INSTRUCTION

BOOK

EC-1

SERIES

EC-1B

SERIES

LU

A

STITCH

AHEAD

OF

THE

TIMES

T

OMO

TA

sewing

machines

IMPORTANT

PLEASE

READ

CAREFULLY

The

wires

in

this

mains

lead

are

coloured

in

accordance

with

the

following

code:

BLUE-NEUTRAL

BROWN-LIVE

(OR

ACTIVE)

As

the

colours

of

the

mains

lead

of

this

appliance

may

not

correspond

with

the

coloured

markings

identifying

the

terminals

in

your

plug

-

PROCEED

AS

FOLLOWS:

The

earth

plug

pin

is

unnesessary.

As

the

Machine

is

designed

under

double

insulation

structure,

the

earth

wire

is

removed

from

the

machine.

The

wire

coloured

BROWN

must

be

connected

to

the

terminal

marked

L

or

A

or

coloured

RED.

The

wire

coloured

BLUE

must

be

connected

to the

terminal

marked

N

or

coloured

BLACK.

Neither

core

is

to

be

connected

to

the

earth

terminal

of

a

three-pin

plug.

When

leaving

the

machine

or

when

servicing

or changing

mechanical

parts

or

accesso-

ries,

the

machine

must

be

disconnected

from

the

supply

by

removing

the

plug

from

the

socket

outlet.

MAXIMUM

INPUT

OF

LAMP:

15

WATTS

Please

retain

the

packagings

not to

damage

your

machine

in

transit

for

the possible

return

of

repairs

in

the

future.

N.B

(1) If

you

have

purchased

EC-1B,

your

machine

has

the

following

additional

features

in

comparision

with

the

specifications

mentioned

in

this

instruction

book.

1.

Clip

on

Feet

*

2.

Thread

Cutter

3.

Carry

Handle

*

4.

Saftey

Clutch

•

For

some

models,

these

specifications

are

already

mentioned

in

the

book.

(2)

Accessories

shown

in

this

book

in

some

cases

are

optional.

CONTENTS

1 .

N

A M E

S O F

P A R

T S ..

.

-..

..

.

.....

.. .........

2

2.. A C C

ES

SO

R

IES

............

.........

3....

...........

............

...

3

3.

BEFO

RE

SEW

IN

G

......

4...

.......

......

...........

.........

.....

.... 4

Detachable

Extension

Table

.........................

4

Connecting

Foot

Controller

and

Power

Cord

.....

C

hanging

Foot

6..................

........

.

C

hanging

N

eedle

......................................

.................

7

Bobbin

Winding

-------.

....

a

Inserting

Bobbin

.........

...

.......

....

11

Adjusting

Low

er

Thread

....

.......

........

.......

.........

12

D

rop

Feed

Lever

.................................

.................

12

Threading

Upper

Thread

---- 13

Draw

ing

Up

Low

er

Thread

.........................................

14

Foo

t P ressure

........................

...

..........

.........

...........

14

Fabric.

Thread

and

Needle

Table

.15

4.

STRA

IGHT

SEW

ING

....................

1....6....

.......

......

....

i6

Pattern

Selection

Dial

.............

..........

-16

Stitch

Length

D

ial

..........................................

. ..

16

Starting

to

Sew

..........

............

1.........

....

.......

......

17

Double

Presser

Foot

Lifter

-..................

.........

17

Reverse

S

ew

ing

...........

.........

-. .

...........-

.....

.

.....

17

Adjusting

Thread

Tension

.......................

1........

.......

18

S.

ZIG

ZA

G

SEW

IN

G

......

........-............................................

18

Zigzag

Width

Control

..............

....................

19

Thread

Tension

for

Zigzag

Stitch

-............

19

6.

OVERCASTING

.........................................

...................

20

7.

MAKING

BUTTONHOLES

.............................

........

21

D

eterm

ing

Length

.......................................................

2 1

Determ

ine

W

idth

.....................................

............

2 1

Left

and

Right

Side Balance

of Buttonhole

................

23

Cutting

Buttonholes

....................................--....

24

Corded

Buttonholes

..................................................

2 4

8.

BLIND

HEM

STITCH

.......................................

26

Elastic

Blind

Hem

Stitch

...........................................

26

9.

SHELL

STITC

H

ING

..............-..

...................

........

.... ... 27

10.

ZIPPER

STITC

H

IN

G

..

.....................................................

28

1 1 .

M E N D IN G .......................

.....................................

.

.......

- 2

9

P a tc

h

in

g

2 9......................................

.........................

. 2 9

M

ending

a R ip

..........

........

.

.................

...... ......

2

9

12.

A

PPLIQ

U

E W O

RK

...................

...........

........

.....

...

.......

.

30

13.

EM

B

R

O ID

ER Y .......

............................................

3 1

14

.

M A IN T EN

A

N C E

...............................................................

32

C

leaning

..........

.....................

. 3 2

O

ilin g .............................................

...........

..........

.... 3 3

16

.

T

RO U B

LE

C

H A RT

.............................................................

34

C

hanging

Light

Bulb

................

..............

................

35

12

174

25

19

22*

20-2

*22-2

23-'-1-

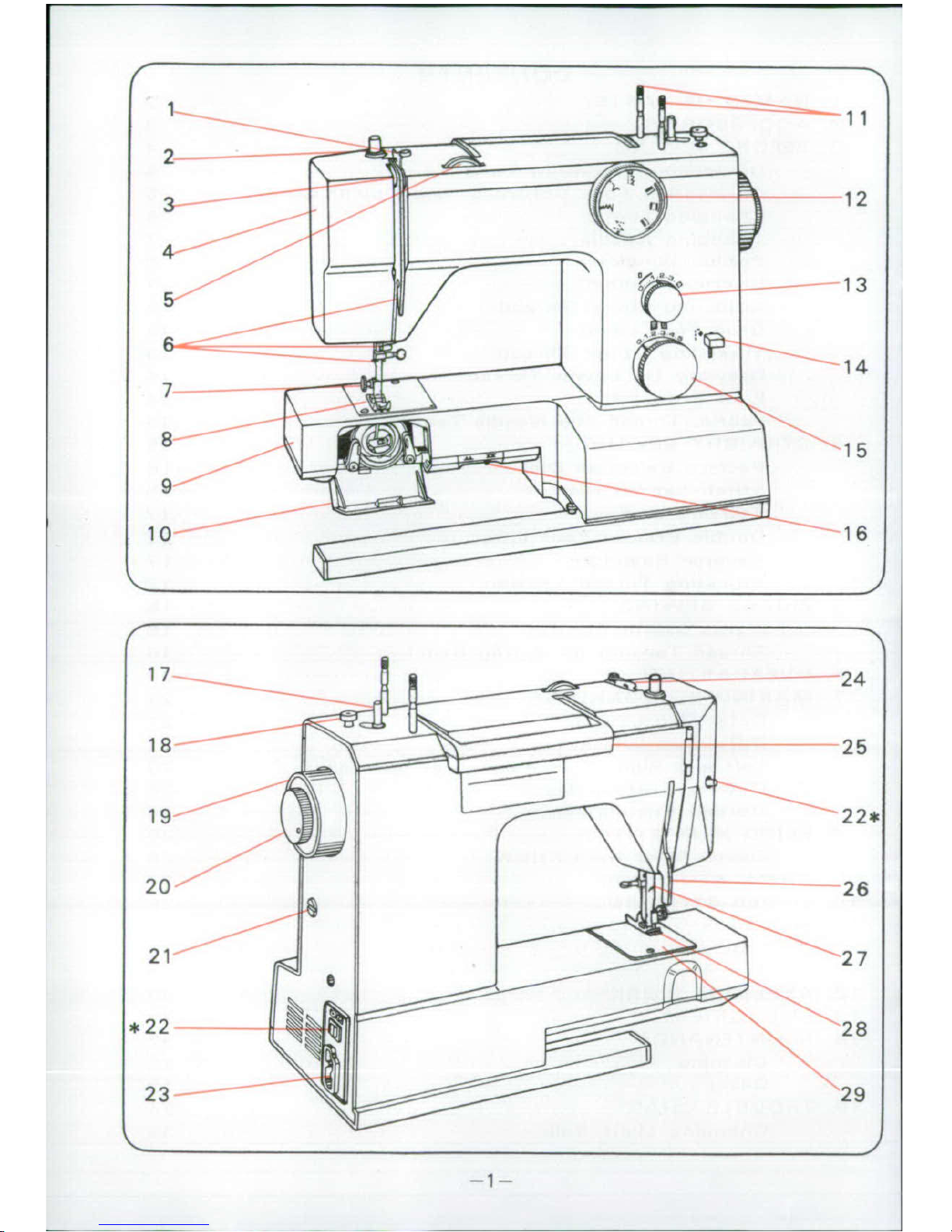

1. NAMES

OF

PARTS

1.

Thread

guide

for

bobbin

winding

2.

Pressure

regulator

3.

Take-up

lever

4.

Face

cover

5.

Upper

thread tension

dial

6.

Thread

guide

for

upper

threading

7.

Presser

foot

thumb

screw

8.

Presser

foot

9.

Free arm

10,

Shuttle cover

11

Spool

pins

12.

Pattern

selection

dial

13.

Stitch

length

dial

14.

Reverse

sewing

lever

15.

Zigzag

width

control

16.

Drop

feed

lever

17.

Bobbin

winding

spindle

18.

Bobbin

winding

stopper

19.

Handwheel

20.

Stop

motion

knob

21.

Special

buttonhole

adjustment

22.

switch,

23.

Socket

24.

Thread guide

for

upper

threading

25.

Handle

26

Presser

foot

lifter

27

Thread

cutter

28

Feed

dog

29

Needle

plate

*Specifications

vary

from

country

to

country.

-2--

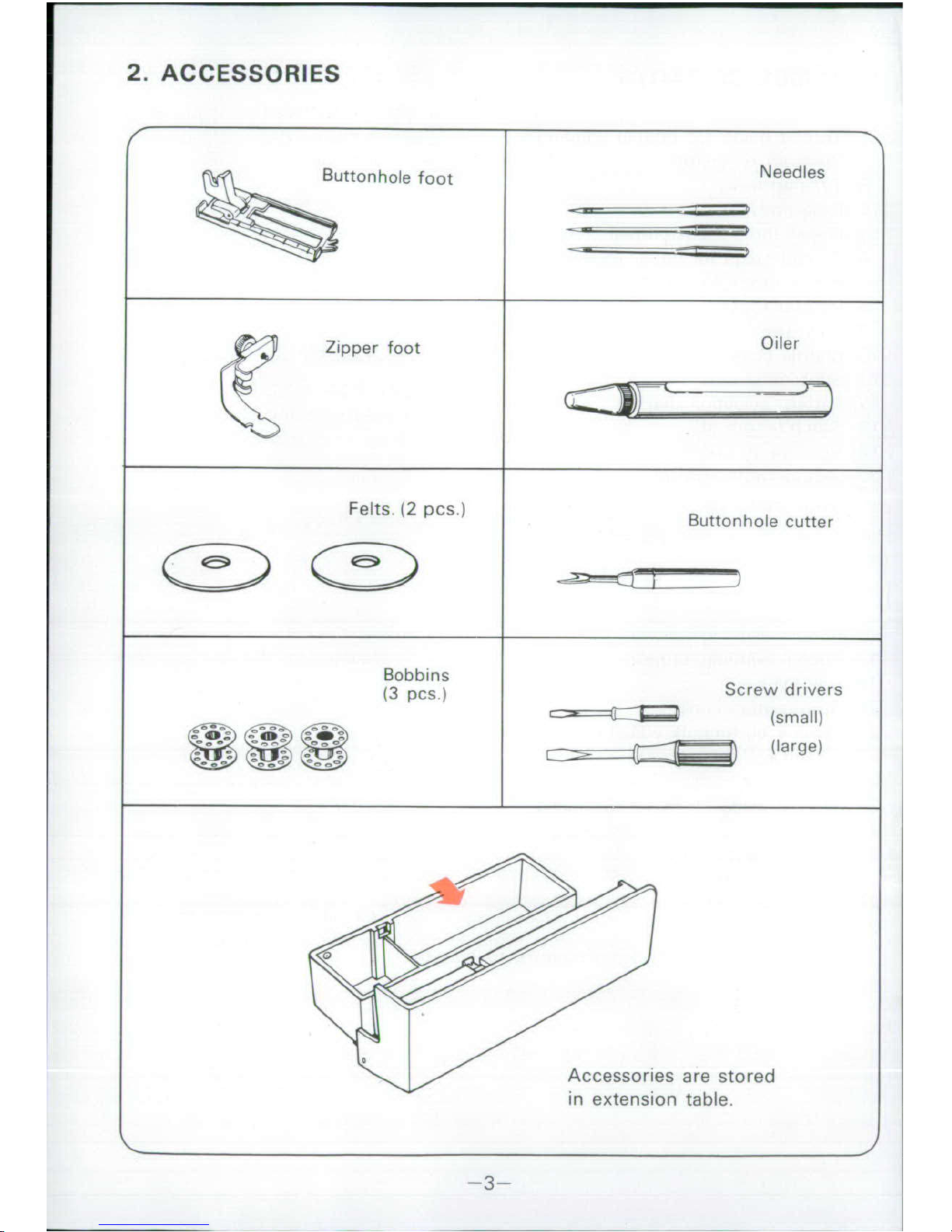

2.

ACCESSORIES

uttonhole

foot

Needles

Zipper

foot

Oiler

Felts.

J2

pcs.)

Buttonhole

cutter

Bobbins

(3

pcs.)

Screw

drivers

(small)

_

_

_

_

_

(large)

Accessories

are

stored

in

extension

table.

-3-3

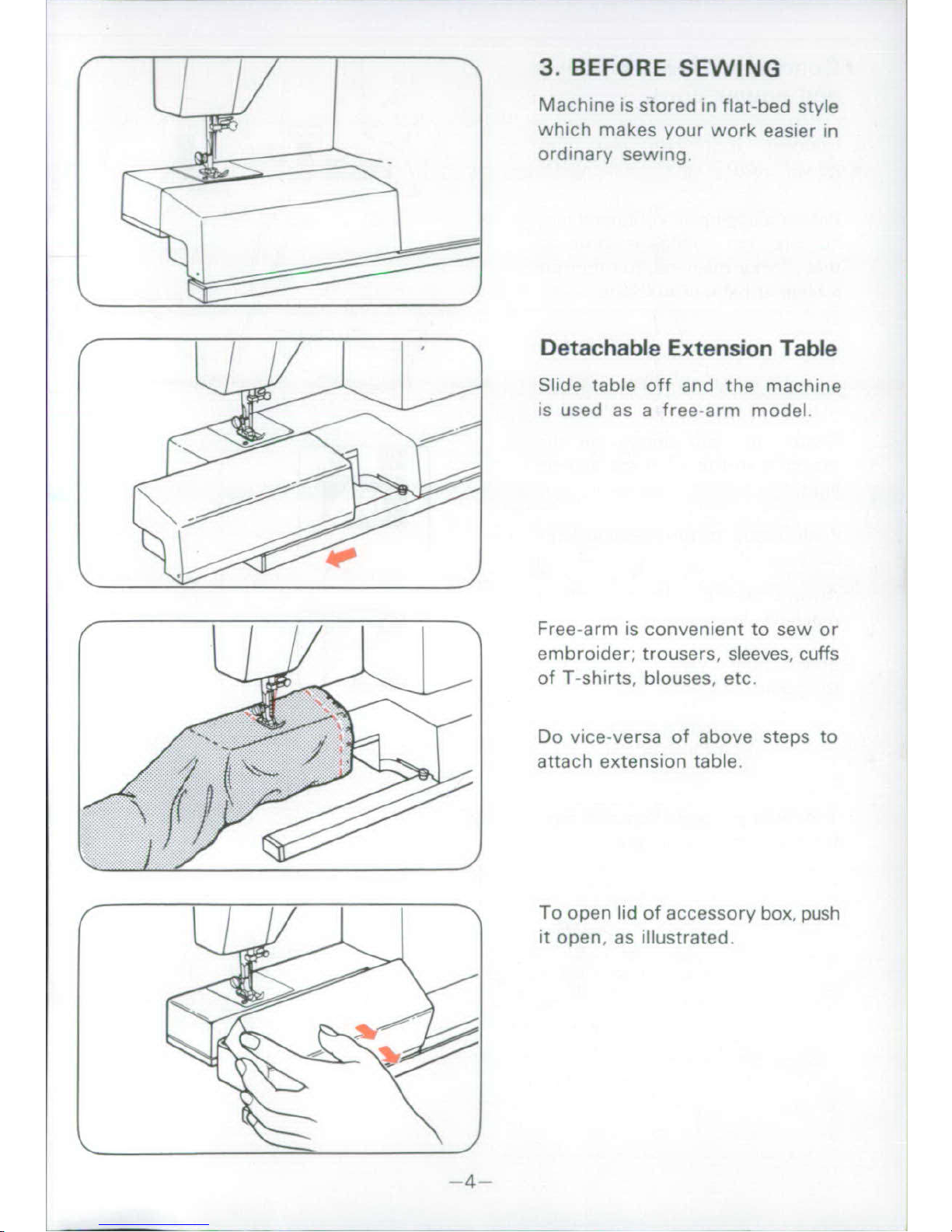

3.

BEFORE

SEWING

Machine

is

stored

in

flat-bed

style

which

makes

your

work

easier

in

ordinary

sewing.

Detachable

Extension

Table

Slide

table

off

and

the

machine

is

used

as

a

free-arm

model

Free-arm

is

convenient

to

sew

or

embroider;

trousers,

sleeves,

cuffs

of

T-shirts,

blouses,

etc.

Do

vice-versa

of

above

steps

to

attach

extension

table.

To

open

lid

of

accessory

box,

push

it

open,

as

illustrated.

-4

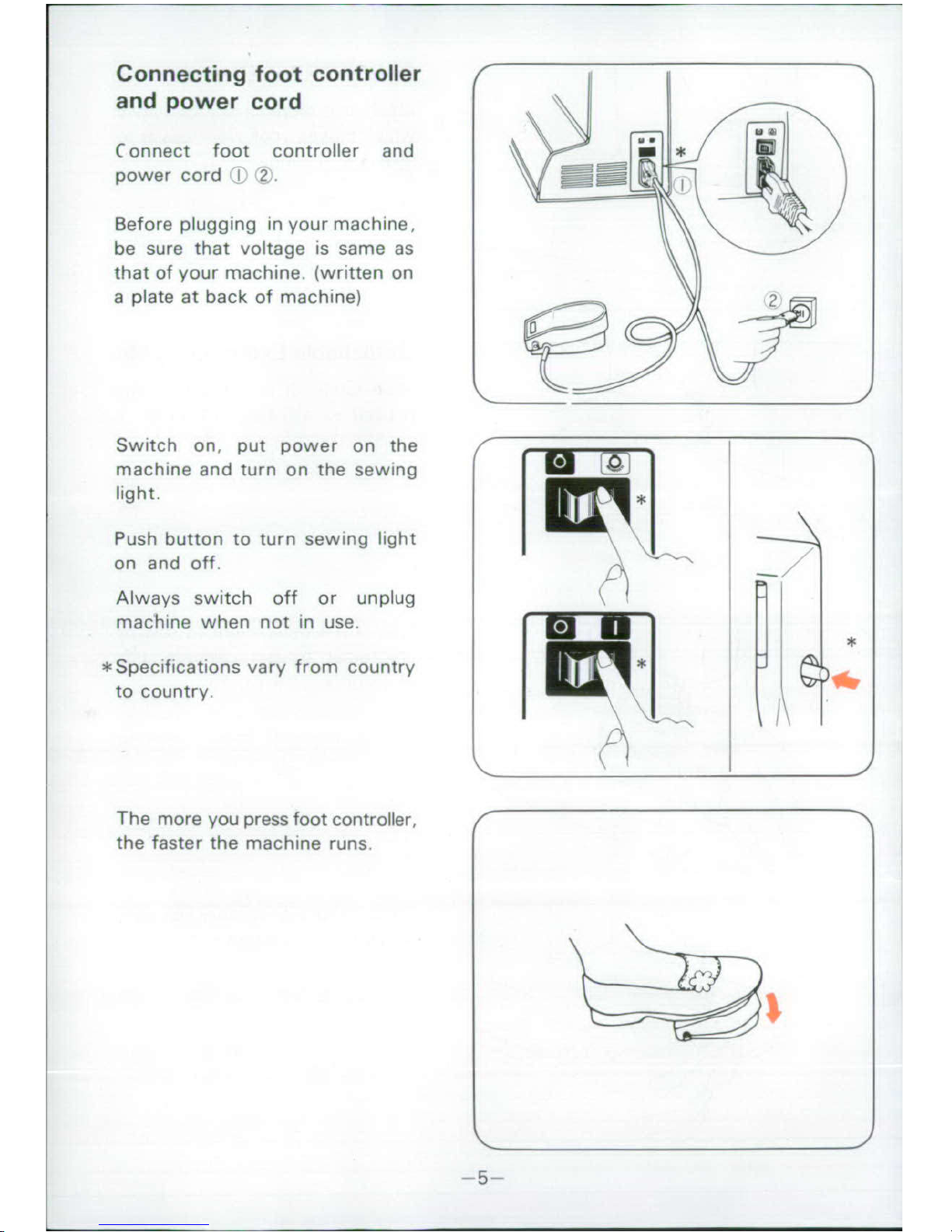

Connecting

foot

controller

and

power

cord

Connect

foot

controller

and

power

cord 1 2.

4

Before

plugging

in

your

machine,

be

sure

that

voltage

is

same

as

that

of

your

machine.

(written

on

a

plate

at

back

of

machine)2

Switch

on,

put

power

on

the

machine

and

turn

on

the

sewing

light.

Push

button

to

turn

sewing

lightF M

on

and

off.

Always

switch

off

or

unplug

machine

when

not

in

use.

*Specifications

vary

from

country

to

country.

The

more

you

press

foot

controller,

the

faster

the machine

runs.

-5--

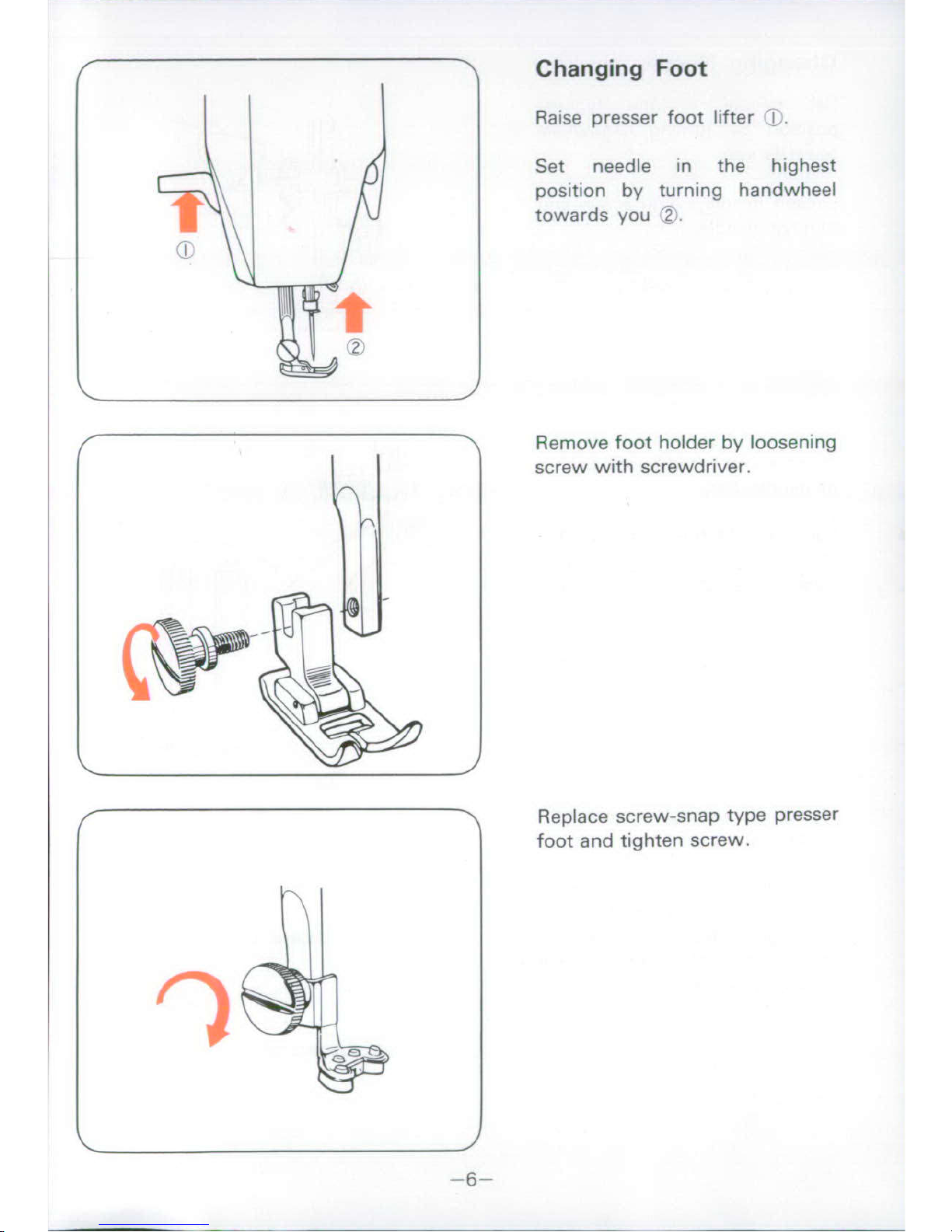

Changing

Foot

Raise

presser

foot

lifter

<>..

Set

needle

in

the

highest

position

by

turning

handwheel

towards

you

2.

At

itce

wt

cewrvr

_,

Remove

foot

holder

by

loosening

screw

with

screwdriver.

Replace

screw-snap

type

presser

foot

and

tighten

screw.

)6-

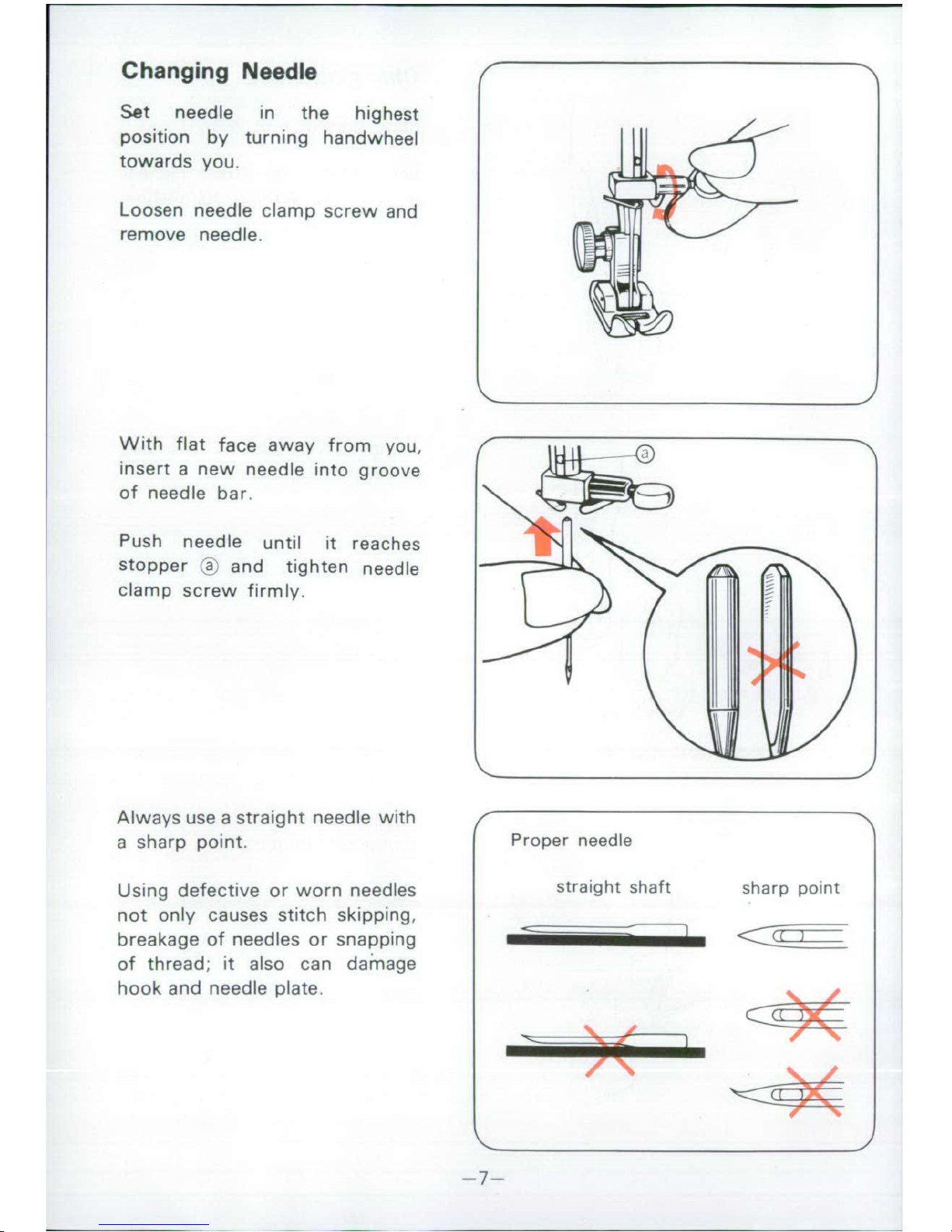

Changing

Needle

Set

needle

in

the

highest

position

by

turning

handwheel

towards

you.

Loosen

needle

clamp

screw

and

remove

needle.

With

flat

face

away

from

you,

insert

a

new

needle

into

groove

of

needle

bar.

Push

needle

until

it

reaches

stopper

O

and

tighten

needle

clamp

screw

firmly.

Always

use

a

straight

needle

with

a

sharp

point.

Proper

needle

Using

defective

or

worn

needles

straight

shaft

sharp

point

not

only

causes

stitch

skipping,

breakage

of

needles

or

snapping

of

thread;

it

also

can

dam-age

hook

and

needle

plate.

-7-

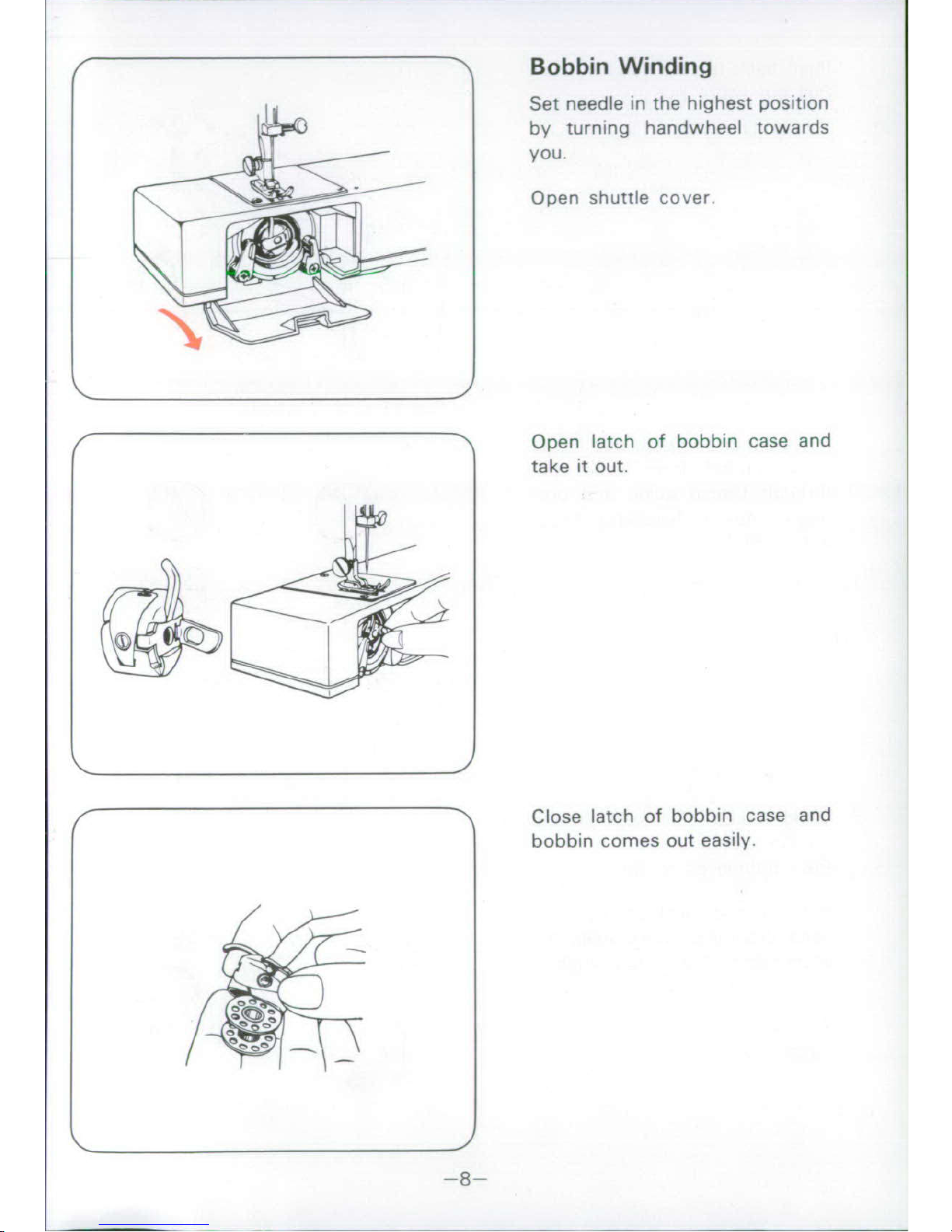

Bobbin

Winding

Set needle

in

the

highest

position

by

turning

handwheel

towards

you.

Open

shuttle

cover.

Open

latch

of

bobbin

case

and

take

it

out.

Close

latch

of

bobbin

case

and

bobbin

comes

out

easily.

--8--

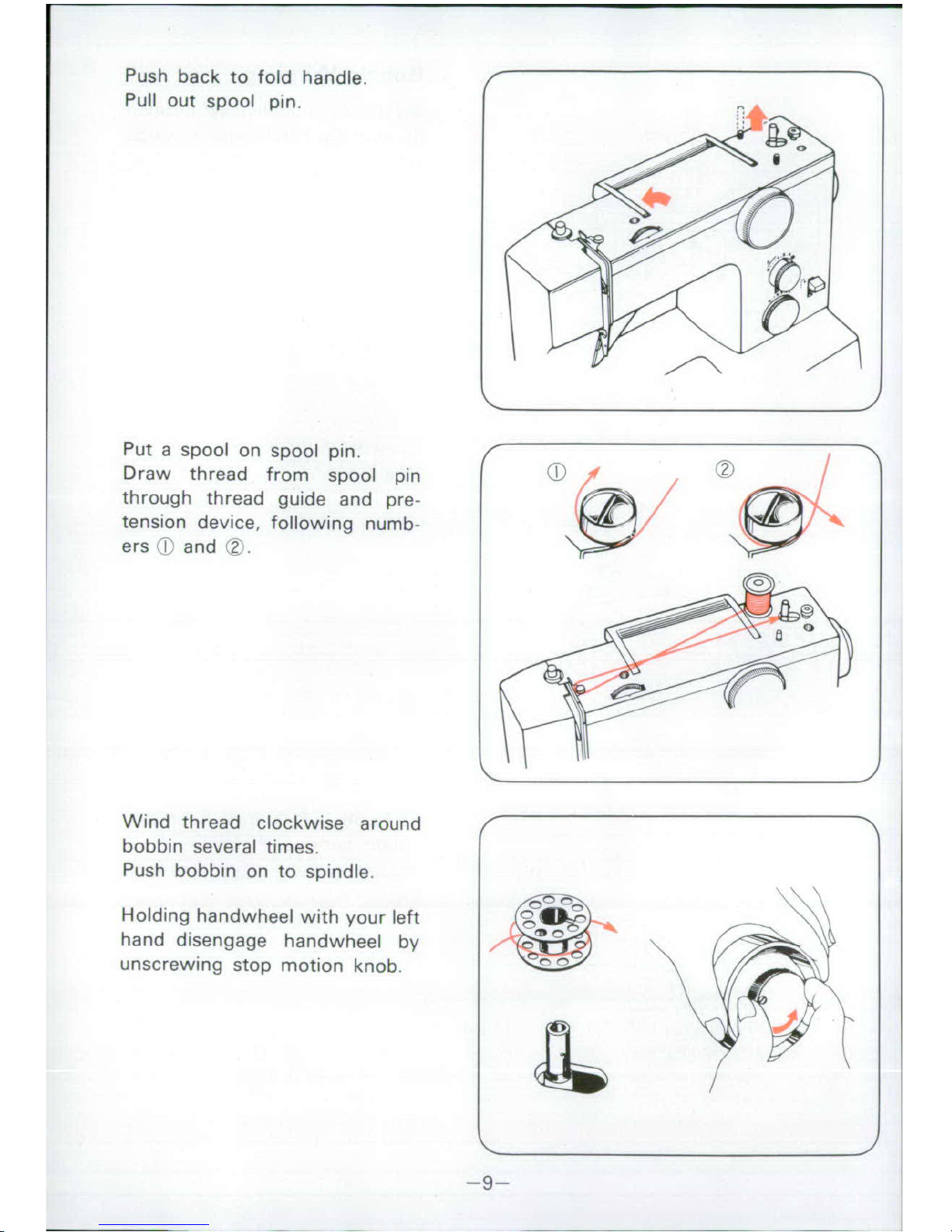

Push

back

to

fold

handle.

Pull

out

spool

pin.

Put

a

spool

on

spool

pin.

Draw

thread

from

spool

pin

through

thread

guide

and

pre-

tension

device,

following

numb-

ers

T1

and

,Z.

Wind

thread

clockwise

around

bobbin

several

times.

Push

bobbin

on

to

spindle.

Holding

handwheel

with

your

left

hand

disengage

handwheel

by

unscrewing

stop

motion

knob.

-9-

Loading...

Loading...