Page 1

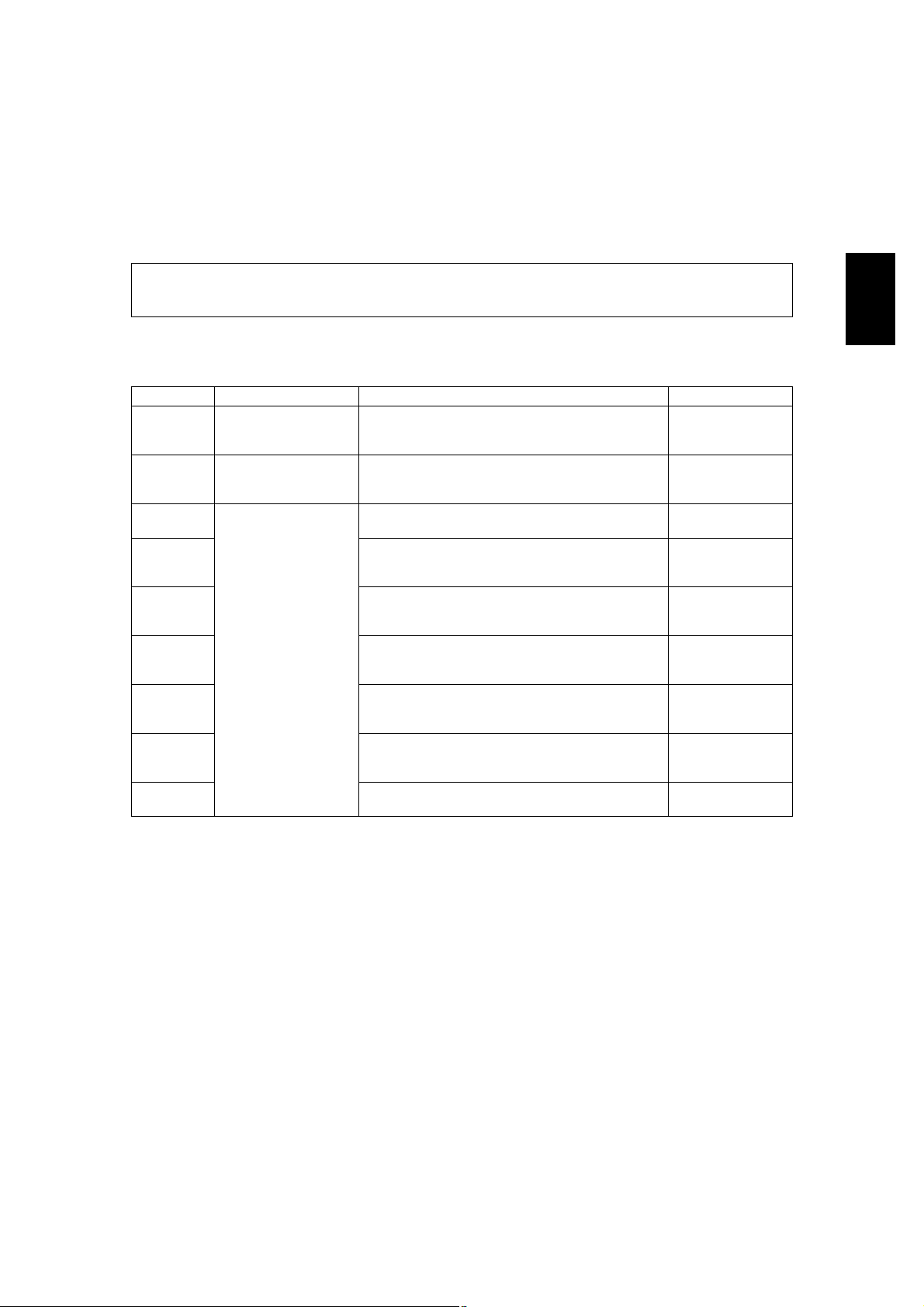

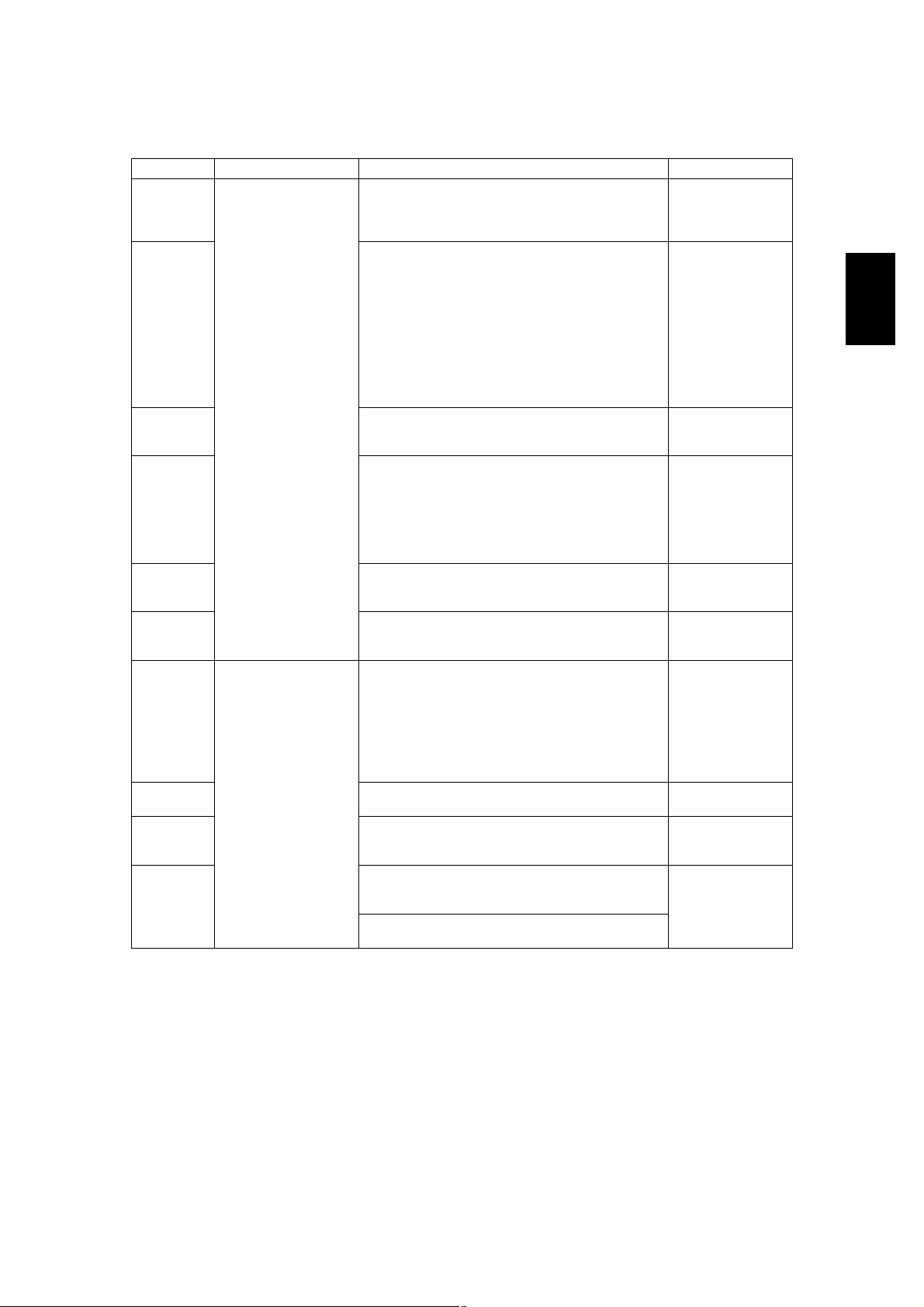

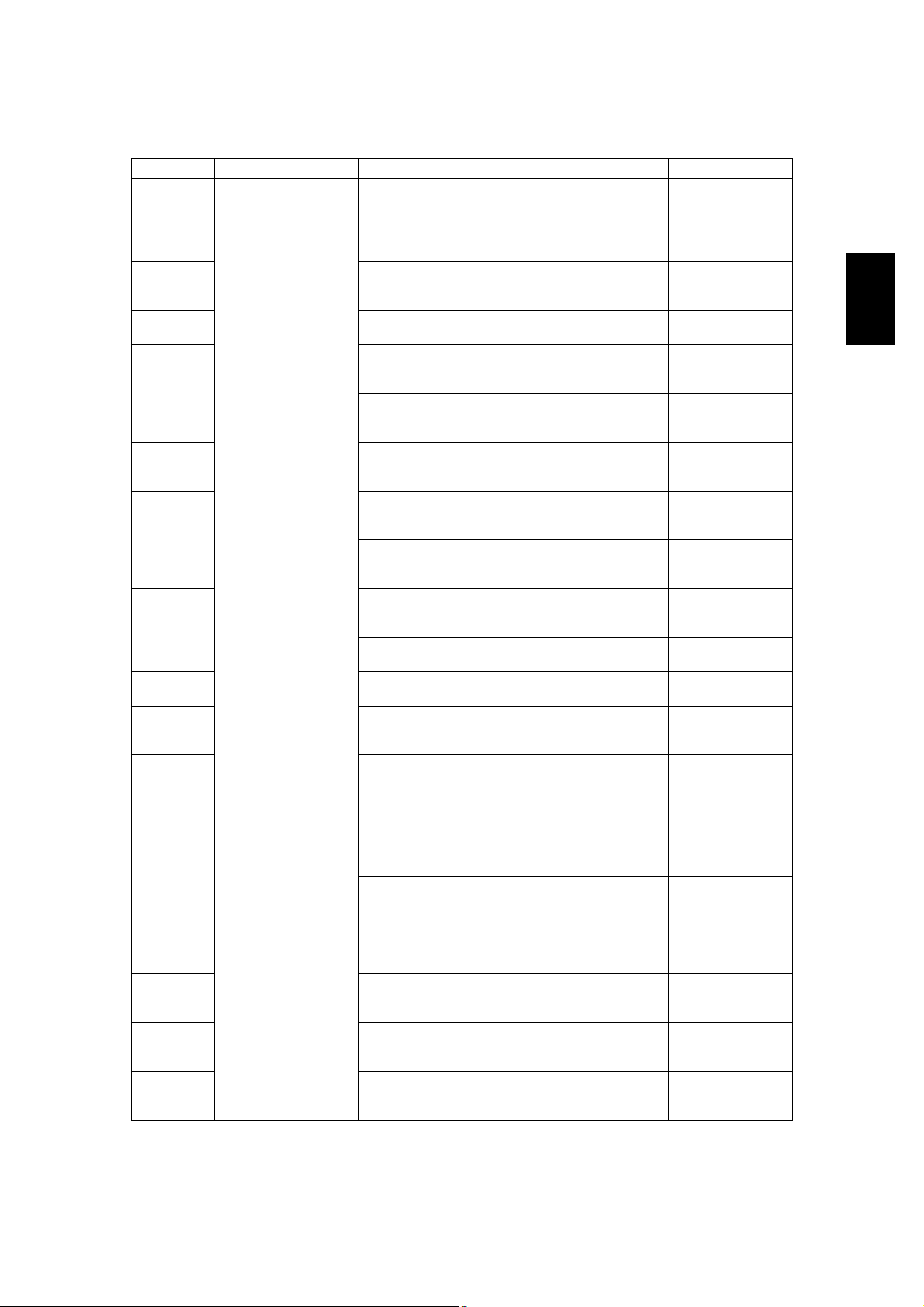

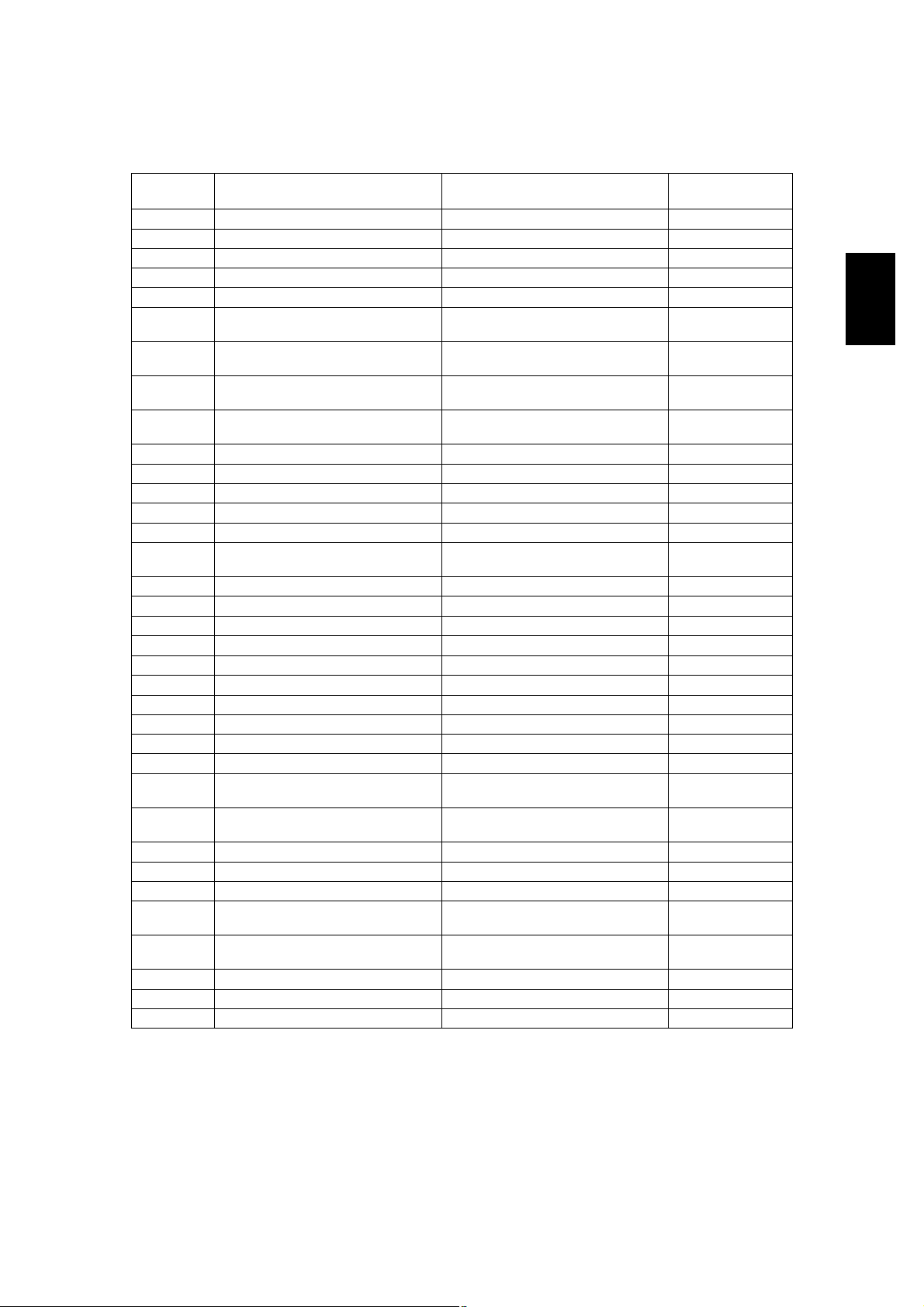

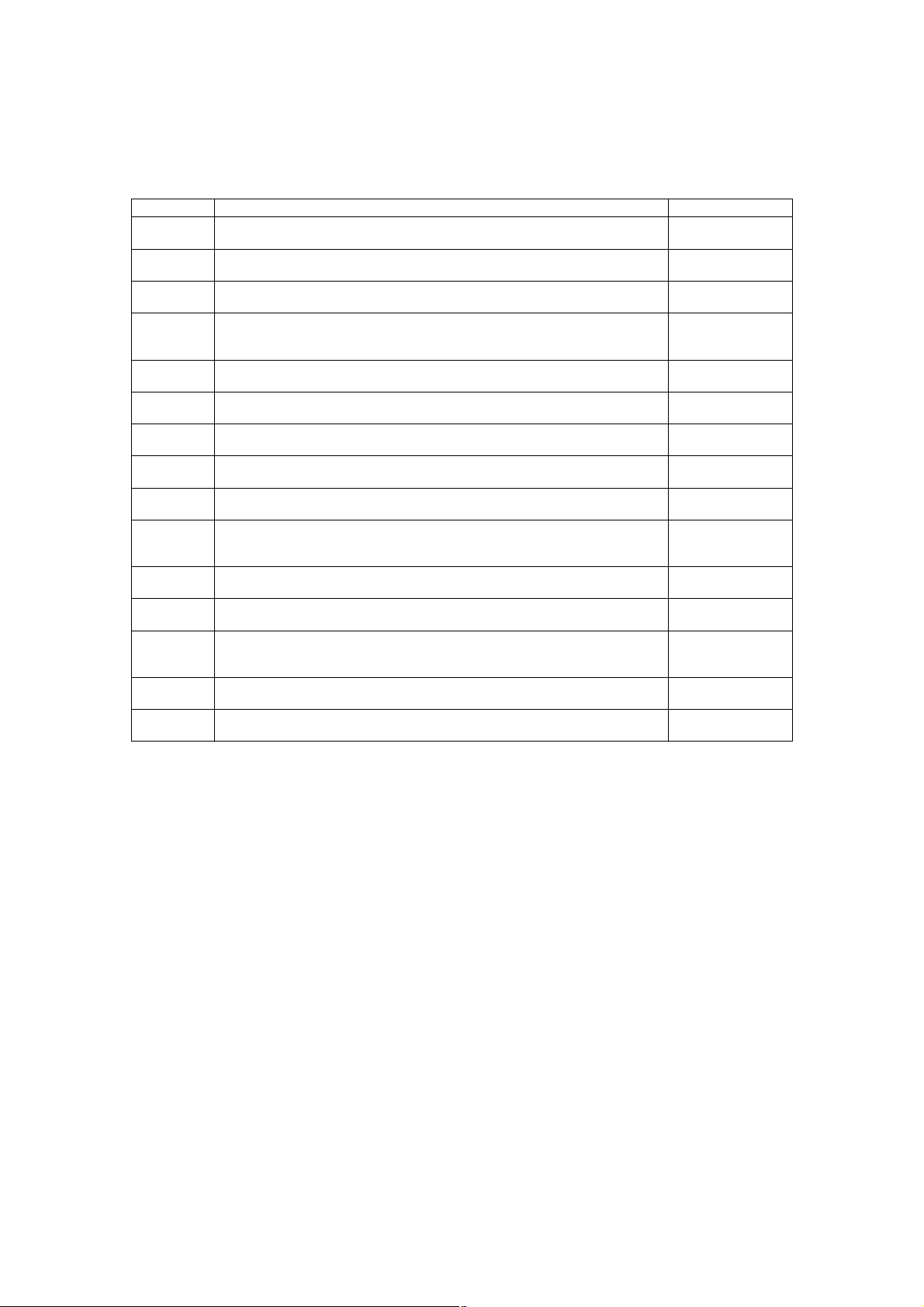

2.ERROR CODE AND SELF-DIAGNOSTIC MODE

2.1Error Code List

The following error codes is displayed at the upper right of the screen when the CLEAR PAPER! or CALL

SERVICE! symbol is blinking.

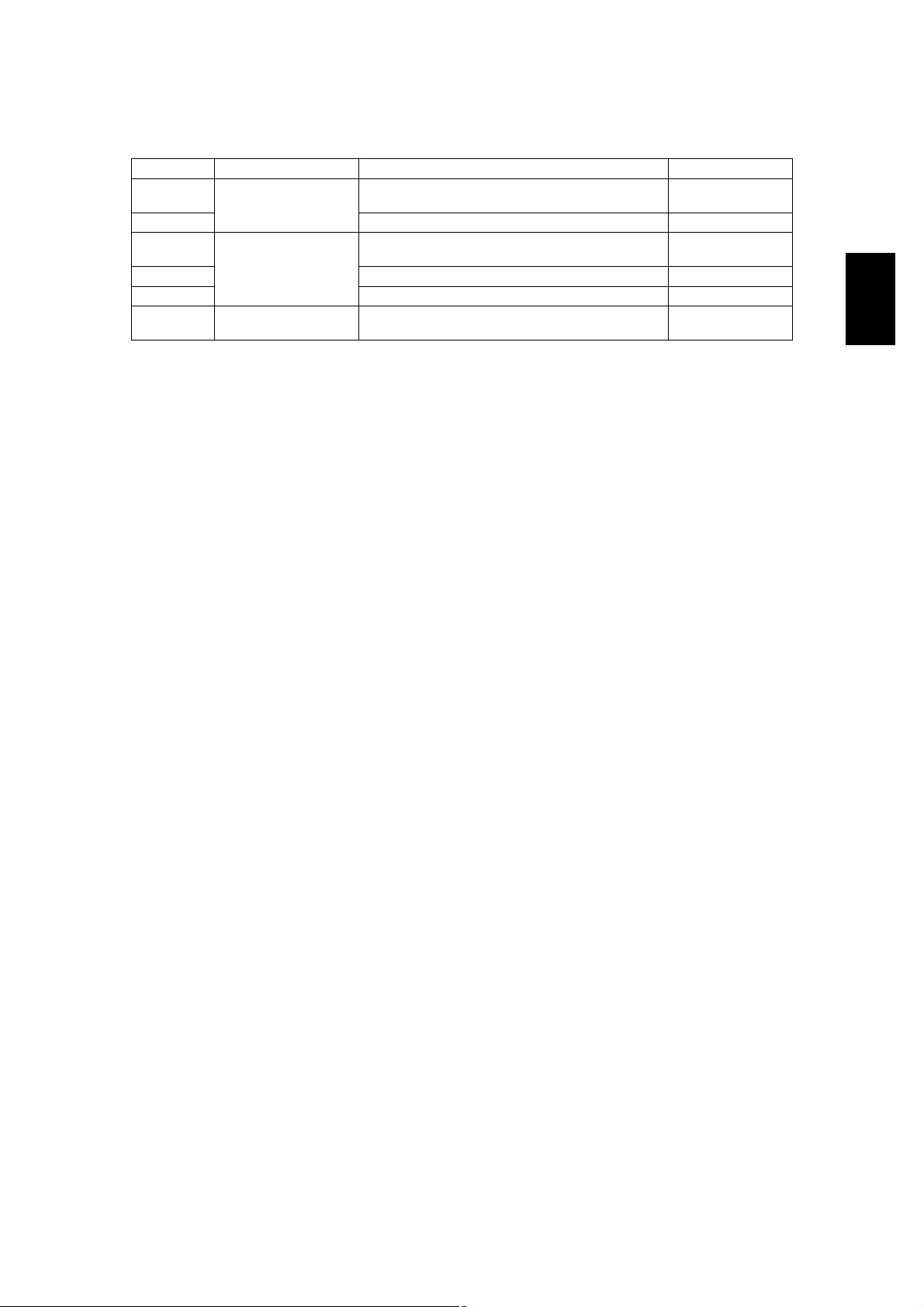

2.1.1Jam

Error codeClassificationContentsTroubleshooting

E010Paper exit jamJam not reaching the exit sensor : The paper which

has passed through the fuser unit does not reach

the exit sensor.

E020Paper exit jamStop jam at the exit sensor: The trailing edge of the

paper does not pass the exit sensor after its leading

edge has reached this sensor.

E030Other paper jamPower-ON jam: The paper is remaining on the

paper transport path when power is turned ON.

E061Incorrect paper size setting for upper drawer: The

size of paper in the 1st drawer differs from size setting of the equipment.

E062Incorrect paper size setting for lower drawer: The

size of paper in the 2nd drawer differs from size setting of the equipment.

E063Incorrect paper size setting for PFP upper drawer:

The size of paper in the 3rd drawer differs from size

setting of the equipment.

E064Incorrect paper size setting for PFP lower drawer:

The size of paper in the 4th drawer differs from size

setting of the equipment.

E065Incorrect paper size setting for bypass tray: The

size of paper in the bypass tray differs from size

setting of the equipment.

E090Image data delay jam: Image data to be printed

cannot be prepared.

P. 5-1

P. 5-2

P. 5-18

P. 5-18

P. 5-18

P. 5-18

P. 5-18

P. 5-18

P. 5-19

2

© June 2005 TOSHIBA TECe-STUDIO281c/351c/451c ERROR CODE AND SELF-DIAGNOSTIC MODE

2 - 1

Page 2

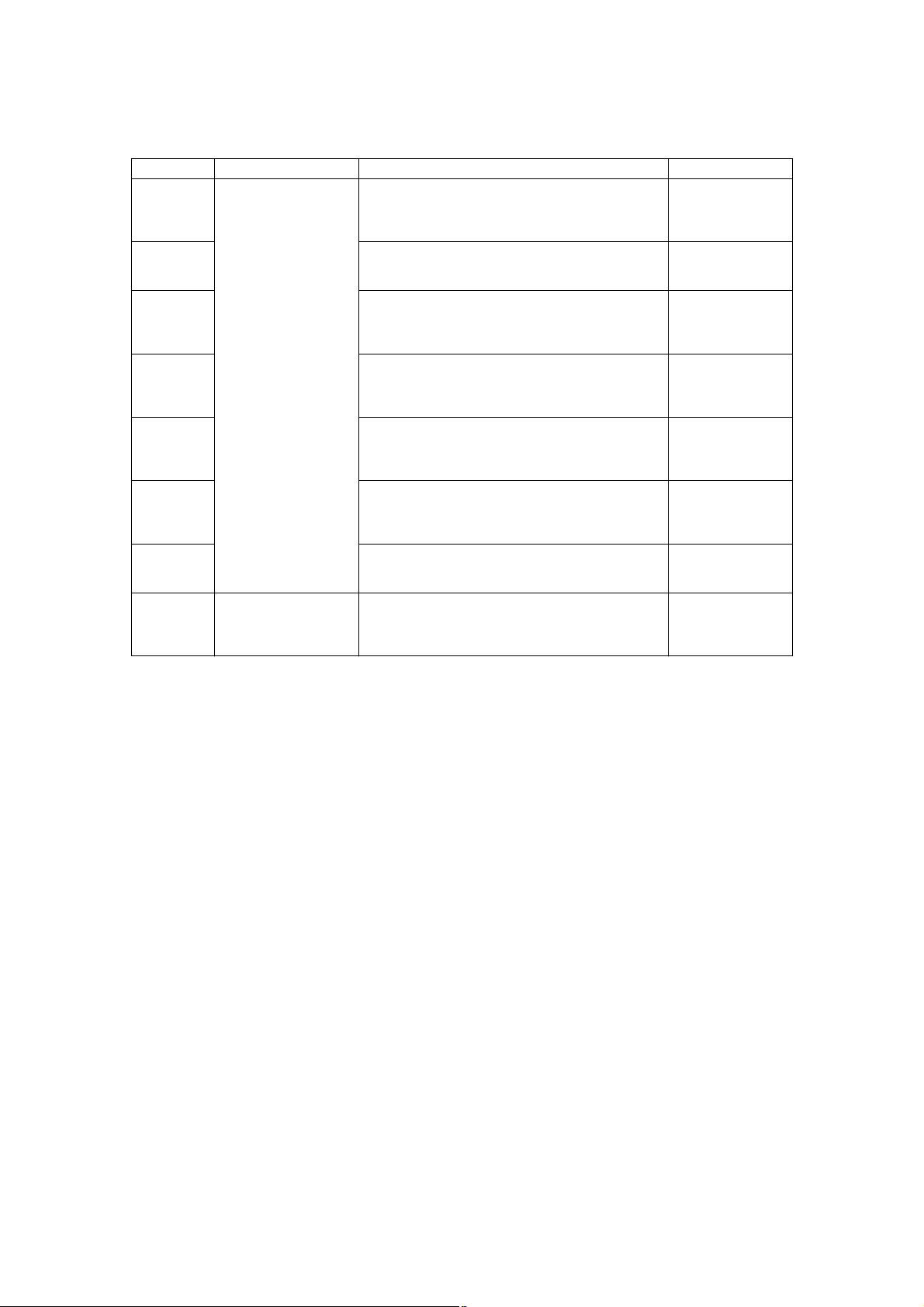

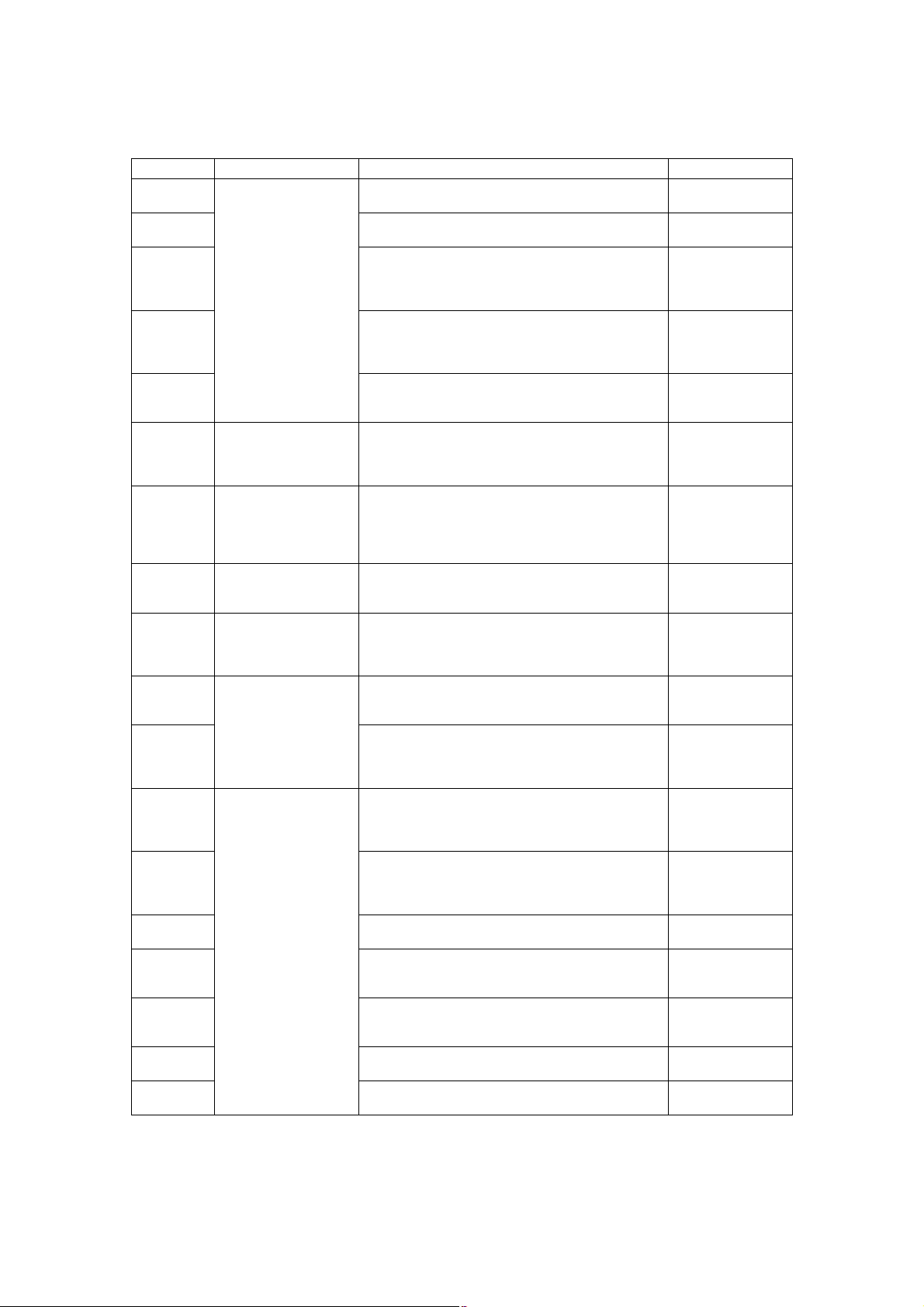

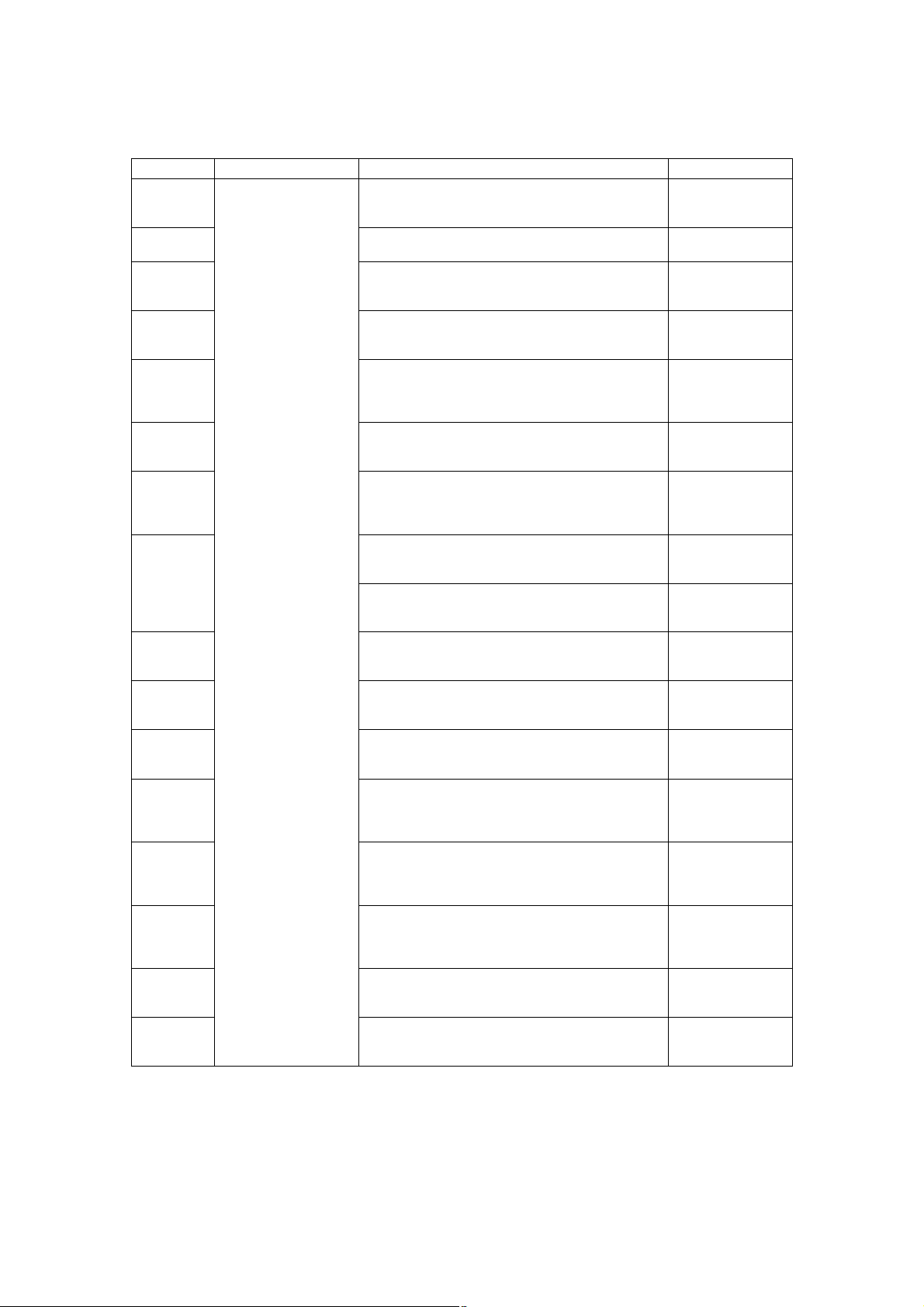

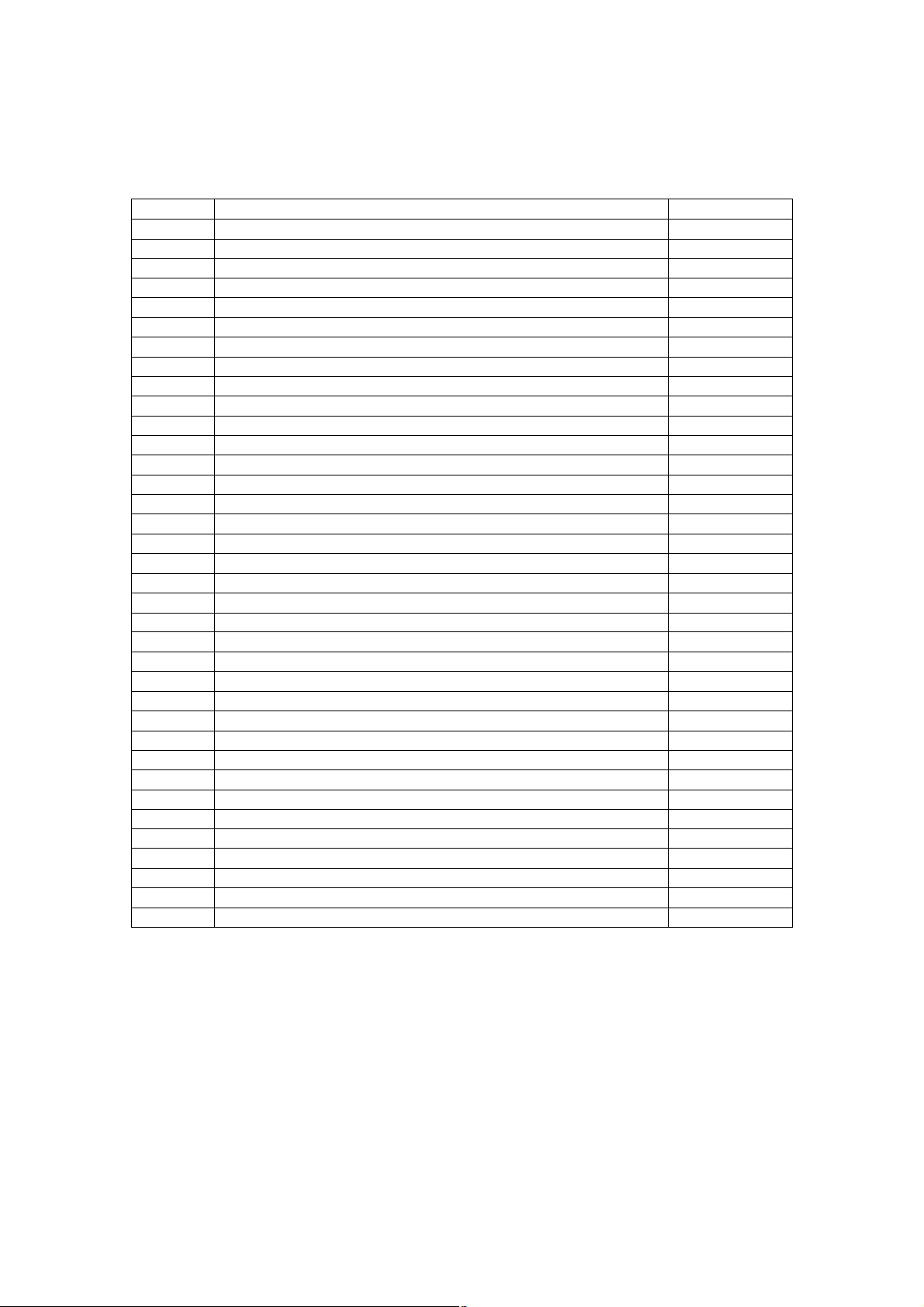

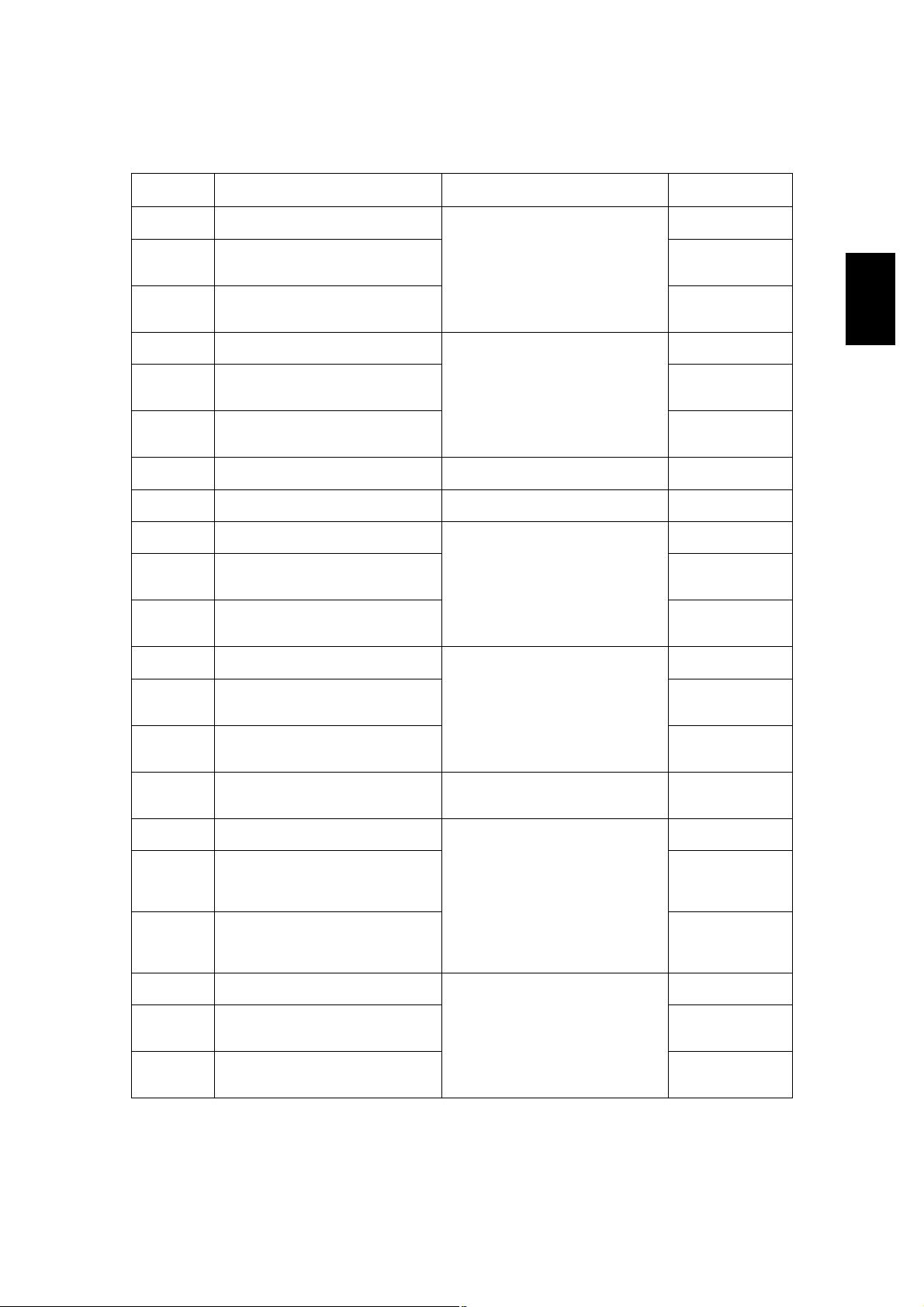

Error codeClassificationContentsTroubleshooting

E110Paper misfeedingADU misfeeding (Paper not reaching the registra-

P. 5-3

tion sensor): The paper which has passed through

ADU does not reach the registration sensor during

duplex printing.

E120Bypass misfeeding (Paper not reaching the regis-

P. 5-4

tration sensor): The paper fed from the bypass tray

does not reach the registration sensor.

E130Upper drawer misfeeding (Paper not reaching the

P. 5-5

upper drawer feed sensor): The paper fed from the

upper drawer does not reach the upper drawer feed

sensor.

E140Lower drawer misfeeding (Paper not reaching the

P. 5-6

lower drawer feed sensor): The paper fed from the

lower drawer does not reach the lower drawer feed

sensor.

E150PFP upper drawer misfeeding (Paper not reaching

P. 5-7

the PFP upper drawer feed sensor): The paper fed

from the PFP upper drawer does not reach the PFP

upper drawer feed sensor.

E160PFP lower drawer misfeeding (Paper not reaching

P. 5-8

the PFP lower drawer feed sensor): The paper fed

from the PFP lower drawer does not reach the PFP

lower drawer feed sensor.

E190LCF misfeeding (Paper not reaching the LCF feed

P. 5-9

sensor): The paper fed from the LCF does not

reach the LCF feed sensor.

E200Paper transport jamUpper drawer transport jam (Paper not reaching the

P. 5-10

registration sensor): The paper does not reach the

registration sensor after it has passed the upper

drawer feed sensor.

e-STUDIO281c/351c/451c ERROR CODE AND SELF-DIAGNOSTIC MODE© June 2005 TOSHIBA TEC

2 - 2

Page 3

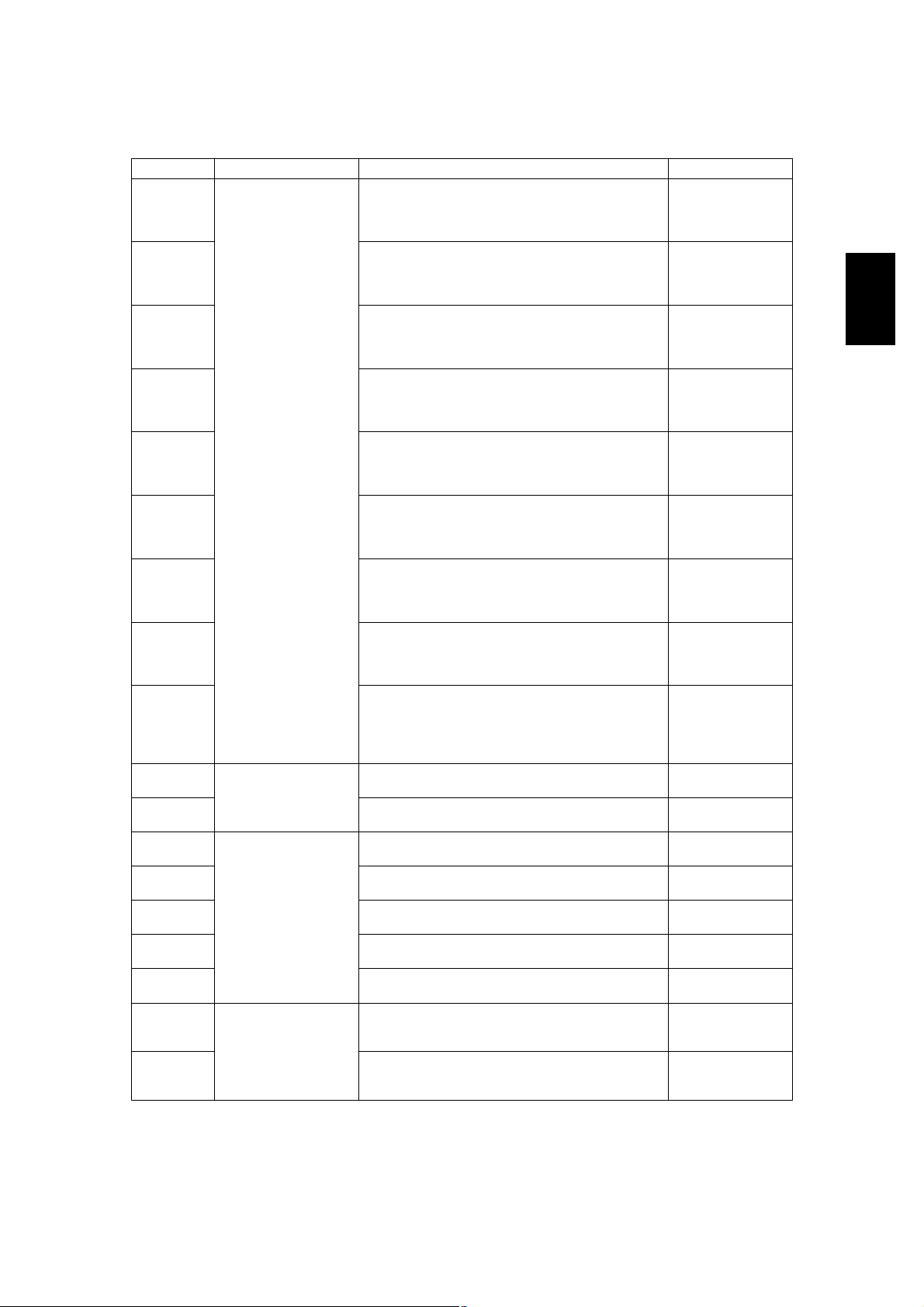

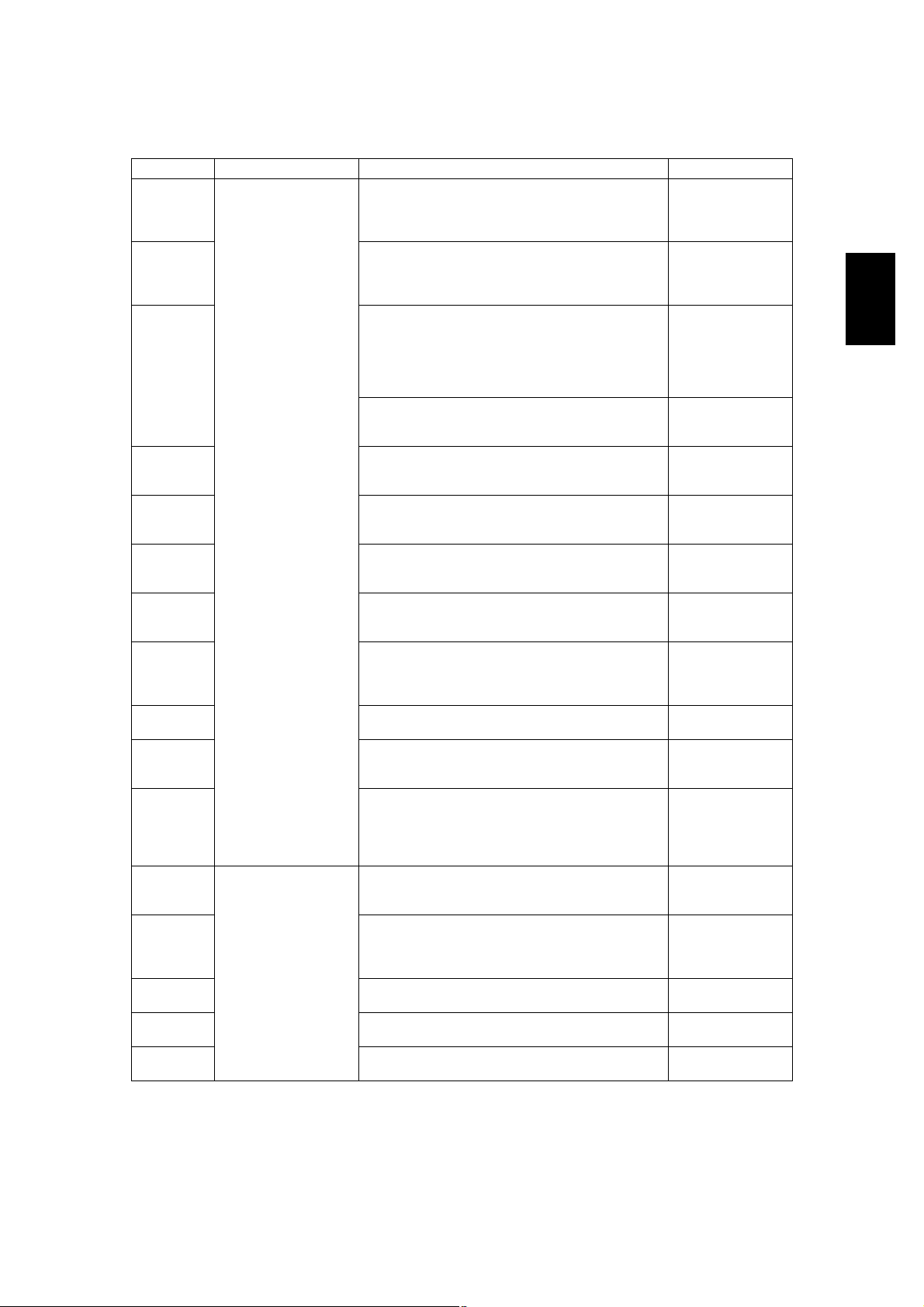

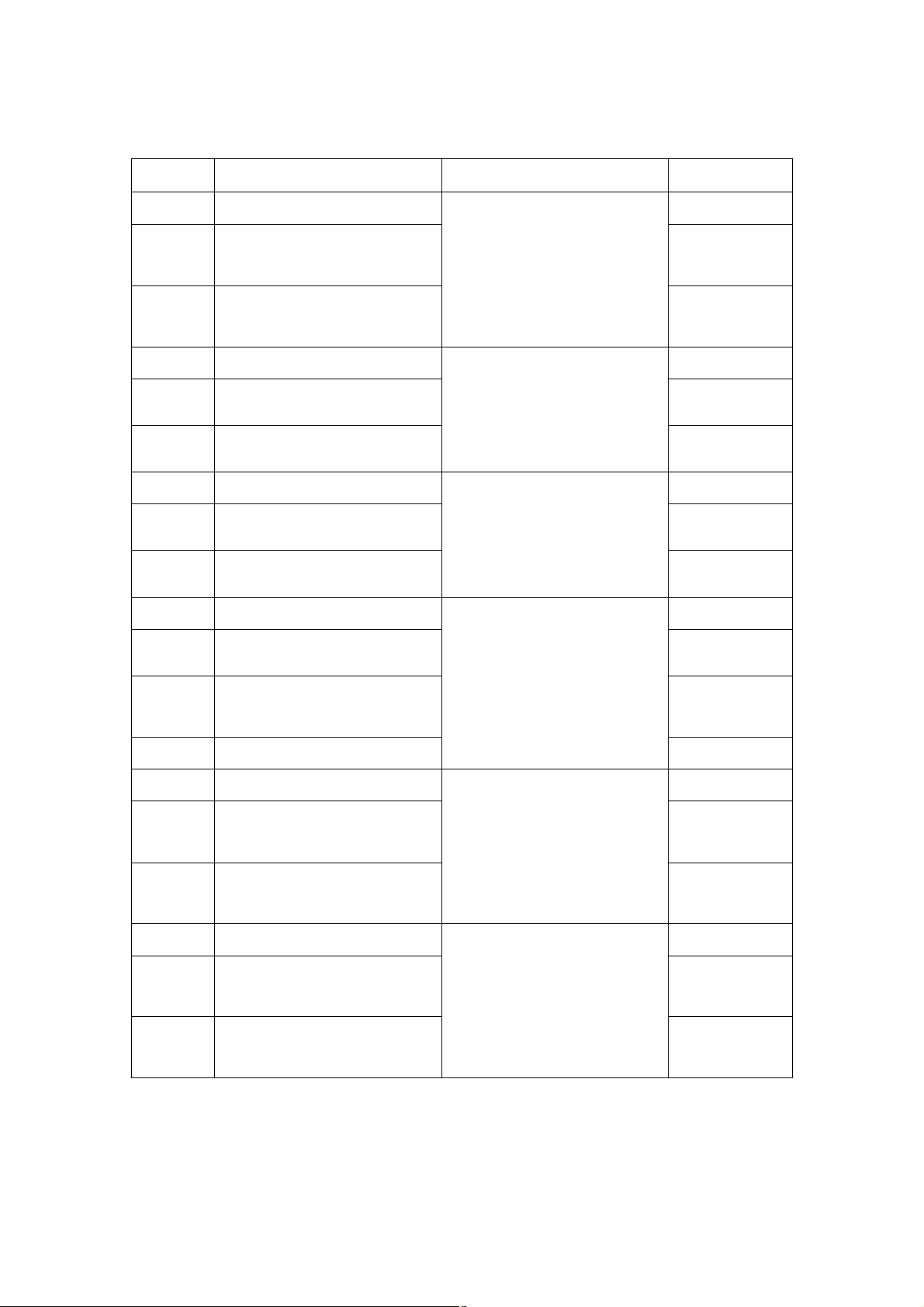

Error codeClassificationContentsTroubleshooting

E210Paper transport jamLower drawer transport jam (Paper not reaching the

E220Lower drawer transport jam (Paper not reaching the

E300PFP upper drawer transport jam (Paper not reach-

E310PFP upper drawer transport jam (Paper not reach-

E320PFP upper drawer transport jam (Paper not reach-

E330PFP lower drawer transport jam (Paper not reach-

E340PFP lower drawer transport jam (Paper not reach-

E350PFP lower drawer transport jam (Paper not reach-

E360PFP lower drawer transport jam (Paper not reach-

E400Cover open jamJam access cover open jam: The jam access cover

E410Front cover open jam: The front cover has opened

E420Cover open jamPFP side cover open jam: The PFP side cover has

E430ADU open jam: The ADU has opened during print-

E440Side cover open jam: The side cover has opened

E450LCF side cover open jam: The LCF side cover has

E480Bridge unit open jam: The bridge unit has opened

E510Paper transport jam

(ADU section)

E520Stop jam in the ADU: The paper does not reach the

registration sensor): The paper does not reach the

registration sensor after it has passed the upper

drawer feed sensor.

upper drawer feed sensor): The paper does not

reach the upper drawer feed sensor after it has

passed the lower drawer feed sensor.

ing the registration sensor): The paper does not

reach the registration sensor after it has passed the

upper drawer feed sensor.

ing the upper drawer feed sensor): The paper does

not reach the upper drawer feed sensor after it has

passed the lower drawer feed sensor.

ing the lower drawer feed sensor): The paper does

not reach the lower drawer feed sensor after it has

passed the PFP upper drawer feed sensor.

ing the registration sensor): The paper does not

reach the registration sensor after it has passed the

upper drawer feed sensor.

ing the upper drawer feed sensor): The paper does

not reach the upper drawer feed sensor after it has

passed the lower drawer feed sensor.

ing the lower drawer feed sensor): The paper does

not reach the lower drawer feed sensor after it has

passed the PFP upper drawer feed sensor.

ing the PFP upper drawer feed sensor): The paper

does not reach the PFP upper drawer feed sensor

after it has passed the PFP lower drawer feed sensor.

has opened during printing.

during printing.

opened during printing.

ing.

during printing.

opened during printing.

during printing.

Jam not reaching the ADU entrance sensor: The

paper does not reach the ADU entrance sensor

after it is switchbacked in the exit section.

ADU exit sensor after it has passed the ADU

entrance sensor.

P. 5-10

P. 5-11

P. 5-10

P. 5-11

P. 5-12

P. 5-10

P. 5-11

P. 5-12

P. 5-13

P. 5-20

P. 5-20

P. 5-21

P. 5-21

P. 5-22

P. 5-22

P. 5-23

P. 5-14

P. 5-15

2

© June 2005 TOSHIBA TECe-STUDIO281c/351c/451c ERROR CODE AND SELF-DIAGNOSTIC MODE

2 - 3

Page 4

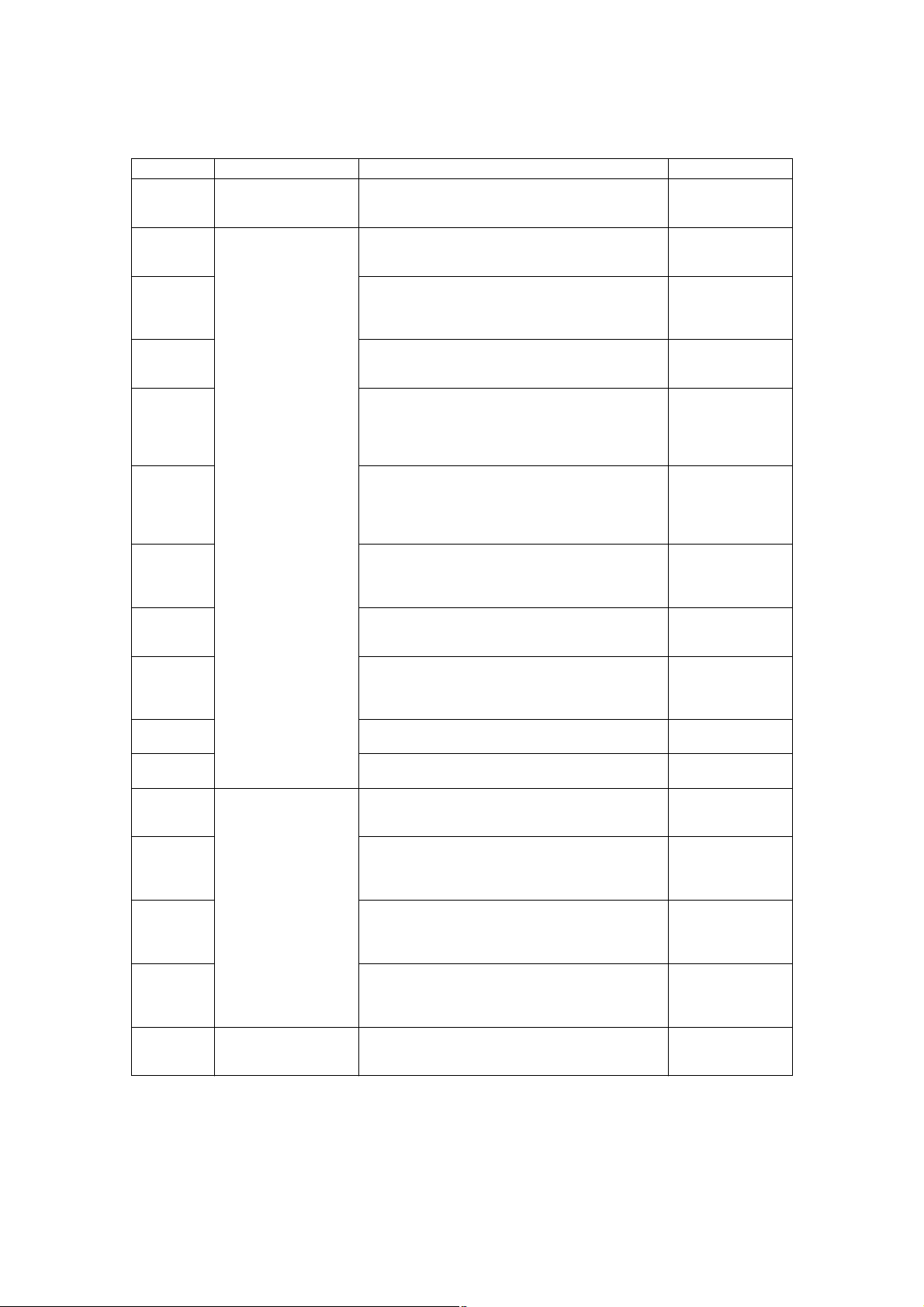

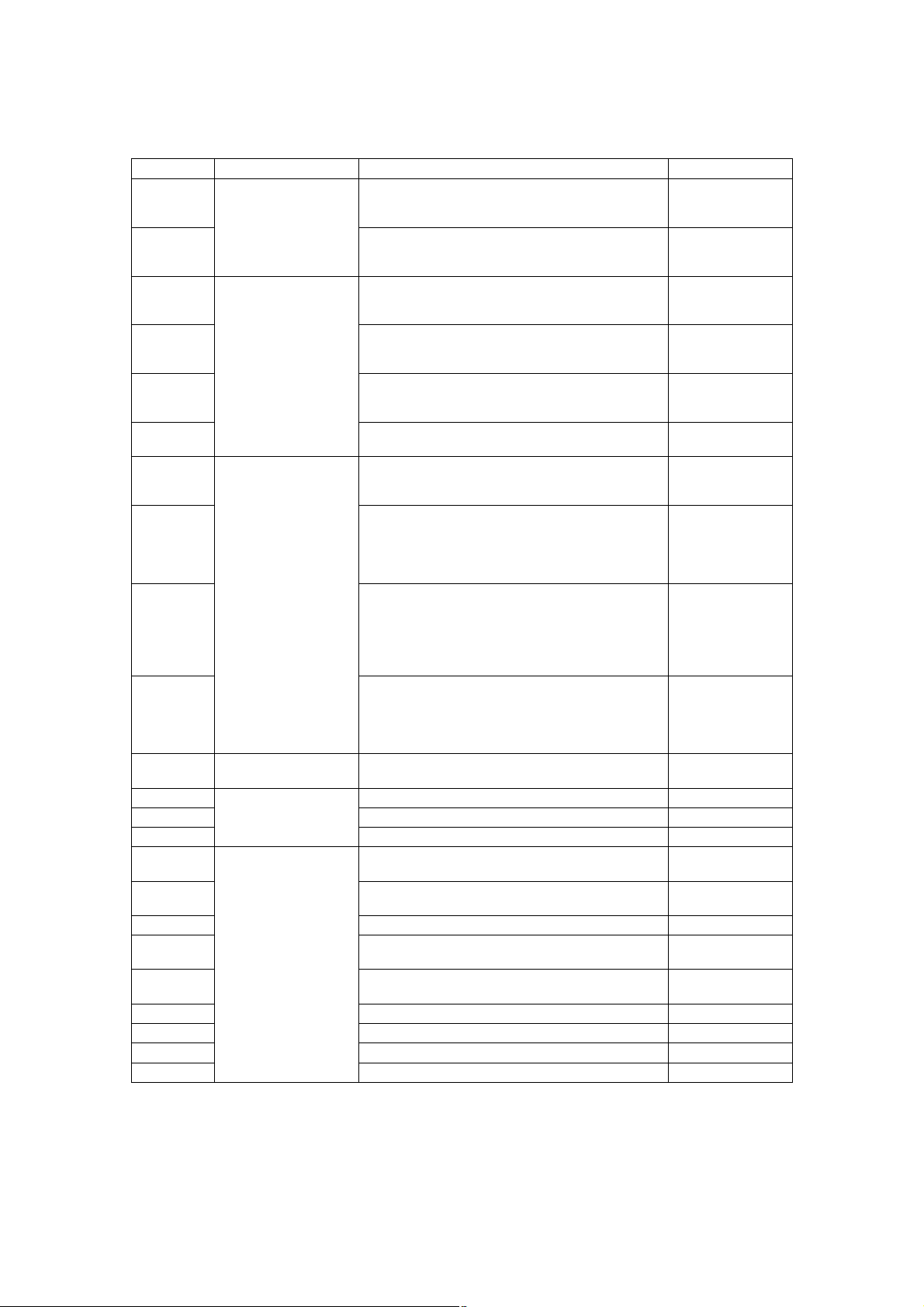

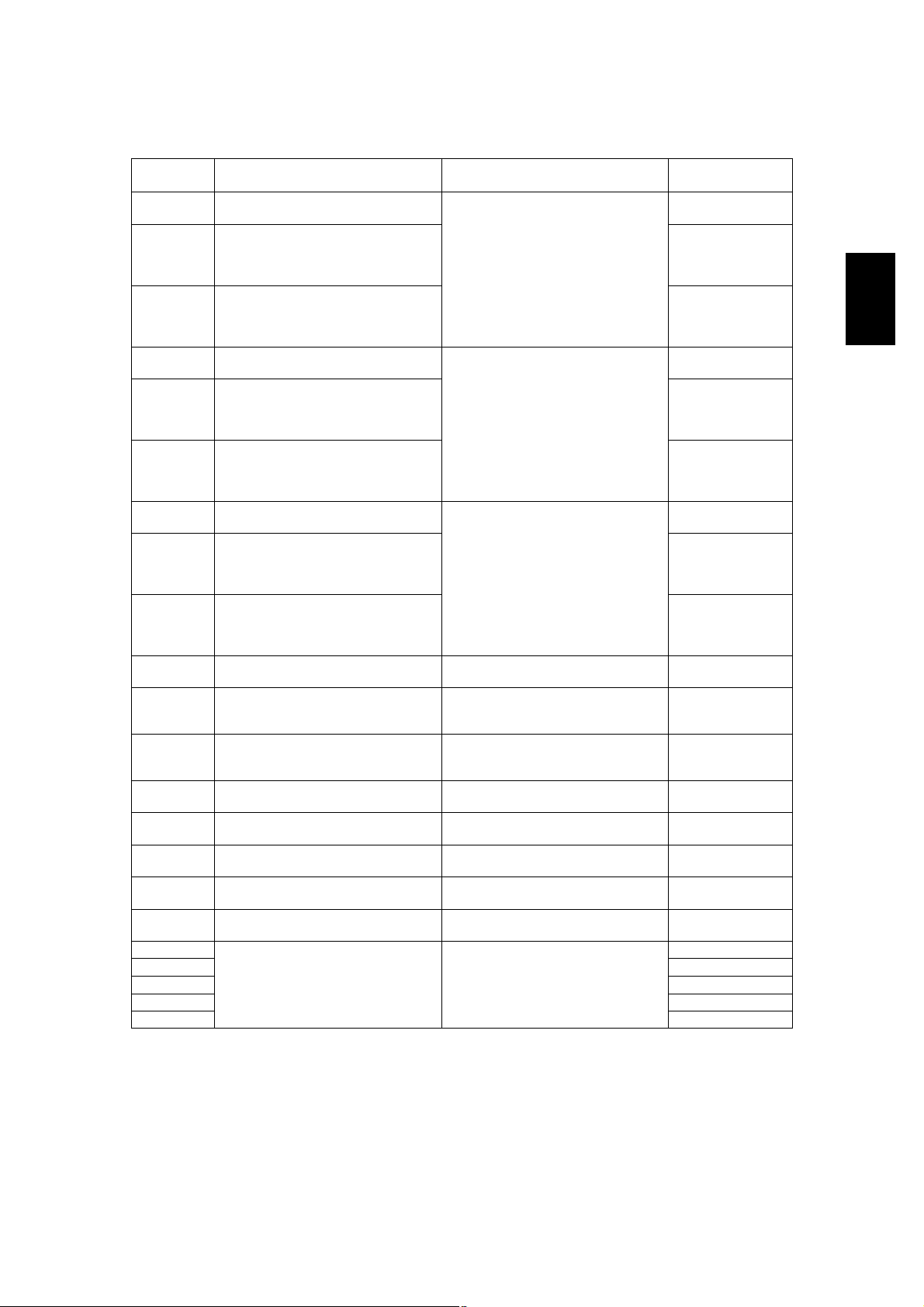

Error codeClassificationContentsTroubleshooting

E550Other paper jamPaper remaining jam on the transport path: The

P. 5-19

paper is remaining on the transport path when printing is finished (caused by a multiple paper feeding).

E712RADF jamJam not reaching the original registration sensor:

P. 5-24

The original fed from the original feeding tray does

not reach the original registration sensor.

E713Cover open jam in the read ready status: Jam

P. 5-24

caused by opening of the RADF jam access cover

or front cover while the RADF is waiting for the

scanning start signal from the equipment.

E714Feed signal reception jam: The feed signal is

P. 5-25

received even no original exists on the original

feeding tray.

E721Jam not reaching the read sensor: The original

P. 5-25

does not reach the read sensor after it has passed

the registration sensor (when scanning obverse

side) or the reverse sensor (when scanning reverse

side).

E722Jam not reaching the original exit/reverse sensor

P. 5-26

(during scanning): The original which passed the

read sensor does not reach the original exit/reverse

sensor when it is transported from the scanning

section to exit section.

E724Stop jam at the original registration sensor: The

P. 5-26

trailing edge of the original does not pass the original registration sensor after its leading edge has

reached this sensor.

E725Stop jam at the read sensor: The trailing edge of the

P. 5-27

original does not pass the read sensor after its leading edge has reached this sensor.

E731Stop jam at the original exit/reverse sensor: The

P. 5-27

trailing edge of the original does not pass the original exit/reverse sensor after its leading edge has

reached this sensor.

E860RADF jam access cover open: The RADF jam

P. 5-27

access cover has opened during RADF operation.

E870RADF open jam: RADF has opened during RADF

P. 5-28

operation.

E910Finisher jam

(Bridge unit)

Jam at the bridge unit transport sensor 1: The

paper does not reach the bridge unit transport sen-

P. 5-29

sor 1 after it has passed the exit sensor.

E920Stop jam at the bridge unit transport sensor 1: The

P. 5-29

trailing edge of the paper does not pass the bridge

unit transport sensor 1 after its leading edge has

reached the sensor.

E930Jam at the bridge unit transport sensor 2: The trail-

P. 5-29

ing edge of the paper does not reach the bridge unit

transport sensor 2 after its leading edge has

reached the bridge unit transport sensor 1.

E940Stop jam at the bridge unit transport sensor 2: The

P. 5-29

trailing edge of the paper does not pass the bridge

unit transport sensor 2 after its leading edge has

reached the bridge unit transport sensor 2.

E9F0Finisher jam

(Punch unit)

Punching jam: Punching is not performed properly.

[MJ-1023/1024 (when MJ-6004 is installed)]

P. 5-46

[MJ-1101 (when MJ-6101 is installed)]

e-STUDIO281c/351c/451c ERROR CODE AND SELF-DIAGNOSTIC MODE© June 2005 TOSHIBA TEC

2 - 4

06/08

Page 5

Error codeClassificationContentsTroubleshooting

EA10Finisher jam

(Finisher section)

Paper transport delay jam: The paper which has

passed the bridge

P. 5-30

unit does not reach the inlet sensor. [MJ-1022/

1023/1024/1101]

EA20 Paper transport stop jam:

P. 5-32

(1) The paper does not pass through the inlet sen-

sor.

[MJ-1022/1023/1024]

(2) The paper has passed through the inlet sensor

but does not reach or pass the feed path sensor

or processing tray sensor.

[MJ-1023/1024]

(3)The paper which has passed through the inlet

sensor does not reach the transport sensor.

[MJ-1101]

EA21Paper size error jam: Paper does not reach the sen-

P. 5-33

sor because the paper is shorter than spec. [MJ1101]

EA30Power-ON jam:

P. 5-34

(1) Paper exists at the inlet sensor when power is

turned ON.

[MJ-1022/1023/1024]

(2) Paper exists at the feed path sensor or pro-

cessing tray sensor when power is turned ON.

[MJ-1023/1024]

EA31Transport path paper remaining jam: The paper

P. 5-35

which has passed through the inlet sensor does not

reach the transport sensor. [MJ-1101]

EA32Exit paper remaining jam: The paper is remaining

P. 5-35

on the finishing tray when the power is turned ON.

[MJ-1101]

EA40Finisher jam

(Finisher section)

Door open jam:

1)The finisher has been released from the equip-

P. 5-36

ment during printing. [MJ-1022]

2)The upper/front cover of the finisher section or

the upper/ front door of the puncher section has

opened during printing. [MJ-1023/1024]

3)The front cover or stationary tray cover is

opened during paper transport. [MJ-1101]

EA50Stapling jam: Stapling is not performed properly.

P. 5-38

[MJ-1022/1023/1024/1101]

EA60Early arrival jam: The inlet sensor detects the paper

P. 5-40

earlier than a specified timing. [MJ-1022/1023/

1024/1101]

EA70Stack delivery jam: It cannot deliver the stack of

P. 5-41

paper on the intermediary process tray to the stack

tray. [MJ-1022]

Stack exit belt home position error: The stack exit

belt is not at the home position. [MJ-1101]

2

© June 2005 TOSHIBA TECe-STUDIO281c/351c/451c ERROR CODE AND SELF-DIAGNOSTIC MODE

2 - 5

06/08

Page 6

Error codeClassificationContentsTroubleshooting

EA80Finisher jam

(Saddle stitcher sec-

EA90Door open jam: The delivery cover or inlet cover

tion)

Stapling jam: Stapling is not performed properly.

[MJ-1024]

P. 5-43

P. 5-43

has opened dur-ing printing [MJ-1024].

EAA0Power-ON jam: Paper exists at No.1 paper sensor,

P. 5-44

No. 2 paper sensor, No.3 paper sensor, vertical

path paper sensor or delivery sensor when power is

turned ON. [MJ-1024]

EAB0Transport stop jam: The paper which passed

P. 5-44

through the inlet sensor does not reach or pass

No.1 paper sensor, No. 2 paper sensor, No.3 paper

sensor or delivery sensor. [MJ-1024]

EAC0Transport delay jam: The paper which has reached

P. 5-45

the inlet sensor does not pass through the inlet sensor. [MJ-1024]

EAD0Other paper jamPrint end command time-out jam: The printing has

P. 5-47

not finished normally because of the communication error between the SYS board and LGC board

at the end of printing.

EAE0Finisher jamReceiving time time-out jam: The printing has been

P. 5-47

interrupted because of the communication error

between the equipment and finisher when the

paper is transported from the equipment to the finisher.

EAF0Finisher jam

(Finisher section)

Stack return jam: It cannot load the paper which

passed through the delivery roller on the intermedi-

P. 5-42

ary process tray. [MJ-1022]

EB30Finisher jamReady time time-out jam: The equipment judges

P. 5-47

that the paper transport to the finisher is disabled

because of the communication error between the

equipment and finisher at the start of printing.

EB50Paper transport jamPaper remaining on the transport path: The multiple

P. 5-16

feeding of preceding paper caused the misfeeding

of upcoming paper.

EB60Paper remaining on the transport path: The multiple

P. 5-17

feeding of preceding paper caused the misfeeding

of upcoming paper (redetection after no jam is

detected at [EB50]).

ED10Finisher jamSideways adjustment motor (M2) home position

P. 5-48

detection error: The Sideways adjustment motor is

not at the home position. [MJ-1101 (when MJ-6101

is installed)]

ED11Skew adjustment motor (M1) home position detec-

P. 5-48

tion abnormality: The Skew adjustment motor is not

at the home position. [MJ-1101 (when MJ-6101 is

installed)]

ED12Shutter home position error: The shutter is not at

P. 5-49

the home position. [MJ-1101]

ED13Front alignment plate home position error: The front

P. 5-49

alignment plate is not at the home position. [MJ1101]

ED14Rear alignment plate home position error: The rear

P. 5-50

alignment plate is not at the home position. [MJ1101]

ED15Paddle home position error: The paddle is not at the

P. 5-50

home position. [MJ-1101]

ED16Buffer tray home position error: The buffer tray is

P. 5-51

not at the home position. [MJ-1101]

e-STUDIO281c/351c/451c ERROR CODE AND SELF-DIAGNOSTIC MODE© June 2005 TOSHIBA TEC

2 - 6

06/08

Page 7

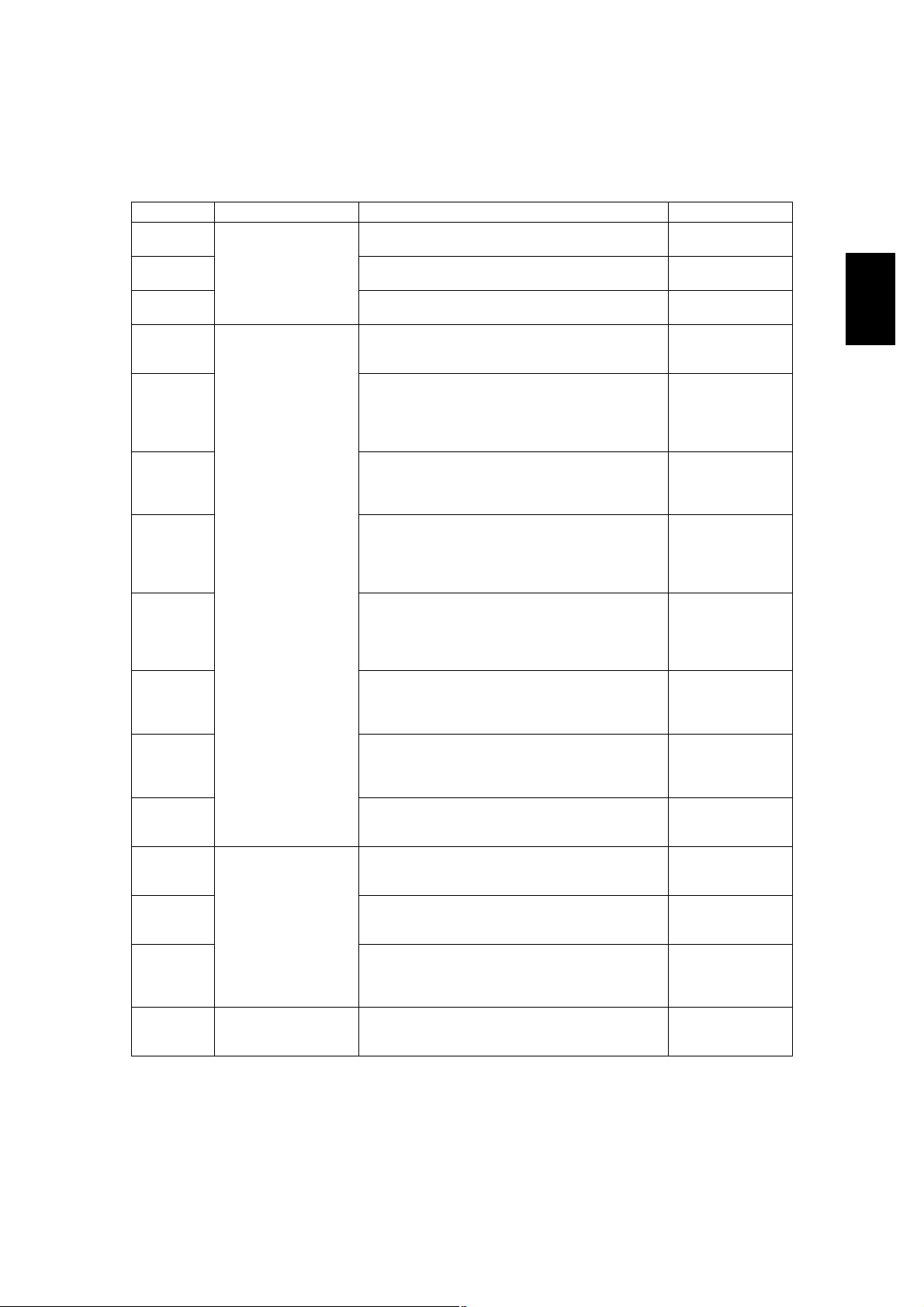

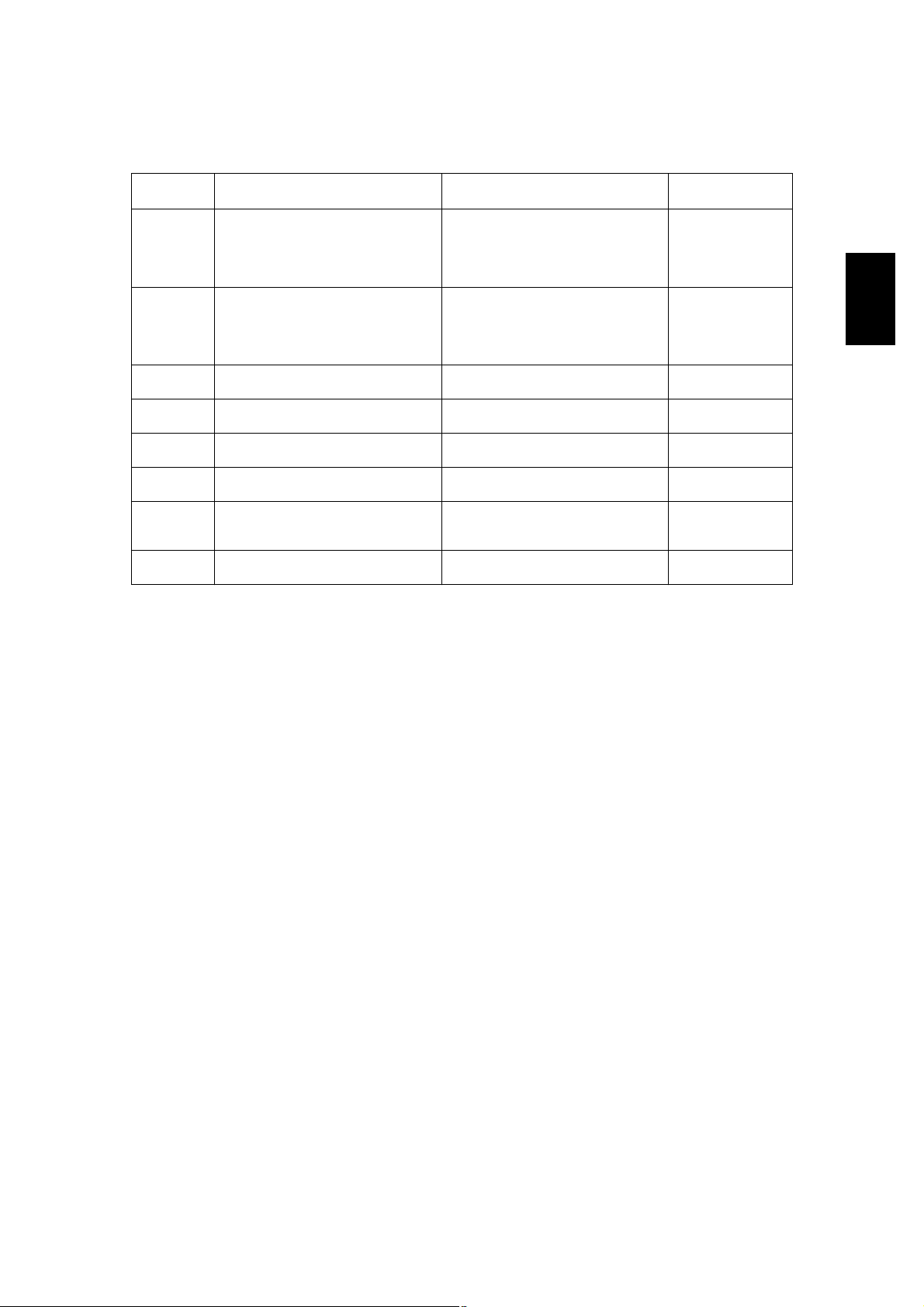

2.1.2Service call

Error codeClassificationContentsTroubleshooting

C010Drive system related

service call

C020Developer motor abnormality: The developer motor

C030Transport motor abnormality: The transport motor is

C040Paper feeding system

related service call

C130Upper drawer tray abnormality: The upper drawer

C140Lower drawer tray abnormality: The lower drawer

C150PFP upper drawer tray abnormality: The PFP upper

C160PFP lower drawer tray abnormality: The PFP lower

C180LCF tray-up motor abnormality: The LCF tray-up

C1A0LCF end fence motor abnormality: The LCF end

C1B0LCF transport motor abnormality: The LCF trans-

C260Scanning system

related service call

C270Carriage home position sensor not turning OFF

C280Carriage home position sensor not turning ON

C360Copy process related

service call

Main motor abnormality: The main motor is not

rotating normally.

is not rotating normally.

not rotating normally.

PFP motor abnormality: The PFP motor is not rotating normally. (the case that paper can be fed from

any drawer except the PFP)

tray-up motor is not rotating or the upper drawer

tray is not moving normally. (the case that paper

can be fed from any drawer except the upper

drawer)

tray-up motor is not rotating or the lower drawer tray

is not moving normally. (the case that paper can be

fed from any drawer except the lower drawer)

drawer tray-up motor is not rotating or the PFP

upper drawer tray is not moving normally. (the case

that paper can be fed from any drawer except the

PFP upper drawer)

drawer tray-up motor is not rotating or the PFP

lower drawer tray is not moving normally. (the case

that paper can be fed from any drawer except the

PFP lower drawer)

motor is not rotating or the LCF tray is not moving

normally. (the case that paper can be fed from any

drawer except the LCF)

fence motor is not rotating or the LCF end fence is

not moving normally. (the case that paper can be

fed from any drawer except the LCF)

port motor is not rotating normally. (the case that

paper can be fed from any drawer except the LCF)

Peak detection error: Lighting of the exposure lamp

(white reference) is not detected when power is

turned ON.

within a specified period of time: The carriage does

not shift from its home position in a specified time.

within a specified period of time: The carriage does

not reach to its home position in a specified period

of time.

Charger cleaner motor abnormality: Charger

cleaner motor is not rotating or wire cleaner is not

moving normally.

P. 5-52

P. 5-52

P. 5-52

P. 5-53

P. 5-54

P. 5-54

P. 5-55

P. 5-55

P. 5-56

P. 5-57

P. 5-58

P. 5-59

P. 5-59

P. 5-59

P. 5-89

2

© June 2005 TOSHIBA TECe-STUDIO281c/351c/451c ERROR CODE AND SELF-DIAGNOSTIC MODE

2 - 7

Page 8

Error codeClassificationContentsTroubleshooting

C411Fuser unit related ser-

vice call

Thermistor or heater abnormality at power-ON:

Abnormality of the thermistor is detected when

P. 5-60

power is turned ON or the temperature of the fuser

roller does not rise in a specified period of time after

power is turned ON.

C412Thermistor/heater abnormality at power-ON: Ther-

P. 5-60

mistor abnormality is detected at power-ON or the

fuser roller temperature does not rise within a specified period of time after power-ON.

C443Heater abnormality after abnormality judgment (not

P. 5-61

reaching to intermediate temperature)

C445Heater abnormality after abnormality judgment

P. 5-61

(pre-running end temperature abnormality)

C446Heater abnormality after abnormality judgment

P. 5-61

(pre-running end temperature abnormality)

C447Heater abnormality after abnormality judgment

P. 5-61

(temperature abnormality at ready status)

C449Heater abnormality after abnormality judgment

P. 5-61

(overheating)

C471IH power voltage abnormality or IH initial abnormal-

P. 5-61

ity

(IH board initial abnormality)

C472IH power voltage abnormality (power supply abnor-

P. 5-61

mality)

C475IH power voltage abnormality (power supply abnor-

P. 5-61

mality when door is opened)

C480Overheating of IGBT: The temperature of the IGBT

P. 5-61

rises abnormally.

C490IH control circuit or IH coil abnormality: Abnormality

P. 5-62

is detected in IH control circuit or IH coil is broken/

shorted.

C4B0Fuser unit counter abnormalityP. 5-62

C550Optional communica-

tion related service call

C570Communication error between Engine-CPU and

RADF I/F error: Communication error has occurred

between the RADF and the scanner.

P. 5-63

P. 5-63

IPC board

C580Communication error between IPC board and fin-

P. 5-63

isher

C900Circuit related service

call

Connection error between SYS board and LGC

board

P. 5-64

C940Engine-CPU abnormalityP. 5-64

C950LGC board memory abnormalityP. 5-64

C960Connection error between LGC board and DRV

P. 5-64

board, ID abnormality

C970Process related ser-

vice call

C9E0Circuit related service

call

CA10Laser optical unit

related service call

CA20H-Sync detection error: H-Sync signal detection PC

High-voltage transformer abnormality: Leakage of

the main charger is detected.

Connection error between SLG board and SYS

board, ID abnormality

Polygonal motor abnormality: The polygonal motor

is not rotating normally.

P. 5-89

P. 5-65

P. 5-66

P. 5-66

board cannot detect laser beams.

e-STUDIO281c/351c/451c ERROR CODE AND SELF-DIAGNOSTIC MODE© June 2005 TOSHIBA TEC

2 - 8

Page 9

Error codeClassificationContentsTroubleshooting

CB10Finisher related

service call

CB11Buffer tray guide motor abnormality: The buffer tray

Entrance motor abnormality: The entrance motor is

not rotating normally. [MJ-1101]

P. 5-67

P. 5-67

guide motor is not rotating or the buffer tray guide is

not moving normally. [MJ-1101]

CB12Buffer roller drive motor abnormality: The buffer

P. 5-67

roller drive motor is not rotating or the buffer roller is

not moving normally. [MJ-1101]

CB20Delivery motor abnormality: Delivery motor or deliv-

P. 5-68

ery roller is not rotating normally. [MJ-1022]

CB30Tray 1/Tray 2 shift motor abnormality: Tray 1/Tray 2

P. 5-68

shift motor is not rotating or delivery tray is not moving normally. [MJ-1023/1024]

Movable tray shift motor abnormality: The movable

P. 5-68

tray shift motor is not rotating or the movable tray is

not moving normally. [MJ-1101]

CB31Movable tray paper-full detection error: The actua-

P. 5-69

tor of the movable tray paper-full detection sensor

does not move smoothly. [MJ-1101]

CB40Rear aligning plate motor abnormality: Rear align-

P. 5-69

ing plate motor is not rotating or aligning plate is not

moving normally. [MJ-1023/1024]

Front alignment motor abnormality: The front align-

P. 5-69

ment motor is not rotating or the front alignment

plate is not moving normally. [MJ-1101]

CB50Staple motor abnormality: Staple motor is not rotat-

P. 5-70

ing or stapler is not moving normally. [MJ-1022/

1023/1024]

Stapler home position error: The stapler home posi-

P. 5-70

tion sensor does not work. [MJ-1101]

CB51Stapler shift home position error: The stapler is not

P. 5-70

at the home position. [MJ-1101]

CB60Stapler shift motor abnormality: Stapler shift motor

P. 5-71

is not rotating or staple unit is not moving normally.

[MJ-1023/1024/1101]

CB80Backup RAM data abnormality:

P. 5-71

1)Abnormality of checksum value on finisher con-

troller PC board is detected when the power is

turned ON. [MJ-1023/1024]

2)Abnormality of checksum value on punch con-

troller PC board is detected when the power is

turned ON. [MJ-1023/1024 (when MJ-6004 is

installed)]

RAM abnormality: Abnormality of checksum value

P. 5-71

on finisher controller PC board is detected when the

power is turned on. [MJ-1101]

CB81Flash ROM abnormality: Abnormality of checksum

P. 5-72

value on finisher controller PC board is detected

when the power is turned on. [MJ-1101]

CB90Paper pushing plate motor abnormality: Paper

P. 5-72

pushing plate motor is not rotating or paper pushing

plate is not moving normally. [MJ-1024]

CBA0Stitch motor (front) abnormality: Stitch motor (front)

P. 5-72

is not rotating or rotary cam is not moving normally.

[MJ-1024]

CBB0Stitch motor (rear) abnormality: Stitch motor (rear)

P. 5-72

is not rotating or rotary cam is not moving normally.

[MJ-1024]

2

© June 2005 TOSHIBA TECe-STUDIO281c/351c/451c ERROR CODE AND SELF-DIAGNOSTIC MODE

2 - 9

06/08

Page 10

Error codeClassificationContentsTroubleshooting

CBC0Finisher related

service call

Alignment motor abnormality: Alignment motor is

not rotating or aligning plate is not moving normally.

P. 5-72

[MJ-1024]

CBD0Guide motor abnormality: Guide motor is not rotat-

P. 5-73

ing or guide is not moving normally. [MJ-1024]

CBE0Paper folding motor abnormality: Paper folding

P. 5-73

motor or paper folding roller is not rotating normally.

[MJ-1024]

CBF0Paper positioning plate motor abnormality: Paper

P. 5-73

positioning plate motor is not rotating or paper positioning plate is not moving normally. [MJ-1024]

CC00Sensor connector abnormality: Connector of guide

P. 5-74

home position sensor, paper pushing plate home

position sensor or paper pushing plate top position

sensor is disconnected. [MJ-1024]

CC10Micro switch abnormality: With all covers closed,

P. 5-74

inlet door switch, delivery door switch or front cover

switch is open. [MJ-1024]

CC20Communication error between finisher and saddle

P. 5-74

stitcher: Communication error between finisher controller PC board and saddle stitcher controller board

[MJ-1023/1024]

CC30Stack processing motor abnormality: The stack pro-

P. 5-75

cessing motor is not rotating or the stack delivery

belt is not moving normally. [MJ-1022]

Stack transport motor abnormality: The stack trans-

P. 5-76

port motor is not rotating or the stack transport belt

is not moving normally. [MJ-1101]

CC31Transport motor abnormality: The transport motor is

P. 5-76

not rotating or the stack transport roller -1 and -2 is

not rotating normally. [MJ-1101]

CC40Swing motor abnormality: Swing motor is not rotat-

P. 5-76

ing or swing unit is not moving normally. [MJ-1023/

1024]

CC41Paper holder cam home position abnormality: The

P. 5-77

paper holder cam is not at the home position. [MJ1101]

CC50Horizontal registration motor abnormality: Horizon-

P. 5-77

tal registration motor is not rotating or puncher is

not shifting normally. [MJ-1023/1024 (when MJ6004 is installed)]

CC51Sideways adjustment motor (M2) abnormality:

P. 5-77

Sideways adjustment motor is not rotating or

puncher is not shifting normally. [MJ-1101 (when

MJ-6101 is installed)

CC52Skew adjustment motor (M1) abnormality: Skew

P. 5-78

adjustment motor is not rotating or puncher is not

shifting normally. [MJ-1101 (when MJ-6101 is

installed)]

CC60Punch motor abnormality: Punch motor is not rotat-

P. 5-78

ing or puncher is not shifting normally. [MJ-1023/

1024 (when MJ-6004 is installed)]

CC61Punch motor (M3) home position detection error:

P. 5-79

Punch motor is not rotating or puncher is not shifting normally. [MJ-1101 (when MJ-6101 is installed)]

e-STUDIO281c/351c/451c ERROR CODE AND SELF-DIAGNOSTIC MODE© June 2005 TOSHIBA TEC

2 - 10

06/08

Page 11

Error codeClassificationContentsTroubleshooting

CC71Finisher related

service call

Punch ROM checksum error: Abnormality of checksum value on Hole punch controller PC board is

P. 5-79

detected when the power is turned on. [MJ-1101

(when MJ-6101 is installed)]

CC72Punch RAM read/write error: Abnormality of check-

P. 5-79

sum value on Hole punch controller PC board is

detected when the power is turned on. [MJ-1101

(when MJ-6101 is installed)]

CC80Front alignment motor abnormality: Front alignment

P. 5-80

motor is not rotating or front aligning plate is not

moving normally. [MJ-1022]

Front aligning plate motor abnormality: Front aligning plate motor is not rotating or aligning plate is not

moving normally. [MJ-1023/1024]

Rear alignment motor abnormality: The rear align-

P. 5-80

ment motor is not rotating or the rear alignment

plate is not moving normally. [MJ-1101]

CC90Upper stack tray lift motor abnormality: The upper

P. 5-81

stack tray lift motor is not rotating or the upper stack

tray is not moving normally. [MJ-1022]

CCA0Lower stack tray lift motor abnormality: The lower

P. 5-82

stack tray lift motor is not rotating or the lower stack

tray is not moving normally. [MJ-1022]

CCB0Rear jogging motor abnormality: The rear jogging

P. 5-82

motor is not rotating or the rear jogging plate is not

moving normally. [MJ-1022]

CCD0Stack ejection motor abnormality: Stack ejection

P. 5-83

motor or stack ejection roller is not rotating normally. [MJ-1023/1024]

CCE0Paper trailing edge assist motor abnormality: Paper

P. 5-83

trailing edge assist motor is not rotating or paper

trailing edge assist is not moving normally. [MJ1023/1024]

CCF0Gear changing motor abnormality: Gear changing

P. 5-83

motor is not rotating normally. [MJ-1023/1024]

CDE0Paddle motor abnormality: The paddle motor is not

P. 5-84

rotating or the paddle is not rotating normally. [MJ1101]

CE00Communication error between finisher and punch

P. 5-84

unit: Communication error between finisher controller PC board and punch controller PC board [MJ1023/1024 (when MJ-6004 is installed)]

[MJ-1101 (when MJ-6101 is installed)]

CE10Image control related

service call

Image quality sensor abnormality (OFF level): The

output value of this sensor is out of a specified

P. 5-85

range when sensor light source is OFF.

CE20Image quality sensor abnormality (no pattern level):

P. 5-86

The output value of this sensor is out of a specified

range when the image quality control test pattern is

not formed.

CE40Image quality control test pattern abnormality: The

P. 5-87

test pattern is not formed normally.

CE50Temperature/humidity sensor abnormality: The out-

P. 5-88

put value of this sensor is out of a specified range.

CE90Drum thermistor abnormality: The output value of

P. 5-88

the drum thermistor is out of a specified range.

2

© June 2005 TOSHIBA TECe-STUDIO281c/351c/451c ERROR CODE AND SELF-DIAGNOSTIC MODE

2 - 11

06/08

Page 12

Error codeClassificationContentsTroubleshooting

CEA0Copy process related

service call

Revolver home position detection abnormality: It

cannot detect that the revolver is at its home posi-

P. 5-89

tion.

CEB0Black developer unit lifting movement abnormality:

P. 5-90

The black developer unit does not move up or down

normally (lifting cam does not operate normally).

CEC0Copy process related

service call

2nd transfer roller position detection abnormality:

The 2nd transfer roller does not contact/release

P. 5-91

normally.

CEE0Transfer belt position detection abnormality (normal

P. 5-92

speed): The home position of the transfer belt cannot be detected.

CEE1Transfer belt position detection abnormality (when

P. 5-92

decelerating): Reference position of the transfer

belt cannot be detected.

CEF0Revolver motor abnormality: Revolver motor is not

P. 5-92

rotating or revolver is not moving normally.

CF20Toner density control

related service call

Toner density detection voltage abnormality: The

output value of the color auto-toner sensor in print-

P. 5-93

ing is out of a specified range.

CF30Reference plate detection voltage abnormality: The

P. 5-94

output value of the color auto-toner sensor against

the reference plate is out of a specified range at the

light amount correction during an auto-toner adjustment or when a print job has finished.

CF40Light amount correction voltage abnormality: The

P. 5-95

light amount correction is not finished normally during an auto-toner adjustment or when a print job

has finished, or the output value of the sensor is out

of a specified range when the light amount correction has finished.

CF50Color auto-toner sensor abnormality: The connec-

P. 5-96

tion of the color auto-toner sensor cannot be

detected at the initialization, or the output value of

color auto-toner sensor when the revolver starts

rotating for initialization is out of a specified range.

F070Communication

related service call

F090Circuit related service

F091NVRAM abnormality on the SYS boardP. 5-65

call

Communication error between System-CPU and

P. 5-63

Engine-CPU

SRAM abnormality on the SYS boardP. 5-65

F092SRAM and NVRAM abnormality on the SYS boardP. 5-65

F100Other service callHDD format error: HDD cannot be initialized nor-

P. 5-97

mally.

F101HDD unmounted: Connection of HDD cannot be

P. 5-97

detected.

F102HDD start error: HDD cannot become "Ready# state.P. 5-97

F103HDD transfer time-out: Reading/writing cannot be

P. 5-97

performed in the specified period of time.

F104HDD data error: Abnormality is detected in the data

P. 5-97

of HDD.

F105HDD other errorP. 5-97

F106Point and Print partition damageP. 5-97

F107/BOX partition damageP. 5-97

F108/SHA partition damageP. 5-97

e-STUDIO281c/351c/451c ERROR CODE AND SELF-DIAGNOSTIC MODE© June 2005 TOSHIBA TEC

2 - 12

Page 13

Error codeClassificationContentsTroubleshooting

F110Communication

related service call

Communication error between System-CPU and

Scanner-CPU

P. 5-63

F111Scanner response abnormalityP. 5-63

F120Other service callDatabase abnormality: Database is not operating

P. 5-97

normally.

F130Invalid MAC addressP. 5-97

F200Data overwrite kit (GP-1060) is taken offP. 5-98

F350Circuit related service

SLG board abnormalityP. 5-65

call

2

© June 2005 TOSHIBA TECe-STUDIO281c/351c/451c ERROR CODE AND SELF-DIAGNOSTIC MODE

2 - 13

05/11

Page 14

2.1.3Error in Internet FAX / Scanning Function

1)Internet FAX related error

Error codeClassificationTroubleshooting

1C10System access abnormalityP. 5-98

1C11Insufficient memoryP. 5-98

1C12Message reception errorP. 5-98

1C13Message transmission errorP. 5-98

1C14Invalid parameterP. 5-98

1C15Exceeding file capacityP. 5-98

1C20System management module access abnormalityP. 5-98

1C21Job control module access abnormalityP. 5-98

1C22Job control module access abnormalityP. 5-98

1C30Directory creation failureP. 5-99

1C31File creation failureP. 5-99

1C32File deletion failureP. 5-98

1C33File access failureP. 5-99

1C40Image conversion abnormalityP. 5-99

1C60HDD full failure during processingP. 5-99

1C61Address Book reading failureP. 5-99

1C62Memory acquiring failureP. 5-99

1C63Terminal IP address unsetP. 5-99

1C64Terminal mail address unsetP. 5-99

1C65SMTP address unsetP. 5-99

1C66Server time time-out errorP. 5-99

1C67NIC time time-out errorP. 5-99

1C68NIC access errorP. 5-99

1C69SMTP server connection errorP. 5-99

1C6AHOST NAME errorP. 5-99

1C6BTerminal mail address errorP. 5-100

1C6CDestination mail address errorP. 5-100

1C6DSystem errorP. 5-99

1C70SMTP client OFFP. 5-100

1C71SMTP authentication errorP. 5-100

1C72POP before SMTP errorP. 5-100

1C80Internet FAX transmission failure when processing E-mail job receivedP. 5-100

1C81Onramp Gateway transmission failureP. 5-100

1C82Internet FAX transmission failure when processing FAX job receivedP. 5-100

1CC0Job canceling -

1CC1Power failureP. 5-100

e-STUDIO281c/351c/451c ERROR CODE AND SELF-DIAGNOSTIC MODE© June 2005 TOSHIBA TEC

2 - 14

Page 15

2)RFC related error

Error code

2500Syntax error, command unrecog-

2501Syntax error in parameters or argu-

2503Bad sequence of commandsDestination mail address error

2504Command parameter not imple-

2550Mailbox unavailableDestination mail address error

2551User not localDestination mail address error

2552Insufficient system storageTerminal/Destination mail address

2553Mailbox name not allowedDestination mail address error

Message displayed in

the TopAccess screen

nized

ments

mented

ContentsTroubleshooting

HOST NAME error(RFC: 500)

Destination mail address error

(RFC: 500)

Terminal mail address error

(RFC: 500)

HOST NAME error(RFC: 501)

Destination mail address error

(RFC: 501)

Terminal mail address error

(RFC: 501)

(RFC: 503)

HOST NAME error

(RFC: 504)

(RFC: 550)

(RFC: 551)

error

(RFC: 552)

(RFC: 553)

P. 5-101

P. 5-101

P. 5-101

P. 5-101

P. 5-101

P. 5-101

P. 5-101

P. 5-101

2

© June 2005 TOSHIBA TECe-STUDIO281c/351c/451c ERROR CODE AND SELF-DIAGNOSTIC MODE

2 - 15

Page 16

3)Electronic Filing related error

Error code

2B10There was no applicable job.No applicable job error in job control

2B11Job status failed.JOB status abnormalityP. 5-102

2B20Failed to access file.File library function errorP. 5-102

2B30Insufficient disk space.Insufficient disk space in /BOX parti-

2B31Failed to access Electronic Filing.Status of specified Electronic Filing

2B32Failed to print Electronic Filing docu-

2B50Failed to process image.Image library errorP. 5-102

2B51Failed to process print image.List library errorP. 5-102

2B71Document(s) expire(s) in a few daysDocuments expiring in a few days

2B80Hard Disk space for Electronic Filing

2B90Insufficient Memory.Insufficient memory capacityP. 5-102

2BA0Invalid Box password specified.Invalid Box passwordP. 5-102

2BB0Job canceledJob canceling-

2BB1Power failure occurredPower failureP. 5-102

2BC0System fatal error.Fatal failure occurredP. 5-102

2BC1Failed to acquire resource.System management module

2BD0Power failure occurred during e-Fil-

2BE0Failed to get machine parameter.Machine parameter reading failureP. 5-103

2BF0Maximum number of page range is

2BF1Maximum number of document

2BF2Maximum number of folder range is

Message displayed in

the TopAccess screen

ment.

nearly full.

ing restoring.

reached.

range is reached.

reached.

ContentsTroubleshooting

module

tion

or folder is undefined or being created/deleted

Electronic Filing printing failure:

Specified document can not be

printed because of client#s access

(being edited, etc.).

exist

Hard disk space in /BOX partition is

nearly full (90%).

resource acquiring failure

Power failure occurred during restoring of Electronic Filing

Exceeding maximum number of

pages

Exceeding maximum number of documents

Exceeding maximum number of folders

P. 5-102

P. 5-102

P. 5-102

P. 5-102

-

-

P. 5-102

P. 5-102

P. 5-103

P. 5-103

P. 5-103

e-STUDIO281c/351c/451c ERROR CODE AND SELF-DIAGNOSTIC MODE© June 2005 TOSHIBA TEC

2 - 16

Page 17

4)E-mail related error

Error code

2C10Illegal Job statusSystem access abnormalityP. 5-104

2C11Not enough memoryInsufficient memoryP. 5-104

2C12Illegal Job statusMessage reception errorP. 5-104

2C13Illegal Job statusMessage transmission errorP. 5-104

2C14Invalid parameter specifiedInvalid parameterP. 5-104

2C15Message size exceeded limit or max-

2C20Illegal Job statusSystem management module access

2C21Illegal Job statusJob control module access abnor-

2C22Illegal Job statusJob control module access abnor-

2C30Failed to create directoryDirectory creation failureP. 5-104

2C31Failed to create fileFile creation failureP. 5-104

2C32Failed to delete fileFile deletion failureP. 5-104

2C33Failed to create fileFile access failureP. 5-104

2C40Failed to convert image file formatImage conversion abnormalityP. 5-104

2C60Failed to process your Job. Insuffi-

2C61Failed to read AddressBookAddress Book reading failureP. 5-104

2C62Not enough memoryMemory acquiring failureP. 5-104

2C63Invalid Domain AddressTerminal IP address unsetP. 5-104

2C64Invalid Domain AddressTerminal mail address unsetP. 5-105

2C65Failed to connect to SMTP serverSMTP address unsetP. 5-105

2C66Failed to connect to SMTP serverServer time time-out errorP. 5-105

2C67Failed to send E-Mail messageNIC time time-out errorP. 5-105

2C68Failed to send E-Mail messageNIC access errorP. 5-105

2C69Failed to connect to SMTP serverSMTP server connection errorP. 5-105

2C6AFailed to send E-Mail messageHOST NAME error (No RFC error)P. 5-105

2C6BInvalid address specified in From:

2C6CInvalid address specified in To: fieldDestination mail address error (No

2C6DNIC system errorSystem errorP. 5-105

2C70SMTP service is not availableSMTP client OFFP. 5-105

2C71Failed SMTP AuthenticationSMTP authentication errorP. 5-105

2C72POP Before SMTP Authentication

2C80Failed to process received E-mail jobE-mail transmission failure when pro-

2C81Failed to process received Fax jobProcess failure of FAX job receivedP. 5-105

2CC0Job canceledJob canceling-

2CC1Power failure occurredPower failureP. 5-106

Message displayed in

the TopAccess screen

imum size

cient disk space.

field

Failed

ContentsTroubleshooting

2

Exceeding file capacityP. 5-104

P. 5-104

abnormality

P. 5-104

mality

P. 5-104

mality

HDD full failure during processingP. 5-104

Terminal mail address errorP. 5-105

P. 5-105

RFC error)

POP before SMTP errorP. 5-105

P. 5-105

cessing E-mail job received

© June 2005 TOSHIBA TECe-STUDIO281c/351c/451c ERROR CODE AND SELF-DIAGNOSTIC MODE

2 - 17

Page 18

5)File sharing related error

Error code

2D10Illegal Job statusSystem access abnormalityP. 5-107

2D11Not enough memoryInsufficient memoryP. 5-107

2D12Illegal Job statusMessage reception errorP. 5-107

2D13Illegal Job statusMessage transmission errorP. 5-107

2D14Invalid parameter specifiedInvalid parameterP. 5-107

2D15There are too many documents in the

2D20Illegal Job statusSystem management module access

2D21Illegal Job statusJob control module access abnor-

2D22Illegal Job statusJob control module access abnor-

2D30Failed to create directoryDirectory creation failureP. 5-107

2D31Failed to create fileFile creation failureP. 5-107

2D32Failed to delete fileFile deletion failureP. 5-107

2D33Failed to create fileFile access failureP. 5-107

2D40Failed to convert image file formatImage conversion abnormalityP. 5-107

2D60Failed to copy fileFile library access abnormalityP. 5-107

2D62Failed to connect to network destina-

2D63Specified network path is invalid.

2D64Logon to file server failed. Check

2D65There are too many documents in the

2D66Failed to process your Job. Insuffi-

2D67FTP service is not availableFTP service not availableP. 5-108

2D68File Sharing service is not availableFile sharing service not availableP. 5-108

2DA0Expired scan documents deleted

2DA1Expired Sent Fax documents deleted

2DA2Expired Received Fax documents

2DA3Scanned documents in shared folder

2DA4Sent Fax Documents in shared folder

2DA5Received Fax Documents in shared

2DA6Failed to delete file.File deletion failureP. 5-107

2DA7Failed to acquire resource.Resource acquiring failureP. 5-107

2DC0Job canceledJob canceling2DC1Power failure occurredPower failureP. 5-108

Message displayed in

the TopAccess screen

folder. Failed in creating new document.

tion. Check destination path

Check destination path

username and password

folder. Failed in creating new document.

cient disk space.

from share folder.

from shared folder.

deleted from shared folder.

deleted upon user#s request.

deleted upon user#s request.

folder deleted upon user#s request.

ContentsTroubleshooting

Exceeding document numberP. 5-107

P. 5-107

abnormality

P. 5-107

mality

P. 5-107

mality

File server connection errorP. 5-107

Invalid network pathP. 5-107

Login failureP. 5-108

Exceeding documents in folder:

P. 5-108

Creating new document is failed.

HDD full failure during processingP. 5-108

Periodical deletion of scanned docu-

-

ments completed properly.

Periodical deletion of transmitted

-

FAX documents completed properly.

Periodical deletion of received FAX

-

documents completed properly.

Manual deletion of scanned docu-

-

ments completed properly.

Manual deletion of transmitted FAX

-

documents completed properly.

Manual deletion of received FAX

-

documents completed properly.

e-STUDIO281c/351c/451c ERROR CODE AND SELF-DIAGNOSTIC MODE© June 2005 TOSHIBA TEC

2 - 18

06/08

Page 19

6)E-mail reception related error

Error code

3A10MIME Error has been detected in the

3A11MIME Error has been detected in the

3A12MIME Error has been detected in the

3A20Analyze Error has been detected in

3A21Analyze Error has been detected in

3A22Analyze Error has been detected in

3A30Whole partial mails were not reached

3A40Partial Mail Error has been detected

3A50HDD Full Error has been occurred in

3A51HDD Full Error has been occurred in

3A52HDD Full Error has been occurred in

3A60HDD Full Warning has been occurred

3A61HDD Full Warning has been occurred

3A62HDD Full Warning has been occurred

3A70Receiving partial mail was aborted

3A80Partial mail was received during the

3A81Partial mail was received during the

3A82Partial mail was received during the

3B10Format Error has been detected in

3B11Format Error has been detected in

3B12Format Error has been detected in

Message displayed in

the TopAccess screen

received mail.

received mail. This mail has been

transferred to the administrator.

received mail. This mail could not be

transferred to the administrator.

the received mail.

the received mail. This mail has been

transferred to the administrator.

the received mail. This mail could not

be transferred to the administrator.

by timeout.

in the received mail.

this mail.

this mail. This mail has been transferred to the administrator.

this mail. This mail could not be

transferred to the administrator.

in this mail.

in this mail. This mail could not be

transferred to the administrator.

in this mail. This mail could not be

transferred to the administrator.

since the partial mail setting has

been changed to Disable.

partial mail setting is disabled.

partial mail setting is disabled. This

mail has been transferred to the

administrator.

partial mail setting is disabled. This

mail could not be transferred to the

administrator.

the received mail.

the received mail. This mail has been

transferred to the administrator.

the received mail. This mail could not

be transferred to the administrator.

ContentsTroubleshooting

E-mail MIME errorP. 5-109

P. 5-109

P. 5-109

E-mail analysis errorP. 5-109

P. 5-109

P. 5-109

Partial mail time-out errorP. 5-109

Partial mail related errorP. 5-109

Insufficient HDD capacity errorP. 5-109

P. 5-109

P. 5-109

Warning of insufficient HDD capacityP. 5-109

P. 5-109

P. 5-109

Warning of partial mail interruptionP. 5-109

Partial mail reception setting OFFP. 5-109

P. 5-109

P. 5-109

E-mail format errorP. 5-109

P. 5-109

P. 5-109

2

© June 2005 TOSHIBA TECe-STUDIO281c/351c/451c ERROR CODE AND SELF-DIAGNOSTIC MODE

2 - 19

Page 20

Error code

Message displayed in

the TopAccess screen

3B20Content-Type Error has been

detected in the received mail.

3B21Content-Type Error has been

detected in the received mail. This

mail has been transferred to the

administrator.

3B22Content-Type Error has been

detected in the received mail. This

mail could not be transferred to the

administrator.

3B30Charset Error has been detected in

the received mail.

3B31Charset Error has been detected in

the received mail. This mail has been

transferred to the administrator.

3B32Charset Error has been detected in

the received mail. This mail could not

be transferred to the administrator.

3B40Decode Error has been detected in

the received mail.

3B41Decode Error has been detected in

the received mail. This mail has been

transferred to the administrator.

3B42Decode Error has been detected in

the received mail. This mail could not

be transferred to the administrator.

3C10Tiff Analyze Error has been detected

in the received mail.

3C11Tiff Analyze Error has been detected

in the received mail. This mail has

been transferred to the administrator.

3C12Tiff Analyze Error has been detected

in the received mail. This mail could

not be transferred to the administrator.

3C13Tiff Analyze Error has been detected

in the received mail.

3C20Tiff Compression Error has been

detected in the received mail.

3C21Tiff Compression Error has been

detected in the received mail. This

mail has been transferred to the

administrator.

3C22Tiff Compression Error has been

detected in the received mail. This

mail could not be transferred to the

administrator.

3C30Tiff Resolution Error has been

detected in the received mail.

3C31Tiff Resolution Error has been

detected in the received mail. This

mail has been transferred to the

administrator.

3C32Tiff Resolution Error has been

detected in the received mail. This

mail could not be transferred to the

administrator.

ContentsTroubleshooting

Content-Type errorP. 5-109

P. 5-109

P. 5-109

Charset errorP. 5-109

P. 5-109

P. 5-109

E-mail decode errorP. 5-109

P. 5-109

P. 5-109

TIFF analysis errorP. 5-109

P. 5-109

P. 5-109

P. 5-109

E-mail format errorP. 5-109

P. 5-109

P. 5-109

Content-Type errorP. 5-110

P. 5-110

P. 5-110

e-STUDIO281c/351c/451c ERROR CODE AND SELF-DIAGNOSTIC MODE© June 2005 TOSHIBA TEC

2 - 20

Page 21

Error code

3C40Tiff Paper Size Error has been

3C41Tiff Paper Size Error has been

3C42Tiff Paper Size Error has been

3C50Offramp Destination Error has been

3C51Offramp Destination Error has been

3C52Offramp Destination Error has been

3C60Offramp Security Error has been

3C61Offramp Security Error has been

3C62Offramp Security Error has been

3C70Power Failure has been occurred in

3D10SMTP Destination Error has been

3D20Offramp Destination limitation Error

3D30Fax Board Error has been occurred

3E10POP3 Connection Error has been

3E20POP3 Connection Timeout Error has

3E30POP3 Login Error has been occurred

3E40POP3 Login Error occurred in the

3F00File I/O Error has been occurred in

3F10 P. 5-110

3F20 P. 5-110

3F30 P. 5-110

3F40 P. 5-110

Message displayed in

the TopAccess screen

detected in the received mail.

detected in the received mail. This

mail has been transferred to the

administrator.

detected in the received mail. This

mail could not be transferred to the

administrator.

detected in the received mail.

detected in the received mail. This

mail has been transferred to the

administrator.

detected in the received mail. This

mail could not be transferred to the

administrator.

detected in the received mail.

detected in the received mail. This

mail has been transferred to the

administrator.

detected in the received mail. This

mail could not be transferred to the

administrator.

Email receiving.

detected in the received mail. This

mail was deleted.

has been detected in the received

mail.

in the received mail.

occurred in the received mail.

been occurred in the received mail.

in the received mail.

received mail.

this mail. The mail could not be

received until File I/O is recovered.

ContentsTroubleshooting

Charset errorP. 5-110

E-mail decode errorP. 5-110

TIFF analysis errorP. 5-110

Power failure errorP. 5-110

Destination address errorP. 5-110

Offramp destination limitation errorP. 5-110

FAX board errorP. 5-110

POP3 server connection errorP. 5-110

POP3 server connection time-out

error

POP3 login errorP. 5-110

POP3 login method errorP. 5-110

File I/O errorP. 5-110

P. 5-110

P. 5-110

P. 5-110

P. 5-110

P. 5-110

P. 5-110

P. 5-110

2

© June 2005 TOSHIBA TECe-STUDIO281c/351c/451c ERROR CODE AND SELF-DIAGNOSTIC MODE

2 - 21

Page 22

2.1.4Printer function error

Following codes are displayed at the end of the user name on the print job log screen.

Error codeContentsTroubleshooting

402FPage memory size error - 1200 dpi network print is performed by the equip-

ment with 128 MB (standard) memory.

4031HDD full during print - Large quantity image data by private print or invalid

network print are saved in HDD.

4032Private-print-only error: Jobs other than Private print jobs cannot be per-

formed.

4033Printing data storing limitation error: Printing with its data being stored to the

HDD temporarily (Proof print, Private print, Scheduled print, etc.) cannot be

performed.

4034e-Filing storing limitation error: Printing with its data being stored to the HDD

(print and e-Filing, print to e-Filing, etc.) cannot be performed.

4035Local file storing limitation error: Network FAX or Internet FAX cannot be sent

when "Local" is selected for the destination of the file to save.

4036User authentication error: The user who intended to print a document is not

registered as a user.

A221Print job cancellation - Print job (copy, list print, network print) is deleted from

the print job screen.

A222Print job power failure - The power of the equipment is turned OFF during

print job (copy, list print, network print).

A290Limit over error (Black): The numbers of output pages have exceeded those

specified with both of the department code and the user code at the same

time.

A291Limit over error (Black): The number of output pages has exceeded the one

specified with the user code.

A292Limit over error (Black): The number of output pages has exceeded the one

specified with the department code.

A2A0Limit over error (Color): The numbers of output pages have exceeded those

specified with both of the department code and the user code at the same

time.

A2A1Limit over error (Color): The number of output pages has exceeded the one

specified with the user code.

A2A2Limit over error (Color): The number of output pages has exceeded the one

specified with the department code.

P. 5-111

P. 5-111

P. 5-111

P. 5-111

P. 5-111

P. 5-111

P. 5-111

P. 5-111

P. 5-111

P. 5-111

P. 5-111

P. 5-111

P. 5-111

P. 5-111

P. 5-111

e-STUDIO281c/351c/451c ERROR CODE AND SELF-DIAGNOSTIC MODE© June 2005 TOSHIBA TEC

2 - 22

Page 23

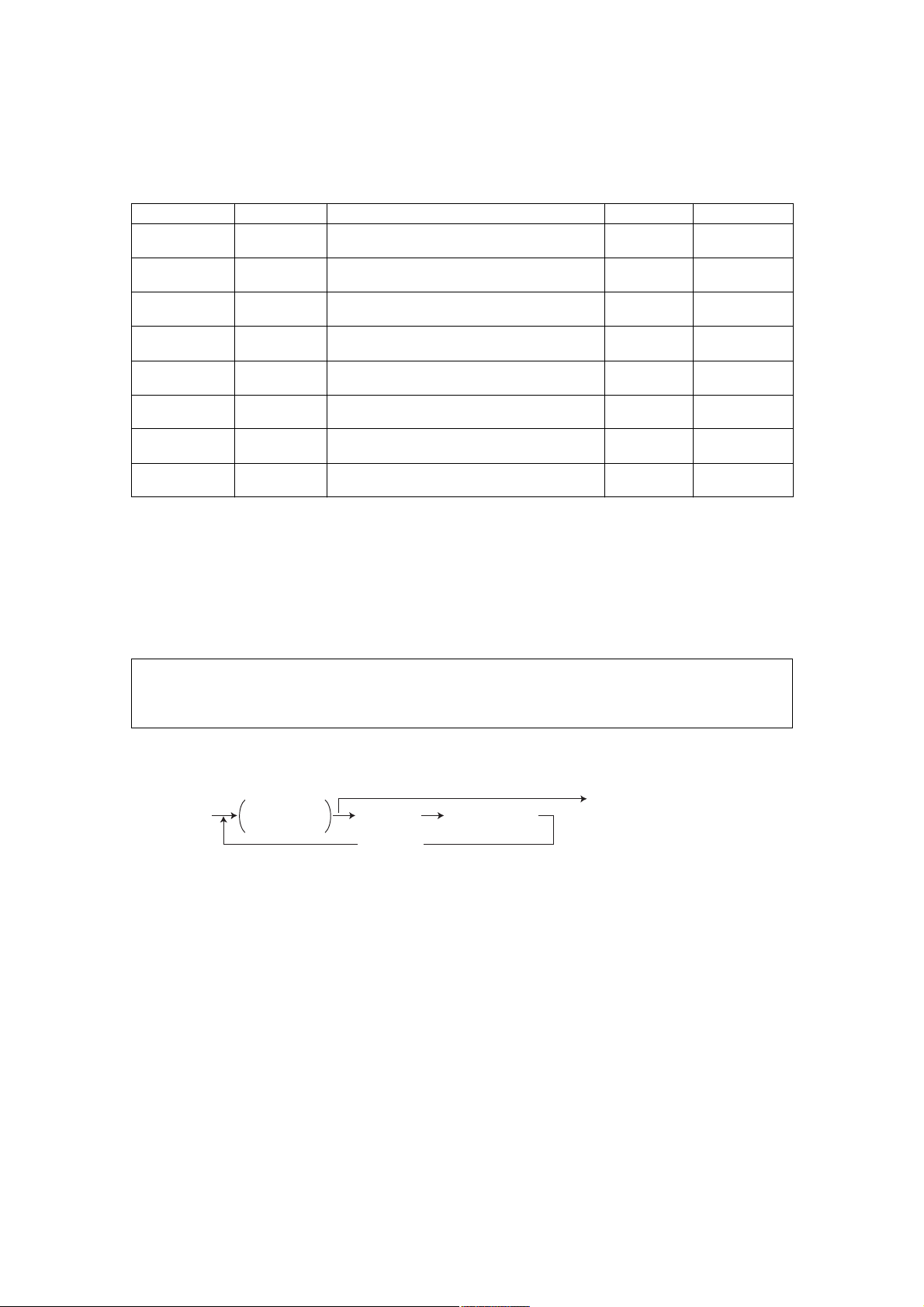

<<Error history>>

In the setting mode (08-253), the latest twenty groups of error data will be displayed.

Display example

EA10 99999999 05 06 14 17 57 32 064 064 23621000000

Error codeTotal counterYY MM DD HH MM SSMMMNNNABCDEFHIJLO

4 digits8 digits12 digits (Year is indicated

3 digits3 digits11 digits

with its last two digits.)

APaper source

0: Not selected 1: Bypass feed 2: LCF 3: Upper drawer 4: Lower drawer 5: PFP upper drawer

6: PFP lower drawer 7: Unused 8: Unused

BPaper size code

0: A5/ST 1: A5-R 2: ST-R 3: LT, 4: A4 5: B5-R 6: LT-R 7: A4-R 8: OTHER/UNIV 9: B5,

A: FOLIO/COMP B: LG C: B4 D: LD E: A3 F: 13"LG G: Unsed H: A6-R I: Post card J: 8.5"SQ

K: A3-wide L: 305×457 mm M: 8K N: 16K-R O: 16K Z: Not selected

CSort mode/staple mode

0: Non-sort/Non-staple 1: Group 2: Sort 7: Front staple

8: Double staple 9: Rear staple A: Saddle stitch

DADF mode

0: Unused 1: AUTO FEED (SADF) 2: STACK FEED

EAPS/AMS mode

0: Not selected 1: APS 2: AMS

FDuplex mode

0: Not selected 1: Book 2: Double-sided/Single-sided 4: Double-sided/Duplex copying

8: Single-sided/Duplex copying

GUnused

HImage shift

0: Unused 1: Book 2: Left 4: Right

IEditing

0: Unused 1: Masking 2: Trimming 3: Mirror image 4: Unused

JEdge erase/Dual-page

0: Unused 1: Edge erase 2: Dual-page 3: Edge erase & Dual-page

KUnused

LFunction

0: Unused 1: Copying 2: FAX/Internet FAX transmission 3: FAX/Internet FAX/E-mail reception printing

4: Unused 5: Printing/List print 6: Scan/E-mail transmission

MMMPrimary scanning reproduction ratio (Display in hexadecimal)

(Mx256)+(Mx16)+M

NNNSecondary scanning reproduction ratio (Display in hexadecimal)

(Nx256)+(Nx16)+N

OColor mode

0: Auto color 1: Full color 2: Black 3: Unused 4: Twin color copy 5: Gray scale

6: Unused 7: Image smoothing

2

© June 2005 TOSHIBA TECe-STUDIO281c/351c/451c ERROR CODE AND SELF-DIAGNOSTIC MODE

2 - 23

Page 24

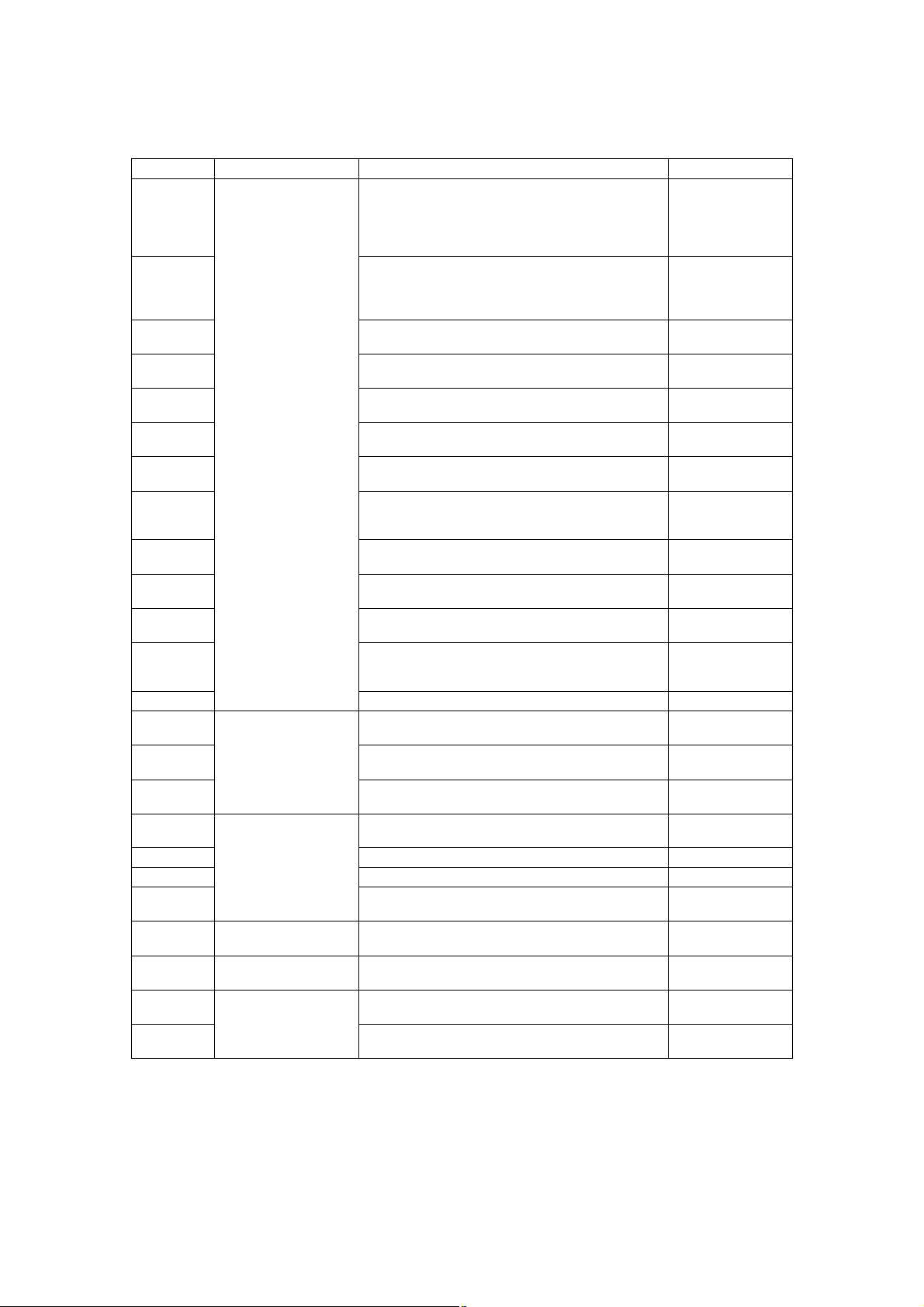

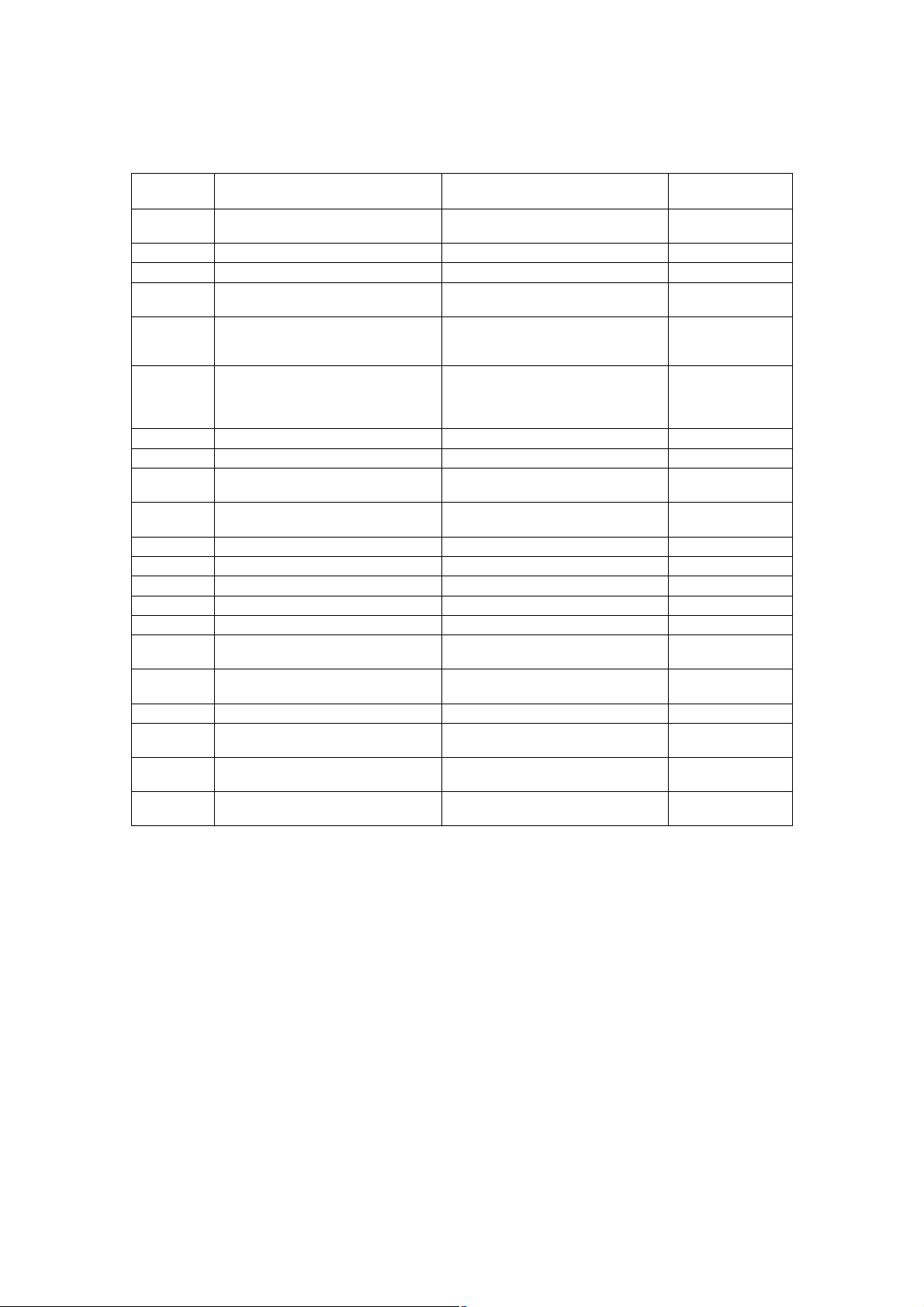

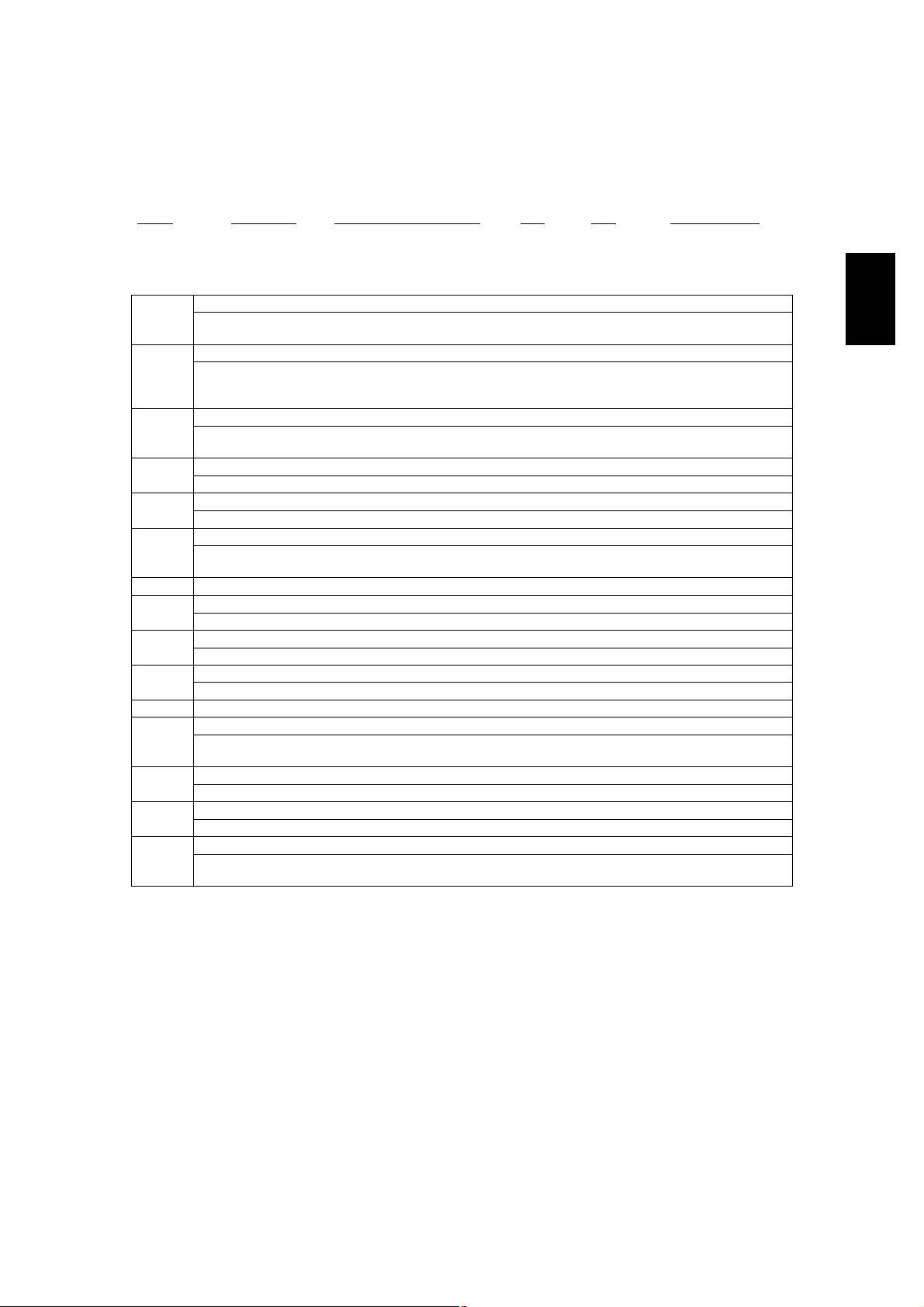

2.2Self-diagnosis Modes

ModeFor startContentsFor exitDisplay

Control panel

check mode

Test mode[0]+[3]+

Test print mode[0]+[4]+

Adjustment

mode

Setting mode[0]+[8]+

List print mode[9]+[START]+

PM support

mode

Firmware

update mode

Notes:

1.To enter the desired mode, turn ON the power while two digital keys designated to each mode

(e.g. [0] and [5]) are pressed simultaneously.

2.When the optional FAX unit is installed, Faxes received automatically during the self-diagnosis mode may not be printed out. Be sure to disconnect the modular code from the line connectors (LINE1, LINE2) of the equipment before starting the self-diagnosis mode. Also, be

sure to finish the self-diagnosis mode by turning the power OFF and back ON before connecting the modular code.

[0]+[1]+

[POWER]

[POWER]

[POWER]

[0]+[5]+

[POWER]

[POWER]

[POWER]

[6]+[START]+

[POWER]

[8]+[9]+

[POWER]

All LEDs on the control panel are lit, and all

the LCD pixels blink.

Checks the status of input/output signals.[POWER]

Outputs the test patterns.[POWER]

Adjusts various items.[POWER]

Sets various items.[POWER]

Prints out the data lists of the codes 05 and

08, PM support mode and pixel counter.

Clears each counter.[POWER]

Performs updating of the system firmware.[POWER]

[POWER]

OFF/ON

OFF/ON

OFF/ON

OFF/ON

OFF/ON

[POWER]

OFF/ON

OFF/ON

OFF/ON

-

100% C A4

TEST MODE

100% P A4

TEST PRINT

100% A A4

TEST MODE

100% D

TEST MODE

100% UA A4

LIST PRINT

100% K

TEST MODE

-

To exit from Adjustment mode and Setting mode:

Shut down the equipment. When the power should be turned OFF, be sure to shut down the equipment by pressing the [ENERGY SAVER] button for a few seconds.

<Operation procedure>

$ Control panel check mode (01):

ЕрГЕпГ

ЕРСЙЫОГ

ÔÛÜ ´·¬ñ

ÔÝÜ ¾´·²µ·²¹

ЕНМЯОМГ

ЕНМЯОМГ

øÞ«¬¬±² ½¸»½µ÷

ЕРСЙЫОГ СЪЪсСТ

øÛ¨·¬÷

Notes:

1.A mode can be canceled by [POWER] OFF/ON when the LED is lit and the LCD is blinking.

2.Button Check

Buttons with LED(Press to turn OFF the LED.)

Buttons without LED(Press to display the message on the control panel.)

Button on touch panel(Press to display the screen on the control panel at power-ON.)

$ Test mode (03): Refer to 2.2.1. Input check (test mode 03)! and 2.2.2. Output check (test mode

03)!.

$ Test print mode (04): Refer to 2.2.3. Test print mode (04)!.

$ Adjustment mode (05): Refer to 2.2.4. Adjustment mode (05)!.

$ Setting mode (08): Refer to 2.2.5. Setting mode (08)!.

e-STUDIO281c/351c/451c ERROR CODE AND SELF-DIAGNOSTIC MODE© June 2005 TOSHIBA TEC

2 - 24

06/08

Page 25

$ List print mode (9S): The procedure varies depending on the code.

ЕзГЕНМЯОМГ

ЕРСЙЫОГ

øݱ¼»÷

ïðïæ ß¼¶«-¬³»²¬ ³±¼» øðë÷

ïðîæ Í»¬¬·²¹ ³±¼» øðè÷

øݱ¼»÷

ïðíæ ÐÓ -«°°±®¬ ³±¼»

ïðìæ ͬ±®»¼ ·²º±®³¿¬·±² ±º °·¨»´ ½±«²¬»® ø¬±²»® ½¿®¬®·¼¹» ®»º»®»²½»÷

ïðëæ ͬ±®»¼ ·²º±®³¿¬·±² ±º °·¨»´ ½±«²¬»® ø-»®ª·½» ¬»½¸²·½·¿² ®»º»®»²½»÷

ïðêæ Û®®±® ¸·-¬±®§ øÓ¿¨·³«³ ïððð ·¬»³-÷

ïðéæ Û®®±® ¸·-¬±®§ øÔ¿¬»-¬ èð ·¬»³-÷

ЕНМЯОМГЕНМЯОМГ

ÅÜ·¹·¬¿´ µ»§-Ã

Õ»§ ·² ¬¸» º·®-¬

½±¼» ¬± ¾» °®·²¬»¼

ÅÜ·¹·¬¿´ µ»§-Ã

Õ»§ ·² ¬¸» ´¿-¬

½±¼» ¬± ¾» °®·²¬»¼

$ PM support mode (6S):

ЕкГЕНМЯОМГ

ЕРСЙЫОГ

îæ ÐÓ Í«°°±®¬ ͽ®»»²

øݱ¼»÷

ЕНМЯОМГ

øÑ°»®¿¬·±² -¬¿®¬»¼÷

ЕРСЙЫОГ СЪЪсСТ

$ Firmware update mode (89): Refer to 6. FIRMWARE UPDATING!.

ЕРСЙЫОГ

ÑÒ

Ì»-¬ °®·²¬

³±¼»

ß¼¶«-¬³»²¬

³±¼»

Í»¬¬·²¹

³±¼»

É¿®³·²¹ «°

λ¿¼§

Ò±®³¿´

ݱ²¬®±´ °¿²»´

½¸»½µ ³±¼»

ЕрГЕпГЕрГЕнГЕрГЕмГЕрГЕлГЕрГЕиГЕзГЕНМЯОМГЕкГЕНМЯОМГЕиГЕзГ

Ì»-¬ ³±¼»

øÛ¨·¬÷

Ô·-¬ °®·²¬

³±¼»

ЕНМЯОМГ

Ô·-¬ -¬¿®¬- ¬±

¾» °®·²¬»¼

ÐÓ -«°°±®¬

³±¼»

ЕРСЙЫОГ

СЪЪсСТ

øÛ¨·¬÷

Ú·®³©¿®»

«°¼¿¬» ³±¼»

2

ЕРСЙЫОГ

ÑÚÚ

öï

̱ «-»®

ͬ¿¬» ¬®¿²-·¬·±² ¼·¿¹®¿³ ±º -»´ºó¼·¿¹²±-·- ³±¼»-

Fig. 2-1

*1Turn OFF the power after using the self-diagnosis mode, and leave the equipment to the user.

© June 2005 TOSHIBA TECe-STUDIO281c/351c/451c ERROR CODE AND SELF-DIAGNOSTIC MODE

2 - 25

Page 26

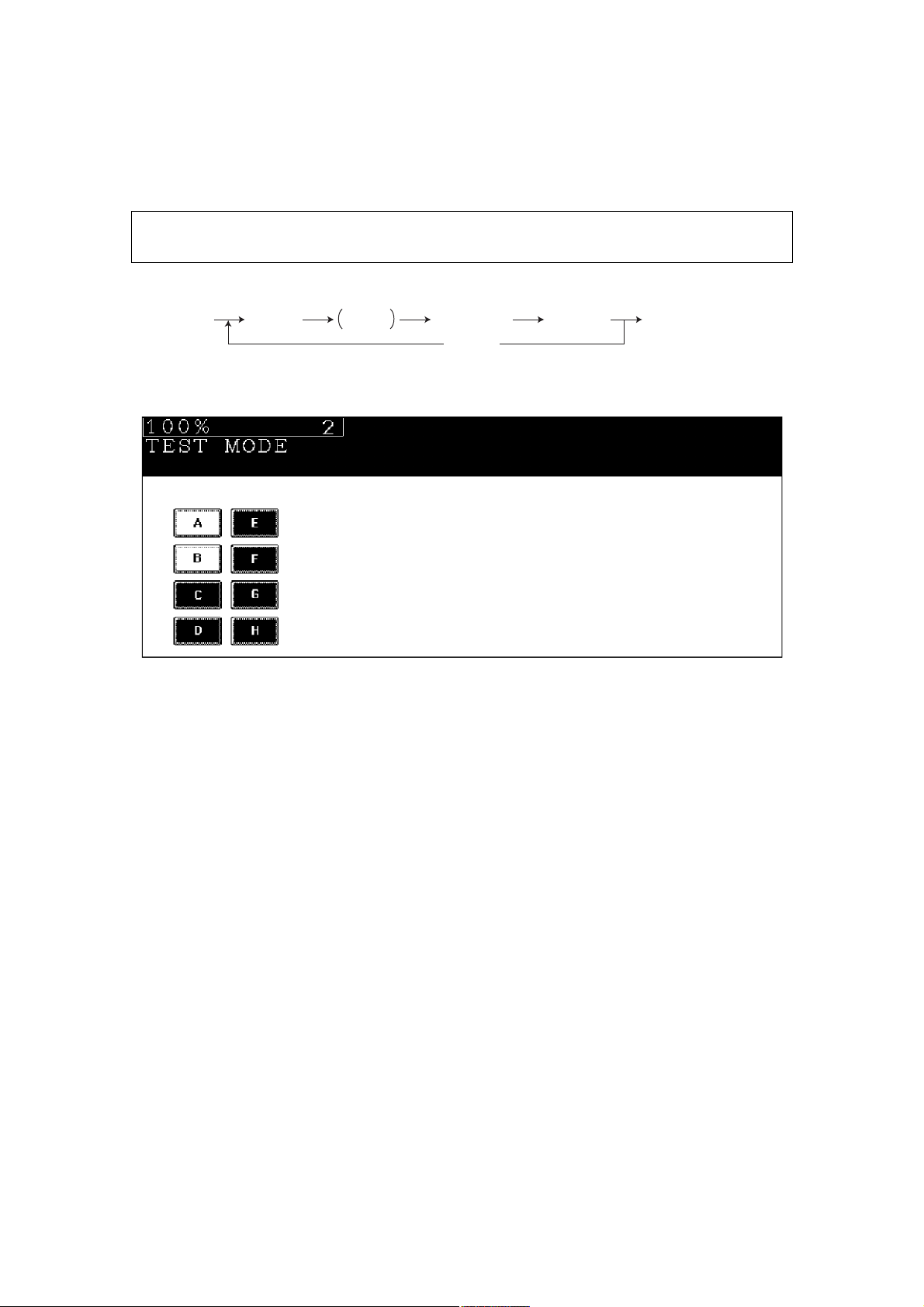

2.2.1Input check (Test mode 03)

The status of each input signal can be checked by pressing the [FAX] button, [COPY] button and

the digital keys in the test mode (03).

<Operation procedure>

ЕрГЕнГ

ЕРСЙЫОГ

ЕНМЯОМГ

ЕЪЯИГ

±®

ЕЭСРЗГ

ÅÜ·¹·¬¿´ µ»§-Ã

ЕЭФЫЯОГ

øÔÝÜ ÑÒ÷

ЕРСЙЫОГ СЪЪсСТ

øÛ¨·¬÷

Note: Note:

Initialization is performed before the equipment enters the test mode.

Fig. 2-2 Example of display during input check

Items to be checked and the condition of the equipment when the buttons [A] to [H] are highlighted are

listed in the following pages.

e-STUDIO281c/351c/451c ERROR CODE AND SELF-DIAGNOSTIC MODE© June 2005 TOSHIBA TEC

2 - 26

Page 27

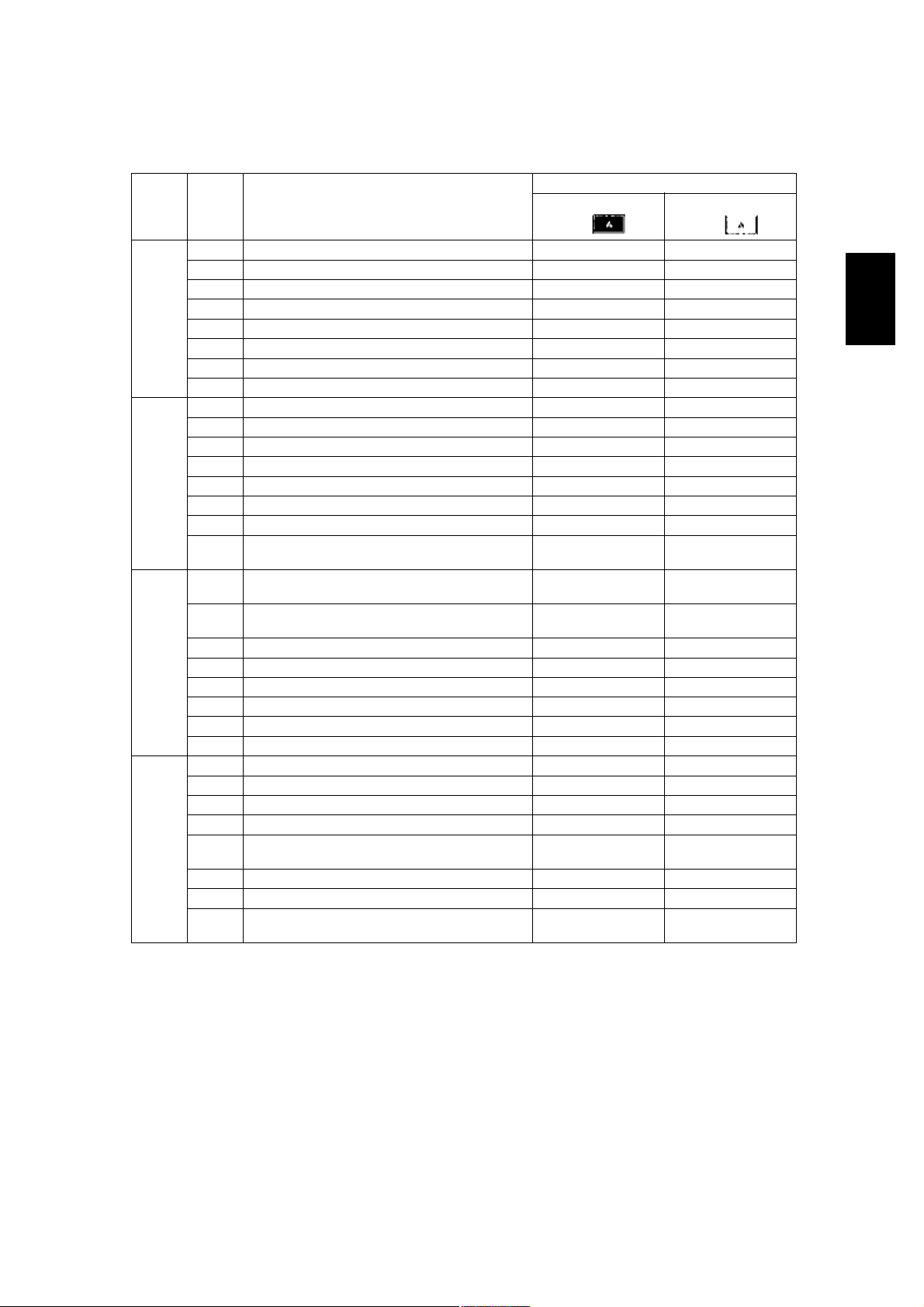

[FAX] button: OFF/[COPY] button: OFF ([FAX] LED: OFF/[COPY] LED: OFF)

Digital

key

[1]

[2]

[3]

[4]

ButtonItems to check

ABypass unit connectionNot connectedConnected

BADU connectionNot connectedConnected

C---

DLCF connectionNot connectedConnected

E---

F---

G---

HLCF drawer detection switchDrawer not installedDrawer present

APFP upper drawer detection switchDrawer not installedDrawer present

B---

CPFP upper drawer paper stock sensorPaper almost emptyPaper present

DPFP upper drawer feed sensorPaper presentNo paper

EPFP connectionNot connectedConnected

FPFP side cover open/close switchCover openedCover closed

GPFP upper drawer empty sensorNo paperPaper present

HPFP upper drawer tray-up sensorTray at upper limit

ALCF tray bottom sensorTray at bottom posi-

BLCF standby side paper misload detection sen-

sor

C---

D---

E---

F---

G---

HPaper stock sensor at LCF feed sidePaper presentNo paper

APFP lower drawer detection switchDrawer not installedDrawer present

B---

CPFP lower drawer paper stock sensorPaper almost emptyPaper present

DPFP lower drawer feed sensorPaper presentNo paper

EPFP motor rotation status (Motor is rotating at

output mode (03))

F---

GPFP lower drawer empty sensorNo paperPaper present

HPFP lower drawer tray-up sensorTray at upper limit

Highlighted display

e.g.

position

tion

Properly loadedPaper misload

Abnormal rotationNormal rotation

position

Contents

Normal display

e.g.

2

Other than upper

limit position

Other than upper

limit position

Other than upper

limit position

© June 2005 TOSHIBA TECe-STUDIO281c/351c/451c ERROR CODE AND SELF-DIAGNOSTIC MODE

2 - 27

Page 28

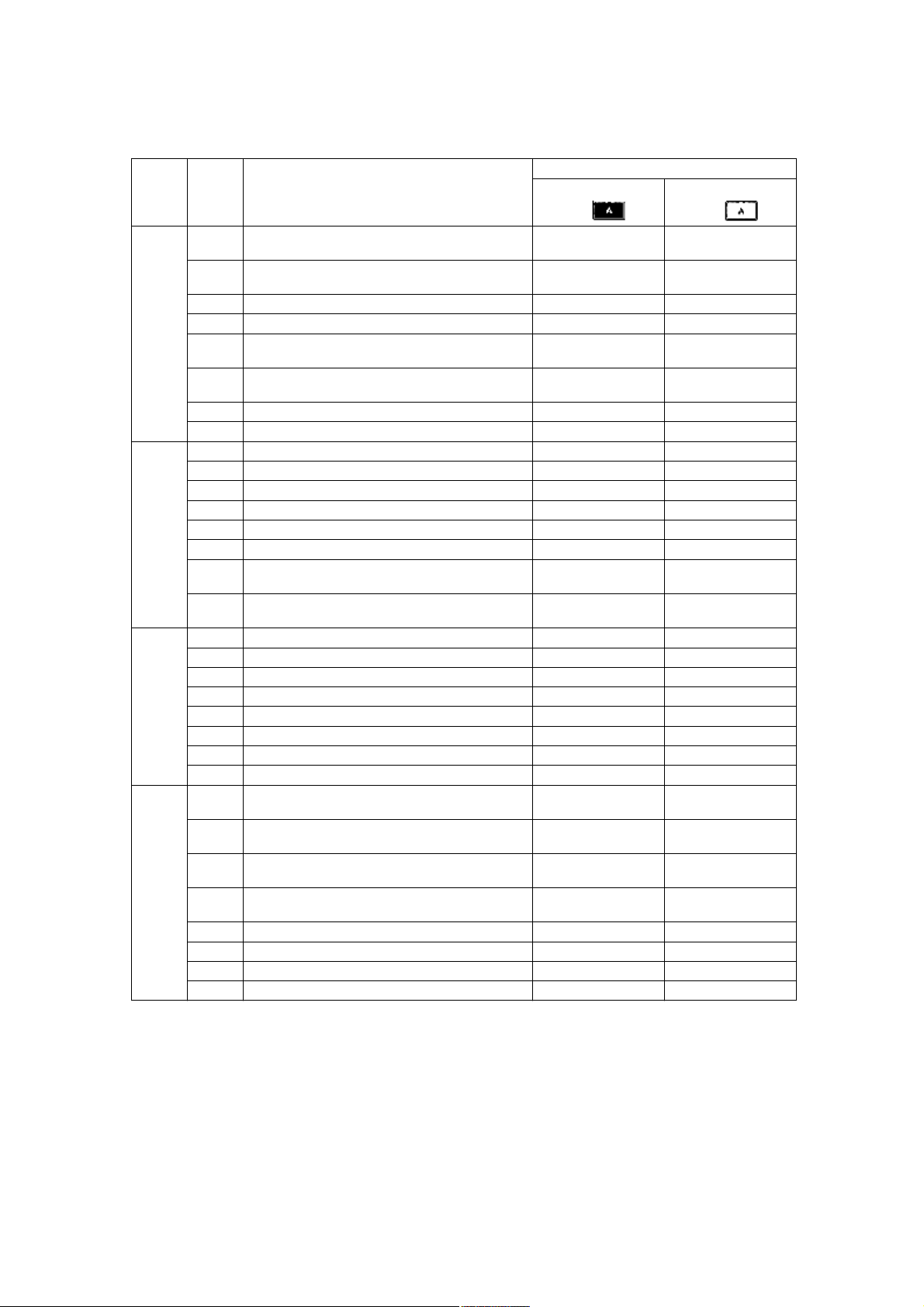

Digital

key

[5]

[6]

[7]

[8]

Contents

ButtonItems to check

Highlighted display

e.g.

ALCF end fence home position sensorFence home posi-

tion

Normal display

e.g.

Other than home

position

BLCF end fence stop position sensorFence stop positionOther than stop

position

CEmpty sensor at LCF standby sideNo paperPaper present

DLCF side cover open/close switchCover closedCover opened

ELCF motor rotation status (Motor is rotating at

Abnormal rotationNormal rotation

output mode (03))

FLCF tray-up sensorTray at upper limit

position

Other than upper

limit position

GLCF feed sensorNo paperPaper present

HEmpty sensor at LCF feed sideNo paperPaper present

ALower drawer detection switchDrawer not installedDrawer present

BUpper drawer detection switchDrawer not installedDrawer present

CLower drawer paper stock sensorPaper almost emptyPaper present

DUpper drawer paper stock sensorPaper almost emptyPaper present

ELower drawer empty sensorNo paperPaper present

FUpper drawer empty sensorNo paperPaper present

GLower drawer tray-up sensorTray at upper limit

position

HUpper drawer tray-up sensorTray at upper limit

position

Other than upper

limit position

Other than upper

limit position

A---

B---

C---

D---

ESide cover open/close switchCover openedCover closed

FFront cover opening/closing switchCover openedCover closed

G---

HExit sensorPaper presentNo paper

ABypass feed paper width sensor 3

Bit 1Bit 0

(Refer to table1)

BBypass feed paper width sensor 2

Bit 1Bit 0

(Refer to table1)

CBypass feed paper width sensor 1

Bit 1Bit 0

(Refer to table1)

DBypass feed paper width sensor 0

Bit 1Bit 0

(Refer to table1)

EBypass sensorNo paperPaper present

FADU opening/closing switchADU openedADU closed

GADU exit sensorPaper presentNo paper

HADU entrance sensorPaper presentNo paper

e-STUDIO281c/351c/451c ERROR CODE AND SELF-DIAGNOSTIC MODE© June 2005 TOSHIBA TEC

2 - 28

Page 29

Contents

Digital

key

[9]

[0]

ButtonItems to check

A---

B---

C---

D---

E---

FKey copy counter connectionNot connectedConnected

G---

H---

A---

B---

C---

D---

E---

F---

G---

H---

Highlighted display

e.g.

Normal display

e.g.

Table 1. Relation between the status of the bypass paper width sensor and paper size (width).

Bypass paper width sensor

3210

0111A3/LD

1011A4-R/LT-R

1101A5-R/ST-R

1110Card size

0011B4-R/LG

1001B5-R

Paper width size

2

© June 2005 TOSHIBA TECe-STUDIO281c/351c/451c ERROR CODE AND SELF-DIAGNOSTIC MODE

2 - 29

Page 30

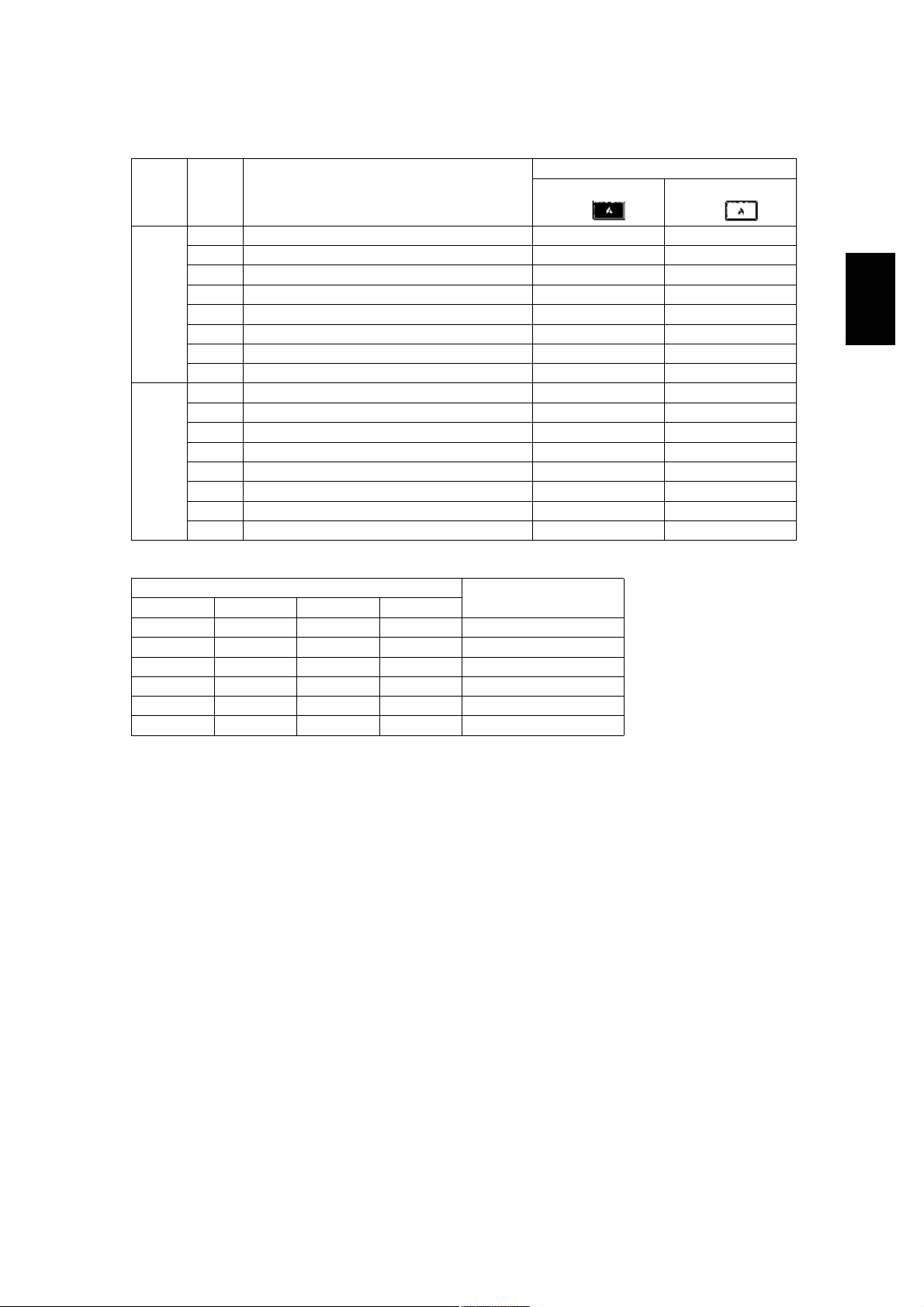

[FAX] button: ON/[COPY] button: OFF ([FAX] LED: ON/[COPY] LED: OFF)

Digital

key

[1]

[2]

[3]

[4]

ButtonItems to check

A2nd transfer roller position detection sensorReleasedContacted

BBlack developer contact timing detection sensorReleasing move-

CBlack developer contact position detection sen-

sor

DMain motor rotation status

(Motor is rotating at Output Mode (03))

EDeveloper motor rotation status

(Motor is rotating at Output Mode (03))

FTransport motor rotation status

(Motor is rotating at Output Mode (03))

GPolygonal motor rotation status

(Motor is rotating at Output Mode (03))

H24V Power supplyPower OFFPower ON

AIPC board connectionNot connectedConnected

BColor toner cartridge sensorNormallyInstallation fault

CRevolver home position sensorHome positionOther than home

D---

E---

FToner bag full detection sensorToner bag fullNot full

GBlack auto-toner sensor connectionNot connectedConnected

H---

A---

B---

C---

D---

E---

F---

GLower drawer feed sensorNo paperPaper present

HUpper drawer feed sensorPaper presentNo paper

A---

B---

C---

D---

EBridge unit connectionNot connectedConnected

FColor auto-toner sensor connectionNot connectedConnected

G---

H---

Highlighted display

e.g.

ment

Released positionContacted position

Abnormal rotationNormal rotation

Abnormal rotationNormal rotation

Abnormal rotationNormal rotation

Abnormal rotationNormal rotation

Contents

Normal display

e.g.

Contacting movement

position

e-STUDIO281c/351c/451c ERROR CODE AND SELF-DIAGNOSTIC MODE© June 2005 TOSHIBA TEC

2 - 30

Page 31

Digital

key

[5]

[6]

[7]

[8]

[9]

Contents

ButtonItems to check

A---

B---

C---

D---

E---

FRADF connectionRADF connectedNot connected

GPlaten sensorPlaten cove openedPlaten cover closed

HCarriage home position sensorHome positionOther than home

A---

B---

C---

DAPS sensor (APS-R)No originalOriginal present

EAPS sensor (APS-C)No originalOriginal present

FAPS sensor (APS-3)No originalOriginal present

GAPS sensor (APS-2)No originalOriginal present

HAPS sensor (APS-1)No originalOriginal present

ARADF tray sensorOriginal presentNo original

BRADF empty sensorOriginal presentNo original

CRADF jam access cover sensorCover openedCover closed

DRADF open/close sensorRADF openedRADF closed

ERADF exit sensorOriginal presentNo original

FRADF intermediate sensorOriginal presentNo original

GRADF read sensorOriginal presentNo original

HRADF registration sensorOriginal presentNo original

A---

B---

C---

D---

ERADF original length sensorOriginal presentNo original

FRADF original width sensor 1Original presentNo original

GRADF original width sensor 2Original presentNo original

H---

ABlack toner cartridge switchCartridge not

B---

C---

DBypass feed sensorNo paperPaper present

ERegistration sensorPaper presentNo paper

F---

G---

HTransfer belt home position sensorHome positionOther tha home

Highlighted display

e.g.

installed

Normal display

e.g.

position

Cartridge installed

position

2

© June 2005 TOSHIBA TECe-STUDIO281c/351c/451c ERROR CODE AND SELF-DIAGNOSTIC MODE

2 - 31

Page 32

Digital

key

[0]

Contents

ButtonItems to check

Highlighted display

e.g.

Normal display

e.g.

ABridge unit transport sensor 2Paper presentNo paper

BBridge unit cover open/close detection switchCover openedCover closed

CBridge unit transport sensor 1Paper presentNo paper

DBridge unit paper full detection sensorPaper not fullPaper full

E---

FCharger cleaner front position detection switchCleaner home posi-

tion

GCharger cleaner rear position detection switchCleaner rear posi-

tion

Other than home

position

Other than rear position

H---

e-STUDIO281c/351c/451c ERROR CODE AND SELF-DIAGNOSTIC MODE© June 2005 TOSHIBA TEC

2 - 32

Page 33

[FAX] button: OFF/[COPY] button: ON ([FAX] LED: OFF/[COPY] LED: ON)

Digital

key

[1]

[2]

[3]

[4]

[5]

[6]

[7]

[8]

ButtonItems to check

-Temperature/humidity sensor (displays temperature inside of the equipment)

-Temperature/humidity sensor (displays humidity

inside of the equipment)

-Drum thermistor (displays drum surface temperature)

A---

B--C--D--E--F--G--H--A--B--C--D--E--F--G--H--A--B--C--D--E--F--G--H--A--B--C--D--E--F--G--H--A--B--C--D--E--F--G--H---

Highlighted display

e.g.

-Temperature [°C]

-Humidity [%RH]

-Temperature [°C]

Contents

Normal display

e.g.

2

© June 2005 TOSHIBA TECe-STUDIO281c/351c/451c ERROR CODE AND SELF-DIAGNOSTIC MODE

2 - 33

Page 34

Digital

key

[9]

[0]

ButtonItems to check

A--B--C--D--E--F--G--H--A--B--C--DDongles for other equipments / Other USB

devices

EJudgement for acceptable USB storage device

(*1)

F--G--H---

Highlighted display

e.g.

ConnectableNot connectable

AcceptableNot acceptable

Contents

Normal display

e.g.

*1

$ Be sure to install the USB storage device to the equipment and check if the device can be used with

this code.

$ Be sure to turn OFF the write protection (the function to prevent data from erasure by the accidental

recording or deleting) of the USB storage device before performing the check, otherwise this code

cannot be used.

$ It may take some time (2 sec. to 10 sec.) before this check is completed depending on the USB stor-

age device.

e-STUDIO281c/351c/451c ERROR CODE AND SELF-DIAGNOSTIC MODE© June 2005 TOSHIBA TEC

2 - 34

05/11

Page 35

2.2.2Output check (test mode 03)

Status of the output signals can be checked by entering the following codes in the test mode 03.

<Operation procedure>

Procedure 1

ЕрГЕнГ

ЕРСЙЫОГ

øݱ¼»÷

ЕНМЯОМГ

Ñ°»®¿¬·±²

ÑÒ

ͬ±°

½±¼»

ЕНМЯОМГ

Ñ°»®¿¬·±²

ÑÚÚ

ЕРСЙЫОГ СЪЪсСТ

øÛ¨·¬÷

Procedure 2

ЕрГЕнГ

ЕРСЙЫОГ

øݱ¼»÷

ЕНМЯОМГЕЭФЫЯОГ

Ñ°»®¿¬·±²

Ѳ» ¼·®»½¬·±²

Ì»-¬ ³±¼»

-¬¿²¼¾§

ЕРСЙЫОГ СЪЪсСТ

øÛ¨·¬÷

Procedure 3

ЕрГЕнГ

ЕРСЙЫОГ

øݱ¼»÷ ЕНМЯОМГ ЕНМЯОМГ

Ñ°»®¿¬·±²

ÑÒ

Ñ°»®¿¬·±²

ÑÚÚ

ЕЭФЫЯОГ

Ì»-¬ ³±¼»

-¬¿²¼¾§

ЕРСЙЫОГ

СЪЪсСТ

øÛ¨·¬÷

Procedure 4

ЕрГЕнГ

ЕРСЙЫОГ