VDC),

CV=2.7 (60 psig)

8 = 2-way, analog (2-10VDC),

CV=3.3 (60 psig)

9 = 3-way, analog (2-10VDC),

CV=3.8 (60 psig)

Digit 29 — Piping Packages

0=None

A = Basic ball valve supply and

return

B = Basic ball valve supply/manual

circuit setter

C = Basic ball valve supply and

return with auto circuit setter

D = Deluxe ball valve supply and

return

E = Deluxe ball valve supply/manual

circuit setter

F = Deluxe ball valve supply and

return with auto circuit setter

8 UNT-SVX07E-EN

Page 9

Model Number Descriptions

Digit 30 — Control Type

A = Fan mode switch

E = Tracer ZN010

F = Tracer ZN510

G = Tracer ZN520

H = Customer Supplied Terminal

Interface (CSTI)

J = Tracer UC400, single-zone VAV

K = Tracer UC400 with WCI

Digit 31 — Control Option

D = Unit-mounted fan mode switch

K = Wall-mounted fan mode switch

V = Unit-mounted fan speed switch

with setpoint dial zone sensor

W = Wall-mounted fan speed switch

with setpoint dial zone sensor

X = Unit-mounted fan speed switch

with wall-mounted setpoint dial

zone sensor

Y = Unit-mounted fan speed switch

and wall-mounted setpoint dial

with comm.

Z = Unit-mounted fan speed switch,

On/Cancel, setpoint dial

with comm.

1 = Wall-mounted On/Cancel

with comm.

2 = Wall-mounted fan speed switch,

setpoint dial, On/Cancel

with comm.

0 = Without control option

3 = Unit-mounted low voltage fan

speed switch (Off /Hi /Med /Low)

4 = Wall-mounted digital zone

sensor (OALMH, setpoint,

On/Cancel, comm jack)

5 = Wall-mounted digital zone

sensor (On/Cancel, comm jack)

6 = Wireless zone sensor

7 = Wireless display sensor, unit-

mounted receiver

Digit 32 — IAQ Options (Fan C oil

only)

0 = Without IAQ options

1 = Dehumidification

4 = Dehumidification with sensor

Digit 33 —FLA Motor Option

0 = Standard FLA ECM mode

A = Reduced FLA ECM mode

Digit 34

0 = None

Digit 35 — Control Function #3

(Fan Coil only)

0=None

2 = Condensate overflow detection

Digit 36 — Control Function #4

(Fan Coil only)

0=None

2 = Low temperature detection

Digits 37, 38 — Future Control

Functions

Digit 39 — Projection Panels

and Falsebacks

0=None

A = 5/8-in. standard recessed panel

(vertical recessed units only)

B = 2-in. projection panel

C = 2.5-in. projection panel

D = 3-in. projection panel

E = 3.5-in. projection panel

F = 4-in. projection panel

G = 4.5-in. projection panel

H = 5-in. projection panel

J = 5.5-in. projection panel

K = 6-in. projection panel

L = 2-in. Falseback

M = 3-in. Falseback

N = 4-in. Falseback

P = 5-in. Falseback

Q = 6-in. Falseback

R = 7-in. Falseback

T = 8-in. Falseback

Digit 40 — Main Autoflow GPM

0=None H=3.5

A=0.5 J=4.0

B = 0.75 K = 4.5

C=1.0 L=5.0

D=1.5 M=6.0

E=2.0 N=7.0

F=2.5 P=8.0

G=3.0

Digit 41 — Auxiliary Autoflow

GPM (Fan Coil only)

0 = None H = 3.5

A=0.5 J=4.0

B = 0.75 K = 4.5

C=1.0 L=5.0

D=1.5 M=6.0

E=2.0 N=7.0

F=2.5 P=8.0

G=3.0

Digit 42 — Subbases

0=None

A = 2-in. subbase

B = 3-in. subbase

C = 4-in. subbase

D = 5-in. subbase

E = 6-in. subbase

F = 7-in. subbase

Digit 43 — Recessed Flange

0=None

A = Recessed flange

Digit 44 — Wall Boxes

0=None

A = Anodized wall box

UNT-SVX07E-EN 9

Page 10

Model Number Descriptions

UniTrane™ Fan Coil

Low Vertical Model

Following is a complete description

of the UniTrane fan coil low height

vertical model.

Digits 1, 2 — Unit Type

FC = UniTrane Fan Coil

Digit 3 — Cabinet Type

K = Low vertical concealed

L = Low vertical cabinet

Digit 3 — Development

Sequence

B = Development sequence B

Digit 4, 5, 6 — Unit Size

030= Size 030

040= Size 040

060= Size 060

Digit 7 — Unit Voltage

1 = 115v/60hz/1ph

2 = 208v/60hz/1ph

3 = 277v/60hz/1ph

4 = 230v/60hz/1ph

Digit 8 — Piping system/

placement

C = Without piping, right hand, with

aux drain pan

D = Without piping, left hand, with

aux drain pan

J = With right hand piping

K = With left hand piping

Digit 9, 10 — Design Sequence

** = Factory assigned

Digit 11 — Inlet Style

A = Front toe space inlet

B = Front bar grille inlet

Digit 12 — Fresh Air Damper

0 = Without fresh air damper

B = Manual fresh air damper, back

opening

E = Auto, 2 position damper, back

opening

Digit 13 — Outlet Style

G = Top quad grille outlet

H = Top bar grille outlet

J = Top duct collar outlet

Digit 14 — Unit Color

0 = Unpainted unit (concealed units)

1 = Deluxe Beige

2=Soft Dove

3=Cameo White

4 = Driftwood Grey

5 = Stone Grey

6=Rose Mauve

Digit 15 — Tamperproof Locks

and Leveling Feet

0 = Without locks or leveling feet

B = Keylock access door

D = Leveling feet

F = Keylock access door with

leveling feet

Digit 16 — Main Coil Type

A = 2-row cooling/heating

B = 3-row cooling/heating

C = 4-row cooling/heating

D = 2-row cooling, 1-row heating coil

E = 2-row cooling, 2-row heating coil

F = 3-row cooling, 1-row heating coil

K = 2-row cooling/heating

P = 2-row cooling/heating

Q = 2-row cooling/heating

R = 3-row cooling/heating

X = 2-row cooling only, electric heat

Note:

electric heat coil

1-row heating coil

2-row heating coil

1-row heating coil

1

Designates coils provided with a

changeover sensor.

1

1

1

1

with

1

with

1

with

1

with

Digit 17 — Coil air vent

A = Auto air vent

M = Manual air vent

Digit 18, 19, 20 — Electric Heat

000= Without electric heat

010 = 1.0 kW [0.75 208v]

015= 1.5 kW [1.1 208v]

020= 2.0 kW [1.5 208v]

025= 2.5 kW [1.9 208v]

030= 3.0 kW [2.2 208v]

040= 4.0 kW [3.0 208v]

Digit 21 — Auxiliary Coil Type

0 = Without auxiliary option

C = Electric heat

Digit 22 — Disconnect Switch

0 = Without disconnect switch

D = With disconnect switch

Digit 23 — Filter Type

0 = Without filter

1 = 1 inch. throwaway filter

Digit 24 — Main Control Valve

X = Field-supplied N/O control valve

Y = Field-supplied N/C control valve

Z = Field-supplied 3-wire modulating

control valve

1 = Field-supplied analog valve

(2-10VDC)

A = 2-way, 2-position, NO (30 psig)

Cv = 2.3

B = 3-way, 2-position, NO (28 psig)

Cv = 3.0

C = 2-way, 2-position, NC (30 psig)

Cv = 2.3

D = 3-way, 2-position, NC (20 psig)

Cv = 4.4

E = 2-way, 2-position, NO (50 psig)

Cv = 1.0

F = 3-way, 2-position, NO (28 psig)

Cv = 1.5

G = 2-way, 2-position, NC (50 psig)

Cv = 1.0

H = 3-way, 2-position, NC (28 psig)

Cv = 1.5

J = 2-way, modulating Cv=0.6

(60 psig)

K = 3-way, modulating Cv=0.6

(60 psig)

L = 2-way, modulating Cv=1.1

(60 psig)

M = 3-way, modulating Cv=1.1

(60 psig)

N = 2-way, modulating Cv=2.3

(60 psig)

P = 3-way, modulating Cv=2.7

(60 psig)

Q = 2-way, modulating Cv=3.3

(60 psig)

R = 3-way, modulating Cv=3.8

(60 psig)

0 = Without cooling control valves

2 = 2 way, analog(2-10VDC), Cv=0.6

(60 psig)

3 = 3 way, analog(2-10VDC), Cv=0.6

(60 psig)

4 = 2 way, analog(2-10VDC), Cv=1.1

(60 psig)

5 = 3 way, analog(2-10VDC), Cv=1.1

(60 psig)

6 = 2 way, analog(2-10VDC), Cv=2.3

(60 psig)

7 = 3 way, analog(2-10VDC), Cv=2.7

(60 psig)

8 = 2 way, analog(2-10VDC), Cv=3.3

(60 psig)

9 = 3 way, analog(2-10VDC), Cv=3.8

(60 psig)

10 UNT-SVX07E-EN

Page 11

Model Number Descriptions

Digit 25 — Auxiliary Control

Valve

X = Field-supplied N/O control valve

Y = Field-supplied N/C control valve

Z = Field supplied 3-wire modulating

control valve

1 = Field-supplied analog valve

(2-10VDC)

A = 2-way, 2-position, NO (30 psig)

Cv = 2.3

B = 3-way, 2-position, NO (28 psig)

Cv = 3.0

C = 2-way, 2-position, NC (30 psig)

Cv = 2.3

D = 3-way, 2-position, NC (20 psig)

Cv = 4.4

E = 2-way, 2-position, NO (50 psig)

Cv = 1.0

F = 3-way, 2-position, NO (28 psig)

Cv = 1.5

G = 2-way, 2-position, NC (50 psig)

Cv = 1.0

H = 3-way, 2-position, NC (28 psig)

Cv = 1.5

J = 2-way, modulating, Cv=0.6

(60 psig)

K = 3-way, modulating, Cv=0.6

(60 psig)

L = 2-way, modulating, Cv=1.1

(60 psig)

M = 3-way, modulating, Cv=1.1

(60 psig)

N = 2-way, modulating, Cv=2.3

(60 psig)

P = 3-way, modulating, Cv=2.7

(60 psig)

Q = 2-way, modulating, Cv=3.3

(60 psig)

R = 3-way, modulating, Cv=3.8

(60 psig)

0 = Without heating control valves

2 = 2-way, analog(2-10VDC), Cv=0.6

(60 psig)

3 = 3-way, analog(2-10VDC), Cv=0.6

(60 psig)

4 = 2-way, analog(2-10VDC), Cv=1.1

(60 psig)

5 = 3-way, analog(2-10VDC), Cv=1.1

(60 psig)

6 = 2-way, analog(2-10VDC), Cv=2.3

(60 psig)

7 = 3-way, analog(2-10VDC), Cv=2.7

(60 psig)

8 = 2-way, analog(2-10VDC), Cv=3.3

(60 psig)

9 = 3-way, analog(2-10VDC), Cv=3.8

(60 psig)

Digit 26 — Piping Packages/End

Valves

0 = Without piping

A = Basic ball valve supply and

return

B = Basic ball valve supply, manual

circuit setter return

D = Deluxe ball valve supply and

return

E = Deluxe ball valve supply, manual

circuit setter return

Digit 27 — Control Type

A = Fan speed switch

D=Tracer ZN 010

E=Tracer ZN 510

F = Tracer ZN 520

H = CS T-Stat Interface

J = Tracer UC400, single zone VAV

K = Tracer UC400, with wireless

comm

Digit 28 — Control Option

0=None

D = Unit-mounted fan speed switch,

line voltage

K = Wall-mounted fan speed switch,

line voltage

V = Unit-mounted zone sensor

(OALMH and setpoint dial)

3 = Unit-mounted fan speed switch,

low voltage

W = Wall-mounted zone sensor

(OALMH and setpoint dial)

X = Unit-mounted fan switch and

wall-mounted setpoint dial

Y = Unit-mounted fan switch and

wall-mounted (setpoint, comm)

Z = Unit-mounted temp sensor

(OALMH, SP, ON/CNC)

1 = Wall-mounted temp sensor

(OCC/UNOCC, COMM)

2 = Wall-mounted temp sensor

(OALMH,SP,O/C,COMM)

4 = Wall-mounted sensor (SP,

OALMH, O/C,COM)

6 = Wireless temp sensor, unit

receiver (SP)

7 = Wireless display sensor, unit

rec (OALMH)

Digit 29 — Drain Pan Material

3 = Polymer drain pan

4 = Stainless steel drain pan

Digit 30 — FLA Motor Option

0 = Standard FLA ECM

A = Reduced FLA ECM

Digit 31 — Control Function 2

0 = Without occupant call or IAQ

status

Digit 32 — Control Function 3

0 = Without occupied/unoccupied or

condensate overflow

2 = Condensate overflow detection

Digit 33 — Control Function 4

0 = Without smoke input or low limit

detect

2 = Low limit detection

Digit 34 — Control Function 5

0 = Without external interlock or fan

status

Digit 35 — Control Function 6

0 = Without motion input or filter

status

2 = Filter status

UNT-SVX07E-EN 11

Page 12

General Information

Smaller unit footprint

Factory-installed and

tested controls

Removable, noncorrosive,

positively-sloped drain pan

Built-in field service

tool with real

language LED

Easy-to-remove

fan assembly

18 gage steel

construction

Easy filter access

with front panel

removal

Energy efficient

electronically commutated

motor (ECM)

Damper allows up to

100 percent fresh air

Cleanable closedcell insulation

(non-fiberglass)

Factory-assembled, -installed, and

-tested piping package with IAQ

drain pan to collect condensate

Two-, three-, or

four-row coils

Quiet operation

UniTrane™ fan coils and Force Flo™ cabinet heaters are

intended for single zone applications. These units have

load capabilities of 200 to 1200 cfm. See Figure 1 for unit

components.

Fan coils provide cooling and heating, and are available as

two-pipe, with or without electr ic heat (one hydronic

circuit) or four-pipe (two hydronic circuits).

Cabinet heaters are for heating only, and feature two-pipe

hydronic, electric heat only, or steam only.

These units feature a variety of factory mounted piping

packages.

three-speed switch option, whic h ships separately, comes

with a low voltage (24 volt AC) transformer.

The T racer ZN010, ZN510, ZN520, and UC400 controllers

are included inside the units control box assembly. These

controllers utilize analog signals from a unit-mounted

control device or from a control device mounted in the

occupied space.

The Customer Supplied Terminal Interface (CSTI) option,

includes a 24 volt AC transformer, and an interface

terminal board. Controls provided by an external source

can be tied into the interface terminal board utilizing the

integrated terminal block with 3mm screw connections.

Units with the three-speed fan switch only, are available

with the switch mounted on the unit, or shipped

separately, to be mounted in the occupied space. The

Figure 1. UniTrane fan-coil and Force Flo cabinet heater components (vertical cabinet model shown)

12 UNT-SVX07E-EN

Page 13

Pre-Installation

Receiving Checklist

WARNING

Hazardous Voltage w/Capacitors!

Disconnect all electric power, including remote

disconnects and discharge all motor start/run

capacitors before servicing. Follow proper lockout/

tagout procedures to ensure the power cannot be

inadvertently energized. For variable frequency drives

or other energy storing components provided by Trane

or others, refer to the appropriate manufacturer’s

literature for allowable waiting periods for discharge of

capacitors. V er i fy with an appropr iate v oltmeter that all

capacitors have discharged. Failure to disconnect

power and discharge capacitors before servicing could

result in death or serious injury.

For additional information regarding the safe discharge of

capacitors, see PROD-SVB06A-EN

Receiving and Handling

Inspection

Upon delivery, thoroughly inspect all components for any

shipping damage that may have occurred, and confirm

that the shipment is complete. See “Receiving Chec klist”

section for detailed instructions.

Note: Delivery cannot be refused. All units are shipped

F.O.B. factory . T rane is not responsible for shipping

damage.

Packaging/Shipping

UniTrane fan coils and Force-Flo cabinet heaters ship in

individual cartons for handling and storage ease.

Field-installed sensors ship separately inside the unit’s

main control panel. Piping pac kages and mixing boxes are

packaged separately and ship on the same skid as the unit.

Identification

Each carton has tagging information such as the model

number, sales order number, serial number, unit size,

piping connections, and unit style to help properl y locate

the unit in the floor plan. If specified, the un it will ship with

tagging designated by the customer.

Complete the following checklist immediately after

receiving shipment to detect possible shipping damage.

Check to ensure that the shipment is complete. Small

components may ship inside the unit or ship

separately. Chec k the parts list to ensure all materials

are present.

Check all uni ts, components, connections, and pipi ng.

Check fan wheel for free rotation by spinning

manually. Chec k all doors, latc hes and hinges. Inspect

interior of each unit or section. Inspect coils for

damage to fin surface and coil connections. Check for

rattles, bent corners, or other visible indicati ons of

shipping damage. Tighten loose co nnections.

If a unit is damaged, make specific notations

concerning the damage on the freight bill. Do not

refuse delivery.

Notify the carrier’s terminal of the damage

immediately by phone and mail. Request an

immediate joint inspection of the damage by the

carrier and consignee.

Notify your Trane sales representative of the damage

and arrange for repair. Do not attempt to repair the unit

without consulting the Trane representative.

Inspect the unit for concealed damage as soon as

possible after delivery. Report concealed damage to

the freight line. It is the receiver’s responsibility to

provide reasonable evidence that concealed damage

did not occur after delivery. Take photos of damaged

material if possible.

Note: Concealed damage must be reported within 15

days of receipt.

Jobsite Storage

This unit is intended for indoor use only. It is the sole

responsibility of the customer to provide the necessary

protection to prevent vandalism and weather protection of

the equipment. Under no circumstance shoul d the unit be

left unprotected from the elements.

Handling

Trane recommends leaving units and acces sories in their

shipping pac kages/skids for protection and handling ease

until installation. Remove the skids before placing the unit

in its permanent location.

UNT-SVX07E-EN 13

NOTICE:

Microbial Growth!

Wet interior unit insulation can become an

amplification site for microbial growth (mold), which

could result in o dors and damag e t o the equipm ent and

building materials. If there is evidence of microbial

growth on the interior insulation, it shou ld be removed

and replaced prior to operating the system.

Page 14

Pre-Installation

If indoor storage is not possible, Trane makes the

following recommendations to prevent damage:

Note: Keep the equipment on the original wooden blocks/

skid for protection and ease of handling.

• Select a well-drained area, preferably a concrete pad or

blacktop surface.

• Place the unit on a dry surface or raised off the ground

to assure adequate air circulation beneath the unit and

to assure no portion of the unit will contact standing

water at any time.

• Cover the unit securely with a canvas tarp.

NOTICE:

Corrosion!

Use only canvas tarps to cover air handlers. Plastic

tarps can cause condensation to form in and on the

equipment, which could result in corrosion damage or

wet storag e stains.

• Do not stack units.

• Do not pile other material on the unit.

Site Preparation

• Ensure the installation site can support the total weight

of the unit (see “Dimensions and Weigh ts” on page 15

for approximate section weights; refer to the unit

submittals for actual weights).

• Allow sufficient space for adequate free air and

necessary service access (see “Service Clearances” on

page 15). Refer to submittals for specific minimums.

• Allow one and one half fan diameters above the un it

before the discharge ductwork makes any turns.

• Allow room for supply and return piping, ductwork,

electrical connections, and coil removal. Support all

piping and ductwork independently of the unit to

prevent excess noise and vibration.

• Ensure there is adequate height for coil piping and

condensate drain requirements. See “Condensate

Drain Connections,” on page 56.

• Consider coil piping and condensate drain

requirements. Verify condensate line is continuously

pitched one inch per 10 feet of condensate line run to

adequately drain condensate.

• Confirm the floor or foundation is level. For proper unit

operation, the unit must be level (zero tolerance) in

both horizontal axis.

.

NOTICE:

Microbial Growth!

The floor or foundation must be level and the

condensate drain at the proper height for proper coil

drainage and condensate flow. Standing water and wet

surfaces inside the equipment can become an

amplification site for microbial growth (mold), which

could cause odors and damage to the equipment and

building materials.

• If the unit is to be ceiling mounted, the installer/

contractor must provide threaded suspension rods. All

units must be installed level.

• Vertical recessed/concealed units require wall/ceiling

openings. Refer to submittal for specific dimensions

before attempting to install.

• Horizontal recessed/concealed units must meet the

requirements of the National Fire Protection

Association (NFPA) Standard 90A or 90B concerning

the use of concealed ceiling spaces as return air

plenums. Refer to the submittal for specific

dimensions of ceiling openings.

• Touch up painted panels if necessary. If panels need

paint, sanding is not necessary. However, clean the

surface of any oil, grease, or dirt residue so the paint

will adhere. Purchase factory approved touch up epoxy

paint from your local Trane Service Parts Center and

apply.

• Units have either right or left hand piping. Reference

piping locations by facing the front of the unit (airflow

discharges fr om the front). The control panel is always

on the end opposite the piping.

• The fan board assembly and main drain pan are easily

removable for cleaning. See “Routine Maintenance,”

on page 121 for more details on servicing.

14 UNT-SVX07E-EN

Page 15

Dimensions and Weights

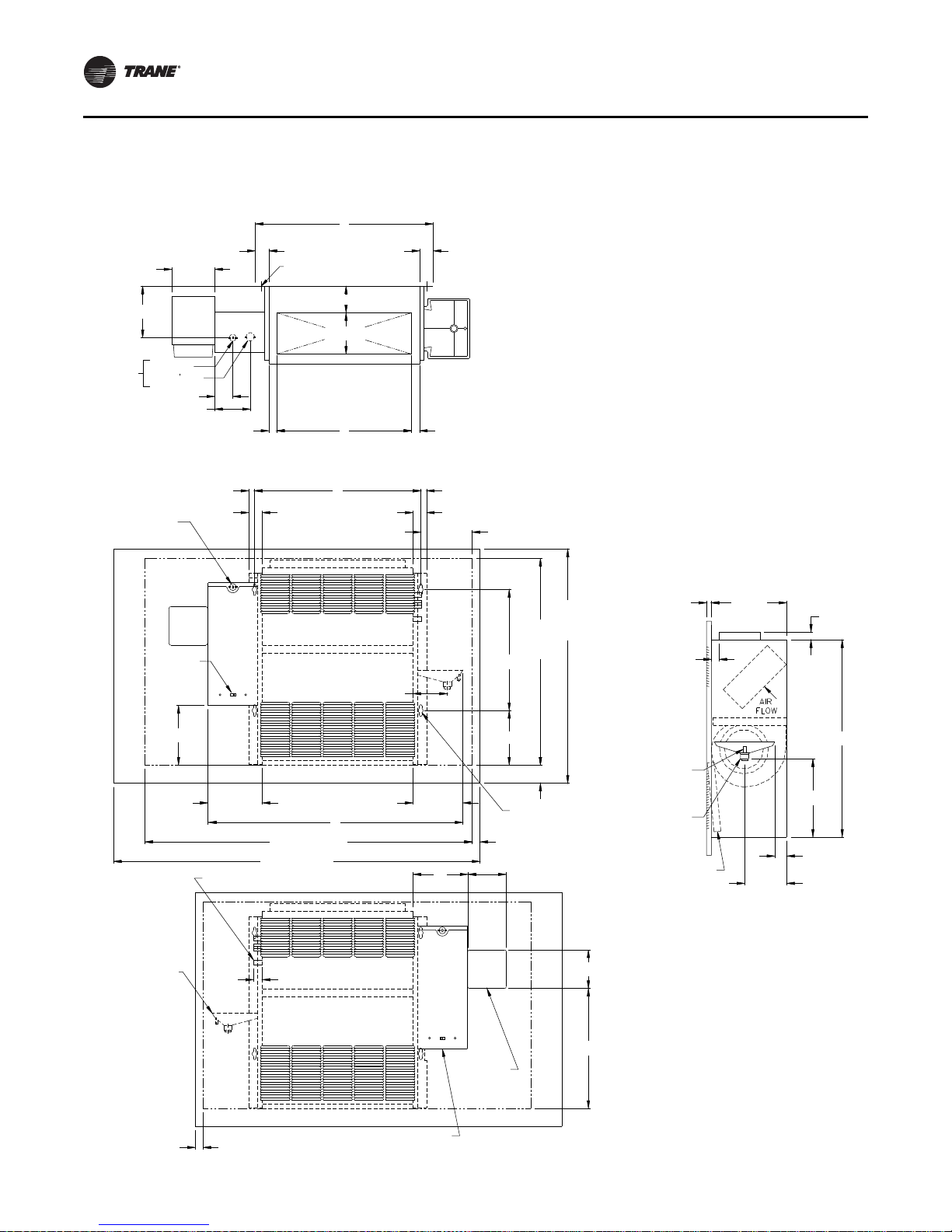

Model B Vertical Cabinet

Model L Low Vertical Cabinet

Model A Vertical Concealed

Model K Low Vertical Concealed

Model H Vertical Recessed

36 in.

8.5 in.

both sides

12 in.

both sides

24 in.

3 in.

Model D Horizontal Cabinet

Model C Horizontal Concealed

Model E Horizontal Recessed

28 in.

8.5 in.

both sides

12 in.

both sides

24 inches

front discharge

28 in.

Service Clearances

Service access is available from the front on vertical units

and from the bottom on horizontal units. Cabinet and

recessed units have removable front or bottom panels to

Figure 2. Recommended service clearances for vertical units

allow access into the unit. See Figure 2 and Figure 3 for

recommended service and operating clearances.

Figure 3. Recommended service clearances for horizontal units

UNT-SVX07E-EN 15

Page 16

Dimensions and Weights

Component Data

Table 1. Fan coil and cabinet heater component data

Unit Size 02 03 04 06 08 10 12

Coil Data

Face Area (ft2) 0.80 0.80 1.10 1.60 2.10 3.20 3.20

L x D x H (in.)

2-Row 15 x 1.7 x 8 15 x 1.7 x 8 20 x 1.7 x 8 29.5 x 1.7 x 8 38 x 1.7 x 8 57 x 1.7 x 8 57 x 1.7 x 8

3-Row 15 x 2.6 x 8 15 x 2.6 x 8 20 x 2.6 x 8 29.5 x 2.6 x 8 38 x 2.6 x 8 57 x 2.6 x 8 57 x 2.6 x 8

4-Row 15 x 3.5 x 8 15 x 3.5 x 8 20 x 3.5 x 8 29.5 x 3.5 x 8 38 x 3.5 x 8 57 x 3.5 x 8 57 x 3.5 x 8

Volume (gal.)

1-Row (Heat) 0.06 0.06 0.08 0.11 0.14 0.21 0.21

2-Row 0.120.120.150.220.280.420.42

3-Row 0.18 0.18 0.23 0.33 0.42 0.62 0.62

4-Row 0.240.240.300.440.560.830.83

Fins per inch

2-Row 12121212121212

3-Row 12 12 12 12 12 12 12

4-Row 12121212121212

Reheat Coil Data (1-Row), Standard or High-Capacity

Hot Water or Steam

Face Area (ft2) 0.60 0.60 0.80 1.20 1.60 2.40 2.40

L x D x H (in.) 15 x 1.5 x 6 15 x 1.5 x 6 20 x 1.5 x 6 29.5 x 1.5 x 6 38 x 1.5 x 6 57 x 1.5 x 6 57 x 1.5 x 6

Volume (gal.) 0.12 0.12 0.15 0.22 0.28 0.42 0.42

Standard Capacity

High-Capacity1 Fins/in. 12 12 12 12 12 12 12

Fan/Motor Data

Fan Quantity 1 1 1 2 2 3 3

Size — Dia x Width (in.) 6.31 x 4 6.31 x 6.5 6.31 x 7.5 6.31 x 6.5 6.31 x 7.5 (1) 6.31 x 7.5 6.31 x 7.5

Size — Dia x Width (in.) (2) 6.31 x 6.5

Motor Quantity 1111122

Filter Data

1-in. Throwaway and Pleated Media

Quantity 1 1 1 1 1 1 1

Size (in.) 8-7/8 x 19-1/8 8-7/8 x 19-1/8 8-7/8 x 24-1/8 8-7/8 x 33-5/8 8-7/8 x 42-1/8 8-7/8 x 61-1/8 8-7/8 x 61-1/8

1-in. Fresh Air Filter (only on cabinet styles D, E, and H with bottom return and fresh air opening)

Quantity 1111111

Size (in.) 5-1/2 x 19-1/8 5-1/2 x 19-1/8 5-1/2 x 24-1/8 5-1/2 x 33-5/8 5-/2 x 42-1/8 5-1/2 x 61-1/8 5-1/2 x 61-1/8

Note:1Standard and high-capacity reheat coils share the same component data except that standard capacity reheat coils have 4 fins/in. while high-capacity

reheat coils have 12 fins/in.

1

Fins/in. 4444444

1

Table 2. Low vertical fan coil component data

Unit Size 03 04 06

Coil Data

Face Area (ft2) 1.10 1.60 2.10

L x D x H (in.)

2-Row 20 x 1.7 x 8 29.5 x 1.7 x 8 38 x 1.7 x 8

3-Row 20 x 2.6 x 8 29.5 x 2.6 x 8 38 x 2.6 x 8

Volume (gal.)

1-Row (Heat) 0.08 0.11 0.14

2-Row 0.15 0.22 0.28

3-Row 0.230.330.42

Fins per inch

2-Row 121212

3-Row 12 12 12

Fan/Motor Data

Fan Quantity 1 1 1

Size — Dia x Width (in.) 5.00 x 23.00 5.00 x 32.00 5.00x 41.00

Motor Quantity 1 1 1

Filter Data

1-in. Throwaway

Quantity 111

Size — in. 8-7/8 x 24-1/8 8-7/8 x 33-5/8 8-7/8 x 42-1/8

Note: Low vertical model not available for Force Flo cabinet heaters.

16 UNT-SVX07E-EN

Page 17

Available Models

Figure 4. Available UniTrane fan coils and Force Flo cabinet heaters

Dimensions and Weights

Model A:

Vertical Concealed

Model E:

Horizontal Recessed

Model K:

Low Vertical Concealed

Model B:

Vertical Cabinet

Model F:

Wall Hung Cabinet

(Force-Flo units only)

Model L:

Low Vertical Cabinet

Model C:

Horizontal Concealed

Model H:

Vertical Recessed

Model M:

Inverted Vertical Cabinet

(Force-Flo units only)

Model D:

Horizontal Cabinet

Model J:

Vertical Slope Top Cabinet

Model N:

Inverted Vertical Recessed

(Force-Flo units only)

Model P:

Compact Concealed

UNT-SVX07E-EN 17

Page 18

Top View

Power

wiring

bottom

only

1 3/32 in. KO

7/8 in. KO

1 3/4 in. 1 3/4 in.

3 3/8 in.

5 5/16 in.

Top outlet

duct collar

D

1 in.

1 in.

Auxiliary

control

box opt.

6 1/4 in.

Control

box

1 3/8 in.

2 7/8 in.

C

Front View

RH Piping

5/8 in. bolt hole

7/8 in. KO

control wiring

Optional

disconnect switch

Auxiliary

control box

optional

5 1/4 in.

6 7/8 in.

Control

box

6 15/16 in.

A

E

6 7/16 in.

9/16 in.

4 1/2 in.

7 in.

15 1/2 in.

26 1/4 in.

1 5/8 in.

1 in. duct collar

(4) 5/8 in. dia keyslot

hanger holes

3/4 in.

Front inlet

open

4 7/16 in.

3/4 in.

1 3/4 in.

1 3/4 in.

Side

View

10 1/16 in.

Air

flow

Secondary drain

connection for

3/8 in. ID tube

Main drain connection

for 7/8 in. OD copper

tube and clamp

5 7/16 in.

1 9/16 in.

10 1/16 in.

Front View

LH Piping

Coil connections

1 1/8 in.

Auxiliary

drain pan

Power wiring 7/8 in.

or 1 3/32 in. KOs

Aux

Box

Control

Box

Filters

Dimensions and Weights

Model A Vertical Concealed

Figure 5. Model A Vertical Concealed

18 UNT-SVX07E-EN

Page 19

Dimensions and Weights

Table 3. Model A Vertical concealed unit dimensions (inches)

Unit Size 200-300 400 600 800 1000-1200

No. Fans1122 3

No. Motors 1 1 1 1 2

A 32 11/16 37 11/16 47 3/16 55 11/16 74 11/16

B 21 5/16 26 5/16 35 13/16 44 5/16 63 5/16

C 22 13/16 27 13/16 37 5/16 45 13/16 64 13/16

D 17 5/16 22 5/16 2’-7 13/16 40 5/16 59 5/16

E 19 5/16 24 5/16 33 13/16 42 5/16 61 5/16

Notes: Coil connections are always on the drain pan side and opposite the control box. Coil connections are 5/8-in. O.D. sweat. See page 43 for

locations. All duct collar dimensions are to the outside of the collar. See page 47 for dimensions for outside air openings.

UNT-SVX07E-EN 19

Page 20

Dimensions and Weights

Top View

(4) 5/8 in dia keyslot

hanger holes

(4) Unit leveling devices

(optional)

6 5/8 in.

1 in.

6 5/8 in.

6 1/2 in.

Unit control

top

Top outlet quadrifuser

or bar grille

CD

C

Power

wiring

bottom

only

2 7/8 in.

1 3/8 in.

6 1/4 in.

7/8 in. KO

1 3/32 in. KO

(2) 5/8 in. bolt holes

6 in.

6 in.

B

(4) 5/8 in. dia keyslot

hanger holes

7/8 in. KO

Control

wiring

Front View

RH Piping

Optional

disconnect

switch

Auxiliary

control box

optional

5 1/4 in.

6 7/8 in. Front inlet

open or bar grille

4 7/16 in.

7 in. E

A

7 in.

8 in.

Control

box

F Optional extended end pocket

Front View

LH Piping

Coil connections

Auxiliary

drain pan

1 1/8 in.

Filters

Control

box

Aux

box

Power wiring 7/8 in.

or 1 3/32 in. KOs

1 5/8 in.

25 3/16 in.

15 1/2 in.

6 15/16 in.

5 1/16 in.

Secondary drain

connection for

3/8 in. ID tube

Main drain connection

for 7/8 in. OD copper

tube and clamp

5 7/16 in.

1 9/16 in.

10 in.

Air

flow

9 7/8 in.

Side

View

Model B Vertical Cabinet

Figure 6. Model B vertical cabinet

20 UNT-SVX07E-EN

Page 21

Dimensions and Weights

Table 4. Model B Vertical cabinet unit dimensions (i nches)

Unit Size 200-300 400 600 800 1000-1200

No. Fans1122 3

No. Motors 1 1 1 1 2

A 33 5/16 38 5/16 47 13/16 56 5/16 75 5/16

B 21 5/16 26 5/16 35 13/16 44 5/16 63 5/16

C 7 5/8 7 1/8 8 7/8 7 1/8 7 5/8

D 1’-16 24 30 42 60

E 19 5/16 24 5/16 33 13/16 42 5/16 61 5/16

F 41 5/16 46 5/16 55 13/16 64 5/16 83 5/16

Notes: Coil connections are always on the drain pan side and opposite the control box. Coil connections are 5/8-in. O.D. sweat. See page 43 for locations.

All duct collar dimensions are to the outside of the collar. See page 47 for dimensions for outside air openings.

UNT-SVX07E-EN 21

Page 22

Dimensions and Weights

Top View

2 5/16 in.

E

Back inlet duct collar

9/16 in.

9/16 in.

Optional

disconnect

switch

Aux

box

5 1/4 in.

15 1/2 in.

7/8 in. KO

control

wiring

1 5/8 in.

3 1/4 in.

2 in.

1 3/4 in.

1 3/4 in.

2 5/16 in.

3 1/4 in.

(4) 5/8 in. dia keyslot

hanger holes

Secondary drain connection

for 3/8 in. ID tube

Main drain connection

for 7/8 in. OD copper

tube and clamp

Control

box

(2) 5/8 in. bolt holes

3/4 in. 3/4 in.

Front View

RH Piping

6 15/16 in.

B

C

D

1 11/16 in. 1 11/16 in.

6 3/8 in.

Aux box

optional

6 1/4 in.

Control box

1 3/8 in.

2 7/8 in.

1 3/32 in. KO

7/8 in. KO

Power

wiring

bottom

only

A

2 7/16 in.

8 7/8 in.

5 5/16 in.

Front outlet

duct collar

Front View

LH Piping

1 1/8 in.

Aux box optional

Control box

Auxiliary

drain pan

Coil connections

26 3/4 in.

4 7/8 in. x F

Bottom inlet

open

10 1/16 in.

Filters

Air

flow

1 in. duct collar

27 3/16 in.

Back duct collar

5/8 in.

Filter door used with

back duct collar only

Back inlet duct collar

14 1/8 in.

6 1/8 in.

5/8 in.

1 in. duct collar

Side View

Inlet Options

Model C Horizontal Concealed

Figure 7. Model C Horizontal concealed unit

22 UNT-SVX07E-EN

Page 23

Dimensions and Weights

Table 5. Model C Horizontal concealed unit dimensions (inches)

Unit Size 200-300 400 600 800 1000-1200

No. Fans1122 3

No.Motors 1 1 1 1 2

A 32 11/16 37 11/16 47 3/16 55 11/16 74 11/16

B 21 5/16 26 5/16 35 13/16 44 5/16 63 5/16

C 22 13/16 27 13/16 37 5/16 45 13/16 64 13/16

D 19 3/8 24 3/8 33 7/8 42 3/8 61 3/8

E 18 1/8 23 1/8 32 5/8 41 1/8 60 1/8

F 19 5/16 24 5/16 33 13/16 42 5/16 61 5/16

Notes: Coil connections are always on the drain pan side and opposite the control box. Coil connections are 5/8-in. O.D. sweat. See page 43 for

locations. All duct collar dimensions are to the outside of the collar. See page 47 for dimensions for outside air openings.

UNT-SVX07E-EN 23

Page 24

Top View

E

Back inlet duct collar

8 in. 8 in.

J

Back and bottom

inlet louvers

Optional

disconnect

switch

Aux

box

Control

box

(4) 5/8 in. dia keyslot

hanger holes

Secondary drain

connection for

3/8 in. ID tube

Main drain connection

for 7/8 in. OD copper

tube and clamp

15 1/2 in.

7/8 in.

KO control

wiring

(2) 5/8 in.

bolt holes

Front View

RH Piping

Unit control

front

Front outlet

duct collar (optional)

H

B

G

6 in.

G

6 in.

3 3/4 in.

13 3/4 in.

3 3/4 in.

1 5/8 in.

Front outlet

quadrifuser or bar grille

C

D

C

A

8 in.

F Optional extended end pocket

2 7/8 in.

1 3/8 in.

Aux box opt.

6 1/4 in.

Control box

1 3/32 in.

KO

7/8 in. KO

Power

wiring

bottom

only

Front View

LH Piping

Coil connections

1 1/8 in.

Aux Box

optional

Control boxAuxiliary

drain pan

Filters

2 1/4 in.

Bottom inlet

louvers

7 5/16 in.

1 in. duct

collar

Side View

Inlet and outlet

options

1 3/4 in.

7 in.

Filters

Back inlet

duct collar

1 in. front outlet

duct collar

27 13/16 in.

26 13/16 in.

1 3/4 in.

7 in.

10 5/16 in.

Back inlet

louvers

Bottom access panel - all units

90° to fully open

8 7/8 in.

3 5/8 in.

4 in.

Air

flow

Filters

Dimensions and Weights

Model D Horizontal Cabinet

Figure 8. Model D Horizontal Cabinet

24 UNT-SVX07E-EN

Page 25

Dimensions and Weights

Table 6. Model D Horizontal cabinet dimensions (inches)

Unit Size 200-300 400 600 800 1000-1200

No. of Fans 1 1 2 2 3

No. of Motors 1 1 1 1 2

A 33 5/16 38 5/16 47 3/16 56 5/16 75 5/16

B 21 5/16 26 5/16 35 13/16 44 5/16 63 5/16

C 7 5/8 7 1/8 8 7/8 7 1/8 7 5/8

D 18 24 30 42 60

E 17 1/4 22 1/4 19 3/4 40 1/4 40 1/4

F 41 1/4 46 5/16 55 3/16 64 5/16 83 5/16

G 8 5/8 8 1/8 9 7/8 8 1/8 8 5/8

H 16 22 28 40 58

Notes: Coil connections are always on the drain pan side and opposite the control box. Coil connections are 5/8-in. O.D. sweat. See page 43 for locations.

J 19 3/4 23 3/4 31 3/4 39 3/4 59 3/4

All duct collar dimensions are to the outside of the collar. See page 47 for dimensions for outside air openings.

UNT-SVX07E-EN 25

Page 26

Dimensions and Weights

Top View

8 13/16 in.

(4) 5/8 in. dia

keyslot hanger holes

Optional

disconnect

switch

5 1/4 in.

Aux

box

3 1/4 in.

15 1/2 in.

Control

box

E

Back inlet duct collar

H

Bottom inlet louvers

8 13/16 in.

1 1/2 in.

3/4 in.

29 7/8 in.

1 5/8 in.

5 5/16 in.

2 in.

7/8 in. KO

control wiring

1 11/16 in.

3/4 in.

3/4 in.

1 3/4 in.

1 3/4 in.

3/4 in.

B

F Access Panel

G Ceiling opening

Secondary drain

connection for

3/8 in. ID tube

Main drain

connection for

7/8 in. OD copper

tube and clamp

28 3/8 in.

ceiling

opening

26 7/8 in.

bottom

access panel

Side View

Inlet Options

15 5/16 in.

Front View

RH Piping

1 1/2 in.

3/4 in.

1 11/16 in.

3/4 in.

2 7/8 in.

1 3/8 in.

Aux box

optional

6 1/4 in.

Control

box

8 3/16 in.

1 7/16 in.

7/8 in. KO

1 3/32 in. KO

Power wiring

back only

1 1/8 in.

Coil connections

Auxiliary

drain pan

Front View

LH Piping

Ctrl

box

A

C

1 11/16 in.1 11/16 in.

(4) 5/8 in. dia keyslot

hanger holes

2 7/16 in.

8 7/8 in.

5 5/16 in.

8 3/16 in.

1 7/16 in.

Bottom access panel - all units

90° to

full open

Back inlet

duct collar

1 7/16 in.

1 1/8 in.

D

Front outlet

duct collar

1 in. duct collar

27 3/16 in.

back duct collar

26 3/16 in.

bottom inlet louvers

2 3/16 in.

1 in. duct collar

5/8 in.

6 1/8 in.

Filters

Air

flow

7 5/16 in.

Bottom inlet

louvers

3 13/16 in.

11 1/2 in. - 12 3/4 in.

bottom inlet

10 1/2 in. - 12 1/2 in.

back inlet

Filters

Model E Horizontal Recessed

Figure 9. Model E Horizontal Recessed

26 UNT-SVX07E-EN

Page 27

Dimensions and Weights

Table 7. Model E Horizontal recessed unit dimensions (inches)

Unit Size 200-300 400 600 800 1000-1200

No. Fans 1 1 2 2 3

No. Motors 1 1 1 1 2

A 35 13/16 40 13/16 50 5/16 58 13/16 77 13/16

B 21 5/16 26 5/16 35 13/16 44 5/16 63 5/16

C 22 13/16 27 13/16 37 5/16 45 13/16 64 13/16

D 19 3/8 24 3/8 33 7/8 42 3/8 61 3/8

E 18 1/8 23 1/8 32 5/8 41 1/8 60 1/8

F 32 7/16 37 7/16 46 15/16 55 7/16 74 7/16

G 34 5/16 39 5/16 48 13/16 57 5/16 76 5/16

H 19 3/4 23 3/4 31 3/4 39 3/4 59 3/4

Notes: Coil connections are always on the drain pan side and opposite the control box. Coil connections are 5/8-in. O.D. sweat. See page 43 for

locations. All duct collar dimensions are to the outside of the collar. See page 47 for dimensions for outside air openings.

UNT-SVX07E-EN 27

Page 28

Dimensions and Weights

Top View

Unit control

top

C

D

C

Top outlet quadrifuser

or bar grille

6 in.

B

6 in.

7 in.

E

7 in.

Front View

RH Piping

(4) 5/8 in. dia keyslot

hanger holes

Power

wiring

bottom

only

7/8 in. KO

1 3/32 in. KO

6 1/4 in.

1 3/8 in.

2 7/8 in.

(2) 5/8 in. bolt holes

Side

View

10 5/16 in.

1 5/8 in.

15 1/2 in.

26 13/16 in.

8 9/16 in.

Bottom and front

inlet and outlet louvers

8 5/16 in.

5 1/4 in.

Front inlet louvers

Front outlet louvers

(optional)

Optional

disconnect

switch

Auxiliary

control box

optional

Control

box

F

A

Air

flow

1 1/4 in.

4 in.

Bottom inlet

louvers

Front View

LH Piping

Coil connections

7/8 in. KO

control wiring

Control

box

1 1/8 in.

Filters

Model F Vertical Wall Hung Cabinet

Force Flo Units Only

Figure 10. Model F Vertical Wall Hung Cabinet (Force Flo only)

28 UNT-SVX07E-EN

Page 29

Dimensions and Weights

Table 8. Model F Vertical wall hun g ca bin et unit dimensions (inches)

Unit Size 200-300 400 600 800 1000-1200

No. Fans 1 1 2 2 3

No. Motors 1 1 1 1 2

A 33 5/16 38 5/16 47 13/16 56 5/16 75 5/16

B 21 5/16 26 5/16 35 13/16 44 5/16 63 5/16

C 7 5/8 7 1/8 8 7/8 7 1/8 7 5/8

D 18 24 30 42 60

E 19 5/16 24 5/16 33 13/16 42 5/16 61 5/16

F 19 3/4 23 3/4 31 3/4 39 3/4 59 3/4

Notes: Coil connections are always on the drain pan side and opposite the control box. Coil connections are 5/8-in. O.D. sweat. See page 43 for locations.

All duct collar dimensions are to the outside of the collar. See page 47 for dimensions for outside air openings.

UNT-SVX07E-EN 29

Page 30

Dimensions and Weights

Top View

Front View

RH Piping

Front View

LH Piping

Side

View

5 1/2 in.

C

1 3/4 in. 1 3/4 in.

(4) 5/8 in. dia keyslot

hanger holes

3 7/16 in.

5 5/16 in.

Top outlet

duct collar (optional)

6 5/8 in.

Power

wiring

bottom

only

7/8 in. KO

1 3/32 in. KO

2 5/16 in.

4 9/16 in.

1 in.

D

1 in.

3/4 in.

1 3/4 in.

3/4 in.

1 3/4 in.

6 5/8 in.

7/8 in. KO

control wiring

Front outlet louvers

Control

box

Optional

disconnect

switch

7 5/8 in.

4 7/16 in.

6 15/16 in.

Front inlet louvers

6 7/16 in.

A

H Wall opening

F

Front

panel

J

Wall

opening

15 1/2 in.

7 in.

G

B

(4) 5/8 in. dia keyslot

hanger holes

1 in.

4 15/16 in.

7 in.

E Front panel

Coil connections

Auxiliary

drain pan

1 1/8 in.

1 in.

Wall opening

Power wiring 7/8 in.

or 1 3/32 in. KOs

Front

control

access

(optional)

15 3/8 in.

4 15/16 in.

Control

box

5/8 in.

1 in. duct

collar

25 1/4 in.

10 1/16 in.

1 9/16 in.

5 7/16 in.

Filters

Main drain connection

for 7/8 in. OD copper

tube and clamp

Secondary

drain connection

for 3/8 in. ID tube

9 3/4 in.

1 in.

Model H Vertical Recessed

Figure 11. Model H Vertical Recessed

30 UNT-SVX07E-EN

Page 31

Dimensions and Weights

Table 9. Model H Vertical Recessed Unit

Unit Size 200-300 400 600 800 1000-1200

No. Fans 1 1 2 2 3

No. Motors 1 1 1 1 2

A 32 11/16 37 11/16 47 3/16 55 11/16 74 11/16

B 21 5/16 26 5/16 35 13/16 44 5/16 63 5/16

C 22 13/16 27 13/16 37 5/16 45 13/16 64 13/16

D 17 5/16 22 5/16 31 13/16 40 5/16 59 5/16

E 47 51 63 65 1/2 89 1/2

F 30 30 30 33 1/2 33 1/2

G 2 3/8 2 3/8 2 3/8 4 1/8 4 1/8

H 42 48 57 63 87

J 26 1/2 26 1/2 26 1/2 27 1/2 27 1/2

Notes: Coil connections are always on the drain pan side and opposite the control box. Coil connections are 5/8-in. O.D. sweat. See page 43 for

locations. All duct collar dimensions are to the outside of the collar. See page 47 for dimensions for outside air openings.

UNT-SVX07E-EN 31

Page 32

Dimensions and Weights

Top View

6 5/8 in.

1 1/16 in.

6 1/2 in.