Page 1

STE 58761

INSTRUCTION MANUAL

INDUSTRIAL ROBOT SR SERIES

OPERATING MANUAL

Notice

1. Make sure that this Instruction Manual is delivered to the final user

of the Toshiba Industrial Robot.

2. Please read this manual before installing or operating the Toshiba

Industrial Robot, and keep the manual nearby for further reference

during use of the robot.

TOSHIBA MACHINE CO.,LTD.

1998- 3

Page 2

Copyright 1997 by Toshiba Machine Co., Ltd.

All rights reserved.

No part of this document may be reproduced in any form without obtaining prior written

permission from the Toshiba Machine Co., Ltd.

The information contained in this manual is subject to change without notice.

STE 58761

i

- -

Page 3

STE 58761

PREFACE

This Manual describes how to utilize various robot system functions in order to manually guide

the robot with the teach pendant, edit programs, compile data and carry out automatic operation.

This manual is directed at the robot operator. Before reading this manual, he or she should first

read the Introductory Manual and the Start-up Manual.

This Manual is divided into fourteen chapters:

Chapter 1 "Before Operating Your Robot"

Chapter 2 "Basic Operation"

Chapter 3 "Manual Operation"

Chapter 4 "Auxiliary Signals"

Chapter 5 "Program Editing"

Chapter 6 "Data Editing"

Chapter 7 "Test Operation"

Chapter 8 "Internal Automatic Operation"

Chapter 9 "External Automatic Operation"

Chapter 10 "System Control"

Chapter 11 "File Management"

Chapter 12 "Utilities"

Chapter 13 "Self Diagnosis"

Chapter 14 "Joint Limit Setting"

ii

- -

Page 4

STE 58761

NOTE!

FOR EUROPEAN UNION (EU)

In the European Union (EU), there are following limitations and notes to approve the CE

Marking EMC Direction. In other countries and areas, it is not necessary to apply to these

limitations and notes.

(1) Setup conditions

The following type of power line transformer must be used.

◆

Frequency: 50 or 60 Hz

Secondary voltage: 3-phase, 200~230 VAC

Power capacity: Min. 2.7 kVA

(2) Input power condition

Core wires: 3.5 mm

◆

Voltage short interruption: 0.5 cycle

◆

(3) Ground

Core wires: 3.5 mm

◆

Ground condition: Exclusive ground line for robot ground impedance must be

◆

less than 100Ω

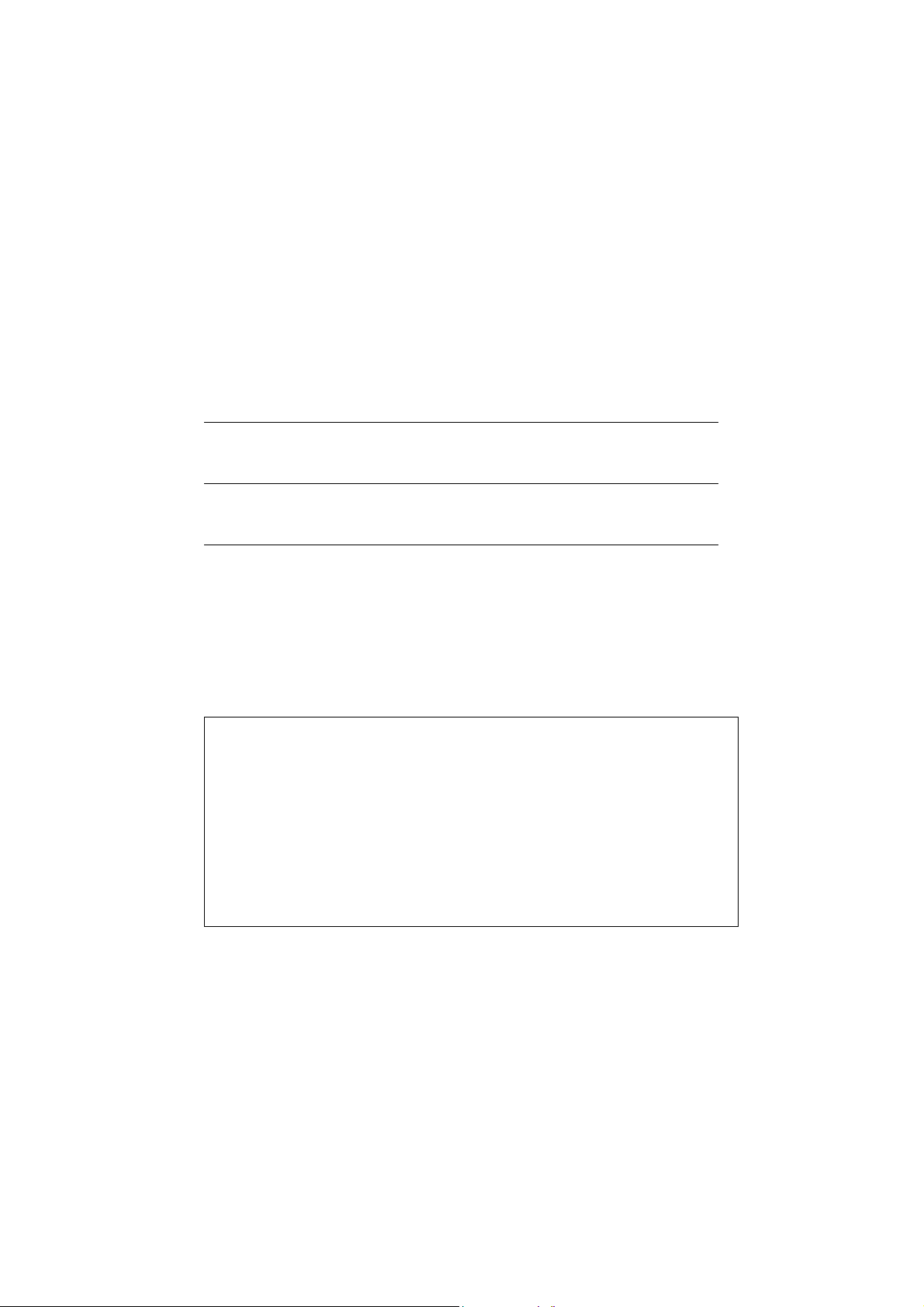

(4) External input/output line/Optional input/output line

Core wires: 0.08 mm

◆

Shield: Ground shield

◆

Cable length: Max. 10 m

◆

Manufacturing method: Refer to Figure A.

◆

Signal ground: Voltage potential between signal ground PGBA and controller

◆

frame ground F.G. must be same.

(5) Serial communication line

Only 1 of 4 serial communication ports (connector name; J1~J4) can be used at the same

◆

time.

Core wires: 0.08 mm

◆

Shield: Ground shield

◆

Cable length: Max. 10 m

◆

Twisted pair: Not required for RS-232C, required for RS-422

◆

Manufacturing method: Refer to Figure A.

◆

2

~ 5.5 mm2

2

~ 5.5 mm2

2

~ 0.5 mm2

2

~ 0.5 mm2

iii

- -

Page 5

(6) Limitation on the robot specifications

Cable length from robot to controller: Max. 8 m

◆

Cable length of teach pendant: Max. 8 m

◆

Optional axis 5: Can not be used.

◆

Optional input/output signals (type; SR-5500IO): Only one optional board can be

◆

Optional relay output signals (type; SR-5500RO): Can not be used.

◆

Optional conveyer tracking system (type; SR-5500CV): Can not be used.

◆

Separated operation panel: Can not be used.

◆

STE 58761

used.

iv

- -

Page 6

STE 58761

This Manual describes how to utilize various robot system functions in order to manually guide

the robot with the teach pendant, edit programs, compile data and carry out automatic operation.

This manual is directed at the robot operator. Before reading this manual, he or she should first

read the Introductory Manual and the Start-up Manual.

v

- -

Page 7

STE 58761

Cautions on Safety

This manual contains the important information on the robot and controller to prevent injury to the

operators and persons nearby, to prevent damage to assets and to ensure correct use.

Make sure that the following details (indications and symbols) are well understood before reading

this manual. Always observe the information that is noted.

[Explanation of indications]

Indication Meaning of indication

This means that "incorrect handling will lead to fatalities or serious injuries."

Danger

!

This means that "incorrect handling may lead to personal injuries *1) or

!

Caution

physical damage *2)."

*1) Injuries refer to injuries, burns and electric shocks, etc., which do not require hospitalization

or long-term medical treatment.

*2) Physical damage refers to damages due to destruction of assets or resources.

[Explanation of symbols]

Symbol Meaning of symbol

This means that the action is prohibited (must not be done).

!

!

!

The details of the actions actually prohibited are indicated with pictures or

words in or near the symbol.

This means that the action is mandatory (must be done).

The details of the actions that must be done are indicated with pictures or

words in or near the symbol.

This means danger.

The details of the actual danger are indicated with pictures or words in or near

the symbol.

This means caution.

The details of the actual caution are indicated with pictures or words in or near

the symbol.

vi

- -

Page 8

[Operation]

STE 58761

Prohibited

!

Danger

!

• During operation, NEVER enter the dangerous area of the robot.

Otherwise, you will be injured seriously.

• DO NOT leave in the working range any machinery or materials which will

hinder the operation. If the equipment went wrong, a person nearby will

be injured or involved in an accident.

• Anyone other than the operator MUST NOT approach the equipment.

Should he negligently touch a dangerous part of the equipment, he will get

injured or involved in a serious accident.

• NEVER perform an inappropriate operation which is not described in the

instruction manual. Otherwise, the equipment will start by mistake,

resulting in personal injury or serious accident.

• If you feel even a little that you are exposed to danger or the equipment

works abnormally, press the EMERGENCY STOP pushbutton switch to

stop the equipment. If the equipment is used as it is, you will be injured or

involved in a serious accident. When this happens, ask our after-sale

service agent for repair.

• During operation, be sure to close the equipment cover. Should the cover

be opened during operation, you will be struck by an electric shock or get

injured.

• Only a well-trained and qualified person is allowed to perform the

operation. Should the equipment be operated improperly, it will start by

mistake, causing a personal injury or serious accident.

Danger

• If the equipment has malfunctioned, turn the power off, identify and remove

the cause of the abnormality, maintain the peripheral equipment and

completely restore the malfunctioned equipment. Then start the

equipment at a low speed. If the equipment starts, leaving the

abnormality, you will be involved in a serious accident.

vii

- -

Page 9

STE 58761

Prohibited

!

Mandatory

!

• DO NOT change the data of the system structure file. Otherwise, the

robot will operate abnormally, resulting in damage or an accident.

• In principle, teaching operation should be performed outside the dangerous

area of the robot. If it should be performed inevitably within the dangerous

area, strictly observe the following matters.

(1) The teaching operation should be always performed by two (2)

persons. One person performs the job and the other person watches

outside the dangerous area. Also, both persons should try to prevent

mis-operation with each other.

(2) The operator should do the job in an attitude ready to press the

EMERGENCY STOP pushbutton switch at any time. Also, he should

perform the job at a position from which he can evacuate immediately

at the time of an emergency after confirming the robot working range

and shields nearby.

(3) The supervisor should keep watch on the job at a position where he

can see the entire robot system and operate the EMERGENCY STOP

pushbutton switch at the time of an emergency. Also, he should keep

• If an abnormality has generated or the POWER LED lamp on the control

anyone from entering the dangerous area. Unless an operator or

other person follows the instructions of the supervisor, accidents will be

caused.

panel remains off after the main power switch of the equipment was turned

on, turn off the main power immediately and confirm the wiring.

Otherwise, you will be struck by an electric shock or a fire will break out.

Caution

• Unless the robot operates toward a designated direction at manual guide,

turn off the servo power. Otherwise, the robot will be damaged or you will

be involved in an accident. When this happens, call us at the after-sale

service agent.

• Pushbutton operations of the control panel and teach pendant should be

confirmed visually. Otherwise, you will be involved in an accident due to

mis-operation.

• Before the hot start in automatic operation, be sure to reset a program. If

the program is executed continuously, the robot will interfere with the

peripheral equipment, resulting in damages or accidents.

viii

- -

Page 10

STE 58761

Mandatory

!

!

Caution

!

• Before operating the equipment, perform the following inspection.

(1) Make sure that visual appearance of the robot, controller, peripheral

equipment and cables is in good condition.

(2) Make sure that no obstacle stands in or near the operating range of the

If the above prior inspection is skipped, the equipment will be damaged or

• The speed of test operation is initially set at 25 % of the maximum robot

• The speed of automatic operation is initially set at 100 % of the maximum

• Once a cold start has been executed, all data saved in the controller

robot and peripheral equipment.

(3) Make sure that the emergency stop and other safety devices operate

properly.

(4) Make sure that no abnormal noise or vibration is involved in the robot

operation.

you will be involved in an accident.

speed.

robot speed.

memory, such as user program, position data, user parameter and system

parameter files are initialized.

Caution

ix

- -

Page 11

TABLE OF CONTENTS

CHAPTER 1 BEFORE OPERATING YOUR ROBOT

1.1

1.2

1.2.1

1.2.2

1.2.3

1.2.4

1.2.5

1.3

1.3.1

1.4

1.4.1

1.4.2

1.4.3

1.4.4

1.4.5

1.4.6

1.4.7

1.5

1.5.1

1.5.2

1.5.3

1.5.4

1.5.5

CHAPTER 2 BASIC OPERATION

2.1

2.2

2.2.1

2.2.2

2.3

2.4

2.5

OVERVIEW OF CONTROL FUNCTIONS・・・・・・・・・・・・

MODE STRUCTURE

External Automatic Mode

Internal Automatic Mode

Manual Mode

Edit

・・・・・・・・・・・・・・・・・・・・・・・・・・・

Test Operation

PRECAUTIONS FOR USE・・・・・・・・・・・・・・・・・・・

Handling Disks

GENERAL OPERATION・・・・・・・・・・・・・・・・・・・・

Use of the Shift key

Use of the Function keys

Repeating an Entry

Correcting Incorrect Entries

Cancelling an Entry

Use of Wild Cards

Format for Operating Instructions

ASSIGNING NAMES

Assigning the Volume Name

Assigning a File Name

Assigning a Point Name

Assigning a Name to Coordinate Data

Assigning a Name to Load Data

BASIC OPERATING PROCEDURE

TURNING ON THE MAIN POWER・・・・・・・・・・・・・・・

Cold Starting

Hot Starting

TURNING ON THE SERVO POWER

TURNING OFF THE SERVO POWER

TURNING OFF THE MAIN POWER

・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・

STE 58761

・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・

・・・・・・・・・・・・

・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・

・・・・・・・・・・・・・・

・・・・・・・・・・・・・・

1-1

1-3

1-4

1-4

1-5

1-6

1-7

1-8

1-8

1-10

1-10

1-11

1-12

1-12

1-12

1-13

1-14

1-15

1-15

1-16

1-17

1-18

1-19

2-1

2-2

2-2

2-4

2-6

2-7

2-8

x

- -

Page 12

CHAPTER 3 MANUAL OPERATION

3.1

3.2

3.3

3.4

3.5

3.6

CHAPTER 4 AUXILIARY SIGNALS

CHAPTER 5 PROGRAM EDITING

5.1

5.2

5.2.1

5.2.2

5.2.3

5.2.4

5.2.5

5.2.6

5.3

5.3.1

5.3.2

5.4

5.4.1

5.4.2

5.4.3

5.4.4

5.5

5.5.1

5.5.2

5.5.3

5.5.4

5.5.5

5.5.6

5.5.7

5.5.8

5.5.9

SELECTING THE MANUAL MODE・・・・・・・・・・・・・・

GUIDANCE COORDINATES

GUIDE MOVEMENT・・・・・・・・・・・・・・・・・・・・・

GUIDE SPEED

GUIDANCE・・・・・・・・・・・・・・・・・・・・・・・・・

SERVO FREE

INVOKING THE SCREEN EDITOR

CHARACTER INPUT・・・・・・・・・・・・・・・・・・・・・

Character Input Mode Selection

Insert Mode

Typeover Mode

Input Deletion

Character Deletion

Moving the Cursor

INPUTTING SCOL COMMANDS・・・・・・・・・・・・・・・・

SCOL Menu

SCOL Menu Selection

EDITOR COMMAND INPUT

Editor Commands

Command Menu Selection

Input Deletion

Cancelling a Command

EDIT COMMAND DESCRIPTIONS

Jump to First Line

Jump to Last Line

Jump to Specified Line

Jump to Previous Page

Jump to Next Page

Jump to Beginning of Line

Jump to End of Line

Set Block

Delete Present Line

・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・

STE 58761

・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・

3-1

3-3

3-4

3-5

3-6

3-7

5-1

5-6

5-6

5-7

5-10

5-12

5-13

5-14

5-15

5-15

5-17

5-19

5-19

5-20

5-21

5-22

5-23

5-23

5-25

5-27

5-30

5-32

5-34

5-36

5-38

5-41

xi

- -

Page 13

5.5.10

5.5.11

5.5.12

5.5.13

5.5.14

5.5.15

5.5.16

5.5.17

5.5.18

5.5.19

5.5.20

CHAPTER 6 DATA EDITING

6.1

6.2

6.3

6.3.1

6.3.2

6.4

6.4.1

6.4.2

6.5

6.5.1

6.5.2

6.5.3

6.5.4

6.5.5

6.5.6

6.6

6.6.1

6.6.2

6.6.3

6.6.4

6.6.5

6.6.6

6.6.7

6.6.8

INVOKING THE DATA EDITOR・・・・・・・・・・・・・・・・

EDITOR DATA SELECTION

DATA INPUT・・・・・・・・・・・・・・・・・・・・・・・・・

EDITOR COMMAND INPUT

EDIT COMMANDS COMMON TO EACH DATA EDITING

EDITING POSITIONAL DATA・・・・・・・・・・・・・・・・・

Delete Block

Copy Block

Rename File

Search

Replace

Restore Deleted Line

Repeat

Read in File

Change Editor File

Display Status

Quit

Selecting the Data Input Mode

Moving the Cursor

Editor Commands

Command Menu Selection

Jump to First Line

Jump to Last Line

Jump to Previous Page

Jump to Next Page

Display Status

Quit

・・・・・・・・・・・・・・・・・・・・・・・・・・・

Positional-data Edit-mode Selection

Work Coordinate Selection

Point Name Selection

Teaching Positional Data

Numerical Input of Positional Data

Deleting Positional Data

Point Search

Moving to a Taught Point

STE 58761

・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・

・・・・

・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・

5-43

5-45

5-48

5-49

5-52

5-57

5-59

5-61

5-65

5-68

5-71

6-1

6-2

6-3

6-3

6-4

6-5

6-5

6-6

6-8

6-8

6-10

6-12

6-14

6-16

6-18

6-20

6-20

6-22

6-25

6-28

6-33

6-36

6-38

6-41

xii

- -

Page 14

6.7

6.7.1

6.7.2

6.7.3

6.7.4

6.7.5

6.7.6

6.7.7

6.8

6.8.1

6.8.2

6.8.3

CHAPTER 7 TEST OPERATION

7.1

7.2

7.3

7.4

7.5

7.6

7.7

7.8

7.9

7.9.1

7.9.2

7.9.3

7.9.4

7.9.5

7.10

7.10.1

7.10.2

7.10.3

7.10.4

7.11

7.12

EDITING COORDINATE DATA・・・・・・・・・・・・・・・・

Coordinate-data Edit-mode Selection

Teaching Coordinate Data

Numerical Input of Coordinate Data

Deleting Coordinate Data

Base Coordinate Selection

Tool Coordinate Selection

Work Coordinate Selection

EDITING LOAD DATA

Load-data Edit-mode Selection

Numerical Input of Load Data

Deleting Load Data

SELECTING THE TEST OPERATION MODE

PROGRAM SELECTION・・・・・・・・・・・・・・・・・・・

OPERATION MODE SELECTION

SPEED OVERRIDE・・・・・・・・・・・・・・・・・・・・・・

SPEED LIMIT

MACHINE LOCK・・・・・・・・・・・・・・・・・・・・・・・

STEP EXECUTION

START-UP

STOP COMMANDS

Cycle Stop

STOP

BREAK

Feed Hold

Emergency Stop

RESET・・・・・・・・・・・・・・・・・・・・・・・・・・・

DIRECT EXECUTION・・・・・・・・・・・・・・・・・・・・

EXITING THE TEST OPERATION MODE

・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・

Program Reset

Step Reset

Cycle Reset

Output Signal Reset

STE 58761

・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・

・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・

6-42

6-42

6-44

6-49

6-51

6-55

6-58

6-61

6-63

6-63

6-65

6-67

7-2

7-4

7-6

7-8

7-10

7-12

7-14

7-17

7-20

7-20

7-22

7-23

7-24

7-26

7-27

7-27

7-29

7-31

7-33

7-35

7-37

xiii

- -

Page 15

CHAPTER 8 INTERNAL AUTOMATIC OPERATION

8.1

8.2

8.3

8.4

8.5

8.6

8.7

8.7.1

8.7.2

8.7.3

8.7.4

8.7.5

8.8

8.8.1

8.8.2

8.8.3

8.8.4

8.9

CHAPTER 9 EXTERNAL AUTOMATIC OPERATION

9.1

9.2

9.3

9.4

9.5

9.6

9.7

9.7.1

9.7.2

9.7.3

9.7.4

9.7.5

9.8

SELECTING THE INTERNAL AUTOMATIC MODE・・・・・・・

PROGRAM SELECTION

OPERATION MODE SELECTION・・・・・・・・・・・・・・・

SPEED OVERRIDE

SPEED LIMIT・・・・・・・・・・・・・・・・・・・・・・・・

START-UP

STOP COMMANDS

Cycle Stop

STOP

BREAK

Feed Hold

Emergency Stop

RESET

Program Reset

Step Reset

Cycle Reset

Output Signal Reset

DIRECT EXECUTION

SELECTING THE EXTERNAL AUTOMATIC MODE

PROGRAM SELECTION・・・・・・・・・・・・・・・・・・・

OPERATION MODE SELECTION

SPEED OVERRIDE・・・・・・・・・・・・・・・・・・・・・・

SPEED LIMIT

START-UP

STOP・・・・・・・・・・・・・・・・・・・・・・・・・・・・

Cycle Stop

STOP

BREAK

Feed Hold

Emergency Stop

RESET・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・

STE 58761

・・・・・・・

・・・・・・・・・・・・・・・

8-2

8-4

8-6

8-8

8-10

8-12

8-13

8-13

8-15

8-17

8-18

8-20

8-21

8-21

8-23

8-25

8-27

8-29

9-2

9-4

9-6

9-7

9-8

9-9

9-10

9-10

9-11

9-13

9-14

9-16

9-17

xiv

- -

Page 16

CHAPTER 10 SYSTEM CONTROL

10.1

10.2

10.3

10.4

10.4.1

10.4.2

10.4.3

10.4.4

CHAPTER 11 FILE MANAGEMENT

11.1

11.2

11.3

11.4

11.5

11.6

11.7

11.8

11.9

11.10

CHAPTER 12 UTILITIES

12.1

12.2

12.3

12.4

12.5

CHAPTER 13 SELF DIAGNOSIS

13.1

13.2

13.3

13.4

13.5

13.6

13.7

SETTING THE DATE・・・・・・・・・・・・・・・・・・・・

SETTING THE TIME

CHANNEL SELECTION・・・・・・・・・・・・・・・・・・

RESET

INITIALIZATION・・・・・・・・・・・・・・・・・・・・・・

DIRECTORY DISPLAY

FILE COPY・・・・・・・・・・・・・・・・・・・・・・・・

FILE RENAME

FILE DELETE

FILE LOAD

FILE SAVE

FILE PRINT・・・・・・・・・・・・・・・・・・・・・・・・

BATCH PROCESSING

AUTOMATIC EXECUTION FILES・・・・・・・・・・・・・・

SELECTING THE UTILITY MODE・・・・・・・・・・・・・・

WORK COORDINATE SELECTION

TOOL COORDINATE SELECTION

PRESENT POSITION MONITOR

EXTERNAL I/O SIGNAL MONITOR

CLASSIFICATION OF ERRORS

ERROR DISPLAYS・・・・・・・・・・・・・・・・・・・・

ERROR MESSAGE DISPLAYS

ERROR RESETTING・・・・・・・・・・・・・・・・・・・・

ALL ERRORS RESET

ERROR HISTORY DISPLAYS

LIST OF ERRORS

・・・・・・・・・・・・・・・・・・・・・・・・・・

Program Reset

Step Reset

Cycle Reset

Output Signal Reset

・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・

STE 58761

・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・

・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・

・・・・・・・・・・・・・

・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・

10-1

10-4

10-7

10-10

10-10

10-12

10-14

10-16

11-1

11-4

11-7

11-11

11-14

11-17

11-20

11-23

11-26

11-30

12-1

12-2

12-4

12-6

12-8

13-1

13-1

13-2

13-4

13-5

13-6

13-8

xv

- -

Page 17

CHAPTER 14 JOINT LIMIT SETTING

14.1

14.2

14.3

APPENDIX A

APPENDIX B

APPENDIX C

SELECTING JOINT LIMIT SETTING MODE・・・・・・・・・・

JOINT LIMIT TEACHING

INPUTTING NUMERIC VALUES FOR JOINT LIMITS・・・・・・

TEACH PENDANT MESSAGE TABLE

LIST OF COMMANDS

HANDLING ARRAY DATA BY DATA EDITING・・・・・・

STE 58761

・・・・・・・・・・・・・・・・・・

・・・・・・・・・・

・・・・・・・・・・・・・・・・・

14-1

14-3

14-5

15-1

15-10

15-13

xvi

- -

Page 18

CHAPTER 1

BEFORE OPERATING YOUR ROBOT

1.1 OVERVIEW OF CONTROL FUNCTIONS

Function Description

Main power ON/OFF Used to turn the main power on or off.

Servo power ON/OFF Use to turn the power for the servo on or off.

Master mode selection

Start-up and stop Used to start up or stop automatic operation.

Cycle completion

Feed hold Used to temporarily stop automatic operation.

Emergency stop Used to immediately stop automatic operation.

Manual operation

Auxiliary signal

operation

Program editing Used to create and edit programs.

Data editing

File management

Reset

Date setting Used to set the data for use by the system.

The setting Used to set the time for use by the system.

Channel selection Used to select a communication channel.

Error display

Error reset Used to reset errors that have been corrected.

Error history display

Work coordinate

selection

Tool coordinate

selection

Used to select either the Manual Mode, the External

Automatic Mode or the Internal Automatic Mode.

Used to stop automatic operation (after the

completion of one cycle).

Used to manually guide the robot by jogging, inching

and other such movement.

Used to control pneumatic drive shafts (for grippers,

etc.)

Used to create and edit positional data, coordinate

data and load data.

Used to manage files by such operations as loading,

saving, copying and deleting.

Used to reset output signals and execution

conditions.

Used to display errors which have not yet been

reset.

Used to display a historical list of errors which have

been corrected.

Used to select a work coordinate system.

Used to select a tool coordinate system.

Control

Panel

STE 58761

Teaching

pendant

〇

△

〇

(On only)

〇

〇

〇

〇

〇

〇

〇

〇

〇

〇

〇

〇

〇

〇

〇

〇

〇

〇

〇

〇

〇

〇

External

control

signals

〇

〇

〇

〇

〇

1-1

- -

Page 19

Function Description

Present position

monitor

External I/O signal

monitor

File selection Used to select a file for execution.

Move Moves the robot to a point which has been taught.

Used to display the present position of the robot in

terms of the various coordinate system.

Used to display the status of digital I/O signals.

Control

Panel

〇

△

STE 58761

External

control

signals

〇

Teaching

pendant

: Complete operation

: Partial operation

〇

〇

〇

〇

1-2

- -

Page 20

STE 58761

1.2 MODE STRUCTURE

External Automatic

Mode (EXT)

Master Mode

Utility Mode The Utility Mode is used to perform such operations

Error Display Mode The error display mode is used to display and reset

The emergency stop and servo off operations can be used regardless of the present mode.

Internal Automatic

Mode (INT)

Manual Mode (MANU) The Manual Mode is used to perform such

The External Automatic Mode is used to

automatically operate the robot by program. This

operation is performed with external control signals

or signals from a host computer.

The Internal Automatic Mode is used to

automatically operate the robot by program. This

operation is carried out from either the control panel

or the teach pendant.

operations as teaching, guiding, file management

and program test runs. All such operations are

carried out with the teach pendant.

as coordinate selection, position monitoring and

signal monitoring. The Utility Mode is carried out

from the teach pendant and is unrelated to the

master mode.

errors with the teach pendant. The error display

mode has nothing to do with the Master Mode.

1-3

- -

Page 21

STE 58761

1.2.1 External Automatic Mode

External Operation

Signal Mode (SIG)

External

Automatic

Mode (EXT)

The mode with which external automatic operation is carried out is defined in

Host Mode (HOST) This mode is used to perform the program

the system configuration file. See the Start-up Manual for details.

All file selections, execution mode selections, speed override settings and

speed limit settings made in either the Internal Automatic Mode or the Test

Operation Mode are also valid in the External Automatic Mode.

1.2.2 Internal Automatic Mode

Program Selection

(SELECT)

Internal

Automatic

Mode (INT)

Operation Mode

Selection (MODE)

Speed Override

(MSPEED)

Speed Limit

(LSPEED)

Start-up Starts program execution from the control panel.

Stop (STOP,BREAK) Suspends or cancels program execution.

Direct Execution

(DO)

Reset (RESET) Resets the program execution step, variables and

This mode is used to perform the program automatic

operation. This operation is carried out with

external operation signals. For details, see the

Interface Manual.

automatic-operation, file uploading and file

downloading. All operations are carried out by the

host computer through serial communication

channel(s). For details, see the Communications

Manual.

Selects a program for execution.

Selects an operation mode.

Selects the speed override.

Selects the speed limit.

Directly executes a SCOL command.

digital output signals.

1-4

- -

Page 22

1.2.3 Manual Mode

Edit (EDIT) Edits programs and data (positional data, coordinate

Test Operation

(TESTRUN)

Manual

Mode

(MANU)

File Load (LOAD) Loads a file from the disk into the RAM drive.

File Save (SAVE) Saves a file in the RAM drive onto the disk.

Disk Initialization

(FORMAT)

Directory Display

(DIR)

File Copy (COPY) Copies a file in the RAM drive and stores the copy in

File Comparison

(VERIFY)

File Renaming (REN) Renames a file.

File Deletion (DEL) Deletes an unneeded file.

File Printing (PRINT) Prints out the contents of a file on a printer.

Date Setting (DATE) Sets the current date.

Time Setting (TIME) Sets the current time.

Channel Selection

(CHANNEL)

Reset (RESET) Resets the program execution step, variables and

Guidance In conjunction with the control key, the guide teach

STE 58761

data and load data).

Checks to see that programs run properly.

Formats either the disk or the RAM drive.

Displays a list of all the files contained in either the

RAM drive or the disk.

a separate file.

Compares the contents of two files in units of bytes

to see that they are the same.

Switches over between serial channels.

digital output signals.

speed key and the guide coordinate key, the guide

keys are used to move the end effecter. Guidance

is effective only in the Manual Mode; it is not

effective in the Test Operation Mode.

1-5

- -

Page 23

1.2.4 Edit

Editing

Screen editor Program editing

Programs and global data are created and edited by

entering and deleting characters, by selecting

command menus and by selecting SCOL menus.

Data editor

Positional data editing

Positional data are created and edited by teaching

and by entering numbers. Work coordinate

systems are selected; work coordinates are edited.

Coordinate data editing

Coordinate data are created and edited by teaching

and by entering numbers. Base coordinates and

tool coordinates are selected. Work coordinates

are specified.

Load data editing

Load data are created and edited by entering

numbers.

STE 58761

1-6

- -

Page 24

1.2.5 Test Operation

Program Selection

(SELECT)

Operation Mode

Selection (MODE)

Speed Override

(MSPEED)

Speed Limit (LSPEED) Sets the speed limit.

Te st

Operation

(TESTRUN)

Machine Lock

(MACHINE)

Step Execution

(STEP)

Start-up (RUN) Starts program execution from a desired step in the

Stop (STOP,BREAK) Suspends or cancels program execution.

Direct Execution

(DO)

Reset (RESET) Resets the program execution step, variables and

STE 58761

Selects a program for execution.

Selects an operation mode.

Selects the speed override.

Enables and disables the machine lock.

Executes the program one step at a time.

program.

Directly executes a SCOL command.

digital output signals.

1-7

- -

Page 25

1.3 PRECAUTIONS FOR USE

For the connection of FDD unit (option), see the Interface Manual.

1.3.1 Handling Disks

(1) General precautions

(a) Don’t open the shutter section. The disk will be unusable should

any dirt get on the magnetic surface.

' I~

(b) Keep away from speakers or other devices which create strong

magnetic fields. If you don't, the contents of your disks may get

erased.

(c) Keep out of direct sunlight and away from hot objects.

(d) Don't stack books or folders on top of a disk.

A

(e) Stick the label on in the correct position. If you put on a new label,

be sure to take the old label off first.

(f) Store your disk in a location having the following temperature and

humidity range:

Storage temperature : 4 to 53°C

Storage humidity : 8 to 90 %

STE 58761

1-8

- -

Page 26

(2) Inserting a disk

(3) Removing a disk

(4) Disk write protection

STE 58761

(a) With the label up and the metal shutter forward, insert

the disk straight and slowly into the slot until you

hear it click into place.

(a) Push the push button. The floppy disk should pop

out a little ways from the slot.

(b) Grip the disk with your fingers at the label section

and draw it straight out.

Caution

!

Do not try to remove the disk while the disk

drive light is still lit. Data is either being

written to or read from the disk while the light is

lit, and if you remove the disk at this time you

may lose or damage your files.

All 3.5" disks have a write protect tab to prevent files

from being accidentally erased.

(a) Write protect

Slide the write protect tab toward the edge of the

disk (protect position).

(b) Write enable

Slide the write protect tab away from the edge of the

disk (write position).

1-9

- -

Page 27

1.4 GENERAL OPERATION

Only one key can be input at a time with the teach pendant.

1.4.1 Use of the Shift Key

When a key is pushed while the "shift" key is held down, the upper character on that key

will be input.

(1) Entering the lower character

To enter the lower character on a key, simply push that key.

Example) Entering the character "9".

Key operation Display

(2) Entering the upper character

To enter the upper character, push down that key while holding down the "shift" key.

Example) Entering the character "(".

Key operation Display

+

Shift

(

9

(

9

9

STE 58761

9

1-10

- -

Page 28

1.4.2 Use of the Function Keys

In order to make it easier to input data, the teach pendant is provided with six function

keys, i.e., "F1" to "F6".

The functions to which "F1" to "F5" correspond will change depending on the mode. The

names of these functions will appear above the corresponding function key. By pushing

the appropriate key, commands can be executed without having to type in each letter

making up that command.

The "F6" key is the NEXT key. When there are more than five commands in a particular

mode, the NEXT key allows one to display the additional commands.

Example: Selecting the "SAVE" command

> ■

EDIT LOAD SAVE TESTRUN> RESET NEXT

F1 F2 F3 F4 F5 F6

STE 58761

Command names followed by a “>” symbol indicate commands which are executed

immediately when the, corresponding function key is pushed.

Caution

!

The function keys work differently when editing with the screen editor or data editor. For

more information, refer to Chapter 5 "Program Editing" and Chapter 6 "Data Editing."

1-11

- -

Page 29

1.4.3 Repeating an Entry

The repeat operation is available for the following keys.

[Bs], [Esc], [Exec]

Guide key

[Move]

Cursor keys

[Coordinates], [Teach Speed], [Control]

1.4.4 Correcting Incorrect Entries

Use the "Bs" key to erase any characters which were incorrectly entered.

Example:

(Correct) TIME 13:50:00 (Incorrect) TIME 13:60:__

Push the “Bs” key. TIME 13:6__

Push the “Bs” key. TIME 13:__

Keep on pushing the “Bs” key until the incorrect characters are erased. Then type in the

correct characters.

STE 58761

Caution

!

The "Ins", "Del" and cursor keys may not be used when entering a command.

1.4.5 Cancelling an Entry

If you wish to cancel the command you are entering, simultaneously push the "ESC" key.

This will cancel the command you entered and allow you to write the next command on

the following line.

Should an error message or other such message appear while entering a command, that

command line will be negated.

1-12

- -

Page 30

1.4.6 Use of Wild Cards

You may use the wild cards * and ? when specifying files with the directory [DIR], delete

[DEL], print [PRINT], file save [SAVE] or file load [LOAD] command.

Wild cards are used to simultaneously specify multiple files. Using wild cards correctly

can save time and increase efficiency when specifying files.

(1) The asterisk wild card”*”

The asterisk wild card (*) can take the place of a file name or an extension. For

example, the specification “A*.*” refers to all files having a name starting with A and

having any type of extension (or no extension at all). All of the following files would

apply:

ADATA. BAT

ABC.PAR

AFILE

(2) The question mark wild card "?"

The question mark wild card "?" can take the place of any single character in a name or

extension. For example, the specification “A??.*” refers to all files that have a name

starting with A, are three characters long or less. A space or null character is also

treated as one character. All of the following files would apply:

ABC.PAR

ACD.DAT

AAA

In order to be able to use wild cards effectively, you should pay attention to how you assign

file names and extensions.

STE 58761

1-13

- -

Page 31

1.4.7 Format for Operating Instructions

The following format is used in this manual to explain how to use commands.

Title [command name]

(1) Function

Explains the purpose of the command and what it does.

(2) Input format

Explains the input format for operation. An input consists of a command and

parameters. Listed below are notation used to describe the input format.

[ ] Indicates an item (or items) that may be specified if necessary and omitted if not.

< > Indicates an item (or items) to be input.

<d:> Specifies the drive name. One must enter either A or R.

A : FDD unit (option)

R : RAM drive

<file name> Specifies the file name. <file name> may consist of a name having up to

eight alphanumeric characters and an extension having up to three characters. For

example, CONSTRUC.SYS is a valid <file name>.

{ } Indicates that one parameter is to be chosen from among the multiple parameters

enclosed.

... Indicates that multiple parameters may be specified.

Note that the characters [ ], < >, { } and ... are themselves not to be entered.

They are merely symbols use to describe the input format.

(3) Comments

Explains restrictions and things to keep in mind.

(4) Procedure

Explains procedures and system responses for various operations.

(5) Related functions

Explains related functions.

STE 58761

1-14

- -

Page 32

1.5 ASSIGNING NAMES

1.5.1 Assigning the Volume Name

When a disk is initialized, you can assign a name to that disk. This is the volume name.

In order to simplify disk handling, you should keep your files sorted by task and put related

files on the same disk. Also, be sure to give the disk a descriptive, easy to understand

name.

The volume name can be checked by looking at the directory display.

Volume names consist of a volume name proper, a period, and a volume name extension.

An example is shown below:

WORK1

The following characters may be used in the volume name and its extension:

Alphabetic characters: A to Z

Numerals: 0 to 9

The volume name extension may be omitted. In such a case, the period becomes

unnecessary.

. FIL

STE 58761

FIL is the volume name extension.

It may have up to three characters.

A period is used to separate the volume name

and the volume name extension.

WORK1 is the volume name. It may have up to

six characters.

1-15

- -

Page 33

1.5.2 Assigning a File Name

Every file in a disk or in the RAM drive has its own name. This is called the file name.

File names consists of a file name proper, a period, and a file name extension. An

example is shown below:

CONSTRUC

The following characters may be used in the file name and its extension:

Alphabetic characters: A to Z

Numerals: 0 to 9

The file name extension is used to identify the nature (type) of the file. By using different

extensions on the same file name, you can keep related files together while still being able

to differentiate between them by purpose.

The following extensions are used for the following type of special purpose files.

Extension Purpose

STE 58761

. SYS

SYS is the file name extension. It may have up

to three characters.

A period is used to separate the file name and

the file name extension.

CONSTRUC is the file name. It may have up to

eight characters.

SYS Identifies system files.

BAT Identifies batch files.

PAR Identifies parameter files.

LIB Identifies library files.

LOG Identifies maintenance files.

The file name extension may be omitted. In such a case, the period becomes

unnecessary.

When specifying a file having a file name extension, you may not omit that extension. If

you do, the controller will treat that file as a completely different file.

1-16

- -

Page 34

1.5.3 Assigning a Point Name

When entering positional data for a point, you have to assign a name to that point. This

name will be used later in the program when telling the robot where to go.

Point names generally have a format like that shown in the example below:

PNT100

The following characters may be used in the point name. (The first letter of a point name

must be an alphabetic character.)

Alphabetic characters: A to Z

Numerals: 0 to 9

Note: You may not use an identifier reserved for the SCOL language to name a point.

See Appendix B of Robot Language Manual for a list of such identifiers

(reserved words).

If you try to enter more than ten characters when inputting a point name, an error

message ("name over") will be displayed and that entry will be invalidated.

If you try to enter anything other than an alphabetic character for the first character of the

point name, an error message ("illegal key!") will be displayed and that entry will be

invalidated.

If you try to enter anything other than an alphanumeric character when inputting the point

name, an error message ("illegal key!") will be displayed and that entry will be invalidated.

STE 58761

PNT100 is the point name (in this example).

The point name may have up to ten characters.

1-17

- -

Page 35

1.5.4 Assigning a Name to Coordinate Data

When entering coordinate data for a work coordinate system, a tool coordinate system or

the base coordinate system, you have to assign a coordinate name to that data. This

name will be used later in the program when telling the robot which coordinate system to

use.

Coordinate names generally have a format like that shown in the example below:

TAB L E 1

The following characters may be used in the coordinate name. (The first letter must be

an alphabetic character.)

Alphabetic characters: A to Z

Numerals: 0 to 9

Note: You may not use an identifier reserved for the SCOL language to name

coordinate data. See Appendix B of Robot Language Manual for a list of such

identifiers (reserved words).

If you try to enter more than ten characters when inputting a coordinate name, an error

message ("name over") will be displayed and that entry will be invalidated.

If you try to enter anything other than an alphabetic character for the first character of the

name, an error message ("illegal key!") will be displayed and that entry will be invalidated.

If you try to enter anything other than an alphanumeric character when inputting the name,

an error message ("illegal key!") will be displayed and that entry will be invalidated.

STE 58761

TABLE1 is the coordinate name (in this example).

The name may have up to ten characters.

1-18

- -

Page 36

1.5.5 Assigning a Name to Load Data

When entering load data, you have to assign a load name to that data. This name will be

used later in the program when telling the robot which load value to use.

Load names generally have a format like that shown in the example below:

SAMPLE1

The following characters may be used in the load name. (The first letter must be an

alphabetic character.)

Alphabetic characters: A to Z

Numerals: 0 to 9

Note: You may not use an identifier reserved for the SCOL language to name load

data. See Appendix B of Robot Language Manual for a list of such identifiers

(reserved words).

If you try to enter more than ten characters when inputting a load name, an error message

("name over") will be displayed and that entry will be invalidated.

If you try to enter anything other than an alphabetic character for the first character of the

name, an error message ("illegal key!") will be displayed and that entry will be invalidated.

If you try to enter anything other than an alphanumeric character when inputting the name,

an error message ("illegal key!") will be displayed and that entry will be invalidated.

STE 58761

SAMPLE1 is the load name (in this example).

The name may have up to ten characters.

1-19

- -

Page 37

STE 58761

CHAPTER 2

BASIC OPERATION

2.1 BASIC OPERATING PROCEDURE

The following flowchart shows the basic operating procedure for automatic operation. It covers

all operations from turning on the power to turning off the power.

START

Turn on main power

Turn on servo power

NO

program

edit end?

YES

Automatic operation

Job End?

YES

Turn off servo power

Turn off main power

END

NO

NO

edit

Test run

operation

Correct?

YES

2-1

- -

Page 38

STE 58761

2.2 TURNING ON THE MAIN POWER

There are two ways to start up the controller - cold starting and hot starting. Normally, only the

hot starting is required. For details, see Para. 2.2.2.

2.2.1 Cold Starting

Danger

!

If an abnormality has generated or the POWER LED lamp on the control panel remains off after

the main power switch of the equipment was turned on, turn off the main power immediately

and confirm the wiring. Otherwise, you will be struck by an electric shock or a fire will break

out.

Caution

!

Once a cold start has been executed, all data saved in the controller memory, such as user

program, position data, user parameter and system construction files are initialized.

(1) Function

System programs contained on a disk inserted in the FDD unit (option) are loaded into

the RAM drive. The RAM drive is thereby initialized and the controller is booted

(started up).

(2) Input format: None

(3) Comments

Normally, you should hot start the system. Only cold start the system when you cannot

・

hot start it.

After you have completed a cold start, remove the system disk from the controller disk

・

drive. Should you leave the system disk in the disk drive, all the files in the RAM drive

will be erased should the power go out and turn back on again.

Copies of all files necessary for the RAM drive should be kept on disks for safekeeping.

・

For information on how to save files on disks, see the Section "Saving files."

The system disk must contain the following system programs and subscription files.

・

System programs:

SVPMTX. SYS

MCPMTX. SYS

Subscription files:

CONSTRUC. SYS EXTRNSEL. SYS *

ALARM. MES * SCOL. LIB *

SYSTEM. PAR AUTOSTR. BAT *

USER. PAR

2-2

- -

Page 39

STE 58761

Files marked by an asterisk are not absolutely necessary to run the system. However,

you will get an error if you try to execute a function dependent on a missing file.

For more information on these files, see the Start-up Manual.

(4) Procedure

(a) Step 1: Insert the system disk

Insert the system disk into the FDD unit (option).

(b) Step 2: Turn on the main power.

Turn on the main power switch located on the controller.

The POWER lamp and SERVO POWER OFF lamp should light up.

10AT

POWER

The light on the disk drive should also light up around this time. This shows

that the system programs are being loaded into the RAM drive. While these

programs are being loaded, the START lamp on the control panel blink.

When loading is complete, the SERVO POWER OFF lamp, the START lamp,

the STOP and the CYCLE STOP lamp will all momentarily light up at once.

The LCD (liquid crystal display) of the teach pendant will display the initial mode

selection menu. The STOP lamp and the SERVO POWER OFF lamp on the control

panel will be lit.

Following this, parameters will be automatically read in from the disk in the disk drive.

When this is completed, the disk drive light will go out. This marks the end of the

cold start operation.

(c) Step 3: Remove the system disk

Once the cold start is completed, the system is booted and ready to operate.

After checking to make sure that the disk drive light is out, remove the system

disk from the disk drive.

The lamp

turns on

POWER

FAULT

EXT

SERVO POWER

OFF

STOP START

INT

MANU

EMERGENCY

ON

BATTERY

ALARM

CYCLE

STOP

2-3

- -

Page 40

STE 58761

2.2.2 Hot Starting

Caution

!

If an abnormality has generated or the POWER LED lamp on the control panel remains off after

the main power switch of the equipment was turned on, turn off the main power immediately

and confirm the wiring. Otherwise, you will be struck by an electric shock or a fire will break

out. When hot starting has been done, the controller enters a program reset status.

(1) Function

Starts up the controller with files contained in the RAM drive.

(2) Input format

None

(3) Comments

The following subscription files must be in the RAM drive:

CONSTRUC. SYS EXTRNSEL. SYS *

ALARM. MES * SCOL . LIB *

SYSTEM. PAR AUTOSTR. BAT *

USER. PAR

Files marked by an asterisk are not absolutely necessary to run the system.

However, you will get an error should you try to execute a function dependent

on a missing file.

For more information on these files, see the Start-up Manual.

2-4

- -

Page 41

10AT

STE 58761

(4) Procedure

(a) Step 1: Turn on the main power

First, make sure that the system disk is not in the FDD unit (option). Then,

turn on the controller main power. The POWER lamp and the SERVO

POWER OFF lamp on the control panel will light up.

The lamp

POWER

turns on

POWER

FAULT

EXT

INT

SERVO POWER

OFF

STOP START

MANU

ON

CYCLE

STOP

EMERGENCY

BATTERY

ALARM

The controller will start initializing the system. The disk drive light will blink for

about 15 seconds.

When the hot start operation is completed, the STOP lamp on the control panel will

light up and the LCD (liquid crystal display) of the teach pendant will display the

initial mode selection menu.

2-5

- -

Page 42

2.3 TURNING ON THE SERVO POWER

Caution

!

If the robot moves abnormally at the servo power ON, press the EMERGENCY STOP

・

switch immediately to turn the servo power off.

If anyone enters the robot dangerous area, turn the servo power off beforehand.

・

(1) Function

Turns on the main power circuit for the servo drivers. Servo control axes will

change over to the servo-lock state, and any brakes will be released.

(2) Input format: None

(3) Comments

You will not be able to turn on the servo power if the emergency switch is pushed

down. Release the switch first.

In order to turn on the servo power with an external operation signal, the teach pendant

connector (or the dummy connector) must be attached to the control panel. Also, the

contacts for the Emergency Stop and Servo OFF external signals must be open. For

more information, refer to the Interface Manual.

(4) Procedure

(a) Step 1: Turn on the servo power

Push either the SERVO POWER ON switch on the controller or the teach pendant.

The controller SERVO POWER ON lamp should turn on and the OFF lamp should

turn off. The teach pendant SERVO ON lamp should light up.

STE 58761

2-6

- -

Page 43

2.4 TURNING OFF THE SERVO POWER

(1) Function

Turns off the main power circuit for the servo drivers. Servo control axes will

change over to the servo-free state, and any brakes will be activated.

(2) Input format: None

(3) Comments

Do not turn the servo power off while the robot is running. When you wish to stop

the robot in a hurry, push an emergency stop switch instead.

When about to enter the robot work-space envelope, or when no operator is to be present,

turn off the servo power for safety reasons. (Note that this does not apply to automatic

operation.)

For information on how to turn off the servo power with an external operation signal, see

the Interface Manual.

(4) Procedure

(a) Step 1: Turn off the servo power

Push the SERVO POWER OFF switch on the controller. The SERVO POWER

OFF lamp should turn on and the ON lamp should turn off. The teach pendant

SERVO ON lamp should turn off.

The lamp

turns on

STE 58761

2-7

- -

Page 44

2.5 TURNING OFF THE MAIN POWER

(1) Function

Turns off the main power and stops controller processing.

(2) Input format: None

(3) Comments

Do not turn off the main power while the servo power is on or while the controller is

either processing data or manipulating files. Before turning off the main power,

make sure that the servo power is off and that the controller is not running.

(4) Procedure

(a) Step 1: Remove the disk, if any, from the disk drive

If there is a disk in the FDD unit (option), check to see that the disk drive light is off

and then remove the disk.

(b) Step 2: Turn off the main power

Turn off the main power switch located on the controller.

10AT

The POWER lamp on the controller should turn off.

POWER

The lamp

turns off

POWER

FAULT

EXT

SERVO POWER

OFF

STOP START

INT

MANU

STE 58761

EMERGENCY

ON

BATTERY

ALARM

CYCLE

STOP

2-8

- -

Page 45

CHAPTER 3

MANUAL OPERATION

3.1 SELECTING THE MANUAL MODE

(1) Function

Changes over to the Manual Mode in which the robot is manually guided, points

are taught, files are managed and the system is controlled. All of these

operations are performed with the teach pendant.

(2) Input format

None

(3) Comments

The Test Operation Mode is classified as a manual mode. However, the Test

Operation Mode is treated as completely separate in this manual.

For information on the Test Operation Mode, see Chapter 7,"Test Operation."

(4) Procedure

(a) Step 1: Select the Manual Mode

Turn the master mode switch on the control panel to MANU. The following menu

should appear on the teach pendant display.

> ■

----- (a)

EDIT LOAD SAVE TESTRUN> RESET NEXT ----- (b)

STE 58761

3-1

- -

Page 46

a) Display field for command input and messages

b) Display field for function key menu

EDIT Edit

LOAD File load

SAVE File save

TESTRUN Test operation

RESET Reset

DIR Directory display

COPY File copy

DEL File deletion

REN File renaming

PRINT File printing

FORMAT Disk initialization

VERIFY File comparison

ZEROP Zero point teaching

JLMIT Soft limit teaching

CHANNEL Channel selection

DATE Date setting

TIME Time setting

STE 58761

3-2

- -

Page 47

STE 58761

3.2 GUIDANCE COORDINATES

(1) Function

Selects a coordinate system in which to guide the robot from among the joint

coordinates, tool coordinates, work coordinates and world coordinates.

(2) Input format

None

(3) Comments

Refer to the Introductory Manual for information on robot coordinate systems.

If a tool, base or work coordinate system has not been taught to the robot, the

robot will assume:

(a) The tool coordinate system coincides with the surface of the hand mounting flange.

(b) The work and world coordinate systems coincide with the base coordinate system.

When using the tool or work coordinate system, make sure you have selected the

right one.

(4) Procedure

(a) Step 1: Select the tool and work coordinates

It is possible to have several work and/or tool coordinate systems. Therefore, you

must select which ones you are going to use with the WORK and TOOL utilities.

For details, see Chapter 12, "Utilities."

If you are using joint or world coordinates, this operation is unnecessary.

(b) Step 2: Select the coordinates

Push the "Coordinate" key on the teach pendant. Each time you push this key,

the lamp will cycle one step between World, Work, Tool and Joint.

The initial setting is Joint.

3-3

- -

Page 48

STE 58761

3.3 GUIDE MOVEMENT

There are three types of guide movement: jog, inching and free.

In the jog mode, the robot will move in the specified direction at the specified speed in the

specified coordinate system for as long as you hold down the corresponding guide key. The jog

mode is useful for rough positioning of the robot to get it near the target position.

In the inching mode, the robot will move in the specified direction at the specified displacement in

the specified coordinate system. The inching mode is useful for fine positioning of the robot near

the target position.

In the free mode, you may release the servo lock on the desired axes and move around the robot

by hand. The free mode is useful for fine positioning of the robot near workpieces and other

such objects.

(1) Function

Selects the guide movement mode.

(2) Input format: None

(3) Comments

When changing from the free mode to another mode, the servo mechanism on all

axes will lock-up (change to the locked state).

(4) Procedure

(a) Step 1: Select the Manual Mode

Turn the master mode switch on the control panel to "MANU".

(b) Step 2: Select the guide movement mode

Push the "Control" key on the teach pendant. Each time you push this key, the

lamp will cycle one stop between Jog, Inching and Free.

The initial setting is Jog.

3-4

- -

Page 49

3.4 GUIDE SPEED

(1) Function

Selects the guide speed or the guide displacement.

Guide speed will be set if the guide movement mode is set to jog. Guide

displacement will be set if the guide movement mode is set to inching.

Set the guide speed or guide displacement in accordance with how far the robot is from the

target position.

(2) Input format: None

(3) Comments: None

(4) Procedure

(a) Step 1: Select the guide speed mode

Push the "Teach Speed" key on the teach pendant. Each time you push this key,

the lamp will cycle one step between High, Med. and Low.

The initial setting is Low.

STE 58761

3-5

- -

Page 50

3.5 GUIDANCE

Caution

!

If the guidance is performed manually, do not enter the robot dangerous area.

・

If the robot moves abnormally, immediately effect an emergency stop.

・

If the robot will not move in the specified direction, consult Toshiba Machine.

・

(1) Function

The robot can be moved in the desired direction by pushing the appropriate guide

keys when the guide movement mode is set to inching or jog.

(2) Input format

The guidance coordinates, guide movement mode and guide speed do not have to

be set in any particular order. However, they all must be set before pushing any

guide keys.

(3) Comments

When the guide movement mode is set to free, the guide keys do not specify the

direction the robot is to move; rather, they specify axes for which the servo lock is

to be released.

The guide keys will only work while at least one of the deadman switches (on the back of

the teach pendant) is pushed down. This is to prevent accidents.

(4) Procedures

(a) Step 1: Select the Manual Mode

Turn the master mode switch on the control panel to "MANU".

(b) Step 2: Set the guidance conditions

Set the guidance conditions (guidance coordinates, guide movement and guide

speed) as necessary.

(c) Step 3: Guidance

Push the guide keys as appropriate while holding down at least one deadman

switch (on the back of the pendant). The robot will move as directed in the

specified coordinate system.

STE 58761

3-6

- -

Page 51

3.6 SERVO FREE

(1) Function

Servo locks can be released for axes as desired when the guide movement mode

is set to free. Axes in the servo free (i.e., unlocked) state can be moved freely by

hand. This is convenient when moving the robot near workpieces and other such

objects.

(2) Input format

None

(3) Comments

If You change from the servo free state to either the Test Operation Mode, the

Internal Automatic Mode or the External Automatic Mode, the servo lock will be set

for all axes.

The guide keys will only work while at least one of the deadman switches (on the back of

the teach pendant) is pushed down.

If you move the robot by hand in the servo free state, other joints may move as well due to

axial interference.

You cannot cancel the servo free state while in Feed Hold.

You can cancel the servo free state while displaying the Error History.

(4) Procedure

(a) Step 1: Select the Manual Mode

Turn the master mode switch on the control panel to "MANU".

(b) Step 2: Select the guide movement mode

Push the Guide Movement key on the teach pendant as many times as necessary

to select "Free".

(c) Step 3: Release the servo locks

While pushing down on a deadman switch, push the guide keys on the minus (-)

side to release the servo locks for the desired axes. Such axes will change over

to the servo free state.

(d) Step 4: Guide the robot

Guide the robot by hand to where you want it to go.

(e) Step 5: Set the servo locks

STE 58761

3-7

- -

Page 52

STE 58761

While pushing down on a deadman switch, push the guide keys on the plus (+)

side for those axes in the servo free state. Such axes will then change over to the

servo lock state.

3-8

- -

Page 53

(1) Function

Manages auxiliary signals used to control the hand, the air control axes, etc.

(2) Input format

None

(3) Comments

The output signal port and solenoid type corresponding to each function key must

be defined (specified) in the system configuration file. For more information, see

the Start-up Manual.

Press the "Esc" key to exit the Auxiliary Signal Operation Mode and return back to the

original menu.

While under emergency stop or in feed hold, auxiliary signals may be turned on and off.

The initial state including signals which is set for double solenoids in the power ON state is

turned off.

STE 58761

CHAPTER 4

AUXILIARY SIGNALS

4-1

- -

Page 54

(4) Procedure

(a) Step 1: Select the Manual Mode

Turn the master mode switch on the control panel to "MANU".

(b) Step 2: Select the Auxiliary Signal Operation Mode

Push the "Aux. Signal" key on the teach pendant. The Auxiliary Signal Operation

Mode menu should then appear.

Auxiliary signal operation mode

[210] [212] [214]

[208] [209] [211] [213]

Aux 1 Aux 2 Aux 3 Aux 4 Aux 5 Aux 6

The numbers on the screen correspond to the output signal ports. Auxiliary

signals having two output signal ports are set for double solenoids, and those

having one output signal port are set for single solenoids. Those having no

output signal ports are not set for anything.

Ports that are highlighted in the display are on and ports that are not are off.

(c) Step 3: Turn ports on and off as appropriate

Each time you push a function key corresponding to a port, the status of the

solenoid will change from on to off or from off to on. For double solenoids, the

status of the two ports will be transposed.

STE 58761

4-2

- -

Loading...

Loading...