Toshiba RAV-SM800XT-E, RAV-SM800UT-E, RAV-SM560KRT-E, RAV-SM800KRT-E, RAV-SM560UT-E SERVICE MANUAL

...

SERVICE MANUAL

RAV-SM560AT-E/RAV-SM800AT-E

FILE NO. A02-014

Revised Dec. 2003 (1)

SPLIT TYPE

RAV-SM560UT-E/RAV-SM800UT-E

RAV-SM560BT-E/RAV-SM800BT-E

RAV-SM560KR T-E/RAV-SM800KR T-E

RAV-SM560XT-E/RAV-SM800XT-E

File No. A02-014 in the page of the following table has been changed,

and the portion is expressed as mark.

2, 3, 5, 11, 20, 21, 29, 57,

Revised page 59, 60, 63, 64, 168, 170

Cord Heater Installation Work

R410A

PRINTED IN JAPAN, Apr.,2003 ToMo

Revised. Dec. 2003 (1)

CONTENTS

1. SPECIFICATIONS ................................................................................................ 3

2. AIR DUCTING WORK ........................................................................................ 12

3. CONSTRUCTION VIEWS (EXTERNAL VIEWS) ............................................... 13

4. SYSTEMATIC REFRIGERATING CYCLE DIAGRAM ....................................... 20

5. WIRING DIAGRAM ............................................................................................ 22

6. SPECIFICATIONS OF ELECTRICAL PARTS ................................................... 28

7. REFRIGERANT R410A ..................................................................................... 30

8. CONTROL BLOCK DIAGRAM .......................................................................... 38

9. CIRCUIT CONFIGURATION AND CONTROL SPECIFICATIONS .................... 48

10. TROUBLESHOOTING ....................................................................................... 65

11. REPLACEMENT OF SERVICE INDOOR P.C. BOARD ..................................... 88

12. SETUP AT LOCAL SITE AND OTHERS ........................................................... 92

13. ADDRESS SETUP ........................................................................................... 103

14. TROUBLESHOOTING <WALL TYPE> ............................................................ 108

15. DETACHMENTS ............................................................................................... 135

16. EXPLODED VIEWS AND PARTS LIST ........................................................... 168

CORD HEATER INSTALLATION WORK.................................................. APPENDIX-1

– 2 –

1. SPECIFICATIONS

1-1. Indoor Unit

1-1-1. 4-Way Air Discharge Cassette Type

Revised. Dec. 2003 (1)

Model name

Standard capacity (Note 1) (kW)

Heating low temp. capacity (Note 1) (kW)

Energy consumption effect ratio (Cooling)

Power supply

Running current (A)

Electrical

characteristics

Appearance

Outer

dimension

Power consumption (kW)

(Low temp.) (kW)

Power factor (%)

Main unit

Ceiling Panel

(Sold separately)

Main unit Width (mm)

Ceiling panel

(Sold separately)

Model

Panel color

Height (mm)

Depth (mm)

Height (mm)

Width (mm)

Depth (mm)

RAV-SM560UT-E RAV-SM800UT-E

Cooling Heating Average Cooling Heating Average

5.3 5.6 7.1 8.0

(1.5 – 5.6) (1.5 – 6.3) (2.2 – 8.0) (2.2–9.0)

4.9 7

3.01 [B] 3.90 [A] 3.46 3.03 [B] 3.45 [B] 3.24

1 phase 230V (220 – 240V) 50Hz

8.42–7.72 6.87–6.29 11.32–10.37 11.22–10.28

1.76 1.435 2.34 2.32

1.89 2.73

95 95 94 94

Zinc hot dipping steel plate

RBC-U21PG (W) E

Moon-white (Muncel 2.5GY 9.0/0.5)

256

840

840

53

950

950

Total weight

Heat exchanger

Soundproof/Heat-insulating material

Fan unit Standard air flow High (Mid./Low) (m³/h)

Air filter

Controller (Sold separately)

Connecting

pipe

Sound level High (Mid./Low) (Note 2) (dB•A)

Main unit (kg)

Ceiling panel

Fan

Motor (W)

Gas side (mm)

Liquid side (mm)

Drain port (Nominal dia.)

Inflammable polyethylene foam Foamed polyethylen

32 29 27 34 31 28

21 22

4.5

Finned tubu

Turbo fan

1050 1200

60

Attached ceiling panel

RBC-AMT21E

Ø12.7 (1/2”) Ø15.9 (5/8”)

Ø6.4 (1/4”) Ø9.5 (3/8”)

25 (Polyvinyl chloride tube)

Note 1 : The cooling capacities and electrical characteristics are measured under the conditions speciied by JIS B 8616 based

on the reference piping. The reference piping consists of 3 m of main piping and 2 m of branch piping connected with 0

meter height.

Note 2 : The sound level is measured in an anechoic chamber in accordance with JIS B8616. Normally, the values measured in

the actual operating environment become larger than the indicated values due to the effects of external sound.

Note : Rated conditions Cooling : Indoor air temperature 27°C DB/19°C WB, Outdoor air temperature 35°C DB

Heating : Indoor air temperature 20°C DB, Outdoor air temperature 7°C DB/6°C WB

– 3 –

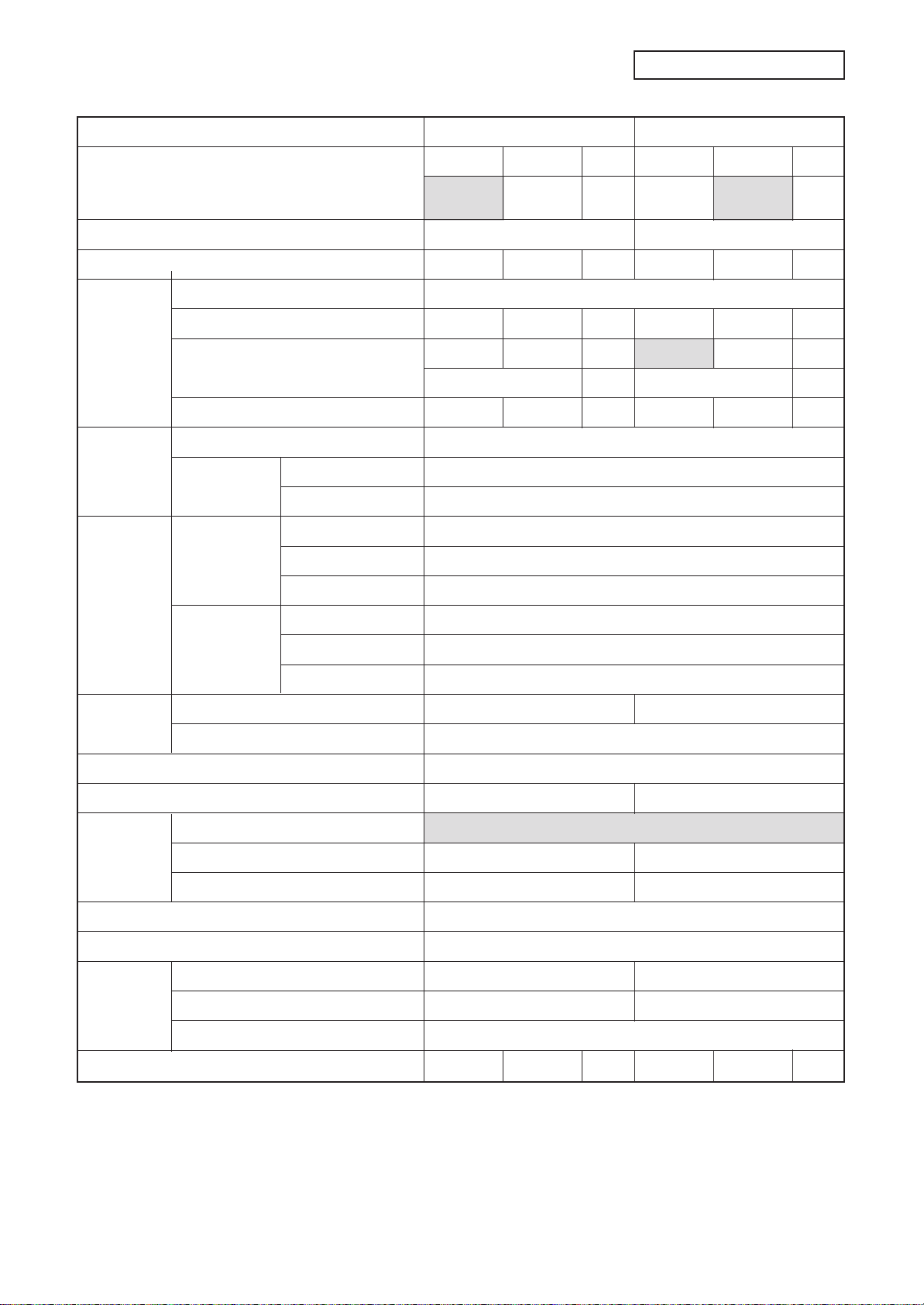

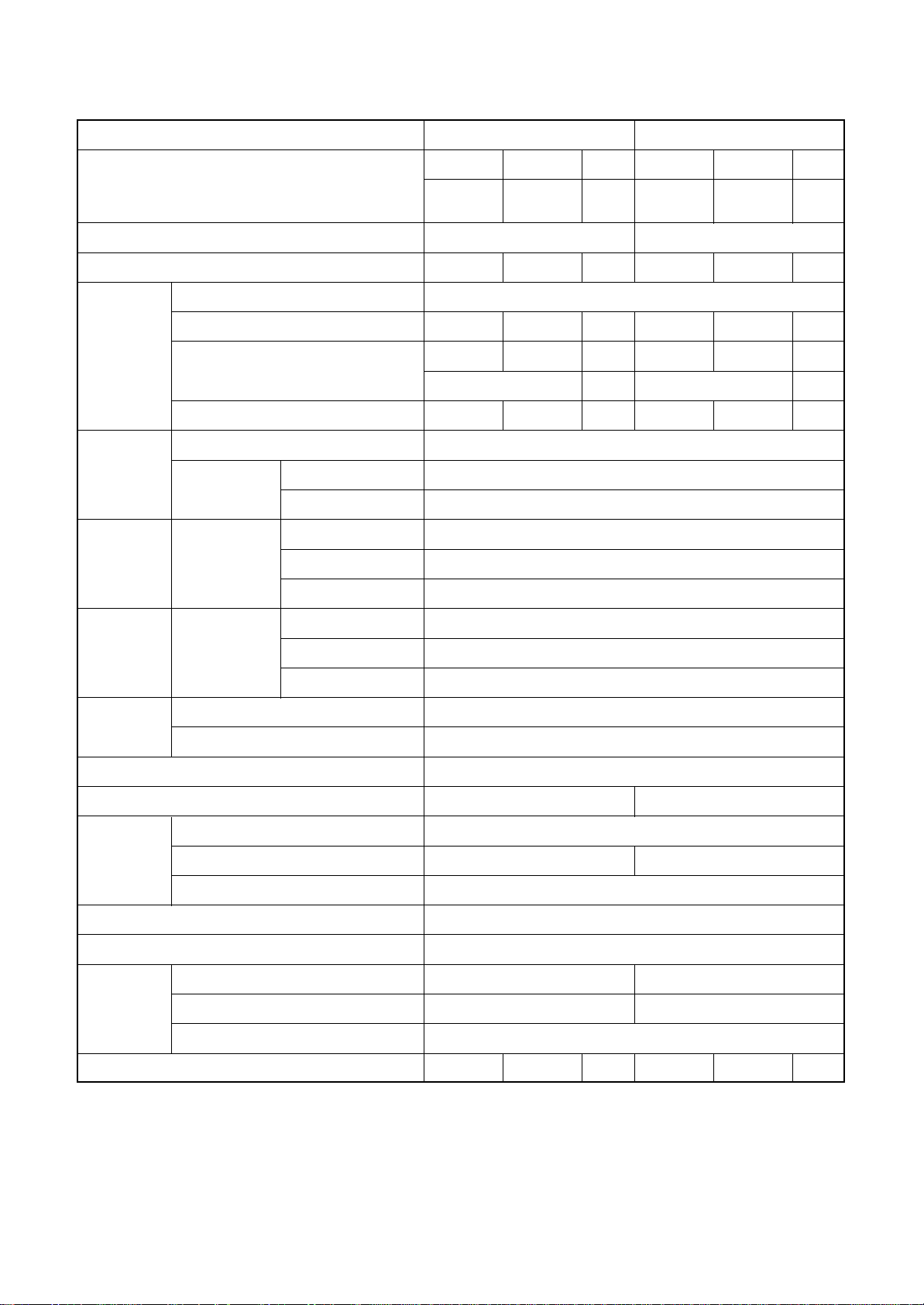

• Operation characteristic curve

<Cooling> <Heating>

14

12

RAV-SM800UT-E

10

8

6

Current (A)

4

2

0

15

020

RAV-SM560UT-E

• Conditions

Indoor : DB27˚C/WB19˚C

Outdoor : DB35˚C

Air flow : High

Pipe length : 7.5m

230V

40 60 70 80 100

Compressor speed (rps)

16

14

12

10

8

Current (A)

6

4

2

0

15

020

RAV-SM800UT-E

RAV-SM560UT-E

• Conditions

Indoor : DB20˚C

Outdoor : DB7˚C/WB6˚C

Air flow : High

Pipe length : 7.5m

230V

40 60 80 90 100

Compressor speed (rps)

• Capacity variation ratio according to temperature

<Cooling> <Heating>

105

100

95

90

120

110

100

90

80

85

70

80

60

75

70

Capacity ratio (%)

65

60

55

• Conditions

Indoor : DB27˚C/WB19˚C

Indoor air flow : High

Pipe length : 7.5m

50

32 33 34 35 36 37 38 39 40 41 42 43

50

40

Capacity ratio (%)

30

20

10

0

-14-12-10-8-6-4-20246810

Outsoor temp. (˚C)

• Conditions

Indoor : DB20˚C

Indoor air flow : High

Pipe length : 7.5m

Outsoor temp. (˚C)

– 4 –

1-1-2. Concealed Duct Type

Revised. Dec. 2003 (1)

Model name

Standard capacity (Note 1) (kW)

Heating low temp. capacity (Note 1) (kW)

Energy consumption effect ratio (Cooling)

Power supply

Running current (A)

Electrical

characteristics

Appearance

Power consumption (kW)

(Low temp.) (kW)

Power factor (%)

Main unit

Ceiling Panel

(Sold separately)

Main unit Width (mm)

Model

Panel color

Height (mm)

RAV-SM560BT-E RAV-SM800BT-E

Cooling Heating Average Cooling Heating Average

5.0 5.6 7.1 8.0

(1.5 – 5.6) (1.5 – 6.3) (2.2 – 8.0) (2.2–9.0)

4.6 6.2

2.60 [D] 3.27 [C] 2.94 2.73 [D] 3.21 [C] 2.97

1 phase 230V (220 – 240V) 50Hz

9.19–8.42 8.18–7.50 12.57–11.52 12.04–11.04

1.92 1.71 2.60 2.49

1.78 2.62

95 95 94 94

Zinc hot dipping steel plate

——

——

320

700

Outer

dimension

Ceiling panel

(Sold separately)

Total weight

Heat exchanger

Soundproof/Heat-insulating material

Fan unit Standard air flow High (Mid./Low) (m³/h)

Air filter

Controller (Sold separately)

Connecting

pipe

Main unit (kg)

Ceiling panel

Fan

Motor (W)

Gas side (mm)

Liquid side (mm)

Drain port (Nominal dia.)

Depth (mm)

Height (mm)

Width (mm)

Depth (mm)

800 (+7.5)

——

——

——

39 53

——

Finned tubu

Inflammable polyethylene foam Foamed polyethylen

Multi-blade fan

840 1140

60 100

Attached main unit

RBC-AMT21E

Ø12.7 (1/2”) Ø15.9 (5/8”)

Ø6.4 (1/4”) Ø9.5 (3/8”)

25 (Polyvinyl chloride tube)

Sound level High (Mid./Low) (Note 2) (dB•A)

42 39 36 43 40 37

Note 1 : The cooling capacities and electrical characteristics are measured under the conditions speciied by JIS B 8616 based

on the reference piping. The reference piping consists of 3 m of main piping and 2 m of branch piping connected with 0

meter height.

Note 2 : The sound level is measured in an anechoic chamber in accordance with JIS B8616. Normally, the values measured in

the actual operating environment become larger than the indicated values due to the effects of external sound.

Note : Rated conditions Cooling : Indoor air temperature 27°C DB/19°C WB, Outdoor air temperature 35°C DB

Heating : Indoor air temperature 20°C DB, Outdoor air temperature 7°C DB/6°C WB

– 5 –

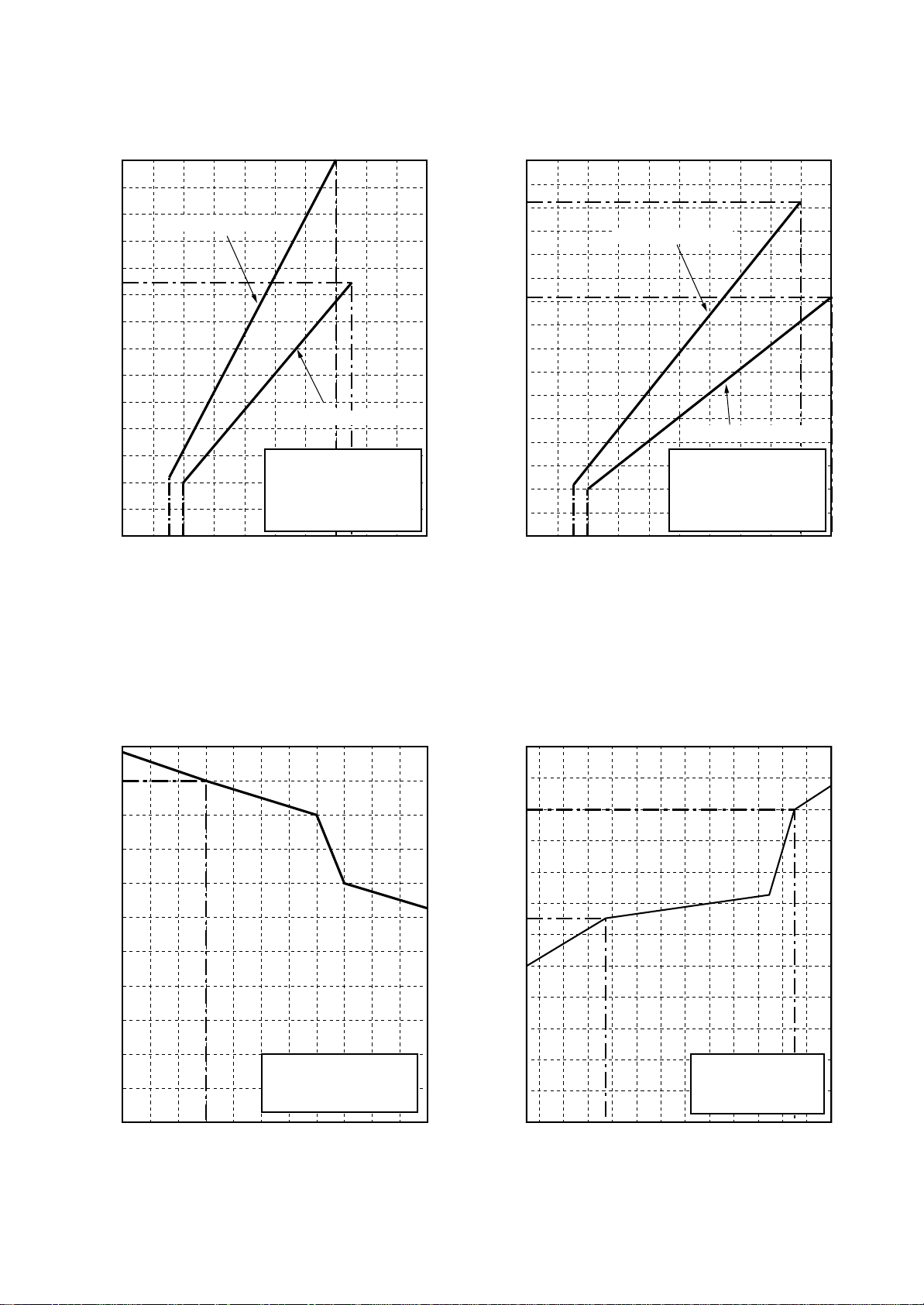

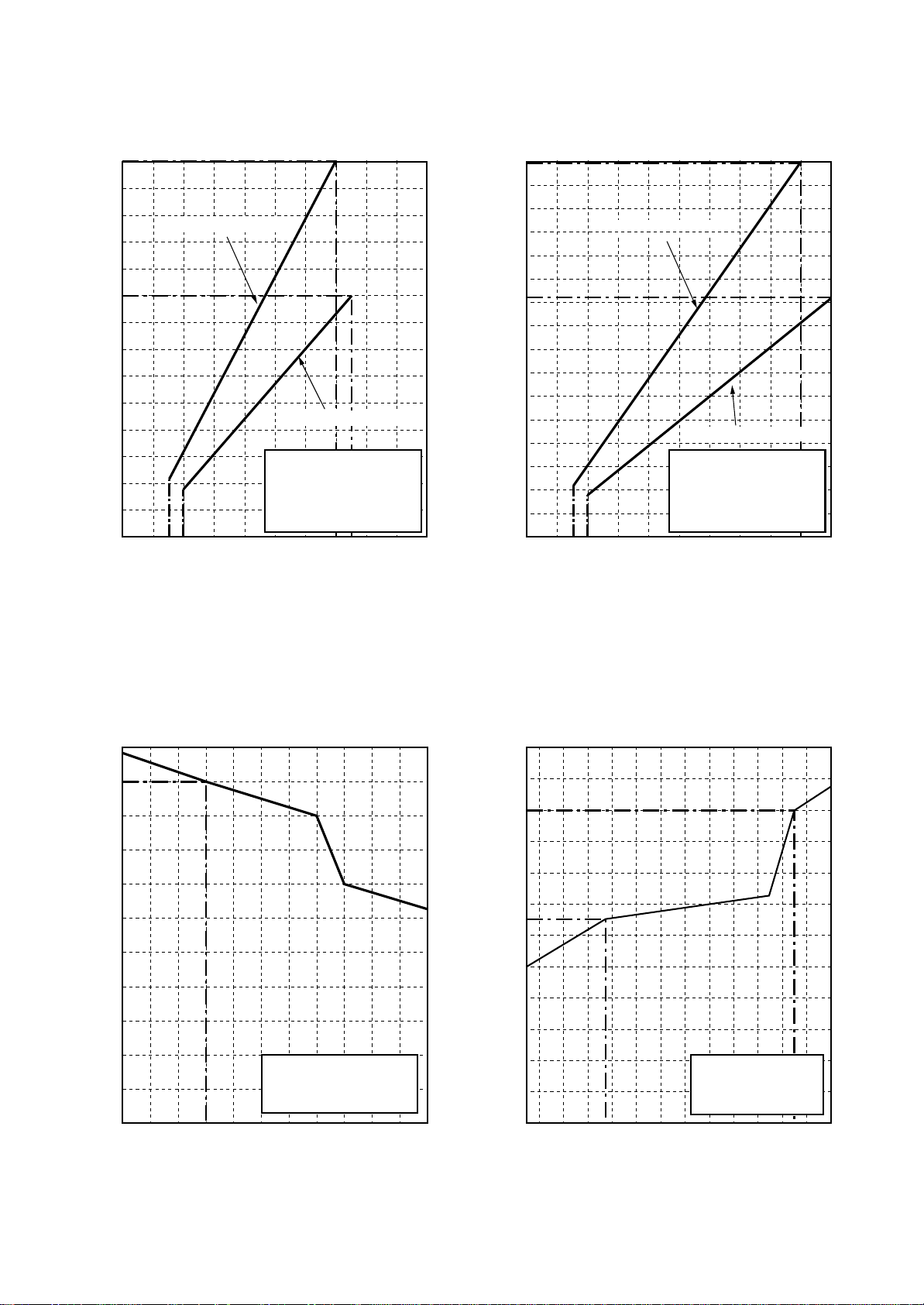

• Operation characteristic curve

<Cooling> <Heating>

14

12

RAV-SM800BT-E

10

8

6

Current (A)

4

2

0

15

020

RAV-SM560BT-E

• Conditions

Indoor : DB27˚C/WB19˚C

Outdoor : DB35˚C

Air flow : High

Pipe length : 7.5m

230V

40 60 70 80 100

Compressor speed (rps)

16

14

12

10

8

Current (A)

6

4

2

0

15

020

RAV-SM800BT-E

RAV-SM560BT-E

• Conditions

Indoor : DB20˚C

Outdoor : DB7˚C/WB6˚C

Air flow : High

Pipe length : 7.5m

230V

40 60 80 90 100

Compressor speed (rps)

• Capacity variation ratio according to temperature

<Cooling> <Heating>

105

100

95

90

120

110

100

90

80

85

70

80

60

75

70

Capacity ratio (%)

65

60

55

• Conditions

Indoor : DB27˚C/WB19˚C

Indoor air flow : High

Pipe length : 7.5m

50

32 33 34 35 36 37 38 39 40 41 42 43

50

40

Capacity ratio (%)

30

20

10

0

-14-12-10-8-6-4-20246810

Outsoor temp. (˚C)

• Conditions

Indoor : DB20˚C

Indoor air flow : High

Pipe length : 7.5m

Outsoor temp. (˚C)

– 6 –

1-1-3. High-Wall T ype

Model name

Standard capacity (Note 1) (kW)

Heating low temp. capacity (Note 1) (kW)

Energy consumption effect ratio (Cooling)

Power supply

Running current (A)

Electrical

characteristics

Appearance

Power consumption (kW)

(Low temp.) (kW)

Power factor (%)

Main unit

Ceiling Panel

(Sold separately)

Main unit Width (mm)

Model

Panel color

Height (mm)

RAV-SM560KRT-E RAV-SM800KRT-E

Cooling Heating Average Cooling Heating Average

5.1 5.6 6.7 8

(1.5 – 5.6) (1.5 – 6.3) (2.2 – 8.0) (2.2–9.0)

4.9 5.8

2.93 [D] 3.29 [C] 3.11 2.46 [E] 3.00 [D] 3.24

1 phase 230V (220 – 240V) 50Hz

8.33–7.63 8.138–7.46 13.15–12.05 12.91–11.84

1.74 1.7 2.72 2.67

1.95 2.21

95 95 94 94

Pure white

——

——

298

998

Outer

dimension

Ceiling panel

(Sold separately)

Total weight

Heat exchanger

Soundproof/Heat-insulating material

Fan unit Standard air flow High (Mid./Low) (m³/h)

Air filter

Controller (Sold separately)

Connecting

pipe

Main unit (kg)

Ceiling panel

Fan

Motor (W)

Gas side (mm)

Liquid side (mm)

Drain port (Nominal dia.)

Depth (mm)

Height (mm)

Width (mm)

Depth (mm)

208

——

——

——

12

——

Finned tubu

Inflammable polyethylene foam Foamed polyethylen

Turbo fan

840 1110

30

Attached main unit

Wired remote controller RBC-AMT21E

Ø12.7 (1/2”) Ø15.9 (5/8”)

Ø6.4 (1/4”) Ø9.5 (3/8”)

25 (Polyvinyl chloride tube)

Sound level High (Mid./Low) (Note 2) (dB•A)

45 41 36 45 41 36

Note 1 : The cooling capacities and electrical characteristics are measured under the conditions speciied by JIS B 8616 based

on the reference piping. The reference piping consists of 3 m of main piping and 2 m of branch piping connected with 0

meter height.

Note 2 : The sound level is measured in an anechoic chamber in accordance with JIS B8616. Normally, the values measured in

the actual operating environment become larger than the indicated values due to the effects of external sound.

Note : Rated conditions Cooling : Indoor air temperature 27°C DB/19°C WB, Outdoor air temperature 35°C DB

Heating : Indoor air temperature 20°C DB, Outdoor air temperature 7°C DB/6°C WB

– 7 –

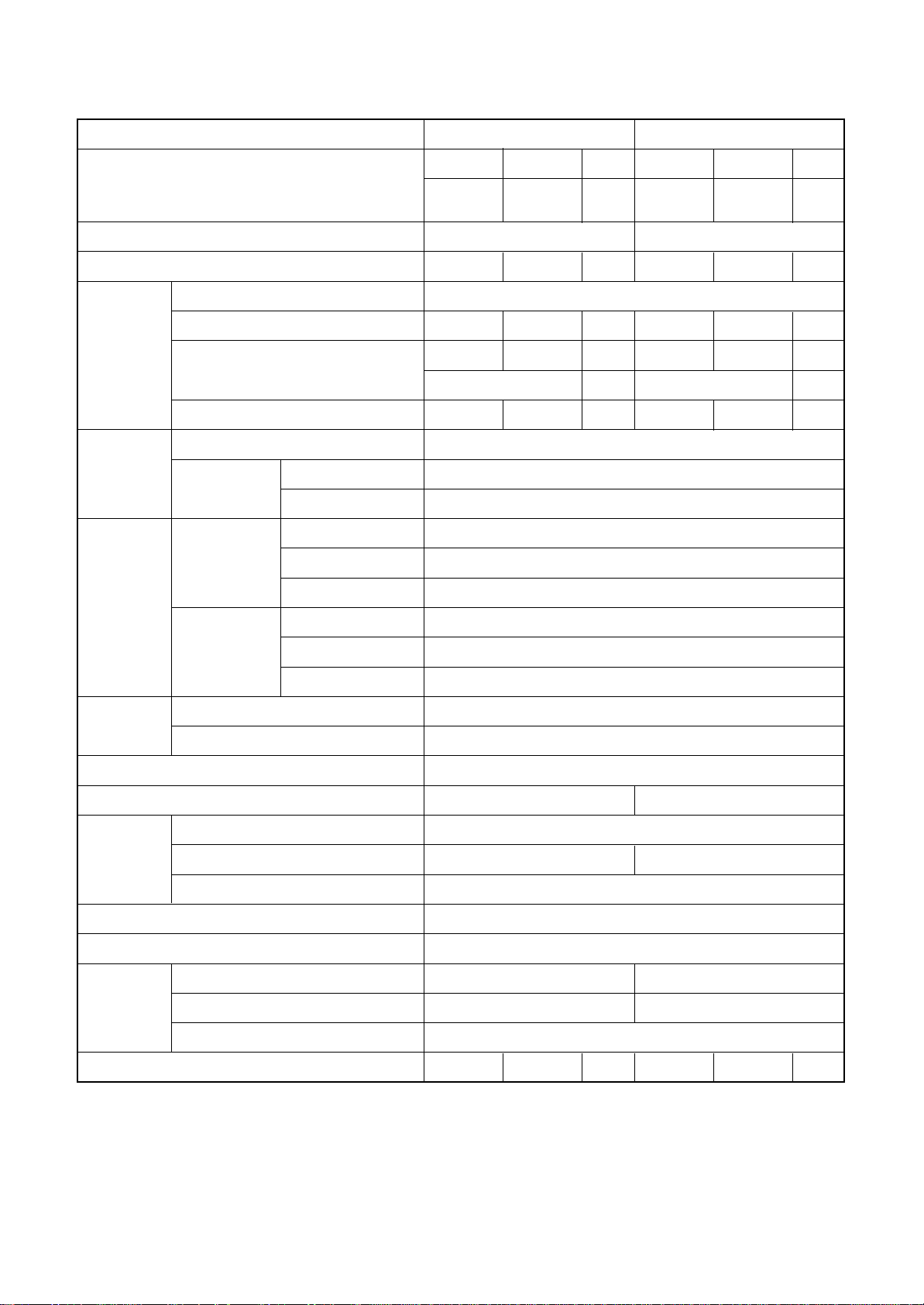

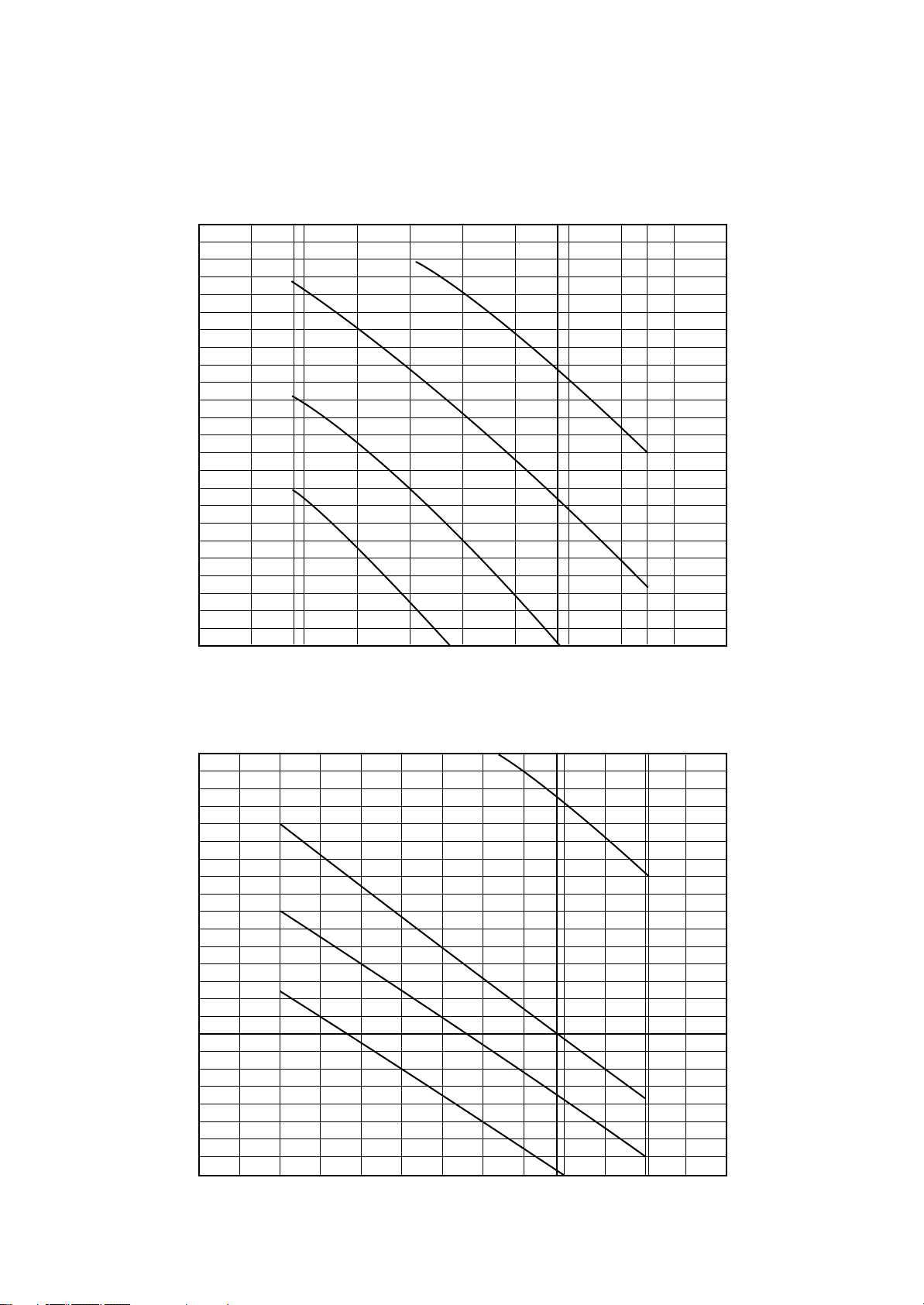

• Operation characteristic curve

<Cooling> <Heating>

14

12

RAV-SM800KRT-E

10

8

6

Current (A)

4

2

0

15

020

RAV-SM560KRT-E

• Conditions

Indoor : DB27˚C/WB19˚C

Outdoor : DB35˚C

Air flow : High

Pipe length : 7.5m

230V

40 60 70 80 100

Compressor speed (rps)

16

14

12

10

8

Current (A)

6

4

2

0

15

020

RAV-SM800KRT-E

RAV-SM560KRT-E

• Conditions

Indoor : DB20˚C

Outdoor : DB7˚C/WB6˚C

Air flow : High

Pipe length : 7.5m

230V

40 60 80 90 100

Compressor speed (rps)

• Capacity variation ratio according to temperature

<Cooling> <Heating>

105

100

95

90

120

110

100

90

80

85

70

80

60

75

70

Capacity ratio (%)

65

60

55

• Conditions

Indoor : DB27˚C/WB19˚C

Indoor air flow : High

Pipe length : 7.5m

50

32 33 34 35 36 37 38 39 40 41 42 43

50

40

Capacity ratio (%)

30

20

10

0

-14-12-10-8-6-4-20246810

Outsoor temp. (˚C)

• Conditions

Indoor : DB20˚C

Indoor air flow : High

Pipe length : 7.5m

Outsoor temp. (˚C)

– 8 –

1-1-4. Flexible T ype

Model name

Standard capacity (Note 1) (kW)

Heating low temp. capacity (Note 1) (kW)

Energy consumption effect ratio (Cooling)

Power supply

Running current (A)

Electrical

characteristics

Appearance

Power consumption (kW)

(Low temp.) (kW)

Power factor (%)

Main unit

Ceiling Panel

(Sold separately)

Main unit Width (mm)

Model

Panel color

Height (mm)

RAV-SM560XT-E RAV-SM800XT-E

Cooling Heating Average Cooling Heating Average

5.1 5.6 6.7 8

(1.5 – 5.6) (1.5 – 6.3) (2.2 – 8.0) (2.2–9.0)

4.9 5.8

2.93 [D] 3.29 [C] 3.11 2.46 [E] 3.00 [D] 3.24

1 phase 230V (220 – 240V) 50Hz

8.33–7.63 8.138–7.46 13.15–12.05 12.91–11.84

1.74 1.7 2.72 2.67

1.95 2.21

95 95 94 94

Pure white

——

——

298

998

Outer

dimension

Ceiling panel

(Sold separately)

Total weight

Heat exchanger

Soundproof/Heat-insulating material

Fan unit Standard air flow High (Mid./Low) (m³/h)

Air filter

Controller (Sold separately)

Connecting

pipe

Main unit (kg)

Ceiling panel

Fan

Motor (W)

Gas side (mm)

Liquid side (mm)

Drain port (Nominal dia.)

Depth (mm)

Height (mm)

Width (mm)

Depth (mm)

208

——

——

——

12

——

Finned tubu

Inflammable polyethylene foam Foamed polyethylen

Cross flow fan

840 1110

30

Attached main unit

Wired remote controller RBC-AMT21E

Ø12.7 (1/2”) Ø15.9 (5/8”)

Ø6.4 (1/4”) Ø9.5 (3/8”)

25 (Polyvinyl chloride tube)

Sound level High (Mid./Low) (Note 2) (dB•A)

39 36 36 45 41 36

Note 1 : The cooling capacities and electrical characteristics are measured under the conditions speciied by JIS B 8616 based

on the reference piping. The reference piping consists of 3 m of main piping and 2 m of branch piping connected with 0

meter height.

Note 2 : The sound level is measured in an anechoic chamber in accordance with JIS B8616. Normally, the values measured in

the actual operating environment become larger than the indicated values due to the effects of external sound.

Note : Rated conditions Cooling : Indoor air temperature 27°C DB/19°C WB, Outdoor air temperature 35°C DB

Heating : Indoor air temperature 20°C DB, Outdoor air temperature 7°C DB/6°C WB

– 9 –

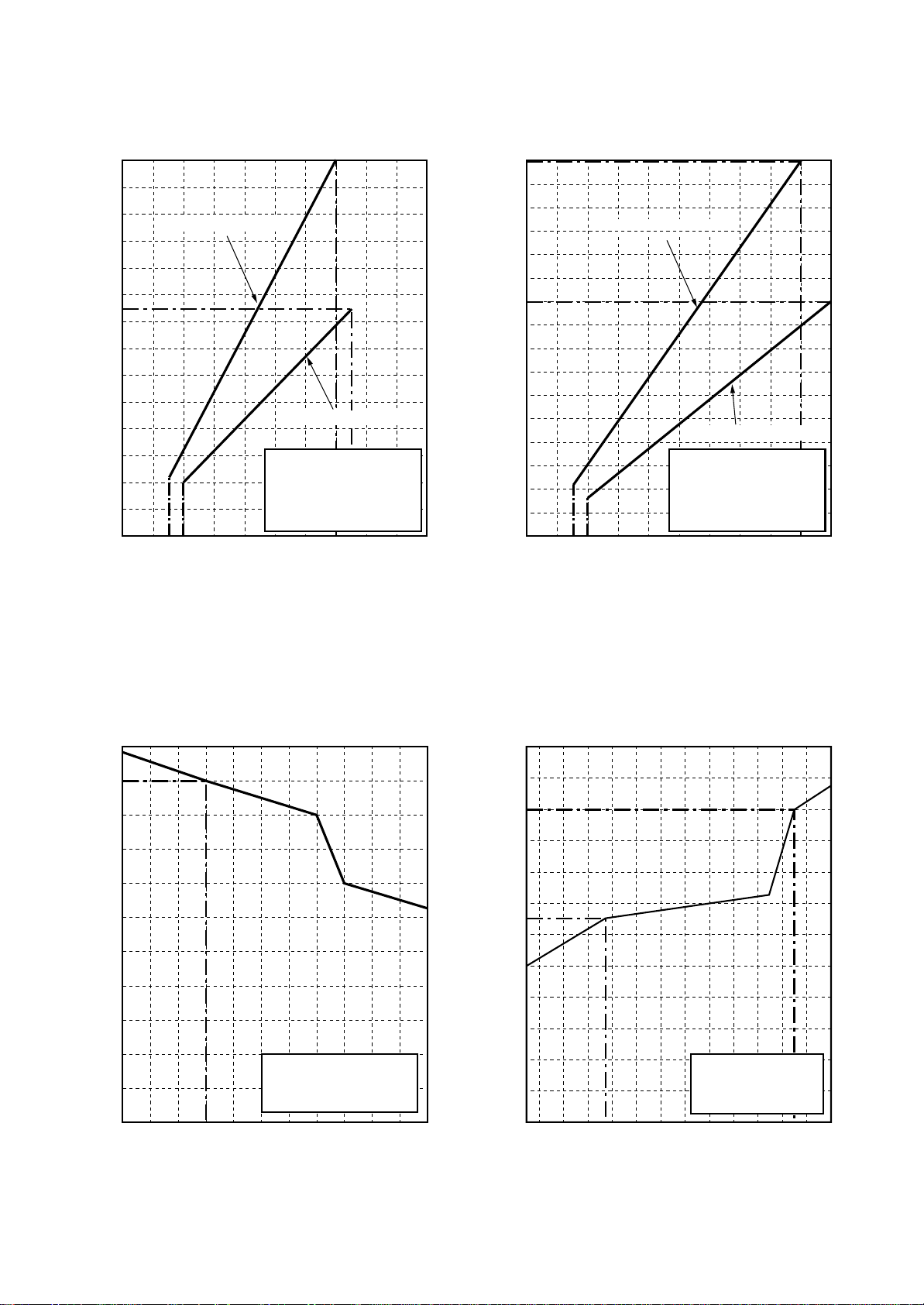

• Operation characteristic curve

<Cooling> <Heating>

14

12

RAV-SM800XT-E

10

8

6

Current (A)

4

2

0

15

020

RAV-SM560XT-E

• Conditions

Indoor : DB27˚C/WB19˚C

Outdoor : DB35˚C

Air flow : High

Pipe length : 7.5m

230V

40 60 70 80 100

Compressor speed (rps)

14

12

10

8

Current (A)

6

4

2

0

15

020

RAV-SM800XT-E

RAV-SM560XT-E

• Conditions

Indoor : DB20˚C

Outdoor : DB7˚C/WB6˚C

Air flow : High

Pipe length : 7.5m

230V

40 60 80 90 100

Compressor speed (rps)

• Capacity variation ratio according to temperature

<Cooling> <Heating>

105

100

95

90

120

110

100

90

80

85

70

80

60

75

70

Capacity ratio (%)

65

60

55

• Conditions

Indoor : DB27˚C/WB19˚C

Indoor air flow : High

Pipe length : 7.5m

50

32 33 34 35 36 37 38 39 40 41 42 43

50

40

Capacity ratio (%)

30

20

10

0

-14-12-10-8-6-4-20246810

Outsoor temp. (˚C)

• Conditions

Indoor : DB20˚C

Indoor air flow : High

Pipe length : 7.5m

Outsoor temp. (˚C)

– 10 –

1-2. Outdoor Unit

Revised. Dec. 2003 (1)

Model name

Appearance

Power supply

Type

Compressor Motor (kW)

Pole

Refrigerant charged (kg)

Refrigerant control

Standard length

Max. total length (m)

Pipe Over 20m

Outdoor lower (m)

Outdoor higher (m)

Outer

dimension

Height difference

Height (mm)

Width (mm)

Depth (mm)

RAV-SM560AT-E RAV-SM800AT-E

Silky shade (Muncel 1Y8.5/0.5)

1 phase 230V (220 – 240V) 50Hz

(Power exclusive to outdoor is required.)

Hermetic compressor

1.1 1.6

4 poles

R410A 0.9 R410A 1.5

Pulse motor valve

20 (without additional charge)

30 50

Add 20g/m (Max. 200g) Add 40g/m (Max. 1200g)

30

50

595 795

780 780

270 270

Total weight (kg)

Heat exchanger

Fan

Fan unit Standard air flow High (m³/h)

Motor (W)

Connecting

pipe

Protection device

Sound level High (Mid./Low)

(Note 2) (Cooling/Heating)

Gas side (mm)

Liquid side (mm)

(dB•A)

35 55

Finned tube

Propeller fan

2400 3400

43 63

Ø12.7 (1/2”) Ø15.9 (5/8”)

Ø6.4 (1/4”) Ø9.5 (3/8”)

Discharge temp. sensor

Over-current sensor

Compressor thermo.

46/48 48/50

Note 1 : The cooling capacities and electrical characteristics are measured under the conditions speciied by JIS B 8616 based

on the reference piping. The reference piping consists of 3 m piping connected with 0 meter height.

Note 2 : The sound level is measured in an anechoic chamber in accordance with JIS B8616. Normally, the values measured in

the actual operating environment become larger than the indicated values due to the effects of external sound.

Note : Rated conditions Cooling : Indoor air temperature 27°C DB/19°C WB, Outdoor air temperature 35°C DB

Heating : Indoor air temperature 20°C DB, Outdoor air temperature 7°C DB/6°C WB

– 11 –

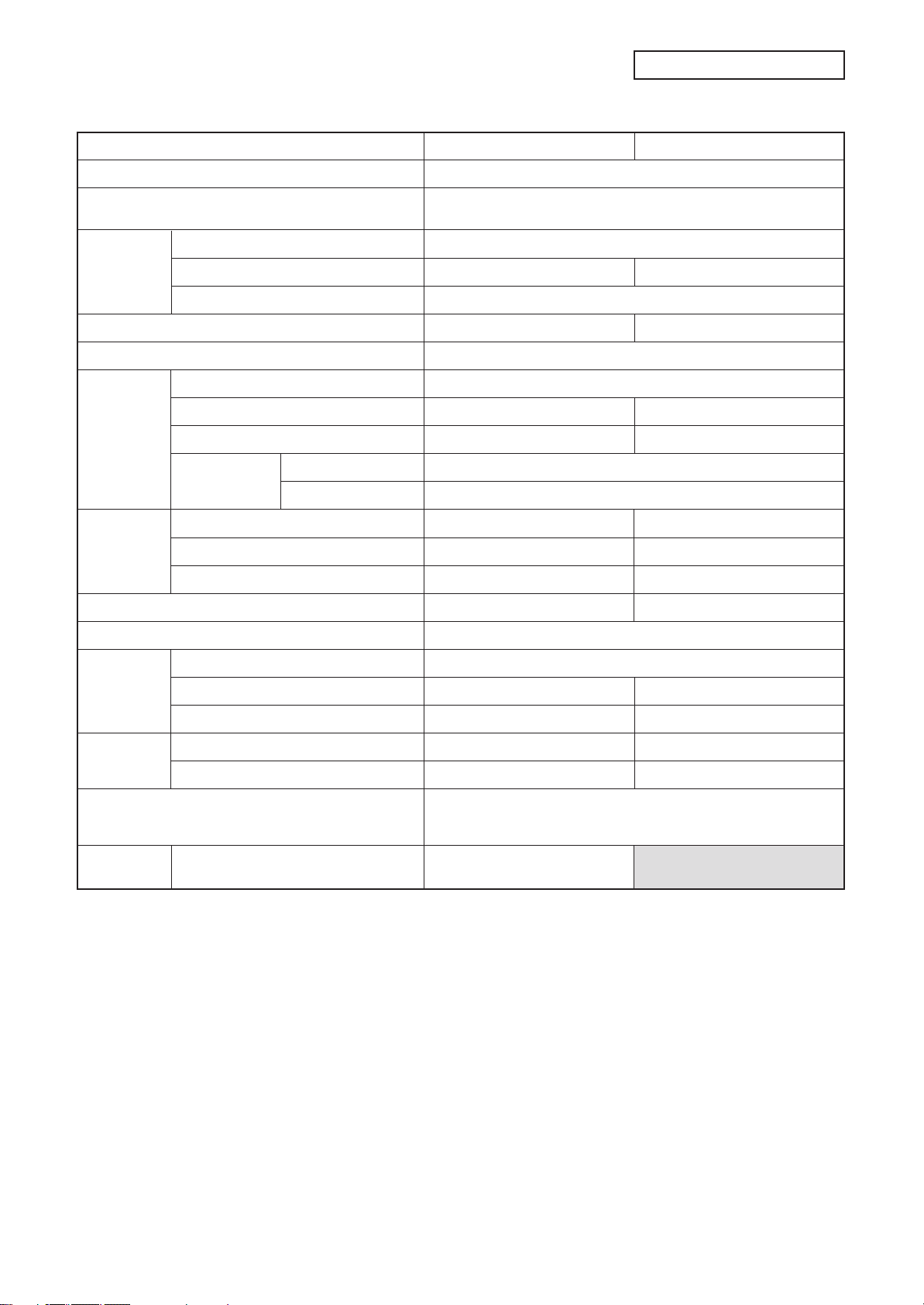

2. AIR DUCTING WORK

2-1. Static Pressure Characteristics of Each Model

Fig. 1 RAV-SM560BT-E

70% (570m³/h) 110% (925m³/h)

Standard air volume : 840m³/h

12

11

Extra High tap

Extra High tap

10

9

8

High tap

High tap

7

6

Middole tap

5

Middle tap

4

External static pressure (mmAq)

3

Low tap

Low tap

2

1

0

500 1000

600570

700 800 900 925

Air volume (m³/hr.)

12

70% (800m³/h) 110% (1255m³/h)

11

10

9

8

7

6

5

4

External static pressure (mmAq)

3

2

1

Fig. 2 RAV-SM800BT-E

Standard air volume : 1140m³/h

Extra High tap

Extra High tap

High tap

High tap

Middole tap

Middle tap

Low tap

Low tap

0

700 1300

800 900 1000 1100 1200 1255

Air volume (m³/hr.)

– 12 –

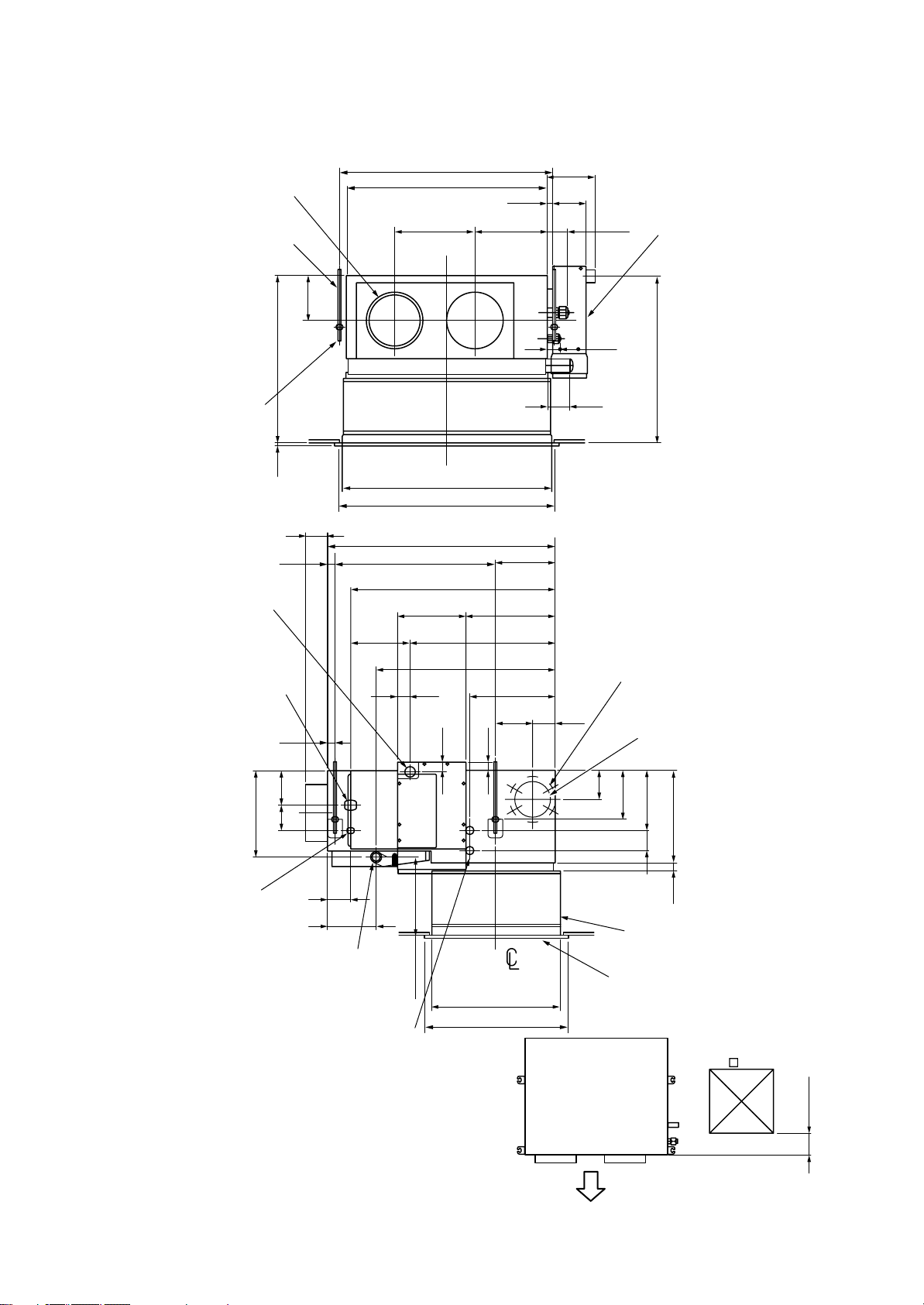

3. CONSTRUCTION VIEWS (EXTERNAL VIEWS)

3-1. Indoor Unit

4-Way Air Discharge Cassette Type

RAV-SM560UT-E/RAV-SM800UT-E

Surface

under ceiling

200

113

173

Refrigerant pipe

connecting port A

130

200

Check port

450)

(

Check port

450)

(

Cable draw-in port

45

Refrigerant pipe

connecting port B

Electric

parts box

860 to 910 Recommended external size

30

105

270

25070

950 Panel external dimension

790 Hanging bolt pitch

346.5

860 to 910 Recommended external size

Surface

under ceiling

Hanging bolt M10 or W3/8

Procured locally

130

210

360

Indoor unit

Standing

640 or less

Standing

850 or less

Drain up standing size

256

Surface

under ceiling

88

SM560

SM800

840 Unit external dimension

A

Ø6.4

Ø9.5

150

105

Ø12.7

Ø15.9

Knockout

97

35

Z view

for

humidifier

Ceiling

panel

(Sold

separately)

Surface

under ceiling

80

Ø162

B

415.0

105105

240

254.5

840 Hanging bolt

480

227

12097

Surface under ceiling

381.6

227

480

723 Hanging bolt pitch

950 Panel external dimension

35

˚

64

57

57.5

25

188

Surface under ceiling

120

– 13 –

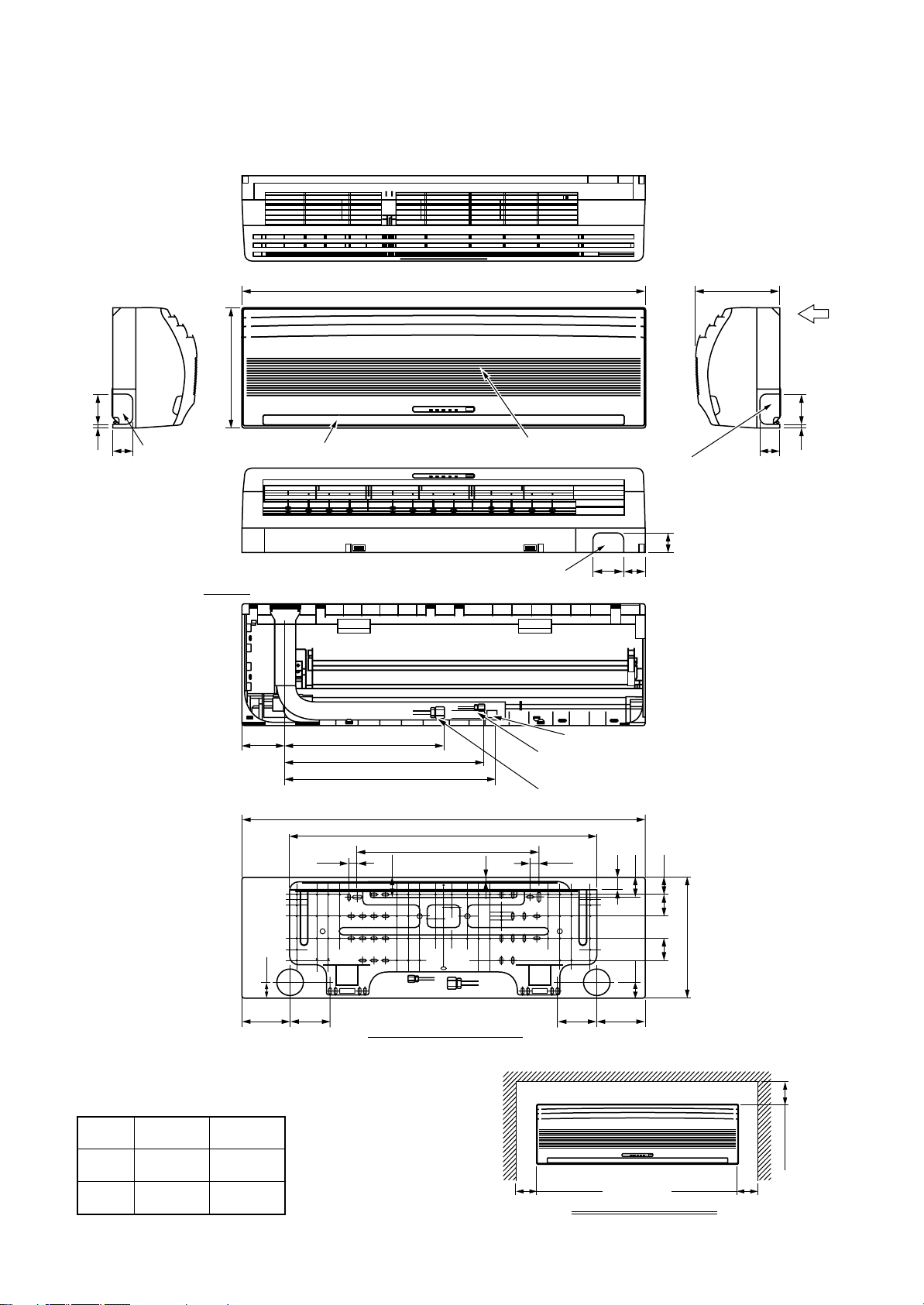

Concealed Duct Type

RAV-SM560BT-E

2-Ø200

Discharge port flange

4-M10

Hanging bolt

(Procured locally)

For hanging bolt M10

(4-12 x 25 long hole)

Drain pipe connecting port

at drain up kit side

(For polyvinyl chloride pipe

(Inner dia. 32, Nominal dia. 25))

750 ± 7.5 Hanging bolt pitch

700 Dimension of main unit

150

160~6405

240

730

210

720

314.5

25

75

800 Dimension of main unit

565 Hanging bolt pitch

780 Ceiling opening size

170

12020

80

60

Drain up kit

(Sold separately)

70252280

457 to 637

Refrigerant pipe

connecting port

(Gas side Ø12.7)

25

305

90 120

Refrigerant pipe

connecting port

(Liquid side Ø6.4)

Drain pipe connecting port

at main unit side

(For polyvinyl chloride pipe

(Inner dia. 32, Nominal dia. 25))

2-Ø26 power supply remote

controller cord draw-out port

80

170

211

509

630

45

35

155 to 335

470 Ceiling opening size

300

130 80

30

Panel

450

Ø125 knockout hole (Only rear side)

(For air suction)

6-Ø4 tapping screw lower hole Ø160

100

170

210

70

Suction port canvas

Suction panel

Plane view of main unit

30 320

Check port A

450

NOTE 1 :

For maintenance of the equipment, be sure to install

a check port A at the position as shown below.

NOTE 2 :

Using the drain up kit sold separately, drain-up by 300 (mm)

from drain pipe draw-out port of the main unit is necessary.

The drain-up over 300mm or more is impossible.

– 14 –

150

(Pipe side)

Discharge side

RAV-SM800BT-E

2-Ø200

Discharge port flange

4-M10

Hanging bolt

(Procured locally)

460~6405

For hanging bolt M10

(4-12 x 25 long hole)

Drain pipe connecting port

at drain up kit side

(For polyvinyl chloride pipe

(Inner dia. 32, Nominal dia. 25))

150

25

1050 Ceiling opening size

75

800 Dimension of main unit

565 Hanging bolt pitch

1050 ± 7.5 Hanging bolt pitch

1000 Dimension of main unit

290

1030

210

720

240

314.5

170

12020

Drain up kit

(Sold separately)

70252290

60

457 to 637

80

Refrigerant pipe

connecting port

(Gas side Ø12.7)

25

305

90 120

Refrigerant pipe

connecting port

(Liquid side Ø6.4)

Drain pipe connecting port

at main unit side

(For polyvinyl chloride pipe

(Inner dia. 32, Nominal dia. 25))

2-Ø26 power supply remote

controller cord draw-out port

80

170

211

45

130 80

30

35

Panel

155 to 335

470 Ceiling opening size

450

509

630

300

Plane view of main unit

Ø125 knockout hole (Only rear side)

(For air suction)

100

Suction panel

6-Ø4 tapping screw lower hole Ø160

170

210

70

30 320

Suction port canvas

Check port A

450

NOTE 1 :

For maintenance of the equipment, be sure to install

a check port A at the position as shown below.

NOTE 2 :

Using the drain up kit sold separately, drain-up by 300 (mm)

from drain pipe draw-out port of the main unit is necessary.

The drain-up over 300mm or more is impossible.

– 15 –

150

(Pipe side)

Discharge side

High-Wall T ype

RAV-SM560KRT-E/RAV-SM800KRT-E

298

998

Z

757

51

Pipe port from left

(Knockout hole)

Z views

Discharge port

110 390

490

540

20

Pipe port from lower side

(Knockout hole)

998

763.5

450

48

10

Suction port

75 56

Drain hose

Refrigerant pipe connecting port B

Refrigerant pipe connecting port A

20

29

48

Pipe port from right

(Knockout hole)

50

41555555

758

50

SM560

SM800

A

Liquid Side

Ø6.4

Ø9.5

40

B

Gas Side

Ø12.7

Ø15.9

298

40

100100 115115

Position of installation plate

55 or more

53 or more 53 or more

Space required for service

– 16 –

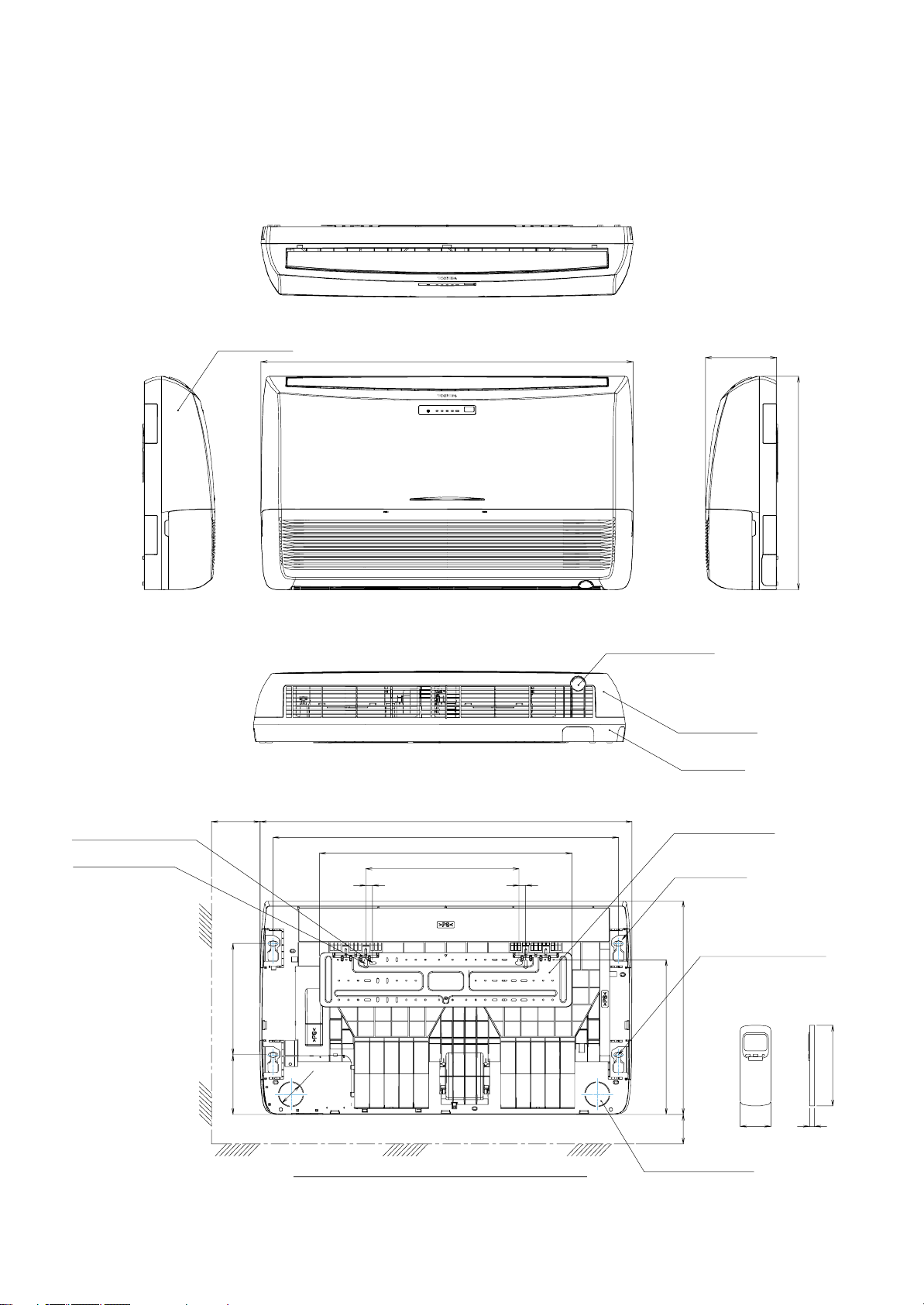

Under Ceiling/Console Type

RAV-SM560XT-E/RAV-SM800XT-E

Front panel

1093

208

633

Knock out system

Grille air inlet

Back body

For stud bolt

(Ø8 – Ø10)

For stud bolt (Ø6)

200 Min

330165

1093

1015

742

450

20 20

Ø74

UNDER CEILING & CONSOLE INSTALLATION

– 17 –

Installation plate

Mount plate

M10 Suspention bolt

633

460

70 Min

Wireless remote control

Knock out system

160

57 18

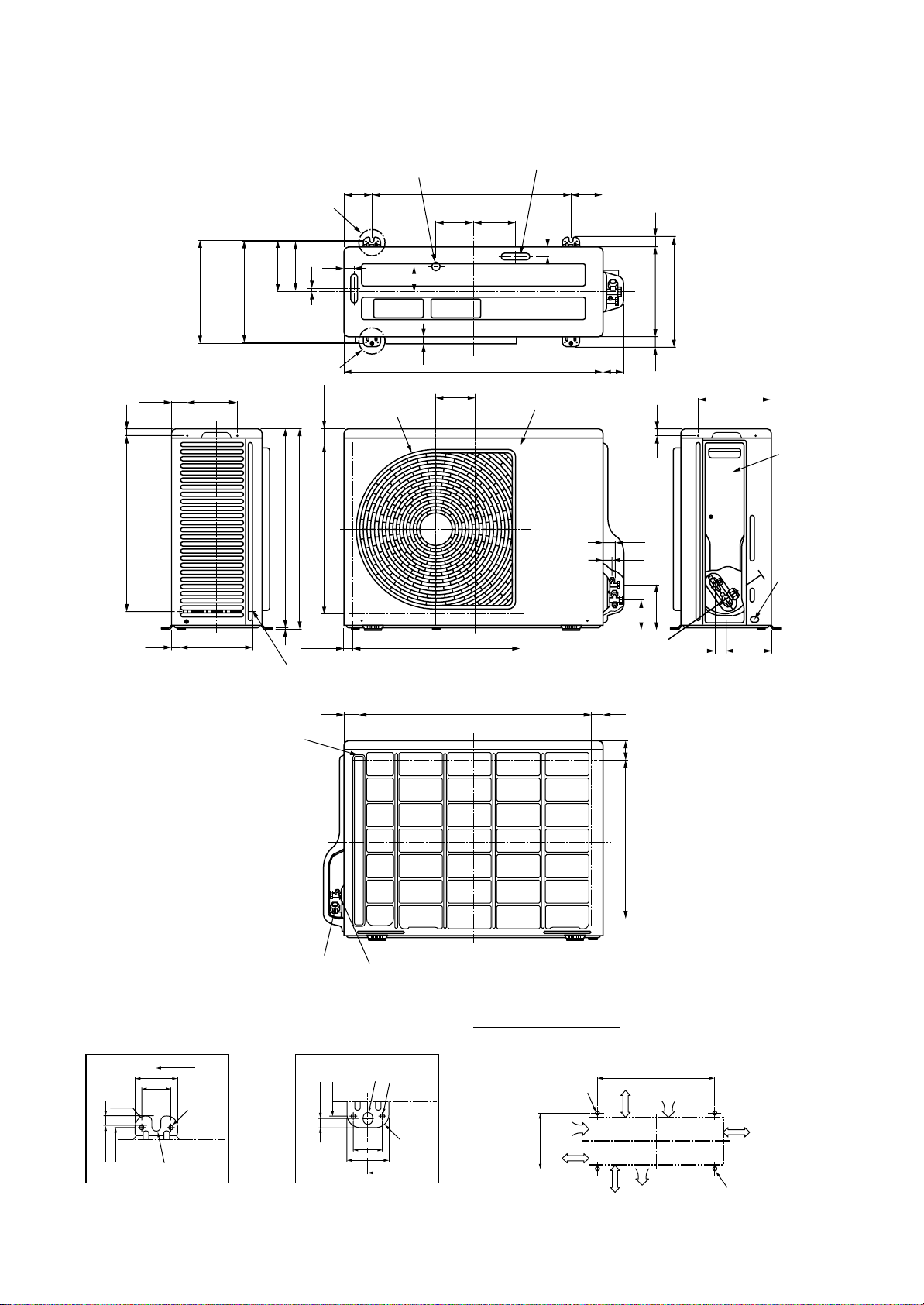

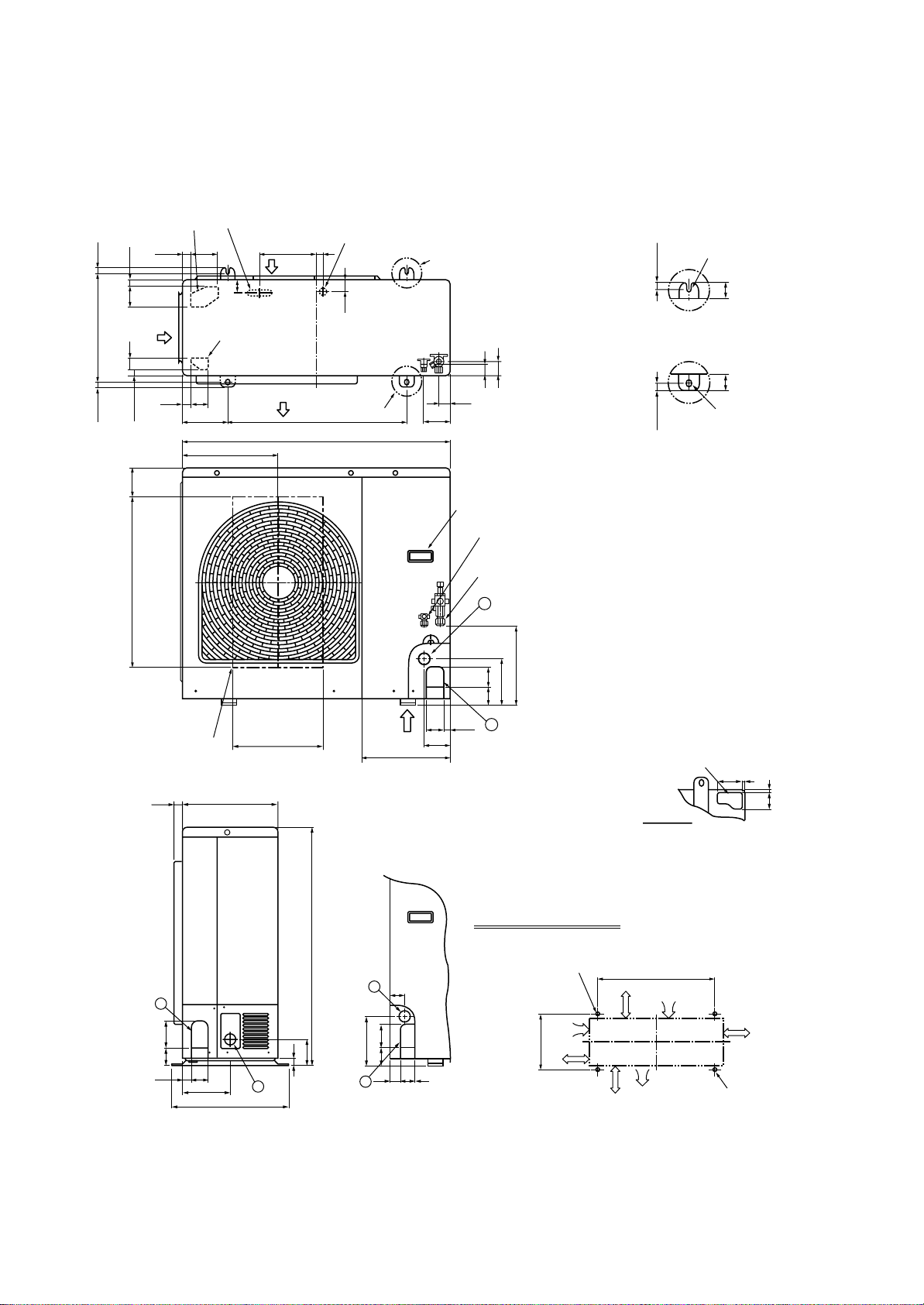

3-2. Outdoor Unit

RAV-SM560AT-E

49.5

521 21

25 220

308

302

Ø6 hole pitch

For anchor bolt)

(Long hole pitch

147

Drain hole (Ø25)

83

A legs

150

11

30

76

153

B legs

Discharge guard

(49.3)

598

593

500 (Fan center dividing)

500 (Fan center dividing)

Protective net mounting hole

(2-Ø4 embossing)

Drain hole (2-Ø20 x 88 long hole)

600

115.3 125

30

21

780

115.3

Discharge guide mounting hole

(4-Ø4 embossing)

97

2927031

330

21

31

23

132

90.6

Charge port

216

31 134

Valve cover

Earth

terminal

43 707 30

Protective net mounting hole

(4-Ø4 embossing)

Refrigerant pipe connecting port

(Ø12.7 flare at gas side)

600

52

36

R15

302

308 11

Ø11 x 14 U-shape hole

Details of A legs Details of B legs

2-Ø6 hole

Product

external line

Ø11 x 14 Ushape holes

308

302

11

Refrigerant pipe connecting port

(Ø6.4 flare at liquid side)

Space required for service

2-Ø11 x 14 U-shape holes

(For Ø8–Ø10 anchor bolt)

36

52

2-Ø6 hole

Product

external

line

R15

600

150

or more

365

500

or more

60

475

Suction port

150

or more

Discharge

port

600

300

or more

Discharge

port

(Minimum

distance up to wall)

2-Ø11 x 14 long hole

(For Ø8–Ø10 anchor bolt)

– 18 –

RAV-SM800AT-E

Knockout

(For draining)

21

Suction

port

365 17.517.5

40 70

(Long hole pitch

for anchor bolt)

21

565 101

Drain hole (Ø20 x 88 burring hole)

29 90 191 20

Suction

port

43

Knockout

(For draining)

6026

Discharge

port

300150

900

314

Drain hole (Ø25 burring hole)

Part B

40

39

Part A

95

43

Handles

(Both sides)

Refrigerant pipe connecting port

(Ø9.5 flare at liquid side)

Refrigerant pipe connecting port

(Ø15.9 flare at gas side)

2

47

Installation bolt hole

(Ø12 x 17 U-shape holes)

17.5

4040

Details of B part

Details of A part

17.5

Installation bolt hole

(Ø12 x 17 U-shape holes)

Discharge guide

mounting hole

(4-Ø4 embossing)

1

60 90

58

27

161

32028

400

264

6760

154

2760

300

Z

307

96

1

Knockout for lower piping

86 7

7

58

Z views

Space required for service

795

2

46

25

85

2

165

60 80

30 45

1

2-Ø12 x 17 U-shape holes

(For Ø8–Ø10 anchor bolt)

150

or more

365

500

or more

Suction port

150

or more

Discharge

port

600

150

or more

Discharge

port

(Minimum

distance up to wall)

2-Ø12 x 17 long hole

(For Ø8–Ø10 anchor bolt)

– 19 –

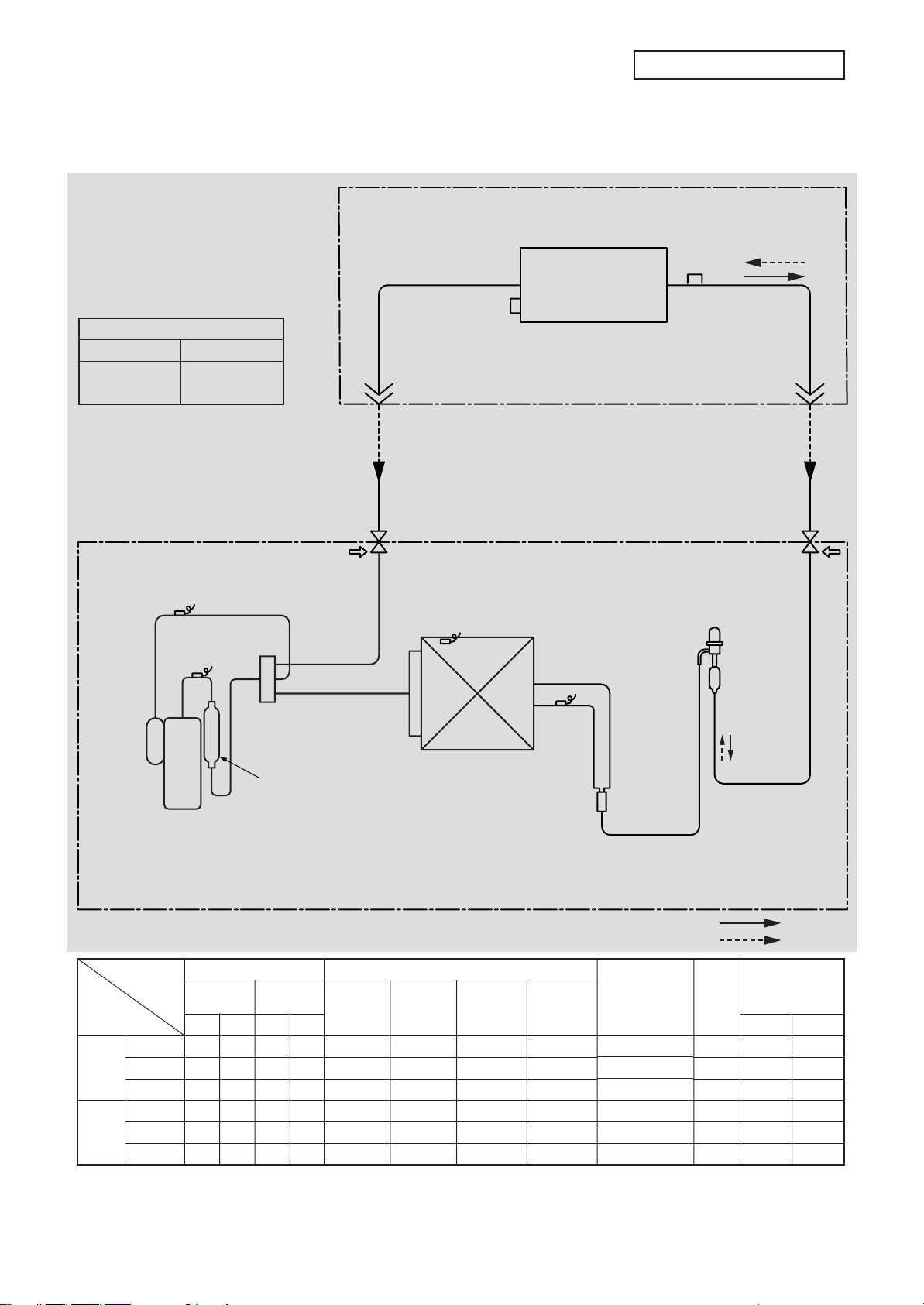

4. SYSTEMATIC REFRIGERATING CYCLE DIAGRAM

Indoor Unit/Outdoor Unit

RAV-SM560UT-E, RAV-SM560BT-E, RAV-SM560KRT-E/RAV-SM560AT-E

Indoor unit

Air heat exchanger

TC sensor

Outer diameter of refrigerant pipe

Gas side ØA Liquid side ØB

12.7mm 6.4mm

Revised. Dec. 2003 (1)

TCJ

sensor

TS sensor

TD sensor

Rotary compressor

(DA130A1F-23F)

4-way valve

(VT7101D)

Muffler

Ø19 × L160

Refrigerant pipe

at liquid side

Outer dia. ØA

Packed valve

Outer dia. ØA

TO sensor

Heat exchanger

Ø8 multiple thread

ripple 1 row 22 stages

FP1.3 flat fin

Outdoor unit

TE

sensor

Distributor

Refrigerant pipe

at gas side

Outer dia. ØB

Max

30m

Packed valve

Outer dia. ØB

PMV

(SKV-18D26)

Strainer

R410A 0.9 kg

Cooling

Heating

Pressure

(MPa) (kg/cm²G)

Pd Ps Pd Ps

Standard

Cooling Overload

Low load

Standard

Heating Overload

Low load

4 poles are provided to this compressor.

*

3.1 0.9 31.9 8.9

3.6 1.0 37.1 10.4

0.9 0.7 9.1 7.1

2.3 0.6 23.6 6.2

3.3 1.2 33.2 11.8

1.7 0.2 16.4 1.8

Pipe surface temperature (°C)

Discharge Suction

(TD) (TS) (TC) (TE)

85 15 10 50

93 20 15 57

20735

71 1 39 3

78 20 54 19

110 –20 26 –22

Indoor heat

exchanger exchanger

Outdoor heat

Compressor

revolutions per

second (rps)

*

74

72

28

84

47

110

Indoor

fan

HIGH

HIGH

LOW

HIGH

LOW

HIGH

Indoor/Outdoor

temp. conditions

(DB/WB) (°C)

Indoor Outdoor

27/19 35/–

32/24 43/–

18/15.5 –5/–

20/– 7/6

30.– 24/18

15/– –20/

The compressor frequency (Hz) measured with a clamp meter is 2 times of revolutions (rps) of the compressor.

– 20 –

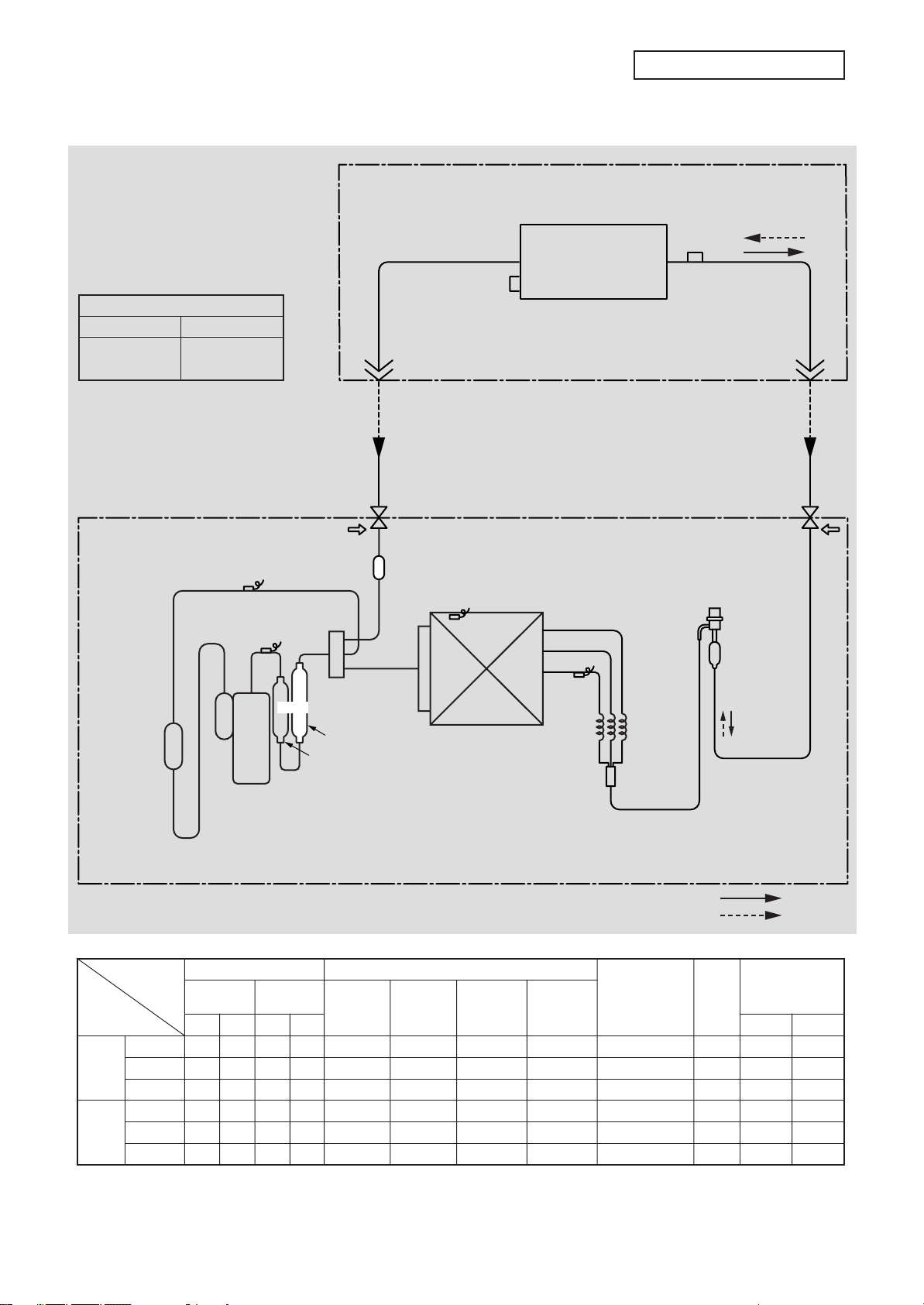

(70%)

Indoor Unit/Outdoor Unit

RAV-SM800UT-E, RAV-SM800BT-E, RAV-SM800KRT-E/RAV-SM800AT-E

Indoor unit

Air heat exchanger

TC sensor

Outer diameter of refrigerant pipe

Gas side ØA Liquid side ØB

15.9mm 9.5mm

Revised. Dec. 2003 (1)

TCJ

sensor

Accumulator

(1500cc)

TS sensor

TD sensor

Muffler

Ø25 × L160

Rotary compressor

(DA220A2F-20L)

Refrigerant pipe

at liquid side

Outer dia. ØA

Pd

Packed valve

Outer dia. ØA

Strainer

4-way valve

(STF-0213Z)

Ø25 × L210

Outdoor unit

TO sensor

TE

sensor

Heat exchangerØ8

1 row 30 stages

FP1.3 flat fin

Refrigerant pipe

at gas side

Outer dia. ØB

Packed valve

Outer dia. ØB

Modulating (PMV)

(SKV-18D26)

Capillary

Ø3×Ø2×

L530

Max

50m

Ps

Strainer

R410A 1.5 kg

Cooling

Heating

Pressure

(MPa) (kg/cm²G)

Pd Ps Pd Ps

Standard

Cooling Overload

Low load

Standard

Heating Overload

Low load

4 poles are provided to this compressor.

*

3.3 0.9 33.4 8.8

3.7 1.1 37.8 11.4

1.0 0.8 10.0 7.9

2.5 0.6 25.8 6.3

3.4 1.1 34.7 11.5

2.0 0.2 20.3 2.3

Pipe surface temperature (°C)

Discharge Suction

(TD) (TS) (TC) (TE)

86 11 9 44

90 21 18 54

19448

67 6 42 2

85 23 55 16

89 –16 34 –18

Indoor heat Outdoor heat

exchanger exchanger

Compressor

revolutions per

second (rps)

*

64

52

27

65

31

90

Indoor

fan

HIGH

HIGH

LOW

HIGH

LOW

HIGH

Indoor/Outdoor

temp. conditions

(DB/WB) (°C)

Indoor Outdoor

27/19 35/–

32/24 43/–

18/15.5 –5/–

20/– 7/6

30.– 24/18

15/– –20/

The compressor frequency (Hz) measured with a clamp meter is 2 times of revolutions (rps) of the compressor.

– 21 –

(70%)

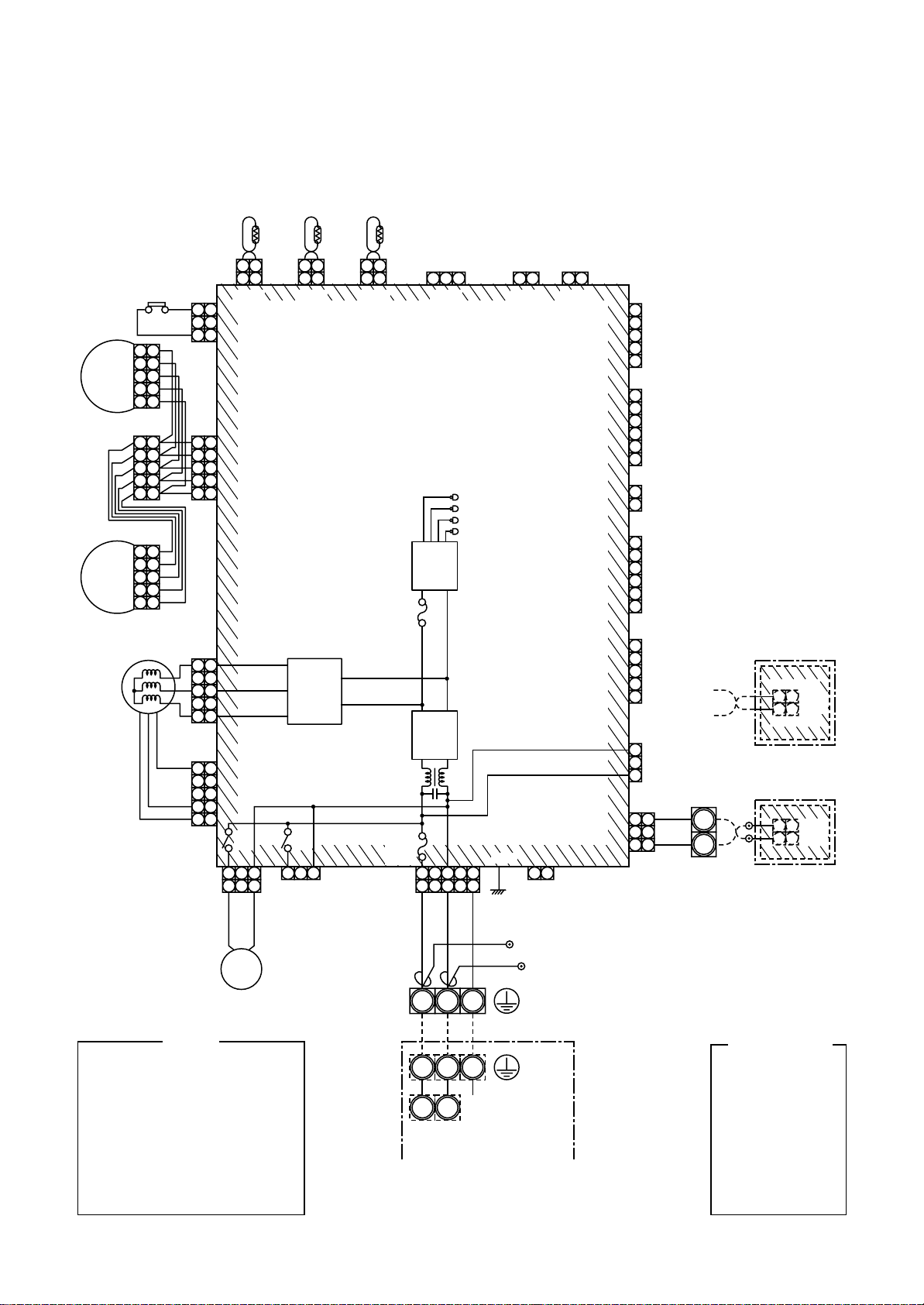

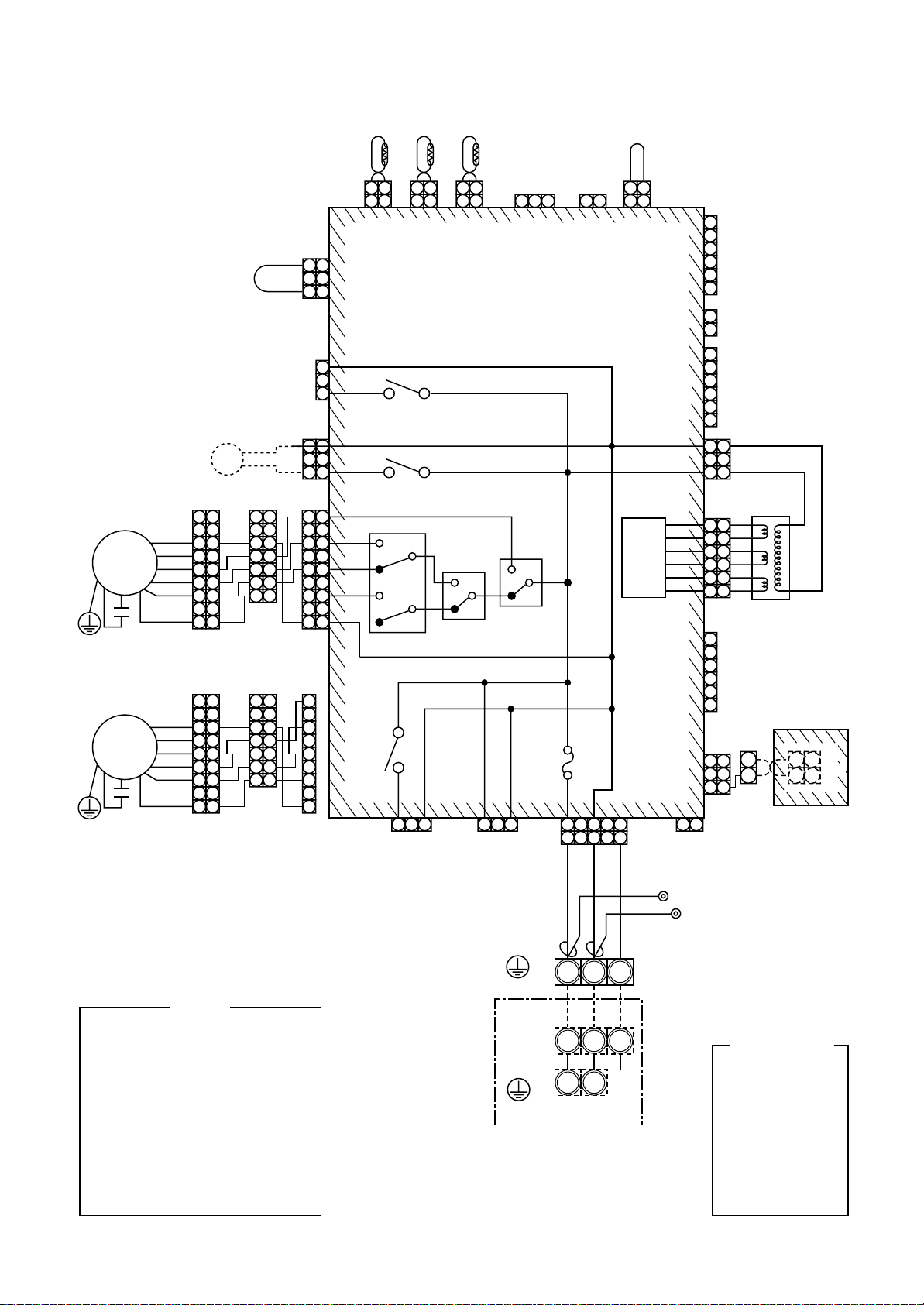

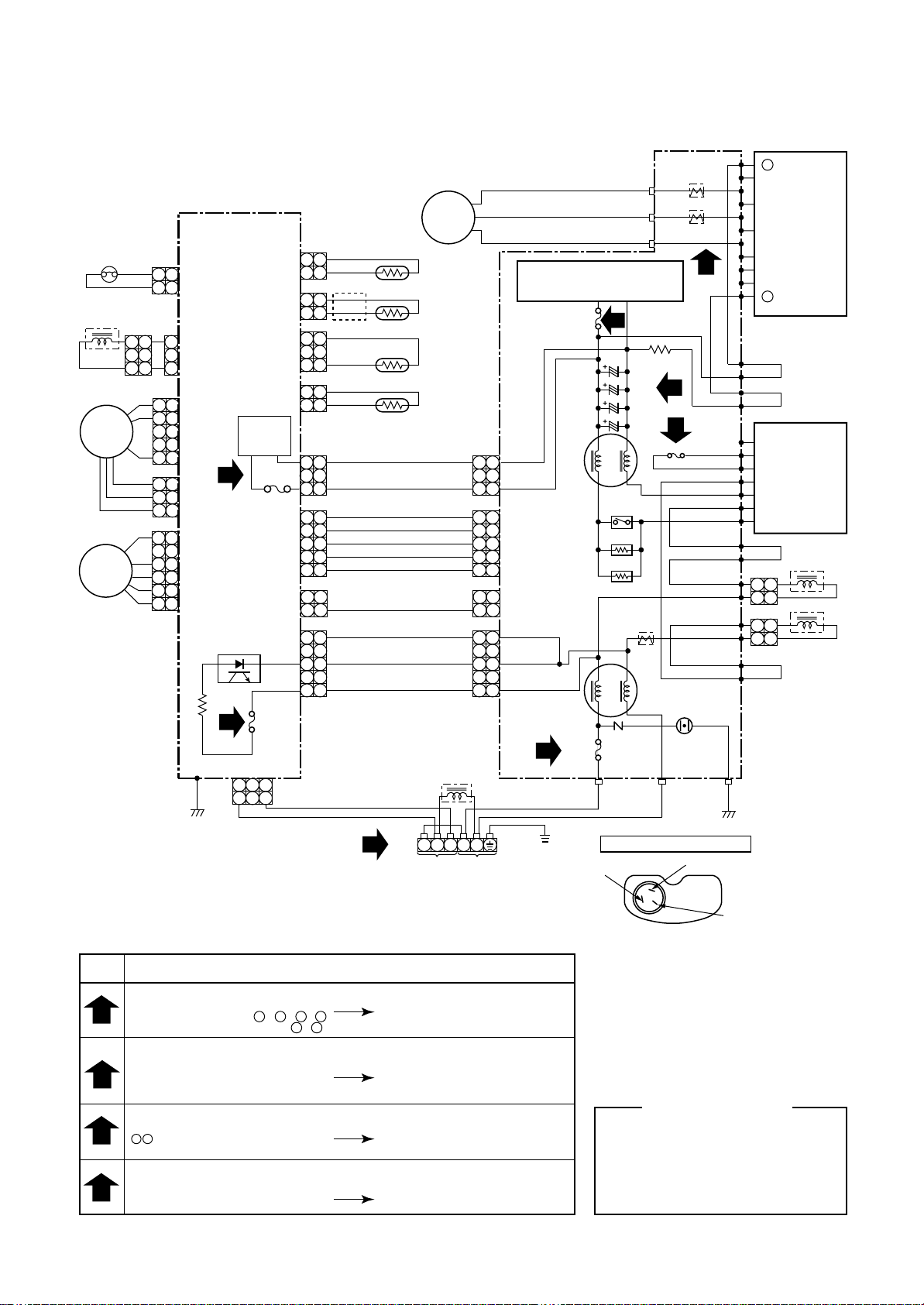

5-1. Indoor Unit

4-Way Air Discharge Cassette Type

RAV-SM560UT-E/RAV-SM800UT-E

5. WIRING DIAGRAM

LM1

LM2

FM

5 5

4 4

3 3

2 2

1 1

5 5

4 4

3 3

2 2

1 1

5 5

4 4

3 3

2 2

1 1

FS

CN34

(RED)

3 3

2 2

1 1

CN33

(WHI)

5 5

4 4

3 3

2 2

1 1

CN333

(WHI)

5 5

4 4

3 3

2 2

1 1

CN334

(WHI)

1 1

2 2

3 3

4 4

5 5

CN68

(BLU)

1 2

1 2

CN104

(YEL)

TA

1 2

1 2

CN102

(RED)

TCJ

1 2

1 2

CN101

(BLK)

TC

1 2 3

CN80

(GRN)

MCC-1402

Control P.C. Board for

Indoor Unit

Power

supply

circuit

Fuse

F302

T3.15A

250V~

Motor

drive

circuit

Motor

drive

circuit

RY

302

1 233 1 2 3

1 2

RY

303

CN304

(GRY)

DP

Fuse

F301

250V~

T6.3A

CN67

(BLK)

RED

1 233

1 2

WHI BLK

DC20V

DC15V

DC12V

DC7V

5

445

RED

WHI

P301

BLK

(EXCT)

1 2

CN73

(RED)

1 2

CN66

(WHI)

Closed-end

connector

12

CN70

(WHI)

5

4

CN620

3

(BLU)

2

1

6

5

CN60

4

(WHI)

3

2

1

CN32

2

(WHI)

1

(FAN DRIVE)

6

5

4

CN61

(YEL)

3

2

1

5

4

CN50

3

(WHI)

2

1

3

CN309

2

(YEL)

1

BLK

3

3

2 2

BLK

1 1

CN41

(BLU)

BLK

WHI

2 2

1 1

CN001

(WHI)

Adapter for

Wireless Remote

Controller

BLK

B

A

WHI

2 2

1 1

CN1

(WHI)

Wired Renote

Controller

FM

TA

TC

TCJ

LM1,LM2

DP

FS

RY302

NOTE

: Fan motor

: Indoor temp. sensor

: Temp. sensor

: Temp. sensor

: Louver motor

: Drain pump motor

: Float switch

: Drain control relay

NL

Single phase

220 to 240V

50Hz

– 22 –

321

321

Serial

signal

Indoor unit

earth screw

Outdoor unit

earth screw

Color

Identification

BLACK

:

BLK

BLUE

:

BLU

RED

:

RED

GRAY

:

GRY

PINK

:

PNK

GREEN

:

GRN

WHITE

:

WHI

BROWN

:

BRW

ORANGE

:

ORN

YELLOW

:

YEL

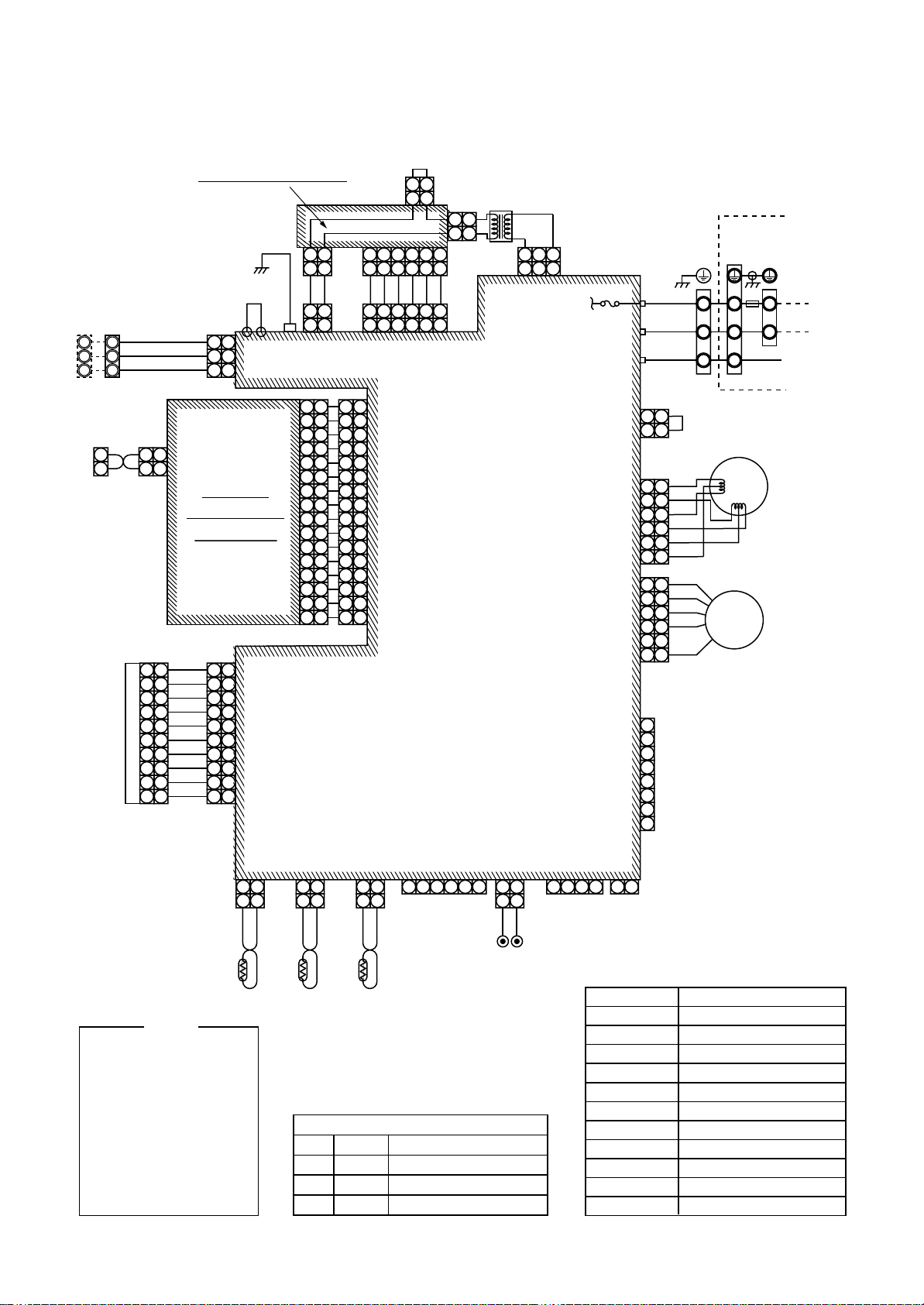

Concealed Duct Type

RAV-SM560BT-E/RAV-SM800BT-E

TA

TCJ

TC

FM

RC

FM

DP

1

1

1

2

RED

3

YEL

4

BLU

5

OPN

6

BLK

7

8

BRW

9

1

2

RED

3

YEL

4

BLU

5

OPN

6

BLK

7

8

BRW

9

(When selecting

high-static pressure)

2

2

3

3

4

4

5

5

6

6

7

7

8

9

1

1

2

2

3

3

4

4

5

5

6

6

7

7

8

9

1

2

3

4

5

6

7

1

2

3

4

5

6

7

FS

CN030

(RED)

LM

CN033

(GRN)

CN068

(BLU)

YEL

BLU

ORN

BLK

RED

CN083

(WHI)

3 3

2 2

1 1

3 3

2 2

1 1

1

2

3

4

5

6

7

8

9

1

2

3

4

5

6

7

8

9

1 2

1 2

CN104

(YEL)

3

2

1

UL

1

2

L

3

4

M

5

6

H

7

8

9

CN102

(RED)

RY001

RY002

RY007

RY

004

1

CN304

(GRY)

1 2

1 2

2 3

1 2

1 2

CN101

(BLK)

RY006

1 2 3

CN080

(GRN)

RY005

1 2 3

CN309

(YEL)

PNL EXCT

1 2

CN073

(RED)

Fuse

F001

T5A

250V~

1 2 3 4 5

1 2 3 4 5

RED

WHI

BLK

1 2

1 2

CN070

(WHI)

Power

supply

circuit

CN067

(BLK)

RED

WHI

CN060

(WHI)

CN032

(WHI)

CN061

(YEL)

CN066

6

5

4

OPTION

3

2

1

2

1

6

5

4

3

2

1

3 3

2 2

1 1

CN074

(WHI)

6

6

5 5

4 4

3 3

2 2

1 1

CN075

(WHI)

6

5

4

3

2

1

CN050

(WHI)

3 3

2 2

1 1

CN041

(BLU)

1 2

(WHI)

Closed-end

connector

FAN

DRIVE

B

A

TR

2

2

CN1

1

1

Remote

Controller

FM

RC

TR

LM

TA

TC, TCJ

RY001

RY002

RY005~007

DP

NOTE

: Fan motor

: Runing capacitor

: Transformer

: Louver motor

: Indoor temp. sensor

:

Indoor heat exchanger sensor

: Louver control relay

: Drain control relay

: Air volume control relay

: Drain pump motor

Indoor unit

earth screw

– 23 –

Outdoor unit

earth screw

321

321

NL

Color

Identification

BLACK

:

BLK

BLUE

:

BLU

RED

:

RED

GRAY

:

GRY

PINK

:

PNK

GREEN

:

GRN

WHITE

:

WHI

BROWN

:

BRW

ORANGE

:

ORN

YELLOW

:

YEL

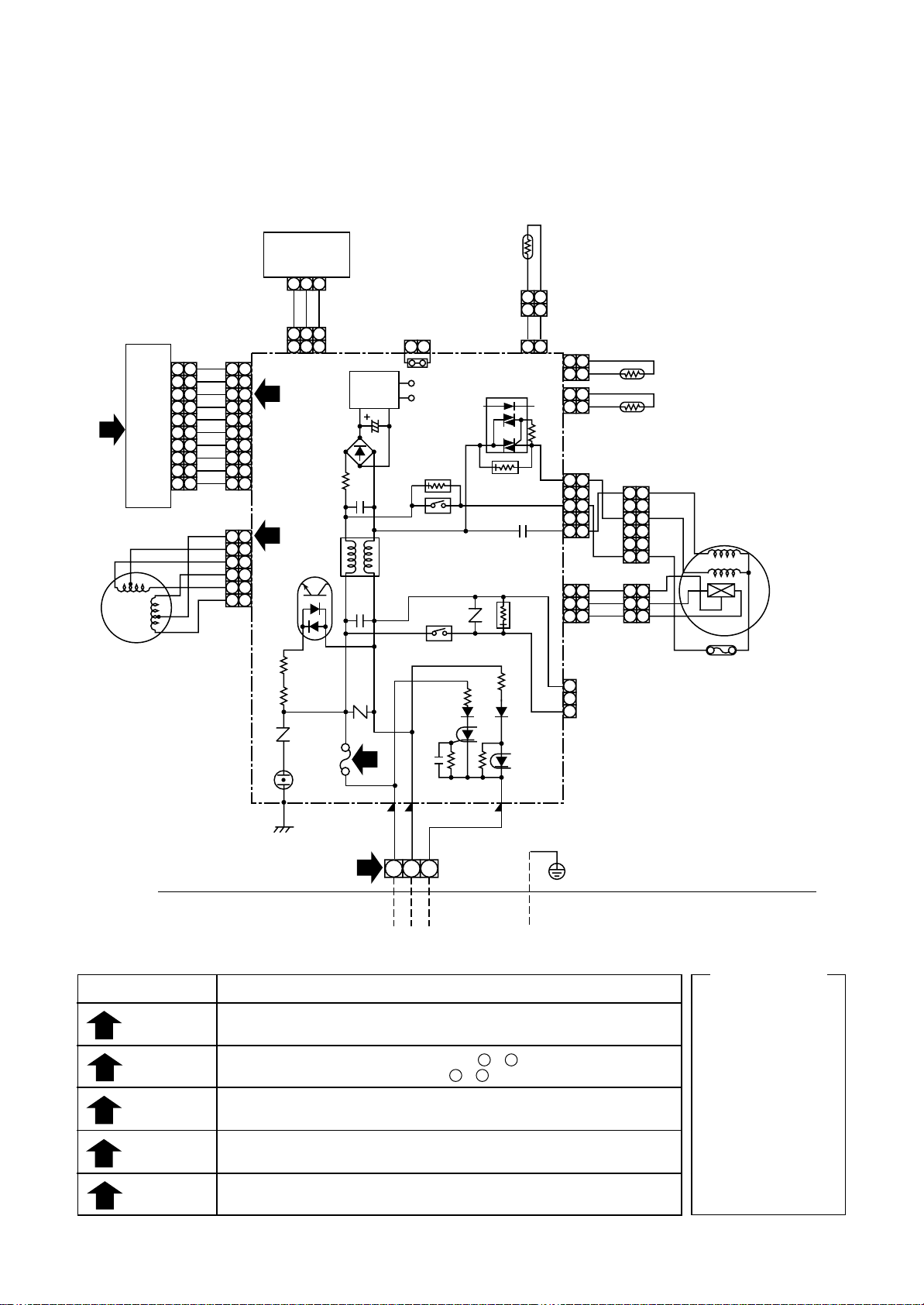

High-Wall T ype

RAV-SM560KRT-E/RAV-SM800KRT-E

Remote Controller

(Option)

ORG

A

A

YEL

B

B

BLU

C

C

Central Centroller

Connection (Option)

1 1

X

2

Y 2

CN01

RED

1 1

2 2

3 3

4 4

5 5

6 6

7 7

8 8

Infra-Red Receiver

9 9

10 10

CN25

SUB-CONTROL P.C. BOARD

CN

240

BLK

P02

P03

1 1

2 2

3

3

CN02

WHI

AI-NET

P.C. BOARD

MCC-1337

BLU

1

2

3

4

5

6

7

8

9

10

CN213

WHI

1

2

3

4

5

6

7

8

9

10

BLU

BLU

BLU

BLU

BLU

BLU

BLU

BLU

WHI

WHI

1

CN01

122

BLK

TR

CN12

1 1

2 2

1

1

1

1

1 1

2 2

3 3

4 4

5 5

6 6

7 7

8 8

9 9

10

10

11 11

12 12

13 13

14 14

15 15

16 16

CN02

WHI

2

2

2

2

CN63

WHI

CN64

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

CN31

WHI

6

6

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

1

2

3344556

1

2

1

2

3344556

1

2

CN62

WHI

CN61

WHI

CN16

BLU

MCC-1370A

1

12233

Control P.C. Board for

Indoor Unit

F201

T3,15A

250V~

Indoor unit

GRN&YEL

RED

CN230

WHI

CN231

BLK

CN223

CN11

WHI

2 2

1 1

CN207

WHI

BLU

6 6

PNK

5 5

YEL

4 4

OPG

3 3

RED

2 2

BRN

1 1

BLU

6 6

YEL

5 5

WHI

4 4

BLK

3 3

2 2

RED

1 1

CN210

WHI

1

2

3

4

CN14

5

WHI

6

7

8

Outdoor unit

(1 Phase model)

F2

1

1

2

2

3

3

LM

FM

Earth

Screw

L

Power Supply

220/240 50Hz

N

Serial Signal

NOTE

: Fuse (PCB)

F

: Fan motor

FM

: Louver motor

LM

: Temperature sensor

TA

: Temperature sensor

TC

: Temperature sensor

TCJ

: Transformer

TR

: Outdoor

O/D

: Remote Contoller

R/C

2

2

BLK

TA

1

1

BLK

CN04

WHI

2

2

BLK

TC

D05

D02

D13

D11

1

1

BLK

CN05

WHI

Orange

Green

Orange

Green

2

2

BLK

TCJ

1

1

BLK

CN20

YEL

CN13

WHI

234

LED Detall

O/D Serial Signal Input

O/D Serial Signal Output

R/C Serial Signal Input

R/C Serial Signal Output

– 24 –

1

1

2

1

2

CN50

WHI

GRY

PNK

CN06

WHI

121

23456

CN21

WHI

Chack Code

04

08

09

0C

0d

0F

11

12

97

98

99

Diagnosis

Serial Signal Error

4-Way Valve Error

I/D Heart Exchange Error

TA Sensor Error

TC Sensor Error

TCJ Sensor Error

Indoor Fan Error

Indoor unit Error

LAN Comms Circuit Error

LAN Adress Setting

R/C Mis-Wiring

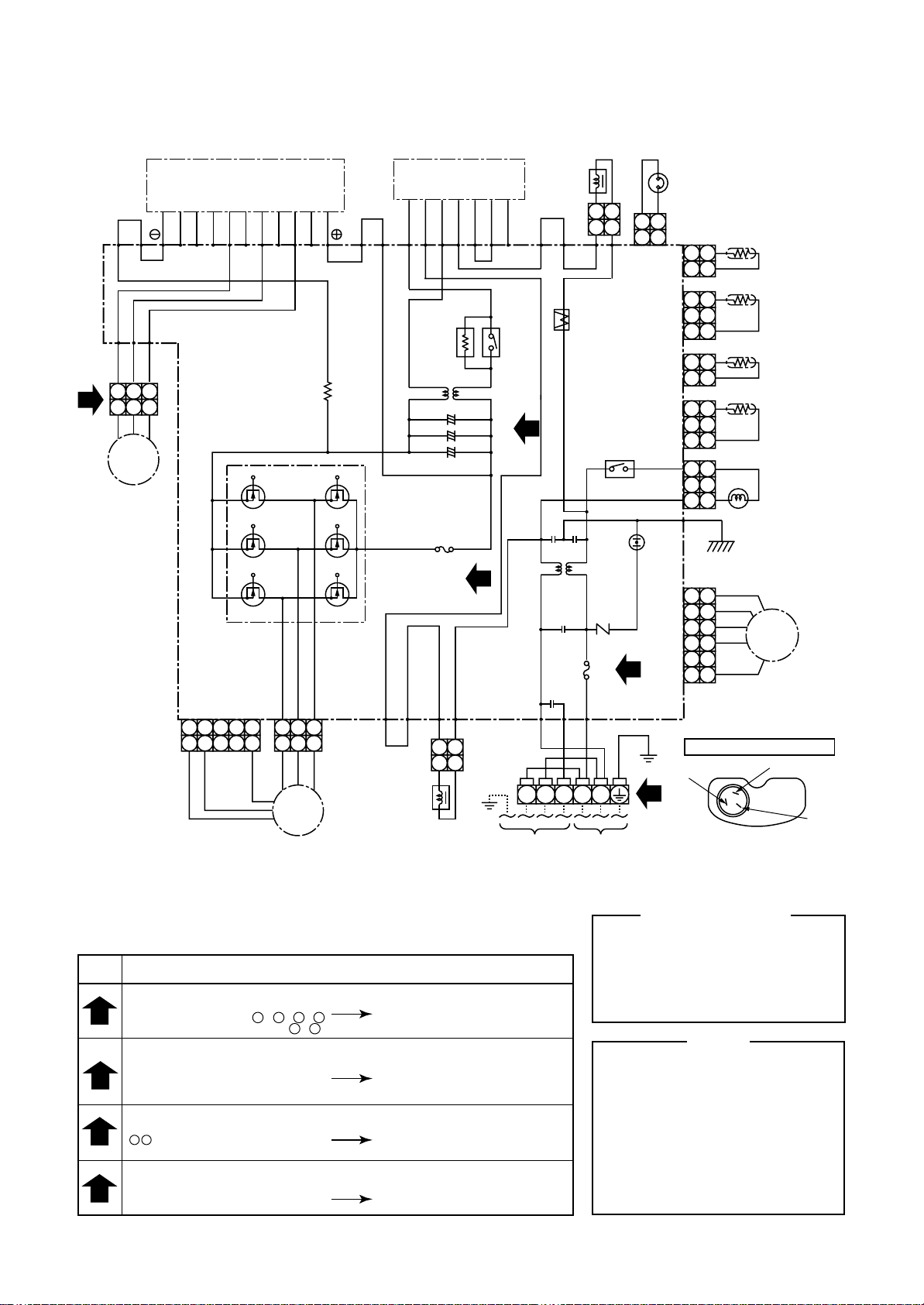

RAV-SM560XT-E/RAV-SM800XT-E

SWITCH PCB

MCC-1428B

2

LOUVER

MOTOR

WHI

10

10

BLU

9

9

BLU

8

8

BLU

7

7

BLU

6

6

BLU

5

5

BLU

4

4

BLU

3

3

BLU

2

2

BLU

1

1

AND INDICATION PARTS

CN25

INFRARED RAYS RECEIVE

BRW

RED

ORN

YEL

PNK

BLU

10

9

8

7

6

5

4

3

2

1

CN13

1

2

3

4

5

CN07

CN101

CN100

10

9

8

7

6

5

4

3

2

1

1

2

3

4

5

66

R507

R09

R22

SG01

4

5

IC04

21 3

WHI

GRY

21 3

21

250VAC

GRY

3

DB01

FUSE

F01

T6.3A

FOR FLOAT SWITCH

(OPTION)

When you use float

switch you should cut J401

CN402

POWER

SUPPLY

CIRCUIT

C02

R01

C01

C15

R21

3

EXCHANGER

SENSOR

21

J401

DC12V

DC5V

CR502

RY501

MCC-1428A

R405

RY401

HEAT

(TCJ)

CN05

IC03

CR501

C501

CR401

21

21

CN03

21

2

121

2

121

CN01

R506

1

1

2

2

3

3

4

4

5

5

CN10

3

3

2

2

1

1

CN11

3

FOR DRAIN PUMP

2

1

CN401

BLK

BLK

BLK

BLK

WHI

RED

BLK

BRW

GRY

YEL

(OPTION)

1

1

2

2

3

3

4

4

5

5

66

3

3

2

2

1

1

THERMO

SENSOR

(TA)

HEAT

EXCHANGER

SENSOR

(TC)

WHI

RED

BLK

BLU

PUR

GRY

FAN-MOTOR

100”C

Check items

OPERATION

1

indicator

Terminal

2

block

Fuse

3

6.3A

DC 5V

4

DC 12V

5

BLK

P04

CN30

2

BLK

CN31

WHI

21

RED

INDOOR

TERMINAL

3

BLOCK

CN23

GRN&YEL

SIMPLE CHECK POINTS FOR DIAGNOSING FAULTS

Diagnosis result

Check to see if OPERATION indicator goes on and off when the main switch

or breaker is turned on.

Check the power supply voltage between 1 - 2 (Refer to the name plate.)

Chack the fluctuate voltage between 2 - 3 (DC15 to 60V)

Check to see if the fuse blows out. (Check the varistor. : R22, R21)

Check the voltage at the No.8 pin on CN13 connector of the infrared receiver.

(Check the transformer and the power supply circuit of the rated voltage.)

Check the voltage at the brown lead of the louver motor.

(Check the transformer and the power supply circuit of the rated voltage.)

INDOOR

UNIT

OUTDOOR

UNIT

Identification

BRW

RED

GRY

PNK

ORN

GRN&YEL

GRN

PUR

Color

WHI

YEL

BLU

BLK

BROWN

:

RED

:

WHITE

:

YELLOW

:

BLUE

:

BLACK

:

GRAY

:

PINK

:

ORANGE

:

GREEN&

:

YELLOW

GREEN

:

PURPLE

:

– 25 –

5-2. Outdoor Unit

RAV-SM560AT-E

Q200

BLU

P17 P18

P21

P22

P23

RED

WHI

BLK

4

2 1

233 1

CM

COMPRESSOR

CN301

IGBT MODULE

BZBYBXEWBWEVBVEUBU

P.C. BOARD

(MCC-813)

5

5

GRY

4 3

PNK

2 1

YEL

3

3

BLK

2 1

2 1

WHI

RED

2 1

4 3

FM

FAN MOTOR

Q300

CN300

BRW

P14

PUR

REACTOR

DB01

CONVERTER

MODULE

~

–

+

P19P20

ELECTRONIC

STARTER

F04

FUSE

T3. 15A

250V~

P13

P12

–

–

–

2 1

2 1

REACTOR

ORN

~

GEA

P10

2 1

2 1

P09

P08 P07

CT

POWER

RELAY

+

C12

+

+

C13

C14

3

RELAY

THERMOSTAT

FOR

COMPRESSOR

CN500

2 1

2 1

CN600

CN601

CN602

CN603

TE

11

22

TD

11

22

33

TO

11

22

TS

11

22

33

11

P11

2

P02

WHI

2

1

TO

INDOOR

UNIT

FUSE

T25A

250V~

P03

ORN

3

VARISTOR

F01

P01

BLK

L

N

POWER

SUPPLY

220 to 240

50Hz

CN701

P06

SURGE

ABSORBER

2

1

22

33

COIL FOR

11

22

33

44

55

66

BLK

YEL

RED

ORN

RED

GRY

4-WAY VALVE

PMV

PULSE

MODULATING

VALVE

BLACK (C)

RED (R)

BLK

CN703

TERMINAL OF COMPRESSOR

WHITE (S)

The sign in ( ) is displayed

in the terminalcover

Check

items

1

2

3

4

SIMPLE CHECK POINTS FOR DIAGNOSING FAULTS

Diagnosis result

TERMINAL BLOCK

There is no supply voltage

(AC220 to 240V) between L - N , 1 - 2

There is no voltage (DC15 to 25V) 2 - 3

FUSE

T25A 250V to fuse (F01) blown

T3.15A 250V to fuse (F04) blown

ELECTROLYTIC CAPACITOR VOLTAGE (C12, C13, C14)

DC320V not available between

+ – terminal of electrolytic capacitor

INVERTER OUTPUT (Inverter and compressor connector out of position)

(Please confirm within six minutes after instructing in the drive.)

Voltage between each line of in v erter side

conector pins are not equal.

Power supply and connecting

cable check

Converter module (DB01) and

electrolytic capacitor (C12 to C14) check

IGBT module (Q200) check

Fan motor check

T25A fuse (F01) check

P.C. board and converter

module (DB01) check

IGBT module and

P.C. board check

– 26 –

Color Identification

BLK

BLU

RED

GRY

PNK

GRN

BLACK

:

BLUE

:

RED

:

GRAY

:

PINK

:

GREEN

:

WHI

BRW

ORN

YEL

PUR

NOTE

: Compressor

CM

: Pulse modulating valve

PMV

: Fan motor

FM

: Heat exchanger Temp. Sensor

TE

: Discharge Temp. Sensor

TD

: Outdoor Temp. Sensor

TO

: Suction Temp. Sensor

TS

: Insulated Gate Bipolar Transistor

IGBT

: Converter module

DB01

: Curreut Transformer

CT

: Fan motor driver module

Q300

:

WHITE

:

BROWN

:

ORANGE

:

YELLOW

:

PURPLE

RAV-SM800AT-E

THERMOST AT

FOR

COMPRESSOR

ORN

212

ORN

4-WAY VALVE COIL

313

1

FAN MOTOR

5

4

FM

1

3

2

1

6

5

PMV

SUB

P.C. BOARD

(MCC-1398)

4

3

2

1

SIMPLE CHECK POINTS FOR DIAGNOSING FAULTS

CN500

1

3

CN700

1

5

4

CN300

3

232

1

3

2

1

6

5

4

3

2

1

2

CN301

CN702

PHOTO COUPLER

2

CN02

Fan

circuit

CN302

F300

FUSE

T5A

CN800

2 31

2 31

Compressor

212

CN604

CN605

CN600

CN601

CN04

CN01

F01

FUSE

T3.15A

1

212

GRN

1

3

2

131

212

1

313

1

5 5 5 5

4 4 4 4

3 3 3 3

212

1

212

1

5 5 5 5

4 4 4 4

3 3 3 3

212

1

GRY

WHI

BLU

YEL

BLK

WHI

BLU

RED

PNK

ORN

BLK

WHI

RED

RED

1

CM

TE

TS

TD

TO

REACTOR

TO

INDOOR

UNIT

313

212

212

212

L N2 31

POWER

SUPPL Y

220-240V

~50Hz

RED

WHI

BLK

POWER SUPPLY CIRCUIT

(FOR P.C. BOARD)

F04

FUSE

3.15A

CN04

1

CN06

P.C. BOARD

1

(MCC-1359)

CN05

1

1

CN13

F01

FUSE

2

25A

WHITE(S)

+

BU

EU

BV

EV

BW

EW

BX

BY

BZ

CN09

CN10

CN11

T03

CT

T04

CT

4

2

P20

P10

P11

P13

P12

P09

P08

P15

P14

CN03

BLKWHIRED

P19

P18

P17

G

E

A

~

~

+

REACTOR

212

REACTOR

212

RED(R)

C13

3

C12

C11

C10

POWER

RELAY

RY01

R05

R06

T02

CT

VARISTOR

CN02CN01

TERMINAL OF COMPRESSOR

F02

2

FUSE

15A

SURGE

ABSORBER

BLACK(C)

IGBT

module

Q200

YEL

BLU

Converter

module

DB01

ORN

1

1

BRN

The sign in ( )

is displayed

in the terminal

cover

Check

items

1

2

3

4

Diagnosis result

TERMINAL BLOCK

There is no supply voltage

(AC220 to 240V) between L - N , 1 - 2

There is no voltage (DC15 to 25V) 2 - 3

FUSE

25A fuse (F01) blown, 15A fuse (F02) blown

3.15A fuse (F04) blown,

T5A fuse (F300) blown (SUB P.C. board)

T3.15A fuse (F01) blown (SUB P.C. board)

ELECTROLYTIC CAPACITOR VOLTAGE (C10, C11, C12, C13)

DC320V not available between

+ terminal of electrolytic capacitor

INVERTER OUTPUT (CN09, CN10, CN11)

(Please confirm within six minutes after instructing in the drive.)

Voltage between each line of inverterside

conector pins are not equal.

Connecting cable check

Converter module (DB01) and electrolytic

capacitor (C10 to C13) check IGBT

module (Q200) check, Fan motor check

SUB P.C. board check

25A fuse (F01) check

P.C. board and coverter

module (DB01) check

IGBT module and

P.C. board check

– 27 –

Color Identification

BLACK

:

BLK

BLU

RED

GRY

PNK

GRN

BLUE

:

RED

:

GRAY

:

PINK

:

GREEN

:

WHI

BRN

ORN

YEL

PUR

:

WHITE

:

BROWN

:

ORANGE

:

YELLOW

:

PURPLE

6. SPECIFICATIONS OF ELECTRICAL PARTS

6-1. Indoor Unit

4-Way Air Discharge Cassette Type

RAV-SM560UT-E/RAV-SM800UT-E

No.

1

Fan motor (for indoor)

2

Thermo. sensor (TA-sensor)

3

Heat exchanger sensor (TCJ-sensor)

4

Heat exchanger sensor (TC-sensor)

5

Float switch

6

Drain pump motor

Parts name

Concealed Duct Type

RAV-SM560BT-E/RAV-SM800BT-E

No.

1

Fan motor (RAV-SM800BT-E)

2

Fan motor (RAV-SM560BT-E)

3

Capacitor (RAV-SM800BT-E)

4

Capacitor (RAV-SM560BT-E)

5

Thermo. sensor (TA-sensor)

Parts name

Type

SWF-230-60-1

155 mm

Ø6 mm, 1200 mm

Ø6 mm, 1200 mm

FS-0218-106

ADP-1406

Type

STF-230-80-4C

STF-220-80-4C

EAG40M805UF1

CMPS400-4.0

818 mm

Specifications

Output (Rated) 60 W, 220–240 V

10 kΩ at 25°C

10 kΩ at 25°C

10 kΩ at 25°C

Specifications

Output (Rated) 80 W, 220–240 V, 4P

Output (Rated) 80 W, 220–240 V, 4P

400WV, 5µF

400WV, 4.0µF

10 kΩ at 25°C

6

Heat exchanger sensor (TC-sensor)

7

Heat exchanger sensor (TCJ-sensor)

High-Wall T ype

RAV-SM560KRT-E/RAV-SM800KRT-E

No.

1

Fan motor (for indoor)

2

Grille motor

3

Thermo. sensor (TA-sensor)

4

Heat exchanger sensor (TC-sensor)

5

Heat exchanger sensor (TCJ-sensor)

Parts name

RAV-SM560XT-E/RAV-SM800XT-E

No.

1

Fan motor (for indoor)

2

Grille motor

Parts name

Ø6 mm, 1200 mm

Ø6 mm, 1200 mm

Type

ICF340-30-1

MP35EA12

268 mm

Ø6 mm, 400 mm

Ø6 mm, 400 mm

Type

AFP-220-50-4A

MP35EA

10 kΩ at 25°C

10 kΩ at 25°C

Specifications

Output (Rated) 30 W, 220–240 V

10 kΩ at 25°C

10 kΩ at 25°C

Specifications

Output (Rated) 50 W, 220–240 V

DC 12 V

3

Thermo. sensor (TA-sensor)

4

Heat exchanger sensor (TC-sensor)

5

Heat exchanger sensor (TCJ-sensor)

mm

Ø6 mm, mm

Ø6 mm, mm

– 28 –

10 kΩ at 25°C

10 kΩ at 25°C

6-2. Outdoor Unit

RAV-SM560AT-E

Revised. Dec. 2003 (1)

No.

1

Fan motor

2

Compressor

3

Reactor

4

Outdoor temp. sensor (To-sensor)

5

Heat exchanger sensor (Te-sensor)

6

Suction temp. sensor (Ts-sensor)

7

Discharge temp. sensor (Td-sensor)

8

Fuse (Switching power (Protect))

9

Fuse (Inverter, input (Current protect)

10

4-way valve solenoid coil

11

Compressor thermo. (Protection)

RAV-SM800AT-E

No.

1

Fan motor

Parts name

Parts name

Type

ICF-140-43-1

DA130A1F-23F

CH-57

—

—

—

—

STF-0108G

US-622

Type

ICF-140-63-1

Specifications

Output (Rated) 40 W

3 phase, 4P, 1100 W

10 mH, 16A

10 kΩ at 25°C

10 kΩ at 25°C

10 kΩ at 25°C

50 kΩ at 25°C

T3.15 A, AC 250 V

25 A, AC 250 V

ON : 90 ± 5°C, OFF : 125 ± 4°C

Specifications

Output (Rated) 63 W, 220–240 V

2

Compressor

3

Reactor

4

Outdoor temp. sensor (To-sensor)

5

Heat exchanger sensor (Te-sensor)

6

Suction temp. sensor (Ts-sensor)

7

Discharge temp. sensor (Td-sensor)

8

Fuse (Switching power (Protect))

9

Fuse (Inverter, input (Current protect))

10

4-way valve solenoid coil

11

Compressor thermo. (Protection)

6-3. Accessory Separate Sold Parts

RBC-U21PG (W) E (Ceiling panel)

No.

1

2

Motor-louver

Parts name

DA220A2F-20L

CH-47

—

—

—

—

DKV-M0ZS743B0

Type

MP24GA

3 phase, 4P, 1600 W

8 mH, 16 A

10 kΩ at 25°C

10 kΩ at 25°C

10 kΩ at 25°C

50 kΩ at 25°C

T3.15 A, AC 250 V

25 A, AC 250 V

ON : 90 ± 5°C, OFF : 125 ± 4°C

Specifications

DC 12 V

TCB-DP11E (Drain up pump)

No.

1

2

Pump-drain

Parts name

Type

PJD-05230TF-1

– 29 –

Specifications

AC 220–240 V

7. REFRIGERANT R410A

This air conditioner adopts the new refrigerant HFC

(R410A) which does not damage the ozone layer.

The working pressure of the new refrigerant R410A

is 1.6 times higher than conventional refrigerant

(R22). The refrigerating oil is also changed in

accordance with change of refrigerant, so be careful

that water, dust, and existing refrigerant or refrigerating oil are not entered in the refrigerant cycle of the

air conditioner using the new refrigerant during

installation work or servicing time.

The next section describes the precautions for air

conditioner using the new refrigerant. Conforming to

contents of the next section together with the

general cautions included in this manual, perform

the correct and safe work.

7-1. Safety During Installation/Servicing

As R410A’s pressure is about 1.6 times higher than

that of R22, improper installation/servicing may

cause a serious trouble. By using tools and materials exclusiv e for R410A, it is necessary to carry out

installation/servicing safely while taking the following

precautions into consideration.

(1) Ne ver use refrigerant other than R410A in an air

conditioner which is designed to operate with

R410A.

If other refrigerant than R410A is mixed, pressure in the refrigeration cycle becomes abnormally high, and it may cause personal injury, etc.

by a rupture.

(2) Confirm the used refrigerant name, and use

tools and materials exclusiv e for the refrigerant

R410A.

The refrigerant name R410A is indicated on the

visible place of the outdoor unit of the air conditioner using R410A as refrigerant. To prevent

mischarging, the diameter of the service port

differs from that of R22.

(3) If a refrigeration gas leakage occurs during

installation/servicing, be sure to ventilate fully.

If the refrigerant gas comes into contact with fire,

a poisonous gas may occur.

(4) When installing or removing an air conditioner,

do not allow air or moisture to remain in the

refrigeration cycle. Otherwise, pressure in the

refrigeration cycle may become abnormally high

so that a rupture or personal injury may be

caused.

(5) After completion of installation work, check to

make sure that there is no refrigeration gas

leakage.

If the refrigerant gas leaks into the room, coming

into contact with fire in the fan-driven heater,

space heater, etc., a poisonous gas may occur.

(6) When an air conditioning system charged with a

large volume of refrigerant is installed in a small

room, it is necessary to exercise care so that,

even when refrigerant leaks , its concentration

does not exceed the marginal level.

If the refrigerant gas leakage occurs and its

concentration exceeds the marginal level, an

oxygen starvation accident may result.

(7) Be sure to carry out installation or removal

according to the installation manual.

Improper installation may cause refrigeration

trouble, water leakage, electric shock, fire, etc.

(8) Unauthorized modifications to the air conditioner

may be dangerous. If a breakdown occurs

please call a qualified air conditioner technician

or electrician.

Improper repair’s may result in water leakage,

electric shock and fire, etc.

7-2. Refrigerant Piping Installation

7-2-1. Piping Materials and Joints Used

For the refrigerant piping installation, copper pipes

and joints are mainly used. Copper pipes and joints

suitable for the refrigerant must be chosen and

installed. Furthermore, it is necessary to use clean

copper pipes and joints whose interior surfaces are

less affected by contaminants.

(1) Copper Pipes

It is necessary to use seamless copper pipes

which are made of either copper or copper alloy

and it is desirable that the amount of residual oil

is less than 40 mg/10 m. Do not use copper

pipes having a collapsed, deformed or discolored portion (especially on the interior surface).

Otherwise, the expansion valve or capillary tube

may become blocked with contaminants.

As an air conditioner using R410A incurs

pressure higher than when using R22, it is

necessary to choose adequate materials.

Thicknesses of copper pipes used with R410A

are as shown in Table 7-2-1. Never use copper

pipes thinner than 0.8 mm even when it is

available on the market.

– 30 –