Page 1

Architectural

Hydronic Wall Fin

FIN-PRC004-ENOctober 2001

Page 2

A Complete Line of Wall Fin

Trane architectural wall fin is ideal for

heating modern commercial,

institutional or industrial buildings.

Attractive styling and wide application

flexibility allow wall fin cabinet designs

to be used for virtually any application.

Available for hydronic or steam heating,

Trane wall fin can also be used in

combination with convectors for smaller

areas, allowing for the use of one source

when designing a radiation heating

system. (See FIN-DS-2 for convector

applications.)

Trane Wall Fin — Simply the Best

Wall fin effectively meets the heating

needs of long, open areas. It counters

cold air downdrafts common to

expansive glass areas used in many of

today’s most prestigious buildings.

Provides continuous heat along room

•

perimeter.

Allows removal of any unit panel for

•

service accessibility.

The front panel never touches the wall

•

— only Trane’s exclusive mounting

strip.

The front panel can be raised or

•

removed without disturbing the unit or

damaging wallpaper, paint or the

plaster seal.

Operates quietly because there are no

•

moving parts.

Type T

Features

and Benefits

An effective heating system for any office. Attractive styling that blends with any

architectural design.

Type S

Type F

Type TA

Controls with the damper or valve

•

individually.

Blends well with any decor.

•

Works effectively with cooling-only

•

VAV and heat recovery systems.

Includes 14 or 16-gauge front panels.

•

Unit vent draft barrier enclosures.

•

Pipe enclosures for use with ForceFlo

•

and Fan Coil Units.

Wall Fin

I=B=R Certified Ratings for Trane Wall

Fin

The I=B=R symbol is the registered

trademark of the Hydronics Institute

which tests and rates in strict accordance

with published standard wall fin

elements and elements with enclosures.

The wall fin heating units must conform

to appropriate test standards to have

certified I=B=R ratings.

Why Hydronics?

Besides the reliability of equipment

ratings, and the well established

reliability of hydronic accessories, there

are many good reasons why hydronic

systems have long been recognized as

the standard method for providing

indoor comfort.

Hydronic heating, whether steam or hot

water, provides positive, controlled

circulation of the heating medium.

Systems are basically self-balancing, and

in larger, more complicated heating

systems, balancing is positively

controlled by familiar valves and

thermostats.

The life of some hydronic equipment

may be measured in decades; some

existing boilers are more than fifty years

old. In addition to the high efficiency of

boilers (some over 85%) the losses

through the distribution system are

extremely low on modern installations.

Temperature control is close to ideal with

hydronics. Any well-designed system

can provide excellent comfort, without

drafts or sharp swings in temperature.

The flexibility of hydronic installations

permits a variety of piping

arrangements, simple or sophisticated

controls, and a large choice of room

distribution units for all comfort

applications.

© 2001 American Standard Inc. All rights reserved.

FIN-PRC004-EN

Page 3

Contents

Architecural Wall Fin

Features and Benefits

Application Considerations

Selection Procedure

Performance Data

Dimensional Data

Options

Mechanical Specifications

Security Wall Fin

Features and Benefits

Accessories

Model Number Description

Performance and General Data

2

6

7

14

41

54

56

74

75

76

77

FIN-PRC004-EN

Dimensional Data

Mechanical Specifications

Hydronic Light Commercial

Slope Top Wall Fin — Model 11S

Features and Benefits

Performance and General Data

Dimensional Data

Cover and Accessory Layout

Mechanical Specifications

85

91

93

96

98

100

101

3

Page 4

Features and

Benefits

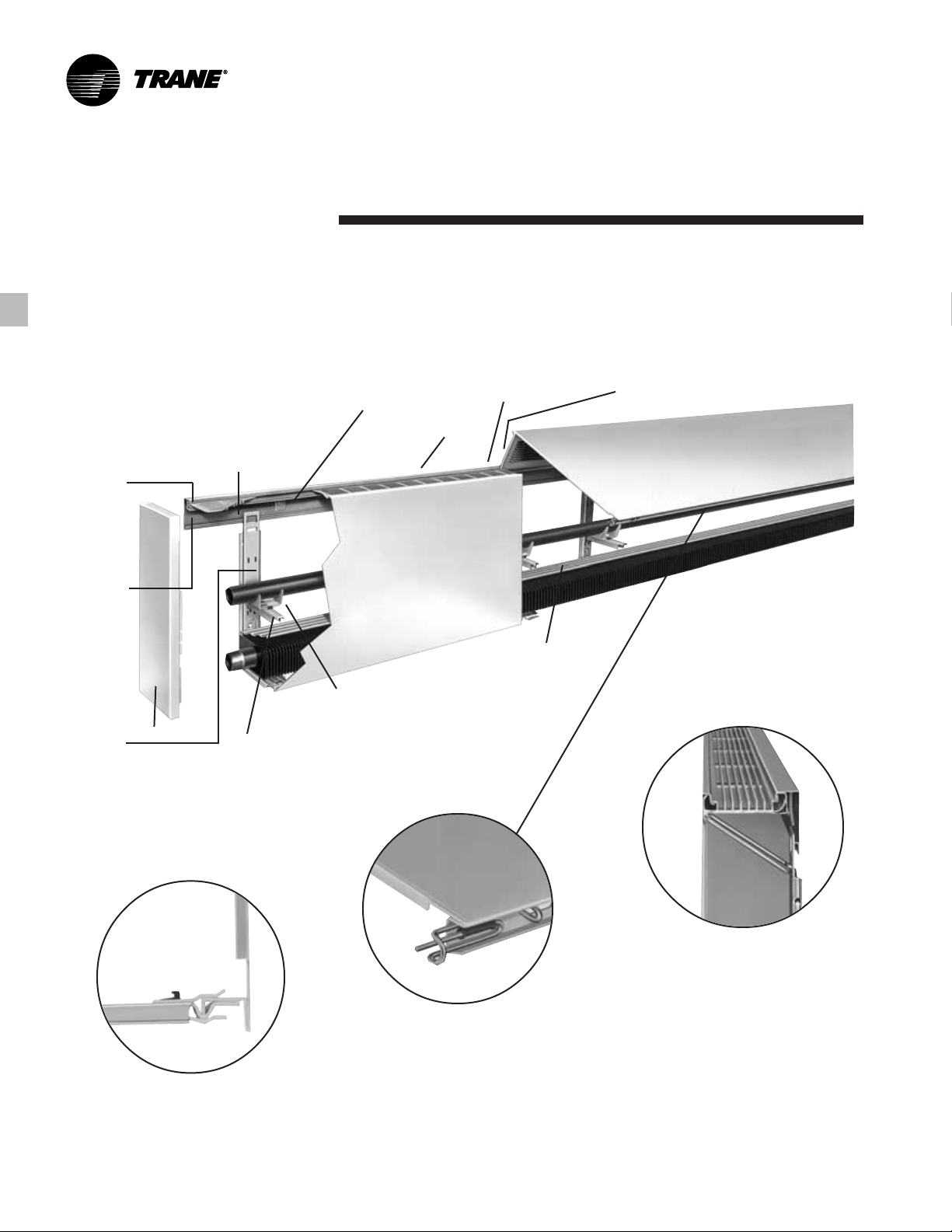

A simple installation designed to last

without visible fasteners — Trane’s

exclusively designed mounting strip

makes it possible.

Cabinet

enclosures

and

accessory

panels

hinge-lock

easily into

mounting

strip.

Roll-formed

indentation

runs full

length of

mounting

strip for

easy bolt

hole

location.

Ribbed steel

enclosure

brackets

provide

element

support base

and brace the

Mounting strip keys entire

installation, attaches to any

wall, and assures the tightest

fit possible — even against

the most imperfect wall.

End Panel

Element/pipe

supports

position in slots

in the enclosure

bracket to allow

two-tier

element and

pipe

installation.

Curved rectangular

metal washers to

assure tight fit against

the wall.

Serves as wall

panel stop.

Cradle and nylon cradle

guides assure exact element

location and allow element

cradles to slide freely and

noiselessly.

Serves as plaster

stop for semirecessed

installations.

Rigid element damper

provides heat

modulation.

Roll-formed front panels hinge

invisibly into the mounting strip.

Locking clip slides over panel lip to hold it

securely to bracket.

Deluxe unit with extruded grille. The grille is

separate and hinges into the mounting strip.

Panel clip and slide bolt fastener for front

panel alignment are hidden from view.

FIN-PRC004-EN4

Page 5

Features and

Benefits

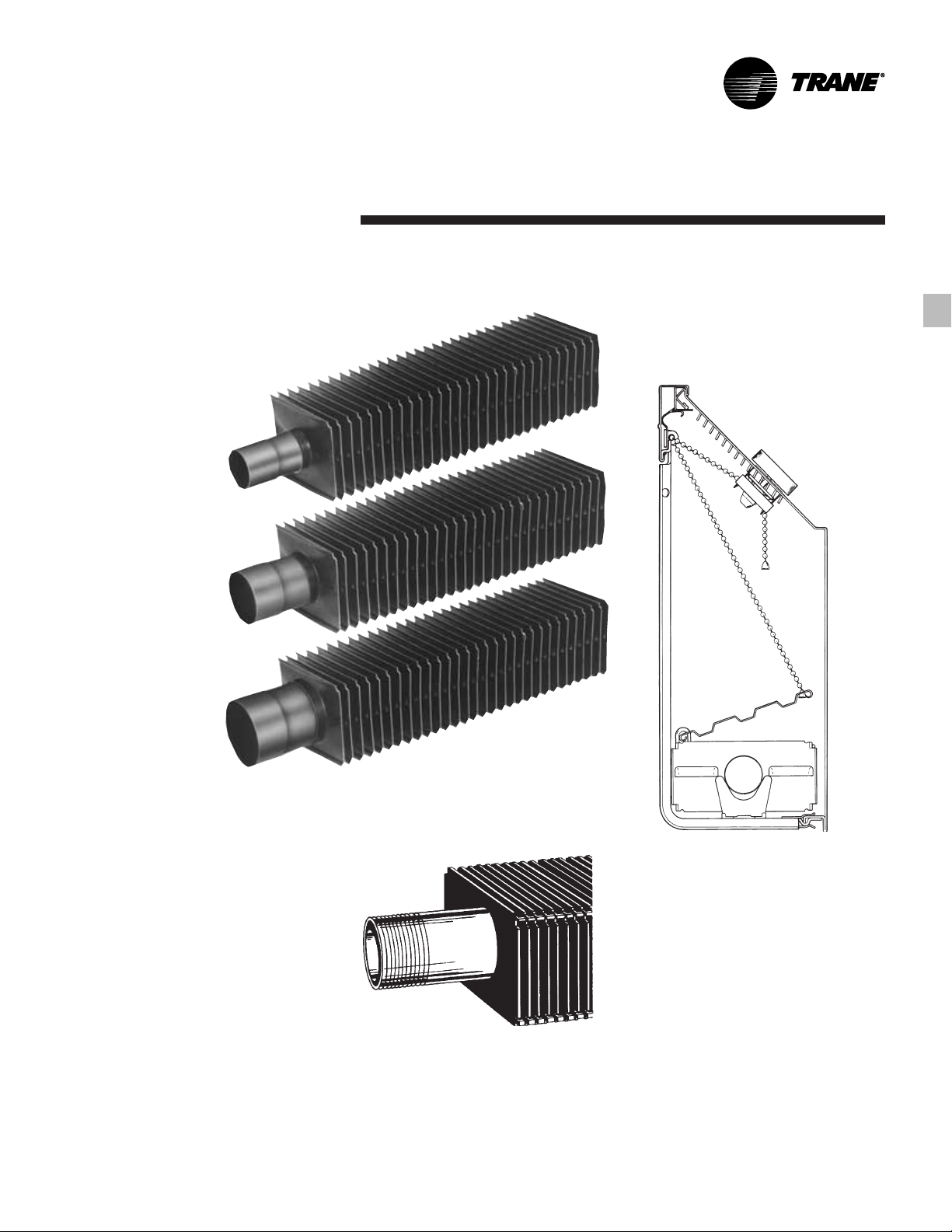

Hydronic Heating Elements — Copper/

Aluminum and Steel

Copper-Aluminum Elements

3

/4”, 1” and 1 1/4” (19 mm, 25 mm and 32

mm) Copper Tubes With 40, 50 or 58

Aluminum Fins per foot (131, 164 190

per meter).

3

/4” (19 mm)

1” (25 mm)

1

/4” (32 mm)

1

Positive Temperature Control

Efficient element-mounted damper.

•

Reduces unit capacity by 70 percent.

•

Has jam-proof bead chain control

•

system.

Control knob is mounted on the outlet

•

grille.

Steel Elements — Standard options

feature 1

steel fins per foot (171 per meter).

1

1

/4” (32 mm) steel tube with 52

1

/4” (32 mm)

For Models S, F, T & TA

Elements available in copper-

•

aluminum or steel.

Elements are efficient and long lasting.

•

Element tubes mechanically expanded

•

into fin collars.

Fin collars provide even and positive

•

spacing for even air distribution.

The mechanical bond assures an

•

efficient and durable element

assembly.

Fins cannot work loose.

•

5FIN-PRC004-EN

Page 6

Application

Considerations

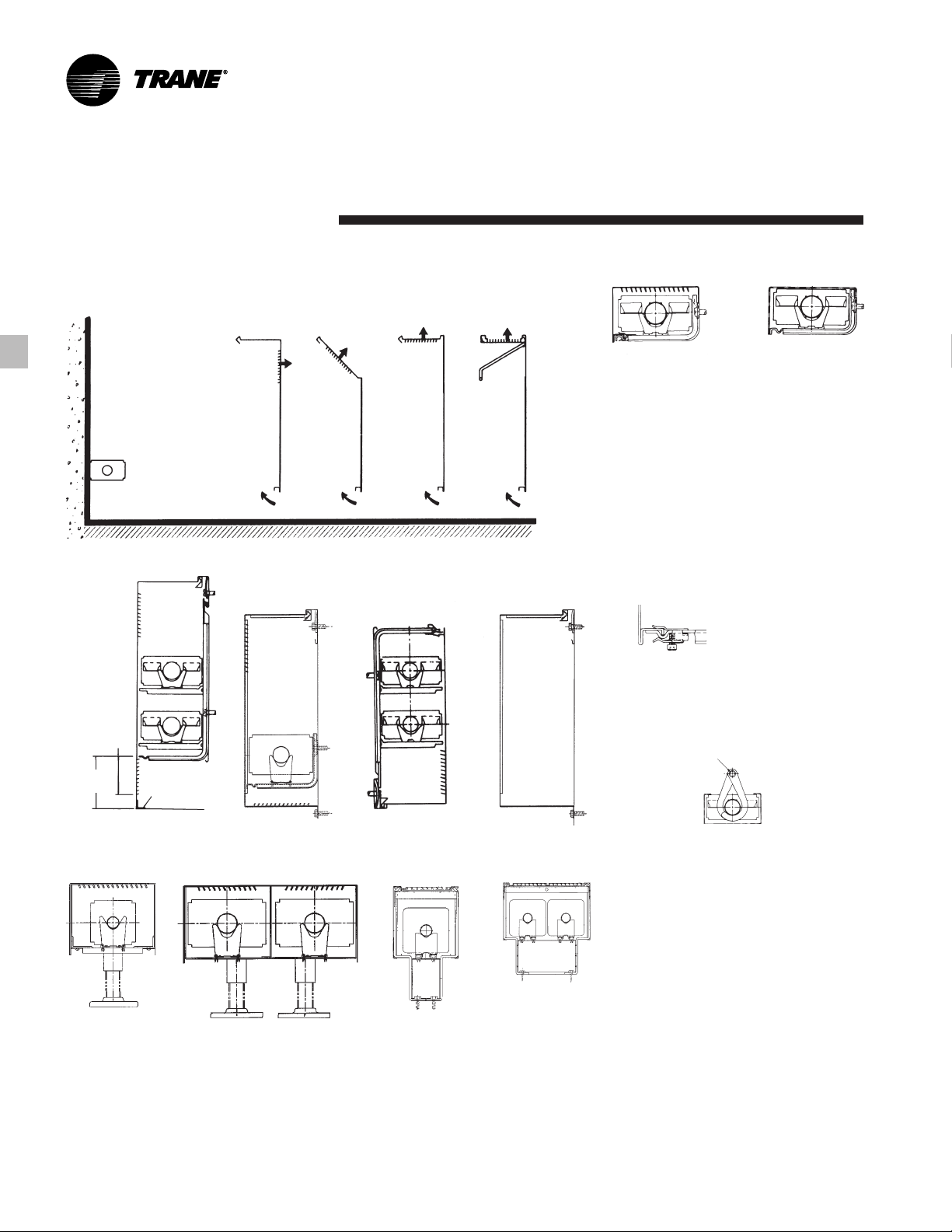

A Heating System and Style to Suit Any Application

Wall Mounted

T

Top Outlet

Top Outlet

Extruded

Front Outlet

Wall Mounted Cabinet Options

3

/8”

3

(86 mm)

FS

Slope Top

Outlet

With

Grille

TA

Type E Type X

Enclosure styles meet the heating needs

of long, open areas in any interior.

Wall-mounted wall fin enclosures

•

available in depths of four and six

inches (102 mm, 152 mm).

Enclosure depth is determined by the

•

type of element to be used.

See pages 13 through 43 and Tables

•

PD-1 through PD-25 for details.

Front inlet grilles.

•

Bottom inlet grilles.

•

Inverted enclosures for styles S, F and

•

T enclosures only.

Tamperproof fastener option.

•

Pipe Enclosures

•

Tamperproof

Fastener

Ceiling Mounted

Type CS

1

/2” (13 mm) Dia. Mtg. Hole

4 1/2”

(114 mm)

Front Inlet Grille

Floor Mounted

Type E3

Continuous

Sheet Metal

Angle

Type E3-2W

Inverted Enclosure

Type E3A-1W

Pipe EnclosureBottom Inlet Grille

Type E3A-2W

Ceiling-mounted wall fin enclosures

•

available in depths of four and six

inches (102 and 105 mm).

See pages 13, 14, 15 and 49.

•

Pedestal wall fin enclosures available

•

with one or two wide elements.

See pages 36, 37, 42, 53, 54, 55, 56, 57

•

and 58 and Tables PD-24, PD-25, M-1,

M-2, M-3, M-4 and M-5.

FIN-PRC004-EN6

Page 7

Selection

Procedure

Hydronic/Steam Wall Fin

Selection

Hot Water Systems

The capacity rating of wall fin in a hot

water heating system depends on the

difference between average water

temperature and entering air

temperature, and on the velocity at

which water is circulated through the

tube. The effect of water velocity on the

capacity rating is appreciable (see Chart

S-1) and should be taken into account

when selecting wall fin. Following are

example selections for hot water

systems.

Hot Water Systems

Example 1

Assume a two-pipe system is being used

with 180°F average water temperature,

20°F temperature drop and 65°F entering

air temperature. Assume a calculated

heat loss of 20,000 Btu, for which one

row of 1 1/4” steel element in a Type 12S

enclosure is desired.

From Chart S-1, reading from 20,000 Btu

(under 20°F temperature drop) across to

1

/4” steel element and down, indicates

a 1

a water velocity of approximately .45 ft/

sec. The water velocity correction factor

corresponding to .45 ft/sec is .920. The

radiation is selected so that it would

deliver

20,000 Btu (calculated heat loss)

0.920 (velocity correction factor)

or 21,739 Btu if the water velocity were 3

ft/sec. It will then deliver the required

20,000 Btu at the actual water velocity of

.45 ft/sec.

1

From Table PD-8, the output of 1

steel, Series 52 element in a Type 12S

enclosure is (looking under 180°F

average water, 65°F entering air) 1060

Btu/lineal foot at 3 ft/sec water velocity.

Wall fin required:

21,739 Btu = 20.5 lineal feet.

1060 Btu/ft

Length Selection — Loop Systems

Example 2

If the unit in Example 1 above was part

of a 100,000 Btu loop with a 20°F drop

(across the entire loop) the water

velocity through the loop would be 2.20

ft/sec and the water velocity correction

factor for all units on this loop would be

approximately .987. For the unit being

considered, the radiation would be

selected to deliver 20,300

20,000

/4”

( .987 )

Btu at 3 ft/sec water velocity.

Steam Systems — Selecting Wall Fin

Lengths

The capacity rating of wall fin in a steam

heating system depends upon the

difference between the steam

temperature and the entering air

temperature. For any steam system, to

establish the lineal feet of wall fin

required: divide the heat loss by the

capacity rating per foot at the steam

system and entering air conditions.

Ratings for 1 psi steam and 65°F

entering air can be found on Tables

PD-1 through PD-21. Ratings for other

steam and air conditions can be

obtained by multiplying the 1 psi —

65°F capacity ratings by the proper

steam correction factor from Table S-2.

Example 1

Assume a steam system with 1 psi

steam and 65°F entering air conditions.

Also assume a 15,000 Btu heat loss for

which a 1” copper-aluminum element 40

fins/foot in a Type 10S enclosure is

desired.

Wall fin required:

15,000 Btu = 13.9 lineal feet.

1080 Btu/ft

Example 2

Assume a steam system with 20 psi

steam and 55°F entering air conditions.

Also assume a 25,000 Btu heat loss for

which 2 rows of 1

element on 9

without a cover. The capacity rating per

lineal foot from Table PD-3 at 1 psi steam

and 65°F entering air is 2120 Btu/ft.

Multiplying this capacity rating by 1.52

(steam correction factor from Table S-2)

gives a rating of 3222 Btu/ft with 20 psi

steam and 55°F entering air.

Wall fin required:

3222 Btu/ft

= 8 lineal feet, 2 rows high.

1

/4” steel, Series 40

1

/2” centers will be used

25,000 Btu

7FIN-PRC004-EN

Page 8

Selection

Procedure

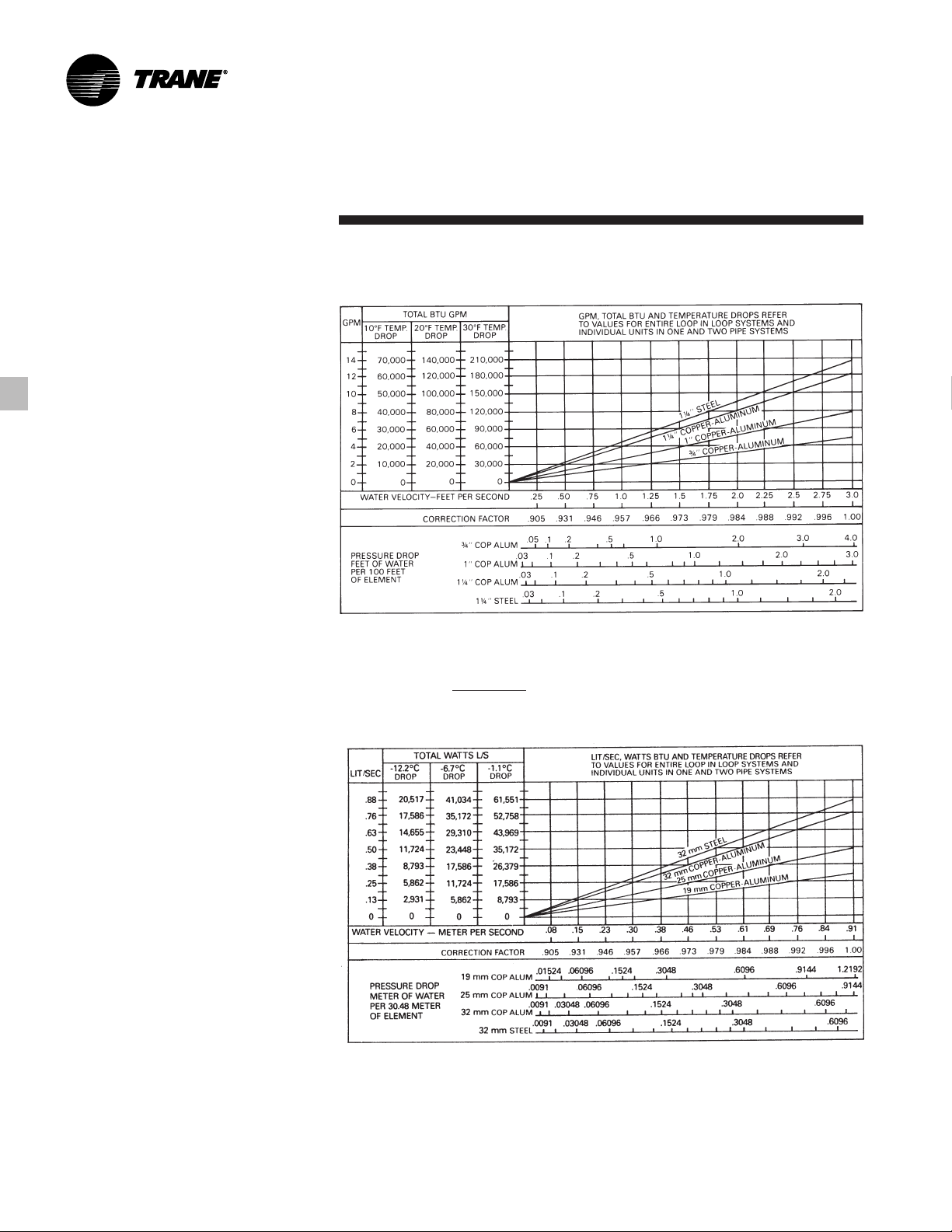

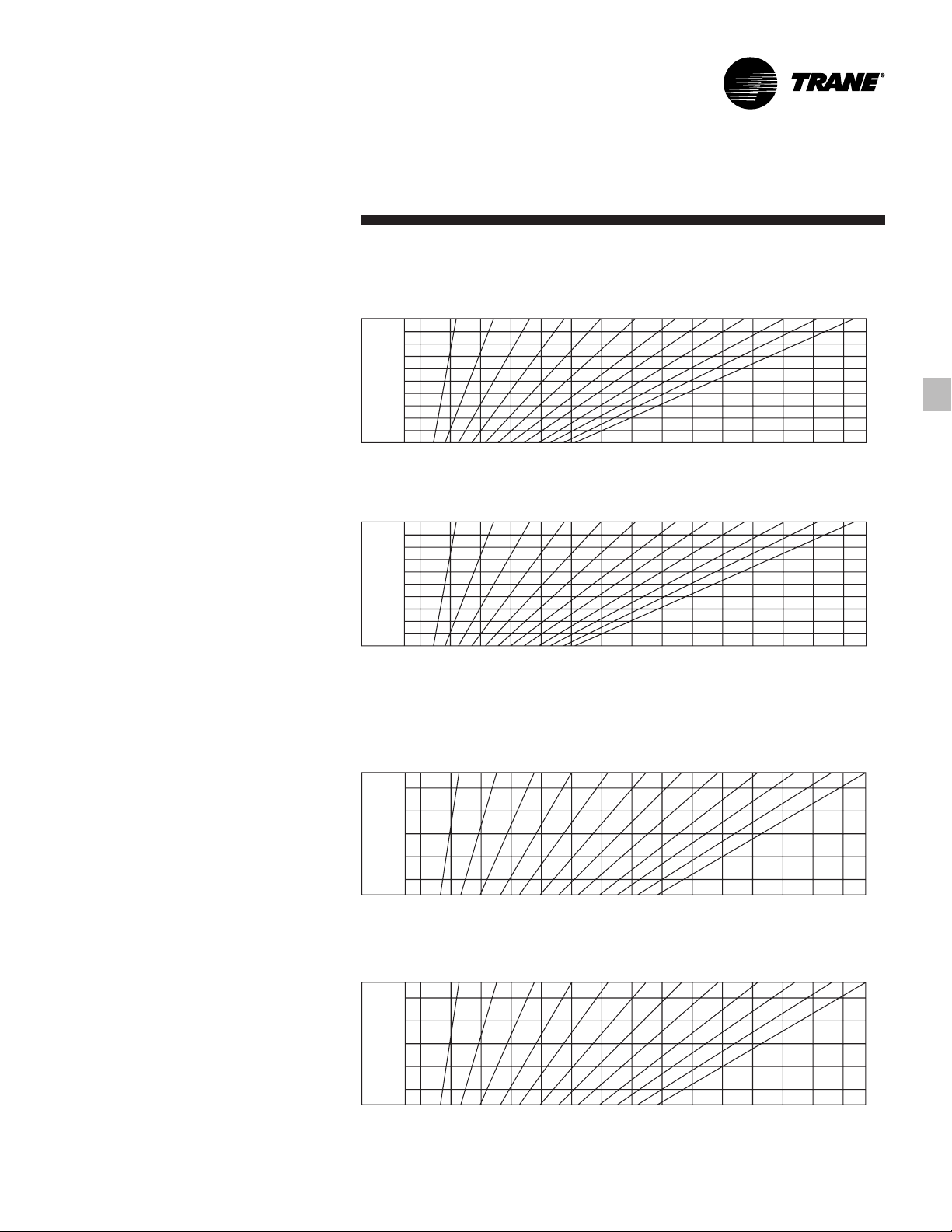

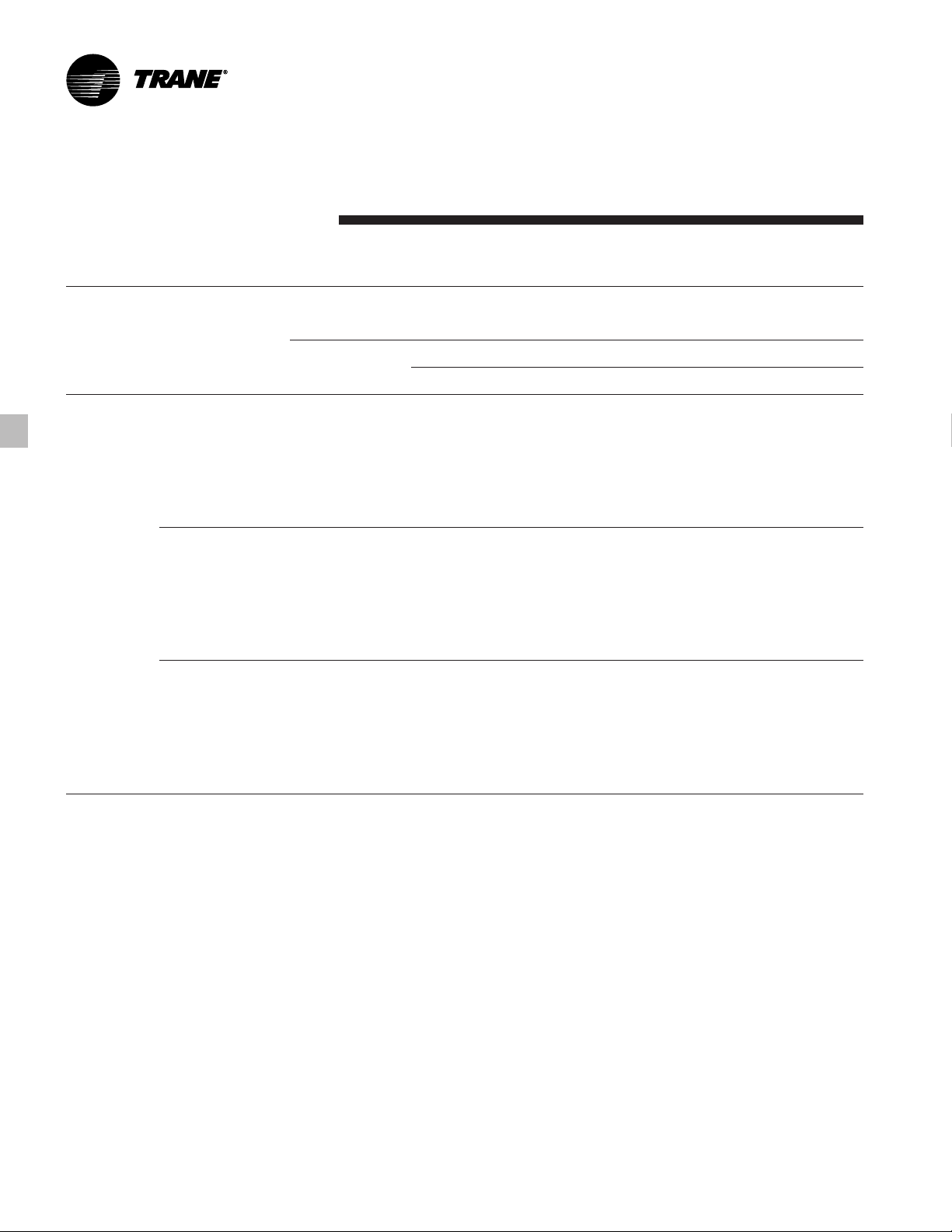

Chart S-1 — Water Velocity Correction

Factors — Pressure Drops ENGLISH

All Catalog Capacities Based On 3.0

Feet Per Second Water Velocity.*

*Correction Factor = .04

Water Velocity

( 3 )

SI

FIN-PRC004-EN8

Page 9

Selection

Procedure

Effect of Temperature Drop On

Fin-Tube Ratings

The effect of temperature drop on heat

output of a wall fin element can be

readily determined. Select the heating

element using average water

temperature (entering water

temperature minus

1

/2 water

temperature drop) and correct for water

velocity as follows:

By use of the relationship,

GPM =

BTU

*500 x Water Temperature Drop

the waterflow rate for a wall fin unit of

the required Btu and at a definite

temperature drop, is easily calculated.

(Many engineers use gallons per minute

as the basis for selecting pipe sizes, since

charts are set up on this basis in the

The heat output of a given wall fin unit

will vary somewhat with different water

velocities, all other conditions being

equal. From Chart S-1, the water velocity

can be found for a wall fin element of the

particular tube size and gpm waterflow

required. The velocity correction factor

can be determined by using Chart S-1.

ASHRAE Guide. Therefore, this would

not be an extra step.)

Table S-1 — Pipe Water Capacities and Quantities Circulated at Velocity of 3* Feet Per Second (.91 m/s)

Nominal Expanded Gals. Per Liters Per Gals./Min. @ 3’ Liters per Sec. Lbs./Hr. @ 3’ Kg/S @ .91 m

Pipe Size ID Linear Ft. Meter Sec. Vel.* @ .91 M/Sec. Vel. Sec. Vel.* Sel. Vel.

3

/4” CA (19 mm) 0.836” (21 mm) .029 .36 5.13 .324 2,555 .322

1” CA (25 mm) 1.073” (27 mm) .047 .58 8.45 .533 4,215 .531

1 1/4” CA (32 mm) 1.311” (33 mm) .070 .87 12.6 .795 6,285 .792

1 1/4” ST (32 mm) 1.40” (36 mm) .080 .99 14.39 .908 7,170 .903

*3 Ft./Sec. (.91 m/Sec) Velocity is Basis for Hot Water Rating Factors Shown in Chart S-1.

Velocity Ft./Sec. =

For quiet operation, a maximum of 5 ft/sec (1.5 m/Sec) velocity is recommended.

Table S-2 — Wall Fin Rating Correction Factors*

Steam Press. Steam Temp. 45°F55°F65°F70°F75°F80°F85°F90°F 100°F 110°F 120°F 130°F 140°F 150°F

PSIG kPa (F) (c) 7°C13°C 18C 21°C24°C27°C29°C32°C38°C43°C49°C54°C60°C66°C

0 0 212.0 100.0 1.19 1.09 0.97 0.92 0.87 0.82 0.77 0.70 0.63 0.54 0.46 0.38 0.31 0.25

.899 6.2 215.0 101.7 1.22 1.11 1.00 0.95 0.90 0.84 0.80 0.75 0.65 0.57 0.48 0.40 0.33 0.26

5 34.5 227.1 108.4 1.34 1.22 1.11 1.05 1.00 0.95 0.90 0.81 0.75 0.66 0.57 0.49 0.41 0.34

10 69.0 239.4 115.2 1.45 1.33 1.22 1.17 1.11 1.05 1.00 0.91 0.85 0.75 0.66 0.58 0.50 0.42

20 137.9 258.8 126.0 1.63 1.52 1.40 1.33 1.28 1.23 1.17 1.07 1.02 0.92 0.82 0.73 0.64 0.55

30 206.9 274.0 134.4 1.78 1.66 1.54 1.48 1.42 1.37 1.31 1.21 1.15 1.05 0.95 0.85 0.76 0.68

40 275.8 286.7 141.5 1.91 1.79 1.66 1.61 1.54 1.49 1.43 1.32 1.27 1.16 1.06 0.97 0.87 0.78

50 344.8 297.7 147.6 2.02 1.90 1.77 1.71 1.65 1.60 1.54 1.42 1.37 1.26 1.16 1.06 0.96 0.87

100 689.5 337.9 169.9 2.43 2.31 2.18 2.11 2.05 2.00 1.94 1.81 1.77 1.65 1.54 1.44 1.33 1.23

*For steam pressures and air temperatures other than 1 psi and 65°F (6.895 kPa and 18.3°C). For process applications, deduct heating effect after applying above factor to 1 psi, 65°F (6.895 kPa,

18.3°C air) air rating for desired element arrangement.

Lbs. Per Hour

(Gals. Per Ft.) (3600) (8.3)

Entering Air Temperature

9FIN-PRC004-EN

Page 10

Selection

Procedure

Table S-3 — Correction Factors for Non-Standard Average Water Temperatures

Average Entering Air Temperature

Water Temp. 45°F50°F55°F60°F65°F70°F75°F80°F85°F

(F) (C) 7°C10°C13°C16°C18°C21°C24°C27°C29°C

170 77 .82 .77 .72 .67 .61 .57 .53 .48 .44

180 82 .91 .86 .81 .75 .69 .65 .61 .56 .52

190 88 1.00 .94 .89 .84 .78 .73 .69 .64 .60

200 93 1.09 1.03 .97 .92 .86 .81 .77 .72 .68

210 99 1.18 1.12 1.06 1.01 .95 .90 .85 .80 .76

220 104 1.27 1.21 1.15 1.09 1.05 .98 .93 .88 .84

230 110 1.37 1.30 1.24 1.19 1.14 1.08 1.03 .98 .93

240 116 1.47 1.41 1.35 1.29 1.25 1.17 1.12 1.07 1.02

250 121 1.57 1.50 1.44 1.38 1.32 1.26 1.20 1.15 1.10

260 127 1.67 1.60 1.52 1.46 1.40 1.34 1.29 1.24 1.20

270 132 1.78 1.70 1.62 1.56 1.50 1.44 1.39 1.34 1.29

280 138 1.88 1.80 1.72 1.66 1.60 1.54 1.48 1.43 1.38

290 143 1.98 1.90 1.82 1.75 1.69 1.63 1.58 1.52 1.48

300 149 2.08 2.00 1.92 1.85 1.79 1.73 1.67 1.62 1.57

NOTE: To determine capacity of non-standard conditions, multiply the corresponding factor above by the BTU (Watts/

meter) steam rating found on pages 13-37.

*The weight of a U.S. gallon of water at

60°F is 8.33 pounds. At a flow rate of

1 U.S. gpm, the weight of the water

circulated through the system in one

hour is 1.0 x 8.33 multiplied by 60 minute

= 500 pounds.

Table S-4 — Factors Used to Convert 1 PSI

Steam Ratings to Hot Water Ratings at

Temperatures Indicated

Average Water Temperature Correction

(F) (C) Factor

100°F38°C0.15

110°F43°C0.20

120°F49°C0.26

130°F54°C0.33

140°F60°C0.40

150°F66°C0.45

155°F68°C0.49

160°F71°C0.53

165°F74°C0.57

170°F77°C0.61

175°F79°C0.65

180°F82°C0.69

185°F85°C0.73

190°F88°C0.78

195°F91°C0.82

200°F93°C0.86

205°F96°C0.91

210°F99°C0.95

215°F 102°C1.00

220°F 104°C1.05

225°F 107°C1.09

230°F 110°C1.14

235°F 113°C1.20

240°F 116°C1.25

Note: To determine capacity at non-standard conditions,

multiply the corresponding factor above by the BTU

(Watts/meter) steam rating found on pages 13-37.

FIN-PRC004-EN10

Page 11

Selection

Procedure

Rating Adjustment for Greater Than

Cataloged Installed Height-Heating

Effect

Ratings in Tables PD-1 through PD-25

include the factor shown in Table S-5 for

installed heights recommended.

Installed height defines the installed

location that is the basis for the

published rating and determines the

percentage which may be added to

condensation capacity. If the unit is

installed at a different height than

recommended, the following

computation applies:

Capacity at actual installed height =

(Table S-5 factor for

Rated Capacity x

actual installed height)

(Table S-5 factor for

recom. installed height)

Example

A 12S enclosure is to be installed 6”

above the recommended installed

height. Compute the new capacity rating:

Wall Fin Correction Factors Selection

1

Actual installed height is 19 7/32” (13 7/32”

from Table PD-8 + 6” (152 mm) ).

Interpolating from Table S-5, the heating

effect factor is 1.065.

2

Recommended installed height is 13 7/32

(from Table PD-8). From Table S-5, the

heating effect is 1.075.

3

Actual capacity = rated capacity

(Table PD-8) x 1.065

1.075

Determining Pressure Drop

(Refer To Chart S-1)

One-Row Units

— Read pressure drop

per 100 feet (30.5 m) on one row

assembly below the water velocity.

Two-Row Units, Serpentined (piped in

— All water passes through both

series)

rows, so pressure drop per 100 feet (30.5

m) of assembly is twice the pressure

drop below the water velocity.

Two-Row Units, Headered (piped in

parallel)

— Half the water flows through

each row. The actual water velocity in

each row is one-half the water velocity.

The water velocity correction factor

appears below the actual water velocity.

Pressure drop will be the same for each

row, so the drop per 100 (30.5 m) feet of

assembly appears below the actual

water velocity.

Table S-5 — Heating Effect Factors for Greater Than Cataloged Installed Heights

Type Enclosure 457 mm mm mm mm mm mm mm mm mm mm mm mm mm mm mm mm

Bare Element 1.15 1.14 1.13 1.12 1.11 1.10 1.09 1.08 1.07 1.06 1.05 1.04 1.03 1.02 1.01 1.00

S 1.075 1.07 1.065 1.06 1.055 1.05 1.045 1.04 1.035 1.03 1.025 1.02 1.015 1.01 1.005 1.00

F 1.15 1.14 1.3 1.12 1.11 1.10 1.09 1.08 1.07 1.06 1.05 1.04 1.03 1.02 1.01 1.00

T, TA, E 1.00 1.00 1.00 1.00 1.00 1.00 1.00 1.00 1.00 1.00 1.00 1.00 1.00 1.00 1.00 1.00

Installed height is vertical distance from floor to top of upper element for bare element; top of outlet grille for Type F enclosure; center of outlet grille for Type S enclosure; and

underside of the outlet grille for Type T, TA or E unit.

18” Or Less 483 508 533 559 584 610 635 660 686 711 737 762 813 864 914

19” 20” 21” 22” 23” 24” 25” 26” 27” 28” 29” 30” 32” 34” 36” or More

Installed Heights (Inches)

11FIN-PRC004-EN

Page 12

Selection

Procedure

Maximum Installed Lengths

Hot water systems velocity and pressure

drop are two factors that will influence

the maximum installed lengths of wall fin

hot water systems. Velocity in any pipe

size is dependent upon the capacity of

the installed wall fin and the water

temperature drop through the unit. Table

S-6 gives the maximum installed

capacity for any single wall fin unit or

loop based on *5 ft./sec (1.5 m/sec).

velocity through the tube (maximum

recommended for quiet operation) and a

20°F (-6.7°C) water temperature drop.

The maximum recommended installed

length for any element and enclosure

combination can be determined by

dividing the maximum recommended

capacity from Table S-6 by the lineal foot

capacity of the element and enclosure

combination from the capacity table.

For headered two-row element

installations (elements piped in parallel),

the maximum capacity from Table S-6 can

be doubled.

For water temperature drop other than

20°F (-6.7C), the maximum capacity may

be determined as follows:

Maximum Capacity =

Max. Cap. (Table S-6) x Actual Temp. Drop

20°F Temp. Drop

Table S-6 — Hot Water Systems, Maximum Capacity*

Tube Size 1 1/4” Steel 2” Steel 1 1/4” Copper 1” Copper 3/4” Copper

Maximum (32 mm) (51 mm) (32 mm) (25 mm) (19 mm)

Capacity

(Btu Hr.) 240,000 530,000 210,300 140,800 85,500

(Watts) 70,344 155,343 61,639 41,268 25,060

*For low pressure systems. Based on 1/4 psi (1.7kPa) pressure drop per 100 feet (30.5 m).

Wall fin elements having the smallest

tube sizes and highest velocities will give

the most efficient heat output and the

lowest pipe fitting costs. However, this

should be balanced against lower

pressure drops and perhaps a more

economical circulating pump selection

made possible with large tube sizes or

larger temperature drops.

*Tables based on 3 ft/sec. (.91 m/sec.)

velocity should not exceed 8 ft/sec

(2.4 m/sec.) due to pipe corrosion.

FIN-PRC004-EN12

Page 13

Selection

Procedure

Provisions For Expansion

Copper tube wall fin elements and

copper tubing, when installed at 40°F

(4.4°C) and operated at 200°F (93°C)

average water temperature, will expand

as much as 1/8” (3.2 mm) in each 10’ (3

m) length. Provisions must be made to

accommodate this expansion at the

heating element supports and at the

ends of the wall fin elements and piping.

Packless expansion joints and flexible

connectors are commercially available

to accommodate expansion in a

horizontal run of wall fin or at the ends

of piping. Manufacturer’s literature

should be consulted for details.

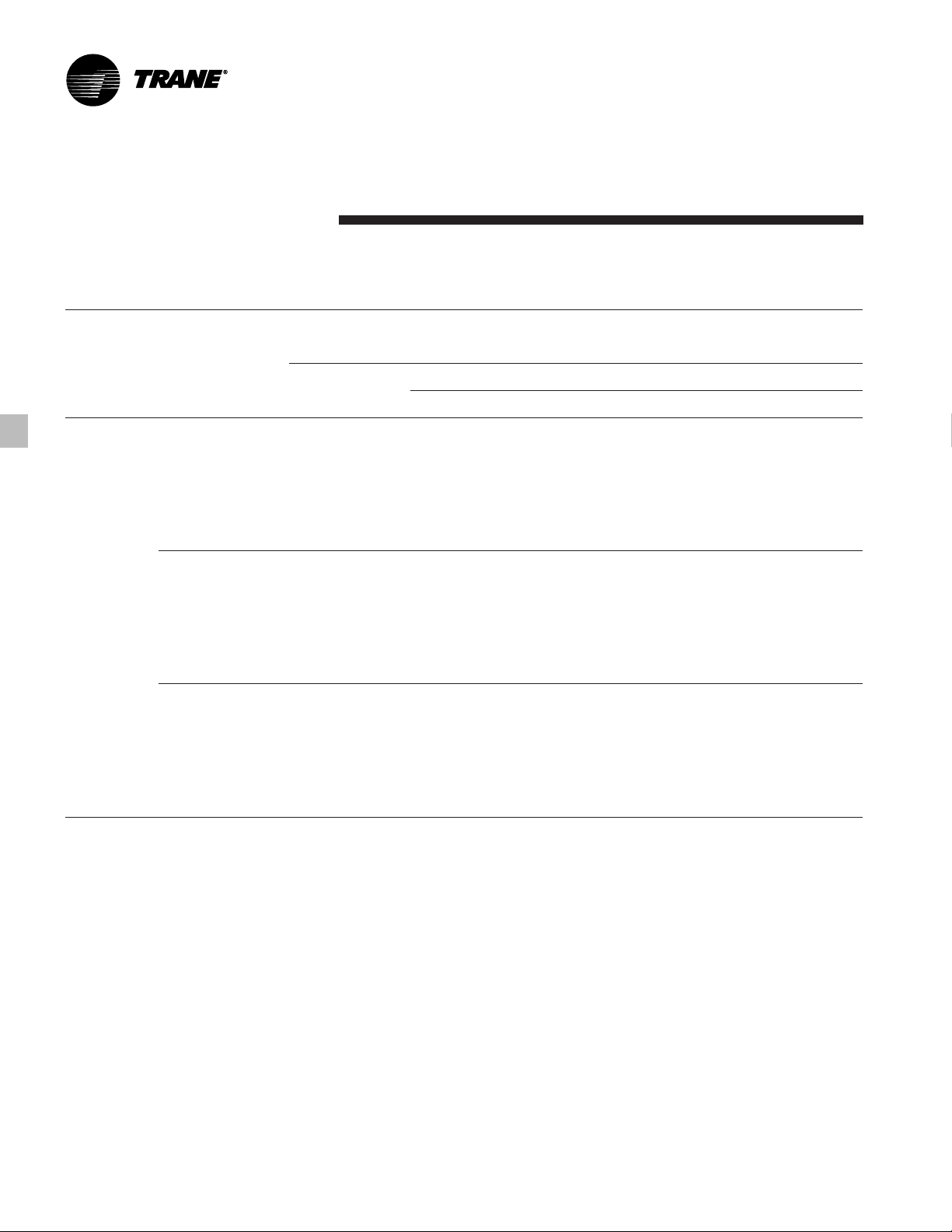

Charts S-2 and S-3 give the total amount

of expansion for various lengths of

copper or steel tube when installed at

40°F (4.4°C) and operated at different hot

water or steam temperatures.

*Based on wall fin installed at 40°F (4.4°C). For wall fin

installed at other temperatures, subtract the installation

temperature from the operating temperature to find the

actual temperature difference. Add this difference to

40°F (4.4°C). Now read in Chart S-2 or S-3 from the

temperature obtained across to installed length and

down to the amount of expansion.

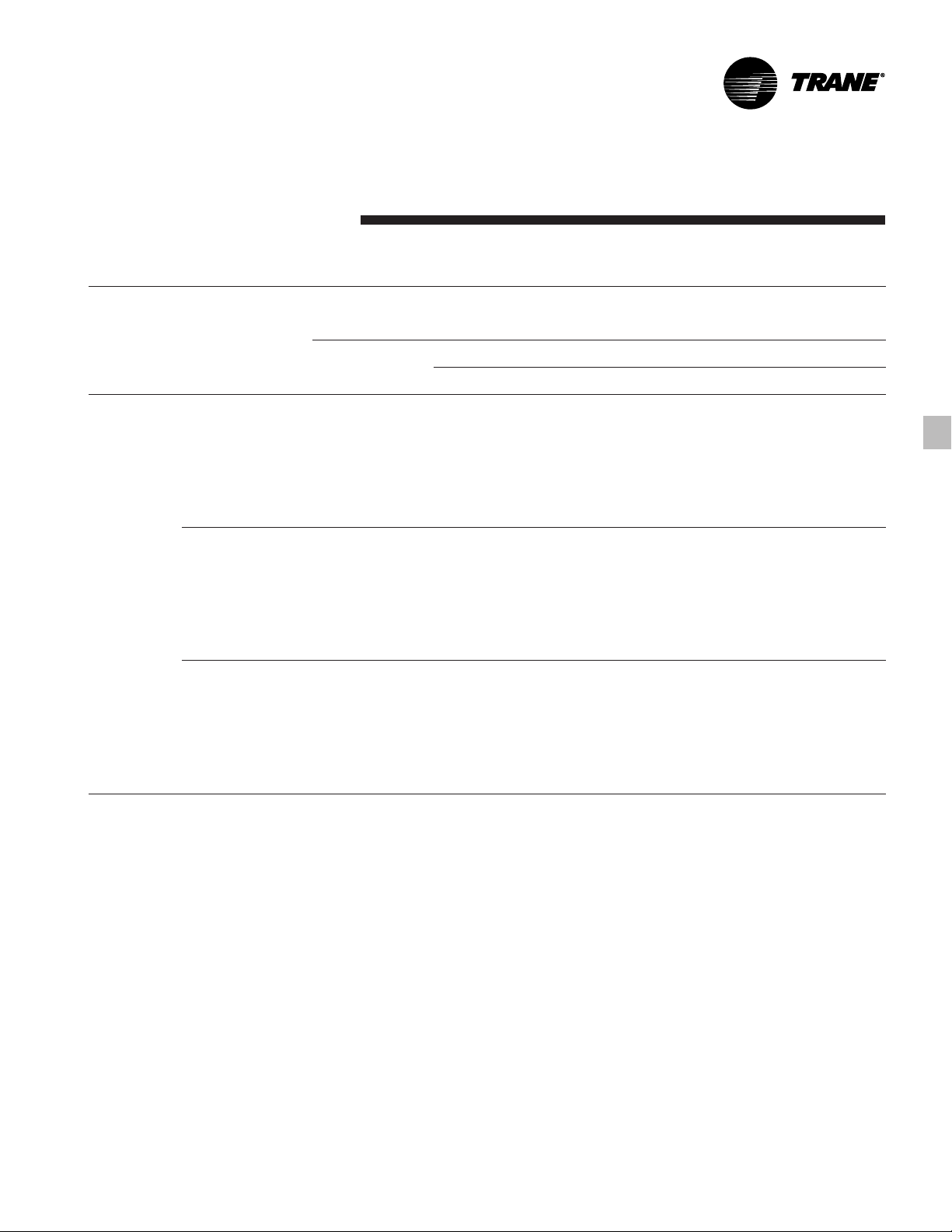

Chart S-2— Expansion in Steel Elements and Steel Pipe

OPERATING

TEMP* 5 10 15 20 2530 3540 45 5055 60

INSTALLED LENGTH (IN FEET) ENGLISH

400°F

350°F

300°F

250°F

200°F

0

OPERATING

TEMP*

204°C

177°C

149°C

121°C

93°C

1

/4

1.5 3.1 4.6 6.1 7.6 9.1 10.7 12.2 13.7 15.2 16.8 18.3

1

/2

AMOUNT OF EXPANSION (IN INCHES)

INSTALLED LENGTH (IN METERS)

3

/4 11

1

/4 1 1/2 1 3/4

SI

0 6 13 19 25 32 38 44

AMOUNT OF EXPANSION (IN MILLIMETERS)

Chart S-3 — Expansion in Copper-Aluminum Elements and Copper Tube

OPERATING

TEMP* 5 1015202530354045505560

300°F

250°F

200°F

0

1

/4

INSTALLED LENGTH (IN FEET) ENGLISH

1

/2

AMOUNT OF EXPANSION (IN INCHES)

3

/4 11

1

/4 1 1/2 1 3/4

OPERATING

TEMP*

149°C

121°C

93°C

1.5 3.1 4.6 6.1 7.6 9.1 10.7 12.2 13.7 15.2 16.8 18.3

INSTALLED LENGTH (IN METERS) SI

0 6 13 19 25 32 38 44

AMOUNT OF EXPANSION (IN MILLIMETERS)

13FIN-PRC004-EN

Page 14

Performance

Data

Bare Element Capacities

Table PD-1 — Ratings of Wall Fin Copper/Aluminum Elements Without Enclosures

Fin Series Height EDR 104°C99°C93°C88°C82°C77°C71°C66°C60°C54°C49°C43°C38°C

Element Per Meter Tiers mm Sq. M Watts/Meter 1.05 0.95 0.86 0.78 0.69 0.61 0.53 0.45 0.40 0.33 0.26 0.20 0.15

3

/4” CA 40 2** 18 8.70 2090 2195 1985 1800 1630 1440 1275 1105 940 835 690 545 420 315

19 mm 131m 457 94 2010 2110 1910 1730 1570 1380 1230 1060 904 803 664 524 404 303

Copper Tube 3** 27

Alum. Fins 699 126 2710 2850 2580 2330 2120 1870 1650 1440 1220 1090 894 707 543 404

Fins 3 1/4 “ x 3 1/4” 1†—3.93 945 990 900 810 735 650 575 500 425 380 310 245 190 140

83 x 83 mm 42 909 952 865 779 707 625 553 481 409 365 298 236 183 135

Thickness .0135” 18 1/2 512 1230 1290 1170 1060 960 850 750 650 555 490 405 320 245 185

.34 mm 216 5510 1180 1240 1120 1020 923 817 721 625 534 471 389 308 236 178

Per Foot Inches Sq. Ft. Btu/Hr./Ft. IBR Factor — Steam to Hot Water

50 2** 18 9.33 2240 2350 2130 1925 1745 1545 1365 1185 1010 895 740 580 450 335

164 m 457 100 2150 2260 2050 1850 1680 1490 1310 1140 971 861 712 558 433 322

58 2** 18 9.66 2320 2435 2205 1995 1810 1600 1415 1230 1045 930 765 605 465 350

190 m 457 104 2230 2340 2120 1920 1740 1540 1360 1180 1000 894 736 582 447 337

Install. 220°F 210°F 200°F 190°F 180°F 170°F 160°F 150°F 140°F 130°F 120°F 110°F 100°F

18 1/2 4.62 1110 1055 1165 955 865 765 680 590 500 445 365 290 220 165

2* 14 8.33 2000 2100 1900 1720 1560 1380 1220 1060 900 800 660 520 400 300

2* 14 8.70 2090 2195 1985 1795 1630 1440 1275 1110 940 835 690 545 420 315

3** 27

1†—4.35 1045 1095 990 900 815 720 635 555 470 420 345 270 210 155

18 1/2 5.41 1300 1365 1235 1120 1015 895 795 690 585 520 430 340 260 195

2* 14 8.87 2130 2235 2025 1830 1660 1470 1300 1130 960 850 705 555 425 320

3** 27

1†—4.60 1105 1160 1050 950 860 760 675 585 500 440 365 285 220 165

Steam Capacity Hot Water Capacity

Per Ft.-1 Psi at 65°F Air Btu/Hr./Ft. — At 65°F Air, Average Water Temperature

Per Meter - 6.895 kPa Watts/Meter — At 18.3°C Air, Average Water Temperature

at 18.3°C Air

216 50 1070 1010 1120 918 832 736 654 567 481 428 351 279 212 159

356 90 1920 2020 1830 1650 1500 1330 1170 1020 865 769 635 500 385 288

1

/2 11.75 2820 2960 2680 2425 2200 1945 1720 1495 1270 1130 930 735 565 420

356 94 2010 2110 1910 1730 1570 1380 1230 1070 904 803 664 524 404 303

1

/2 12.41 2980 3130 2830 2560 2325 2055 1815 1580 1340 1190 975 775 595 445

699 134 2870 3010 2720 2460 2240 1980 1740 1520 1290 1140 947 745 572 428

47 1000 1050 952 865 784 692 611 534 452 404 332 260 202 149

216 58 1250 1310 1190 1080 976 861 764 664 563 500 413 327 250 188

356 95 2050 2150 1950 1760 1600 1410 1250 1090 923 817 678 534 409 308

1

/2 12.75 3060 3215 2905 2630 2385 2110 1865 1620 1375 1225 1010 795 610 460

699 137 2940 3090 2790 2530 2290 2030 1790 1560 1320 1180 971 764 587 442

50 1060 1120 1010 914 827 731 649 563 481 423 351 274 212 159

FIN-PRC004-EN14

Page 15

Performance

Data

Table PD-1 — Ratings of Wall Fin Copper/Aluminum Elements Without Enclosures

Steam Capacity Hot Water Capacity

Per Ft.-1 Psi at 65°F Air Btu/Hr./Ft. — At 65°F Air, Average Water Temperature

Per Meter - 6.895 kPa Watts/Meter — At 18.3°C Air, Average Water Temperature

Fin Series Height EDR 104°C99°C93°C88°C82°C77°C71°C66°C60°C54°C49°C43°C38°C

Element Per Meter Tiers mm Sq. M Watts/Meter 1.05 0.95 0.86 0.78 0.69 0.61 0.53 0.45 0.40 0.33 0.26 0.20 0.15

1” CA 40 2** 18 8.70 2090 2195 1985 1800 1630 1440 1275 1105 940 835 690 545 420 315

25 mm 131m 457 94 2010 2110 1910 1730 1570 1380 1230 1060 904 803 664 524 404 303

Copper Tube 3** 27

Alum. Fins 699 126 2710 2850 2580 2330 2120 1870 1650 1440 1220 1090 894 707 543 404

1

Fins 3

/4” x 3 1/4” 1†—3.93 945 990 900 810 735 650 575 500 425 380 310 245 190 140

83 x 83 mm 42 909 952 865 779 707 625 553 481 409 365 298 236 183 135

Thickness .0135” 18 1/2 5.08 1220 1280 1160 1050 950 840 745 645 550 490 400 315 245 185

.34 mm 216 55 1170 1230 1120 1010 914 808 716 620 529 471 385 303 236 178

*5 1/2” (140 mm) Centers

1

**9

/2” (241 mm) Centers

† At Ceiling

Dimensions in bold indicate metric units.

Per Foot Inches Sq. Ft. Btu/Hr./Ft. IBR Factor — Steam to Hot Water

50 2** 18 9.25 2220 2330 2110 1910 1730 1530 1355 1175 1000 890 730 575 445 330

164 m 457 100 2140 2240 2030 1840 1660 1470 1300 1130 962 856 702 553 428 317

58 2** 18 9.50 2280 2395 2165 1960 1780 1575 1390 1210 1025 910 750 590 455 340

190 m 457 102 2190 2300 2080 1880 1710 1520 1340 1160 986 875 721 567 438 327

Install. 220°F 210°F 200°F 190°F 180°F 170°F 160°F 150°F 140°F 130°F 120°F 110°F 100°F

18 1/2 4.62 1110 1165 1055 955 865 765 680 590 500 445 365 290 220 165

216 50 1070 1120 10101 918 832 736 654 567 481 428 351 279 212 159

2* 14 8.33 2000 2100 1900 1720 1560 1380 1220 1060 900 800 660 520 400 300

356 90 1920 2020 1830 1650 1500 1330 1170 1020 865 769 635 500 385 288

2* 14 8.58 2060 2165 1955 1770 1605 1420 1255 1090 925 825 680 535 410 310

356 92 1980 2080 1880 1700 1540 1360 1210 1050 889 793 654 514 394 298

3** 27

699 132 2840 2980 2690 2440 2210 1960 1730 1500 1270 1140 938 736 567 423

1†—4.33 1040 1090 990 895 810 715 635 550 470 415 340 270 210 155

18 1/2 5.33 1280 1345 1215 1100 1000 885 780 680 575 510 420 330 255 190

216 57 1230 1290 1170 1060 962 851 750 654 553 490 404 317 245 183

2* 14 8.75 2100 2205 1995 1805 1640 1450 1280 1115 945 840 695 545 420 315

356 94 2020 2120 1920 1740 1580 1390 1230 1070 909 808 668 524 404 303

3** 27

699 135 2890 3040 2750 2490 2260 2000 1760 1530 1300 1160 957 750 577 433

1†—4.54 1090 1145 1035 935 850 750 665 575 490 435 360 285 220 160

at 18.3C Air

1

/2 11.75 2820 2960 2680 2425 2200 1945 1720 1495 1270 1130 930 735 565 420

1

/2 12.29 2950 3095 2800 2535 2300 2035 1800 1565 1325 1180 975 765 590 440

47 1000 1050 952 861 779 688 611 529 452 399 327 260 202 149

1

/2 12.54 3010 3160 2860 2590 2350 2075 1835 1595 1355 1205 995 780 600 450

49 1050 1100 995 899 817 721 639 553 471 418 346 274 212 154

15FIN-PRC004-EN

Page 16

Performance

Data

Table PD-2 — Ratings of Wall Fin Copper/Aluminum Elements Without Enclosures

Steam Capacity Hot Water Capacity

Per Ft.-1 Psi at 65°F Air Btu/Hr./Ft. — At 65°F Air, Average Water Temperature

Per Meter - 6.895 kPa Watts/Meter — At 18.3°C Air, Average Water Temperature

Fin Series Height EDR 104°C99°C93°C88°C82°C77°C71°C66°C60°C54°C49°C43°C38°C

Element Per Meter Tiers mm Sq. M Watts/Meter 1.05 0.95 0.86 0.78 0.69 0.61 0.53 0.45 0.40 0.33 0.26 0.20 0.15

1

/4” CA 40 2** 18 8.75 2100 2205 1995 1805 1640 1450 1280 1115 945 840 695 545 420 315

1

32 mm 131 m 457 94 2020 2120 1920 1740 1580 1390 1230 1070 909 808 668 524 404 303

Copper Tube 3** 27

Alum. Fins 699 126 2710 2850 2580 2330 2120 1870 1650 1440 1220 1090 894 707 543 409

1

Fins 3

/4” x 3 1/4” 1†—3.95 950 1000 900 815 740 655 580 505 430 380 315 245 190 140

83 x 83 mm 43 914 962 865 784 712 630 558 486 413 365 303 236 183 135

Thickness .0135” 18 1/2 5.08 1220 1280 1160 1050 950 840 745 650 550 490 400 315 245 185

.34 mm 216 55 1170 1230 1120 1010 914 808 716 625 529 471 385 303 236 178

Per Foot Inches Sq. Ft. Btu/Hr./Ft. IBR Factor — Steam to Hot Water

50 2** 18 9.16 2200 2310 2090 1890 1715 1520 1340 1165 990 880 725 570 440 330

164 m 457 99 2120 2220 2010 1820 1650 1460 1290 1120 952 846 697 548 423 317

58 2* 14 8.58 2060 2165 1955 1770 1605 1420 1255 1090 925 825 680 535 410 310

190 m 356 92 1980 2080 1880 1700 1540 1360 1210 1050 889 793 654 514 394 298

Install. 220°F 210°F 200°F 190°F 180°F 170°F 160°F 150°F 140°F 130°F 120°F 110°F 100°F

18 1/2 4.66 1120 1175 1065 965 875 770 685 595 505 450 370 290 225 170

216 50 1080 1130 1020 928 841 740 659 572 486 433 356 279 216 163

2* 14 8.37 2010 2110 1910 1730 1565 1385 1225 1065 905 805 665 520 440 300

356 90 1930 2030 1840 1660 1500 1330 1180 1020 870 774 639 500 385 288

2* 14 8.50 2040 2140 1940 1755 1590 1405 1245 1080 920 815 675 530 410 305

356 91 1960 2060 1870 1690 1530 1350 1200 1040 885 784 649 510 394 293

3** 27

699 130 2800 2940 2660 2400 2180 1930 1710 1480 1260 1120 923 726 558 418

1†—4.33 1040 1090 990 895 810 720 635 550 470 415 345 270 210 155

18 1/2 5.29 1270 1335 1205 1090 990 875 775 675 570 510 420 330 255 190

216 57 1220 1280 1160 1050 952 841 745 649 548 490 404 317 245 183

2** 18 9.37 2250 2360 2140 1935 1755 1550 1370 1190 1010 900 740 585 450 335

457 101 2160 2270 2060 1860 1690 1490 1320 1140 971 865 712 563 433 322

3** 27

699 133 2850 2990 2700 2450 2220 1960 1740 1510 1280 1140 938 740 567 428

1†—4.50 1080 1135 1025 930 840 745 660 570 485 430 355 280 215 160

at 18.3C Air

1

/2 11.75 2820 2960 2680 2425 2200 1945 1720 1495 1270 1130 930 735 565 425

1

/2 12.12 2910 3055 2765 2500 2270 2010 1775 1540 1310 1165 960 755 580 435

47 1000 1050 950 860 780 690 610 530 450 400 330 260 200 150

1

/2 12.33 2960 3105 2810 2545 2310 2040 1805 1570 1330 1185 975 770 590 445

48 1040 1090 986 894 808 716 635 548 466 413 341 269 207 154

FIN-PRC004-EN16

Page 17

Performance

Data

Table PD-2 — Ratings of Wall Fin Copper/Aluminum Elements Without Enclosures

Steam Capacity Hot Water Capacity

Per Ft.-1 Psi at 65°F Air Btu/Hr./Ft. — At 65°F Air, Average Water Temperature

Per Meter - 6.895 kPa Watts/Meter — At 18.3°C Air, Average Water Temperature

Fin Series Height EDR 104°C99°C93°C88°C82°C77°C71°C66°C60°C54°C49°C43°C38°C

Element Per Meter Tiers mm Sq. M Watts/Meter 1.05 0.95 0.86 0.78 0.69 0.61 0.53 0.45 0.40 0.33 0.26 0.20 0.15

1

/4” CA 40 2** 18 12.16 2920 3065 2775 2510 2275 2015 1780 1545 1315 1170 965 760 585 440

1

32 mm 131 m 457 131 2810 2950 2670 2410 2190 1940 1710 1490 1260 1120 928 731 563 423

Copper Tube 3** 27

Alum. Fins 699 177 3790 3980 3600 3260 2960 2620 2310 2010 1710 1520 1250 986 760 567

1

Fins 3

/4” x 5 1/4” 1†—5.52 1325 1390 1260 1140 1035 915 810 700 595 530 435 345 265 200

83 x 133 mm 59 1270 1340 1210 1100 995 880 779 673 572 510 418 332 255 192

Thickness .0135” 18 1/2 7.33 1760 1850 1670 1515 1370 1215 1075 930 790 705 580 460 350 265

.34 mm 216 79 1690 1780 1610 1460 1320 1170 1030 894 760 678 558 442 337 255

*5 1/2” (140 mm) Centers

1

**9

/2” (241 mm) Centers

† At Ceiling

Dimensions in bold indicate metric units.

Per Foot Inches Sq. Ft. Btu/Hr./Ft. IBR Factor — Steam to Hot Water

50 2** 18 12.87 3090 3245 2935 2655 2410 2130 1885 1635 1390 1235 1020 805 620 465

164 m 457 139 2970 3120 2820 2550 2320 2050 1810 1570 1340 1190 981 774 596 447

58 2** 18 13.20 3170 3330 3010 2725 2470 2185 1935 1680 1425 1270 1045 825 635 475

190 m 457 142 3050 3200 2890 2620 2380 2100 1860 1620 1370 1220 1000 793 611 457

Install. 220°F 210°F 200°F 190°F 180°F 170°F 160°F 150°F 140°F 130°F 120°F 110°F 100°F

18 1/2 6.50 1560 1640 1480 1340 1215 1075 950 825 700 625 515 405 310 235

216 70 1500 1580 1420 1290 1170 1030 914 793 673 601 495 389 298 226

2* 14 11.66 2800 2940 2660 2410 2185 1930 1710 1485 1260 1120 925 730 560 420

356 126 2690 2830 2560 2320 2100 1860 1640 1430 1210 1080 889 702 538 404

2* 14 12.08 2900 3045 2755 2495 2260 2000 1770 1535 1305 1160 955 755 580 435

356 130 2790 2930 2650 2400 2170 1920 1700 1480 1260 1120 918 726 558 418

3** 27

699 182 3890 4090 3700 3350 3040 2690 2380 2060 1750 1560 1280 1010 779 587

1†—6.23 1495 1570 1420 1285 1165 1030 910 790 670 600 495 390 300 225

18 1/4 7.75 1860 1955 1765 1600 1450 1285 1135 985 835 745 615 485 370 280

210 83 1790 1880 1700 1540 1390 1240 1090 947 803 716 591 466 356 269

2* 14 12.33 2960 3110 2810 2545 2310 2040 1805 1570 1330 1185 975 770 590 445

356 133 2850 2990 2700 2450 2220 1960 1740 1510 1280 1140 938 740 567 428

3** 27

699 184 3950 4150 3760 3400 3080 2730 2410 2100 1780 1580 1300 1030 789 591

1†—6.58 1580 1660 1500 1360 1230 1090 965 840 710 630 520 410 315 240

at 18.3C Air

1

/2 16.41 3940 4135 3745 3390 3075 2720 2405 2090 1775 1575 1300 1025 790 590

1

/2 16.87 4050 4250 3850 3485 3160 2795 2470 2145 1820 1620 1335 1055 810 610

67 1440 1510 1360 1240 1120 990 875 760 644 577 476 375 288 216

1

/2 17.12 4110 4315 3905 3535 3205 2835 2505 2180 1850 1645 1355 1070 820 615

71 1520 1600 1440 1310 1180 1050 928 808 683 606 500 394 303 231

17FIN-PRC004-EN

Page 18

Performance

Data

Table PD-3 — Ratings of Wall Fin Steel Elements Without Enclosures

Steam Capacity Hot Water Capacity

Per Ft.-1 Psi at 65°F Air Btu/Hr./Ft. — At 65°F Air, Average Water Temperature

Per Meter - 6.895 kPa Watts/Meter — At 18.3°C Air, Average Water Temperature

Fin Series Height EDR 104°C99°C93°C88°C82°C77°C71°C66°C60°C54°C49°C43°C38°C

Element Per Meter Tiers mm Sq. M Watts/Meter 1.05 0.95 0.86 0.78 0.69 0.61 0.53 0.45 0.40 0.33 0.26 0.20 0.15

1

1

/4” Steel 229 64 1380 1440 1310 1180 1080 952 837 731 615 548 452 356 274 207

32 mm 2* 13 8.60 2060 2160 1960 1770 1610 1420 1260 1090 925 825 680 535 410 310

Steel Tube 330 93 1980 2080 1880 1700 1550 1360 1210 1050 889 793 654 514 394 298

Steel Fins 52 2** 17 9.90 2370 2490 2250 2040 1850 1640 1450 1255 1065 945 780 615 475 355

1

/2” x 5 1/4” 171m 432 107 2280 2390 2160 1960 1780 1580 1390 1210 1020 909 750 591 457 341

Fins 2

64 x 133 mm 3** 23 13.25 3180 3340 3020 2730 2480 2190 1940 1685 1430 1270 1050 825 635 475

Thickness .027” 584 143 3060 3210 2900 2620 2380 2110 1870 1620 1380 1220 1010 793 611 457

.69 mm 1†—5.00 1200 1260 1140 1030 940 830 730 635 540 480 395 310 240 180

*4” (102 mm) Centers

** 8” (203 mm) Centers

† At Ceiling

Dimensions in bold indicate metric units.

Per Foot Inches Sq. Ft. Btu/Hr./Ft. IBR Factor — Steam to Hot Water

Install. 220°F 210°F 200°F 190°F 180°F 170°F 160°F 150°F 140°F 130°F 120°F 110°F 100°F

1 9 5.95 1430 1500 1360 1230 1120 990 870 760 640 570 470 370 285 215

at 18.3°C Air

54 1150 1210 1100 990 904 798 702 611 519 462 380 298 231 173

Metric Conversions

1 Psi = 6.895 kPa (Kilo Pascals) at 65°F Air = 18.3°C Air

Sq. Ft. EDR at 1 Psi (6.895 kPa) at 65°F Air (18.3°C) Air x 240 BTU = Total BTU’s (Watts)

1 BTU/HR. = 0.2931 Watts

1 Foot = 0.3048 Meters - 1 Meter = 3.2808 Feet

1 BTU/HR/FT = 0.9616 Watts/Meter

10.7639 Sq. Feet = 1 Square Meter

1 Lbs = 0.4536 Kg (Kilograms)

1 Inch = 25.4 mm (Millimeters)

Note:

All shown capacities based on finned length at a water velocity of three feet per second or 0.9144 meter per second or greater.

FIN-PRC004-EN18

Page 19

Performance

Sloping

Data

Top

Table PD-4 — Ratings 4” (102 mm) Deep, Type S - Enclosure With Copper/Aluminum Elements

Steam Capacity Hot Water Capacity

Per Ft.-1 Psi at 65°F Air Btu/Hr./Ft. — At 65°F Air, Average Water Temperature

Per Meter - 6.895 kPa Watts/Meter — At 18.3°C Air, Average Water Temperature

Fin Series Height EDR 104°C99°C93°C88°C82°C77°C71°C66°C60°C54°C49°C43°C38°C

Element Per Meter Tiers Encl. mm Sq. M Watts/Meter 1.05 0.95 0.86 0.78 0.69 0.61 0.53 0.45 0.40 0.33 0.26 0.20 0.15

3

/4” CA 40 2* 14S 16 1/8 7.04 1690 1775 1605 1455 1320 1165 1030 895 760 675 555 440 340 255

19 mm 131 m 410 76 1620 1710 1540 1400 1270 1120 990 861 731 649 534 423 327 245

Copper Tube 18S 20 1/8 7.62 1830 1920 1740 1575 1425 1260 1115 970 825 730 605 475 365 275

Alum. Fins 511 82 1760 1850 1670 1520 1370 1210 1070 933 793 702 582 457 351 264

1

Fins 3

/4” x 3 1/4” 2** 24S 26 1/8 8.04 1930 2025 1835 1660 1505 1330 1175 1025 870 770 635 500 385 290

83 x 83 mm 664 87 1860 1950 1760 1600 1450 1280 1130 986 837 740 611 481 370 279

Thickness .0135” 10S 12 1/8 5.16 1240 1300 1180 1065 965 855 755 655 560 495 410 320 250 185

.34 mm 308 56 1190 1250 1140 1020 928 822 726 630 538 476 394 308 240 178

*5 1/2” (140 mm) Centers

1

**9

/2” (241 mm) Centers

24” (610 mm) High ratings not IBR approved.

Dimensions in bold indicate metric units.

Per Foot Inches Sq. Ft. Btu/Hr./Ft. IBR Factor — Steam to Hot Water

1 18S 20 1/8 4.70 1130 1185 1075` 970 880 780 690 600 510 450 370 295 225 170

1 18S 20

50 2* 14S 16 1/8 7.33 1760 1850 1670 1515 1370 1215 1075 930 790 705 580 460 350 265

164 m 410 79 1690 1780 1610 1460 1320 1170 1030 894 760 678 558 442 337 255

2** 24S 26

1 18S 20 1/8 6.58 1580 1660 1500 1360 1230 1090 965 835 710 630 520 410 315 235

58 2* 14S 16 1/8 7.45 1790 1880 1700 1540 1395 1235 1090 950 805 715 590 465 360 270

190 m 410 80 1720 1810 1640 1480 1340 1190 1050 914 774 688 567 447 346 260

2** 24S 26 1/8 9.58 2300 2415 2185 1980 1795 1585 1405 1220 1035 920 760 600 460 345

Install. 220°F 210°F 200°F 190°F 180°F 170°F 160°F 150°F140°F130°F 120°F 110°F 100°F

10S 12 1/8 4.45 10.70 1125 1015 920 835 740 650 565 480 430 355 280 215 160

308 48 1030 1080 976 885 803 712 625 543 462 413 341 269 207 154

14S 16 1/8 4.62 1110 1165 1055 955 865 765 675 590 500 445 365 290 220 165

410 50 1070 1120 1010 918 832 736 649 567 481 428 351 279 212 159

511 51 1090 1140 1030 933 846 750 664 577 490 433 356 284 216 163

24S 26

664 52 1120 1180 1070 966 875 774 688 596 505 452 370 293 226 168

14S 16

410 60 1290 1350 1230 1110 1000 889 784 683 582 514 423 337 260 192

511 64 1380 1440 1310 1180 1070 947 837 731 620 548 452 356 274 207

24S 26

664 68 1450 1520 1380 1250 1140 1000 885 769 654 582 481 375 288 216

18S 20 1/8 8.33 2000 2100 1900 1720 1560 1380 1220 1060 900 800 660 520 400 300

511 90 1920 2020 1830 1650 1500 1330 1170 1020 865 769 635 500 385 288

664 96 2070 2170 1960 1780 1610 1430 1260 1100 928 827 683 538 413 308

10S 12 1/8 5.54 1330 1395 1265 1145 1035 920 810 705 600 530 440 345 265 200

308 60 1280 1340 1220 1100 995 885 779 678 577 510 423 332 255 192

14S 16

410 65 1400 1480 1330 1210 1100 966 856 702 630 563 462 365 279 212

511 71 1520 1600 1440 1310 1180 1050 928 803 683 606 500 394 303 226

24S 26

664 76 1640 1720 1550 1400 1270 1130 995 865 736 654 538 423 327 245

18S 20 1/8 8.70 2090 2195 1985 1795 1630 1440 1275 1105 904 835 690 545 420 315

511 94 2010 2110 1910 1730 1570 1380 1230 1060 869 803 664 524 404 303

664 103 2210 2320 2100 1900 1730 1520 1350 1170 995 885 731 577 442 332

at 18.3°C Air

1

/8 4.87 1170 1230 1110 1005 910 805 715 620 525 470 385 305 235 175

1

/8 5.58 1340 1405 1275 1150 1045 925 815 710 605 535 440 350 270 200

1

/8 5.95 1430 1500 1360 1230 1115 985 870 760 645 570 470 370 285 215

1

/8 6.29 1510 1585 1435 1300 1180 1040 920 800 680 605 500 390 300 225

1

/8 8.95 2150 2260 2040 1850 1675 1485 1310 1140 965 860 710 560 430 320

1

/8 6.08 1460 1535 1385 1255 1140 1005 890 730 655 585 480 380 290 220

1

/8 7.08 1700 1785 1615 1460 1325 1175 1035 900 765 680 560 440 340 255

NOTE: Rating is Btu/hr/ft (Watts/meter) of finned length (for element dimensions see page 49). Hot water ratings determined by applying correction factor to steam ratings, are for

water velocities of 3 ft/sec (.91 m/s) or greater. See page 9, Chart S-1 for correction factors for water velocities other than 3 ft/sec (.91 m/s). For definition of installed height and heating

effect factors, see page 11. For heating ratings at other steam pressures and/or entering air temperatures, see page 10, Table S-2.

19FIN-PRC004-EN

Page 20

Performance

Sloping

Data

Top

Table PD-5 — Ratings 4” (102 mm) Deep, Type S - Enclosure With Copper/Aluminum Elements

Steam Capacity Hot Water Capacity

Per Ft.-1 Psi at 65°F Air Btu/Hr./Ft. — At 65°F Air, Average Water Temperature

Per Meter - 6.895 kPa Watts/Meter — At 18.3°C Air, Average Water Temperature

Fin Series Height EDR 104°C99°C93°C88°C82°C77°C71°C66°C60°C54°C49°C43°C38°C

Element Per Meter Tiers Encl. mm Sq. M Watts/Meter 1.05 0.95 0.86 0.78 0.69 0.61 0.53 0.45 0.40 0.33 0.26 0.20 0.15

1” CA 40 2* 14S 16 1/8 7.04 1690 1775 1605 1455 1320 1165 1030 895 760 675 560 440 340 255

25 mm 131 m 410 76 1620 1710 1540 1400 1270 1120 990 861 731 649 538 423 327 245

Copper Tube 18S 20 1/8 7.62 1830 1920 1740 1575 1425 1260 1115 970 825 730 605 475 365 275

Alum. Fins 511 82 1760 1850 1670 1520 1370 1210 1070 933 793 702 582 457 351 264

1

Fins 3

/4” x 3 1/4” 2** 24S 26 1/8 8.04 1930 2025 1835 1660 1505 1330 1175 1020 870 770 635 500 385 290

83 x 83 mm 664 87 1860 1950 1760 1600 1450 1280 1130 981 837 740 611 481 370 279

Thickness .0135” 10S 12 1/8 5.16 1240 1300 1180 1065 965 855 755 655 560 495 410 320 250 185

.34 mm 308 56 1190 1250 1140 1020 928 822 726 630 538 476 394 308 240 178

*5 1/2” (140 mm) Centers

1

**9

/2” (241 mm) Centers

24” (610 mm) High ratings not IBR approved.

Dimensions in bold indicate metric units.

Per Foot Inches Sq. Ft. Btu/Hr./Ft. IBR Factor — Steam to Hot Water

1 18S 20

1 18S 20

50 2* 14S 16 1/8 7.16 1720 1805 1635 1480 1340 1185 1050 910 775 690 570 445 345 260

164 m 410 77 1650 1740 1570 1420 1290 1140 1010 875 745 664 548 428 332 250

2** 24S 26

1 18S 20

58 2* 14S 16 1/8 7.21 1730 1815 1645 1490 1350 1195 1055 915 780 690 570 450 345 260

190 m 410 78 1660 1740 1580 1430 1300 1150 1010 880 750 664 548 433 332 250

2** 24S 26

Install. 220°F 210°F 200°F 190°F 180°F 170°F 160°F 150°F140°F130°F 120°F 110°F 100°F

10S 12 1/8 4.50 1080 1135 1025 930 842 745 660 570 485 430 355 280 215 160

308 48 1040 1090 986 894 810 716 635 548 466 413 341 269 207 154

14S 16

24S 26

14S 16 1/8 5.62 1350 1420 1280 1160 1055 930 825 715 610 540 445 350 270 200

24S 26 1/8 6.33 1520 1595 1445 1305 1185 1050 925 805 685 610 500 395 305 230

18S 20 1/8 8.16 1960 2060 1860 1685 1530 1350 1195 1040 880 785 645 510 390 295

10S 12 1/8 5.50 1320 1385 1255 1135 1030 910 805 700 595 530 435 345 265 200

14S 16

24S 26

18S 20 1/8 8.45 2030 2130 1930 1745 1585 1400 1240 1075 915 810 670 530 405 305

1

410 50 1080 1130 1020 928 841 740 659 572 486 433 356 279 216 163

1

511 52 1110 1160 1050 952 861 764 673 587 500 442 365 288 221 168

1

664 53 1140 1200 1090 986 894 789 697 606 514 457 375 298 231 173

410 60 1300 1360 1230 1120 1010 894 793 688 587 519 428 337 260 192

1

511 65 1380 1450 1320 1190 1080 957 846 736 625 553 457 361 279 207

664 68 1460 1530 1390 1260 1140 1010 889 774 659 587 481 380 293 221

511 88 1880 1980 1790 1620 1470 1300 1150 1000 846 755 620 490 375 284

1

664 94 2020 2120 1920 1740 1580 1390 1240 1070 909 808 668 524 404 303

308 59 1270 1330 1210 1090 990 875 774 673 572 510 418 332 255 192

1

410 66 1410 1490 1340 1220 1100 976 861 750 635 567 466 365 284 212

1

511 72 1540 1620 1460 1320 1200 1060 938 817 692 615 510 399 308 231

1

664 77 1650 1740 1570 1420 1290 1140 1010 875 745 664 543 428 332 250

511 91 1950 2050 1860 1680 1520 1350 1190 1030 880 779 644 510 389 293

1

664 100 2150 2260 2040 1850 1680 1480 1310 1140 966 861 712 558 428 322

at 18.3°C Air

/8 4.66 1120 1175 1065 965 875 770 685 595 505 450 370 290 225 170

/8 4.79 1150 1210 1090 990 895 795 700 610 520 460 380 300 230 175

/8 4.96 1190 1250 1130 1025 930 820 725 630 535 475 390 310 240 180

/8 6.00 1440 1510 1370 1240 1125 995 880 765 650 575 475 375 290 215

/8 8.77 2105 2210 2000 1810 1640 1450 1285 1115 945 840 695 545 420 315

/8 6.12 1470 1545 1395 1265 1145 1015 895 780 660 590 485 380 295 220

/8 6.66 1600 1680 1520 1375 1250 1105 975 850 720 640 530 415 320 240

/8 7.16 1720 1805 1635 1480 1340 1185 1050 910 775 690 565 445 345 260

/8 9.31 2235 2345 2125 1920 1745 1540 1365 1185 1005 895 740 580 445 335

FIN-PRC004-EN20

Page 21

Performance

Sloping

Data

Top

Table PD-6 — Ratings 4” (102 mm) Deep, Type S - Enclosure With Copper/Aluminum Elements

Steam Capacity Hot Water Capacity

Per Ft.-1 Psi at 65°F Air Btu/Hr./Ft. — At 65°F Air, Average Water Temperature

Per Meter - 6.895 kPa Watts/Meter — At 18.3°C Air, Average Water Temperature

Fin Series Height EDR 104°C99°C93°C88°C82°C77°C71°C66°C60°C54°C49°C43°C38°C

Element Per Meter Tiers Encl. mm Sq. M Watts/Meter 1.05 0.95 0.86 0.78 0.69 0.61 0.53 0.45 0.40 0.33 0.26 0.20 0.15

1 1/4” CA 40 2* 14S 16 1/8 7.04 1690 1775 1605 1455 1320 1165 970 895 760 675 560 430 340 255

32 mm 131 m 410 76 1620 1710 1540 1400 1270 1120 990 861 731 649 538 413 327 245

Copper Tube 18S 20 1/8 7.58 1820 1910 1730 1565 1420 1255 1110 965 820 730 600 475 365 275

Alum. Fins 511 82 1750 1840 1660 1500 1360 1210 1070 928 789 702 577 457 351 264

Fins 3 1/4” x 3 1/4” 2** 24S 26 1/8 8.00 1920 2015 1825 1650 1500 1325 1170 1020 865 770 635 500 385 290

83 x 83 mm 664 86 1850 1940 1760 1590 1440 1270 1120 981 832 740 611 481 370 279

Thickness .0135” 10S 12 1/8 5.12 1230 1290 1170 1060 960 850 750 650 555 490 405 320 245 185

.34 mm 308 55 1180 1240 1120 1020 923 817 721 625 534 471 389 308 236 178

*5 1/2” (140 mm) Centers

1

**9

/2” (241 mm) Centers

24” (610 mm) High ratings not IBR approved.

Dimensions in bold indicate metric units.

Per Foot Inches Sq. Ft. Btu/Hr./Ft. IBR Factor — Steam to Hot Water

1 18S 20

1 18S 20

50 2* 14S 16 1/8 7.00 1680 1765 1595 1445 1310 1160 990 890 755 670 555 435 335 250

164 m 410 75 1620 1700 1530 1390 1260 1120 986 857 726 644 534 418 322 240

2** 24S 26

1 18S 20

58 2* 14S 16 1/8 7.00 1680 1765 1595 1445 1310 1160 995 890 755 670 555 435 335 250

190 mm 410 75 1620 1700 1530 1390 1260 1120 986 856 726 644 534 418 322 240

2** 24S 26

Install. 220°F 210°F 200°F 190°F 180°F 170°F 160°F 150°F140°F130°F 120°F 110°F 100°F

10S 12 1/8 4.54 1090 1145 1035 935 850 750 665 580 490 435 360 285 220 160

308 49 1050 1100 995 899 817 721 639 558 471 418 346 274 212 154

14S 16 1/8 4.75 1140 1195 1085 980 890 785 695 605 515 455 375 295 230 170

410 51 1100 1150 1040 942 856 755 668 582 495 438 361 284 221 163

511 52 1120 1180 1070 966 875 774 688 596 505 452 370 293 226 168

24S 26

664 54 1160 1220 1110 1000 909 803 712 615 524 466 385 303 231 173

14S 16

410 61 1310 1380 1240 1120 1020 904 798 692 587 524 433 341 260 197

511 65 1400 1480 1330 1210 1100 966 856 745 630 563 462 365 279 212

24S 26

664 69 1480 1550 1410 1270 1150 1020 904 784 668 591 490 385 298 221

18S 20 1/8 8.00 1920 2015 1825 1650 1500 1325 1170 1020 865 770 635 500 385 290

511 86 1850 1940 1760 1590 1440 1270 1120 981 832 740 611 481 370 279

664 93 1990 2090 1880 1710 1550 1370 1210 1050 894 793 654 514 399 298

10S 12 1/8 5.45 1310 1375 1245 1125 1020 905 800 695 590 525 430 340 260 195

308 59 1260 1320 1200 1080 981 870 769 668 567 505 413 327 250 188

14S 16

410 66 1410 1490 1340 1220 1100 976 861 750 635 567 466 365 284 212

511 73 1560 1640 1480 1340 1220 1080 952 827 702 625 514 404 313 231

24S 26

664 78 1670 1760 1590 1440 1300 1150 1020 885 750 668 553 433 337 250

18S 20 1/8 8.16 1960 2060 1860 1685 1530 1350 1195 1040 880 785 645 510 390 295

511 88 1880 1980 1790 1620 1470 1300 1150 1000 846 755 620 490 375 284

664 97 2070 2170 1970 1780 1620 1430 1260 1100 933 827 683 538 413 313

at 18.3°C Air

1

/8 4.87 1170 1230 1110 1005 910 805 715 620 525 470 385 305 235 175

1

/8 5.04 1210 1270 1150 1040 945 835 740 640 545 485 400 315 240 180

1

/8 5.66 1360 1430 1290 1170 1060 940 830 720 610 545 450 355 270 205

1

/8 6.08 1460 1535 1385 1255 1140 1005 890 775 655 585 480 380 290 220

1

/8 6.41 1540 1615 1465 1325 1200 1060 940 815 695 615 510 400 310 230

1

/8 8.60 2065 2170 1960 1775 1610 1425 1260 1095 930 825 680 535 415 310

1

/8 6.12 1470 1545 1395 1265 1145 1015 895 780 660 590 485 380 295 220

1

/8 6.75 1620 1700 1540 1395 1265 1120 990 860 730 650 535 420 325 240

1

/8 7.25 1740 1825 1655 1495 1355 1200 1060 920 780 695 575 450 350 260

1

/8 8.98 2155 2260 2045 1855 1680 1485 1315 1140 970 860 710 560 430 325

21FIN-PRC004-EN

Page 22

Performance

Sloping

Data

Top

Table PD-7 — Ratings 6” (152 mm) Deep, Type S - Enclosure With Copper/Aluminum Elements

Steam Capacity Hot Water Capacity

Per Ft.-1 Psi at 65°F Air Btu/Hr./Ft. — At 65°F Air, Average Water Temperature

Per Meter - 6.895 kPa Watts/Meter — At 18.3°C Air, Average Water Temperature

Fin Series Height EDR 104°C99°C93°C88°C82°C77°C71°C66°C60°C54°C49°C43°C38°C

Element Per Meter Tiers Encl. mm Sq. M Watts/Meter 1.05 0.95 0.86 0.78 0.69 0.61 0.53 0.45 0.40 0.33 0.26 0.20 0.15

1 1/4” CA 40 2* 16S 17 1/4 10.70 2570 2695 2440 2210 2005 1775 1570 1360 1155 1030 850 670 515 385

32 mm 131 m 438 115 2470 2590 2350 2120 1930 1710 1510 1310 1110 990 817 644 495 370

Copper Tube 20S 21 1/4 11.25 2700 2835 2565 2320 2105 1865 1645 1430 1215 1080 890 700 540 405

Alum. Fins 540 121 2600 2730 2470 2230 2020 1790 1580 1380 1170 1040 856 673 519 389

1

Fins 3

/4” x 5 1/4” 2** 24S 25 1/4 11.87 2850 2990 2710 2450 2220 1965 1740 1510 1280 1140 940 740 570 425

83 x 133 mm 641 128 2740 2880 2610 2360 2140 1890 1670 1450 1230 1100 904 712 548 409

Thickness .0135” 12S 13 1/4 7.83 1880 1975 1785 1615 1465 1300 1145 995 845 750 620 490 375 280

.34 mm 337 84 1810 1900 1720 1550 1410 1250 1100 957 813 721 596 471 361 269

*5 1/2” (140 mm) Centers

1

**9

/2” (241 mm) Centers

24S High ratings not IBR approved.

Dimensions in bold indicate metric units.

Per Foot Inches Sq. Ft. Btu/Hr./Ft. IBR Factor — Steam to Hot Water

1 20S 21

1 20S 21

50 2* 16S 17 1/4 11.08 2660 2795 2525 2290 2075 1835 1620 1410 1195 1065 880 690 530 400

164 m 438 119 2560 2690 2430 2200 2000 1760 1560 1360 1150 1020 846 664 510 385

2** 24S 25

1 20S 21 1/4 10.12 2430 2550 2310 2090 1895 1675 1480 1285 1095 970 800 630 485 365

58 2* 16S 17 1/4 11.29 2710 2845 2575 2330 2115 1870 1655 1435 1220 1085 895 705 540 405

190 m 438 122 2610 2740 2480 2240 2030 1800 1590 1380 1170 1040 861 678 519 389

2** 24S 25 1/4 14.20 3410 3580 3240 2930 2660 2350 2080 1805 1535 1365 1125 885 680 510

Install. 220°F 210°F 200°F 190°F 180°F 170°F 160°F 150°F140°F130°F 120°F 110°F 100°F

12S 13 1/4 6.58 1580 1660 1500 11360 1230 1090 965 835 710 630 520 410 315 235

337 71 1520 1600 1440 1310 1180 1050 928 803 683 606 500 394 303 226

16S 17

24S 25

16S 17

24S 25

20S 21 1/4 12.33 2960 3110 2810 2545 2310 2040 1805 1570 1330 1185 975 770 590 445

12S 13 1/4 8.50 2040 2140 1940 1755 1590 1410 1245 1080 920 815 675 530 410 305

16S 17

24S 25

20S 21 1/4 12.91 3100 3255 2945 2665 2420 2140 1890 1645 1395 1240 1025 805 620 465

1

438 73 1570 1640 1490 1350 1220 1080 957 832 707 625 514 409 313 236

1

540 74 1600 1680 1520 1380 1240 1100 971 846 716 639 529 413 317 240

1

641 77 1650 1740 1570 1420 1290 1140 1010 875 745 664 548 428 332 250

1

438 91 1960 2060 1870 1690 1530 1360 1200 1040 885 784 649 510 394 293

1

540 97 2090 2190 1980 1790 1620 1440 1270 1110 938 837 688 543 418 313

1

641 103 2200 2310 2090 1890 1720 1520 1340 1170 990 880 726 572 442 332

540 133 2850 2990 2700 2450 2220 1960 1740 1510 1280 1140 938 740 567 428

1

641 143 3060 3210 2900 2630 2380 2110 1870 1620 1380 1220 1010 793 611 457

337 91 1960 2060 1870 1690 1530 1360 1200 1040 885 784 649 510 394 293

1

438 101 2170 2280 2060 1870 1700 1500 1330 1150 976 870 716 567 433 327

540 109 2340 2450 2220 2010 1820 1610 1420 1240 1050 933 769 606 466 351

1

641 117 2510 2640 2380 2160 1960 1730 1530 1330 1130 1000 827 654 500 375

540 139 2980 3130 2830 2560 2330 2060 1820 1580 1340 1190 986 774 596 447

641 153 3280 3440 3120 2820 2560 2260 2000 1740 1480 1310 1080 851 654 490

at 18.3°C Air

/4 6.79 1630 1710 1550 1400 1270 1125 995 865 735 650 535 425 325 245

/4 6.91 1660 1745 1575 1430 1295 1145 1010 880 745 665 550 430 330 250

/4 7.16 1720 1805 1635 1480 1340 1185 1050 910 775 690 570 445 345 260

/4 8.50 2040 2140 1940 1755 1590 1410 1245 1080 920 815 675 530 410 305

/4 9.04 2170 2280 2060 1865 1690 1495 1325 1150 975 870 715 565 435 325

/4 9.54 2290 2405 2175 1970 1785 1580 1395 1215 1030 915 755 595 460 345

/4 13.25 3180 3340 3020 2735 2480 2195 1940 1685 1430 1270 1050 825 635 475

/4 9.41 2260 2375 2145 1945 1765 1560 1380 1200 1015 905 745 590 450 340

/4 10.87 2610 2740 2480 2245 2035 1800 1590 1385 1175 1045 860 680 520 390

FIN-PRC004-EN22

Page 23

Performance

Sloping

Data

Top

Table PD-8 — Ratings 6” (152 mm) Deep, Type S - Enclosure With Steel Elements

Steam Capacity Hot Water Capacity

Per Ft.-1 Psi at 65°F Air Btu/Hr./Ft. — At 65°F Air, Average Water Temperature

Per Meter - 6.895 kPa Watts/Meter — At 18.3°C Air, Average Water Temperature

Fin Series Height EDR 104°C99°C93°C88°C82°C77°C71°C66°C60°C54°C49°C43°C38°C

Element Per Meter Tiers Encl. mm Sq. M Watts/Meter 1.05 0.95 0.86 0.78 0.69 0.61 0.53 0.45 0.40 0.33 0.26 0.20 0.15

1

/4” Steel 1 20S 21 7/32 7.25 1740 1830 1650 1500 1360 1200 1060 920 780 695 575 450 345 260

1

32 mm 539 78 1670 1760 1590 1440 1310 1150 1020 885 750 668 553 433 332 250

Steel Tube 24S 25

Steel Fins 640 82 1760 1850 1670 1520 1380 1220 1070 933 793 702 582 457 351 264

Fins 2 1/2” x 5 1/4” 52 16S 17 7/32 9.15 2200 2310 2090 1890 1720 1520 1340 1165 990 880 725 570 440 330

64 x 133 mm 171 m 437 98 2120 2220 2010 1820 1650 1460 1290 1120 952 846 697 548 423 317

Thickness .027” 2* 20S 21 7/32 9.90 2380 2500 2260 2050 1860 1640 1450 1260 1070 950 785 620 475 355

.69 mm 539 107 2290 2400 2170 1970 1790 1580 1390 1210 1030 914 755 596 457 341

*4” (102 mm) Centers

**8” (203 mm) Centers

24S High ratings not IBR approved.

Dimensions in bold indicate metric units.

Per Foot Inches Sq. Ft. Btu/Hr./Ft. IBR Factor — Steam to Hot Water

2** 24S 25

Install. 220°F 210°F 200°F 190°F 180°F 170°F 160°F 150°F140°F 130°F 120°F 110°F 100°F

12S 13 7/32 6.40 1530 1610 1450 1320 1190 1060 930 810 685 610 505 395 305 230

336 69 1470 1550 1390 1270 1140 1020 894 779 659 587 486 380 293 221

16S 17

24S 25

20S 21 7/32 10.25 2460 2580 2340 2120 1920 1700 1500 1305 1105 985 810 640 490 365

7

437 74 1590 1660 1510 1360 1240 1100 971 841 712 635 524 413 317 236

7

7

640 112 2400 2520 2280 2070 1880 1660 1470 1270 1080 962 793 625 481 361

539 110 2370 2480 2250 2040 1850 1640 1400 1260 1060 947 779 615 471 351

7

640 116 2490 2620 2370 2140 1940 1720 1520 1320 1120 995 822 649 500 375

at 18.3°C Air

/32 6.90 1650 1730 1570 1420 1290 1140 1010 875 740 660 545 430 330 245

/32 7.62 1830 1920 1740 1575 1430 1265 1115 970 825 730 605 475 365 275

/32 10.41 2500 2625 2375 2150 1950 1725 1525 1325 1125 1000 825 650 500 375

/32 10.78 2590 2720 2460 2225 2020 1785 1580 1375 1165 1035 855 675 520 390

23FIN-PRC004-EN

Page 24

Performance

Front

Data

Outlet

Table PD-9 — Ratings 4” (102 mm) Deep, Type F - Enclosure With Copper/Aluminum Elements

Steam Capacity Hot Water Capacity

Per Ft.-1 Psi at 65°F Air Btu/Hr./Ft. — At 65°F Air, Average Water Temperature

Per Meter - 6.895 kPA Watts/Meter — At 18.3°C Air, Average Water Temperature

Fin Series Height EDR 104°C99°C93°C88°C82°C77°C71°C66°C60°C54°C49°C43°C38°C

Element Per Meter Tiers Encl. mm Sq. M Watts/Meter 1.05 0.95 0.86 0.78 0.69 0.61 0.53 0.45 0.40 0.33 0.26 0.20 0.15

3

/4” CA 40 2* 14F 16 3/4 7.23 1735 1820 1650 1490 1355 1195 1060 920 780 695 570 450 345 260

19 mm 131 m 425 78 1670 1750 1590 1430 1300 1150 1020 885 750 668 548 433 332 250

Copper Tube 18F 20 3/4 7.89 1895 1990 1800 1630 1480 1305 1155 1005 850 760 625 490 380 285

Alum. Fins 527 85 1820 1910 1730 1570 1420 1260 1110 966 817 731 601 471 365 274

1

Fins 3

/4” x 3 1/4” 2** 24F 26 3/4 8.31 1995 2095 1895 1715 1555 1375 1215 1055 895 800 660 520 400 300

83 x 83 mm 679 89 1920 2020 1820 1650 1500 1320 1170 1010 861 769 635 500 385 288

Thickness .0135” 10F 12 3/4 5.04 1210 1270 1150 1040 945 835 740 640 545 485 400 315 240 180

.34 mm 324 54 1160 1220 1110 1000 909 803 712 615 524 466 385 303 231 173

*5 1/2” (140 mm) Centers

1

**9

/2” (241 mm) Centers

All two tier and 24F high ratings not IBR approved.

Dimensions in bold indicate metric units.

Per Foot Inches Sq. Ft. Btu/Hr./Ft. IBR Factor — Steam to Hot Water

1 18F 20

1 18F 20

50 2* 14F 16 3/4 7.37 1770 1860 1680 1520 1380 1220 1080 940 795 710 585 460 355 265

164 m 425 79 1700 1790 1620 1460 1330 1170 1040 904 764 683 563 442 341 255

2** 24F 26 3/4 8.91 2140 2245 2035 1840 1670 1475 1305 1135 965 855 705 555 430 320

1 18F 20

58 2* 14F 16 3/4 7.45 1790 1880 1700 1540 1395 1235 1090 950 805 715 590 465 360 270

190 m 425 80 1720 1810 1640 1480 1340 1190 1050 914 774 688 567 447 346 260

2** 24F 26

Install. 220°F 210°F 200°F 190°F 180°F 170°F 160°F 150°F140°F 130°F120°F 110°F 100°F

10F 12 3/4 4.50 1080 1135 1025 930 840 745 660 570 485 430 355 280 215 160

324 48 1040 1090 986 894 808 716 635 548 466 413 341 269 207 154

14F 16 3/4 4.75 1140 1195 1085 980 890 785 695 605 515 455 375 295 230 170

425 51 1100 1150 1040 942 856 755 668 582 495 438 361 284 221 163

3

527 52 1120 1180 1070 966 875 774 688 596 505 452 370 293 226 168

24F 26

14F 16

24F 26

18F 20 3/4 8.45 2030 2130 1930 1745 1585 1400 1240 1075 915 810 670 525 405 305

10F 12 3/4 5.33 1280 1345 1215 1100 1000 885 780 680 575 510 420 330 255 190

14F 16 3/4 6.08 1460 1535 1385 1255 1140 1005 890 775 655 585 480 380 290 220

24F 26 3/4 6.98 1675 1760 1590 1440 1305 1155 1020 885 755 670 550 435 335 250

18F 20 3/4 8.60 2065 2170 1960 1775 1610 1425 1260 1095 930 825 680 535 415 310

3

679 54 1160 1220 1110 1000 909 803 712 615 524 466 385 303 231 173

3

425 60 1300 1360 1230 1120 1010 894 793 688 582 519 428 337 260 192

3

527 65 1390 1460 1320 1200 1090 962 851 740 625 558 462 361 279 207

3

679 69 1470 1540 1400 1260 1150 1010 899 779 664 587 486 385 293 221

527 91 1950 2050 1860 1680 1520 1350 1190 1030 880 779 644 505 389 293

679 96 2060 2160 1960 1770 1610 1420 1260 1090 928 822 678 534 413 308

324 57 1230 1290 1170 1060 962 851 750 654 553 490 404 317 245 183

425 65 1400 1480 1330 1210 1100 966 856 745 630 563 462 365 279 212

3

527 70 1500 1580 1420 1290 1170 1030 914 793 673 601 495 389 298 226

679 75 1610 1690 1530 1380 1260 1110 981 851 726 644 529 418 322 240

527 93 1990 2090 1880 1710 1550 1370 1210 1050 894 793 654 514 399 298

3

679 99 2130 2240 2020 1830 1660 1470 1300 1130 957 851 702 553 428 317

at 18.3°C Air

/4 4.87 1170 1230 1110 1005 910 805 715 620 525 470 385 305 235 175

/4 5.04 1210 1270 1150 1040 945 835 740 640 545 485 400 315 240 180

/4 5.62 1350 1415 1280 1160 1055 930 825 715 605 540 445 350 270 200

/4 6.04 1450 1520 1375 1245 1130 1000 885 770 650 580 480 375 290 215

/4 6.37 1530 1605 1455 1315 1195 1055 935 810 690 610 505 400 305 230

/4 6.50 1560 1640 1480 1340 1215 1075 950 825 700 625 515 405 310 235

/4 9.23 2215 2325 2105 1905 1725 1530 1350 1175 995 885 730 575 445 330

NOTE: Rating is Btu/hr/ft (Watts/meter) of finned length (for element dimensions see page 49). Hot water ratings determined by applying correction factor to steam ratings, are for

water velocities of 3 ft/sec (.91 m/s) or greater. See page 9, Chart S-1 for correction factors for water velocities other than 3 ft/sec (.91 m/s). For definition of installed height and heating

effect factors, see page 11. For heating ratings at other steam pressures and/or entering air temperatures, see page 10, Table S-2.

FIN-PRC004-EN24

Page 25

Performance

Front

Data

Outlet

Table PD-10 — Ratings 4” (102 mm) Deep, Type F - Enclosure With Copper/Aluminum Elements

Steam Capacity Hot Water Capacity

Per Ft.-1 Psi at 65°F Air Btu/Hr./Ft. — At 65°F Air, Average Water Temperature

Per Meter - 6.895 kPa Watts/Meter — At 18.3°C Air, Average Water Temperature

Fin Series Height EDR 104°C99°C93°C88°C82°C77°C71°C66°C60°C54°C49°C43°C38°C

Element Per Meter Tiers Encl. mm Sq. M Watts/Meter 1.05 0.95 0.86 0.78 0.69 0.61 0.53 0.45 0.40 0.33 0.26 0.20 0.15

1” CA 40 2* 14F 16 3/4 7.23 1735 1820 1650 1490 1355 1195 1060 920 780 695 570 450 345 260

25 mm 131 m 425 78 1670 1750 1590 1430 1300 1150 1020 885 750 668 548 433 332 250

Copper Tube 18F 20 3/4 7.89 1895 1990 1800 1630 1480 1310 1155 1005 850 760 625 490 380 285

Alum. Fins 527 85 1820 1910 1730 1570 1420 1260 1110 966 817 731 601 471 365 274

1

Fins 3

/4” x 3 1/4” 2** 24F 26 3/4 8.14 1955 2050 1855 1680 1525 1350 1190 1035 880 780 645 510 390 295

83 x 83 mm 679 88 1880 1970 1780 1620 1470 1300 1140 995 846 750 620 490 375 284

Thickness .0135” 10F 12 3/4 5.00 1200 1260 1140 1030 935 830 730 635 540 480 395 310 240 180

.34 mm 324 54 1150 1210 1100 990 899 798 702 611 519 462 380 298 231 173

*5 1/2” (140 mm) Centers

1

**9

/2” (241 mm) Centers

All two tier and 24F high ratings not IBR approved.

Dimensions in bold indicate metric units.

Per Foot Inches Sq. Ft. Btu/Hr./Ft. IBR Factor — Steam to Hot Water

1 18F 20

1 18F 20

50 2* 14F 16 3/4 7.16 1720 1805 1635 1480 1340 1185 1059 910 775 690 565 445 345 260

164 m 425 77 1650 1740 1570 1420 1290 1140 1010 875 745 664 543 428 332 250

2** 24F 26

1 18F 20

58 2* 14F 16 3/4 7.10 1705 1790 1620 1465 1330 1175 1040 905 765 680 560 440 340 255

190 m 425 76 1640 1720 1560 1410 1280 1130 1000 870 736 654 538 423 327 245

2** 24F 26

Install. 220°F 210°F 200°F 190°F 180°F 170°F 160°F 150°F140°F 130°F120°F 110°F 100°F

10F 12 3/4 4.54 1090 1145 1035 935 850 750 665 575 490 435 360 285 220 160

324 49 1050 1100 995 899 817 721 639 553 471 418 346 274 212 154

14F 16

425 52 1110 1160 1050 952 861 764 673 587 500 442 365 288 221 163

527 53 1140 1200 1090 986 894 789 697 606 514 457 375 298 231 173

24F 26

679 55 1180 1240 1120 1020 923 817 721 625 534 471 389 308 236 178

14F 16 3/4 5.62 1350 1420 1280 1160 1055 930 825 715 610 540 445 350 270 200

425 60 1300 1360 1230 1120 1010 894 793 688 587 519 428 337 260 192

527 65 1400 1480 1330 1210 1100 966 856 745 630 563 462 365 279 212

24F 26 3/4 6.41 1540 1615 1465 1325 1200 1060 940 815 695 615 510 400 310 230

679 69 1480 1550 1410 1270 1150 1020 904 784 668 591 490 385 298 221

18F 20 3/4 8.29 1990 2090 1890 1710 1550 1375 1215 1055 895 795 655 515 400 300

527 89 1910 2010 1820 1640 1490 1320 1170 1010 861 764 630 495 385 288

679 94 2020 2120 1910 1730 1570 1390 1230 1070 904 808 664 524 404 303

10F 12 3/4 5.25 1260 1325 1195 1085 980 870 770 665 565 505 415 330 250 190

324 57 1210 1270 1150 1040 942 837 740 639 543 486 399 317 240 183

14F 16

425 65 1390 1460 1330 1200 1090 962 851 740 625 558 462 361 279 207

527 72 1540 1620 1460 1320 1200 1060 938 817 692 615 510 399 308 231

24F 26

679 77 1650 1740 1570 1420 1290 1140 1010 875 745 664 548 428 332 250

18F 20 3/4 8.46 2030 2130 1930 1745 1585 1400 1240 1075 915 810 670 530 405 305

527 91 1950 2050 1860 1680 1520 1350 1190 1030 880 779 644 510 389 293

679 98 2100 2200 1990 1800 1640 1450 1280 1110 942 837 692 543 418 313

at 18.3°C Air

3

/4 4.79 1150 1210 1090 990 895 795 700 610 520 460 380 300 230 170

3

/4 4.95 1190 1250 1130 1025 930 820 725 630 535 475 390 310 240 180

3

/4 5.13 1230 1290 1170 1060 960 850 750 650 555 490 405 320 245 185

3

/4 6.08 1460 1535 1385 1255 1140 1005 890 775 655 585 480 380 290 220

3

/4 8.75 2095 2200 1990 1800 1635 1445 1280 1110 940 840 690 545 420 315

3

/4 6.04 1450 1520 1380 1245 1130 1000 885 770 650 580 480 375 290 215

3

/4 6.66 1600 1680 1520 1375 1250 1105 975 850 720 640 530 415 320 240

3

/4 7.16 1720 1805 1635 1480 1340 1185 1050 910 775 690 570 445 345 260

3

/4 9.08 2180 2290 2070 1875 1700 1505 1330 1155 980 870 720 565 435 325

25FIN-PRC004-EN

Page 26

Performance

Front

Data

Outlet

Table PD-11 — Ratings 4” (102 mm) Deep, Type F - Enclosure With Copper/Aluminum Elements

Steam Capacity Hot Water Capacity

Per Ft.-1 Psi at 65°F Air Btu/Hr./Ft. — At 65°F Air, Average Water Temperature

Per Meter - 6.85 kPa Watts/Meter — At 18.3°C Air, Average Water Temperature

Fin Series Height EDR 104°C99°C93°C88°C82°C77°C71°C66°C60°C54°C49°C43°C38°C

Element Per Meter Tiers Encl. mm Sq. M Watts/Meter 1.05 0.95 0.86 0.78 0.69 0.61 0.53 0.45 0.40 0.33 0.26 0.20 0.15

1 1/4” CA 40 * 14F 16 3/4 7.16 1720 1805 1635 1480 1340 1185 1050 910 775 690 565 445 345 260

32 mm 131 m 425 77 1650 1740 1570 1420 1290 1140 1010 875 745 664 543 428 332 250

Copper Tube 18F 20 3/47.77 1865 1960 1770 1605 1455 1285 1140 990 840 745 615 485 375 280

Alum. Fins 527 84 1790 1880 1700 1540 1400 1240 1100 952 808 716 591 466 361 269

1

Fins 3

/4” x 3 1/4” 2** 24F 26 3/4 8.04 1930 2025 1835 1660 1505 1330 1175 1020 870 770 635 500 385 290

83 x 83 mm 679 87 1860 1950 1760 1600 1450 1280 1130 981 837 740 611 481 370 279

Thickness .0135” 10F 12 3/4 4.95 1190 1250 1130 1025 930 820 725 630 535 475 390 310 240 180

.34 mm 324 53 1140 1200 1090 986 894 789 697 606 514 457 375 298 231 173

*5 1/2” (140 mm) Centers

1

**9

/2” (241 mm) Centers

All two tier and 24F high ratings not IBR approved.

Dimensions in bold indicate metric units.

Per Foot Inches Sq. Ft. Btu/Hr./Ft. IBR Factor — Steam to Hot Water

1 18F 20

1 18F 20

50 2* 14F 16 3/4 6.95 1670 1755 1585 1435 1300 1150 1020 885 750 670 550 435 335 250

164 m 425 75 1610 1690 1520 1380 1250 1110 981 851 721 644 529 418 322 240

2** 24F 26 3/4 8.50 2049 2140 1940 1755 1590 1410 1245 1080 920 815 675 530 410 305

1 18F 20

58 2* 14F 16 3/4 6.91 1660 1745 1575 1430 1295 1145 1010 880 745 665 550 430 330 250

190 m 425 74 1600 1680 1520 1380 1240 1100 971 846 716 639 529 413 317 240

2** 24F 26

Install. 220°F 210°F 200°F 190°F 180°F 170°F 160°F 150°F140°F 130°F120°F 110°F 100°F

10F 12 3/4 4.58 1100 1155 1045 945 860 760 670 585 495 440 365 285 220 165

324 49 1060 1110 1000 909 827 731 644 563 476 423 351 274 212 159

14F 16 3/4 4.83 1160 1220 1100 1000 905 800 710 615 520 465 380 300 230 175

425 52 1120 1170 1060 962 870 769 683 591 500 447 365 288 221 168

3

527 54 1150 1210 1100 990 899 798 702 611 519 462 380 298 231 173

24F 26

14F 16

24F 26

18F 20 3/4 8.06 1935 2030 1840 1665 1510 1335 1180 1025 870 775 640 505 385 290

10F 12 3/4 5.20 1250 1310 1190 1075 975 860 760 660 560 500 410 325 250 185

14F 16 3/4 6.04 1450 1520 1380 1245 1130 1000 885 770 650 580 480 375 290 215

24F 26 3/4 7.21 1730 1815 1645 1490 1350 1195 1055 915 780 690 570 450 345 260

18F 20 3/4 8.12 1950 2050 1850 1675 1520 1345 1190 1035 880 780 645 505 390 290

3

679 56 1190 1250 1140 1020 928 822 726 630 538 476 394 308 240 178

3

425 60 1300 1360 1230 1120 1010 894 793 688 587 519 428 337 260 192

3

527 66 1410 1490 1340 1220 1100 976 861 750 635 567 466 365 284 212

3

679 70 1490 1570 1410 1280 1160 1030 909 789 673 596 490 389 298 221

527 87 1860 1950 1770 1600 1450 1280 1140 986 837 745 615 486 370 279

679 91 1960 2060 1870 1690 1530 1360 1200 1040 885 784 649 510 394 293

324 56 1200 1260 1140 1030 938 827 731 635 538 481 394 313 240 178

425 65 1390 1460 1330 1200 1090 962 851 740 625 558 462 361 279 207

3

527 72 1550 1620 1470 1330 1210 1070 942 822 697 620 510 404 308 231

679 78 1660 1740 1580 1430 1300 1150 1010 880 750 664 548 433 332 250

527 87 1880 1970 1780 1610 1460 1290 1140 995 846 750 620 486 375 279

3

679 94 2020 2120 1910 1730 1570 1390 1230 1070 904 808 664 524 404 303

at 18.3°C Air

/4 5.00 1200 1260 1140 1030 935 830 730 635 540 480 395 310 240 180

/4 5.17 1240 1300 1180 1065 965 855 755 655 560 495 410 320 250 185

/4 5.62 1350 1420 1280 1160 1055 930 825 715 610 540 445 350 270 200

/4 6.12 1470 1545 1395 1265 1145 1015 895 780 660 590 485 380 295 220

/4 6.46 1550 1630 1470 1335 1210 1070 945 820 700 620 510 405 310 230

/4 6.70 1610 1690 1530 1385 1255 1110 980 855 725 645 530 420 320 240

/4 8.75 2095 2200 1990 1800 1635 1445 1280 1110 940 840 690 545 420 315

FIN-PRC004-EN26

Page 27

Performance

Front

Data

Outlet

Table PD-12 — Ratings 6” (152 mm) Deep, Type F - Enclosures With Copper/Aluminum Elements

Steam Capacity Hot Water Capacity

Per Ft.-1 Psi at 65°F Air Btu/Hr./Ft. — At 65°F Air, Average Water Temperature