Toyota Cressida 1991 User Manual

FOREWORD

This repair manual covers Disassembly, Inspection and Assembly procedures for the following Automatic Transmissions:

Automatic Transmission

A340E

A340F

A340H

For On−vehicle Servicing (Inspection, Adjustment, Troubleshooting, Removal and Installation) of Automatic Transmission,

refer to the repair manual for the applicable vehicle model.

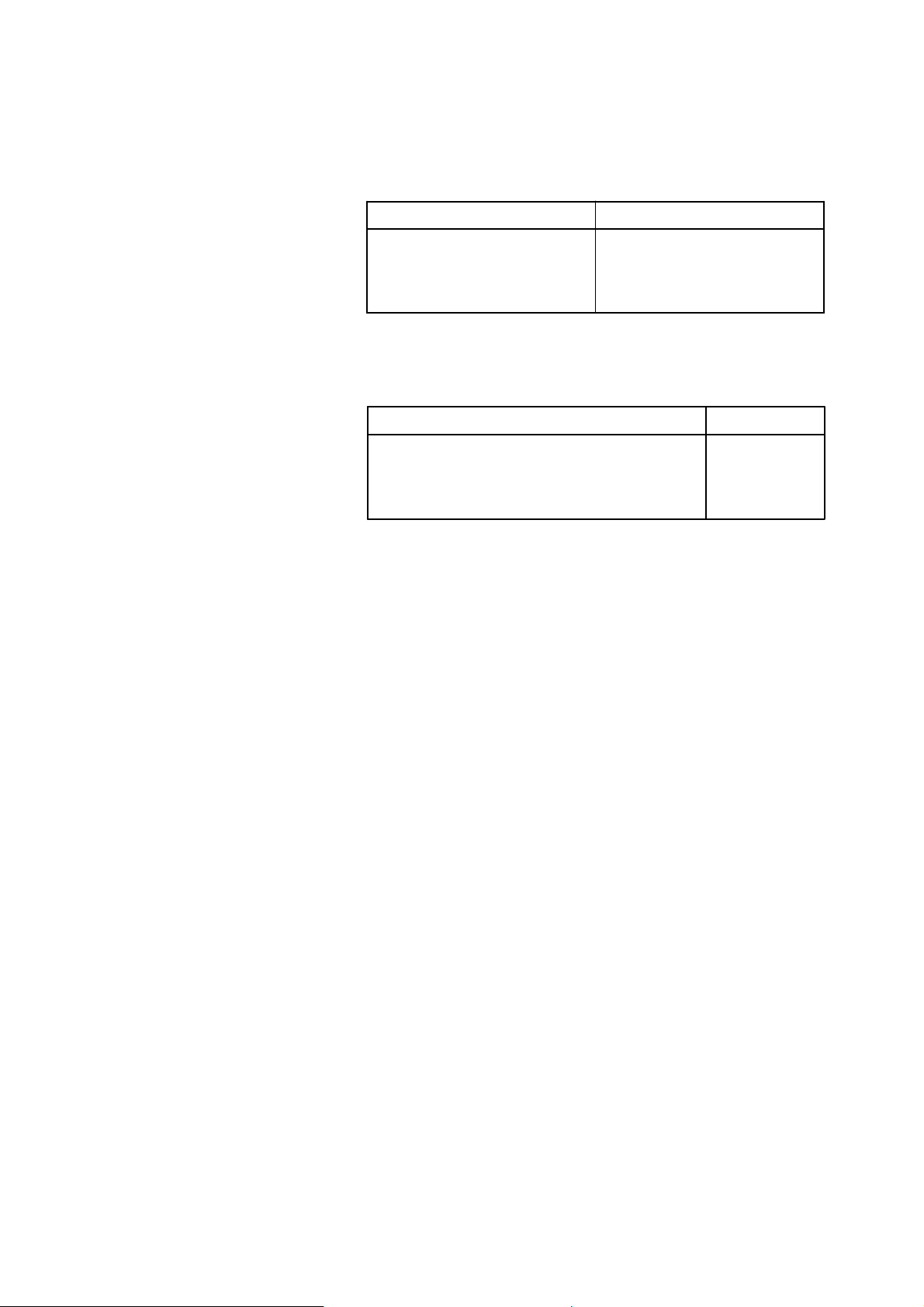

Pub. Name

’91 Supra Repair Manual

’91 Cressida Repair Manual

’91 Truck Repair Manual

’91 4 runner Repair Manual

All information contained in this manual is the most up−to−

date at the time of publication. However, specifications and

procedures are subject to change without notice.

TOYOTA MOTOR CORPORATION

Applicable Model

’91 Supra, ’91 Cressida

’91 Truck, ’91 4 runner

”91 Truck, ”91 4 runner

’91 Truck, ’91 4 runner

Pub. No.

RM198U

RM200U

RM201U2

RM202U2

IN−2

−INTRODUCTION How to Use This Manual

HOW TO USE THIS MANUAL

To assist you in finding your way through the manual, the

Section Title and major heading are given at the top of every

page.

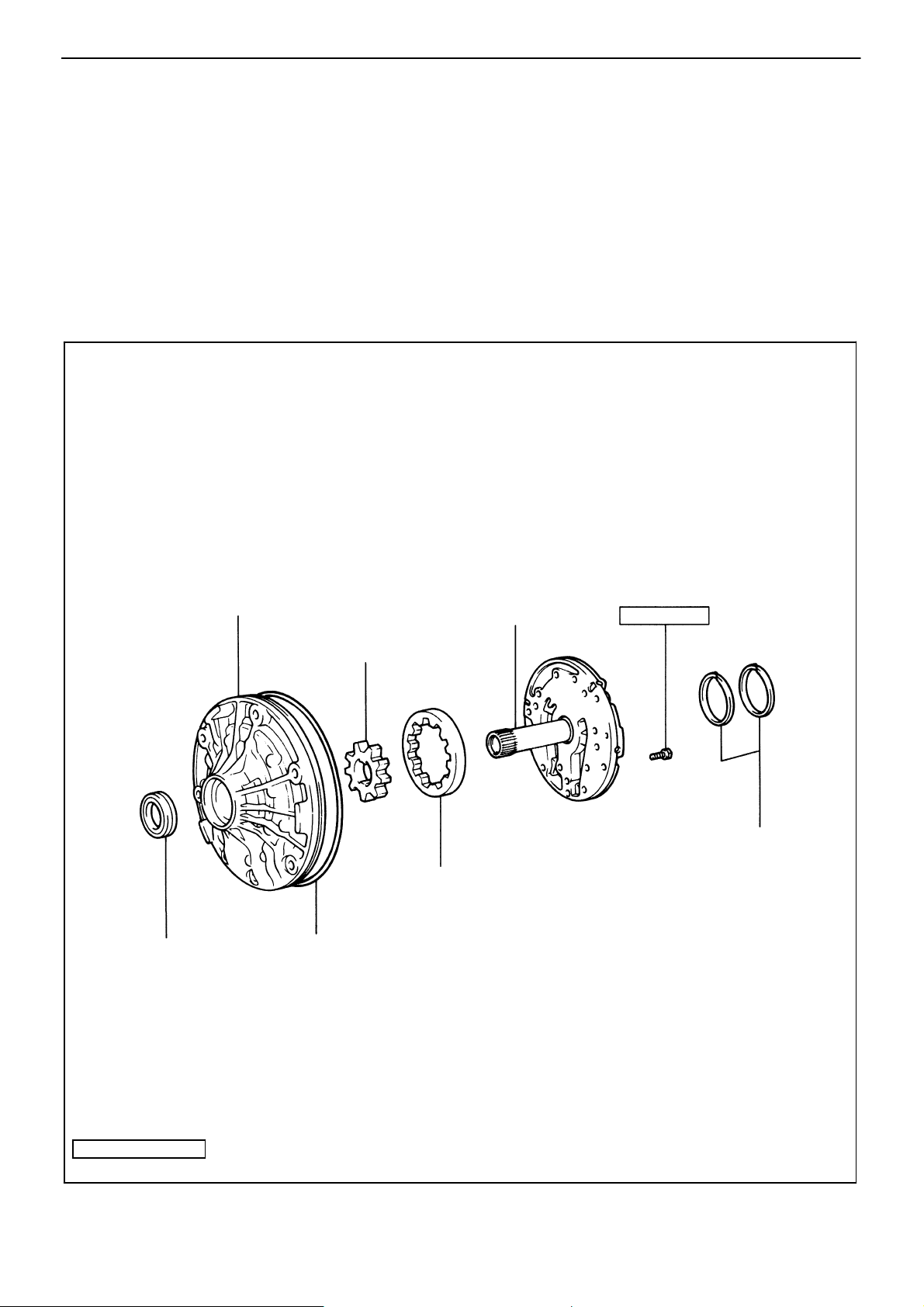

REPAIR PROCEDURES

Most repair operations begin with an overview illustration. It

identifies the components and shows how the parts fit together.

Example:

♦ Oil Seat

Oil Pump Body

Oil Pump Driven Gear

Oil Pump Drive Gear

♦ O−Ring

Startor Shaft

100 (7, 10)

Oil Seal Ring

kg−cm (ft−Ib, N−m)

♦ Non−reusable part

: Specified torque

AT5461

−INTRODUCTION How to Use This Manual

The procedures are presented in a step−by−step format:

S Illustration shows what to do and where to do it.

S The task heading tells what to do.

S The detailed text tells how to perform the task and

gives other information such as specifications and

warnings.

IN−3

Illustration:

What to do and where

Example:

Task heading: what to do

7. CHECK PISTON STROKE OF FORWARD CLUTCH

If replacing the disc, plate or flange, check the piston

stroke:

Detail text: how to do it

Using a dial indicator (long type pick or SST), measure

the forward clutch piston stroke applying and releasing

the compressed air (4 − 8 kg/cm

2

or 57 − 114 psi or

392 − 785 kPa) as shown.

SST 09350−32014 (09351−32190)

Set part No.

Component part No.

Piston stroke: 1.41 − 1.82 mm (0.0555 − 0.0717 in.)

Specification

This format provides the experienced technician with a FAST

TRACK to the information needed. The upper case task heading can be read at a glance and only when necessary, the text

below it provides detailed information. Important specifications

and warnings always stand out in bold type.

REFERENCES

References have been kept to a minimum. However, when

they are required you are given the page to go to.

SPECIFICATIONS

Specifications are presented in bold type throughout the text in

the applicable step. You never have to leave the procedure to

look up your specs. All specifications are also found in Appendix A, specifications for quick reference.

CAUTIONS, NOTICES, HINTS:

S CAUTIONS are presented in bold type, and indicate

there is a possibility of injury to you or other people.

S NOTICES are also presented in bold type, and indicate

the possibility of damage to the components being repaired.

S HINTS are separated from the text but do not appear in

bold. They provide additional information to help you efficiently perform the repair.

IN−4

Seal Lock Adhesive

IN0036

−INTRODUCTION General Repair Instructions

GENERAL REPAIR INSTRUCTIONS

1. Use fender, seat and floor covers to keep the vehicle

clean and prevent damage.

2. During disassembly, keep parts in order to facilitate

reassembly.

3. Observe the following:

(a) Before performing electrical work, disconnect the

negative cable four the battery terminal.

(b) If it is necessary to disconnect the battery for in-

spection or repair, always disconnect the cable from

the negative (−) terminal which is grounded to the

vehicle body.

(c) To prevent damage to the battery terminal post,

loosen the terminal nut and raise the cable straight

up without twisting it or prying it.

(d) Clean the battery terminal posts and cable termi-

nals with a shop rag. Do not scrape them with a file

or other abrasive object.

(e) Install the cable terminal to the battery post with the

nut loose, and tighten the nut after installation. Do

not use a hammer or such to tap the terminal onto

the post.

(f) Be sure the cover for the positive (+) terminals are

properly in place.

4. Check hoses and wiring connectors to make sure

that they are secure and correct.

5. Non−reusable parts

(a) Always replace cotter pins, gaskets, O−rings and oil

seals etc. with new ones.

(b) Non−reusable parts are indicated in the component

illustrations by the ”♦” symbol.

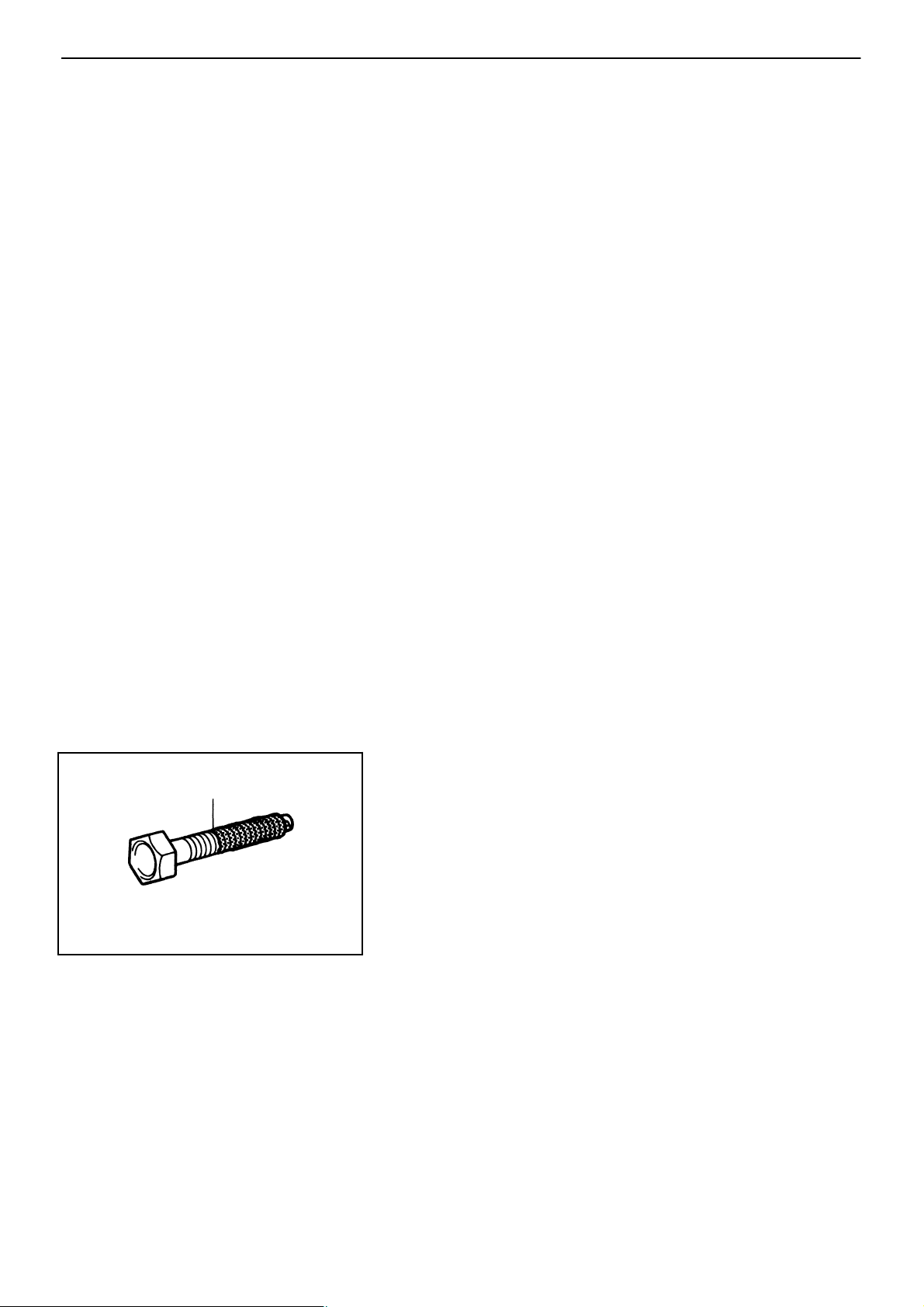

6. Precoated parts

Precoated parts are the bolts and nuts, which have

been coated with a seal lock adhesive at the factory.

(a) If a precoated part is retightened, loosened or

caused to move in any way, it must be recoated

with the specified adhesive.

(b) Recoating of precoated parts

(1) Clean off the old adhesive from the bolt, nut

or installation part threads.

(2) Dry with compressed air.

(3) Apply the specified seal lock adhesive to the

bolt or nut threads.

(c) Precoated parts are indicated in the component il-

lustrations by the ”L” symbol.

−INTRODUCTION General Repair Instructions

IN−5

7. When necessary, use a sealer on gaskets to prevent

leaks.

8. Carefully observe all specifications for bolt tightening torques. Always use a torque wrench.

9. Use of special service tools (SST) and special service materials (SSM) may be required, depending on

the nature of the repair. Be sure to use SST and SSM

where specified and follow the proper work procedure. A list of SST and SSM can be found at the back

of this manual.

10. When replacing fuses, be sure the new fuse has the

correct amperage rating. DO NOT exceed the fuse

amp rating or use one of a lower rating.

11. Care must be taken when jacking up and supporting

the vehicle. Be sure to lift and support the vehicle at

the proper locations.

(a) If the vehicle is to be jacked up only at the front or

rear end, be sure to block the wheels in order to

ensure safety.

(b) After the vehicle is jacked up, be sure to support it

on stands. It is extremely dangerous to do any

work on the vehicle raised on jack alone, even for a

small job that can be finished quickly.

IN−6

−INTRODUCTION Abbreviations Used in This Manual

ABBREVIATIONS USED IN THIS MANUAL

ADD Automatic Disconnecting Differential

A/T ATM Automatic Transmission

ATF Automatic Transmission Fluid

B

Overdrive Brake

0

B

Second Coast Brake

1

B

Second Brake

2

B

First and Reverse Brake

3

C

Overdrive Clutch

0

C

Forward Clutch

1

C

Direct Clutch

2

D Disc

Ex. Except

MP Multipurpose

O/D Overdrive

P Plate

SSM Special Service Materials

SST Special Service Tools

w/ With

w/o Without

−AUTOMATIC TRANSMISSION Description

AT−3

DESCRIPTION

General

The A340E is a 4−speed, Electronic Controlled Transmission (hereafter called ECT) developed for use

with high−performance engine. A lock−up mechanism is built into the torque converter.

The A340F automatic transmission is a 4−speed automatic transmission with mechanically controlled

4WD transfer, developed with the aim of producing an easy−driving 4WD vehicle. The transmission section has fundamentally the same construction as the A340E automatic transmission.

The A340H automatic transmission is a 4−speed automatic transmission with electronically controlled

4Wd transfer, developed with the aim of producing an easy driving 4WD vehicle.

The transfer section consists of planetary gears, hydraulic clutches and hydraulic brake. The operation of

these is fully controlled by the Engine & ECT ECU.

The A340E, A340F and A340H automatic transmissions are mainly composed of the torque converter,

the overdrive (hereafter called O/D) planetary gear unit, 3−speed planetary gear unit, the hydraulic control system and the electronic control system.

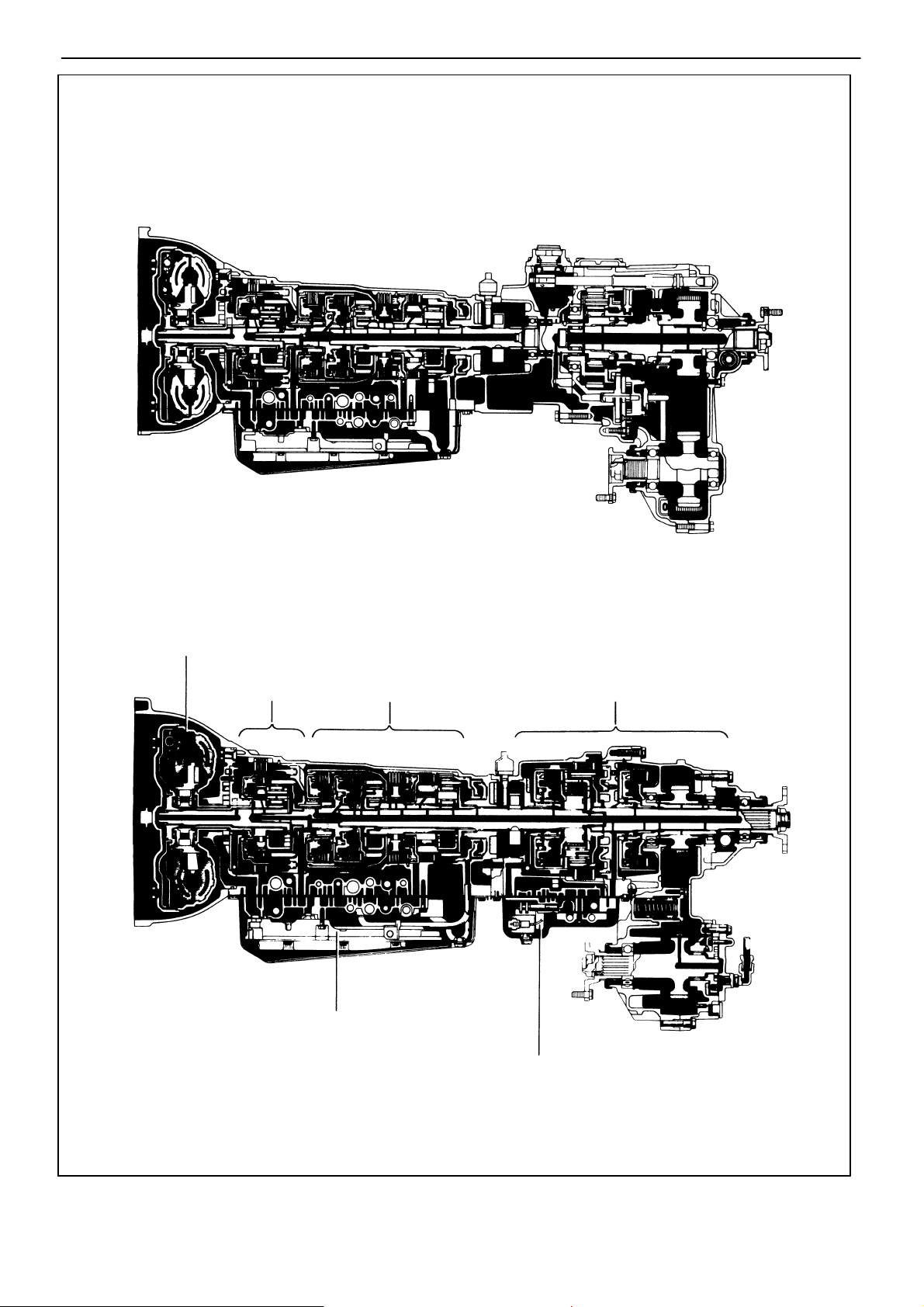

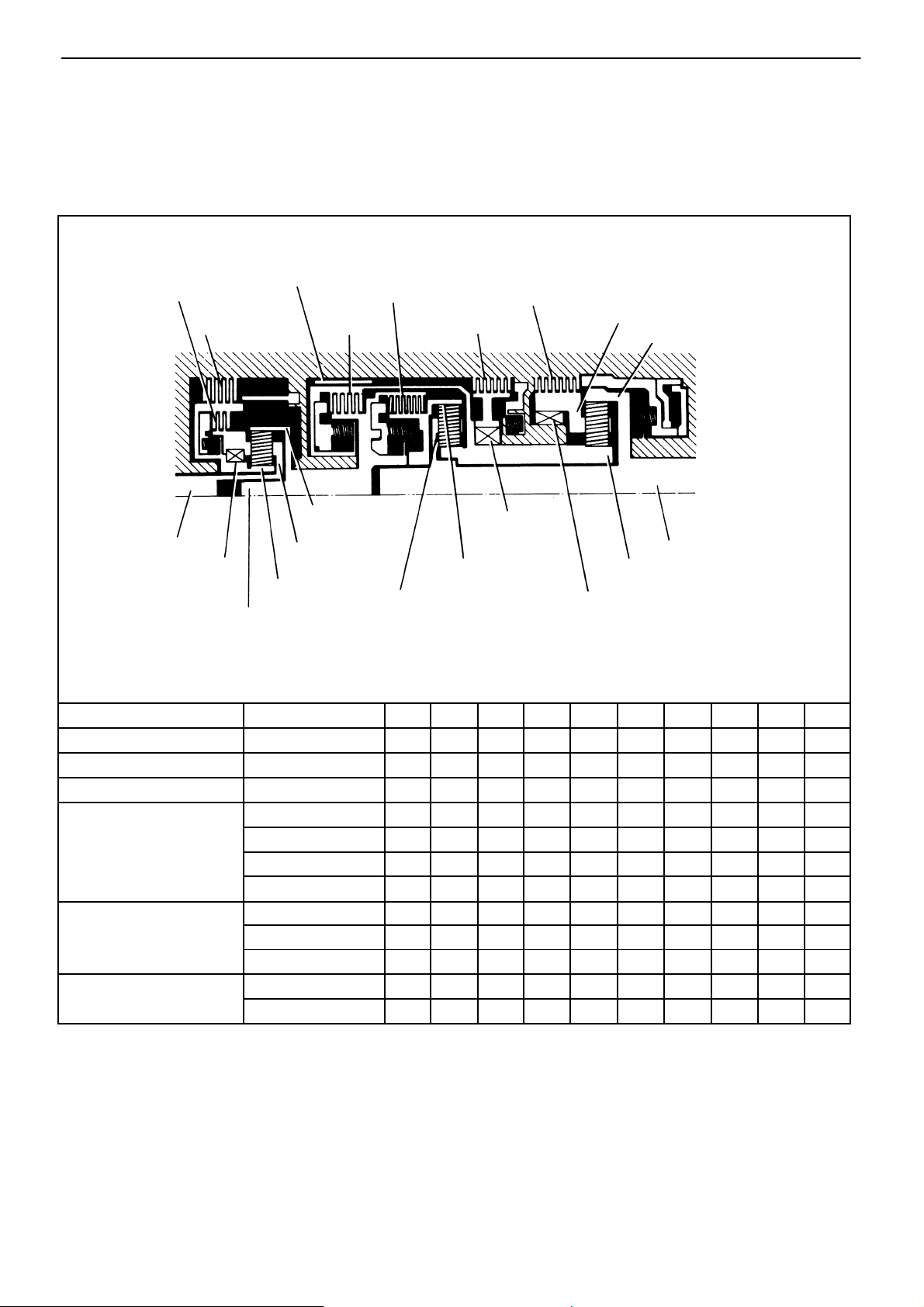

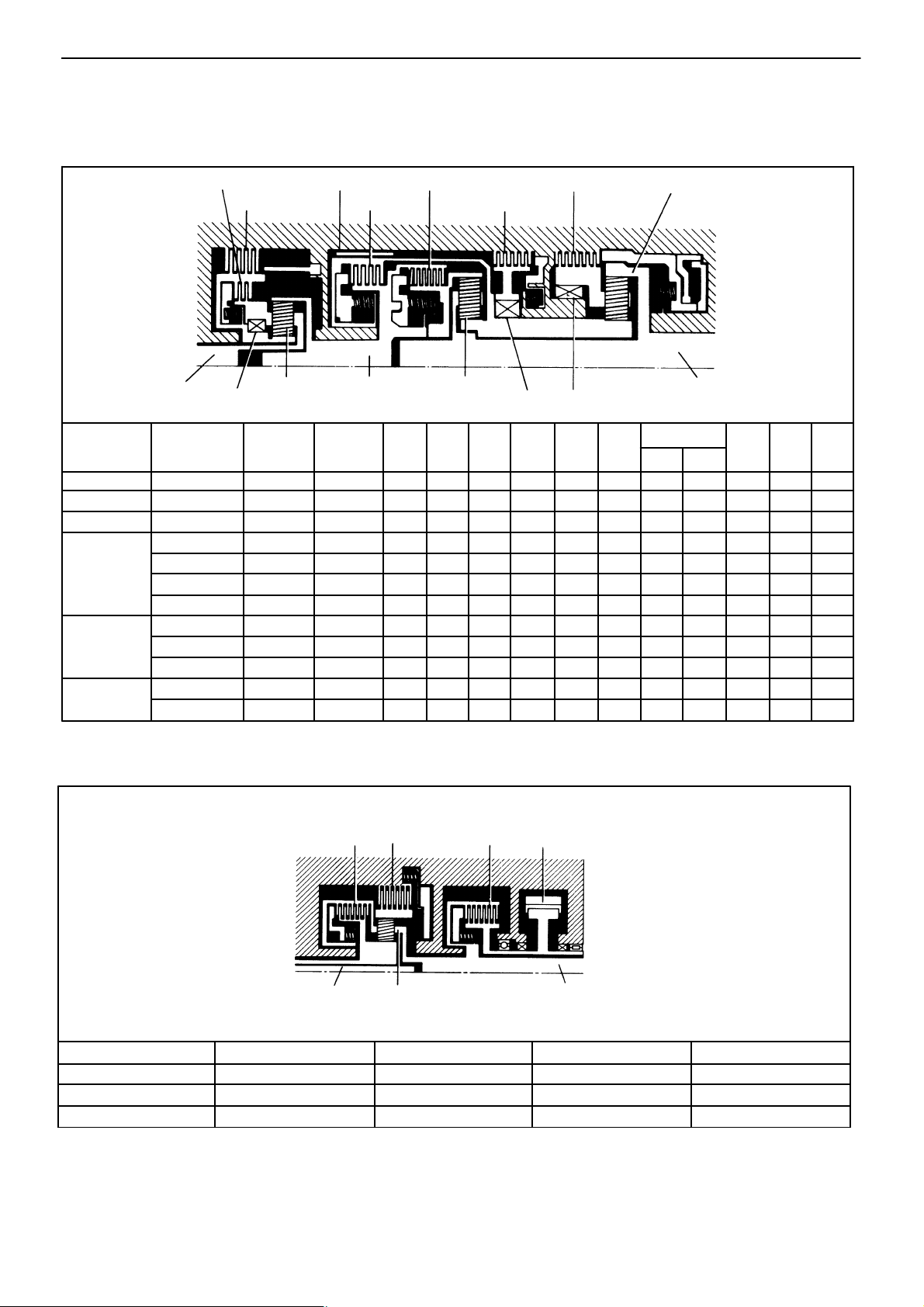

Sectional View

(A340E)

AT4366

AT−4

Sectional View

(A340F)

−AUTOMATIC TRANSMISSION Description

(A340H)

Torque Converter with

Lock−Up Clutch

O/D Planetary

Gear Unit

Transmission Hydraulic

Control Unit

3−Speed Planetary

Gear Unit

2−Speed Transfer

Transfer Hydraulic

Control Unit

AT5744

AT5068

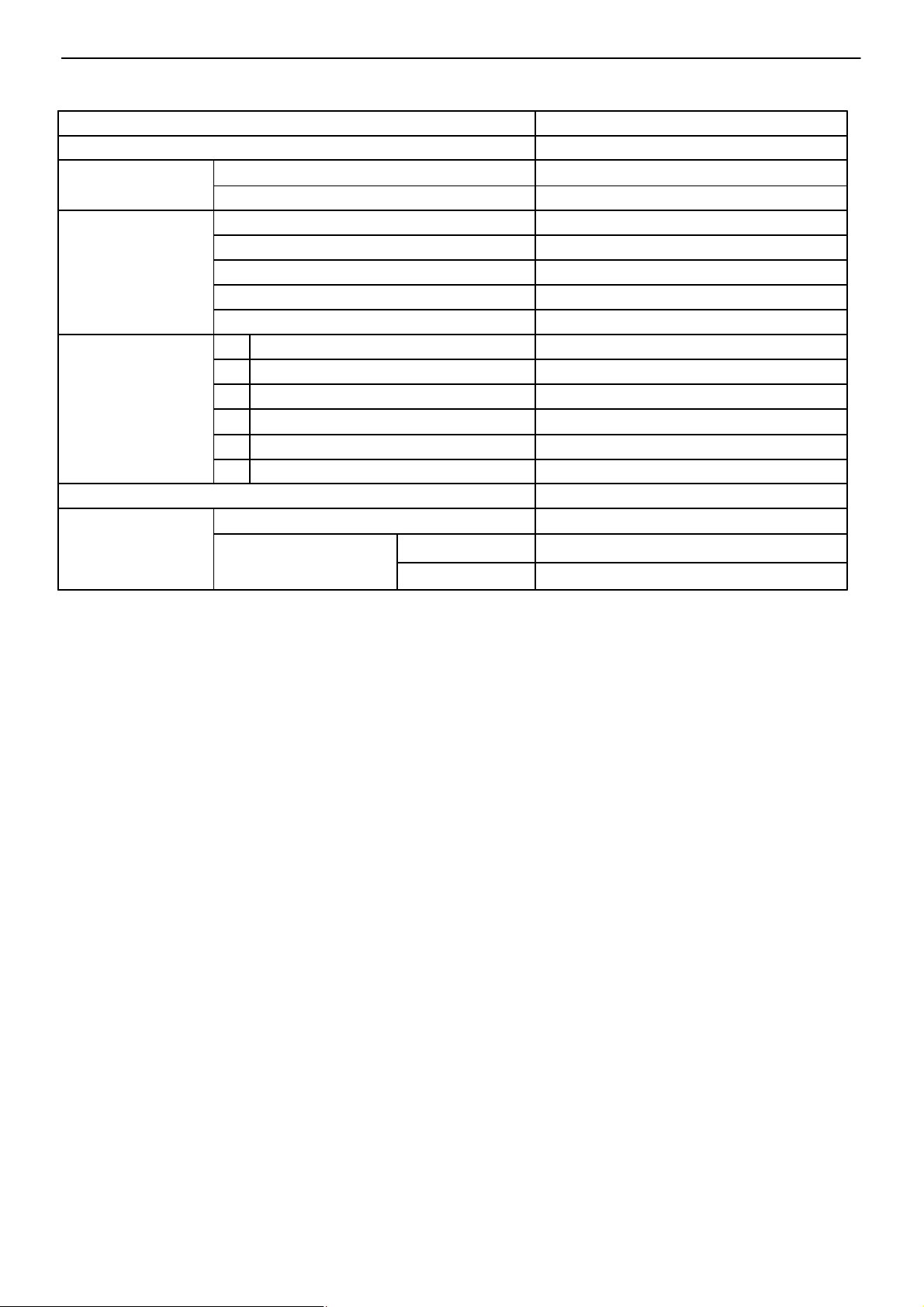

General Specifications

−AUTOMATIC TRANSMISSION Description

AT−5

Type of Transmission

Type of Engine

Torque Converter

Gear Ratio

Plates (Disc/Plate)

Second Coast Brake Band Width

ATF

Stall Torque Ratio

Lock−Up Mechanism

1st Gear

2nd Gear

3rd Gear

O/D Gear

Reverse Gear

C

0

C

1

C

2

B22nd Brake

B

3

B0O/D Brake

Type

liters (US qts, Imp. qts)

O/D Direct Clutch

Forward Clutch

Direct Clutch

1st & Reverse Brake

Capacity

mm (in.)

Total

Drain and Refill

A340E

7M−GE, 7M−GTE, 3VZ−E

Truck : C & C 2.0 : 1 Others 2.1 : 1

Equipped

2.804

1.531

1.000

0.705

2.393

2/2

5/5

4/4

5/5

6/6

4/3

40 (1.57)

ATF DEXRONR II

7.2 (7.6, 6.3)

1.6 (1.7, 1.4)

AT−6

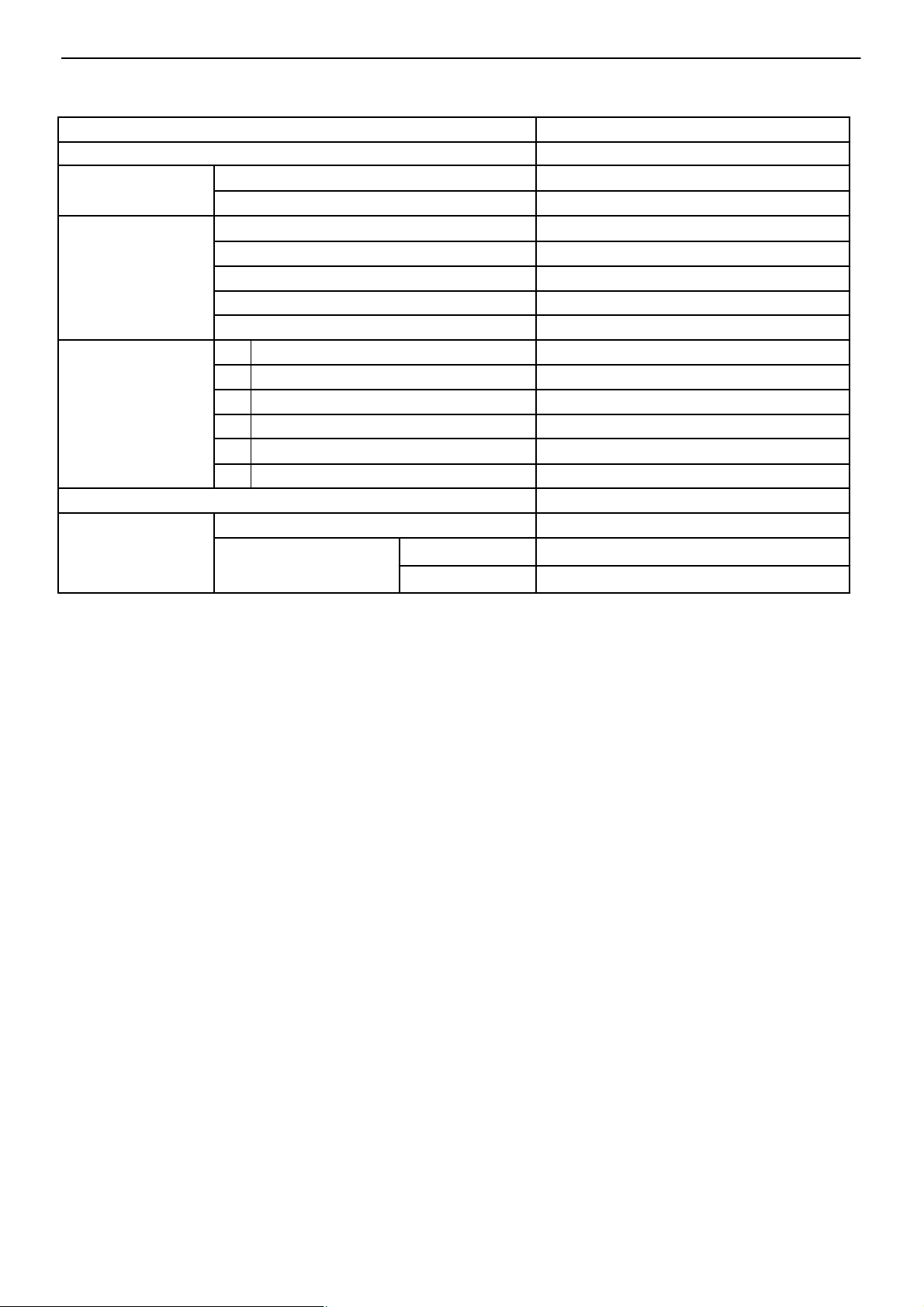

General Specifications (Cont’d)

−AUTOMATIC TRANSMISSION Description

Type of Transmission

Type of Engine

Torque Converter

Gear Ratio

Plates (Disc/Plate)

Second Coast Brake Band Width

ATF

Stall Torque Ratio

Lock−Up Mechanism

1st Gear

2nd Gear

3rd Gear

O/D Gear

Reverse Gear

C

0

C

1

C2Direct Clutch

B22nd Brake

B31st & Reverse Brake

B0O/D Brake

Type ATF DEXRONR II

O/D Direct Clutch

Forward Clutch

Capacity

liters

(US qts, Imp. qts)

A340F

22R−E

2.3 : 1

Equipped

2.804

1.531

1.000

0.705

2.393

2/2

5/5

4/4

5/5

6/6

4/3

mm (in.)

Total 7.6 (8.0, 6.7)

Drain and Refill

40 (1.57)

1.6 (1.7, 1.4)

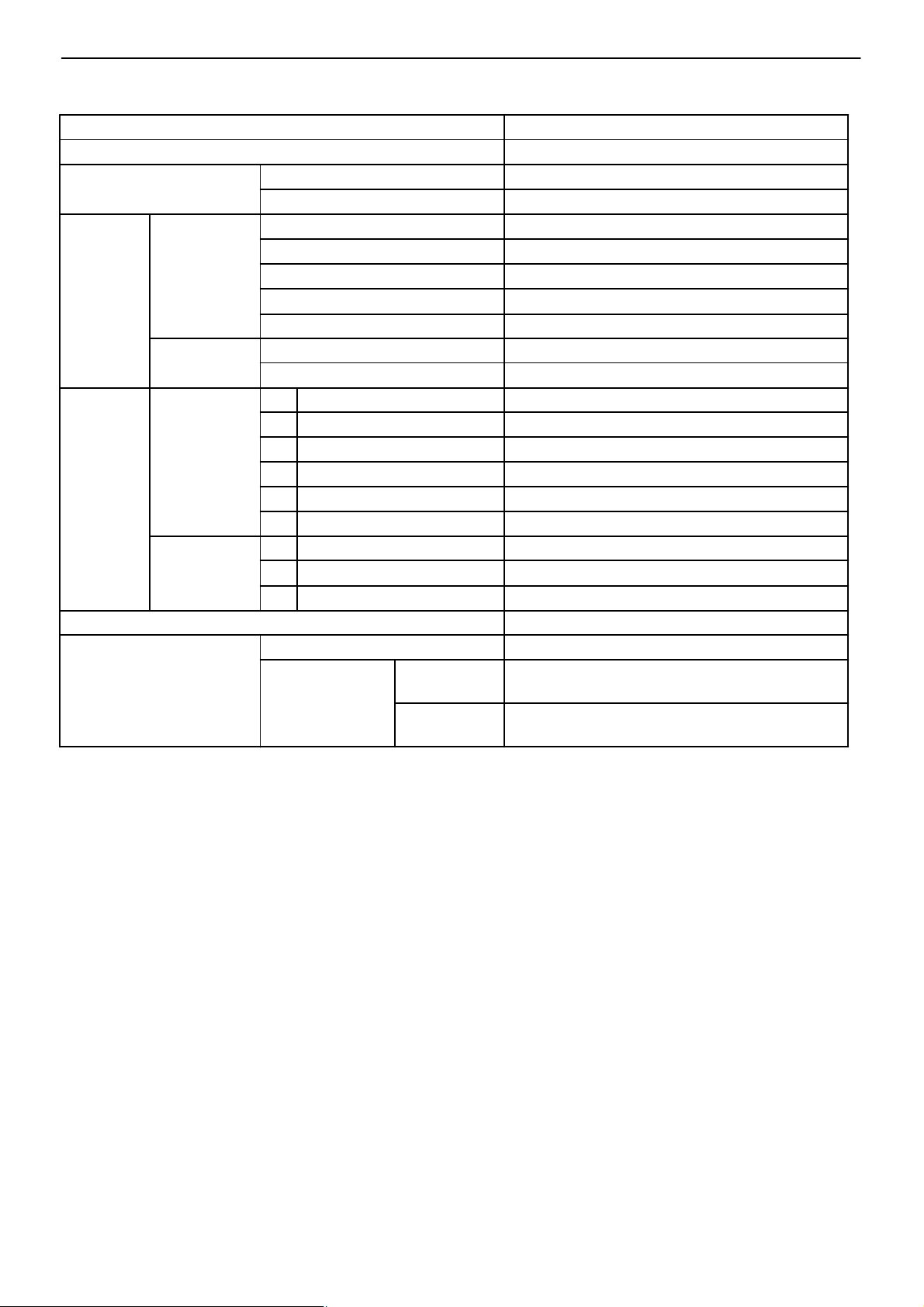

General Specifications (Cont’d)

−AUTOMATIC TRANSMISSION Description

AT−7

Type of Transmission

Type of Engine

Torque Converter

Transmission

Gear Ratio

Transfer

Number of

Discs and

Plates

(Disc

/Plate)

Transmission

Transfer

Second Coast Brake Band Width

ATF

A340H

3VZ−E

Stall Torque Ratio

2.1 : 1

Lock−Up Mechanism Equipped

1st Gear 2.804

2nd Gear 1.531

3rd Gear

1.000

O/D Gear 0.705

Reverse Gear

High (H2, H4)

Low (L4)

Forward Clutch 4/4

C

1

Direct Clutch

C

2

O/D Direct Clutch 1/1

C

0

2nd Brake

B

2

1st & Reverse Brake

B

3

O/D Brake

B

0

Transfer Direct Clutch

C

3

C4Front Drive Clutch

Low Speed Brake

B

4

mm (in.)

Type

Transmission: 10.3 (10.9, 9.1),

Transfer: 1.1 (1.2, 1.0)

Transmission: 4.5 (4.8, 4.0),

Transfer: 0.8 (0.8, 0.7)

Capacity liter

(US qts, Imp. qts)

Total

Drain & Refill

2.393

1.000

2.659

3/3

4/4

5/5

3/2

6/6

6/6

7/6

40 (1.57)

ATF DEXRONR II

AT−8

OPERATION

Mechanical Operation

OPERATING CONDITIONS

(A340E, A340F)

−AUTOMATIC TRANSMISSION Operation

O/D Direct

CIutch (C0)

O/D Input Shaft

O/D One−Way

Clutch (F

Shift lever position

P

R

N Neutral

D

2

L

2nd Coast Brake (B1)

O/D Brake (B

)

0

Input Shaft

Forward Clutch (C1)

Direct

0

)

Clutch (C

)

2

2nd Brake (B

O/D Planetary

Ring Gear

O/D Planetary

Carrier

O/D Planetary

Sun Gear

Front Planetary

Front Planetary

Ring Gear

Carrier

Gear position

Parking

Reverse f

1st

2nd

3rd

O/D

1st

2nd

3rd ff

1st

*2nd

C

0

f

f

ff

f

f

ff

f

ff

ff

1st & Reverse

Brake (B

)

2

)

3

Rear Planetary Carrier

Rear Planetary Ring Gear

No. 1 One−Way

Clutch (F

)

1

Output Shaft

Front & Rear Planetary

Sun Gear

No. 2 One−Way

Clutch (F

C

C

1

f

ff

ff

ff

f

B

2

f

0

ff

)

2

B

ff

B

1

2

f

f

f

f

f ..... Operating

B

3

f

f

AT2157

F

f

f

f

f

ff

ff

f

f

ff

F

0

F

1

2

f

f

f

* Down−shift only in the L range and 2nd gear − no up−shift.

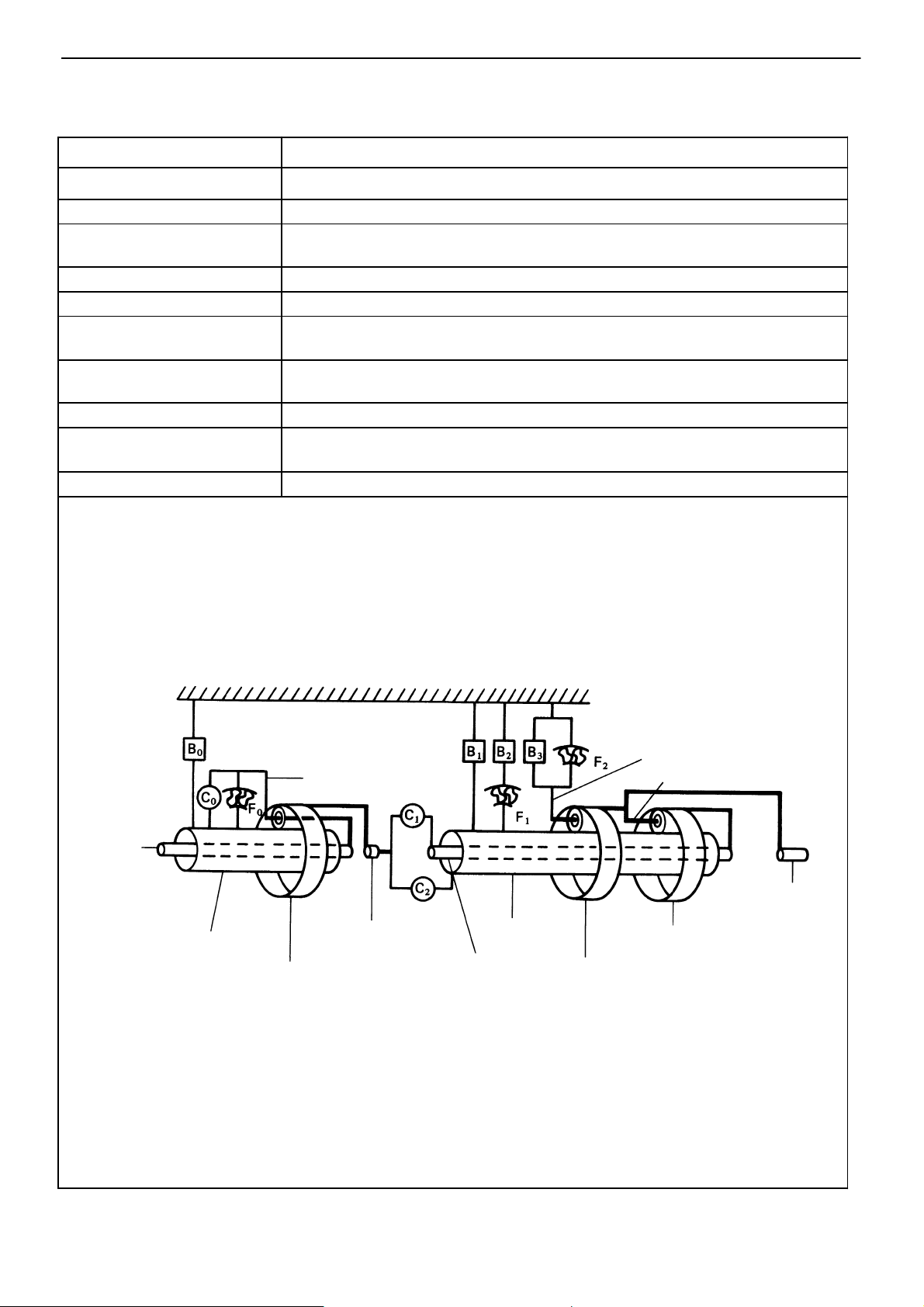

FUNCTION OF COMPONENTS

(A340E, A340F)

−AUTOMATIC TRANSMISSION Operation

AT−9

NOMENCLATURE

O/D Direct Clutch (C0)

O/D Brake (B

O/D One−Way Clutch (F

Forward Clutch (C1)

Direct Clutch (C2) Connects input shaft and front & rear planetary sun gear

2nd Coast Brake (B1)

2nd Brake (B2)

1st & Reverse Brake (B3)

No. 1 One−Way Clutch (F1)

No. 2 One−Way Clutch (F2)

) Prevents overdrive sun gear from turning either clockwise or counterclockwise

0

0)

Connects overdrive sun gear and overdrive carrier

When transmission is being driven by engine, connects overdrive sun gear and overdrive carrier

Connects input shaft and front planetary ring gear

Prevents front & rear planetary sun gear from turning either clockwise or counterclockwise

Prevents outer race of F1 from turning either clockwise or counterclockwise, thus preventing

front & rear planetary sun gear from turning counterclockwise

Prevents rear planetary carrier from turning either clockwise or counterclockwise

When B2 is operating, prevents front & rear planetary sun gear from turning counterclockwise

Prevents rear planetary carrier from turning counterclockwise

OPERATION

O/D Input

Shaft

O/D Sun Gear

O/D Planetary Ring Gear

O/D Planetary Carrier

Input Shaft

Sun Gear

Intermediate

Shaft

Front Planetary Carrier

Rear Planetary Carrier

Output Shaft

Rear Planetary Ring Gear

Front Planetary

Ring Gear

AT3282

AT−10

−AUTOMATIC TRANSMISSION Operation

FUNCTION OF COMPONENTS (Cont’d)

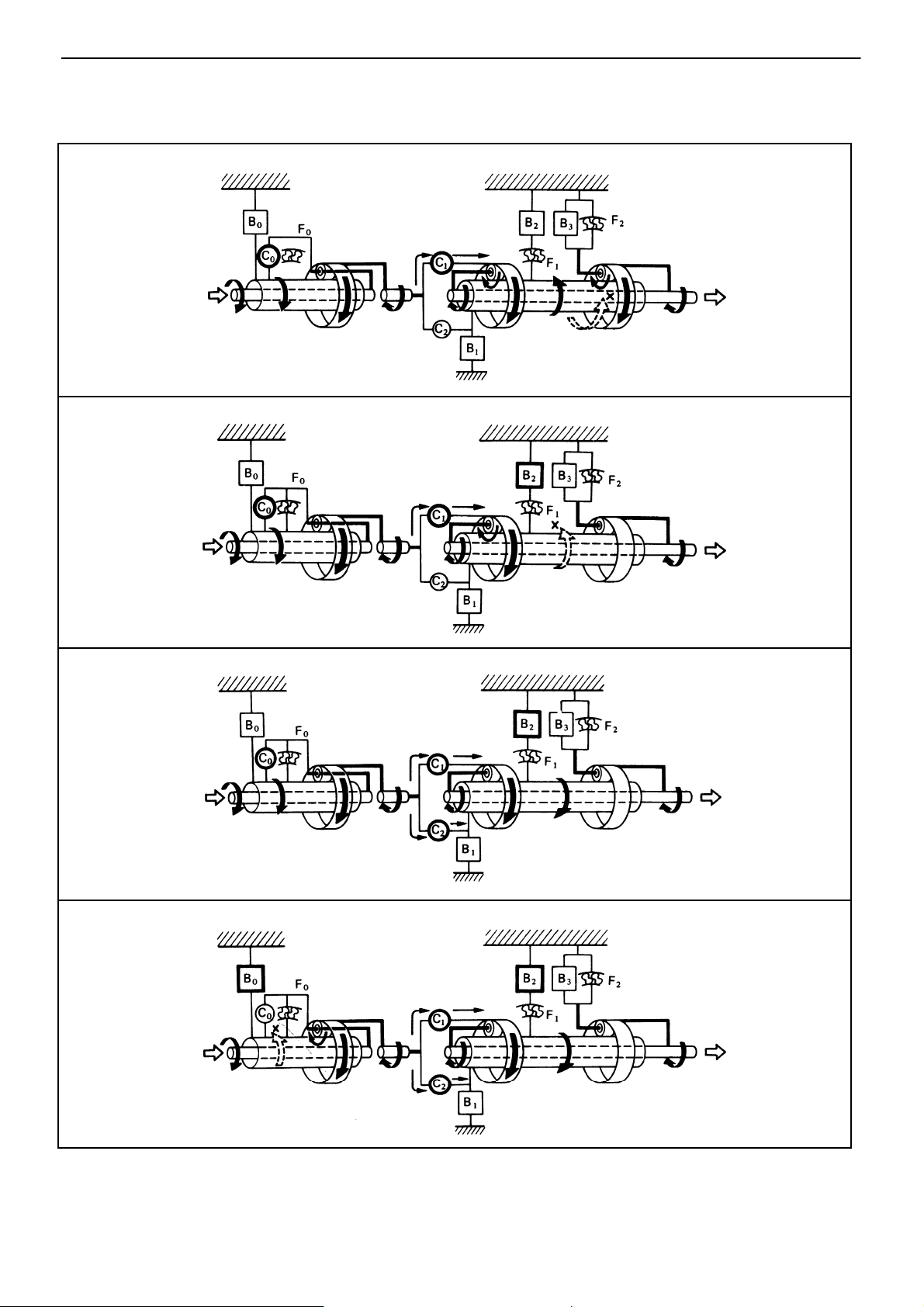

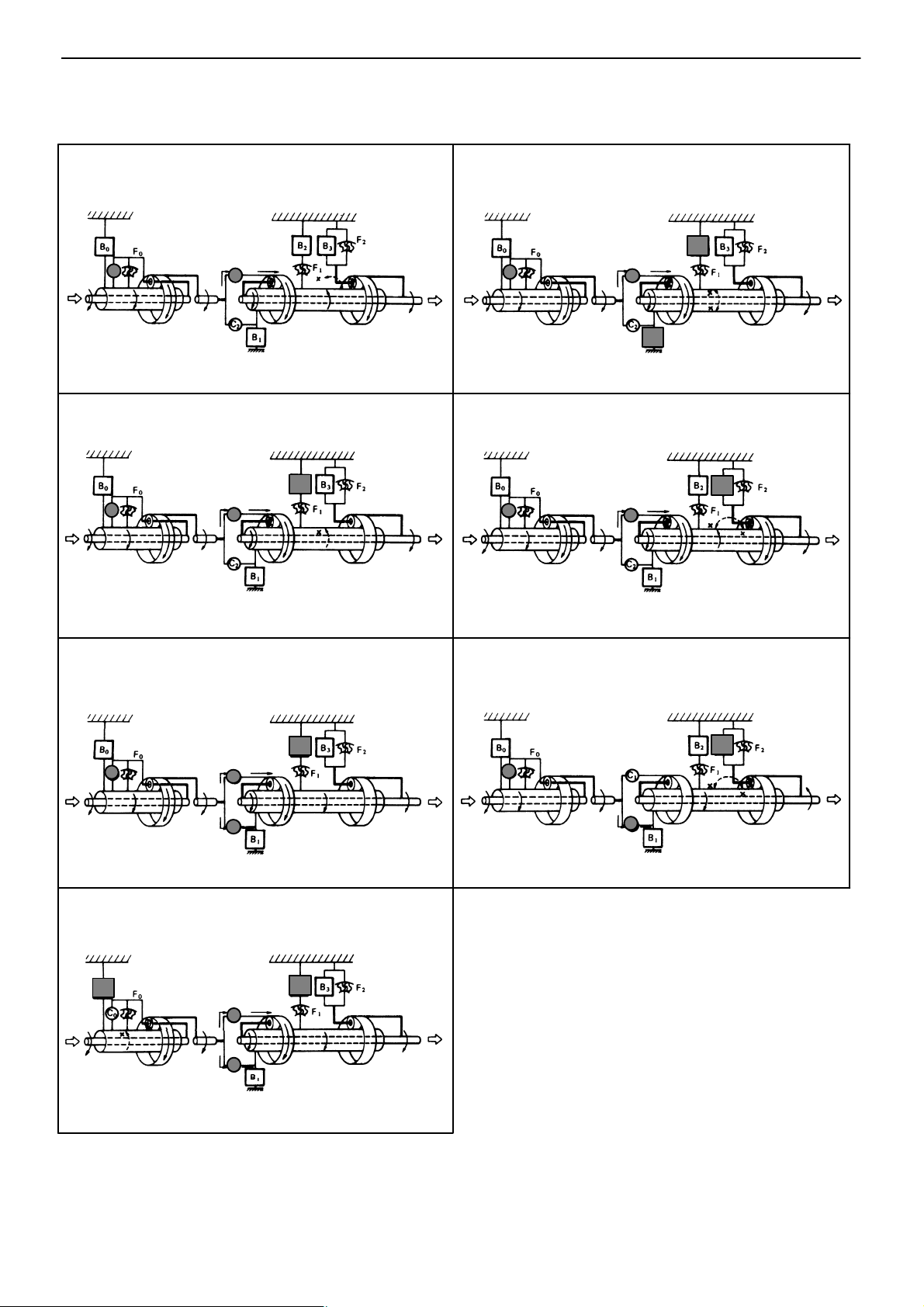

The conditions of operation for each gear position are shown in the following illustrations:

D or 2 Range 1st Gear

D Range 2nd Gear

D or 2 Range 3rd Gear

AT6675

AT6676

D Range O/D

AT6677

AT6678

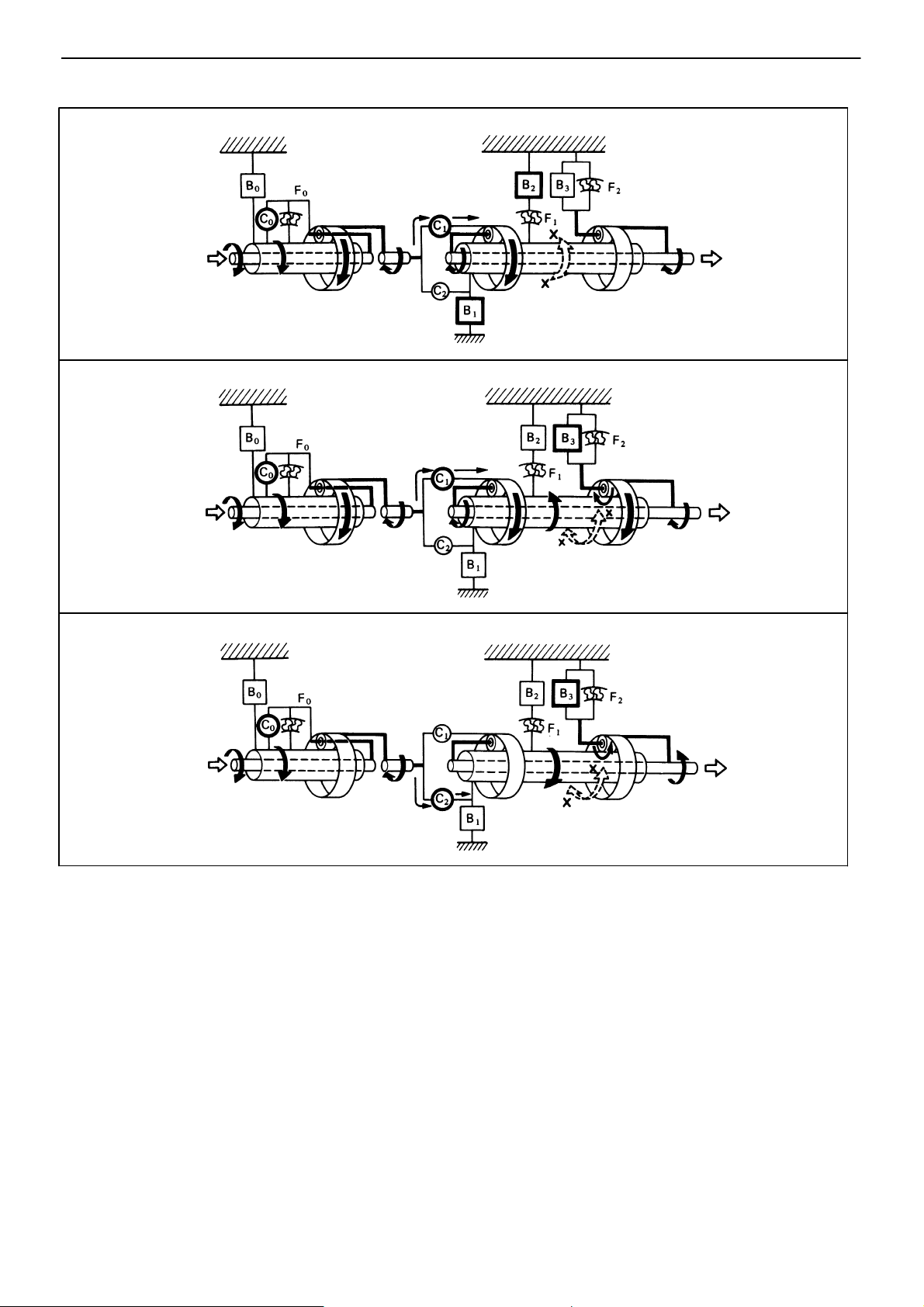

FUNCTION OF COMPONENTS (Cont’d)

2 or L Range 2nd Gear

L Range 1st Gear

−AUTOMATIC TRANSMISSION Operation

AT−11

AT6679

R Range Reverse Gear

AT6680

AT6681

AT−12

−AUTOMATIC TRANSMISSION Operation

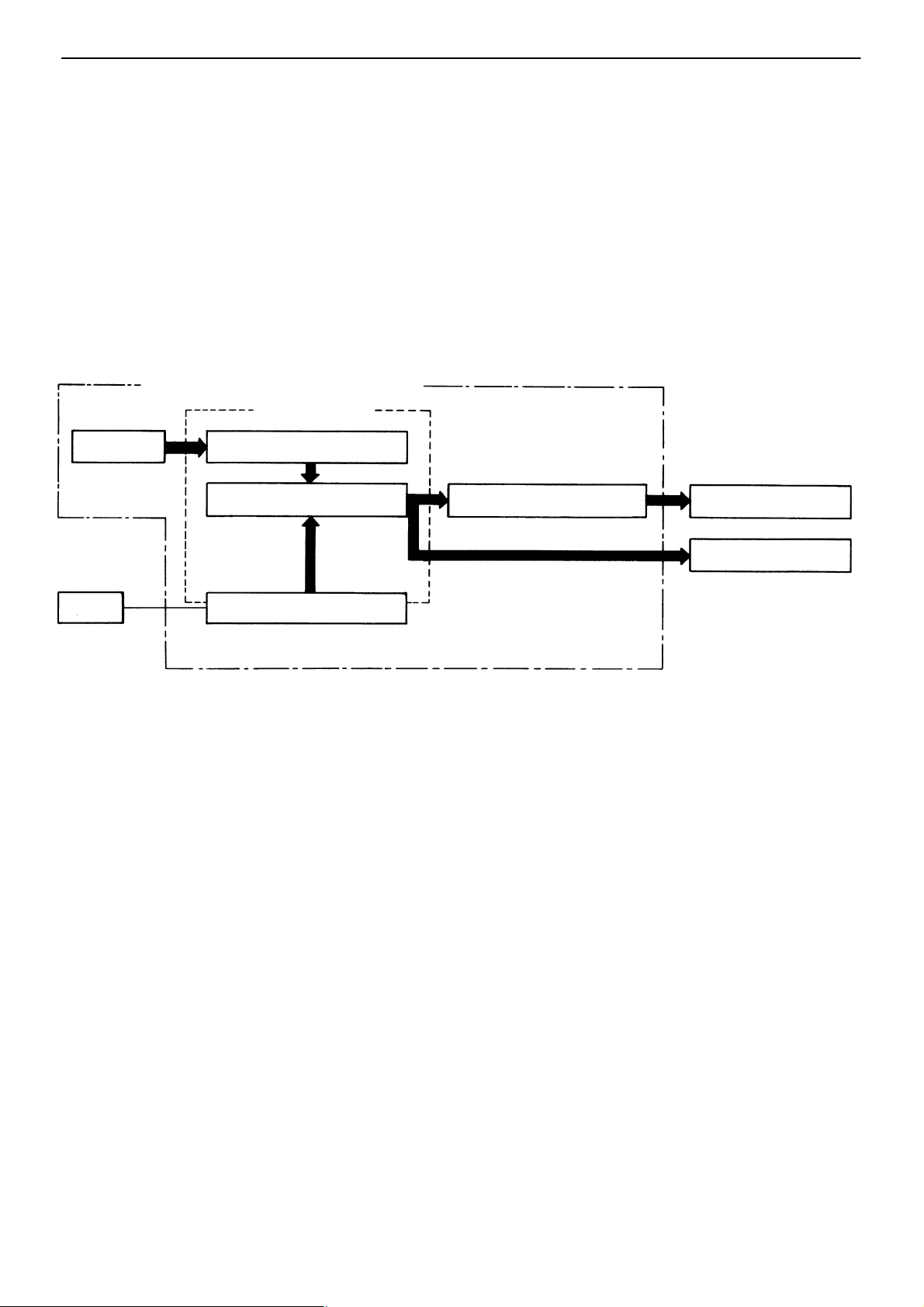

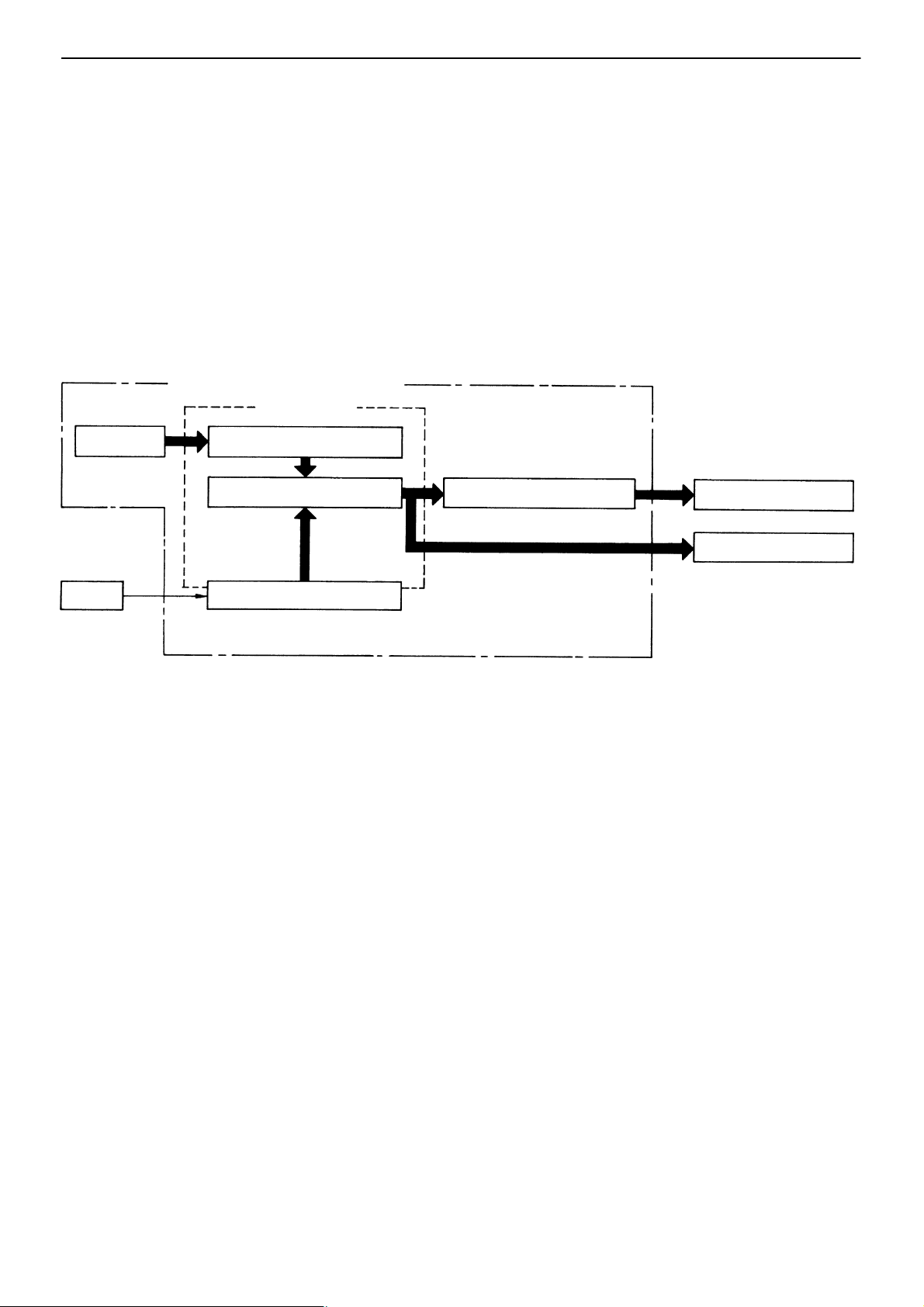

HYDRAULIC CONTROL SYSTEM

(A340E, A340F)

The hydraulic control system is composed of the oil pump, the valve body, the solenoid valves, and the

clutches and brakes, as well as the fluid passages which connect all of these components. Based on the

hydraulic pressure created by the oil pump, the hydraulic control system governs the hydraulic pressure

acting on the torque converter, clutches and brakes in accordance with the vehicle driving conditions.

There are three solenoid valves on the valve body. These solenoid valves are turned on and off by signals from the ECU to operate the shift valves. These shift valves then switch the fluid passages so that

fluid goes to the torque converter and planetary gear units.

(Except for the solenoid valves, the hydraulic control system of the ECT is basically the same as that of

the fully hydraulic controlled automatic transmission.)

HYDRAULIC CONTROL SYSTEM

VALVE BODY

OIL PUMP

ECU

S LINE PRESSURE

Hydr. pressure control

Fluid passage switching

SOLENOID VALVES

Line pressure is the most basic and important pressure used in the automatic transmission,

because it is used to operate all of the clutches and brakes in the transmission.

If the primary regulator valve does not operate correctly, line pressure will be either too high or

too low. Line pressure that is too high will lead to shifting shock and consequent engine power

loss due to the greater effort required of the oil pump; line pressure that is too low will cause

slippage of clutches and brakes, which will, in extreme cases, prevent the vehicle from moving. Therefore, if either of these problems are noted, the line pressure should be measured to

see if it is within standard.

S THROTTLE PRESSURE

Throttle pressure is always kept in accordance with the opening angle of the engine throttle

valve.

This throttle pressure acts on the primary regulator valve and, accordingly, line pressure is

regulated in response to the throttle valve opening.

In the fully hydraulic controlled automatic transmission, throttle pressure is used for regulating

line pressure and as signal pressure for up−shift and down−shift of the transmission. In the

ECT, however, throttle pressure is used only for regulating line pressure. Consequently, improper adjustment of the transmission throttle cable may result in a line pressure that is too

high or too low. This, in turn, will lead to shifting shock or clutch and brake slippage.

CLUTCHES & BRAKES

Planetary gear sets

Torque Converter

−AUTOMATIC TRANSMISSION Operation

AT−13

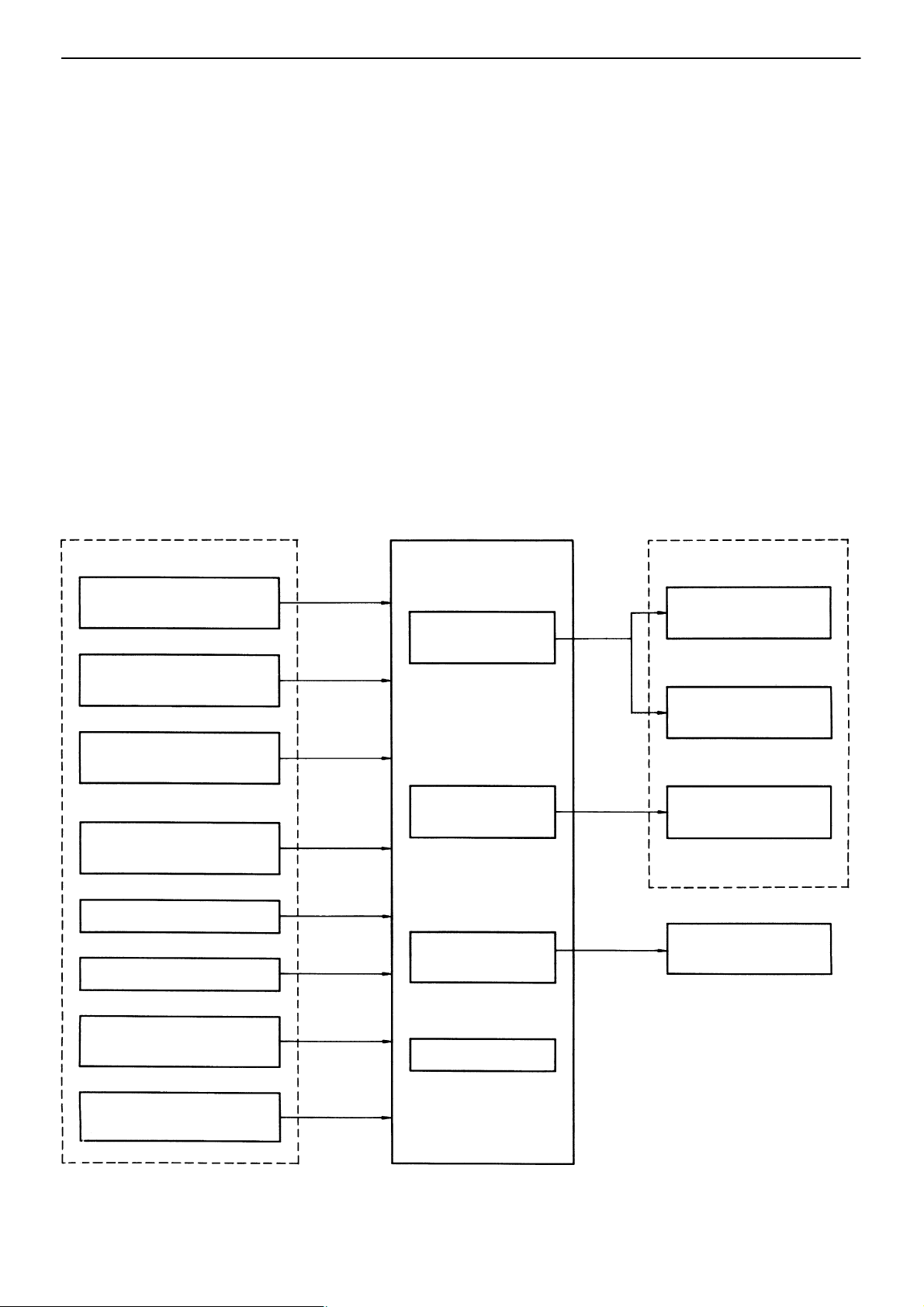

ELECTRONIC CONTROL SYSTEM

(A340E, A340F)

The electronic control system, which controls the shift points and the operation of the lock−up clutch, is

composed of the following three parts:

1. Sensors

These sensors sense the vehicle speed, throttle opening and other conditions and send these

data to the ECU in the form of electrical signals.

2. ECU

The ECU determines the shift and lock−up timing based upon the signals from sensors, and

controls the solenoid valves of the hydraulic control unit accordingly.

3. Actuators

These are three solenoid valves that control hydraulic pressure acting on the hydraulic valves

to control shifting and lock−up timing.

SENSORS

DRIVING PATTERN

SELECTOR

NEUTRAL START

SWITCH

THROTTLE POSITION

SENSOR

VEHICLE SPEED

SENSOR

BRAKE LIGHT SWITCH

O/D MAIN SWITCH

ECU

Control of shift

timing

Control of lock−

up timing

Self−diagnostic

system

ACTUATORS

NO. 1

SOLENOID VALVE

NO. 2

SOLENOID VALVE

LOCK−UP

SOLENOID VALVE

O/D OFF

INDICATOR LIGHT

CRUISE CONTROL

ECU

WATER TEMPERATURE SENSOR

Back−up system

AT−14

OPERATING CONDITIONS

(A340H)

1. Transmission

−AUTOMATIC TRANSMISSION Operation

O/D Input

Shaft

Range (i.e.,

Shift Lever

Position)

P Parking

R

N

D

2

L

C

0

B

0

O/D Planetary

F

0

Gear Unit

Gear

Reverse

Neutral ON

1st ON

2nd

3rd OFF

O/D

1st ON

2nd

3rd

1st

* 2nd

No. 1

Solenoid

Valve

ON

ON

ON

OFF

ON ON F

OFF

ON

ON

B

1

C

2

Input

Shaft

No. 2

Solenoid

Valve

OFF F

OFF F

OFF

OFF F

ON

ON FF

OFF

OFF F

ON F

OFF FF

ON

C

1

Front Planetary

Gear Unit

C

C

0

F

F

F

F

FF

F

F

FF

F

F

B

2

C

1

2

F

F

* Down−shift only in the L range and 2nd gear − no up−shift.

2. Transfer

B

F

F

1

B

B

0

F

F

F

Rear Planetary Gear Unit

3

2

B

1

2

I.P. O.P.

FF

F

F

F

F

F

FF

F

Output Shaft

B

3

AT2157

F

F

0

F

F

F

F

F

F

F

F

F

F

1

2

F

F

F

F

F

F

I.P. ....... Inner Piston

O.P. ..... Outer Piston

Transfer gear position

H2 OFF

H4 OFF

L4 ON

B

C

4

3

C

4

Transmission Output Shaft Transfer Planetary Gear Unit

No. 4 solenoid valve

C

3

F

F

Chain

Transfer Rear Output Shaft

C

4

F

F

ND0045

B

4

F

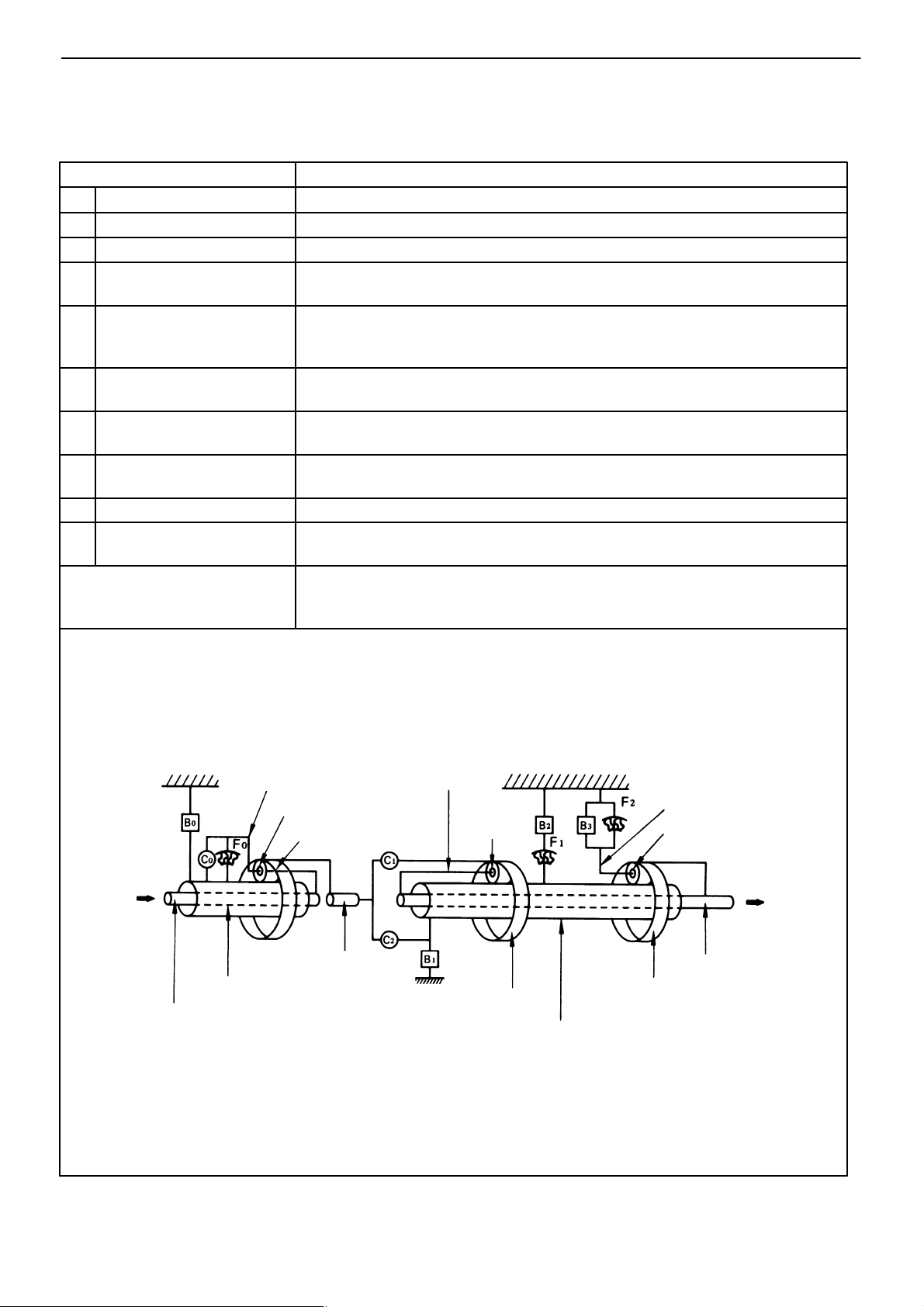

FUNCTION OF COMPONENTS

(A340H)

1. Transmission

−AUTOMATIC TRANSMISSION Operation

AT−15

Component

C

Forward Clutch

1

C

Direct Clutch

2

C

O/D Direct Clutch

0

2nd Coast Brake Prevents front & rear planetary sun gear from turning either clockwise or counterclockwise.

B

1

B22nd Brake

B31st & Reverse Brake Prevents rear planetary carrier from turning either clockwise or counterclockwise.

B0O/D Brake Prevents overdrive sun gear from turning either clockwise or counterclockwise.

F1No. 1 One−Way Clutch

F

No. 2 One−Way Clutch Prevents rear planetary carrier from turning counterclockwise.

2

F0O/D One−Way Clutch

Planetary Gears

Connects input shaft and front planetary ring gear.

Connects input shaft and front & rear planetary sun gear.

Connects overdrive sun gear and overdrive planetary carrier.

Prevents outer race of F1 from turning either clockwise or counterclockwise thus

preventing the front & rear planetary sun gear from turning counterclockwise.

When B2 is operating, this clutch prevents the front & rear planetary sun gear from turning

counterclockwise.

When the transmission is being driven by the engine, this clutch connects the overdrive sun

gear and overdrive planetary carrier.

These gears change the route through which driving force is transmitted in accordance

with the operation of each clutch and brake in order to increase or reduce the input and

output speed.

Function

IN

O/D Input

Shaft

O/D Carrier

O/D Sun Gear

O/D Pinion

O/D Ring Gear

Input Shaft

Front Carrier

Front Ring Gear

Front

Pinion

Front & Rear Sun Gear

Rear Carrier

Rear Pinion

OUT

Output Shaft

Rear Ring Gear

AT5440

AT−16

−AUTOMATIC TRANSMISSION Operation

FUNCTION OF COMPONENTS (Cont’d)

The conditions of operation for each gear position are shown in the following illustrations:

D or 2 Range 1st Gear

C

0

D Range 2nd Gear

C

0

2 or L Range 2nd Gear

B

2

C

C

1

AT5854

0

C

1

B

1

AT5854

L Range 1st Gear

B

2

C

C

1

0

C

1

B

3

D or 2 Range 3rd Gear

C

0

D Range O/D

B

0

AT5854

AT5854

R Range Reverse Gear

B

2

C

C

1

C

2

AT5854

B

2

C

1

C

2

0

C

2

B

3

AT5854

AT5854

FUNCTION OF COMPONENTS (Cont’d)

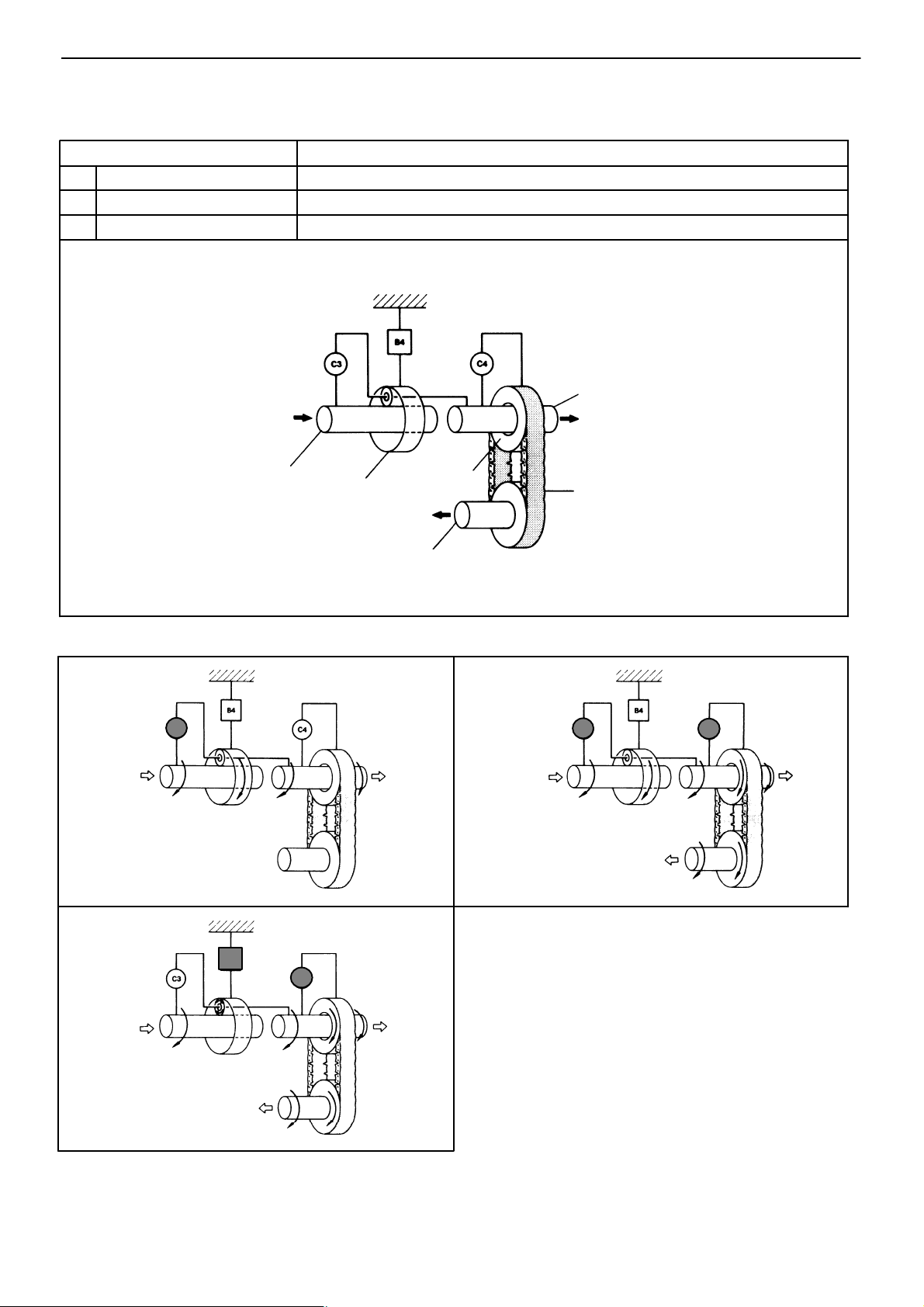

2. Transfer

−AUTOMATIC TRANSMISSION Operation

AT−17

Component

C3Forward Clutch

C

Direct Clutch

4

O/D Direct Clutch

B

4

IN

Transmission

Output Shaft

Function

Connects transmission output shaft and transfer pinion gear.

Connects transfer rear output shaft and front drive gear.

Prevents transfer ring gear from turning either clockwise or counterclockwise.

Transfer Rear Output Shaft

OUT

Ring Gear

Front Drive Gear

Chain

OUT

Transfer Front

Output Shaft

The conditions of operation for each gear position are shown in the following illustrations:

H2 Range

L4 Range

C

3

ND0047

B4

C

4

H4 Range

C

3

C

4

ND0047

ND0047

ND0047

AT−18

−AUTOMATIC TRANSMISSION Operation

HYDRAULIC CONTROL SYSTEM

(A340H)

1. Transmission

The hydraulic control system is composed of the oil pump, the valve body, the solenoid valves, and the

clutches and brakes, as well as the fluid passages which connect all of these components. Based on the

hydraulic pressure created by the oil pump, the hydraulic control system governs the hydraulic pressure

acting on the torque converter, clutches and brakes in accordance with the vehicle driving conditions.

There are three solenoid valves on the valve body. These solenoid valves are turned on and off by signals from the Engine & ECT ECU to operate the shift valves. These shift valves then switch the fluid

passages so that fluid goes to the torque converter and planetary gear units.

HYDRAULIC CONTROL SYSTEM

VALVE BODY

OIL PUMP

ECU

Hydr. pressure control

Fluid passage switching

SOLENOID VALVES

CLUTCHES & BRAKES

2. Transfer

The hydraulic control system consists of a valve body, No. 4 solenoid valve, a brake (B

clutches (C

, C4) and passages that connect these elements. It hydraulically controls the planetary gear

3

unit either manually, or automatically by the Engine & ECT ECU.

Planetary gear sets

Torque converter

) and two

4

−AUTOMATIC TRANSMISSION Operation

AT−19

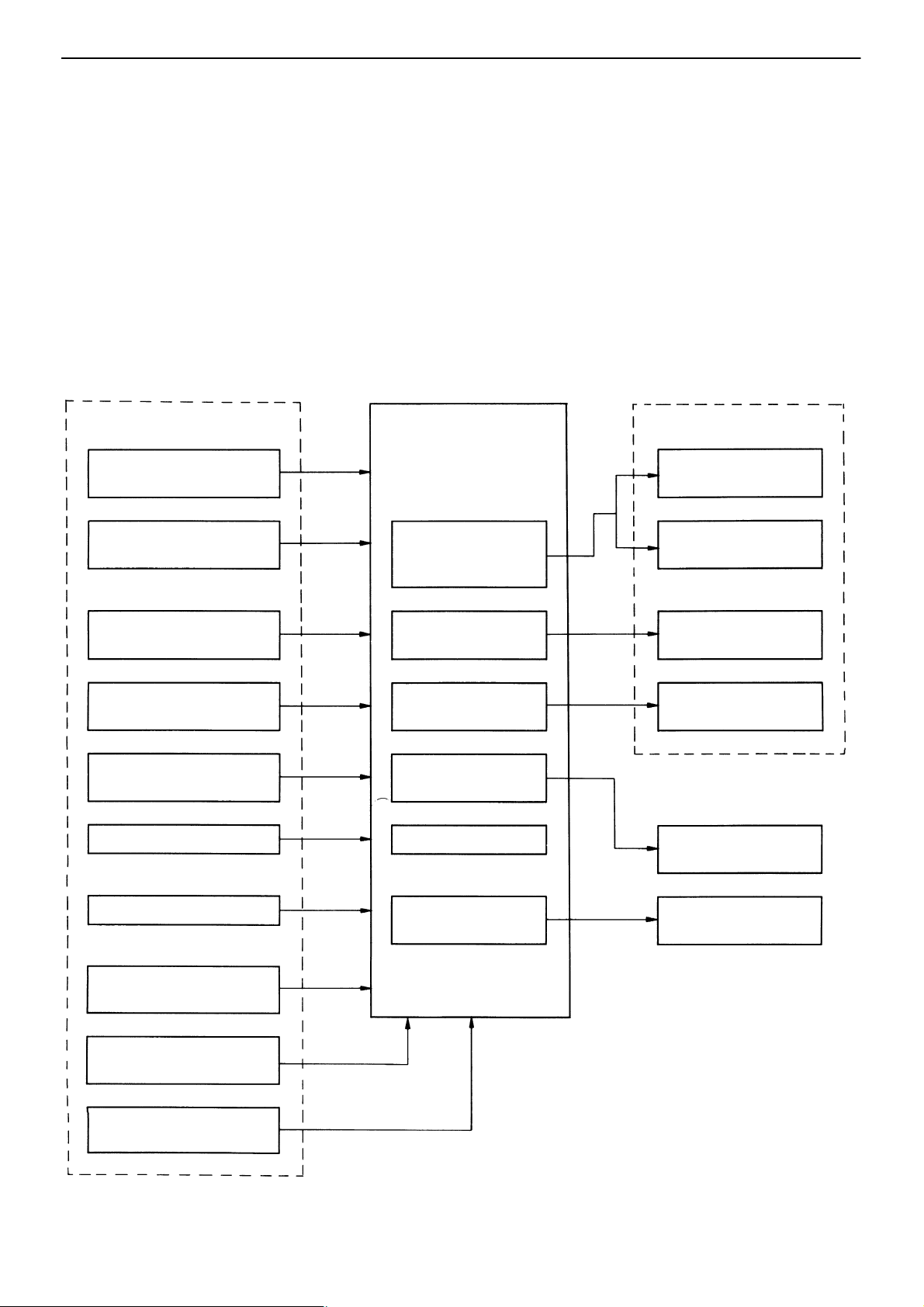

ELECTRONIC CONTROL SYSTEM

(A340H)

The electronic control system, which controls the transmission and transfer shift timing and the operation

of the lock−up clutch, is composed of the following three parts:

1. Sensors

These sensors sense the vehicle speed, throttle opening and other conditions and send these data

to the Engine & ECT ECU in the form of electrical signals.

2. Engine & ECT ECU

The Engine & ECT ECU determines the transmission and transfer shift timing and lock−up timing

based upon the signals from sensors, and controls the solenoid valves of the hydraulic control unit

accordingly.

3. Actuators

These are four solenoid valves that control hydraulic pressure acting on the hydraulic valves to

control shifting and lock−up timing.

SENSORS

DRIVING PATTERN

SELECTOR

NEUTRAL START

SWITCH

TRANSFER SHIFT

POSITION SWITCH

THROTTLE POSITION

SENSOR

VEHICLE SPEED

SENSOR

BRAKE LIGHT SWITCH

Engine & ECT ECU

Control of

transmission

shift timing

Control of

lock−up timing

Control of transfer

shift timing

Self−diagnostic

system

Back−up system O/D OFF INDICATOR

ACTUATORS

NO. 1

SOLENOID VALVE

NO. 2 SOLENOID

VALVE

LOCK UP SOLENOID

VALVE

NO. 4

SOLENOID VALVE

LIGHT

O/D MAIN SWITCH

CRUISE CONTROL

ECU

WATER TEMPERATURE

SENSOR

FLUID TEMPERATURE

SENSOR

Fluid temperature

warning system

A.T. OIL TEMP.

WARNING LIGHT

AT−20

PREPARATION

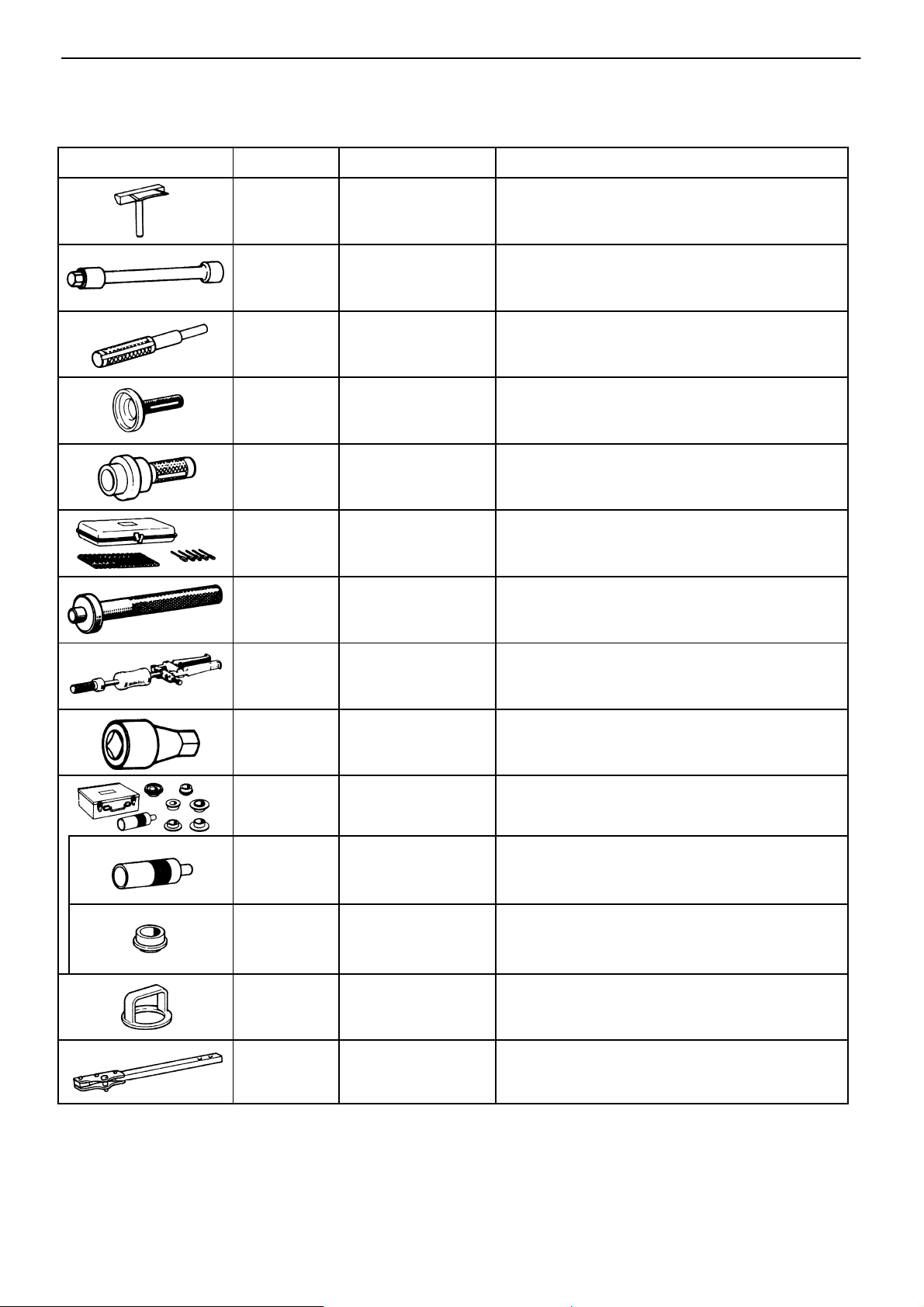

SST (SPECIAL SERVICE TOOLS)

−AUTOMATIC TRANSMISSION Preparation

Illustration

Part No.

09032−00100

09043−38100

09201−60011

09223−15010

09223−22010

09240−00020

09304−12012

Part Name

Oil Pan Seal

Cutter

Hexagon 10 mm

Wrench

Valve Guide Bushing

Remover & Replacer

Crankshaft Front

Oil Seal Replacer

Crankshaft Front

Oil Seal Replacer

Wire Gauge Set

Input Shaft Front

Bearing Replacer

Note

Transfer (A340F)

Transfer (A340F)

Transfer (A340F)

Transfer (A340F)

Transfer (A340F)

09308−00010

09313−30021

09316−60010

(09316−00010)

(09316 − 00070)

09320−89010

09330−00021

Oil Seal Puller

Detent Ball Plug

Socket

Transmission &

Transfer Bearing

Replacer

Replacer ”A”

Replacer ”F” Transfer (A340F)

Transfer Clutch

Spring Compressor

Companion Flange

Holding Tool

Transfer (A340F)

Transfer (A340F)

Transfer (A340F)

A340H

A340H

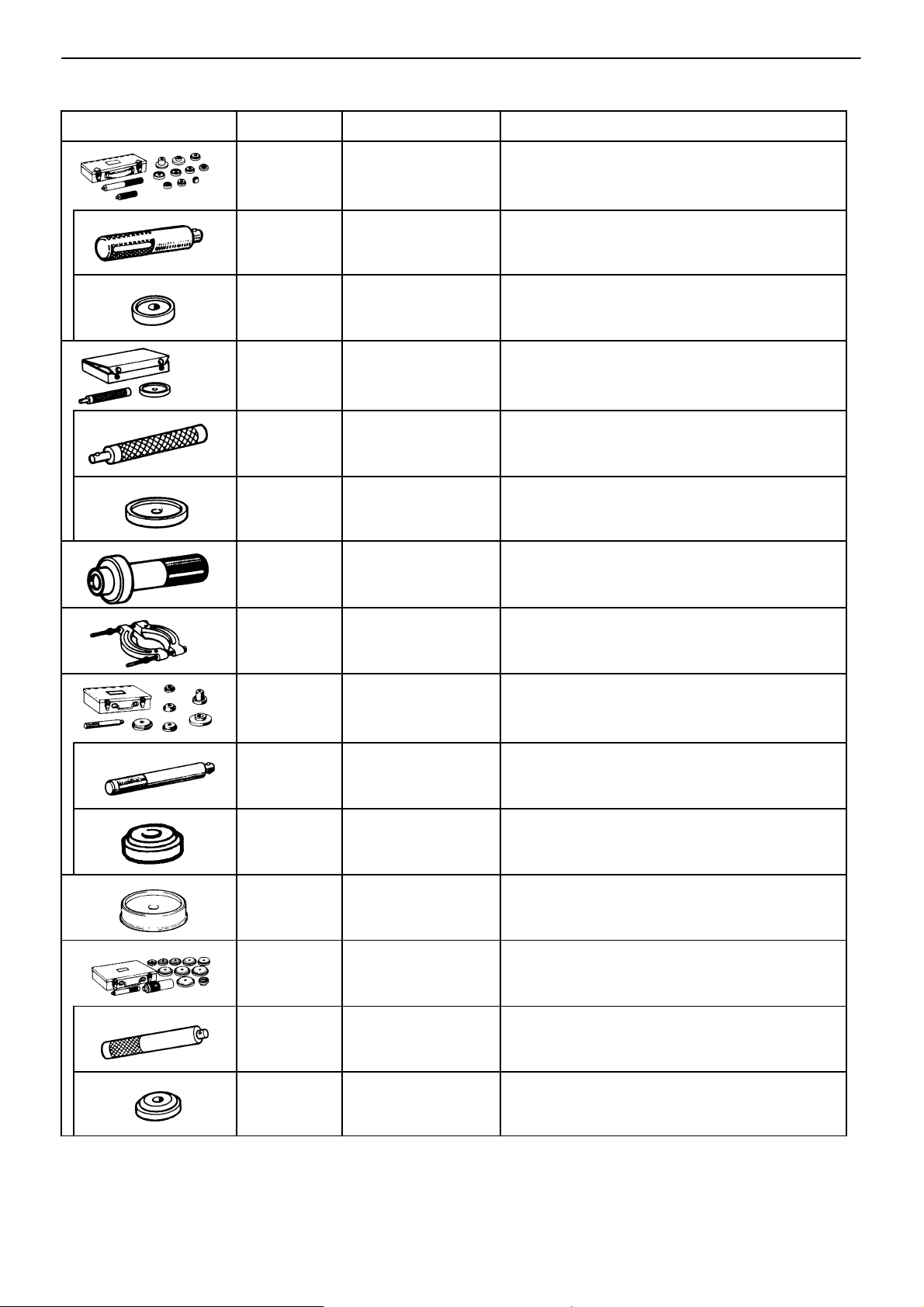

SST (SPECIAL SERVICE TOOLS) (Cont’d)

−AUTOMATIC TRANSMISSION Preparation

AT−21

Illustration

Part No.

09350−30020

(09350−06120)

(09350−07020)

(09350−07030)

(09350−07040)

(09350−07050)

(09350−07060)

Part Name

TOYOTA Automatic

Transmission Tool

Set

No. 2 Measure

Terminal

Oil Pump Puller

No. 1 Piston Spring

Compressor

No. 2 Piston Spring

Compressor

No. 3 Piston Spring

Compressor

No. 1 Snap Ring

Expander

Note

A340E

(09350−07070)

(09350−07080)

(09350−07090)

(09350−07110)

(09351−32140)

09350−36010

(09350−06090)

No. 2 Snap Ring

Expander

Brake Reaction Sleeve

Puller

Brake No. 1 Piston

Puller

Oil Seal Replacer

Oil Seal Replacer

TOYOTA Automatic

Transmission Tool

Set

Plate

A340E

09515−30010

Rear Wheel Bearing

Replacer

Transfer (A340F)

AT−22

SST (SPECIAL SERVICE TOOLS) (Cont’d)

−AUTOMATIC TRANSMISSION Preparation

Illustration

Part No.

09550−10012

(09252−10010)

(09557−10010)

09550−22011

(09550−00020)

(09550−00031)

09554−30011

Part Name

Replaces Set ”B”

No. 1 Replacer Handle Transfer (A340F)

Differential Drive

Pinion Front Bearing

Replacer

Rear Axle Bearing

& Differential Tool

Set

Handle Transfer (A340F)

(Replacer Transfer (A340F)

Differential Oil

Seal Replacer

Transfer (A340F)

Transfer (A340F)

Transfer (A340F)

Transfer (A340F)

Note

09555−55010

09608−12010

(09608−00020)

(09608−00040)

09608−32010

09608−35014

(09608−06020)

Differential Drive

Pinion Bearing

Replacer

Front Hub & Drive

Pinion Bearing

Replacer Set

Remover & Replacer

Handle

Front Hub Outer

Bearing Cup Replacer

Steering Knuckle Oil

Seal Replacer

Axle Hub &

Drive Pinion Bearing

Tool Set

Handle

Transfer (A340F)

Transfer (A340F)

Transfer (A340F)

Transfer (A340F)

A340H

A340H

A340H

(09608−06100)

Front Hub Outer

Replacer

A340H

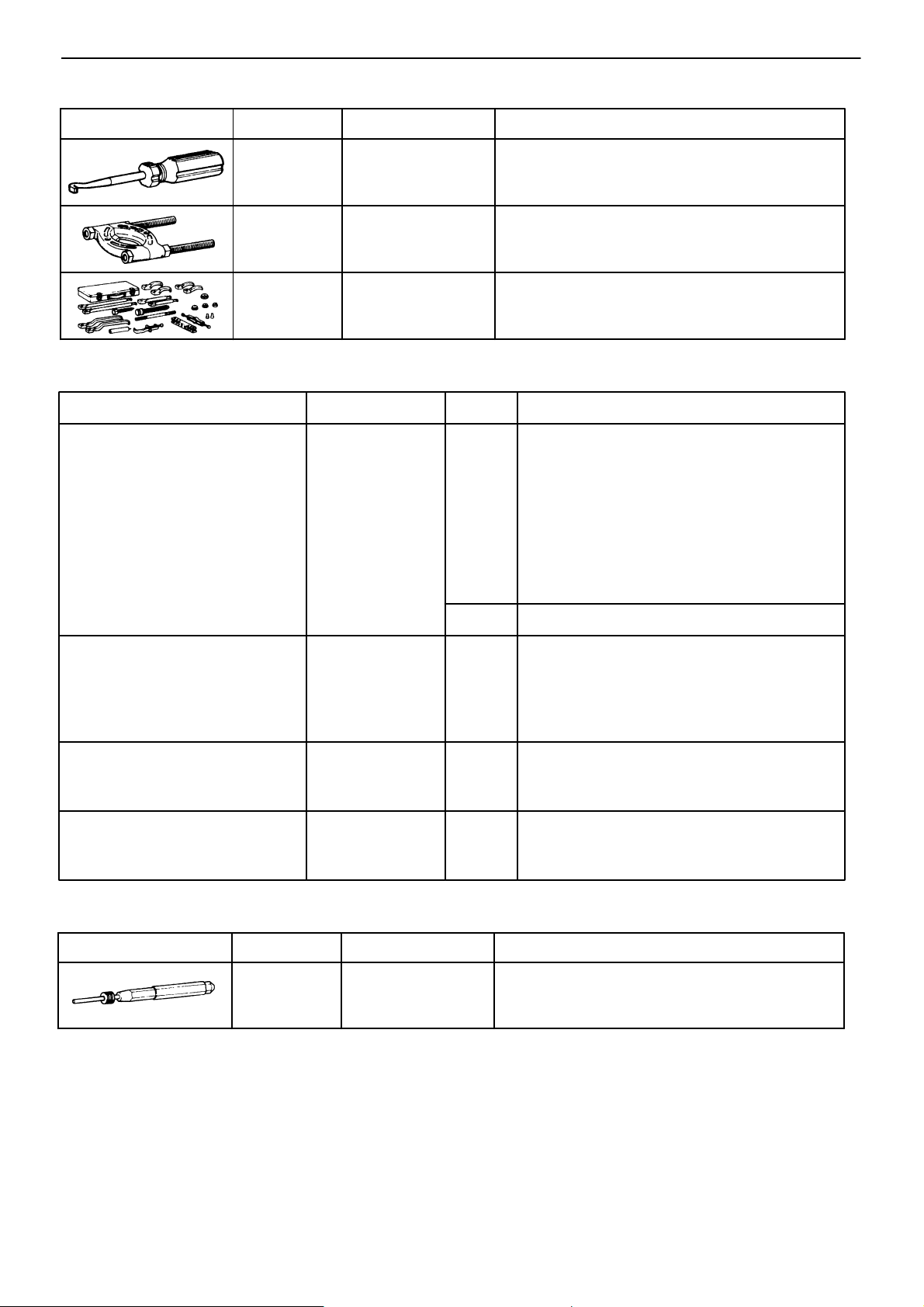

SST (SPECIAL SERVICE TOOLS) (Cont’d)

−AUTOMATIC TRANSMISSION Preparation

AT−23

Illustration

Part No. Part Name

09921−00010

09950−00020

09950−20017

Spring Tension Tool

Bearing Remover

Universal Puller

SSM (SPECIAL SERVICE MATERIALS)

Part Name

Seal packing 1281,

Three bond 1281 or equivalent

Part No. Sec. Use etc.

08826−00090

Transfer (A340F)

Transfer (A340F)

Transfer (A340F)

AT

Note

(A340E)

Oil pan

(A340H)

Transfer case

Transfer chain front case

Transfer chain rear case

Transfer oil pump

Transfer oil pan

Transmission oil pan

Adhesive 1324,

Three bond 1324 or equivalent

Adhesive 1344,

Three bond 1344,

Loctite 242 or equivalent

Adhesive 1131,

Three bond 1131,

Loctite 518 or equivalent

RECOMMENDED TOOLS

Illustration

Part No.

09031−00030

08833−00070

08833−00080

08833−00090

Part Name

Pin Punch

AT

AT

TF

TF

Rear companion flange

(A340H)

Transfer oil strainer set bolts

Transfer chain front case set bolts

Transfer chain oil receiver set bolts

Transfer oil pan set bolts

Straight screw plug

Extension housing set bolt

Front reatainer set bolt

(A340H)

Transfer extension housing

Note

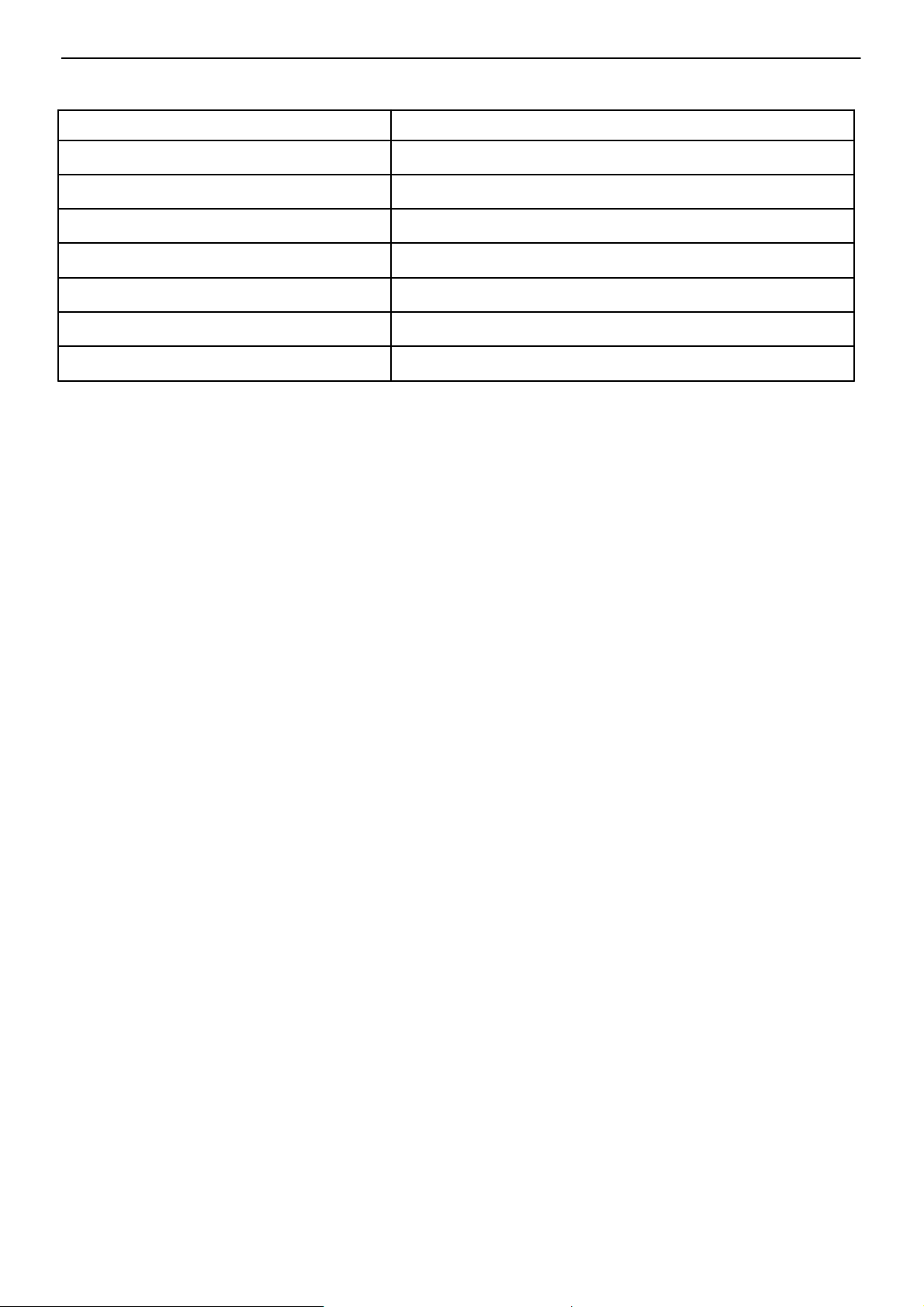

AT−24

EQUIPMENT

−AUTOMATIC TRANSMISSION Preparation

Part Name

Feeler gauge

Vernier caliper with depth gauge

Dial indicator with magnetic base

Dial indicator

Straight edge

Torque wrench

Cylinder gauge

Note

Check major clearance.

Check length of second coast brake piston rod.

Check piston stroke and end play of the output shaft.

Check inside diameter of major bushing.

Check side clearance of oil pump.

Check inside diameter of the transmission case rear bushing.

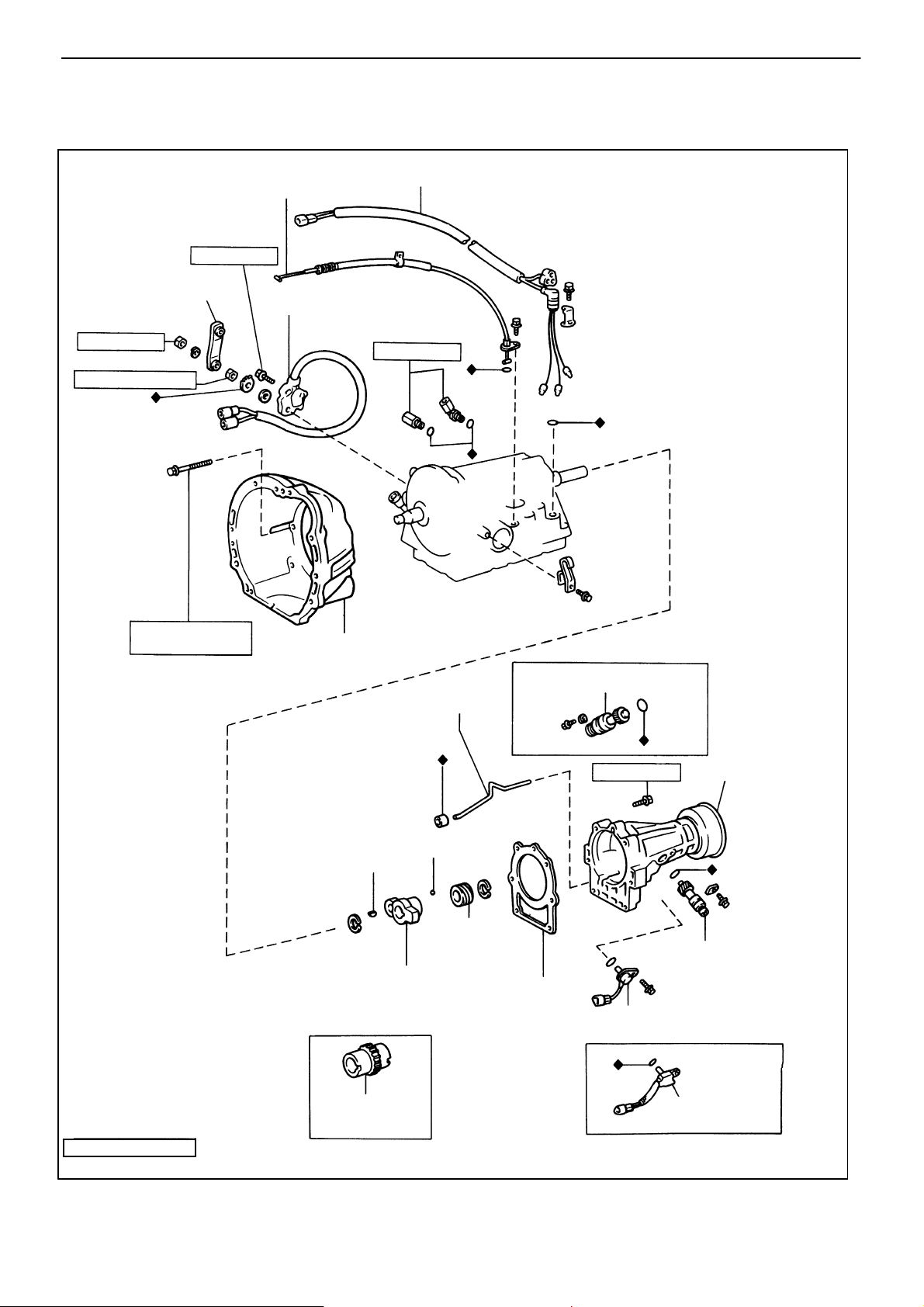

−AUTOMATIC TRANSMISSION (A340E) Removal of Component Parts

AT−25

REMOVAL OF COMPONENT PARTS (A340E)

COMPONENTS (SUPRA and CRESSIDA)

Control Shaft Lever

160 (12, 16)

70 (61 in.−lb, 6.9)

Throttle Cable

Adjusting Bolt

130 (9, 13)

Neutral Start Switch

Solenoid Wire

Union

300 (22, 29)

10 mm 345 (25, 34)

12 mm 580 (42, 57)

Transmission Housing

Oil Apply Tube

Key

Sensor Rotor

Ball

Speedometer

Drive Gear

(w/o ABS)

(SUPRA)

♦ Gasket

Speedometer

Drive Gear

370 (27, 36)

Speed Sensor

(w/o ABS)

Extension Housing

Speedometer

Drive Gear

(CRESSIDA)

kg−cm (ft−lb, N−m)

♦ Non−reusable part

: Specified torque

Sensor Rotor

(w/ ABS)

Speed Sensor

(w/ ABS)

AT8370

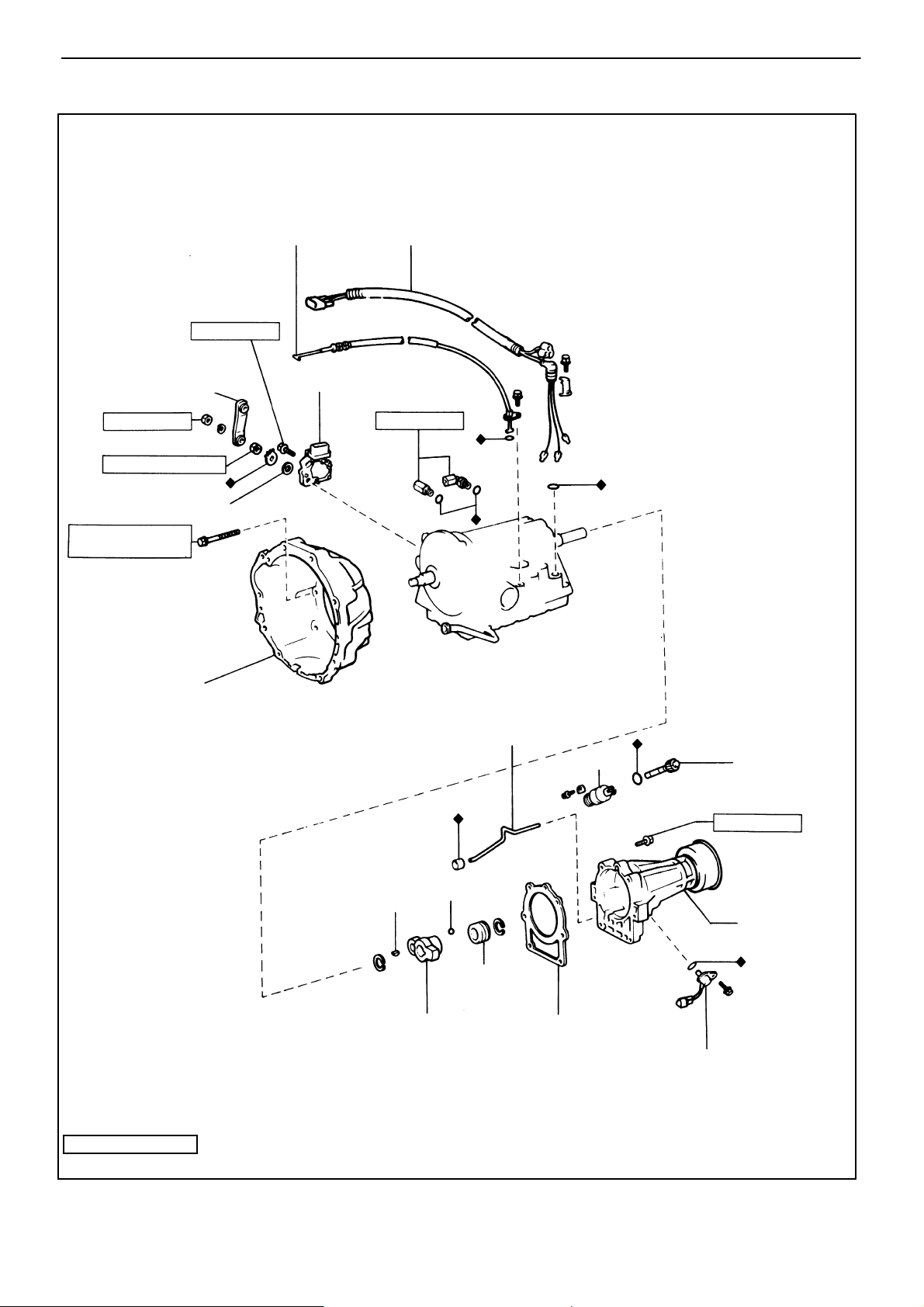

AT−26

−AUTOMATIC TRANSMISSION (A340E) Removal of Component Parts

COMPONENTS (TRUCK and 4 RUNNER)

Throttle Cable

Adjusting Bolt

130 (9, 13)

Control Shaft Lever Neutral Start Switch

160 (12, 16)

70 (61 in.−lb, 6.9)

Grommet

10 mm 345 (25, 34)

12 mm 580 (42, 57)

Solenoid Wire

Union

300 (22, 29)

Transmission Housing

Key

Ball

Speedometer

Drive Gear

Sensor Rotor

Oil Apply Tube

♦ Gasket

Sleeve

Speedometer

Driven Gear

370 (270, 36)

Extension

Housing

Speed Sensor

kg−cm (ft−lb, N−m) : Specified torque

♦ Non−reusable part

AT4622

Loading...

Loading...