Page 1

E6581741h

TOSVERT VF-MB1/S15

EtherNet/IP™ - Modbus® TCP option

Function Manual

IPE002Z

1. Read this manual before installing or operating. Keep this instruction manual on hand

of the end user, and make use of this manual in maintenance and inspection.

2. All information contained in this manual will be changed without notice. Please

contact your Toshiba distributor to confirm the latest information.

NOTICE

Page 2

E6581741

Introduction

Thank you for purchasing the “EtherNet/IP™ - Modbus® TCP option (IPE002Z)” for

TOSVERT VF-MB1/S15 inverter. Before using EtherNet/IP™ - Modbus

carefully read this function manual in order to completely and correctly utilize its excellent

performance.

This option needs the option adaptor to connect VF-S15 which type form is SBP009Z.

Please match here and buy it when SBP009Z is not at hand yet.

After reading this function manual, please keep it handy for future reference.

For details of its general handling, see an instruction manual attached with the option

unit.

- TOSVERT VF-MB1 Instruction Manual ························································· E6581697

- TOSVERT VF-S15 Instruction Manual ·························································· E6581611

- TOSVERT VF-MB1/S15 communication option Precautions Manual···········E6581739

- TOSVERT VF-MB1 Communication Function Instruction Manual················ E6581726

- TOSVERT VF-S15 Communication Function Instruction Manual················· E6581913

EtherNet/IP™ is a trademark of ControlNet International, Ltd.

Modbus

Handling in general

Prohibited

Do not connect or disconnect a network cable while the Inverter power is on.

It may lead to electric shocks or fire.

®

TCP module,

®

TCP is a registered trademark of AEG Schneider Automation International S.A.S.

Warning

Mandatory

Network control

Prohibited

Mandatory

Mandatory

See the instruction manual attached with the option unit for cautions the handling.

Otherwise, it may lead to electric shocks, fire, injuries or damage to product.

Warning

Do not send the value out of the valid range to objects and attributes.

Otherwise, the motor may suddenly start/stop and that may result in injuries.

Use an additional safety device with your system to prevent a serious accident due to the

network malfunctions. Usage without an additional safety device may cause an accident.

Caution

Set up “Communication error trip function (see below)” to stop the Inverter when the

option unit is deactivated by an unusual event such as tripping, an operating error,

power outage, failure, etc.

- Network Time-Out, Inverter operation at disconnection, Preset speed operation

selection

(Refer to " 3.2.3 Network error detection (c100 - c103, c523)" for details)

Deactivated the option module may cause an accident, if the “Communication error trip

function” is not properly set up.

Make sure that the operation signals are STOP before resetting Inverter’s fault. The

motor may suddenly start and that may result in injuries.

Notes on operation

Notes

When the control power is shut off by the instantaneous power failure, communication

will be unavailable for a while.

The Life of EEPROM is approximately 100,000 times. Avoid writing a command more

than 100,000 times to the same parameter of the Inverter and the option module.

- 1 -

- 1 -

Page 3

E6581741

Table of Contents

1. OVERVIEW.................................................................................................................................................4

2. NAMES AND FUNCTIONS ........................................................................................................................4

2.1. Outline ..................................................................................................................................................4

2.2. RJ45 connector pin layout ...................................................................................................................5

2.3. Example of connection to an EtherNet/IP™ and Modbus® TCP .........................................................5

2.4. LED indicator........................................................................................................................................6

3. PARAMETERS ...........................................................................................................................................7

3.1. Communication parameters.................................................................................................................7

3.2. The details of the parameter setting ..................................................................................................11

3.2.1. Device name (c081-c096).................................................................................................11

3.2.2. Assigning IP addresses (c504, c505-c516) ...............................................................12

3.2.3. Network error detection (c100 - c103, c523) ...............................................................13

3.2.4. Command data (c001-c006), Monitor data (c021-c026).........................................14

4. OBJECTS..................................................................................................................................................22

4.1. Identity Object (0x01) .........................................................................................................................23

4.2. Message Router Object (0x02) ..........................................................................................................25

4.3. Assembly Object (0x04) .....................................................................................................................26

4.4. Connection Manager Object (0x06) ...................................................................................................27

4.5. Motor Data Object (0x28)...................................................................................................................28

4.6. Control Supervisor Object (0x29).......................................................................................................29

4.6.1. Run/Stop Event Matrix ................................................................................................................31

4.6.2. State of the drive.........................................................................................................................31

4.6.3. Control Supervisor State Transition Diagram .............................................................................31

4.7. AC/DC Drive Object (0x2A) ...............................................................................................................32

4.8. Parameter Objects (0x64)..................................................................................................................33

4.9. Parameter Objects (0x65)..................................................................................................................35

4.10. Port Object (0xF4) ..........................................................................................................................36

4.11. TCP/IP interface Object (0xF5) ......................................................................................................37

4.12. Ethernet link object (0xF6) .............................................................................................................40

5. CONFIGURATION OF THE ASSEMBLIES.............................................................................................44

5.1. List of Assembly Object Instance .......................................................................................................44

5.1.1. Instance 20: CIP basic speed control output ..............................................................................45

5.1.2. Instance 70: CIP basic speed control input ................................................................................45

5.1.3. Instance 21: CIP extended speed control output........................................................................46

5.1.4. Instance 71: CIP extended speed control input..........................................................................46

5.1.5. Instance 100: Native drive output ...............................................................................................47

5.1.6. Instance 150: Native drive input .................................................................................................47

5.1.7. Instance 101: Native drive output ...............................................................................................49

5.1.8. Instance 151: Native drive input .................................................................................................49

5.1.9. Instance 102: Native drive output ...............................................................................................51

5.1.10. Instance 152: Native drive input..............................................................................................51

5.1.11. Instance 105: TOSHIBA specific output..................................................................................52

5.1.12. Instance 155: TOSHIBA specific input....................................................................................52

6. ABOUT EDS FILE ....................................................................................................................................54

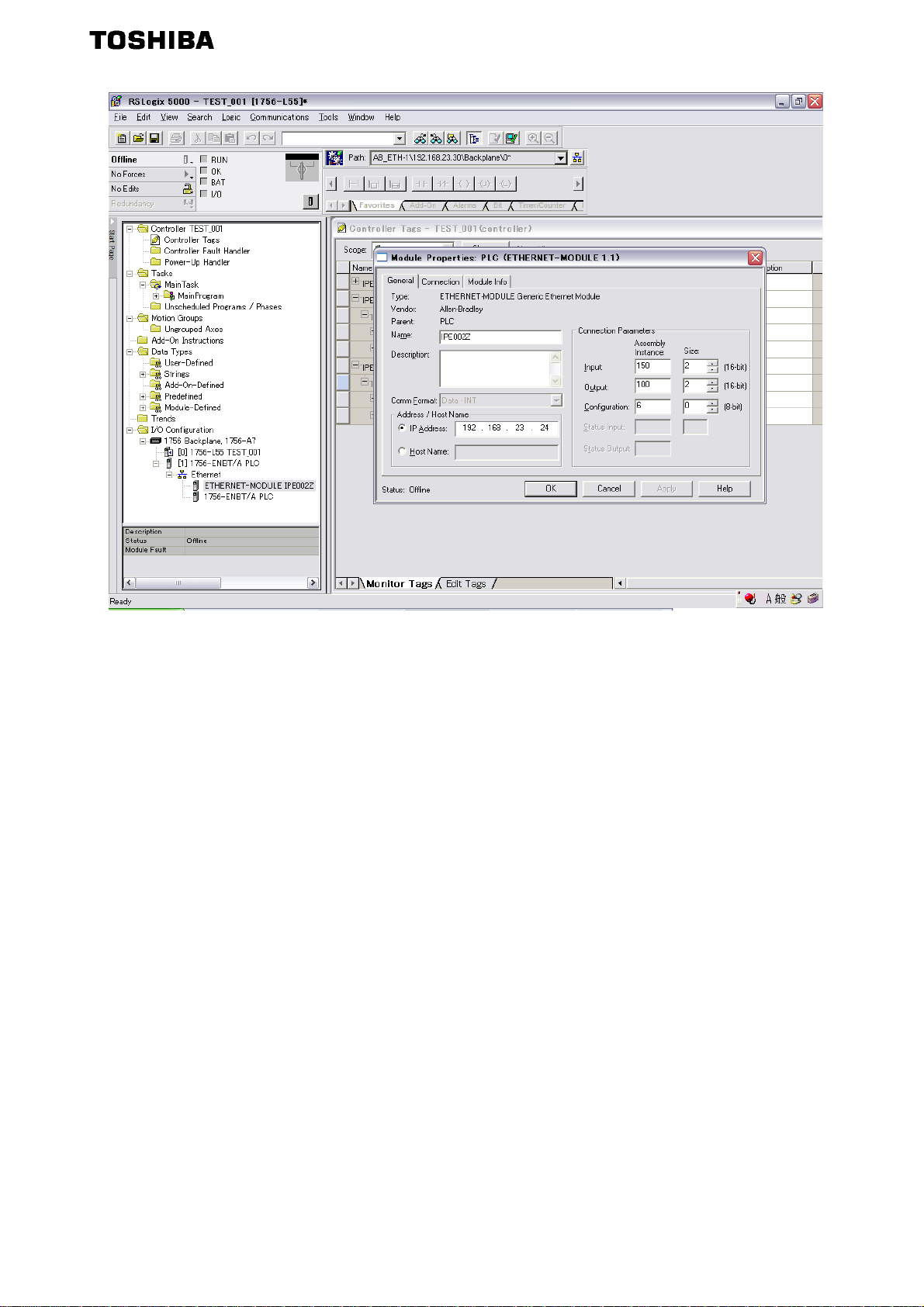

7. INTEGRATION IN RSLOGIX™................................................................................................................54

7.1. Create a new project ..........................................................................................................................54

7.2. Add a EtherNet/IP scanner to the I/O configuration...........................................................................55

7.3. Configure the VF-MB1/S15 EtherNet/IP module ...............................................................................57

7.4. Download the program to the PLC.....................................................................................................59

7.5. Edit the I/O scan data.........................................................................................................................61

8. MODBUS TCP SERVER ..........................................................................................................................64

8.1. Modbus TCP frames ..........................................................................................................................64

8.2. Drive Modbus servers ........................................................................................................................64

8.3. List of Modbus functions supported ...................................................................................................64

8.4. "03 (0x03) Read Holding Registers" function ....................................................................................65

8.5. "06 (0x06) Write Single Register" function.........................................................................................66

8.6. "16 (0x10) Write Multiple Registers" function ....................................................................................67

- 2 -

Page 4

E6581741

8.7.

"23 (0x17) Read/Write Multiple Registers" function...........................................................................68

8.8. "43 (0x2B) Read Device identification" function ................................................................................69

8.9. Parameter data ..................................................................................................................................71

9. IO SCANNING SERVICE..........................................................................................................................72

9.1. Presentation .......................................................................................................................................72

9.2. Periodic variables...............................................................................................................................72

10. EXAMPLE OF THE SETUP WITH PL7™.............................................................................................73

10.1. Defining the hardware configuration...............................................................................................73

10.2. BOOTP configuration .....................................................................................................................74

10.3. Configuring Modbus messaging.....................................................................................................75

10.4. Configuring periodic variables ........................................................................................................76

11. COMMAND & SETPOINT SELECTION (LOCAL/REMOTE)...............................................................77

12. UNUSUAL DIAGNOSIS........................................................................................................................79

12.1. Option error ....................................................................................................................................79

12.2. Disconnection error of network cable.............................................................................................79

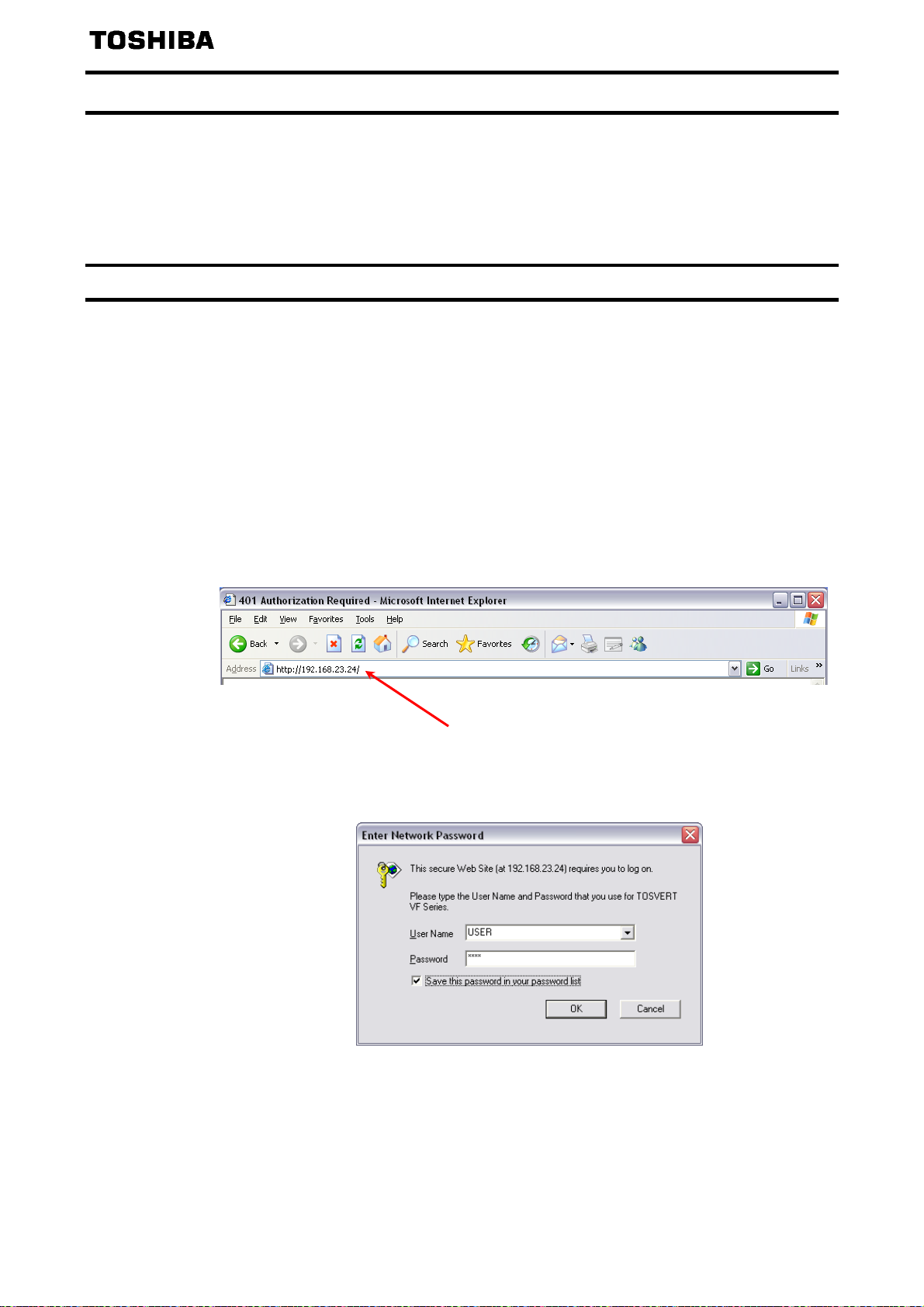

13. WEBSERVER........................................................................................................................................80

13.1. Access to the webserver ................................................................................................................80

13.2. Web pages structure ......................................................................................................................81

13.3. Drive monitor (Main menu: Monitoring) ..........................................................................................82

13.4. Drive parameters (Main menu: Monitoring)....................................................................................83

13.5. Network parameters (Main menu: Network Setup)........................................................................85

13.6. Modbus scanner (Main menu: Network Setup)..............................................................................85

13.7. EthIP scanner (Main menu: Network Setup)..................................................................................86

13.8. Administration (Main menu: Network Setup)..................................................................................87

13.9. TCP/IP statistics (Main menu: Diagnostics) ...................................................................................88

- 3 -

Page 5

E6581741

1. Overview

The EtherNet/IP™ - Modbus® TCP option (IPE002Z) allows the VF-MB1/S15 inverter to be connected

into the EtherNet/IP™ - Modbus

®

TCP network.

2. Names and functions

The drawing below shows names and functions of main parts.

2.1. Outline

MAC address Label

(Back side)

Release tab

Connector to the inverter

MS

LNK

(Port L)

LED indicator (See 2.4)

Shielded female RJ45

EtherNet/IP Connector

NS

LNK

Shielded female RJ45

EtherNet/IP Connector

(Port R)

- 4 -

Page 6

E6581741

2.2. RJ45 connector pin layout

The EtherNet/IP™ - Modbus® TCP option is equipped with two shielded RJ45

connectors.

When you use VF-MB1, the shielding is connected to the drive ground. When you use

VF-S15, the shielding is connected to the grounding terminal of option adapter.

Use an STP (shielded twisted pair) Ethernet cable.

The transmission speed is detected automatically by the unit (10 Mbps or 100 Mbps).

The card can operate in half duplex or full duplex mode, whether connected to a hub or a

switch and regardless of the transmission speed (10 Mbps or 100 Mbps).

Port L and Port R

8………………1

* Fix a cable so that a communication connector may be not taken the weight of wire.

Pin Signal

1 TD+

2 TD-

3 RD+

4 -

5 -

6 RD-

7 -

8 -

2.3. Example of connection to an EtherNet/IP™ and Modbus® TCP

Example of daisy chain topology and star topology

Daisy chain topology Star topology

PLC

Ethernet switch

- 5 -

Page 7

E6581741

2.4. LED indicator

The LED shows the present

status of the network and module.

The behavior of LNK LED

Link Activity

Protocol Color and behavior Meaning

EtherNet/IP

&

Modbus TCP

The behavior of MS LED

Module Status

Protocol Color and behavior Meaning

EtherNet/IP

Modbus TCP

The behavior of NS LED

Network Status

Protocol Color and behavior Meaning

EtherNet/IP

Modbus TCP

OFF No link

Flashing Green/Red Power up testing

Green ON Link at 100Mbps

Yellow ON Link at 10Mbps

Green Blink Activity at 100Mbps

Yellow Blink Activity at 10Mbps

OFF No power is supplied to the device

Flashing Green/Red Power up testing

Green ON The option is operating correctly

Green flashing The option has not been configured

Red flashing The option has detected a recoverable minor fault

Red on The option has detected a non-recoverable major fault

OFF The option does not have an IP address or powered off

Flashing Green/Red Power up testing

Green ON The option is ready

Green flashing The option is not ready (waiting for cable connection or etc.)

Red flashing The option has detected a communication error (err8)

Red ON The option has detected a option module error (e-23)

OFF The option does not have IP address or powered off

Flashing Green/Red Power up testing

Green ON The option has at least one established connection

Green flashing The option does not have at least one established connection

Red flashing One or more of the connections in which this device is the target

has time out. This shall be left only if all time out connections are

re-established or if the device is reset

Red on Error: duplicate IP address

OFF The option does not have an IP address or powered off

Flashing Green/Red Power up testing

Green ON At least one port is connected and an IP address has been

obtained

Green flashing 3 times All ports are unplugged, but the card has an IP address

Green flashing 4 times Error: duplicate IP address

Green flashing 5 times The card is performing a BOOTP or DHCP sequence

MS

LNK

NS

LNK

- 6 -

Page 8

E6581741

3. Parameters

3.1. Communication parameters

Set up the inverter parameters as follows. It is necessary to reset the inverter to update the parameter.

This option doesn't operate if these parameters are not correctly set.

Title

cmod 0003 Command mode selection

fmod 0004

f856 0856

f899 0899 Communication function reset

(*1): There selections are effective in only VF-S15.

Title

c001 C001 Scanner input 1 address (*3)

c002 C002 Scanner input 2 address (*3)

c003 C003 Scanner input 3 address (*3)

c004 C004 Scanner input 4 address (*3)

c005 C005 Scanner input 5 address (*3)

c006 C006 Scanner input 6 address (*3)

(*2): The unit depends on the f519 setting.

(*3): This parameter is effective by reset. Please reset (power supply reset or f899=1) after changing a set point.

Communi

cation No.

Communi

cation No.

Function Description

Frequency setting mode

selection 1

Number of motor pole pair for

communication

Function Description

0: Terminal board

1: Panel keypad (including remote keypad)

2: RS485 communication

3: CANopen communication

4: Communcation option

0: Setting dial 1 (save even if power is off)

1: Terminal board VIA

2: Terminal board VIB

3: Setting dial 2 (press in center to save)

4: RS485 communication

5: UP/DOWN from external logic input

6: CANopen communication

7: Communication option

8: Terminal board VIC

9, 10: 11: Pulse train input

12, 13: - (*1)

14: sr0 (*1)

1: 2 poles

2: 4 poles

3: 6 poles

4: 8 poles

5: 10 poles

6: 12 poles

7: 14 poles

8: 16 poles

0: 1: Reset (after execution: 0)

0: 1: fa06 (Communication command 1)

2: fa23 (Communication command 2)

3: fa07 (Frequency command, 0.01Hz)

5: fa50 (Terminal output data)

6: fa51 (FM analog output)

8: f601 (Stall prevention level, %)

13: acc (Acceleration time 1, 0.1s) (*2)

14: dec (Deceleration time 1, 0.1s) (*2)

15: ul (Upper limit, 0.01Hz)

16: vb (Torque boost value 1, 0.1%)

17: vlv (Base frequency voltage 1, 0.1V)

0-17 (Same as c001)

0-17 (Same as c001)

0-17 (Same as c001)

0-17 (Same as c001)

0-17 (Same as c001)

Factory

setting

1

0

2

0

Factory

setting

1

3

0

0

0

0

- 7 -

Page 9

E6581741

Title

c021 C021 Scanner output 1 address (*3)

c022 C022 Scanner output 2 address (*3)

c023 C023 Scanner output 3 address (*3)

c024 C024 Scanner output 4 address (*3)

c025 C025 Scanner output 5 address (*3)

c026 C026 Scanner output 6 address (*3)

c081-

c096

c100 C100

c101 C101

Communi

cation No.

C081-

C096

Function Description

Device Name 1-16 (*4)

Communication error

detection delay time

Inverter operation at the

communication loss action

0: -

1: fd01 (Status information 1)

2: fd00 (Output frequency, 0.01Hz)

3: fd03 (Output current, 0.01%)

4: fd05 (Output voltage, 0.01%)

5: fc91 (Alarm information)

6: fd22 (PID feedback value, 0.01Hz)

7: fd06 (Input terminal board status)

8: fd07 (Output terminal status)

9: fe36 (VIB input, 0.01%)

10: fe35 (VIA input, 0.01%)

11: fe37 (VIC input, 0.01%)

12: fd04 (Input voltage (DC detection), 0.01%)

13: fd16 (Estimated speed 0.01Hz)

14: fd18 (Torque, 0.01%)

15: 16: 17: 18: 19: f880 (Free notes)

20: fd29 (Input power, 0.01kW)

21: fd30 (Output power, 0.01kW)

22: fe14 (Cumulative operation time, hour)

23: fe40 (FM terminal output monitor, 0.01%)

24: 25: fd20 (Torque current, 0.01%)

26: fd23 (Motor overload factor, 0.01%)

27: fd24 (Drive overload factor, 0.01%)

28: fd25 (PBR overload factor, %)

29: fd26 (Motor load factor, %)

30: fd27 (Drive load factor, %)

31: fe56 (Pulse train input, pps)

32: fe70 (Drive rated current, 0.1A)

33: fe76 (Input Watt-hour, 0.1kWh 10

34: fe77 (Output Watt-hour, 0.1kWh 10

35: fd83 (IGBT temperature, degree C)

0-35 (Same as c021)

0-35 (Same as c021)

0-35 (Same as c021)

0-35 (Same as c021)

0-35 (Same as c021)

16 characters

The device name is required if the card uses

DHCP to obtain its IP Address.

Refer to " 3.2.1 Device name (c081-c096) for the

details.

0.0 - 100.0 sec.

0: Stop and controlled by cmod, fmod

1: Operation continue

2: Deceleration stop

3: Coast stop

4: Network error stop (err8 trip)

5: Preset speed operation (by c102 setting)

f749

f749

)

)

Factory

setting

1

2

0

0

0

0

0,0,0,0,

0,0,0,0

0.0

4

c102 C102

c103 C103

(*3): This parameter is effective by reset. Please reset (power supply reset or f899=1) after changing a set point.

(*4): (V[R) does not work for this parameter.

Preset speed operation

selection

Communication time-out

condition selection

0: None

1 to 15: Preset speed

0: Disconnection detection

1: When communication mode enable (Both

cmod and fmod are set CANopen or

communication option) only

2: 1 + Driving operation

0

0

- 8 -

Page 10

E6581741

Title

c500 C500

c501 C501

c502 C502

c503 C503

c504 C504

c505-

c508

c509-

c512

c513-

c516

c517-

c522

c523 C523 Time out

c524-

c527

c528-

c531

c532-

c535

Communi

cation No.

C505-

C508

C509-

C512

C513-

C516

C517-

C522

C524-

C527

C528-

C531

C532-

C535

Protocol (*3)

Rate Setting (*3)

Actual Rate (L port)

Actual Rate (R port)

IP mode (*3)

IP address (*3)

Subnet Mask (*3)

IP Gate (*3)

MAC address (*5)

IP address actual

IP Mask actual

IP Gate actual

Function Description

This parameter is used to set the protocol of the option

card.

0: Modbus TCP (default)

1: EtherNet/IP

This field is used to set the transmission speed and the

transmission mode of the card.

0: Autodetect(default)

1: 10Mbps Full

2: 10Mbps Half

3: 100Mbps Full

4: 100Mbps Half

This field displays the baud rate and the transmission

mode currently used by the communication card.

(Display only)

0: unconnected

1: 10Mbps Full

2: 10Mbps Half

3: 100Mbps Full

4: 100Mbps Half

Use this parameter to select the IP address assignment

method.

0: Manual

1: BOOTP

2: DHCP

Refer to "

The IP address of the option module.

3.2.2 Assigning IP addresses" for the details.

These fields are effective settings at c504 = 0.

Refer to " 3.2.2 Assigning IP addresses" for the details.

The subnet mask of the option module.

These fields are effective settings at c504 = 0.

Refer to " 3.2.2 Assigning IP addresses" for the details.

The gateway IP address of the option module.

These fields are effective settings at c504 = 0.

Refer to " 3.2.2 Assigning IP addresses" for the details.

The MAC address of the option module.

[C517 - C518 - C519 - C520 - C521 - C522]

The waiting time from the occurrence of the

Factory

setting

0

0

-

0

0.0.0.0

0.0.0.0

0.0.0.0

----

2

network error to detection can be adjusted.

* When you are using unconnected

communication of the EtherNet/IP protocol, time

out is not detected.

0.0: Disable

0.5 - 60 sec.

The current IP address of the option module.

Refer to "

The subnet mask actual of the option module.

Refer to "

The gateway IP address actual of the option module.

Refer to "

3.2.2 Assigning IP addresses" for the details.

3.2.2 Assigning IP addresses" for the details.

3.2.2 Assigning IP addresses" for the details.

-

-

-

(*3): This parameter is effective by reset. Please reset (power supply reset or f899=1) after changing a set point.

(*5): .These values are displayed by decimal number format on panel of VFMB1/S15.

- 9 -

Page 11

E6581741

EtherNet/IP parameters

Title

c536 C536 EtherNet Error

c554 C554 Web service (*3)

c555 C555 Drive Status

Communi

cation No.

Function Description

Modbus TCP parameters

Title

c600-

c603

c604 C604 IO Scan active (*3)

Communi

cation No.

C600-

C603

Function Description

IP Master (*3) The IP address for PLC(Master) of the Modbus TCP.

Monitor of the EtherNet error.

0: No error/clear error

1: Modbus TCP IO Scanning timeout

2: Network overload

3: Loss of Ethernet carrier

Enables web server.

0: Disable

1: Enable

Monitor the inverter status.

3: Gate Block

4: Run

23: Fault

Enables IO Scan function.

0: Non-active

1: Active

Factory

setting

-

1

-

Factory

setting

0.0.0.0

0

(*3): This parameter is effective by reset. Please reset (power supply reset or f899=1) after changing a set point.

Warning

Mandatory

action

Set up “Communication error trip function (c100 to c103 and c523)” to stop the

inverter when EtherNet/IP™ - Modbus® TCP communication is deactivated.

When the parameters are changed, please reset (power supply reset or f899=1) the

inverter for the changes to take effect.

- 10 -

Page 12

E6581741

3.2. The details of the parameter setting

3.2.1. Device name (c081-c096)

This option module can set the "Device name" of 16 characters.

(Device name (c081-c096) is 1 character within one parameter.)

The device name is required if the option module uses DHCP to obtain its IP Address.

Please set the setting of the device name according to the following rules.

1. The parameter is displayed by the hexadecimal number.

2. One parameter shows an ASCII character.

3. The relation between the device name and the parameter is as follows.

Example for Device Name =’VFMB1-4007PL’

Chars No. Parameter Character (Ex.) ASCII (Ex.)

1 c081 ‘V’ 56H

2 c082 ‘F’ 46H

3 c083 ‘M’ 4DH

4 c084 ‘B’ 42H

5 c085 ‘1’ 31H

6 c086 ‘-‘ 2DH

7 c087 ‘4’ 34H

8 c088 ‘0’ 30H

9 c089 ‘0’ 30H

10 c090 ‘7’ 37H

11 c091 ‘P’ 50H

12 c092 ‘L’ 4CH

13 c093 - 14 c094 - 15 c095 - 16 c096 - -

- 11 -

Page 13

E6581741

3.2.2. Assigning IP addresses (c504, c505-c516)

The drive needs 3 (4-Modbus TCP) IP addresses.

*The drive IP address.

*The subnet mask.

*The gateway IP address.

(*The IP Master address.- Modbus TCP protocol only)

These parameters are effective settings at c504 = 0 (IP mode: Manual).

If the address has been given by a BOOTP or a DHCP server, these parameters are

invalidity.

• After dynamic addressing by a BOOTP or DHCP server, the new address value is

displayed in the parameters. (c524-c535)

They can be provided by:

*BOOTP server (correspondence between the MAC address and the IP addresses).

*DHCP server (correspondence between Device Name and the IP addresses).

The address is assigned according to the IP mode parameter.

c504: IP mode Comments

0 The option uses the address defined in c505-c516.

1 The option receives its address from a BOOTP server.

2 The option receives its address from a DHCP server.

*Device name contains (c081-c096) a valid name.

Note: The IP mode parameter may be modified according to the configuration control

attribute of the TCP/IP interface object (CIP standard).

- 12 -

Page 14

E6581741

3.2.3. Network error detection (c100 - c103, c523)

▼Display of trip information

err8 (Optional unit fault 1: 1BH): Network error stop

▼Related parameter

Title Function Setting range Description

The waiting time from when a network error occurs

can be adjusted. If a network error continues past

the time set in c100, it is recognized as a

communication error and the operation of the

inverter follows the setting of c101.

When normal communication returns during the

setting time, a communication error is not displayed

and operation is continued.

c100

c101

c102

c103

c523 Time out

Communication error

detection delay time

Inverter operation at the

communications loss action

Preset speed operation

selection

Communication time-out

condition selection

0.0-100.0 sec

0-5

1-15

0-2

0.0: Disable

0.5 - 60 sec.

*The case of Modbus

The time-out detection time provides by c523

parameter.

Disconnection detection time =

c523 (Time out) +

c100 (

Communication error detection delay time)

*The case of EtherNet/IP

-At I/O scanning and connected communication

Time-out time =

RPI42

Connection Timeout Multiplier

(communication error detection delay time) [0.1s]

RPI: Request Packet Interval

-At Unconnected communication

Time-out is not operating.

The operation of the inverter when the

communication fault occurs can be specified.

The operation frequency of the inverter when the

communication fault occurs can be specified. (Only

when c101 is set to 5)

Select the communication time-out condition.

The waiting time from the occurrence of the

network error to detection can be adjusted.

* When you are using unconnected communication

of the EtherNet/IP protocol, time-out is not

detected.

®

TCP protocol

TM

protocol

[μs] + c100

- 13 -

Page 15

E6581741

3.2.4. Command data (c001-c006), Monitor data (c021-c026)

The outline is indicated about the setting item of parameter c001 – c006 and

c021 – c026 in Instance 102/152 and 105/155 of use. Please refer to a

communication functional description for details.

3.2.4.1. How to use Instance 102/152 and 105/155

Instance 102/152 and 105/155 choose a command or the monitor of the driving state by a menu of c001

- c006 and c021 - c026 and can perform the communication that is cyclic of EtherNet/IP™ and

Modbus

Example 1: Command transmitting by output Instance 102

VF-MB1/S15

"0xC400" is set to parameter fa06

Example 2: State monitoring by the input instance 152.

VF-MB1/S15

The value of a parameter fd03 (0x1234)

is outputted.

®

TCP (ID = 255).

If the command value “c400” set to parameter fa06, Choose parameter fa06 (a communication

option command) for command data (c001=1 (fa06)).

For example, please set C400 in FA06 when you want to send the command from an EtherNet/IP™

option and the availability of the frequency order and a driving order. (Please refer to ” 3.2.4.2”)

IPE002Z

Parameter Value

c001 1 (fa06)

c002 ...

c003 ...

... ...

EtherNet/IP Master

Output Instance 102

Byte Value

0 00

1 C4

2 ...

3 ...

... ...

When you want to monitor the output current, set “3 (fd03)” to parameter c021.

The value of the parameter

fd03 specified as 0 and 1 byte of the input instance 152 with the parameter

c021 is inputted.

IPE002Z

Parameter Value

c021 3 (fd03)

c022 ...

c023 ...

... ...

EtherNet/IP Master

Input Instance 152

Byte Value

0 34

1 12

2 ...

3 ...

... ...

- 14 -

Page 16

E6581741

3.2.4.2. fa06 (Communication command1)

bit Function 0 1 Note

Preset speed

0

operation frequencies

1

Preset speed

1

operation frequencies

2

Preset speed

2

operation frequencies

3

Preset speed

3

operation frequencies

4

Motor selection (1 or 2)

4

(THR 2 selection)

5 PI D control Normal operation PI D off -

Acceleration/deceleration pattern selection

6

(1 or 2)

(AD2 selection)

7 DC braking OFF

8 Jog run OFF Jog run -

Forward/reverse run

9

selection

10 Run/stop Stop Run 11 Coast stop command Standby Cost stop 12 Emergency stop OFF Emergency stop Always enable, "E" trip

13 Fault reset OFF Reset No data is returned from the drive

Frequency priority

14

selection

Command priority

15

selection

(*1): When 14(sr0) is set to fmod, preset speed operation frequency 0 is selected in using VFS15,.

0000: Preset speed operation OFF

(*1)

0001-1111: Setting of preset speed

operation frequencies (1-15)

Motor 1

(THR 1)

Acceleration/decel

eration pattern 1

(AD1)

Forward run Reverse run -

OFF Enabled

OFF Enabled

Motor 2

(THR 2)

Acceleration/dec

eleration pattern

2

(AD2)

Forced DC

braking

Preset speed operation is

disabled or preset speed

operation frequencies (1-15) are

set by specifying bits for preset

speed operation frequencies 1-4.

THR 1: pt = setting value, thr

THR 2: pt = 0, f170,

f171, f172, f173

AD1: acc, dec

AD2: f500, f501

Enabled regardless of the setting

of fmod

Enabled regardless of the setting

of cmod

-

- 15 -

Page 17

E6581741

3.2.4.3. fa23 (Communication command 2)

bit Function 0 1 Note

0 (Reserved) - - -

Electric power quantity

1

reset

2 (Reserved) - - 3 (Reserved) - - 4 (Reserved) - - 5 (Reserved) - - 6 (Reserved) - - -

Maximum deceleration

7

forced stop

Acceleration/decele-

8

ration selection 1

Acceleration/decele-

9

ration selection 2

10 (Reserved) - - -

11 (Reserved) - - -

12 OC stall level switch OC stall 1 OC stall 2

13 (Reserved) - - 14 (Reserved) - - 15 (Reserved) - - -

Note: Set 0 to reserved bit.

OFF Reset

Normal Enabled -

00: Acceleration/deceleration 1

01: Acceleration/deceleration 2

10: Acceleration/deceleration 3

Electric power quantity (fe76,

fe77) reset

Select acceleration/deceleration

1-3 by combination of two bits..

AD1: acc, dec

AD2: f500, f501

AD3: f510, f511

OC stall 1: f601

OC stall 2: f185

- 16 -

Page 18

E6581741

3.2.4.4. fa07 (frequency reference from internal option)

Frequency reference is set up by 0.01Hz unit and the hexadecimal number.

For example, when "Frequency reference" is set up to 80Hz, since the minimum unit is 0.01Hz,

80 / 0.01 = 8000 = 0x1F40 (Hex.)

3.2.4.5. fa50 (Terminal output data from communication)

The output data on the terminal board can be directly controlled with the computer.

To use this function, select functions from 92 to 95 in advance for the output terminal selection

parameters f130, f131, f132. If bit 0 through bit1 of the data (fa50) is set with the computer,

the specified data (0 or 1) can be output to the selected output terminal.

Data composition of output data on the terminal board (FA50)

bit Output TB function name 0 1

0

1

2-15 (Reserved) - -

Specified data output 1

(Output terminal No.: 92, 93)

Specified data output 2

(Output terminal No.: 94, 95)

Note: Set 0 to reserved bit

Example of use: To control only the RY-RC terminal with the computer

To turn on the RY terminal, set the output terminal selection 1A parameter (f130) to 92

(Designated data output 1) and set 0001H to fa50.

BIT15 BIT0

FA50:

0 0 0 0 000000000001

OFF ON

OFF ON

0

0

0

1

3.2.4.6. fa51 (Analog output (FM) data from communication)

Use this function, set the FM terminal meter selection parameter (fmsl) to 18 (communication data

output).

This makes it possible to send out the data specified as FM analog output data (fa51) though the FM

analog output terminal. Data can be adjusted in a range of 0 to 1000 (resolution of 10 bit).

Please refer to "Meter setting and adjustment" Section of the inverter’s instruction manual.

- 17 -

Page 19

E6581741

3.2.4.7. fd01 (Inverter operating status 1)

bit Function 0 1 Note

0 Failure FL No output

1 Failure Not tripped Tripped

2 Alarm No alarm Alarm issued 3 Under voltage (moff) Normal Under voltage -

Motor selection (1 or 2)

4

(THR 2 selection)

5 PID control off

Acceleration/deceleratio

6

n pattern selection (1 or

2)

7 DC braking OFF

8 Jog run OFF Jog run -

9 Forward / reverse run Forward run Reverse run 10 Run/stop Stop Run 11 Coast stop (ST = OFF) ST=ON ST=OFF -

12 Emergency stop

13 Standby ST=ON Start-up process Standby

14 Standby Start-up process Standby

15 (Reserved) Undefined -

Note: Don’t use the reserved bit for the judgment.

Motor 1 (THR1) Motor 2 (THR2)

PID control

permitted

Acceleration/dec

eleration pattern

1 (AD1)

No emergency

stop status

Under in

progress

PID control

prohibits

Acceleration/dec

eleration pattern

2 (AD2)

Forced DC

braking

Emergency

stop status

-

Trip status includes rtry and

the trip retention status are also

regarded as tripped statuses.

THR1: pt = setting value, vl,

vlv, vb, thr

THR2: pt = 0, f170, f171,

f172, f173

-

AD1: acc, dec

AD2: f500, f501

-

-

Standby: Initialization

completed, not failure stop

status, not alarm stop status

(moff, ll forced stop),

ST=ON, and RUN=ON

Standby: Initialization completed,

not failure stop status and not

alarm stop status (moff, ll

forced stop)

3.2.4.8. fd00 (Output frequency)

The current output frequency is read into 0.01Hz of units and by the hexadecimal number.

For example, when the output frequency is 80Hz, 0x1F40 (hexadecimal number) are read.

Since the minimum unit is 0.01%,

0x1F40 (Hex.) = 8000(Dec.) * 0.01 = 80 (Hz)

Also about the following parameters, these are the same as this.

- fd22 (Feedback value of PID)............................................... Unit: 0.01Hz

- fd16 (Estimated speed) ........................................................ Unit: 0.01Hz

- fd29 (Input power) ................................................................Unit: 0.01kW

- fd30 (Output power) ............................................................. Unit: 0.01kW

- 18 -

Page 20

E6581741

3.2.4.9. fd03 (Output current)

The output current is read into 0.01% of units and by the hexadecimal number.

For example, when the output current of the rated current 4.8A drive is 50% (2.4A), 0x1388 (hexadecimal

number) is read out.

Since the minimum unit is 0.01%,

0x1388 (Hex.) = 5000 (Dec.) * 0.01 = 50 (%)

Also about the following parameters, these are the same as this.

- fd05 (Output voltage (real time))............................................. Unit: 0.01% (V)

- fd04 (Voltage at DC bus (real time)) ....................................... Unit: 0.01% (V)

- fd18 (Torque) ..........................................................................Unit: 0.01% (Nm)*

* When the motor information connected to the drive set to the parameter (f405 - f415), torque

monitor value "100%" is same as the rated torque of a motor in general.

3.2.4.10. fe35, fe36, fe37 (Monitoring of the analog input VIA, VIB, VIC)

VIA terminal board monitor: "Communication Number fe35"

VIB terminal board monitor: "Communication Number fe36"

VIC terminal board monitor: "Communication Number fe37"

These monitors can also be used as A/D converters irrespective of the drive's control.

VIA / VIC terminal board monitor is capable of reading the data from external devices in a range of 0.01

to 100.00% (unsigned data: 0x0000 to 0x2710).

VIB terminal board monitor is capable of reading the data from external devices in a range of -100.00 to

100.00% (signed data: 0xD8F0 to 0x2710).

If analog input mode is selected with the frequency setting mode selection parameter, however, keep in

mind that any data entered via an analog terminal is regarded as a frequency command.

3.2.4.11. fe14 (Cumulative run time)

The operated cumulative time is read by the hexadecimal number.

For example, when cumulative operation time is 18 hours, 0x0012 (18 hours) is read.

0x0012 = 18 (Dec., hour)

3.2.4.12. fe40 (Analog output (FM))

The output value of FM terminal is read.

The value range is set to 0 to 10000 (0x0000 to 2710H) which is corresponded to 0.00% to 100.00%.

For example, when analog output is 50.00%, 0x1388 is read.

0x1388 = 50.00(Dec., %)

- 19 -

Page 21

E6581741

3.2.4.13. fc91 (Alarm code)

Remarks

bit

0 Over-current alarm Normal Alarming c flicking

1 Inverter over load alarm Normal Alarming l flicking

2 Motor over load alarm Normal Alarming l flicking

3 Over heat alarm Normal Alarming h flicking

4 Over voltage alarm Normal Alarming p flicking

5 Main circuit undervoltage alarm Normal Alarming -

6 main device overheat alarm Normal Alarming l flicking

7 Under current alarm Normal Alarming -

8 Over-torque alarm Normal Alarming -

9 Braking resistor overload alarm Normal Alarming 10 Cumulative operation hours alarm Normal Alarming 11 Option communication alarm Normal Alarming 12 Serial communication alarm Normal Alarming 13 MOFFMS (MSrelay off or MOFF) Normal Alarming -

14 Stop after instantaneous power off -

15 Stop after LL continuance time -

Function 0 1

Dec., Under

(Code displayed on

the panel)

Refer to f302

stop

Dec., Under

Refer to f256

stop

value

value

3.2.4.14. fd06 (Input TB Status)

bit TB Name Function (Parameter) 0 1

0 F Input terminal function selection 1 (f111)

1 R Input terminal function selection 2 (f112)

2 RES Input terminal function selection 3 (f113)

3 S1 Input terminal function selection 4 (f114)

4 S2 Input terminal function selection 5 (f115)

5 S3 Input terminal function selection 6 (f116)

6 VIB*1 Input terminal function selection 7 (f117)

7 VIA*1 Input terminal function selection 8 (f118)

5 to 15 (Reserved) - Undefined

Note: Don't use the reserved bit for the judgment.

*1: VIA/ VIB are input terminal function when f109 is logic input.

*The input terminal function is selected by each parameter.

Example: Data set for FE06 when the F and RES terminals are ON = 0005H

BIT15 BIT0

FE06:

0 0 0 0 000000000101

0

0

0

5

OFF ON

- 20 -

Page 22

E6581741

3.2.4.15. fd07 (Output TB Status)

bit TB Name Function (Parameter) 0 1

0 RY-RC Output terminal function selection 1A (f130) OFF ON

1 OUT Output TB Function select 2A (f131) OFF ON

2 FL Output TB Function select 3 (f132) OFF ON

3 - 15 (Reserved) - Undefined

Note: Don't use the reserved bit for the judgment.

Example: Data set for FE07 when the RY and FL terminals are ON = 0005H

BIT15 BIT0

FE07:

0 0 0 0 000000000101

0

0

0

5

- 21 -

Page 23

4. Objects

E6581741

This section contains the object specifications for all EtherNet/IP objects currently

supported by the “IPE002Z”. Table 1 outlines those objects covered:

Class Code

Hex. Dec.

0x01 1 Identity Object

0x02 2 Message Router Object

0x04 4 Assembly Object

0x06 6 Connection Manager Object

0x28 40 Motor Data Object

0x29 41 Control Supervisor Object

0x2A 42 AC/DC Drive Object

0x64 100 Parameter Object

0x65 101 Parameter Object

0xF4 244 Port Object

0xF5 245 TCP/IP Interface Object

0xF6 246 Ethernet Link Object

Table 1: Supported Objects

For definitions of all data types referred to in these object specifications, refer to the

ODVA EtherNet/IP™ Specifications. In general, however, the following are some of the

most prevalent types:

BOOL .......................... Boolean 0(False) or 1(TRUE)

SINT............................ Signed Short Integer -128 to 127

INT ..............................Integer -32768 to 32767

DINT............................ Double Integer -2

USINT .........................Unsigned Short Integer 0 to 255

UINT............................ Unsigned Integer 0 to 65535

UDINT .........................Unsigned Double Integer 0 to 2

STRING ......................character string (1 byte per character)

SHORT_STRING........ character string (1 byte per character, 1 byte length indicator)

BYTE........................... Bit string - 8-bits

WORD......................... Bit string - 16-bits

DWORD ......................Bit string - 32-bits

EPATH ........................ CIP path segments

Object Class Page

23

25

26

27

28

29

32

33

35

36

37

39

31

to 231-1

32

-1

- 22 -

Page 24

E6581741

4.1. Identity Object (0x01)

Class code 0x01.

This object provides identification of and general information about the device.

Class Attributes

Instance Attribute ID Access Name Data type Details Value

1 Get Revision UINT Revision of this object 1

2 Get Max Instances UINT Maximum instance number of an

object currently created in this class

level of the device.

3 Get Number of Instances UINT Number of object instances currently

created at this class level of the

device.

4 Get

0

6 Get Max ID of class

7 Get Max ID of instance

Optional attribute list STRUCT

of

Number of attributes UNIT Number of attribute in the optional

Optional attributes ARRAY of

UNIT

UINT The attribute ID number of the last

attributes

UINT The attribute ID number of the last

attribute

List of optional instance attributes

utilized in an object class

implementation.

attribute list.

List of optional attribute numbers. -

class attribute of the class definition

implemented in the device.

instance attribute of the class

definition implemented in the device.

Class Service

Service Code Service Name Description of Service

0x01 Get_Attribute_All Read all attributes

0x0E Get_Attribute_Single Read one attribute

Instance Attributes

Instance Attribute ID Access Name Data type Details Value

1 Get Vendor ID UINT

2 Get Device type UINT AC/DC Drive profile 2

3 Get Product code UINT

4 Get

1

5 Get Status WORD See “Attribute 5 State Description” *

6 Get Serial number UDINT 4 last bytes of MAC Address 7 Get Product name SHOT_

Revision STRUCT

of

Major revision USINT Major revision of drive 1 (*1)

Minor revision USINT Minor revision of drive 8 (*1)

STRING

Identification of vendor by number

Identification No. of a drive

(case of VF-MB1) 32000

(case of VF-S15) 32001

Revision of the item the Identity

Object represents

Human readable identification

(case of VF-MB1 drive) 6,

(case of VF-S15 drive) 6,

*1: These values depend on firmware version and revision.

Instance Services

Service Code Service Name Description of Service

0x01 Get_Attribute_All Read all attributes

0x05 Reset Invokes the Reset for the device

0x0E Get_Attribute_Single Read one attribute

1

1

0

-

7

7

377

VF-MB1

VF-S15

- 23 -

Page 25

E6581741

Attribute 5 State Descriptions

Adapted from document [CIP] “

THE CIP NETWORKS LIBRARY”

Bit Called Definition

TRUE indicates the device (or an object within the device) has an owner.

Within the Master/Slave paradigm the setting of this bit means that the

0 Owned

Predefined Master/Slave Connection Set has been allocated to a master.

Outside the Master/Slave paradigm the meaning of this bit is TBD.

Æ unsupporteed

1 - (System reserved)

TRUE indicates the application of the device has been configured to do

2 Configured.

something different than the “out–of–box” default. This shall not include

configuration of the communications.

3 - (System reserved)

0000 Self-Testing or unknown

0001 Firmware update in progress

0010 At least one faulted I/O connection

0011 No I/O connections established

Extended Device

4-7

Status

0100 Non-Volatile configuration bad

0101 Major Fault – either bit 10 or bit 11 is true (1)

0110 At least one I/O connection in run mode

0111 At least one I/O connection established, all in idle mode

1000-

Unused

1111

Minor Recoverable

8

Fault

Minor

9

Unrecoverable

Fault.

Major Recoverable

10

Fault.

Major

11

Unrecoverable Fault

TRUE indicates the device detected a problem with itself, which is thought to

be recoverable. The problem does not cause the device to go into one of the

faulted states.

TRUE indicates the device detected a problem with itself, which is thought to

be unrecoverable. The problem does not cause the device to go into one of

the faulted states.

TRUE indicates the device detected a problem with itself, which caused the

device to go into the “Major Recoverable Fault” state.

TRUE indicates the device detected a problem with itself, which caused the

device to go into the “Major Unrecoverable Fault” state.

12-15 - (System reserved)

Note: Don’t use the “System reserved” bit and Bit0 for the judgement.

- 24 -

Page 26

E6581741

4.2. Message Router Object (0x02)

Class code 0x02.

The Message Router Object provides a messaging connection point through which a Client may

address a service to any object class or instance residing in the physical device.

Class Attributes

Instance Attribute ID Access Name Data type Details Value

1 Get Revision UINT Revision of this object 1

2 Get Max Instances UINT Maximum instance number of an

object currently created in this class

level of the device.

3 Get Number of Instances UINT Number of object instances currently

created at this class level of the

device.

4 Get

0

6 Get Max ID of class

7 Get Max ID of instance

Optional attribute list STRUCT

of

Number of attributes UNIT Number of attribute in the optional

Optional attributes ARRAY of

UNIT

UINT The attribute ID number of the last

attributes

UINT The attribute ID number of the last

attribute

List of optional instance attributes

utilized in an object class

implementation.

attribute list.

List of optional attribute numbers. 3

class attribute of the class definition

implemented in the device.

instance attribute of the class

definition implemented in the device.

Class Service

Service Code Service Name Description of Service

0x0E Get_Attribute_Single Read one attribute

Instance Attribute

Instance Attribute ID Access Name Data type Details Value

2 Get Number Available UNIT

1

3 Get Number active UNIT Number of connections currently

Maximum number of connections

supported

used by system components

Instance Services

Service Code Service Name Description of Service

0x0E Get_Attribute_Single Read one attribute

1

1

2

2

7

3

16

0

- 25 -

Page 27

E6581741

4.3. Assembly Object (0x04)

Class code 0x04.

The Assembly Object binds attributes of multiple objects, which allows data to or from each object to

be sent or received over a single connection. Assembly objects can be used to bind input data or

output data. The terms ”input” and ”output” are defined from the network’s point of view. An input will

produce data on the network and an output will consume data from the network

Class Attributes

Instance Attribute ID Access Name Data type Details Value

1 Get Revision UINT Revision of this object 2

2 Get Max Instances UINT Maximum instance number of an

object currently created in this class

level of the device.

3 Get Number of Instances UINT Number of object instances currently

0

6 Get Max ID of class

attributes

7 Get Max ID of instance

attribute

UINT The attribute ID number of the last

UINT The attribute ID number of the last

created at this class level of the

device.

class attribute of the class definition

implemented in the device.

instance attribute of the class

definition implemented in the device.

Class Service

Service Code Service Name Description of Service

0x0E Get_Attribute_Single Read one attribute

Instance Attribute

Instance Attribute ID Access Name Details

See below

3 Get/Set* Data Settable Only on Output Assembly.

See below

See below

4 Get Size Number of bytes in Attribute 3.

199

13

7

4

Output Assembly:

Instance Type Size Page

20 CIP basic speed control output 2 words (4 bytes) 45

21 CIP extended speed control output 2 words (4 bytes) 46

100 Native drive output 2 to 8 words (4 to 16 bytes) 47

101 Native drive output 4 words (8 bytes) 49

102 Native drive output 6 words (12 bytes) 51

105 TOSHIBA specific output 9 words (18 bytes) 52

Input Assembly:

Instance Type Size Page

70 CIP basic speed control input 2 words (4 bytes) 45

71 CIP extended speed control input 2 words (4 bytes) 46

150 Native drive input 2 to 8 words (4 to 16 bytes) 47

151 Native drive input 4 words (8 bytes) 49

152 Native drive input 6 words (12 bytes) 51

155 TOSHIBA specific output 9 words (18 bytes) 52

Instance Services

Service Code Service Name Description of Service

0x0E Get_Attribute_Single Read one attribute

0x10 Set_Attribute_Single Write one attribute

- 26 -

Page 28

E6581741

4.4. Connection Manager Object (0x06)

Class code 0x06.

Use this object for connection and connectionless communications, including establishing

connections across multiple subnets.

Class Attributes

Instance Attribute ID Access Name Data type Details Value

1 Get Revision UINT Revision of this object 1

2 Get Max Instances UINT Maximum instance number of an

object currently created in this class

level of the device.

3 Get Number of Instances UINT Number of object instances currently

created at this class level of the

device.

4 Get

0

6 Get Max ID of class

7 Get Max ID of instance

Optional attribute list STRUCT

of

Number of attributes UNIT Number of attribute in the optional

Optional attributes ARRAY of

UNIT

UINT The attribute ID number of the last

attributes

UINT The attribute ID number of the last

attribute

List of optional instance attributes

utilized in an object class

implementation.

attribute list.

List of optional attribute numbers. 1, 2, 3,

class attribute of the class definition

implemented in the device.

instance attribute of the class

definition implemented in the device.

Class Services

Service Code Service Name Description of Service

0x0E Get_Attribute_Single Read one attribute

Instance 1 Attribute

Instance Attribute ID Access Name Data type Details

1 Get Open Requests UINT Number of Forward Open service requests

received.

2 Get Open Format Rejects UINT Number of Forward Open service requests

which were rejected due to bad format.

3 Get Open Resources Rejects UINT Number of Forward Open service requests

which were rejected due to lack of resources.

4 Get Open Other Rejects UINT Number of Forward Open service requests

which were rejected for reasons other than

bad format or lack of resources.

1

5 Get Close Requests UINT Number of Forward Close service requests

received.

6 Get Close Format Requests UINT Number of Forward Close service requests

which were rejected due to bad format.

7 Get Close Other Requests UINT Number of Forward Close service requests

which were rejected for reasons other than

bad format.

8 Get Connection Timeouts UINT Total number of connection timeouts that have

occurred in connections controlled by this

Connection Manager

Instance Services

Service Code Service Name Description of Service

0x0E Get_Attribute_Single Read one attribute

0x4E Forward_Close Closes a connection

0x54 Forward_Open Opens a connection, maximum data size is 511 bytes

1

1

-

8

4, 5, 6,

7, 8

7

8

- 27 -

Page 29

E6581741

4.5. Motor Data Object (0x28)

Class code 0x28.

This object serves as a database for motor parameters.

Class Attributes

Instance Attribute ID Access Name Data type Details Value

1 Get Revision UINT Revision of this object 1

2 Get Max Instances UINT Maximum instance number of an

object currently created in this class

level of the device.

3 Get Number of Instances UINT Number of object instances currently

0

6 Get Max ID of class

attributes

7 Get Max ID of instance

attribute

UINT The attribute ID number of the last

UINT The attribute ID number of the last

created at this class level of the

device.

class attribute of the class definition

implemented in the device.

instance attribute of the class

definition implemented in the device.

Class Services

Service Code Service Name Description of Service

0x0E Get_Attribute_Single Read one attribute

Instance 1 Attribute

Instance Attribute ID Access Name Data type Details

1 Get AttrNb UINT Number of attributes supported

2 Get AttrList ARRAY of

USINT

3 Get MotorType USINT 7:

1

6 Get/Set RatedCurrent UINT Motor Rated Current (f415)

7 Get/Set RatedVoltage UINT Motor Rated Volt (vlv)

8 Get/Set RatedPower UDINT Motor rated Power (f405)

9 Get/Set RatedFreq UINT Motor Base Freq (vl)

12 Get PoleCount UINT Motor pole number

15 Get/Set BaseSpeed UINT Motor Base Speed (f417)

List of attributes supported

1, 2, 3, 6, 7, 8, 9, 12, 15

Squirrel Cage Induction Motor

(f856(number of motor pole pair) 2)

Instance Services

Service Code Service Name Description of Service

0x0E Get_Attribute_Single Read one attribute

0x10 Set_Attribute_Single Write one attribute

1

1

7

15

- 28 -

Page 30

E6581741

4.6. Control Supervisor Object (0x29)

Class code 0x29.

This object models all the management functions for devices within the “Hierarchy of Motor Control

Devices”. The behavior of motor control devices is described by the State Transition Diagram.

Class Attributes

Instance Attribute ID Access Name Data type Details Value

1 Get Revision UINT Revision of this object 1

2 Get Max Instances UINT Maximum instance number of an

object currently created in this class

level of the device.

3 Get Number of Instances UINT Number of object instances currently

0

6 Get Max ID of class

attributes

7 Get Max ID of instance

attribute

UINT The attribute ID number of the last

UINT The attribute ID number of the last

created at this class level of the

device.

class attribute of the class definition

implemented in the device.

instance attribute of the class

definition implemented in the device.

Class Services

Service Code Service Name Description of Service

0x0E Get_Attribute_Single Read one attribute

Instance 1 Attribute

Instance Attribute ID Access Name Data type Details

1 Get Number of attributes UINT Number of attributes supported

2 Get AttrList LIST of

USINT

3 Get/Set Run 1 BOOL

4 Get/Set Run 2 BOOL

5 Get/Set NetCtrl BOOL Request Run/Stop control to be local or from

6 Get State USINT

7 Get Running 1 BOOL 1 = (Enabled and Run1) or

1

8 Get Running 2 BOOL 1 = (Enabled and Run2) or

9 Get Ready BOOL 1 = Ready or Enabled or Stopping

10 Get Faulted BOOL 1 = Fault Occurred (latched)

11 Get Warning BOOL 1 = Warning (not latched)

12 Get/Set FaultRst BOOL 0->1 = Fault Reset

15 Get CtrlFromNet BOOL Status of Run/Stop control source.

List of attributes supported

Refer to " 4.6.1 Run/Stop Event Matrix."

00 = Stop

01 = Run (On edge)

Refer to " 4.6.1 Run/Stop Event Matrix."

00 = Stop

01 = Run (On edge)

network.

0 = Local Control(default)

1 = Network Control

Note that the actual status of Run/Stop control is

reflected in attribute 15, CtrlFromNet.

Refer to " 4.6.2

(Stopping and Running1) or

(Fault Stop and Running1)

0 = Other state

(Stopping and Running2) or

(Fault Stop and Running2)

0 = Other state

0 = Other state

0 = No Faults present

0 = No Warnings present

0 = No action

0 = Control is local

1 = Control is from network

State of the drive."

1

1

7

15

- 29 -

Page 31

E6581741

Instance Services

Service Code Service Name Description of Service

0x05 Reset Resets the drive to the start-up state.

0x0E Get_Attribute_Single Read one attribute

0x10 Set_Attribute_Single Write one attribute

- 30 -

Page 32

E6581741

4.6.1. Run/Stop Event Matrix

Run1 Run2 Trigger Event Run Type

0 0 Stop No Action

0 -> 1 0 Run Run1

0 0 -> 1 Run Run2

0 -> 1 0 -> 1 No Action No Action

1 1 No Action No Action

1 -> 0 1 Run Run2

1 1 -> 0 Run Run1

4.6.2. State of the drive

The Control Supervisor class State attribute (Att. ID= 6) shows state of the drive.

1 (=BN: 00000001): Startup

2 (=BN: 00000010): Not ready

3 (=BN: 00000011): Ready

4 (=BN: 00000100): Enabled

5 (=BN: 00000101): Stopping

6 (=BN: 00000110): Fault Stop

7 (=BN: 00000111): Faulted

4.6.3. Control Supervisor State Transition Diagram

Non-Existent

Switch On

Reset

Initialization Complete

Main Power On

Not_Ready

Run

Startup

Main Power Off

Ready

Enabled

Switch Off

Fault Detected

Fault Reset

Stop

Complete

Stopping

Stop

Faulted

Fault Detected

Fault_Stop

Main Power Off

Fault_Stop

Complete

Fault

Detected

- 31 -

Page 33

E6581741

4.7. AC/DC Drive Object (0x2A)

Class code 0x2A.

This object models the functions specific to an AC or DC Drive. e.g. speed ramp, torque control etc.

Class Attributes

Instance Attribute ID Access Name Data type Details Value

1 Get Revision UINT Revision of this object 1

2 Get Max Instances UINT Maximum instance number of an object

currently created in this class level of the

device.

3 Get Number of Instances UINT Number of object instances currently

0

6 Get Max ID of class

attributes

7 Get Max ID of instance

attribute

UINT The attribute ID number of the last

UINT The attribute ID number of the last

created at this class level of the device.

class attribute of the class definition

implemented in the device.

instance attribute of the class definition

implemented in the device.

Class Services

Service Code Service Name Description of Service

0x0E Get_Attribute_Single Read one attribute

Instance 1 Attribute

Instance Attribute ID Access Name Data type Details Value or Unit

1 Get NumAttr USINT Number of Attributes supported 19

2 Get Attrbutes ARRAY of

USINT

3 Get AtReference BOOL 1 = Drive actual at reference 4 Get/Set NetRef BOOL Requests torque and speed

6 Get Drive mode USINT Drive Mode -

1

7 Get SpeedActual INT Actual Speed rpm

8 Get/Set SpeedRef * INT Reference Speed rpm

9 Get CurrentActual UINT Drive Current 0.1 A

10 Get/Set CurrentLimit UINT Drive Current Limit 0.1 A

11 Get Torque Actual UINT Drive Actual Torque Nm

15 Get PowerActual UINT Drive Power W

18 Get/Set AccelTime UINT Drive Acceleration ms

19 Get/Set DecelTime UINT Drive Deceleration ms

20 Get/Set LowSpdLimit UINT Drive minimum speed rpm

21 Get/Set HighSpdLimit UINT Drive maximum speed rpm

26 Get/Set Power scaling UINT Power scaling factor 0

28 Get/Set Time scaling UINT Time scaling factor 0

29 Get RefFromNet BOOL Status of speed reference

46 Get HoursOn UDINT Number of hours h

List of Attributes supported 1, 2, 3, 4, 6, 7,

reference to be local or from the

network.

0 = Set Reference not DN

Control

1 = Set Reference at DN

Control

0=Local speed reference

1=Network speed reference

* The output frequency of the drive follows fh though the frequency of fh or more can be written.

Instance Services

Service Code Service Name Description o f Service

0x0E Get_Attribute_Single Read one attribute

0x10 Set_Attribute_Single Write one attribute

1

1

7

46

8, 9, 10, 11, 15,

18,19, 20, 21,

26, 28, 29, 46

-

-

- 32 -

Page 34

E6581741

4.8. Parameter Objects (0x64)

Class code 0x64. This object provides VF-MB1/ S15’s Parameter access.

Range Address accessed:

Input Instance Real Logical address in Drive accessed

0x4000-0x4FFF 0x0000-0x0FFF

0x7000-0x7FFF 0xF000-0xFFFF

Class Attributes

Instance Attribute ID Access Name Data type Details Value

1 Get Revision UINT Revision of this object

2 Get Max Instances UINT Maximum instance number of an

object currently created in this class

level of the device.

3 Get Number of Instances UINT Number of object instances currently

0

6 Get Max ID of class

attributes

7 Get Max ID of instance

attribute

UINT The attribute ID number of the last

UINT The attribute ID number of the last

created at this class level of the

device.

class attribute of the class definition

implemented in the device.

instance attribute of the class

definition implemented in the device.

Class Services

Service Code Service Name Description of Service

0x0E Get_Attribute_Single Read one attribute

Instance 1 Attribute

Instance Attribute ID Access Name Data type Details

See

below

3 Get/Set parameter UINT

Parameter corresponding to the Instance

address

1

32767

8190

7

3

- 33 -

Page 35

E6581741

Instance Services

Service Code Service Name Description of Service

0x0E Get_Attribute_Single Read one attribute

0x10 Set_Attribute_Single Write one attribute

Attribute ID of all parameters are 3. Moreover, about the instance ID of each parameter, it

becomes "parameter communication number + 4000H".

In the case of the parameter from which a communication number begins in "F", it

becomes "parameter communication number - 0x8000 (same as bit15 set to 0)".

About the detail contents of a parameter, please refer to a VF-MB1 or VF-S15

instructions manual.

Example 1:

In case of Basic parameter “cmod - Command mode selection”,

Communication No: 0003 -> Instance ID: 4003

Example 2:

In case of Extended parameter “f268 - Updown frequency default value”,

Communication No: 0268 -> Instance ID: 4268

Example 3:

In case of Monitor parameter “fe03 - Output current”,

Communication No: FE03 -> Instance ID: 7E03

* Monitor parameter can access "Get" only.

For example, when "Acc. time" is set to 5 sec., since the minimum unit is 0.1s,

5 / 0.1 = 50 = 32H

Since the communication number of "Acc. time" is "0009", it writes "32H" in instance ID

"4009."

Moreover, when the "highest frequency" is read, "1F40H" is read.

0x1F40 = 8000 (Dec.)

Since the minimum unit is 0.01Hz,

8000 * 0.01 = 80Hz

- 34 -

Page 36

E6581741

4.9. Parameter Objects (0x65)

Class code 0x65. This object provides VF-MB1/S15’s Parameter access.

Range Address accessed:

Input Instance Real Logical address in Drive accessed

0x0001-0xFFFF 0x0001-0xFFFF

* Refer to "Class Attributes" when the instance is 0.

* If you want to access the au1, please use the "Application Objects (64 hex)."

Class Attributes

Instance Attribute ID Access Name Data type Details Value

1 Get Revision UINT Revision of this object

2 Get Max Instances UINT Maximum instance number of an

object currently created in this class

level of the device.

3 Get Number of Instances UINT Number of object instances currently

0

6 Get Max ID of class

attributes

7 Get Max ID of instance

attribute

UINT The attribute ID number of the last

UINT The attribute ID number of the last

created at this class level of the

device.

class attribute of the class definition

implemented in the device.

instance attribute of the class

definition implemented in the device.

Class Services

Service Code Service Name Description of Service

0x0E Get_Attribute_Single Read one attribute

Instance 1 Attribute

Instance Attribute ID Access Name Data type Details

See

below

3 Get/Set parameter UINT

Parameter corresponding to the Instance

address

1

65535

65535

7

3

Instance Services

Service Code Service Name Description of Service

0x0E Get_Attribute_Single Read one attribute

0x10 Set_Attribute_Single Write one attribute

Attribute ID of all parameters are 3. Moreover, about the instance ID of each parameter, it

becomes "parameter communication number".

About the details of the contents of a parameter please refer to VF-MB1 instruction

manual or VF-S15 instruction manual.

Example 1:

When "ACC. time" is set to 5 s, since the minimum unit is 0.1s,

5 / 0.1 = 50 = 32H

Since the communication umber of "Acc. time" is "0009", it writes "32H" is instance ID "0009."

- 35 -

Page 37

E6581741

4.10. Port Object (0xF4)

Class code 0xF4.

The Port Object enumerates the CIP ports present on the device.

One instance exists for each CIP port.

Class Attributes

Instance Attribute ID Access Name Data type Details Value

1 Get Revision UINT Revision of this object

2 Get Max Instances UINT Maximum instance number of an

object currently created in this class

level of the device.

3 Get Number of Instances UINT Number of object instances currently

created at this class level of the

device.

6 Get Max ID of class

attributes

0

7 Get Max ID of instance

attribute

8 Get Entry Port UINT Returns the instance of the Port

9 Get All Ports STRUCT

UINT The attribute ID number of the last

class attribute of the class definition

implemented in the device.

UINT The attribute ID number of the last

instance attribute of the class

definition implemented in the device.

Object that describes the port

through which this request entered

the device.

Array of structures containing

of

Port Type

Port

Number

instance attributes 1 and 2 from

each instance.

Note: Attribute 9

00 00 00 00 -> port type = 0 (Connection terminated) / instance number = 0 (class)

00 00 02 00 -> port type = 2 (TCP/IP Port) / port number = 2

Class Services

Service Code Service Name Description of Service

0x01 Get_Attribute_All Read all attributes

0x0E Get_Attribute_Single Read one attribute

Instance 1 Attribute

Instance Attribute ID Access Name Data type Details Value