Toshiba MM-U080, MM-TU028, MM-U112, MM-U140, MM-TU042 Installation Instructions Manual

...

Indoor

Installation Instructions

Air Conditioner – Multi Split Type System

Installationsanleitung

für Innenanlagen

Klimaanlage – Geteilte Multi-Bauweise

Instructions

d’Installation Intérieure

Climatiseur – Système de Type Multi Split

Inpandig

Installatievoorschrift

Airconditioning – Multi-delig Type Systeem

GB

F

D

E

I

NL

Istruzioni per

l’installazione dell’unità interna

Condizionatore d’aria – Tipo Multi Split

Modular Multi System

Instrucciones

de Instalación en Interiores

Aire Acondicionado – Sistema de Tipo Multi Split

HFCR407C

1401957701R01

~ 2 ~

GB

Please read these instructions carefully before starting the installation.

This equipment should only be installed by suitably trained operatives.

In all cases ensure safe working practice: Observe precautions for persons in the vicinity of the

works.

Ensure that all local, national and international regulations are satisfied.

Check that the electrical specifications of the unit meet the requirements of the site.

Carefully unpack the equipment, check for damage or shortages. Please report any damage

immediately.

These units comply with EC Directive:

73/23/EEC (Low Voltage Directive) and 89/336/EEC (Electro Magnetic Compatibility)

Accordingly, they are designated for use in commercial and industrial environments.

The Modular Multi Indoor Units can operate under the following conditions when part of a Modular Multi

System:

!

!

!

!

!

!

R407C outdoor units use synthetic oils which are extremely hygroscopic. Therefore ensure that

the refrigerant system is NEVER exposed to air or any form of moisture.

Mineral oils are unsuitable for use in these units and may lead to premature system failure.

Use only equipment which is suitable for use with R407C. Never use equipment which has

been used with R22.

R407C should only be charged from the service cylinder in the liquid phase. It is advisable to

use a gauge manifold set equipped with a liquid sight glass fitted in the centre (entry) port.

!

!

!

!

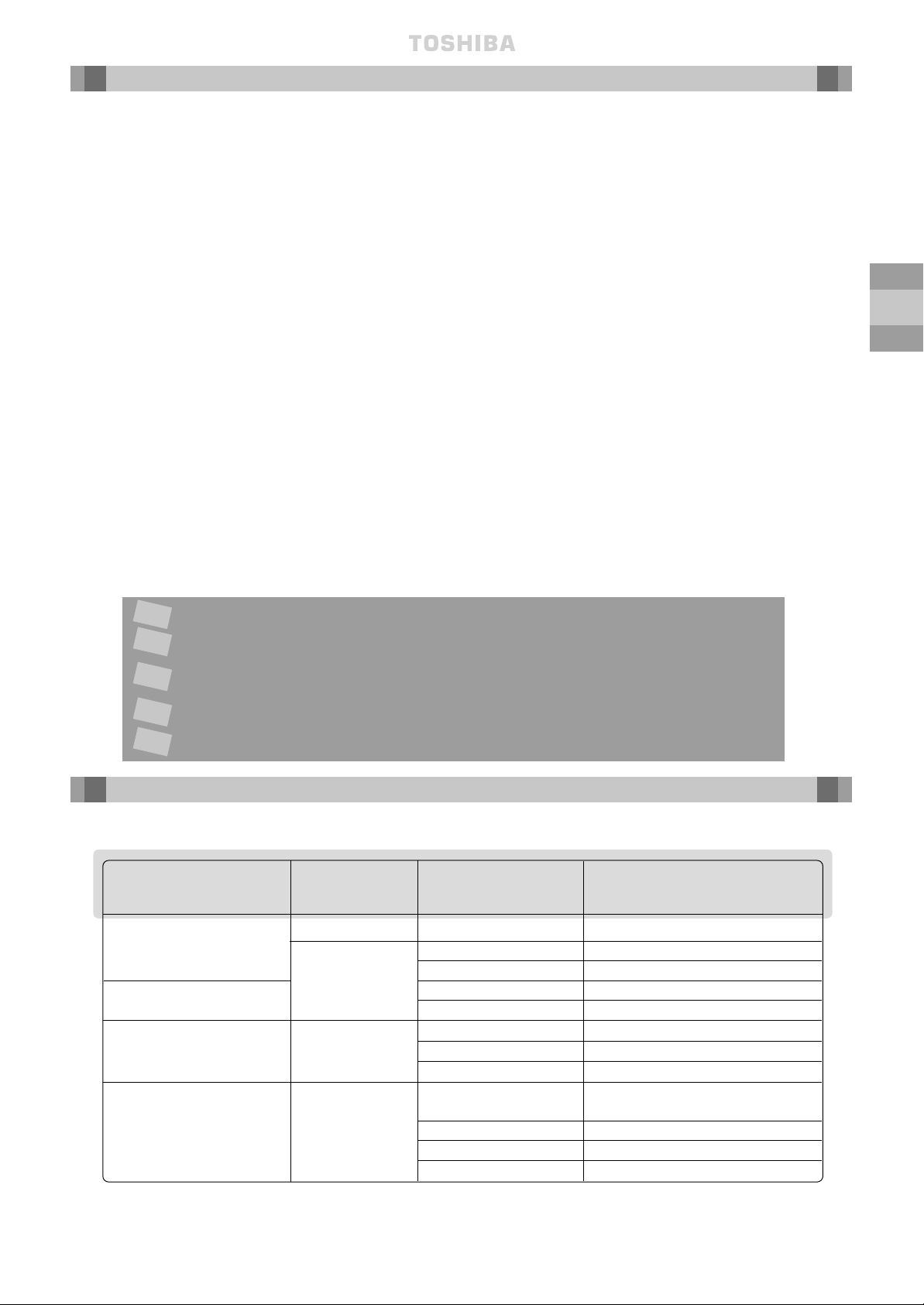

OUTDOOR TEMPERATURE

–5 ~ 43˚CCOOLING

–15 ~ 21˚CHEATING

ROOM TEMPERATURE

18 ~ 32˚CCOOLING

15 ~ 29˚CHEATING

ROOM HUMIDITY <80% COOLING

INSTALLATION INSTRUCTIONS

PRECAUTIONS FOR R407C SYSTEMS

OPERATING CONDITIONS

~ 3 ~

GB

The following optional accessories are available:

Installation Instructions, Precautions for R407C Systems, Operating Conditions 2

Optional Accessories 3

Key to Model Names 4

Accessories 5

Indoor Unit Location, Location Precautions, Service and Installation Space 6 – 8

Unit Installation MM-B units 9 – 10

Unit Installation MM-C/MM-CR units 11 – 12

Unit Installation MM-K/MM-KR units 13

Unit Installation MM-N units 14

Unit Installation MM-SB unit 15

Unit Installation MM-S/MM-SR units 16 – 17

Unit Installation MM-TU units 18

Unit Installation MM-U units 19 – 20

Fresh Air Inlet, Details of Cut Out Hole 21

Air Outlet Duct, Details of Cut Out Hole 22

Drain Piping, Precautions, Piping Material and Heat Insulator 23

Fixing the Drain Pan, Drain Hose Attachment 23

Drainage Check, Trial Run, Wired Remote Controller, Infra-Red Remote Controller 24

Refrigerant Piping, Pipework Installation, System Purging, Heat Insulation 25

Electrical Wiring, Precautions, Power Supply Specifications, Indoor Unit Wiring Connections 26

Connecting the Remote Controller, Group Control, Precautions 27

Remote Controller, Installation of Remote Controllers, Precautions, AI Models 28

Flush Wall Mounting, Wall Surface Mounting, Wiring of two Remote Controllers 28

Installation of AI Room Remote Controllers, Precautions, Flush Wall Mounting, Wall Surface Mounting 29

Installation of Infra-Red Remote Controllers, Infra-Red Remote Controller Mounting 30

Improving System Efficiency, Air Flow Adjustment, Increasing Heating Effect 31

Indoor Unit De-Rating Option 31

Trial Operation, Indoor Unit PMV, PMV Operation using Indoor Unit PCB/Outdoor Unit PCB 32

Final Installation Checks, Environmental 33

ACCESSORY MODEL TYPE ACCESSORY N

O

BASE MODEL N

O

2-WAY CASSETTE RBC-U134PG(W)-E MM-TU028/TU042/TU056

CEILING PANEL RBC-U264PG(W)-E MM-U056/U080

4-W

AY CASSETTE RBC-U464PG(W)-E MM-U112/U140

INFRA RED CEILING PANEL

RBC-U264PGR(W)-E MM-U056/U080

RBC-U464PGR(W)-E MM-U112/U140

RBC-RK162BE-PE MM-B056

FILTER KIT BUILT IN DUCT RBC-RK262BE-PE MM-B080

RBC-RK462BE-PE MM-B112/B140

43A01006 MM-C042/CR042

PAINTED BACK PANEL KIT MM-C056/CR056

(10 pack) CEILING 43A01007 MM-C080/CR080

43A01008 MM-C112/CR112

43A01009 MM-C140/CR140

CONTENTS

OPTIONAL ACCESSORIES

Passer à la page 34 pour lire le manuel d’installation en français.

Die deutsche Montageanleitung finden Sie auf Seite 66.

Por favor, vaya a la página 98 para seguir las instrucciones del manual de

instalacíon en lengua española.

Il manuale d’installazione italiano è a pagina 130.

Zie bladzijde 162 voor de Nederlandse Installatichandleiding.

F

D

E

I

NL

~ 4 ~

GB

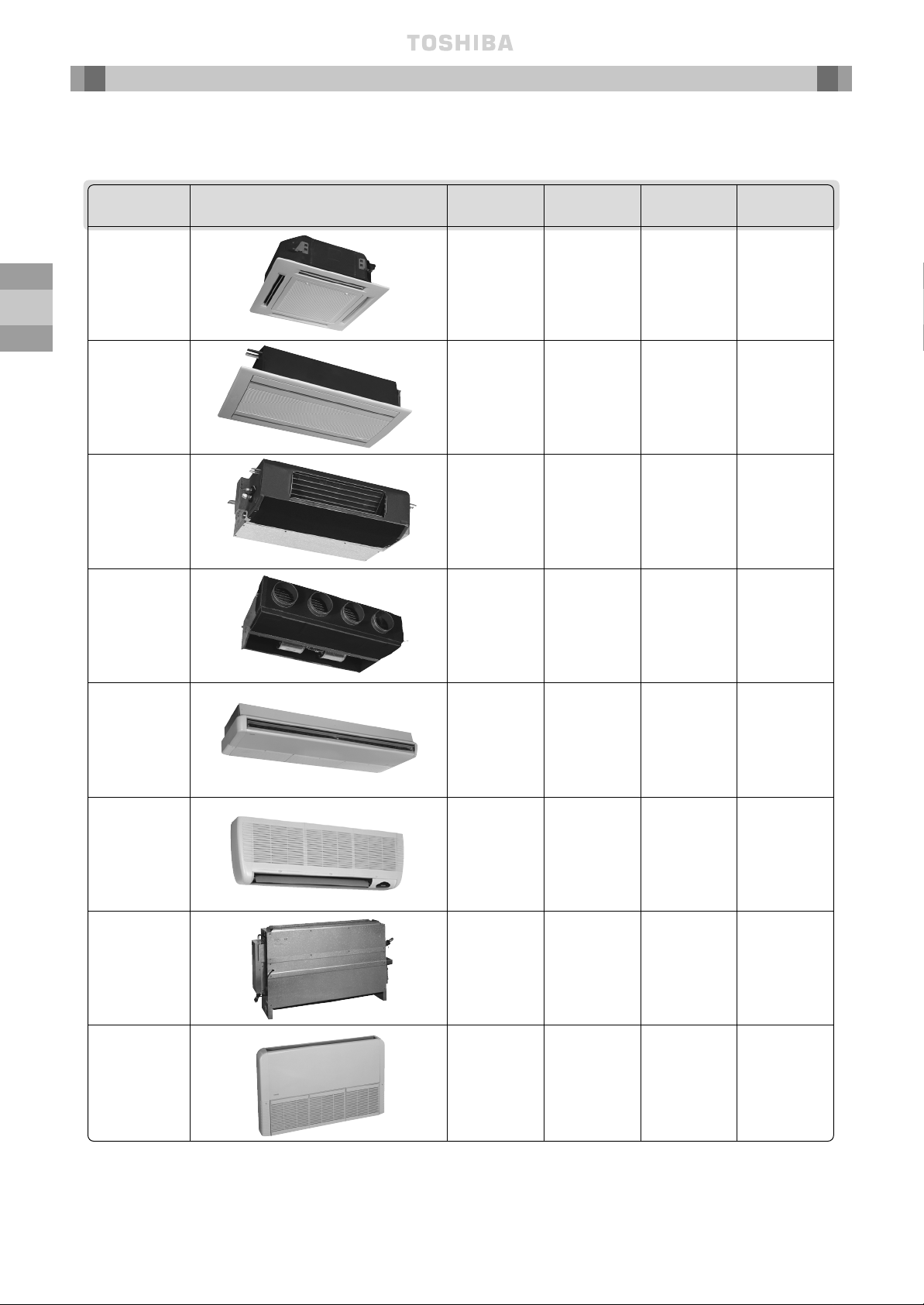

Throughout this booklet, various types of indoor units will be referred to by model codes.

Details are shown in the table below:

KEY TO

MODEL NAMES

TYPE APPEARANCE MODEL NAME CAPACITY CODE/COOLING CAPACITY HEATING CAPACITY

HP (KW) (KW)

MM-U056 2 5.6 6.4

MM-U080 3 8.0 9.6

MM-U112 4 11.2 12.8

MM-U140 5 14.0 15.8

MM-TU028 1 2.8 3.2

MM-TU042 1.5 4.2 4.8

MM-TU056 2 5.6 6.4

MM-SB028 1 2.8 3.2

MM-B056 2 5.6 6.4

MM-B080 3 8.0 9.6

MM-B112 4 11.2 12.8

MM-B140 5 14.0 15.8

MM-C/CR042 1.5 4.2 4.8

MM-C/CR056 2 5.6 6.4

MM-C/CR080 3 8.0 9.6

MM-C/CR112 4 11.2 12.8

MM-C/CR140 5 14.0 15.8

MM-K/KR042 1.5 4.2 4.8

MM-K/KR056 2 5.6 6.4

MM-K/KR080 3 8.0 9.6

MM-N028 1 2.8 3.2

MM-N042 1.5 4.2 4.8

MM-N056 2 5.6 6.4

MM-N080 3 8.0 9.6

MM-S/SR056 2 5.6 6.4

MM-S/SR080 3 8.0 9.6

4 Way Cassette

Type ‘U’

2 Way Cassette

Type ‘TU’

Built-In Slim

Duct Type ‘SB’

Built-In Duct,

Type ‘B’

Ceiling

Type ‘C’

High Wall

Type ‘K’

Carcase

Type ‘N’

Low Wall

Type ‘S’

~ 5 ~

GB

~ 5 ~

DESCRIPTION QUANTITY DIAGRAM APPLICATION

Owner’s Manual 1 — For use by customers

Installation instructions 1 This book —

COMMON

MM-B Units

MM-TU Units

DESCRIPTION QUANTITY DIAGRAM APPLICATION

PVC Socket 1 For drainpipe connection

Connector assembly 1 For fan motor tap changing

Pipe insulation 2 For insulating the pipe connections

DESCRIPTION QUANTITY DIAGRAM APPLICATION

Screws – 5.1mm dia x 45mm long

8 For fixing the installation bracket

Template for installation of 1 For ease of marking the

indoor unit location of installation bracket

Installation bracket* 1 For mounting the indoor unit on the wall

*This part is temporarily attached to the back of the indoor unit

MM-N Units

DESCRIPTION QUANTITY DIAGRAM APPLICATION

Pipe insulation 2 For insulating the pipe connections

DESCRIPTION QUANTITY DIAGRAM APPLICATION

Pipe insulation 2 For insulating the pipe connections

Cardboard template 1

For installation of the cassette and ceiling panel

Bolt (M5 x 20mm) 4 To secure the panel to the cassette

MM-U Units

D

ESCRIPTION QUANTITY DIAGRAM APPLICATION

Pipe insulation 2 For insulating the pipe connections

Cardboard template 1

For installation of the cassette and ceiling panel

Insulation block

4 (056/080)

For 2-directional and

2 (112/140)

3-directional air outlet

MM-C Units

MM-K Units

DESCRIPTION QUANTITY DIAGRAM APPLICATION

Hexagon bolt 4 For securing the hangers

Drain piping fixing plate 1 For fixing rear side drain piping

Pipe insulation 2 For insulating the pipe connections

Nylon band 10

For fixing drain piping and pipe insulation

Tapping Screw 2

For fixing the side panels after installing the unit

Insulator 1 For insulating the knock-out position

MM-SB Units

DESCRIPTION QUANTITY DIAGRAM APPLICATION

PVC Socket 1 For drainpipe connection

Pipe insulation 2 For insulating the pipe connections

ACCESSORIES

~ 6 ~

GB

Avoid installing the indoor unit in the following locations:

Where there is danger of flammable gas leakages.

Where there are high concentrations of oil.

Where the atmosphere contains an excess of salt (as in coastal areas).

The air conditioner is prone to failure when used under this condition unless special maintenance

is provided.

Where high concentrations of organic solvent are present.

Where a machine that generates high frequencies is operated.

Where the unit will not be horizontal.

Where the ceiling height is more than 3m.

Where the floor/wall/ceiling structure is unable to support the weight of the unit.

Where it is not possible to fix the unit hangers, e.g. window glass.

Locate the unit so as to provide uniform circulation of chilled air.

Location Precautions

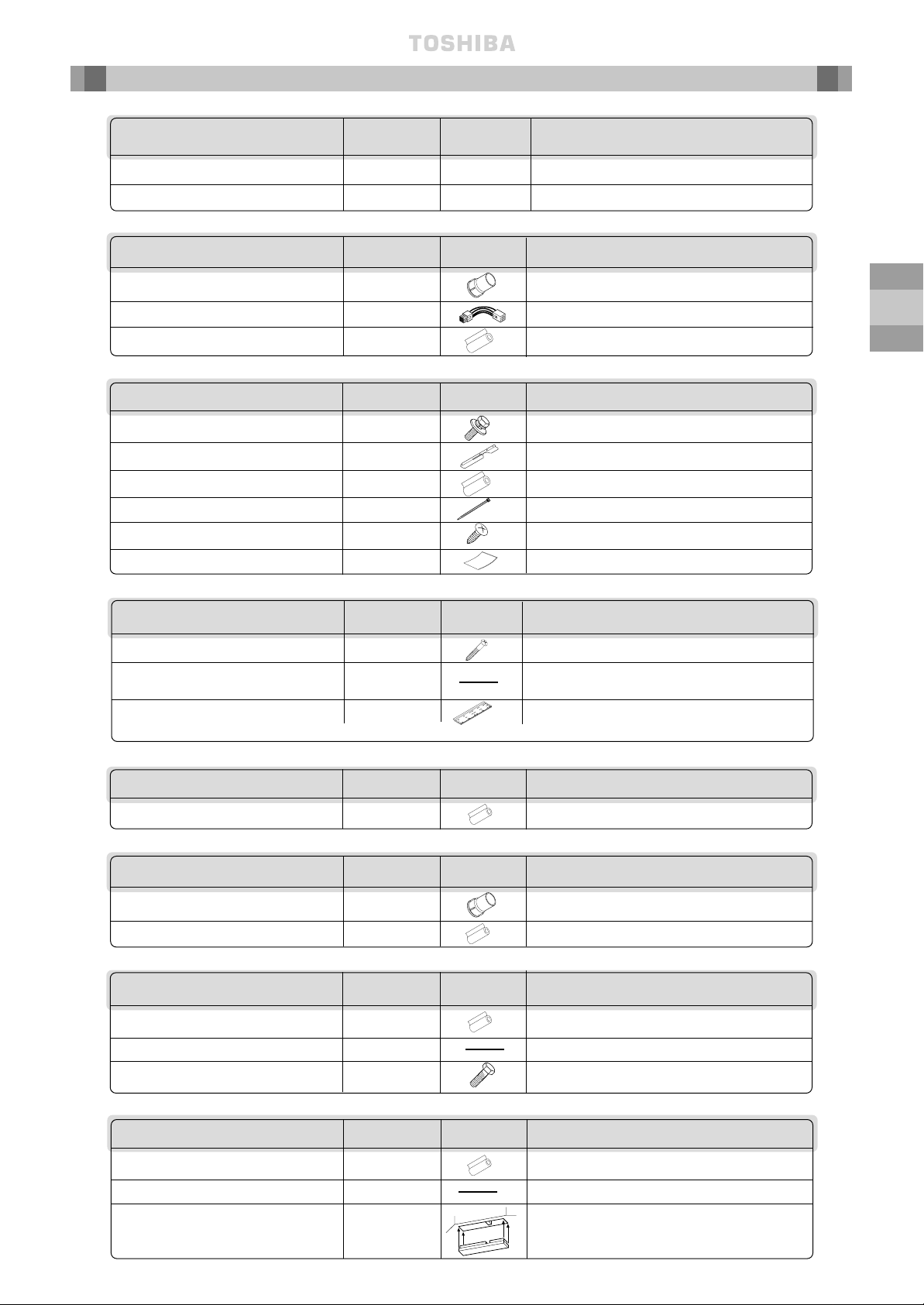

Good location —

Evenly cooled

Bad location —

Oblique-line

area not well

cooled \\\\\

Bad location —

Oblique-line

area not well

cooled /////

✗

✗

If a good location is not possible, use a fan to circulate the air evenly throughout the room.

— MM-U Units only —

Choose the number of airflows that are required, depending on the shape of the room and the

location of the indoor unit.

Insulation

Block

MM-U056/U080 MM-U112/U140

!

!

!

!

!

!

!

!

!

!

!

!

— MM-C and MM-K Units only —

Avoid locating the unit as shown in the ✗-marked figures below:

It is not possible to block the air flow from the longer sides of the unit (U112/U140).

The number of airflow directions cannot be adjusted after installation.

Insert insulation blocks, which are supplied as accessories,

at each side where the airflow is not required,

as shown in the diagram opposite.

3-way 3-way 3-way

3-way 3-way 2-way

3-way 2-way 2-way

INDOOR

UNIT LOCATION

~ 7 ~

GB

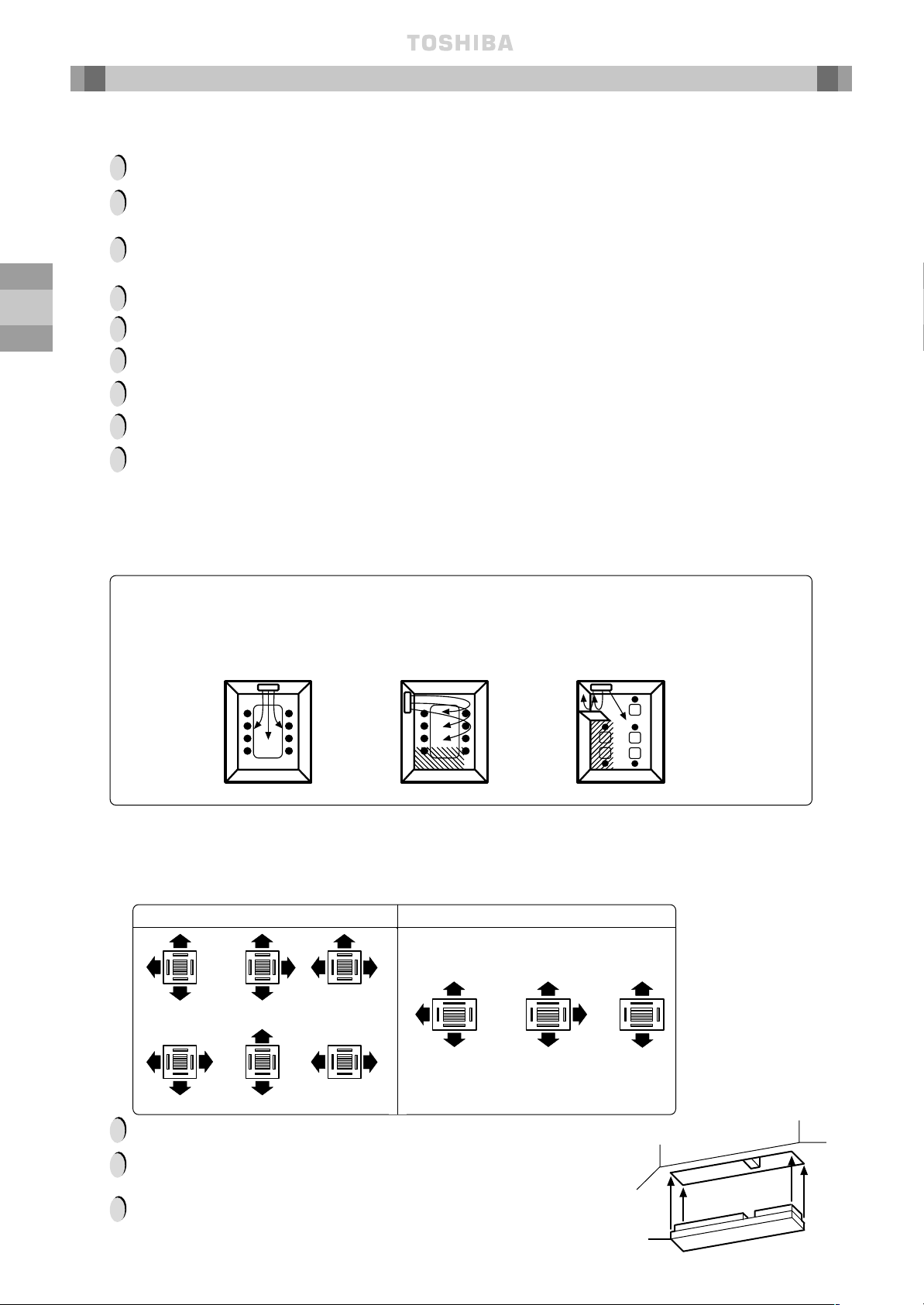

ALWAYS ENSURE THAT THERE IS SUFFICIENT SPACE AROUND THE INDOOR UNITS FOR

INSTALLATION AND SERVICING:

Service and Installation Space

MM-B Units

MM-C, CR Units

MM-K, KR Units

300mm or more

30mm or more

300mm or more

500mm or

more

400mm

or

more

150mm

or more

300 – 400mm

200mm

450mm

450mm

!

Provide an inspection

hole in this position

Inspection hole

150mm

or more

MM-N Units

Minimum

Upper Plate/Duct Plate

Minimum

60mm

25mm

20mm

148mm

65mm

90mm

150mm

100mm

Drain Catch

Fixing location to

floor/base

160mm

145mm

Air Outlet

150mm

INDOOR

UNIT LOCATION

~ 8 ~

GB

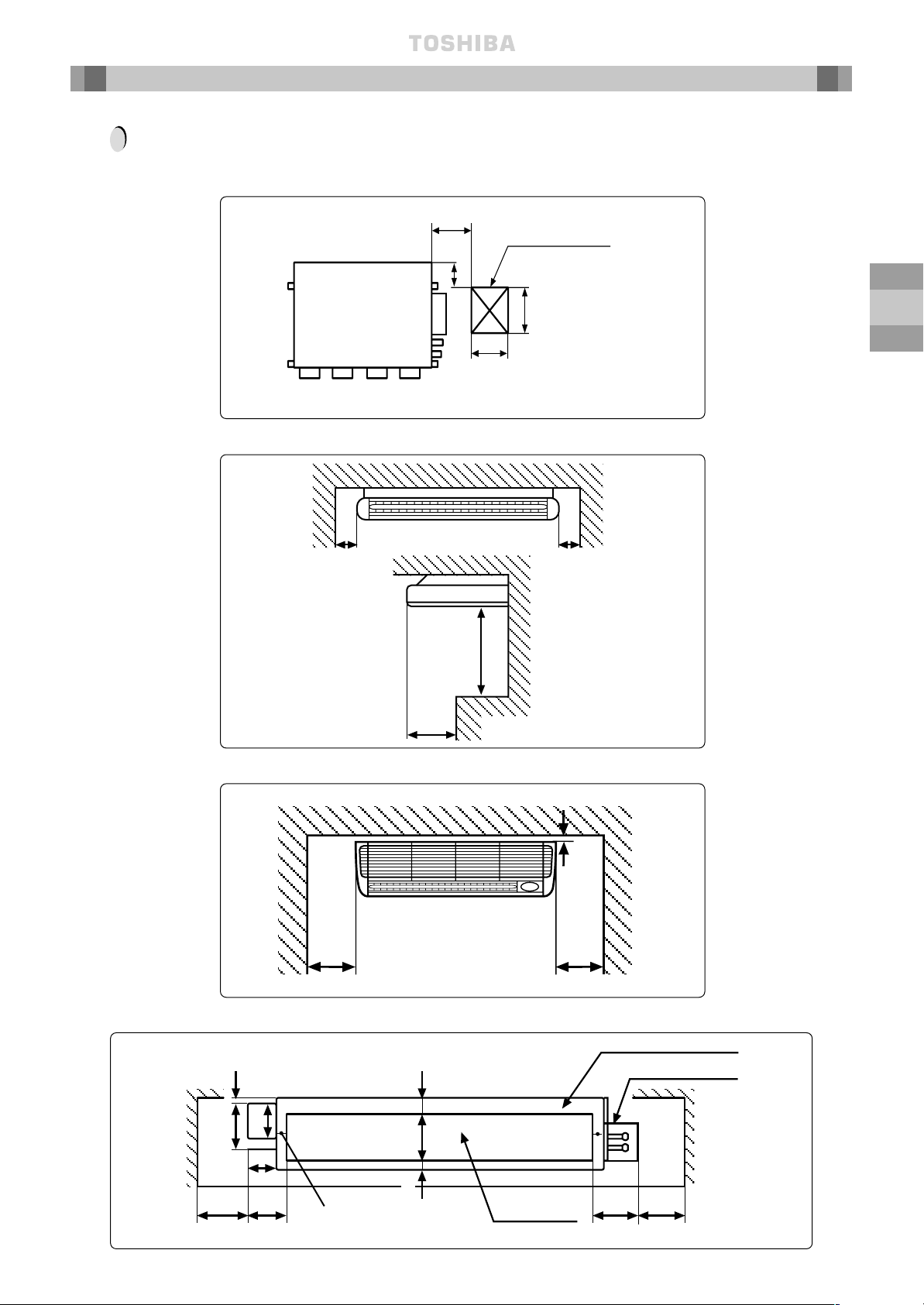

Service and Installation Space continued

MM-SB Units

MM-S, SR Units

MM-TU Units

MM-U Units

Plan View

150mm

or more

150mm

or more

400mm

or more

500mm

or more

150mm

or more

15mm or more

1000mm

or more

Obstacle

1000mm

or more

Ceiling

1000mm or more

Drain pipe connections

Air Outlet

Electrical box

INDOOR

UNIT LOCATION

600mm 600mm

600mm

200mm

~ 9 ~

GB

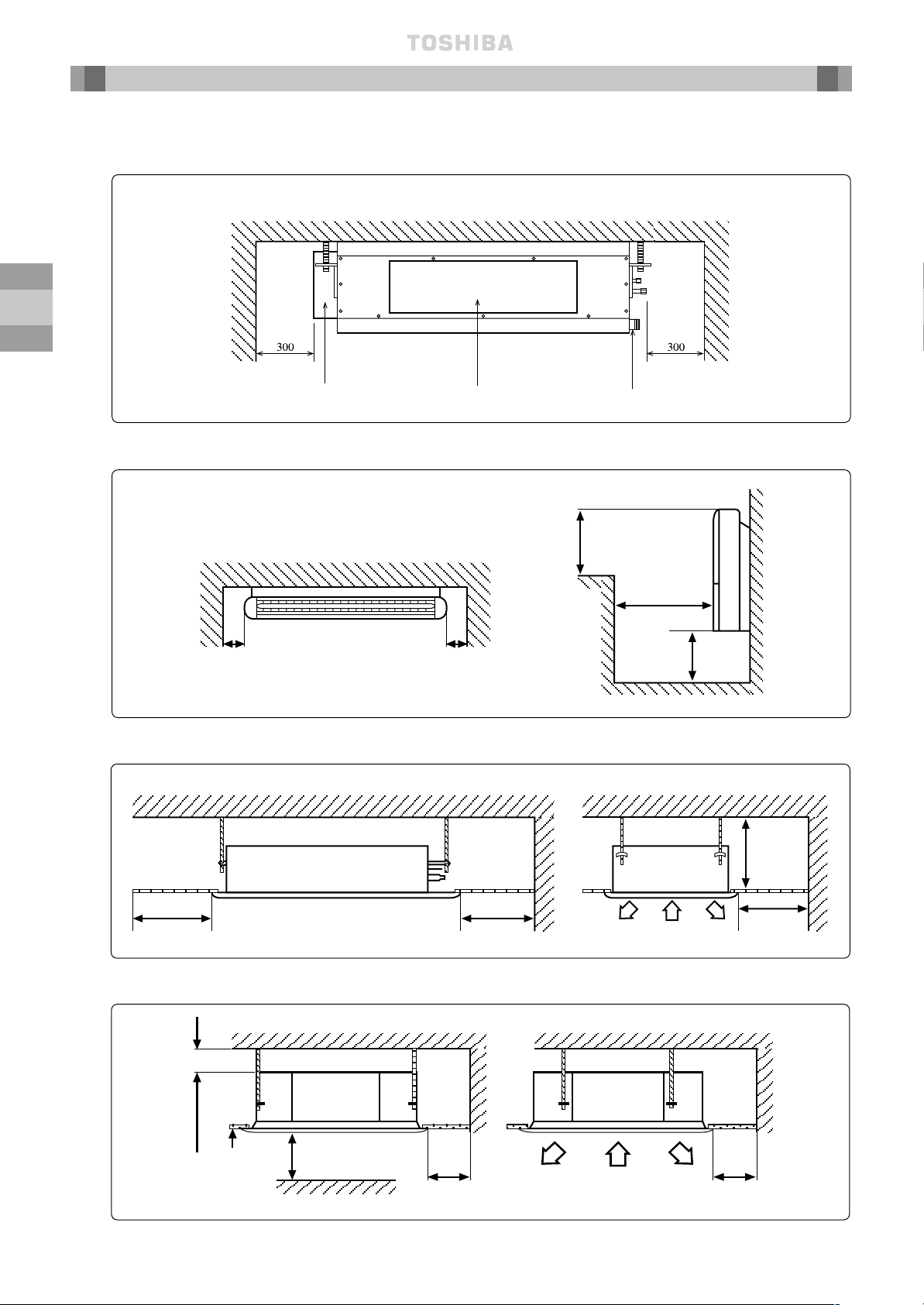

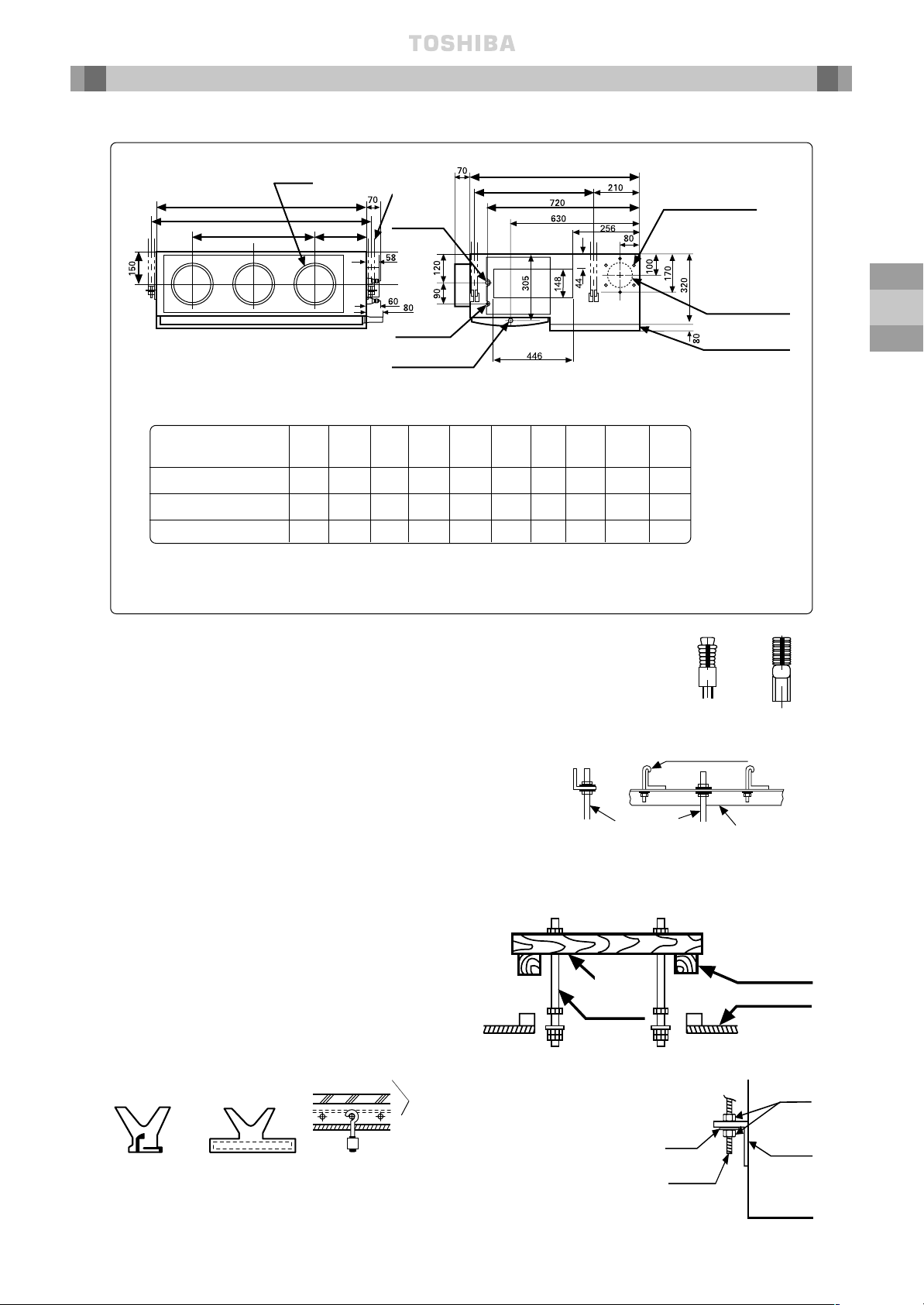

Check the dimensions of the unit illustrated in the following figure:

Unit Installation – MM-B Units

Installing Ø 10 Hanging Bolts (4 pieces)

Install the hanging bolts at the intervals shown in the

following figure.

Use Ø 10 hanging bolts (to be locally procured).

Ceiling preparation: The actual procedure differs according

to the structure. Consult your builder or whoever was

responsible for the interior of the house/building.

Removal of part of the ceiling plate:

(1) In order to ensure that the ceiling is kept perfectly

horizontal and to prevent the ceiling from vibrating, the

ceiling framework must be reinforced.

(2) Cut and remove part of the ceiling framework.

(3) Reinforce the ends of the ceiling framework where it was

cut and add framework to secure the ends.

Some piping and wiring connections must be made in the

ceiling after the unit has been suspended. After selecting where

the unit will be installed, decide on the direction of the piping

connection. If the ceiling is already installed, prepare the

refrigerant pipes, drain pipe, indoor to outdoor unit connection

wiring and the remote control cord at the piping and wiring

connection positions before suspending the indoor unit.

Hanger

bolt

Hanging bolt

Hanging

bolt

Beam

Ceiling

Model (MM-) A B E Ø F Ø G H J K M N

B056 700 750 780 12.7 6.4 252 280 280 1 2

B080 1000 1050 1080 15.9 9.5 252 580 290 2 3

B112, B140 1350 1400 1430 19.0 9.5 252 930 310 3 4

Sliding bracket

Reinforcing

bar

Foundation bolt

(Foundation bolt for

hanging the piping)

Angular bracket

for support

Installation on a wooden structure:

Place a length of wood of the appropriate size across two

beams and install the hanging bolts onto this length of wood.

Installation on a steel frame:

Use the angular

bracket in

the structure

or install

one for support.

Installation on an existing

concrete slab:

Use hole-in anchors, hole-in plugs

or hole-in bolts for the installation.

Hanging Unit

(1) Raise the unit by using a

lifting device, then secure

the hangers to the hanging

bolts. Be sure to fix the nuts

onto both the upper and

under side of the hanger

and the washer (under side

only);

(2) Install the unit horizontally

by using a level. Failure to

do this will cause water

leakages.

Nut

Hanger

Hanging

Bolt

Washer

How to Install the Hanging Bolts

Installation on a newly installed concrete slab:

Use insert brackets or foundation bolts for the installation.

Cross

length of

wood

Knife shaped

bracket

(Gas ø F)

Hanging Bolt Pitch B

Refrigerant Pipe

Connection

Unit Dimension A

Hanging Bolt

4-M10

Provided at site

Nx Ø200

Air Outlet

Drain pipe connection

(inner diameter 32)

(diameter 32 minimal for PVC pipes)

Refrigerant pipe

connection

(liquid ø G)

Hanging Bolt Pitch:565

Unit Dimension:800

J = M x K

(H)

6 x Ø4 holes (Ø160)

Fresh air inlet Ø125

cut-out (other side)

Filter kit

INDOOR

UNIT LOCATION

~ 10 ~

GB

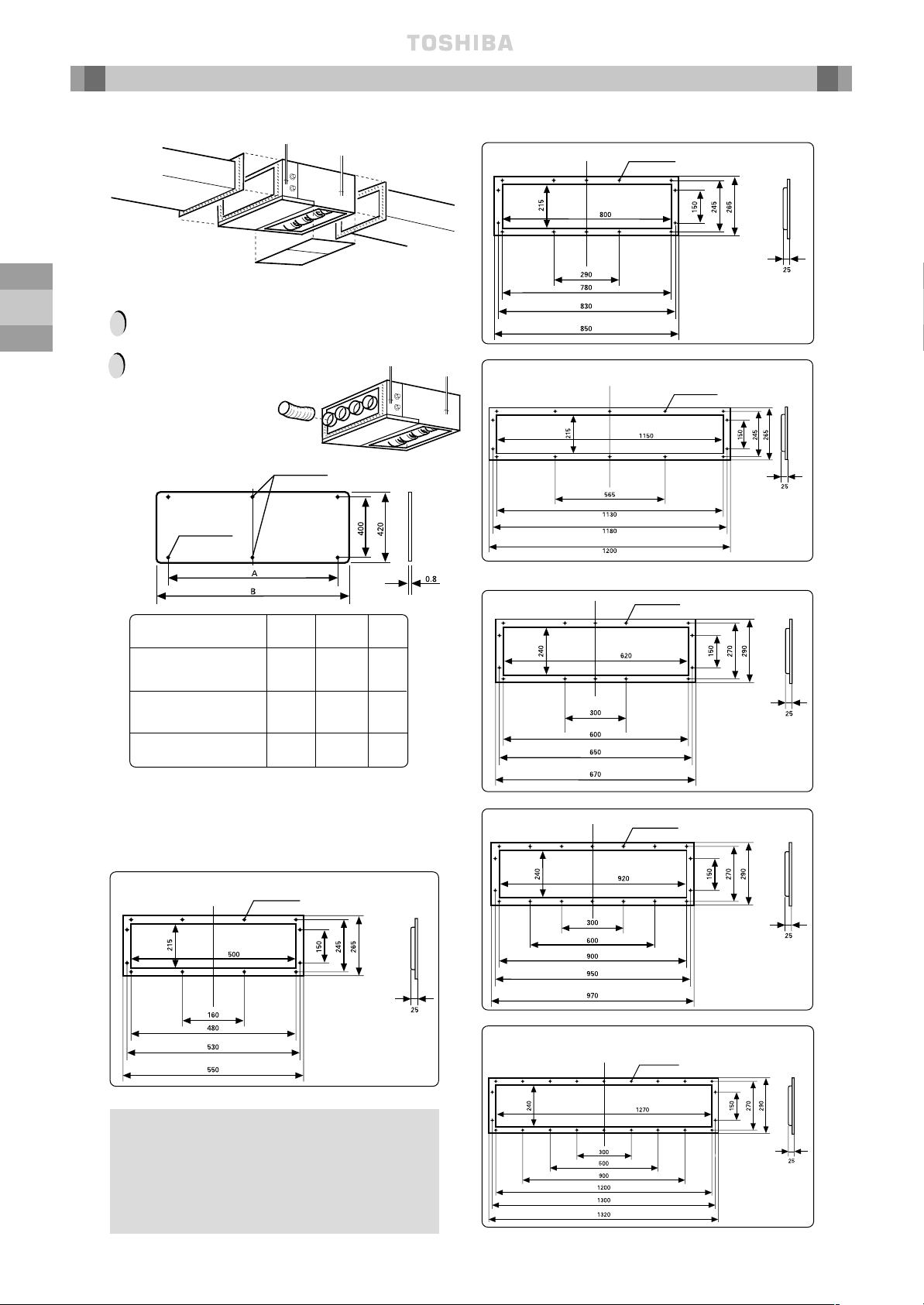

Unit Installation – MM-B Units continued

Connection of Ducting

Remove the duct connection assembly (attachment)

before connecting the supply duct.

!

Flexible duct

The maximum length of

flexible ducting is 10m.

To connect the shelter

board under the lower air

inlet of unit, prepare the

shelter board locally, as

shown below.

!

Model (MM-) A B C

B056 400 700 —

B080 700 1000 2

B112, B140 1050 1350 2

Optional Accessory

A TOSHIBA Long-Life Filter Kit is available as an

optional accessory.

The Filter Kit can be installed on either the lower or

rear air inlet of the Duct Type unit.

To connect square duct, prepare the connection flange

locally as shown below:

MM-B056

Supply Flanges

Supply Flanges Continued

MM-B080

MM-B112, MM-B140

Return Flanges

MM-B056

MM-B080

MM-B112, MM-B140

Shelter Board C x Ø6 holes

Supply duct

(local procurement)

12 – ø 6 holes

14 – ø 6 holes

14 – ø 6 holes

14 – ø 6 holes

18 – ø 6 holes

22 – ø 6 holes

4 x Ø6 holes

Return duct (local

procurement)

Shelter board

(local procurement)

INDOOR

UNIT LOCATION

~ 11 ~

GB

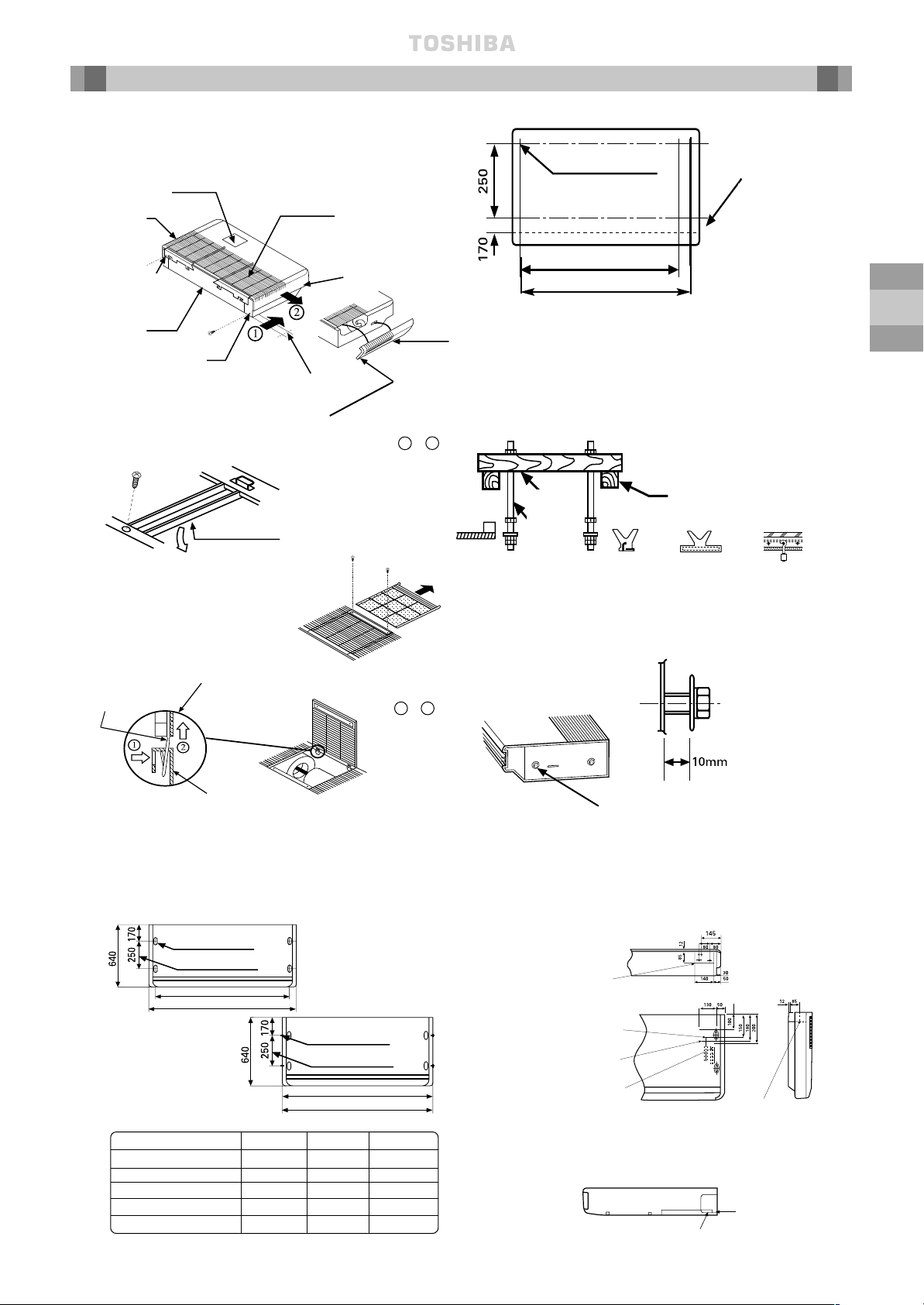

Unit Installation – MM-C, MM-CR Units

Before Installation

1 Take off the accessories.

2 Remove

the hanger

(left, right).

4 Remove the side panels by hand.

Slide them in order of 1 - 2 .

5 Pull the air filter

out then remove

the inlet grille fixing

screws.

Side

panel

(left)

Body

Inlet grille

10-20mm

Securely fix left

and right side

panels with a screw

supplied after unit

installation.

Installing Ø 10 Hanging Bolts

Ø Hanging Bolts are procured locally

Install hanging bolts at the spacings shown below.

Shipping fixture

(centre)

Detail figure of the hinge

portion

INNER HANGING

OUTER HANGING

Hole for hanging bolt

Bmm (Hanging bolt pitch)

Amm

Model (MM-) Amm Bmm Cmm

MM-C/CR042 1030 920 1020

MM-C/CR056 1030 920 1020

MM-C/CR080 1230 1120 1220

MM-C/CR112 1430 1320 1420

MM-C/CR140 1630 1520 1620

The positions of the hanging bolts are printed on the

carton box. (The size is not printed.)

Position of hanging bolt

(ø10 printed)

Bmm (inner hanging)

Cmm (outer hanging)

Installing method of the Hanging Bolt

Newly-built concrete slab

Install hanging bolts with

inserts, embedded bolts, etc.

Wooden-strutted room

Install hanging bolts on a square

wooden piece placed over beams.

Edge

(sharp

insert)

(Slide

insert)

Embedded bolt

of piping

Reinforcing bar

Installing Hexagon Bolt (accessory)

Allow a spacing of

about 10mm

M8 x 25mm hexagon bolts (4)

Determining installation position and direction

of the piping and wiring

BACK VIEW

Knock out

(rear attachment)

Gas line connection

Knock out

(right or left attach-

ment)

Liquid line connection

TOP VIEW

Opening Knock Out Hole

Cut the slit

portion by a

saw or knife

In case of

right or left

attachment

Slit

3 Remove all the

metal shipping

fixtures (left

corner, centre,

right corner).

Side panel

(right)

Wooden

piece

Hanging

bolt

Drain connection

(OD 20mm)

Beam

Hole for hanging bolt

Cmm (Hanging bolt pitch)

Amm

(4 – 12 x 27 slots)

Hanging bolt pitch

(4 – 12 x 27 slots)

Hanging bolt pitch

The dotted

line indicates

the rear end

of the unit. To

be detached

on the dotted

line.

Embedded

bolt

SIDE VIEW

To remove the

inlet grille take the

hinge portion off in

order of 1 - 2 .

Hinge

Body

INDOOR

UNIT LOCATION

Loading...

Loading...