Page 1

FILE NO.SVM-05053-1

SERVICE MANUAL

HI WALL TYPE (INDOOR UNIT)

RAV-SM562KRT-E

RAV-SM802KRT-E

R410A

Rev. Mar, 2006

Page 2

CONTENTS

1. SPECIFICATIONS................................................................................................ 2

2. CONSTRUCTION VIEWS (EXTERNAL VIEWS) ................................................. 4

3. SYSTEMATIC REFRIGERATING CYCLE DIAGRAM ......................................... 5

4. WIRING DIAGRAM .............................................................................................. 6

5. SPECIFICATIONS OF ELECTRICAL PARTS ..................................................... 7

6. REFRIGERANT R410A ....................................................................................... 8

7. INDOOR UNIT CONTROL ................................................................................. 16

8. TROUBLESHOOTING ....................................................................................... 27

9. HOW TO REPLACEMENT OF SERVICE INDOOR P.C. BOARD....................... 50

10. SETUP AT LOCAL SITE AND O THERS ........................................................... 54

11. ADDRESS SETUP ............................................................................................. 71

12. EXPLODED VIEWS AND PARTS LIST.............................................................. 76

NOTE :

This Service Manual describes explanation for the Under Ceiling type indoor unit.

For the combined outdoor unit, refer to the following Service Manual.

Outdoor unit Model name SVM to be referred

RAV-SMXX0AT-E A03-007

RAV-SPXXXAT-E A03-014

RAV-SMXX1AT-E A05-001

– 1 –

Page 3

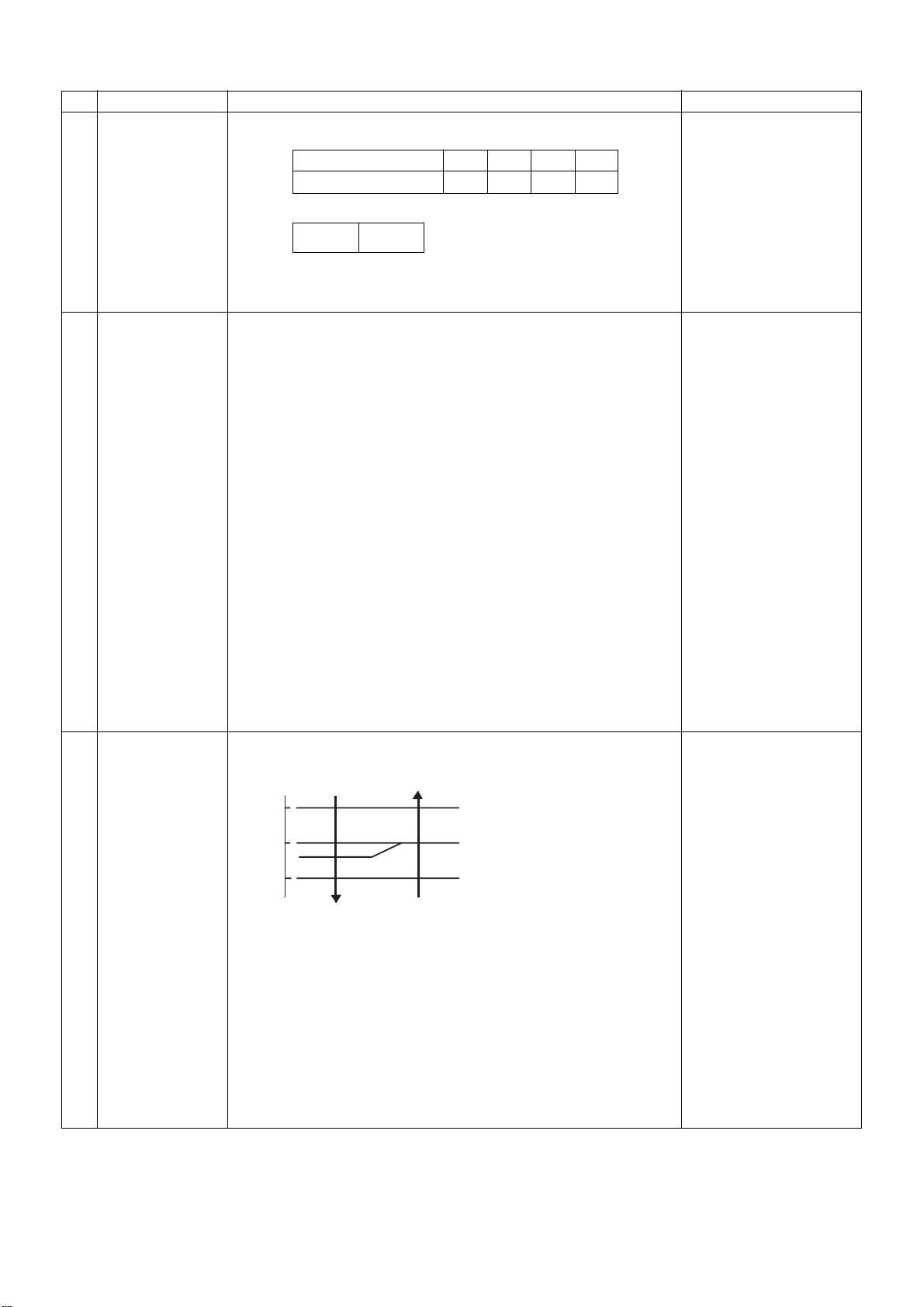

1-1. High-Wall Type (Indoor Unit)

1. SPECIFICATIONS

Model name

Standard capacity (Note 1) (kW)

Heating low temp. capacity (Note 1) (kW)

Energy consumption effect ratio (Cooling)

Power supply

Running current (A)

Electrical

characteristics

Appearance

Power consumption (kW)

(Low temp.) (kW)

Power factor (%)

Main unit

Ceiling Panel

(Sold separately)

Main unit Width (mm)

Model

Panel color

Height (mm)

RAV-SM562KRT-E RAV-SM802KRT-E

Cooling Heating Average Cooling Heating Average

5.1 5.6 6.7 8

(1.5 – 5.6) (1.5 – 6.3) (2.2 – 8.0) (2.2–9.0)

4.9 5.8

2.93 [D] 3.29 [C] 3.11 2.46 [E] 3.00 [D] 3.24

1 phase 230V (220 – 240V) 50Hz

8.33–7.63 8.138–7.46 13.15–12.05 12.91–11.84

1.74 1.7 2.72 2.67

1.95 2.21

95 95 94 94

Pure white

——

——

298

998

Outer

dimension

Ceiling panel

(Sold separately)

Total weight

Heat exchanger

Soundproof/Heat-insulating material

Fan unit Standard air flow High (Mid./Low) (m³/h)

Air filter

Controller (Sold separately)

Connecting

pipe

Main unit (kg)

Ceiling panel

Fan

Motor (W)

Gas side (mm)

Liquid side (mm)

Drain port (Nominal dia.)

Depth (mm)

Height (mm)

Width (mm)

Depth (mm)

221

——

——

——

12

——

Finned tubu

Inflammable polyethylene foam Foamed polyethylen

Turbo fan

840 1110

30

Attached main unit

Wired remote controller RBC-AMT21E

Ø12.7 (1/2”) Ø15.9 (5/8”)

Ø6.4 (1/4”) Ø9.5 (3/8”)

25 (Polyvinyl chloride tube)

Sound level High (Mid./Low) (Note 2) (dB•A)

45 41 36 45 41 36

Note 1 : The cooling capacities and electrical characteristics are measured under the conditions speciied by JIS B 8616 based

on the reference piping. The reference piping consists of 3 m of main piping and 2 m of branch piping connected with 0

meter height.

Note 2 : The sound level is measured in an anechoic chamber in accordance with JIS B8616. Normally, the values measured in

the actual operating environment become larger than the indicated values due to the effects of external sound.

Note : Rated conditions Cooling : Indoor air temperature 27°C DB/19°C WB, Outdoor air temperature 35°C DB

Heating : Indoor air temperature 20°C DB, Outdoor air temperature 7°C DB/6°C WB

– 2 –

Page 4

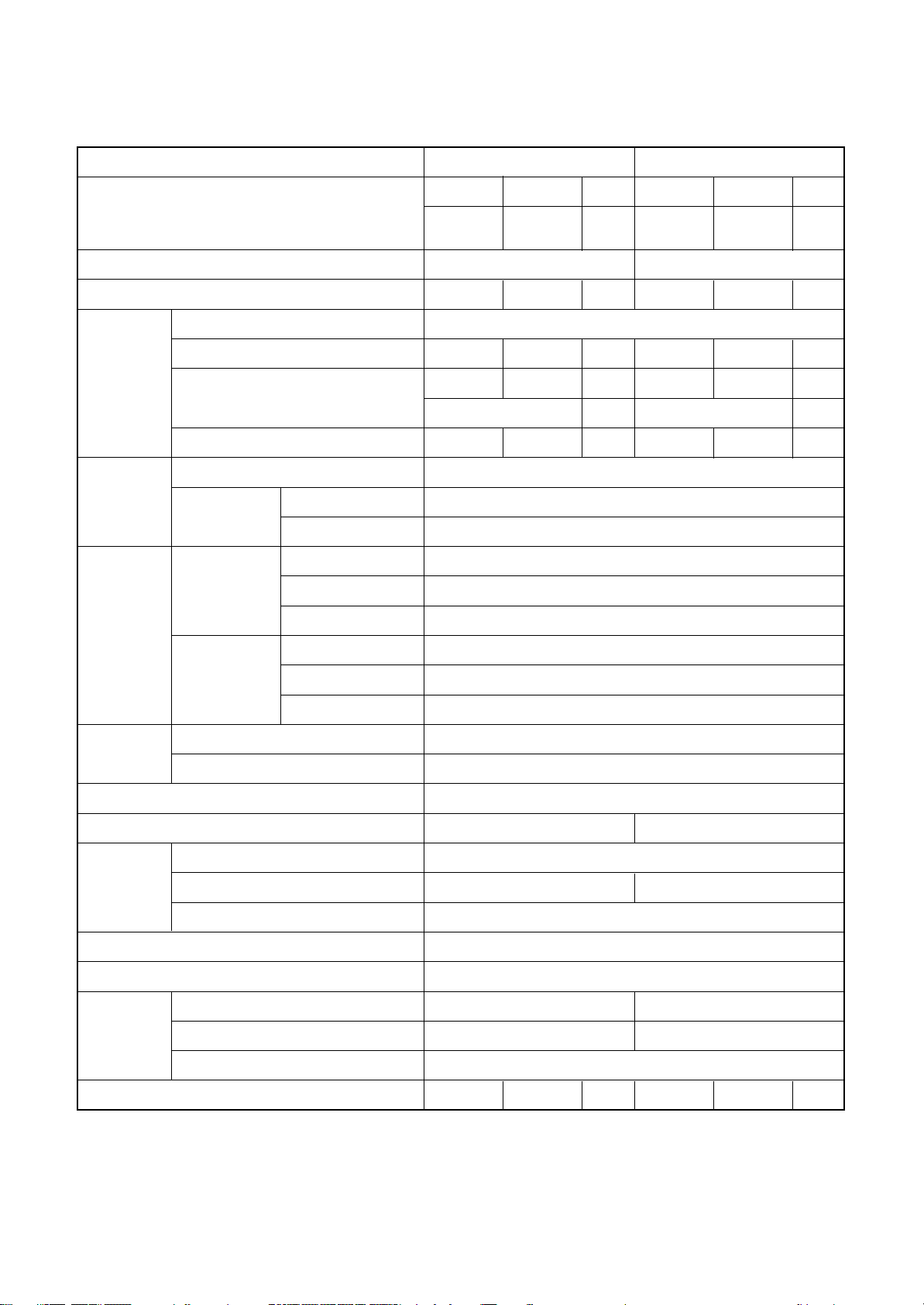

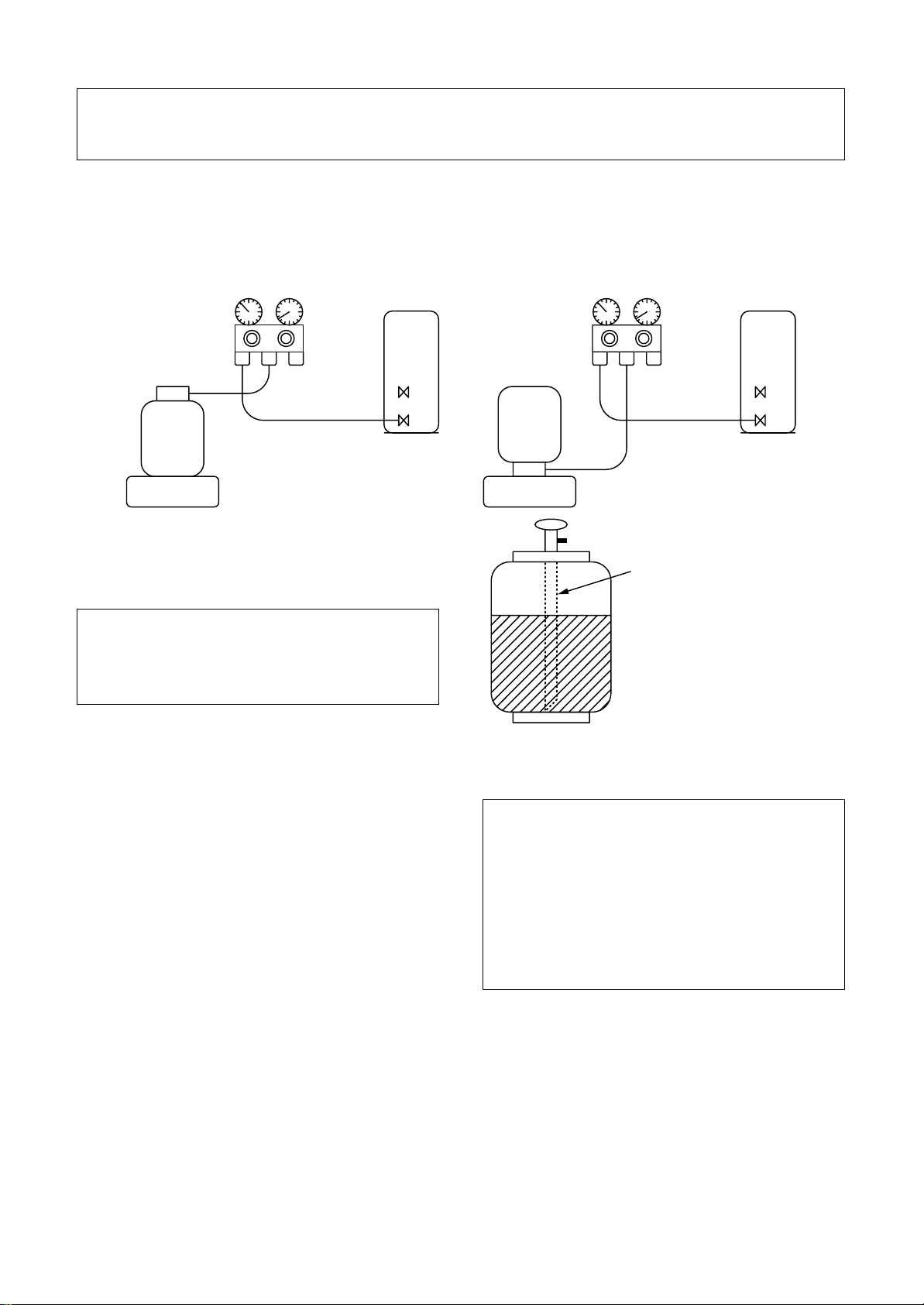

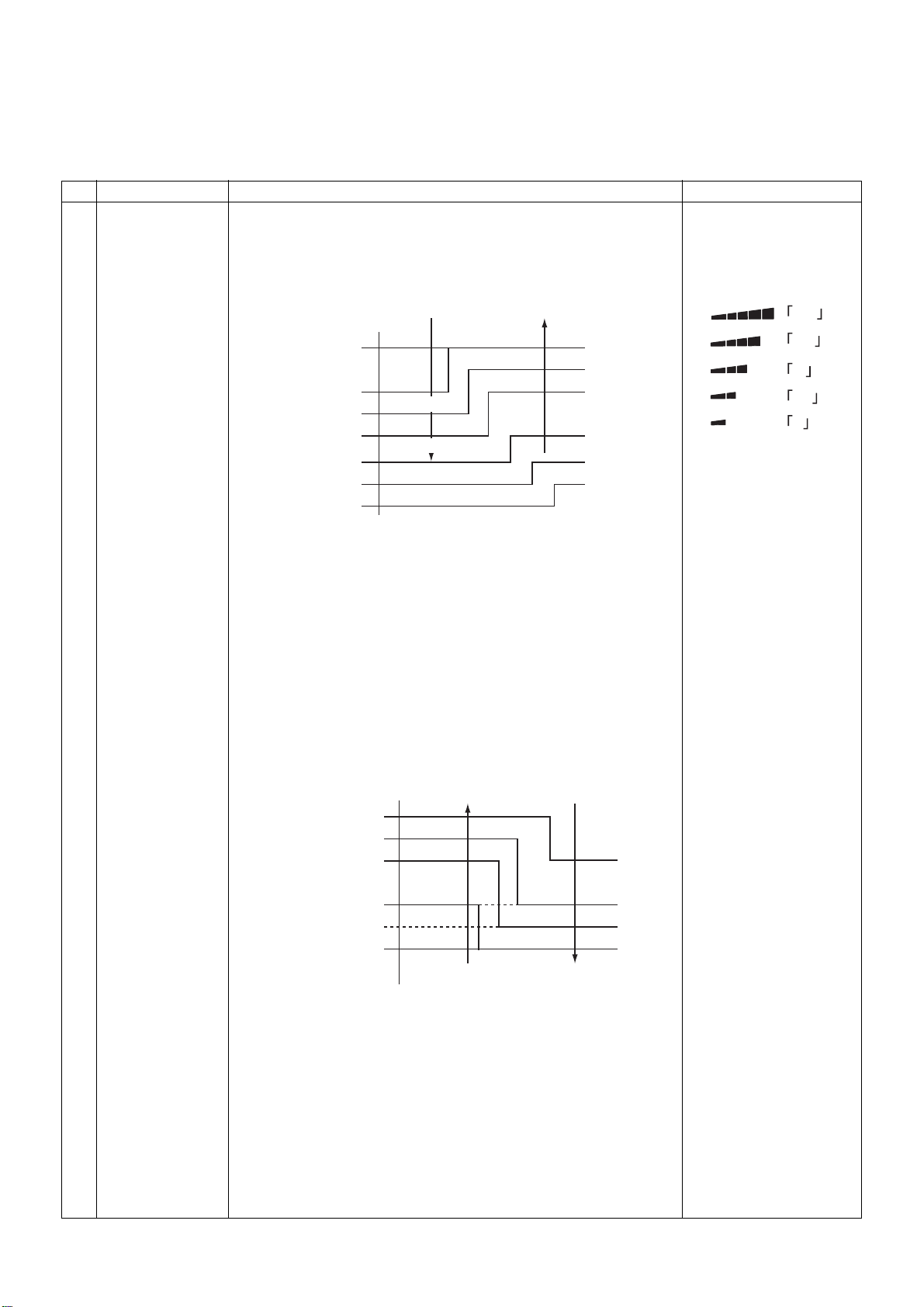

Operation characteristic curve

<Cooling> <Heating>

14

12

RAV-SM802KRT-E

10

8

6

Current (A)

4

2

0

0201540 60 70 80 100

RAV-SM562KRT-E

• Conditions

Indoor : DB27 C/WB19°C

Outdoor : DB35°C

Air flow : High

Pipe length : 7.5m

230V

Compressor speed (rps)

16

14

12

10

8

Current (A)

6

4

2

0

15

020

RAV-SM802KRT-E

RAV-SM562KRT-E

• Conditions

Indoor : DB20°C

Outdoor : DB7 C/WB6°C

Air flow : High

Pipe length : 7.5m

230V

40 60 80 90 100

Compressor speed (rps)

•Capacity variation ratioaccor ding to temperature

<Cooling> <Heating>

105

100

95

90

120

110

100

90

80

85

70

80

60

75

70

Capacity ratio (%)

65

60

55

• Conditions

Indoor : DB27 C/WB19°C

Indoor air flow : High

Pipe length : 7.5m

50

32 33 34 35 36 37 38 39 40 41 42 43

50

40

Capacity ratio (%)

30

20

10

0

-14-12-10-8-6-4-20246810

Outsoor temp. (°C)

• Conditions

Indoor : DB20°C

Indoor air flow : High

Pipe length : 7.5m

Outsoor temp. (°C)

– 3 –

Page 5

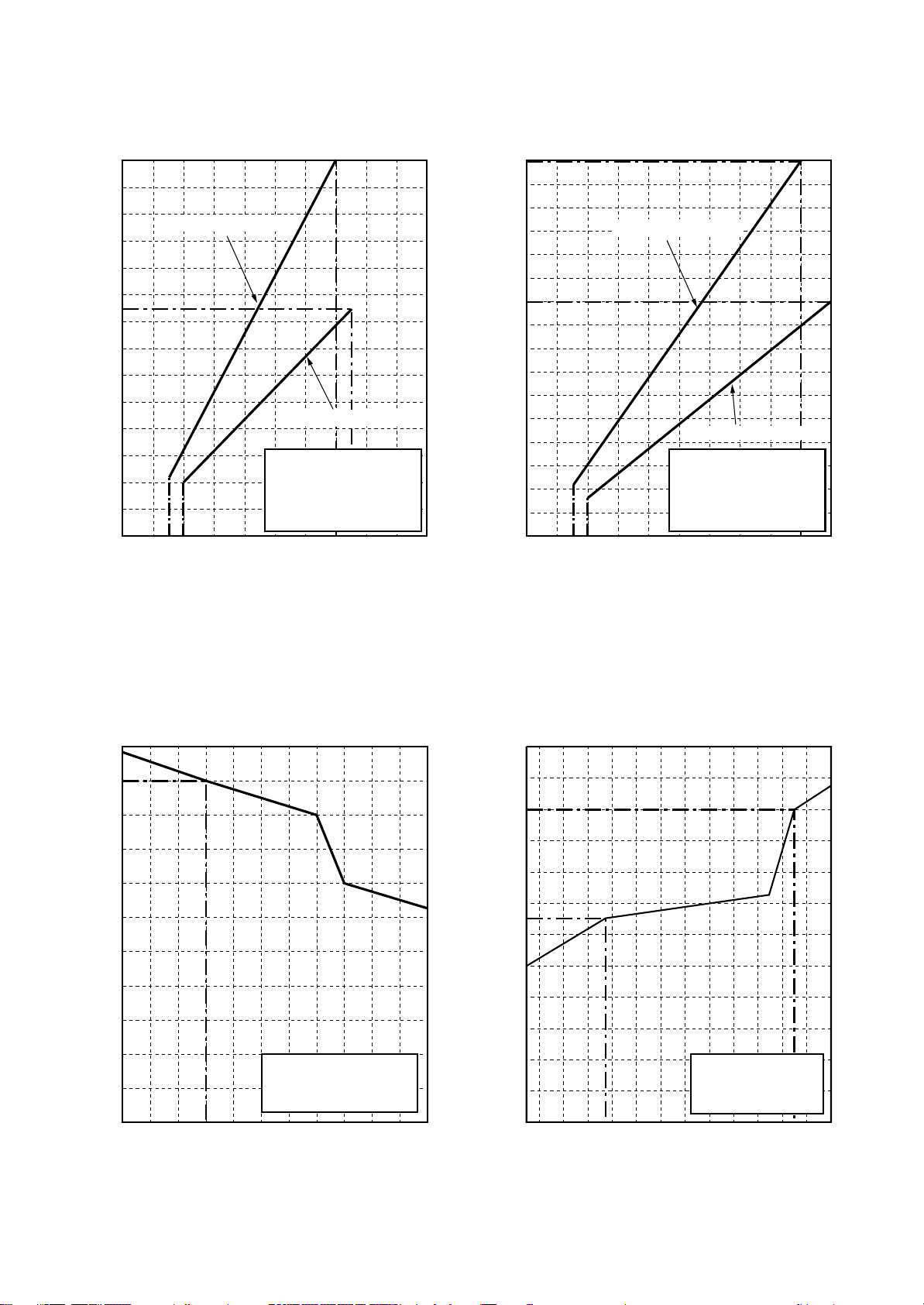

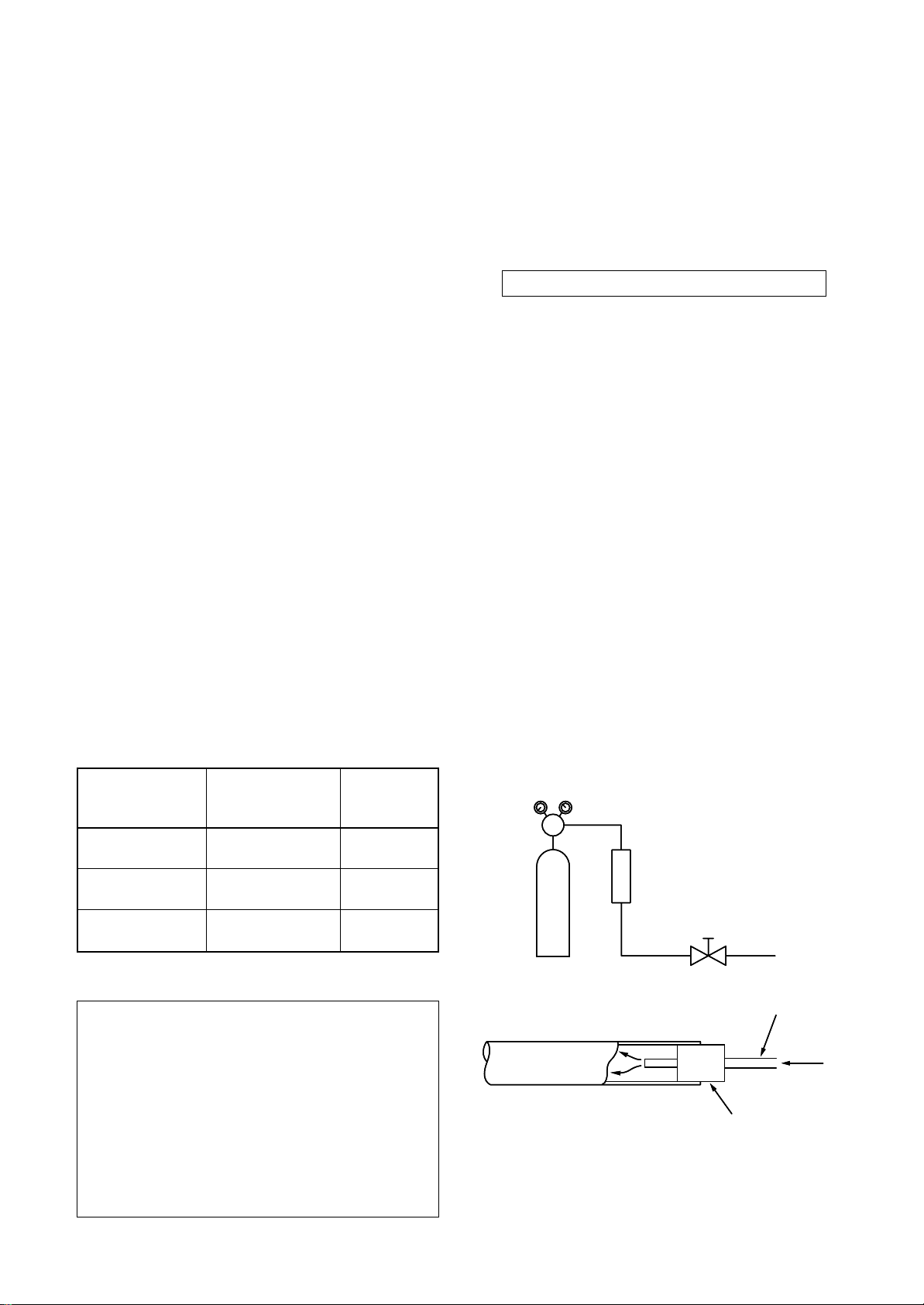

2. CONSTRUCTION VIEWS (EXTERNAL VIEWS)

High-Wall Type

RAV-SM562KRT-E/RAV-SM802KRT-E

75

7

51

Knock out system

Back body

Front panel

Grille inlet

298

Air inlet

Air outlet

998

75

56

220

Knock out system

50

50

75

8

Connection pipe (0.39 m)

(For SM802 : Flare ∅15.88)

(For SM562 : Flare ∅12.7)

55 or more

Outline of indoor unit

298

Minimum distance

to ceiling

∅65

100

20

48

998

763.5

450

Installation

Plate outline

Drain hose (0.54 m)

Connection pipe (0.49 m)

(Flare ∅6.35)

20

10

100

57

Wireless remote control

(For stud bolt ∅6)

(For stud bolt ∅8 -∅10)

29

41

55

5555

∅6

40

5

160

18

48

– 4 –

Page 6

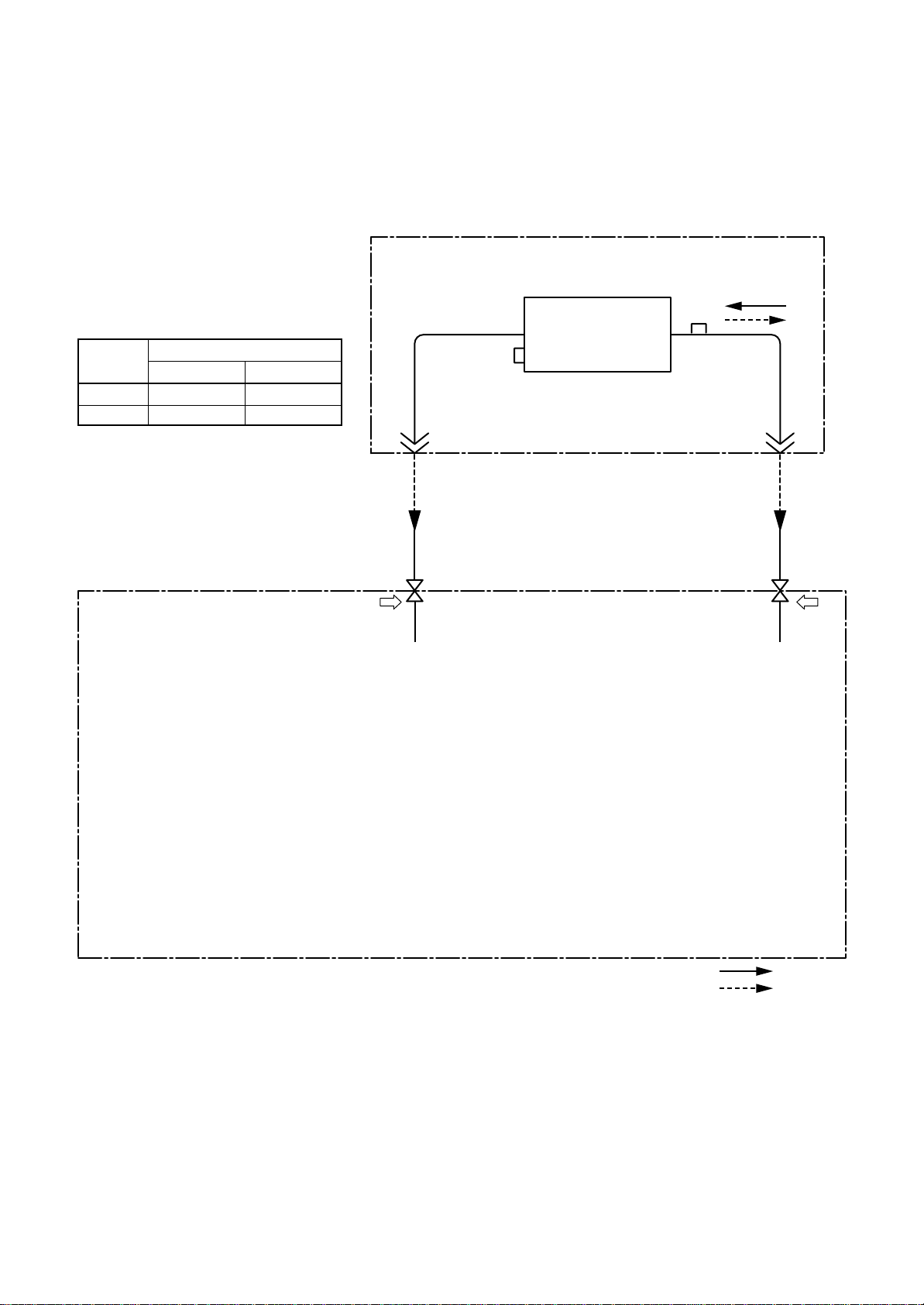

3. SYSTEMATIC REFRIGERATING CYCLE DIAGRAM

3-1. Hi Wall type

RAV-SM562KRT-E/SM802KRT-E

Outer diameter of refrig erant pipeModel

RAV-SM

562KRT-E

802KRT-E

Gas side ØA Liquid side ØB

12.7 mm 6.4 mm

15.9 mm

9.5 mm

Indoor unit

TCJ

sensor

Air heat exchanger

TC sensor

Refrigerant pipe

at gas side

Outer dia. ØA

Pd PsPacked valve

Packed valve

Outer dia. ØA

Refrigerant pipe

at liquid side

Outer dia. ØB

Outer dia. ØB

Outdoor unit

NOTE :

The refrigerating cycle differs according to the combined outdoor units.

For the cycle diagram, cycle pressure, etc., refer to the following Service Manual.

RAV-SMXXX0AT-E : A03-007

RAV-SPXXXXAT-E : A03-014

RAV-SMXXX1AT-E : A05-001

– 5 –

Cooling

Heating

Page 7

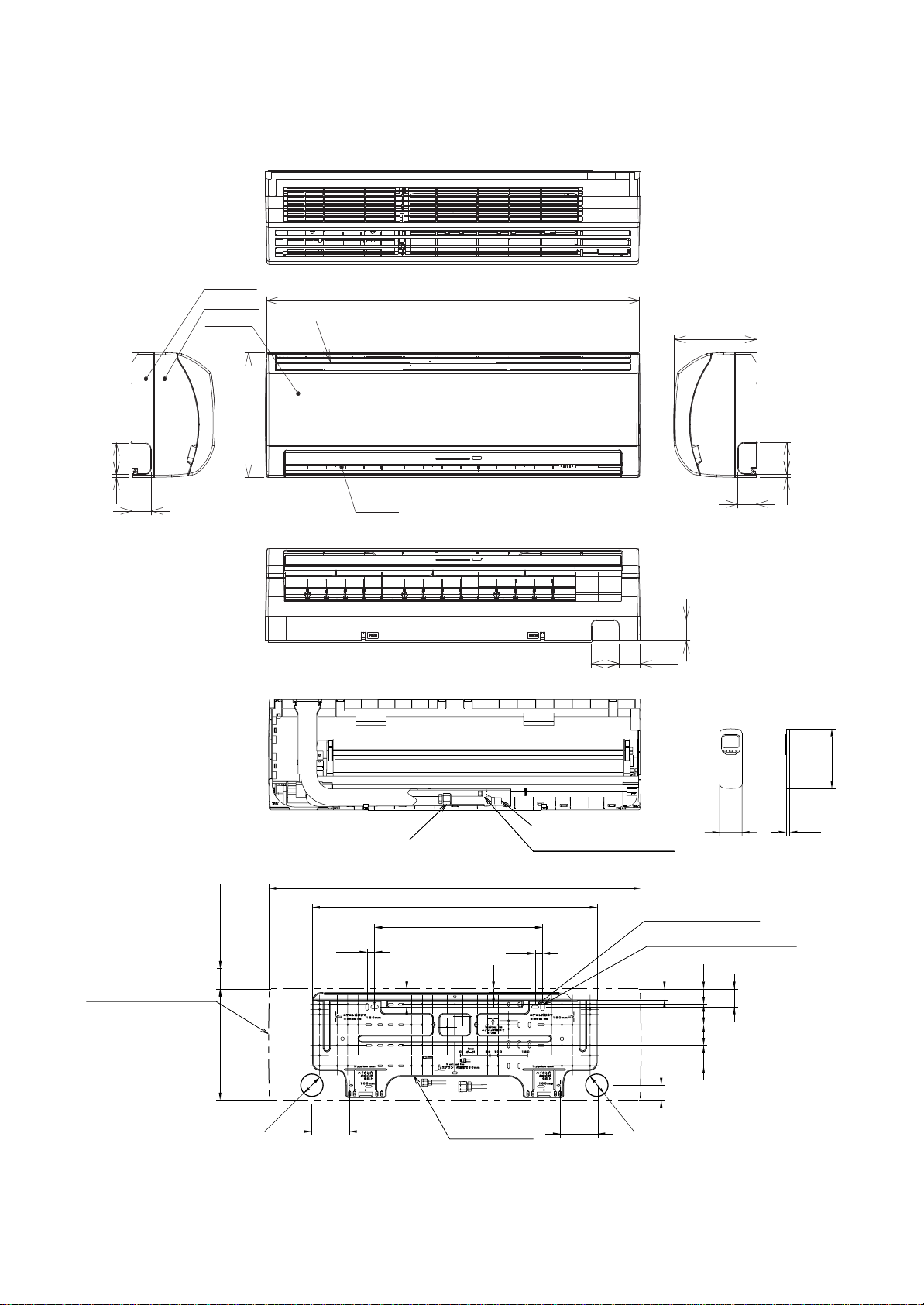

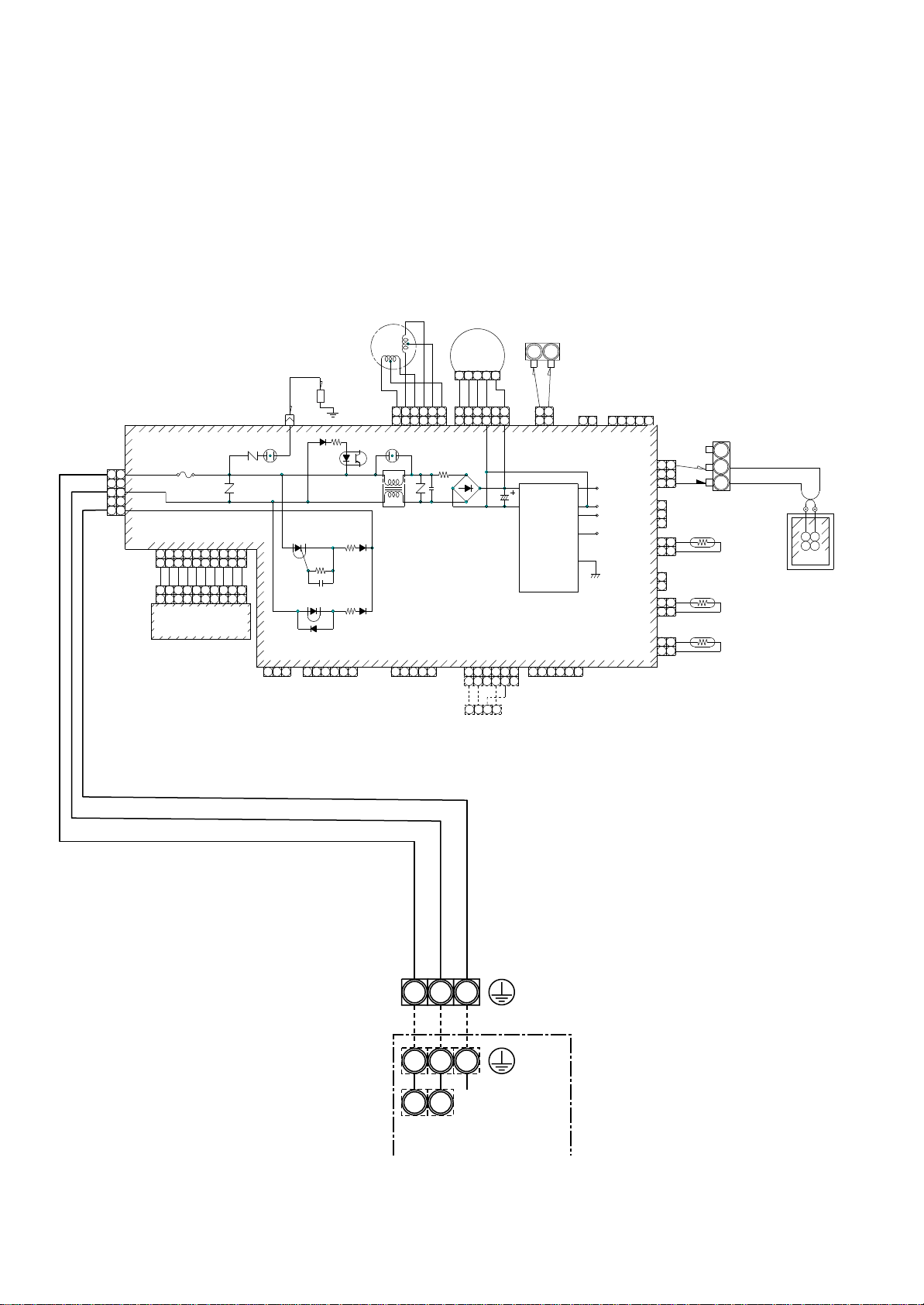

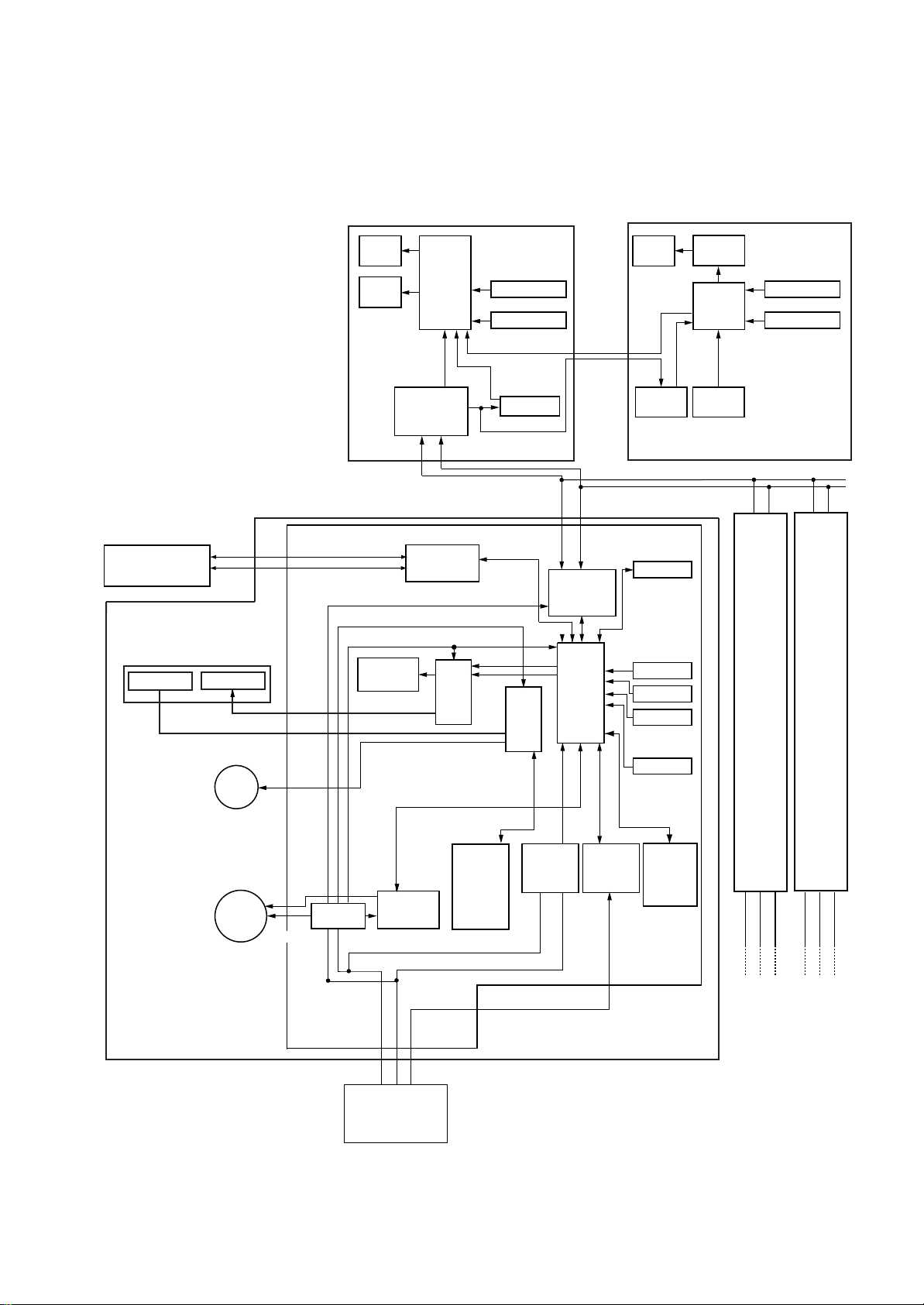

4-1. Hi Wall type (Indoor unit)

RAV-SM562KRT-E/SM802KRT-E

LOUVER

MOTOR

BLK

F

S

CN22

F301 FUSE

T3.15A 250V〜

1

1

3

3

5

5

CN67

(BLK)

CN213(WHI)

9

5 876

6 7 85

BLUBLUBLUBLUBLUBLUBLUBLU

BLUBLUBLUBLUBLUBLUBLUBLU

6 7 85

5 876

BLUBLUBLUBLUBLUBLUBLUBLU

BLUBLUBLUBLUBLUBLUBLUBLU

10

10

9

WHI

BLUBLUBLUBLUBLUBLUBLU

BLU

9

10

9

10

CN80

(GRN)

1 2 3

CN82

(BLU)

1

42 3

1

32 4

BLUBLUBLUBLUBLUBLUBLUBLU

BLUBLUBLUBLUBLUBLUBLUBLU

BLUBLUBLUBLUBLUBLUBLUBLU

BLUBLUBLUBLUBLUBLUBLUBLU

1

32 4

1

42 3

INFRARED RAYS RECEIVE

AND INDICATION PARTS

(MCC−819)

PNL/EMG

4. WIRING DIAGRAM

TERMINAL

2 145 3

RED

BLK

1

34

1

CN61

(YEL)

53 4 621

53 4 62

3 42

BLOCK

U3

U4

BLU

BLU

112

2

CN40

(BLU)

POWER

SUPPLY

CIRCUIT

CN60

(WHI)

2 5431 6

OPTION

FAN

MOTOR

YEL

WHI

BRW

RED

ORN

BLU

YEL

PNK

BLU

13 2

123

CN210

(WHI)

5566

4 3

6 5

4

56

4

CN33

(WHI)

(MCC−1510)

ControlP.Cboard

forindoorunit

CN81

(BLK)

6321 4 5

4 51 2 3

1

1

HA

BUS

EMG

1 2

CN44

(BRW)

DC15V

DC 0V

DC12V

DC7V

21 543

CN50

(WHI)

3

CN41

2

1

(BLU)

1

CN100

2

(BRW)

3

1

CN101

(BLU)

1

CN103

2

(GRN)

1

CN102

2

(YEL)

1

CN104

2

(WHI)

3

2

1

212

1

2

1

2

BLK

BLK

BLK

BLK

BLK

BLK

BLK

BLK

TERMINAL

BLOCK

B

A

HEAT

EXCHANGER

SENSOR

(TC)

HEAT

EXCHANGER

SENSOR

(TCJ)

THERMO

SENSOR

(TA)

WHI

BLK

1

2

1

2

CN1(WHI)

WIERDREMOTE

CONTROLLER

NOTE

: Fan motor

FM

: Indoor temp. sensor

TA

: Temp. sensor

TC

: Temp. sensor

TCJ

: Louver motor

LM

WHI BLK

RED

321

321

Serial

NL

signal

Single phase 220V, 50Hz

– 6 –

Indoor unit

earth screw

Outdoor unit

earth screw

Color

Identification

BLACK

:

BLK

BLUE

:

BLU

RED

:

RED

GRAY

:

GRY

PINK

:

PNK

GREEN

:

GRN

WHITE

:

WHI

BROWN

:

BRW

ORANGE

:

ORN

YELLOW

:

YEL

Page 8

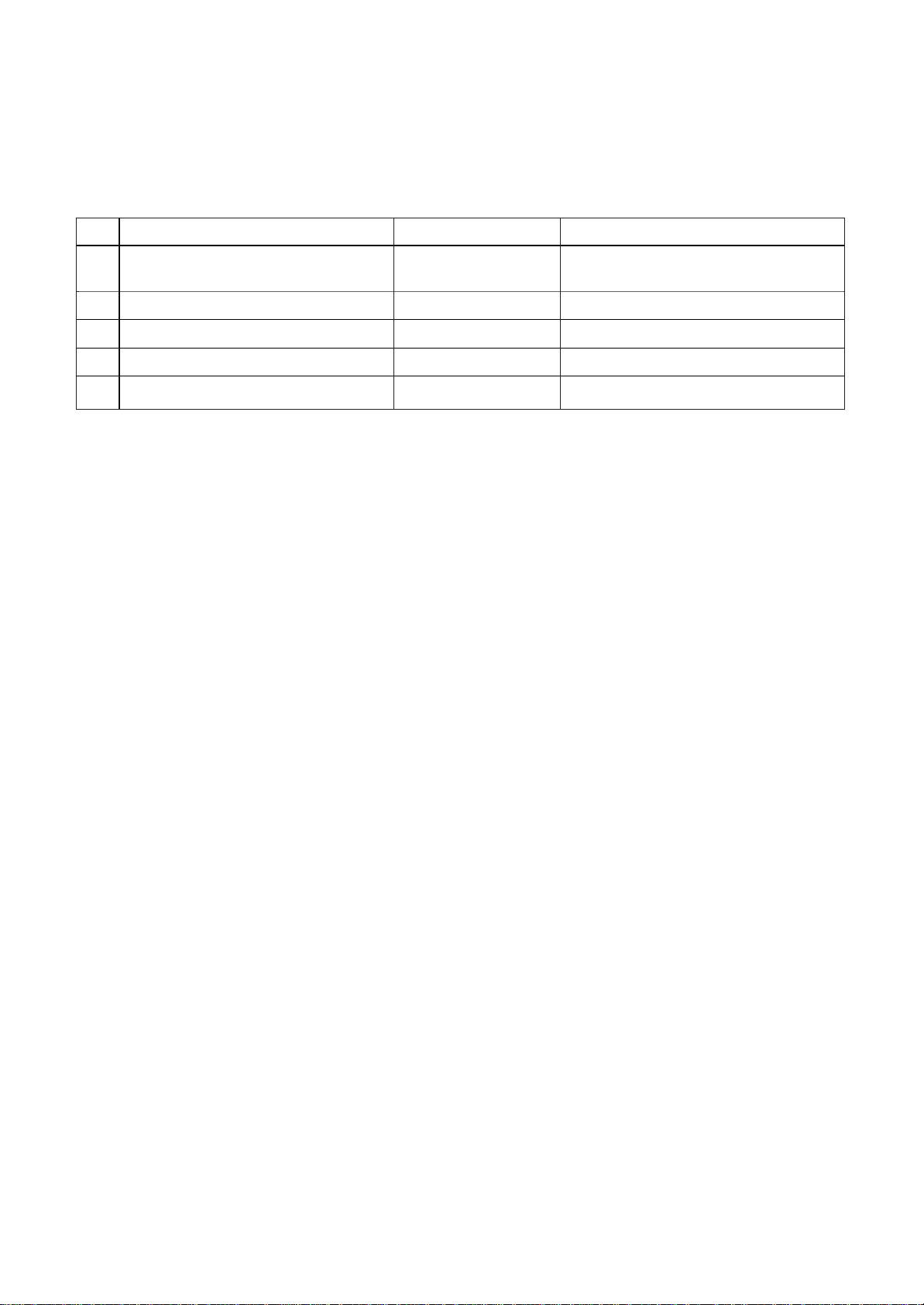

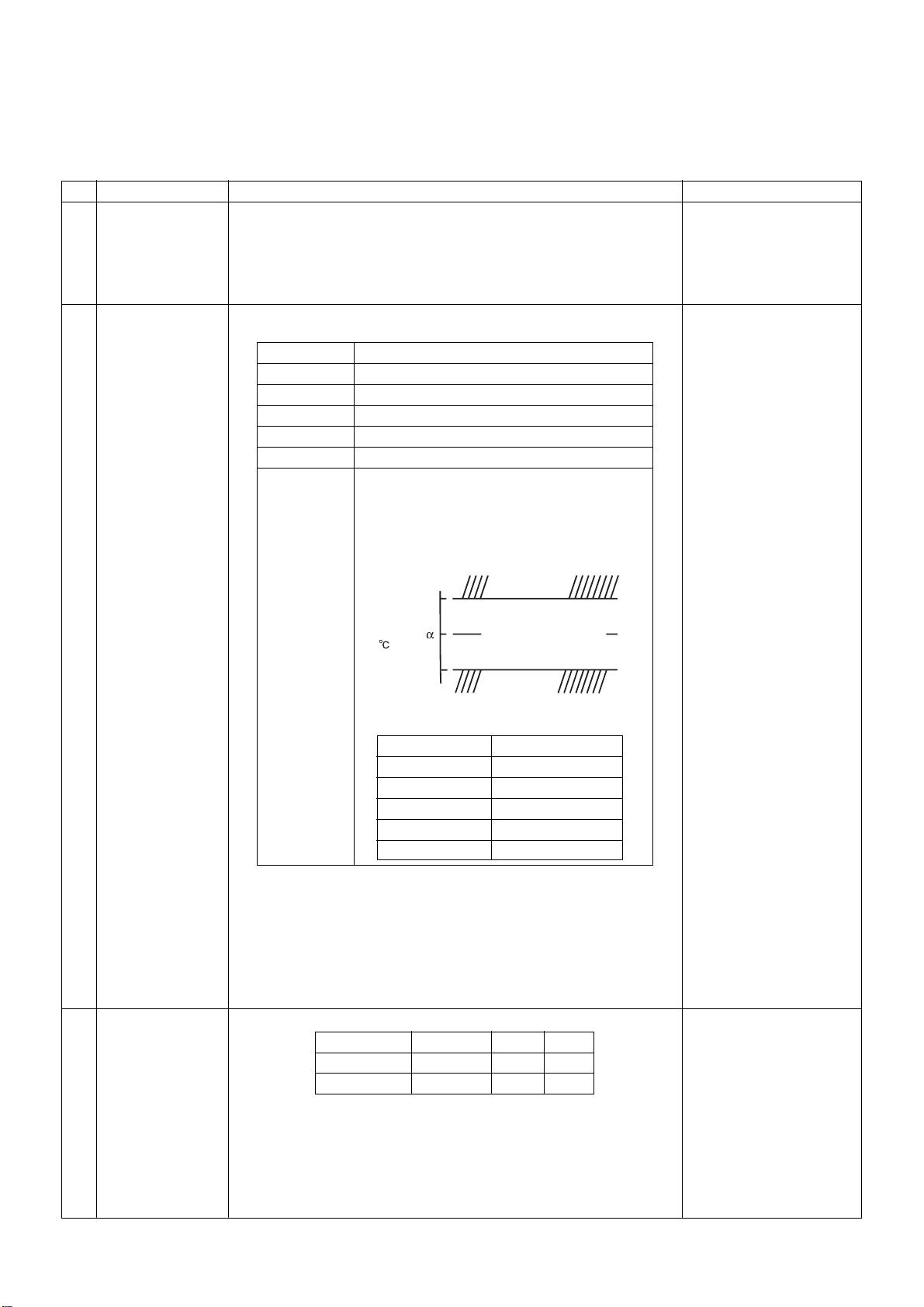

5. SPECIFICATIONS OF ELECTRICAL PARTS

5-1. Indoor Unit

High-Wall Type

RAV-SM562KRT-E/RAV-SM802KRT-E

No.

1

Fan motor (for indoor)

2

Grille motor

3

Thermo. sensor (TA-sensor)

4

Heat exchanger sensor (TC-sensor)

5

Heat exchanger sensor (TCJ-sensor)

Parts name

Type

ICF340-30-X

MF-340-30-X

MP35EA12

268 mm

Ø6 mm, 400 mm

Ø6 mm, 400 mm

Specifications

Output (Rated) 30 W, 220–240 V

10 kW at 25°C

10 kW at 25°C

– 7 –

Page 9

6. REFRIGERANT R410A

This air conditioner adopts the new refrigerant HFC

(R410A) which does not damage the ozone layer.

The working pressure of the new refrigerant R410A

is 1.6 times higher than conventional refrigerant

(R22). The refrigerating oil is also changed in

accordance with change of refrigerant, so be careful

that water, dust, and existing refrigerant or refrigerating oil are not entered in the refrigerant cycle of the

air conditioner using the new refrigerant during

installation work or servicing time.

The next section describes the precautions for air

conditioner using the new refrigerant. Conforming to

contents of the next section together with the

general cautions included in this manual, perform

the correct and safe work.

6-1. Safety During Installation/Servicing

As R410A's pressure is about 1.6 times higher than

that of R22, improper installation/servicing may

cause a serious trouble. By using tools and materials exclusive for R410A, it is necessary to carry out

installation/servicing safely while taking the following

precautions into consideration.

(1) Never use refrigerant other than R410A in an air

conditioner which is designed to operate with

R410A.

If other refrigerant than R410A is mixed, pressure in the refrigeration cycle becomes abnormally high, and it may cause personal injury, etc.

by a rupture.

(2) Confirm the used refrigerant name, and use

tools and materials exclusive for the refrigerant

R410A.

The refrigerant name R410A is indicated on the

visible place of the outdoor unit of the air conditioner using R410A as refrigerant. To prevent

mischarging, the diameter of the service port

differs from that of R22.

(3) If a refrigeration gas leakage occurs during

installation/servicing, be sure to ventilate fully.

If the refrigerant gas comes into contact with fire,

a poisonous gas may occur.

(4) When installing or removing an air conditioner,

do not allow air or moisture to remain in the

refrigeration cycle. Otherwise, pressure in the

refrigeration cycle may become abnormally high

so that a rupture or personal injury may be

caused.

(5) After completion of installation work, check to

make sure that there is no refrigeration gas

leakage.

If the refrigerant gas leaks into the room, coming

into contact with fire in the fan-driven heater,

space heater, etc., a poisonous gas may occur.

(6) When an air conditioning system charged with a

large volume of refrigerant is installed in a small

room, it is necessary to exercise care so that,

even when refrigerant leaks, its concentration

does not exceed the marginal level.

If the refrigerant gas leakage occurs and its

concentration exceeds the marginal level, an

oxygen starvation accident may result.

(7) Be sure to carry out installation or removal

according to the installation manual.

Improper installation may cause refrigeration

trouble, water leakage, electric shock, fire, etc.

(8) Unauthorized modifications to the air conditioner

may be dangerous. If a breakdown occurs

please call a qualified air conditioner technician

or electrician.

Improper repairÕs may result in water leakage,

electric shock and fire, etc.

6-2. Refrigerant Piping Installation

6-2-1. Piping Materials and Joints Used

For the refrigerant piping installation, copper pipes

and joints are mainly used. Copper pipes and joints

suitable for the refrigerant must be chosen and

installed. Furthermore, it is necessary to use clean

copper pipes and joints whose interior surfaces are

less affected by contaminants.

(1) Copper Pipes

It is necessary to use seamless copper pipes

which are made of either copper or copper alloy

and it is desirable that the amount of residual oil

is less than 40 mg/10 m. Do not use copper

pipes having a collapsed, deformed or discolored portion (especially on the interior surface).

Otherwise, the expansion valve or capillary tube

may become blocked with contaminants.

As an air conditioner using R410A incurs

pressure higher than when using R22, it is

necessary to choose adequate materials.

Thicknesses of copper pipes used with R410A

are as shown in Table 6-2-1. Never use copper

pipes thinner than 0.8 mm even when it is

available on the market.

– 8 –

Page 10

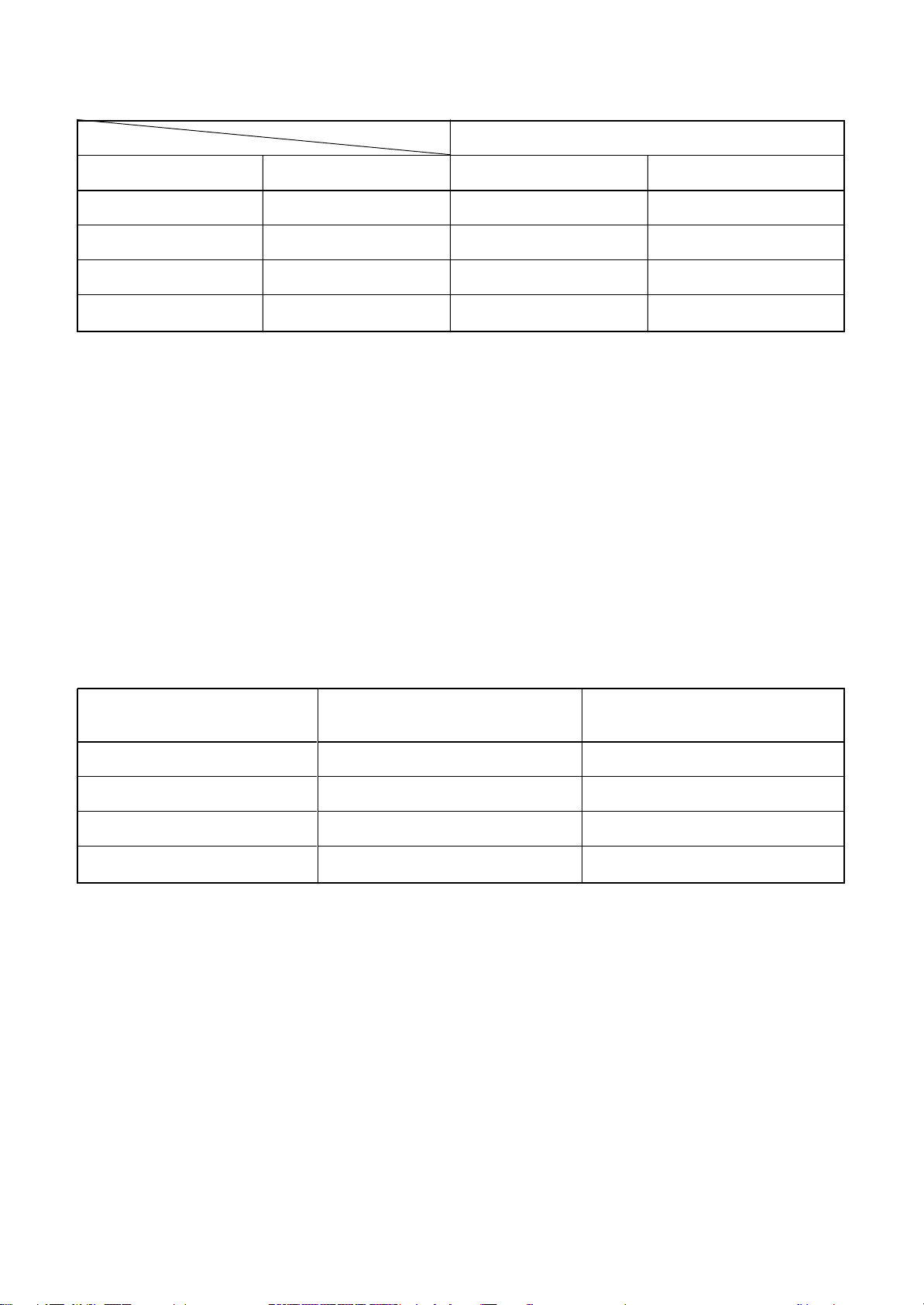

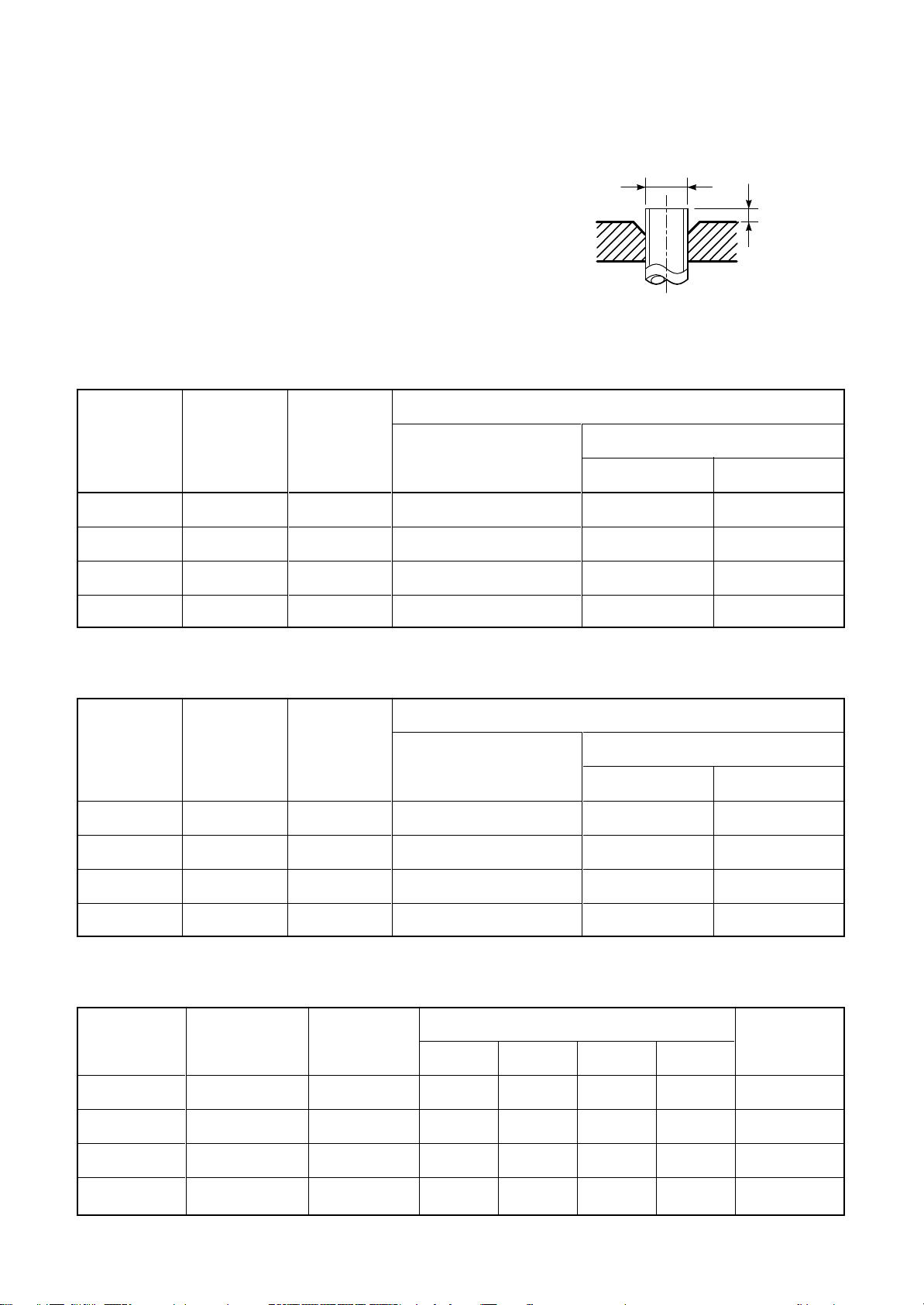

Table 6-2-1 Thicknesses of annealed copper pipes

Thickness (mm)

Nominal diameter

1/4

3/8

1/2

5/8

(2) Joints

For copper pipes, flare joints or socket joints are

used. Prior to use, be sure to remove all contaminants.

a) Flare Joints

Flare joints used to connect the copper pipes

cannot be used for pipings whose outer

diameter exceeds 20 mm. In such a case,

socket joints can be used.

Sizes of flare pipe ends, flare joint ends and

flare nuts are as shown in Tables 6-2-3 to 62-6 below.

Outer diameter (mm)

6.35

9.52

12.70

15.88

R410A R22

0.80 0.80

0.80 0.80

0.80 0.80

1.00 1.00

b) Socket Joints

Socket joints are such that they are brazed

for connections, and used mainly for thick

pipings whose diameter is larger than 20 mm.

Thicknesses of socket joints are as shown in

Table 6-2-2.

Table 6-2-2 Minimum thicknesses of socket joints

Nominal diameter

1/4

3/8

1/2

5/8

Reference outer diameter of

copper pipe jointed (mm)

6-2-2. Processing of Piping Materials

When performing the refrigerant piping installation,

care should be taken to ensure that water or dust

does not enter the pipe interior, that no other oil

other than lubricating oils used in the installed air

conditioner is used, and that refrigerant does not

leak. When using lubricating oils in the piping

processing, use such lubricating oils whose water

content has been removed. When stored, be sure to

seal the container with an airtight cap or any other

cover.

6.35

9.52

12.70

15.88

Minimum joint thickness

(mm)

0.50

0.60

0.70

0.80

(1) Flare Processing Procedures and Precautions

a) Cutting the Pipe

By means of a pipe cutter, slowly cut the pipe

so that it is not deformed.

b) Removing Burrs and Chips

If the flared section has chips or burrs,

refrigerant leakage may occur. Carefully

remove all burrs and clean the cut surface

before installation.

– 9 –

Page 11

c) Insertion of Flare Nut

d) Flare Processing

Make certain that a clamp bar and copper

pipe have been cleaned.

By means of the clamp bar, perform the flare

processing correctly.

Use either a flare tool for R410A or conventional flare tool.

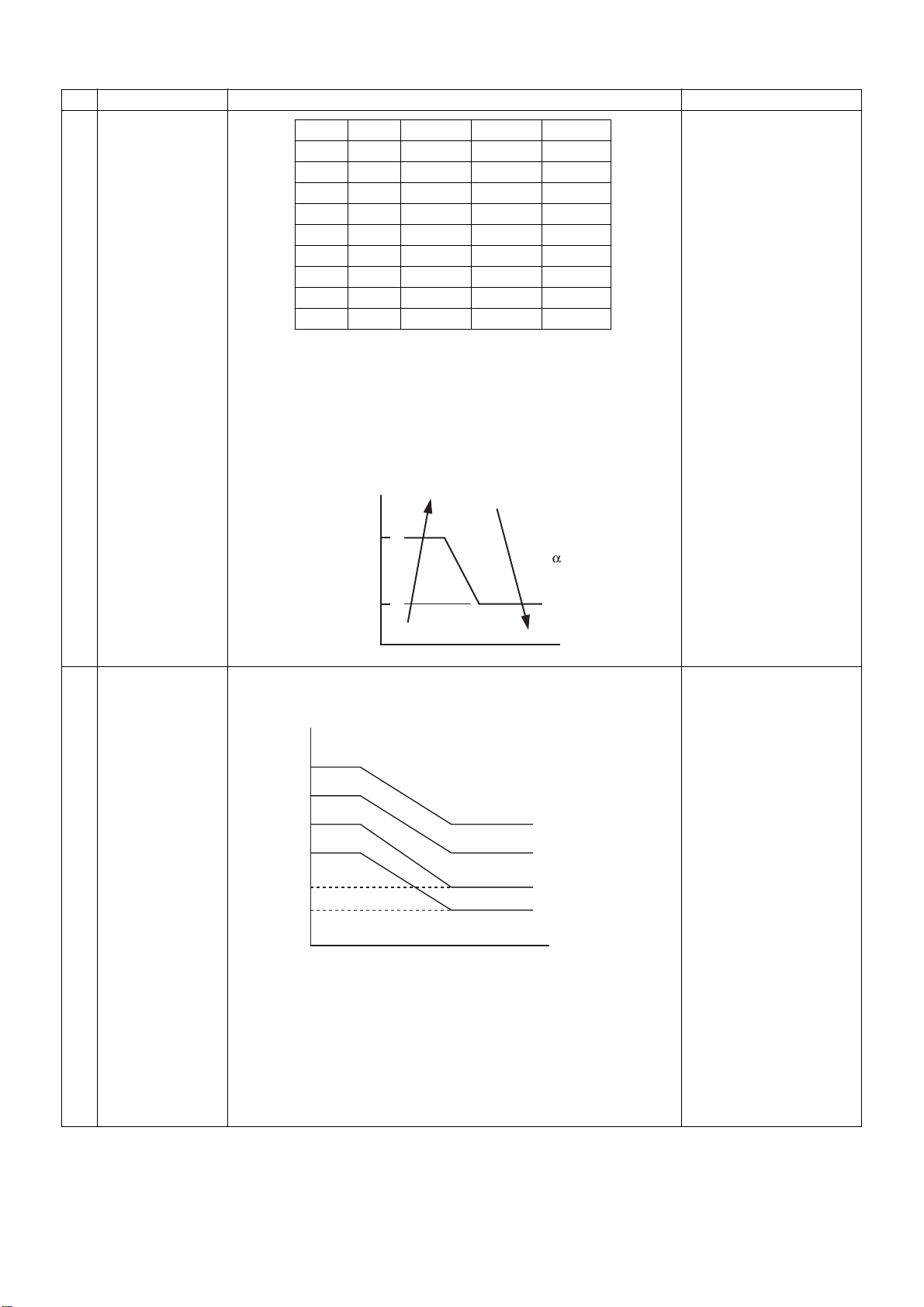

Table 6-2-3 Dimensions related to flare processing for R410A

Flare processing dimensions differ according

to the type of flare tool. When using a conventional flare tool, be sure to secure "dimension A" by using a gauge for size adjustment.

ØD

A

Fig. 6-2-1 Flare processing dimensions

Nominal

diameter

1/4

3/8

1/2

5/8

Nominal

diameter

1/4

3/8

Outer

diameter

(mm)

6.35

9.52

12.70

15.88

Thickness

(mm)

0.8

0.8

0.8

1.0

Flare tool for

R410A clutch type

0 to 0.5

0 to 0.5

0 to 0.5

0 to 0.5

Table 6-2-4 Dimensions related to flare processing for R22

Outer

diameter

(mm)

6.35

9.52

Thickness

(mm)

0.8

0.8

Flare tool for

R22 clutch type

0 to 0.5

0 to 0.5

A (mm)

Conventional flare tool

Clutch type Wing nut type

1.0 to 1.5 1.5 to 2.0

1.0 to 1.5 1.5 to 2.0

1.0 to 1.5 2.0 to 2.5

1.0 to 1.5 2.0 to 2.5

A (mm)

Conventional flare tool

Clutch type Wing nut type

0.5 to 1.0 1.0 to 1.5

0.5 to 1.0 1.0 to 1.5

1/2

5/8

Nominal

diameter

1/4

3/8

1/2

5/8

12.70

15.88

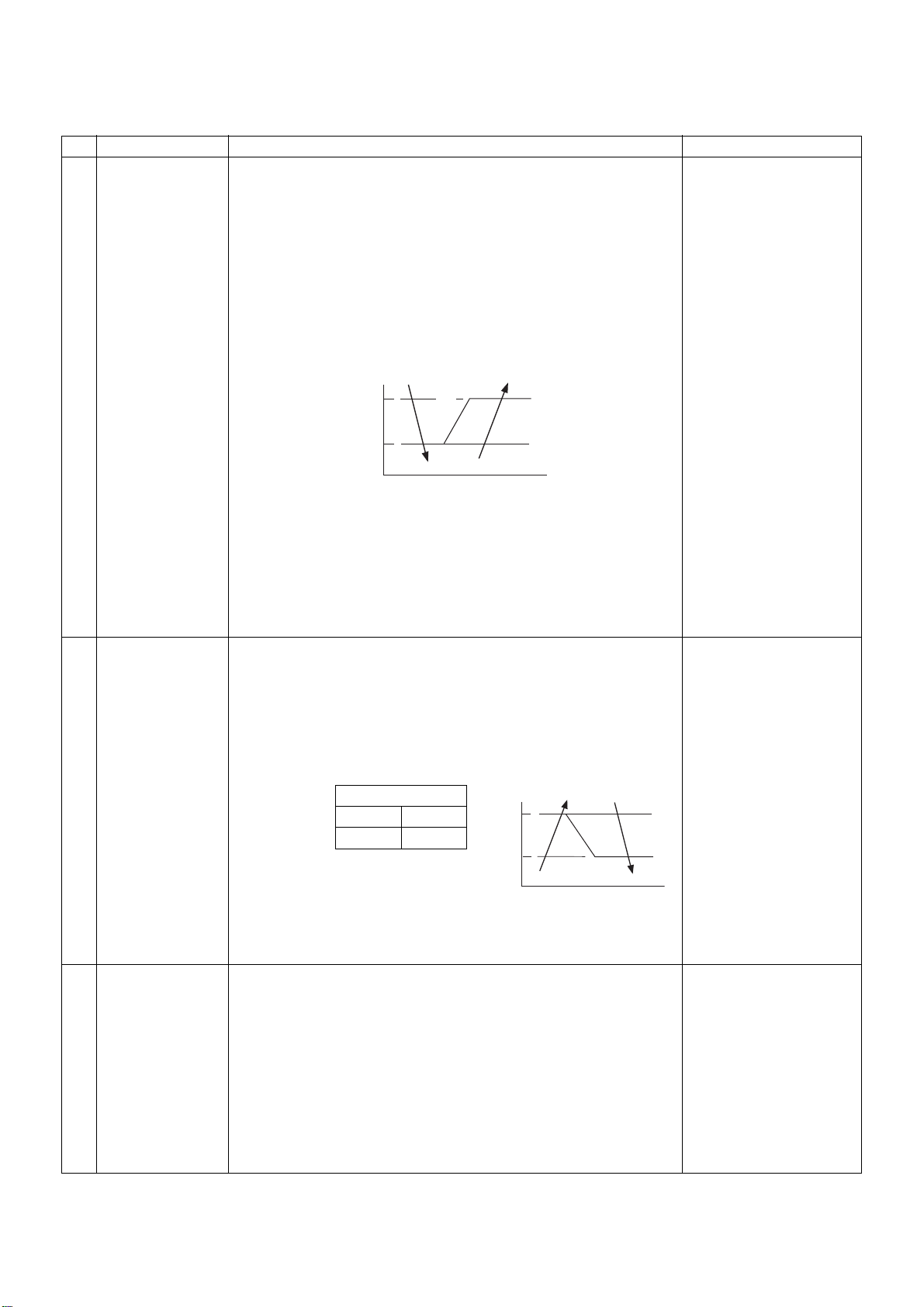

Table 6-2-5 Flare and flare nut dimensions for R410A

Outer diameter

(mm)

6.35

9.52

12.70

15,88

0.8

1.0

Thickness

(mm)

0.8

0.8

0.8

1.0

0 to 0.5

0 to 0.5

0.5 to 1.0 1.5 to 2.0

0.5 to 1.0 1.5 to 2.0

Dimension (mm)

ABCD

9.1 9.2 6.5 13

13.2 13.5 9.7 20

16.6 16.0 12.9 23

19.7 19.0 16.0 25

– 10 –

Flare nut

width (mm)

17

22

26

29

Page 12

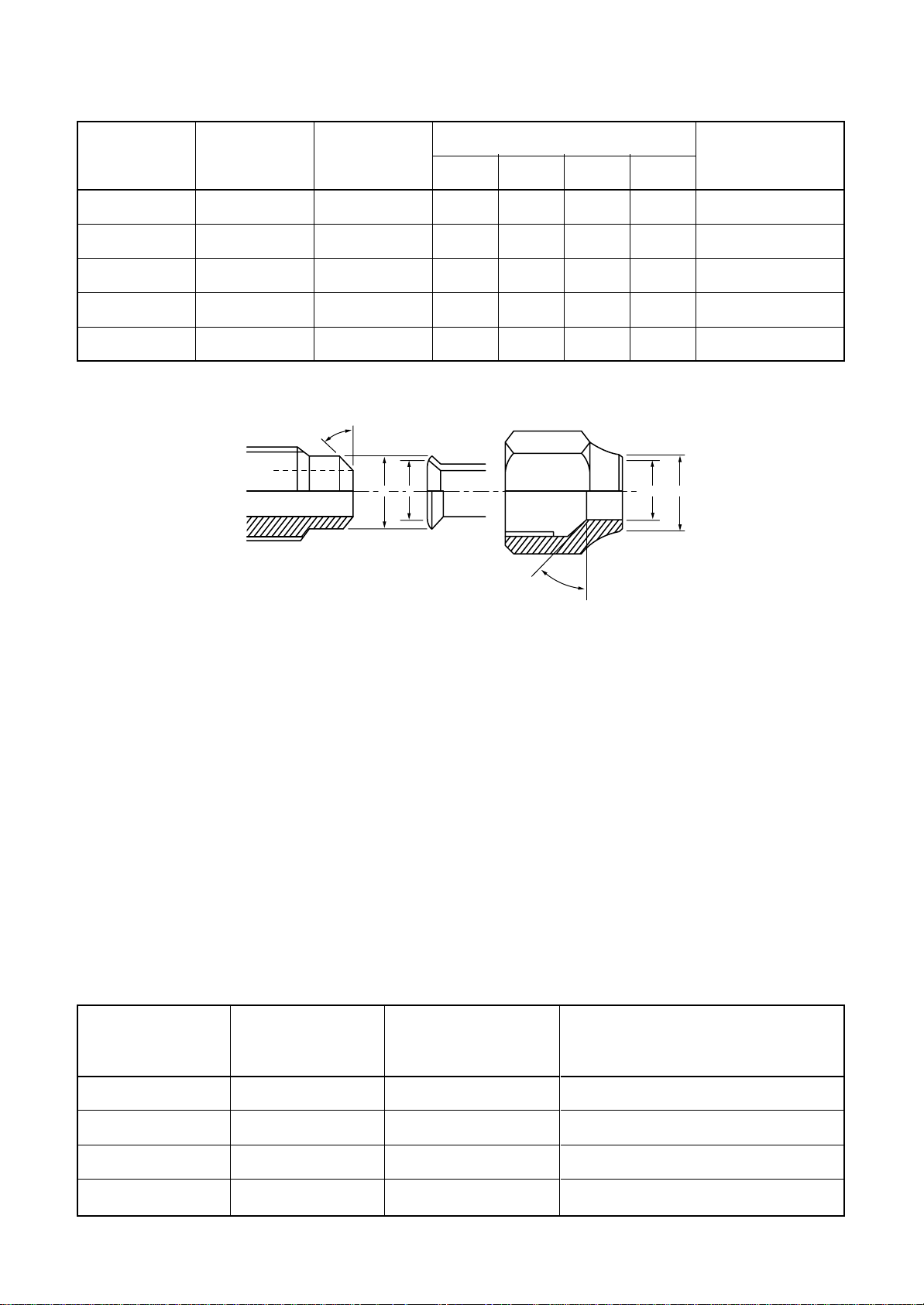

Table 6-2-6 Flare and flare nut dimensions for R22

Nominal Outer diameter Thickness

diameter (mm) (mm)

1/4 6.35 0.8

3/8 9.52 0.8

1/2 12.70 0.8

5/8 15.88 1.0

3/4 19.05 1.0

°

to 46

°

45

B A

Dimension (mm)

ABCD

9.0 9.2 6.5 13

13.0 13.5 9.7 20

16.2 16.0 12.9 20

19.4 19.0 16.0 23

23.3 24.0 19.2 34

D

C

43

°

to 45

°

Flare nut width

(mm)

17

22

24

27

36

Fig. 6-2-2 Relations between flare nut and flare seal surface

(2) Flare Connecting Procedures and Precautions

a) Make sure that the flare and union portions

do not have any scar or dust, etc.

b) Correctly align the processed flare surface

with the union axis.

c) Tighten the flare with designated torque by

means of a torque wrench. The tightening

torque for R410A is the same as that for

conventional R22. Incidentally, when the

torque is weak, the gas leakage may occur.

Table 6-2-7 Tightening torque of flare for R410A [Reference values]

Nominal Outer diameter Tightening torque

diameter (mm) N.m (kgf.cm)

1/4 6.35 14 to 18 (140 to 180)

When it is strong, the flare nut may crack and

may be made non-removable. When choosing

the tightening torque, comply with values

designated by manufacturers. Table 6-2-7

shows reference values.

NOTE:

When applying oil to the flare surface, be sure to use

oil designated by the manufacturer. If any other oil is

used, the lubricating oils may deteriorate and cause

the compressor to burn out.

Tightening torque of torque

wrenches available on the market

N.m (kgf.cm)

16 (160), 18 (180)

3/8 9.52 33 to 42 (330 to 420)

1/2 12.70 50 to 62 (500 to 620)

5/8 15.88 63 to 77 (630 to 770)

– 11 –

42 (420)

55 (550)

65 (650)

Page 13

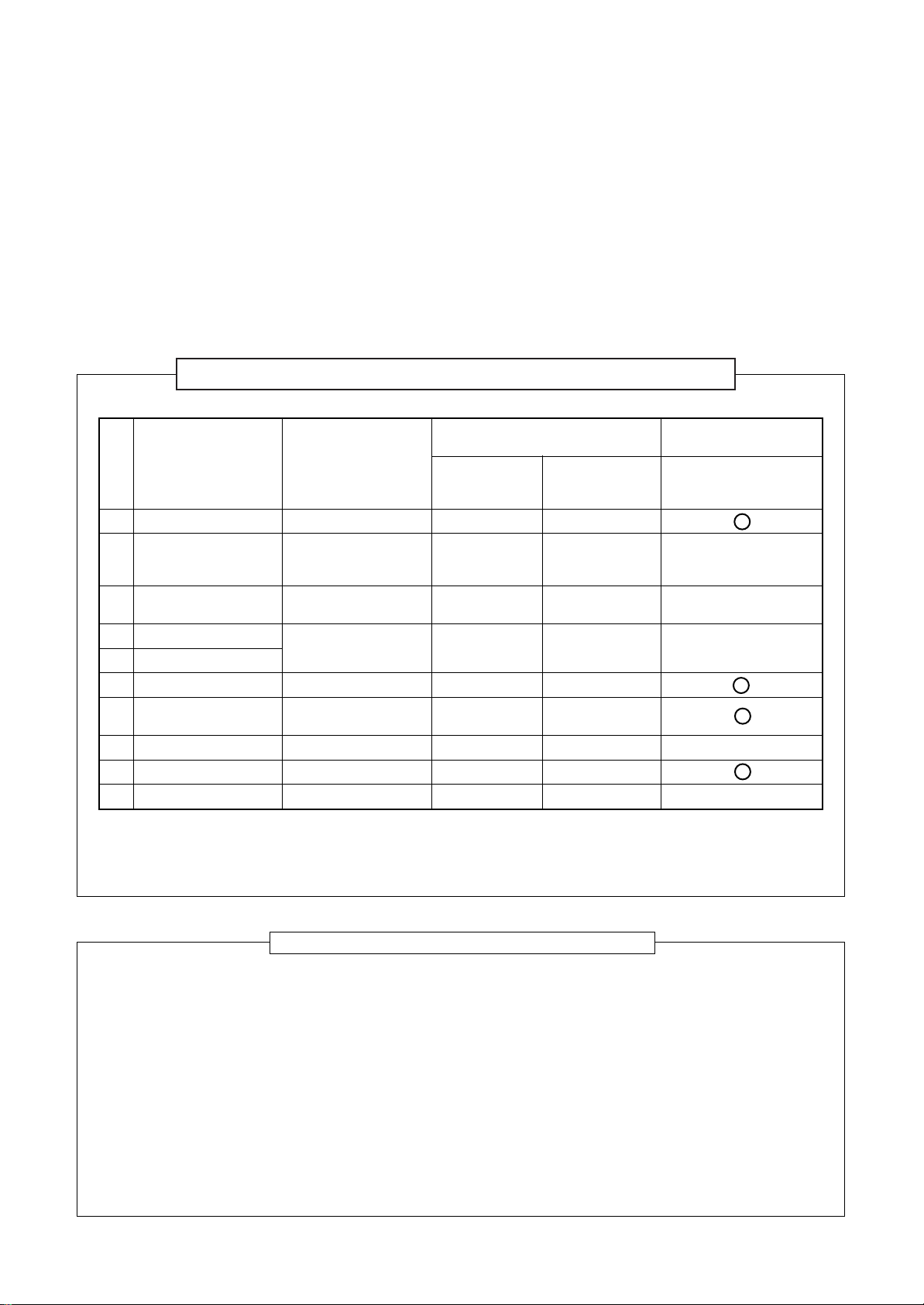

6-3. Tools

6-3-1. Required Tools

The service port diameter of packed valve of the outdoor unit in the air conditioner using R410A is changed to

prevent mixing of other refrigerant. To reinforce the pressure-resisting strength, flare processing dimensions and

opposite side dimension of flare nut (For Ø12.7 copper pipe) of the refrigerant piping are lengthened.

The used refrigerating oil is changed, and mixing of oil may cause a trouble such as generation of sludge,

clogging of capillary, etc. Accordingly, the tools to be used are classified into the following three types.

(1) Tools exclusive for R410A (Those which cannot be used for conventional refrigerant (R22))

(2) Tools exclusive for R410A, but can be also used for conventional refrigerant (R22)

(3) Tools commonly used for R410A and for conventional refrigerant (R22)

The table below shows the tools exclusive for R410A and their interchangeability.

Tools exclusive for R410A (The following tools for R410A are required.)

Tools whose specifications are changed for R410A and their interchangeability

No. Used tool

Flare tool

1

Copper pipe gauge for

adjusting projection

2

margin

3

Torque wrench

Gauge manifold

4

Charge hose

5

Vacuum pump adapter

6

Electronic balance for

7

refrigerant charging

Refrigerant cylinder

8

Leakage detector

9

Charging cylinder

10

Usage

Pipe flaring

Flaring by conventional

flare tool

Connection of flare nut

Evacuating, refrigerant

charge, run check, etc.

Vacuum evacuating

Refrigerant charge

Refrigerant charge

Gas leakage check

Refrigerant charge

air conditioner installation

Existence of Whether convennew equipment tional equipment

for R410A can be used

Ye s

Ye s

Ye s

Ye s

Ye s

Ye s

Ye s

Ye s

(Note 2)

R410A

(Note 1)

*

(Note 1)

*

X

X

X

X

X

X

X

Conventional air

conditioner installation

Whether new equipment

can be used with

conventional refrigerant

(Note 1)

*

X

X

X

X

(Note 1) When flaring is carried out for R410A using the conventional flare tools, adjustment of projection

margin is necessary. For this adjustment, a copper pipe gauge, etc. are necessary.

(Note 2) Charging cylinder for R410A is being currently developed.

General tools (Conventional tools can be used.)

In addition to the above exclusive tools, the following equipments which serve also for R22 are necessary

as the general tools.

(1) Vacuum pump

Use vacuum pump by

attaching vacuum pump adapter.

(2) Torque wrench

(3) Pipe cutter

(4) Reamer

(5) Pipe bender

(6) Level vial

(7) Screwdriver (+, - )

(8) Spanner or Monkey wrench

(9) Hole core drill (Ø65)

(10) Hexagon wrench

(Opposite side 4mm)

(11) Tape measure

(12) Metal saw

Also prepare the following equipments for other installation method and run check.

(1) Clamp meter

(2) Thermometer

(3) Insulation resistance tester

(4) Electroscope

– 12 –

Page 14

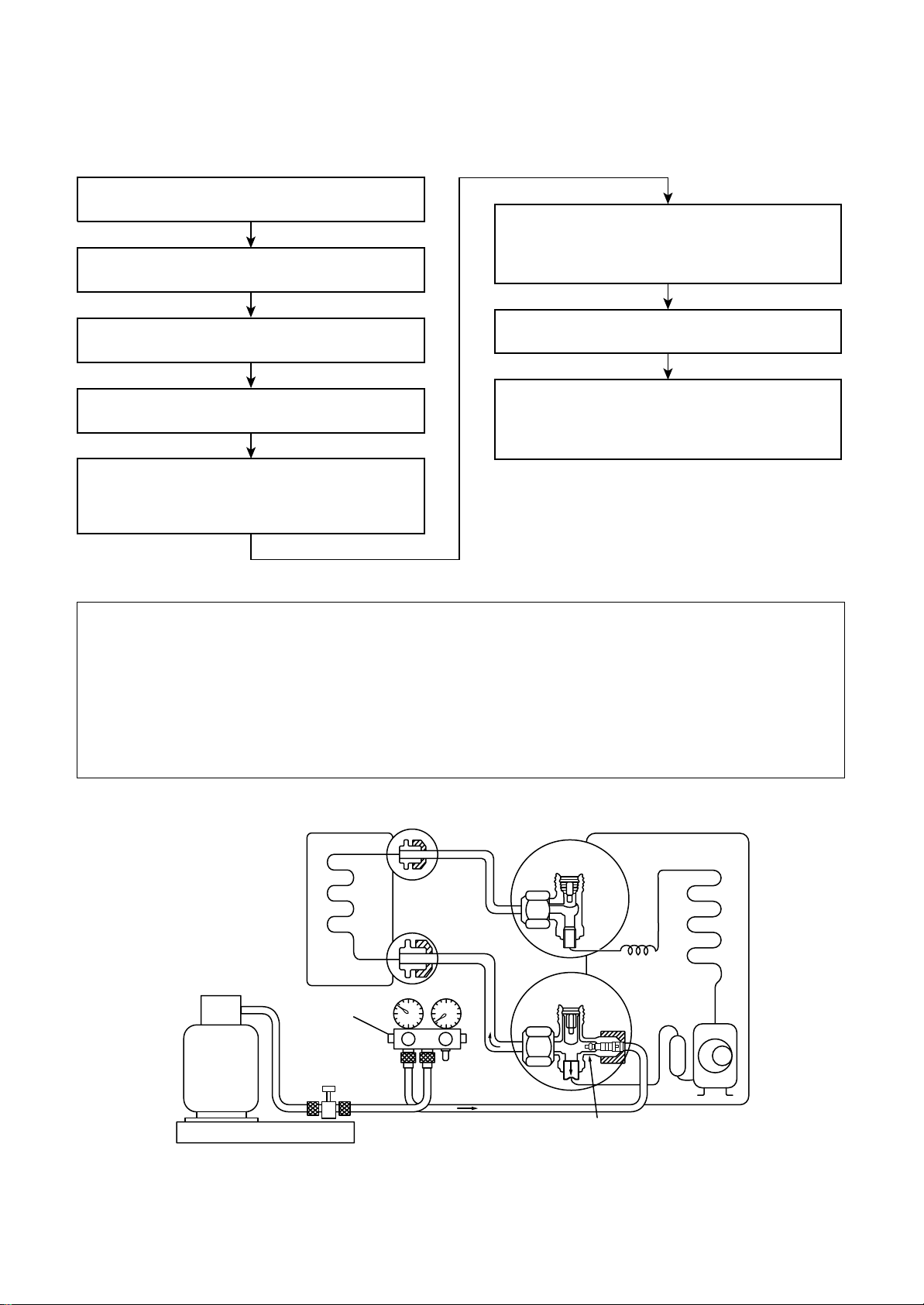

6-4. Recharging of Refrigerant

When it is necessary to recharge refrigerant, charge the specified amount of new refrigerant according to the

following steps.

Recover the refrigerant, and check no refrigerant

remains in the equipment.

Connect the charge hose to packed valve service

port at the outdoor unit's gas side.

When the compound gauge's pointer has indicated

- 0.1 Mpa (- 76 cmHg), place the handle Low in the

fully closed position, and turn off the vacuum pump's

power switch.

Connect the charge hose of the vacuum pump

adapter.

Open fully both packed valves at liquid and gas

sides.

Place the handle of the gauge manifold Low in the

fully opened position, and turn on the vacuum pump's

power switch. Then, evacuating the refrigerant in the

cycle.

Never charge refrigerant exceeding the specified amount.

1.

If the specified amount of refrigerant cannot be charged, charge refrigerant bit by bit in COOL mode.

2.

Do not carry out additional charging.

3.

Keep the status as it is for 1 to 2 minutes, and ensure

that the compound gauge's pointer does not return.

Set the refrigerant cylinder to the electronic balance,

connect the connecting hose to the cylinder and the

connecting port of the electronic balance, and charge

liquid refrigerant.

(For refrigerant charging, see the figure below.)

When additional charging is carried out if refrigerant leaks, the refrigerant composition changes in the

refrigeration cycle, that is characteristics of the air conditioner changes, refrigerant exceeding the

specified amount is charged, and working pressure in the refrigeration cycle becomes abnormally high

pressure, and may cause a rupture or personal injury.

(INDOOR unit)

Refrigerant cylinder

(With siphon pipe)

Check valve

Open/Close valve

for charging

Electronic balance for refrigerant charging

Fig. 6-4-1 Configuration of refrigerant charging

(Liquid side)

(Gas side)

– 13 –

(OUTDOOR unit)

Opened

Closed

Service port

Page 15

Be sure to make setting so that liquid can be charged.

When using a cylinder equipped with a siphon, liquid can be charged without turning it upside down.

It is necessary for charging refrigerant under condition of liquid because R410A is mixed type of refrigerant.

Accordingly, when charging refrigerant from the refrigerant cylinder to the equipment, charge it turning the

cylinder upside down if cylinder is not equipped with siphon.

[ Cylinder with siphon ] [ Cylinder without siphon ]

Gauge manifold

OUTDOOR unit

Refrigerant

cylinder

Gauge manifold

OUTDOOR unit

cylinder

Refrigerant

Electronic

balance

R410A refrigerant is HFC mixed refrigerant.

Therefore, if it is charged with gas, the composition of the charged refrigerant changes and the

characteristics of the equipment varies.

6-5. Brazing of Pipes

6-5-1. Materials for Brazing

(1) Silver brazing filler

Silver brazing filler is an alloy mainly composed

of silver and copper. It is used to join iron,

copper or copper alloy, and is relatively expensive though it excels in solderability.

(2) Phosphor bronze brazing filler

Phosphor bronze brazing filler is generally used

to join copper or copper alloy.

(3) Low temperature brazing filler

Low temperature brazing filler is generally called

solder, and is an alloy of tin and lead. Since it is

weak in adhesive strength, do not use it for

refrigerant pipes.

Fig. 6-4-2

Electronic

balance

Siphon

Phosphor bronze brazing filler tends to react

1.

with sulfur and produce a fragile compound

water solution, which may cause a gas

leakage. Therefore, use any other type of

brazing filler at a hot spring resort, etc., and

coat the surface with a paint.

2.

When performing brazing again at time of

servicing, use the same type of brazing filler.

6-5-2. Flux

(1) Reason why flux is necessary

1.By removing the oxide film and any foreign

matter on the metal surface, it assists the flow

of brazing filler.

2.In the brazing process, it prevents the metal

surface from being oxidized.

3.By reducing the brazing filler's surface tension,

the brazing filler adheres better to the treated

metal.

– 14 –

Page 16

(2) Characteristics required for flux

Nitrogen gas

cylinder

Pipe

Flow meter

M

Stop valve

From Nitrogen cylinder

Nitrogen

gas

Rubber plug

Nitrogen gas

cylinder

Pipe

Flow meter

M

Stop valve

From Nitrogen cylinder

Nitrogen

gas

Rubber plug

1.Activated temperature of flux coincides with

the brazing temperature.

2.Due to a wide effective temperature range, flux

is hard to carbonize.

3.It is easy to remove slag after brazing.

4.The corrosive action to the treated metal and

brazing filler is minimum.

5.It excels in coating performance and is harmless to the human body.

As the flux works in a complicated manner as

described above, it is necessary to select an

adequate type of flux according to the type and

shape of treated metal, type of brazing filler and

brazing method, etc.

(3) Types of flux

Noncorrosive flux

Generally, it is a compound of borax and boric

acid.

It is effective in case where the brazing temperature is higher than 800°C.

Activated flux

Most of fluxes generally used for silver brazing

are this type.

It features an increased oxide film removing

capability due to the addition of compounds

such as potassium fluoride, potassium chloride

and sodium fluoride to the borax-boric acid

compound.

(4) Piping materials for brazing and used braz-

ing filler/flux

6-5-3. Brazing

As brazing work requires sophisticated techniques,

experiences based upon a theoretical knowledge, it

must be performed by a person qualified.

In order to prevent the oxide film from occurring in

the pipe interior during brazing, it is effective to

proceed with brazing while letting dry Nitrogen gas

(N2) flow.

Never use gas other than Nitrogen gas.

(1) Brazing method to prevent oxidation

1.

Attach a reducing valve and a flow-meter to

the Nitrogen gas cylinder.

2.

Use a copper pipe to direct the piping material, and attach a flow-meter to the cylinder.

Apply a seal onto the clearance between the

3.

piping material and inserted copper pipe for

Nitrogen in order to prevent backflow of the

Nitrogen gas.

4.

When the Nitrogen gas is flowing, be sure to

keep the piping end open.

5.

Adjust the flow rate of Nitrogen gas so that it

is lower than 0.05 m³/Hr or 0.02 MPa (0.2kgf/

cm²) by means of the reducing valve.

6.

After performing the steps above, keep the

Nitrogen gas flowing until the pipe cools

down to a certain extent (temperature at

which pipes are touchable with hands).

Remove the flux completely after brazing.

7.

Copper - Copper

Copper - Iron

1.

2.

3.

4.

Piping

material

Iron - Iron

Used brazing

filler

Phosphor copper

Silver

Silver

Used

flux

Do not use

Paste flux

Vapor flux

Do not enter flux into the refrigeration cycle.

When chlorine contained in the flux remains

within the pipe, the lubricating oil deteriorates.

Therefore, use a flux which does not contain

chlorine.

When adding water to the flux, use water

which does not contain chlorine (e.g. distilled

water or ion-exchange water).

Remove the flux after brazing.

Fig. 6-5-1 Prevention of oxidation during brazing

– 15 –

Page 17

7-1. Indoor Control Circuit

7. INDOOR UNIT CONTROL

Max. 8 units are connectable.*1

*1 When group and twin combination.

main remote controller shal be connected

follower indoor unit

*2 Weekly timer is not connectable to the

sub remote controller.

Indoor unit

#1 Header unit

Indoor control P.C. board (MCC-1510)

Central control

remote controller

(Sold separatrly)

Reciver and Display P.C board

(MCC-819)

Reciver unit

Display LED

U3

U4

Main (Sub) master remote controller

(Wired)

Display

LCD

Display

LED

DC20V

DC12V

DC5V

Buzzer

CPU

Remote

controller

communication

circuit

Central control

communication

circuit

Driver

Function setup

Key switch

CN2 CN1

DC5V

Power circuit

Sold separatrly Sold separatrly

AB

Remote

controller

communication

circuit

CPU

Driver

H8/3039

Weekly timer

Display

LCD

2

*

Powe r

circuit

EEPROM

TA sensor

TC sensor

TCJ sensor

LCD

driver

CPU

DC5V

Secondary

battery

Follower unit

AB

#2

Same as

the left

Function setup

Key switch

#3

AB

Same as

the left

Louver

motor

Indoor

fan

motor

DC280V

Power

circuit

DC15V

Outdoor unit

Fan motor

control

circuit

123

3

12

Outside

output

Run

Warning

Ready

Thermo. ON

Cool

Heat

Fan

AC

synchronous

signal input

circuit

Serial

send/

receive

circuit

HA

Wireless

remote

signal

Setting

(A/B)

123

Outdoor

unit

123

Outdoor

unit

– 16 –

Page 18

INDOOR UNIT CONTROL CIRCUIT (Continued)

7-2. Control Specifications

NO.

1

Control at

power-on reset

Operation mode

2

switching

Item

Overview of specifications

(1) Identification of outdoor unit

Identifies outdoor unit at power-on reset, and switches control

according to the identification result.

(2)

Setting of indoor unit fan speed and adjustment of air flow direction

Switches indoor unit fan speed, setting of air flow direction

adjustment, etc. based on EEPROM data.

(1) Switches operation mode according to mode select instruction

from remote controller.

R/C instructions

OFF

FAN

COOL

DRY

HEAT

AUTO

Turns OFF air conditioner

“Fan only” operation

Cooling operation

Dehumidifying operation

Heating operation

• Selects COOL or HEAT mode

Outline of control

automatically according to Ta, Ts, and To.

• The first operation is as follows according

to Ta. (COOL thermo sensor continues

OFF (FAN mode with set fan speed) within

the range of Ts +α-1<Ta< Ts +α+1.)

COOL

operation

FAN mode with

set fan speed

Ta

( )

+1.0

Ts+

Remarks

The “PREPARING” lamp

lights during initial setting

(model recognition) after

power-on reset.

Fan speed, adjustment of

air flow direction

Ta : Room temperature

Ts : Set temperature

To : Outside air temperature

Room temperature

3

control

-1.0

HEAT

operation

• α is corrected according to outside air

temperature.

Outside air temp. Corrected value (α)

No To 0 K

>

To

24°C -1 K

=

>

24>To

18°C 0 K

=

To<18°C +1 K

Abnormal To 0 K

(2) Operation instruction permission mode

HEAT and AUTO modes are not available for COOL only models.

When instruction is issued from wireless remote controller in the

HEAT or AUTO mode, it is indicated by a reception sound “pi, pi”

and by alternate blinking of “TIMER” and “PREPARING” lamps. To

cancel this alternate blinking, issue an instruction of mode other

than HEAT or AUTO.

(1) Adjustment range Remote controller set temperature (°C)

COOL/DRY HEAT AUTO

Wired type 18 - 29 18 - 29 18 - 29

Wireless type 17 - 30 17 - 30 17 - 30

* When use of remote controller sensor is set (with DN32), even

when sensor value is within the above range in HEAT or AUTO

mode, the thermo sensor turns OFF when Ta sensor value

exceeds 35 °C.

k=deg

– 17 –

Page 19

NO.

Room temperature

3

control

Capacity auto

4

control

(GA control)

Item

Overview of specifications

(2) The set temperature for HEAT operation can be corrected by code

No. 06.

Set data 0246

Correction of set temp. +0°C +2°C +4°C +6°C

Factory setting

Set data 2

* When use of remote controller sensor is set (with DN32), no

correction is performed.

(1) Issues instruction of operating frequency to outdoor unit according

to the difference between Ta and Ts.

(2) COOL operation

Calculates room temp. difference between Ta and Ts as well as

room temp. variation every 90 seconds to find correction value of

specified operating frequency and to correct the current operating

frequency.

Ta(n)–Ts(n) : Room temp. difference n : Number of detection times

Ta(n-1)–Ta(n) : Room temp. variation n–1 : Number of detection times

(90 seconds before)

(3) HEAT operation

Calculates room temp. difference between Ta and Ts as well as

room temp. variation every 60 seconds to find correction value of

specified operating frequency and to correct the current operating

frequency.

Ts(n)–Ts(n) : Room temp. difference n : Number of detection times

Ta(n)–Ta(n_1) : Room temp. variation n–1 : Number of detection times

(60 seconds before)

(4) DRY operation

The frequency correction control is the same as that for COOL

operation.

However, the maximum frequency is limited to S6 or so.

Note) When LOW fan speed is set, the maximum frequency is

limited to SB or so.

Remarks

Heat intake temperature

shift

(When unit’s temperature

sensor is used)

COOL/HEAT/

5

AUTO control

(1) Switching between COOL and HEAT is determined based on the

following control.

Ta

(˚C)

+1.5

Tsc

or

Tsh

COOL

(COOL ON)

(COOL OFF)

-1.5

After 10 minutes pass from

thermo sensor OFF,

operation mode changes

from HEAT (thermo sensor

OFF) to COOL if Ta exceeds

Tsh +1.5.

( ) shows an example of

HEAT

COOL ON/OFF.

After 10 minutes pass from

thermo sensor OFF,

operation mode changes

from COOL (thermo sensor

OFF) to HEAT if Ta lowers

below Tsc -1.5.

(2) The GA control after determination of operation mode follows the

description in No. 4.

(3) The room temperature control and temperature correction follow

the descriptions in No. 3 and No. 15.

Tsc : COOL set temp.

Tshc : HEAT set temp. +

room temp. control/

correction

– 18 –

Page 20

INDOOR UNIT CONTROL CIRCUIT (Continued)

NO.

6

Fan speed control

Item

Overview of specifications

(1) A fan speed HH (quick high), H (high), L (low) or AUTO is selected

according to the instruction from remote controller for FAN mode

operation.

(2) Fan speed is switched according to the difference between Ta and

Ts in the AUTO mode.

[Cooling]

Ta (˚C)

+3.0

+2.5

+2.0

+1.5

+1.0

+0.5

Tsc

-0.5

HH

(HH)

H+(HH)

H(HH)

L+(H+)

L(H)

L(H)

L(L+)

A

B

C

D

E

F

G

• The fan speed control is the same for temperature setting by remote

controller or the unit.

• Once fan speed is changed, it remains unchanged for 3 minutes

unless different fan speed is selected by instruction.

• At the beginning of cooling, a falling gradient (higher fan speed) is

selected.

• When the temperature difference between Ta and Ts is on a

threshold line, fan speed does not change.

• ( ): Auto cooling

Remarks

HH>H+>H>

L+>L>UL

Wireless type allows HH,

H+, H, L+, L, and AUTO.

HH

H+

H

L+

L

[Heating]

Ta (˚C)

(-0.5)

(0)

(+0.5)

(+1.0)

(+1.5)

(+2.0)

-1.0

Tsh

+1.0

+2.0

+3.0

+4.0

L( L+)

L+(H)

H(H+)

H+

(HH)

HH

(HH)

E

D

C

B

A

( ): Temperature setting by remote controller

Other than ( ): Temperature setting by unit

• Once fan speed is changed, it remains unchanged for one minute

unless different fan speed is selected by instruction.

• At the beginning of heating, a rising gradient (higher fan speed) is

selected.

• When the temperature difference between Ta and Ts is on a

threshold line, fan speed does not change.

• ( ): Auto heating

• Fan speed is switched to a higher level when Tc reaches 60 °C.

Tc : Indoor unit heat

exchange sensor

temp.

– 19 –

Page 21

NO.

6

Fan speed control

Item

COOL

HH

H+

H

L+

L

UL

Overview of specifications

HEAT

HH

AP40-56

1220

AP63

1180

H+

H

1140

1120

1060

L+

L

1060

990

940

UL

500

1360

1300

1240

1200

1120

1120

1020

970

500

Remarks

AP71-80

1480

1340

1320

1300

1200

1200

1100

1040

500

7

Cool air prevention

control

(3) When thermo sensor turns OFF during heating, the fan speed

mode becomes UL (weak).

(4) When Ta is 25 °C or above at the beginning of HEAT operation or

when canceling defrost mode, H or HH mode continues for one

minute from the time when Tc enters zone E shown in the figure in

No.7 below.

(5) The HH fan speed for auto cooling/heating is set to a speed higher

than that for normal cooling/heating. However, it varies depending

on the temperature difference of Tc during auto heating.

Tc

(˚C)

47

HH+

42

HH

(1) Performs indoor unit fan control in the HEAT mode according to

the Tc (or Tcj) sensor detect temperature. The maximum speed is

limited as shown below.

Tc

Tcj

(˚C)

36

34

32

30

24

20

HH

H

L

UL

OFF

Shifts Tc control value by +6 °C

during defrosting. However, zone

B is regarded as zone C after 6

minutes pass from the startup of

compressor.

Zone E

Zone D

Zone C

Zone B

Zone A

“HEAT PREPARING”

indication

Fan speed select setting

by remote controller takes

precedence in zones D

and E.

“HEAT PREPARING” is

indicated in zones A and

B.

– 20 –

Page 22

INDOOR UNIT CONTROL CIRCUIT (Continued)

NO.

8

Freezing

prevention control

(low-temp.

release)

9

High-temp. release

control

Item

Overview of specifications

(1) Performs the following operation control in the COOL or DRY

mode according to the Tc (or Tcj) sensor detect temperature.

When zone J in the figure below is detected for 6 minutes, the

specified operating frequency is decreased from the actual

operating frequency, and the specified operating frequency is

changed every 30 seconds in zone J.

Timer count stops and is maintained in zone K.

Timer count is cleared to restore normal operation when zone I is

detected.

If the specified operating frequency becomes SO due to

continuation of zone J, return temperature A is raised from 5 to

12 °C, and operation with L fan speed continues until zone I is

detected.

Tc(˚C)

I5

2

J

A

K

If 4-way valve cannot be switched during heating and the following

conditions become true, freezing prevention control is performed.

(However, zone J entering control temperature is changed from 2

to -5 °C.)

[Conditions]

The following A or B becomes true after 5 minutes pass from

operation start.

<

A Tcn

B Tcn<Tc(n–1)–1 and Tcn

Tc(n–1)–5

=

<

Ta<5°C

=

(1) Performs the following operation control in the HEAT mode

according to the Tc (or Tcj) sensor detect temperature.

•

When zone M is detected, the specified operating frequency is

decreased from the actual operating frequency, and the specified

operating frequency is changed every 30 seconds in zone M.

• The specified operating frequency is maintained in zone N.

• When zone L is detected, the specified operating frequency is

returned by approx. 6 Hz every 60 seconds.

Factory setting

Control temp. (°C)

AB

Tc

Tcj

(˚C)

A

56 (54) 52 (52)

B

L

Remarks

Tcj : Indoor unit heat

exchange sensor

temp.

Tcn :

Tc after 5 minutes

from operation start

Tc (n-1):

Tc at operation start

This control is disabled for

twin follower indoor units.

M

N

Note) At the beginning of operation or when Tc (or Tcj) lowers below

30 °C after operation start, values (54) and (52) in the table are

used as control temperature.

10 Runs indoor unit fan in L (low) mode for about 30 seconds after HEAT

Residual heat

removal

operation stops to remove residual heat.

– 21 –

Even when the thermo is

set to OFF, the control is

implemented in the same

way.

Page 23

NO.

11

Item

Flap control

Overview of specifications

(1) During the first operation after power on, flap position is controlled

automatically according to operation mode (COOL/HEAT).

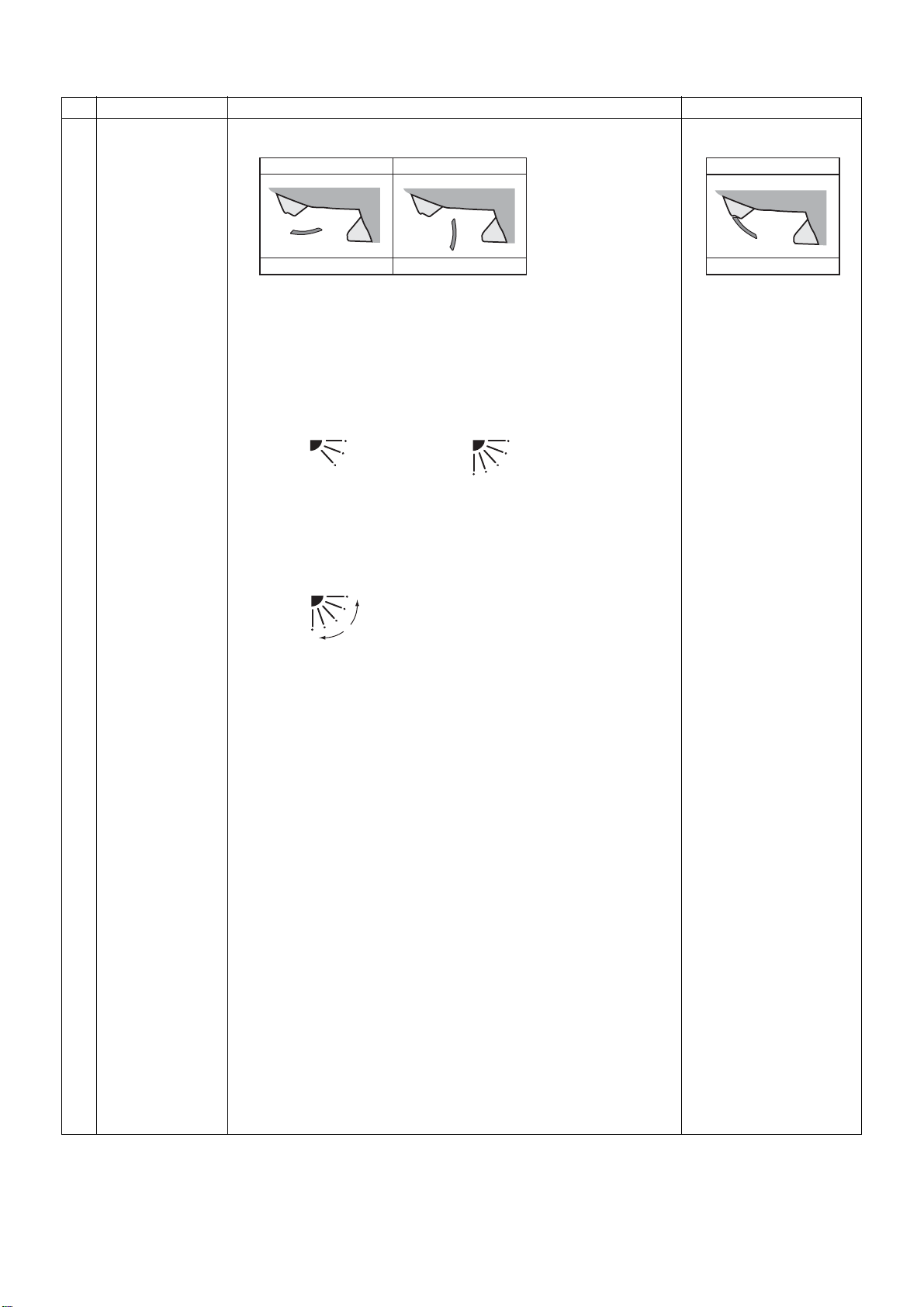

Cooling Heating

Remarks

Louver angle: 0 °C (full

close)

Full close

45°

103°

(2) When louver position is controlled by remote controller, the unit’s

microcomputer memorizes the position for use in the next

operation.

* The memorized louver position is cleared when power is turned

off, and returns to the state of (1) above.

(3) Flap position setting

• Flap position can be set within the range below.

COOL/DRY HEAT/FAN

• Flap position can be set collectively or individually in the group

twin or triple operation mode. (Wireless remote controller allows

individual setting only.)

(4) Swing setting

• Flap moves within the range below.

All operation modes

• Flap swing range can be set collectively or individually in the

group twin or triple operation mode. (Setting by wireless remote

controller is disabled when the main remote controller is used.)

(5) When air conditioner operation stops, flap closes automatically. It

keeps its position in the event of an alarm.

(6) Flap tilts upward automatically during preparation for heating.

(7) In the twin or triple operation mode selected by wireless remote

controller, swing setting interlocks with the header indoor unit. If

this setting is transmitted from a follower indoor unit, operation

does not change with a reception sound “pi, pi, pi” if operation

mode differs between header unit and follower unit.

0°

Alarm : A code number

(except F08 and

L31) appears on

the remote

controller and the

indoor unit stops.

– 22 –

Page 24

INDOOR UNIT CONTROL CIRCUIT (Continued)

NO.

12

Item

HA control

Overview of specifications

(1) When connected to a remote control system (tele-control or

remote on/off interface), operation ON/OFF can be controlled by

the HA signal input.

(2) Outputs operation ON/OFF status to the HA output terminal.

(3) HA signal input/output specifications conform to the JEMA

standard.

Remarks

A connector (separately

available) is required

when using the HA

terminal CH61 for remote

ON/OFF control.

When group operation is

in use, connect the

connector to either header

or follower indoor unit.

13

Filter sign

indication

(unavailable for

wireless type)

(1) Transmits filter replacement signal to remote controller for

indication on the LCD when accumulated operation hours of

indoor unit fan exceeds the specified time (150 hours).

(2) Clears accumulation timer upon receiving the filter reset signal

from remote controller. At this time, when the specified time has

already passed, the accumulated time is reset and the filter sign

disappears from the LCD.

“FILTER” lamp ON

– 23 –

Page 25

NO.

14

15 (1) Power-saving operation is available in the AUTO mode.

16

Item

Central control

mode switching

Power-saving

control

Maximum

frequency limit

control

(1) The scope of operation by remote controller on the indoor unit

side can be switched by the setting of remote controller.

(2) Scope of operation by remote controller on the indoor unit side

[Individual] : All settings and ON/OFF operations are available.

[Central 1] : ON/OFF operations are disabled.

[Central 2] : ON/OFF operations, operation mode selection, and

[Central 3] : Operation mode selection and temperature setting

[Central 4] : Operation mode selection is disabled.

(2) The set temperature is corrected using various sensor data within

the range where comfort is maintained.

(3) By using various sensor data including room temp. Ta, outside air

temp. To, fan speed, and indoor unit heat exchange sensor temp.

Tc, 20-minute data is averaged to calculate a set temperature

correction value.

(4) The set temperature is corrected every 20 minutes with the

following shift range.

Cooling : +1.5 to -1.0K

Heating : -1.5 to +1.0K

(1) This control is performed when AUTO mode is selected.

(2) COOL mode: When To is under 28 °C, the control is as follows.

Ta(˚C)

+4

+3

Tsc

Overview of specifications

temperature setting are disabled.

are disabled.

Normal control

Maximum frequency is

limited to the rating of cooling.

Remarks

No indication

“CENTRAL CONTROL”

lamp ON

“CENTRAL CONTROL”

lamp ON

“CENTRAL CONTROL”

lamp ON

“CENTRAL CONTROL”

lamp ON

When wired remote

controller is not used,

operation range is the

same as above though

lamp indication remains

unchanged.

If an unavailable operation

mode is transmitted from

wireless remote controller,

it is indicated with a

reception sound “pi, pi, pi,

pi, pi”.

(3) HEAT mode: When To is over 15 °C, the control is as follows.

Ta(˚C)

Tsh

-3

-4

Normal control

Maximum frequency is limited

to the rating of heating.

– 24 –

Page 26

INDOOR UNIT CONTROL CIRCUIT (Continued)

7-3. P. C. Board of Indoor Unit

MCC-1510

HA (T10)

CN61, DC12V

Option output

CN60, DC12V

CHK

CN71, DC5V

DISP

CN72, DC5V

External alarm input

CN80, DC12V

EXCT

CN73, DC5V

R/C power LED

D203

TA sensor

CN104, DC5V

Remote controller

CN41, DC20V

TC sensor TCJ sensor

CN101, DC5V CN102, DC5V D02

Microcomputer

run LED

EEPROM

IC10 CN67, AC200V

Indoor unit - outdoor unit wire

Optional power supply

CN309, AC200V

Central control

CN40, DC

Terminating resistor

provided/not provided

Remote controller A/B

selection

SW01

5V

FAN DRIVE

CN32, DC12V

Indication output/wireless receptionDC fan input/outputLouver

CN213, DC5VCN210CN33, DC12V

– 25 –

Page 27

7-4. Optional Onboard Connector Specifications

Description

Factory setting OFF: No terminating resistor ON for one unit when performing

central control by custom air conditioner only.

Factory setting OFF: Remote controller A

Specification

OFF: No terminating resistor

ON: Terminating resistor provided

OFF: R/C A, ON: R/C B

Bit 1

Pin No.

Connector No.

Bit 2

SW01

.

Single operation setting is performed with VENT button on the remote controller

(DN=31)

Factory setting: Interlocking with indoor unit operation ON/OFF

*

HA ON/OFF input (J01: input/no input=pulse (factory setting) / static input

changeover)

Enables/disables operation OFF by remote controller using the R/C prohibition

input.

ON during operation (answerback of HA)

DC12V

A

CN32

ON/OFF input

Output

B

A

CN61

OV (COM)

R/C prohibition input

Operation ON output

B

C

DEFABCDEFAB

ON during alarm

ON while outdoor unit is defrosting

DC12V (COM)

Alarm output

DC12V (COM)

Defrost output

CN60

ON when thermo sensor is ON (compressor ON)

ON in cooling mode (COOL/DRY/auto cooling)

ON in heating mode (HEAT/auto heating)

ON while indoor unit fan is ON

Factory setting: External alarm input setting (DN: 2A=2)

Indicates alarm code “L30” when an alarm continues for one minute and

performs forcible operation OFF.

(DN: 2A=1) Performs option alarm input control (indication of unit protection

attached externally).

* Remote control performs setting of option alarm input controller.

Used for checking indoor unit operation. (Outputs specified operations such as indoor

Thermo sensor ON output

COOL output

HEAT output

FAN output

DC12V (COM)

DC12V (COM)

Filter/option/external alarm input

C

CN80

Check mode input

ABA

CN71

unit fan speed H, without communication with outdoor unit or remote controller.)

DISP mode enables communication only between indoor unit and remote

controller. (at power on)

Timer short-circuited (always)

Turns OFF indoor unit thermo sensor forcibly.

OV

Display mode inputOVDemand input

B

CN72

OV

A

B

CN73

Function

Terminating resistor

Remote controller A/B

Ventilation output

HA

Option output

– 26 –

External

alarm input

CHK Operation

check

DISP DISP mode

EXCT Demand

Page 28

9

8. Troubleshooting

1. Guide to Troubleshooting

[Wired Remote Controller Type]

(1) Before starting troubleshooting

(a) Necessary tools/measuring equipment

• Phillips screwdrivers, flat-blade screwdrivers, wrenches, pliers, nipper, etc.

• Multimeter, thermometer, pressure gauge, etc.

(b) Precheck

A The following operations are normal.

1) Compressor does not work.

• Is 3-minute delay operation functioning? (for 3 minutes after compressor OFF)

• Is thermo sensor OFF?

• Is FAN mode or TIMER mode operation going?

• Is water overflow alarm detected?

• Is high outside air temperature operation control working during heating?

2) Indoor unit fan does not work.

• Is cool air prevention control working during heating?

3) Outdoor unit fan does not work or its fan speed changes.

• Is high-temp. release operation control working during heating?

• Is low outside air temperature operation control working during cooling?

• Is defrosting operation going?

4) Operation ON/OFF by remote controller is disabled.

• Is any remote controller or external control working?

• Is auto address setting in progress?

(At t he first power on or when indoor unit address is changed, operation control is disabled for

about 5 minutes after power on.)

B Are all cables/wiring set in the initial state?

C Are indoor unit and remote controller connected correctly?

(2) Troubleshooting procedure

When an error occurs, check the unit in the following procedure.

Error Check indication of check code Check faulty location and parts

(Note) Other than the check items in the table, malfunction or wrong diagnosis of microcomputer

due to effect of power or external noise is considered. If there is any source of noise, shield

the remote controller wiring.

→→

[Wireless Remote Controller Type]

(1) Before starting troubleshooting

(a) Necessary tools/measuring equipment

• Phillips screwdrivers, flat-blade screwdrivers, wrenches, pliers, nipper, etc.

• Multimeter, thermometer, pressure gauge, etc.

(b) Precheck

A The following operations are normal.

1) Compressor does not work.

• Is 3-minute delay operation functioning? (for 3 minutes after compressor OFF)

• Is thermo sensor OFF?

• Is FAN mode or TIMER mode operation going?

• Is high outside air temperature operation control working during heating?

2) Indoor unit fan does not work.

• Is cool air prevention control working during heating?

– 27 –

Page 29

3) Outdoor unit fan does not work or its fan speed changes.

• Is high-temp. release operation control working during heating?

• Is low outside air temperature operation control working during cooling?

• Is defrosting operation going?

4) Operation ON/OFF by remote controller is disabled.

• Is forcible operation OFF mode set?

• Is any remote controller or external control working?

• Is auto address setting in progress?

(At the first power on or when indoor unit address is changed, operation control is disabled for

about 5 minutes after power on.)

B Are all cables/wiring set in the initial state?

C Are indoor unit and receiver unit connected correctly?

(2) Troubleshooting procedure

When an error occurs, check the unit in the following procedure.

Error Check indication of lamps Check faulty location and parts

→→

(Note) Other than the check items in the table, malfunction or wrong diagnosis of microcomputer

due to effect of power or external noise is considered. If there is any source of noise, shield

the signal lines.

(a) Outline of judgment

The following describes the primary judgment of locating faulty unit (indoor unit or outdoor unit). (In

the case of group control operation, the header unit also indicates errors of follower unit by lamp.)

Judging from lamp status of indoor unit

The indoor unit monitors the operating status of air conditioner. When the protection circuit is

activated, the indoor unit indicates the following self-diagnosis contents.

: OFF : ON : Blinking (0.5 seconds interval)

Lamp indication

TIMER PREPARINGOPERATION

All OFF

TIMER PREPARINGOPERATION

Blinking

TIMER PREPARINGOPERATION

Check code

–

E01

E02

E03

E08

E09

E18

E04

Power OFF

Poor connection/contact between receiver/indication unit and

indoor unit control board

Reception error

Transmission error

Communication error

Duplication of indoor unit No.

Duplication of remote controller header

Poor connection/contact between indoor units or indoor unit

power OFF

(Communication error between header and follower indoor

units or between twin header and follower indoor units)

Wrong connection or poor contact between indoor unit and

outdoor unit

(Communication error between indoor and outdoor units)

Possible causes

Wired remote

controller

Wrong connection or

poor contact between

wired remote controller

and indoor unit

Invalid setting

Blinking

TIMER PREPARINGOPERATION

Alternate blinking

P12

Failure of indoor unit DC fan (Protection device of indoor unit is

activated.)

– 28 –

Page 30

Troubleshooting (Continued)

Outline of judgment (Contenued)

Lamp indication Check code

TIMER PREPARINGOPERATION

Alternate blinking

TIMER PREPARINGOPERATION

Alternate blinking

TIMER PREPARINGOPERATION

Alternate blinking

TIMER PREPARINGOPERATION

P03

P04

P19

P22

P26

P29

P31

F01

F02

F10

F04

F06

F08

F29

Possible causes

Abnormal outdoor unit discharge

temperature

Outdoor u

nit high-pressure system error

(*) Protection device

of outdoor unit is

activated.

Four-way valve system error (judged by indoor unit)

Outdoor unit: Malfunction of fan

Outdoor unit: Inverter Idc activated

Outdoor unit: Position detect error

Protection device of

outdoor unit is activated.

Header and follower indoor units in the group are not running

due to the following alarm.

(Alarm code: E03, L03, L07, L08)

Heat exchange sensor (TCJ) error

Heat exchange sensor (TC) error

Indoor unit sensor error

Room temperature sensor (TA) error

Discharge temperature sensor (TD) error

Temperature sensor (TE, TS) error

Outside air temperature sensor (TO) error

(*) Outdoor unit

sensor error

Failure of indoor unit EEPROM

Simultaneous blinking

TIMER PREPARINGOPERATION

Blinking

TIMER PREPARINGOPERATION

Simultaneous blinking

H01

H02

H03

H06

L03

L07

L08

L09

Compressor breakdown

Compressor locking

Current detect circuit error

Outdoor unit low-pressure system error

Duplication of header indoor unit

Group connection indoor unit for

→

individual indoor unit

Group address not set

No setting (indoor unit capacity)

(*) Outdoor unit

Auto address

*If group configuration

or address at power on

is invalid, the unit

enters address setting

mode automatically.

TIMER PREPARINGOPERATION

L20

L29

L30

L31

Duplication of indoor unit collective address

Other errors of outdoor unit (*)

External interlock error

Phase sequence error

Simultaneous blinking

(*) Check code detected by outdoor unit is a typical example. It varies with outdoor unit of combination.

For details, see the Service Guide of applicable outdoor unit.

compressor

system error

Others

– 29 –

Page 31

Others (Excluding check code)

Lamp indication Check code

TIMER PREPARINGOPERATION

Simultaneous blinking

TIMER PREPARINGOPERATION

Alternate blinking

–

–

Trial operation in progress

Invalid setting

(Auto cooling/heating setting for auto cooling/heating

unavailable unit or heating setting for cool only unit)

Possible causes

Error mode detected by remote controller or central controller

Diagnosis function

Check code

No

indication

(remote

controller

disabled)

E01

*2

E02

E09

L20

Central

controller

L20

–

*3

Central

controller

(Transmission)

C05

(Reception)

C06

–

Central

controller

P30/b7

*2

No check code can be indicated by wired remote controller. (Normal operation of air conditioner cannot be controlled by wired remote controller.)

Check codes are indicated by the lamps for wireless models.

*3 This is an error related to communication of remote controller (A, B) or central control system (TCC-LINK U3, U4).

Remote controller indicates E01, E02, E03, E09, E18 or no code according to situation.

Possible causes

No communication with

header indoor unit

Remote controller is not

connected correctly.

Indoor unit is not powered

on.

Auto address setting is not

completed.

No communication with

header indoor unit

Disconnection between

remote controller and header

indoor unit (detected by R/C)

Signal transmission error

to indoor unit (detected by

R/C)

Multiple remote controller

headers (detected by R/C)

Duplication of indoor unit

collective address during

communication of central

control system

(detected by indoor unit/

central controller)

Failure of central control

communication circuit

(detected by central

controller)

Failure of indoor unit group

follower unit.

Air conditioner status

OFF

OFF (auto reset)

*Operation

continues under

central control

OFF (auto reset)

*Operation

continues under

central control

OFF (Follower R/C

continues

operation)

OFF (auto reset)

Operation

continues (following

R/C)

Continue/OFF

(depending on

situation)

Conditions

–

Indicated when an

error is detected

Indicated when an

error is detected

Indicated when an

error is detected

Indicated when an

error is detected

Indicated when an

error is detected

Indicated when an

error is detected

Judgment and action

Failure of remote controller power

supply or indoor unit EEPROM

1.Check remote controller wires.

2.Check remote controller.

3.Check indoor unit power wiring.

4.Check indoor unit P. C. board.

5.Check indoor unit EEPROM and

insertion into socket.

Auto address repetition occurs.

...

Remote controller signal reception error

1.Check remote controller wires.

2.Check remote controller.

3.Check indoor unit power wiring.

4.Check indoor unit P. C. board.

Remote controller transmission error

1.

Check remote controller transmitter.

... Replace remote controller.

1.

Check for multiple remote

controller headers.

... One header only, others are

follower R/C.

1.Check central control network

address setting.

1.Check communication line,

wrong connection, and indoor

unit power supply.

2.Check communication circuit

(U3, U4, XY terminals).

3.Check central controller

(including central control R/C).

4.Check terminating resistors

(TCC-LINK).

Check the unit's check code with

remote controller

– 30 –

Page 32

Troubleshooting (Continued)

Check Code Table (Indoor Unit)

Operation

continuation

A/C operation

Auto

reset

–

Operation

continuation

Auto

reset

–

A/C operation

–

–

A/C operation

Operation

Auto

continuation

reset

–

–

–

–

–

–

–

–

Description of failures

No signal from remote controller (no communication with central controller system)

When indoor unit – out door unit serial communication is abnormal

When same address as mine is detected

When communication between main motor microcomputers is abnormal

When communication between header and follower indoor units is disabled

When open-circuit or short-circuit of TCJ is detected

When open-circuit or short-circuit of TC is detected

Main faulty location

Indoor unit – R/C communication error

Indoor unit – out door unit serial communication error

Duplication of indoor unit address

Communication error between indoor unit MCUs

Communication error between header and follower indoor units

Indoor unit heat exchange sensor TCJ

Indoor unit heat exchange sensor TC

When open-circuit or short-circuit of TA is detected

Failure of EEPROM (Other errors are also detected in some cases.

Auto address repeated with no other errors.)

When multiple header units exist in the group

When there is at least one group connection indoor unit in individual indoor unit

When indoor group address is not set

Indoor unit room temp. sensor TA

Indoor unit other boards

Duplication of indoor group header unit setting

Group line in individual indoor unit

Indoor group address not set

Indoor unit capacity is not set.

Duplicated central control refrigerant line address is set.

Alarm stop by external alarm input (CN80)

When indoor unit AC fan alarm is detected (Fan motor thermal relay is activated.)

When float switch is turned on

When indoor unit DC fan alarm (overcurrent, locking, etc.) is detected

When an alarm is detected during heating due to temperature drop of

heat exchange sensor

Follower units in the group are disabled due to alarm (E03/L03/L07/L08) of header unit

Indoor unit capacity not set

Duplication of central control refrigerant line address

External alarm input into indoor unit (interlock)

Indoor unit AC fan

Indoor unit water overflow

Indoor unit DC fan

Four-way valve system

Other indoor unit errors

Description of failures

When signals cannot be received from indoor unit or when header R/C is

not set (including two R/Cs)

When signal transmission to indoor unit is disabled

When two remote controllers are set as header by double R/C control

(Header unit stops alarm, and follower continues operation.)

Main faulty location

No header R/C, R/C reception error

R/C transmission error

Duplication of header R/C

:When this alarm is detected before checking group configuration and address at power on, the unit enters auto address setting mode automatically.

:When this alarm is detected before checking group configuration and address at power on, the unit enters auto address setting mode automatically.

Description of failures

When transmission of central control signals is disabled or when there

are multiple central controllers with same address (AI-NET)

Main faulty location

Central control system transmission error

When signal transmission to indoor unit is disabled

A device connected to general equipment control interface (for TCC-

LINK/AI-NET only) is abnormal.

Group follower unit is abnormal. (R/C indicates unit No. and details.)

Central control system reception error

General equipment control I/F total alarm

Group follower unit error

Lamp indication

ON, Blinking, OFF, Alternate: Two LEDs blink alternately, Simultaneous: Two LEDs blink simultaneously

Check code

(Detected by indoor unit)

Blinking

Block indication

OPERATION TIMER PREPARING

E03

E04

E08

and remote controller

TCC-LINK central control

E10

E18

Alternate

F01

Alternate

F02

Alternate

Simultaneous

F10

F29

Simultaneous

Simultaneous

Simultaneous

L03

L07

L08

Simultaneous

Simultaneous

Simultaneous

L09

L20

L30

Alternate

P01

Alternate

Alternate

P10

P12

– 31 –

Alternate

P19

Alternate

Lamp indication

P31

Check code

(Detected by remote controller)

Blinking

Block indication

OPERATION TIMER PREPARING

E01

E02

Remote controller

E09

Blinking

Block indication

Lamp indication

OPERATION TIMER PREPARING

control

Check code

TCC-LINK central

(Detected by central controller)

–

(when R/C is used together)

No indication

C05

C06

C12

Depends on alarm No. above

P30

Note: Check code varies in some cases depending on the unit which detects errors even if its content is the same.

Check codes detected by R/C or central controller are not always related to air conditioner operation. This table does not include check codes detected by outdoor unit or thermal storage unit.

Page 33

Check Code Table (Outdoor Unit)

Operation

continuation

A/C operation

Auto

reset

Description of failures

Lamp indication

ON, Blinking, OFF, Alternate: Two LEDs blink alternately, Simultaneous: Two LEDs blink simultaneously

Typical error of thermal storage unit (Details are checked by R/C.)

When open-circuit or short-circuit of TD is detected

Main faulty location

Thermal storage unit error

Outdoor unit heat discharge sensor TD error

Blinking

Simultaneous

Alternate

Block indication

OPERATION TIMER PREPARING

When open-circuit or short-circuit of TE,TS is detected

When open-circuit or short-circuit of TO is detected

Short-circuit current Idc after direct current excitation is detected when

reaching minimum frequency in current release control.

When compressor locking is detected

Outdoor unit temp. sensor TE, TS error

Outdoor unit outside air temp. sensor TO error

Compressor breakdown

Compressor locking

Alternate

Alternate

Other outdoor unit errors 1) MCU communication error between PDU and

CDB, 2) IGBT heatsink temp. detect error

When phase sequence of 3-phase current is abnormal (thermo sensor

OFF operation continued) or other errors

When discharge temperature release control detects an error

When abnormal current is detected by AC-CT or when phase loss is

detected

Ps pressure sensor error. Low-pressure protection circuit is activated.

Current detect circuit error

Low-pressure system error

Other outdoor unit errors

Phase sequence error or others

Simultaneous

Simultaneous

When high-pressure switch or IOL is activated or when high-pressure