Page 1

CONTENTS

CONTENTS

Quick Start 2

1. Caution Statements

1.1 Cautions and warnings ............................................ 3

2. General Description

2.1 Feature list .............................................................. 4

2.2 Part Number format ................................................ 4

3. Specifications

3.1 Current ratings ........................................................ 5

3.2 Dimensions & weights ............................................. 7

3.3 Semiconductor fuses .............................................. 7

3.4 Power terminations ................................................. 8

3.5 General technical data ............................................ 8

4. Installation

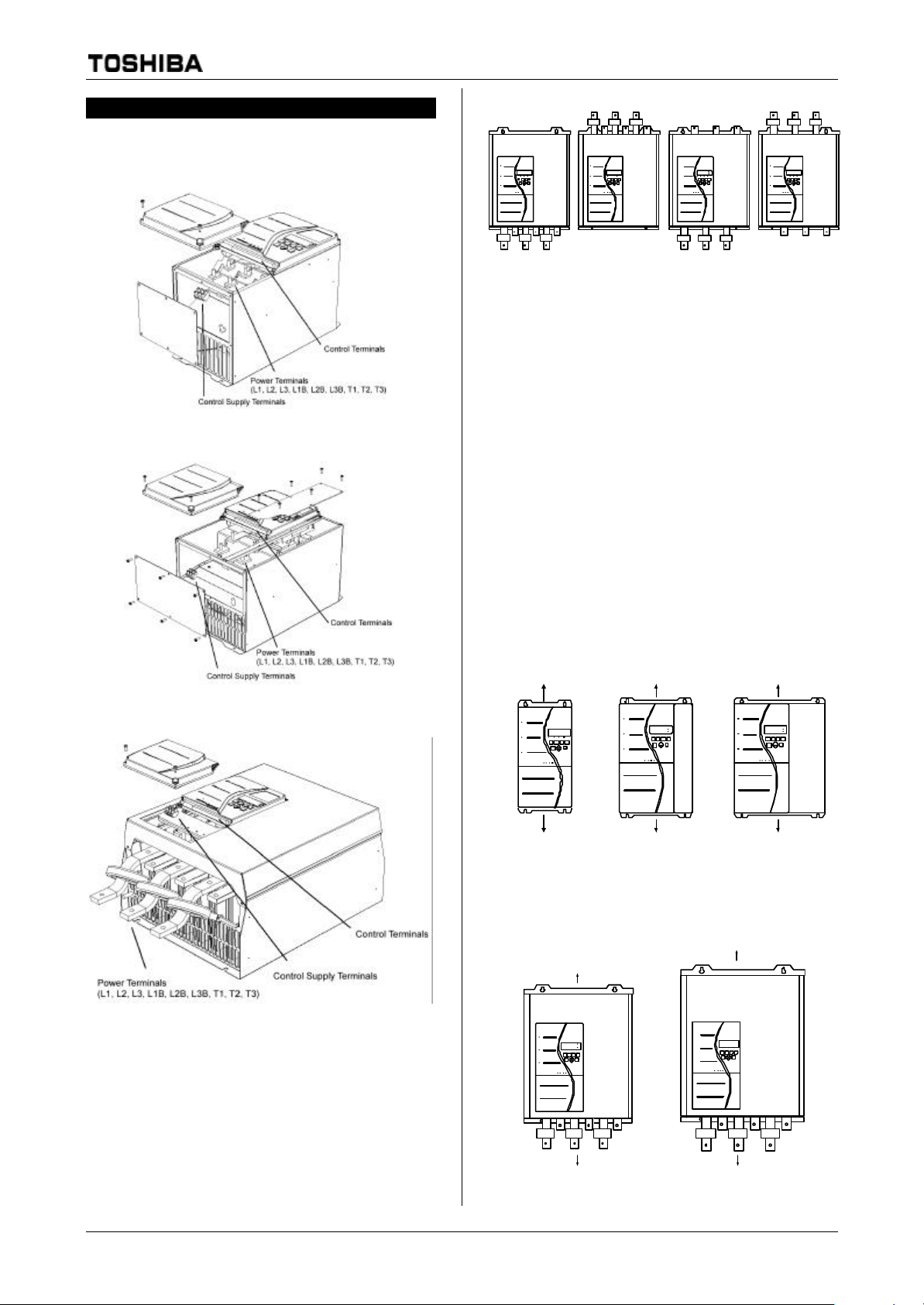

4.1 General layout diagrams ......................................... 9

4.2 Power termination configuration .............................. 9

4.3 Mounting instructions .............................................. 9

4.4 Ventilation ............................................................. 10

10.3 AC53b Utilisation Codes ....................................... 32

5. Power Circuits

5.1 Overview .............................................................. 11

5.2 3 Wire connection ................................................. 11

5.3 3 Wire connection (Bypass operation) ................... 11

5.4 6 Wire connection ................................................. 11

5.5 6 Wire connection (Bypass operation) ................... 11

5.6 Power factor correction ......................................... 11

5.7 Line contactors ..................................................... 12

6. Control Circuits

6.1 Electrical Schematic .............................................. 13

6.2 Control Supply ...................................................... 13

6.3 Control Wiring ....................................................... 13

6.4 RS485 Serial Communication ............................... 14

7. Programming & Operation

7.1 Programming Procedure ....................................... 17

7.2 Function List ......................................................... 18

7.3 Function Descriptions ........................................... 18

7.4 Operation .............................................................. 24

8. Application Examples

8.1 Installation With Line Contactor ............................. 26

8.2 Installation With Bypass Contactor ........................ 26

8.3 Soft Braking .......................................................... 27

8.4 Two Speed Motor ................................................. 28

9. Trouble Shooting

9.1 Trip Codes ............................................................ 29

9.2 Trip Log ................................................................ 30

9.3 General Faults ...................................................... 30

9.4 Tests and Measurements ...................................... 31

10. Appendix

10.1 Typical Start Current Requirements ...................... 32

10.2 AC53a Utilisation Codes ....................................... 32

TMS7 SERIES ME00070B 1

Page 2

QUICK START

QUICK START

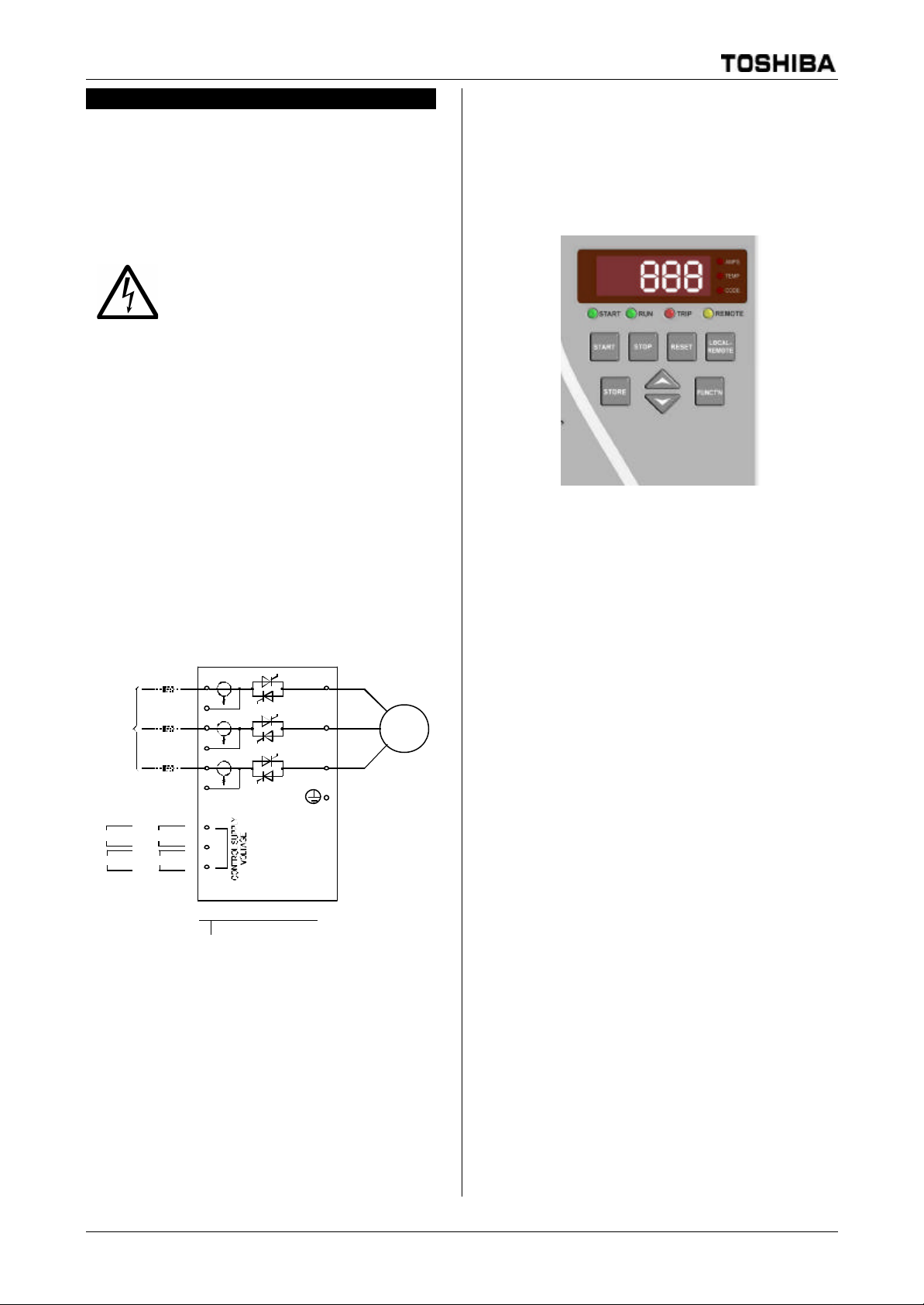

For simple applications TMS7 soft starters can be installed using

the three simple steps outlined below. For applications with

advanced control, protection or interface requirements a

comprehensive review of this Users Manual is recommended.

1. Installation & Connection

WARNING - ELECTRICAL SHOCK HAZARD

The TMS7 contains dangerous voltages when connected to

line voltage. Only a competent electrician should carry out

the electrical installation. Improper installation of the motor

or the TMS7 may cause equipment failure, serious injury or

death. Follow this manual and National Electrical Codes

(NEC®) and local safety codes.

1. Ensure the correct TMS7 model has been selected for the

connected motor and application type.

2. Mount the TMS7 making sure to allow adequate clearance

top and bottom for the free circulation of air through the

starter. (Refer to section 4.3 Mounting Instructions for further

detail.)

3. Connect the supply cables to starter input terminals L1, L2 &

L3.

4. Connect the motor cables to starter output terminals T1, T2

& T3.

5. Connect a control supply to starter input terminals A1 & A2

or A2 & A3. (Refer to section 6.2 Control Supply for further

detail).

(OPTIONAL)

F1

3 PHASE

SUPPLY

C45 models

460V

575V

L1

L1B

L2

L2B

L3

L3B

C24 models

+10

400V

-15

OROR

+10

230V

-15

A1

+10

-15

A2

+10

A3

-15

T1

T2

T3

E

M

4. Use the <UP> and/or <DOWN> keys adjust the FLC

setting to match the FLC of the connected motor.

5. Press the <STORE> key to store the new FLC setting.

6. Exit the programming mode by simultaneously pressing

then releasing the <FUNCTION> and <STORE> keys.

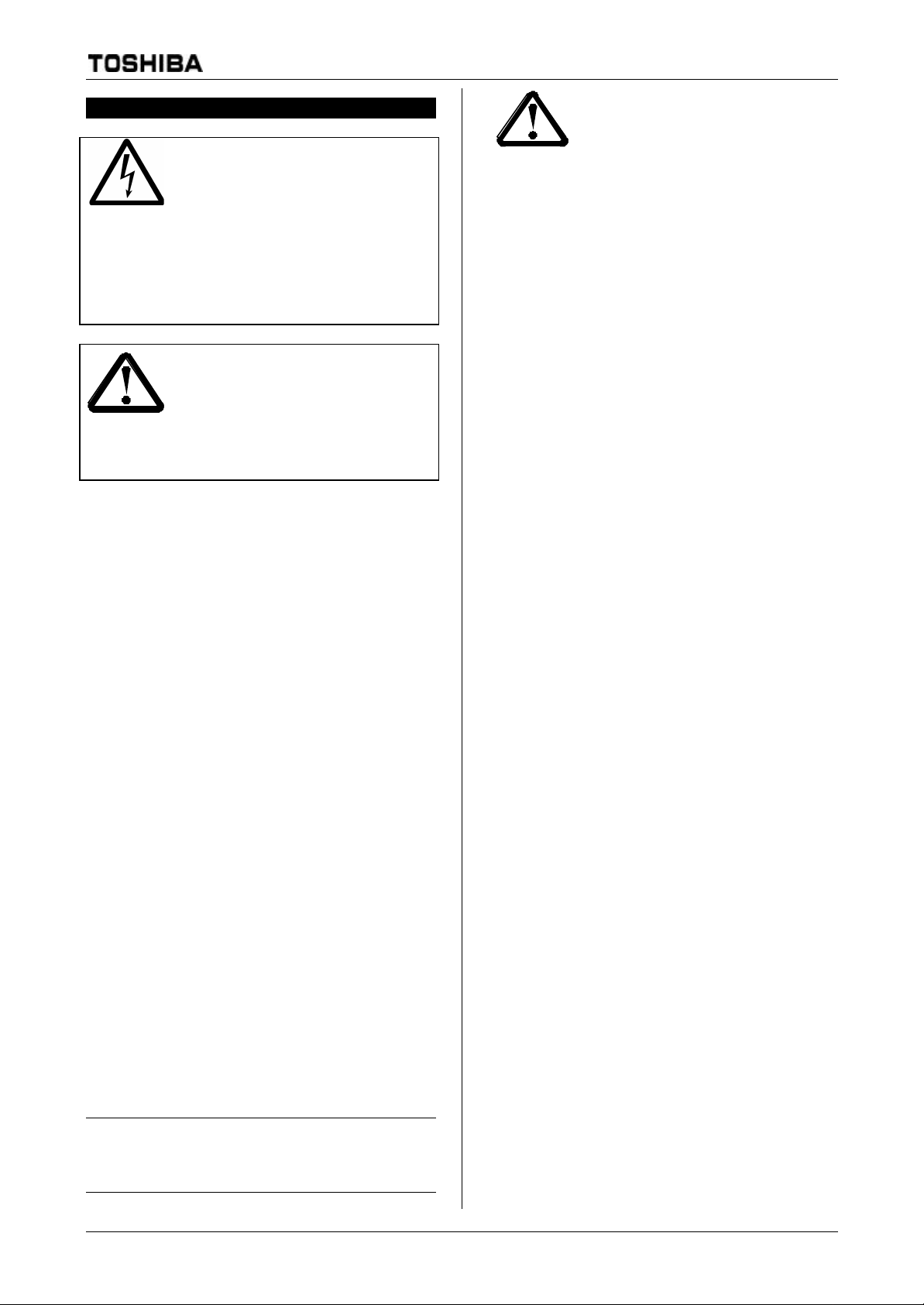

3. Operation

The TMS7 is now ready to control the motor. Motor operation

can be controlled using the <START> and <STOP> keys on the

TMS7 local control panel. Two other commonly used functions

that may be useful for basic installations are Function 2. Current

Limit and Function 5. Stop Ramp Ti me. These functions can be

adjusted in the same manner as described above. (For a more

detailed description of the programming procedure refer to

section 7.1 Programming Procedure.)

Legend

F1 Semiconductor Fuses

2. Programming

Basic application requires only that the TMS7 be programmed

with the connected motor's nameplate full load current (FLC). To

program the TMS7 with the motor's FLC do the following:

1. Put the TMS7 into program mode by simultaneously

pressing then releasing the <FUNCTION> and <STORE>

keys.

2. Select Function 1. Motor Full Load Current by holding

down the <FUNCTION> key and then press the <UP> key

until the display shows "1".

3. Release the <FUNCTION> key to display the currently

stored value of Function 1. Motor Full Load Current.

2 ME00070B TMS7 SERIES

Page 3

CAUTION STATEMENTS

Caution Statements

WARNING - ELECTRICAL SHOCK

HAZARD

The TMS7 contains dangerous voltages when

connected to line voltage. Only a competent

electrician should carry out the electrical

installation. Improper installation of the motor

or the TMS7 may cause equipment failure,

serious injury or death. Follow this manual

and National Electrical Codes (NEC®) and

local safety codes.

GROUNDING AND BRANCH

CIRCUIT PROTECTION

It is the responsibility of the user or person

installing the TMS7 to provide proper

grounding and branch circuit protection

according to the National Electric Code

(NEC®) and local codes .

It is the installers responsibility to adhere to all instructions in

this manual, to follow good electrical practice and to seek advice

before operating this equipment in a manner other than as

detailed in this manual.

This symbol is used throughout this manual to

draw attention to topics of special importance

to the installation and operation of the TMS7

soft starter.

• Ensure that the TMS7 is completely isolated from the power

supply before attempting any work on the unit.

• Do not apply voltage to the control input terminals. These

are active 12/24VDC inputs and must be controlled with

potential free circuits.

• Ensure contacts/switches operating the control inputs are

suitable for low voltage, low current switching ie, gold flash

or similar.

• Ensure cables to the control inputs are segregated from AC

power and control wiring.

• Entry of metal swarf into the cabinet can cause equipment

failure.

• Do not connect Power Factor Correction capacitors to the

output of the TMS7. If static power factor correction is

employed, it must be connected to the supply side of the

TMS7.

• Before installing the TMS7 without a line contactor ensure

such connection meets local regulations and by-laws.

• If installing the TMS7 within a non-ventilated enclosure a

bypass contactor must be utilised to prevent excessive heat

build-up.

• If installing a by-pass contactor ensure phase connections

are correctly made

ie L1B-T1, L2B-T2, L3B-T3

• Removing control voltage resets the thermal model.

The examples and diagrams in this manual are included solely for illustrative

purposes. Users are cautioned that the information contained in this manual

is subject to change at any time and without prior notice. In no event will

responsibility or liability be accepted for direct or indirect or consequential

damages resulting from the use or application of this equipment.

TMS7 SERIES ME00070B 3

Page 4

GENERAL DESCRIPTION

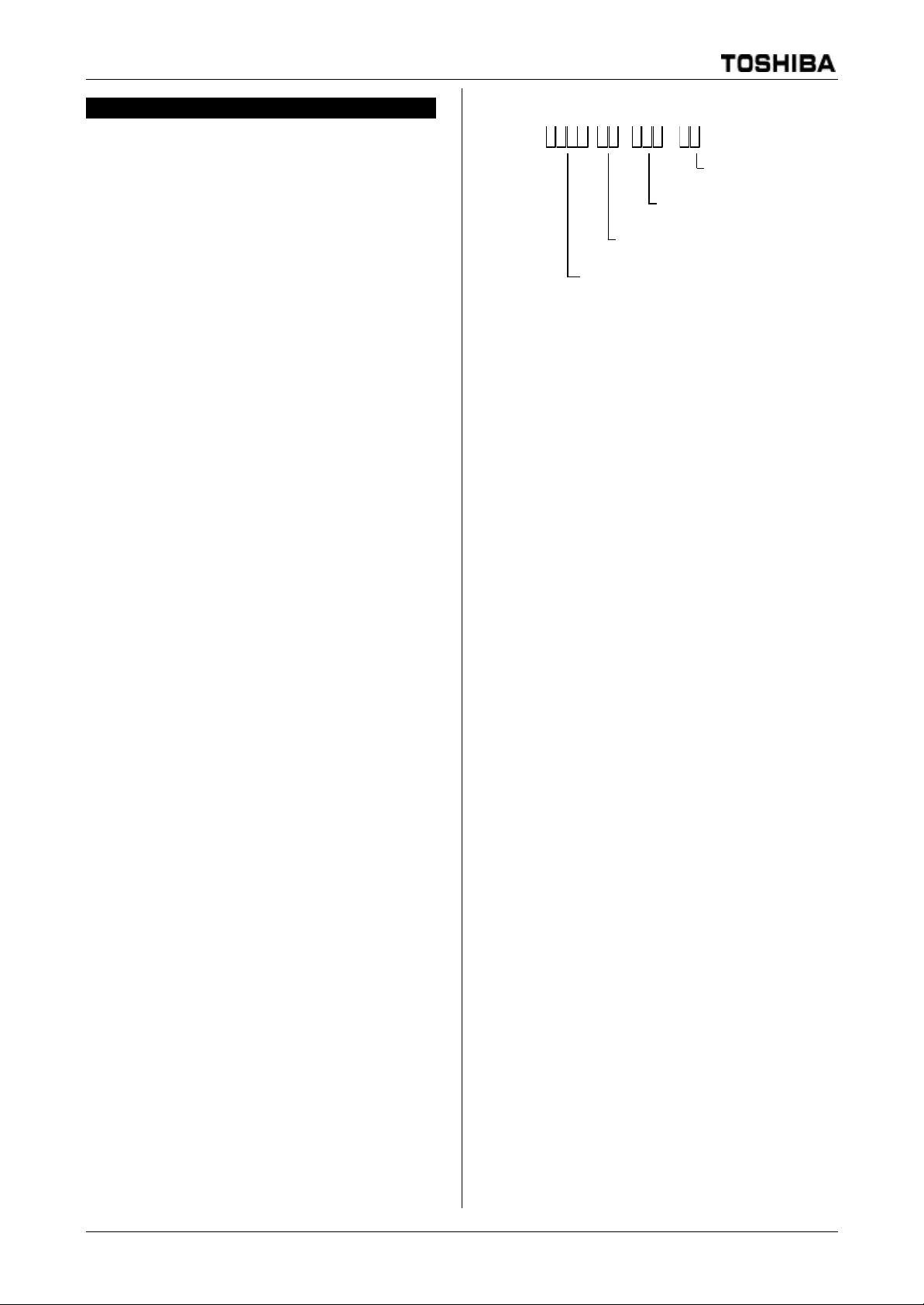

eg. 4022 = 22kW

General Description

2.1 Feature List

Starting

• Current Limit mode.

• Ramp Start mode.

Stopping

• Soft stop.

• Pump stop.

• Soft braking.

Protection

• Overcurrent protection.

• Motor thermistor input.

• Current imbalance.

• Phase rotation.

• Stall protection.

• Undercurrent.

• Supply frequency.

• Shorted SCR.

• Power circuit.

• Motor connection.

• RS485 failure.

Interface

• Remote control inputs

(4 x fixed).

• Relay outputs

(1 fixed, 3 x programmable).

• 4-20mA output (1 x fixed).

• RS485 link.

Human Interface

• Local push buttons.

(Start, Stop, Reset, Local/Remote)

• Local programming buttons.

(Function,Up,Down, Store)

• LED parameter display

• Phase indicator LEDs

2.2 Part Number Format

TMS7- - -

Supply Voltage

V5 = 200 VAC ~ 525 V AC

V7 = 200 VAC ~ 690 V AC

Nominal kW Ratings

-

Enclosure

E0 = IP00

Control Supply V oltage

C24 =230 VAC & 400 V AC

C45 =460 VAC & 575 V AC

E4 = IP42

(@ AC53a 3-30:70-10)

Power connection.

• 3 Wire

• 6 Wire

• Bypass connections to retain motor

protection even when bypassed.

• 17 Amps to 1562 Amps (3 Wire)

26 Amps to 2345 Amps (6 Wire)

• 200VAC to 525VAC (V5 models)

• 200VAC to 690VAC (V7 models)

Sundry features

• IP42 (<253 Amps)

• IP00 (>302 Amps)

• Current read-out

• Motor temperature read-out

• Fault History (eight position).

• Multiple function sets.

• Restart Delay.

• Low current alarm.

• High current alarm.

• Motor overtemperature alarm.

• Auto-reset.

• Function lock/Password protection.

• Load defaults function settings.

4 ME00070B TMS7 SERIES

Page 5

SPECIFICATIONS

Specifications

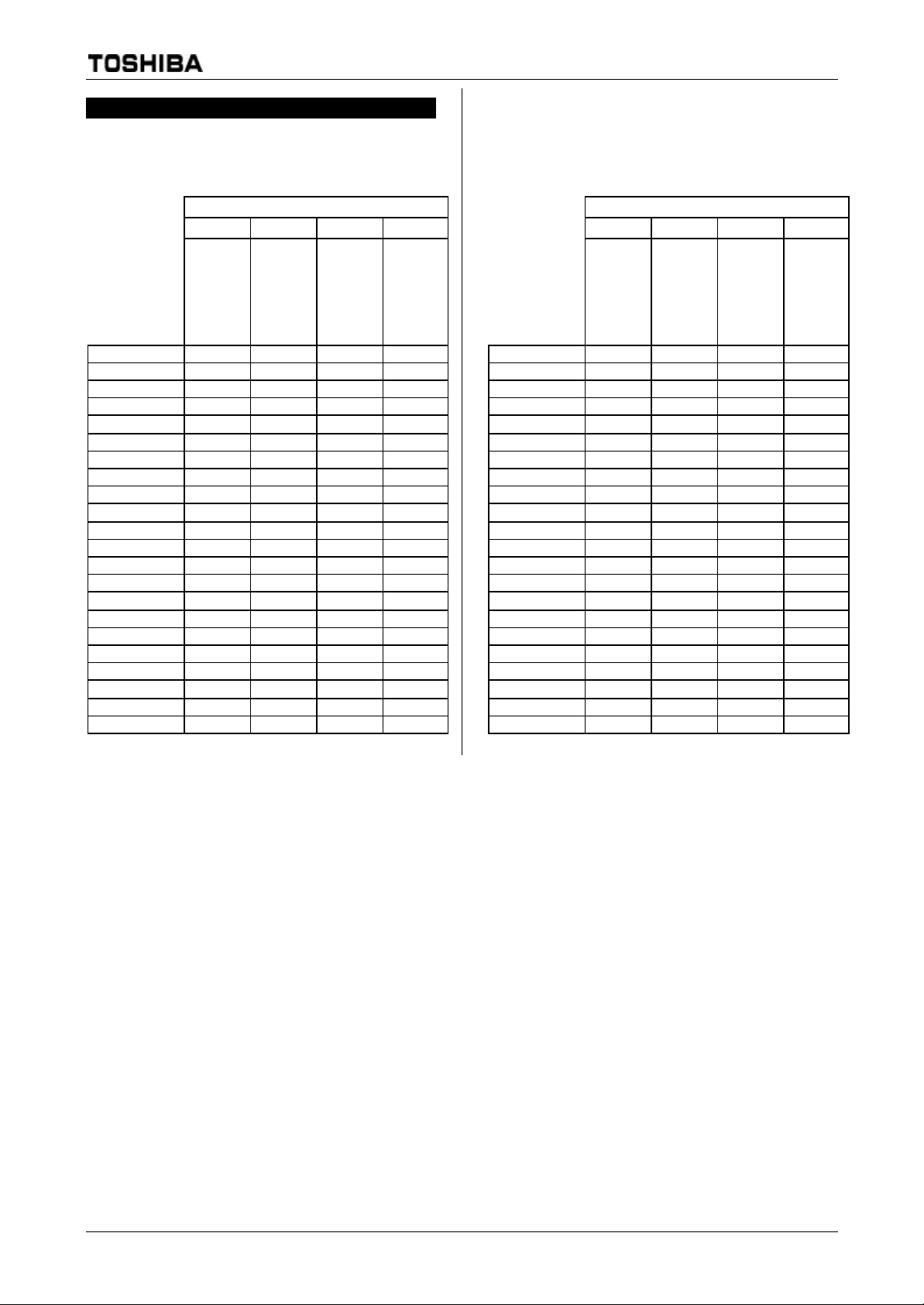

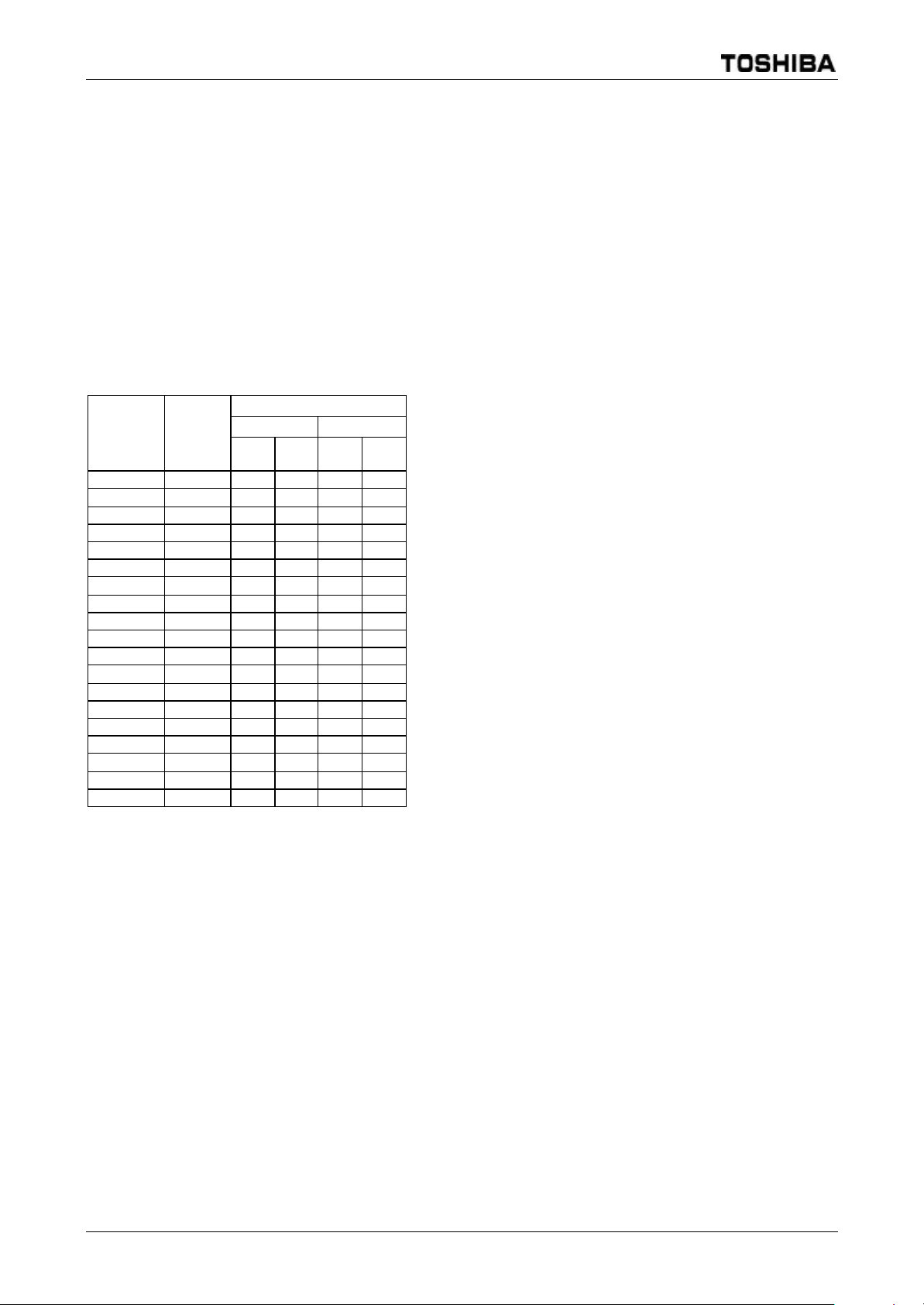

3.1 Current Ratings

Continuous Operation (Not Bypassed), 3 Wire Connection

300% 350% 400% 450%

TMS7-4007 17 15 14 12

TMS7-4015 33 29 26 22

TMS7-4018 38 34 30 26

TMS7-4022 44 39 35 30

TMS7-4030 67 58 51 45

TMS7-4037 87 75 66 58

TMS7-4045 94 81 71 62

TMS7-4055 123 106 93 81

TMS7-4075 137 119 105 92

TMS7-4090 198 171 151 132

TMS7-4110 236 204 179 156

TMS7-4132 244 211 186 164

TMS7-4150 302 267 233 201

TMS7-4185 405 361 313 267

TMS7-4220 513 456 393 331

TMS7-4250 585 524 450 376

TMS7-4315 628 568 489 412

TMS7-4400 775 710 606 502

TMS7-4500 897 831 706 578

TMS7-4600 1134 989 872 759

TMS7-4700 1385 1210 1066 921

TMS7-4800 1563 1366 1202 1030

Start Current (%FLC)

C <1000 metres

o

AC53a 3-10:70-10

45

o

AC53a 3.5-15:70-10

C <1000 metres

45

C <1000 metres

o

AC53a 4-20:70-10

45

AC53a 4.5-30:70-10

Continuous Operation (Not Bypassed), 6 Wire Connection

300% 350% 400% 450%

C <1000 metres

o

45

TMS7-4007 26 23 21 18

TMS7-4015 50 44 39 33

TMS7-4018 57 51 45 39

TMS7-4022 66 59 53 45

TMS7-4030 101 87 77 68

TMS7-4037 131 113 99 87

TMS7-4045 141 122 107 93

TMS7-4055 185 159 140 122

TMS7-4075 206 179 158 138

TMS7-4090 297 257 227 198

TMS7-4110 354 306 269 234

TMS7-4132 366 317 279 246

TMS7-4150 453 401 350 302

TMS7-4185 608 542 470 401

TMS7-4220 770 684 590 497

TMS7-4250 878 786 675 564

TMS7-4315 942 852 734 618

TMS7-4400 1163 1065 909 753

TMS7-4500 1346 1247 1059 867

TMS7-4600 1701 1484 1308 1139

TMS7-4700 2078 1815 1599 1382

TMS7-4800 2345 2049 1803 1545

Start Current (%FLC)

C <1000 metres

o

AC53a 3-10:70-10

45

o

AC53a 3.5-15:70-10

C <1000 metres

45

C <1000 metres

o

AC53a 4-20:70-10

45

C <1000 metres

o

45

AC53a 4.5-30:70-10

TMS7 SERIES ME00070B 5

Page 6

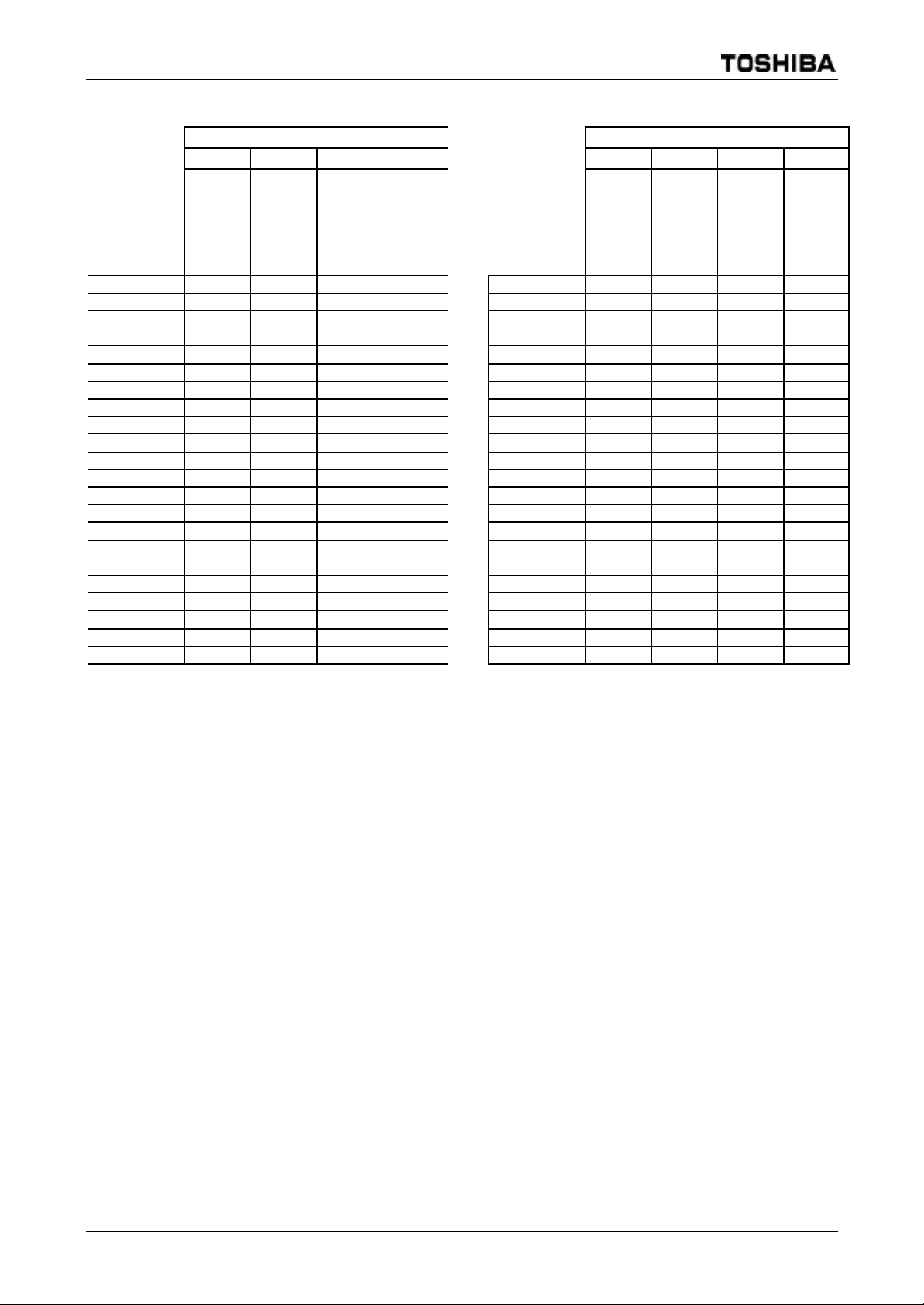

SPECIFICATIONS

Bypassed Operation ,3 Wire Connection

300% 350% 400% 450%

Start Current (%FLC)

C <1000 metres

o

AC53b 3-10:350

45

C <1000 metres

o

AC53b 3.5-15:345

45

C <1000 metres

o

AC53b 4-20:340

45

AC53b 4.5-30:330

TMS7-4007 18 18 16 14

TMS7-4015 34 34 34 28

TMS7-4018 41 41 41 34

TMS7-4022 47 47 47 39

TMS7-4030 67 62 54 47

TMS7-4037 88 82 71 61

TMS7-4045 96 90 78 66

TMS7-4055 125 120 103 88

TMS7-4075 141 127 111 96

TMS7-4090 202 187 162 140

TMS7-4110 238 224 194 166

TMS7-4132 254 228 198 172

TMS7-4150 302 285 245 209

TMS7-4185 405 395 336 282

TMS7-4220 513 513 435 356

TMS7-4250 585 585 504 410

TMS7-4315 628 626 528 436

TMS7-4400 775 775 672 542

TMS7-4500 897 897 798 632

TMS7-4600 1153 1153 1006 850

TMS7-4700 1403 1403 1275 1060

TMS7-4800 1574 1574 1474 1207

Bypassed Operation, 6 Wire Connection

300% 350% 400% 450%

Start Current (%FLC)

C <1000 metres

o

45

C <1000 metres

o

AC53b 3-10:350

45

C <1000 metres

o

AC53b 3.5-15:345

45

C <1000 metres

o

AC53b 4-20:340

45

C <1000 metres

o

AC53b 4.5-30:330

45

TMS7-4007 27 27 24 20

TMS7-4015 51 51 51 42

TMS7-4018 62 62 62 52

TMS7-4022 71 71 71 59

TMS7-4030 101 94 82 71

TMS7-4037 132 122 106 91

TMS7-4045 144 136 117 99

TMS7-4055 188 181 155 132

TMS7-4075 212 190 166 145

TMS7-4090 303 281 243 210

TMS7-4110 357 336 290 250

TMS7-4132 381 342 297 259

TMS7-4150 453 427 368 314

TMS7-4185 608 592 504 424

TMS7-4220 770 770 653 534

TMS7-4250 878 878 756 614

TMS7-4315 942 939 793 654

TMS7-4400 1163 1163 1009 813

TMS7-4500 1346 1346 1197 948

TMS7-4600 1730 1730 1509 1276

TMS7-4700 2105 2105 1912 1591

TMS7-4800 2361 2361 2212 1811

6 ME00070B TMS7 SERIES

Page 7

SPECIFICATIONS

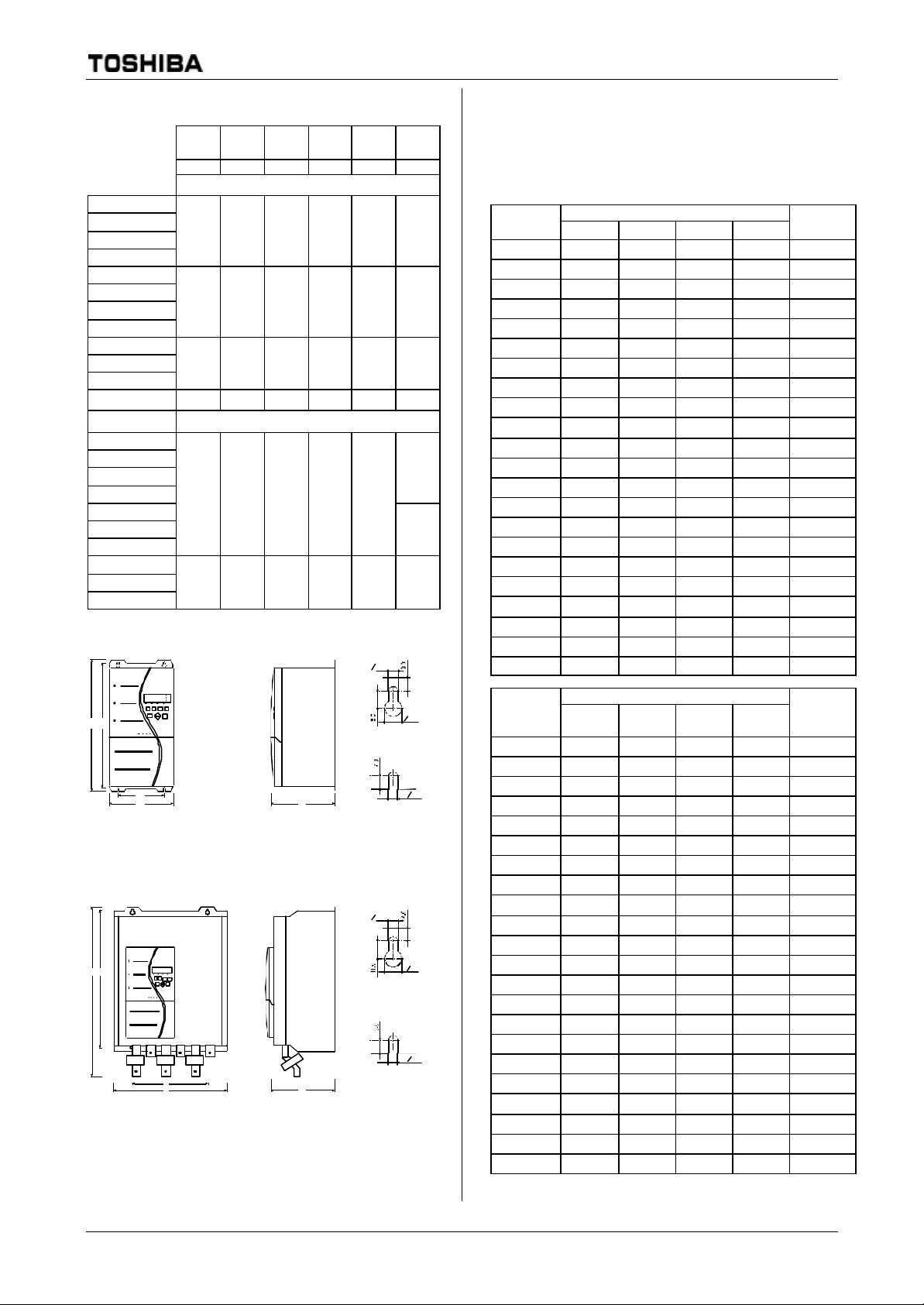

3.2 Dimensions & Weights

TMS7-4007

TMS7-4015

TMS7-4018

TMS7-4022

TMS7-4030

TMS7-4037

TMS7-4045

TMS7-4055

TMS7-4075

TMS7-4090

TMS7-4110

TMS7-4132

IP00

TMS7-4150

TMS7-4185

TMS7-4220

TMS7-4250

TMS7-4315

TMS7-4400

TMS7-4500

TMS7-4600

TMS7-4700

TMS7-4800

TMS7-4007 ~ TMS7 -4132

A a

b

B

TMS7-4150 ~ TMS7 -4800

A a

A B C a b Wei

mm mm mm mm mm Kg

IP42/NEMA 1

380 185 180 365 130 6

380 185 250 365 130 7

425 270 275 410 200 17.5

425 390 275 410 300 23

690 430 294 522 320

855 574 353 727 500 120

b

B

3.3 Semiconductor Fuses

Semiconductor fuses can be used with the TMS7 to reduce the

ght

42

49

o 6.5

o 12.0

C

o 6.5

o 9.0

o 16

o 9.0

C

potential of damage to SCRs from transient overload currents

and for Type 2 coordination. Suitable Bussman semiconductor

fuses are detailed below.

Fuses

TMS7-4007

TMS7-4015

TMS7-4018

TMS7-4022

TMS7-4030

TMS7-4037

TMS7-4045

TMS7-4055

TMS7-4075

TMS7-4090

TMS7-4110

TMS7-4132

TMS7-4150

TMS7-4185

TMS7-4220

TMS7-4250

TMS7-4315

TMS7-4400

TMS7-4500

TMS7-4600

TMS7-4700

TMS7-4800

Series

Fuses

TMS7-4007

TMS7-4015

TMS7-4018

TMS7-4022

TMS7-4030

TMS7-4037

TMS7-4045

TMS7-4055

TMS7-4075

TMS7-4090

TMS7-4110

TMS7-4132

TMS7-4150

TMS7-4185

TMS7-4220

TMS7-4250

TMS7-4315

TMS7-4400

TMS7-4500

TMS7-4600

TMS7-4700

TMS7-4800

Supply Voltage F Series

≤415VAC ≤525VAC ≤575VAC ≤695VAC

63AFE 63AFE 63AFE 63AFE

160AFEE 160AFEE 160AFEE 160AFEE

200FM 180FM 180FM 180FM

200FM 180FM 180FM 180FM

200FM 180FM 180FM 180FM

250FM 250FM 250FM 250FM

250FM 250FM 250FM 250FM

250FM 250FM 250FM 250FM

280FM 280FM 280FM 280FM

500FMM 450FMM 450FMM 450FMM 145,000

630FMM 630FMM 630FMM 630FMM 414,000

630FMM 630FMM 630FMM 630FMM 414,000

630FMM 500FMM 500FMM 500FMM 211,000

500FMM 500FMM 500FMM 500FMM 320,000

700FMM 700FMM 700FMM 700FMM 781,000

*500FMM *500FMM *500FMM *500FMM 1,200,000

*500FMM *500FMM *500FMM *500FMM 1,200,000

*700FMM *700FMM *700FMM *700FMM 2,532,000

- - - - 4,500,000

- - - - 4,500,000

- - - - 6,480,000

- - - - 12,500,000

Supply Voltage 170M

≤415VAC ≤525VAC ≤575VAC ≤695VAC

170M1315 170M1314 170M1314 170M1314

170M1319 170M1317 170M1317 170M1317

170M1319 170M1318 170M1318 170M1318

170M1319 170M1318 170M1318 170M1318

170M1319 170M1318 170M1318 170M1318

170M3017 170M3017 170M3017 170M3017

170M1322 170M1321 170M1321 170M1321

170M1322 170M1322 170M1322 170M1322

170M1322 170M1322 170M1322 170M1322

170M6141 170M6141 170M6141 170M6141 145,000

170M3023 170M3023 170M3023 170M3023 414,000

170M3023 170M3023 170M3023 170M3023 414,000

170M5144 170M5144 170M5144 170M5144 211,000

170M6012 170M4016 170M6011 170M6011 320,000

170M6014 170M6014 170M4018 170M4018 781,000

170M5017 170M6015 170M6014 170M6014 1,200,000

170M6019 170M6018 170M6017 170M6017 1,200,000

170M6021 170M6020 170M6017 170M6017 2,532,000

170M6021 170M6020 170M6151 170M6151 4,500,000

170M6021 170M6020 170M6151 170M6151 4,500,000

170M6021 170M6021 *170M5018 *170M5018 6,480,000

170M6021 170M6021 *170M5018 *170M5018 12,500,000

Starter

Starter

*Two parallel connected fuses required per phase

I2t

1,150

10,500

15,000

18,000

15,000

51,200

80,000

97,000

97,000

I2t

1,150

10,500

15,000

18,000

15,000

51,200

80,000

97,000

97,000

TMS7 SERIES ME00070B 7

Page 8

SPECIFICATIONS

TMS7-4600 ~ TMS7-4800

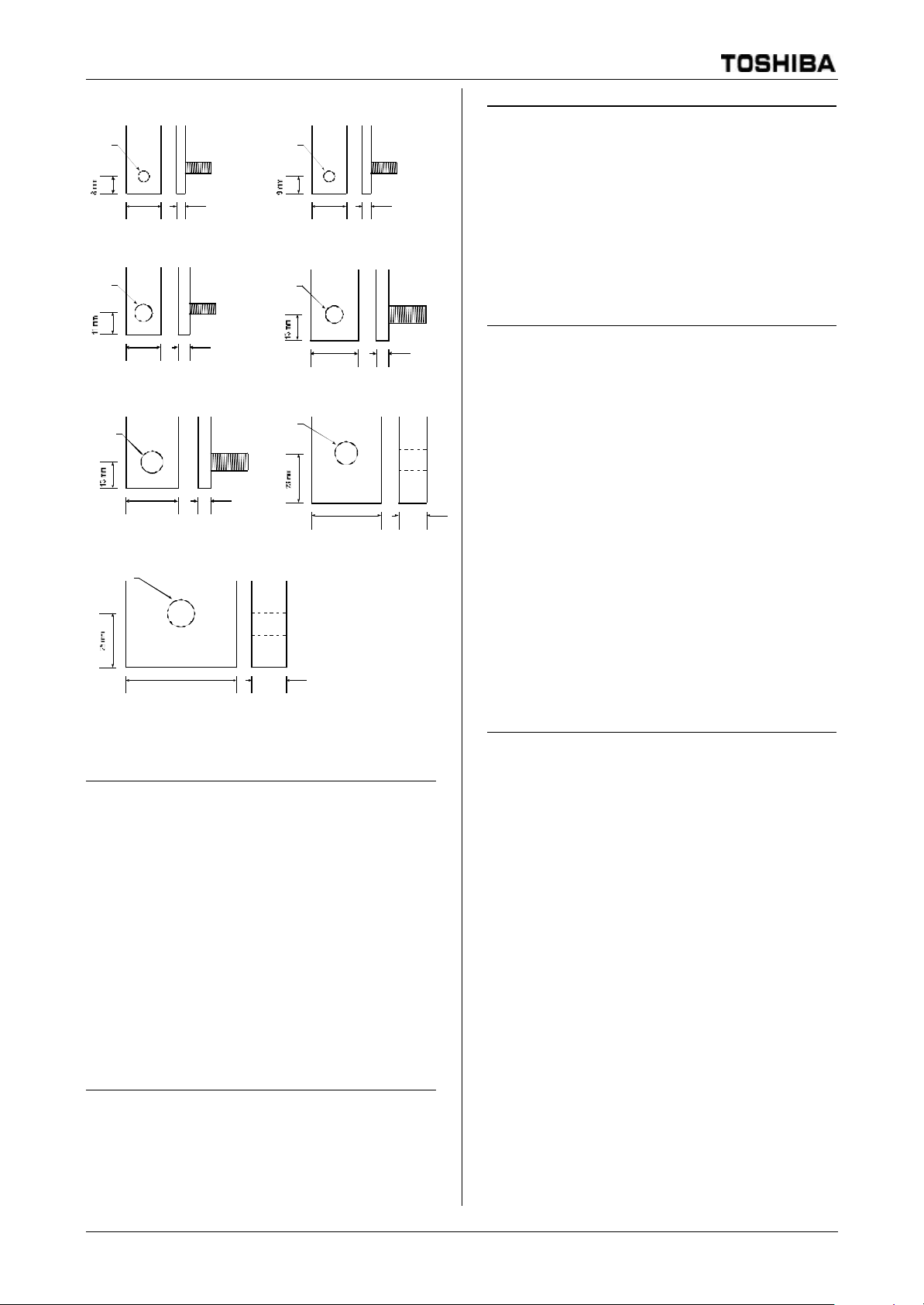

3.4 Power Terminations

6 mm

3 mm14 mm

TMS7-4007~ TMS7-4022

(3.5 NM, 2.6 FT-LBS)

8 mm

5 mm20 mm

TMS7-4075

(8.5 NM, 6.3 FT-LBS)

10 mm

6 mm28 mm

TMS7-4132

(17 NM, 12.5 FT-LBS)

12.5 mm

3.5 General Technical Data

Supply

Supply voltage (V5 models) ...... 3 x 200~525VAC (3 Wire Connection)

3 x 200~440VAC (6 Wire Connection)

Supply voltage (V7 models) .... 3 x 200~ 690VAC (3 Wire Connection)

3 x 200~440VAC (6 Wire Connection)

Electronics Supply (C24 models) ................... 230VAC (+10%/ -15%)

or 400VAC (+10%/ -15%)

Electronics Supply (C45 models) ................... 460VAC (+10%/ -15%)

or 575VAC (+10%/ -15%)

Supply frequency (at start) ......................................... 50Hz (± 2Hz)

or 60Hz (±2Hz)

Supply frequency (during start) ...................... > 45Hz (50Hz supply)

or > 55Hz (60Hz supply)

Supply frequency (during run) .......................... >48Hz (50Hz supply)

or > 58Hz (60Hz supply)

Control Inputs

Start (I34,I33) ................ Normally Open, Active 24VDC, 8mA approx.

Stop (I22,I21) ............. Normally Closed, Active 24VDC, 8mA approx.

Reset (I12,I11) ............ Normally Closed, Active 24VDC, 8mA approx.

FLC Select (I44,I43) .......Normally Open, Active 24VDC, 8mA approx.

6 mm

TMS7-4030~ TMS7-4055

(3.5 NM, 2.6 FT-LBS)

8 mm

10.5 mm

16 mm51 mm

4 mm16 mm

TMS7-4090 ~ TMS7-4110

(8.5 NM, 6.3 FT-LBS)

TMS7-4150 ~ TMS7-4500

6 mm26 mm

13 mm32 mm

Outputs

Run Output (R34,R33) .......... Normally Open, 5A @ 250VAC/360VA

...................................................................5A @ 30VDC resistive

Prog. Output A (R44,R43) ..... Normally Open, 5A @ 250VAC/360VA

...................................................................5A @ 30VDC resistive

Prog. Output B (R24,R23) .... Normally Open, 5A @ 250VAC/360VA,

...................................................................5A @ 30VDC resistive

Prog Output C (R14,R12,R11) ... Changeover, 5A @ 250VAC/360VA

....................................................................5A @ 30VDC resistive

Analogue Output (C6,C7).................................................. 4-20mA

Sundry

Enclosure Rating TMS7-4007~4132 ........................ IP42 (NEMA 1)

Enclosure Rating TMS7-4150~4800................. IP00 (Open Chassis)

Rated short-circuit current (with semi-conductor fuses) ............ 100kA

Rated insulation voltage ...................................................... 690 V

Surges ......................................... 2kV line to earth, 1kV line to line

Fast transients ...................................................... 2.0kV / 5.0 kHz

Rated impulse withstand voltage ............................................ 2 kV

Form designation .............................................................. Form 1

Electrostatic discharge ...... 4kV contact discharge, 8 kV air discharge

Equipment class (EMC) ................................................... Class A1

Radio-frequency electromagnetic field 0.15 MHz - 80 MHz: 140dBµV

.................................................................80 MHz - 1 GHz: 10 V/m

Pollution degree ................................................ Pollution Degree 3

Operating Temperatures ............................................ -5oC / +60oC

Relative Humidity ........................... 5 – 95% (max non condensing)

1

This product has been designed for class A equipment. Use of

the product in domestic environments may cause radio

interference, in which case the user may be required to employ

additional mitigation methods.

Standards Approvals

CE ..................................................................... IEC 60947-4-2

UL1 ................................................................................ UL508

C-UL1 ............................................................. CSA 22.2 No.14

Cü .............................................. AS/NZS 3947-4-2, CISPR-11

1

Requires the use of semi-conductor fuses; is applicable for

supply voltages up to 600V; excludes models TMS -4600 ~

TMS7-4800.

8 ME00070B TMS7 SERIES

Page 9

INSTALLATION

Input/OutputInputOutput

100mm Minimum Clearance100mm Minimum Clearance100mm Minimum Clearance

200mm Minimum Clearance200mm Minimum Clearanc

e

Installation

6.1 General Layout Diagrams

TMS7-4007 ~ TMS7 -4055

TMS7-4075 ~ TMS7 -4132

Input/Output Output Input

To adjust the bus bar configuration first remove the TMS7 cover

and main control module. Next loosen and remove the bus bar

fixing bolts. The bus bars can then be removed and reinstalled

into the starter in the desired configuration. The fixing bolts

should then be refitted and tightened to a torque of 8.5NM.

When re-orienting bus bars L1, L2, L3 the current transformers

must also be relocated.

Care must be taken to ensure that foreign matter does not

contaminate the jointing compound and become trapped

between the bus bar and its mounting plate. If the paste does

become contaminated, clean and replace with a jointing

compound suitable for aluminium to aluminium, or aluminium to

copper joints.

4.3 Mounting Instructions

Models TMS7-4007 ~ 4132 can be wall mounted or installed

inside another enclosure. These models can be mounted side

by side with no clearance but a 100mm allowance must be

made top and bottom for air intake and exhaust.

100mm Minimum Clearance100mm Minimum Clearance100mm Minimum Clearance

TMS7-4150 ~ TMS7 -4800

4.2 Power Termination Configuration

The bus bars on models TMS7-4150 ~ TMS7-4800 can be

adjusted to provide four different input/output power terminal

configurations.

Models TMS7-4150 ~ 4800 have an IP00 rating and must be

mounted in another enclosure. These models can be mounted

side by side with no clearance but a 200mm allowance must be

made top and bottom for air intake and exhaust.

200mm Minimum Clearance

200mm Minimum Clearance

TMS7 SERIES ME00070B 9

Page 10

INSTALLATION

4.4 Ventilation

When installing TMS7 starters in an enclosure there must be

sufficient air flow through the enclosure to limit heat rise within

the enclosure. Temperature within the enclosure must be kept

at, or below, the TMS7 maximum ambient temperature rating.

If installing an TMS7 within a totally sealed enclosure a bypass

contactor must be employed to eliminate heat dissipation from

the soft starter during run.

Soft starters dissipate approximately 4.5 watts per amp. The

table below shows air flow requirements for selected motor

currents. If other heat sources are installed in an enclosure

along with the TMS7 an additional air flow allowance must be

made for these items. Note that heat generation from

semiconductor fuses, if used, can be eliminated by installing

these within the bypass loop.

Motor

Amps

100 450 4.5 2.3 270 135

125 563 5.6 2.8 336 168

150 675 6.8 3.4 408 204

175 788 7.9 3.9 474 237

200 900 9.0 4.5 540 270

250 1125 11.3 5.6 678 339

300 1350 13.5 6.8 810 405

350 1575 15.8 7.9 948 474

400 1800 18.0 9.0 1080 540

450 2025 20.3 10.1 1218 609

500 2250 22.5 11.3 1350 675

550 2475 24.8 12.4 1488 744

600 2700 27.0 13.5 1620 810

Heat

(watts)

10 45 0.5 0.2 30 15

20 90 0.9 0.5 54 27

30 135 1.4 0.7 84 42

40 180 1.8 0.9 108 54

50 225 2.3 1.1 138 69

75 338 3.4 1.7 204 102

Required Airflow

m3/min m3/hour

5oC

10oC

5oC

Rise

Rise

Rise

10oC

Rise

10 ME00070B TMS7 SERIES

Page 11

POWER CIRCUITS

Power Circuits

5.1 Overview

TMS7 starters can be wired with a number of different power

circuits depending on application requirements.

5.2 3 Wire Connection

This is the standard connection format. Supply voltage is

connected to the starter input terminals L1, L2 & L3. The motor

cables are connected to the soft starter output terminals T1, T2

& T3.

3 PHASE

SUPPLY

Legend

K1 Line Contactor

F1 Semiconductor Fuses

5.3 3 Wire Connection (Bypassed Operation)

TMS7 starters can be bypassed while the motor is running.

Special terminals (L1B, L2B, L3B) are provided for connection of

the bypass contactor. Use of these terminals enables the TMS7

to continue to provide all protection and current monitoring

functions even when bypassed.

The TMS7 Run Output (Terminals R34 & R33) should be used

to control operation of the bypass contactor. The bypass

contactor can be AC1 rated for the motor full load current.

3 PHASE

SUPPLY

Legend

K1M Line Contactor

K2M Bypass Contactor

F1 Semiconductor Fuses

5.4 6 Wire Connection

TMS7 units are capable of 6 Wire (Inside Delta) connection as

well as 3 Wire connection. When connected in this configuration

the soft starter carries only phase current, this means the motor

FLC current can be 50% greater than the soft starter’s FLC

current rating.

3 PHASE

SUPPLY

Legend

K1 Line Contactor

F1 Semiconductor Fuses

K1M F1

K1M F1

(OP TIONA L)

K1M F1

(OPTIONAL)(OPTIONAL)

L1

L1B

L2

L2B

L3

L3B

K2M

(OPTIONAL)(OPTIONAL)

L1

L1B

L2

L2B

L3

L3B

Run Output

L1

L1B

L2

L2B

L3

L3B

T1

T2

T3

E

T1

T2

T3

E

R33

R34

T1

U1

T2

V1

M

W1

T3

E

M

M

K2M

U2

V2

W2

Connect the three OUTPUT terminals (T1, T2, T3) of the TMS7

to the motor windings ensuring that the connections are made to

one end of each winding only. It is imperative to connect the

output of the TMS7 to the same end of each winding and this is

usually marked on the motor terminations.

L1

L2

L3

MOTOR TERMINALS

6 WIRE CONNECTION

T1

T2

T3

The six terminations to the motor windings are usually arranged

in two rows of three so that the links can be fitted across from

the top three terminations to the lower terminations. In this case

connect the TMS7 to the top terminations only. Connect the

other three motor terminals to the input of the TMS7 in a manner

that connects the end of each winding to a different phase from

the input.

This is most easily achieved by replacing each delta link in the

motor terminal box by one phase of the controller. For example

if the delta links are fitted U1-V2,V1-W2,W1-U2

- Connect the incoming phases to L1,L2,L3 on the TMS7.

- Connect the TMS7 to the motor. T1-U1, T2 -V1, T3 -W1

- Connect the other motor terminals to the TMS7’S input W2-L1,

U2-L2, V2-L3

5.5 6 Wire Connection (Bypassed Operation)

TMS7 units are capable of 6 Wire (Inside Delta) connection and

can be bypassed.

K2 M

(OPTIONAL)

K1M F1

3 PHAS E

S UP PLY

Legend

K 1M Line Con tactor

K 2M Bypass Co ntacto r

F1 Semiconductor Fuses

L1

L1B

L2

L2B

L3

L3B

Run Output

T 1

T2

T3

E

R33

R34

U1

U2

V1

V 2

M

W1

W2

K 2M

5.6 Power Factor Correction

If static power factor correction is employed, it must be

connected to the supply side of the soft starter.

CAUTION:

Under no circumstance should power factor

correction capacitors be connected between the

soft starter and the motor. Connecting power

factor correction capacitors to the output of the

soft starter will result in damage to the soft

starter.

TMS7 SERIES ME00070B 11

Page 12

POWER CIRUCITS

5.7 Line contactors

The TMS7 is designed to operate with or without a line

contactor. In many regions there is a statutory requirement that

a line contactor be employed with electronic motor control

equipment. From a safety point of view, this is the preferable

option, however is not necessary for starter operation. An

additional benefit gained by use of a line contactor is isolation of

the starter SCR’s in the off state, when they are most

susceptible to damage from voltage transients.

The TMS7 can directly control a line contactor via the Main

Contactor Control output.

As an alternative to a line contactor, either a circuit breaker with

a no volt release coil operated by the TMS7 trip output, or a

motor operated circuit breaker can be considered. If a motor

operated circuit breaker is used as a line contactor, the potential

delay between the breaker being told to close and phase power

being applied to the TMS7 could cause the TMS7 to trip on

installation faults. Closing the motorized breaker directly and

using the breaker’s auxiliary contacts, or preferably a slave relay

with gold flash contacts, to control the TMS7 can avoid this.

Line contactors must be selected such that their AC3 rating is

equal to or greater than the full load current rating of the

connected motor.

12 ME00070B TMS7 SERIES

Page 13

CONTROL CIRCUITS

* = default functionality

n

t

Control Circuits

6.1 Electrical Schematic

L1

L1B

3 PHASE

SUPPLY

C45 models

+10

460V

-15

+10

575V

-15

FLC SELECT

START

STOP

RESET

MOTOR

THERMISTOR

C24 models

400V

OROR

230V

L2

L2B

L3

L3B

A1

+10

-15

A2

+10

A3

-15

I44

I43

I34

I33

I22

I21

I12

I11

C1

C2

6.2 Control Supply

Voltage must be connected to the TMS7 control voltage

terminals. The required control voltage is dependent upon the

TMS7 model ordered.

• TMS7xxxx-xx-C24-xx models: 230VAC (A2-A3) or 400VAC

(A1-A2)

• TMS7xxxx-xx-C45-xx models: 460VAC (A1-A2) or 575VAC

(A2-A3)

TMS7 Model Maximum VA

TMS7-4007~TMS7-4022 11VA

TMS7-4030~TMS7-4055 18VA

TMS7-4075~TMS7-4110 24VA

TMS7-4132~TMS7-4500 41VA

TMS7-4600~TMS7-4800 56VA

For circumstances where the available control supply voltage is

not suitable for direct connection to the TMS7 the following

range of auto-transformers are available as accessories. These

auto-transformers can be mounted within the TMS7 in models.

Part Number Input

Voltages

(C24

Models)

110/460

VAC

110/575

VAC

TMS7-4007~

TMS7-40047

995-00821-

00

995-00825-

00

TMS7-4030~

T1

T2

T3

E

C3

C4

GND

C5

R44

R43

R34

R33

R24

R23

R14

R12

R11

C6

C7

TMS7-4110

995-00823-

00

995-00827-

00

TO MOTOR

RS485 SERIAL

INTERFACE

PROGRAMMABLE

OUTPUT A

(Main Contactor)

RUN OUTPUT

PROGRAMMABLE

OUTPUT B

(Start/Run)

PROGRAMMABLE

OUTPUT C

(Tripped)

4-20mA OUTPUT

(MOTOR CURRENT)

TMS7-4132~

TMS7-4800

995-00824-

00

995-00828-

00

Part Number Input

Voltages

(C45

Models)

110/230

VAC

TMS7-4007~

TMS7-4022

995-00829-

00

TMS7-4030~

TMS7-4110

995-00831-

00

TMS7-4132~

TMS7-4800

995-00832-

00

6.3 Control Wiring

TMS7 operation can be controlled using either the local push

buttons, remote control inputs or the serial communications link.

The <LOCAL/REMOTE> push button can be used to switch

between local and remote control. Refer to Function 20.

Local/Remote Operation for details.

Remote Control Inputs

The TMS7 has four remote control inputs. Contacts used for

controlling these inputs should be low voltage, low current rated

(Gold flash or similar).

Remote push button control

I44

FLC Select

I43

I34

Start

I33

I22

Stop

I21

I12

Reset

I1 1

CAUTION:

Do not apply voltage to the control inputs. The

inputs are active 24VDC and must be controlled

with potential free circuits.

Ensure contacts/switches operating the control

inputs are suitable for low voltage, low current

switching ie, gold flash or similar.

Ensure cables to the control inputs are

segregated from AC power and control wiring.

Relay Outputs

The TMS7 provides four relay outputs, one fixed and three

programmable. Functionality of the programmable outputs is

determined by the settings of Functions 21, 22 & 23.

Programmable

R44

Output A

R43

(*Main Contactor)

R34

Run Output

R33

Programmable Output B

R24

(*Start/Run)

R23

R14

Programmable

R12

Output C

(*Tripped)

R1 1

Two wire control

I44

FLC Select

I43

I34

Start

I33

I22

Stop

I21

I12

Reset

I1 1

Functionality Assignme

- Tripped

- Overcurrent trip

- Undercurrent trip

- Motor thermistor trip

- Starter overtemperature

- Phase imbalance trip

- Electronic shearpin trip

- Low current alarm

- High current alarm

- Motor overload alarm

- Start/Run

- Main Contactor

TMS7 SERIES ME00070B 13

Page 14

CONTROL CIRCUITS

Power cabling should be kept at least 300mm away

Start signal

Output voltage

RELAY FUNCTIONS

Main contactor

Start/Run

Run

Pre-start T ests

Motor Thermistors

Motor thermistors (if installed in the motor) may be connected

directly to the TMS7. A trip will occur when the resistance of the

thermistor circuit exceeds approximately 2.8kΩ. The TMS7 can

be reset once the thermistor circuit resistance falls below

approximately 2.8kΩ

No motor thermistors

Motor thermistors

C1

Thermistor Input

C2

C1

Thermistor Input

C2

NOTE:

The thermistor circuit must be closed before the

TMS7 will run.

The thermistor circuit should be run in screened

cable and must be electrically isolated from earth

and all other power and control circuits.

If no motor thermistors are connected to the TMS7

thermistor input there must be a link across the

thermistor input terminals C1 & C2.

6.4 RS485 Serial Communication

The TMS7 has a non-isolated RS485 serial communication link.

C3

-

RS485 GND

NOTE:

from communications cabling. Where this cannot

be avoided magnetic shielding should be provided

to reduce induced common mode voltages.

Data transmitted to and from the TMS7 must be in 8 bit ASCII,

no parity, 1 stop bit.

Baud rate is set by Function. 61 RS485 Baud Rate.

The TMS7 can be programmed to trip if the RS485 link fails by

setting Function 60. RS485 Timeout.

The starter address is assigned using Function 62. RS485

Satellite Address.

The flow charts below show typical form of communication

between an TMS7 and host controller.

C4

+

C5

Host controller to TMS7

START

SEND TMS7

LRC

ERROR

SEND REQUEST

TIMEOUT

RECEIVE DA TA

N

DATA

RECIEVED

N

LRC

VALID

Y

SLAVE ADDRESS

ACK

N

RECEIVED TIMEOUT

Y

D C

DATA/

COMMAND

N

Y

TIMEOUT

ERROR

END

N

SEND COMMAND

YY

TIMEOUT

N

ACK

RECEIVED

Y

Y

N

TMS7 to host controller

START

N

EOT

DETECT

Y

RECEIVE

ADDRESS

ENQ

Y

N

LRC

VALID

Y

N

ADDRESS

VALID

Y

SEND ACK

N

STX EOT

Y

RECEIVE DATA

N

ETX

Y

N

LRC

VALID

SEND

DATA

SEND DATA SEND ACK

SEND NAK

Y

N

CONTROL TMS7

Y

N

YN

EOT

N

Y

N

Y

EOT

The following code sequences are used in the communications

between the host and the TMS7 (network).

Address slave unit.

ASCII EOT [nn] LRC

ENQ

or 04h [n1]h [n2]h [LRC1]h [LRC2]h

05h

Slave response.

ASCII ACK

or 06h

14 ME00070B TMS7 SERIES

Page 15

CONTROL CIRCUITS

NOTE:

If no TMS7 starter is configured to the specific

slave address, no response will be received by the

host. The host software timeout should be set to a

minimum of 250 ms.

NOTE:

Slave address must be two digit, addresses less

than 10 must have a leading zero (0).

Master command to slave.

ASCII STX [command] LRC ETX

or 02h [c1]h [c2]h [c3]h [LRC1]h [LRC2]h 03h

[command] = 3 byte ASCII command (or request) selected from

the tables below.

LRC = Longitudinal Redundancy Check.

Slave response if Command and LRC correct

ASCII ACK

or 06h

Slave response if Command and LRC incorrect

ASCII NAK

or 15h

Slave response of Read request correct and LRC correct.

ASCII STX [data] LRC

ETX

or 02h [d3]h [d2]h [d1]h [d0]h [LRC1]h [LRC2]h

03h

Slave response if Read request or LRC invalid.

ASCII NAK

or 15h

Each command, status or data request is a 3 byte string as

detailed below. Invalid command/request strings cause the

TMS7 to respond with a NAK (15h).

Command ASCII Comment

Start B10 Initiates a start.

Stop B12 Initiates a stop

Reset B14 Resets a trip state

Coast to

stop

Status

Read

Status C10 Requests the configuration status of the

Status_1 C12 Requests the operational status of the

Trip C14 Requests the trip status of the TMS7.

Version C16 RS485 protocol version number.

Trip Code C18 255 = No trip

B16 Initiates an immediate removal of

voltage from the motor. Any soft

settings are ignored.

ASCII Comment

TMS7.

TMS7.

0 = Shorted SCR

1 = Reserved

2 = Motor Thermal model trip

3 = Motor thermistor

4 = Current imbalance trip

5 = Supply frequency trip

Status

Read

Data Read ASCII Comment

Current D10 Requests motor current. The data is 4

Temp D12 Requests the calculated value of the

Each command string sent to and from the TMS7 includes a

check sum. The form used is the Longitudinal Redundancy

Check (LRC) in ASCII hex. This is an 8-bit binary number

represented and transmitted as two ASCII hexadecimal

characters.

To calculate LRC:

1. Sum all ASCII bytes

2. Mod 256

3. 2's complement

4. ASCII convert

For example Command String (Start);

ASCII STX B 1 0

or 02h 42h 31h 30h

ASCII Hex Binary

STX 02h 0000 0010

B 42h 0100 0010

1 31h 0011 0001

0 30h 0011 0000

A5h 1010 0101 SUM (1)

A5h 1010 0101 MOD 256 (2)

5Ah 0101 1010 1's COMPLEMENT

01h 0101 1011 + 1 =

5Bh 0101 1011 2's COMPLEMENT (3)

ASCII 5 B ASCII CONVERT (4)

or 35h 42h LRC CHECKSUM

The complete command string becomes

ASCII STX B 1 0 5 B ETX

or 02h 42h 31h 30h 35h 42h 03h

To verify a received message containing an LRC;

1. Convert the last two bytes of message from ASCII to

binary.

2. Left shift 2nd to last byte 4 bits.

3. Add this result to the last byte to get the binary LRC.

4. Add up all the bytes of the message, except the last two.

5. Add the binary LRC.

6. The least significant byte should be zero.

For example:

ASCII STX B 1 0 5 B

ETX

ASCII Comment

6 = Phase rotation trip

7 = Stall trip

8 = Power circuit fault

9 = Undercurrent trip

10 = Starter heatsink

overtemperature

11 = Invalid motor connection

byte decimal ASCII. Minimum value

0000, Maximum value 9999 Amps.

motor thermal model as a % of Motor

Thermal Capacity. The data is 4 byte

decimal ASCII. Minimum value 0000%.

Trip point 0105%.

TMS7 SERIES ME00070B 15

Page 16

CONTROL CIRCUITS

or 02h 42h 31h 30h 35h 42h

03h

1. 35h (ASCII hex) = 5H = 00000101

42h (ASCII hex) = Bh = 00001011

Note: 03h is the EXT character (end of transmission) and is

not part of the message.

2. 00000101 = 01010000

3. 01010000 + 00001011 = 01011011

4. 02h + 42h + 31h + 30h = A5h

5. A5h + 5Bh = 100h

6. The least significant byte is zero so the message and

LRC match.

Response or status bytes are sent from the TMS7 as an ASCII

string.

STX [d1]h [d2]h [d3]h [d4]h LRC1 LRC2 ETX

d1 = 30h

d2 = 30h

d3 = 30h plus upper nibble of status byte right shifted by four

binary places.

d4 = 30h plus lower nibble of status byte.

For example status byte = 1Fh, response is

STX 30h 30h 31h 3Fh LRC1 LRC2 ETX

Status bits (positive logic 1 = true)

Status

Bit

Status.7 50 Hz Only one of either Status.7 or

Status.6 60 Hz

Status.5 - Unallocated

Status.4 Soft stop

Status.3 Positive

Status.2 - Unallocated

Status.1 - Unallocated

Status.0 - Unallocated

Status_1 bits (negative logic 0 = true)

Status Bit Function Comment

NOT

Status_1.7

NOT

Status_1.6

NOT

Status_1.5

NOT

Status_1.4

NOT

Status_1.3

NOT

Status_1.2

NOT

Status_1.1

NOT

Status_1.0

Function Comment

Status.6 can be at logic 1 when the

TMS7 is operating.

Will be at logic 0 when there is a

phase

rotation

Restart

Delay

Overload Motor is operating in an overload

Run

Output On

Power On

negative phase rotation.

-

-

-

condition.

Trip bits (negative logic 0 = true). The table below shows the

complement of these bits to give positive logic (1 = true).

Status Bit Function

NOT Trip.7 Phase Loss

NOT Trip.6 Undercurrent

NOT Trip.5 Phase Rotation

NOT Trip.4 Overcurrent

NOT Trip.3 Over Temperature

NOT Trip.2 Installation

NOT Trip.1 Stall Protection

NOT Trip.0 Thermistor

16 ME00070B TMS7 SERIES

Page 17

PROGRAMMING

Programming

7.1 Programming Procedure

Step 1. Enter program mode.

1. Simultaneously press and release the <FUNCTION> and

<STORE> keys. (When in program mode the three LEDs

to the right of the numeric display will be illuminated.)

Step 2. Select the function number to be viewed

or adjusted.

1. Press and hold the <FUNCTION> key.

2. Using the <UP> and <DOWN> keys select the required

function number. (Function numbers are left justified

and blink).

3. When the required function number is dispalyed,

release the <FUNCTION> key. The display changes to

show the function set point currently stored in memory.

(Function values are right justified and do not blink)

Step 4. Store the new function set point.

1. Press the <STORE> key to store the displayed setting

into memory.

2. Verify the new set point has been correctly stored by

pressing and then releasing the <FUNCTION> key. The

LED display should now show the new set point.

Step 5. Exit program mode.

1. Once all function settings have been made, exit the

programming mode by simultaneously pressing and

releasing the <FUNCTION> and <STORE> keys.

Step 3. Alter the function set point.

1. Review the current function set point and, if necessary,

use the <UP> or <DOWN> keys to adjust the setting.

(Pressing the <FUNCTION> key will restore the original

setting).

TMS7 SERIES ME00070B 17

Page 18

PROGRAMMING

7.2 Function List

No. Function

Primary Motor Settings

Default

Setting

1 Motor full load current 2 Current limit 350

3 Minimum current 350

4 Start ramp time 1

5 Stop ramp time 0

6 Motor trip class 10

7 Current imbalance sensitivity 5

8 Undercurrent protection 20

9 Stall protection 400

Start/Stop Formats

10 Soft stop mode 0

Starter Functionality

20 Local/Remote operation 0

21 Relay output A functionality 11

22 Relay output B functionality 10

23 Relay output C functionality 0

Protection Settings

30 Phase rotation 0

31 Restart delay 15

32 Current imbalance 0

Set Points

40 Low current alarm 50

41 High current alarm 105

42 Motor temperature alarm 80

43 Field calibration 100

Analogue Output (Motor Current - % FLC)

50 4-20mA output range - max 100

51 4-20mA output range - min 0

Serial Communications

60 RS485 timeout 0

61 RS485 baud rate 4

62 RS485 satellite address 20

Auto Reset

70 Auto-reset - configuration 0

71 Auto-reset - number of resets 1

72 Auto-reset - group A & B delay 5

73 Auto-reset - group C delay 5

Secondary Motor Settings

80 Motor full load current 81 Current limit 350

82 Minimum current 350

83 Start ramp time 1

84 Stop ramp time 0

85 Motor trip class 10

86 Current imbalance sensitivity 5

87 Undercurrent protection 20

88 Stall protection 400

Protection Delays

90 Current imbalance trip delay 3

Read Only Data

100 Model Number 101 Fault History -

Restricted Functions

110 Access code 0

111 Update access code 0

112 Function lock 0

113 Restore function settings 0

7.3 Function Descriptions

1. Motor Full Load Current

Range: Model Dependant (Amps)

Default Setting: Model Dependant (Amps)

Description: Sets the TMS7 for the connected motor’s full load

current.

Adjustment: Set to the Full Load Current (amps) rating shown

on the motor nameplate.

2. Current Limit

Range: 100 – 550 % FLC

Default Setting: 350% FLC

Description: Sets the current limit for the Constant Current start

mode.

eg. Function 2. Current Limit = 350% x FLC

700%

500%

300%

100%

50% 100%

ROTOR SPEED

(% Full Speed)

Adjustment: The required setting for the Current Limit function

is installation dependant and should be set such that:

• The motor is supplied with sufficient start current to enable

it to produce torque adequate to easily accelerate the

connected load.

• Desired starting performance is obtained.

• TMS7 ratings are not exceeded.

3. Minimum Curr ent

Range: 100 – 550 % FLC

Default Setting: 350% FLC

Description: Sets the minimum current level for the Ramp Start

mode.

Function. 2 Current Limit = 350% x FLC

Function. 3 Minimum Current = 200% x FLC

Function. 4 Start Ramp Time = 10 secs

700%

500%

300%

100%

50% 100%

ROTOR SPEED

(% Full Speed)

18 ME00070B TMS7 SERIES

Page 19

PROGRAMMING

thermal model. Use this setting only if another form

Using a reduced MTC figure has the advantage

display, and adjusting the MTC parameter such

MTC = 5 Sec

MTC = 20 Sec

Adjustment: Function 3 Minimum Current and Function 4 Start

Ramp Time are used together to activate and control the Ramp

Start mode.

If the Ramp Start mode is required, set the Minimum Current so

that the motor begins to accelerate immediately a start is

initiated. Ramp Start mode is not required, set the Minimum

Current equal to the Current Limit.

Ramp Start mode should be considered in preference to Current

Limit start mode in applications where:

• Required start torque can vary from start to start. For

example conveyors may start loaded or unloaded. In this

case set Function 3 Minimum Current to a level that will

start motor in the light load condition and Function 2

Current Limit to a level that will start the motor in the high

load condition.

• Starting time of an easily broken away load needs to be

extended, for example pumps.

• A generator set supply is limited and a slower application

of load will allow greater time for the generator set to

respond.

4. Start Ramp Time

Range: 1 – 30 Seconds

Default Setting: 1 Second

Description: Sets the ramp time for the Current Ramp start

mode.

Adjustment: Set the Start Ramp Time to optimise start

performance.

5. Stop Ramp Time

Range: 0 – 100 Seconds

Default Setting: 0 Second (Off)

Description: Sets the soft stop ramp time for soft stopping of

the motor.

Adjustment: Set the Stop Ramp Time to produce the desired

motor stopping performance.

Two soft stop modes are provided by the TMS7. Use Function

10. Soft Stop Mode to select the desired mode.

If utilising the Soft Stop function and a line contactor, the

contactor must not be opened until the end of the stop ramp

time. The TMS7 programmable outputs A,B or C can be set for

control of the line contactor. Refer Functions 21, 22, 23 for

programmable output assignment details.

6. Motor Trip Class

Range: 0 – 60 Seconds

Default Setting: 10 Seconds

Time or Maximum DOL Start Time. This information is available

from the motor data sheet or direct from the motor supplier.

NOTE:

The TMS7 motor thermal model assumes a

locked rotor current of 600%. If the connected

motor’s locked rotor current differs from this,

greater accuracy can be achieved by using a

normalised MTC figure. A normalised MTC

figure can be calculated as follows:

600

2

Time StartMax X

%LRC

= MTC

NOTE:

Setting Function 6 Motor Trip Class according

to the motor’s actual thermal capacity allows

safe use of the motor’s full overload capability

both to start the load and ride through overload

conditions. Additionally, a more conservative

approach can be taken by setting a reduced

MTC for easy to start loads that will not

experience transient operating overloads as a

part of normal operation.

of maximising motor life. The life of a motor is

strongly influenced by its maximum winding

temperature, with a 'rule of thumb' stating that

the expected life span of a motor is halved for

every ten degree rise in temperature. The

temperature rise is dependent on the motor

losses and the motor cooling. The highest

stress on the motor is during start, and can be

minimised by restricting the duration and

frequency of starts. A reduced MTC setting

(Function 6) will also cause the TMS7

protection to operate before the motor is

thermally stressed.

A suitable reduced MTC figure can be

established by observing the modeled motor

temperature as shown on the TMS7 LED

that after a normal start which has been

preceded by a period of running at maximum

load, the calculated motor temperature is

approaching 90%.

10000

1000

t(s)

Cold start curves

NOTE:

A setting of 0 seconds disables the TMS7 motor

of motor protection is used.

Description: Sets the motor thermal capacity used by the TMS7

motor thermal model.

Adjustment: Set the Motor Trip Class (MTC) according to the

motor’s thermal capacity.

A motor’s thermal capacity is expressed as the maximum time

(seconds) a motor can maintain locked rotor current conditions

from cold, and is often referred to as Maximum Locked Rotor

TMS7 SERIES ME00070B 19

100

10

1

100 300 500 700

MTC = 30 Sec

MTC = 10 Sec

I (% FLC)

Page 20

PROGRAMMING

7. Current Imbalance Sensitivity

Range: 1 – 10

1 = Highest sensitivity (lowest imbalance)

I

5 = Average sensitivity

I

10 = Lowest sensitivity (highest imbalance)

Default Setting: 5

Description: Sets the sensitivity of the current imbalance

protection.

Adjustment: The factory setting is suitable for most applications

however the sensitivity can be adjusted to accommodate site

specific tolerances

8. Undercurrent Protection

Range: 15% – 100% FLC

Default Setting: 20% FLC

Description: Sets the trip point for the TMS7 undercurrent

protection as a percentage of motor full load current.

Adjustment: Set to a level below the motors normal working

range and above the motor’s magnetising (no load) current.

To disable the undercurrent protection make a setting less than

the magnetising current of the motor, typically 25% - 35% of

rated Full Load Current.

NOTE:

Undercurrent protection is only operative during

‘run’.

1 = TMS7 Local/Remote push button disabled while motor

running.

2 = Local control only. (TMS7 push buttons enabled, remote

inputs disabled)

3 = Remote control only. (TMS7 push buttons disabled, remote

inputs enabled)

Default Setting: 0 (Local/Remote button enabled)

Description: Enables and disables the local push buttons and

remote control inputs. Also determines when and if the

Local/Remote push button can be used to switch between local

and remote control.

Adjustment: Set as required

21. Relay Output A Functionality

Range: 0 –11

0 = Tripped

1 = Overcurrent trip

2 = Undercurrent trip

3 = Motor thermistor trip

4 = Starter overtemperature trip

5 = Phase imbalance trip

6 = Electronic shearpin trip

7 = Low current alarm

8 = High current alarm

9 = Motor overload alarm

10 = Start/Run

11 = Main contactor.

Start signal

Output voltage

9. Stall Protection

Range: 80% – 550% FLC

Default Setting: 400% FLC

Description: Sets the trip point for the TMS7 stall protection as

a percentage of motor full load current.

Adjustment: Set as required.

NOTE:

Stall protection is operative only during ‘run’.

10. Soft Stop Mode

Range: 0 – 1

0 = Standard soft stop

1 = Pump control

Default Setting: 0 (Standard soft stop)

Description: Sets the active soft stop mode.

Adjustment: The standard soft stop mode automatically

monitors motor deceleration and will provide optimum control for

most applications. Pump control may however offer superior

performance in some applications and can be of particular

benefit in some pumping applications.

20. Local/Remote Operation

Range: 0 – 3

0 = TMS7 Local/Remote push button always enabled.

RELA Y FUNCTIONS

Main contactor

Start/Run

Run

Pre-start Tests

Default Setting: 11 (Main Contactor)

Description: Assigns the functionality of programmable relay

output A.

Adjustment: Set as required

22. Relay Output B Functionality

Range: 0 - 11

Default Setting: 10 (Start/Run)

Description: Assigns the functionality of programmable relay

output B.

Adjustment: Refer Function 21 Relay Output A Functionality for

adjustment detail.

23. Relay Output C Functionality

Range: 0 - 11

Default Setting: 0 (Tripped)

Description: Assigns the functionality of programmable relay

output C.

20 ME00070B TMS7 SERIES

Page 21

PROGRAMMING

Adjustment: Refer Function 21 Relay Output A Functionality for

adjustment detail.

30. Phase Rotation

Range: 0 – 2

0 = Off (forward and reverse rotation accepted)

1 = Forward rotation only (reverse rotation prohibited)

2 = Reverse rotation only (forward rotation prohibited)

Default Setting: 0 (Off)

Description: Sets the valid phase rotations for the TMS7 phase

rotation protection. The TMS7 examines the incoming three

phases and trips if phase rotation does not match the allowable

rotations specified by Function 30.

Adjustment: Set as required.

31. Restart Delay

Range: 1 – 254 seconds

Default Setting: 15 Second

Description: Sets the minimum time between the end of a stop

and the beginning of the next start.

Adjustment: Set as required. During the restart delay period the

LEDs to the right of the TMS7 LED display will flash indicating

the motor cannot yet be restarted.

32. Current Imbalance

Range: 0 – 1

0 = On

1 = Off

Default Setting: 0 (On)

Description: Enables or disables the phase imbalance

protection.

Adjustment: Set as required.

40. Low Current Alarm

Range: 1 – 100% FLC

Default Setting: 50% FLC

Description: Sets the current level (% FLC) at which the low

current alarm operates.

Adjustment: The low current alarm can be assigned to the

Programmable Relay Outputs A, B or C for indication of a motor

current lower than the programmed value.

41. High Current Alarm

Range: 50 – 550% FLC

Default Setting: 105% FLC

Description: Sets the current level (% FLC) at which the high

current alarm operates.

Adjustment: The high current alarm can be assigned to the

Programmable Relay Outputs A, B or C for indication of a motor

current in excess of the programmed value.

42. Motor Temperature Alarm

Range: 0 – 105% Motor Temperature

Default Setting: 80%

Description: Sets the temperature (%) at which the motor

overtemperature alarm operates.

Adjustment: The motor overtemperature alarm can be assigned

to the Programmable Relay Outputs A, B or C for indication of a

motor temperature (as calculated by the Motor Thermal Model)

in excess of the programmed value.

A trip condition occurs when motor temperature reaches 105%.

43. Field Calibration

Range: 85% - 115%

Default Setting: 100%

Description: Adds a gain to the TMS7 current monitoring

circuits. The TMS7 is factory calibrated with an accuracy of ±

5%. The field calibration function can be used to match the

TMS7 current readout with an external current metering device.

Adjustment: Use the following formula to calculate the setting

required.

Field Calibration

(Function 43)

e.g. 96% =

NOTE:

All current based functions are affected by this

adjustment.

Current shown on TMS7 display

=

Current measured by external device

108 Amps

112 Amps

50. 4-20mA Output Range - Max

Range: 0 – 255%

Default Setting: 100 %

Description: Determines the value represented by a 20m A

signal from the analogue output.

Adjustment: Set as required to show percentage of motor

current.

51. 4-20mA Output Range - Min

Range: 0 – 255%

Default Setting: 0 %

Description: Determines the value represented by a 4mA signal

from the analogue output.

Adjustment: Set as required to show percentage of motor

current.

60. RS485 Timeout

Range: 0 – 100 Seconds

Default Setting: 0 seconds (Off)

Description: Sets the maximum allowable period of RS485

serial inactivity.

Adjustment: Set as required.

NOTE:

A setting of 0 seconds disables the RS485 –

Timeout Protection and enables the TMS7 to

continuing operating even if the RS485 link

becomes inactive.

TMS7 SERIES ME00070B 21

Page 22

PROGRAMMING

61. RS485 Baud Rate

Range: 1 – 5

1 = 1200 baud

2 = 2400 baud

3 = 4800 baud

4 = 9600 baud

5 = 19200 baud

Default Setting: 4 (9600 baud)

Description: Sets the baud rate for RS485 serial activity.

Adjustment: Set as required.

62. RS485 Satellite Address

Range: 1 - 99

Default Setting: 20

Description: Assigns the TMS7 an address for RS485 serial

communication.

Adjustment: Set as required.

70. Auto-Reset - Configuration

Range: 0 – 3

0 = Off

1 = Reset Group A trips

2 = Reset Group A & B trips

3 = Reset Group A, B & C trips

Default Setting: 0 (Off)

Description: Determines which trips will be automatically reset.

Adjustment: A setting of other than 0 causes the TMS7 to

automatically reset, and after a delay if the start signal is still

present, attempt to start the motor. The Auto -reset function can

be programmed to reset faults according to the table below:

Trip Group Trip Conditions

A Phase imbalance, Phase loss

B Undercurrent, Electronic shearpin

C Overcurrent, Motor thermistor, Starter

overtemperature

Operation of the Auto-reset function is controlled according to

the following function settings:

Function 70. Auto-reset – Configuration

Function 71. Auto-reset – Number of resets

Function 72. Auto-reset – Group A & B Delay

Function 73. Auto-reset – Group C Delay

CAUTION:

Operation of the auto-reset function will reset a

trip state and if the start signal is still present,

allow the motor to restart. Ensure that personal

safety is not endangered by such operation and

that all relevant safety measures and/or

regulations are complied with before utilising this

function.

71. Auto-Reset – Number Of Resets

Range: 1 - 5

Default Setting: 1

Description: Sets maximum number of reset attempts for the

Auto-reset function.

Adjustment: The Auto-reset counter increases by one after

each trip, up to the maximum number of resets set in Function

71. Auto-Reset – Number Of Resets. The fault is then latched

and a manual reset is required.

The Auto-reset counter decreases by one, to a minimum of zero,

after each successful start/stop cycle.

Refer Function 70 Auto-Reset – Configuration for further detail.

72. Auto-Reset – Group A & B Delay

Range: 5 – 999 seconds

Default Setting: 5 seconds

Description: Sets the delay for resetting of Group A & B trips.

Adjustment: Refer Function 70 Auto-Reset – Configuration for

further detail.

73. Auto-Reset – Group C Delay

Range: 5 – 60 minutes

Default Setting: 5 minutes

Description: Sets the delay for resetting of Group C trips.

Adjustment: Refer Function 70 Auto-Reset – Configuration for

further detail.

TMS7 soft starters can be programmed with two separate

sets of motor data. The primary motor settings are adjusted

using Functions 1 ~ 9. The secondary motor settings are

adjusted using Functions 80 ~ 88.

When commanded to start the TMS7 checks the state of the

FLC Select input (Terminals I43 & I44). In the event of an

open circuit the primary motor settings are used. In the

event of a closed circuit the secondary motor settings are

used.

80. Motor Full Load Current

Range: Model Dependant (Amps)

Default Setting: Model Dependant (Amps)

Description: Sets the TMS7 for the connected motor’s full load

current.

Adjustment: Refer to Function 1 for further detail.

81. Current Limit

Range: 100 – 550 % FLC

Default Setting: 350% FLC

Description: Sets the current limit for the Constant Current start

mode.

Adjustment: Refer to Function 2 for further detail.

82. Minimum Current

Range: 100 – 550 % FLC

Default Setting: 350% FLC

Description: Sets the minimum current level for the Ramp Start

mode.

Adjustment: Refer to Function 3 for further detail.

22 ME00070B TMS7 SERIES

Page 23

PROGRAMMING

thermal model. Use this setting only if another form

83. Start Ramp Time

Range: 1 – 30 Seconds

Default Setting: 1 Second

Description: Sets the ramp time for the Current Ramp start

mode.

Adjustment: Refer to Function 4 for further detail.

84. Stop Ramp Time

Range: 0 – 100 Seconds

Default Setting: 0 Second (Off)

Description: Sets the soft stop ramp time for soft stopping of

the motor.

Adjustment: Refer to Function 5 for further detail.

85. Motor Trip Class

Range: 0 – 60 Seconds

Default Setting: 10 Seconds

NOTE:

A setting of 0 seconds disables the TMS7 motor

of motor protection is used.

Description: Sets the motor thermal capacity used by the TMS7

motor thermal model.

Adjustment: Refer to Function 6 for further detail.

86. Current Imbalance Sensitivity

Range: 1 – 10

1 = Highest sensitivity (lowest imbalance)

I

5 = Average sensitivity

I

10 = Lowest sensitivity (highest imbalance)

Default Setting: 5

Description: Sets the sensitivity of the current imbalance

protection.

Adjustment: Refer to Function 7 for further detail.

87. Undercurrent Protection

Range: 15% – 100% FLC

Default Setting: 20% FLC

Description: Sets the trip point for the TMS7 undercurrent

protection as a percentage of motor full load current.

Adjustment: Refer to Function 8 for further detail.

88. Stall Protection

Range: 80% – 550% FLC

Default Setting: 400% FLC

Description: Sets the trip point for the TMS7 stall protection as

a percentage of motor full load current.

Adjustment: Refer to Function 9 for further detail.

90. Current Imbalance Trip Delay

Range: 3 – 254 Seconds

Default Setting: 3 Seconds

Description: Sets the delay period between detection of a

phase imbalance greater than allowed by the setting made in

Function 7 & 86. Current Imbalance Sensitivity and a trip

condition.

Adjustment: Set as required.

100. Model Number

Range: 1 - 22

Default Setting: Model Dependant

Description: A diagnostic parameter used to identify the power

assembly type.

101. Fault History

Range: n/a

Default Setting: n/a

Description: Displays the TMS7 Fault History.

Adjustment: Use the <UP> and <DOWN> keys to scroll

through the trip log.

Refer to Section 9, Trouble Shooting Procedure for a description

of the trip log and fault conditions.

110. Password

Range: 0 - 999

Default Setting: 0

Description: Entering the correct password does two things

1. Temporarily changes the function lock to Read/Write

irrespective of the state specified by Function 112 Function

Lock. This allows function settings to be adjusted during the

current programming session. On exit of the current

programming session function settings are again protected

according to Function 112. Function Lock.

2. Provides access to parameters 111 - 113.

Adjustment: Enter password. The default password is 0.

Contact your supplier if the password is lost or forgotten

111. Update Password

Range: 0 - 999

Default Setting: 0

Description: Changes the current password.

Adjustment: Set as required, remembering to make note of the

new password.

112. Function Lock

Range: 0 – 1

0 = Read/Write

1 = Read Only

Default Setting: 0 (Read / Write)

Description: Allows protection of all function settings. Note that

when this function has been changed from 0 (Read/Write) to 1

(Read Only) the new setting takes effect only when program

mode is exited.

Adjustment: Set as required.

113. Restore Function Settings

Range: 0, 50

TMS7 SERIES ME00070B 23

Page 24

PROGRAMMING

Default Setting: 0

Description: Allows function adjustments be returned to the

factory defaults.

Adjustment: Set to 50 to load default parameter settings.

7.4 Operation

Once installed, wired and programmed according to the

instructions earlier in this manual the TMS7 can be operated.

Local control panel.

1. Numeric LED Display: The information being displayed is

indicated by the LEDs to the right of the display. During

operation either motor current (Amps) or the calculated

motor temperature (%) can be displayed. Use the <UP> or

<DOWN> keys select what information is displayed. In the

event of a trip state the relevant trip code will be shown.

If motor current exceeds the maximum current able to be

shown on the numeric display, the display will show

dashes.

2. Starter Status LEDs:

Start: Voltage is being applied to the motor terminals.

Run: Full voltage is being applied to the motor terminals.

Trip: The TMS7 has tripped.

Remote: The TMS7 is in remote control mode.

3. Operational Push Buttons: These push buttons can be

used to control TMS7 operation when in local control

mode. The <LOCAL/REMOTE> push button can be used

to switch between local and remote control.

NOTE:

When control power is applied to the TMS7 it may

be in either local or remote control mode according

to the mode it was in when control power was

removed. The factory default is local control.

24 ME00070B TMS7 SERIES

Page 25

PROGRAMMING

push button is

NOTE:

Function 20. Local/Remote Operation can be used

to limit operation to either local or remote mode

operation. If the <LOCAL/REMOTE>

used in an attempt to switch to a prohibited mode

the numeric display will show 'OFF'.

NOTE:

Simultaneously pressing the <STOP> and

<RESET> push buttons causes the TMS7 to

immediately remove voltage from the motor,

resulting in a coast to stop. Any soft settings are

ignored.

4. Programming Buttons: Refer to section 7.1.

5. Remote Control Inputs Status: These LEDs indicate the

state of the circuits across the TMS7 remote control inputs.

NOTE:

All LEDs and the Numeric display are illuminated

for approximately 1 second to test their operation

when control power is first applied .

Remote control.

TMS7 operation can be controlled via the remote control inputs

when the soft starter is in remote mode. Use the

<LOCAL/REMOTE> push button to switch between local and

remote modes. Refer to section 6.3 Control Wiring for further

detail.

Restart delay.

Function 31. Restart Delay sets the delay period between the

end of a stop and the beginning of the next start. During the

restart delay period the LEDs to the right of the numeric display

will flash indicating that a restart cannot yet be attempted.

Pre-start tests.

Before applying voltage to the motor when a start is initiated, the

TMS7 first performs a series of tests to check the motor

connection and supply conditions.

circuit the primary motor settings are used. In the event of a

closed circuit the secondary motor settings are used.

Primary Motor Settings

Function Settings 1 ~ 9

Primary Motor Settings

Function Settings 80 ~ 88

I44

I43

I44

I43

FLC Select

FLC Select

Secondary motor settings.

TMS7 starters can be programmed with two motor parameter

sets. The primary motor parameters are set using functions 1~9.

The secondary motor parameters are set using functions 80~88.

When commanded to start the TMS7 checks the state of the

FLC Select input (Terminals I43 & I44). In the event of an open

TMS7 SERIES ME00070B 25

Page 26

APPLICATION EXAMPLES

Application Examples

8.1 Installation With Line Contactor

Description:

The TMS7 is applied with a line contactor (AC3 rated). The line

contactor is controlled by the TMS7 Main Contactor output,

which by default is assigned to RELAY OUTPUT A (terminals

R44, R43).

The control supply must be sourced from before the contactor.

Function Settings:

- Function 21. Relay Output A Functionality = 11

(Assigns the Main Contactor function to Relay Output A)

3 PHASE

SUPPLY

C45 models

460V

575V