Page 1

Outdoor

Installation Instructions

Air Conditioner – Multi Split Type System

Außengerät

Installationsanleitung

Klimaanlage – Geteilte Multi-Bauweise

Instructions

d’Installation Extérieure

Climatiseur – Système de Type Multi Split

Buiten

Installatievoorschriften

Airconditioning – Multi-delig Type Systeem

GB

F

D

E

I

NL

Istruzioni per

l’installazione dell’unità esterna

Condizionatore d’aria – Tipo Multi Split

Modular Multi System

Exterior

Instrucciones de Instalación

Aire acondicionado – Sistema de Tipo Multi Split

HFC

R407C

1402241301R01

Page 2

Page 3

GB

3

Contents

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Trial Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .38

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .48

Environmental . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .64

Passer à la page 65 pour lire le manuel d’installation en

français.

Die deutsche Montageanleitung finden Sie auf Seite 127.

Por favor, vaya a la página 189 para seguir las instrucciones del

manual de instalacíon en lengua española.

Il manuale d’installazione italiano è a pagina 251.

Zie bladzijde 313 voor de Nederlandse Installatichandleiding.

F

D

E

I

NL

Page 4

GB

Introduction

Contents

4

Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Operating Conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Metric/Imperial pipe conversion . . . . . . . . . . . . . . . . . . . . .7

Page 5

GB

Please read these instructions carefully before starting the installation.

This equipment should only be installed by suitably trained operatives.

In all cases ensure safe working practice: Observe precautions for persons in the vicinity of

the works.

Ensure that all local, national and international regulations are satisfied.

Check that the electrical specifications of the unit meet the requirements of the site.

Carefully unpack the equipment, check for damage or shortages. Please report any damage

immediately.

These units comply with EC Directive:

73/23/EEC (Low Voltage Directive) and 89/336/EEC (Electro Magnetic Compatibility).

Accordingly, they are designated for use in commercial and industrial environments.

Avoid installation in the following locations:

Where the water drainage may cause a nuisance or a hazard when frozen.

Where there is a danger of flammable gas leakage.

Where there are high concentrations of oil.

Where the atmosphere contains an excess of salt (as in coastal areas). Special maintenance

is required to maintain product design life.

Where the airflow from the outdoor unit may cause annoyance.

Where the operating noise of the outdoor unit may cause annoyance.

Where the foundation is not strong enough to fully withstand the weight of the outdoor unit.

Where strong winds may blow against the air inlet of the outdoor unit.

Precautions for R407C Systems

R407C outdoor units use synthetic oils which are extremely hygroscopic. Therefore ensure

that the refrigerant system is NEVER exposed to air or any form of moisture.

Mineral oils are unsuitable for use in these units and may lead to premature system failure.

Use only equipment which is suitable for use with R407C. Never use equipment which has

been used with R22.

R407C should only be charged from the service cylinder in the liquid phase. It is advisable to

use a gauge manifold set equipped with a liquid sight glass fitted in the centre (entry) port.

5

Introduction

Precautions

Page 6

GB

6

Introduction

Operating Conditions

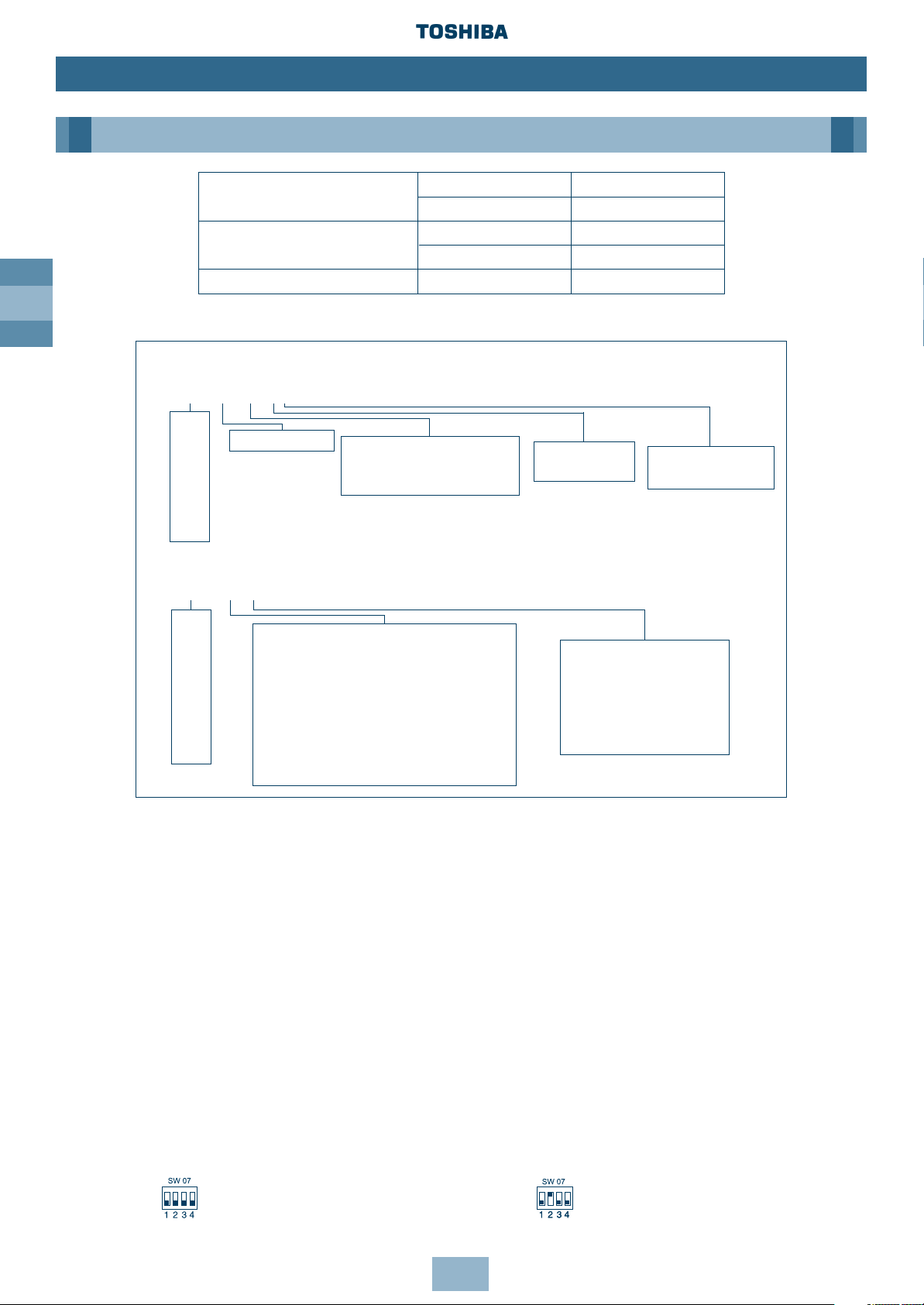

1. Allocation standard of Model name

2. Range of combined units

No. of combined units : 1 to 5 units

Capacity range : Equivalent to 14HP (0384kW type) to 46HP (1288kW)

3. Restriction for combination units

(1) The Inverter Unit should have the maximum capacity among all units in

that combination.

(2) The 6HP fixed-speed unit is available only with the combination of 14HP

and 22HP. (It cannot be used for any other combination.)

4. Rated conditions

Cooling : Indoor air temperature 27°C DB/19°C WB

Outdoor air temperature 35°C DB/25°C WB

Heating : Indoor air temperature 21°C DB/15.5°C WB

Outdoor air temperature 7°C DB/6° C WB

5. Mode Priority

This Outdoor Unit is set to operate with the Heating mode taking precidence. This

precidence can be switched between Heat and Cool mode using the DIP switch 07

on the Outdoor Unit Interface PCB (MCC-1343-01) as follows:

Outdoor Temperature

–5 ~ 43°C Cooling

–15 ~ 21°C Heating

Room Temperature

18 ~ 32°C Cooling

15 ~ 29°C Heating

Room Humidity <80% Cooling

T – Inverter

X – Fixed Speed

0280 – 28.0kW (10HP)

0224 – 22.4kW (8HP)

0160 – 16.0kW (6HP)

C – Cooling

H – Heating

MM–A0280HT

INDOOR

OUTDOOR

A – Outdoor

Modular Multi

028 – 2.8kW (1HP)

042 – 4.2kW (1.5HP)

056 – 5.6kW (2HP)

080 – 8.0kW (3HP)

112 – 11.2kW (4HP)

140 – 14.0kW (5HP)

MM–TU056

Modular Multi

B – Built-In Duct Type

C (CR) – Ceiling Type (IR Remote)

K (KR) – High Wall Type (IR Remote)

N – Carcase Type

S (SR) – Low Wall Type (IR Remote)

SB – Built-In Slim Duct Type

TU – 2 Way Cassette Type

U – 4 Way Cassette Type

ON

OFF

ON

OFF

Heat Priority (factory set) Cool Priority

Page 7

GB

7

Introduction

Components

Metric/Imperial pipe conversion

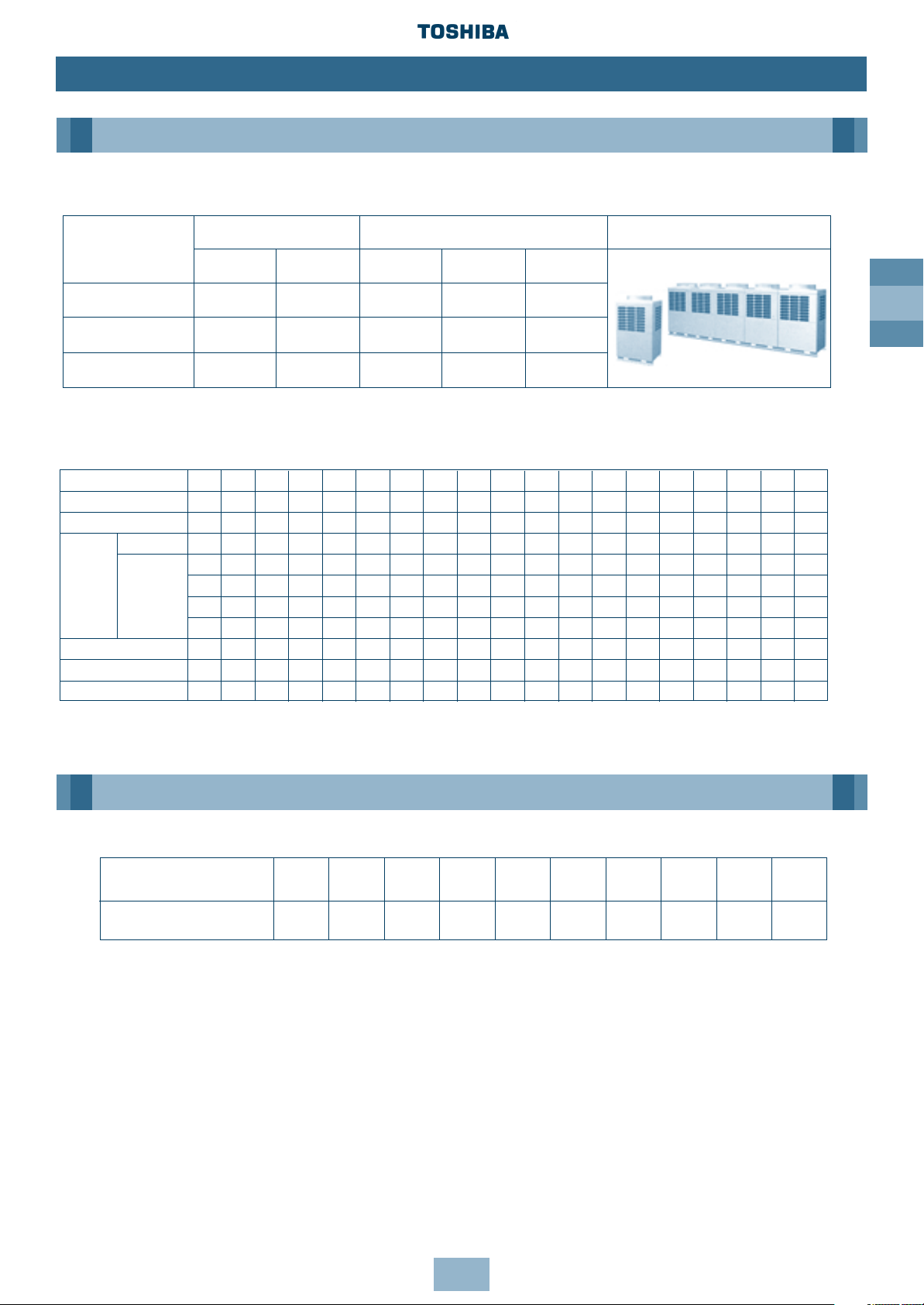

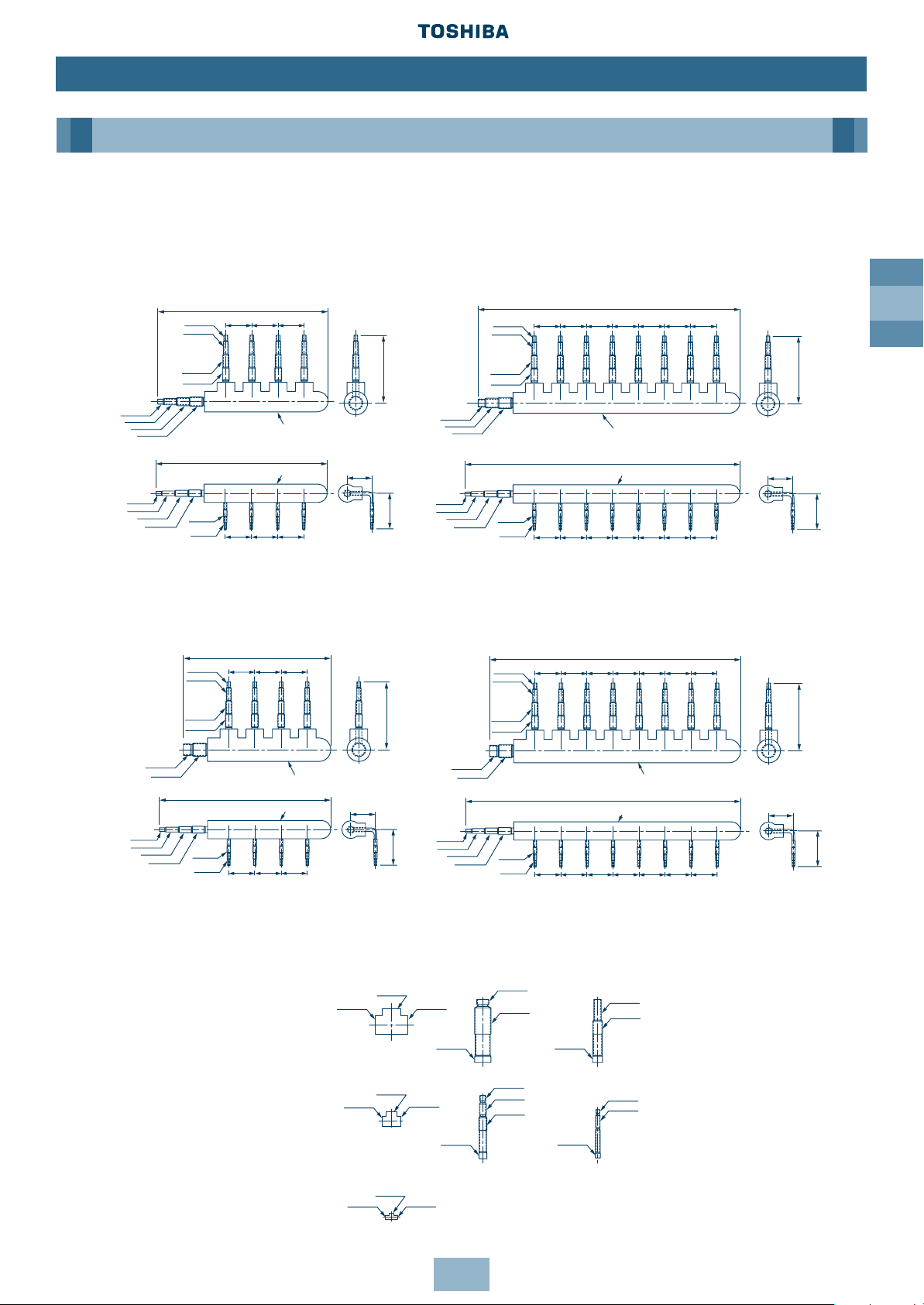

Inverter unit Fixed-speed unit Appearance

Corresponding HP

8HP 10HP 6HP 8HP 10HP

Model name MM-A0224HT MM-A0280HT MM-A0160HX MM-A0224HX MM-A0280HX

Cooling capacity (kW) 22.4 28.0 16.0 22.4 28.0

Heating capacity (kW) 25.0 31.5 18.0 25.0 31.5

Corresponding HP 8HP 10HP 14HP 16HP 18HP 20HP 22HP 24HP 26HP 28HP 30HP 32HP 34HP 36HP 38HP 40HP 42HP 44HP 46HP

Combined Model MM-A~HT

0224 0280 0384 0440 0504 0560 0608 0672 0728 0784 0840 0896 0952 1008 1064 1120 1176 1232 1288

Cooling capacity (kW) 22.4 28.0 38.4 44.8 50.4 56.0 60.8 67.2 72.8 78.4 84.0 89.6 95.2 100.8 106.4 112.0 117.6 123.2 128.8

Inverter unit 8HP 10HP 8HP 8HP 10HP 10HP 8HP 8HP 10HP 10HP 10HP 8HP 10HP 10HP 10HP 10HP 10HP 10HP 10HP

— — 6HP 8HP 8HP 10HP 8HP 8HP 8HP 10HP 10HP 8HP 8HP 10HP 10HP 10HP 8HP 10HP 10HP

— — — — — — 6HP 8HP 8HP 8HP 10HP 8HP 8HP 8HP 10HP 10HP 8HP 8HP 10HP

——— ————— ———8HP8HP8HP8HP10HP 8HP 8HP 8HP

——— ————— ————————8HP8HP8HP

13 16 16 18 18 20 22 24 26 28 30 32 34 36 38 40 40 40 40

Min. HP Connection 4 5 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23

Max. HP Connection 10.8 13.5 18.9 21.6 24.3 27 29.7 32.4 35.1 37.8 40.5 43.2 45.9 48.6 51.3 54 56.7 59.4 62.1

Combined

outdoor

units

No. of connectable

indoor units

Fixedspeed unit

1. Outdoor Unit

2. Outdoor Units (Combination of Outdoor Units)

Diameter (mm) 6.4 9.5 12.7 15.9 19.0 22.0 28.6 34.9 41.3 54.1

Nominal Diameter (inch)

1

/4

3

/8

1

/2

5

/8

3

/4

7

/8 1 1/8 1 3/8 1 5/8 2 1/8

Note: 1.0MPaG = 10.2kgf/cm2G

Page 8

GB

8

Introduction

Components

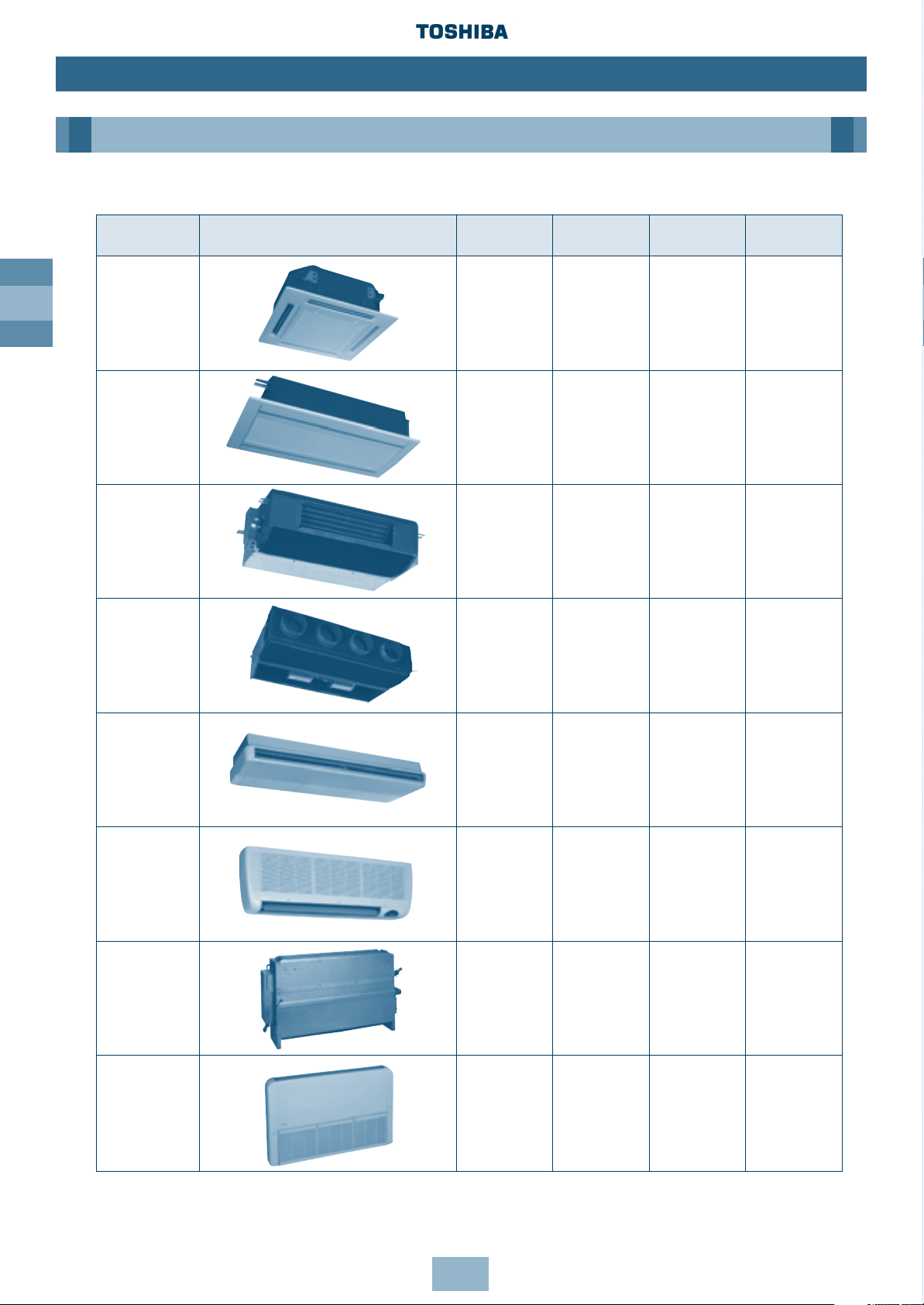

Type Appearance Model name Capacity code/

Cooling Capacity Heating Capacity

HP (kW) (kW)

MM-U056 2 5.6 6.4

MM-U080 3 8.0 9.6

MM-U112 4 11.2 12.8

MM-U140 5 14.0 15.8

MM-TU028 1 2.8 3.2

MM-TU042 1.5 4.2 4.8

MM-TU056 2 5.6 6.4

MM-SB028 1 2.8 3.2

MM-B056 2 5.6 6.4

MM-B080 3 8.0 9.6

MM-B112 4 11.2 12.8

MM-B140 5 14.0 15.8

MM-C/CR042 1.5 4.2 4.8

MM-C/CR056 2 5.6 6.4

MM-C/CR080 3 8.0 9.6

MM-C/CR112 4 11.2 12.8

MM-C/CR140 5 14.0 15.8

MM-K/KR042 1.5 4.2 4.8

MM-K/KR056 2 5.6 6.4

MM-K/KR080 3 8.0 9.6

MM-N028 1 2.8 3.2

MM-N042 1.5 4.2 4.8

MM-N056 2 5.6 6.4

MM-N080 3 8.0 9.6

MM-S/SR056 2 5.6 6.4

MM-S/SR080 3 8.0 9.6

4 Way Cassette

Type ‘U’

2 Way Cassette

Type ‘TU’

Built-In Slim

Duct Type ‘SB’

Built-In Duct,

Type ‘B’

Ceiling

Type ‘C’

High Wall

Type ‘K’

Carcase

Type ‘N’

Low Wall

Type ‘S’

3. Indoor Unit

Page 9

GB

9

Installation

Contents

Outdoor Unit

Transportation of the Outdoor Unit . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Installation of Outdoor Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

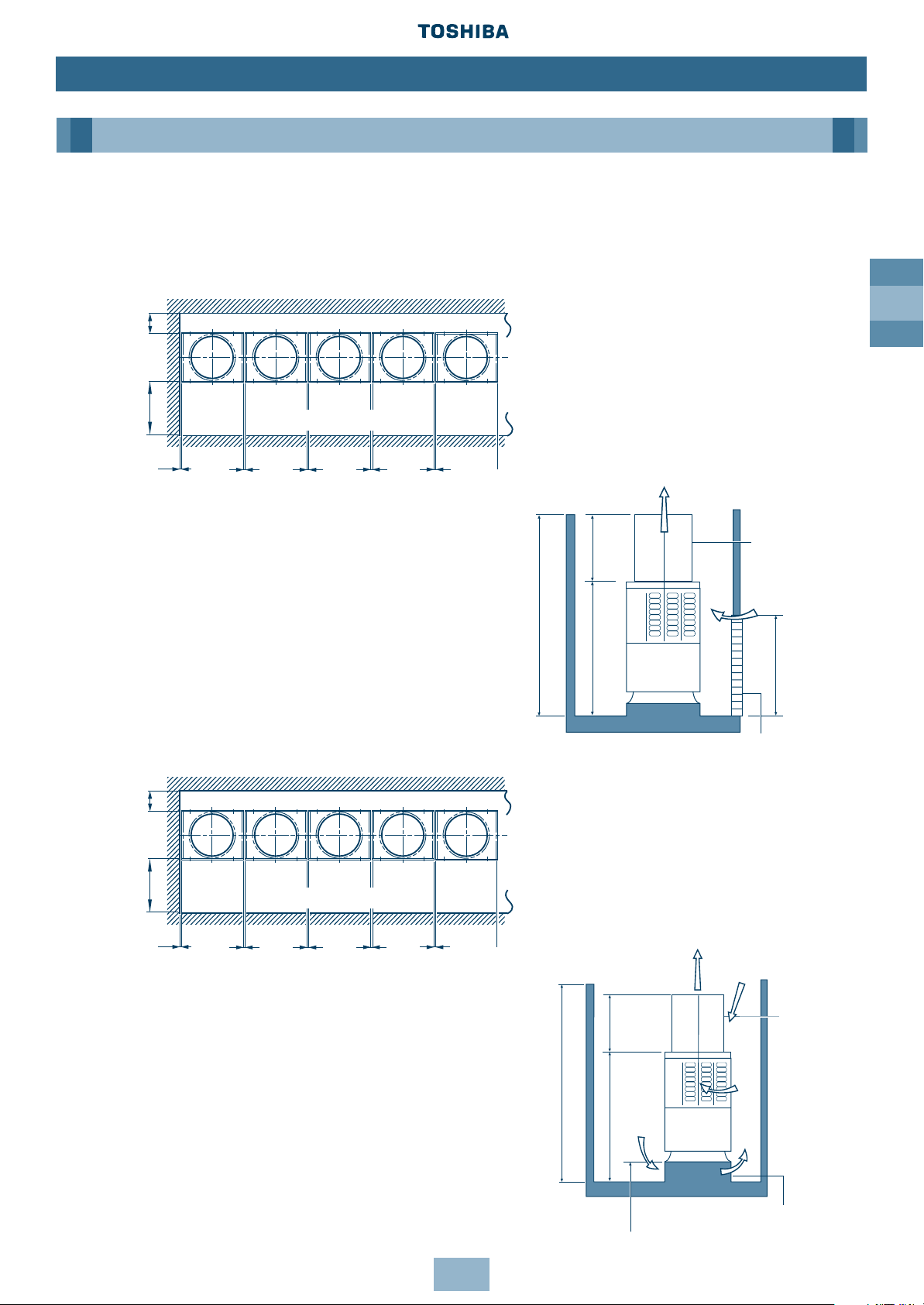

Dimensional Drawings Outdoor Unit . . . . . . . . . . . . . . . . . . . . . . . . . .12

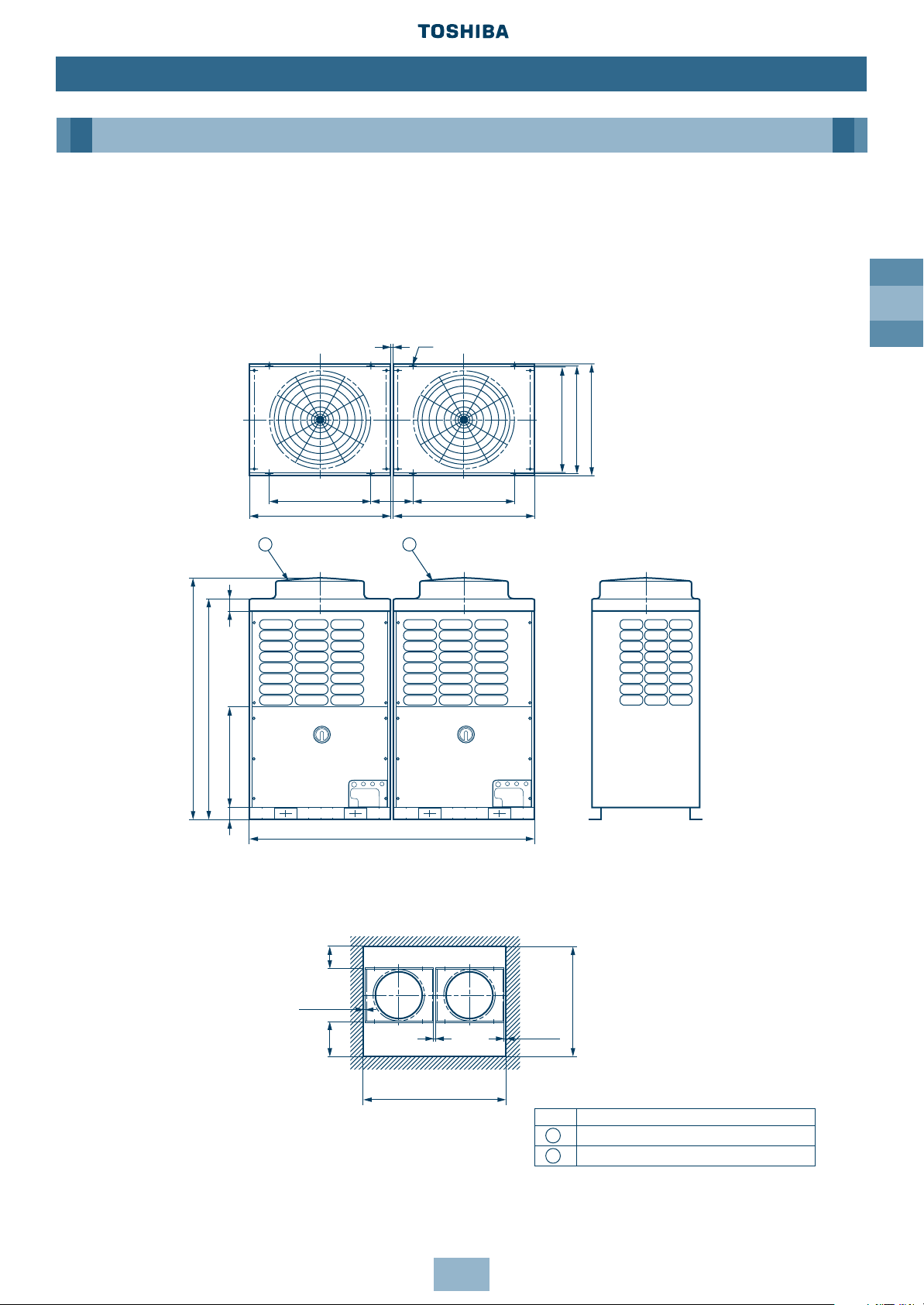

Dimensional Drawings Two Units Connected . . . . . . . . . . . . . . . . . . . .13

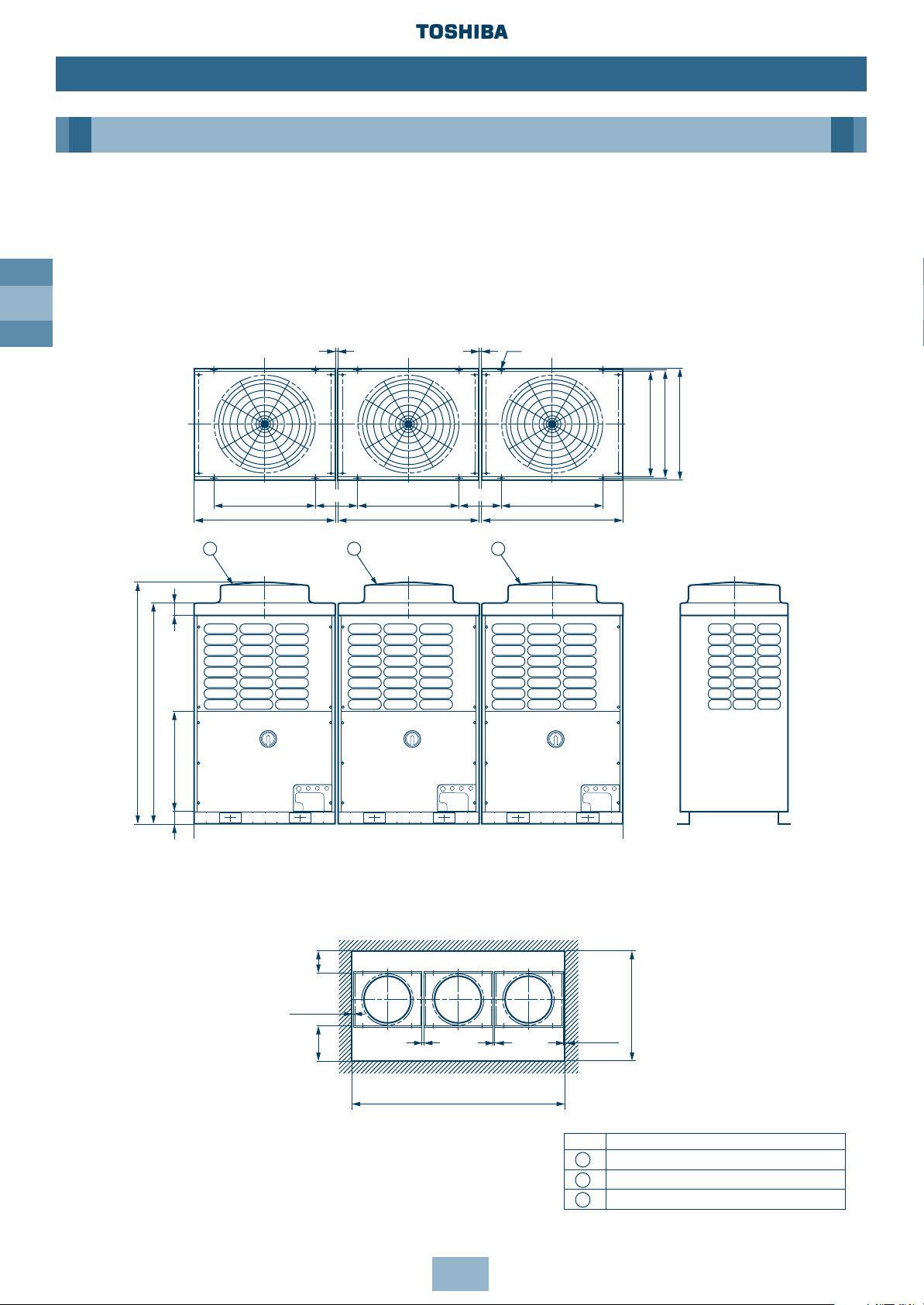

Dimensional Drawings Three Units Connected . . . . . . . . . . . . . . . . . . .14

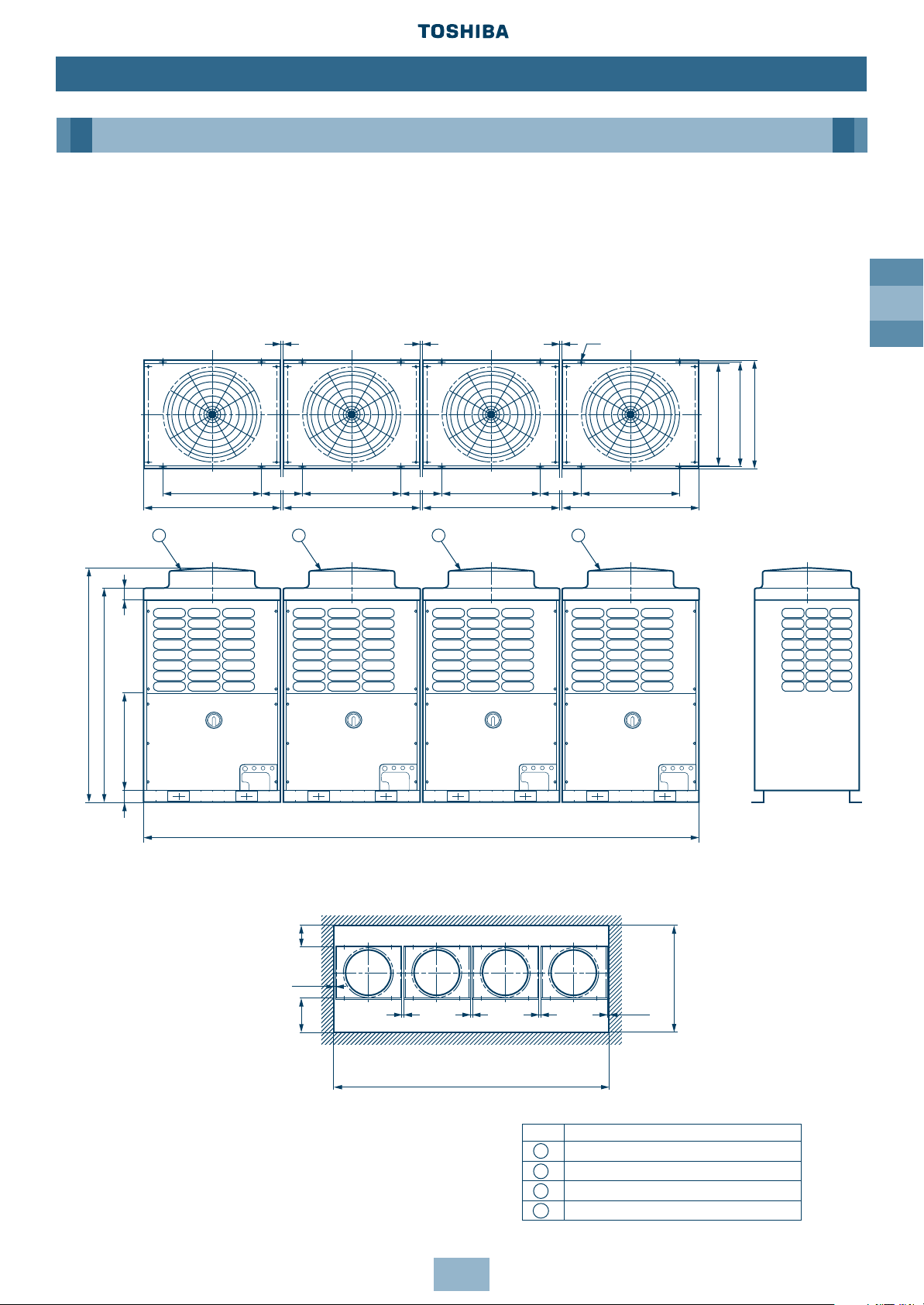

Dimensional Drawings Four Units Connected . . . . . . . . . . . . . . . . . . . .15

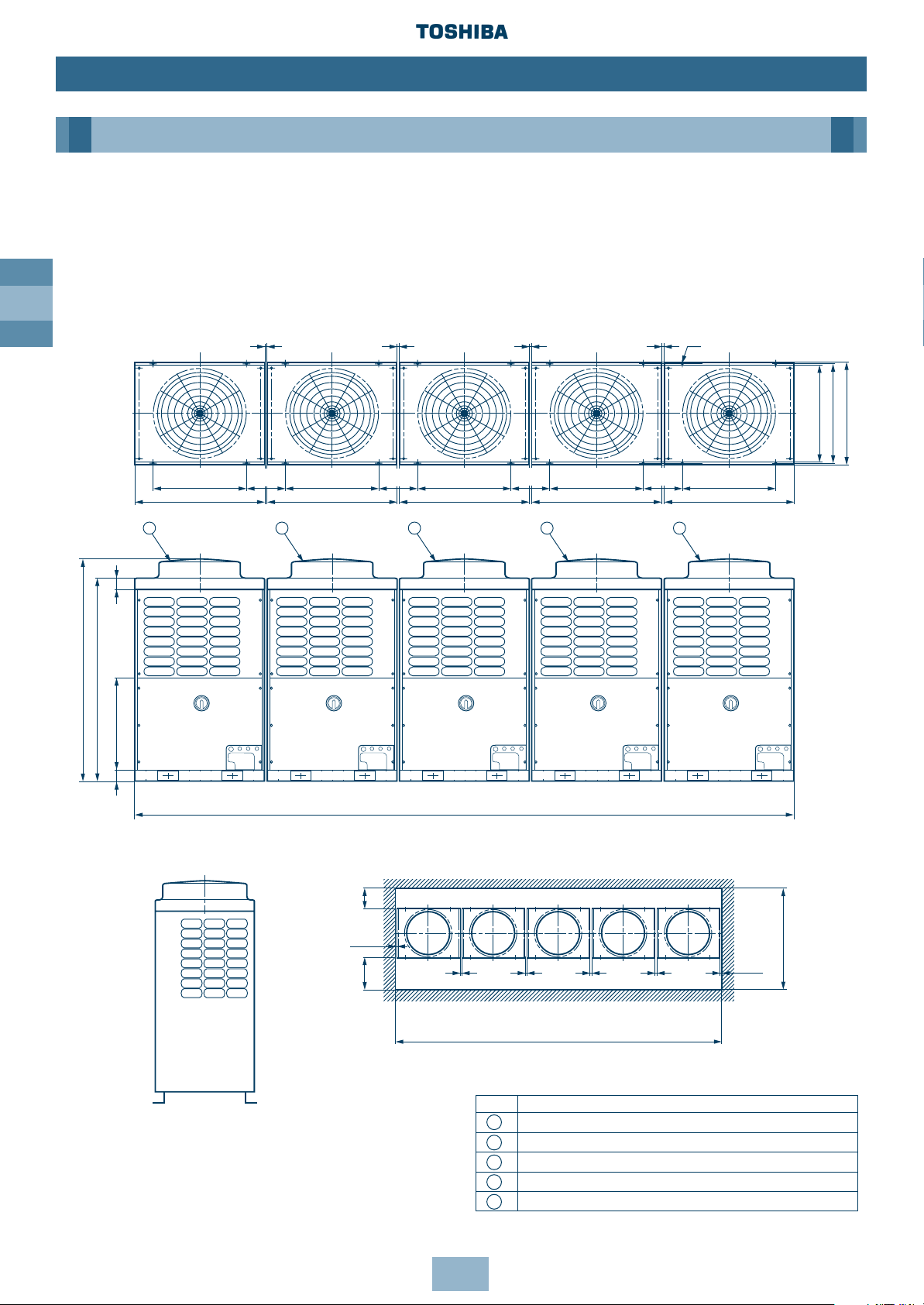

Dimensional Drawings Five Units Connected . . . . . . . . . . . . . . . . . . . .16

Multiple Installation on the Rooftop . . . . . . . . . . . . . . . . . . . . . . . . . . .17

Piping

Free Branching System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

Connecting Refrigerant Pipes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

Permissible Length/Height Separation of Refrigerant Piping . . . . . . . .21

Selection of Refrigerant Piping and Charge Requirement . . . . . . . . . .22

Branch Headers/Branch Joints (Accessories) . . . . . . . . . . . . . . . . . . . . .24

Branch Header/T-shape Branch Joint . . . . . . . . . . . . . . . . . . . . . . . . . .25

Connecting the Branching Kit/Y-shape Branching Joint . . . . . . . . . . . .26

Heat Insulating the Branching Pipes/Branching Header . . . . . . . . . . .27

T-shape Branching Joint – to Connect Outdoor Units . . . . . . . . . . . . . .29

Installation of Gas/Liquid Branching Pipes . . . . . . . . . . . . . . . . . . . . . .30

Airtight Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31

Leak Position Check/Air Purge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .32

Calculating the Additional Refrigerant Required . . . . . . . . . . . . . . . . .33

Additional Charge Amounts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .34

Wiring

General/Wiring System Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . .35

Connecting Power Source Cable/Control Cable . . . . . . . . . . . . . . . . . .36

Control Wiring Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .37

Page 10

GB

10

Installation

Outdoor Unit

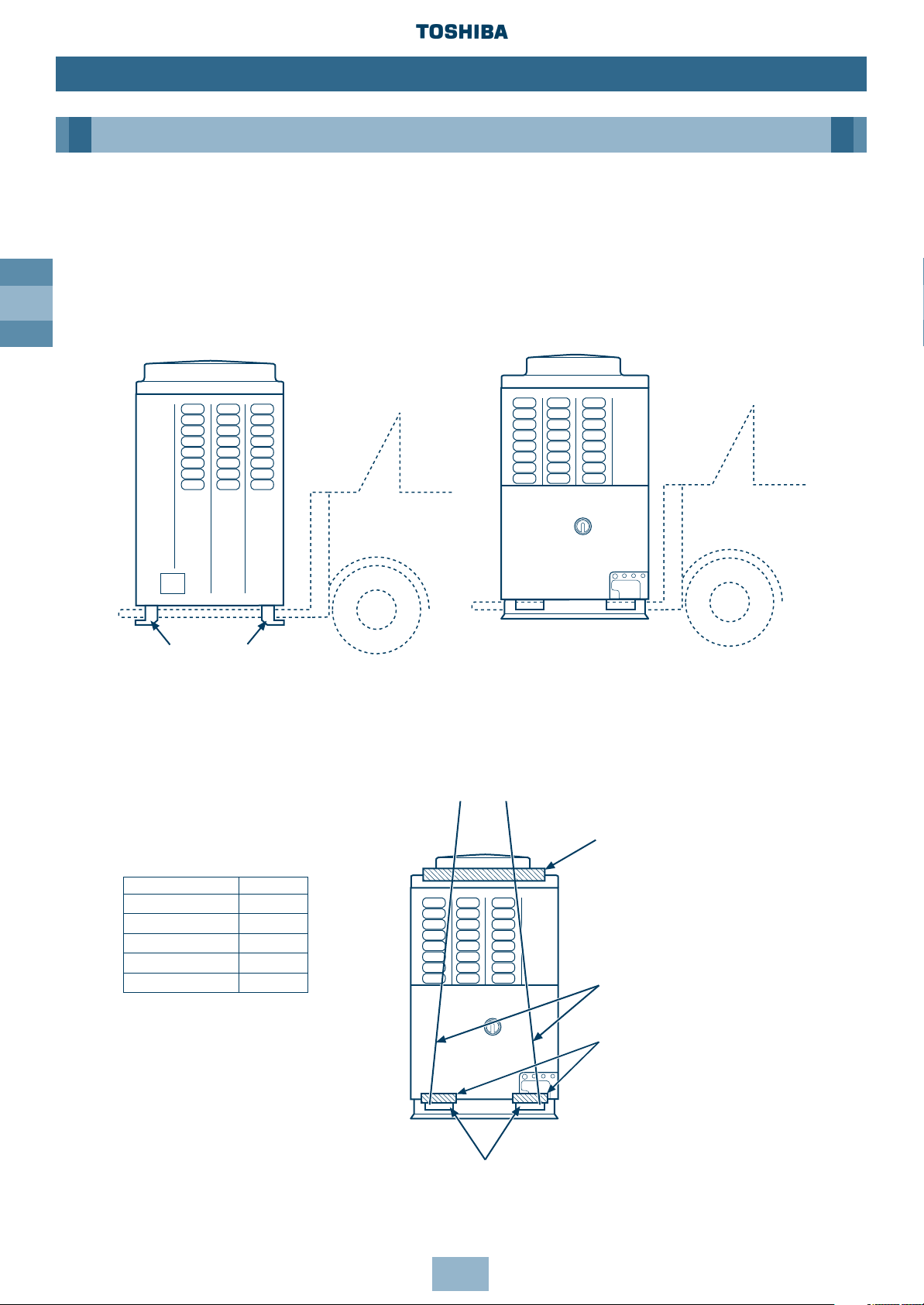

Transportation of the Outdoor Unit

Fork Lift

• Front Access – insert the forks into the slots on the fixing legs.

• Side Access – see diagram.

Fork lift

Fork lift/

Hand Truck

Transportation Slots

Protection

Fixing Leg

Protection

Rope

Crane

• Check the suitability of the lifting rope (see table).

• Secure lifting rope through transportation slot.

• Protect the unit where rope contact could scratch or deform it.

Model Weight

MM-A0280HT 284.0kg

MM-A0224HT 282.0kg

MM-A0280HX 280.0kg

MM-A0224HX 278.0kg

MM-A0160HX 204.0kg

Front Access Side Access

Page 11

GB

Installation

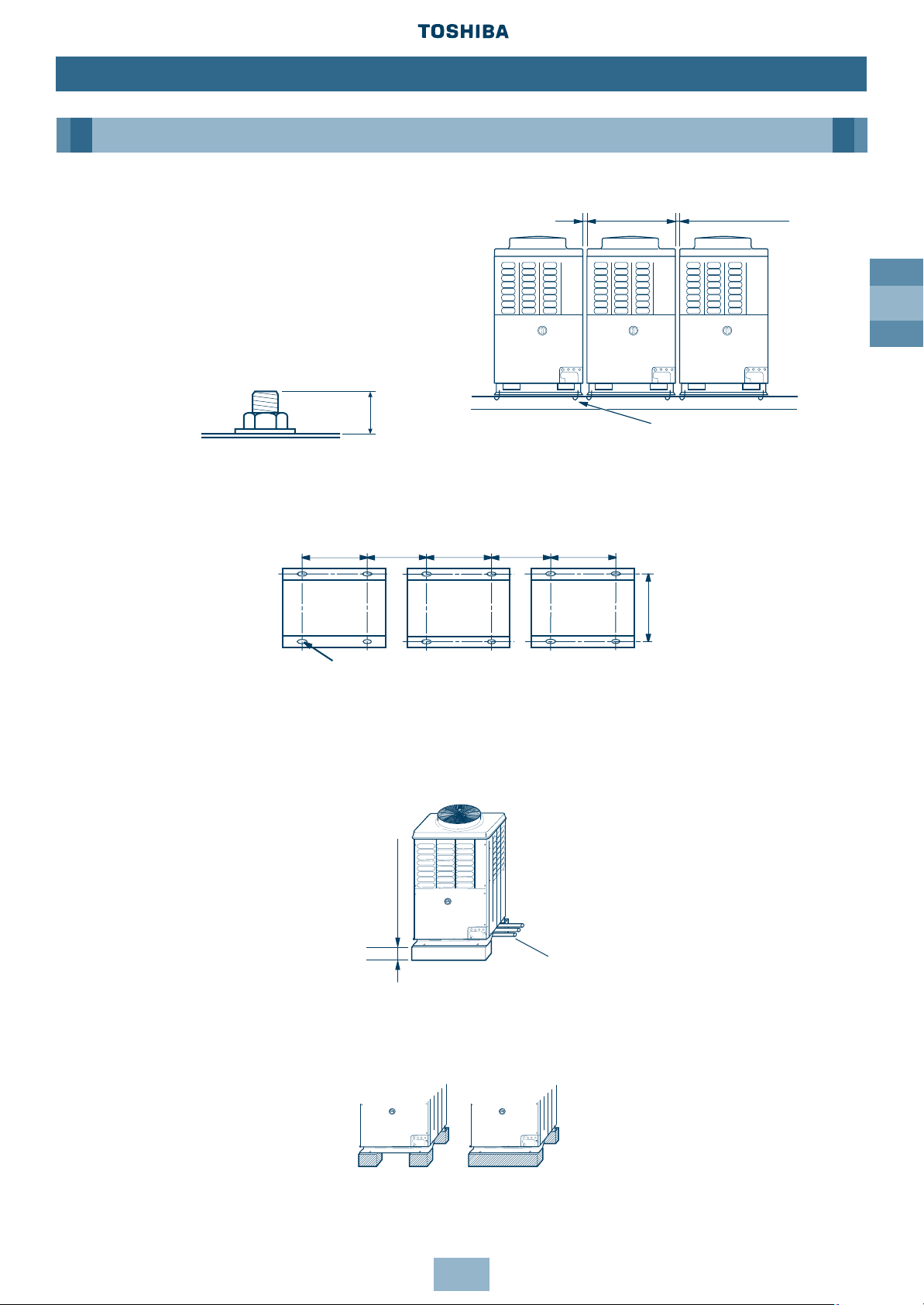

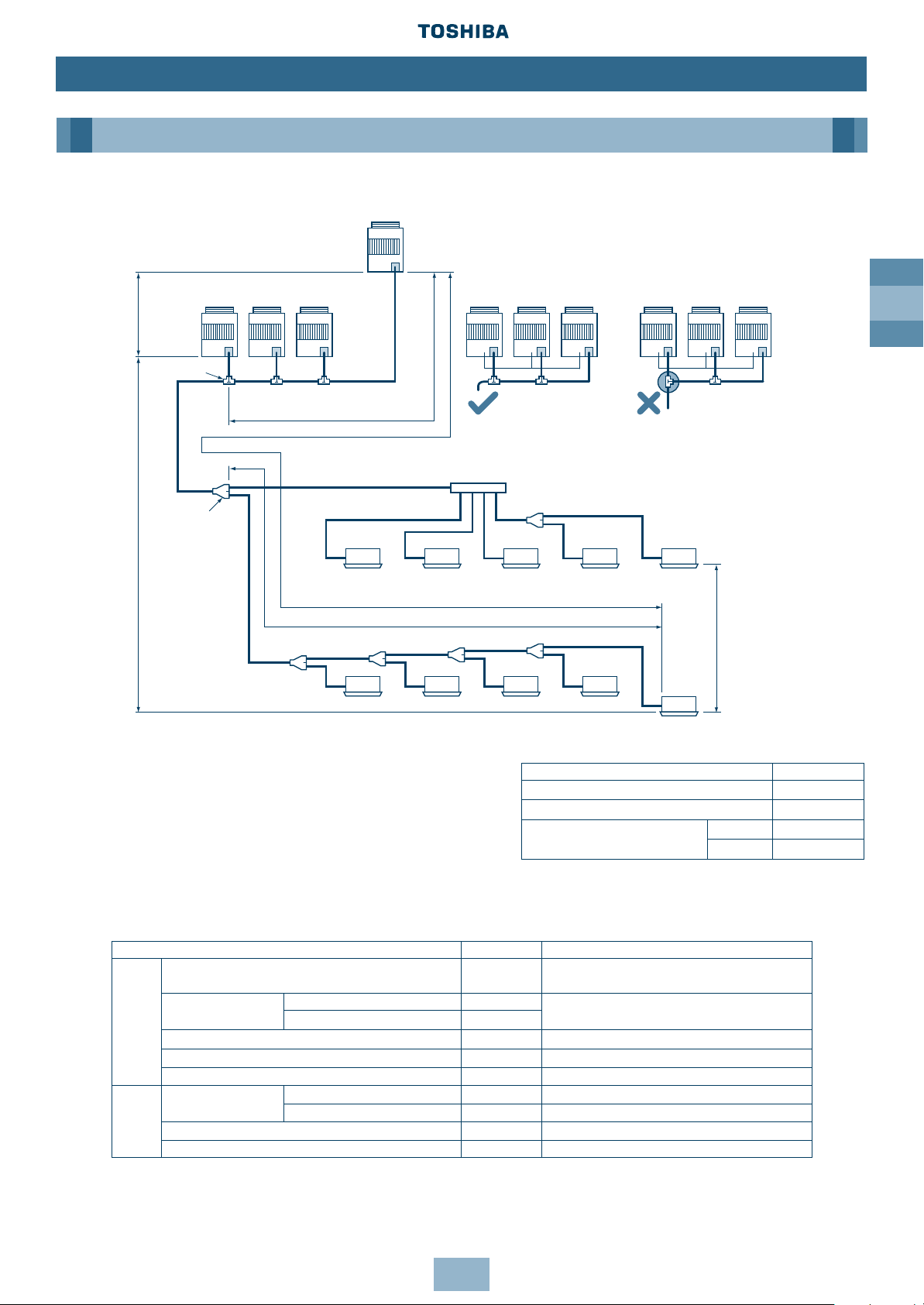

Installation of Outdoor Unit

1. Align the outdoor units at intervals of 20mm

or more.

Fix the outdoor units with M12 anchor bolts.

(4 positions per unit.)

Anchor bolt with 20mm length is suitable.

• Anchor bolt pitch is as shown in the following figure.

• However, the equivalent pipe length between the nearest outdoor unit and farthest outdoor

unit of the refrigerating cycle system should not exceed 20m.

2. When routing the refrigerant piping through the base, the fixing height of the base

(two-divided foundations) must be 500m or more.

3. Correct foundation mounts for supporting the Outdoor unit:

Note: The leading outdoor unit to be connected to the main refrigerant piping for the indoor

units must be an inverter unit.

Outdoor Unit

11

M12 anchor bolt,

4 positions per unit

≥ 20mm

700mm ≥ 310mm 700mm ≥ 310mm 700mm

755mm

≥ 500mm

20mm

≥ 20mm

15 x 20mm slot

Refrigerant Piping

✖

✔

Page 12

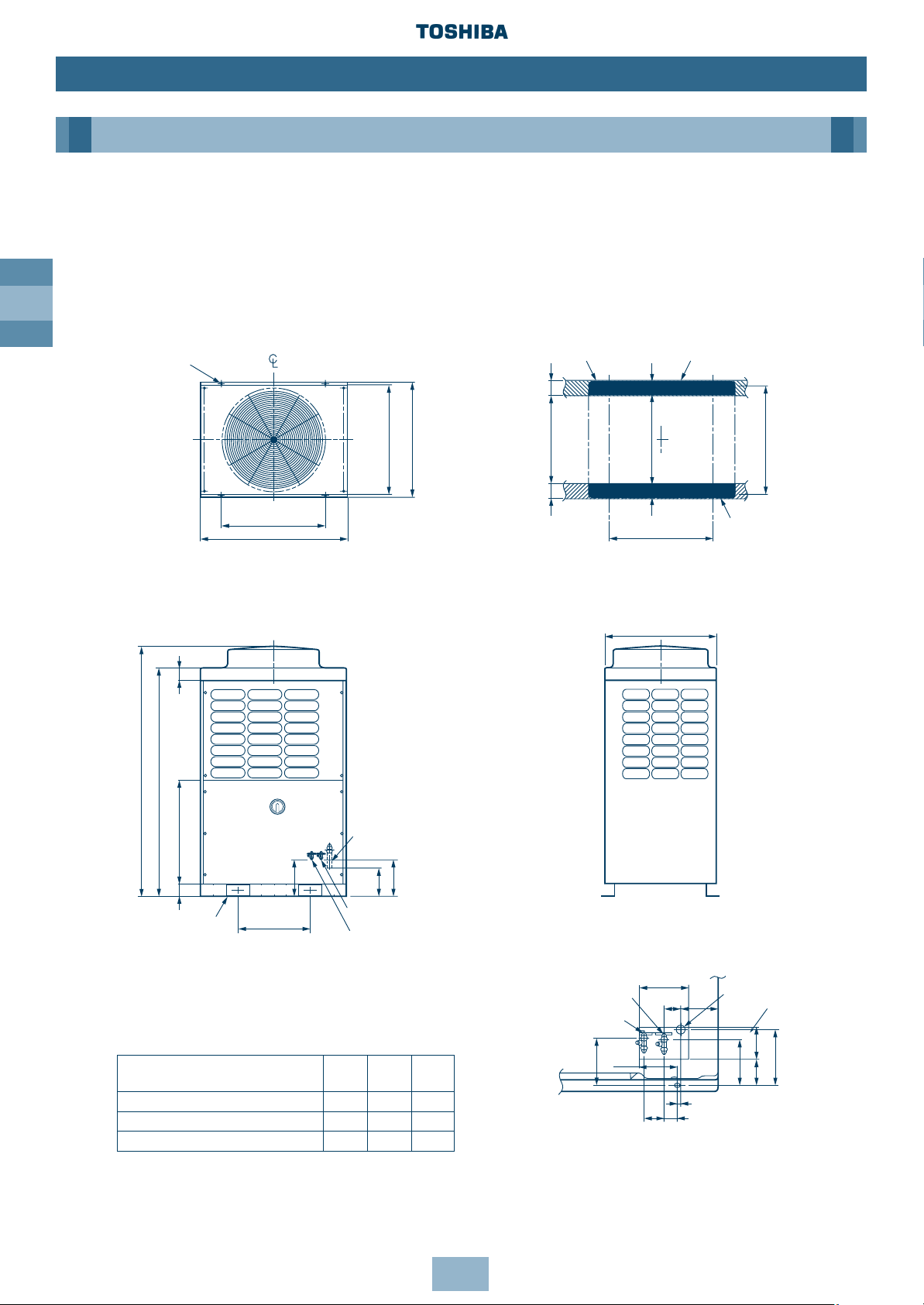

GB

12

Dimensional Drawings

Outdoor Unit

Model Name:

MM-A0280HT, MM-A0224HT, MM-A0280HX, MM-A0224HX, MM-A0160HX

Installation

Outdoor Unit

700

990

790

500

1700

1560

700 9088

130

145

140

170

125

64

20

65

35

60

115

173

610 100

700

750

100

630 80

755

80

245

190

755

235

Model

ØA ØB ØC

mm mm mm

MM-A0280HT, MM-A0280HX 28.6 12.7 9.52

MM-A0224HT, MM-A0224HX 22.2 12.7 9.52

MM-A0160HX 22.2 9.52 9.52

4-15 x 20 (Slot)

Fixing bolt pitch

Fixing bolt pitch

(including fixed leg)

Grounding part

of bottom plate

Base

Fixing bolt pitch

Base

Fixing bolt pitch

Refrigerant pipe connecting port

(Gas side) braze connection (ØA)

Refrigerant pipe connecting port

(Liquid side) flare connection (ØB)

Balance pipe connecting

port flare connection (ØC)

(Slot pitch)

2-60 x 150 Slot

(for transport)

(knock out)

Refrigerant pipe

connecting port

(Liquid side)

Balance pipe

connecting port

Refrigerant pipe

connecting port

(Gas side)

(knock out)

Details of piping

connections

Base bolt position

Note: All dimensions in (mm)

Page 13

GB

13

Installation

Dimensional Drawings

Two Units Connected

Model Name:

MM-A0384HT, MM-A0440HT, MM-A0504HT, MM-A0560HT

Outdoor Unit

2000

700

990 990

700

750

790

1700

1560

700

90

88

1 2

8-15 x 20 (Slot)

755 Fixing bolt pitch

Fixing bolt pitch

Fixing bolt pitch

(including fixed leg)

≥ 20

(Rear side)

≥ 300

≥ 10

≥ 500

(Front side)

≥ 20

≥ 2020

≥ 10

≥ 1550

No. Name

Outdoor Unit (Inverter type)

Outdoor Unit (Fixed-speed type)

1

2

Note: All dimensions in (mm)

Page 14

GB

14

Dimensional Drawings

Three Units Connected

Model Name:

MM-A0608HT, MM-A0672HT, MM-A0728HT, MM-A0784HT, MM-A0840HT

Installation

Outdoor Unit

700

990 990 990

700 700

750

790

1700

1560

700

90

88

1

2

3

310

310

≥ 20

≥ 20

12-15 x 20 (Slot)

755 Fixing bolt pitch

(including fixed leg)

Fixing bolt pitch

Fixing bolt pitch

Fixing bolt pitch

(Rear side)

≥ 300

≥ 10

≥ 500

(Front side)

≥ 20

≥ 20

≥ 3030

≥ 10

≥ 1550

No. Name

Outdoor Unit (Inverter type)

Outdoor Unit (Fixed-speed type 1)

Outdoor Unit (Fixed-speed type 2)

1

2

3

Note: All dimensions in (mm)

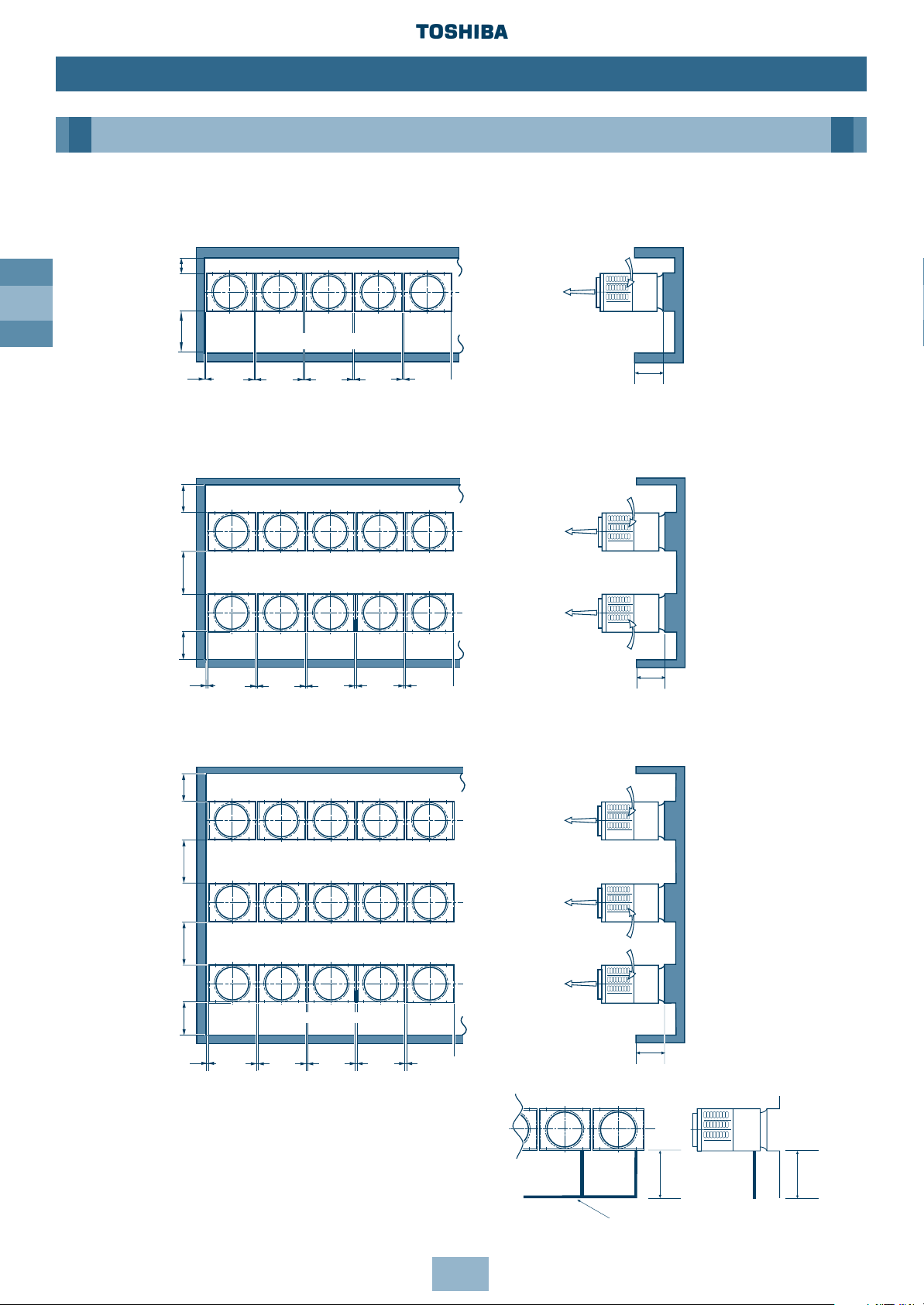

Page 15

GB

15

Dimensional Drawings

Four Units Connected

Model Name:

MM-A0896HT, MM-A0952HT, MM-A1008HT, MM-A1064HT, MM-A1120HT

Installation

Outdoor Unit

≥ 20

≥ 20 ≥ 20

16 - 15 x 20 (Slot)

755 Fixing bolt pitch

(including fixed leg)

(Rear side)

≥ 300

≥ 10

≥ 500

(Front side)

4020

1700

1560

700

90

88

700

990

700

990

700

990

700

750

790

1

2

3

4

990

310

310

310

≥ 20

≥ 20

≥ 20

≥ 4040

No. Name

Outdoor Unit (Inverter type)

Outdoor Unit (Fixed-speed type 1)

Outdoor Unit (Fixed-speed type 2)

Outdoor Unit (Fixed-speed type 3)

1

2

3

4

Fixing bolt pitch

Fixing bolt pitch Fixing bolt pitch Fixing bolt pitch

≥ 1550

≥ 10

Note: All dimensions in (mm)

Page 16

GB

16

Dimensional Drawings

Five Units Connected

Model Name:

MM-A1176HT, MM-A1232HT, MM-A1288HT

Installation

Outdoor Unit

5030

1700

1560

700

90

88

700

990

700

990

700

990

700

1

2

3

4

990

700

700

790

5

990

310

310

310

310

≥ 20 ≥ 20 ≥ 20 ≥ 20

20 - 15 x 20 (Slot)

755 Fixing bolt pitch

(including fixed leg)

Fixing bolt pitch Fixing bolt pitch Fixing bolt pitch Fixing bolt pitch Fixing bolt pitch

(Rear side)

≥ 300

≥ 10

≥ 500

(Front side)

≥ 10

≥ 1550

≥ 20 ≥ 20 ≥ 20 ≥ 20

≥ 5050

No. Name

Outdoor Unit (Inverter type)

Outdoor Unit (Fixed-speed type 1)

Outdoor Unit (Fixed-speed type 2)

Outdoor Unit (Fixed-speed type 3)

Outdoor Unit (Fixed-speed type 4)

1

2

3

4

5

Note: All dimensions in (mm)

Page 17

GB

17

Multiple Installation on the Rooftop

When the Outer Wall is Higher than the Outdoor Unit

If a hole can be made in the wall:

1. Set an aperture ratio so that suction air volume

Vs from the hole becomes 1.5m/s or less.

2. Height of discharge duct: HD = H - h.

If a hole cannot be made:

1. Set a base with 500 to 1,000mm height.

2. Height of discharge duct: HD = H - h.

Installation

Outdoor Unit

≥ 300

≥ 600

≥ 20 ≥ 20 ≥ 20 ≥ 20≥ 10

(Front side)

Discharge duct

≥ 1000

Hole in wall

Vs

HD

h

H

Discharge duct

Base

500 – 1000

Vs

HD

H

≥ 300≥ 600

≥ 20 ≥ 20 ≥ 20 ≥ 20≥ 10

(Front side)

h

Note: All dimensions in (mm)

Page 18

GB

18

Installation

Outdoor Unit

When the Outer Wall is Lower than the Outdoor Unit

1-line installation

2-parallel lines installation

3-parallel lines installation

*When refrigerant piping is routed from the front

of the unit, distance between Outdoor Unit and

Connecting piping must be 500mm or more.

≥ 300

≥ 500

≥ 20 ≥ 20 ≥ 20 ≥ 20≥ 10

(Front side)

≥ 600

*(≥ 1000)

≥ 300

≥ 300

≥ 20 ≥ 20 ≥ 20 ≥ 20

≤ 800

≥ 10

(Front side)

≥ 600

*(≥ 1000)

≥ 300

≥ 500 ≥ 600

≥ 20 ≥ 20 ≥ 20 ≥ 20≥ 10

(Front side)

(Front side)

≤ 800

≤ 800

≥ 500

≥ 500

Connecting Piping

Piping

Note: All dimensions in (mm)

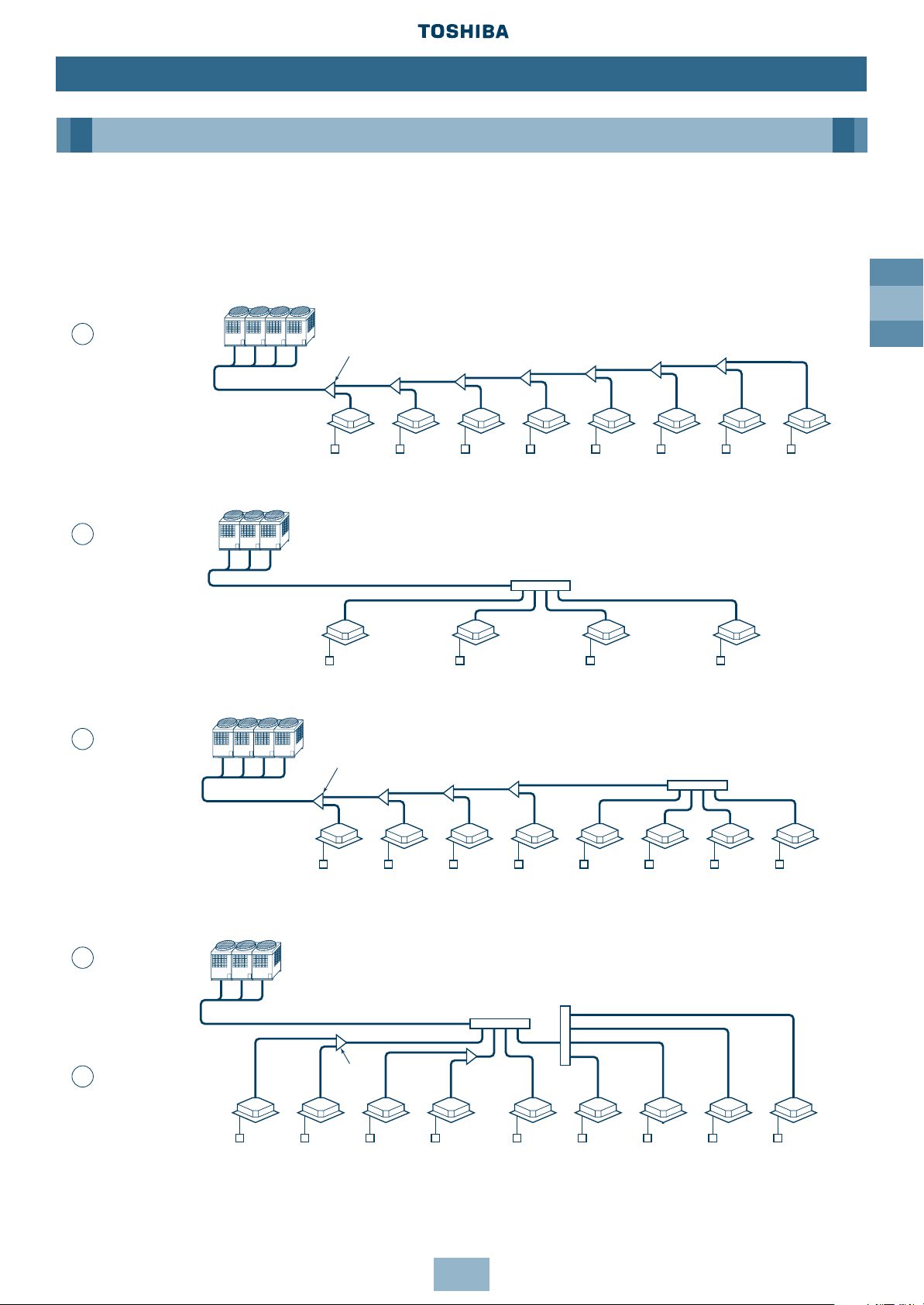

Page 19

GB

19

Installation

Piping

Free Branching System

The following five branching systems are available to increase the flexibility of refrigerant

piping design.

Outdoor units

Branching joint

Indoor

units

Line

branching

system

Remote

controller

Outdoor units

Branching

joint

Indoor

units

Line

branching

system after

header

branching

Header

branching

system after

header

branching

Remote

controller

Outdoor units

Branching joint

Indoor

units

Header

branching

system

after line

branching

Remote

controller

Outdoor units

Branching header

Branching header

Branching header

Indoor

units

Header

branching

system

Remote controller

1

2

3

4

5

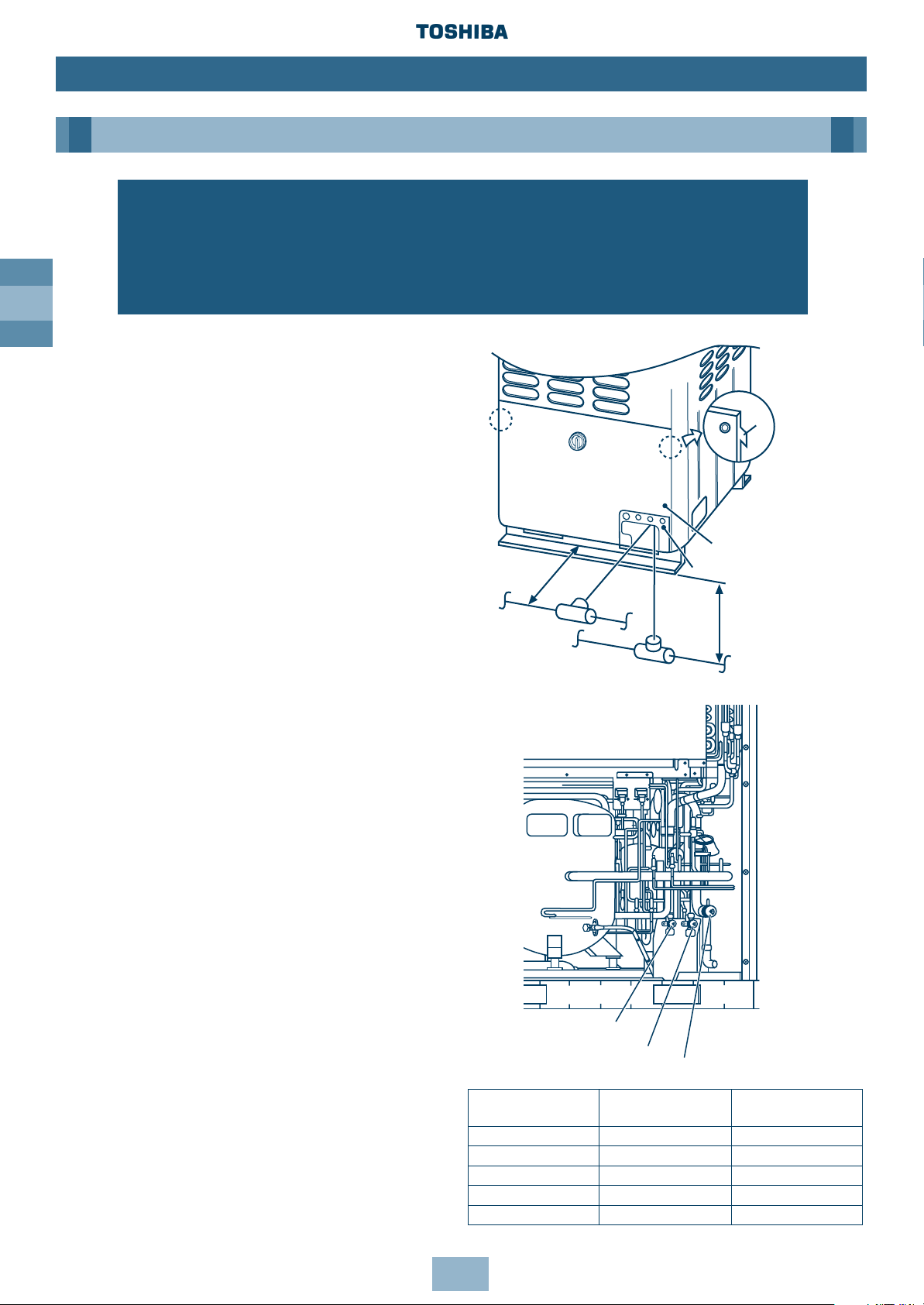

Page 20

GB

20

Installation

Piping

Connecting Refrigerant Pipes

1. To access the refrigerant piping

connections and electrical wiring

terminals, remove the 7xM5 securing

bolts in the front panel. To remove the

panel, lift it up and away from its hanging

tabs – See diagram.

2. The refrigerant pipes can be routed

forwards, downwards or sideways.

3. If the pipes are routed forwards, make

sure they exit through the Piping/Wiring

Panel – (remove knock out section) and

allow at least 500mm between the

Outdoor Unit and the main pipe

connecting it to the Indoor Unit. This is for

servicing access. (Replacing the

compressor, for example, requires a space

of at least 500mm.)

4. If the pipes are routed downwards,

remove the knockout section in the

baseplate of the Outdoor Unit. This will

enable access. They can then be

connected to the left or right, or the rear

side. (Leading pipe of the balancing

should be within 4m.)

Notes:

1. When brazing, use nitrogen. This prevents

internal oxidisation of the pipes.

2. Always use clean new pipe, and ensure it

is not contaminated by water or dust.

3. Always use a double spanner on the flare

nut – and tighten to the specified torque:

(see table).

Connecting pipe Tightening Re-tightening

outer dia. (mm) torque (Nm) torque (Nm)

Ø6.4 11.8 (1.2kgf m) 13.7 (1.4kgf m)

Ø9.5 24.5 (2.5kgf m) 29.4 (3.0kgf m)

Ø12.7 49.0 (5.0kgf m) 53.9 (5.5kgf m)

Ø15.9 78.4 (8.0kgf m) 98.0 (10.0kgf m)

Ø19.0 98.0 (10.0kgf m) 117.7 (12.0kgf m)

WARNING!

During installation – if the refrigerant gas leaks, ventilate the room.

After installation – check for gas leakages.

If refrigerant gas comes into contact with fire – noxious gas may result!

Front panel

Piping/Wiring Panel

Within 4m

Pipes routed downwards

Pipes routed

forward

≥ 500

Ta b

Valve at balance side (oil)

Valve at liquid side

Valve at gas side

Note: All dimensions in (mm)

Page 21

GB

21

Installation

Piping

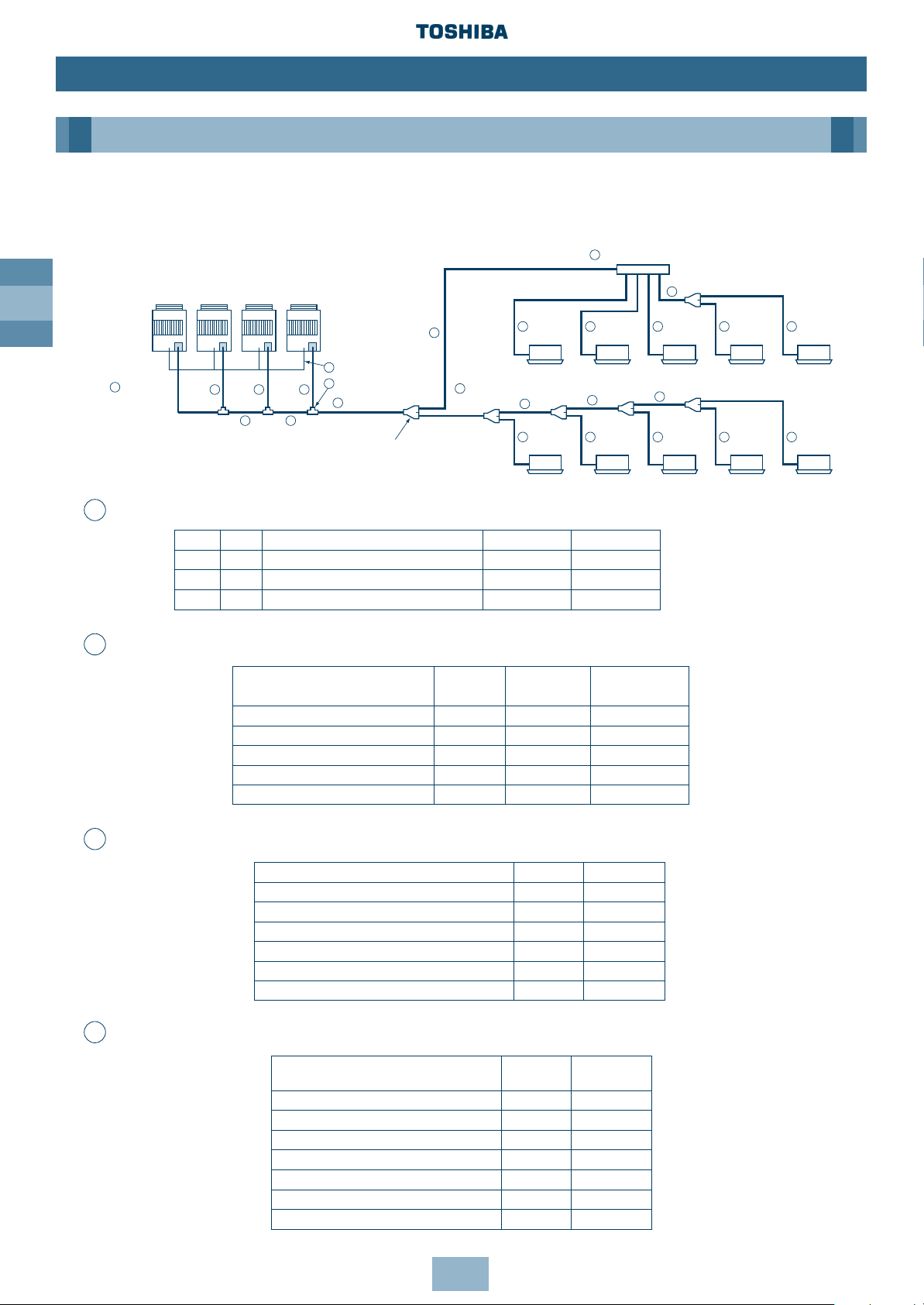

Permissible Length/Height Separation of Refrigerant Piping

La

LA LB

Lb Lc

L1

L2

L7

bc dea

ghi jf

L4

L5

L6

L3

Ld

(a)

(d)

(b) (c)

Fixed-speed

Unit n

Valve for

additional Units

Valve for

additional Units

Note: In <Ex.2>, a large amount of refrigerant and oil may

return to the Inverter Unit. Therefore, set the

T-shape joint so that oil does not enter directly.

Branching header

Branching piping

Connecting piping of Indoor Unit

Indoor Unit

Length corresponded to farthest piping L≤ 125m

Length corresponded to farthest piping after 1st branching L≤ 50m

Height difference

between Indoor

Units

H2≤ 30m

Indoor Unit

1st branching

section

Main

piping

Main connecting piping between Outdoor Units

Length corresponded to farthest piping

between Outdoor Units LO≤ 20m

Connecting

piping of

Outdoor

Unit

Fixedspeed

Unit 2

Fixedspeed

Unit 1

Inverter

Unit

Fixed-

speed

Unit 2

Fixedspeed

Unit 1

Inverter

Unit

Fixedspeed

Unit 2

Fixedspeed

Unit 1

Inverter

Unit

Outdoor

Unit

Height

difference

between

Outdoor

Units

H3≤ 4m

Height

difference

between

Outdoor

Units

H1≤ 50m

T-shape branching

joint

Y-joint

System Restrictions

Notes: Combination of Outdoor Units: Inverter Unit +

Fixed-speed Unit (0 to 4 units).

Combination of Fixed-speed Units without

Inverter Unit is not permissible.

The Inverter Unit is the master Outdoor Unit

and is directly connected to the indoor

distribution pipe.

Install the Outdoor Units in order of capacity.

(Inverter Unit≥ Fixed-speed Unit 1> Fixed-speed Unit 2>Fixed-speed Unit n).

Max. No. of combined outdoor units 5 units

Max. capacity of combined outdoor units 128.8kW/46HP

Max. No. of connected indoor units 40 units

Max. capacity of combined H2≤ 15 135%

indoor units H2>15 105%

Allowable value Piping section

Total extension of pipe (Liquid pipe, real length) 250m

LA + LB + La + Lb + Lc + Ld + L1 + L2 + L3 + L4+

L5 + L6 + L7 + a + b + c + d + e + f + g + h + i + j

Farthest piping length L (*)

Real length 100m

LA + LB + Ld + L1 + L3 + L4 + L5 + L6 + j

Piping Equivalent length 125m

length Equivalent length of farthest piping from 1st branching Li (*) 50m L3 + L4 + L5 + L6 + j

Equivalent length of farthest piping between outdoor units LO (*) 20m LA + LB + Ld, LA + Lb, LA + LB + Lc

Max. equivalent length of outdoor unit connecting piping 10m Ld, La, Lb, Lc

Height between indoor

Upper outdoor unit 50m ——

Height

and outdoor units H1

Lower outdoor unit 30m ——

difference Height between indoor units H2 30m ——

Height between outdoor units H3 4m ——

*(d) is Outdoor Unit farthest from branching and (j) is Indoor Unit farthest from 1st branching.

<Ex. 1> <Ex. 2>

Page 22

GB

22

Installation

Piping

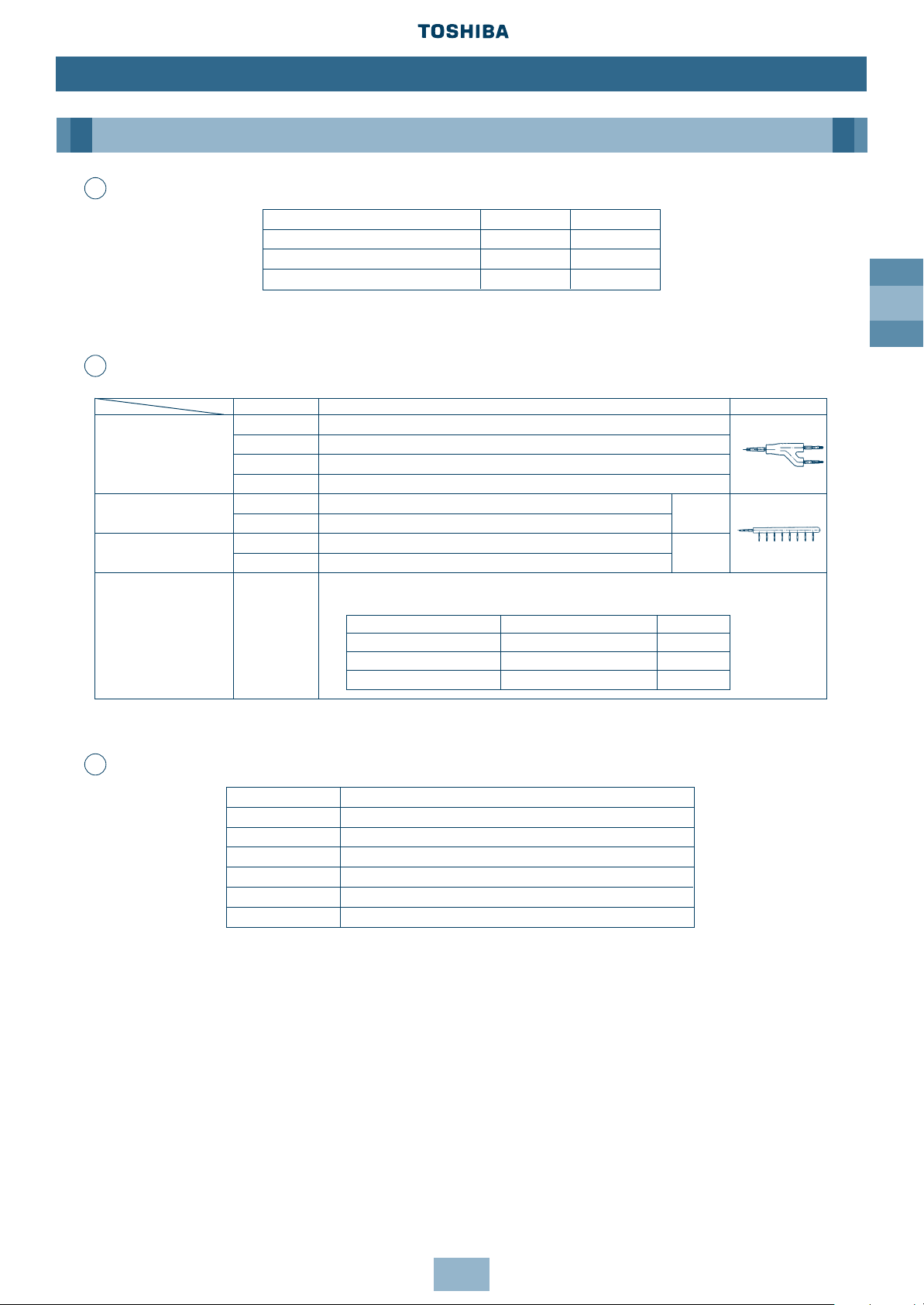

Selection of Refrigerant Piping and Charge Requirement

3

1

1 1 1

22

4

5 5 5

4

4

4

4

5 5

5 5 5 5 5

2

6

6

6

Fixedspeed

Unit n

Fixedspeed

Unit 2

Fixedspeed

Unit 1

Inverter

Unit

Branching piping

Header Branching Pipe

Outdoor Unit

Outdoor

Unit

connecting

piping

Main connecting

piping between

Outdoor Units

Main piping

T-shape branching joint

Balance pipe

Y-shape branching

joint

Indoor Unit

connecting

piping

1st branching

section

Indoor Unit

Indoor Unit

Indoor Unit connecting pipe

kW HP Model name Gas side Liquid side

16.0 6 MM-A0160HX Ø22.2 Ø9.5

22.4 8 MM-A0224HT, MM-A0224HX Ø22.2 Ø12.7

28.0 10 MM-A0280HT, MM-A0280HX Ø28.6 Ø12.7

Total capacity code of all outdoor units Gas side Liquid side

Below 10 Ø22.2 Ø12.7

10 to Below 14 Ø28.6 Ø12.7

14 to Below 20 Ø34.9 Ø15.9

20 to Below 26 Ø41.3 Ø19.0

26 to Below 32 Ø41.3 Ø22.2

32 or more Ø54.1 Ø22.2

Total capacity code of indoor units

Gas side Liquid side

downstream (*1)

Below 4.0 Ø15.9 Ø9.5

4.0 to Below 6.4 Ø19.0 Ø9.5

6.4 to Below 13.2 Ø22.2 Ø12.7

13.2 to Below 19.2 Ø34.9 Ø15.9

19.2 to Below 25.2 Ø41.3 Ø19.0

25.2 to Below 31.2 Ø41.3 Ø19.0

31.2 or more Ø54.1 Ø22.2

Total capacity code of outdoor

Gas side Liquid side Balance pipe

units

Below 16 Ø28.6 Ø15.9 Ø9.5

16 to Below 20 Ø34.9 Ø15.9 Ø9.5

20 to Below 26 Ø41.3 Ø19.0 Ø9.5

26 to Below 32 Ø41.3 Ø22.2 Ø9.5

32 or more Ø54.1 Ø22.2 Ø9.5

Pipe Size of Outdoor Unit

Connecting Pipe Size Between Outdoor Units

Size of Main Pipe

Size Between Branching Sections

1

2

3

4

Note: All dimensions in (mm)

Page 23

GB

23

Installation

Piping

Unit Gas side

(*4)

Liquid side

028 type to 056 type Ø12.7 Ø 6.4

080 type Ø15.9 Ø 9.5

112 type to 140 type Ø19.0 Ø 9.5

i.e. MM-SB028 = Gas Ø12.7, Liquid Ø6.4

Liquid pipe size Additional refrigerant amount for liquid pipe 1m (kg)

Ø6.4 0.030

Ø9.5 0.065

Ø12.7 0.115

Ø15.9 0.190

Ø19.0 0.290

Ø22.2 0.420

Piping of Indoor Unit

Additional Refrigerant Amount

(*1) Code is determined according to the capacity code of the Indoor Units connected. For

details, refer to the Introduction section in this manual.

(*2) If the total capacity code value of Indoor Units exceeds that of Outdoor Units, apply the

capacity code of Outdoor Units.

(*3) When using a branch header, Indoor Units with a maximum of 6.0 capacity code in total

can be connected to each branch.

(*4) If the length of the gas pipe exceeds 30m from the 1st branching to an Indoor Unit,

increase the Gas pipe section by 1 size, i.e. MM-U140 = Gas Ø22.2, Liquid Ø9.5.

5

6

7

Note: All dimensions in (mm)

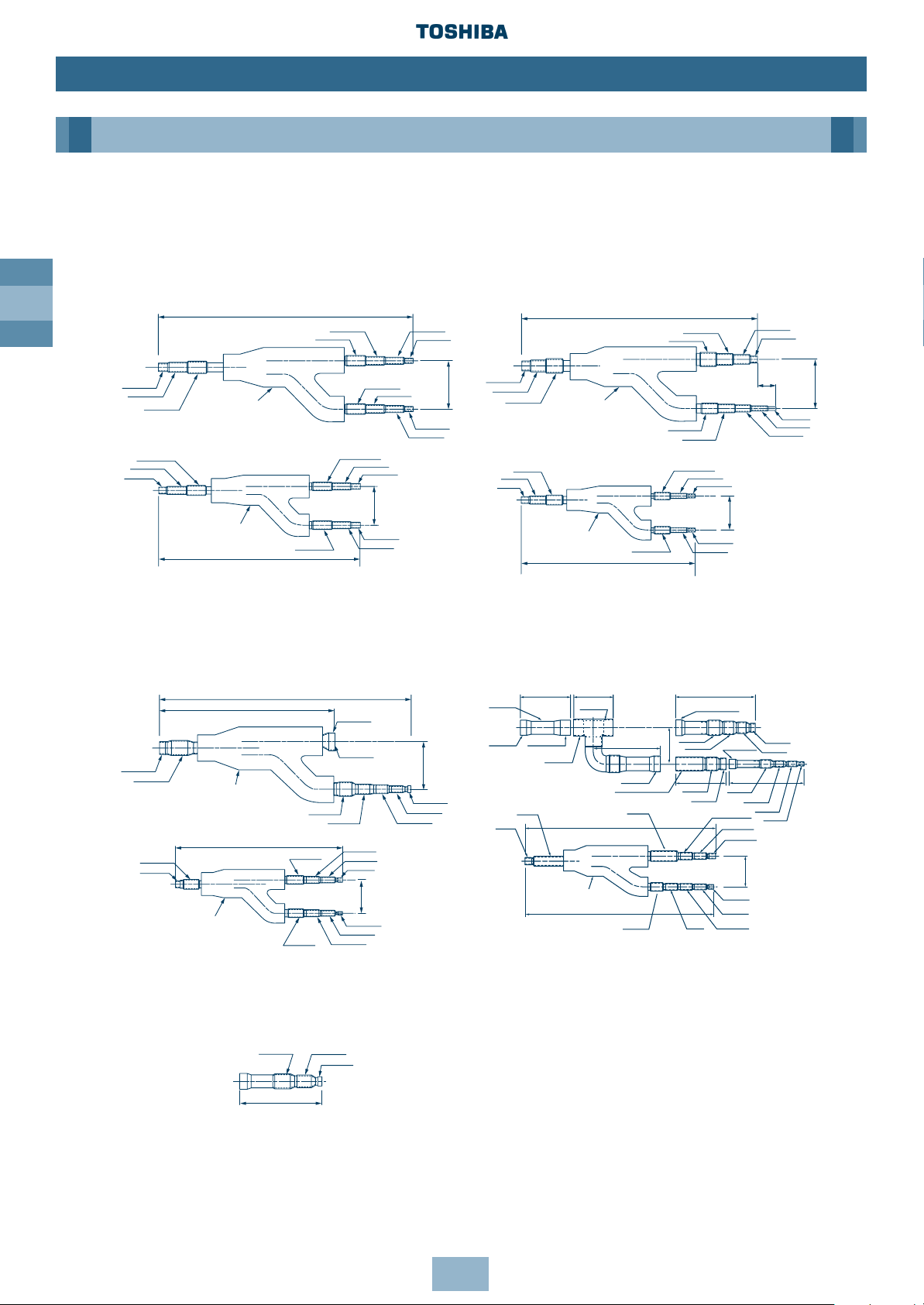

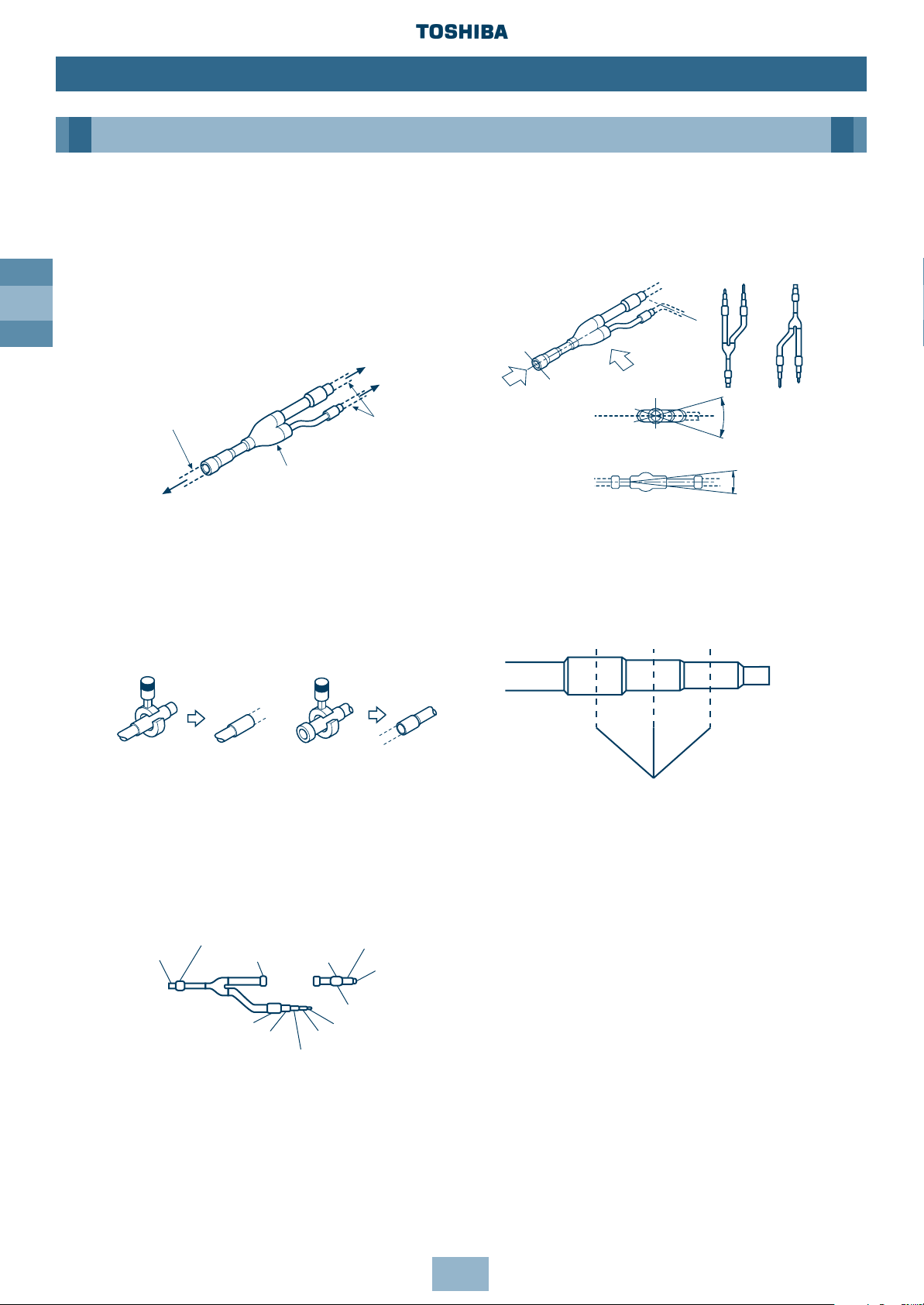

Model name Usage Appearance

RBM-Y018 Indoor unit capacity code (*1): Total below 6.4

Y-shape RBM-Y037 Indoor unit capacity code (*1): Total 6.4 or more and below 13.2 (*2)

branching joint RBM-Y071 Indoor unit capacity code (*1): Total 13.2 or more and below 25.2 (*2)

RBM-Y129 Indoor unit capacity code (*1): Total 25.2 or more (*2)

4-branching header (*3)

RBM-H4037 Indoor unit capacity code (*1): Total below 13.2

Max. 4

RBM-H4071 Indoor unit capacity code (*1): Total 13.2 or more and below 25.2

branches

8-branching header (*3) RBM-H8037 Indoor unit capacity code (*1): Total below 13.2

Max. 8

RBM-H8071 Indoor unit capacity code (*1): Total 13.2 or more and below 25.2

branches

1 set of 3 types of T-shape joint pipes as described below:

The required quantity is arranged and they are combined at the site.

T-shape branching joint

(For connection of RBM-T129

outdoor unit)

Connecting pipe Corresponding dia. (mm) Qty

Balancing pipe Ø9.52 1

Piping at liquid side Ø12.7 to Ø22.2 1

Piping at gas side Ø22.2 to Ø54.1 1

Branching joints/headers

Page 24

GB

24

Installation

Piping

Branch Headers/Branch Joints (Accessories)

Note:

This additional connecting pipe is used if the

gas pipe size is Ø41.3 or less. When brazing,

the minimum insertion margin is 15mm.

Y-shape Branch Joint

Note: All dimensions in (mm)

[Gas side]

[Liquid side]

[Liquid side]

[Gas side]

Heat insulator

Heat insulator

RBM-Y018

RBM-Y037

Heat insulator

Heat insulator

Ø9.5

Ø9.5

Ø6.4

Ø6.4

Ø9.5

Ø19.0

Ø19.0

Ø28.6

571

Ø22.2

Ø22.2

Ø28.6

Ø9.5

Ø12.7

Ø15.9

Ø15.9

Ø12.7

Ø12.7

Ø12.7

Ø12.7

Ø9.5

Ø9.5

Ø9.5

Ø6.4

Ø6.4

420

Ø15.9

Ø19.0

Ø19.0

Ø15.9

Ø19.0

Ø9.5

Ø22.2

528

Ø15.9

Ø15.9

Ø12.7

Ø9.5

Ø22.2

Ø31.8

100

80

Ø12.7

Ø12.7

Ø12.7

44

Ø15.9

80

120

420

Heat insulator

Heat insulator

[Gas side]

[Gas side]

[Liquid side]

[Liquid side]

RBM-Y071

RBM-Y129

Ø12.7

Ø9.5

Ø6.4

85

Ø15.9

Ø19.0

518

Heat insulator

523

Ø19.0

Ø22.2 Ø22.2

Ø41.3

Ø41.3

Ø34.9

Ø34.9

Ø41.3

Ø22.2

Ø19.0

Ø15.9

Ø19.0

Ø19.0

Ø6.4

Ø9.5

Ø15.9

Ø15.9

Ø15.9

122.5

85

Ø12.7

Ø12.7

Ø12.7

Ø9.5

A

444

423

638

Ø54.1

(outer dia.)

Ø54.1

Ø54.1

Ø41.3

Ø54.1

212

Ø41.3

(outer dia.)

Ø19.0

Ø19.0

Ø22.2

237

Ø34.9

160

Ø41.3

Ø15.9

Ø15.9

Ø12.7

Ø12.7

Ø34.9

Ø22.2

Ø54.1

(outer dia.)

253.5

126160

Ø34.9

(outer dia.)

Ø41.3

Ø41.3

Ø19.0

194

Ø34.9

Ø22.2

Page 25

GB

25

Installation

Piping

Branch Header

Note: Pipe dia. shown indicates dia. of pipe to be connected.

T-shape Branch Joint

Note: All dimensions in (mm)

RBM-H8037

[Gas side]

[Liquid side]

Heat insulator

RBM-H4037

[Gas side]

[Liquid side]

Heat insulator

Heat insulator

Heat insulator

515

Ø15.9

Ø12.7

Ø12.7

Ø15.9

Ø15.9

Ø19.0

Ø19.0

80 80 80

80 80 80

204

109

522

75

Ø19.0

Ø9.5

Ø6.4

Ø9.5

Ø9.5

Ø22.2

Ø28.6

Ø9.5

Ø9.5

Ø9.5

Ø6.4

80 80 80 80 80 80 80

80808080808080

75

109

204

842

795

Ø12.7

Ø12.7

Ø19.0

Ø19.0

Ø19.0

Ø2.22

Ø28.6

Ø15.9

Ø15.9

RBM-H4071

RBM-H8071

[Gas side]

[Gas side]

[Liquid side]

[Liquid side]

Heat insulator

Heat insulator

Heat insulator

Heat insulator

80 80 80

8080 80

209

109

449

522

Ø9.5

Ø9.5

Ø9.5

Ø6.4

Ø19.0

Ø19.0

Ø34.9

Ø41.3

Ø15.9

Ø15.9

Ø12.7

Ø12.7

75

Ø9.5

Ø9.5

Ø34.9

Ø9.5

Ø6.4 80 8080808080 80

80 80 80 80 80 80 80

75

209

109

842

769

Ø12.7

Ø12.7

Ø41.3

Ø15.9

Ø19.0

Ø19.0

Ø15.9

RBM-T129

[Gas side]

[Liquid side]

[Balance side]

Outside

diameter

Outside

diameter

2 pieces

included

3 pieces

included

3 pieces

included

2 pieces

included

Outside

diameter

Ø54.1

Ø54.1

Ø54.1

Ø54.1

Ø22.2

Ø22.2

Ø22.2

Ø22.2

Ø9.52

Ø9.52

Ø9.52

Ø22.2

Ø19.0

Ø34.9

Ø34.9

Ø41.3

Ø28.6

Ø22.2

Ø12.7

Ø9.53

Ø15.9

Ø15.9

Page 26

GB

26

Piping

Installation

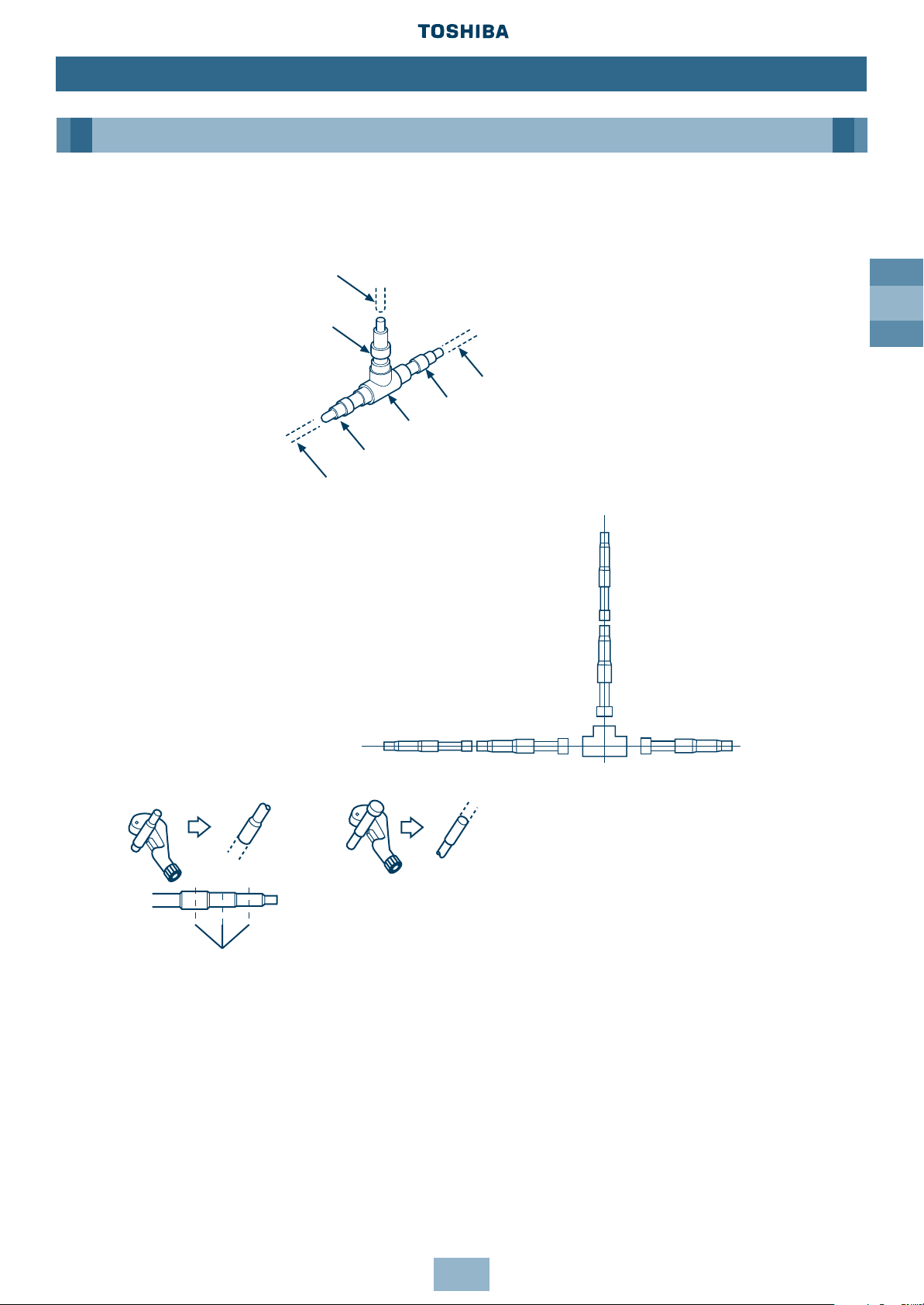

Connecting the Branching Kit

Y-shape Branching Joint

Y-shape Branching Joint for gas and liquid

distribution

When the selected pipe size differs from the

size of the y-shape branching joint pipe, cut

the centre of the connecting section with a

pipe cutter, as shown below.

• Use the attached auxiliary pipe to adjust

the pipe dia. of the Y-shape branching

joint at gas or liquid side (RBM-Y071,

RBM-Y129). Cut the branched pipe and

auxiliary pipe to the specified size, and

then braze.

Piping at site

Piping at site

To Outdoor Unit

Y-shape branching joint for

gas side/liquid distribution

To other Branching Pipe

or Indoor Unit

Inlet

Outlet (1)

Outlet (2)

Ø34.9

Ø41.3

Ø41.3

Ø34.9

Ø22.2

Ø19.0

Auxiliary pipe

at gas side

Ø12.7

Ø15.9

Ø19.0

Ø34.9

Ø22.2

Y-shape Joint for gas and liquid distribution

• Install Y-shape branching joint so that it

branches horizontally or vertically.

• Be sure to fit the insulation to the Y-shape

branching joint supplied in the kit.

• Cutting position

Cut the pipe at the centre of each

connecting section, and remove burr.

A

(Horizontal line)

(Horizontal line)

(A view)

(B view)

Within ± 30°

Within ± 30°

B

or

Cut at the centre

Note: All dimensions in (mm)

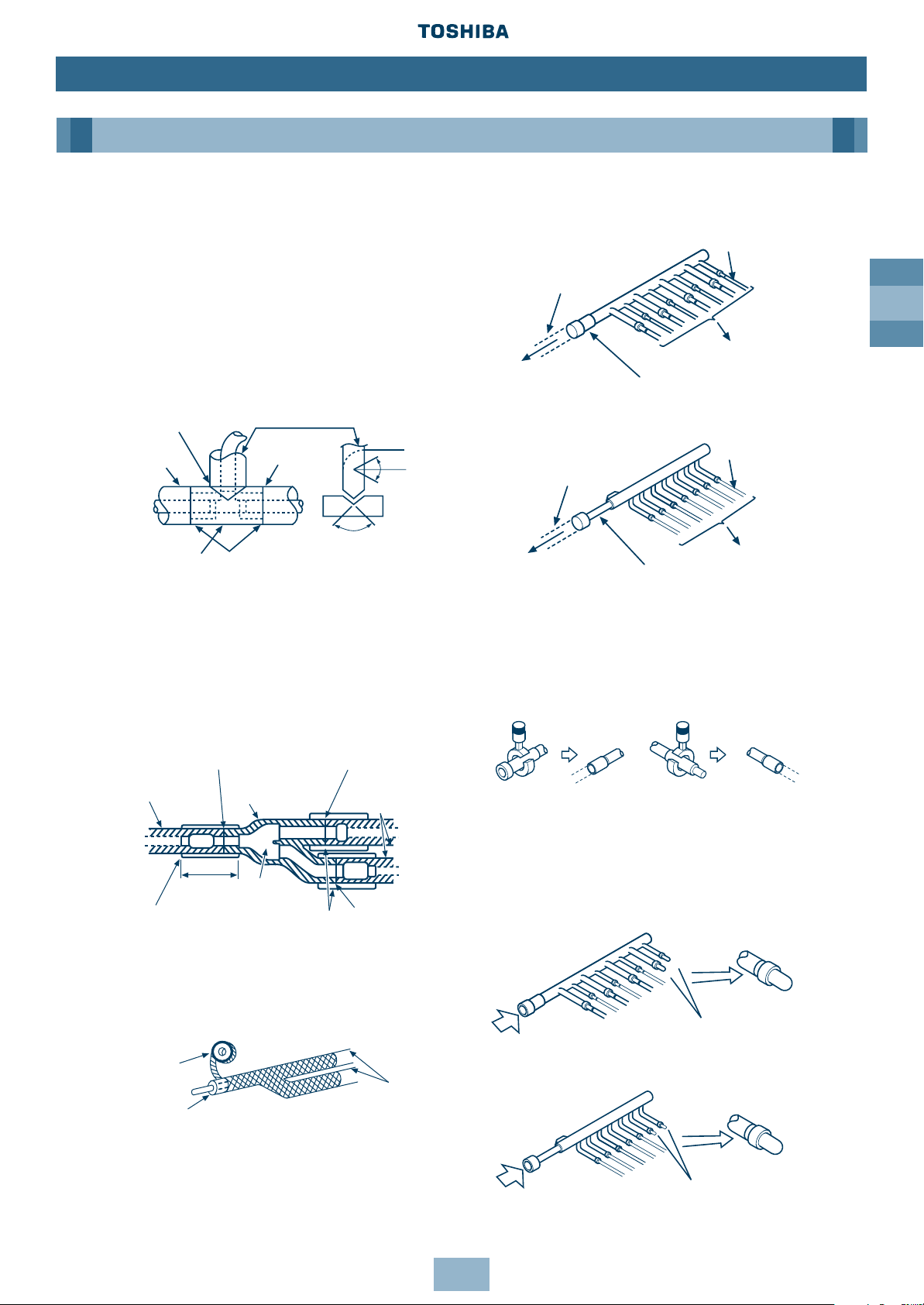

Page 27

GB

27

Installation

Piping

Branching Header

When the selected pipe size prepared at

site differs from the size of the branching

header pipe, cut the centre of the

connecting section with a pipe cutter

as shown.

If the number of Indoor Units to be

connected is less than the number of

connections on the Branching Header, braze

a pipe cap to the unused connectors.

Heat Insulating the Branching Pipes

Ensure the pipe insulation covers the piping

up to the brazed accessory joints, as this will

eliminate ingress of water – tape the pipe

insulation to a thickness of 10mm or more,

as shown.

RBM-Y129 (Gas side) (Prepared at site)

RBM-Y071 (Gas side, Liquid side),

RBM-Y129 (Liquid side)

Use insulator with a heat resistance of 120° C

or over for gas pipes. To insulate the

Branching Pipes, use a T-Shaped Joint cover

with a thickness of 10mm or over – or a

machined insulation portion, as shown.

• After the heat insulating, tape to seal.

Seal the joint with

urethane foaming

agent, etc.

Pipe heat

insulator

Cut by

approx.

60°

Cut by

approx. 90°

Seal with

vinyl tape

Heat insulating

pipe for piping

Heat insulating

pipe for piping

Bring them face

to face

Pipe heat insulator

prepared at site

Heat insulator (prepared at site),

10mm or over

150

Branching Pipe

Heat insulator

included accessory

Pipe heat

insulator

prepared at site

Place them edge to edge

Place them

edge to edge

Place them edge to edge

Taping

(prepared

at site)

Heat insulator

(prepared at site)

Heat insulator

(prepared

at site)

Prepared at site

Prepared at site

Prepared at site

To Indoor Unit

Gas branching header

Liquid branching header

To Indoor Unit

Prepared at site

To Outdoor

Unit

To Outdoor

Unit

Liquid side

Gas side

Gas side

Liquid side

B

B

Pipe cap

Pipe cap

Inlet

Inlet

Page 28

GB

28

Installation

Piping

• Install the branching header so that it

branches horizontally. DO NOT install

vertically.

• Be sure to insulate the branching header

with the insulation provided.

• When routing the branching header at

the liquid side from the opposite side,

cut both ends and use a pipe cap (not

supplied), as shown.

• Support of branching header

Set a hanging metal support (prepared at

site) for the branching header, after fitting

heat insulation.

• Cutting position

Cut the centre of each connecting section,

and remove burr.

Use a mini-cutter to cut branching headers

up to Ø22.2.

(Horizontal line)

(Horizontal line)

Gas side

Liquid side

(B view)

Gas side

(B view)

Liquid side

To B

B

Cut

A

Cut

C

Cut

To C

Pipe cap

Cut at the centre

Notes:

1. Make sure there’s a straight run of pipe at least 300mm long at the inlet side of

Y-shaped Branching Joints and Branching Headers.

2. Install Y-shaped Branching Joint so they branch horizontally or vertically. In horizontal

installations, set within ± 30°.

3. Install Branching Headers so they branch horizontally.

4. Do not use T-shaped Branching Joints for Branching Sections.

5. When using Y-Branches or Header Branches to prevent incorrect piping, attach a line number

or name to each pipe.

Note: All dimensions in (mm)

Page 29

GB

29

Installation

Piping

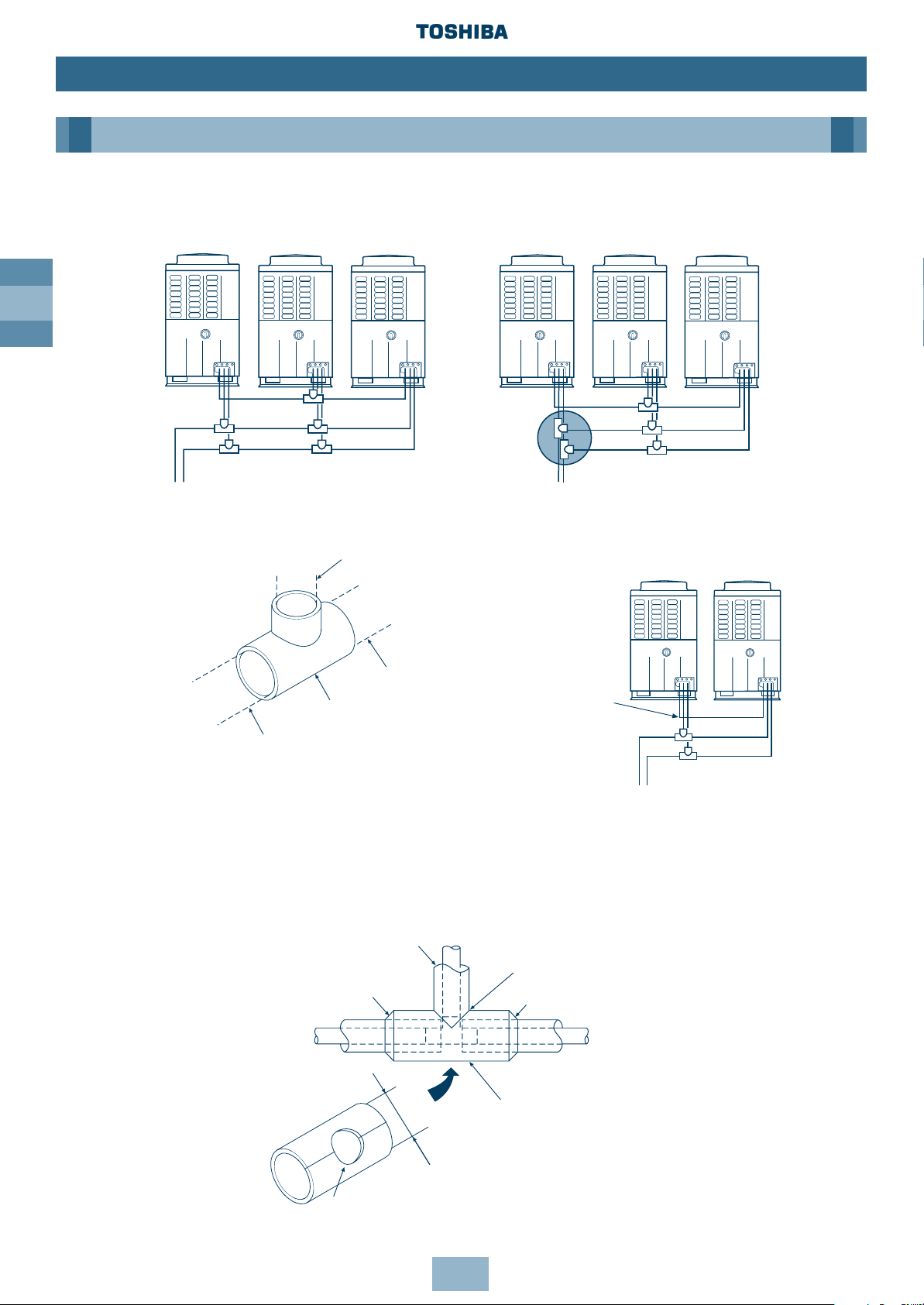

T-shape Branching Joint – to Connect Outdoor Units

Branching Pipes at Gas Side/Liquid Side

Pipe prepared at site

Pipe arranged at site

Pipe arranged at site

Connecting pipe at gas/liquid side

Connecting pipe at gas/liquid side

Branching Pipe at gas/liquid side

To other Branching

Pipe or Outdoor Unit

To other Branching

Pipe or Branching

Section of main pipe

To Outdoor Unit

Connecting pipe at

gas/liquid side

To Outdoor Unit

To other

Branching Pipe

or Outdoor Unit

To other Branching

Pipe or Branching

Section of main pipe

Cut the centre

• Use the included connecting pipes for

gas/liquid sides to match to the

appropriate pipe size. (The diagram shows

a connecting example.)

• Cutting position of connecting pipe

When the selected pipe size prepared

at site differs from the size of the

Branching Pipe, cut the centre of the

connecting section with a pipe cutter.

Page 30

GB

30

Installation

Piping

Installation of Gas/Liquid Branching Pipes

When

combining two

units, connect

directly.

Balancing Branch Pipes (Oil)

Heat Insulation

Insulate liquid side, gas side and Balancing Pipes separately.

Use insulator with a resistance of 120°C + for gas pipes.

To insulate the Branching Pipes, use a T-Shaped Joint cover with a thickness of 10mm or over

– or the machined one included. (Insulation for branching is not included.)

To prevent condensation or dripping – seal the Branching Pipe securely, with no gaps.

Inverter

Outdoor Unit

Fixed-speed

Outdoor Unit

Inverter

Outdoor Unit

Fixed-speed

Outdoor Unit

INCORRECT

ROUTING

To Outdoor

Unit

Branching Pipe for

Balancing Pipe (included)

Pipe prepared at site

Pipe prepared

at site

Pipe prepared

at site

To other

Branching Pipe

or Outdoor Unit

To other

Branching Pipe

or Outdoor Unit

Inverter

Outdoor Unit

Connect

Balancing

Pipe directly

Fixed-speed

Outdoor Unit

Seal with vinyl tape

Heat insulator

External dia. of

Branching Pipe

Seal the joint with urethane

foaming agent, etc.

Heat insulating pipe for piping

Heat insulating pipe for piping

Drill a hole with dia. larger than external

dia. of heat insulating pipe for piping

✖

✔

Page 31

GB

31

Installation

Piping

Airtight Test

Carry out an airtight test after the refrigerant piping is complete. For an airtight test, connect a

nitrogen gas bottle as shown, and apply pressure.

• Be sure to carry out the test from the service ports of the packed valves at both the gas side

and balance side.

• Complete the airtight test on the service ports at liquid, gas and balance sides of the Inverter

Outdoor Unit ONLY.

• Keep all of the valves at gas, liquid and balance sides fully closed. Nitrogen may enter the

cycle of the Outdoor Unit. Therefore, re-tighten the valve rod before applying pressure. (For

all valves at gas, liquid and balance sides.)

• For each refrigerant line, apply pressure gradually at gas, liquid and balance sides.

Be sure to apply pressure at gas, liquid and balance sides.

Never use oxygen, or a flammable noxious gas.

To detect a large leakage

STEP 1: 0.3MPa (3.0kg/cm

2

G) Apply pressure for 3 minutes or more

STEP 2: 1.5MPa (15kg/cm2G) Apply pressure for 3 minutes or more

To detect a fine leakage

STEP 3: 3.0MPa (30kg/cm2G) Apply pressure for 24 hours

• Check for a reduction in pressure.

If there is no reduction in pressure this is acceptable.

If there is a reduction in pressure check for leakage.

(Note: If there is a difference of ambient temp. between when the pressure was applied and

24 hours later, then pressure could change by approx. 0.01MPa (0.1kg/cm2G) – so correct the

pressure change.)

Detailed drawing of packed valve

To gauge manifold

Service port

at liquid side

Packed valve

at liquid side

Service port at

balance side

Packed valve at

balance side

Piping at site

Service port

at gas side

Packed valve

at gas side

Piping

at site

Piping at site

To main

unit

To main

unit

To main

unit

Connected to Indoor Unit

Connected to other fixed-speed Outdoor Unit

Packed valve fully

closed (liquid side)

Packed valve fully

closed (balance side)

Inverter Outdoor Unit

Service port

Service port

Gauge

manifold

Nitrogen

gas

Regulator

Ø6.4

Copper

pipe

Ø6.4

Copper

pipe

Packed valve fully

closed (Gas side)

Flare

connection

Flare

connection

Brazing

Lowpressure

gauge

Highpressure

gauge

Main pipe

Note: All dimensions in (mm)

Page 32

GB

32

Installation

Piping

• Use a vacuum pump with high vacuum carry-over degree (0.750mmHg or less) and large

displacement (40L/min. or more).

• Perform vacuuming for 2 or 3 hours, though time depends on pipe length. Confirm that all

packed valves at liquid, gas and balance sides are fully closed.

• If vacuum does not reach 0.750mmHg or less even after pumping for 2 hours or more, carry

on for another hour. If it is still not reached even after 3 hours, check for leaks.

• When vacuum has reached 0.750mmHg or less after 2 hours or more, fully close valves VL

and VH on the gauge manifold, stop the vacuum pump, leave for 1 hour, and then confirm

the vacuum reading has not changed. If it has, there may be a leak – so carry out a full

piping check.

• After the procedure has been completed, replace the vacuum pump with a refrigerant bottle

and add the refrigerant.

Leak Position Check

If a pressure drop is detected, check for leakage at connecting points. Locate the leakage by

listening, feeling, using foaming agent etc. – then re-braze or re-tighten.

Air Purge

Using a vacuum pump, complete an air purge. Never use refrigerant gas.

• After the airtight test, discharge the nitrogen gas.

• Connect a gauge manifold to the service port at liquid side, gas side and balance side,

and connect a vacuum pump as shown.

• Be sure to vacuum at liquid, gas and balance sides.

Detailed drawing of packed valve

To gauge

manifold

Service port

at liquid side

Packed valve

at liquid side

Service port at

balance side

Packed valve at

balance side

Service port

at gas side

Packed valve fully

closed (Gas side)

Lowpressure

gauge

Gauge

manifold

Vacuum

pump

Highpressure

gauge

Packed valve fully

closed (liquid side)

Packed valve fully

closed (balance side)

Packed valve

at gas side

Piping at site

Piping at site

Piping

at site

To main

unit

To main

unit

To main

unit

Connected to Indoor Unit

Inverter Outdoor Unit

Service port

Service port

Brazing

Flare

connection

Flare

connection

Main pipe

Page 33

GB

33

Adding the Refrigerant

After the airtight test, replace the vacuum pump with a refrigerant bottle to charge the system.

Calculating the Additional Refrigerant Required

The refrigerant amount at shipment does not include the refrigerant needed for the piping – so

first calculate this amount, and then add it.

Refrigerant charge amount shipped from the factory

The amount of additional refrigerant is calculated from the size of the liquid pipe, and its

real length.

Additional refrigerant charge amount at site =

Real length of liquid pipe x Additional refrigerant charge amount per liquid pipe 1m.

Example:

Additional charge amount R (kg) = (L1 x 0.030kg/m) + (L2 x 0.065kg/m)+ (L3 x 0.115kg/m)

L1: Real total length of liquid pipe Ø6.4 (m)

L2: Real total length of liquid pipe Ø9.5 (m)

L3: Real total length of liquid pipe Ø12.7 (m)

Charging the System

• Keeping the Outdoor Unit valve closed, charge the refrigerant from the service port on the

liquid side.

• If the specified amount of refrigerant cannot be charged – fully open the Outdoor Unit’s

valves on the liquid, gas and balance sides, then perform the cooling operation with the

valve at the gas side slightly closed.

• If leaks cause a shortage of refrigerant – recover the refrigerant from the system, and

recharge with new refrigerant to the total refrigerant charge.

Installation

Piping

Outdoor Unit Model name MM- A0224HT A0280HT A0160HX A0224HX A0280HX

Charging amount (kg) 15.5 17.0 5.0 7.0 9.0

Pipe dia. at liquid side Additional refrigerant amount/1m

Ø6.4 0.030kg

Ø9.5 0.065kg

Ø12.7 0.115kg

Ø15.9 0.190kg

Ø19.0 0.290kg

Ø22.2 0.420kg

Note: All dimensions in (mm)

Page 34

GB

34

Additional Charge Amounts

Installation

Piping

Pipe Length Liquid Pipe Diameter (mm)

(m) Ø6.4 Ø9.5 Ø12.7 Ø15.9 Ø19.0 Ø22.2

1 0.030 0.065 0.115 0.190 0.290 0.420

2 0.060 0.130 0.230 0.380 0.580 0.840

3 0.090 0.195 0.345 0.570 0.870 1.260

4 0.120 0.260 0.460 0.760 1.160 1.680

5 0.150 0.325 0.575 0.950 1.450 2.100

6 0.180 0.390 0.690 1.140 1.740 2.520

7 0.210 0.455 0.805 1.330 2.030 2.940

8 0.240 0.520 0.920 1.520 2.320 3.360

9 0.270 0.585 1.035 1.710 2.610 3.780

10 0.300 0.650 1.150 1.900 2.900 4.200

11 0.330 0.715 1.265 2.090 3.190 4.620

12 0.360 0.780 1.380 2.280 3.480 5.040

13 0.390 0.845 1.495 2.470 3.770 5.460

14 0.420 0.910 1.610 2.660 4.060 5.880

15 0.450 0.975 1.725 2.850 4.350 6.300

16 0.480 1.040 1.840 3.040 4.640 6.720

17 0.510 1.105 1.955 3.230 4.930 7.140

18 0.540 1.170 2.070 3.420 5.220 7.560

19 0.570 1.235 2.185 3.610 5.510 7.980

20 0.600 1.300 2.300 3.800 5.800 8.400

21 0.630 1.365 2.415 3.990 6.090 8.820

22 0.660 1.430 2.530 4.180 6.380 9.240

23 0.690 1.495 2.645 4.370 6.670 9.660

24 0.720 1.560 2.760 4.560 6.960 10.080

25 0.750 1.625 2.875 4.750 7.250 10.500

26 0.780 1.690 2.990 4.940 7.540 10.920

27 0.810 1.755 3.105 5.130 7.830 11.340

28 0.840 1.820 3.220 5.320 8.120 11.760

29 0.870 1.885 3.335 5.510 8.410 12.180

30 0.900 1.950 3.450 5.700 8.700 12.600

31 0.930 2.015 3.565 5.890 8.990 13.020

32 0.960 2.080 3.680 6.080 9.280 13.440

33 0.990 2.145 3.795 6.270 9.570 13.860

34 1.020 2.210 3.910 6.460 9.860 14.280

35 1.050 2.275 4.025 6.650 10.150 14.700

36 1.080 2.340 4.140 6.840 10.440 15.120

37 1.110 2.405 4.255 7.030 10.730 15.540

38 1.140 2.470 4.370 7.220 11.020 15.960

39 1.170 2.535 4.485 7.410 11.310 16.380

40 1.200 2.600 4.600 7.600 11.600 16.800

41 1.230 2.665 4.715 7.790 11.890 17.220

42 1.260 2.730 4.830 7.980 12.180 17.640

43 1.290 2.795 4.945 8.170 12.470 18.060

44 1.320 2.860 5.060 8.360 12.760 18.480

45 1.350 2.925 5.175 8.550 13.050 18.900

46 1.380 2.990 5.290 8.740 13.340 19.320

47 1.410 3.055 5.405 8.930 13.630 19.740

48 1.440 3.120 5.520 9.120 13.920 20.160

49 1.470 3.185 5.635 9.310 14.210 20.580

50 1.500 3.250 5.750 9.500 14.500 21.000

51 1.530 3.315 5.865 9.690 14.790 21.420

52 1.560 3.380 5.980 9.880 15.080 21.840

53 1.590 3.445 6.095 10.070 15.370 22.260

54 1.620 3.510 6.210 10.260 15.660 22.680

55 1.650 3.575 6.325 10.450 15.950 21.100

56 1.680 3.640 6.440 10.640 16.240 23.520

57 1.710 3.705 6.555 10.830 16.530 23.940

58 1.740 3.770 6.670 11.020 16.820 24.360

59 1.770 3.835 6.785 11.210 17.110 24.780

60 1.800 3.900 6.900 11.400 17.400 25.200

kg

Page 35

GB

35

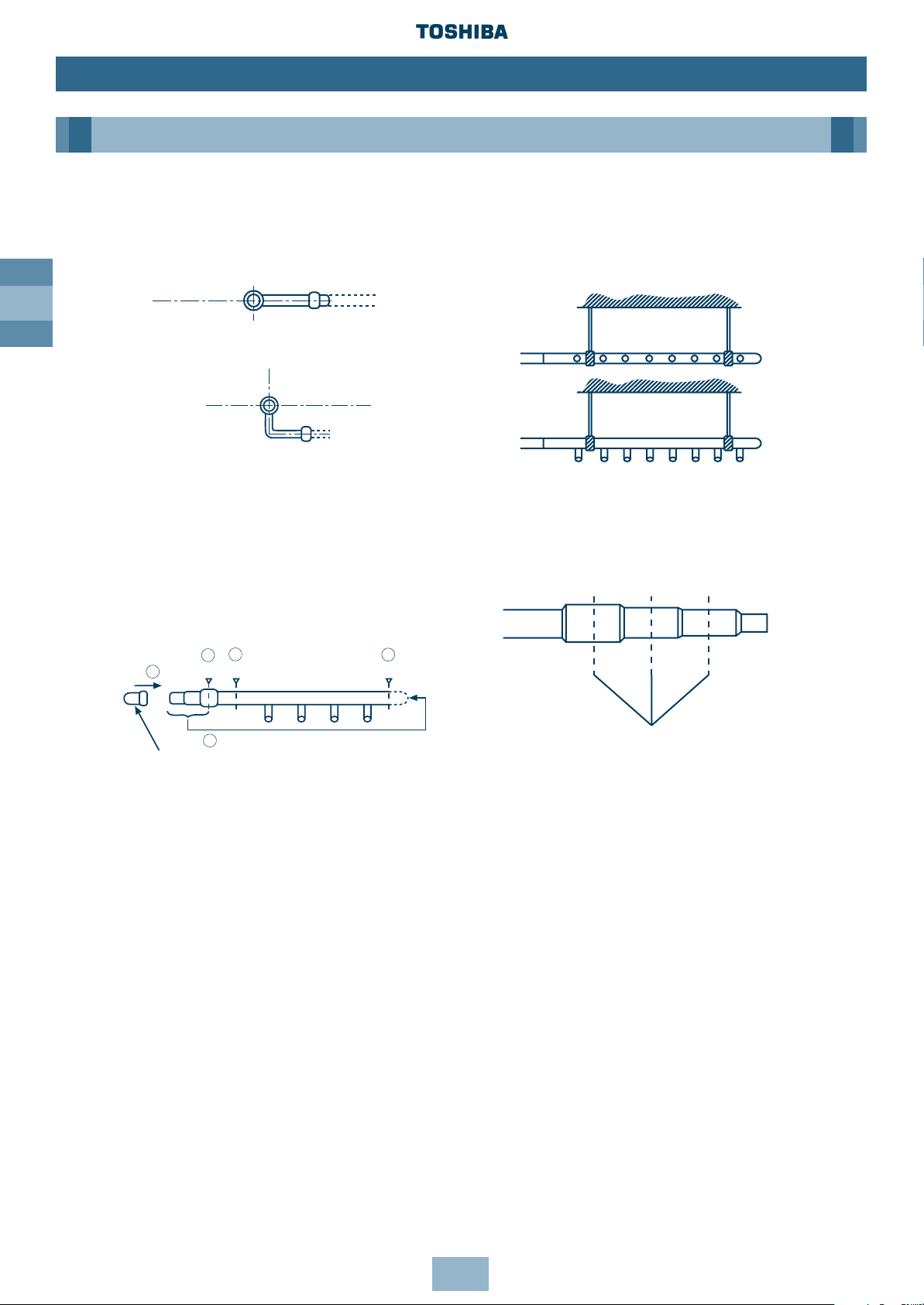

Installation

Wiring

General

• Observe the Electrical Equipment Engineering Standard and Indoor Wiring Regulations.

• The refrigerant piping and corresponding control wiring should be routed closely together.

• For the control wires connecting the Indoor Units, Outdoor Units, and between indoor and

Outdoor Units, the use of double-core shielded wires is recommended to prevent interference.

• Provide each Indoor Unit with a separate method of isolation.

• Supply power to each Outdoor Unit via a dedicated branch circuit, and provide a circuit breaker

for each Outdoor Unit.

• Connect the power supply cables to the Outdoor Unit via the built in isolator.

Note: Provide separate power supplies for indoor and Outdoor Units.

Wiring System Overview

Precautions

The circuit protection device will protect the supply cable against over current. The circuit

protection must be selected having due regard to the compressor starting current, such that

the supply cables when sized correctly, are protected.

The cable should be selected to match the nominal load of the system, in addition to the

losses associated with corrections for length, temperature, impedance etc., in accordance

with local codes of practice.

3-phase 380/400/415V

Circuit breaker

Power switch

Outdoor

power

source

Indoor

power

source

Earth

Single phase 220/230/240V

Circuit breaker

power switch

Page 36

GB

36

Installation

Wiring

Connecting the Power Source Cable and Control Cable

Insert power source cable and control cable after removing the knockout in the Piping/Wiring

Panel on the front side of the main unit.

Power Source cable

• Connect the electric cables and earth wire to the Outdoor isolator terminal block through a

notched section at side of the electric parts box, and fix with a clamp.

• Bundle the electric cables using the hole so that they are in the notched section of the

electric parts box.

Control Cable

• Connect the control cable between Indoor and Outdoor Units plus the control cable between

Outdoor Units to P-Q terminal section through a hole at the side of the electric parts box,

and fix with a clamp.

• Use control cable with 2-core shield wire (1.25mm2or more) in order to prevent interference.

(Non-polarity.)

Knock out (x4) for control cable

and power source cables.

Piping/Wiring Panel

P-Q terminal block

(For wiring for control cable between Indoor/Outdoor Unit

For wiring for control cable between Outdoor Units)

Earth Screw (Shield Wire)

Earth Screw

Isolator

Power Supply

Connections

Electric parts box

X-Y terminal block

(For Central Remote

Controller)

Notes:

1 Be sure to separate the power source

cables and each control cable.

2 Arrange the power source cables and

each control cable so they are not in

contact with the bottom surface of the

main unit.

3 A terminal block (X-Y) for connecting

the optional Central Remote

Controller is provided on the Inverter

Unit.

MODEL STARTING CURRENT (A) RUNNING CURRENT (A) POWER COMSUMPTION (KW)

MM-A0280HT 60 19.7 12.6

MM-A0224HT 60 16.2 10.2

MM-A0280HX 60 21.8 12.8

MM-A0224HX 60 18.7 10.6

MM-A0160HX 60 10.6 5.9

Table below shows the supply requirements

Note: The above data is based on the following conditions:

Indoor Temperature: 27ºC DB/19ºC WB

Outdoor Temperature: 35ºC DB/25ºC WB

Page 37

GB

37

Installation

Wiring

Control Wiring Overview

Power source

Single phase

220/230/240V

Standard

Remote

Controller

Central Remote Controller (Option)

*RBC-CR64-PE (For Line 64)

Shield wire must be connected

to each Outdoor Unit

Shield wire must be connected to

each Indoor Unit

Transmission wire for control

between Outdoor Units

Transmission wire for control

between Outdoor Unit and

Indoor Unit

Earth

Earth

Release

Wire specification, quantity, size of crossover wire (transmission wire) and Remote

Controller wire.

1. Crossover lines and lines from the central Remote Controller use double-core non-polar

wires. Use double-core shielded wires to prevent interference. Connect the ends of shielded

wires and insulate the final end. Provide two ground points: one at the central Remote

Controller and the other for the Outdoor Units.

2. Use 3-core and polar wire for Remote Controller (A, B, C terminals).

Use 2-core wire for grouping wiring of Remote Controller (B,C terminals).

3. Be sure to divide the earth shield wires of the central Remote Controller and crossover into

the separate lines (not crossed halfway).

Name Qty Size Specification

Crossover wire (between indoor and

outdoor units, between outdoor units)

2 cores 1.25mm

2

≤ 500m

Remote controller wiring 3 cores 0.3mm ≤ 200m, 200m < 0.75mm ≤ 500m Shielded wire

Central control remote controller

transmission wire

2 cores 1.25mm ≤ 500m, 500m < 2.0mm ≤ 1000m

Page 38

38

Final Installation Checks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .39

Adjustment Before Trial Operation . . . . . . . . . . . . . . . . . . . . . . .39

Service Support Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .40

Check Function for Connection of Refrigerant Pipes and Control

Transmission Lines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .40

Function to Start/Stop Indoor Units From an Outdoor Unit . . . . . . . . . .41

Trial Cooling Operation Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . .42

Collective Start/Stop (On/Off) Function . . . . . . . . . . . . . . . . . . . . . . . .43

Individual Start/Stop (On/Off) Function . . . . . . . . . . . . . . . . . . . . . . . .44

Alarm Clear Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .45

Clearing a Central Remote Controller/with 7 day Timer . . . . . . . . . . . .45

Clearing the Interface PCB of an Inverter Outdoor Unit . . . . . . . . . . . .45

Clearing an Alarm by Resetting the Power Source . . . . . . . . . . . . . . . .46

Remote Controller Identification Function . . . . . . . . . . . . . . . . . . . . . .46

Forcing the Electronic Control Valve (PMV)

‘Fully Open’– on the Indoor Unit . . . . . . . . . . . . . . . . . . . . . . . . . . .47

Forcing the Electronic Control Valve (PMV)

‘Fully Opened/Fully Closed’ – on the Outdoor Unit . . . . . . . . . . . . .47

Contents

Trial Operation

GB

Page 39

GB

39

Adjustment Before Trial Operation

Trial Operation

Final Installation Checks

Automatic Address Between Indoor and Outdoor Units

Turning on the power for the first time after the system has been installed starts the

Automatic Address procedure. It usually takes between 3 and 5 minutes to complete – but in

some cases, can take up to 20 minutes.

During Automatic Address the System cannot be Operated

If the Operate button on the indoor unit is pressed during Automatic Address, the following

will happen:

1. The operation light on the remote control will come on;

2. The fan on the Indoor Unit will start or stop, according to the mode;

3. Cool air will not come out, because the Outdoor Unit is off.

When Automatic Address procedure is complete, normal operation starts automatically.

Automatic Address Reactivation

Once control of the Indoor Unit has been confirmed, Automatic Address will only be

reactivated when:

• the PC board of the Indoor Unit is replaced, and power is turned on for the first time.

• a new Indoor Unit is added, and power is turned on for the first time.

Precautions

Ensure that the electrical cable used for power supply and control of the system is unable to

come into contact with either service valves or pipework which are not insulated.

Electrical Wiring

When installation is complete, check that all power supply and interconnecting wiring has

been appropriately protected.

Refrigerant Piping

When refrigerant and drain piping have been completed, ensure that all pipework is fully

insulated and apply finishing tape to seal the insulation.

Page 40

GB

40

Trial Operation

Service Support Functions

Check Function for Connection of Refrigerant Pipes and Control

Transmission Lines

This function is provided to check misconnection of the refrigerant piping and the control

transmission line between Indoor and Outdoor Units by the switches on the interface PCB of the

Inverter Outdoor Unit.

However, be sure to check items described here before implementing this check function.

• When grouping operation of the Remote Controller is performed and the connected Outdoor

Units are used, the check function does not work.

• Only use this facility to check lines one by one in a single Outdoor Unit. Checking multiple

lines at the same time may cause faulty readings.

Procedure

SW02 SW03

Address of indoor unit

Displayed on

7 segment LED [A]

1 to 16 1 1 to 16

1 to 16 2 17 to 32

1 to 16 3 33 to 40

System capacity check

When setting SW01 on the I/F PCB of the Inverter

Outdoor Unit to "1", SW02 to "3", and SW03 to "3’, the

number of the Outdoor Units (including Inverter Unit)

connected to the system is displayed on the 7-segment

LED (A). Check that this display agrees with the expected

number of Outdoor Units.

Checking the number of Indoor Units

When setting SW01 on the interface PCB of the Inverter

Outdoor Unit to "1", SW02 to "4", and SW03 to "3", the

number of Indoor Units connected to the system is

displayed on 7-segment LED (A). Check that this display

is consistent with the expected number of Indoor Units.

Set the switch on the interface PCB of the Inverter

Outdoor Unit to the following values.

SW01 to "2", SW02 to "1", SW03 to "1": Cooling

operation.

Push the push-switch SW04 on the interface PCB of the

Inverter Outdoor Unit for 2 seconds or more. Check that

the display of the 7-segment LED (B) is "CC" for the

cooling operation.

After 15 minutes, check 7-segment LED (B) for the

number of Indoor Units miswired.

("00" is displayed if there is no applicable unit.)

Then, set SW01 to "5" and SW02 and SW03 to the

address of each unit (*2) to view the check code.

When the switch setting has matched the address of

the miswired Indoor Unit, "9A" is displayed on the

7-segment LED (B).

After check, return display select switches SW01, SW02

and SW03 on the interface PCB of the Inverter Outdoor

Unit to "1".

*1 Besides the miswired Unit(s), the

number of Units displayed on the

7-segment LED includes the Indoor

Units sending a check code. Verify the

miswired Unit(s) using the check code.

*2

Indoor temp. (˚C)

Outdoor temp. (˚C)

Both outdoor/Indoor Unit sides

Operation

It takes 15 minutes for 1 system check.

Completion

SW01, 02, 03: Rotary switch

SW04, 05: Push switch

SW08: Dip switch

Power ON

SW02 to "2"

SW02 to "1"

Page 41

GB

41

Trial Operation

Service Support Functions

Function to Start/Stop Indoor Units From an Outdoor Unit

Note:

This start/stop function only sends mode signals for starting, stopping, operation, etc., from the

Outdoor Unit to the Indoor Unit(s). If the Indoor Unit did not follow the sent signal, there is no

function to re-send the signal and force the Unit to follow the command.

No. Function Outline Clear Setup

(1) Trial cooling The modes of all the connected indoor [Setup]

operation units are collectively changed to trial Push SW04 for at least 2 seconds under

cooling operation modes. condition of SW01 “2”, SW02 “5”.

NOTE: [Clear]

Control operation as same as that of Cleared from the remote controller when

normal trial operation from the remote SW01 and SW02 are changed to other

controller is performed. positions.

(2) Collective All the connected indoor units are operated [Setup]

operation collectively. Push SW04 for at least 2 seconds under

NOTE: condition of SW01 “2”, SW02 “7”.

Operation contents follow to the setup on [Clear]

the remote controller. Cleared from the remote controller.

Collective All the connected indoor units are stopped [Setup]

stop collectively. Push SW05 for at least 2 seconds under

condition of SW01 “2”, SW02 “7”.

[Clear]

Cleared from the remote controller.

(3) Individual The specified indoor unit is operated. [Setup]

operation NOTE: To start an indoor unit, set “16” in SW01 and

Operation contents follow to the setup on the address number of the indoor unit

the remote controller. (1 to 20) in SW02 and SW07, and then push

Other indoor units stay as they are. SW04 for at least 2 seconds.

[Clear]

Cleared from the remote controller.

Individual The specified indoor unit is stopped. [Setup]

stop NOTE: Push SW05 for at least 5 seconds.

Other indoor units stay as they are. [Clear]

Cleared from the remote controller.

Page 42

GB

42

Operation

Trial Operation

Service Support Functions

Trial Cooling Operation Function

This function changes the modes of all the Indoor Units to trial operation modes. It is operated

by the switch on the interface PCB of the Inverter Outdoor Unit.

Procedure

SW01, 02, 03: Rotary switch

SW04, 05: Push switch

SW08: Dip switch

Set SW01 on the interface PCB of the Inverter Outdoor

Unit to "2", SW02 to "5", and SW03 to "1".

Push the switch SW04 on the PCB of the Inverter

Outdoor Unit for 2 seconds and more.

Check that the mode on the Remote Controller of the

Indoor Unit is Trial Cooling.

("L" is displayed.)

Check that "-C" is displayed on the 7-segment LED (B) of

the interface PCB of the Inverter Outdoor Unit.

Return SW01 to "1", SW02 to "1", and SW03 to "1" on

the interface PCB of the Inverter Outdoor Unit.

Operation check

Stop/Completion

Power ON

Page 43

GB

43

Operation

Trial Operation

Service Support Functions

Collective Start/Stop (On/Off) Function

This function starts/stops all the Indoor Units by the switch on interface PCB of the Inverter

Outdoor Unit.

Procedure

SW01, 02, 03: Rotary switch

SW04, 05: Push switch

SW08: Dip switch

Set the operation mode of the Remote Controller.

(If Setup is not executed, operation is performed under

the present mode.) (FAN, COOL, HEAT)

If an alarm has been already displayed as

SW01 "1’, SW02 "2", SW03 "1", return the

status to Normal (see Troubleshooting), and

then execute a trial operation.

Set SW01 to "2", SW02 to "7", and SW03 to "1" on

interface PCB of the Inverter Outdoor Unit.

Push the switch SW04 for 2 seconds or more on

interface PCB of the Inverter Outdoor Unit.

Indoor Units operate.

Push the push-switch SW05 for 2 seconds or more on

interface PCB of the Inverter Outdoor Unit.

After trial operation, return the display select switches

SW01, SW02, and SW03 to "1".

Operation Check

(When the discharge temp. does not change,

even if COOL/HEAT is set on the Remote

Controller, then miswiring is likely.)

Stop

Completion

Power ON

Page 44

GB

44

Operation

Trial Operation

Service Support Functions

Individual Start/Stop (On/Off) Function

This function starts/stops the Indoor Units individually by the switch on the interface PC board

of the Inverter Outdoor Unit.

Set SW01 to "16", and SW02 and SW03 to the Indoor Unit to be operated. (See table.) The

nominated Units will now operate.

(If the rotary switch of a nominated unit is set at anything from 2 to 16, it cannot start or stop

individually. "_ _" is displayed on LED ‘B’.)

Procedure

Set the operation mode on the Remote Controller.

(If not set, operation continues under the present mode.)

(FAN, COOL, HEAT)

When an alarm has been already displayed

with setting of SW01 to "1", SW02 to "1", and

SW03 to "1", return the status to Normal (see

Troubleshooting) and then perform the Trial

Operation.

The Trial Operation is not performed for

Indoor Units with group operation on the

Remote Controller.

Match the display on the interface PCB of the Inverter

Outdoor Unit in the following table.

Push switch SW04 Unit for 2 seconds or more.

The Indoor Unit starts operation.

Push switch SW05 for 2 seconds or more.

After trial operation, return SW01, SW02, and SW03

to "1".

Operation check

(If the temperature of discharged air does not

change, even if Cool mode is set on the

Remote Controller, miswiring is likely.)

Stop

SW01 SW02 SW03 To be operated

16 1 ~ 16 1 From address 1 to

address 16 individually

16 1 ~ 16 2 From address 17 to

address 32 individually

16 1 ~ 8 3 From address 33 to

address 40 individually

To be started/stopped individually

Power ON

SW01, 02, 03: Rotary switch

SW04, 05: Push switch

SW08: Dip switch

Page 45

GB

45

Trial Operation

Alarm Clear Function

Clearing a Central Remote Controller/with 7 day Timer

This clears the alarm so that the Outdoor Unit can resume operation without having to

reset power.

• Push the ‘CHECK’ button on the remote control panel for at least 5 seconds.

• To clear the check code for that Remote Controller – push the ‘CHECK’ button for at least

15 seconds. (Using the ‘Reset’ hole can also clear the check code.)

Clearing the Interface PCB of an Inverter Outdoor Unit

This clears the alarm so that the Outdoor Unit can resume operation without having to reset

power. However, this does not clear the check code in the Remote Controller – this is done

either by the method described previously, or by using the ‘Reset’ hole.

Procedure

Service Support Functions

"CHECK" button

Set the switches on interface PCB of the Inverter Outdoor

Unit, SW01 to "2", SW02 to "16", and SW03 to "1".

Push switch SW04 for 5 seconds or more.

Display on 7-segment LED (B) changes to "CL"

(for 5 seconds).

Also alarms in the indoor and lock alarm

are released.

(However, the check code remains in the

Remote Controller.)

After then, alarms are detected as usual.

SW01, 02, 03: Rotary switch

SW04, 05: Push switch

SW08: Dip switch

Page 46

GB

46

Trial Operation

Service Support Functions

Clearing an Alarm by Resetting the Power Source

Be sure to reset the power sources of both the Outdoor and Indoor Units.

• Turn the power OFF.

• Turn the power ON for the Outdoor Unit first.

• Turn the power ON for the Indoor Unit next.

Note:

Even if the power source of the Outdoor Unit is re-set, the fault code is still displayed on

the Indoor Unit. To clear this, hold down the ‘CHECK’ button on the Remote Controller for

at least 15 seconds.

Remote Controller Identification Function

This function identifies the Remote Controller connected to each Outdoor Unit.

Procedure

SW01, 02, 03: Rotary switch

SW04, 05: Push switch

SW08: Dip switch

Operation

Set the switches on interface PCB of the Inverter

Outdoor Unit, SW01 to "2", SW02 to "4", and SW03

to "1".

Push switch SW04 for 2 seconds and more.

"NON-PRIORITY" display on the connected Remote

Controller flashes. "11" is displayed on 7-segment LED B.

Push switch SW04 or SW05 for 2 seconds or more.

Check connected remote

controller

Completion

Power ON

Other completion conditions:

1. Send operation continued for 10 minutes.

2. SW01, SW02 or SW03 moved to other position.

Page 47

GB

47

Trial Operation

Forcing the Electronic Control Valve (PMV) ‘Fully Open’ – on the

Indoor Unit

This function forces the electronic control valves open in all the Indoor Units for 2 minutes. It is

activated by a switch on the interface PCB of the outdoor Inverter Unit.

Usually, turning on the power to an Indoor Unit once fully closes the PMV – this function is used

when you want to open the PMV fully for operation after the power has been turned off a

second time.

Procedure

Set SW01 to "2", SW02 to "3" and SW03 to “1” on interface PCB of the Inverter Outdoor Unit,

and push SW04 for 2 seconds or more.

(7-segment LED [B] changes to "FF" for 2 minutes.)

Clear

Following Setup, the PMV automatically returns to its normal open pulse after 2 minutes.

It is only opened fully for 2 minutes when it receives the FULL OPEN signal from the

Outdoor Unit.

Forcing the Electronic Control Valve (PMV) ‘Fully Opened/Fully Closed’

– on the Outdoor Unit

This function opens or closes the electronic control valve of an Outdoor Unit for 2 minutes.

Fully Open

Short circuit CN30 on the interface PC board of the Inverter Outdoor Unit.

Fully Closed

Short circuit CN31 on the interface PC board of the Inverter Outdoor Unit.

Clear

Both Fully Open and Fully Closed return to the normal open pulse after 2 minutes. Be sure to

remove the short circuit after confirmation.

Notes:

If bit 1 of DIP SW08 is ON PMV1 and PMV2 (Refrigerant Control) electronic control valves are

turned on.

If bit 1 of DIP SW08 is OFF PMV3 (Cooling Bypass) electronic control valve is turned off.

Service Support Functions

Page 48

48

Contents

48

Remote Controller ‘Check’ Display . . . . . . . . . . . . . . . . . . . . . . .49

Main Remote Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .49

Operating and Reading the Check Display . . . . . . . . . . . . . . . . . . . . .49

Room Remote Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .51

Operating and Reading the Check Display . . . . . . . . . . . . . . . . . . . . .51

Self-Diagnostic Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .53

Check Codes – Remote Controller/Outdoor Unit . . . . . . . . . . .54

Cautions on Refrigerant Leakage . . . . . . . . . . . . . . . . . . . . . . . .62

Troubleshooting

GB

Page 49

GB

49

Troubleshooting

Remote Controller ‘Check’ Display

Main Remote Controller

Operating and Reading the Check Display

Push the CHECK button, and the identification number of the faulty Indoor Unit is shown in the

Temperature Setup section of the display – and the check code is shown in the TIME section of

the display.

If the air filter cleaning sign is displayed, the number of Indoor Units with a filter problem is

indicated, followed by the check code.

LCD Display "Standby" Mode:

• When combination of Indoor Units is over the capacity.

• When Indoor Unit with command excepted by

operation mode select switch.

• When phase-sequence of power wiring is incorrect.

Reset Switch

• Push the switch inside the hole with pin.

The Remote Controller resets initialised.

(All data is cleared.)