Page 1

Installation Instructions

Roof Curbs for Performance Climate Changer™

Air Handlers

Model CSAA and PSCA

Only qualified personnel should install and service the equipment. The installation, starting up, and servicing

of heating, ventilating, and air-conditioning equipment can be hazardous and requires specific knowledge and

training. Improperly installed, adjusted or altered equipment by an unqualified person could result in death or

serious injury. When working on the equipment, observe all precautions in the literature and on the tags,

stickers, and labels that are attached to the equipment.

May 2018

SAFETY WARNING

CLCH-SVN05C-EN

X-39641204010

Page 2

Introduction

Read this manual thoroughly before operating or servici ng

this unit.

Warnings, Cautions, and Notices

Safety advisories appear throughout this manual as

required. Your personal safety and the proper operation of

this machine depend upon the strict observance of these

precautions.

The three types of advisories are defined as follows:

WARNING

CAUTIONs

NOTICE

Important Environmental Concerns

Scientific research has shown that certain man-made

chemicals can affect the earth’s naturally occurring

stratospheric ozone layer when released to the

atmosphere. In particular, several of the identified

chemicals that may affect the ozone layer are refrigerants

that contain Chlorine, Fluorine and Carbon (CFCs) and

those containing Hydrogen, Chlorine, Fluorine and

Carbon (HCFCs). Not all refrigerants containing these

compounds have the same potential impact to the

environment. Trane advocates the responsible handling of

all refrigerants-including industry replacements for CFCs

and HCFCs such as saturated or unsaturated HFCs and

HCFCs.

Important Responsible Refrigerant

Practices

Trane believes that responsible refrigerant practices are

important to the environment, our customers, and the air

conditioning industry. All technicians who handle

refrigerants must be certified according to local rules. For

the USA, the Federal Clean Air Act (Section 608) sets forth

the requirements for handling, reclaiming, recovering and

recycling of certain refrigerants and the equipment that is

used in these service procedures. In addition, some states

or municipalities may have additional requirements that

must also be adhered to for responsible management of

refrigerants. Know the applicable laws and follow them.

Indicates a potentially hazardous

situation which, if not avoided, could

result in death or serious injury.

Indicates a potentially hazardous

situation which, if not avoided, could

result in minor or moderate injury. It

could also be used to alert against

unsafe practices.

Indicates a situation that could result in

equipment or property-damage only

accidents.

WARNI NG

Proper Field Wiring and Grounding

Required!

Failure to follow code could result in death or serious

injury. All field wiring MUST be performed by qualified

personnel. Improperly installed and grounded field

wiring poses FIRE and ELECTROCUTION hazards. To

avoid these hazards, you MUST follow requirements for

field wiring installation and grounding as described in

NEC and your local/state electrical codes.

WARNI NG

Personal Protective Equipment (PPE)

Required!

Failure to wear proper PPE for the job being undertaken

could result in death or serious injury. Technicians, in

order to protect themselves from potential electrical,

mechanical, and chemical hazards, MUST follow

precautions in this manual and on the tags, stickers,

and labels, as well as the instructions below:

• Before installing/servicing this unit, technicians

MUST put on all PPE required for the work being

undertaken (Examples; cut resistant gloves/sleeves,

butyl gloves, safety glasses, hard hat/bump cap, fall

protection, electrical PPE and arc flash clothing).

ALWAYS refer to appropriate Material Safety Data

Sheets (MSDS)/Safety Data Sheets (SDS) and OSHA

guidelines for proper PPE.

• When working with or around hazardous chemicals,

ALWAYS refer to the appropriate MSDS/SDS and

OSHA/GHS (Global Harmonized System of

Classification and Labelling of Chemicals) guidelines

for information on allowable personal exposure

levels, proper respiratory protection and handling

instructions.

• If there is a risk of energized electrical contact, arc, or

flash, technicians MUST put on all PPE in accordance

with OSHA, NFPA 70E, or other country-specific

requirements for arc flash protection, PRIOR to

servicing the unit. NEVER PERFORM ANY

SWITCHING, DISCONNECTING, OR VOLTAGE

TESTING WITHOUT PROPER ELECTRICAL PPE AND

ARC FLASH CLOTHING. ENSURE ELECTRICAL

METERS AND EQUIPMENT ARE PROPERLY RATED

FOR INTENDED VOLTAGE.

© 2018 Ingersoll Rand CLCH-SVN05C-EN

Page 3

WARNING

Follow EHS Policies!

Failure to follow instructions below could result in

death or serious injury.

• All Ingersoll Rand personnel must follow Ingersoll

Rand Environmental, Health and Safety (EHS)

policies when performing work such as hot work,

electrical, fall protection, lockout/tagout, refrigerant

handling, etc. All policies can be found on the BOS

site. Where local regulations are more stringent than

these policies, those regulations supersede these

policies.

• Non-Ingersoll Rand personnel should always follow

local regulations.

Copyright

This document and the information in it are the property of

Trane, and may not be used or reproduced in whole or in

part without written permission. Trane reserves the right

to revise this publication at any time, and to make changes

to its content without obligation to notify any person of

such revision or change.

Introduction

Trademarks

All trademarks referenced in this document are the

trademarks of their respective owners.

Revision History

Updated dimensional data.

CLCH-SVN05C-EN 3

Page 4

Table of Contents

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Overview of Manual . . . . . . . . . . . . . . . . . . . 5

Nameplate . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Pre-Installation . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Site Preparation . . . . . . . . . . . . . . . . . . . . . . . 6

Roof Curb Installation Checklist . . . . . . . . . . 6

Dimensions and Weights . . . . . . . . . . . . . . . . . 7

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Placement . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Assembly and Installation . . . . . . . . . . . . . 10

Unit Roof Curb . . . . . . . . . . . . . . . . . . . . . 10

Pipe Cabinet Roof Curb . . . . . . . . . . . . . . 12

Specialty Roof Curbs . . . . . . . . . . . . . . . . 12

Ductwork Recommendations . . . . . . . . . . . 13

Sound Attenuation . . . . . . . . . . . . . . . . . . 13

Supply and Return Air Ductwork . . . . . . 14

Parts Information . . . . . . . . . . . . . . . . . . . . . 15

4 CLCH-SVN05C-EN

Page 5

Introduction

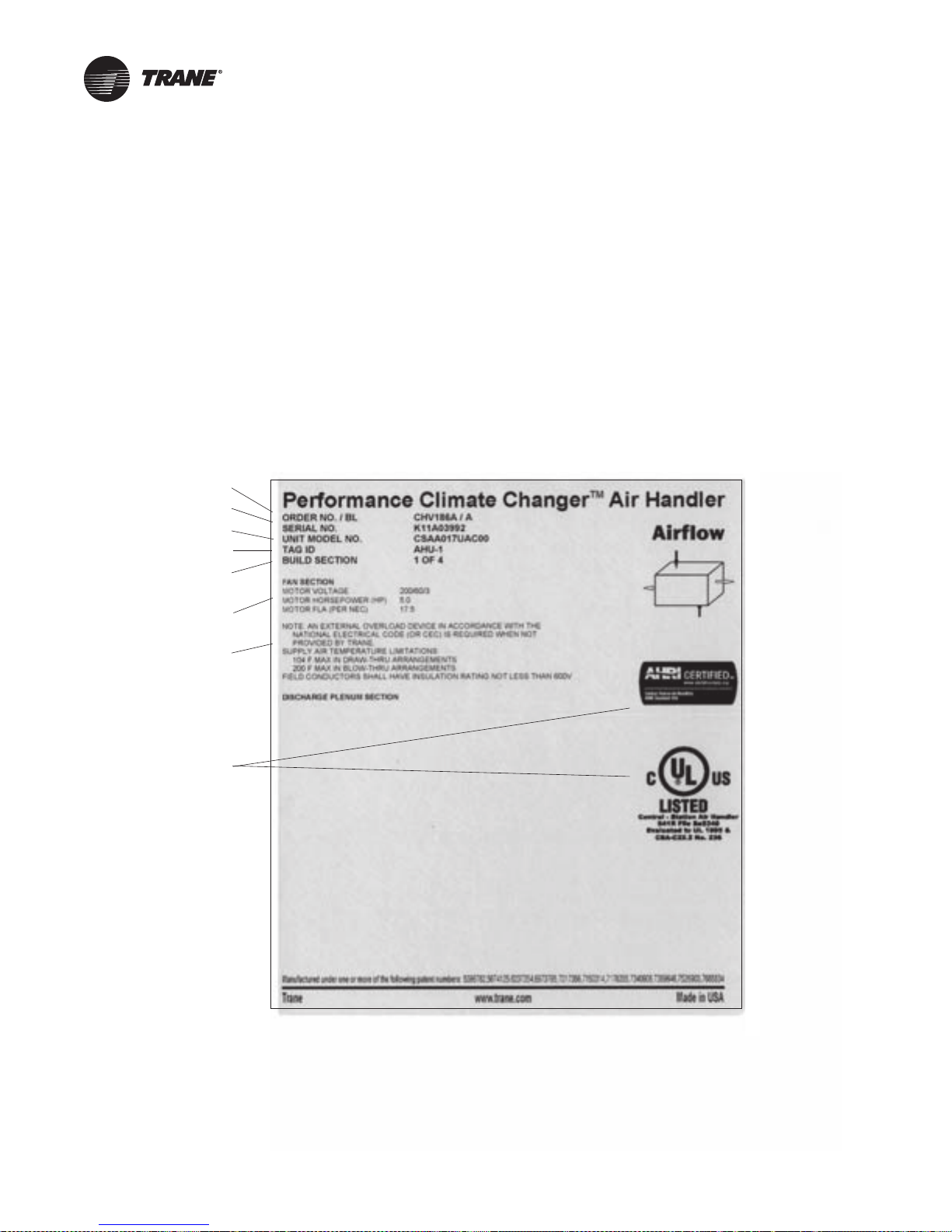

Agency listings and/or

agency certifications

Trane order number

Unit level serial number

Service model number

Unit tagging

Section location

Functional section type

Notes and additional

section information

Overview of Manual

Performance Climate Changer™ air handlers may be

mounted on the roof with a roof curb or pier mount. This

manual includes the assembly instructions. Before

proceeding with the installation, refer to the unit submittal

drawings and unit tagging for correct placement of air

handler sections. Failure to review the submittal drawings

could result in performance or assembly problems. If there

are any discrepancies, contact your local Trane sales

engineer before proceeding. Carefully review the

procedures discussed in this manual to minimize

installation and startup difficulties.

Figure 1. Performance air handler section nameplate

Nameplate

Each air handler section includes at least one nameplate/

label, which identifies the type of section and functional

components, customer tagging information, the unit

serial number, the unit order number, the build section

position for installation, and the unit model number. Refer

to this information when ordering replacement parts or

requesting service.

Note: The unit serial number and order number is

required when ordering parts or requesting service

for a Trane air handler.

CLCH-SVN05C-EN 5

Page 6

Pre-Installation

As-built submittals show the intended layout of the

various air handler sections to meet job site requirements.

Installation information (unit dimensions, clearances,

weights, curb location and roof opening dimensions and

locations) may vary with special equipment and

applications. For exact information, always refer to the

specific unit submittals, which can be obtained from your

local Trane sales office.

Roof curbs are shipped “knocked down” for assembly at

the job site.

Site Preparation

Ensure the installation site can support the total weight of

the air-handling unit, including accessories and the roof

curb. For approximate air handler section weights, refer to

Performance Climate Changer™ Air Handler IOM, CLCHSVX07*-EN. Units with special options or arrangements

will differ in dimensions, clearances, weights and roof

opening dimensions and locations. Always refer to unit

submittals before marking off the dimensions of the unit

roof curb, pipe ca binet curb (if pipe cabinet is ordered),

and roof openings. For roof curbs supplied by Trane,

approximate roof curb weights are in Tab le 1 .

Note: To calculate the total curb weight, find the unit

length, multiply by the factor supplied in Tab l e 1 for

the applicable roof curb height, and add the curb

end weight for the applicable roof curb height.

Roof Curb Installation Checklist

It is recommended that the curb be installed directly on the

support members and fastened to the supports using tack

welds or other equivalent methods. Properly supported

decking should be installed inside the air handler section

of the curb when this method is used.

Verify that the roof structure can adequately support

the combined weight of the unit and curb assembly.

Ensure that the selected installation location provides

sufficient service and operational clearances.

Remove any twist within the curb due to roof supports

and square the curb.

Level the curb.

Secure the curb to the roof support members.

Install 2-inch thick boards or rigid insulation around the

curb.

Install cant strips around the curb.

Bring field supplied roofing felt up to the top of the

curb nailing strips. Nail felt into place.

Install field supplied flashing under the lip of the curb

flanges and over the felt.

Apply sealant to the four corners.

Caulk all joints between the curb and the roof. Attach

the gasket material to the curb’s top flanges (entire

perimeter) and to the supply and return air duct open

panel flanges.

6 CLCH-SVN05C-EN

Page 7

Dimensions and Weights

Table 1. CSAA Curb weights

Curb

height

14-inch

18-inch

22-inch

26-inch

30-inch

36-inch

Curb

height Unit Size 30 35 40 50 57 66 80 100 120

14-inch

18-inch

22-inch

26-inch

30-inch

36-inch

Note: Example: Size 21 Performance air handler with airfoil damper mixing section, small coil section, medium access section, medium coil section, small

blank section, VFD control section, and fan section (down discharge) total unit length is 156.75 inches. Total roof curb weight for the 18-inch curb

would be 502.80 lbs (156.75 x 1.05 = 164.5875 lbs + 338.21 = 502.7975 lbs.)

Unit Size 3 4 6 8 10 12 14 17 21 25

Curb end and duct

support weight

Curb side weight Take total length in inches, multiply by 0.56 pounds, and add to the above curb end & duct support weight.

Curb end and duct

support weight

Curb side weight T ake total length in inches, multiply by 1.05 pound s, and add to the abov e curb end & duct sup port weight.

Curb end and duct

support weight

Curb side weight Take total length in inches, multiply by 1.22 pounds, and add to the above curb end & duct support weight.

Curb end and duct

support weight

Curb side weight T ake total length in inches, multiply by 2.00 pound s, and add to the abov e curb end & duct sup port weight.

Curb end and duct

support weight

Curb side weight Take total length in inches, multiply by 2.25 pounds, and add to the above curb end & duct support weight.

Curb end and duct

support weight

Curb side weight T ake total length in inches, multiply by 2.63 pound s, and add to the abov e curb end & duct sup port weight.

Curb end and duct

support weight

Curb side weight Take total length in inches, multiply by 0.56 pounds, and add to the above curb end & duct support weight.

Curb end and duct

support weight

Curb side weight T ake total length in inches, multiply by 1.05 pound s, and add to the abov e curb end & duct sup port weight.

Curb end and duct

support weight

Curb side weight Take total length in inches, multiply by 1.22 pounds, and add to the above curb end & duct support weight.

Curb end and duct

support weight

Curb side weight T ake total length in inches, multiply by 2.00 pound s, and add to the abov e curb end & duct sup port weight.

Curb end and duct

support weight

Curb side weight Take total length in inches, multiply by 2.25 pounds, and add to the above curb end & duct support weight.

Curb end and duct

support weight

Curb side weight T ake total length in inches, multiply by 2.63 pound s, and add to the abov e curb end & duct sup port weight.

117.23 155.82 155.82 175.88 209.84 225.27 242.25 242.25 266.94 266.94

148.76 197.59 197.59 222.98 265.95 285.48 306.96 306.96 338.21 338.21

171.54 227.14 227.14 256.05 304.98 327.22 351.68 351.68 387.26 387.26

215.31 286.02 286.02 322.78 385.00 413.28 444.39 444.39 489.64 489.64

240.72 319.23 319.23 360.06 429.15 460.56 495.11 495.11 545.36 545.36

278.82 369.05 369.05 415.98 495.38 531.48 571.18 571.18 628.93 628.93

308.62 328.68 367.27 407.39 407.39 453.70 453.70 496.91 581.80

390.95 416.34 465.17 515.95 515.95 574.54 574.54 629.23 736.65

447.31 476.22 531.82 589.64 589.64 656.36 656.36 718.63 840.95

566.00 602.77 673.47 747.00 747.00 831.85 831.85 911.03 1066.58

630.15 670.98 749.50 831.15 831.15 925.37 925.37 1013.31 1186.04

726.38 773.30 863.54 957.38 957.38 1065.66 1065.66 1166.73 1365.24

CLCH-SVN05C-EN 7

Page 8

Installation

Discharge

Intake

Airflow

Auxillary support

loaded under curbs

Roof mounting curb

inside edge

Main roof support member

capable of supporting unit

weight

Main roof support member

or auxillary support located

under center of unit or under

section joints

Piers

4 ft

Placement

Note: Isolation rails should not be installed on top of

Trane roof curbs. If isolation rails or isolation curbs

are required, the entire curb system should be

supplied by a specialty curb company.

The roof curb must be supported along its entire

perimeter. The curb may be set parallel or at right angles

to roof support members. If at right angles to the support

members, there must be adequate supporting roof cross

members between the ends (in the direction of airflow). Be

sure the cross members do not interfere with the

connection of supply and return ducts to the unit. See

figure below for details.

Figure 2. Unit set perpendicular to roof curb members

Figure 3. Pier locations (typical)

Figure 4. Side view with shipping splits

• When mounting the unit on its roof curb, make sure

that the gasketing between the roof curb and unit base

provides an airtight seal.

Note: When pulling shipping split sections together, the

field-supplied gasket material may bunch up

between bases. Make certain this does not prevent

tight contact between shipping sections.

• If a unit is pier-mounted, at a minimum, locate one pier

at each corner directly underneath any shipping split

(ensure full support under each side), and then every

four feet at equally spaced intervals around the

perimeter of the unit. Both the unit and the pipe cabinet

should be supported by their base channel around the

entire perimeter (see Figure 3 and Figure 4).

8 CLCH-SVN05C-EN

Note: Piers beneath shipping splits must be structurally sound to support

the weight of the unit.

See Figure 5 for typical cross section for pier- or slabmounted base.

Page 9

Installation

3.0 in. - sizes 3-50

4.0 in. - sizes 57-120

6.0 in. - sizes 3-120

2 x 4

Nailer

Roof

curb

Gasket

Nail

Counter

flashing

Flashing

Roofing/insulating

material

Figure 5. Typical cross section for pier mounted or

slab-mounted base

Note: For PSCA, the base rail height is 7.25 in. Verify the base rail width

in unit submittal.

• For new building construction, the roof curb may be

installed as soon as the roof support members are in

place. Trane recommends that the roof curb be placed

directly on the roof support members and welded into

place. If the curb is mounted on the roof deck,

additional support is necessary directly below the curb

flanges to minimize vibration.

• Do not overlap counter flashing over the top of the roof

curb. Counter flashing should extend to the bottom of

the roof curb drip lip. Attach counter flashing with

fastener through the wooden nailer. Figure 6, Figure 7

and Figure 8 show typical roof curb installations and

detail.

Note: Materials that attach to the roof curb are supplied

by the installer, including flashing, insulating

material and cant. Gasket and 2 x 4 nailer are

supplied by Trane.

Figure 6. Typical roof curb installation - existing

building

Gasket

2 x 4 nailer

Roof curb

Wooden nailer

Roof structure

Nail

Counter flashing

Flashing

Roof/insulating material

4 x 4 cant

Roof insulation

Figure 7. Typical roof curb installation - new

construction

Gasket

2 x 4 nailer

Roof curb

Nail

Counter flashing

Flashing

Roof/insulating material

4 x 4 cant

Roof structure

Roof insulation

Roof deck

Figure 8. Detail of installation

Roof deck

CLCH-SVN05C-EN 9

Page 10

Installation

Assembly and Installation

The following procedure explains how to assemble and

install roof curbs provided by Trane. An attachment

specific to your roof curb is shipped with your Traneordered roof curb. See typical exploded view and parts list

in Figure 22, p. 15 and Tab l e 4 , p . 16 . In order to properly

locate the duct supports (if required) and external piping

cabinet (if ordered), it is recommended that you have a

copy of the as-built curb drawings from the submittal

package. For specialty or field-fabricated roof curbs please

see the section entitled “Specialty Roof Curbs,” p. 12 for

important information.

Unit Roof Curb

Figure 9. Typical roof curb provided by Trane

Figure 10. Side splice detail

Nut

Washer

Washer

Bolt

Splice

plate

2. Attach outer and inner corner splice plates (4 places) as

shown in the figure below.

Figure 11. Corner splice detail

Cross brace

WARNING

Risk of Roof Collapsing!

Failure to ensure proper structural roof support could

cause the roof to collapse, which could result in death

or serious injury and property damage. Confirm with a

structural engineer that the roof structure is strong

enough to support the combined weight of the roof

curb and the unit. Refer to “Dimensions and Weights,”

p. 7 for typical curb weights.

1. Attach cross brace and outer side splice plates at splice

locations (refer to the following figure).

Roof curb

Washer

Washer

Bolt

Nut

Inner corner

angle

Outer corner

angle

10 CLCH-SVN05C-EN

Page 11

Installation

A

B

C

D

79

61 1/4

8 7/8

17 3/4

38

13 1/2

14

9 1/2

23 1/8

37 7/8

5 1/2

15 7/8

19 7/8

55 5/8

134 1/4

155 7/8

75 1/2

Note: Open side of 1301 crossbrace

must face to the left.

Notes:

1. 1306-xx (PTAF duct support) is field cut to length.

2. Use self drillers (included) to attach 1307-xx (duct

support angle) to 1305-xx and 1606-xx.

1307-01

1305-01

1384-01

1301-01

1306-02

1305-02

1384-02

1385-01

1306-01

Unit roof curb

2 x 4 nailer

Pipe chase

roof curb

Roof curb

angle

Check curb dimensions for squareness as shown in the

figure below. Measurements from A-B should equal

measurement from C-D (± 1/8-inch).

Note: Measurements A-C, D-B, A-D, and B-C are inside

curb dimensions and are supplied with the unitspecific roof curb manual.

Figure 12. Unit roof curb perimeter

3. Tighten nuts/bolts at all locations. Ensure lock nuts are

securely tightened.

4. Review the details curb plan view as-built to determine

the location of the supply and/or return openings and

placement of duct support members. See figure below.

Figure 13. Typical as-built curb detail plan view (inches)

from submittal package

5. Attach duct support members to each side of roof curb

perimeter wall with self-drill screws. See figure below.

Figure 14. Duct support detail

6. Assemble the pipe cabinet roof curb (when supplied).

See the figure below.

Note: If pipe cabinet roof curb interferes with splice

plates, field drill holes to match those in the splice

plate. Attach the pipe cabinet roof curb with splice

plate bolts. Self-drill the other end.

Figure 15. Pipe cabinet roof curb assembly

CLCH-SVN05C-EN 11

7. Install gasket along the perimeter of the pipe chase

roof curb and unit roof curb. Gasketing is provided

with the roof curb when ordered from Trane.

8. Install the curb. The curb may be set on structural

framing (by others). This curb is designed to transfer

the load to a continuous underlying structural frame.

The structural members (by others) should span the

perimeter of the curb.

Page 12

Installation

Unit Roof Curb

Pipe Chase

Roof Curb

1.4 in.

2.88 in. - sizes 3-50

3.88 in. - sizes 57-120

6.0 in. - sizes 3-120

9. Complete all ductwork, piping, and electrical

connections only after mounting the unit. Refer to unit

submittals.

Pipe Cabinet Roof Curb

Pipe cabinets ordered from Trane for field installation

require special attention with regard to joining the unit

roof curb and pipe cabinet roof curb. A good joint will

prevent any water management problems within the pipe

cabinet.

The pipe cabinet roof curb should be three-sided and have

dimensions as shown in the figure below, a top view of the

pipe cabinet roof curb, and Ta b l e 2 . Dimension ‘L’ is from

the outside of the unit roof curb to the outside of the pipe

cabinet roof curb. Dimension ‘X’ is the outside-to-outside

width dimension of the pipe cabinet roof curb. Dimension

‘Z’ locates the pipe chase roof curb along the unit roof curb

in the direction of airflow. This measurement is from the

outside of the unit roof curb to the outside of the pipe

cabinet roof curb.

The basic formula becomes:

• Z = LDS – 3 for CSAA sizes 3 to 50

• Z = LDS - 3.5 for CSAA sizes 57 to 120

• Z = LDS - 3.5 for all PSCA sizes

where LDS is the total length of the sections downstream

of the pipe cabinet.

Table 2. Pipe cabinet roof curb dimensions

L dimension

Unit size

3 to 50 CSAA 26.00 38.00 50.00

57 to 120 CSAA 26.50 38.50 50.50

All PSCA 36.50 38.50 50.50

All unit sizes X dimension

Note: Lp is the sum of the section length(s) covered by

the pipe cabinet. Refer to submittal.

Reduced Standard Extended

Reduced Lp + 5

Standard Lp + 5

Extended Lp + 5

Specialty Roof Curbs

Units to be mounted on a roof curb not supplied by Trane

require special attention.

Center the unit base on the roof curb as shown in the figure

below.

Figure 17. Cross section

Figure 16. Top view of unit and pipe cabinet roof curb

Note: For PSCA, the base rail height is 7.25 in. Verify the base rail width

in unit submittal.

12 CLCH-SVN05C-EN

Page 13

A typical unit roof curb and unit base cross-section without

a pipe cabinet is shown in the figure below.

Installation

Figure 19. Top view of unit and pipe cabinet roof curb

Figure 18. Roof curb with flashing

The table below lists the outside-to-outside dimensions

for over all width and length of the roof curb for each size

unit. Length is dependent on the various unit options

ordered. Refer to submittals for section lengths.

Note: Center the unit base on the roof curb.

Table 3. CSAA Specialty roof curb dimensions

Unit Size Width Length

3 30.50 Ls-1

4 43.00 Ls-1

6 43.00 Ls-1

8 49.50 Ls-1

10 60.50 Ls-1

12 65.50 Ls-1

14 71.00 Ls-1

17 71.00 Ls-1

21 79.00 Ls-1

25 79.00 Ls-1

30 92.50 Ls-1

35 99.00 Ls-1

40 111.50 Ls-1

50 124.50 Ls-1

57 123.50 Ls-2

66 138.50 Ls-2

80 138.50 Ls-2

100 152.50 Ls-2

120 180.00 Ls-2

Notes:

1. Where Ls is the sum of all section lengths in the unit.

2. For PSCA, the curb width is 2 in. less than the unit width (Ls-2) and

the curb length is 2 in. less than the unit length (Ls-2).

Unit Roof Curb

Pipe Chase

Roof Curb

Figure 20. Pipe cabinet roof curb dimensions

L dimension

Unit size

3 to 50 CSAA 26.00 38.00 50.00

57 to 120 CSAA 26.50 38.50 50.50

All PSCA 26.50 38.50 50.50

All unit sizes X dimension

Note: Lp is the sum of the section length(s) covered by

the pipe cabinet. Refer to submittal.

Reduced Standard Extended

Reduced Lp + 5

Standard Lp + 5

Extended Lp + 5

Ductwork Recommendations

Sound Attenuation

Noise is produced by unit supply fans, and exhaust fans.

Supply fan noise is substantially attenuated by the

ductwork, provided it is properly constructed.

SMACNA recommendations for metal gauge thickness

and installation should be followed carefully. Lightly

constructed ductwork can produce “oil canning”-a rapid

in-and-out pulsating motion of the duct walls-resulting in

sound problems.

Note: If roof decking cannot be placed under the unit, an

acoustical barrier can be installed.

Corrugated steel decking is acoustically ideal for the

installation of the roof curb and connecting ductwork.

Closely toleranced holes must be cut in the roof deck for

the supply and return ductwork. When the duct is installed,

caulking must be used to seal the decking to the duct. Even

CLCH-SVN05C-EN 13

Page 14

Installation

Coil

space

Vertical

discharge

3 fan

diameters

Return

air

Use lined duct for all returns (1-inch thick, 6-pound density fiberglass recommended).

a small air leak between the duct and the deck will destroy

most of the attenuation available from the steel decking.

In addition, special consideration may be required to

ensure that the weight of the unit does not crush the roof

deck at those points where the deck is between the curb

and support joist. Poured insulation will usually add the

required strength, while the use of rigid insulation may

require placement of three-inch support channels on the

decking.

As a general rule, exhaust fan noise is not a problem and

can be adequately attenuated by the return ductwork. For

critical applications where return ductwork is not required,

however, installation of an acoustically-lined “return T” is

recommended; see Figure 21.

Supply and Return Air Ductwork

Ductwork for all units must be fabricated and installed by

the installing contractor; to ensure proper duct

construction and installation, SMACNA recommendations

should be closely followed.

Figure 21. Typical supply and return ductwork

Below are several typically used guidelines for ductwork

construction:

• Elbows with turning vanes or splitters are

recommended to minimize air noise and resistance.

• The first elbow in the ductwork leaving the unit should

be no closer than 3 fan diameters from the unit,

thereby minimizing noise and resistance.

In those instances where the unit is installed over an

acoustically critical area, additional treatment of the

ductwork is recommended. Both supply and return

ductwork should be lined internally with glass fiber duct

liner 1-inch thick. The external surface of the supply duct

should be covered with an acoustical barrier material such

as one or two pound/sq. ft. sheet lead (1/64-inch or 1/32inch) or loaded vinyl sheet or gypsum board for the first 10

ft. of ductwork. The lining should extend from the point

where the duct penetrates the roof to a distance of 10 ft.

beyond the vertical drop from the unit.

14 CLCH-SVN05C-EN

Page 15

Parts Information

Figure 22. Typical exploded view of curb with part numbers

Installation

1385-02

1304-04

1384-06

1303-04

1302-02

1306-04

1305-04

1306-03

1384-04

1302-02

1303-03

1305-03

1304-03

1307-05

1301-02

1384-02

1384-05

1304-02

1301-01

1306-01

1305-02

1303-01

1302-03

1384-03

1306-01

1302-01

1305-01

1387R-01

1303-06

1386-01

1303-05

1387L-01

1384-01

1304-01

1307-01

1303-01

1385-01

CLCH-SVN05C-EN 15

Page 16

Installation

Table 4. Typical customer parts list

Customer Parts List

Thank you for purchasing the roof curb accessory for the Trane Performance Climate Changer™ air handler for this project.

We at Trane appreciate your business, and strive constantly to improve products. To that end, we welcome any comments

or suggestions you may have regarding this product.

Job Number

Length (I.D.)

Width (I.D.)

Weight (EST.): Washers:

Project Name: Self Drillers: 56

Tags:

Part Description Dimensions Qty

TP1301 Cross Brace

TP1301-01 Cross Brace 45.50 x 14.00 x 14.00 1

TP1301-02 Cross Brace 45.50 x 14.00 x 14.00 1

TP1302 Outer Side Plate

TP1302-01 Outer Side Plate 9.88 x 5.00 1

TP1302-02 Outer Side Plate 9.88 x 5.00 1

TP1302-03 Outer Side Plate 9.88 x 5.00 1

TP1302-04 Outer Side Plate 9.88 x 5.00 1

TP1303 Inner Corner Angle

TP1303-01 Inner Corner Angle 13.88 1

TP1303-02 Inner Corner Angle 13.88 1

TP1303-03 Inner Corner Angle 13.88 1

TP1303-04 Inner Corner Angle 13.88 1

TP1303-05 Inner Corner Angle 13.88 1

TP1303-06 Inner Corner Angle 13.88 1

123456-1-1

157.25 in.

45.50 in.

RTU-1

E-Bolts:

Bolts:

Nuts:

Weight:

20

60

80

140

267.33

TP1304 Outer Corner Angle

TP1304-01 Outer Corner Angle 9.88 1

TP1304-02 Outer Corner Angle 9.88 1

TP1304-03 Outer Corner Angle 9.88 1

TP1304-04 Outer Corner Angle 9.88 1

TP1305 Duct Support

TP1305-01 Duct Support 56.50 1

TP1305-02 Duct Support 56.50 1

TP1305-03 Duct Support 42.50 1

TP1305-04 Duct Support 42.50 1

TP1305 Duct Support Cross

TP1306-01 Duct Support Cross 45.50 1

TP1306-02 Duct Support Cross 45.50 1

TP1306-03 Duct Support Cross 45.50 1

TP1306-04 Duct Support Cross 45.50 1

TP1305 Duct Support Angle

TP1307-01 Duct Support Angle 5.00 x 2.00 x 2.00 1

TP1307-02 Duct Support Angle 5.00 x 2.00 x 2.00 1

TP1307-03 Duct Support Angle 5.00 x 2.00 x 2.00 1

TP1307-04 Duct Support Angle 5.00 x 2.00 x 2.00 1

TP1307-05 Duct Support Angle 5.00 x 2.00 x 2.00 1

TP1307-06 Duct Support Angle 5.00 x 2.00 x 2.00 1

TP1307-07 Duct Support Angle 5.00 x 2.00 x 2.00 1

TP1307-08 Duct Support Angle 5.00 x 2.00 x 2.00 1

TP1384 Side Wall

TP1384-01 Side Wall 58.88 x 14.00 x 14.00 1

TP1384-02 Side Wall 58.88 x 14.00 x 14.00 1

TP1384-03 Side Wall 58.13 x 14.00 x 14.00 1

TP1384-04 Side Wall 58.13 x 14.00 x 14.00 1

TP1384-05 Side Wall 40.25 x 14.00 x 14.00 1

TP1384-06 Side Wall 40.25 x 14.00 x 14.00 1

16 CLCH-SVN05C-EN

Page 17

Table 4. Typical customer parts list (continued)

TP1385 End Wall Dog Ear Both Ends

TP1385-01 End Wall Dog Ear Both Ends 49.50 x 14.00 x 14.00 1

TP1385-02 End Wall Dog Ear Both Ends 49.50 x 14.00 x 14.00 1

TP1386 Chase Side

TP1386-01 Chase Side 35.00 x 14.00 x 14.00 1

TP1386 Left Chase End

TP1386-01 Chase Side 39.00 x 14.00 x 14.00 1

TP1387 Right Chase End

TP1387-01 Right Chase End 39.00 x 14.00 x 14.00 1

Tools Required for Assembly: 2 Sockets with 9/16 Drive

Installation

CLCH-SVN05C-EN 17

Page 18

Page 19

Page 20

Ingersoll Rand (NYSE:IR) advances the quality of life by creating comfortable, sustainable and efficient

ingersollrand.com

environments. Our people and our family of brands—including Club Car®, Ingersoll Rand®, Thermo King® and

Trane®—work together to enhance the quality and comfort of air in homes and buildings; transport and protect

food and perishables; and increase industrial productivity and efficiency. We are a global business committed to a

world of sustainable progress and enduring results.

Ingersoll Rand has a policy of continuous product and product data improvement and reserves the right to change design and specifications

without notice.

We are committed to using environmentally conscious print practices.

CLCH-SVN05C-EN 19 May 2018

Supersedes CLCH-SVN05B-EN (Feb 2016)

©2018 Ingersoll Rand

Loading...

Loading...