Page 1

AIR TO WATER HEAT PUMP

Installation manual

Outdoor Unit

Model name:

HWS-802H-E

HWS-1102H-E

HWS-1402H-E

Installation manual

Air to Water Heat Pump

Manuel d’installation

Pompe à chaleur air/eau

Installations-handbuch

Luft-/Wasserwärmepumpe

Installationshandbok

Luft-till-vatten-värmepump

2

24

46

68

English

Français

Deutsch

Svenska

Page 2

Air to Water Heat Pump

Please read this Installation Manual carefully before installing the Air to Water Heat Pump.

• This Manual describes the installation method of the outdoor unit.

• For installation of the hydro unit, follow the Installation Manual attached to the hydro unit.

Outdoor Unit Installation Manual

ADOPTION OF NEW REFRIGERANT

This Air to Water Heat Pump is a new type which adopts a new refrigerant HFC (R410A) instead of the

conventional refrigerant R22 in order to prevent destruction of the ozone layer.

Contents

1 ACCESSORY PARTS AND REFRIGERANT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2 PRECAUTIONS FOR SAFETY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

3 INSTALLATION OF NEW REFRIGERANT AIR TO WATER HEAT PUMP . . . . . . . . . 5

4 SELECTION OF INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

5 REFRIGERANT PIPING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

6 AIR PURGING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

7 ELECTRICAL WORK . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

8 EARTHING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

9 FINISHING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

10 TEST RUN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

11 ANNUAL MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

12 FUNCTIONS TO BE IMPLEMENTED LOCALLY . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

13 TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

14 APPENDIX . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

1-EN

–2–

Page 3

Air to Water Heat Pump

Outdoor Unit Installation Manual

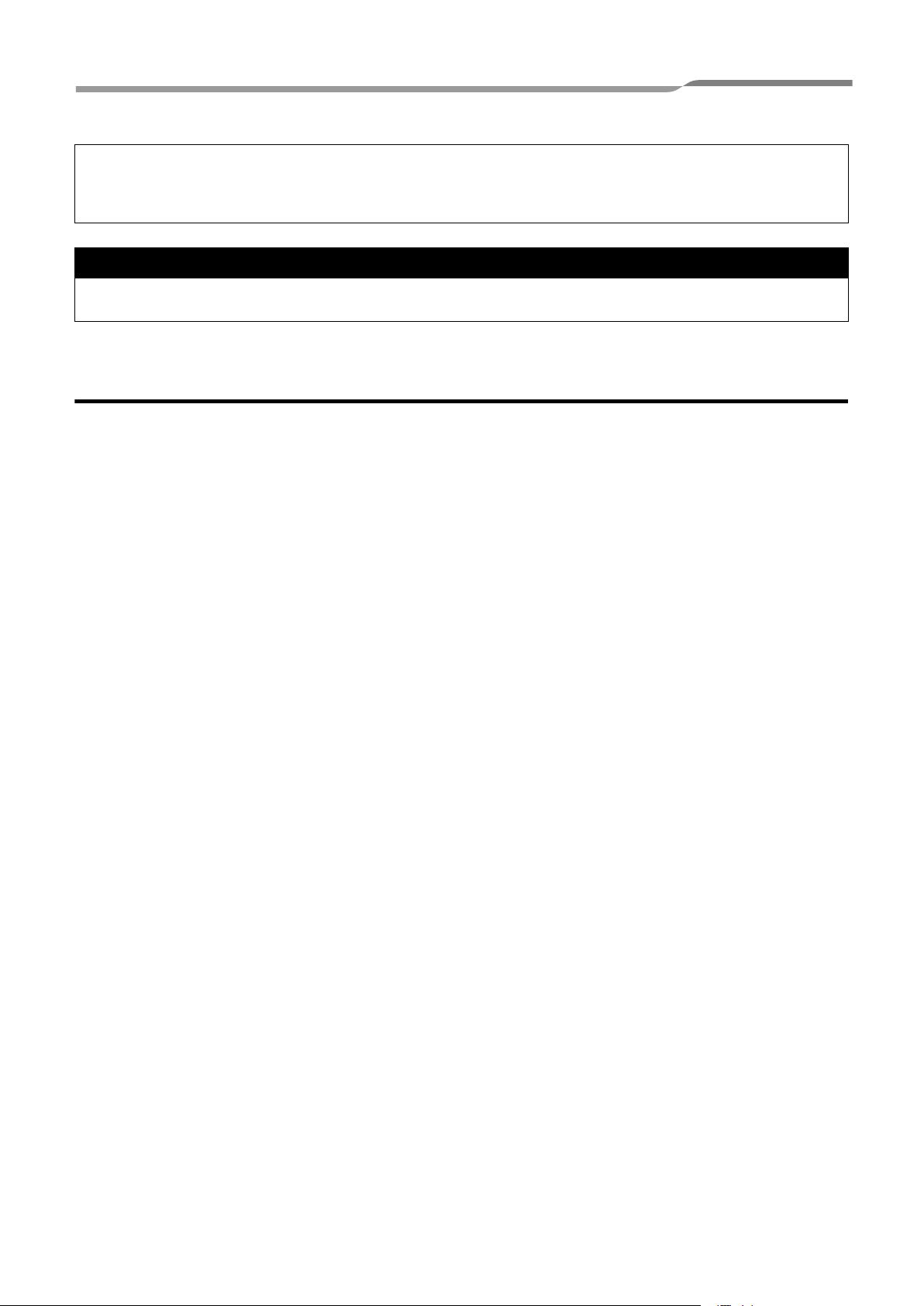

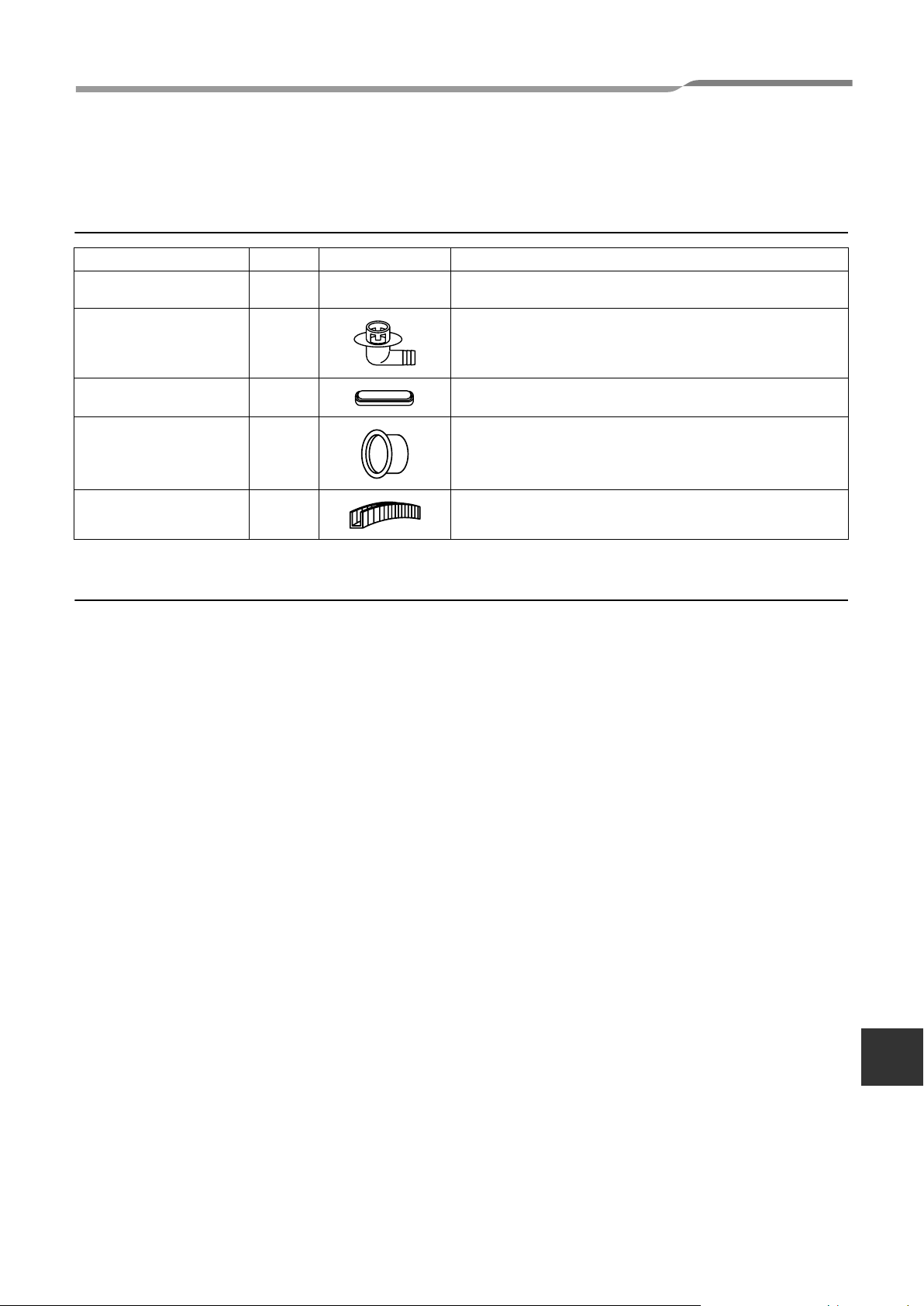

1 ACCESSORY PARTS AND REFRIGERANT

Accessory parts

Part name Q’ty Shape Usage

Outdoor unit

Installation manual

Drain nipple 1

Waterproof rubber cap 5

Protective bush 1 For protecting wires (pipe cover)

1 This manual (Hand this directly to the customer.)

Guard material for passage

part

1 For protecting passage part (pipe cover)

Refrigerant Piping

• Piping kit used for the conventional refrigerant cannot be used.

• Use copper pipe with 0.8 mm or more thickness for Ø9.5 mm.

Use copper pipe with 1.0 mm or more thickness for Ø15.9 mm.

• Flare nut and flare works are also different from those of the conventional refrigerant.

Take out the flare nut attached to the Air to Water Heat Pump, and use it.

–3–

EN

2-EN

Page 4

Air to Water Heat Pump

Outdoor Unit Installation Manual

2 PRECAUTIONS FOR SAFETY

• Ensure that all Local, National and International regulations are satisfied.

• Read this “PRECAUTIONS FOR SAFETY” carefully before Installation.

• The precautions described below include the important items regarding safety.

Observe them without fail.

• After the installation work, perform a trial operation to check for any problem.

Follow the Owner’s Manual to explain how to use and maintain the unit to the customer.

• Turn off the main power supply switch (or breaker) before the unit maintenance.

• Ask the customer to keep the Installation Manual together with the Owner’s Manual.

WARNING

•

Ask an authorized dealer or qualified installation professional to install/maintain the Air to Water Heat Pump.

Inappropriate installation may result in water leakage, electric shock or fire.

• Be sure to connect earth wire. (grounding work)

Incomplete grounding cause an electric shock.

Do not connect ground wires to gas pipes, water pipes, lightning rods or ground wires for telephone wires.

• Turn off the main power supply switch or breaker before attempting any electrical work.

Make sure all power switches are off. Failure to do so may cause electric shock.

Use an exclusive power circuit for the Air to Water Heat Pump. Use the rated voltage.

• Connect the connecting wire correctly.

If the connecting wire is connected in a wrong way, electric parts may be damaged.

• When moving the Air to Water Heat Pump for the installation into another place, be very careful not to enter

any gaseous matter other than the specified refrigerant into the refrigeration cycle.

If air or any other gas is mixed in the refrigerant, the gas pressure in the refrigeration cycle becomes abnormally high

and it may resultingly causes pipe burst and injuries on persons.

• Do not modify this unit by removing any of the safety guards or by by-passing any of the safety interlock

switches.

• After unpacking the unit, examine it carefully if there are possible damage.

• Do not install in a place that might increase the vibration of the unit.

• To avoid personal injury (with sharp edges), be careful when handling parts.

• Perform installation work properly according to the Installation Manual.

Inappropriate installation may result in water leakage, electric shock or fire.

• When the Air to Water Heat Pump hydro unit is installed in a small room, provide appropriate measures to

ensure that the concentration of refrigerant leakage occur in the room does not exceed the critical level.

• Tighten the flare nut with a torque wrench in the specified manner.

Excessive tightening of the flare nut may cause a crack in the flare nut after a long period, which may result in

refrigerant leakage.

• Wear heavy gloves during the installation work to avoid injury.

• Install the Air to Water Heat Pump securely in a location where the base can sustain the weight adequately.

• Perform the specified installation work to guard against an earthquake.

If the Air to Water Heat Pump is not installed appropriately, accidents may occur due to the falling unit.

• If refrigerant gas has leaked during the installation work, ventilate the room immediately.

If the leaked refrigerant gas comes in contact with fire, noxious gas may generate.

• After the installation work, confirm that refrigerant gas does not leak.

If refrigerant gas leaks into the room and flows near a fire source, such as a cooking range, noxious gas might

generate.

• Electrical work must be performed by a qualified electrician in accordance with the Installation Manual. Make

sure the Air to Water Heat Pump uses an exclusive power supply.

An insufficient power supply capacity or inappropriate installation may cause fire.

• Use the specified wires for wiring connect the terminals securely fix.

To prevent external forces applied to the terminals from affecting the terminals.

3-EN

–4–

Page 5

Air to Water Heat Pump

Outdoor Unit Installation Manual

WARNING

• When the Air to Water Heat Pump cannot cool or heat water well, contact the dealer from whom you

purchased the Air to Water Heat Pump as refrigerant leakage is considered as the cause.

In the case of repair that requires refill of refrigerant, ask service personnel about details of the repair.

The refrigerant used in the Air to Water Heat Pump is harmless.

Generally, the refrigerant does not leak. However, if the refrigerant leaks in a room and a heater or stove burner in

the room catches fire, it may generate toxic gas.

When you ask service personnel for repairing refrigerant leakage, confirm that the leakage portion has been

completely repaired.

• Conform to the regulations of the local electric company when wiring the power supply.

Inappropriate grounding may cause electric shock.

• Do not install the Air to Water Heat Pump in a location subject to a risk of exposure to a combustible gas.

If a combustible gas leaks, and stays around the unit, a fire may occur.

• Install the refrigerant pipe securely during the installation work before operating the Air to Water Heat Pump.

If the compressor is operated with the valve open and without the refrigerant pipe, the compressor sucks air and the

refrigeration cycle is overpressurized, which may cause a burst or injury.

• For the refrigerant recovery work (collection of refrigerant from the pipe to the compressor), stop the

compressor before disconnecting the refrigerant pipe.

If the refrigerant pipe is disconnected while the compressor is working with the valve open, the compressor sucks air

and the refrigeration cycle is overpressurized, which may cause a burst or injury.

CAUTION

New Refrigerant Air to Water Heat Pump Installation

• THIS AIR TO WATER HEAT PUMP ADOPTS THE NEW HFC REFRIGERANT (R410A) WHICH DOES NOT

DESTROY OZONE LAYER.

• The characteristics of R410A refrigerant are ; easy to absorb water, oxidizing membrane or oil, and its pressure is

approx. 1.6 times higher than that of refrigerant R22. Accompanied with the new refrigerant, refrigerating oil has also

been changed. Therefore, during installation work, be sure that water, dust, former refrigerant, or refrigerating oil does

not enter the refrigerating cycle.

• To prevent charging an incorrect refrigerant and refrigerating oil, the sizes of connecting sections of charging port of

the main unit and installation tools are changed from those for the conventional refrigerant.

• Accordingly the exclusive tools are required for the new refrigerant (R410A).

• For connecting pipes, use new and clean piping designed for R410A, and please care so that water or dust does not

enter.

To Disconnect the Appliance from Main Power Supply

• This appliance must be connected to the main power supply by means of a switch with a contact separation of at

least 3 mm.

• The installation fuse 25 A (All type fuse can be used) must be used for the power supply line of this unit.

3 INSTALLATION OF NEW REFRIGERANT

AIR TO WATER HEAT PUMP

EN

• The R410A refrigerant is more susceptible to impurities such as water, oxide membrane, oils, and fats. With the

adoption of the new refrigerant, refrigerating oil has also been changed.

Be careful so that water, dust, conventional refrigerant, and/or conventional refrigerating oil do not enter the

refrigerating cycle of the new refrigerant Air to Water Heat Pump.

• To prevent different refrigerant or refrigerating oil being mixed, the sizes of the charging port of the unit and the

installation tool connecting sections are different from the conventional refrigerant. Accordingly the following

exclusive tools are required for the new refrigerant R410A.

–5–

4-EN

Page 6

Air to Water Heat Pump

Outdoor Unit Installation Manual

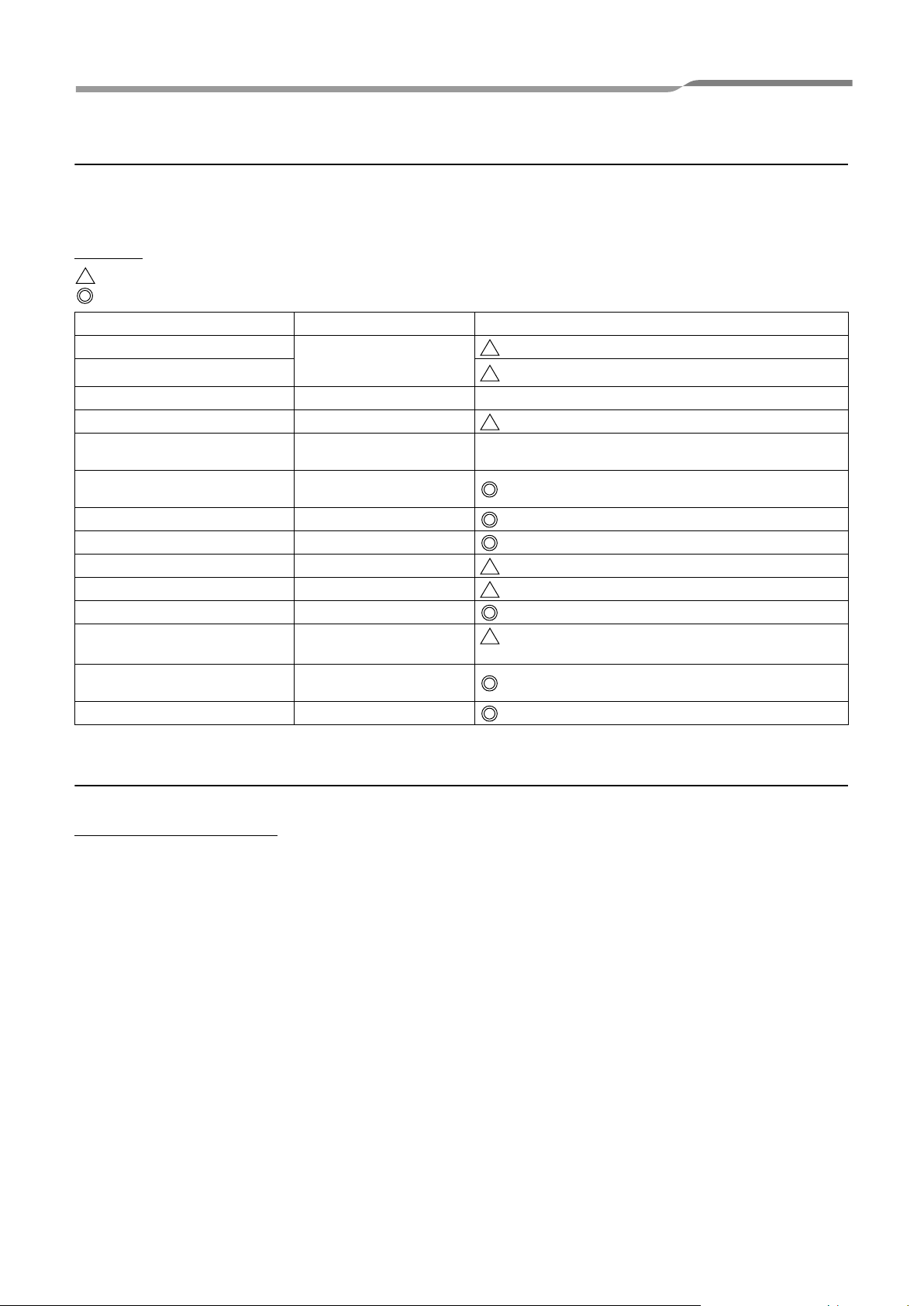

Required Tools/Equipment and Precautions for Use

Prepare the tools and equipment listed in the following table before starting installation work.

Newly prepared tools and equipment must be used exclusively.

Legend

: Prepared newly (Use for R410A only. Do not use for refrigerant R22 or R407C etc..)

: Conventional tools/equipment are available

Tools/equipment Use How to use tools/equipment

Gauge manifold Vacuuming/charging

Charging hose Prepared newly for R410A only

Charging cylinder Can not be used Unusable (Use the refrigerant charging measure instead.)

Gas leak detector Gas leak check Prepared newly

Vacuum pump with backflow

prevention function

Vacuum pump with backflow

prevention function

Flare tool Flare machining of pipes Usable if dimensions are adjusted.

Bender Bending pipes R22 (Conventional tools)

Refrigerant recovery equipment Refrigerant recovery For R410A only

Torque wrench Tightening flare nuts Exclusive for Ø12.7 mm and Ø15.9 mm

Pipe cutter Cutting pipes R22 (Conventional tools)

Refrigerant cylinder Charging refrigerant

Welding machine and nitrogen

cylinder

Refrigerant charging measure Charging refrigerant R22 (Conventional tools)

refrigerant and operation

check

Vacuum drying Unusable

Vacuum drying R22 (Conventional tools)

Welding pipes R22 (Conventional tools)

Prepared newly for R410A only

For R410A only

Discriminated by the refrigerant name on the cylinder.

Refrigerant Piping

New refrigerant (R410A)

When using the conventional piping kit

• When using the conventional piping kit that has no indication of applicable refrigerant types, be sure to use it with

a wall thickness of 0.8 mm for Ø6.4 mm, Ø9.5 mm, and Ø12.7 mm, and with a wall thickness of 1.0 mm for Ø15.9

mm. Never use the conventional piping kit with a wall thickness less than these thicknesses due to insufficient

pressure capacity.

When using general copper pipes

• Use general copper pipes with a wall thickness of 0.8 mm for Ø6.4 mm, Ø9.5 mm, and Ø12.7 mm, and with a

wall thickness of 1.0 mm for Ø15.9 mm.

Never use any copper pipes with a wall thickness less than these thicknesses.

Flare nuts and flare machining

• The flare nuts and flare machining are different from those for the conventional refrigerant.

Use the flare nuts supplied with the Air to Water Heat Pump or those for R410A.

• Before performing flare machining, carefully read “REFRIGERANT PIPING”

5-EN

–6–

Page 7

Air to Water Heat Pump

Outdoor Unit Installation Manual

4 SELECTION OF INSTALLATION

Before installation

Be careful to the following items before installation.

Length of refrigerant pipe

Length of refrigerant

pipe connected to hydro/

outdoor unit

3 m to 30 m

* Do not connect a refrigerant pipe shorter than 3m.

This may cause a malfunction of the compressor or

other devices.

Addition of refrigerant is

unnecessary at the local site.

Item

Airtight test

1. Before starting an airtight test, further tighten the

spindle valves on the gas side and liquid side.

2. Pressurize the pipe with nitrogen gas charged from

the service port to the design pressure (4.15 Mpa) to

conduct the airtight test.

3. After the airtight test is completed, evacuate the

nitrogen gas.

Air purge

• For air purge, use a vacuum pump.

• Do not use refrigerant charged in the outdoor unit for

air purge. (The refrigerant for air purge is not

contained in the outdoor unit.)

Electrical wiring

Be sure to fix the power wires and hydro/outdoor

connecting wires with clamps so that they do not

contact with the cabinet, etc.

Earthing

WARNING

Make sure that proper earthing is provided.

Improper earthing may cause electric shock. For how

to check earthing, contact the dealer who installed the

Air to Water Heat Pump or a professional installation

company.

• Proper earthing can prevent charging of electricity on

the outdoor unit surface due to high frequency of the

frequency converter (inverter) in the outdoor unit, as

well as prevent electric shock. If the outdoor unit is

not properly earthed, you may feel electric shock.

• Be sure to connect earth wire. (grounding work)

Incomplete grounding cause an electric shock.

Do not connect ground wires to gas pipes, water

pipes, lightning rods or ground wires for telephone

wires.

Test Run

• Start test run when the water piping work is

completed and the system is filled with the proper

amount of water.

• Turn on the leakage breaker at least 12 hours before

starting a test run to protect the compressor during

startup.

CAUTION

Incorrect work may result in a malfunction or

complaints of customers.

–7–

EN

6-EN

Page 8

Air to Water Heat Pump

Outdoor Unit Installation Manual

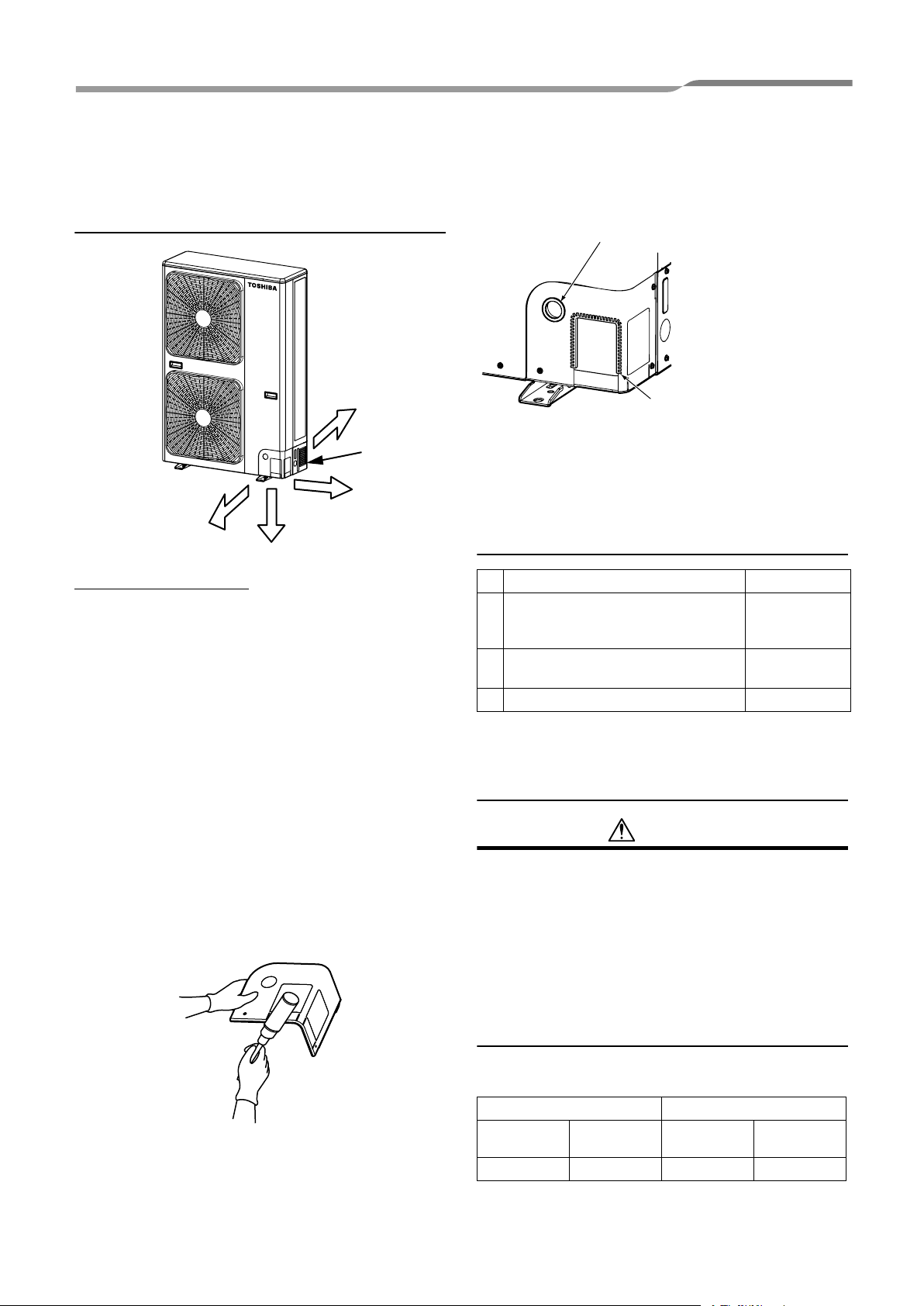

Installation Place

WARNING

Install the outdoor unit properly at a place that is

durable enough to the weight of the outdoor unit.

Insufficient durability may cause the outdoor unit to fall,

which may result in injury.

CAUTION

Do not install the outdoor unit at a place subject to

combustible gas leak.

Accumulation of combustible gas around the outdoor

unit may cause a fire.

Install the outdoor unit at a place that meets the

following conditions after customer’s consent is

obtained.

• A well-ventilated place free from obstacles near the

air inlets and air outlet

• A place that is not exposed to rain or direct sunlight

• A place that does not increase the operating noise or

vibration of the outdoor unit

• A place that does not cause any drainage problem

with discharged water

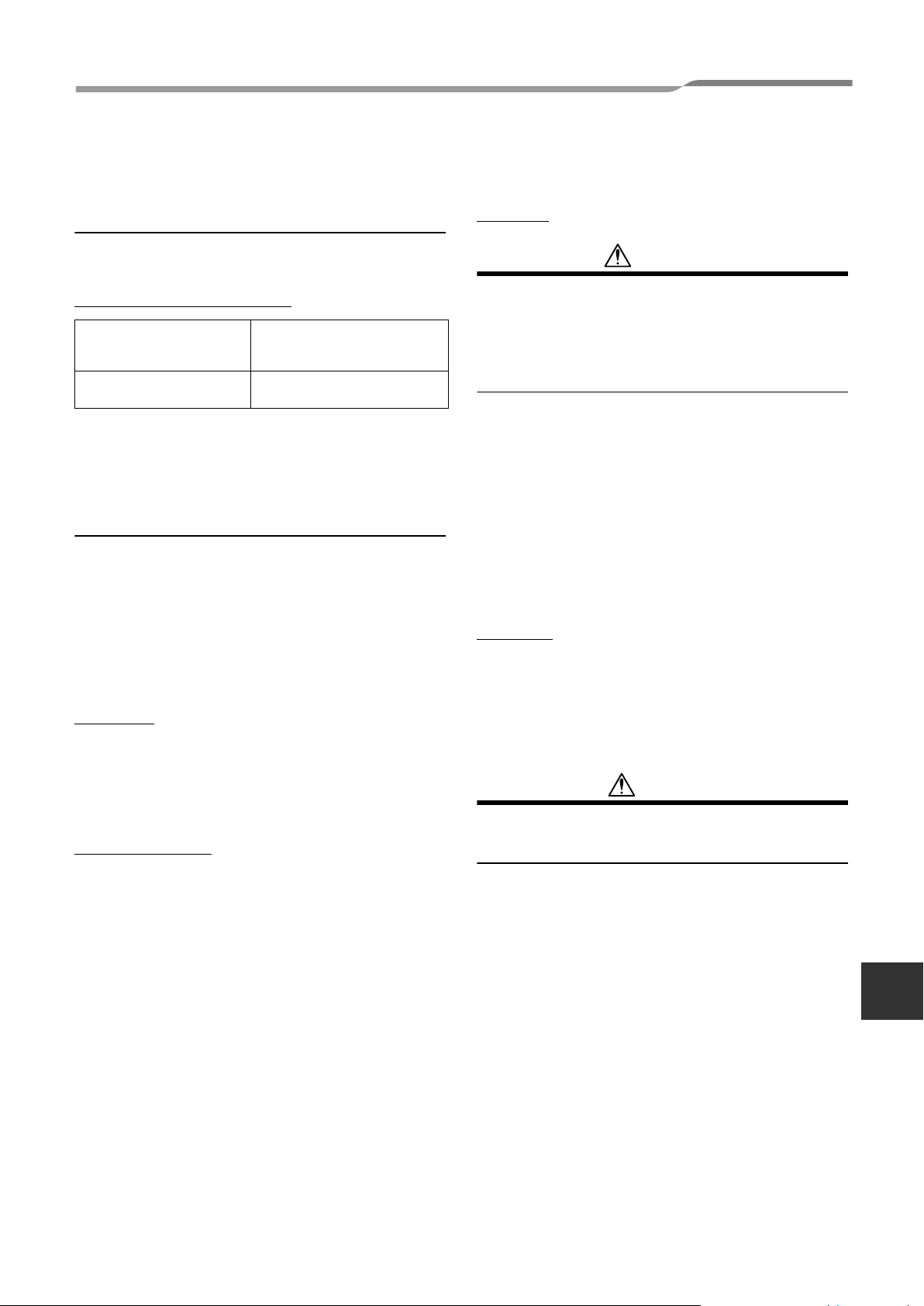

CAUTION

1. Install the outdoor unit at a place where

discharge air is not blocked.

2. When an outdoor unit is installed in a place that

is always exposed to a strong wind like a coast

or on a high storey of a building, secure a

normal fan operation by using a duct or a wind

shield.

3. When installing the outdoor unit in a place that

is constantly exposed to a strong wind such as

the upper stairs or rooftop of a building, apply

the windproof measures referring to the

following examples.

1) Install the unit so that its discharge port faces

to the wall of the building.

Keep a distance 500 mm or more between the

unit and the wall surface.

500

Do not install the outdoor unit at the following

places.

• A place full of saline atmosphere (coastal area) or

sulfide gas (hot-spring area)

(Special maintenance is required.)

• A place subject to oil, vapor, oily smoke, or corrosive

gas

• A place where organic solvent is used

• A place where high-frequency equipment (including

inverter equipment, private power generator,

medical equipment, and communication equipment)

is used

(Installation in this place may cause malfunction of

the Air to Water Heat Pump, abnormal control or

problems due to noise to such equipment.)

• A place where the discharged air of the outdoor unit

blows against the window of the neighboring house

• A place where the operating noise of the outdoor unit

is transmitted

• When the outdoor unit is installed in an elevated

position, be sure to secure its feet.

• A place where the drain water does not make any

problem.

2) Supposing the wind direction during the

operation season of the Air to Water Heat

Pump, install the unit so that the discharge port

is set at right angle to the wind direction.

Strong

Strong

wind

• When using an Air to Water Heat Pump under low

outside temperature condition (Outside temp.:-5 °C or

lower) with COOL mode, prepare a duct or wind shield

so that it is not affected by the wind.

<Example>

Wind shield

wind

Wind shield

Wind shield

7-EN

–8–

Page 9

Air to Water Heat Pump

Outdoor Unit Installation Manual

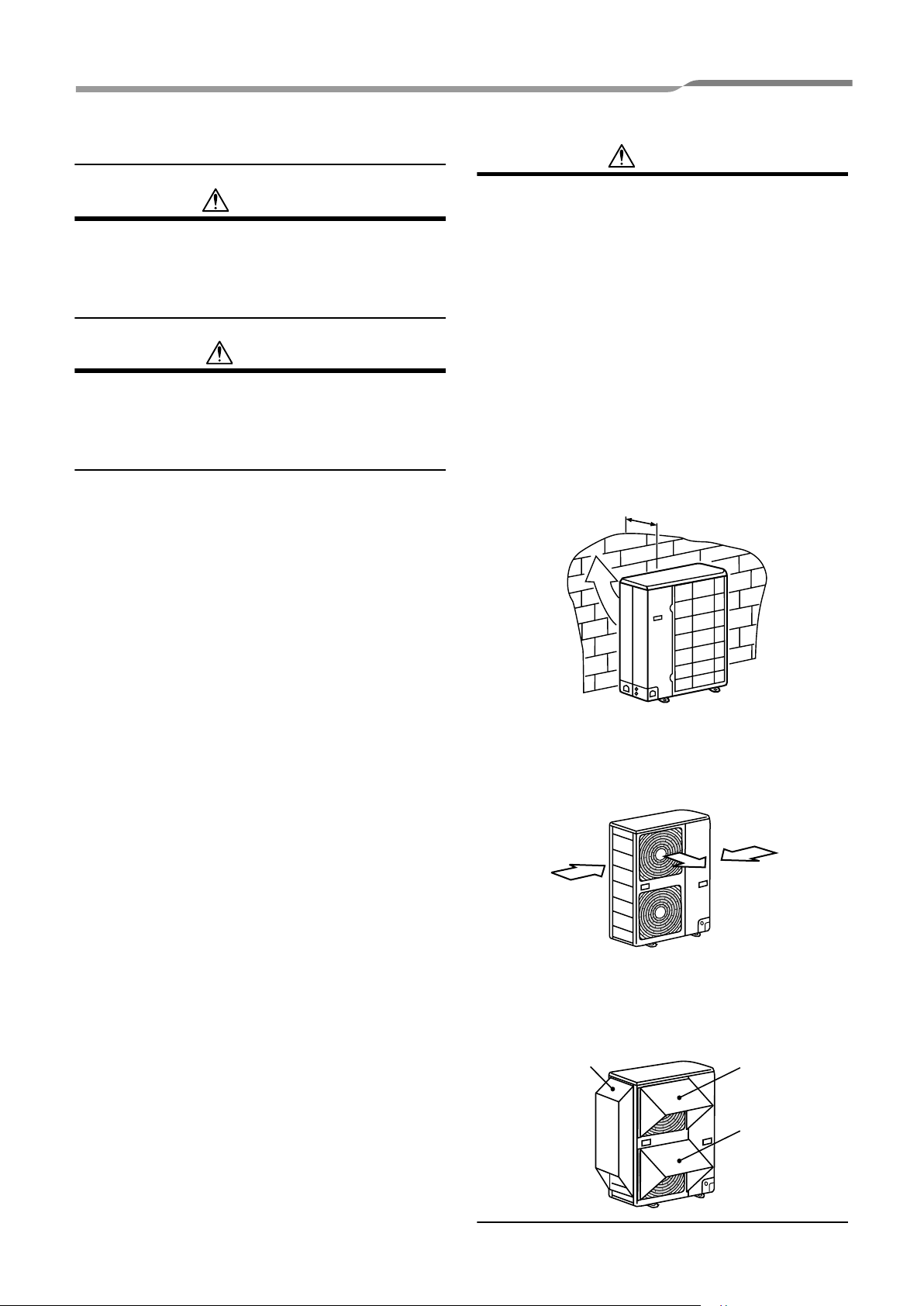

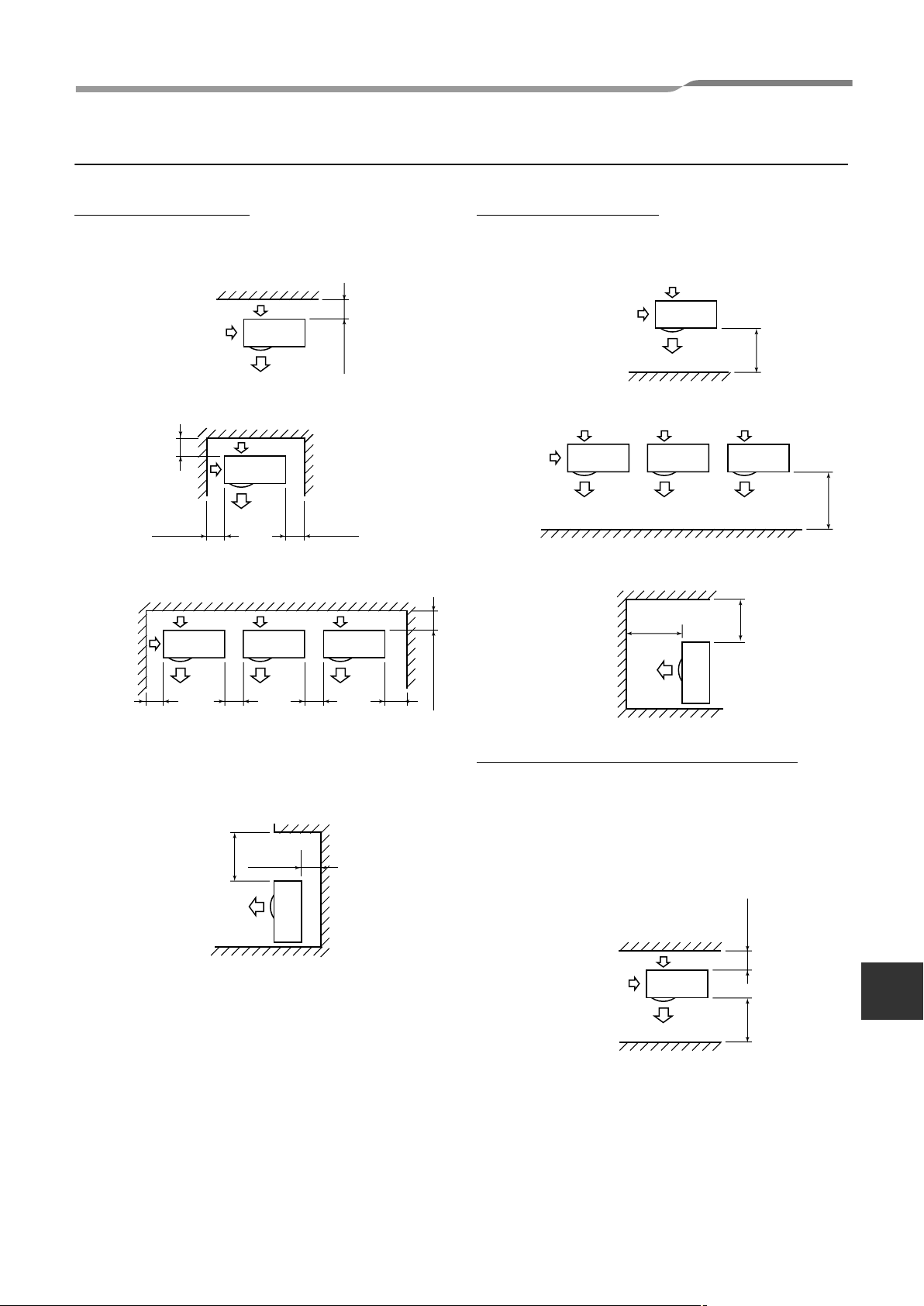

Necessary Space for Installation (Unit:mm)

Obstacle at rear side

▼ Upper side is free

1. Single unit installation

150

2. Obstacles at both right and left sides

200

or more

150

or more

3. Serial installation of two or more units

The height of the

obstacle should be

lower than the height

of the outdoor unit.

300

or more

or more

Obstacle at front side

▼ Upper side is free

1. Single unit installation

2. Serial installation of two or more units

▼ Obstacle also at the upper side

1000

or more

1000

or more

500

or more

1000

or more

150

or more

The height of the obstacle should be lower

than the height of the outdoor unit.

300

or more

300

or more

▼ Obstacle also at the upper side

150

or more

500

or more

300

or more

200 or more

Obstacles at both front and rear sides

Open the upper side and both right and left sides.

The height of obstacle at both front and rear side,

should be lower than the height of the outdoor unit.

▼ Standard installation

1. Single unit installation

150

or more

EN

1000

or more

–9–

8-EN

Page 10

Air to Water Heat Pump

Outdoor Unit Installation Manual

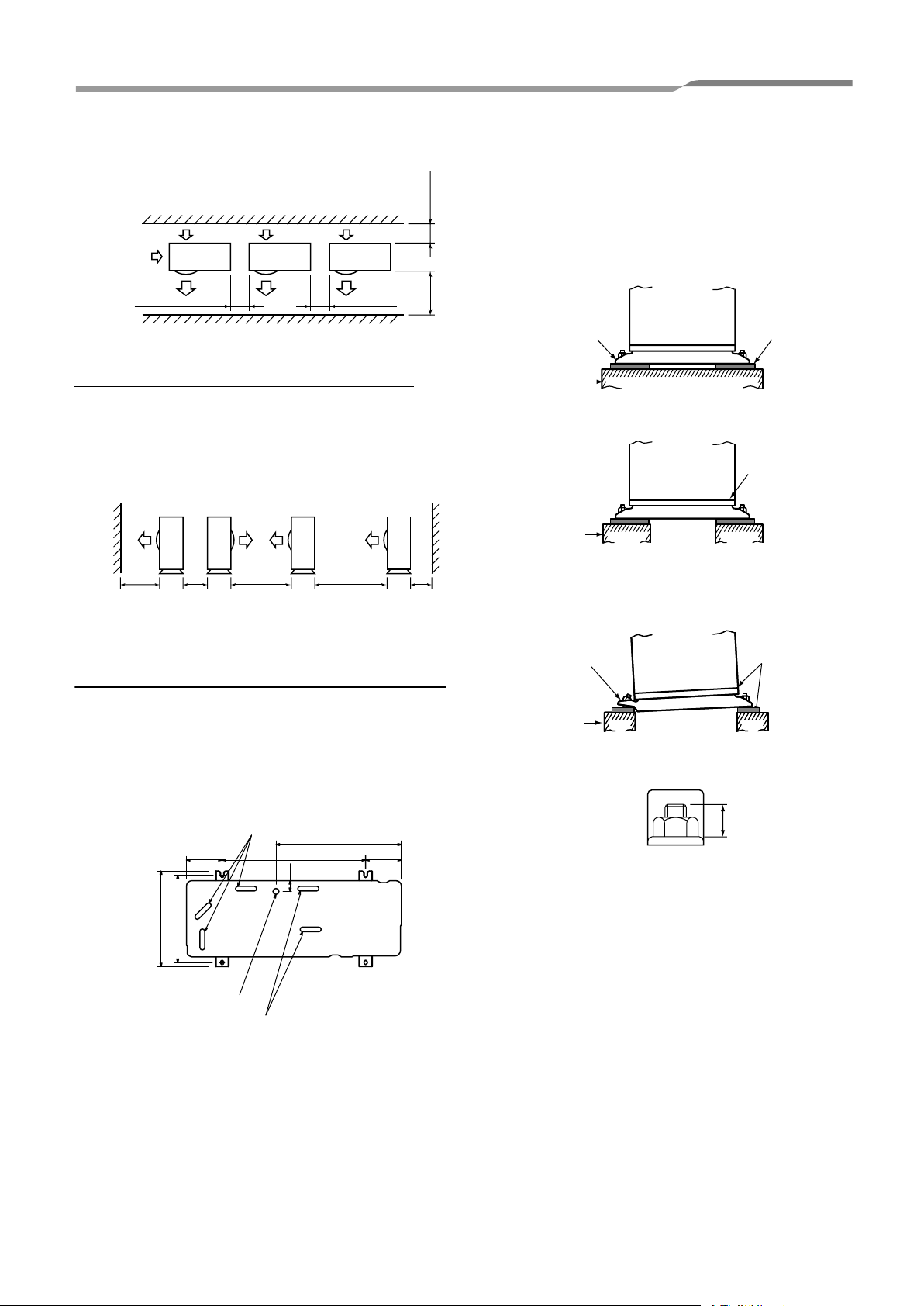

2. Serial installation of two or more units

300

or more

300

or more

Serial installation at front and rear sides

Open the upper side and both right and left sides.

The height of obstacle at both front and rear sides

should be lower than the height of the outdoor unit.

▼ Standard installation

1000

or more

300

or more

1500

or more

2000

or more

or more

Installation of Outdoor Unit

200

1000

200

• As shown in the figure below, install the foundation

and vibration-proof rubbers to directly support the

bottom surface of the fixing leg that is in contact with

or more

the bottom plate of the outdoor unit.

* When installing the foundation for an outdoor unit

with downward piping, consider the piping work.

GOOD

or more

Fixing leg

Foundation

Absorb vibration

with vibration-

proof rubbers

GOOD

Bottom plate

of outdoor unit

Foundation

Support the bottom surface of

the fixing leg in contact with

the bottom plate of the outdoor

unit.

If only the end of the

fixing leg is

supported, it may be

deformed.

NO GOOD

Do not support

the outdoor unit

only with the

fixing leg.

• Before installation, check strength and horizontality

of the base so that abnormal sound does not

generate.

• According to the following base diagram, fix the base

firmly with the anchor bolts.

(Anchor bolt, nut: M10 x 4 pairs)

150

400

365

Drain

nipple mounting hole

Drain hole

Drain hole

525

600

45

150

Foundation

Set the out margin of the anchor bolt to 15 mm or less.

15 or less

9-EN

–10–

Page 11

Air to Water Heat Pump

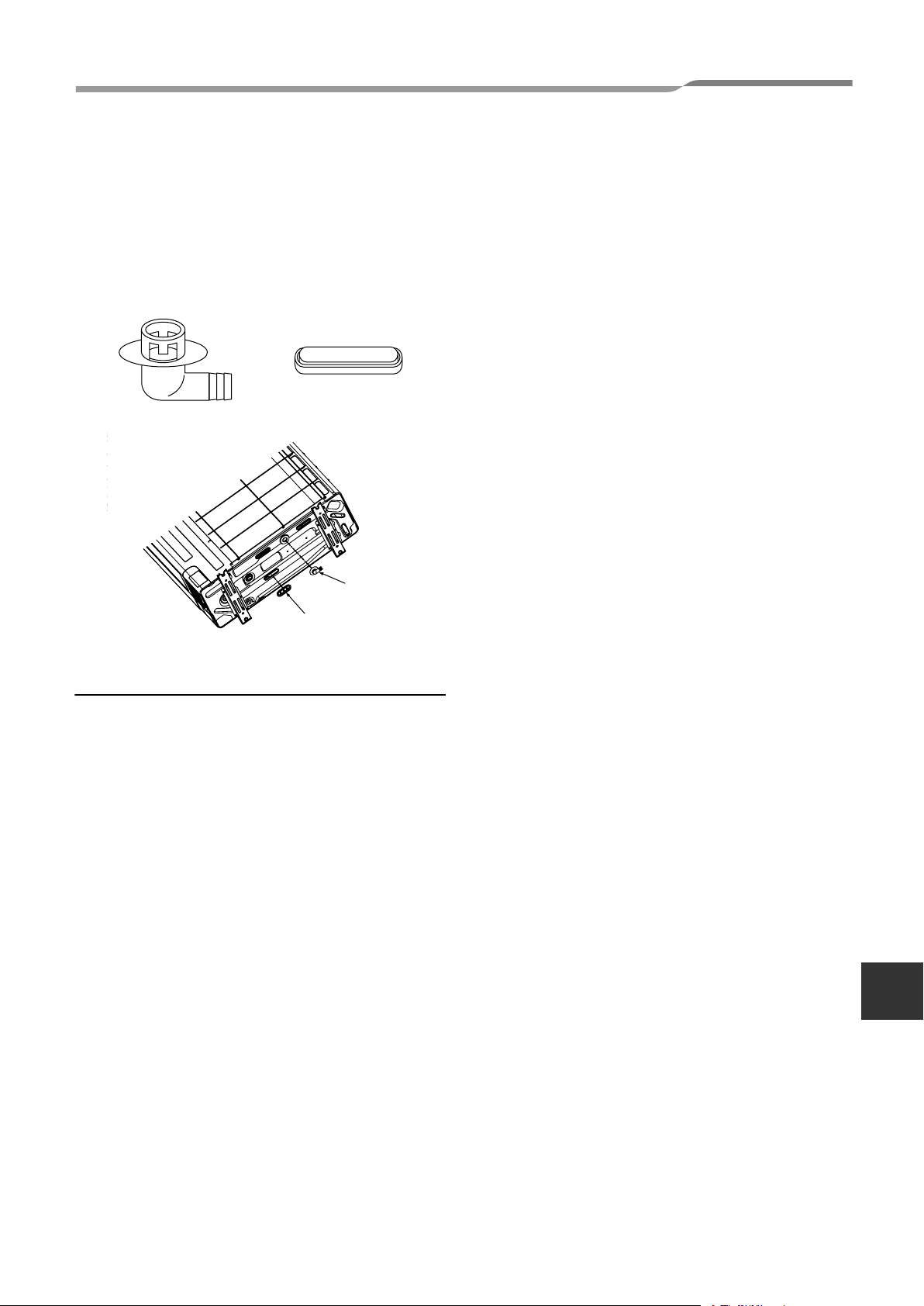

• In case of draining through the drain hose, attach the

following drain nipple and the waterproof rubber cap,

and use the drain hose (Inner diam.: 16 mm) sold on

the market. And also seal the screws securely with

silicone material, etc. so that water does not drop

down. Some conditions may cause dewing or

dripping of water.

• When collectively draining discharged water

completely, a drain pan must be made locally.

Outdoor Unit Installation Manual

Drain nipple

Waterproof rubber cap

(5pcs.)

Drain nipple

Waterproof rubber cap

For Reference

If a heating operation would be continuously performed

for a long time under the condition that the outdoor

temperature is 0 °C or lower, draining of defrosted

water may be difficult due to freezing of the bottom

plate, resulting in a trouble of the cabinet or fan.

It is recommended to procure an anti-freeze heater

locally for a safety installation of the Air to Water Heat

Pump.

For details, contact the dealer.

–11–

EN

10-EN

Page 12

Air to Water Heat Pump

5 REFRIGERANT PIPING

Outdoor Unit Installation Manual

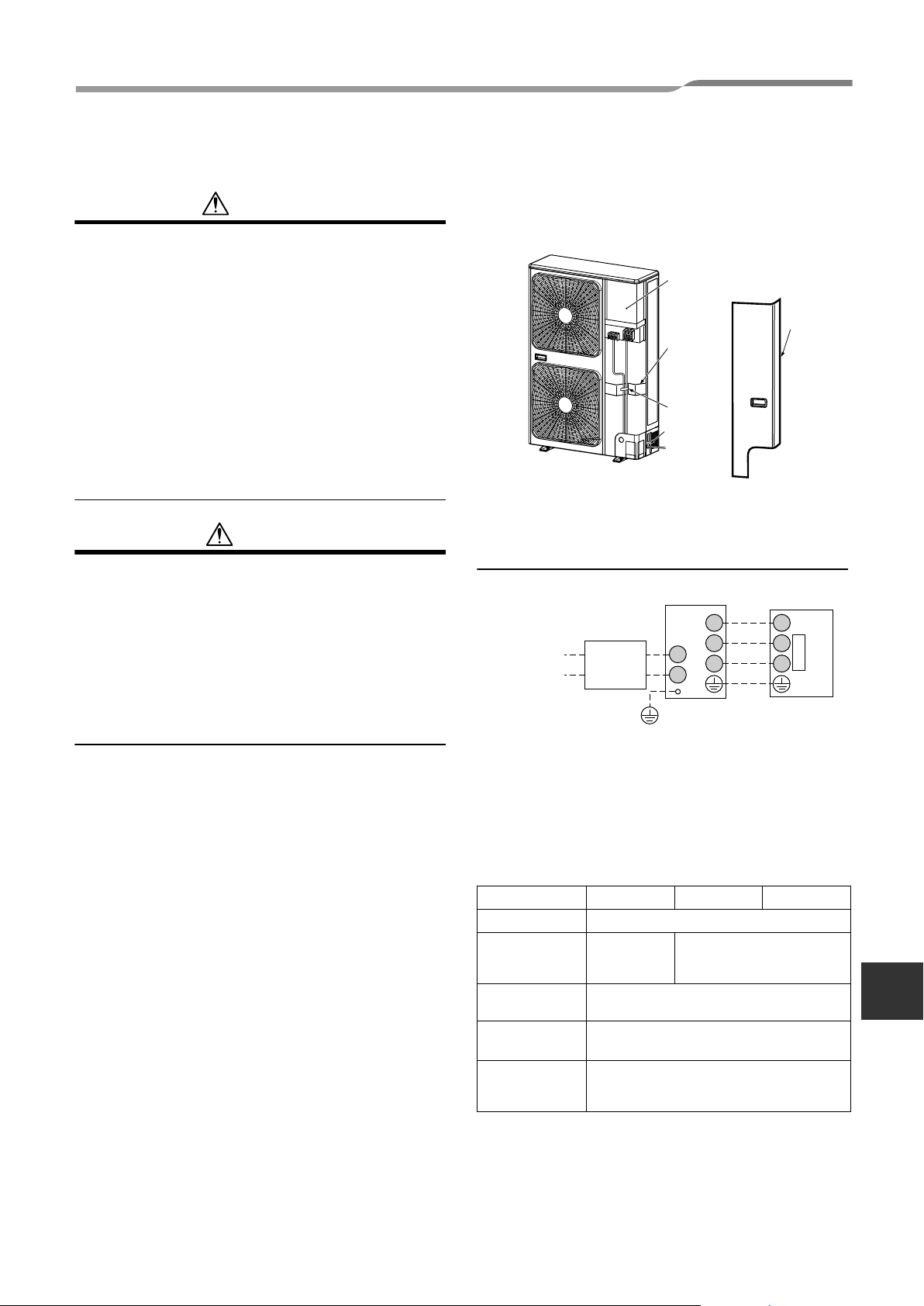

Knockout of Pipe Cover

Rear direction

Pipe cover

Side direction

Front direction

Down direction

Knockout procedure

• The hydro/outdoor connecting pipes can be

connected to 4 directions.

Take off the knockout part of the pipe cover in which

pipes or wires pass through the base plate.

• Detach the piping cover and give an impact on the

knockout section a few times with the shank of a

screwdriver. A knockout hole can easily be punched.

Supplied protective bush

Supplied passage hole guard

material

* Attach the guard material

securely so that it does not

come loose.

Optional Installation Parts

(Local Procure)

Parts name Q’ty

Refrigerant piping

A

Liquid side : Ø9.5 mm

Gas side : Ø15.9 mm

Pipe insulating material

B

(polyethylene foam, 10 mm thick)

C Putty, PVC tapes Each one

Each one

1

• After punching the knockout hole, remove burrs of

the hole and then install the supplied protective bush

and guard material for passage part to protect wires

and pipes.

Be sure to attach the pipe covers after pipes have

been connected. Cut the slits under the pipe covers

to facilitate the installation.

After connecting the pipes, be sure to mount the pipe

cover. The pipe cover is easily mounted by cutting off

the slit at the lower part of the pipe cover.

* Be sure to wear heavy work gloves while working.

Refrigerant Piping

Connection

CAUTION

TAKE NOTICE THESE IMPORTANT

4 POINTS BELOW FOR PIPING WORK

1. Keep dust and moisture away from inside the

connecting pipes.

2. Tightly connect the connection between pipes

and the unit.

3. Evacuate the air in the connecting pipes using

VACUUM PUMP.

4. Check gas leak at connected points.

▼ Piping connection

Liquid side Gas side

Outer

diameter

Ø9.5 mm 0.8 mm Ø15.9 mm 1.0 mm

Thickness

Outer

diameter

Thickness

11-EN

–12–

Page 13

Air to Water Heat Pump

Outdoor Unit Installation Manual

Flaring

1. Cut the pipe with a pipe cutter.

Be sure to remove burrs that may cause gas

leak.

2. Insert a flare nut into the pipe, and then flare the

pipe.

Use the flare nuts supplied with the Air to Water

Heat Pump or those for R410A.

Insert a flare nut into the pipe, and flare the pipe.

As the flaring sizes of R410A differ from those of

refrigerant R22, the flare tools newly manufactured

for R410A are recommended.

However, the conventional tools

can be used by adjusting

projection margin of the copper

pipe.

▼ Projection margin in flaring : B (Unit : mm)

Rigid (Clutch type)

Outer diam. of

copper pipe

15.9

R410A tool used

R410A

0 to 0.5

▼ Flare nut width: H and flare matching size: A.

Flare nut width: H

Copper pipe

outer diam.

H

For R410A 17 22 26 29 36

Ø6.4 Ø9.5 Ø12.7 Ø15.9 Ø19.0

Conventional

tool used

1.0 to 1.59.5

(mm)

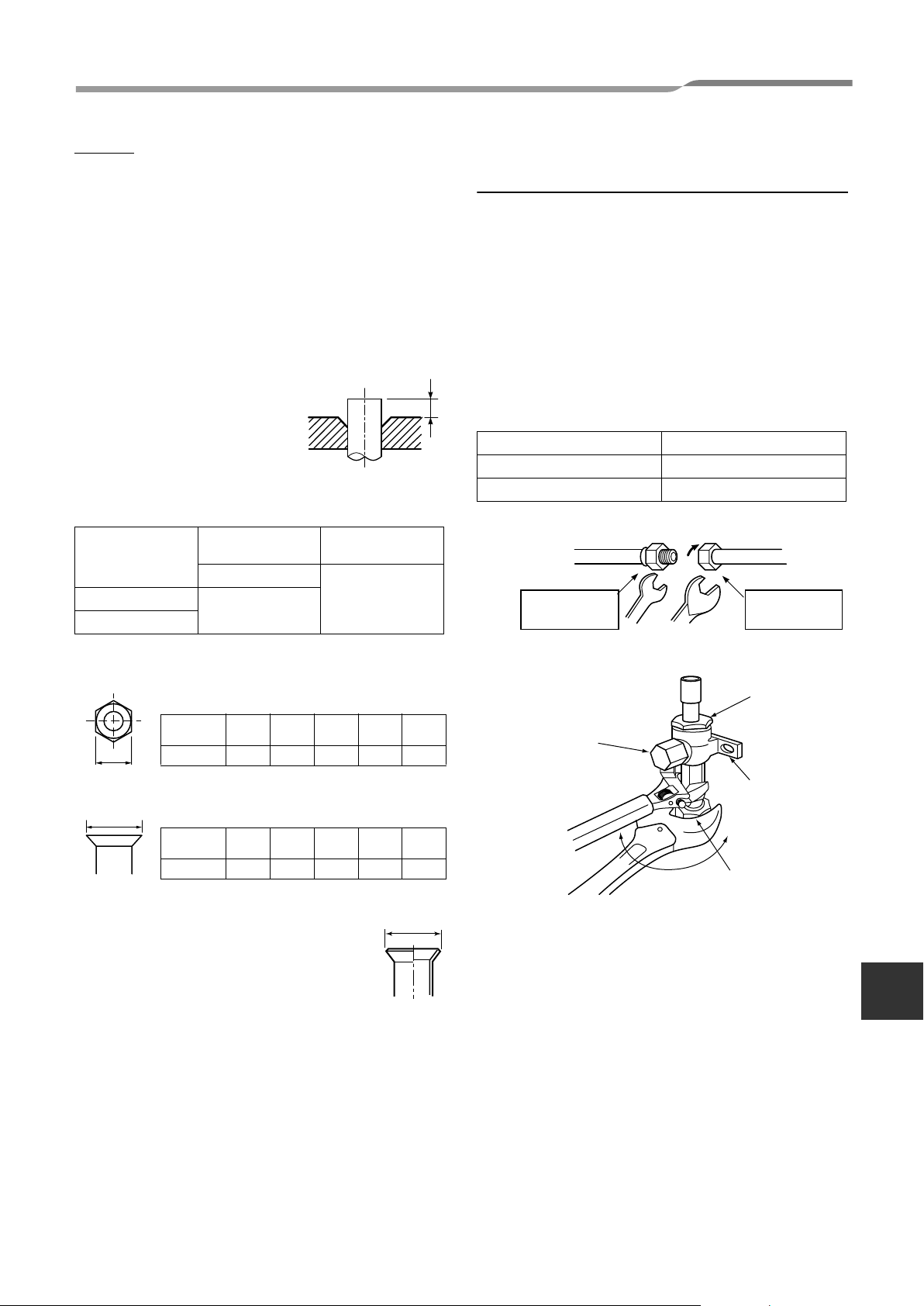

Tightening of Connecting

Part

1. Align the centers of the connecting pipes and fully

tighten the flare nut with fingers. Then fix the nut with

a spanner as shown in the figure and tighten it with

a torque wrench.

2. As shown in the figure, be sure to use two spanners

to loosen or tighten the flare nut of the valve on the

gas side. If you use a single spanner, the flare nut

cannot be tightened to the required tightening

torque.

B

On the other hand, use a single spanner to loosen or

tighten the flare nut of the valve on the liquid side.

Outer diam. of copper pipe Tightening torque

9.5 mm (diam.) 33 to 42 (3.3 to 4.2 kgf•m)

15.9 mm (diam.) 68 to 82 (6.8 to 8.2 kgf•m)

Half union or packed valve Flare nut

Externally

threaded side

Fix with spanner. Tighten with torque wrench.

Cover

Cap

(Unit: N•m)

Internally

threaded side

Flare machining size: A

A

Copper pipe

outer diam.

For R410A 9.1 13.2 16.6 19.7 24.0

Ø6.4 Ø9.5 Ø12.7 Ø15.9 Ø19.0

A +0, -0.4 (mm)

Do not apply the refrigerator oil to the flare surface.

* In case of flaring for R410A with the

A

conventional flare tool, pull it out approx.

0.5 mm more than that for R22 to adjust

to the specified flare size.

The copper pipe gauge is useful for

adjusting projection margin size.

Piping valve

Loosened

Tightened

Flare nut

Valve at gas side

EN

–13–

12-EN

Page 14

Air to Water Heat Pump

Outdoor Unit Installation Manual

CAUTION

1. Do not put the spanner on the cap or cover.

The valve may be broken.

2. If applying excessive torque, the nut may be

broken according to some installation

conditions.

• After the installation work, be sure to check gas leak

of connecting part of the pipes with nitrogen.

NO GOOD

Cover

Cap

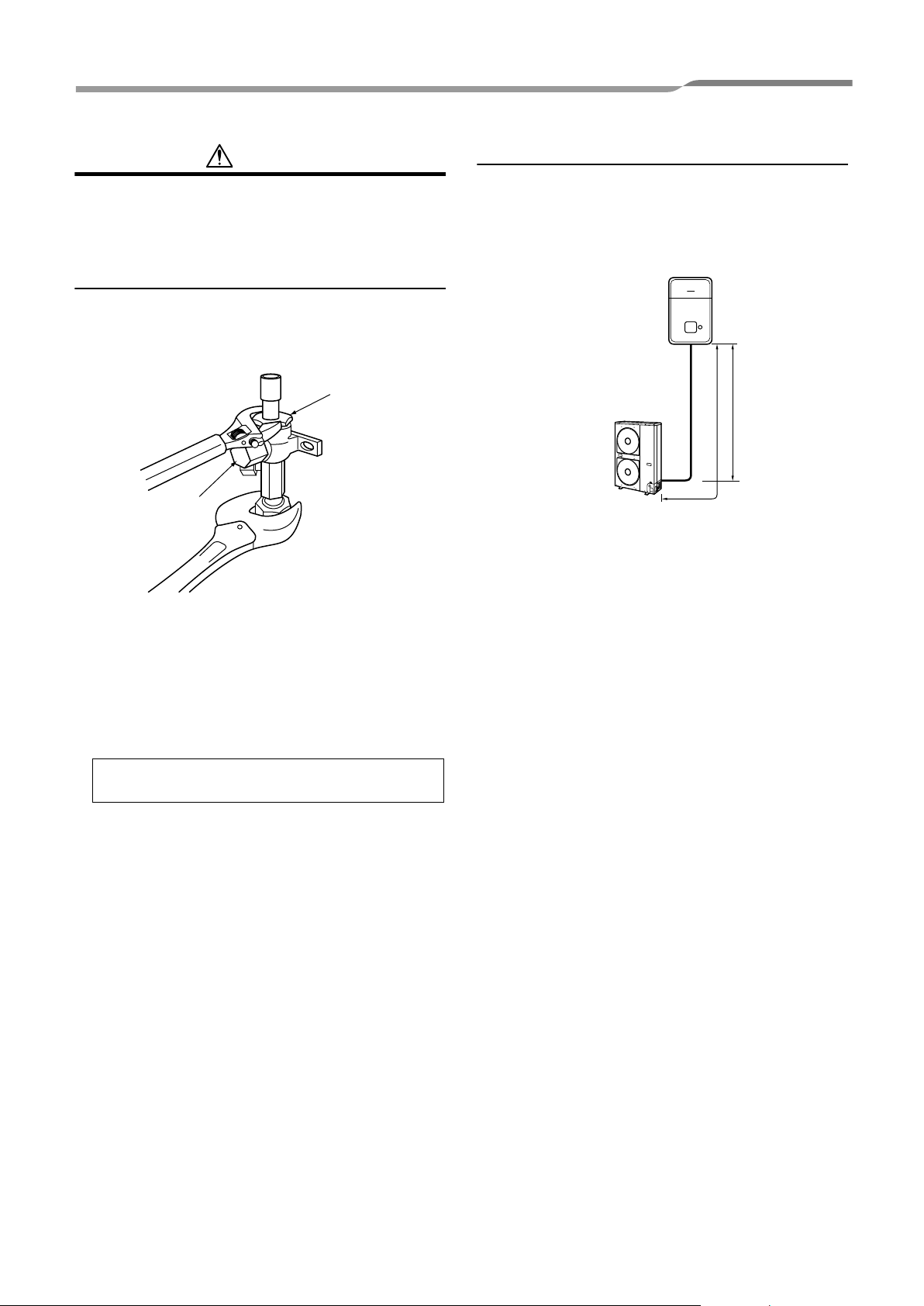

Refrigerant Pipe Length

Refrigeration pipe

H: max. ±30 m (above/below)

L: max. 30 m, min. 3 m

Hydro Unit

Outdoor unit

L

H

30 m chargeless

• Pressure of R410A is higher than that of R22

(Approx. 1.6 times).

Therefore, using a torque wrench, tighten the flare

pipe connecting sections which connect the hydro/

outdoor units at the specified tightening torque.

Incomplete connections may cause not only a gas

leak, but also a trouble of the refrigeration cycle.

Do not apply refrigerating machine oil to the

flared surface.

13-EN

–14–

Page 15

Air to Water Heat Pump

Outdoor Unit Installation Manual

6 AIR PURGING

Airtight test

Before starting an airtight test, further tighten the spindle valves on the gas side and liquid side.

Pressurize the pipe with nitrogen gas charged from the service port to the design pressure (4.15 Mpa) to conduct

the airtight test.

After the airtight test is completed, evacuate the nitrogen gas.

Air Purge

With respect to the preservation of terrestrial environment, adopt “Vacuum pump” for air purge

(Evacuate air in the connecting pipes) when installing the unit.

• Do not discharge the refrigerant gas to the atmosphere to preserve the terrestrial environment.

• Use a vacuum pump to discharge the air (nitrogen, etc.) remained in the set. If the air remains,

the capacity may decrease.

For the vacuum pump, be sure to use one with backflow preventer so that the oil in the pump

does not backflow into the pipe of the Air to Water Heat Pump when the pump stops.

(If oil in the vacuum pump is put in an Air to Water Heat Pump including R410A, it may cause trouble on the

refrigeration cycle.)

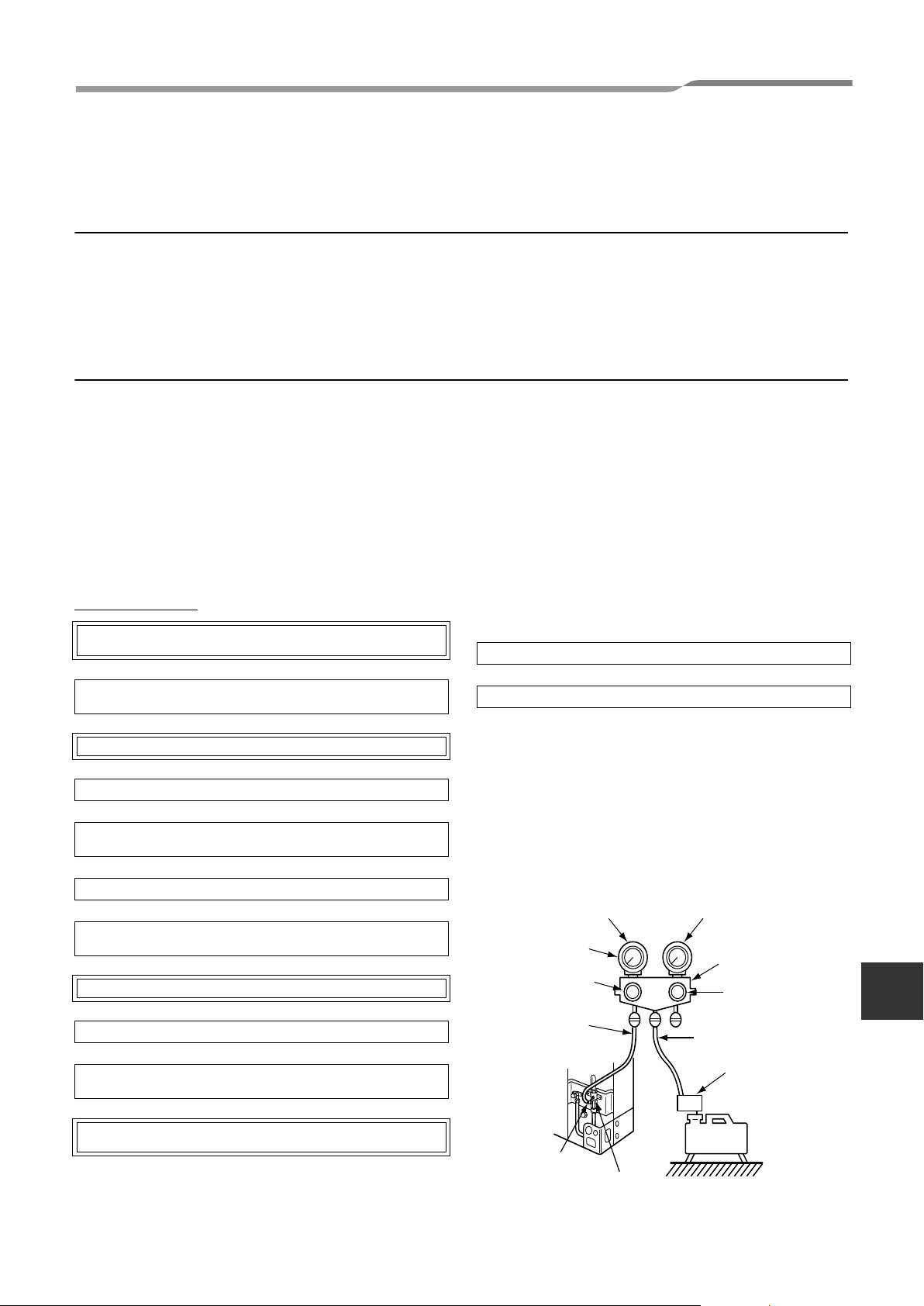

Vacuum pump

As shown in the figure, connect the charge hose after the manifold

valve are closed completely.

È

Attach the connecting port of the charge hose with a projection to

push the valve core (setting pin) to the charge port of the set.

È

Open handle Low fully.

È

Turn ON the vacuum pump (*1)

È

Loosen the flare nut of the packed valve (Gas side) a little to check

the air passes through. (*2)

È

Tighten the flare nut again.

È

Execute vacuuming until the compound pressure gauge indicates –

101kPa (–76cmHg). (*1)

È

Close handle Low completely.

È

Turn OFF the vacuum pump.

È

Leave the vacuum pump as it is for 1 or 2 minutes, and check the

indicator of the compound pressure gauge does not return.

È

Open fully the valve stem or the valve handle. (First, at liquid side,

then gas side)

È

(continued)

Disconnect the charge hose from the charge port.

Tighten valve and caps of the charge port surely.

È

È

*1Use the vacuum pump, vacuum pump adapter, and

gauge manifold correctly referring to the manuals

supplied with each tool before using them.

Check that the vacuum pump oil is filled up to the

specified line of the oil gauge.

2

*

When air is not charged, check again whether the

connecting port of the discharge hose, which has a

projection to push the valve core, is firmly connected

to the charge port.

Compound pressure gauge

–101 kPa

(–76 cmHg)

Handle Lo

Charge hose

(For R410A only)

Charge port

(Valve core

(Setting pin))

Packed valve

at gas side

Pressure gauge

Gauge manifold

valve

Handle Hi

(Keep fully

closed)

Charge hose

(For R410A only)

Vacuum pump

adapter for

counter-flow

prevention

(For R410A only)

Vacuum

pump

EN

–15–

14-EN

Page 16

Air to Water Heat Pump

Outdoor Unit Installation Manual

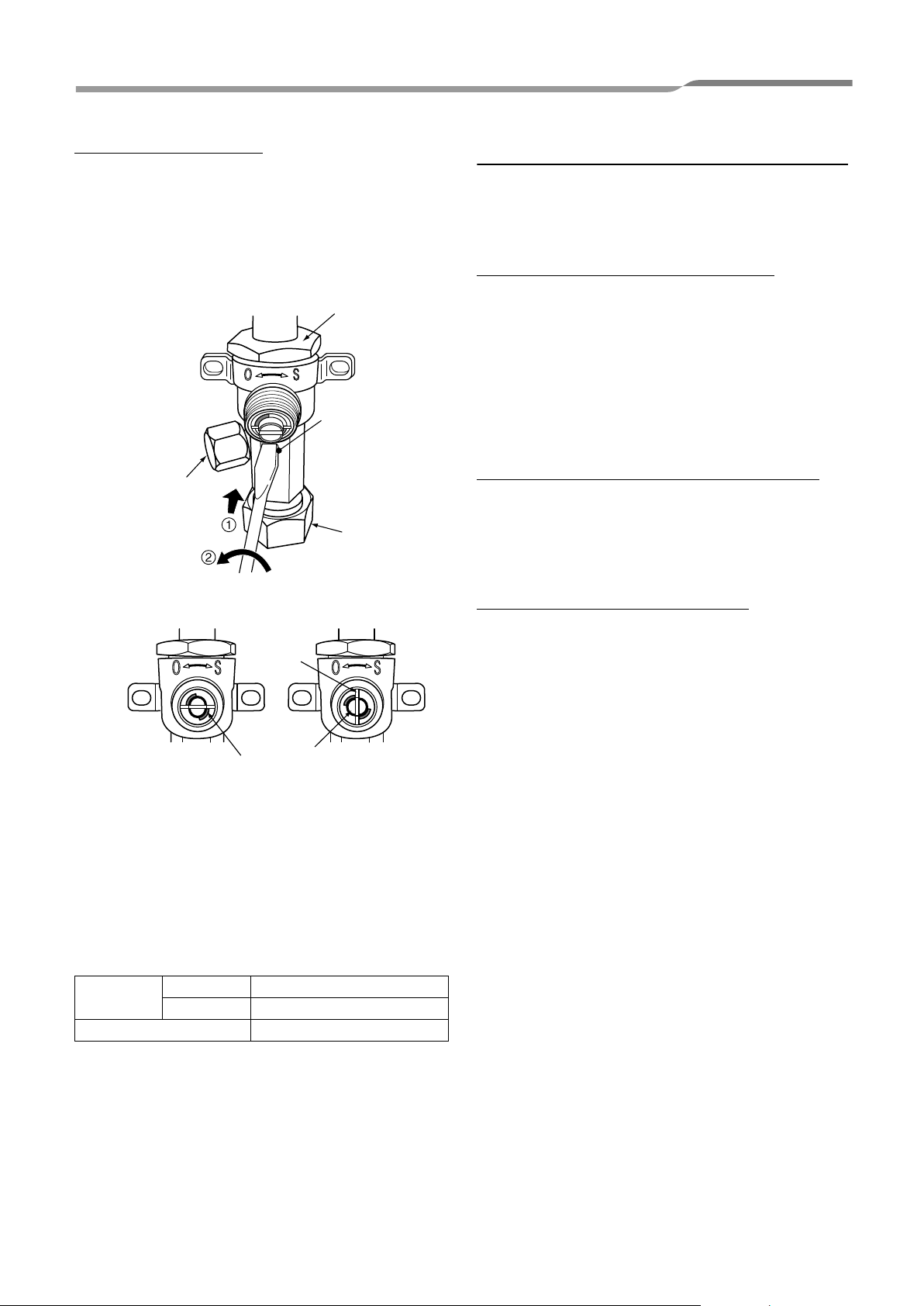

How to open the valve

Confirm the structure surely and then open or close the

valve.

▼ Liquid side

Open the valve with a 4-mm hexagon wrench.

▼ Gas side

Valve unit

Using a minus

screwdriver, turn it

counterclockwise by

90° until it hits the

stopper. (Full open)

Charge port

Flare nut

Replenishing refrigerant

This model is a 30 m chargeless type that does not

need to replenish refrigerant for refrigerant pipes up to

30 m.

Refrigerant replenishing procedure

1. After the vacuuming of the refrigerant pipe is

completed, close the valves and then charge

refrigerant while the Air to Water Heat Pump is not

working.

2. When the refrigerant cannot be charged to the

specified amount, charge the required amount of

refrigerant from the charge port of the valve on the

gas side during cooling.

Requirement for replenishing refrigerant

Replenish liquid refrigerant.

When gaseous refrigerant is replenished, the

refrigerant composition varies, which disables normal

operation.

Handle position

Closed completely Opened fully

Stopper pin

Main stopper

Movable part of valve (Stem)

• While the valve is fully opened, after the screwdriver

has reached the stopper, do not apply torque

exceeding 5N•m. Applying excessive torque may

damage the valve.

Valve handling precautions

• Open the valve stem until it strikes the stopper.

It is unnecessary to apply further force.

• Securely tighten the cap with a torque wrench.

• Cap tightening torque

Valve size

Charge port 14 to 18 N•m (1.4 to 1.8 kgf•m)

Ø9.5 mm 33 to 42 N•m (3.3 to 4.2 kgf•m)

Ø15.9 mm 20 to 25 N•m (2.0 to 2.5 kgf•m)

Additional amount of refrigerant

The refrigerant need not be reduced for a 30 meter (or

less) refrigerant pipe.

15-EN

–16–

Page 17

Air to Water Heat Pump

7 ELECTRICAL WORK

Outdoor Unit Installation Manual

WARNING

1. Using the specified wires, ensure to connect the

wires, and fix wires securely so that the external

tension to the wires do not affect the connecting

part of the terminals.

Incomplete connection or fixation may cause a fire,

etc.

2. Be sure to connect earth wire. (grounding work)

Incomplete grounding cause an electric shock.

Do not connect ground wires to gas pipes, water

pipes, lightning rods or ground wires for telephone

wires.

3. Appliance shall be installed in accordance with

national wiring regulations.

Capacity shortage of power circuit or incomplete

installation may cause an electric shock or a fire.

CAUTION

• Wrong wiring may cause a burn-out to some electrical

parts.

• Be sure to use the cord clamps attached to the

product.

• Do not damage or scratch the conductive core and

inner insulator of power and inter-connecting wires

when peeling them.

• Use the power and Inter-connecting wires with

specified thickness, specified type and protective

devices required.

Furthermore, be sure to secure these wires with the

pipe valve fixing plate and cord clamps stored in the

electric parts box.

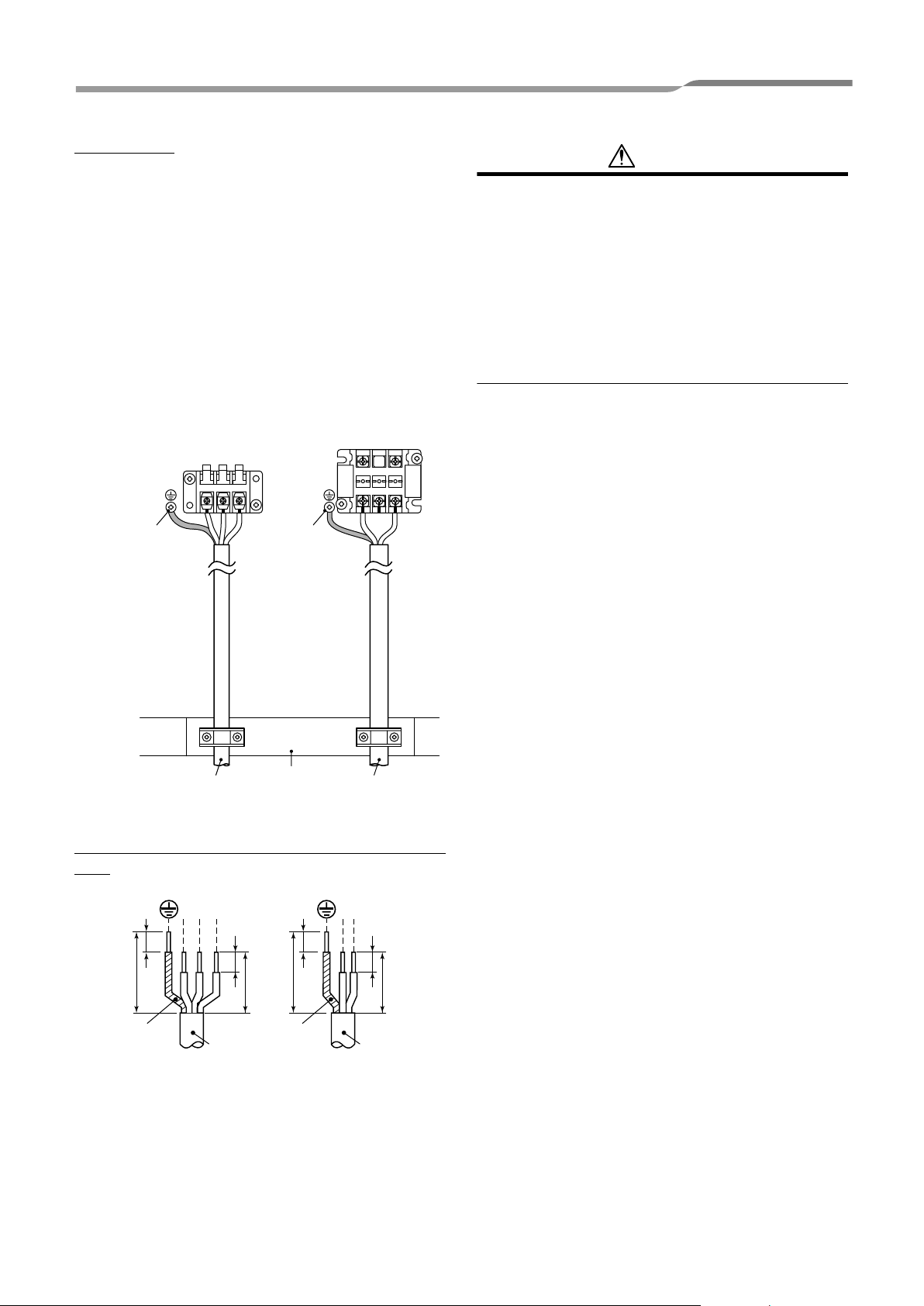

Electric parts box

Pipe valve

fixing plate

Cord

clamp

Pipe hole

Panel

Wiring between Hydro Unit

and Outdoor Unit

The dashed lines show on-site wiring.

11

Input power

230 V

50 Hz

Leakage

breaker

30 mA

L

N

Outdoor Unit

22

TB01

33

Hydro Unit

• Remove the panel, and you can see electric parts on

the front side.

• A metal pipe can be installed through the hole for

wiring. If the hole size does not fit the wiring pipe to

be used, drill the hole again to an appropriate size.

• Be sure to clamp the power wires and hydro/outdoor

connecting wires with banding band along the

connecting pipe so that the wires do not touch the

compressor or discharge pipe. (The compressor and

the discharge pipe become hot.)

• Connect the hydro/outdoor connecting wires to the

identical terminal numbers on the terminal block of

each unit.

Incorrect connection may cause a failure.

For the Air to Water Heat Pump, connect a power wire

as mentioned below.

Model HWS- 802H-E 1102H-E 1402H-E

Power supply 230 V~, 50 Hz

Maximum

running

current

Installation

fuse rating

Power wire

Hydro/outdoor

connecting

wires

20.8 A 22.8 A

(2.5 mm

(1.5 mm

25 A

2

or more)

2

or more)

(all types can be used)

H07 RN-F or 60245 IEC 66

H07 RN-F or 60245 IEC 66

EN

–17–

16-EN

Page 18

Air to Water Heat Pump

Outdoor Unit Installation Manual

How to wire

1. Connect the connecting wire to the terminal as

identified with their respective numbers on the

terminal block of hydro and outdoor unit.

H07 RN-F or 60245 IEC 66 (1.5 mm

2. When connecting the connecting wire to the outdoor

unit terminal, prevent water coming in the outdoor

unit.

3. Insulate the unsheathed cords (conductors) with

electrical insulation tape. Process them so that they

do not touch any electrical or metal parts.

4. For inter connecting wire, do not use a wire jointed

to another on the way.

Use wires long enough to cover the entire length.

To Hydro unit

terminal block

123

Earth screw

Earth screw

2

or more)

Power supply

terminal block

LN

CAUTION

• The installation fuse must be used for the power

supply line of this outdoor unit.

• Incorrect/incomplete wiring might cause an electrical

fire or smoke.

• Prepare the exclusive power supply for the Air to

Water Heat Pump.

• This product can be connected to the mains.

Connection to the fixed wiring :

A switch which disconnects all poles and has a

contact separation of at least 3 mm must be

incorporated in the fixed wiring.

Connecting wire

Pipe valve fixing

plate

Power supply

wire

Stripping length power cord and connecting

wire

10

LN

10

50

40

Earth lineEarth line

Power supply

wire

50

10

123

10

30

(mm)

Connecting wire

17-EN

–18–

Page 19

Air to Water Heat Pump

Outdoor Unit Installation Manual

8 EARTHING

WARNING

• Be sure to connect earth wire. (grounding work)

Incomplete grounding cause an electric shock.

Connect the earth line properly following applicable technical standards.

Connecting an earth line is essential to prevent electric shock and to reduce noise and electricity charge on the

outdoor unit surface due to high frequency generated by the frequency converter (inverter) in the outdoor unit.

If you touch the charged outdoor unit without earth line, you may feel electric shock.

9 FINISHING

After the refrigerant pipe and the inter-unit wires have been connected, cover them with finishing tape and clamp

them to the wall with off-the-shelf support brackets or equivalent.

Keep the power wires and hydro/outdoor connecting wires off the valve on the gas side or pipes that have no heat

insulator.

10TEST RUN

• The test run, on the outdoor unit, can only be completed when the complete Air to Water Heat Pump system has

been installed. (Hydro unit, heating system or/and the others)

• Please refer to the hydro unit installation manual for the details of the test run procedure.

11ANNUAL MAINTENANCE

• For Air to Water system which is operated regularly, cleaning and maintenance of the hydro/outdoor units are

strongly recommended.

As a general rule, if an hydro unit is operated for about 8 hours daily, the hydro/outdoor units will need to be

cleaned at least once every 3-month. This cleaning and maintenance shall be carried out by a qualified person.

Failure to clean the hydro/outdoor units regularly will result in poor performance, icing, water leaking and even

compressor failure.

EN

–19–

18-EN

Page 20

Air to Water Heat Pump

Outdoor Unit Installation Manual

12

FUNCTIONS TO BE IMPLEMENTED LOCALLY

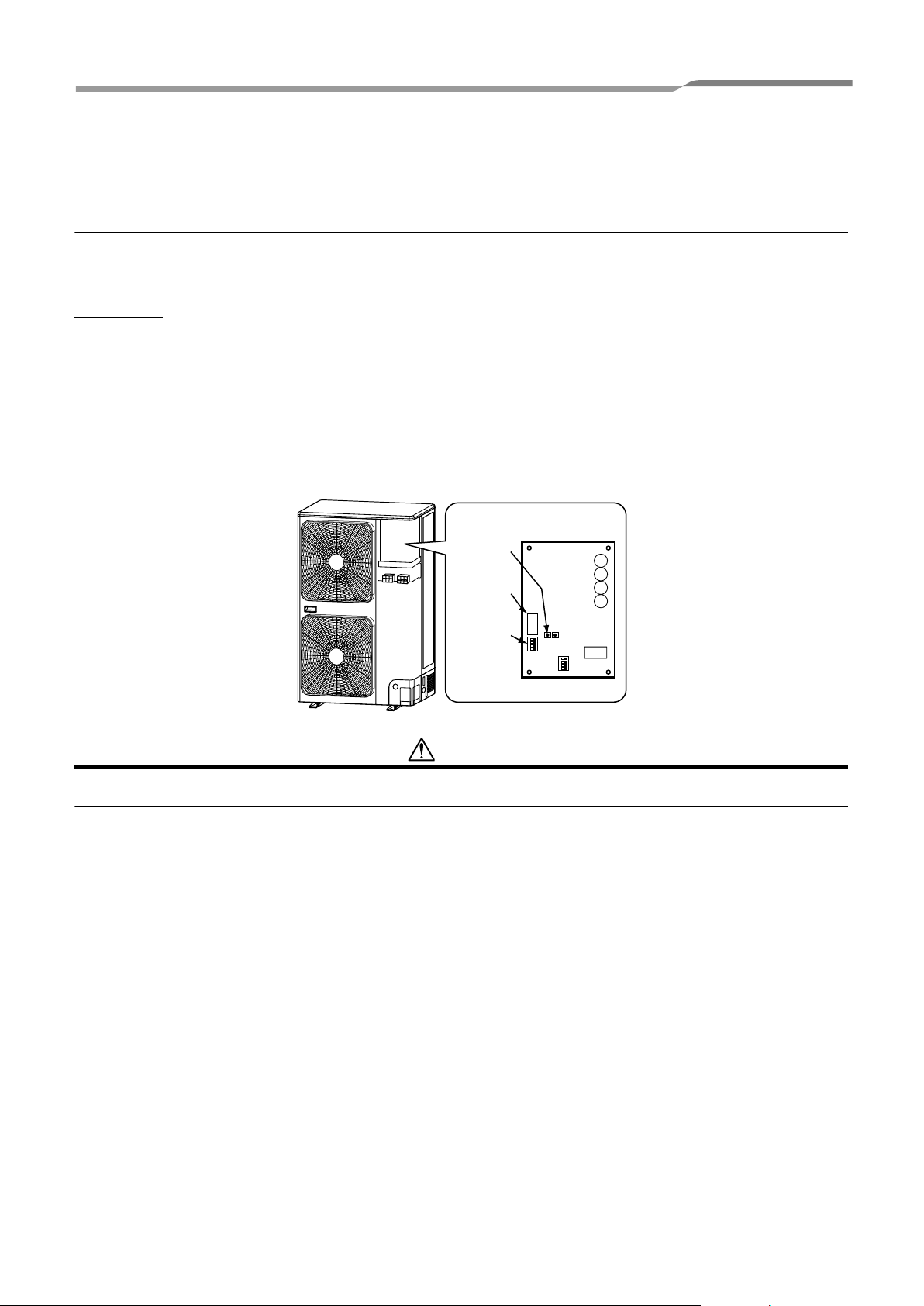

Recovering Refrigerant

• Use the refrigerant recovery switch SW801 on the P.C. board of the outdoor unit to recover refrigerant when the

hydro unit or outdoor unit is moved.

Procedure

1. Drain off the water in the hydro unit.

2. Turn on the power of the Air to Water Heat Pump.

3. Set SW804 on the P.C. board of the outdoor unit to all OFF, and then press SW801 for one second or more.

The Air to Water Heat Pump enters the forced cooling mode for up to 10 minutes. Operation or handling the

valve to recover refrigerant during this time period.

4. Upon completion of refrigerant recovery, close the valve and press SW801 for at least one second to stop

operation.

5. Turn off the power.

Refrigerant

recovery

switch

SW801

Optional

connector

CN610

P.C. board

Special

operation

select switch

SW804

DANGER

Take care for an electric shock because the P.C.board is electrified.

1234

ON

1234

ON

19-EN

–20–

Page 21

Air to Water Heat Pump

Outdoor Unit Installation Manual

13TROUBLESHOOTING

You can perform fault diagnosis of the outdoor unit with the LEDs on the P.C. board of the outdoor unit in addition

to check codes displayed on the wired remote controller of the hydro unit.

Use the LEDs and check codes for various checks. Details of check codes displayed on the wired remote controller

of the hydro unit are described in the Installation Manual of the hydro unit.

Check of the current abnormal status

1. Check that DIP switch SW803 is set to all OFF.

2. Jot down the states of LED800 to LED804. (Display

mode 1)

3. Press SW800 for at least one second. The LED

status changes to display mode 2.

4. Check the code whose display mode 1 equals the

jotted LED status and display mode 2 equals the

current flashing status of LED800 to LED804 from

the following table to identify the cause.

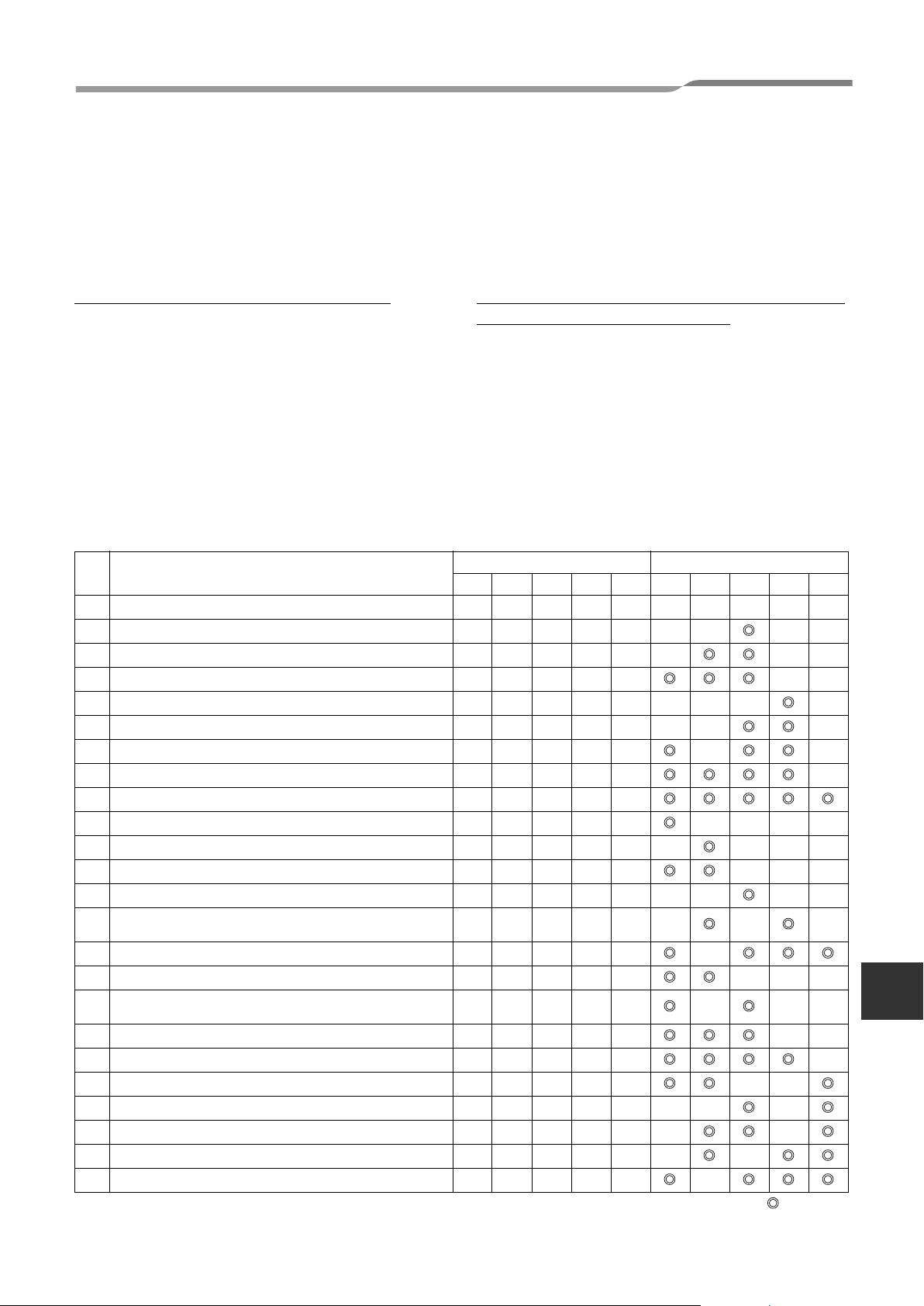

No. Cause

1Normal

2 Discharge (TD) sensor error

3 Heat exchanger (TE) sensor error

4 Heat exchanger (TL) sensor error

5 Outside air temperature (TO) sensor error

6 Suction (TS) sensor error

7 Heat sink (TH) sensor error

8 Outdoor temperature sensor (TE/TS) connection error

9 Outdoor EEPROM error

10 Compressor lock

11 Compressor lock

12 Current detect circuit error

13 Thermostat for compressor activated

Model data not set

14

(on the service P.C. board)

15 MCU-MCU communication error

16

Discharge temperature error

Abnormal power

17

(open phase detected or abnormal voltage)

18 Heat sink overheat

19 Gas leak detected

20 4-way valve reverse error

21 High pressure release operation

22 Outdoor fan motor error

23 Compressor driver short-circuit protection

24 Position detect circuit error in one-line display

Check of the abnormal status in the past although the

abnormal status is not occurred now.

1. Set bit 1 of DIP switch SW803 to ON.

2. Jot down the states of LED800 to LED804. (Display

mode 1)

3. Press SW800 for at least one second. The LED

status changes to display mode 2.

4. Find an error whose display mode 1 equals the jotted

LED status and display mode 2 equals the current

flashing status of LED800 to LED804 from the

following table to identify the error.

• An outside air temperature (TO) sensor error can

be checked only while an error occurs.

Display mode 1 Display mode 2

D800 D801 D802 D803 D804 D800 D801 D802 D803 D804

●●●●●●●●●●

{{●●{ ●● ●●

{{●●{ ●●●

{{●●{ ●●

{{●●{ ●●● ●

{{●●{ ●● ●

{{●●{ ●●

{{●●{ ●

{{●●{

●●{ ● { ●●●●

●●{ ● { ●●●●

●●{ ● { ●●●

●●{ ● { ●● ●●

● {{● { ●●●

● {{● { ●

{{{● { ●●●

EN

{{{● { ●●●

{{{● { ●●

{{{● { ●

{{{● { ●●

{{{● { ●● ●

{{{● { ●●

{{{● { ●●

{{{● { ●

(●:OFF {:ON :Flashing)

–21–

20-EN

Page 22

Air to Water Heat Pump

Outdoor Unit Installation Manual

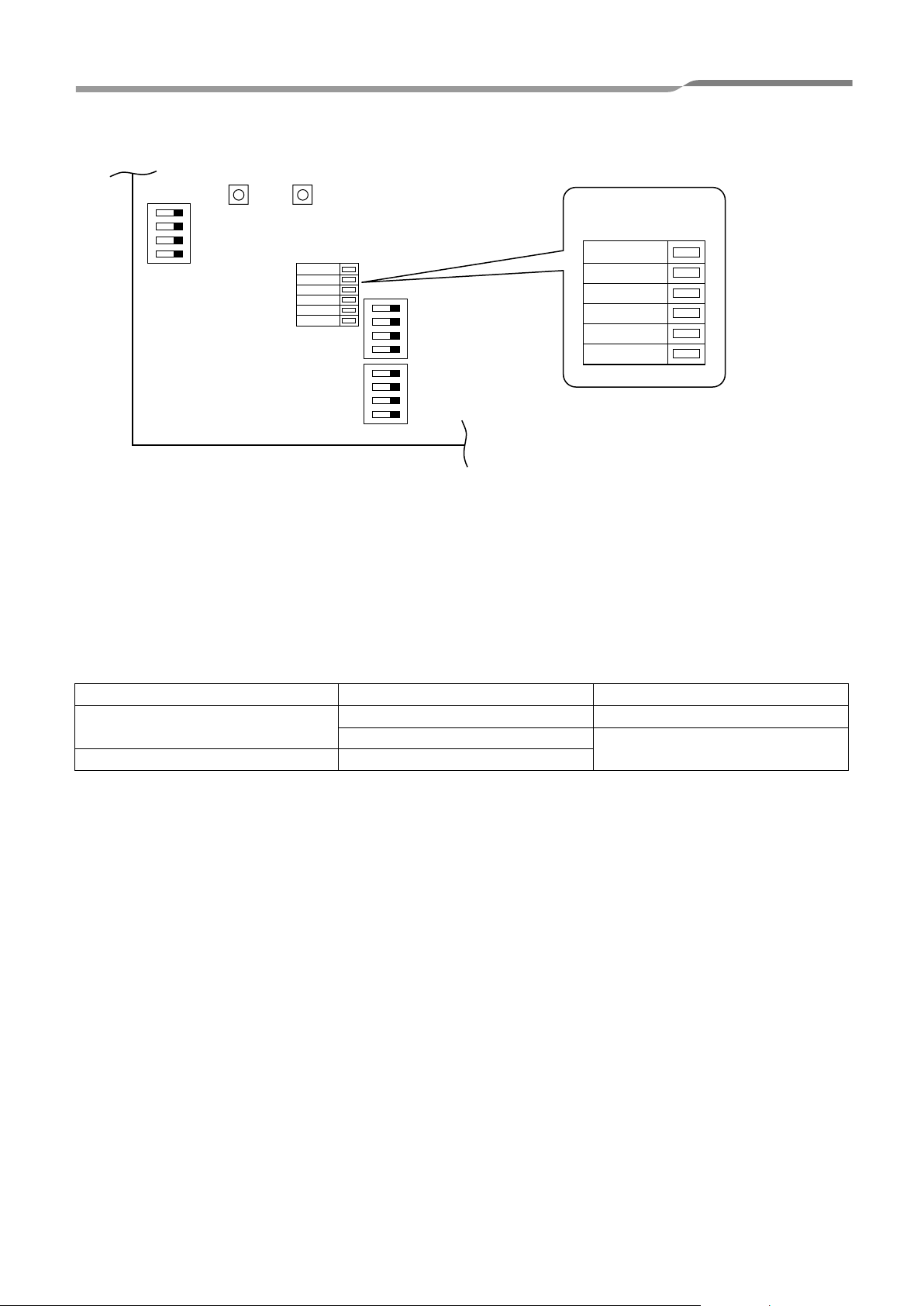

* The LEDs and DIP switches are located at the lower left of the P.C. board of the outdoor unit.

SW801

SW800

Enlarged view

of LEDs

ON

SW804

1234

D800

D801

D802

D803

D804

D805

LED

SW803

1234

ON

D800

D801

D802

D803

D804

D805

SW802

1234

ON

14APPENDIX

Curing of pipes

When removing and opening the hydro unit or outdoor unit for a long time, cure the pipes as follows:

• Otherwise rust may generate when moisture or foreign matter due to dewing enters in the pipes.

• The rust cannot be removed by cleaning, and a new piping work is necessary.

Place position Term Curing manner

Outdoors

Hydro units Every time

1 month or more Pinching

Less than 1 month

Pinching or taping

21-EN

–22–

Page 23

Air to Water Heat Pump

Outdoor Unit Installation Manual

IMPORTANT INFORMATION AND WARNING:

READ BEFORE INSTALLING THE UNIT. KEEP IN A SAFE PLACE THE INFORMATION IN THIS BOOKLET IS NEEDED

FOR END OF LIFE, DISPOSAL OR REUSE OF THE UNIT

• We are very sensitive to environment and welcomes the 2002/96/EC Directive WEEE (Waste Electrical and Electronic Equipment).

• This product is compliant with EU directive 2002/96/EC. It must be collected separately after its use is completed, and cannot be disposed

as unsorted municipal waste.

• The objectived of EU directive 2002/96/EC are to tackle the fast increasing waste stream of electrical and electronic equipment, increase

recycling of electric & electronic equipment ("EEE"), and to limit the total quantity of waste EEE ("WEEE") going to final disposal.

• The crossed out wheeled bin symbol that is affixed to the product means that this product falls under the Directive.

• The user is responsible for returning the product to the appropriate collection facility, as specified by your municipality or the distributor.

In case of installation of a new product, it may be possible to have the distributor pick up old WEEE directly.

• The producer, importer and distributor of are responsible for collection and treatment of waste, either directly or through a collective system.

The list of our distributor in each country is shown in the attached table.

• In case of violation of the Directive, sanctions are set in each country.

• We are in general following the "CECED interpretation", and consider the WEEE applicable to Portable units, Dehumidifiers, WRACs

(Window Room Air to Water Heat Pumps), Split Systems up to 12 kW, plug in refrigerators and freezers.

• Nevertheless, there may be difference among member state laws. In case country law exclude some products from WEEE scope, country

law must be followed, and WEEE obligations do not have to be followed for products that fall out of country low scope.

• This directive does not apply to products sold outside European Community. In case the product is sold out of Eu, WEEE obligations do

not have to be followed, while compliance with local regulation must be ensured.

• For additional information, please contact the municipal facility, the shop/dealer/installer that have sold the product, or the producer.

➊ Country

➋ Name of Company responsible for WEEE.

➊➋

AIRCOND, Klimaanlagen

Austria

Belgium

Cyprus

Denmark

Estonia

Finland

France

Germany

Greece

Handelsgesellshcaft m.b.H

Petesgasse 45, A-8010

Graz Austria

DOLPHIN NV, Fotografi

elaan 12, B-2610,

Antwerpen Belgium

Carrier Hellas

Airconditioning S.A.- 4g

Andersen street-11525

Athens Greece

GIDEX A/S, Korshoj 10,

3600 Frederikssund,

Denmark

Carrier OY Linnavuorentie

28A 00950 Helsinki Finland

Carrier OY Linnavuorentie

28A 00950 Helsinki Finland

Carrier S.A. Route de Thil

BP 49 01122 Montiuel

Cedex France

Carrier GmbH & Co. KG

Edisonstrasse 2 85716

Unterschleissheim

Carrier Hellas

Aircondilioning S.A.- 4g

Andersen street-11525

Athens Greece

➊➋

INTERCOOL Technics BV

Holland

Ireland

Italy

Latvia

Lithuania

Luxembourg

Malta

Norway

Poland

Nikkelstraat 39, Postbus 76

2980 AB Ridderkerk

Netherlands

GT Phelan Unit 30 Southern

Cross Business Park Bray

Co Wicklow Ireland

Carrier SpA Via R. Sanzio, 9

20058 Villasanta (Milano)

Italy

Carrier OY Linnavuorentie

28A 00950 Helsinki Finland

Carrier OY Linnavuorenlie

28A 00950 Helsinki Finland

DOLPHIN NV Fotografi

elaan 12, B-2610,

Antwerpen Belgium

CUTRICO Services Ltd,

Cutrico Building Psala

Street, Sta Venea HMR 16

Malta

Carrier AB - P.O.BOX 8946Arods Industrivag 32. S-402

73 Gothenburg Sweden

Carrier Polska Sp. Z.o.o.

Postepu 14 02-676 Warsaw

Poland

➊➋

Carrier Portugal - AR

Portugal

UK

Czech

Republic

Slovakia

Slovenia

Spain

Sweden

Hungary

Condicionado LDA Avenida

do Forte, Nr. 3 Editi cio

Suecia l,Piso 1 Camaxide

2794-043 Portugal

Toshiba Carrier UK Ltd

Porsham Close, Belliver Ind.

Est. Plymouth, Devon, PL6

7DB

AIRCOND, , Klimaanlagen

Handelsgesellshcaft m.b.H

Petersgasse 45, A-8010

Graz Austria

AIRCOND, , Klimaanlagen

Handelsgesellshcaft m.b.H

Petersgasse 45, A-8010

Graz Austria

AIRCOND, , KlimaanlagenHandelsgesellshcaft m.b.H,

Petersgasse 45, A-8010

Graz, Austria

Carrier Espana S.L. - Paseo

Castellana 36-38, 28046

Madrid

Carrier AB - P.O.BOX 8946Arods Industrivag 32 . S-402

73 Gothenburg

AIRCOND, Klimaanlagen

Handelsgesellshcaft m.b.H

Petersgasse 45, A-8010

Graz Austria

EN

The manufacturer reserves the right to change any product specifications without notice.

–23–

22-EN

Page 24

Air to Water Heat Pump

Avant d’installer la pompe à chaleur air/eau, lisez attentivement ce Manuel d’installation.

• Ce manuel décrit la méthode d’installation de l’unité extérieure.

• Pour l’installation de l’unité hydroélectrique, reportez-vous au Manuel d’installation fourni avec l’unité

hydroélectrique.

Outdoor Unit Installation Manual

ADOPTION DU NOUVEAU REFRIGERANT

Cette pompe à chaleur air/eau est un nouveau type qui adopte un nouveau réfrigérant HFC (R410A) au lieu

du réfrigérant traditionnel R22 en vue d’éviter la destruction de la couche d’ozone.

Sommaire

1 PIECES ACCESSOIRES ET REFRIGERANT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

2 MESURES DE SECURITE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

3 INSTALLATION DU NOUVEAU REFRIGERANT DANS LA

POMPE A CHALEUR AIR/EAU . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

4 CHOIX DE L’INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

5 TUYAUX DE REFRIGERANT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

6 PURGE D’AIR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

7 INSTALLATION ELECTRIQUE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

8 MISE A LA TERRE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

9 FINITION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

10 ESSAI DE FONCTIONNEMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

11 ENTRETIEN ANNUEL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

12 FONCTIONS A EXECUTER LOCALEMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

13 DEPANNAGE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

14 ANNEXE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

1-FR

–24–

Page 25

Air to Water Heat Pump

Outdoor Unit Installation Manual

1 PIECES ACCESSOIRES ET REFRIGERANT

Pièces accessoires

Nom de la pièce Quantité Forme Emploi

Manuel d’installation de

l’unité extérieure

Raccord d’évacuation 1

1 Ce manuel (Remettez celui-ci directement au client.)

Bouchon en caoutchouc

étanche

Manchon de protection 1 Pour la protection des câbles (protection des tuyaux)

Matériau de protection

pour passages

5

1 Pour la protection des passages (protection des tuyaux)

Tuyaux de réfrigérant

• Le kit de tuyaux utilisé pour le réfrigérant traditionnel ne peut être utilisé.

• Utilisez un tuyau en cuivre de 0,8 mm ou plus d’épaisseur pour Ø9,5 mm.

Utilisez un tuyau en cuivre de 1,0 mm ou plus d’épaisseur pour Ø15,9 mm.

• Les écrous évasés et l’évasement diffèrent également de ceux des tuyaux du réfrigérant traditionnel.

Retirez l’écrou évasé fourni avec la pompe à chaleur air/eau et utilisez-le.

–25–

FR

2-FR

Page 26

Air to Water Heat Pump

Outdoor Unit Installation Manual

2 MESURES DE SECURITE

• Assurez-vous de respecter toutes les règles locales, nationales et internationales.

• Lisez attentivement ces « MESURES DE SECURITE » avant l’installation.

• Les mesures décrites ci-après comprennent des points importants concernant la sécurité.

Observez-les scrupuleusement.

• Après l’installation, faites un essai de fonctionnement pour vous assurer de l’absence de problèmes.

Reportez-vous au Manuel du propriétaire pour expliquer au client comment utiliser l’unité et effectuer son

entretien.

• Mettez l’interrupteur général (ou le disjoncteur) hors tension avant d’effectuer l’entretien de l’unité.

• Demandez au client de conserver le Manuel d’installation avec le Manuel du propriétaire.

AVERTISSEMENT

•

Demandez à un revendeur autorisé ou à un installateur professionnel d’installer la pompe à chaleur air/eau ou

d’effectuer son entretien.

Une installation inadéquate peut se solder par une fuite d’eau, une électrocution ou un incendie.

• Veillez à raccorder les fils de terre. (mise à la terre)

Une mise à la terre incomplète provoque une électrocution.

Ne raccordez pas les fils de terre aux tuyaux de gaz, aux tuyaux d’eau, aux paratonnerres ou aux fils de terre des

câbles téléphoniques.

• Mettez l’interrupteur général ou le disjoncteur hors tension avant d’entreprendre l’installation électrique.

Assurez-vous que tous les interrupteurs sont hors tension. La non-observation de cet avertissement peut se solder

par une électrocution.

Utilisez un circuit d’alimentation exclusif pour la pompe à chaleur air/eau. Utilisez la tension nominale.

• Branchez correctement le câble de raccordement.

Si le câble de raccordement est mal branché, les composants électriques peuvent s’endommager.

• Lorsque vous déplacez la pompe à chaleur air/eau pour l’installer ailleurs, faites très attention à ce qu’aucun

corps gazeux autre que le réfrigérant spécifié ne pénètre dans le circuit de réfrigération.

Si l’air ou tout autre gaz se mélange au réfrigérant, la pression gazeuse du circuit de réfrigération augmentera

anormalement et pourra faire éclater les tuyaux et blesser quelqu’un.

• Ne modifiez pas cette unité en démontant ses carters de protection ou en by-passant ses verrous de sûreté.

• Après avoir déballé l’unité, examinez-la attentivement pour vous assurer qu’elle n’est pas endommagée.

• Ne l’installez pas dans un endroit susceptible d’augmenter ses vibrations.

• Afin d’éviter de vous blesser (avec des bords tranchants), faites attention lorsque vous manipulez les pièces.

• Effectuez l’installation conformément au Manuel d’installation.

Une installation inadéquate peut se solder par une fuite d’eau, une électrocution ou un incendie.

• Si l’unité hydroélectrique de la pompe à chaleur air/eau est installée dans une petite pièce, prenez les

mesures appropriées pour garantir que la concentration de fuite de réfrigérant dans la pièce ne dépasse pas

le niveau critique.

• Serrez l’écrou évasé avec une clé dynamométrique de la manière spécifiée.

Un serrage excessif de l’écrou évasé peut se solder par une rupture de l’écrou évasé après une longue période, ce

qui peut entraîner une fuite de réfrigérant.

• Portez des gants épais pendant l’installation pour éviter de vous blesser.

• Installez solidement la pompe à chaleur air/eau dans un endroit qui supporte son poids de manière adéquate.

• Effectuez l’installation spécifiée pour protéger le climatiseur contre un tremblement de terre.

Si la pompe à chaleur air/eau n’est pas installée de manière appropriée, elle peut tomber et provoquer des accidents.

• Si le gaz réfrigérant a fui durant l’installation, aérez immédiatement la pièce.

Si le gaz réfrigérant qui a fui entre en contact avec le feu, un gaz nocif peut se dégager.

• Après l’installation, assurez-vous que le gaz réfrigérant ne fuit pas.

Si le gaz réfrigérant fuit dans la pièce et s’écoule près d’un appareil ignigène, comme une cuisinière, un gaz nocif

peut se dégager.

• L’installation électrique doit être effectuée par un électricien professionnel conformément au Manuel

d’installation. Assurez-vous que la pompe à chaleur air/eau utilise une alimentation exclusive.

Une alimentation de puissance insuffisante ou une installation inappropriée peuvent provoquer un incendie.

• Utilisez les câbles spécifiés et raccordez-les bien aux bornes.

Evitez qu’une pression externe ne s’exerce sur les bornes et ne les affecte.

3-FR

–26–

Page 27

Air to Water Heat Pump

Outdoor Unit Installation Manual

AVERTISSEMENT

• Lorsque la pompe à chaleur air/eau ne peut pas refroidir ou chauffer convenablement une pièce, contactez

le revendeur qui vous l’a vendue si une fuite de réfrigérant est susceptible d’être la cause.

En cas de réparation requérant le remplissage de réfrigérant, demandez les détails de la réparation au

personnel chargé de l’entretien.

Le réfrigérant utilisé dans la pompe à chaleur air/eau est inoffensif.

Généralement, le réfrigérant ne fuit pas. Cependant, si le réfrigérant fuit dans une pièce et qu’un chauffage ou une

cuisinière prend feu, un gaz toxique peut se dégager.

Si vous demandez au personnel chargé de l’entretien de réparer la fuite de réfrigérant, vérifiez que la partie qui fuyait

a été complètement réparée.

• Observez les règles de la compagnie d’électricité locale lorsque vous raccordez les câbles d’alimentation.

Une mise à la terre inappropriée peut provoquer une électrocution.

• N’installez pas la pompe à chaleur air/eau dans un endroit susceptible d’être exposé à des gaz inflammables.

Si un gaz inflammable fuit et stagne autour de l’unité, il peut provoquer un incendie.

• Installez solidement le tuyau de réfrigérant pendant l’installation avant d’utiliser la pompe à chaleur air/eau.

Si le compresseur fonctionne avec la soupape ouverte et sans le tuyau de réfrigérant, le compresseur aspire l’air et

le circuit de réfrigération est surpressurisé, ce qui peut faire éclater l’unité et blesser quelqu’un.

• Pour la récupération du réfrigérant (collecte du réfrigérant du tuyau vers le compresseur), arrêtez le

compresseur avant de débrancher le tuyau de réfrigérant.

Si le tuyau de réfrigérant est débranché alors que le compresseur fonctionne avec la soupape ouverte, le

compresseur aspire l’air et le circuit de réfrigération est surpressurisé, ce qui peut faire éclater l’unité et blesser

quelqu’un.

ATTENTION

Installation du nouveau réfrigérant dans la pompe à chaleur air/eau

• CETTE POMPE A CHALEUR AIR/EAU UTILISE LE NOUVEAU REFRIGERANT HFC (R410A) QUI NE DETRUIT

PAS LA COUCHE D’OZONE.

• Le réfrigérant R410A se distingue par son absorption aisée de l’eau, de la membrane oxydante ou de l’huile ainsi

que par sa pression, qui est d’environ 1,6 fois celle du réfrigérant R22. Outre l’utilisation du nouveau réfrigérant,

l’huile réfrigérante a elle aussi été remplacée. Par conséquent, durant l’installation, assurez-vous que l’eau, la

poussière, le réfrigérant précédent ou l’huile réfrigérante n’entrent pas dans le circuit de réfrigération.

• Pour éviter de remplir du réfrigérant et de l’huile réfrigérante inappropriés, la taille des sections de raccordement de

l’orifice de remplissage de l’unité principale et les outils d’installation sont différents de ceux qui sont utilisés pour le

réfrigérant traditionnel.

• En conséquence, les outils exclusifs sont requis pour le nouveau réfrigérant (R410A).

• Quant aux tuyaux de raccordement, utilisez des tuyaux neufs et propres conçus pour le R410A et veillez à ce que

l’eau ou la poussière n’y entrent pas.

Pour déconnecter l’appareil du secteur

• Cet appareil doit être connecté au secteur via un interrupteur ayant une séparation de contact d’au moins 3 mm.

• Vous devez utiliser le fusible d’installation 25 A (vous pouvez utiliser n’importe quel type de fusible) sur la ligne

d’alimentation de cette unité.

3

INSTALLATION DU NOUVEAU REFRIGERANT

DANS LA POMPE A CHALEUR AIR/EAU

• Le réfrigérant R410A est plus sensible aux impuretés telles que l’eau, la membrane oxydante, les huiles et les

graisses. Outre l’adoption du nouveau réfrigérant, l’huile réfrigérante a elle aussi été remplacée.

Veillez à ce que l’eau, la poussière, le réfrigérant traditionnel et/ou l’huile réfrigérante traditionnelle ne pénètrent

pas dans le circuit de réfrigération de la pompe à chaleur air/eau utilisant le nouveau réfrigérant.

• Pour éviter le mélange de différents réfrigérants ou huiles réfrigérantes, la taille des sections de raccordement

de l’orifice de remplissage de l’unité et l’outil d’installation sont différents de ceux utilisés pour le réfrigérant

traditionnel. En conséquence, les outils exclusifs suivants sont requis pour le nouveau réfrigérant (R410A).

–27–

FR

4-FR

Page 28

Air to Water Heat Pump

Outdoor Unit Installation Manual

Outils/équipements nécessaires et mesures d’utilisation

Préparez les outils et les équipements repris dans le tableau ci-dessous avant de commencer l’installation.

Les outils et les équipements récemment préparés doivent être utilisés de manière exclusive.

Légende

: Outil récemment préparé (à utiliser uniquement pour R410A. Ne l’utilisez pas pour le réfrigérant R22 ou

R407C, etc.)

: Les outils/équipements traditionnels sont disponibles

Outils/équipements Utilisation Mode d’utilisation des outils/équipements

Collecteur manométrique Pompage à vide/

Tuyau de remplissage Outil récemment préparé uniquement R410A pour

Bouteille de remplissage Ne peut pas être utilisée

Détecteur de fuite de gaz

Pompe à vide pourvue de la

fonction de clapet anti-retour

Pompe à vide pourvue de la

fonction de clapet anti-retour

Outil d’évasement

Cintreuse Cintrage des tuyaux R22 (Outils traditionnels)

Equipement de récupération du

réfrigérant

Clé dynamométrique Serrage des écrous évasés Exclusive pour Ø12,7 mm et Ø15,9 mm

Coupe-tube Découpe des tuyaux R22 (Outils traditionnels)

Bouteille de réfrigérant Remplissage du réfrigérant

Machine à souder et bouteille

d’azote

Mesure de remplissage du

réfrigérant

remplissage du réfrigérant

et vérification du

fonctionnement

Vérification des fuites de

gaz

Séchage à vide Inutilisable

Séchage à vide R22 (Outils traditionnels)

Usinage en évasement des

tuyaux

Récupération du réfrigérant Uniquement R410A pour

Soudage des tuyaux R22 (Outils traditionnels)

Remplissage du réfrigérant R22 (Outils traditionnels)

Outil récemment préparé uniquement R410A pour

Inutilisable (utilisez la mesure de remplissage du réfrigérant

à la place.)

Outil récemment préparé

Utilisable si les dimensions sont adaptées.

Uniquement R410A pour

Caractérisé par le nom du réfrigérant sur la bouteille.

Tuyaux de réfrigérant

Nouveau réfrigérant (R410A)

Utilisation du kit de tuyaux traditionnel

• En cas d’utilisation du kit de tuyaux traditionnel qui n’indique aucun type de réfrigérant applicable, veillez à

utiliser celui-ci sur une épaisseur de paroi de 0,8 mm pour Ø6,4 mm, Ø9,5 mm et Ø12,7 mm, et sur une

épaisseur de paroi de 1,0 mm pour Ø15,9 mm. N’utilisez jamais le kit de tuyaux traditionnel sur une épaisseur

de paroi inférieure à ces épaisseurs en raison d’une capacité de pression insuffisante.

Utilisation de tuyaux en cuivre généraux

• Utilisez des tuyaux en cuivre généraux sur une épaisseur de paroi de 0,8 mm pour Ø6,4 mm, Ø9,5 mm et

Ø12,7 mm, et sur une épaisseur de paroi de 1,0 mm pour Ø15,9 mm.

N’utilisez jamais des tuyaux en cuivre sur une épaisseur de paroi inférieure à ces épaisseurs.

Ecrous évasés et usinage d’évasement

• Les écrous évasés et l’usinage d’évasement sont différents de ceux utilisés pour le réfrigérant traditionnel.

Utilisez les écrous évasés fournis avec la pompe à chaleur air/eau ou ceux prévus pour le R410A.

• Lisez attentivement « TUYAUX DE REFRIGERANT » avant de commencer l’usinage d’évasement.

5-FR

–28–

Page 29

Air to Water Heat Pump

4 CHOIX DE L’INSTALLATION

Outdoor Unit Installation Manual

Avant l’installation

Veillez aux points suivants avant l’installation.

Longueur du tuyau de réfrigérant

Longueur du tuyau de

réfrigérant raccordé à

l’unité hydroélectrique/

extérieure

De 3 m à 30 m

* Ne raccordez pas un tuyau de réfrigérant inférieur à

3m.

Le compresseur ou les autres dispositifs peuvent

être défaillants.

L’ajout de réfrigérant est inutile

sur place.

Point

Essai d’étanchéité

1. Avant de commencer un essai d’étanchéité, serrez

encore les soupapes d’axe côté gaz et côté liquide.

2. Pressurisez le tuyau à l’azote gazeux par l’orifice de

service à la pression spécifiée (4,15 Mpa) pour

effectuer l’essai d’étanchéité.

3. Une fois l’essai d’étanchéité terminé, évacuez

l’azote gazeux.

Mise à la terre

AVERTISSEMENT

Assurez-vous que la mise à la terre appropriée est

fournie.

Une mise à la terre incorrecte peut provoquer une

électrocution. Pour le mode de vérification de la mise à

la terre, contactez le revendeur qui a installé la pompe

à chaleur air/eau ou une entreprise d’installation

professionnelle.

• Une mise à la terre appropriée peut empêcher la

charge d’électricité sur la surface de l’unité

extérieure en raison de la fréquence élevée du

convertisseur de fréquence (inverseur) dans l’unité

extérieure, et éviter une électrocution. Si l’unité

extérieure n’est pas correctement mise à la terre,

vous pouvez vous électrocuter.

• Veillez à raccorder les fils de terre. (mise à la

terre)

Une mise à la terre incomplète provoque une

électrocution.

Ne raccordez pas les fils de terre aux tuyaux de gaz,

aux tuyaux d’eau, aux paratonnerres ou aux fils de

terre des câbles téléphoniques.

Purge d’air

• Pour évacuer l’air, utilisez une pompe à vide.

• N’utilisez pas le réfrigérant rempli dans l’unité

extérieure pour évacuer l’air. (Le réfrigérant sujet à

purge n’est pas contenu dans l’unité extérieure.)

Raccordement électrique

Assurez-vous de fixer les câbles d’alimentation et les

câbles de raccordement des unités hydroélectrique/

extérieure avec des serre-fils de sorte qu’ils ne

touchent pas le boîtier, etc.

Essai de fonctionnement

• Procédez à l’essai de fonctionnement après avoir

effectué les travaux de tuyauterie et après avoir

rempli d’eau le système au niveau adéquat.

• Mettez le disjoncteur sous tension au moins

12 heures avant de commencer un essai de

fonctionnement pour protéger le compresseur

durant la mise en marche.

ATTENTION

Une installation incorrecte peut donner lieu à une

défaillance ou à des plaintes des clients.

FR

–29–

6-FR

Page 30

Air to Water Heat Pump

Outdoor Unit Installation Manual

Lieu d’installation

AVERTISSEMENT

Installez correctement l’unité extérieure dans un

lieu assez durable pour le poids de l’unité

extérieure.

Si la durabilité est insuffisante, l’unité peut tomber et

blesser quelqu’un.

ATTENTION

N’installez pas l’unité extérieure dans un lieu sujet

à des fuites de gaz inflammable.

L’accumulation de gaz inflammable autour de l’unité

extérieure peut provoquer un incendie.

Installez l’unité extérieure dans un lieu qui satisfait

aux conditions suivantes une fois l’accord du

client obtenu.

• Un lieu bien aéré exempt d’obstacles près des

entrées d’air et de la sortie d’air.

• Un lieu qui n’est pas exposé à la pluie ou à la lumière

directe du soleil.

• Un lieu qui n’augmente pas le bruit de

fonctionnement ou les vibrations de l’unité

extérieure.

• Un lieu qui ne provoque aucun problème

d’évacuation de l’eau rejetée.

N’installez pas l’unité extérieure dans les lieux

suivants.

• Un lieu saturé d’air salin (zone côtière) ou de gaz

sulfhydrique (zone de source chaude)

(Un entretien spécial est requis.)

• Un lieu soumis à l’huile, à la vapeur, aux fumées

huileuses ou aux gaz corrosifs.

• Un lieu où des solvants organiques sont utilisés.

• Un lieu où des équipements haute fréquence (y

compris des équipements d’inverseur, des

générateurs privés, des équipements médicaux et

des équipements de communication) sont utilisés.

(L’installation dans ce lieu peut provoquer une

défaillance de la pompe à chaleur air/eau, un

contrôle anormal ou des problèmes dus au bruit de

ces équipements.)

• Un lieu où l’air de l’unité extérieure est refoulé contre

la fenêtre de la maison voisine.

• Un lieu où le bruit de fonctionnement de l’unité

extérieure est répercuté.

• Lorsque l’unité extérieure est installée en hauteur,

assurez-vous de fixer ses pieds.

• Un lieu où l’eau s’écoule sans problèmes.

ATTENTION

1. Installez l’unité extérieure dans un endroit où

l’air refoulé n’est pas bloqué.

2. Lorsque l’unité extérieure est installée dans un

endroit constamment exposé au vent fort,

comme un bord de mer ou un toit de gratte-ciel,

assurez le fonctionnement normal du ventilateur

à l’aide d’un conduit ou d’un pare-vent.

3. Lorsque l’unité extérieure est installée dans un

endroit constamment exposé au vent fort, comme

le haut d’un escalier ou le toit d’un immeuble,

appliquez les mesures de protection contre le

vent en vous reportant aux exemples suivants.

1) Installez l’unité de sorte que son orifice de

refoulement soit face au mur de l’immeuble.

Maintenez une distance de 500 mm ou plus

entre l’unité et la surface du mur.

500

2) En supposant la direction du vent durant la

saison de fonctionnement de la la pompe à

chaleur air/eau, installez l’unité de sorte que

l’orifice de refoulement soit à angle droit par

rapport à la direction du vent.

Vent

Vent

fort

• Si vous utilisez la pompe à chaleur air/eau alors que

la température extérieure est très basse (température

extérieure : -5 °C ou inférieure) en mode COOL,

prévoyez une gaine ou un pare-vent afin que le vent

n’ait aucune incidence.

<Exemple>

Pare-vent

fort

Pare-vent

Pare-vent

7-FR

–30–

Page 31

Air to Water Heat Pump

Outdoor Unit Installation Manual

Espace nécessaire à l’installation (Unité : mm)

Obstacle à l’arrière

▼ Le haut est libre

1. Installation d’une seule unité

150

ou plus

2. Obstacles à droite et à gauche

200

ou plus

150

ou plus

3. Installation en série de deux unités ou plus

La hauteur de

l’obstacle doit être

inférieure à celle de

l’unité extérieure.

300

ou plus

Obstacle à l’avant

▼ Le haut est libre

1. Installation d’une seule unité

500

ou plus

2. Installation en série de deux unités ou plus

▼ Obstacle aussi en haut

1000

ou plus

1000

ou plus

1000

ou plus

150

ou plus

La hauteur de l’obstacle doit être inférieure

à celle de l’unité extérieure.

300

ou plus

▼ Obstacle aussi en haut

ou plus

500

ou plus

150

300

ou plus

300

ou plus

200 ou plus

Obstacles à l’avant et à l’arrière

Ouvrez le haut et les côtés droit et gauche.

La hauteur de l’obstacle à l’avant et à l’arrière doit être

inférieure à celle de l’unité extérieure.

▼ Installation standard

1. Installation d’une seule unité

150

ou plus

1000

ou plus

FR

–31–

8-FR

Page 32

Air to Water Heat Pump

Outdoor Unit Installation Manual

2. Installation en série de deux unités ou plus

200

ou plus

300

ou plus

300

ou plus

1000

ou plus

Installation en série à l’avant et à l’arrière

Ouvrez le haut et les côtés droit et gauche.

La hauteur de l’obstacle à l’avant et à l’arrière doit être

inférieure à celle de l’unité extérieure.

▼ Installation standard

1000

ou plus

300

ou plus

1500