Page 1

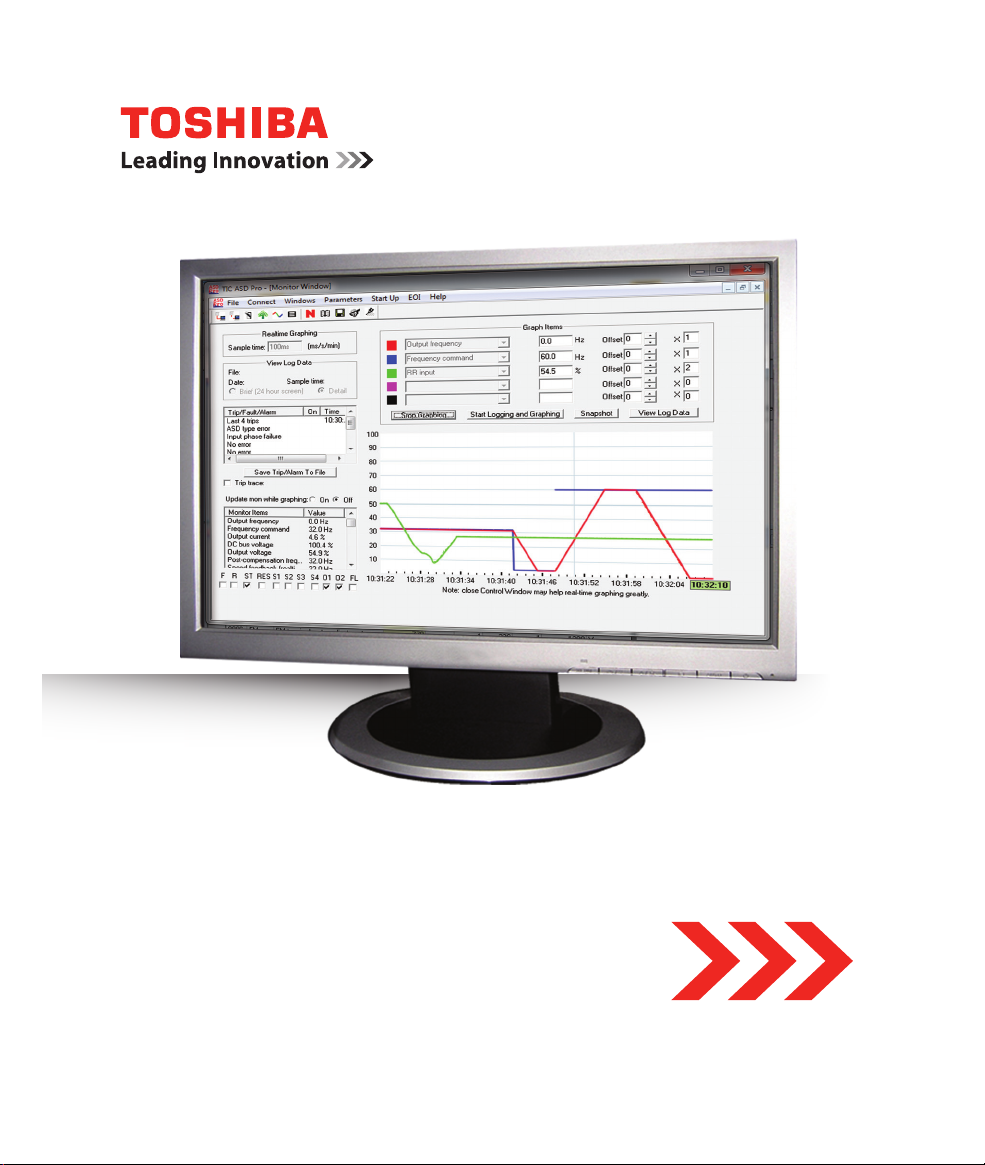

ASD PRO

INSTALLATION & OPERATION MANUAL

Page 2

Page 3

Document Number: 59443-001

Date: September, 2011

ASD Pro Software

Installation & Operation Manual

Page 4

Page 5

Introduction

Congratulations on receiving the ASD Pro Software from Toshiba International Corporation!

This product may be used for demonstration purposes as well as for system setup and troubleshooting.

And now has Wireless compatibility!

Monitored parameter settings and motor control programmed settings of an ASD, as well as system

performance variables, may be displayed and adjusted in real time or stored in a file for reference at a later

time. Setup configurations are also transferable to other ASDs as required.

The user-friendly Control and Monitoring windows are easy to read and collapsible when not required.

Because we are continuously updating our products to meet the constantly changing needs of our

customers, visit our web site to ensure that you have the latest release of the ASD Pro Software and this

manual.

To maximize the abilities of your new ASD Pro Software, a working familiarity with this manual will be

required. This manual and the ASD Pro Software has been prepared for the 7-Series and the 9-Series

ASD installer, software user, and maintenance personnel. This manual may also be used as a reference

guide or for training. With this in mind, use this manual to develop a system familiarity before attempting

to install or operate the software.

Important Notice

The instructions contained in this manual are not intended to cover all details or variations in equipment

types, nor may it provide for every possible contingency concerning the installation, operation, or

maintenance of this equipment. Should additional information be required contact your Toshiba Sales

Representative.

The contents of this manual shall not become a part of or modify any prior or existing agreement,

commitment, or relationship. The sales contract contains the entire obligation of Toshiba International

Corporation (TIC). The warranty contained in the contract between the parties is the sole warranty of

Toshiba International Corporation and any statements contained herein do not create new warranties or

modify the existing warranty.

Any electrical or mechanical modifications to this equipment without prior written consent of

Toshiba International Corporation may void all warranties and may void the UL/CUL listing or

other safety certifications. Unauthorized modifications may also result in a safety hazard or

equipment damage.

Misuse of this equipment could result in injury and equipment damage. In no event will Toshiba

Corporation be responsible or liable for direct, indirect, special, or consequential damage or injury

that may result from the misuse of this equipment.

Page 6

Page 7

About This Manual

This manual was written by the Toshiba Technical Publications Group. This group is tasked with

providing technical documentation for the ASD Pro Software. Every effort has been made to provide

accurate and concise information to you, our customer.

At Toshiba we’re continuously searching for better ways to meet the constantly changing needs of our

customers. E-mail your comments, questions, or concerns about this publication to

Technical-Publications-Dept@tic.toshiba.com.

Manual’s Purpose and Scope

This manual provides information on how to download, install, and operate the ASD Pro Software. The

information provided in this manual applies to the ASD Pro Software and how the software is used

with related Toshiba products.

Safe and proper operation of the ASD Pro Software will require that the user be familiar with the

contents of this manual and the contents of the manual of the ASD for which the ASD Pro Software is

to support.

The ASD Pro Software is designed to support the 7-Series and 9-Series family of ASDs. Because of the

inherent differences in the ASD types, there may be some accessible parameters for a given ASD for

which there will be no function. An example would be as with the My Function feature and its related

parameters of the 9-Series family — when connected to a 7-Series ASD, the related parameters will

have no function.

This operation manual provides information on the various features and functions of this software,

including

• Acquisition,

• Installation,

•Operation,

• Configuration instructions, and

• Menu options.

Included is a section on general safety instructions. Read the manual completely before installing or

operating the software.

Because of our commitment to continuous improvement, Toshiba International Corporation reserves the

right, without prior notice, to update information, make product changes, or to discontinue any product

or service identified in this publication.

Toshiba International Corporation (TIC) shall not be liable for direct, indirect, special, or

consequential damages resulting from the use of the information contained within this manual.

This manual is copyrighted. No part of this manual may be photocopied or reproduced in any form

without the prior written consent of Toshiba International Corporation.

© Copyright 2011 Toshiba International Corporation.

TOSHIBA® is a registered trademark of Toshiba Corporation. All other product or trade references

appearing in this manual are registered trademarks of their respective owners.

All rights reserved.

Printed in the U.S.A.

Page 8

stome

r

r

pport Cente

Contacting Toshiba’s Customer Support

Center

Toshiba International Corporation’s Customer Support Center can be contacted to obtain help in

resolving any Adjustable Speed Drive system problem that you may experience or to provide

application information.

The Support Center is open from 8 a.m. to 5 p.m. (CST), Monday through Friday. The Center’s toll free

number is US (800) 231-1412/Fax (713) 937-9349 CAN (800) 872-2192 MEX 01 (800) 527-1204.

For after-hours support follow the directions in the outgoing message when calling.

You may also contact Toshiba International Corporation by writing to:

Toshiba International Corporation

13131 West Little York Road

Houston, Texas 77041-9990

Attn: ASD Product Manager.

For further information on Toshiba International Corporation’s products and services, please visit our

website at www.toshiba.com/ind/.

Page 9

Toshiba International Corporation

Software Licensing Agreement

USE OF THE SOFTWARE IS SUBJECT TO THE TOSHIBA INTERNATIONAL CORPORATION

(TIC) SOFTWARE LICENSE TERMS SET FORTH BELOW. YOU AGREE TO BE BOUND BY

THESE LICENSE TERMS BY DOWNLOADING, INSTALLING, COPYING, OR OTHERWISE

USING THIS SOFTWARE. IF YOU DO NOT AGREE, DO NOT DOWNLOAD, INSTALL, COPY, OR

USE THIS SOFTWARE.

Toshiba International Corporation SOFTWARE LICENSE TERMS

The following terms govern the use of the enclosed Software unless governed by the terms in a separate

written agreement with TIC.

License Grant

TIC grants a non-exclusive and non-transferable license to use one copy of the Software and

documentation. Use means storing, loading, installing, executing or displaying the Software for internal

use only. Except as authorized by TIC, the Software may not be modified to disable any licensing or

control features of the Software. If the Software is licensed for concurrent use, no more than the maximum

number of authorized users may use the Software concurrently.

Ownership

The Software is owned and copyrighted by TIC. Your license confers no title or ownership of the Software

and is not a sale of any rights in the Software. TIC's third party suppliers may protect their rights in the

event of any violation of these License Terms.

Copies and Adaptations

One copy may be produced for archival purposes or if copying is an essential step in the authorized use of

the Software. All copyright notices of the original Software must be reproduced on all copies or

adaptations. The Software may not be copied onto any bulletin board or similar system.

No Disassembly or Decryption

The software may not be disassembled or decompiled without the prior written consent of TIC. Nor may

the Software be decrypted unless decryption is a necessary part of the operation of the Software.

Ter m i n a ti on

TIC reserves the right to terminate the license to use this Software upon failure to comply with any of the

License Terms. Upon termination, the original Software, all copies, adaptations, and merged portions in

any form must be destroyed.

Export Requirements

The Software may not be exported or re-exported. Nor may any copy or adaptation be exported or reexported in violation of any applicable laws or regulations.

Page 10

AS-IS WARRANTY STATEMENT

1. To the extent allowed by local law, this TIC Software product is provided “as is” without warranties

or conditions of any kind, whether oral or written, expressed or implied. TIC specifically disclaims

any implied warranties or conditions of merchantability, satisfactory quality, non-infringement, or

fitness for a particular purpose.

2. The limitation of liability is as follows: except to the extent prohibited by law, in no event will

TIC or its subsidiaries, affiliates, or suppliers be liable for direct, special, incidental,

consequential or other damages (including lost profit, lost data, or downtime costs), arising

out of the use, inability to use, or the results of use of the Software, whether based in

warranty, contract, tort, or other legal theory, and whether or not advised of the possibility of

such damages.

3. Use of the Software is entirely at your own risk. Should the Software prove defective, the user

assumes the entire cost of all service, repair, or correction. Some countries, states, and provinces do

not allow the exclusion or limitation of liability for incidental or consequential damages, so the

above limitation may not apply.

Page 11

Table of Contents

General Safety Information ....................................................................................................1

Safety Alert Symbol ...........................................................................................................1

Signal Words ......................................................................................................................1

Special Symbols .................................................................................................................2

Qualified Personnel ............................................................................................................2

Equipment Inspection .........................................................................................................3

ASD Pro Software Precautions ...............................................................................................4

Software Installation Precautions .......................................................................................4

Software Operation Precautions .........................................................................................4

ASD-to-PC Connectivity Precautions ................................................................................5

System Protection ...............................................................................................................6

ASD Setup Requirements ...................................................................................................6

ASD Pro Software and Serial Comm .....................................................................................7

Getting Started ....................................................................................................................7

Load the ASD Pro Software ...............................................................................................7

Load the Driver Software ...................................................................................................9

Verify Port Installation and Connection ...........................................................................10

ASD-to-PC Connection ..........................................................................................................11

Setup and Connection Requirements ................................................................................11

PC-to-ASD Connection Procedure ...................................................................................12

Connect-to-ASD Selections .............................................................................................. 12

ASD Pro Software Operation ...............................................................................................13

Using the ASD Pro Software ............................................................................................13

ASD Pro Menu Navigation and Icons ..................................................................................14

Menu Items .......................................................................................................................14

Icons ..................................................................................................................................15

Windows .................................................................................................................................16

Control Window ...............................................................................................................16

Monitor Window ..............................................................................................................17

Tree Window ....................................................................................................................23

Table Window ..................................................................................................................25

Network Window ..............................................................................................................30

Parameters ..............................................................................................................................31

Read All From ASD (to Table) ........................................................................................31

Save (from Table) To File ................................................................................................32

Load From File (to Table) ................................................................................................34

Write All To ASD (from Table) .......................................................................................34

ASD Pro Software Installation and Operation Manual i

Page 12

Start Up ...................................................................................................................................35

Acc/Dec Settings ..............................................................................................................35

Pattern Run Settings .........................................................................................................38

PID Settings ......................................................................................................................40

Preset Speed Setting .........................................................................................................41

Terminal Settings ..............................................................................................................42

Torque Settings ................................................................................................................. 44

(Logic) My Function Settings ...........................................................................................46

EOI ..........................................................................................................................................49

EOI FPWizard ..................................................................................................................49

Help ...................................................................................................................................50

Manuals .............................................................................................................................50

ii ASD Pro Software Installation and Operation Manual

Page 13

General Safety Information

DANGER

WARNING

CAUTION

CAUTION

DO NOT attempt to install, operate, or maintain this software until you have read and understood all of

the product safety information and directions that are contained in this manual and the manual of the

connected ASD.

Safety Alert Symbol

The Safety Alert Symbol is comprised of an equilateral triangle enclosing an exclamation mark. This

indicates that a potential personal injury hazard exists.

Signal Words

Listed below are the signal words that are used throughout this manual followed by their descriptions

and associated symbols. When the words DANGER, WARNING, or CAUTION are used in this

manual they will be followed by important safety information that must be carefully adhered to.

The word DANGER preceded by the safety alert symbol indicates that an imminently hazardous

situation exists that, if not avoided or if instructions are not followed precisely, will result in serious

injury to personnel or loss of life.

The word WARNING preceded by the safety alert symbol indicates that a potentially hazardous

situation exists that, if not avoided or if instructions are not followed precisely, could result in serious

injury to personnel or loss of life.

The word CAUTION preceded by the safety alert symbol indicates that a potentially hazardous

situation exists that, if not avoided or if instructions are not followed precisely, may result in minor or

moderate injury.

The word CAUTION without the safety alert symbol indicates a potentially hazardous situation exists

that, if not avoided or if instructions are not followed precisely may result in equipment and property

damage.

ASD Pro Software Installation and Operation Manual 1

Page 14

Special Symbols

To identify special hazards, other symbols may appear in conjunction with the DANGER, WARNING,

or CAUTION signal words. These symbols indicate areas that require special and/or strict adherence to

the procedures to prevent serious injury to personnel or loss of life.

Electrical Hazard Symbol

A symbol that is comprised of an equilateral triangle enclosing a lightning

bolt that indicates a hazard of injury from electrical shock or burn.

Explosion Hazard Symbol

A symbol that is comprised of an equilateral triangle enclosing an explosion

that indicates a hazard of injury from exploding parts.

Read Manual

A symbol that is comprised of an encircled manual that indicates that the user

shall read and understand

attempting to install, operate, perform maintenance, or dispose of the

equipment.

the Installation and Operation Manual before

Qualified Personnel

Installation, operation, and maintenance operations shall be performed by Qualified Personnel Only. A

qualified person is one that has the skills and knowledge relating to the installation, operation, and

maintenance of the equipment and software and has received safety training on the hazards involved

(refer to the latest edition of NFPA 70E for additional safety requirements).

Qualified Personnel shall:

• Have carefully read the entire software operation manual and the Installation and Operation

Manual of the connected ASD.

• Be familiar with the construction and function of the ASD, the equipment being driven, and the

hazards involved.

• Be able to recognize and properly address hazards associated with the application of motor-driven

equipment.

• Be trained and authorized to safely energize, de-energize, ground, lockout/tagout circuits and

equipment, and clear faults in accordance with established safety practices.

• Be trained in the proper care and use of protective equipment such as safety shoes, rubber gloves,

hard hats, safety glasses, face shields, flash clothing, etc., in accordance with established safety

practices.

For additional information on workplace safety visit www.osha.gov.

2 ASD Pro Software Installation and Operation Manual

Page 15

Equipment Inspection

• Before connecting the PC to the target equipment, inspect the equipment for damage and/or

missing parts.

• DO NOT energize equipment that has been damaged. Damaged equipment may fail during

operation resulting in further equipment damage or injury to personnel.

• Ensure that the rated capacity and the model number specified on the nameplate conforms to the

parameters being downloaded to the equipment.

• Modification of this equipment is dangerous and is to be performed by factory trained personnel.

When modifications are required contact your Toshiba Sales Representative.

• Perform any system or application inspections required to avoid personnel exposure to high

voltage.

ASD Pro Software Installation and Operation Manual 3

Page 16

ASD Pro Software Precautions

WARNING

WARNING

Software Installation Precautions

• ONLY qualified personnel should install the software.

• DO NOT attempt to install this software until you have read and understood all of the user

directions that are contained in this manual and the directions that are contained in the Installation

and Operation Manual of the connected ASD.

• Equipment connected to the PC is to be installed in a secure and upright position in a wellventilated area.

• It is the responsibility of the ASD installer/maintenance personnel and the software user to ensure

that all of the required safety and precautionary measures are in place and that the ASD Pro

Software setup will not cause an unexpected startup of the motor.

Software Operation Precautions

• ONLY qualified personnel should operate the software and equipment.

• Read and understand the section titled General Safety Information on pg. 1 before operating the

ASD, loading the ASD Pro Software, or making parameter changes.

•The ASD Pro Software was designed and is intended to be used for the temporary diagnostics and

monitoring of demonstration units or permanently-connected equipment ONLY.

• DO NOT use the software for permanent or long-term command and/or control functions. The

ASD Pro Software is not intended for permanent field use.

• DO NOT attempt to operate this software until you have read and understood all of the user

directions that are contained in this manual and the directions that are contained in the Installation

and Operation Manual of the connected ASD.

• ASDs produced by TIC are installed as part of a larger system and may present hazards to

equipment or personnel if programmed improperly. ONLY qualified personnel should make

changes to the parameters of the ASD using the ASD Pro Software.

• The software shall be operated with the connected equipment in a secure and upright position in a

well-ventilated area. Any connecting cables must be routed away from high voltages.

• Understand and document any changes being made to the connected equipment while using the

ASD Pro Software.

• By using a demo ASD with the ASD Pro Software, the motor may be connected and disconnected

easily and various configurations may be tested easily and safely.

• When using serial communication to control an ASD, care must be taken to ensure the safe

operation of the ASD, which may include restoring the system to the starting configuration upon

completion of the ASD Pro Software diagnostics.

• For additional information on the ASD parameters that may be monitored and controlled by the

ASD Pro Software, see the Installation and Operation Manual of the connected ASD.

4 ASD Pro Software Installation and Operation Manual

Page 17

ASD-to-PC Connectivity Precautions

DANGER

WARNING

ASD-to-PC connectivity may be carried out via the Toshiba NetPac Wireless System or via the USBto-RJ45 cable. The content of this manual will cover the RJ45 cable connection method as the primary

means of connectivity for software use. The Toshiba NetPac Wireless System is discussed only as it

applies to the Network Window of the software that is used to manage the connected nodes of the

Toshiba NetPac Wireless System.

Note: See the NetPac Wireless System Installation and Operation Manual for specifics on

the setup, installation, and use of the wireless system.

Connecting a personal computer (PC) to an ASD via a communication cable is potentially very

dangerous. When using a communication cable, ensure that the cable is not in contact with any

energized part of the ASD.

Ensure that all personnel are in a safe location and that the equipment connected to the ASD will not

cause equipment damage or injury to personnel from any sudden or unexpected starting or stopping of

the motor.

ASD parameter changes made using the ASD Pro Software may cause unexpected starting or stopping

of the connected motor. Always turn off ASD power and then turn it on again before the final checkout.

This ensures that parameters are written to the ASD memory correctly.

DO NOT use a cable that is frayed or that shows any signs of damage when connecting the PC to the

ASD.

The routing of the cable through the ASD is critical. Avoid areas of the ASD where electrical noise may

be induced into the cable. The cable must be routed and secured to avoid any areas where high voltages

may be present. High voltage entering the cable may result in equipment damage, injury to personnel or

loss of life.

DO NOT exert any force on the RJ45 wires or connections. Tension from pulling on RJ45 cables may

damage the connections within the connector shell. Damaged wires can result in intermittent

communication or no communication.

DO NOT plug an EOI/keypad into an energized ASD. The ASD should always be Off prior to removal

or installation of an EOI/keypad.

The ASD Pro Software enhances the programmability of TIC’s ASDs. ASDs produced by TIC are

installed as a part of a larger system and may present hazards to equipment or personnel if improperly

programmed.

If using the Toshiba NetPac Wireless System to connect the ASD to the PC, once connectivity is

established, DO NOT swap the routers of the connected ASDs.

If using the Toshiba NetPac Wireless System to connect the ASD to the PC, set the ASD

Communications Time Out Time and the Communications Time Out Action parameters to a

disposition in the event of a loss of communication.

ONLY qualified personnel should make changes to the parameters of the ASD.

ASD Pro Software Installation and Operation Manual 5

Page 18

System Protection

DANGER

• Ensure that primary protection exists for the input wiring to the equipment. This protection must be

able to interrupt the available fault current from the power line. The equipment may or may not be

equipped with an (optional) input disconnect.

• Improper programming of the ASD Pro Software can result in loss of control. Ensure that the

Emergency Off braking system of the ASD is properly set up. The function of the Emergency Off

braking function is to remove output power from the drive in the event of an emergency. A

supplemental braking system may also be engaged in the event of an emergency.

Note: A supplemental emergency stopping system should be used with the ASD. Emergency

stopping should not be a task of the ASD alone.

• Follow all warnings and precautions and do not exceed equipment ratings.

ASD Setup Requirements

• When using the ASD Pro Software as an integral part of a larger system, it is the responsibility of

the ASD installer/maintenance personnel and the software user/installer to ensure that there is a

fail-safe in place (i.e., an arrangement designed to switch the system to a safe condition if there is a

fault or failure).

• System safety features should be employed and designed into the integrated system in a manner

such that system operation, even in the event of system failure or programming error, will not cause

harm or result in system damage or injury to personnel (i.e., E-Off, Auto-Restart settings, System

Interlocks, etc.).

• The programming setup and system configurations of the ASD Pro Software may allow it to start

the motor unexpectedly. A familiarity with the Auto-Restart and system protection settings are a

requirement to use this product.

• Improperly designed or improperly installed system interlocks, or improper system settings may

render the motor unable to start or stop on command. Know and understand the parameter values

and settings that are being changed.

• Use of the built-in system protective features of the ASD Pro Software is highly recommended

(i.e., E-Off, Overload Protection, etc.).

• It is the responsibility of the ASD installer/maintenance personnel and the software user/installer to

know the outcome of changes made to the ASD parameters while using the ASD Pro Software.

6 ASD Pro Software Installation and Operation Manual

Page 19

ASD Pro Software and Serial Comm

Getting Started

The ASD Pro Software (P/N 59073) enhances the programmability of the 7-Series and the 9-Series

families of ASDs by allowing the user to control the ASD, and monitor parameter settings and

performance variables from a PC via serial communication.

Using serial communication via the Toshiba NetPac Wireless System or the ASD-CAB-USB cable,

the ASD Pro Software may be used to control and monitor all of the ASD functions that are accessible

via serial communication.

The TIC_USB_RS485 driver must first be installed onto the PC in order to use the ASD Pro Software.

The ASD Pro Software and the TIC_USB_RS485 driver may be acquired from the CD received with

the ASD system or from the Toshiba web site and loaded onto the PC as described below.

The ASD Pro Software, used in conjunction with the ASD-EOI-HH-G9 assembly (see Figure 17 on

pg. 50), may also be used to program (flash) the display modules of the 7-Series and 9-Series ASDs that

may require flashing as a program update.

Load the ASD Pro Software

The ASD Pro Software may be acquired via 1) the www.toshiba.com/ind web site, 2) the All Products

CD (P/N 60652) supplied with the ASD system, or 3) a complimentary copy may be acquired from the

Customer Support Center.

Downloading from the Toshiba Web Site

1. From the www.toshiba.com/ind web site click Drives G9 LV Severe Duty Industrial Setup

Software (tab) ASD Pro Software Zip File.

2. Sign in to download from the web site when prompted and click ASD Pro Software Zip File.

3. At the resulting dialog box either click Cancel to return to the Toshiba web site, click Open to

unzip the zipped file, or click Save and follow the subsequent prompts to store the ASD Pro

Software Zip File. Once unzipped, the application may be launched from the resulting ASD Pro

Software desktop shortcut.

Loading from the All Products CD

1. Place the CD into the CD ROM drive.

2. At the home page of the CD under the Quick Links section, click Features.

3. From the expanded listing, click ASD Pro Software.

4. At the resulting ASD Pro Software screen, within the final sentence of the page, click the word

“here” within the sentence: Click here to download the ASD Pro Software Zip File.

Remove Older ASD Pro Software Version (if Required)

1. Launch the Setup.exe file of the unzipped files.

Should there be an existing version of ASD Pro Software loaded onto the PC, continue to step 2. If

a first-time install, go to the section titled Install the New ASD Pro Software Version on pg. 8.

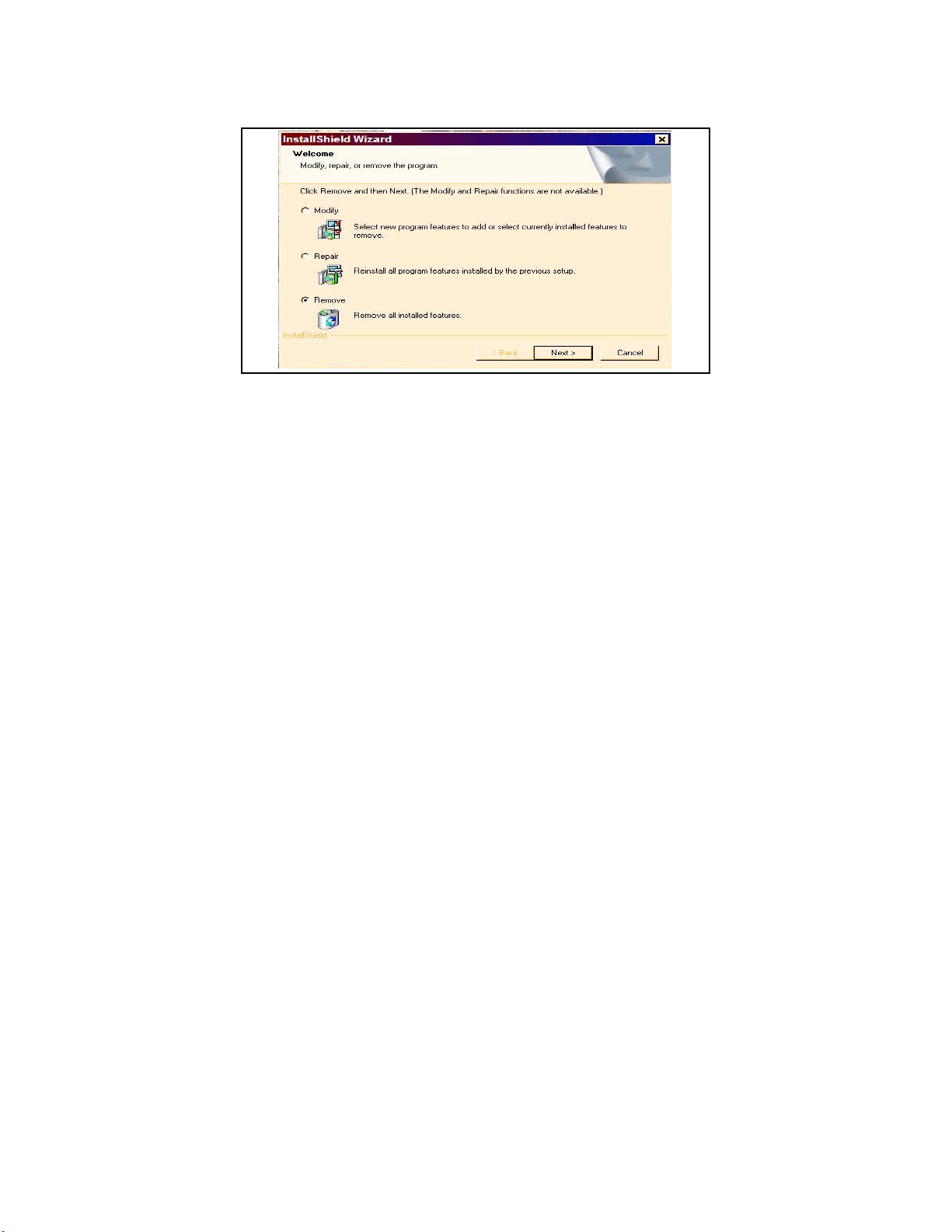

2. Click the radio button Remove and then click Next (see Figure 1 on pg. 8).

ASD Pro Software Installation and Operation Manual 7

Page 20

Figure 1. Modify, Repair, or Remove Dialog Box.

3. When queried Do You Want To Completely Remove The Application And All Of Its Features?

click OK.

4. Upon completion of the removal, click Finish at the Maintenance Complete screen. The older

version has been successfully removed from the PC.

5. Continue to the next section to Install the New ASD Pro Software Version.

Install the New ASD Pro Software Version

1. Launch the Setup.exe file (of the unzipped file group) to start the program installation.

2. Click Next at the Welcom e screen.

3. Read the License Agreement and click Yes .

4. Enter the appropriate information at the customer information fields and select All Users.

5. Click Next.

6. When prompted to Choose Destination Location for the installation, note the default location and

click Next, or click Browse to select a different location and click Next — this will be the location

from which the application may be launched once installed. The setup file will also place a shortcut

on the desktop of the PC which may also be used to launch the ASD Pro Software application.

7. Click Next to open the Start Copying Files dialog box.

8. At the Start Copying Files dialog box, click Next to start the file copy process.

9. Upon completion of the copy process, select No, I Will Restart My Computer Later and click

Finish.

The ASD Pro Software is now loaded onto your computer.

8 ASD Pro Software Installation and Operation Manual

Page 21

Load the Driver Software

In conjunction with the ASD Pro Software, the TIC_USB_RS485 software driver is required for ASD-

to-PC serial communication.

Loading the driver is required during the initial setup only and need not be repeated for subsequent uses.

Follow the procedure below to load the ASD-to-PC serial communication driver.

1. From the web site http://toshiba.com/ind/special/download.jsp, click the link Click here to

download the Toshiba Inter Corp USB Driver Ver 2.06 zip file.

2. From the subsequent dialog box, click Save to download the file.

3. Select the destination of the saved files for subsequent extraction.

4. From the saved location, unzip/extract the downloaded file.

5. Plug in the ASD-CAB-USB cable into an unused USB port of the PC.

6. The Found New Hardware Wizard Welcom e dialog box appears.

7. Click the radio button Install From A List Or Specific Location (Advanced) and click Next.

8. The Found New Hardware Wizard Search dialog box appears.

9. From the Search box click Browse and path to the location selected in step 3 — default settings are

to remain unchanged. Click Next.

Note: Depending on your PC system, the Hardware Installation screening dialog box may

appear. If so, click Continue Anyway.

Note: Depending on your PC system, the search phase of the installation may take

approximately one minute or longer. Allow the search to complete.

10. If queried for the driver location, path to the location selected in step 3. Click Next.

11. Click Finish at the subsequent dialog box.

12. The Found New Hardware Wizard Welcome dialog box appears.

13. Click the radio button Install From A List Or Specific Location (Advanced) and click Next.

14. The Found New Hardware Wizard Search dialog box appears.

15. From the Search box click Browse and path to the location selected in step 3. Leave default

settings as they are and click Next.

Note: Depending on your PC system, the search phase of the installation may take

approximately one minute or longer. Allow the search to complete.

16. Click Finish to complete the port installation.

ASD Pro Software Installation and Operation Manual 9

Page 22

Verify Port Installation and Connection

1. From the desktop of the PC, right-click on the My Computer icon and select Properties.

2. At the subsequent (System Properties) dialog box and depending on the Windows operating system

being used, click either the Device Manager selection, or click the Hardware tab and then click

the Device Manager button.

3. Expand the line item Ports and see a listing of the configured ports.

4. The port to which the ASD-CAB-USB cable is connected will display the following text: To sh ib a

Inter. Corp. USB to RS485 (COMX).

Note: Where “X” is the numbered port identifier (i.e., 3, 4, etc.).

10 ASD Pro Software Installation and Operation Manual

Page 23

ASD-to-PC Connection

WARNING

DANGER

DO NOT TERMINATE THE PC-TO-ASD COMMUNICATION

LINK OR REMOVE THE ASD-CAB-USB CABLE WHILE THE

MOTOR AND/OR THE ASD PRO SOFTWARE IS RUNNING!

STOP THE MOTOR USING THE ASD PRO SOFTWARE AND

THEN CLOSE THE ASD PRO SOFTWARE APPLICATION

BEFORE REMOVING THE ASD-CAB-USB CABLE.

Setup and Connection Requirements

This manual is written for the 7- and 9-Series ASD systems. The requirements for use with the 7-Series

ASD and the 9-Series ASD are the same except where noted.

The ASD-CAB-USB cable provides a bidirectional communication link between the RS485 I/O signal

of the ASD and the USB I/O signal of the PC which is required for ASD-to-PC communication.

The communication settings of the ASD must correspond to the settings of the connecting ASD. See the

Installation and Operation Manual of the connecting ASD for the applicable parameter numbers of the

communication settings.

If using the Toshiba NetPac Wireless System or the ASD-CAB-USB cable for connectivity, set the

port selection to the setting of Step

If using the Toshiba NetPac Wireless System for connectivity, set the ASD baud rate (speed) to 19200

and the parity setting to Even.

For all ASD-CAB-USB cable connected sessions, ensure that the PC settings of the ASD Pro Software

correspond to the ASD settings.

4 on pg. 10.

THE ASD-CAB-USB CABLE IS DESIGNED AND INTENDED FOR

MONITORING AND DOWNLOADING PARAMETERS ONLY!

CRITICAL START AND STOP OF CONTROL APPLICATIONS ARE NOT

TO BE ATTEMPTED USING THE ASD-CAB-USB CABLE.

Note: Stop the motor and close the ASD Pro Software application before removing the

ASD-CAB-USB cable from any of the ASD/PC system components.

Note: Disabling the PC-to-ASD communication link while the ASD Pro Software is running

and/or if the motor is running removes user-control of the connected motor. An

Emergency Off command (double-press Stop at the EOI) will halt the motor at the

programmed deceleration rate or by the rate allowed by the load inertia — whichever

is greater.

ASD Pro Software Installation and Operation Manual 11

Page 24

PC-to-ASD Connection Procedure

DANGER

COM6 (USB)

For single-ASD use.

For multiple-ASD use (daisy-chained).

For Toshiba NetPac Wireless System use.

For Ethernet use.

Note: The following connection procedure uses the USB setting of the ASD Pro Software

— application-specific communication ports may be selected as required.

1. Remove all power sources from the ASD (lockout and tagout).

2. Disconnect the motor to prevent unexpected motor responses during the ASD setup or during the

preliminary testing phase.

3. Open or remove any covers, doors, or guards to gain access to the ASD and the I/O connectors/

terminals (requirements are typeform- and model-specific).

4. Connect the RJ45 end of the ASD-CAB-USB cable to the terminal board connector S4 of the 9Series ASD, or CNU1 of the 7-Series ASD.

5. Close all PC applications that are not required.

6. Connect the USB end of the ASD-CAB-USB cable to the USB port of the PC referenced in Step 5

on pg. 9.

7. Turn on the PC and allow the PC to complete the boot sequence. If the PC is already on, ensure that

the ASD Pro Software is not running.

8. Apply power to the ASD — the motor is to remain disconnected until the final testing phase

(i.e., programming has been confirmed as safe for the application).

9. Click the desktop shortcut to start the ASD Pro Software application — DO NOT move the ASD-

CAB-USB cable from one ASD to another or from one PC to another while the ASD Pro Software

is running — DO NOT HOT SWAP.

Connect-to-ASD Selections

Launch the ASD Pro Software and the Connect to ASD dialog box appears (see Figure 2).

To connect an ASD while the ASD Pro Software is running, from the Connect pull-down menu, select

Connect ASD to access the Connect to ASD dialog box.

At the Connect to ASD dialog box, click the appropriate means of connectivity as shown in Figure 2.

Note: For USB use, select the PC Port COMX. Where “X” is the numbered USB port

identifier defined in Step

At the Control Window the Connected/Comm Lost image switches from red to green to indicate a

successful connection.

Figure 2. Connect to ASD Dialog Box.

4 on pg. 10 (i.e., 3, 4, etc.)

12 ASD Pro Software Installation and Operation Manual

Page 25

ASD Pro Software Operation

DANGER

From the ASD Pro main screen the ASD Pro Software can be used to easily control and monitor all of

the ASD functions that can be accessed via serial communication.

Using the ASD Pro Software

The Following Procedure Is To Be Performed By Qualified Personnel ONLY.

Use the following procedure to set up and run the ASD using the ASD Pro Software.

UPON THE COMPLETION OF THE ASD PRO SOFTWARE SETUP A

CONNECTED MOTOR MAY TURN ON AND RUN.

1. Disconnect the motor from the ASD. Connect the motor ONLY after testing the ASD program

changes and confirming that the ASD program changes have been performed correctly and

function as expected and as required for the application.

2. From the Table Window, record and store the existing ASD parameter settings before making any

changes (see the section titled Read All From ASD for information on saving ASD parameter

settings).

3. Place the ASD in the Remote mode (Local/Remote LED off).

Note: The settings of steps 4 and 5 may also be carried out from the EOI of the connected

ASD.

4. From the Tree Window, set Fundamental\Standard Mode Selection\Command Mode Selection to

RS485 (from the Val ue field pull-down menu). Click the Write button to transfer the new setting

to the ASD.

Note: With each write-to-ASD function, an indication of a successful write will appear (e.g.,

Write 3: RS485 to 0003 successfully). An unsuccessful write attempt should be

investigated for a systemic anomaly and corrected before continuing.

5. From the Tree Window, set the Fundamental\Standard Mode Selection\Frequency Setting Mode

Selection 1 to RS485 (from the Valu e field pull-down menu). Click the Write button to transfer

the new setting to the ASD.

6. From the Control window, provide a frequency command in the Frequency Input field

(see Figure 4 on page 16).

7. Click the Run/F or the Run/R button and the motor will run at the commanded frequency.

From the Control window, the output frequency may be changed while running using either of the

following three methods:

1. Click and hold the slide-cursor of the Frequency Control Window,

2. Click the Up/Down Frequency Control Arrow buttons, or

3. Enter a new value into the Frequency Input field and click the Run/F or Run/R button.

Note: The frequency controls are limited to the range of the Lower Limit to Upper Limit

settings of the ASD.

4. Click the Stop button of the ASD Pro Software to halt the motor.

Note: Using the E-Off function at the ASD EOI will terminate the ASD output — however,

only the Stop button of the ASD Pro Software should be used to stop the motor while

using the ASD Pro Software.

ASD Pro Software Installation and Operation Manual 13

Page 26

ASD Pro Menu Navigation and Icons

Menu Items

Tabl e 1 lists the ASD Pro Software menu items and their paths.

Table 1. ASD Pro Software Menu Navigation.

ASD Pro Software Menu Items

Pull-Down Menu Pull-Down Menu Items Description

Stores the opened windows as they are displayed when the ASD Pro

F

ILE

C

ONNECT

W

INDOWS

P

ARAMETERS

(Table Window

functions)

S

TART UP

EOI

H

ELP

Save Window Configuration

Exit Closes the ASD Pro Software application.

Connect ASD Opens the Connect-to-ASD dialog box.

Disconnect ASD Disconnects all connected ASDs from the PC.

Control Window Speed/direction control and read only typeform information.

Monitor Window Graphing, logging, trip/alarm information, and parameter monitoring.

Tree Window Read from and write to the ASD parameter locations.

Table Window Manage parameter read/write functions.

Network Window Wireless system monitoring support (for NetPac Wireless System).

Read All From ASD (to Table)

Save (from Table) To File Saves the Table Window parameter settings to a CSV file.

Load From File (to Table)

Write All To ASD (from Table)

Acc/Dec Settings Accel/Decel settings may be viewed or changed.

Pattern Run Settings The Pattern Run settings may be viewed or changed.

PID Settings PID settings may be viewed or changed.

Preset Speed Setting Preset Speed settings may be viewed or changed.

Terminal Settings Discrete and Analog I/O terminal settings may be viewed or changed.

Torque Settings Torque Control settings may be viewed or changed.

My Function Settings My Function settings maybe viewed, or setup and run.

EOI FPWizard

EOI Reading Reads the EOI memory (EOI Flash Docking Station required).

About ASD Pro Software ASD Pro Software version and release information.

7S

9S

Manuals

Software application is closed. Re-opens the saved windows at the

next session.

Reads and displays the parameter settings of the ASD in the Table

Window.

Loads the parameter settings from a CSV file to the Table Window

(Edit Table mode only).

Writes the contents of the Table Window into the ASD (Edit Table

mode only).

Used to update (flash) the EOI memory (EOI Flash Docking Station

required).

Provides parameter descriptions and usage assistance for the 7-series

ASD.

Provides parameter descriptions and usage assistance for the 9-series

ASD.

Provides the Installation and Operation Manuals for the 7-series and

9-series families of ASDs.

14 ASD Pro Software Installation and Operation Manual

Page 27

Icons

— Disconnect ASD(s)

— Open Control Window

— Open Tree Window

— Open Monitor Window

— Open Table Window

— Read All from ASD to Table

— Save Parameters from Table to File

— Load Parameters from File to Table

— Write All from Table to ASD

— Connect ASD

— Open Network Window

Icon Function

The icons of the top section of the ASD Pro Software main screen provide quick access to some of the

most commonly used pull-down menu items. The icons and functions are listed below.

Figure 3. ASD Pro Software Icons.

ASD Pro Software Installation and Operation Manual 15

Page 28

Windows

ASD-to-PC Connection Status

Commanded Frequency Input Field

Up/Down Frequency Control Arrows

Forward, Reverse, and Stop Control Buttons

ASD Status (Run/Alarm/Trip)

ASD Typeform/Firmware Ver. and Rev.

ASD ID, PC Port, and

Communication Speed

Slide-Cursor Frequency Control

Output Frequency

(Click-And-Hold to Adjust)

Control Window

The Control Window is accessed via the pull-down menu Windows Control Window and provides

access to the 7-series and 9-series ASD controls and monitors as shown in

Figure 4. Control Window.

Figure 4.

ASD-to-PC Connection Status — Green while connected to the PC — Red while not connected.

Output Frequency — Displays the output frequency of the ASD in Hz.

Commanded Frequency Input Field — The desired frequency command may be keyed into this

field and run by clicking the Run/F or the Run/R button.

Up/Down Frequency Control Arrows — Increments/decrements the commanded frequency

0.01 Hz per click.

Slide-Cursor — Use the left mouse button to click-and-hold the slide-cursor. Move the cursor either

to the left or right to change the commanded frequency. The resulting commanded frequency is

displayed in the Commanded Frequency Input Field.

Run/F and Run/R — Click the appropriate button to execute a Run Forward or Run Reverse

frequency as keyed in at the Commanded Frequency Input Field.

Stop — Click the Stop button once to terminate the ASD output. The motor will stop at the

programmed deceleration rate or at the rate determined by the inertia of the load (whichever is greater).

Double-click either the Stop button of the Control Window or the Stop button of the ASD EOI to

execute an Emergency Off or, if tripped, to return the ASD to the ready-to-run condition.

ASD Status — Displays the run status of the ASD — Running forward, running reverse, stopped, or

alarm/trip status.

ASD Typeform/Firmware Ver. and Rev. — ASD type and software version and revision.

ASD Identification, Port, and Speed — Displays the connected ASD ID, the PC connection port

being used, and the output speed of the ASD.

16 ASD Pro Software Installation and Operation Manual

Page 29

Monitor Window

Realtime Graphing

View Log

Data

Trip/Alarm

Record

Monitor

Items

Graph

Items

Acc/Dec

Freq. Command

The Monitor Window is accessed via the pull-down menu Windows Monitor Window. The

Monitor Window (see

simultaneously plot up to five user-selected ASD Monitor parameter values to the PC screen. Monitor

Window data may be saved as a file and recalled as required for analysis.

The Monitor Window is comprised of five sections: Realtime Graphing, Graph Items, View Log

Data, Trip/Alarm Record, and the Monitor Items sections.

Figure 5. Monitor Window.

Figure 5) allows the user to display the ASD Monitor parameters and to

Realtime Graphing

The Sample Time setting (time between each sample) is set from the Realtime Graphing section and

is used to scale the real-time graphical display. The unit of measurement for the sample time may be

entered as milli seconds, seconds, or minutes — however, if the unit is milli seconds, the entered value

must be a multiple of 10. Values entered that are not a multiple of 10 will be reduced to the next lower

multiple of 10 (e.g., 119mS entered becomes 110mS).

The minimum time between samples is 20mS. The unit of measure must be entered along with the

numerical value with no spaces (key in ms, s, or min).

ASD Pro Software Installation and Operation Manual 17

Page 30

Graph Items

The Graph Items section contains the on-screen controls required to graphically display and log the

activity of user-selected parameters. The on-screen controls allow for up to five parameter items to be

simultaneously displayed in real time. Only the first of duplicate parameter items will be monitored and

updated. A log of the parameter items may be recorded as a file and recalled for viewing as required.

Listed below are the on-screen controls and the read-only monitored items along with a description of

each. See

Start/Stop Graphing

The Start Graphing button initiates the on-screen display of up to five user-selected parameters on the

Monitor Window graph. The label of the Start Graphing button toggles to Stop Graphing once

activated.

The Start Graphing function is enabled for activation by providing at least one user-selected parameter

to appear on the graph. Click any of the pull-down menus of the Graph Items section to select an item

from the listing to be monitored in the graph section. If None is selected or if blank for each, there will

be no response when clicking the Start Graphing button.

Click Start Graphing to initiate graphing of the selected item(s). Click Stop Graphing when finished.

The Start Graphing function only provides a display on the Monitor Window Graph; no logging file

is created.

The sample graphed image of Figure 5 on pg. 17 shows the ASD response to the Commanded

Frequency of 10 Hz, 30 Hz, 50 Hz, 60 Hz, 40 Hz, 20 Hz, 5 Hz, and then to off.

Figure 5 on pg. 17 for the on-screen location of each item.

The blue trace (Horz./Vert.) is set to display the Frequency Command. The red trace (diagonal) is set

to the (actual) Output Frequency and depicts the Acc/Dec setting response.

Graph/Trace Color

The graph background color may be changed by double-clicking the graph. Click the desired color from

the resulting palette and click OK.

The color of the trace for a given parameter trace display may be changed by double-clicking the color

box adjacent to the applicable Graph Item. Click the desired color from the resulting palette and click

OK.

Start/Stop Logging and Graphing

The Start Logging and Graphing button allows the user to record and save the displayed parameter

data of a running ASD to a log file. Activating the Start Logging and Graphing button toggles the

button label to Stop Logg ing and toggles the Start Graphin g button label to Stop Graphing (as shown

in

Figure 5 on pg. 17).

The Start Logging and Graphing function is enabled by providing at least one user-selected parameter

to appear on the graph by selecting a parameter from the Graph Items section pull-down selections.

Click Start Logging and Graphing to initiate the logging and graphing functions. The selected Graph

Item(s) will appear in the resulting Select Logging Parameters dialog box — the item(s) to be

included in the log file must be selected.

Parameters that are selected at the Graph Items pull-down menu that are not selected at the Select

Logging Parameters dialog box will be displayed on the Graph Items graph, but will not be included

in the saved log file.

18 ASD Pro Software Installation and Operation Manual

Page 31

Place a check in the appropriate box of the Select Logging Parameters dialog box. Checked

parameters will be recorded in the log file. Click OK when finished.

Note: If the items listed in the Select Logging Parameters dialog box (below) do not match

the user selections of the

Graph Items section, a selection table from a previously run

ASD may still be loaded. From the Connect pull-down menu, disconnect the ASD and

then reconnect the ASD to load the correct table.

Select a location for the saved Comma-Separated Value (CSV) file. Select a unique file name and a

location to store the log file and click Save. Duplicate file names will be overwritten when saved.

CSV files may be opened using MS Excel®.

ASD Pro Software Installation and Operation Manual 19

Page 32

Snapshot

The Snapshot feature records the readings of the selected Graph Items and saves the information as a

log file. Snapshots are used to produce brief recordings of ASD activity.

Click Start Graphing or click Start Logging and Graphing to enable the Snapshot feature. Click the

Snapshot button to record the Graph Item(s). A Snapshot is comprised of 480 samples of the selected

Graph Item(s).

The recorded entries are input to the file at the rate set by the Sample Time field of the Monitor

Window — thus, the time length of the recorded Snapshot will be a function of the Sample Time

setting of the Realtime Graphing section (i.e., a higher sample rate will result in a shorter Snapshot file

— 480 samples over a shorter period).

The saved Snapshot file may be opened and displayed in the Monitor Window. Duplicate Snapshot

file names will be overwritten when saved.

Unit of Measure

The field adjacent to the measured value of the user-selected parameter displays the associated unit of

measure for the reading. The unit of measure is not affected by the A/V setting of parameter F701.

Offset

The Offset setting is useful if the displayed parameter has a positive and a negative property. This

function may be used to change the position of the measured quantity on the graph. By default, the zero

reference is zero and the Offset is set to -50 when displaying bipolar values.

The Offset may be changed for a given parameter using the up/down arrows to raise or lower the

display of the measured quantity. This feature is also useful when viewing two values that have the

same amplitude on a given axis. The Offset of either may be changed to provide non-overlapping traces

on the display.

Note: The measured value remains unchanged. This setting affects how the value is

displayed only.

Multiplication Factor (X)

The Multiplication Factor (X) is used to display data that would otherwise exceed the range of the

graph (greater than 100 or outside of the -50 to +50 range). The Multiplication Factor is selected

automatically and is not user-selectable. The Multiplication Factor scales the reading to fit the

Monitor Window screen. A reading of 150 is displayed as 75 with a multiplication factor of 2 in the

X field.

View Log Data

The View Log Data button allows the user to select and display previously recorded log and Snapshot

files. The resulting file data is displayed in the Monitor Window graph as the Graph Items that were

selected for logging or selected for a Snapshot when saved.

Note: Items that were not selected at the Select Logging Parameters dialog box when saved

will not be included in the log or

Snapshot file.

The log file name, date that the log file was created, and the sample time are displayed in the View Log

Data section of the Monitor Window. The Brief and Detail radio buttons of the View Log Data

section scale the Monitor Window graph display. The Brief and Detail buttons are only used (and

enabled) while viewing recorded log and Snapshot files.

20 ASD Pro Software Installation and Operation Manual

Page 33

The graph view may be set to Brief or Detail to view only a section of a saved file or to view the entire

saved file, respectively. The Brief button displays the data log of 24 hours. The Detail button displays

approximately 90 seconds of the data log per screen.

Note: Because the logs are created using the time clock of the PC as a time stamp, ensure

that the PC clock is set to the correct time and date.

To view log data, click the View Log Data button of the Graph Items section. From the Open dialog

box, path to the recorded log or Snapshot file to be viewed, and click Open. The Detail button of the

Log Data View section will be used for most log views. However, to locate the start of a log that is less

than a few hours long may require using the Brief view.

Trip/Alarm Record

Any trip and/or alarm events are recorded and listed in this section for the active session. To clear this

information, stop the motor, close the ASD Pro Software, and then restart the ASD Pro Software.

Save Trip/Alarm to File

Click the Save Trip/Alarm to File button to record the trips and alarms for the active session. The

record is saved as a CSV file. Give the file to be saved a unique name and note the destination of the

saved file — the destination is user-selectable. Duplicate file names will be overwritten when saved.

Trip Trace (9-Series ONLY)

Place a check in the box to enable the Tri p Trace function. This feature is used to monitor and store up

to four ASD output waveform data points. The data may be read from the ASD and stored as a function

of a trip (At Trip) or it may be initiated by the activation of a discrete terminal activation (At Trigger).

The Tri p Trace feature is set up and operates in accordance with the settings of parameter F740 —

F745 of the connected ASD.

See the Installation and Operation Manual of the connected 9-Series ASD for more information on this

feature.

Monitor Items

The Monitor Items list contains all of the ASD monitored parameters and is updated at 2-second

intervals. The Monitor Items section is read-only and provides the status of ASD input, ASD output,

and control/system variables.

The Update Mon While Graphing On/Off radio buttons are used to enable or disable updates of the

Monitor Items list. While off, with the exception of the output frequency value, the listed items are

neither monitored nor updated.

Disabling the Monitor Items list terminates Monitor Items updates and is effective in providing better

throughput of ASD-to-PC read/write data for the graphing functions.

Note: Graph quality is dependent upon the speed and features of the PC being used.

Turning off the Update Mon While Graphing radio button, closing all other

windows, and using a shorter sample time will improve the graph resolution.

ASD Pro Software Installation and Operation Manual 21

Page 34

Terminal Status

The Terminal Status section shows the status of the discrete input and discrete output terminals. When

configuring a discrete output terminal (from the Tree Window), NC is used as a suffix to denote

Normally Closed. No suffix is used to denote Normally Open.

The Terminal Status display is updated at 2-second intervals. The Terminal Status section is updated

regardless of the Update Mon While Graphing setting.

22 ASD Pro Software Installation and Operation Manual

Page 35

Tree Window

The Tree Window (see Figure 6) is accessed via the pull-down menu Windows Tree Window and is

used to read from or to write to all of the ASD memory locations that are accessible via serial

communication.

Clicking a parameter from the Tree Window reads the current value (or setting) for the selected

parameter and displays it in the Va lu e field. The Val u e field may be changed for the parameter of the

communication number displayed in the Comm. No. field.

Click another parameter to exit without loading the new value (or setting) into the ASD or click the

Write button to accept the change.

Note: Clicking the Write button updates the Table Window and the EOI display of the

connected ASD for the changed parameter.

Note: To display changes made via the EOI of the ASD at the Tree Window, click the

changed parameter at the Tree Window. If the communication number of the

changed parameter is displayed at the Tree Window Comm No. field during the EOI

change, the updated value (or setting) may not appear. Click to another parameter of

the Tree Window and then back to the changed parameter to update the changed

parameter at the Tree Window Value field.

A known communication number may also be keyed into the Comm No. (Communication Number)

field to view or change the setting of the parameter entered (four digits are required for the

Communication Number field, i.e., 0009, 0109, etc.). Once changed, click the Write button to transfer

the new setting to the ASD. Otherwise, the changed setting will not be written to the ASD.

To use either method to change a parameter value (or setting), the Communication Number of the

parameter must appear in the Comm No. field. The desired parameter value may then be keyed in or

selected from the Val ue field pull-down menu.

Exit the Tree Window to discard any changes or click the Write button to load the new value (or

setting) into the ASD memory.

Note: For additional information on the parameters of the Tree Window, see the

Installation and Operation Manual of the connected ASD.

Figure 6. Tree Window.

ASD Pro Software Installation and Operation Manual 23

Page 36

Tree Window Items

Name — Selected parameter name.

Comm No. — Communication Number of the selected parameter.

Write — Click to transfer a new setting to the ASD.

RAM Only — When the RAM Only box is checked, any values (or settings) written to the ASD will

be used, but are only stored in the ASD RAM. Upon the conclusion of the active ASD Pro Software

session, or if the ASD is reset, the RAM contents will be erased and the pre-existing values (or settings)

will be used.

Auto Update — This function, when enabled (box checked), allows for parameter changes made from

the

Table Window or from the EOI of the ASD to be conveyed to the associated Tree Window field

without user intervention. The Tree Window becomes read-only and is disabled for input of parameter

changes while the Auto Update feature is enabled.

The Auto Update function requires that the user click the item from the Tree Window list to display

the updated parameter value (or setting) in the Val ue field of the Tree Window.

Changes made to a parameter via the EOI of the connected ASD will update the Table Window for that

parameter without user intervention. Table Window updates in this manner require that the ASD Read/

Write feature of the Table Window be enabled (radio button checked).

If the Auto Update feature is not enabled, click the Val ue field of a given parameter of the Ta bl e

Window to display/update ASD parameter changes made via the EOI.

Hex — The Hex check box is used to convert the numerical contents of the Val ue field from decimal to

hex when required. Because the bits of a word may be easier to identify if using C1

as opposed to 193

Value — Current value or setting of the selected parameter.

Unit — Unit of measure for the selected parameter.

Default — Factory default parameter value (or setting).

Minimum — Minimum value to which the selected parameter may be set.

Maximum — Maximum value to which the selected parameter may be set.

Changeable During Run — Parameter changeability-while-running status. Parameters that are NOT

changeable while running will return a Write Error if, while running, a write-to-ASD is attempted.

Stop the ASD and retry.

.

D

(i.e., 1100 0001B)

H

24 ASD Pro Software Installation and Operation Manual

Page 37

Table Window

Edit Value Field

Edit Value

The Table Window (see Figure 7) is accessed via the pull-down menu Windows Table Window.

The Table Window allows the user to read from or to write to all ASD memory locations that are

accessible via serial communication.

The Tab le W i nd o w is a file creation, editing, and transfer mechanism that may be used to create or edit

a transferable ASD configuration (e.g., group-transfer of one or more parameter changes or settings).

All of the parameter changes or settings of the Table Window may be saved as a file, recalled, and

applied to an ASD as required or transferred to multiple ASDs of the same typeform.

Click the Comm, Title, or Function field of a given parameter column for Help information on the

selected parameter.

The Table Window must be populated with the parametric profile of a given system type as a starting

point to perform any Table Window file transfer functions.

Populate the Table Window

The Table Window may be populated via either of the following methods:

• Click the Read All From ASD button (if connected to an ASD),

• Click the Load From File button (Edit Table mode and path to an existing CSV file), or

• Click the Connect (pull-down) Connect ASD Work Offline Select Parametric Profile

(G7, G9, P9, etc.).

Either method will open and/or populate the Table Window with the parameters of the connected ASD

or selected profile.

Figure 7. Table Window.

ASD Pro Software Installation and Operation Manual 25

Page 38

Using the Table Window

The following procedure is to be performed by qualified personnel ONLY.

1. A) If modifying the settings of a connected ASD, save the starting ASD configuration by clicking

Read All From ASD button of the Table Window. The Va lu e column will then be

the

populated with the current values (and settings) of the connected ASD for each item of the Title

column (see the section titled

the ASD).

Click the Save To File button to save the starting configuration. Select the descriptive Items To

Save from the resulting dialog box — all parameter additions/changes will be saved regardless

of the dialog box selections. Selecting from the Items To Save list increases the information

included in the saved file for each saved parameter.

If no items are selected (Comm Number and Value selections are fixed and may not be

de-selected) the resulting file will include the communication number and the setting for each

parameter only. Give the file to be saved a unique name. Duplicate file names will be

overwritten when saved. The resulting file contains the starting parameter settings of the ASD

and may be re-loaded into the ASD upon completion of the ASD Pro Software diagnostics, if

required.

B) If populating the table from a CSV file, click the Edit Table button (enabled), and then click the

Load From File button. Path to the CSV file to be used to populate the table [see the section

titled Load From File (to Table)].

Read All From ASD on pg. 31 for information on reading from

rite To ASD

rite All to

SD

The table may also be populated by clicking Work Offline at the Connect to ASD dialog box.

At the subsequent Select ASD Type pull-down selection list, select the ASD type and click OK.

No values are loaded to the table for this function. Only the parameters for the selected ASD

type are loaded to the table.

C) If creating a new CSV file from an existing file, upon completion of the additions/changes, click

the

Save To File button. And using a new file name, follow the Save To File instructions of Step

1A.

2. Single parameter changes made to the table may be transferred to the ASD individually or

accumulated and transferred as a group. Click the Write To ASD button to transfer the individual

setting displayed at the

transfer the entire table to the ASD.

Click the RAM Only check box to write to the ASD RAM. When the RAM Only box is checked,

any values (and settings) written to the ASD will be used, but are only stored in the ASD RAM.

Upon the conclusion of the active ASD Pro session, or if the ASD is reset, the RAM contents will

be erased and the pre-existing values (and settings) will be used.

3. Perform the ASD Pro Software diagnostic functions on a running ASD as required (see ASD Pro

Menu Navigation and Icons on pg. 14 for operational information).

4. The starting ASD parameter settings saved at Step 1A may be restored to the ASD upon

completion of the diagnostics by clicking Load From File (Edit Table mode required). Path to the

saved file of Step 1A and click Open.

Table Window Val u e field to the ASD or click Write All To ASD to

26 ASD Pro Software Installation and Operation Manual

Page 39

5. Once the saved file from Step 1A is opened (and has populated the displayed table), from the Ta bl e

WARNING

WARNING

Window click Write All To ASD to load the original ASD configuration file into the ASD.

Closing the ASD Pro Software program while the motor is running will NOT stop the

motor. Stop the motor using the Stop button of the ASD Pro Software before closing the

ASD Pro Software application.

6. Ensure that the motor is stopped.

7. Close the ASD Pro Software application.

Note: Only after the motor is stopped and the ASD Pro Software is closed at the PC should

the power be removed from the ASD.

8. Remove power from the ASD.

9. Disconnect the ASD-CAB-USB cable from the ASD and the PC or remove the NetPac Wireless

Router and Coordinator.

10. Close or replace any ASD covers, doors, and/or guards.

Only after Qualified Personnel have confirmed that the ASD operation is as expected

and as required for the application should the motor be connected and final-tested.

11. Reconnect the system to the pre-test condition.

12. Re-apply ASD power and verify that the ASD operation is correct and as expected.

ASD Pro Software Installation and Operation Manual 27

Page 40

ASD Read/Write — Edit Table Functions

The ASD configuration may be loaded into the Table Window (Read All From ASD), changed, and

then transferred back into the ASD or the new (or an old) configuration may be saved as a file to be

loaded into other ASDs.

The ASD Pro Software operating modes, ASD Read/Write and Edit Table, are designed for specific

Table Window/CSV file-to-ASD data management functions.

The available functions for either operating mode are shown in Table 2.

Table 2. Operating Mode Functions.

Mode Setting

Function Button ASD Read/Write Edit Table

Full List Available Not Available

Changed Only Available Not Available

Write To ASD Available Not Available

Write to Table Not Available Available

Read All From ASD Available Available

Save To File Available Available

Load from File Not Available Available

Write All To ASD Not Available Available

Clear All Values Not Available Available

ASD Read/Write

The ASD Read/Write mode allows the ASD configuration to be read from the ASD, modified, saved as

a CSV file, and then transferred back into the ASD or into multiple ASDs. In the ASD Read/Write

mode the Wr it e To Tab l e button label changes to Write To ASD and is used to transfer parameter

settings to the ASD individually.

Note: Click the Value field of a any Tab l e Wi n do w parameter to update the table with

changes that have been made from the EOI of the ASD.

The Read All From ASD function reads the parameter settings of the ASD, displays them in the table,

and may be saved as a file to be used on other same-series ASDs and/or to be reloaded when finished

editing the file. Because residual data from a previous session may be displayed and should be cleared,

always perform a Read All From ASD before starting a new ASD Read/Write session.

Clicking an item within the Va lu e column displays the Communication Number (Comm No field) and

the Val ue of the item in the fields at the lower part of the screen. The value (or setting) may be changed

by keying in a new value or selecting a new setting from the pull-down menu at the Val u e field and

clicking the Write To ASD button. Repeat the process to change other parameter settings individually

where required.

Note: The Value field information is preceded by the number used to select an item if

creating a new Parameter Table or if using serial communication to write to a

parameter location in memory (e.g., F000

2:Automatic Acc Only, etc.).

0:Manual, 1: Automatic Acc/Dec,

28 ASD Pro Software Installation and Operation Manual

Page 41

ear All

lues

rite to Table

Edit Table

The Edit Table mode is used to create a new Parameter Table or modify an existing Parameter Table

and does not require that an ASD be connected to the PC. However, the table must be populated with

the parameters of either an existing CSV file, a connected ASD, or an ASD type if operating offline (see

the section titled

Transfers of the new settings to the ASD are optional. See the section titled Short Tables on pg. 32 for

additional information on creating a new table.

In the Edit Table mode the Write To ASD button label changes to Wri t e To Ta bl e and the Clear All

Va lu es button appears. The Clear All Values button clears all of the values from the Table Window

and allows for the entry of values to be used for user-selected parameter items. The Load From File

and the

Write All To ASD buttons become available for use (undithered).

Create a CSV File

Click the Edit Table radio button (enabled). Click the Read All From ASD, the Load from File