Toyota Sienna 2004 User Manual

Technical Service

A

BULLETIN

November 12, 2004

Title:

REPAIR MANUAL SUPPLEMENT:

LEV II EVAP SYSTEM CHECK DTC P0441, P0442, P0446, P0451,

P0452, P0453, P0455 & P0456

Models:

’03 -- ’04 4Runner & Tundra, ’04 Camry, Highlander,

Sienna & Solara

ENGINE

EG048-04

Introduction

pplicable

Vehicles

This TSB provides detailed instructions for a new LEV II EVAP System Check function

using the Diagnostic Tester.

The LEV II System Check allows the Diagnostic Tester to display the fuel tank vapor

pressure as the EVAP VSV and the CCV are operated in a specific six--step pattern.

Problems with the EVAP system are quickly isolated by observing the change in vapor

pressure during each step.

Once the vehicle condition is corrected, the LEV II System Check can also be used to

confirm the repair before the vehicle is returned to the customer.

The inspection procedure using the LEV II System Check (LEV II SYS CHECK) is

described in this bulletin. This function is available using a Diagnostic Tester with version

11.0a software (or newer).

S 2003 -- 2004 model year 4Runner vehicles equipped with 2UZ--FE and

1GR--FE engines.

S 2003 -- 2004 model year Tundra vehicles equipped with 5VZ--FE and

2UZ--FE engines.

S 2004 model year Camry vehicles equipped with 2AZ--FE, 1MZ--FE and

3MZ--FE engines.

S 2004 model year Highlander and Sienna vehicles equipped with 3MZ--FE engine.

S 2004 model year Solara vehicles equipped with 2AZ--FE and 3MZ --FE engines.

Tab l e of

Contents

Warranty

Information

T oyota Supports ASE Certification

SECTION TITLE PAGE

OP CODE DESCRIPTION TIME OFP T1 T2

N/A Not Applicable to Warranty – – – –

A LEV II SYS CHECK Description 3

B DTC Check 4

C LEV II SYS CHECK (Diagnostic Tester System Test) 5

D Air Inlet Restriction Inspection 13

E EVAP VSV Stuck--Open Inspection 16

F Leak Check or No Vacuum Drawn on System Inspection 17

G CCV Diagnostics 22

H EVAP VSV Diagnostics 25

I EVAP System Description 30

J EVAP System DTC Descriptions 33

K EVAP Monitor Description 35

L OBD II EVAP Monitor Specifications 39

Page 1 of 41

REP A IR MANUAL SUPPLEMENT: LEV II EVAP SYSTEM CHECK -- EG048-04 November 12, 2004

Required

SSTs

SPECIAL SERVICE TOOLS (SSTs) PART NUMBER QUANTITY

Toyota Diagnostic Tester Kit*

12 Megabyte Diagnostic Tester Program Card

with version 11.0a Software (or later)*

EVAP Tester Kit*

01001271 1

01002593-005 1

00002--6872A 1

00002--6872A--FC

EVAP Tester Fuel Cap Adapter*

or

00002--6872A--FCA

* Essential SSTs.

NOTE:

Additional Diagnostic Tester Kits, Program Cards or other SSTs may be ordered by

calling SPX/OTC at 1-800-933-8335.

1

Terms &

Definitions

TERM DEFINITION

CCV Evaporative Emissions Canister Control Valve

Charcoal Canister Evaporative Emissions Canister

DTC(s) Diagnostic Trouble Code(s)

ECM (SAE term: PCM) Engine Control Module (SAE term: Powertrain Control Module)

ECT Engine Coolant Temperature

EVAP Evaporative Emissions

EVAP VSV, Purge VSV Evaporative Emissions Canister Purge Valve

FTP Fuel Tank Pressure

IAT Intake Air Temperature

LEV II Low Emissions Vehicle Phase 2

MIL Malfunction Indicator Lamp

mmHg--a Unit of Absolute Pressure (762 mmHg--a at sea level)

mmHg--g Unit of Gauge Pressure (0 mmHg--g at sea level)

Vapor Pressure Sensor Fuel Tank Pressure Sensor

Page 2 of 41

REP A IR MANUAL SUPPLEMENT: LEV II EVAP SYSTEM CHECK -- EG048-04 November 12, 2004

A

.LEVII

SYS CHECK

Description

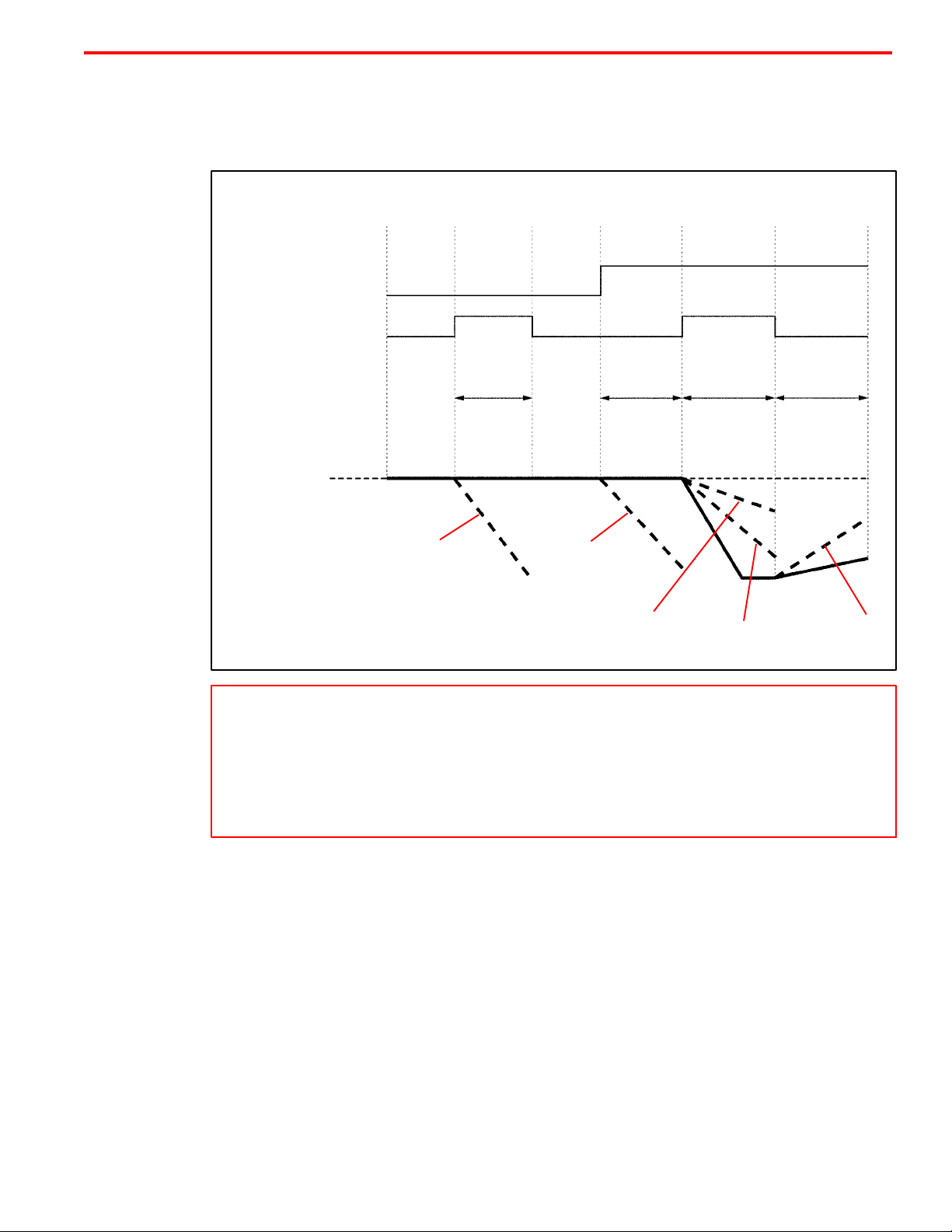

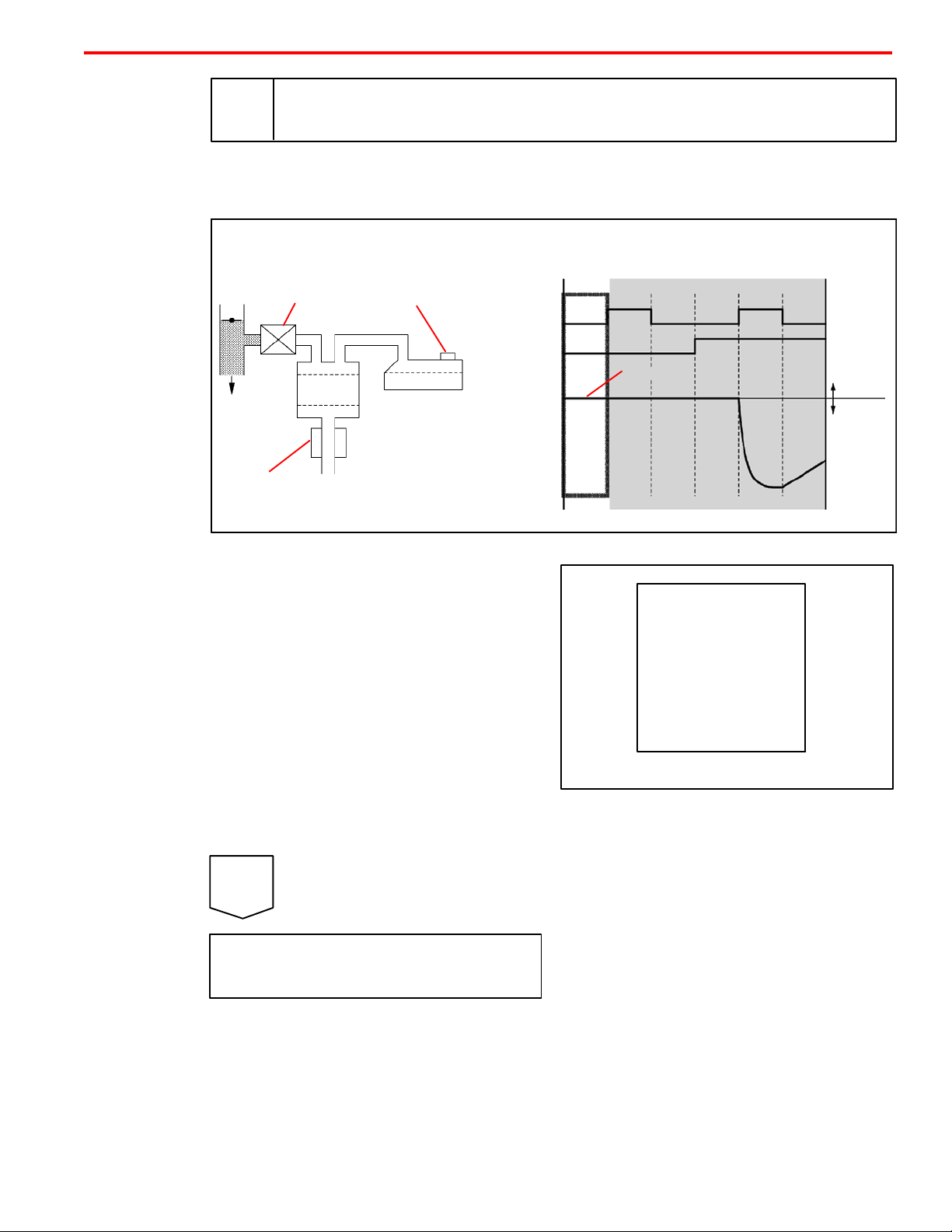

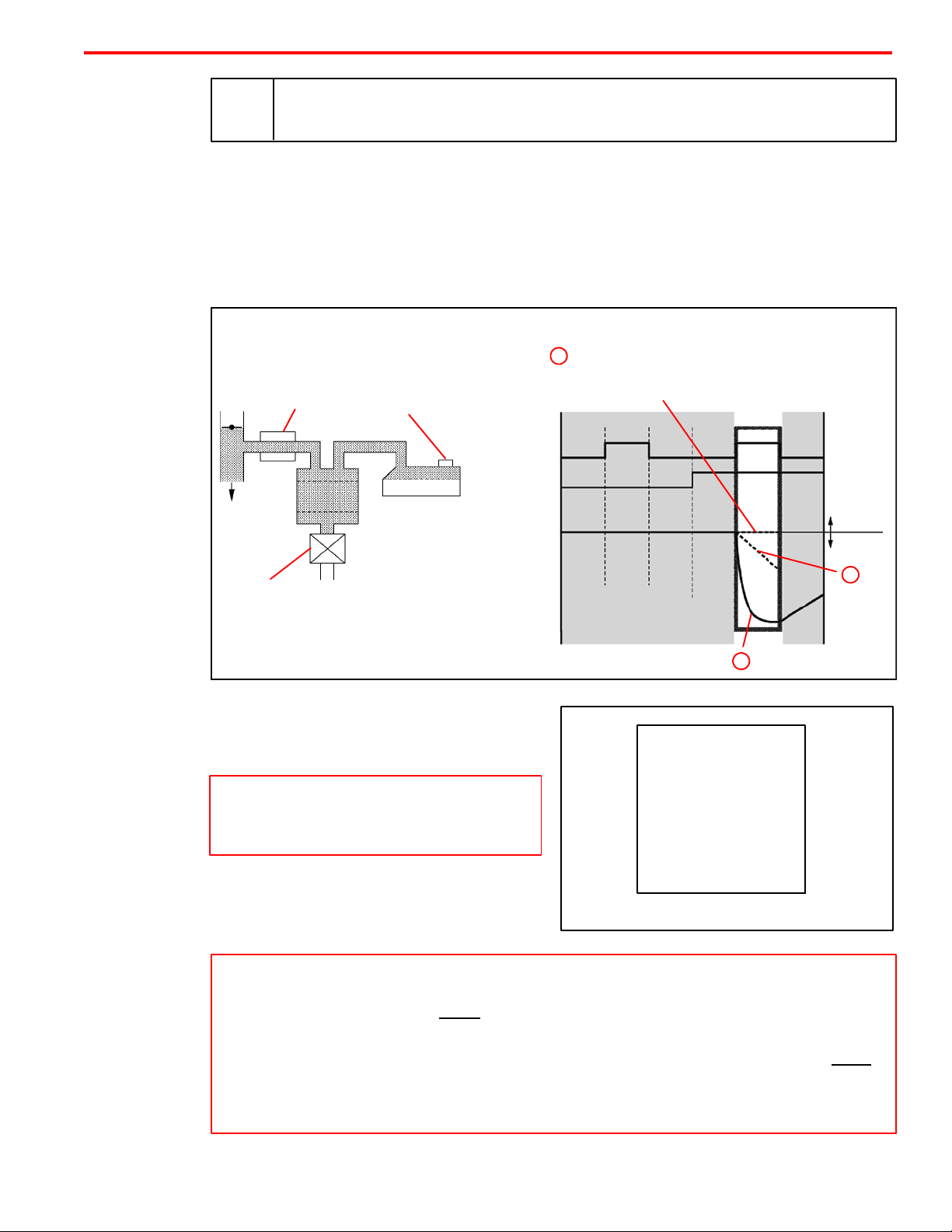

The LEV II System Check allows the Diagnostic Tester to display the fuel tank vapor

pressure as the EVAP VSV and the CCV are operated in a specific six--step pattern.

Problems with the EVAP system are quickly isolated by observing the change in vapor

pressure during each step.

Detail of “LEV II SYS CHECK”

System Check Steps

(Normally Open)

EVAP VSV

(Normally Closed)

Required Time

Ambient

Pressure

Step 1

CCV

CLOSED

Step 2 Step 3 Step 4 Step 5 Step 6

OPEN

OPEN OPEN

30 sec 15 sec 30 sec 300 sec

CLOSED

CLOSED

CCV Stuck Closed

Air Inlet Line Restriction

CCV Stuck

Open

Large Leak

System Line Restriction

CCV Stuck Open

EVAP VSV Stuck Closed

Medium

Leak

Medium Leak

Small Leak

NOTE:

The EVAP system pressure can be affected by ambient temperature, atmospheric

pressure, and fuel level. This test is most accurate when the following conditions

are met.

S The vehicle is at sea level and at an atmospheric pressure of approximately

762 mmHg--a (0 mmHg--g).

S The external fuel tank temperature is between 4 to 35_C (40 to 90_F).

S The fuel level in the fuel tank is approximately 1/4 to 3/4 full.

Page 3 of 41

REP A IR MANUAL SUPPLEMENT: LEV II EVAP SYSTEM CHECK -- EG048-04 November 12, 2004

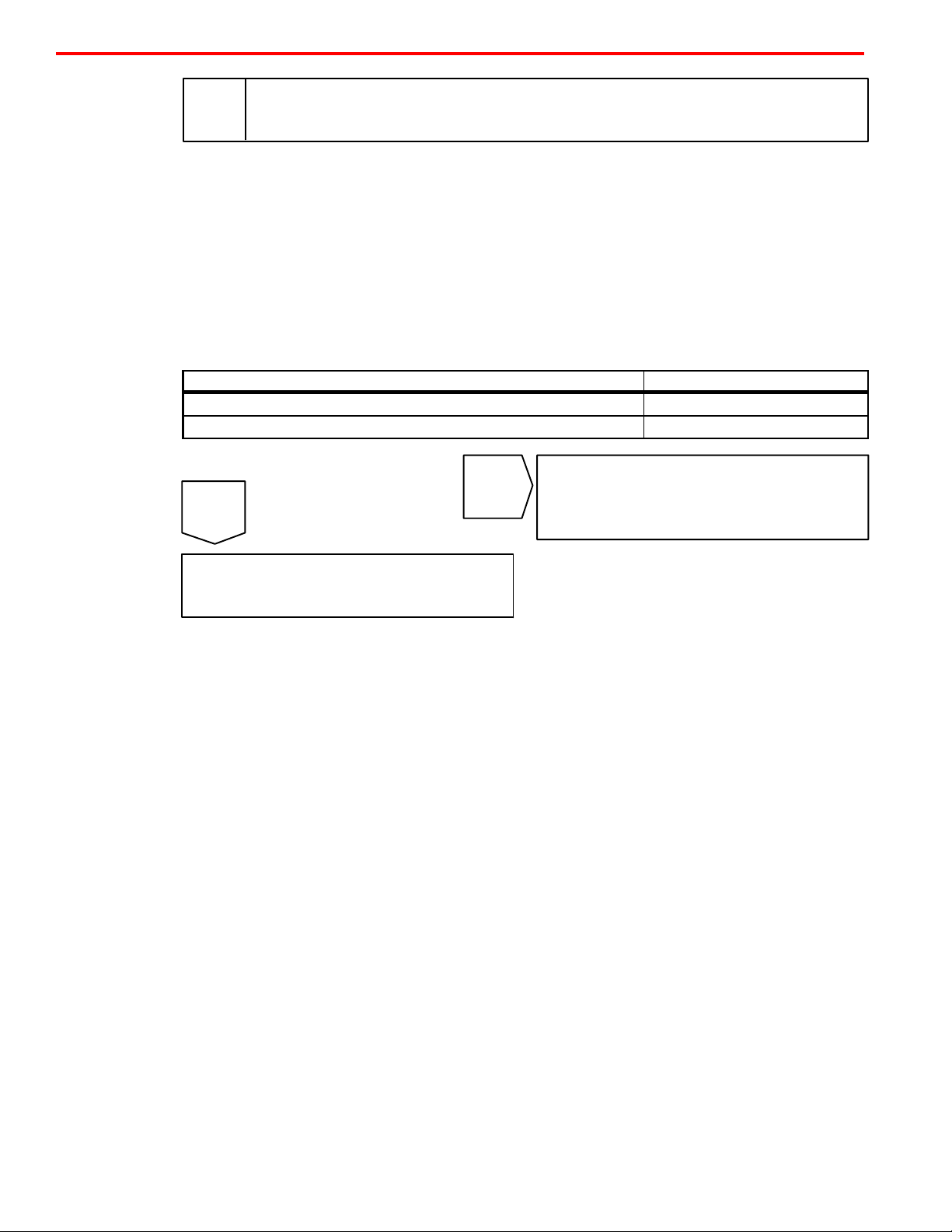

k

B. DTC Chec

1

Check for current and pending DTCs to determine which part of the

EVAP system may be malfunctioning.

A. Connect the Diagnostic Tester to DLC3.

B. Enter the following menus:

DIAGNOSIS / ENHANCED OBD II / DTC INFO / PENDING DTCS.

C. Enter the following menus:

DIAGNOSIS / ENHANCED OBD II / DTC INFO / CURRENT DTCS.

D. Make a note of any pending and/or current DTCs.

RESULT:

DTC GO TO

P0441, P0442, P0446, P0455 and/or P0456 A

P0451, P0452 or P0453 B

Check vapor pressure sensor

B

A

(refer to Repair Manual in the Technical

Information System [TIS]: Diagnostics:

SFI System: DTC P0451, P0452, or P0453

Go to Step 1 of “C: LEV II SYS CHECK”

(page 5).

Page 4 of 41

REP A IR MANUAL SUPPLEMENT: LEV II EVAP SYSTEM CHECK -- EG048-04 November 12, 2004

C. LEVII SYS

CHECK

1

Pressure Equalize

In Step 1, the EVAP actuators are at rest and the system pressure should equalize with

outside atmospheric pressure. This step ensures the test starts without any vacuum

and/or pressure on the system.

Step 1. Pressure Equalize

EVAP VSV: Closed

(Normally Closed)

CCV: Open

(Normally Open)

Vapor Pressure

Sensor

A. Start the engine.

B. Enter the following menus:

DIAGNOSIS / ENHANCED

OBD ll / SYSTEM CHECK /

LEV ll SYS CHECK.

C. Read the vapor pressure sensor

value (VAPOR PRESS).

D. Vapor Pressure should equalize

with the atmosphere within

30 seconds.

Continue to the next step when

pressure is 760 to 764 mmHg--a

(--2 to 2 mmHg--g).

Order

EVAP VSV

CCV

VAP OR

PRESS

EVAP Pressure Change During System Check

Step 1

Closed

Open

Normal

Positive

Negative

LEVII SYSTEM CHECK

Step 1. Pressure Equalize

EVAP VSV CLOSE......

CCV OPEN.............

VAPOR PRESS

762 mmHg -- a....

Time 030 seconds

Press [RIGHT]

Sample Screen

NEXT

Press the right arrow key on the

Diagnostic Tester to go to the

next step.

Page 5 of 41

REP A IR MANUAL SUPPLEMENT: LEV II EVAP SYSTEM CHECK -- EG048-04 November 12, 2004

C. LEVII SYS

CHECK

(Continued)

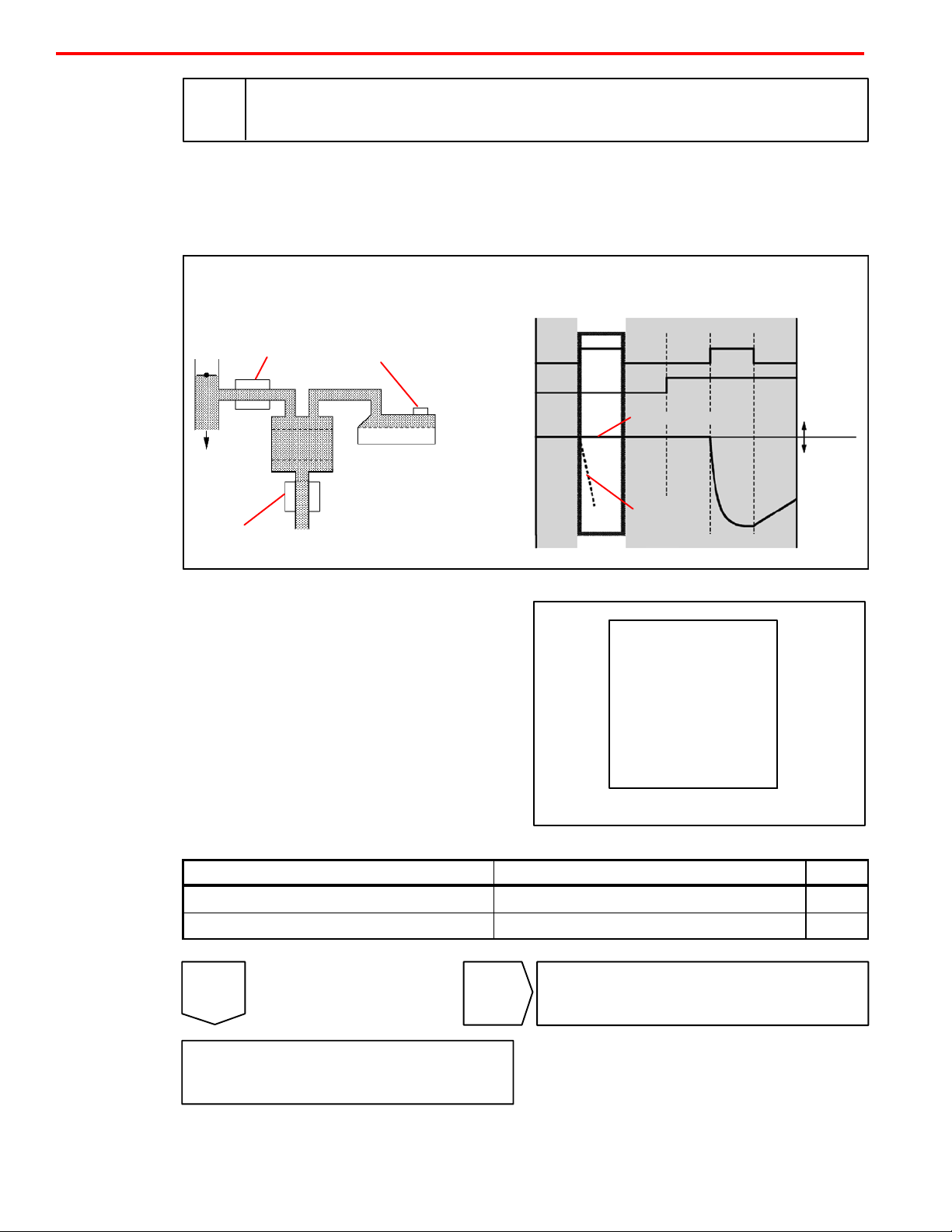

2

Purge w/CCV Open

During Step 2, while the engine is running, the ECM (PCM) energizes/de--energizes

(duty cycles) the EVAP VSV and a vacuum is applied to the entire system. The LEV ll

system uses a high flow CCV. Since the CCV is open, there should be little or no drop in

system pressure.

Step 2. Purge w/CCV Open

EVAP VSV: Open

(Normally Closed)

CCV: Open

(Normally Open)

Vapor Pressure

Sensor

CHECK:

Wait for 30 seconds. Read the vapor

pressure sensor value

(VAPOR PRESS).

Order

EVAP VSV

CCV

VAP OR

PRESS

EVAP Pressure Change During System Check

Step 2

Open

Open

Normal (OK)

CCV Stuck

Closed

(NG)

LEVII SYSTEM CHECK

Step 2. Purge w/CCV

Open

EVAP VSV OPEN.......

CCV OPEN.............

Positive

Negative

Page 6 of 41

VAPOR PRESS

Time 030 seconds

VAPOR PRESS VALUE CONCLUSION GO TO

761 mmHg -- a....

Press [RIGHT]

Sample Screen

753 to 762 mmHg--a (--9 to 0 mmHg--g) No trouble found in this step OK

732 to 752 mmHg--a (--30 to --10 mmHg--g) CCV stuck closed or air inlet line restriction NG

OK

NG

Go to “D. Air Inlet Restriction

Inspection” (page 13).

Press the right arrow key to go to

the next step.

REP A IR MANUAL SUPPLEMENT: LEV II EVAP SYSTEM CHECK -- EG048-04 November 12, 2004

C. LEVII SYS

CHECK

(Continued)

3

Pressure Equalize

During Step 3, the ECM (PCM) closes the EVAP VSV shutting off vacuum to the system.

The CCV remains open, therefore allowing fresh air into the system. The system should

equalize to atmosphere within 30 seconds.

Step 3. Pressure Equalize

EVAP Pressure Change During System Check

EVAP VSV: Closed

(Normally Closed)

Vapor Pressure

Sensor

Order

EVAP VSV

CCV

Step 3

Closed

Open

CCV: Open

(Normally Open)

A. Read the vapor pressure sensor

value (VAPOR PRESS).

B. The vapor pressure value should

be 760 to 764 mmHg--a

(--2 to 2 mmHg-- g) (equal to

ambient pressure) within

30 seconds.

C. Continue to the next step.

NEXT

VAP OR

PRESS

Positive

Negative

Normal

LEVII SYSTEM CHECK

Step 3. Pressure Equalize

EVAP VSV CLOSE......

CCV OPEN.............

VAPOR PRESS

762 mmHg -- a....

Time 030 seconds

Press [RIGHT]

Sample Screen

Press the right arrow key to go to

the next step.

Page 7 of 41

REP A IR MANUAL SUPPLEMENT: LEV II EVAP SYSTEM CHECK -- EG048-04 November 12, 2004

C. LEVII SYS

CHECK

(Continued)

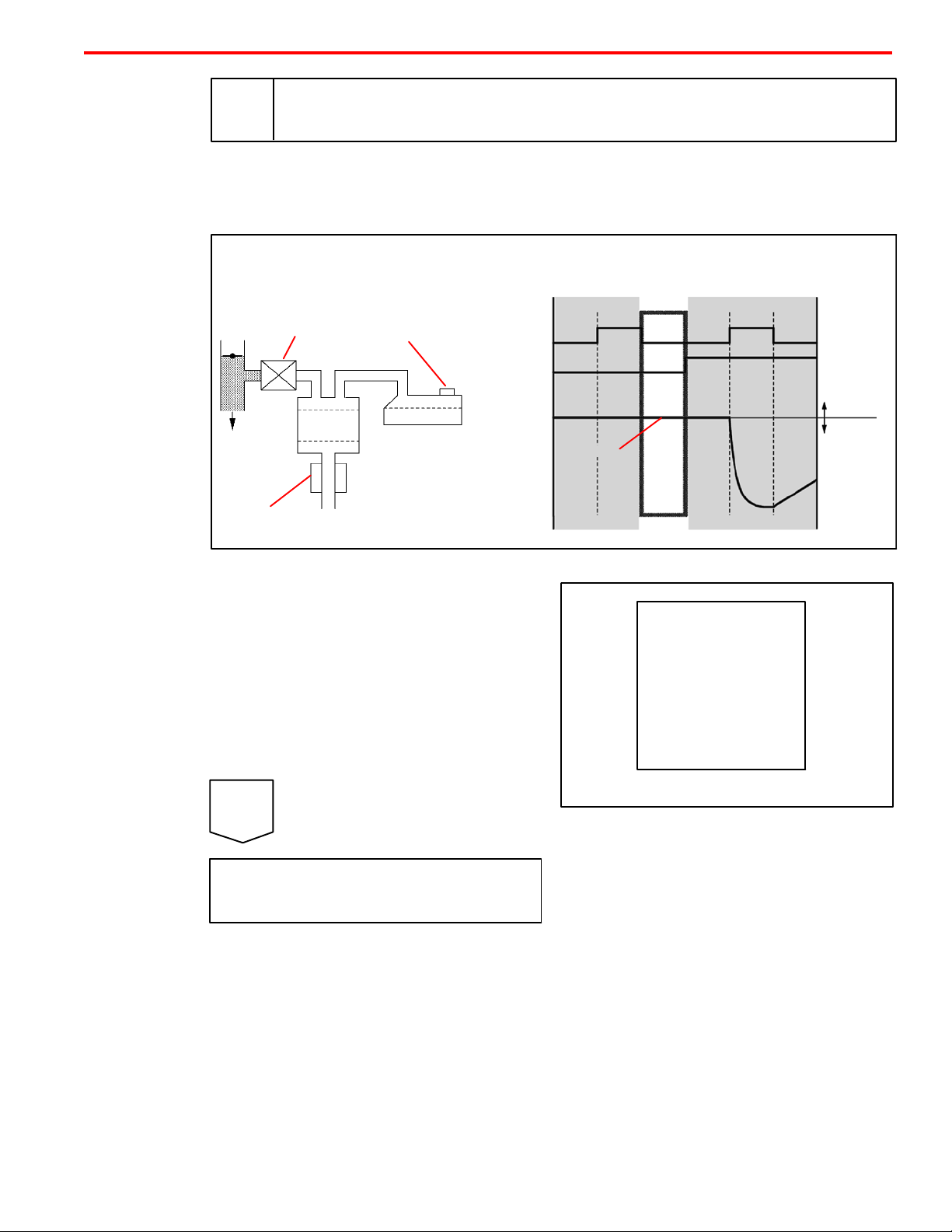

4

Sealing System

During step 4, the CCV is closed and the system is sealed. Since the EVAP VSV is

closed, there should be no drop in system pressure.

Step 4. Sealing System

EVAP VSV: Closed

(Normally Closed)

CCV: Closed

(Normally Open)

Vapor Pressure

Sensor

EVAP VSV

CHECK:

Wait 15 seconds and check the vapor

pressure sensor value (VAPOR PRESS).

EVAP Pressure Change During System Check

Order

CCV

Normal (OK)

VAP OR

PRESS

EVAP VSV

Stuck Open

(NG)

EVAP VSV CLOSE......

CCV CLOSE............

Step 4

Closed

Closed

LEVII SYSTEM CHECK

Step 4. Sealing System

Positive

Negative

VAPOR PRESS

Time 015 seconds

VAPOR PRESS VALUE CONCLUSION GO TO

762 mmHg -- a....

Press [RIGHT]

Sample Screen

758 to 768 mmHg--a (--4 to 6 mmHg--g) No trouble found in this step OK

732 to 757 mmHg--a (--30 to --5 mmHg--g) EVAP VSV stuck open NG

OK

NG

Go to “E. EVAP VSV Stuck--Open

Inspection” (page 16)

Press the right arrow key to go to

the next step.

Page 8 of 41

REP A IR MANUAL SUPPLEMENT: LEV II EVAP SYSTEM CHECK -- EG048-04 November 12, 2004

V

C. LE

CHECK

(Continued)

II SYS

5

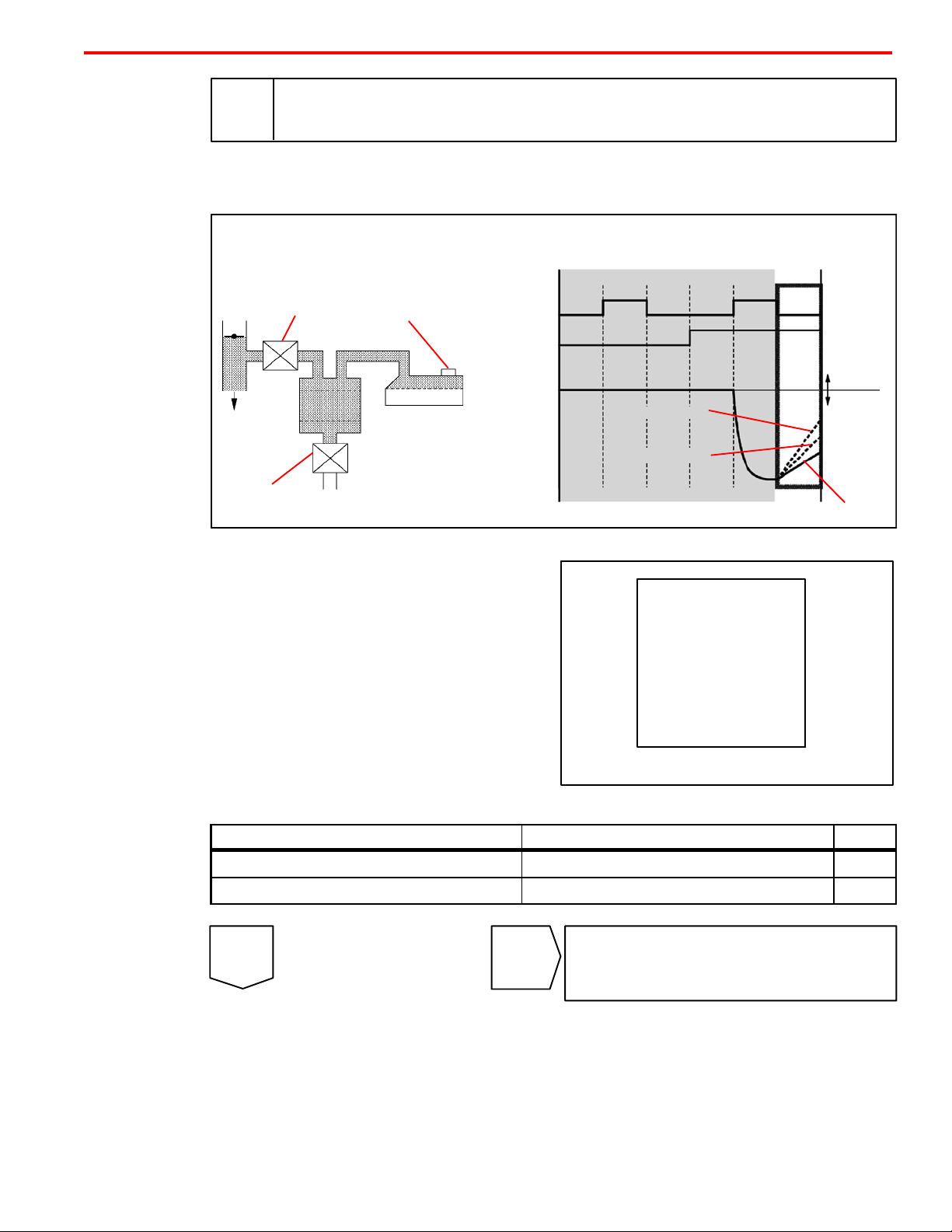

Applying Vacuum

During step 5, vacuum is applied to the EVAP system. The fuel tank’s interior should

develop negative pressure within 30 seconds (see example “A” in the diagram below).

If the pressure does not decrease sufficiently within 30 seconds, (for example, “B” in

diagram below) this indicates a leak or restriction in the system.

A moderate drop in pressure (for example, “C” in diagram below) indicates that a medium

leak is occurring in the system.

Step 5. Applying Vacuum

EVAP VSV: Open

(Normally Closed)

Vapor Pressure

Sensor

EVAP VSV

VAP OR

PRESS

EVAP Pressure Change During System Check

1. Large Leak

B

2. System Line Restriction

3. CCV Stuck Open

4. EVAP VSV Stuck Closed

Order

CCV

Step 5

Open

Closed

Positive

Negative

CCV: Closed

(Normally Open)

A

Normal

CHECK:

Wait for 30 seconds. Read the vapor

pressure sensor value (VAPOR PRESS).

NOTE:

Fuel level should be between 1/4 to 3/4

of a tank for proper vacuum testing.

NOTE:

S If the pressure drops to 740 mmHg--a (--22 mmHg--g) at any point during this test,

the Diagnostic Tester will close

OR:

S If the pressure drops to 735 mmHg--a (--27 mmHg--g) the Diagnostic Tester will abort

the LEV II SYS CHECK.

This usually happens when the fuel level in the tank is above 3/4 full.

Recheck proper fuel level, then restart the LEV II SYS CHECK.

the EVAP VSV to prevent system damage.

LEVII SYSTEM CHECK

Step 5. Applying vacuum

EVAP VSV OPEN.......

CCV CLOSE............

VAPOR PRESS

740 mmHg -- a....

Time 030 seconds

Press [RIGHT]

Sample Screen

C

Medium

Leak

Page 9 of 41

REP A IR MANUAL SUPPLEMENT: LEV II EVAP SYSTEM CHECK -- EG048-04 November 12, 2004

C. LEVII SYS

CHECK

(Continued)

VAPOR PRESS VALUE CONCLUSION GO TO

732 to 742 mmHg--a (--30 to --20 mmHg--g) No trouble found in this step A

Medium to large leak, EVAP line restriction,

743 to 768 mmHg--a (--19 to 6 mmHg--g)

EVAP VSV stuck closed or CCV

stuck open

Go to “F. Leak Check or No Vacuu m

A

B

Drawn on System Inspectio n ”

(page 17).

Press the right arrow key to go to

the next step.

B

Page 10 of 41

REP A IR MANUAL SUPPLEMENT: LEV II EVAP SYSTEM CHECK -- EG048-04 November 12, 2004

C. LEVII SYS

CHECK

(Continued)

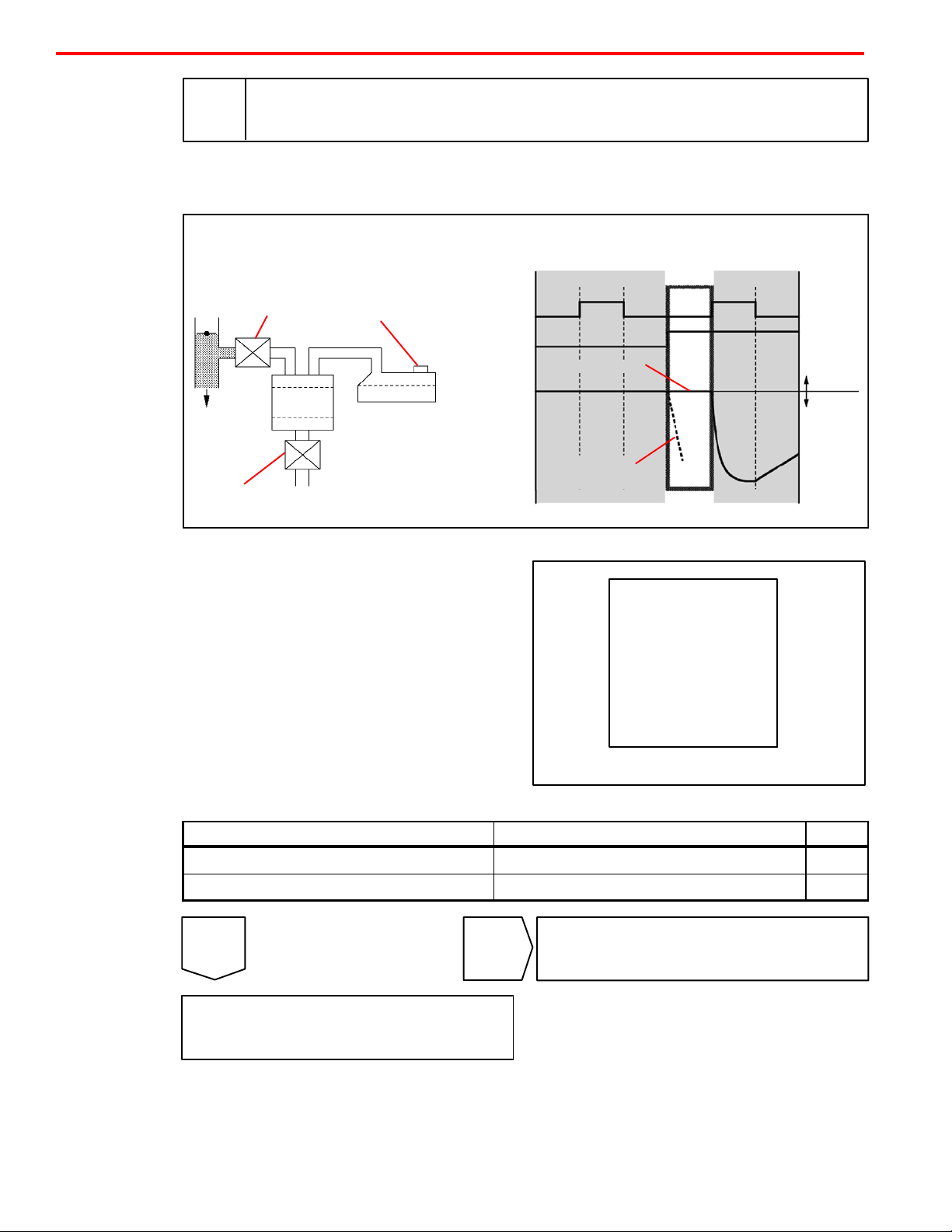

Sealing Vacuum

6

During step 6, the EVAP system is sealed and the change in fuel tank interior pressure

is monitored.

Step 6. Sealing Vacuum

EVAP VSV: Closed

(Normally Closed)

CCV: Closed

(Normally Open)

Vapor Pressure

Sensor

EVAP VSV

CHECK:

Wait 300 seconds (5 minutes) and check

the vapor pressure.

EVAP Pressure Change During System Check

Order

CCV

VAP OR

PRESS

Small Leak (NG)

Very Small Leak

(NG)

LEVII SYSTEM CHECK

Step 6. Sealing Vacuum

EVAP VSV CLOSE......

CCV CLOSE............

Step 6

Closed

Closed

Positive

Negative

Normal (OK)

VAPOR PRESS

Time 300 seconds

VAPOR PRESS VALUE CONCLUSION GO TO

752 mmHg -- a....

Press [RIGHT]

Sample Screen

732 to 758 mmHg--a (--30 to --4 mmHg--g) No trouble found in this step OK

759 to 768 mmHg--a (--3 to 6 mmHg--g) Small leak or very small leak NG

OK

NG

Go to “F. Leak Check or No Vacuum

Drawn on System Inspection”

(page 17).

Page 11 of 41

REP A IR MANUAL SUPPLEMENT: LEV II EVAP SYSTEM CHECK -- EG048-04 November 12, 2004

C. LEVII SYS

CHECK

(Continued)

No leak detected and VSV operation is normal.

Before returning the vehicle to the customer, perform the following:

A. Clear all DTCs.

B. Perform a drive pattern test and confirm that no pending DTCs are recorded.

C. Make sure the monitors pass.

Page 12 of 41

REP A IR MANUAL SUPPLEMENT: LEV II EVAP SYSTEM CHECK -- EG048-04 November 12, 2004

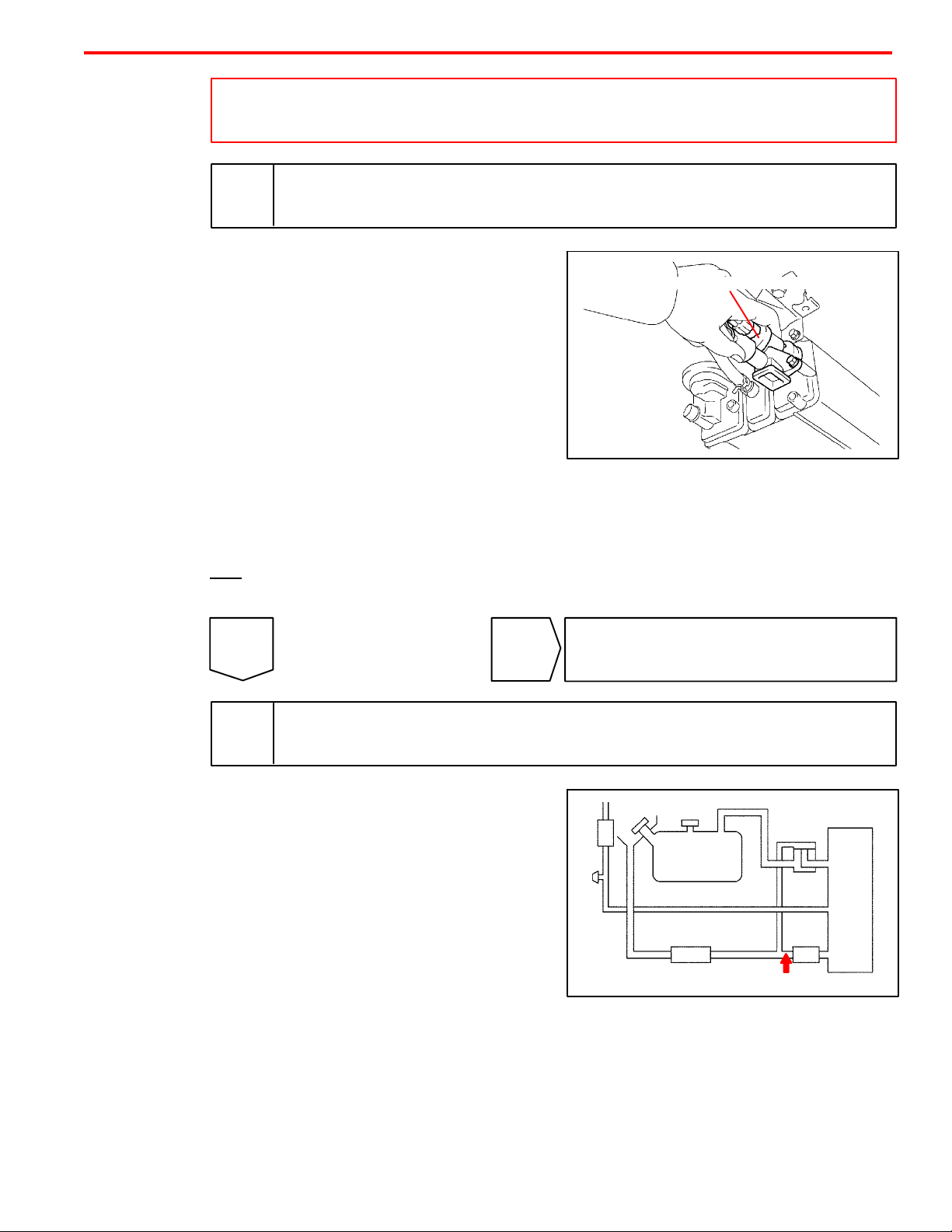

D. Air Inlet

Restriction

Inspection

NOTE:

Before starting this procedure, perform the “LEV II SYS CHECK” (see page 5).

1

Perform CCV Active Test using the Diagnostic Tester.

PREPARATION:

A. Turn the ignition switch ON.

Feel Motion of Valve Inside CCV

B. Enter the following menus:

DIAGNOSIS / ENHANCED

OBD ll / ACTIVE TEST /

CAN CTRL VSV.

C. Then press the right or left

arrow key to activate the CCV.

CHECK:

Operate the CCV through the ACTIVE

TEST and touch the CCV with your hand.

Check that the motion of the valve inside

theCCVcanbefelt.

OK:

Motion of valve inside CCV can be felt.

OK

2

Determine source of air flow restriction.

NG

PREPARATION:

A. Turn off the engine.

B. Disconnect the air inlet line

from CCV.

C. Remove and reinstall fuel tank

cap to relea se system pressure.

D. Restart the engine.

Go to “G. CCV Diagnostics”

(see step 2 on page 22).

EVAP VSV

Fuel Tank

Charcoal

Canister Filter

Disconnect

CCV

Charcoal Canister

Page 13 of 41

Loading...

Loading...