Trane Flex II 170, Flex II, Flex II 175, Flex II 180, Flex II 177 Original Instructions Manual

...Page 1

Installation

Operation

Maintenance

Flex II

Air-to-water heat pumps with fixed

speed scroll compressors

CG-SVX048A-GB

Original instructions

Page 2

Contents

1 OVERVIEW ..................................................................................................................................... 4

2 SAFETY REGULATIONS ................................................................................................................... 4

3 OPERATING LIMITS ........................................................................................................................ 7

4 INSTALLATION ............................................................................................................................. 10

5 ACOUSTIC PROTECTION .............................................................................................................. 12

6 ELECTRICAL POWER SUPPLY ....................................................................................................... 12

7 WATER CONNECTIONS ................................................................................................................. 13

8 ELECTRICAL PANEL ..................................................................................................................... 24

9 OPERATOR RESPONSABILITIES ..................................................................................................... 27

10 START-UP PRELIMINARY PROCEDURES ....................................................................................... 27

12 CHECK LIST – MANDATORY OPERATION CONTROL BEFORE START-UP ........................................ 28

13 START-UP ................................................................................................................................... 33

14 MAINTENANCE ............................................................................................................................ 35

15 RECOMMENDED SPARE PARTS ..................................................................................................... 39

16 TROUBLESHOOTING .................................................................................................................... 40

17 IMPROPER USES ......................................................................................................................... 43

Page 3

1 OVERVIEW

1.1

WARRANTY

A. Warranty is based on th e general terms and conditions of the manufactu r e r . The warranty is void if t he equipment

is repaired or modified without the written approval of the manufacturer, if the operating limits are exceeded or if the

control system or the electrical wiring is modified. Damage due to m isu se , lack of maintenance or f ail u r e to comply

with the manufact urer’s instructions or re c omm e n dations is not cove r e d b y t h e warran ty obligation. If the user does

not conform to the ru l e s o f t his manu al, it may entail cance l l at io n of warranty and liabilities by the manufacturer.

B. Warranty is twelve (12) months as from the dat e of first start up at installat io n place or eighteen ( 18) mo n ths

after delivery at the project or other delivery location indicated by the customer. The date the unit is operated for

the first time mean s the date reported in the “1st start up form” contained into the “unit log book ” . This form should

be filled in and sen t, within 8 days from the start up, to Trane.

C. The warranty is valid if all the installat ion and start-up instructions have been adhered to (both those which may

have come from Trane an d those coming from current practice), if the “ 1st start up form” has been f il led in and sent

to the Trane after sal e s department.

D. The warranty is subject to any faults or defects being reported within eight days from their discovery. The

warranty will only be applied if and when the p u rc h aser suspends use of the equipment as soon as a defect has been

found.

E. The warrant y is v al id if the first running of the unit is carried out b y a T ran e authorized assistance center.

F. The warrant y is su bject to regular maintenan c e of the unit which is appropriately indicat e d in the “unit log book”

located inside the electrical panel.

G. Warranty automat ical l y e n ds in case of payment s n ot fulfilled, non-performance of the contract and even if the

units show tampering without TRANE written approvals.

1.2

RECEIVING THE UNIT

On receiving the unit, it is up to the customer to check that there is no obviou s damage or pie ces missing. If this is so,

an immediate complaint must be made to the carrier for damage or for not-delivery and the Receiving Card to be found

inside the unit electrical panel must be filled in. Photographic evidence must be provided for macroscopic damage. The

card must be sent to Trane with in 8 days of receiving the goods: if it is not se n t b ack or de lay ed, the complaint will not

be accepted.

1.3

FACTORY INSPECTION

Trane units are inspected into the factory, in appropriate areas, in accordance with internal procedures. Each performance

test carried out on t he unit is possible only if the same condit ions are reproduced and maintained ( charge consistency ,

constant temperature and evaporation - condensation and recovery capacity, quality and tolerance of the measuring

instruments etc. ) in the test rooms.

The inspection conditions are those indicated by the customer in the ordering phase: if not otherwise specified, reference

should be made to the nominal performance indicated in the technical bulletin in force at the date of the Confirmation of

the Order.

2 SAFETY REGULATIONS

2.1

ACCESS TO DANGEROUS AREA

The access to the u n it d an gerous areas is usually obstru c t ed through protection panels, which are rem ovable, by using a

tool. Axial fans are p ro tected with accident p r e vention grilles.

For all the units which al l ow access to the cooling piping without security gratings (optional) o r c l osin g panelling, the

following precaut ion s mu st be taken:

-mark the areas with c ontact risks.

-apply warning sign s.

The danger zone mu st be of a suitable size to avoid an y c on tact, even accidental c on tact.

Trane declines any r e sponsibility for damage to things and unauthoriz ed personnel in case of absence of clear and

static limiting systems of the risk areas and of the relevant warning an d danger signs.

2.2

GENERAL PRECAUTIONS

The operator must only intervene on the unit commands; he or she must not open any panels except for the one which

gives access to the c omm an d module.

The installer must only intervene on the connections between the plant and the machine; he or she must not open any

machine panels nor carry out any commands.

The following precautions should be made when approaching or working on the unit:

• Use appropriate protection (glove s, glasses etc.) when u sin g an open flame (welding) or c om p r e sse d air.

• If the unit is loc ated in a closed environm e n t, wear hearing protection.

Page 4

• Before disconnecting, rem oving tubes, filt e rs, joints or other line parts in tercept the connect ion tubes, empty them

until the pressure reaches that of the atmosphere.

• Do not use your h an ds to check for possible pressure losses.

• Always use tools w h ic h ar e in good condition; make sure the instructions h av e b een fu lly understood before using them.

• Make sure that any tools, e le ctrical cables or other loose objects have been removed before closing the unit and

starting it up again.

2.3

PRECAUTIONS AGAINST RISKS DUE TO THE REFRIGERANT

Refer to Safety Data Sheet. Refrigerant shall be always recovered before ope n ing any part of refrigeratin g circuit.

2.4

PRECAUTIONS AGAINST RESIDUAL RISKS

Prevention from risk s d u e to the command system

• make sure the instructions for use have been understood before carrying out any work on the control panel.

• always keep t h e instruction manual close at hand when working on the control panel.

• start up the unit only after having certified that it is correctly connected to the plant.

• inform the technician promptly of any alarms which appear on the unit.

• do not reset t he al ar ms to manual restart wit h ou t having first identified the cause and removed it.

2.5

PREVENTION AGAINST RESIDUAL MECHANICAL RISKS

• install the un it in accordance with the provisions of the f o llowin g manual.

• carry out all the maintenance op e r at io n s provided for by this manual regularly.

• wear a protective helmet before entering inside the unit.

• before open in g a machine panel make sure that it is firmly conne c ted by means of a hinge.

• do not touch t he air condensation batter ie s without having first put on protective gloves.

• do not remove the protections to the moving parts while the unit is running.

• before rest arting the unit make sure that the moving part prot e c tions are in the correct position.

2.6

PREVENTION AGAINST RESIDUAL ELECTRICAL RISKS

• connect the unit to the mains in accordance with the provisions of this manual.

• carry out all maint e nance operations regularly.

• before opening the control panel disconnect the unit from the mains by means of the external knife switch.

• check that the unit has been earthen correctly before starting it up.

• control all the electrical connect ions and the connection cable s paying particular attention to the state of iso lation;

replace the cables which are clearly worn or damaged.

• carry out periodic checks of the w irin g inside the panel.

• do not use cabl e s with an inappropriate se c tion or flying connect ions not even for a limite d p e r iod or in an emergency.

2.7

PREVENTION AGAINST RESIDUAL RISKS OF A DIFFERENT NATURE

• the r e sidual risks due to pressur e ar e m ain ly coming from a failure of the safety devices. To prev e nt them it is

necessary to check and replace them when required

• carry out the plant connections to the unit by following the indications reported on the following manual and on the

panels of the unit itself.

• if a part is disassembled, make sure t h at it is correctly reassembl e d before restarting t h e unit.

• do not tou ch t h e discharg e l ine of the compressor, the compressor itself or any other tube or component which is

inside the machine without putting on protective gloves.

• keep a fire ex t inguisher which is able t o p u t ou t fires on electrical equip m e n t near the machine.

• on units install e d inside, connect the refrigerant circuit sh ut off valve to a network o f tube s which are able to lead

the possible spillag e of refrigerating fl u id outside.

• eliminate any f l u id l oss inside or outside th e unit.

• collect the d isc h ar ge liquid and clean up an y possible oil leakage.

• periodically clean the compressor casing of t h e accumu late d d irt deposits.

• do not keep inflammable liquids near the unit.

• do not dispose o f the refrigerant fluid and the lubricating oil in the environment.

• welding should only be carried out on empty tubes; do not approach the tubes containing refrigerant fluid with

flames or other sources of heat.

• do not bend or strike tubes containing pressurized fluids.

2.8

PRECAUTIONS TO BE OBSERVED DURING MAINTENANCE OPERATIONS

Only authorised technic ian s may carry out maintenanc e op erations. Before carr ying out any mainten an c e the

following must be performed:

• isolate the unit from the mains electric ity by using the extern al k n ife switch.

• place a notice on t h e external knife swit ch w h ic h say s “do not use - maintenance in progress”.

Page 5

WARNING! DO NOT REMOVE THE HIGH PRESSURE SWITCHES HP IF THE UNIT IS NOT COMPLETELY

SERIOUS INJURY!

• make sure that any possible on-off commands are disabled.

• use appropriate safety equipmen t (helmet, isolating g l oves, protective glasse s, safety shoes etc.).

If measurements or con trols must be carried ou t which require the mach in e to be running the followin g observations

must be followed:

• operate with the electrical pan e l open for as short a time as is possible.

• close the ele c t r ic al panel as soon as the individual measurement or co n trol has been carried out.

• for un its which are located outside, do not carry out interventions in dangerou s atmospheric conditions such as rain,

snow, fog etc.

The following pr e c au tions should also be taken at al l times:

• never dispose of fluids contained in the refrigerant circuit in to the environment.

• when replacing the el e ctr on ic car d always use appropriate equipment (extractor, anti-static brace l e t, etc.).

• if a compressor, the evaporator, th e c on densation batteries or an y other heavy part is to be re placed, make sure that

the lifting equipment matches the weight to be lifted.

• if the unit has an indepe nden t compre ssor compartment, do not open the ventilator compartment without having

first isolated the mac h in e using the main switch on the side of the pan el and only after having plac e d a sign which says

“do not use - maintenance in progress”.

• if modifications must be carried o u t to the cooling, hydraulic or electrical circuit of the unit, or to its command

logic, contact Trane.

• if particularly co mplicated assembly o r disassembly operations are to be carried out c ontact Trane.

• always use orig inal spare parts bought directly from Trane or from official dealers of the companies reporte d in the

list of recommended spare parts.

• if the unit is t o be m oved after a year of being in the site or if it has to be dismantled contact Trane.

VERY IMPORTANT

No high pressure safety valve is installed on the unit.

The unit fail safe is assured by cut-out of the electrical power sup p l y to the coils of the compressor contactors. T he cu t out action is carried ou t by the electrical cont ac t of the unit high pre ssu r e switch.

No Schrader valve is instal l e d in the port the unit h igh pressure switch is plugged into.

This implies that fol lo w in g instruction must be observed:

VOID OF REFRIG ERANT. FAILURE TO FOLLOW THIS INSTRUCTION COULD RESULT IN DEATH OR

2.9

MANUAL ALARM RESET

If there is an alarm the u n it must not be manually r e set before having located an d e l imin ated the cause of the f au l t.

Repeated manual r e se ts may cause unit damage an d the warranty to be annulled.

Page 6

CHILLER MODE

kit -10°C

3 OPERATING LIMITS

3.1

STORAGE

The units can be st o red within the following environmental cond it io n s:

Min ambient temper ature : -10°C

Max ambient tempe r ature : 53°C

Max relative humidity : 95% not condensable

CAUTION: The storage in a very hig h h u midity space (condensation ) can damage electron ic components.

3.2

OPERATING LIMITS

Unit operation is perm itted within the lim its indicated in the d iag r am provided in 3.3.

CAUTION: The operation outside the limits specified may c au se the activation of t h e protections and disrupt

the operation of t h e un it and, in extreme cases, damage the unit.

In case of doubt, con tact Trane.

These operating lim it s apply to unit operating at full load.

3.3

OPERATING RANGE

OAT

= Outdoor Air Temperature [°C]

LWT

= Leaving Water Temperature [°C]

Low ambient kit down to -10°C:

• EC fans

Glycol

Page 7

HEAT PUMP MODE

kit

-15°C

OAT

= Outdoor Air Temperature [°C]

LWT

= Leaving Water Temperature [°C]

Low ambient kit down to -15°C:

• Heater in control box

Page 8

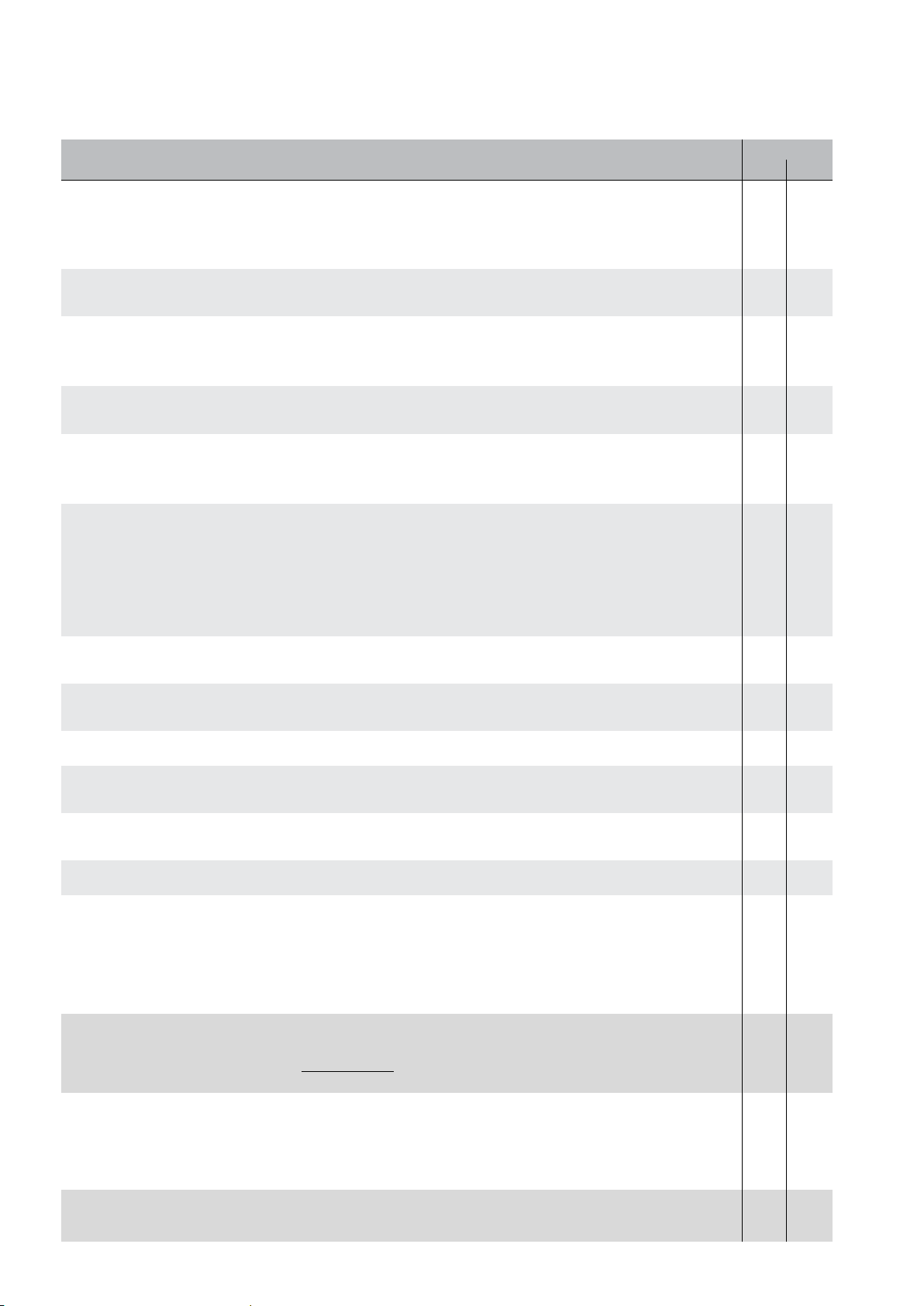

Pressure drop coefficient

Flow rate coefficient

1,02

1,033

1,05

1,072

1,095

1,124

ETHYLENE GLYCOL CORRECTION TABLE

% Ethylene glycol weight

Freezing temperature

Suggested security limit Cooling

capacity coefficient

Power input coefficient

Flow rate coefficient

In order to calculate performance with glycoled solutions multipl y main sizes by respect i ve co ef fici ent s.

°C -2 -3,9 -6,5 -8,9 -11,8 -15,6 -19 -23,4

°C 3 1 -1 -4 -6 -10 -14 -19

- 0,995 0,99 0,985 0,981 0,977 0,974 0,971 0,968

- 0,997 0,993 0,99 0,988 0,986 0,984 0,982 0,981

- 1,003 1,01 1,02 1,033 1,05 1,072 1,095 1,124

- 1,029 1,06 1,09 1,118 1,149 1,182 1,211 1,243

GLYCOL PERCENTAGE DEPENDING ON FREEZINGTEMPERATURE

% glycol according to the freezing temperature

Freezing temperature 0°C -5°C -10°C -15°C -20°C -25°C

% Ethylene glycol

5% 10% 15% 20% 25% 30% 35% 40%

5% 12% 20% 28% 35% 40%

In order to calculate performance with glycoled solutions multipl y main sizes by respect i ve co ef fici ent s.

IMPORTANT: Ove r sized water pump as on board un it pump is required for operation with glycol > 25%. If any doubt please contact

your local sales office.

Page 9

IMPORTANT:

Correct lifting procedure

Figure 1

4 INSTALLATION

4.1

MOVING AND POSITIONING THE UNIT

The units have bee n d esigned to be lifted from above by means of eyebolts and h o les in the base members.

Use retractor bars t o keep the lifting wires or c h ain s away from the unit.

Lifting procedures provided with the unit have to be respected.

CAUTION

Do not use forklift trucks to lift the unit from below.

If equipment for lifting from above is not avail ab l e , using rollers may move the unit.

The surface on which the unit is placed must be flat and strong enough to withstand the weight of the unit while

running. In order to reduce the transmission of vibrations to the su p porting structures, f it sh oc k absorbers in every

fastening point. Rubber shock absorbers are recommended for units installed on the ground , spring shock absorber s f o r

units installed on roof s. Open spaces around th e unit must be provided for in order to allow for t h e passage of necessary

airflow and in order to allow normal maintenance to be carried out (as shown on general catalogues).

For example horizont al positioning of the u n it can l e ad to irreversible damage to the compressors.

Damage arising from incorrect transport will not be under warranty by the manufact ure r.

Immediately report an incorrect receipt of goods.

An arrow positioned up ward indicates the vertical position of the unit.

Make sure that dur in g transport the unit ALWAY S remains in the correct p osition!

Page 10

minimum space requirements [mm]

Figure 2

4.2

MINIMUM SPACE REQUIREMENTS

Dimensional drawing sh al l be respected to avoid:

• Noise

• Incorrect heat exchange and ventilat ion

• Difficult mainten an ce or inaccessibility to components

It is fundamental to respect minimum distan c e s on all u n its, in order to en su re optimum ventilation for

the condenser coils. Limited installati on space could reduce th e normal air flow, thus signif ic an tly reducing

the unit performance and considerably increasing consumption of e le ct rical ene rg y .

CAUTION: in case two stand-alone units have to be inst all e d side by side, the distance of respect must

be doubled.

** As far as modular units are concerned no side space is required between any of the units and the

adjacent one. The minimum side space of 500 mm featured in Figure 2 is required only for the units

placed at the far sides of the modular system.

After the unit has re ach ed the final position, f ix the antivibration bolts.

4.3

PRECAUTIONS FOR DOMINANT WINDS

Avoid obstacles on suction and discharge sid es of the units. Respect the safety distances as sho w n on the units

dimensional drawings.

In case of presence of dominant winds in the installation area it is strict l y n e c e ssar y to avoid (for unit s with horizontal

flow fans) that such winds blow in front of the u n it (fans discharge side). In case of unit with vertical flow fans it is

strictly necessary to av o id installations w h e r e the dominant winds cou ld cause rejected hot air to co me back to the

condensing coils.

4.4

PRECAUTIONS AGAINST DIRECT SUNSHINE

Direct solar radiation c an raise the temperat u r e of condensation until it cau se s the unit shutdown or failure start-up of

the same by action of the high pressure switch.

4.5

PRECAUTIONS AGAINST THE PRESENCE OF FIREPLACES AND EXHAUST HOT AIR

Avoid installation of the machines downwind of chimneys, smokestacks and different e ffluent discharges.

4.6

PRECAUTIONS AGAINST THE PRESENCE OF FOLIAGE AND FOREIGN BODIES

Page 11

Avoid installing the unit in the immediate v icin ity of plants that can p r e vent proper intake and discharge air.

4.7

CONTROL OF COMPRESSOR FASTENING

The compressors are fitted on shock absorber s. For fixing through spr in g anti-vibration moun ts, it is necessary to remove

blockages put to fast e n the compressors, as indicat e d on the label on compr e ssor s b o d y .

5 ACOUSTIC PROTECTION

When the sound level must be checked in particular, it is necessary to pay maximum WARNING in isolation from

the base of the unit properly applying the anti-vibration mounts (provided optionally). A lso, install flexible

joints on water connections.

6 ELECTRICAL POWER SUPPLY

The mains power supply characteristics have to match the unit’s absor p tion. The mains power su p ply tension must

correspond to the nominal value ± 10%, with a maximum difference between the phases of 2%.

All power supply w irin g must be sized and sele cted accordingly by the p roject engineer in accordance with standard IEC

60364. All wiring must comply with local code.

6.1

POWER CONNECTIONS

Protect the unit electric box power supply circuit with p rotection d evices (not included in the supplied

equipment). Connect the line terminals with a three-core cable of a section wh ich is ap propriate to the

machine absorption. The switch and the fu se s l ik e all the power connect ion s m u st co mp ly with the regulations

in force.

6.2

IMBALANCE BETWEEN THE SUPPLY TENSION PHASES

Do not run the electrical motors when the voltage unbalance between the phases is more than 2%.

Use the following formula to check:

% Imbalance = [(Vx – Vave) x 100/Vave]

Vave = (V1 + V2 + V3)/3

Vx = phase with greatest d i f ferenc e from Vave (without

regard to the sign)

IMPORTANT: If the mains voltage has an imbalance of above 2%, con t act the company, which distributes the electrical

energy. If the unit functions with a unit voltage imbalance between the phases of above 2% the warranty is invalid.

6.3

UNIT VOLTAGE PHASING

It is important that proper rotation of the compressors be establish ed before the unit is started. Proper mot or

rotation requires confirmation of the el e c t r ic al phase sequence of th e p ower supply. The motor is internally

connected for cloc k wise rotation with the in c om in g power supply phases A-B-C.

Page 12

7 WATER CONNECTIONS

7.1

EVAPORATOR

The connection tubes have to be supported adequately in order that their weight does not damage the plant. The

following parts hav e to be installed on the w ater circuit of the evaporato r:

• Two pressure gaug e s o f adequate scale (in and out of the unit)

• Two shock-absorbing joints (in and out of the unit)

• One shut off valve (normal one in input)

• One setting valve (in output)

• Two thermomet e r s ( in and out)

• One circulation pump

• One safety valve on the water buffer

• One aut om at ic air vent valve

• One expansion tank

• An inlet filter placed as near as possible to the evaporator

• One flo w switch

The above-mention ed installation indications represent nece ssar y c on ditions for the warranty to be valid.

Trane is at your dispo sal t o e xamine any different requirements, which have to be approved before starting up the un it.

It is necessary that t he wat er flow rate to the un it is compat ible wit h the ev aporator on e. It is also n ecessar y that t he

water flow rate is ke pt un iform while th e un it is runnin g: it is sugg est ed t o use alw ays a pu mp syst em d edic ated to the

unit and independent from the remaining part of the plant.

Before stalling unit s with temperature ar ou n d 0°C please evacuate the exchanger with compr e sse d air in order to avoid

breakings due to ic e .

If the unit is installed in order to replace another, the entire hydraulic system must be emptied and cleaned before

the new unit is installed. Regular tests and proper chemical treatment of water are recommended before starting

up the new unit.

In the event that glycol is added to the hydraulic system as anti-freeze protection, pay attention to the fact that

intake pressure will be lower, the unit’s performance will be lower and water pressure drops will be greater. All

unit-protection methods, such as anti-freeze, and low-pressure protection will need to be reset. Before insulating

water piping, check that there are no leaks.

CAUTION: Install a mechanical water filter at the water inlet of each heat exchange r. Fail u re to install the filt e r al lo w s

access of solid partic les and / or welding sl ag inside the heat exch an ger. We recommend the in stallation of a filter

having a filtering n et with holes not exceed in g 0.5 mm in diameter.

Trane cannot be held responsible for any damage to he at exchangers due to the lack of good quality water fil ters.

** In case the unit is a modular one the water filter and the flow switch are on board the unit so the installation of

water filter and flow switch in the customer plant is not needed

Page 13

Cold water heat production

Hot water heat production

150

155

157

160

165

170

180

190

1100

1110

1115

7.1.1

The machine needs a minimum water content according to the following values:

Calculation of total minimum water content and flow rates

FLEX II

V K Q min Q max V K Q min Q max

[m3] [m3/h] [m3/h] [m3] [m3/h] [m3/h]

- 202,5 5,3 14,1 200,4 6,0 16,1 0,48

- 199,1 5,8 15,6 197,0 6,7 17,9 0,54

- 196,4 6,1 16,4 194,2 7,0 18,8 0,56

- 195,6 6,5 17,3 193,3 7,5 20,0 0,60

- 84,8 7,0 18,7 84,2 7,9 21,1 0,63

- 84,1 7,3 19,6 83,5 8,3 22,2 0,67

- 81,9 8,2 21,8 81,3 9,2 24,5 0,74

- 80,2 9,3 24,8 79,5 10,5 28,0 0,84

- 43,0 10,6 28,2 42,7 11,7 31,3 0,94

- 42,5 11,5 30,6 42,2 12,7 33,9 1,02

- 41,8 12,3 32,8 41,5 14,1 37,6 1,13

LEGEND:

V

: minimum water content of the plant

Q min

Q max

: minimum water flow to the heat exchanger

: maximum water flow to the heat exchanger

∆Tmax chiller = 8 °C

∆Tmax heat pump = 8 °C

dpw = K·Q² / 1000 Q = 0,86 P/∆T

IMPORTANT: If pumps driven by inverters (either unit onboard pump or external pump) in every working condition the variation of

the water flow rate mu st be as low as possible. Vari ation must be less th an 10% o f the nominal flow rate per minu t e

7.2

WATER CIRCUIT REGULATION EQUIPMENT

Centrifugal motor pump block

Assures the discharge an d the prevalence n e c e ssar y to supply tube nest e v aporator, the tank and th e u tility.

Automatic filling unit

Assures the water p r e ssu r e in the plant is maintained at least 1.5 bar, automatically resetting it when necessary.

Safety valve

Takes care of openin g the plant in atmospher e if the pressure exceeds the value of 6 bar.

Expansion tank

Takes care of compen sating small water hammering and variations of volume for different temperatures.

Check valves

Take care of interc e pting the pump for possibl e m ain tenance.

Page 14

W / m

7.3

WATER TREATMENT

Before putting the unit into operation, cl e an the hydraulic circuit. Dirt, scales, corros io n residue and other e xtraneous

material can accumulate inside the h eat exchanger and reduce it s h e at exchanging capacity. Pressure drops can

increase, as well, thus reducing water flow. Prope r water treatmen t t h ere f ore re d uce s the risk of corrosion, e rosion,

scaling, etc. T h e most appropriate water tr e atment must be determined locally with a specializ ed company, according

to the type of system an d t o the l oc al c h arac teristics of the pr oc e ss water.

Trane is not responsible for damage to or malf u n c tioning of equipment caused by failure to treat water or by improperly

treated water.

7.4

PRECAUTION AGAINST FROST RISK OF THE HYDRAULIC PIPES

It is necessary to insulate pipes in the plan t to avoid extreme heat loss an d to protect them from we at h er conditions.

The problem of water pipes freezing could appear in tw o different situation s:

1. Stand by, with mode on, but electrically conne c ted: in this case, the u n it has frost resistances, which protect the

water locally contained in th e exchangers and in t h e p ip es from ice formation. These resistances do not ensure the

protection against the frost in the outdoor connection pipes, to be prevented by frost protection systems. Trane suggest

to insert frost thermostatic resistances on every outdoor pipes. In the following table there are the indicative electric

powers per pipe linear meter

Table – Heating cable required power

dn inch

8

10

15

20

25

40

50

65

80

100

125

150

2. Electrically unconnected unit: in this case the frost resistances of the unit could not ensure the protection. It is

necessary to add the correct glycol quantity indicated in the chapter: “ethylene glycol correction table” (§3.3).

Please consult Trane service for % of glycol required.

5

1/4"

3/8" 5

1/2"

3/4" 10

1" 13

1" 1/2 30

2" 50

2" 1/2 80

3" 120

4" 200

5" 300

6" 450

5

Page 15

7.4.1

In case of installation conditi o n s with a very low temperature:

Precaution for very low outdoor temperatures

1. If there is a storage on board the unit, insert elect ric resistances to be calculated by:

PrWatt = V x (10 – tmin) / 860

where: PrWatt is the resistance power (Watt) and tmin is the l ow er temperature (°C)

2. If there is no sto rage, maintain the water temperature higher than 10°C b y in serting thermostatic resistance

with power calculat ed as in case 1.

7.5

Two or more protect io n methods should be foresee n when designing the syst em as a whole:

1. Continuous water flow circulation inside piping and exchanger when ambient air temperature is holding

below 5 °C. This implies what follows:

2. Addition of an appropriate amount of glycol inside the water circuit.

3. Additional heat insulation and sufficient heating of exposed piping.

IMPORTANT: Trane can provide various optional kits (they are not included either in the Low ambient kit down

to -10°C in chiller mode or in the Low ambient kit down to -15°C in heat pump mode) for the protection of all

the components of the hydraulic circuit inside the unit (pumps, pipes and tank). Contact Trane for more

information.

4. Emptying and cleaning of the heat exchanger during the winter season.

It is the responsibil ity of the installer and/or of local maintenance personnel to ensure tw o or mo re of the described

antifreeze methods. Continuously verify, through routine checks, that appropriate anti-freeze protection is maintained.

Failure to follow the in structions above could result in damage to some of the unit’s components. Damage from freezing

is not covered by the warranty.

CAUTION: The unit water pipes are not protected against the risk of water freeze-up when the unit is not electrically

powered and when the power and control of the external water pumps is not managed by the un it con t roller. The

owner must provide appropriate solutions to prevent freezing.

ANTIFREEZE PROTECTION ON THE HEAT EXCHANGER

- if the water flow inside piping and exchanger of the unit is due to an external pump installed by the

customer, the on/off command of this pump must always be the one provided by the unit controller through

the relevant free potential contact in the electrical cabinet.

- as long as the ambient air temperature is holding below 5 °C the unit must always be electrically supplied.

Moreover the customer pump, if present, must always be electrically supplied alike and functioning

properly.

Page 16

Relief Valve

Gauges

Water Charge

Check Valve

Water Tank

FIlter

2 Way Valve With ON/OFF Servo Control

7.6

HYDRAULIC VERSIONS

FLEX II units are av ail ab l e in six hydraulic versions characterized b y comple t e kits of all major hydraulic component s for

an easier installation, with reduced t ime , cost and space.

−

Stand-alone version w ith single pump

−

Stand-alone version w ith single pump and tank

−

Stand-alone version w ith double pump and stand-by pump

−

Stand-alone version w ith double pump and stand-by pump and tank

−

Modular version with sin gle pump

−

Modular version with double pump and stan d -by pump

**

Units can be installed in modular configuration up to a maximum of 6 units by means of a dedicated hydraulic

connection kit

Figure 3

7.6.1 Hydraulic diagram for stand-alone FLEX II units with single pump

Water Differential Pressure Switch

Temperature Probe

Expansion Vessel

Safety Valve (6 bar)

Shut Off Valve

Pump

Water DIscharge

Remote connections by

the installer

Antivibration System

Flow S witch

Figure 4

Page 17

Temperature Probe

Gauges

Water Charge

Check Valve

Water Tank

FIlter

2 Way Valve With ON/OFF Servo Control

Water Differential Pressure Switch

Temperature Probe

Expansion Vessel

Gauges

Pump

Water Charge

Check Valve

Water Tank

FIlter

2 Way Valve With ON/OFF Servo Control

7.6.2 Hydraulic diagram for stand-alone FLEX II units with single pump and tank

Relief Valve

Remote connections by

the installer

Safety Valve (6 bar)

Shut Off Valve

Water DIscharge

Antivibration System

Flow S witch

Figure 5

7.6.3 Hydraulic diagram for stand-alone FLEX II units with single pump + stand-by pump

Figure 6

Water Differential Pressure Switch

Relief Valve

Expansion Vessel

Safety Valve (6 bar)

Shut Off Valve

Pump

Water DIscharge

Antivibration System

Flow S witch

Remote connections by

the installer

Page 18

Water Differential Pressure Switch

Relief Valve

Gauges

Safety Valve (6 bar)

Shut Off Valve

Pump

Water Charge

Check Valve

Water Tank

FIlter

2 Way Valve With ON/OFF Servo Control

Water Differential Pressure Switch

Relief Valve

Expansion Vessel

Gauges

Shut Off Valve

Water Charge

Check Valve

Water Tank

2 Way Valve With ON/OFF Servo Control

6” VICTAULIC MANIFOLD

6” VICTAULIC MANIFOLD

7.6.4 Hydraulic diagram for stand-alone FLEX II units with single pump + stand-by pump

and tank

Temperature Probe

Remote connections by

Expansion Vessel

Water DIscharge

the installer

Antivibration System

Flow S witch

Figure 7

7.6.5 Hydraulic diagram for modular FLEX II units with no on board unit pump

Temperature Probe

Safety Valve (6 bar)

Pump

Water DIscharge

Antivibration System

Flow S witch

FIlter

Figure 8

Page 19

Water Differential Pressure Switch

Temperature Probe

Relief Valve

Expansion Vessel

Gauges

Safety Valve (6 bar)

Shut Off Valve

Pump

Water Charge

Check Valve

Water Tank

FIlter

2 Way Valve With ON/OFF Servo Control

FIlter

2 Way Valve With ON/OFF Servo Control

6” VICTAULIC MANIFOLD

6” VICTAULIC MANIFOLD

Water Differential Pressure Switch

Relief Valve

Gauges

Shut Off Valve

Pump

Water Charge

Check Valve

Water Tank

6” VICTAULIC MANIFOLD

6” VICTAULIC MANIFOLD

7.6.6 Hydraulic diagram for modular FLEX II units with single pump

Water DIscharge

Antivibration System

Flow S witch

Figure 9

7.6.7 Hydraulic diagram for modular FLEX II units with single pump + stand by pump

Temperature Probe

Expansion Vessel

Safety Valve (6 bar)

Water DIscharge

Antivibration System

Flow S witch

Figure 10

Page 20

Primary Pump

Steel Mesh Strainer

CUSTOMER PLANT

WATER TANK

FANCOIL

AIR CONDITIONING WATER PUMP

7.7

7.7.1

CUSTOMER PLANT SKETCHES

Customer plant sketch with primary pump for a stand-alone unit with no on board pump

Secondary Pump

Temperature Probe

Flow S witch

Drainage

Vent Valve

Expansion Vessel

Filling Group

Check Valve

Safety Valve

Interception Valve

Figure 11

IMPORTANT: the flow switch and the water strainer in the customer plant are obligatory in order to keep the warranty

Page 21

Temperature Probe

AIR CONDITIONING WATER PUMP

WATER TANK

FANCOIL

CUSTOMER PLANT

7.7.2

Customer plant sketch without primary pump for a stand-alone unit with on board single pump or single

pump+ stand-by pump

Primary Pump

Secondary Pump

Flow S witch

Drainage

Vent Valve

Expansion Vessel

Filling Group

Steel Mesh Strainer

Check Valve

Safety Valve

Interception Valve

Figure 12

IMPORTANT: the flow switch and the water strainer in the customer plant are obligatory in order to keep the warranty

Page 22

WATER TANK

FANCOIL

AIR CONDITIONING WATER PUMP

WATER TANK

FANCOIL

Filling Group

Safety Valve

CUSTOMER PLANT

CUSTOMER PLANT

7.7.3

Customer plant sketch with primary pump for modular units with no on board pump

AIR CONDITIONING WATER PUMP

Primary Pump

Secondary Pump

Temperature Probe

Flow S witch

Drainage

Vent Valve

Expansion Vessel

Steel Mesh Strainer

Check Valve

Interception Valve

Figure 13

7.7.4

Customer plant sketch without primary pump for mod ul ar units with on board single pump or single

pump + stand by pump

Primary Pump

Secondary Pump

Temperature Probe

Flow S witch

Drainage

Vent Valve

Expansion Vessel

Filling Group

Steel Mesh Strainer

Check Valve

Safety Valve

Interception Valve

Figure 14

Page 23

Mounting instructions

Dimensions (mm)

Paddle (model without “T” piece)

7.7.5 Flow switch installation

To ensure adequate water flow through the evaporator, it is essential to install a flow switch on the water circuit. The flow

switch must be installed on the inlet pipe of the water on which the pump is. The purpose of the flow switch is to stop the

unit in case of an interruption of the water flow while protecting the evaporator from freezing.

The flow switch can be mounted in any position far from elbows or bottlen eck s an d with the arrow in the direction of flow.

For installations on vertical piping is necessary to calibrate the device to compensate for the weight of the headstock. If

the unit is mounted to the bottom, WARNINGS on deposits that can form must be made. The appliance must be installed in

a straight pipe with no filters, valves, etc.

Have at least 5 times its diameter, both upstream and downstream.

Blade type flow switches are available as loose accessories and are suit able for harsh environments and for

pipes with diameters from 1 ” to 8”. Th e flow switch has a contact which must be wired, by the c ontract or, on

the jobsite. Check the unit wiring diagram for more information. See the instruction sheet inside the flow

switch box for information about positioning and settings.

PIPES TABLES

Page 24

INDEX

INDEX

EVAPORATING/CONDENSING

COIL

DESUPERHEATER (IF PRESENT) FOR

PARTIAL RECOVERY

DISCHARGE TEMPERATURE

PROBE

SUCTION TEMPERATURE

PROBE

8 STANDARD REFRIGERANT SCHEMATIC

C COMPRESSOR

BCE

VE ELECTRONIC EXPANSION VALVE

EWR EVAPORATOR/CONDENSER

PA HP PRESSURE SWITCH

PB LP PRESSURE SWITCH

RC CARTER HEATER

AA LIQUID SEPARATOR

PS SERVICE VALVE

V FAN

VS SIGHT GLASS

Tsc

Tas

VIC CYCLE REVERING VALVE

D

Rliq LIQUID RECEIVER

VA SAFETY VALVE

FE FILTER DRIER

KA HP TRANSDUCER

KB LP TRANSDUCER

TW in INLET WATER TEMPERATURE PROBE

TW out OUTLET WATER TEMPERATURE PROBE

Tair EXTERNAL AIR TEMPERATURE PROBE

Page 25

9 ELECTRICAL PANEL

All field-installed wiring must be in accordance with local regulation. Be sure to satisfy proper equipment groun d ing

requirements

The standardized values - Maximum Amps –Maximum kW atts are displayed o n u n it nameplate.

All field-installed wiring must be checked for p r oper terminations, and for p ossible shorts or ground s.

Ensure total prote ction against the possible penetration of water into the connection point.

All the cables and th e terminals are univocally numbered according t o the electrical scheme in order to avoid possible

misinterpretati on . The identification system of the cable s connected to the componen ts allow also an easy and intuitive

recognition of the componen t. Each component of the electrical panel is provid ed with an identific at io n plate according

to what is shown on the electrical scheme. All the connection to the ele ctrical panel are made f rom th e b ot t om and are

equipped with cover preventing from break. The electrical panel supply is 400V/3ph+n/50H z (TN-S system) and no

additional power sup ply is necessary. The e ntrance for the power cables is provided on the bot tom of the box where a

dismountable flang e su itable for the purpo se is provided. The electric al p ower supply without ne u tral 400V/3ph/50Hz is

available as option.

The control circuit is powered with 24 VAC. Each unit is provided w ith auxiliary transformer control circuit 230/24V. It

requires no additional power cable for the control equipment.

The unit has an antifreeze heater installed directly into the evaporator. The circuit al so h as an electric resistance

installed in the compressor in order to ke e p w arm the oil and thus avoid t h e t ransmigration of the ref r ig erant in its

interior. Obviou sly the operation of the e l e c trical resistors is ensured as long as the unit is power supplie d.

The unit is equipped with an alarm relay, w h ic h c h an ges state every time an al ar m oc c u rs in on e of the cooling circuits .

Connect the terminal s as per the wiring diagram on the unit - terminal “X ” - a visual or audible alarm or any external

supervision system .

BMS to monitor its operation is allowe d. See the wiring of the unit for wiring.

WARNING Hazardous Voltag e with Capacitor! Disconn e c t all electric powe r , including remote discon n e c ts and discharge

all motor start/run and capacitors before servicing. Follow prop e r lock out /t agou t p roced u re s to e nsure t h e power

cannot be inadvertently energized.

For variable frequency drives or other energy storing components, refer to the appropriate manufacturer’s literature for

allowable waiting p e r iod s f o r discharges capacitors. V erify with an appropriate voltmeter that all capacitors have

discharged below 60V .

After disconnectin g input power, wait f ive (5) minutes for units which are equipped with EC fans an d w ait twenty (20)

minutes for units which are equipped with variable frequency drive (0V DC) before touching any internal components.

Failure to follow the se instructions could re sult in death or serious inj u ry .

Page 26

10 USER RESPONSABILITIES

It is important that the operator is properly trained and familiar with t h e equipment before w o rking on the unit. In

addition to reading this manual, the operator must study the manual ope r at io n of the microprocessor an d the wiring

diagram to understand the sequence of start- up, operation, shutdown sequen ces, and the criterion of ope ration of all

safety devices. D u ring the initial start-up of the unit an authorized t echnician is available to answer any questions an d

educate on the proper functioning. We recommend the operator to maintain a record of the op e r ating data for each

unit installed and al l main tenance activitie s an d periodic service. If the operator observes ab n o rmal o r u n usual

operating condition s, consult the author ized service technician.

11 START-UP PRELIMINARY PROCEDURES

11.1

Before starting the unit, even only momentarily, all the equipment connected to the chilled water, like the air h an dling

units, pumps, etc. have to be checked. The pump auxiliary contacts and the flow switch have to be connected to the

control panel as indicat ed in the electrical diagram. Before carrying o u t in terventions on the valve regulations, loosen

the relevant valve gland. Open the discharge valve of the compressor. Open the liquid shutoff valve placed on the liquid

line. Measure the su ction pressure. If it is low e r than 0.42 MPa jumper an d strain the solenoid valve on the liquid line.

Bring the suction pressure to 0.45 MPa, then remove the jumper. Ch arg e all t h e water circuit progre ssively . S tarts up

the water pump of the evaporator with the calibration valve shut and then slowly open it.

Discharge the air from t h e high points of the water circuit and check the direction of the water f lo w . Carry out a setting

of the flow by using a measurer (if present or av ailable) or by means of a comb in ation of the readings of the

manometers and the thermometers. In the starting phase set the valve on the pressure d ifference read on the

manometers, carry out drainage of the tubes and then carry out fine setting on the temperature difference between the

water in and the water out. The regulation is set in the factory for water in to the evaporator at 12°C and water out at

7°C. With the general switch open, check that the electrical connections are tightly clamped. Check for any possible

refrigerant leaks. Check that the electrical data on the label correspond to those of th e mains sup p l y . Check that the

thermal charge availab l e is appropriate for starting.

11.2

Units are sent with the complete charge of ref rigerant and are at a sufficie n t pressure to check t h e se al after installing.

If system if not under pressure, remove remain in g refrigerant with recovery system. Charge the system with dry

nitrogen to find the leak(s). Repair the leak.

After having elimin ated the leakage, t h e sy stem has to be dehydrated w ith a vacuum pump up to at least 1mm Hg absolute pressure (1 Torr o 133.3 Pa). This is t h e min imum recommended value to dehydrate the plan t.

WARNING! Do not use the compressor to vacuum the system.

STARTING CHECK

REFRIGERANT SEALS CONTROL

11.3

Units are supplied w ith a complete charge of re frigerant. If bubbles c an be seen through the peep h ol e with the

compressor running with a full charge and ste adily, it means that the ref rigerant charge is insufficient

REFRIGERANT CHARGE CHECK

Page 27

DATE

N.

UNIT

COMPLIANCE

THE HYDRAULIC

PLEASE NOTE THAT

AND THE WATER LOAD IS AVAILABLE

THE UNIT DISPLAYS DENTS OR DAMAGES ON THE

TRANSPORTATION OR POSITIONING.

IF ANY, SPECIFY BELOW:

WARNING:

RESULT IN THE CALL

THE UNIT HAS BEEN INSTALLED IN

DIMENSIONAL DRAWING AND TECHNICAL DOCUMENTATION PROVIDED.

THE UNIT IS INSTALLED NEXT TO THE: PHOTOVOLTAIC SYSTEM, ELECTRONIC TRANSMITTERS,

SIMILAR DEVICES.

THE UNIT IS POSITIONED ON

ANTI

THE UNIT DISPLAYS DEFECTS OR DAMAGES RESULTING FROM MODIFICATIONS OR CHANGES (UNIT

TAMPERING / UNAUTHORIZED MODIFICATIONS TO THE REFRIGERANT CIRCUIT OR THE HYDRAULIC CIRCUIT

OR THE ELECTRICAL PANEL OR CHANGES TO THE UNIT OPERATING PARAMETERS) MADE BY A THI

WITHOUT A WRITTEN AUTHORIZATION ISSUED BY

DIAGRAMS AND TECHNICAL DOCUMENTATION) IN CASE OF RELEVANT DIFFERENCE BETWEEN THE UNIT AND

TRANE

WARNING:

RESULT IN THE CALL

THE UNIT HAS BEEN INSTALLED VERY CLOSE TO

INSTALLATION ENVIRONMENT

WARNING:

RESULT IN THE CALL

SPOTTED PRESENCE OF MOLD, MUSHROOMS, BACTERIA, MICROBIAL OF ANY TYPE.

THE UNIT DISPLAYS DAMAGES CAUSED BY: FLOODS, LIGHTNING, FIRE, ANY ACCIDENT BEYOND

CON

12 CHECK LIST – MANDATORY OPERATION CONTROL BEFORE START-UP

CUSTOMER:

SITE:

ADDRESS:

POSTCODE:

COUNTRY:

GENERAL

1

2

3

4

5

6

-VIBRATIONS DAMPERS HAVE BEEN INSTALLED BETWEEN THE UNIT AND THE FLOOR.

CIRCUIT IS COMPLETE AND READY TO BE USED AND THE THERMAL LOAD IS AVAILABLE.

THE FIRST START-UP SHALL NOT BE CARRIED OUT U NL ESS THE PLANT IS READY

.

EXTERNAL CASING OCCURRED DURING THE

PLEASE BE AWARE THAT RELEVANT DAMAGES CAUSED BY THE QUOTED CIRCUMSTANCES MAY

-OFF OF THE WARRANTY.

ACCORDANCE WITH THE MINIMUM DISTANCE PROVIDED IN THE

ANTENNAS OR

A PERFECTLY FLAT (NOT INCLINED) SURFACE.

YES

NO

TRANE. THE UNIT SHALL BE CONFORM TO TRANE WIRING

7

8

9

10

STANDARD CONFIGURATION PLEASE CONTACT TRANE.

PLEASE BE AWARE THAT RELEVANT DAMAGES CAUSED BY THE QUOTED CIRCUMSTANCES MAY

-OFF OF THE WARRANTY.

A MARINE ENVIRONMENT OR AN AGGRESSIVE

(HIGHLY CORROSIVE CHEMICAL AGENT).

PLEASE BE AWARE THAT RELEVANT DAMAGES CAUSED BY THE QUOTED CIRCUMSTANCES MAY

-OFF OF THE WARRANTY.

TROL.

RD PERSON

TRANE

Page 28

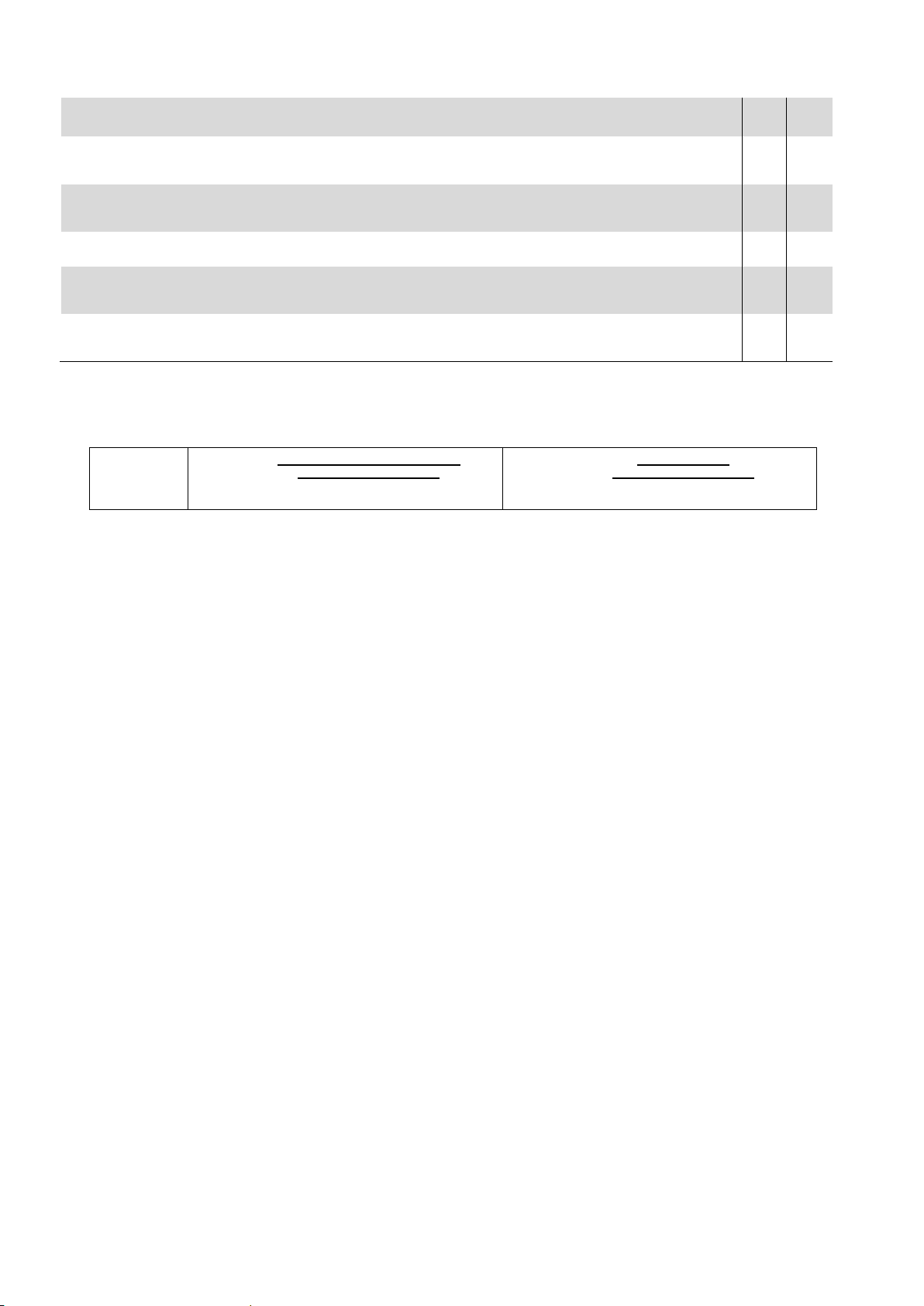

COMPLIANCE

THE UNIT IS ELECTRICALLY POWERED AND ALL THE RELEVANT ELECTRICAL WIRES ARE PROPERLY

ELECTRICAL SUPPLY HAS BEEN INSTALLED IN ACCORDANCE WITH THE INSTRUCTIONS PROVIDED IN THE NAME

PLATE AND IN THE TECHNICAL DOCUMENTATION. (ELECTRICAL POWER SUPPLY: 230V/400V +/

MAXIMUM “%” OF PHASE IMBALANCE: +/

VOLTAGE VALUE ( BETWEEN PHASES AND BETWEEN PHASE AND NEUTRAL)

PHASES ARE CONNECTED IN THE PROPER SEQUENCE.

ELECTRICAL CABLES SIZE ARE CONFORM TO FLA MAX

BOTH EXTERNAL AND INTERNAL

THE COMPRESSOR CRANCKCASE HEATERS HAVE BEEN POWERED AND HEATED AT LEAST 8 HOURS BEFORE THE

START

AN ELECTRONIC SUPERVISOR (OR ANY ADDITIONAL CONTROLLER) HAS BEEN

THE CONNECTION WIRES ARE

REMOTE CONTROL DEVICES OR INTERFACES ARE CONNECTED TO THE ELECTRICAL PANEL IN CONFORMITY

WITH

ELECTRONIC DEVICES ARE INTACT AND DON’T DISPLAY ANY

AN EXTERNAL

WIRING

THE ELECTRICAL ABSORP

COMPLIANCE

ALL CONNECTIONS ON THE REFRIGERANT

THE ELECTRONIC LEAKAGE DETECTOR OR THE PRESSURE GAUGE LEVEL INSTALLED ON THE REFRIGERANT

CIRCUIT HAVE DETECTED ANY LEAKAGE.

IF ANY, SPECIFY BELOW:

THE COMPRESSOR OIL INDICATOR LIGHT POINTS THE MAXIMUM LEVEL.

THE FILTER INDICATOR LIG

WARNING:

PLEASE CONTACT

ELECTRIC AND ELECTRONIC

11

12

13

14

15

16

17

18

19

ELECTRICAL WIRES ARE WELL TIGHTENED.

-UP

SHIELDED.

TRANE WIRING DIAGRAMS

- 2% ) . IT IS RECOMMENDABLE TO CHECK BY USING A TESTER THE

YES

CONNECTED.

- 10% -

VALUE.

INSTALLED.

NO

20

21

22

WATER PUMP IS ELECTRICALLY CONNECTED TO THE ELECTRICAL PANEL IN ACCORDANCE WITH THE

DIAGRAMS PROVIDED BY TRANE

TION AND THE WATER PUMP OVERHEATING ARE STANDARD.

REFRIGERANT CIRCUIT

23

24

25

HT ON THE LIQUID LINE IS GREEN.

26

THE YELLOW INDICATOR LIGHT INDICATES PRESENCE OF MOISTURE IN THE CIRCUIT. IN THIS CASE

TRANE.

DAMAGE.

CIRCUITS ARE WELL TIGHTENED.

YES

NO

Page 29

THE FILTER IS INSTALLED ON

FROM THE UNIT.

PLEASE NOTE THAT THE FILTER INSTALLATION IS

RELATING THE FILTER PLEASE REFER TO THE TECHNICAL DOCUMENTA

WATER CIRCUIT

27

THE FLOW SWITCH HAS BEEN INSTALLED AND ELECTRICALLY CONNECTED. PLEASE NOTE THAT FLOW SWITCH

28

INSTALLATION IS MANDATORY.

THE VALVES ON THE WATER PLANT MUST BE OPENED. PLEASE BE AWARE THAT IF THE MACHINE IS POWERED

29

(OR IN STAND-BY MODE) PUMPS WILL START IF THE WATER TEMPERATURE IS EQUAL OR BELOW 4°C. CLOSING

THE VALVES MAY THEREFORE CAUSE SEVERE DAMAGES.

DRAINAGE VALVES ARE INSTALLED. THE DRAINAGE VALVES ARE INSTALLED ON THE LOWEST POINT. THE

30

UTILIZATION OF AUTOMATIC DRAINAGE VALVES IS RECOMMENDED.

AUTOMATIC OR MANUAL PURGE VALVES ARE INSTALLED.

31

AUTOMATIC OR MANUAL PURGE VALVES ARE INSTALLED ON THE HIGHEST POINT.

THE HYDRAULIC CIRCUIT HAS BEEN FILLED AND PURGED.

THE HEAT EXCHANGER INLET PIPES AT A MAXIMUM DISTANCE OF 2 METERS

MANDATORY. FOR FURTHER TECHNICAL INFORMATION

TIONS.

THE PLANT SHALL BE PURGED SEVERAL TIMES BEFORE STARTING UP THE UNIT. THE FILTER INSTALLED NEXT

TO THE HEAT EXCHANGER SHALL BE CLEANED SEVERAL TIMES BEFORE STARTING UP THE UNIT, UNTIL THE

32

CORRECT DELTA T IS ASSURED AND THE HYDRAULIC PRESSURE IS CONFORM TO THE PLANT AND TO THE

WATER PRESSURE DROPS.

FOR FURTHER TECHICAL INFORMATION, REFER TO DOCUMENTATION AND PROCEDURE FOR THE FIRST START

UP.

COMPLIANCE

YES

NO

HYDRAULIC CONNECTIONS TO THE UNIT ARE COMPLIANT WITH THE UNIT NAME PLATE AND DIMENSIONAL

33

DRAWINGS (HOT WATER INLET, HOT WATER OUTLET, COLD WATER INLET, COLD WATER OUTLET, ETC.).

RUBBER JOINTS ARE INSTALLED ON THE HYDRAULIC CONNECTIONS, IN ORDER TO MINIMIZE VIBRATIONS

34

BETWEEN THE UNIT AND WATER PIPES.

35

SHUTOFF VALVES ARE INSTALLED ON THE HYDRAULIC CIRCUIT.

THE EXPANSION TANK IS INSTALLED ON THE HYDRAULIC CIRCUIT. EXPANSION TANK CAPACITY CONCURS

36

WITH THE WATER PLANT CAPACITY.

TEMPERATURE PROBES AND PRESSURE GAUGES ARE INSTALLED ON THE HYDRAULIC CIRCUIT, BOTH INLET

37

AND OUTLET SIDE.

THE HYDRAULIC CIRCUIT IS FREE FROM OBSTRUCTION OR ANY KIND OF CONSTRAINT.

38

BUFFER TANKS ARE INSTALLED IN THE HYDRAULIC CIRCUIT. THE BUFFER TANKS INSTALLATION IS STRONGLY

RECOMMENDED IN ORDER TO WARRANTY THE OPTIMAL UNIT OPERATION.

39

SPECIFY BUFFER TANK CAPACITY:LT

THE PRESSURE RELIEF VALVE IS INSTALLED BETWEEN DELIVERY AND RETURN PIPES.

40

41

42

WARNING: IN ORDER TO AVOID WATER-HAMMER, THE RELIEF VALVE PRESSURE SHALL BE SET UP IN

ACCORDANCE WITH THE STANDARD OPERATING PRESSURE OF THE WATER CIRCUIT.

THE AUXILIARY HEATING SYSTEM IS INSTALLED IN THE WATER CIRCUIT IN ORDER TO AVOID THE START-UP

OF THE UNIT WITH WATER TEMPERATURE BELOW 18°C. BEFORE STARTING UP THE UNIT THE INLET WATER

TEMPERATURE MUST BE EQUAL OR HIGHER THAN 18°C.

WARNING: THE UNIT SHALL NEVER WORK (NOT EVEN FOR SHORT PERIODS) WITH AN INLET WATER

TEMPERATURE LOWER THAN 18°C.

ANTIFREEZE PROTECTIONS ARE INSTALLED IN THE WATER CIRCUIT (ELECTRICAL HEATERS ARE INSTALLED ON

WATER PIPES AND TANKS).

Page 30

FOR FURTHER TECHNICAL INFORMATION PLEASE REFER TO TECHNICAL DOCUMENTATION PROVIDED. PLEASE

3°C.

DATE:

NOTE THAT ANTIFREEZE PROTECTIONS ARE MANDATORY FOR OUTDOOR AIR TEMPERATURE LOWER THAN

THE WATER CIRCUIT IS FILLED WITH ETHYLENE GLYCOL. ETHYLENE GLYCOL “%” SHALL CONFORM WITH

43

THE DATA PROVIDED IN THE TECHNICAL DOCUMENTATION.

ALL WATER PIPES ARE GROUND CONNECTED (IN ORDER TO AVOID ABNORMAL VOLTAGES THAT CAN CAUSE

44

DANGEROUS CORROSIONS).

45

THE EVAPORATOR WATER FLOW IS COMPLIANT TO THE TECHNICAL DOCUMENTATION PROVIDED BY TRANE.

THE WATER PUMPS ARE CORRECTLY SET UP IN ACCORDANCE WITH THE PLANT WATER FLOW, AVAILABLE HEAD

46

PRESSURE AND PRESSURE DROP.

THE PUMP IMPELLERS ARE MECHANICALLY UNBLOCKED AND UNCLOGGED (FREE FROM ANY KIND OF

47

CONSTRAINTS.)

AUTHORIZED SERVICE:

NAME AND SIGNATURE

CUSTOMER:

NAME AND SIGNATURE

Page 31

Refrigerant charge in the liquid phase

Refrigerant circuit diagram connection to vacuum pump

High pressure

Low pressure

port

High pressure

gauge

Vacuum meter

Vacuum pump

Oil trap

Low

pressure

gauge

Liquid sight glass

HR port

LP port

HP gauge

Scale

LP gauge

12.1

12.1.1

REFRIGERANT CHARGE

Refrigerant replacement procedure with unit stopped and in vacuum (refrigerant charge in

the liquid phase)

Open the shut off v alve as far as possible so that it cl oses the service coupling. Connect the refrig e r an t cylinder to the

service coupling without tightening the coupling. Half close the liquid shut off val v e. If the circuit has been deh y d r ated

and is in vacuum, charge the liquid by turn in g the cylinder upside down. Weigh and charge the ap propriate quantity.

Open the valve completely. Start up the unit and leave it running at full charge for some minutes. Check that the

indicator is clear wit h n o bubbles. Make sure th at th e transparency condition without bubbles is d u e to the liquid and

not to the vapour. Correct functioning of the unit allows for overheating of 4 - 7° C and sub cooling of 4 - 8°C. Values of

overheating which are t o o h igh may be caused by a lack of refrigerant, where as h igh sub cooling values may me an an

excess of charge. A f te r in t ervention on the charg e , it is ap propriate to check that the unit runs within the declared

values: with unit steadily running on a full charge, measure the temperature of the suction line downstream of the

thermostatic valve bulb; read the balance pressure to the evaporat o r o n the low pressure manometer and the

corresponding saturation temperature.

Overheating is equal to the difference between the temperatures measured in this way. Then measure the temperature

of the liquid line coming out of the condenser and read the balance pressure to the condenser on the high -pressure

manometer and the corresponding saturation temperature. The sub cooling is the difference between these

temperatures.

Danger While refrigeran t is being added do not ex c lu de any control system and le t the water circulate in th e evaporator

to avoid the formation of ice.

port

Page 32

Refrigerant charge in the vapour phase

Liquid sight glass

HR port

LP port

HP gauge

LP gauge

Scale

Gauge manifold

12.1.2

Caution: charge vapour only. Do not charge liqu id b e c au se it may damage the comp r e ssor .

Connect the refrigerant cylinder to the service valve without tightening the coupling. Drain the connection piping and

tighten the coupling. Charge the circuit until the indicator indicates l iquid without bubbles. Now the unit has the

required charge. Make sure not to overcharge the circuit. Charging more t han necessary leads to a h igher delivery

pressure, greater power consumption and p ossible damage to the com p r e ssor .

Refrigerant replacement procedure with unit running (refrigerant charge in the vapour phase)

The symptoms of a low refrigerant charge are:

Low evaporation pre ssu r e .

High value of supe rheating.

Low value of sub cooling.

In this case, add re frigerant R410A. The sy stem is provided with a charging port between th e e xp ansion valve and the

evaporator. Charge refrig e rant u nt il cond itions ret u rn t o work normal. R e memb e r t o rep lace the cap closing t he v alv e

at the end.

IMPORTANT!

If the unit has not been provided with integrated pump on board, do not turn off the external pump before 3 minutes

have elapsed after turning off the last compressor. The early shutdow n o f th e pump causes a water flow alarm failure.

13 START-UP

13.1

Before starting up the equipment it is ver y important to check that al l the operations described in t h e paragraph

“CHECK LIST – MANDATORY OPERATION CONTROL BEFORE START UP” have been carried out correctly.

Moreover check t ha t all the mechanical and electric equi p ment has been tightened perfectly. P art icular attent ion

should be paid t o the main components (compressor, exchangers, ventilators, electrical mot or s, and pump) if loos e

fastenings are found, t ighten t hem well before start ing up the machine.

The oil heaters hav e to be inserted at least 8 h ours before starting up. Ensure that the compressors’ carter is hot. O p en

the compressor valve and the cooling circuit one, which may have b e e n shut f or charg ing. C ont rol all t he machine ry

connected to the unit.

PRELIMINARY CONTROLS

Page 33

13.2

All the compressors mounted on units are factor y c h ar g ed with oil whose chemic al characteristic of stability are very

good, so it is not nec e ssar y to change frequentl y the lubricant oil.

The scroll compressors are equipped wit h an oil sight glass from which you can cont rol t he le v e l. In tandem or trio

performances, pay particular attent ion to oil level. Not perfe c t l y l e veled sight glasses between compressors in parallel,

but falling in th e up per and lower limits, are con sidered normal.

Next to the lamp the re is a connection on every c om p r e ssor for draining the o il an d a conne c tion for refilling.

To refill oil, there is a ¼” Schrader connection.

To refill oil, it is ne c e ssar y to discharge the ref rigerant in the unit, recovering it in adequate cylinders. Then vacuum

until you reach a pre ssu re of about 6 Pa to remove any trace of humidity from the circuit. Then load the unit with a

small amount of refrigerant and fill oil from the proper connection f or re f illing.

Add oil until the oil sight glass is flat within the upper and lower limits indicated by the correspon ding notches.

At this point refill the previously discharge d am ou n t of refrigerant as in the indications above. Restart the compre sso r.

Run for 20 minutes at full load and check the oil level. The units use POE oil.

STARTING UP

In case of burns for the electrical motor or fault of t he compressor, it is nece ssary to make a test to check the acidity of

the lubricant oil and, eventually, clean the circuit t o re d u ce the acidit y to correct values, mounting for instance an

antiacid filter and c h an ging the oil in the circuit.

13.3

In order to keep all the machine components in good condition and to optimise their use, during the warm up it is necessary

to bring the circuit to the right temperature before rele asing cooling or heating energ y to th e u tilities.

The following steps must be followed for this to be carried out:

*

start up the machine

*

wait for the water in temperature to reach the running temperature

*

start up the consumers

Follow the above mentioned procedure every time the plant is stopped long enough for the water temperature contai ned

in it to vary considerably.

WARM UP OF THE PLANT

13.4

All the compressors are factory charged with oil whose chemical char acteristic of stability are very good, so it is n ot

necessary to change frequently the lubricant oil.

The scroll compressors are equipped with an oil sight glass from which you can control t h e lev e l. In t and e m or trio

performances, pay particular attent ion to oil level. Not perfe c t l y l e veled sight glasses between compressors in parallel,

but falling in th e up per and lower limits, are con sidered normal.

CONTROL OF THE OIL CHARGE

Page 34

13.5

1) With the switch closed, open the electrical panel and exclude compressor (refer to the wiring dia gram on the

unit). Close the panel, set switch to “ON” (to give power to the unit).

2) Wa

The oil temperature must be at least 5°C higher than the saturation temperature of the refrigerant inside the

compressor.

3) Place the unit in the “ON” and wait until the unit is indicated on the display-On.

4) Turn on the pumps (at max speed if with inverter).

5) Verify that the loss of load of the evaporator is equal to that of the project and correct if necessary. The

pressure drop on the evaporator must be read on the service valves instal led on the evaporator piping as a

standard. Do not measure the load losses in points where any valves and

6) Check for air in cleaning filters, and then drain the system.

7) Return the pump to the factory setting.

8) Turn off the power (into standby mode) and make sure the pumps stop after about 2 minutes.

Verify that the local temperature subcooling is set to the required value by pressing the Set button.

9) Turn the main switch to “OFF”. Open the cabinet. Reactivate the compressors. Close the cabinet. Turn the main

switch to “ON” (to give power to the unit).

10) Wait for the start of the microprocessor and control.

11) When the compressor is started, wait about 1 minute for the system begins to stabilize.

12) Check the pressure of evaporation and condensation of refrigerant.

13) Verify that, after a period of time necessary for the stabilization of the refrigerant circuit, the liquid indicator

placed on the inlet pipe to the expansion valve is completely filled (no bubbles), and that the moisture indicator

signs ‘Dry’. The passage of bubbles within the liquid indicator may indicate a low amount of refrigerant, or an

excessive pressure drop through the filter drier, or an expansion valve blocked at the maximum opening position

14) In addition to checking the sight glass, check the operating parameters of the circuit controlling:

a) - O

b) - Overheat ing compr esso r discharge

c) – Sub cooling of the liquid exiting the condenser coil

d) - Evaporation pressure

c) - Condensing pressure

15) Measure the values of pressure and temperature by means of the suitable instrumentation and make comparison

by reading the corresponding values directly on the display of the microprocessor on board

16) To temporarily turn off the unit put on standby the unit key or open the remote contact (terminals shown in the

wiring diagram provided with the unit) of the terminal X (by means of a remote switch installed by the customer)

or set time zones. The microprocessor will activate the shutdown procedure that will take a few seconds. The unit

water pump will be running on for two minutes after the unit has been switched off. Do not remove the main

power to not turn off the electrical resistances of the compressor and the evaporator.

START UP PROCEDURE

it for the start of the microprocessor and control. Make sure that the temperature of the oil is hot enough.

/

or filters are interposed.

verheat in g co m pr e ss o r

14 MAINTENANCE

Maintenance operations are fundamental in order to keep the units running properly, from a purely functional and an

energetic and environmental points of view.

Every unit comes with a logbook, in which the user to machine maintenance can keep all the required notes, in order to

keep a historical log of the unit.

A lack of notes in the logbook could be considere d proof of careless maintenance .

14.1

IMPORTANT!

Beyond the cadences of checks recommended in the following, in order to keep the unit at optimum levels of

performance and ef ficiency and prevent in c ip ie nt failures, we recom me n d periodic visits of in spection and control of

the unit by qualified personnel.

In particular, we recommend:

4 annual visits to units that operate about 36 5 days / year (quarterly)

2 visits per year for un its with seasonal operation about 180 days / year (one at the start of the se ason and another one

at mid-season)

1 annual visit for unit s w ith seasonal operation of about 90 days / year (st arting seasonal)

It’s important t h at during the initial start -up and periodically during operation routine che ck s are carried out. Among

them we must also ch e c k the suction and condensation as well as the sight glass located on the liq u id lin e.

Check through the microprocessor installed on the unit if the unit is wor k in g within normal paramete r s of superheating

GENERAL

Page 35

and sub cooling. A r ou tine maintenance prog r am recommended is show n at the end of this chapter while a card

collection of operat in g data is at the end of t h is man ual. It is suggested to record on a weekly basis all th e operating

parameters of the u n it. The collection of the se data will be very useful to technicians, in case technical assistance is

requested

Compressor Maintenance IMPORTANT!

The analysis of vibrat ion is a great tool for chec king the mechanical condit io n s of the compressor.

It is recommended to check the value of the vibration immediately after starting and periodicall y o n an an n u al basis.

Compressor Electrical Connections

It is very important that all the compressors are wired correctly f or p rope r rot at ion. These compressors will not tolerate

reverse rotation. Verify correct rotation/ p h asing using a rotation meter.

If wired incorrectly the compressor will make excessive noise , will not pump and will draw about half the normal

current. It will also become very hot if allowed to run for an extended period.

NOTICE: Do not “bump” the compressor to check rotation as incorrect rotation could cause compressor motor

failure in as little as 4 to 5 seconds!

Improper rotation of the compressors is indicated by a compressor modul e trip, noisy operation, n o pressure difference

on manifold gauges and low amp d r aw .

Compressor Replac emen t

If the chiller suffers a failed compressor, use t hese steps for replace ment:

Each compressor has lifting eyes. Both lifting eyes must be used to lift the failed compressor.

After a mechanical failu r e of a compressor, it is n e c e ssar y to change the oil in t h e rem ain in g compressor and also

replace the liquid line filter drier. After an elect rical failure of a compre ssor, it w ill also be ne ce ssary to chang e t h e oil

in the remaining comp ressor, replace the filters driers and add a suct ion filter drier with clean -up cores.

Change filters and oil until the oil no longe r test acidic.

Make sure that a heater is correctly installed on the compressor. T h e heater helps prevent dry starts.

Note: Do not alter the refrigerant piping in any way as this can affect compressor lubrica tion.

Refrigerant System Open Time

Units use POE oil and t her e fore refrigerant syst e m open time must be kept to a minimu m . The following procedure is

recommended:

Leave a new compresso r sealed until it is read y to be installed in the unit. Maximum system open time is dependent

upon ambient conditions, but do not e xceed one hour open time.

Plug the open ref rigerant line to minimize moisture absorption. Always change the liquid line filter drier.

Do not leave POE oil containe rs op e n t o t h e atmosphere. Always keep them sealed.

14.2

The risks due to the pr e ssu r e insid e the circuit have bee n elimin ated or (when it is not possible) reduced b y

means of safety dev ic e s. It is important to check periodically the status of this device and to carry out the

components inspect ions and repositioning as follows.

14.3

Check the liquid receiver state at least one a year.

It is important to ch e c k that the surface does not get rusty and that neith e r co rr osion nor deformations are v isible.

In case the superf ic ial oxidation and the c or rosio n ar e n ot properly controlle d an d stopped in time, c au se a thickness

reduction with a con se q uent reduction of the receiver mechanical resistance.

Use antioxidant p ain t or products to protect.

SIGHT CHECK OF THE LIQUID RECEIVER

SAFETY DEVICES

Page 36

Recommended

basis

Power supply and auxiliary power

voltage check

Refrigerant charge check through sight

glass

Compressors carter heaters operation

check

Fans and compressors contactors state

check

14.4

It is mandatory to clean regularly the coils for a proper unit operation. Pollution and oth e r residual material clearing

helps extend the life of the coils and the whole unit

STANDARD CONTROLS

Compressors oil level check monthly

Inlet temperature check (overheating) monthly

Water circuits filling check monthly

Fans and compressors motors electrical

input check

Tightening all electrical connections monthly

Coils cleanliness monthly

Compressors and liquid circuit solenoid

valve check

Operations description

monthly

monthly

monthly

monthly

semiannual

quarterly

Evaporator heater operation check quarterly

Motor and fan bearing noise check semiannual

Pressure vessels conditions check yearly

Temperature and pressure probes –

The unit comes factory-equipped with all the sensors listed bel ow. Periodically

check that their measurements are correct by means of samp le inst rume nt s (manometers, thermometers); correct

readings if necessary u sing the microprocessor keyboard. Well- c alibrated sensors ensure better efficiency for the unit

and a longer lifetim e .

Note: refer to th e micro p r oc essor use and maintenance manual for a complete description of ap plications, setting an d

adjustments.

All sensors are preassembled and connected to the microprocessor. T h e descriptions of each se n sor are listed below:

Outgoing water temp erature sensor –

by the microprocessor

for antifreeze protection and

This sensor is locat ed on the evaporator out going water connect io n an d is u se d

to control the unit load according to the system thermal load

IMPORTANT

In case a temperature control based on ingoing water temperature is needed, contact Trane before trying to set it

autonomously

.

Ingoing wat e r temperatu re sensor –

This sensor is located on the evaporator ingoing water connect ion and is used for

monitoring the return water temperature.

External air temperat ur e se nso r –

display.

High pressure transdu cer –

This allows to monitor the delivery pressure and to control the ve nt ilators. Sh ould an

This sensor allows to mon itor the external air temperature on the microprocessor

increase in condensation pressure occur, the microprocessor will control the circuit load in orde r to allow it to function

even if choked. It contributes to complementing the oil control logic.

Low-pressure transducer –

This allows to monitor th e c ompressor suction pressur e al ong with low pressure al ar ms. It

contributes to complementing the oil control logic.

Compressors discharge temperature sensor –

This allows to monitor the refrigerant temperature on compressor

delivery. It contributes to prevent compressors breakages.

.

Page 37

X

X

X

X

X

Check pressure safety accessories (PED)

8) TAN (Total Acid Number):

0.10:

No action

Repositioning filters antacid and occurs after 1000 hours

of operation. Continue to replace the filters until the

Changing the oil, oil filter and the filter drier, Refer to

14.5