Toyota PRIUS 2006 Hybrid Transmission Transaxle

HYBRID TRANSMISSION / TRANSAXLE – HYBRID TRANSAXLE SYSTEM

HYBRID TRANSAXLE SYSTEM

ON-VEHICLE INSPECTION

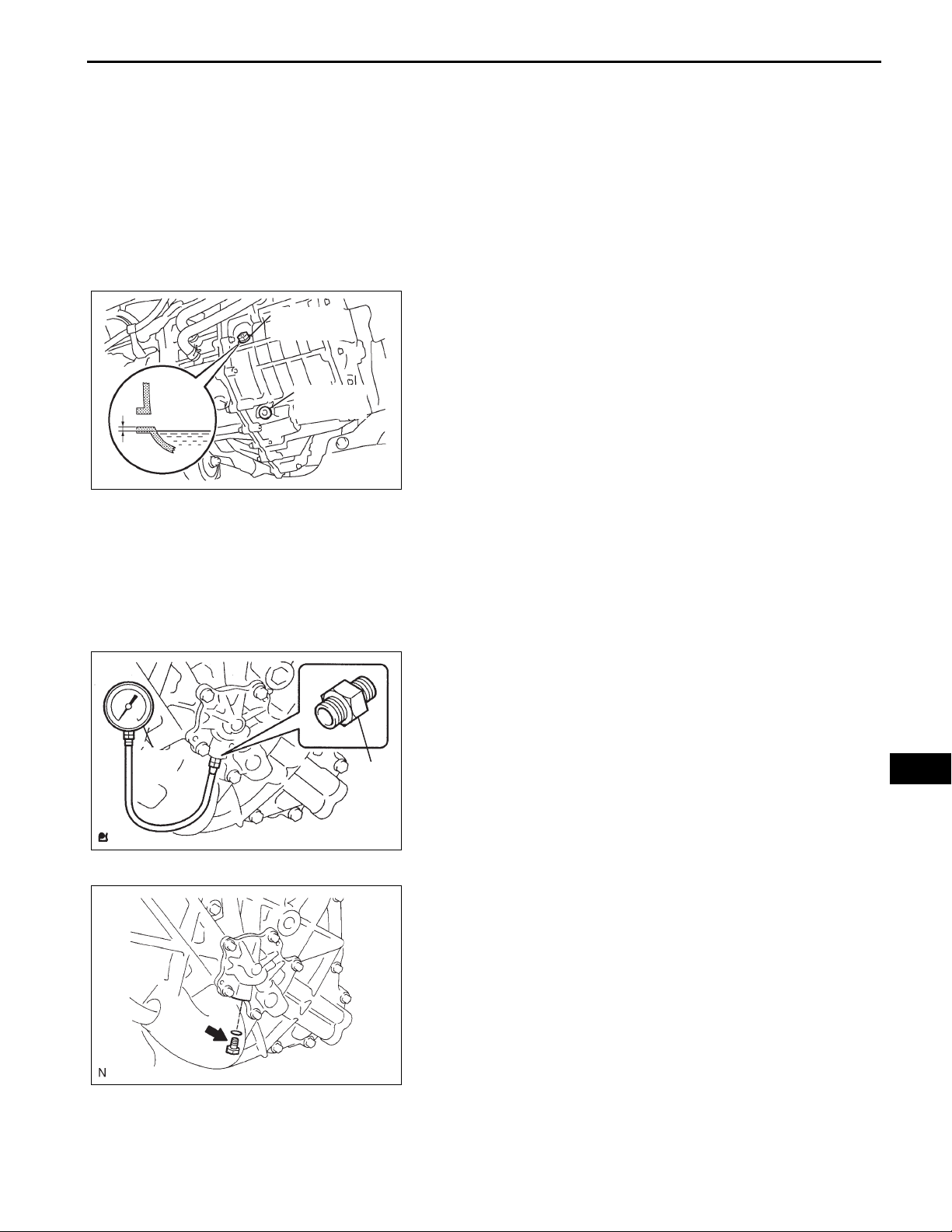

1. CHECK TRANSAXLE FLUID LEVEL

NOTICE:

• Insufficient or excessive amounts of transaxle oil

may be the cause of some trouble.

• Place the vehicle on level surface.

• Use genuine ATF WS.

(a) Remove the filler plug.

Filler Plug

Drain Plug

G030993E01

(b) Ensure that the transaxle oil level is within 0 to 5

mm (0 to 0.20 in.) of the filler plug hole.

NOTICE:

Recheck the transaxle oil level after driving the

vehicle when exchanging oil.

HINT:

Transaxle fluid quantity: 3.8 liters (4.0 US qts, 3.3

Imp. qts.)

(c) Check for leaks if the quantity of oil is low.

(d) Install the filler plug with a new gasket.

Torque: 39 N*m (400 kgf*cm, 29 ft.*lbf)

HX–1

SST

SST

G030394E01

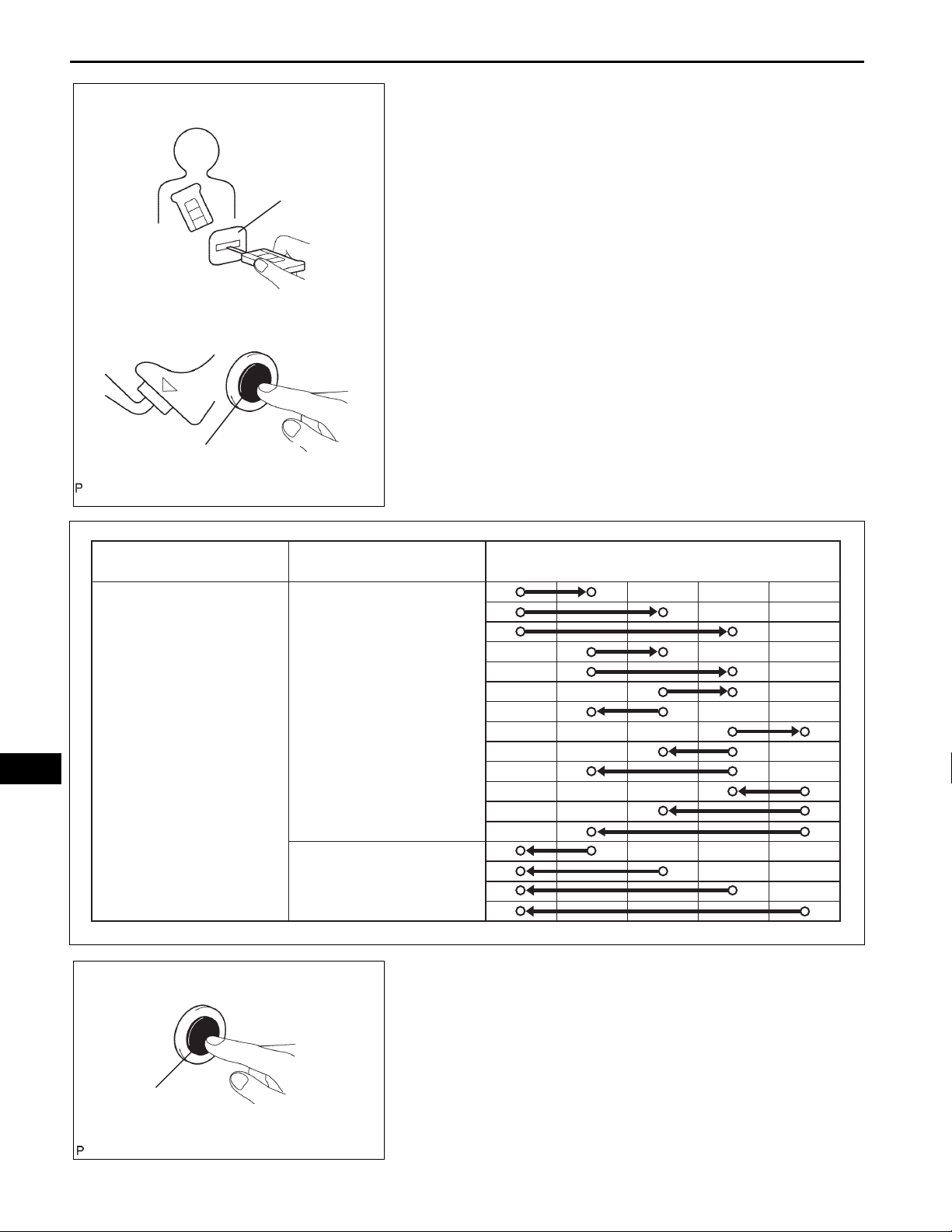

2. INSPECT OIL PRESSURE

NOTICE:

Perform the test at normal operating oil temperature

50 to 80°C (122 to 176°F).

(a) Lift up the vehicle.

(b) Remove the fluid pump cover plug and install SST.

SST 09992-00095 (09992-00112, 09992-00271)

(c) Set the blower switch to HI.

(d) Turn the A/C switch on.

(e) Push the power switch with the brake pedal

depressed to start the engine (start the hybrid

system).

(f) Keeping the engine speed of 1,200 rpm, measure

the oil pressure.

Standard oil pressure:

9.8 kPa (0.1 kgf/cm

2

, 1.4 psi) or more

(g) Install a new O-ring and fluid pump cover plug.

Torque: 7.4 N*m (75 kgf*cm, 65 in.*lbf)

HX

G030396E01

HX–2

HYBRID TRANSMISSION / TRANSAXLE – HYBRID TRANSAXLE SYSTEM

Turn the power switch ON

Key Slot

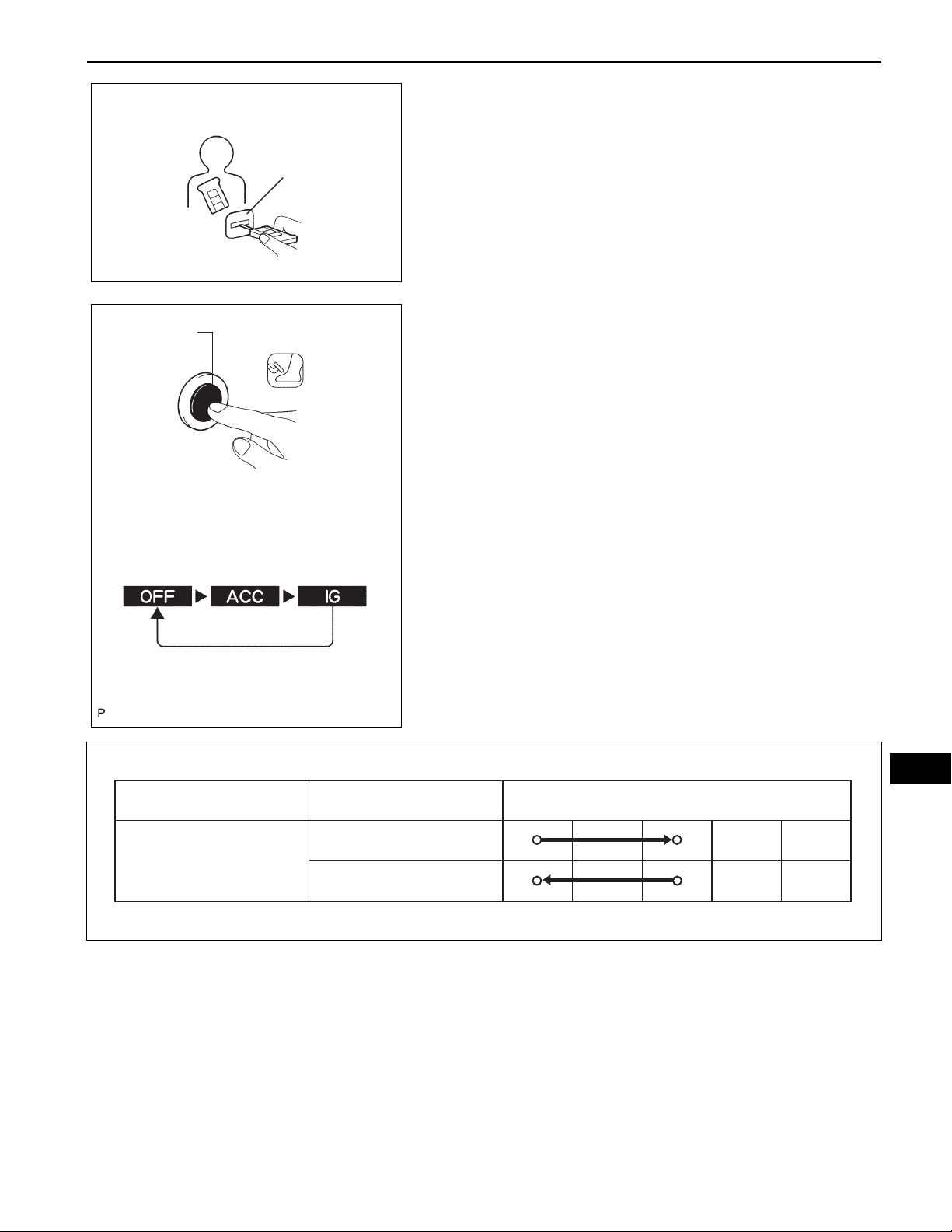

3. INSPECT SHIFT LEVER

(a) Inspect the shift lever operation with the hybrid

system operating.

(1) Carry the key into the indoor electrical key

oscillator detection area or insert the key in the

key slot.

(2) Turn the power switch ON (READY ON) while

depressing the brake pedal.

Check that the gear changes according to the

shift operation pattern. If the check result is

abnormal, replace the shift lever assembly.

HINT:

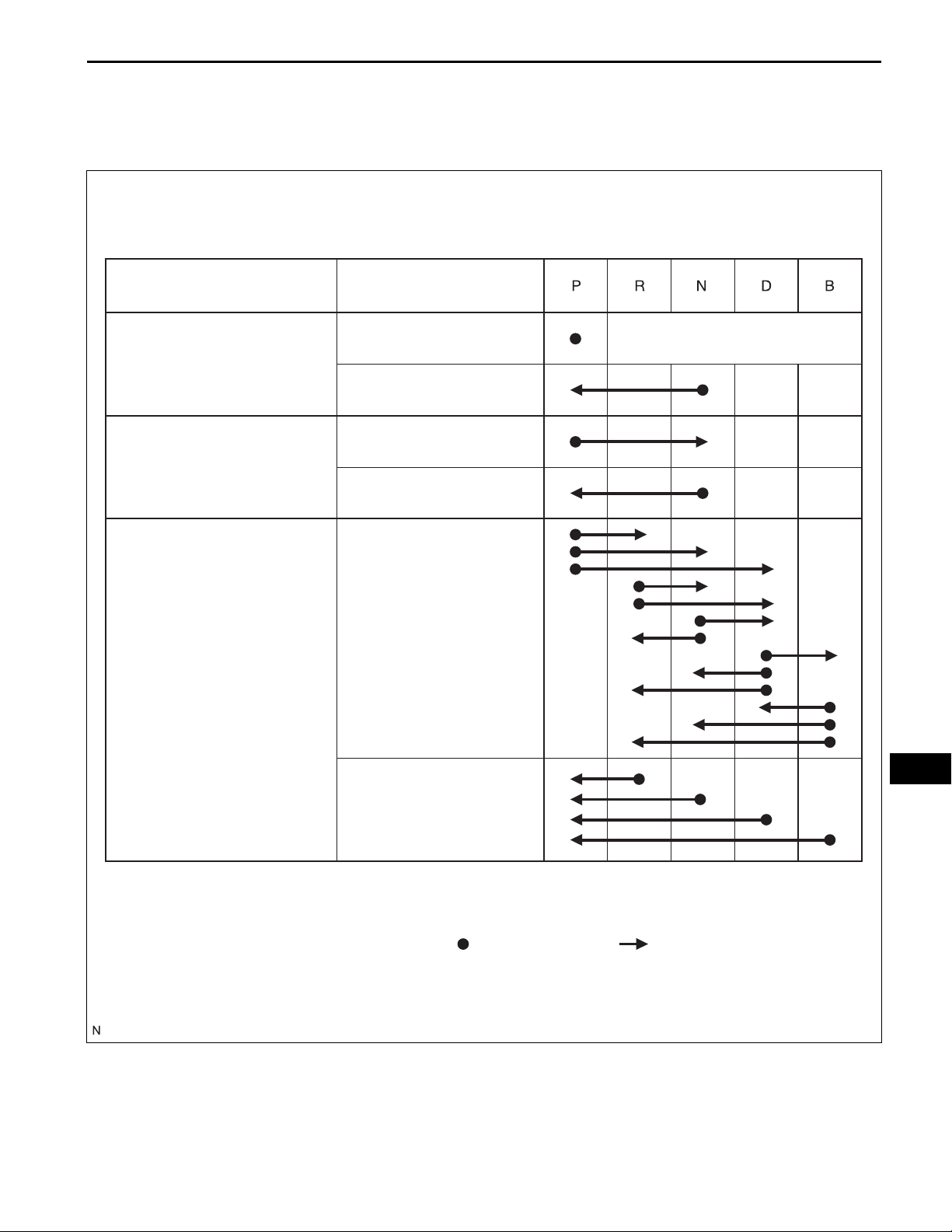

The shift operation pattern in power switch ON

(READY ON) (when the vehicle is stopped) is

shown below.

C097702E02

HX

Power Mode

Hybrid System in operation

(driving possible)

Operation

Shift Lever Operation

P Position Switch Operation

(b) Turn the power switch OFF when the vehicle is

PR

stopped.

ND

B

C130921E01

Power Switch

G021872E01

HYBRID TRANSMISSION / TRANSAXLE – HYBRID TRANSAXLE SYSTEM

Key Slot

Power Switch

Turn the power switch ON without

depressing the brake pedal.

HX–3

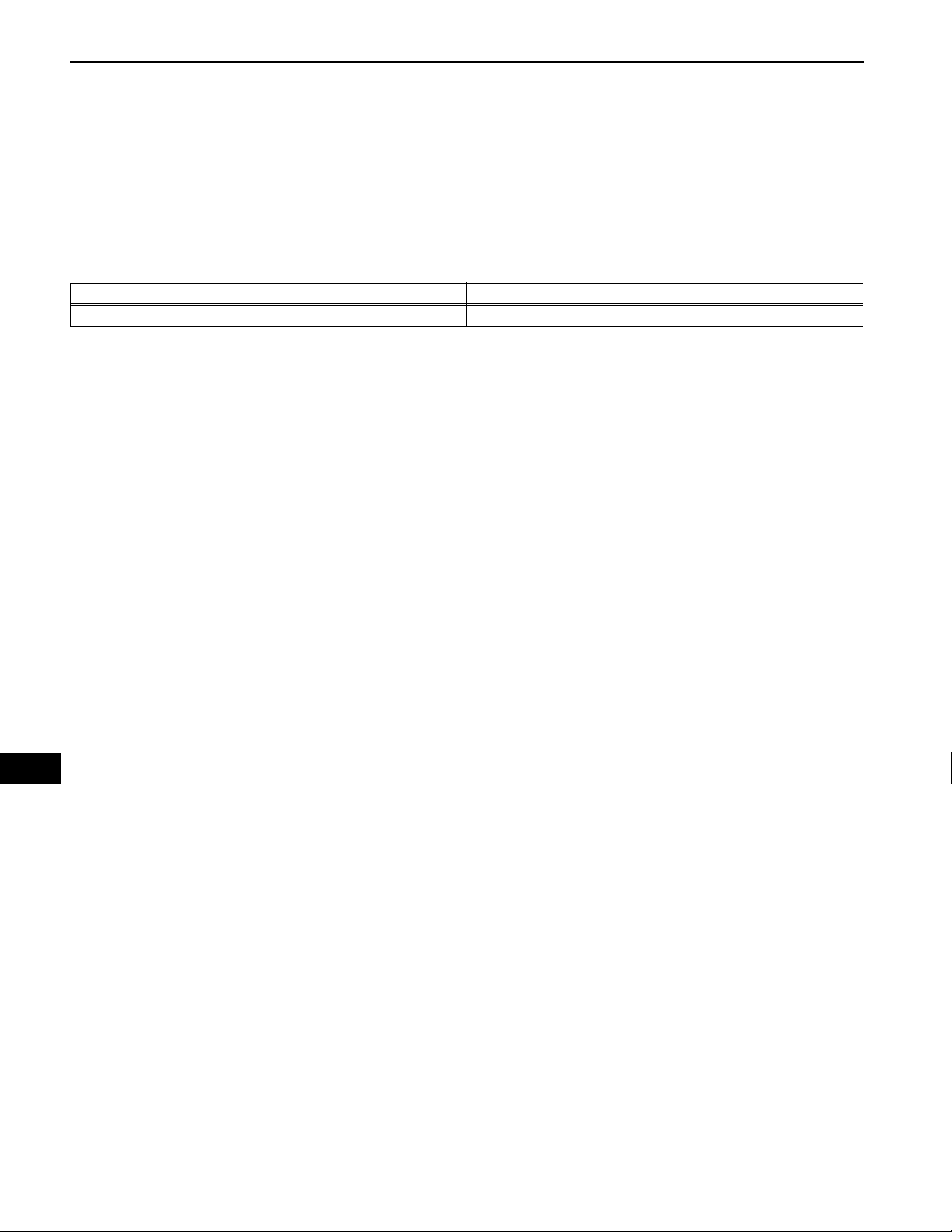

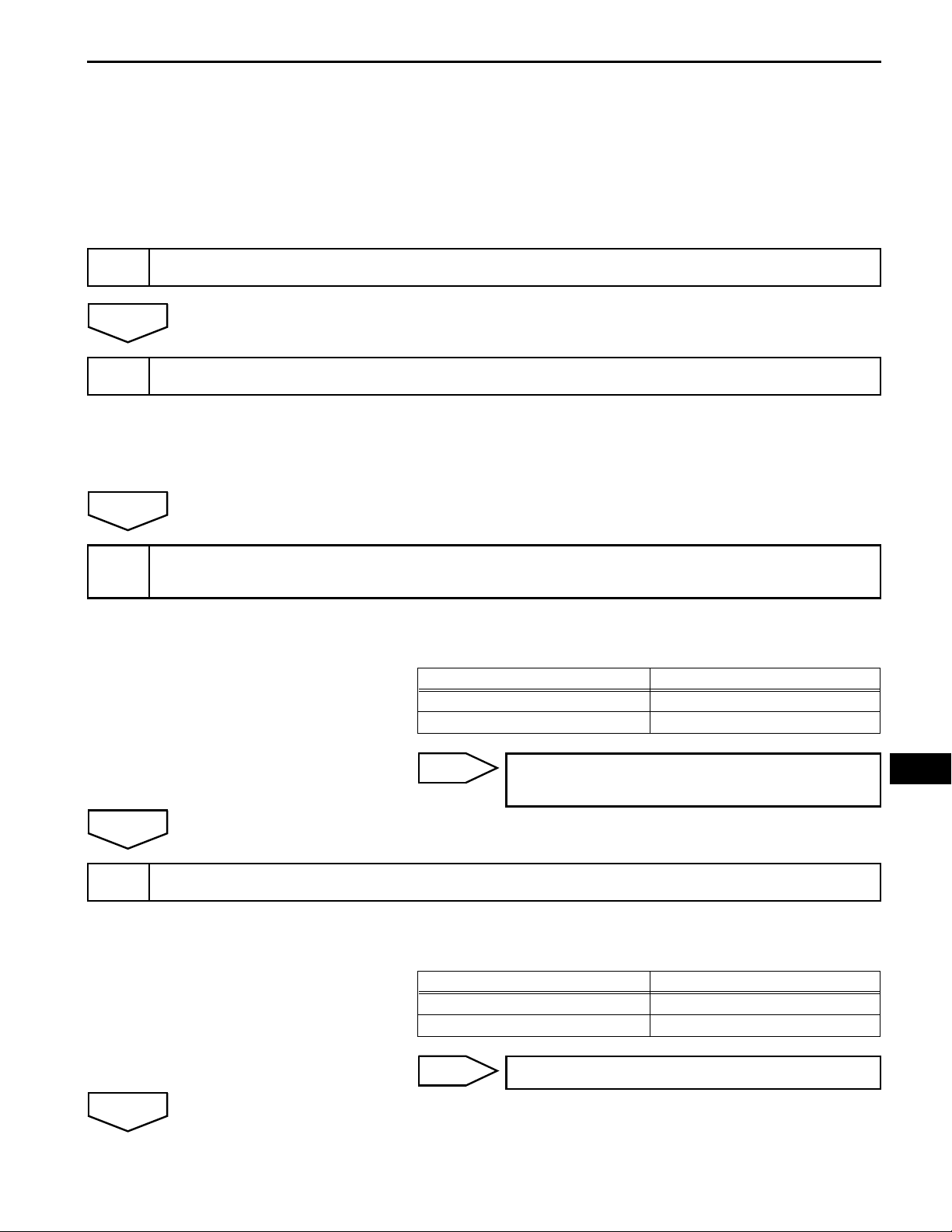

(c) Inspect the shift lever operation with the power

switch's power mode ON (IG).

(1) Carry the key into the indoor electrical key

oscillator detection area or insert the key in the

key slot.

G030999E01

(d) Turn the power switch ON (IG) without depressing

the brake pedal.

HINT:

The power switch's power mode changes between

OFF, ON (ACC) and ON (IG) each time the power

switch is pressed.

(e) Check that the gear changes according to the shift

operation pattern. If the check result is not as

specified, replace the shift lever assembly.

HINT:

The shift operation pattern with the power switch's

power mode ON (IG) is shown below.

Power Mode

Power switch ON (IG)

(Driving not possible)

G030998E02

Operation

Shift Lever Operation

P Position Switch Operation

PR

HX

N

DB

C130922E01

HX–4

HYBRID TRANSMISSION / TRANSAXLE – ELECTRONIC SHIFT LEVER SYSTEM

ELECTRONIC SHIFT LEVER SYSTEM

PRECAUTION

1. NOTICE FOR INITIALIZATION

When the cable of the negative (-) battery terminal is

disconnected, initialize the following systems after the

cable is reconnected.

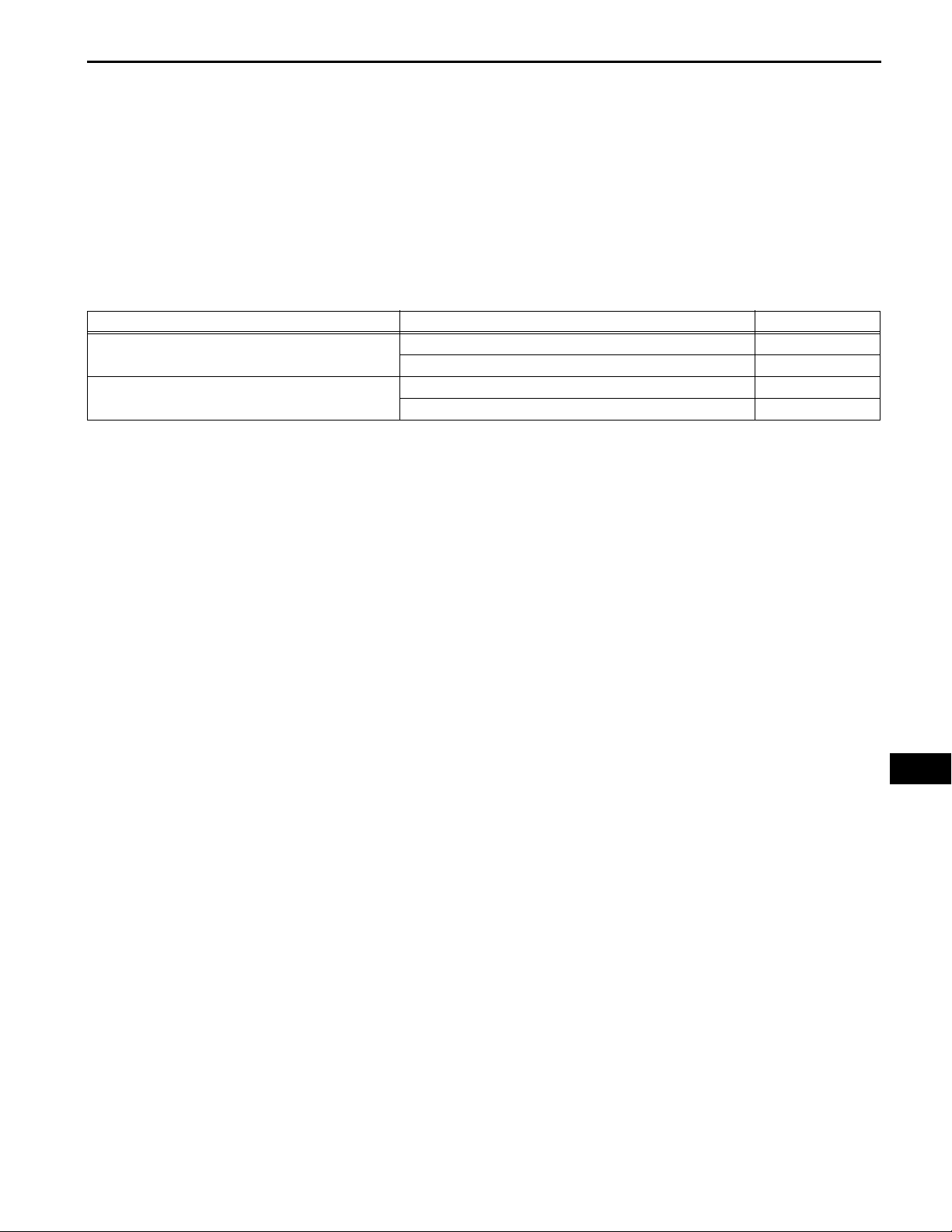

System Name See procedure

Power Window Control System IN-32

2. NOTICE FOR HYBRID SYSTEM ACTIVATION

• When the warning light is illuminated or the battery has

been disconnected and reconnected, pressing the power

switch may not start the system on the first try. If so, press

the power switch again.

• With the power switch's power mode changed to ON (IG),

disconnect the battery. If the key is not in the key slot

during reconnection, DTC B2799 may be output.

HX

HYBRID TRANSMISSION / TRANSAXLE – ELECTRONIC SHIFT LEVER SYSTEM

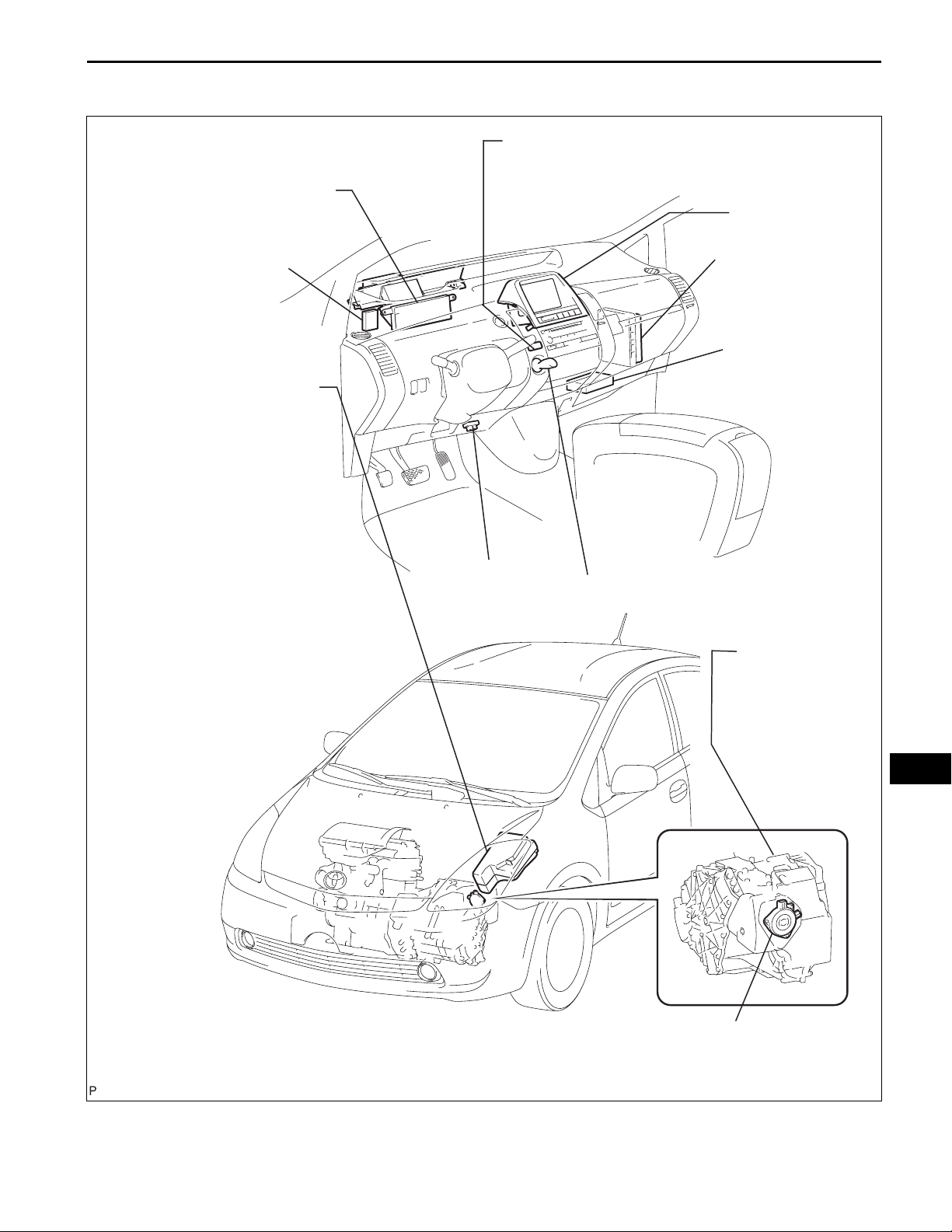

PARTS LOCATION

COMBINATION METER

- MASTER WARNING LIGHT

HX–5

P POSITION SWITCH

(P POSITION SWITCH INDICATOR LIGHT)

MULTI-DISPLAY

POWER SOURCE

CONTROL ECU

ENGINE ROOM RELAY BLOCK

AND JUNCTION BLOCK

- TRANSAXLE PARKING LOCK

CONTROL RELAY

(Marking: P CON)

- INTEGRATION RELAY

(unit B: IGCT RELAY)

- P CON MTR H-FUSE

- P CON MAIN FUSE

- HEV FUSE

DLC3

HYBRID VEHICLE

CONTROL ECU

TRANSMISSION

CONTROL ECU

SELECTOR LEVER

HYBRID VEHICLE

TRANSAXLE

SHIFT CONTROL ACTUATOR

HX

C126757E01

HX–6

HYBRID TRANSMISSION / TRANSAXLE – ELECTRONIC SHIFT LEVER SYSTEM

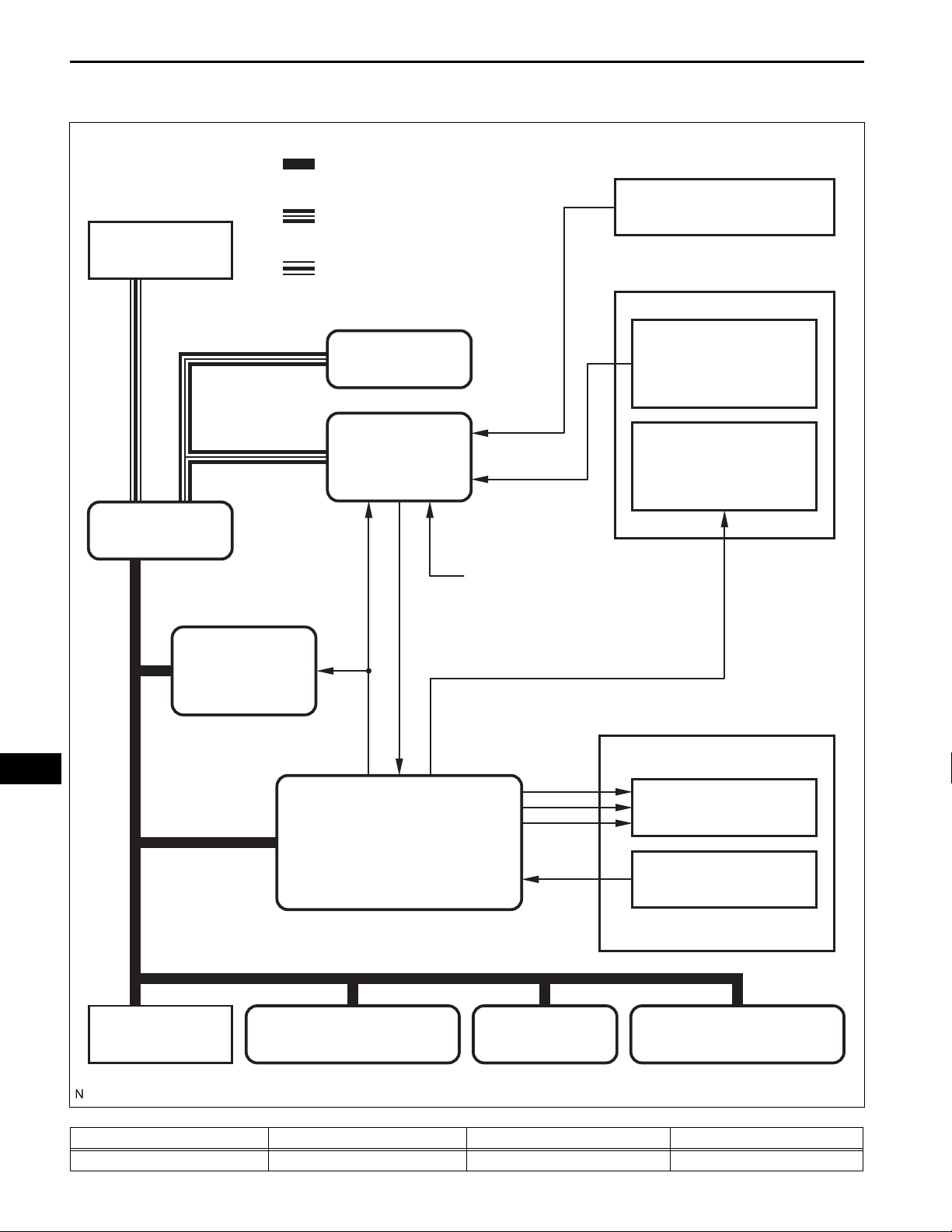

Multi-display

:

BEAN

:

CAN

:

AVC-LAN

SYSTEM DIAGRAM

Selector Lever

P Position Switch

HX

Gateway ECU

Power Source

Control ECU

Skid Control ECU

Hybrid Vehicle

Control ECU

P Position Switch

Indicator Light

Vehicle Information

- Vehicle Speed Signal

- Stop Light Switch Signal

Skid Control Actuator

Parking Lock Motor

Transmission Control ECU

Rotation Angle Sensor

Combination Meter

Transponder Key ECU Certification ECU

Multiplex Network Body ECU

Input and output signals of each ECU

Transmitting ECU (transmitter) Receiving ECU Signals Communication method

Skid Control ECU Transmission Control ECU PKB switch signal CAN, BEAN

C126758E01

HYBRID TRANSMISSION / TRANSAXLE – ELECTRONIC SHIFT LEVER SYSTEM

Transmitting ECU (transmitter) Receiving ECU Signals Communication method

Power Source Control ECU Transmission Control ECU Power off preparation signal BEAN

Main Body ECU Transmission Control ECU • Power switch signal

• ACC switch signal

Transmission Control ECU Power Source Control ECU • P position state signal

• Transmission control ECU

trouble condition signal

• Auto P cancel signal

• Non-P position state signal

• Auto P permit signal

Transmission Control ECU Multi-display Transmission control ECU trouble

signal

Transmission Control ECU Combination Meter Transmission control ECU trouble

signal

Transmission Control ECU Transponder Key Amplifier • P position state signal

• Key condition signal

Transmission Control ECU Certification ECU P position state signal BEAN

BEAN

BEAN

AVC-LAN, BEAN

BEAN

BEAN

HX–7

HX

HX

HX–8

HYBRID TRANSMISSION / TRANSAXLE – ELECTRONIC SHIFT LEVER SYSTEM

SYSTEM DESCRIPTION

1. SYSTEM DESCRIPTION

The electronic shift lever system electrically controls the

parking lock mechanism by using the actuator.

The transmission control ECU controls the shift control

actuator, and also controls the entire system based on

information from the hybrid vehicle control ECU.

The transmission control ECU detects DTCs when there

are any malfunctions in the system, and informs the

driver of the malfunction by illuminating the P position

switch indicator light and master warning light, and

indicating an error message on the multi-display.

2. FUNCTION OF EACH COMPONENT

Parts name Function

Shift Control Actuator • Composed of the parking lock motor and the rotation angle

sensor. The motor is activated by electric current from the

transmission control ECU.

• Motor rotation is reduced by the cycloid reduction mechanism in

the shift control actuator and then output.

• The rotation angle sensor detects the motor rotation angle with the

3 Hall ICs.

Transmission Control ECU • This ECU activates the shift control actuator based on signals

Parking Lock Mechanism The parking lock pawl rotates according to the movement of the

Hybrid Vehicle Control ECU This ECU sends a P lock or P unlock demand signal to the

Power Source Control ECU This ECU sends a signal with power off information to the

P Position Switch Indicator Light This light comes on/goes off to indicate the P lock/unlock status and

Combination Meter A malfunction in the transmission control ECU is indicated by the

Multi-display A malfunction in the transmission control ECU is indicated on the

from the hybrid vehicle control ECU and the power source control

ECU.

• This ECU controls the application timing of current to the parking

lock motor based on signals from the rotation angle sensor.

parking lock rod when the parking lock motor rotates, and engages

with the parking gear on the transaxle side, causing the parking lock

mechanism to lock or unlock.

transmission control ECU based on information from the selector lever

and the P position switch.

transmission control ECU. The transmission control ECU then sends

the signal to the hybrid vehicle control ECU.

blinks to indicate a malfunction in the electronic shift lever system.

illumination of the master warning light on the combination meter.

multi-display.

HYBRID TRANSMISSION / TRANSAXLE – ELECTRONIC SHIFT LEVER SYSTEM

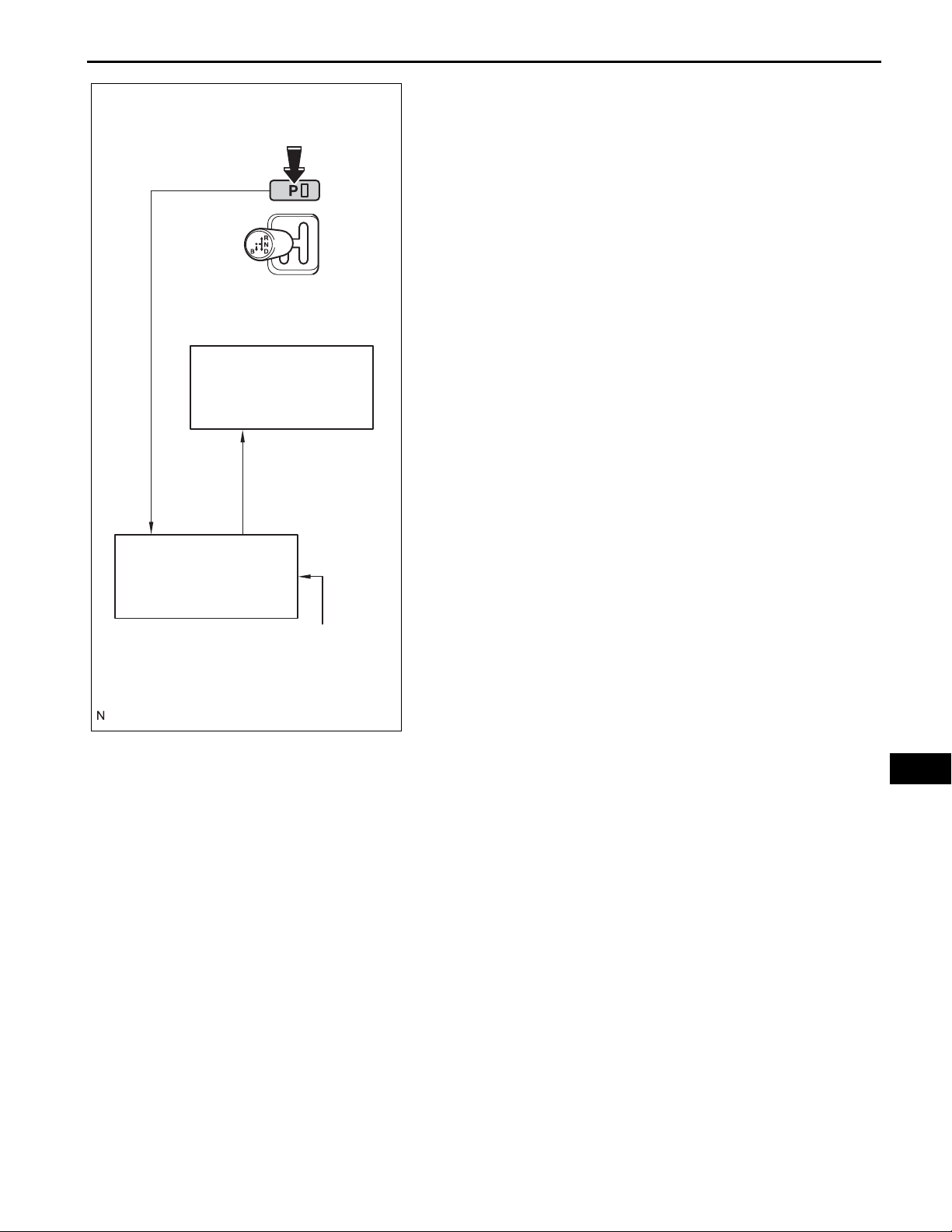

P Position Switch “ON”

Switch Operation Signal

Transmission

Control ECU

“P Lock” Operation

Signal

HX–9

3. OPERATION DESCRIPTION

(a) Operation to switch to the P position:

(1) When the P position switch is turned on to

activate parking lock, a signal is sent to the

hybrid vehicle control ECU.

(2) The hybrid vehicle control ECU determines

whether "P lock" is possible or not based on this

signal and other vehicle information.

(3) If the hybrid vehicle control ECU determines that

"P lock" is possible, it sends a "P lock" operation

demand signal to the transmission control ECU.

Hybrid Vehicle

Control ECU

Vehicle Speed

Signal

C126759E01

HX

HX–10

HYBRID TRANSMISSION / TRANSAXLE – ELECTRONIC SHIFT LEVER SYSTEM

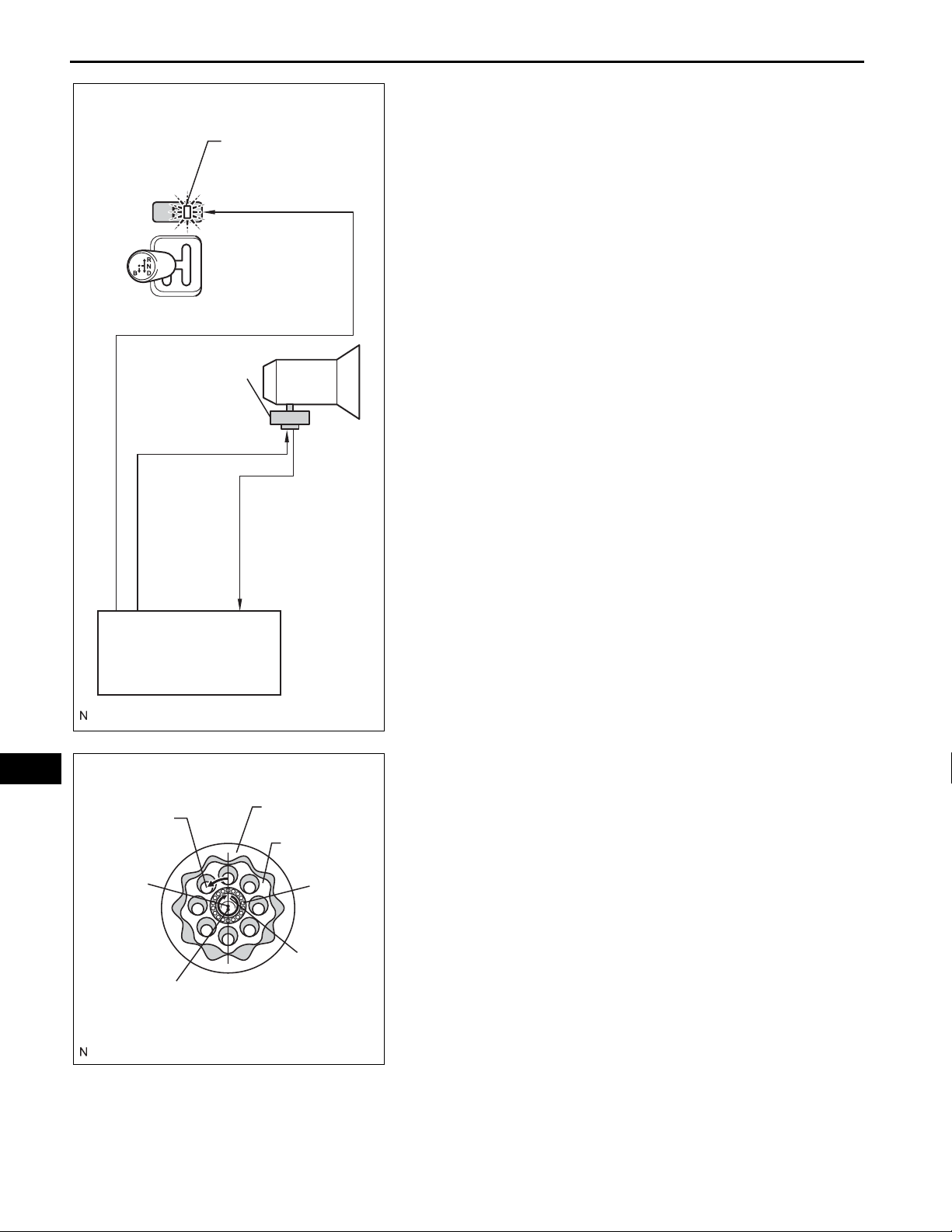

(4) After receiving the signal, the transmission

control ECU activates the shift control actuator in

P Position Switch

Indicator Light

ON Demand Signal

Skid Control

Actuator

“P Lock”

Switch

Control

order to lock the parking lock mechanism, and

turns on the P position switch indicator light.

HX

Rotation Angle

Sensor Signal

Transmission

Control ECU

Cycloid Reduction Mechanism

Output Shaft

Center of

Eccentric

Adapter

Center of Motor

Input Shaft

Internal Gear

C126760E01

External Gear

Bearing

Eccentric

Adapter

(5) The transmission control ECU controls motor

rotation angle based on signals from the rotation

angle sensor in the shift control actuator.

HINT:

In the cycloid reduction mechanism, the output

shaft is linked to the external gear. Together,

they rotate only a single tooth when the

eccentric adapter, which is linked to the motor,

rotates once. Driving force is increased in this

way so that the parking lock mechanism can be

switched even when high output is required for

parking on a hill, etc.

C126761E01

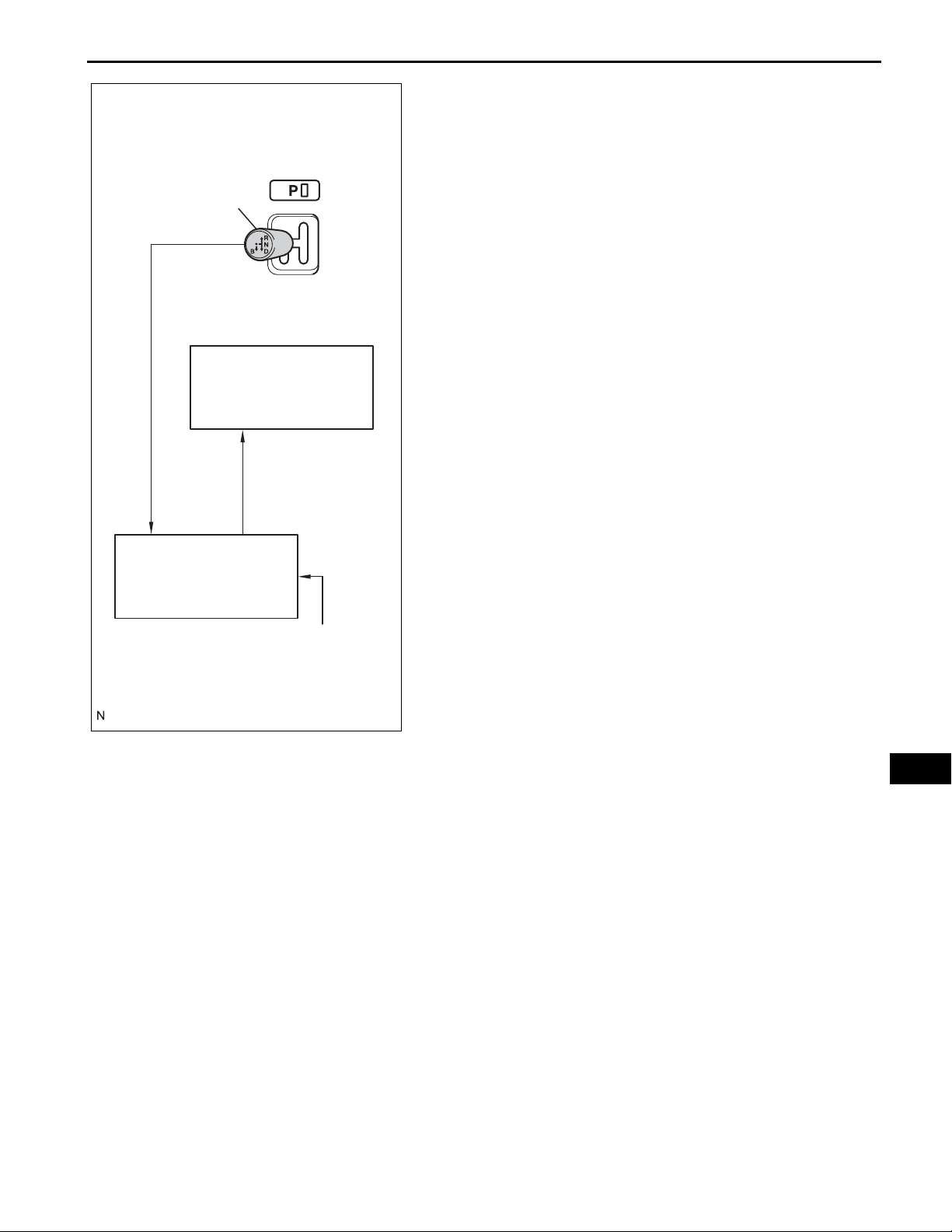

HYBRID TRANSMISSION / TRANSAXLE – ELECTRONIC SHIFT LEVER SYSTEM

Selector Lever

Selector Lever

Operation Signal

HX–11

(b) Operation to switch to a non-P position:

(1) When the hybrid system is started (the vehicle is

ready to be driven) and the selector lever is

moved to the R, N, or the D position with the

brake pedal depressed, a signal is sent to the

hybrid vehicle control ECU.

(2) This signal is then sent from the hybrid vehicle

control ECU to the transmission control ECU as

a "P lock release" operation demand signal.

Transmission

Control ECU

“P Lock Release”

Operation Signal

Hybrid Vehicle

Control ECU

Stop Light

Switch Signal

C126762E01

HX

HX–12

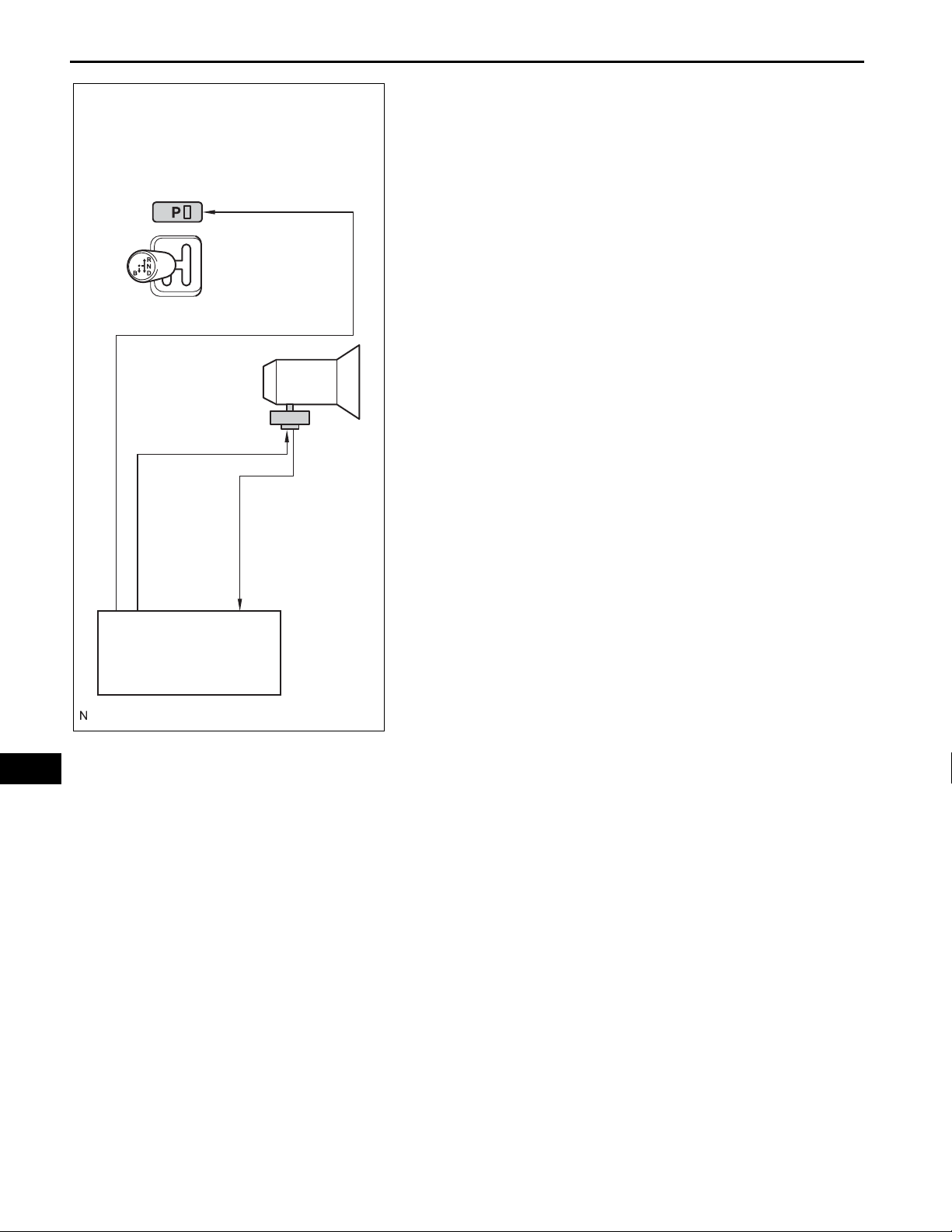

HYBRID TRANSMISSION / TRANSAXLE – ELECTRONIC SHIFT LEVER SYSTEM

(3) After receiving the signal, the transmission

control ECU activates the shift control actuator in

order to unlock the parking lock mechanism, and

P Position Switch

Indicator Light

turns off the P position switch indicator light.

(4) The transmission control ECU controls motor

rotation angle based on signals from the rotation

angle sensor in the shift control actuator.

OFF Demand Signal

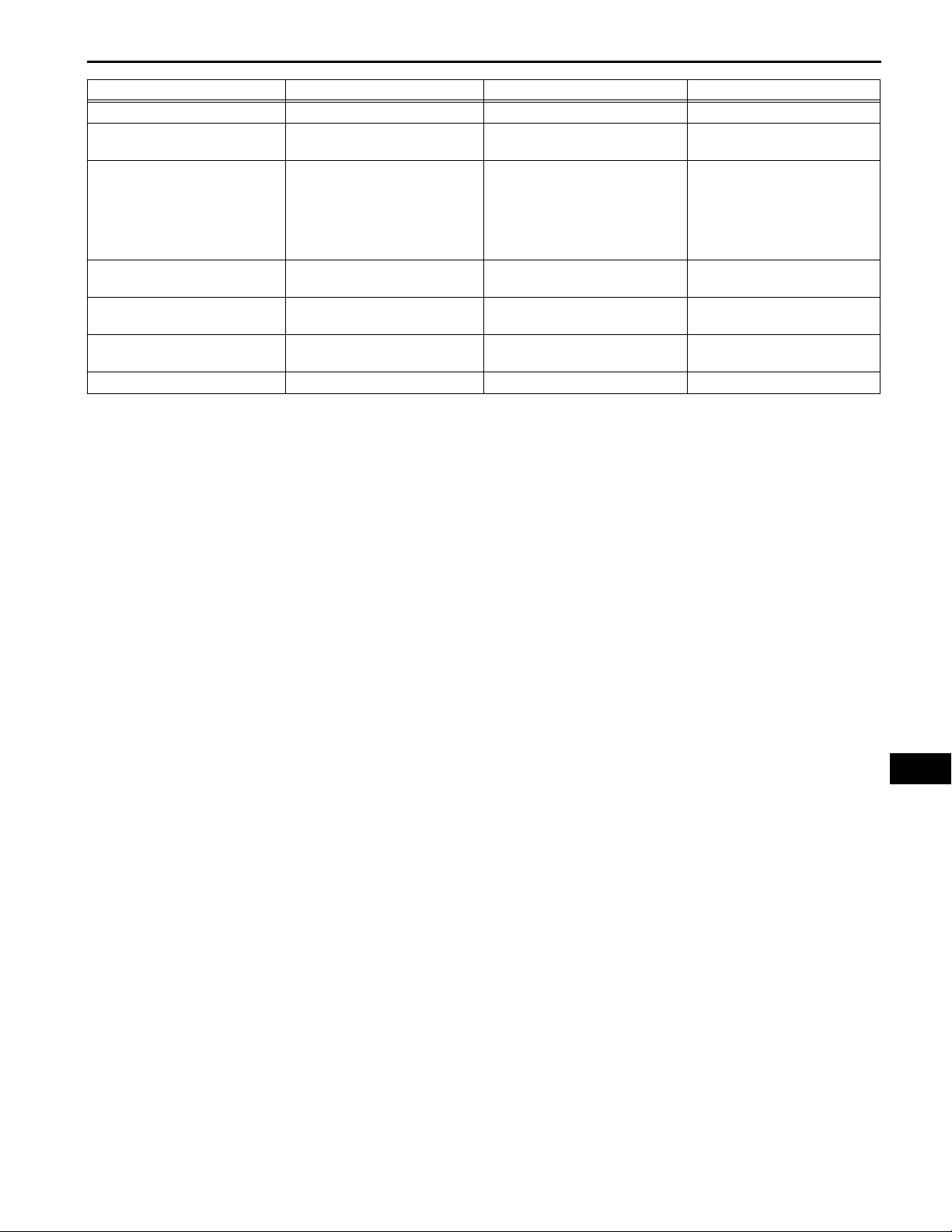

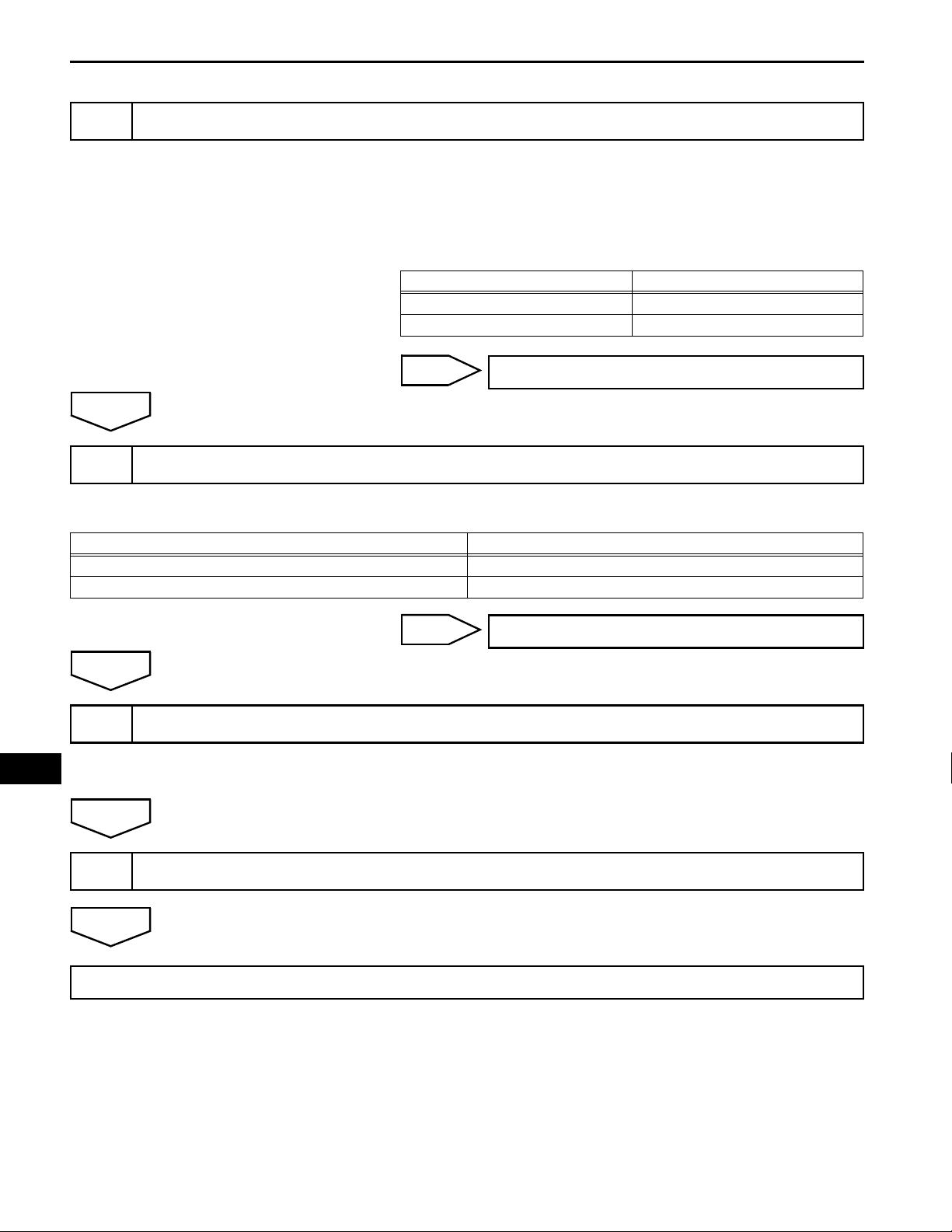

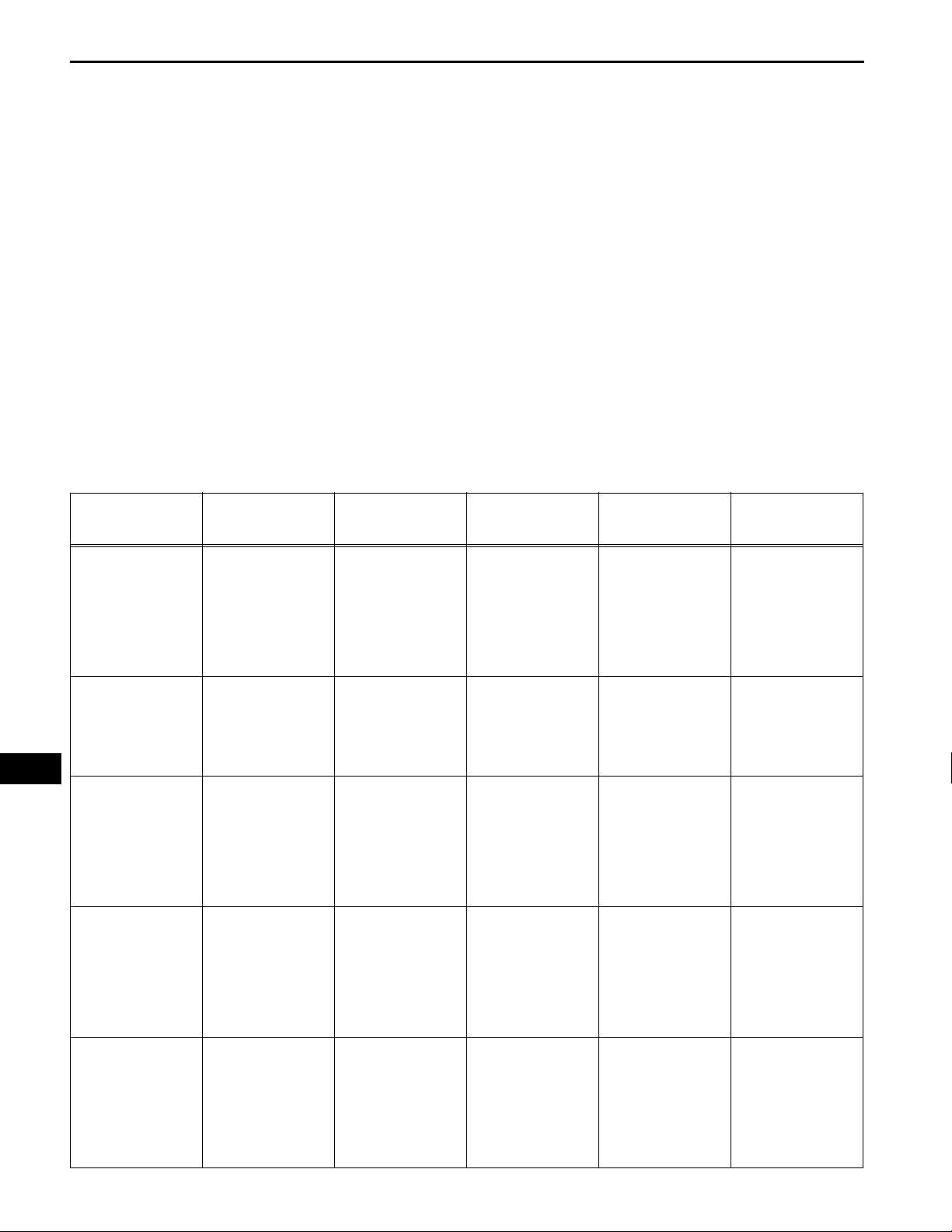

4. SHIFT POSITION CHANGE FUNCTION

(a) The electronic shift lever system comprehensively

determines vehicle conditions and changes the shift

position, as shown in the following chart, by

cooperating with the shift control function of the

hybrid system (except when the reject function,

described later, is in operation).

Shift Control

Actuator

“P Lock

Release”

Switch Control

HX

Rotation Angle

Sensor Signal

Transmission

Control ECU

C126763E01

HYBRID TRANSMISSION / TRANSAXLE – ELECTRONIC SHIFT LEVER SYSTEM

(b) Other than indicated in the following chart, when the

power switch is turned OFF with the vehicle

stopped, the shift position is automatically changed

to the P position.

Power Status Operation

HX–13

ON (ACC)*

(The vehicle cannot be driven.)

ON (IG)*

(The vehicle cannot be driven.)

The hybrid system is started.

(The vehicle can be driven.)

Selector lever operation

P position switch operation

Selector lever operation

P position switch operation

Selector lever operation

P position switch operation

Unable to change the shift position

HX

*: The vehicle cannot be driven because the

hybrid system has not been started.

: Current position

: Positions to which the shift

position can be changed

C126764E01

HX–14

HYBRID TRANSMISSION / TRANSAXLE – ELECTRONIC SHIFT LEVER SYSTEM

5. REJECT FUNCTION

(a) In the electronic shift lever system, there may be a

situation in which a shift change cannot be done for

safety reasons. When attempting to move the

selector lever in such a situation, the system sounds

a reject buzzer inside the meter and changes the

shift position as shown in the following table.

Shift operation which causes reject function to operate Shift position after rejection

Shifting from the P position without depressing the brake pedal Held in the P position

Shifting to the P position while driving Changed to the N position

Shifting between forward and reverse positions while driving Changed to the N position

Shifting to the B position from the position other than D Changed to the N position

HX

1

NEXT

2

HYBRID TRANSMISSION / TRANSAXLE – ELECTRONIC SHIFT LEVER SYSTEM

HOW TO PROCEED WITH TROUBLESHOOTING

HINT:

• Use these procedures to troubleshoot the electronic shift

lever system.

• *: Use the intelligent tester.

VEHICLE BROUGHT TO WORKSHOP

INSPECT BATTERY VOLTAGE

Standard voltage:

11 to 14 V

If the voltage is below 11 V, recharge or replace the battery

before proceeding.

HX–15

NEXT

3

A

4

CHECK COMMUNICATION FUNCTION OF MULTIPLEX COMMUNICATION SYSTEM

(BEAN)*

(a) Use the intelligent tester to check if the Multiplex

Communication System (MPX) is functioning normally.

Result

Result Proceed to

MPX DTC is not output A

MPX DTC is output B

B

CHECK COMMUNICATION FUNCTION OF CAN COMMUNICATION SYSTEM*

(a) Use the intelligent tester to check if the CAN

communication system is functioning normally.

Result

Result Proceed to

CAN DTC is not output A

CAN DTC is output B

Go to MULTIPLEX COMMUNICATION

SYSTEM

HX

B

A

Go to CAN COMMUNICATION SYSTEM

HX–16

5

HYBRID TRANSMISSION / TRANSAXLE – ELECTRONIC SHIFT LEVER SYSTEM

CHECK FOR DTC*

(a) Check for DTCs and note any codes that are output.

(b) Delete the DTC.

(c) Recheck for DTCs. Based on the DTCs output above, try

to force output of the electronic shift lever system DTC

by simulating the operation indicated by the DTC.

Result

Result Proceed to

DTC is not output A

DTC is output B

HX

B

A

PROBLEM SYMPTOMS TABLE

6

Refer to the problem symptoms table (see page HX-15).

Result

Result Proceed to

Fault is not listed in problem symptoms table A

Fault is listed in problem symptoms table B

B

A

OVERALL ANALYSIS AND TROUBLESHOOTING*

7

(a) DATA LIST / ACTIVE TEST (see page HX-19)

(b) Terminals of ECU (see page HX-15)

NEXT

Go to step 8

Go to step 8

8

NEXT

END

REPAIR OR REPLACE

HYBRID TRANSMISSION / TRANSAXLE – ELECTRONIC SHIFT LEVER SYSTEM

Electronic shift lever system

Symptom Suspected area See page

P position switch indicator light does not come on.

P position switch indicator light does not go off.

HX–17

PROBLEM SYMPTOMS TABLE

HINT:

• Use the table below to help determine the cause of the

problem symptom. The potential causes of the symptoms

are listed in order of probability in the "Suspected area"

column of the table. Check each symptom by checking the

suspected areas in the order they are listed. Replace p arts

as necessary.

• Inspect the fuses and relays related to this system before

inspecting the suspected areas below.

1. P position switch indicator light circuit HX-54

2. Transmission control ECU HX-15

1. P position switch indicator light circuit HX-54

2. Transmission control ECU HX-15

HX

HX

HX–18

HYBRID TRANSMISSION / TRANSAXLE – ELECTRONIC SHIFT LEVER SYSTEM

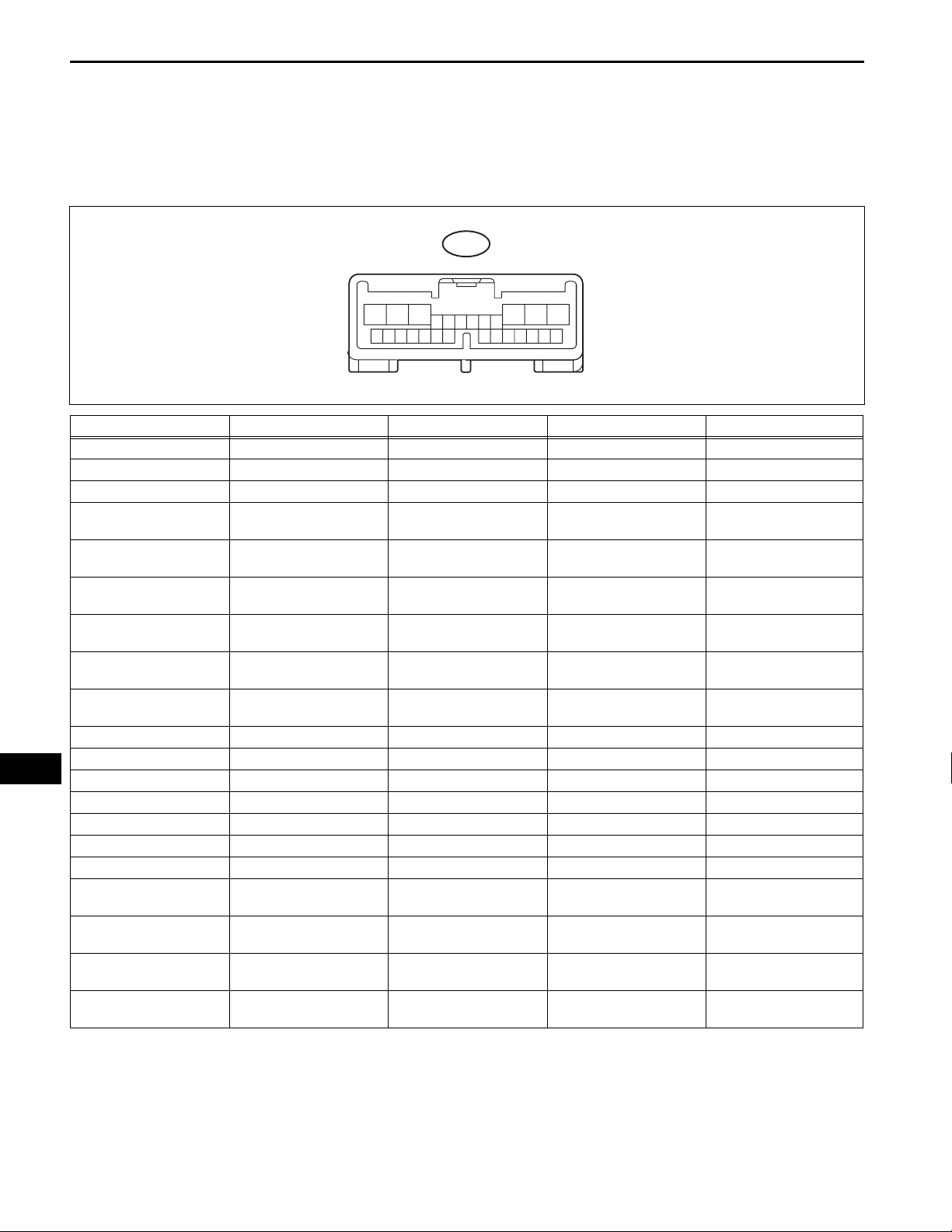

TERMINALS OF ECU

1. CHECK TRANSMISSION CONTROL ECU

HINT:

Inspect the connectors from the back side while the

connector is connected.

T4

1

23101112

456789

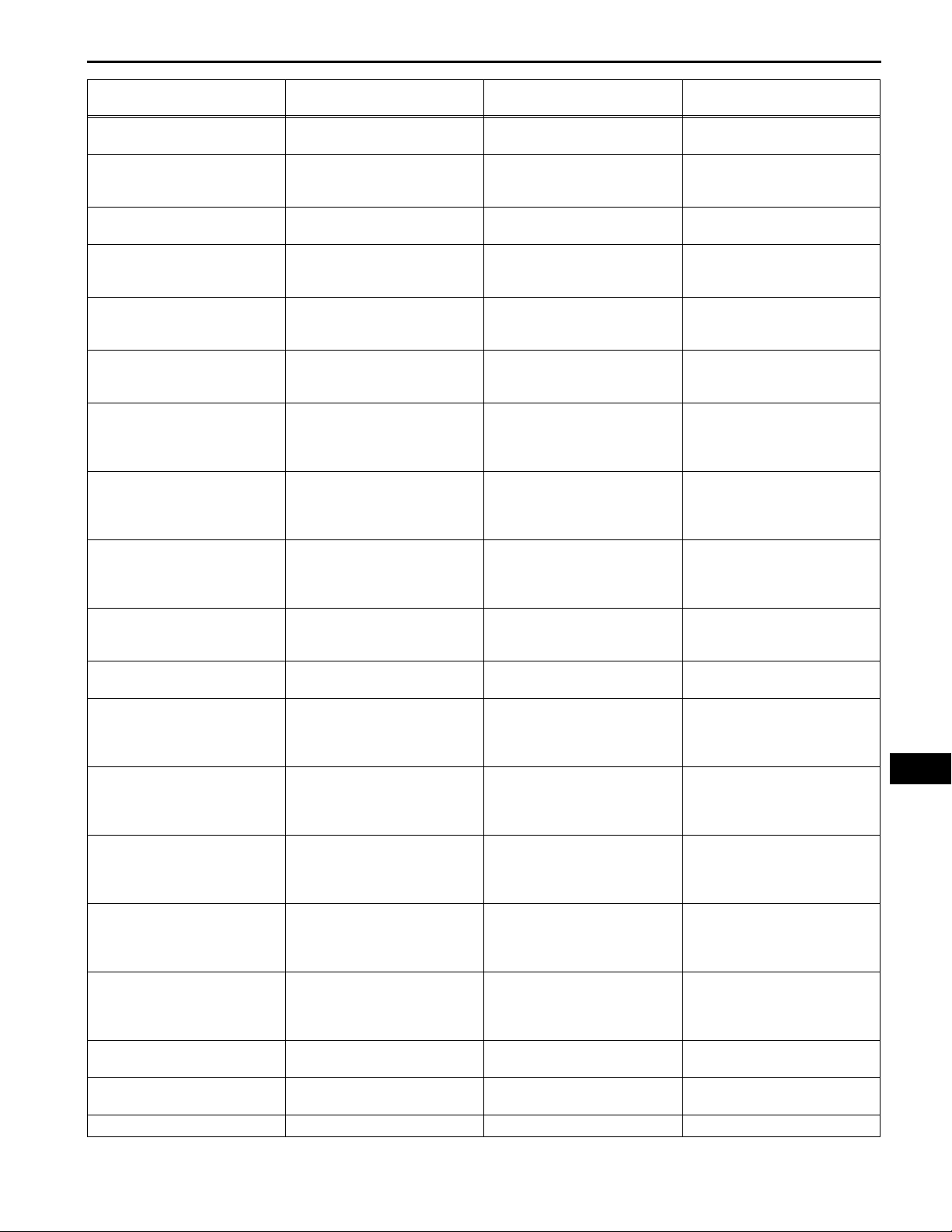

Symbols (Terminal No.) Wiring Color Terminal Description Condition Specified Condition

+B (T4-1) - E1 (T4-15) L - W-B Power source Power switch ON (IG) 9 to 14 V

E02 (T4-2) - Body ground W-B - Body ground Ground Always Below 1 V

E01 (T4-3) - Body ground W-B - Body ground Ground Always Below 1 V

RZ1 (T4-4) - E2 (T4-16) L - P Rotation angle sensor

signal

RB (T4-5) - E2 (T4-16) GR - P Rotation angle sensor

signal

RA (T4-6) - E2 (T4-16) LG - P Rotation angle sensor

signal

PCON (T4-7) - E1 (T4-15) LG - W-B Communication bus Power switch ON (IG) Pulse generation

PPOS (T4-8) - E1 (T4-15) W - W-B Communication bus Power switch ON (IG) Pulse generation

IND (T4-9) - E1 (T4-15) R - W-B P position switch indicator

light

MWA (T4-10) - E1 (T4-15) W - W-B Parking lock motor Power switch ON (IG) 9 to 14 V

MVA (T4-11) - E1 (T 4-15) R - W-B Parking lock motor Power switch ON (IG) 9 to 14 V

MUA (T4-12) - E1 (T4-15) B - W-B Parking lock motor Power switch ON (IG) 9 to 14 V

BATT (T4-13) - E1 (T4-15) L - W-B Power source (RAM) Always 9 to 14 V

BMA (T4-14) - E1 (T4-15) B - W-B P CON relay Power switch ON (IG) 9 to 14 V

E1 (T4-15) - Body ground W-B - Body ground Ground Always Below 1 V

E2 (T4-16) - Body ground P - Body ground Ground Always Below 1 V

VC (T4-17) - E2 (T4-16) O - P Power source (Rotation

MPX2 (T4-18) - E1 (T4-

15)

MPX1 (T4-19) - E1 (T4-

15)

SIL (T4-20) - E1 (T4-15) W - W-B Diagnosis tester

B - W-B Multiplex communication Power switch OFF

GR - W-B Multiplex communication Power switch OFF

angle sensor)

communication

1314151617181920212223242526

Power switch ON (IG) 4 to 5.5 V

Power switch ON (IG) 4 to 5.5 V

Power switch ON (IG) 4 to 5.5 V

(see wave form 1)

(see wave form 2)

P position switch ON Below 1 V

Power switch ON (IG) 4 to 5.5 V

Power switch ON (IG)

Power switch ON (IG)

Power switch ON (IG) 8 V or higher

Below 1 V

Pulse generation

Below 1 V

Pulse generation

B119765E02

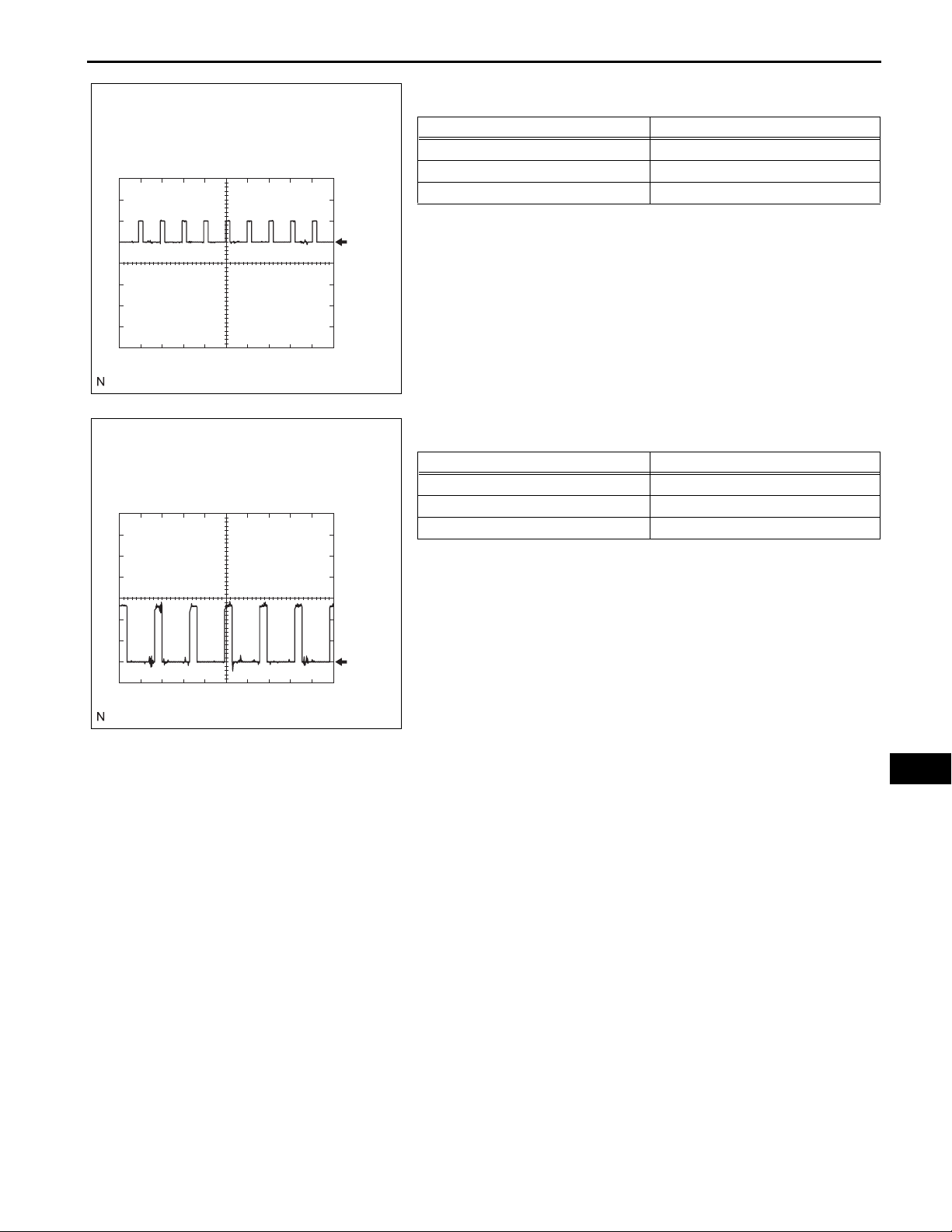

Waveform 1

Waveform 2

HYBRID TRANSMISSION / TRANSAXLE – ELECTRONIC SHIFT LEVER SYSTEM

(a) Using an oscilloscope, check the waveform 1.

Waveform 1 (Reference)

Item Content

Symbols (Terminal No.) P CON (T4-7) - E1 (T4-15)

Tool setting 5 V/DIV., 20 msec./DIV.

Condition Power switch ON (IG)

GND

C126766E01

(b) Using an oscilloscope, check the waveform 2.

Waveform 2 (Reference)

Item Content

Symbols (Terminal No.) PPOS (T4-8) - E1 (T4-15)

Tool setting 5 V/DIV., 20 msec./DIV.

Condition Power switch ON (IG)

HX–19

GND

C126767E01

HX

HX–20

HYBRID TRANSMISSION / TRANSAXLE – ELECTRONIC SHIFT LEVER SYSTEM

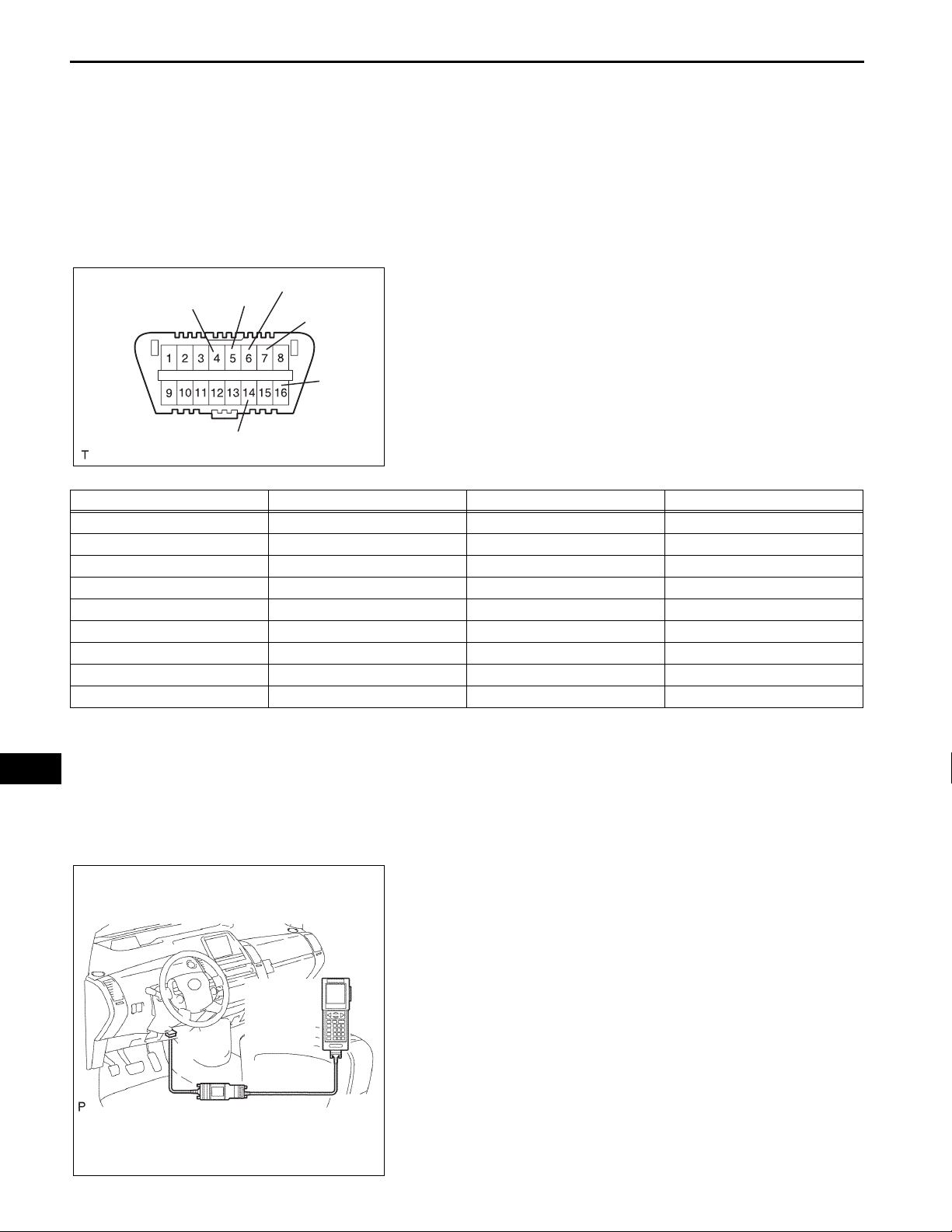

DIAGNOSIS SYSTEM

1. DESCRIPTION

(a) Electronic shift lever system data and the Diagnostic

Trouble Codes (DTCs) can be read in the Dat a Lin k

Connector 3 (DLC3) of the vehicle. When the

system seems to be malfunctioning, use the

intelligent tester to check for malfunctions and

perform repairs.

2. CHECK DLC3

The vehicle uses ISO 15765-4 communication protocol.

The terminal arrangement of the DLC3 complies with

SAE J1962 and matches the ISO 15765-4 format.

CG

SG

CANH

SIL

BAT

HX

CANL

Symbols (Terminal No.) Terminal Description Condition Specified Condition

SIL (7) - SG (5) Bus "+" line During transmission Pulse generation

CG (4) - Body ground Chassis ground Always Below 1 Ω

SG (5) - Body ground Signal ground Always Below 1 Ω

BAT (16) - Body ground Battery positive Always 11 to 14 V

CANH (6) - CANL (14) HIGH-level CAN bus line Power Switch OFF* 54 to 69 Ω

CANH (6) - Battery positive (+) HIGH-level CAN bus line Power Switch OFF* 1 MΩ or higher

CANH (6) - CG (4) HIGH-level CAN bus line Power Switch OFF* 1 kΩ or higher

CANL (14) - Battery positive (+) LOW-level CAN bus line Power Switch OFF* 1 MΩ or higher

CANL (14) - CG (4) LOW-level CAN bus line Power Switch OFF* 1 kΩ or higher

H100769E19

NOTICE:

*: Before measuring the resistance, leave the vehicle

as is for at least 1 minute and do not operate the

power switch, any other switches or the doors.

If the result is not as specified, the DLC3 may have a

malfunction. Repair or replace the harness and

connector.

HINT:

Connect the cable of the intelligent tester (with CAN

VIM) to the DLC3, turn the power switch ON (IG) and

attempt to use the tester. If the displays indicators that a

communication error has occurred, there is a problem

either with the vehicle or with the tester.

Intelligent

Tester

DLC3

• If communication is normal when the tester is

connected to another vehicle, inspect the DLC3 of the

original vehicle.

• If communication is still not possible when the tester

is connected to another vehicle, the problem may be

in the tester itself. Consult the Service Department

CAN VIM

listed in the tester's instruction manual.

A082795E09

HYBRID TRANSMISSION / TRANSAXLE – ELECTRONIC SHIFT LEVER SYSTEM

DTC CHECK / CLEAR

1. CHECK DTC

(a) Connect the intelligent tester to the DLC3.

(b) Turn the power switch ON (IG).

(c) Read the DTC by following the prompts on the

Intelligent

Tester

DLC3

2. CLEAR DTC

CAN VIM

A082795E09

tester screen.

HINT:

Refer to the intelligent tester operator's manual for

further details.

(a) Connect the intelligent tester to the DLC3.

(b) Turn the power switch ON (IG).

(c) Erase the DTC by following the directions on the

tester screen.

HINT:

Refer to the intelligent tester operator's manual for

further details.

HX–21

HX

HX

HX–22

HYBRID TRANSMISSION / TRANSAXLE – ELECTRONIC SHIFT LEVER SYSTEM

FREEZE FRAME DATA

1. CHECK FREEZE FRAME DATA

(a) The vehicle status, stored during system operation

or at the time of an error code detection, can be

displayed by the intelligent tester.

(b) Only one record of freeze frame data is stored and

the freeze frame data generated during system

operation are updated whenever the vehicle status

is changed. After storing the DTC, the freeze frame

data is not updated.

Tester Display Measurement Item Reference Value

SHFT POS P Shift position display (P) ON or OFF

SHFT POS N-P Shift position display (not P) ON or OFF

MAS CAUTION Master caution displa y DISP or NONDISP

PSW INDICATOR PSW indicator mode OFF, ON, FAST, or SLOW

U VOL VAL U phase voltage value min: 0 V, max: 20 V

V VOL VAL V phase voltage value min: 0 V, max: 20 V

W VOL VAL W phase voltage value min: 0 V, max: 20 V

BATT VOL VAL BATT voltage value min: 0 V, max: 20 V

IG (+B) VOL VAL IG (+B) voltage value min: 0 V, max: 20 V

P SPLY OFF SIG Power supply off preparation request signal ON or OFF

LRN LOCK POS Completion of learning lock position OK or NG

LRN UNLOCK POS Completion of learning unlock position OK or NG

TRIP CNTR Number of trip counter after learning min: 0, max: 65535

MTR MAIN RELAY Main relay for motor drive ON or OFF

ELCTRCL KEY SIG Signal of electrical key condition ON or OFF

CURRENT U U phase current-carrying status ON or OFF

CURRENT V V phase current-carrying status ON or OFF

CURRENT W W phase current-carrying status ON or OFF

U VOL U phase voltage status ON or OFF

V VOL V phase voltage status ON or OFF

W VOL W phase voltage status ON or OFF

BATT VOL BATT voltage status ON or OFF

IG VOL IG (+B) phase voltage status ON or OFF

ACC SIG ACC condition signal ON or OFF

INIT CNTRL Initial drive control completed OK or NG

DTCT LOCK POS Completion of detecting lock position OK or NG

DTCT UNLOCK POS Completion of detecting unlock position OK or NG

SHFT RANGE P/Not P movable shift range SET or UNSET

MAIN RELAY Main relay NORMAL or ABNOML

VHCL COND Vehicle condition STOP or MOVE

FAIL RANK Fail rank min: 0, max: 255

ECU TYPE Type of ECU min: 0, max: 65535

DETAIL INFO1 Detailed information 1 Failure information is displayed in

DETAIL INFO2 Detailed information 2 Failure information is displayed in

DETAIL INFO3 Detailed information 3 Failure information is displayed in

hexadecimal

hexadecimal

hexadecimal

HYBRID TRANSMISSION / TRANSAXLE – ELECTRONIC SHIFT LEVER SYSTEM

FAIL-SAFE CHART

If the transmission control ECU detects a malfunction, the failsafe functions shown in the table below are activated.

DTC No. Fail-safe Function Problem Symptoms

C2300

C2301

C2303 - The battery is dead.

C2304

C2305

C2306

C2307 The transaxle parking lock control relay is

C2311 - The parking lock mechanism cannot be

C2312 - The hybrid system does not start up.

C2318 - The parking lock mechanism cannot be

Only the P position release operation is

possible and the shift control actuator is

activated.

The transaxle parking lock control relay is

turned off.

turned off.

• The shift position is not indicated on the

meter.

• Although the shift position is indicated on

the meter, the vehicle cannot be driven.

The parking lock mechanism cannot be

switched.

• The shift position is not indicated on the

meter.

• Although the shift position is indicated on

the meter, the vehicle cannot be driven.

switched.

switched on a hill.

HX–23

HX

HX

HX–24

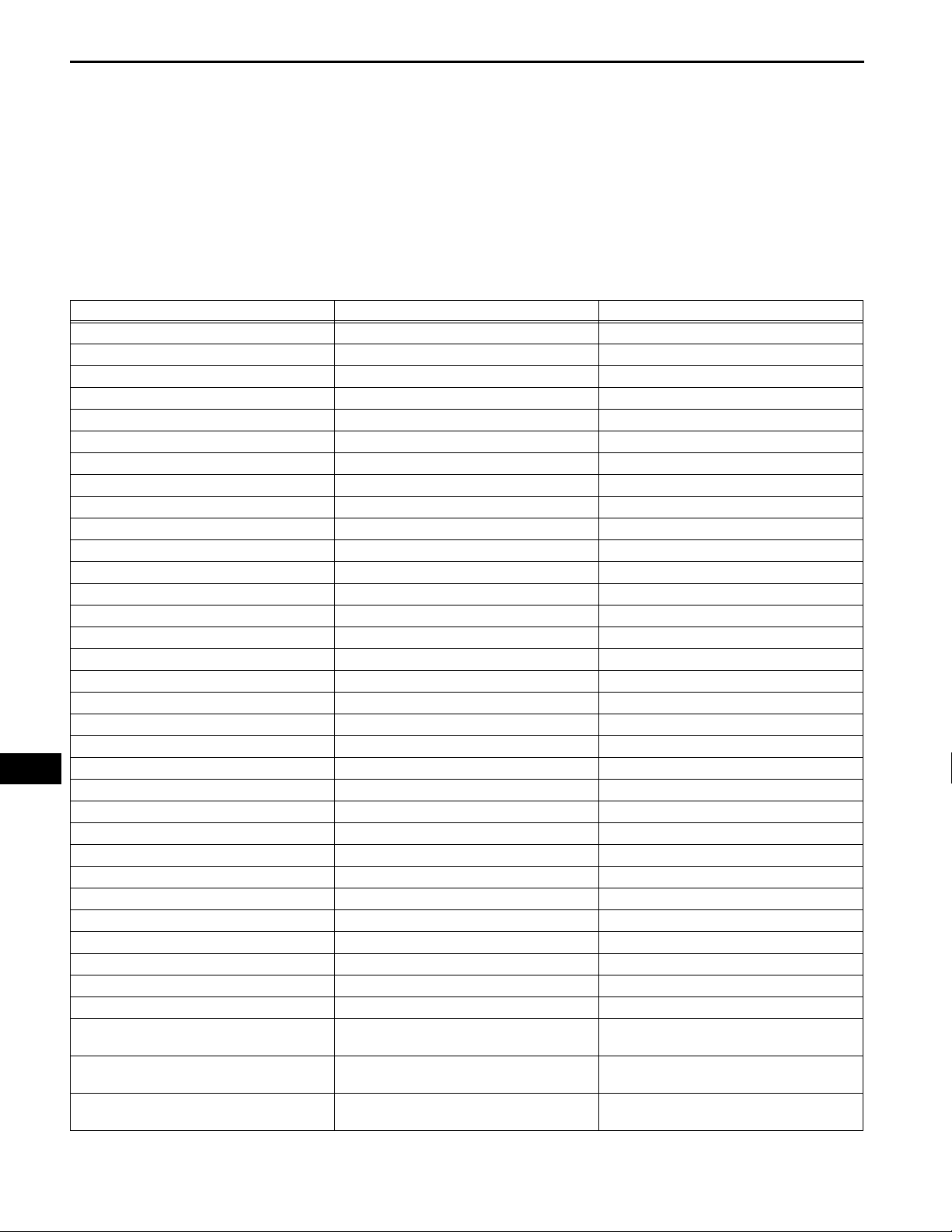

HYBRID TRANSMISSION / TRANSAXLE – ELECTRONIC SHIFT LEVER SYSTEM

DATA LIST / ACTIVE TEST

1. READ DATA LIST

Transmission control ECU

Item Measurement Item / Range

SHFT POS P Shift position display (P) / ON or

SHFT POS N-P Shift position display (not P) / ON

MAS CAUTION Master caution display / DISP or

PSW INDICATOR PSW indicator mode / OFF, ON,

U VOL VAL U phase voltage value / min: 0 V,

V VOL VAL V phase voltage value / min: 0 V,

W VOL VAL W phase voltage value / min: 0 V,

BATT VOL VAL BATT voltage value / min: 0 V,

IG (+B) VOL VAL IG (+B) voltage value / min: 0 V,

P SPLY OFF SIG Power supply off preparation

LRN LOCK POS Completion of learning lock

LRN UNLOCK POS Completion of learning unlock

TRIP CNTR Number of trip counter after

(Display)

OFF

or OFF

NONDISP

FAST, or SLOW

max: 20 V

max: 20 V

max: 20 V

max: 20 V

max: 20 V

request signal / ON or OFF

position / OK or NG

position / OK or NG

learning / min: 0, max: 65535

HINT:

Using the intelligent tester's DATA LIST allows switch,

sensor , actuator and other item values to be read without

removing any parts. Reading the DATA LIST early in

troubleshooting is one way to save time.

(a) Connect the intelligent tester (with CAN VIM) to the

DLC3.

(b) Turn the power switch ON (IG) and press the

intelligent tester main switch on.

(c) Read the DATA LIST by following the directions on

the tester screen.

Normal Condition Diagnostic Note

ON: Parking lock is in P position

OFF: Parking lock is in non-P

position

ON: Parking lock is in non-P

position

OFF: Parking lock is in P position

DISP: Malfunction occurs in this

system

NONDISP: Malfunction does not

occur in this system

OFF: Parking lock is in non-P

position

ON: Parking lock is in P position

FAST: Actuator takes long time to

switch between the P position and

non-P position

SLOW: Malfunction occurs in this

system

Actual U phase voltage 9 to 14 V -

Actual V phase voltage 9 to 14 V -

Actual W phase voltage 9 to 14 V -

Actual power supply voltage 9 to

14 V

Actual power supply voltage 9 to

14 V

ON: Power is turned off by power

source control ECU after

receiving power switch OFF

signal

OFF: Any other condition

OK: Lock position learning is

complete

NG: Lock position learning is not

complete

OK: Unlock position learning is

complete

NG: Unlock position learning is

not complete

Actual number of trip counter Reset the trip counter after 1,000

-

-

-

-

-

-

-

-

-

times

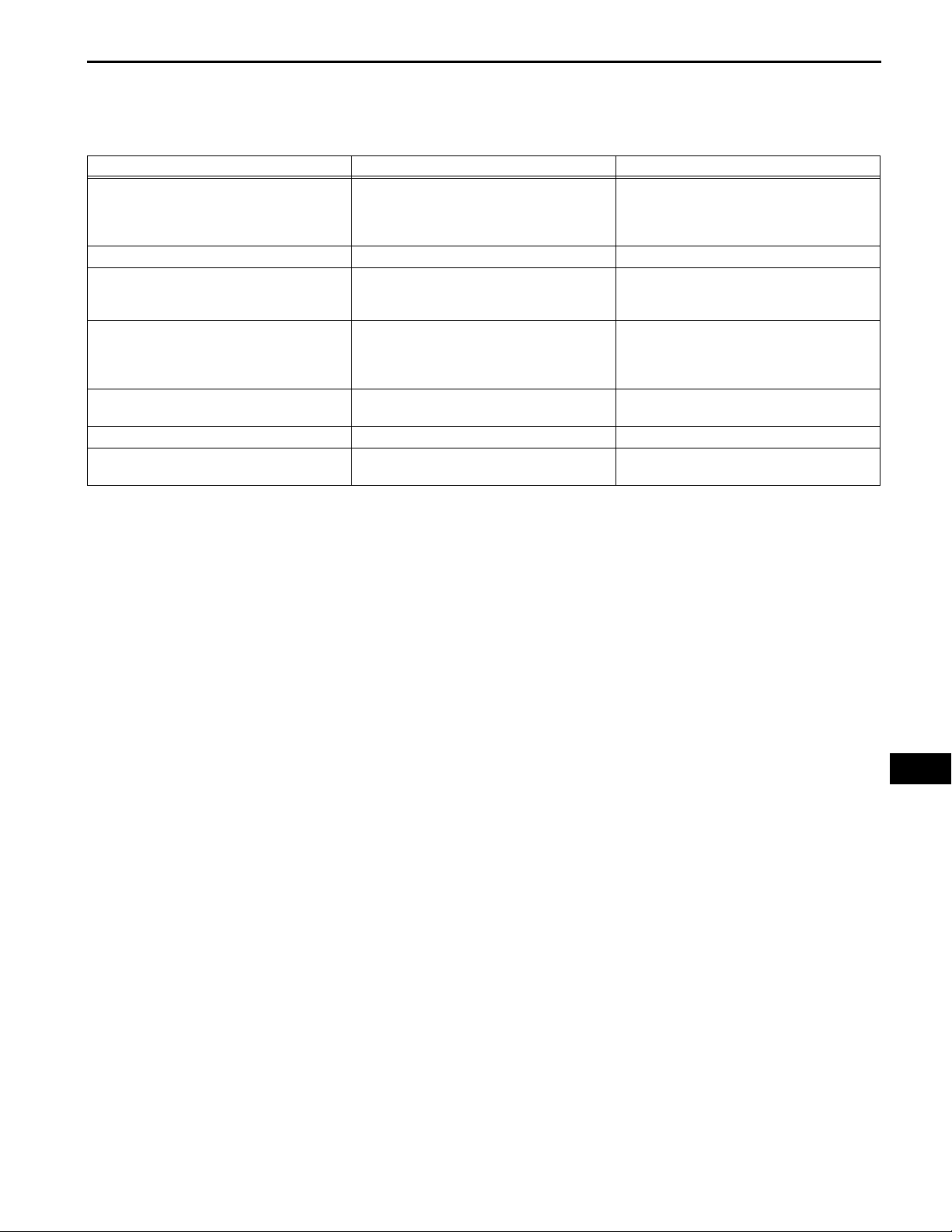

HYBRID TRANSMISSION / TRANSAXLE – ELECTRONIC SHIFT LEVER SYSTEM

HX–25

Item Measurement Item / Range

(Display)

MTR MAIN RELAY Main relay for motor drive / ON or

OFF

ELCTRCL KEY SIG Signal of electrical key condition /

ON or OFF

#CODE Number of diagnosis code / min:

0, max: 255

CURRENT U U phase current-carrying status /

ON or OFF

CURRENT V V phase current-carrying status /

ON or OFF

CURRENT W W phase current-carrying status /

ON or OFF

U VOL U phase voltage status / ON or

OFF

V VOL V phase voltage status / ON or

OFF

W VOL W phase voltage status / ON or

OFF

BATT VOL BATT voltage status / ON or OFF ON: BATT voltage is more than

IG VOL IG (+B) phase voltage status / ON

or OFF

ACC SIG ACC condition signal / ON or OFF ON: ACC condition signal is

INIT CNTRL Initial drive control completed /

OK or NG

DTCT LOCK POS Completion of detecting lock

position / OK or NG

DTCT UNLOCK POS Completion of detecting unlock

position / OK or NG

SHFT RANGE P/Not P movable shift range /

SET or UNSET

MAIN RELAY Main relay / NORMAL or

ABNOML

VHCL COND Vehicle condition / STOP or

MOVE

ECU TYPE Type of ECU / min: 0, max: 65535 Actual type of ECU -

Normal Condition Diagnostic Note

ON: Motor drive main relay on

OFF: Motor drive main relay off

ON: Electrical key is recognized

OFF: Electrical key is not

recognized

Actual number of diagnosis code -

ON: U phase current flows

OFF: U phase current does not

flow

ON: V phase current flows

OFF: V phase current does not

flow

ON: W phase current flows

OFF: W phase current does not

flow

ON: U phase voltage is 6 V or

more

OFF: U phase voltage is less than

6 V

ON: V phase voltage is 6 V or

more

OFF: V phase voltage is less than

6 V

ON: W phase voltage is 6 V or

more

OFF: W phase voltage is less

than 6 V

10 V

OFF: BATT voltage is 10 V or less

ON: +B voltage is more than 10 V

OFF: +B voltage is 10 V or less

normal

OFF: ACC condition signal is

interrupted

OK: Initial drive control is

complete

NG: Initial drive control is not

complete

OK: Detection of lock position is

complete

NG: Detection of lock position is

not complete

OK: Detection of unlock position

is complete

NG: Detection of unlock position

is not complete

SET: P/Not P movable shift range

is set

UNSET: P/Not P movable shift

range is unset

NORMAL: Main relay is normal

ABNOML: Main relay is fault

STOP: Vehicle is stopped

MOVE: Vehicle is running

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

HX

HX–26

HYBRID TRANSMISSION / TRANSAXLE – ELECTRONIC SHIFT LEVER SYSTEM

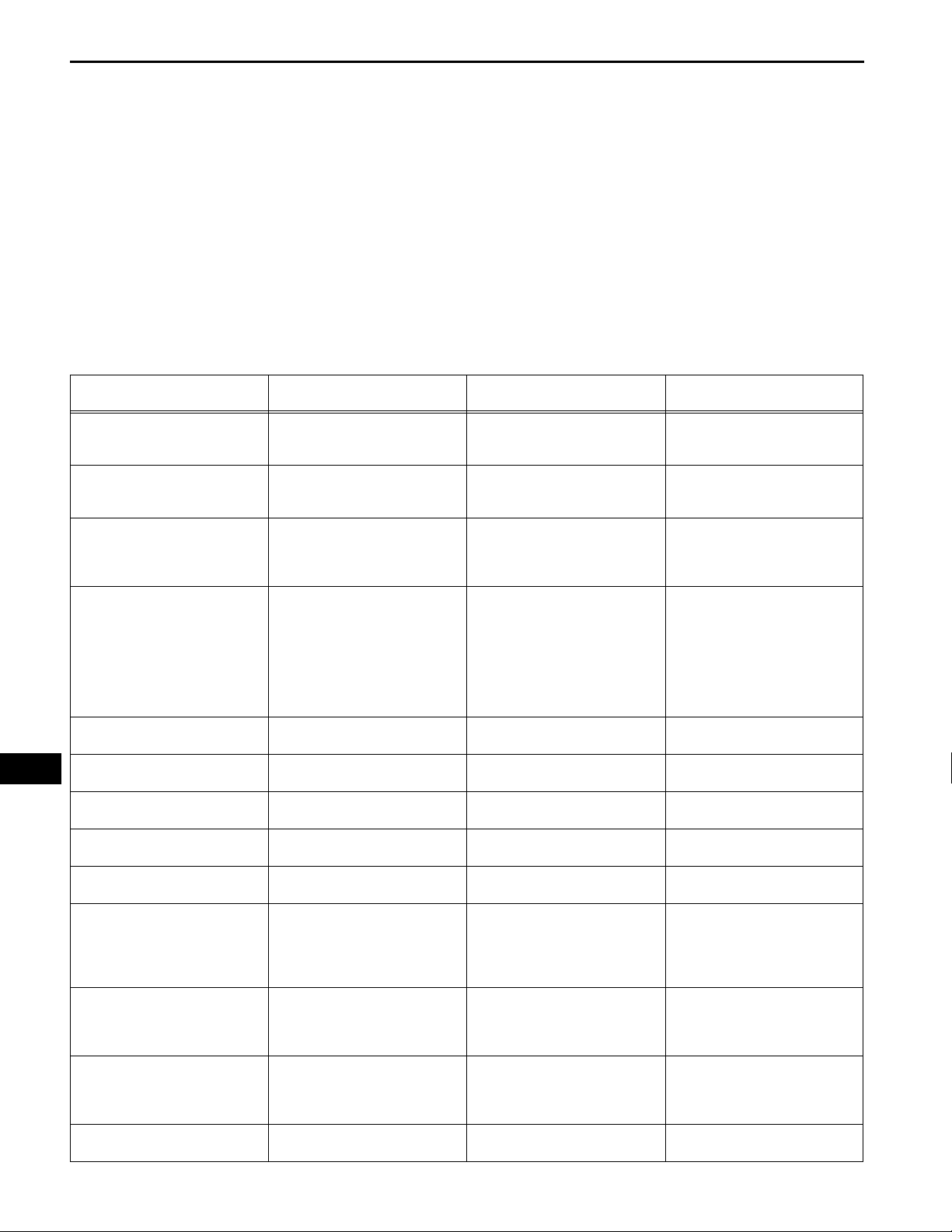

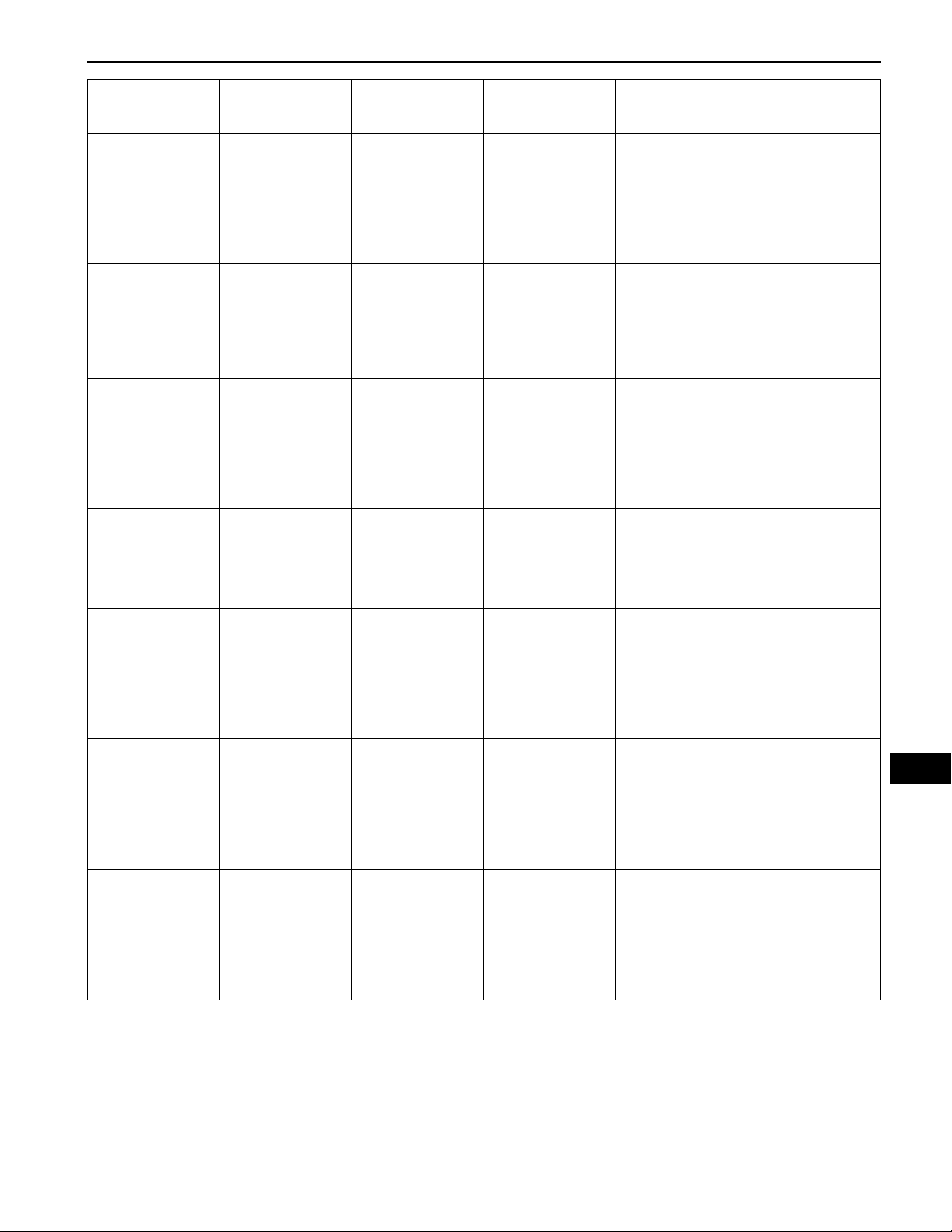

DIAGNOSTIC TROUBLE CODE CHART

If a trouble code is displayed during the DTC check, check

the circuit listed for that code in the table below and proceed

to the appropriate page.

HINT:

• When the DTC C2300, C2301, C2304, C2305, C2306,

C2307, C2311 and C2312 are detected, DTC P3102

indicating the electronic shift lever system malfunctions

are detected for the hybrid system as well. Because of

this, the hybrid system DTCs must be cleared after

clearing the electronic shift lever system DTCs.

• Remove the P CON MAIN fuse to erase DTCs C2300,

C2301, C2303, C2304, C2305, C2306 and C2307

because they cannot be erased with the intelligent tester.

• When a DTC is detected, the master warning light comes

on and an error message is indicated on the multi-display.

• The indicator blinks quickly when it takes a long time to

switch between the P position status and the P position

release status.

HX

DTC No. Detection Item Trouble Area P Position Switch

Indicator Light

Condition

C2300 ACT System

Malfunction

C2301 Shift Changing Time

Malfunction

C2303 Relay Malfunction

(+B Short)

C2304 Open or Short Circuit

in "U" Phase

C2305 Open or Short Circuit

in "V" Phase

- Shift control

actuator

- Transaxle parking

lock control relay

- Transmission

control ECU

- Wire harness or

connector

- Shift control

actuator

- Transmission

control ECU

- Transaxle parking

lock control relay

- Transmission

control ECU

- Wire harness or

connector

- Shift control

actuator

- Transmission

control ECU

- Transaxle parking

lock control relay

- Wire harness or

connector

- Shift control

actuator

- Transmission

control ECU

- Transaxle parking

lock control relay

- Wire harness or

connector

Blinks slowly If DTC C2318 is

Blinks slowly If DTC C2318 is

Normal

- P position status:

the P position switch

indicator light is on.

- P position release

status: the P position

switch indicator light

is off.

Blinks slowly If DTC C2318 is

Blinks slowly If DTC C2318 is

HINT See page

output

simultaneously,

perform

troubleshooting for

DTC C2318 first.

output

simultaneously,

perform

troubleshooting for

DTC C2318 first.

If DTC C2318 is

output

simultaneously,

perform

troubleshooting for

DTC C2318 first.

output

simultaneously,

perform

troubleshooting for

DTC C2318 first.

output

simultaneously,

perform

troubleshooting for

DTC C2318 first.

HX-24

HX-31

HX-32

HX-35

HX-35

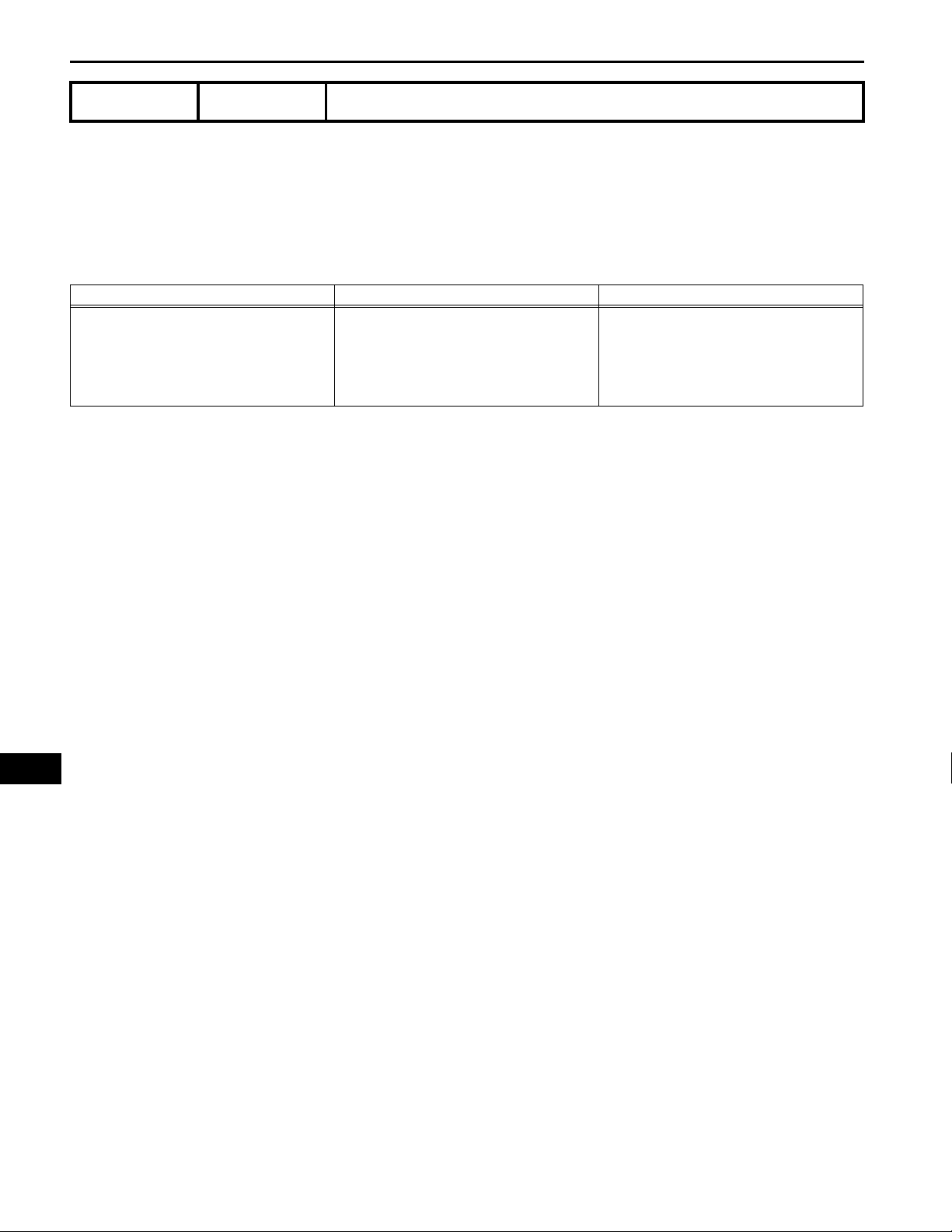

HYBRID TRANSMISSION / TRANSAXLE – ELECTRONIC SHIFT LEVER SYSTEM

HX–27

DTC No. Detection Item Trouble Area P Position Switch

C2306 Open or Short Circuit

in "W" Phase

C2307 Power Source

Malfunction

C2310 Open or Short Circuit

in BATT

C2311 HV Communication

Line Malfunction

C2312 Power Source

Control ECU

Communication Line

Malfunction

C2315 HV System

Malfunction

C2318 Low Voltage Error

(Power Supply

Malfunction)

- Shift control

actuator

- Transmission

control ECU

- Transaxle parking

lock control relay

- Wire harness or

connector

- Transmission

control ECU

- Wire harness or

connector

- Parking lock motor

(Shift control

actuator)

- P CON MAIN fuse

- Transmission

control ECU

- Wire harness or

connector

- Transmission

control ECU

- Hybrid vehicle

control ECU

- Wire harness or

connector

- Transmission

control ECU

- Power source

control ECU

- Hybrid vehicle

control ECU

- P position switch

- Transmission

control ECU

- Wire harness or

connector

- HEV fuse

- IGCT relay

- Wire harness or

connector

- Auxiliary battery

Indicator Light

Condition

Blinks slowly If DTC C2318 is

Blinks slowly If DTC C2318 is

Normal

- P position status:

the P position switch

indicator light is on.

- P position release

status: the P position

switch indicator light

is off.

Blinks slowly - HX-44

Normal

- P position status:

the P position switch

indicator light is on.

- P position release

status: the P position

switch indicator light

is off.

Normal

- P position status:

the P position switch

indicator light is on.

- P position release

status: the P position

switch indicator light

is off.

Normal

- P position status:

the P position switch

indicator light is on.

- P position release

status: the P position

switch indicator light

is off.

HINT See page

HX-35

output

simultaneously,

perform

troubleshooting for

DTC C2318 first.

HX-40

output

simultaneously,

perform

troubleshooting for

DTC C2318 first.

- HX-42

- HX-47

- HX-50

HX

- HX-52

HX–28

HYBRID TRANSMISSION / TRANSAXLE – ELECTRONIC SHIFT LEVER SYSTEM

DTC C2300 ACT System Malfunction

DESCRIPTION

The shift control actuator consists of the parking lock motor and the rotation angle sensor. The

transmission control ECU receives a P position switch signal from the hybrid vehicle control ECU and

activates the parking lock motor by controlling current, causing the p arking lock mechanism to switch. The

transmission control ECU also detects the rotor ro tation angle through the rot ation angle sensor to control

timing of current application to the coils. The transmission control ECU output s this DTC when it detects a

malfunction in the shift control actuator system.

DTC No. DTC Detection Condition Trouble Area

C2300 When both conditions below are met:

• Power switch ON (IG).

• There is an open or short circuit in the

transaxle parking lock control relay and/or

shift control actuator, or an internal

abnormality in the shift control actuator.

• Shift control actuator

• Transaxle parking lock control relay (P

CON Relay)

• Transmission control ECU

• Wire harness or connector

HX

HYBRID TRANSMISSION / TRANSAXLE – ELECTRONIC SHIFT LEVER SYSTEM

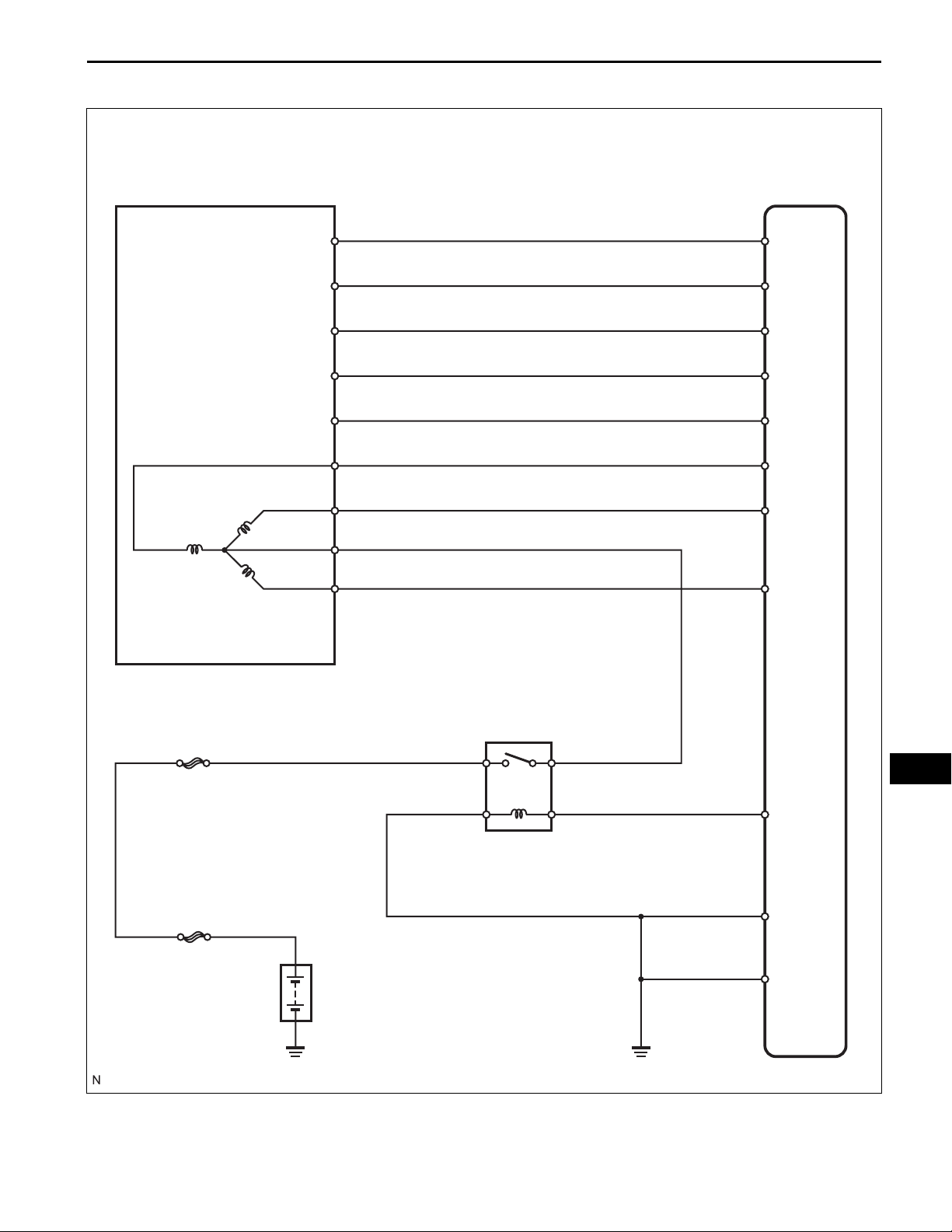

WIRING DIAGRAM

Shift Control Actuator Assembly Transmission Control ECU

HX–29

V Phase

W Phase

U Phase

RE2

RZ1

RB

RA

RVC

MWA

MVA

MGNA

MUA

E2

RZ1

RB

RA

VC

MWA

MVA

MUA

P CON MTR

MAIN

Auxiliary Battery

P CON

HX

BMA

E02

E01

C126768E01

HX–30

HYBRID TRANSMISSION / TRANSAXLE – ELECTRONIC SHIFT LEVER SYSTEM

INSPECTION PROCEDURE

CHECK OTHER DTC OUTPUT (BESIDES DTC C2300)

1

(a) Connect the intelligent tester (with CAN VIM) to the

DLC3.

(b) Turn the power switch ON (IG).

(c) Turn the intelligent tester on.

(d) Read the DTCs.

Result

Display (DTC output) Proceed to

No output A

C2304, C2305, C2306 and C2318 B

HINT:

If any other codes besides C2300 are output, perform

the troubleshooting for those DTCs first.

HX

B

REPAIR CIRCUIT INDICATED BY OUTPUT

CODE

A

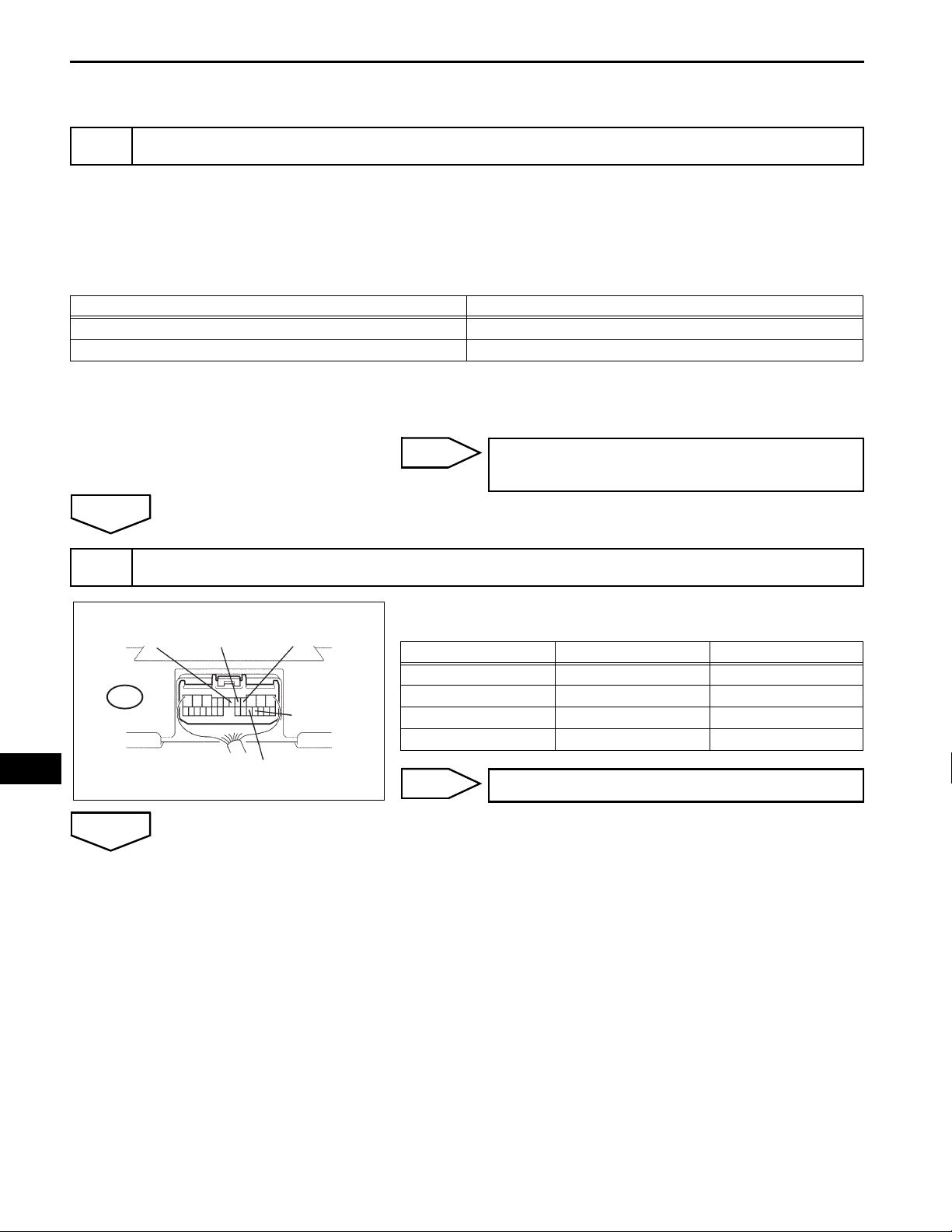

CHECK TRANSMISSION CONTROL ECU (VC, RA, RB, RZ1 VOLTAGE)

2

(a) Measure the voltage of the ECU connector.

Standard voltage

Tester Connection Condition Specified Condition

T4-4 (RZ1) - T4-16 (E2) Power switch ON (IG) 4 to 5.5 V

T4-5 (RB) - T4-16 (E2) Power switch ON (IG) 4 to 5.5 V

T4-6 (RA) - T4-16 (E2) Power switch ON (IG) 4 to 5.5 V

T4-17 (VC) - T4-16 (E2) Power switch ON (IG) 4 to 5.5 V

OK

Go to step 5

T4

RA

RB

RZ1

E2

VC

F044944E02

NG