Page 1

FILE NO : A06-009

Quick reference

R410A

Page 2

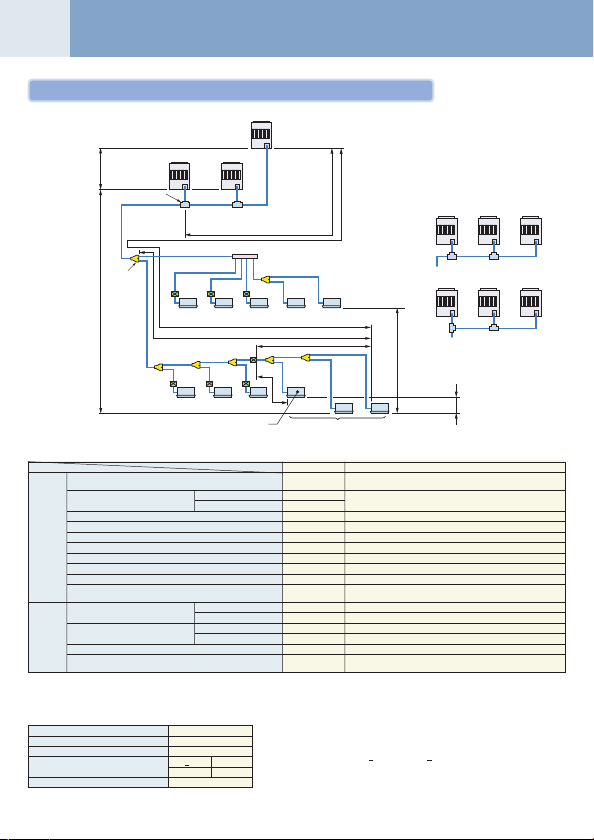

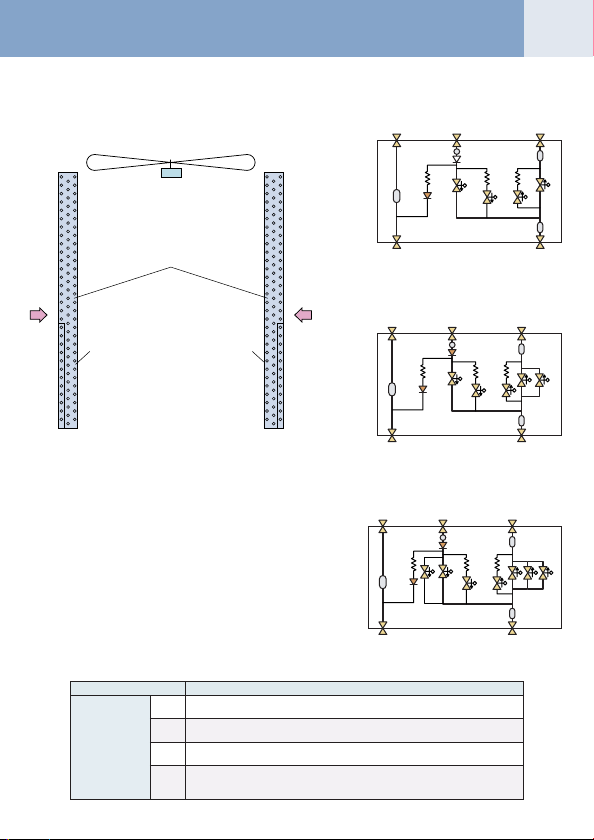

Refrigerant Piping

01

Allowable length of refrigerant pipe and height difference

Follower unit C

Follower unit B

Height difference

between

outdoor units

H3 £ 5 m

Height difference

between outdoor

and indoor units

H1 £ 50 m

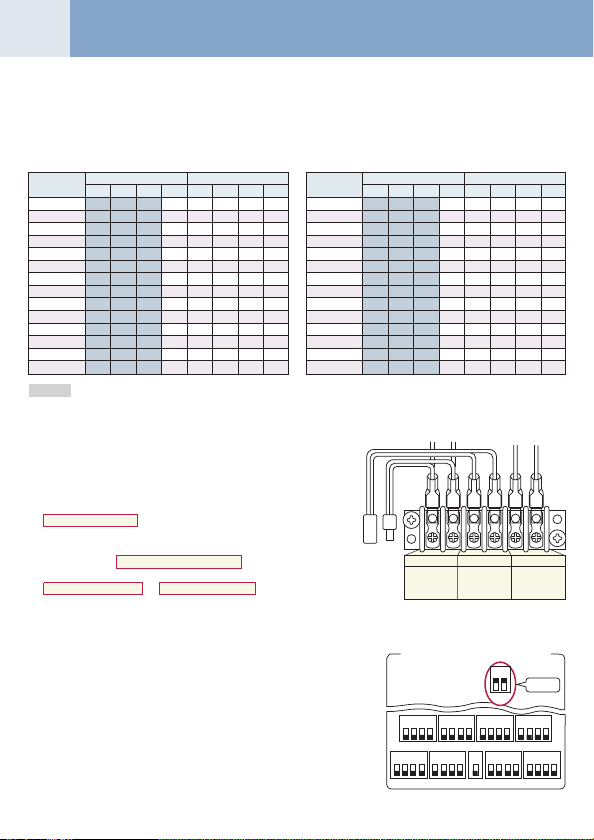

•Allowable length/height difference of the refrigerant pipe

Total extension of pipe (Liquid pipe/real length)

Farthest piping length L (*1)

Max. equivalent length of main piping

Equivalent length of farthest piping from 1 st branching Li (*1)

Pipe

Max. real length of indoor unit connecting piping

length

Max. real length between FS unit and indoor unit (*2)

Max. equivalent length of outdoor unit connecting pipe LO (*1)

Max. real length of outdoor unit connecting pipe

Max. equivalent length between FS unit and indoor unit Lj

Max. real length between FS unit and indoor unit which FS unit

control wiring is connected Lh (*2)

Height between

indoor unit and outdoor unit H1

Height between

Height

indoor unit H2

difference

Height between outdoor units H3

Height difference between indoor units in group control by one

FS unit H4

*1 : The farthest indoor unit from 1st branch to be named C, and fa rthest indoor unit from 1st branch to be named (q).

*2 : Attached connection cable can be used up to 5 m in pipe length between indoor unit and FS unit.

When the pipe length between indoor and FS unit exceeds 5 m, be sure to use the connection cable kit (RBC-CBK15FE).

• Restriction to the system

Max. No. of combined outdoor units

Max. capacity of combined outdoor units

Max. No. of connected indoor units

Max. capacity of connected indoor units

Min. capacity of connected indoor units

*3 : MMY-MAP1202FT8 up to 120%.

Header unit A

Outdoor unit

T-Shape branching

main piping

L1

Branching piping L2

Connecting piping of

1st

indoor unit

branching

section

L3

Indoor unit

Equivalent length corresponded to farthest piping L £ 150 m

Equivalent length corresponded to farthest piping after 1st branching Li £ 50 m

L4

d

FS unit

l

Indoor unit

Indoor unit which FS unit control wiring is connected.

H2 < 15 m 135% (*3)

H2 > 15 m 105%

Outdoor capacity : 70%

Lb Lc

La

LA

Main connecting piping between outdoor units

Length corresponded to farthest piping

between outdoor units LO £ 25 m

bca

hi jkg

L6 L7

L5

f

e

n

m

Real length

Equivalent length

Upper outdoor unit

Lower outdoor unit

Upper outdoor unit

Lower outdoor unit

3 units

84.0 kW

48 units

Branching header

L9

FS unit

<Cooling only> <Cooling only>

L8

FS unit

o

Lh

When connecting the plural indoor units to single FS unit.

Allowable value

Note 1) Combination of outdoor unit : Header unit (1 unit) + Follow unit

Note 2) Install the outdoor units in order of capacity.

Note 3) Refer to outdoor unit combination table in page 5.

Note 4) Piping to indoor units shall be per pendicular to piping to the

•Cautions concerned with installation/construction

1) The leading outdoor unit connected with the indoor

inter-unit pipe is made “A (Header unit)”.

2) Set the units in order of the outdoor capacity.

(A (Header unit) > B > C > D)

3) For the combination of the outdoor units, refer to

“Combination of outdoor unit” list.

Note:

In case of connecting method <Ex.2>, a large amount of

refrigerant and refrigerant oil may return to the head unit.

Therefore, set the T-shape joint so that oil does not enter directly.

Lj

p

q

<Group control>

LA + La + Lb + Lc + L1 + L2 + L3 + L4 + L5 + L6 + L7 + L8 + L9

300 m

+ a + b + c + d + e + f + g + h + i + j + k + l + m + n + o+ p + q

125 m

150 m

85 m

50 m

30 m

15 m

25 m

10 m

30 m

15 m

50 m

30 m

35 m

15 m

5 m

0.5 m

(0 to 2 units). Header unit is outdoor unit nearest to the connected indoor units.

Header

<Ex.1>

unit A

OK

Header

<Ex.2>

unit A

NO GOOD

Height difference between

indoor units H2 £ 35

(Upper outdoor unit)

Height difference between

indoor units in group control

by one FS unit H4 £ 0.5 m

Pipe section

LA + Lc + L1 + L3 + L4 + L5 + L6 + L7 + L8 + q

a + g, b + h, c + i, d + l, e + m, f + m, f + n, j, k

L1

L3 + L4 + L5 + L6 + L7 + L8 + q

g, h, i, l, m, n, L7 + o

LA + Lc (LA + Lb)

La, Lb, Lc

L7 + L8 + p, L7 + L8 + q

L7 + o

——

——

——

——

——

——

(Header unit > Follow unit 1 > Follow unit 2)

head outdoor unit as <Ex. 1>. Do not connect piping to indoor

units in the same direction of head outdoor unit as <Ex. 2>.

Follower

unit B

Follower

unit B

Follower

unit C

Follower

unit C

Page 3

02

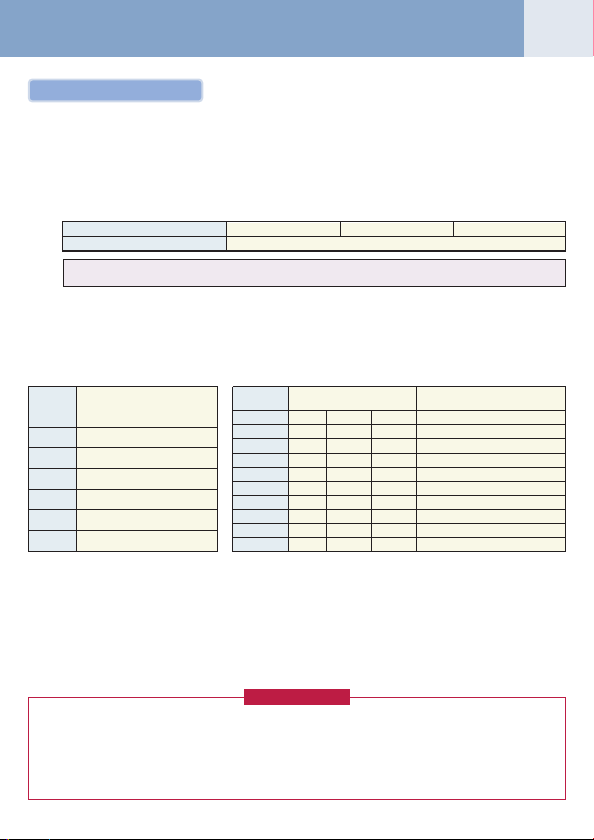

Addition of refrigerant

After vacuuming work, exchange the vacuum pump with the refrigerant bomb and then start the additional charging work

of refrigerant.

Calculation of additional refrigerant charge amount

Refrigerant charge amount at shipment from the factory does not include the refrigerant for pipe at the local site.

For refrigerant to be charged in pipe at the local site, calculate the amount and charge it additionally.

Note) If the additional refrigerant amount indicates minus as the result of calculation, use the air conditioner without

addition of refrigerant.

Outdoor unit Model

Charging amount (kg)

Additional refrigerant

charge amount at local site

Example : Additional charge amount R (kg) = {(L1 × 0.025kg/m) + (L2 × 0.055kg/m) + (L3 × 0.105kg/m)} × 1.3

Table-1 Table-2

Liquid

pipe dia.

Charging of refrigerant

•Keeping valve of the outdoor unit closed, be sure to charge the liquid refrigerant into service port at liquid side.

• If the specified amount of refrigerant cannot be charged, open fully valves of outdoor unit at liquid and discharge/

suction gas sides, balance side operate the air conditioner in COOL mode under condition that valve at suction gas

side is a little returned to close side, and then charge refrigerant into service port at suction gas side. In this time,

choke the refrigerant slightly by operating valve of the bomb to charge liquid refrigerant.

The liquid refrigerant may be charged suddenly, therefore be sure to charge refrigerant gradually.

•When refrigerant leaks and refrigerant shortage occurs in the system, recover the refrigerant in the system and recharge refrigerant newly up to the correct level.

<Entry of refrigerant charge amount>

•Fill the additional refrigerant record column of the wiring diagram indication plate with the additional refrigerant

• The total refrigerant amount means the total value of the refrigerant amount at shipment and the additional refriger-

Additional refrigerant

amount/1m liquid pipe (kg/m)

(mm)

6.4

9.5

12.7

15.9

19.1

22.2

amount at installation work, total refrigerant amount and the name of the service man who charged refrigerant at

installation time.

0.025

0.055

0.105

0.160

0.250

0.350

ant amount at installation time. The refrigerant amount at the shipment is one described on the “Unit nameplate”.

MMY-MAP0802FT8 MMY-MAP1002FT8 MMY-MAP1202FT8

Real length

=× ×

( )

of liquid pipe

Additional refrigerant charge

amount per 1m liquid pipe (Table 1)

L1 : Real total length of liquid pipe Ø6.4 (m)

L2 : Real total length of liquid pipe Ø9.5 (m)

L3 : Real total length of liquid pipe Ø12.7 (m)

System : 10HP

Combined

(HP)

8

10

12

16

18

20

24

26

28

30

Combined outdoor unit

8

10

12

8 8

10 8

10 10

8 8 8

10 8 8

10 10 8

10 10 10

(HP)

11.5

Compensation by

1.3

system HP (Table 2)

C (Corrected refrigerant amount)

–1.5

–4.5

–3.0

–1.5

(kg)

2.0

2.5

3.0

0.0

2.0

0.0

REQUIREMENT

Page 4

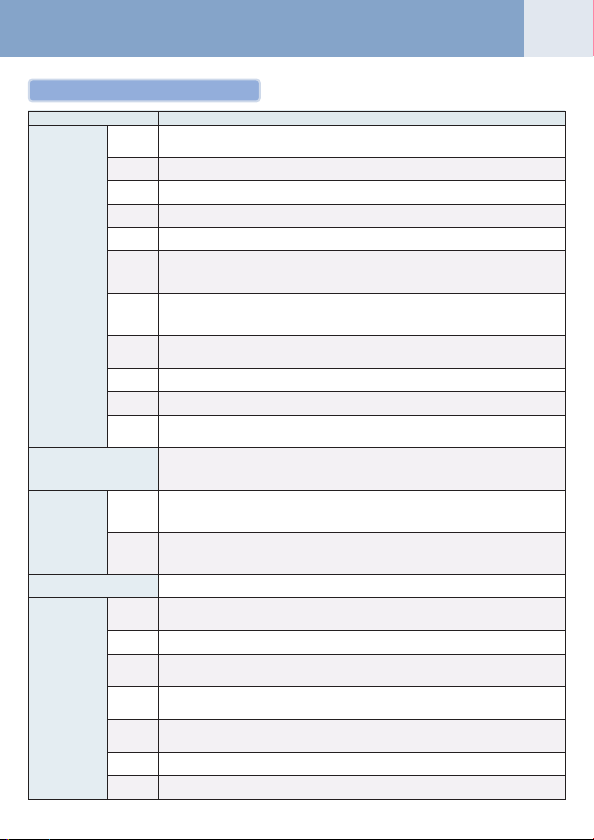

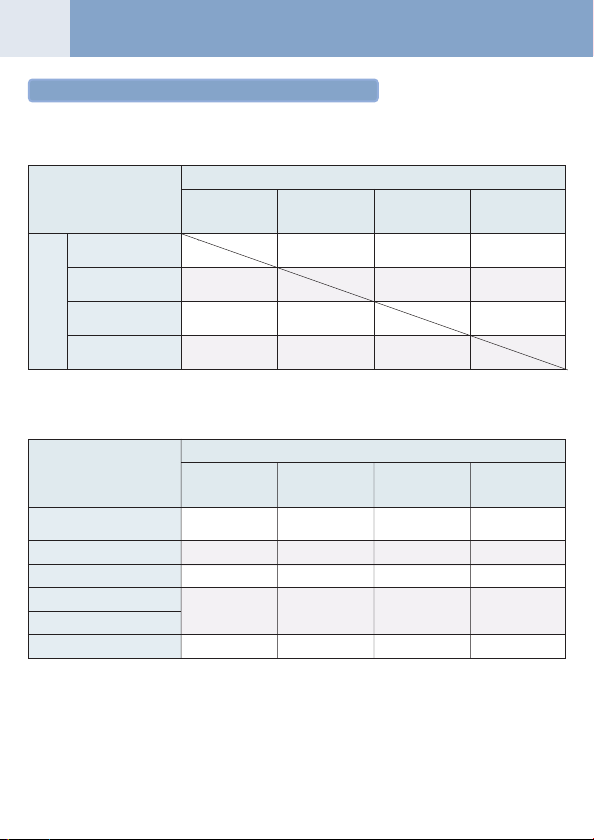

Refrigerant Piping Diagram (Outdoor)

03

Inverter unit (8, 10, 12HP)

Model: MMY-MAP0802FT8, MAP1002FT8, MAP1202FT8

Propeller fan

Fan motor

FM

(Right side)

Main heat exchanger

(Left side)

Main heat exchanger

Sub heat exchanger (Right side)

Sub heat exchanger (Left side)

Solenoid valve (SV11)

Check valve

Solenoid valve

Oil

separator

Strainer

Check valve Check valve

tube

Sensor

(TK3)

Strainer

Check

valve

Sensor

(TK1)

(SV3A)

Check valve

Strainer

Solenoid valve

(SV3C)

Strainer

Check

valve

Capillary tube

Sensor

(TK2)

Oil tank

Solenoid valve

(SV3B)

Check valve

Compressor 2

Capillary

Sensor (TK4)

Solenoid valve

(SV2)

(Inverter)

4-Way valve

Capillary

tube

Capillary tube

Solenoid valve

(SV42)

High-pressure

switch

Sensor

(TD2)

Sensor

(TO)

Pulse motor valve

Solenoid valve

(PMV1) (PMV2)

Check valve

Strainer

Sensor

(TL)

Liquid

tank

Check

joint

Strainer Strainer

Service valve

Service valve at

of balance pipe

discharge gas side

Service valve

Service valve at

at liquid side

suction gas side

Sensor

(TE1)

Strainer

(SV12)

Strainer

(PMV3)

Check valve

Solenoid valve

(SV5)

Capillary

High-pressure

tube

Solenoid valve

(SV6)

Solenoid valve

Solenoid valve

sensor

Check joint

Capillary tube

Strainer

(SV3D)

Capillary tube

(SV41)

High-pressure

switch

Sensor

(TD1)

Compressor 1

(Inverter)

Capillary tube

Solenoid valve

(SV3E)

Capillary tube Capillary tube

Strainer

Sensor

(TS1)

Sensor

(TS2)

Low-pressure

Accumulator

sensor

Check

joint

Page 5

Explanation of functional parts

Functional part name

Solenoid valve

4-way valve

Pulse motor valve

Oil separator

Temp. sensor

(Connector CN324: Red)

SV3A

Closed : Allows oil to collect/remain in the oil tank.

Open : Allows oil to exit the oil tank.

(Connector CN313: Blue)

SV3B

Open : Allows oil to return to the outdoor unit via the balance pipe.

(Connector CN314: Black)

SV3C

Open : Pressurizes the oil tank.

(Connector CN323: White)

SV3D

Open : Supplies oil to the compressor from the oil separator.

(Connector CN323: White)

SV3E

Open : Tu rns on during operation and balances oil between compressors.

(Hot gas bypass) (Connector CN312: White)

1) Low pressure release function

ASV2

2) High pressure release function

3) Gas balance function during stop time

(Gas balance control for compressor start-up) (Connector CN311: Blue)

SV41

1) For gas balance start

SV42

2) High pressure release function

3) Low pressure release function

(Connector CN310: White)

SV5

1) Increase of No. of heating indoor units, Gas balance function in defrost time

2) Low-pressure balance function of discharge gas pipe during all cooling operation

(Connector CN309: White)

SV6

1) Liquid bypass function for discharge temp. release (Cooling bypass circuit)

(Connector CN322: White)

SV11

1) For shutdown discharge gas (During all cooling operation and defrost operation)

(Connector CN319: White)

SV12

1) Flow-rate control function of refrigerant to sub heat exchanger during simultaneous operation

2) Flow-rate control function of refrigerant to sub heat exchanger during defrost operation

(Connector CN317: Blue)

1) Cooling/Heating selection

2) Reverse defrost

3) Main-/Sub-heat exchanger selection

(Connector CN300, 301: White)

1) Super heat control function during all heating operation and mainly heating, partly cooling operation

PMV1, 2

2) Under-cool adjustment function during all cooling operation

3) Divided flow control function during mainly cooling, partly heating operation

(Connector CN302: Red)

1) For flow-rate control of sub heat exchanger during simultaneous operation

PMV3

TD1, TD2

TS1

TS2

TE

TK1, TK2,

TK3, TK4

TL

TO

(Control function of heating divided flow)

2) A function preventive high pressure up during all cooling or all heating operation

1) Prevention for early drop of oil level (Decrease of flow-out of discharge oil to cycle)

2) Reser ve function of surplus oil

(TD1: Connector CN502: White, TD2: Connector CN503: Pink)

1) Protection of compressor discharge temp.

2) Releasing of discharge temp.

(Connector CN504: White)

1) Controls super heat of PMV1 and 2 during all heating operation and simultaneous operation

(Connector CN522: Black)

1) Controls indoor oil recovery during all cooling operation and mainly cooling, partly heating operation

2) Detects overheat of cycle.

(Connector CN505: Green)

1) Controls defrost during all heating operation and simultaneous operation.

2) Controls outdoor fan during all heating operation and simultaneous operation.

TK1: Connector CN514: Black, TK2: Connector CN515: Green,

æ ö

è ø

TK3: Connector CN516: Red, TK4: Connector CN523: Yellow

1) Judges oil level of compressor.

(Connector CN521: White)

1) Detects under-cool during all cooling operation and simultaneous operation.

(Connector CN507: Ye llow)

1) Detects external ambient temperature.

04

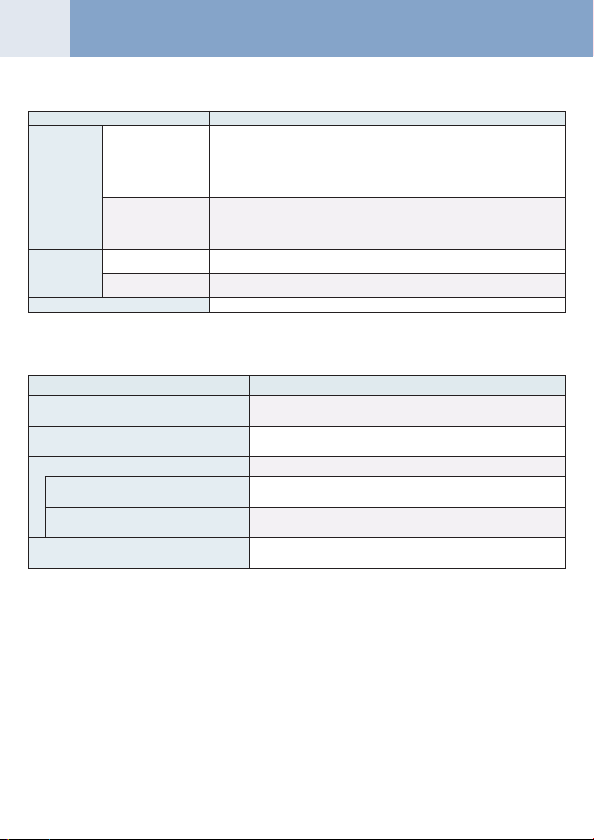

Functional outline

Page 6

Continued

05

Functional part name

High pressure sensor

Pressure sensor

Low pressure sensor

Heater

Balance pipe

Compressor case heater

Accumulator case heater

<Operation mode>

Operation mode

1. All Indoor Unit(s) Operating for Cooling

2. All Indoor Unit(s) Operating fo r Heating

3. Simu ltaneous operation

3-1. Mainly cooling, par tly heating operation

3-2. Mainly heating, par tly cooling operation

4. Defrost

(Connector CN501: Red)

1) Detects high pressure and uses it to control capacity of compressor.

2) Detects high pressure during all cooling operation and uses it to control fan when

cooling with low outside air.

3) Detects under-cool of the indoor unit of which heating thermo.-ON during all heating

operation and simultaneous operation.

4) Controls outdoor fan rpm during mainly cooling, par t heating operation.

(Connector CN500: White)

1) Detects low pressure and uses it to control capacity of compressor during all cooling

operation and simultaneous operation

2) Detects low pressure and uses it to controls super heat during all heating operation

and simultaneous operation

(Compressor 1 Connector CN316: White, Compressor 2 Connector CN315: Blue)

1) Prevents liquid accumulation in the compressor

(Connector CN321: Red)

1) Prevents liquid accumulation to accumulator

1) Oil balancing pipe between outdoor unit (This unit does not use this Balance pipe.)

Only cooling operation without heating operation

Outdoor heat exchanger (Main heat exchanger) is used as condenser.

Only heating operation without cooling operation

Outdoor heat exchanger (Main heat exchanger) is used as evaporator.

MIU for simultaneous operation

Cooling/heating simultaneous operation with subjective cooling operation

Outdoor heat exchanger (Sub heat exchanger) is used as condenser.

Cooling/heating simultaneous operation with subjective heating operation

Outdoor heat exchanger (Main heat exchanger) is used as evaporator.

Using reversing operation of 4-way valve, ice of the outdoor heat

exchanger is dissolved with single cooling cycle.

Functional outline

Outline

Page 7

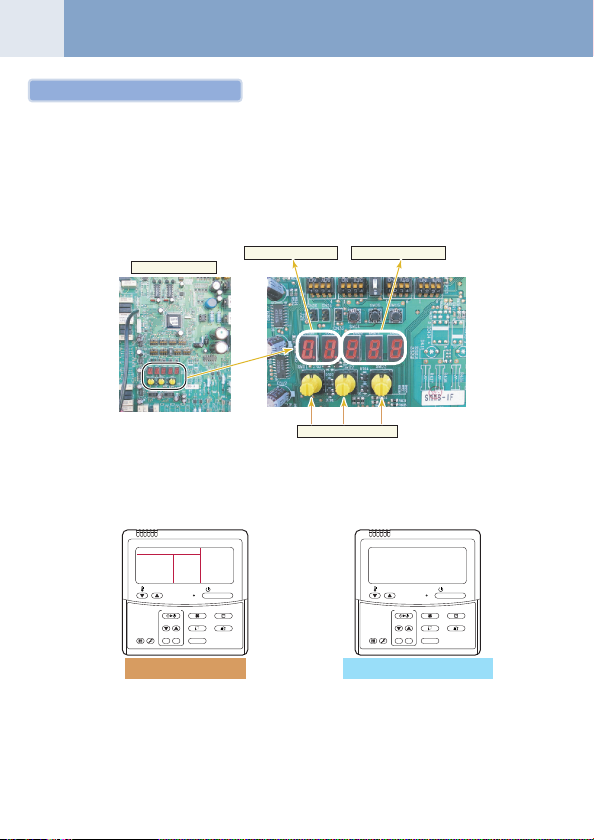

Configuration of outdoor unit heat exchanger Flow Selector Unit (FS Unit)

* RBM-Y1801FE has two “SVS” valves.

Check

valve

Strainer

SVS

SVSS

SVDD

SVD

Liquid pipe

Strainer

Discharge gas pipe Suction gas pipe

To indoor

gas side

To indoor

liquid side

Strainer

Capillary

tube

Capillary

tube

Capillary

tube

Check

valve

Strainer

SVS SVS

SVSS

SVDD

SVD

Liquid pipe

Strainer

Discharge gas pipe Suction gas pipe

To indoor

gas side

To indoor

liquid side

Strainer

Capillary

tube

Capillary

tube

Capillary

tube

* RBM-Y2802FE has three “SVS” valves and two “SVD”.

Check

valve

Strainer

SVS SVS

SVSS

SVDD

SVD

Liquid pipe

Strainer

Discharge gas pipe Suction gas pipe

To indoor

gas side

To indoor

liquid side

Strainer

Capillary

tube

Capillary

tube

Capillary

tube

SVS

RBM-Y1122FE

Propeller fan

Fan motor

Main heat exchanger

RBM-Y1802FE

Wind

Sub heat

exchanger

Front side

(Right)

Sub heat

exchanger

Rear side

(Left)

Wind

RBM-Y2802FE

06

Functional part name

Solenoid valve

(Discharge gas block valve)

SVD

1) High pressure gas circuit during heating operation

(Suction gas block valve)

SVS

1) Low pressure gas circuit during cooling operation

(Pressure valve)

SVDD

1) For pressurizing when No. of heating indoor units increases.

(Reducing valve)

SVSS

1) For recovery of refrigerant of the stopped indoor unit of which cooling thermo-OFF

2) For reducing pressure when No. of heating indoor units decreases.

Functional outline

Page 8

System Refrigerant Cycle Drawing

07

Refrigerant piping systematic diagram in system

<Selection of operation mode>

For the selection of each operation mode, see the table below:

“Stop Once” means the system does not operate for 3 minutes after operation before update has stopped.

After update

All cooling operation Mainly cooling, partly Mainly heating, partlyAll heating operation

(OFF) (ON) (ON) (ON)

All cooling operation

(OFF)

Mainly cooling, partly

heating cooperation (ON)

Before

update

Mainly heating, partly

cooling operation (ON)

All heating operation

(ON)

Note) Phrases in parentheses in the table indicate status of 4-way valve.

Operation continues Operation continues Operation continues

(ON ® OFF) (As ON) (As ON)

Stop Once Operation continues Operation continues

(ON ® OFF) (As ON) (As ON)

Stop Once Operation continues Operation continues

(ON ® OFF) (As ON) (As ON)

<ON-OFF list of Flow Selector Unit (FS Unit) valve>

Indoor operation mode

1. Stop (Remote controller OFF)

<All system stop>

2. Cooling ther mo-OFF

3. Cooling ther mo-ON

4. Heating ther mo-OFF

5. Heating ther mo-ON

6. “E04” error is being detected

SVD SVDD SVS SVSS

(High pressure(Pressure valve (Low pressure (Reducing valve

circuit valve) <For delay>) circuit valve) <For delay>)

OFF OFF OFF ON

<OFF> <OFF> <OFF> <OFF>

OFF OFF OFF ON

OFF OFF ON ON

ON OFF OFF OFF

OFF ON OFF OFF

heating cooperation cooling operation

Operation continues Operation continues Stop once

(OFF ® ON) (OFF ® ON) (OFF ® ON)

Outline of control valve output of FS unit (Basic operation)

Page 9

Check Code List

08

Main

remote

controller

display

Communication error between indoor and remote controller

E01

(Detected at remote controller side)

E02

Sending error of remote controller

Communication error between indoor and remote controller

E03

(Detected at indoor side)

Communication circuit error between indoor and outdoor

E04

(Detected at indoor side)

E06

Decrease of No. of indoor units

Communication circuit error of indoor and outdoor

E07

(Detected at outdoor side)

E08

Duplicated indoor addresses

E09

Duplicated master remote controllers

E10

Communication error in indoor P. C. B ass’y

E12

Automatic address start error

E15

No indoor automatic address

E16

No. of connected indoor units / Capacity over

E18

Communication error between indoor header and follower units

E19

Outdoor header units quantity error

E20

Other line connected during automatic address

E23

Sending error in communication between outdoor units

E25

Duplicated follower outdoor addresses

E26

Decrease of No. of connected outdoor units

E28

Follower outdoor error

E31

IPDU communication error

F01

Indoor TCJ sensor error

F02

Indoor TC2 sensor error

F03

Indoor TC1 sensor error

F04

TD1 sensor error

F05

TD2 sensor error

F06

TE1 sensor error

F07

TL sensor error

F08

TO sensor error

F10

Indoor TA sensor error

F12

TS1, TS2 sensor error

F13

TH sensor error

F15

Outdoor temp sensor misconnecting (TE, TL)

F16

Outdoor pressure sensor misconnecting (Pd, Ps)

F23

Ps sensor error

F24

Pd sensor error

F29

Indoor other error

F31

Outdoor EEPROM error

H01

Compressor break down

Magnet switch error

H02

Overcurrent relay operation

Compressor error (lock)

H03

Current detect circuit system error

Check code name

Main

remote

controller

display

H04

Comp 1 case thermo operation

H06

Low pressure protective operation

H07

Oil level down detective protection

H08

Oil level detective temp sensor error

H14

Comp 2 case thermo operation

Oil level detective circuit error

H16

Magnet switch error

Overcurrent relay operation

L03

Duplicated indoor header units

L04

Duplicated outdoor line addresses

Duplicated indoor units with priority

L05

(Displayed on indoor unit with priority)

Duplicated indoor units with priority

L06

(Displayed in unit other than indoor unit with priority)

L07

Group line in individual indoor unit

L08

Indoor group/Address unset

L09

Indoor capacity unset

L10

Outdoor capacity unset

L17

Inconsistency error of outdoor units

L18

FS unit error

L20

Duplicated central control addresses

L28

Over No. of connected outdoor units

L29

No. of IPDU error

L30

Auxiliary interlock in indoor unit

L31

IC error

P01

Indoor fan motor error

P03

Discharge temp TD1 error

P04

High-pressure SW detection error

P05

Phase-missing detection / Phase order error

P07

Heat sink overheat error

P10

Indoor overflow error

P12

Indoor fan motor error

P13

Outdoor liquid back detection error

P15

Gas leak detection

P17

Discharge temp TD2 error

P19

4-way valve inverse error

P20

High-pressure protective operation

P22

Outdoor fan IPDU error

P26

G-TR short protection error

P29

Comp position detective circuit system error

P31

Other indoor unit error (Group follower unit error)

—

Error in indoor group

—

AI-NET communication system error

—

Duplicated network adaptors

Check code name

Page 10

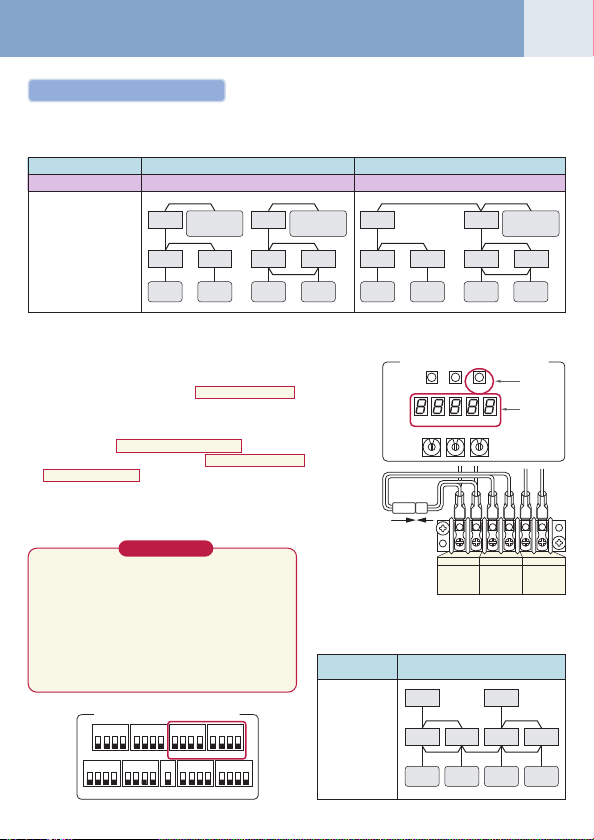

Address Setup

09

Pre-check for address setup

<Check on outdoor unit>

1. Check that all the rotary switches, SW01, SW02, and SW03 on the interface P. C. board of the outdoor unit are set up

to “1”.

2. If other error code is displayed on 7-segment [B], remove the cause of trouble referring to “9. Troubleshooting”.

3. Check that [L08] is displayed on 7-segment display [B] on the interface P. C. board of the outdoor unit.

(L08: Indoor address unset up)

(If the address setup operation has already finished in service time, etc, the above check code is not displayed, and

only [U1] is displayed on 7-segment display [A].)

Interface P. C. board

7-segment display [A] 7-segment display [B]

SW01 SW02 SW03

<Check on indoor unit>

1. Display check on remote controller (In case of wired remote controller)

Check that a frame as shown in the following left figure is displayed on LC display section of the remote controller.

GOOD

TEMP.

FILTER

TEST

RESET

(Power and operation stop)

If a frame is not displayed as shown in the above right figure, the power of the remote controller is not normally turned

on. Therefore check the following items.

• Check power supply of indoor unit.

• Check wiring between indoor unit and remote controller.

• Check whether there is cutoff of cable around the indoor control P. C. board or not, and check connection failure of

connectors.

• Check failure of transformer for the indoor microcomputer.

FAN

TIMER SET

SWING/FIXTIME

UNITSET CL

Normal status

ON / OFF

MODE

VENT

NO

GOOD

FILTER

RESET

(Power is not normally turned on.)

TEMP.

TIMER SET

SWING/FIXTIME

TEST

Abnormal status

ON / OFF

FAN

MODE

VENT

UNITSET CL

Page 11

Automatic Address Setup

Without central control : To the address setup procedure 1

With central control: To the address setup procedure 2

(Example)

Address setup procedure

Cable systematic diagram

(However, go to the procedure 1 when the central control is performed in a single refrigerant line.)

In case of central control in a single refrigerant line

Outdoor

Indoor

Remote

controller

To procedure 1

Central

remote controller

Indoor

Remote

controller

Outdoor

Indoor

Remote

controller

Central

remote controller

Indoor

Remote

controller

In case of central control over refrigerant lines

Outdoor

Indoor

Remote

controller

To procedure 2

Indoor

Remote

controller

Outdoor

Indoor

Remote

controller

Central

remote controller

Indoor

Remote

controller

10

Address setup procedure 1

1. Tu rn on power of indoor/outdoor units.

(In order of indoor

2. After approx. 1 minute, check that U. 1. L08 (U. 1. flash) is displayed in

7-segment display section on the interface P. C. board of the outdoor unit.

3. Push SW15 to start the setup of the automatic addressing.

(Max. 10 minutes for 1 line (Usually, approx. 5 minutes))

4. When the count Auto 1 ® Auto 2 ® Auto 3 is displayed in 7-segment

display section, and it changes from U. 1. - - - (U. 1. flash) to

U. 1. - - - (U. 1. light) , the setup finished.

5. When performing an automatic address setup on a single refrigerant

line with central control, connect relay connected between [U1, U2]

and [U3, U4] terminals in the header unit.

®®

® Outdoor)

®®

REQUIREMENT

•When a group control is performed over the multiple

refrigerant lines, be sure to turn on the power supplies

of all the indoor units connected in a group at the time

of address setup.

• If turning on the power for each refrigerant line to set

up address, a header indoor unit is set for each line.

Therefore, an alarm code “L03” (Duplicated header

indoor units) is output in operation after address setup.

In this case, change the group address from the wired

remote controller for only one header unit is set up.

Header unit interface P. C. board

ON

1

2 3 4

1ON2 3 4

1ON2 3 4

1ON2 3 4

SW11

SW12

SW13

11 2 3 4

SW09SW08

SW14

1 2 3 4

SW10

ON ONON ON

1ON2 3 4

1

2 3 4

SW06

SW07

(Example)

Cabling systematic

diagram

Header unit interface P. C. board

SW04

SW05 SW15

D600 D601 D602 D603 D604

SW01

SW02 SW03

111

3

2, 4

5

U1 U2

U3 U4

For internal

wiring between

indoor and

outdoor

Group control over

multiple refrigerant lines

Outdoor

Indoor

Indoor

Remote

Remote

controller

controller

For wiring of

central control

system

Outdoor

Indoor

Remote

controller

For internal

wiring between

outdoor units

controller

U5 U6

Indoor

Remote

Page 12

Continued

U1 U2

For internal

wiring between

indoor and

outdoor

U3 U4

For wiring of

central control

system

U5 U6

2

For internal

wiring between

outdoor units

11

Address setup procedure 2

1. Using SW13 and 14 on the interface P. C. board of the outdoor unit in each system, set up the address for each system. (At shipment from factory: Set to Address 1)

Note) Be careful not to duplicate addresses with the other refrigerant line.

Line address switch on outdoor interface P.C. board

Line

address

1

2

3

4

5

6

7

8

9

10

11

12

13

14

SW13 SW14

12341234

ЧЧЧЧЧ

Ч ×××

¡

×× ××

¡

× ××

¡

¡

××× ×

× × ×

×× ×

× ×

××××

× ××

×× ×

× ×

×××

× ×

¡

¡ ¡

¡ ¡

¡

¡ ¡

¡ ¡

¡

¡¡¡

¡ ¡

¡ ¡

¡

¡

¡

Line

address

15

16

17

18

19

20

21

22

23

24

25

26

27

28

(¡ : Switch ON, × : Switch OFF)

SW13 SW14

12341234

××

¡ ¡ ¡

×

¡¡¡¡

××××

¡

×××

¡¡

× ××

¡¡

¡

×× ×

¡ ¡

× ×

¡ ¡¡

× ×

¡

¡¡

×××

¡

××

¡¡

× ×

¡

¡

¡

¡¡

: Is not used for setup of system address. (Do not change setup.)

2. Check that the relay connectors between [U1, U2] and [U3, U4]

terminals are not connected in all the outdoor units to which the

central control is connected.

(At shipment from factory: Connector not connected)

3. Tu rn on power of indoor/outdoor. (In order of indoor

4. After approx. 1 minute, check that 7-segment display is

U.1.L08 (U.1. flash) on the interface P.C. board of the outdoor unit.

5. Push SW15 to start the setup of automatic addressing.

(Max. 10 minutes for 1 line (Usually, approx. 5 minutes))

6. When the count Auto 1 ® Auto 2 ® Auto 3 is displayed in

7-segment display section, and it changes from

U. 1. - - - (U. 1. flash) to U. 1. - - - (U. 1. light) , the setup finished.

7. Procedure 4. to 6. are repeated in other refrigerant lines.

8. How to set up the terminal resistance

When all the address setups have finished in the same refrigerant

circuit system, put the terminal resistance in the same central

control line into one.

• Remain only SW30-2 of the header outdoor unit with address 1 as

ON. (With end terminal resistance)

• Set up SW30-2 of the other header outdoor units to OFF.

(Without terminal resistance)

9. Connect the relay connector between [U1, U2] and [U3, U4] of the

header unit for each refrigerant line.

10. Then set up the central control address.

(For the central control address setup, refer to the Installation

manual of the central control devices.)

®®

® outdoor)

®®

Header unit interface P. C. board

1ON2

SW30

1ON2 3 4

1ON2 3 4

1ON2 3 4

SW11

SW12

SW13

ON ONON ON

1ON2 3 4

1

2 3 4

11 2 3 4

SW06

SW07

SW09SW08

¡

××

¡¡

¡¡

×

SW30

1ON2 3 4

SW14

1 2 3 4

SW10

¡

×

¡

¡

¡

¡

Page 13

11

Before address setup

During setup of address

After address setup

Outdoor interface

P.C. board

SW13, 14

(Refrigerant line address)

SW30-2

Terminal-end resistance of

indoor/outdoor communi

cation line/central control

communication line

Relay connector

Indoor side (Automatic setup)

Refrigerant line address

Indoor unit address

Group address

Relay

connector

1 2 3

U5 U6 U1 U2

U1 U2

controller

Individual

21

ON

OFF

U5 U6 U1

U1 U2

controller

Individual

Follower unitHeader unit

U3 U4

A B

Remote

Follower unitHeader unit

U3 U4

U2 U5 U6

A B

Remote

U5 U6

21

ON

OFF

Relay

connector

Relay

connector

U3 U4

U1 U2

U1 U2

A B

Remote

controller

Group

U3 U4

SW30 SW30

U1

U2

U1 U2

A B

Remote

controller

Group

U3 U4

U1 U2

U1 U2

A B

Remote

controller

U3 U4

SW30 SW30

U1

U2

U1 U2

A B

Remote

controller

Header unit Follower unit Follower unitHeader unit Header unit

1

ON

Connect short

after

address setup

1

1

0

(Setup is

unnecessary.)

(Setup is

unnecessary.)

Open

1

2

0

2 3

OFF after

address setup

Connect short

after

address setup

2

1

1

Follower unitHeader unit

U3 U4

U5 U6 U1 U2

U5 U6 U1

21

ON

OFF

U1 U2

A B

Follower unitHeader unit

U3 U4

U2 U5 U6

U1 U2

A B

(Setup is

unnecessary.)

(Setup is

unnecessary.)

U5 U6

21

ON

OFF

connector

Relay

Open Open

2

2

2

U3 U4

U1 U2

U1 U2

Remote

controller

U3 U4

SW30

U1

U2

U1 U2

Remote

controller

OFF after

address setup

Connect short

after

address setup

Header unit

U5 U6

A B

Header unit

21

U5 U6

A B

3

1

0

ON

OFF

Relay

connector

12

Setup at

shipment from

factory

1

ON

Never connect a relay connector until address setup for all the refrigerant lines has been completed ;

NOTE

otherwise address cannot be correctly set up.

Page 14

Continued

13

Manual address setup from remote controller

In case to decide an address of the indoor unit prior to finish of indoor wiring work and unpracticed outdoor wiring work

(Manual setup from remote controller)

Arrange one indoor unit and one remote controller set to 1 by 1.

Turn on the power.

(Wiring example in 2 lines)

#1

Outdoor

Indoor Indoor Indoor

Line address ® 1

Indoor address ® 1

Group address ® 1

In the above example, under condition of

no inter-unit wire of the remote controller,

set the address after individual connecting of the wired remote controller.

Group address

Individual : 0000

Header unit : 0001

Follower unit : 0002

Operation procedure

Remote

controller

Header

In case of group control

}

#2

Outdoor

Indoor Indoor

1

1

2

2

3

1

2

2

2

Follower

1 ® 2 ® 3 ® 4 ® 5 ® 6

7 ® 8 ® 9 ® 10 ® 11

2,

5,

8

SET

Data Item code

4,

FILTER

11

7,

RESET

End

DATA

SETTING

UNIT No.

R.C. No.

TEMP.

FAN

TIMER SET

SWING/FIXTIME

UNITSET CL

TEST

10

1 Push si multaneously

more.

LCD changes to flashing.

(Line address)

2 Using the setup temp. / buttons, set

item code.

3 Using the timer time / buttons, set up the line ad-

dress.

(Match it with the line address on the interface P.C. board of the

outdoor unit in the identical refrigerant line.)

SET

4 Push

button.

(OK when display goes on.)

5 Using the setup temp. / buttons, set

item code.

6 Using the timer time / buttons, set up the indoor

address.

SET

7 Push

button.

(OK when display goes on.)

8 Using the setup temp. / buttons, set

item code.

9 Using the timer time / buttons, set Individual =

Header unit =

SET

button.

(OK when display goes on.)

TEST

button.

Setup operation finished. (Status returns to normal stop status.)

3,

6,

®

ON / OFF

2

2

2

CODE No.

MODE

VENT

(Indoor address)

(Group address)

10 Push

11 Push

9

1

SET

TEST

+ CL +

buttons for 4 seconds or

12

to the

13

to the

14

to the

0001

, Follower unit =

Note 1)

When setting the line address from the remote

controller, do not use address 29 and 30.

The address 29 and 30 cannot be set up in the

outdoor unit. Therefore if they are incorrectly set up,

a check code [E04] (Indoor/outdoor communication

circuit error) is output.

0002

0000

.

,

Page 15

Clearance of address (Return to status (Address undecided) at shipment from factory)

Method 1

An address is individually cleared from a wired remote controller.

“0099” is set up to line address, indoor address, and group address data from the remote controller.

(For the setup procedure, refer to the abovementioned address setup from the remote controller.)

Method 2

Clear the indoor addresses in the same refrigerant line from the outdoor unit.

1. Tu rn off the power of the refrigerant line to be returned to the status at shipment, and change the header unit to the

following status.

1) Remove the relay connector between [U1U2] and [U3U4].

(If it has been already removed, leave it as it is.)

2) Turn on SW30-2 on the interface P. C. board of the header unit if it is OFF.

(If it has been already ON, leave it as it is.)

Central control

device

U1U3U2

Header unit

2. Tu rn on the indoor/outdoor power of which address is to be cleared. After approx. 1 minute, check that “U.1. - - -” is

displayed, and then execute the following operation on the interface P. C. board of the header unit of which address is

to be cleared in the refrigerant line.

SW01 SW02 SW03

212

222

3. After “A.d. c.L.” has been displayed on 7-degment display, return SW01/SW02/SW03 to 1/1/1.

4. When the address clearing has correctly finished, “U.1.L08” is displayed on 7-degment display after a while.

If “A.d. n.G.” is displayed on 7-degment display, there is a possibility which is connected with the other refrigerant line.

Check again the relay connector between [U1U2] and [U3U4] terminals.

Note) Be careful that the other refrigerant line address may be also cleared if clearing operation is not correctly

executed.

5. After clearing of the address, set up an address again.

U3 U4

U1 U2 U5 U6

U1 U2

A B

Remote

controller

Follower unit

U1 U2 U5 U6

U1 U2

A B

Remote

controller

Center unitCenter unit Center unitCenter unitHeader unit Header unit

U3 U4

Unit of which address is to be returned to the initial status

U3 U4

U1 U2 U5 U6

U1 U2

A B

Remote

controller

Follower unit

U1 U2 U5 U6

U1 U2

A B

SW04

After checking that “A.d.buS” is displayed on 7-degment

display, and then push SW04 for 5 seconds or more.

After checking that “A.d.nEt” is displayed on 7-degment display,

and then push SW04 for 5 seconds or more.

U3 U4

U1 U2 U5 U6

U1 U2

U4

U3 U4

A B

Remote

controller

Address which can be cleared

Line + Indoor + Group address

Central address

14

Page 16

Troubleshooting in Test Operation

15

If the phenomena appear, such as a check code is output or the remote controller is not accepted in power-ON after cabling work or

in address setup operation, the following causes are considered.

1 A check code is displayed on the remote controller

Check code

displayed on

remote controller

(*) [L05] : Displayed on the indoor unit set up with priority

Outdoor unit

E04

E16

E25

L04

L05 (*)

L06 (*)

L08

7-segment

display

E19-00

Outdoor power is formerly turned on.

There is none of outdoor terminator resistor, or there are

two or more resistances. (After address setup)

After address was decided, all the

indoor units do not correctly response

after power-ON in outdoor unit.

L08

Address setup error

•Only line addresses of the connected indoor units are

undefined.

• The outdoor line address and the line addresses in all

indoor units do not match.

• The indoor addresses are duplicated.

(Units except those displaying E04 are duplicated.)

•A header unit is not set up in a group.

(Except group displaying E04)

E08-XX

Duplication of indoor addresses.

(Address No in which sub-code of the check code are

duplicated)

E07

There is none of outdoor terminal

resistance, or there are two or more

resistances.

(After address setup, when terminal

resistance setup is changed after

power-ON.)

Transmission circuit error at interface side

(P.C. board failure)

E06

After address setup, communication from all the indoor

units interrupted under condition that a normal operation

can be performed.

Exceeded No of connected indoor units or exceeded

E16-XX

capacity.

Duplication of outdoor addresses.

E25

(Only when outdoor address was manually set up)

Duplication of outdoor line addresses

L04

•Line address setup error, occurred after connection

between U1, U2 and U3, U4 connectors

Duplicated of indoor units with priority

L06

There are two or more indoor units set up with priority.

Address setup error

L08

•Only indoor addresses of all the connected indoor units

are undefined.

Cause

ON

ON

SW30

1

SW30

1

2

[L06] : Displayed on the indoor unit except one set up with priority

Countermeasures

Turn on the power again.

(In order of Indoor ® Outdoor)

Check SW30 bit 2 of the outdoor unit.

No connection between multiple refrigerant lines: SW30 bit

20N

Connection between multiple refrigerant lines: SW30 bit 2

of the connected outdoor unit is turned on only in one line.

2

Check and modifies disconnection of indoor/outdoor

communication line. (Communication line between outdoor

unit and the leading indoor unit)

Check influence of communication noise.

Set up address again.

Set up address again.

Check SW30 bit 2 of the outdoor unit.

No connection between multiple refrigerant lines: SW30 bit

20N

Connection between multiple refrigerant lines: SW30 bit 2

of the connected outdoor unit is turned on only in one line.

Replace the interface P. C. board.

Check and correct disconnection of indoor/outdoor

communication line.(Communication line between outdoor

unit and the leading indoor unit)

Check influence of communication noise.

Adjust No of connected indoor units or capacity.

Do not use a manual setup for outdoor address.

Modify line address setup of the outdoor unit between

lines. (Set up SW 13 and 14 on the interface P. C. board.)

The Heat Recovery Multi is not set up on priority.

Set up address again.

Page 17

2 Operation from remote controller is not accepted and a check code is displayed on 7-segment

display of the interface P.C. board of the outdoor unit.

7-segment

Remote

controller status

No response

3 There is no display of a check code on 7-segment display on the interface P.C. board of the outdoor

controller status

No response

No display on

remote controller

(No line is output.)

4 In check for No. of connected outdoor units and connected Indoor units after address setup,

Number of

connected outdoor

units is short.

Number of

connected indoor

units is short.

Number of outdoor

units connected to

group is short in

group operation

from remote

controller.

display of

outdoor unit

L08

Line addresses and indoor addresses of all the connected indoor

units are unset.

There is no outdoor unit of group control.

E19-00

Indoor unit power is not turned on.

Indoor/outdoor communication line is not correctly connected to

the outdoor unit.

(Indoor/outdoor cannot communicate before address setup.)

There is none of outdoor terminator resistor,

or there are two or more resistances.

(Before address setup)

E20-01

Address setup is performed with connecting indoor/outdoor

communication line between outdoor units.

Address setup is performed under condition of connecting

between multiple refrigerant lines.

unit though there is indoor unit which does not accept the operation from the remote controller.

7-segment

Remote

display of

outdoor unit

None

Communication line is not connected between indoor and

outdoor.

Line and indoor addresses are unset.

(Unit which does not response to remote controller)

The power of the header unit of the group is not turned on in

indoor group control.

(Unit which does not response to remote controller)

Group address is set up to follower unit in the individual control.

(Unit which does not response to remote controller)

None

The power is not turned on.

(Unit which is not displayed on remote controller)

Remote controller is not connected with cable.

(Unit which is not displayed on remote controller)

Miscabling of remote controller

(Unit which is not displayed on remote controller)

Remote controller communication circuit error

(Unit which is not displayed on remote controller)

If 230V is incorrectly applied to the remote controller terminal, the

remote controller communication circuit fails.

diminished No. of connected units displayed.

(There are outdoor/indoor units which do not operate in a test operation.)

Status

Miswiring of communication line between

outdoor units or unconnected cable.

(Address setup operation has finished without

recognition of miswired follower unit.)

Miswiring of communication line between indoor

units or unconnected cable.

(Address setup operation has finished without

recognition of miswired indoor unit.)

Remote controller is not connected with wire.

Miscabling of remote controller

Remote controller communication circuit error

If 230V is incorrectly applied to the remote

controller terminal, the remote controller

communication circuit fails.

Cause

Cause

Set up addresses.

Set up group address.

Turn on the power again.

(In order of indoor ® outdoor)

Correct wiring.

Check SW30 bit 2 of the outdoor unit.

ON

No connection between multiple refrigerant lines: SW30

1

2

bit 2 0N

Connection between multiple refrigerant lines: SW30 bit 2

of the connected outdoor unit is turned on only in one line.

SW30

Correct wiring.

Correct wiring.

Cause

Modify wiring.

Set up address.

Turn on the power.

Set [0] to group address in case of individual control.

Turn on the power.

Correct wiring.

Correct wiring.

Remove FASTON terminal connected to remote controller

terminals (A/B), and check the voltage.

If voltage is not applied, replace P. C. board.

(15 to 18V usually)

After modification of wiring, set up address again and check No. of the connected

outdoor units.

After modification of wiring, set up address again and check No. of the connected

indoor units.

Using the main remote controller connected to a group, start a test operation, specify

the unit which does not operate (Unit unconnected to group), and then check wiring.

Using the main remote controller connected to a group, start a test operation, specify

the unit which does not operate (Unit unconnected to group).

Remove Fasten receptacle connected to remote controller terminals (A/B), and check

the voltage. If voltage is not applied, replace P. C. board. (15 to18V in normal time)

Countermeasures

Countermeasures

Countermeasures

16

Page 18

Monitor Function of Remote Controller Switch

17

n When using a remote controller with the model name RBC-ATM21E, the following monitor

functions can be used.

<Calling of display screen>

[Contents]

The temperature or the operation status of the remote controller, indoor

unit, or each sensor of the outdoor unit can be known by calling up the

service monitor mode from the remote controller.

[Procedure]

CL

1 Push

2 Push the temperature setup / buttons to select the

3 Push

4 Pushing

TEST

+

to call up the service monitor mode.

The service monitor goes on, and temperature of the item

code

item number (Item code) to be monitored.

For displayed codes, refer to the table below.

Then monitor the indoor unit and sensor temperature or

operation status in the corresponding refrigerant line.

buttons simultaneously for 4 seconds or more

00

is firstly displayed.

UNIT

button to change the item to one to be monitored.

TEST

button returns the display to the normal display.

TEMP.

4

TIMER SET

FILTER

TEST

RESET

1

Operation procedure

1 ® 2 ® 3 ® 4

Returns to the normal display

CODE No.

UNIT No.

ON / OFF

FAN

MODE

SWING/FIXTIME

VENT

UNITSET CL

2

3

Item

code

00

01

02

03

04

05

Indoor unit data (NOTE 2)System data

06

08

0A

0b

0C

0d

Note 1) Only a part of indoor unit types is installed with the discharge temperature sensor.

Note 2) When the units are connected to a group, data of the header indoor unit only can be displayed.

Note 3) 01 : Compressor 1 only is ON. 10 : Compressor 2 only is ON. 11 : Both compressor 1 and 2 are ON.

Note 4) The item codes are described as the example of the header unit.

Note 5) The upper digit of an item code represents the outdoor unit number.

Data name

Room temp (During control)

Room temp (Remote controller)

Indoor suction temp (TA)

Indoor coil temp (TCJ)

Indoor coil temp (TC2)

Indoor coil temp (TC1)

Indoor discharge temp (Tf) Note 1)

Indoor PMV opening

No. of connected indoor units

Total HP of connected indoor units

No. of connected indoor units

Total HP of outdoor units

This temperature is not displayed for other types.

1 : Header unit (A) 2 : Follower unit (B) 3 : Follower unit (C)

Unit

pulse

Display

Item

format

code

10

°C

°C

°C

× 1

°C

× 1

°C

× 1

°C

× 1

°C

× 1

× 1/10

unit

HP

× 10

unit

HP

× 10

Compressor 1 discharge temp (Td1)

11

Compressor 2 discharge temp (Td2)

12

High-pressure sensor detention pressure (Pd)

13

Low-pressure sensor detention pressure (Ps)

14

Suction temp (TS)

15

Outdoor heat exchanger temp (TE)

16

Temp at liquid side (TL)

17

Outside ambient temp (TO)

18

Low-pressure saturation temp (TU)

19

Compressor 1 current (I1)

1A

Compressor 2 current (I2)

Outdoor unit individual data (NOTE 4, 5)

1b

PMV1 + 2 opening

1d

Compressor 1, 2 ON/OFF

1E

Outdoor fan mode

1F

Outdoor unit HP

Data name

Unit

MPa

MPa

pulse

HP

Display

°C

°C

°C

°C

°C

°C

°C

A

A

—

—

format

× 1

× 1

× 100

× 100

× 1

× 1

× 1

× 1

× 1

× 10

× 10

× 1/10

Note 3)

0 to 31

× 1

Page 19

Confirmation of indoor unit address and position by using the remote controller

[Confirmation of indoor unit address and the position]

1 When you want to know the indoor address though position of the indoor unit itself can be

recognized;

<Procedure> (Operation while the air conditioner operates)

1 If it stops, push

2 Push

The unit No.

(Disappears after several seconds)

The displayed unit No indicates the line address and indoor

address.

(If there is other indoor unit connected to the same remote

controller (Group control unit), other unit No. is displayed every

pushing

UNIT

button.

1-1

is displayed on the LCD.

UNIT

button.)

ON / OFF

button.

1

Operate

UNIT No.

TEMP.

FAN

TIMER SET

SWING/FIXTIME

FILTER

RESET

UNITSET CL

TEST

ON / OFF

CODE No.

MODE

VENT

18

2

2 When you want to know position of the indoor unit using the address

• To confirm the unit numbers in a group control;

<Procedure> (Operation while the air conditioner stops)

The indoor unit numbers in a group control are successively displayed,

and the corresponding indoor fan is turned on.

(Operation while the air conditioner stops)

VENT

1 Push

or more.

• Unit No. is displayed.

• The fans of all the indoor units in a group control are turned

2 Every pushing

the

group control are successively displayed.

• The firstly displayed unit No. indicates the address of the

• Only fan of the selected indoor unit is turned on.

3 Push

All the indoor units in group control stop.

TEST

+

buttons simultaneously for 4 seconds

on.

UNIT

button, the indoor unit numbers in

header unit.

TEST

button to finish the procedure.

1

3

2

End

Operation procedure

1 ® 2

TIMER SET

CODE No.

UNIT No.

R.C. No.

ON / OFF

FAN

SWING/FIXTIME

UNITSET CL

End

DATA

SET

SETTING

TEMP.

FILTER

TEST

RESET

Operation procedure

1 ® 2 ® 3

MODE

VENT

Page 20

Continued

19

•To confirm all the unit numbers from an arbitrary wired remote controller;

<Procedure> (Operation while the air conditioner stops)

The indoor unit No. and position in the same refrigerant line can be confirmed.

An outdoor unit is selected, the indoor unit numbers in the same refrigerant line are successively displayed, and then its

indoor unit fan is turned on.

1 Push the timer time +

seconds or more.

Firstly, the line 1, item code AC (Address Change) is displayed.

(Select outdoor unit.)

UNIT

2 Using

3 Using

4 Every pushing

[To select another line address]

5 Push

6 Push

+

SET

button, determine the selected line address.

• The indoor unit address, which is connected to the refrigerant pipe

of the selected outdoor unit is displayed and the fan is turned on.

identical pipe are successively displayed.

• Only fan of the selected indoor unit operates.

CL

button to return to procedure 2 ).

• The indoor address of another line can be successively confirmed.

TEST

button to finish the procedure.

TEST

buttons simultaneously for 4

SWING/FIX

buttons, select the line address.

UNIT

button, the indoor unit numbers in the

DATA

SET

TEMP.

1

FILTER

TEST

RESET

6

3

Operation procedure

1 ® 2 ® 3 ®

4 ® 5 ® 6

TIMER SET

CODE No.

UNIT No.

R.C. No.

ON / OFF

FAN

MODE

SWING/FIXTIME

VENT

UNITSET CL

End

SETTING

Change of indoor address from remote controller

Change of indoor address from wired remote controller

•To change the indoor address in individual operation (Wired remote controller : Indoor unit = 1 : 1) or

group control (When the setup operation with automatic address has finished, this change is available.)

<Procedure> (Operation while air conditioner stops)

1 Push simultaneously

(The firstly displayed unit No. indicates the header unit in group control.)

2 In group control, select an indoor unit No. to be changed by

UNIT

button.

(The fan of the selected indoor unit is turned on.)

3 Using the setup temp. / buttons, set

code.

4 Using the timer time / buttons, change the displayed

setup data to a data which you want to change.

SET

5 Push

6 Using the

7 After the above change, push

button.

the next time. Repeat the procedure 4 to 6 and change the

indoor address so that it is not duplicated.

changed contents.

8 If it is acceptable, push

SET

TEST

+ CL +

buttons for 4 seconds or more.

13

to the item

UNIT

button, select the unit No. to be changed at

UNIT

button to confirm the

TEST

button to finish confirmation.

DATA

SET

SETTING

TEMP.

3

5

FILTER

TEST

RESET

8

1

Operation procedure

1 ® 2 ® 3 ® 4

5 ® 6 ® 7 ® 8

TIMER SET

CODE No.

UNIT No.

R.C. No.

ON / OFF

FAN

MODE

SWING/FIXTIME

VENT

UNITSET CL

®

End

2

4

5

4

2,

6,

7

Page 21

20

•To change all the indoor addresses from an arbitrary wired remote controller;

(When the setup operation with automatic address has finished, this change is available.)

Contents :Using an arbitrary wired remote controller, the indoor unit address can be changed for each same refrigerant line

* Chang e the address in the address check/change mode.

<Procedure> (Operation while air conditioner stops)

1 Push the timer time +

Firstly, the line 1, item code AC (Address Change) is displayed.

UNIT

2 Using

3 Push

4 The indoor address of the setup data moves up/down by the timer time / buttons.

5 Push

6 Every pushing

7 Push

8 Push

+

SET

button.

• The indoor unit address, which is connected to the refrigerant pipe of the selected outdoor unit is displayed and the

fan is turned on.

First the current indoor address is displayed on the setup data. (Line address is not displayed.)

Change the setup data to a new address.

SET

button to determine the setup data.

Only fan of the selected indoor unit operates.

Repeat the procedure 4 to 6 and change all the indoor addresses so that they are not duplicated.

SET

button.

(All the displays on LCD go on.)

TEST

button to finish the procedure.

TEST

buttons simultaneously for 4 seconds or more.

SWING/FIX

buttons, select the line address.

UNIT

button, the indoor unit numbers in the identical pipe are successively displayed.

DATA

SET

SETTING

TEMP.

TIMER SET

FILTER

1

TEST

RESET

3

Here, if the unit No is not called up, the outdoor unit in this line

does not exist.

Push CL button, and then select a line according to procedure 2 .

CODE No.

UNIT No.

R.C. No.

ON / OFF

FAN

MODE

SWING/FIXTIME

VENT

UNITSET CL

Cancel of line selection

2

DATA

SET

SETTING

TEMP.

4

FILTER

TEST

RESET

8

5, 7

Operation procedure

1 ® 2 ® 3 ® 4 ®

5 ® 6 ® 7 ® 8

TIMER SET

UNIT No.

R.C. No.

CODE No.

ON / OFF

FAN

MODE

SWING/FIXTIME

VENT

UNITSET CL

To finish the set

End

6

Page 22

Error Clearing Function

21

Clearing from the main remote controller

n [Error clearing in outdoor unit]

Error of the outdoor unit is cleared by the unit of one refrigerant circuit system to which the indoor units operated by

the remote controller. (Error of the indoor unit is not cleared.)

For clearing errors, the service monitor function of the remote controller is used.

<Method>

CL

1 Change the mode to service monitor mode by pushing

or more.

2 Using / buttons, set

The display in Section A in the following figure is counted with interval of 5 seconds as

“

0005

” → “

0004

When the count arrives “

*However, counting from “

TEST

3 When

” → “

button is pushed, the status returns to the normal status.

to item code.

“FF”

0003

” → “

0000

0002

”, the error is cleared.

0005

” is repeated on the display.

” → “

0001

TEST

+

buttons simultaneously for 4 seconds

” → “

0000

”.

Operation procedure

1 ® 2 ® 3

The status returns to the normal status.

CODE No.

Section A

3

UNIT No.

R.C. No.

TEMP.

FILTER

TEST

RESET

TIMER SET

ON / OFF

FAN

MODE

SWING/FIXTIME

VENT

UNITSET CL

1

n [Error clearing in indoor unit]

Error in the indoor unit is cleared by

(Only error of the indoor unit connected with operating remote controller is cleared.)

ON / OFF

button on the remote controller.

2

Page 23

Applied control

Setup of Selecting Function in Indoor Unit

(Be sure to Execute Setup by a Wired Remote Controller)

<Procedure> Execute the setup operation while the unit stops.

SET, CL

1 Push

The firstly displayed unit No. indicates the master indoor unit address in the group control.

In this time, the fan of the selected indoor unit is turned on.

2 Every pushing

In this time, the fan of the selected indoor unit only is turned on.

3 Specify the item code (DN) using the setup temperature

and buttons.

4 Select the setup data using the timer time and buttons.

(When selecting the DN code to “33”, change the temperature

indication of the unit from “°C” to “°F” on the remote controller.)

5 Push

•To change the selected indoor unit, return to procedure 2 .

•To change the item to be set up, return to procedure 3 .

6 Pushing

TYPE

Item code [10]

Setup data

0000

0001

0002

0003

0004

0005

0006

0007

0008

0010

0011

0013

~

TEST

, and

buttons simultaneously for 4 seconds or more.

UNIT

button, the indoor unit numbers in the group control are successively displayed.

SET

button. (OK if display goes on.)

TEST

button returns the status to normal stop status.

1-way Air Discharge Cassette

4-way Air Discharge Cassette

2-way Air Discharge Cassette

1-way Air Discharge Cassette (Compact type)

Concealed Duct Standard

Slim Duct

Concealed Duct High Static Pressure

Under Ceiling

High Wall

Floor Standing Cabinet

Floor Standing Concealed

Floor Standing

Type

—

3

5

6

1

Abbreviated Model name

MMU-AP XXX SH

MMU-AP XXX H

MMU-AP XXX WH

MMU-AP XXX YH

MMD-AP XXX BH

MMD-AP XXX SPH, SH

MMD-AP XXX H

MMC-AP XXX H

MMK-AP XXX H

MML-AP XXX H

MML-AP XXX BH

MMF-AP XXX H

UNIT No.

TEMP.

TIMER SET

SWING/FIXTIME

FILTER

TEST

RESET

Indoor unit capacity

Item code [11]

Setup data

0001

0003

0005

0007

0009

0011

0012

0013

0015

0017

0018

0021

0023

~

22

CODE No.

ON / OFF

FAN

MODE

4

VENT

UNITSET CL

2

Model

007

009

012

015

018

024

027

030

036

048

056

072

096

—

Page 24

Continued

23

(Items necessary to perform the applied control at the local site are described.)

DN

01

02

03

04

06

0d

0E

0F

10

11

12

13

14

19

1E

28

29

2A

2E

30

31

32

33

40

5d

60

62

Item

Filter display delay timer

Dirty state of filter

Central control address

Specific indoor unit priority

Heating temp shift

Existence of [AUTO] mode

Follows operation mode of the

header unit

Cooling only

Type

Indoor unit capacity

Line address

Indoor unit address

Group address

Louver type

(Adjustment of air direction)

Temp difference of [AUTO] mode

selection

COOL ® HEAT, HEAT ®COOL

Automatic restart of power failure

Operation condition of humidifier

Selection of option/error input

(CN70)

HA terminal (CN61) select

Automatic elevating grille

Ventilating fan control

TA sensor selection

Temperature unit select

Drain pump control

High ceiling selection

(Air volume selection)

Timer set

(Wired remote controller)

Anti-ceiling

smudging control

Table: Function selecting item code (DN)

0000 : None 0001 : 150H

0002 : 2500H 0003 : 5000H

0004 : 10000H

0000 : Standard

0001 :High degree of dirt (Half of standard time)

0001 :No.1 unitto0064 :No.64 unit

0099 : Unfixed

0000 :No priority 0001 :Priority

0000 : No shift 0001 : +1°C

0002 : +2°Cto0010 : +10°C (Up to +6 recommended)

0000 : Provided

0001 : Not provided (Automatic selection from connected outdoor unit)

0000 :Does not follow

0001 :Follows

0000 : Heat pump

0001 : Cooling only (No display of [AUTO] [HEAT])

0000 :(1-way air discharge cassette)

0001 :(4-way air discharge cassette) to 0037

0000 : Unfixed 0001 to 0034

0001 :No.1 unitto0030 :No.30 unit

0001 :No.1 unitto0064 :No.64 unit

0000 :Individual 0001 : Header unit of group

0002 :Follower unit of group

0000 : Not provided 0001 :Swing only

0004 : [4-way Air Discharge Cassette type] and [Under Ceiling type]

0000 :0 deg to 0010 : 10 deg

(For setup temperature, reversal of COOL/HEAT by ± (Data value)/2)

0000 : None 0001 : Restart

0000 : Usual

0001 :Condition ignored (Detection control for heat exchanger temperature)

0000 : Filter input 0001 :Alarm input (Air washer, etc.)

0002 : None

0000 : Usual 0001 : Leaving-ON prevention control

0000 : Unavailable0001 :Available

0000 : Unavailable0001 :Available

0000 : Body TA sensor 0001 : Remote controller sensor

0000 : °C (at factory shipment)0001 :°F

0000 : None 0001 : Pump ON

0002 : None 0003 : Pump OFF

[4-way Air Discharge Cassette type] and [Under Ceiling type]

0000 :Standard filter0001 : Super-long life filter

0003 :High efficiency filter

[Concealed Duct Standard type]

0000 : Standard static pressure (40Pa)

0001 : High static pressure 1 (70Pa)

0003 :High static pressure 2 (100Pa)

0005 :Correspond to quiet sound

0006 :Low static pressure (20Pa)

0000 :Ava ilable (Operable)

0001 :Unavailable (Operation prohibited)

0000 :Clear

Description

At shipment

According to type

0000 : Standard

0099 : Unfixed

0000 : No priority

0002 : +2°C

(Floor type 0000: 0°C)

0001 : Not provided

0000 : Not provided

0000 : Heat pump

According to model type

According to capacity type

0099 : Unfixed

0099 : Unfixed

0099 : Unfixed

According to type

0003 :3 deg

(Ts±1.5)

0000 : None

0000 : Usual

0002 : None

0000 :Usual (HA terminal)

0000 : Unavailable

0000 : Unavailable

0000 : Body TA sensor

0000 :°C

0003 : Pump OFF

0000 : Standard

0000 :Available

4- way Air Discharge

Cassette type only

Page 25

Service Support Function

n Function to start/stop (ON/OFF) indoor unit from outdoor unit

The following functions enables the start and stop of the indoor units using the switches on the interface P.C. board of

the header unit.

No.

Function

1

All cooling

Changes the mode of all the connected indoor

test operation

units collectively to cooling test operation.

Note) Control operation same as test operation

2

All heating

Changes the mode of all the connected indoor

test operation

units collectively to heating test operation.

Note) Control operation same as test operation

3

Batch start

Starts all the connected indoor units collectively.

Note) The contents follow the setup of remote

Batch stop

Stops all the connected indoor units collectively.

4

Individual

Starts the specified indoor unit.

start

Notes)

• Control operation same as test.

• The other indoor units keep existing status.

Stops the specified indoor unit.

Individual

stop

Note) The other indoor units keep existing

Operates the specified indoor unit.

Individual test

operation

Note) The other indoor units keep existing

Note 1) This start/stop function only sends the

command signals from the outdoor unit to

the indoor unit, such as start, stop, operation

mode, etc.

Once it does not resend the signals even if

the indoor unit does not follow the sent

signals.

Note 2) The above controls are not available when

an error has caused the system to stop.

Outline

for remote controller.

for remote controller.

controller.

status.

status.

Setup/Release

[Setup]

Push SW04 for 2 seconds or more with

SW01”2”, SW02”5”, SW03”1”.

[Release]

Return SW01, SW02, SW03 to “1”.

[Setup]

Push SW04 for 2 seconds or more with

SW01”2”, SW02”6”, SW03”1”.

[Release]

Return SW01, SW02, SW03 to “1”.

[Setup]

Push SW04 for 2 seconds or more with

SW01”2”, SW02”7”, SW03”1”.

[Release]

Return SW01, SW02, SW03 to “1”.

[Setup]

Push SW05 for 2 seconds or more with

SW01”2”, SW02”7”, SW03”1”.

[Release]

Return SW01, SW02, SW03 to “1”.

[Setup]

Push SW04 for 2 seconds or more set

SW01 “16” and set SW02 and SW03 to

address No. (1 to 64) to be started.

[Release]

Return SW01, SW02, SW03 to “1”.

[Setup]

Push SW05 for 2 seconds or more set

SW01 “16” and set SW02 and SW03 to

address No. (1 to 64) to be stopped.

[Release]

Return SW01, SW02, SW03 to “1”.

[Setup]

Push SW04 for 10 seconds or more set

SW01 “16” and set SW02 and SW03 to

address No. (1 to 64) to be operated.

[Release]

Return SW01, SW02, SW03 to “1”.

Interface P.C. board

7-segment display [A]

7-segment display

Section A Section B

[C ][ –C]

Section A Section B

[H ][ –H]

Section A Section B

[CH] [ 11]

[ 11] is displayed on Section

B for 5 seconds.

Section A Section B

[CH] [ 00]

[ 00] is displayed on Section

B for 5 seconds.

Section A Section B

[ ][ ]

Section A:

Displays the corresponding

indoor address.

Section B:

Displays [ 11] for 5 seconds

from operation-ON.

Section A Section B

[ ][ ]

Section A:

Displays the corresponding

indoor address.

Section B:

Displays [ 00] for 5 seconds

from operation-OFF.

Section A Section B

[ ][ ]

Section A:

Displays the corresponding

indoor address.

Section B:

Displays [ FF] for 5 seconds

from test operation-ON.

7-segment display [B]

SW04 SW05

SW01 SW02 SW03

Rotary switch

24

Page 26

Continued

25

1 Data display of system information (Displayed on the header outdoor unit only)

SW011SW02

SW03

1

3

Refrigerant name Displays refrigerant name.A B

2

System capacity A[ 5] to [48] : 5 to 48HP

3

No. of outdoor units A[ 1] to [ 4] : 1 to 4 units

4

No. of connected indoor units/ A[ 0] to [48] : 0 to 48 units (No. of connected units)

No. of units with cooling thermo ON

5

No. of connected indoor units/ A[ 0] to [48] : 0 to 48 units (No. of connected units)

No. of units with heating thermo ON

6

Compressor command A Data is displayed with hexadecimal notation

correction amount

7

Release control A Normal time : [ r], During release control: [r1]

8

Oil-equalization control A Nor mal time : [oiL-0]

9

Oil-equalization request A Displays with segment LED lighting pattern