Page 1

Installation Instructions

AFDH E-Frame Upgrade Adaptive

Frequency Drive

For Tracer® AdaptiView™ Centrifugal Chiller

Controllers

Direct Mount Transition Mount LiquiFlo Mou nt

Models:

Design Sequence:

Only qualified personnel should install and service the equipment. The installation, starting up, and servicing of

heating, ventilating, and air-conditioning equipment can be hazardous and requires specific knowledge and training.

Improperly installed, adjusted or altered equipment by an unqualified person could result in death or serious injury.

When working on the equipment, observe all precautions in the literature and on the tags, stickers, and labels that are

attached to the equipment.

May 2020

CVHE, CVHF, AFDH

F0

SAFETY WARNING

AFDH-SVN004C-EN

Page 2

Introduction

Read this manual thoroughly before operatingor servicing

this unit.

Warnings, Cautions, and Notices

Safety advisories appear throughout this manual as

required. Your personal safety and the proper operation of

this machine depend upon the strict observance of these

precautions.

The three types of advisories are defined as follows:

WARNING

Proper Field Wiring and Grounding

Required!

Failure to follow code could result in death or serious

injury. All field wiring MUST be performed by qualified

personnel. Improperly installed and grounded field

wiring poses FIRE and ELECTROCUTION hazards. To

avoid these hazards, you MUST follow requirements for

field wiring installation and grounding as described in

NEC and your local/state electrical codes.

WARNING

CAUTIONs

NOTICE

Indicates a potentially hazardous

situation which, if not avoided, could

result in death or serious injury.

Indicates a potentially hazardous

situation which, if not avoided, could

result in minor or moderate injury. It

could also be used to alert against

unsafe practices.

Indicates a situation thatcould result in

equipment or property-damage only

accidents.

Important Environmental Concerns

Scientific research has shown that certain man-made

chemicals can affect the earth’s naturally occurring

stratospheric ozone layer when released to the

atmosphere. In particular, several of the identified

chemicals that may affect the ozone layer are refrigerants

that contain Chlorine, Fluorine and Carbon (CFCs) and

those containing Hydrogen, Chlorine, Fluorine and

Carbon (HCFCs). Not all refrigerants containing these

compounds have the same potential impact to the

environment. Trane advocates the responsible handling of

all refrigerants-including industry replacements for CFCs

and HCFCs such as saturated or unsaturated HFCs and

HCFCs.

Important Responsible Refrigerant

Practices

Trane believes that responsible refrigerant practices are

important to the environment, our customers, and the air

conditioning industry. All technicians who handle

refrigerants must be certified according to local rules. For

the USA, the Federal Clean Air Act (Section 608) sets forth

the requirements forhandling, reclaiming, recovering and

recycling of certain refrigerants and the equipment that is

used in these service procedures. In addition, some states

or municipalities may have additional requirements that

must also be adhered to for responsible management of

refrigerants. Know the applicable laws and follow them.

WARNING

Personal Protective Equipment (PPE)

Required!

Failure to wear proper PPE for the job being undertaken

could result in death or serious injury. Technicians, in

order to protect themselves from potential electrical,

mechanical, and chemical hazards, MUST follow

precautions in this manual and on the tags, stickers,

and labels, as well as the instructions below:

• Before installing/servicing this unit, technicians

MUST put on all PPE required for the work being

undertaken (Examples; cut resistant gloves/sleeves,

butyl gloves, safety glasses, hard hat/bump cap, fall

protection, electrical PPE and arc flash clothing).

ALWAYS refer to appropriate Safety Data Sheets

(SDS) and OSHA guidelines for proper PPE.

• When working with or around hazardous chemicals,

ALWAYSreferto the appropriateSDSandOSHA/GHS

(Global Harmonized System of Classification and

Labeling of Chemicals) guidelines for information on

allowable personal exposure levels, proper

respiratory protection and handling instructions.

• If there is a risk of energized electrical contact, arc, or

flash, technicians MUST put on all PPE in accordance

with OSHA, NFPA 70E, or other country-specific

requirements for arc flash protection, PRIOR to

servicing the unit. NEVER PERFORM ANY

SWITCHING, DISCONNECTING, OR VOLTAGE

TESTING WITHOUT PROPER ELECTRICAL PPE AND

ARC FLASH CLOTHING. ENSURE ELECTRICAL

METERS AND EQUIPMENT ARE PROPERLY RATED

FOR INTENDED VOLTAGE.

© 2020 Trane AFDH-SVN004C-EN

Page 3

Introduction

WARNING

Follow EHS Policies!

Failure to follow instructions below could result in

death or serious injury.

• All Trane personnel must follow the company’s

Environmental, Health and Safety (EHS) policies

when performing work such as hot work, electrical,

fall protection, lockout/tagout, refrigerant handling,

etc. Where local regulations are more stringent than

these policies, those regulations supersede these

policies.

• Non-Trane personnel should always follow local

regulations.

WARNING

Refrigerant under Positive Pressure!

Failure to follow instructions below could result in an

explosion which could result in death or serious injury

or equipment damage. System contains oil and

refrigerant and may be under positive pressure. Recover

refrigerant to relieve pressure before opening the

system. See unit nameplate for refrigerant type. Do not

use non-approved refrigerants, refrigerant substitutes,

or refrigerant additives.

NOTICE

Stand-Mounted AFDH Supported by

Equipment Room Floor!

Trane assumes no responsibility for equipment damage

caused by the installation of an AFDH drive version that

is specified as being incorrect for the application. A

stand-mounted version of an AFDH drive is designed to

be rigidly supported by the equipment room floor.

Therefore, a stand-mounted AFDH drive is not

recommended for use with a chiller that is equipped

with spring-type vibration or seismic isolators. Trane

recommends using a remote floor-mounted AFDH drive

in this application.

Copyright

This document andthe information in itare the property of

Trane, and may not be used or reproduced in whole or in

part without written permission. Trane reserves the right

to revise thispublication at anytime, and tomake changes

to its content without obligation to notify any person of

such revision or change.

Trademarks

All trademarks referenced in this document are the

trademarks of their respective owners.

Revision History

• Updated cover page figure.

• Updated

• Updated for HUB document numbers in General

Information chapter.

• Updated mounting drawings in Pre-Installation

chapter.

• Updated unit dimensional drawings in AFDH Drive

Package Specifications

• Updated steps for Direct Mount Drive to Replace

Direct Mount Starter and mounting installation

figures in Installation chapter.

• Updated Trane default settings table in AFDH

Startup Procedure chapter.

• Updated job specific settings and Trane default

settings tables in AFDH Startup Procedure.

• Part number updated in table for Air filter in

Recommended Periodic Maintenance and

Inspection chapter.

Model Number Descriptions chapter.

NOTICE

Incorrect Application! Adapting a Floor

Stand Kit to an E-Frame AFDH!

The smallest model E-Frame drive weighs 1203 pounds.

Any attempt to adapt the 50689890010 Floor Stand Kit

to an E-Frame model AFDH drive will be considered an

unsupported field modification to the drive unit design.

Trane assumes no responsibility for the equipment

damage caused by a stress or fatigue failure of the floor

stand kit due to any use outside of its intended

application.

AFDH-SVN004C-EN 3

Page 4

Table of Contents

Model Number Descriptions .............. 5

Unit Model Number .................... 5

Nameplates ............................. 7

General Information ..................... 8

Other Literature Required Before Ordering or

Installing an AFDH Upgrade

............. 8

Pre-Installation .......................... 9

Confirming the AFDH Package can be Properly

Installed .............................. 9

Installation Considerations for Unit-Mounted

AFDH Drives ........................ 9

Confirm Chiller Controller System Compatibility with AFDH Drive

................... 12

Equipment Room Ambient Temperature and

Environmental Considerations

......... 12

Chiller Upgrades ..................... 12

Electrical Cable Size Specifications for AFDH

Drives

............................... 13

Requirements for Installation Technicians 14

Tools Required ....................... 14

Miscellaneous Field-Provided Material .. 14

Recommended Rigging and Lifting Proce-

dures for AFDH Drive Units ............ 15

Unit Lifting Points ................... 15

Alternative Lifting Method ............ 16

Center of Gravity Reference (FEA Method)

16

AFDH Drive Package Specifications ...... 18

Transition Mount Unit Dimensions ...... 19

LiquiFlo 1.0/1.5 Frame 4 Unit Dimensions 20

Drive Unit Weights and Heat Rejection .. 22

E-Frame Drive Unit Components ....... 23

Drive Unit Component Parts Housed within

the Custom Enclosure ............... 23

Additional Hardware Shipped with Tracer®

AdaptiView™ AFDH Packages ......... 32

Installation ............................. 34

Removal of Electrical Connections to the Existing Starter

......................... 34

Mechanical Removal of Existing Unit-Mounted Starter

............................ 34

Mechanical Removal of Existing Unit-Mount-

ed LiquiFlo 1.0/1.5 Adaptive Frequency Drive

35

Mechanical Installation of a Unit-Mounted

AFDH E-Frame

Transition Mount Drive to Replace Transition

Mount Starter .......................36

........................36

LiquiFlo Frame 3 Drive Replacement .....38

Direct Mount Drive to Replace Direct Mount

Starter

...............................41

Linkage Bracket Installation for a Unit- Mounted Direct Mount E-Frame

Circuit Breaker Adjustment to Accommodate

Power Line Wiring ...................45

...............43

LiquiFlo 1.0/1.5 Frame 4 Replacement ....45

Electrical Installation (All AFDH Models) ..46

Install Shorting Buss Bars .............46

Input Power Wire Installation ..........47

Grounding AFDH Cabinet .............48

Output Wiring from the AFDH to the CTV Mo-

tor ................................48

Routing of Control Wiring to AFDH Cabinet .

49

Control Wiring Connections (Tracer® AdaptiView™ Model AFDH Only)

.............49

Required Reprogramming of Tracer® AdaptiView™ Controls.

Reprogramming Factory Installed Tracer®

AdaptiView™ Controls (CTV Simplex Firm-

ware) ..............................50

.....................50

AFDH Startup Procedure .................51

Drive Settings .........................51

TR200 Drive Configuration ..............52

Troubleshooting .........................53

Startup Test Log .........................54

Recommended Periodic Maintenance and Inspection

................................55

Inspection Frequency ..................55

Visual Inspection—Power Removed ......55

Operational Inspection—Power Applied ..55

Air Filter ..............................55

Wiring Diagram Matrix ...................56

4 AFDH-SVN004C-EN

Page 5

Model Number Descriptions

Unit Model Number

For service purposes, Trane®Model

AFDH Air-Cooled drive upgrade

packages are assigned a multiple

character alphanumeric model

number that preciselyidentifies each

unit.

An explanation of the identification

code that appears on the unit

nameplate is shown below. Use of

the service model number will

enable the owner/operator, installing

contractors, and service technicians

to define theoperation, components,

and options for any specific unit.

Refer to the model number printed

on the nameplate when ordering

replacement parts or requesting

service.

Digits 1, 2,

Adaptive Frequency Drive

AFD = Air Cool ed Ad apti ve Frequen cy

Drive

Digit 4 — Development

Sequence

H

Digits 5, 6, 7, 8 — Starter Size

(Performance RLA rating)

Performance RLA = Performance RLA

Digit 9 — Chille r Vo ltage

D = 380V 60 Hz 3 Phase

E = 440V 60 Hz 3 Phase

F = 460V 60 Hz 3 Phase

G = 480V 60 Hz 3 Phase

H = 575V 60 Hz 3 Phase

J = 600V 60 Hz 3 Phase

R = 380V 50 Hz 3 Phase

T = 400V 50 Hz 3 Phase

U = 415V 50 Hz 3 Phase

Digits 10, 11— Design Sequence

** = Factory assigned

Digit 12 — N ew Sh ort Circuit

Ra t ing

C = 35K Short Circuit

A = 65K Short Circuit

B = 100K Short Circuit

Digits 13, 14 — Maxim um RLA

1B = 190 Maximum RLA - 60 Hz

1C = 240 Maximum RLA - 60 Hz

0C = 302 Maximum RLA - 60 Hz

0D = 361 Maximum RLA - 60 Hz

0E = 443 Maximum RLA - 60 Hz

3 — Air Cooled

(460/480)

(460/480)

(460/480)

(460/480)

(460/480)

1A = 535 Maximum RLA - 60 Hz

(460/480)

0H = 590 Maximum RLA - 60 Hz

(460/480)

0J = 678 Maximum RLA - 60 Hz

(460/480)

0K = 730 Maximum RLA - 60 Hz

(460/480)

01 = 780 Maximum RLA - 60 Hz

(460/480)

02 = 890 Maximum RLA - 60 Hz

(460/480)

1D = 131 Maximum RLA - 60 Hz

(575/600)

1E = 155 Maximum RLA - 60 Hz

(575/600)

1F = 192 Maximum RLA - 60 Hz

(575/600)

0L = 242 Maximum RLA - 60 Hz

(575/600)

0M = 290 Maximum RLA - 60 Hz

(575/600)

0N = 344 Maximum RLA - 60 Hz

(575/600)

0P = 400 Maximum RLA - 60 Hz

(575/600)

0R = 450 Maximum RLA - 60 Hz

(575/600)

0T = 500 Maximum RLA - 60 Hz

(575/600)

0U = 570 Maximum RLA - 60 Hz

(575/600)

0V = 630 Maximum RLA - 60 Hz

(575/600)

03 = 729 Maximum RLA - 60 Hz

(575/600)

04 = 850 Maximum RLA - 60 Hz

(575/600)

1G = 212 Maximum RLA - 50 Hz

(380/400)

1H = 260 Maximum RLA - 50 Hz

(380/400)

0W = 315 Maximum RLA - 50 Hz

(380/400)

0X = 395 Maximum RLA - 50 Hz

(380/400)

0Y = 480 Maximum RLA - 50 Hz

(380/400)

0Z = 588 Maximum RLA - 50 Hz

(380/400)

05 = 658 Maximum RLA - 50 Hz

(380/400)

06 = 745 Maximum RLA - 50 Hz

(380/400)

07 = 800 Maximum RLA - 50 Hz

(380/400)

08 = 880 Maximum RLA - 50 Hz

(380/400)

09 = 990 Maximum RLA - 50 Hz

(380/400)

Digit 15 — Chille r Con t r ol Ty pe

3 = AdaptiView Controls Only

Digit 16 — Ag e ncy List i ng

1 = UL Listing (includes Canada and

California)

0 = No Listing

Digit 17 — AFD Typ e

C = NEMA 1 Upgrade Enclosure

Digit 18 — Mou n t ing Ty pe

C = Remote Mount

A = Transition Mount

L = LiquiFlo Mount

P = Direct Mount 440E, 5000, 5800

Frame

T = Direct Mount 400 Frame

Digit 19 — AFD t o M otor

Tr a n si t io n

0 = No Motor Transition

A = 6" Sheetmetal Transition

C = 12" Sheetmetal Transition

B = 18" Sheetmetal Transition

Digit 20 — Fr a m e Size

D = D - Frame

E = E - Frame

Digit 21 — Evaporator Shell Size

0 = For Transition, LiquiFlo, or

Remote

5 = 050S Short Evaporator Shell

6 = 050L Long Evaporator Shell

7 = 080S Short Evaporator Shell

8 = 080L Long Evaporator Shell

A = 142E Extended Evaporator Shell

B = 142M Medium Evaporator Shell

C = 142L Long Evaporator Shell

E = 210L Long Evaporator Shell

Digit 22 — Replacement Bracket

for LF1.0/LF1.5

0 = No Bracket Needed

1 = Replacement Bracket Kit Needed

Digit 23

0

Digit 24 — Lug Sizes

0 = All Applicable Lugs

N = Two Wire 3/0 - 250 KCmil

B = Two Wire 400 - 500 KCmil

C = Four Wire 4/0 - 400 KCmil

D = Three Wire 4/0 - 400 KCmil

E = Three Wire 500 - 750 KCmil

F = Two Wire 2/0 - 250 KCmil

G = One Wire 2/0 - 500 KCmil

H = Three Wire 3/0 400 KCmil

J = Two Wire 500 - 750 KCmil

K = One Wire 200 - 500 KCmil

L = Two Wire 3/0 - 350 KCmil

M = Two Wire 2AWG - 500 KCmil

P = Three Wire 4/0 - 500 KCmil

Q = Four Wire 4/0 - 500 KCmil

R = Four Wire 3/0 - 400 KCmil

Digit 25 — Jumper Bar Kit

0 = No Jumper Bars Required

A = Bar Kit 1 (distance between holes

5.385 and dia. .812)

B = Bar Kit 2 (distance between holes

5.831 and dia. .812)

C = Bar Kit 3 (distance between holes

6.103 and dia. .812)

D = Bar Kit 4 (distance between holes

6.103 and dia. 1.187)

E = All Bars Included

Digits 26, 27 — Design Specials

00 = No Design Special

AFDH-SVN004C-EN 5

Page 6

Model Number Descriptions

Digits 28, 29 — Harmonic

Attenuation

00 = No Attenuation

Line Reactors

0A = Line /Load Reactor, 0.125mH, 320

Amps, NEMA1

0B = Line /Load Reactor, 0.105mH, 400

Amps, NEMA1

0C = Line /Load Reactor, 0.085mH, 500

Amps, NEMA1

0D = Line /Load Reactor, 0.065mH, 600

Amps, NEMA1

0E = Line /Load Reactor, 0.048mH, 750

Amps, NEMA1

0F = Line /Load Reactor, 0.042mH, 850

Amps, NEMA1

0G = Line /Load Reactor, 0.040mH, 900

Amps, NEMA1

0H = Line /Load Reactor, 0.0038mH,

1000 Amps, NEMA1

Advanced Filter

1A = Advanced Filter -208 Amp free

standing harmonic filter

1B = Advanced Filter -240 Amp free

standing harmonic filter

1C = Advanced Filter -320 Amp free

standing harmonic filter

1D = Advanced Filter -403 Amp free

standing harmonic filter

1E = Advanced Filter -482 Amp free

standing harmonic filter

1F = Advanced Filter -636 Amp free

standing harmonic filter

1G = Advanced Filter -786 Amp free

standing harmonic filter

1H = Advanced Filter -850 Amp free

standing harmonic filter

1J = Advanced Filter -1000 Amp free

standing harmonic filter

1K = Advanced Filter -1200 Amp free

standing harmonic filter

1L = Advanced Filter -208 Amp free

standing harmonic filter

1M = Advanced Filter -208 Amp free

standing harmonic filter

1N = Advanced Filter -208 Amp free

standing harmonic filter

1P = Advanced Filter -208 Amp free

standing harmonic filter

1Q = Advanced Filter -208 Amp free

standing harmonic filter

6 AFDH-SVN004C-EN

Page 7

Nameplates

A nameplate is installed on each AFDH Air-Cooled Drive

unit. Always provide the model number and serialnumber

Figure 1. Nameplate

that is printed on this nameplate when making warranty

inquiries, ordering parts, or ordering literature for the unit.

AFDH-SVN004C-EN 7

Page 8

General Information

This manual describes the procedures required to install

NEMA 1 AFDH Air-Cooled Adaptive Frequency Drive

package in place of existing direct mount starter,

Transition mount starter, and LiquiFlo 1.0/1.5 drive on

Trane CVHE, CVHF, CVHG model centrifugal chillers and

retrofit LiquiFlo1.0/1.5 drives.This only applies to chillers

with Tracer® AdaptiView™ controller.

E-Frame AFDH can be ordered in a unit-mounted

configuration. Voltage options include 380/400V, 460/

480V, and 575/600V.

The E-Frame units can be equipped with drive rating:

• 658 amps, 745 amps,800 amps, 880 amps,or 990 amps

for 380V/400V.

• 590 amps, 678 amps,730 amps, 780 amps,or 890 amps

for 460V/480V.

• 450 amps, 500 amps, 570 amps, 630 amps, 730 amps,

or 850 amps for 575V/600V.

Note: Thefactory installed Tracer CH530 chiller controller

system will not support an AFDH Air-Cooled

Adaptive Frequency drive. The controller system

must be upgradedto Tracer® AdaptiView™before

an AFDH

The AFDH series of upgrade air-cooled Adaptive

Frequency

installation on existing Trane chillers with CVHE, CVHF, or

CVHG model centrifugal compressors. Trane makes no

claim of suitability or performance regarding upgrade

AFDH drives on older Trane centrifugal compressor

models or on chillers made by other manufacturers.

Although there may exist successful drive retrofits to

these units, users are cautioned that Trane has not

evaluated these installations. Accordingly, Trane cannot

provide assurances regarding performance, reliability or

suitability of upgrade AFDH installations to other than

Trane model CVHE, CVHF, and CVHG compressors.

upgrade package can be installed.

drive packages are only intended for

HUB Document DOC-155220: MCT 10 Installation

Instructions.docx (Danfoss VLT MotionControl Tools MCT

10 Set-up Software manual)

HUB Document DOC-179427: Creating a Project a Master

File and Configuration for AFDH D & E Frame Drive.docx

(AFDH D & E-Frame Drive Configuration Instructions

Using MCT 10 Tool).

Other Literature Required Before

Ordering or Installing an AFDH

Upgrade

This manual must be used in conjunction with the

following publications:

ECTV-PRB009*-EN, Engineering Bulletin, Chiller

Upgrades Selection and Application Guideline for

Aircooled Adaptive Frequency Drive Retrofit

BAS-SVP04*-EN, TR200 Programming Guide

CVRE-SVP01*-EN, Tracer® AdaptiView™ Panel Upgrade

Programming Guide

CTV-SVP02*-EN, TracerTU Service Tool for Water-Cooled

CenTraVac Chillers with Tracer® AdaptiView™ Controls

Programming Guide

8 AFDH-SVN004C-EN

Page 9

Pre-Installation

Confirming the AFDH Package can

be Properly Installed

This chapter details potential interference fit problems,

mechanical incompatibility situations, electrical code

stipulations, and electrical conduit and wiring issues that

can prevent the successful installationand/or operation of

an AFDH upgrade drive package.

Installation Considerations for UnitMounted AFDH Drives

Important: Route Incoming Power Conduit to the Roof

of AFDH Cabinet! The air-cooled AFDH drive

is designed to have the incoming power

conduit routed vertically into the unit

through the removable conduit connection

cover located onthe left-hand rear corner of

the cabinet roof. If the starter that is being

replaced by the AFDH drive has the

incoming power conduit routed

horizontally across the top of the starter, or

connected to theside or to thebottom of the

starter cabinet, an electrician will be

required to reconfigure the conduit and

wiring. Routing the incoming power

conduit into the AFDH cabinet anywhere

other than through the specified locationon

the cabinet roof, will be considered an

unsupported field modification to the

cabinet design.

NOTICE

Route Incoming Power Conduit to the

Roof of AFDH Cabinet!

Routing the incoming power conduit into the AFDH

cabinet anywhere other than through the specified

location on the cabinet roof, will be considered an

unsupported field modification to the cabinet design.

The air-cooled AFDH drive is designed to have the

incoming power conduit routed vertically into the unit

through the removable conduit connection cover

located on the left-hand rear corner of the cabinet roof.

If the starter that is being replaced by the AFDH drive

has the incoming power conduit routed horizontally

across the top of the starter, or connected to the side or

to the bottom of the starter cabinet, an electrician will

be required to reconfigure the conduit and wiring.

Evaluate Space Available for Rigging/

Installing Unit-mounted AFDH

All models of the E-Frame AFDH unit-mounted upgrade

drives are taller, wider, and deeper than the typical Wye

Delta unit-mounted starter they are intended to replace.

Accordingly any project should start with a careful

evaluation on whether there is ample enough space to rig

the AFDH into place and if any of the existing building

piping and conduit will not interfere with its mounting.

AFDH-SVN004C-EN 9

Page 10

Pre-Installation

Direct Mount. Transition Mount.

Figure 2. Comparison of direct-mounted AFDH to

typical unit-mounted starter

㼃㼅㻱㻌㻰㻱㻸㼀㻭㻌㻿㼀㻭㻾㼀㻱㻾

㻢㻜䇿㻌㼀㻌㼄㻌㻟㻤䇿㻌㼃㻌㼄㻌㻝㻠䇿㻌㻰

㼃㼅㻱㻌㻰㻱㻸㼀㻭㻌㻿㼀㻭㻾㼀㻱㻾㻌㼣㼕㼠㼔㻌㻼㻲㻯㻯㼟

㻢㻜䇿㻌㼀㻌㼄㻌㻠㻥䇿㻌㼃㻌㼄㻌㻝㻠䇿㻌㻰

㻰㻵㻾㻱㻯㼀㻌㻹㻻㼁㻺㼀㻵㻺㻳㻌㻭㻲㻰㻴

㻢㻜䇿㻌㼀㻌㼄㻌㻢㻢䇿㻌㼃㻌㼄㻌㻞㻟㻚㻞䇿㻌㻰

Figure 3. Open direct mount AFDH internal view

Figure 4. Comparison of transition-mounted AFDH to

typical unit-mounted starter

㼃㼅㻱㻌㻰㻱㻸㼀㻭㻌㻿㼀㻭㻾㼀㻱㻾

㻢㻜䇿㻌㼀㻌㼄㻌㻟㻤䇿㻌㼃㻌㼄㻌㻝㻠䇿㻌㻰

㼃㼅㻱㻌㻰㻱㻸㼀㻭㻌㻿㼀㻭㻾㼀㻱㻾㻌㼣㼕㼠㼔㻌㻼㻲㻯㻯㼟

㻢㻜䇿㻌㼀㻌㼄㻌㻠㻥䇿㻌㼃㻌㼄㻌㻝㻠䇿㻌㻰

㼀㻾㻭㻺㻿㻵㼀㻵㻻㻺㻭㻸㻌㻹㻻㼁㻺㼀㻵㻺㻳㻌㻭㻲㻰㻴

㻢㻤㻚㻢䇿㻌㼀㻌㼄㻌㻠㻤䇿㻌㼃㻌㼄㻌㻞㻟㻚㻞䇿㻌㻰

Figure 5. Open transition mount AFDH internal view

10 AFDH-SVN004C-EN

Page 11

Pre-Installation

LiquidFlo.

Figure 6. Comparison of LiquiFlo AFDH to AFDB

LF MOUNTI NG AFDH

AFDB

9. 2" D EEPER

THAN A FDB

AFDB STA RTER

68 .8" T X 6 4" W X 1 4" D

LF MOUNTI NG AFDH

68 .8" T X 6 4" W X 2 3.2 " D

Figure 7. Open LiquiFlo AFDH internal view

Important:

• Verify

electrical disconnect switch installation height

meets requirements of current NEC and/or local

codes.Typical requirement is that switch can be no

higher than 72 inchesabove the surface ofthe operator

area floor or platform. Check the potential mounted

height of the AFDH disconnect switch specially if the

chiller has large shells or mounted on structural steel.

• Other

factors that affect the space required to

successfully install a stand-mounted AFDH drive

include the clearance distances specified by the local

electrical codes. Typical code regulations require an

average of 36 inches of clearance from the panel to

nonconducting

surface.

surfaces and 47 inchesto a conducting

Check and confirm that when installed, the

drive clearances will conform to all local codes. Do not

forget to account for cabinet door swing clearances.

Note: Refer

Specifications,”

to manual section

for the dimensions and weights of

“AFDH Drive Package

all models of AFDH drives.

AFDH-SVN004C-EN 11

Page 12

Pre-Installation

Confirm Chiller Controller System

Compatibility with AFDH Drive

NOTICE

Excessive Cable Lengths Between AFDH

Drive and Compressor Motor!

Trane assumes no responsibility for equipment damage

caused by use of improper cable lengths. The variable

frequency drive industry recommends that the length of

the electrical cables connecting a drive unit to a motor

should be kept to less than 250 feet to protect the

motor from reflected voltage waves that can cause the

motor to fail. Cable lengths that exceed 250 feet

between the drive and the motor create the potential

for damage to occur to the motor windings and/or

insulation.

Before starting the process of installing the AFDH, first

confirm that the existing chiller controller system has the

hardware and/or software componentsrequired to make it

compatible with an AFDH upgrade.

The controller systems that can accept an AFDH upgrade

is Tracer® AdaptiView™.

Note: UC800 controller must be equipped with a

Tracer® AdaptiView™ software version

released in January 2019 or newer. Upload the

correct Tracer® AdaptiView™ softwareversion

as required.

Table 1. Environmental conditions

Con d it io n Sp ecif ica tion

Operat ing Temper at ur e (i nsi de

NEMA 1 e ncl osure)

Am bi ent Tem perat ur e (out sid e

NEMA 1 e ncl osure)

St orage Temper at ur e (Am bient ) - 40° F to 1 49 ° F ( -40 °C t o 6 5° C)

Humi dity 5% t o 95 % (non -conden sin g)

32 ° F t o 131° F ( 0° C t o 55 ° C)

32 ° F t o 104° F ( 0° C t o 40 ° C)

Chiller Upgrades

The chiller condenserloop setpoint should bereset to fully

exploit the energy savings possible with a upgrade AFDH

drive. It is recommended to use Trane Option Analyzer or

a similar software to determine the optimum setpoint.

Important: Under

low condenser water conditions, use

of an oil recovery system is recommended.

These systems are found on all Trane

chillers built since 1985.

®

Equipment Room Ambient

Temperature and Environmental

Considerations

An air-conditioned equipment room is not a prerequisite

for the installation and operation of NEMA 1 AFDH

upgrade drive package.

However, be advised that all models of the AFDH aircooled drives are not suitable for installation into

equipment rooms where the ambient temperature

conditions are expected to exceed either 104°F for a

continuous 24-hour period, or where the potential

maximum ambient temperatures can exceed 113°F.

If the ambient temperatures exceed either of these

conditions, the potential existstotrigger a drive shutdown

from an over temperature fault—effectively disabling the

chiller until the drive temperature drops to the factory set,

non-adjustable, safe temperature level that will allow the

drive to be restarted.

If the ambient temperature routinely exceeds either of

these conditions, the overall service life of the drive may

be compromised. Verify the drive location will meet the

environmental conditions specified in the table below.

12 AFDH-SVN004C-EN

Page 13

Electrical Cable Size

Specifications for AFDH Drives

Table 2. Input/output power wire cable sizes AFDH E-Frame drives (380V/400V)

3 8 0 V / 4 0 0 V E- Fr a m e AFDH Max im um a m p s 6 5 8 7 4 5 80 0 8 8 0 9 90

I N COM I NG PO W ER T O DRI V E CI R CUI T BREAKER: N um be r

of Cabl e Lug s per Ph ase an d Ran ge of W ir e S iz es St an da rd

Lu gs W ill Acce pt

I N COM I NG PO W ER T O DRI V E CI R CUI T BREAKER: N um be r

of Cab le Lu gs p er Ph ase and Ran ge of W ire Size s Op tion al

Lu gs W ill Acce pt

PH AS E W I RE BETW EEN D RI V E AN D CB: N u m ber of W ire

Cabl e Pe r P ha se an d Siz e of F ac tor y I nstal le d W ires

OU TP UT P OW ER TO CO MP RES SOR M OT OR: N u m be r of W i r e

Cabl e Pe r P ha se an d Siz e of F ac tor y I nstal le d W ires

Four w ir e

lu gs

4/ 0– 50 0

KCm il

Thr ee wire

lu gs

50 0- 750

KCm il

Four w ir e

lu gs

3/ 0 - 40 0 K Cmi l

Thr ee

4/ 0 DLO

wi re s

Thr ee

4/ 0 DLO

wi re s

Four w ir e

lu gs

4/ 0– 50 0

KCm il

Thr ee wire

lu gs

50 0- 750

KCMI

Four w ir e

lu gs

3/ 0- 400

KCm il

Thr ee

4/ 0 DLO

wi re s

Thr ee

4/ 0 DLO

wi re s

Four w ir e

lu gs

4/ 0– 50 0

KCm il

Thr ee wire

lu gs

50 0- 750

KCm il

Four w ir e

lu gs

3/ 0- 400

KCm il

Thr ee

31 3 MCM D LO

wi re s

Thr ee

31 3 MCM D LO

wi re s

Pre-Installation

Four w ir e

lu gs

4/ 0– 50 0

KCm il

Thr ee wire

lu gs

50 0- 750

KCm il

Four w ir e

lu gs

3/ 0- 400

KCm il

Thr ee

31 3 M CM D LO

wi r es

Thr ee

31 3 M CM D LO

wi r es

Four w ir e

lu gs

4/ 0– 50 0

KCm il

Thr ee wire

lu gs

50 0- 750

KCm il

Four w ir e

lu gs

3/ 0- 400

KCm il

Four

4/ 0 DLO

wi re s

Four

4/ 0 DLO

wi re s

Table 3. Input/output power wire cable sizes AFDH E-Frame drives (460V/480V)

4 6 0 V / 4 8 0 V E- Fr a m e AFDH Max im um a m p s 5 9 0 6 7 8 7 30 7 8 0 8 90

I N COM I NG PO W ER T O DRI V E CI R CUI T BREAKER: N um be r

of Cabl e Lug s per Ph ase an d Ran ge of W ir e S iz es St an da rd

Lu gs W ill Acce pt

I N COM I NG PO W ER T O DRI V E CI R CUI T BREAKER: N um be r

of Cab le Lu gs p er Ph ase and Ran ge of W ire Size s Op tion al

Lu gs W ill Acce pt

PH AS E W I RE BETW EEN D RI V E AN D CB: N u m ber of W ire

Cabl e Pe r P ha se an d Siz e of F ac tor y I nstal le d W ires

OU TP UT P OW ER TO CO MP RES SOR M OT OR: N u m be r of W i r e

Cabl e Pe r P ha se an d Siz e of F ac tor y I nstal le d W ires

Four w ir e

lu gs

4/ 0- 500

KCm ilKCmi l

Thr ee wire

lu gs

50 0- 750

KCm il

Four w ir e

lu gs

3/ 0- 4 00 KCm il

Tw o

31 3 MCM D LO

wi re s

Tw o

31 3 MCM D LO

wi re s

Four w ir e

lu gs

4/ 0- 500

KCm il

Thr ee wire

lu gs

50 0- 750

KCm il

Four w ir e

lu gs

3/ 0- 400

KCm il

Thr ee

4/ 0 DLO

wi re s

Thr ee

4/ 0 DLO

wi re s

Four w ir e

lu gs

4/ 0- 500

KCm il

Thr ee wire

lu gs

50 0- 750

KCm il

Four w ir e

lu gs

3/ 0- 400

KCm il

Thr ee

4/ 0 DLO

wi re s

Thr ee

4/ 0 DLO

wi re s

Four w ir e

lu gs

4/ 0- 500

KCm il

Thr ee wire

lu gs

50 0- 750

KCm il

Fou r wi re

lu gs

3/ 0- 400

KCm il

Thr ee

31 3 MCM DLO

wi res

Thr ee

31 3 MCM DLO

wi re s

Four w ir e

lu gs

4/ 0- 500

KCm il

Thr ee wire

lu gs

50 0- 750

KCm il

Fou r wi re

lu gs

3/ 0- 400

KCm il

Thr ee

31 3 MCM D LO

wi re s

Thr ee

31 3 MCM D LO

wi re s

AFDH-SVN004C-EN 13

Page 14

Pre-Installation

Table 4. Input/output power wire cable sizes AFDH E-Frame drives (575V/600V)

5 7 5 V / 6 0 0 V E- Fr a m e AFDH Max im um a m p s 4 5 0 5 0 0 57 0 6 3 0 7 3 0 8 50

I NCOM I N G P OW ER TO D RI V E CI R CUI T

BR EAK ER: N u m b e r o f Ca b le Lu gs p e r P ha s e a n d

Ra ng e of W ire Siz es Sta nd ar d Lugs Will Acc ep t

I NCOM I N G P OW ER TO D RI V E CI R CUI T

BR EAK ER: N u m b e r o f Ca b le Lu gs p e r P ha s e a n d

Ra n ge of W ir e Si zes Op t io nal Lu gs W il l Acce pt

PH AS E W I RE BETW EEN D RI V E AN D CB:

N um be r o f W ir e Cab le Pe r Ph a se a n d Siz e o f

Fa ct or y I n st a ll ed W ir e s

OU TP UT P OW ER TO COMP RES SOR M OTO R:

N um be r o f W ir e Cab le Pe r Ph a se a n d Siz e o f

Fa ct or y I n st a ll ed W ir e s

Fou r w ire l ugs

4/ 0 -5 00 KCm il

Thr ee wire

lu gs

50 0- 750

KCm il

Four w ir e lug s

3/ 0- 4 0 0 K Cm il

Tw o

4/ 0 DLO

wi re s

Tw o

4/ 0 DLO

wi re s

Four w ir e lug s

4/ 0- 500

KCm il

Thr ee wire

lu gs

50 0- 750

KCm il

Fou r wi re lu gs

3/ 0- 400

KCm il

Tw o

4/ 0 DLO

wi re s

Tw o

4/ 0 DLO

wi re s

Four w ir e lugs

4/ 0- 500

KCm il

Thr ee wire

lu gs

50 0- 750

KCm il

Fou r wi re lu gs

3/ 0- 400

KCm il

Tw o

31 3 MCM D LO

wi re s

Tw o

31 3 MCM D LO

wi re s

Four wire lugs

4/ 0- 500

KCm il

Thr ee wire

lu gs

50 0- 750

KCm il

Four wire lugs

3/ 0- 400

KCm il

Thr ee

4/ 0 D LO w ire s

Thr ee

4/ 0 DLO

wi re s

Four w ir e lugs

4/ 0- 500

KCm il

Thr ee wire

lu gs

50 0- 750

KCm il

Four w ir e lugs

3/ 0- 400

KCm il

Thr ee

4/ 0 DLO

wi re s

Thr ee

4/ 0 DLO

wi re s

Four wire lugs

Th re e w ire

50 0- 750

Four wire lugs

31 3 MCM DLO

31 3 MCM DLO

4/ 0- 500

KCm il

lu gs

KCm il

3/ 0- 400

KCm il

Thr ee

wi res

Thr ee

wi res

Requirements for Installation

Technicians

To properly install an AFDH upgrade Adaptive Frequency

Drive package, the technician must have a good working

knowledge of the centrifugal chiller controller system

involved in the application. Training is highly

Recommended before beginning this upgrade.

Tools Required

Normal tools are required to perform the work. An HVAC

service technician with a well-stocked tool chest should

already have the majority of the normal tools needed for

this job.

In addition to the normally carried service tools and

hardware, the following is a partial list of specific field

supplied hardware and software components and special

tools that will also be required to perform the drive

upgrade:

• The

Important: A spreader bar will be required if the drive

• Torque wrench capable of 40-170 foot-pounds.

• A

Note: Refer to BAS-SVP04*-EN (Programming Guide:

appropriate lifting device or devices (including

all necessary rigginghardware) with the capacity to

safely lift up to 1500 lb.

unit will be hoisted into position using a

single lifting device that is capable of

making only a single-point lift.

PC or laptop computer equipped with the correct

software tools for the chiller controller involved in

the application.

– Tracer TU service software version 10.2.174 or

newer.

TR200) for full program parameter details and

descriptions, and the instructions necessary to

operate the Local Control Panel(LCP) and program

the necessary drive parameters.

Note: The most current CTV and CVR microprocessor

(MP) firmware files are included with the program

files for the Tracer TU service software tools.

• Type A to Type B USB cable to connect the computer

to a Tracer UC800 controller.

• South

pole magnet screwdriver (TOL01343).

Miscellaneous Field-Provided

Material

Some field provided material will be required to perform

the drive upgrade. Apartial list of materialis provided here

to help the technician to plan ahead and to avoid material

shortages at the job site.

• Self-adhesive

ties.

– Used to help “clean up” wiring runs during the

installation

• Loctite

®

applications (Trane part number SEL00528).

– Used in applications where a pressure

transducer needs to be installed.

Direct Mount Drive install, have 3" X 3" Slotted

• For

Shim Full Assortment Kit available.

– Used to shim between the enclosure and the

evaporator attached bracket.

cable tie mounting bases and cable

process.

554 thread sealant for refrigerant

14 AFDH-SVN004C-EN

Page 15

Pre-Installation

Recommended Rigging and

Lifting Procedures for AFDH Drive

Units

WARNING

Heavy Objects!

Failure to follow instructions below or properly lift unit

could result in unit dropping and possibly crushing

operator/technician which could result in death or

serious injury, and equipment or property-only damage.

Ensure that all the lifting equipment used is properly

rated for the weight of the unit being lifted. Each of the

cables (chains or slings), hooks, and shackles used to

lift the unit must be capable of supporting the entire

weight of the unit. Lifting cables (chains or slings) may

not be of the same length. Adjust as necessary for even

unit lift.

WARNING

Improper Unit Lift!

Failure to properly lift unit in a LEVEL position could

result in unit dropping and possibly crushing operator/

technician which could result in death or serious injury,

and equipment or property-only damage. An AFDH

cabinet assembly is top heavy. Test lift unit

approximately 24 inches (61 cm) to verify proper center

of gravity lift point. To avoid dropping of unit,

reposition lifting point if unit is not level.

Do not lift such that any angle is placed on the lifting

tabs. They must only be lifted vertically.

Unit Lifting Points

Figure 8. Unit lifting points and center of gravity

1. Fact ory p rovided unit lift t ab s.

2. AFDH E- Fram e Un it f ro nt - to -rea r center of gr av it y.

Preferred Lifting Method

The preferred method for lifting an AFDH drive unit to

AFDH-SVN004C-EN 15

position it for installation, is to use an identical individual

hoisting device at each lift point.

Page 16

Pre-Installation

Figure 9. Preferred lifting method using two identical

individual hoists

Alternative Lifting Method

If it is only possible to use a single hoisting device to lift an

AFDH drive unit to position it for installation, a spreader

bar should be used to allow adjusting the rigging as

necessary to balance the unit around its center-of-gravity

to ensure full control of the unit during lifting.

Figure 10. Alternative lifting method using a single

hoist and spreader bar

Center of Gravity Reference (FEA Method)

Figure 11. Direct mount

24 .65

CENTER OF GRAVI TY

0

0

ORIGI NAL

29 .51

ORIGI NAL

CENTER OF GRAVI TY

0

CENTER OF GRAVI TY

Y

ORIGI NAL

X

Z

12 .24

ORIGI NAL 0 0 0

CENTER OF

GRAVITY

XYZ

12 .24 24. 65 29. 51

16 AFDH-SVN004C-EN

Page 17

Figure 12. Transition mount and LiquiFlo 1.0/1.5 frame 3

Pre-Installation

CENTER OF GRAVI TY

39 .5 7

0

ORI GINAL

0

27 .2 8

Figure 13. LiquiFlo 1.0/1.5 frame 4

ORI GINAL

CENTER OF GRAVI TY

0

10 .7 3

CENTER OF GRAVI TY

Y

ORI GINAL

X

Z

XYZ

ORI GINAL 0 0 0

CENTER OF

GRAVI TY

10 .7 3 3 9. 57 27. 28

35 .83

0

ORIGI NAL

CENTER OF GRAVI TY

0

28 .53

ORIGI NAL

CENTER OF GRAVI TY

0

10 .38

Y

ORIGI NAL

X

Z

ORI GINAL 0 0 0

CENTER OF

GRAVI TY

CENTER OF GRAVI TY

XYZ

10 .38 3 5.8 3 28. 53

AFDH-SVN004C-EN 17

Page 18

AFDH Drive Package Specifications

Direct Mount Unit Dimension

Figure 14. Top, front, and side view of E-Frame AFDH cabinet with dimensions - Direct mount drive

18 AFDH-SVN004C-EN

Page 19

AFDH Drive Package Specifications

Transition Mount Unit

Dimensions

Figure 15. Top, front, and side view of E-Frame AFDH cabinet with dimensions - Transition mount drive

AFDH-SVN004C-EN 19

Page 20

AFDH Drive Package Specifications

LiquiFlo 1.0/1.5 Frame 4 Unit

Dimensions

Figure 16. Top, front, and side view of LF 1/1.5 frame 4 E-Frame AFDH cabinet with dimensions - LiquiFlo drive

1. Z -bra cke t m ount in g stu ds ( each stu d = 3/ 8- 16 x 1. 75 i n. )

2. Two-piece a ccess do or co ver on t op of t he 9.3 in. x 1 4.9 in . in com ing po we r wi re cu to ut .

3. Elect ri cal di scon nect swit ch

20 AFDH-SVN004C-EN

Page 21

AFDH Drive Package Specifications

Figure 17. Rear view of LF 1/1.5 frame 4 E-Frame AFDH cabinet with dimensions - LiquiFlo drive

58. 40

2

57. 62

1

1. Tor t er m inal access co ver. Size o f cut out i s 7 .2 i n. x 1 7. 6 in .

2. Cent er lin e of Z- br ack et m oun ti ng st uds

AFDH-SVN004C-EN 21

Page 22

AFDH Drive Package Specifications

Drive Unit Weights and Heat

Rejection

Table 5. AFDH E-Frame unit weights (380V/480V)

3 8 0 V / 4 8 0 V

E- Fr a m e AF DH

Max im um a m p s

Enclo su re Ty pe

Un it W eigh t ( lb )

Hea t Re jecti on

( Btu/ h )

Direct

6 5 8 7 4 5 8 0 0 8 8 0 9 9 0

Transit i

14 02 1 43 7. 5 15 16.2 14 02 143 7. 5 1516. 2 1402 1437.5 1 51 6. 2 1 45 2 14 87 .5 15 66 .2 14 52 1 48 7. 5 1 56 6. 2

24 30 6 28 08 4 3 06 32 32 98 4 3 85 39

on

LF Direct

Transit i

on

Table 6. AFDH E-Frame unit weights (460V/480V)

4 6 0 V / 4 8 0 V

E- Fr a m e AF DH

Max im um a m p s

Enclo su re Ty pe

Un it W eigh t ( lb )

Hea t Re jecti on

( Btu/ h )

Direct

5 9 0 6 7 8 7 3 0 78 0 89 0

Transit i

14 02 1437.5 1 516.2 14 02 1437.5 15 16 .2 1402 1437.5 1 51 6. 2 1 45 2 14 87 .5 15 66 .2 14 52 1 48 7.5 1 56 6. 2

20 83 5 2 43 23 27 85 6 27310 32 17 6

on

LF Direct

Transit i

on

Table 7. AFDH E-Frame unit weights (575V/600V)

5 7 5 V / 6 0 0 V E- Fr a m e

AFDH M ax im um a m ps

Enclo su re Ty pe

Un it W eigh t ( lb )

Hea t Re jecti on ( Bt u / h)

5 7 5 V / 6 0 0 V E- Fr a m e

AFDH M ax im um a m ps

Enclo su re Ty pe

Un it W eigh t ( lb )

Hea t Re jecti on ( Bt u / h)

Direct Transit ion LF Direct Transit ion LF Direct Transit ion LF

14 02 1437.5 151 6. 2 1402 1 43 7. 5 1 51 6. 2 14 02 1 43 7. 5 15 16 .2

Direct Transit ion LF Direct Transit ion LF Direct Transit ion LF

14 02 1437.5 151 6. 2 1452 14 87 .5 1566. 2 1 45 2 1 48 7. 5 1 56 6. 2

4 5 0 5 0 0 5 7 0

21 35 3 24 13 9 28 22 1

6 3 0 7 3 0 8 5 0

32 08 1 35 96 1 44 06 7

LF Direct

LF Direct

Transit i

on

Transit i

on

LF Direct

LF Direct

Transit i

on

Transit i

on

LF Direct

LF Direct

Transit i

on

Transit i

on

LF

LF

22 AFDH-SVN004C-EN

Page 23

E-Frame Drive Unit Components

Drive Unit Component Parts Housed

within the Custom Enclosure

Figure 18. Custom enclosure parts

AFDH Drive Package Specifications

E-Frame

AFDH-SVN004C-EN 23

D and E-Frame

Page 24

AFDH Drive Package Specifications

Table 8. Custom enclosure parts: E-Frame 658 amps model drives (380V/400V)

Tr a ne Assem bly Pa r t N um be r s for all Op t io nal M ode l Ve rsion s of 3 80 V/ 4 00 V E- Fra m e 658 a m p s A FD H

Figu re 1 8

Callo ut

Pa r t Descri pt ion

Tr a n e X - Co de Pa r t

N u m b e r

Tr a ne Mn em oni c

N um be r

Su pp li er Pa rt

N um be r

Qu a nt ity

24 AFDH-SVN004C-EN

Page 25

AFDH Drive Package Specifications

Table 10. Custom enclosure parts; E-Frame 800 amps model drives (380V/400V)

Tr a ne Assem bly Pa r t N um be r s for all Op t io nal M ode l Ve rsion s of 3 80 V/ 4 00 V E- Fr am e 8 0 0 am ps AFDH

Figu re 1 8

Callo ut

Pa r t Descri pt ion

Tr a n e X - Cod e Pa r t

N u m b e r

Tr a ne Mn em oni c

N um be r

Su pp li er Pa rt

N um be r

Qu a nt ity

AFDH-SVN004C-EN 25

Page 26

AFDH Drive Package Specifications

Table 12. Custom enclosure parts: E-Frame 990 amps model drives (380V/400V)

Tr a ne Assem bly Pa r t N um be r s for all Op t io nal M ode l Ve rsion s of 3 80 V/ 4 00 V E- Fr am e 9 9 0 am ps AFDH

Figu re 1 8

Callo ut

Pa r t Descri pt ion

Tr a n e X - Co d e P a r t

N u m b e r

Tr a ne Mn em oni c

N um be r

Su pp li er Pa rt

N um be r

Qu a nt ity

26 AFDH-SVN004C-EN

Page 27

AFDH Drive Package Specifications

Table 14. Custom enclosure parts; E-Frame 678 amps model drives (460V/480V)

Tr a ne Assem bly Pa r t N um be r s for all Op t io nal M ode l Ve rsion s of 4 60 V/ 4 80 V E- Fr am e 6 7 8 am ps AFDH

Figu re 1 8

Callo ut

Pa r t Descri pt ion

Tr a n e X - Co d e P a r t

N u m b e r

Tr a ne Mn em oni c

N um be r

Su pp li er Pa rt

N um be r

Qu a nt ity

AFDH-SVN004C-EN 27

Page 28

AFDH Drive Package Specifications

Table 16. Custom enclosure parts; E-Frame 780 amps model drives (460V/480V)

Tr a ne Assem bly Pa r t N um be r s for all Op t io nal M ode l Ve rsion s of 4 60 V/ 4 80 V E- Fr am e 7 8 0 am ps AFDH

Figu re 1 8

Callo ut

Pa r t Descri pt ion

Tr a n e X - Co d e P a r t

N u m b e r

Tr a ne Mn em oni c

N um be r

Su pp li er Pa rt

N um be r

Qu a nt ity

28 AFDH-SVN004C-EN

Page 29

AFDH Drive Package Specifications

Table 18. Custom enclosure parts; E-Frame 450 amps model drives (575V/600V)

Tr a ne Assem bly Pa r t N um be r s for all Op t io nal M ode l Ve rsion s of 5 75 V/ 6 00 V E- Fr am e 4 5 0 am ps AFDH

Figu re 1 8

Callo ut

Pa r t Descri pt ion

Tr a ne X- Code

Pa r t N um be r

Tr a ne Mn em oni c

N um be r

Su pp lie r Pa r t Nu m be r

Qu a nt ity

AFDH-SVN004C-EN 29

Page 30

AFDH Drive Package Specifications

Table 20. Custom enclosure parts; E-Frame 570 amps model drives (575V/600V)

Tr a ne Assem bly Pa r t N um be r s for all Op t io nal M ode l Ve rsion s of 5 75 V/ 6 00 V E- Fr am e 5 7 0 am ps AFDH

Figu re 1 8

Callo ut

Pa r t Descri pt ion

Tr a n e X - Co d e Pa r t

N u m b e r

Tr a ne Mn em oni c

N um be r

Su pp li er Pa rt

N um be r

Qu a nt ity

30 AFDH-SVN004C-EN

Page 31

AFDH Drive Package Specifications

Table 22. Custom enclosure parts; E-Frame 730 amps model drives (575V/600V)

Tr a ne Assem bly Pa r t N um be r s for all Op t io nal M ode l Ve rsion s of 5 75 V/ 6 00 V E- Fr am e 7 3 0 am ps AFDH

Figu re 1 8

Callo ut

Pa r t Descri pt ion

Tr a n e X - Co de Pa r t

N u m b er

Tr a ne Mn em oni c

N um be r

Su pp li er Pa rt

N um be r

Qu a nt ity

AFDH-SVN004C-EN 31

Page 32

AFDH Drive Package Specifications

Additional Hardware Shipped with

Tracer® AdaptiView™ AFDH Packages

Table 24. Tracer® AdaptiView™ miscellaneous hardware contents

Tr a ce r® Adap t iV ie w ™ Misce lla neo us H a rdw ar e Co m p on e nt Pa r ts Li st

Pa r t D escr ip t ion Qu a nti ty

Low pr essu re tr ans duce r; 0 –7 0 PSI A, I PC3 OUTPUT, 2 4 VDC, 0- 70 PSIA, 0 .2 5 - 1 8 NPTF 1 X13 79 03 620 90 T DR007 33

Bra nch in g cabl e; Male t o t wo Fem ale, 3 9. 37 inch es lon g 1 X19 05 16 22 02 0 CAB0 11 47

Ext en sion cabl e; Male t o Female, 3 9. 37 inch es lon g 1 X19 05 16 23 01 0 CAB0 11 49

Execut iv e Beige Pain t; 1 0 oz. ae ro sol can 1 X35 02 04 76 02 0 PAI 00 29 7

TR20 0 Prog ram mi ng Gu ide 1 BAS- SVP04 * -EN

UC80 0 to D rive Mod bus Cab le 1 50 71 23 90

Schem at ics 1 50 71 21 27

AFDH E-Fram e Upgr ade Ad apti ve Freque ncy D ri ve I nstallation m anual 1 AFDH- SVN0 04 * -EN

Tr a ne X- Code

Pa r t N um be r

Mne m onic

N um be r

Note: Shorting buss bars that could be required for a

upgrade AFDH drive installation are not included

within the Tracer® AdaptiView™ miscellaneous

match the spacing and size of the compressor

motor terminal lugs onthe specific chiller receiving

the drive upgrade.

hardware package kit. Use the buss bars that best

Figure 19. Buss bars specifications: Tracer® AdaptiView™ hardware packages

1. Ex am pl e o f s hor t ing b uss bar s cont ai ned i n

ki t BAR0177

2. Ex am pl e o f s hor t ing b uss bar s cont ai ned i n

ki t BAR0163

3. Ex am pl e o f s hor t ing b uss bar s cont ai ned i n

ki t BAR00176

4. Ex am pl e o f s hor t ing b uss bar s cont ai ned i n

ki t BAR00165

32 AFDH-SVN004C-EN

Page 33

Motor panel transition covers for Transition

Mount and LiquiFlo

• It is possible to order a complete new motor panel

transition cover assembly if one is needed, either as

part of the drive package order or separately if

necessary.

• The transition cover assembly when properly

installed,

lead sections thatemerge from the accesscutout at the

back of a unit-mounted or stand-mounted AFDH drive,

and connect to the compressor motor terminal board.

Table 25. Part numbers for motor paneltransition covers

prevents direct access to the output motor

AFDH Drive Package Specifications

Pa r t D escr ip t ion

6- inch m oto r panel t ra nsi ti on cov er

asse mbly

12 - inch motor pa nel t ransi tion cover

asse mbly

18 - inch motor pa nel t ransi tion cover

asse mbly

Tr a ne Pa r t

N um be r

50 68 20 00 01 00 COV02 94 6

50 68 59 44 01 00 COV03 20 3

50 68 19 75 01 00 COV02 94 5

Mne m onic

N um be r

AFDH-SVN004C-EN 33

Page 34

Installation

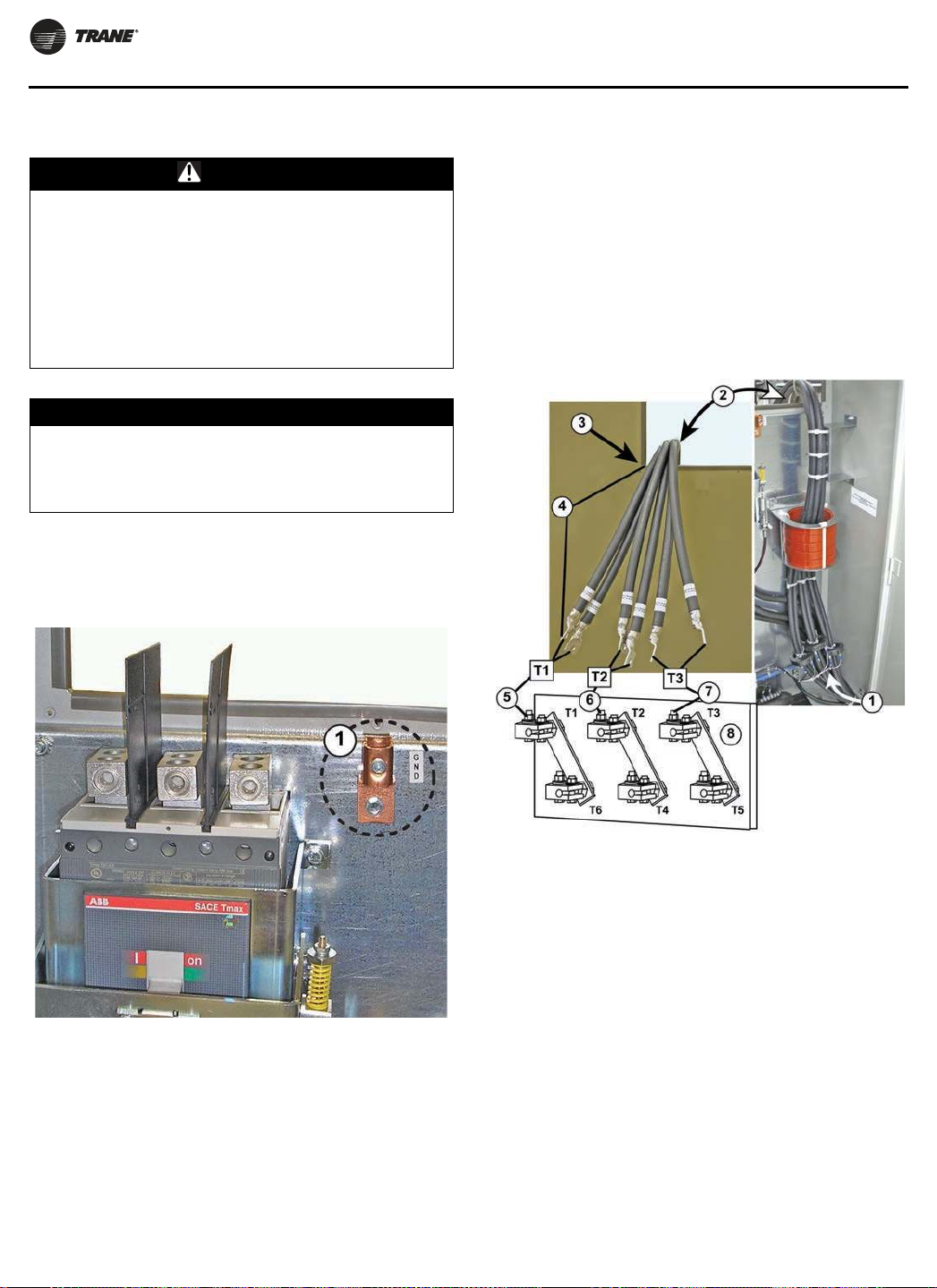

Removal of Electrical Connections

to the Existing Starter

WARNING

Hazardous Voltage w/Capacitors!

Failure to disconnect power and discharge capacitors

before servicing could result in death or serious injury.

Disconnect all electric power, including remote

disconnects and discharge all motor start/run

capacitors before servicing. Follow proper lockout/

tagout procedures to ensure the power cannot be

inadvertently energized. Forvariable frequency drivesor

other energy storing components provided by Trane or

others, refer tothe appropriate manufacturer’s literature

for allowable waiting periods for discharge of

capacitors. Verify with a CAT III or IV voltmeter rated per

NFPA 70E that all capacitors have discharged.

For additional information regarding the safe discharge of

capacitors, see PROD-SVB06*-EN.

1. Turn off the main power disconnect to the chiller and

then follow the correct lockout/tagout safety

procedures to ensure that main power to the machine

cannot be inadvertently restored.

a. For additional safety, also open all starter and

control

in the open position.

b. Depending upon the starter type, proceed to verify

that no electrical power exists at either the starter

breaker, or starter disconnect switch, or starter

terminal block, and other starter components

before starting the process of wiring removal.

2. Note the orientation of thepower cable connections to

the

starter terminal block.

a. Identify and clearly label the L1, L2, L3, and Ground

wiring

3. Identify and clearly labelthe power wiring cablesat the

compressor motor terminal lugs T1, T2, T3, T4,T5, and

T6 and then disconnect them.

a. Also disconnect the cables from their connection

points

cabinet area to prevent them from getting in the

way during the rest of the starter removal process.

b. Keep the motor terminal lugs. They will be reused

later in the installation.

4. At the starter cabinet, identify and clearly label the

control

starter panel.

a. Also identify and record the termination point of

each wire at the terminal block and then disconnect

them.

panel disconnect switches and secure them

starter breaker, or starter disconnect switch, or

cables before they are disconnected.

on the starter and remove them from the

and communication wiring running to the

b. Remove and save the conduit fittings from the line,

load,

and control power entrances and exits on the

starter cabinet.

c. Remove and save the conduit top plate for possible

reuse

later in the installation.

Mechanical Removal of Existing

Unit-Mounted Starter

WARNING

Heavy Objects!

Failure to follow instructions below or properly lift unit

could result in unit dropping and possibly crushing

operator/technician which could result in death or

serious injury, and equipment or property-only damage.

Ensure that all the lifting equipment used is properly

rated for the weight of the unit being lifted. Each of the

cables (chains or slings), hooks, and shackles used to

lift the unit must be capable of supporting the entire

weight of the unit. Lifting cables (chains or slings) may

not be of the same length. Adjust as necessary for even

unit lift.

WARNING

Improper Unit Lift!

Failure to properly lift unit in a LEVEL position could

result in unit dropping and possibly crushing operator/

technician which could result in death or serious injury,

and equipment or property-only damage. An AFDH

cabinet assembly is top heavy. Test lift unit

approximately 24 inches (61 cm) to verify proper center

of gravity lift point. To avoid dropping of unit,

reposition lifting point if unit is not level.

1. Depending upon model type, a unit-mounted starter

can weigh up to 750 pounds.

a. Verify that the intended lifting device and rigging

has the capacity to safely handle the load before

hooking up to the designated lifting points on the

starter unit.

Note: On

2. Using safe lifting practices, slowly begin taking up the

slack

a. Tension the rigging only to the point that is

necessary to take up enough of the weight of the

starter panel to enable loosening the bolts

connecting the panel.

some existing starters, lifting tabs are spotwelded to the enclosure.These welds can break

if not lifted straight up. To ensure a safe lift,

Trane recommends drilling a hole and bolting

the tabs to the enclosure to ensure a safe lift.

in the rigging.

34 AFDH-SVN004C-EN

Page 35

Installation

3. While steadying the starter panel to prevent it from

tipping forward, carefully begin removing the

retaining bolts that connect it to the lower motor panel

transition cover (Z-Bracket). See

Transition Mount and LiquiFlo only. For Direct Mount

remove

Note: The existing Z-bracket and transition cover on

4. Remove the bolts securing the bottom of the starter to

the

5. Carefully remove the starter panel from the chiller and

set it down in a safe location.

Important:

• Do

to the evaporator shell as they will be reused!

• Do

angle-iron clips that were used to attach the starter

panel tabs to the evaporator bracket as they will all be

reused!

motor flange bolts.

Transition and LF 1/1.5 installations will be

reused and do not need to be removed unless

greater access is required to the motor

terminals during drive installation.

brackets on the evaporator.

not cut off thestarter panel brackets thatare welded

not discard any of the nuts, bolts, washers, or the

Figure 42 for the

Mechanical Removal of Existing

Unit-Mounted LiquiFlo 1.0/1.5

Adaptive Frequency Drive

WARNING

Heavy Objects!

Only attach cables (chains or slings) to the designated

lifting points. Each of the cables (chains or slings) used

to lift the unit must be capable of supporting the entire

weight of the unit. Lifting cables (chains or slings) may

not be of the same length. Adjust as necessary for even

unit lift. Other lifting arrangements may cause

equipment or property-only damage. Failure to properly

lift unit could result in death or serious injury.

device and rigging hasthecapacity to safely handle the

load before hooking up to the designated lifting points

on the LiquiFlo drive.

Note: On

4. Using safe lifting practices, slowly begin taking up the

5. While steadying the starter panel to prevent it from

Note: The existing Z-bracket and transition cover will be

6. Remove the bolts securing the bottom of the LiquiFlo

7. Carefully remove the starter panel from the chiller and

Important:

8. Remove the bottom panel bracket from the starter

some existing LiquiFlo drives, lifting tabs are

spot-welded to the enclosure. These weld scan

break if not lifted straight up. To ensure a safe lift,

Trane recommends drilling a hole and bolting the

tabs to the enclosure to ensure a safe lift.

slack

in the rigging.Tension the rigging only to the

point that is necessary to take upenough of the weight

of the starter panel to enable loosening the bolts

connecting the panel to the Z-bracket on the motor

flange.

tipping

retaining bolts that connect it to the Z-bracket.

drive to the brackets on the evaporator.

set

• Do

• Do not discard any of the nuts, bolts,washers,or the

panel brackets as shown in below figure.

forward, carefully begin removing the

reused and do not need to be removed unless

greater access is required to the motor terminals

during drive installation.

it down in a safe location.

not cut off the starter panel brackets that are

welded to the evaporator shell as they will be

reused!

angle-iron clips that were used to attach the starter

panel tabs to the evaporator bracket as they will all

be reused!

WARNING

Improper Unit Lift!

Most unit-mounted starter designs tend to be top

heavy. Test lift unit to an approximate height of no

greater than 24 inches to verify proper center of gravity

lift point. To avoid dropping the unit, reposition lifting

point if unit is not level. Failure to properly lift unit

could result in death or serious injury or possible

equipment or property only damage.

1. Isolate the LiquiFlo drive water-side with isolation

valves.

2. Cut and cap the LiquiFlo drive water-side connections.

3. Depending upon model type, a LiquiFlo drive can

up to 970pounds. Verify that the intended lifting

weigh

AFDH-SVN004C-EN 35

Page 36

Installation

Figure 20. Removing bottom panel bracket from starter

panel brackets

Mechanical Installation of a UnitMounted AFDH E-Frame

Transition Mount Drive to Replace

Transition Mount Starter

WARNING

Heavy Objects!

Failure to follow instructions below or properly lift unit

could result in unit dropping and possibly crushing

operator/technician which could result in death or

serious injury, and equipment or property-only damage.

Ensure that all the lifting equipment used is properly

rated for the weight of the unit being lifted. Each of the

cables (chains or slings), hooks, and shackles used to

lift the unit must be capable of supporting the entire

weight of the unit. Lifting cables (chains or slings) may

not be of the same length. Adjust as necessary for even

unit lift.

WARNING

Improper Unit Lift!

Failure to properly lift unit in a LEVEL position could

result in unit dropping and possibly crushing operator/

technician which could result in death or serious injury,

and equipment or property-only damage. An AFDH

cabinet assembly is top heavy. Test lift unit

approximately 24 inches (61 cm) to verify proper center

of gravity lift point. To avoid dropping of unit,

reposition lifting point if unit is not level.

WARNING

Unit Lowering!

Do not drop the drive cabinet assembly onto the

evaporator mounting brackets when setting it into

position! Dropping the cabinet onto the brackets could

result in damage to the drive cabinet, the brackets, and/

or the evaporator shell.

36 AFDH-SVN004C-EN

Page 37

Installation

Figure 21. Removal of Z-bracket weldment nuts

1. Z -bra cke t

2. We ldm e nt n ut s (4 t ot al on b ra cket , o nly 2 sh ow n) dr ill ou t or g ri nd

of f flu sh.

1. Inspect the Z-bracket on the chiller motor flange. If the

Z-bracket is equipped with weldment nuts, these nuts

must either be ground off or drilled out to allow the

M8X25 bolts on the back of the new drive cabinet to

slide into the bracket at these locations.

2. Prepare lifting equipment and rigging.

a. Depending upon the model type, a unit-mounted

AFDH

can weigh up to 1400 pounds. Confirm the

weight of theAFDH unit to be installed. For E-Frame

units refer to Table.

b. Verify that the intended lifting device and rigging

has the capacity to safely handle the load before

hooking up to thetwofactory provided lifting points

on top of the cabinet assembly.

c. Use the appropriate rigging techniques to ensure

that

the cabinet assembly will be balanced about its

center of gravity during lifting. Refer to

“Recommended Rigging and LiftingProcedures for

AFDH Drive Units,”

.

Figure 22. Transition mounting

345

1

2

67

1. Panel m ou nt ing p lat e

2. Evap orator m oun tin g bracke t

3. Bolt

4. Lock washer

5. Wash er

6. Wash er

7. Nut

3. Using safe lifting practices, carefully liftthe cabinetand

position it over the brackets on the evaporator.

4. Slowly lower the cabinet until the lower mounting

bracket makes contact with the evaporator brackets

but do not place the full weight of the cabinet onto the

brackets at this time. Keep tension on the lift rigging to

support the weight of the cabinet.

a. Adjust the position of the lower mounting bracket

as

necessary until the back of the cabinet is level

and lined up against the Z-bracket, then attach the

cabinet to the bracket using the kit hardware

provided (screws for the motor terminal access).

Shims may be necessary to level the lower

mounting bracket. The front edgeof the evaporator

brackets may need to be ground down to allow for

more adjustment.

b. Secure the lower mounting bracket to the

evaporator

brackets with the bolts provided and

previously used (if needed) to secure the old starter

panel to them.

c. Ensure that all nuts are properly tightened at all

cabinet mounting points.

5. Confirm that the drive is firmly attached to all brackets

is stable before slowly lowering the lifting device

and

to slacken the rigging and remove it from the lifting

points.

AFDH-SVN004C-EN 37

Page 38

Installation

Figure 23. Position cabinet base over evaporator

brackets

Figure 24. Leveling the AFDH drive cabinet against the

Z-bracket

LiquiFlo Frame 3 Drive

Replacement

WARNING

Heavy Objects!

Failure to follow instructions below or properly lift unit

could result in unit dropping and possibly crushing

operator/technician which could result in death or

serious injury, and equipment or property-only damage.

Ensure that all the lifting equipment used is properly

rated for the weight of the unit being lifted. Each of the

cables (chains or slings), hooks, and shackles used to

lift the unit must be capable of supporting the entire

weight of the unit. Lifting cables (chains or slings) may

not be of the same length. Adjust as necessary for even

unit lift.

WARNING

Improper Unit Lift!

Failure to properly lift unit could result in unit dropping

and possibly crushing operator/technician which could

result in death or serious injury, and equipment or

property-only damage. An AFDH cabinet assembly is

top heavy. Test lift unit approximately 24 inches to

verify proper center of gravity lift point. To avoid

dropping of unit, reposition lifting point if unit is not

level.

WARNING

Unit Lowering!

Do not drop the drive cabinet assembly onto the

evaporator mounting brackets when setting it into

position! Dropping the cabinet onto the brackets could

result in damage to the drive cabinet, the brackets, and/

or the evaporator shell.

1. The AFDH drive angle bracket has slotted holes to

allow for adjustment. Loosen the nuts to allow for

adjustment. Make sure not to take the nuts completely

out.

38 AFDH-SVN004C-EN

Page 39

Installation

Figure 25. AFDH drive angle bracket adjustment Figure 26. Starter panel welded brackets markings to

trim

2. Mark to trim the starter panel brackets that are welded

to the evaporator shell as they will interfere with the

drive. Make sure to lineup the motor terminal access

with the starter panel bracket and only trim the extra

length. Refer to the below figures.

Figure 27. Starter panel brackets markings to trim extra

length

AFDH-SVN004C-EN 39

Page 40

Installation

3. Use a saw-zaw to trim the starter panel brackets. Refer

to the below figure.

Figure 28. Starter panel brackets during trimming

Figure 29. Starter panel brackets after trimming

of the new drive cabinet to slide into the bracket at

these locations.

5. Prepare lifting equipment and rigging.

a. Depending upon the model type, a unit-mounted

AFDH

can weigh up to 1400 pounds. Confirm the

weight of the AFDH drive. See

Table 7.

b. Verify that the intended lifting device and rigging

has the capacity to safely handle the load before

hooking up to thetwofactory provided lifting points

on top of the cabinet assembly.

c. Use the appropriate rigging techniques to ensure

that

the cabinet assembly will be balanced about its

center of gravity during lifting. Refer to

“Recommended Rigging and LiftingProcedures for

AFDH Drive Units,”

6. Implement safe lifting practices, carefully lift the

cabinet

the evaporator. Slowly lower the cabinet until the

panel and angle bracket make contact with the

evaporator brackets and rests on the brackets. The

cabinet angle bracket is slotted if the AFDHneeds to be

moved for adjustment. Do NOT place the full weight of

the cabinet onto the brackets at this time.Keep tension

on the lift rigging to support the weight of the cabinet.

7. Keep the upper part of the AFDH panel flush with the Zbracket

AFDH panel in position.

8. Verify that the Z-bracket is flush against the AFDH

panel. See

9. Attach the Z-bracket at the top of the panel, make sure

the AFDH panel is level.

10. Once the upper Z-bracket is secured, leave the lift

rigging in place and attach a C-clamp to the cabinet

angle bracket and starter panel brackets to hold the

cabinet angle bracket in place. Refer to the below

figure.

and position it over the mounting brackets on

face. Keep tensionon the lift riggingto hold the

Figure 24, p. 38.

.

Table 5, Table 6 and

4. Inspect the lower panel transition cover (Z-bracket) on

the chiller motor flange. If the Z-bracket is equipped

with weldment nuts, these nuts must either be ground

off or drilled out to allow the M8X25 bolts on the back

40 AFDH-SVN004C-EN

Page 41

Installation

Figure 30. Installing bolts on mounting brackets on the

evaporator and cabinet angle bracket

Direct Mount Drive to Replace

Direct Mount Starter

WARNING

Heavy Objects!

Failure to follow instructions below or properly lift unit

could result in unit dropping and possibly crushing

operator/technician which could result in death or

serious injury, and equipment or property-only damage.

Ensure that all the lifting equipment used is properly

rated for the weight of the unit being lifted. Each of the

cables (chains or slings), hooks, and shackles used to

lift the unit must be capable of supporting the entire

weight of the unit. Lifting cables (chains or slings) may

not be of the same length. Adjust as necessary for even

unit lift.

WARNING

Improper Unit Lift!

Failure to properly lift unit could result in unit dropping

and possibly crushing operator/technician which could

result in death or serious injury, and equipment or

property-only damage. An AFDH cabinet assembly is

top heavy. Test lift unit approximately 24 inches to

verify proper center of gravity lift point. To avoid

dropping of unit, reposition lifting point if unit is not

level.

11. Use a lubricateddrill bit (for M16bolt) and drill through

the mounting brackets on the evaporator and cabinet

angle bracket.

12. Bolt cabinet angle bracket to the evaporator support

brackets with M16bolts, nuts, and washers (washer on

top and bottom).

Figure 31. Cabinet angle bracket and evaporator

support bracket in position

AFDH-SVN004C-EN 41

Unit Lowering!

Do not drop the drive cabinet assembly onto the

evaporator mounting brackets when setting it into

position! Dropping the cabinet onto the brackets could

result in damage to the drive cabinet, the brackets, and/

or the evaporator shell.

1. Prepare lifting equipment and rigging.

a. Depending upon the model type, a unit-mounted

can weigh up to 1400 pounds. Confirm the

AFDH

weight of the AFDH drive. See

Table 7.

b. Verify that the intended lifting device and rigging

has

the capacity to safely handle the load before

hooking up to thetwofactory provided lifting points

on top of the cabinet assembly.

c. Use the appropriate rigging techniques to ensure

that

the cabinet assembly will be balanced about its

center of gravity during lifting. Refer to

“Recommended Rigging and LiftingProcedures for

AFDH Drive Units,”

2. Implement safe lifting practices, carefully lift the

cabinet

the evaporator.Slowly lower the cabinet untilthe AFDH

panel flush and lineup with the motor terminal access

bolt pattern.

and position it over the mounting brackets on

.

Table 5, Table 6 and

WARNING

Page 42

Installation

3. Reuse the motor terminal access bolts and bolt the

cabinet to the motor at the motor terminal. Do NOT

place the full weight of the cabinet onto the brackets at

this time. Keeptension on the liftrigging to support the

weight of the cabinet.

4. The 400 frame motorrequiresan adapter plate tocover

the excess gap at the AFDH drive motor terminal

access opening.

1. 400 Mot or A dapt er

2. M12 Flat Wash er

3. M12 Hex Nut

4

2

4. Screw, M12 X 30MM Hex Cap

3

1

5. Make sure the cabinet is level and bolt the cabinet to

the evaporator support brackets with the provided

bolts, nuts, and washers.

6. Shim the space between the cabinet and the

evaporator support brackets with 3”X 3”slotted shims.

Place the shims slots around the bolts. Ease the

tension on the lifting rigging, confirm the shims are

snug, and then tighten the bolts to secure the cabinet

on top of the evaporator support brackets.

42 AFDH-SVN004C-EN

Page 43

Linkage Bracket Installation for a

Unit- Mounted Direct Mount E-

Installation

WARNING

Unit Lowering!

Do not drop the drive cabinet assembly onto the