Page 1

TOSHIBA 2877 DB

General Information

Also Covers

3377 DB

C7SS Chassis

Recommended Safety Parts

Item Part No. Description

C801 24082927 PF, 0.22uF, ±20%, AC275V

C813 24092557 CD, 2200pF, ±20%, AC125V

C814 24092557 CD, 2200pF, ±20%, AC125V

R899 24005007 MetaI-Glazed Resistor, 8.2M ohm, 1W

L901 23200276 Coil, Degaussing, TSB-2330BR (2877DB)

L901 23200215 Coil, Degaussing, TSB-2340AR (3377DB)

T461 23236447 Transformer, Flyback, TFB4115AR

T803 23217301 Transformer, Converter, TPW3336AR

Q826 A8643108 Photo Coupler, TLP621(GR-LF

F470 23144502 Fuse, 1.0A

F801 23144507 Fuse, 3.15A

F802 23144506 Fuse, 2.5A

S801 23344395 Switch, Power

V9O1A 23902891 Socket, CRT, 10P

Z889 23144543 Protector, PRF50005491, 125V, 5A

Z890 23144543 Protector, PRF50005491, 125V, 5A

Z891 23144543 Protector, PRF50005491, 125V, 5A

Z895 23144450 Protector, PRF2000, 125V, 2A

V901 23312715 Picture Tube, A66EAK552X21 (2877DB)

V901 23312653 Picture Tube, A80EFF002X11 (3377DB)

X-Ray Note

1. Excessive high voltage can produce potentially hazardous X-RAY RADIATION. To avoid

such hazards, the high voltage must not be

above the specified limit. The nominal value

of the high voltage of this receiver is 31 .5 kV

at zero beam current (minimum brightness)

under a 240V AC power source. The high

voltage must not, under any circumstances,

exceed (A) kV.

2877DB 3377DB

(A) 32kV 33kV

Each time a receiver requires servicing, the

high voltage should be checked following the

HIGH VOLTAGE CHECK procedure in this

manual. It is recommended that the reading of

the high voltage be recorded as a part of the

service record. It is important to use an

accurate and reliable high voltage meter.

2. The only source of X-RAY RADIATION in this

TV receiver is the picture tube. For continued

X-RAY RADIATION protection, the replacement tube must be exactly the same type tube

as specified in the parts list.

3. Some parts in this receiver have special

safety-related characteristics for X-RAY

RADIATION protection. For continued safety,

parts replacement should be undertaken only

after referring to the PRODUCT SAFETY

NOTICE below.

The following adjustments should be made

when a complete realignment is required or a

new picture tube is installed.

Perform the adjustments in order as follows:

1. Color Purity

2. Convergence

3. White Balance

Note: The PURITY/CONVERGENCE MAGNET

assembly and rubber wedges need mechanical

positioning.

Refer to figure 2.

COLOR PURITY ADJUSTMENT

NOTE : Before attempting any purity adjust-

ments, the receiver should be operated for at

least fifteen minutes.

1. Demagnetize the picture tube and cabinet

using a degaussing coil.

2. Set the brightness and contrast to maximum.

3. Use a green raster from among the built-in

test signals.

4. Loosen the clamp screw holding the yoke and

slide the yoke backward or forward to provide

vertical green belt (zone) in the picture

screen.

5. Remove the Rubber Wedges.

6. Rotate and spread the tabs of the purity

magnet (See figure 3.) around the neck of the

picture tube until the green belt is in the

center of the screen. At the same time, enter

the raster vertically.

7. Slowly move the yoke forward or backward

until a uniform green screen is obtained.

Tighten the clamp screw of the yoke temporarily.

8. Check the purity of the red and blue raster.

Figure 2

CONVERGENCE ADJUSTMENTS

NOTE: Before attempting any convergence

adjustments, the receiver should be operated for

at least fifteen minutes.

CENTER CONVERGENCE ADJUSTMENT

1. Use the cross-dot pattern from among the

built-in test signals.

2. Set the brightness and contrast for well

defined pattern.

3. Adjust two tabs of the 4-Pole Magnets to

change the angle between them (See figure

3.) and superimpose red and blue vertical

lines in the center area of the picture screen.

4. Turn the both tabs at the same time keeping

the angle constant to superimpose red and

blue horizontal lines at the center of the

screen.

5. Adjust two tabs of 6-Pole Magnets to

superimpose red/blue line and green one.

Adjusting the angle affects the vertical lines

and rotating both magnets affects the horizontal lines.

6. Repeat adjustments 3, 4, 5 keeping in mind

red, green and blue movement, because 4Pole Magnets and 6-Pole. Magnets have

mutual interaction and make dot movement

complex.

CIRCUMFERENCE CONVERGENCE ADJUSTMENT

1. Loosen the clamping screw of deflection yoke

slightly to allow the yoke to tilt.

2. Temporarily put a wedge as shown in figure 2.

(Do not remove cover paper on adhesive part

of the wedge.)

3. Tilt front of the deflection yoke up or down to

obtain better convergence in circumference.

(See figure 4.) Push the mounted wedge into

the space between picture tube and the yoke

to fix the yoke temporarily.

4. Put other wedge into bottom space and

remove the cover paper to stick.

5. Tilt front of the yoke right or left to obtain

better convergence in circumference. (See

figure 4.)

6. Keep the yoke position and put another

wedge in either upper space. Remove cover

paper and stick the wedge on picture tube to

fix the yoke.

7. Detach the temporarily mounted wedge and

put it in another upper space. Stick it on

picture tube to fix the yoke.

8. After fixing three wedges, recheck overall

convergence. Tighten the screw firmly to fix

the yoke and check the yoke is firm.

9. Stick three adhesive tapes on wedges as

shown in figure 2.

Figure 3

Figure 4.

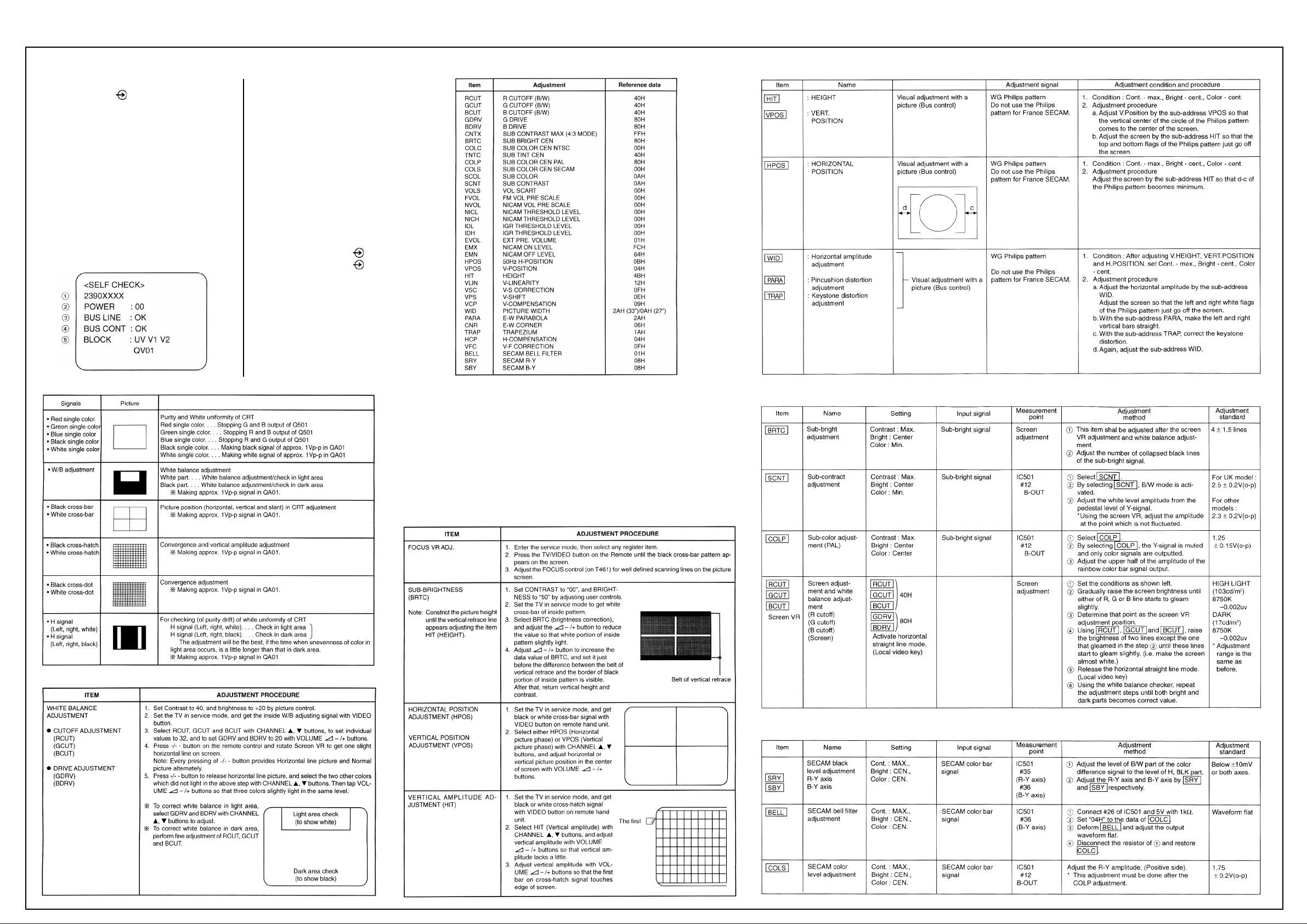

1. ENTERING SERVICE MODE

1) Press button once on Remote Control.

2) Press button again to keep pressing.

3) While pressing the button, press MENU

button on TV set.

2. DISPLAYING THE ADJUSTMENT MENU

1) Press MENU button on TV.

3. KEY FUNCTION IN THE SERVICE MODE

The following key entry during display of

adjustment menu provides special functions. A

single horizontal line ON/OFF:

-/-- button (on Remote)

Test signal selection: button (on Remote)

Selection of the adjustment items: Channel UP/

DOWN (on TV & Remote)

Change of the data value:

Volume. +/- (on TV & Remote)

Adjustment menu mode ON/OFF: MENU button

(on TV)

Initialisation of the memory (QA02) :

CALL + Channel button on TV (UP)

Reset the count of operating protect circuit to

“00”: CALL + Channel button on TV (DOWN)

“RCUT” selection: 1 button

“GCUT” selection: 2 button

“BCUT” selection: 3 button

“CNTX” (or “SCNT”) selection: 4 button

“COLC” selection: 5 button

Color thickness

“TNTC” selection: 6 button correction

Test audio signal ON/OFF (1 kHz):

8 button note: Displayed differently as shown

below, depending on the setting of the receiving

color system.

COLP (PAL)

COLC (NTSC)

COLS (SECAM)

Self diagnostic display ON/OFF: 9 button

4. SELECTING THE ADJUSTING ITEMS

Every pressing of CHANNEL UP button

changes the adjustment items in the following

order. (DOWN button for reverse order.)

(See Table Opposite).

This item may require adjustments by models

after initialization, when QA02 is replaced.

5. ADJUSTING THE DATA

Pressing of VOLUME +/- button will change the

value of data in the range from 00 to FF. The

variable range depends on the adjusting item.

6. EXIT FROM SERVICE MODE

Press POWER button to turn off the TV once.

INITIALIZATION OF MEMORY DATA OF QA02

After replacing QA02, the following initialization

is required.

1) Enter the service mode, then select any

register item.

2) Press and hold the CALL button on the

Remote, then press the CHANNEL UP button

on the TV. The initialization of QA02 has been

completed.

3) Check the picture carefully. If necessary,

adjust any adjustment item above. Perform

“AUTO Search Memory”.

CAUTION: Never attempt to initialize the data

unless QA02 has been replaced.

Page 2

TOSHIBA 2877 DB

Adjustments Cont’d

TEST SIGNAL SELECTION

Every pressing of button in the service mode

changes the test patterns on screen as described in SERVICE MODE.

Signal off NTSC signals (14 patterns)

PAL signals (14 patterns)

About inside signal: The inside signal is output

at video input terminal from QA01, and is not

output with the pin inserted into terminal. (Single

color signal can be output.)

SELF DIAGNOSTIC FUNCTION

1) Press “9” button on Remote Control during

display of adjustment menu in the service

mode. The diagnosis will begin to check if

interface among IC’s are executed properly.

2) During diagnosis, the following displays are

shown.

Model C7SS Series (Reference factory adjustment)

(1) Part number of microcomputer (QA01)

(2) Operation number of protecting circuit “00”,

is normal.When indication is other than “00”,

overcurrent apts to flow, and circuit parts may

possibly be damaged.

(3) BUS LINE CHECK ----“OK” is normal.

“SDA1-GND” means that SDA line is shorted to

ground.

“SCL1-GND” means that SCL line is shorted to

ground.

“SCL1-SDA1” means that SDA line is shorted to

SCL line.

(4) BUS CONT ----“OK” is normal.

When indication shows “Q OOO NG”, the device

with the number may possibly be damaged.

(5) BLOCK

UV : TV reception mode

V1: VIDEO 1 input mode ( 1)

V2: VIDEO 2 input mode ( 2)

Indicated color of mode now selected : Green

and Red Indicated color of other modes : White

Green: Normal

Red: The microcomputer operates to provide

judgement of no video signal. The red color is

still indicated though the signal is input, failure

may exist in input signal line including QV01.

QV01: In case of indication green ---Normal

In case of indication red with input signal ---Failure may exist in output line including QV01.

Model C7SS Series

Model C7SS Series (Only for the sets with SECAM function)

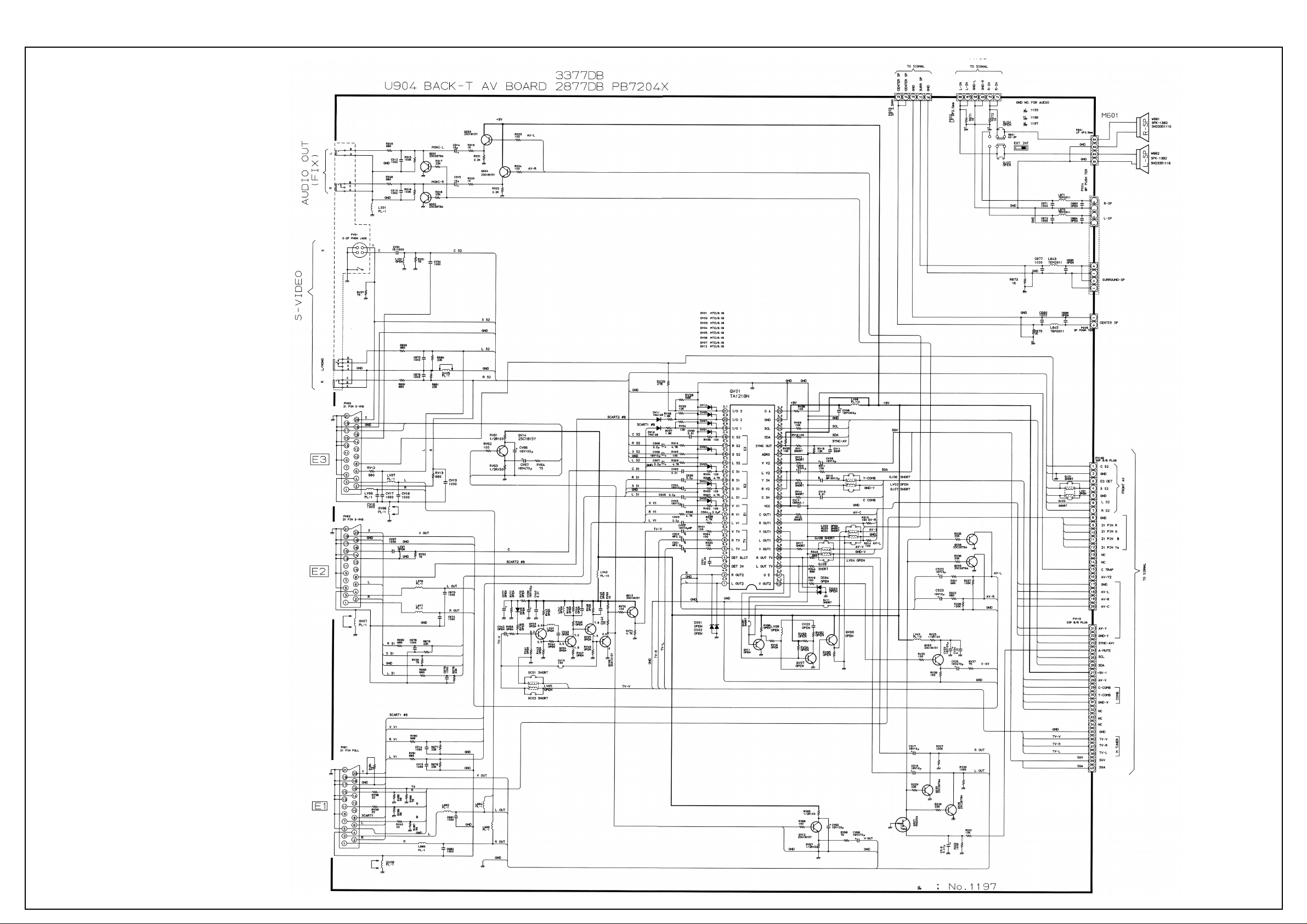

Page 3

TOSHIBA 2877 DB

Back PCB Diagram

(2877DB)

Page 4

TOSHIBA 2877 DB

Back PCB Diagram

(3377DB)

Page 5

TOSHIBA 2877 DB

CRT Diagram

(2877DB)

CRT Diagram

(3377DB)

Page 6

TOSHIBA 2877 DB

Dolby Diagram

(2877DB)

Page 7

TOSHIBA 2877 DB

Dolby Diagram

(3377DB)

Page 8

Page 9

Page 10

Page 11

Loading...

Loading...