Page 1

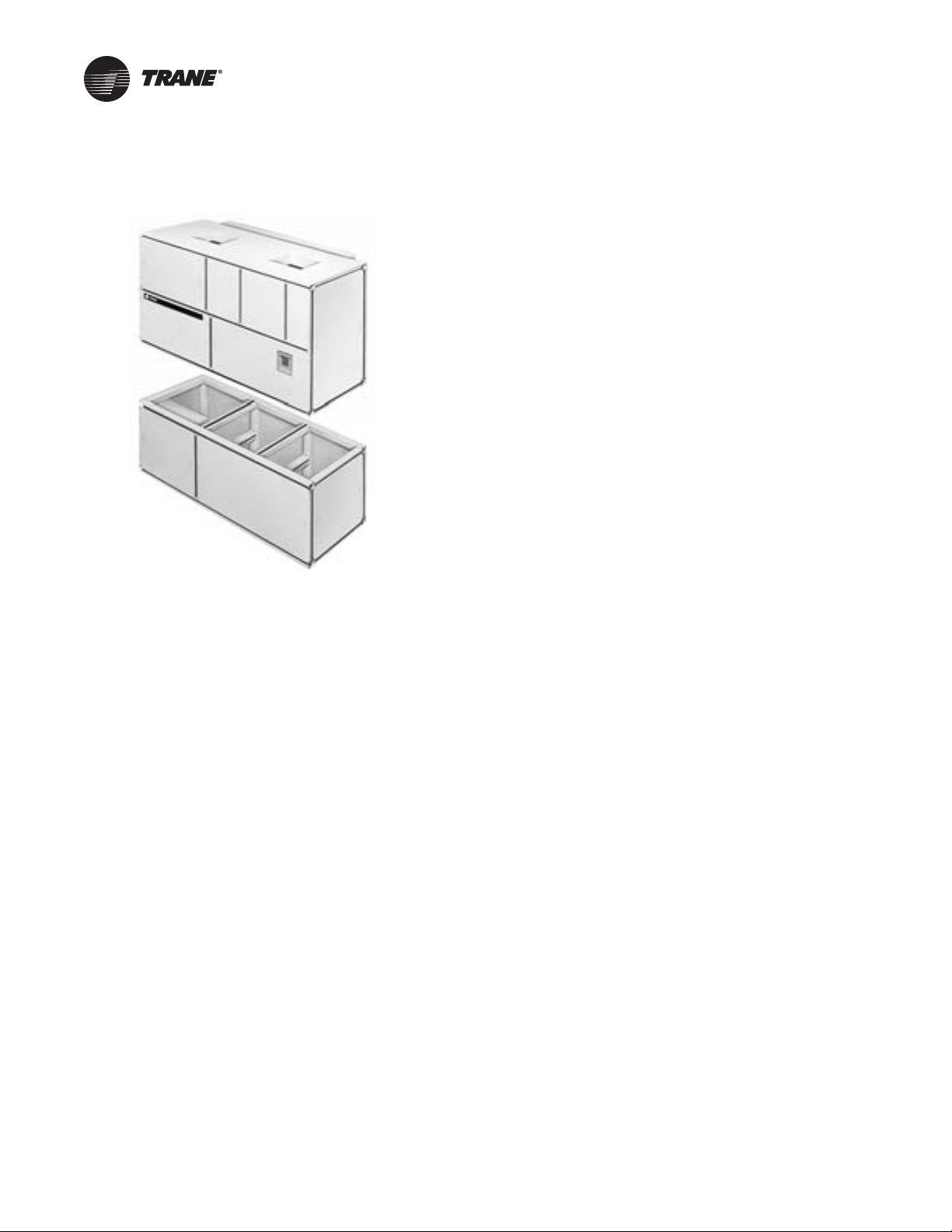

Product Catalog

Commercial Self-Contained

Modular Series

20-35Ton Water-Cooled Air Conditioners

20-32Ton Air-Cooled Air Conditioners

Remote Air Cooled Condensers

June 2014

PKG-PRC003U-EN

Page 2

Introduction

Figure 1. Affordable self-contained value from Trane

Copyright

• Modular design allows the fan/coil section to “split-apart”

from the compressor section

• 35” wide base that fits through standard door openings

• Trane 3-D® Scroll compressors give reliable, efficient,

and quiet operation

• Unit mounted microprocessor control with human

interface panel

• Hinged and removable control panel door for easy access

• Waterside or airside economizer for “free cooling”

• Two-bolt connection on cleanable condenser for quick,

easy maintenance

• Waterside valve package option to enhance system

efficiency

• Sight glasses with ports for viewing unit while running

• 2-inch flat filter box inside unit casing

• Energy saving with variable frequency drive (VFD)

• Sloped drain pan for indoor air quality

This document and the information in it are the property ofTrane, and may not be used or

reproduced in whole or in part without written permission.Trane reserves the right to revise this

publication at any time, and to make changes to its content without obligation to notify any person

of such revision or change.

Trademarks

Trane and theTrane logo are trademarks of Trane in the United States and other countries. All

trademarks referenced in this document are the trademarks of their respective owners.

Revision History

PKG-PRC003U-EN (09 Jun 2014)

Updated to correct460V, 7.5HP, ODPFan motor FLAvalue, and input line current for 575V, 15HP, with

bypass.

PKG-PRC003-EN (04 Apr 2013)

Add wireless comm interface (WCI).

PKG-PRC003-EN (15 Oct 2012)

Corrected fan motor information. Updated fan FLA and LRA values in Electrical Data tables

© 2014 Trane All rights reserved PKG-PRC003U-EN

Page 3

Table of Contents

Introduction ......................................................2

Features and Benefits ..............................................5

Why consider Modular Series self-contained floor-by-floor systems? .... 6

Integrated Self-Contained Systems ................................. 9

Trane R-410A 3-D™ Scroll Compressor ............................ 11

Application Considerations .........................................12

Free Cooling Opportunities and Alternatives ........................ 14

Isolation Recommendations ...................................... 14

Condenser Water Piping ......................................... 15

Selection Procedure ...............................................17

Modular Series Self-Contained ................................... 19

Model Number Descriptions ........................................19

Self-Contained Ship-With Accessory Model Number ................. 21

Remote Air-Cooled Condenser ................................... 21

General Data .....................................................22

Performance Data ................................................25

Airside Pressure Drop ........................................... 25

Waterside Pressure Drop ........................................ 28

Water-Cooled Unit Performance .................................. 30

Air-Cooled Unit Performance ..................................... 38

Heating Performance ........................................... 41

Controls ........................................................42

Heat Module Option ............................................ 42

Generic BAS Option (GBAS) ..................................... 42

LonTalk™ Building Automation System ............................ 43

BACnet™ Building Automation System ............................ 43

Standard Control Features on IntelliPak™ Units ..................... 44

Airside Options ................................................ 49

IntelliPak™ Units - Zone Temp Control (Sequence Of Operation) ....... 49

IntelliPak™ Units - Supply Air Temp Control (Sequence Of Operation) . . 51

Zone Sensor Options ........................................... 53

Electrical Data ....................................................56

Selection Procedures ........................................... 56

Determination of Minimum Circuit Ampacity (MCA) .................. 56

PKG-PRC003U-EN 3

Page 4

Table of Contents

Dimensions and Weights ..........................................59

Variable Frequency Drive Without ByPass .......................... 69

Variable Frequency Drive With ByPass ............................. 74

Service Clearances ............................................. 78

Mechanical Specifications ..........................................79

Modular Series Self-Contained ................................... 79

IntelliPak™ Control Options ...................................... 81

Remote Air-Cooled Condenser CCRC/CIRC .......................... 86

4 PKG-PRC003U-EN

Page 5

Features and Benefits

The industry leader in self-contained systems since 1988 is now even better!Trane’s modular series

unit is easy to install, flexible, and now has the latest control technology. New modular DDC

controls with human interface (HI) panel make self-contained units easier to operate.

The modular series design fits the needs of the retrofit/renovation market.The unit easily “splits”

apart to fit into freight elevators. In addition, we can ship the compressor section separate from the

fan/coil section for field installation. Filter, economizer, and heating coil sections are all removable

for added flexibility.Also, the modular series is smallenough tofit through a standard 35-inch door

opening.

The IntelliPak™ unit’s DDC controls areTrane-designed to work withTrane equipment for optimum

efficiency. The factory installs and commissions each control component to ensure simple and

reliable operation. Also, the IntelliPak® self-contained unit has a unit mounted human interface

panel as standard and a remote option that will monitor up to four units.

Easy to install

• Passes through standard 35-inch door opening

• Removable fan/coil section from compressor section for those applications that requirethe unit

to be “split apart”

• Ship separate fan/coil section for field installation

• Removable filter, economizer and heating coil sections for added flexibility

Flexible

• Left or right hand condenser connections for field piping\Condenser piping factory manifolded

and extended to the unit exterior for a single inlet and outlet

• Economizer factory piped for either right or left hand connections and extended to the unit

exterior for a single inlet and outlet

• Free cooling with either waterside or airside economizer options

• Hot water, steam, and electric heating coil options

• Control system choices include:

• Thermostat interface for simple constant volume applications

• Direct digital controls (DDC) available on the IntelliPak self-contained, offers the most

advanced unit control for constant volume or variable air volume applications — available

with aTracer™ LCI-I, BCI-I, or generic building automation system interface.

Easy to operate

The Intellipak self-contained unit’s control design allows greater application flexibility.You can

order exactly what the job requires as options, instead of one large control package. Unit features

are distributed among multiple field replaceable printed circuit boards.

All set-up parameters are preset from the factory, requiring less startup time during installation.

In addition, IntelliPak self-contained unitshave a humaninterface panel thatdisplays unit operating

parameters and conditions in English, Spanish, or French language, making it easy to adjust

setpoints or service. It also requires less time for building maintenance personnel to learn to

interact with the unit. Human interface panel displays all of the self-contained unit’s control

parameters, such as system on/off; demand limiting type; night setback setpoints. All setpoint

adjustments are done through human interface key-pad.You can also monitor diagnostic points,

suchas sensor failures; supply airflow loss; and inoperative refrigerant circuit.Diagnostics are held

in memory, even during power loss.This allows operator/servicer to diagnose failure root cause.

PKG-PRC003U-EN 5

Page 6

Features and Benefits

Why consider Modular Series self-contained floor-by-floor systems?

Improved Cash Management

• Factory-installed and tested options reduce field labor and installation risk, while improving

system reliability

• Requires less sophisticated maintenance than built-up systems

Tenant Satisfaction

• Complete HVAC system on each floor minimizes tenant inconvenience during routine

maintenance

• Tenants can control system after hours to increase productivity and minimize expense

Low First Cost

• Reduce field labor, installation time, and cost with factory packaged controls and piping

• Reduce installed tonnage up to 20% by taking advantage of building diversity and VAV

flexibility

• Flexible air discharge arrangement matches most building configurations

Lower Installed Cost

• Single-point power connection

• Single-point water connection

• Factory commissioned and tested controls

• Factory installed options

• Internally trapped drain connection

Economical Operation

• Free cooling year-round with waterside or airside economizer

• Energy savings with floor-by-floor system since only units on floors requiring cooling need to

operate

• Significant annual energy consumption reduction compared to a central chilled water system

due to partial occupancy after-hours

• Simple heating alternatives include perimeter radiation and fan-powered VAV

• Energy savings from the integrated water valve control using pump unloading

Assured Acoustical Performance

• Flexible, horizontal discharge plenum provides smooth airflow, reducing static pressure losses

for optimum acoustical performance

• Multiple compressor design reduces acoustical levels. Scroll compressor design smooths gas

flow for quieter operation

Indoor Air Quality (IAQ) Features

• Sloped drain pan

• Stainless steel sloped drain pan option

• Internally trapped drain connection

• Double wall construction option

• Matt-faced fiberglass insulation

• High efficiency throwaway filter option

6 PKG-PRC003U-EN

Page 7

Features and Benefits

• Easily cleanable evaporator, condensers, and waterside economizers

• Filter access door allows easy removal to encourage frequent filter changing

• Airside economizer option with Traq™ damper allows direct measurement and control of

outdoor air

Enhanced Serviceability

• Self-supporting removable panels

• Quick access service panel fasteners

• Refrigerant line sight glasses in view during operation

• Easy to adjust setpoints and operating parameters using the human interface panel on

IntelliPak units.

Standard Features

• 20 through 35 ton industrial and commercial water-cooled self-contained units

• 20 through 32 ton industrial/commercial remote air-cooled self-contained units

• IntelliPak™ DDC controls or thermostat interface

• ImprovedTrane 3-D™ scroll compressor

• Constant volume (CV) or variable air volume (VAV) operation

• Low ambient compressor lockout adjustable control input

• EISA efficiency supply fan open drip proof (ODP) or totally enclosed fan cooled (TEFC) motor

options

• Emergency stop input

• Refrigeration circuits are completely factory piped and tested on water-cooled units

• Water-cooled condensers are factory piped and tested, mechanically cleanable

• Two-bolt removable condenser waterboxes for quick and easy cleaning

• Sloped drain pans to ensure complete condensate removal for IAQ

• Internally trapped drain connection with cleanout

• Internally isolated centrifugal supply fan

• Sturdy galvanized steel framework with easily removable painted exterior galvanized steel

panels

• UL listing on standard options

• Fan belts and grease lines are easily accessible

• Access panels and clearance provided to clean evaporator and waterside economizer coil fins

• Condensing pressure control on all variable water flow systems with valves

• Complete factory run–in test with power and water

Standard Control Features

• Unit mounted human interface panel with a two line x 40 character language (English, Spanish,

or French) display and a 16-function keypad that includes custom, diagnostics, and service test

mode menu keys

• Compressor lead/lag

• FROSTAT™ coil frost protection on all units

• Daytime warmup (occupied mode) and morning warmup operation

• Supply air static over pressurization protection on units with variable frequency drives (VFDs)

• Supply airflow proving

PKG-PRC003U-EN 7

Page 8

Features and Benefits

• Supply air tempering control with heating option

• Supply air heating control on VAV with hydronic heating option

• Mappable sensors and setpoint sources

• Occupied/unoccupied switching

• Timed override activation

• Programmable water purge during unoccupied mode

• High entering air temperature limit

• Low entering air temperature limit with waterside economizer or hydronic heat

Optional Features

• Trane LCI-I communication interface module: ICS interface control module

• BACnet Communications Interface Module

• Generic BAS interface

• Comparative enthalpy control

• Ventilation override with up to five external inputs

• Remote human interface controls up to four units

• Waterside modulating condensing temperature control valves include factory installed piping

• Removable cast iron headers on cleanable waterside economizer

• Refrigerant suction discharge line service (shut-off) valves

• Protective coating on unit and/or evaporator coils

• Double wall construction

• Stainless steel sloped drain pan

• Medium efficiency throwaway filters

• Through-the-door non-fused disconnect switch

• High duct temperature thermostat

• Dual electrical power connection

• CO2 reset input

• Trane’s air qualityTraq™ damper in mixing box

and control wiring

Factory Installed or Ship Separate Options

• Waterside economizer with factory installed piping and controls

• Flexible horizontal discharge plenum with or without factory cut holes, double wall perf

• Heating options include hot water, steam, and electric (field installed only)

Field Installed Accessories

• Airside economizer control with or without mixing box

• Wireless comm interface (WCI)

• Programmable sensors with or without night set back - CV and VAV

• ICS zone sensors used withTracer™ system for zone control

• Field installed module kits available to upgrade controls

• Ultra low leak dampers for 0-100% & modulating fresh air economizer

• Fully integrated variable frequency drive (VFD) control with or without optional integrated

bypass

8 PKG-PRC003U-EN

Page 9

Integrated Self-Contained Systems

Integrated Comfort™ System (ICS)

Figure 2. You can control, monitor, and service your facility using Trane’s ICS and your PC

Features and Benefits

Trane’s Integrated Comfort™ system (ICS)

increases job control by combining IntelliPak™

Modular Series self-contained units and aTracer

building management system.This integrated

system provides total building comfort and

control. Building owners and managers not only

save energy when using ICS — they have the

ability to automate their facilities and the

convenience of a control system interface.

Simplifying The Comfort System

Trane’s designers combined new technology and

innovation to bring you more system capabilities

and flexibility. Our Integrated Comfort™ system

(ICS) with HVAC equipment is easy to use, install,

commission, and service.

Everything you need to know about your self-contained VAV system is available usingTracer

building automation products.Tracer is a software package that minimizes custom programming

requirements and allows easy system setup and control using your personal computer. Operating

data from all system components is readily available for evaluation.You can control, monitor, and

service your facility — all from your personal computer.

The IntelliPak self-contained unit, as part ofTrane ICS, provides powerful maintenance monitoring,

control, and reporting capabilities.Tracer places the self-contained unit in the appropriate

operating mode for: system on/off, night setback, demand limiting, setpoint adjustment based on

outside parameters and much more.You can monitor unit diagnostic conditions throughTracer

such as: sensor failures, loss of supply airflow, and an inoperative refrigerant circuit.

IntelliPak Modular Series Self-Contained Monitoring Points Available Using

Tracer

• Compressor on/off status

• Ventilation status

• Condenser water flow status

• Heat status

• Supply air pressure

• Supply air temperature

• Suction temperature of each circuit

• Entering economizer water temperature

• Zone temperature

• Entering condenser water temperature

• Supply air temperature reset signal

• Morning warmup sensor temperature

• Entering air temperature

PKG-PRC003U-EN 9

Page 10

Features and Benefits

Tracer Control Points for IntelliPak Modular Series Self-Contained Units

• Cooling and heating setpoints

• VAV discharge air temperature setpoints

• Supply air pressure setpoint

• Cooling and heating enable/disable

• Air economizer enable/disable

• Air-side economizer minimum position

• Unit priority shutdown

Interoperability with BACnet

TheTraneTracer SC BACnet Control Interface (BCI) for IntelliPak self-contained offers a building

automation control systemwith outstanding interoperabilitybenefits. BACnet, whichis an industry

standard, is an open, secure and reliable network communication protocol for controls, created by

American Society of Heating, refrigerating and Air-Conditioning Engineers, Inc. (ASHRAE)

Interoperability allows application or project engineers to specify the best products of a given type,

rather than one individual supplier's entire system. It reduces product training and installation

costs by standardizing communications across products. Interoperable systems allow building

managers to monitor and control IntelliPak equipment withTracer SC controls or a 3rd party

building automation system. It enables integration with many different building controls such as

access/intrusion monitoring, lighting, fire and smoke devices, energy management, and a wide

variety of sensors (temperature, pressure, humidity, occupancy, CO2 and air velocity).

Commissioning, control, efficiency, and information…it simply all adds up to one reliable

source…Trane.

Trane Wireless Comm Interface (WCI)

TheTrane®Wireless Comm Interface (WCI) is the perfect alternative toTrane’s BACnet™ wired

communication links (for example, Comm links between aTracer™ SC and aTracer™ UC400).

Minimizing communication wire used between terminal products, zone sensors, and system

controllers has substantial benefits. Installation time and associated risks are reduced. Projects are

completed with fewer disruptions. Future re-configurations, expansions, and upgrades are easier

and more cost effective.

10 PKG-PRC003U-EN

Page 11

Trane R-410A 3-D™ Scroll Compressor

The R-410ATrane 3-D™ Scroll provides

important reliability and efficiency benefits

inherent in its design.The 3-D™ Scroll allows

the orbiting scrolls to touch in all three

dimensions, forming a completely enclosed

compression chamberwhich leads toincreased

efficiency. In addition, the orbiting scrolls only

touch with enough force to create a seal,

eliminating wear between the scroll involutes.

The fixed and orbiting scrolls are made of high

strength cast iron which results in less thermal

distortion and minimal leakage. In addition,

improved part isolation provides reduced

compressor sound levelscompared to previous

designs.

Features listed below optimize the compressor design and performance:

• Optimized scroll profile

• Heat shield protection to reduce heat transfer between discharge and suction gas

• Improved sealing between high side and low side

Additional features are incorporated in the compressor design for greater reliability:

• Patented design motor cap for improved motor cooling

• Improved bearing alignment

• Improved resistance to dry start-up

• Oil sight glass for evaluating proper oil levels

Features and Benefits

LowTorque Variation

The 3-D™ Scroll has a very smooth compression cycle, imposing very little stresson the motor and

resulting in greater reliability. Low torque variation reduces noise and vibration.

Suction Gas Cooled Motor

Compessor motor efficiency and reliability is further optimized with the latest scroll design.The

patented motor cap directs suction gas over the motor, resulting in cooler motor temperatures for

longer life and better efficiency.

Proven Design through Testing and Research

The new R-410A 3-D™ Scroll compressor is the next generation of reliable Trane 3-D™ Scroll

compressors provided byTrane, the leader in scroll compressor technology

.

Figure 3. One of two matched scroll plates - the distiguishing feature of the scroll compressor

PKG-PRC003U-EN 11

Page 12

Application Considerations

Self-Contained Acoustical Recommendations

Successful acoustical results are dependent on manysystem design factors. Following are general

acoustical recommendations. For more information, or if there is concern about a particular

installation, contact a professional acoustical consultant.

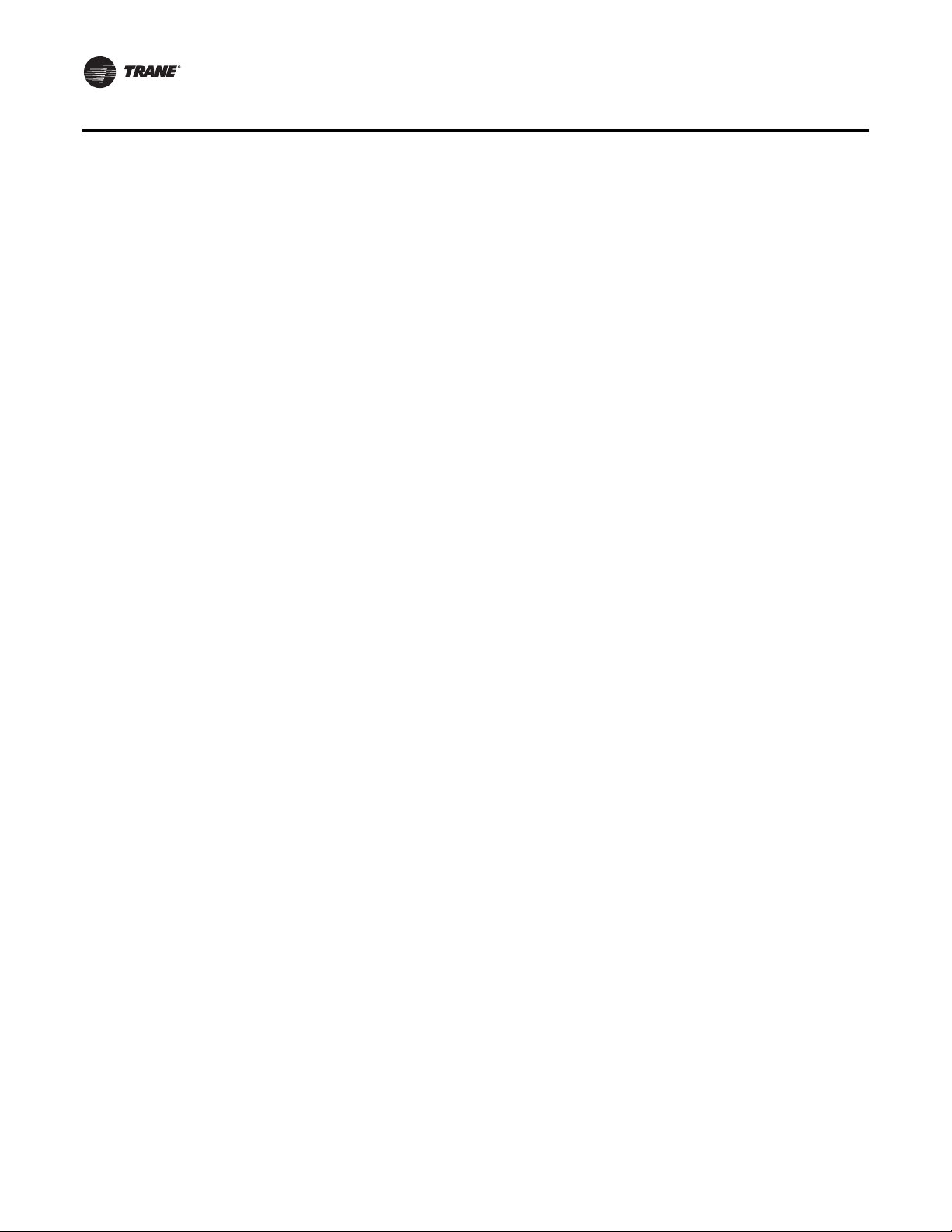

Location and Orientation of the Mechanical Equipment Room

Locate the equipment room adjacent to stairwells, utility rooms, electrical closets, and rest rooms

if possible. See Figure 4, p. 12.This minimizes the acoustic effects and risk of workmanship or

installation errors. Place the discharge and return air ductwork over these less acoustically

sensitive areas, using vertical orhorizontal fresh air shafts. Consult code requirements for fresh air

and smoke purge constraints.

Figure 4. Equipment room location and orientation

Return Air Ductwork

Duct the return air into the mechanical equipment room. Connect ductwork to the unit if local code

dictates.The return air ductwork must have an elbow inside the equipment room. Extend the

ductwork from the elbow far enough to block the “line of sight” to the exterior of the equipment

room. Use aminimum ductwork lengthof 15 feetto the equipmentroom exterior. Line theduct with

two-inch, three-pound density insulation. Use multiple, small return ducts for better acoustical

performance to the occupied space.

Supply Air Ductwork

Insulate the supplyair duct with two-inch, three-pound densityinsulation. Extend thislining at least

15 feet out from the equipment room wall, keeping the duct aspect ratio as small as possible.

Minimize large flat panels since they transmit sound. In addition, small aspect ratios will minimize

potential “oil canning” of the duct due to flow turbulence.

12 PKG-PRC003U-EN

Page 13

Application Considerations

The flexible horizontal discharge plenum option helps avoid complicated ductwork transitions.

Ductwork turning vanes typically improve pressure drop but degrade acoustical performance.

Recommended Maximum Air Velocities

The maximum recommended velocity for the discharge air duct is 2,000 fpm. The maximum

recommended velocity for the return air duct is 1,000 fpm. Limit air velocities below these

operating points to minimize the risk of flow turbulence that causes regenerated noise. Using

round supply duct and static regain allows maximum discharge air velocities up to 3,000 fpm.

Lining round supply duct also substantially lowers frequency noise attenuation. However, flow

regenerated noise potential increases dramatically at air velocities over 3000 fpm.

Equipment Room Construction Options

The preferred equipment room wall construction is concrete block. If this is not feasible then a

double stud offset wall is suggested. See Figure 5, p. 13.This removes physical contact that would

transmit sound through the equipment room wall to the occupied space. Interweave fiberglass

insulation between the wall studs. Use two layers of sheetrock on each side of the wall.

Workmanship details are critical to acoustical performance. Seal all wall and floor penetrations by

the ductwork, water piping, and equipment room access doors with a flexible material such as

caulk and/or gasketing to stop noise and air leaks.

Locate the equipment room door away from acoustically sensitive areas like conference rooms.

The door should swing out of the equipment room, if possible, so that the low pressure in the

equipment room pulls the door in to help maintain a tight seal.

Figure 5. Double stud offset wall with interwoven insulation

PKG-PRC003U-EN 13

Page 14

Application Considerations

Equipment Options

The flexible horizontal discharge plenum allows multiple tested outlet options.This minimizes the

risk of acoustic and/or pressure drop problems by avoiding complex transitions close to the fan

discharge.

Static PressureVersus Acoustics

Design the system to minimize the total static pressure required from the self-contained unit fan.

Typically a change in static pressure of only 0.5 inches can reduce NC level by approximately 2 or

3 in the occupied space.

Free Cooling Opportunities and Alternatives

Free cooling is available with either airside or waterside economizers.The advantages and

disadvantages of each type are listed as follows:

Waterside Economizer

The waterside economizer substantially reduces the compressor energy requirements because it

uses the cooling water before it enters the condensers. Additional equipment room space is not

required since the coils are contained within the overall unit dimensions.

Disadvantages include higher airside pressure drop and a higher head on condenser water pumps.

The coils may be mechanically cleanable (optional) for ease in maintenance versus expensive and

difficult chemical cleaning methods.

Airside Economizer

The airside economizer substantially reduces compressor, cooling tower, and condenser water

pump energy requirements using outside air for free cooling. It also reduces tower make up water

needs and related water treatment.

Disadvantages include building requirements that locate the mechanical room and self-contained

unit toward an exterior wall to minimize ductwork, building barometric control, or additional air

shafts. Also, airside economizers require additional mechanical room space.

Isolation Recommendations

Unit

The Modular Series unit is internally isolated so that external isolation is not required. Consult a

vibration specialist before using external isolation.TheTrane Company does not recommend

double isolation. If isolation external to the unit is preferred, remove internal isolators.

Ductwork

Design duct connections to the unit using a flexible material. Consult local codes for approved

flexible duct material to prevent fire hazard potential.

Piping Connections

Rubber isolator connectors are recommended for condenser piping to prevent vibration

transmission to or from thebuilding plumbing.The Modular Seriesself-contained unit is internally

isolated and does not require additional isolation. However, do not forget to design proper system

vibration isolation to prevent vibration transmission from the building plumbing to the unit. Also

be sure that the drain line is properly isolated.

14 PKG-PRC003U-EN

Page 15

Condenser Water Piping

Piping Location and Arrangement

Provide at least 24 inches of clearance between the piping and the unit for service. Place the risers

away from the side of the unit if possible. Be sure to allow sufficient space for valves and unions

between the piping andthe self-contained unit. Layout condenser piping in reverse returns to help

balance the system.This is accomplished by equalizing the supply and return pipe length. Multistory buildings may use a direct return system with balancing valves at each floor. Install all heat

exchangers and most cooling tower piping below the sump operating water level to prevent

overflow during unit and/or system shut down.

Recommended Pump Location

Pump location is preferred downstream of the cooling tower and upstream of the self-contained

unit.This provides smoother and more stable unit operation.

When the tower and pump are both roof mounted, be sure to provide the necessary net positive

suction head pressure to prevent cavitation. Raise the tower or submerge the pump in a sump to

provide positive suction.To prevent an on-line pump failure, use a standby pump to avoid a

complete system shutdown. Use several partial capacity pumps or variable speed pumps. Review

the economics of these alternate pumping options.

Strainers and WaterTreatment

Water strainers are required at the unit inlet to eliminate potential unit damage from dirty water.

Specify a water basket strainer to avoid an incorrect application of a stream strainer. Untreated or

poorly treated water may result in equipment damage. Consult a water treatment specialist for

treatment recommendations.

Application Considerations

Isolation Valves

Install isolation valves at each unit before the strainer and after the condenser.This allows periodic

servicing of the unit or strainer while allowing other units in the system to remain in operation.

Pressure Gauges

Install pressure gauges on the inlet and outlet of the self-contained unit. Select the gauge’s scale

so that the unit design operating point is approximately mid-scale.

Thermometers

Install thermometers on the condenser water inlet and outlet linesto each unit for system analysis.

Trane recommends using athermometer temperature range of 40to 140°F, using a2°F temperature

increment.

Drains

The unit condensate drain is internally trapped to offset the pressure differential that exists during

fan operation. Install a trapped drain in the low point of the mechanical equipment room floor to

collect water from cleaning operations.

Condensing Pressure Control

(Water-Cooled condensers)

Often cold condensing water applications between 54°F and 35°F require a condensing pressure

control valve. Any unit with variable-flow waterside valves can modulate water flow to maintain

a user defined condensing temperature. However, to utilize this feature, the building water system

must be capable of operating at reduced water flow rates through the self-contained units. It is

imperative to install variable volume pumps or an external bypass in the water distributionsystem.

PKG-PRC003U-EN 15

Page 16

Application Considerations

Waterside Economizer Flow Control

Units equipped with waterside economizer control valves can be set up for variable or constant

water flow. Use constant water flow setup on water systems that are not capable of unloading

water supply to the unit.The economizer and condenser valves will operate in complement to one

another to provide continuous water flow.

Use variable water flow setup with water flow systems that can take advantage of pump unloading

for energy savings. Since non-cooling operation restricts water flow during part load economizing

or condensing temperature control, it is imperative to install variable volume pumpsor an external

bypass in the water distribution system.

Airflow Limitations

The minimum recommended airflow for proper VAV system staging and temperature control is

35% of nominal design airflow. However, using VAV boxes at the appropriate minimum settings

will prevent the self-contained unit fromoperating in a surge condition at airflows below thispoint.

Continuous operation in a surge condition can cause fan failure. See Table 1, p. 22 for minimum

airflow conditions.

Modular Series self-contained units use fixed pitch sheaves. Adjust air balancing by obtaining

alternate fixed pitch sheave selections from the localTrane sales office.

Waterflow Limitations

Use 3 gpm/ton for optimum unit capacity and efficiency. Use 2.5 or 2 gpm/ton to reduce pump

energy, cooling tower and piping costs. However, these reduced waterflows may impact unit

capacity and efficiency by one or two percent. Consult the general data section for unit specific

waterflow ranges.

Air Cooled Condenser Location

Unobstructed condenser airflow is essential to maintaining capacity and operating efficiency.

When determining unitplacement, give carefulconsideration to assure sufficient airflow across the

condenser coils. Avoid these two detrimental conditions:warm air recirculation and coil starvation.

Both warm air recirculation and coil starvation cause reductions in unit efficiency and capacity

because of the higher head pressure associated with them. In more severe cases, nuisance unit

shutdowns will result from excessive head pressures.

Clearances

Ensure vertical condenser air discharge is unobstructed. While it is difficult to predict the degree

of warm air recirculation, a unit installed with a ceiling or other obstruction above itwill experience

a capacity reduction that will reduce the maximum ambient operation. Nuisance high head

pressure tripouts may also occur.

The coil inlet must also be unobstructed. A unit installed closer than the minimum recommended

distance to a wall or other vertical riser will experience a combination of coil starvation and warm

air recirculation.This may result in capacityand efficiency reductions, as well as possible excessive

head pressures. Reference the service clearance section for recommended lateral distances.

Ambient Limitations

Standard ambient control allows operation down to 45°F with cycling of condenser fans. Units with

the low ambient option are capable of starting and operating in ambient temperatures down to 0°F.

Optional low ambient units use a condenser fan damper arrangement that controls condenser

capacity by modulating damper airflow in response to saturated condenser temperature.

Maximum cataloged ambient temperature operation of a standard condenser is 115°F. Operation

at design ambient above 115°F can result in excessive head pressures.

16 PKG-PRC003U-EN

Page 17

Selection Procedure

Following is a sample selection for a standard applied water-cooled self-contained at particular

operating conditions. UseTrane Official Product Selection System,TOPSS™, for making all final

selections or contact your localTrane sales office.

Unit Capacities

1. Determine entering air temperature dry bulb and wet bulb and entering water temperature.

2. Refer to performance Table 7, p . 30 through Table 19, p. 41 to find gross total and sensible

capacity that best meets capacity requirements.

3. Apply the cfm correction factors from the capacity correction factor Table 6, p. 29 to determine

gross total and gross sensible capacities at desired cfm.

4. Multiply condenser water deltaT by the total capacity cfm correction factor to determine new

condenser water deltaT.

5. Using design cfm, determine static air pressure drops for accessories from the air pressure

drop

Figure 6, p. 25 through Figure 11 , p . 27. Add accessory static pressure drops to external

supply and return static air pressure drops. Use the total air pressure drop to determine rpm

and brake horsepower requirements from the appropriate fan curve. Note: The fan curves

include refrigerant coil and internal cabinet static loses.

6. Calculate supply fan motor heat by using the following equation:

Fan motor heat (MBh) = 2.8 x fan motor brake horsepower

7. Determinenet total capacity andnet sensible capacity bysubtracting fan motor heatfrom gross

total capacity and gross sensible capacity.

8. Refer to theTrane psychometric chart to determine leaving air temperatures.

Waterside Economizer Capacity

1. After determining that the unit will meet the required mechanical cooling capacity, determine

the waterside economizer capacity by referring to the appropriate two-row (low capacity) or

four-row (high capacity) waterside economizer capacity tables for the unit size.

2. Determine entering air temperature dry bulb and wet bulb, condenser water flow (gpm), and

economizer entering water temperature.

3. Refer to the appropriate waterside economizer table to find gross total and sensible capacity

and the leaving water temperature.

4. Apply the cfm correction factor for the waterside economizer from the appropriate table to

determine the gross total and sensible capacities at the desired cfm.

5. Multiply the condenser water deltaT by the total capacity cfm correction factor to determine

the new deltaT.

6. Calculate supply fan motor heat by using the following equation:

Fan motor heat (MBh) = 2.8 x fan motor brake horsepower

7. Determine net total and sensible capacity by subtracting fan motor heat from gross total and

sensible capacity.

8. Refer to theTrane psychometric chart to determine leaving air temperatures.

Selection Example

Design Conditions

Total gross capacity required = 368.7 MBh = 31Tons

Total sensible capacity required = 259 MBh

Entering air temperature = 80/67°F

Entering water temperature = 85

gpm = 105

PKG-PRC003U-EN 17

Page 18

Selection Procedure

Selection Procedure

Airflow = 14200 cfm at 2.5-inch duct static pressure

Unit to include:

Constant Volume

Waterside economizer

Medium velocity throwaway filters

Unit Selection

Tentatively select a 35 ton unit. Refer to Table 13, p. 36 to obtain gross total and sensible unit

capacities, and gpm at the design conditions:

Total capacity = 370 MBh

Sensible capacity = 282 MBh

LWT = 95.4°F

Since the design cfm is greater than the nominal cfm, adjust the capacities and condenser water

deltaT to reflect the higher cfm:

design cfm/nominal cfm 14,240/14,000 + 3% from nom. Cfm

Refer to Table 6, p. 29 to obtain the capacity correction factors for +3% of nominal cfm:

Cooling capacity multiplier = 1.005

Sensible capacity multiplier = 1.014

Multiply the capacities by the correction factors:

370 MBh x 1.005 = 371.85 MBh

282 MBh x 1.014 = 285.95 MBh

The SCWG 35 meets the total and sensible design requirements.

Multiply the deltaT of 10.4°F, by the cooling capacity correction factor of 1.005 to obtain new delta

T of 10.45 and add this to the entering water temperature to obtain the actual leaving water

temperature, 95.45°F.

Determine static air pressure drops through the accessories at the design cfm by referring to

Figure 6, p. 25 through Figure 11, p. 27.

4-row waterside economizer = 0.55 in.Medium velocity filters = 0.41 in.Add this to the 2.5-inchduct

static pressure fora total external staticpressure of 3.46 inches. Refer tothe fan curvewith Constant

Volume, Figure 18, p. 37 to determine approximate brake horsepower and fan rpm:

Fan brake horsepower = 25 bhp

Fan rpm = 1850 rpm

Determine net capacities by subtracting fan motor heat from gross capacities:

2.8 x 25 bhp = 70.0 MBh

Net total capacity = 371.85 MBh - 70.0 MBh = 301.85 MBh

Net sensible capacity = 285.95 MBh - 70.0 MBh = 215.95 MBh

Determine waterside economizer (full coil) capacity by referring to Table 13, p. 36. Use entering air

of 80/67°F and entering water temperature of 55°F at 105 gpm. The table provides a gross total

capacity of 263.6 MBh and gross sensible capacity of 263.6 MBh and 60.0°F leaving water

temperature at nominal cfm.

Determine gross capacities at design cfm by applying the cfm correction factors from waterside

economizer from Table 6, p. 29. Use the following correction factors:

263.6 MBh x 1.005 = 264.92 MBh

263.6 MBh x 1.014 = 267.29 MBh

Apply the cooling correction factor to water deltaT to determine new delta T of 5.03°F.

Determine net capacities by subtracting fan motor heat for net total capacity of 194.92MBh andnet

sensible capacities of 197.29 MBh.

18 PKG-PRC003U-EN

Page 19

Model Number Descriptions

Modular Series SelfContained

Digit 1 - Unit Model

S = self contained

Digit 2 - Unit Type

C = commercial

I = industrial

Digit 3 - Condenser Medium

W = water-cooled

R = remote air-cooled

Digit4-Development Sequence

G = modular series

Digit 5 - Refrigerant Circuit

Configuration

U = independent, R-410A refrigerant

Digits 6, 7 - Unit Nominal

Capacity

20 = 20Tons (water or air cooled)

25 = 25Tons (water or air cooled)

30 = 30Tons (water cooled only)

32 = 32Tons (air cooled only)

35 = 35Tons (water cooled only)

Digit 8 - Unit Voltage

6 = 200 volt/60 hz/3 ph

4 = 460 volt/60 hz/3 ph

5 = 575 volt/60 hz/3 ph

Digit 9 - Air Volume/Temp

Control

2 = I-Pak &VFD & supply air temp ctrl

3 = I-Pak &VFD w/ bypass & supply

air temp ctrl

4 = I-Pak w/o vol. ctrl, w/ zone temp

cool

5 = I-Pak w/o vol. ctrl, w/ zone temp

heat/cool

6 = I-Pak w/o vol. ctrl, w/ supply air

temp ctrl

8 = thermostat interface

Digits 10, 11 - Design Sequence

** = Factory Assigned

Digit 12 - Unit Construction

A = vertical discharge

B = vertical discharge with double

wall

C = horizontal discharge

D = horizontal discharge w/ double

wall

E = vertical discharge, ship separate

F = vert. dis. w/ double wall, ship sep.

G = horizontal discharge, ship

separate

H = horiz. dis. w/ double wall, ship

sep.

Digit 13 - Plenum Type

B = std plenum w/ factory cut holes

C = low plenum w/ factory cut holes

E = std plenum w/ field cut holes

F = low plenum w/ field cut holes

H = std plenum double wall (perf)

w/ field cut holes

J = low plenum double wall (perf)

w/ field cut holes

L = std. plenum w/factory cut holes,

ship separate

M = low plenum w/ factory cut holes,

ship separate

P = std plenum w/ field cut holes, ship

separate

R = low plenum w/ field cut holes,

ship separate

U = std plenum double wall (perf) w/

field cut holes, ship separate

V = low plenum double wall (perf) w/

field cut holes, ship separate

0 = without plenum

Digit 14 - Motor Type

2 = ODP motor

3 = TEFC motor

Digits 15, 16 - Motor HP

05 = 5 hp

07 = 7.5 hp

10 = 10 hp

15 = 15 hp

20 = 20 hp

25 = 25 hp

Digits 17, 18, 19 - Fan RPM

085 = 850 rpm

090 = 900 rpm

095 = 950 rpm

100 = 1000 rpm

105 = 1050 rpm

110 = 11 0 0 r p m

115 = 1150 rpm

120 = 120 0 rpm

125 = 1250 rpm

130 = 130 0 rpm

135 = 1350 rpm

140 = 1400 rpm

145 = 1450 rpm

150 = 150 0 rpm

155 = 1550 rpm

160 = 160 0 rpm

165 = 1650 rpm

170 = 170 0 rpm

175 = 1750 rpm

180 = 180 0 rpm

185 = 1850 rpm

Digit 20 - Heating Type

A = steam coil, LH

B = hot water coil, LH

C = electric heat, 1 stage

F = hydronic heat ctrl interface

G = elec. heat ctrl interface,1 stage

K = steam coil ship separate, LH

L = hot water coil ship separate, LH

M = steam coil, RH

N = hot water coil, RH

P = steam coil ship separate, RH

R = hot water coil ship separate, RH

T = hi-cap. hot water coil, LH

U = hi-cap hot water coil, LH, ship sep

V = hi-cap hot water coil, RH

W = hi-cap hot water coil, RH, ship sep

0 = none

Digit 21 - Unit Isolators

A = isopads

B = spring isolators

0 = none

Digit 22 - Unit Finish

1 = paint - slate gray

2 = protective coating

3 = protective coating w/ finish coat

Digit 23

0 = none

Digit 24 - Unit Connection

1 = disconnect switch

2 = terminal block

3 = dual point power

Digit 25 - Industrial Options

A = protective coated evaporator coil

B = silver solder

C = stainless steel screws

D = A and B

E = A and C

F = B and C

G = A, B and C

0 = none

Digit 26 - Drain Pan Type

A = galvanized sloped

B = stainless steel sloped

Digit 27 - Waterside Economizer

A = mechanical clean full capacity

(4-row)

B = mechanical clean low capacity

(2-row)

C = chemical clean full capacity

(4-row)

D = chemical clean low capacity

(2-row)

E = mechanical clean full capacity

(4-row) ship separate

F = mechanical clean low capacity

(2-row) ship separate

G = chemical clean full capacity

(4-row) ship separate

H = chemical clean low capacity

(2-row) ship separate

0 = none

PKG-PRC003U-EN 19

Page 20

Model Number Descriptions

Digit 28 - Ventilation Control

B = airside econ w/Traq™ damper

(top O/A inlet)

C = airside econ w/ standard

dampers (top O/A inlet)

E = airside econ w/ Traq™ damper

and comparative enthalpy

(top O/A)

F = airside econ w/ std dampers and

comparative enthalpy (top O/A)

H = none/ventilation for 2-position

control interface

J = airside economizer interface

K = airside economizer interface w/

comparative enthalpy

0 = None

Digit 29 - Water Piping

A = RH condenser connection

B = LH condenser connection

C = RH basic piping

D = LH basic piping

E = RH intermediate piping

F = LH intermediate piping

J = RH basic w/ flow switch

K = LH basic w/ flow switch

L = RH intermediate w/ flow switch

M = LH intermediate w/ flow switch

0 = none

Digit 30 - Condenser Tube Type

A = standard condenser tubes

B = 90/10 CuNi condenser tubes

0 = none

Digit 31 - Compressor Service

Valves

1 = with service valves

0 = none

Digit 32 - Miscellaneous System

Control

1 = timeclock

2 = interface for remote HI (IPCB)

3 = dirty filter switch

4 = 1 and 2

5 = 1 and 3

6 = 2 and 3

7 = 1, 2, and 3

0 = none

Digit 33 - Control Interface

Options

A = Generic BAS Module; 0-5VDC

(GBAS)

B = Ventilation Override Module

(VOM)

D = Remote Human Interface (RHI)

G = GBAS &VOM

H = GBAS & RHI

J = VOM & RHI

M = GBAS & VOM & RHI

N = BACnet Communications

Interface (BCI)

P = BCI and GBAS

Q = BCI and VOM

R = BCI and RHI

T = BCI and GBAS andVOM

U = BCI and GBAS and RHI

V = BCI and VOM and RHI

W = BCI and GBAS andVOM and RHI

0 = None

1 = LonTalk Comm5 Interface (LCI)

2 = LCI and GBAS

3 = LCI and VOM

4 = LCI and RHI

5 = LCI and GBAS andVOM

6 = LCI and GBAS and RHI

7 = LCI and VOM and RHI

8 = LCI and GBAS andVOM and RHI

Digit 34 - Agency

T = UL agency listing

0 = none

Digit 35 - Filter Type

1 = 2-inch construction throwaway

2 = 2-inch med eff. throwaway

Digit 36 - Miscellaneous Control

Option

A = low entering air temp. protect

device (LEATPD)

B = high duct temp t-stat

C = plenum high static switch

D = kit for heat mode output (w/t’stat)

E = A and B

F = A and C

G = B and C

H = A, B, and C

0 = None

20 PKG-PRC003U-EN

Page 21

Model Number Descriptions

Self-Contained Ship-

With Accessory

Model Number

Digit1-Parts/Accessories

P = parts/accessories

Digit 2 - Unit Model

S = self-contained

Digit 3 - Shipment

W = with unit

Digit4-Development Sequence

F = signature series

G = modular series

Digit5-Sensors and Other

Accessories

S = sensors

Digit6-Sensors and

Thermostats (Field Installed)

A = BAYSENS077 - zone temp only

(CV and VAV)

B = BAYSENS073- zone temp with

timed override button (CV and

VAV)

C = BAYSENS074 - zone temp with

timed override button, setpoint

dial (CV and VAV)

E = BAYSENS108 - CV zone sensor

-dual setpoint, man/auto

changeover

F = BAYSENS110 - CV zone sensor-

dual setpoint, man/auto

changeover w, indicastor lights

G = BAYSENS119 - CV/VAV program-

mable night setback Sensor

H = BAYSENS021 -VAV zone sensor

with indicator lights

K = BAYSTAT150 2H/2C ProgTstat w/

BAYSTAT077 Remote Sensor

L = outside air temperature sensor kit

M = outside air humidity sensor kit

N = BAYSTAT155 3H/2CTstat

P = BAYSTAT150 2H/2C

ProgrammableTstat

0 = none

Digit 7 - Mixed Air Temperature

Protection Kit (Field Installed)

1 = mixed air temperature protection

kit

0 = none

Digit 8 - Carbon Dioxide Sensor

(Field Installed)

1 = carbon dioxide sensor kit

0 = none

Digit9-Future Option

0 = none

Digits 10, 11 - Design Sequence

** = Factory Assigned

Remote Air-Cooled Condenser

Digit 1 - Unit Model

C = Condenser

Digit 2 - Unit Type

C = Commercial

I = Industrial

Digit 3 - Condenser Medium

R = Remote

Digit4-Development Sequence

C=C

Digits 5, 6, 7 - Nominal Capacity

020 = 20Tons

029 = 29Tons

032 = 32Tons

Digit 8 - Unit Voltage

4 = 460 Volt/60 Hz/3 ph

5 = 575 Volt/60 Hz/3 ph

6 = 200 Volt/60 Hz/3 ph

Digit 9 - Control Option

0 = No Low Ambient, I-Pak

A = No Low Ambient, T-stat

B = Low Ambient, I-Pak

C = Low Ambient, T-stat

Digits 10, 11 - Design Sequence

** = Factory Assigned

Digit 12 - Unit Finish

1 = Paint - Slate Gray

2 = Protective Coating

3 = Protective Coating with

Finish Coat

4 = Unpainted Unit

Digit 13 - Coil Options

A = Non-Coated Aluminum

C = Protective Coated Aluminum

Digit 14 - Unit Isolators

0 = None

A = Spring Isolators

B = Isopads

Digit 15 - Panels

0 = None

1 = Louvered Panels

Digit 16 - Agency

0 = None

T = UL Listing

PKG-PRC003U-EN 21

Page 22

General Data

Table 1. SCWG/SIWG/SCRG/SIRG general data

Water-Cooled Units Air-Cooled Units

Unit Size 20 25 30 35 20 25 32

Compressor Data

Quantity 2 2 1/1 2 2 1/1 2

Nominal Ton/Comp 10 10 10/15 15 10 10/15 15

Circuits 2 2 2 2 2 2 2

Evaporator Coil Data

Rows 2 4 4 4 3 4 4

Sq. Ft. 22.5 25.0 25.0 25.0 25.0 25.0 25.0

FPF 144 144 144 144 144 144 144

Condenser Data

Minimum GPM w/o Econ 36 36 46 54 - - Minimum GPM w/ Econ 41 41 60 65 - - Maximum GPM 80 80 102 119 - - -

Evaporator Fan Data

Quantity 2 2 2 2 2 2 2

Size (Dia. x width - inches) 12 5/8"x8" 12 5/8"x9" 12 5/8"x11" 12 5/8 x11" 12 5/8"x8" 12 5/8"x9" 12 5/8"x11"

Minimum HP 5 5 5 5 5 5 5

Maximum HP 20 25 25 25 20 25 25

Minimum Design CFM 6350 7250 7250 7250 7250 7250 7250

Maximum Design CFM 8500 10,625 12,750 14,875 8500 10,625 13600

R-410A Refrigerant Data

EER 14.0 14.3 14.1 14.0 10.0 10.1 10.4

IEER (CV) 14.1 14.8 15.4 15.6 10.8 11.8 11.9

IEER (VFD) 17.1 18.1 18.2 17.7 13.4 13.3 13.8

Refrigerant Charge - lb (kg)

Circuit A 19.0 (8.6) 24.0 (10.9) 24.5 (11.1) 23.0 (10.4) See Note 3 See Note 3 See Note 3

Circuit B 19.0 (8.6) 24.0 (10.4) 23.0 (10.4) 23.0 (10.4) See Note 3 See Note 3 See Note 3

Capacity Steps - % 100/53/0 100/53/0 100/65/42/6 100/53/0

Filter Data

Quantity 4 4 4 4 4 4 4

Size (inches) 16x25x2 16x25x2 16x25x2 16x25x2 16x25x2 16x25x2 16x25x2

Quantity 4 4 4 4 4 4 4

Size (inches) 20x25x2 20x25x2 20x25x2 20x25x2 20x25x2 20x25x2 20x25x2

CCRC/CIRC Condenser

Match

Notes:

1. Compressors are Trane 3D™scroll.

2. EER and IEER are rated in accordance to the AHRI Standard 340/360-2010. Based on 80/67°F (26.7/19.4°C) to the evaporator coil, nominal airflow

and 85-95°F (29.4-35°C) condenser water or 95° F (35° C) ambient.

3. All units operate with R-410A. Water Cooled units ship with full operating charge. Air-cooled Units ship with dry nitrogen charge. Field refrigerant

system charge required. Refer to Table 3, p. 23 for amounts required.

4. Maximum cfm limits are set to prevent moisture carryover on the evaporator coil.

5. Minimum cfm limits are set to ensure stable thermal expansion valve operation at low load conditions.

6. Filter sizes are for units without hot water or steam heating coils

- - - - 20 29 32

22 PKG-PRC003U-EN

Page 23

General Data

Table 2. SCWG/SIWG/SCRG/SIRG self-contained heating coil

Filter Data for Heating Coil

Quantity 4

Size (inches) 20x18x2

Size (mm) (508x457x51)

Quantity 8

Size (inches) 20x20x2

Size (mm) (508x508x51)

Coil Data Type Rows No. - Size (in) No. - Size (mm) fpf

Steam Coil NS 1 2 - 24 x 58 2 - 609.6x1473.2 42

Hot Water Coil, std. cap 5W 1 1 - 48 x 62 1 - 1219 x 1575 80

Hot Water Coil, hi-cap. 5W 2 1 - 48 x 62 1 - 1219 x 1575 108

Notes:

1. Hot water and steam heating coils have Prima-Flo® fins and do not have turbulators.

2. For coil capacities, use TOPSS™ (Trane Official Product Selection Program).

Table 3. SCRG/SIRG self-contained and CCRC/CIRC remote air-cooled condenser, refrigerant data

SCRG/SIRG & CCRC/CIRC Unit Size 20/20 25/29 32/32

No. of Refrigerant Circuits 222

Operating Charge - lbs R-410A 36.5/36.5 48.5/36 46/46

Operating Charge - kg R-410A 16.6/16.6 22/16.3 20.9/20.9

Cond. Storage Cap. - lbs R-410A 37/37 51/37 51/51

Cond. Storage Cap. - kg R-410A 16.8/16.8 23.1/16.8 23.1/23.1

Notes:

1. Refrigerant charges are listed as circuit 1/circuit 2 and provide only an estimate. Final charge requires sound field charging practice.

2. Operating charge estimate includes the air-cooled self-contained, remote air-cooled condenser, and 25 feet of interconnecting refrigerant piping.

3. At conditions of 95°F (35°C), condenser storage capacity is 95% full.

4. To determine the correct amount of refrigerant needed for a particular application, reference the Trane Reciprocating Refrigeration Manual.

Table 4. Waterside economizer coil physical data

Model Unit Size Type Rows FPF height (in) length (in)

SCXG 20, 25, 30 & 35 Chemically Cleanable 2 108 50 72

SCXG 20, 25, 30 & 35 Mechanically Cleanable 2 108 50 72

SCXG 20, 25, 30 & 35 Chemically Cleanable 4 108 50 72

SCXG 20, 25, 30 & 35 Mechanically Cleanable 4 108 50 72

PKG-PRC003U-EN 23

Page 24

General Data

Table 5. CCRC/CIRC remote air-cooled condenser general data

Unit Size 20 29 32

Condenser Fan Data

Number/Type/Drive 4/Prop/Direct 4/Prop/Direct 4/Prop/Direct

Size (inches) 26 26 26

HP ea. 111

Nominal Cfm 18,800 21,200 32,000

Condenser Coil Data

Circuit 1 Size (in.) 1/46x71 1/46x71 1/64x71

Circuit 2 No./Size (in.) 1/46x71 1/64x71 1/64x71

Face Area (sq. ft.) 45.4 54.2 63.1

Rows/fpf 4/144 4/144 4/144

Ambient Temperature Operating Range

Standard Ambient (°F) 50-115 50-115 50-115

Low Ambient Option (°F) 0-115 0-115 0-115

24 PKG-PRC003U-EN

Page 25

Performance Data

Airside Pressure Drop

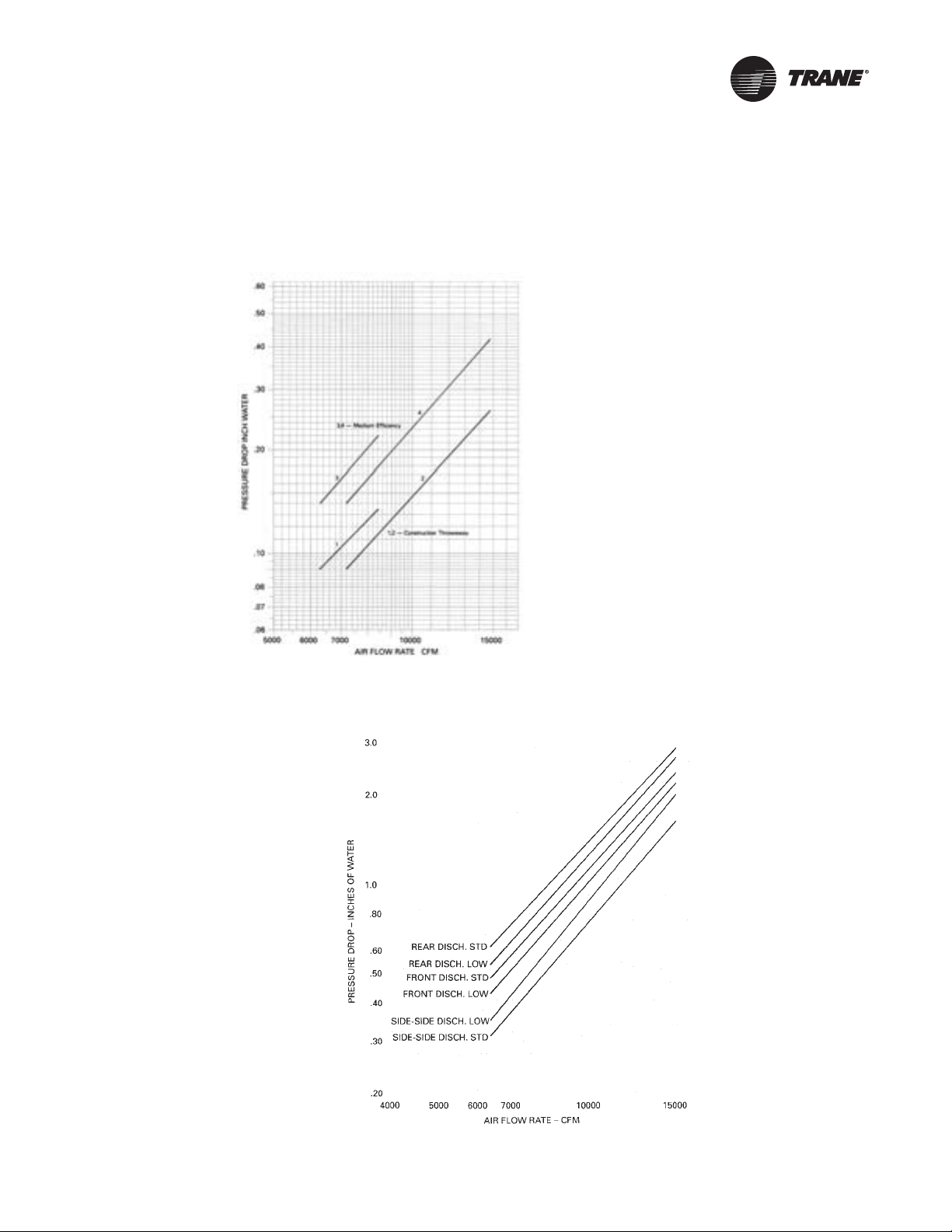

Figure 6. Filter airside pressure drop

Note: In Figure 6, p. 25, lines 1 and 3 are for the SXWG 20 ton only. Lines 2 and 4 are for all air-cooled units and all SXWG

25-35 tons.

Figure 7. Horizontal discharge plenum airside pressure drop

PKG-PRC003U-EN 25

Page 26

Performance Data

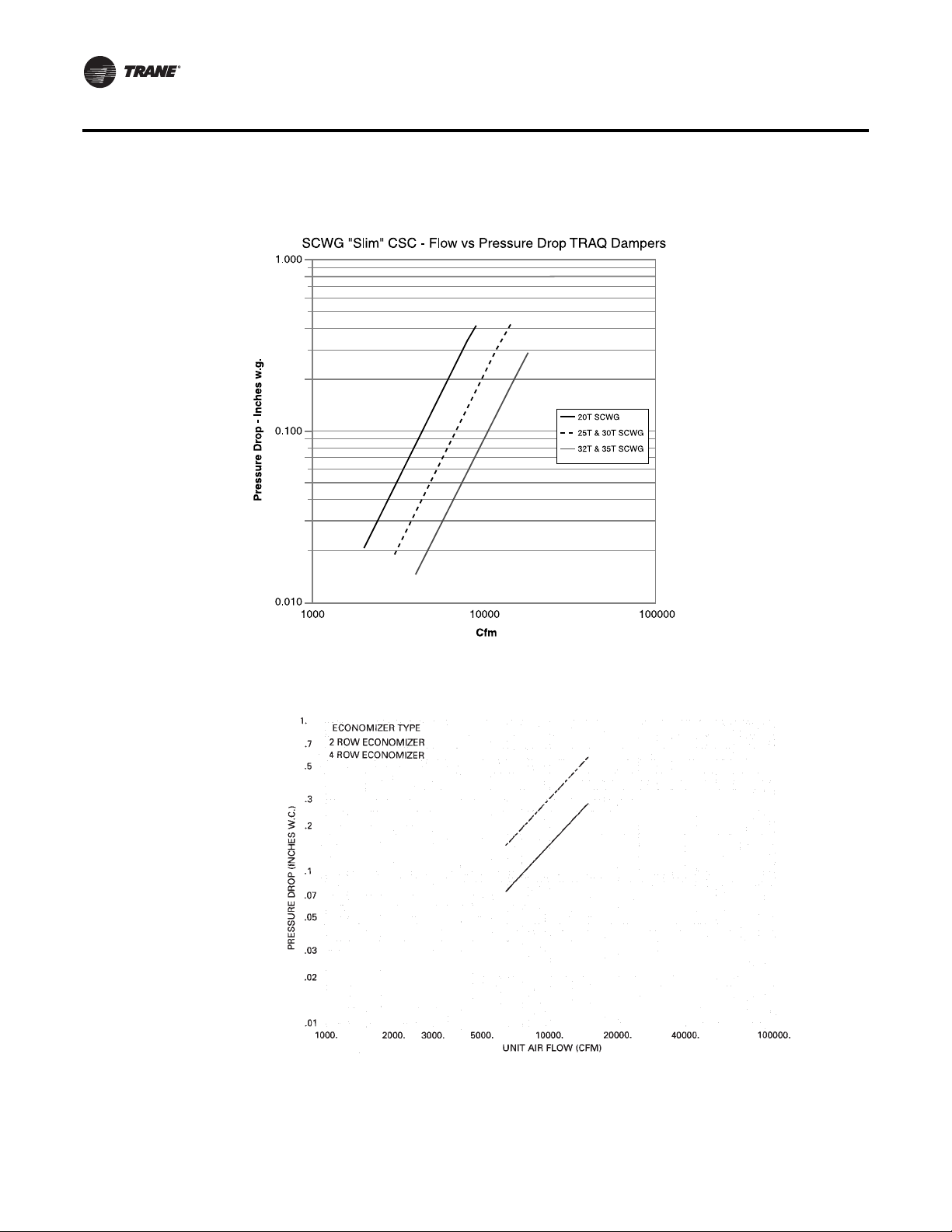

Figure 8. Traq™ damper airside pressure drop

Figure 9. Waterside economizer airside pressure drop

26 PKG-PRC003U-EN

Page 27

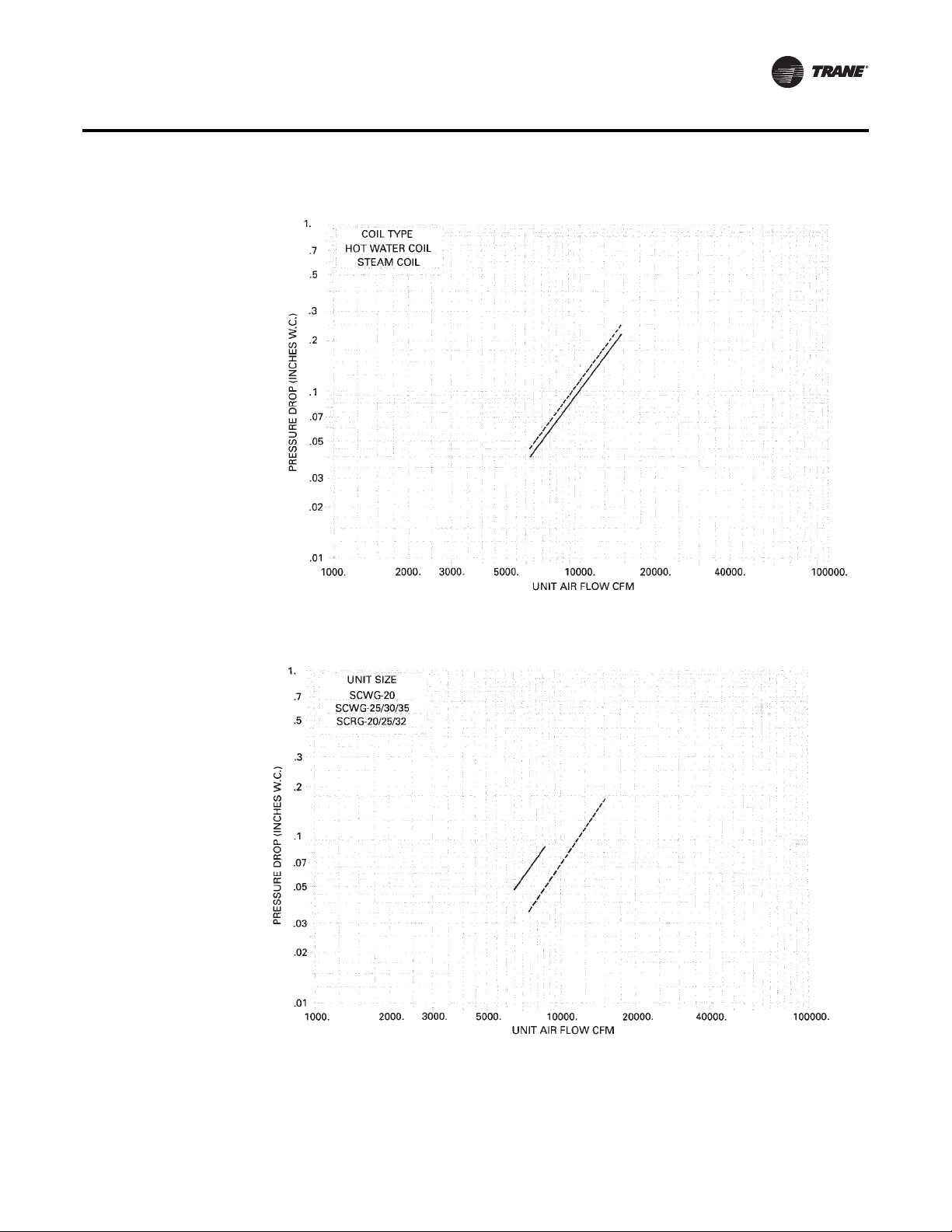

Figure 10. Steam coil airside pressure drop

Performance Data

Figure 11. Airside economizer airside pressure drop

PKG-PRC003U-EN 27

Page 28

Performance Data

Waterside Pressure Drop

Figure 12. Waterside economizer waterside pressure drop

Figure 13. Unit without piping water pressure drop

28 PKG-PRC003U-EN

Page 29

Figure 14. Unit with piping waterside pressure drop

Performance Data

Note: “Primary” refers to the side where the static pressure drop was measured. This value must be added to the unit external

static pressure for proper fan horsepower determination.

Table 6. CFM capacity correction table

DX cooling

Waterside economizer

CFM compared to rated

quantity

-20% 0.970 0.910

-10% 0.985 0.955

Std 1.000 1.000

+3% 1.005 1.014

+6% 1.009 1.027

-20% 0.970 0.910

-10% 0.985 0.955

Std 1.000 1.000

+3% 1.005 1.014

+6% 1.009 1.027

cooling capacity

multiplier

sensible capacity

multiplier

PKG-PRC003U-EN 29

Page 30

Performance Data

Water-Cooled Unit Performance

20-ton Water-Cooled

Table 7. SCWG/SIWG 20 economizer full capacity - 8,000 cfm

full capacity coil low capacity coil

45°F 55°F 45°F 55°F

EDB EWB flow total sensible LWT total sensible LWT total sensible LWT total sensible LWT

°F °F gpm MBh MBh °F MBh MBh °F MBh MBh °F MBh MBh °F

50 215.3 192.8 53.6 135.9 135.9 60.4 142.6 142.6 50.7 96.5 96.5 58.9

62

60 225.9 197.3 52.5 139.7 139.7 59.6 152.1 149.8 50.1 99.9 99.9 58.3

70 233.9 200.7 51.7 142.3 142.3 59.1 157.5 152.0 49.5 102.4 102.4 57.9

50 270.4 163.0 55.8 158.5 121.2 61.3 179.3 118.3 52.2 104.8 91.6 59.2

75

67

60 289.4 170.5 54.6 167.9 124.5 60.6 192.5 123.3 51.4 110.9 93.7 58.7

70 303.9 176.4 53.7 175.4 127.2 60.0 202.3 127.0 50.8 115.8 95.4 58.3

50 344.7 135.8 58.8 224.9 94.1 64.0 229.0 92.7 54.1 149.8 66.3 61.0

72

60 370.7 145.4 57.3 242.1 99.9 63.1 246.2 98.7 53.2 160.6 69.8 60.3

70 390.2 152.8 56.1 255.5 104.4 62.3 259.1 103.3 52.4 169.1 72.5 59.8

50 235.6 235.6 54.4 169.8 169.8 61.8 166.4 166.4 51.6 120.6 120.6 59.8

62

60 242.7 242.7 53.1 174.5 174.5 60.8 172.9 172.9 50.7 124.8 124.8 59.2

70 251.2 250.5 52.2 177.8 177.8 60.1 177.5 177.5 50.1 127.9 127.9 58.7

50 277.2 208.3 56.1 175.5 169.9 62.0 182.9 155.4 52.3 120.9 120.9 59.8

80

67

60 294.0 215.0 54.8 182.7 172.5 61.1 194.4 159.7 51.5 125.1 125.1 59.2

70 306.9 220.2 53.7 188.2 174.5 60.4 203.3 163.1 50.8 128.2 128.2 58.7

50 344.0 179.0 58.7 226.2 137.7 64.0 228.6 128.4 54.1 149.5 102.1 61.0

72

60 369.8 188.7 57.3 242.2 143.1 63.1 245.6 134.4 53.2 160.1 105.5 60.3

70 389.2 196.1 56.1 255.0 147.4 62.3 258.5 139.0 52.4 168.5 108.2 59.8

50 269.3 269.3 55.7 203.7 203.7 63.1 190.3 190.3 52.6 144.8 144.8 60.8

62

60 277.2 277.2 54.2 209.2 209.2 62.0 197.6 197.6 51.6 149.8 149.8 60.0

70 282.7 282.7 53.1 213.2 213.2 61.1 202.8 202.8 50.8 153.5 153.5 59.4

50 290.3 256.0 56.6 204.4 204.4 63.2 190.7 190.7 52.6 145.1 145.1 60.8

85

67

60 304.9 261.8 55.1 210.0 210.0 62.0 204.4 199.1 51.8 150.1 150.1 60.0

70 316.0 266.3 54.0 214.0 214.0 61.1 211.8 201.9 51.0 153.8 153.8 59.4

50 347.4 223.1 58.9 235.8 183.7 64.4 228.8 164.3 54.1 155.9 140.0 61.2

72

60 371.1 232.0 57.3 249.6 188.4 63.3 245.2 170.1 53.1 164.6 142.8 60.5

70 389.3 238.9 56.1 260.5 192.1 62.4 258.0 174.6 52.3 171.6 145.1 59.9

30 PKG-PRC003U-EN

Page 31

Performance Data

Table 8. SCWG/SIWG 20 gross cooling capacity - 8,000 cfm, 60 gpm

entering water temp

entering air 75°F 85°F 95°F

EDB EWB total sensible total sensible total sensible

°F °F MBh MBh LWT MBh MBh LWT MBh MBh LWT

62 269 197 84.8 259 192 94.7 249 187 104.6

75

80

85

Figure 15. Fan performance for CV or with VFD

67 294 162 85.6 283 158 95.5 271 153 105.3

72 321 127 86.5 309 122 96.3 296 117 106.1

62 270 230 84.8 261 226 94.7 250 220 104.6

67 294 197 85.6 284 192 95.5 272 187 105.4

72 321 161 86.5 309 157 96.3 296 151 106.1

62 270 270 84.8 262 262 94.8 253 253 104.7

67 295 230 85.6 285 225 95.5 273 219 105.4

72 322 195 86.5 310 191 96.3 297 186 106.1

Note: Fan curves include refrigerant coil and internal cabinet static losses. T o determine static pressure to use with these curves,

add filter; economizer; flexible horizontal discharge plenum; and heat pressure drops to external duct static pressure.

PKG-PRC003U-EN 31

Page 32

Performance Data

25-ton Water-Cooled

Table 9. SCWG/SIWG 25 economizer - 10,000 cfm

full capacity coil low capacity coil

45°F 55°F 45°F 55°F

EDB EWB flow total sensible LWT total sensible LWT total sensible LWT total sensible LWT

°F °F gpm MBh MBh °F MBh MBh °F MBh MBh °F MBh MBh °F

105.1

110.2

111.8

103.7

106.3

107.3

71.6

76.1

77.7

131.5

137.8

139.8

131.7

138.0

140.1

113.9

118.3

119.9

157.9

165.4

167.9

158.2

165.7

168.2

159.1

162.7

164.0

75

80

85

62

67

72

62

67

72

62

67

72

63

75

80

63

75

80

63

75

80

63

75

80

63

75

80

63

75

80

63

75

80

63

75

80

63

75

80

236.9

251.4

256.4

292.6

317.7

326.5

372.7

406.4

418.1

266.7

277.9

281.6

301.5

405.5

331.8

371.9

405.5

417.2

305.0

223.0

321.8

319.3

339.0

345.8

376.5

407.4

418.3

225.2

231.2

233.3

184.8

194.5

197.9

149.0

161.0

165.2

266.7

277.9

281.6

240.4

213.6

252.2

201.4

213.6

217.9

305.0

223.0

321.8

299.4

307.1

309.8

255.5

266.7

270.7

52.5

51.7

51.4

54.3

53.5

53.2

56.8

55.8

55.5

53.5

52.4

52.0

54.6

55.8

53.3

56.8

55.8

55.4

54.7

50.9

53.0

55.1

54.0

53.7

57.0

55.9

55.5

154.9

160.9

162.8

174.1

186.1

90.4

245.1

267.0

274.6

193.7

201.1

203.5

194.3

267.2

209.4

246.6

267.2

274.4

232.5

168.9

244.1

233.2

242.0

244.9

259.0

276.8

283.1

154.9

160.9

162.8

141.4

145.6

147.2

105.5

112.7

115.2

193.7

201.1

203.5

194.3

165.4

206.2

158.7

165.4

167.8

232.5

168.9

244.1

233.2

242.0

244.9

215.2

221.1

223.2

59.9

59.3

59.1

60.5

60.0

60.0

62.8

62.1

61.9

61.2

60.4

60.1

61.2

62.1

60.2

62.8

62.1

61.9

62.4

59.5

61.1

62.4

61.5

61.1

63.2

62.4

62.1

153.6

162.0

164.7

184.6

202.1

208.2

235.1

257.9

265.8

179.4

189.1

192.3

190.1

205.3

210.6

234.7

257.4

265.3

205.3

216.3

219.9

205.7

216.7

220.3

235.6

257.2

264.8

153.6

162.0

164.7

129.7

136.2

138.4

97.5

105.2

107.9

179.4

189.1

192.3

173.9

179.5

181.5

139.7

147.4

150.1

205.3

216.3

219.9

205.7

216.7

220.3

182.3

189.6

192.2

49.9

49.3

49.1

50.9

50.4

50.2

52.5

51.9

51.6

50.7

50.0

49.8

51.0

50.5

50.3

52.5

51.9

51.6

51.5

50.8

50.5

51.5

50.8

50.5

52.5

51.9

51.6

105.1

110.2

111.8

110.6

118.3

121.1

155.8

169.9

174.9

131.5

137.8

139.8

131.7

138.0

140.1

155.6

169.4

174.3

157.9

165.4

167.9

158.2

165.7

168.2

164.6

175.9

179.9

58.3

57.9

57.8

58.5

58.2

58.0

59.9

59.5

59.4

59.2

58.7

58.5

59.2

58.7

58.5

59.9

59.5

59.4

60.0

59.4

59.2

60.0

59.4

59.2

60.2

59.7

59.5

32 PKG-PRC003U-EN

Page 33

Performance Data

Table 10. SCWG/SIWG 25 gross cooling capacity - 10,000 cfm, 75 gpm

entering water temp

entering air 75°F 85°F 95°F

EDB EWB total sensible total sensible total sensible

°F °F MBh MBh LWT MBh MBh LWT MBh MBh LWT

62 297 245 84.1 286 240 94.0 272 233 103.8

75

80

85

Figure 16. Fan performance for CV or with VFD

67 324 195 84.9 311 190 94.7 296 184 104.4

72 352 142 85.6 337 136 95.4 320 130 105.1

62 298 295 84.2 287 287 94.0 273 273 103.8

67 325 244 84.9 312 239 94.7 297 232 104.5

72 353 193 85.6 338 187 95.4 322 181 105.2

62 317 317 84.7 307 307 94.6 295 295 104.4

67 326 294 84.9 313 288 94.7 298 281 104.5

72 354 243 85.7 339 238 95.4 323 232 105.2

Note: Fan curves include refrigerant coil and internal cabinet static losses. T o determine static pressure to use with these curves,

add filter; economizer; flexible horizontal discharge; and heat pressure drops to external duct static pressure.

PKG-PRC003U-EN 33

Page 34

Performance Data

30-ton Water-Cooled

Table 11. SCWG/SIWG 30 economizer capacity - 12,000 cfm

full capacity coil low capacity coil

45°F 55°F 45°F 55°F

EDB EWB flow total sensible LWT total sensible LWT total sensible LWT total sensible LWT

°F °F gpm MBh MBh °F MBh MBh °F MBh MBh °F MBh MBh °F

120.4

125.9

129.7

119.6

122.4

124.6

82.2

86.9

90.5

150.7

157.4

162.2

150.9

157.7

162.5

131.3

135.9

139.5

180.9

188.9

194.7

181.2

189.3

195.0

183.6

187.3

190.3

75

80

85

62

67

72

62

67

72

62

67

72

75

90

105

75

90

105

75

90

105

75

90

105

75

90

105

75

90

105

75

90

105

75

90

105

75

90

105

274.7

290.5

302.5

338.7

366.4

387.7

431.4

468.5

496.8

310.4

323.0

331.8

348.8

373.4

392.4

430.5

467.4

495.7

354.9

369.1

379.1

369.9

391.3

407.7

434.9

469.2

495.8

264.2

270.7

275.7

215.8

226.4

234.8

173.0

186.3

196.5

310.4

323.0

331.8

281.5

291.0

298.4

235.0

248.2

258.6

354.9

369.1

379.1

351.3

359.6

366.1

298.6

311.0

320.7

52.3

51.5

50.8

52.3

51.5

50.8

54.0

53.1

52.4

56.5

55.4

54.5

54.3

53.3

52.5

56.5

55.4

54.4

54.5

53.2

52.2

54.9

53.7

52.8

56.6

55.4

54.4

179.9

186.6

191.3

200.7

213.7

224.1

282.5

306.4

324.8

224.9

233.2

239.1

225.5

233.9

245.7

283.9

306.4

324.1

270.0

279.8

286.8

270.7

280.7

287.7

298.3

317.6

332.8

179.9

186.6

191.3

165.6

170.1

173.8

122.4

130.2

136.3

224.9

233.2

239.1

225.5

233.9

243.4

185.2

192.6

198.4

270.0

279.8

286.8

270.7

280.7

287.7

252.1

258.4

263.5

59.8

59.2

58.6

60.4

59.8

59.3

62.5

61.8

61.2

61.0

60.2

59.6

61.0

60.2

59.7

62.6

61.8

61.2

62.2

61.2

60.5

62.2

61.2

60.5

63.0

62.1

61.3

176.8

185.7

192.1

212.2

230.7

244.8

270.2

294.3

312.6

206.5

216.7

224.1

218.2

234.2

246.7

269.8

293.7

312.0

236.2

247.9

256.2

236.6

248.3

256.7

270.4

293.3

311.4

176.8

185.7

192.1

149.9

156.7

161.9

112.2

120.4

126.7

206.5

216.7

224.1

201.0

206.9

211.5

161.2

169.4

175.7

236.2

247.9

256.2

236.6

248.3

256.7

210.5

218.3

224.5

49.7

49.1

48.7

50.7

50.1

49.7

52.2

51.5

51.0

50.5

49.8

49.3

50.8

50.2

49.7

52.2

51.5

50.9

51.3

50.5

49.9

51.3

50.5

49.9

52.2

51.5

50.9

120.4

125.9

129.7

126.3

134.3

140.8

177.9

192.8

204.3

150.7

157.4

162.2

150.9

157.7

162.5

177.6

192.2

203.6

180.9

188.9

194.7

181.2

189.3

195.0

187.8

199.6

208.8

58.2

57.8

57.5

58.4

58.0

57.7

59.7

59.3

58.9

59.0

58.5

58.1

59.0

58.5

58.1

59.7

59.3

58.9

59.8

59.2

58.7

59.8

59.2

58.7

60.0

59.4

59.0

34 PKG-PRC003U-EN

Page 35

Performance Data

Table 12. SCWG/SIWG 30 gross cooling capacity - 12,000 cfm, 87 gpm

Entering Water Temp

Entering Air 75°F 85°F 95°F

EDB EWB Total Sensible Total Sensible Total Sensible

°F °F MBh MBh LWT MBh MBh LWT MBh MBh LWT

62 360 294 84.6 347 288 94.4 330 280 104.3

75

80

85

Figure 17. Fan performance for CV or with VFD

67 392 234 85.3 376 228 95.2 359 221 104.9

72 425 171 86.1 408 165 95.9 388 158 105.6

62 362 353 84.6 348 344 94.5 332 332 104.3

67 393 293 85.4 377 286 95.2 360 278 105.0

72 426 231 86.1 409 225 95.9 390 218 105.7

62 382 382 85.1 370 370 95.0 356 356 104.9

67 394 351 85.4 379 344 95.2 361 336 105.0

72 428 291 86.2 410 285 96.0 391 278 105.7

Note: Fan curves include refrigerant coil and internal cabinet static losses. T o determine static pressure used with these curves,

add filter; economizer, flexible horizontal discharge; and heat pressure drops to external duct static pressure.

PKG-PRC003U-EN 35

Page 36

Performance Data

35-ton Water-Cooled

Table 13. SCWG/SIWG 35 economizer capacity - 14,000 cfm

full capacity coil low capacity coil

45°F 55°F 45°F 55°F

EDB EWB flow total sensible LWT total sensible LWT total sensible LWT total sensible LWT

°F °F gpm MBh MBh °F MBh MBh °F MBh MBh °F MBh MBh °F

134.5

139.8

143.1

134.4

137.0

138.8

92.0

96.5

99.5

254.4

262.9

268.1

255.0

263.6

268.9

210.6

217.9

222.9

168.3

174.8

178.9

168.6

175.1

179.2

147.4

151.8

154.8

75

80

85

6288105

119

6788105

119

7288105

119

6288105

119

6788105

119

7288105

119

6288105

119

6788105

119

7288105

119

310.4

325.9

335.9

382.4

410.1

428.2

487.2

524.2

548.1

351.7

364.5

372.3

393.4

417.8

433.8

486.1

523.0

546.8

402.1

416.6

425.3

417.5

438.6

452.3

491.0

524.5

547.1

301.6

308.0

312.2

245.5

256.1

263.1

195.8

209.0

217.7

351.7

364.5

372.3

320.9

330.2

336.4

267.1

280.2

288.9

402.1

416.6

425.3

401.0

409.2

414.6

340.2

352.2

360.4

52.1

51.2

50.7

53.7

52.8

52.2

56.1

55.0

54.2

53.0

51.9

51.3

53.9

53.0

52.3

56.1

55.0

54.2

54.1

52.9

52.2

54.5

53.4

52.6

56.2

55.0

54.2

203.5

210.3

214.5

225.6

238.4

247.2

317.8

341.7

357.5

254.4

262.9

268.1

255.0

263.6

268.9

319.1

341.5

356.7

305.3

315.4

321.6

306.1

316.2

322.5

335.2

354.3

367.2

203.5

210.3

214.5

188.6

193.1

196.2

138.5

146.3

151.5

254.4

262.9

268.1

255.0

263.6

268.9

210.6

217.9

222.9

305.3

315.4

321.6

306.1

316.2

322.5

287.4

293.6

297.9

59.6

59.0

58.6

60.1

59.5

59.2

62.2

61.5

61.0

60.8

60.0

59.5

60.8

60.0

59.5

62.3

61.5

61.0

61.9

61.0

60.4

62.0

61.0

60.4

62.6

61.8

61.2

198.2

206.8

212.1

237.9

255.7

267.1

302.8

325.9

340.8

231.4

241.4

247.5

244.0

259.4

269.5

302.2

325.3

340.2

264.7

276.0

282.9

265.1

276.4

283.4

302.6

324.7

339.5

198.2

206.8

212.1

168.6

175.1

179.4

125.9

133.7

138.9

231.4

241.4

247.5