Page 1

Digital Key Telephone Systems

DK8 & DK16

INSTALLATION AND MAINTENANCE MANUAL

© COPYRIGHT 1993

TOSHIBA AMERICA INFORMATION SYSTEMS, INC.

Telecommunication Systems Division

All rights reserved. No part of this manual, covered by the copyrights hereon,

may be reproduced in any form or by any means—graphic, electronic, or

mechanical, including photocopying, recording, taping, or information retrieval

systems—with the exception of the System Record forms, without written

permission of the publisher of this material.

SERIAL NO. DK8 & DK16

DK8-MA-IN/MT-R1

4025021

Page 2

Page 3

TOSHIBA SYSTEM PRACTICES

DIGITAL KEY TELEPHONE SYSTEMS

INSTALLATION-INTRODUCTION

SECTION 100-816-201

MARCH 1993

INSTALLATION

Chapter One — Introduction Section 100-816-201

Chapter Two — Site Requirements Section 100-816-202

Chapter Three — System Configuration Section 100-816-203

Chapter Four — DK8 KSU and PCB Installation Section 100-816-204

Chapter Five — DK16 KSU and PCB Installation Section 100-816-205

Chapter Six — Station Apparatus Installation Section 100-816-206

Chapter Seven — Peripheral Installation Section 100-816-207

Chapter Eight — Wiring Diagrams Section 100-816-208

Page 4

INSTALLATION-INTRODUCTION

SECTION 100-016-201

NOVEMBER 1992

Page 5

TOSHIBA SYSTEM PRACTICES

DIGITAL KEY TELEPHONE SYSTEMS

INSTALLATION-INTRODUCTION

SECTION 100-816-201

MARCH 1993

INSTALLATION

CHAPTER ONE

INTRODUCTION

Page 6

INSTALLATION-INTRODUCTION

SECTION 100-816-201

MARCH 1993

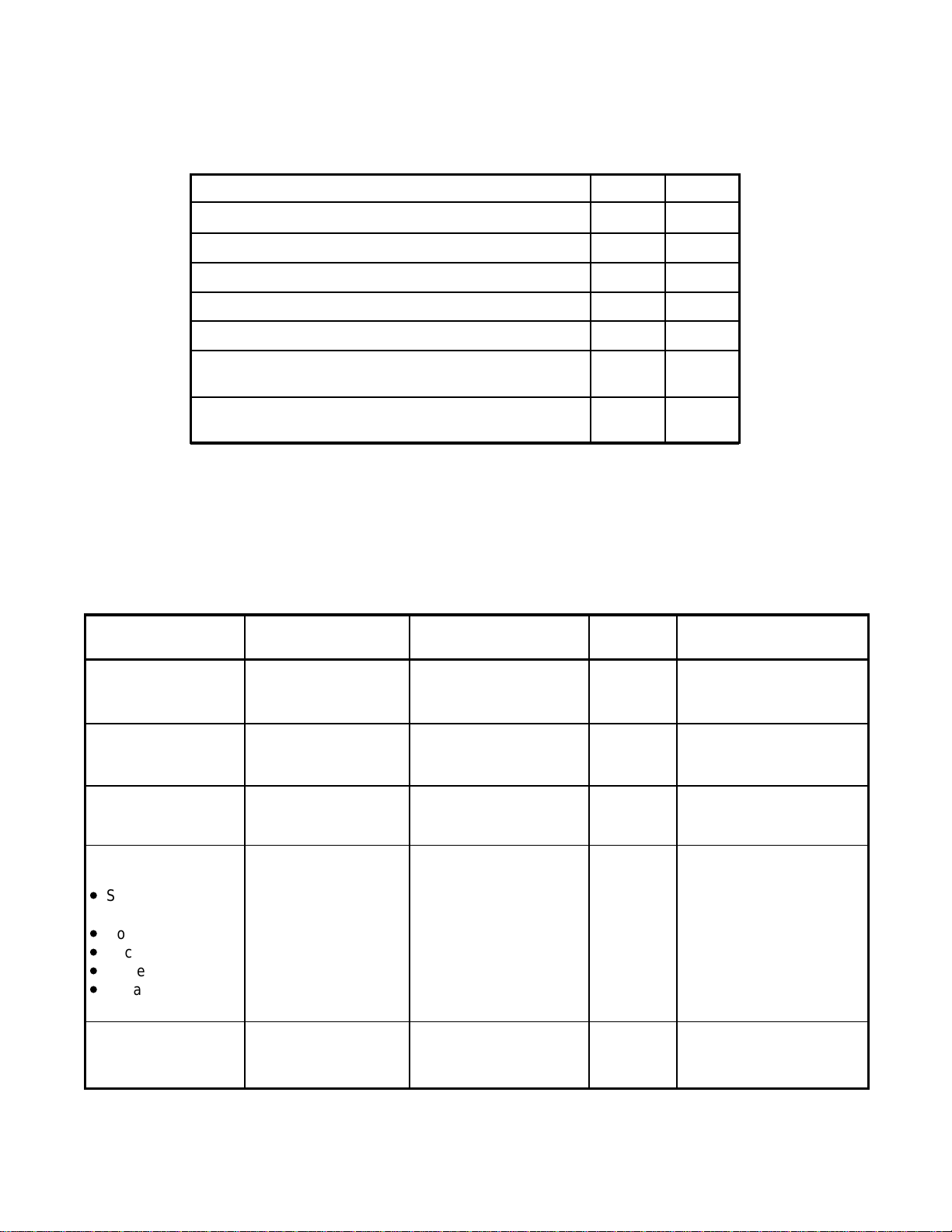

TABLE OF CONTENTS

PARAGRAPH SUBJECT PAGE

1 PURPOSE.............................................................................................................. 1-1

2 ORGANIZATION .................................................................................................... 1-1

3 REFERENCE DOCUMENTATION ........................................................................ 1-1

3.10 General Description............................................................................................ 1-1

3.20 Programming ...................................................................................................... 1-1

3.30 User Guides........................................................................................................ 1-1

3.40 Fault Finding Procedures ................................................................................... 1-1

3.50 Remote Maintenance and Administration........................................................... 1-1

4 SYSTEM MNEMONICS/TERMS............................................................................ 1-1

4.10 Use of Notes, Important Notes, Cautions, and Warnings.................................... 1-5

1-i

Page 7

INSTALLATION-INTRODUCTION

SECTION 100-816-201

MARCH 1993

1 PURPOSE

1.00 The purpose of this section is to provide

detailed step-by-step instructions for installing the

STRATA DK8 and STRATA DK16 systems.

1.01 This chapter provides an overview of the

entire installation section, and includes a list of

reference documentation that supports the installed system; a list of system mnemonics is also

provided.

2 ORGANIZATION

2.00 This manual is organized in modular chap-

ters for easy removal and replacement of updated

materials. The chapters are as follows:

Chapter One - Introduction

Chapter Two - Site Requirements

Chapter Three - System Configuration

Chapter Four - STRATA DK8 KSU and PCB

Installation

Chapter Five - STRATA DK16 KSU and PCB

Installation

Chapter Six - Station Apparatus Installation

Chapter Seven - Peripherals Installation

Chapter Eight - System Wiring and Main Dis-

tribution Frame Arrangements

3 REFERENCE DOCUMENTATION

telephones, standard telephones, direct station

selection consoles, add-on modules and data interface units.

3.40 Fault Finding Procedures: Hardware troubleshooting and diagnostic information presented

in flowchart form.

3.50 Remote Maintenance and Administration:

Programming and maintenance procedures specially adapted for remote maintenance and administration terminal use. Detailed, step-by-step instructions are provided, complete with the terminal

responses.

4 SYSTEM MNEMONICS/TERMS

4.00 Mnemonics are used to identify the system’s

hardware, operation, and features. The following

alphabetical listing describes the mnemonics used

in this manual.

ADM: Add-on Module—A telephone upgrade that

provides 20 Direct Station Selection (DSS) buttons with busy LED indication on STRATA DK16

and 10 DSS buttons plus 8 speed dial buttons

(one for every station), one night transfer and

one all call page button on STRATA DK8. Can

be installed on any or all 2000-series Digital

Telephones in the system. Attaches to the telephone and uses the same port assigned to the

telephone. ADM buttons are fixed and cannot

be changed in system programming.

3.00 The STRATA DK8 and DK16 digital key

systems are supported by the following complement of reference documentation:

3.10 General Description: An overview of the

STRATA DK8 and DK16 systems and their features.

3.20 Programming: Detailed step-by-step instructions on how to enter data in the System

Record sheets, and how to program the system

from the completed System Record Sheets. LCD

responses are included to provide clear guidance

for the programmer.

3.30 User Guides: Detailed step-by-step guides

on how to operate digital telephones, electronic

BPS: Bits Per Second—Unit of measure that re-

fers to the transmission speed (baud rate) of

electronic signals. It is used when describing

data interface unit and modem operation.

CO: Central Office—The facility which houses

switching equipment that provides telephone

service (CO lines, Centrex lines, etc.) for the

immediate geographical area.

CO Line: A term used to define the STRATA

hardware circuit that connects to the Central

Office network line pair. Each CO line is assigned a CO line number in system software.

1-1

Page 8

INSTALLATION-INTRODUCTION

SECTION 100-816-201

MARCH 1993

CODECs: Coder/Decoders—Semiconductors that

allow the system to process analog-to-digital

and digital-to-analog conversions.

DDCB: Digital Door Phone/Lock Control Unit—A

peripheral hardware unit that can be connected

to designated digital telephone circuits/ports.

The DDCB has three interfaces, two of which

are dedicated to door phones (MDFB), and one

that can be connected to a MDFB or a door lock.

DISA: Direct Inward System Access—A feature

available for CO lines that allows an outside

party to access a STRATA system’s internal

stations or outgoing CO lines without going

through an operator or automated attendant. An

optional security code and/or account codes

may be set to prevent unauthorized access to

outgoing CO lines for through system calling.

DK: Digital Key.

DKSU8: Key Service Unit (STRATA DK8 only)—

The standard key service unit which includes

the system's motherboard, power supply, two

CO line circuits, four digital telephone circuits,

relay service, and interface for Music-on-hold

(MOH)/Background Music (BGM) and External

Page.

DKSUB16: Base Key Service Unit (STRATA DK16

only)—The standard key service unit which includes the system's motherboard, power supply, four CO line circuits, eight digital telephone

circuits, relay service, and interface for Musicon-hold (MOH)/Background Music (BGM) and

External Page.

DKSUE16: Expansion Key Service Unit (STRATA

DK16 only)—The optional key service unit which

has four universal slots that can support CO line,

station, and external option printed circuit boards

that are compatible with the larger STRATA DK

systems (DK24/DK56/DK96).

There are two types of DSS consoles: the DDSS

console and the HDSS console. The chief difference between them is that the DDSS console

can be connected to designated digital telephone circuits, while the HDSS console can

only be connected to designated electronic telephone circuits.

DTMF: Dual-tone Multi-frequency—Push-button

dialing.

DVSU: Off-hook Call Announce Upgrade—A sub-

assembly that allows a digital telephone to receive Off-hook Call Announce.

EOCU: Off-hook Call Announce Upgrade (STRATA

DK16 only)—An optional subassembly to the

Electronic Telephone Interface Unit PCB (PEKU)

or Standard/Electronic Telephone Interface Unit

(PESU) that provides support for electronic telephones that must receive Off-hook Call Announce. Electronic telephones that must receive Off-hook Call Announce must also have

an HVSU2 subassembly or the combined HVSU/

HVSI subassemblies.

FCC: Federal Communication Commission—The

telecommunication industry’s federal regulatory

agency. All Toshiba hardware is FCC listed or

approved.

HESB: External Speaker Box—A speaker/ampli-

fier that can be configured with the system and

telephones to provide a variety of functions.

HESC-65A: A cable that connects an HHEU-

equipped digital telephone or electronic telephone to an HESB for a Loud Ringing Bell .

HHEU: Loud Ringing Bell/Headset Jack Interface

Upgrade—A small subassembly for use inside a

digital telephone or a 6500-series electronic

telephone that allows a speaker (HESB) and/or

a headset to be installed with the station.

DSS: Direct Station Selection Console (STRATA

DK16 only)—A console designed to facilitate

the processing of a heavy load of incoming calls.

HVSU2: Off-hook Call Announce Upgrade—A

subassembly that enables an electronic telephone to receive Off-hook Call Announce.

1-2

Page 9

INSTALLATION-INTRODUCTION

SECTION 100-816-201

MARCH 1993

IMDU: Remote Maintenance Modem Interface

Unit (STRATA DK16 only)—A subassembly

installed on a PIOU or PIOUS PCB in the optional DK16 Expansion Key Service Unit that

allows the system to be connected with a remote

maintenance/administration terminal.

KCDU: CO Line/Digital Telephone Interface Unit

(STRATA DK16 only)—Optional printed circuit

board providing two loop start CO line circuits

and four digital telephone circuits that can be

installed in the Expansion Unit. The digital telephone circuits support the same devices as the

PDKU except for the DDSS console.

KCOU: CO Line Interface Unit (STRATA DK16

only)—Factory-installed printed circuit board that

comes standard with the Base Key Service Unit

to provide four loop start CO line circuits. Available as a spare unit for field replacements.

KFCU: (STRATA DK16 only) Option feature car-

tridge that plugs into the Base Unit to provide

feature upgrades to DK16.

LED: Light Emitting Diode—Status indicators lo-

cated on printed circuit boards, digital telephones,

and electronic telephones.

LSI: Large Scale Integration—Related to circuit

design technology. STRATA DK8 and STRATA

DK16 printed circuit boards use LSI circuit design.

MDF: Main Distribution Frame—The wiring frame

usually located in a phone closet.

MDFB: Door Phone Box—A peripheral two-way

speaker box option. Each MDFB connects to a

DDCB. A DDCB can support as many as three

MDFBs.

OCA: Off-hook Call Announce.

PBX: Private Branch Exchange—Industry-stan-

dard term which refers to a telephone switch,

usually on-premises, which serves an individual

company, and is connected to a public telephone exchange through the CO.

KPSU16: (STRATA DK16 only) Power supply that

comes factory-installed in the Base Key Service

Unit. This power supply provides power to the

entire system, in its standard and expanded

configurations. Available as a spare unit for field

replacements.

K4RCU: (STRATA DK16 only) Optional unit that

can be installed in the Base Key Service Unit to

provide a 4-circuit Dual-tone Multi-frequency

receiver for CO lines and standard telephones.

It also provides busy tone detection for Auto

Busy Redial.

KSTU: Standard Telephone Interface Unit

(STRATA DK16 only)—Optional printed circuit

board that can be installed in the Base Key

Service Unit to provide four standard telephone

circuits.

LCD: Liquid Crystal Display—Display used for

messaging, identification, and status that appears on some digital and electronic telephones.

PCB: Printed Circuit Board.

PCM: Pulse Code Modulation—A widely used

form of digital telephone switching.

PCOU1: CO Line Interface Unit (STRATA DK16

only)—A printed circuit board that can be installed in the optional Expansion Key Service

Unit to provide the system with four loop start

CO lines circuits.

PCOU2: (STRATA DK16 only) The PCOU2 is a

direct replacement for the PCOU1. Their fit/

form/function is identical; however, for manufacturing reasons, the PCOU1 was phased out

in favor of the PCOU2.

PDIU-DI/PDIU-DI2: Integrated Data Interface

Unit—Replaces the normal digital telephone

base to enable the telephone to transmit and

receive data between a terminal/personal computer connected to the telephone and data

devices connected to other PDIU-DIs, or to

modems, printers, and computers connected to

1-3

Page 10

INSTALLATION-INTRODUCTION

SECTION 100-816-201

MARCH 1993

Stand-alone Data Interface Units (PDIU-DSs).

The PDIU-DI is also used to provide personal

computer access to outside dial-up data services and/or bulletin boards.

NOTE:

The PDIU-DI and the PDIU-DI2 are identical,

except that the PDIU-DI attaches to 1000series Digital Telephones, while the PDIUDI2 attaches to 2000-series Digital Telephones.

PDIU-DS : Stand-alone Data Interface Unit—Used

for modem pooling, printer sharing, and access

to a host/mainframe computer.

PDKU1: Digital Telephone Interface Unit (STRATA

DK16 only)—A printed board that can be installed in the optional Expansion Key Service

Unit to provide the system with eight digital

telephone circuits. In addition to digital telephones, the PDKU can support data interface

units (Stand-alone and Integrated), a digital

DSS console (DDSS), and a digital door phone/

lock control unit (DDCB).

PDKU2: Digital Telephone Interface Unit (STRATA

DK16 only)—Provides same function as the

PDKU1, except that the PDKU1 can only support data interface units on Circuits 1 ~ 7, while

the PDKU2 can support data interface units on

Circuits 1 ~ 8.

PEKU: Electronic Telephone Interface Unit

(STRATA DK16 only)—An optional PCB that

provides the system with eight electronic telephone circuits, which can support electronic

telephones, a Background Music source, an

electronic DSS console (HDSS), and an amplifier for two CO line conference calls.

PESU:

Standard/Electronic Interface Unit

DK16 only)

standard telephone circuits and four electronic

telephone circuits that can be installed in the

optional Expansion Key Service Unit. The electronic telephone circuits can support the same

devices as the PEKU, except for the HDSS

console. The standard telephone circuits can

—A printed circuit board with two

(STRATA

support the same single-line devices as the KSTU

and the PSTU.

PFT: Power Failure Transfer Interface—Dedicated

standard telephone interface located on the

motherboard in the DKSUB16 (STRATA DK16)

or DKSU8 (STRATA DK8) to provide emergency

service during a system power failure.

PIOU: Option Interface Unit (STRATA DK16 only)—

A printed circuit board that can be installed in the

optional Expansion Key Service Unit to provide

support and/or circuit interface for optional hardware peripherals and upgrades.

PIOUS: (STRATA DK16 only) The same as the

PIOU, except the PIOUS has one external paging interface zone, while the PIOU has four.

NOTE:

The system cannot support the PIOU and

PIOUS simultaneously. Only one or the other

can be installed.

PORT: There are two types of ports: physical and

logical. A physical port is an actual station circuit

location; a logical port is the set of characteristics—features, station intercom number, etc.—

assigned to the physical port. Logical ports are

mobile. They can be moved from one physical

port to another.

PBTC: A Toshiba-supplied cable used to connect

customer-supplied batteries to the power supply in the DKSUB for emergency reserve power.

PPTC: (STRATA DK16 only) A Toshiba-supplied

adapter that is used to connect the modular

SMDR and/or maintenance ports to the DB-25

connector of a printer, terminal, modem or call

accounting machine. The SMDR/Maintenance

(TTY) port is located on the optional QSMU PCB

(STRATA DK8), or PIOU or PIOUS PCB

(STRATA DK16).

PSTU1: Standard Telephone Interface Unit

(STRATA DK16 only)—A printed circuit board

with a built-in ring generator that can be installed

in the optional Expansion Key Service Unit to

1-4

Page 11

INSTALLATION-INTRODUCTION

SECTION 100-816-201

MARCH 1993

provide interface for eight standard telephones

or optional hardware peripherals (voice mail

devices, fax machine, Background Music source,

etc).

PSTU2: Standard Telephone Interface Unit

(STRATA DK16 only)—Provides the same function as the PSTU with the addition of a switch to

select high or low ringing generator voltage.

QCDU: CO Line/Digital Telephone Interface Unit

(STRATA DK8 only)—Optional printed circuit

board providing one loop start CO line circuit

and two digital telephone circuits that can be

installed in the KSU. A maximum of two QCDUs

may be installed in the DK8.

QCNU: Conference Unit (STRATA DK8 only)—

Standard factory-installed printed circuit board

provides two conference circuits that can be

installed in the KSU. The PCB allows two simultaneous conferences: four parties for the first,

and three parties for the second simultaneous

conference.

(STRATA DK8 only)—Optional printed circuit

board that can be installed in the KSU to provide

two standard telephone circuits.

RAM: Random Access Memory—Refers to the

type of system memory that holds individual

system configuration and feature programming.

RAM is read/write memory, and can be easily

revised in programming.

ROM: Read Only Memory—Refers to the type of

system memory that holds static software that

comprises the mechanics of the features’ functions. ROM is only revised by Toshiba software

engineers.

4.10 Use of Notes, Important Notes, Cautions,

and Warnings

4.11 Notes call attention to specific items to elabo-

rate, or to refer the reader to other information.

4.12 Important Notes are used when the information is considered to be very important.

QPSU: (STRATA DK8 only)—Power supply that

comes factory-installed in the KSU. This power

supply provides power to the entire system.

Available as a spare unit for field replacements.

QRCU: Optional printed circuit board that can be

installed in the KSU to provide a 3-circuit Dualtone Multi-frequency receiver for DISA CO lines

and standard telephones. It also provides busy

tone detection for Auto Busy Redial.

QSMU: SMDR/TTY Interface Unit (STRATA DK8

only)—Optional printed circuit board which

provides either SMDR, or Remote Maintenance

Terminal (TTY) or external modem interface.

QSMU configuration is selectable in system

programming.

QSTU: Standard Telephone Interface Unit

4.13 Cautions call attention to the possibility of

equipment being damaged if the instructions are

not followed closely.

4.14 Warnings are used when the given tasks

involved could cause the possibility of personal

injury or death to the technician.

1-5

Page 12

Page 13

TOSHIBA SYSTEM PRACTICES

DIGITAL KEY TELEPHONE

SYSTEMS

INSTALLATION-SITE REQUIREMENTS

SECTION 100-816-202

MARCH 1993

INSTALLATION

CHAPTER TWO

SITE REQUIREMENTS

Page 14

INSTALLATION-SITE REQUIREMENTS

SECTION 100-816-202

MARCH 1993

TABLE OF CONTENTS

PARAGRAPH SUBJECT PAGE

1 GENERAL .............................................................................................................. 2-1

2 INPUT POWER REQUIREMENTS ........................................................................ 2-1

3 SITE CONSIDERATIONS ...................................................................................... 2-1

3.00 Clearance and Location Requirements .............................................................. 2-1

3.10 Electrical/Environmental Requirements and Characteristics............................... 2-2

4 GROUNDING REQUIREMENTS ........................................................................... 2-2

4.10 Third Wire Ground Test...................................................................................... 2-2

4.20 Alternate or Additional Ground ........................................................................... 2-4

TABLE LIST

TABLE TITLE PAGE

2-A SUMMARY OF ELECTRICAL/ENVIRONMENTAL CHARACTERISTICS.............. 2-3

FIGURE LIST

FIGURE TITLE PAGE

2-1 DK8 BASE KEY SERVICE UNIT AND HPFB MINIMUM CLEARANCE

REQUIREMENTS................................................................................................... 2-1

2-2 BASE KEY SERVICE UNIT MINIMUM CLEARANCE REQUIREMENTS .............. 2-1

2-3 DK16 COMBINED BASE AND EXPANSION KEY SERVICE UNIT

MINIMUM CLEARANCE REQUIREMENTS .......................................................... 2-2

2-4 KSU GROUNDING DIAGRAM............................................................................... 2-3

2-i

Page 15

INSTALLATION-SITE REQUIREMENTS

SECTION 100-816-202

MARCH 1993

1 GENERAL

1.00 This chapter defines the installation site re-

quirements necessary to ensure a proper operating environment for the STRATA DK8 and DK16.

Also included are grounding requirements.

2 INPUT POWER REQUIREMENTS

2.00 The system requires an input power source

of 117VAC nominal (85VAC ~ 135VAC), 50/60 Hz,

15 amps. The AC outlet is recommended to be

dedicated

ground (refer to Paragraph 4). This is to eliminate

interference from branch circuit motor noise or the

like, and to prevent accidental power-off.

2.01 To avoid accidental power turn-off, it is recommended that an ON/OFF wall switch

used on this dedicated AC circuit.

and unswitched, with a solid third wire

not

be

2.02 An option Reserve Power Battery and

Charger (HPFB) is available for use with the

STRATA DK8 to serve as a power failure backup.

For the STRATA DK16, a reserve power source

(two customer-supplied 12-volt batteries) may be

connected to the system to serve as a power

failure backup.

3 SITE CONSIDERATIONS

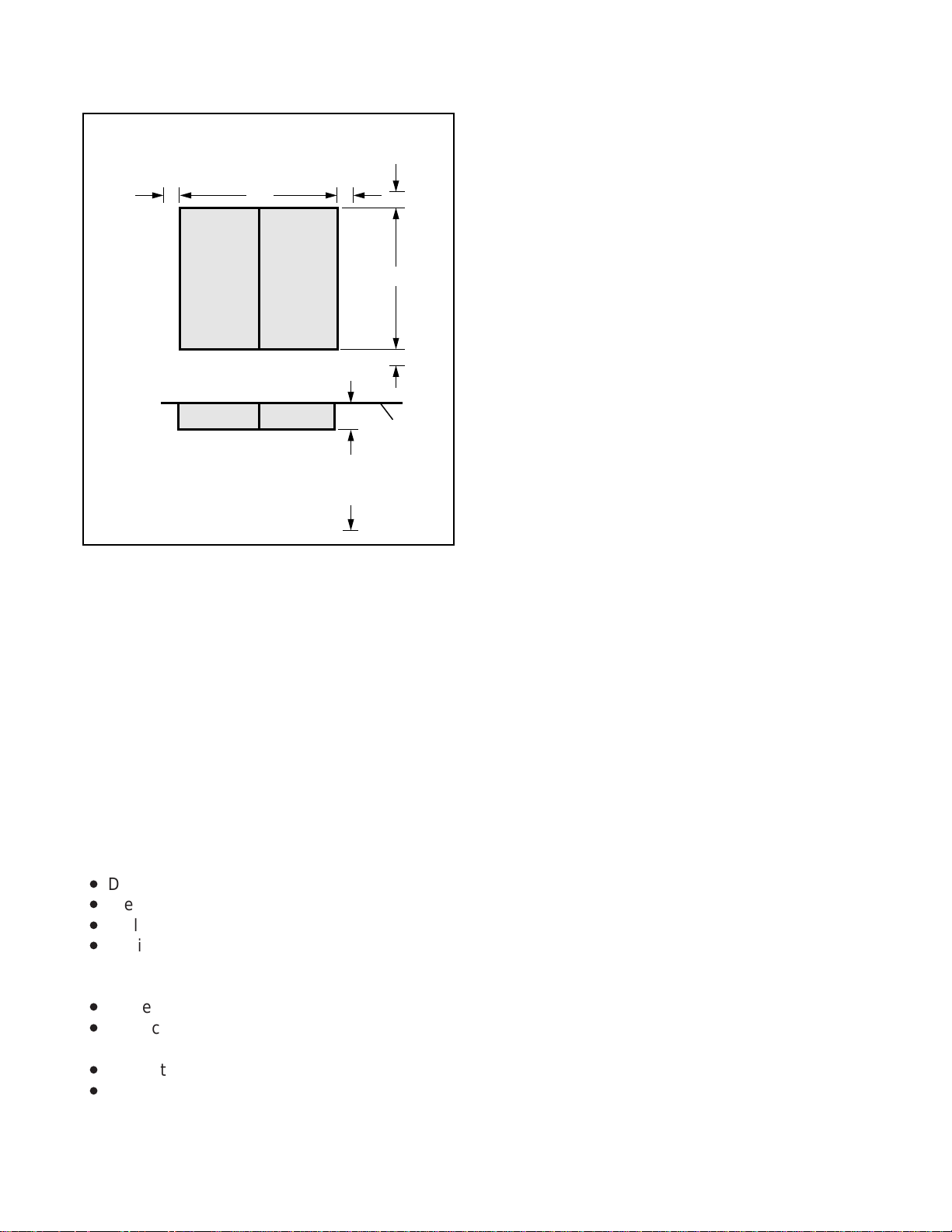

3.00 Clearance and Location Requirements

3.01 The key service units must be wall mounted.

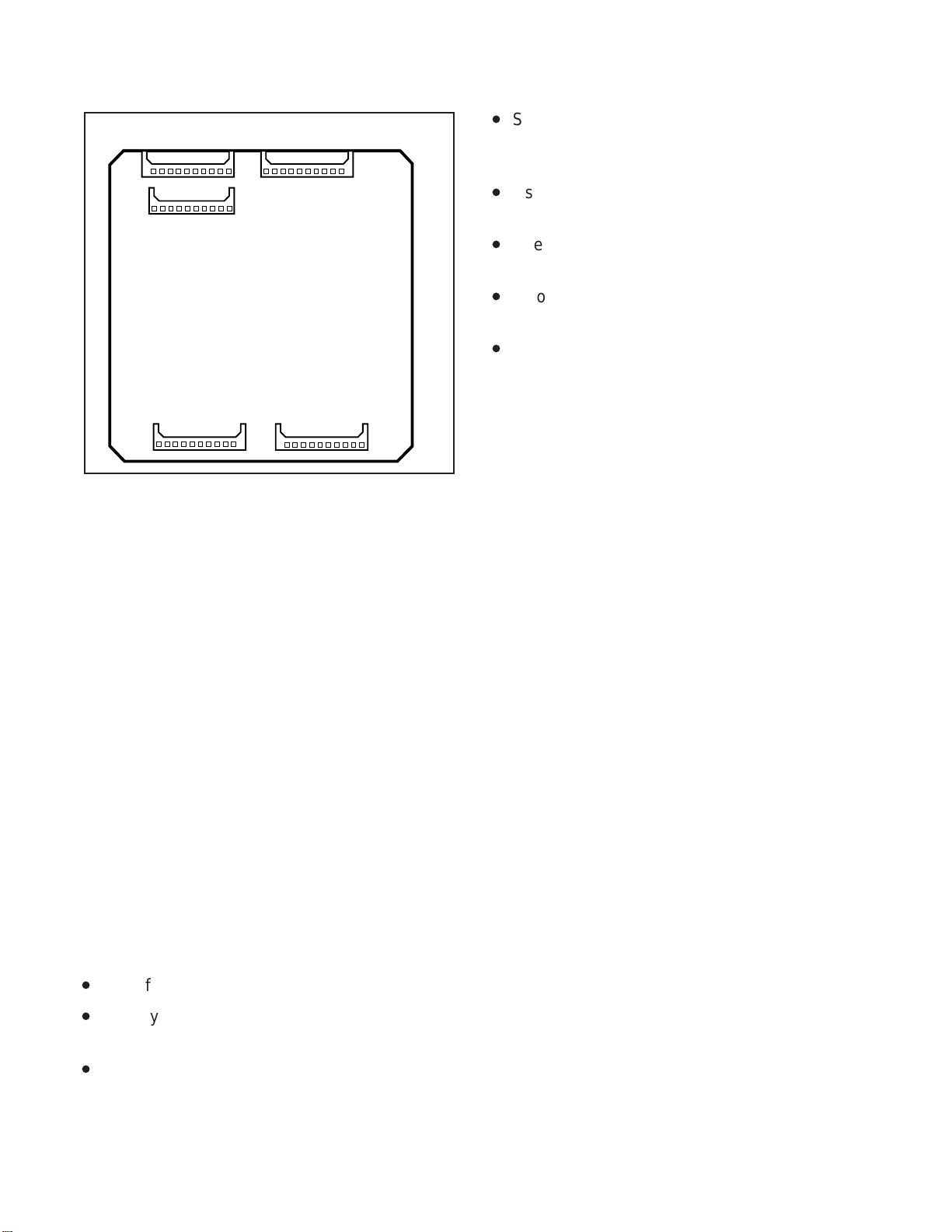

Figure 2-1 shows the minimum clearance requirements for the STRATA DK8 system, and includes

the recommended mounting location and clearance requirements for the optional HPFB. Figures

2-2 (Base Key Service Unit) and 2-3 (Base and

Expansion Key Service Unit together) show the

minimum clearance requirements for the standard

DK8 KEY SERVICE UNIT

AND HPFB CLEARANCE

FRONT VIEW

HPFB

DK 8 KSU

2" 2"10"

TOP VIEW

3"

3 FEET

2"

2"

16.4"

2"

WALL

DK16 BASE KEY SERVICE UNIT CLEARANCE

FRONT VIEW

2" 2"

TOP VIEW

12.25"

DK 16

BASE KSU

3.5"

3 FEET

2"

18"

2"

WALL

FIGURE 2-1

DK8 KEY SERVICE UNIT AND HPFB

MINIMUM CLEARANCE REQUIREMENTS

FIGURE 2-2

DK16 BASE KEY SERVICE UNIT

MINIMUM CLEARANCE REQUIREMENTS

2-1

Page 16

INSTALLATION-SITE REQUIREMENTS

SECTION 100-816-202

MARCH 1993

DK16 BASE AND EXPANSION

UNIT CLEARANCE

FRONT VIEW

2"

TOP VIEW

20"

BASEEXP

BASEEXP

2"

3.5"

3 FEET

2"

18"

2"

WALL

FIGURE 2-3

DK16 COMBINED BASE AND

EXPANSION KEY SERVICE UNIT

MINIMUM CLEARANCE REQUIREMENTS

and optioned STRATA DK16 system. Refer to

Chapter 4 for DK16 key service unit wall mounting

instructions.

3.03 If reserve power is to be installed for the

STRATA DK16, the batteries will require a wellventilated location close (within nine feet) to the

DKSUB16 (the optional Toshiba-supplied battery

cable is 9 feet in length). The STRATA DK8

reserve battery (HPFB) should be mounted directly above the DKSU8 as shown in Figure 2-1.

3.10 Electrical/Environmental Requirements

and Characteristics

3.11 The electrical/environmental requirements

and characteristics for each system are provided

in Table 2-A.

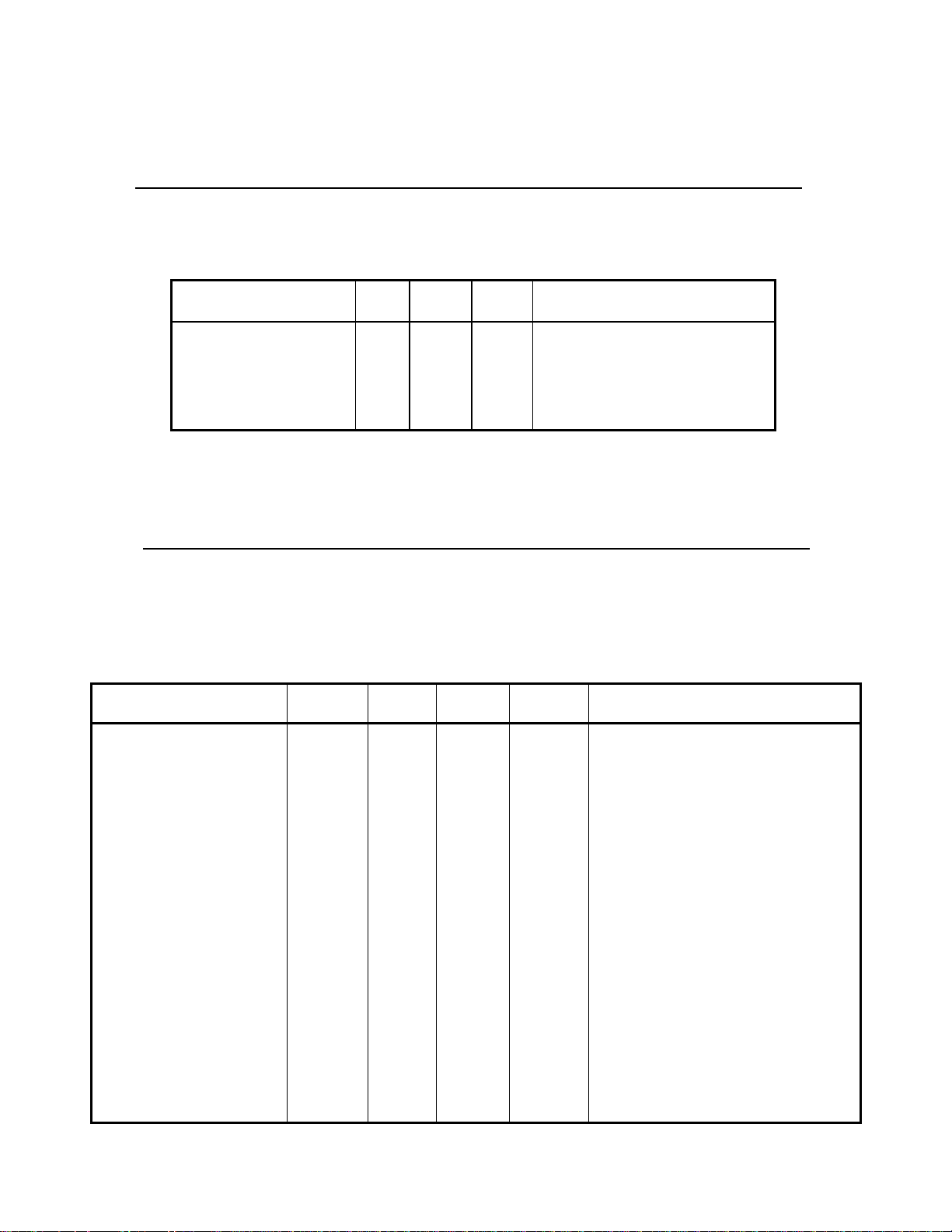

4 GROUNDING REQUIREMENTS

4.00 The systems require a solid earth ground for

proper operation. Failure to provide ground may

lead to confusing trouble symptoms and, in extreme cases, system failure. The AC power cord

contains a conductor for the "third wire ground"

provided by the commercial power outlet. The

third-wire ground should be the only ground necessary for the DK8/DK16; this ground must originate at the buildings main power distribution panel

and have a solid connection to earth ground.

(Figure 2-4)

4.10 Third Wire Ground Test

3.02 The following conditions must be considered

when selecting a location for the key service unit(s):

The location MUST BE:

•

Dry and clean

•

Well ventilated

•

Well illuminated

•

Easily accessible

The location MUST NOT BE:

•

Subject to extreme heat or cold

•

Subject to corrosive fumes, dust, or other air-

borne contaminants

•

Subject to excessive vibration

•

Next to television, radio, office automation, or

high frequency equipment

4.11 Test the "third wire ground" for continuity by

either measuring the resistance between the third

prong terminal (earth ground) and a metal cold

water pipe (maximum: 1 ohm), or by using a

commercially available earth ground indicator. If

neither procedure is possible, perform the following earth ground test procedure:

WARNING!

Hazardous voltages that may cause death

or injury are exposed during the following

test. Use great care when working with AC

power line voltage.

1) Obtain a suitable voltmeter, and set it for a

possible reading of up to 250 VAC.

2-2

Page 17

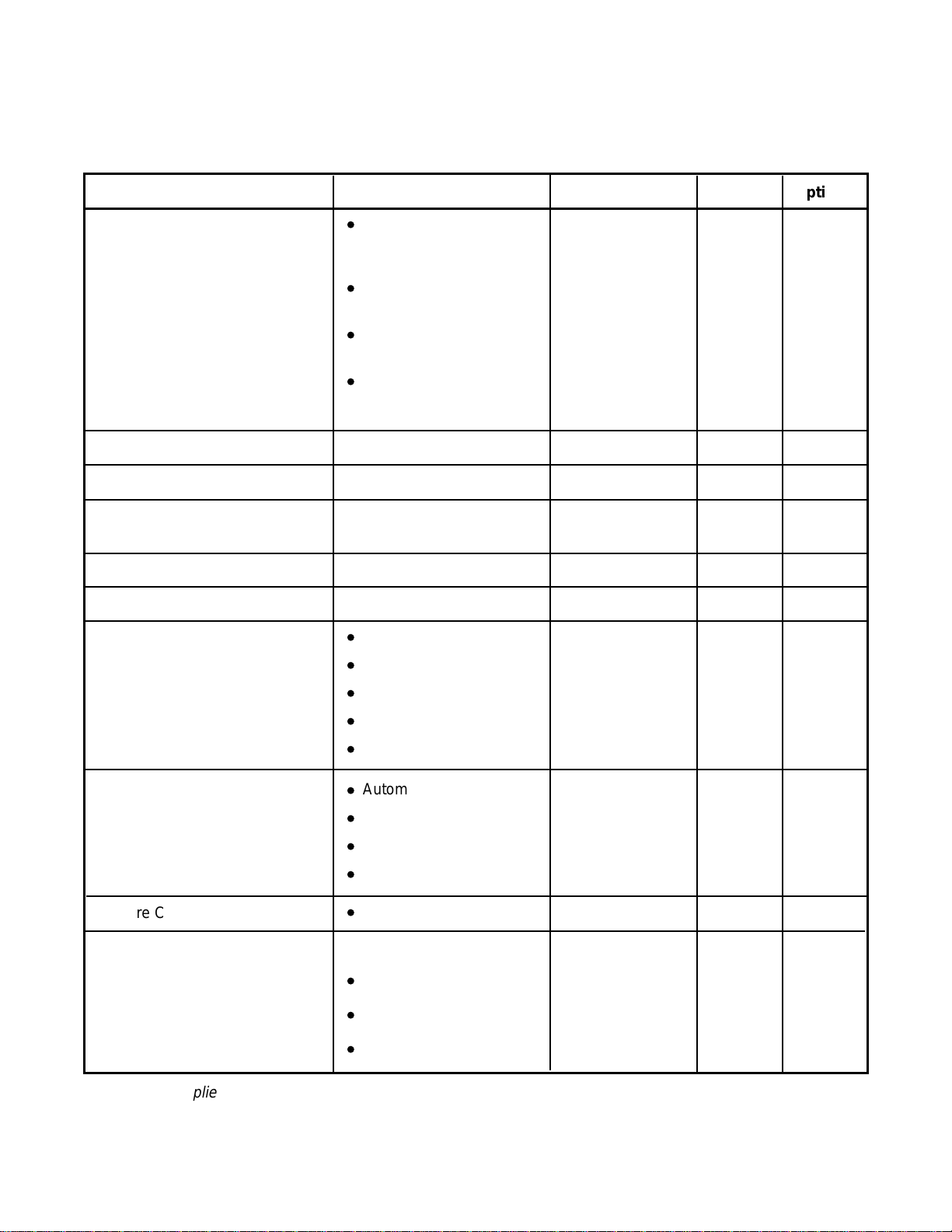

SUMMARY OF ELECTRICAL/ENVIRONMENTAL CHARACTERISTICS

GENERAL

Primary power

Input AC

AC frequency

Power

Environmental specifications

Operating temperature

Operating humidity

Storage temperature

Power supply

DC voltage output

specification

Battery charger characteristics

(DK16 only)

INSTALLATION-SITE REQUIREMENTS

SECTION 100-816-202

TABLE 2-A

85 ~ 135VAC

50/60 Hz

DK8-46 watts maximum, DK16-75 watts maximum

32 ~ 104°F (0 ~ 40°C)

20 ~ 80% relative humidity without condensation

- 4 ~ 158°F (-20 ~ 70°C)

DK16

–24VDC: (–26.3 ~ –27.8VDC)

+5VDC: ( +4.5 ~ +5.5VDC)

–5VDC: ( –4.5 ~ –5.5VDC)

Charger: current limiting

Nominal float voltage: 2.275 volts/cell

Charge current: 0.7 amps maximum

Battery discharge cut-off voltage: 20.5 ± 0.5VDC

DK8

+24VDC: (+26.3 ~ +27.8VDC)

+5VDC: ( +4.5 ~ +5.5VDC)

Note: +5V converter

on KSU PCB

MARCH 1993

QSTU, KSTU, PSTU or PESU (circuits 1 & 2)

Ring voltage

Ringing capability

GROUND 1 THIRD WIRE GROUND

TO AC POWER CORD

THIRD WIRE

AC GROUND

A

ELECTRICAL

SYSTEM GROUND

DK8 OR DK16 KSU

POWER

SUPPLY

FG

FIGURE 2-4

KSU GROUNDING DIAGRAM

Square wave output with high/low option jumper:

Low position, 130 ± 20VDC peak–to–peak (no-load)

High position, 190 ± 25VDC peak–to–peak (no-load)

Two ringers maximum per circuit, high or low position

2) Connect the meter probes between the two

main AC voltage terminals (white and black

wires) on the wall outlet. The reading obtained

should be between 100 ~ 120 VAC.

3) Move one of the meter probes to the third

terminal (green wire ground). Either the same

reading or a reading of zero volts should be

obtained.

4) If the reading is zero volts, leave one probe on

the ground terminal and move the other probe

to the second voltage terminal.

CAUTION!

If a reading of zero volts is obtained on

both voltage terminals (white wire to green

wire, black wire to green wire), the outlet is

not properly grounded. Omit steps 5 and

6, and proceed directly to step 7.

2-3

Page 18

INSTALLATION-SITE REQUIREMENTS

SECTION 100-816-202

MARCH 1993

5) If a reading of zero volts on one terminal, and

a reading of 100 ~ 120 VAC on the other

terminal is obtained, remove both probes from

the outlet.

6) Set the meter to the “OHMS/Rx1” scale. Place

one probe on the ground terminal, and the

other probe on the terminal that produced a

reading of zero volts. The reading should be

less than 1 ohm.

CAUTION!

If the reading is more than one ohm, then

the outlet is not adequately grounded.

7) If the above tests show the outlet is not properly grounded, the condition should be corrected (per Article 250 of the National Electrical Code) by a qualified electrician before the

system is connected.

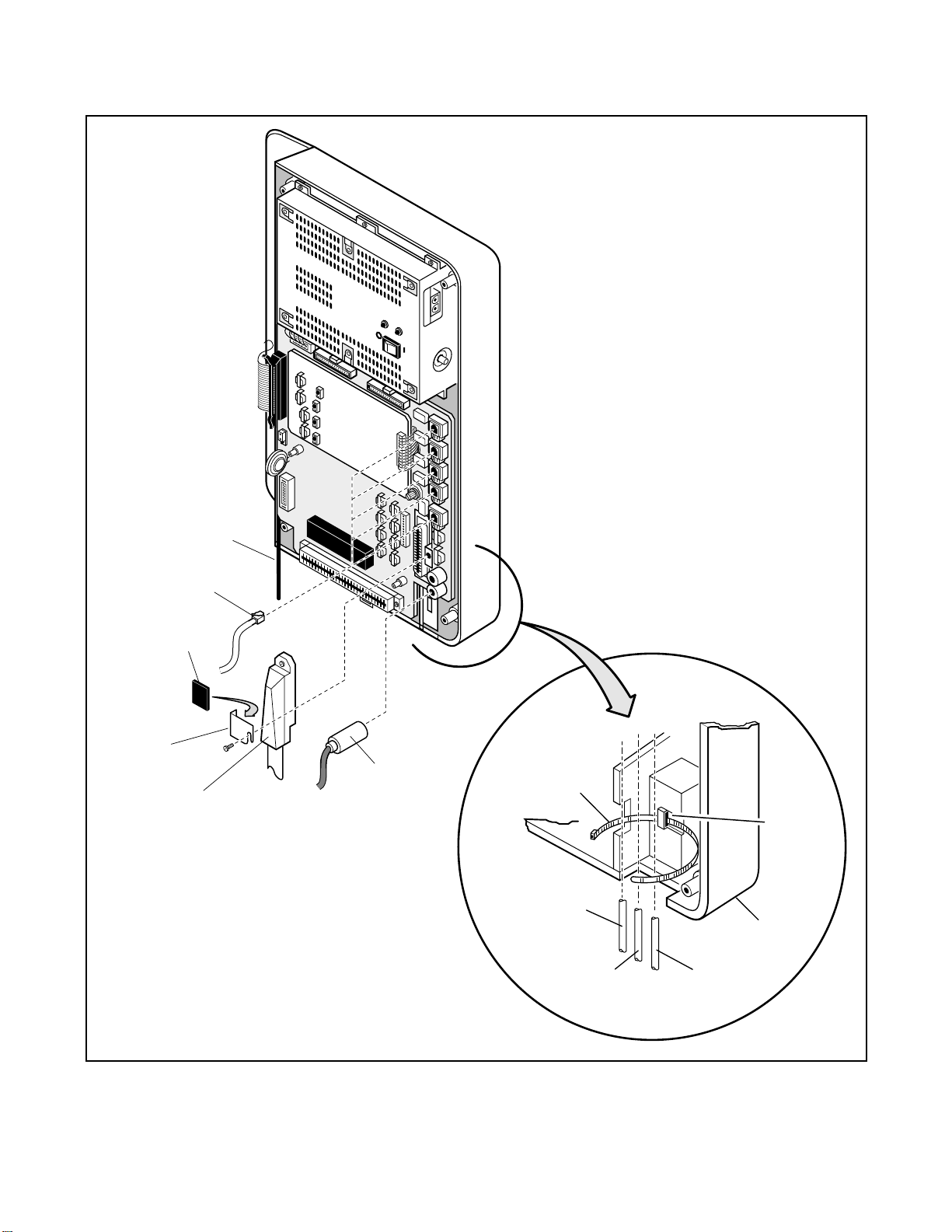

4.20 Alternate or Additional Ground

4.21 If the “third wire” AC ground can not practi-

cally be improved or if extreme motor noise or

other disturbance causes system malfunction, or if

local area lightning storms exist, a separate direct

ground may be warranted.

4.22 Connect a separate earth ground from a cold

water pipe or earth grounding rod directly to the FG

screw terminal on the DK8/DK16 power supply.

See Figure 4-5 of Section 100-816-204 (for

STRATA DK8) or Figure 5-8 of Section 100-816-

205 (for STRATA DK16).

2-4

Page 19

TOSHIBA SYSTEM PRACTICES

DIGITAL KEY TELEPHONE SYSTEMS

INSTALLATION-CONFIGURATION

SECTION 100-816-203

MARCH 1993

INSTALLATION

CHAPTER THREE

SYSTEM CONFIGURATION

Page 20

Page 21

INSTALLATION-CONFIGURATION

SECTION 100-816-203

MARCH 1993

TABLE OF CONTENTS

PARAGRAPH SUBJECT PAGE

1 INTRODUCTION ...................................................................................................... 3-1

2 SYSTEM CAPACITY................................................................................................ 3-1

2.00 Total System Capacity.......................................................................................... 3-1

2.10 The DK8 Key Service Unit.................................................................................... 3-1

2.20 The DK16 Base Key Service Unit......................................................................... 3-1

2.30 The DK16 Expansion Key Service Unit................................................................ 3-1

3 STATION CONSIDERATIONS ................................................................................ 3-5

3.10 Telephone Circuit (Port) Types............................................................................. 3-5

3.20 Digital Telephone Circuit Connections ................................................................. 3-5

3.30 Electronic Telephone Circuit Connections (STRATA DK16 Only) ........................ 3-8

3.40 Standard Telephone Circuit Options .................................................................... 3-8

4 TELEPHONE UPGRADES ...................................................................................... 3-9

4.10 Digital Telephone Upgrades................................................................................. 3-9

4.20 Electronic Telephone Upgrades ........................................................................... 3-9

5 CONFIGURATION EXAMPLES............................................................................... 3-9

5.10 Strata DK8 - Example 1 (Small Retail Store)........................................................ 3-9

5.20 Strata DK8 - Example 2 (Home Office) ................................................................ 3-9

5.40 Strata DK16 - Example 1 (Bank) .......................................................................... 3-10

5.50 Strata DK16 - Example 2 (Office/Warehouse)...................................................... 3-10

6 CONFIGURATION WORKSHEET ........................................................................... 3-10

TABLE LIST

TABLE TITLE PAGE

3-A DK8 CO LINE/STATION CONFIGURATION GUIDE............................................... 3-2

3-B DK16 CO LINE/STATION CONFIGURATION GUIDE (BASE AND

EXPANSION UNIT).................................................................................................. 3-2

3-C DK8 KEY SERVICE UNIT COMPONENTS ............................................................. 3-3

3-D DK16 BASE KEY SERVICE UNIT COMPONENTS................................................. 3-4

3-E DK16 EXPANSION KEY SERVICE UNIT PCBs ...................................................... 3-5

3-F INTERFACE OPTION .............................................................................................. 3-6

3-G STRATA DK8 STATION APPARATUS OVERVIEW ............................................... 3-6

3-H STRATA DK16 STATION APPARATUS OVERVIEW ............................................. 3-7

WORKSHEETS

NUMBER TITLE PAGE

1 DK8 STATION AND CO LINE TOTALS................................................................... 3-11

2 DK8 KEY SERVICE UNIT AND PCBs ..................................................................... 3-12

3 DK8 PERIPHERALS AND UPGRADES .................................................................. 3-13

1 DK16 STATION AND CO LINE TOTALS................................................................. 3-15

2 DK16 KEY SERVICE UNIT AND PCBs ................................................................... 3-16

3 DK16 PERIPHERALS AND UPGRADES ................................................................ 3-17

4 DK16 SYSTEM POWER CHECK ............................................................................ 3-19

3-i

Page 22

INSTALLATION-CONFIGURATION

SECTION 100-816-203

MARCH 1993

3-ii

Page 23

INSTALLATION-CONFIGURATION

SECTION 100-816-203

MARCH 1993

1 INTRODUCTION

1.00 This chapter offers guidelines and consider-

ations on how to configure a STRATA DK8/DK16

system, which can support a wide variety of stations and peripherals.

2 SYSTEM CAPACITY

2.00 Total System Capacity

2.01 The STRATA DK8/DK16 systems have a

modular design which allows them to support a

number of station and CO line configurations. The

main component of each system is the Key Service Unit. The DK8 KSU can have up to 10 stations

and four CO lines. The DK16 Base Key Service

Unit can have up to 12 stations and four CO lines.

An Expansion Key Service Unit can be added to

the DK16 to increase the station capacity to 20 and

the CO line capacity to eight. Station and CO line

configurations are shown in Table 3-A (for DK8)

and Table 3-B (for DK16).

2.10 The DK8 Key Service Unit

2.11 Station and CO Lines. The DK8 Key Service

Unit comes standard with four digital telephone

circuits (ports) and two CO line circuits (Table

3-C). An optional printed circuit board called the

QCDU can be added to the KSU to provide one CO

line circuit and two digital telephone circuits. A

maximum of two QCDUs may be added to provide

a total of four additional digital telephone circuits

and two additional CO line circuits. Another optional printed circuit board called the QSTU can be

added to the DK8 KSU to provide two standard

telephone circuits.

2.12 Peripherals. The DK8 Key Service Unit can

support a number of peripherals, which are not

considered as stations and do not affect the maximum station and CO line capacities. A customersupplied Music-on-hold source, optional reserve

power battery and charger, a customer-supplied

emergency standard telephone for system power

failure occurrences and an amplifier with speaker

for paging and night ringing can all be connected

to the Key Service Unit (Table 3-C). A relay contact

is also provided to control one of the following

peripherals: Music-on-hold source, night bell, or

page amplifier mute control.

2.20 The DK16 Base Key Service Unit

2.21 Station and CO Lines. The DK16 Base Key

Service Unit comes standard with eight digital

telephone circuits (ports) and four CO line circuits

(Table 3-D). An optional printed circuit board called

the KSTU can be added to the unit to provide four

standard telephone circuits (ports).

2.22 Peripherals. The DK16 Base Key Service

Unit can support a number of peripherals, which

are not considered as stations and do not affect

the maximum station and CO line capacities. A

customer-supplied Music-on-hold source, customer-supplied separate background music

source, customer-supplied reserve power batteries, a customer-supplied emergency standard telephone for system power failure occurrences and an amplifier with speaker for paging

and night ringing can all be connected to the

Base Key Service Unit (Table 3-D). A relay

contact is also provided to control one of the

following peripherals: Music-on-hold source, night

bell, or Page Amplifier mute control.

2.30 The DK16 Expansion Key Service Unit

2.31 Station and CO Lines. The optional DK16

Expansion Key Service Unit has four universal

slots which can support a maximum of four CO

lines and eight stations. Printed circuit boards

(PCBs) that support CO lines and can be installed

in the Expansion Unit are the PCOU and KCDU

(Table 3-E). PCBs that can support stations and be

installed in the Expansion Unit are the PDKU,

PEKU, PSTU, PESU, and KCDU.

2.32 Peripherals. The Expansion Unit can support either a PIOU or PIOUS PCB, which both

provide, among other features, Station Message

Detail Recording (SMDR), an interface for a local

programming terminal, and connectors for an internal modem (IMDU) for remote maintenance

and administration (Table 3-F). Any device that

connects to the PIOU or PIOUS should not be

considered a station and does not affect the

system's station capacity.

3-1

Page 24

INSTALLATION-CONFIGURATION

SECTION 100-816-203

MARCH 1993

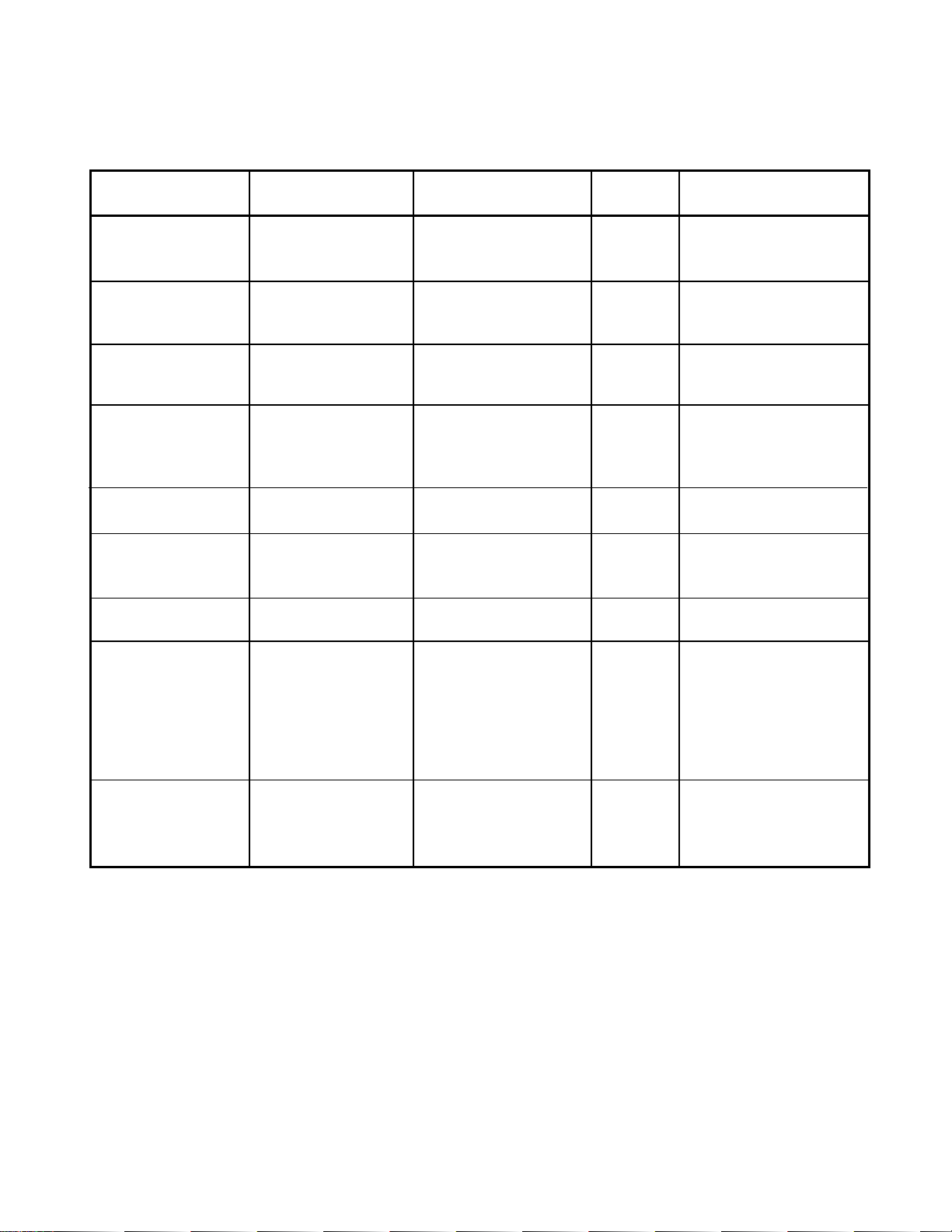

DK8 CO LINE/STATION CONFIGURATION GUIDE

TABLE 3-A

EQUIPMENT

KSU = Key Service Unit ·2 CO Lines/4 digital circuits)

QCDU = Optional PCB (1 CO line/2 digital circuits)

QSTU = Optional PCB (2 standard circuits)

CONFIGURATION CO

LINES BY STATION

2 by 4

2 by 6

3 by 6

3 by 8

4 by 8

4 by 10

COs DKTs SLTs EQUIPMENT

2

2

3

3

4

4

4

4

6

6

8

8

2

2

2

CO = Central Office

DKT = Digital Telephone

SLT = Standard Telephone

KSU

KSU + QSTU

KSU + QCDU

KSU + QCDU + QSTU

KSU + QCDU + QCDU

KSU + QCDU + QCDU + QSTU

TABLE 3-B

DK16 CO LINE/STATION CONFIGURATION GUIDE (BASE AND EXPANSION UNIT)

EQUIPMENT

BU

KSTU

EU

PDKU

KCDU

PEKU

PESU

Base Unit (4 CO lines/8 digital circuits)

=

Base Unit Option (4 standard circuits)

=

Expansion Unit

=

EU option (8 digital circuits)

=

EU option (2 CO lines/4 digital circuits)

=

EU option (8 electronic circuits)

=

EU option (2 standard/4 electronic circuits)

=

PSTU

PCOU

CO

DKT

EKT

SLT

EU option (8 standard circuits)

=

EU option (4 CO lines)

=

Central Office line

=

Digital telephone

=

Electronic telephone

=

Standard telephone

=

CONFIGURATION CO

LINES BY STATION

4 by 8

4 by 12

4 by 14

4 by 16

4 by 16

4 by 16

4 by 18

4 by 20

4 by 20

4 by 20

6 by 12

6 by 16

8 by 8

8 by 12

8 by 14

8 by 16

8 by 16

8 by 16

8 by 18

8 by 20

8 by 20

8 by 20

8 by 20

COs DKTs EKTs SLTs EQUIPMENT

4

4

4

4

4

4

4

4

4

4

6

6

8

8

8

8

8

8

8

8

8

8

8

16

16

12

12

16

16

16

16

8

8

8

8

8

8

8

8

8

8

8

8

8

8

8

4

8

4

8

4

8

4

8

4

2

8

6

4

4

12

4

4

2

6

4

4

4

12

BU

BU + KSTU

BU + EU + PESU

BU + EU + PSTU

BU + EU + PEKU

BU + EU + PDKU

BU + KSTU + PESU

BU + KSTU + EU + PEKU

BU + KSTU + EU + PDKU

BU + KSTU + EU + PSTU

BU + EU + KCDU

BU + KSTU + EU + KCDU

BU + EU + PCOU

BU + KSTU + EU + PCOU

BU + EU + PCOU + PESU

BU + EU + PCOU + PEKU

BU + EU + PDKU + PCOU

BU + EU + KCDU + KCDU

BU + KSTU + EU + PCOU + PESU

BU + KSTU + EU + KCDU + KCDU

BU + KSTU + EU + PCOU + PEKU

BU + KSTU + EU + PCOU + PDKU

BU + KSTU + EU + PCOU + PSTU

3-2

Page 25

Item Connector TypeSupports Standard Optional

Digital Telephone Circuits (4)

CO Line Circuits (2)

Power Failure Transfer Interface

Battery Backup Interface

Music-On-Hold/BGM Interface

600 Ohm page Interface

CO line CKT (1)/

Digital Telephone CKT (2) (QCDU)

(max. 2 QCDU per system)

Standard Telephone

Interface Unit (QSTU)

•

2 standard telephone circuits

•

(1 max.) QSTU per system

DTMF/ABR Tone Receiver

(3-Receiver CKT per QRCU )

Control Relay

Conference Circuit Interface Unit

(QCNU)

SMDR/TTY Interface Unit (QSMU)

(Requires PPTC)

TABLE 3-C

DK8 KEY SERVICE UNIT COMPONENTS

•

Digital Telephones (with

or without PDIU–DI2 or

ADM)

•

Stand-alone Data

Interface Units (PDIU-DS)

•

Door Phone Lock/Control

Unit (DDCB)

•

Loop Start CO Lines

•

Standard Telephone

(one)*

•

Optional HPFB Battery

(one or two per system)

•

Music-on-hold/BGM

Source*

•

Amplifier/Speaker

•

Digital Telephones (with

or without PDIU–DI2 or

ADM)

•

Stand-alone Data

Interface Units (PDIU-DS)

•

Loop Start CO Line

•

Standard Telephones*

•

Other Single-line Devices*

•

Fax Machine*

•

Voice Mail Devices

•

Alternate BGM source*

•

Automatic Busy Redial

•

Standard telephone ports

•

DISA

One of the following:

•

Night Relay

•

External Page Mute

•

MOH Control Relay

•

2 Simultaneous

Conferences

•

SMDR Printer*, or

•

Maintenance Terminal* or

•

Modem*

25-pair Amphenol

RJ11 Modular

RJ11 Modular

Proprietary

Cable/Connector

RCA Jack

RCA Jack

25-pair Amphenol

RJ11 Modular

25-pair Amphenol

Internal

25-pair Amphenol

Internal

6-pin Modular

(PPTC adaptor)

INSTALLATION-CONFIGURATION

SECTION 100-816-203

MARCH 1993

✓

✓

✓

Interface

HPFB

with cable

✓

✓

✓

✓

✓

✓

✓

✓

Customer supplied equipment not offered by Toshiba Telecommunication Systems Division.

*

3-3

Page 26

INSTALLATION-CONFIGURATION

SECTION 100-816-203

MARCH 1993

TABLE 3-D

DK16 BASE KEY SERVICE UNIT COMPONENTS

Item

Digital Telephone Circuits (8)

CO Line Circuits (4)

Power Failure Transfer Interface

Battery Backup Interface with

built-in charger

Music-On-Hold/BGM Interface

600 Ohm page Interface

Standard Telephone

Interface Unit (4-Circuit)

(KSTU)

*

Supports

Digital Telephones (with

•

or without PDIU–DI2 or

ADM)

Stand-alone Data

•

Interface Units (PDIU-DS)

Door Phone Lock/Control

•

Unit (DDCB)

Digital Direct Station

•

Selection Console (DDSS)

Loop Start CO Lines

Standard Telephone (one)

Two 12-volt Batteries

Music-on-Hold/BGM source

Amplifier/Speaker

Standard Telephones

•

Other Single-line Devices

•

Alternate BGM Source

•

Fax machine

•

Voice mail devices

•

*

*

*

*

Connector Type

25-pair Amphenol

RJ11 Modular

RJ11 Modular

*

Proprietary

Connector/Cable

RCA Jack

*

RCA Jack

25-pair Amphenol

*

Standard Optional

✓

✓

✓

✓

Cable and

Batteries

✓

✓

✓

Automatic Busy Redial

DTMF/ABR

Receiver (K4RCU)

Feature Cartridge

Control Relay

Customer supplied equipment not offered by Toshiba Telecommunication Systems Division.

*

•

Standard Telephone Ports

•

Interprets DTMF Tones

•

DISA

•

Future Feature Upgrades

•

Choice of one:

MOH Source Control

•

Night Bell Control

•

BGM Mute Control

•

Internal

Internal

25-pair Amphenol

3-4

✓

✓

✓

Page 27

TABLE 3-E

DK16 EXPANSION KEY SERVICE UNIT PCBs

INSTALLATION-CONFIGURATION

SECTION 100-816-203

MARCH 1993

PCB

PDKU

PEKU

PSTU

PESU

PCOU

Circuits per PCB

8 digital telephone

circuits

8 electronic telephone

circuits

8 standard telephone

circuits

2 standard telephone/

4 electronic telephone circuits

(standard/electronic

telephone ports)

4 CO line circuits

(lines)

Interfaces

• Digital telephones with or

without PDIU-DI2 or ADM

• DDSS console

• PDIU-DSs

• DDCB

• Electronic telephones

• HDSS console

• BGM source

• EOCU PCB for OCA

• Standard telephones

• Voice mail ports

• Background music source

• Off-premises stations

• Other similar devices

Standard: same as PSTU

Electronic: same as PEKU

except PESU does not

support HDSS console

• Central Office loop start

lines

Connector

25-pair amphenol

25-pair amphenol

25-pair amphenol

25-pair amphenol

RJ14C modular

KCDU

PIOU,

PIOUS

2 CO line circuits/

4 digital telephone circuits

See Table 3-D

• Central Office loop

• DKT circuits same as

See Table 3-D

3 STATION CONSIDERATIONS

3.00 For configuration purposes, a station can be

considered as any device which is connected to a

dedicated telephone circuit. Although the words

"telephone" and "station" are often used synonymously and interchangeably in STRATA DK8/

DK16 documentation, devices other than telephones—such as Stand-alone Data Interface units

(PDIU-DSs)—should also be considered as stations when configuring a system, because they

require a dedicated telephone circuit. A station

apparatus overview is shown in Table 3-G (for

STRATA DK8) and Table 3-H (for STRATA DK16).

RJ14C Modular

start lines

PDKU, except no DDSS

(CO Line circuits)

25-pair amphenol

(digital telephone circuits)

25-pair amphenol (PIOU)

Spring clip terminal (PIOUS)

3.10 Telephone Circuit (Port) Types

3.11 There are three types of telephone circuits to

which stations can be connected: digital telephone

circuits, electronic telephone circuits, and standard telephone circuits. All three types of circuits

are available with the STRATA DK16. The STRATA

DK8 does not support electronic telephone circuits.

3.20 Digital Telephone Circuit Connections

3.21 The STRATA DK8 Key Service Unit provides

four digital telephone circuits. The QCDU PCB

provides two.

3-5

Page 28

INSTALLATION-CONFIGURATION

SECTION 100-816-203

MARCH 1993

Expansion Unit Interface Options PIOU PIOUS

TABLE 3-F

PIOU/PIOUS INTERFACE OPTION (DK16 ONLY)

Zone Page Interface (unamplified, 4 zones)

Night Transfer or Music-on-Hold Control Relay

Door Lock or External Amplifier Control Relay

Alarm Sensor

SMDR output (RS-232/6-wire modular connector)

Maintenance Port for a Local ASCII Terminal or

External Modem (RS-232/6-wire modular connector)

Remote Maintenance Modem (IMDU subassembly, no

external connector)

NOTE: X = the option is provided

Station

Digital Telephone

DKT with or without

ADM or PDIUDI

Stand-alone Data

Interface Unit (PDIUDS)

Digital Door

Phone/Lock Control

Unit (DDCB)

Single-wire pair

devices:

•

Standard

Telephone

•

Voice Mail Device

•

Facsimile Machine

•

Modem

•

Dictation

Equipment

Alternate

Background Music

Source

*

TABLE 3-G

STRATA DK8 STATION APPARATUS OVERVIEW

Type and Number of

Circuits Required

Digital, one for each

DKT

Digital, one for each

PDIU-DS

Digital, one for each

DDCB

Standard, one for

each device (voice

mail devices may

require more than one

circuit)

Standard port for the

source

PCB or Interface

KSU (Circuits 1 ~ 4)

QCDU (Circuits 1 ~ 2)

KSU (Circiuts 1 ~ 4)

QCDU (Circuits 1 ~ 2)

KSU Port 02

Port 03

QSTU (Circuits 1 ~ 2)

QSTU (Circuit 2)

Port 19

X

X

X

X

X

X

X

KSU

Capacity

4

4

2

—

1

X

X

X

X

X

X

KSU and Optional PCB

Combined Capacity

8

8

2

2

1

*

May require interface transformer, see Section 100-816-207.

3-6

Page 29

INSTALLATION-CONFIGURATION

TABLE 3-H

STRATA DK16 STATION APPARATUS OVERVIEW

SECTION 100-816-203

MARCH 1993

Station

Digital Telephone

(DKT with or without

ADM or PDIU-DI)

Stand-alone Data

Interface Unit

(PDIU-DS)

Digital Direct Station

Selection Console

(DDSS)

Digital Door

Phone/Lock Control

Unit (DDCB)

Electronic Telephone

(EKT)

Electronic Direct

Station Selection

Console (HDSS)

Conference Amplifier

Single-wire-pair

Devices:

• Standard Telephone

• Voice Mail Device

• Facsimile Machine

• Modem

• Dictation Equipment

Alternate

Background Music

Source

Type and Number of

Circuits Required

Digital, one for each

DKT

Digital, one for each

PDIU-DS

Digital, one for each

DDSS

Digital, one for each

DDCB

Electronic, one for

each EKT

Electronic, two for the

HDSS

Electronic, two for the

amplifier

Standard, one for

each device (voice

mail devices may

require more than one

circuit)

Standard or

Electronic, one for the

source

PCB or Interface

Base Unit (Circuits 1~8)

PDKU2 (Circuits 1~8)

KCDU (Circuits 1~4)

Base Unit (Circuits 1~8)

PDKU2 (Circuits 1~8)

KCDU (Circuits 1~4)

Base Unit (Circuit 8)

PDKU (Circuit 8)

Base Unit (Circuit 5)

PDKU (Circuit 1)

or first

KCDU (Circuit 1)

PEKU (Circuits 1~8)

PESU (Circuit 5~8)

PEKU (Circuits 7 and 8)

PEKU (Circuits 6 and 7)

PESU (Circuits 6 and 7)

KSTU (Circuits 1~4)

PSTU (Circuits 1~8)

PESU (Circuits 1~2)

KSTU (Circuit 4)

PEKU (Circuit 3)

PESU (Circuit 8)

PSTU (Circuit 4)

Base Unit

Capacity

8

8

1

1

0

0

0

4

1

Base and Expansion

Unit Combined Capacity

16

16

2

2

8

1

1

12

1

*

May require interface transformer, see Section 100-816-207.

3-7

Page 30

INSTALLATION-CONFIGURATION

SECTION 100-816-203

MARCH 1993

NOTE:

A maximum of two QCDU PCBs may be

installed in the STRATA DK8.

3.22 The STRATA DK16 Base Key Service Unit

and the PDKU PCB each provide eight digital

telephone circuits. The KCDU PCB provides four.

NOTE:

A maximum of two KCDU PCBs may be

installed in the STRATA DK16. If a KCDU is

installed, no other type of station PCB can be

installed in the STRATA DK16.

3.23 The following devices can be connected to

digital telephone circuits:

•

Digital Telephones (2000- and 1000-series):

Each digital telephone requires one circuit, and

each digital telephone circuit can support a

digital telephone.

•

Stand-alone Data Interface Units (PDIU-DS):

Each PDIU-DS requires one circuit. Any digital

telephone circuit, except for Circuit 8 on a PDKU1

(STRATA DK16), can support a PDIU-DS (see

Note 1).

NOTES:

1. There are two versions of the PDKU:

PDKU1 and PDKU2. The versions are

identical, except that Circuits 1 ~ 8 on the

PDKU2 can each support PDIU-DSs/

PDIU-DI, while only Circuits 1 ~ 7 on a

PDKU1 can support PDIU-DSs or PDIUDIs. Also, PDIU1 does not support 2000series digital telephone continuous DTMF

tones.

2. The Integrated Data Interface Unit (PDIUDI/PDIU-DI2) and the Add-on Module

(ADM) do not require a dedicated circuit.

They share a circuit with the telephone.

3. Only one option (PDIU-DI2 or ADM) can

be installed on a 2000-series digital telephone.

• Digital Direct Station Selection Console

(DDSS): (available with STRATA DK16 only)

Each DDSS Console requires one circuit. DDSS

Consoles can connect only to Circuit 8 in the

Base Key Service Unit and Circuit 8 on a PDKU.

The KCDU cannot support a DDSS console.

• Digital Door Phone/Lock Control Box

(DDCB): Each DDCB requires one circuit.

DDCBs can only connect to Circuits 3 and 4

(Ports 02 and 03) in the STRATA DK8 Key

Service Unit or Circuit 5 (Port 04) in the STRATA

DK16 Base Key Service Unit, and Circuit 1 (Port

12) on either the PDKU or KCDU (STRATA

DK16).

3.30 Electronic Telephone Circuit Connec-

tions (STRATA DK16 Only)

3.31 There are no electronic telephone circuits in

the Base Key Service Unit, and none can be

added to it. However, either the PEKU PCB, which

has eight electronic telephone circuits, or the

PESU, which has four electronic telephone circuits, can be installed in the Expansion Key Service Unit. The following devices can be connected

to electronic telephone circuits.

•

Electronic Telephones (6500-, 6000-, 3000-,

2000-series): An electronic telephone can be

connected to any electronic telephone circuit.

One electronic telephone circuit is required per

electronic telephone.

• Electronic Direct Station Selection Console

(HDSS): The system will support only one HDSS

console. The console must be connected to

both Circuits 7 and 8 on the PEKU. The PESU

will not support an HDSS Console.

• Alternate Background Music Source: The

system will support an alternate Background

Music source which can be heard over digital

and electronic telephone speakers and external

page speakers. This source can be connected

to either Circuit 3 on a PEKU, Circuit 8 on a

PESU, or Circuit 4 on a KSTU or PSTU PCB.

• Conference Amplifier: An amplifier for two CO

line conferencing can be connected to Circuits

6 and 7 (Ports 17 and 18) on a PEKU or PESU.

3.40 Standard Telephone Circuit Options

3.41 In addition to supporting standard telephones,

each of the standard telephone circuits can support any one of a number of single-wire-pair devices, including voice mail/Auto Attendant devices

and modems. The QSTU, which can be installed

in the STRATA DK8 Key Service Unit, has two

3-8

Page 31

INSTALLATION-CONFIGURATION

SECTION 100-816-203

MARCH 1993

standard telephone circuits. The KSTU, which can

be installed in the STRATA DK16 Base Key Service Unit, has four standard telephone circuits; the

PSTU, which can be installed in the DK16 Expansion Key Service Unit, has eight; and the PESU,

which can also be installed in the DK16 Expansion

Unit, has two (Circuits 1 and 2).

4 TELEPHONE UPGRADES

4.00 Digital and Electronic telephones can be

upgraded for a number of features; there are no

upgrades for standard telephones. Each of these

upgrades shares a circuit with the telephone that it

is connected to and is not considered a station.

4.10 Digital Telephone Upgrades

4.11 Digital telephones can be upgraded with the

following subassemblies:

• Integrated Data Interface Unit (PDIU-DI/PDIU-

DI2): A Digital telephone can be upgraded with

a PDIU-DI/PDIU-DI2 to provide the telephone

with data switching capabilities. 2000-series

Digital Telephones use the PDIU-DI2, and 1000series Digital Telephones use the PDIU-DI.

PDIU-DI2 cannot be installed on a telephone if

ADM is installed.

• Add-on Module (ADM): A 2000-series Digital

Telephone can be upgraded with an ADM to

provide 20 Direct Station Selection buttons on

STRATA DK16, or 10 DSS buttons, 8 speed dial

buttons, one night transfer button and one all

call page button on STRATA DK8. The 1000series Digital Telephone models cannot support

ADMs. ADM cannot be installed on a telephone

if PDIU-DI2 is installed.

• Off-hook Call Announce Upgrade (DVSU): A

Digital telephone that must receive Off-hook

Call Announce must be upgraded with a DVSU.

• Loud Ringing Bell/Headset Upgrade (HHEU):

A digital telephone can be upgraded with an

HHEU to provide a dual interface for the Loud

Ringing Bell feature and/or a headset. (Simultaneously with PDIU-DI2 or ADM).

4.20 Electronic Telephone Upgrades

4.21 On STRATA DK16, electronic telephones

can be upgraded with the following subassemblies:

• Off-hook Call Announce Upgrade (HVSU2 or

HVSU/HVSI): An electronic telephone must be

upgraded with the HVSU2 subassembly or the

combined HVSU/HVSI subassemblies to receive Off-hook Call Announce.

NOTE:

A PEKU or PESU PCB that supports electronic telephones that must receive Off-hook

Call Announce must be equipped with an

EOCU.

• Loud Ringing Bell/Headset Upgrade (HHEU):

An electronic telephone can be upgraded with

an HHEU to provide a dual interface for the Loud

Ringing Bell feature and a headset simultaneously.

5 CONFIGURATION EXAMPLES

5.00 The following provides an examples of how to

configure a STRATA DK8.

5.10 Strata DK8 - Example 1 (Smalll Retail

Store)

5.11 Customer Requirements. A store needs

two CO lines and four digital telephones.

5.12 Analysis. The store's system hardware re-

quirements are as follows:

• Two CO line circuits for the CO lines.

• Four digital telephone circuits for the digital

telephones.

5.13 Conclusion. A standard Key Service Unit

would be adequate in this case. The unit's standard four digital telephone circuits and two CO line

circuits could easily accommodate the store's needs

and allow for future expansion.

5.20 Strata DK8 - Example 2 (Home/Office)

5.21 Customer Requirements. In addition to three

CO lines, a home/office needs five digital telephones (three of which will have PDIU-DIs), a

modem, a door phone, one facsimilie machine,

Music-on-hold and Telephone Set Background

Music.

5.22 Analysis. The customer's requirements could

be broken down as follows:

3-9

Page 32

INSTALLATION-CONFIGURATION

SECTION 100-816-203

MARCH 1993

•

3 CO line circuits for the three CO lines

•

7 digital telephone circuits

§

one for each of the five digital telephones;

the PDIU-DIs do not require dedicated circuits.

§

one for a digital door phone/lock control unit

to support a door phone

§

one for the PDIU-DS connected to the modem

•

2 standard telephone circuits

§

one for the modem

§

one for the facsimilie machine

•

A music source for Music-on-hold and Background music can be connected to the Key

Service Unit MOH RCA jacks.

5.23 Conclusion. Several optional PCBs in addition to the Key Service unit would be needed for the

application. Two CO line circuits and four digital

telephone circuits would be provided by the KSU.

The third CO line circuit, as well as two digital

telephone circuits would be provided by an optional QCDU. A second QCDU would be necessary to provide the seventh digital telephone circuit. An optional QSTU would provide the two

standard telephone circuits. An optional QRCU

would be needed for the Dual-tone Multi-frequency

(DTMF) tones generated by the devices (modem

and facsimilie machine) connected to the standard

telephone lines.

5.30 The following provides an examples of how to

configure a STRATA DK16.

5.40 Strata DK16 - Example 1 (Bank)

5.41 Customer Requirements. A bank needs two

CO lines and six digital telephones (three of which

must be equipped with a PDIU-DI). It also wants to

connect a printer to a PDIU-DS.

5.42 Analysis. The bank's system hardware requirements are as follows:

• Two CO line circuits for the two CO lines.

• Seven digital telephone circuits. Six for telephones and one for the PDIU-DS. (The

PDIU-DIs do not require a dedicated circuit.)

5.50 Strata DK16 - Example 2 (Office/Warehouse)

5.51 Customer Requirements. In addition to five

CO lines, a small office-warehouse facility needs

11 digital telephones (three of which will have

PDIU-DIs), two PDIU-DSs, a modem, a facsimile

machine, conference capability, a door phone,

one standard telephone, Music-on-hold, and an

amplifier/speaker for paging.

5.52 Analysis. The customer's requirements could

be broken down as follows:

•

14 digital telephone circuits

§

one for each of the 11 digital telephones; the

PDIU-DIs do not require dedicated circuits.

§

one for each of the two PDIU-DSs

§

one for a digital door phone/lock control unit

to support a door phone

•

3 standard telephone circuits

§

one for the modem

§

one for the facsimile machine

§

one for the standard telephone

•

A music source for Music-on-hold and an amplifier/speaker for paging could both be connected

to the Key Service Unit RCA jacks.

•

A K4RCU would be needed for the Dual-tone

Multi-frequency (DTMF) tones generated by the

devices connected to the standard telephone

circuits.

•

A PCOU would be needed for the fifth CO line.

5.53 Conclusion. An Expansion Key Service Unit

in addition to the Base Key Service Unit would be

needed for this application. The three standard

telephone circuits could be contained on the optional KSTU PCB in the Base Unit. However, a

PDKU installed in the Expansion Unit would be

required for six of the 14 digital telephone circuits.

The Expansion Unit would also be needed for the

PCOU. The optional K4RCU, along with the music

source and the page/amplifier, as noted earlier,

could be connected to the Base Unit.

6 CONFIGURATION WORKSHEETS

5.43 Conclusion. A standard Base Key Service

Unit would be adequate in this case. The unit's

standard eight digital telephone circuits and four

CO line circuits could easily accommodate the

bank's needs.

6.00 Worksheets are provided in this chapter to

help configure the system.

3-10

Page 33

INSTALLATION-CONFIGURATION

SECTION 100-816-203

DK8 WORKSHEET 1, STATION AND CO LINE TOTALS

1. DIGITAL PORTS (CIRCUITS)

Device Quantity x Ports/Per = Ports Used

DDCBs (2 max.) _____ X 1 = ___________

PDIU-DSs (8 max.) _____ X 1 = __________

Digital Telephones (with or _____ X 1 = __________

without PDIU-DIs or ADMs)

(8 max.)

Total Digital Ports = __________

(8 max.)

2. STANDARD PORTS (CIRCUITS)

Device Quantity x Ports/Per = Ports Used

MARCH 1993

Maximum of 2 items

total, including Standard

Telephones:

Standard Telephones _____ X 1 = __________

or

Other Devices:

–Voice Mail

–Auto Attendant

–BGM Source

–Fax

–Modem _____ X 1 = __________

Total Standard Ports = __________

(2 maximum)

3. CO LINES

Number of CO lines required? _______

(Maximum of 4)

3-11

Page 34

INSTALLATION-CONFIGURATION

SECTION 100-816-203

MARCH 1993

DK8 WORKSHEET 2, KEY SERVICE UNIT AND PCBs

1. From Worksheet 1 enter the number of required ports (circuits) and lines.

Digital Ports: _____ (8 max)

Standard Ports: _____ (2 max)

CO Lines: _____ (4 max)

NOTE: The maximum number of digital ports is 8, and standard ports is 2. The

maximum number of CO lines is four.

2. Cross off the printed circuit boards (PCBs)—in addition to the standard Base Key Service Unit lines and

ports— needed to support the ports and lines entered in Step 1 of this worksheet.

KSU Interfaces (built-in)

2 CO lines, 4 digital ports

KSU Optional Unit Station and Line PCBs

QCDU (1 CO line and

2 digital ports): _____ two max.

QSTU (2 standard ports): _____ one max.

3. Refer to Worksheet 3 to determine option and peripheral requirements.

3-12

Page 35

INSTALLATION-CONFIGURATION

SECTION 100-816-203

MARCH 1993

DK8 WORKSHEET 3, PERIPHERALS AND UPGRADES

1. BASE UNIT PERIPHERALS

Battery Backup Interface: Yes or No _____

One or two HPFB batteries can be connected to a backup battery interface (Standard on DK8) to provide

backup battery backup if there is a power failure. (Connecting cable is included. 1-HPFB for .5 ~ 1 hour

backup; 2-HPFBs for 1.5 ~ 2 hours backup.)

QRCU: Yes or No _____

The QRCU is required to interpret Dual-tone Multi-frequency (DTMF) tones from standard telephones, Voice

Mail, Auto Attendant, and DISA CO circuits, or if the Auto Busy Redial (ABR) feature is required.

Music-on-hold/Background Music Source Interface: Yes or No _____

A music source can be connected to this interface (Standard on DK8) to provide Music-on-hold to CO lines

and stations on hold, and to provide Background Music to station speakers and external page speakers.

Power Failure Transfer Interface: Yes or No _____

A standard telephone can be connected to this interface to provide connection to a CO line if there is a power

failure. PFT interface is standard on DK8; one customer-supplied standard telephone is required.

600 ohm page Interface (Standard on DK8): Yes or No _____

This interface connects with customer-supplied speakers and amplifiers for paging (or Toshiba HESB) and

Background Music applications.

QSMU: Yes or No _____

A customer-supplied Station Message Detail Recording (SMDR) printer, or Remote Maintenance Terminal

(TTY) or modem.

PPTC: Yes or No _____

Modular adaptor required for interface to SMDR device or Maintenance Terminal or Modem.

2. TELEPHONE UPGRADES (All upgrades share the telephone port and do not require separate ports.)

Add-on Module (ADM): Total _____

2000-series digital telephones can be equipped with an Add-on Module to provide 10 Direct Station Selection

buttons, autodial buttons, all call page, and night transfer (if PDIU-DI2 is installed, ADM cannot be installed).

DVSU: Total _____

One DVSU is required for each digital telephone that must receive Off-hook Call Announce.

HESC-65A: Total _____

One HESC-65A modular connecting cable is required to connect the HESB to the HHEU in each telephone

requiring the Loud Ringing Bell feature. See HHEU and HESB.

HHEU: Total _____

One HHEU must be installed in each digital telephone that supports a headset or connects to an HESB for

the Loud Ringing Bell feature. See HESC-65A.

PDIU-DI2: Total_____ for 2000-series Digital Telephones;

(If ADM is installed, PDIU-DI2 cannot be installed).

PDIU-D1: Total_____ for 1000-series Digital Telephones

Digital telephones must be equipped with a PDIU-DI2 or a PDIU-DI to transmit and receive voice and data

calls.

3-13

Page 36

INSTALLATION-CONFIGURATION

SECTION 100-816-203

MARCH 1993

DK8 WORKSHEET 3, PERIPHERALS AND UPGRADES (continued)

Miscellaneous Peripherals

HESB (Amplifier/Speaker): Total _____

1. One HESB and HHEU is required for each digital telephone with the Loud Ringing Bell feature.

2. One HESB is optional to provide single-zone external page connected to the KSU's 600 ohm external

page output. (Customer-supplied amplifiers/speakers may be used in place of the HESB.)

3. One HESB is optional to provide a talkback amplifier/page speaker connected to the KSU's 600 ohm

external page output. (Customer-supplied amplifiers/speakers may be used in place of the HESB.) Talkback

requires MDFB also.

DDCB/MDFB (Door Phone): Total DDCBs _____ Total MDFBs _____

The MDFB plugs into the DDCB to provide a door phone. Each DDCB can support up to three MDFBs; a

maximum of two DDCBs and 6 MDFBs can be connected to the system. Each DDCB requires a digital

telephone circuit. The MDFB may also be connected to the HESB amplifier/speaker to provide page

talkback.

NOTE:

Worksheet 4, System Power Check, is not required for DK8. The DK8 power supply will support any DK8

maximum configuration.

3-14

Page 37

INSTALLATION-CONFIGURATION

SECTION 100-816-203

DK16 WORKSHEET 1, STATION AND CO LINE TOTALS

1. DIGITAL PORTS (CIRCUITS)

Device Quantity x Ports/Per = Ports Used

DDSS Consoles (2 max.) _____ X 1 = __________

DDCBs (2 max.) _____ X 1 = __________

PDIU-DSs (16 max.) _____ X 1 = __________

Digital Telephones (with or _____ X 1 = __________

without PDIU-DIs or ADMs)

(16 max. Total Digital Ports = __________

(16 max.)

2. ELECTRONIC PORTS (CIRCUITS)

Device Quantity x Ports/Per = Ports Used

HDSS Console (1 max.) _____ X 2 = __________

Alternate BGM Source (1 max.) _____ X 1 = __________

Conference Amplifier (1 max.) _____ X 2 = __________

Electronic Telephones _____ X 1 = __________

(8 max.)

MARCH 1993

Total Electronic Ports = __________

(8 max.)

3. STANDARD PORTS (CIRCUITS)

Device Quantity x Ports/Per = Ports Used

Maximum of 12 items

total, including Standard

Telephones:

Standard Telephones _____ X 1 = __________

or

Other Devices:

–Voice Mail _____ X 1 = __________

–Auto Attendant _____ X 1 = __________

–Fax _____ X 1 = __________

–Modem _____ X 1 = __________

–Alternate Background

Music (BGM) Source _____ X 1 = __________

Total Standard Ports = __________

(12 maximum)

4. CO LINES

Number of CO lines required? _______

(8 maximum)

3-15

Page 38

INSTALLATION-CONFIGURATION

SECTION 100-816-203

MARCH 1993

DK16 WORKSHEET 2, KEY SERVICE UNIT AND PCBs

1. From Worksheet 1 enter the number of required ports (circuits) and lines.

Digital Ports: _____

Electronic Ports: _____

Standard Ports: _____

CO Lines: _____

NOTE: The maximum number of combined digital, electronic, and standard ports

is 20. The maximum number of CO lines is eight.

2. Cross off the printed circuit boards (PCBs)—in addition to the standard Base Key Service Unit lines and

ports— needed to support the ports and lines entered in Step 1 of this worksheet.

Base Unit Interfaces/PCBs

Base Unit (4 CO lines, 8 digital ports): X built-in

KSTU (4 standard ports): _____ one max.

Expansion Unit Station and line PCBs

KCDU (2 CO lines and

4 digital ports): _____ two max. (KCDU cannot be installed

with any other type of

- or - station PCB or PCOU PCB)

PDKU (8 digital ports): _____ one max.

- or -

PEKU (8 electronic ports): _____ one max.

- or -

PSTU (8 standard ports): _____ one max.

- or PESU (2 standard ports and

(4 electronic ports): _____ one max.

PCOU (4 CO lines): _____ one max. (PCOU can be installed with

PDKU, PEKU, PESU, or

PSTU, but not with KCDU)

NOTES:

1. The Base Unit by can only support up to 12 stations (8 digital and 4 standard)

and four CO lines.

2. The Expansion Unit can support up to eight stations and four CO lines.

3. If installing two DDCBs, a PDKU or a KCDU is required to support the second

DDCB—no matter what the total number of digital ports.

4. If installing two DDSS Consoles, a PDKU is required to support the second

DDSS Console—no matter the total number of digital ports. (KCDU does not

support DDSS.)

3. Refer to Worksheet 3 to determine option and peripheral requirements.

4. Refer to Worksheet 4 to determine the amount of power used by the system.

3-16

Page 39

INSTALLATION-CONFIGURATION

SECTION 100-816-203

MARCH 1993

DK16 WORKSHEET 3, PERIPHERALS AND UPGRADES

1. BASE UNIT PERIPHERALS

Battery Backup Interface: Yes or No _____

Two 12-volt customer-supplied batteries can be connected to this interface to provide backup battery backup

if there is a power failure. See PBTC-3M.

K4RCU: Yes or No _____

The K4RCU is required to interpret Dual-tone Multi-frequency (DTMF) tones from standard telephones, Voice

Mail, Auto Attendant, and DISA CO circuits.

Music-on-hold/Background Music Source Interface: Yes or No _____