Toshiba MMY-MAP0801HT8-E, MMY-MAP1202FT8-E, MMY-MAP1201HT8-E, MMY-MAP1001HT8-E, MMY-MAP0802FT8-E SERVICE MANUAL

...

FILE NO. A07-004

SERVICE MANUAL

R410A

• This manual describes about the model which is installed with the passive filter to the fan driving

circuit as the measure against the Europe Harmonic Regulation EN61000-3-12.

The indoor units are same as those of the existing models and they are not especially changed.

For the standard servicing method, refer to the FILE NO. A03-009, A04-008 and A05-004-1.

New models compliance with EMC: IEC61000-3-12

< Outdoor Unit >

Heat Pump Model

MMY-MAP0501HT8-E, MMY-MAP0601HT8-E, MMY-MAP0801HT8-E,

MMY-MAP1001HT8-E, MMY-MAP1201HT8-E

Cooling Only Model

MMY-MAP0501T8-E, MMY-MAP0601T8-E, MMY-MAP0801T8-E,

MMY-MAP1001T8-E, MMY-MAP1201T8-E

Heat Recovery Model

MMY-MAP0802FT8-E, MMY-MAP1002FT8-E, MMY-MAP1202FT8-E

PRINTED IN JAPAN, Dec.,2007 ToMo

CONTENTS

1. DIFFERENT POINTS OF THE MAIN PARTS ............................................... 3

2. WIRING DIAGRAM ...................................................................................... 4

2-1. Outdoor Unit .......................................................................................................... 4

3. TROUBLESHOOTING (Passive Filter Circuit) ........................................... 7

4. CONFIGURATION OF CONTROL CIRCUIT ................................................ 9

4-1. Outdoor Unit .......................................................................................................... 9

5. RUNNING CHANGE .................................................................................. 10

5-1. Remote Controller Switch .................................................................................. 10

5-2. Parts Layout in Outdoor Unit ............................................................................. 11

5-3. Refrigerant Piping Systematic Drawing ............................................................ 13

5-4. Refrigerant Recovery When Replacing the Compressor ................................. 15

5-5. Replacing Method of Parts ................................................................................. 16

5-6. P.C. Board Exchange Procedures (Outdoor Unit)............................................. 20

6. DETACHMENTS (Passive Filter Circuit) .................................................. 21

7. EXPLODED VIEWS AND PARTS LIST...................................................... 24

7-1. Outdoor Unit (MMY-MAP

Refrigeration Circuit Diagram ............................................................................ 28

7-2. Outdoor Unit (MMY-MAP

Refrigeration Circuit Diagram ............................................................................ 35

7-3. Outdoor Unit (MMY-MAP

Refrigeration Circuit Diagram ............................................................................ 42

∗∗∗∗∗∗

∗∗∗HT8-E) ................................................................... 24

∗∗∗∗∗∗

∗∗∗∗∗∗

∗∗∗T8-E) ...................................................................... 31

∗∗∗∗∗∗

∗∗∗∗∗∗

∗∗∗FT8-E) .................................................................... 38

∗∗∗∗∗∗

2

1. DIFFERENT POINTS OF THE MAIN PARTS

This model is added with the passive filter to the fan driving circuit of the existing model and then Type name is

changed. (“-E” is added to the end of the Type name.)

1. Newly changed contents

Addition of passive filter against the harmonic

Existing model

SMMS SHRM

MCC-1439-05

None

Power supply P.C.

1

board for fan IPDU

2

Passive filter

Item

2. Contents change of running

1) Reduction in refrigerant amount

Applied models: MMY-MAP0801HT8 (-E), MAP1001HT8 (-E), MAP1201HT8 (-E)

(Only for SMMS heat pump models) Unit: kg

System HP

5

6

8

10

12

Existing model

SMMS

—

—

12.5

12.5

12.5

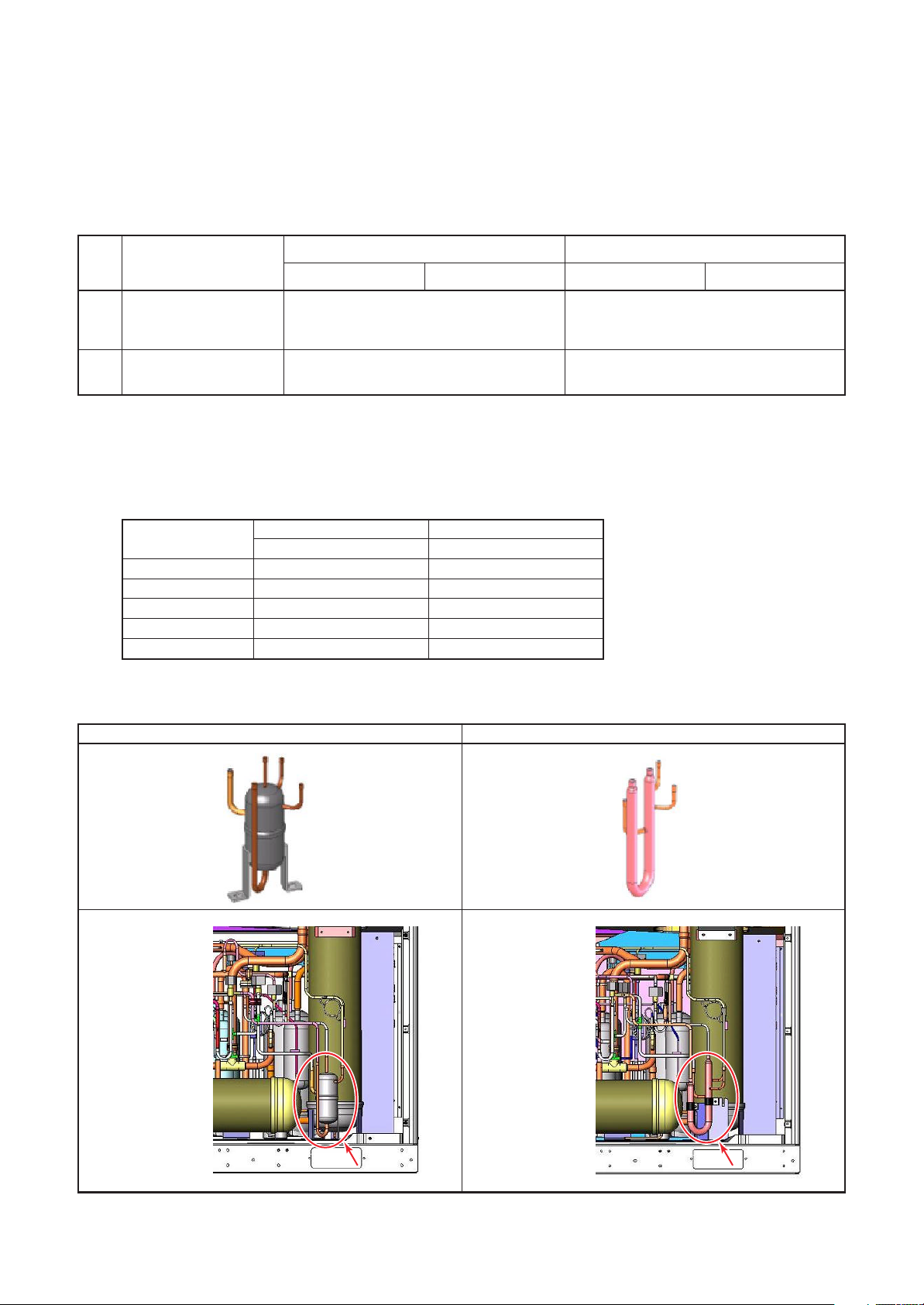

2) Change of oil tank appearance

Applied models: SMMS series, SHRM series

Model in tis time

SMMS

—

—

12.0

12.0

12.0

Model in this time

SMMS SHRM

MCC-1439-06

Addition of connector

to connect the passive filter

Electrolytic capacitor (MCC-1580),

Resistance, Diode, Reactor (CH-68)

(Appearance)

(Layout)

– Rear view —

Tank type of Oil tank (past)

Tube type of Oil tank (current)

(Appearance)

(Layout)

– Rear view —

<Reference: Product Bulletin No.2007-13>

3

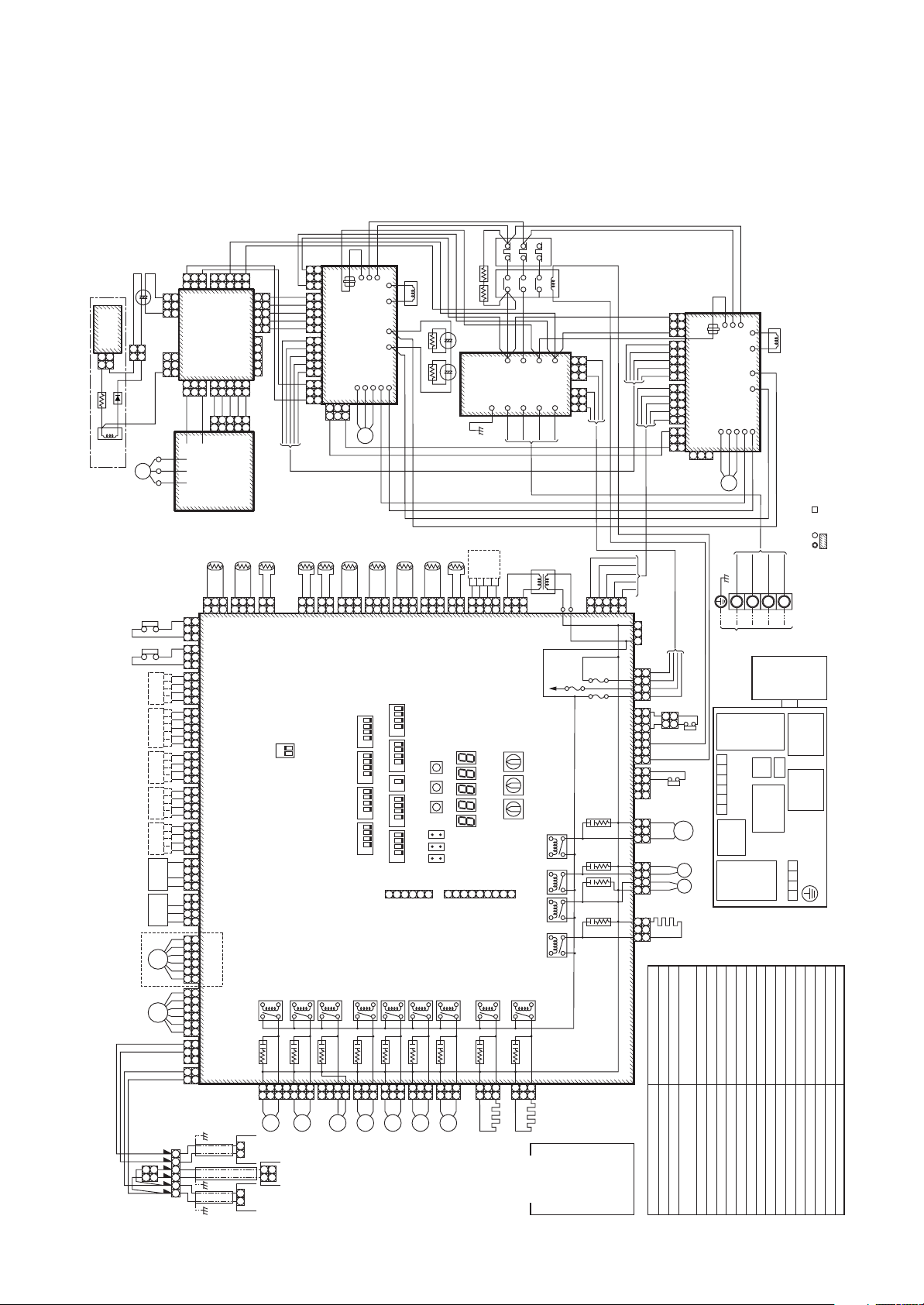

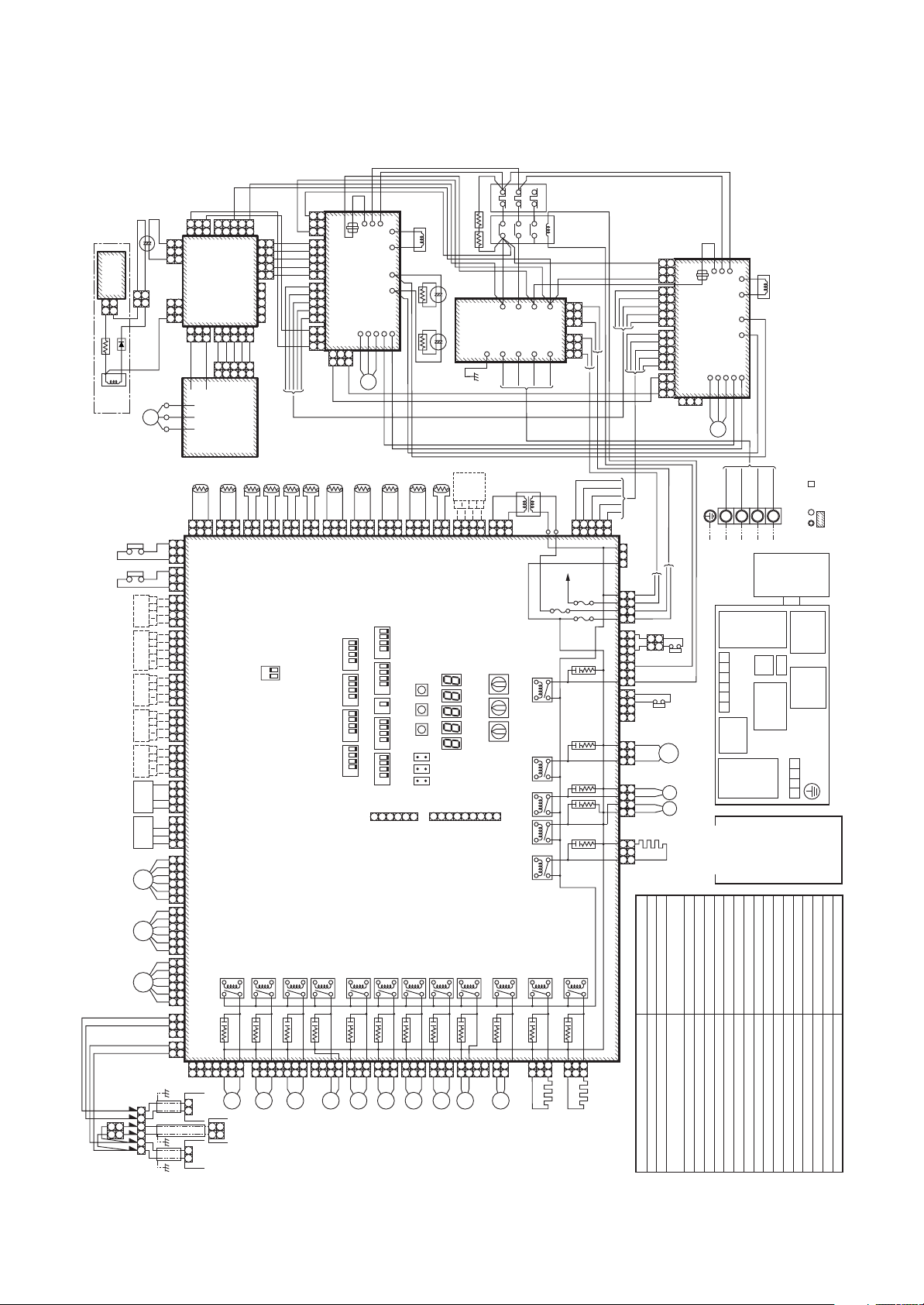

2. WIRING DIAGRAM

2-1. Outdoor Unit

Model: MMY-MAP0501HT8-E, MMY-MAP0601HT8-E, MMY-MAP0801HT8-E,

MMY-MAP1001HT8-E, MMY-MAP1201HT8-E

246

BLU

BLK

BLK

+–+–

YEL

YEL

(GRN)

TL

BLK

BLK

BLU(BLK)

1

1

2

(YEL)

CN521

SW06

SW05SW04

CN32

CN30

2

1

CN800

RY509

CR509

3

1

3

1

BLU

BLU

SV3C

CN314(BLK)

RED

PTC Themistor

P.C. board

Noise filter

BLK

(WHI)

1

122 2

(WHI)

3

CN316(WHI)

RED

246

135

Mg-SW OCR

RED

CN21

MCC-1366

board

Option

1

3

134 4

(GRN)

CN511

D603D602D601D600 D604

SW02 SW03

SW01

6

549

7

RY516

CR516

1

3

1

3

BRW

RED

RED

CN17

CN01

RED

BLU

3

3

CN100

8

1

1

Heater 1

CN315(BLU)

WHI

CN18

CN02

WHI

BLU

1

1

(BLK)

CN802

RY517

CR517

BRW

BLK

Flash

Color

A1 A2

GRY

GRY

BLK

CN19

CN03

BLK

GRY

RY521RY511

RY510

RY518

3

3

T Heater 2

indication

RED : RED

GRY

CN20

CN23(BLU)CN22(WHI)

CN04

Transformer

WHI

CN402

L1

WHI : WHITE

YEL : YELLOW

1 3

1 3

1 3

1 3

RED

CN600(WHI)

CN401

T6.3A

FUSE

BLU : BLUE

BLK : BLACK

5 5

T6.3A

FUSE

T6.3A

FUSE

CR521CR511

CR

510

CR

518

GRY : GRAY

PNK : PINK

1

3

134 4

2 2

CN305(RED)

CN307(WHI)

L3

ORN: ORANGE

BRN : BRWN

VLT : VIOLET

BLK

WHI

BLU

RED

PNK

3 1

3 1

CN17

(BLK)

PNK

RED

BLU

3 2 1

3 2

CN18

(RED)

WHI

BLK

5 4

5 4 1

PNK

RED

BLU

3 2 1

3 2

CN06

(WHI)

WHI

BLK

5 4

5 4 1

CN26

3 1

3 1

1

CN25

(WHI)

(YEL)

CN325

(WHI)

CN400

GRY

4

4

N

BLK

3

3

L3

WHI

2

21

L2

RED

1

1

L1

ORN

3 1

3 1

5 3 1 3 2 17

4 3 2 1

CN317

1 2

CN323

4

3

2

1

CN321

1 2

3

7 5

2 1

(BLU)

1 2

(WHI)

4

3

2

1

(RED)

1 2

BLK BLK

ORN

ORN

PNK

PNK

PNK

PNK

RED

BLU

BRN

ORN

BLK(PNK)

4WV1

BLK(PNK)

3E

SV

3D

SV

Accumulator

Comp1

Comp2

heater

Parts name

Compressor

Pulse motor valve

2-way valve coil

Symbol

CM1, CM2

PMV1, PMV2

SV2, SV41, SV42, SV51, SV3A,

SV3B, SV3C, SV3D, SV3E

(BLU)

Parts layout

4-way valve coil

4WV1

Passive filter

MCC-1580

CN01(WHI)

2

1

2

1

YEL

WHI YEL

RED

Reactor

BLU

+

~

BLU

+–

YEL

1

2

1

2

FM

Except 5HP, 6HP

2

1

BLU

YEL

RED

63H2

63H1

Board

Option

Board

Option

Board

Option

Board

Option

Board

Option

PD

Sensor

Pressure

PS

Sensor

Pressure

PMV2

PMV1

2

1

CN506

3

1

3

1

CN507

BLK

WHI

RED

3

3

(BLK)

3

1

CN506(BLK)

3

1

3

3

(YEL)

BLU

–

1 3

1 3

4 3 2 1

4 3 2 1

5

4 3 2 1

4 3 2 1

4 3 2 1

WHI

BLK

RED

4 3 1

WHI

BLK

RED

4 3 2

WHI

YEL

ORN

BLU

BRN

RED

6 5 4 3 2 1

WHI

YEL

ORN

BLU

BRN

RED

6 5 4 3 2 1

WHI

1

WHI

2

3

BLU

1

BLU

2

U1 U2 U3 U4 U5 U6

CN502

CN500

WVU

1 3

1 3

4 3 2 1

4

5 3 2 1

4 3 2 1

4 3 2 1

4 3 2 1

4 3 2 1

4 3 2 1

6 5 4 3 2 1

6 5 4 3 2 1

1

2

3

1

2

(BLU)

(WHI)

YEL

+

531

1

531

1

Power supply

P.C. board for FAN

54321

1

54321

1

BLK

WHI

54321

54321

FAN IPDU

P.C. Board

TD1

(YEL)

BLU(BLK)

BLU(BLK)

3

3

(BLU)

CN308

(WHI)

CN306

(BLU)

CN512

(BLU)

CN513

(WHI)

CN510

(BLK)

CN509

(RED)

CN508

(RED)

CN501

(WHI)

CN500

(WHI)

CN301

(WHI)

CN300

CN03

(WHI)

CN01

(BLU)

GRY

RED

(RED)

CN501

MCC-1439

CN504 CN505(RED)

(WHI)

CN503

BLU

RED

PNK

CN01

(WHI)

MCC-896, 897

TD2

(RED)

BLU(BLK)

BLU(BLK)

1

3

1

3

(WHI)

(PNK)

CN502

CN503

U1 U2 U5 U6

3 4

1 2 53 41 2 5

BLK

1

1

BLU

unit

Outdoor

unit

Indoor

YEL

BLU

3 4 5

1 2

TS1

(GRY)

BLK

2

1

2

1

(WHI)

CN504

ON

Interface Control P.C. Board

RY503

CR503

753

753

BLU

SV42

U3 U4

U1 U2

Central remote

3 1

3 1

BLK

WHI

BLU

3 4 5

3 4

RED

PNK

1 2

1 2 5

PNK

RED

BLU

3 2 1

3 2

WHI

BLK

5 4

5 4 1

3 1

3 1

CN25

(WHI)

TE1

(BLK)

TO

BLK

BLK

BLK

2

1

2

2

1

2

(GRN)

CN505

CN507

SW30

MCC-1429

RY502

CR502

1

432

1

BLU

BLU

SV41

CN311(BLU)

CN310(WHI)

controller

YEL

BLK

CN17

1 1

(BLK)

1

1

(YEL)

RY504

(BLK)

CN18

(RED)

CN06

(WHI)

CN26

2 2

BLU(BLK)

CR504

2

BLU

SV51

IPDU P.C. Board (1)

W

(BLU)

3 3

BLK

BLU

TK1

(BLK)

BLU(BLK)

3

3

(BLK)

CN514

1

1

BLU

BLU

CN312(WHI)

BLK

WHI

RED

T

S

R

CN03

CN02

CN01

CN13

MCC-1502

CN15

CN22

CN11

CN10

CN09

V

U

WHI

RED

YEL

CM1

TK2

(BLU)

BLU(BLK)

BLU(BLK)

1

3

1

3

(GRN)

CN515

4

31

2

SW14

ON

431

2

SW13

ON

4

31

2

SW12

ON

431

2

SW11

ON

RY506

CR506

3

1

3

1

BLU

BLU

SV2

CN324(RED)

CN23

BLU

BLU(BLK)

1

1

431

2

ON

431

2

ON

1

ON

431

2

ON

431

2

ON

RY507

3

3

SV3A

CN20

CN21

TK3

3

3

CR507

1

1

BLU

CN516

WHI

Reactor

WHI

BLU

(BLU)

BLU(BLK)

BLU(BLK)

1

1

(RED)

SW10

SW09

SW08

SW07

CN31

SW06

321

(Srvice)

RY508

CR508

3

3

BLU

SV3B

CN313(YEL)

3

3

BLU

BLK

TK4

CN523

654

1

1

BLK

WHI

RED

T

S

R

CN03

CN02

CN01

CN15 CN13

MCC-1502

IPDU Board (2)

CN22

CN23

CN11

CN10

CN09

V

U

W

3

WHI

RED

YEL

BLU

BLK

CM2

Earth screw

RED

WHI

L1L2L3

Power Supply, 3phase

380-415V 50Hz

380V 60Hz

(I/F)

control

Interface

P.C. board

U1 U2 U3 U4 U5 U6

Connecting terminal

MCC-896

Fan IPDU

P.C. board

Noise filter

MCC-1366

Compressor case thermo.

Pipe temp. sensor (Inlet)

Pipe temp. sensor (Outlet)

Heat exchange temp. sensor

Air temp. sensor

COMP1, COMP2

TS1

TD1, TD2

TE1TOTK1, TK2, TK3, TK4

CN07

WHI

Reactor

CN08

WHI

BLU

YEL

accessories sold separately and service cables, respectively.

1. The two-dot chain line indicates wiring at the local site, and the dashed line indicates

2. , , and indicate the ter minal blocks and the numerals indicate the terminal numbers.

3. indicates P.C. board.

BLK

GRY

N

filter

Passive

No.2

MCC-1429

SW

MG-

Power supply

OCR

for fan

MCC-1439

Comp. IPDU

No.1

Comp. IPDU

Power supply

MCC-1502

MCC-1502

terminal

L1 L2 L3 N

Oil temp. sensor

Liquid temp. sensor

Case heater, 230V, 26W

Fan motor (DC)

Low pressure sensor

High pressure sensor

High pressure switch

TL

HEATER1, HEATER2, ACCUMULATORFMPSPD63H1, 63H2

(Otherwise water enters into the box resulting in a trouble.)

* Be sure to fix the electric par ts cover surely with two screws.

Passive filter box

Electric parts box

Magnet switch

Overcurrent relay

MG-SW

OCR

4

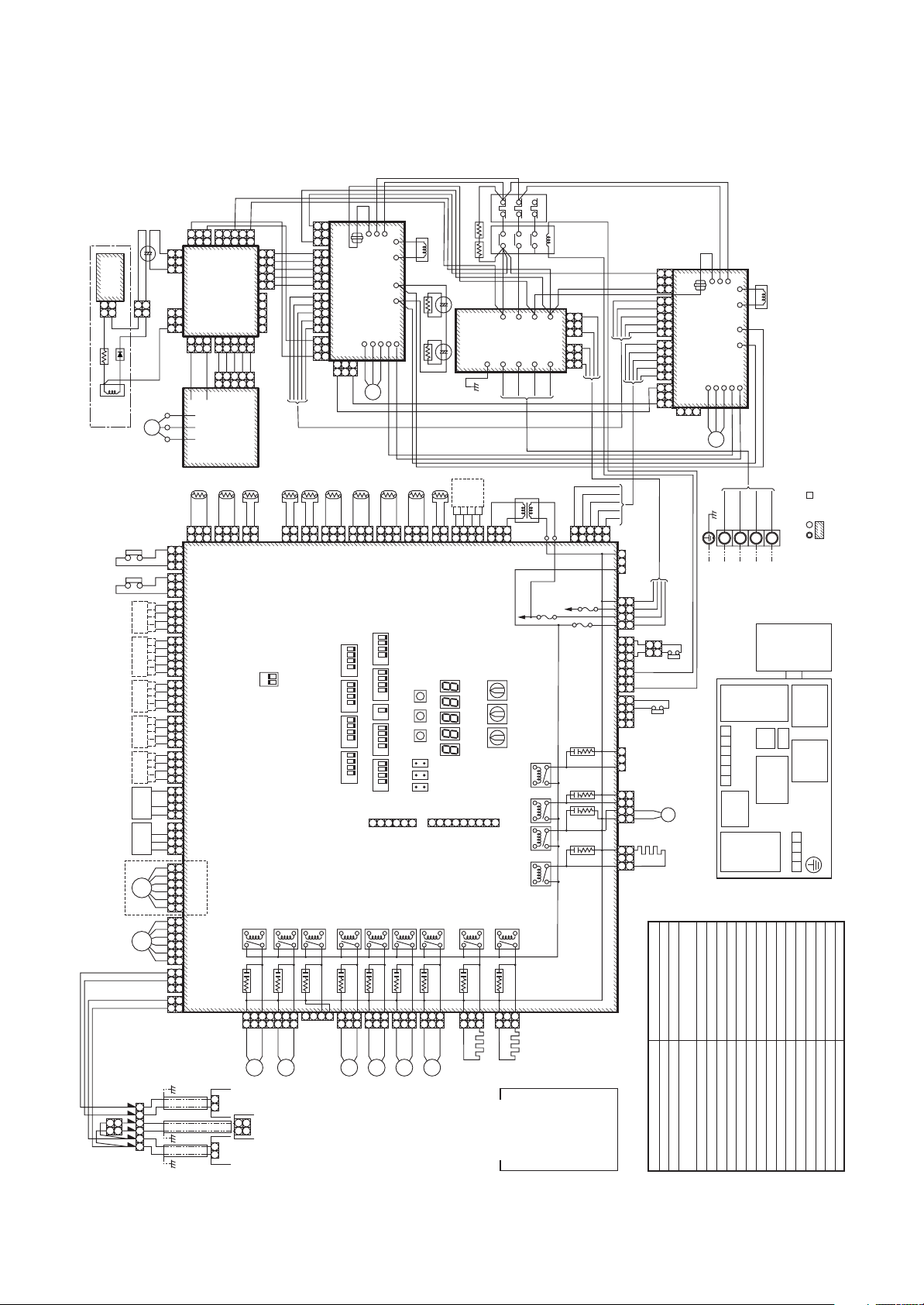

Model: MMY-MAP0501T8-E, MMY-MAP0601T8-E, MMY-MAP0801T8-E,

MMY-MAP1001T8-E, MMY-MAP1201T8-E

246

Reactor 1

BLU

BLU

BLK

BLK

YEL

YEL

RED

RED

PTC Themistor

P.C. board

Noise filter

+– +–

BLK

246

135

Mg-SW OCR

RED

RED

CN17

CN21

CN01

MCC-1366

RED

WHI

WHI

CN18

CN02

A1 A2

RED

3 1

GRY

GRY

GRY

BLK

BLK

1 3

1 3

CN19

CN20

CN23(BLU)CN22(WHI)

CN03

CN04

1 3

1 3

BLK

GRY

PNK

RED

BLU

WHI

BLK

PNK

RED

BLU

WHI

BLK

3 1

3 2

5 4 1

3 2

5 4 1

3 1

CN25

3 2 1

5 4

3 2 1

5 4

3 1

(WHI)

MCC-1580

CN01(WHI)

2

1

2

1

YEL

Passive filter

WHI YEL

RED

Reactor

BLU

+

~

BLU

+–

YEL

1

2

1

2

FM

RED

GRY

RED

531

3

1

531

3

1

BLU

(BLK)

CN506

3

3

(BLU)

CN502

1

1

YEL

3

3

1

1

3

3

(YEL)

CN507

BLU

–

BLK

WHI

RED

Power supply

P.C. board for FAN

CN500(WHI)

54321

1

54321

1

YEL

BLK

54321

54321

+

UVW

FAN IPDU

P.C. Board

(RED)

CN501

MCC-1439

(WHI)

CN503

WHI

BLU

RED

PNK

CN01

(WHI)

MCC-896, 897

CN504 CN505(RED)

RED

GRY

YEL

BLU

3 1

53 41 2 5

3 4

1 2

BLK

WHI

BLU

3 4 5

3 4

RED

PNK

1 2

1 2 5

PNK

RED

BLU

3 2

WHI

BLK

5 4 1

3 1

CN25

3 1

3 4 5

1 2

3 2 1

5 4

3 1

(WHI)

CN17

1 1

YEL

CN18

CN06

(BLK)

(RED)

(WHI)

CN26

2 2

COMP. IPDU

(BLU)

3 3

BLU

BLK

WHI

RED

L3CTL2

CN03

CN02

MCC-1502

P.C. Board (1)

CN11

CN10

CN09

V

U

W

BLK

WHI

RED

CM1

L1

CN01

YEL

CN13

CN15

CN22

CN20

WHI

CN21

WHI

BLK

CN23

BLU

CN17

CN18

CN06

1

(BLK)

(RED)

(WHI)

CN26

(BLU)

COMP. IPDU

P.C. Board (2)

W

3

BLK

BLK

CN11

WHI

RED

L3CTL2

L1

CN03

CN02

CN01

CN15 CN13

MCC-1502

CN22

CN23

CN10

CN09

V

U

WHI

RED

YEL

BLU

CM2

CN07

CN08

YEL

WHI

Reactor 2

WHI

BLU

5 5

T6.3A

CR

CR

PNK : PINK

T6.3A

FUSE

CR521CR511

510

518

BLK

WHI

BLU

RED

PNK

1

2 2

3

134 4

FUSE

CN305(RED)

CN307(WHI)

(BLU)

CN317

(WHI)

CN323

N

ORN : ORANGE

BRN : BRWN

VLT : VIOLET

CN400

4

3

2

1

5 3 1 3 2 17

4 3 2 1

1 2

432

1

CN321

1 2

CN325

(WHI)

43

3

21

1

7 5

2 1

2

1

(RED)

1 2

(YEL)

GRY

BLK

WHI

RED

BLK BLK

ORN

ORN

Earth screw

N

L3

L2

L1

ORN

3 1

3 1

COMP.1

ORN

RED

BLU

COMP.2

SV

3D

Accumulator

Parts layout

heater

BLU

BLU

BRN

Parts name

Compressor

Pulse motor valve

2-way valve coil

4-way valve coil

Compressor case thermo.

Symbol

CM1, CM2

PMV1, PMV2

SV2, SV41, SV42, SV51, SV3A,

SV3B, SV3C, SV3D, SV3E

4WV1

COMP1, COMP2

RED

WHI

BLK

GRY

L1L2L3

Pipe temp. sensor (Inlet)

TS1

N

3phase

Power Supply

380-415V 50Hz

(I/F)

control

Interface

P.C. board

MCC-1429

SW

MG-

U1 U2 U3 U4 U5 U6

Connecting terminal

for fan

MCC-1439

Power supply

MCC-896

Fan IPDU

P.C. board

Noise filter

MCC-1366

Pipe temp. sensor (Outlet)

Heat exchange temp. sensor

Air temp. sensor

Oil temp. sensor

Liquid temp. sensor

Case heater, 230V, 26W

TD1, TD2

TE1TOTK1, TK2, TK3, TK4

TL

HEATER1, HEATER2, ACCUMULATORFMPSPD63H1, 63H2

(Otherwise water enters into the box resulting in a trouble.)

accessories sold separately and service cables, respectively.

* Be sure to fix the electric par ts cover surely with two screws.

1. The two-dot chain line indicates wiring at the local site, and the dashed line indicates

2. , , and indicate the terminal blocks and the numerals indicate the terminal numbers.

3. indicates P.C. board.

filter

Passive

Passive filter box

No.2

MCC-1502

Comp. IPDU

OCR

No.1

MCC-1502

Comp. IPDU

Electric parts box

terminal

Power supply

L1 L2 L3 N

Fan motor (DC)

Low pressure sensor

High pressure sensor

High pressure switch

Magnet switch

Overcurrent relay

MG-SW

OCR

TK4

TE1

(BLU)

TO

BLK

BLK

2

2

(GRN)

CN505

SW30

RY502

CR502

BLU

BLU

SV41

CN311(BLU)

(BLK)

TK1

(BLK)

TK2

(BLU)

BLK

BLK

BLU(BLK)

BLU(BLK)

BLU(BLK)

3

3

(BLK)

CN514

1

BLU

CN312(WHI)

1

1

3

3

4

31

2

ON

431

2

ON

4

31

2

ON

431

2

ON

3

3

RY506

CR506

BLU

SV2

CN515

1

1

BLU(BLK)

1

1

(GRN)

SW14

SW13

SW12

SW11

3

3

BLU

CN324(RED)

1

2

1

1

2

1

(YEL)

CN507

RY504

CR504

1

432

1

TD1

(YEL)

TD2

(RED)

TS1

(GRY)

BLU(BLK)

BLU(BLK)

BLU(BLK)

BLU(BLK)

BLK

BLK

2

(WHI)

U1 U2 U5 U6

3

3

CN503

(PNK)

unit

Outdoor

unit

Indoor

1

1

Interface Control P.C. Board

BLU

U1 U2

1

2

1

(WHI)

CN504

ON

MCC-1429

RY503

CR503

753

753

BLU

SV42

U3 U4

controller

Central remote

3

1

3

1

63H2

63H1

Board

Option

Board

Option

Board

Option

Board

Option

Board

Option

PD

Sensor

Pressure

PS

Sensor

Pressure

PMV2

Except 5HP, 6HP

PMV1

2

2

1

1

U1 U2 U3 U4 U5 U6

WHI

BLK

RED

WHI

BLK

RED

WHI

YEL

ORN

BLU

BRN

RED

WHI

YEL

ORN

BLU

BRN

RED

WHI

WHI

BLU

BLU

(BLU)

1 3

1 3

CN308

CN502

(WHI)

1 3

1 3

CN306

(BLU)

CN512

4 3 2 1

4 3 2 1

(BLU)

4 3 2 1

4

CN513

5

5 3 2 1

(WHI)

CN510

4 3 2 1

4 3 2 1

(BLK)

CN509

4 3 2 1

4 3 2 1

(RED)

CN508

4 3 2 1

4 3 2 1

(RED)

CN501

4 3 1

4 3 2 1

(WHI)

CN500

4 3 2

4 3 2 1

(WHI)

CN301

6 5 4 3 2 1

6 5 4 3 2 1

(WHI)

CN300

6 5 4 3 2 1

6 5 4 3 2 1

1

1

2

2

CN03

(WHI)

3

3

1

1

CN01

(BLU)

2

2

TK3

BLU(BLK)

3

3

CN516

431

2

ON

431

2

ON

1

ON

431

2

ON

431

2

ON

2

1

RY507

CR507

1

1

BLU

SV3A

(WHI)

BLU(BLK)

BLU(BLK)

1

3

1

3

(RED)

SW10

SW09

SW08

SW07

SW06

SW31

543

(Service)

RY508

CR508

3

3

BLU

BLU

SV3B

CN313(YEL)

(GRN)

BLU(BLK)

1

1

(YEL)

CN523

6

CN800

1

3

1

3

BLU

CN314(BLK)

BLK

SW06

SW05SW04

SW32

SW30

1

RY509

CR509

SV3C

TL

(WHI)

BLK

1

2

122 2

(WHI)

CN521

2

1

1

BLU

3

CN316(WHI)

board

Option

1

3

134 4

(GRN)

CN511

D603D602D601D600 D604

SW02 SW03

SW01

6

549

7

RY516

CR516

1

3

1

3

BRN

BLU

3

3

CN100

8

1

1

Heater 1

CN315(BLU)

Color

BLU

1

1

(BLK)

RY521RY511

Flash

CN802

RY510

RY518

RY517

CR517

3

3

BRN

Heater 2

indication

RED : RED

WHI : WHITE

Transformer

RED

WHI

CN402

CN401

T6.3A

FUSE

L1

YEL : YELLOW

BLU : BLUE

BLK : BLACK

CN600(WHI)

GRY : GRAY

5

Model: MMY-MAP0802FT8-E, MMY-MAP1002FT8-E, MMY-MAP1202FT8-E

246

Reactor

BLU

BLK

BLK

+– +–

YEL

YEL

PTC Themistor

HVC1 HVC2

Noise filter

BLK

RED

RED

Mg-SW OCR

CN21

P.C. board

MCC-1366

246

135

RED

RED

CN17

CN01

RED

WHI

WHI

CN18

CN02

A1 A2

RED

3 1

3 1

CN17

GRY

GRY

GRY

BLK

BLK

1 3

1 3

CN19

CN20

CN23(BLU)CN22(WHI)

CN03

CN04

1 3

1 3

BLK

GRY

PNK

RED

BLU

WHI

BLK

PNK

RED

BLU

WHI

BLK

3 2

5 4 1

3 2

5 4 1

3 1

CN25

3 2 1

5 4

3 2 1

5 4

3 1

(WHI)

CN18

CN06

1

CN26

(BLK)

(RED)

(WHI)

(BLU)

3

Passive filter

MCC-1580

CN01(WHI)

2

1

2

1

YEL

RED

Reactor

+

~

WHI YEL

BLU

2

2

BLU

BLU

+–

YEL

YEL

1

1

RED

FM

(BLK)

CN506

3

1

3

1

(YEL)

CN507

3

1

3

1

BLK

WHI

RED

3

3

(BLU)

CN502

CN500(WHI)

3

3

BLU

–

UVW

1

1

Power supply

P.C. board for FAN

1

1

YEL

BLK

+

FAN IPDU

GRY

531

531

CN501

MCC-1439

(WHI)

CN503

54321

54321

WHI

BLU

RED

54321

54321

CN01

P.C. Board

MCC-896, 897

RED

(RED)

CN504 CN505(RED)

PNK

(WHI)

RED

YEL

BLU

3 1

BLK

WHI

BLU

3 4

3 4 5

3 4

RED

PNK

1 2 5

1 2

1 2 53 41 2 5

PNK

RED

BLU

3 2

WHI

BLK

5 4 1

3 1

CN25

3 1

3 4 5

1 2

3 2 1

5 4

3 1

(WHI)

YEL

CN17

CN18

CN06

1 1

(BLK)

(RED)

(WHI)

CN26

2 2

(BLU)

BLU

3 3

IPDU P.C. Board (1)

W

BLK

BLK

WHI

RED

L1L2L3

CN03

CN02

CN01

CN13

MCC-1502

CN15

CN22

CN11

CN10

CN09

V

U

WHI

RED

YEL

CM1

CN20

WHI

CN21

WHI

BLU

BLK

CN23

BLU

BLK

WHI

L1L2L3

CN03

CN02

MCC-1502

IPDU Board (2)

CN11

CN10

V

U

W

WHI

RED

BLK

CM2

RED

CN09

CN01

CN15 CN13

CN22

YEL

BLU

CN23

CN07

CN08

YEL

WHI

Reactor

WHI

BLU

5 5

T6.3A

T6.3A

CR

CR

RY517

CR517

FUSE

FUSE

CR521 CR519CR511

510

518

1

1

Heater 2

3

2 2

BLK

WHI

BLU

RED

PNK

1

134 4

CN400

4

3

2

1

5 3 1 3 17

CN305(RED)

4 3 2 1

CN307(WHI)

(BLU)

CN317

1 3

(WHI)

CN323

4

3

2

1

(RED)

CN321

1 2

(YEL)

Option

CN325

(WHI)

GRY

4

N

BLK

3

L3

WHI

21

L2

RED

1

L1

3 1

3 1

3

BLK BLK

RED

BLU

7 5

ORN

ORN

2 1

BLU

1 3

BLU

BLU

4

BLU

3

BLU

2

BLU

1

BRN

1 2

Parts name

Compressor

Pulse motor valve

Symbol

CM1, CM2

PMV1, PMV2, PMV3

Earth screw

RED

WHI

L1L2L3

3phase

Power Supply

ORN

Comp1

ORN

Comp2

4WV1

3E

SV

3D

SV

heater

Accumulator

2-way valve coil

SV2, SV41, SV42, SV51, SV3A, SV3B,

SV3C, SV3D, SV3E, SV61, SV11, SV12

U1 U2 U3 U4 U5 U6

Parts layout

Fan IPDU

Color

indication

4-way valve coil

Compressor case thermo.

Pipe temp. sensor (Inlet)

Pipe temp. sensor (Outlet)

Heat exchange temp. sensor

4WV1

COMP1, COMP2

TS1, TS2

TD1, TD2

TE1TOTK1, TK2, TK3, TK4

Interface

Connecting terminal

MCC-896

RED : RED

Air temp. sensor

BLK

GRY

N

380-415V 50Hz

Passive

(I/F)

control

P.C. board

MCC-1429

SW

MG-

OCR

for fan

MCC-1439

Power supply

P.C. board

Noise filter

MCC-1366

WHI : WHITE

YEL : YELLOW

BLU : BLUE

BLK : BLACK

Oil temp. sensor

Liquid temp. sensor

Case heater, 230V, 26W

Fan motor (DC)

Low pressure sensor

TL

HEATER1, HEATER2, ACCUMULATORFMPSPD63H1, 63H2

(Otherwise water enters into the box resulting in malfunction.)

accessories sold separately and service wires, respectively.

* Be sure to fix the electric parts cover surely with two screws.

1. The two-dot chain line indicates wiring at the local site, and the dashed line indicates

2. , , and indicate the ter minal board and the numerals indicate the terminal numbers.

3. indicates P.C. board.

filter

Passive filter box

No.2

MCC-1502

Comp. IPDU

No.1

MCC-1502

Comp. IPDU

Electric parts box

terminal

Power supply

L1 L2 L3 N

GRY : GRAY

PNK : PINK

ORN : ORANGE

BRN : BRWN

VLT : VIOLET

High pressure sensor

High pressure switch

Magnet switch

Overcurrent relay

High voltage capacitor

MG-SW

OCR

HVC1, HVC2

TK4

TS2

TE1

(BLK)

TO

TD1

(YEL)

TD2

(RED)

TS1

(GRY)

3

3

BLU

(WHI)

U3 U4

BLU(BLK)

(PNK)

CN503

RY500

CR500

3

SV61

Central

1

1

1

1

BLU

remote

controller

BLK

BLK

2

1

2

1

(WHI)

CN504

MCC-1429

Interface Control P.C. Board

753

753

BLU

BLK

2

2

CN522

ON

RY503

CR503

SV42

BLU(BLK)

BLU(BLK)

BLU(BLK)

3

1

3

1

63H2

63H1

Board

Option

Board

Option

Board

Option

Board

Option

Board

Option

PD

Sensor

Pressure

PS

Sensor

Pressure

PMV3

PMV2

PMV1

2

2

1

1

U1 U2 U3 U4 U5 U6

WHI

BLK

RED

WHI

BLK

RED

WHI

YEL

ORN

BLU

BRN

RED

WHI

YEL

ORN

BLU

BRN

RED

WHI

YEL

ORN

BLU

BRN

RED

WHI

WHI

BLU

BLU

1 3

1 3

4 3 2 1

4 3 2 1

5

4 3 2 1

4 3 2 1

4 3 2 1

4 3 1

4 3 2

6 5 4 3 2 1

6 5 4 3 2 1

6 5 4 3 2 1

1

2

3

1

2

1 3

1 3

4 3 2 1

4

5 3 2 1

4 3 2 1

4 3 2 1

4 3 2 1

4 3 2 1

4 3 2 1

6 5 4 3 2 1

6 5 4 3 2 1

6 5 4 3 2 1

1

2

3

1

2

753

U1 U2 U5 U6

(BLU)

CN308

(WHI)

CN306

(BLU)

CN512

(BLU)

CN513

(WHI)

CN510

(BLK)

CN509

(RED)

CN508

(RED)

CN501

(WHI)

CN500

(RED)

CN302

(WHI)

CN301

(WHI)

CN300

CN03

(WHI)

CN01

(BLU)

Outdoor

Indoor

unit

unit

CN502

CN309

U1 U2

(WHI)

(BLK)

TK1

(BLK)

TK2

(BLU)

BLK

BLK

BLK

BLK

BLK

BLU(BLK)

BLU(BLK)

BLU(BLK)

BLU(BLK)

3

1

3

1

2

1

2

1

1

2

1

2

1

(BLK)

(YEL)

(GRN)

CN505

CN507

SW30

RY502

RY504

CR502

CR504

1

432

1

BLU

BLU

BLU

SV41

(WHI)

(BLU)

CN310

CN311

3

BLU

(BLK)

CN514

1

2

1

BLU

SV51

1

3

CN515

4

31

2

SW14

ON

431

2

SW13

ON

4

31

2

SW12

ON

431

2

SW11

ON

RY506

CR506

3

3

BLU

SV2

CN312(WHI)

(GRN)

1

1

BLU

1

1

TK3

(BLU)

BLU(BLK)

BLU(BLK)

3

1

3

1

(RED)

CN516

431

2

SW10

ON

431

2

SW09

ON

1

ON

SW08

431

2

SW07

ON

431

2

SW06

ON

321

(Srvice)

RY507

CR507

3

1

3

1

BLU

BLU

SV3A

CN324(RED)

(GRN)

BLU(BLK)

BLU(BLK)

3

3

(YEL)

CN523

CN31

654

CN800

RY508

CR508

3

1

3

1

BLU

BLU

SV3B

CN313(YEL)

TL

(WHI)

BLK

BLK

1

1

2

(WHI)

CN521

SW06

SW05SW04

CN32

CN30

RY509

CR509

3

3

BLU

SV3C

CN314(BLK)

1

122 2

321

1

432

1

4

BLU

BLU

CN322(WHI)

Option

3

CN511

D603D602D601D600 D604

3

BLU

SV11

board

(GRN)

65498

RY513

CR513

BLU

3

1

3

134 4

SW02 SW03

SW01

7

1

BLU

CN319(WHI)

CN100

1

1

BLU

SV12

BLU

(BLK)

CN802

RY514

CR514

3

3

1

1

Flash

Transformer

CN402

RY519RY518

RY521RY511

RY510

RY516

CR516

3

1

3

1

BRN

CN316(WHI)

RED

WHI

CN401

T6.3A

FUSE

Heater 1

CN315(BLU)

CN600(WHI)

3

3

BRN

6

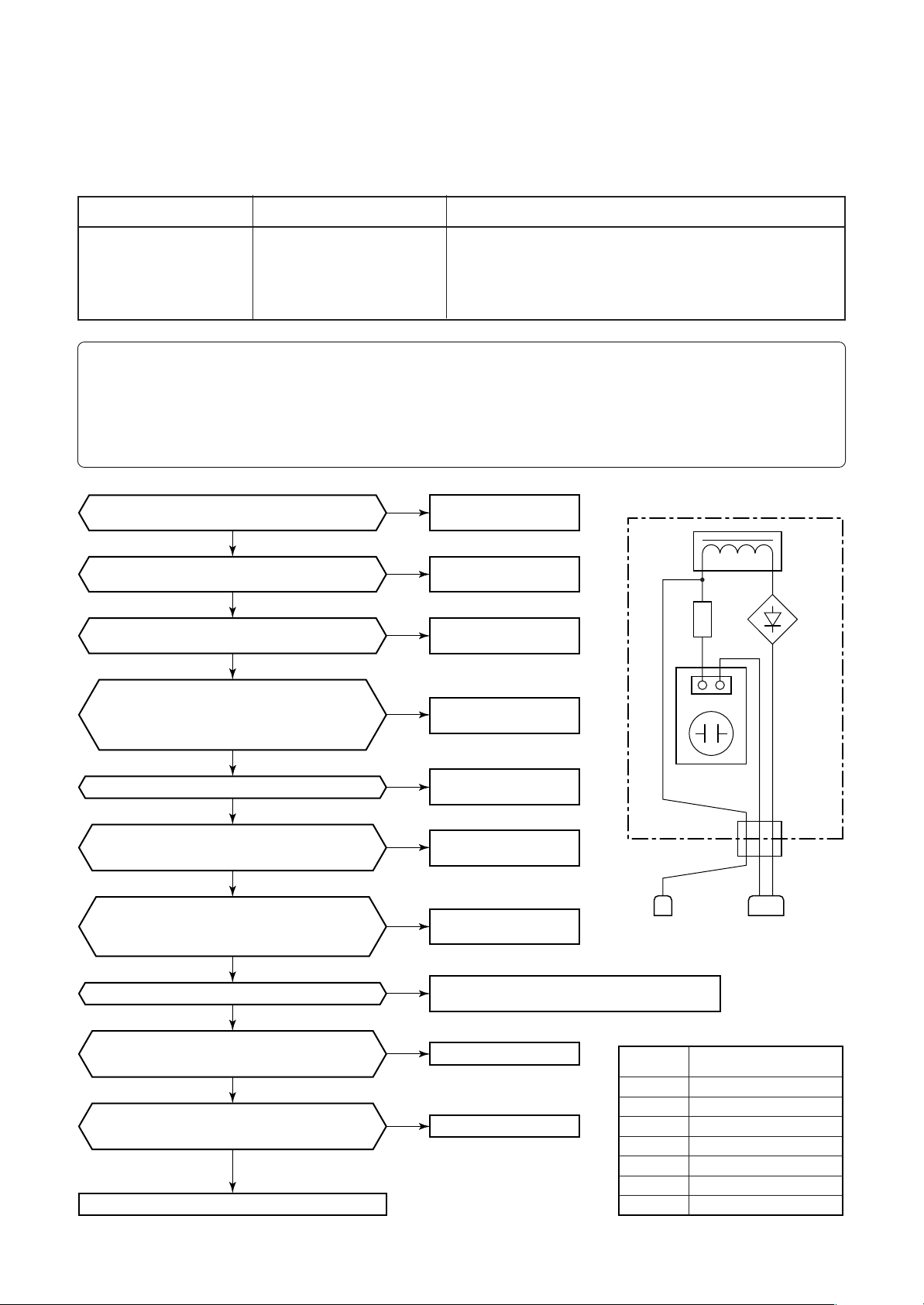

3. TROUBLESHOOTING (Passive Filter Circuit)

n Diagnosis procedure for each check code

<SMMS Series (A03-009, A04-008) >

Check code name

[L29] / [CF]

(d07 / AI-NET)

Check code name

IPDU quantity error

Cause of operation

1. Incorrect model setup in service for I/F P.C. board

2. Communication error between IPDU, fan IPDU and I/F

3. IPDU, fan IPDU, I/F P.C. board error

4. Passive filter error

Sub-code:

01: IPDU1 error 02:IPDU2 error

03: IPDU1, 2 error 04:Fan IPDU error

05: IPDU1, fan IPDU error 06:IPDU2, fan IPDU error

07: All IPDU error, Disconnection of communication line between IPDU-I/F P.C. board,

“I/F control P.C. board” error, “Power supply P.C. boad for FAN” error, “Passive filter” error

Is jumper setup of outdoor I/F P.C. board correct?

Is communication connector between IPDU

Is there no disconnection of communication line

Power supply P.C. board for FAN MCC-1439

The connector No. CN501, CN502, CN503,

Is the passive filter relay connector connected?

Power supply P.C. board for FAN normal?

Power supply P.C. board for FAN normal?

4 and 5 pins of CN600 on I/F P.C. board.

(Measurement by tester: DC0 to 5V, 5 pin GND)

3 and 5 pins of CN600 on I/F P.C. board.

(Measurement by tester: DC0 to 5V, 5 pin GND)

(Jumpers 7, 8, 9 ON)

YES

and I/F P.C. board connected?

YES

between IPDU and I/F P.C. board?

NO

Is the connector of the power supply

P.C. board connected certainly?

CN505, CN506, CN507?

YES

YES

Is the electric fuse of a

F500 10A 250V~

YES

Is the output voltage of a

CN502 or CN500 DC 330V

(Judgment : DC180-370V)

YES

Is a passive filter normal?

YES

Is there voltage fluctuation between

YES

Is there voltage fluctuation between

Both IPDU (No.1, No.2) and fan IPDU

YES

did not return the communication.

Replace IPDU P.C. board with trouble.

NO

NO

YES

NO

NO

NO

NO

NO

NO

NO

Correct connection

of connector.

Correct connection

of connector.

Replace

communication line.

Correct connection

of connector.

Correct connection

of connector.

Replace

the electric fuse.

RED BLUE YELLOW

Power supply

P.C. board error.

Check the short circuit of each part, and opening.

And correct the fault parts.

I/F P.C. board error

IPDU P.C. board error

Connector

(YELLOW)

Auxiliary

code

Passive filter box

Reactor

RED WHITE

Resistor

YELLOW

CN01

Electrolytic

capacitor board

01

02

03

04

05

06

07

IPDU 1

IPDU 2

IPDU 1, 2

Fan IPDU

IPDU 1, fan IPDU

IPDU 2, fan IPDU

IPDU 1, 2, fan IPDU, I/F

~

Diode

+

rectifier

Relay connector

(WHITE)

P.C. board

to be replaced

7

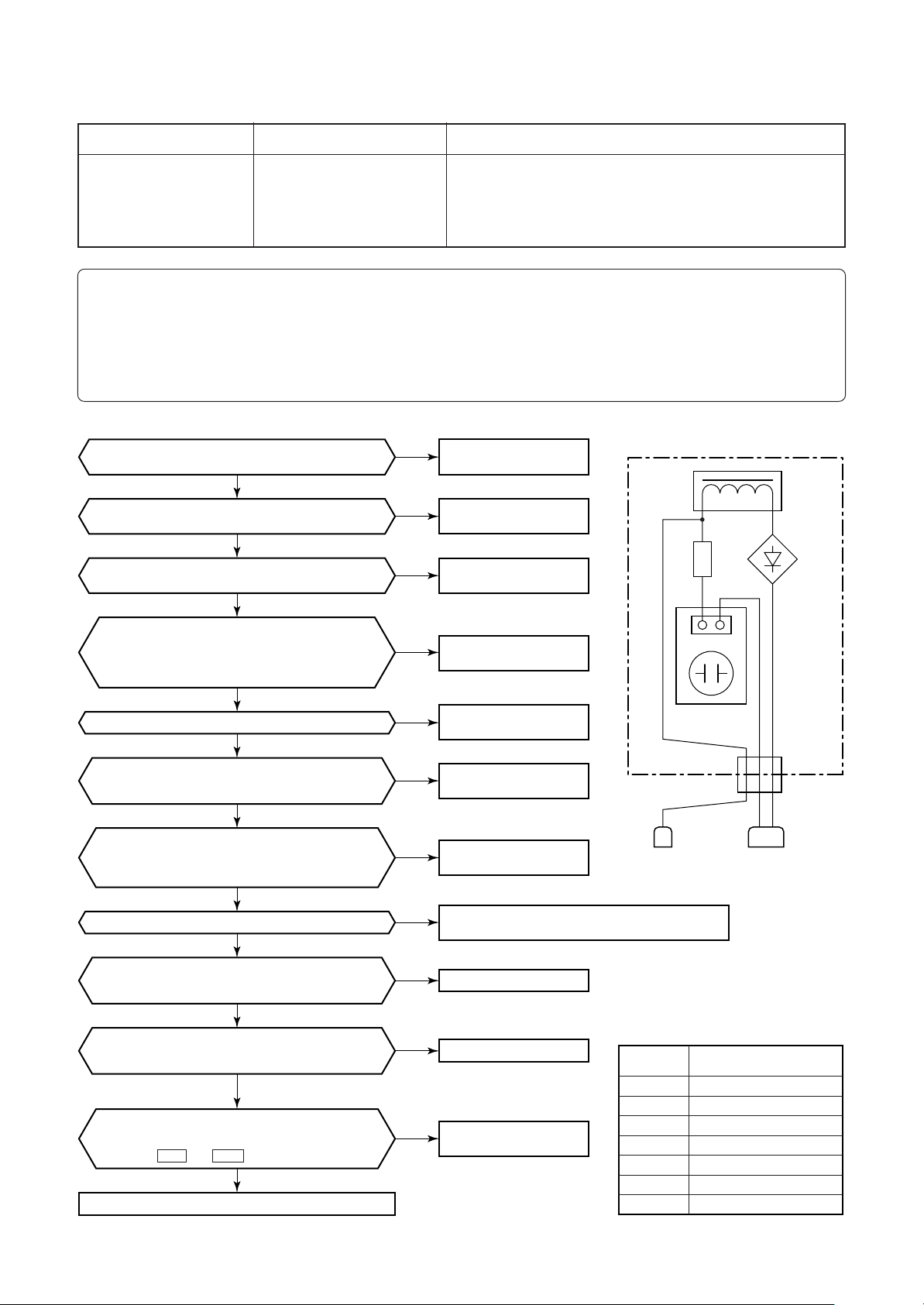

<SHRM Series (A05-004-1) >

Check code name

[L29] / [CF]

(d07 / AI-NET)

Check code name

IPDU quantity error

Cause of operation

1. Incorrect model setup in service for I/F P.C. board

2. Communication error between IPDU, fan IPDU and I/F

3. IPDU, fan IPDU, I/F P.C. board error

4. Passive filter error

Sub-code:

01: IPDU1 error 02:IPDU2 error

03: IPDU1, 2 error 04:Fan IPDU error

05: IPDU1, fan IPDU error 06:IPDU2, fan IPDU error

07: All IPDU error, Disconnection of communication line between IPDU-I/F P.C. board,

“I/F control P.C. board” error, “Power supply P.C. boad for FAN” error, “Passive filter” error

Is jumper setup of outdoor I/F P.C. board correct?

Is communication connector between IPDU

Is there no disconnection of communication line

“Power supply P.C. board for FAN MCC-1439”

The connector No. CN501, CN502, CN503,

Is the passive filter relay connector connected?

“Power supply P.C. board for FAN” normal?

“Power supply P.C. board for FAN” normal?

4 and 5 pins of CN600 on I/F P.C. board.

(Measurement by tester: DC0 to 5V, 5 pin GND)

3 and 5 pins of CN600 on I/F P.C. board.

(Measurement by tester: DC0 to 5V, 5 pin GND)

1) CN503: Between 1 and 5 pins → 12V

2) CN503: Between 2 and 5 pins → 7V

Between +5V and GND at the side of CN505: 5V

3)

Replace IPDU P.C. board with trouble.

(Jumpers 7, 8, 9 ON)

YES

and I/F P.C. board connected?

YES

between IPDU and I/F P.C. board?

NO

Is the connector of the power supply

P.C. board connected certainly?

CN505, CN506, CN507?

YES

YES

Is the electric fuse of a

F500 10A 250V~

YES

Is the output voltage of a

CN502 or CN500 DC 330V

(Judgment : DC180-370V)

YES

Is a passive filter normal?

YES

Is there voltage fluctuation between

YES

Is there voltage fluctuation between

Both IPDU (No.1, No.2) and fan IPDU

YES

did not return the communication.

On the fan power supply P.C. board,

YES

NO

NO

YES

NO

NO

NO

NO

NO

NO

NO

NO

Correct connection

of connector.

Correct connection

of connector.

Replace

communication line.

Correct connection

of connector.

Correct connection

of connector.

Replace

the electric fuse.

Power supply

P.C. board error.

Check the short circuit of each part, and opening.

And correct the fault parts.

I/F P.C. board error

IPDU P.C. board error

Replace fan power supply

on P.C. board.

RED BLUE YELLOW

Connector

(YELLOW)

Auxiliary

code

Passive filter box

Reactor

RED WHITE

Resistor

YELLOW

CN01

Electrolytic

capacitor board

01

02

03

04

05

06

07

IPDU 1

IPDU 2

IPDU 1, 2

Fan IPDU

IPDU 1, fan IPDU

IPDU 2, fan IPDU

IPDU 1, 2, fan IPDU, I/F

~

Diode

+

rectifier

Relay connector

(WHITE)

P.C. board

to be replaced

8

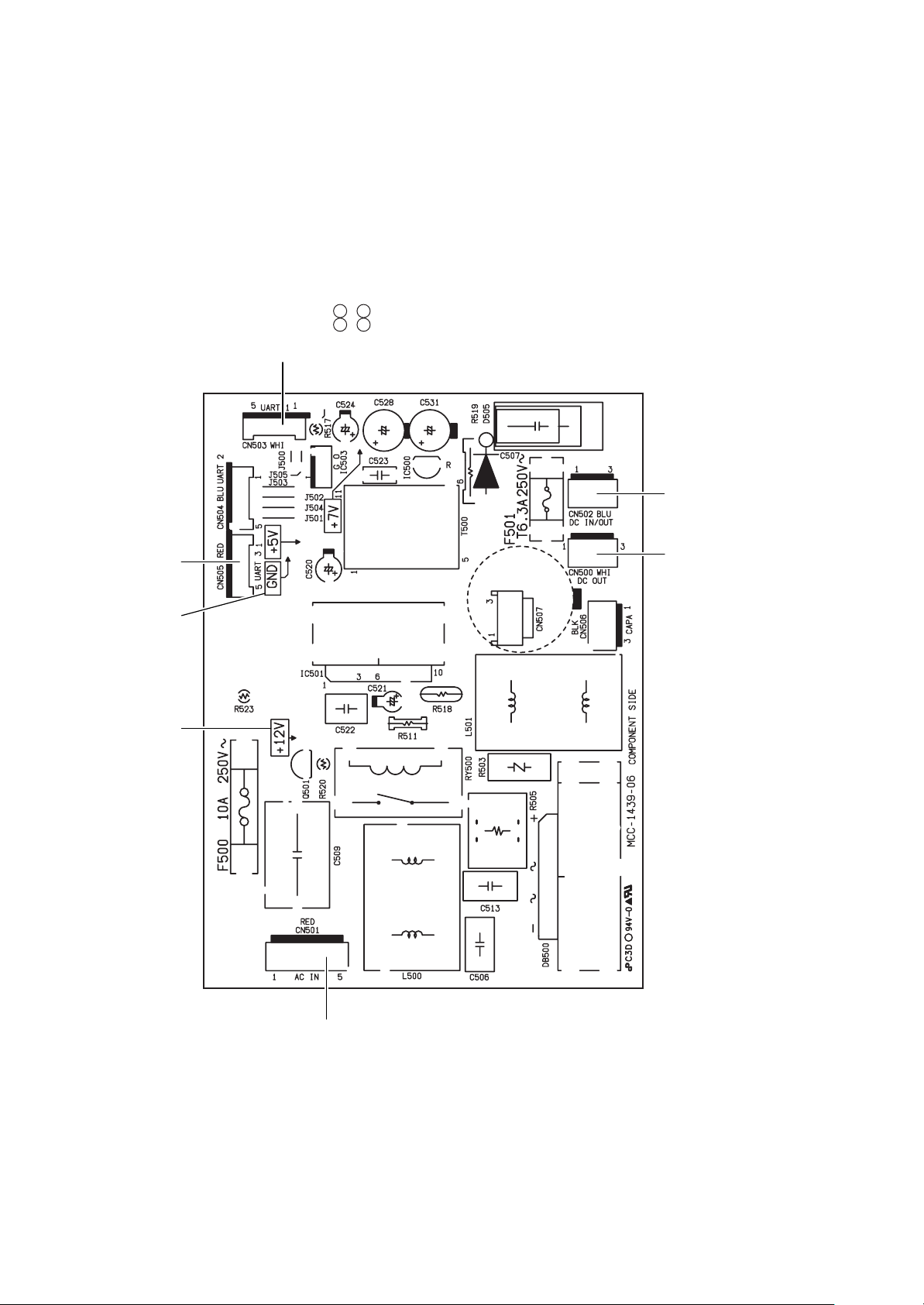

4. CONFIGURATION OF CONTROL CIRCUIT

4-1. Outdoor Unit

Power P.C. board for fan (MCC-1439)

Judgement

+12V terminal 1 – 5

( )

+7V terminal 2 – 5

Communication

between fan IPDU

DC330V output

(For Comp. IPDU)

Communication

betweenI/F and

fan IPDU

GND

+12V

CN500

DC330V output for fan IPDU

(Judgemant : DC 180–370V)

AC230V input

9

5. RUNNING CHANGE

5-1. Remote Controller Switch

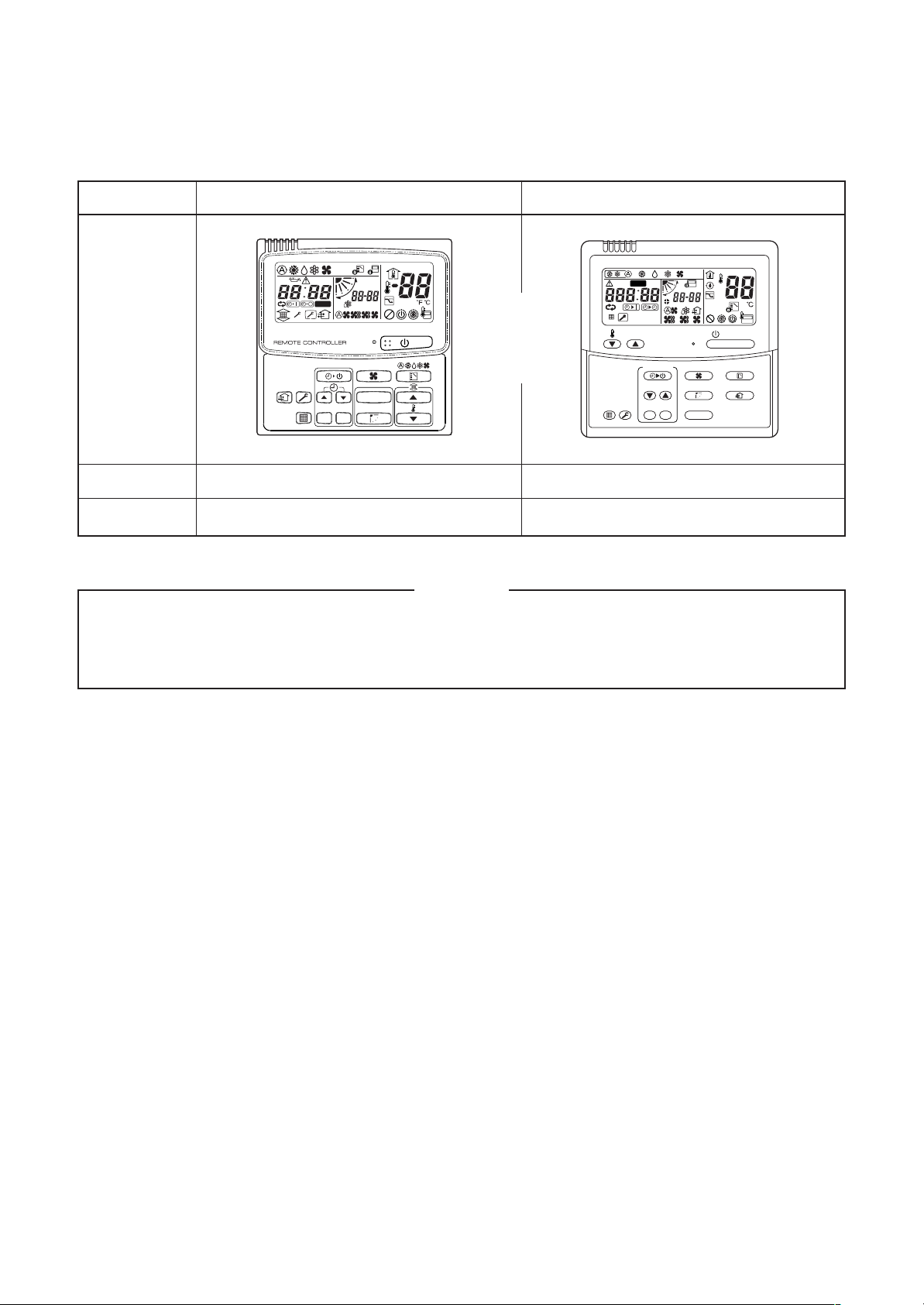

Name

Appearance

Model name

Wired remote controller

SET DATA

SETTING

SET

TEST

R.C. No.

CL

CODE No.

UNIT No.

UNIT

RBC-AMT21E

ð

Wired remote controller

CODE No.

ON / OFF

FAN

MODE

SWING/FIXTIME

VENT

UNITSET CL

FILTER

RESET

SET

DATA

H

TEMP.

TEST

SETTING

TEST

TIMER SET

UNIT No.

R.C. No.

RBC-AMT31E

Type

NOTE

The model name of the Wired remote controller is changed to RBC-AMT31E and some illustrations are

changed. The expression method is a little changed but functionally is not changed.

Explanation for detailed operation method, etc. are omitted.

10

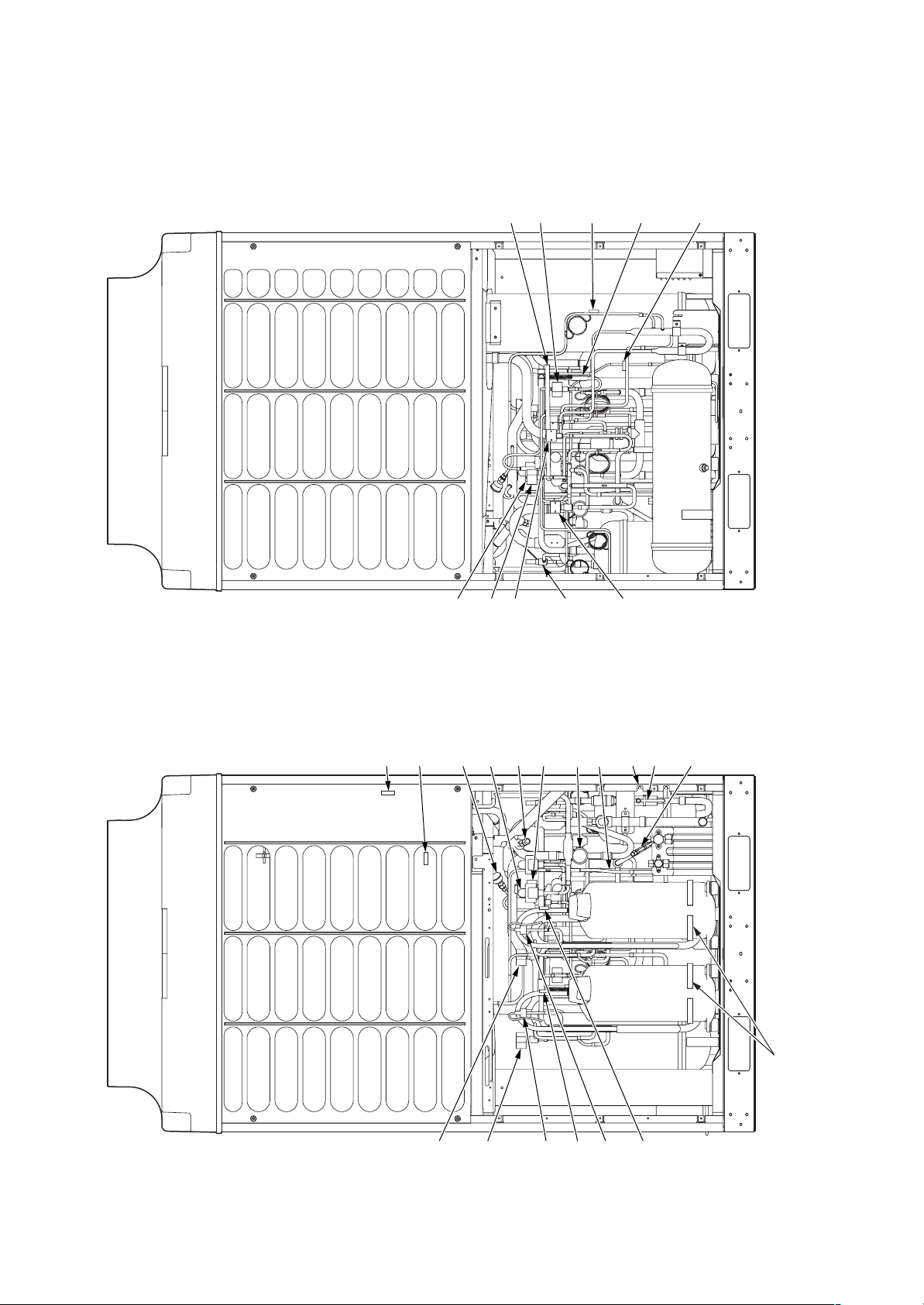

5-2. Parts Layout in Outdoor Unit

<SMMS Series (A03-009, A04-008) >

TK1, TK2

SV3E valve

SV3C valve

sensor

TK3 sensor

TK4 sensor

TE sensor

TO sensor

SV2 valve

SV3D valve

Low pressure

sensor

TS sensor

SV3A valve

Check joint

(Low pressure)

PMV

(Pulse Motor Valve)

SV5 valve

4-way valve

SV3B valve

TL sensor

High pressure

sensor

Check joint

(Liquid pipe)

Check joint

(High pressure)

Front side Rear side

Case heater

SW 1

SV42 valve

SV41 valve

High pressure

SW 2

TD1 sensor

High pressure

TD2 sensor

11

<SHRM Series (A05-004-1) >

SV3E valve

SV3C valve

SV2 valve

SV3A valve

SV3D valve

TK1, TK2 sensor

SV3B valve

TK3 sensor

TL sensor

TK4 sensor

TO sensor

Low pressure sensor

SV42 valve

Check joint

TS sensor

SV41 valve

(Low pressure)

SV5 valve

PMV

(Pulse Motor Valve)

SW 1

TD1 sensor

High pressure

4-way valve

Check joint

(High pressure)

SW 2

TD2 sensor

High pressure

Check joint

High pressure sensor

(Liquid pipe)

Front side Rear side

Case heater

12

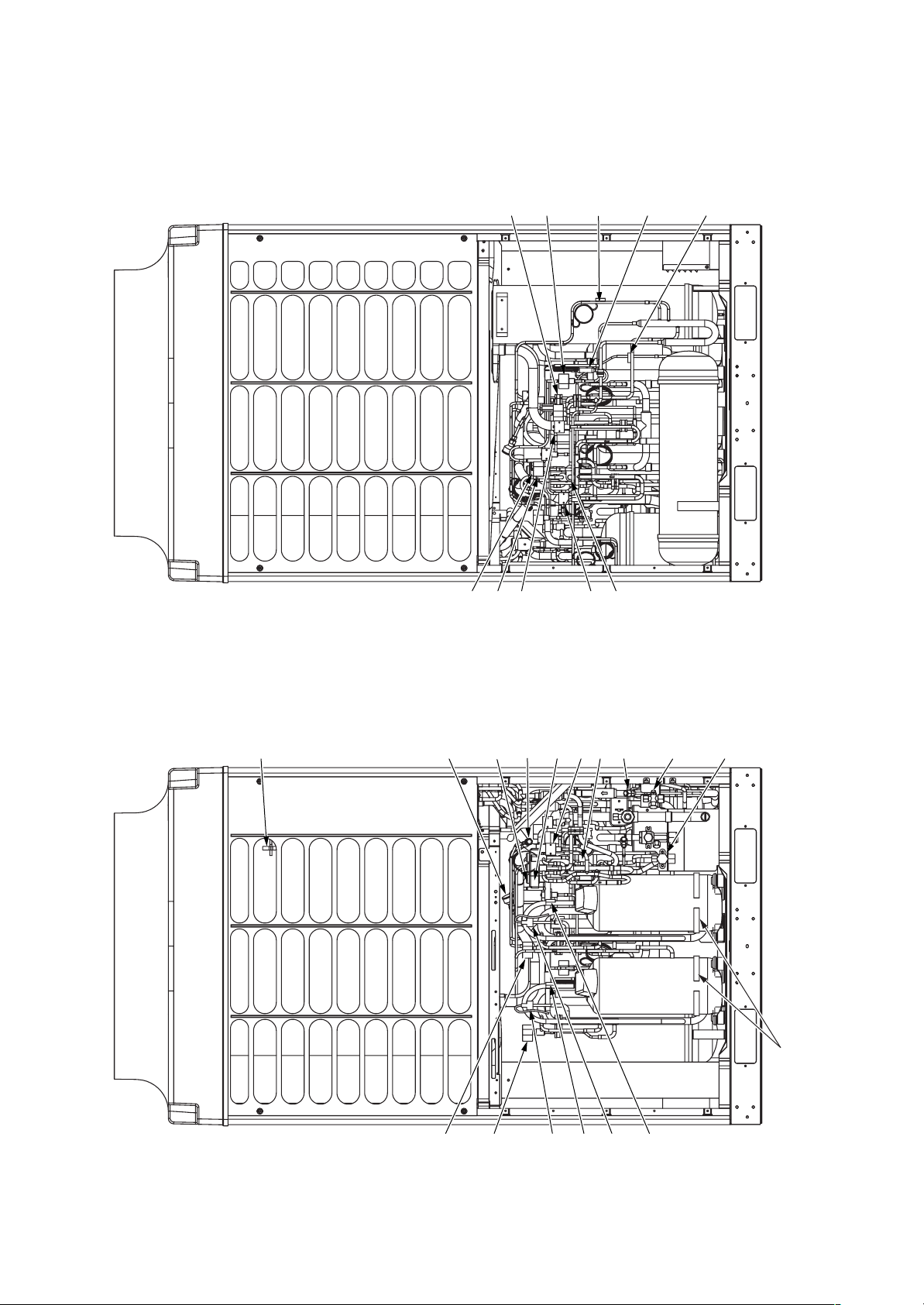

5-3. Refrigerant Piping Systematic Drawing

n Inverter unit (5, 6, 8, 10, 12HP)

Model: MMY-MAP0501HT8-E (T8-E), MMY-MAP0601HT8-E (T8-E), MMY-MAP0801HT8-E (T8-E),

MMY-MAP1001HT8-E (T8-E), MMY-MAP1201HT8-E (T8-E)

(PMV1)

Sensor

(PMV1)

(TL)

Liquid

tank

(8,10,12HP)

(PMV2)

Strainer

Pulse motor

valve (PMV)

(5,6HP)

Strainer

Sensor

(TE1)

Solenoid valve (SV5)

Capillary tube

Solenoid valve

(SV3D)

Capillary tube

Solenoid valve

(SV41)

Propeller fan

(Right side)

Air heat exchanger

at outdoor side

(Left side)

Air heat exchanger

at outdoor side

Check valve

High-pressure

sensor

Check joint

Strainer

Strainer

Check

valve

M

Fan motor

Oil

separator

4-Way valve

Solenoid valve

(SV2)

Capillary tube

Check

Solenoid valve

valve

Sensor

(TE1)

(SV42)

Sensor

(TO)

Sensor (TS1)

Low-pressure

sensor

Check joint

(Right side)

Air heat exchanger

at outdoor side

(Left side)

Air heat exchanger

at outdoor side

(8,10,12HP)

Check

joint

Balance pipe

servise valve

Liquid side

servise valve

StrainerStrainer

Gas side

servise valve

Strainer

High-pressure

switch

Sensor

(TD1)

Solenoid

valve

(SV3E)

Capillary tube

Capillary

tube

Sensor

(TK3)

Strainer

Check

(Inverter)

valve

Compressor 1

Capillary tube

Sensor

(TK1)

Sensor

(TK4)

Check

valve

Solenoid

valve

(SV3C)

Strainer

Check

valve

Capillary tube

Sensor

(TK2)

Oil tank

Solenoid

valve

(SV3A)

High-pressure

switch

Sensor

(TD2)

(Inverter)

Compressor 2

Capillary tube

Solenoid

valve

(SV3B)

Check

valve

Accumulator

Changed positions

As shown in the left, the oil

tank appearance of A03-009,

A04-008 are changed.

As there is especially no

problem in expression of the

refrigerating cycle diagram,

the diagram is not changed.

13

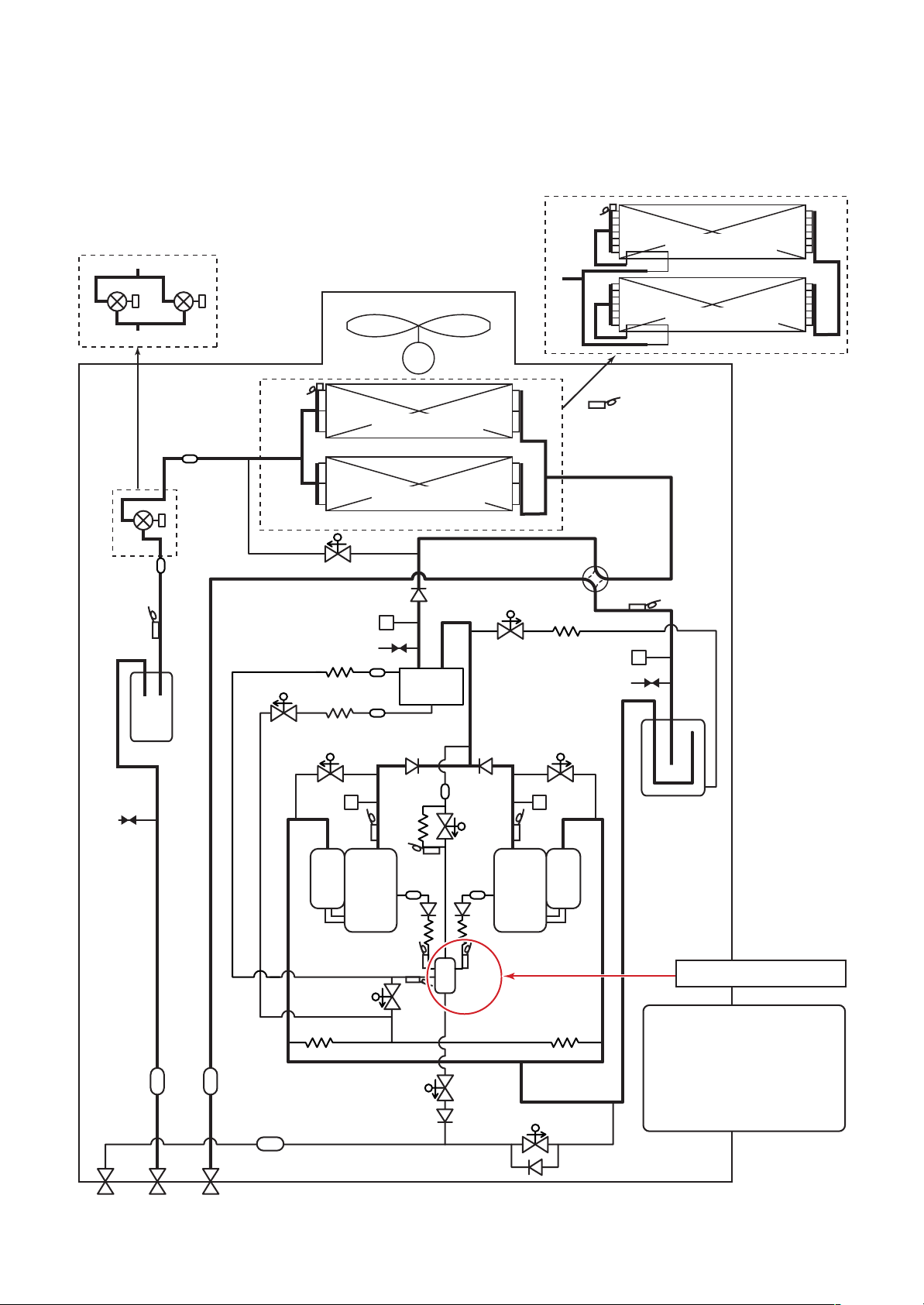

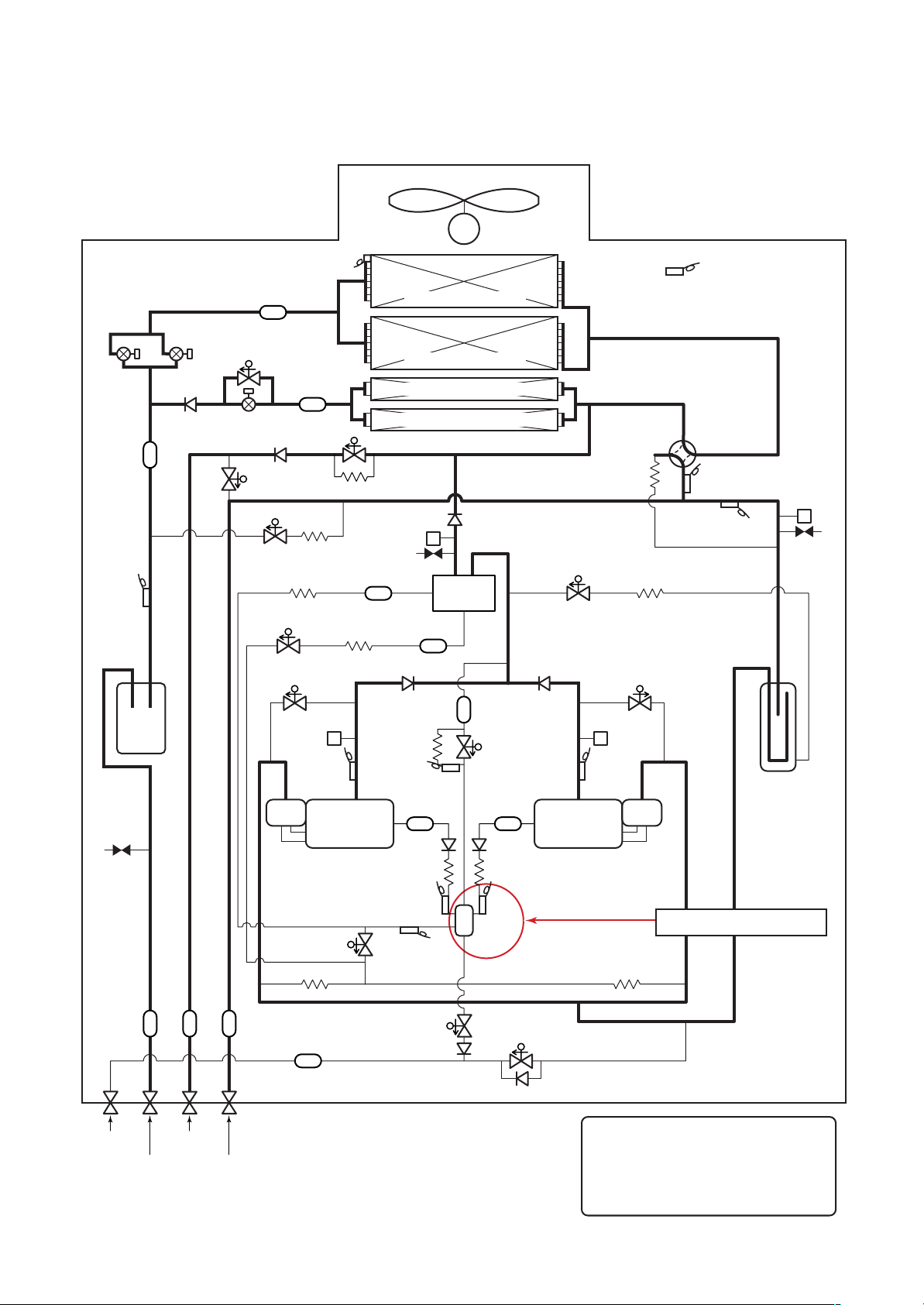

n Inverter unit (8, 10, 12HP)

Model: MMY-MAP0802FT8-E, MMY-MAP1002FT8-E, MMY-MAP1202FT8-E

Propeller fan

Fan motor

FM

Pulse motor valve

(PMV1) (PMV2)

Check valve

Strainer

Sensor

(TL)

Strainer

Solenoid valve

(SV12)

(PMV3)

Check valve

Solenoid valve

(SV5)

Solenoid valve

(SV6)

Capillary tube

Solenoid valve

(SV3D)

Solenoid valve

(SV41)

Sensor

(TE1)

Strainer

Capillary

tube

Capillary tube

(Right side)

Main heat exchanger

(Left side)

Main heat exchanger

Sub heat exchanger (Right side)

Sub heat exchanger (Left side)

Solenoid valve (SV11)

High-pressure

sensor

Check joint

Strainer

Strainer

Check valve Check valve

Check valve

Oil

separator

Capillary

Solenoid valve

(SV2)

Solenoid valve

Sensor

(TO)

4-Way valve

tube

Capillary tube

(SV42)

Sensor

(TS1)

Sensor

(TS2)

Low-pressure

sensor

Check

joint

Liquid

tank

Check

joint

Strainer Strainer

Service valve

of balance pipe

Service valve at

discharge gas side

Service valve

at liquid side

Service valve at

suction gas side

High-pressure

switch

Sensor

(TD1)

Compressor 1

(Inverter)

Solenoid valve

(SV3E)

Capillary tube Capillary tube

Strainer

Capillary

tube

Sensor

(TK3)

Strainer

Check

valve

Capillary tube

Sensor

(TK1)

Sensor (TK4)

Solenoid valve

(SV3A)

Check valve

Strainer

Solenoid valve

(SV3C)

Strainer

Check

valve

Capillary tube

Sensor

(TK2)

Oil tank

Solenoid valve

(SV3B)

Check valve

High-pressure

Sensor

(TD2)

Compressor 2

(Inverter)

switch

As shown in the left, the oil tank

appearance of A05-004-1 is changed.

As there is especially no problem in

expression of the refrigerating cycle

diagram, the diagram is not changed.

Accumulator

Changed positions

14

5-4. Refrigerant Recovery When Replacing the Compressor

n How to operate the system during repairing of the defective outdoor unit

MMY-MAP0501HT8(-E), MMY-MAP0601HT8(-E), MMY-MAP0801HT8(-E),

MMY-MAP1001HT8(-E), MMY-MAP1201HT8(-E)

<Work procedure>

1. Follow to the abovementioned “13-1. Refrigerant Recovery in the Troubled Outdoor Unit”.

2. Next, recover the refrigerant in the system by using a recovery device, etc.

The refrigerant amount to be recovered is determined based upon the capacity of the troubled outdoor unit.

(See the following table.)

Example) In a case of backup for 10HP-outdoor unit in 30HP system:

in the original system HP (30HP system) = 36.0kg

Refrigerant amount in system HP (20HP system) after backup = 27.0kg

Refrigerant amount to be recovered = 36.0 – 27.0 = 9kg

3. For the unit which refrigerant has been recovered, execute “Outdoor Unit Backup Setup” in another section.

All the work has finished.

System

HP

5

6

8

10

12

14

16

18

20

22

24

26

28

30

32

34

36

38

40

42

44

46

48

Combination of outdoor units

5

6

8

10

12

86

88

10 8

10 10

886

12 10

888

12 12

10 8 8

10 10 8

10 10 10

8888

12 10 10

10888

12 12 10

10 10 8 8

12 12 12

10 10 10 8

10 10 10 10

12 10 10 10

12 12 10 10

12 12 12 10

12 12 12 12

Refrigerant amount

(kg)

8.5

8.5

13.5

14.5

15.5

20.5

24.0

24.0

27.0

32.5

29.0

32.0

31.0

32.0

34.0

36.0

42.0

37.0

42.0

39.0

42.0

40.0

42.0

43.0

44.0

46.0

48.0

50.0

15

5-5. Replacing Method of Parts

<SMMS Series (A03-009, A04-008) >

No.

6

exchanged

Pressure

sensor

positions of

2-way valve coil

Part to be

Rear sideRear side

SV41

SV41

Work procedure

AccumulatorAccumulator

SV3C SV3A SV3D SV3B

SV3C SV3A SV3D SV3B

SV3E

SV3E

SV2

SV2

Compressor

Compressor

(1)

(1)

SV42

SV42

Compressor

Compressor

(2)

(2)

PS sensor

PS sensor

Remarks

Liquid tank

Liquid tank

Oil separator

Oil separator

SV5

SV5

7

Temperature

sensor

positions and

identification

Front sideFront side

Inverter assembly

Inverter assembly

<Front side of air conditioner>

TD1 sensor (Yellow) TD2 sensor (Red)

TD1 sensor (Yellow) TD2 sensor (Red)

PD sensor

PD sensor

TS1 sensor (Gray)

TS1 sensor (Gray)

Accumulator

Accumulator

TL sensor (White)

TL sensor (White)

Compressor (1) Compressor (2)

Compressor (1) Compressor (2)

16

No.

7

Part to be

exchanged

Temperature

sensor positions

and identification

Work procedure

<Rear side of air conditioner>

Rear side

Oil

separator

Liquid tank

TK sensor (White)

TK4 sensor

TK4 sensor

(Green)

(Green)

Accumulator

TK1 sensor (Black)

TK1 sensor (Black)

Accumulator side

Accumulator side

(Rear side)

(Rear side)

TK2 sensor (Blue)

TK2 sensor (Blue)

Front side

Front side

Remarks

8

Attachment/

detachment of

pipe fixing rubber

Front side

In this air conditioner, (segmentation system) eyeglass rubber

and SUS fix band are adopted for fixing the vibration system as

one measures to improve the reliability.

<Used positions of SUS fixing band: Total 5 positions>

MAP1201H, 1001H, 0801H: Ø8.0 ↔ Ø25.4

MAP1201H, 1001H, 0801H: Ø8.0 ↔ Ø25.4

MAP0601H, 0501H: Ø8.0 ↔ Ø19.05

MAP0601H, 0501H: Ø8.0 ↔ Ø19.05

between SE3E valve and suction pipe

between SE3E valve and suction pipe

Ø6.35 ↔ Ø15.88 between

Ø6.35 ↔ Ø15.88 between

SV3C valve and discharge pipe

SV3C valve and discharge pipe

Ø8.0 ↔ Ø19.05 between

Ø8.0 ↔ Ø19.05 between

SV42 valve and suction pipe

Ø8.0 ↔ Ø19.05 between

Ø8.0 ↔ Ø19.05 between

SV41 valve and suction pipe

SV41 valve and suction pipe

SV42 valve and suction pipe

17

Ø6.35 ↔ Ø15.88 between

Ø6.35 ↔ Ø15.88 between

SV2 valve and discharge pipe

SV2 valve and discharge pipe

<SHRM Series (A05-004-1) >

No.

6

exchanged

Pressure

sensor

positions of

2-way valve coil

Part to be

Rear sideRear side

SV41

SV41

Work procedure

Accumulator

Accumulator

SV3C SV3A SV3D SV3B

SV3C SV3A SV3D SV3B

SV3E

SV3E

SV2

SV2

Compressor

Compressor

(1)

(1)

SV42

SV42

Compressor

Compressor

(2)

(2)

PS sensor

PS sensor

Remarks

Liquid tank

Liquid tank

Oil separator

Oil separator

SV5

SV5

7

Temperature

sensor

positions and

identification

Front sideFront side

Inverter assembly

Inverter assembly

<Front side of air conditioner>

Front side

TD1 sensor(Yellow)

TS2 sensor

TD2 sensor(Red)

PD sensor

PD sensor

TS1 sensor(Grasy)

Accumulator

Compressor(1)

Compressor(2)

18

No.

7

exchanged

Temperature

sensor positions

and identification

Part to be

Work procedure

<Rear side of air conditioner>

Rear side

Liquid tank

TK3 sensor(White)

Remarks

TK1 sensor(Black)

Accumulator side (Front side)

Accumulator

8

Attachment/

detachment of

pipe fixing rubber

Oil separator

TK4 sensor (Green) TK2 sensor (Blue)

(Rear side)

This air conditioner has been designed so that vibration has been reduced to a minium by

incorporating in the lower section of the unit, the use of eyeglass rubber fixing brackets and

SUS bands. Both of which greatly help to reduce vibration and improve unit reliability.

Used positions of SUS fixing band:Total 5 positions

Ø6.35 ⇔ Ø15.88 between

SV3C valve and discharge pipe

Ø6.35 ⇔ Ø15.88 between

SV3E valve and suction

Ø6.35 ⇔ Ø15.88 between

SV3E valve and suction

Ø8.0 ⇔ Ø19.05 between

SV41 valve and suction pipe

19

Ø8.0 ⇔ Ø19.05 between

SV42 valve and suction pipe

5-6. P.C. Board Exchange Procedures (Outdoor Unit)

n How to Check Fan Power Supply P.C. Board and Fan IPDU

The fan power supply P.C. board supplies DC power. It supplies DC280V for the fan IPDU, and DC12V and

DC7V for the control power supply respectively. If the control power is not supplied, a communication error

(Error code [E31]) is out.

1. How to check fan power supply P.C. board (MCC-1439)

As shown in the following table, measure the voltage of the check positions with a digital tester.

No.

1

2

3

Check item

DC280V output

Control power voltage

Check position

Between CN500 and

Between CN500 and

Between CN500 and

Criteria

DC260 to DC340V

DC12V

DC7V

2. How to check fan IPDU

1. Check that the lead wires are correctly inserted into 250 fasten terminal of DC280V input and into the

communication connector (CN01).

2. After then replace the fan IPDU if an abnormality is recognized.

<MCC-1439 Front View>

CN503

CN500

20

6. DETACHMENTS (Passive Filter Circuit)

No.

10

Part name

Passive filter

Work procedure

CAUTION

Wear protective clothing on your hands as

other components may cause injury etc.

WARNING

Never open the cabinet while 5 minutes after

turn off the power supply.

<Disassembling>

1) Stop unit operation and turn off power suplly to

unit.

2) Remove Front panel. (Screw M5 × 10 , 7pcs)

3) Remove cover of the electric parts box.

(Screw M4 × 10 , 2 pcs)

4) Open connector(CN507,yellow) of “Power

supply P.C. board for FAN”, and open relay

connector (white). <Fig.1>

5) Pssive filter wiring is fixed at 3 places.

Remove the fixation shown in the “Fig.2”.

(Binding band, 2 pcs. Wire clamp, 1pc) <Fig.2>

Remarks

<Fig.1>

CN507 of

“Power supply P.C. board for FAN”

Relay connector Passive filter wiring

<Fig.2>

Binding band (B)

6) Remove screws fixing the electric parts box.

(1 pc. each at upper and lower sides.)

7) Push down lightly the fixing claw at lower side

to take off the claw.

(Lower part of the box is out forward.) <Fig.3>

8) Take off hooking claw at upper side while

holding the ceiling board with both hands.

<Fig.4>

Binding band (A) Wire clamp

<Fig.3>

M5 screws

(2 positions)

Claw for

temporary

hooking

<Fig.4>

Hooks

21

No.

10

Part name

Passive filter

(Continued)

Work procedure

9) Remove rear panel. (Screw M5 × 10 , 7pcs)

10) Remove the screw which is fixing the passive

filter box. (Screw M4 × 10 , 2 pcs) <Fig.6>

11) Take out the passive filter box outside. <Fig.7>

12) Remove The lid of the passive filter box.

(Screw M4 × 10 , 4pcs) <Fig.8>

<Fig.7> <Fig.8>

Remarks

<Fig.6>

13) Check the short circuit of each part, and

opening. And correct the fault parts.

<Fig.9> <Fig.10>

Passive filter box

Reactor

RED WHITE

Resistor

CN01

Electrolytic

capacitor board

YELLOW

~

Diode

+

rectifier

RED BLUE YELLOW

Connector

(YELLOW)

Relay connector

(WHITE)

22

No.

10

Part name

Passive filter

(Continued)

Work procedure

<Assembly>

Assembling by contrary procedure of above

10) → 12).

Is connector of the power supply P.C. board for

fan connected?

Connector No.: CN501, CN502, CN503,

CN505, CN506, CN507

Power supply P.C. board A’SSY for Fan:

MCC-1439

Is the passive filter connector connected?

<Fig. 9> (DC260 to DC340V)

Notice

When a box fixed, it hooks on the hook of

base. <Fig.11>

<Fig.11>

Hooks

Remarks

Box

Base

23

7. EXPLODED VIEWS AND PARTS LIST

7-1. Outdoor Unit

MMY-MAP0501HT8-E (5HP), MMY-MAP0601HT8-E (6HP), MMY-MAP0801HT8-E (8HP),

MMY-MAP1001HT8-E (10HP), MMY-MAP1201HT8-E (12HP)

17

16

92

64 (8, 10, 12,HP)

or

66 (5, 6HP)

95

26

52

73

74

25

65 (8, 10, 12HP)

or

67 (5, 6HP)

93

97

49

94

96

31, 36

(5, 6HP)

or

31, 34

(8, 10, 12HP)

32

27

4 (8, 10, 12HP)

5 (5, 6HP)

91

40, 41

44

46

30

or

44

24

39

50

69

30

81

8

80

7

724

SV3A

SV3B

29

1

29

43

722

723

721

Location

No.

1 43146737 Valve, Checked, YCV5P-33GME-1

4 43041781 Compressor, DA421A3FB-23M

5 43041782 Compressor, DA351A3FB-23M

7 43046442 Valve, Packed, 9.52 DIA

8 43146680 Valve, Packed, 12.7

16 43100265 Cabinet, Up

17 43119466 Guard, Fan

25 43120219 Fan, Propeller, DIA 710, ASG

26 4312C004 Motor, Fan, DC280V, MF-230-600-1R

27 43146715 Valve, Checked, BCV-804DY

29 43146736 Valve, Checked, YCV3-22GME-1

30 43146676 Joint, Check

31 43146722 Coil, Solenoid, STF-01AJ502E1

32 43146727 Valve, Gas, DIA 25

34 43146698 Valve, 4-Way, STF-0731G

36 43146687 Valve, 4-Way, STF-0401G

39 43146734 Valve, Check, ZGV-S55B-A

40 43146709 Valve, PMV, HAM-BD24TF-1

41 43146708 Coil, PMV, HAM-MD12TF-3

43 4314Q060 Strainer, DIA 12.7, C1220T-H

44 4314Q056 Strainer, DIA 25.4, C1220T-H

46 4314Q052 Strainer, DIA 45, C1220T-H

49 43148202 Tank, Liquid

50 43148192 Separator

63 43149325 Band, Fix, SUS304

64 4314G264 Condenser Assembly, Three Row

65 4314G265 Condenser Assembly, Three Row

66 4314G249 Condenser Assembly, One Row

67 4314G250 Condenser Assembly, One Row

69 43157276 Heater, Case, 29W, AC240V

73 43197175 Nut, Flange, M10, SWCH12R

74 43197176 Washer, SPHC

80 4314Q055 Strainer, DIA 19.05, C1220T-H

81 4314Q057 Strainer, DIA 25.4, C1220T-H

91 43100396 Panel, CGCD2-Z08-C77

92 43100406 Cabinet Assembly, Front, Up

93 43100407 Cabinet Assembly, Back, Up

94 43100408 Cabinet Assembly, Side, Right

95 43100409 Cabinet Assembly, Side, Left

96 43100410 Cabinet Assembly, Front, Down

97 43100411 Cabinet Assembly, Back, Down

721 43031110 Diode, 25A, 600V, *GBPC-2506

722 43155214 Resistor, 1Ω, 20W

723 43158207 Reactor, CH-68

724 4316V362 P.C. Board Assembly, Passive, MCC-1580

Part No. Description

Model Name MMY- MAP

1201HT8-E 1001HT8-E 0801HT8-E 0601HT8-E 0501HT8-E

11111

222

22

11122

111

11111

11111

11111

11111

22222

33333

33333

11111

111

111

11

11111

22211

22211

22222

222

111

11111

11111

44444

111

111

11

11

33333

11111

11111

11111

111

11111

11111

11111

11111

11111

11111

11111

11111

11111

11111

11111

25

MMY-MAP0501HT8-E (5HP), MMY-MAP0601HT8-E (6HP), MMY-MAP0801HT8-E (8HP),

MMY-MAP1001HT8-E (10HP), MMY-MAP1201HT8-E (12HP)

52

56, 58, 63

28, 37

(SV4)

28, 33 (SV3C)

28, 33 (SV3E)

12

28, 33 (SV3A)

28, 33 (SV2)

55, 58, 63

28, 33 (SV3D)

28, 38 (SV3B)

61

49

50

57, 59, 63

54

53

68

4 (8, 10, 12HP)

or

5 (5, 6HP)

62, 72

13, 14

26

40, 41

31, 36 (5, 6HP)

31, 34

or

28, 37

30

30

32 or 35 (5, 6HP)

Location

No.

4 43041781 Compressor, DA421A3FB-23M

5 43041782 Compressor, DA351A3FB-23M

12 43049683 Band, DIA 8, EPDM

13 43050407 Thermostat, Bimetal

14 43063317 Holder, Thermostat

28 43146660

30 43146676 Joint, Check

31 43146722 Coil, Solenoid, STF-01AJ502E1

32 43146727 Valve, Gas, DIA 25

33 43146711 Valve, 2-Way, VPV-122DQ1

34 43146698 Valve, 4-Way, STF-0731G

35 43146699 Valve, Ball, B5/8F, Rohs

36 43146687 Valve, 4-Way, STF-0401G

37 43146712 Valve, 2-Way, VPV-303DQ1

38 43146730 Valve, 2-Way, VPV-603DQ2

40 43146709 Valve, PMV, HAM-BD24TF-1

41 43146708 Coil, PMV, HAM-MD12TF-3

49 43148202 Tank, Liquid

50 43148192 Separator

52 43148200 Accumulator, 20L

53 43149377 Sensor Assembly, Low Pressure, 150XA4-L1

54 43149378 Sensor Assembly, High Pressure, 150XA4-H3

55 43149317 Rubber, Supporter, Pipe, DIA 25.4

56 43149318 Rubber, Supporter, Pipe, DIA 19.0

57 43149319 Rubber, Supporter, Pipe, DIA 15.9

58 43149320 Rubber, Supporter, Pipe, DIA 8.0

59 43149321 Rubber, Supporter, Pipe, DIA 6.4

61 43149323 Rubber, Supporter, Pipe, DIA 9.52–12.7

62 43149324 Rubber, Cushion, EPDM

63 43149325 Band, Fix, SUS304

68 43151283 Switch, Pressure, ACB-4UB32W

72 43197184 Bolt, Compressor, M6, SWCH18A

Part No. Description

Coil, Solenoid, AC220–240V, 50Hz,

VPV-MOAJ510B0

Model Name MMY- MAP

1201HT8-E 1001HT8-E 0801HT8-E 0601HT8-E 0501HT8-E

222

22

22222

22222

22222

99999

33333

11111

111

55555

111

11

11

33333

11111

22211

22211

11111

11111

11111

11111

11111

111

22233

11111

33333

11111

22222

66666

44444

22222

66666

27

Refrigeration Circuit Diagram

MMY-MAP0501HT8-E (5HP), MMY-MAP0601HT8-E (6HP), MMY-MAP0801HT8-E (8HP),

MMY-MAP1001HT8-E (10HP), MMY-MAP1201HT8-E (12HP)

29

27

27

or

Valve

Checked

4 (8, 10, 12HP)

High

Pressure

68

or

Valve Checked

4 (8, 10, 12HP)

High

Pressure

TD

5 (5, 6 HP)

Switch

SV42

37

TD

5 (5, 6 HP)

Switch

43

Com-

pressor

Com-

pressor

Strainer

29

Strainer

Valve

Checked

ID 1.2

× 1000 L

77

ID 1.2 × 1000 L

Valve Checked

43

77

ID 2.0 × 1000 L

10

ID 2.0

× 1000 L

10

79

33

50

or

66 (5, 6 HP)

64 (8, 10, 12HP)

TO

Condenser

or

45 (5, 6 HP)

44 (8, 10, 12HP)

68

37

SV2

Separator Oil

High Pressure

Left Side

Strainer

Strainer

79

79

Sensor

54

Strainer

Right Side

Condenser

TE

65 (8, 10, 12HP)

Pulse Motor Valve

SV41

75

ID 0.8

× 1000 L

33

SV3C

ID 1.0

× 1000 L

76

Strainer Strainer

Joint Check

30

SV5

37

or

67 (5, 6 HP)

(5, 6 HP: 1 Valve)

ID 1.0

39

Valve 4-Way

Joint Check

40

81 (8, 10, 12HP)

or

7 (5, 6 HP)

8 (8, 10, 12HP)

× 500 L

76

SV3D

Valve Checked

or

36 (5, 6 HP)

34 (8, 10, 12HP)

TS

Low Pressure

Sensor

53

30

Strainer

TL

Strainer

or

Joint

82 (5, 6 HP)

Valve Packed

Liquid Line

SV3E

33

33

Accumulator

or

49

45 (5, 6 HP)

44 (8, 10, 12HP)

Plug Fusible

FP

Tank Liquid

30

48

7

Oil Balance

Line

Check

37

1

Valve Checked

SV3B

38

52

or

46 (8, 10, 12HP)

Strainer

or

82 (5, 6 HP)

80 (8, 10, 12HP)

or

Valve Packed

35 (5, 6 HP)

32 (8, 10, 12HP)

29

SV3A

Valve Checked

47 (5, 6 HP)

Strainer

Valve Service

(5, 6 HP: Valve Ball)

Gus Line

28

Location

No.

1 43146737 Valve, Checked, YCV5P-33GME-1

4 43041781 Compressor, DA421A3FB-23M

5 43041782 Compressor, DA351A3FB-23M

7 43046442 Valve, Packed, 9.52 DIA

8 43146680 Valve, Packed, 12.7

10 43047527 Tube, Capillary, ID 2.0 × 2000L

27 43146715 Valve, Checked, BCV-804DY

29 43146736 Valve, Checked, YCV3-22GME-1

30 43146676 Joint, Check

32 43146727 Valve, Gas, DIA 25

33 43146711 Valve, 2-Way, VPV-122DQ1

34 43146698 Valve, 4-Way, STF-0731G

35 43146699 Valve, Ball, B5/8F, Rohs

36 43146687 Valve, 4-Way, STF-0401G

37 43146712 Valve, 2-Way, VPV-303DQ1

38 43146730 Valve, 2-Way, VPV-603DQ2

39 43146734 Valve, Checked, ZGV-S55B-A

40 43146709 Valve, PMV, HAM-BD24TF-1

43 4314Q060 Strainer, DIA 12.7, C1220T-H

44 4314Q056 Strainer, DIA 25.4, C1220T-H

45 4314Q058 Strainer, DIA 25.4

46 4314Q052 Strainer, DIA 45, C1220T-H

47 4314Q053 Strainer, DIA 21, C1220T-H

48 43148220 Plug, Fusible, 73 C

49 43148202 Tank, Liquid

50 43148192 Separator

52 43148200 Accumulator, 20L

53 43149377 Sensor Assembly, Low Pressure, 150XA4-L1

54 43149378 Sensor Assembly, High Pressure, 150XA4-H3

64 4314G264 Condenser Assembly, Three Row

65 4314G265 Condenser Assembly, Three Row

66 4314G249 Condenser Assembly, One Row

67 4314G250 Condenser Assembly, One Row

68 43151283 Switch, Pressure, ACB-4UB32W

75 44246235 Tube, Capillary, Bypass, 0.8 DIA

76 44246236 Tube, Capillary, Bypass, 1.0 DIA

77 44246239 Tube, Capillary, 1.2 DIA

79 4314Q054 Strainer, DIA 12.7, C1220T-H

80 4314Q055 Strainer, DIA 19.05, C1220T-H

81 4314Q057 Strainer, DIA 25.4, C1220T-H

82 4314Q059 Strainer, DIA 25.4

Part No. Description

Model Name MMY- MAP

1201HT8-E 1001HT8-E 0801HT8-E 0601HT8-E 0501HT8-E

11111

222

22

11122

111

11111

22222

33333

33333

111

55555

111

11

11

33333

11111

11111

22211

22222

222

22

111

11

11111

11111

11111

11111

11111

11111

111

111

11

11

22222

11111

11111

11111

33333

11111

111

11

29

MMY-MAP0501HT8-E (5HP), MMY-MAP0601HT8-E (6HP), MMY-MAP0801HT8-E (8HP),

MMY-MAP1001HT8-E (10HP), MMY-MAP1201HT8-E (12HP)

706

705

704

716

711

715

707

720

713

708 719 717 709

703

701

712

702

710

Location

No.

701 43050382 Sensor, TC (F6)

702 43063248 Supporter Assembly

703 43150315 Sensor, TD (F6)

704 43155176 Capacitor, 400V DC, 1500µF

705 43158186 Transformer, TT-01-03

706 43158183 Reactor, CH-44

707 43160559 Terminal Block, 4P, AC600V, 30A

708 43160548 Terminal, 6P, AC30V, 1A

709 43163017 Supporter

710 43163048 Supporter Assembly

711 4316V366

712 4316V263 P.C. Board Assembly, Interface, MCC-1429

713 4316V237

714 4316V245 P.C. Board Assembly, A3-IPDU, MCC-1502

715 4316V360 P.C. Board Assembly, Power, MCC-1439

716 43155194 Capacitor, 400V DC, 1000µF

717 43152506 Electro Magnetic Switch, FW-2S

719 43153006 PTC-Thermistor, ZPROYCE101A500

720 43155197 Resistor, 56kΩ, 15W

Part No. Description

P.C. Board Assembly, Noise-Filter,

MCC-1366

P.C. Board Assembly, Fan-IPDU,

IPDU-2D16DA1

714

Model Name MMY- MAP

1201HT8-E 1001HT8-E 0801HT8-E 0601HT8-E 0501HT8-E

44444

33333

66666

22222

11111

22222

11111

11111

22222

11111

11111

11111

11111

22222

11111

11111

11111

22222

22222

30

7-2. Outdoor Unit

MMY-MAP0501T8-E (5HP), MMY-MAP0601T8-E (6HP), MMY-MAP0801T8-E (8HP),

MMY-MAP1001T8-E (10HP), MMY-MAP1201T8-E (12HP)

17

16

92

64 (8, 10, 12,HP)

or

66 (5, 6HP)

95

26

52

73

74

25

65 (8, 10, 12HP)

or

67 (5, 6HP)

93

97

49

94

96

32

27

30

46

4 (8, 10, 12HP)

or

5 (5, 6HP)

91

40, 41

44

44

39

50

69

SV3A

30

81

8

80

7

724

SV3B

29

1

29

43

722

723

721

31

Location

No.

1 43146737 Valve, Checked, YCV5P-33GME-1

4 43041781 Compressor, DA421A3FB-23M

5 43041782 Compressor, DA351A3FB-23M

7 43046442 Valve, Packed, 9.52 DIA

8 43146680 Valve, Packed, 12.7

16 43100265 Cabinet, Up

17 43119466 Guard, Fan

25 43120219 Fan, Propeller, DIA 710, ASG

26 4312C004 Motor, Fan, DC280V, MF-230-600-1R

27 43146715 Valve, Checked, BCV-804DY

29 43146736 Valve, Checked, YCV3-22GME-1

30 43146676 Joint, Check

32 43146727 Valve, Gas, DIA 25

39 43146734 Valve, Check, ZGV-S55B-A

40 43146709 Valve, PMV, HAM-BD24TF-1

41 43146708 Coil, PMV, HAM-MD12TF-3

43 4314Q060 Strainer, DIA 12.7, C1220T-H

44 4314Q056 Strainer, DIA 25.4, C1220T-H

46 4314Q052 Strainer, DIA 45, C1220T-H

49 43148202 Tank, Liquid

50 43148192 Separator

63 43149325 Band, Fix, SUS304

64 4314G264 Condenser Assembly, Three Row

65 4314G265 Condenser Assembly, Three Row

66 4314G249 Condenser Assembly, One Row

67 4314G250 Condenser Assembly, One Row

69 43157276 Heater, Case, 29W, AC240V

73 43197175 Nut, Flange, M10, SWCH12R

74 43197176 Washer, SPHC

80 4314Q055 Strainer, DIA 19.05, C1220T-H

81 4314Q057 Strainer, DIA 25.4, C1220T-H

91 43100396 Panel, CGCD2-Z08-C77

92 43100406 Cabinet Assembly, Front, Up

93 43100407 Cabinet Assembly, Back, Up

94 43100408 Cabinet Assembly, Side, Left

95 43100409 Cabinet Assembly, Side, Right

96 43100410 Cabinet Assembly, Front, Down

97 43100411 Cabinet Assembly, Back, Down

721 43031110 Diode, 25A, 600V, *GBPC-2506

722 43155214 Resistor, 1Ω, 20W

723 43158207 Reactor, CH-68

724 4316V362 P.C. Board Assembly, Passive, MCC-1580

Part No. Description

Model Name MMY- MAP

1201T8-E 1001T8-E 0801T8-E 0601T8-E 0501T8-E

11111

222

22

11122

111

11111

11111

11111

11111

22222

33333

33333

111

11111

22211

22211

22222

222

111

11111

11111