Page 1

“MICRO” ADJUSTABLE SPEED DRIVE INTERFACE

MDB-100

MODBUS RTU / ASCII COMMUNICATIONS INTERFACE

FOR THE TOSHIBA VF-S7 SERIES

ADJUSTABLE SPEED DRIVE

August, 1999

ICC #10207-000

Page 2

Introduction

Thank you for purchasing the ICC MDB-100 Modbus RTU / ASCII Communications

Interface for t he Toshiba VF-S7 Series Micro Adjustable Speed Drive. Before using

the MDB-100 interface, please familiar ize yourself with the pr oduct and be sur e to

thoroughly read the instructions and precautions contained in this manual. In

addition, please make sure that this inst r uction manual is delivered to the end user of

the drive units with which the MDB-100 interface is connected, and keep this

instruction manual in a safe place f or future reference or dr ive/int er face inspection.

This instruction manual describes the device specificat ions, wiring methods,

maintenance procedures, supported functions and usage methods for the MDB-100

Modbus RTU / ASCII communications interface.

In conjunction with this manual, the following manuals ar e supplied by Toshiba, and

are essential both for ensuring a safe, reliable system installation as well as for

realizing the full communication and cont r ol potential of the MDB-100 interface:

• Toshiba TOSVERT VF-S7 Series Instruction Manual

• Toshiba VF-S7 Industrial Invert er Serial Communications Option Manual

If you do not have copies of these documents available, please contact Toshiba or

your local Toshiba distributor to obtain them.

M

ODBUS IS A REGISTERED TRADEMARK OF

CHNEIDER AUTOMATION

AEG S

1

Page 3

Usage Precautions

Operating Environment

•

Please use the MDB-100 only when the ambient temperature of the environment into

which the MDB-100 is installed is within the following specified temperature limits:

Operation

Storage

•

Avoid installation locations that may be subjected to large shocks or vibrations.

•

Avoid installation locations that may be subjected to rapid changes in temperature or

humidity.

: -10 ∼ +40°C (+14 ∼ +104°F)

: -25 ∼ +65°C (-13 ∼ +149°F)

Installation

•

Do not touch charged parts of the drive such as the terminal block while the drive’s

CHARGE lamp is lit. A charge will still be present in the drive’s internal electrolytic

capacitors, and therefore touching these areas may result in an electrical shock.

Always turn all drive input power supplies OFF, and wait at least 5 minutes after the

CHARGE lamp has gone out before connecting communication cables or motor wiring.

•

Route all communication cables separate from the inverter input/output power wiring.

•

To avoid the possibility of electric shock due to leakage currents, always ground the

inverter unit’s E/GND terminal and the motor. To avoid misoperation, do not connect

the MDB-100’s SHIELD terminal to either of the above-mentioned grounds or any other

power ground.

•

When making connections between the MDB-100 and S7 drives, do not use cables

that exceed 5 meters in length.

•

For further drive-specific precaution, safety and installation information, please refer to

the appropriate Toshiba documentation supplied with your S7 drive.

Other Precautions

•

The drive’s EEPROM has a life span of 10,000 write cycles. Do not write to the same

holding register (other than registers 7A00 ∼ 7A02 and FA00 ∼ FA02 or write-only coils)

more than 10,000 times.

•

The MDB-100’s EEPROM has a life span of 100,000 write cycles. Do not write to the

same MDB-100 configuration register more than 100,000 times.

•

Do not touch or insert a rod or any other item into the MDB-100’s case while power is

applied, as this may lead to electrical shock or device damage.

•

Commission the disposal of the MDB-100 to a specialist.

•

Do not assign the same network address to more than one MDB-100 station in the

same network. For a detailed explanation of station addressing, refer to section 8.

•

When the MDB-100 is configured to receive its Modbus RTU / ASCII station address

from the drive on Channel A, be sure to reset the MDB-100 if the inverter number

parameter on the drive on Channel A is changed. Refer to section 8 for more

information.

•

Because the MDB-100 derives its control power from the drive connected to Channel

A, removing power from that drive will also cause the MDB-100 to lose power, even if

power is still applied to the drive connected to channel B.

•

When only 1 drive is connected to the MDB-100, it must be connected to Channel A.

••••

Wiring

2

Page 4

TABLE OF CONTENTS

1.

2.

3.

4.

5.

6.

6.1 Storage ..........................................................................................................10

6.2 Warranty ........................................................................................................10

7.

8.

9.

9.1 Supported Modbus Commands ......................................................................15

9.2 Programmable Pointer Register Function .......................................................15

9.3 Loss of Communications Timer Function.......................................................16

9.4 Response Delay Timer Function .................................................................... 17

Interface Package Diagram..................................................................4

Feature Summary.................................................................................. 5

Installing The MDB-100 ........................................................................7

Equipment Specifications....................................................................9

Maintenance And Inspection ...............................................................9

Storage And Warranty........................................................................10

Network Characteristics Configuration ............................................11

Modbus Station Address Selection...................................................13

Modicon Programming.......................................................................15

10. Modbus Programming Interface........................................................19

10.1

10.2

10.3

10.4

Overview.....................................................................................................19

Holding Registers .......................................................................................24

Write-Only Coils..........................................................................................31

Read-Only Coils..........................................................................................32

11. Notes....................................................................................................33

3

Page 5

)

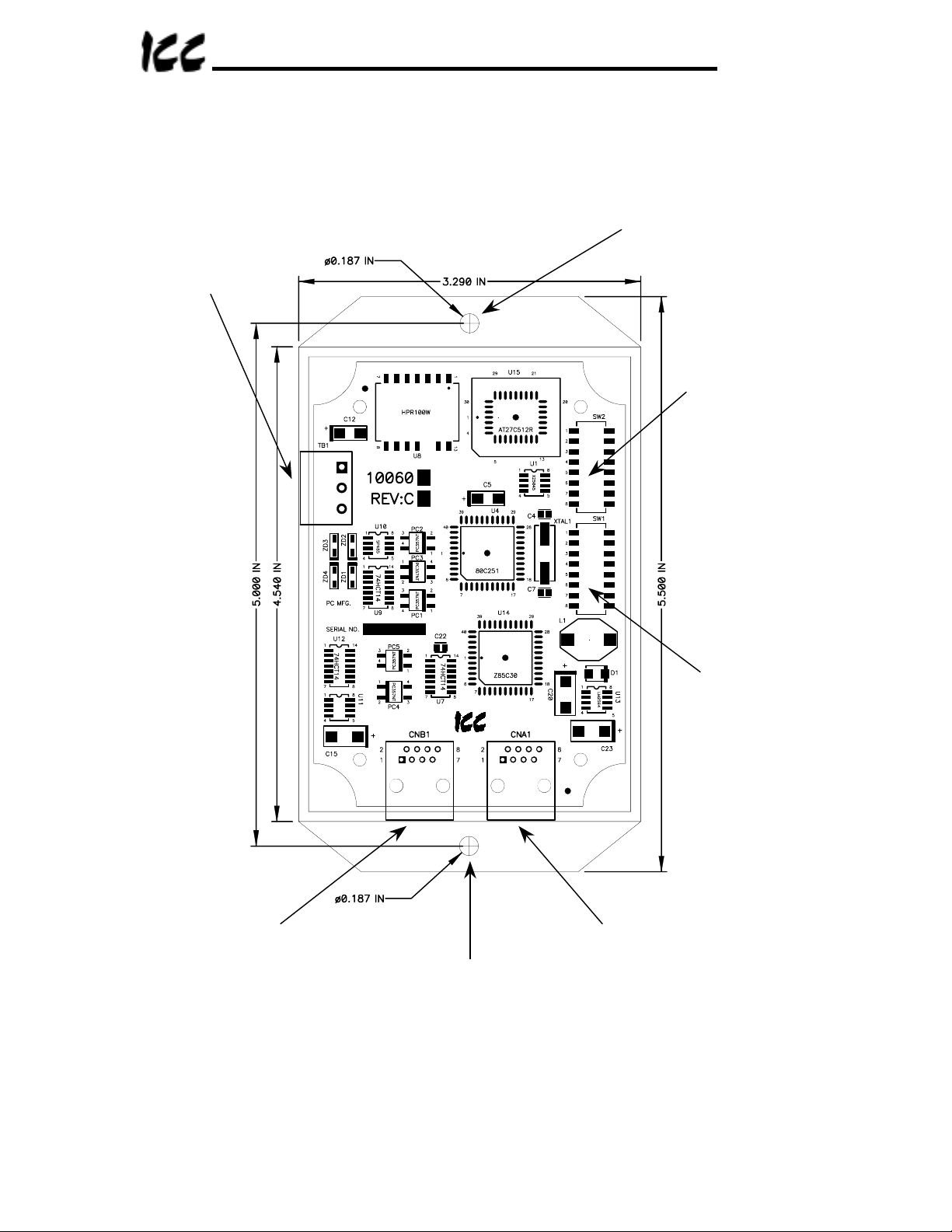

1. Interface Package Diagram

Network connector

(TB1)

Case mounting hole

Switch SW2

(local address)

Switch SW1

(network

characteristics

Drive “B” connector Drive “A” Connector

Case mounting hole

Note that the above diagram shows the MDB-100 with its cover removed. However,

it is only necessary to remove the cover in order to initially configure the MDB-100.

Once configured, the cover should be reinst alled to prevent damage and dust

accumulation.

4

Page 6

2. Feature Summary

The MDB-100 interface provides a wide array of network data access and drive

control features. Combined with the flexible data access methods and universal

acceptance of the Modbus network, this allows powerful networked contr ol and

monitoring systems to be designed. Som e of the main features provided by the

MDB-100 which allow for this control and configurability are briefly described here:

Protocol

Modbus RTU and ASCII as specified in AEG Schneider Automat ion specification

“Modicon Modbus Protocol Reference Guide PI-MBUS-300 Rev. J”.

Implementation

Modbus network is optically isolated RS485 half-duplex 2-wire + shield physical layer,

allowing connection of up to 32 units (masters and slave MDB-100 units) to a single

bus trunk.

Network Baud Rates

Supports all Modbus RTU/ASCII baud rates f rom 300 baud to 38.4kbaud.

Drive Connections

The MDB-100 provides support for simultaneous connection of 2 VF-S7 drives. Both

drives share a common Modbus station address. By supporting 2 drives per

interface, the maximum number of drives that can be connected to 1 Modbus

network segment without requiring r epeat ers increases from 31 (31 drives + 1

master) to 62 (31 MDB-100 units + 1 master).

Power Supply

Self-contained. Powered directly fr om the drive connected to the Channel A

communications port. No external power supply devices or connections are required.

Isolation

The MDB-100 has 3 separate isolated circuitry sections. Each drive is f ully optically

isolated from each other, and bot h dr ives are opt ically isolated from the Modbus

network. By using optically isolated connections to the drives and the Modbus

network, noise immunity is greatly impr oved and g r ounding differential pr oblem s

become a thing of the past.

Drive AutoScan Algorithm

Connections to the drives are automatically established and continuously monitored.

No drive configuration needs to be performed to connect the MDB-100 and

communicate via the Modbus RTU or ASCII network. Just plug it in – it’s that simple.

5

Page 7

Programmable Pointer Registers

32 programmable pointer reg ist ers are provided for user definition. By using these

registers, freq uently-accessed drive parameters that may be scattered throug hout the

register map can be grouped tog ether and accessed with a single holding register

read or write command.

Response Delay Function

A programmable network response delay f unction is available which forces the MDB100 to wait a certain minimum time before generating network responses to Modbus

commands. This function is useful when equipment such as radio modems (which

require a finite time t o switch from receive to transmit mode) are used as Modbus

network bridges.

Network Watchdog

A network watchdog function is available to detect if communication with the master

controller has been interrupted. If an interruption is detected, several different drive

actions can be programmed to ensure that t he pr ocess under control can be safely

and automatically driven to a desired state.

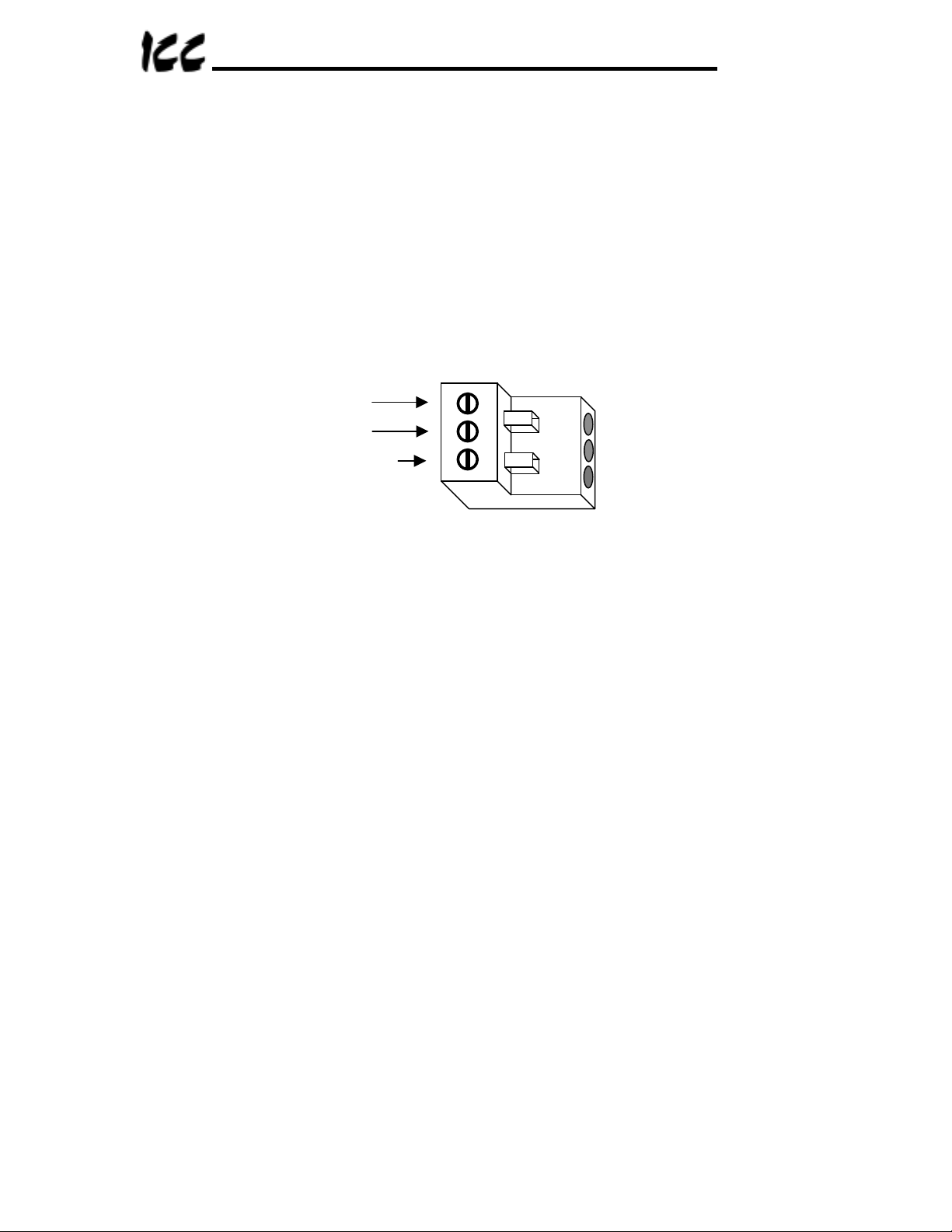

Modbus Network Connector

The network interface is a 3- position pluggable terminal block with the following

signals provided:

Pin Number Function

1 Modbus network RS485 “A” terminal

2 Modbus network RS485 “B” terminal

3 Network shield connection point

No network termination is provided on the MDB-100. Be sure to install proper RS485

network termination on the MDB-100 units that exist on the extreme endpoints of the

network bus. This can be accomplished by placing a 121Ω (±5%) , 1/2W resist or

across the A and B network terminals of t hose 2 unit s .

Drive Network Connectors

Uses standard RJ-45 style 8-pin modular connectors. Any standard category-5

ethernet cable (found in most electronics and office-supply stores) 5 meter s or less in

length can be used to connect the MDB-100 to the drives.

Supported Commands

The MDB-100 presents and receives drive data via Modbus commands 01 (read coil

status), 03 (read holding reg ist er s) , 05 (force single coil), 06 (pr eset single register)

and 16 (preset multiple registers) .

6

Page 8

3. Installing The MDB-100

The MDB-100 connects to each drive via the drive’s communication port, located on

the right-hand side of the dr ive enclosure under a sm all snap- on cover. Although no

drive parameters need to be configur ed in order to use the MDB-100, it is

advantageous to check that the drive’s communicat ion dat a r at e is set to its

maximum speed. Because the MDB-100 will communicate to each drive only at the

drive’s configured data rate, t his will provide the fastest response time for dr ive-t oModbus network data transfers. For information on checking the drive’s

communication data rate, refer to the appropriate manual supplied with your drive.

Note that each drive’s communication data rate settings are independent of the

Modbus network data rate, which is configured solely by the Modbus network

characteristics switch (refer to sect ion 7) . Also not e that the data communication

parameters of each drive are handled independently; the dr ive connected t o Channel

A may simultaneously communicate to the MDB-100 at completely different baud

rates, parity settings, etc. than the drive connected to Channel B.

Installation of the MDB-100 Modbus RTU / ASCII inter face should only be performed

by a qualified technician familiar with the m aintenance and operation of the

connected drives. To install the MDB-100, complete the following steps:

1.

connected have been turned OFF and are locked and tagg ed out .

2.

capacitors to discharge before pr oceeding to the next step.

internal parts with power applied to the drive, or for at least 5 minut es af t er

power to the drive has been removed. A hazard exists temporarily for

electrical shock even if the source power has been removed.

CHARGE LED has gone out before continuing the installation process.

3. Attach the MDB-100 to a sturdy, unmovable object (such as a wall) via the 2 case

mounting holes located on the tabs at the t op and bottom of the enclosure.

4. Remove the drive’s communication port cover, located on the rig ht - hand side of

the drive (as viewed when facing the drive), by pressing against the side of the

cover while sliding it toward the front of the drive. Do not discard this cover, as it

should be reinstalled if the MDB-100 unit is ever disconnected fr om t he drive.

5. Connect the drive’s communication port to Channel A of the MDB-100 with the

communication cable (communication cable is not included with the MDB-100 kit).

When choosing cables for this connection, standard 24 AWG category-5 (CAT 5)

unshielded twisted-pair (UTP) 8-conductor cables f ound in ethernet networks in

most office environments can be used. The maximum allowable length for these

cables is 5 meters. Although there are many varieties and styles of CAT-5 UTP

cables available, ICC strongly recommends using only high- quality cables from

reputable manufacturers to guarantee optimal noise immunity and cable

longevity. Ensure that each end of the cable is fully seated into the modular

connector, and route the cable such that it is locat ed well away from any drive

input power or motor wiring. Also take care to route the cable away from any

sharp edges or positions where it may be pinched.

CAUTION!

DANGER!

Verify that all input power sources to the drives to be

Wait at least 5 minutes for the drive’s electrolytic

Do not touch any

Verify that the

7

Page 9

6. Repeat steps 1, 2, 4 and 5 above to connect another drive to Channel B on the

MDB-100, if desired.

7. Remove the cover of the MDB-100 by removing the 4 cover screws.

8. Configure the Modbus network characteristics such as baud r at e, parity etc. via 8position DIP switch SW1 ( r efer to section 7). If the MDB-100’s station address is

to be configured locally, select the desir ed st ation address via 8-position DIP

switch SW2 (refer to section 8).

9. Reinstall the cover of the MDB-100.

10. Connect the Modbus network cable (2 signal wires + shield) to the 3-position

pluggable terminal block m ar ked “Network” on the left-hand side of the MDB-100.

The terminal ordering for the network cable wiring is as shown in Figure 1.

A

B

SHIELD

Figure 1: Modbus RS485 Network Terminal Wiri ng

Note that some RS485 equipment manufacturers reference t he “ A” and “ B”

terminals reversed from the MDB-100’s hardware, and some manufacturers use

other labels, such as “+” and “-“. If you cannot communicate with the MDB-100

after installation, try switching t he “ A” and “ B” signal wires - swapped signal wires

are the most common cause of communication difficulties in new RS485 network

installations.

Ensure that the Modbus network cable is tightly screwed into the terminals, and

route the cable such that it is located well away from any drive input power or

motor wiring. Also take care to r out e all cables away from any sharp edges or

positions where they may be pinched.

11. Take a moment to verify that the MDB-100 and all network cables have suff icient

clearance from drives, motors , and power-carrying electrical wiring.

12. Turn the power sources to all connected drives ON, and verify that the drives

function properly. If t he dr ives do not appear t o power up, or do not function

properly, immediately turn power OFF.

power from the drives.

Then, verify all connections. Contact ICC or your local

Repeat steps 1 and 2 to remove all

drive distributor or manufacturer for assistance if the problem per sists.

8

Page 10

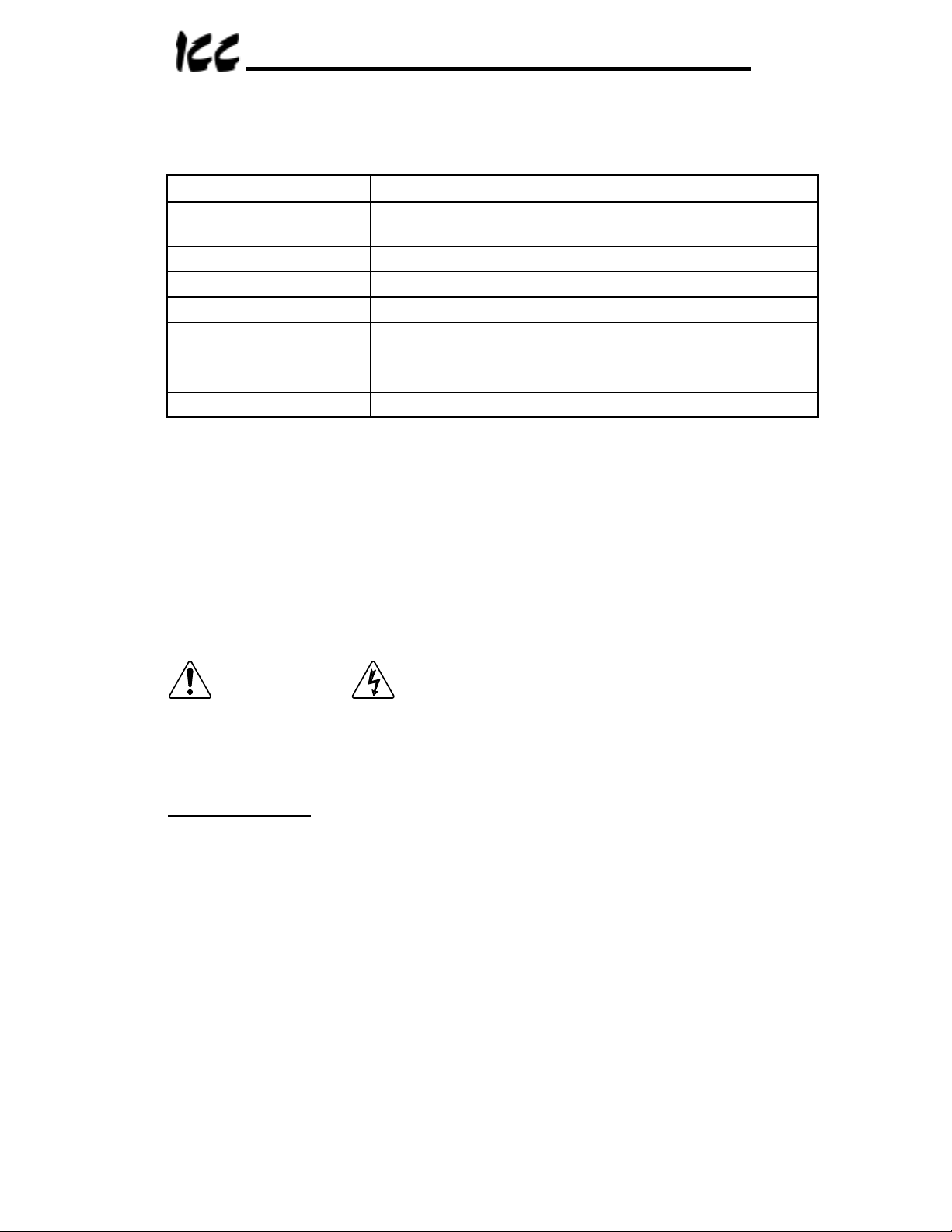

4. Equipment Specifications

Item Specification

Operating Environment

Operating Temperature

Storage Temperature

Relative Humidity

Vibration

Grounding SHIELD terminal connected to isolated network ground

Cooling Method Self-cooled

Indoors, less than 1000m above sea level, do not

expose to direct sunlight or corrosive / explosive gasses

-10 ∼ +40°C (+14 ∼ +104°F)

-25°C ∼ +65°C (-13 ∼ +149°F)

20% ∼ 90% (without condensation)

5.9m/s

via 200Ω resistance.

2

{0.6G} or less (10 ∼ 55Hz)

5. Maintenance And Inspection

Preventive maintenance and inspection is required to maint ain t he MDB-100 Modbus

interface in its optimal condition and t o ensur e a long operational lifetime. Depending

on usage and operating conditions, perform a periodic inspection once every three to

six months. Before starting inspect ions, always turn off all power supplies to

connected drives, and wait at least five minutes after each drive’s “CHARGE” lamp

has gone out.

DANGER!

to the drives, or for at least 5 minutes after power to the drives has been

removed. A hazard exists temporarily for electrical shock even if the source

power has been removed.

Inspection Points

• Check that the Modbus network connector screws and terminal block plug are not

loose. Tighten if necessary.

• Check that the drive communication cables are not loose. Reinsert if necessary.

• Visually check all wiring and cables for damage. Replace as necessary.

• Clean off any accumulated dust and dirt.

Do not touch any internal parts with power applied

• If use of the MDB-100 is discontinued f or extended per iods of time, apply power

at least once every two years and confirm that the unit still functions properly.

• Do not perform hi-pot t est s on t he drives or MDB-100 interface, as they may

damage the units.

Please pay close attention to all periodic inspection points and maintain a g ood

operating environment.

9

Page 11

6. Storage And Warranty

6.1 Storage

Observe the following points when the MDB-100 interface is not used imm ediat ely

after purchase or when it is not used for an extended per iod of time.

• Avoid storing the MDB-100 in places that are hot or humid, or t hat contain large

quantities of dust or m etallic dust. Store the MDB-100 in a well-ventilated

location.

• When not using the MDB-100 interface for an extended period of time, apply

power at least once every two years and confirm that it still functions properly.

6.2 Warranty

The MDB-100 Modbus RTU / ASCII Communications Interface is covered under

warranty by ICC for a period of 12 months from the date of installat ion, but not to

exceed 18 months from the date of shipm ent from the factory. For further warranty

or service information, please contact Industrial Control Communications or your

local distributor.

10

Page 12

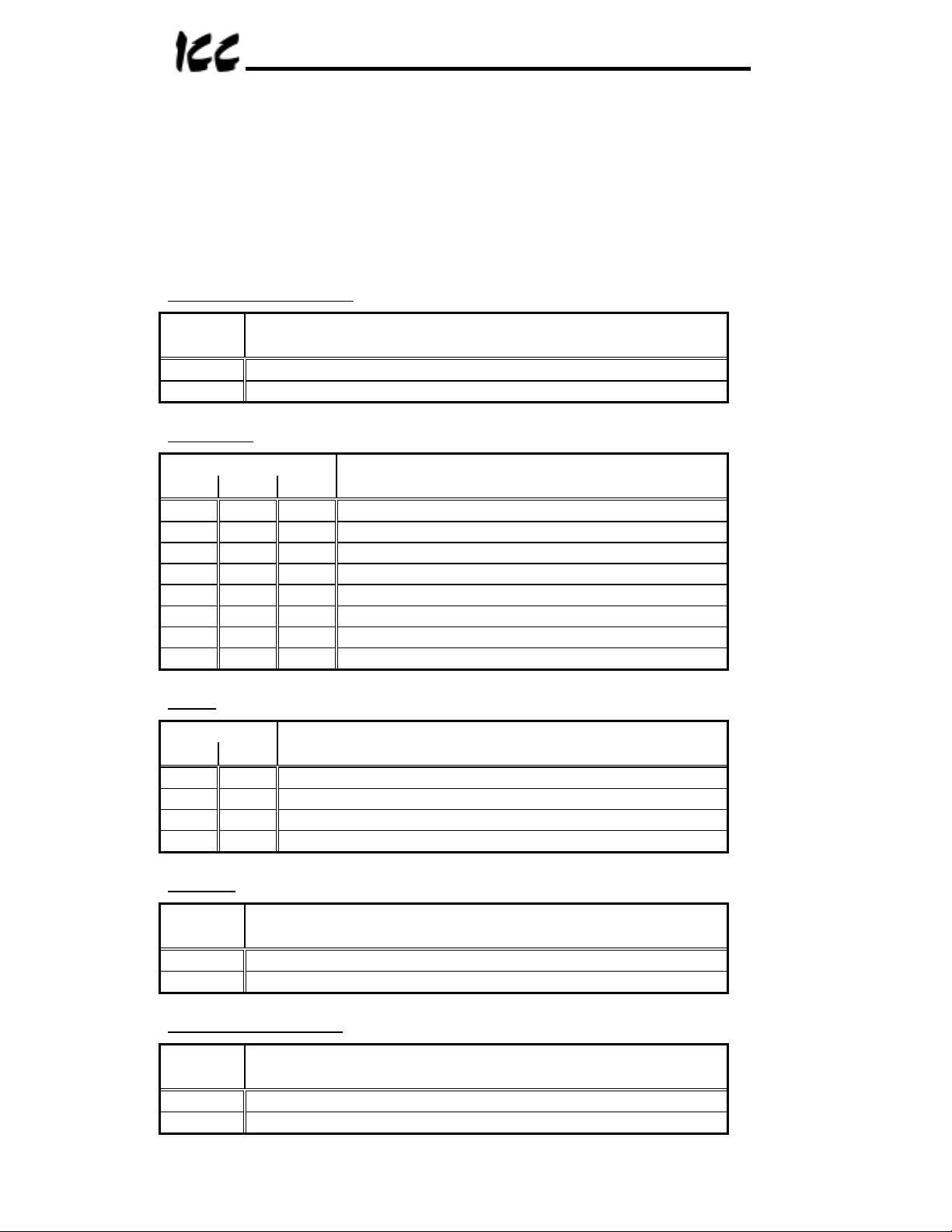

7. Network Characteristics Configuration

The MDB-100 interface board uses an 8-position DIP switch (labeled SW1) to

configure the Modbus network communication characteristics. The switch settings

are only read during initialization, so if a chang e is m ade to any of the switches on

SW1, the MDB-100 must be r eset in order to enable the new settings. The various

configuration setting s of switch SW1 are as follows:

Communication Method:

SW1 #

1

OFF Modbus RTU (factory default)

ON Modbus ASCII

Baud Rate:

4 3 2

OFF OFF OFF 300 baud

OFF OFF ON 600 baud

OFF ON OFF 1200 baud

OFF ON ON 2400 baud

ON OFF OFF 4800 baud

ON OFF ON 9600 baud (factory default)

ON ON OFF 19.2 kbaud

ON ON ON 38.4 kbaud

Parity:

SW1 #

6 5

OFF OFF even parity (factory default)

OFF ON odd parity

ON OFF no parity (2 stop bits)

ON ON no parity (1 stop bit) - applies only to RTU mode

Protocol:

SW1 #

Function

Function

Function

SW1 #

7

OFF Modicon Modbus (factory default)

ON DO NOT SELECT (reserved for future expansion)

Station Number Origin:

SW1 #

8

OFF Drive A’s inverter number parameter (factory default)

ON Switch SW2 address setting

11

(refer to section 8)

Function

Function

Page 13

A Note About Modbus Communicati on Formats

According to the Modicon Modbus Protocol Reference Guide

both Modbus ASCII and RTU communication modes are as f ollows:

ASCII Mode

Coding System:

One hexadecimal character contained in each ASCII character

Bits per Byte:

7 data bits, least signif icant bit sent first

1 bit for even/odd parity; no bit for no parity

1 stop bit if parity is used; 2 bits if no parity

Error Check Field:

RTU Mode

Coding System:

Two hexadecimal characters contained in each 8-bit field of the

Bits per Byte:

8 data bits, least signif icant bit sent first

1 bit for even/odd parity; no bit for no parity

1 stop bit if parity is used; 2 bits if no parity

Error Check Field:

According to the Modicon Modbus specification, theref or e, the number of bits per

byte in ASCII mode is 1 start + 7 data + 1 parity + 1 stop (if parity is used), or 1 start

+ 7 data + 2 stop (if parity is not used). T he ASCII data frame is therefore fixed at 10

bits per byte. Similarly, the number of bit s per byte in RTU mode is 1 start + 8 data +

1 parity + 1 stop (if parity is used), or 1 start + 8 data + 2 stop (if parity is not used),

resulting in an RTU data f r am e that is fixed at 11 bits per byte.

In addition to these standard specified dat a frame sizes, the MDB-100 interface

offers an optional configuration of providing for only 1 stop bit when no parity is

selected in the RTU communication mode. As indicat ed on t he pr evious pag e, by

setting SW5 and SW6 both to “ON”, the RTU data frame size is modified to consist of

1 start + 8 data + 1 stop bit = 10 bits per byte. Please note t hat this setting is only

valid when RTU mode is selected; if SW5 and SW6 ar e both set to “ON” when ASCII

mode is selected, the MDB-100 will halt and will not communicate with the Modbus

network.

...... Hexadecimal, ASCII characters 0 ∼ 9, A ∼ F

of the message

.......... 1 start bit

... Longitudinal Redundancy Check (LRC)

...... 8-bit binary, hexadecimal 0 ∼ 9, A ∼ F

message

.......... 1 start bit

... Cyclical Redundancy Check (CRC)

, the specifications for

12

Page 14

8. Modbus Station Address Selection

The MDB-100 interface provides two differ ent m e t hods for configuring t he node’s

station address. One method uses the inverter num ber parameter read from t he

drive connected to Channel A, and the other method uses a locally-configured

address, set by DIP switches on the MDB-100 control PCB.

When shipped f rom the factory, the MDB-100’s default configuration is to use the

value set in the inverter number parameter (F802) of the drive connected to Channel

A as its Modbus network station address. Depending on the sof tware version of the

drive connected to channel A, this parameter is adjustable from either 0∼31 or 0∼63.

Since Modbus addressing allows for station addresses to be set from 1 ∼ 247,

however, there may be instances where the upper limit of the inverter num ber

parameter setting is not hig h enough to support a desired address (for example, if

you want to set a MDB-100 station to address 95) In these instances, the locallyconfigured station address can be used, which supports the full Modbus station

addressing range of 1 ∼ 247.

Note that the Modbus protocol specification stat es t hat allowable station addresses

are 1 to 247. If a station addr ess is configured with 0 (inverter number or local

address) or 248 to 255 (local address only), the MDB-100 will halt and will not

communicate with the network. To resolve this situat ion, cor rect the station number

and reset the MDB-100. Pay particular attention to this point , as the default factory

setting of the drive’s “inverter number ” parameter is 0, which therefore must be

changed if it is to be used as the MDB-100’s station number .

The selection of whether to use the drive on Channel A’s inverter num ber par am eter

or the locally-set station address is perf or m ed by switch SW1 #8. When SW1 #8 is

OFF (factory default set ting), the MDB-100’s station address is retrieved from drive

A’s inverter number parameter. When SW1 #8 is ON, the MDB-100’s station

address is obtained by the binary number set via DIP switch SW 2 ( factory default

address setting = 1).

SW1 #8 Meaning

OFF

ON

The values of switches SW 1 and SW2 are read only during MDB-100 initialization.

Therefore, if any of these switch settings are changed, the MDB-100 must be

reinitialized to be made aware of the change by:

Drive A’s inverter number parameter (factory default)

Switch SW2 address setting

1. Momentarily powering-off drive A (from which the MDB-100 receives power), or

2. Issuing a reset command to the MDB-100 via the Modbus network by writing to

holding register 0x6111

writing data 0xFEBA will reset the MDB-100 and return all MDB-100 –specific

configuration register s (such as response delay time, loss of communications

timeout time etc.) to t heir factory default values, and writing any other dat a will

cause the MDB-100 to return a Modbus “ILLEGAL DATA VALUE” exception

response (exception code 03). Reading fr om r egister 0x6111 will always return a

value of 0.

13

NOTE 1, NOTE 2

. Wr it ing data 0x5A5A will reset the MDB-100,

Page 15

Holding

Register

0x6111

NOTE 1:

Write Data Meaning

0x5A5A Reset the MDB-100

Reset the MDB-100 and return MDB-100

0xFEBA

configuration regist er s t o factory default

values.

Any other value

Return “ILLEGAL DATA VALUE”

exception

Throughout this document, hexadecimal ( base 16) num ber s will be

represented by a preceding “0x” or by a trailing “H” designator, decimal

(base 10) numbers will be represented by a trailing subscripted “ 10”

designator, and binary (base 2) numbers will be represented by a tr ailing

“B” designator. Binary numbers will always be written with their most

significant bit (MSB) at the left, and their least significant bit (LSB) to the

right (next to the “B”).

For example, 0x6111 = 6111H = 24849

= 0110 0001 0001 0001B.

10

NOTE 2:

The Modbus specification lists two addresses for each holding register (4X

reference) and coil (0X reference). These are ref er r ed to as the

“addressed as” and “known” as values. In all instances, regist er s and

coils are addressed starting at zero; i.e. register 1 is addressed as 0, and

coil 15 is addressed as 14, etc. Throughout this document, all addresses

given for coils and holding register s will be their “ addr essed as” values

unless otherwise specified. In other words, add 1 to the register/coil

address given to obtain its “known as” value. For example, the S7 drive’s

inverter number parameter is 0802H (= 0x0802 = 2050

.) Therefore, this

10

register would be “known as” 2051. Refer to t he Modbus Protocol

Reference Guide for a m or e detailed explanation of this issue.

The station address set via switch SW 2 m ust be set using binary encoding. In this

case, SW2 #1 repr esents bit #0 of the address, and SW2 #8 represents bit #7.

When one of the DIP switches of SW 2 is turned ON, the corresponding address bit is

1, and when one of the switches is turned OFF, the corresponding addr ess bit is 0.

For example, if an address of 169

is desired, the conversion calculation would be

10

performed as follows:

= 0xA9 = 1010 1001B, therefore switches SW2 #1, #4, #6 and #8 should be

169

10

ON, and #2, #3, #5 and #7 should be OFF.

Some more address configurat ion examples (factory default setting = 1) :

Address

(Decimal)

1 (min) 0x01 0000 0001B #1

63 0x3F 0011 1111B

200 0xC8 1100 1000B #4, #7, #8

247 (max) 0xF7 1111 0111B

Address

(Hex)

Address

(Binary)

“ON”

Switches

#1 ∼ #6

#1 ∼ #3, #5 ∼ #8

“OFF”

Switches

#2 ∼ #8

#7, #8

#1 ∼ #3, #5, #6

#4

14

Page 16

9. Modicon Programming

9.1 Supported Modbus Commands

The MDB-100 interface supports 5 Modbus commands: command 1 ( 0x01: r ead coil

status), command 3 (0x03: read holding r egisters), command 5 (0x05: force single

coil), command 6 (0x06: preset single register) and command 16 (0x10: preset

multiple registers). Not all r egisters or coils support all commands (for example,

read-only registers cannot be written to with a command 16). For more information,

refer to section 10. The following limits represent the maximum number of registers

and coils that can be read/written in one packet tr ansact ion:

Command

1 32 coils N/A 32 coils N/A

3 125 registers N/A 61 registers N/A

5 N/A 1 coil only N/A 1 coil only

6 N/A 1 register only N/A 1 register only

16 N/A 123 registers N/A 59 registers

RTU Mode

Read Max

RTU Mode

Write Max

ASCII Mode

Read Max

ASCII Mode

Write Max

9.2 Programmable Pointer Register Function

MDB-100 registers 0x6000 ∼ 0x601F and 0x6080 ∼ 0x609F are used as

programmable pointer and data registers, respectively. Registers 0x6000 ∼ 0x601F

(32 total) are used to define ot her register addresses from which you would like to

read or write, and registers 0x6080 ∼ 0x609F (32 total) are the actual registers used

to access the data located at the register addr esses defined in registers 0x6000 ∼

0x601F. For example, if you would like to continuously read the data from registers

0xFE03, 0xFE04, 0xFE06, and 0xFD00, the standard register configuration would

require 3 read commands to be issued: one reading 2 registers starting at r egister

0xFE03, one reading 1 register starting at register 0xFE06, and one reading 1

register starting at r egister 0xFD00. To conserve network bandwidth and speed

processing time, however, the programm able point er registers can be used to allow

the same information to be accessed, but by only issuing 1 comm and which reads 4

registers.

To configure this function, program as many registers as necessar y (up t o 32) in t he

range 0x6000 ∼ 0x601F with the register numbers of the regist er s you would like to

continuously access. In this example, we would set register 0x6000 to 0xFE03 (the

first register number we want to access), register 0x6001 to 0xFE04, register 0x6002

to 0xFE06, and register 0x6003 to 0xFD00. The data located at t hese dr ive stat us

registers can then be obtained by accessing the corresponding registers in the range

0x6080 ∼ 0x609F (data register 0x6080 corresponds to address register 0x6000,

data register 0x6081 corresponds to address regist er 0x6001, et c. ) Therefore, the 4

registers that are to be monit or ed can now be accessed simply by issuing 1 holding

register read command with a length of 4 starting from reg ist er 0x6080. T he returned

15

Page 17

data will be the data obtained from reg ist er s 0xFE03, 0xFE04, 0xFE06, and 0xFD00

(in that order).

Note that the settings of t he pr ogrammable address registers (0x6000 ∼ 0x601F) are

stored in the MDB-100’s nonvolatile EEPROM. Therefore, do not write t o any of

these registers more than 100,000 t imes. Typically, these registers would only be

written to once, when the interface and Modbus network are fir st commissioned.

When the programmable pointer registers ar e modified, the changes are made

effective in the MDB-100 immediately (the MDB-100 does not need to be r eset for the

changed values to take effect).

9.3 Loss of Communications Timer Function

A configurable "loss of communications" (network watchdog) timer function is

provided, which can detect communication losses and perform cert ain actions if a

valid packet is not received and processed within a set time period.

MDB-100 register 0x6100 sets the loss of communication tim e value (adjustable from

100ms to 60.000s in 1ms increments, f act or y sett ing = 10.000s). If a valid

(exception-free) reception-r esponse or exception- free broadcast does not take place

within this time limit, the timer will expire. If the timer expires, 5 possible actions can

occur for each connected drive, as set by the value of registers 0x6101 and 0xE101

(loss of communications action for drive A and drive B, respectively):

Register

0x6101 / 0xE101

Setting

0 (default) No action: ignore timeout

1 Decelerated stop

2 Coast stop

3 Trip “E” (emergency off)

4 Run a preset speed

When a network t im eout is detected, the timeout action is perf or m ed. When

communications are once again reestablished, the timer function is automatically

reset and will once again begin to monitor network r ecept ions. However, any actions

performed as a result of the timeout occurring will not be reversed by the MDB-100

once communications are reestablished; the Modbus master’s application m ust

explicitly modify the affected condit ions t o fully return the drive to its previous state.

Setting 0 is the default setting; when a communications timeout occurs, no action will

be taken.

For setting 1 (decelerated stop) , the drive will stop in a controlled manner if it was

running. This action clears bit #10 in the select ed dr ive’s comm unicat ion com m and

bit structure (register 0x7A00 / 0xFA00 - also the same data as write-only coil #10 /

#26). Note that the “communication command valid” bit of register 0x7A00 / 0xFA00

(bit #15 of each register, or write-only coil #15 / #31) must already be set by the

master application for this t im eout action to control the drive.

Action Taken Upon Timeout

16

Page 18

For setting 2 (coast stop), the drive will coast stop (free run) if it was running . This

action clears bit #10 in the selected drive’s communication command bit structure

(register 0x7A00 / 0xFA00 - also the same data as write-only coil #10 / #26) and set s

bit #11 (same as coil #11 / #27). Note that t he “communication command valid” bit of

register 0x7A00 / 0xFA00 (bit #15 of each reg ist er , or write-only coil #15 / #31) must

already be set by the master application for this t im eout action to control the drive.

For setting 3 (trip “em er gency off”), the dr ive will trip “E”. This action clears bit #10 in

the selected drive’s communication command bit struct ur e ( r egister 0x7A00 / 0xFA00

- also the same data as write-only coil #10 / #26) and sets bit #12 (same as coil #12 /

#28). Note that in this case the sett ing of the “communication command valid” bit of

register 0x7A00 / 0xFA00 (coil #15 / #31) is irrelevant; t he dr ive will trip regardless of

its value.

Setting 4 (run a preset speed) will modif y the set t ings of bits #0 ∼ #3 of the selected

drive’s communication command bit structure (register 0x7A00 / 0xFA00 - also the

same data as write-only coils #0 ∼ #3 / #16 ∼ #19). The preset speed that is to run is

selected by MDB-100 registers 0x6102 (for drive A) and 0xE102 (for dr ive B). The

possible adjustment range for these registers is 0 ∼ 15, corresponding to “no action”

(0) and each of the drive’s 15 possible preset speeds (1 ∼ 15). Note that the

“communication command valid” and “run/stop” bit s of register 0x7A00 / 0xFA00 (bits

#15 and #10 of each register, or write- only coil #15 & #10 / #31 & #26) m ust already

be set by the master application for t his t im eout action to control the drive.

EXTREME CAUTION WHEN SELECTING THIS SETTING!

there is no possibility of personal injury or equipm ent damage due to the inverter

running at the selected speed, especially with the possibility that network

communications may not be able to be reestablished in a timely fa shion ( depending

on what network condition caused the communications timeout in the first place).

Note that the settings of the timeout time, timeout action and timeout pr eset speed

configuration regist er s are stored in the MDB-100’s nonvolatile EEPROM. Therefore,

do not write to any of these registers mor e t han 100,000 times. Also note that when

the setting of any one of these configuration registers is changed, the MDB-100 must

be reset for the new value to be activated and the change to take effect.

Thoroughly verify that

USE

9.4 Response Delay Timer Function

Register 0x6110 contains the setting f or a r esponse delay timer function. This

function is useful for applications where it may not be desirable for the MDB-100

interface to respond immediat ely to t he net work after a read/write request, such as

when a radio modem that must be switched from receive mode t o t r ansmit mode is

being used.

The response delay timer is adjustable in 1ms increments from 0s to 2.000s (fact or y

setting = 0s). A response delay of 0s means that there is no delay; response packets

will be sent by the MDB-100 as soon as they are available. The delay timer starts

when a complete packet is received by the MDB-100, and a response will not be sent

until the timer has expired (at a minimum). Note that this time value only sets a

minimum response delay value - depending on the quantity and location of r egisters

read / written, much more time m ay actually be req uired before a complete response

is formulated and ready to be returned to the network.

17

Page 19

The response delay timer value is read only upon MDB-100 initialization, requiring

the unit to be reset if the value is chang ed for the new value to take eff ect . This

setting is also non-volatile (written to the MDB-100’s EEPROM). Ther efore, do not

write to this register more than 100, 000 t im es.

18

Page 20

10. Modbus Programming Interface

10.1 Overview

Three types of Modbus data may be accessed via the MDB-100. These are holding

registers (4x reference), read-only coils (0x reference) and write-only coils (0x

reference). In order to access 2 drives within the allocated holding register map

(0x0000 ∼ 0xFFFF), each drive is assigned one half of the register space.

Drive A occupies the area from regist er 0x0000 to 0x7FFF. T his ar ea also contains

several network and drive configuration registers (such as the programmable point er

and data registers, network timeout r egisters, etc.) that reside within the MDB-100

only. The registers which the MDB-100 uses for these funct ions ar e not accessible in

the drive. Currently, these register s ar e unoccupied in t he drive, and therefore no

loss of access to any drive parameters exists. Most of the registers for drive A are

mapped to the exact same “communication number” that they are allocated in the S7

drive by Toshiba. Refer to the VF-S7 Serial Com m unicat ions O ption Manual for a list

of communication numbers. T he only exception to this direct mapping are the

registers that occupy communication numbers larger than 0x8000. For these

parameters, their corresponding Modbus holding registers can be obtained by setting

the MSB (bit #15) of their communicat ion number to 0.

For example, the communication number f or drive A’s bus voltage parameter is

0xFE04 (1111 1110 0000 0100B). Setting bit #15 to 0, we obtain the binary value

0111 1110 0000 0100B, or 0x7E04. Reading from Modbus holding reg ist er 0x7E04

(“known as” 0x7E05), therefor e, will return the bus voltage from drive A.

Drive B occupies the area from regist er 0x8000 to 0xFFFF. T his ar ea also contains

the MDB-100 –specific drive configuration registers that correspond to those

available for drive A. Most of the register s for drive B are not mapped to the exact

same “communication number” that t hey are allocat ed in the S7 drive by Toshiba.

For these parameters, their corresponding Modbus holding registers can be obtained

by setting the MSB (bit #15) of their com m unicat ion num ber to 1.

For example, the communication number f or drive B’s deceleration time #1

parameter is 0x0010 (0000 0000 0001 0000B). Setting bit #15 t o 1, we obtain the

binary value 1000 0000 0001 0000B, or 0x8010. Writing to Modbus holding register

0x8010 (“known as” 0x8011), therefore, will modify the deceleration time #1

parameter for drive B.

The only exception to this mapping modificat ion r equirement for drive B are the

registers that occupy communication numbers larger than 0x8000. For these

parameters, the communication number s given in the VF-S7 Serial Communications

Option Manual correspond exactly to their assigned “addressed as” holding registers

(for example, holding reg ist er 0xFE10 will access the past tr ip #1 value from drive B).

Refer to Figure 2 on page 20 for a graphical representat ion of the holding register

mapping that exists in the MDB-100 Modbus interface.

19

Page 21

Dri v e A Co mm.

Numbers

Figure 2: MDB-100 Holding Register Mappi ng

FFFF

F000

EFFF

E000

DFFF

D000

CFFF

C000

BFFF

B000

AFFF

A000

9FFF

9000

8FFF

8000

7FFF

7000

6FFF

6000

5FFF

5000

4FFF

4000

3FFF

3000

2FFF

2000

1FFF

1000

0FFF

0000

MDB-100

Holding

Registe r Map

MDB-100 registers

Drive B registers

Channel B registers

Drive B registers

Drive B registers

Drive A Registers

Channel A registers

Drive A registers

Drive A registers

Dri v e B Co mm.

Numbers

FFFF

F000

EFFF

E000

DFFF

D000

CFFF

C000

BFFF

B000

AFFF

A000

9FFF

9000

8FFF

8000

7FFF

7000

6FFF

6000

5FFF

5000

4FFF

4000

3FFF

3000

2FFF

2000

1FFF

1000

0FFF

0000

Note: Inaccessible (currently unused) areas are shaded.

20

Page 22

Register #

0000 ∼ 05FF

6000 ∼ 601F

6080 ∼ 609F

6100

6101

6102

6110

6111

6112

6113 ∼ 6FFF

7000 ∼ 7FFF

8000 ∼ E100

E101

E102

E103 ∼ EFFF

F000 ∼ FFFF

Table 1: Holding Register Mapping General Overview

Name / Function

Access drive A

Non-volatile programmable

pointer registers (32 total

available)

Programmable pointer data

registers (each register

corresponds to same one in

6000 ∼ 601F range)

Modbus network loss of

communications timeout time

Modbus network loss of

communications timeout action

for Drive A

Loss of communications preset

speed for Drive A (effective only

when register 6101 is set to 4)

Modbus network response delay

time

Reset/reinitialize MDB-100

interface

MDB-100 firmware

version/revision (read-only)

Access drive A -- -Access drive A communication

numbers F000 ∼ FFFF

Access drive B communication

numbers 0000 ∼ 6100

Modbus network loss of

communications timeout action

for Drive B

Loss of communications preset

speed for Drive B (effective only

when register E101 is set to 4).

Access drive B registers 6103 ∼

6FFF

Access drive B -- --

Factory

Setting

-- --

0000

(all 32)

--

10000

(10.000s)

0

0

0

--

(read always

returns 0)

--

-- --

-- --

0

0

-- --

Adjustment

Any value other than

6000 ∼ 601F or

6080 ∼ 609F

Depends on

registers pointed to

100 ∼ 60000

(0.100s ∼ 60.000s)

0= do nothing

1= decelerated stop

2= coast stop

3= trip “E”

4= run a preset

speed

0 ∼ 2000

(0ms ∼ 2.000s)

0x5A5A: reset only

0xFEBA: return

MDB-100 config

registers to factory

setting values

Version = MSB

Revision = LSB

Same as register

Range

0 ∼ 15

6101

0 ∼ 15

21

Page 23

Sections 10.2 to 10.4 specify the communication num ber → holding register

mappings and coil definitions fo r all cur r ent VF-S7 communication numbers. Note

that the parameters and coils shown are those available at the time of this manual

printing; if new parameters ar e added by the dr ive manufacturer and/or parameter

adjustment limits are modified, etc., this will not affect the operation of the MDB-100

interface. As all available parameters, adjustment ranges etc. are det er mined solely

by the connected drive, and not the MDB-100, future drive firmware versions will

automatically be supported by the MDB-100 with no software upgrades required.

In the case of any discrepancies between the informat ion in t he following tables and

the drive’s documentation, the drive’s documentation should always be followed.

Some other important coil and holding r egister notes:

• Remember that all registers and coils indicated in the following sections are

shown with their “addressed as” coil & register numbers. T hese coil &

register numbers are 1 less than their “ known as” numbers.

• A value indicated by “*” in the following tables indicates that t he set ting is

dependent on the connected drive’s capacity. Refer to the drive’s

documentation for these values.

• If frequency command values (r egisters 0x7A01 / 0xFA01) higher than each

respective drive’s FH or UL parameters are written, the write will be

acknowledged, but the drive will not change its f r equency to this invalid value.

• All writes to holding registers use the drive’s RAM / EEPROM data write (“W”)

command except for registers 0x7A00 ∼ 0x7A02 and 0xFA00 ∼ 0xFA02,

which use the drive’s RAM data write (“P”) command.

• If an attempt is made to access non- existent r egisters or coils, an ILLEGAL

DATA ADDRESS exception (code 02) will be returned.

• If an attempt is made to write invalid data to a register or coil, an ILLEG AL

DATA VALUE exception (code 03) will be returned.

• If a drive connected to the MDB-100 goes “offline”, all coils will hold their last

state, with the exception of read-only coils #115 and/or #131, which will

indicate “offline”. O nce communication with the drive(s) is reestablished,

these coil(s) will again indicate “online”.

• If a drive connected to the MDB-100 goes “of fline”, attempts to access any

register in that drive’s regist er space will return a Modbus “SLAVE FAILURE”

error (code 04), except for t he following registers, which will hold their last

state:

1. Communication command (communication number FA00)

2. Communication frequency command (communication number FA01)

3. Output frequency (comm unication number FD00)

4. Status (communication number FE01)

5. Output current (communicat ion num ber FE03)

6. Output voltage (communication num ber FE05)

• Note that the MDB-100 does not assign drive register and coil functions; they

are entirely drive-dependent, and managed by the drive manuf acturer.

• Each drive’s write-only coils are mapped to the corresponding drive’s

communication command parameter (com munication number #FA00). Also,

22

Page 24

the MDB-100 does not place any restrictions on coils marked as “Reserved”.

These coils may be written to at any time. The data or function associated

with these coils is entirely defined by the connected drive.

• With the exception of coils #115 and #131, each drive’s read-only coils are

mapped to the corresponding drive’s communication stat us register

(communication number #FE01). Also, t he MDB-100 does not place any

restrictions on coils marked as “Reserved”. These coils may be read from at

any time. The data or function associated with these coils is ent irely defined

by the connected drive.

23

Page 25

10.2 Holding Registers

Drive

A

B

A

B

A

B

A

B

A

B

A

B

A

B

A

B

A

B

A

B

A

B

A

B

A

B

A

B

A

B

A

B

A

B

A

B

A

B

A

B

A

B

A

B

A

B

Reg. #

(hex)

0000

8000

0001

8001

0002

8002

0003

8003

0004

8004

0005

8005

0006

8006

0007

8007

0008

8008

0009

8009

0010

8010

0011

8011

0012

8012

0013

8013

0014

8014

0015

8015

0016

8016

0017

8017

0018

8018

0019

8019

0020

8020

0021

8021

0022

8022

Title Function

Automatic acceleration and

AU1

deceleration time

AU2

Automatic torque boost 3 0 No

Automatic environment

AU3

setting

CMOD

FMOD

FMSL

Command mode selection 1 0 Yes

Frequency setting mode

selection

FM terminal function

selection

FM

Connected meter adjustment FF:255 0 Yes

Standard setting mode

tYP

selection

Forward/reverse selection

Fr

(panel)

ACC

Acceleration time #1 (s) 8CA0:3600 A:1.0 Yes

dEC

Deceleration time #1 (s) 8CA0:3600 A:1.0 Yes

FH

Maximum frequency 7D00:320.0 BB8:30.0 No

UL

Upper limit frequency

LL

Lower limit frequency

vL

Base frequency 7D00:320.0 9C4:25.0 Yes

Pt

V/F pattern 3 0 No

vb

Voltage boost BB8:30.0 0 Yes

OLM

OL selection 7 0 Yes

Sr1

Preset speed 1

Sr2

Preset speed 2

Sr3

Preset speed 3

Sr4

Preset speed 4

Sr5

Preset speed 5

Max

(hex:dec)

1 0 Yes

2 0 No

2 0 Yes

1 0 Yes

6 0 No

1 0 Yes

FH

UL

UL LL

UL LL

UL LL

UL LL

UL LL

Min

(hex:dec)

32:0.5 Yes

0:0.0 Yes

Run Mode

Modify

Yes

Yes

Yes

Yes

Yes

24

Page 26

Drive

A

B

A

B

A

B

A

B

A

B

A

B

A

B

A

B

A

B

A

B

A

B

A

B

A

B

A

B

A

B

A

B

A

B

A

B

A

B

A

B

A

B

A

B

A

B

A

B

A

B

Reg. #

(hex)

0023

8023

0024

8024

0100

8100

0101

8101

0102

8102

0103

8103

0104

8104

0110

8110

0111

8111

0112

8112

0113

8113

0114

8114

0115

8115

0130

8130

0131

8131

0200

8200

0201

8201

0202

8202

0203

8203

0204

8204

0210

8210

0211

8211

0212

8212

0213

8213

0240

8240

Title Function

Sr6

Preset speed 6

Sr7

Preset speed 7

F100

F101

F102

F103

F104

F110

F111

F112

F113

F114

F115

F130

F131

F200

F201

F202

F203

F204

F210

F211

F212

F213

F240

Low speed signal output

frequency

Speed reach signal output

frequency

Speed reach detection band

ST signal selection 2 0 Yes

RST signal selection 1 0 Yes

Always active function

selection

Input terminal selection #1 25:37 0 Yes

Input terminal selection #2 25:37 0 Yes

Input terminal selection #3 25:37 0 Yes

Input terminal selection #4 25:37 0 Yes

Input terminal selection #5 25:37 0 Yes

Output terminal selection #1 9 0 Yes

Output terminal selection #2 9 0 Yes

Frequency priority selection 1 0 Yes

VIA reference point #1 64:100 0 Yes

VIA point #1 frequency 7D00:320.0 0:0.0 Yes

VIA reference point #2 64:100 0 Yes

VIA point #2 frequency 7D00:320.0 0:0.0 Yes

VIB reference point #1 64:100 0 Yes

VIB point #1 frequency 7D00:320.0 0:0.0 Yes

VIB reference point #2 64:100 0 Yes

VIB point #2 frequency 7D00:320.0 0:0.0 Yes

Start-up frequency 3E8:10.0 32:0.5 Yes

Max

(hex:dec)

UL LL

UL LL

FH

FH

FH

25:37 0 Yes

Min

(hex:dec)

0:0.0 Yes

0:0.0 Yes

0:0.0 Yes

Run Mode

Modify

Yes

Yes

25

Page 27

Drive

A

B

A

B

A

B

A

B

A

B

A

B

A

B

A

B

A

B

A

B

A

B

A

B

A

B

A

B

A

B

A

B

A

B

A

B

A

B

A

B

A

B

A

B

A

B

A

B

A

B

Reg. #

(hex)

0241

8241

0242

8242

0250

8250

0251

8251

0252

8252

0260

8260

0261

8261

0270

8270

0271

8271

0272

8272

0273

8273

0274

8274

0275

8275

0280

8280

0281

8281

0282

8282

0283

8283

0284

8284

0285

8285

0286

8286

0287

8287

0288

8288

0289

8289

0290

8290

0291

8291

Title Function

F241

F242

F250

F251

F252

F260

F261

F270

F271

F272

F273

F274

F275

F280

F281

F282

F283

F284

F285

F286

F287

F288

F289

F290

F291

Run frequency

Run frequency hysteresis

DC injection starting

frequency

DC injection current 64:100 0 Yes

DC injection time C8:20.0 0:0.0 Yes

Jog run frequency 7D0:20.0 0:0.0 Yes

Jog stop control 2 0 Yes

Jump frequency #1

Jump frequency band #1 BB8:30.0 0:0.0 Yes

Jump frequency #2

Jump frequency band #2 BB8:30.0 0:0.0 Yes

Jump frequency #3

Jump frequency band #3 BB8:30.0 0:0.0 Yes

Preset speed 1

Preset speed 2

Preset speed 3

Preset speed 4

Preset speed 5

Preset speed 6

Preset speed 7

Preset speed 8

Preset speed 9

Preset speed 10

Preset speed 11

Preset speed 12

Max

(hex:dec)

FH

FH

FH

UL LL

UL LL

UL LL

UL LL

UL LL

UL LL

UL LL

UL LL

UL LL

UL LL

UL LL

UL LL

UL LL

UL LL

UL LL

Min

(hex:dec)

0:0.0 Yes

0:0.0 Yes

0:0.0 Yes

Run Mode

Modify

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

26

Page 28

Drive

A

B

A

B

A

B

A

B

A

B

A

B

A

B

A

B

A

B

A

B

A

B

A

B

A

B

A

B

A

B

A

B

A

B

A

B

A

B

A

B

A

B

A

B

A

B

A

B

Reg. #

(hex)

0292

8292

0293

8293

0294

8294

0300

8300

0301

8301

0302

8302

0303

8303

0304

8304

0305

8305

0306

8306

0307

8307

0400

8400

0401

8401

0402

8402

0403

8403

0404

8404

0405

8405

0406

8406

0407

8407

0500

8500

0501

8501

0502

8502

0503

8503

0504

8504

Title Function

F292

F293

F294

F300

F301

F302

F303

F304

F305

F306

F307

F400

F401

F402

F403

F404

F405

F406

F407

F500

F501

F502

F503

F504

Preset speed 13

Preset speed 14

Preset speed 15

PWM carrier frequency (kHz) * 16:2.2 Yes

Auto-restart (motor speed

search)

Regeneration power ridethrough control

Retry selection: number of

times

Regenerative braking

selection

Overvoltage stall protection 1 0 Yes

Output voltage adjustment 78:120 0 Yes

Line voltage compensation 1 0 No

Auto-tuning 2 0 No

Slip frequency gain FF:255 0 Yes

Motor constant 1: R1 gain FF:255 0 No

Motor constant 2: R2 gain FF:255 0 No

Motor constant 3: M gain FF:255 0 No

Load inertia 3 0 Yes

Auto torque boost no load

current

Auto torque boost maximum

boost

Acceleration time #2 8CA0:3600 1:0.1 Yes

Deceleration time #2 8CA0:3600 1:0.1 Yes

Acceleration & deceleration

pattern #1

Acceleration & deceleration

pattern #2

Acceleration & deceleration

pattern #1 & #2

Max

(hex:dec)

UL LL

UL LL

UL LL

3 0 Yes

1 0 Yes

A:10 0 Yes

1 0 Yes

1E:30 0 Yes

1E:30 0 Yes

2 0 Yes

2 0 Yes

1 0 Yes

Min

(hex:dec)

Run Mode

Modify

Yes

Yes

Yes

27

Page 29

Drive

A

B

A

B

A

B

A

B

A

B

A

B

A

B

A

B

A

B

A

B

A

B

A

B

A

B

A

B

A

B

A

B

A

B

Reg. #

(hex)

0505

8505

0600

8600

0601

8601

0602

8602

0603

8603

0604

8604

0605

8605

0700

8700

0701

8701

0702

8702

0800

8800

0801

8801

0802

8802

0803

8803

7A00

FA00

7A01

FA01

7A02

FA02

Title Function

Acceleration & deceleration

F505

F600

F601

F602

F603

F604

F605

F700

F701

F702

F800

F801

F802

F803

FA00

FA01

FA02

pattern #1 & #2 switching

frequency

Motor overload protection

level

Stall protection level C8:200 * Yes

Fault trip saving 1 0 Yes

Emergency stop selection 2 0 Yes

Emergency stop DC injection

time

Open phase detection

parameter

Parameter setting disable

selection

Unit selection 3 0 Yes

Frequency units

multiplication factor

Communication speed 3 0 Yes

Parity 2 0 Yes

Inverter number 1F:31 0 Yes

Communication error trip

time

Communication command FFFF:65535 0 Yes

Communication frequency

command

Panel frequency command

Max

(hex:dec)

UL

64:100 * Yes

C8:20.0 0:0.0 Yes

2 0 Yes

2 0 Yes

4E20:200.0 64:0.01 Yes

64:100 0 Yes

FH

FH

Min

(hex:dec)

0:0.0 Yes

0:0.0 Yes

0:0.0 Yes

Run Mode

Modify

28

Page 30

Status Monitoring Parameters (read-only)

Drive

A

B

A

B

A

B

A

B

A

B

A

B

A

B

A

B

A

B

A

B

A

B

A

B

A

B

A

B

A

B

A

B

Comm #

(hex)

7D00

FD00

7E00

FE00

7E01

FE01

7E02

FE02

7E03

FE03

7E04

FE04

7E05

FE05

7E06

FE06

7E07

FE07

7E08

FE08

7E09

FE09

7E10

FE10

7E11

FE11

7E12

FE12

7E13

FE13

7E14

FE14

Function

Current output frequency

Output Frequency (saves trip

frequency)

Status (saves trip status)

Current frequency command

Output current display

Bus voltage

Output voltage

Input terminal data

Output terminal data

CPU version

EEPROM version

Past trip 1

Past trip 2

Past trip 3

Past trip 4

Cumulative run time

29

Page 31

Trip Data Codes

Display Data Trip Type

nErr

OC1

OC2

OC3

OCL

OCA

EPH1

EPH0

OP1

OP2

OP3

OL1

OL2

OLr

OH

E

EEP1

Err2

Err3

Err4

Err5

OCr

Etn

EtYP

0000 No trip

0001 Overcurrent during acceleration

0002 Overcurrent during deceleration

0003 Overcurrent during constant-speed run

0004 Load-end short circuit trip during star t-up

0005 Phase short circuit

0006 reserved

0007 reserved

0008 reserved

0009 Loss of output phase

000A Overvoltage during acceleration

000B Overvoltage during deceleration

000C Overvoltage during constant-speed run

000D Inverter overload trip

000E Motor overload trip

000F DBR overload

0010 Overheat trip

0011 Emergency stop

0012 EEPROM fault: write error

0013 reserved

0014 reserved

0015 RAM fault

0016 ROM fault

0017 CPU fault

0018 Communication interruption error

0019~0024 reserved

0025 Dynamic braking resistor trip

0026~0027 reserved

0028 Auto-tuning error

0029 Inverter typeform error

30

Page 32

10.3 Write-Only Coils

Coil # S7 ASD Function OFF ON

31 Command source Local Network

30 Frequency command source Local Network

29 Fault reset N/A Reset

28 Emergency OFF command N/A Trip “E”

27 Coast stop command N/A Coast stop

26 Run / stop command Stop Run

25 Forward / reverse selection Forward Reverse

24 Jog command N/A Jog

23

Drive B

22 Accel / decel #1/#2 selection #1 #2

21 Reserved -- -20 Reserved -- -19 Preset speed 4 OFF ON

18 Preset speed 3 OFF ON

17 Preset speed 2 OFF ON

16 Preset speed 1 OFF ON

15 Command source Local Network

14 Frequency command source Local Network

13 Fault reset N/A Reset

12 Emergency OFF command N/A Trip “E”

11 Coast stop command N/A Coast stop

10 Run / stop command Stop Run

9 Forward / reverse selection Forward Reverse

8 Jog command N/A Jog

7

Drive A

6 Accel / decel #1/#2 selection #1 #2

5 Reserved -- -4 Reserved -- -3 Preset speed 4 OFF ON

2 Preset speed 3 OFF ON

1 Preset speed 2 OFF ON

0 Preset speed 1 OFF ON

DC injection braking N/A

DC injection braking N/A

DC injection

command

DC injection

command

31

Page 33

10.4 Read-Only Coils

Coil # S7 ASD Function OFF ON

131 Drive B online / offline status Offline Online

130 Reserved Always “0”

129 Reserved Always “0”

128 Reserved Always “0”

127 Reserved Always “0”

126 Run / stop status Stopped Running

125 Forward / reverse status Forward Reverse

124 Jog status Not jogging Jogging

123

DC injection braking status

Drive B

122 Accel / decel #1/#2 status #1 #2

121 Reserved Always “0”

120 Reserved Always “0”

119 Reserved Always “0”

118 Reserved Always “0”

117 Reserved Always “0”

116 Reserved Always “0”

115 Drive A online / offline status Offline Online

114 Reserved Always “0”

113 Reserved Always “0”

112 Reserved Always “0”

111 Reserved Always “0”

110 Run / stop status Stopped Running

109 Forward / reverse status Forward Reverse

108 Jog status Not jogging Jogging

107

DC injection braking status

Drive A

106 Accel / decel #1/#2 status #1 #2

105 Reserved Always “0”

104 Reserved Always “0”

103 Reserved Always “0”

102 Reserved Always “0”

101 Reserved Always “0”

100 Reserved Always “0”

Not DC injection

braking

Not DC injection

braking

DC injection

DC injection

braking

braking

32

Page 34

11. Notes

33

Page 35

34

Page 36

35

Page 37

36

Page 38

W

2202 Timberloch Place, Suite 210

The Woodlands, TX USA 77380-1163

Tel: [281] 367-3007 Fax: [281] 367-2177

orld Wide Web http://www.iccdesigns.com

Printed in U.S.A

Loading...

Loading...