Page 1

STE 58760

INSTRUCTION MANUAL

INDUSTRIAL ROBOT SR SERIES

START-UP MANUAL

Notice

1.

Make sure that this Instruction Manual is delivered to the final user

of the Toshiba Industrial Robot.

2. Please read this manual before using the Toshiba Industrial

Robot.

3. Please read the “Safety Manual” also.

4. Keep the manual nearby for further reference during use of the

robot.

TOSHIBA MACHINE CO.,LTD.

1998- 3

Page 2

Copyright 1997 by Toshiba Machine Co., Ltd.

All rights reserved.

No part of this document may be reproduced in any form without obtaining prior written

permission from the Toshiba Machine Co., Ltd.

The information contained in this manual is subject to change without notice.

STE 58760

i

- -

Page 3

STE 58760

PREFACE

This manual describes how to start up the Toshiba SR series industrial robot.

Start-up as used in this manual refers to operations from turning on the robot controller to

operating the robot by manual guidance. Before operating the controller, make sure that all

the cables have been correctly connected among the robot, controller, and peripheral

equipment according to the “Transportation and Installation Manual”.

This manual is written for users who have not operated SR series robots before. Users who

have experience or want to know the details of the operations, see the Operating Manual.

This manual consists of the following chapters.

Chapter 1 "Before operating SR Series Robot"

This chapter outlines robot operational procedure, names of controls which should be used for

the start-up operation, and their functions.

A control panel and teach pendant are used to operate the robot. Be sure to learn where the

various switches are.

Chapter 2 "Power-ON to Manual Guidance"

This chapter describes how to turn on the power and how to manually guide the robot. The

last paragraph of this chapter also discusses how to turn off the power. Be sure to follow the

precautions which should be taken before turning off the power.

Chapter 3 "Setting Environmental Conditions for the SR7000 Controller"

This chapter describes items to be set before operating the controller such as date, time and

communication channel assignment.

Chapter 4 "Example of Simple Operation"

This chapter shows how to program and edit data and how to set automatic operations.

Because in the chapter you will actually operate the robot, be sure to follow the precautions.

Chapter 5 "File"

This chapter presents an outline of files used in the robot system and also formatting and

backup operations for floppy disks (option). Files which store programs and parameters

should be backed up on different disks.

ii

- -

Page 4

STE 58760

NOTE!

FOR EUPOREAN UNION (EU)

In European Union (EU), there are following limitations and notes to approve the

CE Marking EMC Direction. In other countries and areas, it

apply to these limitations and notes.

(1) Set up conditions

◆

The following type of power line transformer must be used.

Frequency: 50 or 60 Hz

Secondary voltage: 3 phase 200 ~ 230 VAC

power capacity: Min. 2.7 kVA

(2) Input power condition

◆

Core wires: 3.5 mm2 ~ 5.5 mm2

◆

Voltage short interruption: 0.5 cycle

(3) Ground

◆

Core wires: 0.08 mm2 ~ 0.5 mm

◆

Ground condition: Exclusive ground line for robot ground impedance

must be less than 100

(4) External input and output line / Optional input and output line

◆

Core wires: 0.08 mm2 ~ 0.5 mm

◆

Shield: Ground shield

◆

Cable length: Max. 10 m

◆

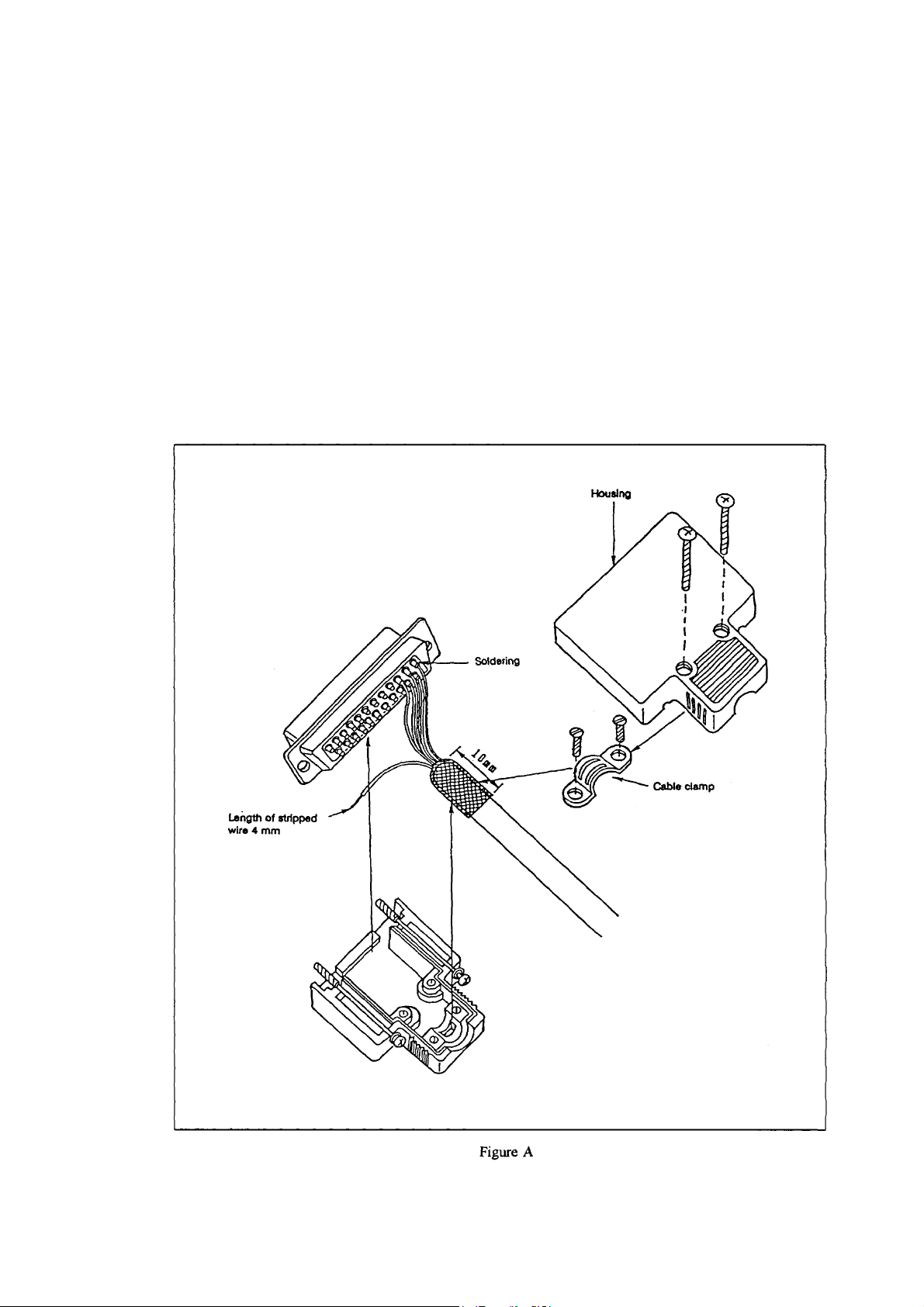

Manufacturing method: Refer to figure A.

◆ S

ignal ground: Voltage potential between signal ground PGBA and

controller frame ground F.G. must be the same.

(5) Serial communication line

◆

Only 1 of 4 serial communication ports (connector name; J1 ~ J4) can be used at

the same time.

◆

Core wires: 0.08 mm2 ~ 0.5 mm

◆

Shield: Ground shield

◆

Cable length: Max. 10 m

◆

Twisted pair: Not required for RS-232C, required for RS-422.

◆

Manufacturing method: Refer to figure A.

is

not necessary to

2

.

Ω

2

2

iii

- -

Page 5

(6) Limitation of the robot specification

◆

Cable length from robot to controller: Max. 8 m

◆

Cable length of teach pendant: Max. 8 m

◆

Optional 5th axis: Cannot be used.

◆

Optional input output signals(type;SR7000IO): Only one optional board

◆

Optional relay output signals (type;SR7000RO): Cannot be used.

◆

Optional conveyer tracking system (type;SR7000CV): Cannot be used.

◆

Separated operation panel: Cannot be used.

STE 58760

can be used.

iv

- -

Page 6

TABLE OF CONTENTS

CHAPTER 1 BEFORE OPERATING SR SERIES ROBOT

1.1

1.1.1

1.1.2

1.2

1.3

1.4

1.5

1.6

1.6.1

1.6.2

CHAPTER 2 POWER ON TO MANUAL GUIDANCE

2.1

2.1.1

2.1.2

2.2

2.3

2.4

2.5

2.6

2.6.1

2.6.2

OVERVIEW・・・・・・・・・・・・・・・・・・・・・・・・・

Structure

Functions

OUTLINE OF OPERATIONAL PROCEDURE

SPECIFICATIONS

COORDINATE SYSTEM・・・・・・・・・・・・・・・・・・・・

SYSTEM CONFIGURATION

NAMES AND FUNCTIONS OF SR7000 CONTROLLER

Control Panel

Teach Pendant

TURNING ON MAIN POWER・・・・・・・・・・・・・・・・・

Cold Starting

Hot Starting

SETTING CONTROLLER ENVIRONMENTAL CONDITIONS

TURNING THE SERVO POWER ON

MANUAL GUIDANCE OF EACH AXIS・・・・・・・・・・・・・

MANUAL GUIDANCE OPERATION

MOTION RANGE LIMIT

Setting Joint Limit Values by Teaching

Setting Joint Limit by Numeric Value Entry

・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・

STE 58760

・・・・・・・・・・

・・・・・

・・・

・・・・・・・・・・・・・・

・・・・・・・・・・・・・・

・・・・・・・・・・・・

・・・・・・・・・・

1-1

1-2

1-4

1-9

1-11

1-14

1-16

1-21

1-21

1-23

2-2

2-2

2-5

2-8

2-9

2-10

2-13

2-16

2-16

2-18

v

- -

Page 7

2.7

2.7.1

2.7.2

CHAPTER 3 SETTING ENVIRONMENTAL CONDITIONS FOR THE SR7000

3.1

3.1.1

3.1.2

3.2

3.3

3.3.1

3.3.2

3.3.3

3.4

3.4.1

3.4.2

3.5

3.5.1

3.5.2

3.5.3

3.6

3.6.1

3.6.2

3.6.3

3.7

3.7.1

3.7.2

3.7.3

3.7.4

3.7.5

3.7.6

TURNING OFF THE POWER・・・・・・・・・・・・・・・・・

Turning OFF Servo Power

Turning OFF the Main Power

CONTROLLER

SETTING DATE AND TIME・・・・・・・・・・・・・・・・・・

Setting Date

Setting Time

CHANGING FILE DATA

SETTING THE SYSTEM CONFIGURATION・・・・・・・・・・・

Outline of Data

File Format

Details of Data

SETTING EXTERNAL SELECTION FILES・・・・・・・・・・・

Signals Used for Selecting File

Contents of File

BATCH PROCESSING

Batch File

Automatic Execution File

Using Batch Processing Effectively

PROGRAM EXECUTION ENVIRONMENT

Program Execution Environment

Resetting Execution Environment

Reset Timing of Program Execution Environment

SETTING COORDINATE SYSTEM

Robot Coordinate Systems

Teaching Coordinate Data

Selecting Coordinate System in Data Editor Mode

Selecting Coordinate System in Utility Mode

Selecting Coordinate System Using Robot Language

Timing of Changing the Coordinate System

・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・

・・・・・・・・・・・

・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・

・・・・・・・

・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・

・・・・・・・

・・・・・・・・・

・・・・・・・・・・

STE 58760

・・・・・

2-21

2-21

2-21

3-1

3-1

3-3

3-6

3-12

3-12

3-14

3-18

3-26

3-26

3-27

3-29

3-29

3-31

3-32

3-34

3-34

3-36

3-37

3-38

3-38

3-40

3-46

3-53

3-56

3-56

vi

- -

Page 8

CHAPTER 4 EXAMPLE OF SIMPLE OPERATION

4.1

4.2

4.2.1

4.2.2

4.2.3

4.3

4.3.1

4.3.2

4.3.3

4.3.4

4.4

CHAPTER 5 FILES

5.1

5.2

5.3

5.3.1

5.3.2

5.3.3

5.4

5.5

5.5.1

5.5.2

5.6

5.7

5.8

EXAMPLE OF ROBOT OPERATION

TEACHING THE PROGRAM AND POSITION DATA・・・・・・・

Inputting A Robot Language Program

Teaching Positional Data

Changing Positional Data

TEST RUN・・・・・・・・・・・・・・・・・・・・・・・・・・

Preparation before Conducting Test Run

Test Run in Step Operation Mode

Test Run in Cycle Operation Mode

Test Run in Continuous Operation Mode

AUTOMATIC OPERATION

TYPES OF FILES

CHECKING FILES・・・・・・・・・・・・・・・・・・・・・・

FILES REQUIRED TO START UP ROBOT

Files Required to Perform the Cold Start Operation

Files Required for the Hot Start Operation

Setting of Distribution I/O Function

FORMATTING FLOPPY DISKS

BACKING UP FILES

Saving Files

Loading Files

COPYING FILES・・・・・・・・・・・・・・・・・・・・・・・

RENAMING FILES

DELETING FILES・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・

STE 58760

・・・・・・・・・・・・・・

・・・・・・・・・・・・

・・・・・・・・・・・

・・・・・・・・・・・・・・

・・・・・・・・・・・・・・

・・・・・・・・・・・

・・・・・・・・・・・・

・・・・・・

・・・・・・・・・・

・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・

4-2

4-3

4-3

4-7

4-13

4-16

4-16

4-22

4-27

4-32

4-38

5-1

5-3

5-6

5-6

5-7

5-8

5-9

5-12

5-12

5-15

5-19

5-23

5-26

vii

- -

Page 9

STE 58760

CHAPTER 1

BEFORE OPERATING SR SERIES ROBOT

This chapter presents an outline of the robot operational procedure, specifications, coordinate

system, system configuration, and their functions.

1.1 OVERVIEW

This paragraph deals with an outline of the SR–HSP series Toshiba system robot. The SR–HSP

series signifies the horizontally articulated robot.

The robot and robot controller feature as follows:

(1) Robot

• High-speed and smooth motion

– Cycle time 0.8 sec. under load of 2 kgf, 0.9 sec. under load of 5 kgf (SR–654HS)

300mm

25mm 25mm

• Wide working range

– A bidirectional rotating type without dead space included in the horizontal zone.

(ST–HS series)

• High reliability

– Maintenance-free, employing AC servo motors and absolute encoders.

• Enough Ni loading capacity

– Max. 20 kgf (SR–1054HS)

• Easy wiring and piping

– As nine cables and two air pipes standardly run in the arm, wiring and piping to the

end effector are necessary.

1-1

- -

Page 10

STE 58760

(2) Robot controller (SR7000)

• Simple programming.

– A program can be created easily according to highly advanced robot language SCOL.

• Excellent operability

– Teaching of positions, programming, adjustment, etc can be performed according to

the menu selection on the teach pendant.

• Extensive interfaces

– As RS232C three ports, computer and printer interface software are standard-

equipped, a diversity of system structure is possible.

• Easy diagnosis of faults

– A number of self-diagnostic functions allow an operator to smoothly address faults.

Fig. 1.1 shows the SR–HSP series system robot.

1.1.1 Structure

The robot consists of the basic robot, controller and teach pendant connected with the controller,

which is intended for teaching positions and entering programs.

To make the robot do a job, programs and position data are necessary so that the robot can

execute the job.

Normally, such programs and position data should be created and stored in the controller memory

beforehand. When operating the robot, the controller interprets the contents of programs and

gives the robot the instructions on motions according to the program sequence to cause the robot to

do the job.

Programs and position data for one process which are put together are called the task program,

which can also be called the file when they are loaded to and saved in the controller.

As the control unit of the controller uses the SCOL language (symbolic code language for robot), a

task program can be easily created and entered as if you were creating a BASIC program.

Entry of position data is possible in the three manners; guiding by the robot and teach pendant,

entry of coordinates through the teach pendant and manual guiding of the robot by the operator

after turning off the servo control.

The teach pendant can be shared by many robots, and automatic operation is possible even when it

is disconnected from the controller.

Also, saving and management of files are very easy, using an optional FDD unit.

In addition to the above, a great number of options and functions including optical sensors for

position data compensation and interface software with a personal computer are also available.

Fig. 1.2 shows a system configuration of SR series Toshiba system robots.

1-2

- -

Page 11

STE 58760

SR–1054 HSP Robot

Robot controller SR7000 Teach pendant

Fig. 1.1 SR Series System Robot

1-3

- -

Page 12

Robot

Robot controller SR–7000

Teach pendant

Fig. 1.2 System Configuration of SR Series System Robot

1.1.2 Functions

Horizontally articulated robot

STE 58760

SR–504 HSP

SR–554 HSP

SR–654 HSP

SR–854 HSP

SR–1054 HSP

(1) Control method

A 32-bit microprocessor serves as the central processor.

A 16-bit microprocessor is used for communication control and a 32-bit microprocessor for

each axis servo control, thus servo control, robot language processing and editing are

possible. Also, an 8-bit microprocessor is employed for the teach pendant to realize a more

intelligent robot.

(2) Motion

The motion comes in three types; PTP (point-to-point) control, CP (continuous path) control

(linear interpolation, circular interpolation (option)) and short-cut.

PTP control: Dedicated SCOL language MOVE

This control is used to move each axis fast to a specified position, irrespective of a path.

Simultaneous operation is executed in which all axes start moving simultaneously and

finish simultaneously.

CP control (linear interpolation): Dedicated SCOL language MOVES

This is the path control in which all paths are predetermined. Each axis moves between

two taught points in the Cartesian coordinate system along the shortest distance. It is

used to move the end effector of the robot along a straight line.

CP control (circular interpolation): Dedicated SCOL language MOVEC

Each axis moves on an arc from the current point to the target point via specified midpoint.

1-4

- -

Page 13

STE 58760

Short-cut

Each axis passes the vicinity of a taught point without reaching and stopping at the same

point, then moves to the next point. The travel time can be reduced.

PNT2

PNT2

PNT2

・Specified mid-point

PNT1

PNT1

PNT1

PTP Linear interpolation Circular interpolation Short-cut

(3) Number of controlled axes

A maximum of five axes can be controlled simultaneously. Additionally, the air cylinder can

be driven.

PNT2

PNT3

PNT4

PNT1

PNT5

(4) Storage capacity

The storage capacity of the RAM drive is 512 K bytes.

To save files, a 1.44 M bytes FDD unit (option) is available.

The rate of file active area is displayed in units of byte on the teach pendant.

Storage capacity of program alone (approximation): 500 points for 1,000 lines

A floppy disk is initialized in the MS-DOS format. It should be noted that reading of the data

contained in floppy disks for the SR-5500 controller is not possible.

(5) Storing method

A file (programs and position data) is stored in the memory backed up by a battery. Check is

performed on battery voltage drop and destruction of memory contents, and if an abnormality

has generated, an alarm is output to inform the operator to that effect.

(6) Number of program files

Up to 256 program files can be registered.

(7) Position detection

Detected by an absolute encoder on the no-load side of the AC servo motor.

(8) External input/output signals

Standard external input

In all, 32 inputs insulated optically are open to the user. Branch of a program and

interlock by input signals can be programmed easily, using the robot language.

1-5

- -

Page 14

STE 58760

Standard external output

In all, 24 outputs of transistor and open collector are open to the user. Output signal

ON/OFF and pulse output can be programmed easily, using the robot language.

Extension external input/output

When an option board is added, addition of 24 inputs and 16 outputs is possible.

Furthermore, sixty-four each of input and output that can operate as the slave station of

our TC200 programmer are available.

(9) External operation signal

To facilitate construction of an FA system, servo ON, servo OFF, start, feed hold, cycle stop,

robot operating speed, program reset, etc. are possible by external signals in the externalautomatic mode.

In any other mode, these external signals are neglected, except for the servo OFF signal.

The low speed instruction becomes effective also in the internal-automatic mode, however.

Also, the signals of ready, automatic operation ON, external-automatic mode ON, fault, servo

ON, emergency stop ON, etc. necessary for external operations are output.

(10) Teaching method

A program can be entered easily through the teach pendant, using the robot language

(SCOL). Position data can be given in the following three manners.

Teaching by remote-guidance through teach pendant.

Entry of coordinates through teach pendant.

Manual guidance in servo-free status.

(11) File editing function

A file can be registered and deleted on the teach pendant. Program editing is also

possible on the display. When the FDD unit (option) is provided, reading and writing of

data contained in a floppy disk of 1.44 MB MS-DOS format are possible. Thus, a program

can be edited on the personal computer.

(12) Speed setting

Program

Robot travel speed can be programmed in the range of 1 to 100 % in 1 % increments.

Override

A programmed speed can be overridden in the range of 1 to 100 % in 1 % increments.

1-6

- -

Page 15

Acceleration/deceleration speed setting

Speed at acceleration can be programmed in the range of 1 to 100 % in 1 % increments,

using the ACCEL instruction.

Likewise, deceleration speed can be programmed in the range of 1 to 100 % in 1 %

increments by means of the DECEL instruction.

Speed limit

A limit can be set on the maximum speed so that the robot speed can always be slower

than this limit. It is convenient to use in the TEST RUN mode.

(13) Servo gain ON/OFF function (servo-free)

Servo control ON and OFF are possible for each axis, using the program instruction (GAIN).

The same operation is also possible through the teach pendant.

(14) Torque limiting function

A limit value for each joint motor torque can be set in the range of 0 to 300 %, using the

program instruction.

When transferring or inserting a workpiece, there are occasions in which the robot motion is

mechanically obstructed due to faulty workpiece, etc., or no excessive force should be

exerted on the workpiece. When this happens, it is possible to prevent damage of the

work hand or robot by limiting the motor torque.

STE 58760

(15) Interruptive function

When any external signal is input during robot motion, the motion can be stopped instantly

and required processing can be executed by means of external input signals.

(16) Coordinate system setting function

Coordinate systems of the robot and peripheral equipment can be established through the

teach pendant.

(17) Program function

When the robot language SCOL is used, jump, subroutine, loop, interruptive processing,

delay time, speed setting, interpolation, hand operation, vertical movement and rotation of

each axis by an air cylinder are possible.

For details, see the Robot Language Manual.

(18) Operation

In the internal-automatic operation mode, the five modes are available; step, motion step,

cycle, continue and machine lock. (The step and machine lock modes can be selected

only in the test operation.)

In the external-automatic operation mode, the continue or cycle mode can be selected.

1-7

- -

Page 16

Step

A program is executed step by step.

Motion step

A motion instruction given in a program is executed once.

Cycle

A program is executed until the END instruction of main task has been executed. That is,

a series of operation is executed only once.

Continue

A program is executed, neglecting motion instructions in the same man-machine lock

program (i.e., the robot will not move).

Machine lock

A program is executed, neglecting motion instructions programmed, as if the robot were

actually moving.

STE 58760

(19) Working range limitation

To detect the stroke end limit, soft limits are provided, which can be set by the user at his

discretion.

(20) Self-diagnosis function

The system performs check on the servo fault, overtravel, transmission error, battery

voltage drop, control power fault, parameter destruction, etc. If an error is detected, an

appropriate error number is displayed on the teach pendant, and the servo power is turned

off according to the error.

(21) FDD unit (option)

Files stored in the controller memory (programs and position data) can be stored in floppy

disks. It is also possible to load the data of the floppy disks into the controller. A floppy

disk is initialized in the MS-DOS format. It should be noted that reading of the data

contained in floppy disks for the SR-5500 controller is not possible.

(22) Personal computer and printer interface

The interface function of an personal computer and printer is standard-equipped. Thus,

management of the robot language and line management can be performed very easily,

using the personal computer. Additionally, management of a group of robots is possible by

the host computer, thus construction of a highly advanced FA system can be realized.

1-8

- -

Page 17

STE 58760

1.2 OUTLINE OF OPERATIONAL PROCEDURE

At the least, the following operations are required to start up the robot.

(1) Installing the robot and controller at the site and connect the cables in place.

Unpack the controller and robot and install them at the site. After the installation work is

complete, connect cables between the controller, robot and peripheral equipment. For details,

see the Transportation and Installation Manual.

(2) Starting up and manually guiding the robot.

After robot installation work is complete, turn on the robot power so that it can be manually

operated. The operation range of the robot should have been set before teaching the

operation. For the setting procedure, see Chapter 2, "Power ON to Manual Guidance".

(3) Teaching the contents of the operation to the robot.

To make the robot work, a robot language program and position data should be prepared.

After the robot has been started up, input the program and position data. An example of the

operation is described in Chapter 4, "Example of Simple Operation". For details, see the

Operating Manual and the Robot Language Manual.

(4) Checking the operation being taught with a test run.

Check that the robot correctly works as taught. An example of the operation is described in

Chapter 4, "Example of Simple Operation". For details, see the Operating Manual.

(5) Making the robot work in an automatic operation mode.

After checking that the robot correctly works as has been taught, make the robot work. An

example of the operation is described in Chapter 4, "Example of Simple Operation". For

details, see the Operating Manual.

After the robot has been installed, the following components are required to make the robot

work.

Robot main body

・

Robot controller

・

Teach pendant

・

1-9

- -

Page 18

STE 58760

Check that cables have been securely connected between the robot body and controller and

between the controller and teach pendant.

Note 1)

In the automatic operation mode, it is not necessary to connect the teach pendant to the robot

body. Even if the teach pendant is not to be used, it is necessary to connect a dummy

connector to the teach pendant connector on the controller. Otherwise, the servo power

cannot be turned on.

Note 2)

The low speed instruction signal, servo OFF signal, and emergency stop signal of the external

control signal cables should be short-circuited even if they are not used. For the connector

locations and terminal numbers to be short-circuited, see the Transportation and Installation

Manual. (For the connectors attached to the controller, such signal cables have already been

short-circuited.)

1-10

- -

Page 19

STE 58760

1.3 SPECIFICATIONS

The basic specifications of SR–HSP series horizontally articulated robots are shown in Table 1.1.

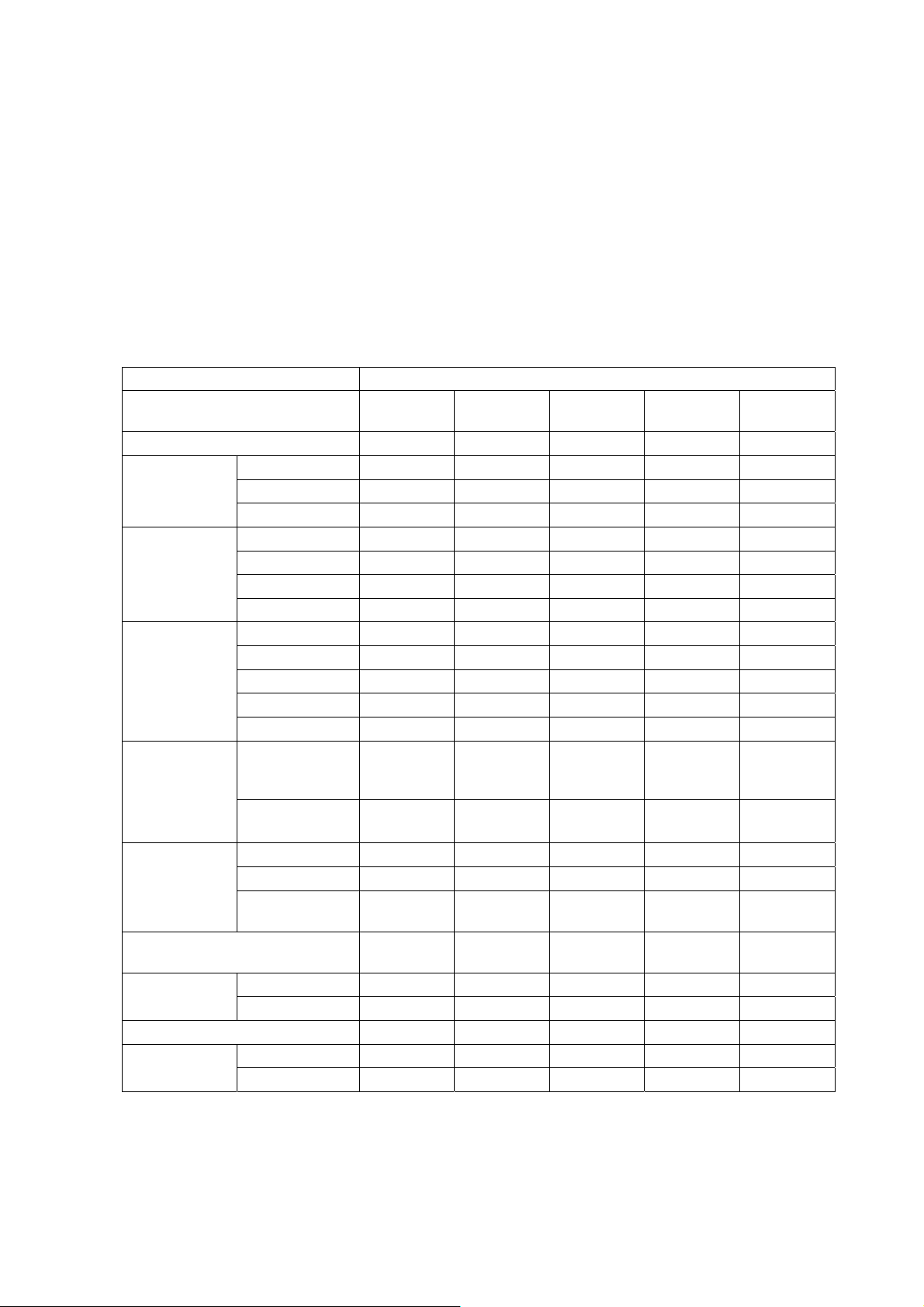

Table 1.1 Basic Specifications of SR–HSP Series Robots

Item Specification

Model SR–

504HSP

Controlled axes 4 axes 4 axes 4 axes 4 axes 4 axes

Arm length Full length 500 mm 550 mm 650 mm 850 mm 1050 mm

Arm 1 250 mm 250 mm 350 mm 550 mm 580 mm

Arm 2 250 mm 300 mm 300 mm 300 mm 470 mm

Working range Axis 1 ±110° ±115° ±115° ±115° ±115°

Axis 2 ±137° ±120° ±140° ±145° ±140°

Axis 3 150 mm 200 mm 200 mm 200 mm 200 mm

Axis 4 ±280° ±280° ±280° ±280° ±360°

Maxi. speed Axis 1 270°/S 255°/S 255°/S 204°/S 170°/S

Axis 2 432°/S 432°/S 432°/S 432°/S 270°/S

Axis 3 1000 mm/S 1000 mm/S 1000 mm/S 1000 mm/S 1000 mm/S

Axis 4 864°/S 864°/S 864°/S 864°/S 576°/S

Resultant 4.24 m/S 4.71 m/S 5.15 m/S 5.28 m/S 5.33 m/S

Load Workpiece

mass

Allowable inertia

moment at end

Repeatability X, Y (plane) ±0.02 mm ±0.02 mm ±0.02 mm ±0.03 mm ±0.03 mm

Axis 3 (vertical) ±0.01 mm ±0.01 mm ±0.01 mm ±0.01 mm ±0.02 mm

Axis 4 (wrist

rotation)

Drive system AC servo

User wiring Input 5 nos. 5 nos. 5 nos. 5 nos. 5 nos.

Output 4 nos. 4 nos. 4 nos. 4 nos. 4 nos.

User air piping 2 pcs. 2 pcs. 2 pcs. 2 pcs. 2 pcs.

Robot body Mass 38 kgf 55 kgf 60 kgf 70 kgf 90 kgf

Painting color Misty white Misty white Misty white Misty white Misty white

2 kgf

(max. 4 kgf)

0.0225

2

kgf·m

±0.03° ±0.03° ±0.03° ±0.03° ±0.03°

motor

SR–

554HSP

5 kgf

10

(max.

kgf)

0.0663

kgf·m2

AC servo

motor

SR–

654HSP

5 kgf

(max. 10 kgf)

0.0663

kgf·m2

AC servo

motor

SR–

854HSP

5 kgf

(max. 10 kgf)

0.0663

kgf·m2

AC servo

motor

SR–

1054HSP

10 kgf

(max. 20 kgf)

0.1 kgf·m

AC servo

motor

2

1-11

- -

Page 20

STE 58760

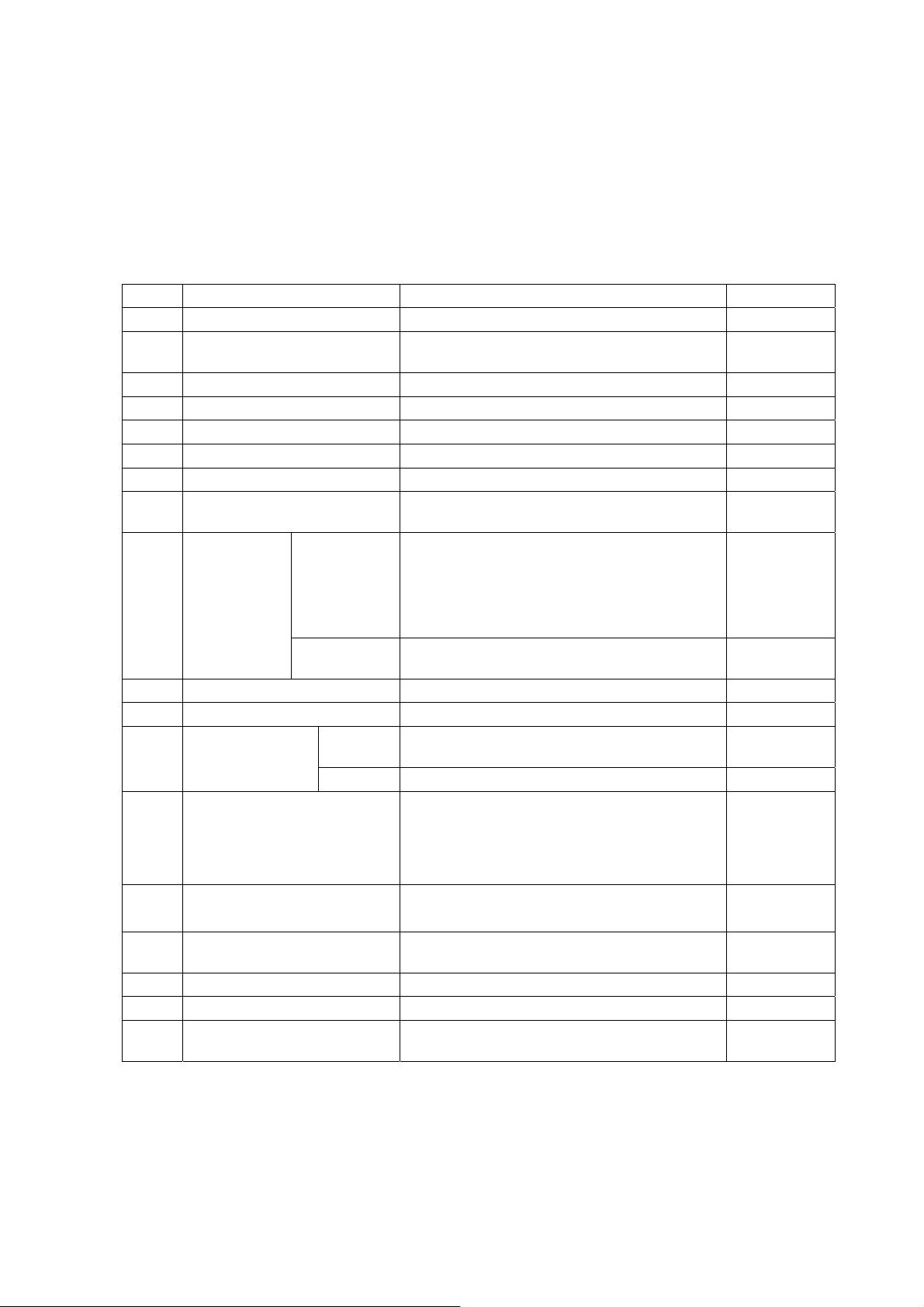

Table 1.2 Basic Specifications of SR7000 Robot Controller

No. Item Specification Remarks

1 No. of controlled axes Simultaneous control of max. 5 axes.

2 Operation mode PTP, CP (linear interpolation, circular

interpolation), short-cut

3 Servo system Digital servo

4 Storage capacity Approx. 6400 points + 12800 steps 512 K bytes

5 No. of registrable programs Max. 256

6 Auxiliary memory 3.5 inch FDD unit (MS-DOS format) (option) 1.44 M bytes

7 Storage Battery backed up RAM

8 Position detection Absolute encoders

(Battery backed up at power failure)

9 Teaching

method

Entry of

10 External I/O signal 32 inputs and 24 outputs

11 Hand control signal 9 lines (5 inputs and 4 outputs)

12 External operation

signal

Output Servo ON, ready, fault, cycle mode, etc.

13 Serial communication port RS232C or RS422 three ports (RS422 option)

14 Speed setting Override, speed limit, program instruction

15 Acceleration/deceleration

speed setting

16 Torque limit Program instruction 0 ~ 300 %

17 Teaching box Teach pendant

18 Coordinate system Base, work, tool (Setting of multiple work or

Point display Remote: To be guided through teach

pendant.

Coordinate value: Entry of X, Y, Z, C, T data

through teach pendant.

Servo-free: Manual movement of arm.

Editing through teach pendant.

program

Input Program selection, start, stop, reset, etc.

Software for personal computer and printer is

standard-equipped.

1 ~ 100 % for each

Program instruction 1 ~ 100 %

tool coordinate systems are possible.)

Among them,

one port is

used

exclusively for

the pendant.

1-12

- -

Page 21

STE 58760

No. Item Specification Remarks

19 Operation limit Soft limit

20 Self-diagnostic function Error detection

21 Interruptive function Start of interruptive program by input signal,

timer, etc.

22 Operation mode Internal-automatic, external-automatic,

external communication

23 Operation Internal Continue, cycle, step, motion step (segment),

machine lock

External Cycle, continue

24 Basic

controller

Mass 18 kgf

Painting color Ivory, gray

25 Power supply 200 ~ 230 VAC (3 phases), 50/60 Hz

Outer

dimensions

430 (W) 230 (H) 330 (D) mm

1-13

- -

Page 22

STE 58760

1.4 COORDINATE SYSTEM

A coordinate system comes in a world coordinate system, base coordinate system and tool

coordinate system. Once the coordinate system is established, positions where the robot has to

move can be set by coordinate values.

A function which offsets the coordinate system is also provided, and even if the robot position or tool

has been changed, the entire program need not be modified accordingly.

In addition to the above, a work coordinate system is also available, which is useful to create

position data for palletizing operation.

Positional relationship of respective coordinate systems is shown in Fig. 1.3.

Fig. 1.3

1-14

- -

Page 23

(1) World coordinate system

A coordinate system the user defines in a space at arranging equipment or workpieces is

called the "world coordinate system."

(2) Base coordinate system

A Cartesian coordinate system based on the robot center is called the "base coordinate

system." Normally, each axis is set based on the origin (0°) orientation.

The base coordinate system can be offset by entering a deviation of each axis of the world

coordinate system. Thus, each time the coordinate system is changed, operation points

need not be taught to the robot.

(3) Tool coordinate system

A Cartesian coordinate system based on the tool set surface (i.e., flange surface) of the

robot end effector is called the "tool coordinate system."

Like the base coordinate system, the tool coordinate system can also be offset so that the

robot can move on the basis of the tool edge. Thus, the operator can teach the robot

based on the tool edge.

STE 58760

(4) Work coordinate system

A coordinate system defined in an actual working space, such as workpiece layout and

pallet, is called the "work coordinate system. Thus, data can be created easily at

palletizing or offline teaching.

1-15

- -

Page 24

STE 58760

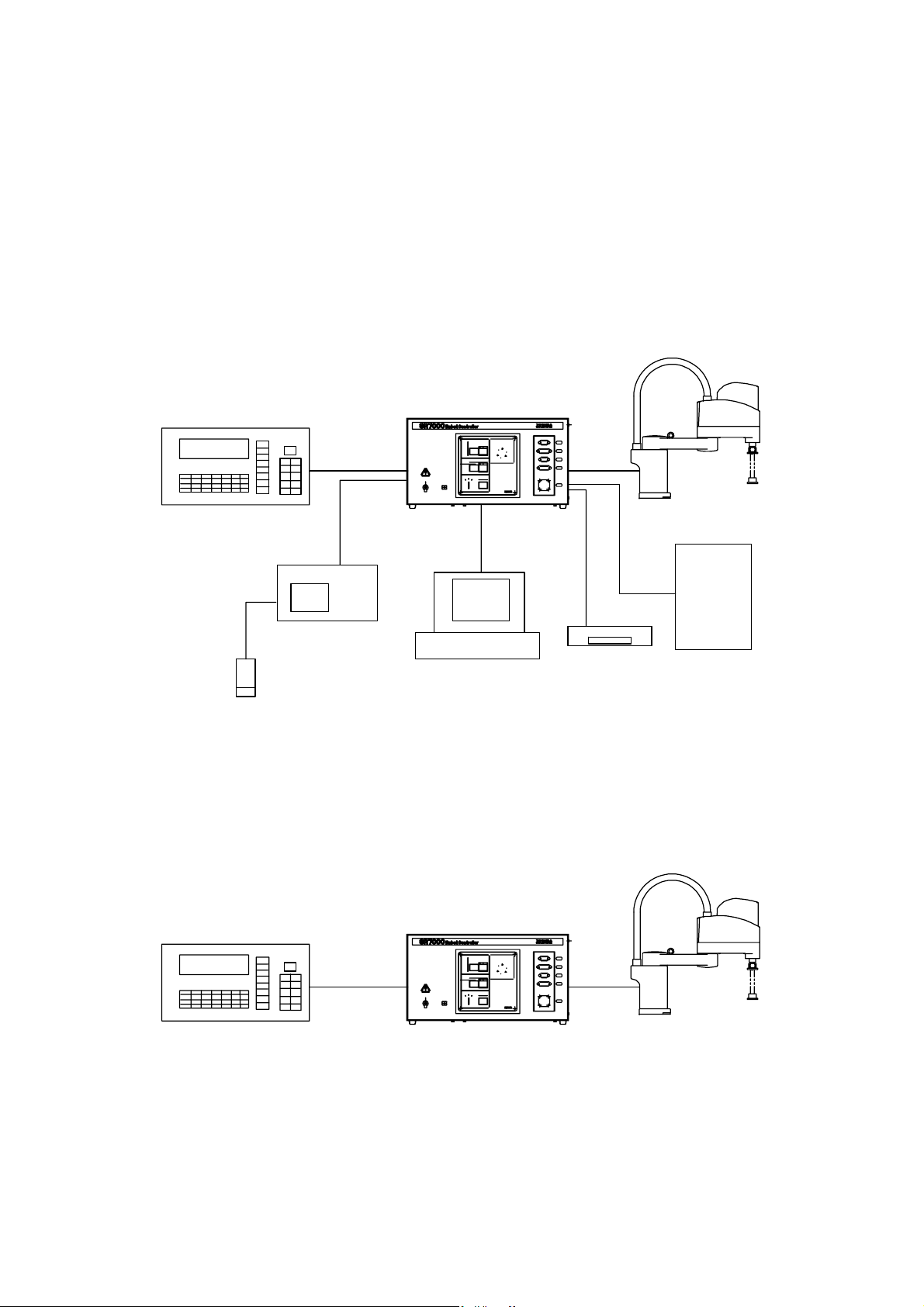

1.5 SYSTEM CONFIGURATION

Basically, the robot system is composed of the basic robot, basic controller and teach pendant.

The controller has comprehensive interface functions to allow construction of various systems.

Fig. 1.4 shows the maximum system configuration.

The basic controller consists of the control panel, CPU printed board serving as the control center,

relay printed boards relaying external output signals and other units (such as servo driver).

* An external control unit required for external-automatic operation is not provided, which

should be prepared by the user at job site.

* A system disk (used for cold-starting the system) is attached to the controller. Keep it in your

custody.

1-16

- -

Page 25

STE 58760

Fig. 1.4 Maximum System Configuration

1-17

- -

Page 26

Equipment configuration by operation

Equipment configuration by operation is illustrated below.

(1) Maximum configuration

Maximum system configuration, including options.

STE 58760

Teach pendant

CCD camera

SR-5500

サーボ ON

Optical sensor

Basic controller

Personal computer

SR7000

FDD unit(option)

Robot

External control unit

(2) Manual guidance, teaching of positions by manual guidance and program editing

These operations can be executed, using the same equipment configuration.

It is possible to remote-control the robot through the teach pendant, which is called the

"manual guidance." This operation is used when the robot is only to be moved manually or

taught the operating positions by manual guidance.

Program editing is also possible by using this configuration.

Teach pendant

SR5500

Basic controller

1-18

- -

Robot

Page 27

STE 58760

(3) Internally controlled automatic operation

Operation of the robot according to files (programs and position data) loaded to the controller

is called the "automatic operation." The automatic operation can be controlled internally and

externally.

Start and stop of the robot through the control panel of the controller is called the "internally

controlled automatic operation."

Note: Automatic operation is possible by connecting or disconnecting the teach pendant to

or from the controller.

When the teach pendant is disconnected, connect a dummy plug to the teach

pendant connector. Unless the dummy plug is connected, the servo power cannot

be turned on.

(4) Externally controlled automatic operation

Automatic start and stop of the robot with external signals is called the "externally controlled

automatic operation."

(5) Floppy disk

Files (programs and position data) stored in the controller can be saved in floppy disks (3.5

inch), using an optional FDD unit. It is also possible to load the data in the floppy disks into

the controller.

(6) Automatic operation, using optical sensors (option)

Automatic operation is possible by using an optical sensor system while recognizing the items

subject to the operation and compensating position data.

1-19

- -

Page 28

STE 58760

1-20

- -

Page 29

STE 58760

1.6 NAMES AND FUNCTIONS OF SR7000 CONTROLLER

The start up operation is conducted using the control panel and teach pendant. The external

views of the control panel and teach pendant are shown in Figures 1.5 and 1.6.

1.6.1 Control Panel

The control panel is used to turn on and off the power and perform automatic operation. This

paragraph outlines names and functions of the controls. The numbers referenced accord with

those in Figure 1.5.

1. Main power switch:

Power switch for the controller.

2. Circuit protector:

Circuit protector for the controller control circuit.

3. J1 connector:

Connector for communication channel 1.

4. J2 connector:

Connector for communication channel 2.

5. TP connector:

Connector for connecting the teach pendant.

6. FDD connector:

Connector for floppy disk drive unit(optional).

7. EMERGENCY switch:

Switch which unconditionally stops the robot operation. When this switch is pressed, the

servo power is turned off and an emergency stop state signal is output. Once this switch

is pressed, it is locked in the pressed position. To unlock this switch, turn the switch in the

direction of the arrow.

8. SERVO POWER OFF switch:

A switch which turns off the servo power to stop robot operation. When the servo power is

turned off, the lamp on the "OFF" switch lights.

1-21

- -

Page 30

STE 58760

9. SERVO POWER ON switch:

A switch which turns on the servo power. When the servo power is turned on, the lamp on

the "ON" switch lights and a servo ON state signal is output. Unless the servo power is

turned on, the robot cannot be operated.

10. STOP switch:

A switch which stops automatic operation. When this switch is pressed in the automatic

operation mode, the lamp on the "STOP" switch lights and the robot stops automatic

operation after it completes the current operation. When the robot stops, the "START"

switch lamp turns off.

11. START switch:

A switch which starts automatic operation. When the robot starts automatic operation, the

lamp on the "START" switch lights.

12. CYCLE STOP switch:

A switch which selects the mode that performs one cycle of automatic operation. This

operation mode is called the cycle operation mode. In the cycle operation mode,

automatic operation stops after the robot has executed the program. When the cycle

operation mode is selected, the lamp on the "CYCLE STOP" switch lights.

13. PC connector:

Connector for connecting a personal computer substituting for a floppy disk unit.

14. MASTER MODE KEY switch:

A key switch which selects one of robot modes; external automatic mode (EXT), internal

automatic mode (INT), and manual mode (MANU). The modes selected with this switch

are called master modes.

15. POWER LED:

Power lamp for the controller. When the main power is turned on, the "POWER" lamp

lights.

16. FAULT LED:

Error lamp for the controller. When a fault is detected, the "FAULT" lamp blinks.

17. Buzzer:

When a fault is detected, the buzzer beeps. When the STOP switch is pressed, the buzzer

stops beeping.

1-22

- -

Page 31

STE 58760

1.6.2 Teach Pendant

The teach pendant is used to guide the robot, teach the robot, and check error messages.

This paragraph outlines names and functions of the controls. The numbers referenced accord

with those in Figure 1.6.

1. Emergency switch:

A switch which unconditionally stops robot operation. When this switch is pressed, the

power to the servo motors is turned off and an emergency stop state signal is output.

When this switch is pressed, it is locked in the pressed state. To unlock this switch, turn

the switch again.

2. Function keys:

Keys which select one of functions displayed at the bottom of the LCD screen. The

function to be selected depends on the mode being executed in the controller.

3. Alphanumeric keys:

Keys which enter alphabet characters, numeric characters, and symbols. To enter

characters marked on the upper key positions, press the keys while holding down the

"Shift" key. To enter characters marked on the lower key positions, simply press the keys.

4. Esc key:

A key which cancels characters and instruction being entered.

5. Ins key:

A key which inserts new characters between those which have been entered. After this

key is pressed, characters being entered are inserted at the position just preceding the

cursor. This mode is called the insert mode. When the insert key is pressed again while

the insert mode is in effect, the insert mode is canceled. After the insert mode is canceled,

characters newly entered will replace existing characters. This mode is called the replace

mode.

1-23

- -

Page 32

6. Del key:

The delete key deletes a character which has been entered. Whenever this key is pressed,

one character at the cursor is deleted. In the replace mode, the portion being deleted

becomes blank. In the insert mode, characters following those being deleted are pushed

right by one space every time a character is deleted.

7. Bs key:

The Bs key deletes a character which has been entered. Whenever this key is pressed, the

character just preceding the cursor is deleted. After a character is deleted, the cursor

moves left one position along with any characters that follow.

8. Ctrl key:

Used together with other key to mainly cancel an input command.

9. Shift key:

The shift key is used to enter characters marked on the upper positions of alphanumeric

keys. When any key is pressed while this key is held, the character marked on the top of

the key is entered.

10. Alt key:

The Alt key edits programs and data. This key is used along with other keys.

11. Exec key:

The execution key is used mainly to enter data.

12.

→←↑↓

Cursor keys move the cursor right, left, up, and down, respectively.

13. Error key:

The error indication key indicates the contents of an error being detected by the controller

on the LCD display. When this key is pressed, the contents of the error are indicated on

LCD display of the teach pendant.

14. Utility key:

A key which executes auxiliary controller functions.

15. Aux. signal key:

A key which operates the robot hand and air control axis. These signals are defined as

auxiliary signals in the system configuration file.

STE 58760

key (Cursor keys):

1-24

- -

Page 33

16. Move key:

A key which moves the robot to a previously taught position. When teaching positions,

specify the position to which you want to move the robot and press this key. The robot will

then move to the specified position. While pressing the move key, it is necessary to press

the Deadman Switch 23. On the other hand, if the move key is released while the robot is

moving, the robot will stop midway.

17. Coordinate key:

A key which selects a coordination system along which to guide the robot. The LED will

light up for the coordinate system currently selected.

18. Teach Speed keys:

Keys which select a robot travel speed to manually guide the robot. High, Med., and Low

represent high speed, medium speed, and low speed, respectively. The LED will light up

for the speed currently selected.

19. Control key:

A key which selects the guidance method for the robot in manual operation. The free

mode is used when moving the robot by hand. Inching is a mode where the robot is

moved a constant amount whenever the Guidance key (22) is pressed. The Jog is a mode

where the robot is moved while the Guidance key is pressed. The LED will light up for the

mode currently selected.

20. Feed hold key:

A key which temporarily stops the current robot operation. When this key is pressed while

the robot is moving, the robot stops moving temporarily. In this state, when this key is

pressed again, the robot resumes its operation. While the robot is in the temporarily stop

state, the LED will be lit.

21. Servo power ON switch:

A switch which turns on the servo power. When the servo power is turned on, the LED

lights up and a servo state ON signal is output. When the servo power is not turned on,

the robot cannot be operated.

22. XYZCT keys (Guidance keys):

Keys which manually guide the robot. The left-hand key and right-hand key of each axis

accord with the + direction and - direction, respectively. When one of these keys and the

Deadman Switch 23 are pressed, the robot can be guided. However, it is impossible to

operate more than one axis at a time.

STE 58760

1-25

- -

Page 34

23. Deadman switches:

Switches which are used to manually guide the robot. Unless one of these keys is

pressed, the robot cannot be manually guided. If this key is released while the robot is

guided, the robot stops. Although there are six Deadman switches on the rear side of the

teach pendant, to guide the robot, you only have to press at least one of them.

24. Liquid Crystal Display (LCD)

Display area is 8 lines × 42 columns.

STE 58760

POWER

10AT

① ②

DC24V

C.P.

⑮⑯

⑧⑨⑩⑪

SERVO POWER EMERGENCY

MANU

ONOFF

STARTSTOP

CYCLE STOP

POWER

FAULT

EXT

INT

BATTERY

ALARM

⑦

FDD

J1

J2

PC

③

④

⑬

⑥

TP

⑤

⑫⑭

⑰⑱

Fig. 1.5 External View of Controller Panel

1-26

- -

Page 35

STE 58760

1-27

- -

Page 36

STE 58760

Fig. 1.6 External View of Teach Pendant

1-28

- -

Page 37

STE 58760

CHAPTER 2

POWER ON TO MANUAL GUIDANCE

This chapter outlines how to turn on the power and how to manually guide the robot. For details of

how to create a robot language program, how to teach positions to the robot, and how to perform an

automatic operation, see Chapter 4, "Example of Simple Operation". Before actually operating the

robot, it is necessary to check that the cables have been correctly connected. For details of how to

install the robot, see the Transportation and Installation Manual.

The operation procedure from the power ON operation to manual guidance operation is as follows:

(1) Turn on the main power of the controller.

(2) Set the environmental conditions of the controller.

(3) Turn on the servo power.

(4) Manually guide each axis and check that the robot works correctly.

(5) Perform the manual guidance operation and check the robot operation.

(6) Set the operation range.

(7) Turn off the power supply.

Note)

When performing operations described in this chapter, be sure to place the MASTER MODE

KEY switch in the "MANU" (manual mode) position.

2-1

- -

Page 38

STE 58760

2.1 TURNING ON MAIN POWER

After checking that there are no problems with the controller and robot cable connections, turn on

the main power to start up the robot. There are two methods to turn on the main power; cold

starting and hot starting. Normally, only the hot starting is required. For details, see Para. 2.1.2.

2.1.1 Cold Starting

After cold starting has been conducted, programs and data necessary for operating the robot

are loaded from the floppy disk to the controller. Once the cold starting has been effected, it

need not be repeated unless the robot went wrong. If there is some problem with the robot,

perform hot starting.

Caution

If an abnormality has generated or the POWER LED lamp on the control panel remains off after the main

power switch of the controller was turned on, turn off the main power immediately and confirm the wiring.

Otherwise, you will be struck by an electric shock or a fire will break out.

Caution

When the cold start operation is conducted, the contents of the controller memory (including a robot

language program, position data, and user parameters) are initialized. To prevent user data from being

erased, be careful not to unintentionally conduct the cold start operation.

Be sure to back up the user programs. It is also recommended to always back up all user programs.

Conduct the cold start operation in the following manner.

(1) Insert the system disk into the FDD unit (option). (For the connections, see the Interface

Manual.)

(2) Hold the floppy disk in the manner that the label side is up and the disk shutter (metal

cover) enters the FDD first. Lightly insert the attached floppy disk (system disk) into the

FDD unit until a click is heard.

2-2

- -

Page 39

STE 58760

Note)

The disk provides a write-protection tab which prevents the user from mistakenly erasing the

contents. When using the system disk, prior to inserting it into the FDD, make sure to slide the

write-protection tab outward. When the tab is in the outward position (figure (a)), data cannot

be written on the floppy disk. On the other hand, when the tab is in the inward position (figure

(b)), data can be written on the floppy disk. In any case, slide the tab all the way until a click

sound is heard.

(3) Turn on the MAIN POWER switch on the control panel.

Turn on the MAIN POWER switch on the control panel. When the main power is turned on,

the POWER LED will light up.

Note)

Should the "POWER LED" not light even if the MAIN POWER switch is turned on, or should

any fault occur, immediately turn off the MAIN POWER switch and check the cables connected

to the controller.

2-3

- -

Page 40

STE 58760

(4) The contents of the system disk are read in by the controller.

The LED on the FDD blinks several times and the contents of the floppy disk are read to the

controller. When the controller is correctly started up, the following message appears on the

LCD screen on the teach pendant.

> ■

EDIT LOAD SAVE TESTRUN> RESET NEXT

F1 F2 F3 F4 F5 F6

When the cold start operation is conducted, the controller works as follows.

When the power is turned on, the controller reads in the system programs from the system disk.

While the system programs are read, the lamp on the "START" switch blinks. When the system

programs have been read in from the disk, the lamps on the "START", "STOP" and "CYCLE

STOP" switches light up for 0.5 sec. After that, the lamp on the "STOP" switch lights up and

the screen as shown above appears. After that, files of parameters and so forth are read to

the controller. After all the required files are read to the controller, the contents in the

automatic execution file are executed. In this state, the controller can be operated.

For details of the automatic execution file, see 3.5, "Batch Process".

When an error occurs during the cold start operation, take proper action corresponding to the

error message appearing on the screen.

(5) After the controller has been started up, remove the system disk from the FDD. When

pressing the FDD pushbutton, the floppy disk is slightly ejected from the disk entrance.

Hold the label portion of the disk and remove the disk.

2-4

- -

Page 41

STE 58760

Note)

While the LED on the FDD lights or blinks, be certain not to remove the floppy disk from the

entrance. Otherwise, the FDD, floppy disk, and/or controller may be damaged.

The cold start operation is now complete.

2.1.2 Hot Starting

While programs and data necessary to operate the controller are stored in memory of the

controller, the controller can be started up directly without performing the cold start operation,

which is called the “hot start”. Once the cold start operation has been conducted, unless any

fault occurs in the robot system, it is not necessary to conduct the cold start operation again.

Caution

!

If an abnormality has generated or the POWER LED lamp on the control panel remains off after the main

power switch of the controller was turned on, turn off the main power immediately and confirm the wiring.

Otherwise, you will be struck by an electric shock or a fire will break out.

When hot starting has been done, the controller enters a program reset status.

Conduct the hot start operation in the following manner.

(1) Turn on the MAIN POWER switch on the control panel.

Turn on the MAIN POWER switch on the control panel. When the MAIN POWER is turned on,

the "POWER LED" on the control panel will light up.

POWER

10AT

2-5

- -

Page 42

STE 58760

Note 1)

Should the "POWER LED" on the control panel not light even if the MAIN POWER switch is

turned on, or should any fault occur in the system, immediately turn off the Main Power switch

and check the cables connected to the controller.

Note 2)

If the system disk was in the FDD unit when the main power was turned on, the controller will

perform cold start. Before turning on the main power, check to see that the system disk has not

been inserted into the FDD unit.

Note 3)

If a floppy disk which contains any of the files CONSTRUC. SYS, SYSTEM. PAR, USER. PAR,

EXTRNSEL. SYS, SCOL. LIB, ALARM.MES, or AUTOSTR. BAT has been inserted into the

FDD unit, the contents of the files will be read to the controller when the main power is turned

on. For an outline of each file, see Chapter 5.

(2) The controller starts up.

When the controller has been correctly started up, the following message appears on the LCD

display on the teach pendant

> ■

EDIT LOAD SAVE TESTRUN> RESET NEXT

F1 F2 F3 F4 F5 F6

2-6

- -

Page 43

STE 58760

During hot start-up, the controller works as follows: When the main power is turned on, the

controller reads in the contents of the floppy disk in the FDD. Unless the system disk has not

been inserted, the system stored in the controller conducts hot starting. During the hot start

operation, the lamp on the "START" switch on the control panel blinks. When the controller is

started up, all the lamps on the "START", "STOP" and "CYCLE STOP" switches light for approx.

0.5 sec. After that, the lamp on the "STOP" switch lights and the screen as shown above

appears. After that, files for parameters and so forth are read in from the floppy disk to the

controller. Any required files are read to the controller.

After all the files have been read, the automatic execution file is executed. In this state, the

controller can be operated.

For details of the automatic execution file, see 3.5, "Batch Processing".

If an error occurs during the hot start operation, take proper action corresponding to the error

message which appears on the display. If the controller cannot be started up using the hot

start operation, conduct the cold start.

The hot start operation is now complete.

2-7

- -

Page 44

STE 58760

2.2 SETTING CONTROLLER ENVIRONMENTAL CONDITIONS

Before operating the robot system, it is necessary to set data for the controller. This data is stored

in the system configuration file (file name: CONSTRUC. SYS).

In addition, the controller requires the operator to set date and time.

This data setting is referred to as setting the environmental conditions of the controller. Details of

how to set individual data items are described in Chapter 3, "Setting Environmental Conditions for

the SR7000 Controller". This paragraph outlines setting environmental conditions for the controller.

Controller environmental conditions should be set only when the robot is installed. The included

system disk stores standard environmental condition values corresponding to the robot being

delivered. If the operator does not need to change the preset values, he or she can use them as

they are. (Date and time have been set at the factory.)

Set the environmental condition values of the controller in the following manner.

(1) Set the current date and time.

(2) Check the contents of the system configuration file.

(3) When selecting files to be executed with external input signals, create an external selection

file.

(4) When changing the contents of the system configuration file or when creating the external

selection file, the contents should be saved on a floppy disk.

(5) Turn off the power supply of the controller and then start up the controller using the hot

start operation.

For details of how to set environmental condition values of the controller, see Chapter 3,

"Setting Environmental Conditions for the SR7000 Controller

2-8

- -

Page 45

STE 58760

2.3 TURNING THE SERVO POWER ON

The power supplied to the servo motors of the robot is called servo power. Unless the servo power

is turned on, the robot will not work. Furthermore, before the operator enters the dangerous area

of the robot, make sure to turn off the servo power.

Turn on the servo power in the following manner.

Caution

• If the robot moves abnormally at servo power ON, press the EMERGENCY STOP switch

immediately to turn the servo power off.

• If anyone enters the robot working range, turn the servo power off beforehand.

(1) Open the transparent cover of the "SERVO POWER ON" switch on the control panel and

press the switch. When the servo power is turned on, the lamp on the "SERVO POWER

ON" switch will light up.

Note 1)

When the contacts of the emergency stop signal and servo OFF signal are open, or when no

cable is connected to the TP (Teach Pendant) connector on the control panel, the servo power

cannot be turned on. For controller cable connections, see the Transportation and Installation

manual. Connect the teach pendant or a dummy connector to the TP connector on the control

panel. In addition, when the emergency stop (EMERGENCY) switch is pressed on the teach

pendant or the control panel, the servo power will not turned on.

Note 2)

If the robot misoperates when the servo power is turned on, immediately press the emergency

stop switch and turn off the servo power.

2-9

- -

Page 46

STE 58760

2.4 MANUAL GUIDANCE OF EACH AXIS

The operation where the robot is operated using the teach pendant is called manual guidance.

When the servo power is turned on, conduct manual guidance for each axis and check to see that

the robot works correctly. When actually operating the robot, make absolutely sure that the robot

will not hit anybody or anything.

Conduct manual guidance in the following manner.

Caution

• If the guidance is performed manually, DO NOT enter the robot dangerous area.

• If the robot moves abnormally, immediately effect an emergency stop.

• If the robot will not move in the specified direction, consult Toshiba Machine.

(1) Select the joint coordinate mode as the coordinates.

Press the "Coordinate" key on the teach pendant several times until the "Joint" LED lights up.

(2) Set the guide speed to low.

Press the "Teach Speed" key on the teach pendant several times until the "Low" LED lights up.

2-10

- -

Page 47

STE 58760

(3) Press the deadman switch.

Press one of the six deadman switches on the rear side of the teach pendant. While guiding

the robot, press this switch inside. The robot will not work while the switch is released.

(4) Press one of the XYZCT keys.

At the time, the joint (axis) corresponding to the switch being pressed moves. The XYZCT

keys correspond to axes 1 to 5, respectively. Check that the robot works for all axes. In

addition, check that the right joint moves in the right direction in accordance with the guidance

key being pressed. The number and types of joints and the direction thereof depend on the

robot type. For details, see the Transportation and Installation Manual.

Note 1)

While the teach speed is set low speed, the robot will move at a very low speed. Thus, it

seems that the robot stops even while guided. This does not mean the robot is malfunctioning.

Note 2)

When two or more of the XYZCT keys are pressed, the robot will not work. In addition, when

any key other than the deadman switch and Servo ON switch on the teach pendant is pressed,

the robot will not work.

2-11

- -

Page 48

STE 58760

Note 3)

In the horizontally articulated type robots, there is an axial interference between the joint axes.

For example, when the axis 2 is moved, the servo motors of axes 3 and 4 also move to keep

axis Z in the same place. When an axis is operated and another axis also moves, it is

conceivable that set parameters are incorrect. In this case, contact us at the after-sale service

department or our agent in your territory.

(5) Check that the robot soft limit switches work correctly.

Guide each axis to the motion limit position and check that it works correctly. When the robot

detects a motion limit position, an error message appears on the teach pendant. The robot

cannot be guided out from the soft limit.

(6) Set the guide speed to the middle and high speed and guide the robot

Press the "Teach Speed" key on the teach pendant several times until the "Med." or "High" LED

lights. After that, press the desired XYZCT key and guide the robot. Check that the robot

moves smoothly.

2-12

- -

Page 49

STE 58760

2.5 MANUAL GUIDANCE OPERATION

The manual guidance operation can move the robot along various coordinate systems as well as

moving each joint (axis). The operation which guides each joint of the robot is named JOINT

guidance, while the operation which guides the robot along a coordinate system is named

coordinate guidance. The operator can select either the world, work, or tool coordinate system in

which to move the robot. The coordinate system in which the robot moves depends on the robot

type. For details of the robot's coordinate system, see the Introductory Manual.

When operating the robot, take care that the robot does not hit workers or anything else. Because

manual guidance is conducted in the manual mode, it is necessary to place the MASTER MODE

KEY switch on the control panel in the "MANU" (manual mode) position.

Conduct manual guidance for the robot in the following manner.

Caution

• If the guidance is performed manually, DO NOT enter the robot dangerous area.

• If the robot moves abnormally, immediately effect an emergency stop.

• If the robot will not move in the specified direction, consult Toshiba Machine.

(1) Select the desired coordinates system.

Press the "Coordinate" key on the teach pendant several times to select the desired coordinate

system.

2-13

- -

Page 50

STE 58760

When the "World" LED lights up, the robot will move along the world coordinate system.

When the "Work" LED lights up, the robot will move along the work coordinates system.

When the "Tool" LED lights up, the robot will move along the tool coordinate system.

When the "Joint" LED lights up, each joint of the robot will move separately.

(2) Set the guide speed to low speed.

Press the "Teach Speed" key on the teach pendant several times until the "Low" LED lights up.

(3) Press the deadman switch.

Press one of six deadman switches on the rear side of the teach pendant. While guiding the

robot, keep this switch held inside. While the switch is released, the robot will not work.

(4) Press one of the XYZCT keys.

The joint (axis) corresponding to the switch being pressed moves. The XYZCT keys

correspond to axes 1 to 5, respectively. Check that the robot works for all axes. In addition,

check that the right joint moves in the right direction in accordance with the guidance key being

pressed. The number and types of joints and the direction thereof depend on the robot type.

For details, see the Introductory Manual.

2-14

- -

Page 51

STE 58760

Note 1)

While the teach speed is set low speed, the robot will move at a very low speed. Thus, it

seems that the robot stops even while guided. This does not mean the robot is malfunctioning.

Note 2)

When two or more keys of the XYZCT keys are pressed, the robot will not work.

Note 3)

If the robot does not move in the direction being specified, it is conceivable that set parameters

are incorrect. In this case, call us at the after-sale service department.

(5) Set the teach speed to the middle speed and high speed and guide the robot.

Press the "Teach Speed" key on the teach pendant several times until the "Med." or "High" LED

lights up. After that, press the desired XYZCT key and guide the robot. Check that the robot

moves smoothly.

2-15

- -

Page 52

STE 58760

2.6 MOTION RANGE LIMIT

In executing the automatic operation or in teaching a position, the operation range and the teaching

range of the robot can be limited. When they are limited, the robot is not moved to a position out of

the operation range in the automatic operation, so that the position out of the operation range

cannot be taught. The limitation of the operation range is called the joint limit. The joint limit

should be set in two directions of + direction and - direction of each joint.

The joint limit can be set in the following two methods. 1st method: Guide the robot and teach

positions. 2nd method: Input the position of each joint with numeric values from the teach

pendant.

When a joint limit is changed, software which used to work may not work anymore. Thus, any joint

limit should not be unintentionally changed.

Each joint limit has been set to the maximum motion range at the factory. Unless there is

necessity to change a joint limit, use it as it has been set at the factory.

Note)

The joint limit values are stored in the user parameter file (USER. PAR). Before the operator

changes the joint limit values, it is recommended to back up the user parameter file. For an

instruction of how to back up the file, see 5.5, "Backing Up Files".

2.6.1 Setting Joint Limit Values by Teaching

The joint limit values are taught in the following manner.

(1) Check that controller monitor command menu appears at the bottom of the LCD display on

the teach pendant.

> ■

FORMAT VERIFY ZEROP> JLIMIT> CHANNEL N E XT

F1 F2 F3 F4 F5 F6

2-16

- -

Page 53

STE 58760

(2) Whenever you press the "F6" key on the teach pendant, the monitor command menu

accordingly changes. Repeat this key operation until the "JLIMIT>" command appears on

the LCD display.

NEXT

F6

(3) Press the function key which accords with the "JLIMIT>" command. After that, the LCD

display on the teach pendant shows the following screen.

JLIMIT

F4

TRAVEL JOINT <NEGATIVE> <POSITIVE>

[mm] <T1> -5.868 111.000

or <T2> -138.000 138.000

[deg] <T3> -0.500 200.500

<T4> -400.000 400.000

<T5> -5729.578 5729.578

> _

N1-mem P1-mem N2-mem P2-mem N3-mem < n ext >

F1 F2 F3 F4 F5 F6

(4) Guide each axis of the robot to the position where the joint limit has been set.

(5) Store the joint limit position value of each axis.

After guiding each axis of the robot to the position where the joint limit has been set, store the

position value by pressing the related function key on the teach pendant. Above the function

keys, a menu such as "Pi-mem", "N1-mem" corresponding to the controller axes appears. The

first letter "P" and "N" represent + direction and - direction of each joint axis. In addition, the

letter following "P" or "N" accords with the robot joint number. Press the key corresponding to

the axis and direction where the joint limit is taught.

2-17

- -

Page 54

STE 58760

If the corresponding axis and direction do not appear on the display, press the "F6" key.

Pressing the "F6" key causes the messages at the bottom of the display to change to those of

remaining axes.

(6) Last, press the "Esc" key to complete the joint limit setting.

2.6.2 Setting Joint Limit by Numeric Value Entry

Set the joint limit by entering numeric values in the following manner.

(1) Check that the controller monitor command menu appears at the bottom of the LCD

display on the teach pendant.

> ■

FORMAT VERIFY ZEROP> JLIMIT> CHANNEL N E XT

F1 F2 F3 F4 F5 F6

(2) When you press the "F6" key on the teach pendant, the monitor command menu changes

accordingly.

2-18

- -

Page 55

STE 58760

Repeat this key operation until the "JLIMIT>" command appears on the LCD display.

NEXT

F6

(3) Press the function key which corresponds with the "JLIMIT>" command. The LCD display

on the teach pendant should then show the following screen.

JLIMIT

F4

TRAVEL JOINT <NEGATIVE> <POSITIVE>

[mm] <T1> -5.868 111.000

or <T2> -138.000 138.000

[deg] <T3> -0.500 200.500

<T4> -400.000 400.000

<T5> -5729.578 5729.578

> _

N1-mem P1-mem N2-mem P2-mem N3-mem < n ext >

F1 F2 F3 F4 F5 F6

(4) Enter joint limit values with numeric keys.

The joint limit position value of the axis to be set should be entered in units of millimeters or

degrees.

(5) Store the joint limit position value of each axis.

After entering the joint limit position values, press the function key on the teach pendant to store

them. Above the function keys, a menu having "P1-mem" "N1-mem ...". corresponding to the

controller axes appears. The first letter "P" and "N" represent + direction and - direction of

each joint axis. In addition, the number following "P" or "N" accords with the robot joint number.

Press the key corresponding to the axis and direction for which the joint limit is to be set.

2-19

- -

Page 56

STE 58760

If the corresponding axis and direction do not appear on the display, press the "F6" key.

Pressing the "F6" key causes the messages at the bottom of the display to change to those of

remaining axes.

Example)

When setting the joint limit in the minus direction of axis 1 to -90 degrees, enter the following

keys in sequence.

[-] [9] [0] [Exec] [F1]

TRAVEL JOINT <NEGATIVE> <POSITIVE>

[mm] <T1> -5.868 111.000

Or <T2> -138.000 138.000

[deg] <T3> -0.500 200.500

<T4> -400.000 400.000

<T5> -5729.578 5729.578

> –90

N1-mem P1-mem N2-mem P2-mem N3-mem < n ext >

F1 F2 F3 F4 F5 F6

(6) Last, press the "Esc" key to complete the joint limit setting.

(7) Finally, turn off the controller power, then effect a hot-start. The joint limit setting

becomes effective. (For details of how to turn the power off, see Para. 2.7.)

2-20

- -

Page 57

STE 58760

2.7 TURNING OFF THE POWER

After the robot operation is complete, turn off the controller power (main power and servo power).

When the main power is turned off, the servo power also turns off at that time. Generally, one

turns off the servo power first and then turns off the main power. It is also possible to turn off the

power source at the controller connection.

2.7.1 Turning OFF Servo Power

Turn off the servo power in the following manner.

(1) Check that the robot is stopped.

Avoid turning off the power while the robot is moving if at all possible.

(2) Press the "SERVO OFF" switch on the control panel.

When the servo power is turned off, the lamp on the switch should light up.

2.7.2 Turning OFF the Main Power

Turn off the main power in the following manner.

(1) Check that the robot is stopped.

Avoid turning off the power if at all possible while the robot is moving.

If the robot is operating in the automatic operation mode, cancel the automatic operation mode.

If the main power is turned off while the robot is in the automatic operation mode, the contents

of the program may be lost.

2-21

- -

Page 58

STE 58760

(2) Turn off the servo power.

(3) Check that the FDD unit (option) is not in operation.

While the FDD is in operation, the LED on the FDD will be lit up. When the power is turned off

while the LED is still lit, the contents of the floppy disk in the FDD may be damaged. While the

FDD is in operation, do not turn off the main power. In addition, to protect the contents of the

floppy disk, it is necessary to remove the disk from the FDD, before turning off the main power.

Note)

If the main power is turned off and then turned on while the system disk is inserted in the FDD,

the controller will be cold started. To prevent this, be sure to turn off the main power after

removing the disk from the FDD.

(4) Check that no editing is being conducted with the controller.

If the main power is turned off while a robot language program is being edited, while position

data is being taught, or while parameters are being edited, data being edited or set may be

lost. (Moreover, other data may be also lost). Editing should be completed before turning off

the main power.

2-22

- -

Page 59

(5) Turn off the Main Power switch on the control panel.

When the main power is turned off, the "POWER LED" on the control panel turns off.

STE 58760

2-23

- -

Page 60

STE 58760

CHAPTER 3

SETTING ENVIRONMENTAL CONDITIONS

FOR THE SR7000 CONTROLLER

The operator should set items such as the robot configuration and the communication channel

modes before he or she operates the robot system. The operator should set the date and time for

the controller for file management and fault display information. The operation for setting such

data is called controller environmental condition setting. Except for the date and time, such data is

stored in a system configuration file (CONSTRUC. SYS).

In addition, to use external signals to select a file to be executed, it is necessary to first create an

external selection file (EXTRNSEL. SYS).

This chapter describes how to set individual data which defines the environmental conditions of the

controller.

3.1 SETTING DATE AND TIME

The controller provides a clock function which indicates the current date and time. When the robot

system detects an error, the function indicates the date and time when the error occurred along with

a related error message.

Date and time have been set at factory. However, when the controller power has been turned off

for a long time, the controller clock may become off. In this case, it is necessary to reset the

correct date and time.

Note)

The accuracy of the controller clock is within 15 sec per month. Thus, it is necessary to

periodically check and adjust the clock.

3.1.1 Setting Date

Set the current date in the following manner.

(1) Turn on the controller main power and place the MASTER MODE KEY switch on the

control panel in the "MANU" position. The following monitor command menu will appear

at the bottom on the teach pendant LCD display.

3-1

- -

Page 61

STE 58760

> ■

EDIT LOAD SAVE TESTRUN> RESET NEXT

F1 F2 F3 F4 F5 F6