Page 1

IN-18

INTRODUCTION

ABBREVIATIONS USED IN THIS MANUAL

For convenience, the following abbreviations are used in this

manual.

ABS Antilock Brake System

A/C Air Conditioner

assy assembly

ECT Electronic Controlled Transmission

ECU Electronic Control Unit

e.g. Exempli Gratia (for Example)

Ex. Except

FWD Front Wheel Drive Vehicles

4WD Four Wheel Drive Vehicles

in. inch

LH Left-hand

LHD Left-hand Drive

MIG Metal Inert Gas

M/Y Model Year

PPS Progressive Power Steering

RH Right-hand

RHD Right-hand Drive

SRS Supplemental Restraint System

SSM Special Service Materials

w/ with

w/o without

Page 2

FOREWORD

This repair manual has been prepared to provide essential information on body panel repair methods (including cutting and

welding operations, but excluding painting) for the SCION xA.

Applicable models: NCP61 series

This manual consists of body repair methods, exploded diagrams and illustrations of the body components and other information relating to body panel replacement such as handling

precautions, etc. However, it should be noted that the front fenders of the SCION model is bolted on and require no welding.

When repairing, don’t cut and join areas that are not shown in

this manual. Only work on the specified contents to maintain

body strength.

Body construction will sometimes differ depending on specifications and country of destination. Therefore, please keep in mind

that the information contained herein is based on vehicles for

general destinations.

For the repair procedures and specifications other than collisiondamaged body components of the SCION xA refer to the repair

manuals.

If you require the above manuals, please contact your SCION

Dealer.

All information contained in this manual is the most up-to-date at

the time of publication. However, specifications and procedures

are subject to change without prior notice.

Page 3

Page 4

Glass Cover

INTRODUCTION

GENERAL REPAIR INSTRUCTIONS

1. WORK PRECAUTIONS

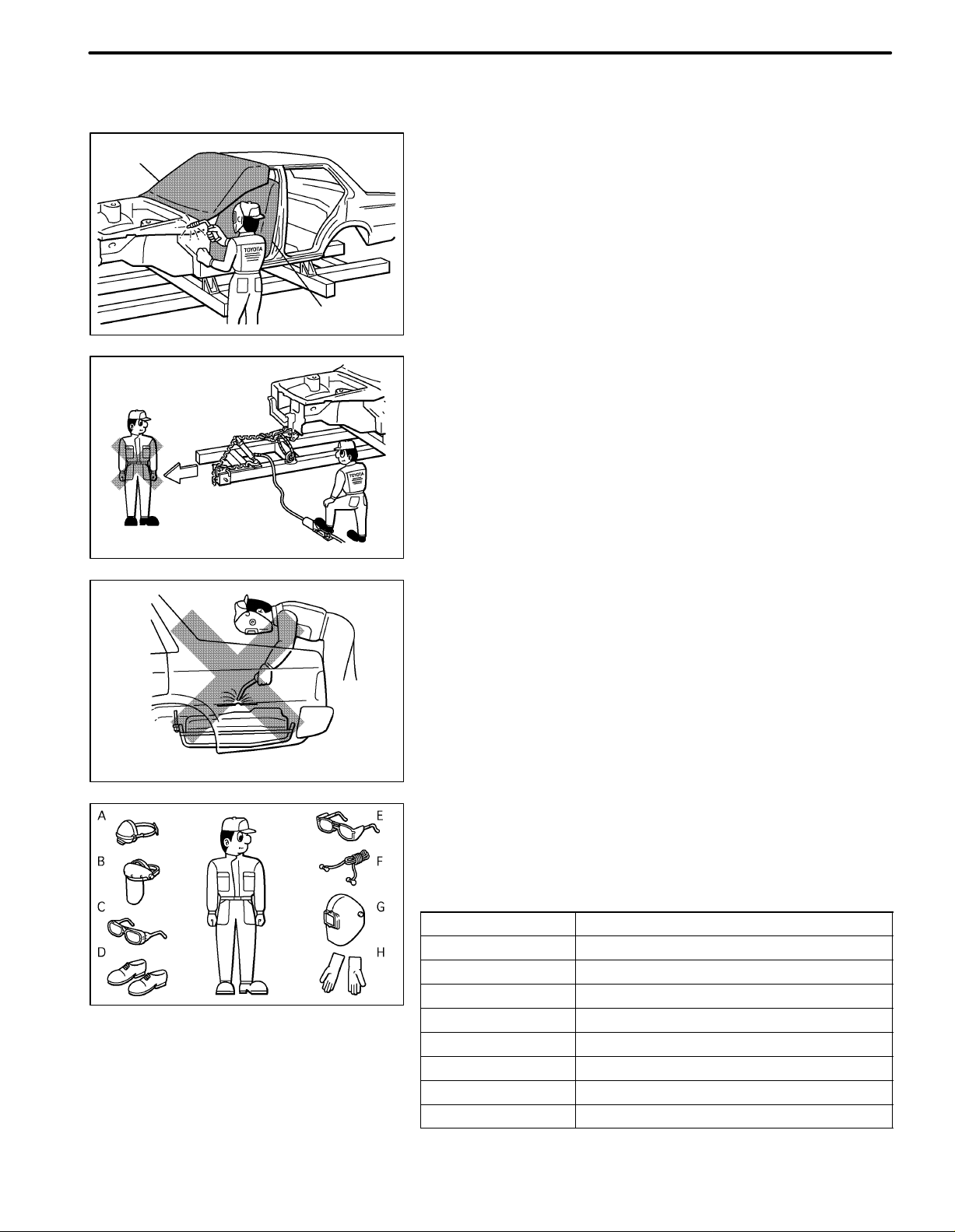

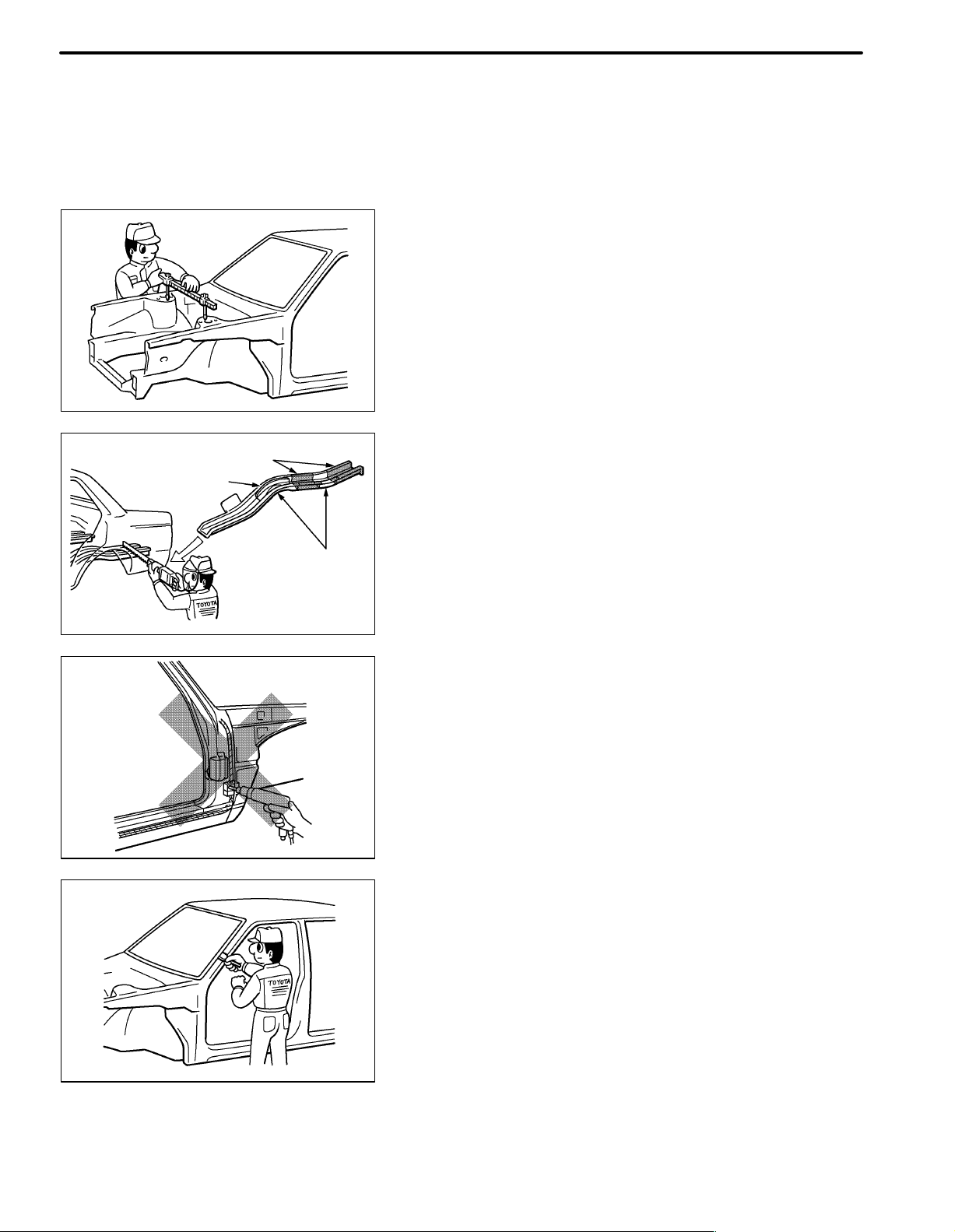

(a) VEHICLE PROTECTION

(1) When welding, protect the painted surfaces, windows,

seats and carpet with heat resistant, fire-proof covers.

IN-1

WRONG

Seat Cover

F10001A

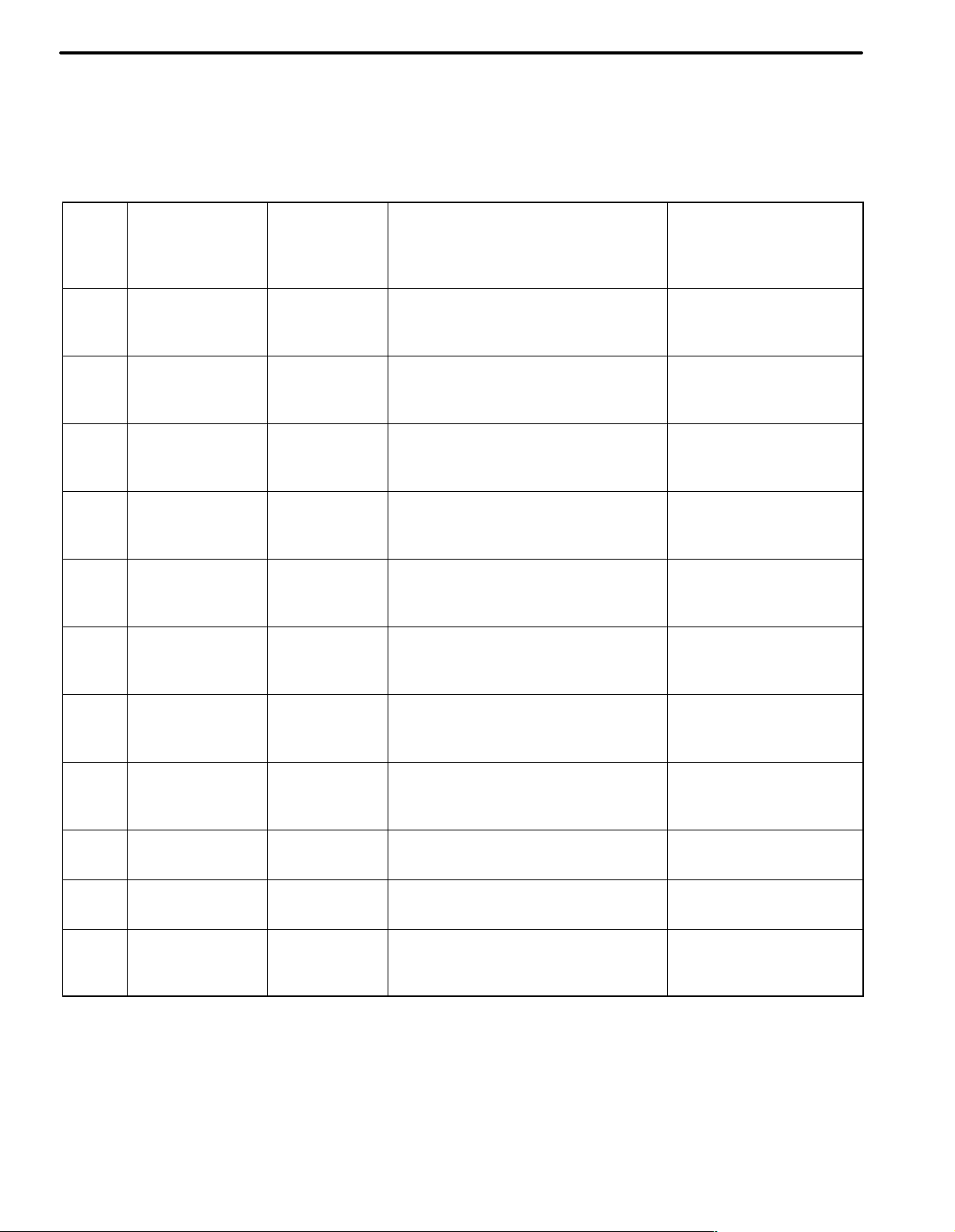

(b) SAFETY

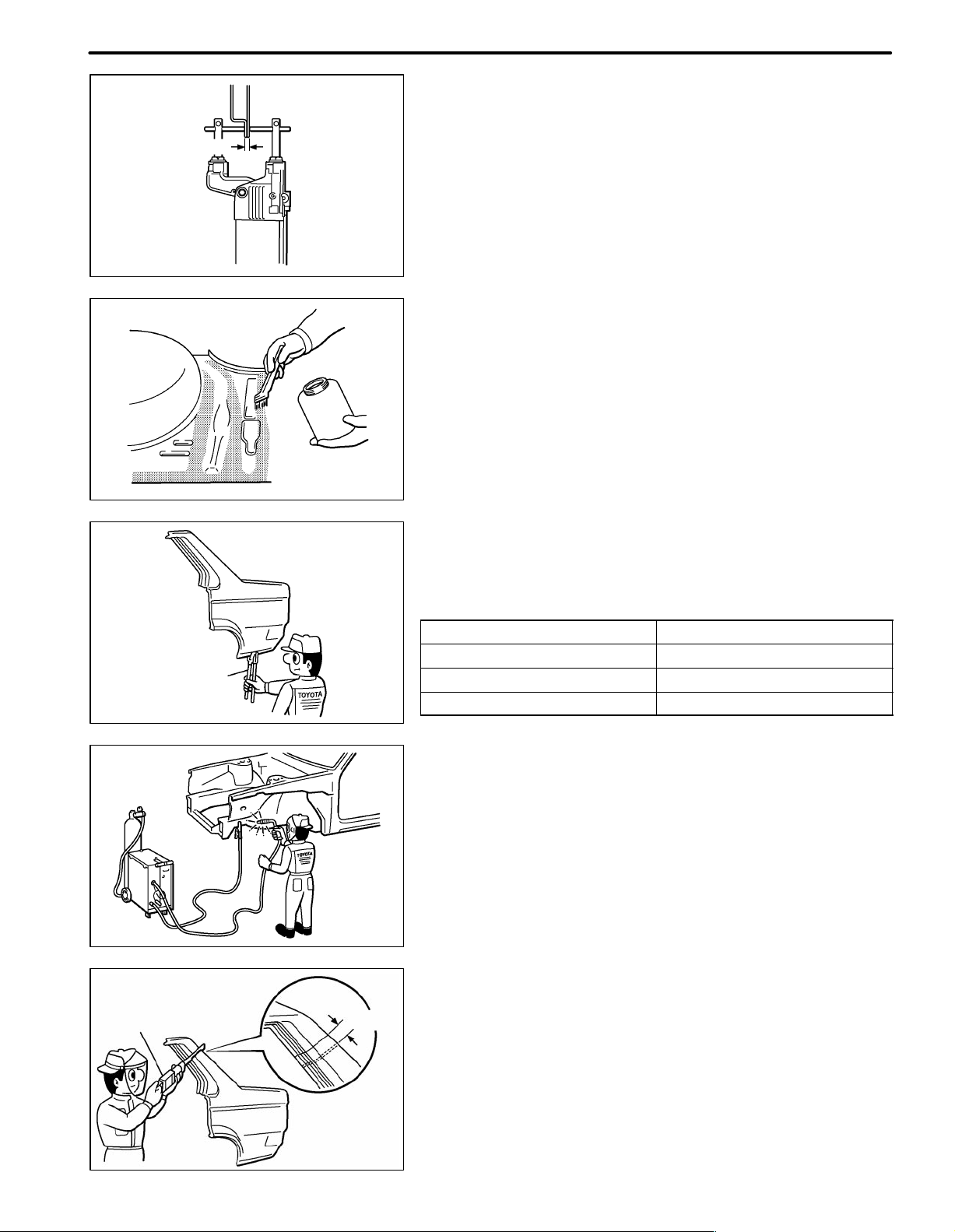

(1) Never stand in direct line with the chain when using a

puller on the body or frame, and be sure to attach a

safety cable.

F10002A

(2) Before performing repair work, check for fuel leaks.

If a leak is found, be sure to close the opening totally.

(3) If it is necessary to use a flame in the area of the fuel

tank, first remove the tank and plug the fuel line.

WRONG

F10003A

F10004

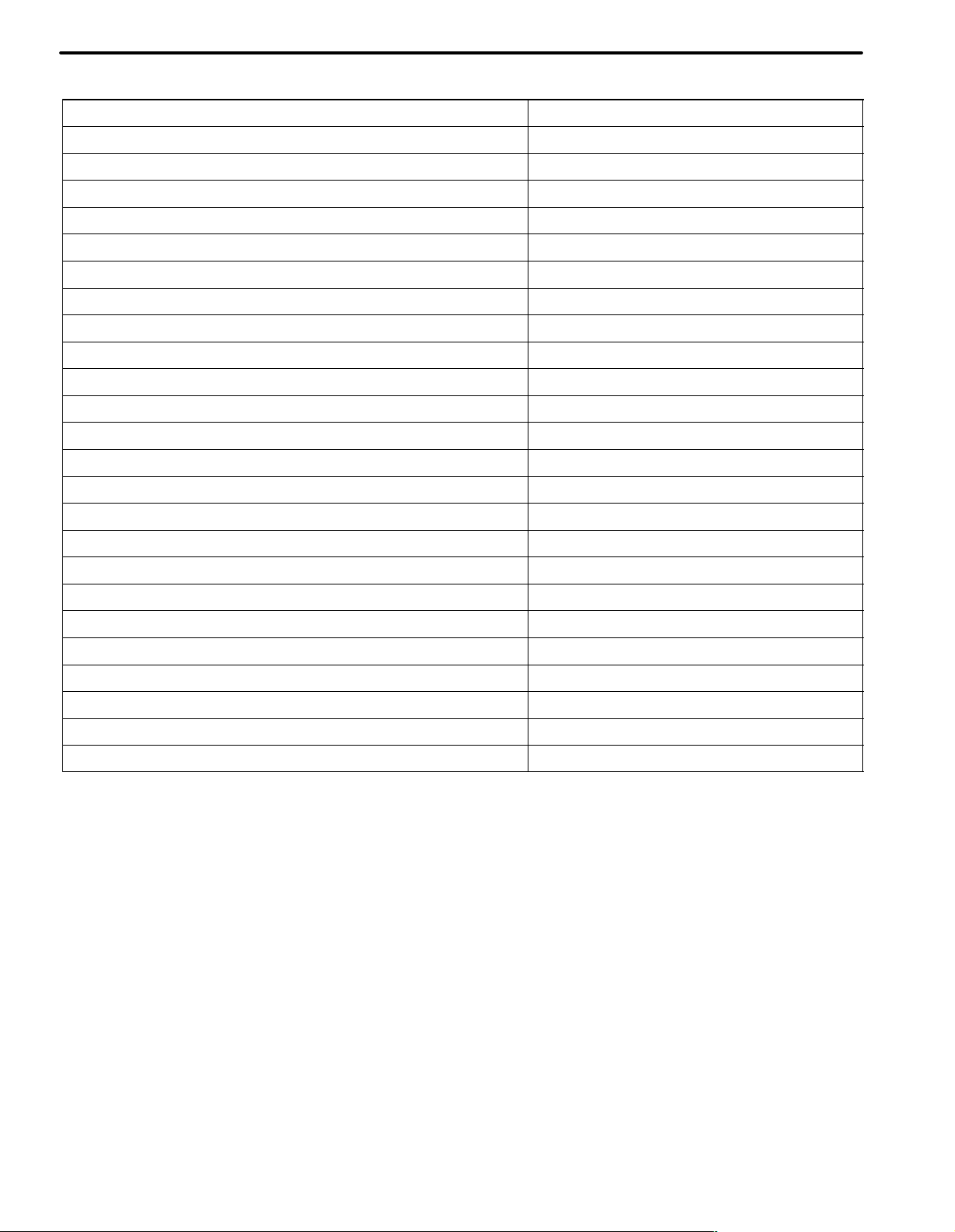

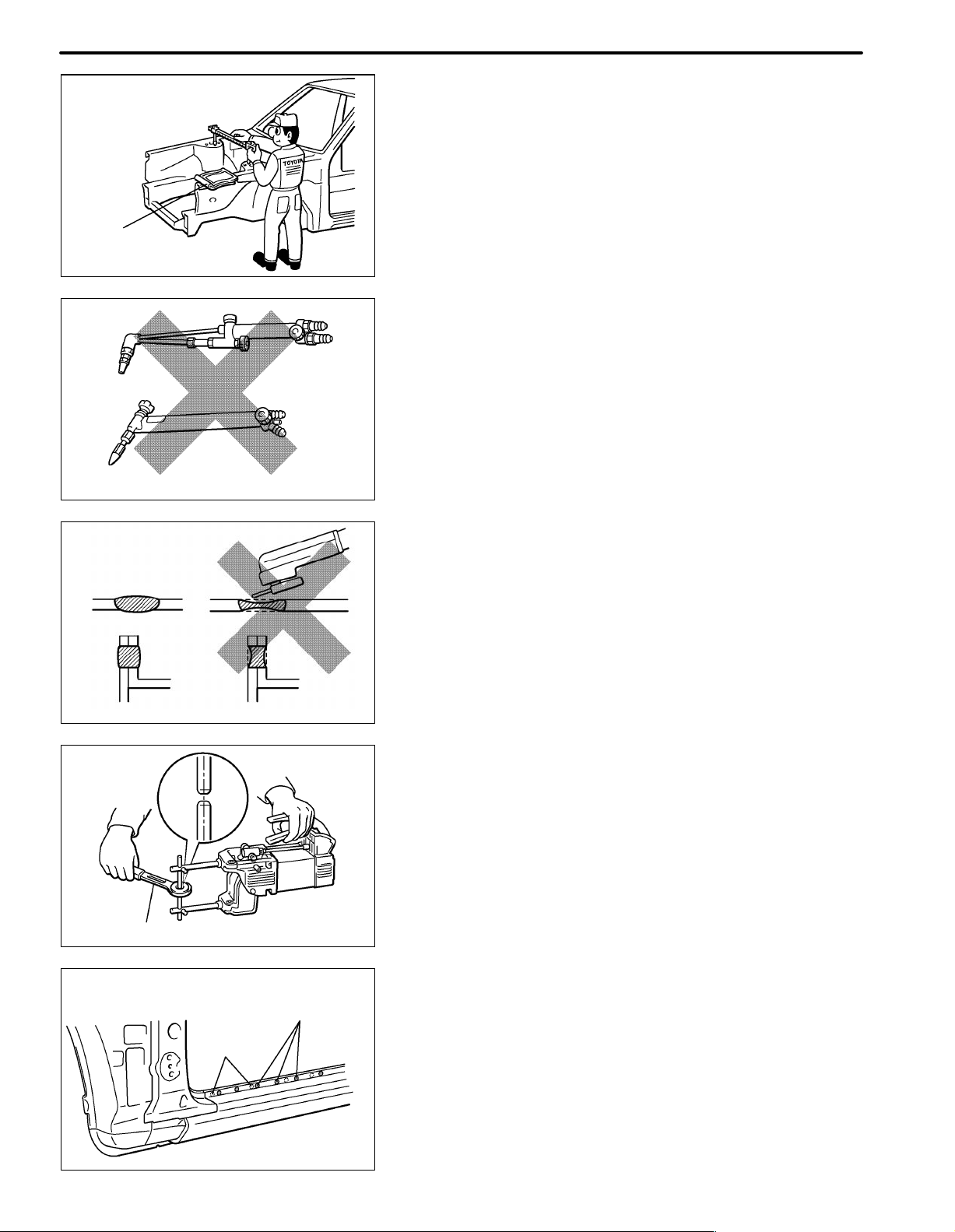

(c) SAFETY WORK CLOTHES

(1) In addition to the usual mechanic’s wear, cap and

safety shoes, the appropriate gloves, head protector,

glasses, ear plugs, face protector, dust-prevention

mask, etc. should be worn as the situation demands.

Code Name

A Dust-Prevention Mask

B Face Protector

C Eye Protector

D Safety Shoes

E Welder’s Glasses

F Ear Plugs

G Head Protector

H Welder’s Gloves

Page 5

IN-2

INTRODUCTION

2. HANDLING PRECAUTIONS OF PLASTIC BODY PARTS

(1) The repair procedure for plastic body parts must conform with the type of plastic material.

(2) Plastic body parts are identified by the codes in the following table.

(3) When repairing metal body parts adjoining plastic body parts (by brazing, frame cutting, welding, paint-

ing etc.), consideration must be given to the property of the plastic.

*

Heat

Code

Material

name

resistant

temperature

limit C (F)

Resistance to

alcohol or gasoline

Notes

AAS

ABS

AES

ASA

CAB

EPDM

FRP

Acrylonitrile

Acrylic Styrene

Acrylonitrile

Butadiene Styrene

Acrylonitrile

Ethylene Styrene

Acrylonitrile

Styrene

Acrylate

Cellulose

Acetate

Ethylene

Propylene

Fiber

Reinforced

Plastics

80

(176)

80

(176)

80

(176)

80

(176)

80

(176)

100

(212)

180

(356)

Alcohol is harmless if applied only for

short time in small amounts (e.g., quick

wiping to remove grease).

Alcohol is harmless if applied only for

short time in small amounts (e.g., quick

wiping to remove grease).

Alcohol is harmless if applied only for

short time in small amounts (e.g., quick

wiping to remove grease).

Alcohol is harmless if applied only for

short time in small amounts (e.g., quick

wiping to remove grease).

Alcohol is harmless if applied only for

short time in small amounts (e.g., quick

wiping to remove grease).

Alcohol is harmless.

Gasoline is harmless if applied only for

short time in small amounts.

Alcohol and gasoline are harmless. Avoid alkali.

Avoid gasoline and organic

or aromatic solvents.

Avoid gasoline and organic

or aromatic solvents.

Avoid gasoline and organic

or aromatic solvents.

Avoid gasoline and organic

or aromatic solvents.

Avoid gasoline and organic

or aromatic solvents.

Most solvents are harmless

but avoid dipping in gasoline,

solvents, etc.

EVA

PA

PBT

PC Polycarbonate

*Temperatures higher than those listed here may result in material deformation during repair.

Ethylene

Acetate

Polyamide

(Nylon)

Polybutylene

Terephthalate

70

(158)

80

(176)

160

(320)

120

(248)

Alcohol is harmless if applid only for short

time in small amounts (e.g., quick wiping

to remove grease).

Alcohol and gasoline are harmless. Avoid battery acid.

Alcohol and gasoline are harmless. Most solvents are harmless.

Alcohol is harmless.

Avoid gasoline and organic

or aromatic solvents.

Avoid gasoline brake fluid,

wax, wax removers and

organic solvents. Avoid alkali.

Page 6

Code

Material

name

*

Heat

resistant

temperature

limit C (F)

INTRODUCTION

Resistance to

alcohol or gasoline

IN-3

Notes

PE Polyethylene

PET

PMMA

POM

PP Polypropylene

PPO

PS Polystyrene

PUR Polyurethane

Polyethylene

Terephthalate

Polymethyl

Methacrylate

Polyoxymethylene

(Polyacetal)

Modified

Polyphenylene

Oxide

80

(176)

75

(167)

80

(176)

100

(212)

80

(176)

100

(212)

60

(140)

80

(176)

Alcohol and gasoline are harmless. Most solvents are harmless.

Alcohol and gasoline are harmless. Avoid dipping in water.

Alcohol is harmless if applied only for

short time in small amounts.

Alcohol and gasoline are harmless. Most solvents are harmless.

Alcohol and gasoline are harmless. Most solvents are harmless.

Alcohol is harmless.

Alcohol and gasoline are harmless if

applied only for short time in small

amounts.

Alcohol is harmless if applied only for very

short time in small amounts (e.g., quick

wiping to remove grease).

Avoid dipping or immersing

in alcohol, gasoline,

solvents, etc.

Gasoline is harmless if

applied only for quick wiping

to remove grease.

Avoid dipping or immersing

in alcohol, gasoline,

solvents, etc.

Avoid dipping or immersing

in alcohol, gasoline,

solvents, etc.

Alcohol and gasoline are harmless if

PVC

SAN

TPO

TPU

TSOP

UP

*Temperatures higher than those listed here may result in material deformation during repair.

Polyvinylchloride

(Vinyl)

Styrene

Acrylonitrile

Thermoplastic

Olefine

Thermoplastic

Polyurethane

TOYOTA

Super

Olefine Polymer

Unsaturated

Polyester

80

(176)

80

(176)

80

(176)

80

(176)

80

(176)

110

(233)

applied only for short time in small

amounts (e.g., quick wiping to remove

grease).

Alcohol is harmless if applied only for

short time in small amounts (e.g., quick

wiping to remove grease).

Alcohol is harmless.

Gasoline is harmless if applied only for

short time in small amounts.

Alcohol is harmless if applied only for

short time in small amounts (e.g., quick

wiping to remove grease).

Alcohol and gasoline are harmless. Most solvents are harmless.

Alcohol and gasoline are harmless. Avoid alkali.

Avoid dipping or immersing

in alcohol, gasoline,

solvents, etc.

Avoid dipping or immersing

in alcohol, gasoline, solvents

etc.

Most solvents are harmless

but avoid dipping in gasoline,

solvents, etc.

Avoid dipping or immersing

in alcohol, gasoline,

solvents, etc.

Page 7

IN-4

INTRODUCTION

3. LOCATION OF PLASTIC BODY PARTS

Parts Name Code

Radiator Grille TSOP

Front Bumper Cover TSOP

Front Bumper Hole Cover TSOP

Headlight PP/PC

Fog light TSOP

Side Turn Signal Light PMMA/ABS

Fender Panel Mudguard TSOP

Front Fender Mudguard PP/EPDM

Cowl Top Ventilator Louver TSOP

Outer Rear View Mirror ABS/PA

Front Pillar Upper Cover AES

Side Mudguard TSOP

Front Door Outside Handle PC/PA

Rear Door Outside Handle PC/PA

Quarter Panel Rear Mudguard TSOP

Rear Wheel House Plate PP/EPDM

Back Door Outside Garnish ABS

Back Door Outside Handle PA

High Mount Stop Light PMMA/ABS

Rear Bumper Cover TSOP

Rear Combination Light PMMA/AAS

License Plate Light PMMA/ABS

Rear Fog Light PC/ABS

Rear Spoiler ABS

Resin material differs with model.

/ Made up of 2 or more kinds of materials.

Page 8

INTRODUCTION

HANDLING PRECAUTIONS ON RELATED COMPONENTS

1. BRAKE SYSTEM

The brake system is one of the most important safety components. Always follow the directions and

notes given in brake (32) section of the repair manual for the relevant model when handling brake system

parts.

NOTICE: When repairing the brake master cylinder or TRAC system, bleed the air out of the TRAC system.

2. DRIVE TRAIN AND CHASSIS

The drive train and chassis are components that can have great effects on the running performance and

vibration resistance of the vehicle. After installing components in the sections listed in the table below,

perform alignments to ensure correct mounting angles and dimensions. Particularly accurate repair of

the body must also be done to ensure correct alignment.

HINT: Correct procedures and special tools are required for alignment. Always follow the directions given in the repair manual for the relevant model during alignment and section DI of this section.

IN-15

Component to be aligned

Front Wheels Front Suspension (26) section

Rear Wheels Rear Suspension (27) section

Section of repair manual

for relevant model

3. COMPONENTS ADJACENT TO THE BODY PANELS

Various types of component parts are mounted directly on or adjacently to the body panels. Strictly observe the following precautions to prevent damaging these components and the body panels during handling.

Before repairing the body panels, remove their components or apply protective covers over the com-

ponents.

Before prying components off using a screwdriver or a scraper, etc., attach protective tape to the tool

tip or blade to prevent damaging the components and the body paint.

Before removing components from the outer surface of the body, attach protective tape to the body to

ensure no damage to painted areas.

HINT: Apply touch-up paint to any damaged paint surfaces.

Before drilling or cutting sections, make sure that there are no wires, etc. on the reverse side.

4. ECU (ELECTRONIC CONTROL UNIT)

Many ECUs are mounted in this vehicle.

Take the following precautions during body repair to prevent damage to the ECUs.

Before starting electric welding operations, disconnect the negative (-) terminal cable from the bat-

tery.

When the negative (-) terminal cable is disconnected from the battery , memory of the clock and audio

systems will be cancelled. So before starting work, make a record of the contents memorized by each

memory system. Then when work is finished, reset the clock and audio systems as before.

When the vehicle has tilt and telescopic steering, power seat and outside rear view mirror, which are

all equipped with memory function, it is not possible to make a record of the memory contents.

So when the operation is finished, it will be necessary to explain this fact to the customer, and request

the customer to adjust the features and reset the memory.

Do not expose the ECUs to ambient temperatures above 80C (176F).

NOTICE: If it is possible the ambient temperature may reach 80C (176F) or more, remove the ECUs

from the vehicle before starting work.

Be careful not to drop the ECUs and not to apply physical shocks to them.

Page 9

INTRODUCTION

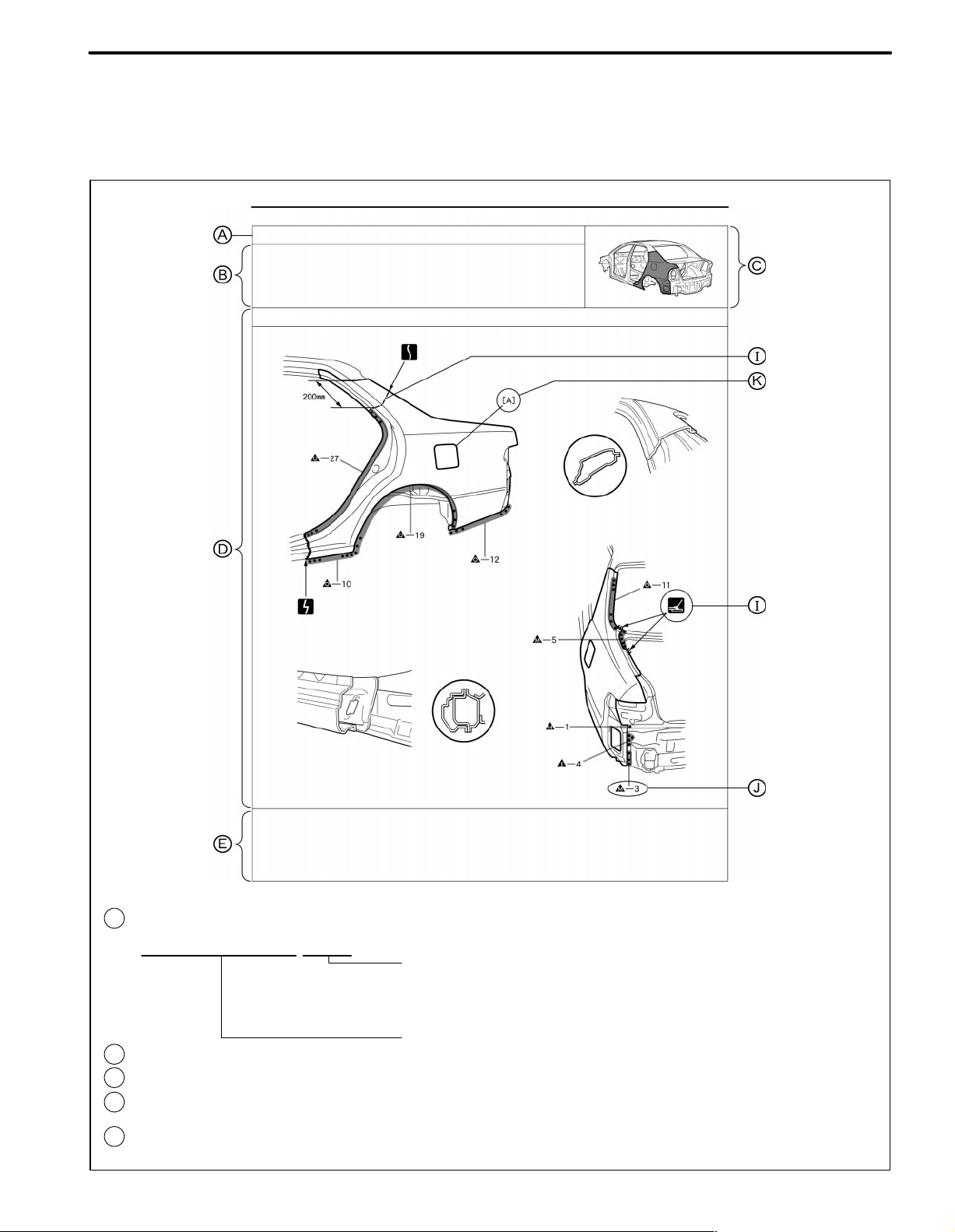

HOW TO USE THIS MANUAL

1. BODY PANEL REPLACEMENT THIS MANUAL

IN-5

BP-34

QUARTER PANEL (CUT)

REPLACEMENT

REMOVAL

BODY PANEL REPLACEMENT

POINT

1 Remove the [A] at the same time.

PART NAME

[A] Fuel Filler Opening Lid

:

REPLACEMENT PART AND METHOD

A

QUARTER PANEL (CUT)

Replacement method

(ASSY) ... Assembly replacement

(CUT) ... Major cutting (less than 1/2 of part used)

(CUT-H) ... Half cutting (about 1/2 of part used)

(CUT-P) ... Partial cutting (most of part used)

:

REMOVAL CONDTIONS

B

:

PART LOCATION

C

:

REMOVAL DIAGRAM

D

Describes in detail removal of the damaged part involving repair by cutting.

:

REMOVAL GUIDE

E

Provides additional information to more efficiently help you perform the removal.

Replacement part

F13890A

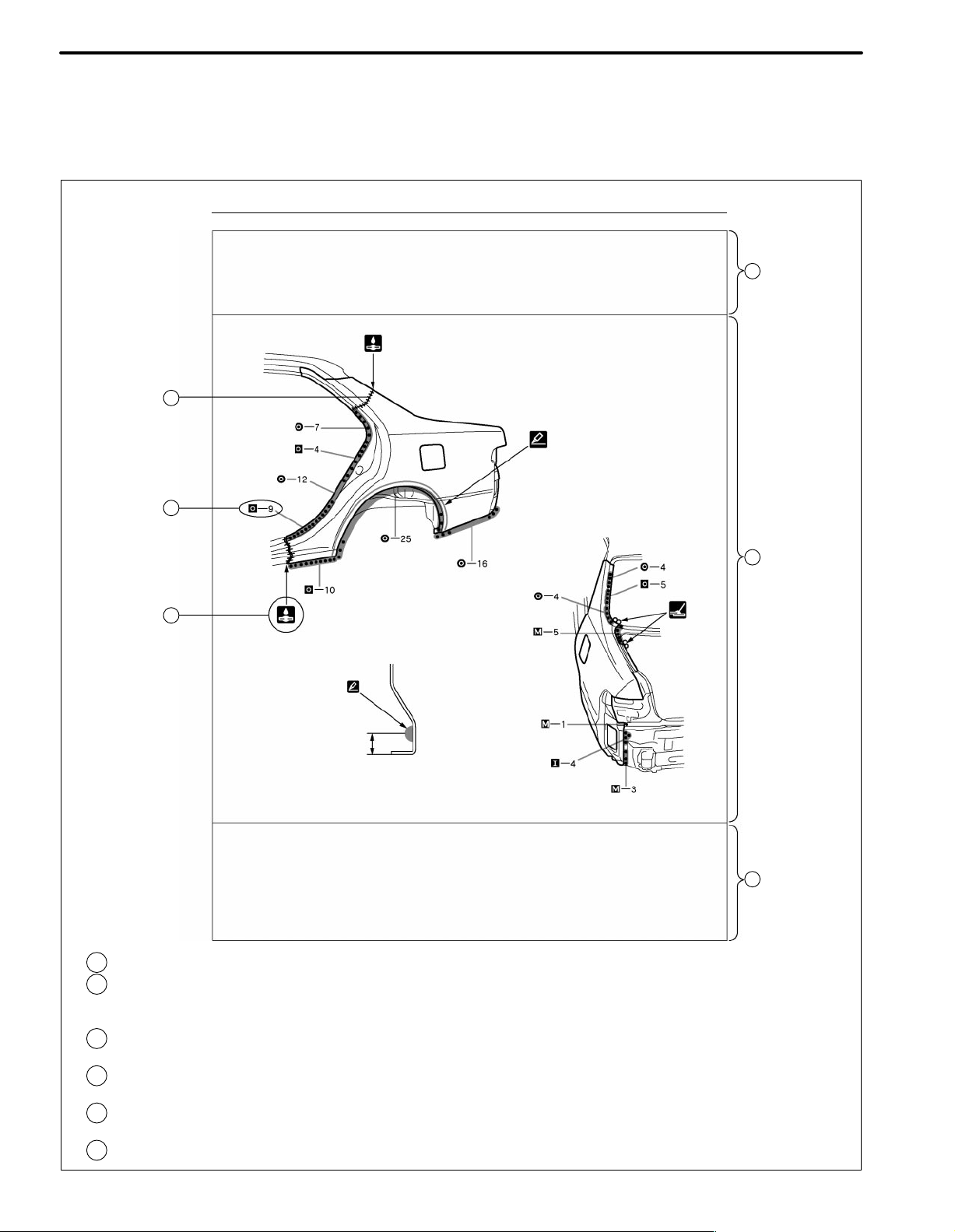

Page 10

IN-6

INTRODUCTION

BODY PANEL REPLACEMENT BP-35

INSTALLATION

Temporaily install the new parts and measure each part of the new parts in accordance with the body dimension

diagram. (See the body dimension diagram)

Inspect the fiting of the related parts around the new parts before welding. This affects the appearance of the

finish.

After welding, apply the polyurethane foam to the corresponding parts.

After welding, apply body sealer and under-coating to the corresponding parts.

After applying the top coat layer, apply anti-rust agent to the inside of the necked section structural weld spots.

I

F

J

G

I

5mm

POINT

1 Before temporarily installing the new parts, apply body sealer to the wheel arch.

HINT:

1) Apply body sealer about 5mm (0.20in.) front the flange, avoiding any oozing.

2) Apply sealer evenly, about 3 - 4mm (0.12 - 0.16in.) in diameter.

3) For other sealing points, refer to section PC.

PART NAME

[A] Fuel Filler Opening Lid [B] Waterproof Rivet

H

:

INSTALLATION CONDITIONS

F

:

INSTALLATION DIAGRAM

G

Describes in detail installation to the new part involving repair by welding and/or

cutting, but excluding painting.

:

INSTALLATIOLN GUIDE

H

Provides additional information to more efficiently help you perform the installation.

:

SYMBOLS

I

(See page IN-7)

:

ILLUSTRATION OF WELD POINTS

J

Weld method and panel position symbols (See page IN-9)

:

PART NAME

K

F13891A

Page 11

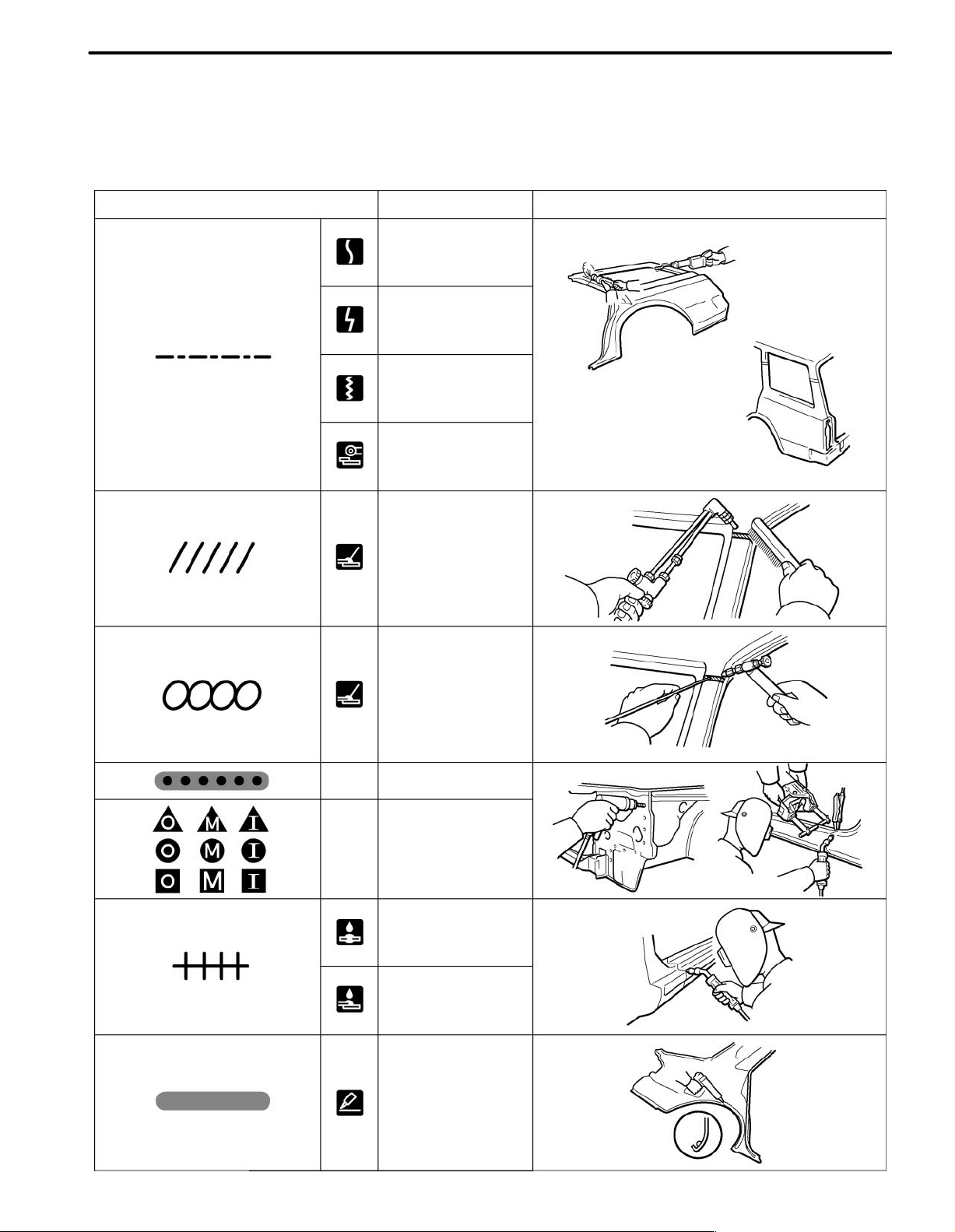

INTRODUCTION

IN-7

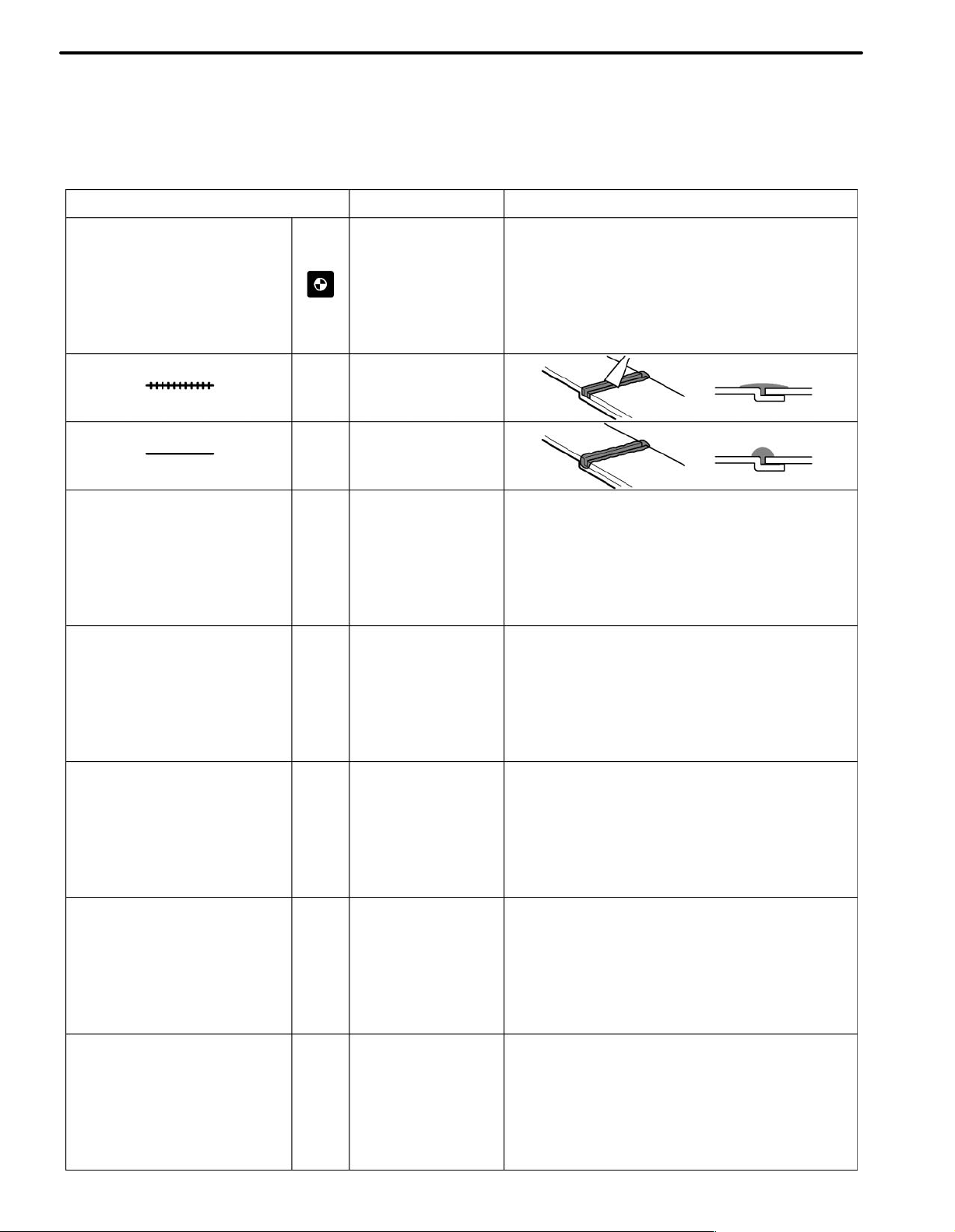

2. SYMBOLS

The following symbols are used in the welding diagrams in section BP of this manual to indicate cutting areas

and the types of weld required.

SYMBOLS MEANING ILLUSTRATION

CUT AND JOIN LOCATION

(SAW CUT)

CUT AND JOIN LOCATION

(Cut Location for

Supply Parts)

CUT LOCATION

CUT WITH DISC

SANDER, ETC.

—

—

BRAZE

(Removal)

BRAZE

(Installation)

WELD POINTS

SPOT WELD OR

MIG PLUG WELD

(See Page IN-9)

CONTINUOUS

MIG WELD

(BUTT WELD)

CONTINUOUS

MIG WELD

(TACK WELD)

BODY SEALER

F13893A

Page 12

IN-8

INTRODUCTION

SYMBOLS MEANING ILLUSTRATION

—

—

—

Assembly Mark

BODY SEALER

(Flat Finishing)

BODY SEALER

(No flat Finishing)

F13894A

Page 13

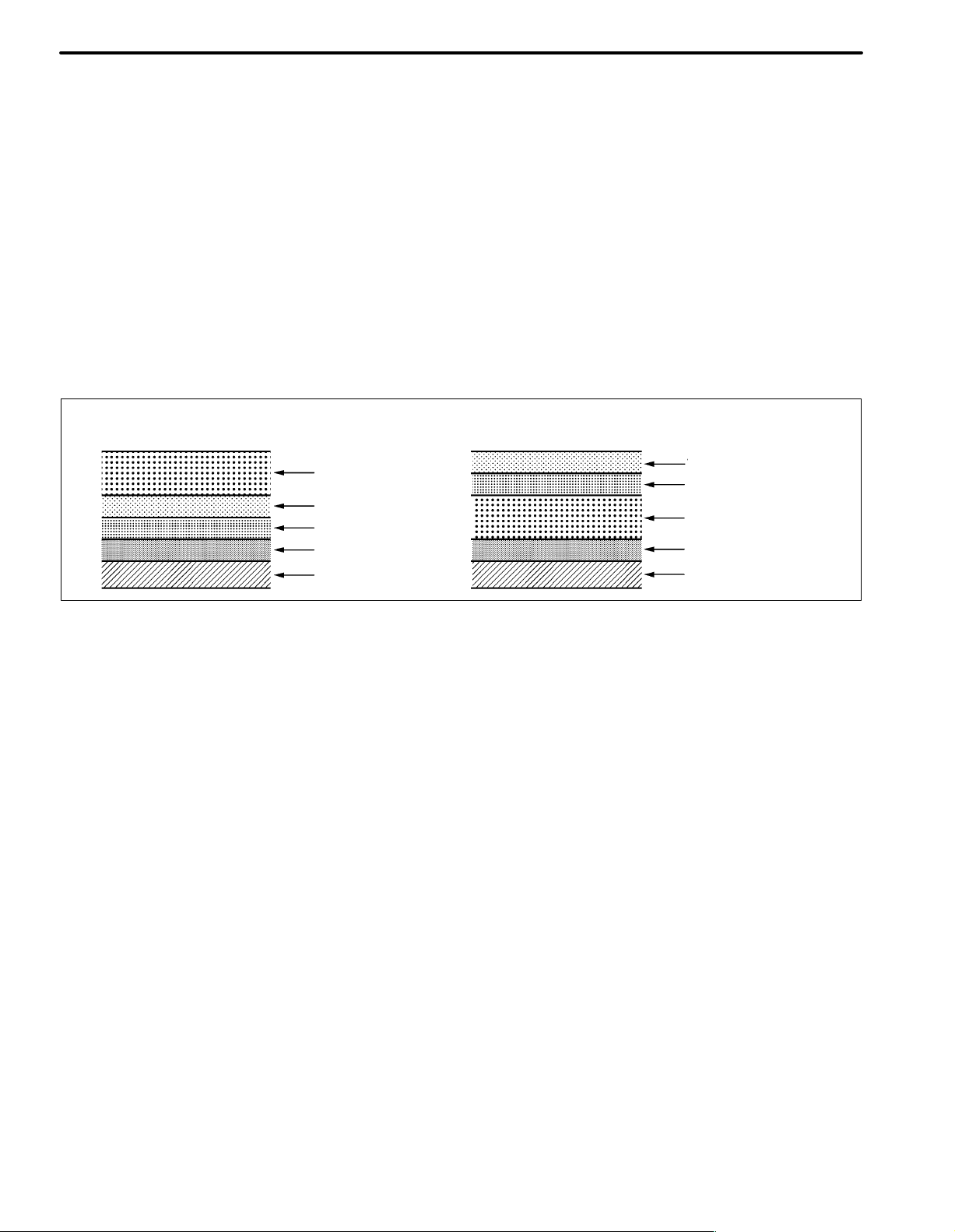

INTRODUCTION

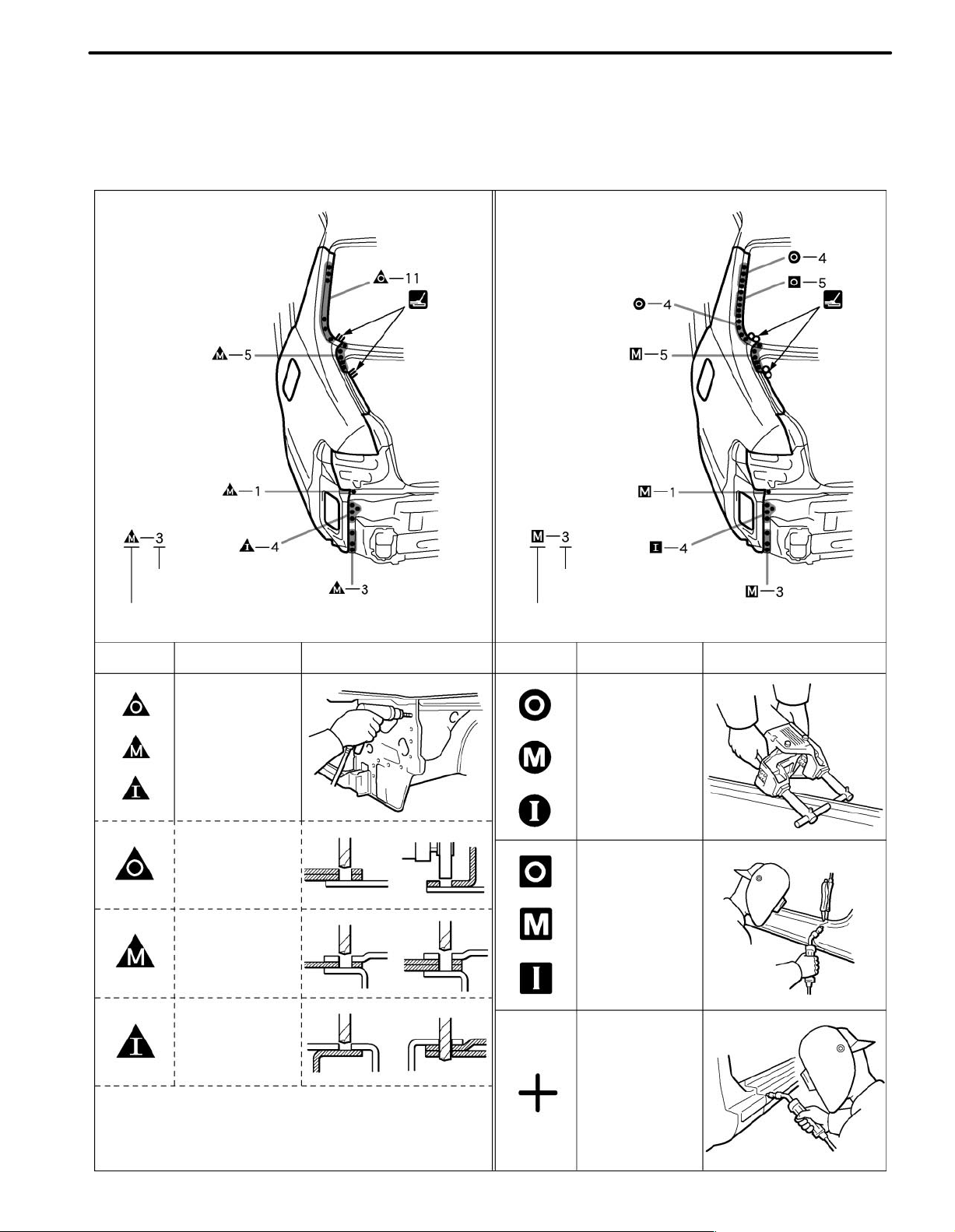

3. ILLUSTRATION OF WELD POINT SYMBOLS

EXAMPLE:

REMOVAL INSTALLATION

IN-9

Weld points

Remove weld point and panel position

SYMBOLS

MEANING ILLUSTRATION SYMBOLS MEANING ILLUSTRATION

Remove

Weld

Points

(Outside)

(Middle)

Weld points

Weld method and panel position

Spot Weld

MIG Plug

Weld

(Inside)

HINT: Panel position symbols are as seen from

the working posture.

Spot MIG

Weld

F13892A

Page 14

IN-16

INTRODUCTION

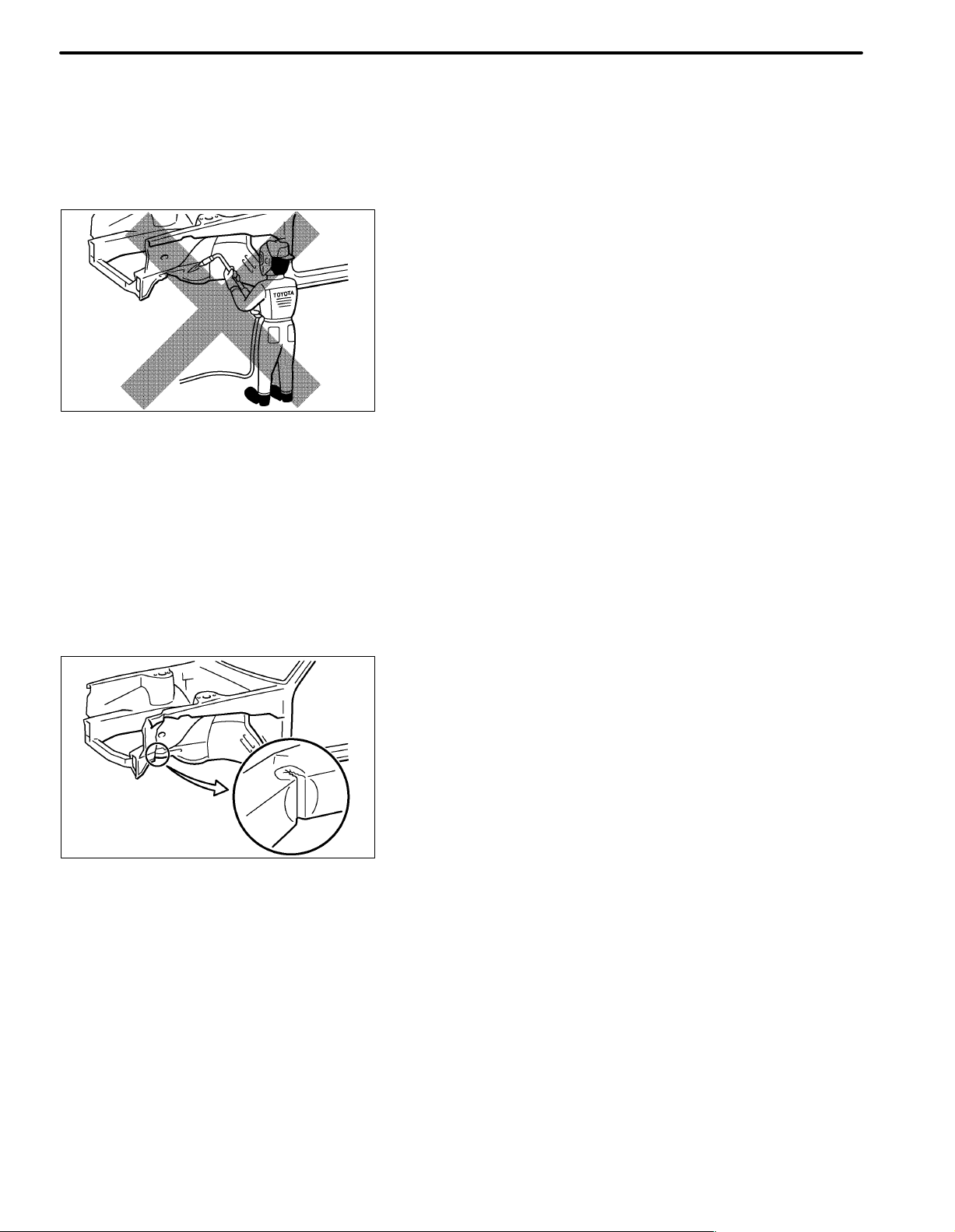

PRECAUTIONS FOR REPAIRING BODY

STRUCTURE PANELS

1. HEAT REPAIR FOR BODY STRUCTURE

PANELS

Toyota prohibits the use of the heat repair method on body

structure panels when repairing a vehicle damaged in a collision.

Panels that have high strength and rigidity, as well as a long

life span for the automobile body are being sought after.

At Toyota, in order to fulfill these requirement, we use high

tensile strength steel sheets and rust preventive steel

sheets on the body.

High tensile steel sheets are made with alloy additives and

a special heat treatment in order to improve the strength.

To prevent the occurrence of rust for a long period of time,

the surface of the steel is coated with a zinc alloy.

If a body structure parts are heat repaired with an acetylene

torch or ot h e r heating source, the crystalline organization of

the steel sheet will change and the strength of the steel

sheet will be reduced.

The ability of the body to resist rust is significantly lowered

as well since the rust resistant zinc coating is destroyed by

heat and the steel sheet surface is oxidized.

2. STRUCTURE PANEL KINKS

A sharp deformation angle on the panel that cannot be returned to its original shape by pulling or hammering is

called a kink.

Since structure parts were designed to exhibit a 100% performance when they were in their original shape, if they are

deformed in an accident, or if the deformed parts are repaired and reused, they become unable to exhibit the same

performance as intended in the design.

It is necessary to replace the part where the kink has occurred.

Page 15

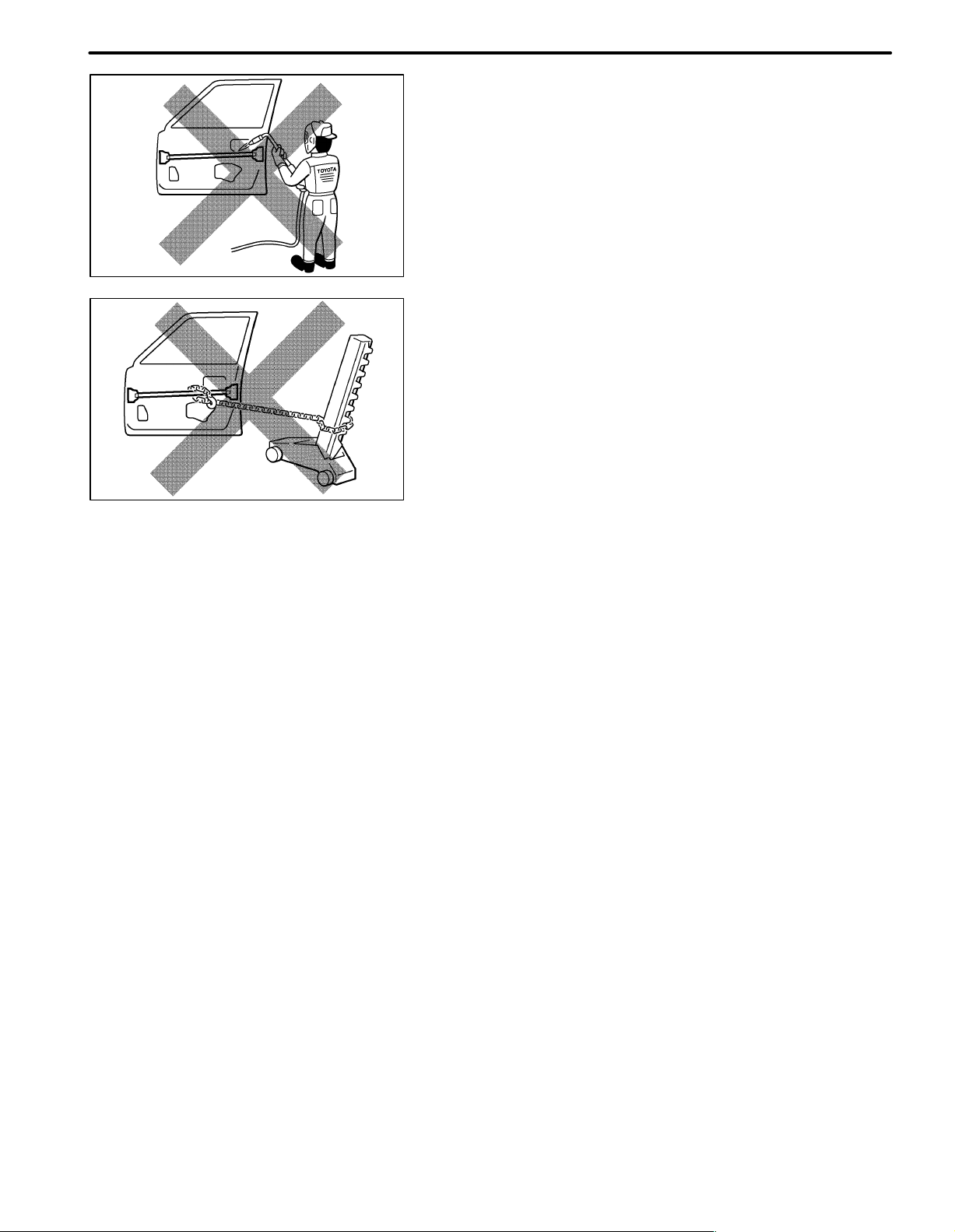

INTRODUCTION

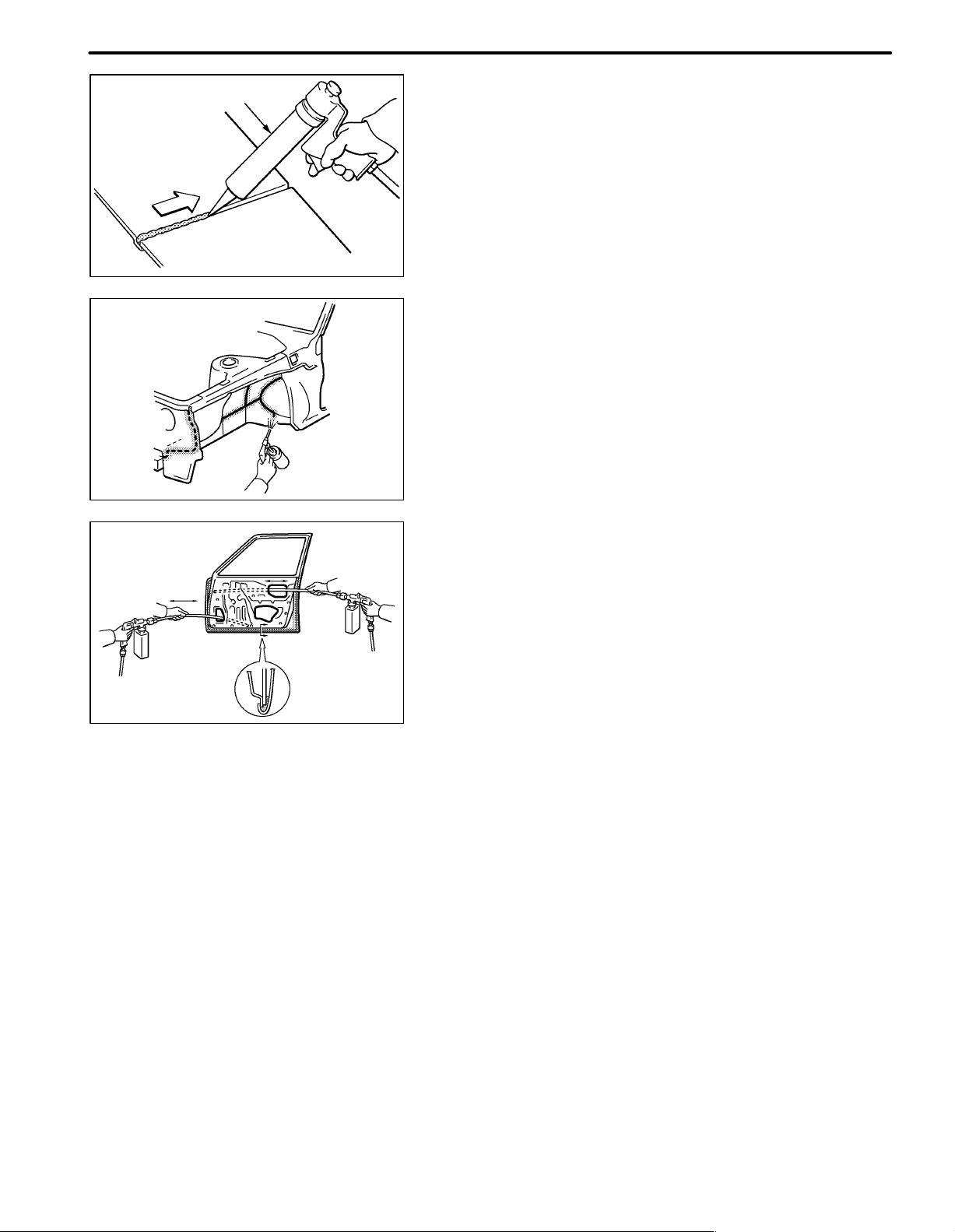

3. IMPACT BEAM REPAIR

The impact beam and bracket are necessary and important

parts in maintaining a survival space for passengers in a

side collision.

For impact beam, we use special high tensile strength

steel.

The high tensile strength steel maintains its special crystalline organization by heat treatment or alloy additives.

Since these parts were designed to exhibit a 100% performance when they were in their original shape, if they are

deformed in an accident, or if the deformed parts are repaired and reused, they become unable to exhibit the same

performance as intended in the design.

It is necessary to replace the door assembly when impact

beam or bracket is damaged.

IN-17

Page 16

IN-10

Cutting Okay

Reinforcement

INTRODUCTION

PROPER AND EFFICIENT WORK

PROCEDURES

1. REMOVAL

(a) PRE-REMOVAL MEASURING

(1) Before removal or cutting operations, take measure-

ments in accordance with the dimension diagram. Always use a puller to straighten a damaged body or

frame.

F10007

(b) CUTTING AREA

(1) Always cut in a straight line and avoid reinforced area.

WRONG

Corners

F10008A

(c) PRECAUTIONS FOR DRILLING OR CUTTING

(1) Check behind any area to be drilled or cut to insure

that there are no hoses, wires, etc., that may be damaged.

HINT: See “Handling Precautions on Related Components” on page IN-15.

F10009A

(d) REMOVAL OF ADJACENT COMPONENTS

(1) When removing adjacent components, apply protec-

tive tape to the surrounding body and your tools to prevent damage.

HINT: See “Handling Precautions on Related Components” on page IN-15.

F10010

Page 17

Less than

3mm

F10011A

F10012

INTRODUCTION

2. PREPARATION FOR INST ALLATION

(a) SPOT WELD POINTS

(1) When welding panels with a combined thickness of

over 3mm (0.12in.), use a MIG (Metal Inert Gas) welder for plug welding.

HINT: Spot welding will not provide sufficient durability

for panels over 3mm (0.12in.) thick.

(b) APPLICATION OF WELD-THROUGH PRIMER

(SPOT SEALER)

(1) Remove the paint from the portion of the new parts

and body to be welded, and apply weld-through primer.

IN-11

Air Saw

Puncher

20 30mm

F10013A

F10014

Overlap

(c) MAKING HOLES FOR PLUG WELDING

(1) For areas where a spot welder cannot be used, use a

puncher or drill to make holes for plug welding.

REFERENCE: mm (in.)

Thickness of welded portion Size of plug hole

1.0 (0.04) under 5 (0.20) ø over

1.0 (0.04) - 1.5 (0.06) 6.4 (0.26) ø over

1.5 (0.06) over 8 (0.31) ø over

(d) SAFETY PRECAUTIONS FOR ELECTRICAL COM-

PONENTS

(1) When welding, there is a danger that electrical compo-

nents will be damaged by the electrical current flowing

through the body.

(2) Before starting work, disconnect the negative terminal

of the battery and ground the welder near the welding

location of the body.

(e) ROUGH CUTTING OF JOINTS

(1) For joint areas, rough cut the new parts, leaving 20 -

30mm (0.79 - 1.18in.) overlap.

F10015A

Page 18

IN-12

Body

Measurement

Diagrams

INTRODUCTION

3. INSTALLATION

(a) PRE-WELDING MEASUREMENTS

(1) Always take measurements before installing under-

body or engine components to insure correct assembly. After installation, confirm proper fit.

F10016A

(b) WELDING PRECAUTIONS

(1) The number of welding spots should be as follows.

Spot weld: 1.3 X No. of manufacturer’s spots.

Plug weld: More than No. of manufacturer’s plugs.

(2) Plug welding should be done with a MIG (Metal Inert

Gas) welder. Do not gas weld or braze panels at areas

other than specified.

WRONG

CORRECT WRONG

Tip Cutter

F10017A

(c) POST-WELDING REFINISHING

(1) Always check the welded spots to insure they are se-

cure.

(2) When smoothing out the weld spots with a disc grind-

er, be careful not to grind off too much as this would

weaken the weld.

F10018A

(d) SPOT WELD LOCATIONS

(1) Try to avoid welding over previous spots.

F10019A

Old

Spot

Locations

New Spot

Locations

F10020A

(e) SPOT WELDING PRECAUTIONS

(1) The shape of the welding tip point has an effect on the

strength of the weld.

(2) Always insure that the seams and welding tip are free

of paint.

Page 19

INTRODUCTION

IN-13

Sealer Gun

4. ANTI-RUST TREATMENT

(a) BODY SEALER APPLICATION

(1) For water-proofing and anti-corrosion measures, al-

ways apply the body sealer to the body panel seams

and hems of the doors, hoods, etc.

F10021A

(b) UNDERCOAT APPLICATION

(1) To prevent corrosion and protect the body from dam-

age by flying stones, always apply sufficient undercoat to the bottom surface of the under body and inside of the wheel housings.

F10022

5. ANTI-RUST TREATMENT AFTER PAINTING

PROCESS

(a) ANTI-RUST AGENT (WAX) APPLICATION

(1) To preserve impossible to paint areas from corrosion,

always apply sufficient anti-rust agent (wax) to the inside of the hemming areas of the doors and hoods,

and around the hinges, or the welded surfaces inside

the boxed cross-section structure of the side member,

body pillar, etc.

F10023

Page 20

IN-14

INTRODUCTION

6. ANTI-RUST TREATMENT BY PAINTING

REFERENCE:

Painting prevents corrosion and protect the sheet

metal from damage. In this section, anti-chipping paint

only for anti-corrosion purpose is described.

(a) ANTI-CHIPPING PAINT

(1) To prevent corrosion and protect the body from dam-

age by flying stones, etc., apply anti-chipping paint to

the rocker panel, wheel arch areas, balance panel,

etc.

HINT:

Depending on the model or the application area, there

are cases where the application of anti-chipping paint

is necessary before the second coat or after the top

coat.

Apply the anti-chipping paint after

the top coat.

Anti-Chipping Paint

Top Coat

Second Coat

Under Coat (ED Primer)

Steel Metal

Apply the anti-chipping paint before

the second coat.

Top Coat

Second Coat

Anti-Chipping Paint

Under Coat (ED Primer)

Steel Metal

F10024A

Page 21

VIEWS OF THIS TEXT

Scope of the repair work explanation

This text explains the welding panel replacement instructions from the vehicle’ s white body condi-

tion. W e have abbreviated the explanations of the removal and reinstallation of the equipment parts

up to the white body condition and of the installation, inspection, adjustment and final inspection of

equipment parts after replacing the weld panel.

Section categories

Each section has been divided as shown below.

Section Title Contents Examples

INTRODUCTION

BODY PANEL REPLACEMENT

BODY DIMENSIONS Body aligning measurements. Dimension diagrams.

PAINT COATING

Explanation of general body repair.

Views of weld panel replacement instructions.

Instructions for replacing the weld panels

from the white body condition, from which

bolted parts have been removed, with

individual supply parts.

Scope and type of anti-rust treatment, etc.

together with weld panel replacement.

Abbreviation of contents in this text.

The following essential procedures have been abbreviated. When actually working, conduct this

work properly.

(1) Jack and lift operations.

(2) Clean and wash removed parts, if necessary.

(3) Visual inspection.

Cautionary items.

Views of weld panel replacement instructions.

Front side member replacement.

Quarter panel replacement.

Under coat.

Body sealer.

Page 22

Page 23

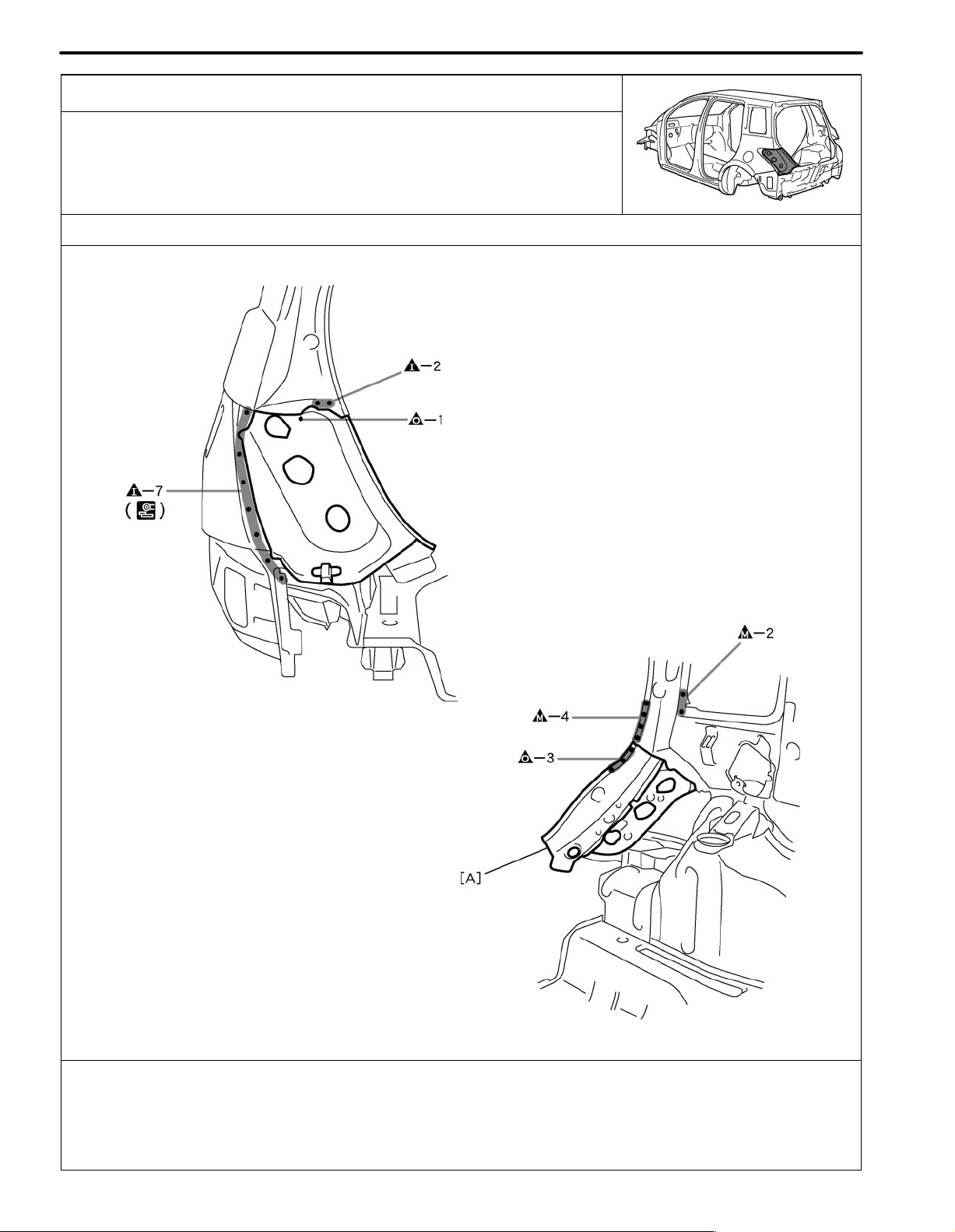

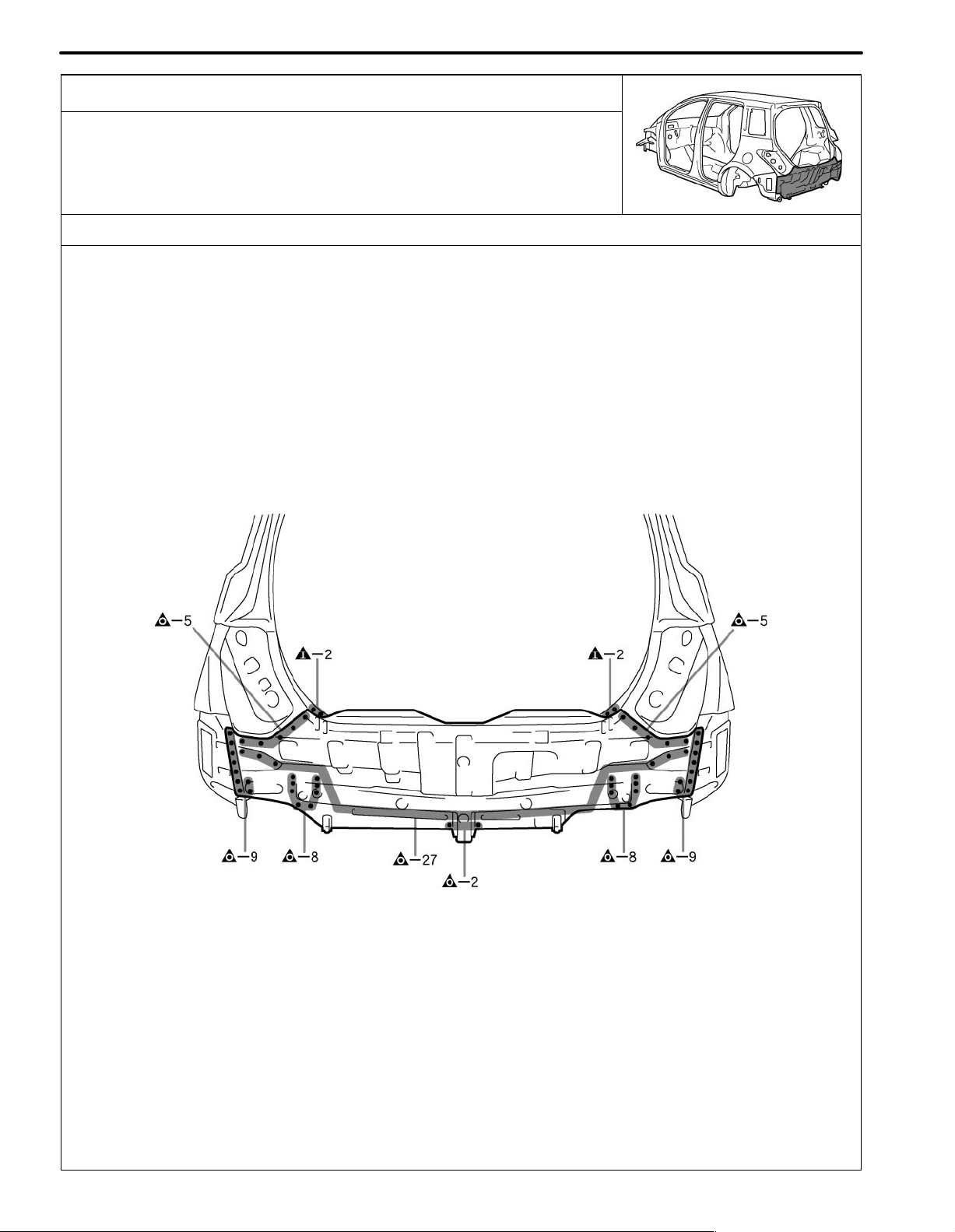

BP-40

BODY PANEL REPLACEMENT

BACK DOOR OPENING TROUGH (ASSY)

REPLACEMENT

With the body lower back panel removed.

REMOVAL

F15540A

POINT

1 Remove the [A] at the same time.

PART NAME

[A] Back door Opening Lower Reinforcement

F15540

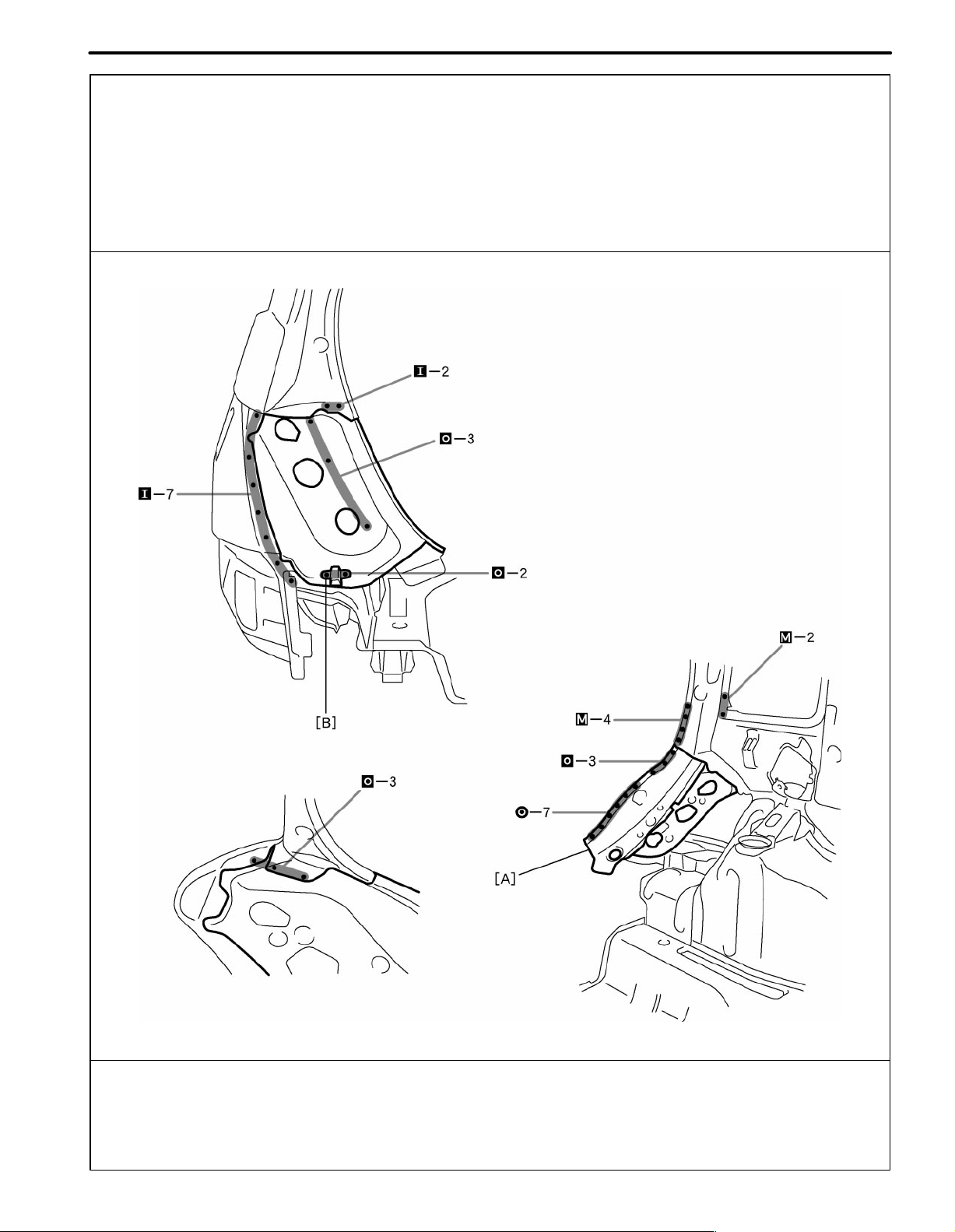

Page 24

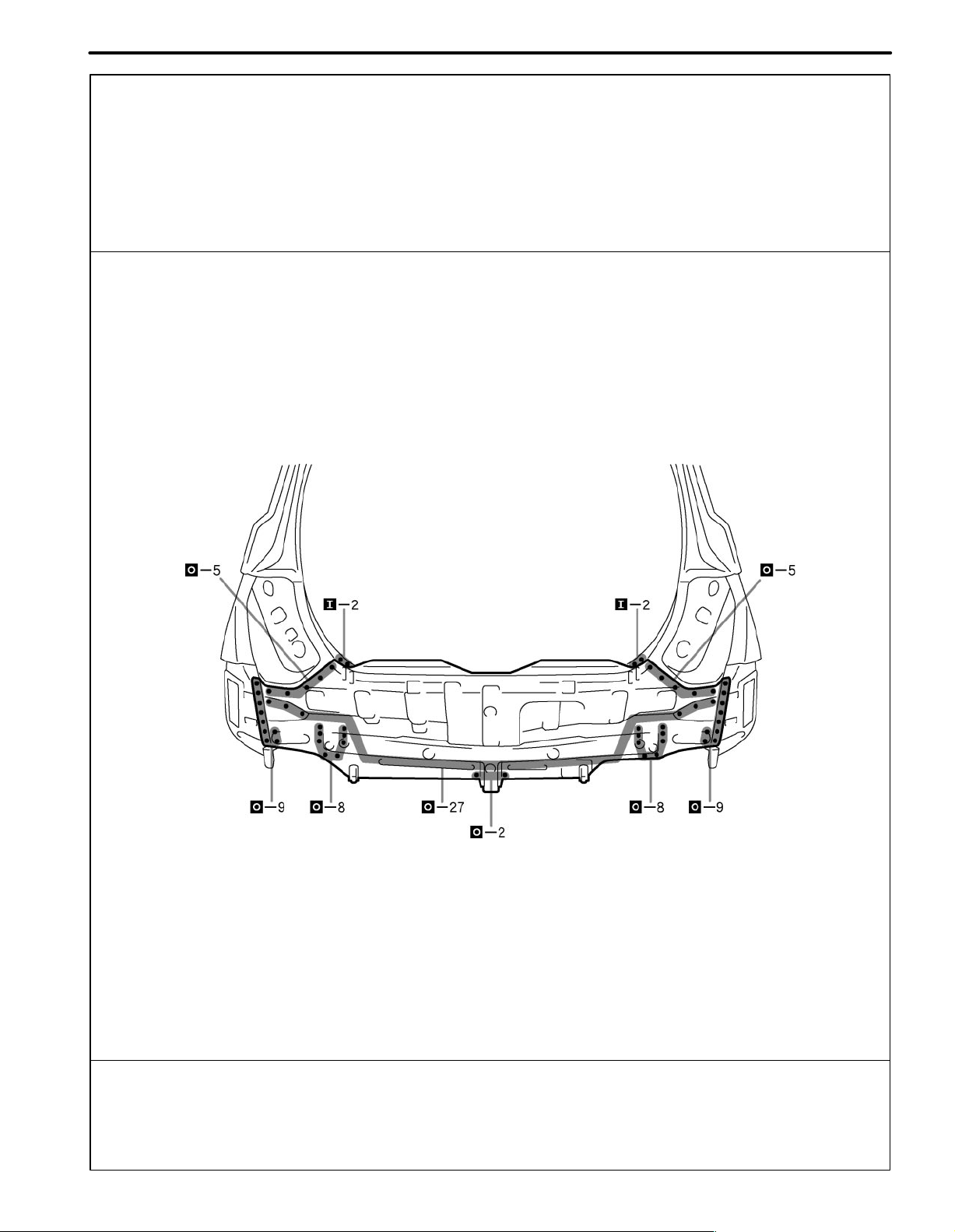

BODY PANEL REPLACEMENT

BP-41

INSTALLATION

Temporarily install the new parts and measure each part of the new parts in accordance with the body dimension

diagram. (See the body dimension diagram)

Inspect the fitting of the related parts around the new parts before welding. This affects the appearance of the

finish.

After welding, apply the polyurethane foam to the corresponding parts.

After welding, apply body sealer and under-coating to the corresponding parts.

After applying the top coat layer, apply anti-rust agent to the inside of the necked section structural weld spots.

F15541

POINT

1 Inspect the fitting of the back door and rear combination light, etc., before welding, since this affects the ap-

pearance of the finish.

PART NAME

[A] Back Door Opening Lower Reinforcement

[B] Rear Bumper Upper Side Retainer

Page 25

BP-38

BODY PANEL REPLACEMENT

BODY LOWER BACK PANEL (ASSY)

REPLACEMENT

REMOVAL

F15538A

F15538

Page 26

BODY PANEL REPLACEMENT

BP-39

INSTALLATION

Temporarily install the new parts and measure each part of the new parts in accordance with the body dimension

diagram. (See the body dimension diagram)

Inspect the fitting of the related parts around the new parts before welding. This affects the appearance of the

finish.

After welding, apply the polyurethane foam to the corresponding parts.

After welding, apply body sealer and under-coating to the corresponding parts.

After applying the top coat layer, apply anti-rust agent to the inside of the necked section structural weld spots.

F15539

POINT

1 Inspect the fitting of the back door and rear combination light, etc., before welding, since this affects the ap-

pearance of the finish.

Page 27

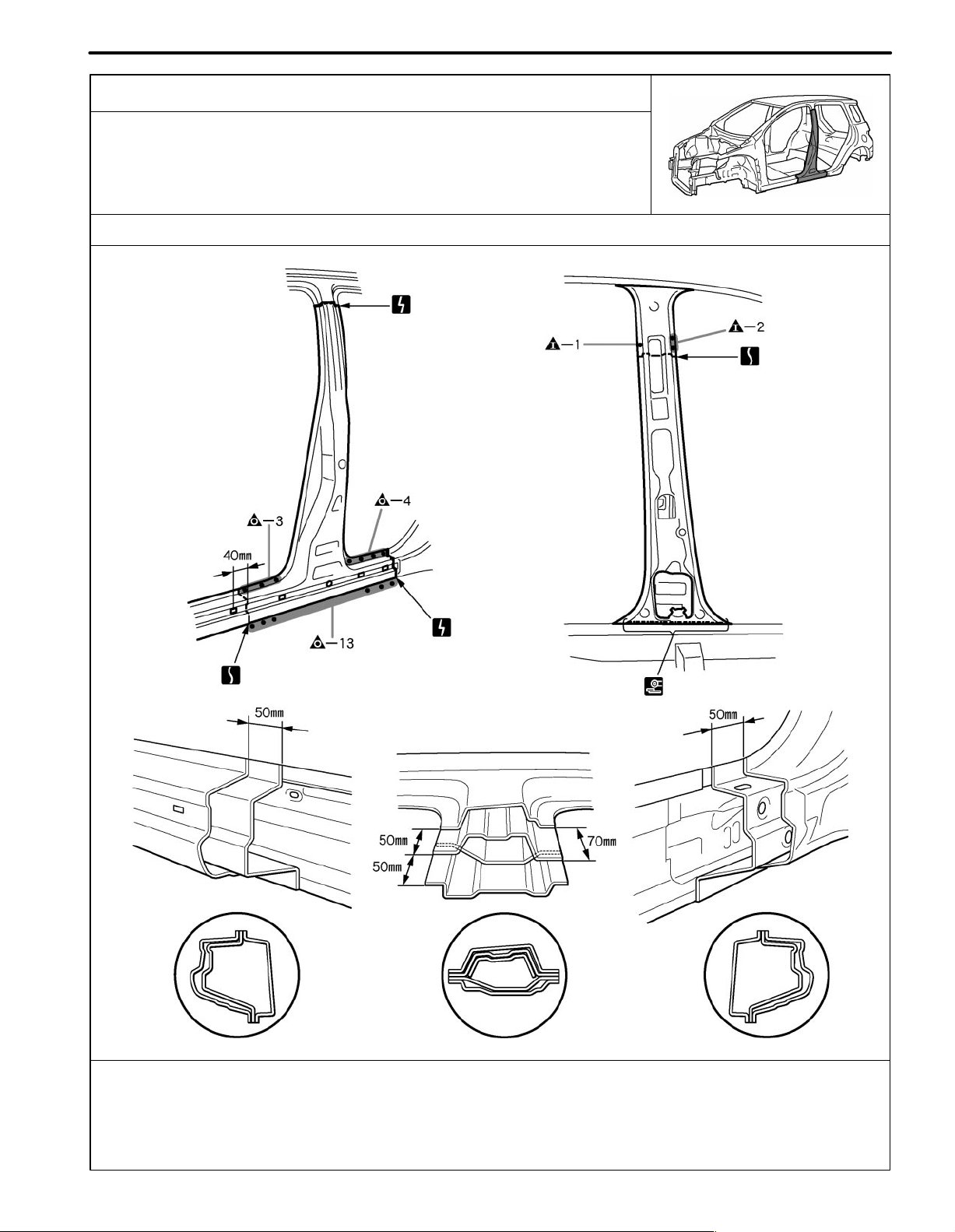

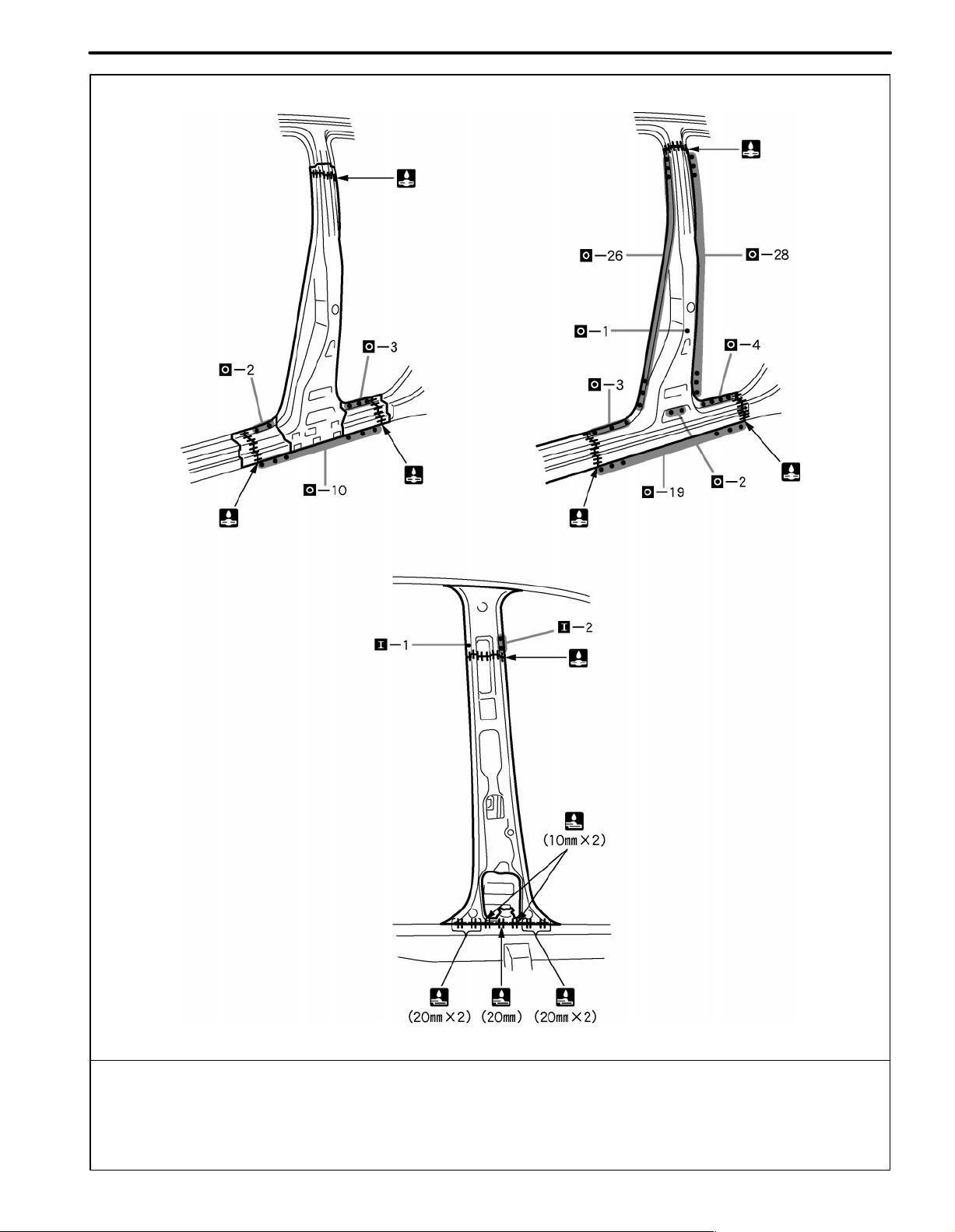

BODY PANEL REPLACEMENT

CENTER BODY PILLAR (CUT)

REPLACEMENT

REMOVAL

BP-27

F15527A

40mm (1.57in.) 50mm (1.97in.) 70mm (2.76in.)

F15527

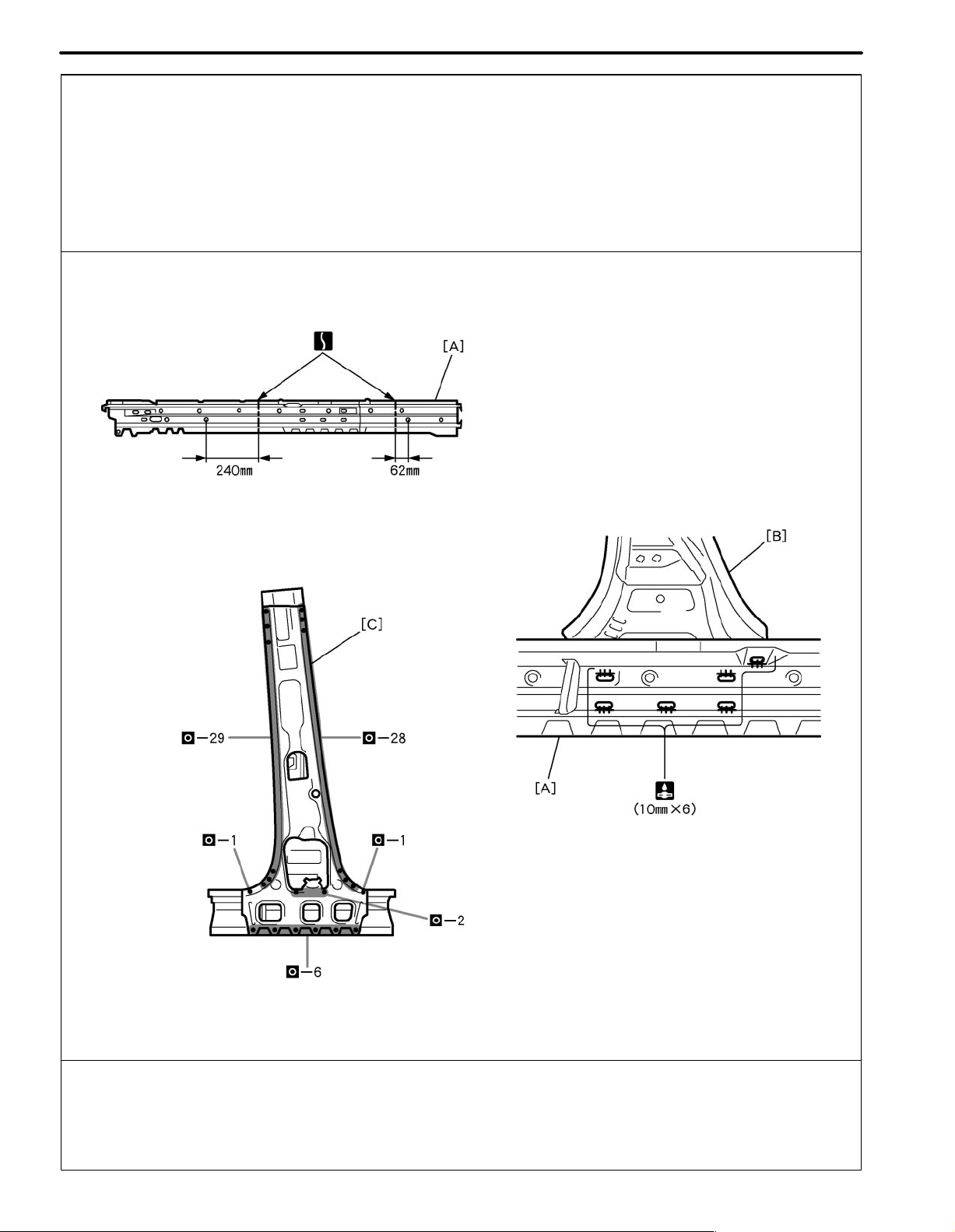

Page 28

BP-28

BODY PANEL REPLACEMENT

INSTALLATION

Temporarily install the new parts and measure each part of the new parts in accordance with the body dimension

diagram. (See the body dimension diagram)

Inspect the fitting of the related parts around the new parts before welding. This affects the appearance of the

finish.

After welding, apply the polyurethane foam to the corresponding parts.

After welding, apply body sealer and under-coating to the corresponding parts.

After applying the top coat layer, apply anti-rust agent to the inside of the necked section structural weld spots.

POINT

1 Before temporarily installing the new parts, weld the [A], [B] and [C] with standard points.

PART NAME

[A] Rocker Outer Reinforcement

[B] Center Body Pillar Lower Reinforcement

[C] Center Body Inner Pillar

10mm (0.39in.) 62mm (2.44in.) 240mm (9.45in.)

F15528

Page 29

BODY PANEL REPLACEMENT

BP-29

F15529

POINT

1 Inspect the fitting of the front door and rear door, etc., before welding, since this affects the appearance of the

finish.

2 After welding the reinforcement to the vehicle side, install the outer panel.

10mm (0.39in.) 20mm (0.79in.)

Page 30

BODY PANEL REPLACEMENT

COWL TOP SIDE PANEL (ASSY)

REPLACEMENT

REMOVAL

BP-21

F15521A

F15521

Page 31

BP-22

BODY PANEL REPLACEMENT

INSTALLATION

Temporarily install the new parts and measure each part of the new parts in accordance with the body dimension

diagram. (See the body dimension diagram)

Inspect the fitting of the related parts around the new parts before welding. This affects the appearance of the

finish.

After welding, apply the polyurethane foam to the corresponding parts.

After welding, apply body sealer and under-coating to the corresponding parts.

After applying the top coat layer, apply anti-rust agent to the inside of the necked section structural weld spots.

25mm (0.98 in.) 30mm (1.18 in.)

F15522

Page 32

BODY PANEL REPLACEMENT

COWL TOP SIDE UPPER PANEL (ASSY)

REPLACEMENT

With the cowl top side panel removed.

REMOVAL

BP-11

F15511A

F15511

Page 33

BP-12

BODY PANEL REPLACEMENT

INSTALLATION

Temporarily install the new parts and measure each part of the new parts in accordance with the body dimension

diagram. (See the body dimension diagram)

Inspect the fitting of the related parts around the new parts before welding. This affects the appearance of the

finish.

After welding, apply the polyurethane foam to the corresponding parts.

After welding, apply body sealer and under-coating to the corresponding parts.

After applying the top coat layer, apply anti-rust agent to the inside of the necked section structural weld spots.

F15512

POINT

1 Inspect the fitting of the front fender and hood, etc. before welding, since this affects the appearance of the

finish.

20mm (0.79in.) 30mm (1.18in.)

Page 34

BODY PANEL REPLACEMENT

FRONT FENDER APRON (ASSY)

REPLACEMENT

With the radiator upper support and cowl top side panel removed.

REMOVAL

BP-15

F15515A

F15515

Page 35

BP-16

BODY PANEL REPLACEMENT

INSTALLATION

Temporarily install the new parts and measure each part of the new parts in accordance with the body dimension

diagram. (See the body dimension diagram)

Inspect the fitting of the related parts around the new parts before welding. This affects the appearance of the

finish.

After welding, apply the polyurethane foam to the corresponding parts.

After welding, apply body sealer and under-coating to the corresponding parts.

After applying the top coat layer, apply anti-rust agent to the inside of the necked section structural weld spots.

F15516

POINT

1 Inspect the fitting of the front fender and hood, etc. before welding, since this affects the appearance of the

finish.

2 Make sure each measurement is correct, as this parts affects the front wheel alignment.

PART NAME

[A] Front Fender Mounting Bracket

[B] Fender Apron Gusset

Page 36

BODY PANEL REPLACEMENT

FRONT SIDE MEMBER (ASSY)

REPLACEMENT

With the radiator side support and front fender apron removed.

REMOVAL

BP-19

F15519A

F15519

Page 37

BP-20

BODY PANEL REPLACEMENT

INSTALLATION

Temporarily install the new parts and measure each part of the new parts in accordance with the body dimension

diagram. (See the body dimension diagram)

Inspect the fitting of the related parts around the new parts before welding. This affects the appearance of the

finish.

After welding, apply the polyurethane foam to the corresponding parts.

After welding, apply body sealer and under-coating to the corresponding parts.

After applying the top coat layer, apply anti-rust agent to the inside of the necked section structural weld spots.

POINT

1 Make sure each measurement is correct, as this parts affects the front wheel alignment.

PART NAME

[A] Front Bumper Mounting Reinforcement (RH: Front Side Member Front Plate)

F15520

Page 38

BODY PANEL REPLACEMENT

FRONT APRON TO COWL SIDE UPPER

MEMBER (ASSY)

REPLACEMENT

With the front fender front apron and cowl top side panel removed.

REMOVAL

BP-13

F15513A

F15513

Page 39

BP-14

BODY PANEL REPLACEMENT

INSTALLATION

Temporarily install the new parts and measure each part of the new parts in accordance with the body dimension

diagram. (See the body dimension diagram)

Inspect the fitting of the related parts around the new parts before welding. This affects the appearance of the

finish.

After welding, apply the polyurethane foam to the corresponding parts.

After welding, apply body sealer and under-coating to the corresponding parts.

After applying the top coat layer, apply anti-rust agent to the inside of the necked section structural weld spots.

F15514

POINT

1 Inspect the fitting of the front fender and hood, etc. before welding, since this affects the appearance of the

finish.

PART NAME

[A] Fender Apron Gusset

Page 40

BODY PANEL REPLACEMENT

FRONT BODY PILLAR (CUT)

REPLACEMENT

With the cowl top side upper panel removed.

REMOVAL

BP-23

F15523A

30mm (1.18in.) 275mm (10.83in.)

F15523

Page 41

BP-24

BODY PANEL REPLACEMENT

F15524

Page 42

BODY PANEL REPLACEMENT

BP-25

INSTALLATION

Temporarily install the new parts and measure each part of the new parts in accordance with the body dimension

diagram. (See the body dimension diagram)

Inspect the fitting of the related parts around the new parts before welding. This affects the appearance of the

finish.

After welding, apply the polyurethane foam to the corresponding parts.

After welding, apply body sealer and under-coating to the corresponding parts.

After applying the top coat layer, apply anti-rust agent to the inside of the necked section structural weld spots.

F15525

POINT

1 Before temporarily installing the new parts, weld the [A], [B], [C] and [d] with standard points.

2 Cut the outer pillar on the rocker section and but-weld the rocker outer reinforcement before installing the outer

pillar.

PART NAME

[A] Rocker Outer Reinforcement

[C] Front Body Upper Outer Pillar

[B] Front Body Pillar Lower Reinforcement

[D] Front Body Inner Pillar

10mm (0.39in.) 15mm (0.59in.) 80mm (3.15in.) 100mm (3.94in.)

Page 43

BP-26

BODY PANEL REPLACEMENT

F15526

POINT

1 Inspect the fitting of the front door, front fender and windshield glass, etc., before welding, since this af fects the

appearance of the finish.

15mm (0.59in.) 20mm (0.79in.)

Page 44

BODY PANEL REPLACEMENT

FRONT FENDER FRONT APRON (ASSY)

REPLACEMENT

With the radiator upper support removed.

REMOVAL

BP-9

F15509A

F15509

Page 45

BP-10

BODY PANEL REPLACEMENT

INSTALLATION

Temporarily install the new parts and measure each part of the new parts in accordance with the body dimension

diagram. (See the body dimension diagram)

Inspect the fitting of the related parts around the new parts before welding. This affects the appearance of the

finish.

After welding, apply the polyurethane foam to the corresponding parts.

After welding, apply body sealer and under-coating to the corresponding parts.

After applying the top coat layer, apply anti-rust agent to the inside of the necked section structural weld spots.

F15510

POINT

1 Inspect the fitting of the front fender and hood, etc. before welding, since this affects the appearance of the

finish.

PART NAME

[A] Engine Front Support Retainer (RH Only)

[B] Front Fender Mounting Bracket

Page 46

BODY PANEL REPLACEMENT

FRONT SIDE MEMBER (CUT-P)

REPLACEMENT

With the radiator side support removed.

REMOVAL

BP-17

F15517A

PART NAME

[A] Front Bumper Mounting Reinforcement

200mm (7.87in.) 215mm (8.46in.)

F15517

[B] Front Side Member Front Plate

Page 47

BP-18

BODY PANEL REPLACEMENT

INSTALLATION

Temporarily install the new parts and measure each part of the new parts in accordance with the body dimension

diagram. (See the body dimension diagram)

Inspect the fitting of the related parts around the new parts before welding. This affects the appearance of the

finish.

After welding, apply the polyurethane foam to the corresponding parts.

After welding, apply body sealer and under-coating to the corresponding parts.

After applying the top coat layer, apply anti-rust agent to the inside of the necked section structural weld spots.

PART NAME

[A] Front Bumper Mounting Reinforcement

[C] Front Bumper Arm

F15518

[B] Front Side Member Front Plate

Page 48

BP-42

BODY PANEL REPLACEMENT

QUARTER WHEEL HOUSING EXTENSION

(ASSY)

REPLACEMENT

With the body lower back panel, quarter panel removed.

REMOVAL

F15542A

POINT

1 Remove the [A] and [B] at the same time.

PART NAME

[A] Quarter Wheel Housing Center Gusset

F15542

[B] Quarter Wheel Housing No.2 Brace

Page 49

BODY PANEL REPLACEMENT

BP-43

INSTALLATION

Temporarily install the new parts and measure each part of the new parts in accordance with the body dimension

diagram. (See the body dimension diagram)

Inspect the fitting of the related parts around the new parts before welding. This affects the appearance of the

finish.

After welding, apply the polyurethane foam to the corresponding parts.

After welding, apply body sealer and under-coating to the corresponding parts.

After applying the top coat layer, apply anti-rust agent to the inside of the necked section structural weld spots.

PART NAME

[A] Quarter Wheel Housing Center Gusset

F15543

[B] Quarter Wheel Housing No.2 Brace

Page 50

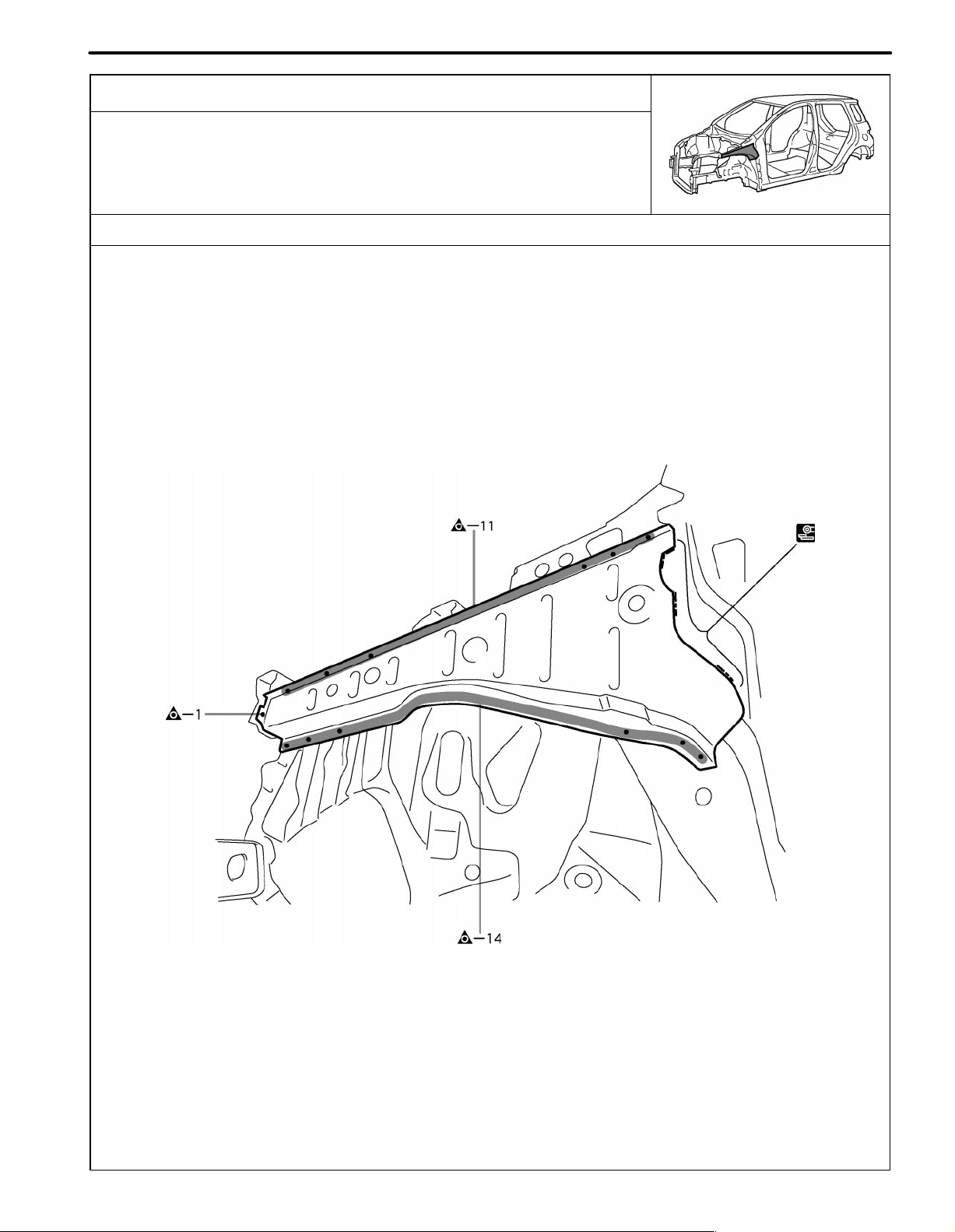

BP-44

BODY PANEL REPLACEMENT

QUARTER PANEL UPPER EXTENSION (CUT)

REPLACEMENT

With the quarter panel, back door opening trough removed.

REMOVAL

F15544A

80mm (3.15in.)

F15544

Page 51

BODY PANEL REPLACEMENT

BP-45

INSTALLATION

Temporarily install the new parts and measure each part of the new parts in accordance with the body dimension

diagram. (See the body dimension diagram)

Inspect the fitting of the related parts around the new parts before welding. This affects the appearance of the

finish.

After welding, apply the polyurethane foam to the corresponding parts.

After welding, apply body sealer and under-coating to the corresponding parts.

After applying the top coat layer, apply anti-rust agent to the inside of the necked section structural weld spots.

F15545

Page 52

BP-34

QUARTER PANEL (CUT)

REPLACEMENT

REMOVAL

BODY PANEL REPLACEMENT

F15534A

200mm (7.87in.) 220mm (8.66in.)

F15534

Page 53

BODY PANEL REPLACEMENT

BP-35

INSTALLATION

Temporarily install the new parts and measure each part of the new parts in accordance with the body dimension

diagram. (See the body dimension diagram)

Inspect the fitting of the related parts around the new parts before welding. This affects the appearance of the

finish.

After welding, apply the polyurethane foam to the corresponding parts.

After welding, apply body sealer and under-coating to the corresponding parts.

After applying the top coat layer, apply anti-rust agent to the inside of the necked section structural weld spots.

F15535

POINT

1 Before temporarily installing the new parts, apply sealer to wheel arch.

HINT:

1) Apply body sealer about 5mm (0.20in.) from the flange, avoiding any oozing.

2) Apply sealer evenly, about 3 - 4mm (0.12 - 0.16in.) in diameter.

2 Inspect the fitting of the rear door, back door and rear combination light, etc., before welding, since this affects

the appearance of the finish.

PART NAME

[A] Fuel Filler Opening Lid

[B] Waterproof Rivets

Page 54

BP-36

BODY PANEL REPLACEMENT

QUARTER WHEEL HOUSING OUTER PANEL

(ASSY)

REPLACEMENT

With the quarter panel removed.

REMOVAL

F15536A

POINT

1 After removing [A], remove the quarter wheel housing outer panel.

PART NAME

[A] Roof Side Outer Panel

80mm (3.15 in.)

F15536

Page 55

BODY PANEL REPLACEMENT

BP-37

INSTALLATION

Temporarily install the new parts and measure each part of the new parts in accordance with the body dimension

diagram. (See the body dimension diagram)

Inspect the fitting of the related parts around the new parts before welding. This affects the appearance of the

finish.

After welding, apply the polyurethane foam to the corresponding parts.

After welding, apply body sealer and under-coating to the corresponding parts.

After applying the top coat layer, apply anti-rust agent to the inside of the necked section structural weld spots.

POINT

1 Determine the position of the new parts by assembly marks of the inner and outer panels.

PART NAME

[A] Roof side Outer Panel

F15537

Page 56

BODY PANEL REPLACEMENT

RADIATOR SIDE SUPPORT (ASSY)

REPLACEMENT

With the radiator upper support removed.

REMOVAL

BP-3

F15503A

F15503

Page 57

BP-4

BODY PANEL REPLACEMENT

INSTALLATION

Temporarily install the new parts and measure each part of the new parts in accordance with the body dimension

diagram. (See the body dimension diagram)

Inspect the fitting of the related parts around the new parts before welding. This affects the appearance of the

finish.

After welding, apply the polyurethane foam to the corresponding parts.

After welding, apply body sealer and under-coating to the corresponding parts.

After applying the top coat layer, apply anti-rust agent to the inside of the necked section structural weld spots.

PART NAME

[A] Front Bumper Side Mounting Bracket

F15504

[B] Radiator Support Reinforcement

Page 58

BODY PANEL REPLACEMENT

RADIATOR LOWER SUPPORT (ASSY)

REPLACEMENT

REMOVAL

BP-5

F15505A

F15505

Page 59

BP-6

BODY PANEL REPLACEMENT

INSTALLATION

Temporarily install the new parts and measure each part of the new parts in accordance with the body dimension

diagram. (See the body dimension diagram)

Inspect the fitting of the related parts around the new parts before welding. This affects the appearance of the

finish.

After welding, apply the polyurethane foam to the corresponding parts.

After welding, apply body sealer and under-coating to the corresponding parts.

After applying the top coat layer, apply anti-rust agent to the inside of the necked section structural weld spots.

F15506

Page 60

BODY PANEL REPLACEMENT

RADIATOR SUPPORT (ASSY)

REPLACEMENT

REMOVAL

BP-7

F15507A

F15507

Page 61

BP-8

BODY PANEL REPLACEMENT

INSTALLATION

Temporarily install the new parts and measure each part of the new parts in accordance with the body dimension

diagram. (See the body dimension diagram)

Inspect the fitting of the related parts around the new parts before welding. This affects the appearance of the

finish.

After welding, apply the polyurethane foam to the corresponding parts.

After welding, apply body sealer and under-coating to the corresponding parts.

After applying the top coat layer, apply anti-rust agent to the inside of the necked section structural weld spots.

F15508

Page 62

BODY PANEL REPLACEMENT

RADIATOR UPPER SUPPORT (ASSY)

REPLACEMENT

REMOVAL

BP-1

F15501A

F15501

Page 63

BP-2

BODY PANEL REPLACEMENT

INSTALLATION

Temporarily install the new parts and measure each part of the new parts in accordance with the body dimension

diagram. (See the body dimension diagram)

Inspect the fitting of the related parts around the new parts before welding. This affects the appearance of the

finish.

After welding, apply the polyurethane foam to the corresponding parts.

After welding, apply body sealer and under-coating to the corresponding parts.

After applying the top coat layer, apply anti-rust agent to the inside of the necked section structural weld spots.

PART NAME

[A] Apron Fender Side Extension [B] Cool Air Intake Duct Mounting Bracket (LH Only)

F15502

Page 64

BP-48

BODY PANEL REPLACEMENT

REAR FLOOR PAN EXTENSION (ASSY)

REPLACEMENT

With the body lower back panel removed.

REMOVAL

F15548A

F15548

Page 65

BODY PANEL REPLACEMENT

BP-49

INSTALLATION

Temporarily install the new parts and measure each part of the new parts in accordance with the body dimension

diagram. (See the body dimension diagram)

Inspect the fitting of the related parts around the new parts before welding. This affects the appearance of the

finish.

After welding, apply the polyurethane foam to the corresponding parts.

After welding, apply body sealer and under-coating to the corresponding parts.

After applying the top coat layer, apply anti-rust agent to the inside of the necked section structural weld spots.

F15549

Page 66

BP-50

BODY PANEL REPLACEMENT

REAR FLOOR SIDE REAR MEMBER (ASSY)

REPLACEMENT

With the body lower back panel removed.

REMOVAL

F15550A

F15550

Page 67

BODY PANEL REPLACEMENT

BP-51

INSTALLATION

Temporarily install the new parts and measure each part of the new parts in accordance with the body dimension

diagram. (See the body dimension diagram)

Inspect the fitting of the related parts around the new parts before welding. This affects the appearance of the

finish.

After welding, apply the polyurethane foam to the corresponding parts.

After welding, apply body sealer and under-coating to the corresponding parts.

After applying the top coat layer, apply anti-rust agent to the inside of the necked section structural weld spots.

F15551

Page 68

BP-52

BODY PANEL REPLACEMENT

REAR FLOOR NO.2 CROSSMEMBER (ASSY)

REPLACEMENT

REMOVAL

F15553A

F15553

Page 69

BODY PANEL REPLACEMENT

BP-53

INSTALLATION

Temporarily install the new parts and measure each part of the new parts in accordance with the body dimension

diagram. (See the body dimension diagram)

Inspect the fitting of the related parts around the new parts before welding. This affects the appearance of the

finish.

After welding, apply the polyurethane foam to the corresponding parts.

After welding, apply body sealer and under-coating to the corresponding parts.

After applying the top coat layer, apply anti-rust agent to the inside of the necked section structural weld spots.

F15554

Page 70

BP-46

REAR FLOOR PAN (ASSY)

REPLACEMENT

With the body lower back panel removed.

REMOVAL

BODY PANEL REPLACEMENT

F15546A

F15546

Page 71

BODY PANEL REPLACEMENT

BP-47

INSTALLATION

Temporarily install the new parts and measure each part of the new parts in accordance with the body dimension

diagram. (See the body dimension diagram)

Inspect the fitting of the related parts around the new parts before welding. This affects the appearance of the

finish.

After welding, apply the polyurethane foam to the corresponding parts.

After welding, apply body sealer and under-coating to the corresponding parts.

After applying the top coat layer, apply anti-rust agent to the inside of the necked section structural weld spots.

PART NAME

[A] Floor Clamp Bracket

[D] Jack Up Bracket

F15547

[B] Fuel Tube Bracket [C] Rear Floor Heat Insulator No.3 Bracket

[E] Spare Wheel Clamp Bracket

Page 72

BP-32

BODY PANEL REPLACEMENT

ROCKER OUTER PANEL (CUT)

REPLACEMENT

REMOVAL

F15532A

80mm (31.5in.)

F15532

Page 73

BODY PANEL REPLACEMENT

BP-33

INSTALLATION

Temporarily install the new parts and measure each part of the new parts in accordance with the body dimension

diagram. (See the body dimension diagram)

Inspect the fitting of the related parts around the new parts before welding. This affects the appearance of the

finish.

After welding, apply the polyurethane foam to the corresponding parts.

After welding, apply body sealer and under-coating to the corresponding parts.

After applying the top coat layer, apply anti-rust agent to the inside of the necked section structural weld spots.

F15533

POINT

1 Inspect the fitting the front door and rear door, etc., before welding, since this affects the appearance of the

finish.

Page 74

BP-30

BODY PANEL REPLACEMENT

ROCKER OUTER PANEL (CUT-P)

REPLACEMENT

REMOVAL

F15530A

350mm (13.78in.)

F15530

Page 75

BODY PANEL REPLACEMENT

BP-31

INSTALLATION

Temporarily install the new parts and measure each part of the new parts in accordance with the body dimension

diagram. (See the body dimension diagram)

Inspect the fitting of the related parts around the new parts before welding. This affects the appearance of the

finish.

After welding, apply the polyurethane foam to the corresponding parts.

After welding, apply body sealer and under-coating to the corresponding parts.

After applying the top coat layer, apply anti-rust agent to the inside of the necked section structural weld spots.

POINT

1 Inspect the fitting of the front door, etc., before welding, since this affects the appearance of the finish.

F15531

Page 76

BP-56

BODY PANEL REPLACEMENT

ROOF PANEL (ASSY): w/ sun roof

REPLACEMENT

REMOVAL

F15557A

POINT

1 If reusing the roof panel reinforcement, trim the hemming location using a disc sander, etc.

F15557

Page 77

BODY PANEL REPLACEMENT

BP-57

INSTALLATION

Temporarily install the new parts and measure each part of the new parts in accordance with the body dimension

diagram. (See the body dimension diagram)

Inspect the fitting of the related parts around the new parts before welding. This affects the appearance of the

finish.

After welding, apply the polyurethane foam to the corresponding parts.

After welding, apply body sealer and under-coating to the corresponding parts.

After applying the top coat layer, apply anti-rust agent to the inside of the necked section structural weld spots.

F15558

POINT

1 Before temporarily installing the new parts, apply body sealer to the windshield header panel, roof panel rein-

forcement and back window frame.

HINT:

1) Apply just enough sealer for the new parts to make contact.

2 Bend the flange hem with a wooden hammer and dolly.

HINT:

1) Perform hemming three steps, being careful not to warp the panel.

Page 78

BP-54

BODY PANEL REPLACEMENT

ROOF PANEL (ASSY): w/o sun roof

REPLACEMENT

REMOVAL

F15555A

F15555

Page 79

BODY PANEL REPLACEMENT

BP-55

INSTALLATION

Temporarily install the new parts and measure each part of the new parts in accordance with the body dimension

diagram. (See the body dimension diagram)

Inspect the fitting of the related parts around the new parts before welding. This affects the appearance of the

finish.

After welding, apply the polyurethane foam to the corresponding parts.

After welding, apply body sealer and under-coating to the corresponding parts.

After applying the top coat layer, apply anti-rust agent to the inside of the necked section structural weld spots.

F15556

POINT

1 Before temporarily installing the new parts, apply body sealer to the windshield header panel reinforcement

and back window frame.

HINT:

1) Apply just enough sealer for the new parts to make contact.

Page 80

PC-6

PAINT COATING

BODY PANEL UNDERCOATING AREAS

HINT:

1) First wipe off any dirt, grease or oil with a rag soaked in a grease, wax and silicone remover.

2) Cover the surrounding areas with masking paper to avoid coating unnecessary areas. If other areas are accidently coated, wipe off the coating immediately.

3) Apply the first coating of undercoat to all welded areas and panel joints, then apply a second coat over the

entire area.

4) Do not coat parts which become hot, such as the tailpipe, or moving parts, such as the propeller shaft.

5) Besides the locations described below, apply undercoating to all weld points under the body to insure corrosion prevention.

6) Be sure to seal the edge of the flange of the member and bracket with undercoating.

7) If undercoat is damaged by peeling, cracks, etc., be sure to repair as necessary.

8) Before the undercoat apply sealer allowing rust prevention to be attained.

REFERENCE

Referring to the notes above, undercoating should be applied according to the specifications for your country.

F15564

Page 81

PC-8

PAINT COATING

BODY PANEL ANTI-RUST AGENT (WAX) APPLICATION AREAS

HINT:

1) Whenever adjusting the doors and hoods, apply anti-rust agent (wax) around the hinges.

2) Even if partially repairing a part, apply anti-rust agent (wax) over the entire application area of the part.

3) Wipe off the anti-rust agent immediately with a rag soaked in a grease, wax and silicone remover, if accidently

applied to other areas.

F15565

Page 82

PC-10

PAINT COATING

BODY PANEL ANTI-CHIPPING PAINT APPLICATION AREAS

HINT:

1) Anti-chipping paint should be applide to some areas before the second coat and to others after the top coat.

2) If other areas are accidentally coated, wipe of the paint immediately with a rag soaked in grease, wax and

silicone remover.

PVC Urethane

F15568

Page 83

PAINT COATING

PC-1

BODY PANEL SEALING AREAS

HINT:

1) Prior to applying body sealer, clean the area with a rag soaked in grease,wax and silicone remover.

2) If weld-through primer was used, first wipe off any excess and coat with anti-corrosion primer before applying

body sealer.

3) Wipe off excess body sealer with a rag soaked in a grease, wax and silicone remover.

4) If body sealer is damaged by peeling, cracks, etc., be sure to repair as necessary.

Flat Finishing No Flat Finishing

1. ENGINE COMPARTMENT

F15559

Page 84

PC-2

2. INSIDE

PAINT COATING

F15560

Page 85

3. REAR LUGGAGE COMPARTMENT

PAINT COATING

PC-3

F15561

Page 86

PC-4

4. DOOR PARTS

PAINT COATING

F15562

Page 87

PAINT COATING

PC-5

F15563

Page 88

PAINT COATING

FOAMED MATERIAL APPLICATION AREAS

The sections shown in the figure below are filled with foamed material to provide noise insullation.

After repairing these sections or their peripheries, refill with foamed materials

HINT:

1) Use the service holes located on the reverse side of the body panel to refill with foamed materials.

2) When handling foamed material, follow the directions of the material’s manufacturer.

PC-7

F15566

Page 89

PAINT COATING

SILENCER SHEET INSTALLATION AREAS

PC-9

non-adhesive sheet

F15567

Page 90

BODY DIMENSIONS

BODY DIMENSION DRAWINGS

ENGINE COMPARTMENT

(Three-Dimensional Distance)

C

332

A

(13.07)

1,330

(52.36)

1,352

(53.23)

DI-3

c

N

B

697

(27.44)

M

720

(28.35)

L

1,254

(49.37)

G

K

1,292

(50.87)

F

1,194

(47.01)

995

(39.17)

(31.26)

794

545

(21.46)

D

1,040

(40.94)

1,001

(39.41)

556

(21.89)

l

1,262

(49.69)

206

n

(8.11)

b

a

m

g

804

(31.65)

884

(34.80)

988

(38.90)

548

(21.57)

e

k

j

h

E

J

594

(23.39)

H

408

(16.06)

I

Vehicle Dimensions Left Right

B-D

or D-E D-e K-k L-l N-n

b-D

523 765 768 1,544 792 1,305

(20.59) (30.12) (30.24) (60.79) (31.18) (51.38)

HINT: For symbols, capital letters indicate right side of vehicle,

small letters indicate left side of vehicle (Seen from rear).

mm (in.)

Symbol Name Hole dia. Symbol Name Hole dia.

A, a

B, b

C, c

D

E, e

F

G, g

Radiator upper support standard hole

Front spring support hole-inner

Hood hinge installation nut

Cowl top outer panel installation nut

Air bag sensor installation nut

Brake tube installation nut

f

ABS actuator installation nut

Radiator upper center support installation nut

12 (0.47)

11 (0.43)

8 (0.31) nut

6 (0.24) nut

8 (0.31) nut

6 (0.24) nut

8 (0.31) nut

6 (0.24) nut

H, h

I

J, j

K, k

L, l

M, m

N, n

—

Radiator support standard hole

Hood lock support installation nut

Front bumper reinforcement installation bolt

Front fender mounting bracket standard hole

Radiator upper center support installation nut

Front fender installation nut

Front fender installation nut

—

10x8(0.39x0.31)

6 (0.24) nut

8 (0.31) bolt

10 (0.39)

6 (0.24) nut

6 (0.24) nut

6 (0.24) nut

—

Page 91

BODY DIMENSIONS

BODY OPENING AREAS (Side View: Rear)

(Three-Dimensional Distance)

DI-5

HINT: For symbols, capital letters indicate right side of vehicle,

small letters indicate left side of vehicle (Seen from rear).

Vehicle Dimensions Left Right

o

n

851

(33.50)

939

(36.97)

522

(20.55)

q

1,084

(42.68)

677

(26.65)

1,052

(41.42)

i

r

s

p

g

N-n O-o P-p Q-q R-r S-s

1,273 1,362 1,365 1,069 1,189 1,363

(50.12) (53.62) (53.74) (42.09) (46.81) (53.66)

G-p I-q N-r N-s O-s P-q R-s

or or or or or or or

g-P i-Q n-R n-S o-S p-Q r-S

1,632 1,284 1,404 1,568 1,459 1,623 1,506

(64.25) (50.55) (55.28) (61.73) (57.44) (63.90) (59.29)

mm (in.)

Symbol Name Hole dia. Symbol Name Hole dia.

G, g

I,i

N, n

O, o

Rocker panel assembly mark

Roof side rail assembly mark

Center body pillar assembly mark

Center body pillar assembly mark

—

—

—

—

P, p

Q, q

R, r

S, s

Rocker panel assembly mark

Roof side rail assembly mark

Quarter panel assembly mark

Quarter panel assembly mark

—

—

—

—

Page 92

DI-6

BODY DIMENSIONS

BODY OPENING AREAS (Rear View)

(Three-Dimensional Distance)

945

(37.20)

A

(29.41)

B

747

a

h

b

1,557

(61.30)

985

(38.78)

C

1,112

c

d

g

e

507

(19.96)

(43.78)

1,069

(42.09)

1,426

(56.14)

985

(38.78)

948

(37.32)

G

F

D

E

f

G-H

or

g-h

1,031

(40.59)

HINT: For symbols, capital letters indicate right side of vehicle,

small letters indicate left side of vehicle (Seen from rear).

mm (in.)

Symbol Name Hole dia. Symbol Name Hole dia.

A, a

B, b

C, c

D, d

Back door hinge installation hole

Back door damper stay installation nut

Roof side inner garnish installation bole

Quarter panel standard hole

RH: 10.2

(0.402)

LH: 13x10.2

(0.51x0.402)

6 (0.24) nut

8.5 (0.335)

10 (0.39)

E, e

F, f

G, g

H, h

—

Deck trim side panel installation hole

Deck trim rear cover installation hole

Rear shock absorber installation hole

Center body pillar assembly mark

—

8.5 (0.335)

7 (0.28)

18 (0.71)

—

—

Page 93

DI-4

BODY DIMENSIONS

BODY OPENING AREAS (Side View: Front)

(Three-Dimensional Distance)

A

1,039

(40.91)

802

(31.57)

B

1,216

(47.87)

1,381

(54.37)

e

b

c

914

(35.98)

1,063

(41.85)

a

816

(32.13)

872

(34.33)

i

1,078

(42,44)

1,171

(46.10)

j

l

k

f

836

(32.91)

1,002

(39.45)

m

d

h

g

HINT: For symbols, capital letters indicate right side of vehicle,

small letters indicate left side of vehicle (Seen from rear).

Vehicle Dimensions Left Right

E-e F-f G-g H-h I-i J-j K-k

1,265 1,366 1,365 1,365 1,084 1,265 1,362

(49.80) (53.78) (53.74) (53.74) (42.68) (49.80) (53.62)

E-f E-h E-j F-j F-k H-i J-k

or or or or or or or

e-F e-H e-J f-J f-K h-I j-K

1,482 1,601 1,505 1,760 1,600 1,625 1,427

(58.35) (63.03) (59.25) (69.29) (62.99) (63.98) (56.18)

mm (in.)

Symbol Name Hole dia. Symbol Name Hole dia.

A, a

B, b

C, c

D, d

E, e

F, f

G, g

Roof panel corner

Cowl top outer panel/Front body pillar adjoining portion

Front door hinge installation nut

Front door hinge installation nut

Front body pillar assembly mark

Front body pillar assembly mark

Rocker panel assembly mark

—

—

8 (0.31) nut

8 (0.31) nut

—

—

—

H, h

I,i

J, j

K, k

L, l

M, m

—

Rocker panel assembly mark

Roof side rail assembly mark

Center body pillar assembly mark

Center body pillar assembly mark

Rear door hinge installation nut

Rear door hinge installation nut

—

—

—

—

—

8 (0.31) nut

8 (0.31) nut

—

Page 94

BODY DIMENSIONS

DI-1

Three-dimensional

distance

Two-dimensional

distance

Vertical distance

in center

Imaginary Standard Line

Center-to-center

straight-line

distance

Center-to-center

Horizontal distance

in forward/rearward

Vertical distance

in lower surface

Under Surface of

The Rocker Panel

GENERAL INFORMATION

1. BASIC DIMENSIONS

(a) There are two types of dimensions in the diagram.

(1) (Three-dimensional distance)

Straight-line distance between the centers of two

measuring points.

(2) (Two-dimensional distance)

Horizontal distance in forward/rearward between the

centers of two measuring points.

The height from an imaginary standard line.

(b) In cases in which only one dimension is given, left and right

are symmetrical.

(c) The dimensions in the following drawing indicate actual dis-

tance. Therefore, please use the dimensions as a reference.

(d) The line that connects the places listed below is the imagi-

nary standard line when measuring the height. (The dimensions are printed in the text.)

Imaginary Standard Line

SYMBOL Name

1

2

3

The place that was lowered A mm from the under surface of

the rocker panel centered on the front jack up point.

The place that was lowered B mm from the under surface of

the rocker panel centered between 1 and 3.

The place that was lowered C mm from the under surface of

the rocker panel centered on the rear jack up point.

Page 95

DI-2

BODY DIMENSIONS

Plate Looseness

Body Looseness

Pointer Looseness

Pointer

Master Gauge

Wrong Correct

Pointer

2. MEASURING

(a) Basically , all measurements are to be done with a tracking

gauge. For portions where it is not possible to use a tracking gauge, a tape measure should be used.

(b) Use only a tracking gauge that has no looseness in the

body, measuring plate, or pointers.

HINT:

1) The height of the left and right pointers must be equal.

2) Always calibrate the tracking gauge before measuring

or after adjusting the pointer height.

3) Take care not to drop the tracking gauge or otherwise

shock it.

4) Confirm that the pointers are securely in the holes.

(c) When using a tape measure, avoid twists and bends in the

tape.

Page 96

UNDER BODY

(Three-Dimensional Distance)

BODY DIMENSIONS

DI-7

RH

LH

Front

(17.32)

988

(38.90)

440

930

(36.61)

489

(19.25)

1,095

(43.11)

(40.59)

(34.84)

1,164

(45.83)

1,031

885

(33.78)

922

(36.30)

300

(11.81)

858

895

(35.24)

256

(10.08)

856

(33.70)

973

(38.31)

1,117

(43.98)

(18.23)

463

452

(17.80)

856

(33.70)

968

(38.11)

1,252

(49.29)

(33.70)

123

100 100 100

(3.94) (3.94) (3.94)

856

374

(14.72)

1,080

(42.52)

1,200

(47.24)

1,066

(41.97)

697

(27.44)

1,451

(57.13)

1,269

(49.96)

936

(36.85)

304

(11.97)

(36.85)

984

(38.74)

936

A,a

388

(15.28)

B,b

154

(6.06)

C,c

310

(12.20)

D,d

295

(11.61)

E,e

100

(3.94)

F,f

57

(2.24)

G,g

57

(2.24)

H,h

58

(2.28)

I,i

137

(5.39)

J,j

147

(5.79)

K,k

287

(11.30)

L,l

283

(11.14)

Imaginary

Standard

Line

mm (in.)

Symbol Name Hole dia. Symbol Name Hole dia.

A, a

B, b

C, c

D, d

E, e

Front bumper reinforcement installation bolt

Radiator lower support standard hole

Front side member standard hole

Front suspension member installation nut

Front suspension member installation nut

F, f

Front side member standard hole

8 (0.31) bolt

15 (0.59)

18 (0.71)

12 (0.47) nut

14 (0.55) nut

18 (0.71)

G, g

H, h

I,i

J, j

K, k

L, l

Front side member standard hole

Front floor under reinforcement standard hole

Rear floor side member standard hole

Trailing arm installation hole-inner

Rear floor side member standard hole

Transport hook installation nut

18 (0.71)

18 (0.71)

18 (0.71)

13 (0.51)

18 (0.71)

10 (0.39) nut

Page 97

DI-8

UNDER BODY (Cont’d)

(Two-Dimensional Distance)

BODY DIMENSIONS

RH

LH

2,069

(81.46)

Front

1,985

(78.15)

(8.66)

494

(19.45)

220

(18.31)

1,882

(74.09)

465

1,394

1,167

(54.88)

443

(17.44)

611

(24.06)

1,393

(54.84)

(45.94)

429

(16.89)

428

(16.85)

915

(36.02)

(17.80)

(16.85)

Wheel base 2,370 (93.31)

452

428

0

520

(20.47)

I

600

(23.62)

322

(12.68)

533

(20.98)

428

(16.85)

428

(16.85)

0

123

100 100 100

(3.94) (3.94) (3.94)

990

(38.98)

468

(18.43)

535

(21.06)

983

(38.70)

468

(18.43)

1,294

(50.94)

A,a

388

(15.28)

B,b

154

(6.06)

C,c

310

(12.20)

D,d

295

(11.61)

E,e

752

(29.61)

F,f

100

(3.94)

G,g

57

(2.24)

H,h

57

(2.24)

I,i

58

(2.28)

J,j

137

(5.39)

K,k

147

(5.79)

L,l

659

(25.94)

M.m

287

(11.30)

N,n

283

(11.14)

Imaginary

Standard

Line

mm (in.)

Symbol Name Hole dia. Symbol Name Hole dia.

A, a

B, b

C, c

D, d

E, e

G, g

Front bumper reinforcement installation bolt

Radiator lower support standard hole

Front side member standard hole

Front suspension member installation nut

Front spring support hole-outer

F, f

Front suspension member installation nut

Front side member standard hole

8 (0.31) bolt

15 (0.59)

18 (0.71)

12 (0.47) nut

11 (0.43)

14 (0.55) nut

18 (0.71)

H, h

I,i

J, j

K, k

L, l

M, m

N, n

Front side member standard hole

Front floor under reinforcement standard hole

Rear floor side member standard hole

Trailing arm installation hole-inner

Rear shock absorber installation hole

Rear floor side member standard hole

Transport hook installation nut

18 (0.71)

18 (0.71)

18 (0.71)

13 (0.51)

18 (0.71)

18 (0.71)

10 (0.39) nut

Loading...

Loading...