Business Networking Solution

Installation Guide

Redundant Power Supply

RPS150

About this Installation Guide

This Installation Guide describes the hardware characteristics, installation methods and the

points that should be attended to during the installation. This Installation Guide is structured as

follows:

Chapter 1 Introduction.

This chapter describes the features and external components of RPS150.

Chapter 2 Installation.

This chapter illustrates how to install RPS150.

Chapter 3 Connection.

This chapter illustrates how to do the physical connection of RPS150.

Appendix A Specifications.

Audience

This Installation Guide is for:

Network Engineer Network Administrator

Conventions

This Guide uses the specific formats to highlight special messages. The following table lists the

notice icons that are used throughout this guide.

Remind to be careful. A caution indicates a potential which may result in device damage.

Remind to take notice. The note contains the helpful information for a better use of the

product.

Related Document

This Installation Guide is also available in PDF on our website. To obtain the latest

documentation and product information, please visit the official website:

http://www.tp-link.com

About this Installation Guide

I

Redundant Power Supply

Contents

Chapter 1 Introduction ——————————— 01

Chapter 2 Installation ——————————— 03

Chapter 3 Connection ——————————— 08

1.1 Product Overview ...........................................................01

1.2 Features ..............................................................................01

1.3 Appearance .......................................................................01

2.1 Package Contents ..........................................................03

2.2 Safety Precautions .........................................................03

2.3 Installation Tools ..............................................................06

2.4 Product Installation ........................................................06

3.1 Connect to Ground .........................................................08

3.2 Connect to the Powered Device................................09

3.3 Power On ............................................................................10

3.4 Verify Installation .............................................................10

II Contents

Appendix A Specications ————————— 11

Chapter 1 Introduction

1.1 Product Overview

The TP-Link Redundant Power Supply (RPS) RPS150 is designed to maximize availability

for the business network. RPS150 is used as a redundant power supply for TP-Link

RPS capable L2 and L3 Managed switches. When worked with these switches, RPS150

provides a quick failover feature to ensure that the connected switches can work

uninterruptedly in the event of an internal power supply failure. Without any necessary

configuration, RPS150 can be easily installed as an independent power supply unit,

or placed inside RPS2 chassis which is designed to accommodate t wo RPS150 for

rack-mount installation. Overall, the system integration between TP-Link’s managed

switches and RPS devices, provides you a resilient and highly available converged

network at an affordable price.

1.2 Features

■

Redundant power supply for the switch’s built-in power supply

■

100 to 240 Volts, 50 to 60Hz AC input range

■

+12V/12.5A DC output

■

Up to 150 watts output power

■

LED status indicators

■

Over current/voltage protection

■

Independent or rack-mount installation.

Redundant Power Supply

1.3 Appearance

■

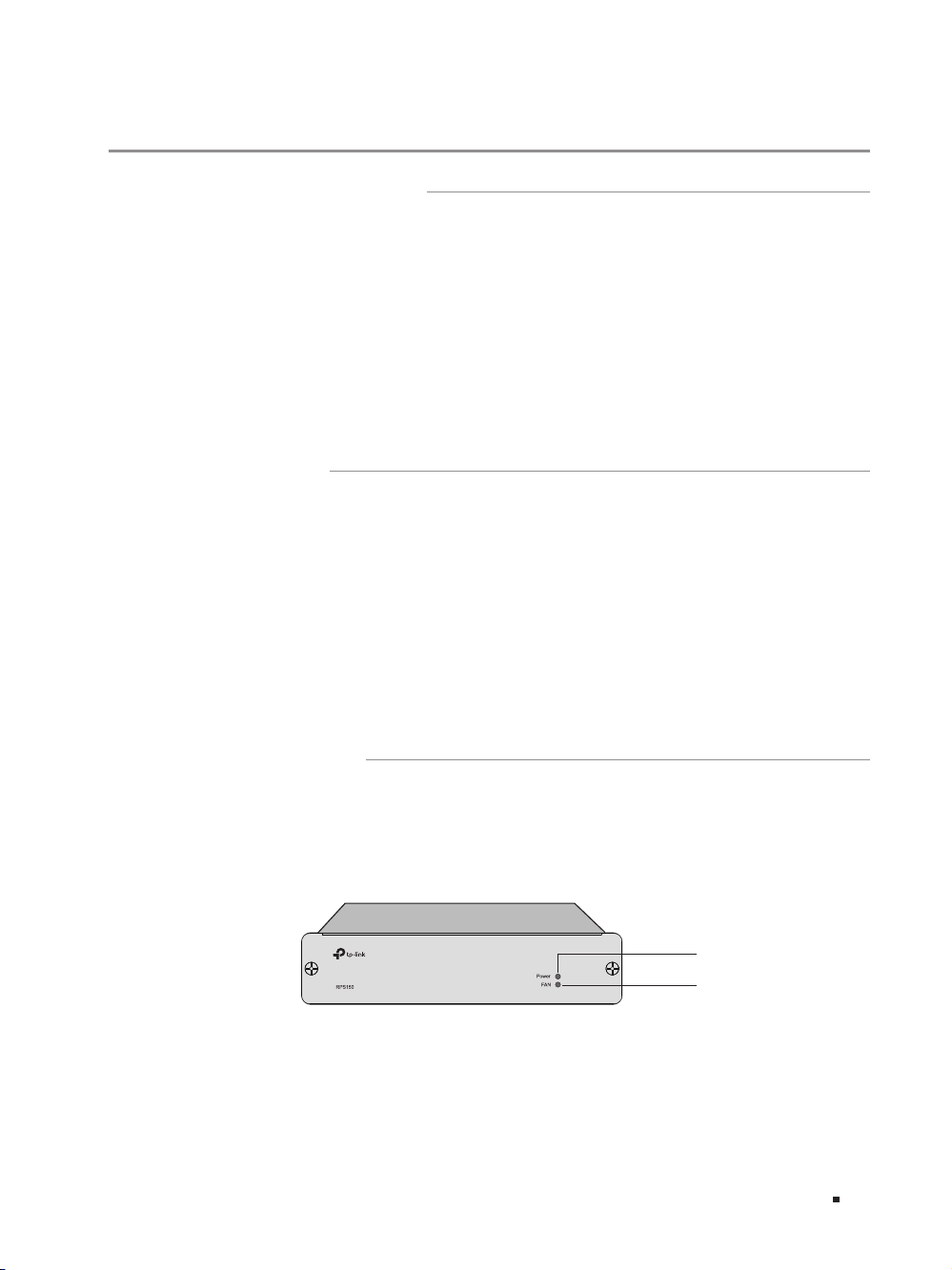

Front Panel

The front panel of RPS150 is shown as the following figure.

Figu re 1-1 Front Panel of R PS150

Power

FAN

Introduction

01

Redundant Power Supply

Indicators

You can monitor the running status of RPS150 through the Power and FAN LEDs.

LED Status Indication

Power

FAN

■

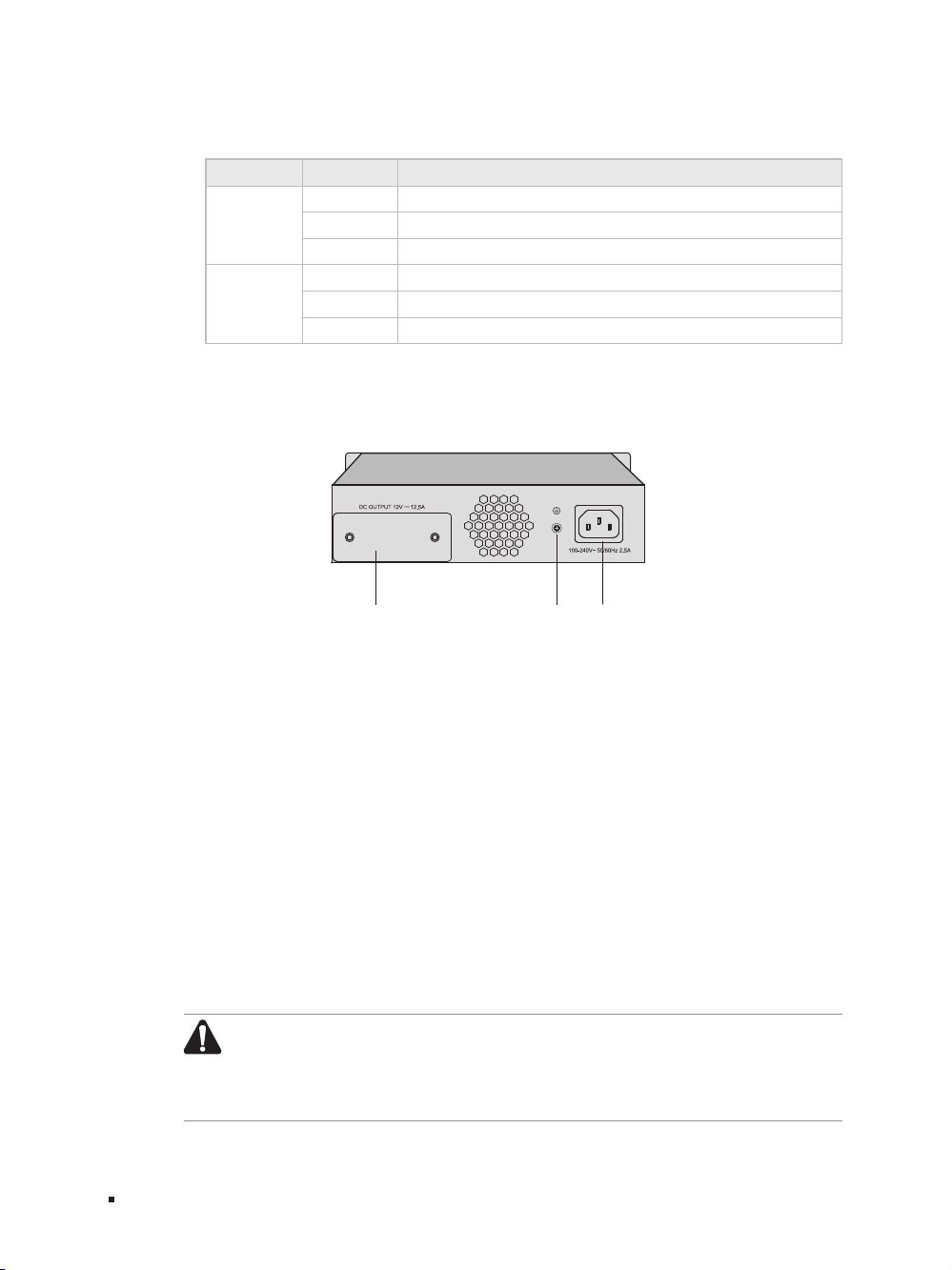

Rear Panel

The rear panel of RPS150 is shown as the following figure.

Figu re 1-2 Rear Panel of R PS150

On The system power supply is normal

Flashing The system power supply is abnormal

Off The system power supply is of f or abnormal

On

The fan works normally

Flashing The fan works abnormally

Off The power supply is of f or the fan works abnormally

Protective Cover

Grounding

Terminal

AC Power

Input

AC Power Input

On the right side of the rear panel, and the input AC power should be 100-240V~

50/60Hz.

Grounding Terminal

On the left side of the AC Power Input, please ground the device with the provided

Ground Cable. You can also ground the device through the PE (Protecting Earth)

cable of AC cord. For detailed information, please refer to section 3.1 Connect to

Ground.

Protective Cover

It is used to protect the DC Power Output Socket. Remove it to connect RPS150 to

the powered device.

Caution:

■

Please use the provided power cord and verify the power supply is

100-240V~50/60Hz.

■

The electrical outlet shall be installed near the device and shall be easily

accessible.

02

Introduction

Chapter 2 Installation

2.1 Package Contents

Make sure that the package contains the following items. If any of the listed items is

damaged or missing, please contact your distributor.

Redundant Power Supply

One RPS150

One DC Power Cord and one

AC Power Cord

This Installation Guide

Business Networking Solution

Installation Guide

Four ttings

2.2 Safety Precautions

To avoid any device damage and bodily injury caused by improper use, please observe

the following rules:

■

Safety Precautions

■

Keep the power off during the installation. Wear an ESD-preventive wrist strap, and

make sure that the wrist strap has a good skin contact and is well grounded.

■

Make sure that the input AC power voltage matches the specifications indicated on the

rear panel of the RPS150.

■

Before switching on the power, make sure that the power circuit will not be overloaded,

otherwise the RPS150 will work abnormally or be damaged.

■

Do not open or remove the cover of the RPS150, even if it is not electrified.

■

Before cleaning the device, cut off the power supply. Do not clean it by the waterish

cloth, and never use any other liquid cleaning method.

■

Site Requirements

To ensure normal operation and long service life of the device, please install it in an

environment that meets the requirements described in the following subsection.

Installation

03

Redundant Power Supply

40℃

Temperature/Humidity

Please keep a proper temperature and humidity in the equipment room. Too high/low

humidity may lead to bad insulation, electricity leakage, mechanical property changes

and corrosions. Too high temperature may accelerate aging of the insulation materials

and can thus significantly shorten the service life of the device. For normal temperature

and humidit y of the device, please check the following table.

Environment Temperature Humidity

Operating 0℃ to 40

Storage -40℃ to 70

Clearness

0℃

℃

℃

20% to 90%RH Non-condensing

10% to 95%RH Non-condensing

04

The dust accumulated on the device can be absorbed by static electricity and result

in poor contact of metal contact points. Some measures have been taken for the

device to prevent static electricity, but too strong static electricity can cause deadly

damage to the electronic elements on the internal circuit board. To avoid the effect of

static electricity on the operation of the device, please attach much importance to the

following items:

■

Dust the device regularly, and keep the indoor air clean.

■

Keep the device well grounded and ensure static electricity has been transferred.

Electromagnetic Interference

Electronic elements including capacitance and inductance on the device can be

affected by external interferences, such as conducted emission by capacitance

coupling, inductance coupling, and impedance coupling. To decrease the interferences,

please make sure to take the following measures:

■

Use the power supply that can effectively filter interference from the power grid.

Installation

Redundant Power Supply

■

Keep the device far from high-frequency, strong-current devices, such as radio

transmitting station.

■

Use electromagnetic shielding when necessary.

Lightening Protection

Extremely high voltage currents can be produced instantly when lightning occurs and

the air in the electric discharge path can be instantly heated up to

20,000℃

. As this

instant current is strong enough to damage electronic devices, more effective lightning

protection measures should be taken.

■

Ensure the rack and device are well earthed.

■

Make sure the power socket has a good contact with the ground.

■

Keep a reasonable cabling system and avoid induced lightning.

■

Use the signal SPD (Surge Protective Device) when wiring outdoor.

Note:

For detailed lightning protection measures, please refer to section 3.1 Connect

to Ground.

Installation Site

When installing the device on a rack or a flat workbench, please note the following

items:

■

The rack or workbench is flat and stable, and sturdy enough to support the weight of

5.5kg at least.

■

The rack or workbench has a good ventilation system. The equipment room is well

ventilated.

■

The rack is well grounded. Keep the power socket less than 1.5 meters away from the

device.

Installation

05

Redundant Power Supply

2.3 Installation Tools

■

Phillips Screwdriver

■

ESD-preventive wrist wrap

2.4 Product Installation

The RPS150 can be installed either in a standard 19-inch rack via RPS2 or directly on a

tabletop.

■

Desktop Installation

To install the device on the desktop, please follow the steps:

Caution:

■

Please set 5 to 10cm gaps around the device for heat dissipation and air circulation.

■

Please avoid any heavy thing placed on the device.

1. Set the device upside down on the flat desktop strong enough to support the entire

weight of the device with all fittings.

2. Remove the adhesive backing papers from the supplied rubber feet and attach the

rubber feet to the recessed areas on the bottom at each corner of the device.

Figu re 2-1 Desktop Installation

06

Feet

Bottom of the Device

Notch

3. Turnover the device and place it stably on the tabletop.

■

Rack Installation

RPS150 can be installed in the standard rack via the RPS2 chassis. One RPS2 chassis is

designed to hold up to 2 RPS150s. You should install the RPS2 chassis to the rack first,

and then insert RPS150 into the RPS2. The detailed instructions are described below:

1. Check the grounding and stability of the rack.

2. Place the RPS2 horizontally to an appropriate position in the rack and then support it

with bracket.

Installation

Redundant Power Supply

3. Secure the RPS2 to each side of the fixed guide slot with screws. Verify the stability

and horizontality of RPS2 in the rack.

Figu re 2-2 Inst all the RPS2 to a standard rack

Rack

RPS2

RPS Slot

4. Insert the RPS150 in to the RPS2 and fix it with screws, as illustrated in the figure

below:

Figu re 2-3 Inse rt RPS150 into RP S2

Note:

■

Do not attach the supplied rubber feet on the bottom of RPS150 if it is supposed

to be inserted into RPS2 in the bracket.

■

A well grounded bracket can largely prevent the device from static electricity,

electric leakage, lightning and electromagnetic interference. Make sure the

grounding cable of the bracket is correctly installed.

■

Ensure the device is well ventilated for the purpose of heat dissipation.

Installation

07

Redundant Power Supply

Ground Cable

Grounding Bar

Chapter 3 Connection

3.1 Connect to Ground

Connecting the device to ground is to quickly release the lightning over-voltage and

over-current of the device, which is also a necessary measure to protect the body from

electric shock.

In different environments, the device may be grounded differently. The following

will instruct you to connect the device to the ground in two ways, connecting to the

grounding bar or connecting to the ground via the power cord. Please connect the

device to ground in the optimum way according to your specific operation environment.

■

Connecting to the Grounding Bar

If the device is installed in the Equipment Room, where a grounding bar is available, you

are recommended to connect the device to the grounding bar as shown in the following

figure.

Figu re 3-1 Connecting to the Grounding Bar

Connection

08

Grounding Terminal

RPS150 (Rear Panel)

Note:

The grounding bar and ground cable are not provided with our product. If

needed, please self purchase them.

■

Connecting to the Ground via the Power Supply

If the device is installed in the normal environment, the device can be grounded via the

PE (Protecting Earth) cable of the AC power supply as shown in Figure 3-4.

To connect the device to the ground via the PE (Protecting Ear th) cable of AC power

cord, please make sure the PE (Protecting Earth) cable in the electrical outlet is well

grounded in advance.

Redundant Power Supply

Protective Cover

RPS DC Output

3.2 Connect to the Powered Device

The RPS150 can be used as a redundant backup power supply unit for multiple switch

models. Follow the steps below to connect the RPS150 to a powered device.

1. Confirm that the power supply of the RPS150 is cut off.

2. Remove the protective covers covering the redundant power socket of RPS150 and

the switch. Here we take the removing process of RPS150 for example:

Figu re 3-2 Remov ing the RPS Protective Cover

Removing the Protective Cover

3. Connect the RPS150 and the switch with DC power cord, as illustrated in Figure 3-3.

One end of the DC power cord is marked by the letters “TOP” and the other end has

a positioning card attached to it. Plug the end with the letters “TOP” into the input

socket of the switch with “TOP” facing up and the other end with positioning card

into the DC output socket of the RPS150 with the positioning card facing up.

Caution:

Make sure the power supply of RPS150 is cut off when connecting or

disconnecting RPS150 and the switch, otherwise both RPS150 and the switch

may work abnormally or even be damaged.

Figu re 3-3 Conn ecting to the Powered Swi tch

RPS150

Switch One connector with letters “TOP”

3

Module

TX432

M1

SFP+

4

M2

SFP+

CLASS 1 LASER PRODUCT

Positioning Card

TOP

Power

PS OK

Fault

PSM150-AC

100-240V~ 50/60Hz 2.5A

4

Connection

3

09

Redundant Power Supply

3.3 Power On

The RPS150 requires 100-240V~50/60HZ AC power input.

1. Confirm that the power supply satisfies the requirement of the input voltage of

RP S15 0;

2. Plug the negative connector of the provided AC power cord into the power socket

of RPS150, and the positive connector into a power outlet as the following figure

shown. After RPS150 is powered on normally, the Power LED and FAN LED indicators

on its front panel will light on all the time.

Figu re 3-4 Conn ecting to Power Sup ply

Caution:

■

■

■

3.4 Verify Installation

After completing the installation, please verify the following items:

■

There is enough room around the sides of RPS150 for heat dissipation and the air flow

is adequate;

■

The voltage of the power supply meets the requirement of the input voltage of the

device;

■

The power socket, device and rack are well grounded.

Connection

10

Make sure that the power supply is well grounded. Locate the switch of the power

supply in advance, so that you can cut it off in time when needed.

Disconnect RPS150 from its AC power supply when plugging or removing the DC

power cable.

The figure is to illustrate the application and principle. The power cord you get

from the package and the socket in your situation will comply with the regulation

in your country, so they may differ from the figure above.

Appendix A Specifications

Item Content

AC Power Input 100-240V~ 50/60Hz 2.5A

DC Power Output 12V 12.5A

Maximum Power Output

LEDs Power, FAN

Operating Temperature 0

Storage Temperature -40

Operating Humidity 20%

Storage Humidity 10%

150W

to

40

℃

℃

to

70

℃

℃

to

90%RH Non-condensing

to

95%RH Non-condensing

Redundant Power Supply

11Appendix A Specications

FCC STATEMENT

This equipment has been tested and found to comply with the limits for a Class A digital device,

pursuant to part 15 of the FCC Rules. These limits are designed to provide reasonable protection

against harmful interference when the equipment is operated in a commercial environment. This

equipment generates, uses, and can radiate radio frequency energy and, if not installed and used in

accordance with the instruction manual, may cause harmful interference to radio communications.

Operation of this equipment in a residential area is likely to cause harmful interference in which case

the user will be required to correct the interference at his own expense.

This device complies with part 15 of the FCC Rules. Operation is subject to the following two

conditions:

1) This device may not cause harmful interference.

2) This device must accept any interference received, including interference that may cause

undesired operation.

Any changes or modifications not expressly approved by the party responsible for compliance could

void the user’s authority to operate the equipment.

CE Mark Warning

This is a class A product. In a domestic environment, this product may cause radio interference, in

which case the user may be required to take adequate measures.

Industry Canada Statement

CAN ICES-3 (A)/NMB-3(A)

Korea Warning Statements

당해 무선설비는 운용중 전파혼신 가능성이 있음.

BSMI Notice

安全 諮詢及注意事 項

• 請使用原 裝電源供應器或只能按照 本產品注明的電源類型使用本產品。

• 清潔本產品之前請先拔掉電源線。請勿使用液體、噴霧清潔劑或濕布進行清潔。

• 注意防潮,請勿將水或其他液體潑灑到本產品上。

• 插槽與開口供通 風使 用,以確保本產品的操作可靠並防止 過熱,請勿堵塞 或覆蓋開口。

• 請勿將本產品置放於靠近熱源的地方。除非有正常的通風,否則不可放在密閉位置中。

• 請不要私自打開機殼,不要嘗試自行維修本產品,請由授權的專業人士進行此項工作。

此為甲類資訊技術設備,于居住環境中使用時,可能會造成射頻擾動,在此種情況下,使用者會被要求採取某些適

當的對策。

Продукт сертифіковано згідно с правилами системи УкрСЕПРО на відповідність вимогам

нормативних документів та вимогам, що передбачені чинними законодавчими ак тами України.

Safety Information

• When product has power button, the power button is one of the way to shut off the product; when

there is no power button, the only way to completely shut off power is to disconnect the product

or the power adapter from the power source.

• Don’t disassemble the product, or make repairs yourself. You run the risk of electric shock and

voiding the limited warranty. If you need ser vice, please contact us.

• Avoid water and wet locations.

Explanation of the symbols on the product label

AC voltage.

RECYCLING

This product bears the selective sorting symbol for Waste electrical and electronic

equipment ( WEEE). This means that this product must be handled pursuant to European

directive 2012/19/EU in order to be recycled or dismantled to minimize its impact on the

environment.

User has the choice to give his product to a competent recycling organization or to the

retailer when he buys a new electrical or electronic equipment.

Website: http://www.tp-link.com Tel: +86 755 26504400 E-mail: support@tp-link.com

© 2016 TP-Link

7106506701 REV2.0.0

Loading...

Loading...