Toshiba RAV-SM562XT-E SERVICE MANUAL

FILE NO. SVM-06012

SERVICE MANUAL

AIR-CONDITIONER

UNDER CEILING / CONSOLE TYPE

RAV-SM562XT-E / RAV-SM562AT-E

AV-SM802XT-E / RAV-SM802AT-E

R

R410A

April, 2006

FILE NO. SVM-06012

CONTENTS

1. SPECIFICATIONS............................................................................................................. 1

2. CONSTRUCTION VIEWS ................................................................................................. 3

3. SYSTEMATIC REFRIGERATING CYCLE DIAGRAM ...................................................... 4

4. WIRING DIAGRAM ........................................................................................................... 5

5. SPECIFICATION OF ELECTRICAL PARTS .................................................................... 6

6. REFRIGERANT R410A .................................................................................................... 7

7. CONTROL BLOCK DIAGRAM ....................................................................................... 15

8. OPERATION DESCRIPTION.......................................................................................... 16

9. TROUBLESHOOTING CHART ...................................................................................... 21

10. DETACHMENTS ............................................................................................................ 27

11. EXPLODED VIEWS AND PARTS LIST ...................................................................... 32

Note :

This Service Manual describes explanation for the Under Ceiling 1 console type indoor unit.

For the combined outdoor unit, refer to the following Service Manual.

Outdoor unit Model name SVM to be referred

RAV-SMXX0AT-E A03-007

RAV-SPXXXAT-E A03-014

RAV-SMXX1AT-E A05-001

RAV-SMXX2AT-E A05-018

1-1. Indoor Unit (Flexi Type)

FILE NO. SVM-06012

1. SPECIFICATIONS

Model

Cooling capacity

Heating capacity

Power supply

Electrical

characteristics

Appearance

Outer

dimension

Total weight

Heat exchanger Finned tube

Fan unit Standard air flow (m3/h) 14.0 / 12.0 / 10.0 18.5 / 13.5 / 10.7

Air filter Attached main unit

Controller Attached main unit (WH-H2UE)

Dimensions pipe

Sound level (dB¥A)

Sound power level

Indoor unit

Outdoor unit

(kW)

(kW)

Cooling

Heating

Running current (A)

Power consumption

Power factor

EER

Energy efficiency class *

Energy rating *

Running current

Power consumption

Power factor

COP

Energy efficiency class *

Energy rating *

(kW)

(%)

(W/W)

(A) 8.13-7.46 12.91-11.84

(kW)

(%)

(W/W)

Main unit

Ceiling panel

(Sold separately)

Main unit

Ceiling panel

(Sold separately)

Main unit (kg)

Ceiling panel

Fan Centrifugal Centrifugal

Motor (W) 50

Gas side (mm) 12.7 15.9

Liquid side (mm) 6.4 9.5

Drain port

Model -

Panel color -

Height (mm)

Width (mm)

Depth (mm)

Height (mm)

Width (mm)

Depth (mm)

(kg)

H/M/L

(mm)

H/M/L

H/M/L

(dB¥A)

RAV-SM562XT-E RAV-SM802XT-E

RAV-SM562AT-E RAV-SM802AT-E

5.0

5.6

1 phase 230V (220-240V) 50Hz

8.95-8.20 13.15-12.06

1.87 2.72

95 94

2.67

D E

2.5 1.5

1.70

95

3.29 3.00

C

3.0

Pure white

208

1093

633 633

-

-

-

23

-

VP16

43 / 39 / 36 46 / 42 / 37

58 / 54 / 51 61 / 57 / 52

* IEC standard

** AS standard

6.7

8.0

2.46

2.67

94

D

2.5

208

1093

-

-

-

23

-

50

– 1 –

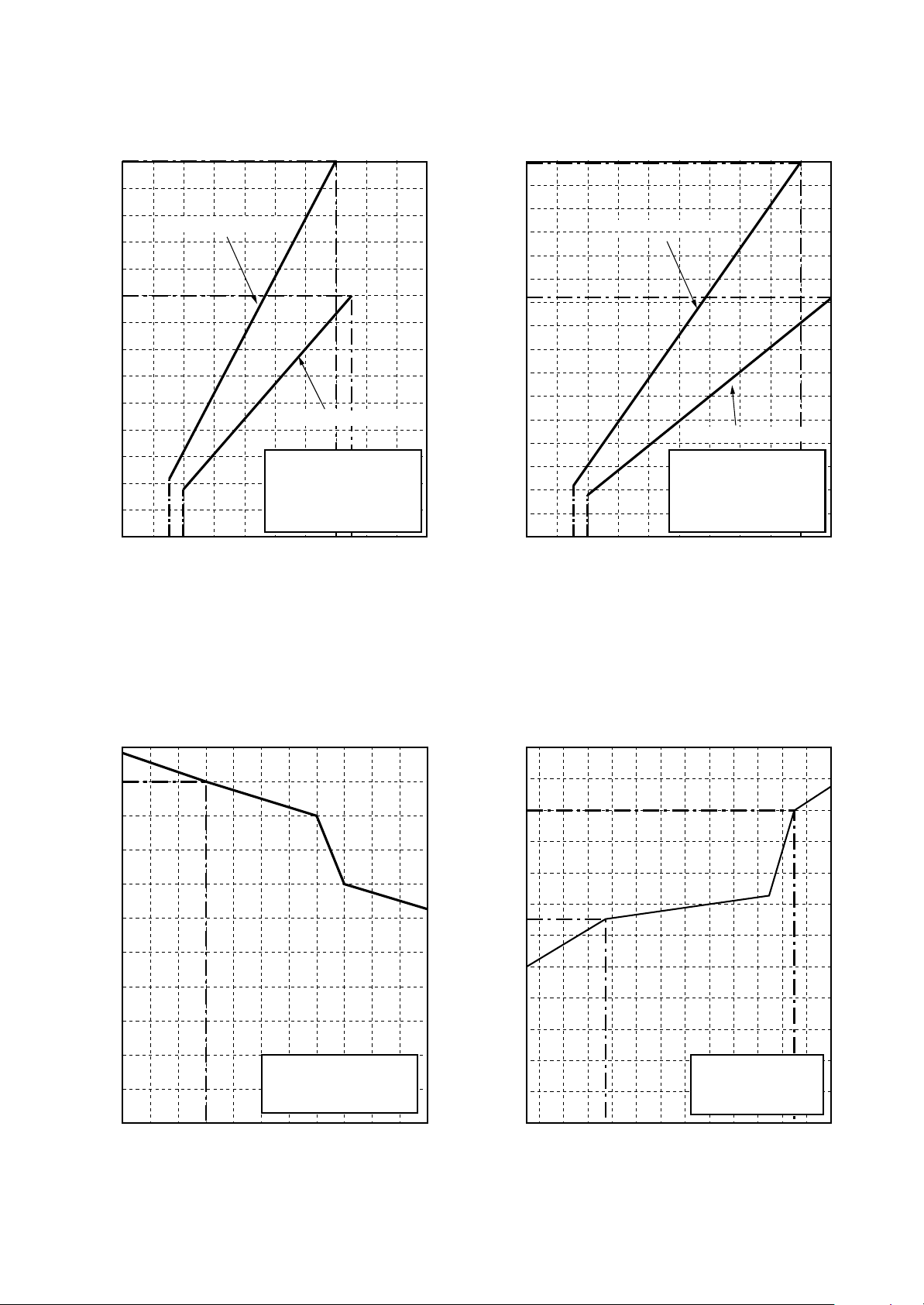

• Operation characteristic curve

<Cooling> <Heating>

14

FILE NO. SVM-06012

12

RAV-SM802XT-E

10

8

6

Current (A)

4

2

0

15

020

RAV-SM562XT-E

• Conditions

Indoor : DB27˚C/WB19˚C

Outdoor : DB35˚C

Air flow : High

Pipe length : 7.5m

230V

40 60 70 80 100

Compressor speed (rps)

14

12

10

8

Current (A)

6

4

2

0

15

020

RAV-SM802XT-E

RAV-SM562XT-E

• Conditions

Indoor : DB20˚C

Outdoor : DB7˚C/WB6˚C

Air flow : High

Pipe length : 7.5m

230V

40 60 80 90 100

Compressor speed (rps)

• Capacity variation ratio according to temperature

<Cooling> <Heating>

105

100

95

90

120

110

100

90

80

85

70

80

60

75

70

Capacity ratio (%)

65

60

55

• Conditions

Indoor : DB27˚C/WB19˚C

Indoor air flow : High

Pipe length : 7.5m

50

32 33 34 35 36 37 38 39 40 41 42 43

50

40

Capacity ratio (%)

30

20

10

0

-14-12-10-8-6-4-20246810

Outsoor temp. (˚C)

• Conditions

Indoor : DB20˚C

Indoor air flow : High

Pipe length : 7.5m

Outsoor temp. (˚C)

– 2 –

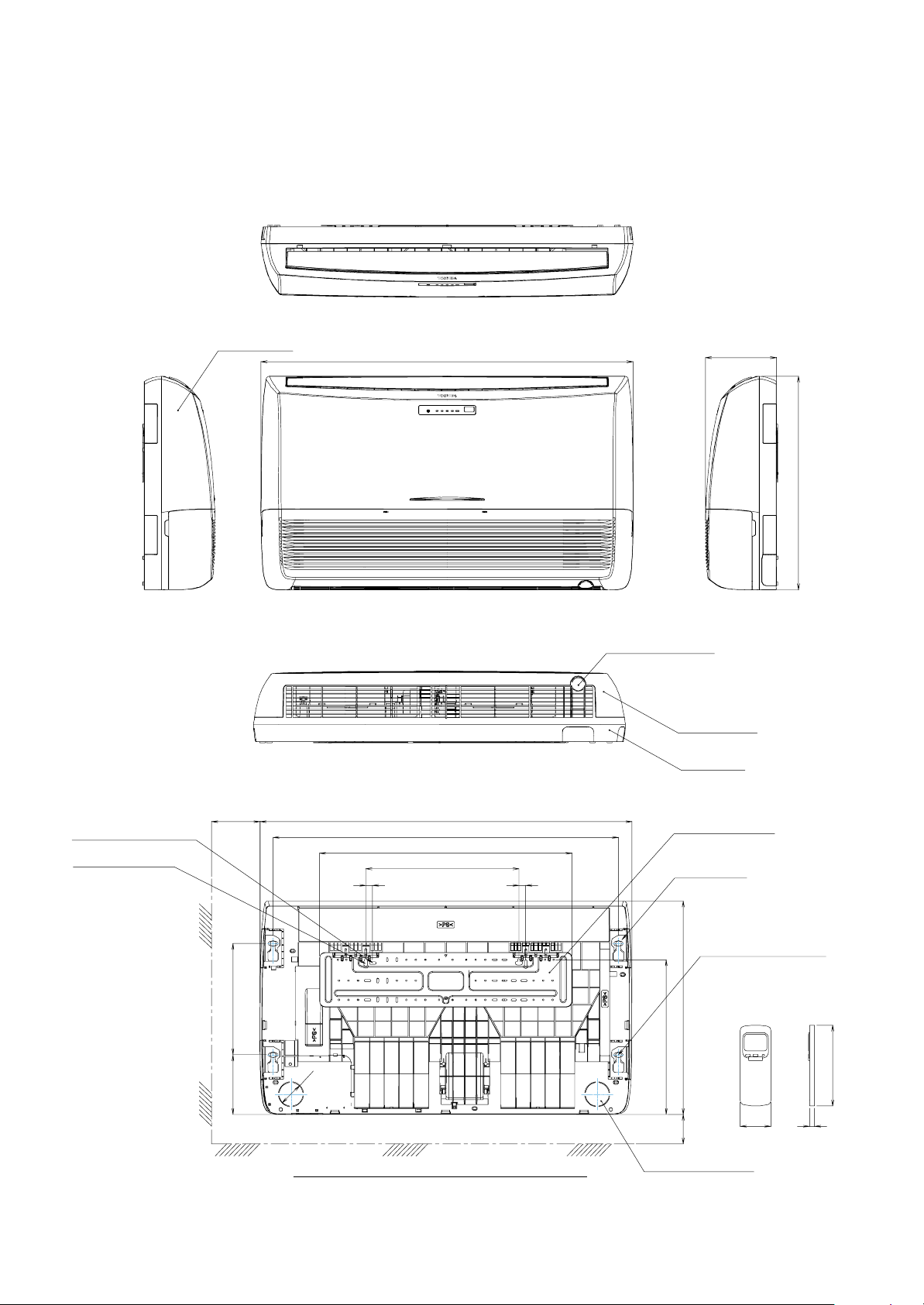

2-1. Indoor Unit

FILE NO. SVM-06012

2. CONSTRUCTION VIEWS

Front panel

1093

208

633

Knock out system

Grille air inlet

Back body

For stud bolt

(Ø8 – Ø10)

For stud bolt (Ø6)

200 Min

330165

1093

1015

742

450

20 20

Ø74

UNDER CEILING & CONSOLE INSTALLATION

– 3 –

Installation plate

Mount plate

M10 Suspention bolt

633

460

70 Min

Wireless remote control

Knock out system

160

57 18

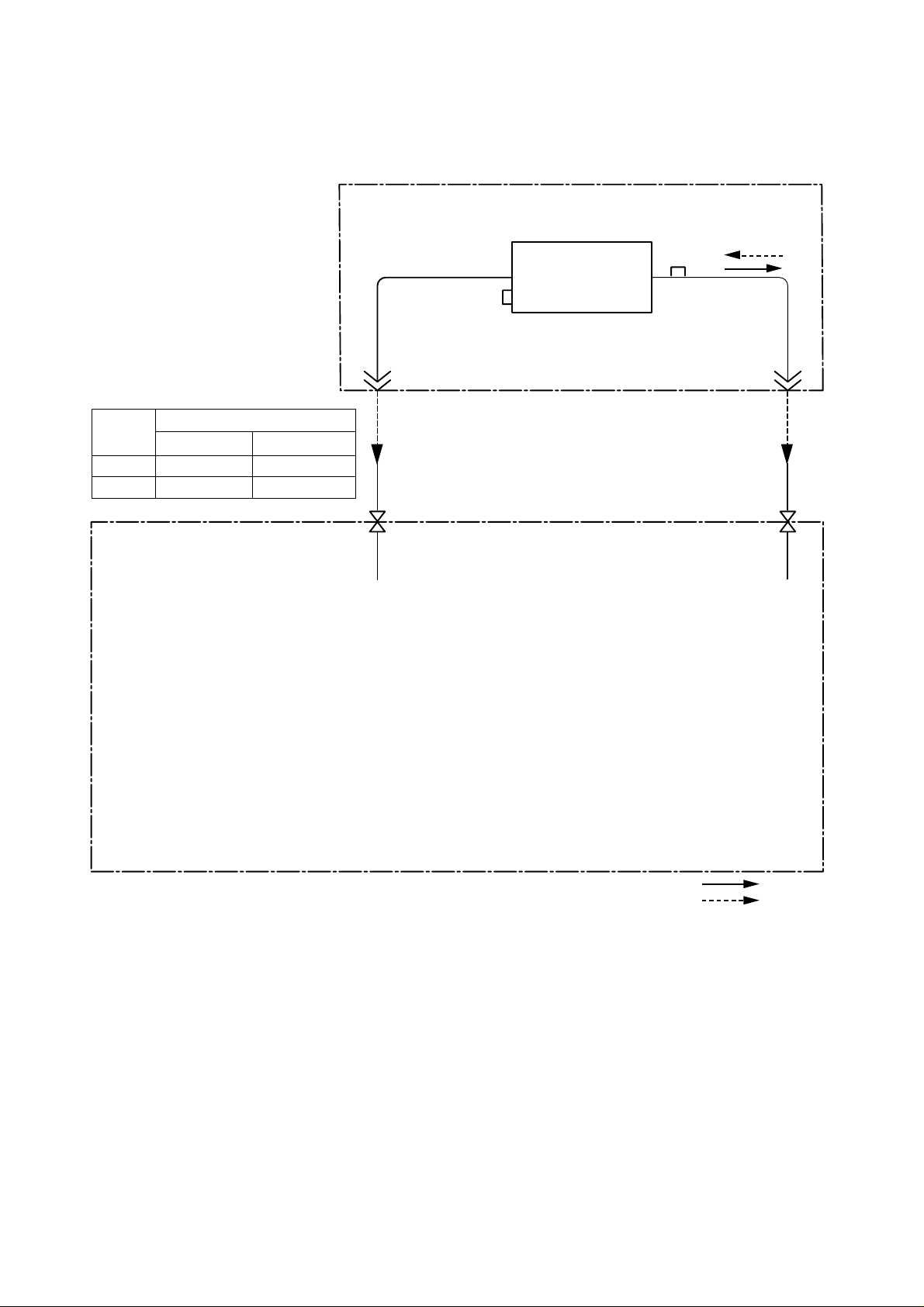

3. SYSTEMATIC REFRIGERATING CYCLE DIAGRAM

3-1. RAV-SM562XT-E / RAV-SM802XT-E

FILE NO. SVM-06012

Indoor unit

TCJ

sensor

Air heat exchanger

TC sensor

Model

RAV-SM

562XT-E

802XT-E

Outer diameter of refrigerant pipe

Gas side ∅A Liquid side ∅ B

12.7 mm 6.4 mm

15.9 mm 9.5 mm

Refrigerant pipe

at liquid side

Outer dia. ∅B

Packed valve

Outer dia. ∅B

Note :

This Service Mamual describes explanation for the Under Ceiling 1 console type indoor unit.

For the combined outdoor unit, refer to the following Service Manual.

Outdoor unit Model name SVM to be referred

RAV-SMXX0AT-E A03-007

RAV-SPXXXAT-E A03-014

RAV-SMXX1AT-E A05-001

RAV-SMXX2AT-E A05-018

Outdoor unit

Refrigerant pipe

at gas side

Outer dia. ∅A

Packed valve

Outer dia. ∅A

Max

30m

– 4 –

Cooling

Heating

Indoor Unit

1

AND INDICATION PARTS

INFRARED RAYS RECEIVE

LOUVER

MOTOR

10

10

9

8

7

6

5

4

3

2

1

CN25

FILE NO. SVM-06012

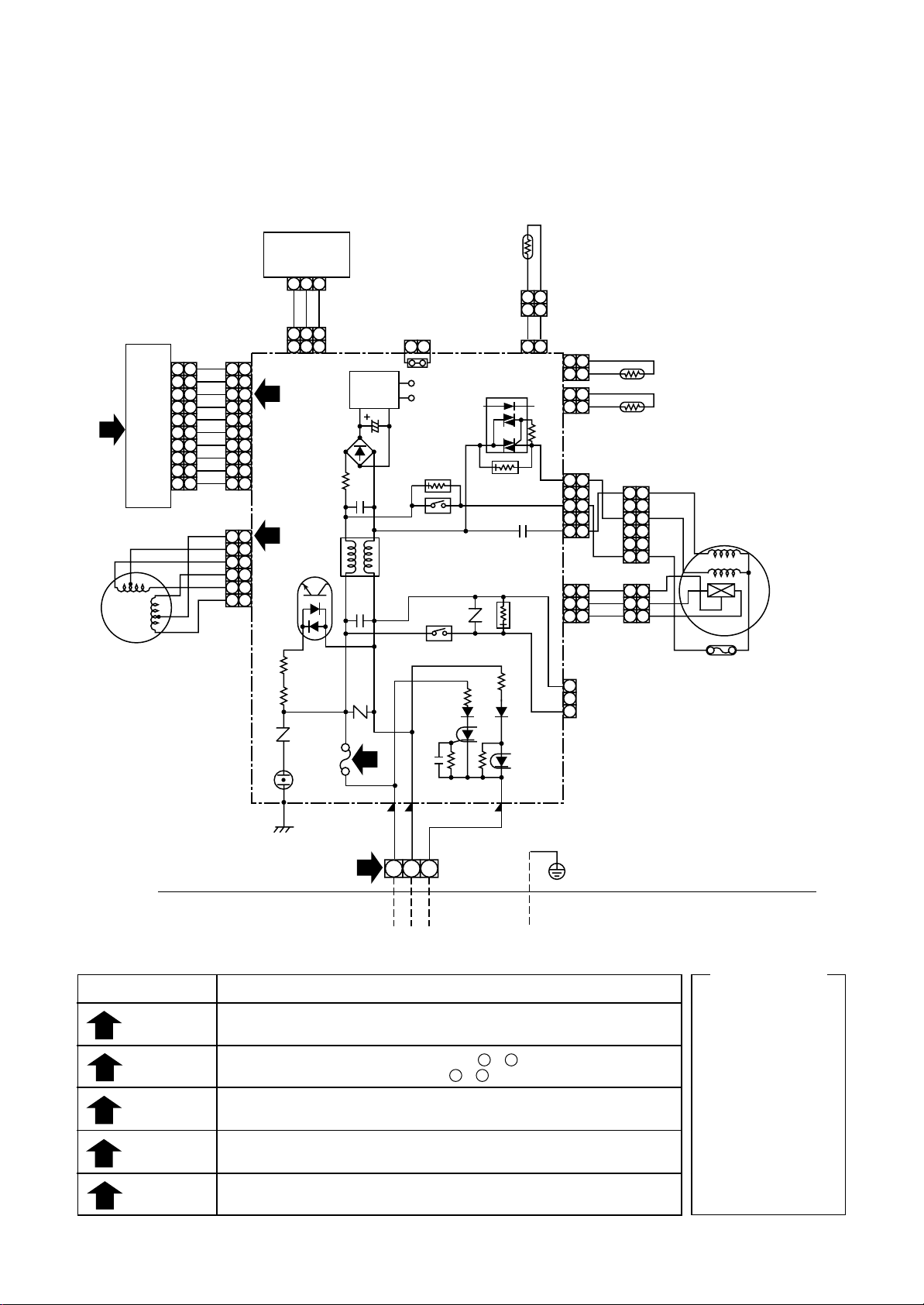

4. WIRING DIAGRAM

HEAT

SWITCH PCB

MCC-1428B

CN101

CN100

WHI

10

10

BLU

9

BLU

BLU

BLU

BLU

BLU

BLU

BLU

BLU

BRW

RED

ORN

YEL

PNK

BLU

8

7

6

5

4

3

2

1

CN13

1

2

3

4

5

CN07

9

8

7

6

5

4

3

2

1

1

2

3

4

5

66

R507

R09

R22

SG01

9

8

7

6

5

4

3

2

1

4

5

IC04

21 3

WHI

GRY

21 3

21

250VAC

GRY

3

DB01

R01

FUSE

F01

T6.3A

FOR FLOAT SWITCH

(OPTION)

When you use float

switch you should cut J401

CN402

POWER

SUPPLY

CIRCUIT

C02

C01

C15

R21

3

EXCHANGER

SENSOR

21

J401

DC12V

DC5V

CR502

RY501

MCC-1428A

R405

RY401

(TCJ)

CN05

IC03

CR501

C501

CR401

21

21

CN03

21

2

121

2

121

CN01

R506

1

1

2

2

3

3

4

4

5

5

CN10

3

3

2

2

1

1

CN11

3

FOR DRAIN PUMP

2

1

CN401

BLK

BLK

BLK

BLK

WHI

RED

BLK

BRW

GRY

YEL

(OPTION)

1

1

2

2

3

3

4

4

5

5

66

3

3

2

2

1

1

THERMO

SENSOR

(TA)

HEAT

EXCHANGER

SENSOR

(TC)

WHI

RED

BLK

BLU

PUR

GRY

FAN-MOTOR

100”C

Check items

OPERATION

1

indicator

Terminal

2

block

Fuse

3

6.3A

DC 5V

4

DC 12V

5

BLK

P04

CN30

2

BLK

CN31

WHI

21

RED

INDOOR

TERMINAL

3

BLOCK

CN23

GRN&YEL

SIMPLE CHECK POINTS FOR DIAGNOSING FAULTS

Diagnosis result

Check to see if OPERATION indicator goes on and off when the main switch

or breaker is turned on.

Check the power supply voltage between 1 - 2 (Refer to the name plate.)

Chack the fluctuate voltage between 2 - 3 (DC15 to 60V)

Check to see if the fuse blows out. (Check the varistor. : R22, R21)

Check the voltage at the No.8 pin on CN13 connector of the infrared receiver.

(Check the transformer and the power supply circuit of the rated voltage.)

Check the voltage at the brown lead of the louver motor.

(Check the transformer and the power supply circuit of the rated voltage.)

– 5 –

INDOOR

UNIT

OUTDOOR

UNIT

Identification

BRW

RED

GRY

PNK

ORN

GRN&YEL

GRN

PUR

Color

WHI

YEL

BLU

BLK

BROWN

:

RED

:

WHITE

:

YELLOW

:

BLUE

:

BLACK

:

GRAY

:

PINK

:

ORANGE

:

GREEN&

:

YELLOW

GREEN

:

PURPLE

:

FILE NO. SVM-06012

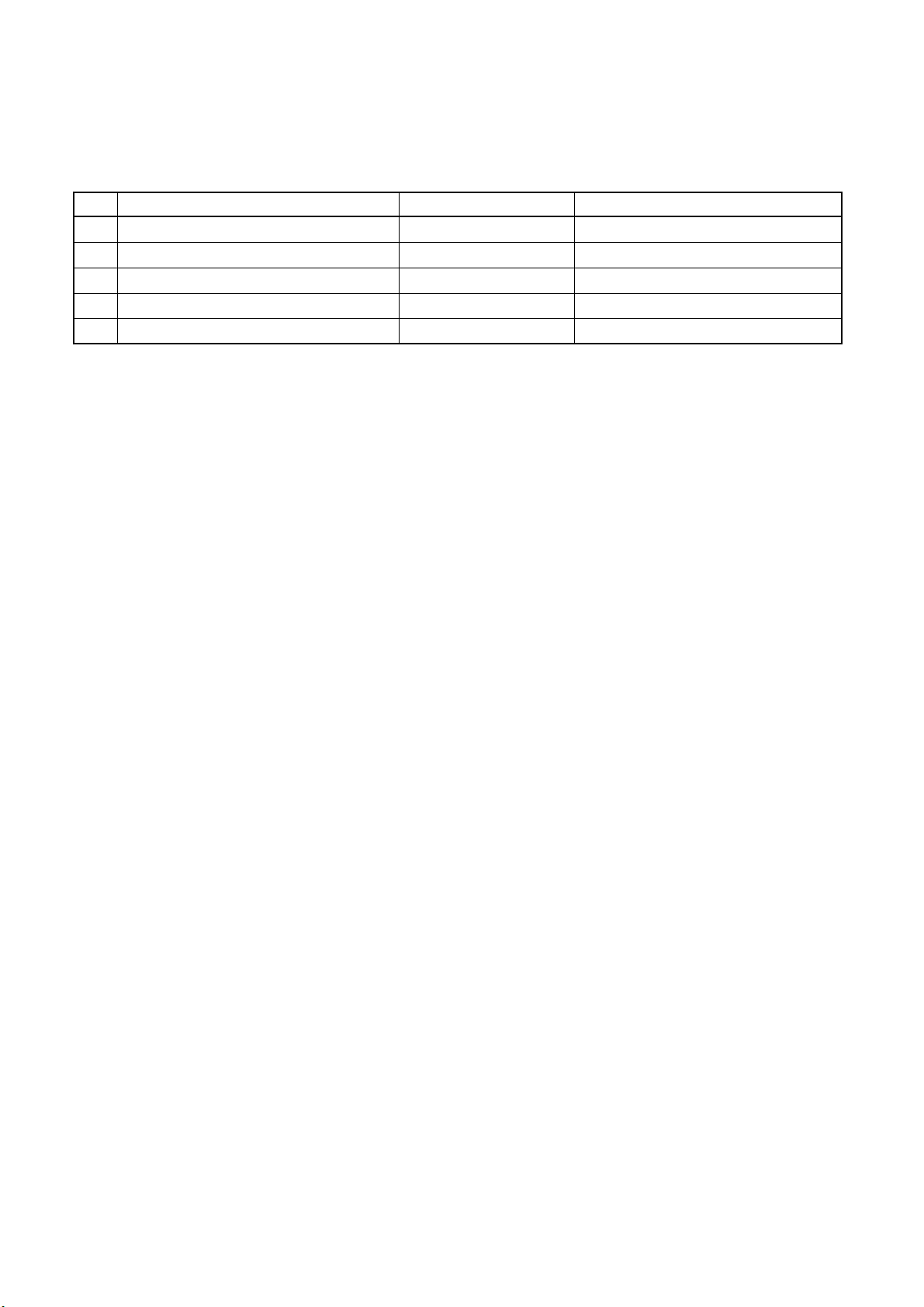

5. SPECIFICATION OF ELECTRICAL PARTS

Indoor Unit

No. Parts name Type Specifications

1 Fan motor (for indoor) AFP-220-50-4A Output (Rated) 50 W, 220 – 240 V

2 Grille motor MP35EA DC 12 V

3 Thermo. sensor (TA-sensor) 550 mm 10 kΩ at 25°C

4 Heat exchanger sensor (TC-sensor) ∅6 mm, 500 mm 10 kΩ at 25°C

5 Heat exchanger sensor (TCJ-sensor) ∅6 mm, 500 mm 10 kΩ at 25°C

– 6 –

6. REFRIGERANT R410A

FILE NO. SVM-06012

This air conditioner adopts the new refrigerant HFC

(R410A) which does not damage the ozone layer.

The working pressure of the new refrigerant R410A is

1.6 times higher than conventional refrigerant (R22).

The refrigerating oil is also changed in accordance

with change of refrigerant, so be careful that water,

dust, and existing refrigerant or refrigerating oil are not

entered in the refrigerant cycle of the air conditioner

using the new refrigerant during installation work or

servicing time.

The next section describes the precautions for air

conditioner using the new refrigerant. Conforming to

contents of the next section together with the general

cautions included in this manual, perform the correct

and safe work.

6-1. Safety During Installation/Servicing

As R410A’s pressure is about 1.6 times higher than

that of R22, improper installation/servicing may cause

a serious trouble. By using tools and materials exclusive for R410A, it is necessary to carry out installation/

servicing safely while taking the following precautions

into consideration.

(1) Never use refrigerant other than R410A in an air

conditioner which is designed to operate with

R410A.

If other refrigerant than R410A is mixed, pressure

in the refrigeration cycle becomes abnormally

high, and it may cause personal injury, etc. by a

rupture.

(2) Confirm the used refrigerant name, and use tools

and materials exclusive for the refrigerant R410A.

The refrigerant name R410A is indicated on the

visible place of the outdoor unit of the air conditioner using R410A as refrigerant. To prevent

mischarging, the diameter of the service port

differs from that of R22

(3) If a refrigeration gas leakage occurs during

installation/servicing, be sure to ventilate fully.

If the refrigerant gas comes into contact with fire,

a poisonous gas may occur.

(4) When installing or removing an air conditioner,

do not allow air or moisture to remain in the

refrigeration cycle. Otherwise, pressure in the

refrigeration cycle may become abnormally high

so that a rupture of personal injury may be

caused.

(5) After completion of installation work, check to

make sure that there is no refrigeration gas

leakage.

If the refrigerant gas leaks into the room, coming

into contact with fire in the fan-driven heater,

space heater, etc., a poisonous gas may occur.

(6) When an air conditioning system charged with a

large volume of refrigerant is installed in a small

room, it is necessary to exercise care so that,

even when refrigerant leaks, its concentration

does not exceed the marginal level.

If the refrigerant gas leakage occurs and its

concentration exceeds the marginal level, an

oxygen starvation accident may result.

(7) Be sure to carry out installation or removal

according to the installation manual.

Improper installation may cause refrigeration

trouble, water leakage, electric shock, fire, etc.

(8) Unauthorized modifications to the air conditioner

may be dangerous. If a breakdown occurs please

call a qualified air conditioner technician or

electrician.

Improper repair’s may result in water leakage,

electric shock and fire, etc.

6-2. Refrigerant Piping Installation

6-2-1. Piping materials and joints used

For the refrigerant piping installation, copper pipes and

joints are mainly used. Copper pipes and joints suitable for the refrigerant must be chosen and installed.

Furthermore, it is necessary to use clean copper pipes

and joints whose interior surfaces are less affected by

contaminants.

(1) Copper pipes

It is necessary to use seamless copper pipes

which are made of either copper or copper alloy

and it is desirable that the amount of residual oil is

less than 40 mg/10 m. Do not use copper pipes

having a collapsed, deformed or discolored

portion (especially on the interior surface).

Otherwise, the expansion valve or capillary tube

may become blocked with contaminants.

As an air conditioner using R410A incurs pressure

higher than when using R22, it is necessary to

choose adequate materials.

Thicknesses of copper pipes used with R410A are

as shown in Table 6-2-1. Never use copper pipes

thinner than 0.8 mm even when it is available on

the market.

– 7 –

FILE NO. SVM-06012

Table 6-2-1 Thicknesses of annealed copper pipes

Thickness (mm)

Nominal diameter Outer diameter (mm) R410A R22

1/4 6.35 0.80 0.80

3/8 9.52 0.80 0.80

1/2 12.70 0.80 0.80

5/8 15.88 1.00 1.00

(2) Joints

For copper pipes, flare joints or socket joints are

used. Prior to use, be sure to remove all

contaminants.

a) Flare joints

Flare joints used to connect the copper pipes

cannot be used for pipings whose outer

diameter exceeds 20 mm. In such a case,

socket joints can be used.

Sizes of flare pipe ends, flare joint ends and

flare nuts are as shown in Tables 6-2-3 to 6-2-6

below.

Table 6-2-2 Minimum thicknesses of socket joints

Nominal diameter

Reference outer diameter of Minimum joint thickness

1/4 6.35 0.50

3/8 9.52 0.60

1/2 12.70 0.70

5/8 15.88 0.80

b) Socket joints

Socket joints are such that they are brazed for

connections, and used mainly for thick pipings

whose diameter is larger than 20 mm.

Thicknesses of socket joints are as shown in

Table 6-2-2.

copper pipe jointed (mm) (mm)

6-2-1. Processing of piping materials

When performing the refrigerant piping installation,

care should be taken to ensure that water or dust does

not enter the pipe interior, that no other oil other than

lubricating oils used in the installed air conditioner is

used, and that refrigerant does not leak. When using

lubricating oils in the piping processing, use such

lubricating oils whose water content has been removed.

When stored, be sure to seal the container with an

airtight cap or any other cover.

(1) Flare Processing procedures and precautions

a) Cutting the pipe

By means of a pipe cutter, slo wly cut the pipe

so that it is not deformed.

b) Removing burrs and chips

If the flared section has chips or burrs,

refrigerant leakage may occur. Carefully

remove all burrs and clean the cut surface

before installation.

c) Insertion of flare nut

– 8 –

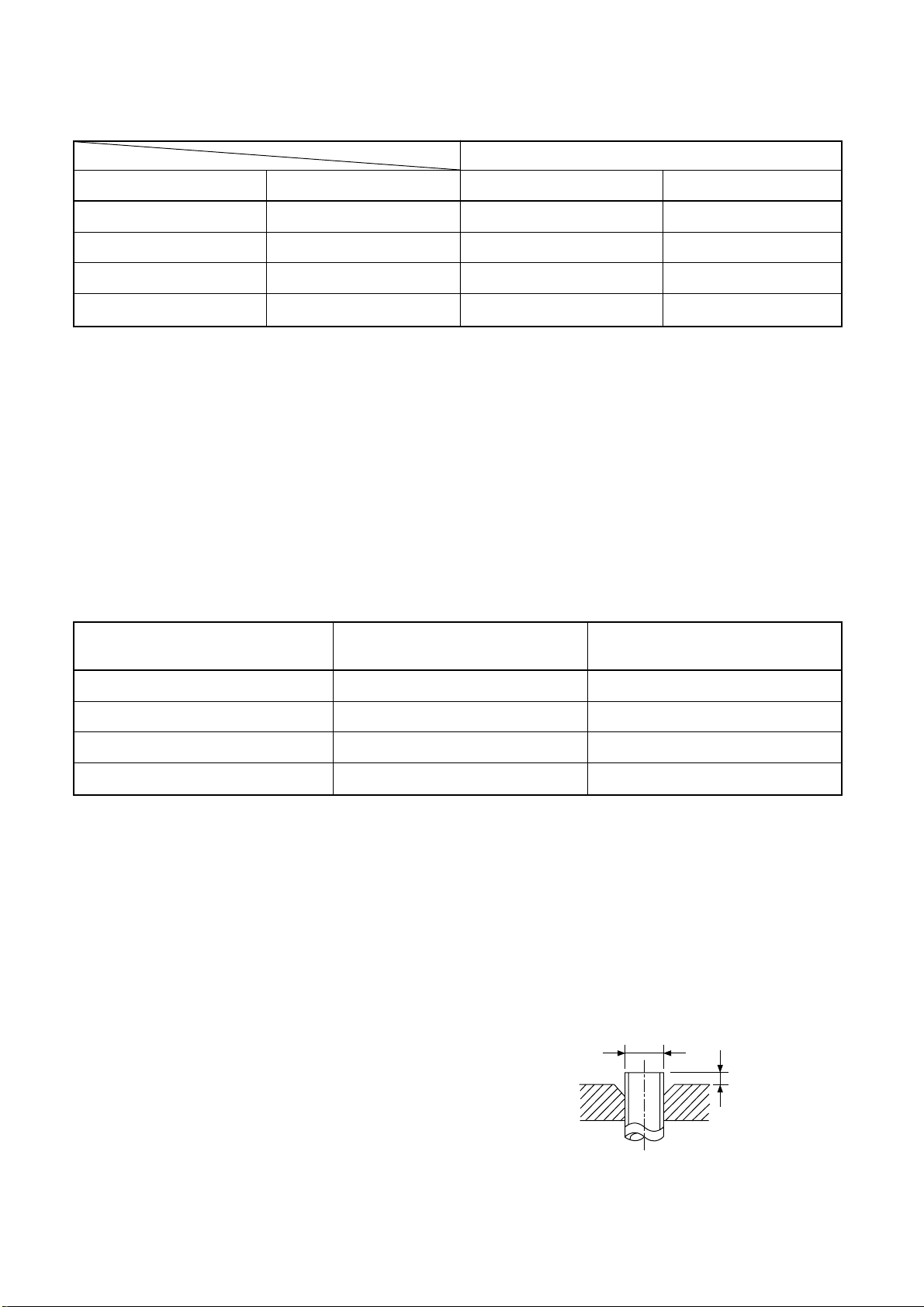

d) Flare processing

Make certain that a clamp bar and copper pipe

have been cleaned.

By means of the clamp bar, perform the flare

processing correctly.

Use either a flare tool for R410A or conventional flare tool.

Flare processing dimensions differ according to

the type of flare tool. When using a conventional flare tool, be sure to secure “dimension A”

by using a gauge for size adjustment.

∅D

A

Fig. 6-2-1 Flare processing dimensions

FILE NO. SVM-06012

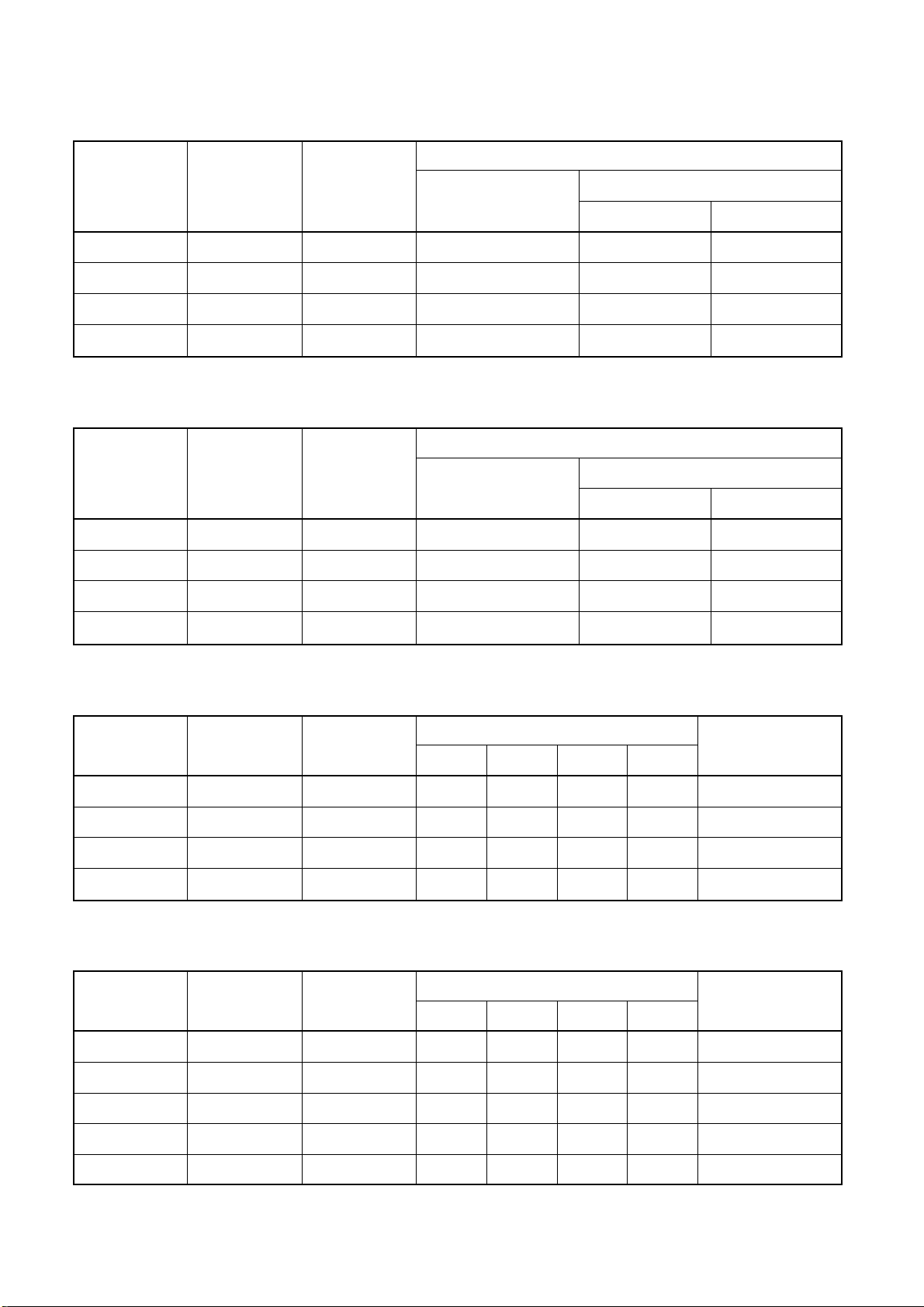

Table 6-2-3 Dimensions related to flare processing for R410A

Nominal

diameter

1/4 6.35 0.8 0 to 0.5 1.0 to 1.5 1.5 to 2.0

3/8 9.52 0.8 0 to 0.5 1.0 to 1.5 1.5 to 2.0

1/2 12.70 0.8 0 to 0.5 1.0 to 1.5 2.0 to 2.5

5/8 15.88 1.0 0 to 0.5 1.0 to 1.5 2.0 to 2.5

Nominal

diameter

1/4 6.35 0.8 0 to 0.5 0.5 to 1.0 1.0 to 1.5

3/8 9.52 0.8 0 to 0.5 0.5 to 1.0 1.0 to 1.5

1/2 12.70 0.8 0 to 0.5 0.5 to 1.0 1.5 to 2.0

Outer

diameter

(mm)

Table 6-2-4 Dimensions related to flare processing for R22

Outer

diameter

(mm)

Thickness

(mm)

Thickness

(mm)

Flare tool for R410A

clutch type

Flare tool for R22

clutch type

A (mm)

Conventional flare tool

Clutch type Wing nut type

A (mm)

Conventional flare tool

Clutch type Wing nut type

5/8 15.88 1.0 0 to 0.5 0.5 to 1.0 1.5 to 2.0

Table 6-2-5 Flare and flare nut dimensions for R410A

Nominal

diameter

1/4 6.35 0.8 9.1 9.2 6.5 13 17

3/8 9.52 0.8 13.2 13.5 9.7 20 22

1/2 12.70 0.8 16.6 16.0 12.9 23 26

5/8 15.88 1.0 19.7 19.0 16.0 25 29

Nominal

diameter

1/4 6.35 0.8 9.0 9.2 6.5 13 17

Outer

diameter

(mm)

Outer

diameter

(mm)

Thickness

(mm)

Table 6-2-6 Flare and flare nut dimensions for R22

Thickness

(mm)

ABCD

ABCD

Dimension (mm)

Dimension (mm)

Flare nut

width

(mm)

Flare nut

width

(mm)

3/8 9.52 0.8 13.0 13.5 9.7 20 22

1/2 12.70 0.8 16.2 16.0 12.9 20 24

5/8 15.88 1.0 19.4 19.0 16.0 23 27

3/4 19.05 1.0 23.3 24.0 19.2 34 36

– 9 –

Loading...

Loading...