Page 1

E6581343 ③

TOSVERT VF-AS1/PS1

PROFIBUS-DP Option Function Manual

PDP002Z

* The data given in this manual are subject to change without notice.

© Toshiba Schneider Inverter Corporation

All rights reserved.

2006

Page 2

E6581343 ③

Contents

1. Introduction...............................................................................................................................................2

2. Connection Information ............................................................................................................................3

2.1. Exterior features...........................................................................................................................3

2.2. PDP002Z Device Data.................................................................................................................4

2.3. Setting a station address .............................................................................................................5

2.4. Status indicator ............................................................................................................................7

2.5. Communications-related parameters...........................................................................................7

3. “PROFIdrive” Profile .................................................................................................................................8

3.1. PPO TYPE ...................................................................................................................................8

3.2. STW Control Word Data ..............................................................................................................9

3.3. ZSW Status Word Data..............................................................................................................10

3.4. State Macine ..............................................................................................................................11

3.4.1. Examples of driving by the State Machine.........................................................................12

3.5. The Access to the PROFIBUS parameter .................................................................................13

3.5.1. Examples of reading or changing the PROFIdrive parameter ...........................................15

3.6. Access to the VF-AS1/PS1 parameter ......................................................................................17

3.6.1. Examples of reading or changing the VF-AS1/PS1 parameter .........................................17

4. ”USER DEFIND” Profile .........................................................................................................................19

4.1. How to use .................................................................................................................................20

4.2. The overview of the VF-AS1/PS1 parameter.............................................................................21

4.2.1. FA06 (Command word 1 from internal option PCB) ..........................................................21

4.2.2. FA23 (Command word 2 from internal option PCB) ..........................................................21

4.2.3. FA07 (Frequency reference from internal option PCB) .....................................................22

4.2.4. FA33 (Torque reference from internal option PCB) ...........................................................22

4.2.5. FA50 (Terminal output data from comm.) ..........................................................................22

4.2.6. FA51 (Analog output (FM) data from comm.) ....................................................................22

4.2.7. FA52 (Analog output (AM) data from comm.) ....................................................................22

4.2.8. FD01 (Inverter status (real time)).......................................................................................23

4.2.9. FD00 (Output frequency (real time)) ..................................................................................23

4.2.10. FD03 (Output current (real time)).......................................................................................23

4.2.11. FE36 (Analog input value VI/II) ..........................................................................................24

4.2.12. FE37 (RX Input) .................................................................................................................24

4.2.13. FE60 - FE63 (My Monitor)..................................................................................................24

4.2.14. FE14 (Cumulative run time) ...............................................................................................24

4.2.15. FE40 (Analog output (FM)) ................................................................................................24

4.2.16. FC91 (Alarm code).............................................................................................................25

4.2.17. FD06 (Input TB Status) ......................................................................................................25

4.2.18. FD07 (Output TB Status) ...................................................................................................25

4.2.19. FC90, FE10 - FE13 (Inverter fault).....................................................................................26

4.3. About GSD file ...........................................................................................................................27

- 1 -

- 1/27 -

Page 3

1. Introduction

Thank you for purchasing the PROFIBUS-DP option “PDP002Z” for the VF-AS1/PS1.

Before using the PROFIBUS-DP option, please familiarize yourself with the product and

be sure to thoroughly read the instructions and precautions contained in this manual.

In addition, please make sure that this manual and “Instruction Manual” is delivered to the

end user, and keep this function manual in a safe place for future reference or

drive/interface inspection.

This manual describes the supported functions for the “PDP002Z”.

In conjunction with this manual, the following manuals are supplied by Toshiba, and they

are essential both for ensuring a safe, reliable system installation as well as for realizing

the full potential of the “PDP002Z”:

- TOSVERT VF-AS1 Instruction Manual ..................................E6581301

E6581442(for WN1/WP1)

- TOSVERT VF-PS1 Instruction Manual ..................................E6581386

- PDP002Z Instruction Manual (Installation, Wiring, etc.)......... E6581279

E6581343 ③

- 2 -

Page 4

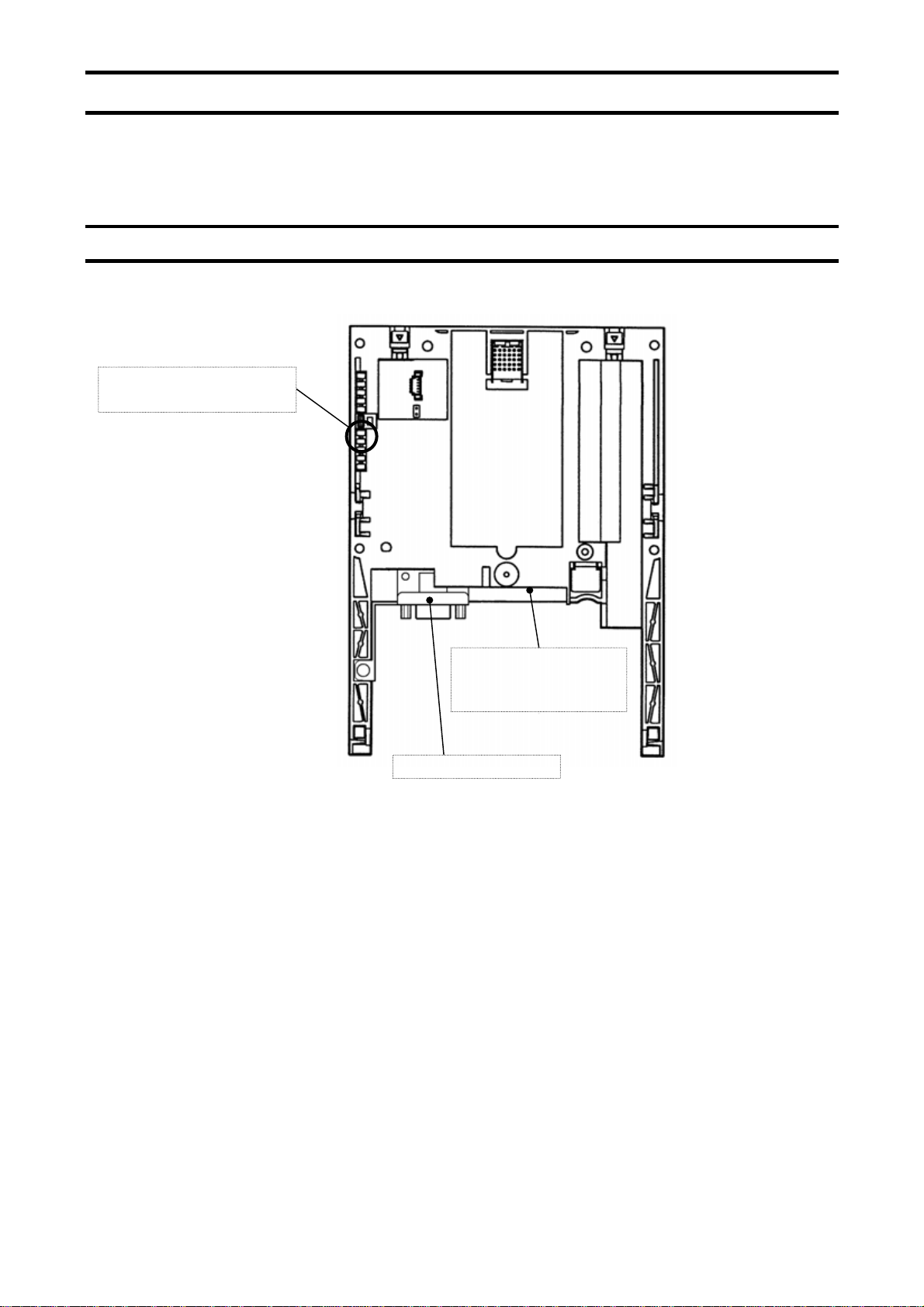

2. Connection Information

This option allows the VF-AS1/PS1 inverter to be communicated with the cyclic command

transmission and monitoring of the original profile ("USER DEFIND", refer to page 19) of

our company other than application profile "Profile for Variable Speed Drives PROFIdrive

(3.072), refer to page 8" which PROFIBUS defines.

2.1. Exterior features

Status LED indicator

(Refer to Section 2.4)

PROFIBUS connector

E6581343 ③

Address

setting Dip switch

(Refer to Section 2.3)

- 3 -

Page 5

2.2. PDP002Z Device Data

Parameter Value Note

Vendor_Name "TSIJ" Model_Name "PDP002Z" Revision "V1.1" Ident_Number 0x093C ID number

Protocol_Ident 0 PROFIBUS-DP

Station_Type 0 DP slave

FMS_supp 0 PROFIBUS-FMS: not supported

Hardware_Release "V1.0" Software_Release "V1.0" -

9.6_supp 1 9.6kbps: supported

19.2_supp 1 19.2kbps: supported

45.45_supp 1 45.45kbps: supported

93.75_supp 1 93.75kbps: supported

187.5_supp 1 187.5kbps: supported

500_supp 1 500kbps: supported

1.5M_supp 1 1.5Mbps: supported

3M_supp 1 3Mbps: supported

6M_supp 1 6Mbps: supported

12M_supp 1 12Mbps: supported

MaxTsdr_9.6 60 60 bit tiime

MaxTsdr_19.2 60 60 bit tiime

MaxTsdr_45.45 250 250 bit tiime

MaxTsdr_93.75 60 60 bit tiime

MaxTsdr_187.5 60 60 bit tiime

MaxTsdr_500 100 100 bit tiime

MaxTsdr_1.5M 150 150 bit tiime

MaxTsdr_3M 250 250 bit tiime

MaxTsdr_6M 450 450 bit tiime

MaxTsdr_12M 800 800 bit tiime

Redundancy 0 not supported

Repeater_Ctrl_Sig 2 TTL level

24V_Pins 0 not used

Freeze_Mode_supp 1 supported

Sync_Mode_supp 1 supported

Set_Slave_Add_Supp 0 not supported

Auto_Baud_supp 1 supported

Min_Slave_Intervall 1 0.1ms

Fail_Safe 0 mode: not supported

Modular_Station 1 Max_Module 1 ID: 1 byte

Max_Input_len 20 Input: 20 bytes

Max_Output_len 20 Output: 20 butes

Max_Data_len 40 Data length: 40 bytes

User_Prm_Data_Len 2 Max_User_Prm_Data_Len 2 -

E6581343 ③

- 4 -

Page 6

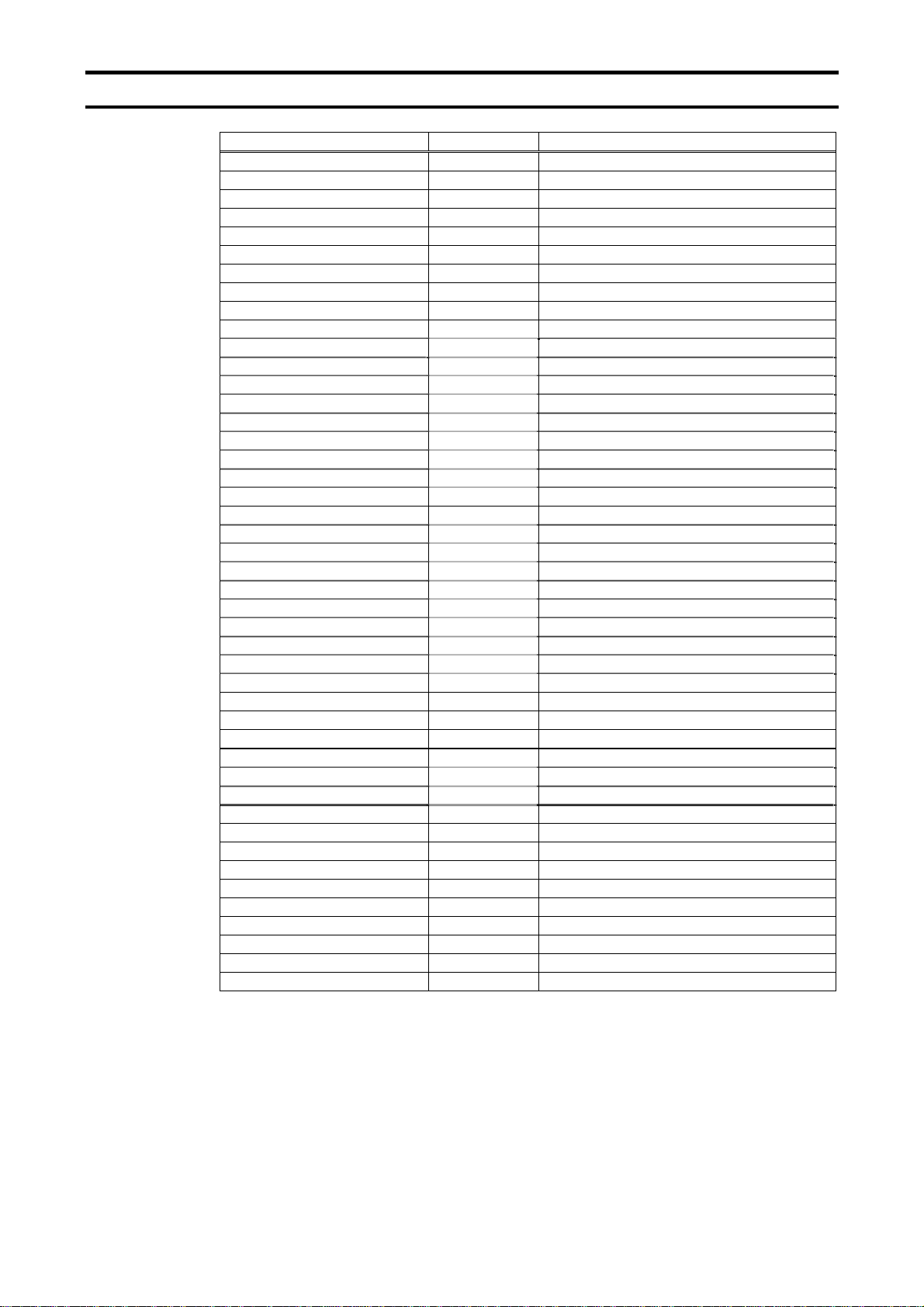

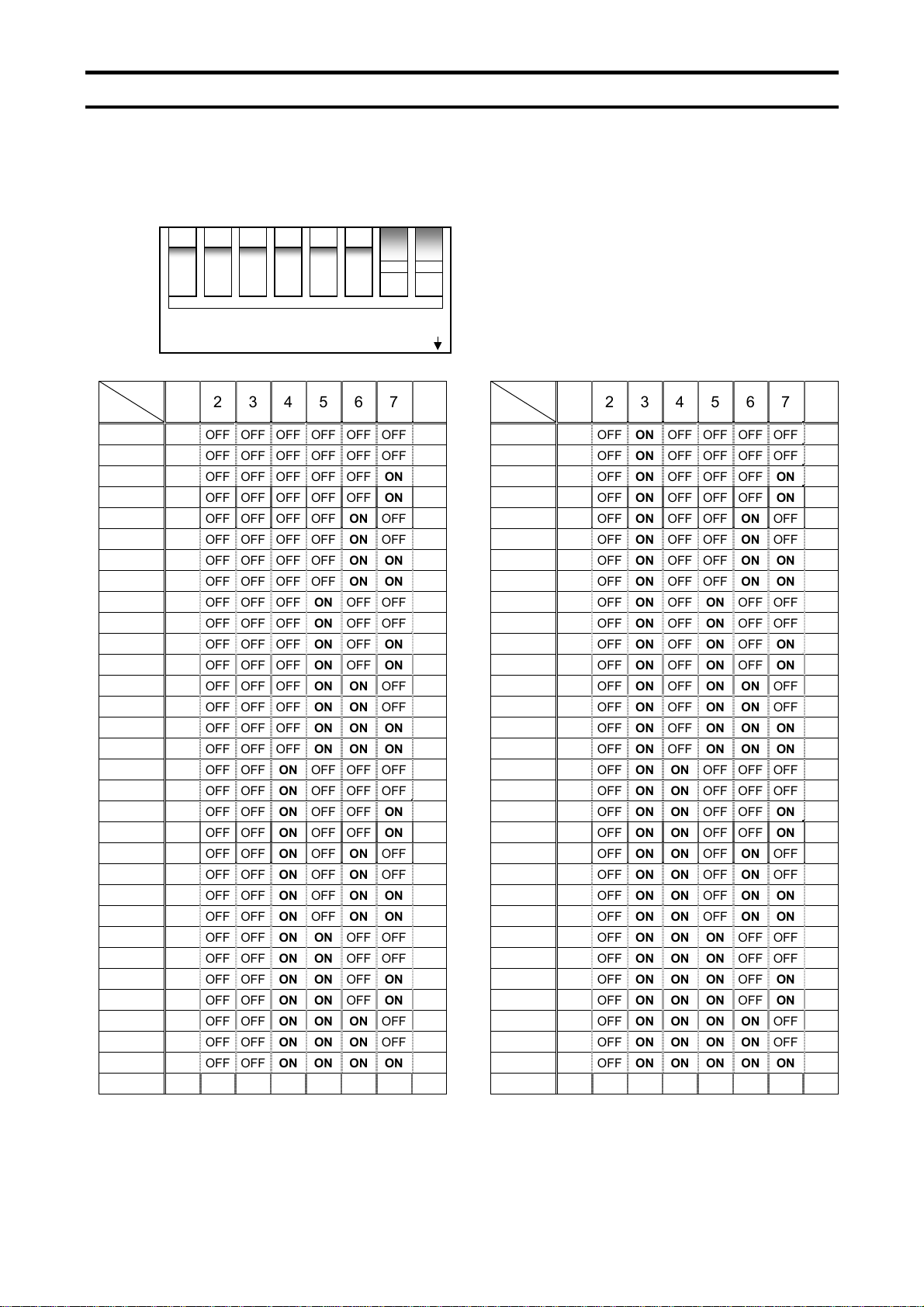

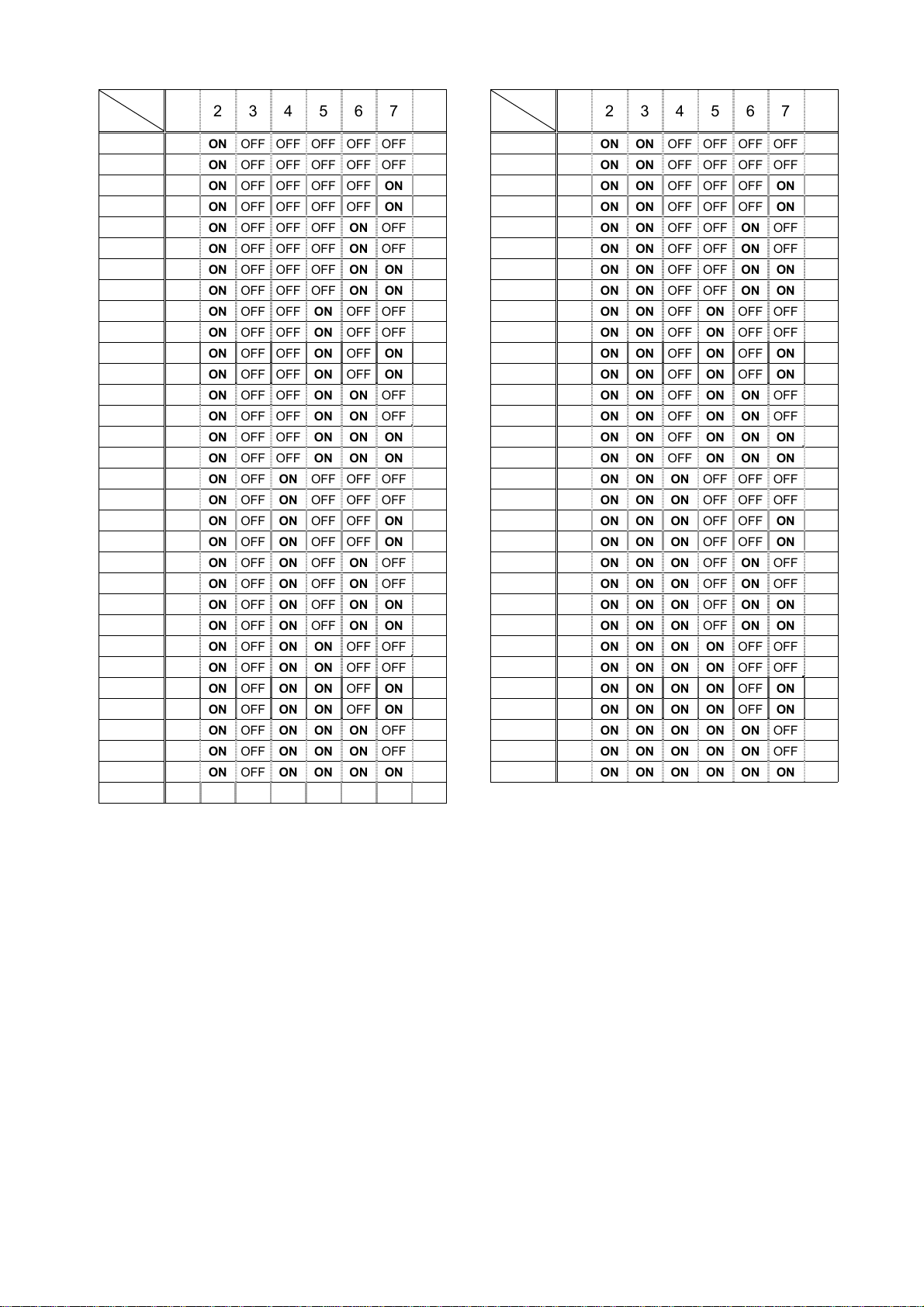

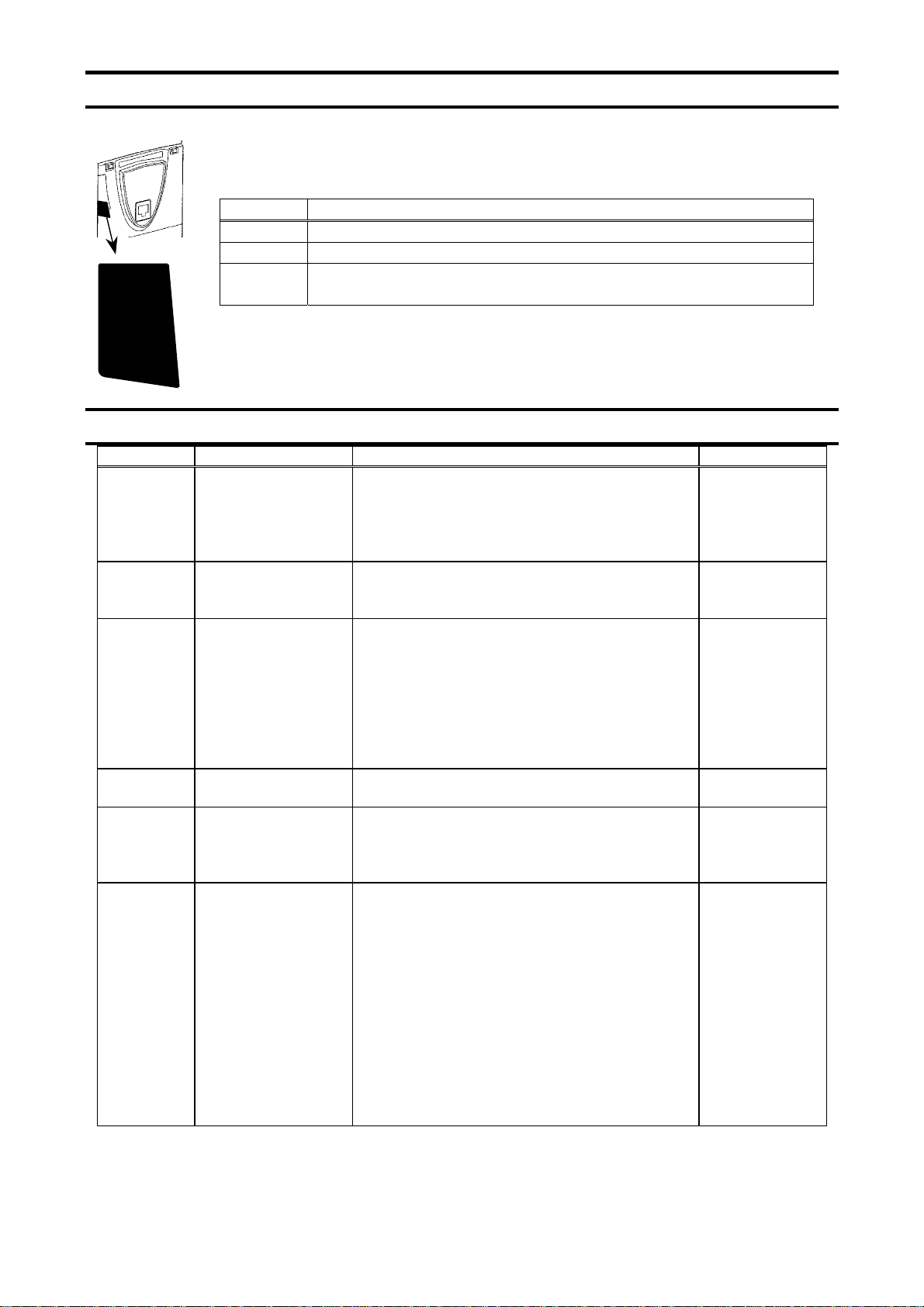

2.3. Setting a station address

The DIP switch on the circuit board of the option is used to set a station address. Each

DIP switch is ON when it is flipped to the lower position. By default, it is

factory-configured to 2.

The station address must be unique and not match any other device on the network.

1 2 3 4 5 6 7 8

DIP ON

SW

ID

OFF OFF OFF OFF OFF OFF OFF OFF

0

OFF OFF OFF OFF OFF OFF OFF ON

1

OFF OFF OFF OFF OFF OFF ON OFF

2

OFF OFF OFF OFF OFF OFF ON ON

3

OFF OFF OFF OFF OFF ON OFF OFF

4

OFF OFF OFF OFF OFF ON OFF ON

5

OFF OFF OFF OFF OFF ON ON OFF

6

OFF OFF OFF OFF OFF ON ON ON

7

OFF OFF OFF OFF ON OFF OFF OFF

8

OFF OFF OFF OFF ON OFF OFF ON

9

OFF OFF OFF OFF ON OFF ON OFF

10

OFF OFF OFF OFF ON OFF ON ON

11

OFF OFF OFF OFF ON ON OFF OFF

12

OFF OFF OFF OFF ON ON OFF ON

13

OFF OFF OFF OFF ON ON ON OFF

14

OFF OFF OFF OFF ON ON ON ON

15

OFF OFF OFF ON OFF OFF OFF OFF

16

OFF OFF OFF ON OFF OFF OFF ON

17

OFF OFF OFF ON OFF OFF ON OFF

18

OFF OFF OFF ON OFF OFF ON ON

19

OFF OFF OFF ON OFF ON OFF OFF

20

OFF OFF OFF ON OFF ON OFF ON

21

OFF OFF OFF ON OFF ON ON OFF

22

OFF OFF OFF ON OFF ON ON ON

23

OFF OFF OFF ON ON OFF OFF OFF

24

OFF OFF OFF ON ON OFF OFF ON

25

OFF OFF OFF ON ON OFF ON OFF

26

OFF OFF OFF ON ON OFF ON ON

27

OFF OFF OFF ON ON ON OFF OFF

28

OFF OFF OFF ON ON ON OFF ON

29

OFF OFF OFF ON ON ON ON OFF

30

OFF OFF OFF ON ON ON ON ON

31

1 2 3 4 5 6 7 8

SW

ID

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

E6581343 ③

1 2 3 4 5 6 7 8

OFF OFF ON OFF OFF OFF OFF OFF

OFF OFF ON OFF OFF OFF OFF ON

OFF OFF ON OFF OFF OFF ON OFF

OFF OFF ON OFF OFF OFF ON ON

OFF OFF ON OFF OFF ON OFF OFF

OFF OFF ON OFF OFF ON OFF ON

OFF OFF ON OFF OFF ON ON OFF

OFF OFF ON OFF OFF ON ON ON

OFF OFF ON OFF ON OFF OFF OFF

OFF OFF ON OFF ON OFF OFF ON

OFF OFF ON OFF ON OFF ON OFF

OFF OFF ON OFF ON OFF ON ON

OFF OFF ON OFF ON ON OFF OFF

OFF OFF ON OFF ON ON OFF ON

OFF OFF ON OFF ON ON ON OFF

OFF OFF ON OFF ON ON ON ON

OFF OFF ON ON OFF OFF OFF OFF

OFF OFF ON ON OFF OFF OFF ON

OFF OFF ON ON OFF OFF ON OFF

OFF OFF ON ON OFF OFF ON ON

OFF OFF ON ON OFF ON OFF OFF

OFF OFF ON ON OFF ON OFF ON

OFF OFF ON ON OFF ON ON OFF

OFF OFF ON ON OFF ON ON ON

OFF OFF ON ON ON OFF OFF OFF

OFF OFF ON ON ON OFF OFF ON

OFF OFF ON ON ON OFF ON OFF

OFF OFF ON ON ON OFF ON ON

OFF OFF ON ON ON ON OFF OFF

OFF OFF ON ON ON ON OFF ON

OFF OFF ON ON ON ON ON OFF

OFF OFF ON ON ON ON ON ON

- 5 -

Page 7

E6581343 ③

SW

ID

64

65

66

67

68

69

70

71

72

73

74

75

76

77

78

79

80

81

82

83

84

85

86

87

88

89

90

91

92

93

94

95

1 2 3 4 5 6 7 8

OFF ON OFF OFF OFF OFF OFF OFF

OFF ON OFF OFF OFF OFF OFF ON

OFF ON OFF OFF OFF OFF ON OFF

OFF ON OFF OFF OFF OFF ON ON

OFF ON OFF OFF OFF ON OFF OFF

OFF ON OFF OFF OFF ON OFF ON

OFF ON OFF OFF OFF ON ON OFF

OFF ON OFF OFF OFF ON ON ON

OFF ON OFF OFF ON OFF OFF OFF

OFF ON OFF OFF ON OFF OFF ON

OFF ON OFF OFF ON OFF ON OFF

OFF ON OFF OFF ON OFF ON ON

OFF ON OFF OFF ON ON OFF OFF

OFF ON OFF OFF ON ON OFF ON

OFF ON OFF OFF ON ON ON OFF

OFF ON OFF OFF ON ON ON ON

OFF ON OFF ON OFF OFF OFF OFF

OFF ON OFF ON OFF OFF OFF ON

OFF ON OFF ON OFF OFF ON OFF

OFF ON OFF ON OFF OFF ON ON

OFF ON OFF ON OFF ON OFF OFF

OFF ON OFF ON OFF ON OFF ON

OFF ON OFF ON OFF ON ON OFF

OFF ON OFF ON OFF ON ON ON

OFF ON OFF ON ON OFF OFF OFF

OFF ON OFF ON ON OFF OFF ON

OFF ON OFF ON ON OFF ON OFF

OFF ON OFF ON ON OFF ON ON

OFF ON OFF ON ON ON OFF OFF

OFF ON OFF ON ON ON OFF ON

OFF ON OFF ON ON ON ON OFF

OFF ON OFF ON ON ON ON ON

SW

ID

96

97

98

99

100

101

102

103

104

105

106

107

108

109

110

111

112

113

114

115

116

117

118

119

120

121

122

123

124

125

126

1 2 3 4 5 6 7 8

OFF ON ON OFF OFF OFF OFF OFF

OFF ON ON OFF OFF OFF OFF ON

OFF ON ON OFF OFF OFF ON OFF

OFF ON ON OFF OFF OFF ON ON

OFF ON ON OFF OFF ON OFF OFF

OFF ON ON OFF OFF ON OFF ON

OFF ON ON OFF OFF ON ON OFF

OFF ON ON OFF OFF ON ON ON

OFF ON ON OFF ON OFF OFF OFF

OFF ON ON OFF ON OFF OFF ON

OFF ON ON OFF ON OFF ON OFF

OFF ON ON OFF ON OFF ON ON

OFF ON ON OFF ON ON OFF OFF

OFF ON ON OFF ON ON OFF ON

OFF ON ON OFF ON ON ON OFF

OFF ON ON OFF ON ON ON ON

OFF ON ON ON OFF OFF OFF OFF

OFF ON ON ON OFF OFF OFF ON

OFF ON ON ON OFF OFF ON OFF

OFF ON ON ON OFF OFF ON ON

OFF ON ON ON OFF ON OFF OFF

OFF ON ON ON OFF ON OFF ON

OFF ON ON ON OFF ON ON OFF

OFF ON ON ON OFF ON ON ON

OFF ON ON ON ON OFF OFF OFF

OFF ON ON ON ON OFF OFF ON

OFF ON ON ON ON OFF ON OFF

OFF ON ON ON ON OFF ON ON

OFF ON ON ON ON ON OFF OFF

OFF ON ON ON ON ON OFF ON

OFF ON ON ON ON ON ON OFF

- 6 -

Page 8

E6581343 ③

2.4. Status indicator

The PDP002Z has two LEDs, ST (status) and DX (data exchange) to indicate the

statuses of PROFIBUS-DP and the PDP002Z itself.

ST (Status): Red LED

LED Meanings

ST

DX

MNS

MNS

MNS

Off No diagnostics present

Flashes Waiting for parameterisation or configuration

Lights

DX (Data exchange): Green LED.

Indicates the status of the PROFIBUS network.

It lights when the PDP002Z is on-line and data exchange is possible.

DP status error

* For example, a station address is not setcorrectly.

2.5. Communications-related parameters

Parameter Function Adjustment range Default setting

f830* Communication

option setting 1

(PPO TYPE)

f831

f846

f851 Inverter operation at

f852 Preset speed

f853 Monitoring of

f854** Monitoring of

Communication option

setting 2 - 13

the communications

loss action

(Network wire breaks)

operation selection

communication

device station

address

communications

device’s baud rate

* When the parameters are changed, the power must be cycled to the VF-AS1/PS1 for

the changes to take effect.

** The baud rate of the PDP002Z is automatically set by configuration a baud rate for the

master.

0: None

1: PPO TYPE 1

2: PPO TYPE 2

3: PPO TYPE 3

4: PPO TYPE 4

Refer to section 4. 0

0: Stop and break of connection

1: None

2: Deceleration stop

3: Coast stop

4: Emergency stop

5: Preset speed operation command

(Operating at the preset speed operation

frequency set with f852)

0: None

1 to 15: Preset speed

Displays the station address assigned with the

DIP switch.

0 to 125

Displays the network communication speed set

with the DIP switch.

0: 12 Mbit/s

1: 6 Mbit/s

2: 3 Mbit/s

3: 1.5 Mbit/s

4: 500 kbit/s

5: 187.5 kbit/s

6: 93.75 kbit/s

7: 45.45 kbit/s

8: 19.2 kbit/s

9: 9.6 kbit/s

255: Disabled

0

0

0

2

0

- 7 -

Page 9

3. “PROFIdrive” Profile

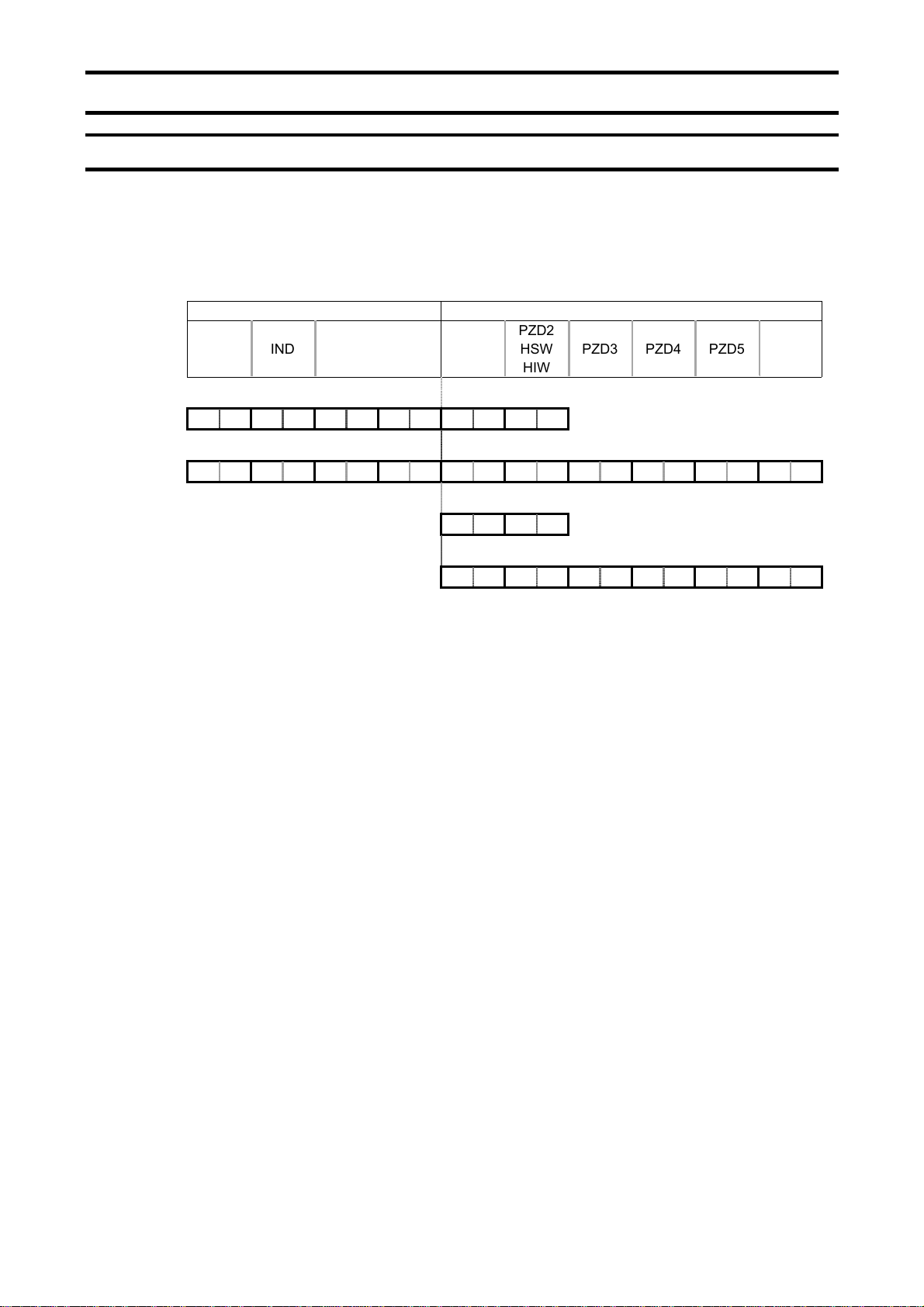

3.1. PPO TYPE

The PPO type of PDP002Z is set up by this parameter.

The PROFIBUS-DP protocol uses so-called PPOs (Parameter/Process Data Objects) in

cyclic communication. The figures below show the PPO types and configurations that the

PDP002Z supports

PKW PZD

PKE IND PWE

PPO TYPE 1: Octet-String 12

PPO TYPE 2: Octet-String 20

PPO TYPE 3: Octet-String 4

PPO TYPE 4: Octet-String 12

PKW: Parameter ID/value

PZD: Process Data, cyclically transferred

PKE: Parameter ID (1st and 2nd octet)

IND: Sub-index (3rd octet), 4th octet is reserved

PWE: Parameter value (5th until 8th octet)

STW: Control word

HSW: Main setpoint

ZSW: Status word

HIW: Main actual value

* There are some by which a high byte / low byte is conversely treated depending on a master.

.

E6581343 ③

PZD1

STW

ZSW

PZD2

HSW

HIW

PZD3 PZD4 PZD5 PZD6

- 8 -

Page 10

3.2. STW Control Word Data

g

PDP002Z supports only speed control mode.

Bit Value Name Note

E6581343 ③

0

1

2

3

4

5

6

1

0

1

0

1

0

1

0

1

0

1

0

1

0

ON

OFF 1 Normal stop.

Operating condition

OFF 2 Coast stop.

Operating condition

OFF 3 Emergency Stop.

Operation

Inhibit operation Normal stop.

Operation condition No function.

Inhibit ramp-function No function.

Enable ramp-function No function.

Stop ramp-function No function.

Enable setpoint Drive can be started if all other start conditions are fulfilled.

inhibit setpoint Reference frequency is set to zero.

Drive can be started if all other start conditions are fulfilled.

Drive can be started if all other start conditions are fulfilled.

Drive can be started if all other start conditions are fulfilled.

Drive can be started if all other start conditions are fulfilled.

7

8

9

10

11

-

15

1

0

1

0

1

0

1

0

----

Acknowledge Fault reset (0 -> 1)

No meaning No function.

Inching 1 ON Inverter drives with jogging speed.

Inching 1 OFF

Inching 2 ON No function.

Inching 2 OFF No function.

Control from

the automation unit

No control

Device-specification (Reserved.)

Jogging stop, if "inching 1" was previously ON. Stop drive

accordin

The control word and frequency setpoint (from Profibus) are

activated.

The control word and frequency setpoint (from Profibus) are

not valid.

to inverter setting parameter.

- 9 -

Page 11

3.3. ZSW Status Word Data

Bit Valur Name Note

E6581343 ③

0

1

2

3

4

5

6

1

0

1

0

1

0

1

0

1

0

1

0

1

0

Ready to switch-on Control word bit 0 = 0 and bit1, 2, 10 are set to 1.

Not ready switch-on

Ready Refer to control word, bit 0.

Not ready -

Operating enabled Refer to control word, bit 3.

Operation inhibited -

Fault Inverter is faulted.

Fault-free Inverter is not tripped.

No OFF 2 -

OFF 2 "OFF 2" command present

No OFF 3 -

OFF 3 "OFF 3" command present

Switch-on inhibit

No switch-on inhibit -

Control word bit 0 = 0, 1, 2 or 10 are set to 0,

or the inverter is tripped.

Control word bit1 or 2 is set to 0

or fault trip has been acknowledged.

1

Alarm

7

No alarm Alarm not present or alarm has disappeared again

Setpoint / actual value

As above, but not

in the tolerance range

Control request

8

0

1

0

1

monitoring in the tolerance

9

0

1

Local operation Control only possible on the VF-AS1/PS1.

f or n reached

10

0

11 ----

12 ----

13 ----

14 ----

15 ----

*Bit 11 - 15 are the ON/OFF status monitor of each terminals.

f or n fallen below -

Device-specification

OUT1 terminal monitor

Device-specification

OUT2 terminal monitor

Device-specification

FL terminal monitor

Device-specification

OUT3 terminal monitor

Device-specification

OUT4 terminal monitor

Drive still operational: Alarm in service parameter: No

acknowledgement.

Run command or frequency setting is valid

via Profibus.

Actual value = comparison value (at reference),

set via the parameter number

OUT1 output terminal monitor

(bit 0 of fd07. Function selection: f130)

OUT2 output terminal monitor

(bit 1 of fd07. Function selection: f131)

FL output terminal monitor

(bit 2 of fd07. Function selection: f132)

OUT3 output terminal monitor

(bit 3 of fd07. Function selection: f133)

OUT4 output terminal monitor

(bit 3 of fd07. Function selection: f134)

-

-

- 10 -

Page 12

3.4. State Macine

A

MAINS OFF

A B

OPERATION

INHIBIT

from any state

OFF1

ACTIVE

Power ON

CW: Bit3 = 0

SW: Bit2 = 0

Operation inhibited

CW: Bit0 = 0

SW: Bit1 = 0

Normal Stop

Frequency = 0

CW: Control Word

ST: Status Word

: Status

SWITCH-ON

NOT READY TO

SWITCH-ON

SWITCH-ON

OPERATION

OPERATING

B

INHIBIT

CW: Bit0 = 0

CW: xxxx xxxx xxxx x110

READY TO

CW: xxxx xxxx xxxx x111

READY TO

OPERATE

CW: Bit3 = 1

ENABLE

CW: Bit6 = 1 and Bit10 = 1

SW: Bit6 = 1

SW: Bit0 = 1

SW: Bit1 = 1

from any state

CW: Bit2 = 0

OFF3

ACTIVE

Frequency = 0

SW: Bit2 = 1

SW: Bit9 = 1

E6581343 ③

from any state

FAULT

FAULT

0 -> 1

from any state

SW: Bit5 = 0

Emergency Stop Coast stop

INCHING

ACTIVE

INCHING

PAUSE

OFF2

ACTIVE

CW: Bit6 = 0

CW: Bit8 = 1

Inching ON

CW: Bit8 = 0

Inching OFF

Frequency = 0

and inching pause expired

SW: Bit3 = 1

CW: Bit7 = 1

CW: Bit1 = 0

SW: Bit4 = 0

- 11 -

Page 13

3.4.1. Examples of driving by the State Machine

When using the PROFIdrive profile, the frequency reference is set to HSW. The setting

value “0x0000” - ”0x4000” is equivalent to ”0” - ”Base frequency (parameter vl)”.

When the reverse operation, the frequency reference is set with two's complement of the

forward frequency reference.

During running, HIW shows a output frequency.

3.4.1.1. Example 1. 60Hz Forward running and Deceleration stop

Set ”0x4000” to HSW and the following is set to STW in order.

① 0000 0100 0000 0110 (= 0x0406)

“READY TO SWITCH-ON”

② 0000 0100 0000 0111 (= 0x0407)

“READY TO OPERATE”

③ 0000 0100 0100 1111 (= 0x044F)

“OPERATION”

④ 0000 0100 0100 1110 (= 0x044E)

“OFF1 ACTIVE (Normal Stop)”

3.4.1.2. Example 2. 30Hz Reverse running

When the reverse operation, “0xE000” is set to HSW. “0xE000” is two's complement of

the “0x2000” as the forward frequency reference 30Hz.

The Setup to STW is same as the Example 1.

3.4.1.3. Example 3. Inching and pause

the following is set to STW in order.

① 0000 0100 0000 0110 (= 0x0406)

“READY TO SWITCH-ON”

② 0000 0100 0000 0111 (= 0x0407)

“READY TO OPERATE”

③ 0000 0101 0000 1111 (= 0x050F)

“INCHING ACTIVE”

④ 0000 0100 0100 1111 (= 0x040F)

“INCHING PAUSE”

* The inching frequency is according to the parameter f260 on VF-AS1/PS1.

E6581343 ③

- 12 -

Page 14

E6581343 ③

3.5. The Access to the PROFIBUS parameter

In the cyclic PROFIBUS-DP communication, the parameter data is transferred via PPO

TYPE1 and 2. If the requirement is not executed, the cause is distinguished by octet 7 and

8.

PKW

(Parameter ID/value)

PKE IND PWE

Octet 1 Octet 2 Octet 3 Octet 4 Octet 5 Octet 6 Octet 7 Octet 8

PKE (Parameter ID)

15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

Process data (cyclically)

PZD1

STW

ZSW

(Task ID/Response ID)

AK

SPM

(Parameter number)

AK (Request from Master to PDP002Z)

Request ID Function Note

0 No task

1 Request parameter value for PNU access

2 Change parameter value (word) for PNU access

6 Request parameter value (array) for PNU access, VF-AS1/PS1 parameter access

7 Change parameter value (array) for PNU access, VF-AS1/PS1 parameter access

AK (Response from PDP002Z to Master)

Response ID Function

0 No response

1 Transfer parameter value (word)

4 Transfer parameter value (array)

7 Task can not be executed, followed by error number

0 = Illegal parameter number

1 = Parameter value cannot be changed

2 = Lower or upper limit violated

3 = Erroneous sub index

11 = No parameter change rights

17 = Task cannot be executed due to operating status

(e.g. parameter is currently read-only)

18 = Other error

102 = Request not supported

SPM: always 0.

PZD

PZD2

HSW

HIW

PNU

- 13 -

Page 15

E6581343 ③

PNU (the parameter number)

PNU R/W data type Note

915 R/W Array [10]

Unsigned16

916 R/W Array [10]

Unsigned16

918 R Unsigned16 Station address monitor (same as the inverter parameter f853).

927 R/W Unsigned16 Operator control rights (parameter identification, PKW).

928 R/W Unsigned16 Control rights (process data, PZD).

929 R Unsigned16 Selected PPO-type (same as the inverter parameter f830)

939 R/W Unsigned16

940 R/W Unsigned16

941 R/W Unsigned16

942 R/W Unsigned16

943 R/W Unsigned16

947 R Array [64]

Unsigned16

963 R Unsigned16 Detected baud rate (same as f854):

964 R Unsigned16 Identification number of the PDP002Z (0x093C)

965 R Octet String2 Profile number of the PDP002Z (0x0302)

967 R Unsigned16 Control word

968 R Unsigned16 Status word

PNU 915, IND 1 = the inverter parameter f831

PNU 915, IND 2 = the inverter parameter f832

PNU 915, IND 3 = the inverter parameter f833

PNU 915, IND 4 = the inverter parameter f834

PNU 915, IND 5 = the inverter parameter f835

PNU 915, IND 6 = the inverter parameter f836

PNU 916, IND 1 = the inverter parameter f841

PNU 916, IND 2 = the inverter parameter f842

PNU 916, IND 3 = the inverter parameter f843

PNU 916, IND 4 = the inverter parameter f844

PNU 916, IND 5 = the inverter parameter f845

PNU 916, IND 6 = the inverter parameter f846

Value: Mode

0: Parameters cannot be written, only read

(927 can be written).

1: Parameters can be written and read (default).

Value: Mode

0: PZD part is disabled.

i.e. Receipt of new PZD data is ignored.

1: PZD part is enabled (default).

Value: PPO TYPE

1: PPO TYPE 1

2: PPO TYPE 2

3: PPO TYPE 3

4: PPO TYPE 4

OUT1 output terminal selection (same as f130).

Monitor is enabled using Status word bit 11.

OUT2 output terminal selection(same as f131).

Monitor is enabled using Status word bit 12.

FL output terminal selection (same as f132).

Monitor is enabled using Status word bit 13.

OUT3 output terminal selection (same as f133).

Monitor is enabled using Status word bit 14.

OUT4 output terminal selection (same as f134).

Monitor is enabled using Status word bit 15.

Fault number

PNU 947, IND 1 = fc90 (Active fault)

PNU 947, IND 9 = fe10 (Last ackn. fault)

PNU 947, IND 17 = fe11 (Second last ackn. fault)

PNU 947, IND 25 = fe12 (Third last ackn. fault)

PNU 947, IND 33 = fe13 (Fourth last ackn. fault)

0 = 12 Mbit/s

1 = 6 Mbit/s

2 = 3 Mbit/s

3 = 1.5 Mbit/s

4 = 500 kbit/s

5 = 187.5 kbit/s

6 = 93.75 kbit/s

7 = 45.45 kbit/s

8 = 19.2 kbit/s

9 = 9.6 kbit/s

255 = Invalid baud rate

- 14 -

Page 16

3.5.1. Examples of reading or changing the PROFIdrive parameter

3.5.1.1. Example 1. Reading the PNU 964 (ID number)

AK = 1 (Request parameter value)

SPM = 0

PNU = 964 (0x03C4)

PKE

0 0 0 1 0 0 1 1 1 1 0 0 0 1 0 0

1 3 C 4

Requirement

PKW PZD

PKE IND PWE

13 C4 00 00 00 00 00 00 ・・・ ・・・

Response (Value: 0x093C)

13 C4 00 00 00 00 09 3C ・・・ ・・・

E6581343 ③

3.5.1.2. Example 2. Reading the PNU 947, IND (Fault history)

AK = 6 (Request parameter value (array))

SPM = 0

PNU = 947 (0x03B3)

IND = 0x0001 (

Active fault)

PKE

0 1 1 0 0 0 1 1 1 0 1 1 0 0 1 1

6 3 B 3

Requirement

PKW PZD

PKE IND PWE

63 B3 00 01 00 00 00 00 ・・・ ・・・

Response (Value: 0x000D = Inverter over load

43 B3 00 01 00 00 00 0D ・・・ ・・・

* Refer to page 26 about the fault code.

*

)

- 15 -

Page 17

3.5.1.3. Example 2. Changing the PNU 933 (Control word, bit 11)

AK = 2 (Change parameter value (word))

SPM = 0

PNU = 933 (0x03A5)

PWE = 10 (0x000A)

PKE

0 0 1 0 0 0 1 1 1 0 1 0 0 1 0 1

2 3 A 5

Requirement (PNU 933 = 10 (f111 = 10))

PKW PZD

PKE IND PWE

23 A5 00 00 00 00 00 0A ・・・ ・・・

Response (Value: 0x000D = Inverter over load)

13 A5 00 00 00 00 00 0A ・・・ ・・・

Example of the error occurrence

Requirement (PNU 933 = 136 (out of the value range))

PKW PZD

PKE IND PWE

23 A5 00 00 00 00 00 88 ・・・ ・・・

Response (Value: 0x0002 = Lower or upper limit violated)

73 A5 00 00 00 00 00 02 ・・・ ・・・

E6581343 ③

- 16 -

Page 18

3.6. Access to the VF-AS1/PS1 parameter

When access to the VF-AS1/PS1 parameter, set “1” to the PNU. The communication

number of the inverter parameter is set to the subindex IND.

Refer to the inverter instruction manual about the communication number and unit.

3.6.1. Examples of reading or changing the VF-AS1/PS1 parameter

3.6.1.1. Example 1. Reading the basic parameter (cmod (command mode selection))

AK = 6 (Request parameter value (array))

SPM = 0

PNU = 1

IND = 0x0003 (cmod communication number)

PKE

0 1 1 0 0 0 0 0 0 0 0 0 0 0 0 1

6 0 0 1

Requirement

PKW PZD

PKE IND PWE

60 01 00 03 00 00 00 00 ・・・ ・・・

Response (Value: 0x0001 = Operation panel))

40 01 00 03 00 00 00 01 ・・・ ・・・

E6581343 ③

3.6.1.2. Example 2. Reading the extended parameter (f219 (RX input point 2 frequency))

AK = 6 (Request parameter value (array))

SPM = 0

PNU = 1

IND = 0x0219 (f219 communication number)

PKE

0 1 1 0 0 0 0 0 0 0 0 0 0 0 0 1

6 0 0 1

Requirement

PKW PZD

PKE IND PWE

60 01 02 19 00 00 00 00 ・・・ ・・・

Response (Value: 0x1770 (= 6000 -> 60.00Hz

40 01 02 19 00 00 17 70 ・・・ ・・・

* “0x1770” as reading value of “RX input point 2 frequency” is

0x1770 = 6000 (decimal number)

Since the unit of “RX input point 2 frequency” is 0.01Hz, set the following value.

6000×0.01 = 60.00Hz

*

))

- 17 -

Page 19

3.6.1.3. Example 3. Reading the status monitor parameter (fe02 (The operation frequency))

AK = 6 (Request parameter value (array))

SPM = 0

PNU = 1

IND = 0xFE02(fe02 communication number)

PKE

0 1 1 0 0 0 0 0 0 0 0 0 0 0 0 1

6 0 0 1

Requirement

PKW PZD

PKE IND PWE

60 01 FE 02 00 00 00 00 ・・・ ・・・

Response (Value: 0x03E8 (= 1000 -> 10.00Hz))

40 01 FE 02 00 00 03 E8 ・・・ ・・・

* The status monitor parameter can not be changed.

E6581343 ③

3.6.1.4. Example 4. Changing the basic parameter (acc (acceleration time))

AK = 7 (Change parameter value (array word))

SPM = 0

PNU = 1

IND = 0x0009 (acc communication number)

PKE

0 1 1 1 0 0 0 0 0 0 0 0 0 0 0 1

7 0 0 1

Requirement (acc = 7.0 sec. -> 70 (= 0x0046)

*

)

PKW PZD

PKE IND PWE

70 01 00 09 00 00 00 46 ・・・ ・・・

Response

40 01 00 09 00 00 00 46 ・・・ ・・・

* When the “Acceleration time” is set to 7.0 sec., set the following value.

(The unit of the “Acceleration time” is 0.1s.)

7.0/0.1 = 70 = 0x0046 (hexadecimal number)

- 18 -

Page 20

4. ”USER DEFIND” Profile

Cyclic command transmission (the value of the parameter f831 - f836) and

monitoring (the value of the parameter f841 - f846) are possible for PDP002Z

by the original profile

Select the ”USER DEFIND” as the profile on the configuration.

Refer to the PLC configurator documents.

f831 - f836 setup value f841 - f846 setup value

0: No action

1: FA06 (ALCAN2 command 1)

2: FA23 (ALCAN2 command 2)

3: FA07 (ALCAN2 frequency command, 0.01Hz)

4: FA33 (Torque command, 0.01%)

5: FA50 (Terminal output)

6: FA51 (Analog output (FM) data from comm.)

7: FA52 (Analog output (AM) data from comm.)

8: F601 (Stall prevention level, %)

9: F441 (Power running torque limit 1 level, 0.01%)

10: F443 (Regenerative braking torque limit 1 level, 0.01%)

11: F460 (Speed loop proportional gain)

12: F461 (Speed loop stabilization coefficient)

0: No action

1: FD01 (Inverter status 1)

2: FD00 (Output frequency, 0.01Hz)

3: FD03 (Output current, 0.01%)

4: FD05 (Output voltage, 0.01%)

5: FC91 (Inverter alarm)

6: FD22 (PID feedback value, 0.01Hz)

7: FD06 (Input terminal status)

8: FD07 (Output terminal status)

9: FE36 (VI/II input)

10: FE35 (RR/S4 input)

11: FE37 (RX input)

12: FD04 (Input voltage (DC detection), 0.01%)

13: FD16 (Speed feedback (real-time value)

14: FD18 (Torque, 0.01%)

15: FE60 (My monitor)

16: FE61 (My monitor)

17: FE62 (My monitor)

18: FE63 (My monitor)

19: F880 (Free notes)

20: FD29 (Input power, 0.01kW)

21: FD30 (Output power, 0.01kW)

22: FE14 (Cumulative operation time, 1 hour)

23: FE40 (FM terminal output monitor)

24: FE41 (AM terminal output monitor)

E6581343 ③

- 19 -

Page 21

4.1. How to use

The purposes are adjustment by real time command transmission, and the monitor of an

operation state by using cyclic communication of PROFIBUS.

Example 1: Command transmitting

When you want to set "0xC400" to parameter fa06, set “1 (FA06)” to parameter

f831.

And Since 0 and 1 byte of the PZD1 supports the parameter f831, if "0xC400" is set

up here, "0xC400" will be set as fa06.

VF-AS1/PS1

Parameter Value

f831 1 (FA06)

f832 ...

f833 ...

... ...

"C400" is set as parameter fa06

Example 2: State monitoring

When you want to monitor the output current, set “3 (FD03)” to parameter f841.

The value of the parameter fd03 specified as 0 and1 byte of the PZD1 with the

parameter f841 is inputted.

VF-AS1/PS1

Parameter Value

f841 3 (FD03)

f842 ...

f843 ...

... ...

The value of a parameter fd03 is outputted.

PDP002Z

PDP002Z

E6581343 ③

PROFIBUS Master

PZD1 PZD2 PZD3

C4 00 ... ... ... ...

PROFIBUS Master

PZD1 PZD2 PZD3

xx xx ... ... ... ...

- 20 -

Page 22

4.2. The overview of the VF-AS1/PS1 parameter

Refer to a communication functional description (VF-AS1: E6581315/VF-PS1: E6581413)

for details.

4.2.1. FA06 (Command word 1 from internal option PCB)

bit Function 0 1 Note

0 Preset Speed1

1 Preset Speed2

2 Preset Speed3

3 Preset Speed4

4 THR1/2

5 PI off Normal PI off -

6 ACC1/ACC2

7 DC braking OFF DC braking 8 Jog OFF JOG RUN -

9 Forward/Reverse Fw. Rev. 10 Run/stop STOP RUN 11 Free run (ST) Free run 12 Emergency stop OFF EMG./ Stop Always enable

13 Reset trip OFF Reset 14 Frequency link OFF Priority Enable in spite of the parameter fmod

15 Command link OFF Priority Enable in spite of the parameter cmod

4.2.2. FA23 (Command word 2 from internal option PCB)

OFF ....................0000,

1 - 15 ..................0001 - 1111

Motor 1

(THR1)

ACC 1

(AD1)

Motor 2

(THR2)

ACC 2

(AD2)

Combination of 4 bits.

THR1: thr

THR2: f173

AD1: acc, dec

AD2: f500, f501

E6581343 ③

bit Function 0 1 Note

0 Speed/Torque Speed Ctrl. Torque Ctrl. -

1 Clear kwh OFF Clear Clear the value of fe76, fe77

2 (Reserved) - - 3* Brake Close (BC) Normal Forced Close 4* Pre magnetic Normal ON 5* Brake Open (B) Brake Close Brake Open 6* Brake Answer (BA) Brake Close Brake Open -

7 Fast Stop Normal ON -

8 ACC1/ACC2

9 ACC3/ACC4*

10 THR 1/2

11 THR 3/4*

12* Torque Limit 1/2

13* Torque Limit 3/4

14* Speed Gain 1/2 Gain 1 Gain 2

15 (Reserved) - - -

* These functions are reserved in VF-PS1.

00: Acc. / Dec. 1

01: Acc. / Dec. 2

10: Acc. / Dec. 3*

11: Acc. / Dec. 4*

00: V/f 1

01: V/f 2

10: V/f 3*

11: V/f 4*

00: Torque limit 1

01: Torque limit 2

10: Torque limit 3

11: Torque limit 4

Combination of 2 bits.

AD1: acc, dec

AD2: f500, f501

AD3: f510, f511*

AD4: f514, f515*

Combination of 2 bits.

Combination of 2 bits.

Gain 1: f460, f461

Gain 2: f462, f463

- 21 -

Page 23

4.2.3. FA07 (Frequency reference from internal option PCB)

Frequency reference is set up by 0.01Hz unit and the hexadecimal number.

For example, when "Frequency reference" is set up to 80Hz, since the minimum unit is

0.01Hz,

80 / 0.01 = 8000 = 0x1F40 (Hex.)

4.2.4. FA33 (Torque reference from internal option PCB)

Torque reference is set up by 0.01% unit and the hexadecimal number.

For example, when "torque reference" is set up to 50%, since the minimum unit is 0.01%,

50 / 0.01 = 5000 = 0x1388 (Hex.)

4.2.5. FA50 (Terminal output data from comm.)

By setting up the data of the bit 0 - 6 of terminal output data (FA50) from communication,

setting data (0 or 1) can be outputted to the output terminal.

Please select the functional number 92 - 105 as the selection (f130 - f138, f168,

f169) of the output terminal function before using it.

bit Output TB function name 0 1

0 Communication data 1 (Output TB select No.: 92, 93)

1 Communication data 2 (Output TB select No.: 94, 95)

2 Communication data 3 (Output TB select No.: 96, 97)

3 Communication data 4 (Output TB select No.: 98, 99)

4 Communication data 5 (Output TB select No.: 100, 101)

5 Communication data 6 (Output TB select No.: 102, 103)

6 Communication data 7 (Output TB select No.: 104, 105)

7 - - -

4.2.6. FA51 (Analog output (FM) data from comm.)

The data set as the parameter FA51 can output to FM terminal.

The data adjustment range is 0 - 1023 (resolution: 10 bits).

Please select 31 (analog output for communication) as FM terminal meter selection

parameter (fmsl) before using it.

Please refer to "Meter setting and adjustment" Section of the VF-AS1/PS1 instructions

manual for details.

4.2.7. FA52 (Analog output (AM) data from comm.)

The data set as the parameter FA52 can output to AM terminal.

The data adjustment range is 0 - 1023 (resolution: 10 bits).

Please choose 31 (analog output for communication) as AM terminal meter selection

parameter (amsl) before using it.

Please refer to "Meter setting and adjustment" Section of the VF-AS1/PS1 instructions

manual for details.

E6581343 ③

OFF ON

- 22 -

Page 24

E6581343 ③

4.2.8. FD01 (Inverter status (real time))

bit Function 0 1 Note

0 FL No output Under output -

The rtry status and the trip

1 EMG No fault Under fault

retention status are also regarded

as tripped statuses.

2 ALARM No alarm Under alarm 3 (Reserved) - - -

4 tHr2(VF2+tH2)

Motor 1

(THR1)

Motor 2

(THR2)

THR1: thr

THR2: f173

5 PI PI enable PI off -

6 ACC1/ACC2

Acc./Dec. 1

(AD1)

Acc./Dec. 2

(AD2)

AD1: acc, dec

AD2: f500, f501

7 DC braking OFF DC braking 8 Jog OFF JOG RUN 9 Forward /Reverse Fwd. RUN Rev. RUN -

10 Run/stop STOP RUN 11 Free run (ST) ST=ON ST=OFF 12 Emergency stop No EMG. Stop Under EMG. Stop -

13 READY with ST/ RUN - -

READY without

14

ST/RUN

- - -

ST = ON and RUN = ON in

addition to “ready for operation”*

15** Local/Remote Remote Local -

* Ready for operation: Initialization completed, not a stop due to a failure, no alarm issued, not moff, not a forced

stop due to ll, not a forced stop due to a momentary power failure.

This function is reserved in VF-AS1.

**

4.2.9. FD00 (Output frequency (real time))

The current output frequency is read into 0.01Hz of units and by the hexadecimal

number.

For example, when the output frequency is 80Hz, 0x1F40 (hexadecimal number) are read.

Since the minimum unit is 0.01%,

0x1F40 (Hex.) = 8000(Dec.) * 0.01 = 80 (Hz)

Also about the following parameters, these are the same as this.

- FD22 (Feedback value of PID (real time))..................................Unit: 0.01Hz

- FD16 (PG feedback or Estimated speed (real time)) .................Unit: 0.01Hz

- FD29 (Input power (real time)) ...................................................Unit: 0.01kW

- FD30 (Output power (real time)) ................................................Unit: 0.01kW

4.2.10. FD03 (Output current (real time))

The current output current is read into 0.01% of units and by the hexadecimal number.

For example, when the output current of the rated current 4.8A inverter is 50% (2.4A),

0x1388 (hexadecimal number) is read.

Since the minimum unit is 0.01%,

0x1388 (Hex.) = 5000 (Dec.) * 0.01 = 50 (%)

Also about the following parameters, these are the same as this.

- FD05 (Output voltage(real time).................................................Unit: 0.01% (V)

- FD04 (Voltage at DC bus (real time) ..........................................Unit: 0.01%(V)

- FD18 (Torque .............................................................................Unit: 0.01% (Nm)*

* When the motor information connected to the inverter set to the parameter (f405 -

f415), torque monitor value "100%" is same as the rated torque of a motor in general.

- 23 -

Page 25

4.2.11. FE36 (Analog input value VI/II)

The value inputted into the VI/II terminal is read.

The value range is 0 - 10000 (0 - 100.00 %).

Also the same as the parameter FE35 (RR Input).

4.2.12. FE37 (RX Input)

The value inputted into the RX terminal is read.

The value range is -10000 - 10000 (-100.00 - +100.00 %).

4.2.13. FE60 - FE63 (My Monitor)

Refer to the function Manual (E6581335).

4.2.14. FE14 (Cumulative run time)

The operated cumulative time is read by the hexadecimal number.

For example, when cumulative operation time is 18 hours, 0x12 (16 hours) is read.

0x12 (Hex.) = 18 (Dec., hour)

4.2.15. FE40 (Analog output (FM))

The output value of FM terminal is read.

The value range is set to 0 - 65535 (0xFFFF).

- Also about FE41 (AM terminal output monitor), it is the same as this parameter.

E6581343 ③

- 24 -

Page 26

E6581343 ③

4.2.16. FC91 (Alarm code)

bit Function 0 1 Note

0 Over current alarm Normal Under alarm “c” blinking

1 Inverter over load alarm Normal Under alarm “l” blinking

2 Motor over load alarm Normal Under alarm “l” blinking

3 Over heat alarm Normal Under alarm “h” blinking

4 Over voltage alarm Normal Under alarm “p” blinking

5 Under voltage of main power Normal Under alarm 6 (Reserved) - - 7 Under current alarm Normal Under alarm 8 Over torque alarm Normal Under alarm 9 OLr alarm Normal Under alarm -

10 Cumulative run-time alarm Normal Under alarm 11 (Reserved) - - 12 (Reserved) - - 13 (Reserved) - - 14 Stop after instantaneous power off - Dec., Under stop Refer to f256 value

15 Stop after LL continuance time - Dec., Under stop Refer to uvc value

4.2.17. FD06 (Input TB Status)

bit TB Name Function (Parameter) 0 1

0 F Input TB Function select 1 (f111)

1 R Input TB Function select 2 (f112)

2* ST Input TB Function select 3 (f113)

3 RES Input TB Function select 4 (f114)

4 S1 Input TB Function select 5 (f115)

5 S2 Input TB Function select 6 (f116)

6 S3 Input TB Function select 7 (f117)

7 S4 Input TB Function select 8 (f118)

8 L1 Input TB Function select 9 (f119)

OFF ON

9 L2 Input TB Function select 10 (f120)

10 L3 Input TB Function select 11 (f121)

11 L4 Input TB Function select 12 (f122)

12 L5 Input TB Function select 13 (f123)

13 L6 Input TB Function select 14 (f124)

14 L7 Input TB Function select 15 (f125)

15 L8 Input TB Function select 16 (f126)

*This function is reserved in VF-PS1 and VF-AS1(WN1/WP1).

4.2.18. FD07 (Output TB Status)

bit TB Name Function (Parameter) 0 1

0 OUT1 Output TB Function select 1 (f130)

1 OUT2 Output TB Function select 2 (f131)

2 FL Output TB Function select 3 (f132)

3 OUT3 Output TB Function select 4 (f133)

4 OUT4 Output TB Function select 5 (f134)

5 R1 Output TB Function select 6 (f135)

OFF ON

6 OUT5 Output TB Function select 7 (f136)

7 OUT6 Output TB Function select 8 (f137)

8 R2 Output TB Function select 9 (f138)

9 R3 Output TB Function select 10 (f168)

10 R4 Output TB Function select 11 (f169)

11 - 15 - - - -

- 25 -

Page 27

4.2.19. FC90, FE10 - FE13 (Inverter fault)

Data

(hexa-

decimal)

Data

(decimal)

Code Description

0 0 nerr No error

1 1 oc1 Over-current during acceleration

2 2 oc2 Over-current during deceleration

3 3 oc3 Over-current during constant speed operation

4 4 ocl Over-current in load at startup

5 5 oca1 U-phase arm over-current

6 6 oca2 V-phase arm over-current

7 7 oca3 W-phase arm over-current

8 8 ephi Input phase failure

9 9 epho Output phase failure

A 10 op1 Over-voltage during acceleration

B 11 op2 Over-voltage during deceleration

C 12 op3 Over-voltage during constant speed operation

D 13 ol1 Over-LOAD in inverter

E 14 ol2 Over-LOAD in motor

F 15 olr Dynamic braking resistor overload

10 16 oh Overheat

11 17 e Emergency stop

12 18 eep1 EEPROM fault

13 19 eep2 Initial read error

14 20 eep3 Initial read error

15 21 err2 Inverter RAM fault

16 22 err3 Inverter ROM fault

17 23 err4 CPU fault

18 24 err5 Communication time-out error

19 25 err6 Gate array fault

1A 26 err7 Output current detector error

1B 27 err8 Option error

1D 29 uc Low current operation status

1E 30 up1 Under-voltage (main circuit)

20 32 ot Over-torque trip

21 33 ef1 Ground fault trip

22 34 ef2 Ground fault trip

24 36 ocr Dynamic braking abnormal element

25 37 oc1p Over-current during acceleration (element overheat)

26 38 oc2p Over-current during deceleration (element overheat)

27 39 oc3p Over-current during fixed speed operation (element overheat)

28 40 etn Tuning error

29 41 etyp Inverter type error

2A 42 e-10 Analog input terminal over-voltage

2B 43 e-11 Abnormal brake sequence

2C 44 e-12 Disconnection of encoder

2D 45 e-13 Speed error

2E 46 oh2 External thermal

2F 47 sout Step-out (for PM motors only)

32 50 e-18 Terminal input error

33 51 e-19 Abnormal CPU2 communication

34 52 e-20 V/f control error

35 53 e-21 CPU1 fault

36 54 e-22 Abnormal logic input voltage

37 55 e-23 Option 1 error

38 56 e-24 Option 2 error

39 57 e-25 Stop position retaining error

3A 58 e-26 CPU2 fault

54 84 etn1 f410 tuning error

55 85 etn2 f412 tuning error

56 86 etn3 Motor constant setting error

E6581343 ③

- 26 -

Page 28

4.3. About GSD file

As for acquisition of an GSD file, it is possible to download from homepage of our

company.

Please use what was in agreement with the software version of usage's VF-AS1/PS1.

VF-AS1: http://www.inverter.co.jp/product/inv/vfas1/pdp/

VF-PS1: http://www.inverter.co.jp/product/inv/vfps1/pdp/

E6581343 ③

- 27 -

- 27E -

Loading...

Loading...