Toshiba HWS-1402XWHT6-E, HWS-1402XWHM3-E, HWS-802XWHM3-E, HWS-802XWHT6-E, HWS-1402XWHT9-E INSTALLATION MANUAL

Page 1

AIR TO WATER HEAT PUMP

Installation manual

Hydro Unit

Model name:

HWS-802XWHM3-E

HWS-802XWHT6-E

HWS-1402XWHM3-E

HWS-1402XWHT6-E

HWS-1402XWHT9-E

Installation manual

Hydro Unit

Manuel d’installation

Unité hydroélectrique

(Pompe à chaleur air/eau)

Installations-handbuch

Hydrogerät

(Luft-Wasser-Wärmepumpe)

Installationshandbok

Hydroenhet

(Luft-till-vatten-värmepump)

(Air to Water Heat Pump)

44

86

128

English

2

Français

Deutsch

Svenska

Page 2

Hydro Unit

Please read this Installation Manual carefully before installing the Air to Water Heat Pump.

• This Manual describes the installation method of the hydro unit.

• For installation of the outdoor unit, follow the Installation Manual attached to the outdoor unit.

Installation Manual

ADOPTION OF NEW REFRIGERANT

This Air to Water Heat Pump is a new type which adopts a new refrigerant HFC (R410A) instead of the

conventional refrigerant R22 in order to prevent destruction of the ozone layer.

Contents

1 GENERAL INFORMATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2 ACCESSORY PARTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

3 PREPARATIONS FOR INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

4 PRECAUTIONS FOR SAFETY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

5 EXAMPLE OF HYDRO UNIT INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

6 MAIN COMPONENTS OF HYDRO UNIT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

7 HYDRO UNIT INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

8 START UP AND CONFIGURATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

9 TEST RUN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

10 MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

11 SENSOR TEMPERATURE MONITORING FUNCTION . . . . . . . . . . . . . . . . . . . . . . . 39

12 TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

1-EN

–2–

Page 3

Hydro Unit

1 GENERAL INFORMATION

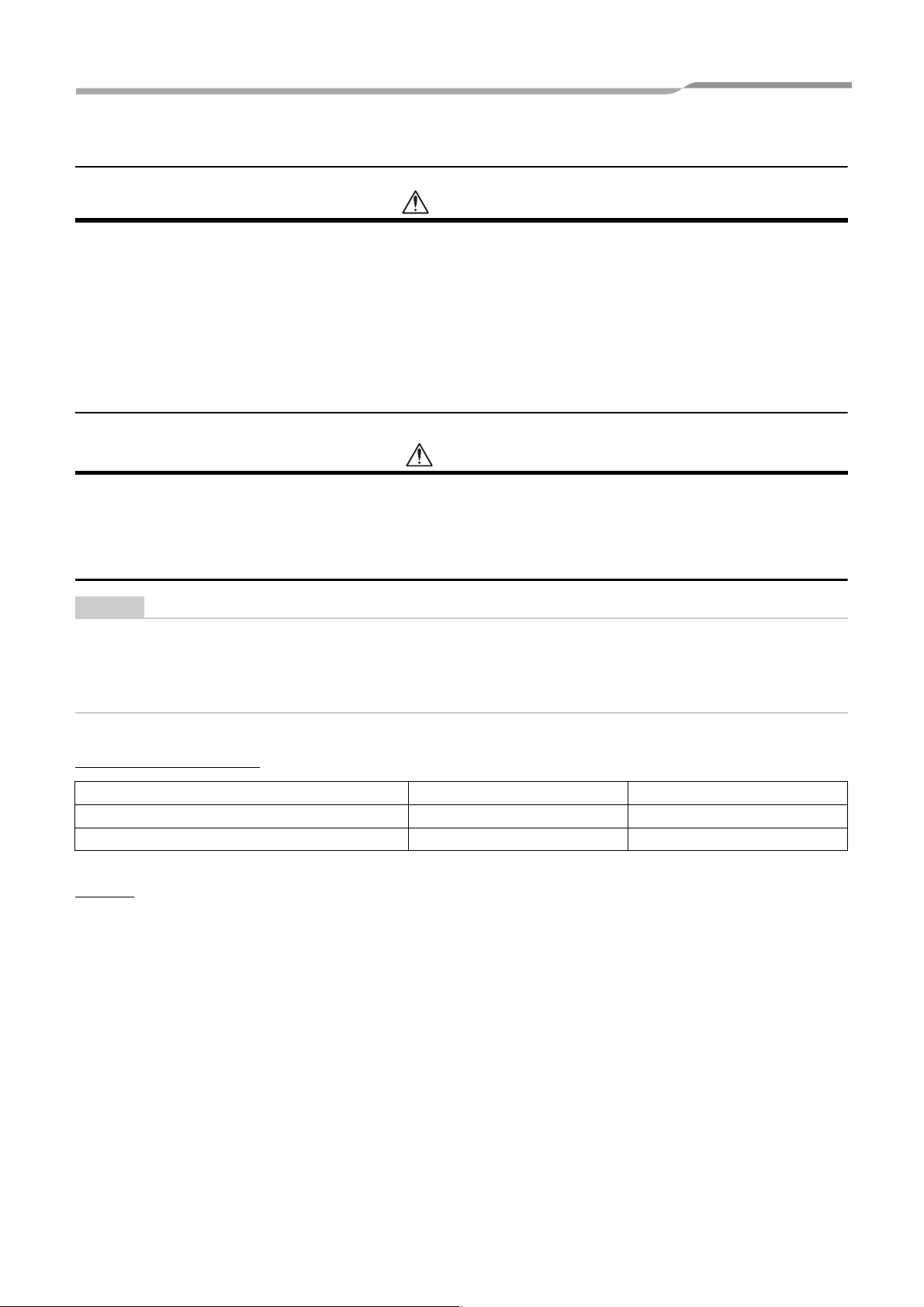

Hydro Unit Description

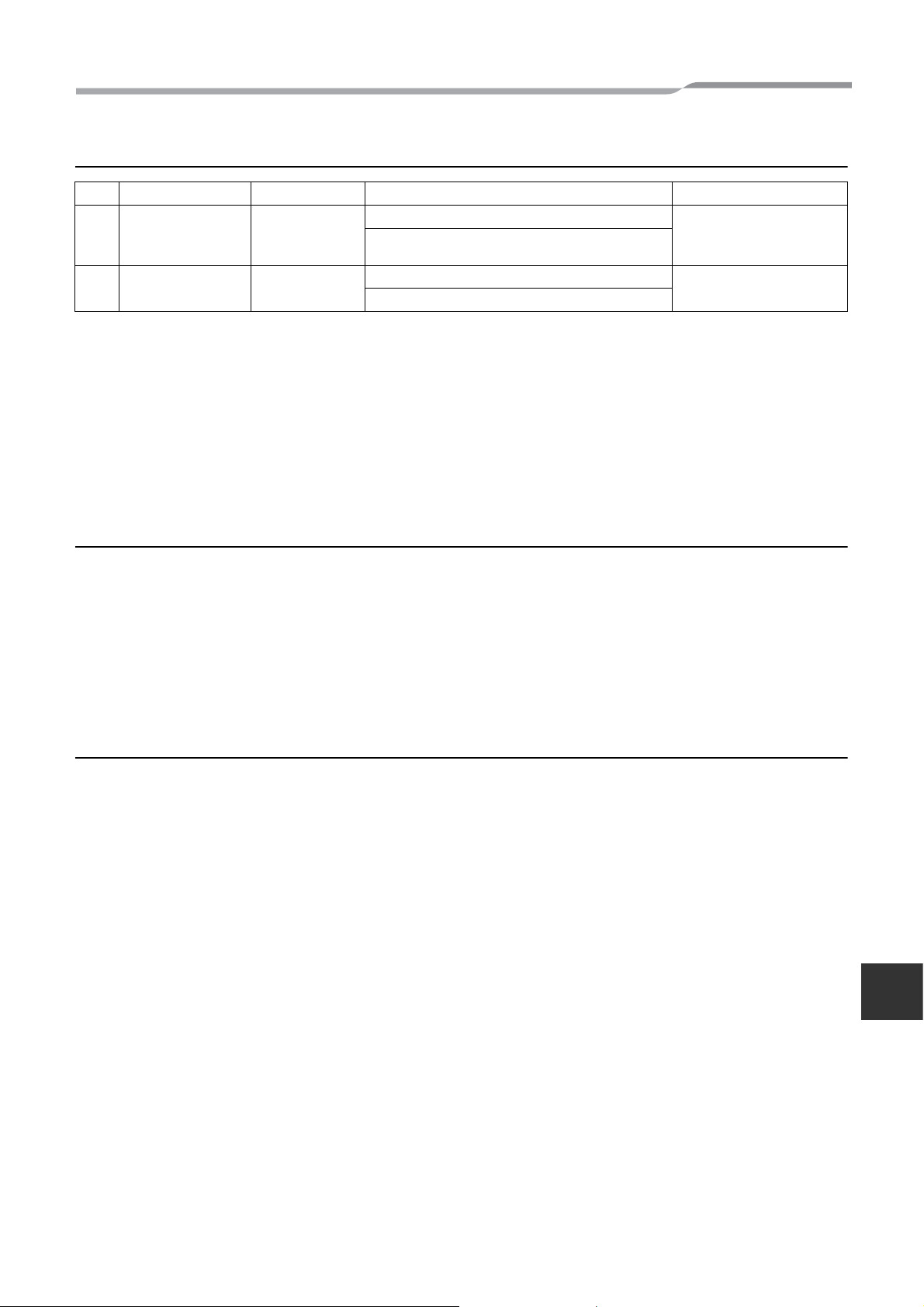

Hydro Unit Model Description

HWS-802XWHM3-E 8 kW Hydro Unit (3 kW 230 V ~ back up heater)

HWS-802XWHT6-E 8 kW Hydro Unit (6 kW 400 V 3N ~ back up heater)

HWS-1402XWHM3-E 11 & 14 kW Hydro Unit (3 kW 230 V ~ back up heater)

HWS-1402XWHT6-E 11 & 14 kW Hydro Unit (6 kW 400 V 3N ~ back up heater)

HWS-1402XWHT9-E 11 & 14 kW Hydro Unit (9 kW 400 V 3N ~ back up heater)

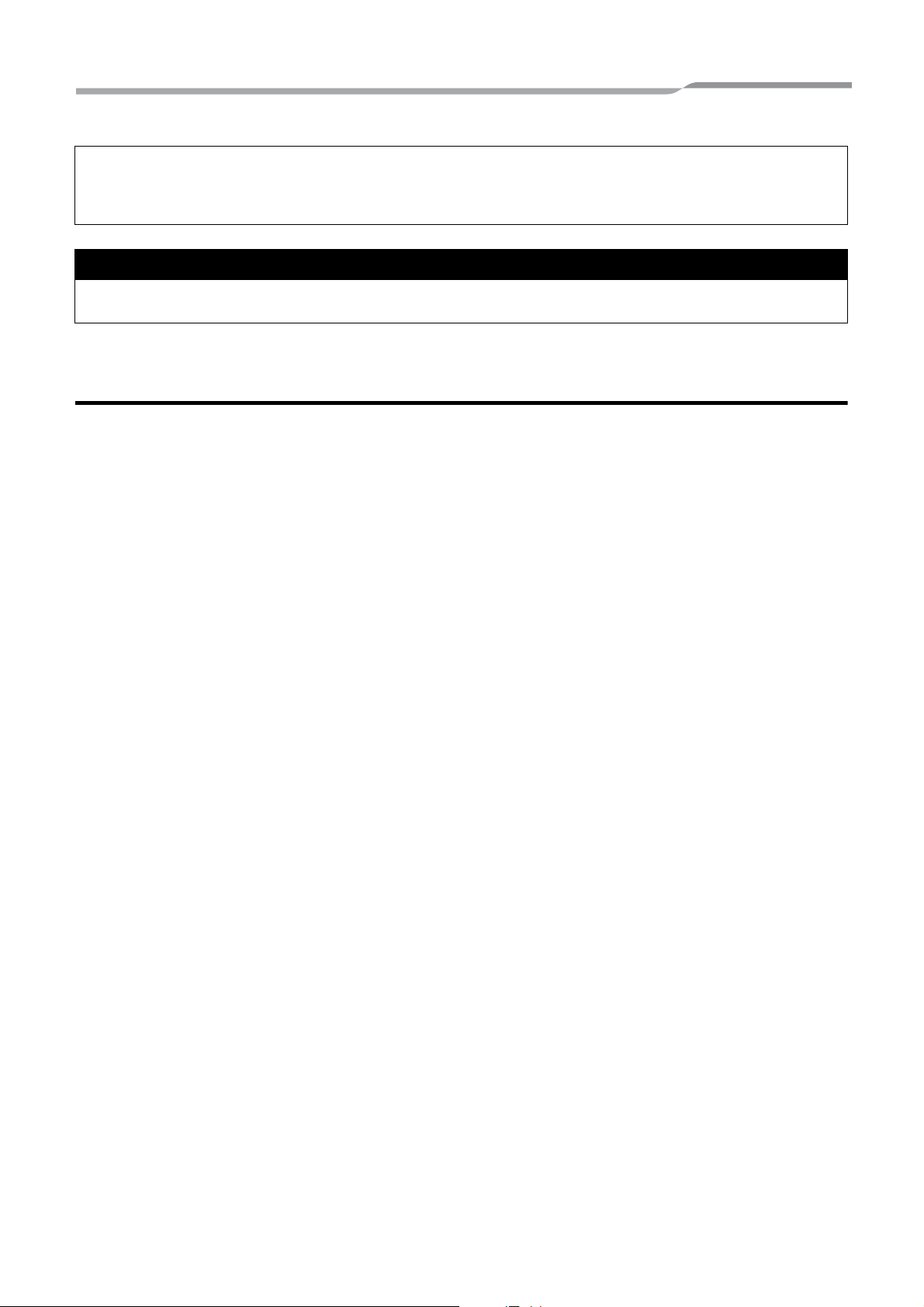

General Specifications

Outdoor unit HWS-802H-E HWS-1102H-E HWS-1402H-E

Type Inverter

Function Heating & Cooling

Capacity (kW) 8.0 11.2 14.0

Heating

Cooling

Power supply 230 V ~

Refrigerant R410A

Dimension HxWxD (mm) 890 x 900 x 320 1,340 x 900 x 320

Input (kW) 1.96 2.40 3.15

COP 4.08 4.66 4.45

Capacity (kW) 6.0 10.0 11.0

Input (kW) 2.13 3.52 4.08

EER 2.82 2.84 2.69

Installation Manual

Hydro Unit

Back up heater capacity 3 kW 6 kW 3 kW 6 kW 9 kW

for backup heater 230 V ~ 400 V 3N ~ 230 V ~ 400 V 3N ~ 400 V 3N ~

Power supply

Leaving water

temperature

For use with HWS-802H-E HWS-1102H-E/HWS-1402H-E

Dimension HxWxD (mm) 925 x 525 x 355

Hot water cylinder (option)

Water volume litres 150 210 300

Max water temperature (°C) 75

Electric heater (kW) 2.75 (230 V ~)

Height (mm) 1,090 1,474 2,040

Diameter (mm) 550

Material Stainless steel

for hot water cylinder

heater(option)

Heating (°C) 20 to 55

Cooling (°C) 10 to 25

HWS-

802XWHM3-E

HWS-1501CSHM3-E

HWS-1501CSHM3-UK

HWS-

802XWHT6-E

HWS-2101CSHM3-E

HWS-2101CSHM3-UK

HWS-

1402XWHM3-E

230 V ~

HWS-

1402XWHT6-E

HWS-3001CSHM3-E

HWS-3001CSHM3-UK

HWS-

1402XWHT9-E

EN

–3–

2-EN

Page 4

Hydro Unit

Installation Manual

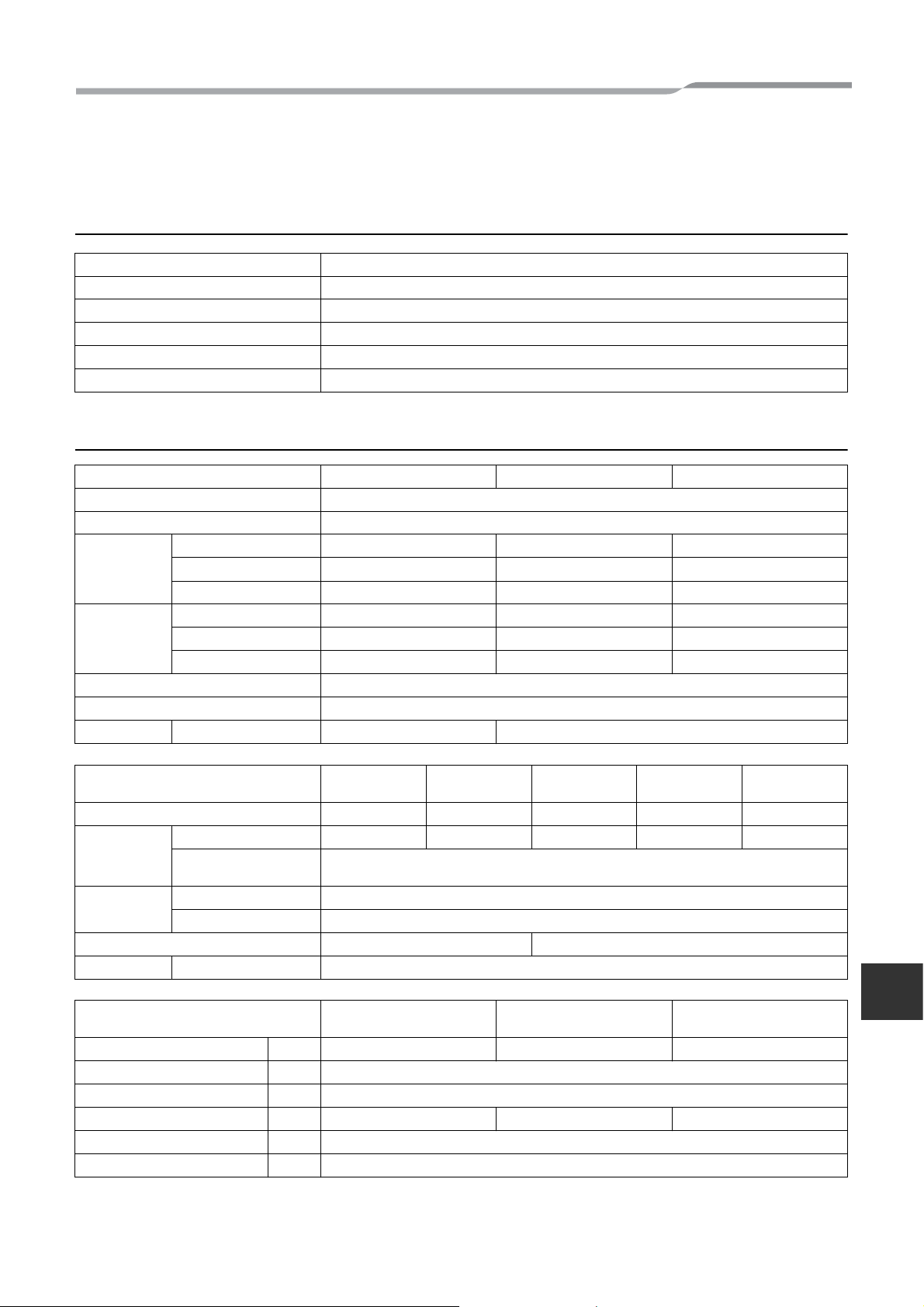

2 ACCESSORY PARTS

No Parts name Quantity No Parts name Quantity

1 Installation manual (this document) 1 3 Insulator for cooling 1

2 Owner’s manual 1

3 PREPARATIONS FOR INSTALLATION

Parts required to connect this product (Common items)

Category Part Specification Quantity

Strainer (water filter) 1 1/4" 30 to 40 meshes 1

Water piping

Electrical system

Drain cock (for water charge) 1

Isolating ball valves

Earth leakage breaker for main power

supply

Earth leakage breaker for backup heater 30 mA 1

(Option)

Earth leakage breaker for hot water cylinder

heater

1 1/4"

for service 1 1/4"

30 mA 1

30 mA 1

2

Options required for each function

Purpose

Heating – –

Heating &Cooling

(all rooms)

Heating & Cooling

(partly heating only)

Hot water supply

2-zone control – –

Interlocking with

boiler

Interlocking with

booster heater

In the Hydro Unit Purchased part

Part name Model name Part name Prescribed specification

– – Fan coil(s)

––

Hot water cylinder

150 L

210 L

300 L

Output control

board kit (1)

Output control

board kit (1)

HWS-1501CSHM3-E

HWS-1501CSHM3-UK

HWS-2101CSHM3-E

HWS-2101CSHM3-UK

HWS-3001CSHM3-E

HWS-3001CSHM3-UK

TBC-PCIN3E Boiler

TBC-PCIN3E Electric heater

Radiator(s), Fan coil(s),

Under floor heating

Motorized 2-way valve (for

cooling)

Motorized 3-way valve

Earth leakage breaker

Motorized mixing valve

Circulator pump Other power supply

Buffer tank

Refer to “Control parts

specifications” on page 23.

Refer to “Control parts

specifications” on page 23.

Refer to “Control parts

specifications” on page 23.

Other power supply

Signal 12 V input function is

required for boiler.

Other power supply.

Signal 230 V input function

is required for booster

heater

3-EN

–4–

Page 5

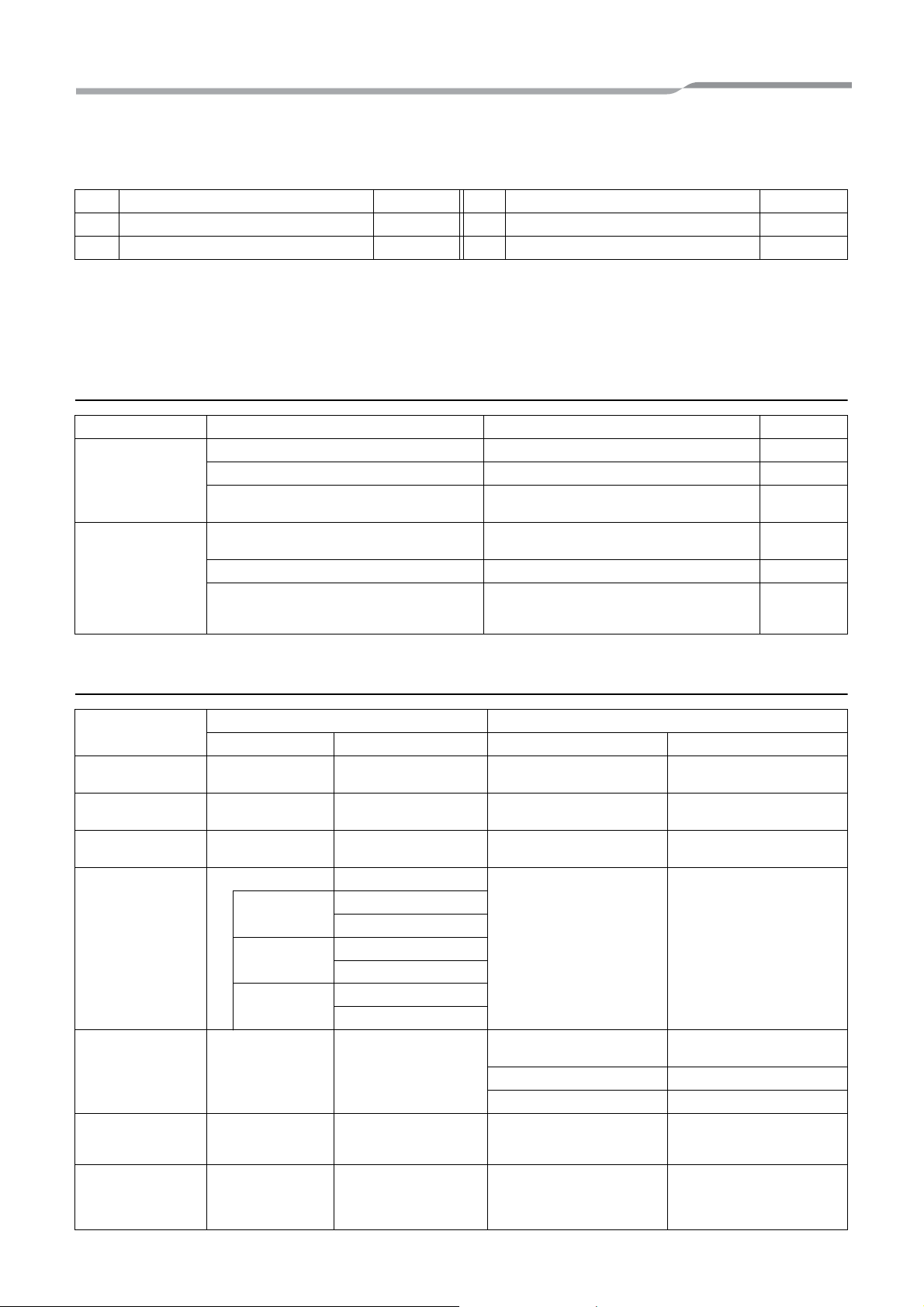

Hydro Unit

Optional Parts

No. Part name Model name Application Remarks

External output

1

board

External input

2

board

Use specified products for the outdoor unit, Hydro Unit, and hot water cylinder.

Do not use commercially available products.

Use parts that conform to prescribed specifications for parts to be connected to the Hydro Unit.

If unspecified products or parts are used, a malfunction, failure or fire may be caused.

TCB-PCIN3E

TCB-PCMO3E

Boiler-linked output, Alarm output

Defrost signal output, compressor operation

signal output

Cooling/heating thermostat input

Forced-stop signal input

Installation Manual

Up to two boards

(according to applications)

Up to two boards

(according to applications)

4 PRECAUTIONS FOR SAFETY

General Safety Precautions

Ensure that all Local, National and International regulations are satisfied.

• Read the “PRECAUTIONS FOR SAFETY” carefully before installation.

• The precautions described below include the important items regarding safety – Observe them without fail.

• After the installation work has been completed, perform a trial operation to check for any problems. Follow the

Owner’s Manual to explain how to use and maintain the unit to the customer.

• Turn off the main power supply switch (or breaker) before unit maintenance.

• Ask the customer to keep the Installation Manual along with the Owner’s Manual.

Refrigerant Precautions

• If a refrigerant leak is suspected contact the dealer who supplied the system, in the case of a recharge of

refrigerant ask service personnel for details of the leak and confirmation of the repairs completed.

The refrigerant used in the system is harmless.

• Generally the refrigerant does not leak, however, if the refrigerant should leak into a room and a heater or stove

burner in the room is lit, toxic gas may be generated.

• Do not install the system in a location subject to a risk of exposure to a combustible gas.

If a combustible gas leaks and stays around the unit a fire may occur.

• Install the refrigerant pipe securely during installation and before operation.

If the compressor is operated with no pipe work connected and valves open the compressor will suck air which

would result in over pressurization of the system which may result in bursting or injury.

Observe the same precautions for refrigerant recovery work (pump back procedure to outdoor unit) and do not

disconnect pipe work until refrigerant is recovered and valves closed.

EN

–5–

4-EN

Page 6

Hydro Unit

Installation Manual

WARNING

Installation Precautions

• Ask an authorized dealer or qualified installation professional to install/maintain the Air to Water Heat Pump System.

Inappropriate installation may result in water leaks, electric shock or fire.

• Electrical work must be performed by a qualified electrician in accordance with the installation manual.

An inappropriate power supply capacity or installation may result in fire.

• When completing any electrical works to the system ensure that all Local, National and International regulations are

satisfied.

Inappropriate grounding may result in electric shock.

• Use the specified electrical cables, fixing securely at all terminations.

• Earth wire connections.

• Install an earth leakage breaker without fail.

Incomplete grounding can cause electric shock.

Do not ground wires to gas pipes, water pipes, lightning rods or telephone cable ground wires.

• This unit must be connected to the main power supply using a circuit breaker or switch with a contact separation of

at least 3 mm.

• Be sure to turn off all main power supply switches or the circuit breaker before starting any electrical work.

Ensure all power switches are off, failure to do so can cause electric shock.

Use an exclusive power circuit for the Air to Water Heat Pump system using the rated voltage.

• Ensure correct connection of interconnecting wire between Outdoor Unit and Hydro Unit.

Incorrect connection of the interconnecting cable may result in the damage of electrical parts.

• Ensure refrigeration system remains sealed to external gases and air.

Should air or other gases contaminate the refrigeration circuit, high system pressures could result in burst pipes and

injuries.

• Do not modify or bypass any of safety guards or switches in this system.

• After unpacking the outdoor unit, examine the unit carefully for any possible damage.

• Do not install in any place that might increase the vibration of the unit.

• To avoid personal injury (with sharp edges), be careful when handling parts.

• Perform installation work properly in accordance with the installation manual.

Inappropriate installation may result in water leaks, electric shock or fire.

• Tighten all flare nuts with a torque wrench in the specified manner.

Excessive tightening of the flare nut may result in cracking of the pipe work or flare nut which may result in a

refrigerant leakage.

• Wear heavy duty gloves during installation work to avoid injury.

• Install the outdoor unit securely in a location where the base can sustain the weight adequately.

• In enclosed areas, if the refrigerant leaks during installation vacate and ventilate immediately.

• After installation is complete ensure and confirm that refrigerant does not leak.

If refrigerant leaks into a room and flows near a fire source noxious gas may be generated.

• Do not block any drain hoses. Hoses may come off and electric shocks may occur.

• Do not hit the manometer, because it is made of glass. It is breakable.

Notes on System Design

• The input water temperature to the Hydro Unit must be 55°C or less.

Especially, be careful when there is an external heating source such as a boiler.

When hot water over 55°C returns, it may result in a failure of the unit or water leakage.

• The flow rate of the circulating water must meet the following range.

11 and 14 kW 18 L/minute or more

8 kW 13 L/minute or more

If the flow rate becomes less than the minimum, the protective device is activated to stop operation.

Ensure the flow rate with a bypass valve, etc. when you use a flow rate valve for the Hydro Unit.

• Do not drive water by power other than the pump built in the Hydro Unit.

• The backup heater operates supplementarily to exert a prescribed capacity when the heat pump cannot exert its

capacity at a low outside temperature.

• Install the Hydro Unit and water pipes in a place in which they do not freeze.

• Make the water circuit closed. Never use it as an open circuit.

• Circulating water must be 20 liters or more. If total water amount is not enough, the unit may not function fully

due to protective operation.

5-EN

–6–

Page 7

Hydro Unit

Installation Manual

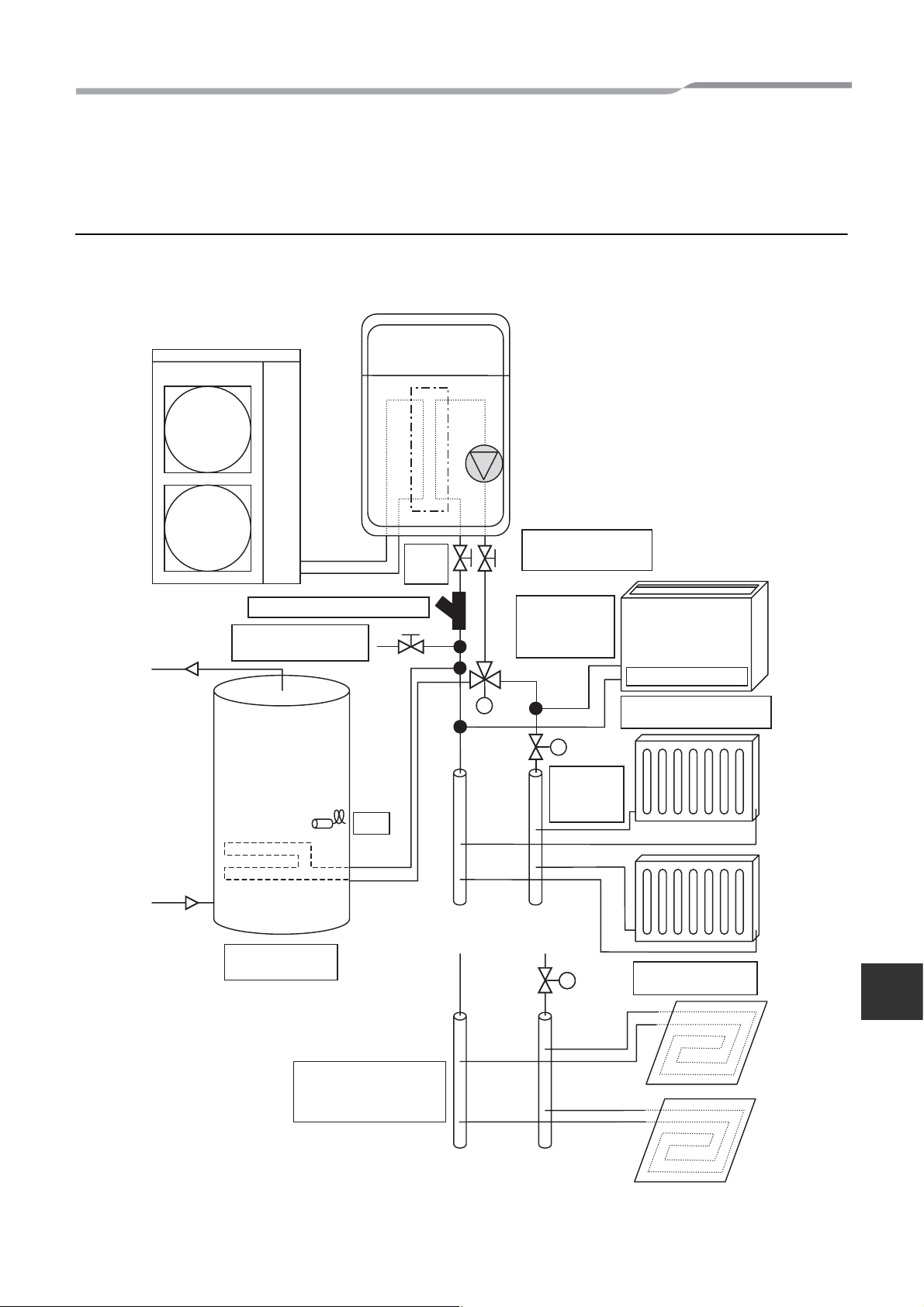

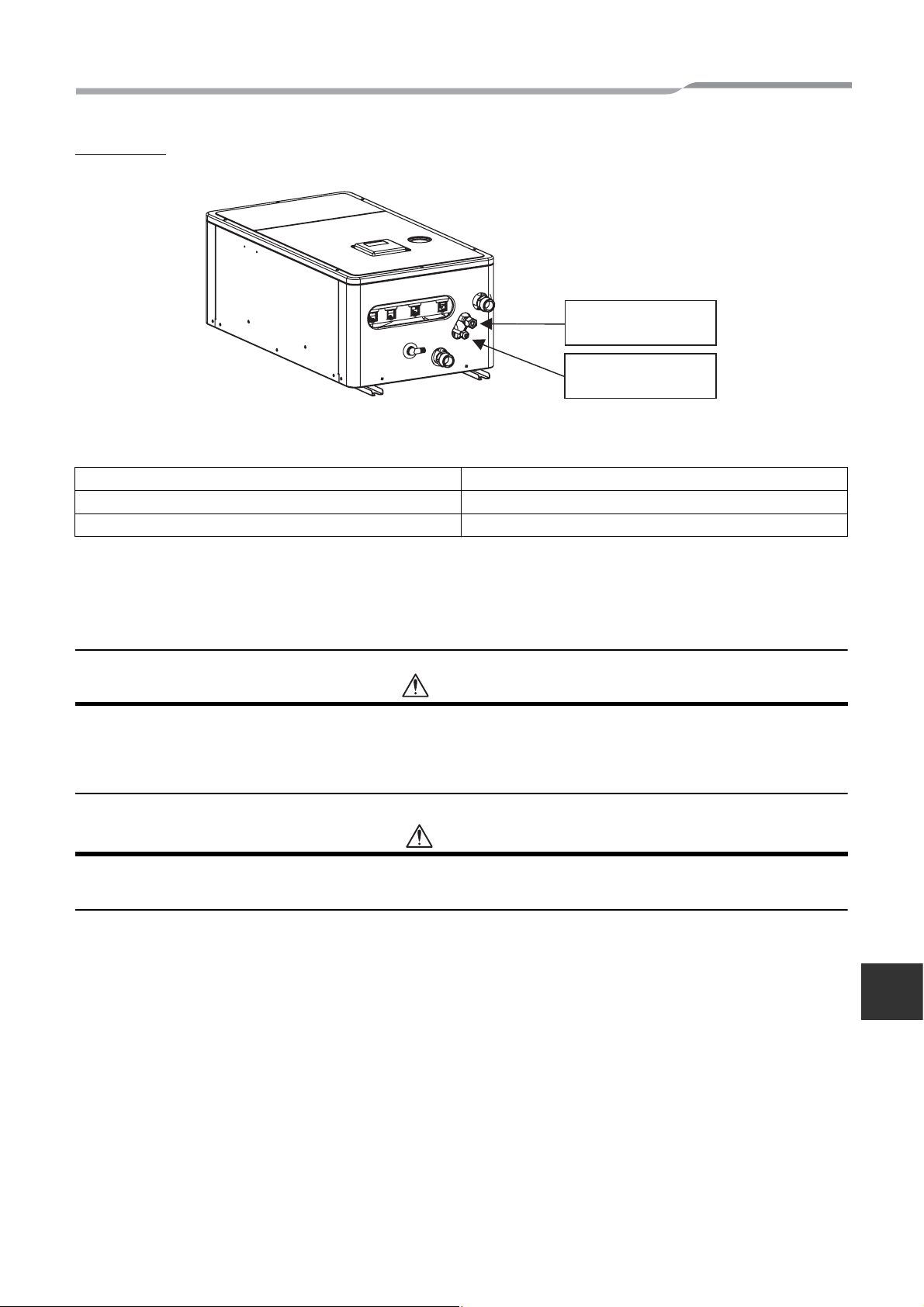

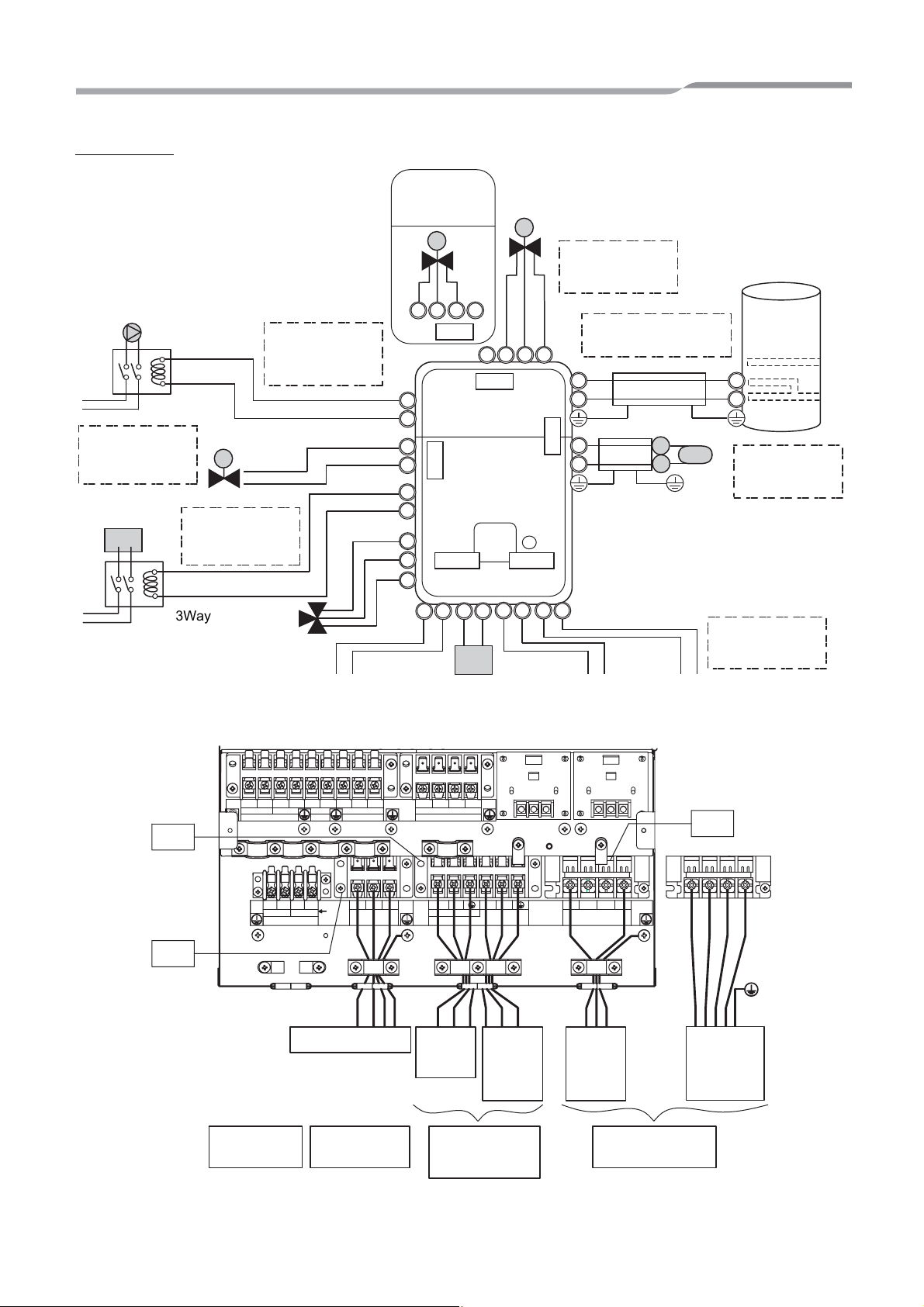

5 EXAMPLE OF HYDRO UNIT INSTALLATION

Example of Installation for Cooling and Heating

When both cooling and heating are used, install a 2-way valve (for cooling) to the pipe to the room for heating only.

▼ Fig. 5-01

Strainer (40 mesh / 0.4 mm)

Drain Cock for water

Charge and Drain

Indirect Sanitary

Hot Water Tank

TTW

Isolating

Ball

Valves

M

Fan Coil Units

(Cooling or Heating)

Diverting 3-Way

Valve for

Sanitary Hot

Water Tank

2-Way

M

Valve

Use it when

do not

operate

cooling.

2-Way

M

Valve

Radiators (Heating Only)

[2-Way Valve Control]

Use it when do not

operate cooling.

EN

Alternative to Radiators

Under-floor Heating

(Heating Only)

[2-Way Valve Control]

–7–

6-EN

Page 8

Hydro Unit

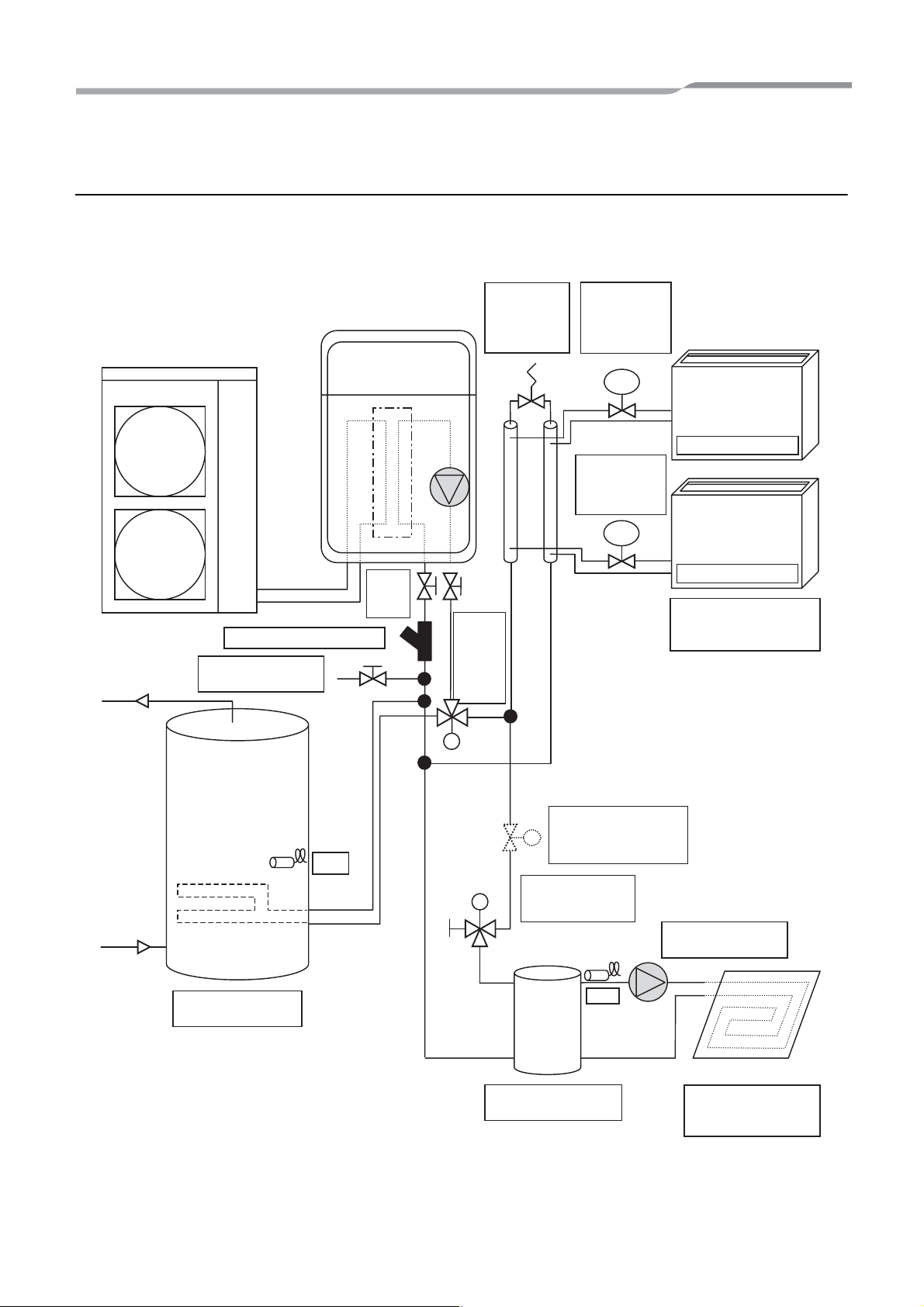

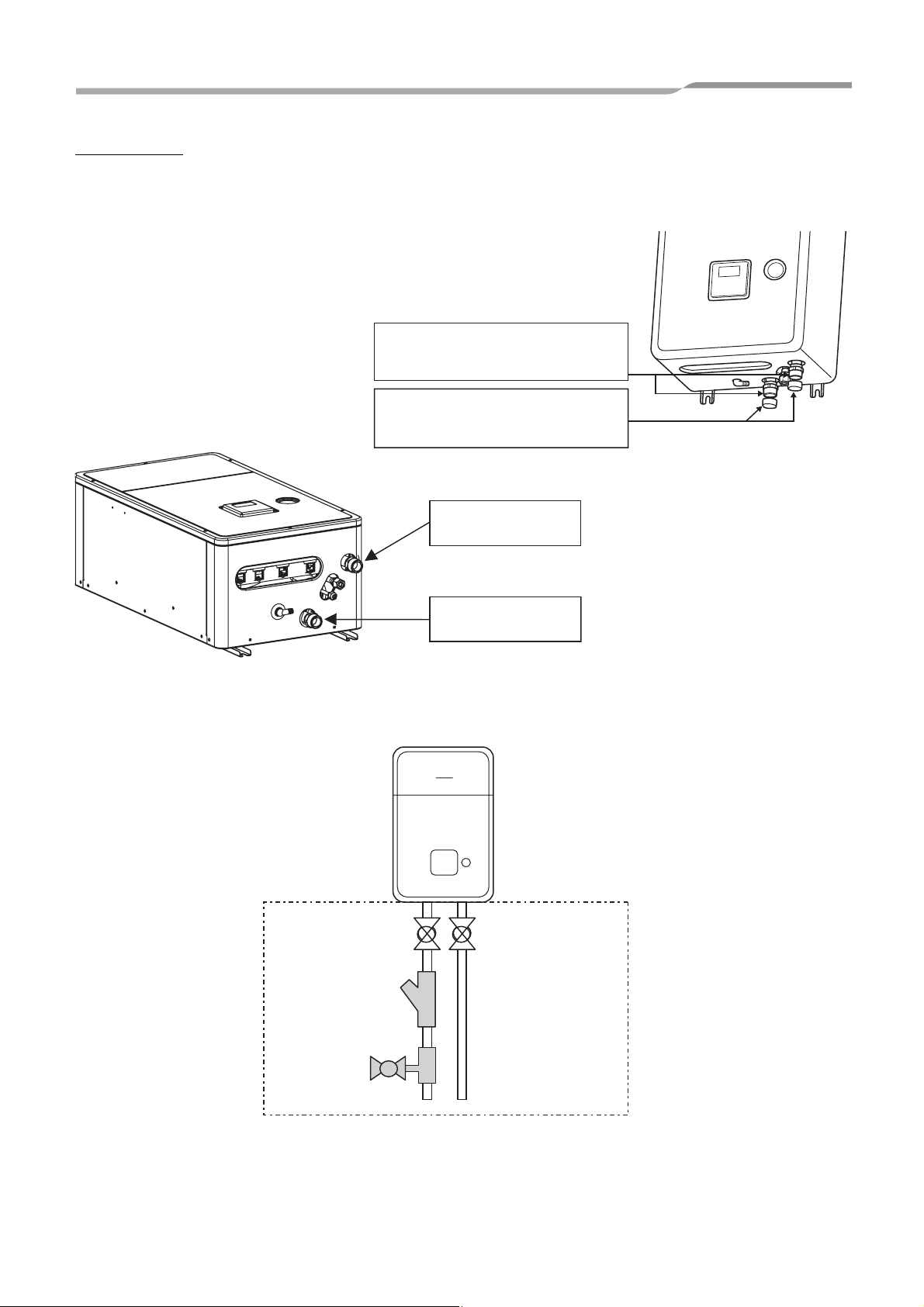

Example of 2-Zone Temperature Control and Hot Water Supply

Installation Manual

System

The following shows an example of the 2-zone temperature control.

A buffer tank and a water pump are required for the 2-zone temperature control.

▼ Fig. 5-02

Hi-Pressure

By-Pass

Valve

Temperature

Regulating

Valve

(Mechanical)

TRV

Temp.

Regulating

Valve

(Mechanical)

Strainer (40 mesh / 0.4 mm)

Drain Cock for water

Charge and Drain

TTW

Isolating

Valves

(Service)

Diverting

3-Way

Valve for

Sanitary

Hot

Water

Tank

M

TRV

Zone 1

Fan Coil Unit (Heating

or Cooling)

Motorized 2-Way Valve

is required if fan coil

M

units are in cooling

operation.

Mixing 3-Way

M

Valve for Under

Floor Heating

External Pump for

Under Floor Heating

7-EN

Indirect Sanitary Hot

Water Tank

–8–

TFI

Direct Buffer tank for

Under Floor Heating

Zone 2

Under-floor Heating

(2-Way Valve Control)

Page 9

Hydro Unit

Installation Manual

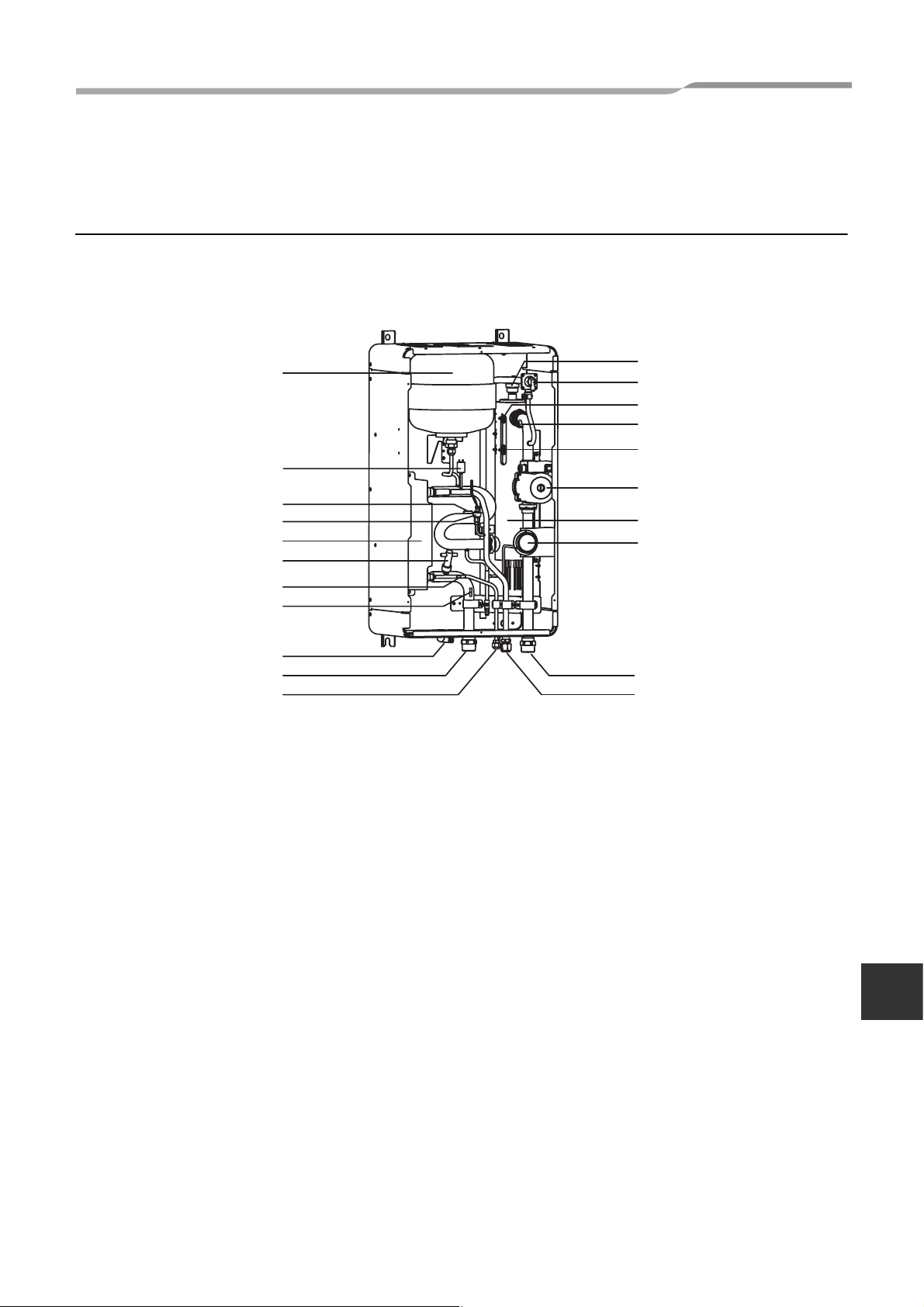

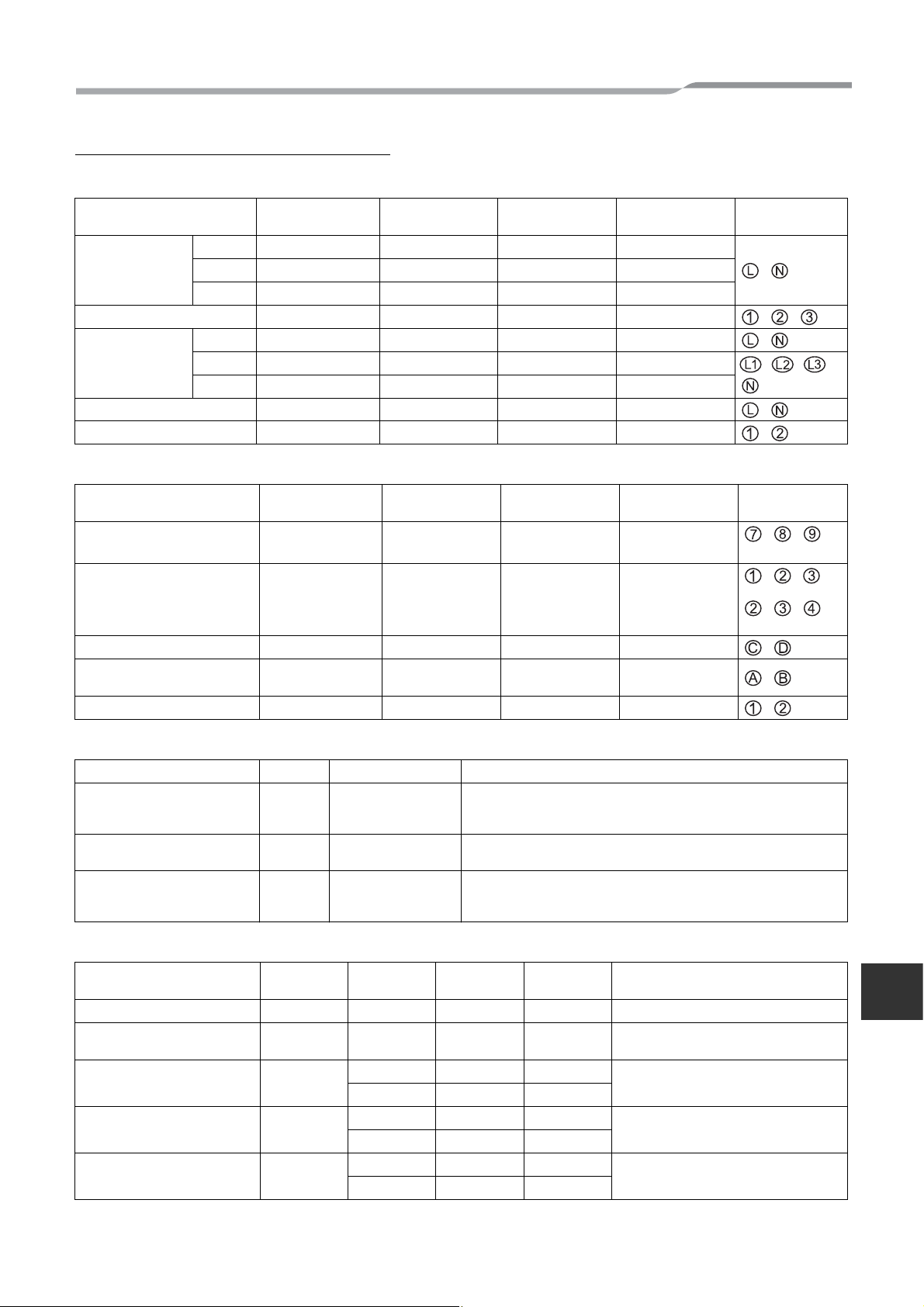

6 MAIN COMPONENTS OF HYDRO UNIT

Exploded view and description for Hydro Unit

▼ Fig. 6-01

1

2

3

4

5

6

7

8

9

10

11

1 : Expansion vessel

2 : Hi pressure switch (4.15 MPa)

3 : Temperature sensor (for Heat pump outlet -TWO)

4 : Pressure sensor

5 : Heat exchanger

6 : Flow switch (13.0 L/min 17.5 L/min)

7 : Temperature sensor (for refrigerant -TC)

8 : Temperature sensor (for water inlet -TWI)

9 : Drain nipple

10 : Water inlet connection

11 : Refrigerant liquid connection

12 : Air relief valve

13 : Pressure relief valve (0.3 MPa (3 bar))

14 : Thermal protector (auto)

15 : Temperature sensor (for water outlet THO)

16 : Thermal protector (Single operation)

17 : Water pump

18 : Backup heater (3 kW, 3 kW x 2, 3 kW x 3)

19 : Manometer

20 : Water outlet connection

21 : Refrigerant gas connection

12

13

14

15

16

17

18

19

20

21

EN

–9–

8-EN

Page 10

Hydro Unit

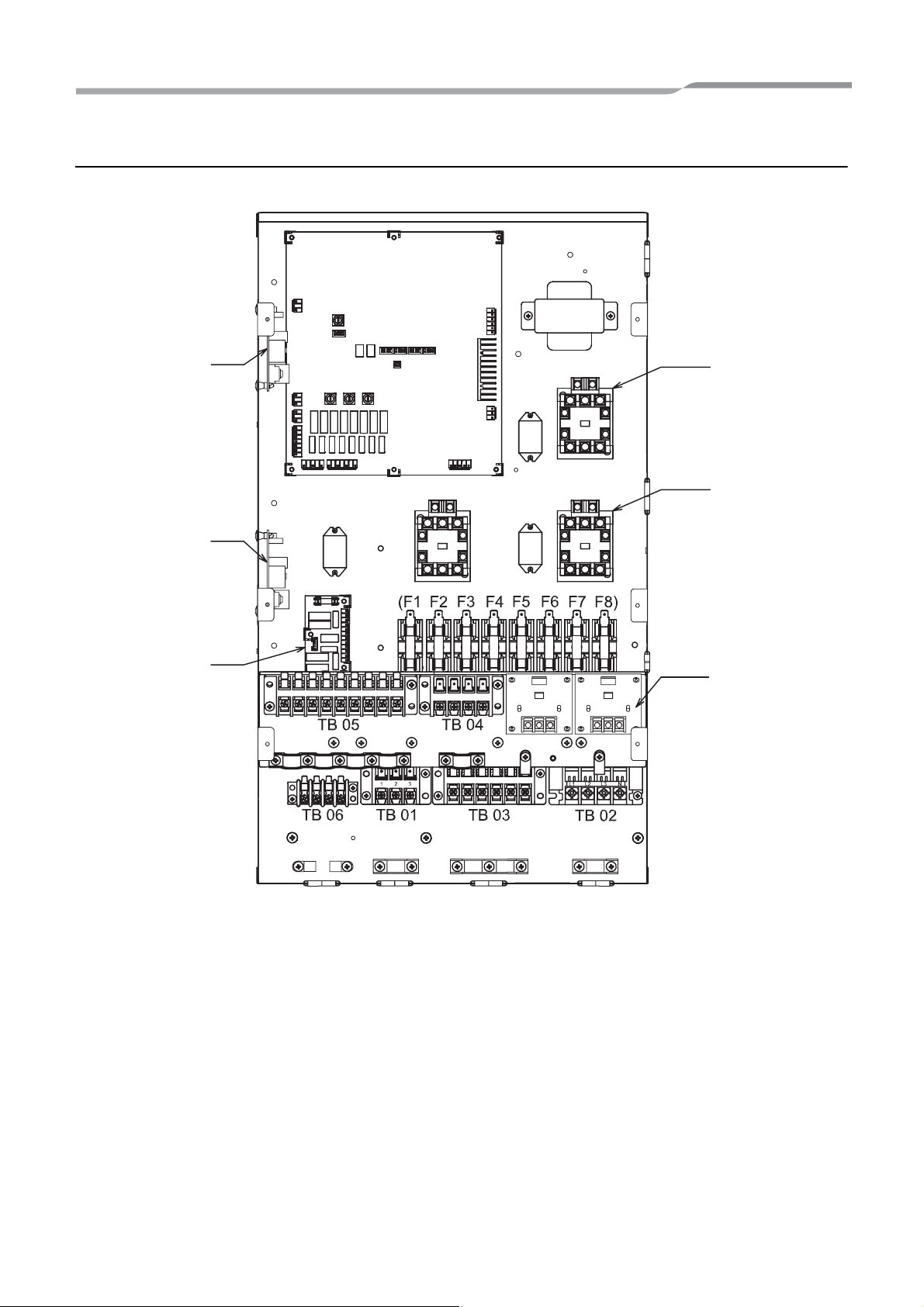

E-Box layout

▼ Fig. 6-02

Installation Manual

P.C. board

MCC-1511

Trans

former

Relay P.C. board

MCC-1217

(Option)

Relay P.C. board

MCC-1217

(Option)

Relay P.C. board

MCC-1431

Relay

(RY06)

MG-SW (RY05)

Relay

(RY03)

Relay

(RY01)

Fuse

MG-SW (RY04)

MG-SW (RY02)

Relay P.C. board

MCC-1214

(Option)

9-EN

–10–

Page 11

Hydro Unit

Installation Manual

7 HYDRO UNIT INSTALLATION

WARNING

• To protect yourself from injury, always use PPE (Personal Protective Equipment), that is, wear gloves.

• Install the Hydro Unit by at least two persons.

• Install the Hydro Unit in a place strong enough to withstand the following weights:

Hydro Unit weight with no water 60 kg (802) 65 kg (1402)

Hydro Unit weight with full water 80 kg (802) 85 kg (1402)

CAUTION

• The operating temperature range is 5 to 32°C (Heating) and 18 to 30°C (Cooling).

Do not install the unit in a place where water freezes.

• Do not install the Hydro Unit in a place where combustible gas may leak.

• Do not install the Hydro Unit in a place exposed to rain or water.

• Do not install the Hydro Unit near equipment which generates heat.

• Do not install the Hydro Unit to a movable object.

• Do not install the Hydro Unit in a place exposed to vibration.

Handling, Unpacking, and Checking the Hydro Unit

• The unit should be checked when it is delivered, and any damage reported immediately to the courier claims the

department.

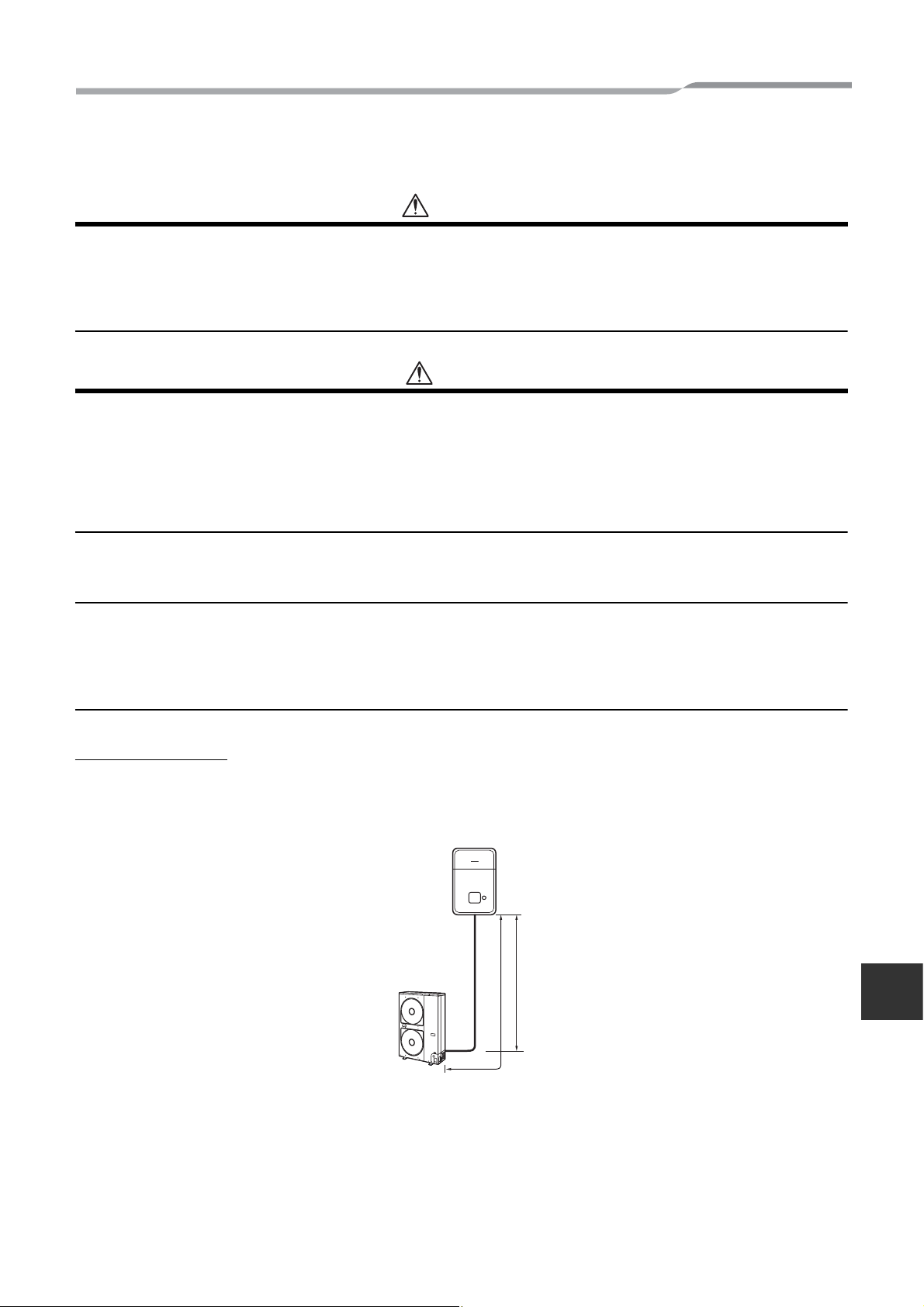

Positioning

Refrigeration pipe

The length and height of the refrigeration pipe must be within the following values.

As long as the Hydro Unit is installed within these ranges, no additional refrigerant is required.

▼ Fig. 7-01

Outdoor unit

L

H

EN

H: Max. ±30 m (above or below)

L: Max. 30 m

Min. HWS-802H-E : 5 m

HWS-1102H-E : 3 m

HWS-1402H-E : 3 m

–11–

10-EN

Page 12

Hydro Unit

Installation Manual

Water pipe

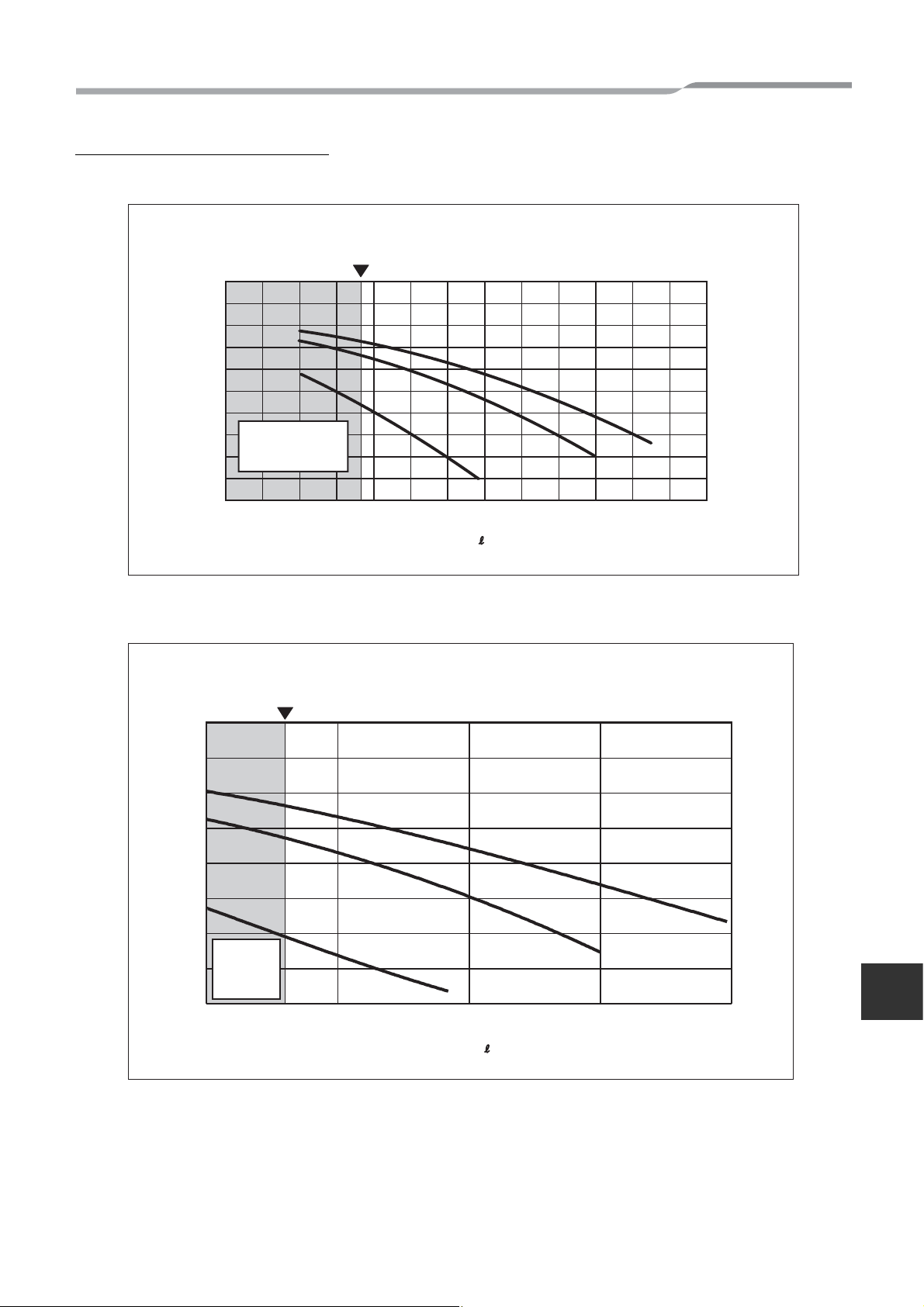

Design the water pipe length within the QH characteristics of the pump (Refe to “Fig. 7-16” and “Fig. 7-17” on page 19).

The height of the pipe must be 7 m or less.

▼ Fig. 7-02

H < 7 m

Service space

Secure a service space for the Hydro Unit.

• Do not install the Hydro Unit in a place where heat stagnates.

▼ Fig. 7-03

200 mm

100 mm

500 mm

350 mm

Mounting

Install M10 bolts at the positions shown below and secure them with nuts.

▼ Fig. 7-04

380 mm

500 mm

M10

11-EN

960 mm

–12–

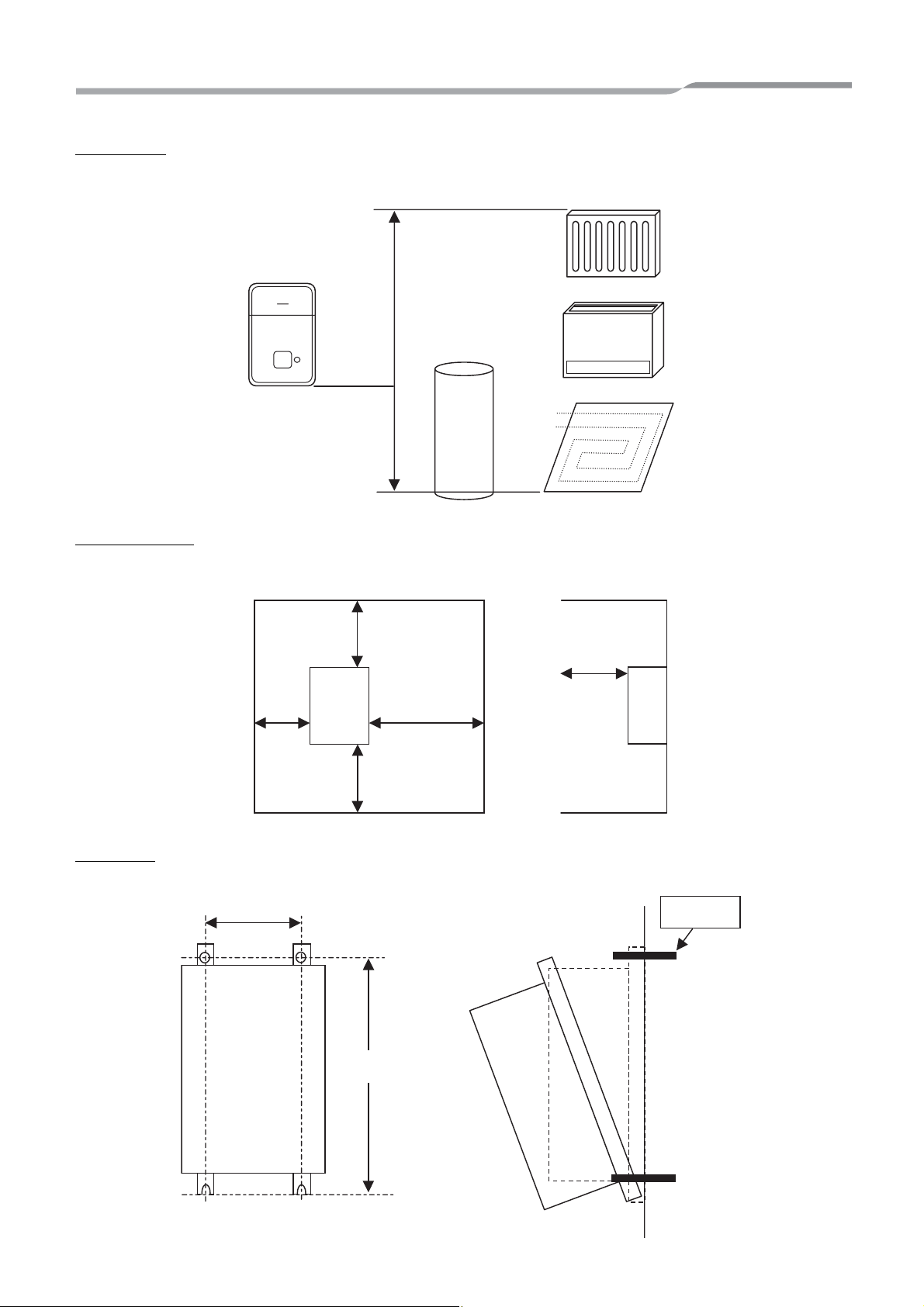

Page 13

Hydro Unit

Installation Manual

The Hydro Unit can be installed directly without using the fixing angles.

However, the back side of the Hydro Unit can be highly heated, therefore, the installing surface must be heat-

resistant.

▼ Fig. 7-05

Remove the M5a screws to

detach the fixing angles.

▼ Fig. 7-06 ▼ Fig. 7-07

380

860

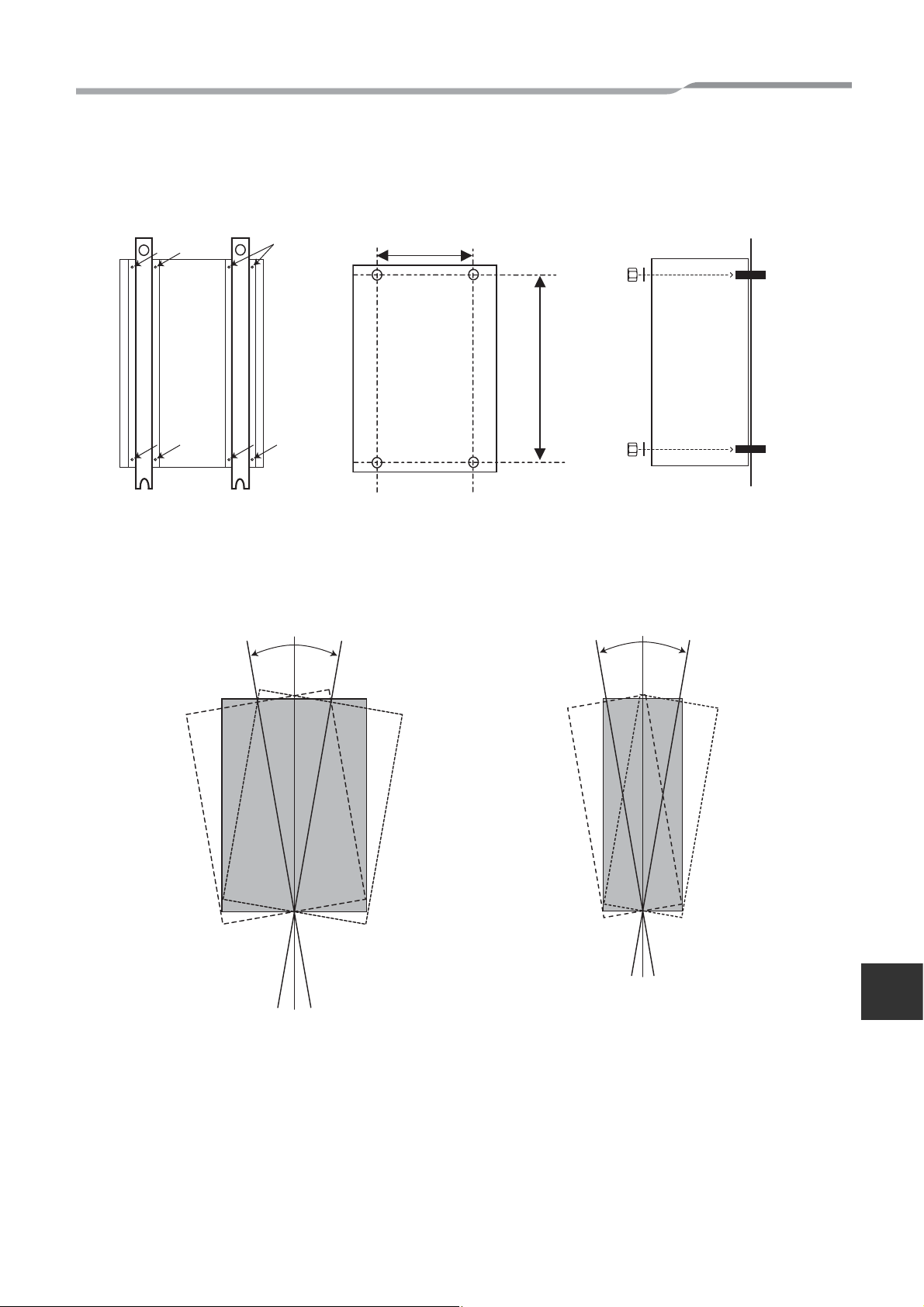

Install the Hydro Unit so that its tilting angle falls within the range below.

▼ Fig. 7-08

± 1°

▼ Fig. 7-09

M10

M10

Secure the Hydro Unit with

plain washers and nuts.

± 1°

–13–

EN

12-EN

Page 14

Hydro Unit

Refrigerant Piping

Installation Manual

WARNING

• THIS SYSTEM ADOPTS HFC REFRIGERANT (R410A) WHICH DOES NOT DESTROY THE OZONE LAYER.

• The characteristics of R410A refrigerant are: ease to absorb water, oxidizing membrane or oil, and its pressure is

approximately 1.6 times higher that of R22. Accompanied with the new refrigerant the oil has also been changed.

Therefore during installation work prevention of the invasion of water, dust, former refrigerant or oil is of a paramount

importance.

To prevent the charging of incorrect refrigerants into the system the service valve connection ports have also

increased in size.

• The use of R410A tools is required for correct installation of the system.

• The use of the correct pipe sizes and wall thicknesses of copper pipe work is required for the correct installation of

the system.

CAUTION

• Ensure all refrigerant pipes are protected from the invasion of dust and water.

• Ensure all pipe work connections are tightened to the required torque settings detailed in this section.

• Perform an air tight using Oxygen Free Nitrogen (OFN) only.

• Evacuate the air in the pipe work using a vacuum pump.

• Check for refrigerant gas leaks at all connections throughout the pipe work.

NOTE

The Air to Water Heat Pump system uses R410A refrigerant. It is important that copper pipes used for refrigerant

piping have the following wall thickness:

• 0.8 mm for Ø6.4 mm, Ø9.5 mm and Ø12.7 mm

• 1.0 mm for Ø15.9 mm

Refrigerant pipe sizes

Hydro Unit Model Gas Side (mm) Liquid Side (mm)

8 kW Hydro Unit Ø 15.88 Ø 9.52

11 & 14 kW Hydro Unit Ø 15.88 Ø 9.52

Flaring

• Cut the refrigerant pipes to the correct length using a pipe cutter. Remove any burrs that may be on the pipes as

these may cause refrigerant leaks or component failure in the refrigeration cycle.

• Place the correct size flare nuts onto the pipes (use the flare nuts supplied with the Hydro Unit or use flare nuts

designed specifically for R410A refrigerant) and then flare the pipes using the correct flaring tool.

13-EN

–14–

Page 15

Hydro Unit

Installation Manual

Tightening

• Connect the refrigerant pipes, from the outdoor unit, to the Hydro Unit as shown below.

Fig. 7-10

Gas line Ø 15.88

Liquid line Ø 9.52

• Align the flare connection on each pipe with the corresponding outlet connection on the Hydro Unit.

Tighten the flare nuts, using fingers, to secure the pipes in place.

• Tighten the flare nuts, using a torque wrench, to the tightening torques shown below:

Outer Ø of Copper Pipe (mm) Tightening Torque (N/m)

9.5 33 to 42

15.9 63 to 77

• To prevent damage, to the refrigerant pipes, use two spanners to tighten the flare nut connections to the required

torque.

Water Pipe

WARNING

• Install water pipes according to the regulations of respective countries.

• Install water pipes in a freeze-free place.

• Make sure that water pipes have sufficient pressure resistance.

The setting value of the pressure relief valve is 0.3 MPa.

CAUTION

• Do not use zinc plated water pipes. When steel pipes are used, insulate both ends of the pipes.

• The water to be used must meet the water quality standard specified in EN directive 98/83 EC.

EN

–15–

14-EN

Page 16

Hydro Unit

Installation Manual

Water circuit

• Install a strainer with 30 to 40 meshes (procured locally) at the water inlet of the Hydro Unit.

• Install drain cocks (procured locally) for water charge and discharge at the lower part of the Hydro Unit.

• Make the piping route a closed circuit. (An open water circuit may cause a failure.)

▼ Fig. 7-11

Attention

To avoid water leak, exchange the seal

tapes to new one.

Attention

Water (used at test in factory before

shipping) may be found in the caps.

Hot water outlet

connection 1 1/4"

▼ Fig. 7-12

Water inlet connection

1 1/4"

Inlet

Isolating Ball Valve

Strainer (30 to 40

meshes)

Drain cock for

water charge

and discharge

15-EN

Local arrangement

–16–

Page 17

Hydro Unit

tohyd

it

Installation Manual

Piping to hot water tank (option)

Water supplied to the hot water cylinder is branched by a motorized 3-way valve (procured locally).

For the specifications of the motorized 3-way valve, refer to “Control parts specifications” on page 23.

Connect the hot water cylinder to port A (open when energized) of the valve.

▼ Fig. 7-13

ro un

room heating or cooling

B

Open when de-energized

AB

to hot water cylinder

A

Open when energized

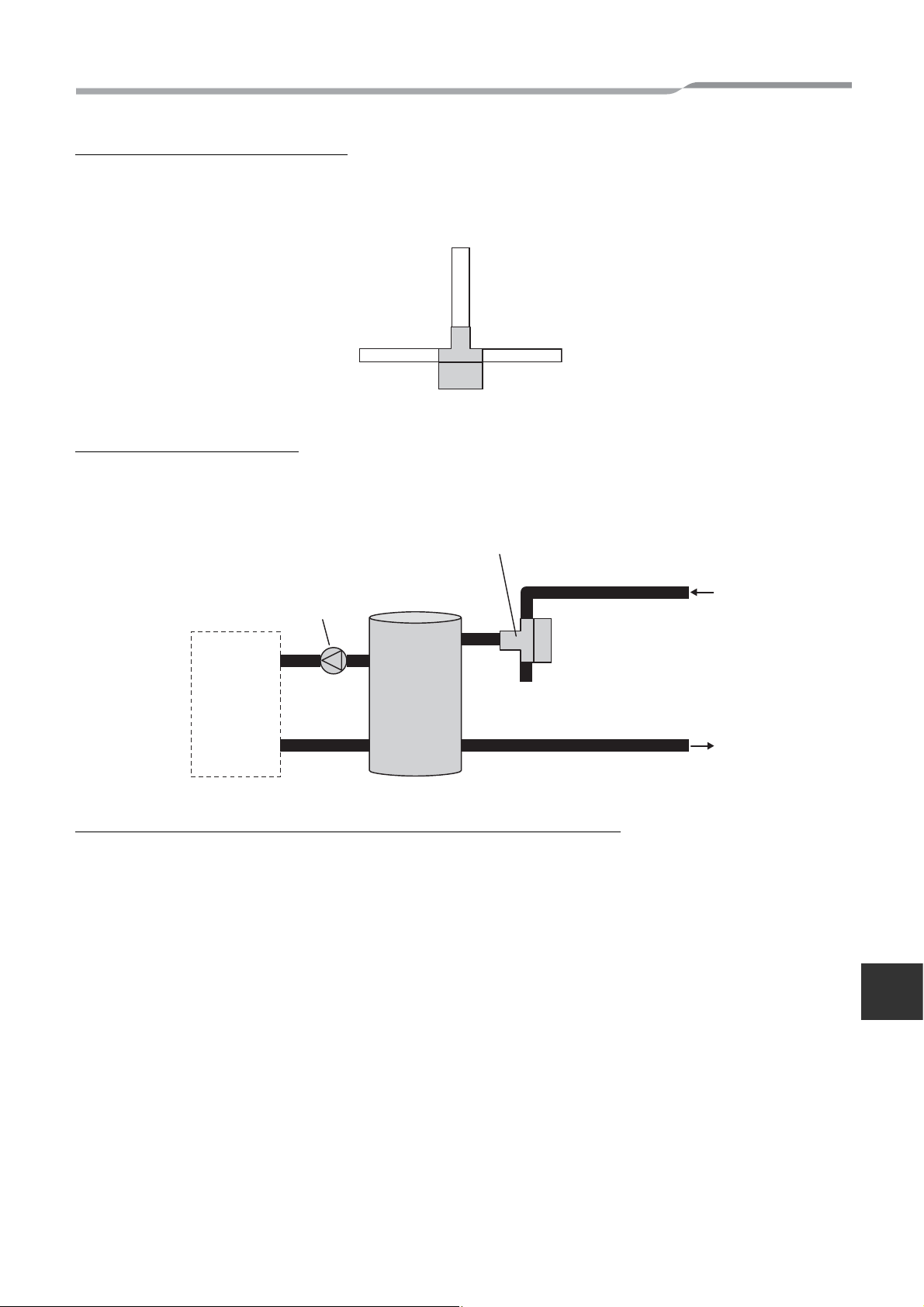

Piping to 2-zone operation

To perform 2-zone temperature control, circulate water by another pump (procured locally) through a motorized

mixing valve (procured locally) and a buffer tank (procured locally).

For the specifications of the motorized mixing valve, Refer to “Control parts specifications” on page 23.

▼ Fig. 7-14

Water pump

(Procured locally)

Zone 2

Motorized mixing valve

(Procured locally)

AB

A

Open when

energized

to hydro unit

B

Open when

de-energized

Buffer tank

(Procured locally)

Checking water volume and initial pressure of expansion vessel

The expansion vessel of the Hydro Unit has a capacity of 12 liters.

The initial pressure of the expansion vessel is 0.1 MPa (1 bar).

The pressure of the safety valve is 0.3 MPa (3 bar).

Verify whether the capacity of the expansion vessel is sufficient using the following expression. If the volume is

insufficient, add the capacity locally.

–17–

EN

16-EN

Page 18

Hydro Unit

Installation Manual

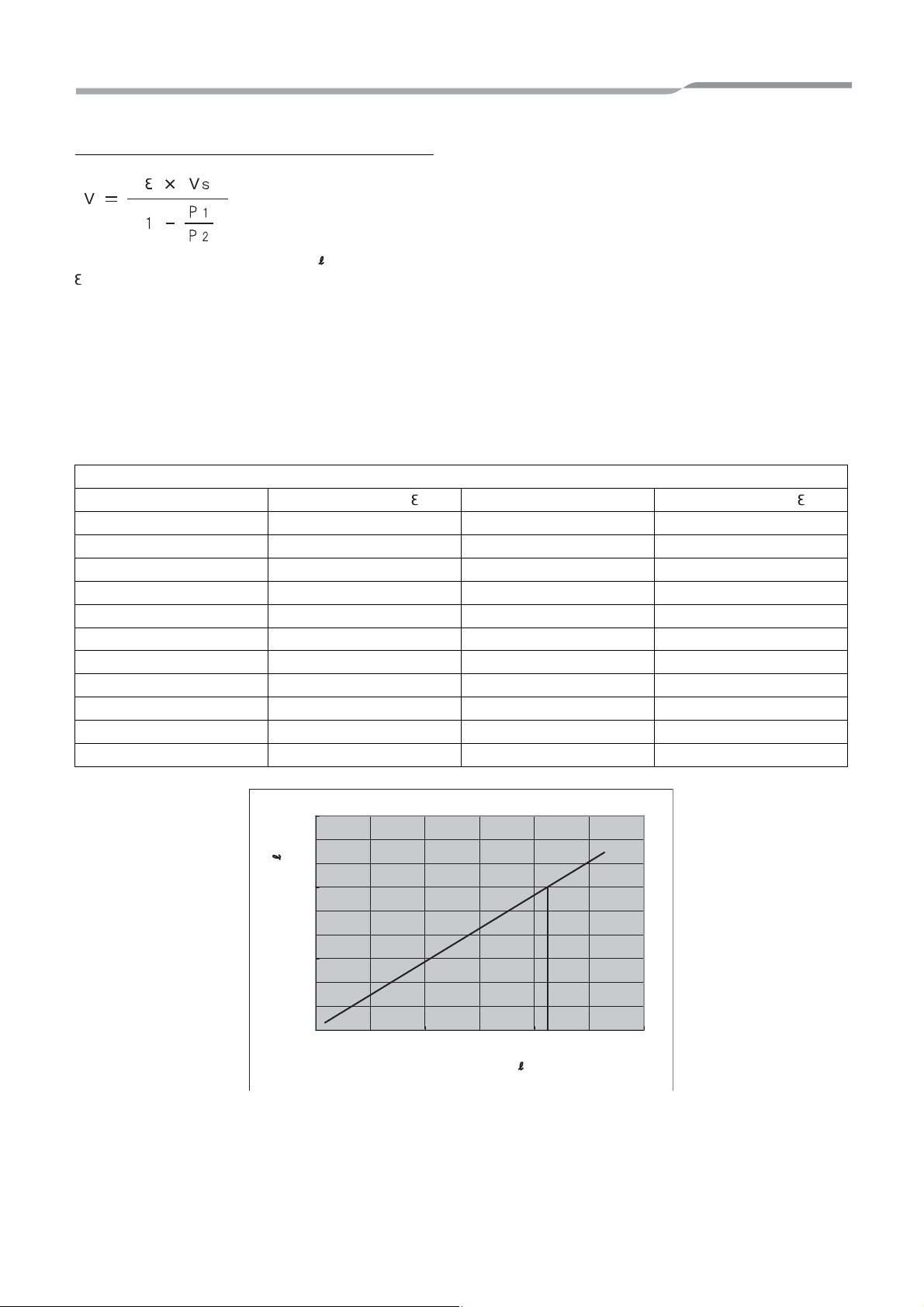

Expression for expansion vessel selection

V: Necessary total tank capacity ( )

: Water expansion coefficient at average hot water temperature

Vs: Total water amount in the system

P1: System pressure at tank setting position (MPaabs.)

(Pipe inner pressure during pump operation before heating device operates = water supply pressure)

P2: Maximum pressure used during operation at tank setting position (MPaabs.)

(= safety valve setting pressure)

* The absolute pressure value (abs.) is obtained by adding the atmospheric pressure (0.1 MPa (1 bar)) to the

gauge pressure.

▼ Tank selection method

Water temperature and expansion coefficient

Hot water temperature (°C) Expansion rate

0 0.0002 50 0.0121

4 0.0000 55 0.0145

5 0.0000 60 0.0171

10 0.0003 65 0.0198

15 0.0008 70 0.0229

20 0.0017 75 0.0258

25 0.0029 80 0.0292

30 0.0043 85 0.0324

35 0.0050 90 0.0961

40 0.0078 95 0.0967

45 0.0100

Hot water temperature (°C) Expansion rate

▼ Fig. 7-15

18

16

14

12

10

8

6

4

2

Expansion vessel volume( )

0

0 50 100 150

Water volume ( )

*Hot water temperature 55ºC

250200 300

Install an external expansion vessel when the capacity of the expansion vessel is insufficient.

17-EN

–18–

Page 19

Hydro Unit

Pump operation/configuration

▼ Fig. 7-16

Hydraulic heat exchanger (14 kW) QH characteristics

10

9

8

7

6

5

4

Pump head (m)

Out of Operation

3

Range

2

1

0

0

51015

Minimum flow rate

SW1

2520 30

Flow rate ( /min)

SW2

35 40 45

Installation Manual

SW3

5550 60 65

▼ Fig. 7-17

Minimum flow rate

8

7

6

5

4

3

Pump head (m)

2

Out of

Operation

1

Range

0

10 15

Hydraulic heat exchanger (8 kW) QH characteristics

SW 2

SW 1

2520 30

Flow rate ( /min)

SW 3

EN

–19–

18-EN

Page 20

Hydro Unit

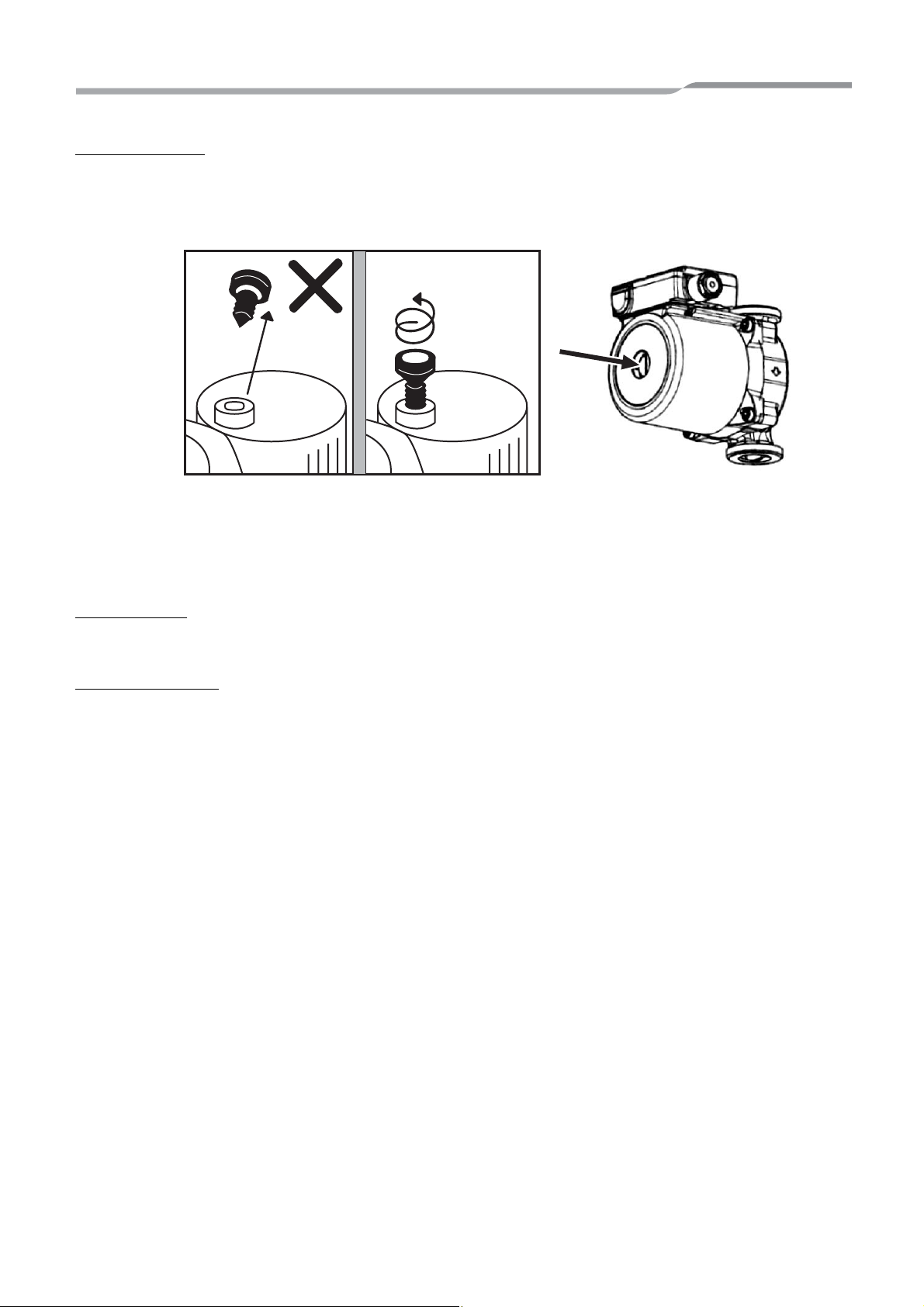

Water charging

Charge water until the pressure gauge shows 0.2 MPa (2 bar).

Hydraulic pressure may drop when the trial run begins. In that case, add water.

Air may enter if the charged hydraulic pressure is low.

Loosen the purge valve cap by two turns to release air.

Installation Manual

▼ Fig. 7-18

Loosen the air vent screw of the pump, pull out air in the pump, and tighten again.

Loosen the cap of the pressure relief valve to release air.

Water may come out of the pressure relief valve.

Release the air completely from the water circuit. Failure to do so may disable correct operation.

Loosen 2 turns for

proper venting

Water quality

The water used must satisfy EN directive 98/83 EC.

Piping insulation

It is recommended that insulation treatment be applied to all pipes. To perform optional cooling operation, apply

insulation treatment of 20 t or more to all pipes.

19-EN

–20–

Page 21

Hydro Unit

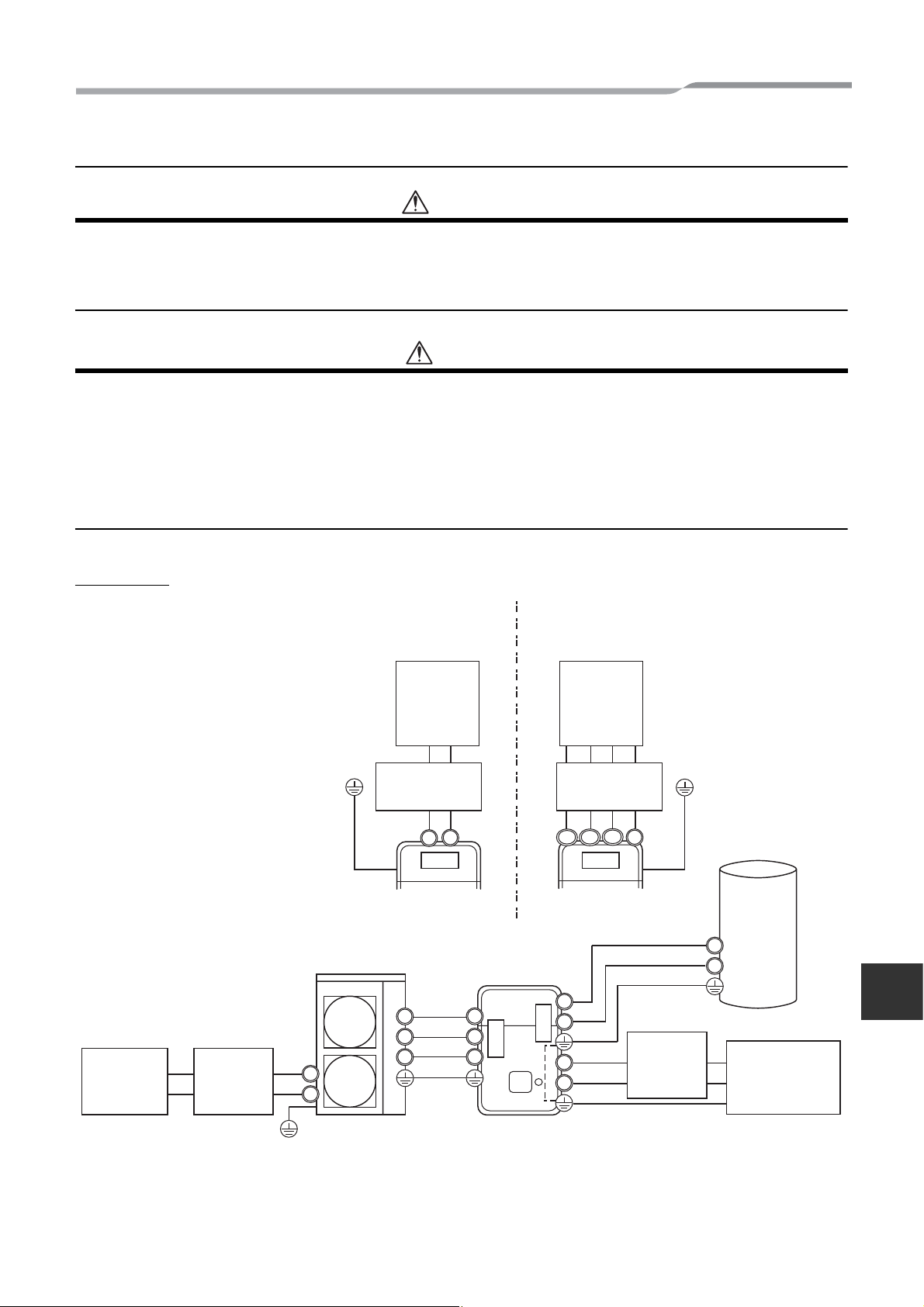

Electrical Installation

Installation Manual

WARNING

• Ensure electrical circuits are isolated before commencing the electrical installation.

• The electrical installation must be completed by a qualified electrician.

• The electrical installation must comply to all Local, National and International electrical installation regulations.

• This product must be earthed in accordance with Local, National and International electrical installation regulations.

CAUTION

• The Hydro Unit must be connected to a dedicated power supply for the back up heater circuit.

• The electrical supply must be protected by a suitably sized over current protection device (fuse, MCB etc) and an

earth leakage protection device.

• The Hydro Unit must be connected to the mains power supply using a isolating switch which disconnects all poles

and has a contact separation of at least 3 mm.

• The cord clamps, attached to the Hydro Unit, must be used to secure the electrical cables.

• Wrong connection of electrical cables may result in electrical component failure or fire.

• Ensure the electrical cables are sized in accordance with the installation instructions.

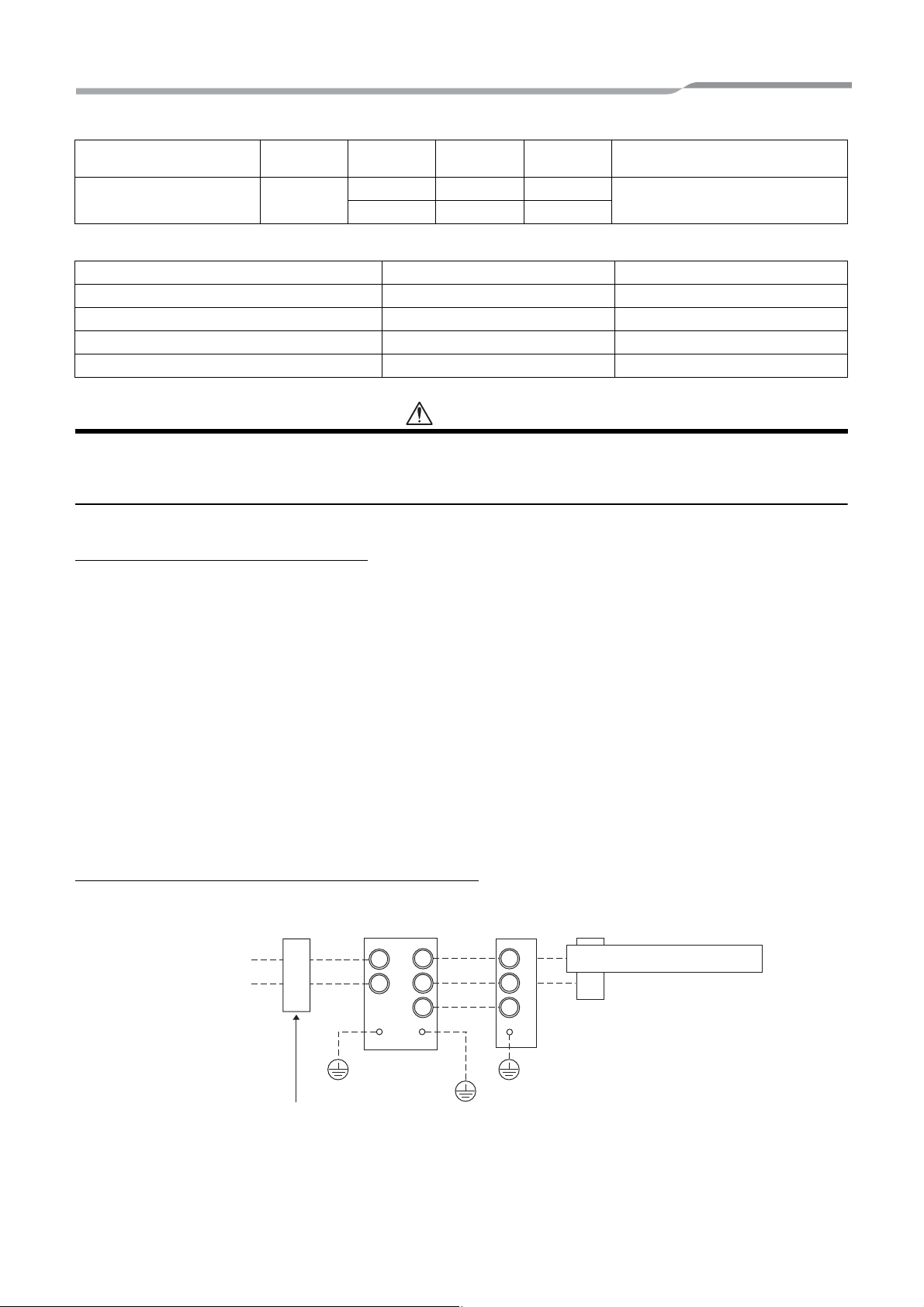

Power line

▼ Fig. 7-19

Input power

230 V ~

50 Hz

Leakage

breaker

30 mA

Backup heater

230 V ~ (3 kW type)

Input power

230 V ~

50 Hz

Leakage

breaker 30 mA

N

L

TB02 TB02

1

2

3

L

N

1

2

TB01

3

Backup heater

400 V 3N ~ (6.9 kW type)

Input power

400 V 3N ~

50 Hz

Leakage

breaker 30 mA

L3

L1

L2

TB03

L1

1

2

L

N

N

Leakage

breaker

30 mA

Hot water cylinder

1

2

EN

Input power for

cylinder heater

230 V ~ 50 Hz

Hydro unitOutdoor unit

–21–

20-EN

Page 22

Hydro Unit

Control line

Installation Manual

▼ Fig. 7-20

Pump (local)

Max 12 m

230 V 100 mA

0.75 mm² or more

Booster heater

(local)

Max 12 m

230 V 1 A

0.75 mm² or more

2Way-Valve for

cooling stop

Max 12 m

230 V 1 A

0.75 mm² or more

3Way-Valve for hot

water cylinder

Alert output

(local)

Mixing-Valve

type 2 for 2

zone control

4

2

3

1

TB04

TB04

1

2

3

4

TB05

5

6

7

8

CN208

OPTION OPTION

9

PJ20

2

1

4

3

Boiler operation

(local)

Mixing-Valve type

1 for 2 zone control

Max 12 m

230 V 100 mA

0.75 mm² or more

N

CW

CCW

4

2

3

1

TB06

CN209

PJ20

2

1

4

3

Defrost output

(local)

Max 5 m shield wire

0.75 mm² or more

A

B

C

D

Temp sensor

for 2 zone

control

Compressor

operation output

(local)

Temp sensor in hot

water cylinder

A

B

Max 5 m shield

wire 0.75 mm² or

more

Max 12 m

non voltage

0.75 mm² or more

▼ Fig. 7-21

TB03

TB01

51

52

WPM

TTW

Sensor

connection

55

53

TB 05

54

2WV

6B6A 6D

6C

TF1

TB 06

565758

BH

Don't apply

220-240V

or

breakdown

will occur.

to Outdoor unit

Outdoor unit

connection

3WV

1

11 12

59

2

TB 01

3

13

43

42

MIXV

TB 04

31 32

HOT WATER CYLINDER

TB 03

44

L

Input

power

230 V ~

41

Hot

water

cylinder

50 Hz

Hot water

cylinder power

supply

TB02

L3

N

L2L1

N

L

N

TB 02

Input

power

230 V ~

50 Hz

Backup heater

power supply

L3

L1 L2

N

Input

power

400 V 3N ~

50 Hz

21-EN

–22–

Page 23

Hydro Unit

Installation Manual

Electrical supply/cable specifications

▼ Wiring specifications

Description POWER SUPPLY

14 kW 230 V ~ 50 Hz 22.8 A 25 A 2.5 mm² or more

Outdoor unit

power

8 kW 230 V ~ 50 Hz 20.8 A 25 A 2.5 mm² or more

Outdoor-Hydro – – 1.5 mm² or more , ,

3 kW 230 V ~ 50 Hz 13 A 16 A 1.5 mm² or more , (TB02)

Hydro inlet heater

power

Hydro cylinder heater power 230 V ~ 50 Hz 12 A 16 A 1.5 mm² or more , (TB03)

Hydro - cylinder – 12 A – 1.5 mm² or more , (TB03)

6 kW 400 V 3N ~ 50 Hz 13 A (13 A x 2P) 16 A 1.5 mm² or more

9 kW 400 V 3N ~ 50 Hz 13 A (13 A x 3P) 16 A 1.5 mm² or more

Maximum

current

▼ Wiring specifications (control line)

Description Line spec

3-way valve control 2 line or 3 line 100 mA 12 m 0.75 mm² or more

Mixing valve control 3 line 100 mA 12 m 0.75 mm² or more

2-zone thermo sensor 2 line 100 mA 5 m 0.75 mm² or more , (TB06)

Cylinder thermo sensor

Second remote controller 2 line 50 mA 50 m 0.75 mm² or more , (TB07)

2+GND(shield

wire)

Maximum

current

100 mA 5 m 0.75 mm² or more , (TB06)

Installation fuse

rating

Maximum length

Power wire

Connection

destination

,11 kW 230 V ~ 50 Hz 22.8 A 25 A 2.5 mm² or more

, , ,

(TB02)

Connection

destination

, ,

(TB05)

, ,

or

, ,

(TB04)

▼ Control parts specifications

Power Maximum current Type

Motorized 3-way valve

(for hot water)

Motorized 2-way valve

(for cooling)

Motorized mixing valve

type 1 (for 2-zone)

AC 230 V 100 mA

AC 230 V 100 mA spring return type (normally open )

AC 230 V 100 mA

Spring return type

Note: 3-wire SPST and SPDT type can be used by changing

DIP switch 13-1.

60 sec 90º. SPDT type

Note: SPST and 20 to 240 sec type can be used by changing

the function code.

▼ Output line specifications

Description Output

External pump No.1 AC230V 1 A – 12 m

External boost heater AC230V 1 A – 12 m

Boiler control

ALARM Output

Compressor operation

output

Non-voltage

contacts

Non-voltage

contacts

Non-voltage

contacts

Maximum

current

0.5 A AC230 V 12 m

1 A DC24 V 12 m

0.5 A AC230 V 12 m

1 A DC24 V 12 m

0.5 A AC230 V 12 m

1 A DC24 V 12 m

Max

voltage

Maximum

length

EN

Output as required when outdoor air

temperature is -20°C or less

Output as required when outdoor air

temperature is -10°C or less

–23–

22-EN

Page 24

Hydro Unit

Installation Manual

Description Output

Defrost Output

Non-voltage

contacts

Maximum

current

0.5 A AC230 V 12 m

1 A DC24 V 12 m

Max

voltage

Maximum

length

▼ Input line specifications

Description Input Maximum length

Emergency stop control Non-voltage 12 m

Cylinder thermostat input Non-voltage 12 m

Cooling thermostat input Non-voltage 12 m

Heating thermostat input Non-voltage 12 m

CAUTION

Earthing arrangements

The Hydro Unit and related equipment must be earthed in accordance with your local and national electrical regulations.

It is essential that the equipment is earthed to prevent the electric shock and damage to the equipment.

Electrical connection to hydro unit

• Remove the front cover and the electrical box cover from the Hydro Unit.

• The Hydro Unit power cable must be sized in accordance with refer to “Electrical supply/cable specifications”.

• Connect the Hydro Unit power cable to Terminal 02 as shown below.

Single Phase Units: Live conductor – Terminal L1

Neutral conductor – Terminal L2

Earth conductor – Earth terminal

Three Phase Units: Phase 1 conductor – Terminal L1

Phase 2 conductor – Terminal L2

Phase 3 conductor – Terminal L3

Neutral conductor – Terminal N

Earth conductor – Earth Terminal

• Ensure the Hydro Unit power cable is secured using the cable clamp fitted in the electrical box.

• Ensure the Hydro Unit power cable connection terminals are tight.

23-EN

Outdoor unit to hydro unit electrical connection

Fig. 7-22

(Main circuit)

Input power

230 V~,

50 Hz

Earth

Earth

Leakage

breaker

• Ensure electrical circuits are isolated before commencing work.

• The Outdoor Unit to Hydro Unit interconnecting cable must be sized in accordance with refer to “Electrical supply/

cable specifications”.

• Connect the Outdoor Unit to Hydro Unit interconnecting cable as shown in the diagram above.

(Hydro/outdoor

connecting wires)

L

N

Outdoor unit

Earth

11

22

33

Earth

Hydro Unit: Terminal 01

Remote controller

Hydro unit

–24–

Page 25

Hydro Unit

Installation Manual

• Ensure the Outdoor Unit to Hydro Unit interconnecting cable is secured using the cable clamp fitted in the

electrical box.

• Ensure the Outdoor Unit to Hydro Unit interconnecting cable connection terminals are tight.

Electrical connection for external booster heater

CAUTION

• The maximum current available from the booster heater output is 1 A. Do not connect the booster

pump directly to Terminal Block 05 on the Hydro Unit. A separate contactor, supplied locally, must

be used to supply the booster heater.

• The booster heater can be installed only for room heating and cannot be used for hot water supply.

• Install the booster heater downstream of the 3-way valve on the indoor unit side.

The booster heater is an external heater, supplied locally, used to assist the Hydro Unit during low ambient

conditions.

• The AC230 V 1 A output from the Hydro Unit must only be used to energize an external contactor. (Supplied locally)

• The output from the Hydro Unit is only enabled when the outdoor air temperature is less than -20°C.

• Ensure the external booster heater is installed and set up in accordance with all Local, National and International

regulations.

• Connect the external booster heater to the Hydro Unit in accordance with the diagram shown below.

• Connect the coil, of the field supplied contactor, to terminals 5 & 6 on Terminal Block 05. The contactor will

energize in the event of low ambient conditions.

• A separate dedicated electrical supply must be used for the external booster heater. This must be connected

through the contacts on the field supplied contactor.

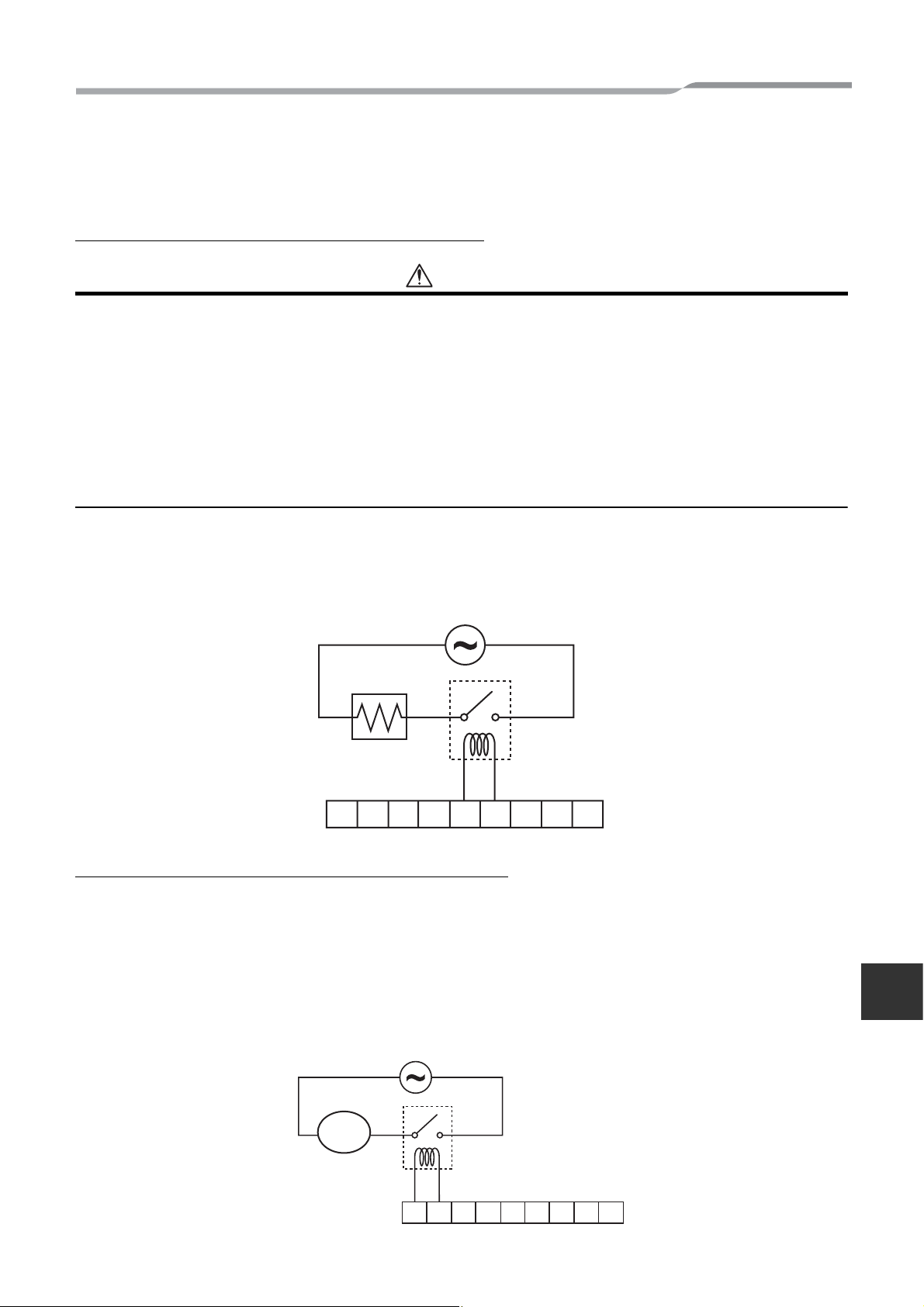

▼ Fig. 7-23

Booster Heater

1234567 8 9

Terminal Block 05

Electrical connection for external additional pumps

• The Hydro Unit has the facility to connect an additional circulating pump, if required, into the heating or cooling

system.

• There is an output available from the Hydro Unit. AC230 V 1 A (maximum) is available from each output. The

output for each additional pump is synchronized with the operation of the main circulating pump inside the Hydro

Unit.

• Connect the additional pumps as shown in the diagram below.

• Connect external pump 1 to terminals 1 & 2 on Terminal Block 05.

• Install external pumps so that their motive power does not affect the internal pump.

EN

▼ Fig. 7-24

Pump

01

1234567 8 9

–25–

Terminal Block 05

24-EN

Page 26

Hydro Unit

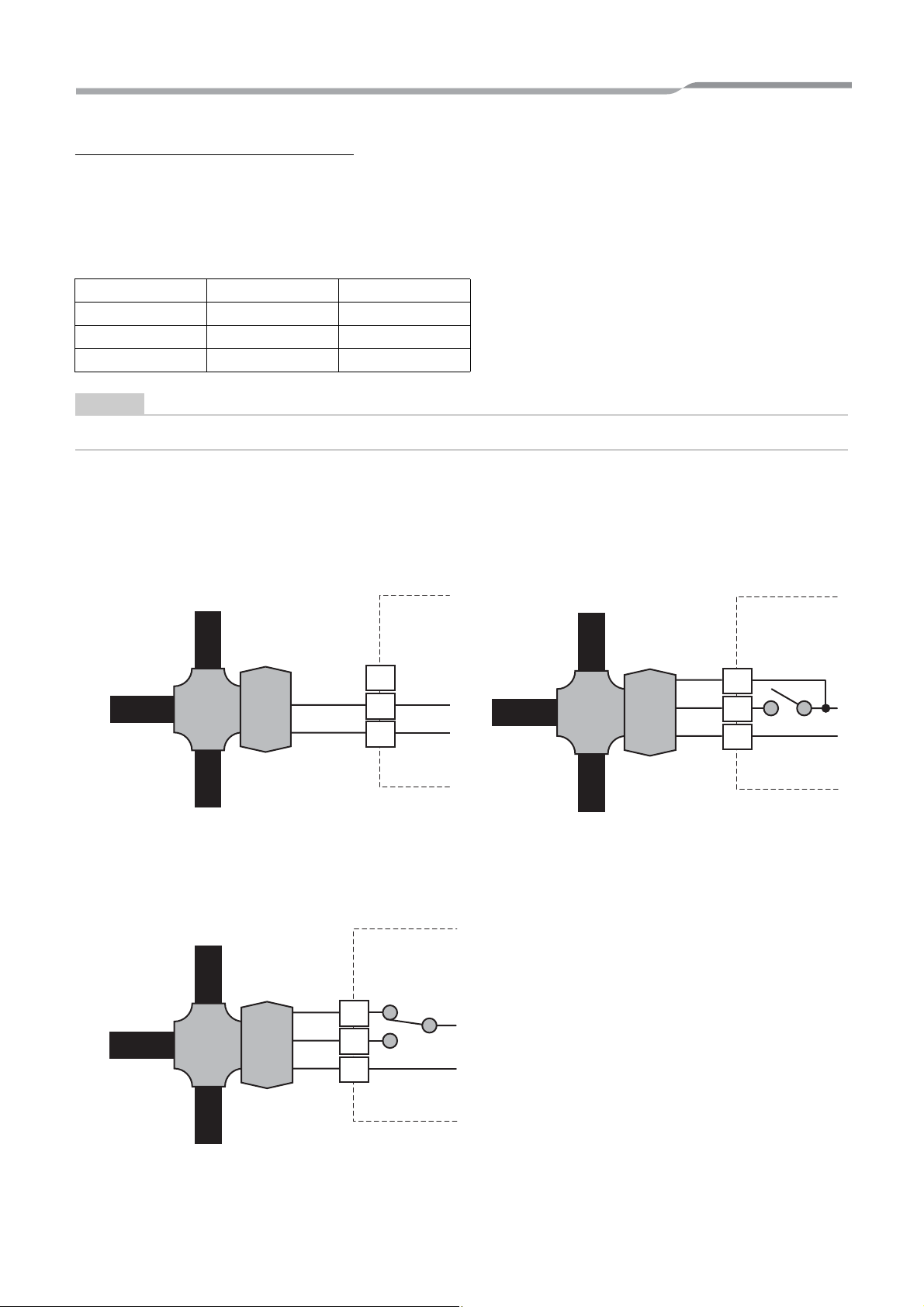

3-way valve (diverter) connection

Required Valve Specification:

Electrical Specification: 230 V; 50 Hz; <100 mA

Valve Diameters: Port A, Port B: Ø 1 1/4"

Return Mechanism: 3 types of 3-way valve (diverter) can be used.

Set the 3-way valve in use with the DIP switch SW13-1 on the Hydro Unit board.

SW13-1

Type 1 2-wire spring return OFF

Type 2 3-wire SPST OFF

Type 3 3-wire SPDT ON

NOTE

Continuous operation of the valve motor at the fully open position is not recommended.

• The 3-way diverter valve is used to select either domestic hot water or space heating.

• Connect the 3-way diverter valve to terminals 7, 8 and 9 on Terminal Block 05.

• Connect the 3-way diverter valve in accordance with the diagram below:-

Installation Manual

▼ Fig. 7-25

▼ Fig. 7-26

Type 1: SPRING RETURN Type 2: SPST

port “A” to Hot water

cylinder

port “AB” to

Hydro unit

port “A” open

Hydro Unit

TB 05

7

8

port “AB” to

Hydro unit

9

port “B” to Room heating

or cooling

▼ Fig. 7-27

Type 3: SPDT

port “A” to Hot water

port “AB” to

Hydro unit

cylinder

port “A”

close

open

Hydro Unit

TB 05

7

8

port “A” to Hot water

cylinder

port “B” to Room heating

or cooling

port “A”

close

open

Hydro Unit

TB 05

7

8

9

25-EN

9

port “B” to Room heating

or cooling

–26–

Page 27

Hydro Unit

Installation Manual

3-way mixing valve connection

Required Actuator Specification

Electrical Specification:230 V; 50 Hz; <100 mA

The 3-way mixing valve is used to achieve the temperature differential needed in a 2-zone heating system.

• Connect the 3-way mixing valve to terminals 2, 3 and 4 on Terminal Block 04 (for Type 1 mixing valve) or on

terminals 1, 2 and 3 on Terminal Block 04 (for Type 2 mixing valve).

• Connect the 3-way mixing valve in accordance with the diagrams below:-

▼ Fig. 7-28

▼ Fig. 7-29

Type 1: SPDT Type 2: SPST

port “A” to Zone 2 Heating

port “AB” to

Hydro unit

port “B” BLANK OFF

open

port “A”

close

Hydro Unit

TB 04

1

2

3

4

port “A” to Zone 2 Heating

port “AB” to

Hydro unit

port “B” BLANK OFF

port “A”

close

open

Hydro Unit

TB 04

1

2

3

4

Hot water cylinder connection (optional)

• Please refer to “Electrical supply/cable specifications” for fuse/cable size and for connection details.

Electrical Connection (Hot Water Cylinder Electric Heater)

• The electric heater, incorporated in the hot water cylinder, requires a separate supply to Hydro Unit.

• Connect the hot water cylinder heater electrical supply in accordance with shown below:

Live conductor: Terminal L on Terminal Block 03

Neutral conductor: Terminal N on Terminal Block 03

Earth Conductor: Earth terminal on Terminal Block 03

• Connect the hot water cylinder heater to the Hydro Unit as shown below:

Live conductor to hot water cylinder: Terminal 1 on Terminal Block 03

Neutral conductor to hot water cylinder: Terminal 2 on Terminal Block 03

Earth conductor to hot water cylinder: Earth terminal on Terminal Block 03

Electrical Connection (Hot Water Cylinder temperature Sensor)

• Connect the hot water cylinder temperature sensor as shown below to terminals A & B on Terminal Block 06 in

the Hydro Unit.

• Please ensure that the interconnecting cable, between the Hydro Unit and the hot water cylinder, is connected

to earth at both ends of the cable using the shield wire.

▼ Fig. 7-30

Earth leakage breaker

INPUT Power 230 V ~ 50 Hz

2

1

12 LN

Hot water cylinder

Terminal block 03

–27–

EN

26-EN

Page 28

Hydro Unit

Hot water cylinder electrical box connections

▼ Fig. 7-31

Installation Manual

Hydro unit

Additional hydro unit outputs

Alarm and Boiler Outputs

Alarm Output: L1: Alarm output

• Output enabled when the system is in alarm/fault condition.

• Volt free contact - specification shown below:

AC230 V; 0.5 A (maximum)

DC24 V; 1 A (maximum)

• Connection details: Terminals 1 and 2 (OPERATION) on MCC-1217 TB (Refer to “Fig. 7-32”)

Boiler Control Output: L2: Boiler drive permission output

• Output enabled when outdoor ambient temperature <-10°C

• Volt free contact - specification shown below:

AC230 V; 0.5 A (maximum)

DC24 V; 1 A (maximum)

• Connection details: Terminals 3 and 4 (EMG) on MCC-1217 TB (Refer to “Fig. 7-32”)

Fig. 7-32

Hydro unit main

control board

CN208

Connection

Cable

Display

Relay

K1

PJ20

TCB-PCIN3E

EMG

4

3

Local Supply

Power Supply

L2

BOILER

CONTROL

OUTPUT

27-EN

OPERATION

Display

Relay

K2

–28–

2

1

Power Supply

L1

ALARM

OUTPUT

Page 29

Hydro Unit

Installation Manual

Defrost and Compressor operation Outputs

Defrost output

• Display relay is ON when the system defrost.

• Volt free contact

AC230 V; 0.5 A (maximum)

DC24 V; 1 A (maximum)

• Connection details: Terminals 1 and 2 (OPERATION) on MCC-1217 TB (Refer to “Fig. 7-33”)

Compressor operation output

• Display relay is ON with outdoor unit compressor operation.

• Volt free contact

AC230 V; 0.5 A (maximum)

DC24 V; 1 A (maximum)

• Connection details: Terminals 3 and 4 (EMG) on MCC-1217 TB (Refer to “Fig. 7-33”)

▼ Fig. 7-33

Hydro unit main

control board

CN209

Connection

Cable

PJ20

TCB-PCIN3E

Display

Relay

K1

EMG

4

3

Local Supply

Power Supply

L2

Compressor

operation

output

OPERATION

Display

Relay

K2

2

1

Power Supply

L1

Defrost

output

EN

–29–

28-EN

Page 30

Hydro Unit

Installation Manual

CAUTION

• Be sure to prepare a non-voltage contact for each terminal.

• Display Relay capacity of “EMG” and “OPERATION”.

Below AC230 V 0.5 A (COS

When connecting loads such as relay coil to “L1, L2” load, insert noise surge absorber.

Below DC24 V 1 A (Non-inductive load)

When connecting load such as relay coil to “L1, L2” load, insert the bypass circuit.

Ø = 100 %)

Optional inputs to hydro unit

Room Thermostat Input:

2–3: Room thermostat input for cooling mode

1–3: Room thermostat input for heating mode

• Output enabled when either heating or cooling mode selected on room thermostat. (locally supplied)

• Volt free contacts

• Connection details:

Cooling Connection: Terminals 3 (COM) and 2 (COOL) on TCB-PCMO3E (Refer to “Fig. 7-34”)

Heating Connection: Terminals 3 (COM) and 1 (HEAT) on TCB-PCMO3E (Refer to “Fig. 7-34”)

▼ Fig. 7-34

CN211

Connection

Cable

TCB-PCMO3E

COM

PJ17

COOL

HEAT

3

2

1

Local supply Thermostat

Cool

Thermostat operation

Mode

Connection

2 - 3 open close – –

1 - 3 – – close open

Cooling Heating

on off on off

CAUTION

• Be sure to prepare a non-voltage continuous contact for each terminal.

• Supplementary Insulation must be added to user touchable part of switches.

Emergency Shutdown input

S2: Emergency stop input

• Non-voltage contacts

• Connection details:

Emergency stop: Terminals 3 (COM) and 1 (HEAT) on TCB-PCMO3E (Refer to “Fig. 7-35”)

▼ Fig. 7-35

CN210

Connection

Cable

TCB-PCMO3E

COM

PJ17

COOL

HEAT

3

2

1

Local Supply

Hot

S2

29-EN

–30–

Page 31

Hydro Unit

Installation Manual

CAUTION

• Be sure to prepare a non-voltage continuous contact for each terminal.

• Supplementary Insulation must be added to user touchable part of switches.

Electrical safety checks

The electrical safety checks must be completed before turning on the electrical supplies to the Air to Water heat

pump system. The electrical safety checks should be completed by a qualified electrician. All results measured

should comply with your local/national electrical installation regulations.

Earth continuity test

On completion of the electrical installation a resistance test should be completed on the earth conductor to ensure

continuity between all pieces of equipment on the earth conductor.

Insulation resistance test

This test must be completed using a 500 V D.C. insulation resistance tester. Insulation resistance tests should be

completed between each live terminal and earth.

–31–

EN

30-EN

Page 32

Hydro Unit

8 START UP AND CONFIGURATION

Set the DIP switches and function codes.

Setting DIP Switches on the Board in the Hydro Unit

• Detach the front cover and the electric parts box cover of the Hydro Unit.

• Set the DIP switches on the main board.

Installation Manual

▼ Fig. 8-01

ON

OFF

SW10 Description

3 External P2 pump operation Continuous operation OFF ON

SW11 Description

1 Internal backup heater operation Operate OFF ON Not operate

2 Hot water cylinder heater operation Operate OFF ON Not operate

3 Booster heater operation Operate OFF ON Not operate

SW12 Description

1 Hot water supply operation Valid OFF ON Invalid

2 Zone 1 operation Valid OFF ON Invalid

3 Zone 2 operation Invalid OFF ON Valid

SW10 SW11 SW12 SW13

ON

ON

4

3

2

1

3

2

1

ON

4

Default setting

Default setting

Default setting

2

1

4

3

Switch mode

Switch mode

Switch mode

ON

4

3

2

1

Interlocked with the

internal pump

synchronized with P1.

31-EN

SW13 Description

1 Type of motorized 3-way valve

2 Interlocking with boiler Invalid OFF ON Valid

3 Auto restart for power failure Auto restart OFF ON Manual restart

4–

SW02 Description Default setting

4 Room thermostat Invalid OFF ON Valid

• 2-wire spring return type

• 3-wire SPST type

Default setting

Switch mode

OFF ON 3-wire SPDT type

–32–

Page 33

Hydro Unit

Setting Function Codes for Hydro Unit and Remote Controller

Set function codes for various operation modes with the remote controller.

There are two types of setting.

1) Hydro Unit function code setting

2) Remote controller function code setting

Setting remote controller mode

<Setting Hydro Unit Function Code>

Installation Manual

1 Press the TEST + SET + SELECT

buttons for four seconds or more

to enter the remote controller function code

setting mode.

2 Set the function code (CODE No.) with the

TEMP. buttons. (CODE No.: 01 to 91)

3 Set data (DATA) with the TIME buttons.

4 Press the SET button to determine the settings.

5 The CL button is enabled only before the SET button is pressed and the function code is

changed.

6 Press the TEST button to end the settings.

<Setting Remote Controller Function Code>

1 Press the TEST + CL + TEMP.

buttons for four seconds or more to enter the

remote controller function code setting mode.

2 Set the function code (CODE No.) with the

TEMP. buttons. (CODE No.: 01 to 13)

3 Set data (DATA) with the TIME buttons.

4 Press the SET button to determine the settings.

5 The CL button is enabled only before the SET button is pressed and the function code is

changed.

6 Press the TEST button to end the settings.

–33–

EN

32-EN

Page 34

Hydro Unit

Installation Manual

Main setting items

(1) Setting Hot Water Temperature Range (function code 18 to 1F)

• Set the temperature range for heating (zone 1, zone 2), cooling, and hot water.

• The upper-limit and lower-limit temperatures of each mode can be set.

(2) Setting Heat Pump Operation Conditions for Hot Water Supply (function code 20 and 21)

• Set the heat pump start water temperature and heat pump stop water temperature.

• The heat pump starts working when the water temperature lowers below the set start water temperature. It

is recommended that the default value be used.

(3) Compensating Hot Water Temperature (function code 24 and 25)

• Compensate the target temperature from the remote controller set temperature when the hot water

temperature lowers below the set outside air temperature.

(4) Setting Hot Water Boost (function code 08 and 09)

• Set the control time and target temperature when the HOT WATER BOOST button on the remote

controller is pressed.

(5) Setting Anti-Bacteria

• Set the control for the hot water cylinder when ANTI BACTERIA is set with the remote controller.

• Set the target temperature, control period, start time (24-hour notation), and target temperature retention

period.

• Make this control setting according to regulations and rules of respective countries.

(6) Setting Priority Mode Temperature

• Set the outside air temperature that changes the preferred operation mode.

• Hot Water - Heating Switching Temperature

Heating operation takes precedence when the temperature lowers the set temperature.

• Boiler HP Switching Temperature

When the temperature lowers the set temperature, the HP operation stops and the external boiler output is

made.

(7) Setting Heating Auto Mode Temperature (function code 27 to 31)

• Compensate the target temperature when Auto is set for temperature setting on the remote controller.

• The outside air temperature can be set to one of three points (T1 and T3) within a range of -15 to 15°C.

• The target temperature can be set to a value from 20 to 55°C.

• However, A > B > C > D > E.

33-EN

▼ Fig. 8-02

(40)

(35)

(30)

(25)

(20)

A

B

C

D

E

T1 T2

(-10)

Outdoor Temperature

0

T3

(10)

20-20

• The entire curve can be adjusted plus and minus 5°C by function code 27.

(8) Setting Frost Protection Temperature (function code 3A to 3B)

• Set the function when the FROST PROTECTION button on the remote controller is pressed.

• Set enabling/disabling of this function and the target water temperature.

• If disabling is set, the frost protection operation is not performed even when the FROST PROTECTION

button is pressed.

–34–

Page 35

Hydro Unit

(9) Setting Frequency of Output to Internal Heater (function code 33 to 34)

• The increase/decrease time is used to set the response time.

(10)Setting Night Setback (function code 26. remote controller function code 0F to 11)

• Set the function when the NIGHT button on the remote controller is pressed.

• Set enabling/disabling of this function, reduction temperature, start time, and end time.

• If disabling is set, the night setback operation is not performed even when the NIGHT button is

pressed.

(11)Setting 2-Way Valve (for Cooling) Operation (function code 3C)

• When using both cooling and heating operations and there is an indoor unit only for heating (such as floor

heating), install the 2-way valve and set this function code.

(12)Setting 3-Way Valve Operation (function code 54)

• This setting is not necessary for normal installation. Make this setting to invert the logic circuit in case ports

A and B of the 3-way valve are wrongly attached and it cannot be rectified on site.

(13)Mixing valve types and setting

• Set the time period from full close to full open of the 2-zone control mixing valve. Set a value that is 1/10 of

the actual time.

(14)Setting Heating/Hot Water Switching when Boiler Is Used (function code 3E)

• When boiler is used, make this setting to operate the Hydro Unit by the instruction from the boiler.

(15)Setting Heat Pump Operating Time for Hot Water Supply Operation

• Set the time period from the start of heat pump run to the start of heater energization at the beginning of hot

water supply operation. If a long period is set, it takes long time for heating water.

(16)Setting Cooling ON/OFF

• Set this function when performing cooling operation.

(17)Remote controller time indication

• 24-hour or 12-hour notation is selected for the timer.

(18)Setting Nighttime Quiet Operation

• Issue an instruction for low-noise mode operation to the outdoor unit. Enabling/disabling of this function, start

time, and end time can be set.

(19)Setting Alarm Tone

• The remote controller alarm tone can be set.

Installation Manual

–35–

EN

34-EN

Page 36

Hydro Unit

Function code settings

Function code setting

01. Upper-limit temperature for

heating Zone 1

02. Lower-limit temperature for

heating Zone 1

03. Upper-limit temperature for

heating Zone 2

04. Lower-limit temperature for

1. Setting

temperature range

2. Hot water

operation

3. Hot water

temperature

compensation

4. Hot Water Boost

5. Anti -bacteria

6. Priority mode

7. Heating Auto

setting

heating Zone 2

05. Upper-limit temperature for

cooling

06. Lower-limit temperature for

cooling

07. Upper-limit temperature for

hot water

08. Lower-limit temperature for

hot water

01. Heat pump start temperature 20 38 20 to 45 °C 1

02. Heat pump stop temperature 21 45 40 to 50 °C 1

01. Temperature compensation

start outside air temperature

02. Compensation temperature 25 3 0 to 15 Degree 1

01. Operation time x 10 min 08 6 3 to 18 Minute 1 (x10)

02. Setting temperature 09 75 40 to 80 °C 1

01. Setting temperature 0A 75 70 to 80 °C 1

02. Operation cycle 0D 7 1 to 10 Day 1

03. Start time 0C 22 0 to 23 Hour 1

04. Operation time 0B 30 0 to 60 Minute 1

01. Hot water and heating

switching temperature

02. Boiler and heat pump

switching temperature

01. Outside temperature T1 29 -10 -15 to 0 °C 1

02. Outside temperature T3 2B 10 0 to 15 °C 1

03. Setting

temperature A at

-20°C

04. Setting

temperature B at T1°C

05. Setting

temperature C at T2°C

06. Setting

temperature D at T3°C

07. Setting

temperature E at

+20°C

08. Ratio of Zone 2 in Zone 1

Auto mode

09. Temperature shift of entire

AUTO curve

When A

t B t C

t D t E

Installation Manual

Function code

setting address

Hydro

unit

1A 55 37 to 55 °C 1

1B 20 20 to 37 °C 1

1C 55 37 to 55 °C 1

1D 20 20 to 37 °C 1

18 25 18 to 30 °C 1

19 10 10 to 18 °C 1

1E 75 60 to 80 °C 1

1F 40 40 to 60 °C 1

24 0 -20 to 10 °C 1

22 0 -20 to 20 °C 1

23 -10 -20 to 20 °C 1

2C 40 20 to 55 °C 1

2D 35 20 to 55 °C 1

2E 30 20 to 55 °C 1

2F 25 20 to 55 °C 1

30 20 20 to 55 °C 1

31 80 0 to 100 % 10

27 0 -5 to 5 Degree 1

Remote

controller

Default Range Unit Unit Note

35-EN

–36–

Page 37

Hydro Unit

Function code

Function code setting

8. Frost Protection

9. Heater control

10. Night setback

11. Room

temperature setting

12. Hydro 2-way

valve operation

control

13. 2-zone mixing

valve drive time

14. Boiler operates

synchronized with

heat pump

15. Maximum

operation time of

hot water heat

pump

16. Cooling

operation

17. Remote

controller indication

18. Nighttime lownoise operation

19. Alarm tone 01. Tone switching 0: OFF, 1: ON 11 1 0, 1 Select

01. Function 0: Invalid, 1: Valid 3A 1 0, 1 Select

02. Setting temperature 3B 15 8 to 20 °C 1

01. Down time (Example) Heater

0: 5 min, 1: 10 min, 2: 15 min,

3: 20 min

02. Up time (Example) Heater

0: 10 min, 1: 20 min, 3: 30 min,

4: 40 min

01. Change temperature range 26 5 3 to 20 Degree 1

02. Start time 0E 22 0 to 23 Hour 1

03. End time 0F 06 0 to 23 Hour 1

01. Room temperature control

adjustment 0: Valid, 1: Invalid.

02. Compensation for

temperature

03. Down time zone B (x 5 min) 36

04. Up time zone C (x 5 min) 37

Activating 2-way valve for cooling

01. (0: Activated during cooling,

1: Not activated during cooling)

Previous drive time x 10 seconds 0C

01. (0: Synchronized, 1: Not

synchronized)

01. Maximum heat pump

operation time in hot water

operation priority mode

01. (0: Cooling and heating, 1:

Heating only)

01. 24-hour or 12-hour notation of

timer 0: 24-hour, 1: 12-hour

01. (1: Valid, 0: Invalid) 09 0 0, 1

02. Start time 0A 22 0 to 23 Hour 1

03. End time 0B 06 0 to 23 Hour 1

setting address

Hydro

unit

33

34

35 1 1 to 5 Degree 1

3C 0 0, 1 Select

3E 0 0, 1 Select

07 30 1 to 120 Minute 1

02 1 0, 1 Select

Remote

controller

Default Range Unit Unit Note

1

(10 min)

0

(10 min)

02 0 0, 1 Select

6

(30 min)

6

(30 min)

6

(60 sec)

05 0 0, 1 Select

0 to 3 Select

0 to 3 Select

1 to 24

(5 to 120

min)

1 to 24

(5 to 120

min)

3 to 24

(30 to

240 sec)

Installation Manual

Minute 1 (x5)

Minute 1 (x5)

1 (x10)

EN

–37–

36-EN

Page 38

Hydro Unit

Settings by Purpose

Installation Manual

Settings when hot water supply function is not used

• When the hot water supply function is not used, set DIP SW12-1 on the Hydro Unit board to ON. (Refer to

page 32.)

Setting for cooling

• For Hydro Units that do not perform cooling (those for floor heating, etc.), procure a motorized 2-way valve (for

cooling) (refer to “Control parts specifications” on page 23 for the details.) locally and attach it to the water pipe

that is not used for cooling. Connect the valve cables to terminals TB05 (3) and (4) of the Hydro Unit.

• Press long the TEST + SET + SELECT switches on the remote controller to change the

Hydro Unit function code, and change address 02 to 0, and then press the SET button to enable the function.

Press the TEST button to exit the setting mode.

• Stick the optional insulator for cooling to the bottom of the Hydro Unit.

Settings for hot water supply

• Prepare the optional hot water cylinder.

• Procure a motorized 3-way valve (refer to “Control parts specifications” on page 23 for the details.) locally and

perform piping. Connect the valve cables to terminals TB05 (7), (8) and (9) of the Hydro Unit.

• Set DIP SW12-1 on the Hydro Unit board to OFF. (Refer to page 32.)

• Connect the power supply unit for the hot water cylinder heater to terminals TB03 L and N of the Hydro Unit.

• Connect cables between the Hydro Unit and the hot water cylinder as follows:

Hydro Unit terminals TB03 (1), (2), and earth — Hot water cylinder (1), (2), and earth

TB06 A, B, and earth — Hot water cylinder A, B, and earth

Settings for 2-zone temperature control

• Procure a motorized mixing valve (refer to “Control parts specifications” on page 23 for the details.) locally and

perform piping. Connect the valve cables to terminals TB04 (1), (2), (3) and (4) of the Hydro Unit.

• Procure a buffer tank locally.

• Procure a water pump locally, and connect its cables to terminals TB05 (1) and (2) of the Hydro Unit.

To inhibit interlocking the water pump with the internal pump of the Hydro Unit, set DIP SW10-3 on the Hydro

Unit board to OFF.

• Set DIP SW12-3 on the Hydro Unit board to ON. (Refer to page 32.)

Attach the temperature sensor (TFI) connected to terminals TB06 C and D of the Hydro Unit near the hot water

inlet of the Hydro Unit.

• Fix TFI sensor on the room heating supply pipe by using the connector procured in locally.

• Cover the cables with insulation tube (minimum 1 mm) or conduit so that the user cannot touch them directly.

• Cover the TFI sensor's cables and sensor with insulation tube (minimum 1 mm) shown in the diagram on the

right.

37-EN

–38–

Page 39

Hydro Unit

▼ Fig. 8-03 ▼ Fig. 8-04

Installation Manual

M

TFI

Direct Buffer tank for

Under Floor Heating

Insulation tube (minimum 1 mm)

2 Zone hot water supply pipe

Zone 2

Under-floor Heating

(2-Way Valve Control)

TFI Sensor

Tying up

More than 4 mm

9 TEST RUN

Use operation buttons usually to conduct a test run.

If the outside air temperature or water temperature is outside the setting value range, press the TEST button

on the remote controller and then start a test run. Since the protection setting is disabled in the TEST mode, do not

continue a test run longer than 10 minutes.

• Press the TEST button on the remote controller. An indication “TEST” appears on the remote controller.

• Press the ZONE1, 2 button and select “heating” with the OPERATE MODE button.

The pump is activated in 30 seconds.

If air is not released completely, the flow rate switch is activated to stop operation. Release air again according

to the piping procedure.

Little air bite is discharged from the purge valve.

• Check that the air bite sound disappears.

• Check that the hydraulic pressure has become the predetermined pressure 0.1 to 0.2 MPa (1 to 2 bar). If the

hydraulic pressure is insufficient, replenish water.

• Heating operation starts. Check that the hydro unit starts heating.

• Press the OPERATE MODE button and select “cooling.”

• Cooling operation starts. Check that the hydro unit starts cooling and that the floor heating system is not cooled.

• Press the ZONE1, 2 button to stop operation.

• Press the HOT WATER button to start hot water supply operation.

• Check that there is no air bite.

• Check that hot water is present at the connection port of the hot water cylinder.

• Press the HOT WATER button to stop the hot water supply operation.

• Press the TEST button to exit the test mode.

–39–

EN

38-EN

Page 40

Hydro Unit

Installation Manual

10MAINTENANCE

Execute periodic maintenance at least once a year.

Check points

• Check all electrical connections and make adjustments if they are necessary.

• Check the water pipes of the heating systems in particular any evidence of leakage.

• Check the expansion tank inner pressure. If it is insufficient, enclose nitrogen or dry air in the tank.

• Check that the hydraulic pressure is 0.1 MPa (1 bar) or more with a water manometer. If it is insufficient, replenish

tap water.

• Pull the lever of the pressure relief valve and check operation.

• Clean the strainer.

• Check the pump for an abnormal sound or other abnormalities.

11SENSOR TEMPERATURE MONITORING

FUNCTION

Sensor Temperature Monitoring Function

The sensor sensing temperature is displayed on the remote controller.

This function allows you to make sure whether the sensor is installed properly.

Press the TEST + CL buttons for four seconds or more.

Select the function code with the TEMP. buttons.

Press the TEST button to exit the test mode.

Function code Location Indication

06

08 Hot water temperature °C

09 2-zone sensor temperature °C

0A Hot water cylinder temperature sensor °C

0B Motorized mixing valve position

60

61 Outside air temperature °C

62 Refrigerant discharge temperature °C

63 Refrigerant intake temperature °C

6A Current value (in the inverter) A

70 Compressor operating frequency

F4

F5 Hot water cylinder heater total operating hours x100 hours

F6 Hydro unit heater total operating hours x100 hours

Hydro unit

Outdoor unit

Operating hours

Return water temperature °C

Heat exchanger temperature °C

Hydro unit AC pump total operating hours x100 hours

39-EN

–40–

Page 41

Hydro Unit

12TROUBLESHOOTING

Fault Symptoms

Symptom Possible cause Corrective action

Check remote controller operation and temperature

setting

Check whether temperature sensor is installed at the

normal position.

Check DIP switch setting on the Hydro Unit board.

Check the setting with the function code table.

Set hydraulic pressure considering pipe height, and

replenish water until manometer shows a value of set

hydraulic pressure or more.

Widen water path to the hydro unit or adopt a bypass

valve.

Check wiring and parts.

Set hydraulic pressure considering pipe height, and

replenish water until manometer shows a value of set

hydraulic pressure or more.

Check expansion tank capacity compared to total water

amount. If it is insufficient, install another expansion

tank.

Room is not heated or

cooled.

Water is not hot enough.

Nothing is displayed on the

remote controller.

Flow rate switch is

activated.

Error code [P01]

Hot water leaks from

pressure relief valve.

Incorrect remote controller setting

Incorrect function code setting Check function code setting with the function code table.

Backup heater disconnected Check backup heater and bimetal thermostat.

Insufficient capacity Check selection of equipment.

Sensor defect

Power is not supplied. Check power supply wiring.

Incorrect setting

Air bite in the pump Release air completely according to the procedure.

Low hydraulic pressure

Strainer is clogged. Clean the strainer.

Large resistance on the hydro side

Malfunction of motorized 3-way valve

for hot water supply

Excessive hydraulic pressure

Insufficient capacity of expansion tank

Expansion tank failure Check the air pressure.

Installation Manual

Alarm

indication

E03

E04

F03

F10

F11

Alarm description and generation/reset conditions

Regular communication error between hydro unit and remote controller (system controller)

If there is no regular communication from the remote controller for three minutes, the hydro unit regards it as no

remote controller. If there is no communication from both sides, alarm E03 occurs.

Auto-reset: When successful regular communication is made

Regular communication error between hydro unit and outdoor unit

When serial signal from the outdoor unit cannot be received though normal serial signal is sent to the outdoor

unit

1) When serial signal cannot be received continuously for 60 seconds (S code communication)

2) Communication is still not successful for 80 seconds through three retries if serial signal cannot be

received for 20 seconds after new communication (f code) starts

When the remote controller starts operation, serial transmission starts with the new communication format.

Auto-reset: When successful regular communication is made

Condensing temperature TC sensor defect

If short-circuit or open-circuit state continues for two seconds, an alarm occurs.

Auto-reset: When normal value is confirmed

Hydraulic heat exchanger inlet temperature TWI sensor defect

If short-circuit or open-circuit state continues for two seconds, an alarm occurs.

Auto-reset: When normal value is confirmed

Hydraulic heat exchanger outlet temperature TWO sensor defect

If short-circuit or open-circuit state continues for two seconds, an alarm occurs.

Auto-reset: When normal value is confirmed

EN

–41–

40-EN

Page 42

Hydro Unit

Installation Manual

Alarm

indication

F14

F17

F18

F20

F23

F29

F30

L07

L09

A01

A02

A03 Excessive water temperature increase in the hot water cylinder

A04

A07

A08

A09

A11

Alarm description and generation/reset conditions

Hot water cylinder temperature TTW sensor defect

If short-circuit or open-circuit state continues for two seconds, an alarm occurs.

Auto-reset: When normal value is confirmed

Floor inlet temperature TFI sensor defect

If short-circuit or open-circuit state continues for two seconds, an alarm occurs.

Auto-reset: When normal value is confirmed

Internal heater outlet temperature TWO sensor defect

If short-circuit or open-circuit state continues for two seconds, an alarm occurs.

Auto-reset: When normal value is confirmed

Floor inlet temperature TFI sensor disconnection or wrong installation

(This alarm is reset by stopping operation and is checked again.)

Low-pressure sensor defect

If open-circuit state continues for two seconds, an alarm occurs.

Auto-reset: When normal value is confirmed

Hydraulic heat exchanger EEPROM defect

One mismatch is detected if there is no verification ACK after data write to the EEPROM

Reset condition: This alarm is inhibited while the unit is not working.

(When EEPROM1K is mounted, this alarm cannot be reset.)

Onboard expansion IC defect

This alarm is not reset automatically.

Group line in an hydro unit

This alarm is checked during initial communication immediately after power-on.

This alarm occurs immediately after operation start.

This alarm is not reset automatically. (This alarm is inhibited while the unit is not working, but occurs again after

the unit operates.)

Hydro unit capacity has not been set.

This alarm is checked immediately after power-on.

This alarm is not reset automatically. (This alarm is inhibited while the unit is not working, but occurs again after

the unit operates.)

Pump defect or abnormal flow rate

This alarm is not reset automatically.

Excessive water temperature increase by the heating heater

Auto-reset:

Freezing is detected.

Auto-reset: