Page 1

UM-TS03***-E020

PROGRAMMABLE CONTROLLER

PROSEC

T3

ASCII INTERFACE MODULE

AS311

USER’S MANUAL

TOSHIBA CORPORATION

Page 2

Important Information

Misuse of this equipment can result in property damage or human injury.

Because controlled system applications vary widely, you should satisfy yourself

as to the acceptability of this equipment for your intended purpose.

In no event will Toshiba Corporation be responsible or liable for either indirect

or consequential damage or injury that may result from the use of this equipment.

No patent liability is assumed by Toshiba Corporation with respect to use of

information, illustrations, circuits, equipment or examples of application in this

publication.

Toshiba Corporation reserves the right to make changes and improvements to this

publication and/or related products at any time without notice. No obligation shall be

incurred other than as noted in this publication.

This publication is copyrighted and contains proprietary material. No part of this book

may be reproduced, stored in a retrieval system, or transmitted, in any form or by any

means electrical, mechanical, photocopying, recording, or otherwise without

obtaining prior written permission from Toshiba Corporation.

Copyright © 1995 by Toshiba Corporation

Tokyo, Japan

All rights reserved

Publication number: UM-TS03***-E020

1st edition May 1995

Page 3

Safety Precautions

Safety Precautions

• This module (AS311) has been designed for Toshiba’s Programmable Contr o ller

PROSEC-T3 (hereaft er called T3). Use this module only on the T3’s rack .

• Read the Safety Precautions described on the T3 User ’s Manual bef or e using the T3 and

this module.

• Follow the instructions described on this manual and on the T3 User’s Manual when

installing and wiring the T3 and this module.

• Do not touch the connector pins or components on the pr inted circuit board of this module.

• The maximum number of AS311s that can be cont rolled by one T3 is not limited by

software. However, this module consumes maximum 1 A of int e r nal 5 Vdc power. Confirm

that the total 5 Vdc consumed current per one power supply module is within the limit (7A).

Symbols Used In This Manual

Pay attention to information preceded by the following symbols.

HINT

NOTE

Refers to helpful sug gestions on how to operate effect ively.

Refers to inform ation considered essential for full under standing of operation.

And refers to conditions that could dam age the equipment or render it

temporarily inoperative.

User’s Manual

1

Page 4

About This Manual

About This Manual

This manual explains the specifications and operations of the ASCII Interface Module

(AS311) for Progr am mable Controller T3. Read this manual car efully before using the

AS311 module.

Inside This Manual

This manual consists of six sections and an appendix as follows.

Section 1 Overview

Introduces The AS311. Outline of the function, applications and the external features are

provided in this section. Read this section at first to understand the general operation of

the AS311. The switch settings of t his m odule are also explained in this section.

Section 2 Specifications

Provides the functional and the transmission specifications of the AS311. Refer to this

section to confirm the application limitations.

Section 3 Cable Connections

Provides the information for hardware preparations. The transmission cable connection

is explained in this section.

Section 4 Register Configuration

Explains the memory contents of the AS311. This information is important to interchange

data between T3 and AS311.

Section 5 Operation Procedure

Provides the information to design the T3 program f or using the AS311. Some sample

programs are provided in this section. Read t his sect ion carefully for progra m m ing.

Section 6 RAS Information

Provides the helpful informa t ion for RAS (Reliability, Availability and Serviceability). Also,

lists the check points in case of unexpected operat ions.

Appendix

The specifications of READ and WRITE instr uctions are described. These instructions are

used for interchanging dat a bet ween T3 and AS311.

ASCII Interface Module (AS311)

2

Page 5

About This Manual

Related Manuals

The following related manuals are available f or T3. Besides this manual, read the following

manuals for your better understanding.

T3 User’s Manual - Hardware

This manual covers the T3’s main body and basic I/O - their specifications, handling,

maintenance and services.

T3 User’s Manual - Functions

This manual explains the functions of the T3 and how to use them. The necessary

information to create user pr ogram is covered in this manual.

T-series Instruction Set

This manual provides the detailed specifications of instructions for T oshiba’s T-series

Programmable Controllers.

T-PDS (Ver. 1.4) Basic Operation Manual

This manual explains how to install the T-series program development system (T-PDS)

into your computer and provides basic programming oper at ions.

T-PDS (Ver. 1.4) Command Reference Manual

This manual explains the T-series program development system (T-PDS) in detail.

T-PDS (Ver. 1.6) Expanded Functions

This manual explains the expanded functions on the T-PDS version 1.6. This manual

supplements the T-PDS (Ver.1. 4) Com mand Reference Manual.

T-series Computer Link Function

This manual provides the information for a computer to communicate with T3 t hrough the

T-series Programmable Cont r oller’s Computer Link function.

Terminology

The following terms and abbreviations are used in this manual.

• ASCII: American Standard Code for Information Interchange

• EIA: Electronic Industries Association

• I/O: Input/Output

• LED: Light Emitting Diode

• RS-232C: An EIA standard for data tr ansmission

• RS-422: An EIA standard for data tr ansm ission

User’s Manual

3

Page 6

Contents

Contents

Safety Precautions .................................................................................. 1

About This Manual .................................................................................. 2

1. AS311 Overview .......................................................................... 7

1.1 Introduction ...................................................................................... 8

1.2 AS311 functions ............................................................................... 9

1.3 External features .............................................................................. 10

2. Specifications ............................................................................ 15

2.1 General specifications ...................................................................... 16

2.2 Functional specifications ................................................................ 16

2.3 Transmission specifications ............................................................. 17

3. Cable Connections ..................................................................... 19

3.1 RS-232C connection ......................................................................... 20

3.2 RS-422 connection ............................................................................ 21

4. Register Configuration .............................................................. 23

4.1 I/O allocation and I/O registers ........................................................ 24

4.2 AS311 buffer memory ........................................................................ 26

4.2.1 Memory map ............................................................................... 26

4.2.2 Buffer memory access ................................................................ 27

4.2.3 Parameter area ............................................................................ 29

4.2.4 Receiving and transmitting data area .......................................... 36

5. Operation Procedure ................................................................. 37

5.1 Transmission message format .......................................................... 38

5.2 Received message read sequence .................................................. 39

5.2.1 Flag control timing ....................................................................... 39

5.2.2 T3 sample program for message receiving ................................... 40

5.3 Write sequence for message transmitting ....................................... 43

5.3.1 Flag control timing ....................................................................... 43

5.3.2 T3 sample program for message transmitting ................................ 44

5.4 Checking the AS311 operation status .............................................. 47

5.5 Resetting the AS311 by software ...................................................... 48

5.6 Setting the trailing code .................................................................... 49

5.7 Setting the time-out check time ........................................................ 50

ASCII Interface Module (AS311)

4

Page 7

Contents

6. RAS Information ......................................................................... 51

6.1 LED indication .................................................................................. 52

6.2 Buffer memory information ................................................................ 53

6.2.1 Module status .............................................................................. 53

6.2.2 Switch setting status ................................................................... 54

6.2.3 Error information for data receiving .............................................. 55

6.2.4 Error information for data transmitting .......................................... 56

6.3 Trouble shooting ............................................................................... 57

Appendix .................................................................................................... 59

A.1 Specification of the READ instruction ............................................... 60

A.2 Specification of the WRITE instruction ............................................ 62

User’s Manual

5

Page 8

ASCII Interface Module (AS311)

6

Page 9

Section 1

AS311 Overview

1.1 Introduction

1.2 AS311 functions

1.3 External features

User’s Manual

7

Page 10

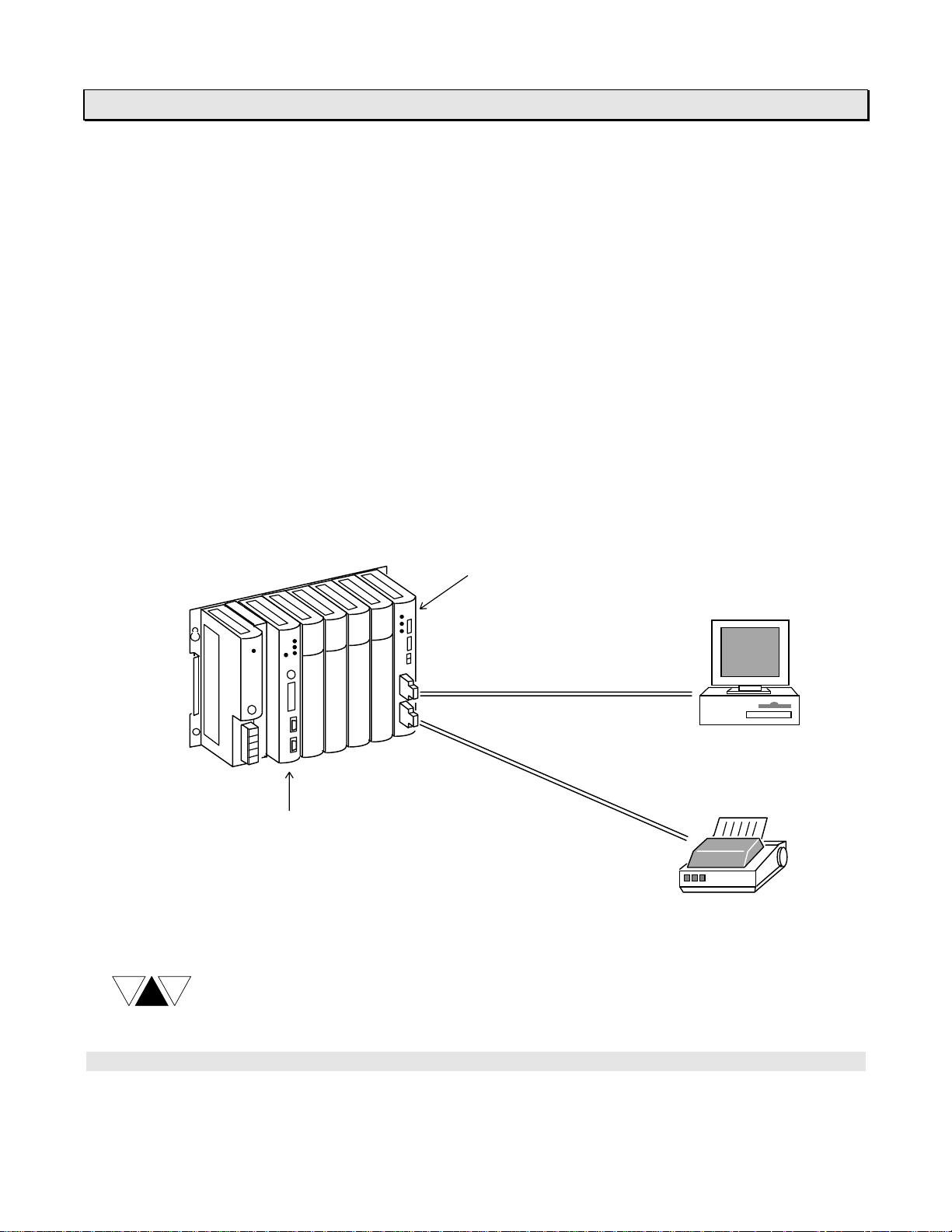

1. AS311 Overview

1.1 Introduction

The ASCI I interface module AS311 (hereaf ter called AS311) is a general purpose data

communicat ion m odule for Toshiba’s Program mable Controller PROSEC-T3 (hereafter

called T3) . By using t he AS311, T3 can communicate with external devices, such as a

micro comput er, bar code reader, printer, display device, sensor, etc., through the

serial inter face RS-232C or RS-422.

The AS311 has t wo ports of the serial interface. One port (channel 1) can be selected

either RS- 232C or RS-422 by switch setting. The other port ( c hannel 2) is RS- 232C

interface. These two ports can be used independently for data receiving and

transmitting.

The t r ansm ission is asynchronous (st ar t - s t op system) .

ASCII is used as t he transmission data code.

The figure below shows the typical system configuration.

NOTE

T3

CPU module

The maximum number of AS311 that can be cont rolled by one T3 is not limited by

software. However, this module consumes maximum 1 A of int ernal 5 Vdc power.

Confirm that the tot al 5 Vdc consum ed current per one power supply module is

within the limit (7 A).

AS311

Channel 1

RS-232C or RS-422

Channel 2

RS-232C

ASCII Interface Module (AS311)

8

Page 11

1. AS311 Overview

1.2 AS311 functions

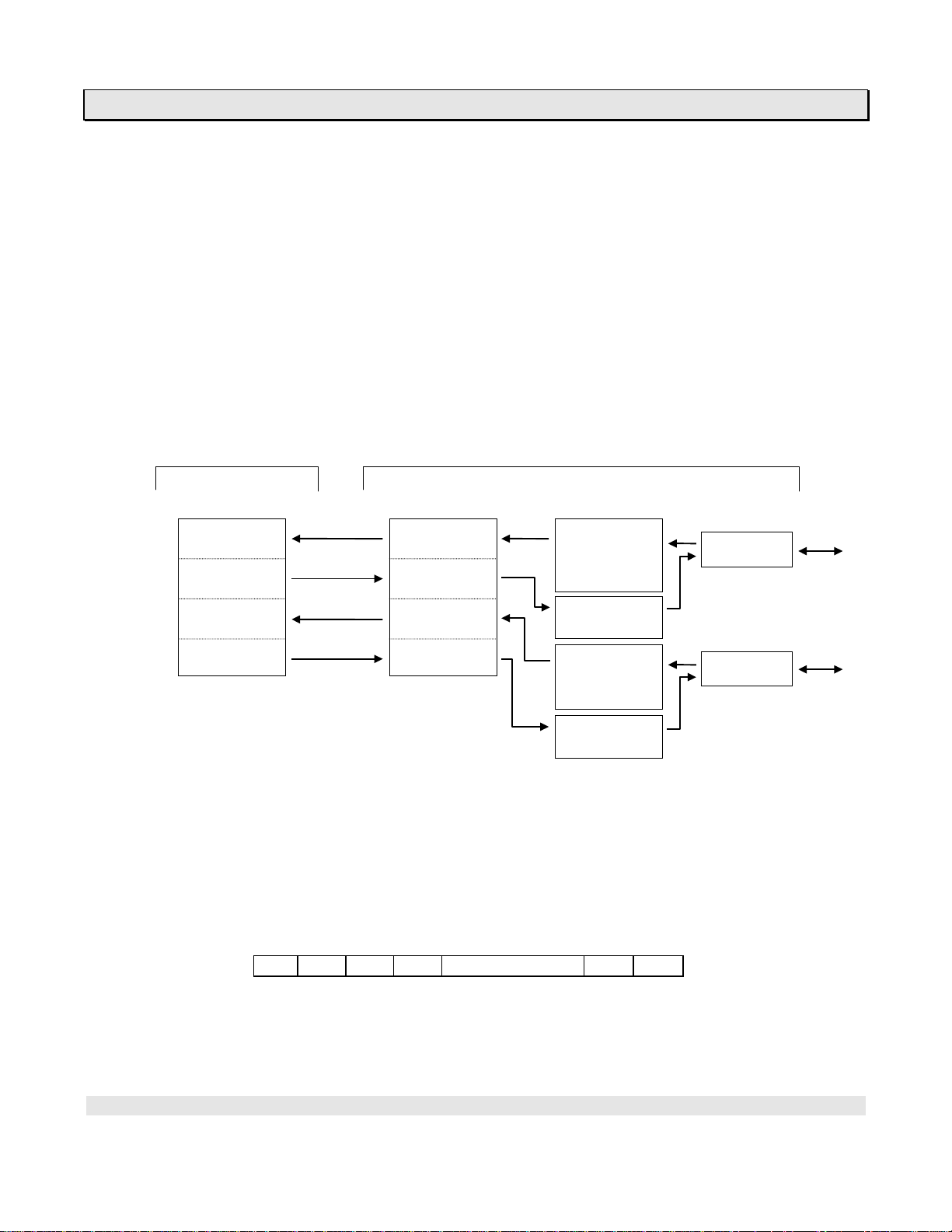

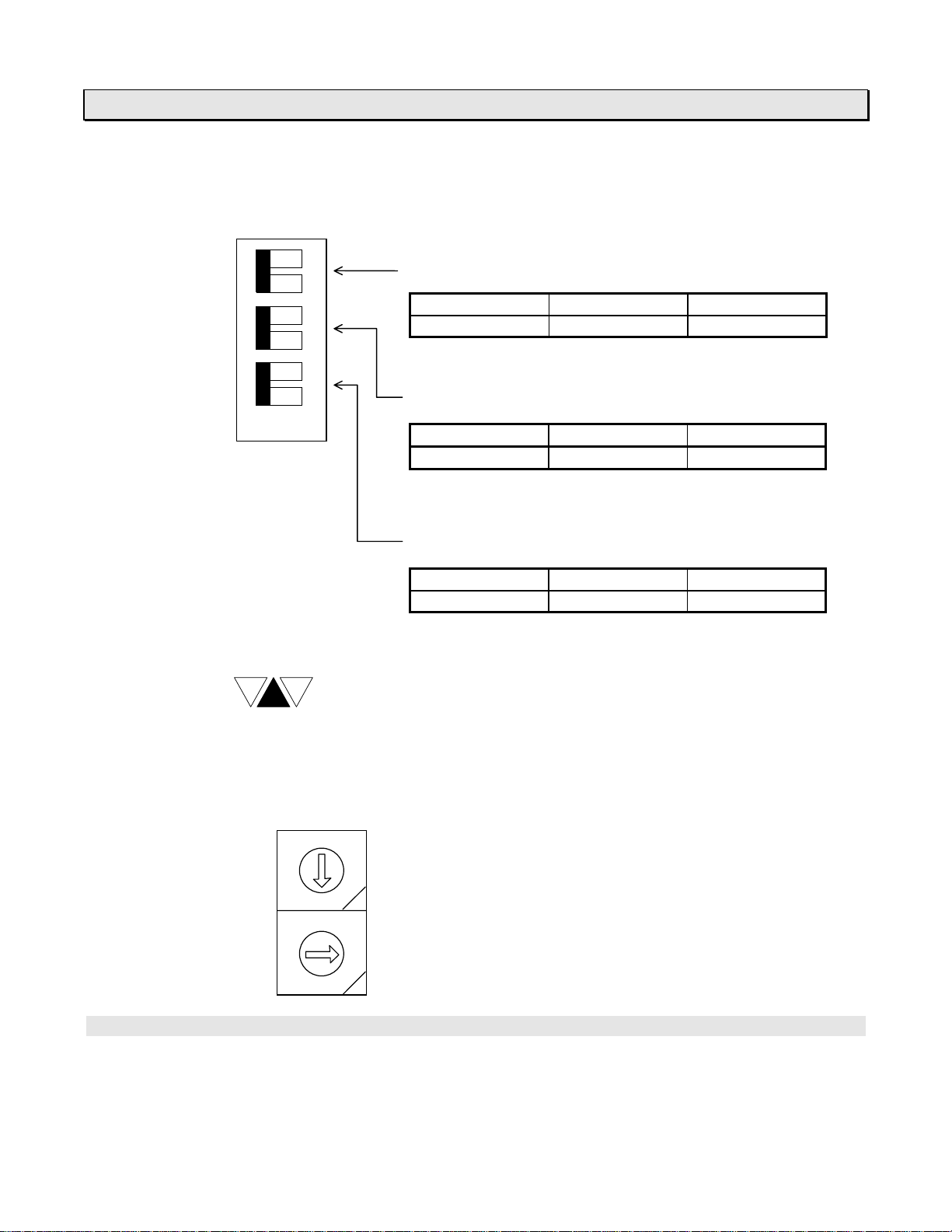

From t he point of view of T3, the AS311 works as communications driver. The

f ollowings are the simplified explanations for T 3 and AS311 functions.

When a message (one set of transmission characters) is received by AS311, the flag

which indicates the receiving complete will come ON. T3 can check the flag status then

read the m essage from the AS311 by using the READ instr u ct ion.

In case of transmitting a message (one set of transmission characters) from T3 through

AS311, T 3 writes t he message into the AS311 by using the WRITE instruction, then

sets the flag which instruct the AS311 to start t r ansm it t ing the message.

T3 AS311

Register Buffer memory

READ Receiving

area Receiving Channel 1

WRITE Transmitting buffer

area

READ Receiving Transmitting

area buffer

WRITE Transmitting

area Receiving Channel 2

buffer

Transmitting

buffer

Here, a m essage (one set of transmission charact er s) means a string of ASCII

character s which is ended by specified trailing code. The default set t ing of the trailing

code is CR (carr iage return code = H0D).

Applicable messag e format (default trailing code):

1 2 3 4 N-1 N

CR

N: message length = 896 bytes max.

In other words, t he AS311 cannot be used for the data communication in which the

transm ission m essage is ended by two or more types of trailing code.

User’s Manual

9

Page 12

1. AS311 Overview

↓

RSW

RSW

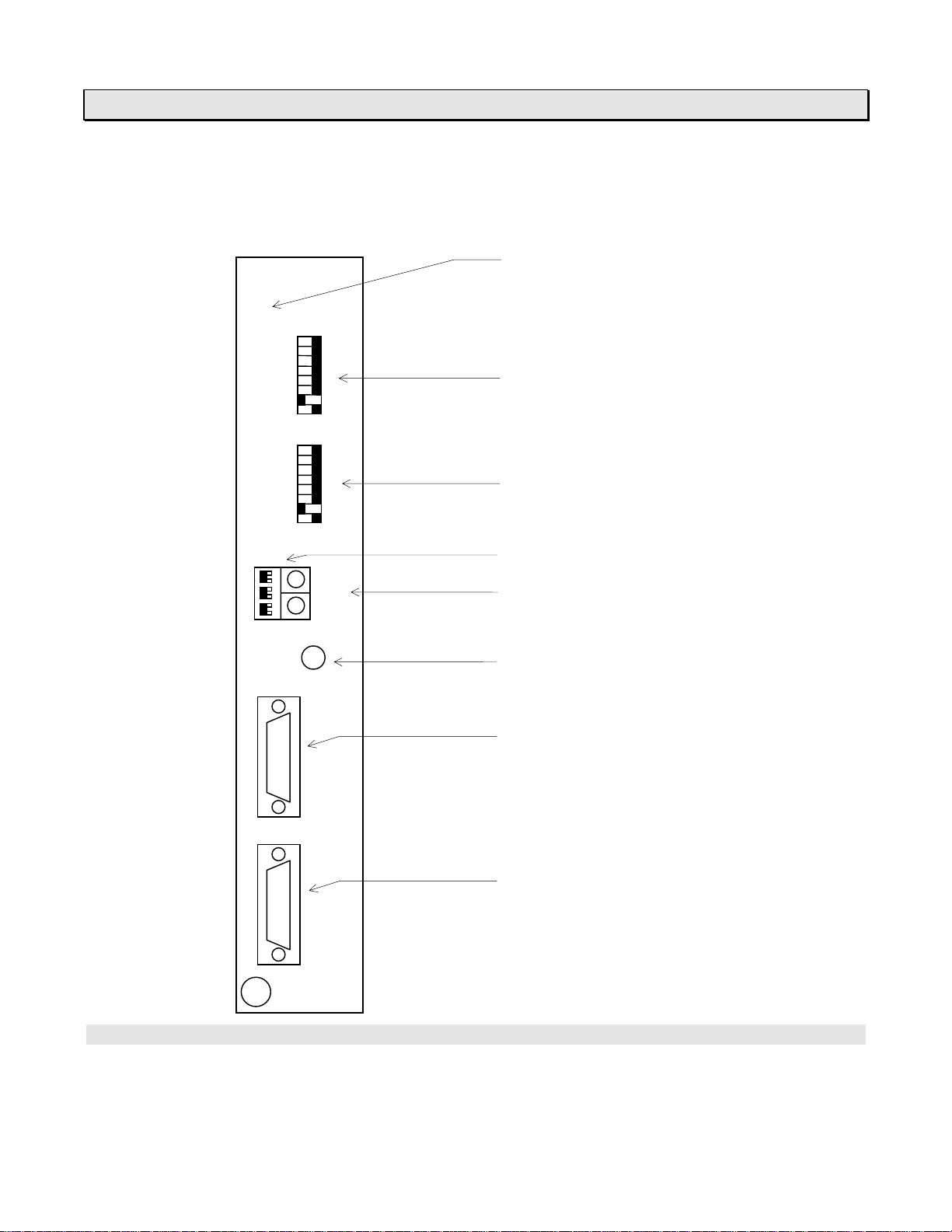

1.3 External features

AS311

•

RUN

•

TX1

•

RX1

•

TX2

•

RX2

ON

SW3

1

2

3

RESET

ON

→

→

SW1

SW2

→

1

2

CH1

CH2

Status LEDs

8

7

6

5

4

3

2

1

Channel 1 transmission parameter

setting switches

8

7

6

5

4

3

2

1

Channel 2 transmission parameter

setting switches

RS-232C/RS-422 selection switches

Optional rotary switches

Hardware reset switch

Channel 1 serial port (RS-232C/RS-422)

D-Sub 25-pin female connector

Channel 2 serial port (RS-232C)

D-Sub 25-pin female connector

ASCII Interface Module (AS311)

10

Page 13

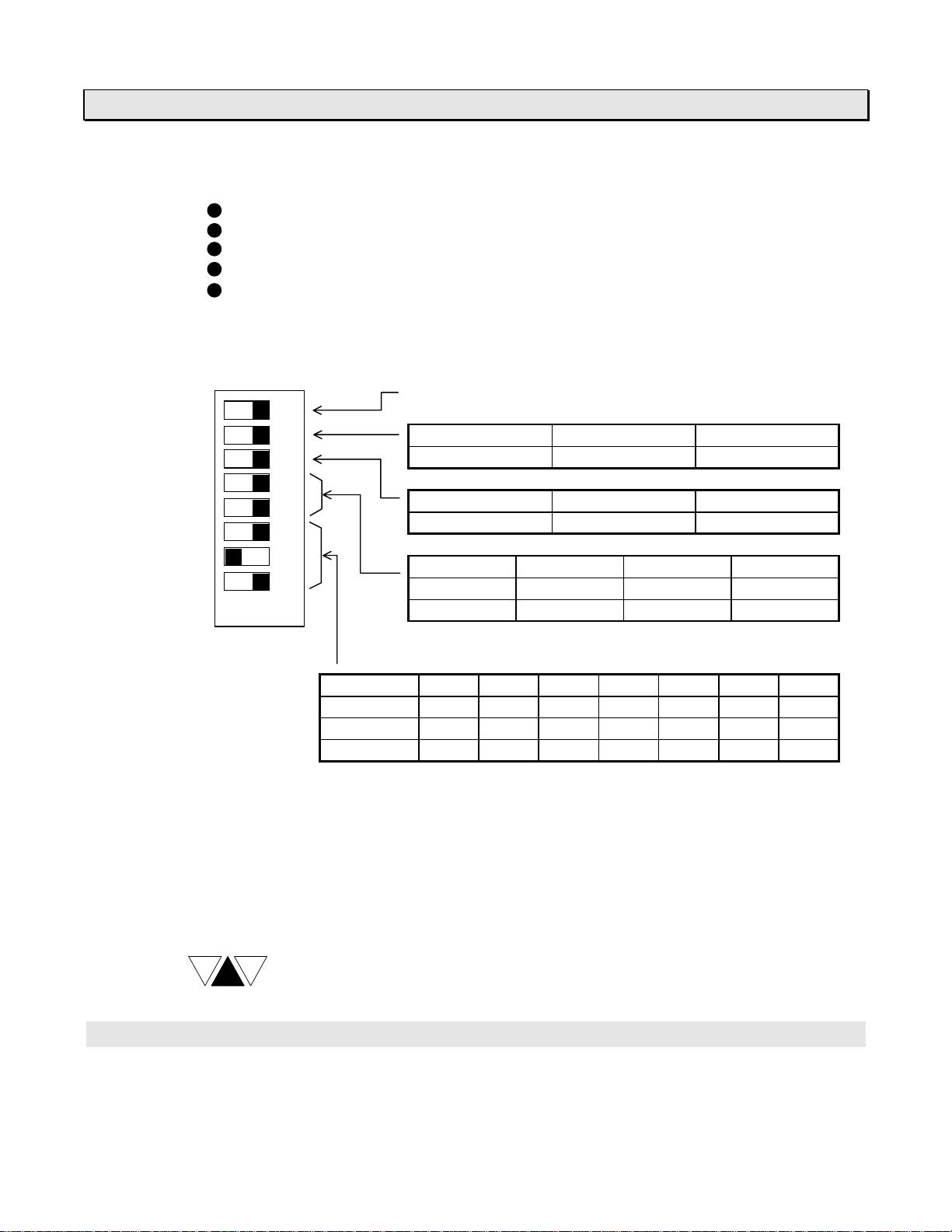

Status LEDs

RUN: Lit when AS311 is operating nor mally

TX 1: Lit while transmit ting data from channel 1

RX1: Lit while receiving data to channel 1

TX 2: Lit while transmit ting data from channel 2

RX2: Lit while receiving data to channel 2

SW1 channel 1 transmission parameter setting switches

8

7

6

5

4

3

2

1

→

ON

No.8 … No use (set always ON)

No.7

OFF ON

Stop bit 2 bit 1 bit

No.6

OFF ON

Data bit length 7 bit 8 bit

No.5

No.4

OFF ON ON

OFF/ON OFF ON

Parity None Even Odd

SW1

1. AS311 Overview

No.3

No.2

No.1

OFF OFF OFF OFF ON ON ON

OFF OFF ON ON OFF OFF ON

OFF ON OFF ON OFF ON OFF

Baud rate 300 600 1200 2400 4800 9600 19200

SW2 channel 2 transmission parameter setting switches

Used to set t he transmission parameters for channel 2. The functions of each switch

are the sam e as the SW1. Set t he transmission parameters independently for

channel 1 and channel 2.

NOTE

The factory settings of the SW1 and SW2 are as shown above figure.

That is, 1 stop bit, 8 data bits, odd parity and 9600 bps.

User’s Manual

11

Page 14

1. AS311 Overview

SW3 RS-232C/RS-422 selection switches (for channel 1)

1

2

3

→

ON

SW3

NOTE

The switches No.2 and No.3 should be set to ON when the AS311

is configured as terminal st at ion on the RS-422 transmission line.

The factory settings of the SW 3 ar e all OFF.

RSW1/RSW2 Optional rotary switches

RSW1

C

80

RSW2

4

C

80

4

Used to select the interface of the channel 1 either

RS-232C or RS-422.

No.1

OFF ON

Interface RS-232C RS-422

Used to connect the terminating resist or ( 120 Ω)

between RXDA and RXDB. (Eff e ct ive for RS-422)

No.2

OFF ON

Terminating Not connect Connect

Used to connect the terminating resist or ( 120 Ω)

between CTSA and CTSB. (Effective for RS-422)

No.3

OFF ON

Terminating Not connect Connect

Always set the RSW1 to 4 and the RSW2 to 0.

(Other settings are f or future use)

Do not set other than above, otherwise the AS311

will not work correctly.

ASCII Interface Module (AS311)

12

Page 15

1. AS311 Overview

Hardware reset switch

When this switch is pressed, the AS311 will be reset. Use t his switch when you

have changed the switch settings.

Channel 1 and channel 2 seri al ports

Used to connect the serial transmission line (RS-232C or RS-422). D- Sub 25-pin

f em ale connectors are provided on the AS311.

The pin assignment is as follows.

Channel 1 Channel 2

(RS-232C/RS-422) (RS-232C)

1 FG

2 TXD

3 RXD

4 RTS

5 CTS

6 6 DSR

7 SG

8 8

9 5 Vdc

10 TXDA

11 RXDA

12 RTSA

13 CTSA

14 14

15 15

16 16

17 17

18 18

19 19

20 DTR

21 TXDB

22 RXDB

23 RTSB

24 CTSB

25 25

• The arrow on the above figure shows the signal direction.

• FG is connected with the T3’s frame g r ound internally. (both channels)

• DTR and RTS are ON while power is on.

• Data transmitting is available when CTS is ON. DSR has no effect for t r ansm ission.

• Pin 9 (5 Vdc) can be used to supply 5 Vdc power. (total max. 50 mA)

↔

→

← for RS-232C

→

←

↔

→

→

← for RS-422

→

←

→ for RS232C

→

← for RS-422

→

←

1 FG

2 TXD

3 RXD

4 RTS

5 CTS

7 SG

9 5 Vdc

10

11

12

13

20 DTR

21

22

23

24

↔

→

←

→

←

←

↔

→

→

User’s Manual

13

Page 16

ASCII Interface Module (AS311)

14

Page 17

Section 2

Specifications

2.1 General specifications

2.2 Functional specifications

2.3 Transmission specifications

User’s Manual

15

Page 18

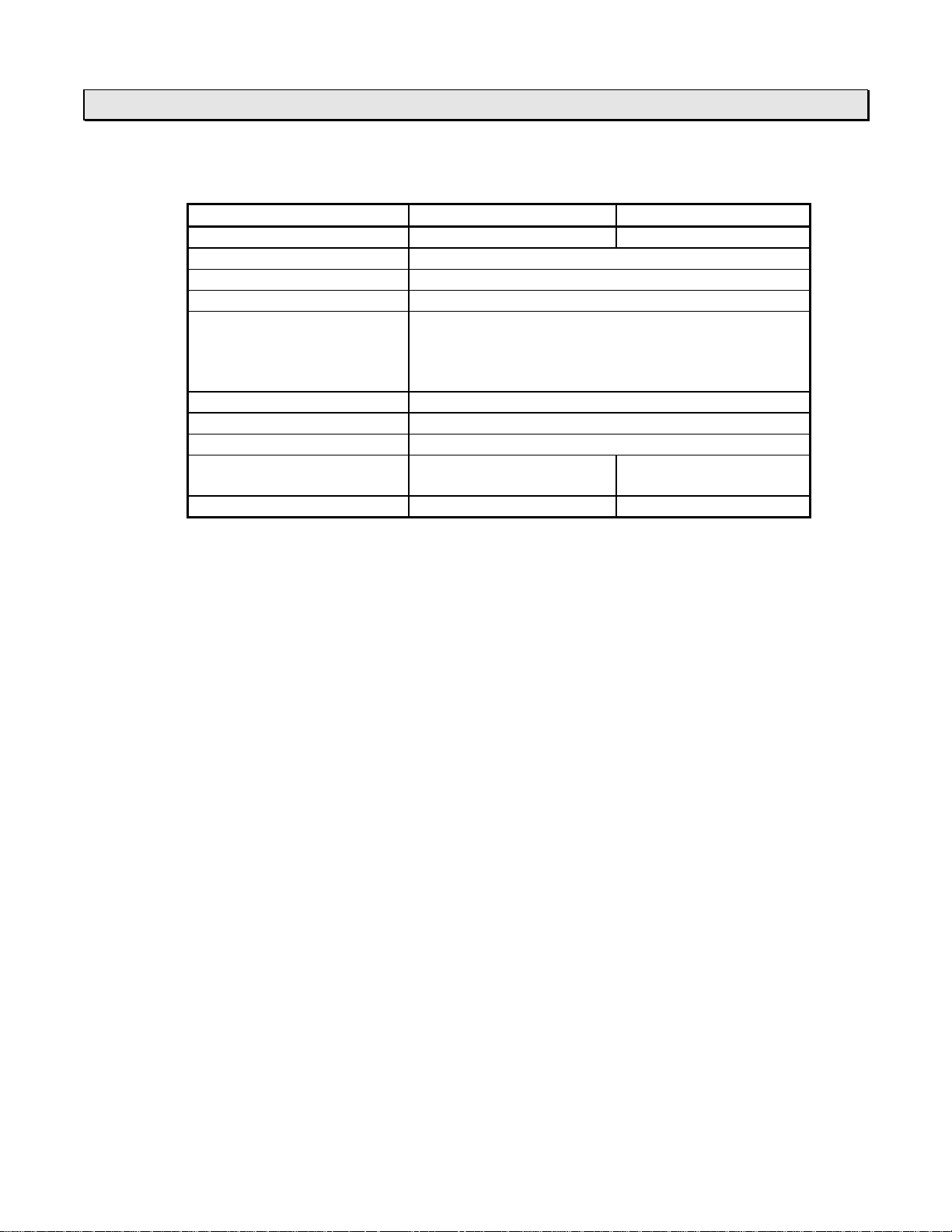

2. Specifications

2.1 General specifications

Item Specifications Remarks

Power voltage 5 Vdc (supplied from back plane bus)

Current consumption 1.0 A (5 Vdc) maximum Note (1)

Environmental conditions Conforms to T3 specifications

Insulation resistance

Withstand voltage 500 Vac - 1 minute Note (2)

Size T3 I/O module size (1 slot)

Weight 500 g

Note (1) The T3’s power supply module can supply maximum 7 A of internal 5 Vdc.

Check that the internal 5 Vdc current consum ption per one power supply

module does not exceed the limit.

Note (2) Between interface connector pins and internal circuit.

10 MΩ (500 Vdc)

2.2 Functional specifications

Item Specifications

Module type Serial communication interface

I/O allocation type iX+Y 4W

Buffer memory capacity 448 words x 4

(accessed from T3 by READ/WRITE instruction)

Transmission interface 2 channels;

Channel 1 … RS-232C or RS-422 (selectable)

Channel 2 … RS-232C

Display Status LEDs;

RUN … lit when operating normally

TX1 … lit while transmitting data from channel 1

RX1 … lit while receiving data to channel 1

TX2 … lit while transmitting data from channel 2

RX2 … lit while receiving data to channel 2

Connectable devices Computer, bar code reader, display device, sensor,

printer, or other serial ASCII device

RAS function Self diagnosis, watch dog timer ( 200 ms),

transmission error check, etc.

Note (2)

ASCII Interface Module (AS311)

16

Page 19

2. Specifications

2.3 Transmission specifications

Item Channel 1 Channel 2

Interface RS-232C or RS-422 RS-232C

Transmission mode Full-duplex

Synchronizing St art-stop method (asynchronous)

Transmission speed 300, 600, 1200, 2400, 4800, 9600, 19200 bps

Frame format Start bit

Data

Parity

Stop bit

Transmission code ASCII

Message length Max. 896 bytes

Configuration One to one (Note)

Transmission distance Max. 15 m (RS-232C)

Max. 1 km (RS-422)

Connector D-sub 25-pin female D-sub 25-pin female

Note) In case of RS- 422 interface, multiple devices can be connected to one AS311

if the connected RS-422 devices work as slave stations and support multi-point

connection. That is, the connected RS-422 devices must have the tr ansm ission

generators which support the passive state. Also, the RS- 422 devices must

support the message form at which contains the select ing address. In this case,

the number of the connected RS-422 devices is limit ed up t o 10.

On the other hand, the AS311’s transmission g enerator does not support the

passive state. Therefore the AS311 m ust be t he master station in the one-to-N

configuration.

1 bit

7 or 8 bits

even / odd / none

1 or 2 bits

Max. 15 m

User’s Manual

17

Page 20

ASCII Interface Module (AS311)

18

Page 21

Section 3

Cable Connections

3.1 RS-232C connection

3.2 RS-422 connection

User’s Manual

19

Page 22

3. Cable Connections

3.1 RS-232C connection

The following figure shows the RS-232C connection.

AS311 Shielded cable RS-232C device

FG

1

TXD

2

RXD

3

RTS

4

CTS

5

(DSR)

6

SG

7

DTR

20

(1) DSR is suppor ted only on the channel 2.

(2) Connect SG each other.

(3) Use shielded cable. The cable shield should be connected to FG at one end.

(4) I t is recommended to use twisted cable for noise imm unity.

NOTE

Do not connect or remove the connector while the AS311 is powered. Otherwise, it

will cause damage to the AS311.

RXD

TXD

DTR

SG

DSR

RTS

CTS

ASCII Interface Module (AS311)

20

Page 23

3. Cable Connections

3.2 RS-422 connection

The channel 1 can be select ed eit her RS-232C or RS-422. The following figure shows

the RS-422 connect ion.

AS311 Shielded cable RS-422 device

FG

1

10

21

11

22

7

12

23

13

24

TXDA

TXDB

RXDA

RXDB

SG

RTSA

RTSB

CTSA

CTSB

FG

RXDA

RXDB

TXDA

TXDB

SG

CTSA

CTSB

RTSA

RTSB

R

R

(1) O n the AS311, connect the built-in terminating resistors (120 Ω) between RXDA

and RXDB and bet ween CTSA and CTSB by setting switches.

(Set t he SW3-2 and SW3-3 to ON)

(2) O n the RS-422 device, connect the terminating resist ors R (120 Ω - 1/2 W)

between RXDA and RXDB and between CTSA and CTSB.

(3) Connect SG each other.

(4) Use shielded t wisted-pair cable. The A (+) and B (-) of the same signal should be

paired.

(5) The cable shield should be connected to FG at one end.

NOTE

Do not connect or remove the connector while the AS311 is powered. Otherwise, it

will cause damage to the AS311.

User’s Manual

21

Page 24

ASCII Interface Module (AS311)

22

Page 25

Section 4

Register Configuration

4.1 I/O allocation and I/O registers

4.2 AS311 buffer memory

User’s Manual

23

Page 26

4. Register Configuration

4.1 I/O allocation and I/O registers

The AS311 has the I/O type ‘

allocation is perf ormed with mounting the AS311, the f ollowing I/O allocation table will

be created in t he T3.

(T - PDS scr een example - in t he case that AS311 is mounted on Slot 0 of Unit 0)

i X+Y 4W

’ for I/O allocation. When the automatic I/O

Then, 4 I/O registers, XW(n), XW(n+1), YW(n+2) and YW(n+3), are assigned to the

AS311.

In the above example, X W000, XW001, YW002 and YW003 are assigned.

Note that the I/O type has ‘i’ designation. It means that t he T3 will not update the

assigned I/O registers in the batch I/O processing. To read or write data through

the I/O registers, the Direct I/O instruction (FUN235) or the direct I/O designation

(I/IW and O/OW instead of X/XW and Y/YW) is necessary.

The r eason of that is because the reading and writing timings are important f or

handshaking between T3 and AS311. Refer to section 5.

ASCII Interface Module (AS311)

24

Page 27

4. Register Configuration

The following table shows the functions of I/O registers assigned to the AS311.

XW(n) CH1 status

XW(n+1) CH2 status

YW(n+2) CH1 command

YW(n+3) CH2 command

Register Bit Name Description

F Write ready 1: ready to write data (transmit) for channel 1

E Transmit complete 1: transmitting has been completed normally

D Transmit error 1: transmitting has been canceled by error

XW(n) C - 8 − No use (always 0)

(CH1) 7 Read ready 1: ready to read the received data

6 Receive complete 1: receiving for channel 1 has been completed

5 Receive error 1: receiving error has occurred

4 - 0 − No use (always 0)

F Write ready 1: ready to write data (transmit) for channel 2

E Transmit complete 1: transmitting has been completed normally

D Transmit error 1: transmitting has been canceled by error

XW(n+1) C - 8 − No use (always 0)

(CH2) 7 Read ready 1: ready to read the received data

6 Receive complete 1: receiving for channel 2 has been completed

5 Receive error 1: receiving error has occurred

4 - 0 − No use (always 0)

F T ransmit start Set to 1 to start transmitting data fr om channel 1

YW(n+2) E - 8 − No use (set to 0)

(CH1) 7 Read star t Set to 1 to start reading data for channel 1

6 - 0 − No use (set to 0)

F T ransmit start Set to 1 to start transmitting data fr om channel 2

YW(n+3) E - 8 − No use (set to 0)

(CH2) 7 Read star t Set to 1 to start reading data for channel 2

6 - 0 − No use (set to 0)

NOTE

F E D C B A 9 8 7 6 5 4 3 2 1 0

No use No use

No use No use

No use No use

No use No use

These bits are used for handshak ing between T3 and AS311. The detailed

function and timing are explained in section 5.

User’s Manual

25

Page 28

4. Register Configuration

4.2 AS311 buffer memory

As explained in the previous section, the I/O registers that are assigned to AS311

are used to cont rol the reading and writing timings ( handshake) between T3 and

AS311.

On the ot her hand, for exchanging the transmission data between T3 and AS311, the

AS311’s buf fer memory is used.

This sect ion explains the buffer memory contents and how to access the buffer

memory.

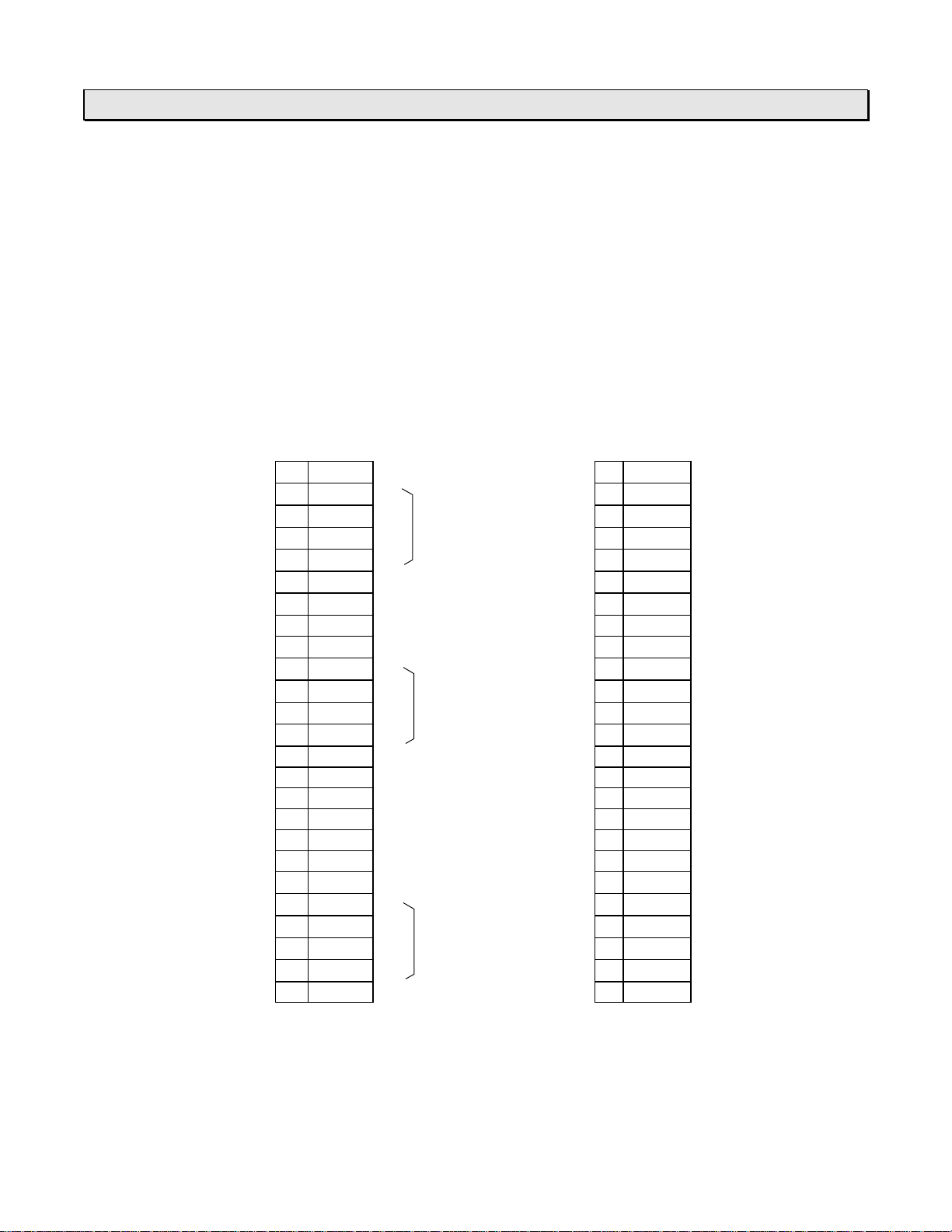

4.2.1 Memory map

The AS311 has t he buffer memory that is used to exchange data with T3. The overall

map of the buffer me m or y is as follows.

Address W ord data

0 Stat us and com mand 4 words - same data as I/O registers

4 Parameter

128 Channel 1

reading (receiving)

data area

576 Channel 1

writing (transmitting )

data area

1024 Channel 2

reading (receiving)

data area

1472 Channel 2

writing (transmitting )

data area

1920 Access inhibited

124 words - transmission parameters, etc.

448 words

448 words

448 words

448 words

128 words

ASCII Interface Module (AS311)

26

Page 29

4. Register Configuration

4.2.2 Buffer memory access

T3 can r ead t he AS311’s buffer memory contents by using READ inst ruction (FUN237).

Also, T 3 can write dat a into the buffer me m or y by using WRITE instruction (FUN238).

READ instruction (FUN237)

Expression:

[ (A) READ (B) → (C) ]

Operands:

(A): I/O register (XW/YW) assigned to the AS311

(B): Starting address of the buffer memory to be read

(B)+1: Number of words to be read (max. 256)

(C): Starting register of the destination

Example:

R0100

[ 00128 MOV D5000 ] [ 00064 MOV D5001 ]

[ X W000 READ D5000 → D1000 ]

When R0100 is ON, 64 words of buffer memory data star t ing with address 128

are read from the AS311 which is allocated to XW000. And the dat a ar e st ored

in D1000 and after.

User’s Manual

27

Page 30

4. Register Configuration

WRI TE inst ruct i on (FUN238)

Expression:

[ (A) WRITE (B) → (C) ]

Operands:

(A): Starting register of the source

(B): Starting address of the buffer memory to be written

(B)+1: Number of words to be written (max. 256)

(C): I/O register (XW/YW) assigned to the AS311

Example:

R0101

[ 00576 MOV D5000 ] [ 00100 MOV D5001 ]

[ D2000 WRITE D5000 → YW002 ]

When R0101 is ON, 100 words of data starting with D2000 (D2000 to D2099)

are written into the buffer memory address 576 and after of the AS311 which is

allocated to YW 002.

ASCII Interface Module (AS311)

28

Page 31

4. Register Configuration

4.2.3 Parameter area

The par am et er area of the buff er m em or y contains t he following contents.

Address Address

0 CH1 status 64

1 CH2 status Status and 65

2 CH1 command command 66

3 CH2 command 67

4 Status 1 68

5 RSW1/2 information 69

6 SW1 information 70

7 SW2 information 71 Reserved

8 CH1, CH2 72

9 common 73

10 parameters 74

11 75

12 Command 1 76

13 77

14 78

15 79

16 CH1 receive error 80 CH2 receive error

17 CH1 transmit error 81 CH2 transmit error

18 CH1 channel status 82 CH2 channel status

19 CH1 receive length 83 CH2 receive length

20 84

21 85

22 86

23 87

24 CH1 trailing code 88 CH2 trailing code

25 CH1 time-out check CH1 89 CH2 time-out check CH2

26 parameters 90 parameters

27 91

28 92

29 93

30 94

31 95

63 127

Note: Blanks are for fut ur e use. ( Reser ved)

User’s Manual

29

Page 32

4. Register Configuration

Status and command (0 - 3)

The addresses 0 to 3 store the same data as the I/O registers that are assigned to the

AS311.

Refer to section 4.1 f or details.

0 CH1 stat us = XW( n)

1 CH2 stat us = XW( n+1)

2 CH1 comm and = YW ( n+2)

3 CH2 comm and = YW ( n+3)

Status 1 (4)

The address 4 shows the AS311 module status. If an er r or has occurred in the AS311,

the error code is stored here.

F E D C B A 9 8 7 6 5 4 3 2 1 0

RDY ERR 0 0 0 0 0 0 Error code

4

Bit F RDY (Ready) 1 = operating normally

Bit E ERR (Error) 1 = error state

Bit 7-0 Er r o r code Shows the detected error item if ERR is 1.

RSW1/2 information (5)

The address 5 stores the rotary switches RSW1 and RSW 2 setting status.

F E D C B A 9 8 7 6 5 4 3 2 1 0

0 0 0 0 0 0 0 0 RSW1 RSW2

5

Bit 7-4 RSW1 Stores the rotary switch 1 (RSW1) setting status.

Bit 3-0 RSW2 Stores the rotary switch 2 (RSW2) setting status.

0 = under initialization or error state

0 = no error (normal)

(H00 when normal)

See section 6.2.1 for details.

0 - F

0 - F

ASCII Interface Module (AS311)

30

Page 33

SW1 information (6)

The address 6 stores the setting status of the channel 1 transmission parameter set ting

switches (SW1).

6

OFF ON

ON: 1 OFF: 0

SW2 information (7)

The address 7 stores the setting status of the channel 2 transmission parameter set ting

switches (SW2).

7

OFF ON

ON: 1 OFF: 0

4. Register Configuration

F E D C B A 9 8 7 6 5 4 3 2 1 0

0 0 0 0 0 0 0 0 SW1

SW1

8

7

6

5

4

3

2

1

F E D C B A 9 8 7 6 5 4 3 2 1 0

0 0 0 0 0 0 0 0 SW2

SW2

8

7

6

5

4

3

2

1

User’s Manual

31

Page 34

4. Register Configuration

Command 1 (12)

The address 12 is used to reset the AS311 by T3 progr am .

Two types of reset commands are available, hot reset and cold r eset .

The hot reset is used to change the tr ailing code and the time-out check time set t ings.

The cold reset is used to initialize the AS311. The t r ailing code and the time-out check

time will be reset to the default sett ing . The operation of the cold reset is the same as the

hard reset switch and power on initialization.

Refer to sections 5.5, 5.6 and 5. 7 for these functions.

F E D C B A 9 8 7 6 5 4 3 2 1 0

RST 0 0 0 0 0 0 0 Command number

12

Bit F RST (Reset) 1 = reset request

Bit 7-0 Com mand

number

CH1 receive error (16) and

CH2 receive error (80)

The address 16 (for channel 1) and the addr ess 80 ( for channel 2) indicate the error

contents if an error has been detect ed in r eceiving a message. This inform at ion is set

during the received message read sequence.

Refer to section 6.2.3 for details.

16 or 80

F E D C B A 9 8 7 6 5 4 3 2 1 0

0 0 0 0 BRK PE FE OE Receive error code

Bit B BRK ( Br eak) 1 = break detected

Bit A PE ( Par ity error) 1 = parity error

Bit 9 FE

(Framing error)

Bit 8 OE

(Overrun error)

Bit 7-0 Receive err or

code

0 = normal (no reset request)

HFE = hot reset

HFF = cold reset

0 = normal

0 = normal

1 = framing error

0 = normal

1 = overrun error

0 = normal

Shows the error code regarding received message.

(H00 when normal)

See section 6.2.3 for details.

ASCII Interface Module (AS311)

32

Page 35

CH1 transmit error (17) and

CH2 transmit error (81)

The address 17 (for channel 1) and the addr ess 81 ( for channel 2) indicate the error

contents if an error has occurred dur ing message transmitting . This information is set

during the write sequence for m essage transmitting.

Refer to section 6.2.4 for details.

17 or 81

CH1 channel status (18) and

CH2 channel status (82)

The address 18 (for channel 1) and the addr ess 82 ( for channel 2) indicate the control

signal status. This inf or m ation is always updated.

18 or 82

Note: (1) The channel 1 does not support DSR. Therefore, bit 7 of the address 18 is

always 0.

( 2) The bit 2 is always 1.

F E D C B A 9 8 7 6 5 4 3 2 1 0

0 0 0 0 0 0 0 0 Transmit error code

Bit 7-0 Transmit error

code

F E D C B A 9 8 7 6 5 4 3 2 1 0

0 0 0 0 0 0 0 IDL DSR 0 0 0 CTS 1 0 0

Bit 8 IDL (Idle) 1 = transmitter is idle state

Bit 7 DSR

(Data set ready)

Bit 3 CTS

(Clear to send)

4. Register Configuration

Shows the error code for transmitting.

(H00 when normal)

See section 6.2.4 for details.

0 = transmitter is non-idle state

1 = DSR is ON

0 = DSR is OFF Note (1)

1 = CTS is ON

0 = CTS is OFF

User’s Manual

33

Page 36

4. Register Configuration

CH1 receive length (19) and

CH2 receive length (83)

The address 19 (for channel 1) and the addr ess 83 ( for channel 2) indicate the length of

the received message (number of bytes) . This information is set during the received

message read sequence.

19 or 83

CH1 trailing code (24) and

CH2 trailing code (88)

The address 24 (for channel 1) and the addr ess 88 ( for channel 2) store the trailing

codes. The default setting is H0D (CR code).

To change the trailing code, write the desired code into this address then write the hot

reset command into the Command 1 (12). See section 5.6 for this procedure.

24 or 88

F E D C B A 9 8 7 6 5 4 3 2 1 0

Bit F-0 Received

message length

F E D C B A 9 8 7 6 5 4 3 2 1 0

0 0 0 0 0 0 0 0 Trailing code

Bit 7-0 Trailing code Stores the trailing code.

Received message length

Shows the received message length (bytes).

0 - 896

Initial value at power on is H0D (carriage retur n ) .

ASCII Interface Module (AS311)

34

Page 37

CH1 time-out check (25) and

CH2 time-out check (89)

The address 25 (for channel 1) and the addr ess 89 ( for channel 2) store the time-out

check times. If the t im e bet ween each receiving charact er exceeds the specified time-out

check time, it becomes the receiving t im e- out error. The default set t ing is 1 second.

To change the setting, write t he desir ed data into this address then write the hot reset

command into the Command 1 (12). See sect ion 5. 7 for this procedure.

25 or 89

F E D C B A 9 8 7 6 5 4 3 2 1 0

Bit F-0 Time-out check

time

4. Register Configuration

Time-out check time

Stores the time-out check tim e ( 0. 1 s units).

Valid data range is 1 to 600 (0.1 to 60 s). If 0 or more

than 600 is specified, the time-out check will not work.

Initial value at power on is 10 (1 s).

User’s Manual

35

Page 38

4. Register Configuration

4.2.4 Receiving and transmitting data area

The r eceiving and transmitting data area is provided to exchange the com m unication

character s between T3 and AS311. The address ranges in the AS311 buf fer memory

are as follows.

Address W ord data

128 Channel 1

reading (receiving)

data area

576 Channel 1

writing (transmitting )

data area

1024 Channel 2

reading (receiving)

data area

1472 Channel 2

writing (transmitting )

data area

When AS311 receives a message (one set of transmission characters), AS311 set s the

character s into the receiving data area starting with the address 128 or 1024. Then T3

can read these char acters from the receiving dat a ar ea by using READ inst r uction.

When T3 attempts to send a message via AS311, T3 writes the characters into the

transm it t ing data area starting with the address 576 or 1472 by using WRITE

instruct ion, and instructs AS311 to start transmit t ing. AS311 recognizes from the

character st or ed in the starting address (576 or 1472) to t he t railing code character as

the one set of transmitting message.

Ref er t o section 5 for message receiving/t r ansmitting procedure.

448 words

448 words

448 words

448 words

ASCII Interface Module (AS311)

36

Page 39

Section 5

Operation Procedure

5.1 Transmission message format

5.2 Received message read sequence

5.3 Write sequence for message tr ansm it t ing

5.4 Checking the AS311 operation status

5.5 Resetting the AS311 by software

5.6 Setting the trailing code

5.7 Setting the time-out check time

User’s Manual

37

Page 40

5. Operation Procedure

5.1 Transmission message format

The t r ansm ission m essage is composed by ASCII characters and a specified t r ailing

code. T he default setting of t he trailing code is CR (carriage ret urn code = H0D).

Ref er to section 5.6 for setting the trailing code other than CR.

The m aximum length of a message is 896 bytes. An example of t he m essage is

shown below.

1 2 3 4 5 6 7 8 9

″0″ ″1″ ″2″ ″A″ ″B″ ″7″ ″8″ ″9″

In the above figure, ″x″ means an ASCII character. For example, ″0″ is H30.

When the above message is received or transm it t ed, the data arrangements in the

T3 r egisters are as follows.

Register F 8 7 0

n

n+1

n+2

n+3

n+4 CR

″1″ ″0″

″A″ ″2″

″7″ ″B″

″9″ ″8″

Transmission message

CR

″0″

″1″

″2″

″A″

″B″

″7″

″8″

″9″

CR

ASCII Interface Module (AS311)

38

Page 41

5. Operation Procedure

5.2 Received message read sequence

5.2.1 Flag control timing

In case of receiving a message, the f ollowing flags are used for handshaking between

T3 and AS311. These flags are the bits of the I/O registers assigned to the AS311.

Ref er t o section 4.1.

Read ready

Receive complete

Receive error

Read start

The m essage receiving procedure is as follows. It is called “received message read

sequence”.

AS311 receives a message

AS311 sets Receive complete to ON

T3 sets Read st art to ON

Normal receiving Receiving error

AS311 sets the message int o buffer AS311 sets the error information into

memory (receiving data area), and buffer memory (parameter area)

sets the received message length into

buffer memory (parameter area)

AS311 sets Read ready to ON, and AS311 sets Receive error to ON, and

resets Receive complete to OFF resets Receive complet e to OFF

T3 reads the message for m buffer T3 r eads t he er r or information from

memory (receiving data area) buffer memory (parameter area)

by READ instruction by READ instruction

T3 resets Read start to OFF T3 resets Read start to OFF

AS311 resets Read ready to OFF AS311 resets Receive error to OFF

Bit 7 of XW(n) for channel 1 or XW(n+1) for channel 2

Bit 6 of XW(n) for channel 1 or XW(n+1) for channel 2

Bit 5 of XW(n) for channel 1 or XW(n+1) for channel 2

Bit 7 of YW(n+2) for channel 1 or YW(n+3) f or channel 2

User’s Manual

39

Page 42

5. Operation Procedure

5.2.2 T3 sample program for message receiving

A sample program for the “received messag e read sequence” is shown below.

This sam ple pr ogram is for the channel 1 of the AS311 that is allocated to XW000 YW003.

(Main program)

Operation for normal received message

Operation for receiving error

(Subrout ine No. 0)

ASCII Interface Module (AS311)

40

Page 43

5. Operation Procedure

In this sam ple program, the following devices/registers are used.

R0100 AS311 status (ON when ready) - Refer to section 5.4

R0200 Receiving normal complete (comes ON when receiving is complete normally)

R0300 Receiving error complete (comes ON when receiving error has occurred)

X0006 Receive complete flag

X0007 Read ready flag

X0005 Receive error flag

Y0027 Read st ar t flag

D0000 - D0063 Received message is stored here

D3000 Receiving error information is st or ed here

D4000 - D4001 Parameters for READ instruction

This sam ple pr ogram works as follows.

Main program

- Rung 1: Calls Subroutine No. 0 when the AS311 is normal and both R0200 and

R0300 are OFF.

- Rung 2: When R0200 comes ON (normal receiving), perform s t he necessary

operation for the received message, then resets R0200 to OFF.

- Rung 3: When R0300 comes ON (r eceiving er r or has occurred), performs t he error

processing , t hen resets R0300 to OFF.

Subroutine No. 0

- Rung 1: Indicates the entry of Subroutine No. 0.

- Rung 2: Reads XW000 and XW001 from the AS311 by direct I/O instruction.

- Rung 3: Sets Y0027 (Read start flag) t o O N if X0006 (Receive complete flag) is O N.

- Rung 4: When X0007 (Read ready flag) comes ON, reads the received message from

the AS311’s buffer memory, 64 words starting with address 128, by READ instr uct ion,

and stores it into D0000 and after. Then reset s Y0027 (Read start flag) to O FF, and

sets R0200 t o O N.

When X0005 (Receive error flag) comes ON, reads the error information from t he

AS311’s buf fer memory, 1 word of address 16, by READ instr uct ion, and stores it into

D3000. T hen r eset s Y0027 ( Read st ar t flag) to OFF, and sets R0300 t o O N.

- Rung 5: Writes YW002 and YW003 into the AS311 by direct I/O instruction.

- Rung 6: Indicates the return of Subr out ine No. 0.

User’s Manual

41

Page 44

5. Operation Procedure

Explanation f or this sample program:

(1) The “ r eceived message read sequence” is programm ed on Subr out ine No. 0.

(2) The Subr outine No. 0 is called from Main program with reset t ing R0200 and R0300

to OFF.

(3) When a message is received norm ally, R0200 will come ON and t he m essage

(ASCII characters) will be stored in D0000 to D0063. In t his sample program, the

received message length information (buffer memory address 19) is not used. The

maximum length of a message is 128 bytes (64 words) because the number of

read words of the READ instruction is programm ed as 64 words.

(4) When an error has occurr ed in r eceiving t he m e ssage, R0300 will come ON and

the error information will be stored in D3000. For details of the error information,

refer to section 6.2.3.

ASCII Interface Module (AS311)

42

Page 45

5. Operation Procedure

5.3 Write sequence for message transmitting

5.3.1 Flag control timing

In case of transmitting a message, t he following flags are used for handshaking

between T3 and AS311. These flags are the bits of the I/O registers assigned to the

AS311. Refer to section 4.1.

Write ready

Transmit complete Bit E of XW(n) for channel 1 or XW(n+1) for channel 2

Transmit error

Transmit start

The m essage transmitting procedure is as follows. It is called “write sequence for

message transmitting”.

T3 checks Write ready is ON

T3 writes a message into buffer

memory (transmitting data ar ea)

by WRITE instruction

T3 sets Transmit start to ON

AS311 resets Write ready to OFF

Normal transmitting Transmitting error

AS311 sends out the message and AS311 sets the err or information into

sets Transmit complete to ON buffer memory (parameter area) and

sets Transmit error to ON

T3 resets Transmit st art to OFF

T3 reads the error information from

buffer memory (parameter area)

AS311 resets Transmit compl ete to by READ instruction, and resets

AS311 resets Transmit error to OFF,

and sets Write ready to ON

OFF, and sets Write ready to ON Transmit start to OFF

Bit F of XW(n) for channel 1 or XW(n+1) for channel 2

Bit D of XW(n) for channel 1 or XW(n+1) for channel 2

Bit F of YW(n+2) for channel 1 or YW(n+3) f or channel 2

User’s Manual

43

Page 46

5. Operation Procedure

5.3.2 T3 sample program for message transmitting

A sample program for the “write sequence for message transmitt ing” is shown below.

This sam ple pr ogram is for the channel 1 of the AS311 that is allocated to XW000 YW003.

(Main program)

Set the transmission message into

D0200 - D0263, and set R0110 to ON

Operation for transmitt ing error

(Subrout ine No. 1)

ASCII Interface Module (AS311)

44

Page 47

5. Operation Procedure

In this sam ple program, the following devices/registers are used.

R0100 AS311 status (ON when ready) - Refer to section 5.4

R0110 Internal flag to star t transmitting

R0201 Transmitting normal complete (comes ON when transmitting is complete

normally)

R0301 Transmitting error com plet e ( comes ON when transmitting error has

occurred)

X000F Write r eady flag

X000E Transmit complete f lag

X000D Transmit er r or flag

Y002F Transmit start flag

D0200 - D0263 Transmitting message is set here

D3010 Transmitting error information is stored here

D4010 - D4011 Parameters for W RI TE instruction

D4000 - D4001 Parameters for READ instruction

This sam ple pr ogram works as follows.

Main program

- Rung 1: Pr epares a transmission message and sets it into D0200 and after (maximum

64 words in this sample). Then sets R0110 to ON.

- Rung 2: Calls Subroutine No. 1 when the AS311 is normal and R0110 is ON.

- Rung 3: When R0201 comes ON (normal transmitting), r esets R0110 and R0201 to

OFF.

- Rung 4: When R0301 comes ON (t r ansm it t ing error has occurred), performs the error

processing , then resets R0110 and R0301 to OFF.

Subroutine No. 1

- Rung 1: Indicates the entry of Subroutine No. 1.

- Rung 2: Reads XW000 and XW001 from the AS311 by direct I/O instruction.

- Rung 3: When X000F (Write ready flag) is ON, writes the message that is st ored in

D0200 to D0263 into t he AS311’s buffer memory, 64 words start ing with address 576,

by WRITE instruction, and sets Y002F (Transmit start flag) to ON.

- Rung 4: When X000E (Transmit complete flag) com es O N, r eset s Y002F ( Transmit

start flag) to OFF, and sets R0201 t o O N.

When X000D (Transmit error flag) comes ON, reads the error information from the

AS311’s buf fer memory, 1 word of address 17, by READ instr uct ion, and stores it into

D3010. T hen r eset s Y002F ( Transmit start flag ) to OFF, and sets R0301 to ON.

- Rung 5: Writes YW002 and YW003 into the AS311 by direct I/O instruction.

- Rung 6: Indicates the return of Subr out ine No. 1.

User’s Manual

45

Page 48

5. Operation Procedure

Explanation f or this sample program:

(1) The “ write seq uence for message transmitt ing ” is programmed on Subroutine

No. 1.

(2) To st ar t transmitting, set the m essage (ASCII characters) into D0200 and after.

Then set R0110 to ON.

The message length is maximum 128 bytes (64 words) in this sample program.

(3) When R0110 is set to ON while the AS311 is ready, the Subroutine No. 1 will be

called and the message transmitting will be started.

(4) When the message is transmitted normally, R0201 will come ON. Then R0110 will

be reset to OFF.

(5) When an error has occurr ed in t r ansm it ting the message, R0301 will come ON and

the error information will be stored in D3010. For details of the error information,

refer to section 6.2.4.

ASCII Interface Module (AS311)

46

Page 49

5. Operation Procedure

5.4 Checking the AS311 operation status

AS311 operation st atus information is stored in the AS311’s buffer memory address 4

(Stat us 1) . T3 can read this informat ion by using READ inst ruction.

A sample program is shown below. This sample program is f or the AS311 that is

allocated to XW000 - YW003.

The above sample program works as follows.

- Rung 1: Reset s S0051 ( I nstruction error flag) t o O FF, and sets parameters for the

READ instruction.

- Rung 2: Reads the operation status information from the AS311’s buffer memory

address 4 (Stat us 1) .

- Rung 3: When S0051 (Inst r uction error flag) is OFF and R050F ( Ready) is ON, turns

R0100 to ON.

It means that the AS311 is operating norm ally when R0100 is ON.

If R050E (Error) is ON, the AS311 is in err or state. In that case, the err or code is

stored in t he lower 8 bits of RW 050. For the error code, refer t o section 6.2.1.

If S0051 (Instruction error flag) is ON, it means that an er r or has occur r ed dur ing the

READ instruction execution.

User’s Manual

47

Page 50

5. Operation Procedure

5.5 Resetting the AS311 by software

AS311 can be reset by T3 pr ogram. Two types of resetting are available, cold reset

and hot reset .

The cold r eset is used t o r eset the AS311 error state. When the cold reset is executed,

the AS311 will be initialized. The t railing code and the time-out check t im e ar e also

reset t o t he default settings. This function is the same as pressing the hardware reset

switch and power on initialization.

On the ot her hand, the hot reset is used to change the trailing code and/or the time-out

check time.

For executing these functions, write the following data into the AS311’s buffer mem ory

address 12 (Comm and 1) . The data writing into this address must be one-shot.

Clod reset: H80FF

Hot reset: H80FE

The writt en dat a will be cleared to 0 by AS311 when the operation is com pleted.

A sample program for the cold reset is shown below. This sample program is for the

AS311 that is allocated to XW000 - YW003.

In this sample program, the cold reset operation will be started by setting R0120 to ON.

(Main program)

(Subrout ine No. 2)

(H80FF)

For the hot r eset, refer to sections 5.6 and 5. 7.

ASCII Interface Module (AS311)

48

Page 51

5. Operation Procedure

5.6 Setting the trailing code

The default setting of the trailing code is CR (carriage return code = H0D). The tr ailing

code can be changed by T3 pr ogram.

To do t his, write desired trailing code into the AS311’s buffer memory address 24 (CH1

trailing code) and/or address 88 (CH2 trailing code), and execute the hot reset (ref er to

section 5.5).

A sample program is shown below. This sample program is f or the AS311 that is

allocated to XW000 - YW003.

In this sample program, the trailing code changing routine will be executed once when

the AS311 stat us is changed to ready (R0100 comes ON - refer to section 5.4), and the

channel 1 trailing code will be changed to H03.

If the channel 2 trailing code and/or the t im e- out check time are also changed, write

these data on the Main program Rung 2 before calling Subr outine No. 3 in the same

manner.

(Main program)

(Subrout ine No. 3)

(H0003)

(H80FE)

User’s Manual

49

Page 52

5. Operation Procedure

5.7 Setting the time-out check time

The default setting of the time-out check time is 1 second. The t ime- out check time

can be changed by T3 pr ogram. The valid setting rang e is 0. 1 to 60.0 seconds in 0.1

second units. Refer to section 4.2.3.

To change the time-out check time, write desired value into the AS311’s buffer mem or y

address 25 (CH1 t ime-out check) and/or address 89 (CH2 time-out check), and

execute the hot r eset ( r efer to section 5.5).

T3 pr ogram for this purpose is almost sam e as that for setting t he t r ailing code (refer to

section 5.6) . Only the difference is writing t he time-out check time instead of the trailing

code. See Rung 2 of the following sample. In this sam ple, the channel 1 time-out check

time is chang ed t o 5 seconds.

If the channel 2 time-out check time and/or the trailing code are also changed, write

these data on the Main program Rung 2 before calling Subr outine No. 3 in the same

manner.

(Main program)

ASCII Interface Module (AS311)

50

Page 53

Section 6

RAS Information

6.1 LED indication

6.2 Buffer memory information

6.3 Trouble shooting

User’s Manual

51

Page 54

6. RAS Information

6.1 LED indication

On the AS311, five status LEDs are provided as follows. These LEDs are useful to

check t he AS311 oper ation status and the communication status.

RUN

TX1

RX1

TX2

RX2

RUN Indicates the AS311 operation status.

Lit when the AS311 is in ready state.

Not lit when the AS311 is in error or under initialization.

TX1 Indicates the channel 1 communication status.

Lit while some data is transmitting f rom the AS311.

RX1 Indicates the channel 1 communication stat us.

Lit while some data is receiving into the AS311.

TX2 Indicates the channel 2 communication status.

Lit while some data is transmitting f rom the AS311.

RX2 Indicates the channel 2 communication stat us.

Lit while some data is receiving into the AS311.

ASCII Interface Module (AS311)

52

Page 55

6. RAS Information

6.2 Buffer memory information

Various RAS information are stored in the AS311’s buffer memory. These information

can be read by READ instruct ion. When some abnormality has occurred, check these

information.

6.2.1 Module status

Address 4 of the buffer mem or y stores the AS311 module status.

F E D C B A 9 8 7 6 5 4 3 2 1 0

RDY ERR 0 0 0 0 0 0 Error code

4

Bit F RDY (Ready) 1 = operating normally

0 = under initialization or error state

Bit E ERR (Error) 1 = error state

0 = no error (normal)

Bit 7-0 Er r o r code Shows the detected error item if ERR is 1.

See the table below (H00 when normal)

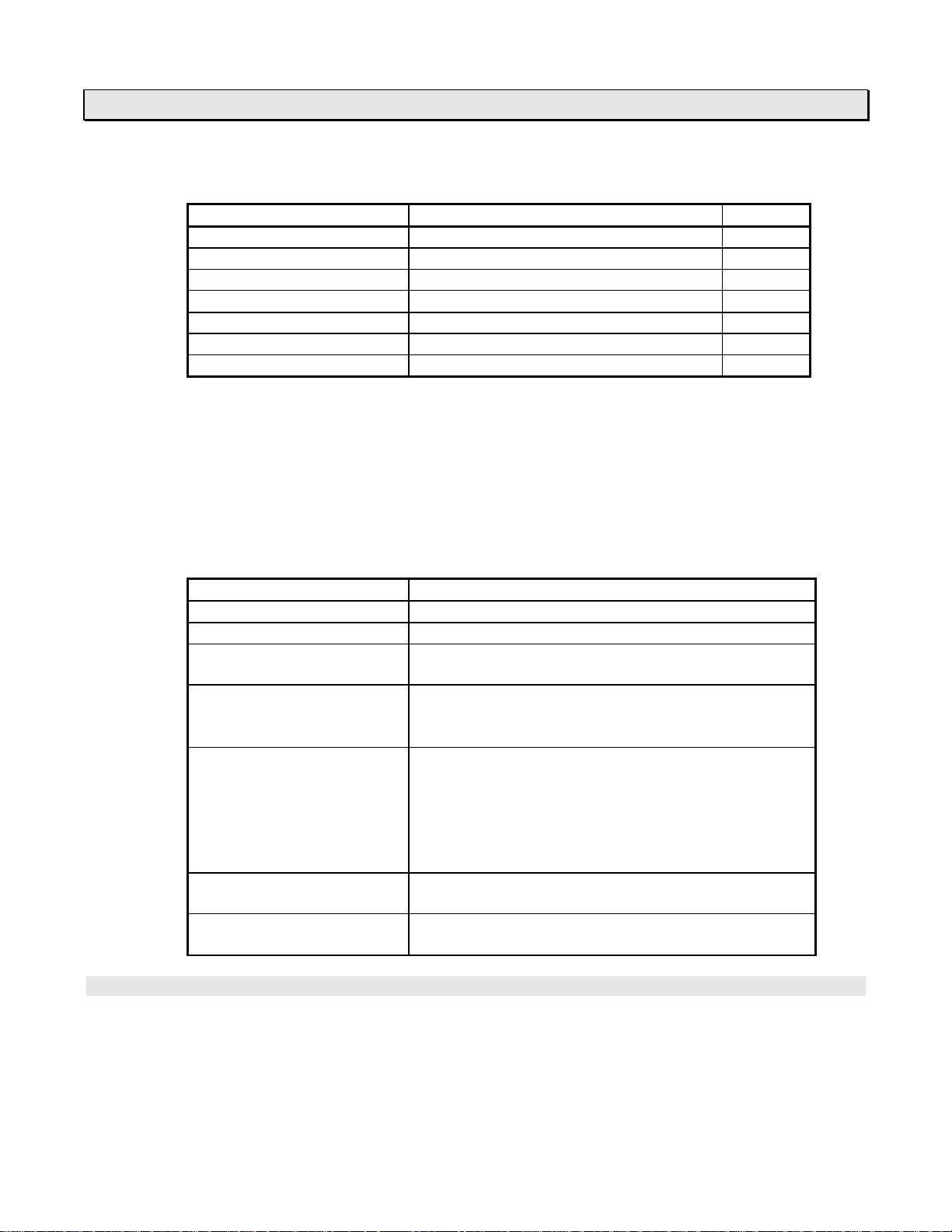

Error

code

H01 CPU error CPU err or has been detected

H02 ROM error ROM error has been detected

H03 RAM error Work RAM error has been

H04 Buffer memory

H05 Switch setting

H10 Watchdog

H11 Trap interrupt

H12 Buffer memory

Type of error Description Status

Operation is stopped.

during initialization.

Operation is stopped.

during initialization.

Operation is stopped.

detected during initialization.

error

abnormal

timer error

error

time-out error

Buffer memory error has been

detected during initialization.

Switch setting abnormality has

been detected during

initialization.

Watchdog timer error has

occurred during operation.

Trap interrupt has occurred by

detecting illegal instruction

during operation.

Buffer memory time-out has

occurred during operation.

Operation is stopped.

Operation is stopped.

Operation is stopped.

Cold reset will be

effective.

Operation is stopped.

Cold reset will be

effective.

Operation is stopped.

Cold reset will be

effective.

User’s Manual

53

Page 56

6. RAS Information

6.2.2 Switch setting status

Addresses 5, 6 and 7 of the buffer m em or y store the switches setting status. Check

that the information agrees with the physical setting status if some abnormality has

occurred.

F E D C B A 9 8 7 6 5 4 3 2 1 0

0 0 0 0 0 0 0 0 RSW1 RSW2

5

Bit 7-4 RSW1 Stores the rotary switch 1 (RSW1) setting status.

0 - F

Bit 3-0 RSW2 Stores the rotary switch 2 (RSW2) setting status.

0 - F

F E D C B A 9 8 7 6 5 4 3 2 1 0

0 0 0 0 0 0 0 0 SW1

6

OFF ON

ON: 1 OFF: 0

F E D C B A 9 8 7 6 5 4 3 2 1 0

0 0 0 0 0 0 0 0 SW2

7

OFF ON

ON: 1 OFF: 0

SW1

8

7

6

5

4

3

2

1

SW2

8

7

6

5

4

3

2

1

ASCII Interface Module (AS311)

54

Page 57

6. RAS Information

6.2.3 Error information for data receiving

Address 16 for channel 1 and address 80 for channel 2 store the er r or information for

data receiving .

16 or 80

F E D C B A 9 8 7 6 5 4 3 2 1 0

0 0 0 0 BRK PE FE OE Receive error code

Bit B BRK ( Br eak) 1 = break detected

0 = normal

When break has been detected, receive buffer is

cleared. The next message can be received.

Bit A PE ( Par ity error) 1 = parity error

0 = normal

When parity err or has occur r ed, the message is

disabled. The next message can be received.

Bit 9 FE

(Framing error)

Bit 8 OE

(Overrun error)

Bit 7-0 Receive err or

code

Error

code

H01 Receive time-

H02 Message

H03 Receive buffer

Type of error Description Stat us

out error

length error

overflow

1 = framing error

0 = normal

When f r aming error has occurred, the message is

disabled. The next message can be received.

1 = overrun error

0 = normal

When overrun error has occur red, the message is

disabled. The next message can be received.

Shows the error code regarding received message.

See the table below. (H00 when normal)

Specified time-out check

time has elapsed between

characters.

The message length has

exceeded the limit. (896

bytes)

Receive buffer overflow

has occurred.

The rest of the message

will be received as the next.

The message is disabled.

The next message can be

received.

The message is disabled.

The next message can be

received.

User’s Manual

55

Page 58

6. RAS Information

6.2.4 Error i n formation for data transmitting

Address 17 for channel 1 and address 81 for channel 2 store the er r or information for

data transmitting.

17 or 81

F E D C B A 9 8 7 6 5 4 3 2 1 0

0 0 0 0 0 0 0 0 Transmit error code

Bit 7-0 Transmit error

code

Error

code

H01 Trailing code

Type of error Description Stat us

missing

Shows the error code for transmitting.

See the table below. (H00 when normal)

The trailing code has not

been written into the

buffer memory.

The message is disabled.

The next message can be

transmitted.

ASCII Interface Module (AS311)

56

Page 59

6. RAS Information

6.3 Trouble shooting

When AS311 does not work properly, check the following points.

W hen AS311’s RUN Does t he PO WER LED on If no, check the power

LED does not light; the T3 power supply module voltage/connection.

light ?

If no, check the inter nal

5 Vdc current

consumption.

Is the AS311 mounted Remove the AS311,

securely on the base ? and mount again

securely.

When RX1/RX2 LED Are the transmission Check the cable

does not light while signals (RXD, SG, etc.) connection.

the connected device is connected properly ?

transmitting a message;

When the received data Does the receive error Check t he transmission

cannot be read pr oper ly; occur ? parameters (baudrate,

parity, etc.).

Check the cable

connection.

Confirm the receive

error information.

I s t he T3 program working Check the T 3 pr ogram.

correctly ?

When a data cannot be Does the t r ansm it er ror Confirm the transmit

transmitted from the occur ? error information.

AS311 (TX1/TX2 LED

does not light); Check the T3 program.

Is the CTS signal Check the cable

connected properly ? connection.

If CTS signal is OFF,

data transmitting

is prohibited.

User’s Manual

57

Page 60

ASCII Interface Module (AS311)

58

Page 61

Appendix

A.1 Specification of the READ instruction

A.2 Specification of the WRITE inst r uction

User’s Manual

59

Page 62

Appendix

A.1 Specification of the READ instruction

FUN 237 Special module data read (READ)

Reads designated range of data from the special module.

Input Execution output

[ A READ B → C ]

Function

• This instruction reads data f r om the buffer memor y of the special module that is

designated by operand A, and stores them in T3’s r egisters starting with operand C.

• The transfer source address (buffer memory

address) is designated by operand B.

• The transfer size (number of words) is

designated by operand B+1.

Operand

Device

Opr Name

Input Action Output ERF

OFF No execution OFF

ON Normal execution ON

Error (see Note 2) ON ON

X Y S L R Z T. C. I O XW YW SW LW RW W T C D F IW OW I J K

Register

Constant

Index

A Special

module

B Transfer

parameter

C Top register

of destination

√ √

√ √ √ √ √ √ √ √ √ √

√ √ √ √ √ √ √ √ √

Program example

R0000

[ XW000 READ RW010 → D0100 ]

• When R0000 is ON, t he buffer memory data of the size indicated by RW011, starting with the

address indicated by RW010 of the special module allocated to XW000, are read and stored in

D0100 and after.

• The maximum number of words to be read is 256 words.

X W000 special module T3

RW010 20

Buf fer memory RW011 16

20 1234 READ D0100 1234

35 5678 16 words D0115 5678

√ √

√

ASCII Interface Module (AS311)

60

Page 63

Appendix

Note 1) The special module can be designated not only by the assigned register , but

also by the mounting position. The mount ing position is designated by a

constant data for the operand A as follows.

(Unit number) × 256 + (Slot number)

H

Slot number (hexadecimal)

Unit number (hexadecimal)

For example, if a special module is mounted on Slot- 4, Unit-0 (basic unit)

and allocated to XW008 - YW 011, the following two READ instructions

function the same.

[ XW008 READ RW010 → D0100 ]

[ H0004 READ RW010 → D0100 ]

Note 2) The READ instruction is not executed as error in the following cases. In

these cases, ERF (instruction error f lag = S0051) is set to ON.

Unit number Hexadecimal

0 H00

1 H01

2 H02

3 H03

• When the operand A is other than a valid constant (see Note 1) or XW/YW

register.

• When the designated special module has been disconnected.

• When no answer error occur s with the desig nated special module.

• When the number of words transferred exceeds 256 words.

• When the source table of transfer is out of the valid range.

• When the dest ination table of transfer is out of the valid range.

Slot number Hexadecimal

0 H00

1 H01

2 H02

3 H03

4 H04

5 H05

6 H06

7 H07

8 H08

9 H09

10 H0A

User’s Manual

61

Page 64

Appendix

A.2 Specification of the WRITE instruction

FUN 238 Special module data write (WRITE)

Writ es designated range of data into t he special m odule.

Input Execution output

[ A WRITE B → C ]

Function

• This instruction transfer s dat a st or ed in T3’s registers starting with operand A int o t he buffer

memory of the special module that is designated by operand C.

• The destination address (buffer memory

address) is designated by operand B.

• The transfer size (number of words) is

designated by operand B+1.

Operand

Device

Opr Name

Input Action Output ERF

OFF No execution OFF

ON Normal execution ON

Error (see Note 2) ON ON

X Y S L R Z T. C. I O XW YW SW LW RW W T C D F IW OW I J K

Register

Constant

Index

A Top register

of source

B Transfer

parameter

C Special

module

√ √ √ √ √ √ √ √ √ √

√ √ √ √ √ √ √ √ √ √

√ √

Program example

R0000

[ D0100 WRI TE RW010 → YW002 ]

• When R0000 is ON, t he register data of the size indicated by RW011, starting with D0100,

are transferred to the buffer memory start ing with the address indicated by RW010 of the

special module allocated to YW002.

• The maximum number of words to be transferred is 256 words.

T3 YW002 special module

RW010 320

RW011 150 Buffer mem o r y

D0100 1234 WRIT E 320 1234

D0249 5678 150 words 469 5678

√

√ √

ASCII Interface Module (AS311)

62

Page 65

Appendix

Note 1) The special module can be designated not only by the assigned register , but

also by the mounting position. The mount ing position is designated by a

constant data for the operand C as follows.

(Unit number) × 256 + (Slot number)

H

Slot number (hexadecimal)

Unit number (hexadecimal)

For example, if a special module is mounted on Slot- 2, Unit-1 (expansion

unit #1) and allocated to XW020 - YW023, the following two WRITE

instructions function the same.

[ D0100 WRITE RW010 → XW020 ]

[ D0100 WRITE RW010 → H0102 ]

Note 2) The WRITE instruction is not executed as error in the following cases. In

these cases, ERF (instruction error flag = S0051) is set t o O N.

Unit number Hexadecimal

0 H00

1 H01

2 H02

3 H03

• When the oper and C is ot her than a valid constant (see Note 1) or XW/YW

register.

• When the designated special module has been disconnected.

• When no answer error occur s with the desig nated special module.

• When the number of words transferred exceeds 256 words.

• When the source table of transfer is out of the valid range.

• When the dest ination table of transfer is out of the valid range.

Slot number Hexadecimal

0 H00

1 H01

2 H02

3 H03

4 H04

5 H05

6 H06

7 H07

8 H08

9 H09

10 H0A

User’s Manual

63

Page 66

TOSHIBA CORPORATION

Industrial Equipment Department

1-1, Shibaura 1-chome, Minato-ku

Tokyo 105-8001, JAPAN

Tel: 03-3457-4900 Fax: 03-5444-9268

Loading...

Loading...