Page 1

No. 2D201-177EN*F

SERVICE MANUAL 2

FOR

TOSHIBA SCANNER

TSX-033A

(2D201-177EN*F)

TOSHIBA MEDICAL SYSTEMS CORPORATION 2011-2013

ALL RIGHTS RESERVED

Page 2

Trademarks

MicrosoftWindows is a registered trademark of Microsoft Corporation in the United States

and other countries.

Alexion is a trademark of Toshiba Medical Systems Corporation.

This manual may include trademarks of other companies.

Note that the mark and the mark may or may not be used in this manual.

IMPORTANT!

1. No part of this manual may be copied or reprinted, in whole or in part,

without prior written permission.

2. The contents of this manual are subject to change without prior notice

and without legal obligation.

3. The contents of this manual are correct to the best of our knowledge.

Please inform us of any ambiguous or erroneous descriptions, missing

information, etc.

No. 2D201-177EN*F

Page 3

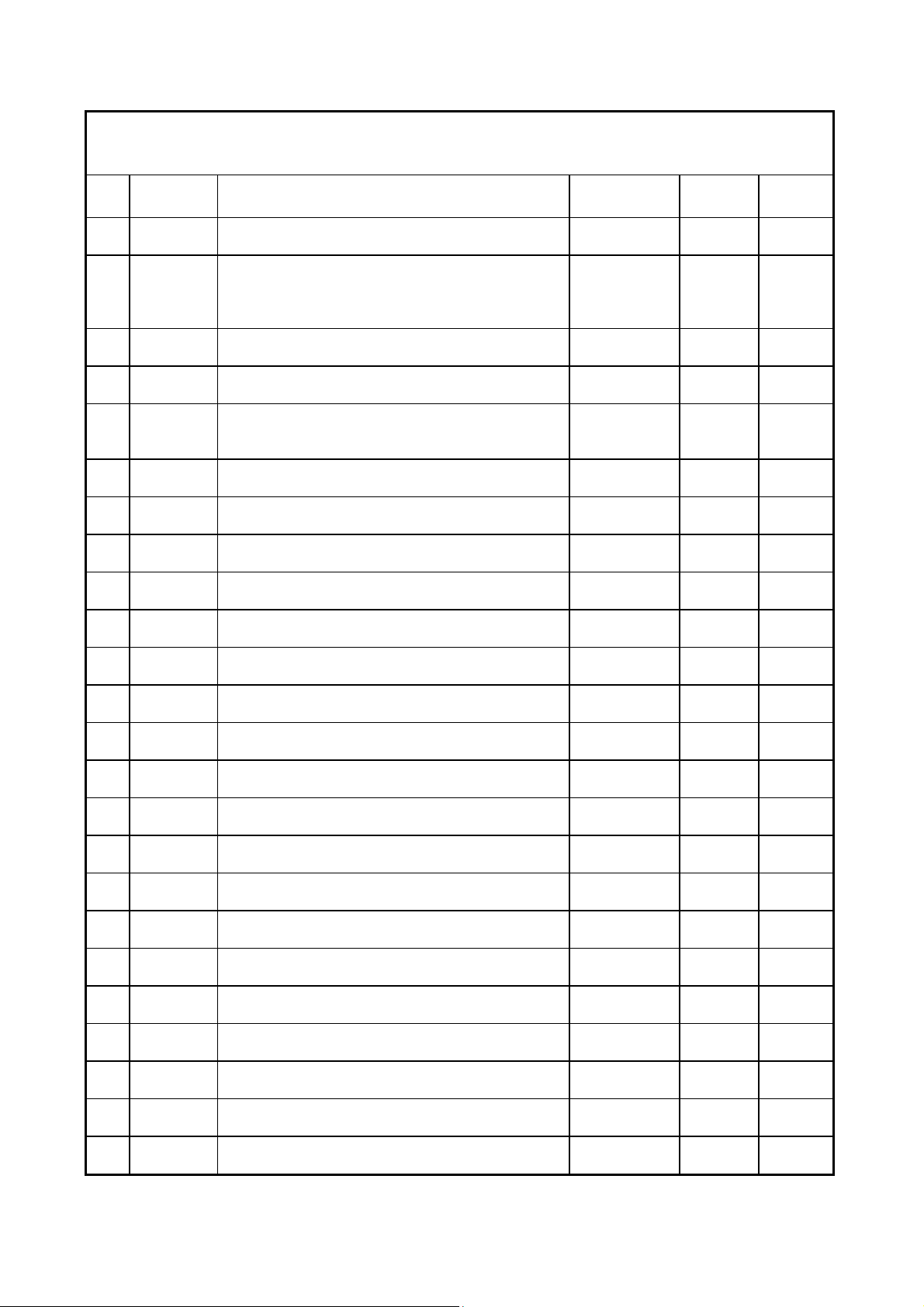

REVISION RECORD

REV. DATE

(YYYY-MM)

REASON

/AUTHOR CHANGED

PAGE

SER. DOC.

No. PRODUCT.

INI. 2011-09 Mr. Tezuka ------- TM-WI2

*A 2012-03 Change of configuration of PC BOX supplied as

service part

Mr. Sato

Subsections

4.5.2.11,

4.5.2.13

*B 2012-04 Support of improvement requests Mr. Tezuka Sections 2, 3

*C 2012-07 Use of GMSC PWB Mr. Oishi All pages TM-WI2G

*D 2012-08 Support of new OPCONTM PWB due to

Section 3

discontinuation of production Mr. Sawanaga

*E 2012-12 Support of EU Installer Mr. Kawanabe Subsection 2.8

*F 2013-05 Change of ADI PWB Mr. Kurihara Section 4

No. 2D201-177EN*F

3

Page 4

THIS PAGE IS LEFT BLANK INTENTIONALLY.

No. 2D201-177EN*F

4

Page 5

How to Use This Manual Effectively

No. 2D201-177EN*F

5

Page 6

1. Notation Conventions

This manual uses the following conventions for word usage in addition to the signal words

(refer to "General Safety Information") that indicate remarks related to safety precautions.

Carefully read the contents of this manual before performing service work.

NOTE: Indicates information of interest to users of equipment as to exceptional

conditions or operating procedures.

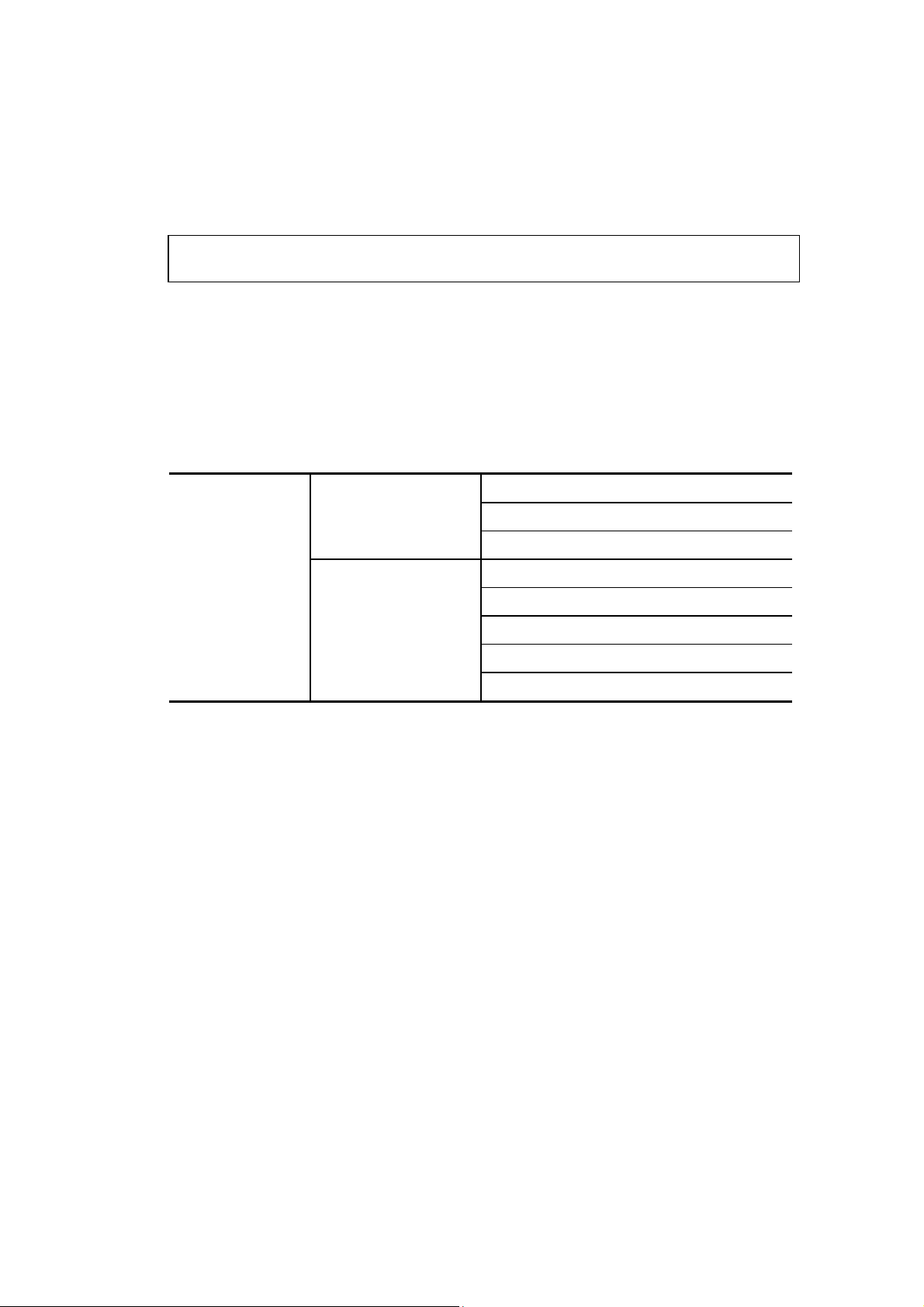

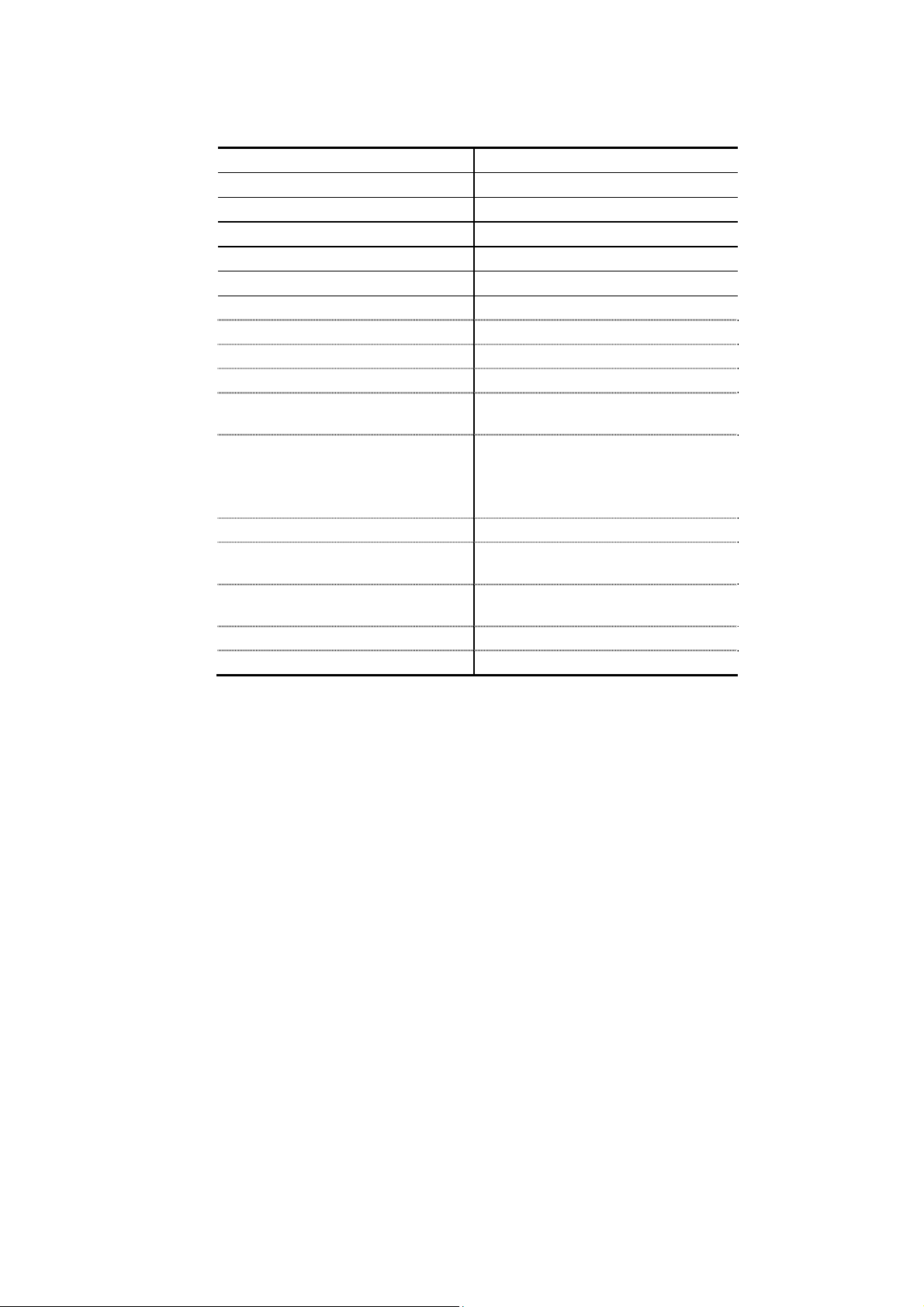

2. Organization of the Service Manuals

The following 2 volumes are provided as service manuals for the Alexion system

(TSX-033A).

Service manual organization

Alexion service

manuals

Service manual 1

(2D201-176EN)

Service manual 2

(2D201-177EN)

Configuration of the gantry

Mechanical section of the patient couch

Gantry/couch control section

X-ray system

Data acquisition section

Data transmission unit

Console

Power distributor

No. 2D201-177EN*F

6

Page 7

Table of Contents

How to Use This Manual Effectively .................................................................. 5

General Safety Information .................................................................................... 13

1. THE X-RAY SYSTEM ................................................................ 21

1.1 Configuration ............................................................................................... 22

1.2 Specifications .............................................................................................. 22

1.3 Principles of Operation ........................................................................ 23

1.4 Operation Method ..................................................................................... 24

1.4.1 Turning ON/OFF the power supply ......................................................... 24

1.4.2 Single unit exposures ................................................................................... 24

1.5 X-ray High-Voltage Generator ......................................................... 25

1.5.1 Composition ...................................................................................................... 25

1.5.2 Operating principle ........................................................................................ 26

1.5.3 Operating principle of the AC/CONTROL section ............................. 27

1.5.4 Operating principle of the INV/HV section ........................................... 28

1.6 Outline of the X-ray Tube System ................................................ 30

1.6.1 Configuration .................................................................................................... 30

1.6.2 Specifications ................................................................................................... 30

1.7 Overload Protection (OLP) Management Functions ...... 32

1.7.1 Functional description .................................................................................. 32

1.7.2 Calculation and monitoring of the anode heat capacity ................ 32

1.7.3 Short-term monitoring of the rating ........................................................ 32

1.7.4 Short-term monitoring of the nominal rating ...................................... 33

1.8 Tools and Instruments .......................................................................... 34

No. 2D201-177EN*F

7

Page 8

1.9 Notices .............................................................................................................. 35

1.9.1 Floating section ............................................................................................... 35

1.9.2 Power cable ....................................................................................................... 35

1.9.3 Precautions for rotation ............................................................................... 36

1.9.4 Handling the high-voltage cable .............................................................. 37

1.9.5 Replacing the fuse ......................................................................................... 40

1.9.6 Using the tube voltage meter .................................................................... 40

1.9.7 Tube ammeter .................................................................................................. 41

1.9.8 Other ..................................................................................................................... 42

1.10 Replacing the X-ray Tube ................................................................... 43

1.10.1 Connection and operation check ............................................................. 43

1.10.2 X-ray tube aging .............................................................................................. 46

1.10.3 If adjustment ..................................................................................................... 47

1.11 Troubleshooting ........................................................................................ 61

1.11.1 X-ray high-voltage generator troubleshooting ................................... 61

1.11.2 Troubleshooting flowchart for main circuit ......................................... 68

1.11.3 X-ray tube troubleshooting ......................................................................... 78

1.11.4 XC error log reference procedures ......................................................... 81

2. DATA ACQUISITION SECTION ................................... 87

2.1 Introduction ................................................................................................... 88

2.2 Configuration ............................................................................................... 88

2.2.1 Components ...................................................................................................... 88

2.2.2 Configuration table ........................................................................................ 89

2.2.3 Layout drawing ................................................................................................ 90

2.3 Overall Operation ...................................................................................... 91

No. 2D201-177EN*F

8

Page 9

2.4 Main Detector ............................................................................................... 92

2.5 REF Detector ................................................................................................ 93

2.5.1 Connections between the main detector, the REF detector,

and the DAS ...................................................................................................... 93

2.5.2 Correspondence between the main detector channels

and the DAS channels .................................................................................. 94

2.6 DAS ................................................................................................................... 103

2.6.1 T-CONVERTER PWB ................................................................................... 103

2.6.2 T-CONTROL PWB ......................................................................................... 103

2.7 DAS Power Supply ................................................................................ 124

2.7.1 5.7 V power supply .................................................................................... 124

2.7.2 3.3 V power supply .................................................................................... 125

2.7.3 24 V power supply ...................................................................................... 125

2.8 Identifying Problems ............................................................................ 126

2.8.1 Notices on work ............................................................................................. 126

2.8.2 Tools and instruments................................................................................ 126

2.8.3 Possible problems and troubleshooting ............................................ 127

2.8.4 DAS integrator-dependent abnormality .............................................. 132

2.8.5 DAS gain-dependent abnormality .......................................................... 132

2.8.6 Slice thickness-dependent abnormalities .......................................... 132

2.8.7 Check of the DAS supply voltage .......................................................... 133

2.9 Repair .............................................................................................................. 133

2.9.1 Before repair ................................................................................................... 133

2.9.2 Replacement of the DAS PWB (Removing and remounting a

PWB) ................................................................................................................... 134

2.9.3 Replacement of the main detector ........................................................ 136

2.9.4 Replacement of the REF detector .......................................................... 141

2.9.5 Setting after replacing the temperature controller ......................... 144

No. 2D201-177EN*F

9

Page 10

3. DATA TRANSMISSION UNIT ....................................... 151

3.1 Introduction ................................................................................................. 152

3.2 Beam Emitting/Receiving Section (MUDAT) ...................... 154

3.2.1 Functions of the MUDAT ........................................................................... 154

3.2.2 Composition .................................................................................................... 154

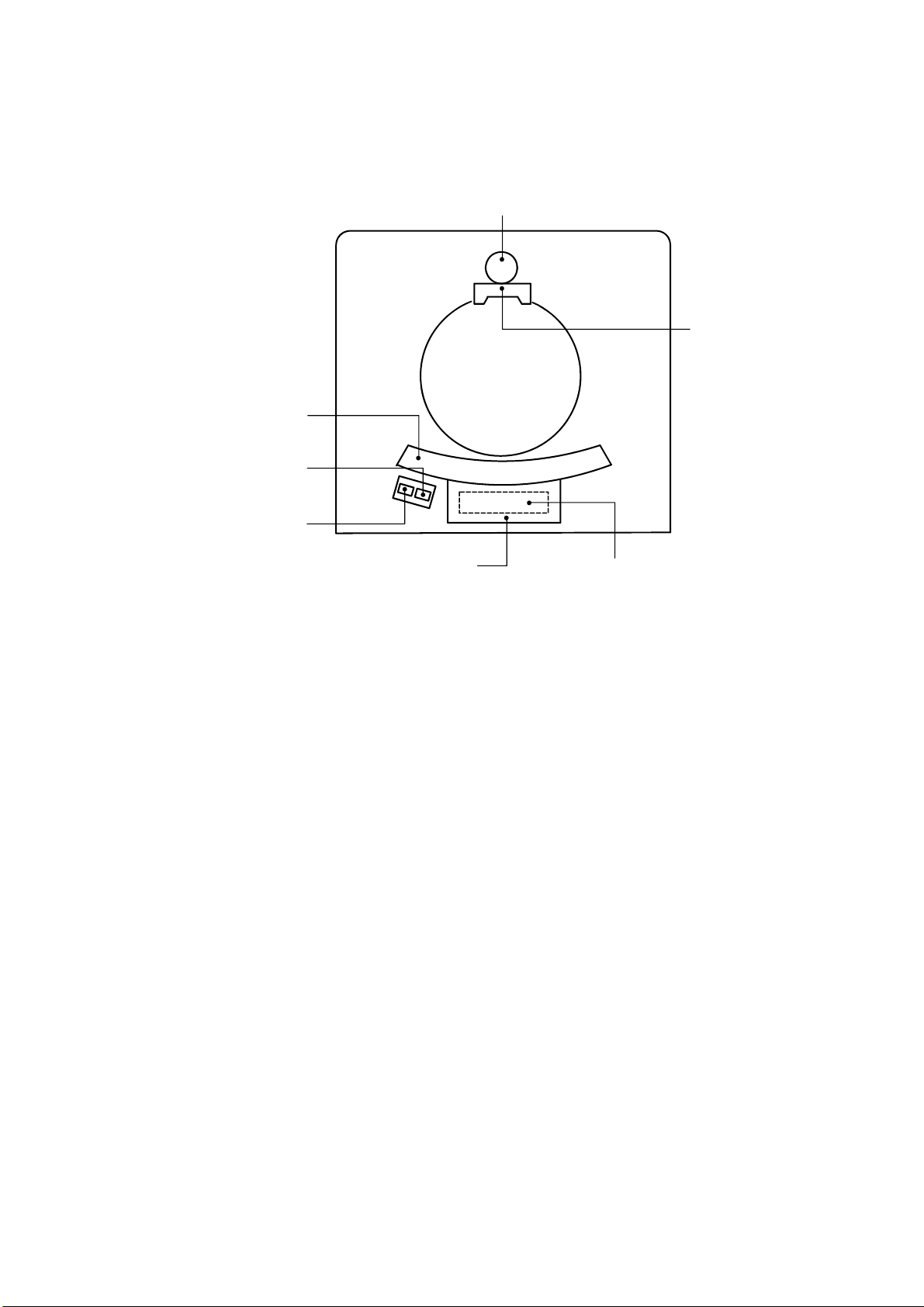

3.2.3 External view .................................................................................................. 159

3.2.4 System diagram and operating principle ........................................... 161

3.3 IF Unit (Interface Unit) [OPCONTM, GCIFM] ....................... 163

3.3.1 Functions of the IF unit .............................................................................. 163

3.3.2 Operating principle ...................................................................................... 163

3.3.3 External appearance .................................................................................... 169

3.4 LED Display and Switch Setting .................................................. 170

3.4.1 OPCONTM PWB ............................................................................................. 170

3.4.2 GCIFM PWB ..................................................................................................... 179

3.5 Installing the CPU Data for the OPCONTM PWB ............. 188

3.5.1 Tools and equipment used ....................................................................... 188

3.5.2 Preparation ...................................................................................................... 188

3.5.3 Installation of the PWB data ..................................................................... 190

3.5.4 Changing the data version identification label ................................ 192

3.6 Troubleshooting ...................................................................................... 194

3.6.1 Malfunction of the data transmission section .................................. 194

3.6.2 Malfunction of control system data communication ..................... 194

3.6.3 Malfunction of DAS data communication ........................................... 199

3.6.4 Procedure for checking the luminescence ........................................ 210

3.6.5 Procedure for disassembling the MUDAT .......................................... 214

3.6.6 Operation check after MUDAT work ..................................................... 215

No. 2D201-177EN*F

10

Page 11

4. CONSOLE .............................................................................................. 217

4.1 Outline ............................................................................................................. 218

4.1.1 The configuration of the console ........................................................... 218

4.1.2 Internal configuration of the Navibox .................................................. 219

4.1.3 Components of the Navibox .................................................................... 220

4.2 Power Supply, Signals, and Connection

Diagrams

4.2.1 Power system connection diagram ...................................................... 221

4.2.2 Signal system connection diagram ...................................................... 222

....................................................................................................... 221

4.3 Power Controller ..................................................................................... 223

4.3.1 External appearance of the power CONT ........................................... 223

4.3.2 Setting the DIP switches of the power CONT ................................... 224

4.3.3 Connection diagram of the power CONT ............................................ 225

4.3.4 Power control ................................................................................................. 226

4.4 Operation Section .................................................................................. 228

4.4.1 Configuration .................................................................................................. 228

4.4.2 Monitor .............................................................................................................. 229

4.4.3 Keyboard .......................................................................................................... 229

4.4.4 Mouse ................................................................................................................ 231

4.5 System/Acquisition Section (Navibox) ................................... 232

4.5.1 Configuration .................................................................................................. 232

4.5.2 PC BOX ............................................................................................................. 233

4.5.3 ADI PWB ........................................................................................................... 254

4.5.4 Multi drive ........................................................................................................ 257

4.5.5 USB port (for option license installation) ........................................... 257

4.5.6 System disk, image disk, and raw data disk ..................................... 258

No. 2D201-177EN*F

11

Page 12

4.5.7 HUB ..................................................................................................................... 261

4.6 Malfunction Diagnosis Program .................................................. 264

4.6.1 Malfunction diagnosis program (hwtest) ............................................ 264

4.6.2 Malfunction diagnosis program (hwtest) menus and details of

each test ........................................................................................................... 266

4.6.3 Executing the independent test program (diag) .............................. 267

4.6.4 Independent test program (diag) execution results ...................... 268

4.7 Signal Tables (External Cables) ................................................... 272

5. POWER DISTRIBUTOR ....................................................... 281

5.1 Functions ...................................................................................................... 282

5.2 Cable Connection ................................................................................... 284

5.3 Settings .......................................................................................................... 285

5.4 Use ..................................................................................................................... 286

5.5 Replacing the Fuse ................................................................................ 286

No. 2D201-177EN*F

12

Page 13

General Safety Information

No. 2D201-177EN*F

13

Page 14

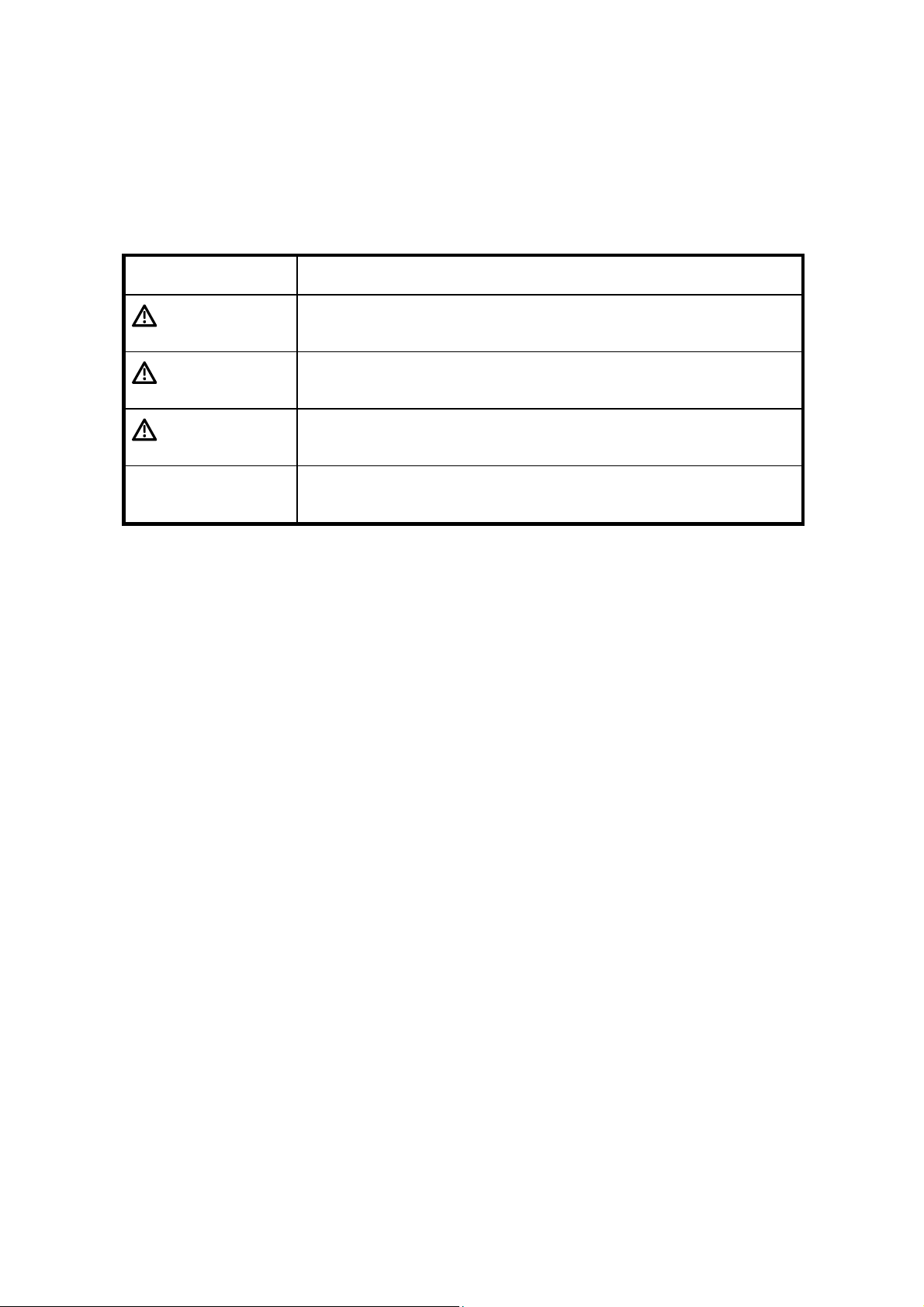

1. Meaning of Signal Words

In this manual, the signal words DANGER, WARNING, and CAUTION are used

regarding important safety instructions. The signal words and their meanings are defined as

follows. Please understand their meanings clearly before reading this manual.

Signal word Meaning

DANGER

WARNING

CAUTION

CAUTION

Indicates an imminently hazardous situation which, if not avoided,

will result in death or serious injury.

Indicates a potentially hazardous situation which, if not avoided,

could result in death or serious injury.

Indicates a potentially hazardous situation which, if not avoided,

may result in minor or moderate injury.

Indicates a potentially hazardous situation which, if not avoided, may

result in property damage.

No. 2D201-177EN*F

14

Page 15

2. Safety Precautions

Please observe the following precautions to ensure the safety of the service engineer as well as

operators when servicing this equipment.

DANGER: 1. This system is not explosion-proof. Therefore, do not use

flammable or explosive gases near the system. If flammable or

explosive gases enter the system, a fire or explosion may occur.

2. Do not remove the covers of the console monitor and X-ray high-

voltage generator in the gantry because there are high-voltage

sections inside them. If the covers are removed, accidental

contact may occur, causing electric shock and possibly death.

When it is necessary to connect measuring instruments such as

an oscilloscope to a circuit of the floating section for any reason,

be sure to observe the following precautions.

Use a differential probe or isolation probe.

Do not leave the probe cable dangling when the probe is

connected to the measuring point. Doing so may cause shock

or short-circuit with the exposed GND section of the connector.

When several measuring points are monitored simultaneously

using an oscilloscope, note that the ground levels of the probes

become common.

3. If it is necessary to rotate the gantry with the cover open, take

special precautions to ensure that persons are not accidentally

caught in the rotation section.

4. When disconnecting the high-voltage cable, observe the following

to fully discharge its residual charge in order to ensure safety

during servicing work.

Turn power OFF and wait 10 minutes or more.

When the high-voltage cable has been disconnected,

simultaneously ground two of the three pins at the top of the

bushing in all three combinations. Repeat all combinations

twice or more.

Do not touch the top of the bushing.

Place a cap, vinyl cover, etc. over the tip of the bushing to

protect it.

5. When it is necessary to touch the slip ring or brushes (for

example, to clean the slip ring or to replace the slip ring brushes),

turn OFF all the breakers on the distribution board in advance.

Otherwise, an electric shock will result.

No. 2D201-177EN*F

15

Page 16

DANGER: 6. Gantry rotation may continue even if an eXam Plan is interrupted.

Particularly when servicing work (phantom replacement etc.) is

performed with the gantry cover open, observe the following.

Be sure to terminate the eXam Plan and confirm that rotation of

the rotation section has stopped.

Turn OFF CP320 (power to the rotation servo motor).

7. Do not remove the covers of the console monitor and X-ray high-

voltage generator in the gantry because there are high-voltage

sections inside them. If the covers are removed, accidental

contact may occur, causing electric shock and possibly death.

WARNING: 1. Before starting service procedures, turn OFF the breaker and all

the system power switches on the distribution board. (To ensure

safety.)

2. Make sure that ground cables are securely connected for

electrical shock prevention and stable system operation.

3. The system employs a laser beam device. Do not look directly

into the laser beam, as doing so could injure your eyes.

4. After opening the gantry front cover, support the cover with two

supporting poles to the rear of the cover. Use the supporting

poles correctly.

If the supporting poles are used incorrectly or the cover is lifted

inadvertently, the supporting poles may fall causing the cover to

close suddenly due to its weight, resulting in injury.

5. Since the rotation section of gantry may rotate suddenly,

carefully install the CT scanner. (For example, when console is

changed to "eXam Plan" during operation or a short-circuit is

caused by any part being touched with the probe of the

measuring instrument.)

6. If a part of the rotation section of gantry is to be removed, be

sure to engage the rotation lock pin of the rotation drive section.

Otherwise, the rotation section may rotate suddenly due to the

weight imbalance caused by removal of the part, and a worker

may get caught in the rotation section and be seriously injured

as a result. Hold the rotation section firmly when pulling out the

rotation lock pin.

7. After completing the work, be sure to confirm that all mounting

screws of the cover are tightened firmly.

If the gantry is tilted with the screws not tightened firmly, the

cover may open, fall, or interfere with objects around it, leading

to injury or damage.

No. 2D201-177EN*F

16

Page 17

CAUTION: 1. Do not modify or repair the system without permission.

Failure to do so may result in system malfunction or incorrect

system operation.

2. When repair or replacement work must be temporarily interrupted,

take appropriate measures such as closing the covers etc. to ensure

safety.

3. Connecting or using any device in combination may cause the

system to operate unstably or dangerously.

4. Make sure that the power supply, frequency, voltage and voltage

fluctuation values conform to the specifications of the system.

5. Make sure that all cable connectors are connected correctly and

that the cables and oil hoses are arranged properly.

6. Make sure that no cooling oil leaks.

7. Before starting X-ray exposure, check whether the necessary

protective measures have been taken, so that the door is closed, no

persons or X-ray sensitive materials such as film are in the scanner

room, and X-rays do not leak from the scanner room.

8. When tilting the gantry, never place your foot on the stand base

cover. Your foot may be caught, resulting in injury.

9. When replacing the X-ray tube, observe the following precautions.

Be careful about the tube because the tube may move

longitudinally during this work.

Insert the rotation lock pin into the rotation lock pin retaining

plate securely.

10. Take precautions against electric shock because power is supplied

up to the input terminal of MC113 in the servo unit even when the

circuit protector CP1 of the gantry stationary section is turned OFF.

11. Disconnect CN451 of the KGTSM (GMSC) PWB to turn OFF the

power of tilt motor, rotation servo system, couch etc.

If the safety circuit is defective or if your operation was incorrect,

the tilt, rotation motor or couch may move.

12. Do not perform high-speed rotation while the SOT mounting plate is

removed. Interference may occur or cables may be caught in the

rotation section.

(Note that this precaution does not need to be observed when all

four SOT mounting plates are removed.)

No. 2D201-177EN*F

17

Page 18

CAUTION: 1. Keep the site room at proper temperature and humidity, and well ventilated.

Keep the system protected from unnecessary vibration or shock.

2. When cleaning or disinfecting the system, take care not to damage the system.

* Use only the specified disinfectants and lubricants in the specified manner

and frequency. Failure to do so may result in discoloration or cracking of the

surface finish, or in damage to rubber or plastic parts.

* Do not clean the unit with organic solvents (such as paint thinner) or

abrasive cleansers because they may cause damage or discoloration.

3. When the gantry is to be tilted with the front cover open, be extremely careful

not to allow the front cover to come into contact with the ceiling or the patient

couch. Otherwise, the system may be damaged.

4. Never pull the cable when disconnecting the connector. Doing so may damage

the cable.

5. When removing the dome cover, be sure to disconnect the connectors located

at the top of the gantry. Otherwise, cables may be severed.

6. When connecting the cables of the starter at the time of replacing the X-ray

tube, be sure to refer to the circuit diagrams and check the marker placed on

the cable to perform correct cable connection. Incorrect connection may cause

damage to the anode rotation mechanism.

7. Do not bend the belt as it contains fiber. The belt will not function normally if

bent.

8. Do not apply an excessive force to the brake release lever when installing the

brake release lever handle. The brake release lever may be damaged.

9. Be extremely careful when handing the hydraulic hose. The hydraulic hose is

very fragile (minimum permissible bending radius: 45 mm). If the hose is bent,

it will be permanently damaged and can no longer be used.

10. Do not perform ON/OFF operation of SW320 during gantry rotation. Doing so

may damage the servo-amplifier. To turn OFF the power, use CP320.

11. Do not perform continuous scanning (that is, a set of start and stop operations

performed consecutively) more than ten times. Doing so may damage the

servo-amplifier.

If repetitions of continuous scanning are required, stop for two minutes after

scanning is performed ten times.

12. When mounting/removing the bushing to/from the X-ray tube receptacle, do not

remove the bushing suddenly or rotate the cable. Doing so may damage the

pin section on the tip of the bushing.

13. When performing wiring again, do not bundle the power cable with the signal

cables.

14. When adjusting the XC maintenance program parameters, do not change the

settings for parameters other than If. Doing so may damage the generator.

No. 2D201-177EN*F

18

Page 19

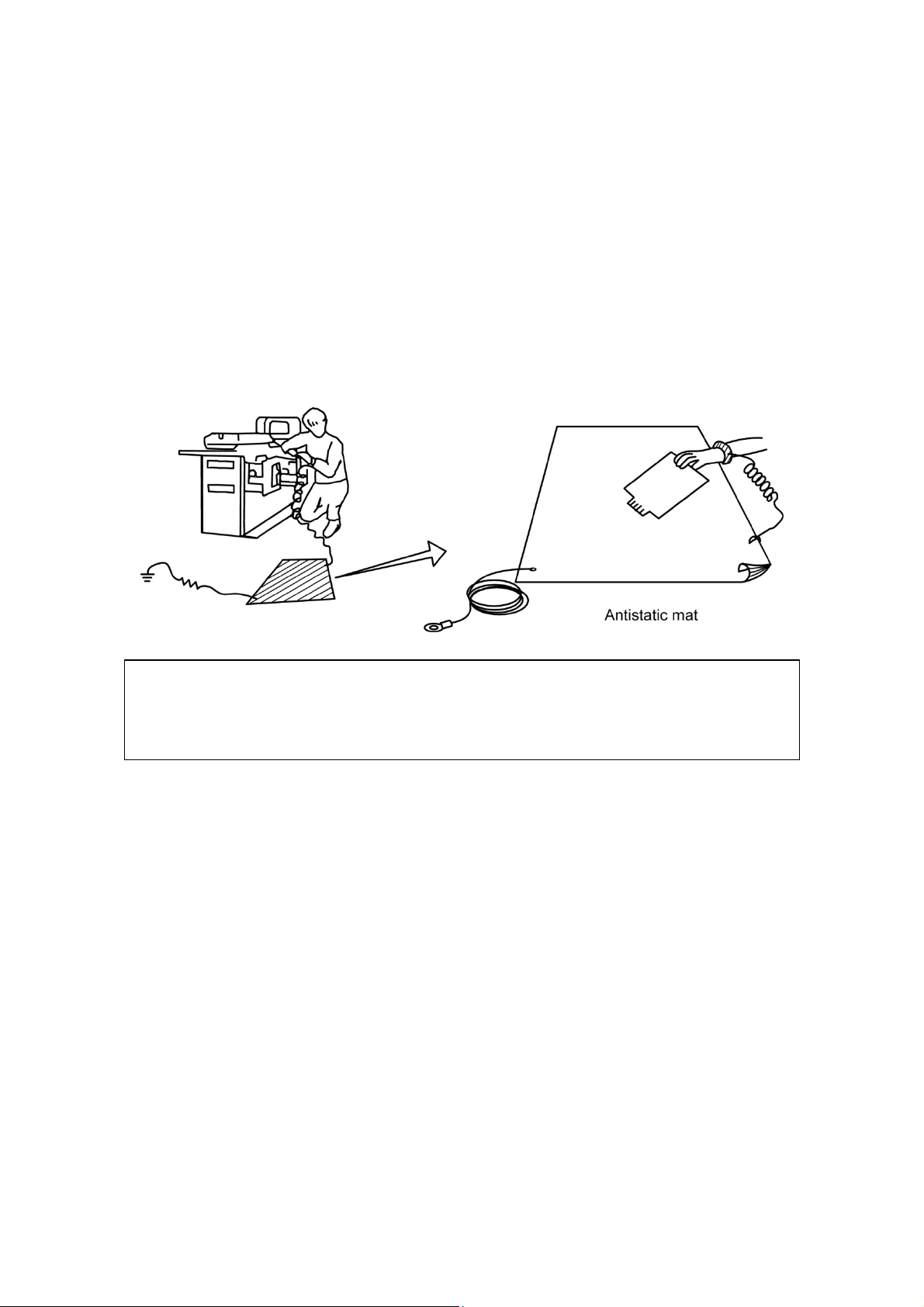

3. Precautions for Service Work

Countermeasures against static electricity

If service work is performed at sites at which countermeasures against static electricity

are not taken, be sure to take countermeasures against static electricity to prevent the

PWBs from being damaged and to ensure quality.

[Examples]

When performing service work such as replacement of PWBs, be sure to wear a wrist

strap.

If PWBs must be put down somewhere, they must be placed on an antistatic mat.

NOTE: Periodic inspection

Be sure to perform periodic inspection to confirm that appropriate countermeasures

against static electricity are being taken (the antistatic mechanism functions normally).

(Perform continuity check.)

<Additional information>

Manufacturer : Sumitomo 3M, Inc.

Model name : 8012J

Product name : Conductive plastic product portable field service kit

Items contained : Antistatic mat ············ 1

Wrist strap ················ 1

4.5-m ground cable ····· 1

No. 2D201-177EN*F

19

Page 20

No. 2D201-177EN*F

20

Page 21

CHAPTER 1

THE X-RAY SYSTEM

No. 2D201-177EN*F

21

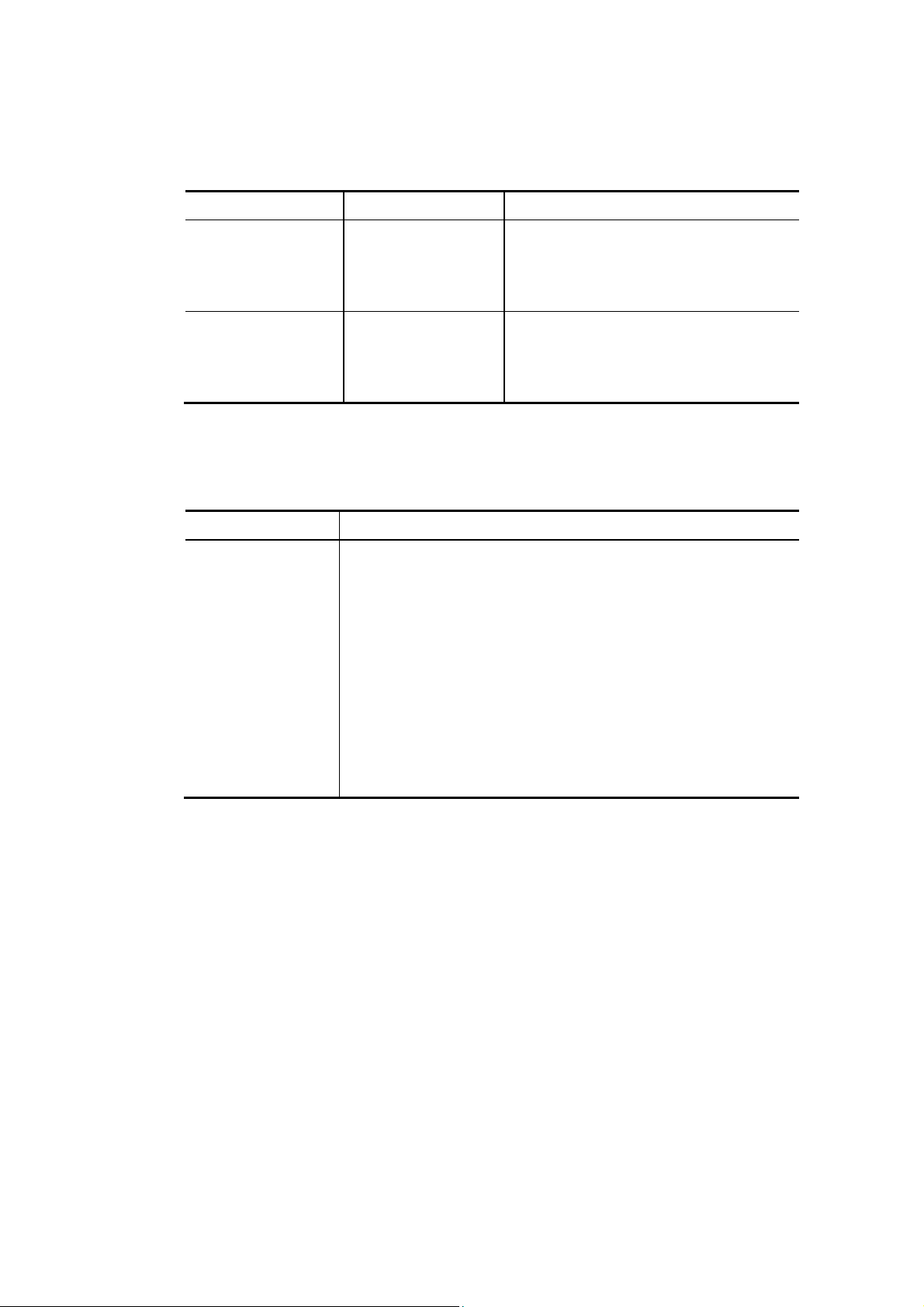

Page 22

1.1 Configuration

The X-ray system comprises the following components:

Component Model Features

X-ray high-voltage

generator

X-ray tube CXB-200E Anode heat capacity: 2000 kHU,

CXB-350A/2A Anode heat capacity: 3500 kHU,

1.2 Specifications

The specifications of the X-ray system are given below:

Item Specifications

Radiation method Continuous

Tube voltage

Tube current 10 to 300 mA*1

Radiation time Differs according to the direction from the central system.

80, 100, 120, or 135 kV (3%)

10-mA increments (3-mA increments up to 5%)

(0 to 100 s: 5%)

CXXG-010A/3 Incorporates the control circuit, high-

frequency inverter.

Maximum output of 36 kW

line voltage of 200 V or more)

made by Varian

made by Varian

*1

(42 kW at a

Focus 2 focuses

Anode rotation 2700 min-1 to 3600 min-1 (depending on line frequency).

Power required 3-phase, 200 VAC, 50/60 Hz

Voltage fluctuation Less than 10% (including -5% fluctuation under load)

*1 The maximum output value and the maximum tube current depend on the system

output limit.

For 16-kW systems, the maximum output value is 16 kW and the maximum tube

current is 200 mA.

No. 2D201-177EN*F

22

Page 23

1.3 Principles of Operation

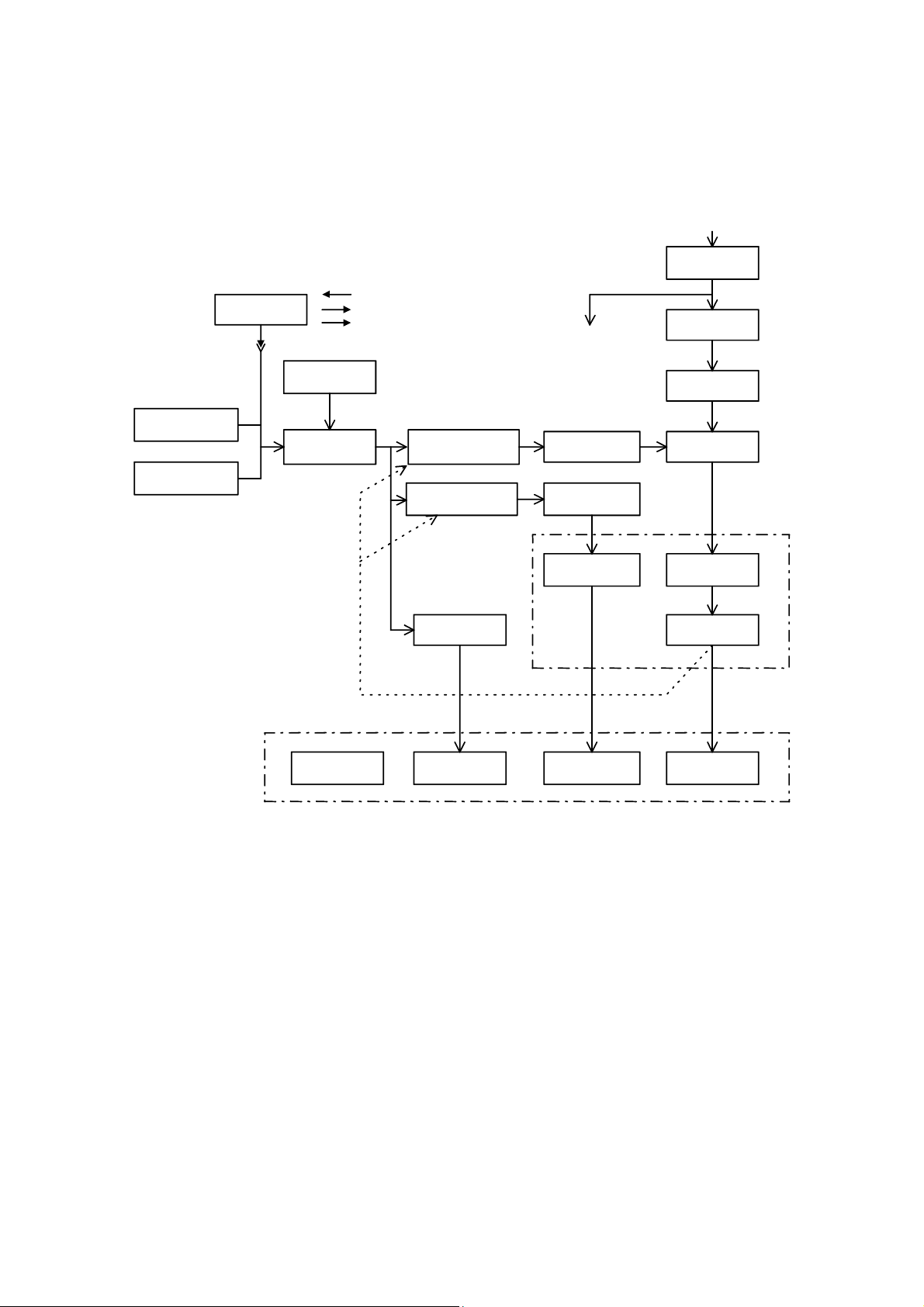

The block diagram of the X-ray system is shown below.

System

communication

Interlock

Control from

outside

Tube voltage

feedback

Tube current

feedback

OLP

management

Operation

control

Door switch

External lamp

Slice counter

Inverter

feedback control

Filament

feedback control

High-voltage

tank

Rotor control

To each

transformer

Inverter driver

Filament

heating circuit

Filament

transformer

3-phase, 200 VAC,

50/60 Hz

Line noise

filter

Rectification

Smoothing

Inverter

High-voltage

transformer

Rectification

X-ray tube

Cooling unit

Block diagram of the X-ray system

FilamentStator coil

Anode and

cathode

No. 2D201-177EN*F

23

Page 24

1.4 Operation Method

Switching of the power supply, the control method as a single unit, and the operating

conditions are explained.

1.4.1 Turning ON/OFF the power supply

Turning ON the power supply

Turn ON the power supply of the

system (console) according to

the normal procedure.

Turning OFF the power supply

Turn OFF the power supply of

the system (console).

*1: The power-ON status may continue for a certain period depending on the DAS

timer setting.

1.4.2 Single unit exposures

Select "DCA test" or "If Remote" from the system maintenance menu at the console

side.

The power is supplied to the gantry, and the

X-ray high-voltage section starts changing the

smoothing capacitor. The main relay is turned on

in about 6 seconds, charging is completed, and the

system becomes ready for operation.

The main relay are turned off and electric discharge

of the smoothing capacitor begins. When heat

build-up of the X-ray tube is high, the gantry power

supply maintains its energized state for cooling.

When the required cooling time elapses, the power

supply will go off automatically.

*1

No. 2D201-177EN*F

24

Page 25

1.5 X-ray High-Voltage Generator

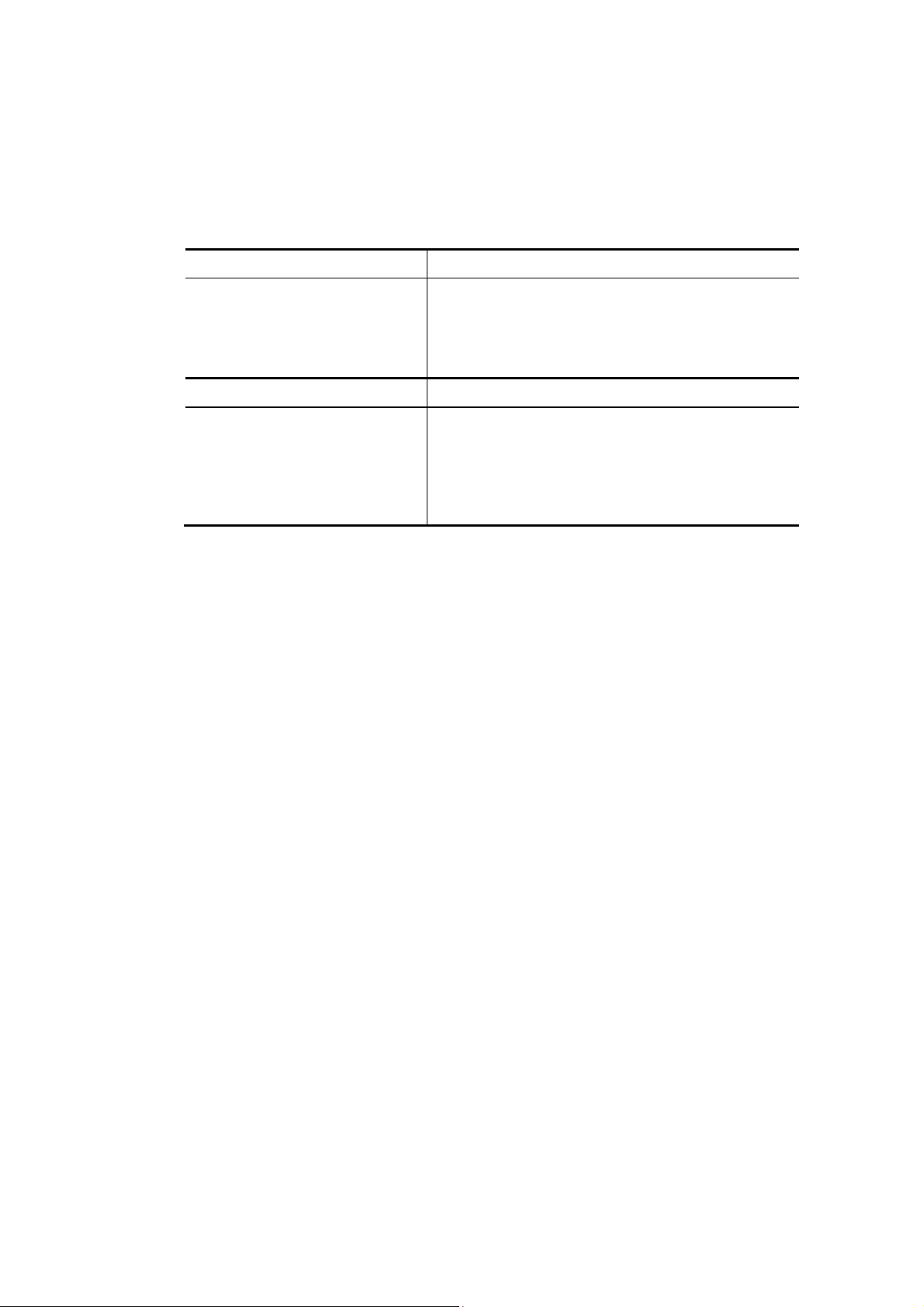

1.5.1 Composition

The configuration of the X-ray high-voltage generator is shown below.

(1) AC/CONTROL section

(2) INV/HV section

(3) Interconnecting cables

X-ray high-voltage generator

No. 2D201-177EN*F

25

Page 26

1.5.2 Operating principle

A three-phase power supply is connected to the AC/CONTROL section.

The input range is from 170 to 230 VAC. The XCS PWB installed in the AC/CONTROL

section functions as an interface with the system.

The AC/CONTROL section outputs approximately 300 VDC. This DC voltage is

supplied to the INVERTER/HV section. The DC voltage is used to supply power to the

inverter and the filament circuit. The output cable of the INVERTER/HV section is

connected to the X-ray tube via the two Federal Standard X-ray connectors. The output

cable from the cathode is also connected to the floating filament of the X-ray tube.

DANGER: Before disconnecting cables or

removing covers, wait for at least 5

minutes after turning OFF the power

supply. Failure to observe this warning

may result in serious injury or death.

The AC/CONTROL and INVERTER/HV sections contain some

parts that are not insulated. A dangerous voltage may be

present even if the contactor is OFF.

No. 2D201-177EN*F

26

Page 27

1.5.3 Operating principle of the AC/CONTROL section

The AC/CONTROL section supplies the required direct current power to the inverter

circuit. The AC/CONTROL section consists of three main subassemblies (chassis

assembly, system control PWB, and AC PWB). Its input is connected to the K1

contactor, the CR1 rectifier, and the DC output connector. The K1 contactor performs

failsafe shutdown of the voltage in the major sections.

(1) AC PWB

The AC PWB has a filtering function, a soft start circuit function, and a monitoring

function.

If a voltage of more than 75 VDC is present in the AC PWB, display is performed

with neon tube DS1.

(2) System control PWB

The system control PWB has an inverter control function, a kV and mA monitoring

function, and an error detection function.

The LED indicator locally displays the status of the generator.

POWER ON : Indicates that +5 V power supply is present in the

system control PWB.

TEST MODE : Indicates that switch SW1 is in test mode.

FAULT (problem) : Indicates that the generator is in error mode. Detailed

data concerning the error is provided by digital I/O.

HV ON (high-voltage ON) : Indicates that a high voltage (more than 10 kV) is

present in the output from the generator.

SPARE : This is mainly used for repair at the factory. This

indicates the phase mode of the inverter. The display

"LED on" indicates outside the phase mode.

FIL ON (filament ON) : Indicates that the filament is ON.

STARTER ON : Indicates that the starter is ON. (Not used)

CONTACTOR ON : Indicates that the contactor is ON.

No. 2D201-177EN*F

27

Page 28

1.5.4 Operating principle of the INV/HV section

The INV/HV section is a DC-DC converter that consists of three main assemblies: the

inverter assembly, the high-voltage multiplier, and the high-voltage transformer.

DC input is applied to the resonance inverter. The inverter operates in phase mode and

frequency mode. The maximum operating frequency of the inverter is approximately

30 kHz. The output of the step-up transformer is approximately 5 kV Pk AC. This is

supplied to the two half-wave multipliers. These multipliers comprise a double-voltage

rectification circuit. The input voltage is sequentially doubled by the serially connected

multipliers.

The rated output of the multiplier is a DC voltage of ±70 kV. This is supplied to the

X-ray tube. The INV/HV section is connected to the AC/CONTROL section via the

control cable and the DC power cable.

(1) Inverter assembly/inverter PWB

The inverter assembly contains the inverter heat sink, the cooling fan, the DC input

connection section, the IGBT, and the inverter PWB.

WARNING: The gate drive circuit and the IGBT inverter circuit are high-

voltage circuits. Do not perform repair or maintenance work

on these circuits and do not attempt to measure these

circuits using a probe. If it is necessary to touch them, be

sure to first check that there is no DC voltage relative to

earth (chassis) using a tester or equivalent device.

NOTE: No calibration is required on site. The generator can be repaired without

performing recalibration. The inverter assembly and the high-voltage module

are components that cannot be replaced on site. Calibration of the highvoltage module is performed by the inverter PWB. Therefore, the high-voltage

module and the inverter PWB cannot be replaced individually.

If a power supply of more than 75 VDC is present in the inverter PWB, the neon

tube lights.

(2) High-voltage module

This high-voltage module contains the high-voltage multiplier, the high-voltage

feedback divider, the filament transformer, and the anode/cathode connectors.

The high-voltage module is fully encapsulated. As described in the previous

subsection, the high-voltage module is not replaceable on site.

No. 2D201-177EN*F

28

Page 29

(3) XCS PWB

PX71-07786 Gr.2

Part Name XCS2

PWB No. YWM1634

ROM No. C10051-XX

Connection diagram 3XW71-1848

Mounting position Within the AC/CONTROL section

Functions

Communication control Y

Output of basic control signals Y

Monitoring of internal status Y

Selection of output voltage and

Y

current

Tube current modulation control Y

(Sure Exposure,

Sure Exposure 3D

(XY modulation)

*1

)

Control of OLP Y

Holding of power supply for

Y

cooling the X-ray tube

Backup of the basic information

Y

memory

Control of the slice counter Y

Control of the dedicated starter Y

*1: Sure Exposure 3D is enabled only when a system supporting this function is

used in combination.

No. 2D201-177EN*F

29

Page 30

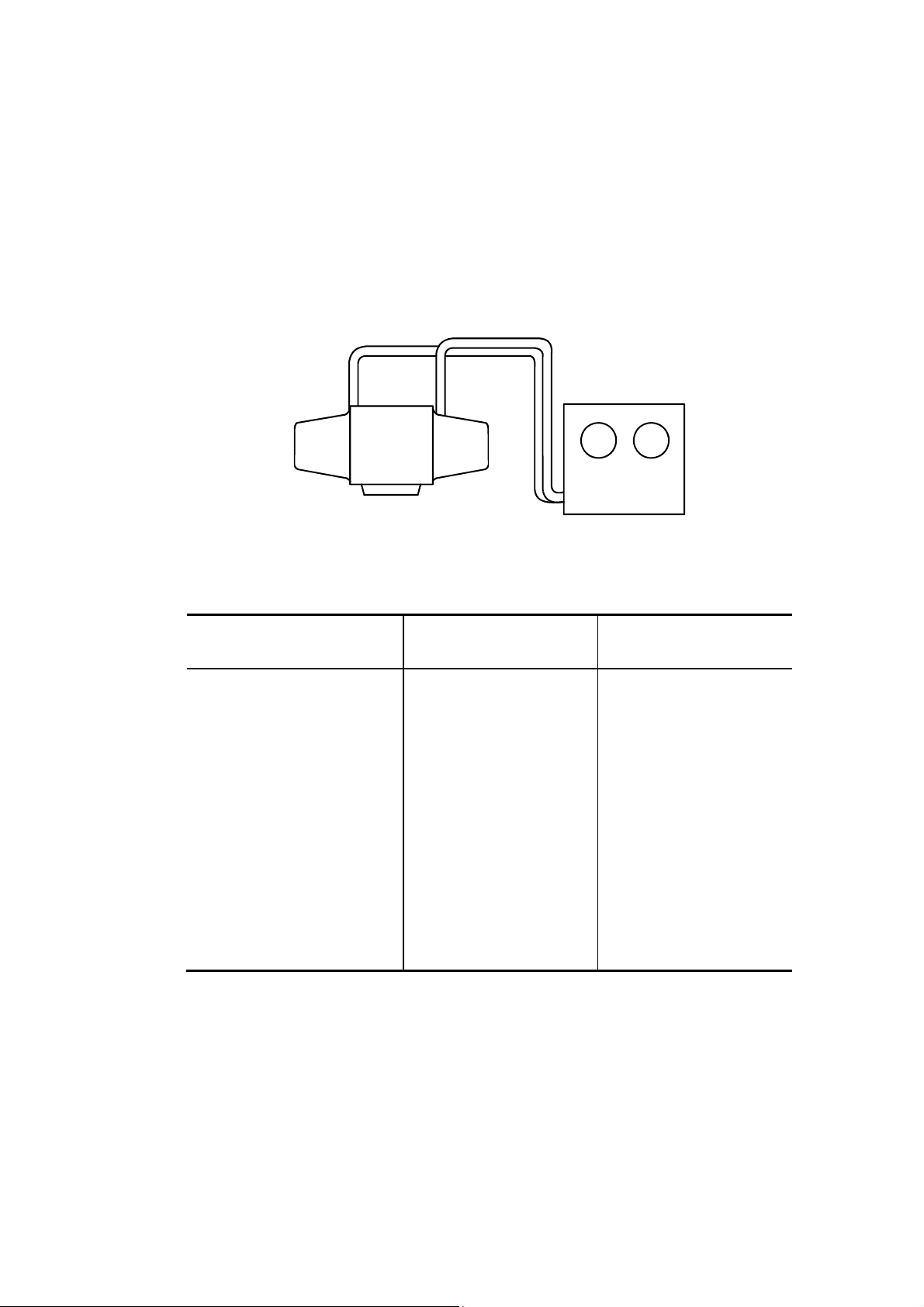

1.6 Outline of the X-ray Tube System

This subsection describes the configuration and specifications of the X-ray tube system.

1.6.1 Configuration

The X-ray tube system comprises the X-ray tube unit and the heat exchanger, which are

connected via the cooling oil circulating hose. The X-ray tube is mounted on the gantry

rotation section. They cannot be separated because of air-tight structure.

Hose

1.6.2 Specifications

Model

Anode heat capacity (kHU) 2000 3500

Anode cooling rate (kHU/min)

(maximum)

Maximum tube voltage (kV) 150 140

Dimensions of the focus (mm)

(Pinhole method)

(Slit method)

X-ray tube mass (kg) Approx. 33 Approx. 34

Heat exchanger mass (kg) Approx. 17 Approx. 17

X-ray tube unit

CXB-200E,

Varian GS-2078/A

252 285

Small: 0.9 0.9

Large: 1.5 1.0

Small: 1.1 1.3

Large: 1.7 1.7

Heart exchanger

CXB-350A/2A

Varian GS-3078/A

Small: 0.9 0.9

Large: 1.5 1.0

Small: 1.1 1.1

Large: 1.7 1.7

No. 2D201-177EN*F

30

Page 31

100

Varian 2000/3500 kHU tube, OLP=100%

%

90

80

70

60

50

CXB-350A/2A

40

30

20

10

0

CXB-200E

60565248444036322824201612840

64

min.

Cooling curve

No. 2D201-177EN*F

31

Page 32

1.7 Overload Protection (OLP) Management Functions

This subsection outlines the overload protection (OLP) management functions of the

X-ray tube system.

1.7.1 Functional description

The X-ray tube system supports the OLP management functions for:

(1) Calculation and monitoring of the anode heat capacity for protection

(2) Short-term monitoring of the rating for protection of the focus

(3) Short-term monitoring of the nominal rating for protection of the focus

Items (1) to (3) are calculated continuously to check the required radiation conditions. If

the radiation conditions exceed the calculated OLP, the system is notified and radiation

is halted. These three items are calculated, managed, and controlled by the XCS PWB

micro-computer. The following subsections give details of items (1) to (3).

1.7.2 Calculation and monitoring of the anode heat capacity

The function is used to protect the anode from overheating.

The current anode heat capacity is calculated from the cooling curve data of the X-ray

tube stored in memory, the anode heat capacity value obtained during the last exposure,

and the elapsed time after radiation.

The anode capacity is calculated when the currently required radiation conditions are

used, and is compared with the calculated limit.

If the calculated anode capacity exceeds the limit, the required waiting time is calculated

and communicated to the system, and SET UP processing is inhibited.

The anode heat capacity and time are retained in memory when the power is turned

OFF.

The residual heat capacity is calculated from backup data and is used as the initial

value of the anode heat capacity when the power is turned ON.

1.7.3 Short-term monitoring of the rating

This function is used to protect the focus from overheating during continuous radiation.

The radiation limit is obtained from the radiation conditions required from the data

concerning "output vs continuous radiation limit" stored in memory.

If the required radiation time exceeds the limit in REMOTE mode, the required radiation

conditions are assumed to be invalid and the system returns a negative response.

No. 2D201-177EN*F

32

Page 33

1.7.4 Short-term monitoring of the nominal rating

This function is used to protect the focus from overheating during continuous radiation

and is applied to a radiation time of less than 5 seconds using the same kV and mA.

When kV and mA are set, the cumulative limit is obtained during repeated exposures

from memory data.

If the next exposure is performed less than 5 seconds after the previous exposure, the

cumulative radiation time is added. If the elapsed time after the previous exposure is 5

seconds or more, the cumulative time is cleared.

When "cumulative time + required radiation time" exceeds the cumulative limit less than

5 seconds after the previous exposure, the residual time is calculated for

communication with the system. During this period SET UP processing is inhibited.

(Example)

5 seconds

or more

3 seconds

A

5 seconds

or more

3 seconds 3 seconds 3 seconds 3 seconds

B

C

Less than

5 seconds

Short-term monitoring of the nominal rating

Scan A calculated during a radiation time of 3 seconds

Scan B calculated during a radiation time of 3 seconds

Scan C calculated during a radiation time of 6 seconds

Scan D calculated during a radiation time of 9 seconds

Scan E calculated during a radiation time of 12 seconds

DE

5 seconds

or more

No. 2D201-177EN*F

33

Page 34

1.8 Tools and Instruments

The table below shows tools and measuring instruments required for installation, check,

adjustment, and repair of the X-ray system.

Tools and instruments for the X-ray system

Instal-

lation

(1) Tube voltmeter

(2) Tube ammeter

(3) Digital storage-type

Check and

adjustment

Repair Remarks

oscilloscope

(4) Torque wrench

(5) Tube voltmeter

(6) Silicone plate

(7) Silicone compound

(8) Absolute alcohol

(9) Toothbrush

kV-201 or kV-201D (manufactured

by ARCO Electric)

MA-1201D (manufactured by

ARCO Electric)

*2

*1

For fixing the high-voltage cable

For fastening the resonance

capacitor terminal

AB-201515D (manufactured by

TOREK)

*3

BSX71-0752E*4

TOSLUBE 42 TSK5542

(AZP393-01) or one provided with

the Varian X-ray tube

Used for cleaning

Used to apply the silicone

compound coating to the inner wall

of the receptacle

(10) Torque driver

*1: The MA-1201 is not used because the waveform at a neutral point contains a large

amount of high-frequency ripple, which makes measurement less precise.

*2: Also used for adjustment of tube currents (set-up) and waveform checks.

*3: Used instead of the tube voltmeter (1) and the tube ammeter (2).

*4: Silicone plate and silicone oil to be used for the CLAYMOUNT high-voltage cable

KANON 20LTDK

No. 2D201-177EN*F

34

Page 35

1.9 Notices

This section describes important safety and protection notices pertaining to work on the

X-ray system.

1.9.1 Floating section

The power supply circuit of the X-ray high-voltage generator is not insulated from the

power supply. If you should touch areas other than the designated spots or connect

measuring instruments, take adequate precautions against electrical shocks and short

circuits.

1.9.2 Power cable

When disconnecting the power cable, first unplug it from the power distribution board.

If the power cable is unplugged at the other side, it is very dangerous if the power is

turned ON.

Always disconnect the grounding wire last.

When connecting the power cable, first connect the grounding wire, connect the other

wires to the device, then connect the wires to the power distribution board.

PS

Handling the power cable

Device

Do not leave the device

with the end of the cable

open.

No. 2D201-177EN*F

35

Page 36

1.9.3 Precautions for rotation

As the X-ray high-voltage generator is mounted in the gantry rotation section, make

sure that no worker is caught in the rotation section during maintenance.

DANGER: 1. When servicing is to be performed with the gantry cover

open, be sure to turn OFF the power of the system at the

distribution board and wait for 5 minutes or more to

prevent workers from receiving electric shocks or being

injured due to unexpected system operations.

2. If it is necessary to perform servicing with the system

turned ON, supply power only to the required parts. At the

same time, take safety measures such as turning OFF the

power of the cover switch and CP320 (power to the rotation

servo motor).

WARNING: When disconnecting the cables, take note to ensure correct

reconnection. In particular, inappropriate routing of the

power cable will cause interface with other cables, which

may adversely affect system performance.

CAUTION: When rotating the rotation section manually, be sure to release the brake

before rotating the rotation section. Rotating the rotation section without

releasing the brake may result in system malfunction.

When the power of the gantry is turned OFF, the brake of the rotation section is

engaged. To rotate the rotation section to the desired position, follow the specified

procedures.

No. 2D201-177EN*F

36

Page 37

1.9.4 Handling the high-voltage cable

This subsection describes the handling of the X-ray tube and the INV/HV bushing

section, and the procedure for replacing the silicone plate.

DANGER: When disconnecting the

high-voltage cable,

observe the following to

fully discharge its residual

charge in order to ensure

safety during servicing

work.

Turn power OFF and wait 10 minutes or more.

When the high-voltage cable has been disconnected,

simultaneously ground two of the three pins at the top of the

bushing in all three combinations. Repeat all combinations

twice or more.

Do not touch the top of the bushing.

Place a cap, vinyl cover, etc. over the tip of the bushing to

protect it.

1.9.4.1 Removing the high-voltage cable

(1) Wait 10 minutes or longer after the power is turned OFF, then start this procedure.

(2) Remove the cable from the high-voltage transformer side first and then on the

X-ray tube side. If only the cable from the X-ray tube needs to be disconnected for

X-ray tube replacement, etc., be sure to perform the discharge procedures

described in step (4) below before touching the tip of the electrode.

(3) When removing the high-voltage cable, loosen the setscrews and flange and hold

up the rim of the bushing with a bladed screwdriver.

Remove the bushing after the electrode is removed. Never extract the bushing by

pulling on the cable.

Lift

Correct

Incorrect

No. 2D201-177EN*F

37

Page 38

(4) After pulling out the bushing, short each of the three pins at the top of the electrode

to the grounded chassis. Repeat this procedure at least twice. Then, short every

combination of two pins among the three pins at the end of the bushing. Use a

screwdriver for shorting. Short each of the three pairs two or more times.

Be sure to short the pins as described above because a high voltage may remain.

(5) Remove both ends on the anode and cathode sides.

1.9.4.2 Cleaning

(1) Prepare a new silicone plate and clean it with absolute alcohol.

When no absolute alcohol is available, wipe the plate thoroughly with a clean cloth.

Replace the used silicone plate with a new one.

If there are any discharge stains which cannot be removed from the silicone plate,

it must be replaced. Stains may cause defects such as discharge.

Clean the pins so that any metal powder or dust is completely removed.

(2) Also clean inside the receptacle. Be sure to remove dust around the inner

electrode.

1.9.4.3 Applying silicone oil (CLAYMOUNT high-voltage cable)

(1) Clean the high-voltage cable plug, the inside of the socket in the X-ray tube, and

the silicone plate with absolute alcohol.

(2) Place the ring nut at the base of the plug by passing the plug through the ring nut.

Attach the supplied polarity labels ((+) and (-)) to the cable.

(3) Mount the partition flange on the ring flange of the high-voltage cable with screws.

(4) Apply silicone oil to the rubber gasket and place it at the ring flange by passing the

plug through it.

(5) Apply silicone oil to both sides of the silicone plate and attach it to the tip of the

plug.

The purpose of applying silicone oil is to smoothen and moisturize the surface of

the silicone plate, enabling closer contact. A small amount of silicone oil should be

applied and spread evenly.

Silicone oil need not be applied to the side of the plug. Note that silicone grease

(Toslube) must not be used. If it is applied, contact with the silicone plate will be

poor, possibly leading to a deterioration in the withstand voltage.

(6) Insert the plug with the silicone plate into the socket to make the connection. Then

tighten the ring nut.

Note: To achieve close contact with the silicone plate, firmly tighten the ring nut.

(7) Tighten the setscrew of the ring nut. Use a hexagonal wrench for M3 setscrews.

No. 2D201-177EN*F

38

Page 39

Screw (2 locations)

Rubber gasket

Silicone plate

Plug

Ring flange

Partition flange

Sleeve

Polarity label

Setscrew

Ring nut

Cable

Silicone oil

The surfaces must

be in close contact.

(8) Be sure to tighten the screws again after X-ray tube seasoning is completed,

because the screws may become loose when the X-ray tube is heated and then

cooled.

Also, perform additional tightening at the time of inspection.

No. 2D201-177EN*F

39

Page 40

1.9.5 Replacing the fuse

When replacing the fuse, be sure to use a fuse with the same rating and type specified.

WARNING: For continued protection against

risk of fire, replace only with

same type and rating fuse.

1.9.6 Using the tube voltage meter

Prepare a high-voltage bleeder (Arco Electrical Machinery kV-201 or equivalent), and

connect between the high-voltage unit and the X-ray tube as shown in the figure below.

For details, refer to the operation manual of the tube voltage meter. Set FUNCTION to

INT.DELAY TIME 10. (The tube voltage after 0.1 s is displayed.)

High-voltage

transformer

When a Torek AB-201515D is used, perform the same connection.

High-voltage cables of

the system

EE

Signal cable

kVp

meter

Connection of the tube voltage meter

High-voltage cables

provided with the kV-201

Oscilloscope

Tube voltage

waveform check

TubeBleeder

With the Torek AB-201515D, the tube voltage and the tube current can be measured

concurrently.

No. 2D201-177EN*F

40

Page 41

1.9.7 Tube ammeter

Connect a tube ammeter (MA-1201D manufactured by ARCO or equivalent) between

the anode of the high-voltage transformer and the anode of the X-ray tube. Set

FUNCTION to RAD.DELAY TIME 4X10. (The tube current is displayed after a delay of

0.4 seconds.)

The measured value is the current on the anode side. The method for calculating the

tube current for the cathode side differs depending on the tube used as described below.

High-voltage

transformer (built

into the X-ray

high-voltage

generator)

Tube ammeter detector tank

Transformer

side

Tube

side

X-ray tube

Connection of the tube ammeter

For the CXB-350A and CXB-200E

Tube current (on cathode) =

Reading of the MA-1201D (anode-side tube current)

Ammeter (mA)

0.88

No. 2D201-177EN*F

41

Page 42

1.9.8 Other

(1) Power cannot be supplied only to the X-ray system. Since the system has no

operation section other than the console, it must be started up even if maintenance

is performed only for the X-ray system.

(2) A center-metal X-ray tube is used. Therefore, be sure to ground the center metal

potential.

(3) The system has a large capacitor (approx. 300 VDC, 36000 F) at the primary side.

Therefore, wait for at least 5 minutes after turning OFF the power of the system

when removing the cover, etc. In addition, confirm that no electrical charges

remain before touching the main circuit (including the floating section). (Check

point: between P2 and N2 of the inverter section)

(4) Never apply a high voltage to a cold X-ray tube (the filament is not heated)

regardless of whether the high-voltage cable is connected or disconnected.

Otherwise, the X-ray tube will be damaged.

When the positive

side is disconnected,

Damage to the X-ray tube

(5) Since the tube voltage (kV) is fed back to the X-ray system, it is impossible to

check the high-voltage circuit with no load (without the X-ray tube).

Use a test tube to isolate a tube-related problem (e.g., OVER mA error).

a strong current flows as shown

damaging the X-ray tube.

No. 2D201-177EN*F

42

Page 43

1.10 Replacing the X-ray Tube

1.10.1 Connection and operation check

(1) Connection and operation check

(a) Change of the output voltage to the X-ray tube

Perform connections at terminal board TBX11 and at the internal terminal

board of the AC/CONTROL as described in the table below according to the

X-ray tube used in combination (CXB-200E and 350A for Alexion).

The connection with the X-ray tube is shown in the figure on the next page.

X-ray tube

TBX11 terminal

(heat exchanger unit)

AC/CONTROL internal terminal board TB1

CXB-200E Nos. 4 and 5 (110 V) VARIAN side

(orange cable -110 V, yellow cable - 65 V)

CXB-350A Nos. 4 and 6 (200 V) VARIAN side

(orange cable -110 V, yellow cable - 65 V)

TBX11

1

2

3

4

5

6 HEAT EXCH_200V

TOSHIBA

VARIAN

100 V

80 V

110 V

65 V

200 V

COM

Purple

Blue

Orange

Yellow

Red

White

TB1

80/65 V RUN

Yellow

Orange

COM

100/110 V

200 V

(b) XCS PWB setting change (settings of the OLP and the focus)

<For XCS2 PWB>

STATOR_COM

MAIN

PHASE

HEAT EXCH_COM

HEAT EXCH_110V

X-ray tube S2-1 S2-2 S2-3 to -8

CXB-200E ON ON OFF

CXB-350A ON OFF OFF

No. 2D201-177EN*F

43

Page 44

No. 2D201-177EN*F

44

Connection diagram for Varian X-ray tube

Page 45

(2) If adjustment (80 kV/100 kV)

Perform If adjustment for 80 kV and 100 kV using the If value remote adjustment

function.

Confirm that the name of the X-ray tube used is displayed in the 'Tube Information'

column.

(3) Seasoning

(4) If adjustment (120 kV/135 kV)

Use the If value remote adjustment function to adjust the If value only for the

conditions of 120 kV/135 kV.

(5) X-ray tube alignment

No. 2D201-177EN*F

45

Page 46

1.10.2 X-ray tube aging

Perform the aging operation from the console.

(1) Select the aging menu and perform it at the console.

(2) Stop 30 minutes or more after exposure is performed. (Leave the system with the

power turned ON.)

NOTE: The scan conditions for X-ray tube warm-up and seasoning are shown below.

For the scan conditions for warm-up, air calibration may be added depending

on the system software settings.

<For CXB-350A>

For warm-up:

100 kV, 250 mA, 4-s exposure, 6-s pause 20 times

100 kV, 250 mA, 4-s exposure, 30-s pause 4 times

For seasoning:

100 kV, 250 mA, 4-s exposure, 6-s pause 20 times

30-s pause

100 kV, 250 mA, 4-s exposure, 30-s pause 10 times

<For CXB-200E>

For warm-up:

For systems with output limited to 16 kW

80 kV, 150 mA, 4-s exposure, 15-s pause 3 times

100 kV, 150 mA, 4-s exposure, 15-s pause 4 times

120 kV, 100 mA, 4-s exposure, 15-s pause 1 time

120 kV, 130 mA, 4-s exposure, 15-s pause 2 times

100 kV, 160 mA, 2.5-s exposure, 18-s pause 20 times

For 36-kW systems

80 kV, 150 mA, 4-s exposure, 15-s pause 3 times

100 kV, 150 mA, 4-s exposure, 15-s pause 4 times

120 kV, 100 mA, 2-s exposure, 15-s pause 1 time

120 kV, 200 mA, 2-s exposure, 15-s pause 1 time

120 kV, 300 mA, 2-s exposure, 15-s pause 1 time

100 kV, 200 mA, 2-s exposure, 18-s pause 20 times

For seasoning:

100 kV, 150 mA, 6-s exposure, 15-s pause 15 times

45-s pause

100 kV, 150 mA, 6-s exposure, 45-s pause 6 times

No. 2D201-177EN*F

46

Page 47

1.10.3 If adjustment

The If value remote adjustment explained below is carried out to smooth out the leading

edge of the tube current. Normally, If adjustment is performed while monitoring the tube

current waveform (TP6 on the SYSTEM-CONTROL PWB).

If the mA waveform on the oscilloscope does not match the If value shown in the figure

below, adjustment is performed automatically.

The smallest overshoot is considered O.K. condition.

Large If

Value decreases

Small If

Value increases

(1) Starting the If value remote adjustment function

Select [If] from the <<System maintenance>> menu by clicking the mouse, to carry

out the remote exposure adjustment of the If value from the Navi-port. The If value

remote adjustment program will start up.

Engineer Utility

Menu

Password entry

Engineering

DCA

If Remote

No. 2D201-177EN*F

CANCEL

(The first page)

47

Page 48

(2) Initial screen display and If value data reading

When the program starts up, the following view port screen is displayed on the

monitor (hereinafter the view port is abbreviated to "vp".)

If value data reading vp screen

Read the If value data used first. Select the medium in which the If value data

used is to be stored and saved.

(The XC information and the tube information currently displayed on the screen

represent the ID information of the XC and the X-ray tube currently connected. If

the connection is not carried out, "******" is displayed.)

Tube Information CXB-200E 2000 kHU/100%

CXB-350A 3000 kHU/100%

[Unix File] : Reads the If value data saved on the console (hereinafter referred to

as "Unix File") in the format specified in advance. (Item (a))

[Standard] : Reads from the standard If value storage file for recommended If

values, the data under the kV/mA conditions predetermined by

Toshiba. (Item (b))

[XC] : Reads the If value data currently set in the XC memory via SS.

(Item (c))

[QUIT] : Closes the If value data reading vp, and the screen returns to the If

value Remote Adjustment vp.

No. 2D201-177EN*F

48

Page 49

(a) If value data read from the Unix File

When If value data read from the Unix File is chosen, the following If value

read vp is displayed. Specify which file containing IF value data is to be read

from the directory.

Read vp screen

Only the directories with file extension "---.ifs" are displayed. (Indicates If

value data.)

In addition, the function of each soft key is as follows:

[Cancel]: Closes the Read screen and the system returns to the If value

Remove Adjustment screen.

[OK] : Executes the read processing.

When Read is completed normally after [OK] is clicked, the If value data read

from the Unix File is displayed in the If column on the vp.

(b) Reading standard If value data

Read If value data from the file in which the recommended If value preset in

the system is saved.

When data read from the standard value file is completed normally, the

standard value will be displayed in the If column in the If value Remote

Adjustment vp. (The value is the same as that of the Std. column.)

(c) Reading the If value data from the XC memory

Read the If value data from the If value table currently set in the XC memory

via SS.

When reading from the XC memory is completed normally as well as (b), the

value read from the XC memory is displayed in the If item in the If Remote

Adjustment vp.

No. 2D201-177EN*F

49

Page 50

(3) Preparation for If value exposure adjustment

Check the validity of the value by performing an actual X-ray exposure using read If

value data. If the value is not appropriate, update the If value, check the validity of

the updated value again, and calculate the appropriate If value. In order to perform

the If value exposure adjustment, the following must be taken into consideration.

<1> Which combination of tube voltage (kV), tube current (mA), and focal size is

the target for If value exposure adjustment? <Selecting the exposure

adjustment conditions>

<2> What is the initial value of If value when If value exposure adjustment is

performed? <Setting the If value>

<3> Should the If value which is not the target of adjustment be interpolated

using the adjusted If value?

<Whether or not interpolation should be performed>

(a) If value Remote Adjustment vp

If value Remote Adjustment vp screen

When the If value data is read, the If value data list of the lowest tube voltage

conditions (80 kV) is displayed. The following value is displayed on each field

on the vp.

No. 2D201-177EN*F

50

Page 51

<XC info.> : XC firmware version (10 bytes), which is obtained via SS,

is displayed.

<Tube info.> : The X-ray tube identification code (10 bytes), which is

controlled by the XC via SS, is displayed.

For CXB-200E [2000 kHU/100%]

For CXB-350A [3000 kHU/100%]

<Tube Voltage>: The tube voltage to be adjusted (kV) is selected.

80, 100, 120, 135 kV

<Focus Information>

: The focus to be adjusted is selected.

Large, Small

<mA/If Table> : The tube current and If value data are displayed as

decimal values.

mA ; Tube current value

Std. ; Standard If conversion value

If ; If conversion value

adj.if ; If conversion value after adjustment (interpolation

calculation data is also included.)

* If value information for which the combination of kV and

mA is impossible becomes std., and "---" is displayed in

the If column.

The functions of the soft keys which are on each vp are as follows:

[Adjust] : Executes If value exposure adjustment of the selected

adjustment conditions.

However, the adjustment must be controlled and

performed under the conditions (mA/focus size) for the

same tube voltage level automatically. (Item (4))

[Write] : Saves or stores the If information currently displayed to

the Unix File or the XC memory. (Item (5))

[Read] : Reads If value information from the Unix File or the XC

memory, or converts If value data to the standard value.

(Item (6))

[QUIT] : Closes this vp, the help vp, and the error vp, and quits If

value remote adjustment processing.

: Used for scroll-control of If value information (data display

for 10 lines) currently displayed. Information for the

previous 10 lines can be displayed using

, and

information for the next 10 lines can be displayed using

.

No. 2D201-177EN*F

51

Page 52

(b) Selecting the exposure adjustment conditions

Use the following procedure to select the conditions for If value exposure

adjustment.

Selecting the conditions to be combined

To adjust a specific tube current condition, click the tube current to be

adjusted. The clicked tube current is highlighted as shown in the figure above

(250 mA and 300 mA are selected in the figure), indicating that the clicked

tube current can be adjusted.

To cancel the specified conditions used in combination, click the specified

conditions again. The highlighted tube current conditions are released.

No. 2D201-177EN*F

52

Page 53

(c) Setting If conversion value data

The If conversion value data can be changed as follows:

When the If conversion value data to be changed is clicked, the item is

highlighted and the following "If Value Entry" vp is displayed. Perform If

conversion value change on this entry vp.

Setting the If conversion value

If another line is clicked when the entry vp is displayed, the entry vp is closed,

then the clicked item is highlighted and the entry vp is displayed again.

The numerical value which can be entered is from 1 to 256.

(4) If value exposure adjustment processing [Adjustment]

When the [Adjustment] key is clicked on the If value Remote Adjustment vp, the

following vp will be displayed; the If value following the X-ray exposure can be

checked, and the If value interpolation can be calculated.

If value Exposure Adjustment vp screen

No. 2D201-177EN*F

53

Page 54

The displayed menus are as follows:

<Exposure conditions>

Tube kV : If tube voltage for adjustment

Tube mA : If tube current for adjustment

Focus : If focus for adjustment

Exp. time : X-ray exposure time (fixed to 0.2 second)

<If value to be set>

If value : The If conversion value stored in the XC memory at the time

of adjustment. During adjustment, it is updated automatically.

The numerical value in [ ] becomes the value preset for If

value adjustment, that is, the initial value at the time of

adjustment. By comparing the set value with the value

displayed on the left, the difference can be checked.

<No. of adjustment>

Remain : The number of adjustments for the same tube voltage is

displayed as the remaining number of adjustments.

(a) Calculating the number of exposure adjustments

The number of adjustments and the order in which they are carried out is

determined from the exposure adjustment conditions specified in (3).

(b) Setting the window limit value of the XC monitor mode

The window limit (maximum/minimum) value is calculated from the If value to

be adjusted, and the result is displayed on the If Exposure Adjustment vp as

well as the Setting If value vp. Moreover, the value is sent to the SS as a

request for switching from XC monitor mode to If value check mode.

(c) Setup of If conversion value data

In order to send If conversion value data of the tube voltage/tube current/focal

size for which exposure adjustment is performed to the XC memory via SS,

the request text of XC memory write is issued to SS.

(d) Preparation for X-ray exposure

The request for warm-up scan is issued to the scan manager with the exposure

adjustment conditions (note that scanning is performed only once.)

(e) Exposure adjustment start

Warm-up scanning is performed once by pressing the [Start] button.

No. 2D201-177EN*F

54

Page 55

(f) Interruption processing during If value exposure adjustment

Interruption processing during exposure adjustment is as follows:

<Exposure interruption by the [Interruption] key>

To stop temporarily the exposure adjustment, or to perform "Interpolation

Calculation" processing, press the [Interruption] key. The "Interruption"

message is sent from the scan manager, and the following message vp is

displayed to ask whether the system should perform "Interpolation

Calculation" processing or should interrupt exposure adjustment.

Do you want to stop If value exposure

adjustment?

Or, perform interpolation calculation?

Execute

adjustment

Interpolation

calculation

Interrupt

adjustment

Exposure interruption vp screen

[Execute adjustment] : After closing the exposure interruption vp, the

system returns to a status where it waits for

instructions to start If value exposure adjustment

under the conditions used in the adjustment

performed last.

[Interpolation calculation] : If there are two or more If value data for which

exposure adjustment was performed, this soft

key becomes active. When the key is clicked,

the interpolation processing check vp shown in

item (g) is displayed and the system asks

whether it should perform interpolation

calculation processing.

[Interrupt adjustment] : When, after the Exposure Interruption vp and the

If value Exposure Adjustment vp are closed,

there is even one If value data adjusted using the

exposure adjustment, the Adjustment Result

Check vp of item (j) will be displayed and it will be

decided whether to employ the If value data.

If exposure adjustment was not performed, the

system returns to the If value Remote Adjustment

vp.

No. 2D201-177EN*F

55

Page 56

(g) Asking whether the system should perform interpolation calculation (at the

time of interruption)

The system replaces If value data not adjusted with interpolation calculation

data, using the If value already exposure-adjusted which is displayed in the

"adj.If" column on the If value Remote Adjustment vp. Select whether or not

the system should perform interpolation processing, using the following

interactive vp. The scroll key on If value Remote Adjustment vp can be used.

Interpolation Processing Check vp screen

[No] : The system closes the Interpolation Processing Check vp without

performing interpolation, and it returns to the Exposure Interruption

vp.

[Yes] : The system closes the Interpolation Processing Check vp shown

above and performs interpolation processing displaying the message

vp. After completing the interpolation, the system closes the

message vp, displays interpolated If value in the "adj.If" column on

the If value Remote Adjustment vp, and returns the Exposure

Interruption vp.

Non-adjusted If value to be interpolated is the value between the

minimum mA and the maximum mA of the adjusted If value conditions.

The method used is the primary interpolation method using two

continuous data.

No. 2D201-177EN*F

56

Page 57

(h) Reading and judging the If value check result

In order to obtain the result of If value check from the XC, the reading request

text of XC and X-ray conditions (U status) is issued to SS.

<1> Check result O.K.

Since If value data currently set is O.K. when the If value check result

data is 0, the system returns to item (b) "Setting the window limit value

of XC monitor mode" if there are other exposure adjustment conditions.

In this case, the system displays the If value checked in the "adj.If"

column of the If value Remote Adjustment vp. If Exposure Adjustment

at the same tube voltage is completed, the system closes the If value

Exposure Adjustment vp and goes to item (i) "Asking whether the

system should perform interpolation calculation (when adjustment is

completed)".

<2> Check result error

When the If value check result data is 1 or 2, set the If conversion value

again and repeat adjustment as described below. The following

messages are displayed to indicate the errors detected during the

check. After this, the system returns to item (b) "Setting the window

limit value of XC monitor mode" and it waits for the [Start] button to be

pressed again.

When data is 1: Since it exceeds the maximum, increase the If

conversion value by 1.

Previously detected If value exceeded the

upper limit.

When data is 2: Since it is below the minimum, decrease the If

conversion value by 1.

Previously detected If value exceeded the

lower limit.

No. 2D201-177EN*F

57

Page 58

(i) Asking whether the system should perform interpolation calculation (when

adjustment is completed).

The system replaces non-adjusted If value data with interpolation calculation

data, using the If value already exposure-adjusted which is displayed in the

"adj.If" column on the If value Remote Adjustment vp. Select whether or not

the system should perform interpolation processing, using the following

interactive vp. The scroll key on the If value Remote Adjustment vp can be

used.

Adjustment Result Check vp screen

The functions of soft keys [No] and [Yes] on the vp are the same as those in

(g) "Asking whether the system should perform interpolation calculation (at the

time of interruption)". However, the difference is that the system goes to (j)