Toshiba RAS-M13NCKV-E, RAS-10NKV-E, RAS-M13NKCV-E, RAS-M10NKCV-E, RAS-M10NKV-E SERVICE MANUAL

...

SERVICE MANUAL

AIR-CONDITIONER

RAS-M10NKV-E, RAS-M13NKV-E, RAS-M16NKV-E

FILE NO.SVM-05019

SUPPLEMENT

SPLIT TYPE

RAS-M10NKCV-E, RAS-M13NKCV-E, RAS-M16NKCV-E

(This service manual provide information only on the indoor units.

For information on the outdoor unit please refer to the service manual

of the outdoor unit.)

R410A

May, 2005

CONTENTS

1. Specifications

2. Construction Views

3. Wiring Diagram

4. Specifications of Electrical Parts (Indoor unit only)

5. Control Block Diagram (Indoor unit only)

6. Operation Description

7. Installation Procedure

FILE NO. SVM-05019

8. How to Diagnose the trouble

9. How to Replace the main parts (Indoor unit only)

10. Exploded Views and Parts list (Indoor unit only)

– 1 –

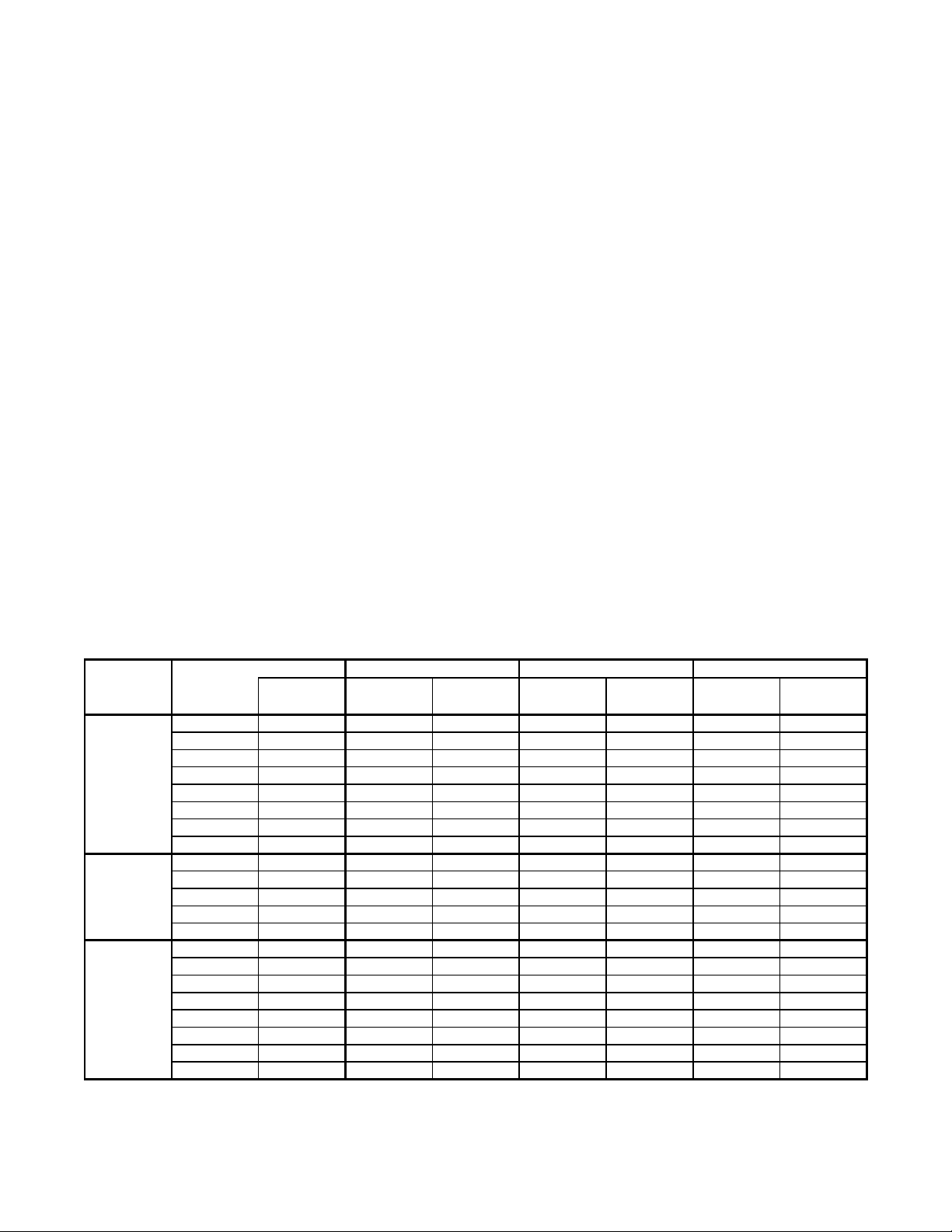

1. SPECIFICATIONS

Specifications

RAS-M10NKV-E, RAS-M13NKV-E, RAS-M16NKV-E

FILE NO. SVM-05019

Power supply

Electric Unit model

characteristice Running current (A)

Power consumption (W)

Power factor (%)

Operating High dB (A)

noise Medium dB (A)

Low dB (A)

Dimension Height (mm)

Width (mm)

Depth (mm)

Net weight (kg)

Fan motor output (W)

Air flow rate

(Cooling/Heating)

Piping Type

connection Liquid side

Gas side

Refrigerant

Wiring connection (Interconnection)

(m3/h) 570/610 590/620 650/660

220/230/240V, 1Ph, 50/60Hz

RAS-M10NKV-E RAS-M13NKV-E RAS-M16NKV-E

0.15 0.15 0.15

303030

87 87 87

36/39

33/35

28/29

275 275275

790

218

10

20

∅6.35

∅9.52

4 wires : includes earth

39/40

35/35

28/29

Flare connection

∅6.35

∅9.52

R410A

790

218

10

20

42/42

39/39

33/33

790

218

10

30

∅6.35

∅12.7

RAS-M10NKCV-E, RAS-M13NKCV-E, RAS-M16NKCV-E

Power supply

Electric Unit model

characteristice Running current (A)

Power consumption (W)

Power factor (%)

Operating High dB (A)

noise Medium dB (A)

Low dB (A)

Dimension Height (mm)

Width (mm)

Depth (mm)

Net weight (kg)

Fan motor output (W)

Air flow rate (m3/h)

Piping Type

connection Liquid side

Gas side

Refrigerant

Wiring connection (Interconnection)

220/230/240V, 1Ph, 50/60Hz

RAS-M10NKCV-E RAS-M13NKCV-E RAS-M16NKCV-E

0.15 0.15 0.15

30 30 30

87 87 87

36 39 42

33 35 39

28 28 33

275 275 275

790 790 790

218 218 218

10 10 10

20 20 30

570 590 650

Flare connection

∅6.35

∅9.52 ∅9.52 ∅12.7

4 wires : includes earth

∅6.35 ∅6.35

R410A

• The specifications may be subject to change without notice for purpose of improvement.

– 2 –

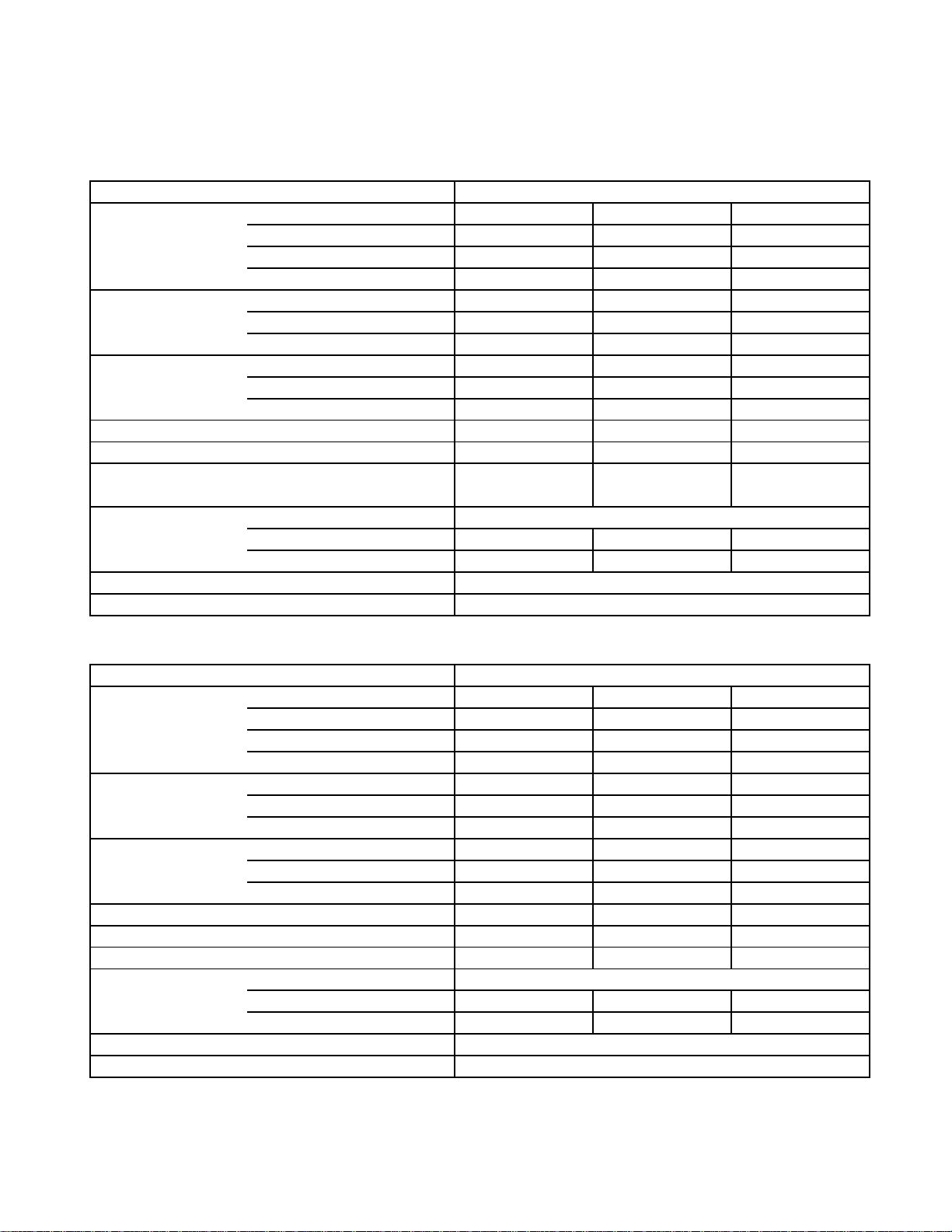

Indoor Unit

FILE NO. SVM-05019

2. CONSTRUCTION VIEWS

Front panel

60

6

Knock out system

Air inlet

Air filter

Heat exchanger

790

275

Air outlet

64

120 80

590

Hanger

218

60

6

48

Knock out system

48

53

Drain hose (0.54m)

Hanger

45

Minimum

distance

to ceiling

275

170 or more

320

620

235 235

215 215

Minimum

distance

to ceiling

65 or more

Hanger

– 3 –

Connecting pipe (0.43m)

(Flare ∅6.35)

Connecting pipe (0.33m)

(For 10,13 series ; Flare ∅9.52

For 16 series ; Flare ∅12.7)

Hanger

For stud bolt (∅6)

Hanger

150150 160160

Installation plate outline

Center line

For stud bolt

(∅8~∅10)

26

Minimum

distance

to ceiling

170 or more

32

9090

4519040

160

57 18

Wireless remote control

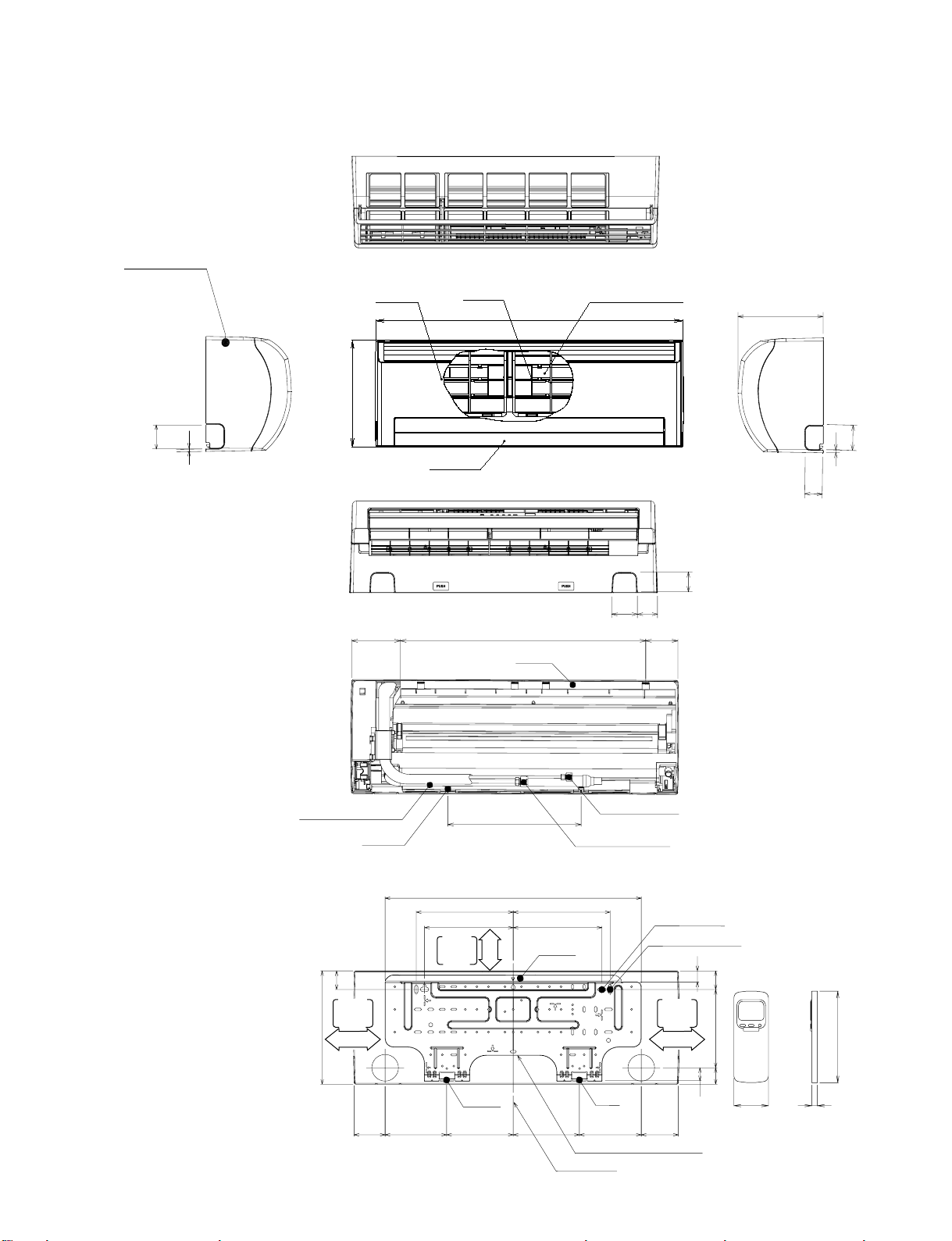

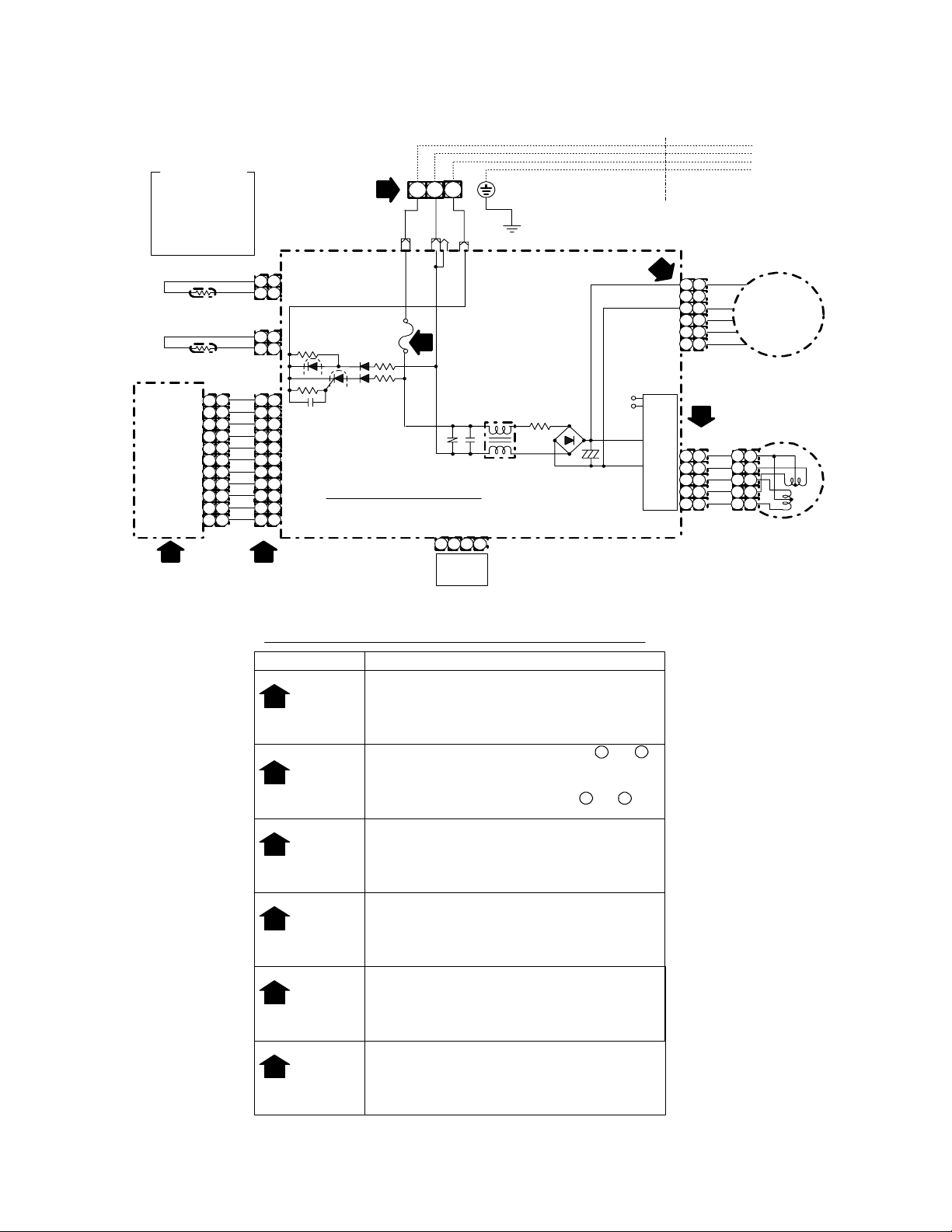

3-1. Indoor Unit (For 10k & 13k)

COLOR INDICATION

:

BROWN

BRW

:

RED

RED

:

WHITE

WHI

:

YELLOW

YEL

:

BLUE

BLU

:

BLACK

BLK

:

GRAY

GRY

:

PINK

PNK

:

ORANGE

ORN

:

GREEN & YELLOW

GRN&YEL

:

GREEN

GRN

BLK

BLK

HEAT EXCHANGER

SENSOR

(TC)

THERMO SENSOR

RECEIVING AND

INFRARED RAYS

MCC-861

MCC-861

(TA)

INDICATING PARTS

CN25

(WH I)

1

2

3

4

5

6

7

8

9

10

11

BLK

BLK

BLU

1

BLU

2

BLU

3

BLU

4

BLU

5

BLU

6

BLU

7

BLU

8

BLU

9

BLU

10

WHI

11

1

CN01

(BLU)

1

2

CN03

(WHI)

1

2

CN13

(WHI)

1

2

3

4

5

6

7

8

9

10

11

4

TERMINAL

1

2

1

2

1

2

3

4

5

6

7

8

9

10

11

BLOCK

MAIN P.C. BOARD

3. WIRING DIAGRAM

3

2

1

2

BLK WHI RED

CN23

CN24

FUSE

F01

T3.15A

250VAC

WP-004

CN21

LINE

FILTER

R04

3

CN11 CN10

1

1

YEL

CN08

3

4

1

2

HA

JEM-A

Drive ci rcuit

2

3

3

2

GRY

1

1

150°C

Fan Motor

BRW

2

3

2

3

supply circ uit

+12 VDC

+5 VDC

4

5

4

5

INDOOR

UNIT

Power

3

5

3

5

BLK

WHI

6

6

FILE NO. SVM-05019

OUTDOOR

UNIT

5

CN07

(WH I)

WHI

1

2

3

4

5

1

1

RED

AC FAN MOTOR

1

1

YEL

2

2

YEL

3

3

YEL

4

4

YEL

5

5

LOUVER MOTOR

6

1

2

3

4

5

Simple Check for Failure Diagnosis

Chec k It em

Check to see if the OPERATION indicator goes on

OPERAT ION

1

INDICATOR

TERMINAL

2

3

4

5

6

(AC 220~24 0V)

and off when t he main s witch or b reaker is turned on.

(Check the primary and secondary voltage of the

transformer.)

Check the power supply voltage b etween and .

(Refer to the name plate.)

(Check the primary and secondary voltage of the

transformer.)

BLOCK

Check the fluctuating voltage between and .

(15~60VDC)

FUSE

Check to see if the fuse blows out.

3.15A

(Check the R04 of the varis tor.)

Check the voltage at the No.4 pin on CN13 connector

of the infr ared receiver.

DC5V

(Check the transform er and the pow er supply ci rcuit

of the rated voltage.)

Check the voltage at the white lead of the louver

motor.

DC12V

(Check the transform er and the pow er supply ci rcuit

of the rated voltage.)

Check the voltage at the No.1 pin on CN10

connecto r and CN24.

(Check the F01)

Refer to the service data for the detailed failure

diagnosis.

Diagnosis Result

1

2

2

3

– 4 –

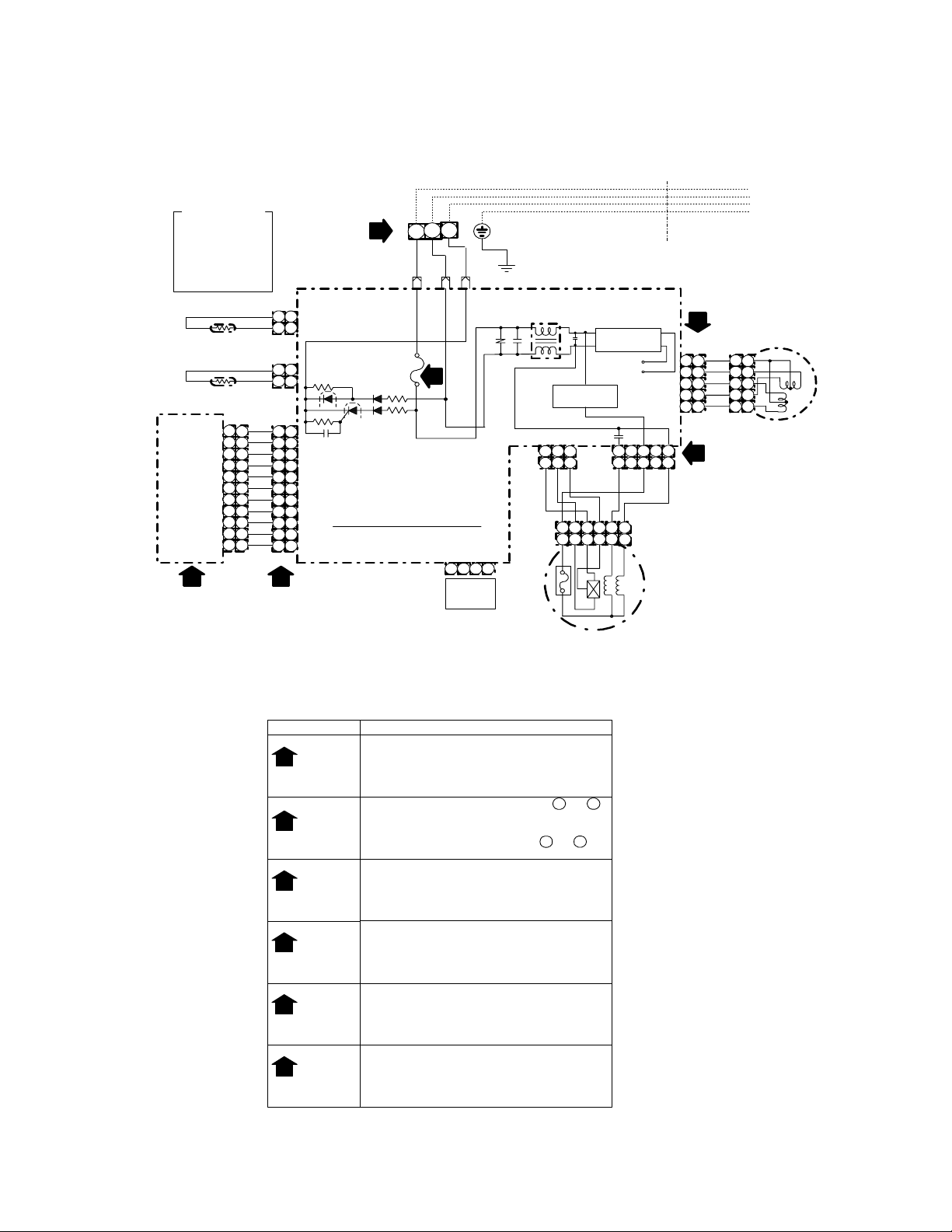

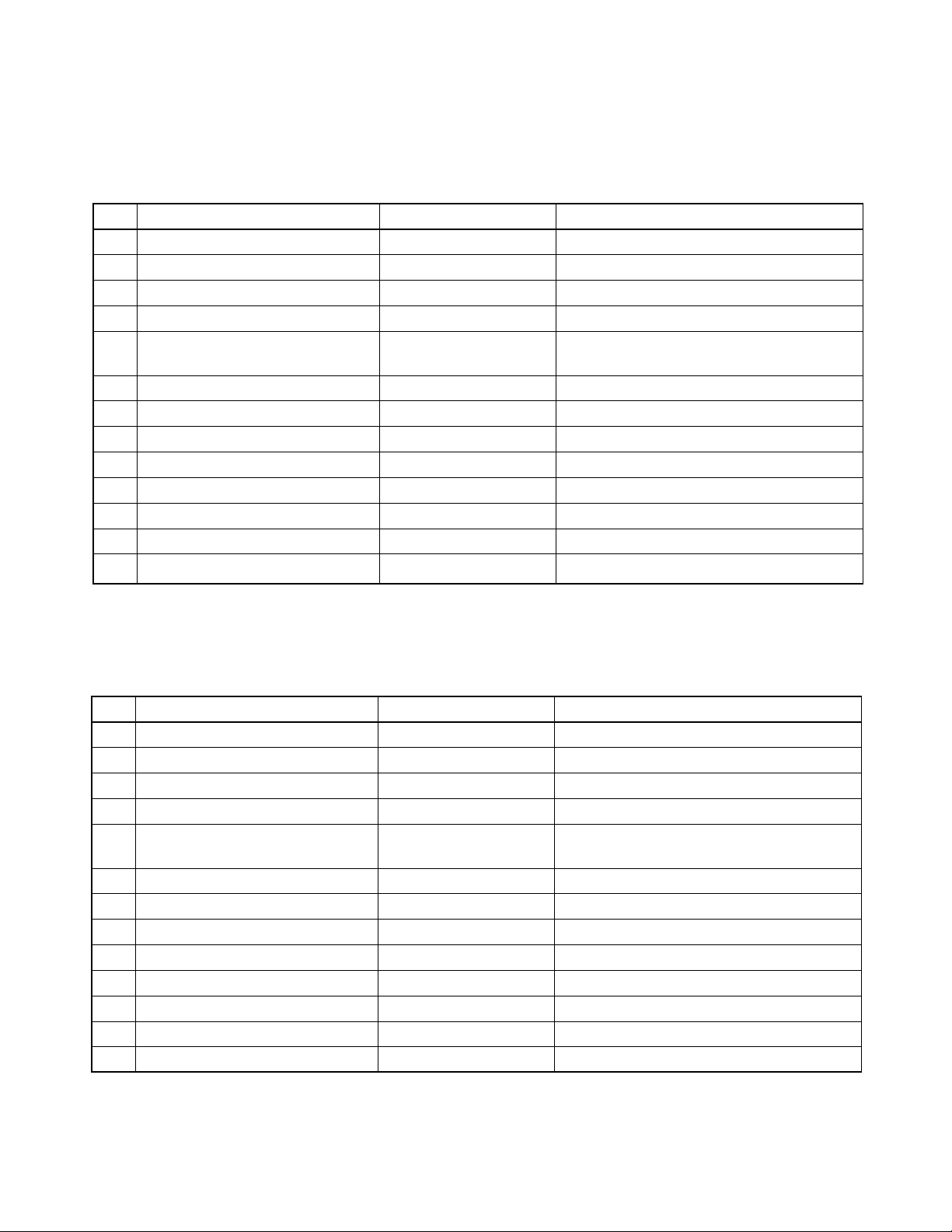

3-2. Indoor Unit (For 16k)

COLOR INDICATION

:

BROWN

BRW

:

RED

RED

:

WHITE

WHI

:

YELL OW

YEL

:

BLUE

BLU

:

BLACK

BLK

:

GRAY

GRY

:

PINK

PNK

:

ORANGE

ORN

:

GREEN & YE LLOW

GRN&YEL

:

GREEN

GRN

HEAT EXCHANGER

SENSOR

(TC)

THERMO SENSOR

(TA)

CN25

(WHI)

1

2

3

4

5

6

7

8

9

RECEIVING AND

INFRARED RAYS

INDICATING PARTS

10

MCC-861

MCC-861

11

1

CN01

(BLU)

BLK

1

1

BLK

2

2

CN03

(WHI)

BLK

1

1

BLK

2

2

CN13

(WHI)

BLU

1

1

1

BLU

2

3

4

5

6

7

8

9

10

11

BLU

BLU

BLU

BLU

BLU

BLU

BLU

BLU

WHI

2

2

3

3

4

4

5

5

6

6

7

7

8

8

9

9

10

10

11

11

4

TERMINAL

BLOCK

FUSE

F01

T3.15A

250VAC

2

CN24

BLK

1

WHI

CN23

3

2

MAIN P.C. BOARD

MCC-867or MCC-5014

1

3

RED

R04

CN08

3

2

HA

JEM-A

CN21

FILTER

4

LINE

R05

DB01

~

-+

~

C03

+

INDOOR

UNIT

DC5V

DC12V

FILE NO. SVM-05019

OUTDOOR

UNIT

CN10

6

(WHI)

1

3

4

5

6

CN07

(WHI)

1

2

CIRCUIT

3

4

POWER SUPPLY

5

FAN MOTOR

RED

1

BLK

3

4

5

6

WHI

YEL

BLU

DC MOTOR

5

WHI

1

1

2

3

4

5

1

YEL

2

2

YEL

3

3

YEL

4

4

YEL

5

5

LOUVER MOTOR

Simple Check for Failure Diagnosis

Check Item

OPERATION

1

INDICATOR

TERMINAL

2

BLOCK

3

4

5

6

(DC310 340V)

DC12V

DC325V

~

Check to see if the OPERATION indicator goes on

and off when the main switch or breaker is turned on.

(Check the primary and secondary voltage of the

transformer.)

Check the power supply voltage between 1 and

(Refer to the name plate.)

(Check the primary and secondary voltage of the

transformer.)

Check the fluctuating voltage between and .

(15

60VDC)

~

Check to see if the fuse blows out.

FUSE

(Check the R04 of the varistor.)

3.15A

Check the voltage at the No.4 pin on CN13 connector

of the infrared receiver.

DC5V

(Check the transformer and the power supply circuit

of the rated voltage.)

Check the voltage at the white lead of the louver

motor.

(Check the transformer and the power supply circuit

of the rated voltage.)

Check the voltage at the No.1 pin on CN10

connector.

(Check the DB01, R05 and C03.)

Refer to the service data for the detailed failure

diagnosis.

Diagnosis Result

2

2

.

3

– 5 –

FILE NO. SVM-05019

4. SPECIFICATIONS OF ELECTRICAL PARTS

RAS-M10NKV-E, RAS-M13NKV-E

RAS-M10NKCV-E, RAS-M13NKCV-E

No. Parts name Type Specifications

1 Fan motor (for indoor) SKF-220-20-4A-1 AC Motor with 150°C thermo fuse

2 Thermo. sensor (TA-sensor) ——— 10 kΩ at 25°C

3 AC-AC transformer (T01) TT-10 187 − 276V, 6VA

4 Microcomputer

5 Heat exchanger sensor

(TC-sensor)

6 Line filter (L01) SS11V-06270 27 µH , AC 0.64A

7 Diode (DB01) KBP06M 1.5A, 420V

8 Capacitor (C50)

9 Fuse (F01) BET 3.15A 250VAC T3.15A, 250 V

10 Regulator IC (IC08) NJM7812 12VDC, 1.5A max

11 Regulator IC (IC11) NJM7805 5VDC, 1.5A max

12 Varistor (R21, R109) 15G561K 560 V

µPD780024AGK

——— 10 kΩ at 25°C

LXV35VB2200MJ20 2200 µF, 35V

13 Louver motor 24BYJ48 DC 12V

RAS-M16NKV-E, RAS-M16NKCV-E

No. Parts name Type Specifications

1 Fan motor (for indoor) ICF-340-30-2 DC 340 V, 30 W

2 Thermo. sensor (TA-sensor) ——— 10 kΩ at 25°C

3 DC-DC transformer (T01) SWT-70 DC 390 V, Secondary DC 15 V, 12 V, 7 V

4 Microcomputer µPD780024AGK

5 Heat exchanger sensor

(TC-sensor)

6 Line filter (L01) SS11V-06270 27mH, AC 0.6A

7 Diode (DB01) D3SBA60 4A, 600 V

8 Capacitor (C03) KMH450VSSN120M25C 120µF, 450 V

9 Fuse (F01) FCU250V, 3.15A T3.15A, 250 V

10 Power supply IC (IC01) STR-L472

11 Varistor (R21, R109) 15G561K 560 V

——— 10 kΩ at 25°C

12 Resistor (R01) RF-5TK4R7 4.7Ω, 5 W

13 Louver motor 24BYJ48 12VDC

– 6 –

5. CONTROL BLOCK DIAGRAM

FILE NO. SVM-05019

5-1. Indoor Unit

Heat Exchanger Sensor

Temperature Sensor

Infrared Rays Signal Receiver

Infrared

Rays

Remote

Control

Initiallizing Circuit

Clock Frequency

Oscillator Circuit

Power Supply

Circuit

Noise Filter

Indoor Unit Control Panel

M.C.U.

Functions

• Louver Control

• 3-minute Delay at Restart for Compressor

• Motor Revolution Control

• Processing

(Temperature Processing)

• Timer

Outdoor unit

ON/OFF Signal

Louver ON/OFF Signal

Louver Driver

Operation

Display

Timer

Display

Filter Sign

Display

Fan Only

Sign Display

Indoor Fan

Motor

Louver Motor

From Outdoor Unit

REMOTE CONTROLLER

RAS-M10NKV-E, RAS-M13N

(Heat pump model)

Remote Controller

Operation ( )

Operation Mode Selection

AUTO, COOL, DRY, HEAT

Thermo. Setting

Fan Speed Selection

ON TIMER Setting

OFF TIMER Setting

Louver AUTO Swing

Louver Direction Setting

KV-E, RAS-M16NKV-E

Infrared

Rays

Outdoor Unit

RAS-M10NKCV-E, RAS-M13N

(Cooling only model)

Remote Controller

Operation ( )

Operation Mode Selection

AUTO, COOL, DRY, FAN ONLY

Thermo. Setting

Fan Speed Selection

ON TIMER Setting

OFF TIMER Setting

Louver AUTO Swing

Louver Direction Setting

KCV-E, RAS-M16NKCV-E

Infrared

Rays

ECONO.

ECONO.

– 7 –

6. OPERATION DESCRIPTION

FILE NO. SVM-05019

6-1. Outline of Air Conditioner Control

This air conditioner is a capacity-variable type air

conditioner. The capacity proportional control

compressor which can change the motor speed is

mounted. The indoor unit motor drive circuit is

mounted to the indoor unit. The compressor and the

inverter to control outdoor unit motor are mounted to

the outdoor unit. The entire air conditioner is mainly

controlled by the indoor unit controller.

The indoor unit controller drives the indoor fan motor

based upon command sent from the remote controller, and transfers the operation command to the

outdoor unit controller.

The outdoor unit controller receives operation

command from the indoor unit side, and controls the

outdoor fan and the pulse modulating valve.

Besides, detecting revolution position of the compressor motor, the outdoor unit controller controls

speed of the compressor motor by controlling output

voltage of the inverter and switching timing of the

supply power (current transfer timing) so that motors

drive according to the operation command.

And then, the outdoor unit controller transfers

reversely the operating status information of the

outdoor unit to control the indoor unit controller.

As the compressor adopts four-pole

brushless DC motor, the frequency of the

supply power from inverter to compressor

is two-times cycles of the actual number of

revolution.

(1) Role of indoor unit controller

The indoor unit controller judges the operation

commands from the remote controller and

assumes the following functions.

• Judgment of suction air temperature of the

indoor heat exchanger by using the indoor

temp. sensor.

• Temperature setting of the indoor heat ex-

changer by using heat exchanger sensor

(Prevent-freezing control)

• Louver motor control

• Indoor fan motor operation control

• LED display control

• Transferring of operation command signal

(Serial signal) to the outdoor unit

• Reception of information of operation status

(Serial signal including outside temp. data) to

the outdoor unit and judgment/display of error

(2) Role of outdoor unit controller

Receiving the operation command signal (Serial

signal) from the indoor controller, the outdoor

unit performs its role.

• Compressor operation

control

• Operation control of

outdoor fan motor

•

P.M.V. control

• Detection of inverter input current and current

release operation

• Over-current detection and prevention opera-

tion to transistor module (Compressor stop

function)

• Compressor and outdoor fan stop function

when serial signal is off (when the serial signal

does not reach the board assembly of outdoor

control by trouble of the signal system)

• Transferring of operation information (Serial

signal) from outdoor unit to indoor unit

• Detection of outdoor temperature and opera-

tion revolution control

• Defrost control in heating operation (Temp.

measurement by outdoor heat exchanger and

control for 4-way valve and outdoor fan)

(3) Contents of operation command signal (Serial

signal) from indoor unit controller to outdoor unit

controller

The following three types of signals are sent

from the indoor unit controller.

• Operation mode set on the remote controller

• Compressor revolution command signal

defined by indoor temperature and set temperature

(Correction along with variation of room

temperature and correction of indoor heat

exchanger temperature are added.)

• For these two types of signals ( [Operation

mode] and [Compressor revolution] ), the

outdoor unit controller monitors the input

current to the inverter, and performs the

followed operation within the range that current

does not exceed the allowable value.

• Temperature of indoor heat exchanger by

indoor heat exchanger sensor

(Minimum revolution control)

Operations followed

to judgment of

serial signal from

indoor side.

− 8 −

FILE NO. SVM-05019

(4) Contents of operation command signal (Serial

signal) from outdoor unit controller to indoor unit

controller

The following signals are sent from the outdoor

unit controller.

• The current operation mode

• The current compressor revolution

• Outdoor temperature

• Existence of protective circuit operation

For transferring of these signals, the indoor unit

controller monitors the contents of signals, and

judges existence of trouble occurrence.

Contents of judgment are described below.

• Whether distinction of the current operation

status meets to the operation command

signal

• Whether protective circuit operates

When no signal is received from the outdoor

unit controller, it is assumed as a trouble.

6-1-1. Capacity Control

The cooling capacity is varied by changing compressor motor speed. The inverter changes compressor

motor speed by changing AC 220–240V power to

DC once, and controls capacity by changing supply

power status to the compressor with transis-tor

module (includes 6 transistors). The outline of the

control is as follows : The revolution position and

revolution speed of the motor are detected by

detecting winding electromotive force of the com

pressor motor under operation, and the revolution

speed is changed so that the motor drives based

upon revolution speed of the operation command by

changing timing (current transfer timing) to ex

change inverter output voltage and supply power

winding.

Detection of the revolution position for controlling is

performed 12 times per 1 revolution of compressor.

The range of supply power frequency to the com

pressor differs according to the operation status

(COOL, DRY).

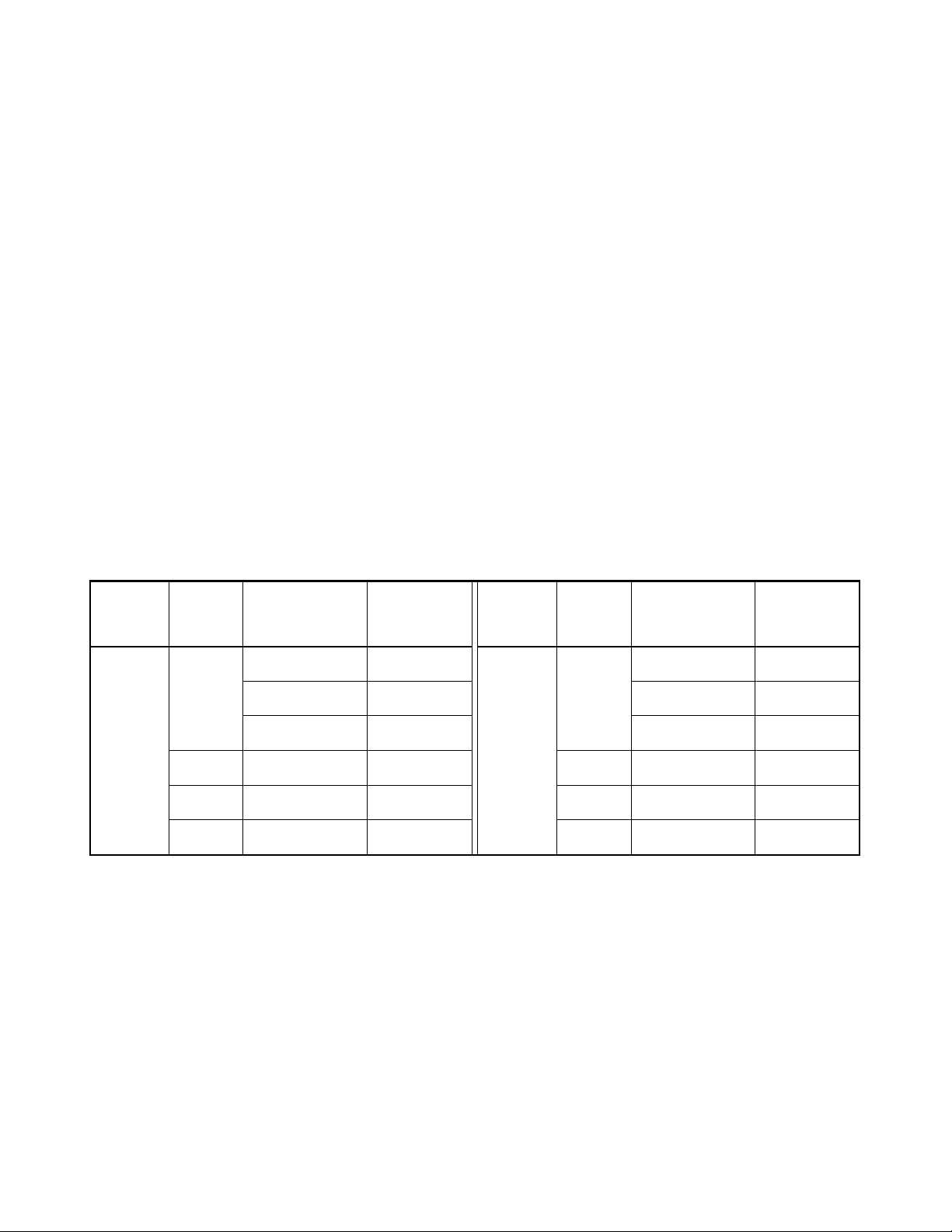

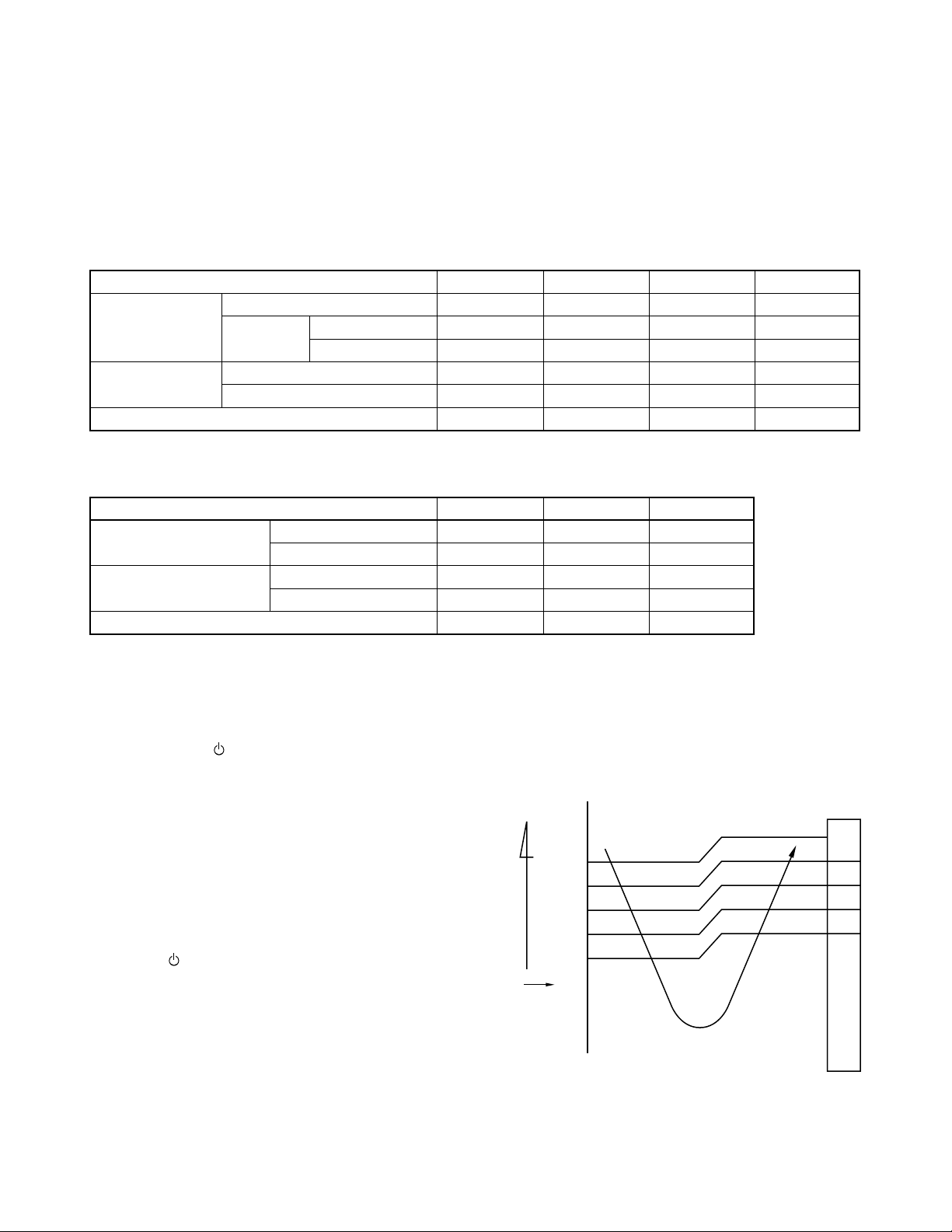

Table 6-1-1 Compressor revolution range

Operation

mode

COOL

No. of

operating

unit

1 unit

2 units

3 units

4 units

Combination

of indoor units

M10

M13

M16

*

*

*

Compressor

revolution

(rps)

20 to 28

20 to 43

20 to 53

20 to 66

31 to 69

31 to 69

* In case that any multiple indoor units are combined.

6-1-2. Current Release Control

The outdoor main circuit control section (Inverter

assembly) detects the input current to the outdoor

unit. If the current value with compressor motor

speed instructed from indoor side exceeds the

specified value, the outdoor main circuit control

section controls compressor motor speed by reducing motor speed so that value becomes closest to

the command within the limited value.

Operation

mode

HEAT

No. of

operating

unit

1 unit

2 units

3 units

4 units

Combination

of indoor units

M10

M13

M16

*

*

*

Compressor

revolution

(rps)

15 to 52

15 to 63

15 to 67

15 to 90

17 to 90

22 to 90

6-1-3. Power Factor Improvement Control

Power factor improvement control is performed

mainly aiming to reduce the current on much power

consumption of cooling/heating operation. Controlling starts from the time when input power has

reached at a certain point. To be concrete, IGBT of

the power factor improvement circuit is used, and the

power factor is improved by keeping IGBT on for an

arbitrary period to widen electro-angle of the input

current.

− 9 −

FILE NO. SVM-05019

6-1-4. Prevent-Freezing Control

The indoor heat exchanger sensor detects refrigerant vapor temperature in COOL/DRY operation. If

the temperature is below the specified value, compressor motor speed is reduced so that operation is

performed in temperature below the specified value

to prevent-freezing of indoor heat exchanger.

6-1-5. P. M. V. (Pulse Modulating Valve)

Using P.M.V., refrigerant flow of refrigeration cycle is

varied for the optimum temperature. Controlling

each unit separately by four P.M.V. corresponds to

difference of pipe length, fan speed, and unit temperature.

If an error occurs on cycle temperature when power

source of the air conditioner has been turned on,

and if start/stop times of the outdoor unit are 30

times, move the valve once until it hits on the stopper

for positioning of the valve. In this case, ticktack

sound may be heard.

6-1-6. Louver Control

(1) Vertical air flow louvers

Positions of vertical air flow louvers are automatically controlled according to the operation status

(AUTO, COOL, DRY, HEAT). Besides, positions of

vertical air flow louvers can be arbitrarily set by

pressing the [FIX] button. The louver position which

has been set by the [FIX] button is stored in microcomputer, and the louver is automatically set at the

stored position in the next operation.

(2) Swing

If the [SWING] button is pressed during running

operation, vertical air flow louvers start swinging.

When the [SWING] button is pressed again, swinging

stops.

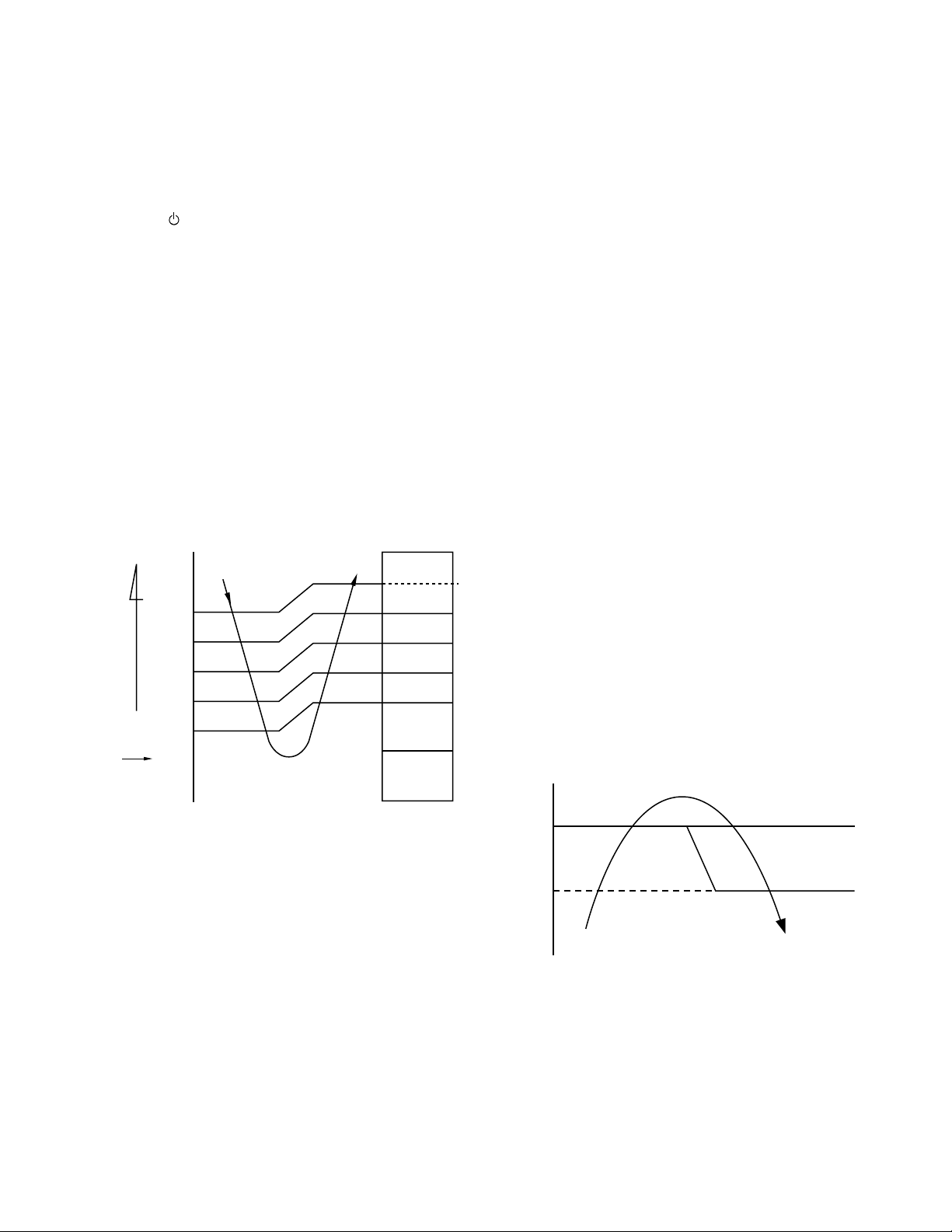

6-1-7. Indoor Fan Control

The indoor fan is operated by motor speed non-step

variable drive system motor. For flow rate, motor

speed is controlled manually in five steps and with

the unit of 10 rpm from upper limit to lower limit in

AUTO mode as described in Table 6-1-2. It is not

selected by relay, so selecting sound does not

generate.

operation

mode

Cooling

and Fan

only

DRY

Heating

Table 6-1-2

Fan

mode

H

M+

M

L+

L

LL+

L

L-

UL

SUL

H

M+

M

L+

L

L-

Remote

Control

HIGH

MED+

MED

LOW+

LOW

HIGH

MED+

MED

LOW+

LOW

Motor speed

(rpm)

M10

Air flow rate

(m3/h)

1190

1120

1120

1050

980

930

910

850

930

910

850

720

660

1250

1200

1160

1060

1000

1050

940

930

570

530

530

490

440

420

410

370

420

410

370

290

260

610

570

550

490

460

490

420

420

Motor speed

(rpm)

1210

1130

1130

1050

M13

Air flow rate

980

930

910

850

930

910

850

750

700

1290

1280

1200

1100

1020

1050

940

930 420

(m3/h)

590

530

530

490

440

420

410

370

420

410

370

310

280

620

620

570

520

470

490

420

M16

Motor speed

(rpm)

Air flow rate

1350

1250

1250

1150

1070

1000

980

920 410

1000

980

920

920

800

1370

1360

1280

1180

1100

1150

1020

1000 460

(m3/h)

650

610

610

550

500

460

440

460

440

410

410

340

660

660

620

560

520

550

470

NOTE :

• UL : Ultra Low, SUL : Super Ultra Low

− 10 −

FILE NO. SVM-05019

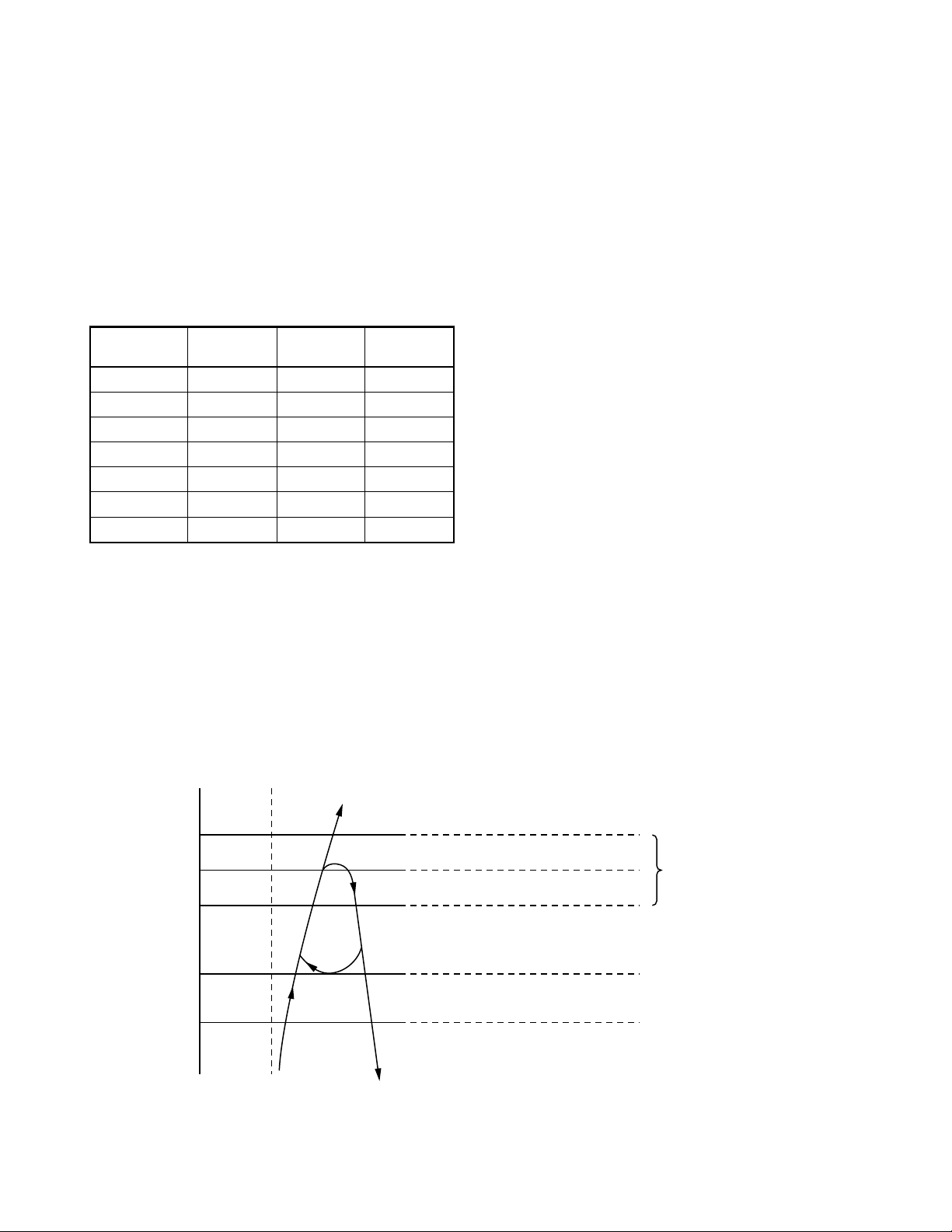

6-1-7. Outdoor Fan Control (DC Fan Motor)

Although the outdoor fan motor drives the outdoor fan by non-step variable system of the revolution speed, the

revolution speed is restricted to three steps on the convenience of controlling.

If a strong wind is lashing outside of the room, the operation may be continued as the outdoor fan stops in order

to protect the outdoor fan motor.

If a fan lock occurred due to entering of foreign matter, the air conditioner stops and an alarm is displayed.

<COOL, DRY>

Table 6-1-3

Compressor revolution (rps)

Outdoor temp.

sensor

TO

ECONO.

operation

TO ≥ 38°C

TO < 38°C

TO ≥ 38°C

TO < 38°C

TO is abnormal

1 to 2 units

3 to 4 units

20.3

390 (rpm) 700 (rpm) 700 (rpm) 700 (rpm)

390 (rpm) 640 (rpm) 640 (rpm) 700 (rpm)

390 (rpm) 500 (rpm) 640 (rpm) 700 (rpm)

390 (rpm) 640 (rpm) 640 (rpm) 640 (rpm)

390 (rpm) 500 (rpm) 500 (rpm) 500 (rpm)

500 (rpm) 640 (rpm) 640 (rpm) 640 (rpm)

~ 50.3 ~ 62.8 63.4 ~

<HEAT>

Table 6-1-4

Compressor revolution (rps)

Outdoor temp. sensor TO ≥ 5°C

TO TO < 5°C

ECONO. operation

TO ≥ 5°C

TO < 5°C

TO is abnormal

20.3 ~ 33.3 ~ 33.9

390 (rpm) 640 (rpm) 640 (rpm)

500 (rpm) 640 (rpm) 640 (rpm)

390 (rpm) 500 (rpm) 500 (rpm)

390 (rpm) 500 (rpm) 500 (rpm)

390 (rpm) 500 (rpm) 640 (rpm)

6-2. Description of Operation Circuit

• Turning [ON] the breaker flashes the operation lamp.

This is the display of power-ON (or notification of po wer failure).

• When pushing [ ] button of the remote controller, receive sound is issued from the main unit, and

the next operations are performed together with opening the vertical air flow louvers.

6-2-1. Fan Only Operation

(The Remote controller [MODE] Button

is Set to the FAN ONLY Operation)

• This mode is only for the cooling only model.

• Once the setting is made, the operation mode is

memorized in the microcomputer so that the same

operation can be effected thereafter simply by

pushing [ ] button.

• When the [FAN] button is set to the AUTO position,

the indoor fan motor operates as shown in Fig. 62-1. When the [FAN] button is set to LOW, LOW

MED, MED+, or HIGH, the motor operates with a

constant air flow.

• ECONO, Hi POWER and COMFORT SLEEP

mode cannot be set.

+

− 11 −

˚C

+3

+2.5

+2

+1.5

+1

+0.5

(Room temp.) – (Set temp.)

Set

temp.

0

(Set temp.) 25˚C

NOTE :

1: Calculated from difference in motor speed of M+

*

and L–, and controlled.

Fig. 6-2-1 Auto setting of air flow

M+

*1

*1

*1

L–

FILE NO. SVM-05019

6-2-2. Cooling Operation

(The Remote controller [MODE] Button

is Set to the COOL Position)

• Once the setting is made, the operation mode is

memorized in the microcomputer so that the same

operation can be effected thereafter simply by

pushing [ ] button.

• A cooling operation signal is transmitted to outdoor

unit.

• The indoor fan motor operates as shown in Fig.62-2 when [FAN] button is set to AUTO.

• The motor operates with a constant air flow when

the [FAN] button is set to LOW, LOW+, MED, MED+,

or HIGH.

• The outdoor unit controls the outdoor fan relay

R01, R02 and R03, and the compressor motor

speed according to the operation command signal

sent from the indoor unit.

˚C

+3

+2.5

+2

+1.5

+1

(Room temp.) – (Set temp.)

+0.5

Set

temp.

0

–0,5

NOTE :

1: Calculated from difference in motor speed of M+

*

and L–, and controlled.

Fig. 6-2-2 Setting of air flow [Air Flow AUTO]

M+

*1

*1

*1

L–

In normal

operation

(1) Cooling capacity control

• The cooling capacity and room temperature

are controlled by changing the compressor

motor speed according to both the difference

between the temperature detected by the room

temperature sensor and the temperature set by

[TEMP] button and also any change in room

temperature.

• When compressor has been activated or

reactivated, it operates with Max. 33 rps for 2

minutes and with Max. 57 rps from 2 to 4

minutes passed.

• When room temperature is lower than set

temperature and indoor fan motor is operated

at fan speed L– as shown in Fig. 6-2-2 while

the outdoor unit stops.

(2) Prevent-freezing control

If temperature of indoor heat exchanger detected

by the indoor heat exchanger sensor is 5°C or

lower, compressor motor speed is gradually

lowered to pre vent freezing of the indoor heat

exchanger. If temperature is 7°C or higher, return

the operation to the above item (1).

(3) Current release control

The input current of compressor and outdoor fan

motor (Precisely inverter main circuit control

section) which occupy most of air conditioner

input is detected by the outdoor current sensor ,

and compressor motor speed is gradually lowered

so that current value does not exceed 11.5A if

current value exceeds 11.5A. When the current

value lowers to 11.0A, return the operation to the

above item (1).

Comp. motor

14.2

13.7

Current value

Normal control

speed down

Comp. motor

speed keep

Fig. 6-2-3

(4) Outdoor temperature release control

The outdoor temperature release is controlled by

changing the current release points 14.2 and 13.7

in the above item according to temperature

detected by the outdoor temperature sensor.

For example, if the outdoor temperature is 43°C,

the value of current release points becomes 9.6A.

− 12 −

FILE NO. SVM-05019

(5) Limit for maximum compressor motor speed

by indoor fan speed

When outdoor temperature sensor detected

32°C or lower, and indoor heat exchanger

sensor detected 17°C or lower, the maximum

compressor motor speed is limited by the indoor

fan speed.

For example, when 1 unit only operates, the

compressor motor speed is limited as described

in the table below.

Table 6-2-1

Air flow

rate

HIGH

M+

MED

L

L–

UL

SUL

M10 M13 M16

(rps) (rps) (rps)

32 48 54

29 42 46

24 28 38

20 20 30

20 20 30

20 20 20

20 20 20

(6) Louver control

The vertical air flow louvers are automatically set

to horizontal or cool memory position.

When temperature of indoor heat exchanger

becomes 5°C or lower by the prevent-freezing

control and the compressor is turned off, the

vertical air flow louvers close once and then

return to the position of previous time.

(7) Discharge temperature control

The discharge temperature of refrigerant gas

from the compressor is detected by the discharge temperature sensor, and controls operating compressor motor speed.

1) Control 1 (A zone) : Normal operation zone

When TD detect value is 101°C or lower, the

operation is performed with operating motor

speed instructed by the serial signal.

2) Control 2 (B zone) : Slow-up zone of motor

speed

When TD detect value is 101°C or higher,

operating motor speed is slowly up.

3) Control 3 (C zone) : Keep zone

When TD detect value is 108°C or higher,

operating motor speed is not changed if

raising operation speed.

4) Control 4 (D zone) : Slow down zone of motor

speed

When TD detect value is 111°C or higher,

operating motor speed is slowly down.

5) Control 5 (E zone) : Normal down of motor

speed

When TD detect value is 115°C or higher,

operating motor speed is down.

6) Control 6 (F zone) : Operation stop zone

If TD detect value exceeds 120°C during

operation, stop the operation immediately.

Then, restart the operation when TD detect

value becomes 108°C or lower.

TD

(˚C)

120

115

111

108

101

Zone

F

E

D

C

B

A

Operation stop zone

Normal down zone of motor speed

Slow down of motor speed

Keep zone : Motor speed is not changed.

Slow-up zone of motor speed

Normal operation zone

Fig. 6-2-4 Compressor motor speed control

– 13 –

Release of motor speed

FILE NO. SVM-05019

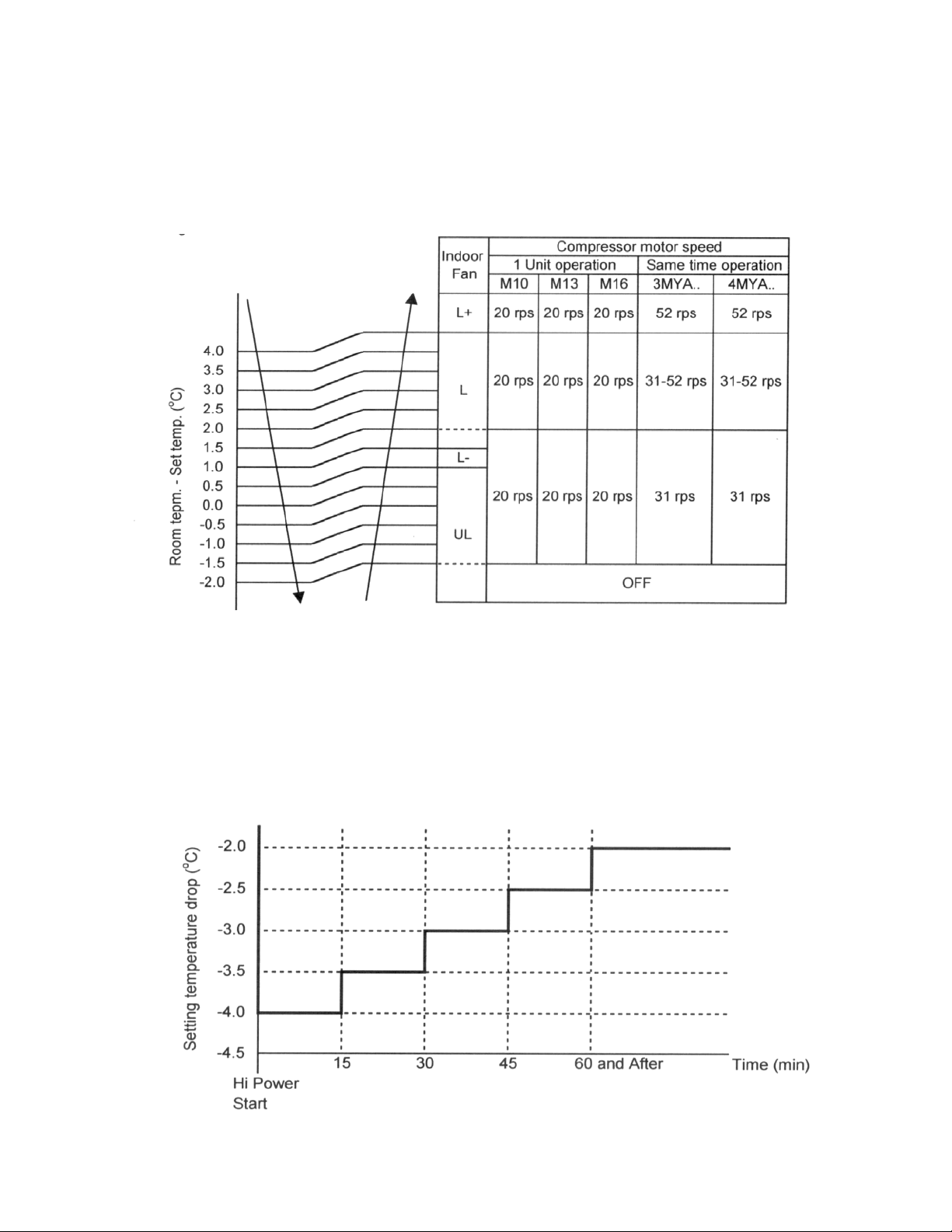

(8) ECONO operation control

When the [ECO] button is pushed, ECONO

operation is performed by restraining air flow

and compressor motor speed. The set

temperature is changed also.

1) The set temperature increased 0.5°C per hour up

to 2°C starting from the set temperature when

ECONO has been received.

2) Indoor air flow is controlled between L+ and UL.

The compressor motor speed in control as shown

in Fig. 6-2-5

(9) COMFORT SLEET operation control.

When the [COMFORT SLEEP] button is

pushed, the ECONO operation activate

together with the timer OFF function. Each

time of pressing [COMFORT SLEEP] button

the off timer setting changes in the sequence

of 1, 3, 5 or 9 hours.

Fig. 6-2-5

(10) Hi POWER operation control.

When the [Hi POWER] button is pushed

Hi Power operation is performed by change

set temperature and air flow (display on the

remote control does not change).

1) Changing of set temperature.

Fig. 6-2-6

− 14 −

FILE NO. SVM-05019

–0.5

0

+0.5

+1.0

+1.5

+2.0

+2.5

*1

L–

SUL

(Room temp.) – (Set temp.)

Set

temp.

2) Changing of air flow (Fan setting : AUTO)

When the Hi POWER is started, the fan of the

indoor unit operates at higher air flow level than

normal air flow AUTO (normal air flow AUTO

is shown in Fig. 6-2-2). Because of the

difference between room temperature and set

temperature are increased automatically.

3) Changing of air flow (Fan setting : One of 5

levels)

When the Hi POWER is started, the fan of the

indoor unit operates at higher consecutive air

flow level. (Fan speed on the display of remote

control does not change)

4) Changing of louver position

If the room temperature is higher than setting

temperature by 3.5 °C or more, the louver is

automatically set to the maximum air flow

position. If it is not, position of louver is not

change. When room temperature is reach to

setting temperature. The louver moves back

to set position.

(11) Quiet operation control.

When the [QUIET] button is pushed, the fan is

restricted the revolution speed at L- level until

the [QUIET] button is pushed once again

(cancel QUIET operation).

Remarks :

QUIET operation is appropriate to work with

less cooling load condition. Because of the

fan speed L- may cause not enough the

cooling capacity.

6-2-3. DRY Operation

(The Remote controller [MODE] Button

is Set to the DRY Position)

• Once the setting is made, the operation mode is

memorized in the microcomputer so that the same

operation can be effected thereafter simply by

pushing [ ] button.

• Dry operation signal is transmitted to outdoor unit.

• The Cooling operation giving priority to dehumidi-

fying, which restrains the indoor fan speed and

compressor motor speed, is performed.

• The indoor fan motor operates as shown in Fig.

6-2-7. (Fan speed is AUTO only.)

• The outdoor unit controls the outdoor fan relay

R01, R02 and R03, and the compressor motor

speed according to the operation command signal

sent from the indoor unit.

NOTE :

1 : Middle motor speed between L– and SUL

*

Fig. 6-2-7 Setting of air flow

(1) Dehumidifying-preferential Cooling capacity

control

• The cooling capacity and room temperature are

controlled by changing the compressor motor

speed according to both the difference between

the temperature detected by the room temperature

sensor and the temperature set by [TEMP] button

and also any change in room temperature.

• When the air conditioner operates in Dry mode, the

maximum compressor motor speed is restricted.

M10 : Max. 20 rps

M13 : Max. 20 rps

M16 : Max. 22 rps

While multiple indoor units operate, compressor

motor speed is calculated in the outdoor unit to

operate.

• When room temperature is lower than set tempera-

ture, indoor fan motor is operated at fan speed SUL

as shown in Fig. 6-2-6 while the outdoor unit stops.

• ECONO Hi POWER, QUIET and COMFORT-

SLEEP mode cannot be set.

• Other controls than the above-mentioned controls

are common to those of cooling operation.

− 15 −

6-2-4. Heating Operation

33

*

3

*

2

32

44

43

20

19

31

30

A

A

−

8

A + 4

A

−

8

HIGH

SUL

SUL

FAN

AUTO

Starting

of FAN

Manual

Approximate

revolution speed

of HIGH and SUL

linear by Tc.

Stop

( NOTE : *1)

Transferring of heating operation signal from indoor

unit to outdoor unit starts.

The indoor fan motor operates by the room temperature when selecting "AUTO" of "FAN" as shown in

Fig. 6-2-8, and operates with a set air flow when

selecting LOW to HIGH.

However, to prevent cold draft, revolution speed of

the fan is restricted by indoor heat exchanger when

air flow is AUTO (Fig.

6-2-9) and sta

rting of FAN

Manual.

[Basic control]

(3) SUL : Super ultra low

[In star ting and in stability]

In star ting

• Until 12 minutes

passed after

operation start

FAN

AUTO

• When 12 to 25

minutes passed

after operation start

and room temp. is

3°C or lower than

set temp.

FILE NO. SVM-05019

In stability

• When 12 to 25

minutes passed

after operation start

and room temp. is

higher than (set

temp. --3°C)

• When 25 minutes or

more passed after

operation start

Set

temp.

−

(Room temp.)

(Set temp.)

1, *2 : Approximate revolution speed of M+ and L to

*

0

−0.5

−

1

−

1.5

−

2

−

5.0

−

5.5

[FAN AUTO]

LOW

1

*

2

*

M+

HIGH

linear according to temperature.

Fig. 6-2-8 Setting of air flow

[Cold draft preventing control]

The upper limit of fan revolution speed is shown

below.

FAN

Manual

• Room temp.≥

Set temp. − 4°C

• Room temp. >

Set temp. − 3,5°C

The outdoor unit controls the outdoor fan based

upon the operation signal sent from the indoor unit,

and also controls revolution speed of the compressor motor.

The power coupler (IC20) for four-way valve is

turned on, and turned off in defrost operation.

(1) Heating capacity control

Calculate the difference between temperature

detected by room temp. sensor every minute and

the set temp. set on "Temp. indicator" and

variation amount of room temp.

Then, obtain the correction amount of the

command signal, and correct the current frequency command signal.

(2) High-temp. release control

If temperature of the indoor heat exchanger

detected by the indoor heat exchanger sensor is

55°C or higher, compressor motor speed is

gradually lowered to prevent over-temp. rising of

compressed pressure.

If temperature becomes below 48°C, return to

above item (1).

Fig. 6-2-9 Cold draft preventing control

NOTES :

(1) Stops for 2 minutes after thermostat-OFF.

(2) 24°C when the set temp. is 24°C or more

Set temp. when the set temp. is below 24°C

(3) Current release control

The input current of compressor and outdoor fan

motor (Precisely inverter main circuit control

section) which occupy most of air conditioner

input is detected by the outdoor current sensor.

The compressor motor speed is lowered gradually according to the range of TO (outside air

temp.) if the input current exceeds the current

value determined in each zone as shown in Fig.

6-2-10 so that the input current does not exceed

the set value.

In case that the current lowered by approx. 0.3A to

0.5A than each set value, return to above item (1).

− 16 −

Loading...

Loading...