Page 1

STE 58762

INSTRUCTION MANUAL

INDUSTRIAL ROBOT SR SERIES

ROBOT LANGUAGE MANUAL

Notice

1.

Make sure that this Instruction Manual is delivered to the final user

of the Toshiba Industrial Robot.

2. Please read this manual before using the Toshiba Industrial

Robot.

3. Please read the “Safety Manual” also.

4. Keep the manual nearby for further reference during use of the

robot.

TOSHIBA MACHINE CO.,LTD.

1998- 3

Page 2

STE 58762

Copyright 1997 by Toshiba Machine Co., Ltd.

All rights reserved.

No part of this document may be reproduced in any form without obtaining prior written permission

from the Toshiba Machine Co., Ltd.

The information contained in this manual is subject to change without notice.

i

- -

Page 3

STE 58762

PREFACE

This manual explains the SCOL robot language, commands and programming procedures as they

apply to Toshiba SR Series industrial robots.

SCOL stands for "Symbolic Code Language for Robots" and is a robot language made up of various

commands used to control the robot. By using these commands, it is possible to create programs

to make the robot do what you want.

This manual is directed at those who have never written a robot program, and at those who have

much programming experience. However, this manual only covers SCOL robot language. For

information on Toshiba SR Series industrial robots themselves, please refer to the following

manuals:

- Introductory Manual

- Start-up Manual

- Operating Manual

This Manual is organized as follows:

[1. An Outline of Robot Language]

This chapter explains the connection between robot language and robot movement, and presents a

rough outline of commands used in robot language. Be sure to read this chapter in order to get a

grasp of the fundamentals of robot language.

[2. Writing Programs in Robot Language]

This chapters describes various rules for writing a program with robot language. Be sure to read

this chapter before starting to write your own programs.

[3. Explanation of Robot Commands]

Here we describe in detail what each command means and does. These commands are listed in

alphabetical order for your convenience. This chapter will come in useful when you write programs

on your own.

[4. Program Examples]

In this chapter, we explain various programming examples. Be sure to use this chapter for

reference when writing your own programs.

ii

- -

Page 4

STE 58762

[5. Programming Hints and Warnings]

This chapter explains timing considerations, things not to do, and things to watch out for when

writing a program. Be sure to read it before beginning work on your own program. Also, be sure

to look this chapter over should your program not be working the way you intended.

iii

- -

Page 5

STE 58762

TABLE OF C O N TENT S

CHAPTER 1 AN OUTLINE OF ROBOT LANGUAGE

1.1

1.2

1.3

CHAPTER 2 WRITING PROGRAMS IN ROBOT LANGUAGE

2.1

2.1.1

2.1.2

2.1.3

2.2

2.3

2.4

2.4.1

2.4.2

2.4.3

2.4.4

2.5

2.5.1

2.5.2

2.6

2.7

ROBOT MOVEMENT ・・・・・・・・・・・・・・・・・・・・・

ROBOT LANGUAGE ・・・・・・・・・・・・・・・・・・・・・

TYPES OF COMMANDS ・・・・・・・・・・・・・・・・・・・

PROGRAM CONFIGURATION

Files ・・・・・・・・・・・・・・・・・・・・・・・・・・

Program

Positional Data ・・・・・・・・・・・・・・・・・・・・・・

CHARACTER SET ・・・・・・・・・・・・・・・・・・・・・・

IDENTIFIERS ・・・・・・・・・・・・・・・・・・・・・・・・

VARIABLES AND CONSTANTS ・・・・・・・・・・・・・・・・

Scalar Data

Vector Data ・・・・・・・・・・・・・・・・・・・・・・・

System Variables

System Constants・・・・・・・・・・・・・・・・・・・・・

MATHEMATICAL FUNCTIONS

Computational Expressions・・・・・・・・・・・・・・・・・

Logical Expressions ・・・・・・・・・・・・・・・・・・・・

LABELS ・・・・・・・・・・・・・・・・・・・・・・・・・・

REMARKS AND COMMENTS・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・

1-1

1-3

1-5

2-1

2-1

2-1

2-2

2-3

2-4

2-5

2-5

2-7

2-10

2-11

2-12

2-13

2-18

2-19

2-20

iv

- -

Page 6

2.8

2.8.1

2.8.2

2.8.3

2.8.4

2.8.5

CHAPTER 3 EXPLANATION OF ROBOT COMMANDS

3.1

3.2

CHAPTER 4 PROGRAM EXAMPLES

CHAPTER 5 PROGRAMMING HINTS AND WARNINGS

5.1

5.1.1

5.1.2

5.1.3

5.2

5.2.1

5.3

5.3.1

5.3.2

5.3.3

5.3.4

5.3.5

5.3.6

5.3.7

5.3.8

PROGRAMS ・・・・・・・・・・・・・・・・・・・・・・・・

Program Declaration・・・・・・・・・・・・・・・・・・・・

Subprograms・・・・・・・・・・・・・・・・・・・・・・・

Library ・・・・・・・・・・・・・・・・・・・・・・・・・

Multitask Processing・・・・・・・・・・・・・・・・・・・・

Global Variable Definition・・・・・・・・・・・・・・・・・・

COMMAND EXPLANATIONS ・・・・・・・・・・・・・・・・・

EXPLANATION OF COMMANDS ・・・・・・・・・・・・・・・

PROGRAM EXECUTION TIMING ・・・・・・・・・・・・・・・

Arm Movement and Signal I/O Timing

Synchronization of Arm Movement and Program Execution・・・

DELAY Command and WAIT Command ・・・・・・・・・・・

THINGS NOT TO DO WHEN PROGRAMMING ・・・・・・・・・

Variables・・・・・・・・・・・・・・・・・・・・・・・・・

THINGS TO WATCH OUT FOR WHEN WRITING A PROGRAM・・

Types of Commands・・・・・・・・・・・・・・・・・・・・

Robot Coordinate Systems

Short-Cut Movement・・・・・・・・・・・・・・・・・・・・

Robot Configuration・・・・・・・・・・・・・・・・・・・・

Data Blocks・・・・・・・・・・・・・・・・・・・・・・・・

Global Data Block・・・・・・・・・・・・・・・・・・・・・

Robot Movement Speed・・・・・・・・・・・・・・・・・・

Robot Acceleration・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・

・・・・・・・・・・・

STE 58762

2-21

2-21

2-22

2-24

2-25

2-28

3-1

3-7

5-1

5-1

5-3

5-4

5-7

5-7

5-8

5-8

5-10

5-16

5-22

5-24

5-27

5-30

5-31

v

- -

Page 7

STE 58762

APPENDIX A

APPENDIX B

APPENDIX C

APPENDIX D

APPENDIX E

LIST OF COMMANDS ・・・・・・・・・・・・・・・・・

LIST OF RESERVED WORDS ・・・・・・・・・・・・・

CONTENTS OF LIBRARY FILE (SCOL.LIB)・・・・・・・・

DOMAINS AND RANGES OF CALCULATOR FUNCTIONS ・・

HOW TO READ SYMBOLS ・・・・・・・・・・・・・・・

6-1

6-4

6-5

6-8

6-9

vi

- -

Page 8

STE 58762

CHAPTER 1

AN OUTLINE OF ROBOT LANGUAGE

This chapter describes the connection between robot language and robot movement, and presents

a rough outline of commands used in robot language.

1.1 ROBOT MOVEMENT

Robots do work in place of people. For example, let’s say that somebody has to attach a part to a

workpiece coming down a conveyor. The employee takes a part from a parts bin and attaches the

part to a workpiece transported to his or her station by a conveyor. If we were to set up a robot to

do this work instead, we would have an arrangement something like that shown in Figure 1.1.

Parts feeder

Wokpiece

Conveyor

Fig. 1.1 Assembly work

Here, the robot grabs a part from the parts feeder and attaches the part to a workpiece coming

down the conveyor. considering this work from the point of view of the robot (and not, for example,

from the point of view of the parts feeder or conveyor), we would come up with a diagram like that of

Figure 1.2. In this Figure, the robot first moves straight down from Point B to Point A, where it

grabs a part. After grabbing the part, the robot moves back up from Point A to Point B. From

Point B, the robot moves the part to Point C, which is directly above the part attachment location

Point D. The robot then drops down from Point C to Point D, and attaches the part to the

workpiece. When the robot is finished attaching the part, it moves back up to Point C, and then

finally back to Point B. This completes one work cycle.

1-1

- -

Page 9

j

j

p

grip

A: Position where robot

B: Position

s a part.

Fig. 1.2 Robot movement

ust above A

STE 58762

C: Position

D: Position where a

ust above D

art is mounted.

1-2

- -

Page 10

STE 58762

1.2 ROBOT LANGUAGE

Robots do assembly work and other tasks in place of people.

However, someone still has to teach the robot what to do.

Robots will only do what you tell them to do, and it's

important to tell them exactly what you want it to do.

Telling a robot what to do is called "teaching." Making a robot do what you taught it to do is called

"playback." Of course, this only applies to what are called "playback robots," which repeat (or

playback) the movements you instructed the robot when teaching. Toshiba SR Series robots are

playback robots.

There are various ways to teach a robot what to do. One way is to physically move the robot

through the work cycle (while, of course, the robot is in the teaching mode). The robot remembers

the locations where it was moved and, in the playback mode, retraces this path and performs the

work. This is the usual method for teaching painting robots and spot welding robots.

However, things get more complicated when dealing with peripheral devices (such as a parts

feeder or a conveyor belt). In such a case, you must coordinate the movements of the robot with

the movements of the peripheral devices. In the previous example, we talked about a robot

attaching a part to a workpiece coming down a conveyor line. However, what if we want to attach

different parts to different workpieces? What do we do if the robot misattaches the part and we

want to try again?

In order to tell the robot what to do, we need to express robot actions in terms the robot

understands. This is the purpose of robot language. A robot language is nothing more than a set

of words describing robot actions. An arrangement of these words used to control the movement

of the robot is called a program. Writing a program is called programming.

There are various robot languages in existence. However, SR Series robots use SCOL (Symbolic

Code Language for Robots), a language developed specifically for robots. Therefore, we will limit

our discussion of robot languages to SCOL in this Manual.

1-3

- -

Page 11

STE 58762

If we were to write a program in SCOL for the previous example (in which we attach a part from a

parts feeder to a workpiece on a conveyor), it would look like this:

PROGRAM ASSEMBLY

MOVE B Move to Point B.

OPEN1 Open Hand 1.

MOVE A Move to Point A.

CLOSE1 Close Hand 1.

DELAY 0.5 Wait 0.5 seconds before grabbing the part.

MOVE B Move to Point B.

MOVE C Move to Point c.

MOVE D Move to Point D.

OPEN1 Open Hand 1.

DELAY 0.5 Wait 0.5 seconds before letting go off the part.

MOVE C Move to Point c.

MOVE B Move to Point B.

END

The word PROGRAM marks the beginning of a program and the word END marks the end of a

program. The name of this particular program is ASSEMBLY. The commands should not be too

hard to understand. MOVE A means to move to Point A. OPENi and CLOSE 1 mean to,

respectively, open and close Hand 1. (There are two hands.) DELAY 0.5 means not to do

anything for 0.5 seconds. Furthermore, the locations of Points A, B, C and D are defined (taught)

beforehand by physically guiding the robot (in the teaching mode) to these points. (To put it

another way, the location of these points is not defined by the program itself.)

By arranging a series of commands in the order that you want things done, SCOL allows you, the

programmer, to express just what the robot is supposed to do in terms that the robot understands.

1-4

- -

Page 12

STE 58762

1.3 TYPES OF COMMANDS

In the previous section, we saw how SCOL is used to express the action of the robot.

Here, we explain a little bit more about SCOL commands themselves.

In addition to commands like "MOVE A" which actually move the robot, there are many other

commands which do such things as send signals to other equipment (such as conveyors, parts

feeders, process computers, etc.) or direct the robot to do the same thing over and over again.

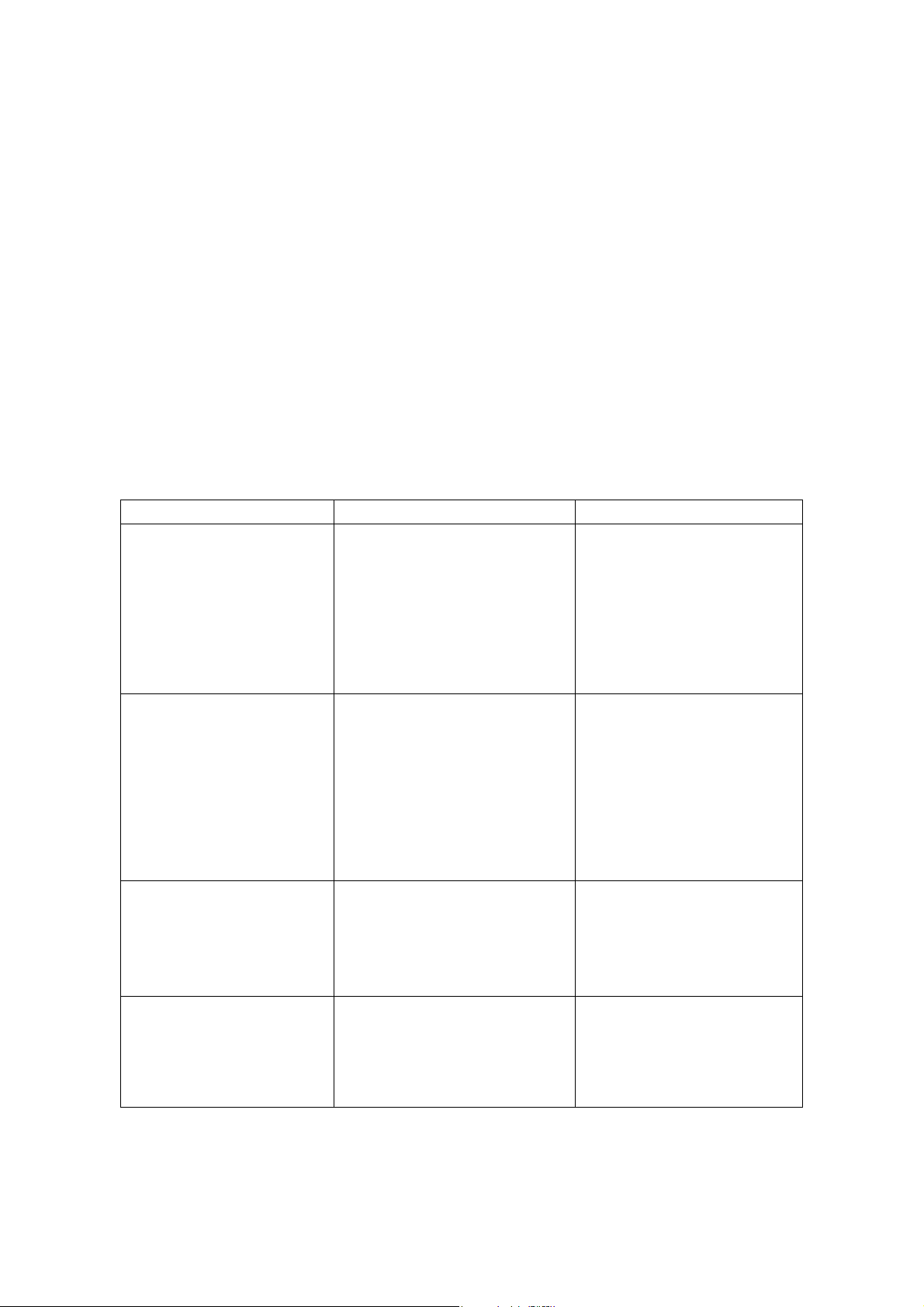

Table 1.1 presents a list of SCOL commands.

All SCOL commands can be roughly classified into one of six categories.

(1) Movement control commands

These commands move the robot. Commands which temporarily stop the robot, interrupt

movement, or restart the robot are also included in this category. Commands which actually move

the robot are called movement commands.

(2) Program control commands

Program control commands control the execution of the program by doing such things as executing

certain parts of the program in accordance with external signals or causing portions of the program

to be carried out repeatedly.

(3) I/O (Input/output) control commands

These commands are used to read in (input) or send out (output) signals to and from external

equipment, such as the teach pendant. Data input/output of hand open/close communication

channel are included in the I/O control command.

(4) Movement condition commands

These commands are used to specify the configuration and speed of various joints of the robot

while it is moving.

(5) Calculator commands

These commands are used to invoke (use) mathematical functions such as the trigonometric

functions (sin, cos, etc.) and the square root function.

1-5

- -

Page 13

STE 58762

(6) Movement reference commands

These commands are used to reference and check the movement of the robot. For example,

these commands could be used to determine what percentage of a certain motion has been

completed at a certain time. By including these commands in your program, you can set timers

and make sure robot motions do not interfere with each other.

These commands are meant to be used in combination with other commands in your program. By

skillfully placing such commands in the right places, you can, for example; (1) Get the robot to send

out a signal to an external device when the robot has completed 70% of a certain motion. (2)

Should one motion not follow another motion within a certain period of time, have the program

branch off to an error loop.

Type Purpose Commands

Movement control commands (1) Move the robot.

(2) Temporarily stop the robot.

(3) Move the robot hand.

(4) Interrupt or restart operation.

Program control commands (1) Monitor external signals,

timers, etc.

(2) Control program execution.

(3) Make remarks (comments)

to aid in program debugging

and modification.

I/O control commands

(1) Input and output of externa

l signals.

(2) Input and output of commu

nication data.

MOVE, MOVES, MOVEC,

MOVEA, MOVE1, READY

DELAY

OPEN1, OPENI1, OPEN2,

OPENI2, CLOSE1, CLOSEI1,

CLOSE2, CLOSEI2, UP,

DOWN, TURNL, TURNR

BREAK, RESUME, PAUSE

ON ~ DO ~,

IF ~ THEN ~ ELSE,

WAIT, IGNORE

PROGRAM, GOTO, RCYCLE,

RETURN, FOR ~ NEXT, STOP,

END

TASK, KILL, SWITCH

REMARK

DIN, DOUT,

PULOUT, RESET,

BCDIN, BCDOUT

PRINT, INPUT

Movement condition

commands

(1) Specify conditions for

controlling robot movement.

1-6

- -

CONFIG, ACCUR, ACCEL,

DECEL, SPEED, PASS,

TORQUE, GAIN, ENABLE,

SETGAIN, DISABLE, NOWAIT,

PAYLOAD, FREELOAD,

SWITCH

Page 14

Type Purpose Commands

Calculator functions (1) Perform calculations for real

numbers.

(2) Perform calculations

involving positional and

coordinate data.

(3) Use an array.

Movement reference

commands

Others (1) Define a variable.

(1) Check robot movement. MOTION, MOTIONT, REMAIN

(2) Check system movement. REMAINT, TIMER, MODE

(3) Assign a coordinate

system.

(2) Restore an updated value in

the program file.

SIN, COS, TAN, ASIN, ACOS,

ATAN, ATAN2, SQRT, ABS,

SGN, INT, REAL, LN, MOD,

LOGIO, EXP, AND, OR, NOT

HERE, DEST, POINT, TRANS

DIM, AS

TOOL, BASE, WORK

GLOBAL, END

RESTORE

STE 58762

1-7

- -

Page 15

STE 58762

CHAPTER 2

WRITING PROGRAMS IN ROBOT LANGUAGE

In Chapter 1, we got a rough idea of what a robot language is and how it works. Now, in Chapter

2, we will describe how to write a program in robot language.

2.1 PROGRAM CONFIGURATION

Below we present a general outline of program configuration with the SCOL language.

2.1.1 Files

In order to get the robot to perform a task, you need both a program written in robot language and

positional data for use by the program. That is, for each job you want the robot to do, you have to

have a matched set of a program (or programs) and data. This matched set is called a file.

Program editing, execution, saving and loading are all done in units of files.

2.1.2 Program

A program is an arrangement of words in robot language that tell the robot what you want it to do.

A program may "call" (use) other programs from inside of the original program. The original

program is referred to as the main program. These other programs are called subprograms since,

from the point of view of the main program, they are secondary. It is often convenient to make

sub- programs for sequences that are used often or for sequences that are more or less selfcontained. These subprograms can then be called when you need them. Subprograms save you

the trouble of having to write the same thing many times and, if used properly, can make your job a

lot easier.

You can include many programs in a single file. Unless you specify differently (in the command

lines at beginning of the file), the robot will assume that the first program in your file is the main

program. In order to call a subprogram, the subprogram must be in the same file as the main

program. Also, just because you may have several programs lined up in the file does not

necessarily mean that all the programs will be executed. As far as the robot is concerned, its job is

over when the main program is completed (i.e., when the robot reaches the final END statement of

the main program), and if the other programs have not been called by that time they will never be

called.

A plural number of programs can be executed at the same time, using the TASK command

(multitask execution). For details of the multitask execution, see Para. 2.8.

2-1

- -

Page 16

STE 58762

Programs are edited with the teach pendant using the controller screen editor function. For

information on how to use the screen editor, see the "operating Manual."

2.1.3 Positional Data

Positional data for use in a program (or programs) must be placed in the same file as the program

(or programs). Positional data in a file can be accessed (used) by all programs in that file.

However, positional data in a file cannot be accessed by any programs not in that file.

Positional data is "fed" to the robot using the data editor function of the controller. See the

operating Manual for information on how to use the data editor.

2-2

- -

Page 17

STE 58762

2.2 CHARACTER SET

The SCOL character set is made up of alphanumeric characters and the following special symbols.

Alphanumeric characters

A B C D E F G H I J K L M N O P Q R S T U V W X Y Z

a b c d e f g h i j k l m n o p q r s t u v w x y z

1 2 3 4 5 6 7 8 9 0

Special symbols

“ ‘ ( ) + - * / , . < > =

! [ ] ( ) % ^ & ?

With the exception almost all of the small letters, these characters and symbols can all be input

from the teach pendant. When executing a program, the robot makes no distinction between

capital letters and small letters. For reading method of symbols, see "Appendix E."

2-3

- -

Page 18

STE 58762

2.3 IDENTIFIERS

In the SCOL robot language, identifiers are used to express commands, program names, variable

names, and labels (which are used to specify program branches). Identifiers must start with an

alphabetic character, although alphabetic

characters, numerals, or any combination of the two may follow. There is no particular limit on

length, although the robot will only differentiate the first ten alphanumeric characters. The robot

does not care whether you use capital or small letters, since it will treat them the same anyway.

For example, as far as the robot is concerned, all four of the following are the same:

T O S H I B A R O B

t o s h i b a r o b

T O S H I B A R O B O T

t o s h i b a r o b o t

With a few exceptions, small letters cannot be input from the teach pendant. Also, you cannot use

any special symbols or include any spaces in the names for identifiers. (Instead, special symbols

or spaces are used to separate identifiers.) For example, the robot will consider the following as

different:

T O S H I B A R O B O T

T O S H I B A R O B O T

“TOSHIBA ROBOT” will be interpreted as two different identifiers, i.e., TOSHIBA and ROBOT.

Some identifiers have already been defined by the SCOL language itself. These are called

reserved words, and you as the programmer cannot use them for any other purpose except for that

already defined. (For example, PROGRAM is a reserved word used to tell the robot when a

program will follow. Therefore you cannot, for example, go and call one of your variables

PROGRAM since the robot will have no idea of what you are talking about.)

A list of reserved words is shown in Appendix B. In addition to SCOL commands, you will find

words used in the computer system and words set assigned for future expansion.

Do not use identifiers with the same name for different meanings. For example, if you decide to

call your program GEORGE, do not go and name any variables GEORGE. If you do, you may get

an error when you try to execute your program. At the very least, you will be sorry when it's time to

debug your program.

2-4

- -

Page 19

STE 58762

2.4 VARIABLES AND CONSTANTS

Not all data takes the same form, and these different forms of data are called data types. Scalar

type (integer type, real number type and character string) and vector type (position type, coordinate

type and load type) can be used in the SCOL language. Variables are divided into global variable

and auto variable according to the definition method. All taught data and variable defined in the

area between GLOBAL and END are called the global variable. These variables can be referred

and changed from any part of the program. For all data types of global variables, the array can be

declared. For descriptions of global variable and array, see Para. 2.8.5.

The work area in the controller is used for all data. The defined value is substituted for the global

variables value at the start of the program, except for the array without a specific initial. If the

value is entered for the variable during program execution, only the work area is changed. If the

power of controller is turned off, execution file is reselected or the file is edited, work area is reset by

the variable’s initial value saved in the file and the changed value is lost accordingly. This is also

applicable for change of the taught data. If the data in the file is to be overwritten, the RESTORE

command should be executed in the program.

2.4.1 Scalar Data

There are three types of scalar data, i.e., integers, real numbers and character strings. Scalar type

auto variables can only be used in the program in which they were declared. That means that if

you use a variable with the same name in another program, the two variables will be completely

independent and have nothing to do with each other. Therefore, when passing data from one

program to another, make it a point to, if possible, redefine the variable as the scalar type global

variable or declare the arguments in the program. (If you did not understand this too well, refer to

Section 2.8 "Programming.")

(1) Integer data

(a) Constants

SCOL can handle integer values ("whole numbers") in the range of - 2147483648 to + 2147483647.

When an integer is used as a constant in a program, if it is positive, directly describe the value; if it

is negative, describe the value following the - symbol. Examples are:

0

234

-39208

5963

2-5

- -

Page 20

STE 58762

(b) Variables

Variables are distinguished by identifiers and can be in the range of - 2147483648 to +

~147483647, just as above. The data type of a variable is determined by the data type of the first

number you assign to that variable. For example, if the first thing you assign to a variable is an

integer, all other numbers substituted into that variable will become integers. That means that if

you later try to insert a real number into this variable, the controller will chop off all the decimal

places and treat what is left as an integer.

The variable comes in two types; the global variable which is valid in the entire program and the

general variable which is valid in a part of the program. The global variable can be changed from

any part of the program.

(c) Logical values

Logical values are used in the program when making conditional judgments. Logical expressions

and commands such as DIN (which check input signals) return logical values.

A logical value may have one of two values; TRUE or FALSE. Internally, logical values are treated

as integers with 1 being TRUE and 0 being FALSE.

Note)

(Strictly speaking, 0 is considered as FALSE and everything else is considered as TRUE.)

(2) Real data

With SCOL, numbers are treated as real types with the exception of certain special cases.

(a) Constants

SCOL can handle real numbers having an absolute value in the range of approximately 5.87 x 10

to 6.80 x 10

significant digits for the mantissa [the mantissa is the part of the number to the right of the decimal

point) is approximately 7 in Base 10. (The precision is 2

38

. This range can also be expressed as 2

-127

to ((223 - 1) x 2

23

).

106

). The number

When a real number is used in the program, if it is positive, directly describe the value; if it is

negative, describe the value following the - symbol.

When the decimal part is 0, it is omissible. However, when the decimal point is omitted, the data

are treated as integer type data. In addition, since the integer part cannot be omitted, even if the

absolute value of a numeric value is less than 1, it is necessary to designate 0 to the integer part.

-3.9

2-6

- -

Page 21

STE 58762

Example)

1234.567

-28.16

0.00985

1234567.

-369.

As mentioned above, the precision of the computer is somewhat limited when handling decimal

values. Usually this is no problem if the number of decimal places is reasonable. Therefore,

when working with the robot, try to use the following as the minimum set units.

Distance (x, y, and z data) 0.001 mm

Angles (C data) 0.001 deg.

Time 0.01 sec.

Rates (Speed, torque, etc.) 1%

Mass 0.01 kg

Inertia 0.01kg.m

(b) Variables

Variables are distinguished by identifiers and have the same range as listed above for constants.

The data type of a variable is determined by the data type of the first number you assign to that

variable. For example, if the first thing you assign to a variable is a real number, that variable will

become a real type.

(3) Character strings

Character strings can only handle constants. They are expressed by placing one or more

characters between quotation marks. In the example below, the character string is SCOL

MESSAGE.

Example) "SCOL MESSAGE"

2.4.2 Vector Data

As opposed to scalar-type data which only holds one data element, vector-type data holds multiple

data elements. There are three types of vector data in SCOL; positional vectors, coordinate

vectors and load vectors.

Vectors hold one to five data elements. With commands such as POINT and TRANS which create

vector-type data, elements are expressed by enclosing them in brackets {___}. With commands

such as MOVE and TORQUE which use vector type data, elements are assigned and expressed by

enclosing them in slightly different brackets {___}.

2-7

- -

Page 22

STE 58762

Vector type data other than the vector type global variable such as data taught by the data editor

are temporarily stored in the working area of the controller. The data are not created in the file.

The vector type variable can be used only in the declared program. Thus, even if the same

variable is used in another program, the content of the former does not accord with that of the latter.

When data are passed from one program to another program, the passed data should be redefined

as the vector type global variable or it should be an argument. For details of arguments, see "2.8.2

Subprograms."

(1) Positional data

Positional data is used by the robot to describe positions. Positional vectors have the following

format.

(X, Y, Z, C, T, <configuration>)

X, Y, Z, C and T are coordinate values represented by real numbers. Units are in millimeters or

degrees.

<Configuration> holds an integer from 0 to 2 that describes the set-up configuration of the system.

0 ... Free (Set-up of the system is undefined)

1 ... Left hand system

2 ... Right hand system

(2) Coordinate data

Coordinate data is used by the robot to specify coordinate systems. Coordinate vectors have the

following format:

(X, Y, z, C)

X, Y, Z and C are coordinate values represented by real numbers. Units are in millimeters or

degrees.

Coordinate vectors allow one to convert between different coordinate systems as shown in Figure

2.1. In the figure, we have an original coordinate system X, Y and Z. Then, with data provided by

a coordinate vector (x, y, z, c), the original coordinate system is shifted parallel along its axes by the

amounts x, y and z. This forms a new coordinate system centered about 0'. Once this is done,

we twist the new coordinate system around the Z' axis by an amount c. We are now finished

orientating our new coordinate system.

2-8

- -

Page 23

STE 58762

What we did above was take an original coordinate system (centered about 0), applied a coordinate

vector (x, y, z, c) to it, and came up with a new coordinate system (centered about 0'). In short,

coordinate vectors allow us to convert between different coordinate systems.

Z

Z’

Y’

Y

X’

O’

z

y

x

X

O

Fig. 2.1 Coordinate transformation

(3) Load data

Load data is used to define the physical loads acting on the end effector (hand) of the robot. Load

vectors have the following format.

{<Mass>, <Center of gravity offset>}

<Mass> is the mass of the load acting on the tip of the robot hand. Units are in kg.

<Center of gravity offset> is the amount representing the distance between the center of gravity

applied to the tip of the robot hand and the center of the tool flange of the robot (unit: mm).

2-9

- -

Page 24

STE 58762

2.4.3 System Variables

The SCOL language provides special variables that are used in the programs to specify and

referent robot operating conditions. These variables are called system variables. Just like other

variables, you can refer to these variables in the program, change their value, etc. However, you

have to be careful when setting or substituting values into system variables since doing this will

directly effect robot operating conditions.

A list of system variables is presented below in Table 2.1.

Table 2.1 List of system variables

Name Description Effective values Initial value Data type

CONFIG Robot configuration 0, 1, 2 0 Integer type

ACCUR Positioning accuracy 0, 1 1 Integer type

ACCEL Acceleration (during acceleration) 0 ~ max% 100 Integer type

DECEL Deceleration (during deceleration) 0 ~ max% 100 Integer type

SPEED Speed of movement 0 ~ max% 100 Integer type

PASS Short-cut movement parameter 0 ~ 100% 100 Integer type

TORQUE Maximum torque on each axis 0 ~ max% 300 Vector type

GAIN Servo gain on each axis 0.1 1 Vector type

TOOL Tool coordinates 0 Coordinate type

BASE Base coordinates 0 Coordinate type

WORK Work coordinates 0 Coordinate type

TIMER Timer 0.1 sec. - Real type

ERROR Error information - Integer type

PLAYLOAD Load on the robot 0 ~ 0 Load type

SWITCH Multitask 0, 1 1 Integer type

TID 1 ~ - Integer type

Note: Maximum values are set separately for each system.

2-10

- -

Page 25

STE 58762

Should you change the contents of a system variable related to movement control, that change will

not take effect until the next motion; it will have no effect at all on a motion in progress at the time;

However, by using a WITH construct, it is possible to temporarily set a system variable with regards

to one motion command. For example:

MOVE Al WITH SPEED = 50

Furthermore, be warned that SCOL does not check to see whether a value substituted into a

system variable is within the permissible range. Should the value not be in the permissible range,

SCOL will do one of two things:

• Should you try to insert a value less than the minimum permissible value, the minimum

permissible value will be entered in its place.

• Should you try to insert a value greater than the maximum permissible value, the maximum

permissible value will be entered in its place.

Refer to Chapter 3 for details on how to use system variables.

2.4.4 System Constants

In order to make programs easier to read (and thereby debug), SCOL provides the system

constants shown in Table 2.2. These names can be substituted into the program in place of

numbers in order to make it easier to see what you are doing. However, be sure to use them only

in the locations specified in the Comments column of Table 2.2. If you use them in other locations,

trying to debug your program can become a real nightmare.

Table 2.2 List of system constants

Name Value Comments (Locations for use)

FREE

LEFTY

RIGHTY

COARSE

FINE

OFF

ON

PAI 3.141593 Pi value

CONT

CYCLE

SEGMENT

0

1

2

0

1

0

1

0

1

2

In the system variable CONFIG

In the POINT command

In the system variable ACCUR

In the system variable GAIN

In the SETGAIN command

In the MODE command

2-11

- -

Page 26

STE 58762

2.5 MATHEMATICAL FUNCTIONS

This section describes the mathematical functions provided by SCOL for substitution, calculation

and judgement.

With SCOL, mathematical functions can either be used independently or included in a command.

A mathematical function included in a command may be a computational expression (in which the

result of a calculation is substituted into a variable), or a logical expression (such as greater-or-lessthan constructs and true/false constructs).

Mathematical functions provided by SCOL are shown in Table 2.3.

Note that 0/0 will return a -1, and 0 ^ 0 will return a 1. One would normally expect these operations

to return an error, but be careful because they don't.

Table 2.3 Mathematical functions

Type Operand Function Example

Arithmetic

functions

Relational

function

Logical

operands

Functions SIN

^

*, /

+, MOD

=

= =

< >, > <

<

>

< =, = <

> =, = >

AND

OR

NOT

COS

TAN

ASIN

ACOS

Exponentiation

Minus sign

Multiplication, division

Addition, subtraction

Remainder

Substitution

Equal

Not equal

Less than

Greater than

Less than or equal

Greater than or equal

Logical product

Logical sum

Negation

Sine

Cosine

Tangent

Arcsine

Arccosine

A ^ B (A to the B power)

-A

A * B, A / B

A + B, A – B

A MOD B (The remainder when A is

divided by B.)

A = B (Puts the value of B into A.)

A = = B

A < > B, A > < B

A < B

A > B

A < = B, A = < B

A > = B, A = > B

A AND B

A OR B

NOT A

SIN (A)

COS (A)

TAN ( A )

ASIN (A)

ACOS (A)

2-12

- -

Page 27

STE 58762

Type Operand Function Example

Functions ATAN

ATAN2

SQRT

ABS

SGN

INT

REAL

LN

LOG10

EXP

Parentheses ( ) may be used inside the expressions.

2.5.1 Computational Expressions

In the SCOL language, the results of computations on the right side of an equal sign are placed in

the register (variable) on the left. Variables and constants may be used in the expressions.

(1) Order of computational priority

The SCOL language uses the same order of priority used by almost all other computer languages.

Specifically;

• When there are brackets, operations inside the brackets are done first.

• Otherwise, operations are performed in the order of: 1.

Assignment of negative signs, 2. Exponentiation, 3.

Multiplication and division, 4. Addition and subtraction

• Should the order of priority be otherwise the same, priority is assigned from the left of the

expression to the right.

For example:

Arctangent

Arctangent

Square root

Absolute value

Sign

Changes number to an

integer.

Changes number to a

real number.

Natural logarithm

Common logarithm

Exponential to base e.

a = b + c * d / (e - f) - g,

ATAN (A)

ATAN2 (A, B) (Arctangent of A / B)

SQRT (A)

ABS (A)

SGN (A)

INT (A)

REAL (A)

LN (A)

LOG10 (A)

EXP (A)

2-13

- -

Page 28

STE 58762

The order of computation for the above expression is:

1.Calculate e - f. e-f

2.Calculate C * d. c * d

3.Divide C * d by e - f. (c * d) / (e - f)

4.Add the above result to b. b + (c * d) / (e - f)

5.Subtract g from the above result. (b + (c * d) / (e - f)) - g

Table 2.4 presents the order of computational priority for various operations.

Table 2.4 Order of computational priority

Priority Operation Operand Grouping convention

High

Low

Note:

Explanation of grouping convention:

Parenthesis

Assignment of vector elements

Assignment of negative signs and negations

Exponentiation

Multiplication, division, remainder

Addition, subtraction

Comparison

Equality, inequality

Logical product, logical sum

Substitution

Left to right ... 1 + 2 - 3 is interpreted as (1 + 2) - 3.

Right to left ... NOT-3 is interpreted as NOT (-3).

( )

.

-, NOT

^

*, /, MOD

+, <, >, < =, > =,

= <, = >

= =, < >, > <

AND, OR

=

Left to right

Left to right

Right to left

Left to right

Left to right

Left to right

Left to right

Left to right

Left to right

Right to left

2-14

- -

Page 29

STE 58762

(2) Computation of scalar type data

Scalar type data can be used in calculations in combination with computational operands.

However, should even one number in an expression be a real number, the output of that expression

will also be a real number. Also, the following functions will all return a real number.

SIN, COS, TAN, ASIN, ACOS, ATAN, ATAN2, SQRT, REAL, LN, LOG10, EXP

When the variable on the left side of the equation is an integer type and the output of the calculation

is not an integer, the output will be converted into an integer before being assigned to the variable.

Do not forget, however, that all decimal points are chopped off when a real number is converted to

an integer. On the other hand, when converting from an integer to a real number, the number of

significant digits is limited. When you want to make it clear what kind of data type you are dealing

with, use the INT or REAL command.

Note that character strings cannot be used in calculations. Calculations may be carried out

between the elements of vector-type variables and scalar data. In this case, an element specifier

is appended to the end of a vector-type variable to specify the element which is involved in the

calculation. The value of the element is then drawn out from the vector-type variable and used in

the calculation.

As element specifiers, ".X", ".Y", ".Z", ".C" and ".T" may be used. You may also numerically specify

the element position with ".1", ".2", ".3", ".4" and ".5."

Examples:

A = POINT1.X/25

GAIN={GAIN. l,GAIN.2,0,0,0}

Note)

You can only use this to return the value of an element from the inside of a vector-type variable.

You cannot change the value of the element itself.

2-15

- -

Page 30

STE 58762

(3) Computation of vector-type data

You can add and subtract corresponding elements of two vectors. Computation is a possib1e only

between the same type variables. The <CONFIG> element is not involved in the calculations but

rather takes the value of the variable substituted into it.

Example:

Given the following two position vectors and two coordinate vectors;

P1: (10, 20, 30, 40, 50, RIGHTY)

P2: (-5, 10, -15, 20, -25, LEFTY)

C1: (100, 50, -50, 0)

C2: (12, 34, 56, 78)

and performing the following operations,

P3 = P1 - P2

C3 = C1 - C2

we obtain:

P3: (15, 10, 45, 20, 75, RIGHTY)

C3: (88, 16, -106, -78)

Notes)

The <CONFIG> element in P3 is indeterminant.

(4) Substitution into vector data types

The following methods are available to substitute (insert) a constant, a variable or the result of a

computation into an element of vector-type data.

(a) Commands to convert a row of scalar-type data into vector-type data

A POINT command and a TRANS command are available to convert rows of scalar data into a

vector data. POINT converts scalar data into positional vector data, and TRANS converts scalar

data into coordinate vector data. For details on how to use these commands, see "Chapter 3."

2-16

- -

Page 31

STE 58762

Examples:

P1 = POINT(P2.X, P2.Y, P2.Z + 50, 0, 0)

C1 = C2 + TRANS(100, 100)

The more alert reader may have noticed that something is missing in the second example. That is,

although the TRANS command is used to create coordinate vector types (which have four

elements), only two numbers (100 and 100) have been assigned in the command. This will not

cause any problems, however, since missing numbers will be assumed to be "0". Here, the

second example will be considered as:

C1 = C2 + TRANS(100, 100, 0, 0)

As you will recall, positional and coordinate vectors have the following format:

Positional data POINT (X, Y, Z, C, T <CONFIG>)

Coordinate data TRANS (X, Y, Z, C)

X, Y, Z, C and T are coordinate values represented by real numbers. Units are in millimeters or

degrees.

<CONFIG> stands for "configuration" and holds an integer from 0 to 2 that is used to describe the

set-up of the system.

0 ... Free (Set-up of the system is undefined)

1 ... Left hand system

2 ... Right hand system

Any omitted elements are taken as "0".

Note 1:

In order to make it clear just what kind of data type you are using, always try to use the POINT

command when creating positional type data and the TRANS command when creating coordinate

type data.

Note 2:

When position data which have not been taught are used in a program of the robot language, the

position data are temporarily stored in the controller memory. Thus, when the program is reset, the

position data are cleared. The position data are only valid in the program which uses data.

Therefore, to use the position data in a subprogram, it is necessary to pass it as an argument. For

details of arguments, see "2.8.2 Subprograms."

2-17

- -

Page 32

STE 58762

Note 3:

The substitution and reference to the array type data (type of variable name [index number]) are

dealt in the same manner as the original data type (scalar type and vector type) of the array type

data.

2.5.2 Logical Expressions

With SCOL, logical expressions can be used in combination with the commands IF, WAIT and ON.

Also, six relational operands are available (<, >, < = (or = <), > = (or = >), < > (or > <), and = =).

Also, logical expressions may be combined using the logical operands AND, OR and NOT. Scalar

constants, scalar variables and the results of calculations may be used as data in logical

expressions.

When evaluating equivalence, use the "= =" sign and not the "=" sign. When comparing real

numbers, differences of 0.001 or less will be ignored.

Logical expressions will return an integer value of 1 if true and 0 if false.

Examples:

1) IF K = =K2 * K3 THEN K = K2

ON MOTION > = 50 DO DOUT (1,2)

2) IF J1 THEN GOTO BRANCH1 ELSE GOTO BRANCH2

Let's take a look at the third example. If J1 is an integer 0 (or a real number with an

absolute value less than or equal to 0.001), the comparison will be considered as

FALSE. The program will then branch off to BRANCH2. Should J1 be anything

other than an integer 0 (or a real number with an absolute value more than 0.001),

the comparison will be considered as TRUE and the program will branch off to

BRANCH1.

2-18

- -

Page 33

STE 58762

2.6 LABELS

With the SCOL language, program branches are specified by labels placed at the beginning of the

branch destination. When labelling a statement as a branch, put a colon at the end of the

identifier.

When directing the program to branch to another location with the GOTO command, do not put a

colon at the end of the identifier.

Program branching may only be carried out within a single program. You cannot branch from one

program to another. Also, you may use the same labels in different programs, but you cannot use

the same label in a single program.

Examples:

LOOP1: MOVE P1

GOTO LOOP1

2-19

- -

Page 34

STE 58762

2.7 REMARKS AND COMMENTS

The SCOL language allows you add comments to your program in order to make it easier to

understand (and debug). Comments can be entered by using the teach pendant to type in

whatever you want to say. However, you have to use one of the following formats so that your

comments do not get mixed in with the program itself.

(1) REMARK command

You can write what you want to say after a REMARK command. The computer will ignore

everything from the REMARK command to the end of the line. This keeps your comments

separate from the program.

Example:

REMARK THIS PROGRAM WAS WRITTEN BY ME

(2) Single quotation mark

Everything written after a single quotation mark (') until the end of the line will be ignored by the

program. The nice thing about this method is that you can write comments on the same line as a

command to keep track of what is going on.

Example)

MOVE P1 'THIS COMMAND MOVES THE ROBOT TO P1

However, the ' mark does not have to follow a command. The following will also work:

'THIS IS A MEANINGLESS EXAMPLE

2-20

- -

Page 35

STE 58762

2.8 PROGRAMS

This section describes SCOL programs.

2.8.1 Program Declaration

A program has to have the following basic structure. If it does not, it is not a valid program.

PROGRAM <name of your program>

Contents of your program

END

A program is made up of everything from the PROGRAM statement to the END statement.

Write a program name after the PROGRAM statement. For example, if you want to call your

program "George," write PROGRAM GEORGE (and not PROGRAM <GEORGE>.) (Note,

however, that the program name becomes an identifier). Put the contents of your program

between the PROGRAM statement and the END statement.

Example)

PROGRAM SAMPLE 'Program name "SAMPLE"

REMARK SAMPLE 'Comment

SPEED=20 'Set the movement speed to 20% of the maximum speed.

MOVE Al 'Move the robot to position Al.

DELAY 0.5 'Wait for 0.5 sec.

MOVE A2 'Move the robot to position A2.

DELAY 0.5 'Wait for 0.5 sec.

END 'End of program

As shown in the example, the body of the program is composed of statements made up of an

arrangement of SCOL commands. A new line is created every time you push the "RETURN" (or

"ENTER") key when writing (or editing) the program. Up to 130 characters can be contained in a

single line. You may add spaces as you wish in order to make the program neater and easier to

read. Note how comments are entered with ' marks.

Note)

No spaces can be placed between characters structuring a word of a command and identifier.

2-21

- -

Page 36

STE 58762

2.8.2 Subprograms

You can call up a subprogram by just writing its name in the main program.

Example:

Here is a main program which calls a subprogram called SUB1.

PROGRAM MAIN

REMARK *** SAMPLE 1 ***

SUB1

END

Here is the subprogram which has been named SUB1.

PROGRAM SUB1

REMARK *** SUBPROGRAM NO. 1 ***

Body of subprogram

RETURN

END

A RETURN command should inserted in subprograms to send control back to the main program.

If you forget to write RETURN, SCOL will forgive you and pretend that there is a RETURN

command in front of the END statement.

When wishing to pass data between subprograms and the main program, you have to first specify

arguments for the subprogram. Arguments are like little "mailboxes" to which values passed

between the programs are sent and received. And, before using these mailboxes, you have to put

a name on each one so the postman knows whose mail goes where. When writing a subprogram

(not a main program), the program statement should be written like this:

PROGRAM <program name> (<names of arguments>)

After writing the program name, write the names of the arguments inside of brackets. Use

commas to separate the names of the arguments. (You cannot specify more than ten arguments

for a single subprogram.) For example, the main program will have the statement:

SUB EXAMPLE (A, B, C)

2-22

- -

Page 37

STE 58762

When calling the subprogram from the main program, write (in the main program) the name of the

subprogram and the data you wish to pass over to that subprogram. For example, the

corresponding subprogram will have the statement:

PROGRAM SUBEXAMPLE (M1, M2, M3)

The subprogram SUBEXAMPLE will now do whatever it does while treating A as M1, B as M2, and

C as M3.

Note that variables changed in the subprogram will automatically change the corresponding value in

the main program. For example, if M3 were to change in the subprogram SUBEXAMPLE, C will

also change simultaneously in the main program.

Example:

Main program

PROGRAM MAIN

REMARK *** SAMPLE 2 ***

K1 = 15

K2 = 28

SUB2(K1, K2, K)

PRINT K

END

Sub program

PROGRAM SUB2(N1, N2, N3)

REMARK *** SUBPROGRAM NO. 2 ****

N3 = N1 + N2

RETURN

END

In the above example, three arguments are being passed off between the main program and

subprogram. Specifically, K1 of the main program is passed over as N1 of the subprogram.

Similarly, K2 of the main program is passed over as N2 of the subprogram. The subprogram adds

N1 and N2, and puts the result in a variable called N3. When this happens, the value of K in the

main program also changes (since K and N3 correspond to each other).

2-23

- -

Page 38

STE 58762

When you execute this program, K1 will be passed off as 15 (to N1 of the subprogram) and K2 will

be passed off as 28 (to N2 of the subprogram). The subprogram will add these together and call

the result (which is 43) N3. The K variable of the main program will also change to 43. The

RETURN command will send control back to the main program, and the PRINT K statement will be

executed. This will cause the number "43" to be displayed on the teach pendant.

Note that subprograms may not call themselves. Also, should you call a subprogram which is in

another file, the controller will not understand you and instead will treat the name of that

subprogram as an error.

Note 1) An expression itself, result of vector data expression such as position data and vector

data element can be designated as an argument.

Note 2) When a constant is used as an argument, it cannot be substituted into a variable

according to a subprogram.

Note 3) For a variable which is an argument to a subprogram, a value should be substituted into

the variable before the subprogram is executed.

2.8.3 Library

The SCOL language does not allow you to use subprograms which are not in the same file as the

main program. However, by putting especially useful subprograms in the library file (SCOL.LIB),

you can access these subprograms from all files.

Many useful subprograms have already been inserted in the library file including subprograms to

get the system ready and subprograms to operate the hand. Appendix C shows the contents of

the library file SCOL.LIB provided as standard on the robot controller system disk.

When writing your own subprogram to add to the library file, enter the program in that file just like

you would enter any other subprogram. For information on how to enter a program into a file, refer

to the Start-up Manual and the Operating Manual. Be sure to put any newly created files at the

very end of the existing library file.

Should a subprogram in the library file and a subprogram in the main file have the same name,

the controller will execute the subprogram in the main file (and not the subprogram in the library

file). The library is reloaded at program selection.

2-24

- -

Page 39

STE 58762

2.8.4 Multitask Processing

This paragraph describes how to use the multitask function of the SCOL language together with the

relevant commands and system variables.

Program execution of single task and multitask operation is shown in Fig. 1 and Fig. 2. The

number in the figure designates the order of the program execution. Specific timing of changeover from program to program (task change) is described later.

Program Program 1 Program 2 Program 3

Fig. 1 Single task

In Fig. 1, program A is executed continuously from the start to the end (single task operation and no

subroutine call).

A program which uses no multitask command is executed in the manner as shown in Fig. 1 (no

subroutine call).

Execution of a program which uses the multitask command is shown in Fig. 2.

operation

A1

A2

A3

A4

Fig. 2 Multitask operation

B1

B2

B3

C1

C2

2-25

- -

Page 40

STE 58762

As shown in Fig. 2, the multitask operation is realized, changing over a plural number of individual

programs by time sharing, as if the programs were executed in parallel. The order of program

execution is shown in the following table.

Order Program to be executed

1 A1 Program 1 start

2 B1 Program 2 start

3 C1 Program 3 start

4 A2

5 B2

6 C2 1-cycle end of program 3

7 A3

8 B3 1-cycle end of program 2

9 C1 Program 3 start

10 A4 1-cycle end of program 1

11 B1 Program 2 start

12 C2

13 A1 Program 1 start

: :

Next, the start of multitask is described.

A program that can be treated as multitask is the program block containing no arguments. The

program block means an area between the PROGRAM command and END command, which

consists of the SCOL language statements. The subroutine without argument can be dealt with as

a task. The argument cannot be kept in the task.

To deal with a program as task, use the TASK command. The TASK command executes a

program specified in the argument as a task. Unless the program starts by the TASK command,

the program is not performed as a task.

The program block (statements between the PROGRAM command and the END command)

described at the head of the program file is an exception. Even if the TASK command is not used,

the program is performed as a task.

To execute the program 2 as a task in the Fig. 2, the TASK (“PROG2”) is required to be executed in

the program 1. (The program 1 is described at the head of the file, and the program starts as a

task without TASK command.)

To execute the program 3 as a task, a new task (“PROG 3”) is required to be executed in the task

(in the program 1 or 2 in this case) which has been already started.

If the task and program which have been started are reset or the task operation is released by the

SCOL language, the task is kept active.

2-26

- -

Page 41

STE 58762

The task ID (the number assigned to the task) is described.

The characteristic numbers (task ID) are assigned to the tasks which have been started by the

TASK command respectively. In the example of Fig. 2, “1” is assigned to the program 1, “2” is

assigned to the program 2 and “3” is assigned to the program 3. This task ID starts from 1 in

sequence and this ID increases one by one every time the task starts (every time the task

executes). If the task is managed by the SCOL language, this task ID is used.

To get the task ID, see the following examples.

Example: I1 = TASK (“PROG 2”)

“I1” is a desired variable of integer type. The task ID of PROG 2 can be obtained. This command

is executed in the program 1. The task ID of its own cannot be referred to in the program 2 in this

example.

Example: I2 = TID

“I2” is a desired variable of integer type. If the system variable TID is referred to, the task ID of its

own can be acquired. If this command is executed in the program 2, the task ID of its own can be

seen in the program 2 (“2” in this occasion).

If this command is executed in the program 1, the task ID of program 1 (“1” in this occasion) is

substituted for “I2”.

If the task ID other than the own task is referred to from other tasks, variables of examples 1 and 2

are required to be defined as the global variable.

Change-over of task is described.

As shown in the Fig. 2, the system executes the program 1 ~ 3 by time sharing. When this

happens, timing of program change-over depends on the following three conditions.

(1) When the program change-over is specified clearly by the SWITCH command of the SCOL.

The SWITCH command is used if the task is changed over clearly by the SCOL language.

Even if the task change-over conditions specified in the system are not satisfied while the

SWITCH command is used, the task can be changed over.

(2) When a new task starts by the TASK command of the SCOL.

If a new task starts by the TASK command, the program control is changed over to the

newly started task.

(3) When the task terminates by the KILL command of the SCOL.

If the task of its own terminates by the KILL command, the program control is changed over

to the next task.

2-27

- -

Page 42

STE 58762

(4) When the predetermined conditions specified in the system are satisfied and the program is

changed over by the system.

The task change-over conditions specified in the system are as follows:

(1) A program in a task is executed for more than 50 msec.

(2) When the data area for movement command becomes full.

Up to four data can be read beforehand by the movement command. If this internal area

for prior reading becomes full, the task is changed over.

(3) When the command requiring communication with an external device has been executed.

The INPUT, PRINT and RESTORE commands are not executed alone by the SCOL

program. They are the commands including such processing as the TP operation by an

operator and RAM file operation. If the system waits for a reply, therefore, the task is

changed over.

To avoid the task change-over by the system, set the system variable SWITCH to

“DISABLE”.

Note: If the task change-over is prohibited, only currently active program is executed and the

other task program which has already started is not executed (single task operation).

2.8.5 Global Variable Definition

If the global variable which can be referred to from the entire program is defined, obey the following

rules.

(1) Global variable declaration

If the global variable is used, the type and identifier (variable name) of the variable to be

used is required to be defined.

This definition must be performed before the first PROGRAM statement.

To define the variable A of real number type and the variable B of integer type, the definition

is as follows:

GLOBAL

A = 1.0 (This value is the initial value of the variable.)

B = 2

END

PROGRAM

:

END

2-28

- -

Page 43

STE 58762

(2) Global variable declaration by type

To define the global variable of each type, use the following formats.

Integer type: A = 1

Real number type: B = 1.0

Position type: C = POINT (1.0, 2.0, 3.0, 4.0, 5.0, 1)

Array type: DIM D(10) AS INT Array of ten integer type elements is

defined. (Note 1)

DIM E(10, 3) AS REAL Array of 10 × 3 real number type elements

is defined.

DIM F(5) AS POINT Array of five position type elements is

defined.

Note 1: The initial value of the array type global variable is indefinite. The variable is required to

be initialized by the user program.

2-29

- -

Loading...

Loading...